Patents

Literature

646 results about "Tantalum oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

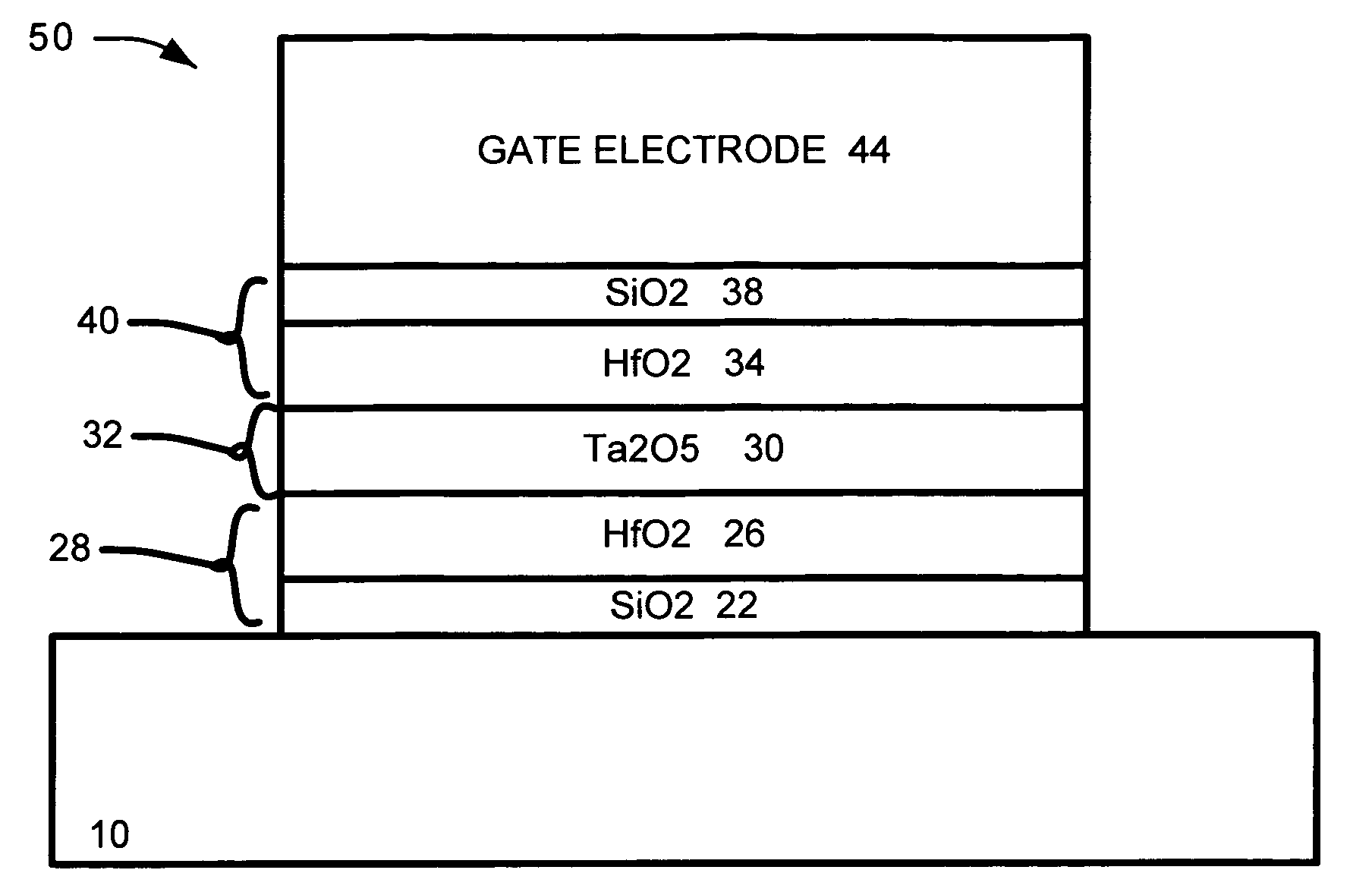

Apparatuses and methods for atomic layer deposition of hafnium-containing high-k dielectric materials

InactiveUS20050271813A1Steam generation heating methodsDecorative surface effectsGas phaseWater vapor

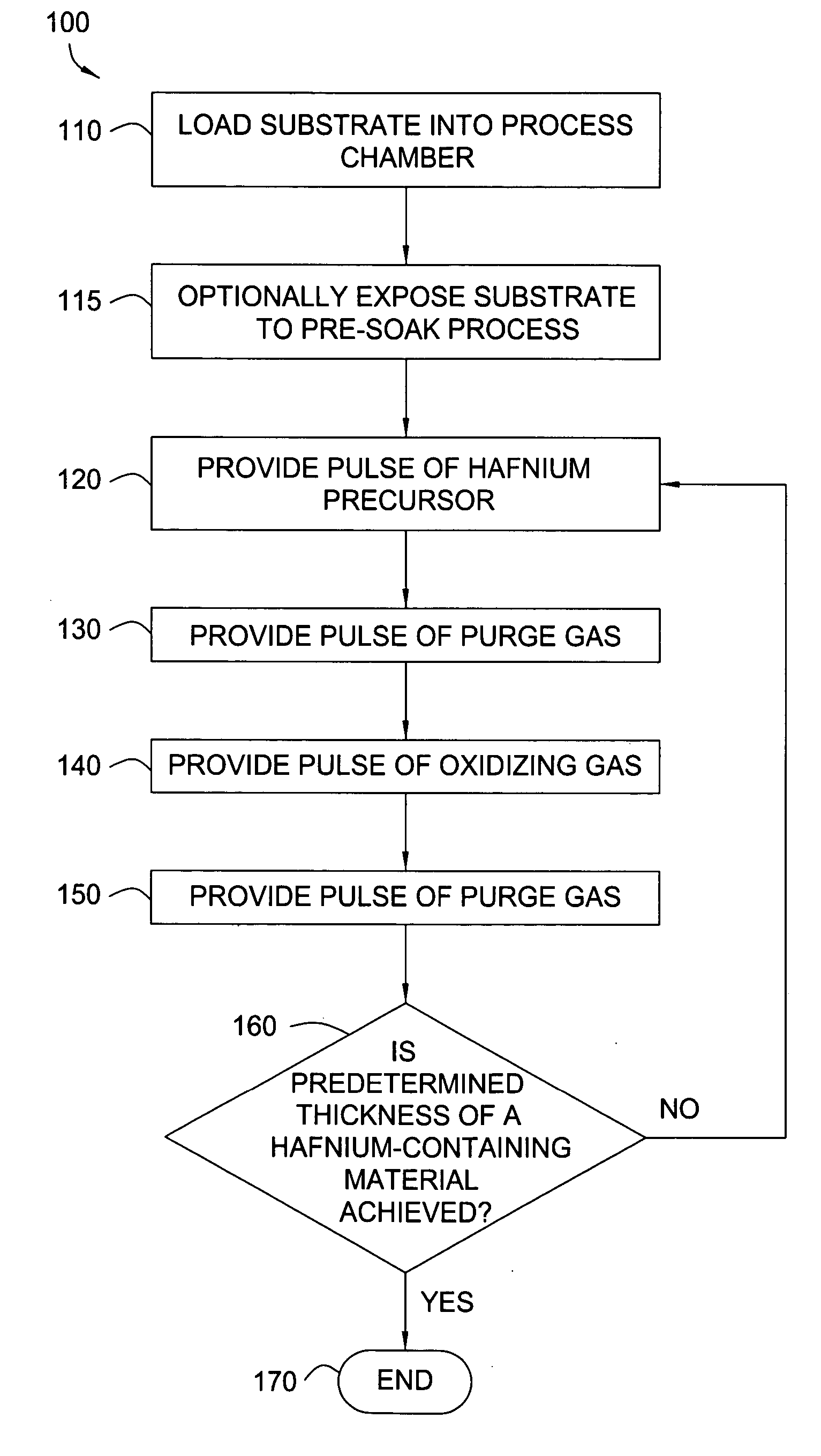

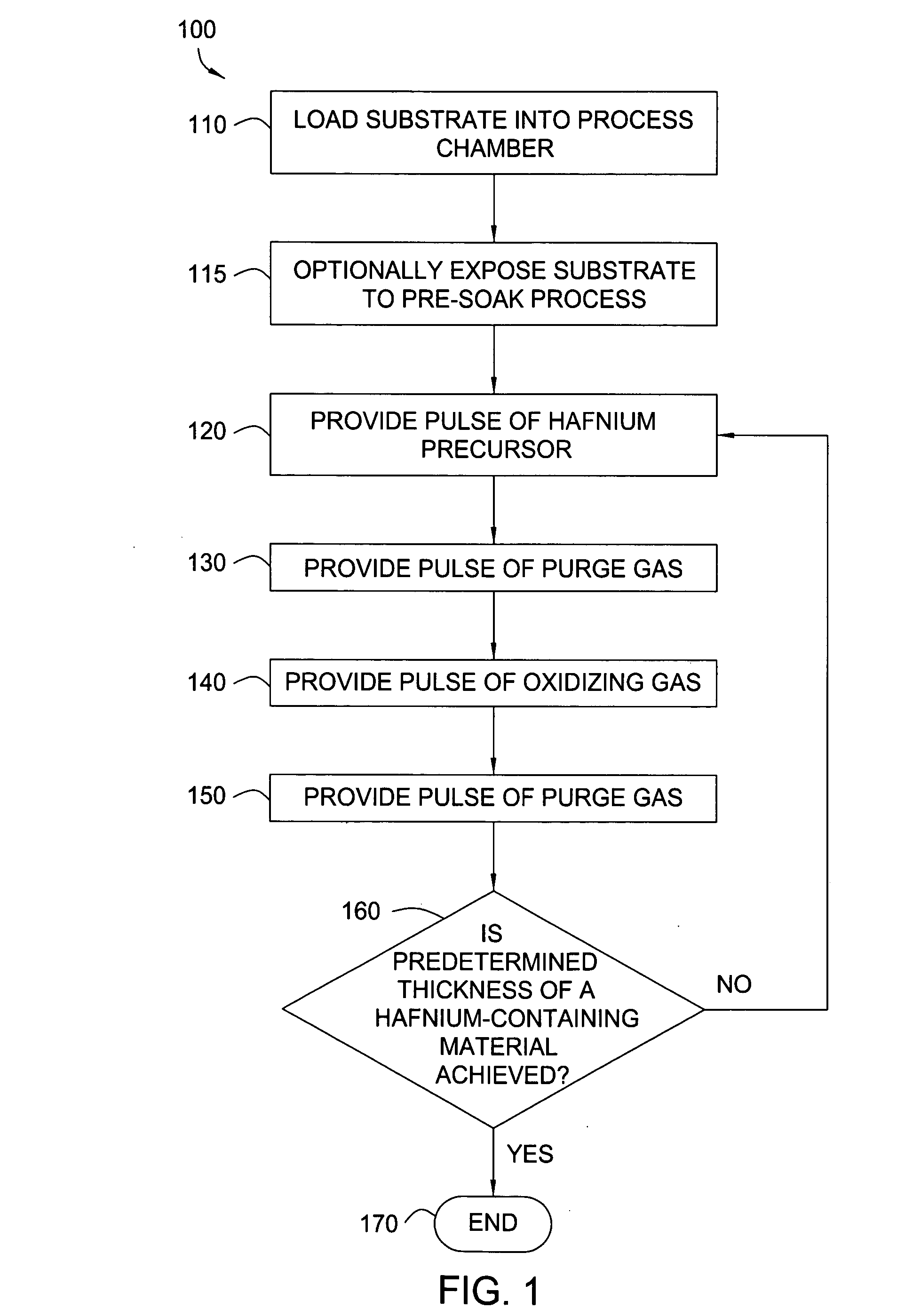

Embodiments of the invention provide methods for depositing dielectric materials on substrates during vapor deposition processes, such as atomic layer deposition (ALD). In one example, a method includes sequentially exposing a substrate to a hafnium precursor and an oxidizing gas to deposit a hafnium oxide material thereon. In another example, a hafnium silicate material is deposited by sequentially exposing a substrate to the oxidizing gas and a process gas containing a hafnium precursor and a silicon precursor. The oxidizing gas usually contains water vapor formed by flowing a hydrogen source gas and an oxygen source gas through a water vapor generator. In another example, a method includes sequentially exposing a substrate to the oxidizing gas and at least one precursor to deposit hafnium oxide, zirconium oxide, lanthanum oxide, tantalum oxide, titanium oxide, aluminum oxide, silicon oxide, aluminates thereof, silicates thereof, derivatives thereof or combinations thereof.

Owner:APPLIED MATERIALS INC

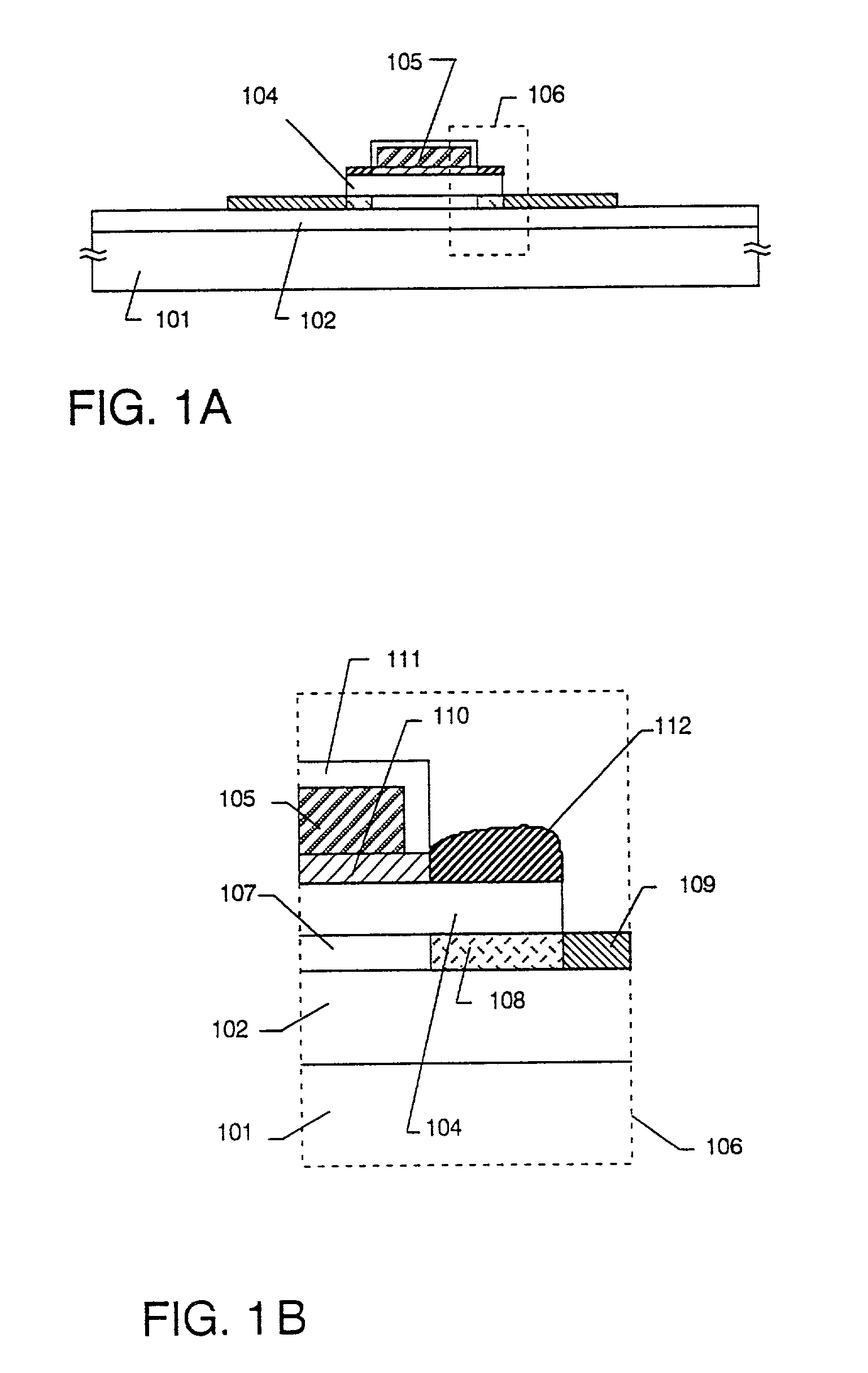

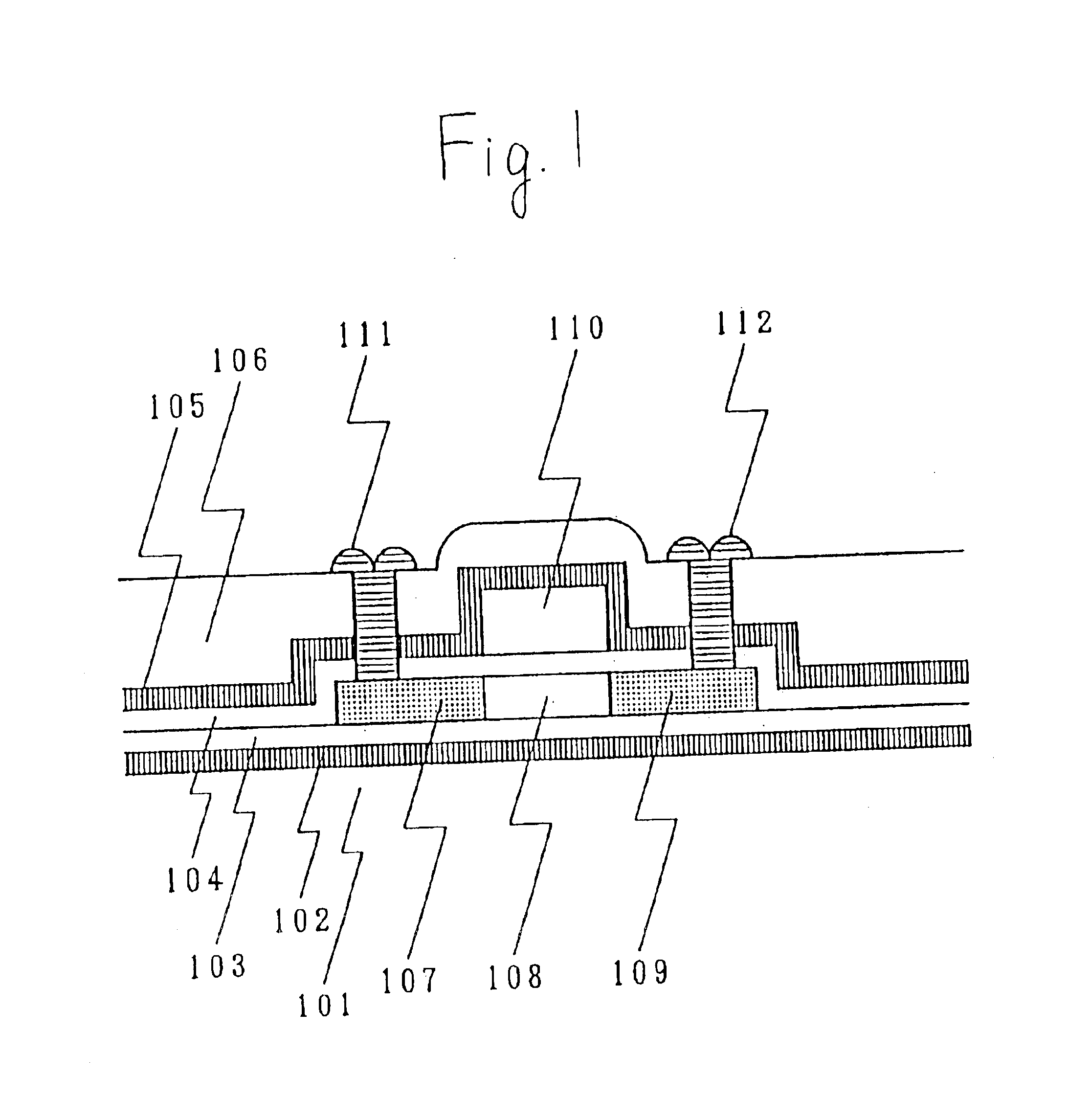

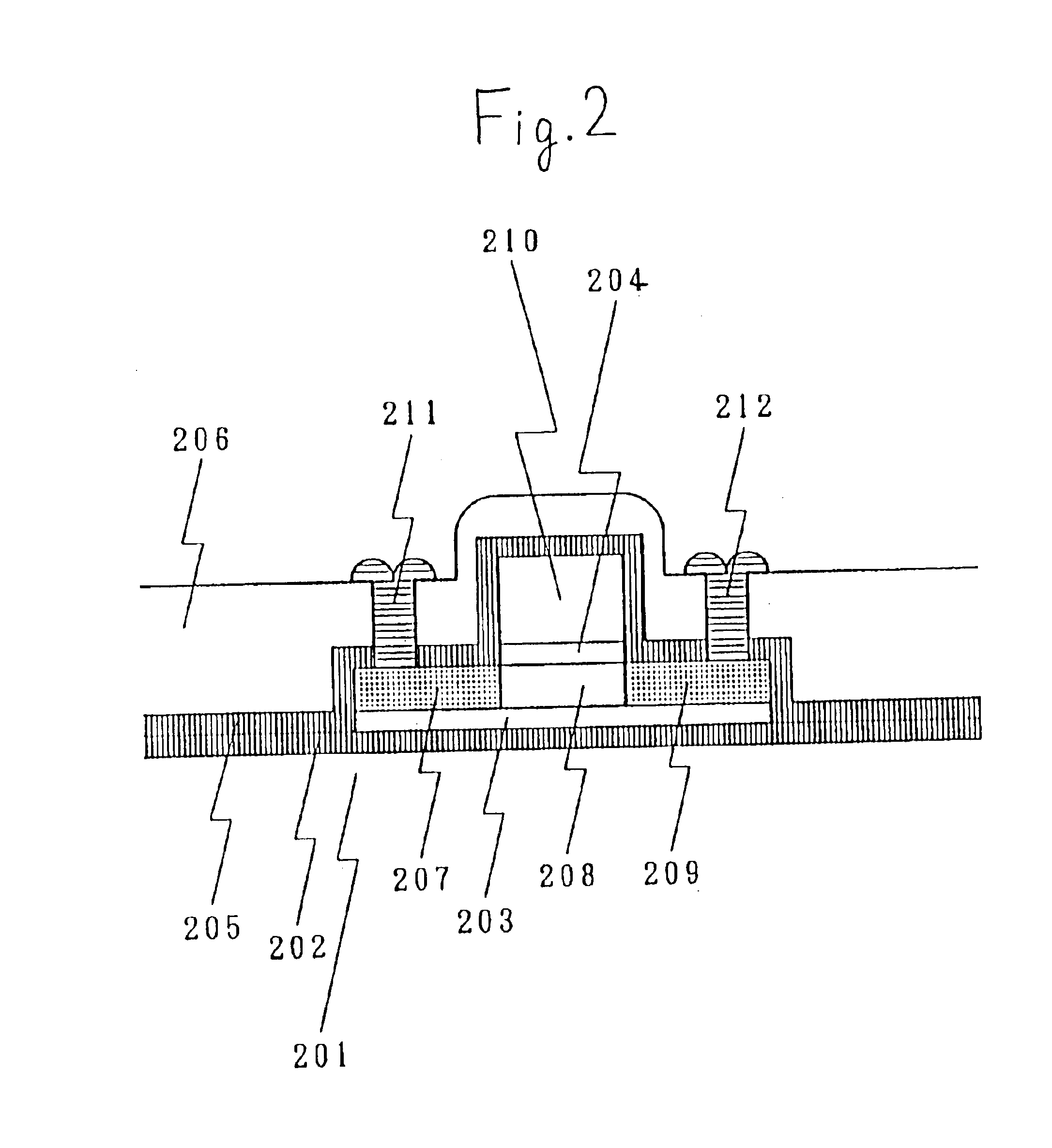

Semiconductor device and method of manufacturing the semiconductor device

InactiveUS20020096681A1TransistorSemiconductor/solid-state device manufacturingActive layerIon implantation

A TFT using an aluminum material for a gate electrode is manufactured at a high yield factor. The gate electrode provided over an active layer and a gate insulating film is constituted by a lamination film of a tantalum layer and an aluminum layer. In this structure, the tantalum layer functions as a stopper, so that it is possible to prevent a constituent material of the aluminum layer from intruding into the gate insulating film. An end portion of the tantalum layer is transformed into tantalum oxide, which has an effect to lower damage at ion implantation to the gate insulating film in the formation of an LDD region.

Owner:SEMICON ENERGY LAB CO LTD

Niobium powder and a process for the production of niobium and/or tantalum powders

InactiveUS6136062APrevent local overheating effectStirring speed is fastElectrolytic capacitorsTantalum compoundsMischmetalRare earth

The process comprises the reduction of niobium and / or tantalum oxides by means of alkaline earth metals and / or rare earth metals, wherein the first reduction stage is carried out as far as an average composition corresponding to (Nb, Ta)Ox where x=0.5 to 1.5 and before the second stage the reduction product from the first stage is freed from alkaline earth oxides and / or rare earth metal oxides which are formed (and optionally from excess alkaline earth metal and / or rare earth metal) by washing with mineral acids.

Owner:H C STARCK TANTALUM & NIOBIUM GMBH

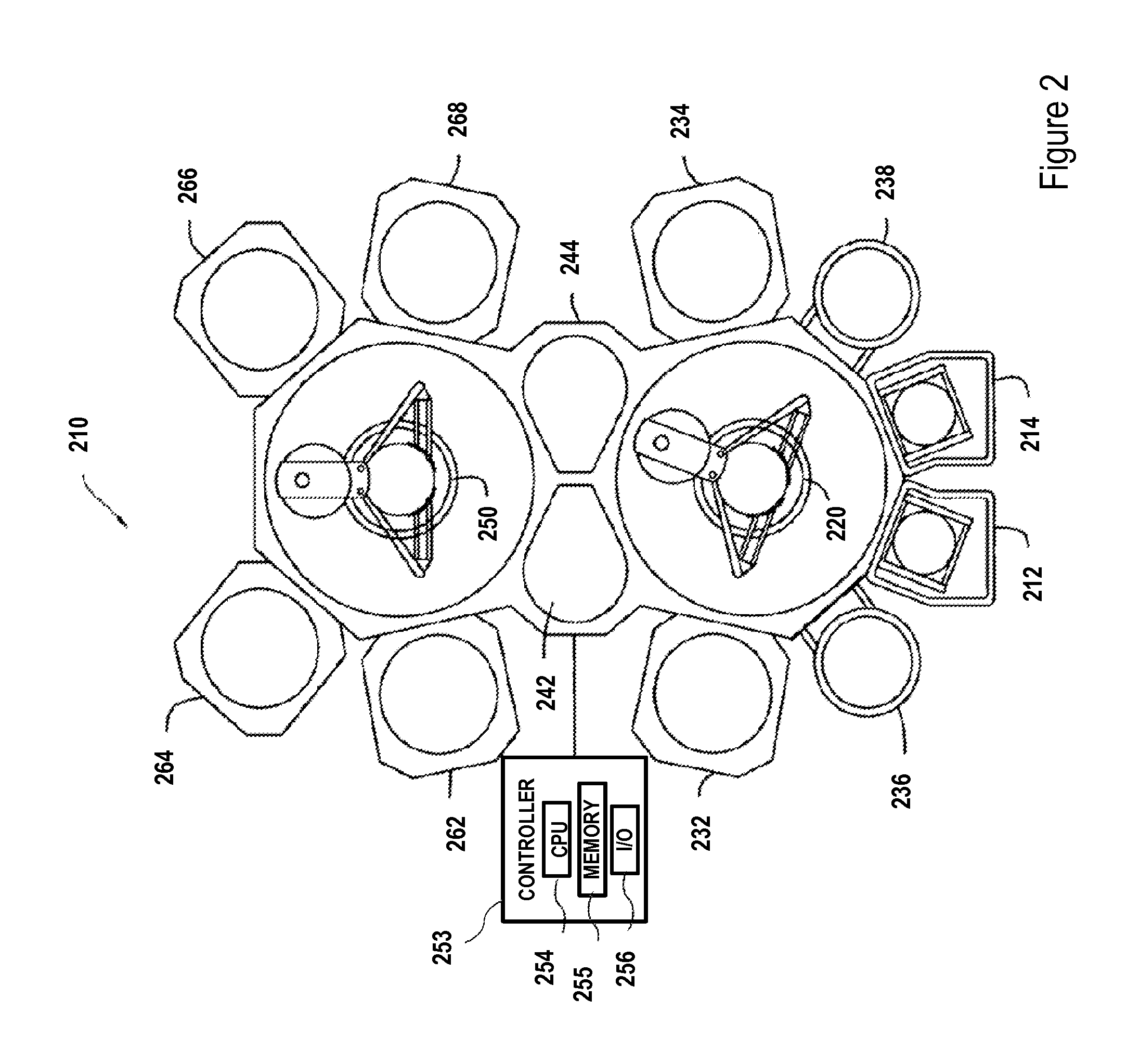

Methods And Apparatus For Forming Tantalum Silicate Layers On Germanium Or III-V Semiconductor Devices

InactiveUS20140065842A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSilicon oxideAtomic layer deposition

Described are apparatus and methods for forming tantalum silicate layers on germanium or III-V materials. Such tantalum silicate layers may have Si / (Ta+Si) atomic ratios from about 0.01 to about 0.15. The tantalum silicate layers may be formed by atomic layer deposition of silicon oxide and tantalum oxide, followed by interdiffusion of the silicon oxide and tantalum oxide layers.

