Patents

Literature

3005results about How to "Reduce process steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

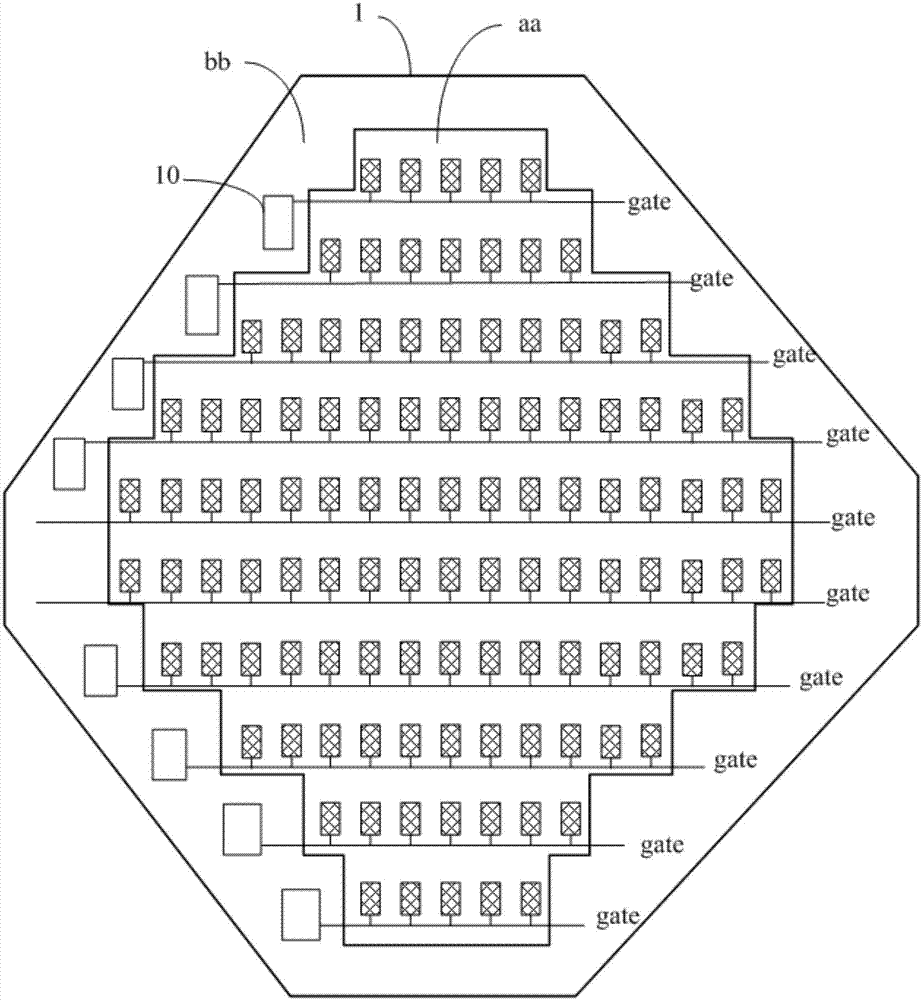

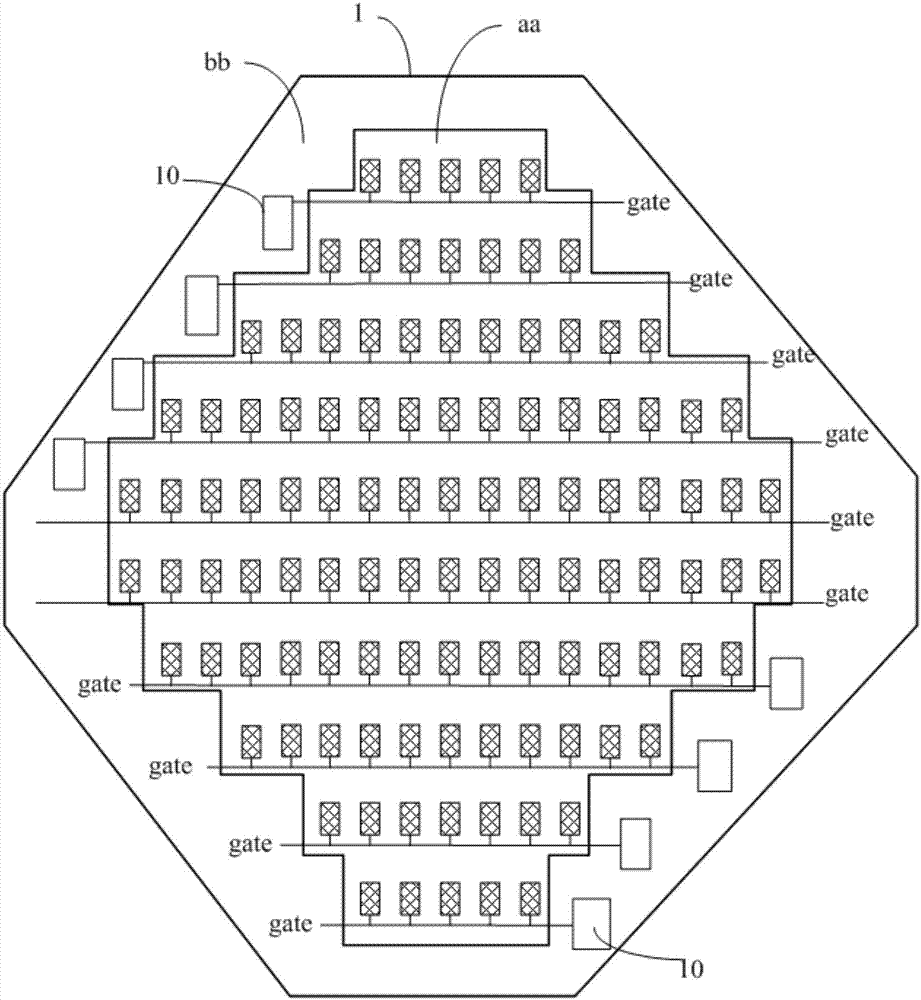

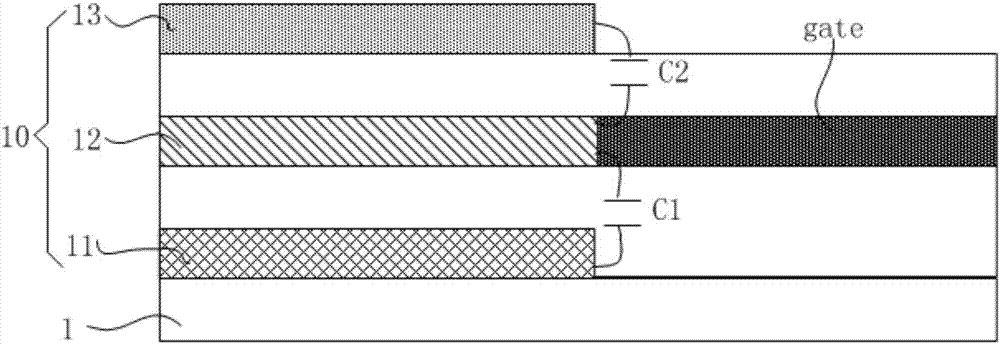

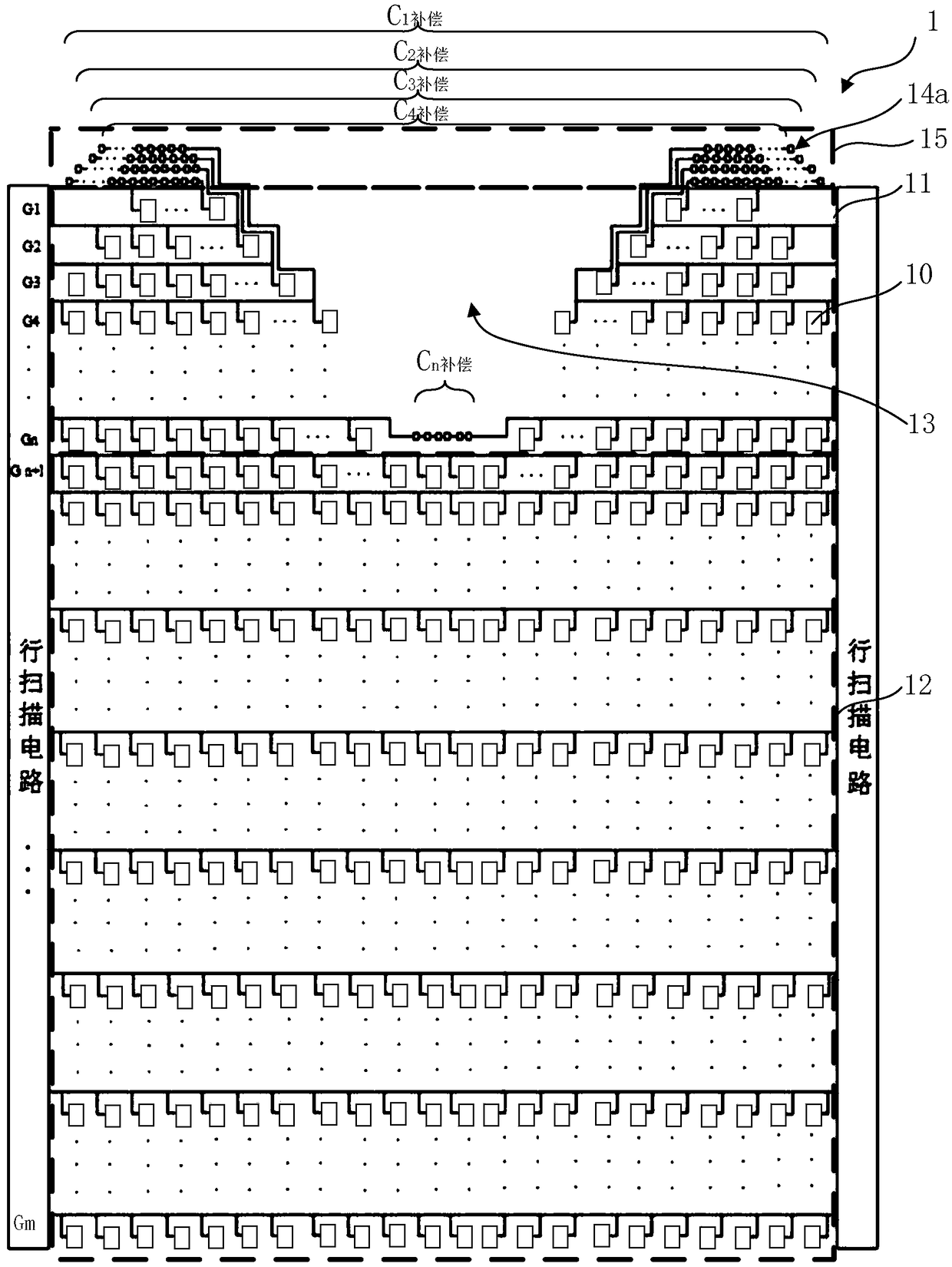

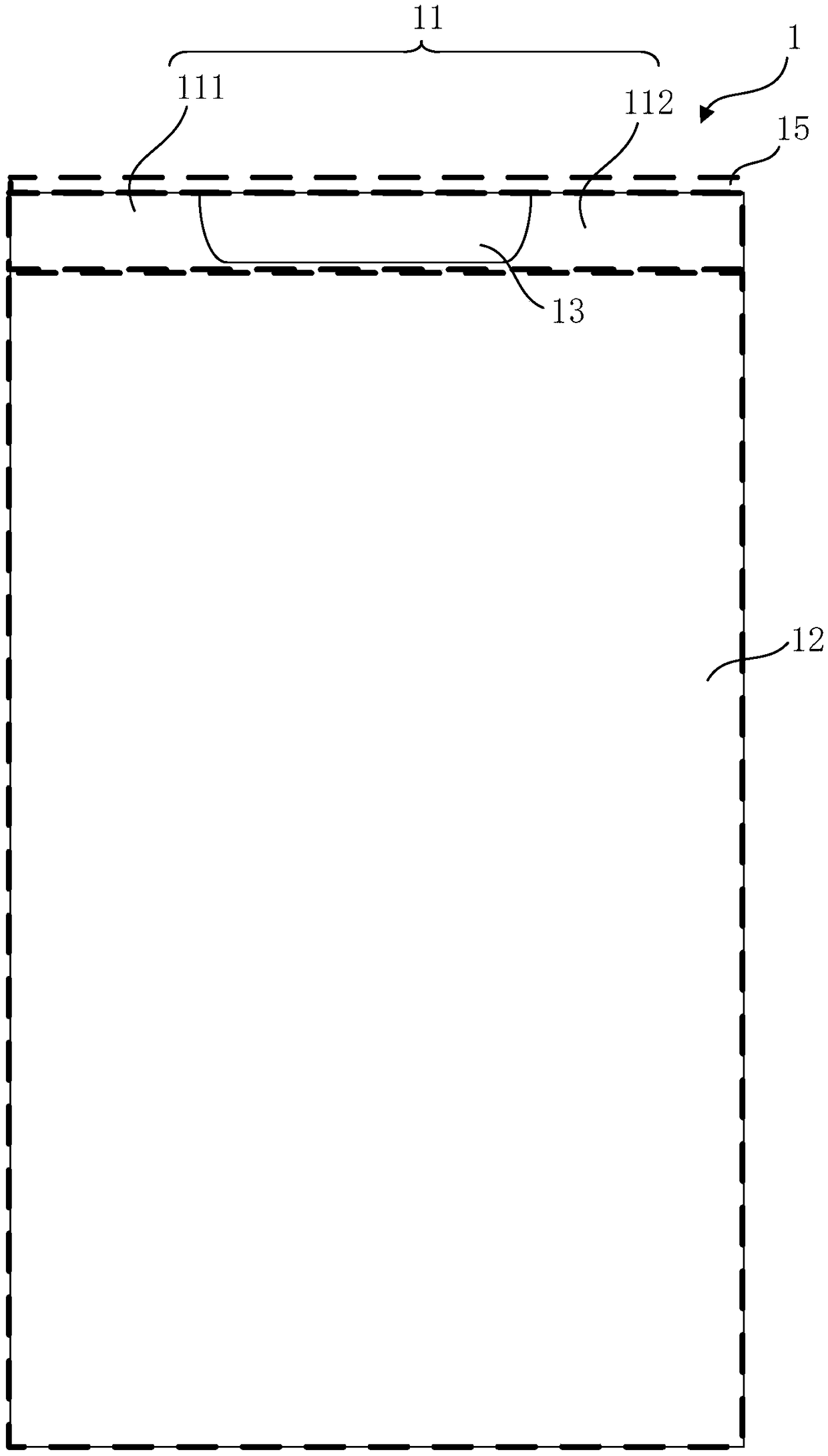

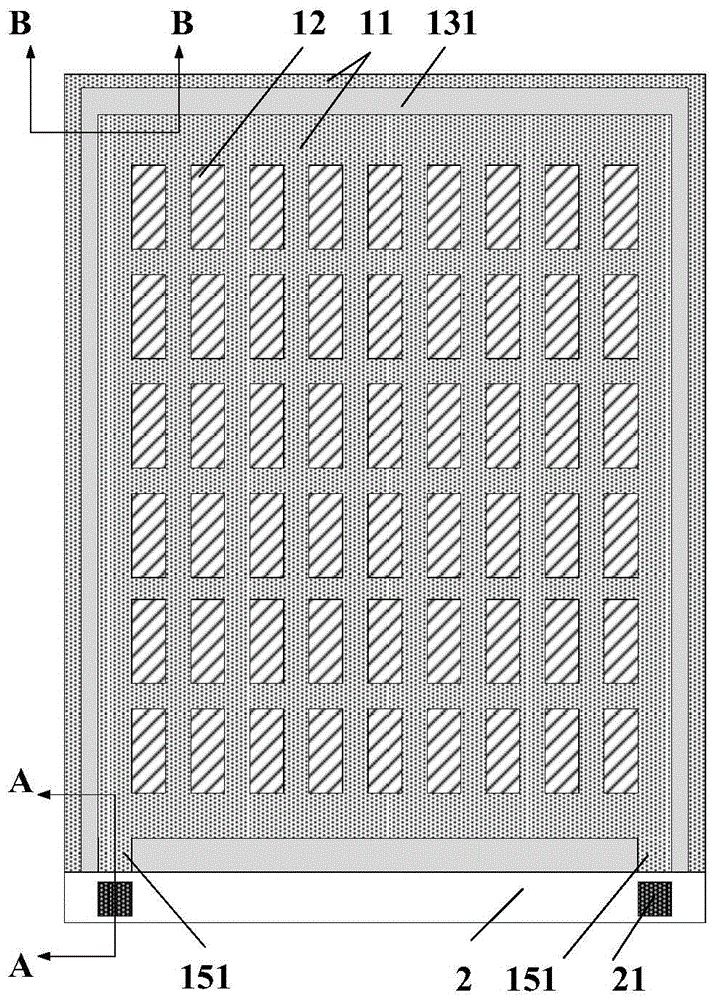

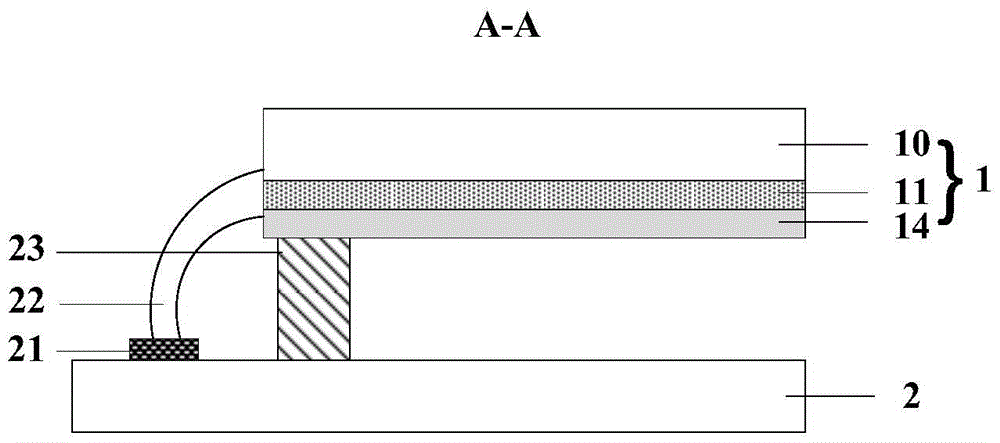

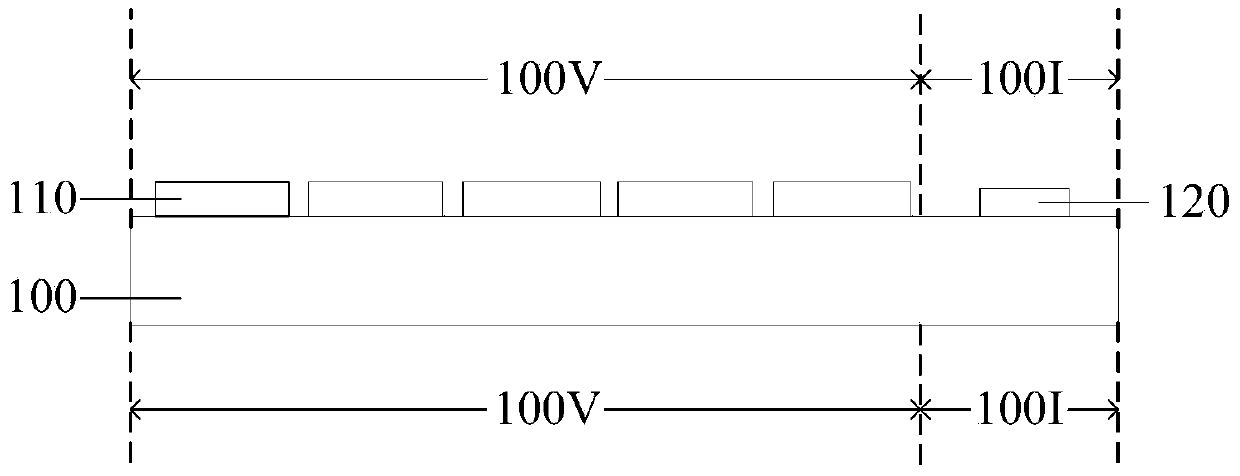

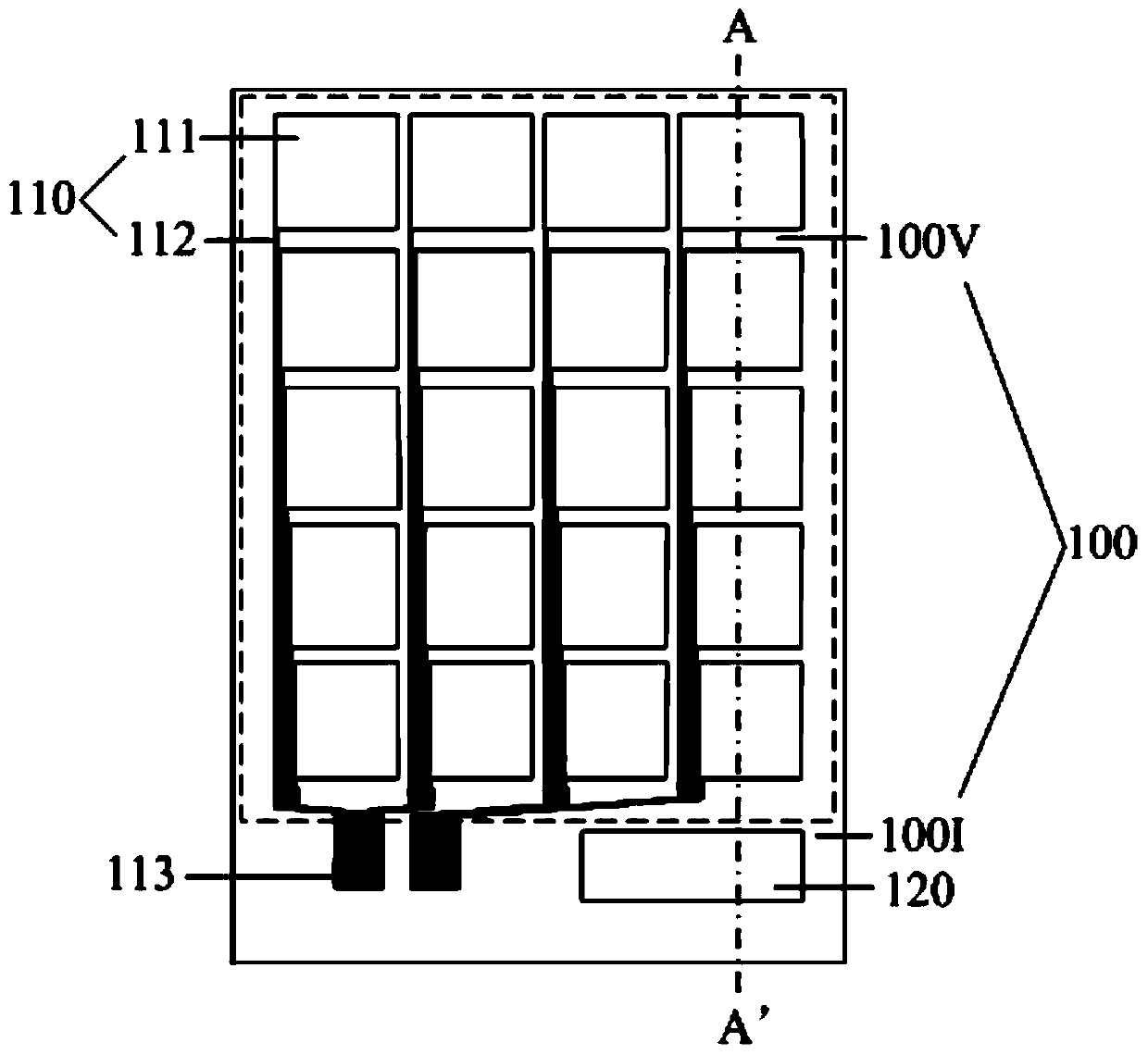

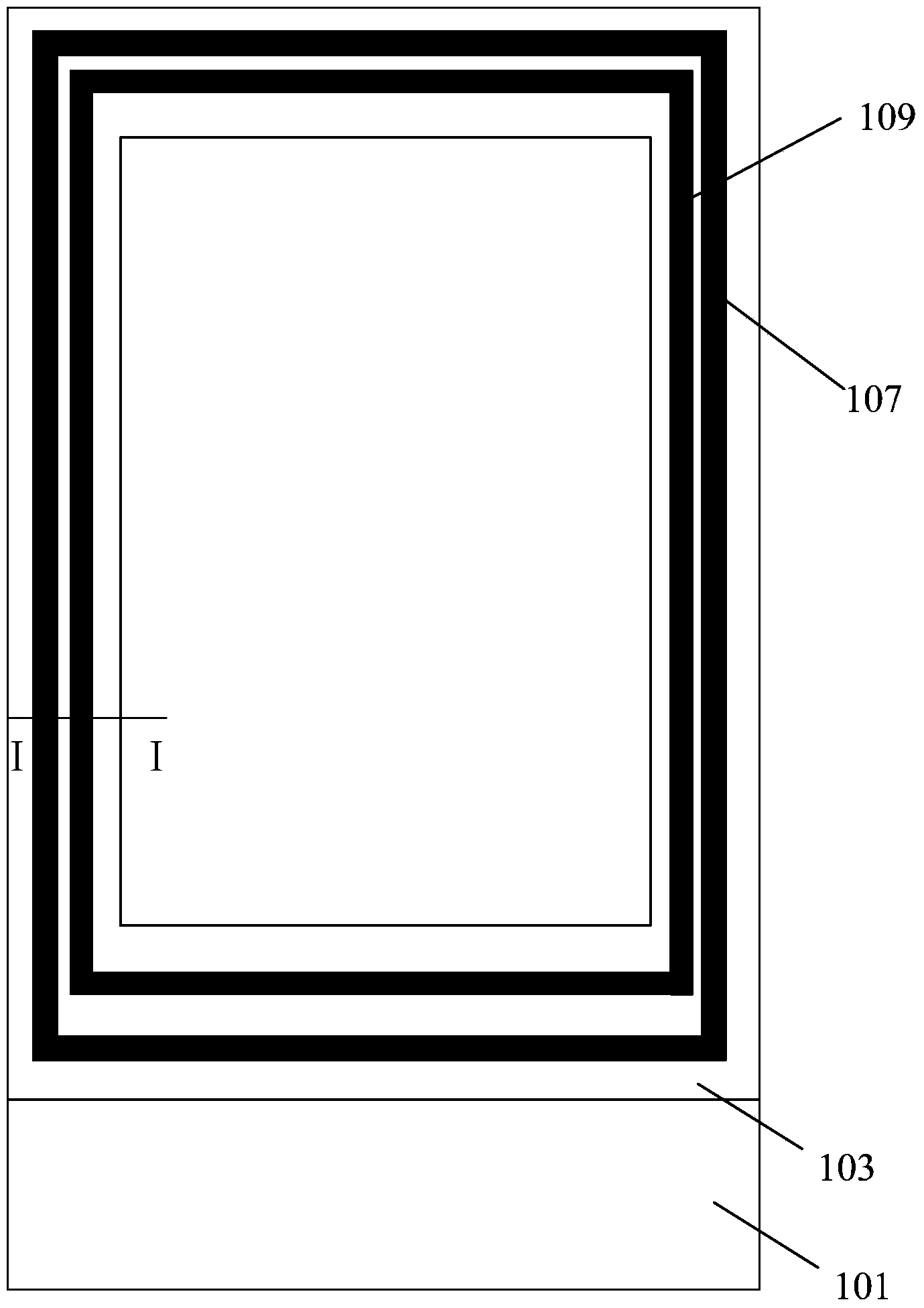

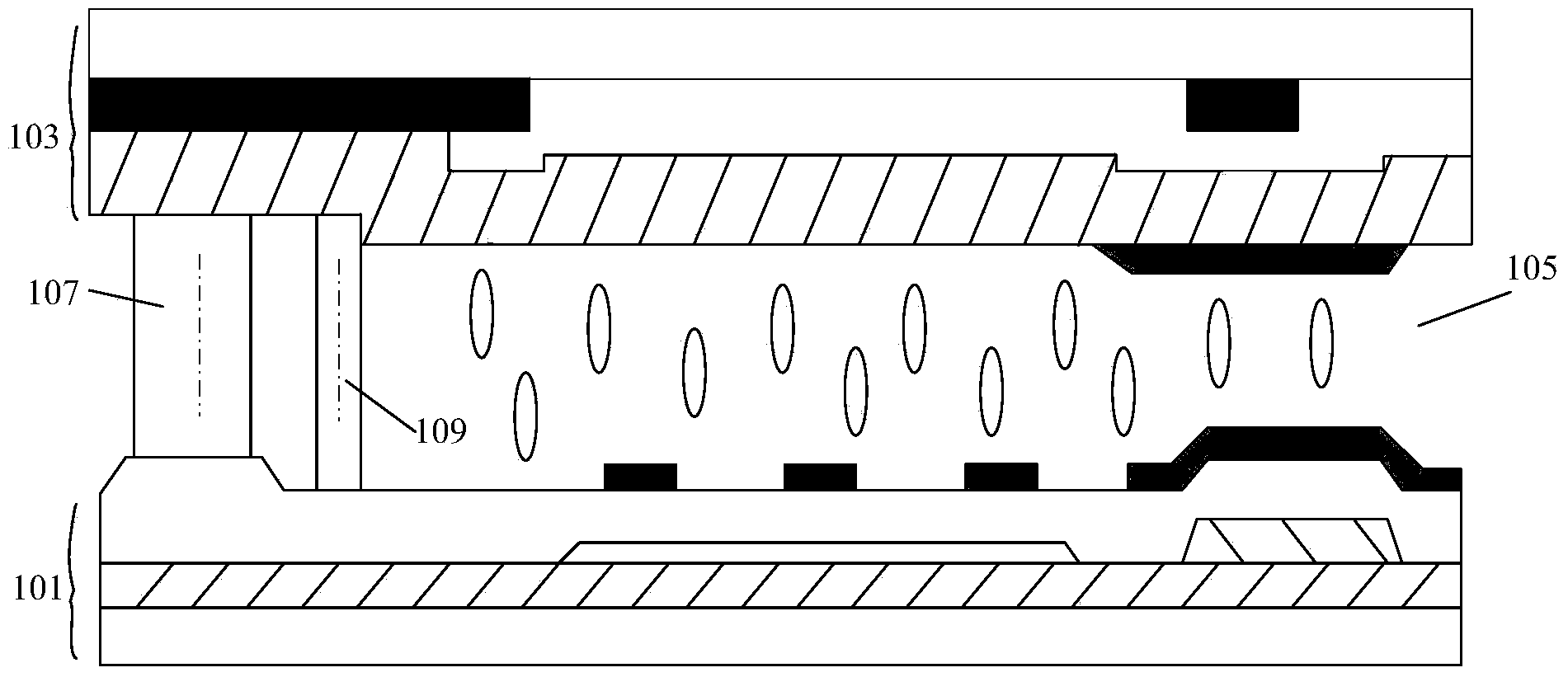

Array substrate, irregularly-shaped display and display device

ActiveCN107221536AIncrease capacitanceImprove display qualityStatic indicating devicesSolid-state devicesCapacitanceImaging quality

