Process and apparatus for producing Dy-Fe alloy by molten salt electrolysis method

A technology for molten salt electrolysis and dysprosium-iron alloy, which is applied in the field of producing dysprosium-iron alloy by molten salt electrolysis method, can solve problems such as reduction of production cost, and achieve the effects of simplifying operation, simplifying production process and reducing production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

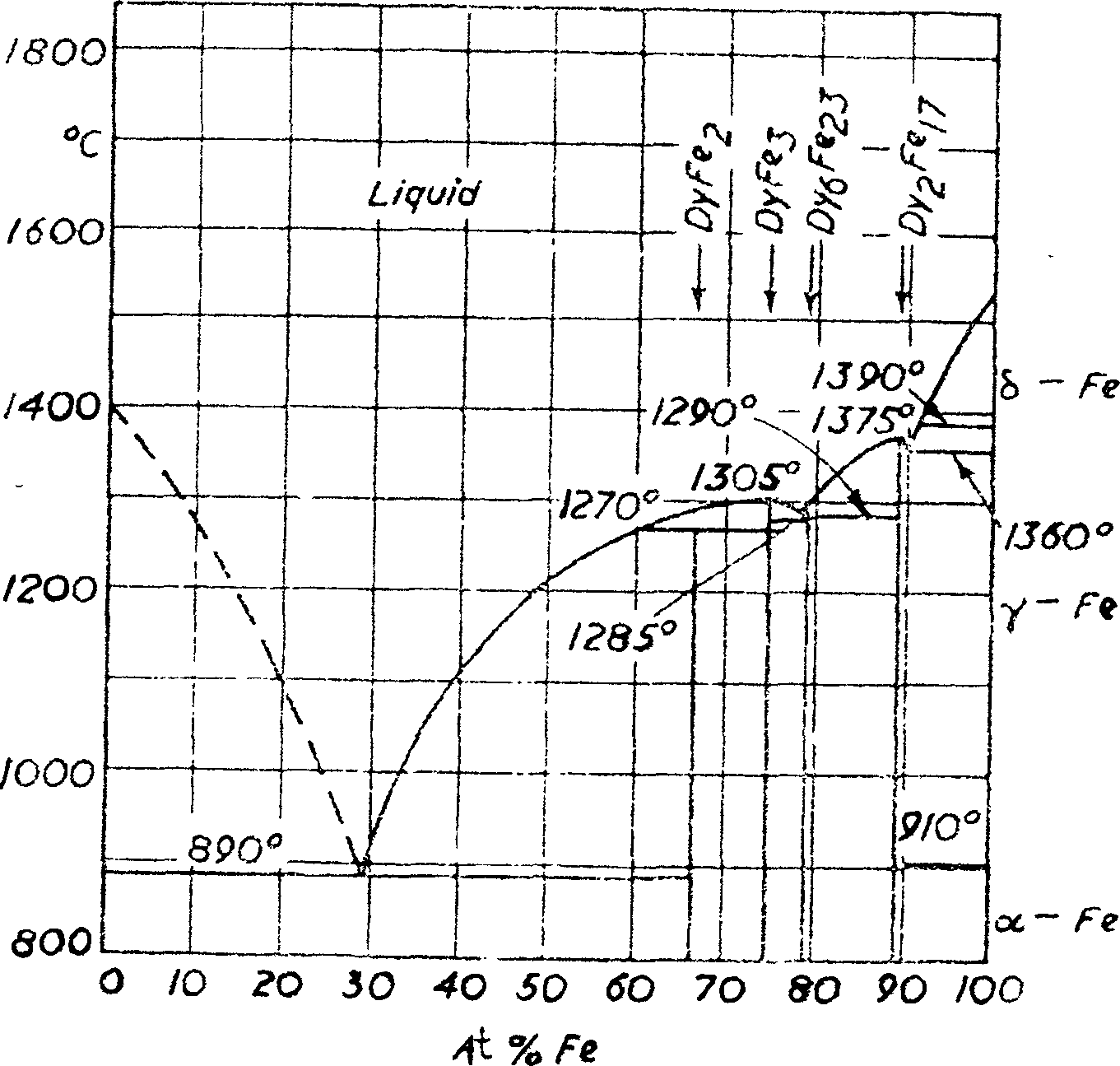

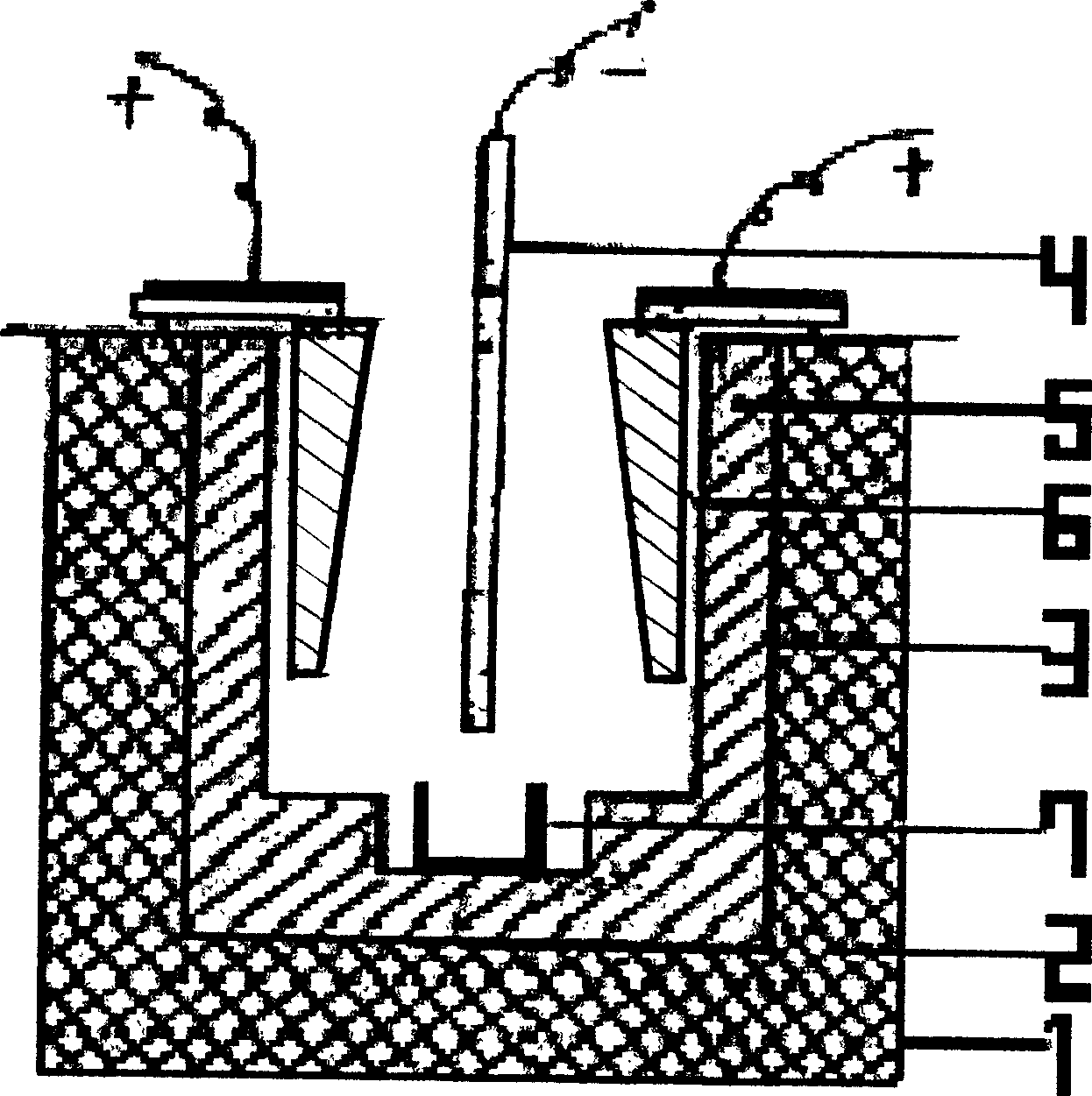

[0026] The present invention uses dysprosium oxide as raw material, dysprosium fluoride and lithium fluoride binary system as electrolyte, and dysprosium oxide is dissolved in fluoride (DyF 3 , LiF) melt, the solubility of dysprosium oxide in the melt is 2% to 5%, and the rare earth dysprosium oxide is electrolyzed by consumable iron cathode to obtain dysprosium iron alloy.

[0027] The electrolytic cell is fully dried, and the arcing machine is used to connect graphite to start arc heating in the electrolytic cell, DyF 3 Mix it with LiF at a ratio of 90:10 and slowly add it to the electrolytic tank to melt. When the electrolyte reaches the required liquid level and the temperature is 950-1050°C, DyO 3 Evenly and quantitatively added by an automatic feeder, under the action of a DC electric field (95V / M), Dy 3+ It precipitates on the surface of the iron cathode and is reduced to Dy, which is alloyed with Fe to form Dy-Fe. o 2- Oxidation to O on the graphite cathode surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com