Owner:APPLIED MATERIALS INC

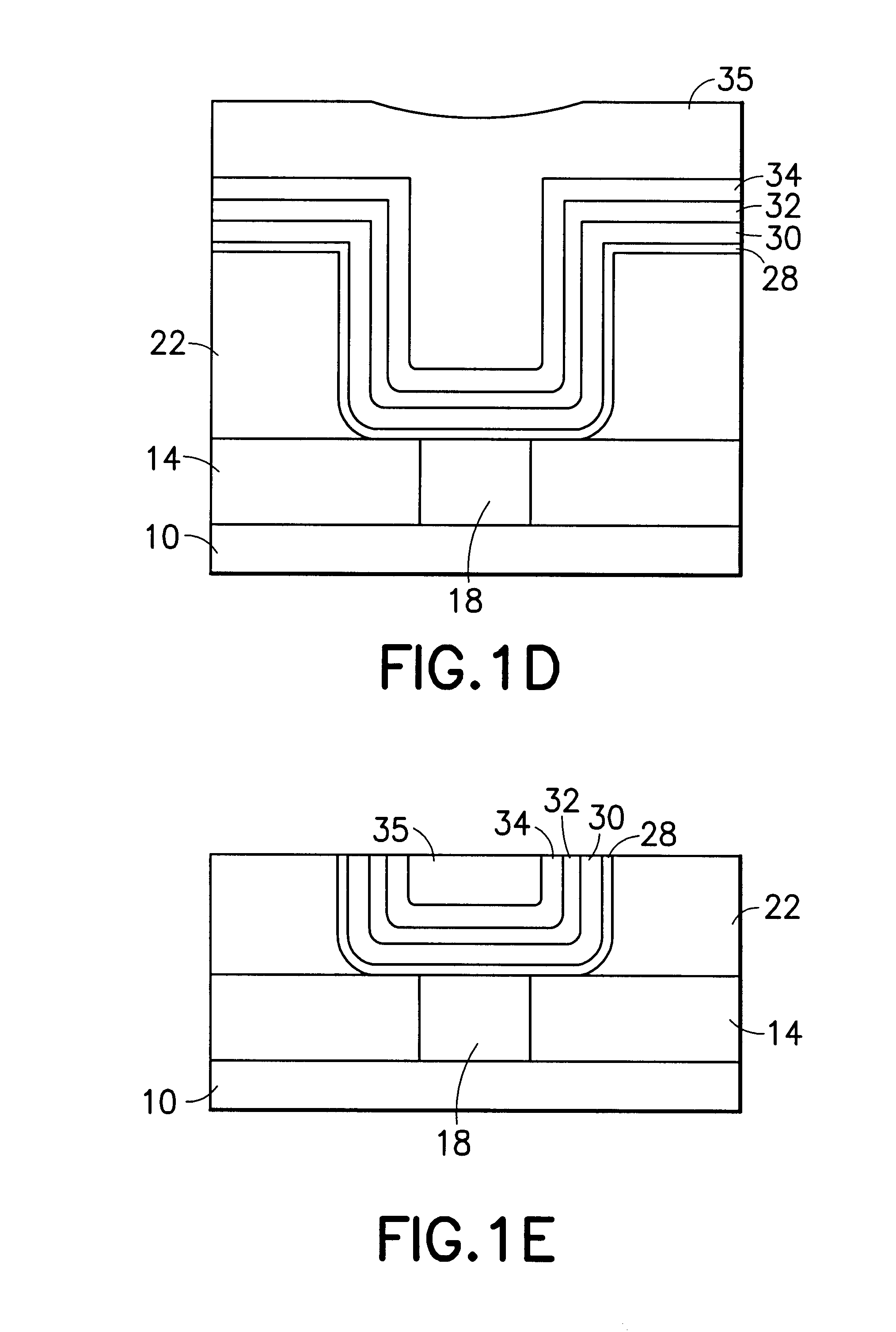

Compositions and structures for chemical mechanical polishing of FeRAM capacitors and method of fabricating FeRAM capacitors using same

InactiveUS6346741B1Easy to manufactureBig advantageOther chemical processesSemiconductor/solid-state device detailsLead zirconate titanateBarium strontium titanate

An integrated circuit structures formed by chemical mechanical polishing (CMP) process, which comprises a conductive pathway recessed in a dielectric substrate, wherein the conductive pathway comprises conductive transmission lines encapsulated in a transmission-enhancement material, and wherein the conductive pathway is filled sequentially by a first layer of the transmission-enhancement material followed by the conductive transmission line; a second layer of transmission-enhancement material encapsulating the conductive transmission line and contacting the first layer of the transmission-enhancement material, wherein the transmission-enhancement material is selected from the group consisting of high magnetic permeability material and high permittivity material. Such integrated circuit structure may comprise a device structure selected from the group consisting of capacitors, inductors, and resistors. Preferably, the transmission-enhancement material comprises MgMn ferrites, MgMnAl ferrites, barium strontium titanate, lead zirconium titanate, titanium oxide, tantalum oxide, etc.

Owner:GULA CONSULTING LLC

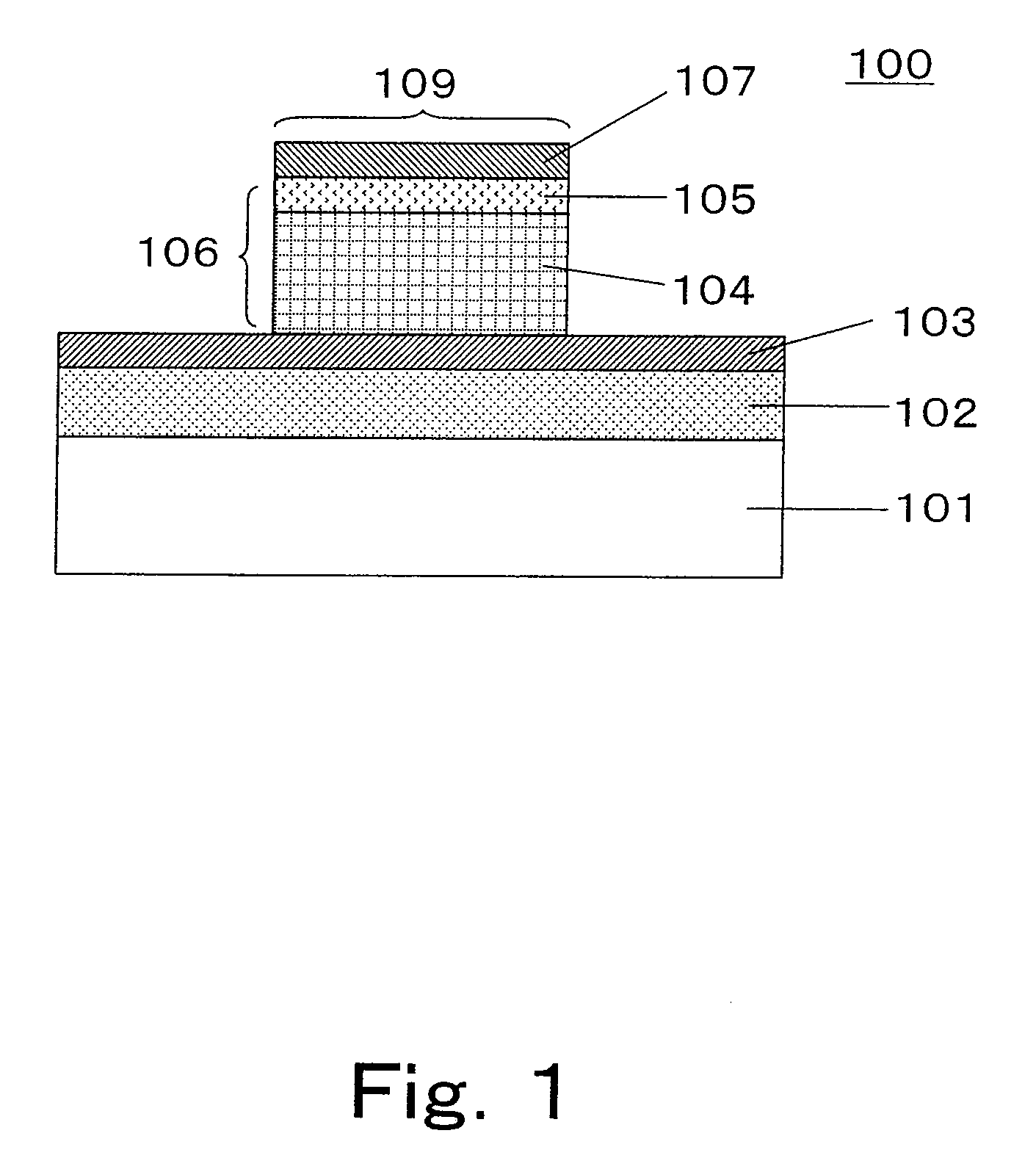

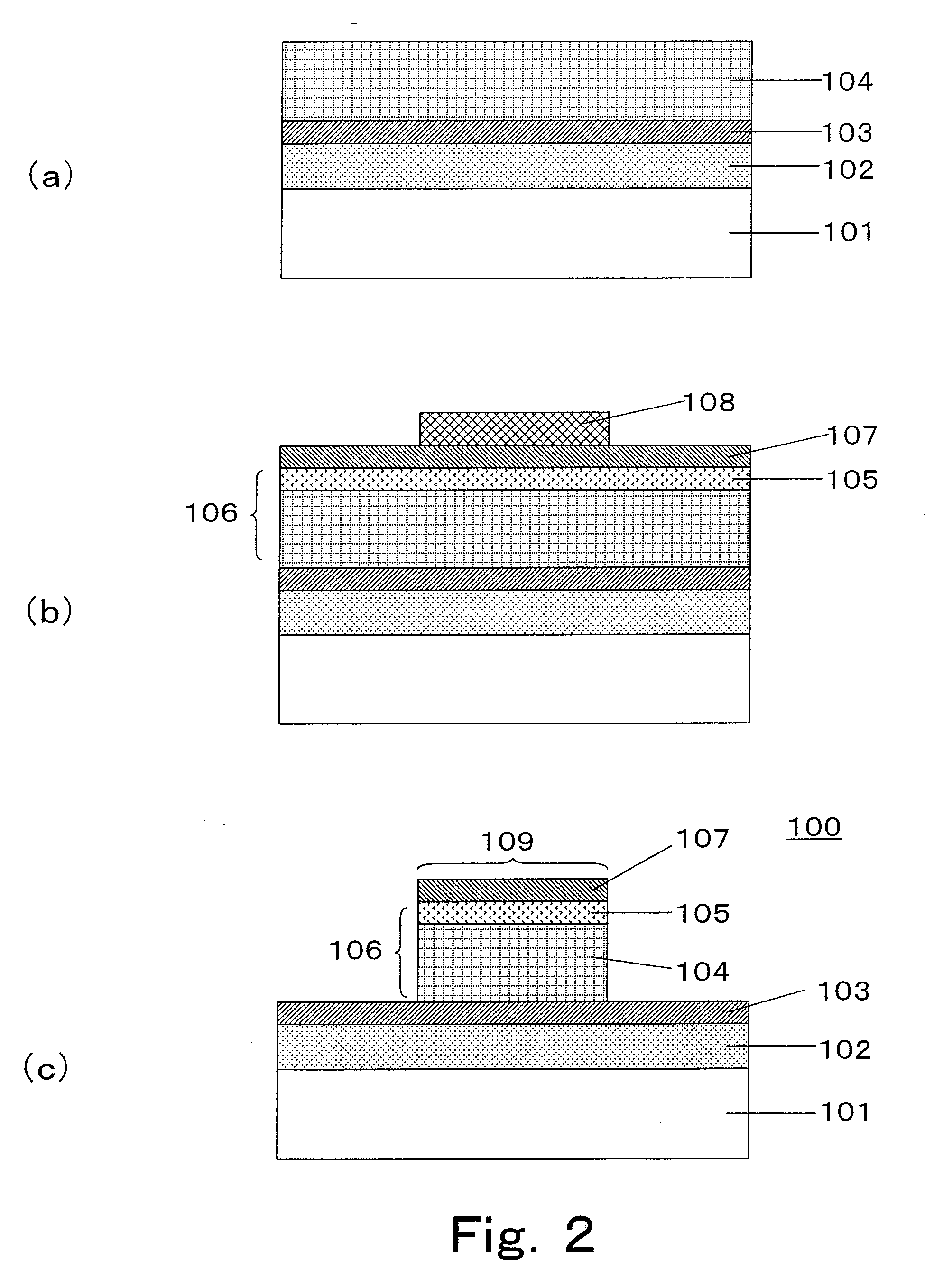

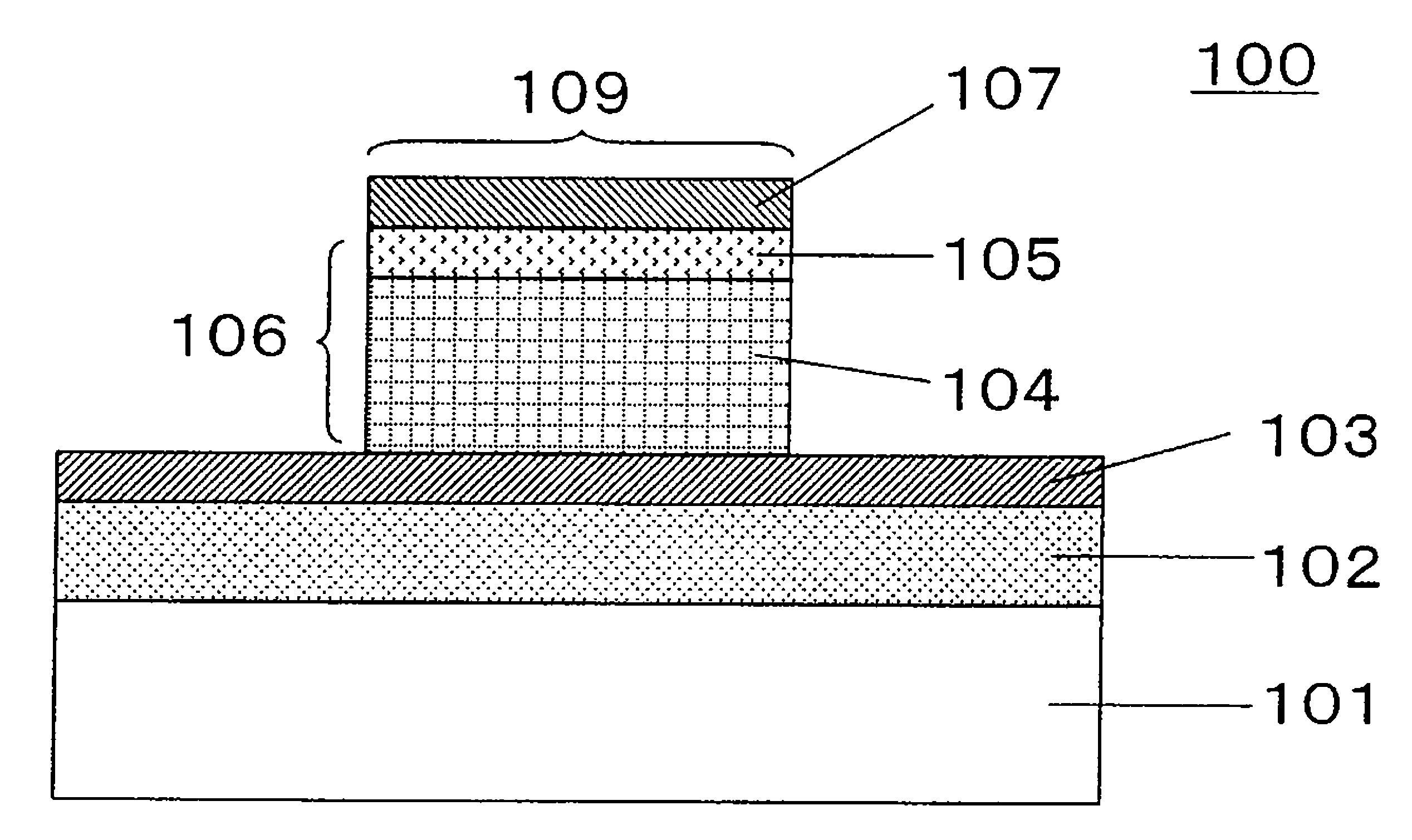

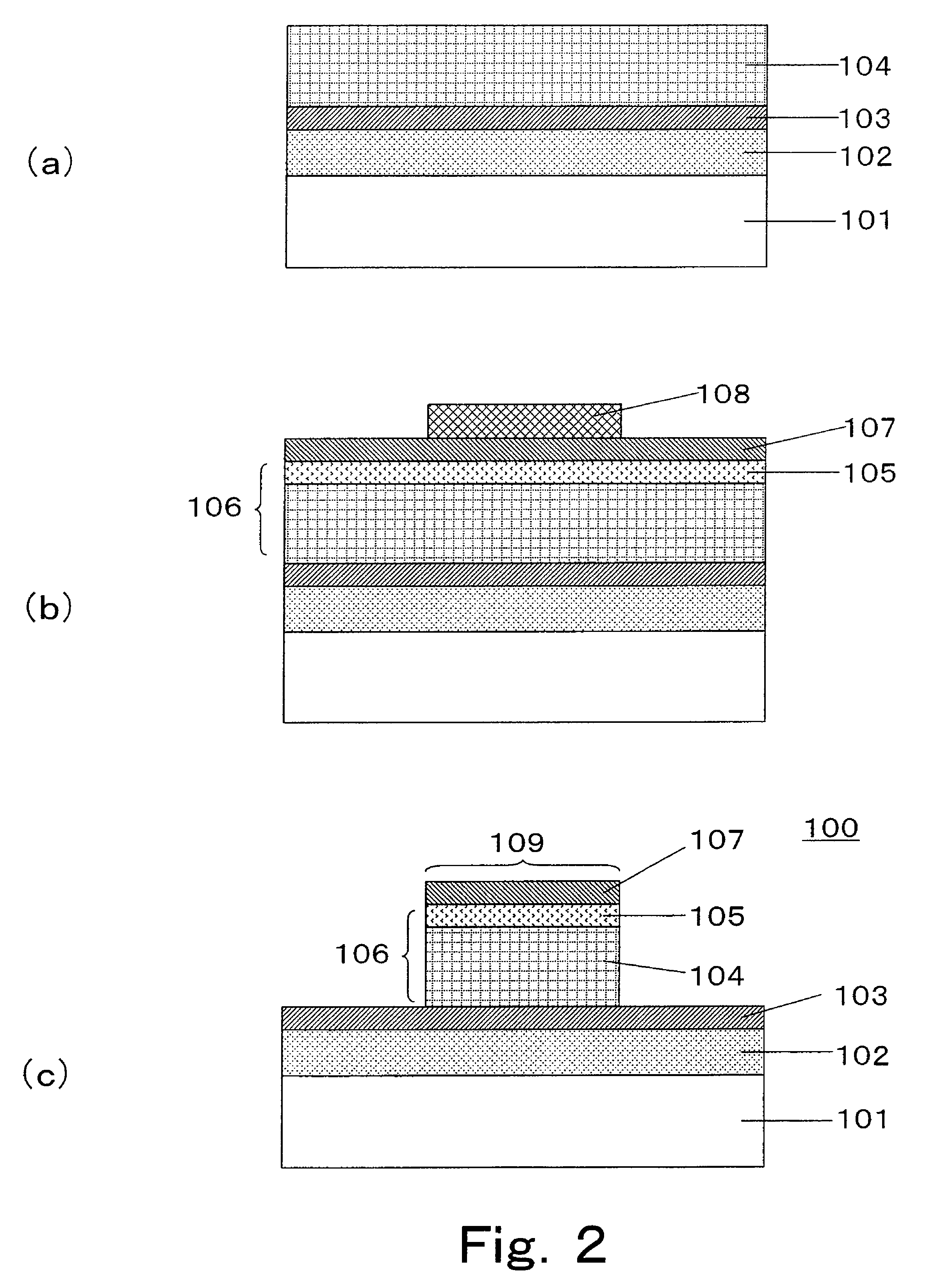

Nonvolatile memory element, manufacturing method thereof, and nonvolatile semiconductor apparatus using the nonvolatile memory element

ActiveUS20090283736A1Reversibly-stable rewrite characteristicHigh affinitySolid-state devicesSemiconductor/solid-state device manufacturingOxygen deficientElectric signal

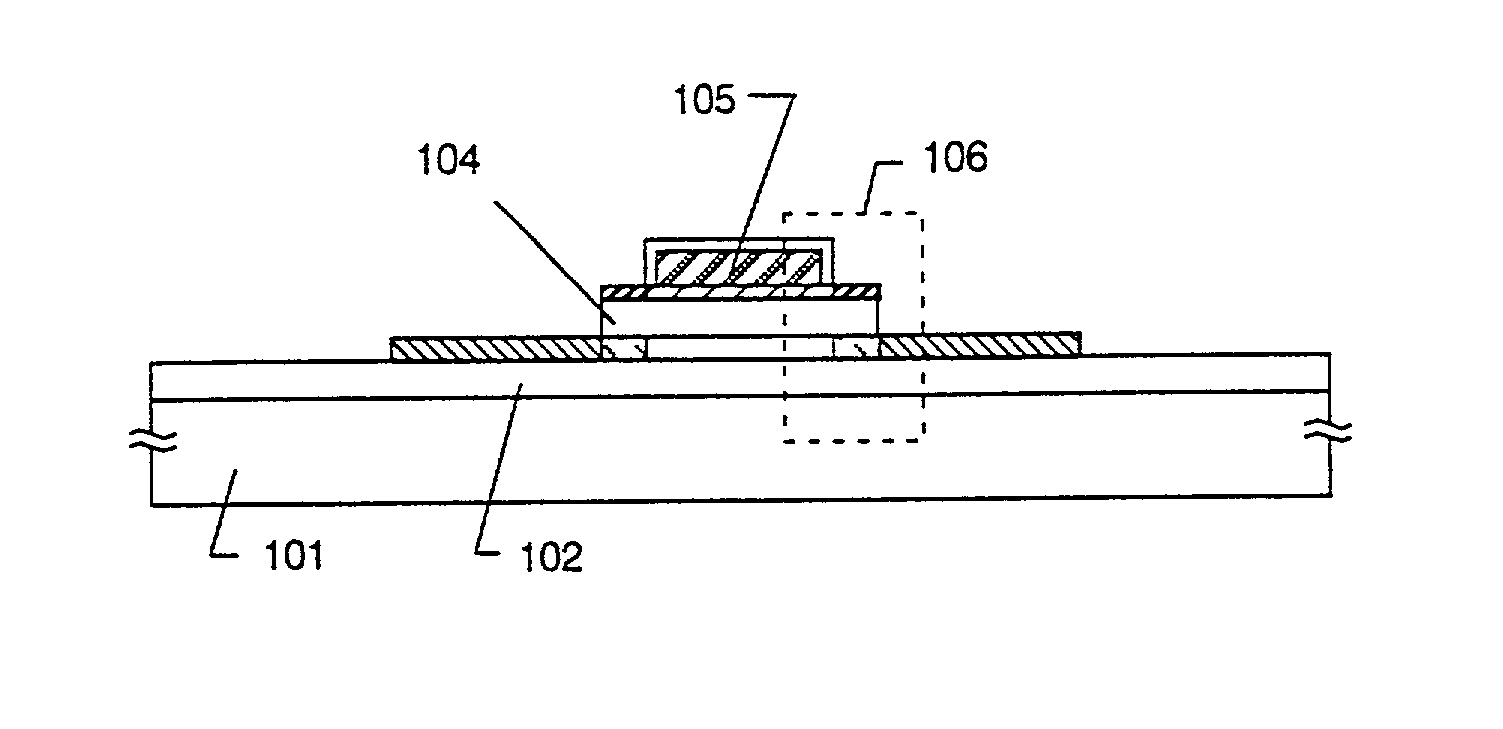

A nonvolatile memory element comprises a first electrode layer (103), a second electrode (107), and a resistance variable layer (106) which is disposed between the first electrode layer (103) and the second electrode layer (107), a resistance value of the resistance variable layer varying reversibly according to electric signals having different polarities which are applied between the electrodes (103), (107), wherein the resistance variable layer (106) has a first region comprising a first oxygen-deficient tantalum oxide having a composition represented by TaOx (0<x<2.5) and a second region comprising a second oxygen-deficient tantalum oxide having a composition represented by TaOy (x<y<2.5), the first region and the second region being arranged in a thickness direction of the resistance variable layer.