The invention discloses an array substrate, an irregularly-shaped display and a display device, and relates to the technical field of display. In the array substrate, a plurality of grid lines with unequal lengths are arranged on a display region, capacitance compensation structures are arranged on a non-display region and are in one-to-one corresponding to a part of the grid lines, each capacitance compensation structure comprises a first electrode, a second electrode and a third electrode which are arranged on a substrate, the first electrode and the second electrode form a first capacitor, the second electrode and the third electrode form a second capacitor, and a coupling capacitance value of the capacitance compensation structure is relevant to the length of the corresponding grid line. According to the technical scheme provided by the invention, the capacitance compensation structures are arranged on the non-display region of the array substrate, the coupling capacitance values of the capacitance compensation structures are relevant to the lengths of the corresponding grid lines, thus, the difference among coupling capacitance of the grid lines with different lengths on the display region is compensated, and the display image quality is improved.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

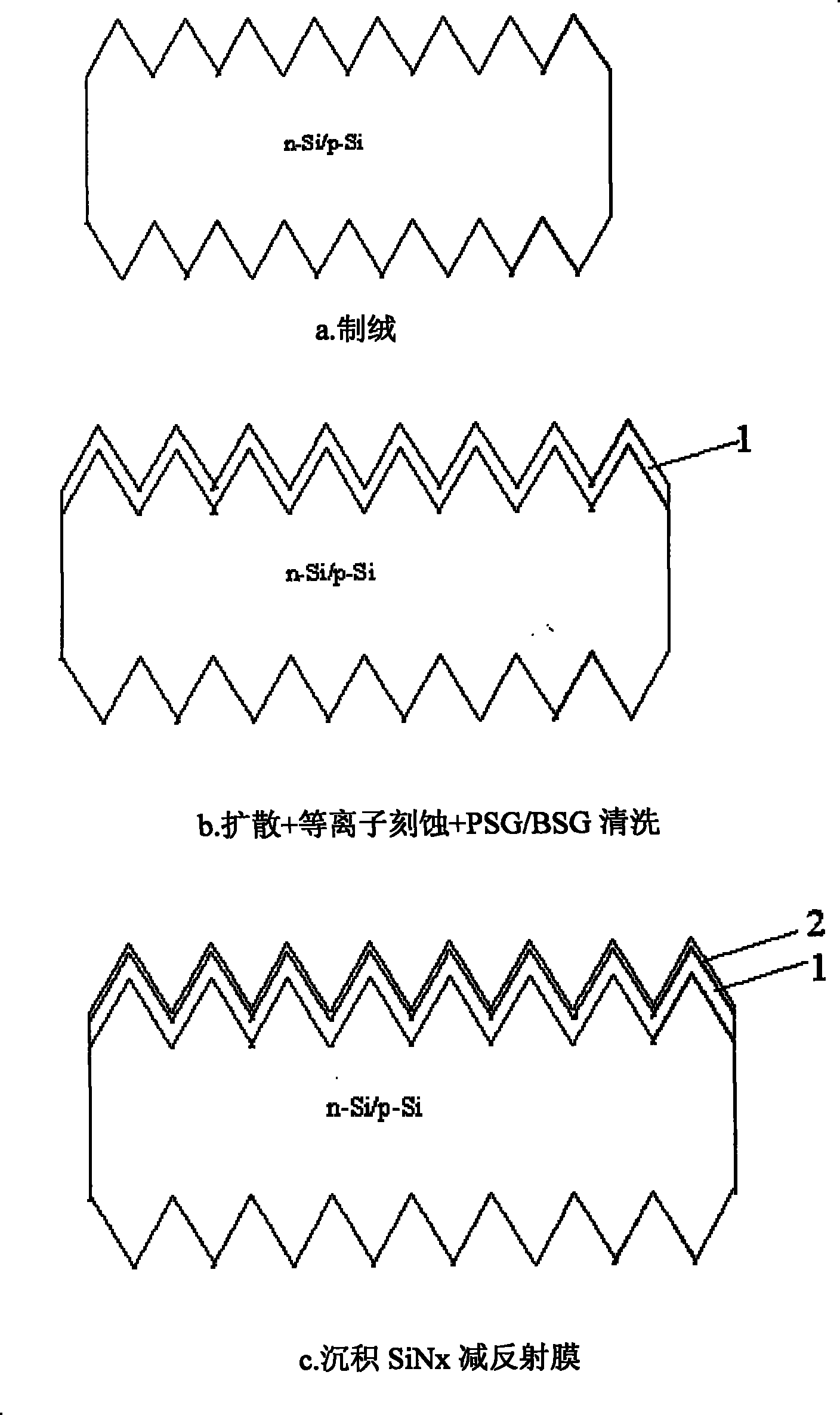

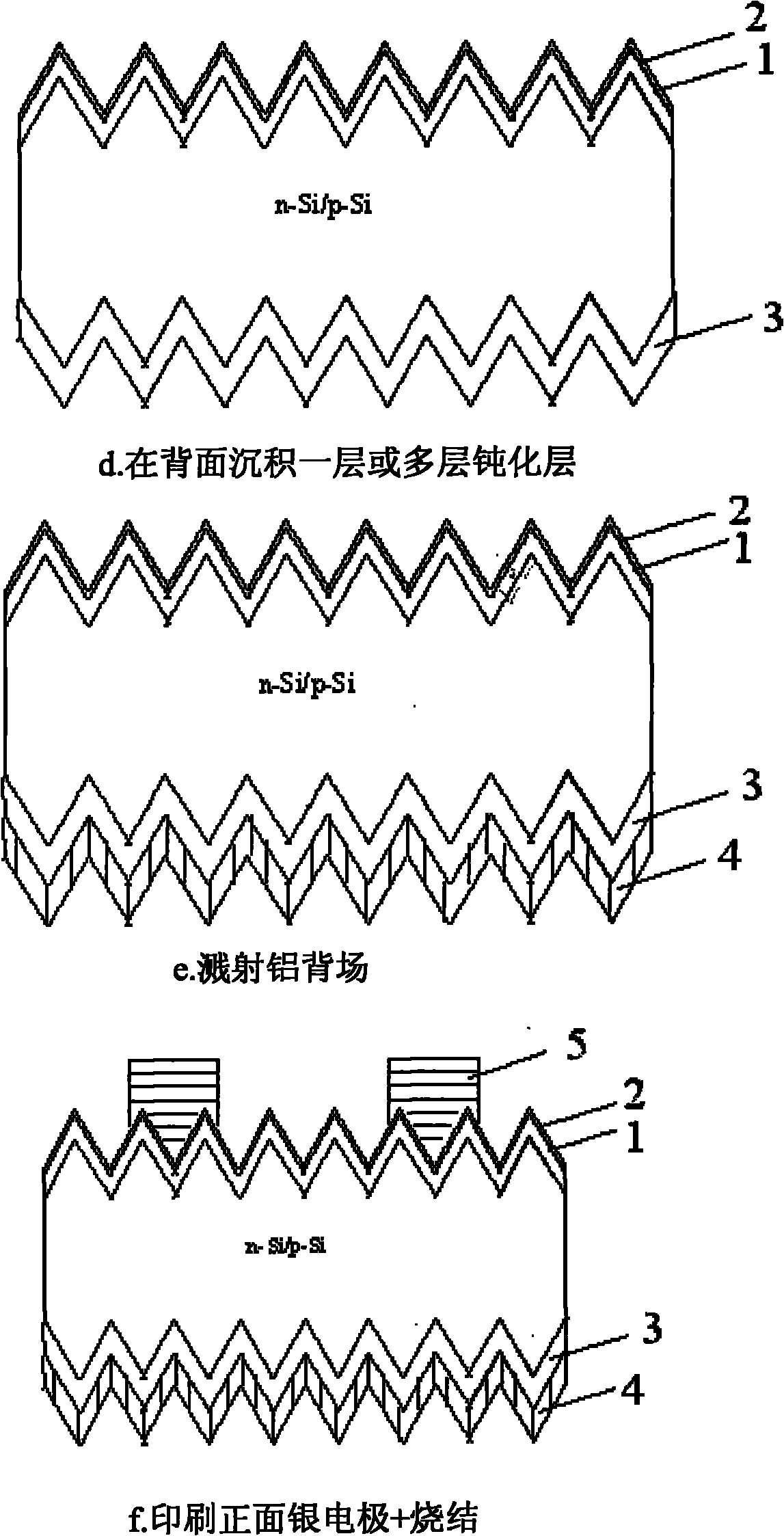

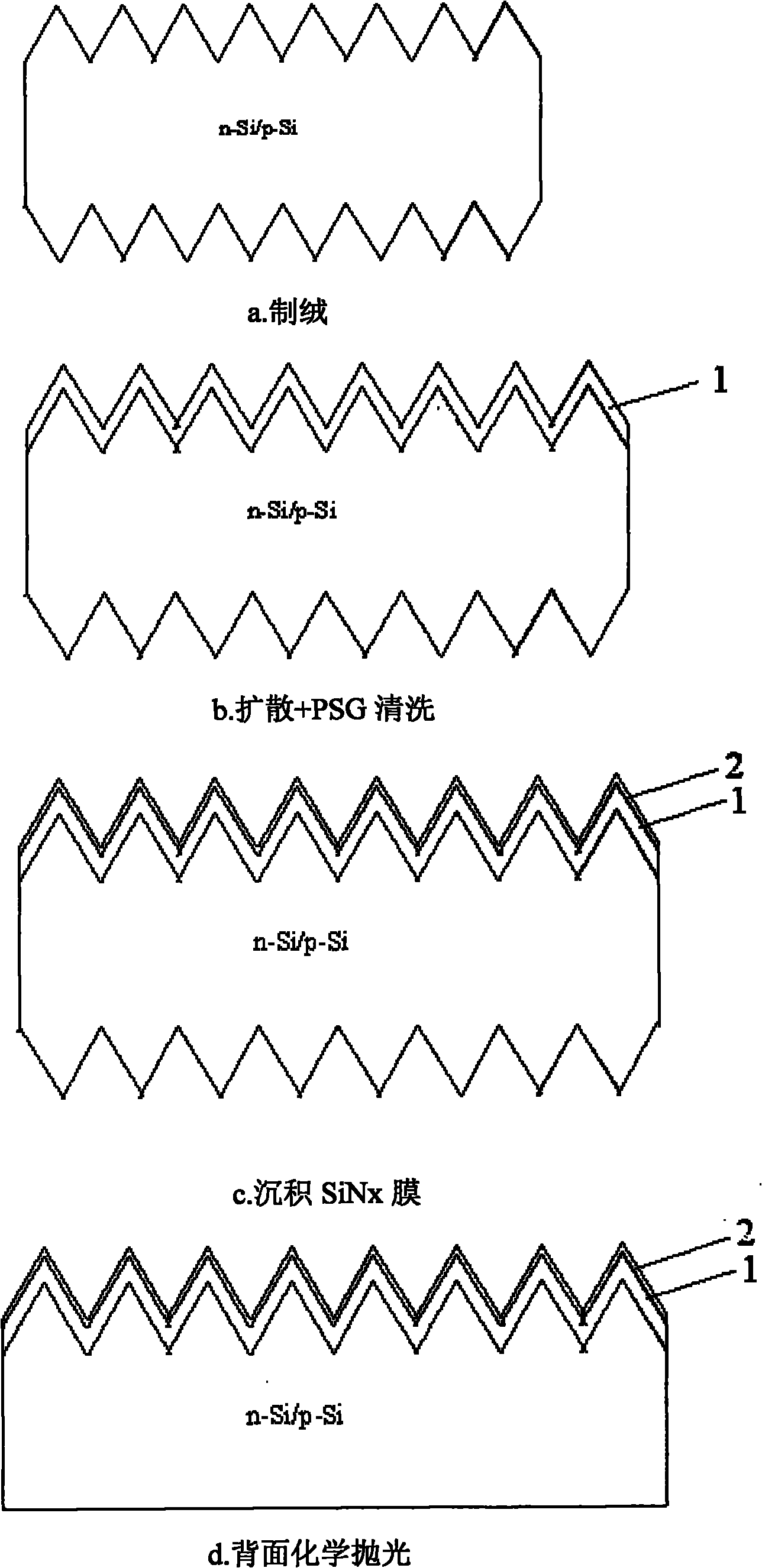

Method for preparing solar cell by using local area back field

ActiveCN101853899AEliminate the etching processSolve the leakFinal product manufactureSemiconductor devicesScreen printingSilver electrode

The invention discloses a method for preparing a solar cell by using a local area back field, which comprises the following steps of: selecting a silicon chip and making the silicon chip into a soft silicon chip, then performing boron or phosphorus dispersion, cleaning a boron-silicon glass layer or a phosphorus-silicon glass layer left on the surface of the silicon chip after the dispersion, depositing a silicon nitride film on the front of the silicon chip by using PECVD, polishing the back of the silicon chip by using hot alkali liquid, and depositing a passive film, performing laser perforation and sputtering an aluminum layer on the polished back; and finally, screen-printing a silver electrode on the front of the silicon chip, and sintering, testing and separating the silicon chip. The method avoids the problem of current leakage caused by lamination during etching; the PECVD process adopted by the passive film on the back is more suitable for large-scale production; the adoption of the back laser perforation improves the manufacturing speed, reduces the process step and avoids pollution brought by corrosive slurry; and the Al layer can be well sintered and contacted with the silicon through pores so that the contact area of the metal and the back surface silicon is smaller and the current carrier compounding rate of the back surface is reduced.

Owner:JA SOLAR TECH YANGZHOU

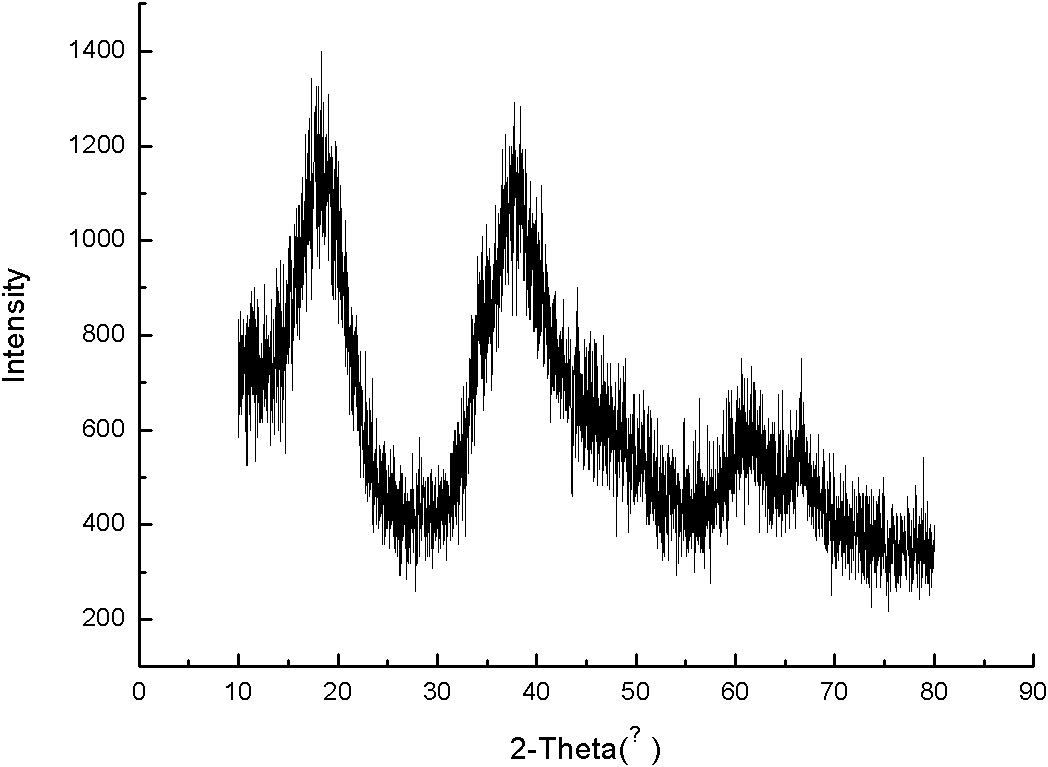

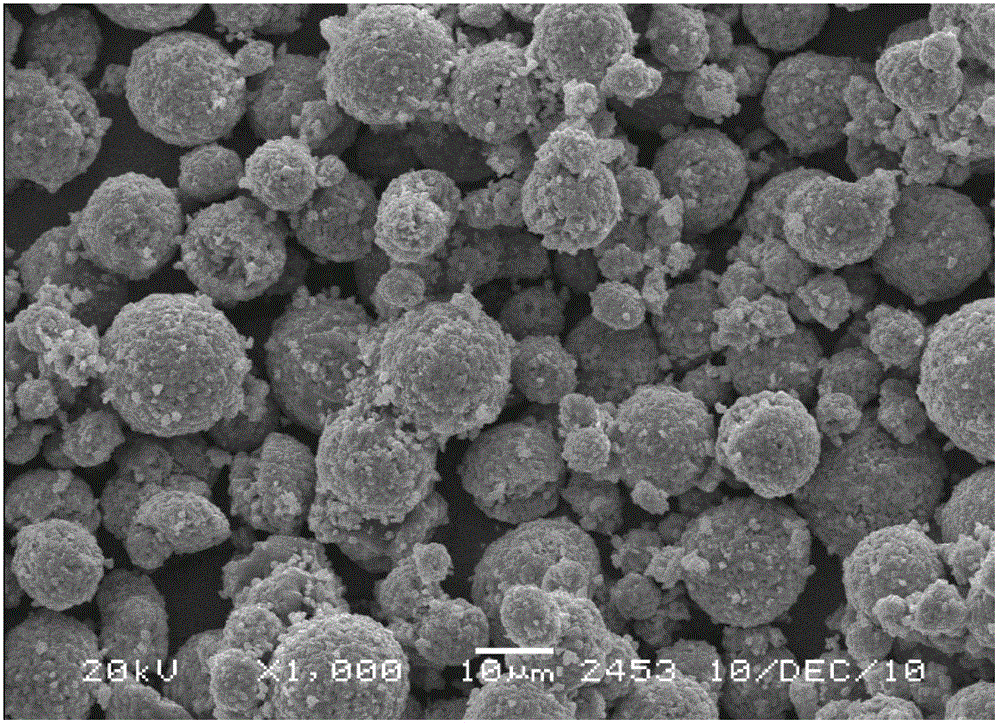

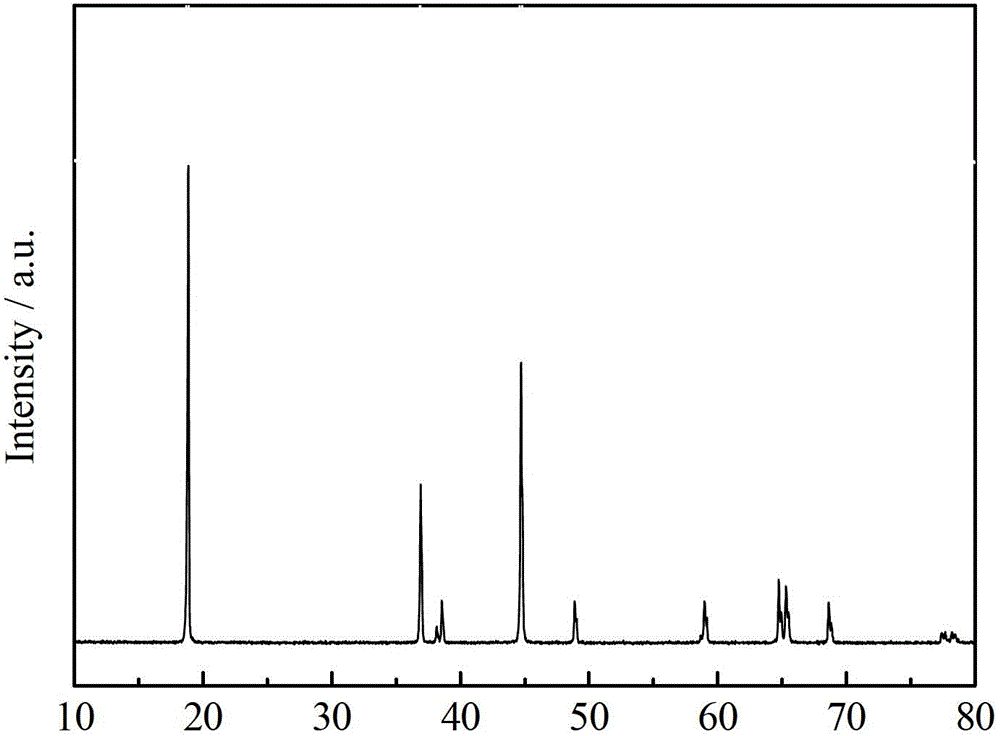

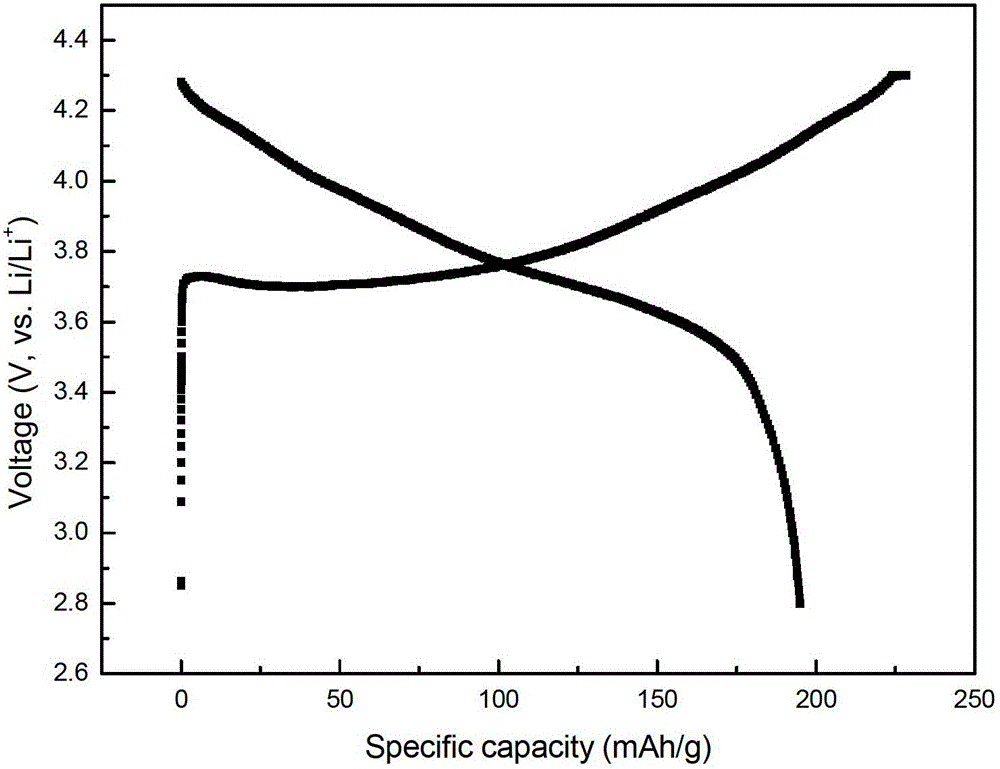

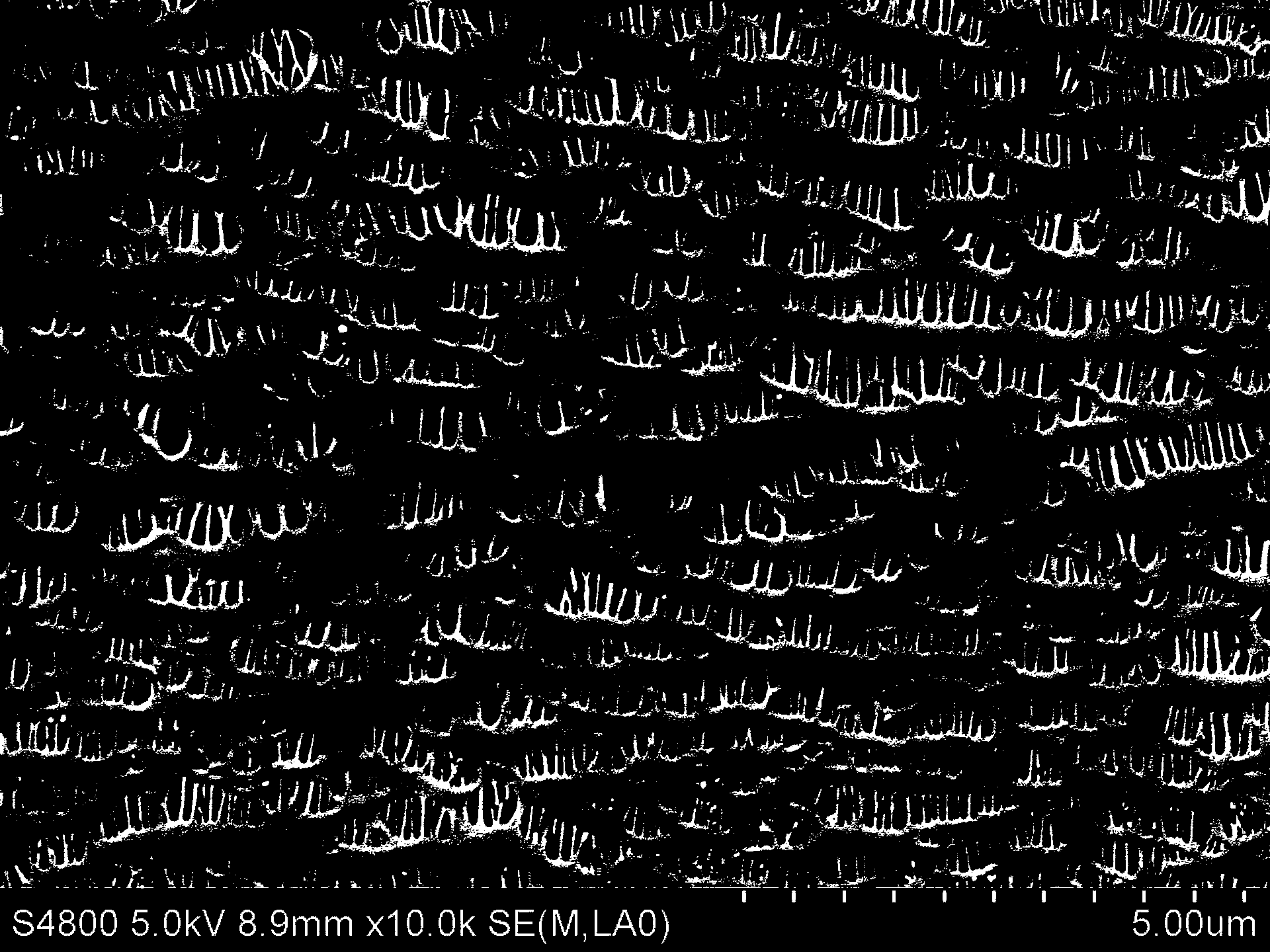

Method for preparing spherical aluminum-doped nickel lithium carbonate for lithium ion battery positive electrode material

ActiveCN102074679AMorphology and particle size distribution controllableGood liquidityCell electrodesLoop stabilityLithium electrode

The invention relates to a method for preparing spherical aluminum-doped nickel lithium carbonate for a lithium ion battery positive electrode material by combining liquid phase oxidation and crystallization controlling. Through controlling of the preparation technique, firstly synthesizing a spherical hydroxyl oxygenized nickel cobalt aluminum precursor with high density, and then calcining at the temperature of 500-800 DEG C for 10-24 hours in a flow oxygen gas atmosphere after mixing the precursor with a lithium source, thus acquire the spherical aluminum-doped nickel lithium carbonate with high density. The synthesized aluminum-doped nickel lithium carbonate is in a single spherical shape, has good stacking density, and can be used for improving the volume ratio capacity of a battery.The aluminum-doped nickel lithium carbonate prepared by the method in the invention has the advantages of high specific capacity and good loop stability. The method provided by the invention has the advantages of simple technique, low cost, less pollution, good product performance and suitability for industrialized production.

