Electrode for electrolysis and electrolysis unit

A technology for electrodes and surface layers, applied in electrolysis components, electrodes, electrolysis processes, etc., can solve problems such as increased device costs, low ozone generation efficiency, and more energy, and achieve production costs, environmental burdens, and power consumption volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

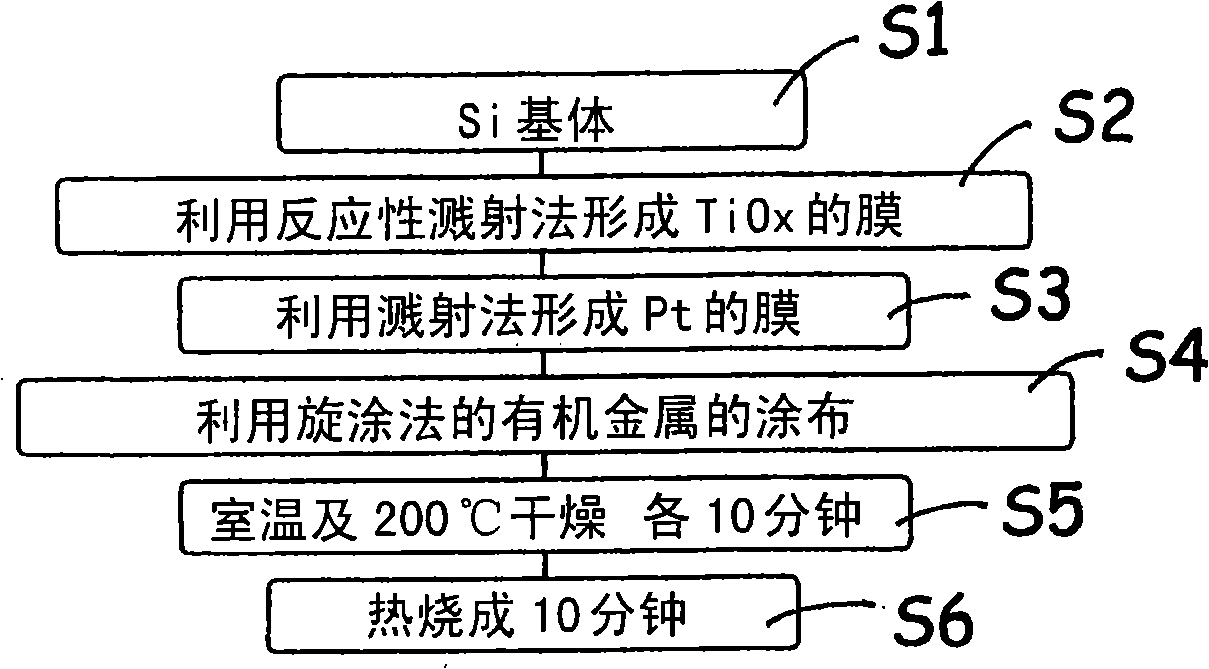

[0054] Below, refer to figure 2 The flow chart of the following describes the method of manufacturing the electrode 1 for electrolysis in Example 1 of the present invention. First, pretreatment of silicon constituting the base body 2 is performed as step S1. Here, silicon is preferably a material in which phosphorus (P), boron (B) and the like are introduced as impurities to increase electrical conductivity. As this silicon, a material with a very flat surface is used. Furthermore, in this embodiment, although silicon is used as the base body 2 , other conductive materials as described above may be used instead.

[0055] In this pretreatment, the silicon substrate 2 was treated with 5% hydrofluoric acid to remove the natural oxide film formed on the surface of the substrate 2 . In this way, the surface of the base body 2 becomes flatter. In addition, this preprocessing does not need to be performed. Thereafter, the surface of the substrate 2 is rinsed with pure water, an...