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

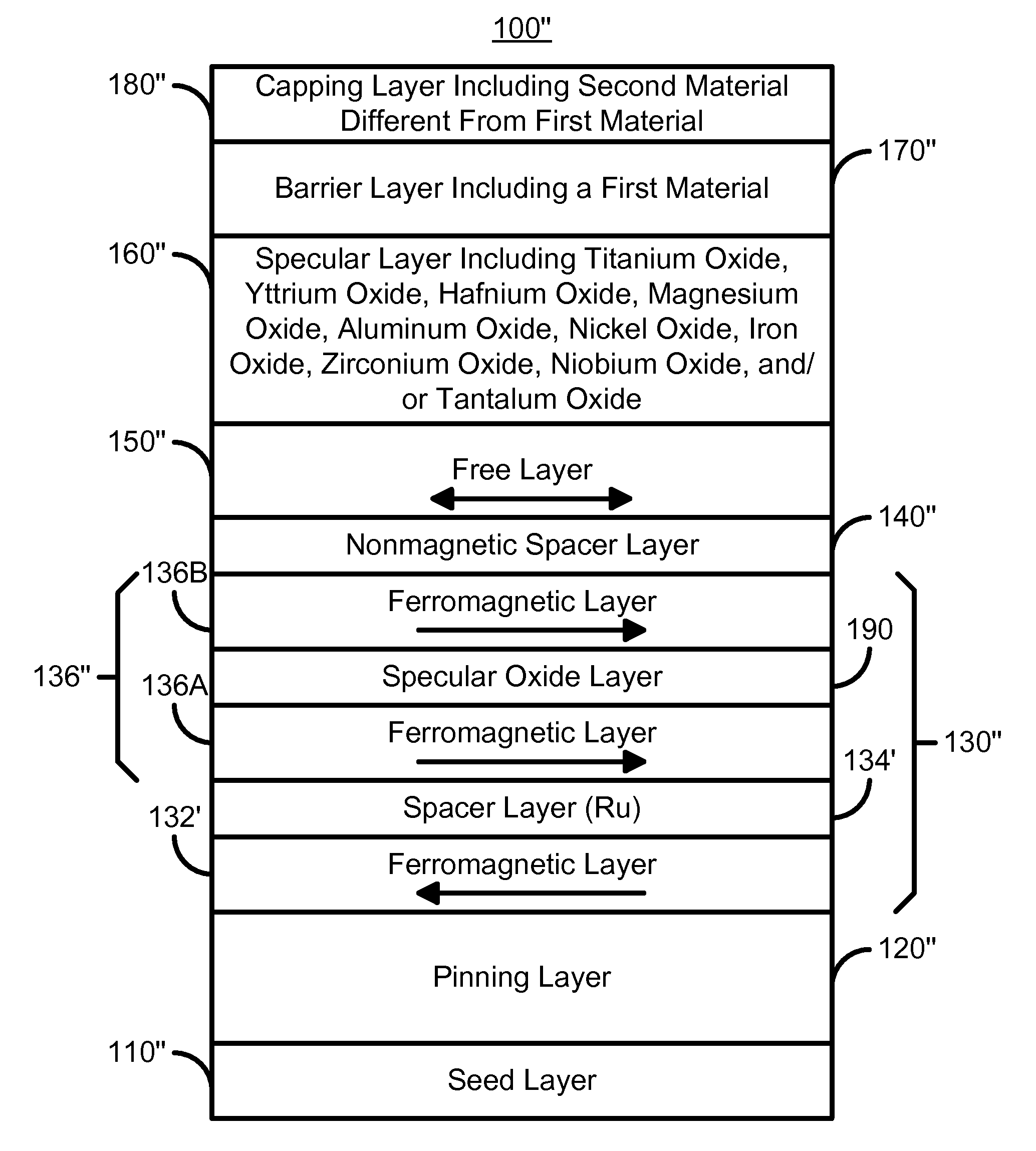

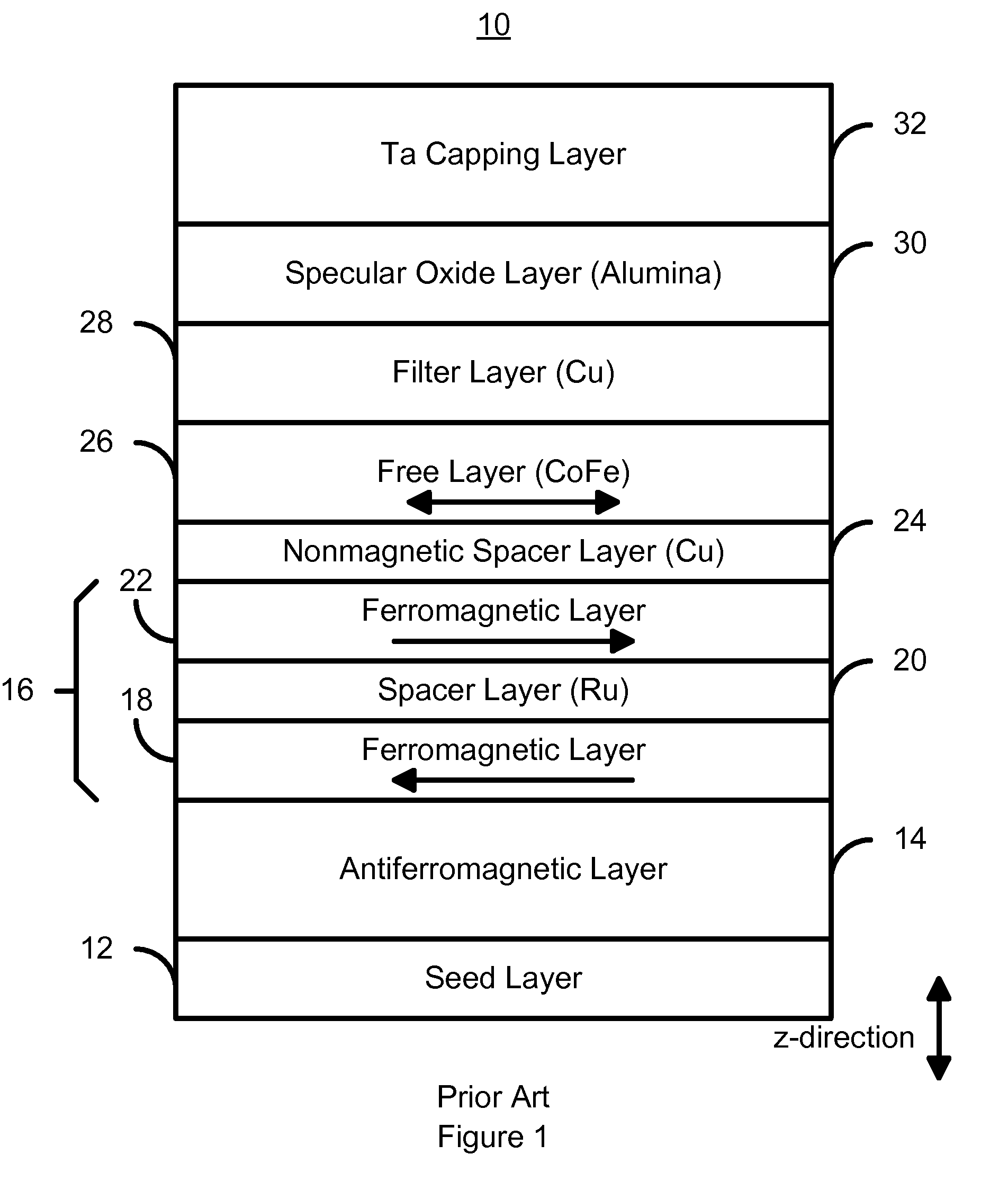

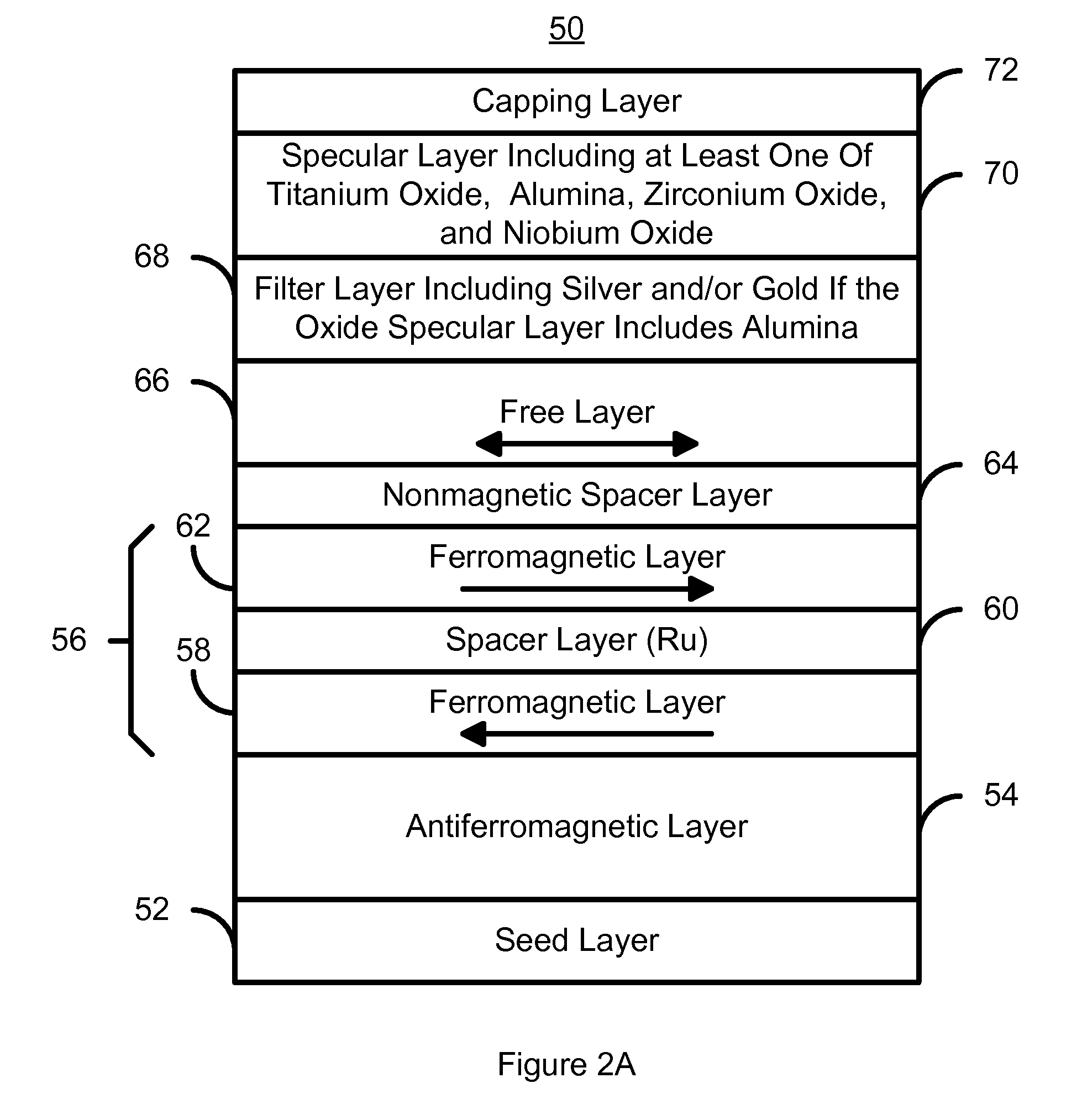

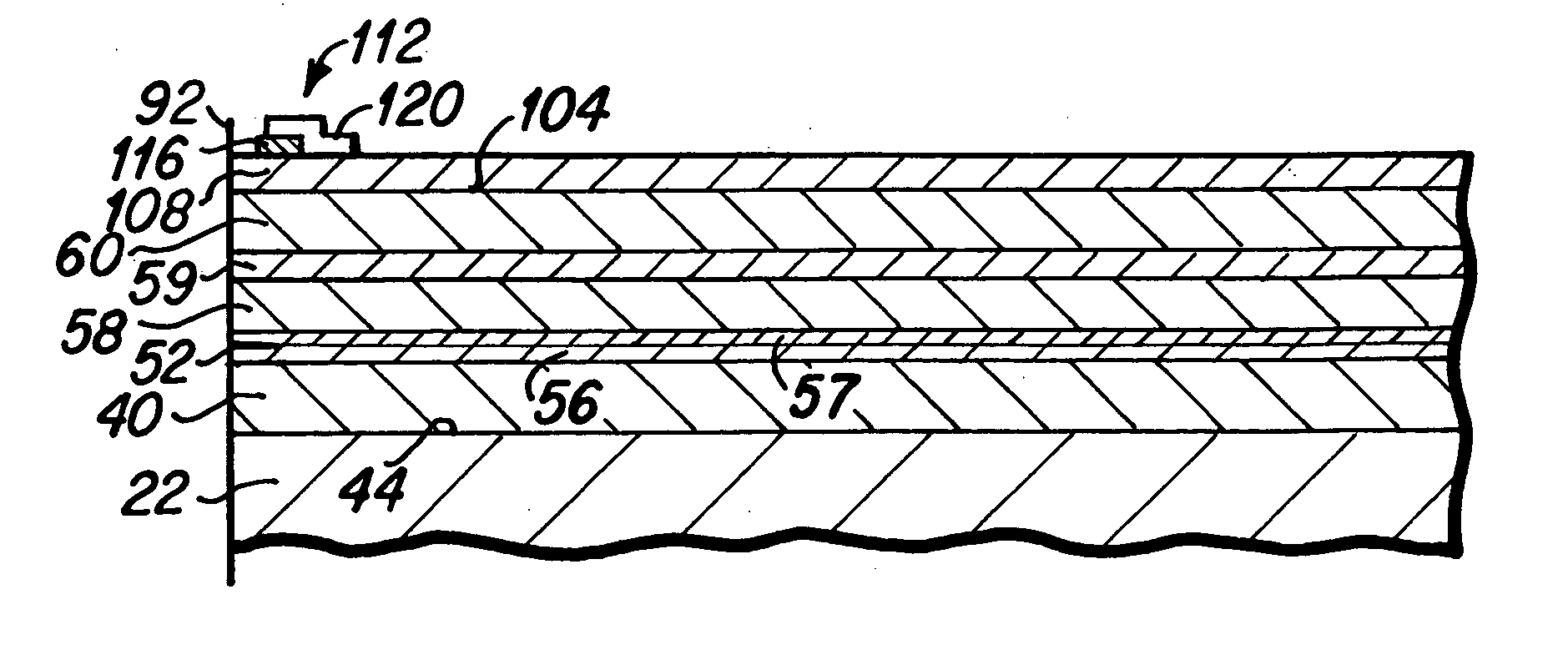

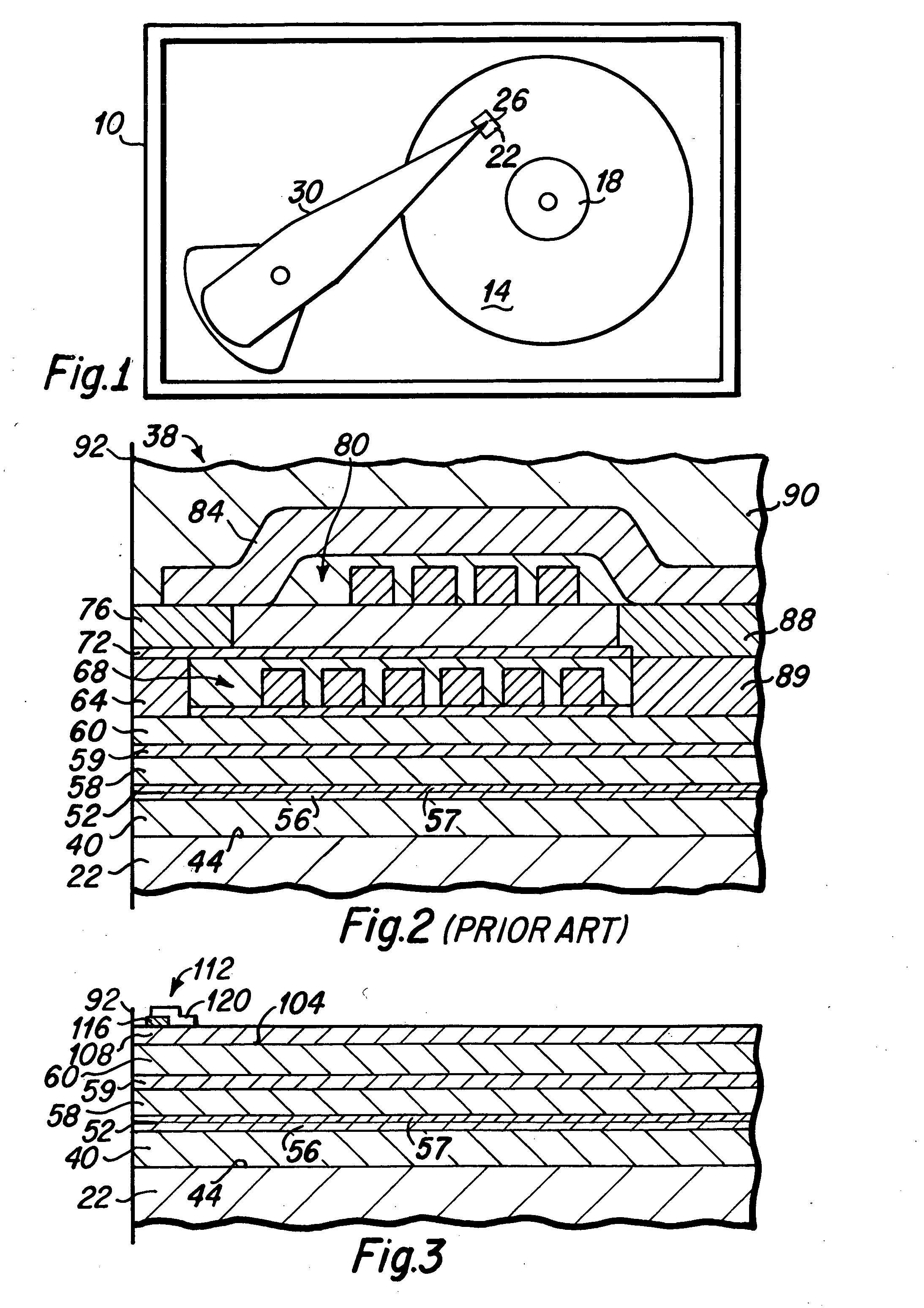

Magnetoresistive structure having a novel specular and barrier layer combination

InactiveUS7684160B1Magnetic-field-controlled resistorsConductive/insulating/magnetic material on magnetic film applicationYttriumTitanium oxide

A method and system for providing a magnetoresistive structure is disclosed. The magnetoresistive structure includes a pinned layer, a nonmagnetic spacer layer, a free layer, a specular layer, a barrier layer, and a capping layer. The spacer layer resides between the pinned layer and the free layer. The free layer is electrically conductive and resides between the specular layer and the nonmagnetic spacer layer. The specular layer is adjacent to the free layer and includes at least one of titanium oxide, yttrium oxide, hafnium oxide, magnesium oxide, aluminum oxide, nickel oxide, iron oxide, zirconium oxide, niobium oxide, and tantalum oxide. The barrier layer resides between the specular layer and the capping layer. The barrier layer is nonmagnetic and includes a first material. The capping layer includes a second material different from the first material.

Owner:WESTERN DIGITAL TECH INC

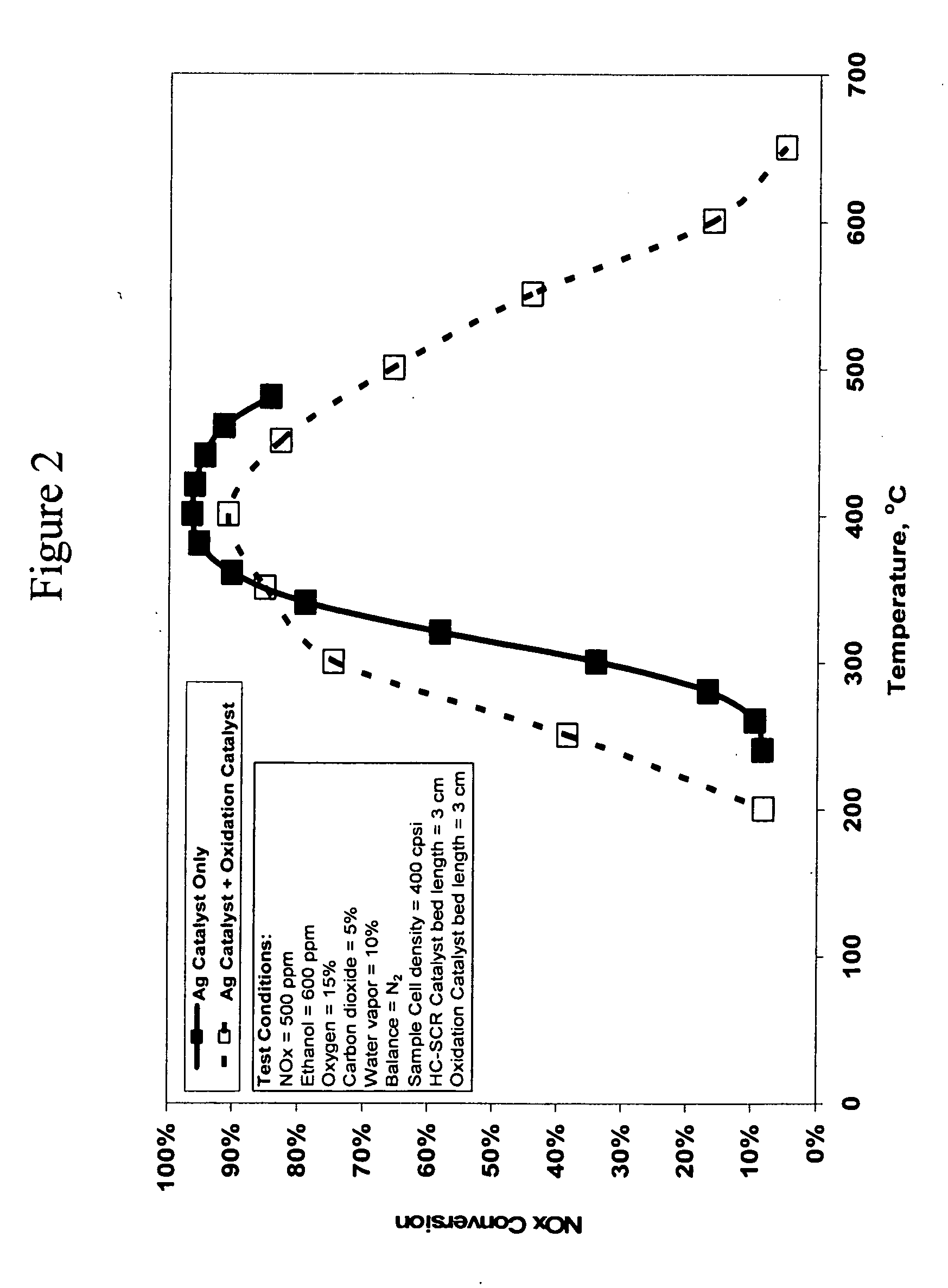

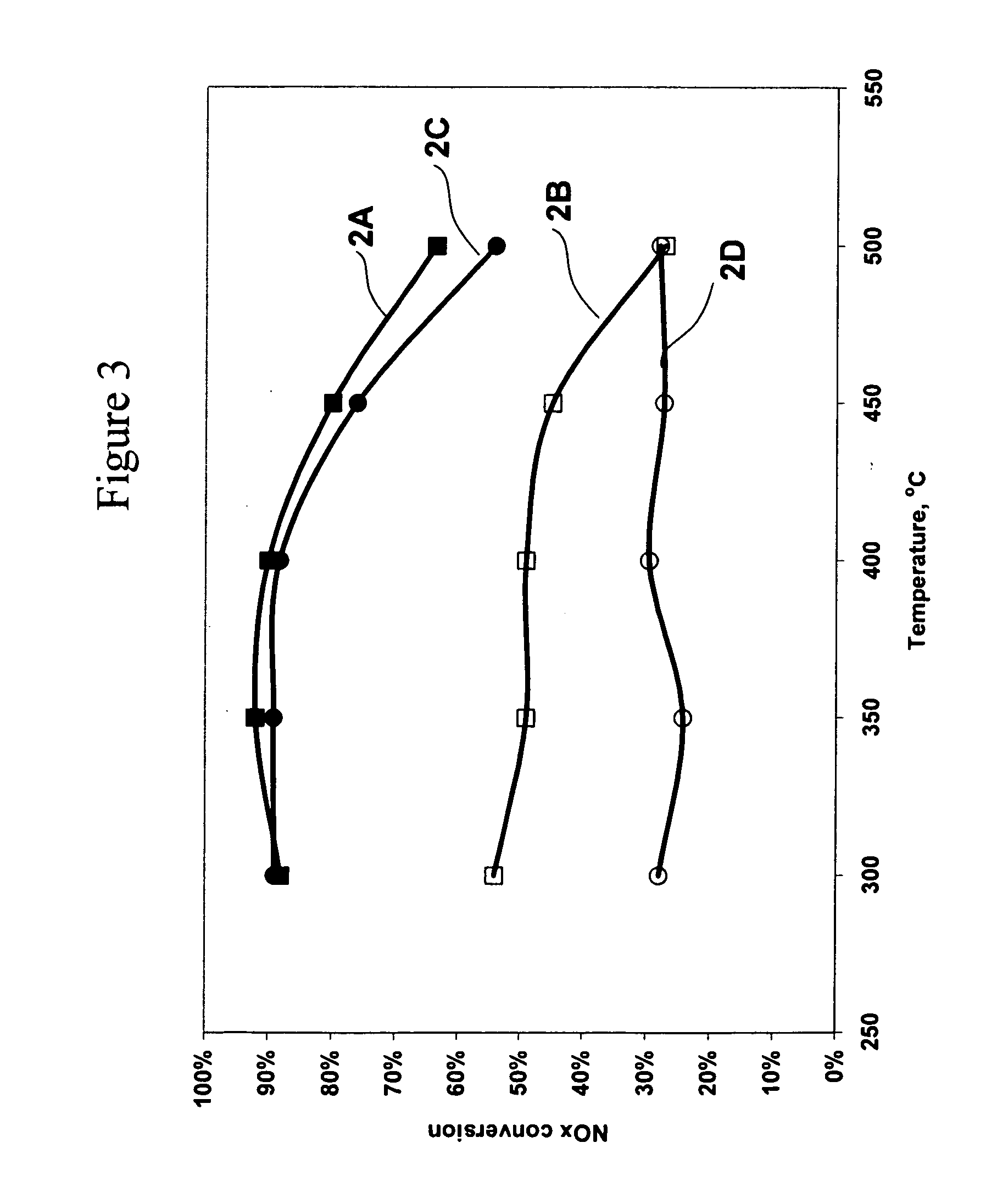

Catalyst and method for reducing nitrogen oxides in exhaust streams with hydrocarbons or alcohols

A catalyst system and a method for reducing nitrogen oxides in an exhaust gas by reduction with a hydrocarbon or oxygen-containing organic compound reducing agent are provided. The catalyst system contains a silver catalyst and a modifier catalyst, where the modifier catalyst contains a modifier oxide, where the modifier oxide is selected from the group consisting of iron oxide, cerium oxide, copper oxide, manganese oxide, chromium oxide, a lanthanide oxide, an actinide oxide, molybdenum oxide, tin oxide, indium oxide, rhenium oxide, tantalum oxide, osmium oxide, barium oxide, calcium oxide, strontium oxide, potassium oxide, vanadium oxide, nickel oxide, tungsten oxide, and mixtures thereof. The modifier oxide is supported on an inorganic oxide support or supports, where at least one of the inorganic oxide supports is an acidic support. The catalyst system of the silver catalyst and the modifier catalyst provides higher NOx conversion than either the silver catalyst or the modifier catalyst alone.

Owner:CATALYTIC SOLUTIONS INC

Thin film transistor

InactiveUS6849872B1Intuitive effectInhibit deteriorationTransistorSolid-state devicesNitrideSemiconductor device

An improved type thin film semiconductor device and a method for forming the same are described. That is, in a thin film semiconductor device such as TFT formed on an insulating substrate, it is possible to prevent the intrusion of a mobile ion from a substrate or other parts, by forming the first blocking film comprising a silicon nitride, an aluminum oxide, an aluminum nitride, a tantalum oxide, and the like, under the semiconductor device through an insulating film used in a buffering, and then, by forming the second blocking film on TFT, and further, by covering TFT with the first and second blocking films.

Owner:SEMICON ENERGY LAB CO LTD

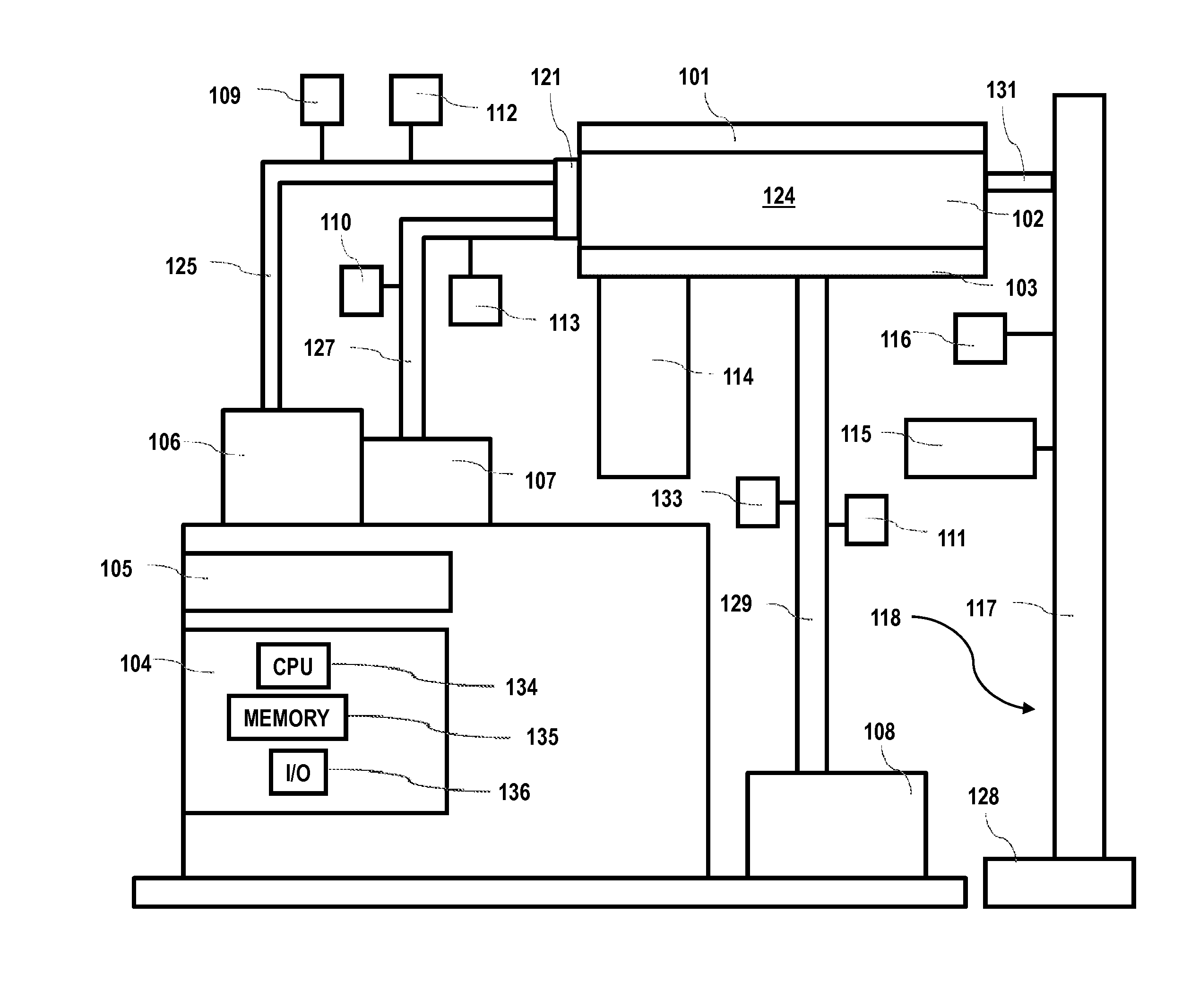

Systems and methods for forming tantalum oxide layers and tantalum precursor compounds

InactiveUS7030042B2Easy to controlReaction become badSemiconductor/solid-state device manufacturingGroup 5/15 organic compounds without C-metal linkagesCompound aGas phase

Owner:MICRON TECH INC

Systems and methods for forming tantalum oxide layers and tantalum precursor compounds

InactiveUS20050019978A1Easy to controlMinimizing detrimental gas phase reactionSolid-state devicesSemiconductor/solid-state device manufacturingCompound aGas phase

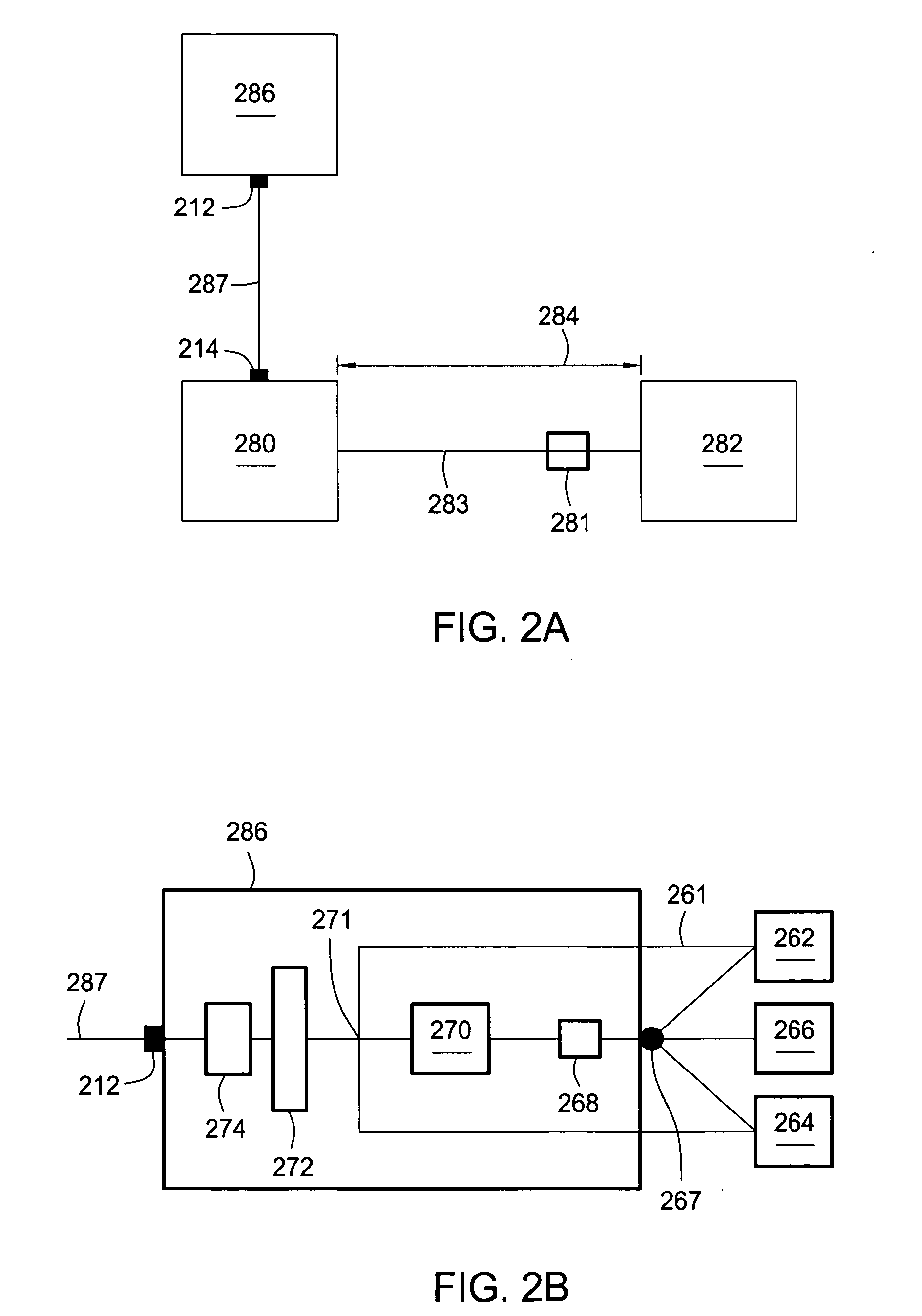

A method of forming (and apparatus for forming) a tantalum oxide layer on a substrate, particularly a semiconductor substrate or substrate assembly, using a vapor deposition process and a tantalum precursor compound that includes alkoxide ligands, for example.