Owner:深圳市费特森新能源有限责任公司

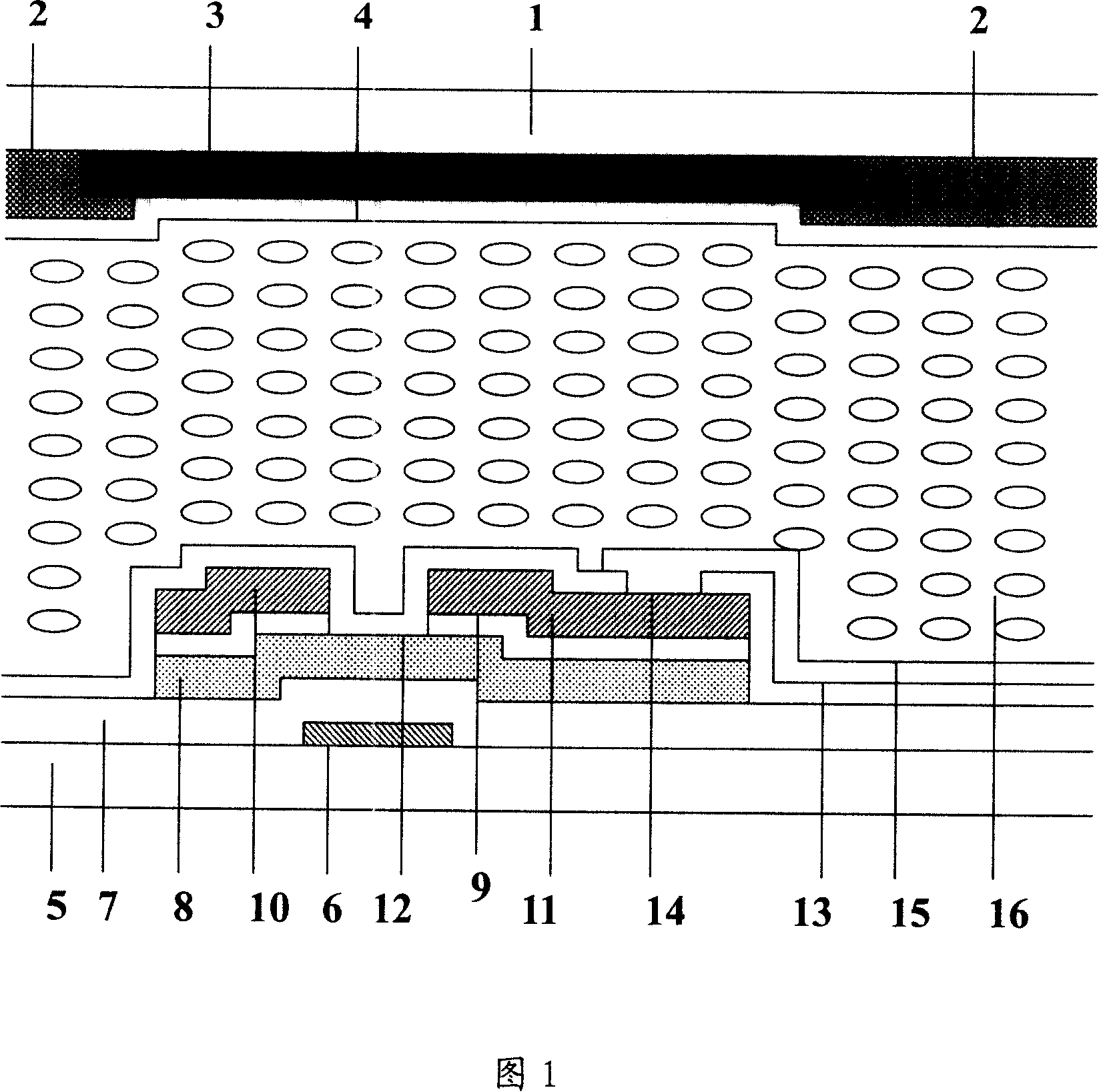

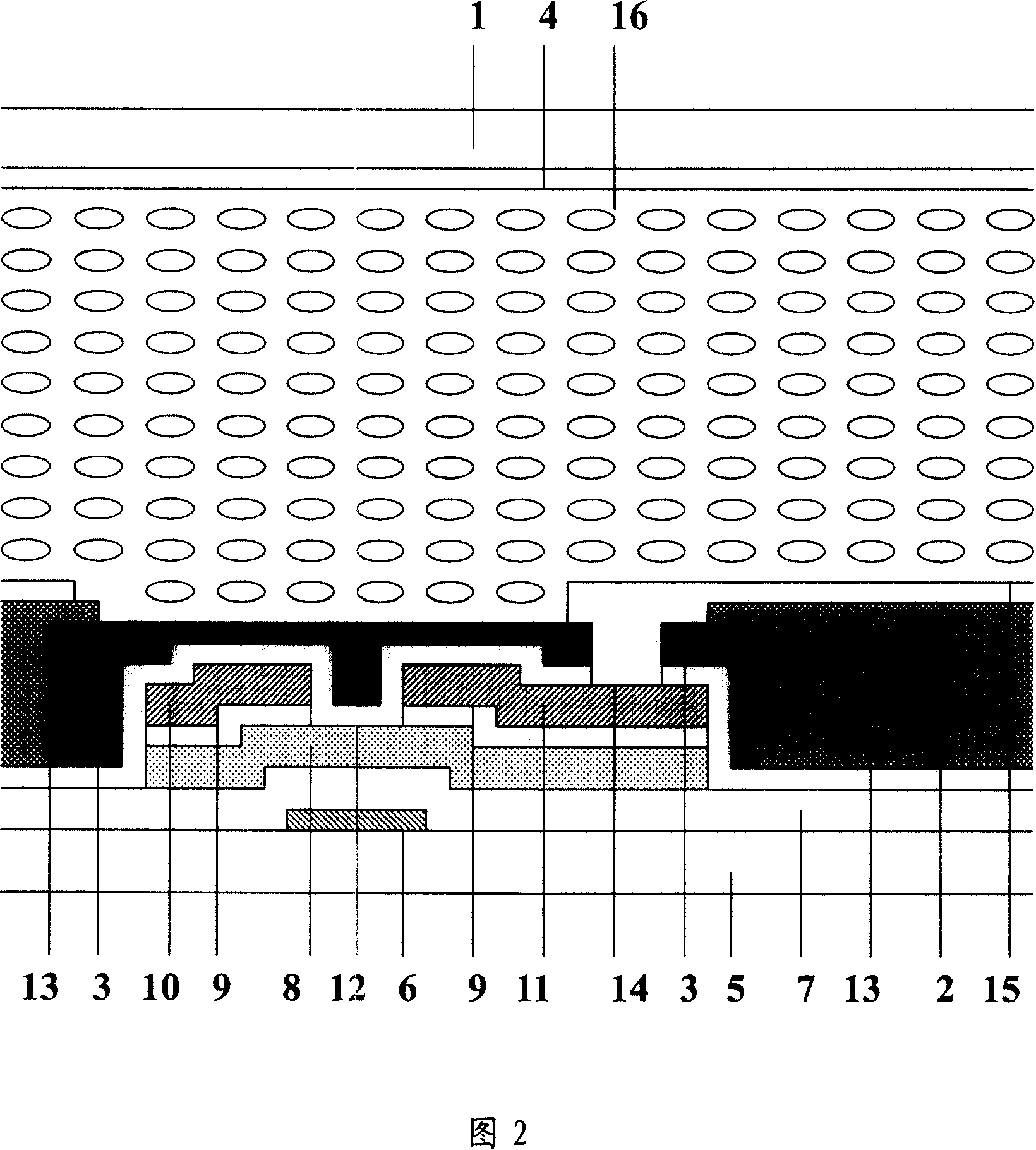

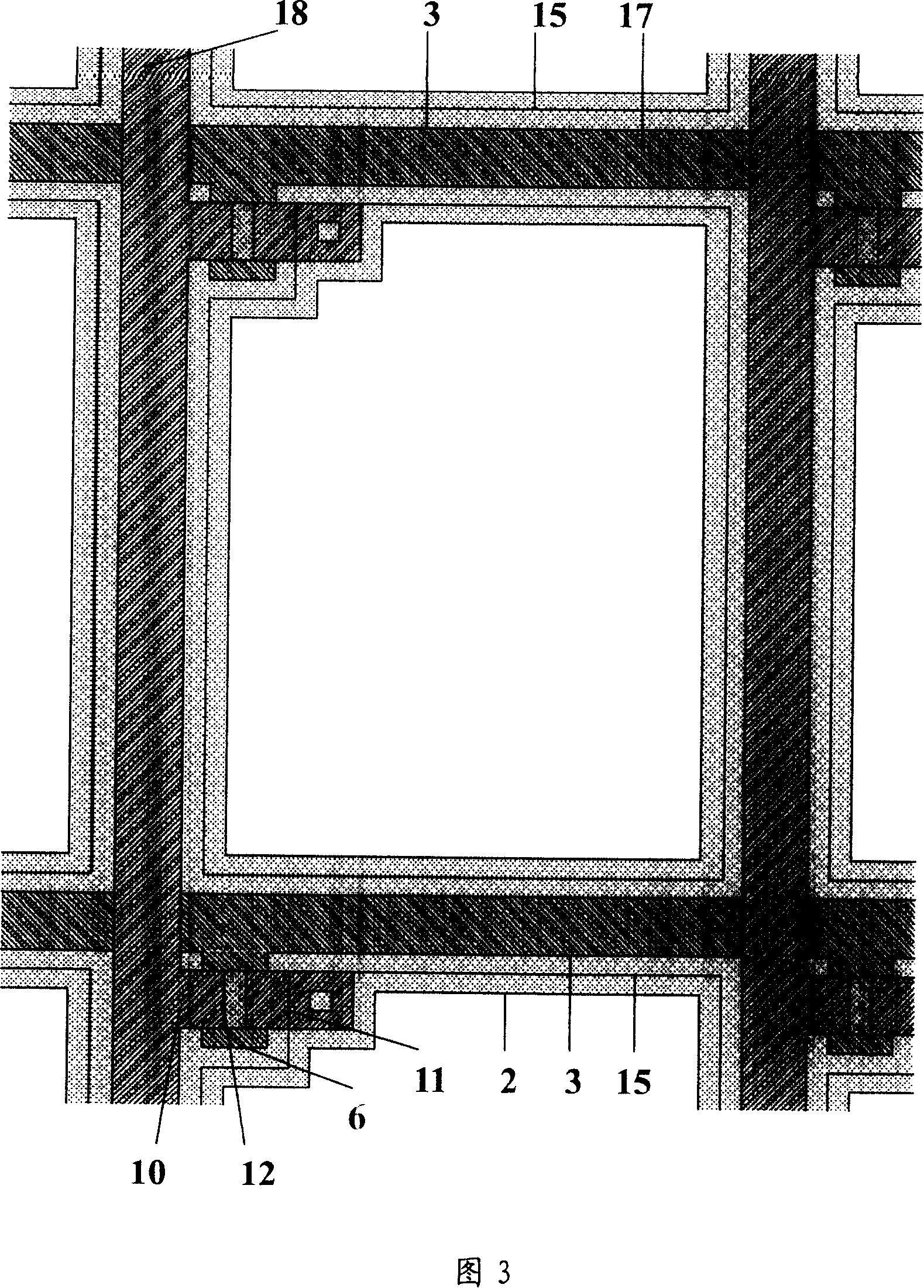

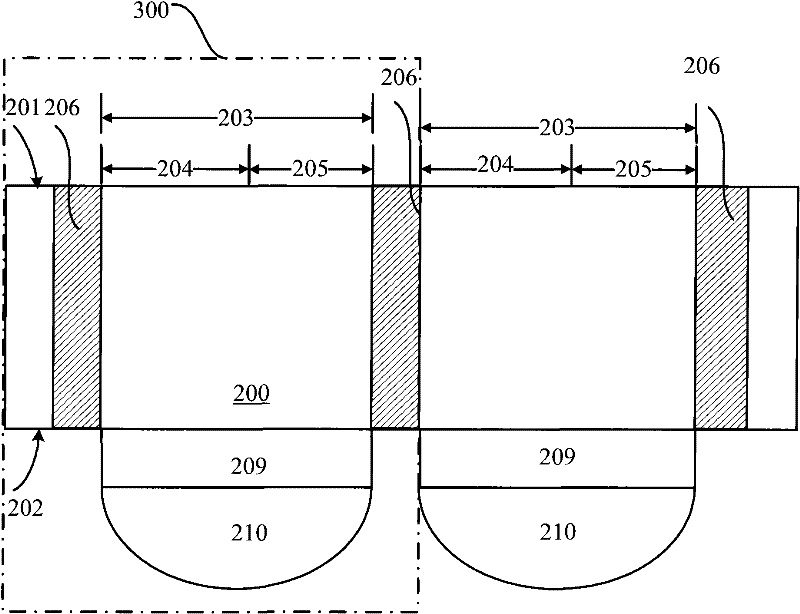

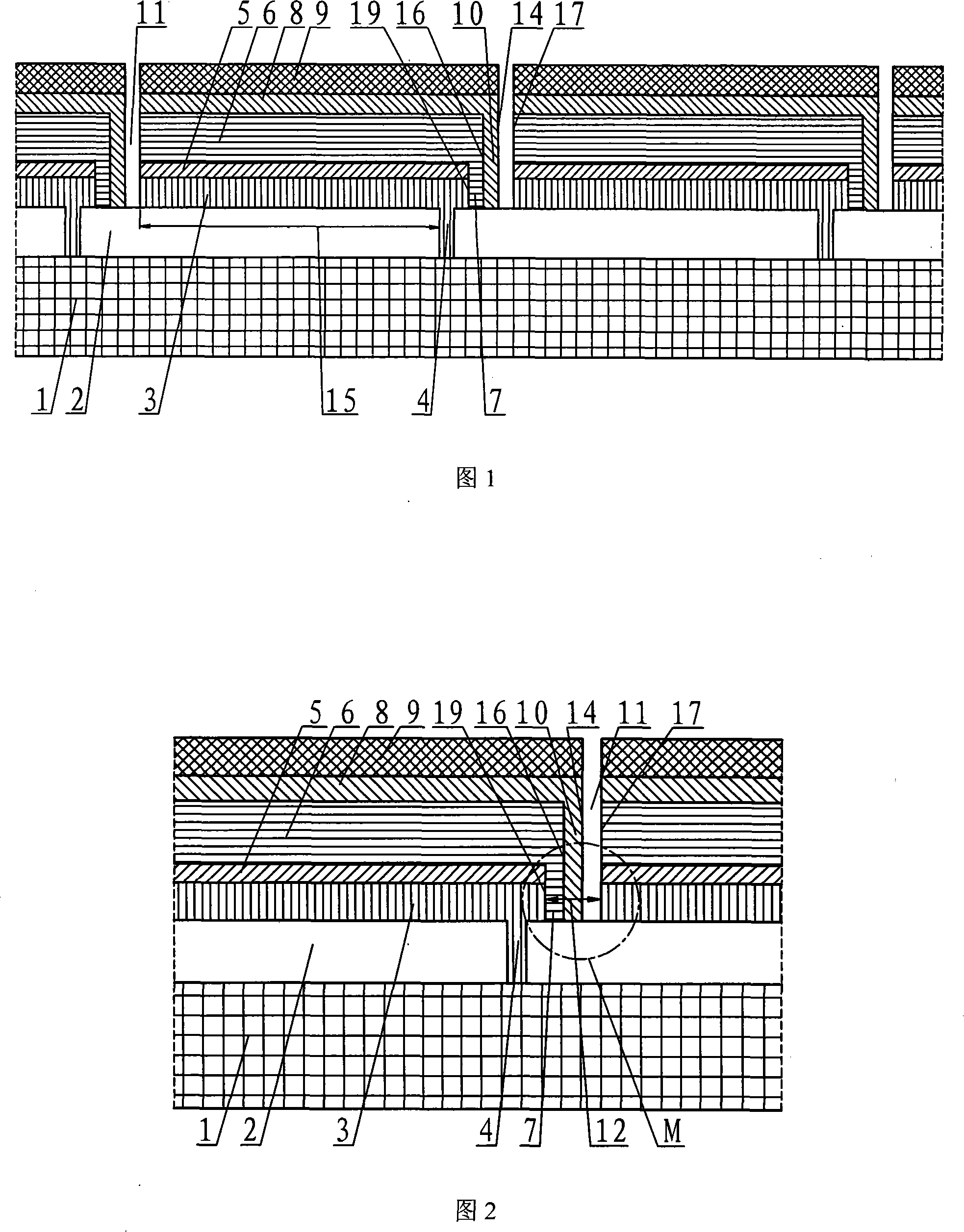

Thin film transistor (TFT) array substrate and display device

InactiveCN102629056AReduce liquid crystal alignment disorder areaIncrease opening ratioSolid-state devicesNon-linear opticsInsulation layerDisplay device

The invention discloses a thin film transistor (TFT) array substrate, which comprises grid lines and data lines, the grid lines and the data lines are formed on the substrate. The grid lines and the data lines cross to define sub-pixel units. Each sub-pixel unit comprises a thin film transistor device, a public electrode, a first pixel electrode layer and a second pixel electrode layer. The first pixel electrode layers or the second pixel electrode layers are connected with public electrodes, and the other ones are connected with source electrodes or drain electrodes of the thin film transistors, the first pixel electrode layers and the second pixel electrode layers are separated through insulation layers, and the second pixel electrode layers are arranged above the first pixel electrode layers. Images of strip pixel electrodes of the second pixel electrode layers are overlapped with images of the first pixel electrode layers, an inclined angle is arranged between the strip pixel electrodes and liquid crystal initial orientation, and the grid lines are parallel to the strip pixel electrodes close to the grid lines or the data lines are parallel to the strip pixel electrodes close to the data lines. The TFT array substrate and the display device guarantee that a liquid crystal orientation chaos phenomenon caused by effects of disorder electric fields at a pixel edge can not occur.

Owner:BOE TECH GRP CO LTD +1

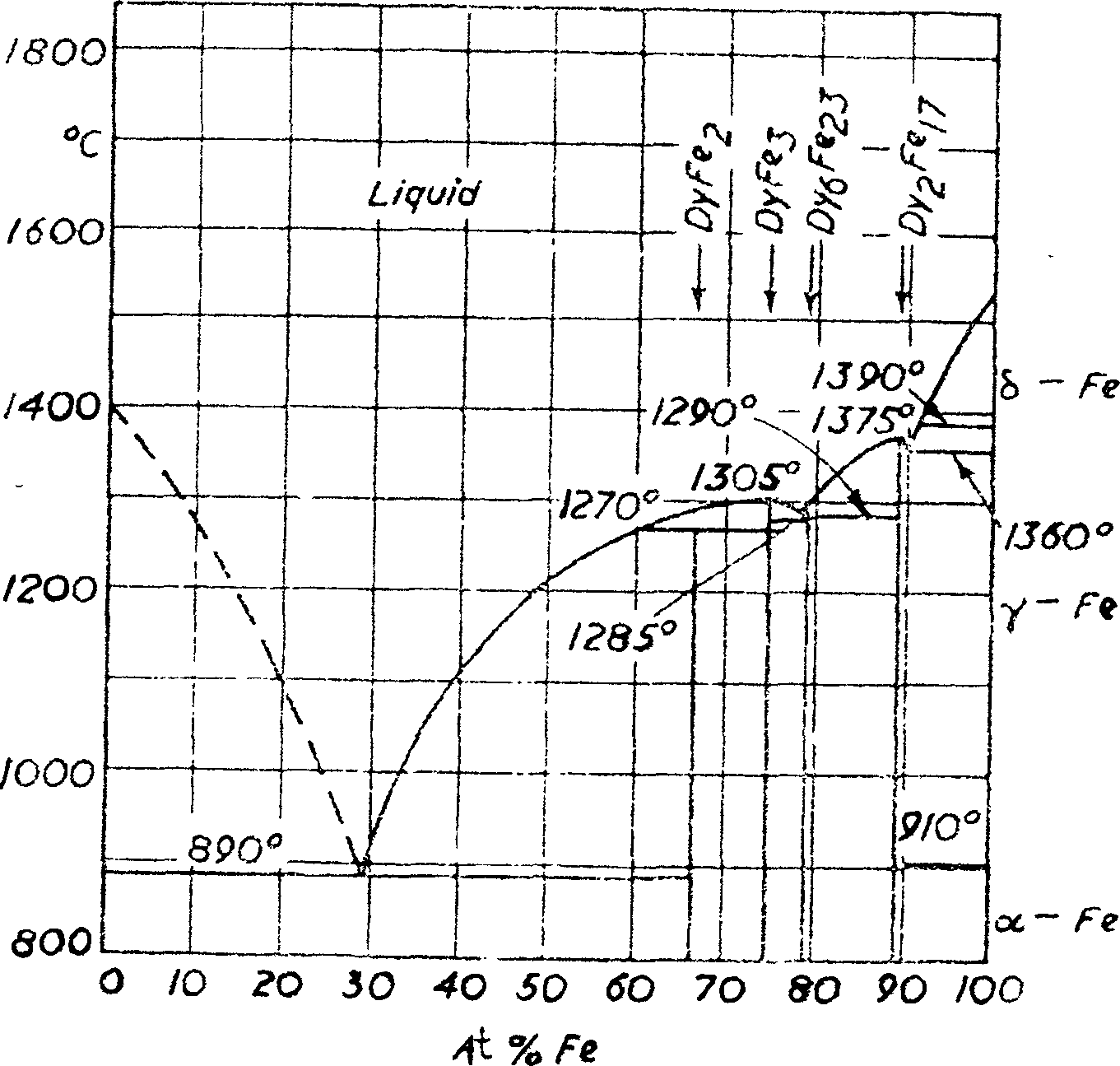

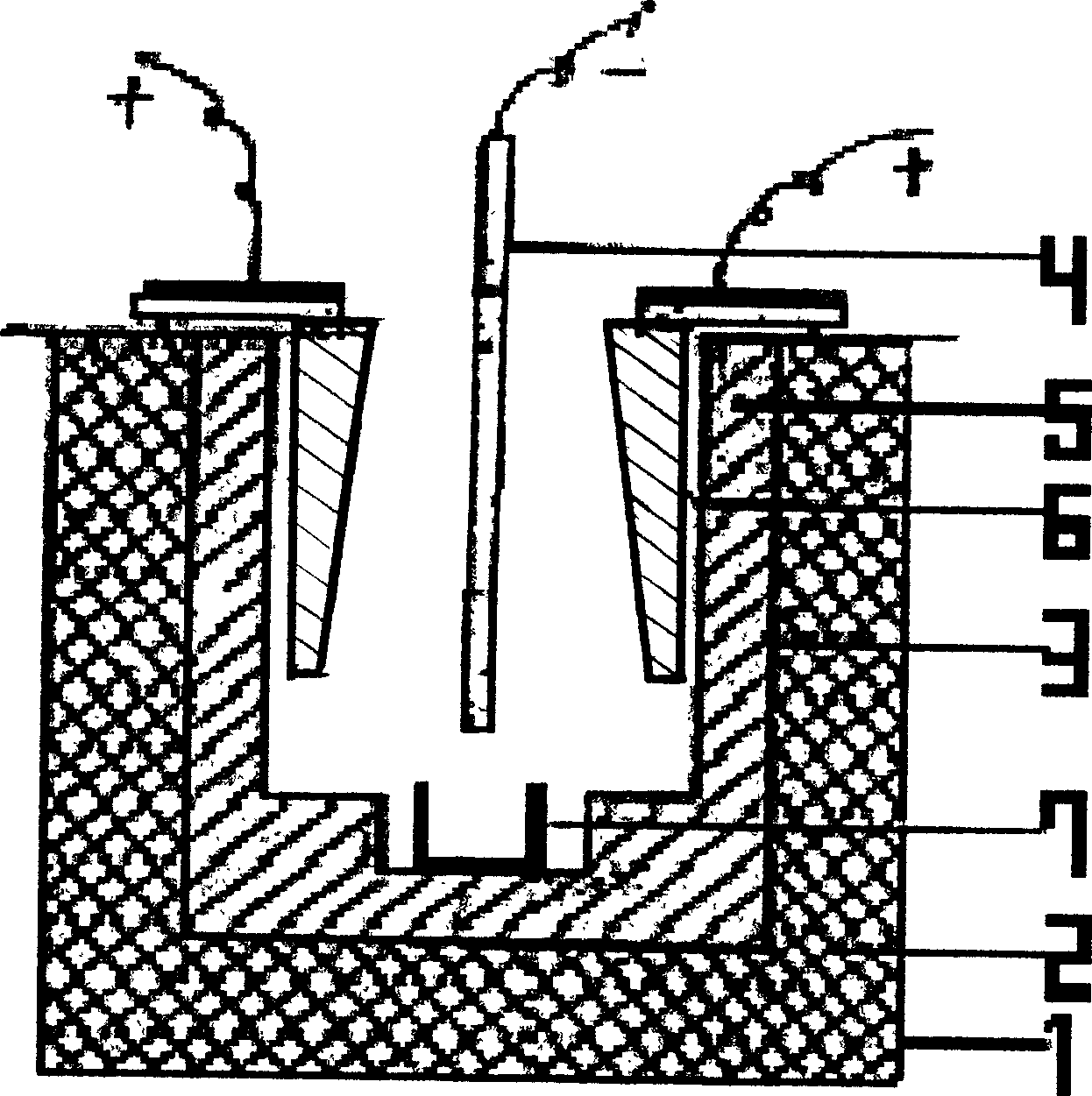

Process and apparatus for producing Dy-Fe alloy by molten salt electrolysis method

The invention relates the dysprosium-iron alloy technology with fused salt electrolysis process and device, belonging to rare-earth products preparing field. The method comprises the following steps: at high temperature, dysprosium oxide melting at fluoride, dysprosium oxide beginning ionizing; at the condition of 95V / M direct current field, separating out Dy3+ on the surface of iron cathode, deacidizing Dy3+ to Dy, and alloying Dy and Fe to form Dy-Fe. O2- is oxygenated to O2 on the surface of graphite cathode, and it reacts with carbite to form CO2. The melting point of dysprosium-iron (20úÑFe) is 1046Deg.C, and the melting point of Dy is 1407Deg.C, so the electrolyzation is carried out at 1050Deg.C. The invention has the advantages of low investment, low cost, simple technology, continuous production and low impurity content.

Owner:包头市稀土应用技术研究所

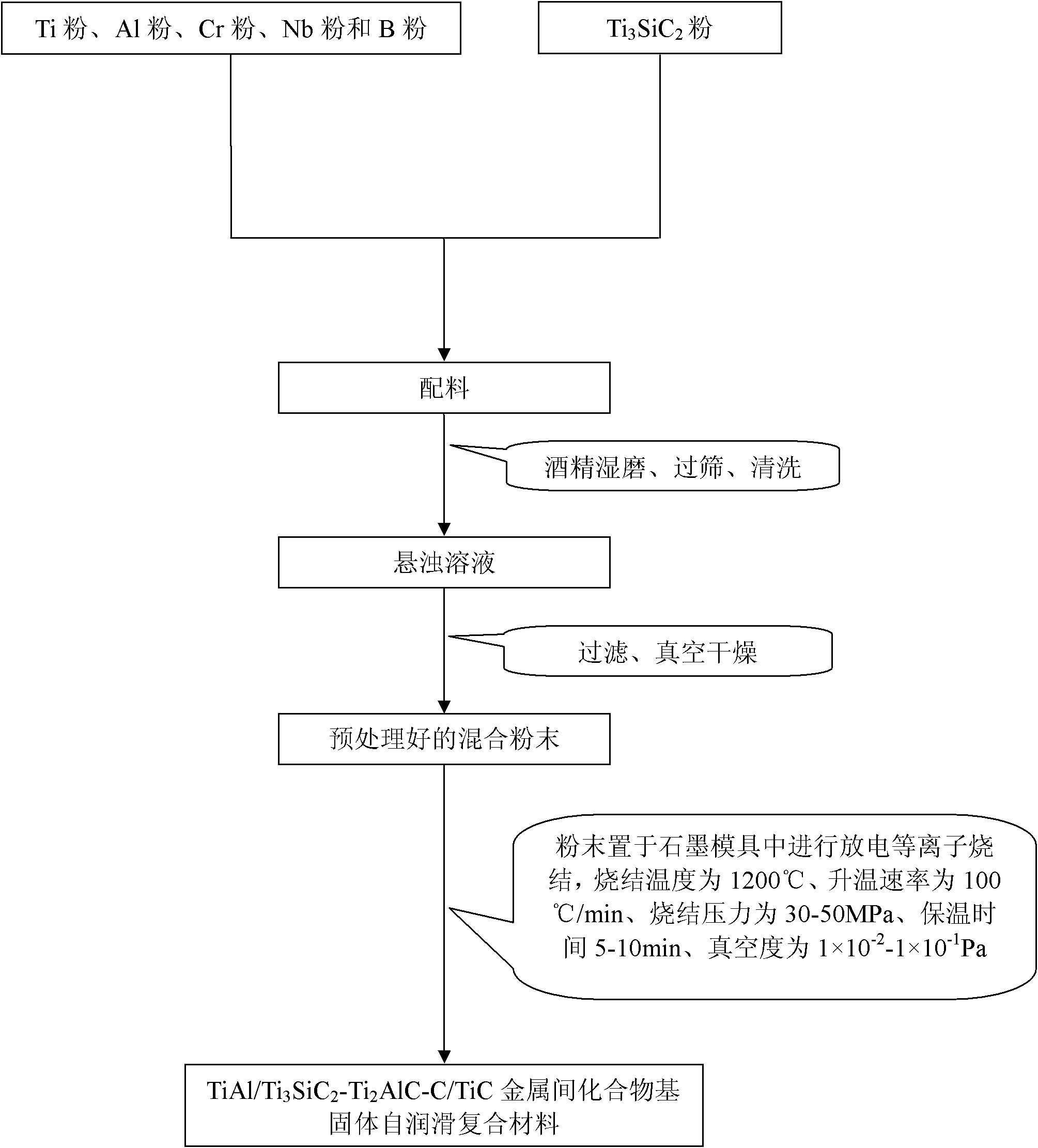

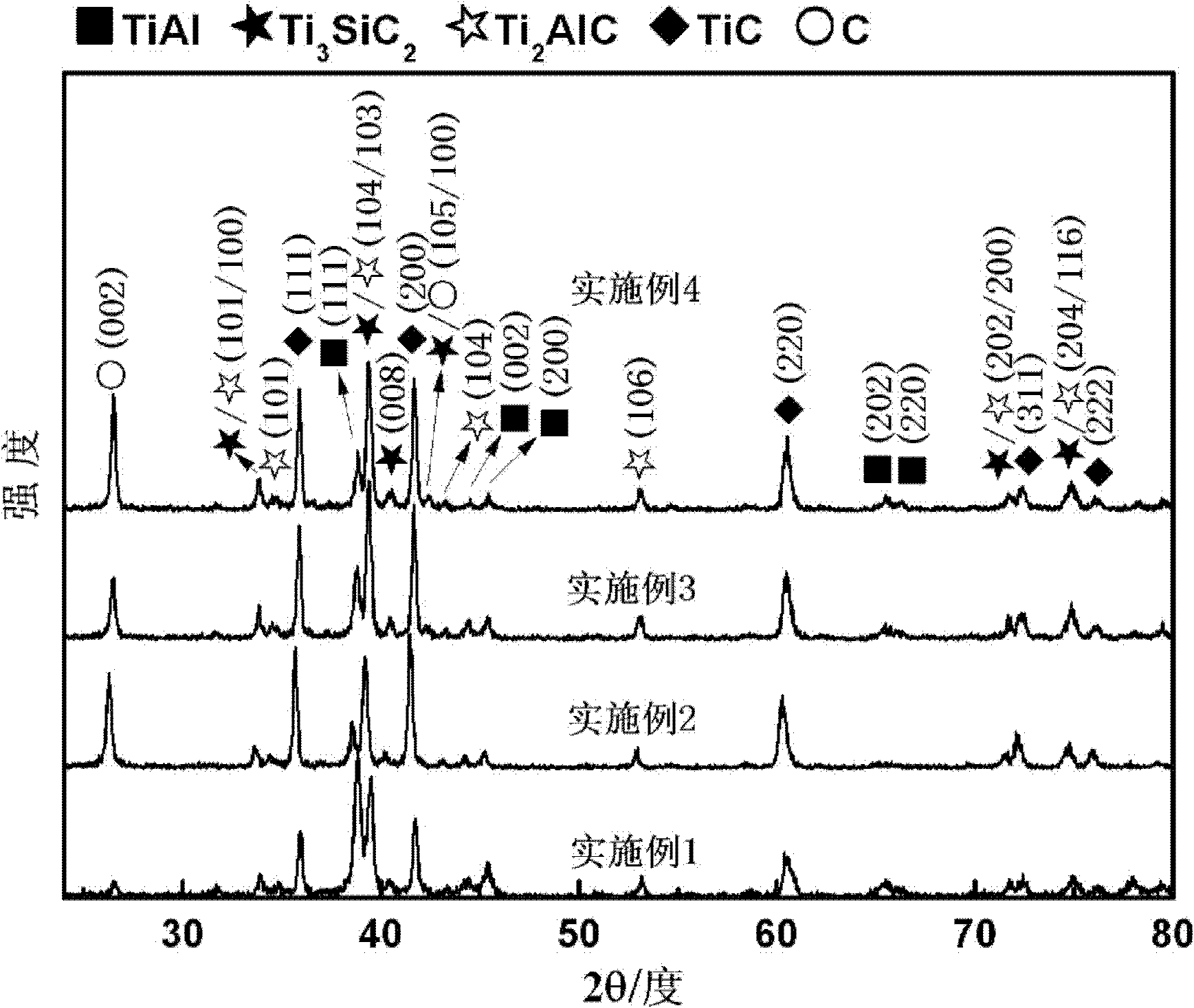

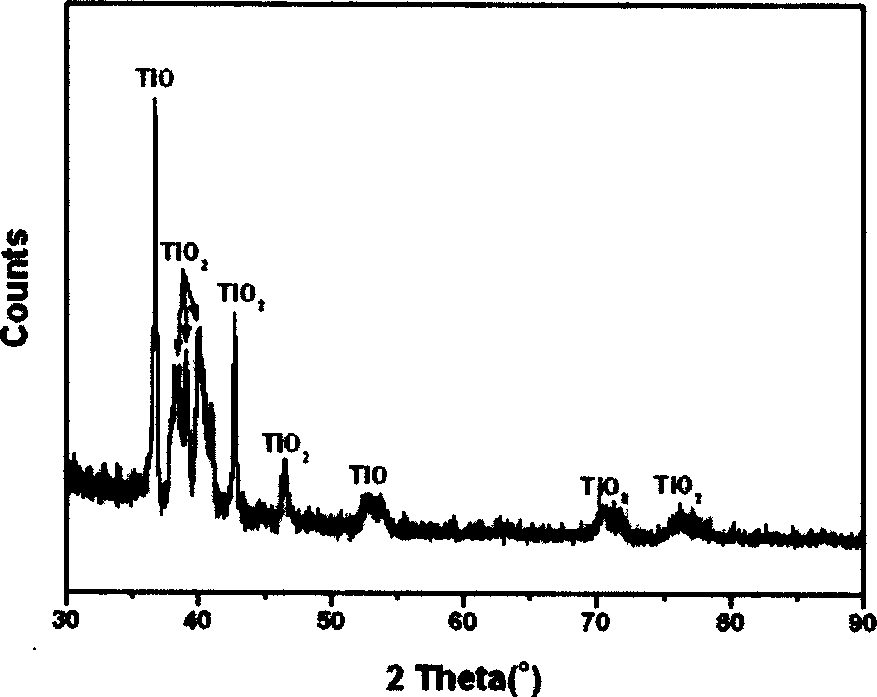

TiAl intermetallic compound-based solid seif-lubricating composite material and preparation method thereof

The invention relates to a TiAl intermetallic compound-based solid seif-lubricating composite material which comprises Ti3SiC2, Ti2AlC and C which are used as the ternary composite lubricating phase and TiC which is used as the reinforced phase, and a preparation method thereof. The TiAl intermetallic compound-based solid seif-lubricating composite material is characterized in that the material is prepared from Ti powder, Al powder, Cr powder, Nb powder, B powder and Ti3SiC2 powder, wherein the molar ratio of Ti, Al, Cr, Nb and B is 48:47:2:2:1 and the dosage of the Ti3SiC2 powder is 5-20wt.% of the total weight of the Ti powder, Al powder, Cr powder, Nb powder and B powder. The TiAl / Ti3SiC2-Ti2AlC-C / TiC intermetallic compound-based solid seif-lubricating composite material synthesized by the method is novel in component design (the intermetallic compound matrix, the composite lubricating phase and the reinforced phase), high in density, good in tribological properties, stable in technological parameters, fast and simple in preparation process and easy in operation and the method is suitable to be used to prepare the high performance TiAl intermetallic compound-based solid seif-lubricating composite material.