Embodiment 2

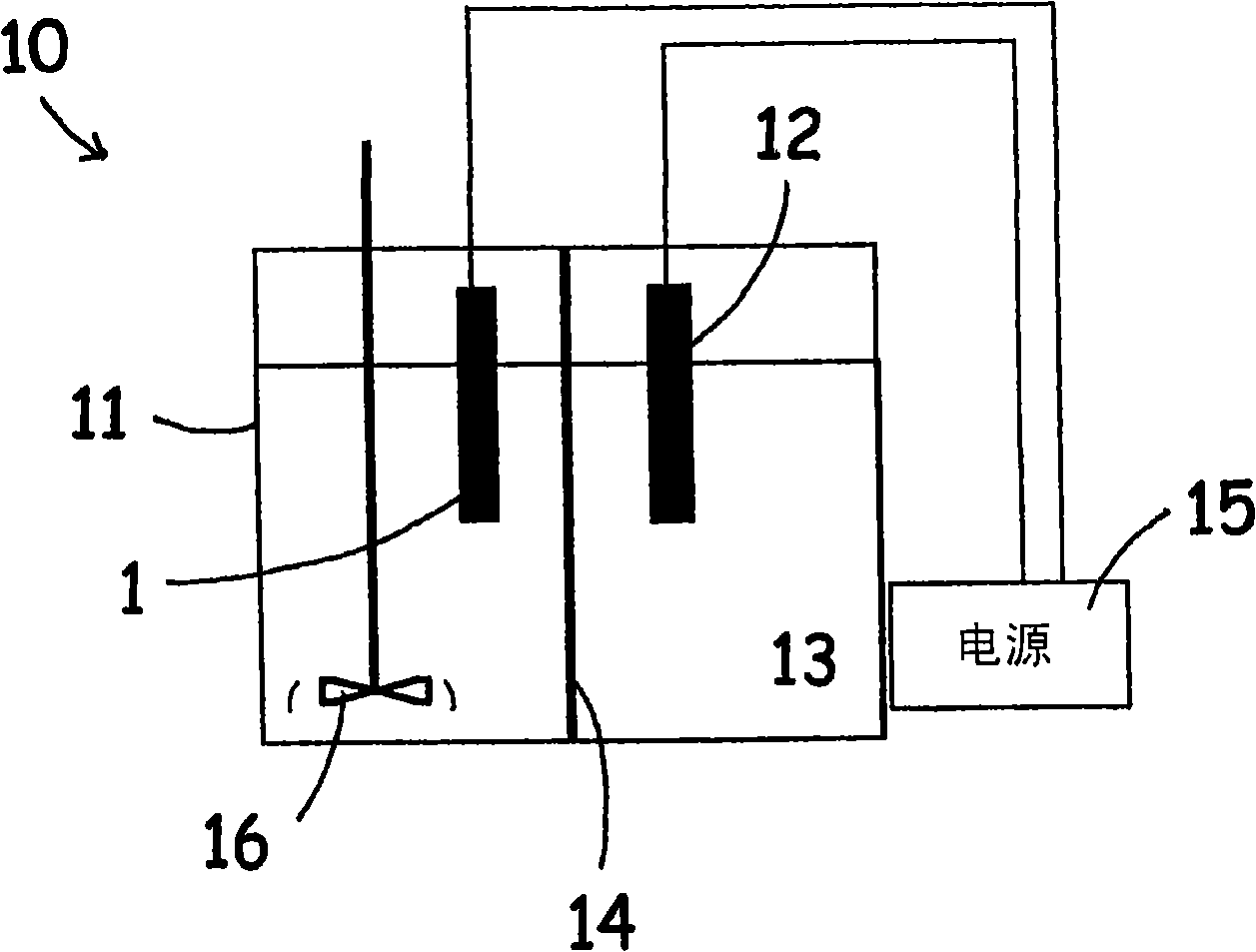

[0091] Below, refer to Figure 6 The flow chart of the following describes the method of manufacturing the electrode 21 for electrolysis according to the second embodiment of the present invention. and, Figure 7 A schematic configuration diagram of the electrolysis electrode 21 obtained in this example is shown. First, preprocessing of silicon constituting the base body 22 is performed in the same manner as in the above-described embodiment as step S11. Since the material of the base body 22 is the same as that of the above-mentioned embodiment, the description thereof is omitted. Thereafter, in step S12, it is introduced into a small chamber of an existing sputtering apparatus, and film formation is performed.

[0092] In step S12 , the adhesion layer 23 for improving the adhesion of the intermediate layer 24 as described above is formed on the surface of the base body 22 . The formation of the adhesion layer 23 on the base body 22 is performed by the reactive sputtering...

Embodiment 3

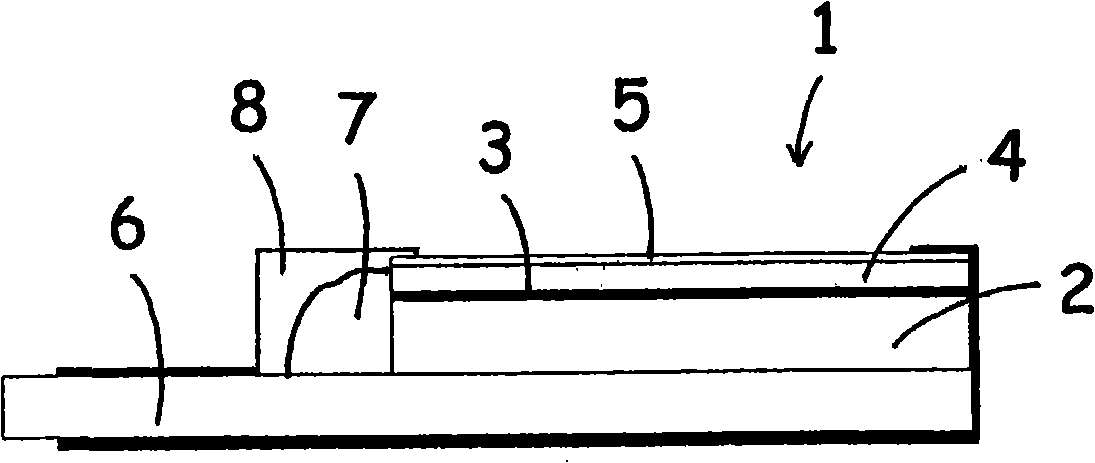

[0111] Next, the electrode for electrolysis of Example 3 of the present invention will be described. Because the manufacturing method of the electrode 31 for electrolysis obtained by utilizing this embodiment is the same as that of the above-mentioned embodiment 1 figure 2 The flow chart is the same as that of figure 1 Since they are substantially the same, description of the detailed manufacturing method is omitted.

[0112] That is, the electrode for electrolysis in this embodiment is the same as in the above-mentioned embodiments. After forming the adhesion layer 3 with tantalum oxide by the sputtering method on the surface of the silicon constituting the substrate, it is formed on the surface of the adhesion layer 3 with platinum by the sputtering method. middle layer4.

[0113] Then, the surface layer 5 is formed on the surface of the substrate 2 on which the intermediate layer 4 is formed. In this embodiment, since the surface layer 5 is formed by the spin coating me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com