Owner:MICRON TECH INC

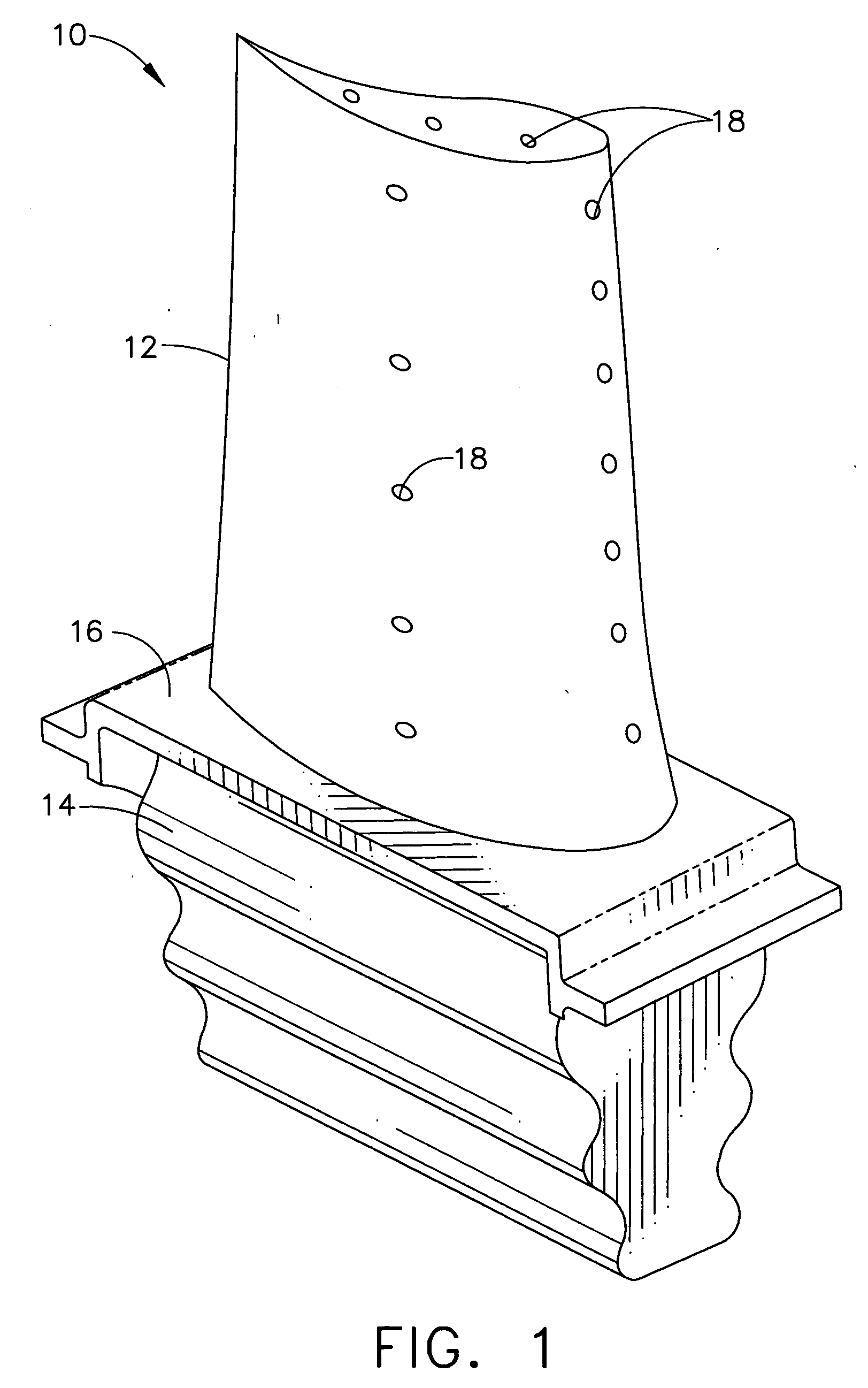

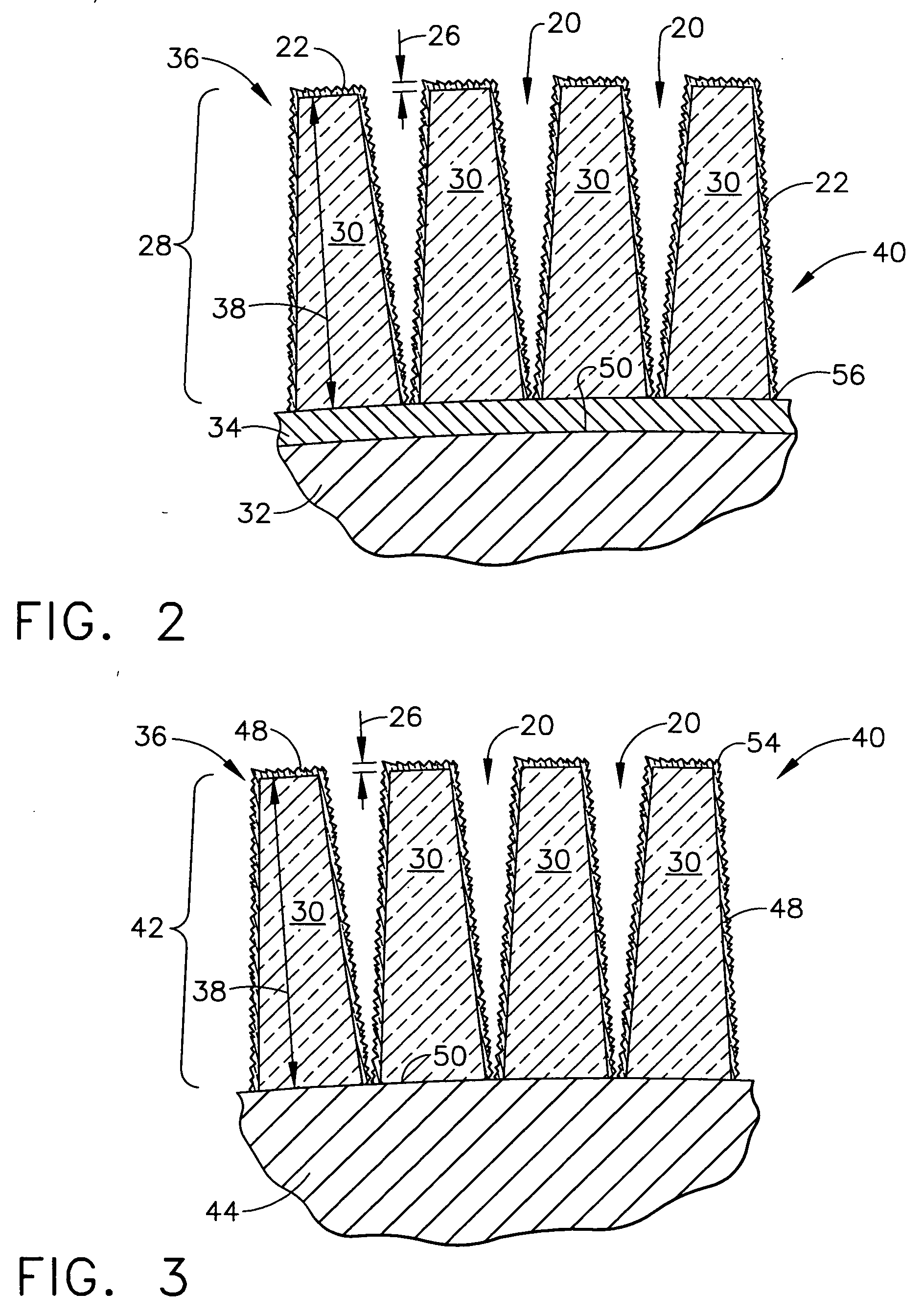

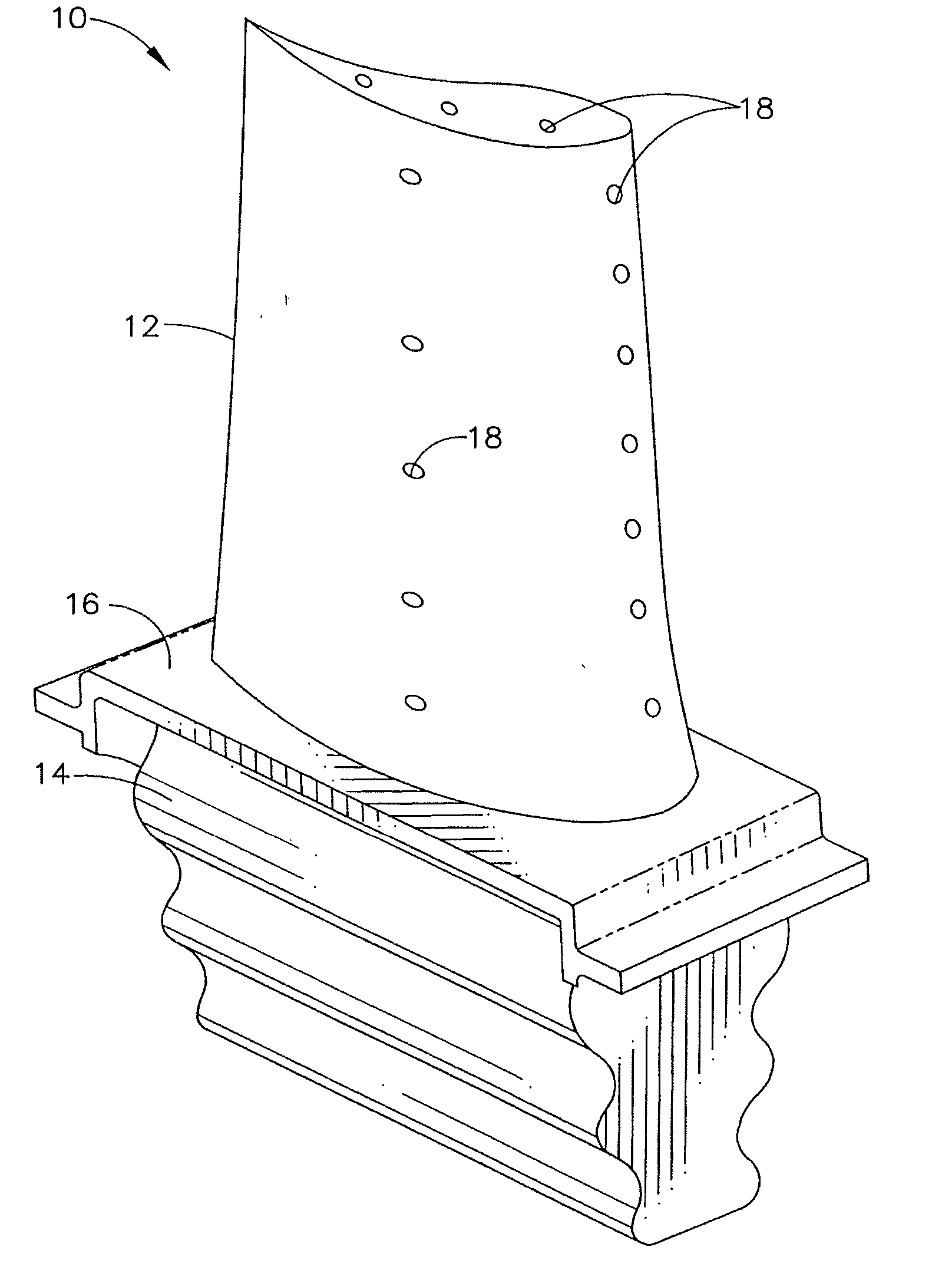

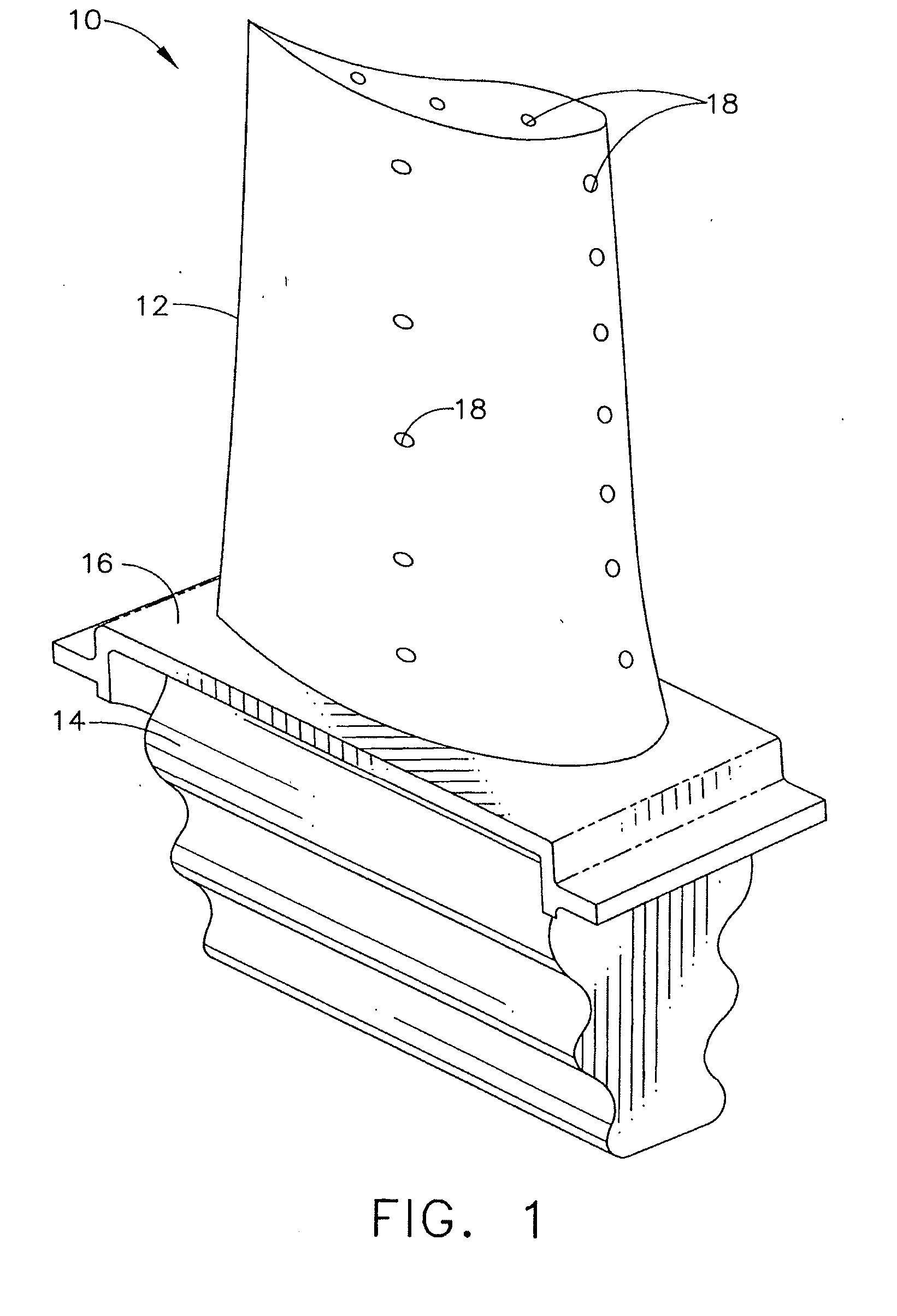

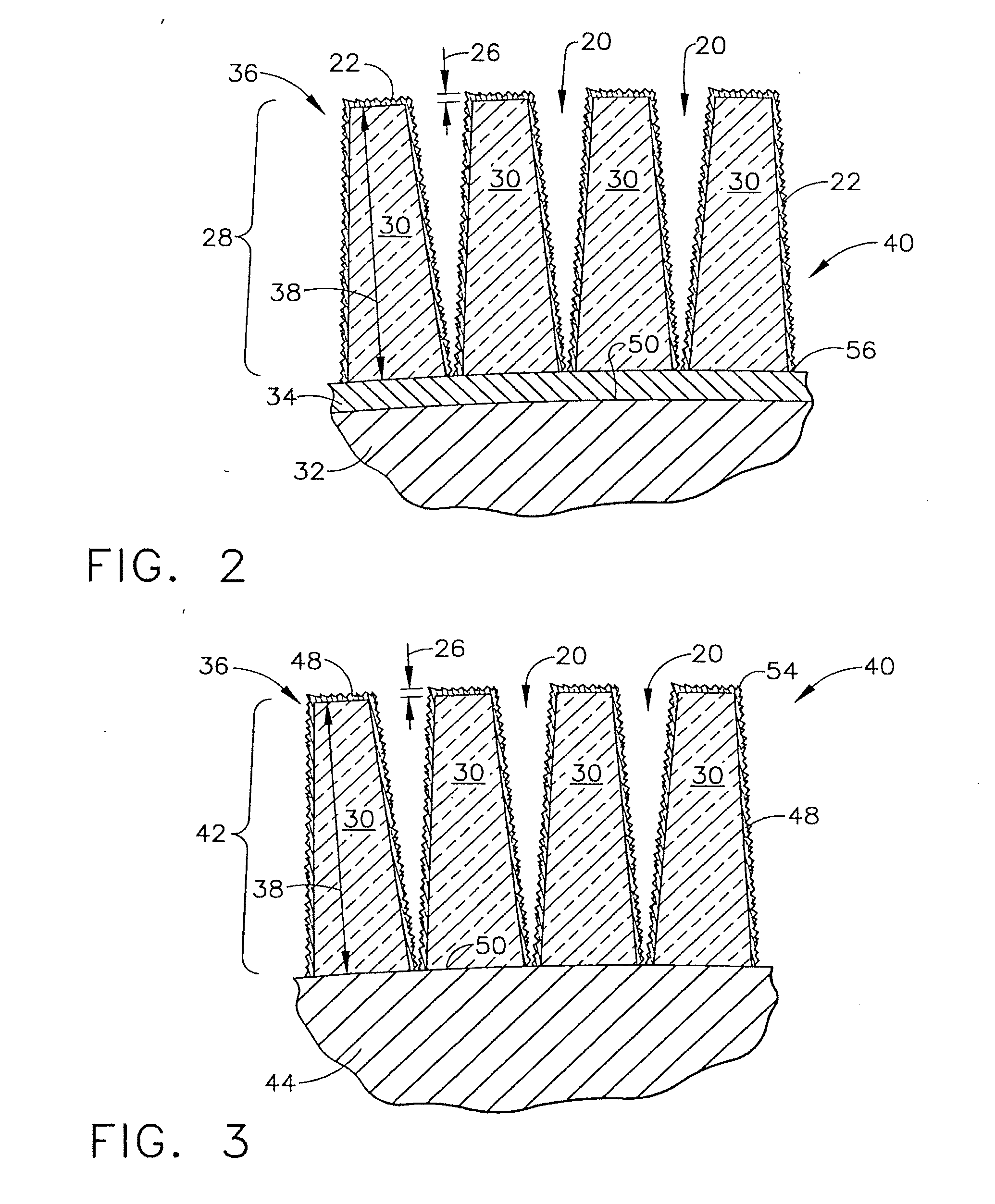

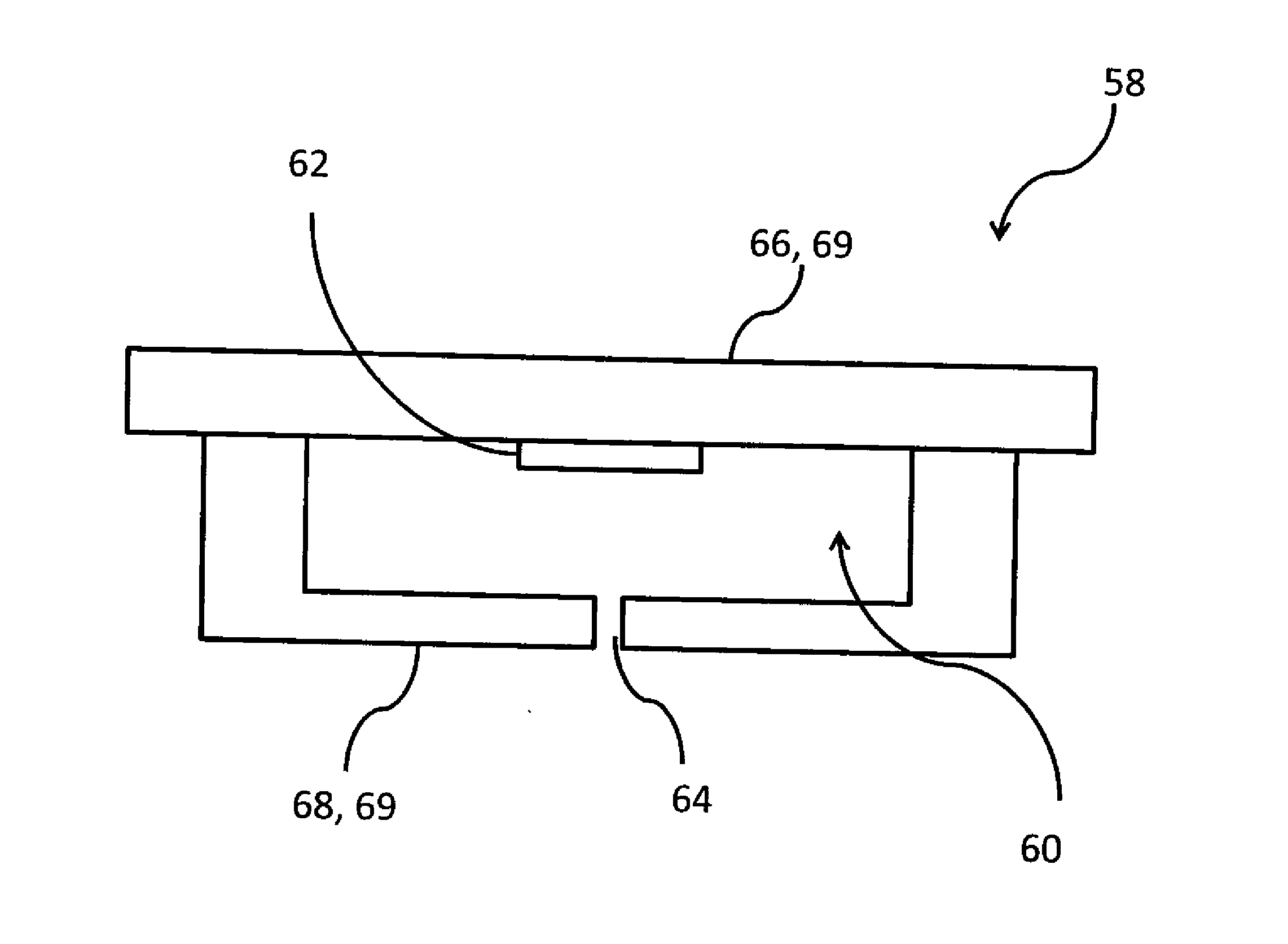

Atomic layer deposition for turbine components

A method and superalloy component for depositing a layer of material onto gas turbine engine components by atomic layer deposition. A superalloy component may have a ceramic thermal barrier coating on at least a portion of its surface, comprising a superalloy substrate and a bonding coat; and aluminum oxide (Al2O3) layer may be deposited on top of an yttria-stabilized zirconia layer and form a bonding coat by atomic layer deposition. The yttria-stabilized zirconia layer may have a plurality of micron sized gaps extending from the top surface of the ceramic coating towards the substrate and defining a plurality of columns of the yttria-stabilized zirconia layer. Also, atomic layer deposition may be used to lay an aluminum oxide (Al2O3) layer over a tantalum oxide (Ta2O5) layer on a silicon-based substrate. Using atomic layer deposition to coat the gas turbine engine components permits conformal coating of the columnar surface to permit gap expansion and contraction without sintering of the columnar surface or spalling of the coating, and form an oxidation resistant bonding coat.

Owner:HONEYWELL INT INC

Atomic layer deposition for turbine components

A method and superalloy component for depositing a layer of material onto gas turbine engine components by atomic layer deposition. A superalloy component may have a ceramic thermal barrier coating on at least a portion of its surface, comprising a superalloy substrate and a bonding coat; and aluminum oxide (Al2O3) layer may be deposited on top of an yttria-stabilized zirconia layer and form a bonding coat by atomic layer deposition. The yttria-stabilized zirconia layer may have a plurality of micron sized gaps extending from the top surface of the ceramic coating towards the substrate and defining a plurality of columns of the yttria-stabilized zirconia layer. Also, atomic layer deposition may be used to lay an aluminum oxide (Al2O3) layer over a tantalum oxide (Ta2O5) layer on a silicon-based substrate. Using atomic layer deposition to coat the gas turbine engine components permits conformal coating of the columnar surface to permit gap expansion and contraction without sintering of the columnar surface or spalling of the coating, and form an oxidation resistant bonding coat.

Owner:HONEYWELL INT INC

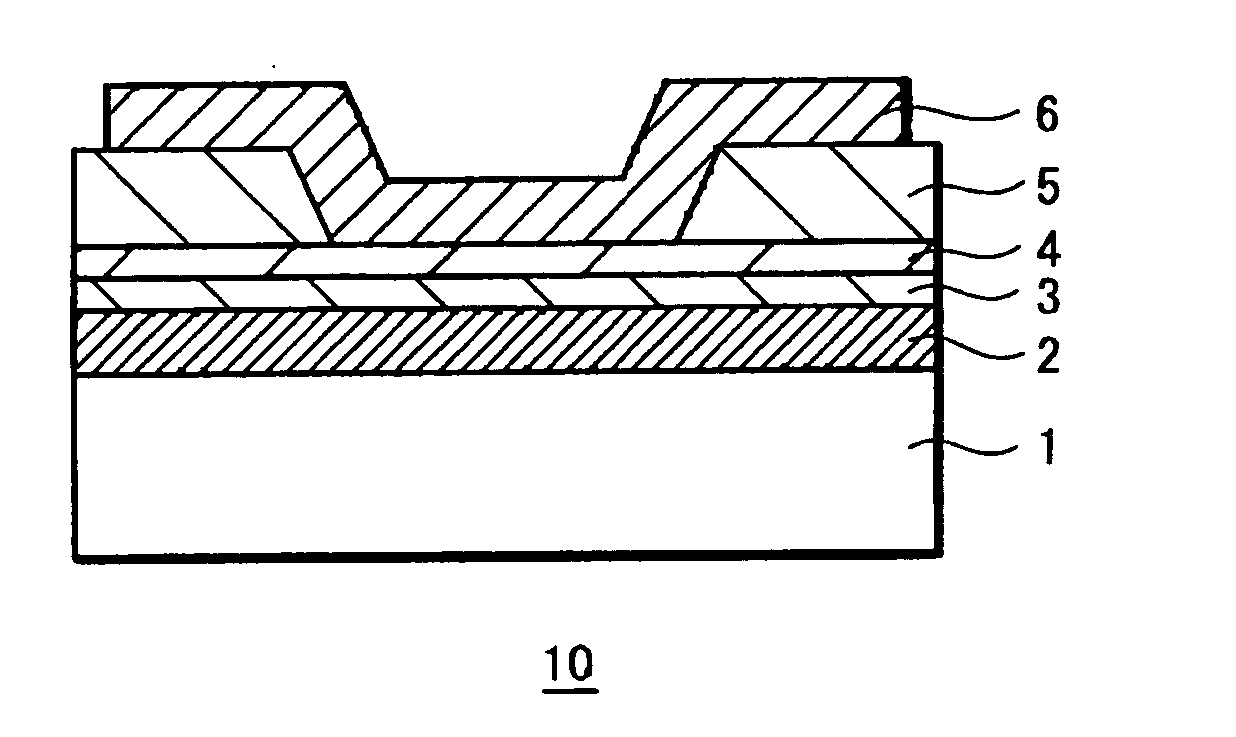

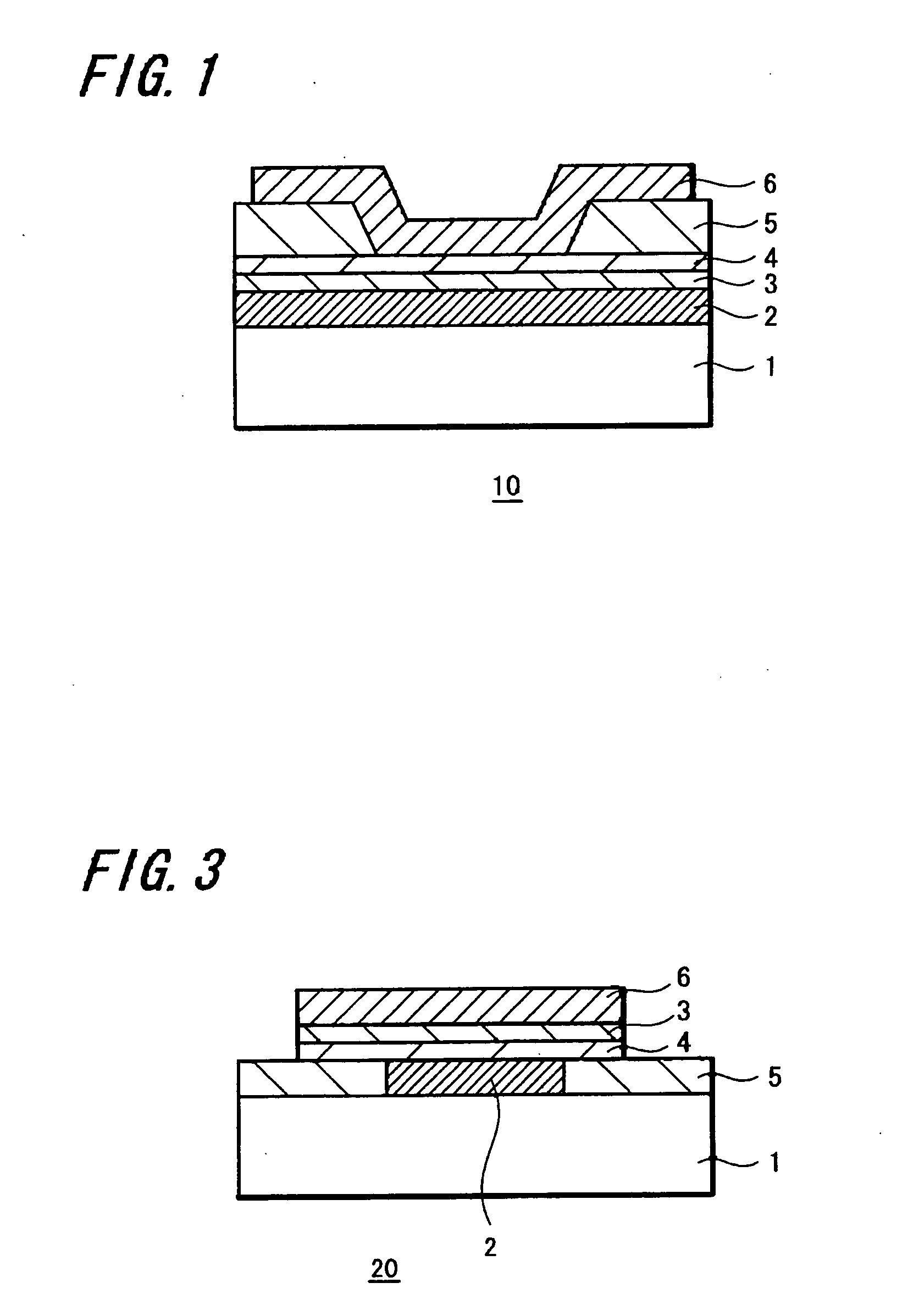

Memory element and memory device

ActiveUS20060126423A1Deterioration of characteristic can be preventedDeterioration of characteristicSolid-state devicesDigital storageData recordingNiobium oxide

A memory element which stably performs operations such as data recording and which has a stable structure with respect to heat is provided. A memory element 10 includes a memory layer 4 and an ion source layer 3 positioned between the first electrode 2 and second electrode 6, in which the ion source layer 3 contains any of elements selected from Cu, Ag and Zn, and any of elements selected from Te, S and Se, and the memory layer 4 is made of any of tantalum oxide, niobium oxide, aluminum oxide, hafnium oxide and zirconium oxide, or is made of mixed materials thereof.