Owner:WUHAN UNIV OF TECH

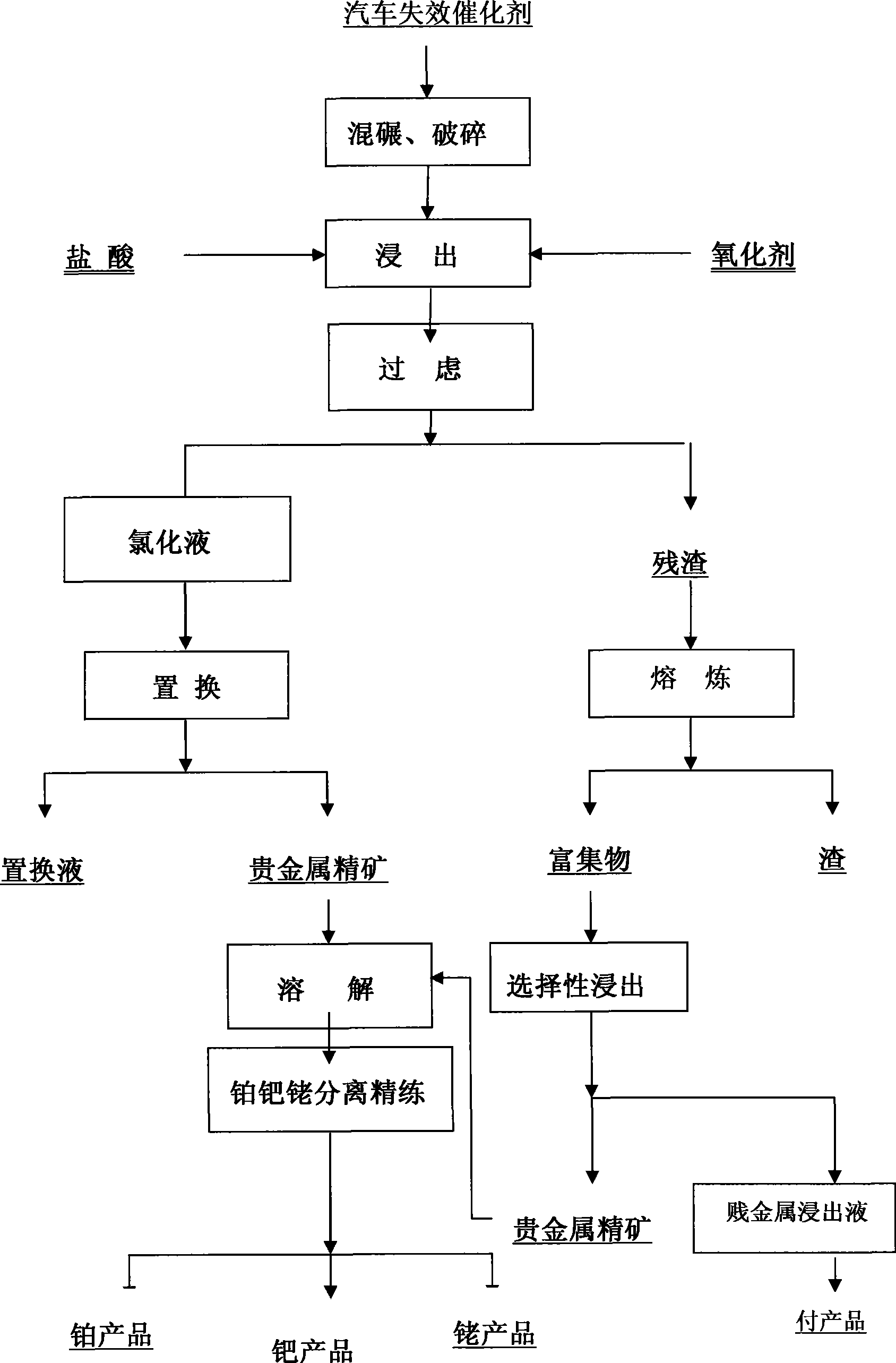

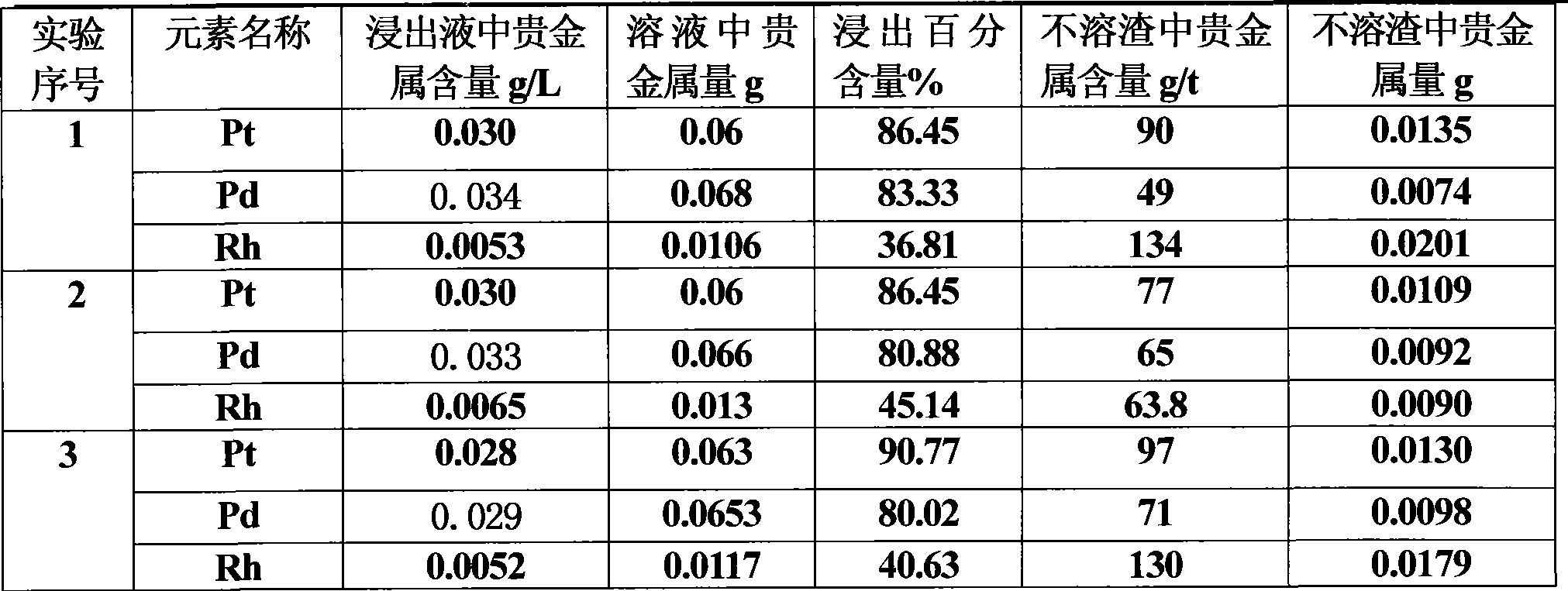

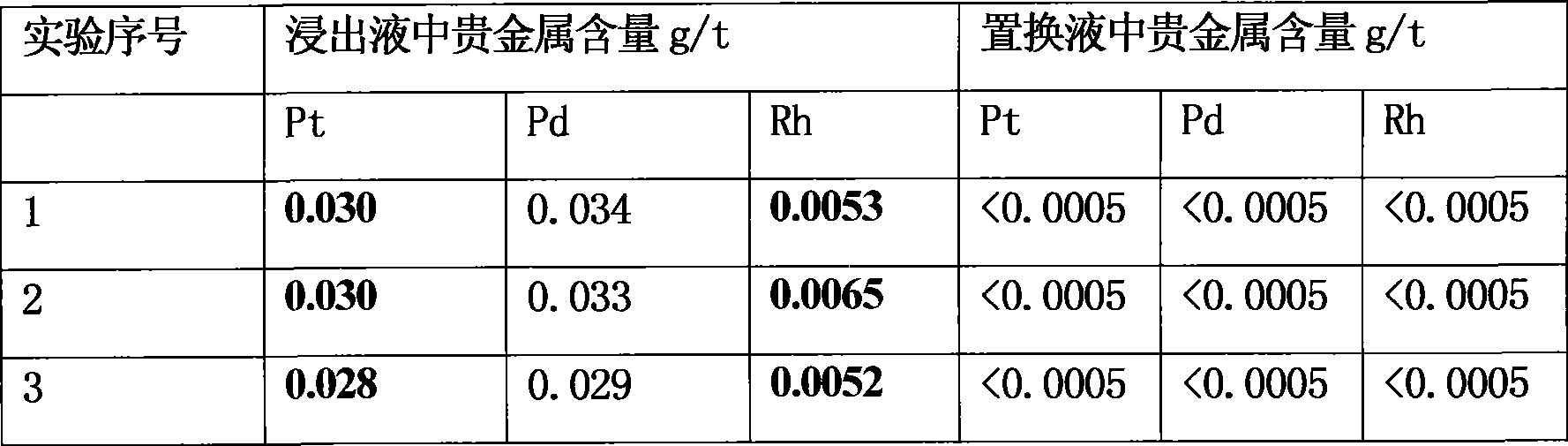

Method for extracting precious metal from auto-exhaust catalyst by hydrometallurgy and pyrometallurgy complex process

InactiveCN101519725ALoose process conditionsImprove leaching rateProcess efficiency improvementPregnant leach solutionPlatinum

The invention relates to a method for extracting precious metal from a disabled auto-exhaust catalyst, which comprises the following steps: 1. lixiviating precious metal from the disabled auto-exhaust catalyst by a hydrometallurgy process and obtaining precious metal concentrates after permuting lixivium; 2. lixiviating slag, collecting precious metal of the slag by a pyrometallurgy process to obtain a precious metal phase and selectively lixiviating base metal in the precious metal phase to obtain precious metal concentrates; and 3 combining the precious metal concentrates obtained in the first two steps and refining the precious metal concentrates to produce platinum, palladium and rhodium products. The invention compensates the deficiency that the percent recovery of the precious metal is low by simply treating the disabled auto-exhaust catalyst with the hydrometallurgy process and has the advantages that the contents of platinum, palladium and rhodium in the waste slag are smaller than 1g / t and the product purity reaches 99.95 percent.

Owner:KUNMING INST OF PRECIOUS METALS

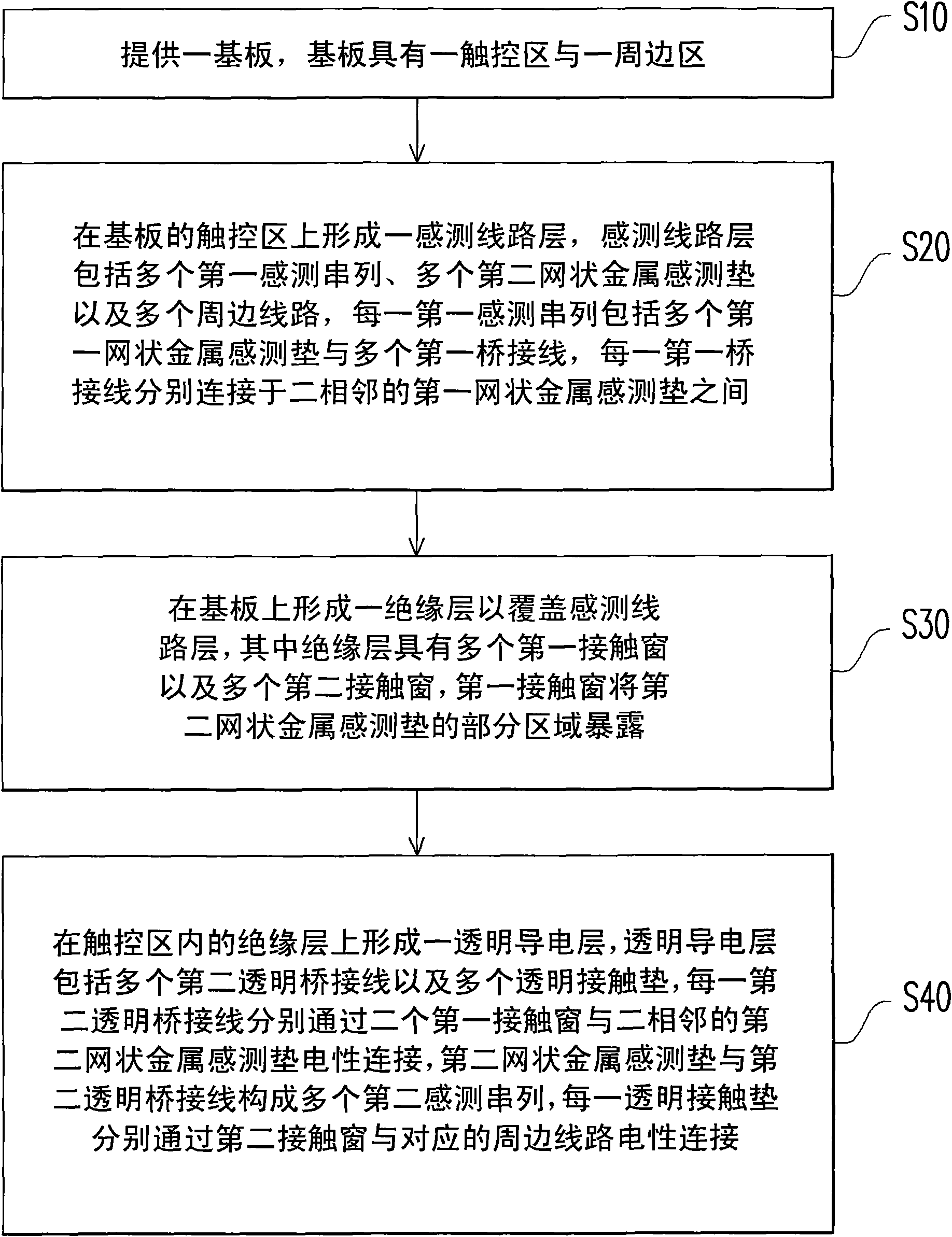

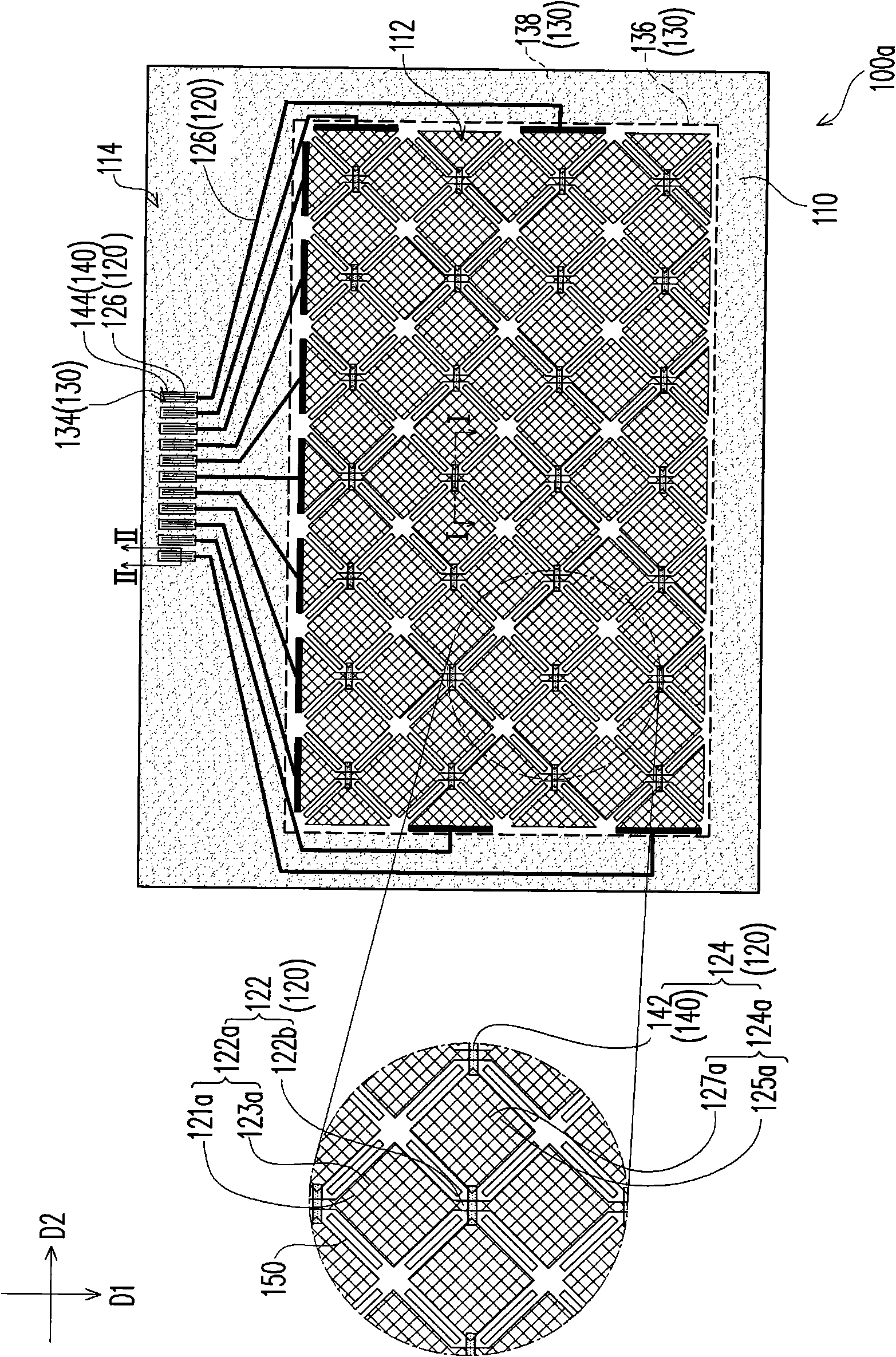

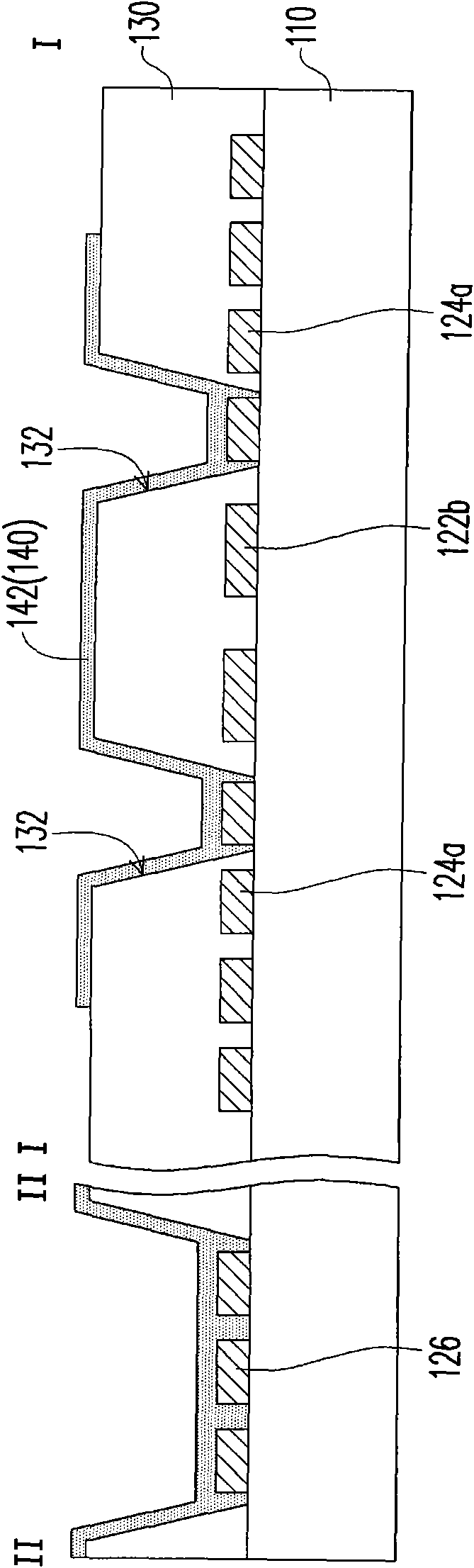

Method for manufacturing touch panel

ActiveCN101976146AImprove reliabilityPrevent oxidationInput/output processes for data processingContact padTouch panel

The invention relates to a method for manufacturing a touch panel, which comprises the steps of: providing a substrate with a touch area and a periphery area; forming a sensing circuit layer comprising a plurality of first sensing series, a plurality of second cellular metal sensing pads and a plurality of periphery circuits on a touch area of the substrate; forming an insulating layer provided with a plurality of first contact windows and a plurality of second contact windows on the substrate so as to cover the sensing circuit layer; exposing the partial areas of the second cellular metal sensing pads by the first contact windows; and forming a transparent conductive layer comprising a plurality of second transparent bridging lines and a plurality of transparent contact pads on the insulating layer in the touch control area of the substrate, wherein each second transparent bridging line is respectively and electrically connected with two adjacent second cellular metal sensing pads by two first contact windows, and each transparent contact pad is respectively and electrically connected with the corresponding periphery circuits by the second contact windows.

Owner:AU OPTRONICS CORP

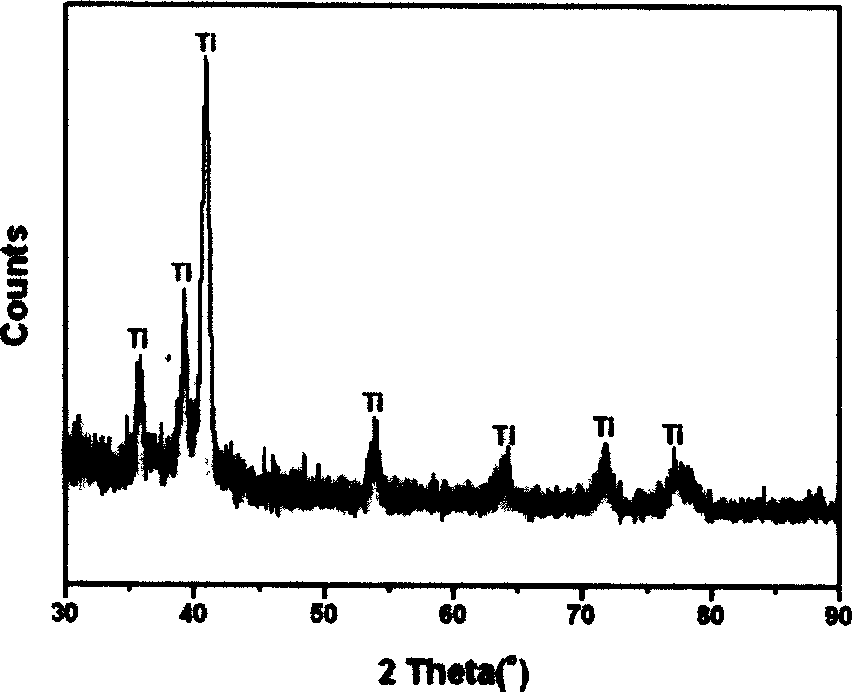

Process for anode oxidation coloration of titanium and titanium alloy surface

InactiveCN1844483ABright colorImprove the decorative effectSurface reaction electrolytic coatingTitaniumTitanium alloy

This invention relates to titanium and titanium alloy surface anode oxidation bepainting method. This invention has following steps: dealing with titanium and titanium alloy in alkali solution for 10-15min under 60-75deg C and ultrasonic condition, then rinsing, and then putting it in acid solution for 0.5-1min, and then rinsing, and then under the condition that the temperature is 15-35deg C, the current density is 5-10Am-2, the voltage is 20-90V, putting it in anode oxidation bepainting solution to bepaint for 15-30min,then rinsing, and then dealing with it closely for 15-30min in non-ionic water, and then drying for 30-60min under 110-130deg C. The advantage in this invention is that the steps are few, the operation is simple, and it is easy to maintain.