Owner:SONY CORP

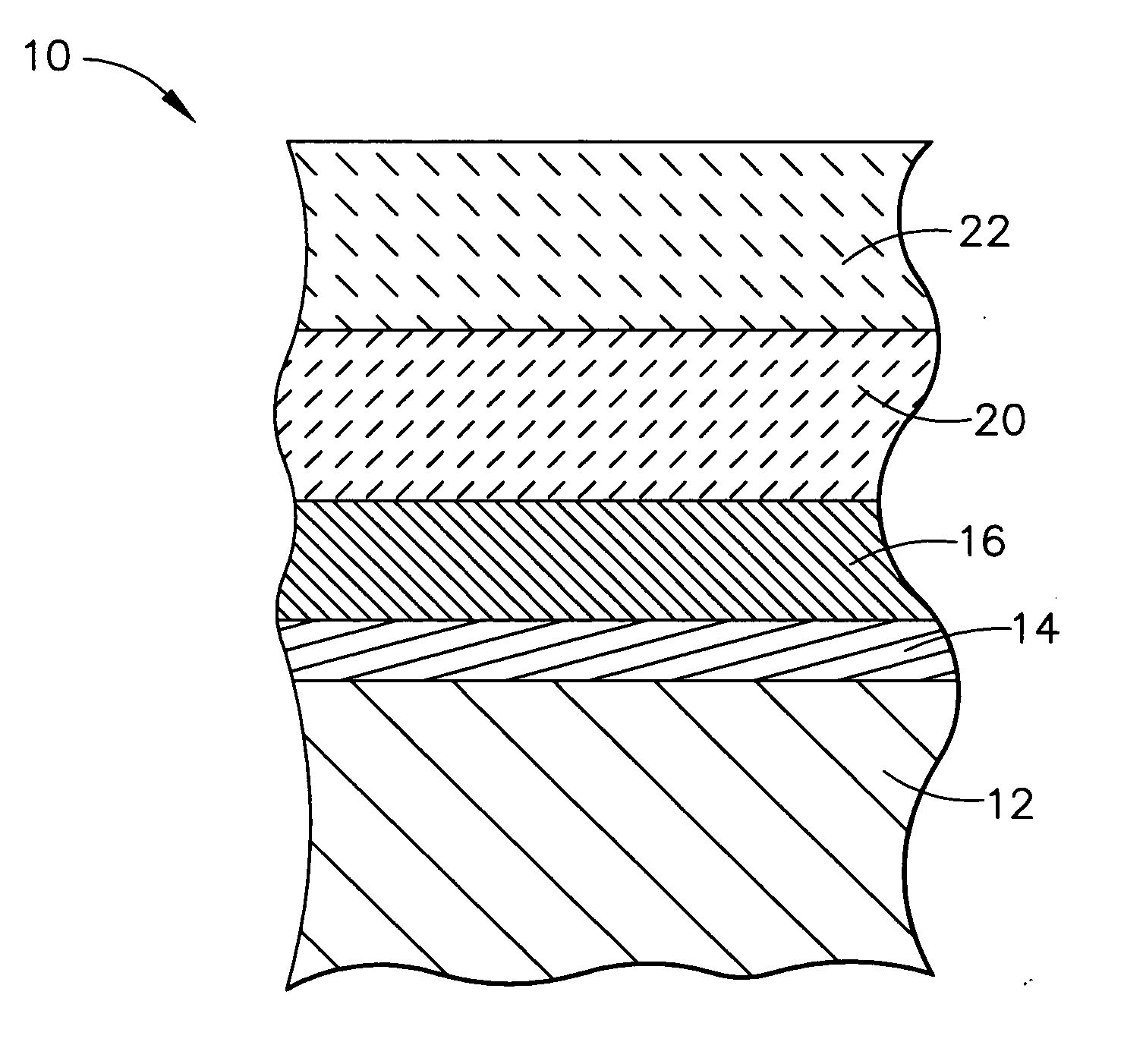

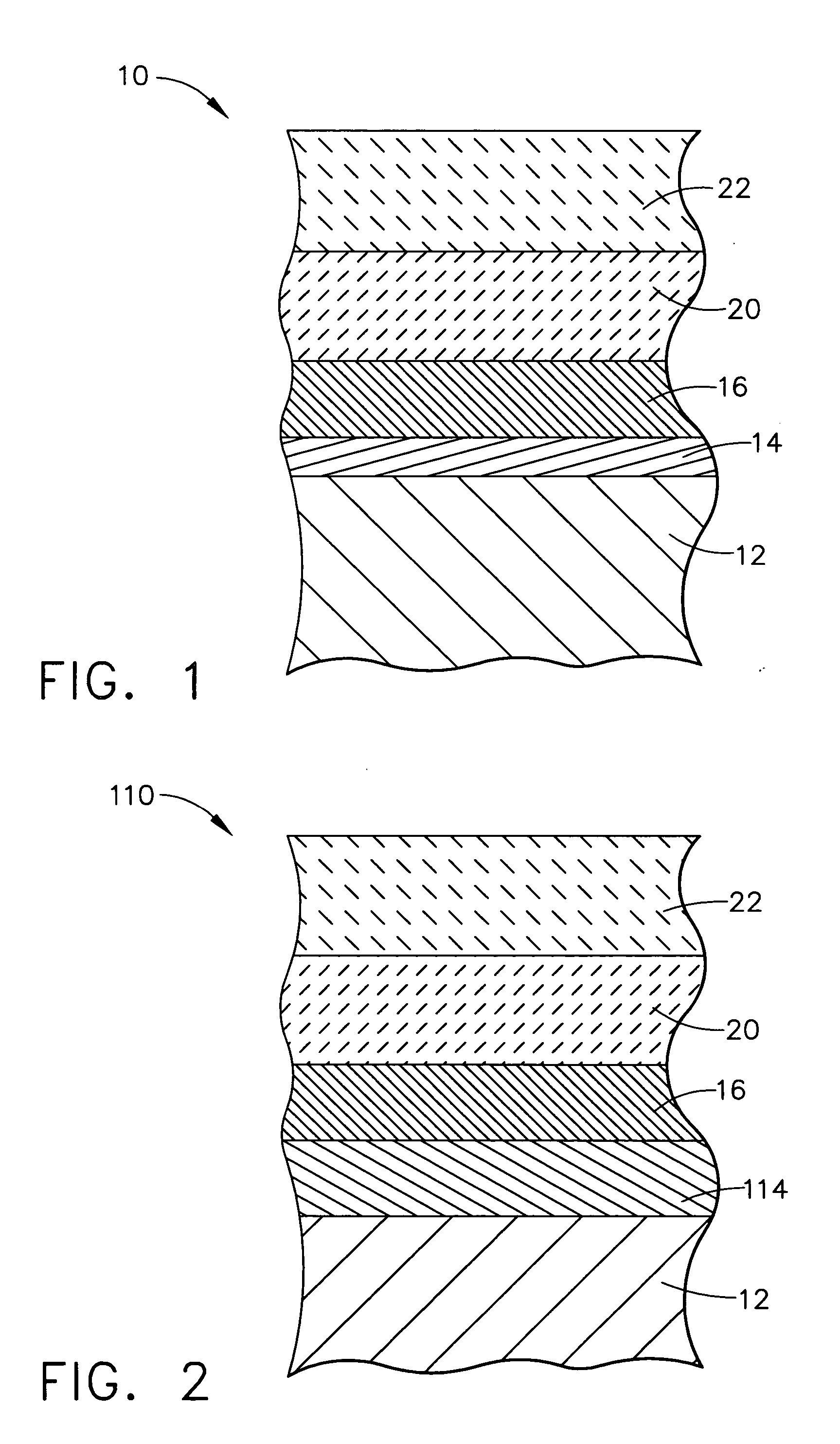

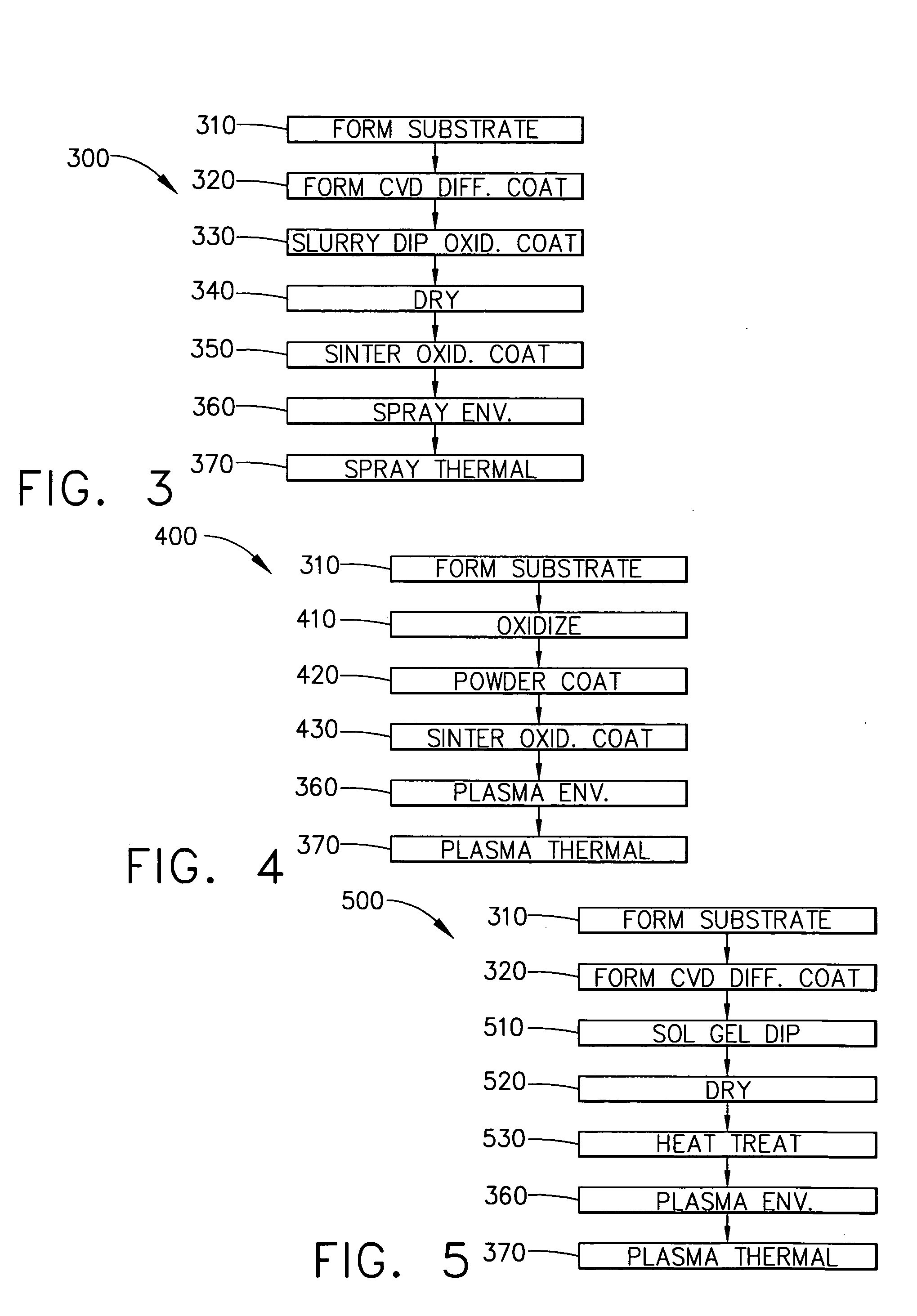

Oxidation barrier coatings for silicon based ceramics

ActiveUS20050112381A1Avoid Explosion HazardsContinuous combustion chamberBlade accessoriesElectron beam physical vapor depositionGas phase

A protective barrier coating system including a diffusion barrier coating and an oxidation barrier coating and method for use in protecting silicon-based ceramic turbine engine components. A complete barrier coating system includes a thermal barrier coating of stabilized zirconia and an environmental barrier coating of an alloyed tantalum oxide. The oxidation barrier coating includes a layer of metallic silicates formed on a substrate of silicon nitride or silicon carbide to be protected. The oxidation barrier coating can include silicates of scandium, ytterbia or yttrium. The oxidation barrier coating may also include an inner layer of Si2ON2 between the diffusion barrier and the metallic silicate layer. The oxidation barrier coating can be applied to the substrate by spraying, slurry dipping and sintering, by a sol-gel process followed by sintering, by plasma spray, or by electron beam-physical vapor deposition. The diffusion layer of essentially pure Si3N4 can be applied to the substrate to prevent the migration of damaging cations from the protective layers to the substrate and is preferably formed by chemical vapor deposition. A method for protecting silicon based substrates can comprise a step of forming an oxidation barrier coating on a substrate, where a step of forming the oxidation barrier includes a step of sintering the oxidation barrier and substrate in a wet gas containing hydrogen.

Owner:HONEYWELL INT INC

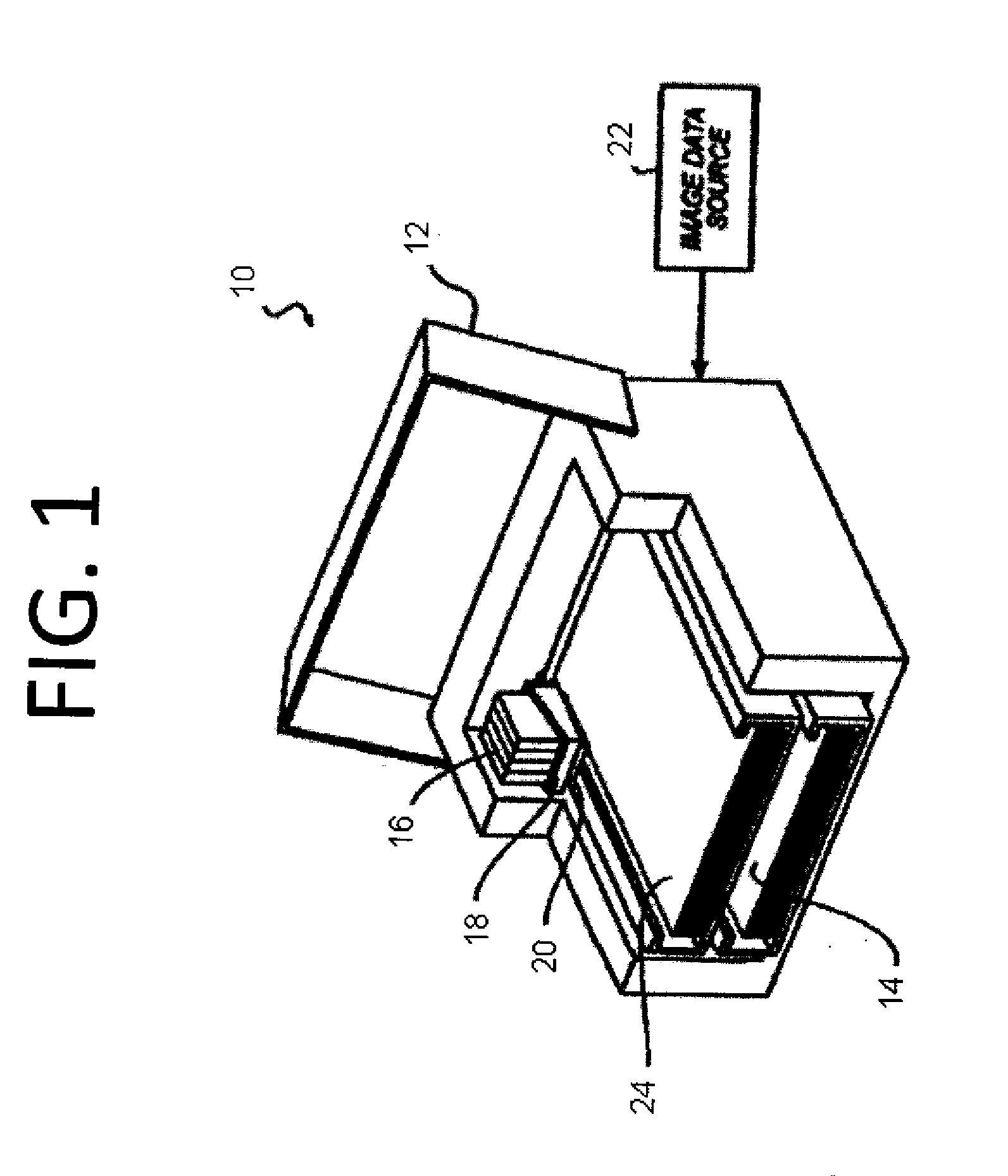

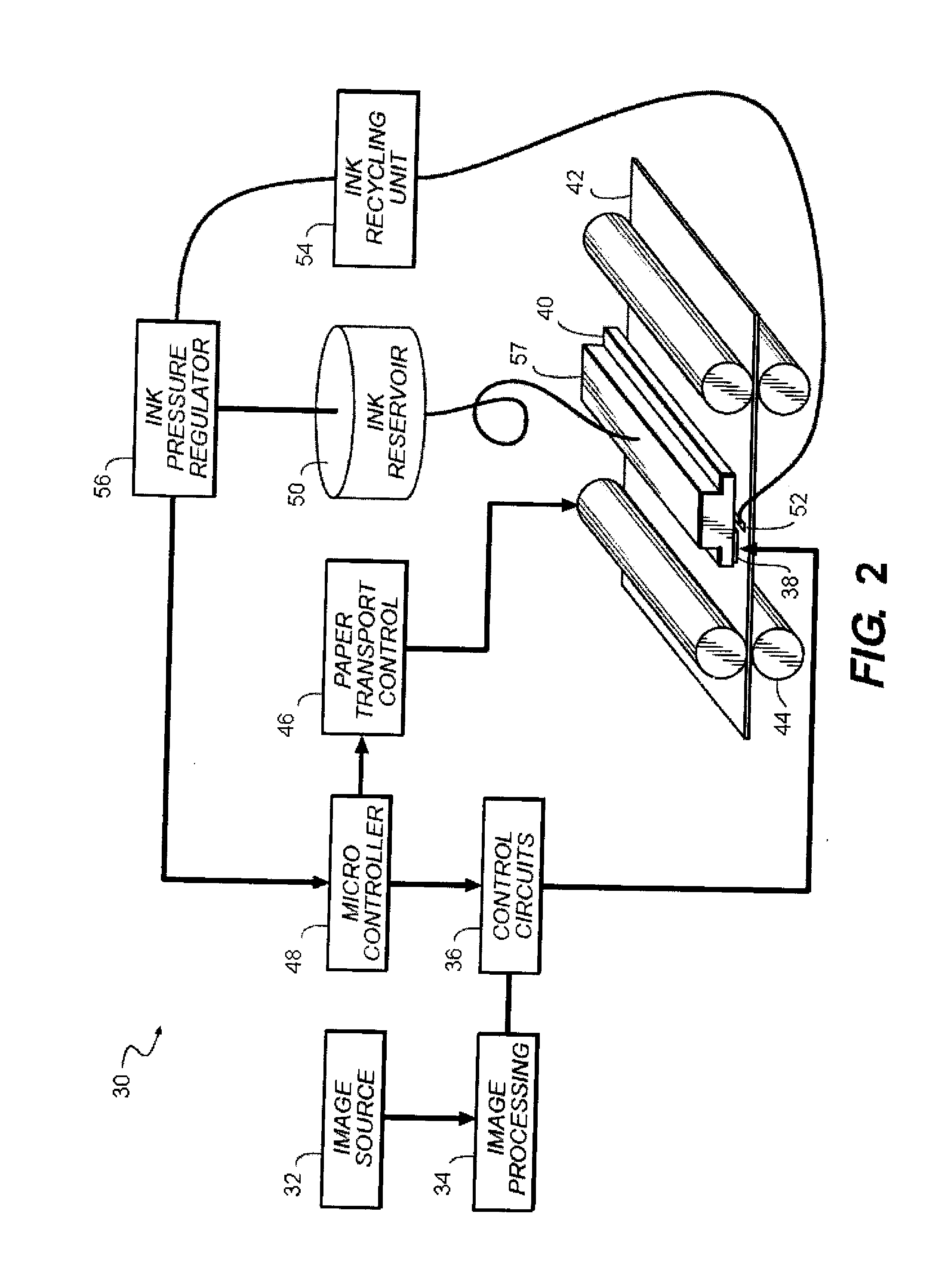

Microfluidic device with multilayer coating

ActiveUS20130065017A1Improve enhance reliable operationImprove performanceLayered productsPrintingFluid transportMicrometer

A microfluidic device comprised of a material layer and a fluid transport feature having at least one characteristic dimension of less than 500 micrometers formed in or on the material layer. A chemically resistant, thermally stable and biocompatible multilayer coating is provided onto and in contact with the microfluidic device, wherein the multilayer coating includes one or more thin film layers comprised primarily of hafnium oxide or zirconium oxide and one or more thin film layers comprised primarily of tantalum oxide, the multilayer coating being located on a surface of the fluid transport feature. The corrosion resistant film can be formed on the surfaces of fluid transport features of microfluidic devices using atomic layer deposition film forming methods that produce conformal films that cover complex geometries, thereby enabling the corrosion resistant film to be formed on all surfaces of the fluid transport features of the microfluidic device.

Owner:EASTMAN KODAK CO

Nonvolatile memory element, manufacturing method thereof, and nonvolatile semiconductor apparatus using the nonvolatile memory element

ActiveUS8022502B2Reversibly-stable rewrite characteristicRun at high speedSemiconductor/solid-state device detailsSolid-state devicesElectrical polarityOxygen deficient