Owner:XIAMEN UNIV

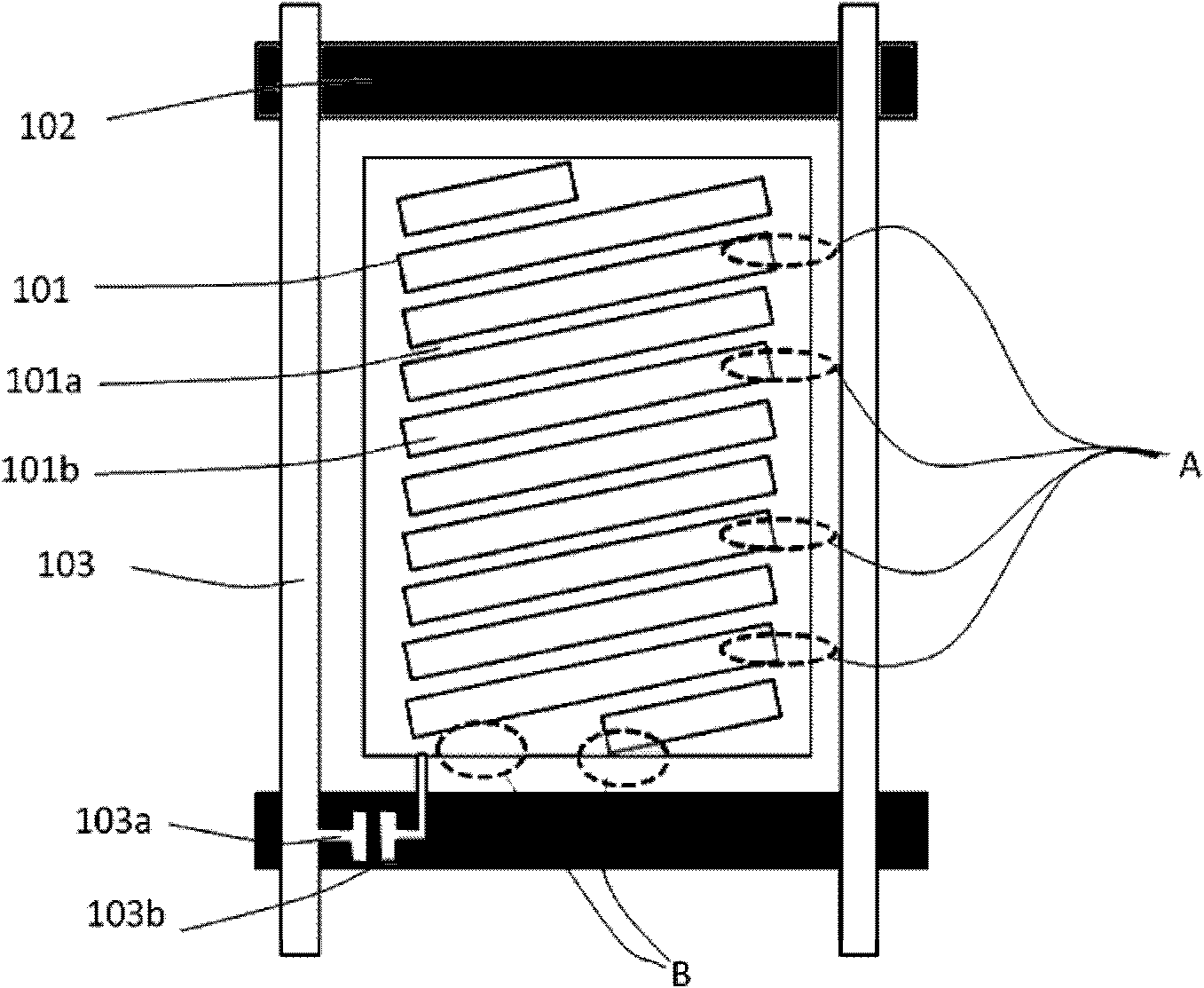

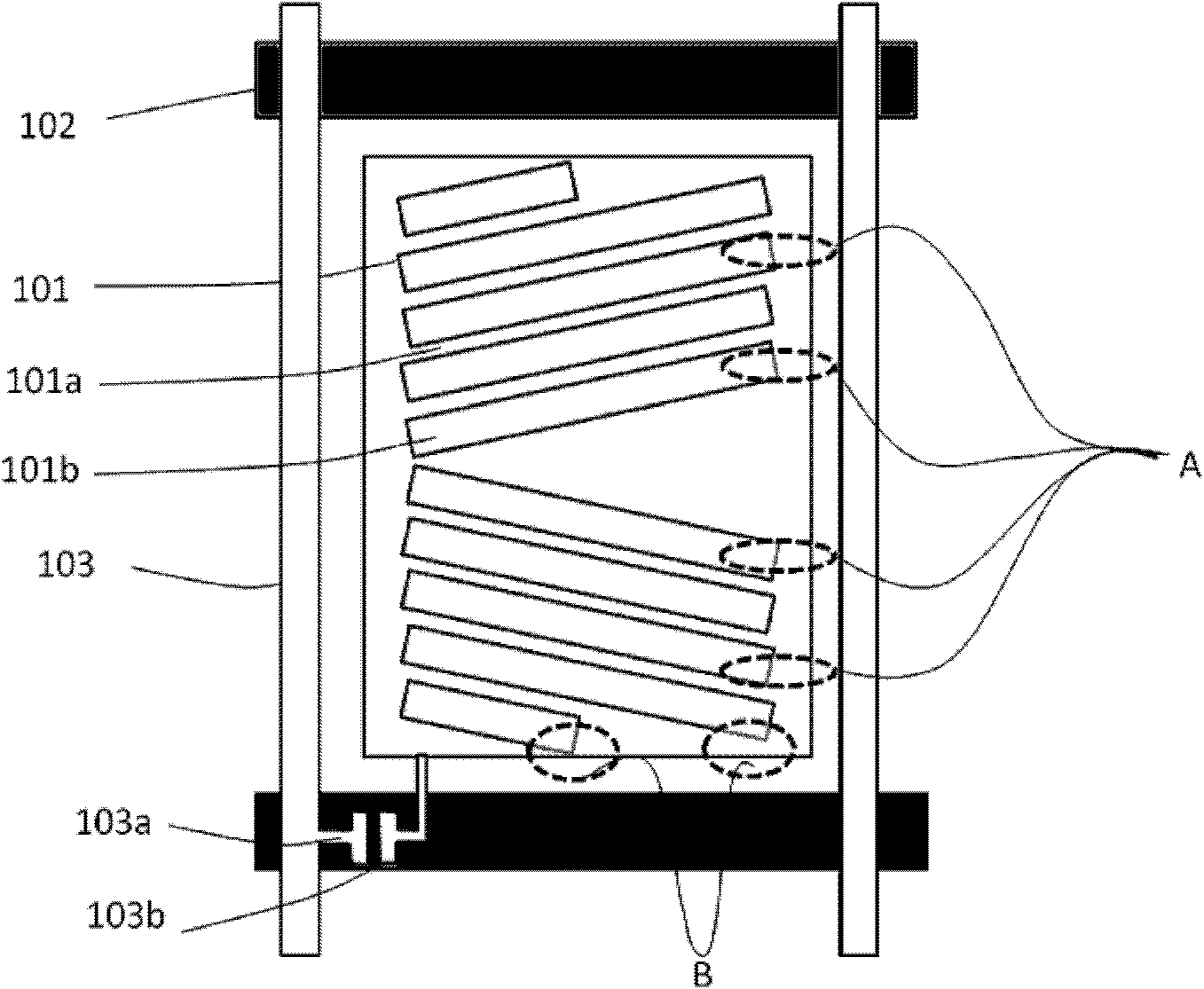

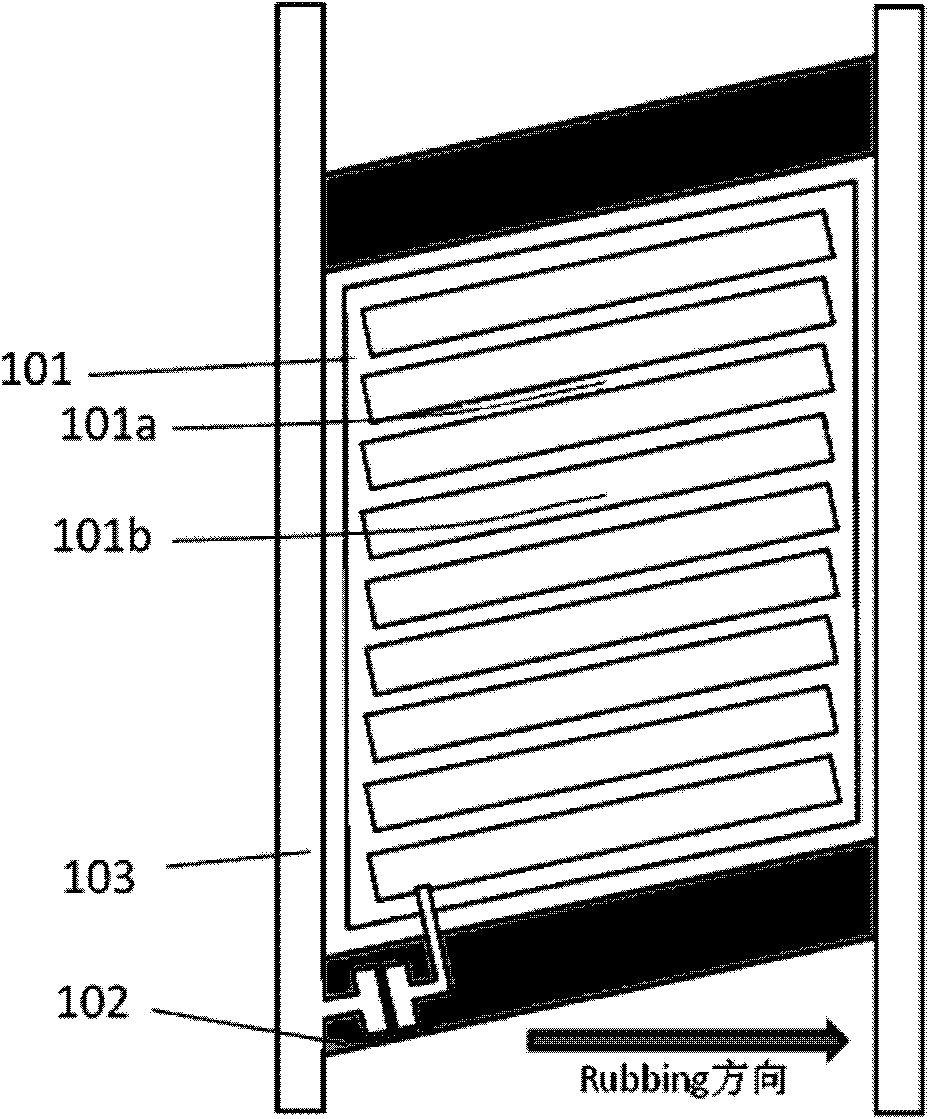

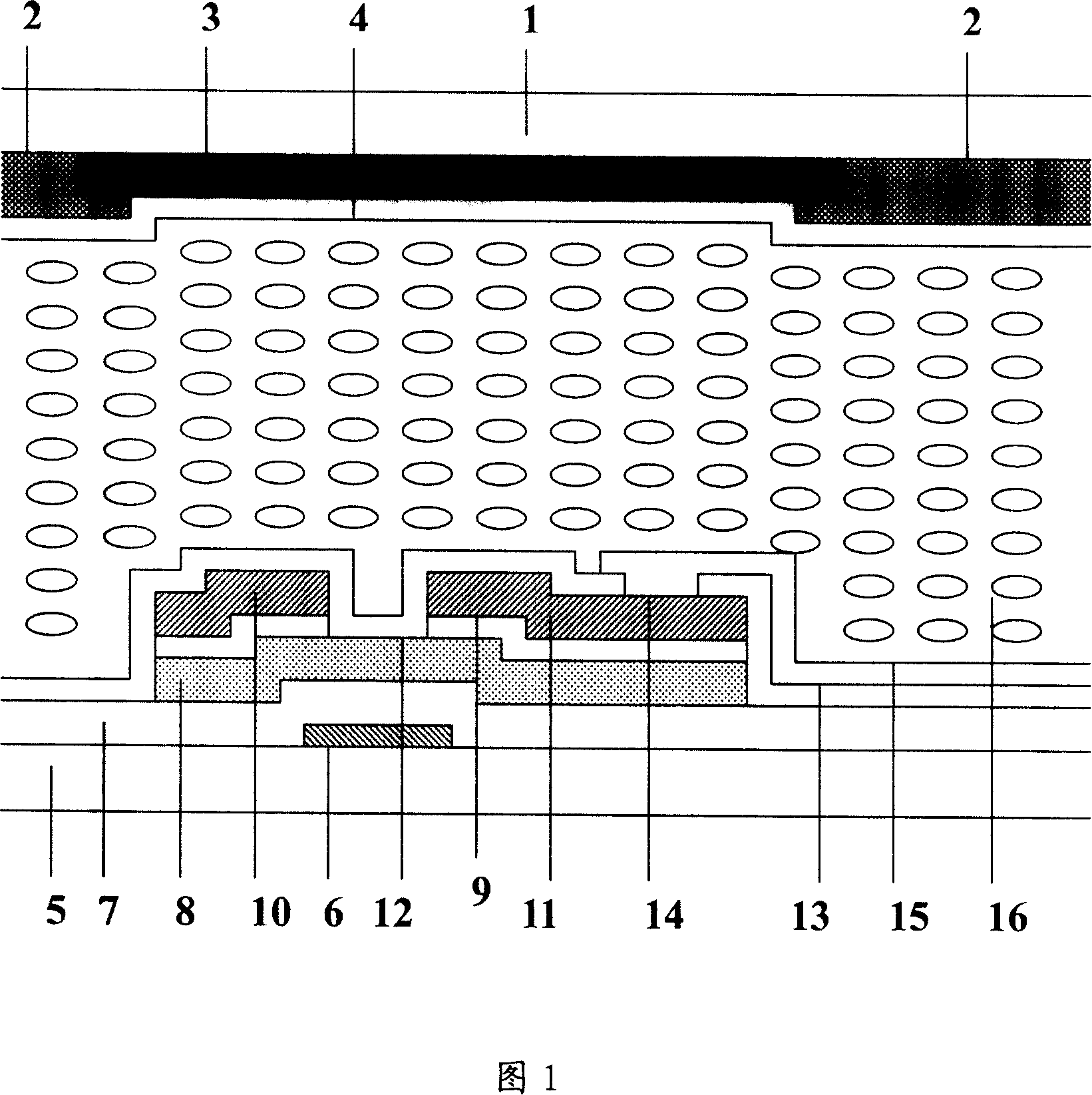

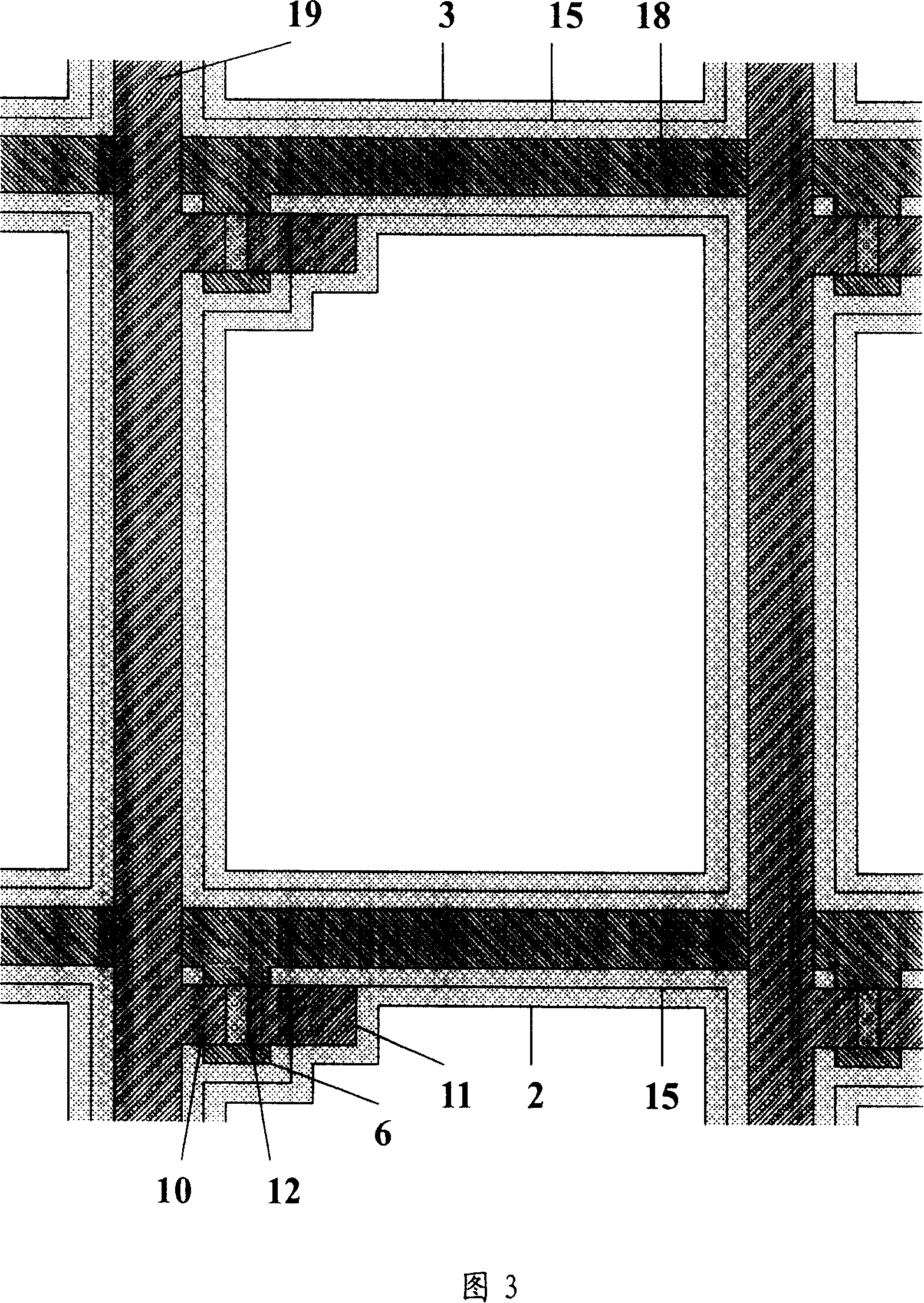

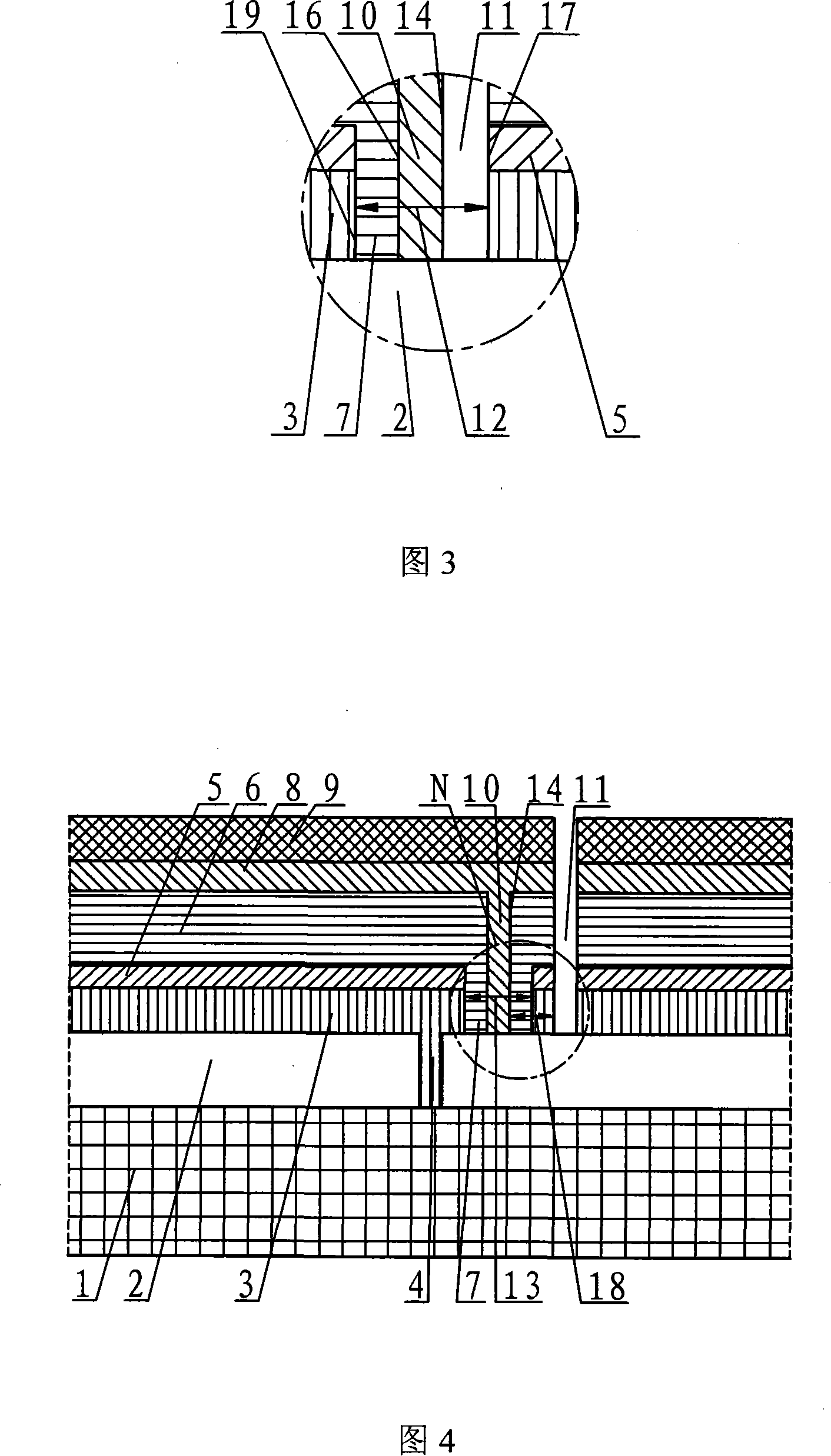

Liquid crystal display device with color film on thin-film transistor and its manufacture method

ActiveCN101149541AEliminate light leaksReduce process stepsSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusGratingBaseboard

This invention discloses a sort of liquid crystal display that the chromatic film is above the thin film transistor, and it consists of the nether baseboard, the grating line, the grating pole, the thin film transistor is formed above the grating pole, the data wire, the power pole which connects with the data wire and the corresponding leakage pole are formed above the thin film transistor, the deactivation protective foil is formed above the channel of the thin film transistor, and it has the bore in the part which is corresponds to the leakage pole, the black matrix is formed above the deactivation protective foil, and it has the bore in that bore position, the hatch of the black matrix corresponds to the picture element area, the chromatic filter layer is formed in the hatch of the black matrix, a picture element pole is formed above the chromatic filter layer, and it connects with the leakage pole by the bore, the upper baseboard, the common pole which is formed above the nether baseboard, a liquid molecule layer is formed between the upper baseboard and the nether baseboard. This invention discloses the manufacturing method of this crystal display at the same time. This invention advances the penetrant rate and the hatch rate of the liquid crystal display, and it predigests the technique.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD +1

Novel method for separating gold and silver from gold mud

InactiveCN101451190AReaction is easy to controlReduce process stepsProcess efficiency improvementFilter cakeSodium chlorate

The invention provides a novel method for separating gold and silver from gold slime, which comprises: wet gold slime is subjected to one-step chloridizing leaching and filtered; filtrate is a gold-containing solution, and filter cakes are silver chloride deposit; the gold-containing solution is reduced to obtain gold powder which is then smelted into gold ingots; and the filter cakes, namely the silver chloride deposit, are converted into coarse silver powder which are then smelted into silver ingots. The method adopts one-step chloridizing gold leaching reaction to overcome the defect of large metal loss due to long pretreatment flow of the gold slime and high frequency of filtration reaction in the prior art, only uses a hydrochloric acid and sodium chlorate during chloridizing and gold leaching, is easy to control the reaction, removes the process of pre-leaching the gold slime and removing impurities in the prior art, removes multi-step reduction, reduces the processing step, greatly reduces the discharge amount of wastewater, reduces the heating duration, saves the cost of water and electricity, and improves the recovery rate of the gold and the silver and the quality of the gold ingots and the silver ingots.

Owner:LINGBAO CITY JINYUAN MINING

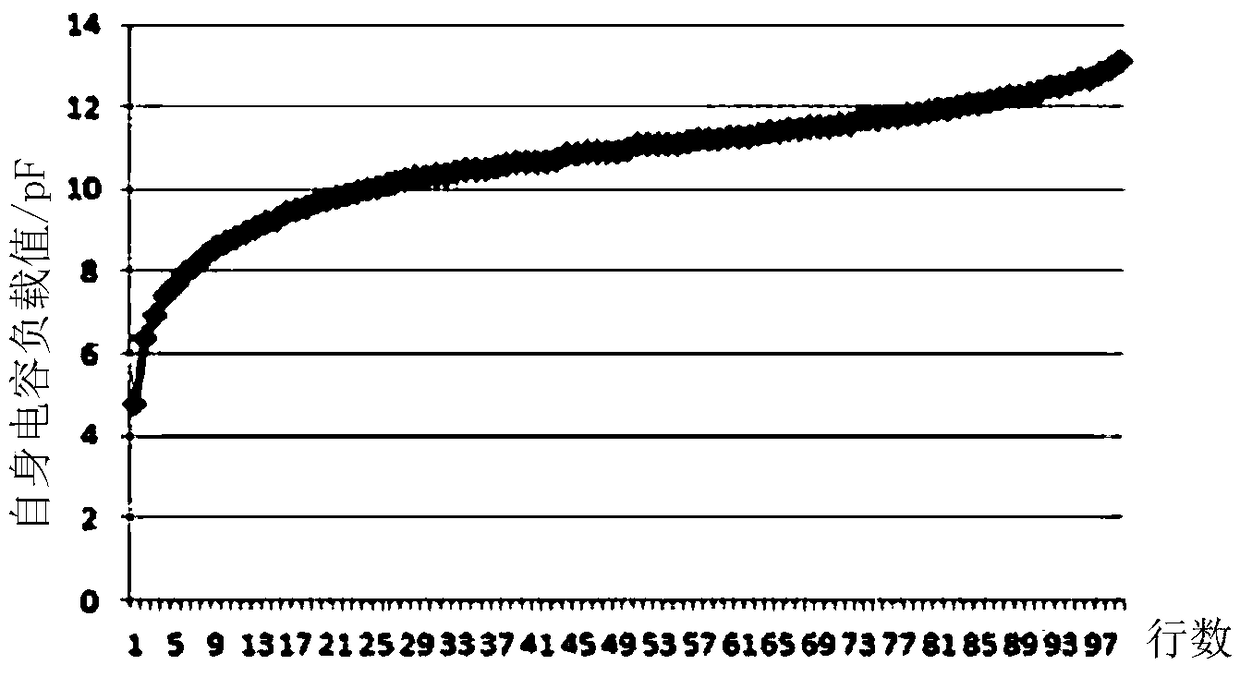

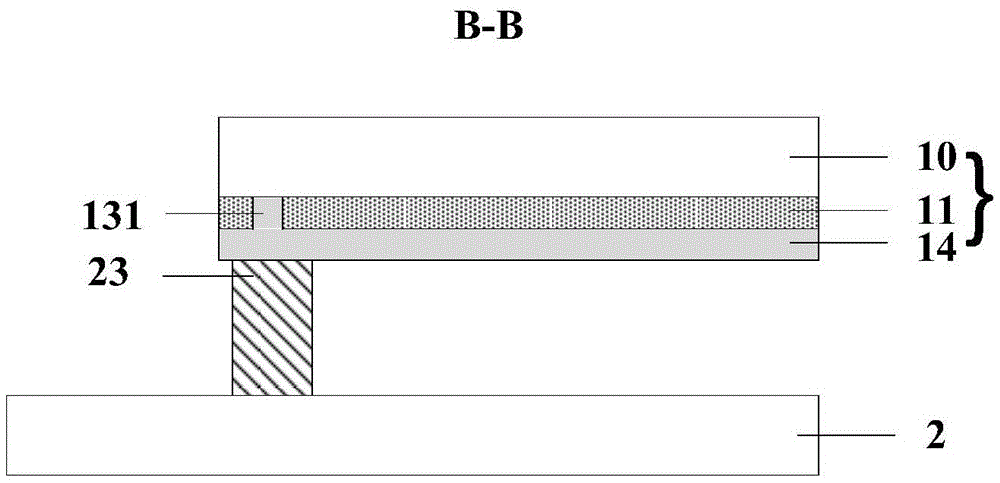

Display device and display panel

InactiveCN109061975AReduce areaIncrease the proportionStatic indicating devicesSolid-state devicesCapacitanceScan line

The invention provides a display device and a display panel. A standard of carrying out capacitor compensation on each line of scan lines of a first display area with relatively few pixel units comprises the fact that a capacitor total load value of the line of scan lines adjacent to a second display area is equal to own capacitor load value of a line of scan lines in the second display area, andthe capacitor total load value of each line of scan lines close to the second display area and the capacitor total load value of each line of scan lines away from the second display area are graduallyreduced. The display device and the display panel have the advantages that through utilization of the feature that human eyes are insensitive to gradually varied brightness variation, mutation of thecapacitor total load value of each line of compensated scan lines in the first display area and at the border of the first display area and the second display area is eliminated, so the display is uniform; and through gradual variation of the capacitor total load values in the first display area, a setting area of compensation capacitors is reduced, reduction of the area of a frame area is facilitated, a narrow frame is realized, and a screen-to-body ratio is increased.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

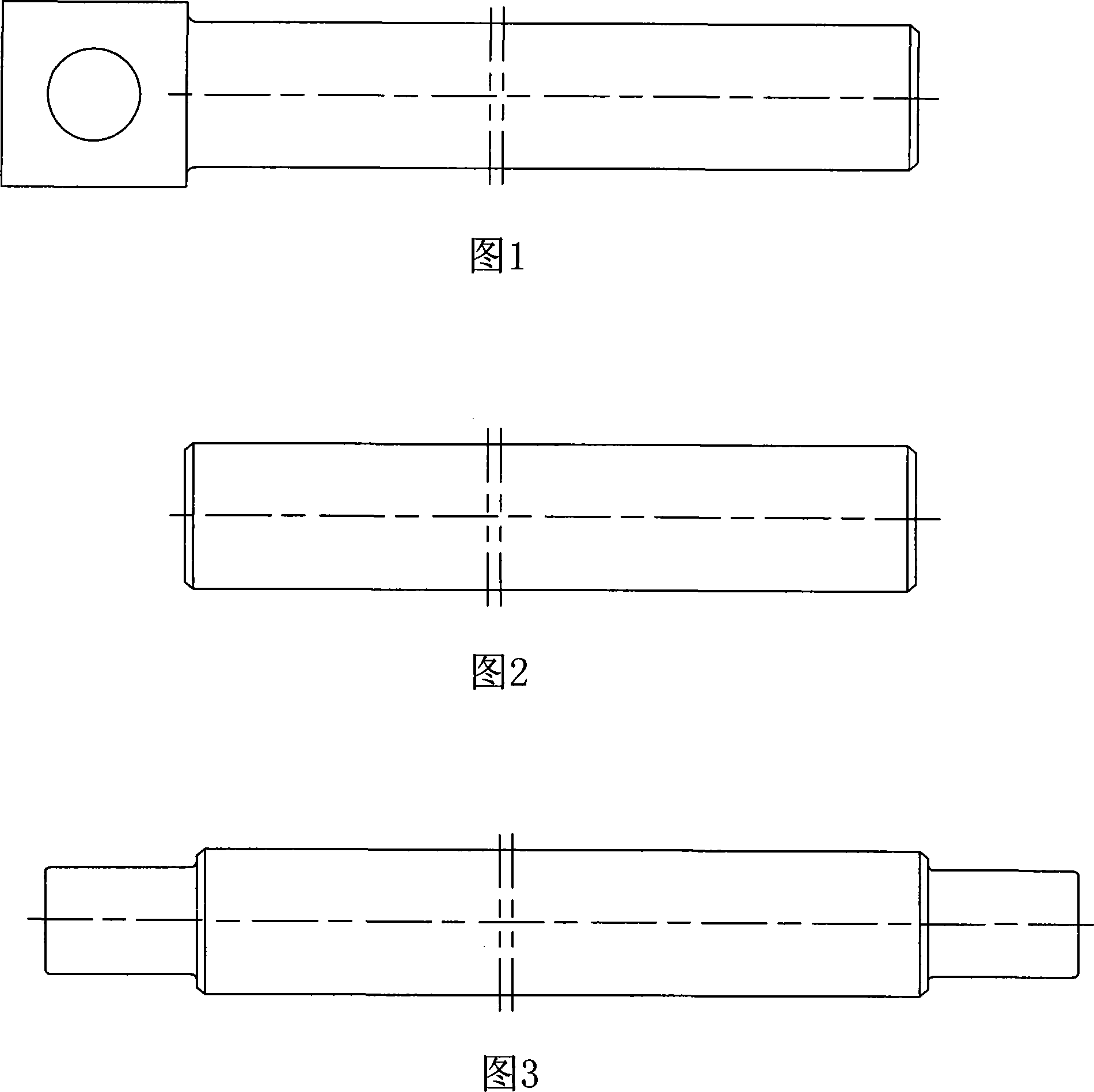

Roller and producing technique

The invention relates to the field of steel rolling machinery, in particular to a roller and a production process for the roller which is made of W6Mo5Cr4V2 high speed steel; the production process comprises the following steps: a. material preparation; b. the processing of two end faces of blanks; c. the processing of central holes of two ends; d. the processing of rough turn; e. the drilling of hoisting holes outside the length of finished products; f. carrying out quenching and tempering treatment to cause the roller hardness to reach 40 to 50 HSD; g. the modification of the central holes of the two ends; h. the processing of half finish turning; i. coarse grinding of the roller body; j. carrying out quenching and tempering treatment to lead the surface of the roller body to reach the quenching hardness of 88 to 93 HSD; k. the processing of the lengths of the two ends to required sizes; l. the processing of finish turning; m. the coarse grinding of the roller body and a roller neck; n. stress relief treatment; o. the repairing of the central holes of the two ends; p. fine grinding of the roller body and the roller neck; q. super grinding of the roller body and the roller neck to finished products. The roller and the production process thereof solves the problem of big size, high production cost, tedious process and great production difficulty of rollers which are produced with conventional materials.

Owner:CHANGZHOU ECCO ROLLER

Color film substrate, display panel and display device

InactiveCN105607332ANo problems with mechanical damageAvoid enteringNon-linear opticsColor filmDisplay device

The invention belongs to the technical field of display, and particularly relates to a color film substrate, a display panel and a display device, wherein the color film substrate comprises a conducting layer positioned at the color film side of the color film substrate; an isolation belt used for isolating external static electricity is arranged on the periphery of the conducting layer; a notch is formed in the isolation belt; extending parts used for outputting static electricity are arranged on the inner side conducting layer on the inner sides of the isolation belt; the extending parts extend to the edge of the color film substrate through the notch. According to the color film substrate, the display panel and the display device, the conducting layer and the isolation belt are arranged at the color film side of the color film substrate, so that the problem in the prior art of static electricity accumulation due to external static electricity's entry into the display device through an ITO thin film prone to mechanical damage is effectively solved.

Owner:BOE TECH GRP CO LTD +1

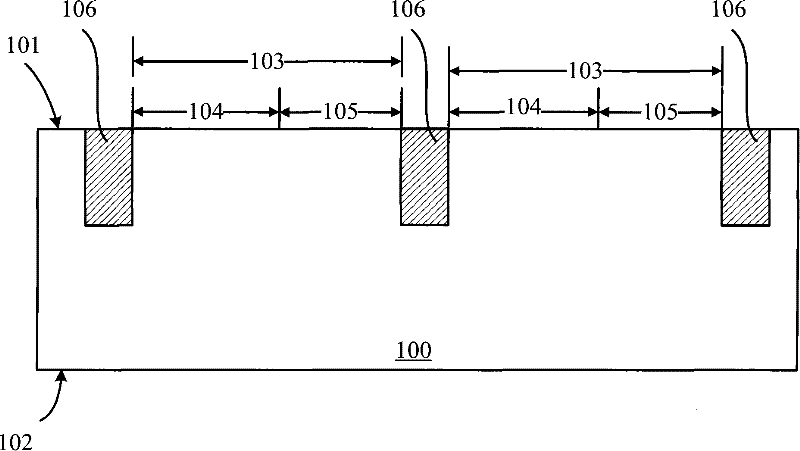

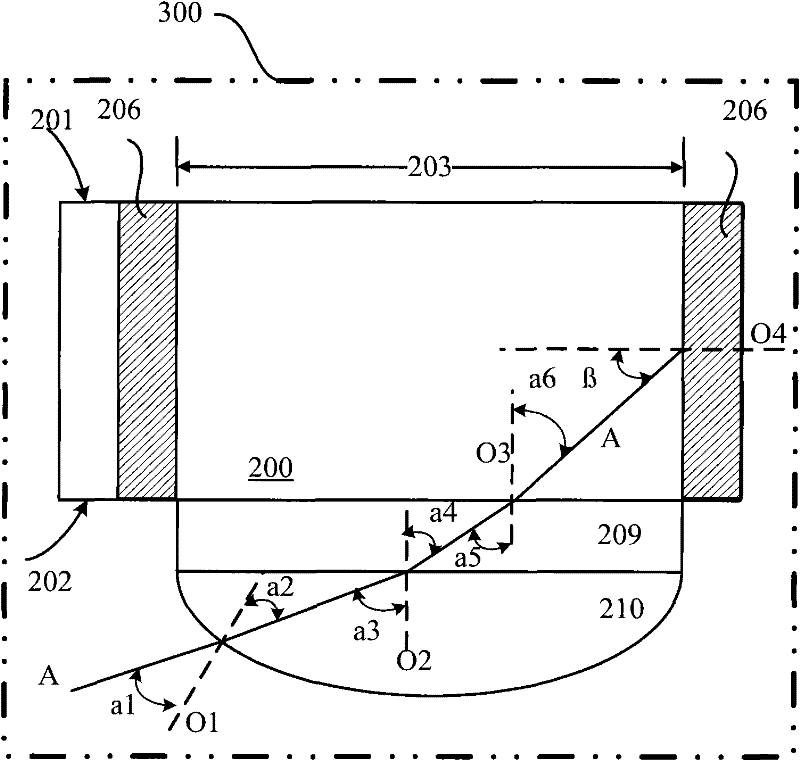

backside illuminated cmos image sensor

InactiveCN102270646APrevent proliferationReduce crosstalkRadiation controlled devicesCMOSImaging quality

The present invention provides a backside illuminated CMOS image sensor, comprising: a semiconductor substrate having a first surface and a second surface opposite thereto; the semiconductor substrate includes at least one pixel unit region; an isolation structure located at Between adjacent pixel unit regions; wherein, the isolation structure is a deep trench isolation structure, and the deep trench isolation structure penetrates the first surface and the second surface of the semiconductor substrate. The invention reduces the crosstalk of electrical signals between adjacent pixel unit areas, improves the display fading of CMOS image sensors, and improves the imaging quality.

Owner:GALAXYCORE SHANGHAI

Color film substrate, array substrate and display device

ActiveCN103955679AReduce thicknessReduce volumePrint image acquisitionInput/output processes for data processingColor filmDisplay device

Provided are a color film substrate, an array substrate and a display device. The color film substrate or the array substrate comprises a substrate body and a fingerprint sensing layer, wherein the substrate body is provided with a display area and a non-display area; and the fingerprint sensing layer is located in the non-display area and used for sensing and recognizing fingerprints. The color film substrate further comprises a color film layer, and the color film layer is arranged in the display area and used for filtering the color of light. The color film substrate or the array substrate integrates the fingerprint sensing layer, and accordingly the display device adopting the color film substrate or the array substrate has a fingerprint sensing and recognizing function; besides, due to the fact that the fingerprint sensing layer is integrated on the substrate body of the color film substrate or the array substrate, the thickness of the display device is not increased, and the cost of the display device is reduced.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

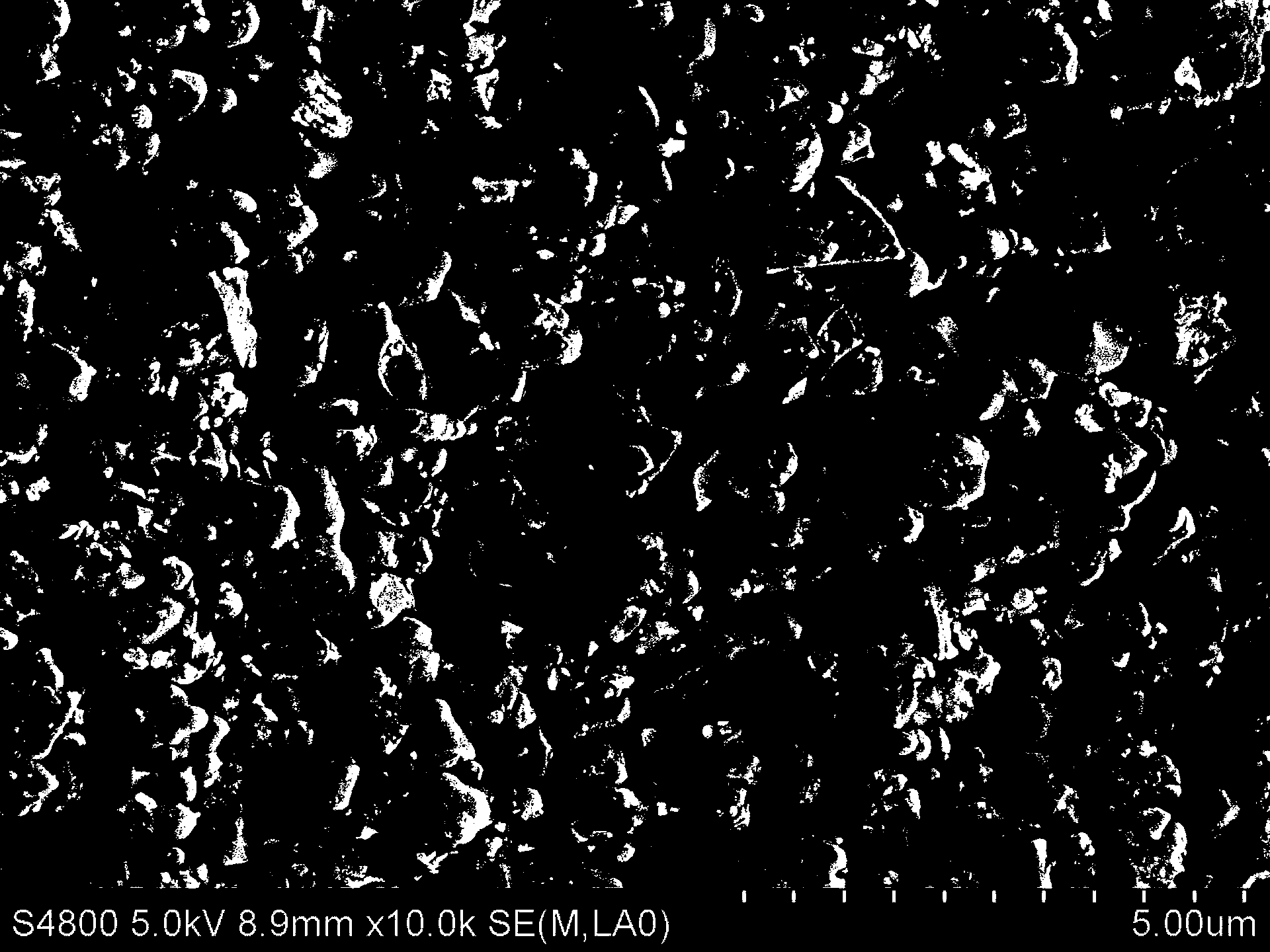

Method for preparing graphene oxide

ActiveCN103332670AReduce the introductionLower the activation energy of chemical reactionsCarbon compoundsStrong acidsEnergy expenditure

The invention discloses a method for preparing a graphene oxide. The graphene oxide is prepared from a graphite raw material in a mode that mechanical action and oxidation reaction are combined. The method comprises the following steps of: mixing an oxidant with the graphite raw material, subsequently preparing the graphene oxide by employing mechanical action, adding the oxidant after the graphite raw material is subjected to mechanical action so as to prepare the graphene oxide, and adding the oxidant after the graphite raw material is subjected to mechanical action so as to carry out oxidation reaction and prepare the graphene oxide. According to the method, strong acids and strong oxidants required in a chemical oxidation method are abandoned, so that the introduction of byproducts and impurities is greatly reduced, the separation and the purification are convenient, the process procedures are reduced, the treatment time of a mechanical milling method is shortened, the energy consumption is reduced, and the yield is greatly increased. With the combination of the two methods, the graphene oxide can be prepared at one step within the shortest time, the yield is greater than 20%, the graphite oxide can be stably suspended under a centrifugal condition of 16,000rpm without ultrasound, and the method has the characteristics of rapidness, simplicity, convenience, environmental-protection and efficiency.

Owner:CHONGQING JIAOTONG UNIVERSITY

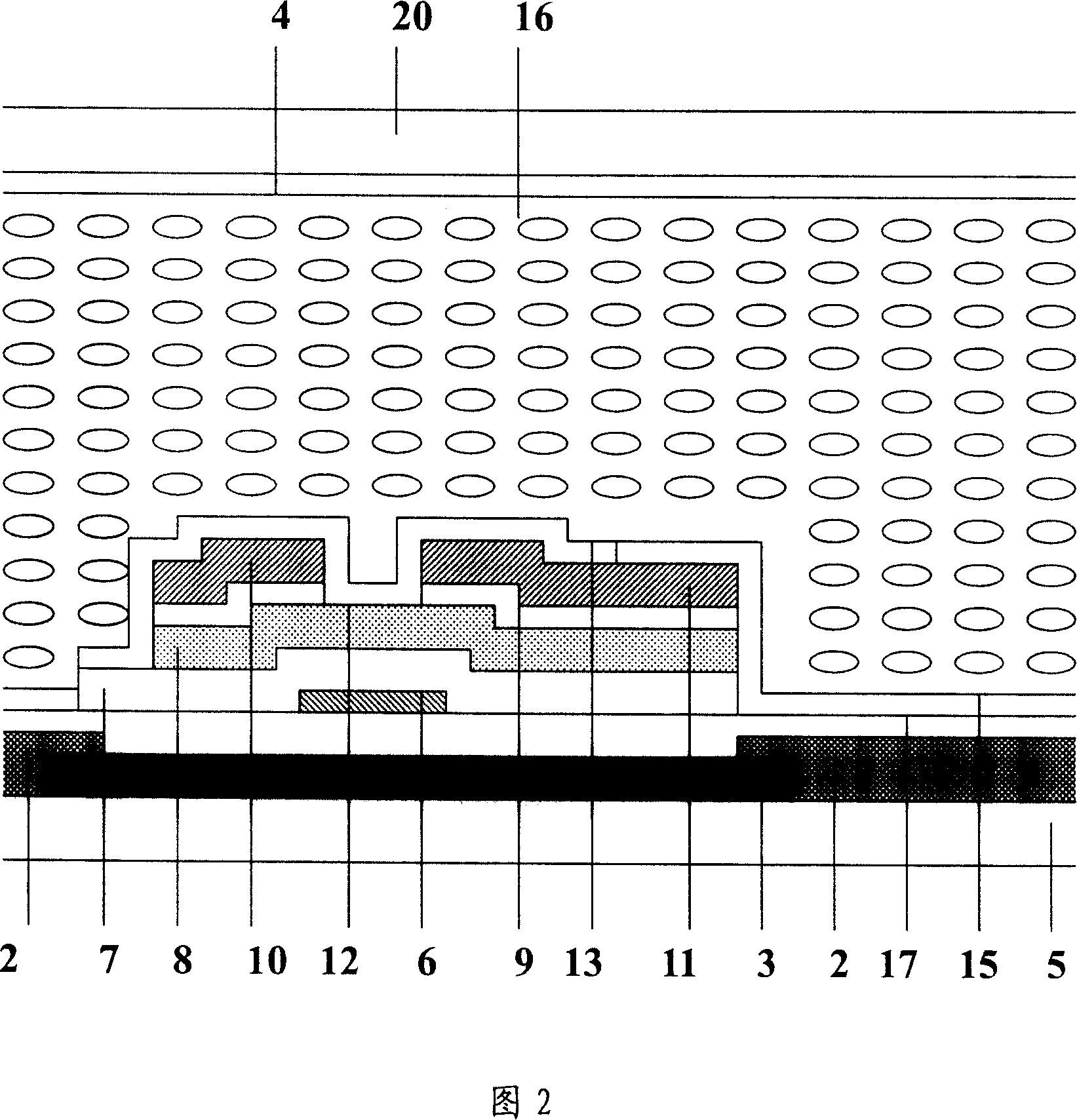

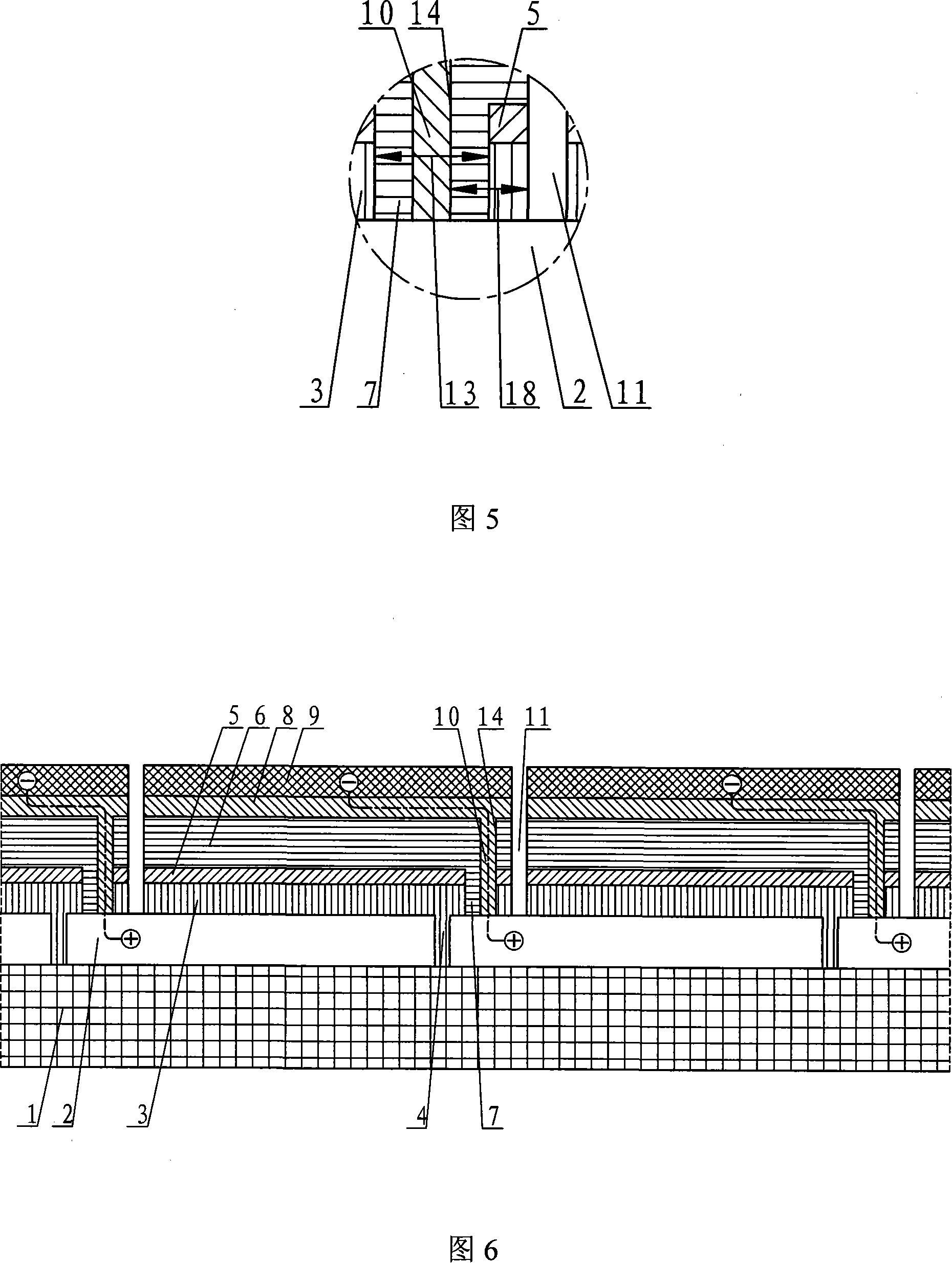

Liquid crystal display device with thin-film transistor on color film and its manufacture method

ActiveCN101149546AImprove transmittanceHigh light transmittanceSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusTectorial membraneGrating

This invention discloses a sort of liquid crystal display that the thin film is above the chromatic film, and it consists of the nether baseboard, the black matrix which is formed under the nether baseboard, the chromatic filter layer which is formed in the hatch of the black matrix and corresponds to the picture element area, the over protective film which is formed above the chromatic filter layer and the black matrix, the grating line and the grating pole which is formed above the over protective film, the thin film transistor which is formed in the grating pole, the data wire and the power pole and the leakage pole are formed above the thin film transistor, the deactivation protective layer which is formed above the area of the leakage and the other exceptant part of the picture element area, the picture element pole which is formed above the picture element area and the over protective film, and it contacts with the part of the leakage pole, the upper baseboard, the common electric pole which is formed above the upper baseboard, the liquid crystal molecular layer which is formed between the upper baseboard and the nether baseboard. This invention advances the penetrant rate and the hatch rate of the liquid crystal display, and it predigests the technique.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD +1

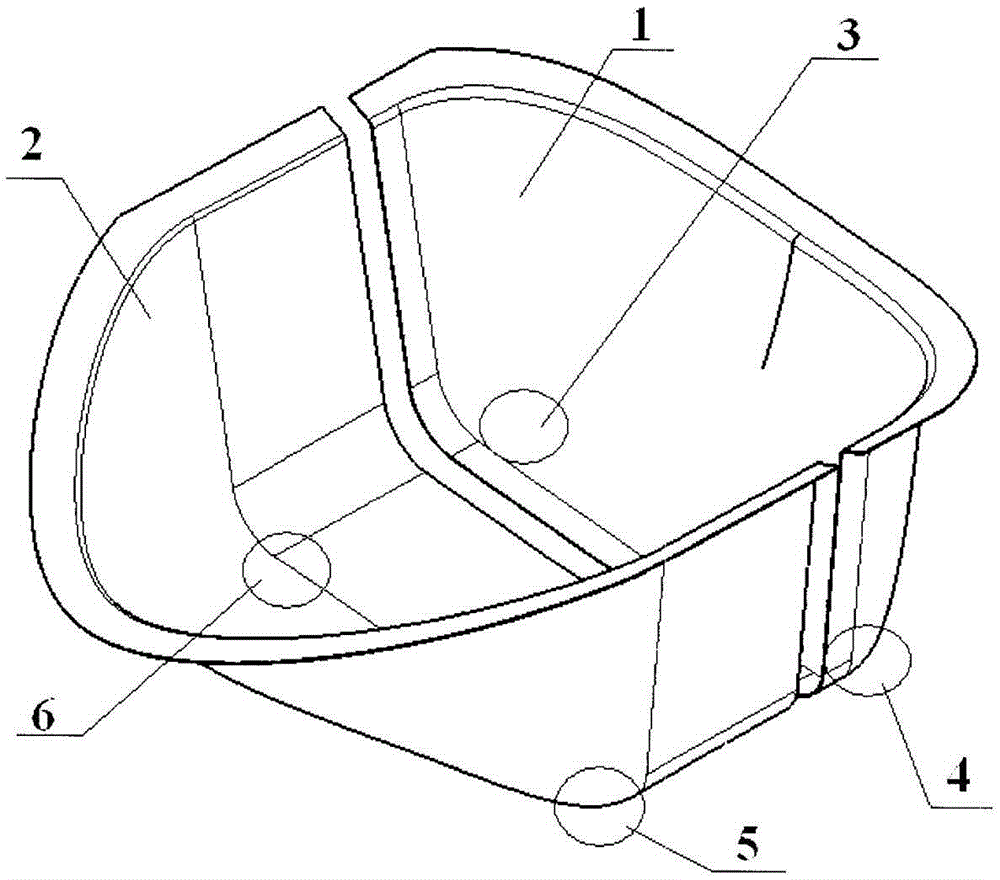

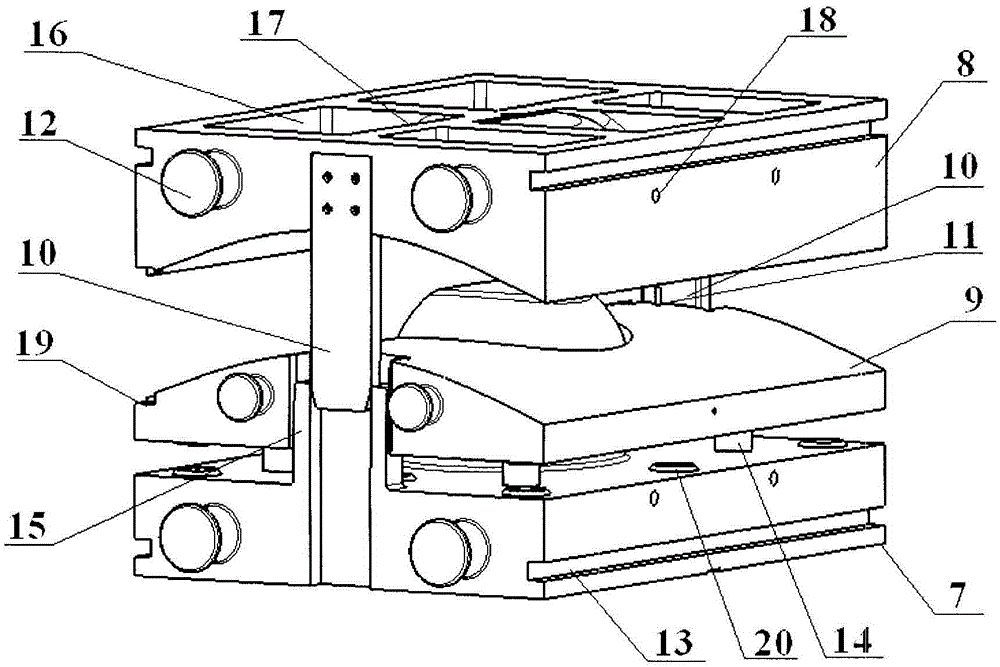

Isothermal forming die of large-curvature titanium alloy covering part and forming method of isothermal forming die

ActiveCN105344819AQuality improvementImprove processing qualityShaping toolsMetallurgyTitanium alloy

The invention relates to an isothermal forming die of a large-curvature titanium alloy covering part. The structure of the isothermal forming die is as follows: a blank holder is arranged between a convex die and a concave die; the lower surface of the blank holder is matched with the molded surface of the convex die; the upper surface of the blank holder is matched with the molded surface of the lower surface of the concave die; the bottom surface of the blank holder is connected with the upper surface of the convex die through a push rod; a limiting groove is formed in the side face of the blank holder and is in sliding connection with the outer edge of a guide structure on the convex die; the upper surface of the blank holder fits the lower surface of the concave die; a guide plate is arranged at the lateral end of the concave die and is in sliding connection with an inner edge groove of the guide structure; a straight pin is arranged on the upper surface of the blank holder and is positioned in a limiting hole of the concave die. The isothermal forming die of the large-curvature titanium alloy covering part provides the effective die for preliminary isothermal forming steps and ensures the final forming of the large-curvature titanium alloy covering part; in addition, according to a forming method of the isothermal forming die, the processing steps of isothermal forming and superplastic forming are sequentially adopted, so that a formed hypocrateriform part is uniform in wall thickness and meets the technical requirements.

Owner:SHENYANG AIRCRAFT CORP

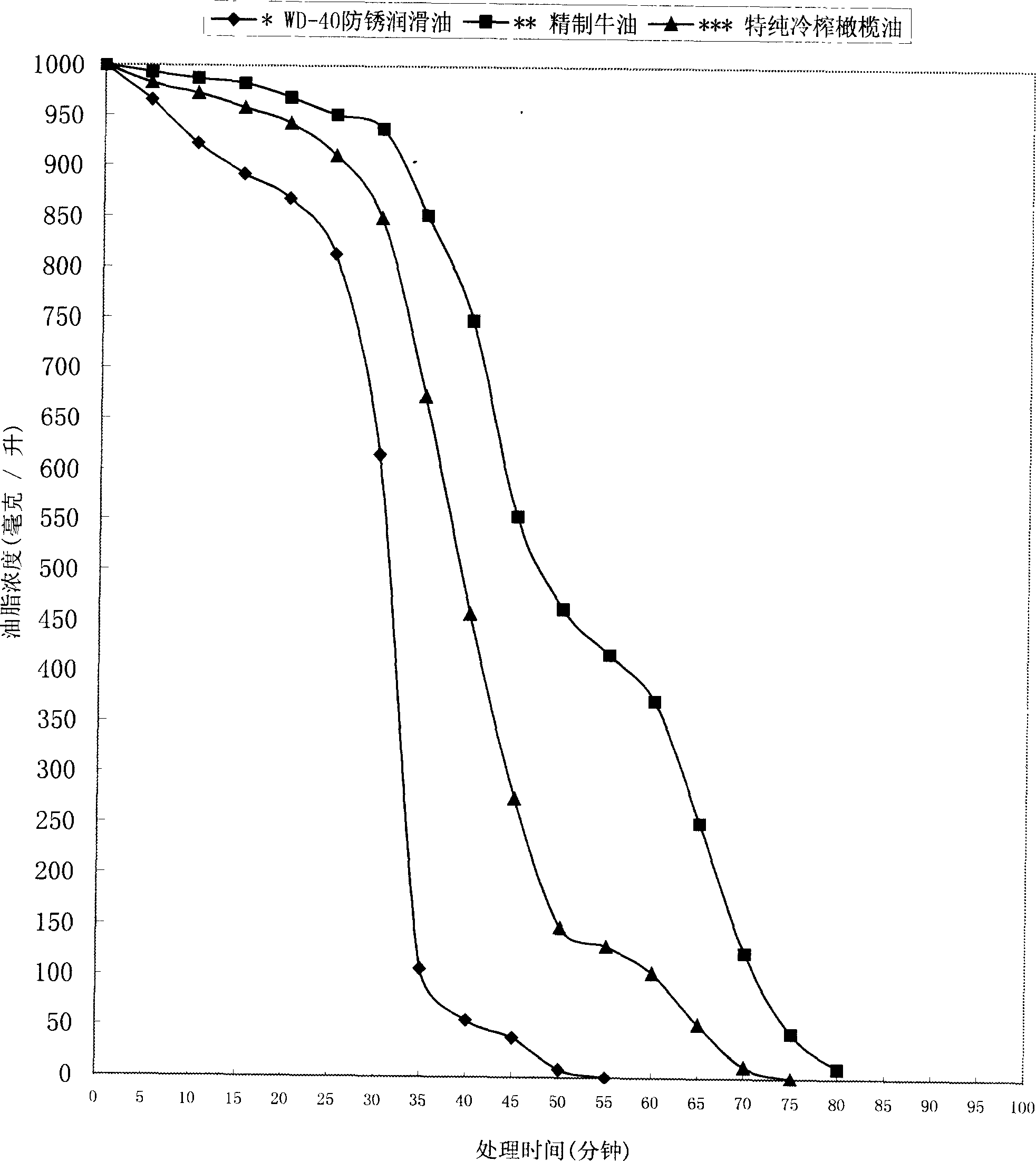

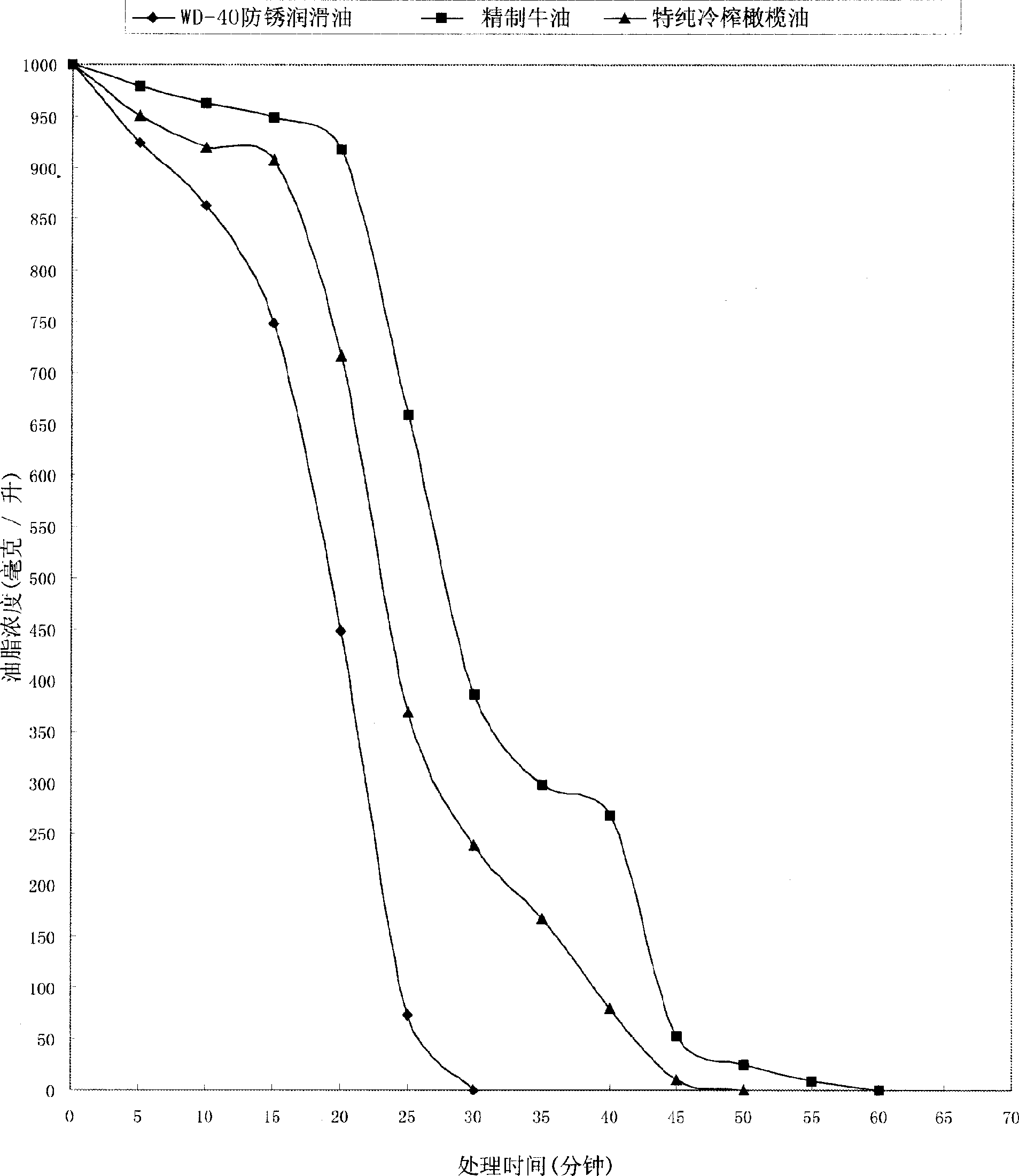

Biological degreasing agent used in metal processing pretreatment of oil removing and degreasing, and method for processing metal surface greasy dirt

The invention discloses a biological degreaser for degreasing pretreatment in metal processing industry and method for processing greasy dirt on metal surfaces, which integrates the two independent processes of grease removing and greasy dirt decomposing, the biological degreaser containing oil-degraded microorganisms can not only scale off greasy dirt from metal surfaces, but also decompose the greasy dirt simultaneously.