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

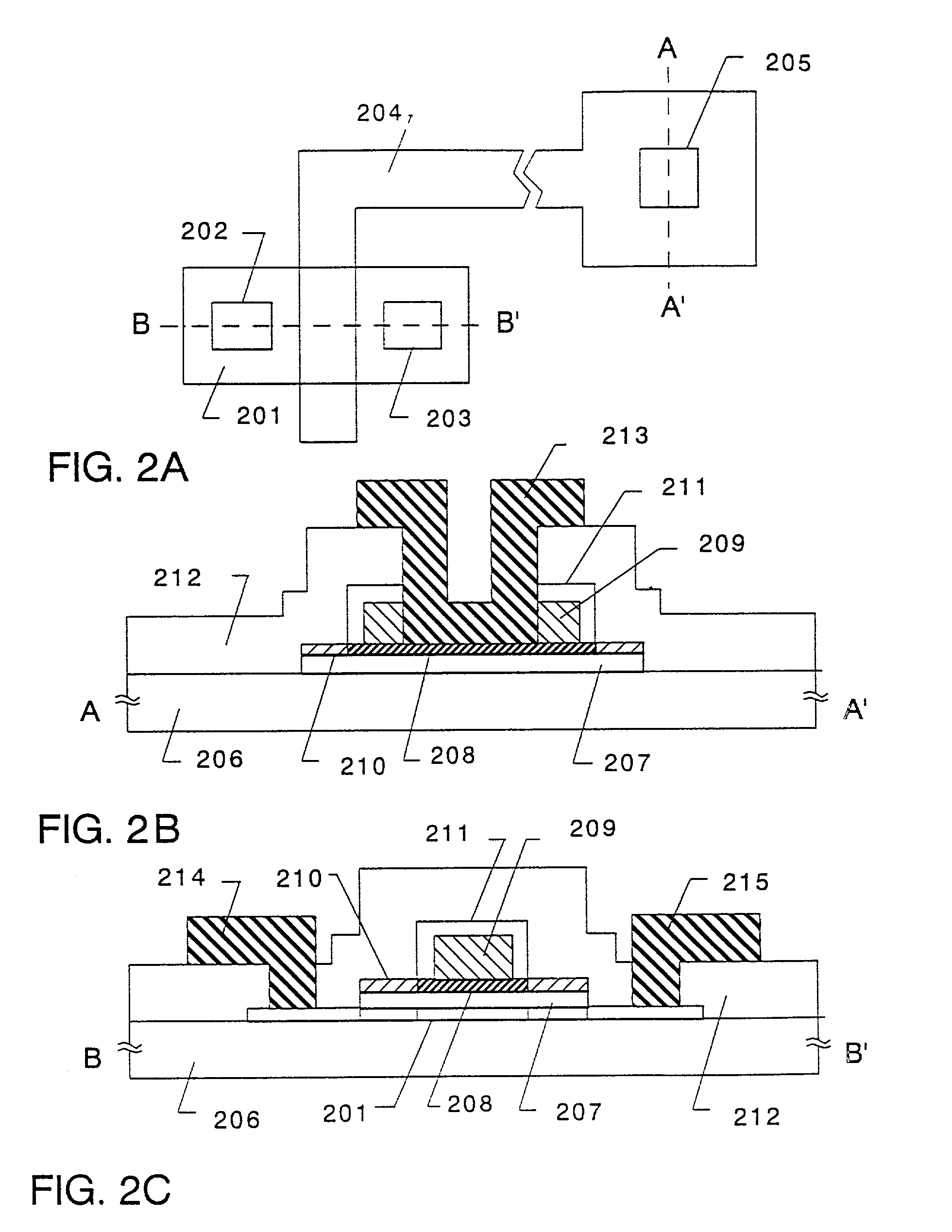

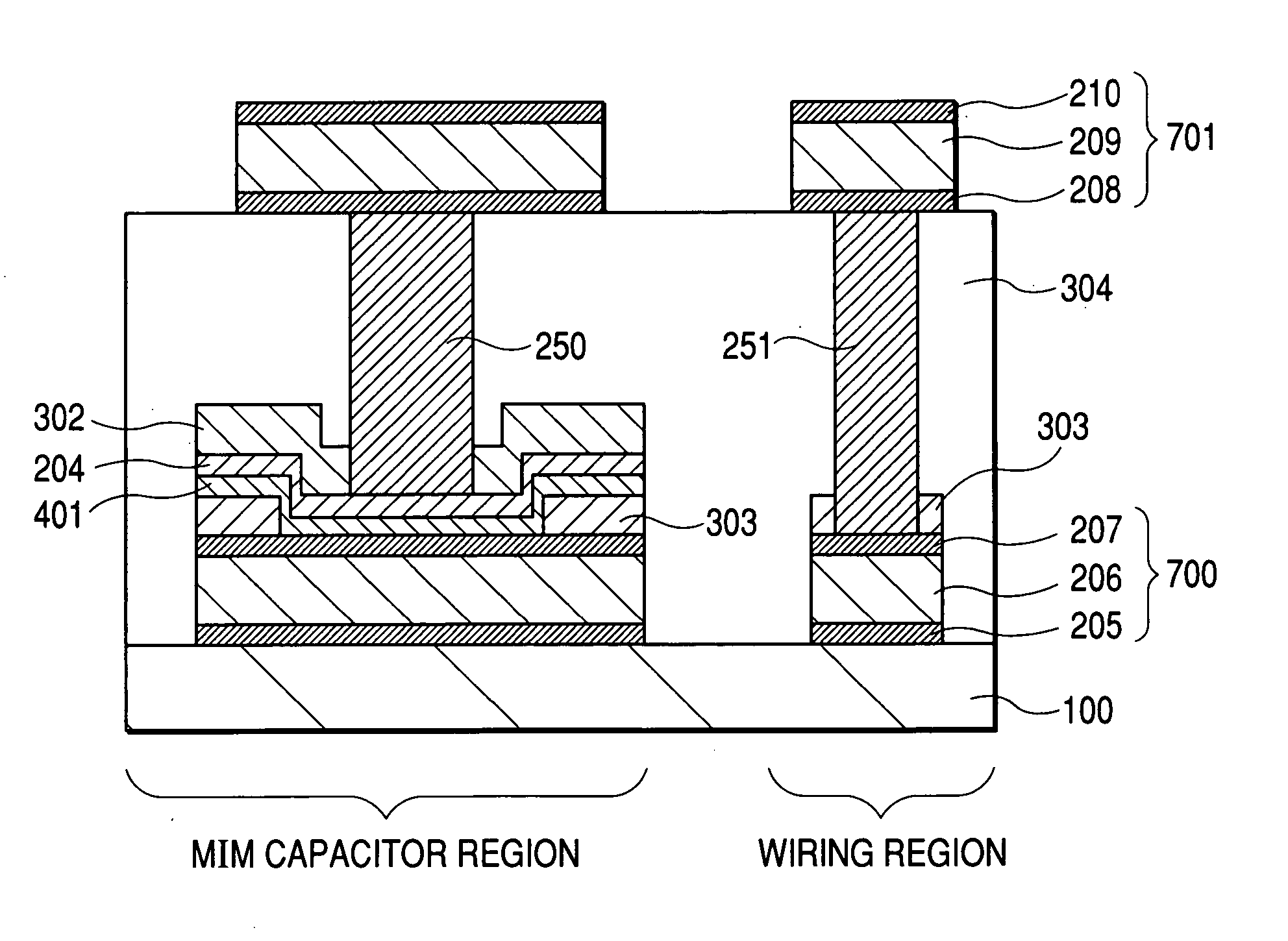

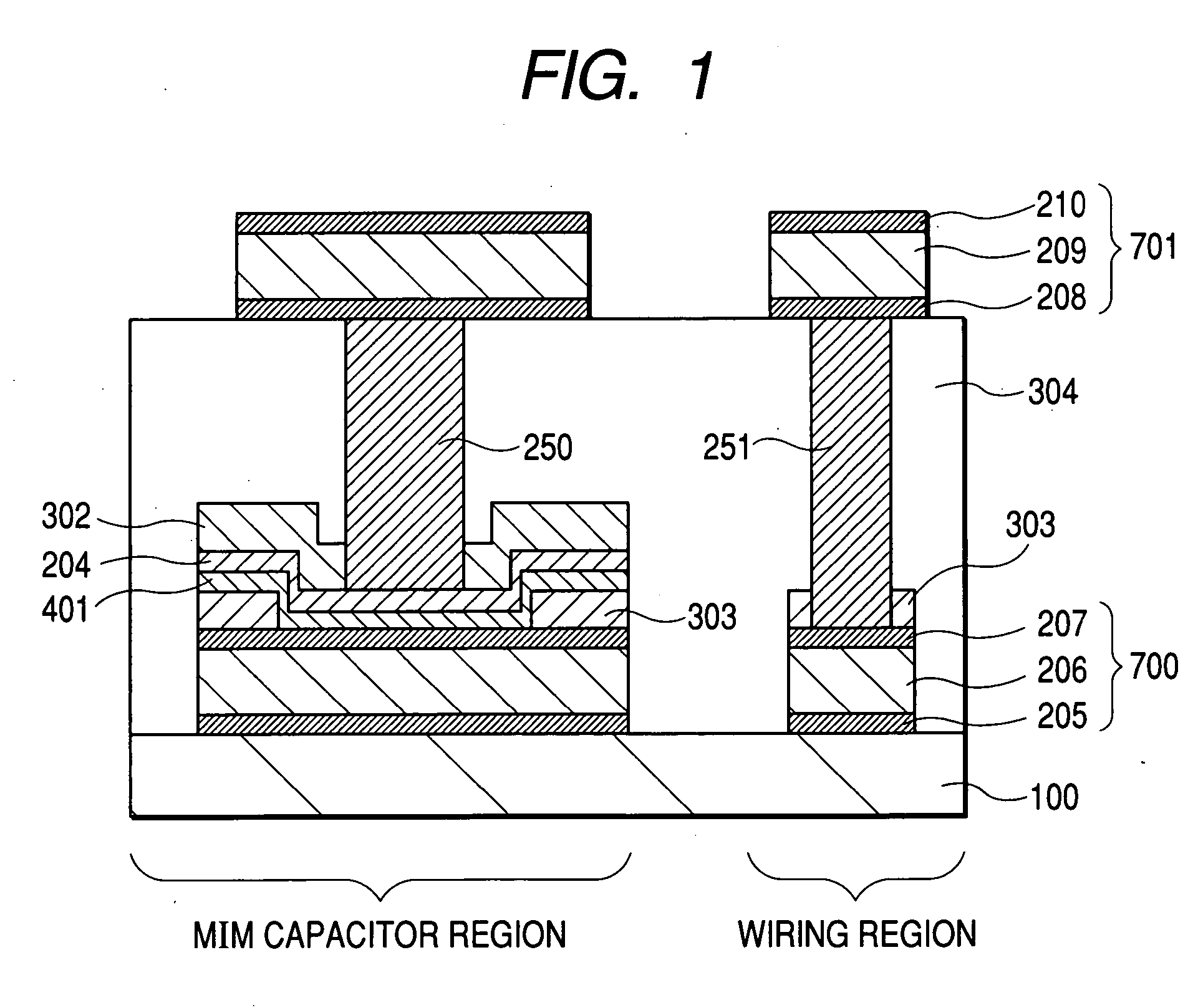

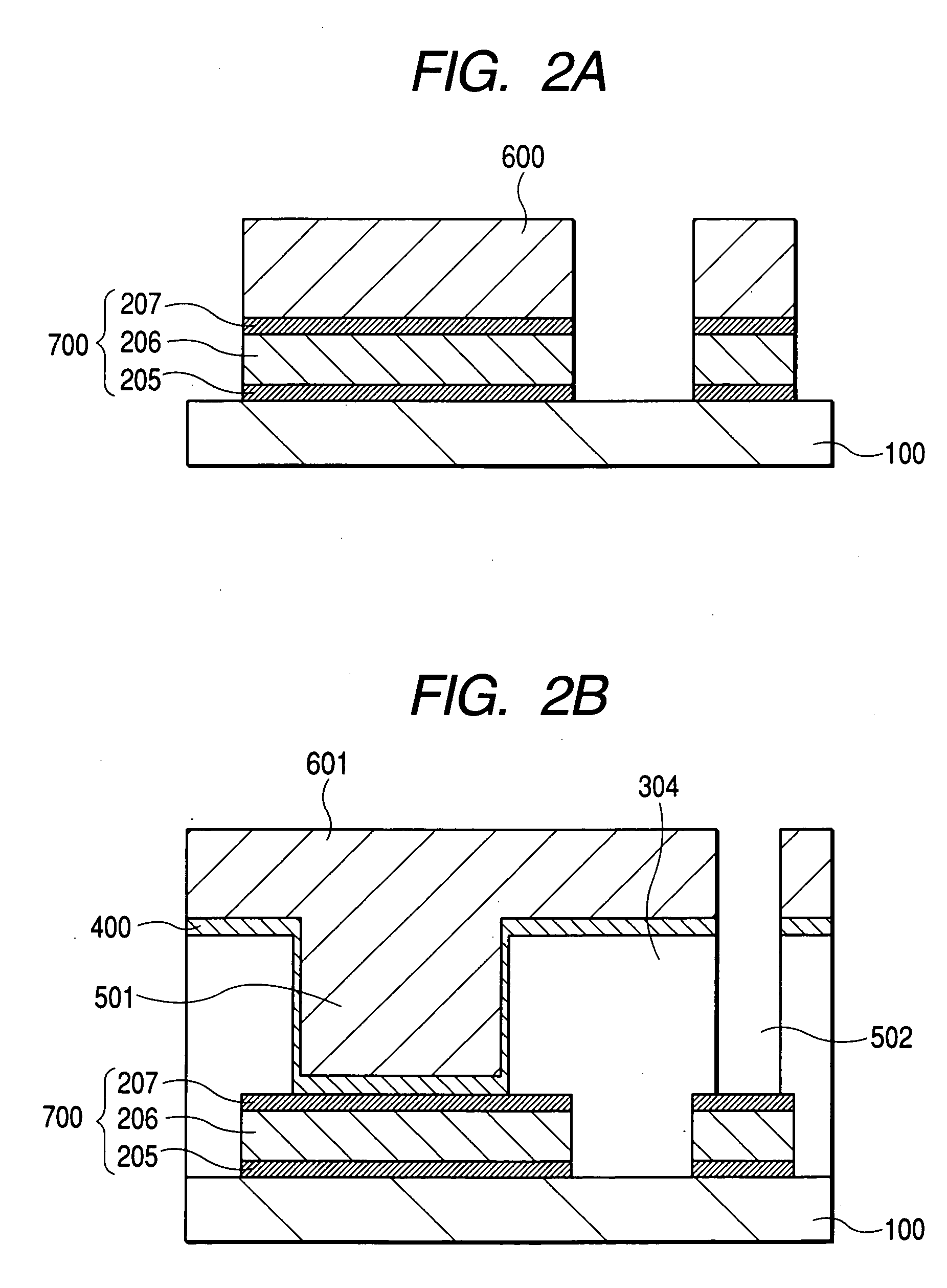

Semiconductor device and manufacturing method thereof

InactiveUS20050212082A1Increase capacitance densityIncrease currentTransistorSolid-state devicesPermittivitySemiconductor

An MIM capacitor using a high-permittivity dielectric film such as tantalum oxide. The MIM capacitor includes an upper electrode, a dielectric film, and a lower electrode. A second dielectric film and the dielectric film are formed between the upper electrode and the lower electrode, at the end of the MIM capacitor. The second dielectric film is formed to have an opening at the top of the lower electrode. The dielectric film abuts the lower electrode via the opening. The upper electrode is formed on the dielectric film. The upper electrode and the dielectric film are formed in such a manner as to embrace the opening entirely, and the second dielectric film and the lower electrode are formed so that the respective widths are the same as, or greater than, the widths of the upper electrode and the dielectric film.

Owner:HITACHI LTD

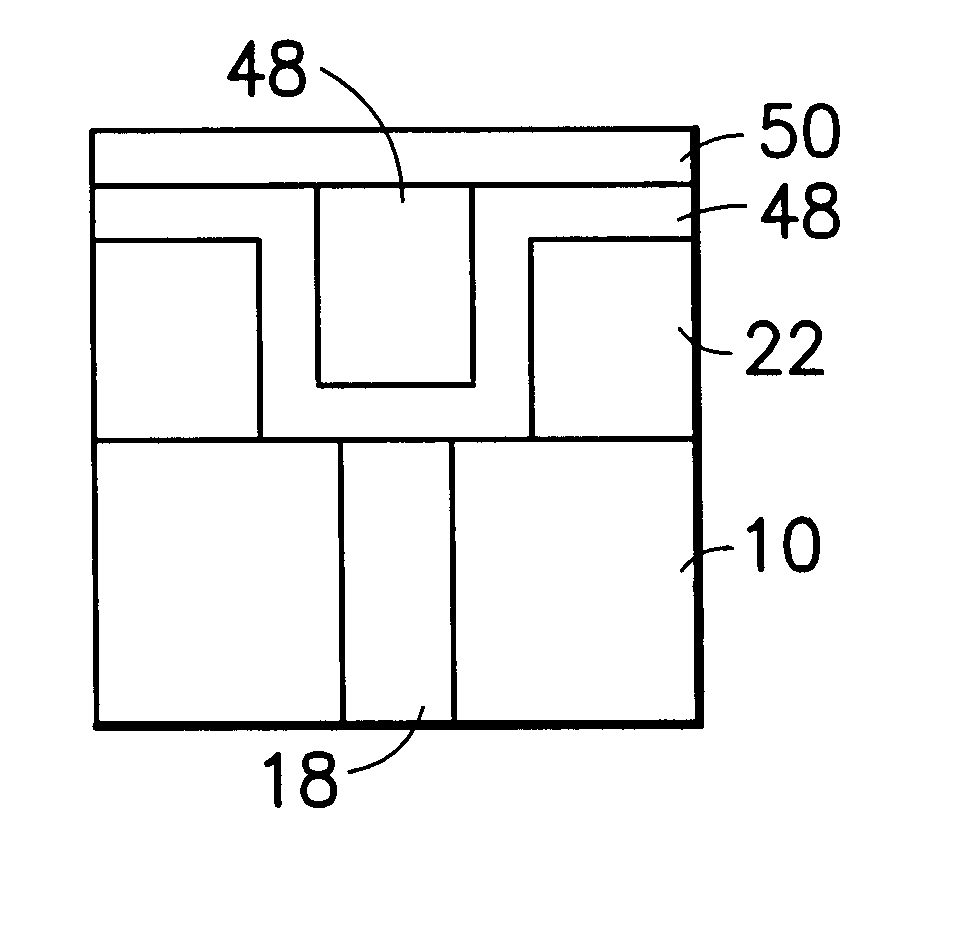

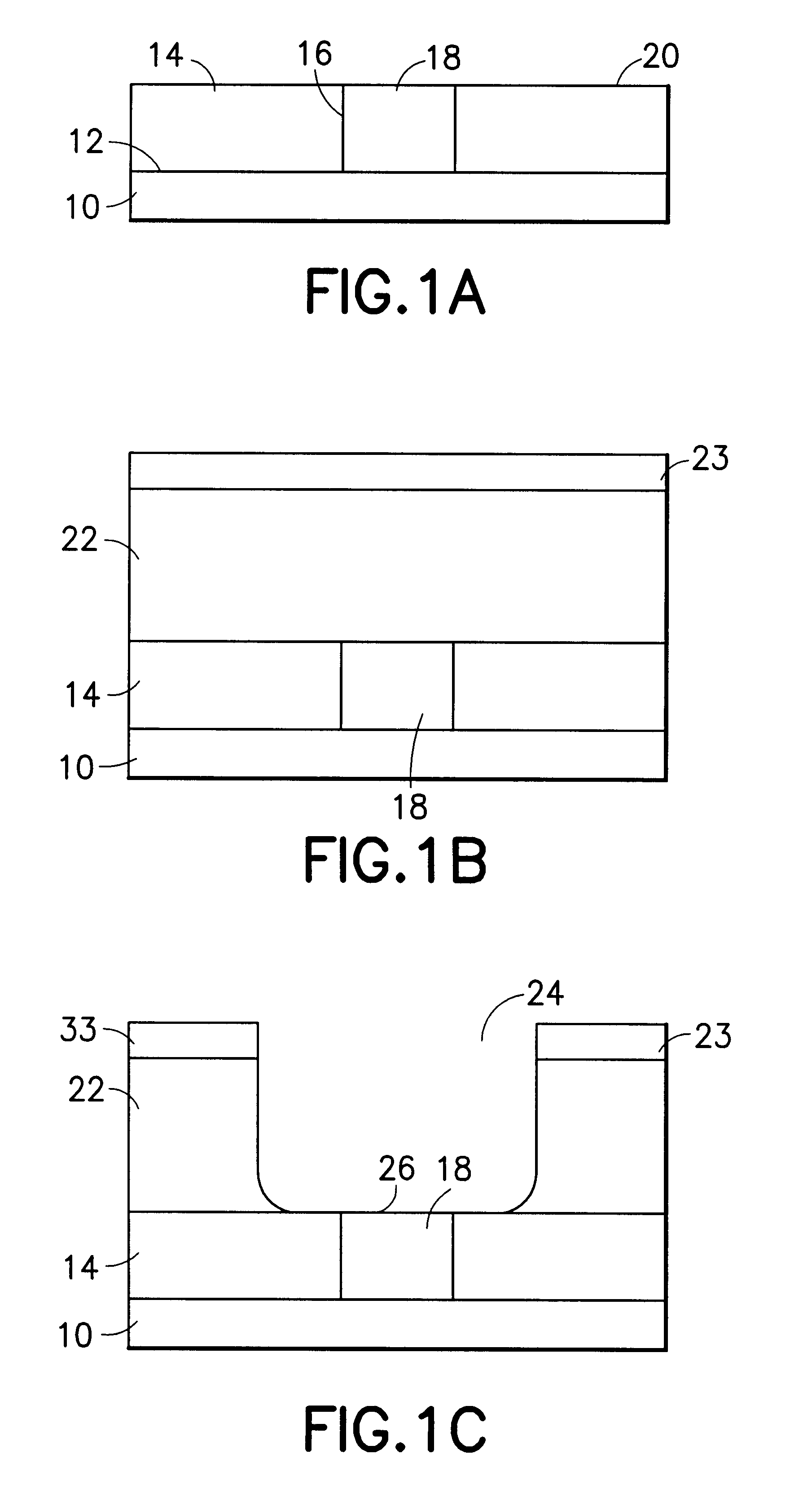

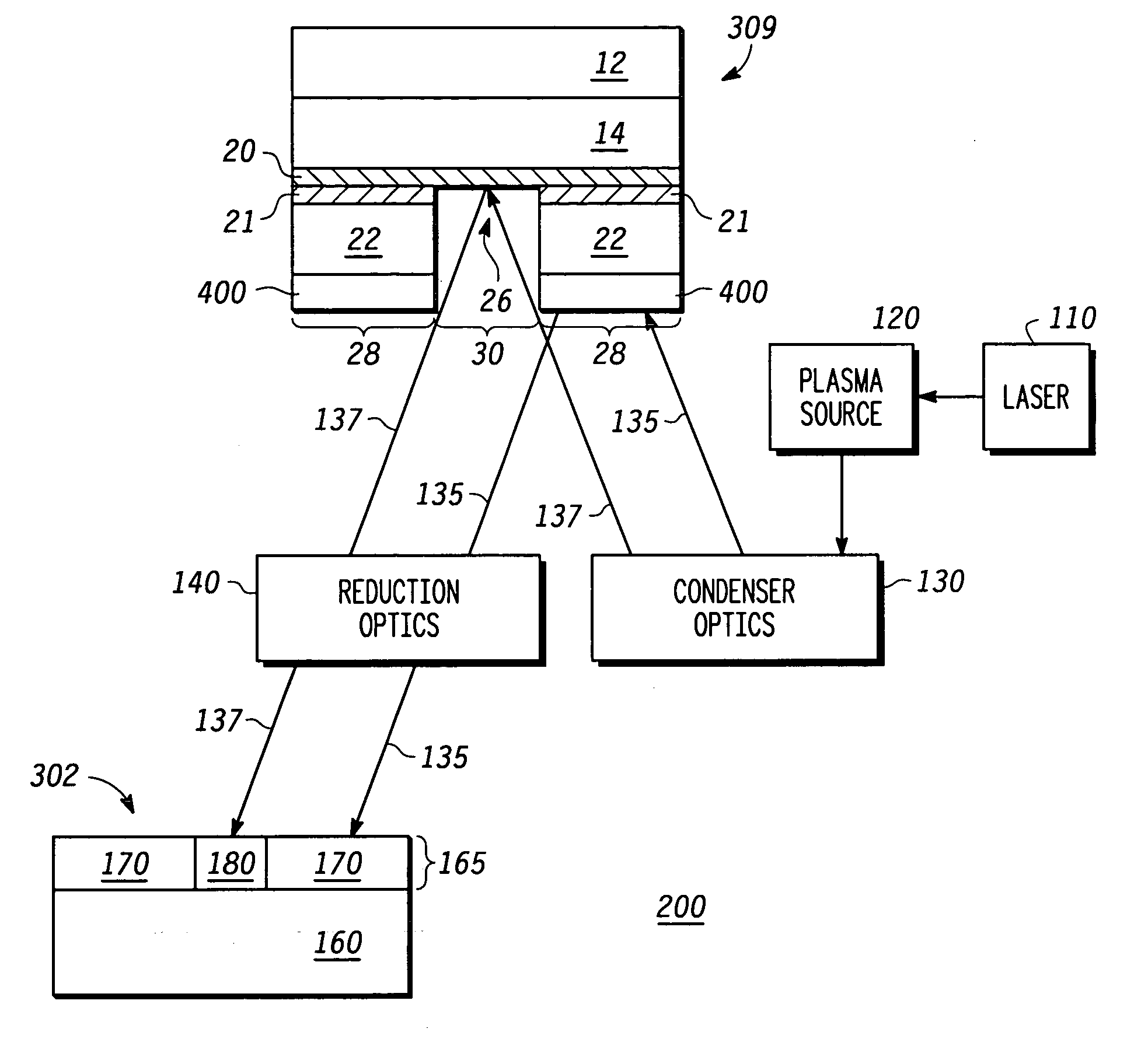

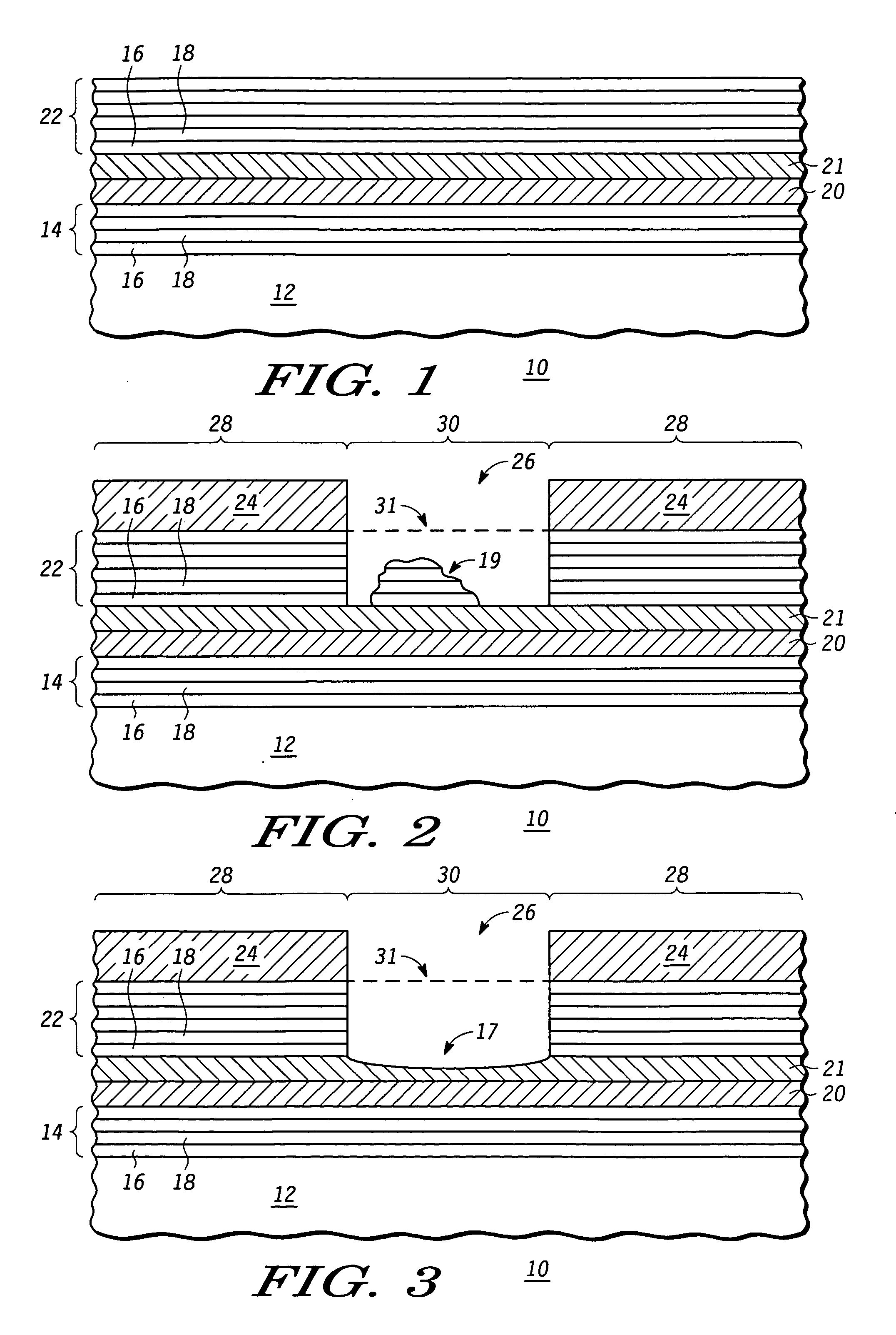

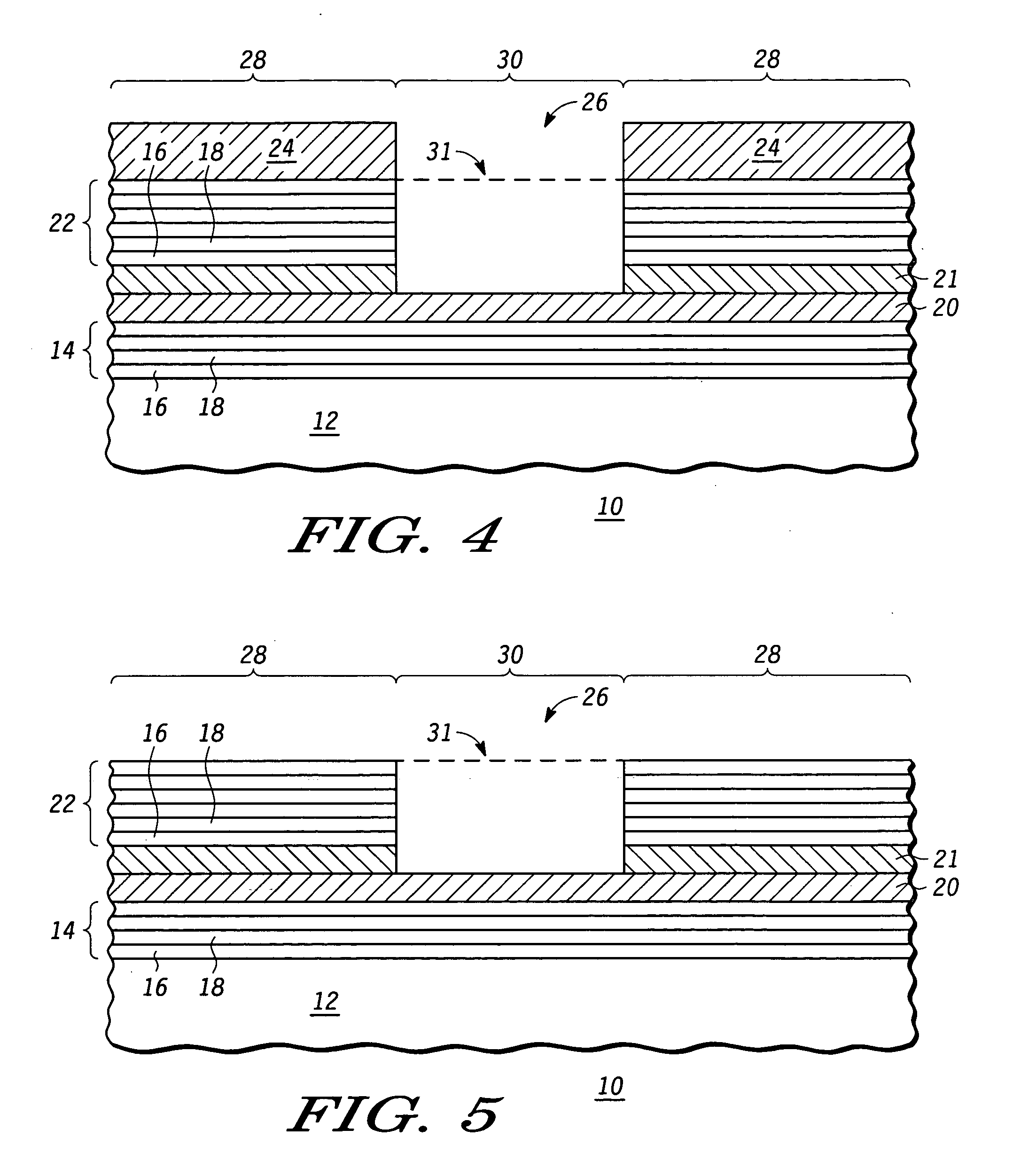

Reflective mask useful for transferring a pattern using extreme ultra violet (EUV) radiation and method of making the same

An EUV mask (10, 309) includes an opening (26) that helps to attenuate and phase shift extreme ultraviolet radiation using a subtractive rather than additive method. A first embedded layer (20) and a second embedded layer (21) may be provided between a lower multilayer reflective stack (14) and an upper multilayer reflective stack (22) to ensure an appropriate and accurate depth of the opening (26), while allowing for defect inspection of the EUV mask (10, 309) and optional defect repair. An optional ARC layer (400) may be deposited in region (28) to reduce the amount of reflection within dark region (28). Alternately, a single embedded layer of hafnium oxide, zirconium oxide, tantalum silicon oxide, tantalum oxide, or the like, may be used in place of embedded layers (20, 21). Optimal thicknesses and locations of the various layers are described.

Owner:NXP USA INC

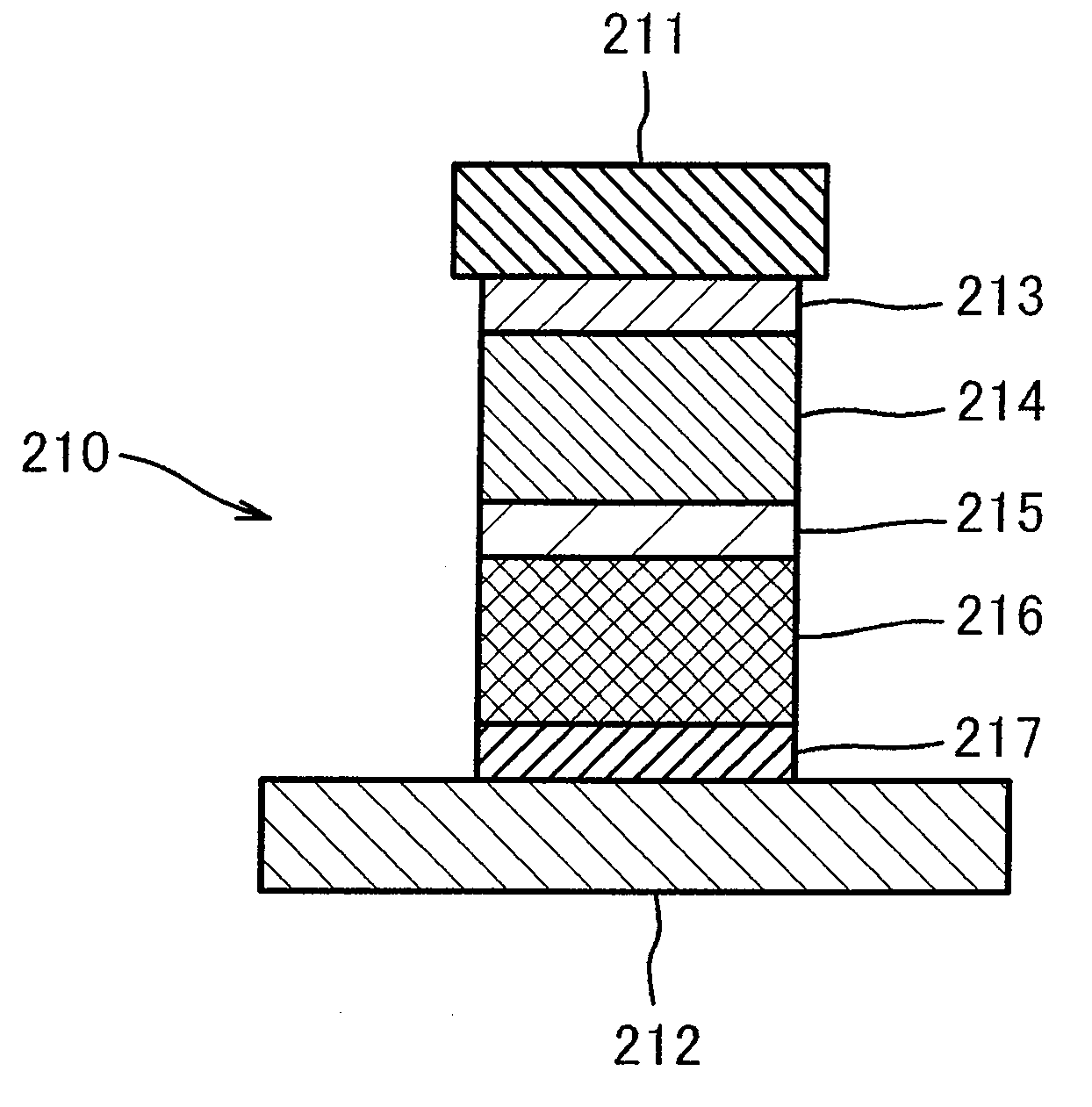

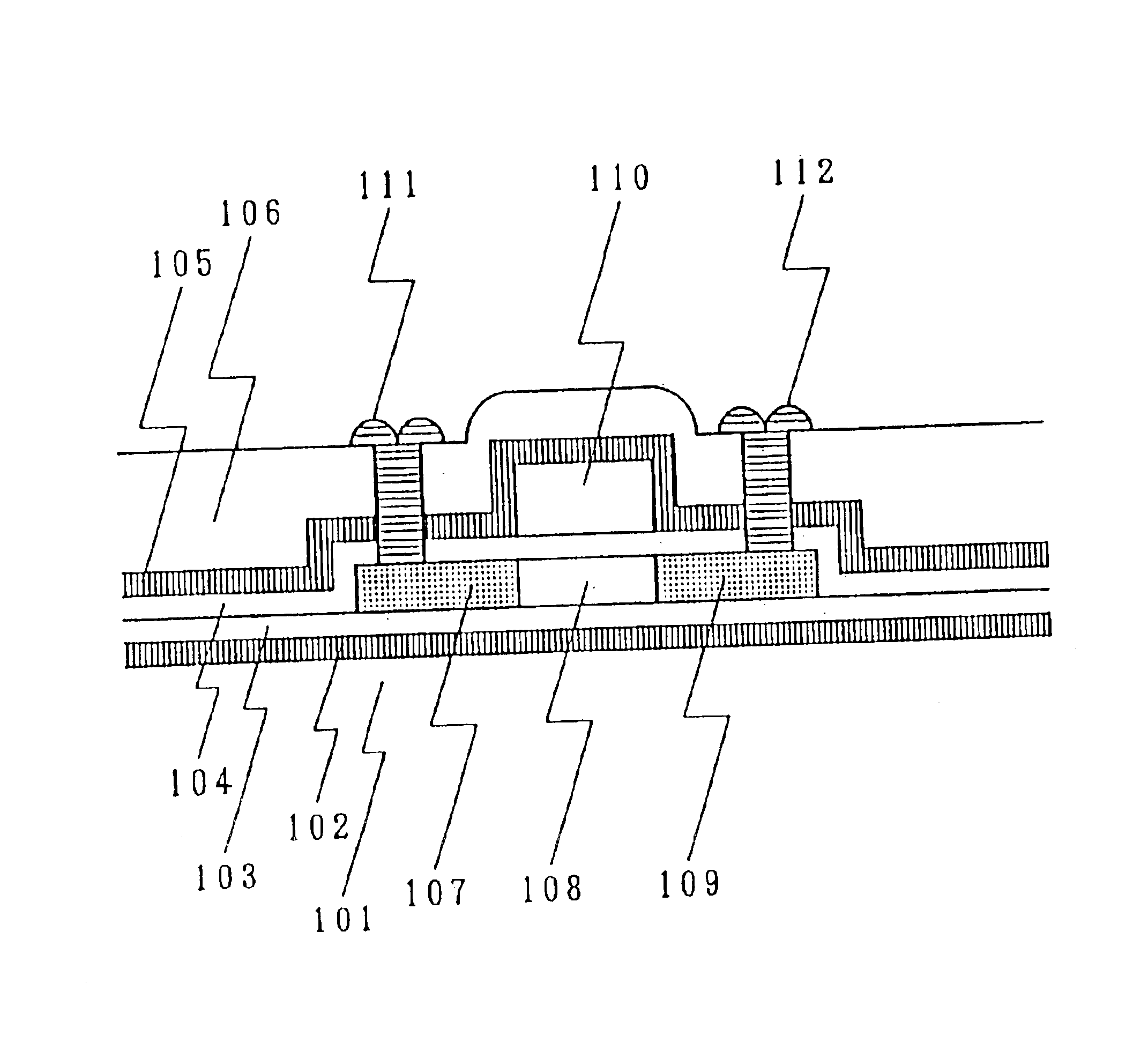

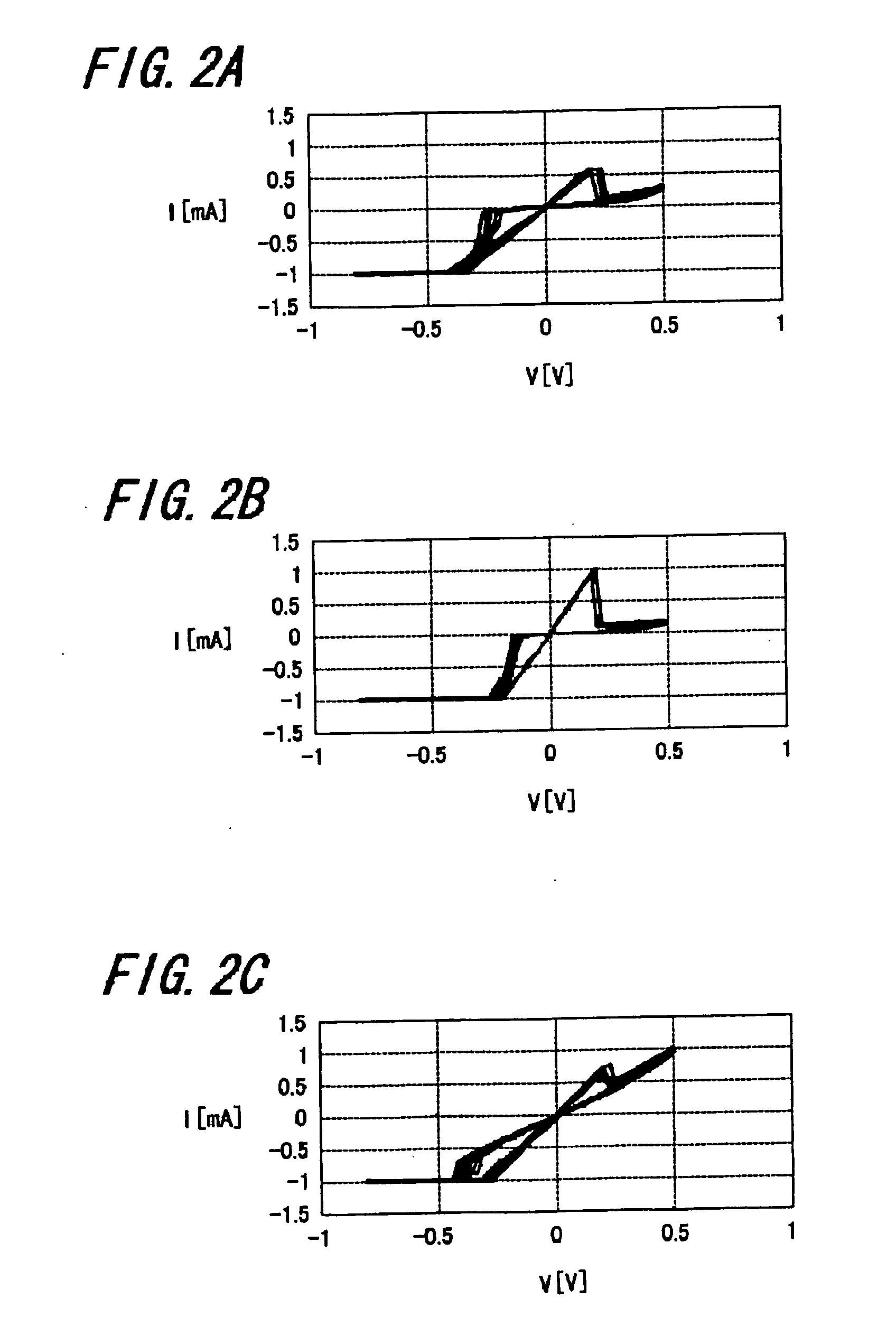

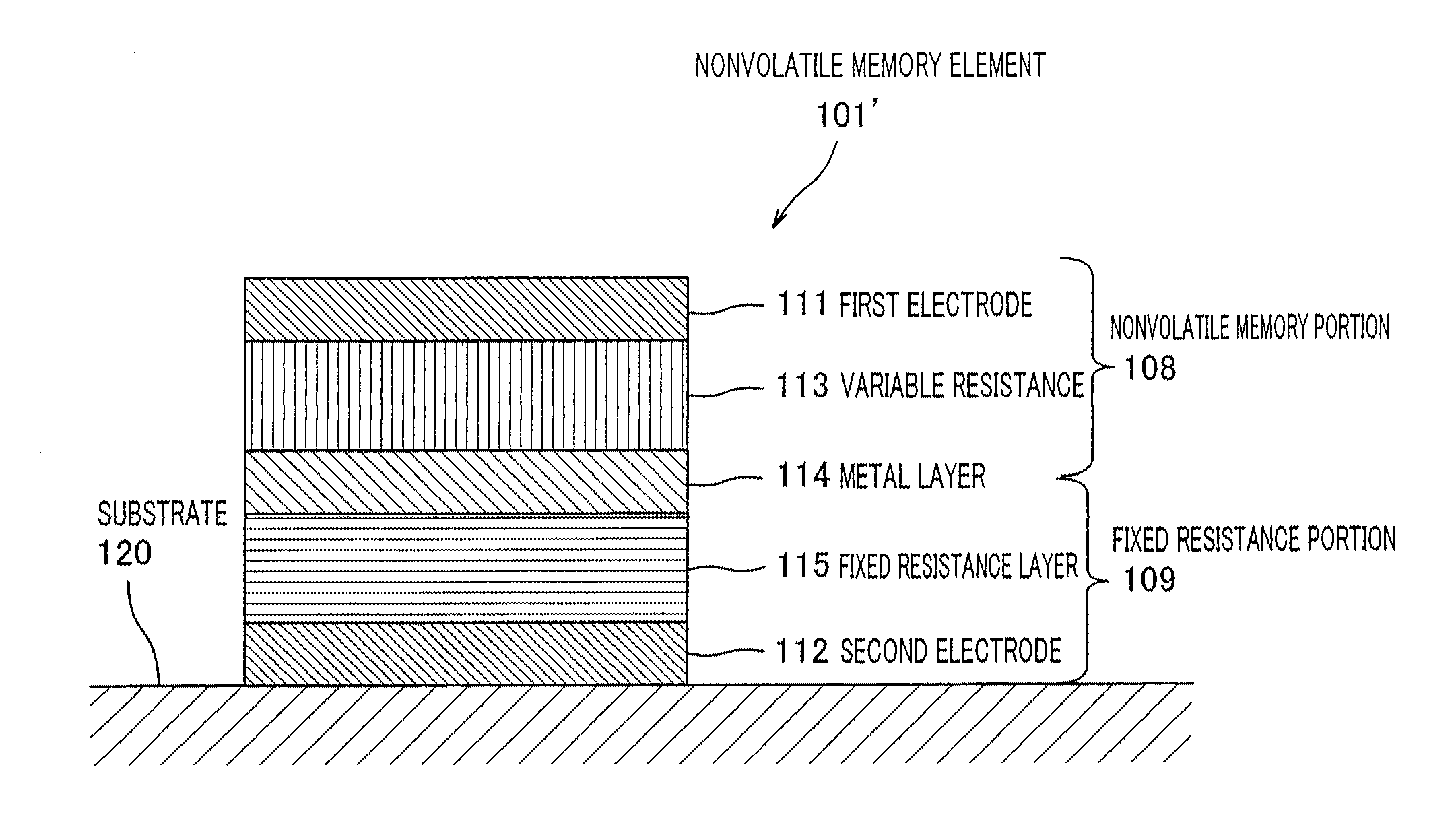

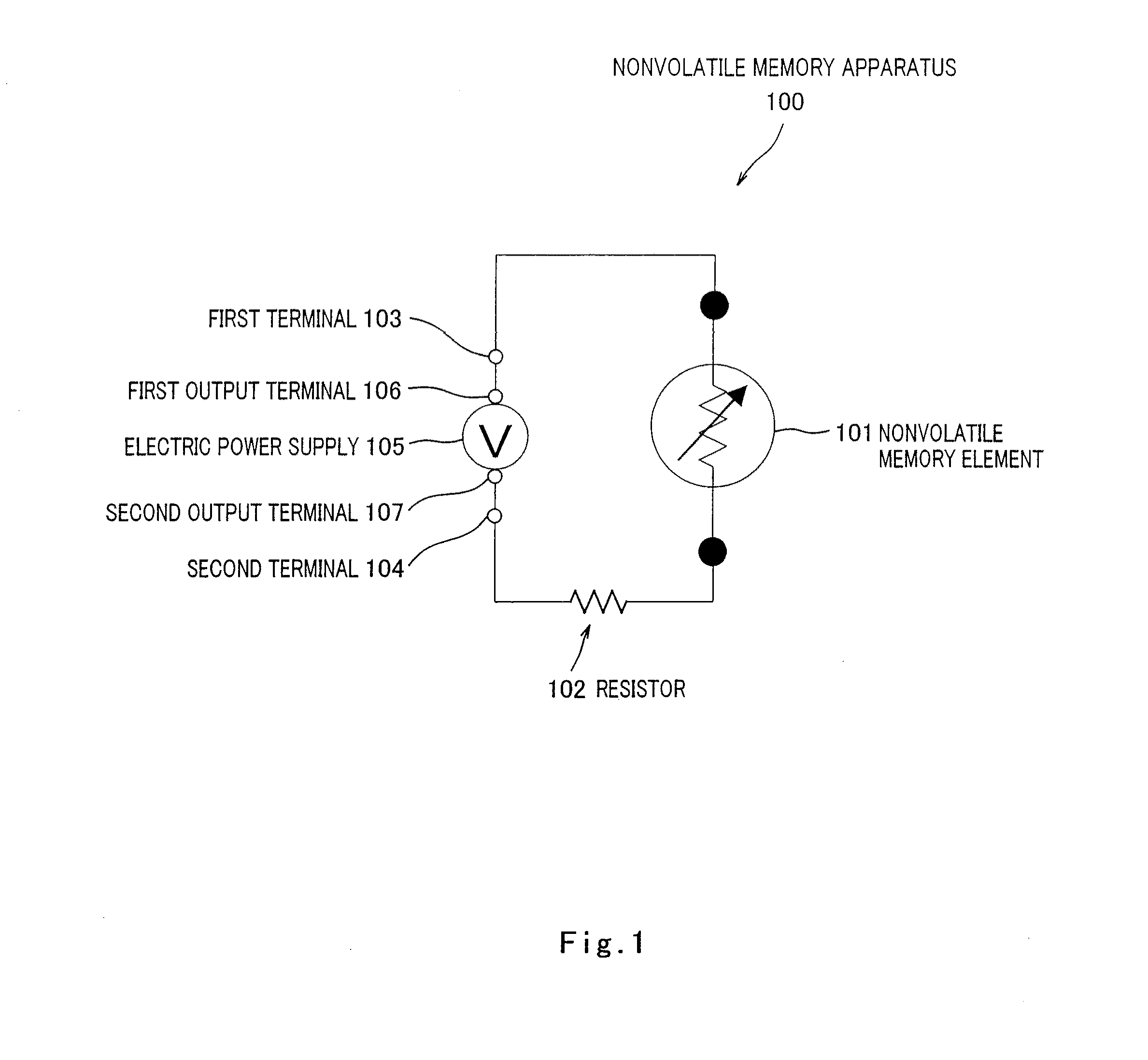

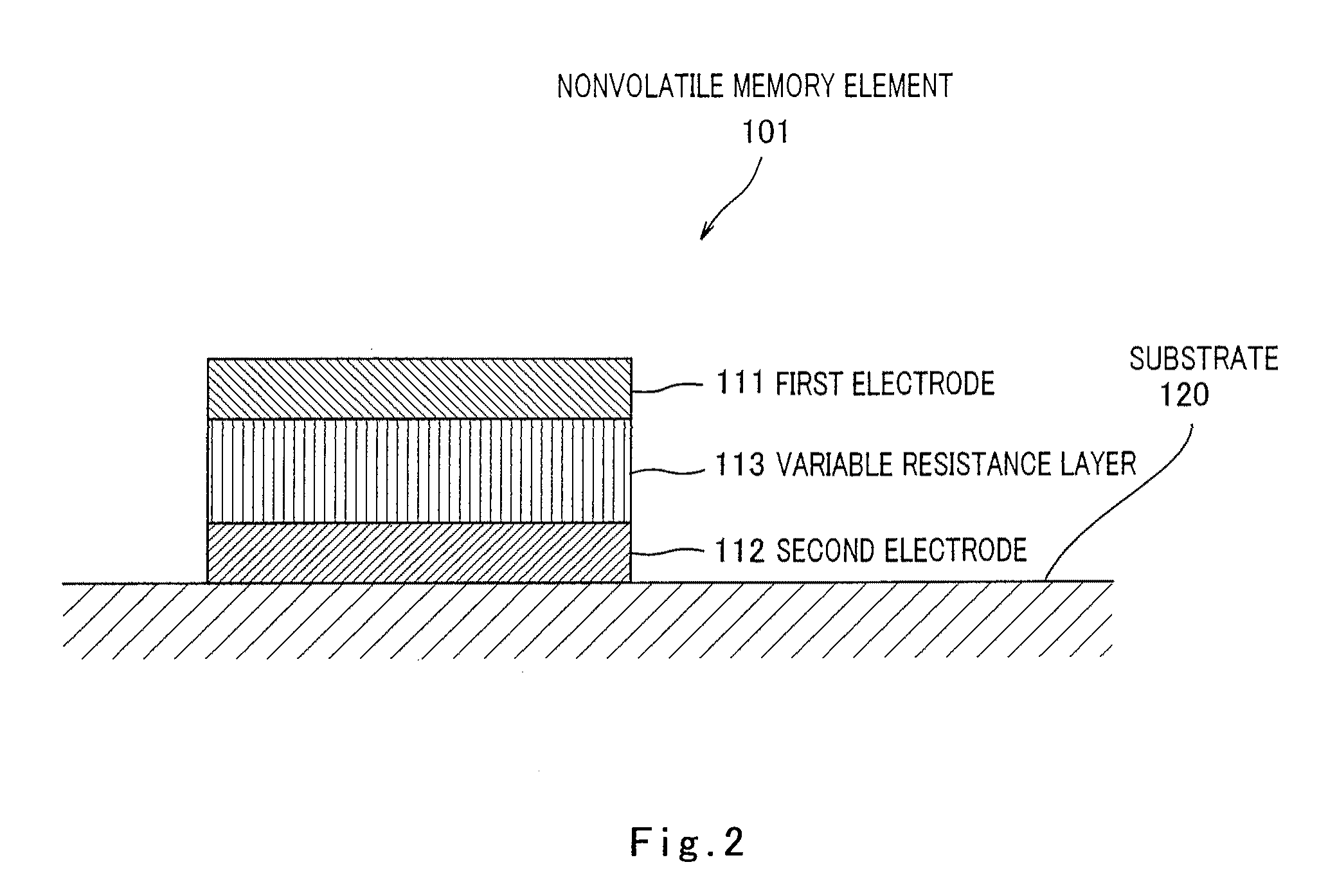

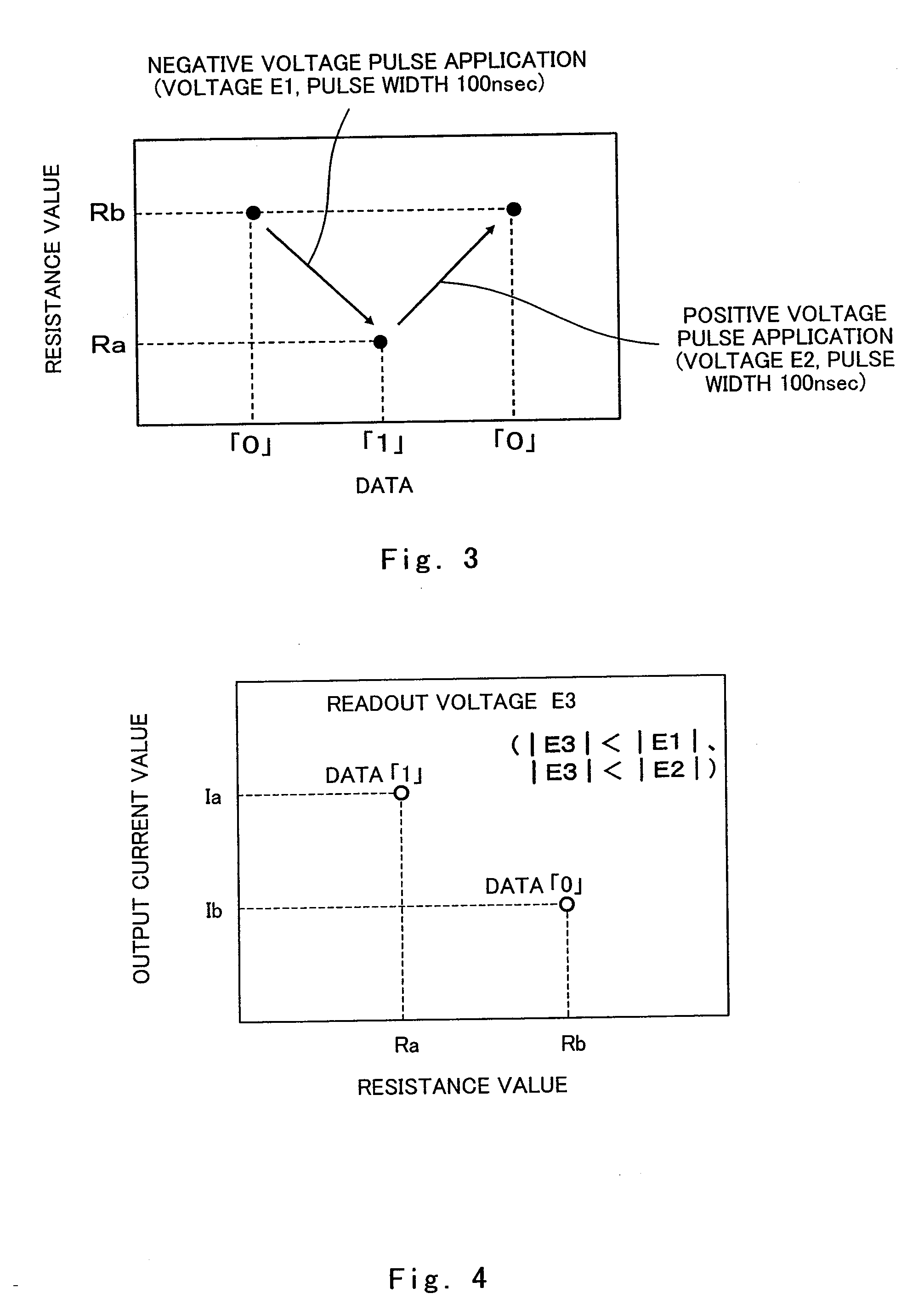

Nonvolatile memory apparatus, nonvolatile memory element, and nonvolatile element array

ActiveUS20090250678A1Run at high speedStably reversible rewrite characteristicSolid-state devicesDigital storageElectrical resistance and conductanceHigh resistance

A nonvolatile memory apparatus comprises a first electrode (111), a second electrode (112), a variable resistance layer (113) which is disposed between the electrodes, a resistance value of the variable resistance layer reversibly varying between a plurality of resistance states based on an electric signal applied between the electrodes, a first terminal (103) connected to the first electrode, and a second terminal (104) connected to the second terminal. The variable resistance layer comprises at least a tantalum oxide, and is configured to satisfy 0<x<2.5 when the tantalum oxide is represented by TaOx; and wherein when a resistance value between the electrodes in a state where the variable resistance layer is in the low-resistance state is RL, a resistance value between the electrodes in a state where the variable resistance layer is in the high-resistance state is RH, and a resistance value of a portion other than the variable resistance layer in a current path connecting the first terminal to the second terminal via the first electrode, the variable resistance layer and the second electrode, is R0, R0 satisfies RL<R0.

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

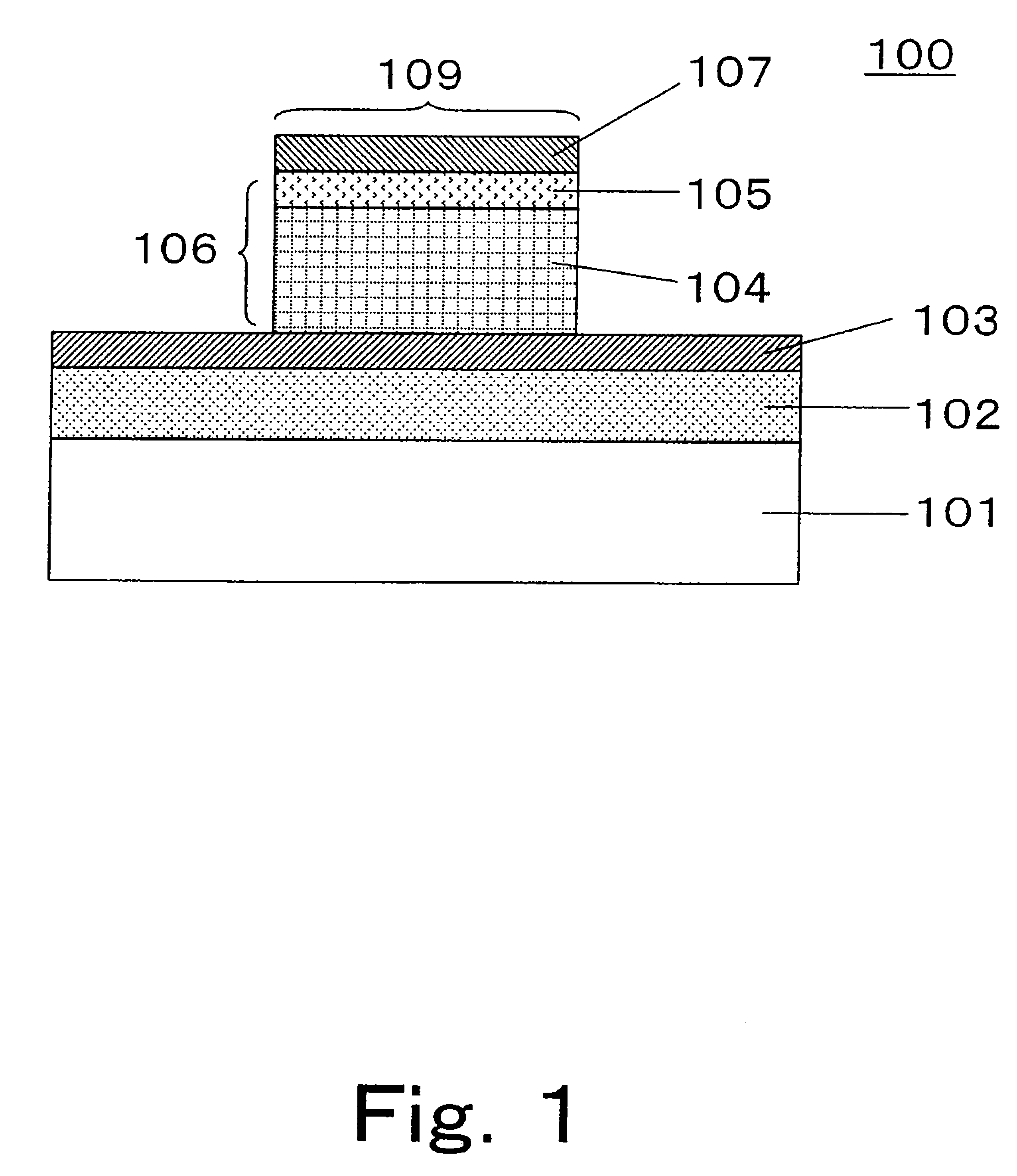

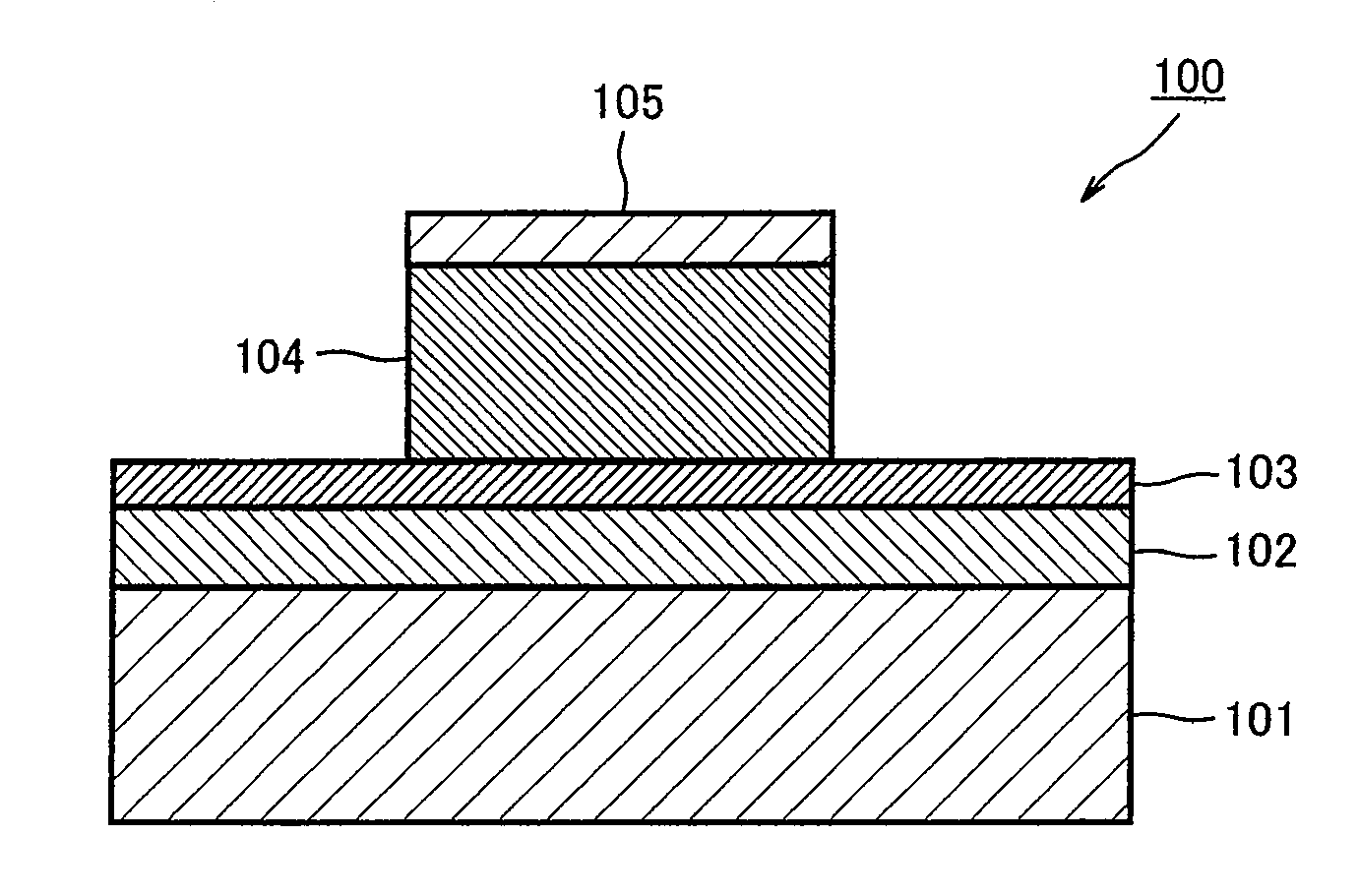

Nonvolatile memory element, nonvolatile memory apparatus, nonvolatile semiconductor apparatus, and method of manufacturing nonvolatile memory element

ActiveUS20090224224A1Stable characteristicsHigh affinitySolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsElectric signal

A nonvolatile memory element of the present invention comprises a first electrode (103), a second electrode (105), and a resistance variable layer (104) disposed between the first electrode (103) and the second electrode (104), a resistance value of the resistance variable layer varying reversibly according to an electric signal applied between the electrodes (103),(105), and the resistance variable layer (104) comprises at least a tantalum oxide, and is configured to satisfy 0<x<2.5 when the tantalum oxide is represented by TaOx.