Owner:TANTZ ENVIRONMENTAL TECH

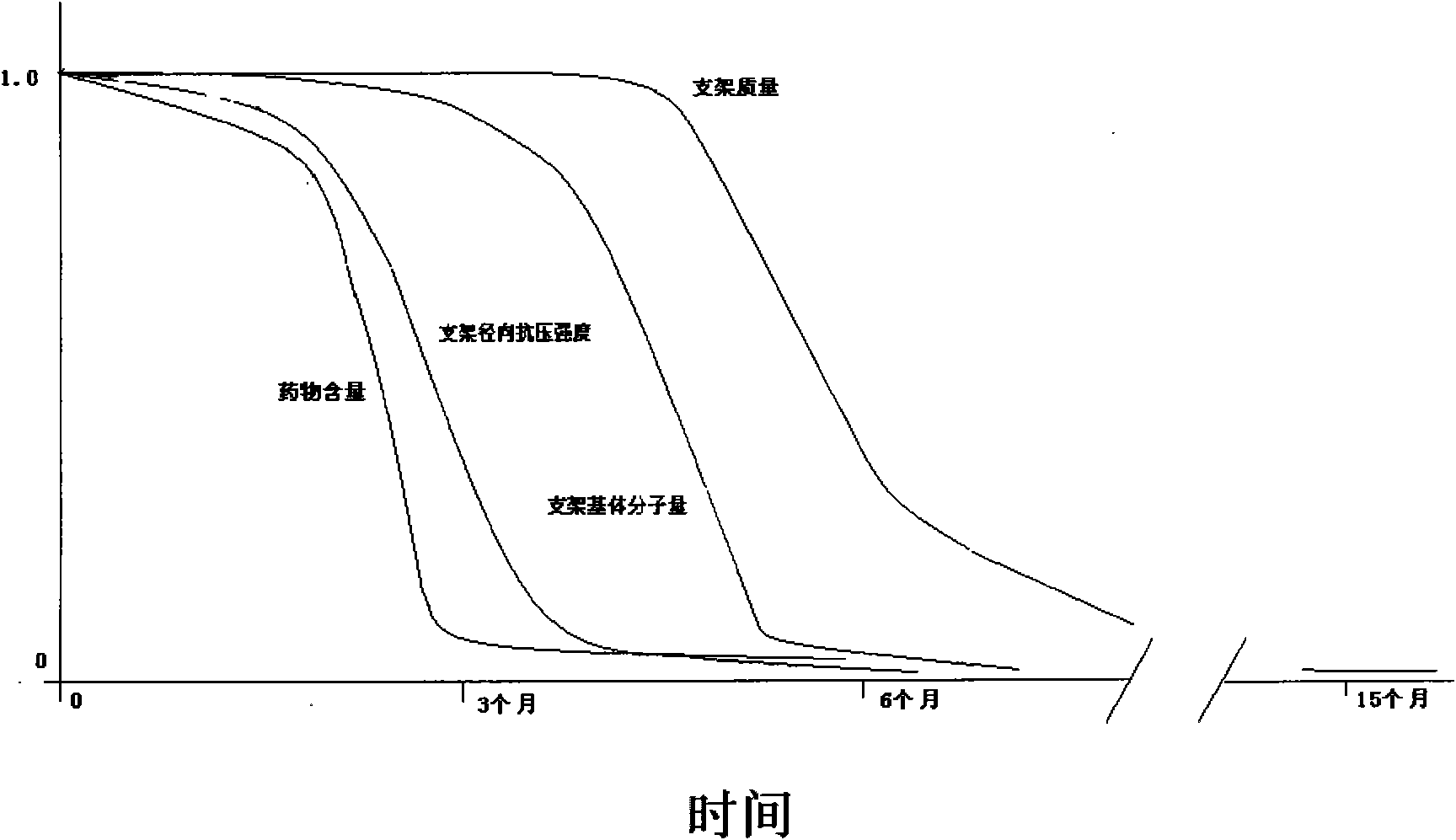

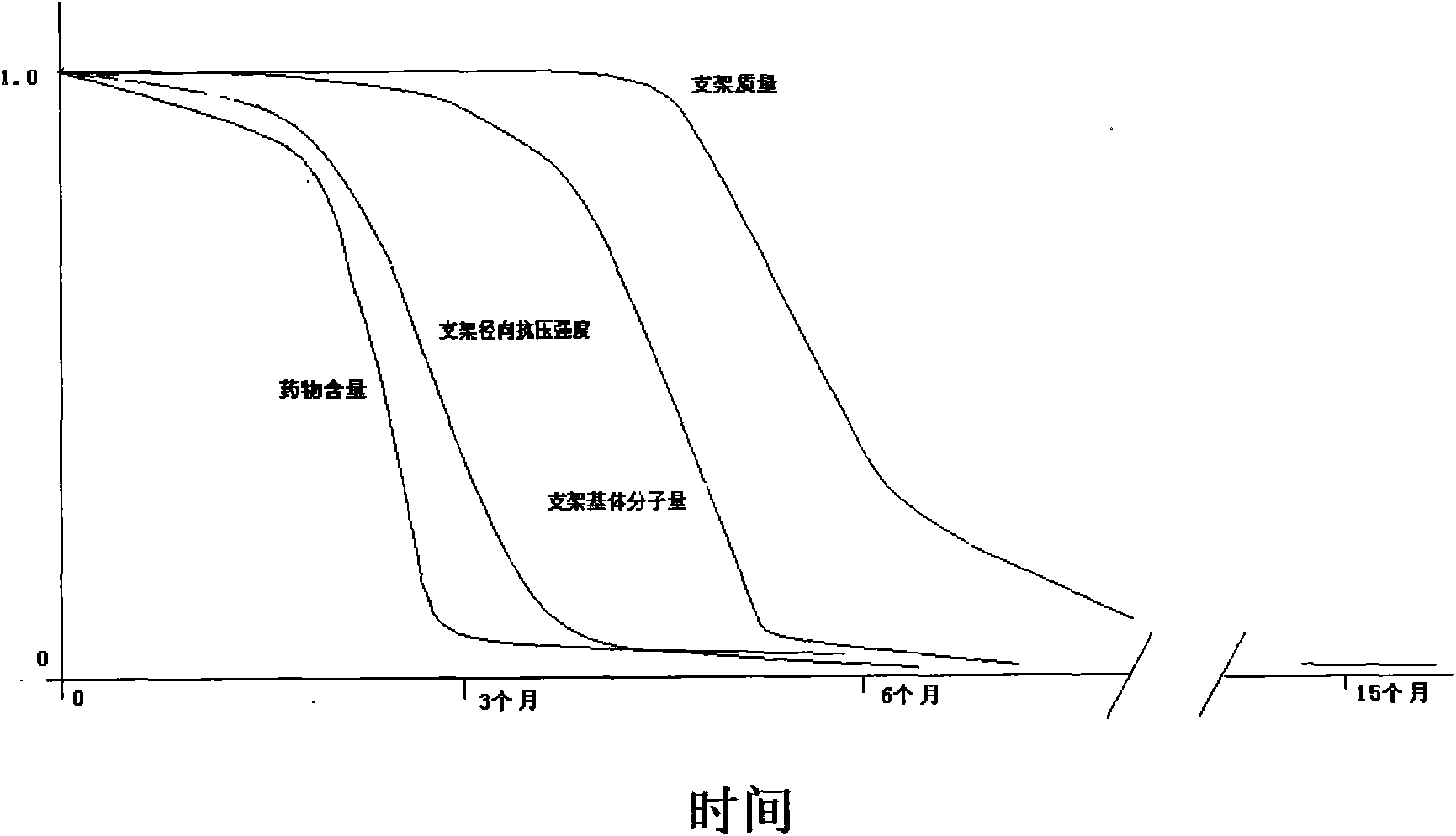

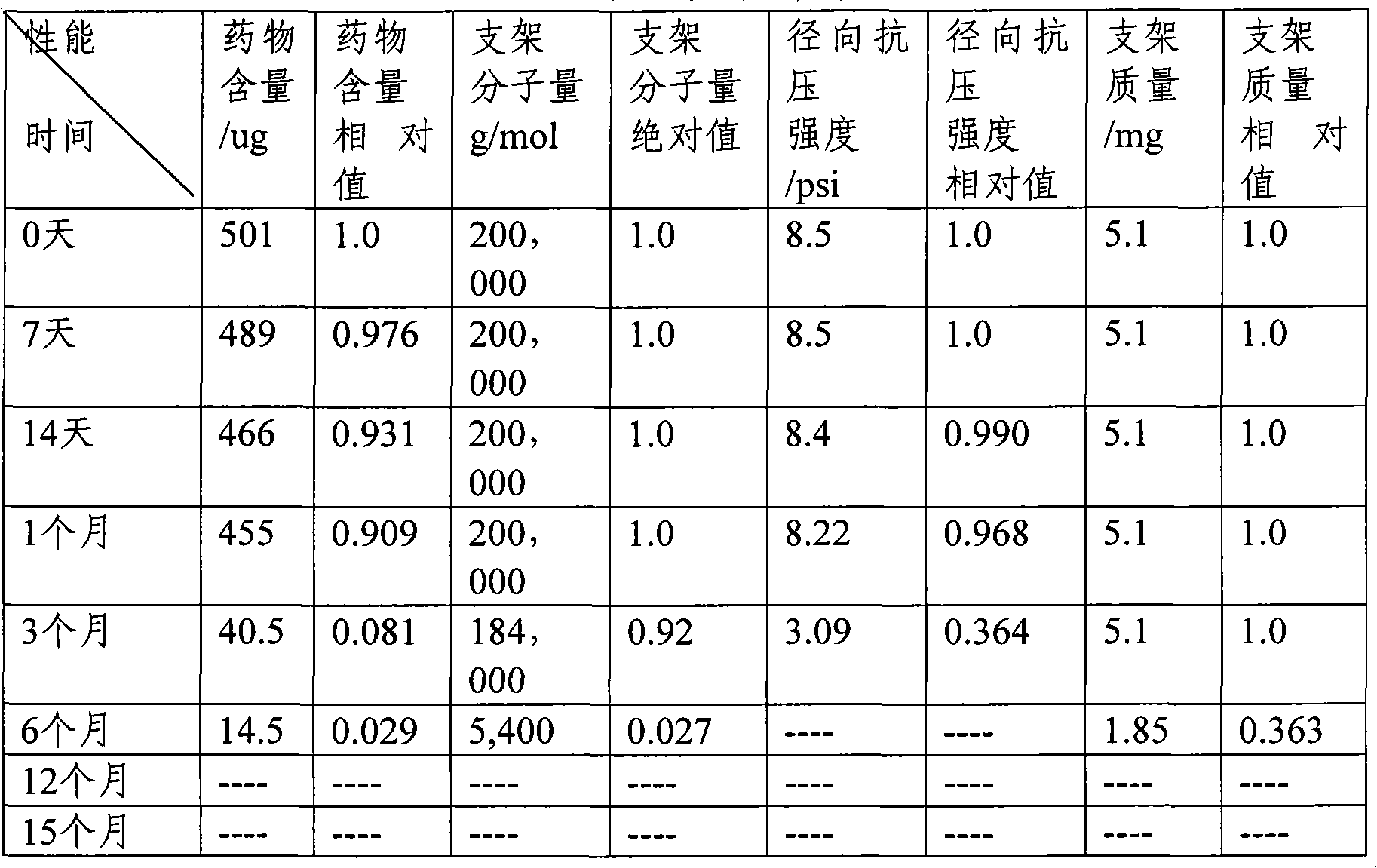

Completely degradable polymer medicine elution stent and preparation method thereof

The invention relates to a completely degradable polymer medicine elution stent and a preparation method thereof. The stent is prepared from the following steps: 1) processing and forming a degradable polymer material into a pipe; 2) subjecting the pipe to laser engraving to form a stent substrate; 3) polishing the surface of the degradable polymer stent substrate and removing processing defects on the surface of the stent; and 4) forming a medicine carrier coating on the surface of the degradable polymer stent substrate. In the invention, a novel light source is used for implementing the laser engraving of the pipe and the processing defects on the surface of the stent is polished by using a polishing technique, so the obtained stent has high structural stability and can has high mechanical supporting performance; and compared with the conventional method, the method has obvious advantages, the prepared stent has high biocompatibility, can effectively treat diseases such as intravascular stenosis and thrombus, has high positive remodeling effect on blood vessels and can effectively prevent a restenosis in later implanting period of the stent.

Owner:LEPU MEDICAL TECH (BEIJING) CO LTD

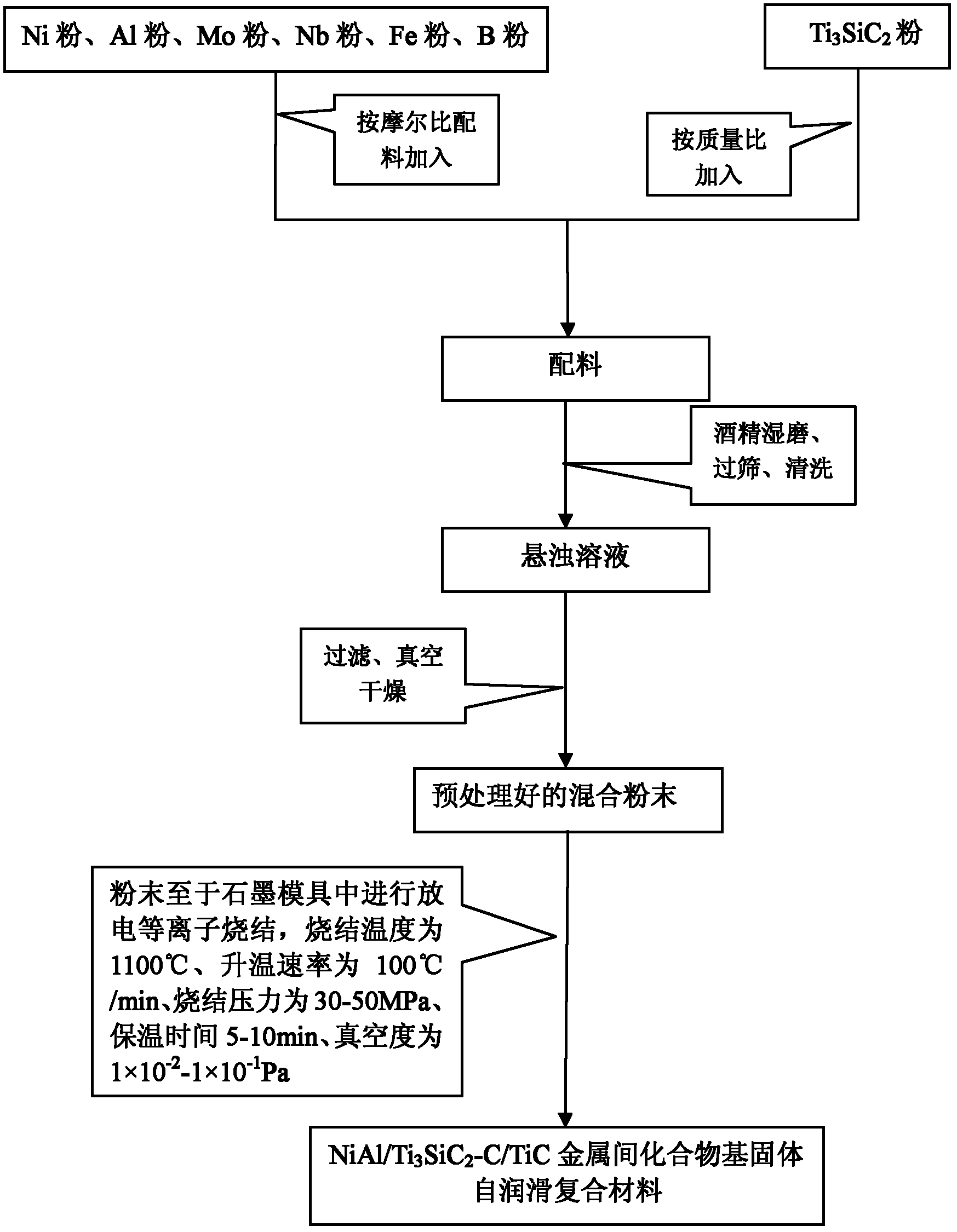

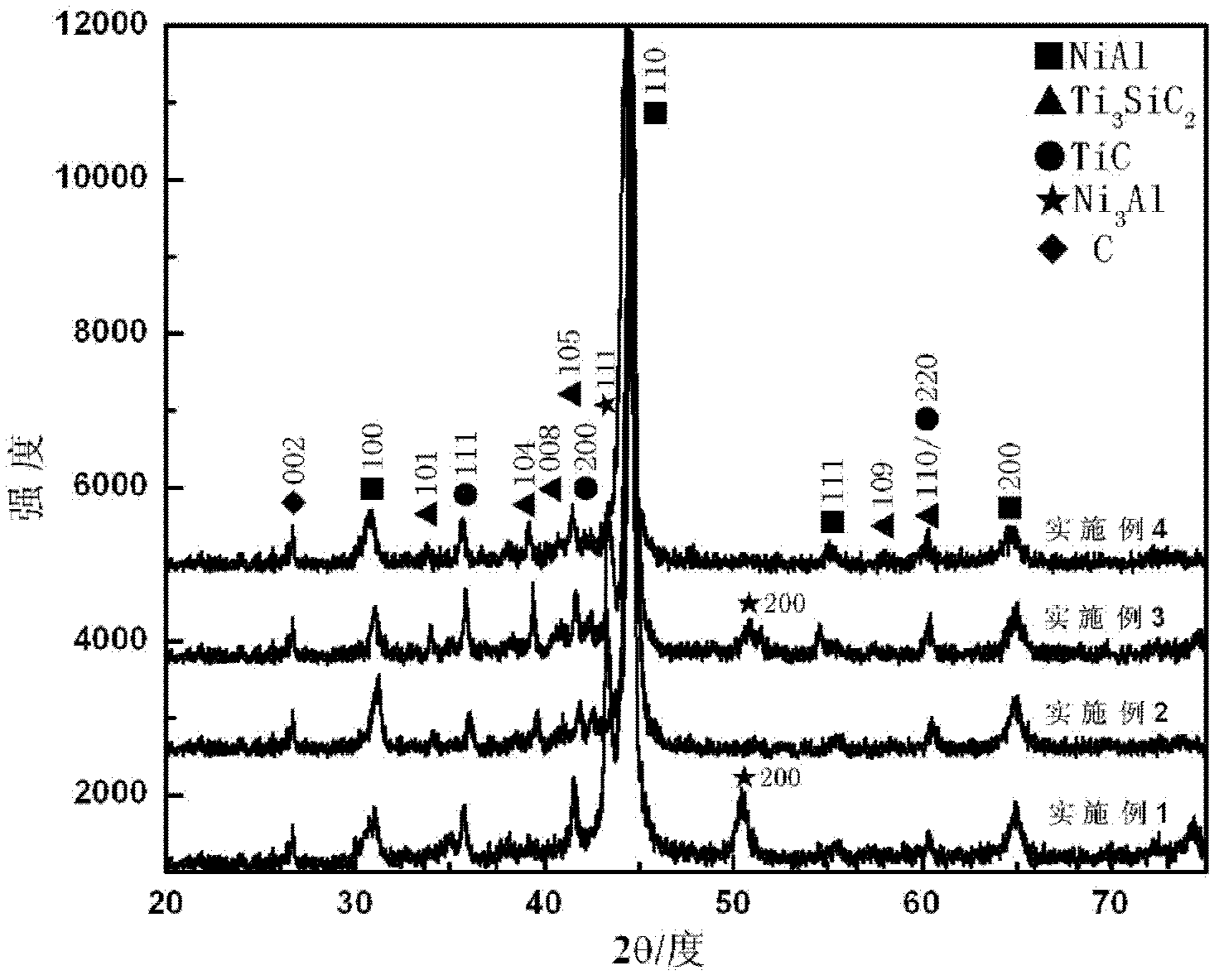

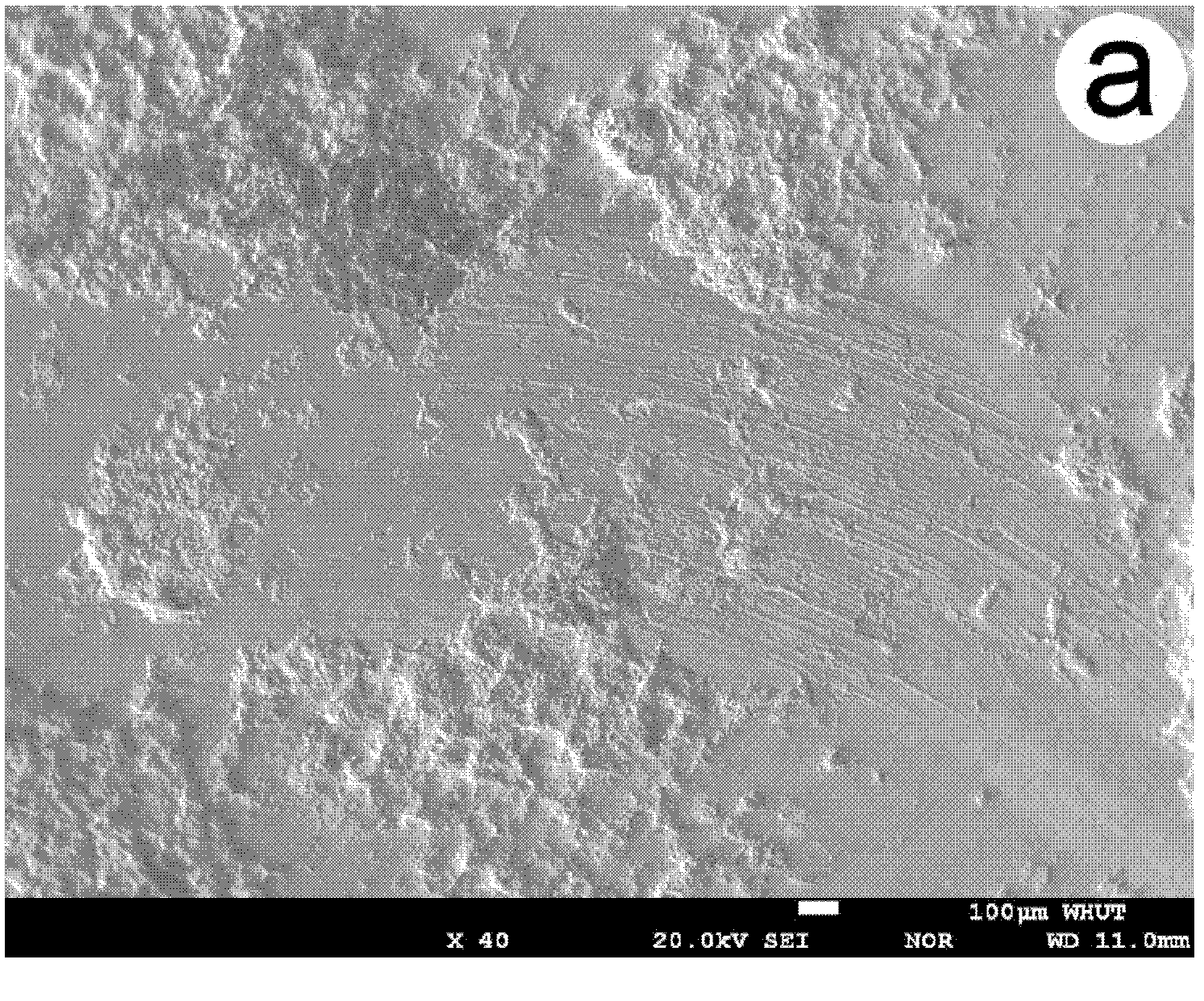

NiAl intermetallic base solid self-lubricating composite material and preparation method thereof

The invention relates to a preparation method of a NiAl intermetallic base solid self-lubricating composite material containing Ti3SiC2 and C binary composite lubrication phase and wild phase TiC. The NiAl intermetallic base solid self-lubricating composite material is prepared from Ni powder, Al powder, Mo powder, Nb powder, Fe powder, B powder and Ti3SiC2 powder, wherein the molar ratio of Ni: Al: Mo: Nb: Fe: B=48: 50: 1: 1: 0.5: 0.02, and the addition quantity of the Ti3SiC2 powder is 5-20 weight percent of the total weight of the Ni powder, the Al powder, the Mo powder, the Nb powder, theFe powder and the B powder. The NiAl / Ti3SiC2-C / TiC intermetallic base solid self-lubricating composite material synthesized by the method has novel component design (intermetallic matrix+ composite lubrication phase+ wild phase), high density, good tribological properties and stable technological parameters. The preparation process is fast and simple, and the method is easily operated and is suitable for preparing NiAl intermetallic base solid self-lubricating composite materials with high performance.

Owner:WUHAN UNIV OF TECH

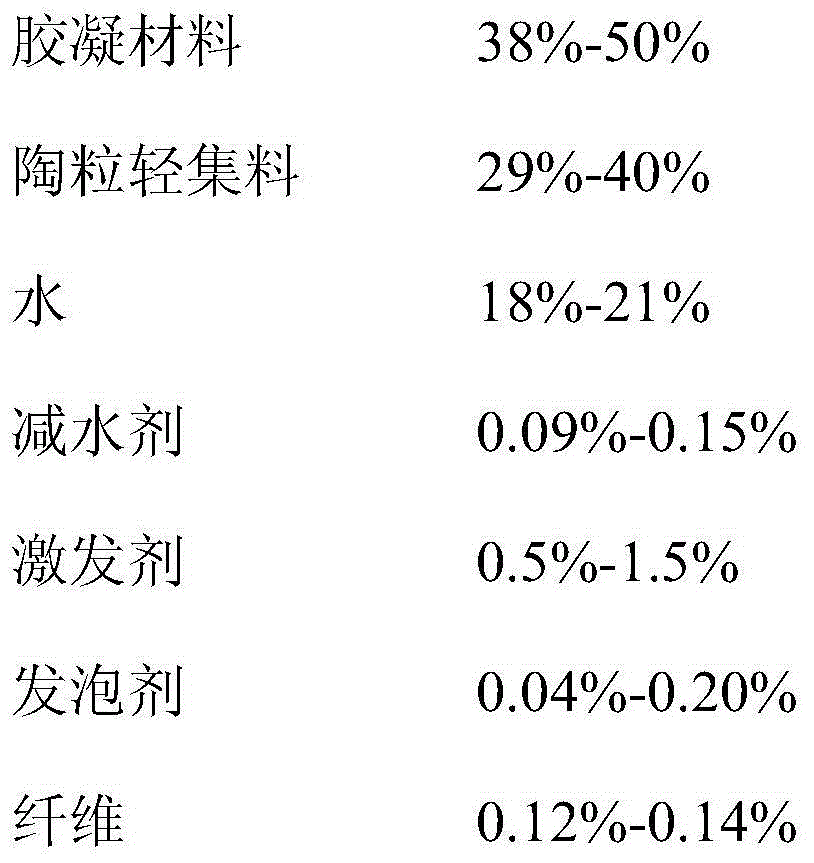

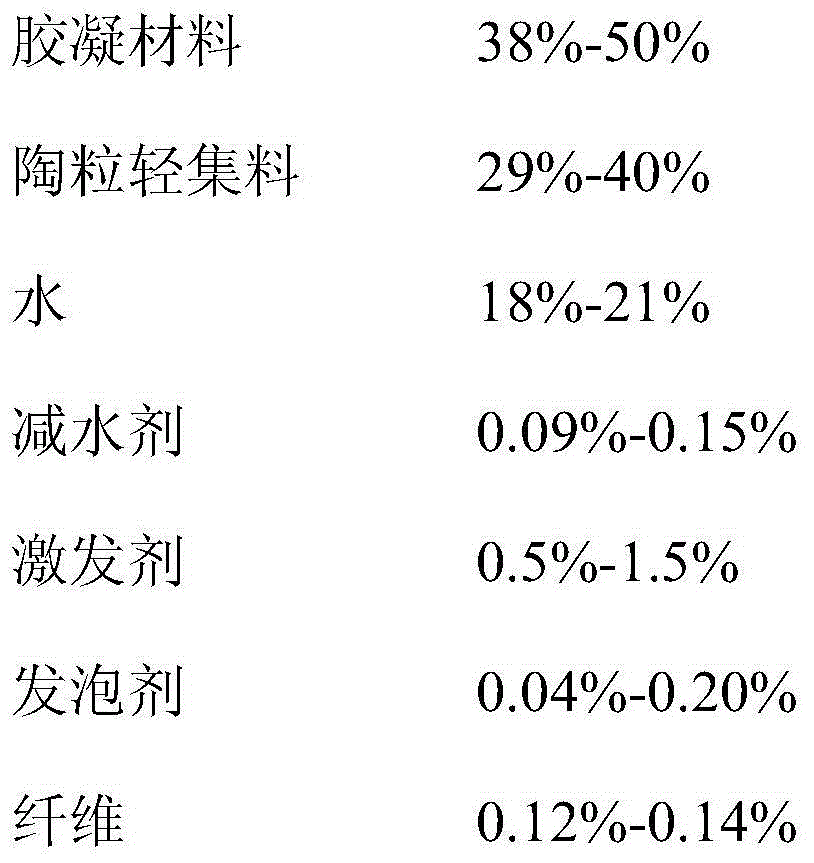

High-volume coal ash ceramsite foam concrete and preparation method thereof

The invention provides a preparation method of high-volume coal ash ceramsite foam concrete. The preparation method of the ceramsite foam concrete comprises the following steps: putting 38%-50% of a binding material, 29%-40% of ceramsite lightweight aggregates, 0.5%-1.5% of an excitant and 0.12%-0.14% of a fiber into a stirrer, and stirring evenly; simultaneously adding 0.04%-0.20% of a foaming agent and foam which is formed by a part of water in a foaming machine and has the particle sizes of 50-1,000mu m, the residual water and 0.09%-0.15% of a water reducer into the stirrer, and stirring with powder evenly to form slurry; adding the foam into the slurry, stirring evenly, and then pouring into a mold to mold; and demolding to prepare the ceramsite foam concrete of which the density is 300-800kg / m<3>. According to the formula provided by the invention, low-cost coal ashes are taken as a main raw material, and the material cost is reduced; meanwhile, the volume-weight of the concrete is reduced by adding the ceramsite lightweight aggregates with different particle sizes; and the mechanical strength and the stability of the concrete are effectively improved.

Owner:中冶武汉冶金建筑研究院有限公司

Preparation method, product and application of catalytic activity nano particle loaded absorbent

InactiveCN102151543AThe preparation method is simple and easyRaw materials are cheap and easy to getOther chemical processesWater contaminantsDesorptionSorbent

The invention discloses a preparation method of a catalytic activity nano particle loaded absorbent, which comprises the step of: with a plurality of kinds of absorbing agents as carriers, surface-loading metal oxide nano particles with catalytic activity to obtain the efficient catalytic activity absorbent in sewage treatment. The invention also discloses an absorbent prepared by using the method and application thereof in the posttreatment of organic phosphorus containing sewage. The absorbent achieves the purpose of synergism of catalysis and absorption through carrying out catalytic oxidization reaction on the surface-loaded nano particles, thereby overcoming the problems of low capacity and difficult desorption of the traditional physical absorbing process and easy loss of components of catalysts in the high-grade oxidization technology in the sewage treatment, remarkably improving efficiency of removing the absorbent, and reducing process links and steps. The absorbent has wide application prospect on the aspects of domestic sewage purification, chemical plant sewage treatment, catalytic degradation of toxic substances in the sewage, and the like.

Owner:ZHEJIANG UNIV +1

Liquid crystal display device

The embodiment of the invention discloses a liquid crystal device, and belongs to the technical field of display. The liquid crystal display device comprises an array substrate, a color filter substrate, a liquid crystal layer and frame glue, wherein the array substrate comprises a plurality of scanning lines in parallel, insulated layers arranged on the surfaces of the scanning lines, a plurality of parallel data lines arranged on the surfaces of the insulated layers, a plurality of pixel electrodes arranged on the surfaces of the insulated layers and distributed in a matrix, passivation layers covering the surfaces of the pixel electrodes and the surfaces of the data lines, and a plurality of first common electrodes which cover the surfaces of the passivation layers and are parallel with the data lines and crossed with the scanning lines; the color filter substrate comprises a black matrix, a color resistance layer, a flat layer and a second common electrode covering the surface of the flat layer, and the second common electrode is of a net-shaped structure, the net-shaped structure is a certain distance away from the data lines and the scanning lines in the vertical direction and the net-shaped structure is relatively overlapped with the data lines and the scanning lines. The penetration rate of the liquid crystal display device rises, and the response speed is improved.

Owner:KUSN INFOVISION OPTOELECTRONICS

Solar cell and manufacturing method

ActiveCN101118914AReduce process stepsSimple production processFinal product manufactureSemiconductor/solid-state device manufacturingHigh volume manufacturingAmorphous silicon solar cell

The present invention relates to a multi-stack amorphous silicon solar battery, which adds a transparent reflection film between the stacks and belongs to the thin film solar battery making field. The present inventionhas the technical characteristics that the transparent conductive film between two stacked photoelectric conversion layers is coated on the N face of one amorphous silicon P-I-N photoelectric conversion layer, while the middle transparent conductive film is made of nanometer conductive material. Moreover, a photoelectric unit consists of a stacked amorphous silicon solar battery, and the P film of the amorphous silicon P-I-N photoelectric conversion layer forms a top battery on the back of the front electrode in a roll coating manner. The present inventionis applicable to the mass production, reducing the cost.

Owner:李毅

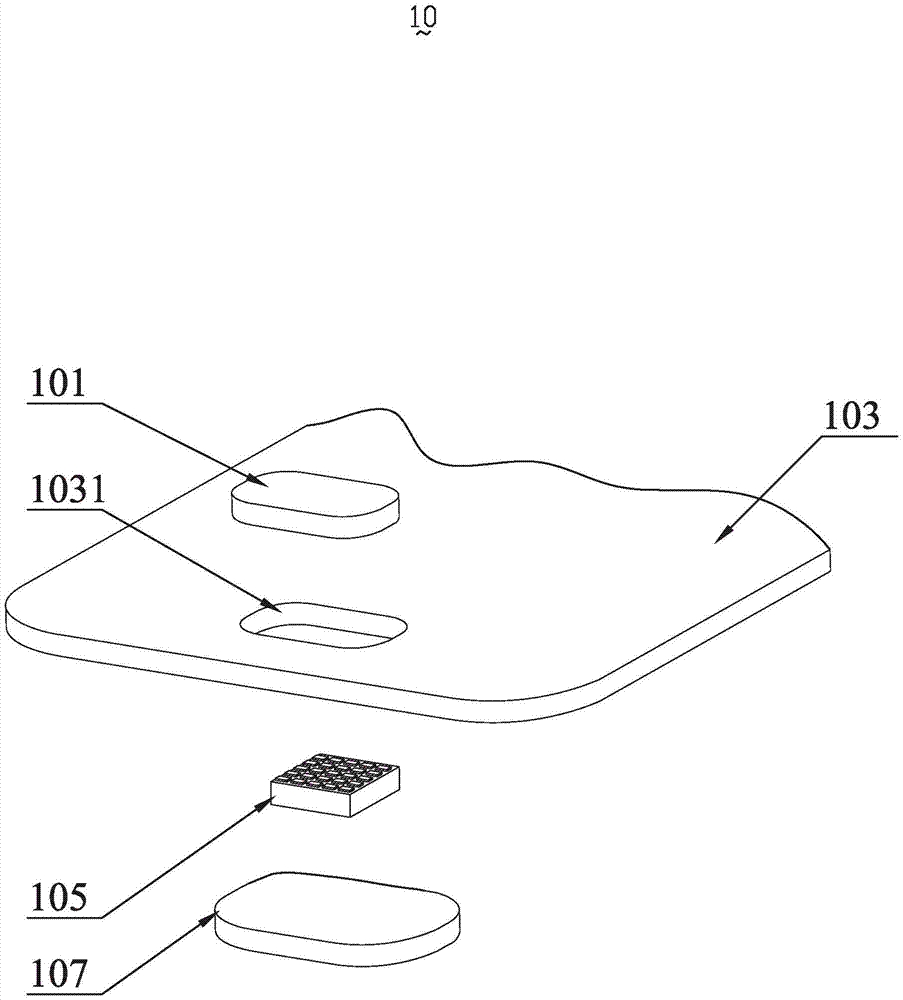

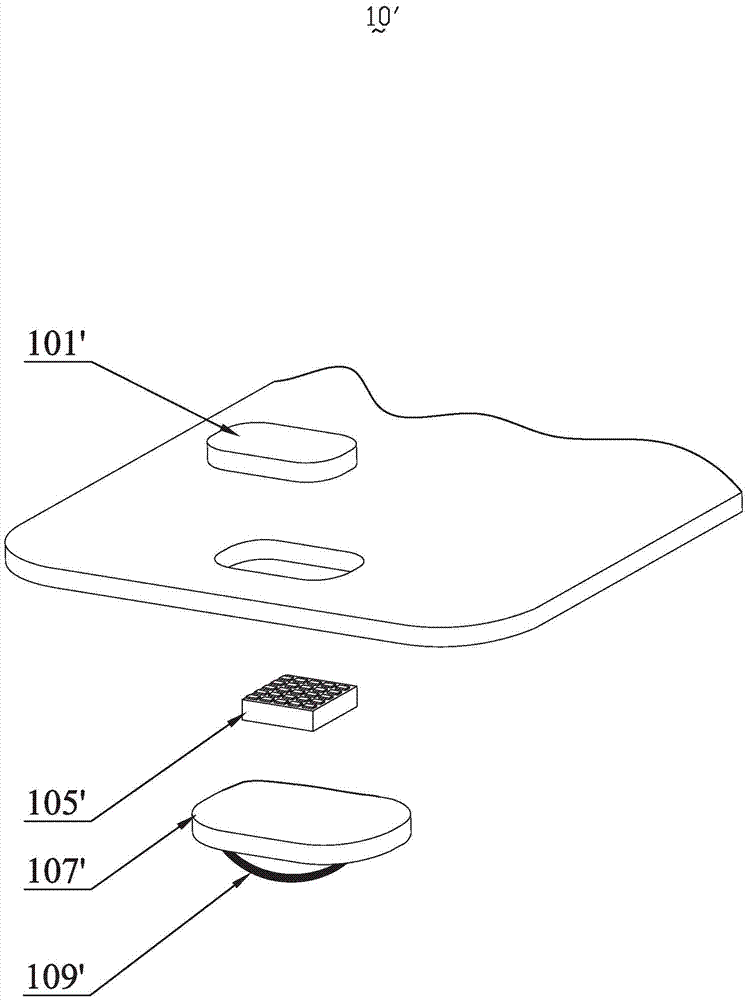

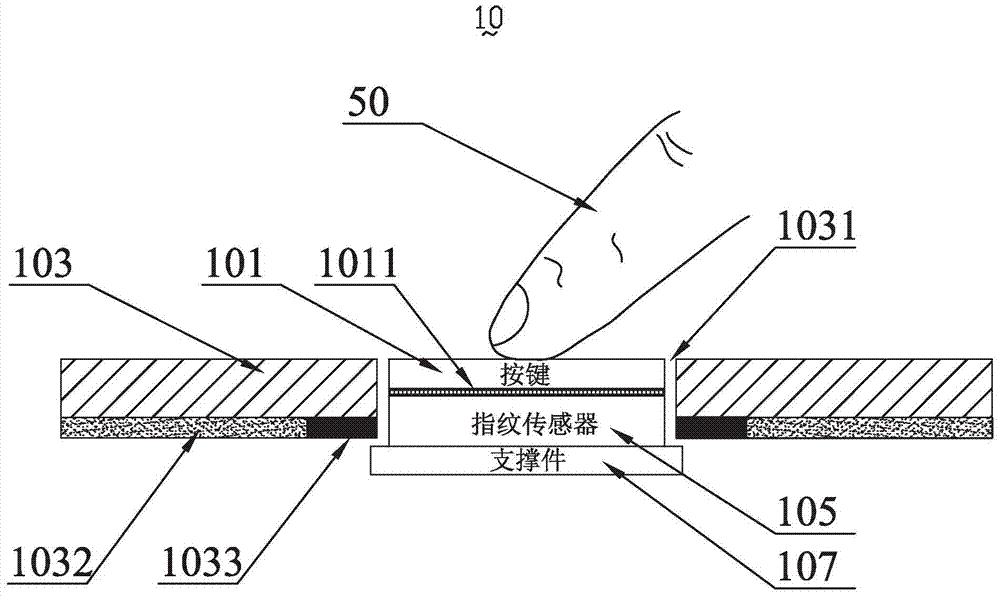

A fingerprint identification apparatus and an electronic apparatus having the fingerprint identification apparatus

ActiveCN105447486AImprove aestheticsFlexible adjustmentCharacter and pattern recognitionEngineeringFingerprint

The invention relates to a fingerprint identification apparatus with a concealed protection member and an electronic apparatus with the fingerprint identification apparatus. The fingerprint identification apparatus comprises a button, a fingerprint sensor which is arranged in a lower portion in the design direction of a button vertical lamination structure, a cover comprising a button hole accommodating the button and a fingerprint sensor positioned below the button and a protection member arranged on below the cover plate or on the side walls of the button hole. The protection member is arranged below the upper surface of the cover plate in a hidden mode. The protection member circes around the surrounding of the fingerprint sensor in order to shield interferences to the fingerprint sensor by outside noise signals. The electronic apparatus with the above fingerprint identification apparatus comprises a housing and a display assembly. The cover plate is embedded in an upper plate of the housing. The display assembly is a display module group or a touch control display module group. The fingerprint sensor is positioned outside of an imaging area of the display assembly.

Owner:TPK UNIVERSAL SOLUTIONS

Preparation method of lithium-nickel-cobalt-aluminum oxide for anode materials of lithium ion batteries

ActiveCN103066257ASolve the problem of complete oxidationPrevent "cation mixing" phenomenonCell electrodesLithium hydroxideOxygen

The invention provides a preparation method of lithium-nickel-cobalt-aluminum oxide for anode materials of lithium ion batteries. The method comprises: step 1, using a nickel-cobalt-aluminum precursor prepared through a coprecipitation method and doped with mixed ions as raw materials, putting the raw materials into a sealed hearth of a pressure furnace, continuously introducing oxygen until a fixed pressure value is formed, then heating to a pre-burning temperature and keeping warm for a period of time, and cooling to obtain an oxidized precursor; and step 2, adding measured lithium salt or lithium hydroxide into the oxidized precursor, ball milling and uniformly mixing; heating the uniformly mixed raw materials to a certain temperature and keeping warm for a period of time, and meanwhile continuously introducing oxygen to complete a sintering process, thereby obtaining the finish product. According to the invention, through a hyperbaric oxygen atmosphere, the oxygen are enabled to fully infiltrate into particles of the raw materials which has a certain accumulation thickness, thereby preventing situations that only surface materials are oxidized under a normal pressure, and ensuring a full conversion of Ni<2+> to Ni<3+> by a full pre-oxidation.

Owner:GUANGZHOU LIBODE NEW MATERIAL

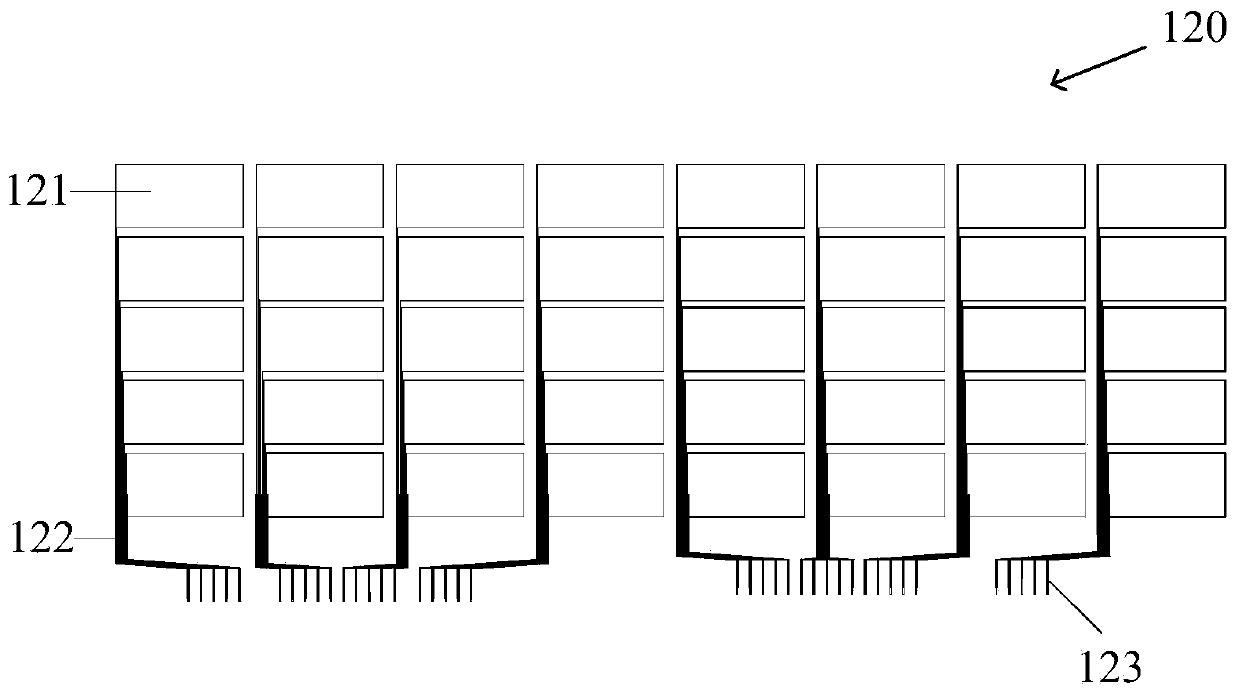

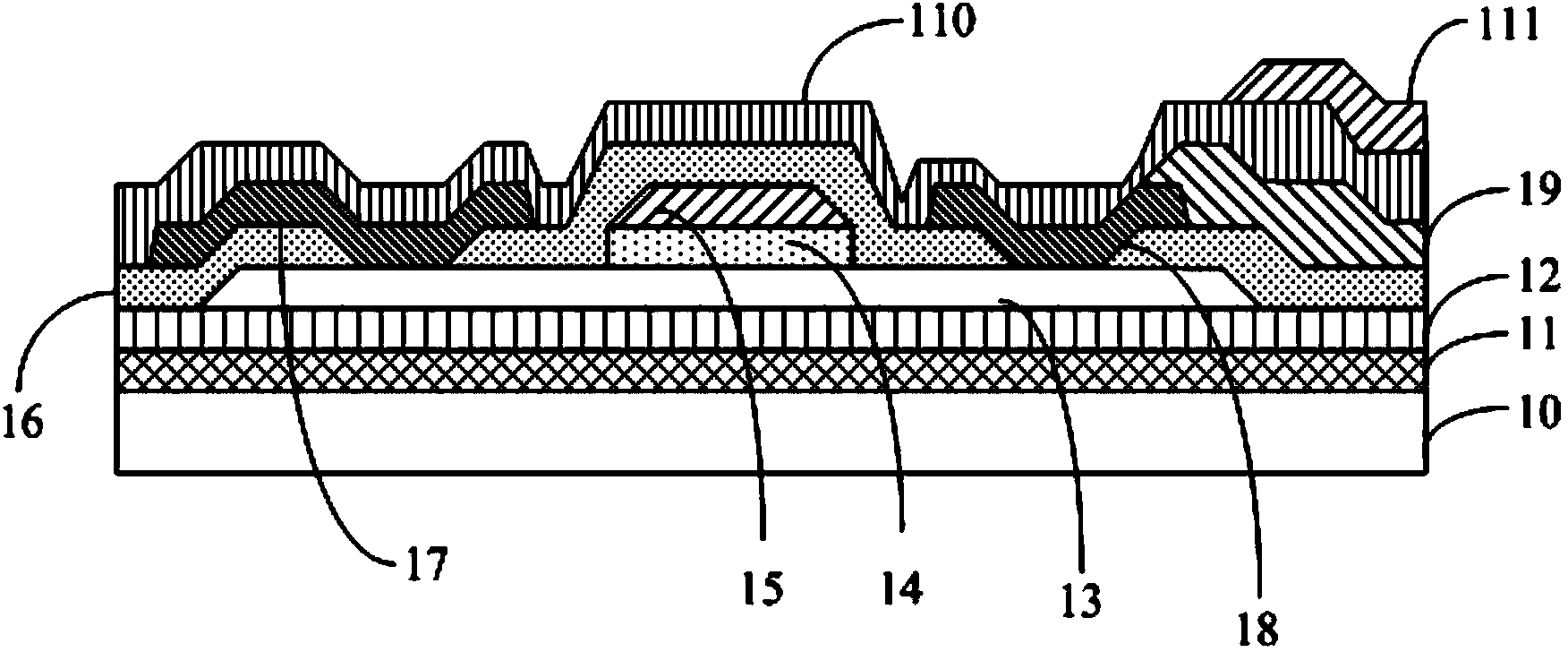

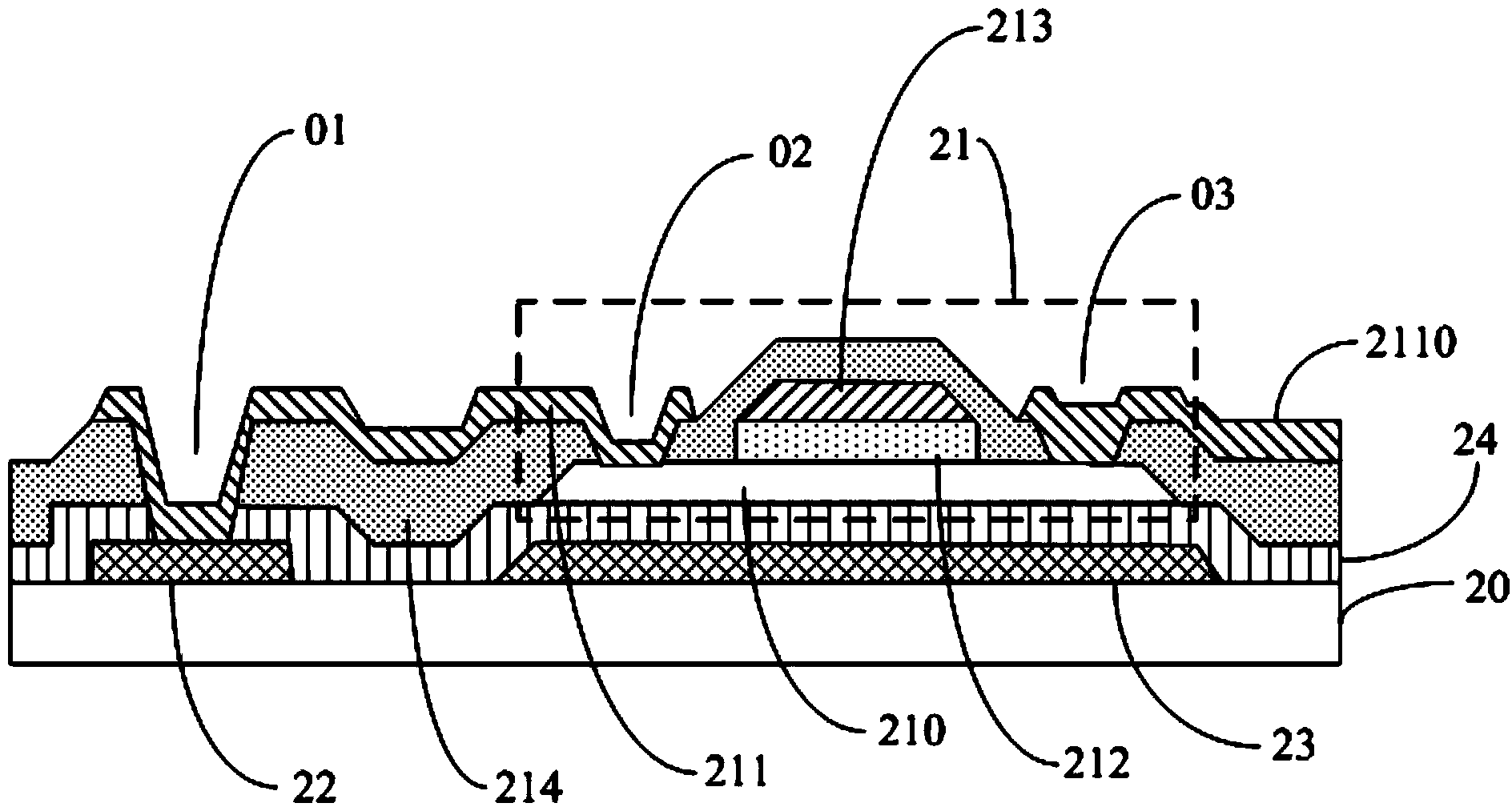

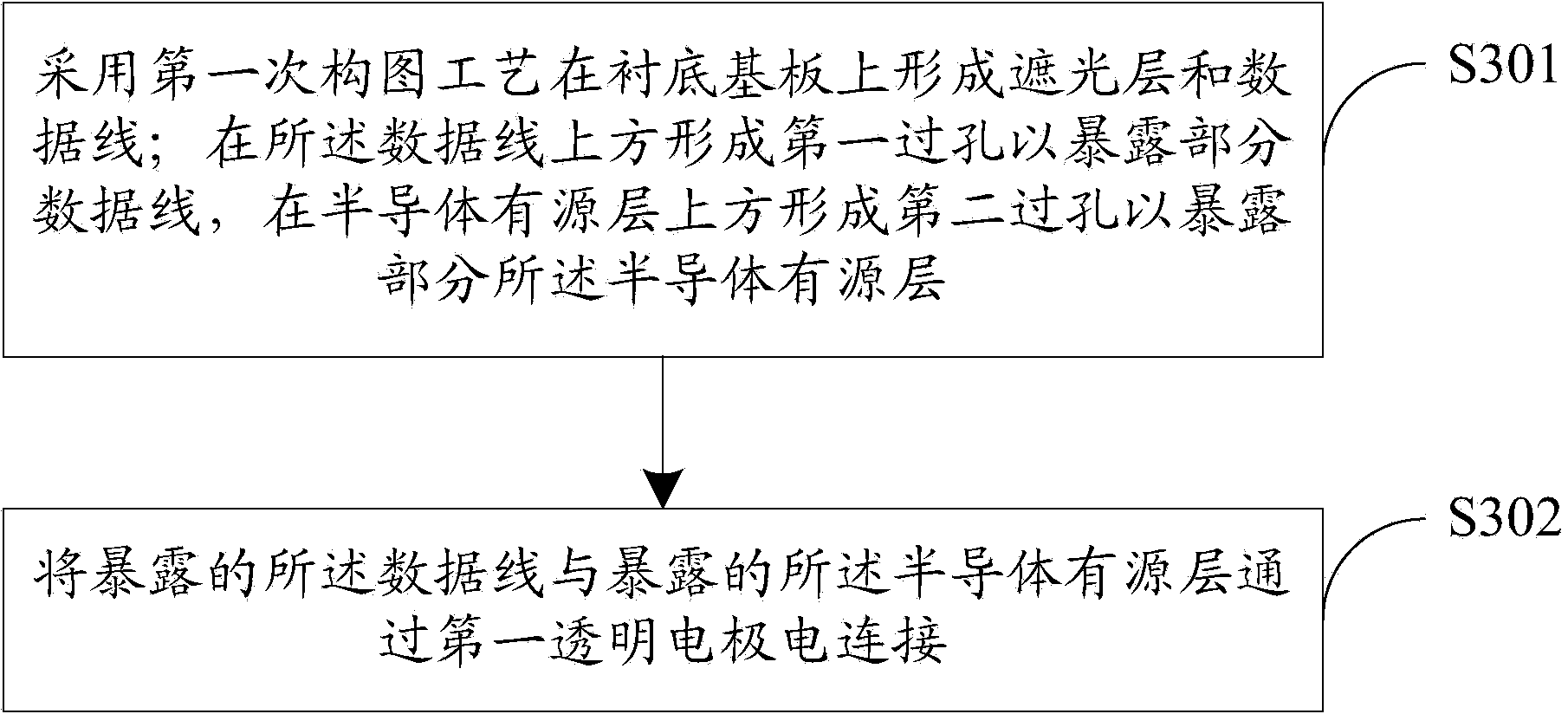

Array substrate and manufacturing method thereof, and display device

ActiveCN104393000AReduce process stepsIncrease productivitySolid-state devicesSemiconductor/solid-state device manufacturingEngineeringData lines

The invention discloses an array substrate and a manufacturing method thereof, and a display device. Therefore, the process steps are reduced, so that the production cost is lowered and the production efficiency is improved. The array substrate includes a substrate base plate, thin-film transistors arranged on the substrate base plate, data lines connected with source electrodes / drain electrodes of all thin-film transistors, and a light shield layer arranged on the substrate base plate. The data lines and the light shield layer are arranged at the same layer. First via holes are formed above the data lines to expose parts of data lines. The thin-film transistors include semiconductor active layers and first transparent electrodes; second via holes are formed above the semiconductor active layers to expose parts of the semiconductor active layers; and the data lines and the semiconductor active layers are electrically connected by the first transparent electrodes through the first via holes and the second via holes.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

Composite ceramic membrane for lithium ion batteries and preparation method thereof

ActiveCN103956451AAvoid thermal runawayImprove high temperature thermal stabilityCell component detailsElectrolytic agentCeramic coating

The invention discloses a composite ceramic membrane for lithium ion batteries and a preparation method thereof, including a ceramic coating modification method and a ceramic lithium battery membrane. The ceramic protective layer is mainly prepared from a ceramic-adhesive mixture subjected to graft modification by a sodium-sulfonate / sodium-carboxylate-group-containing anionic surfactant. The grafting is completed by using a grafting-on process under the action of a coupling agent; the grafting ratio of the ceramic is higher; the high-temperature-resistant large-surface-area nano ceramic is introduced to the conventional PP (polypropylene) membrane surface, the insulativity and electrolyte wettability of the modified ceramic membrane are greatly enhanced; and the membrane has excellent high-temperature heat stability especially at the high temperature of 130 DEG C, 150 DEG C and 180 DEG C. The lithium battery composite membrane avoids the thermal shrinkage of the convention membrane, thereby avoids the thermorunaway in the battery due to thermal shrinkage, and further enhancing the safe reliability of the lithium ion battery.

Owner:中国东方电气集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com