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

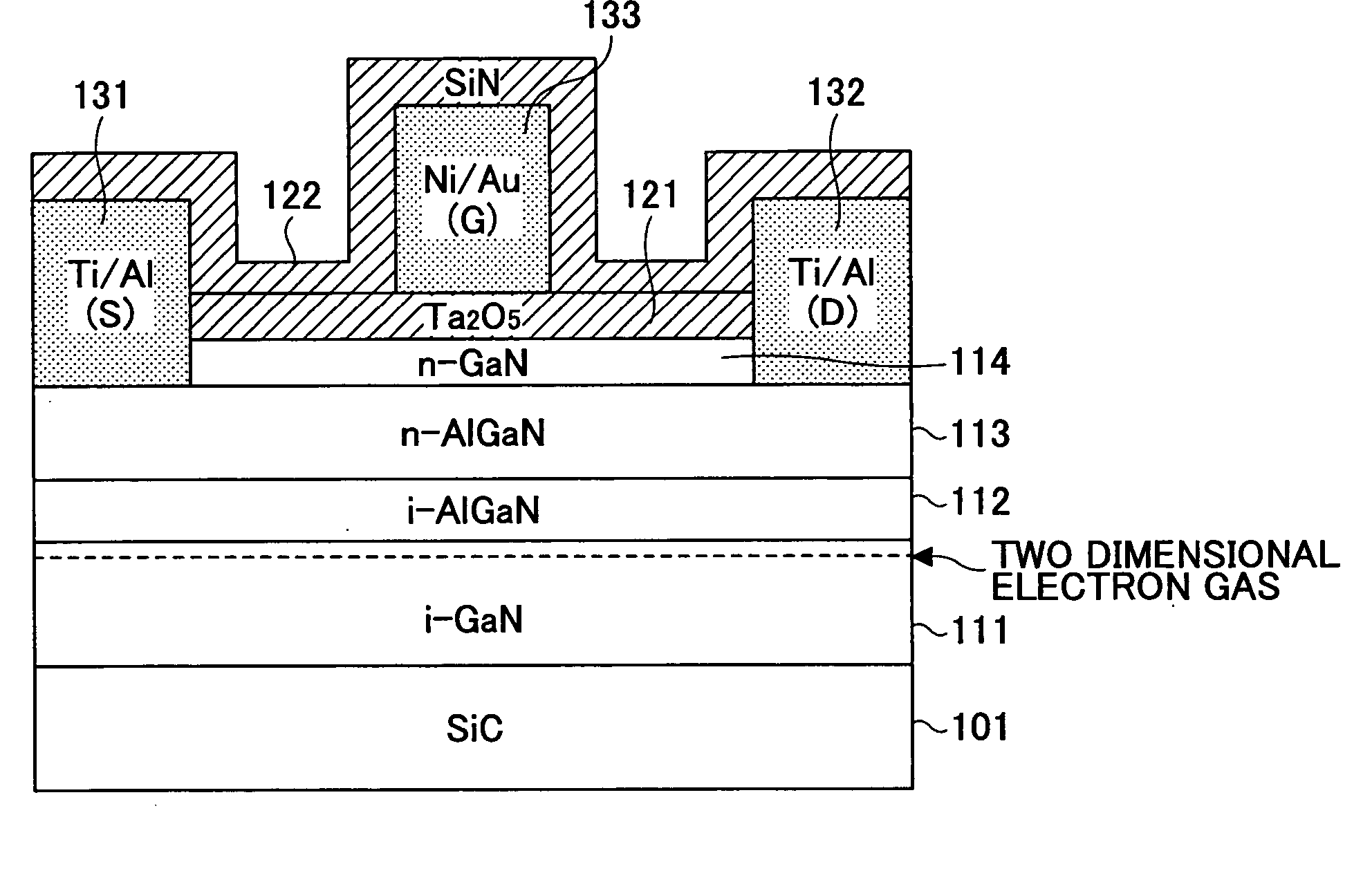

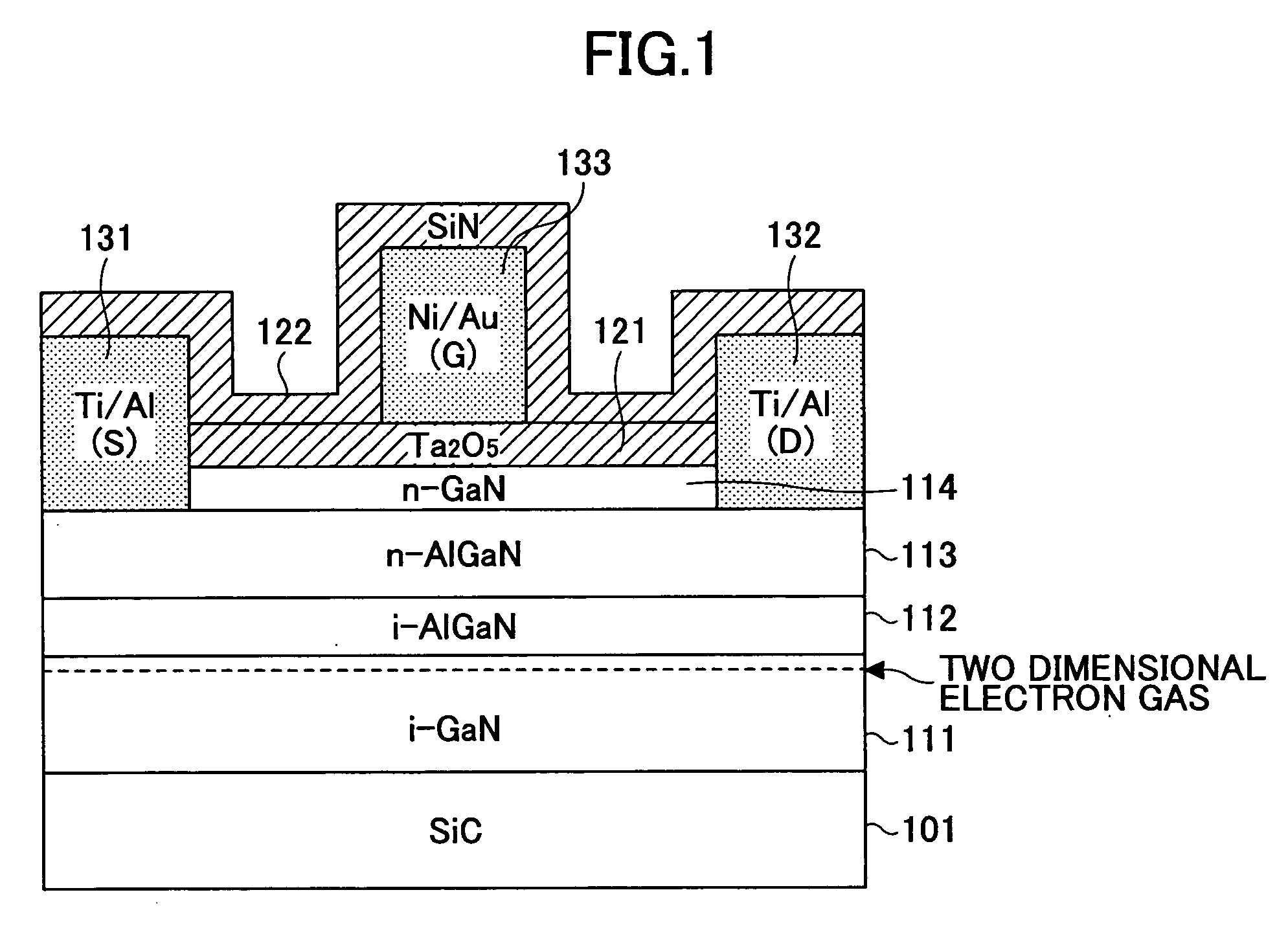

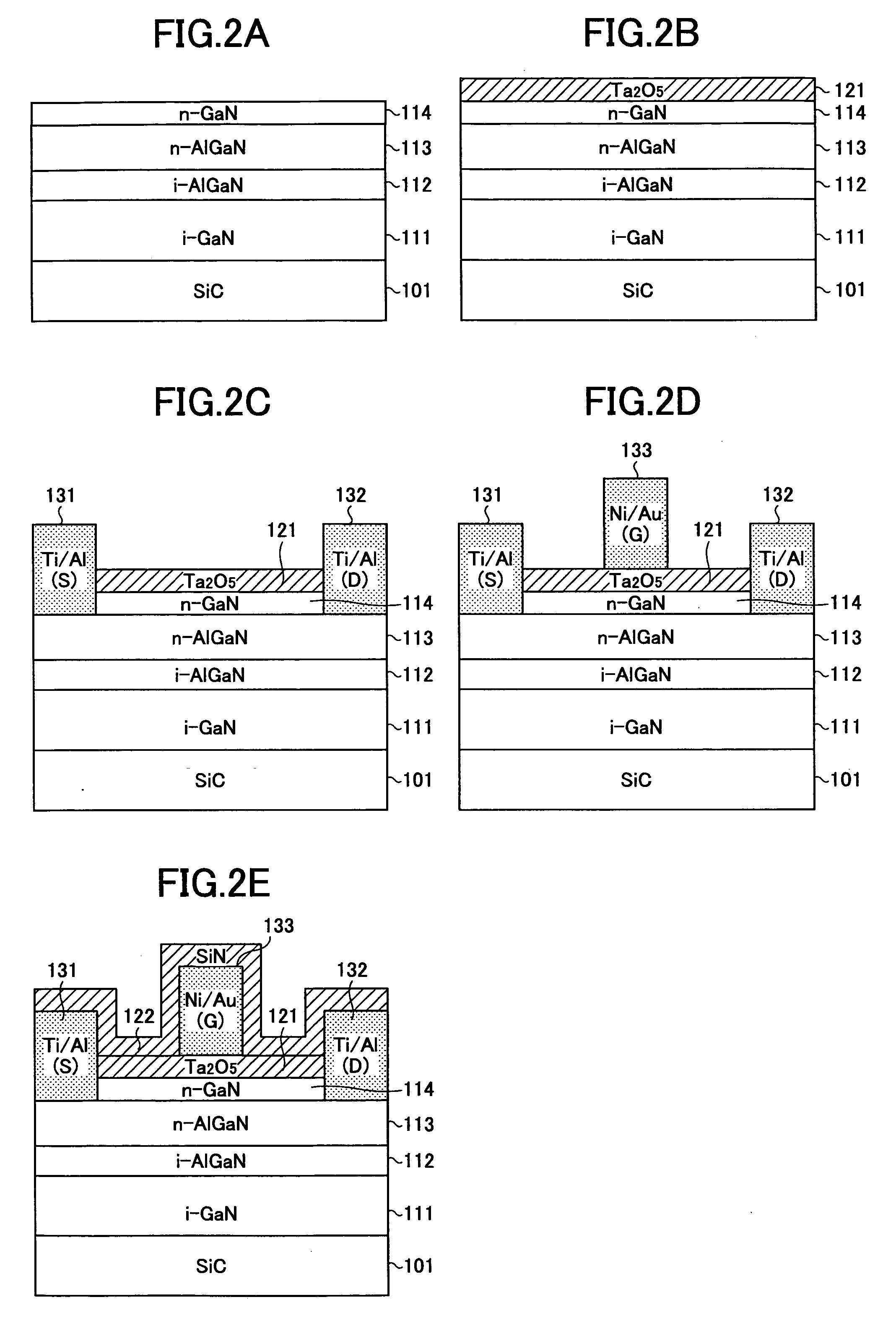

Semiconductor device and production method thereof

InactiveUS20060197107A1Reduce gate leakage currentSimple interfaceSemiconductor devicesGate leakage currentDevice material

A semiconductor device formed from a III-V nitride family semiconductor is disclosed that has a reduced gate leakage current and good interface characteristics between the III-V nitride family semiconductor and a gate insulating film. The semiconductor device includes a semiconductor layer formed from the III-V nitride family semiconductor, a gate insulating film on the semiconductor layer, and a gate electrode on the gate insulating film. The gate insulating film is formed from one of a tantalum oxide, a hafnium oxide, a hafnium aluminum oxide, a lanthanum oxide, and a yttrium oxide.

Owner:FUJITSU LTD

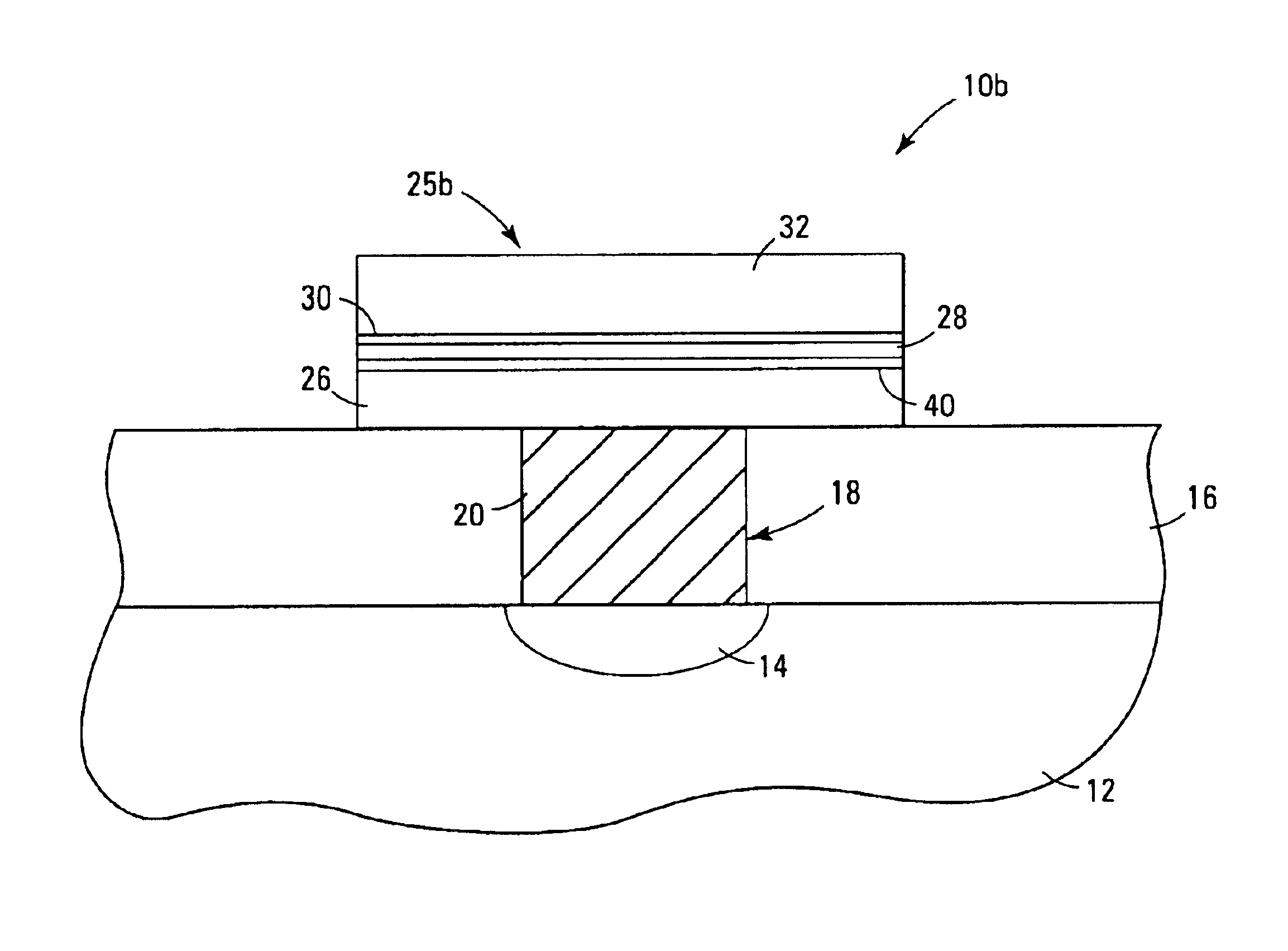

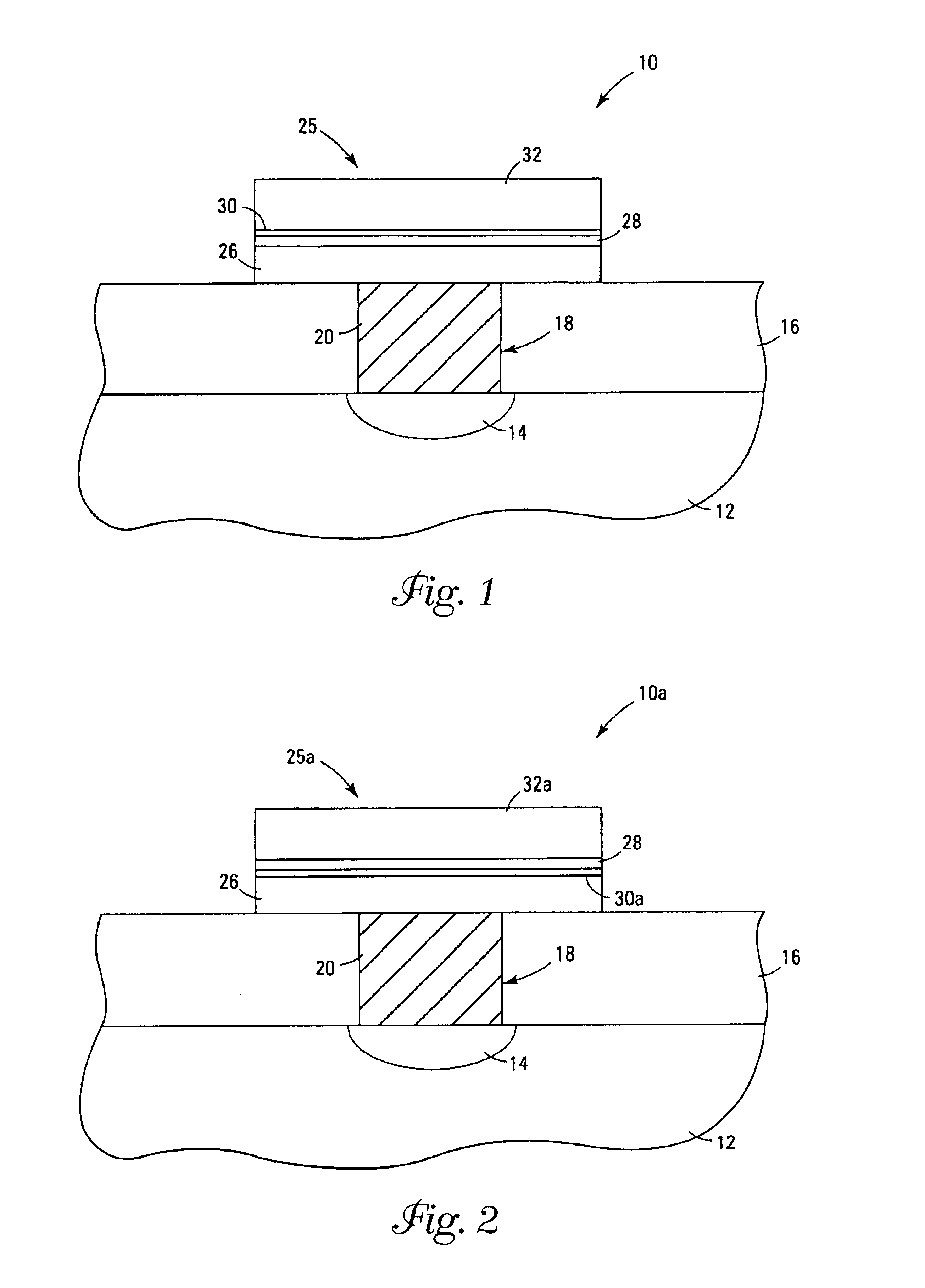

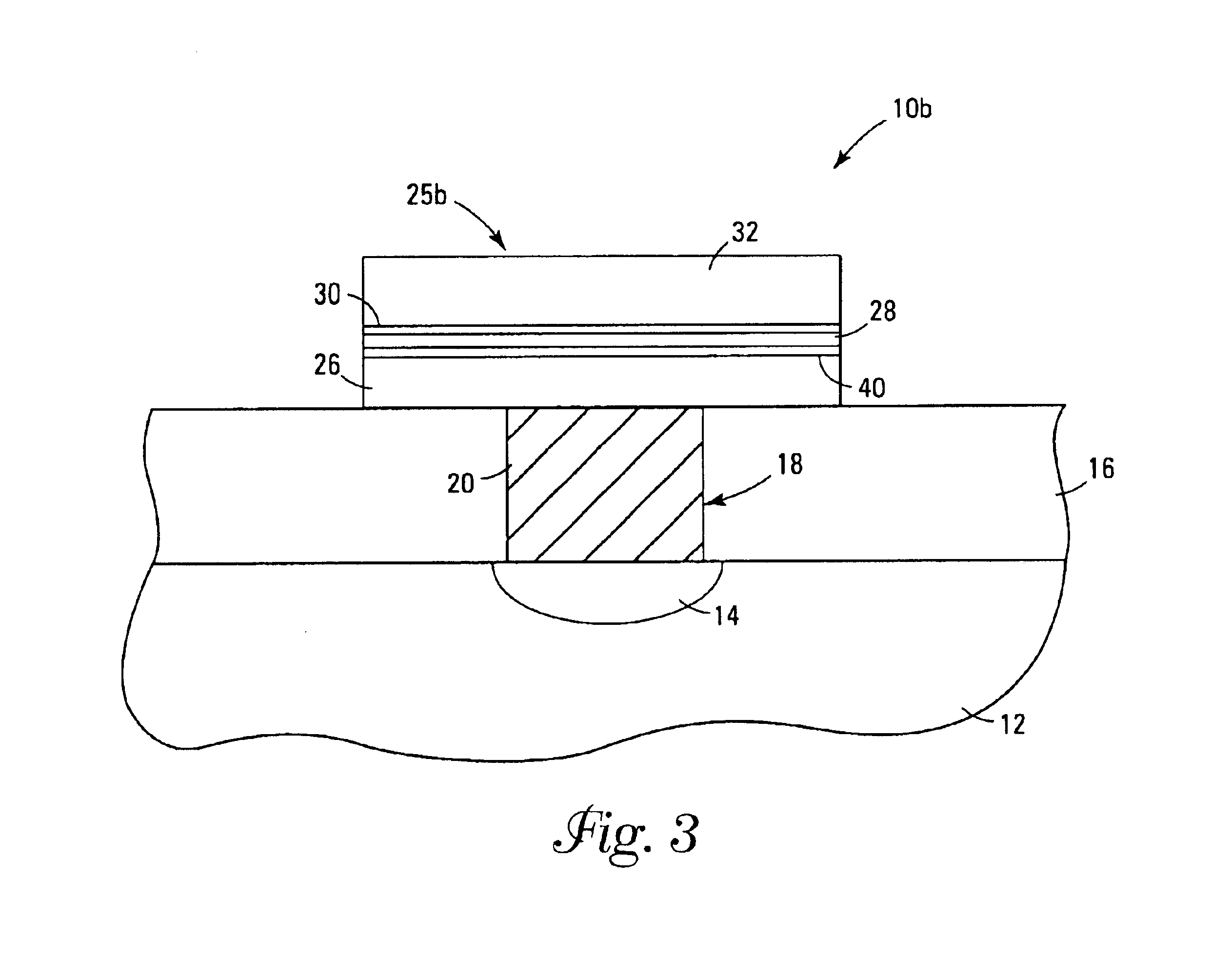

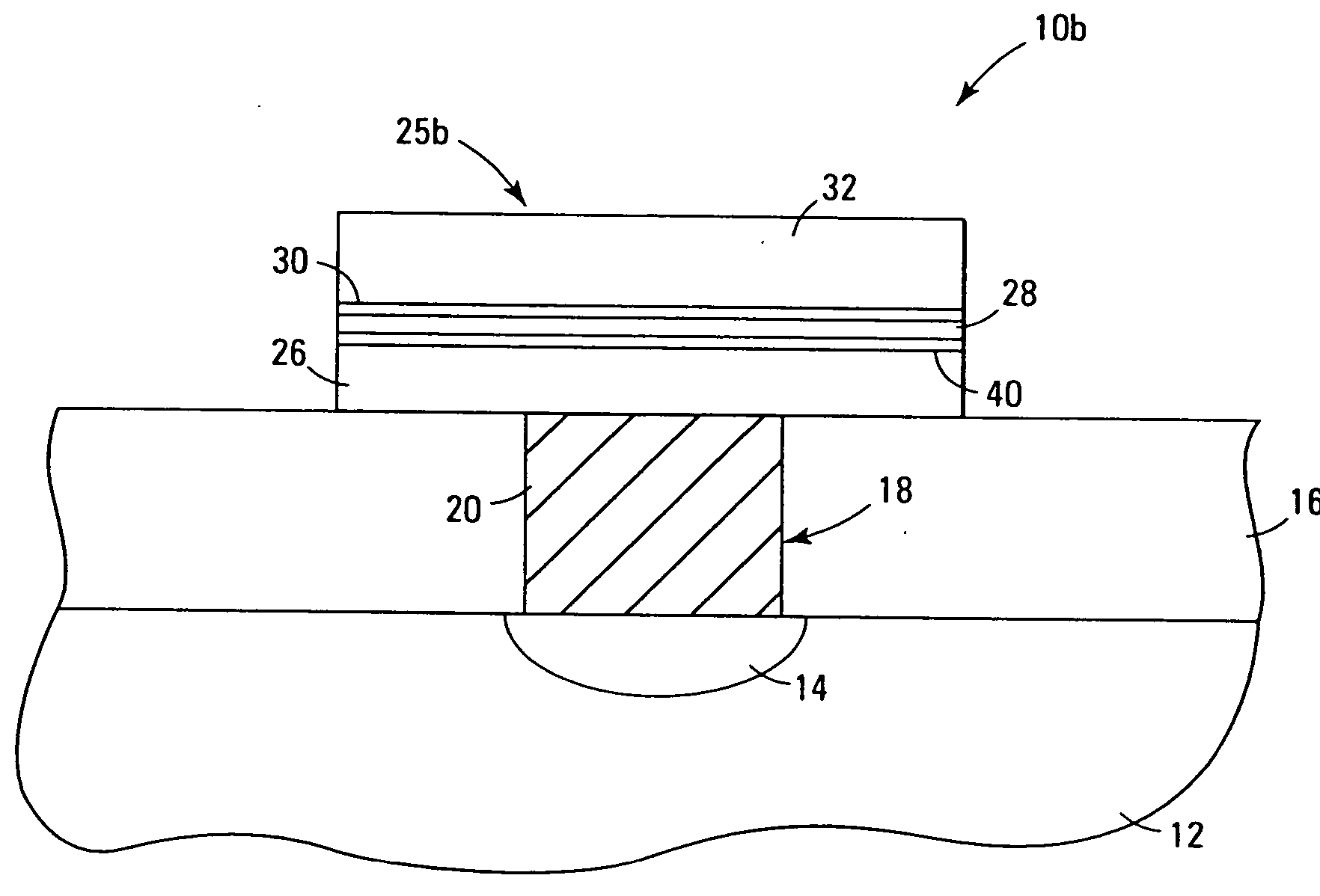

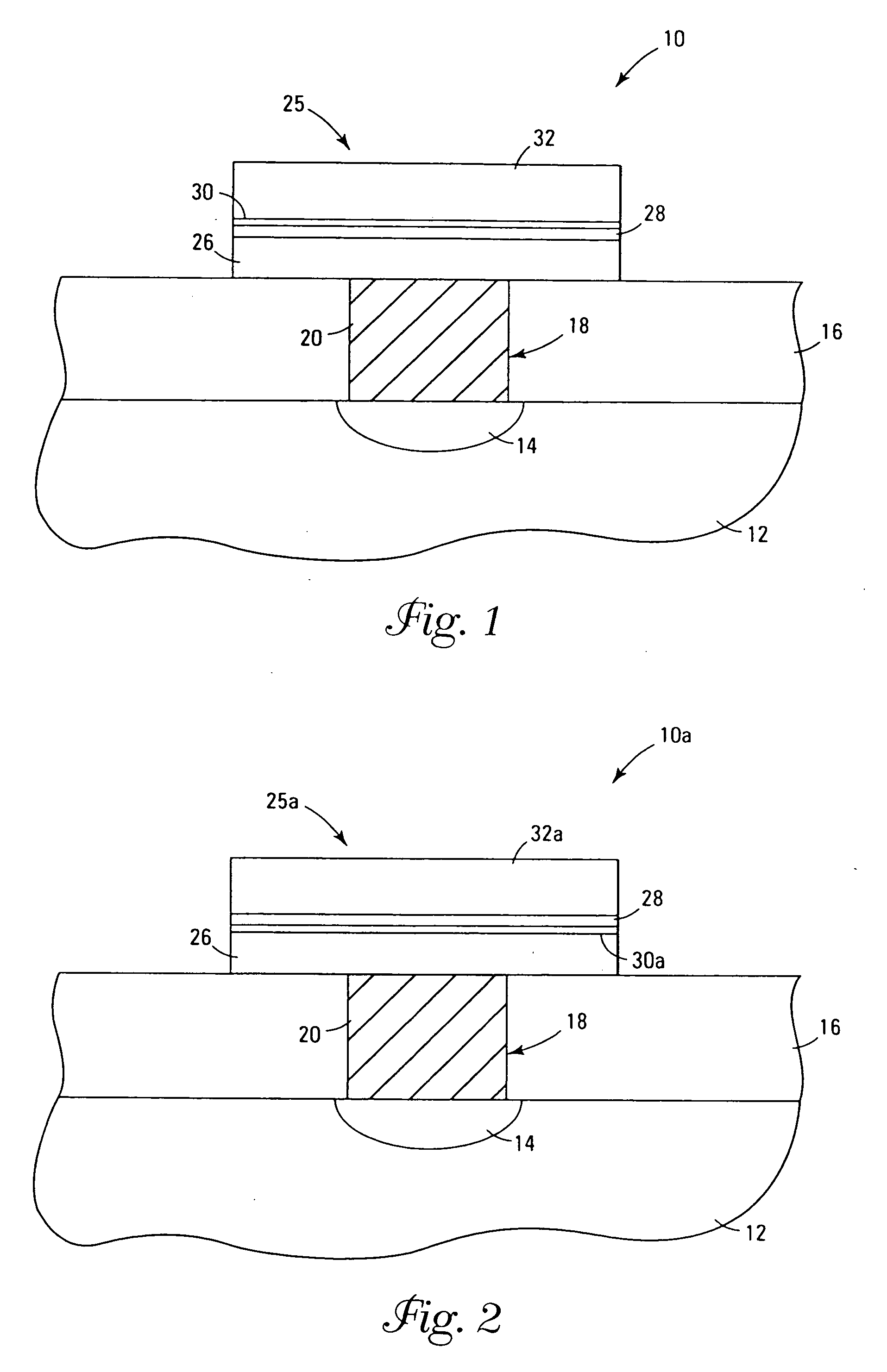

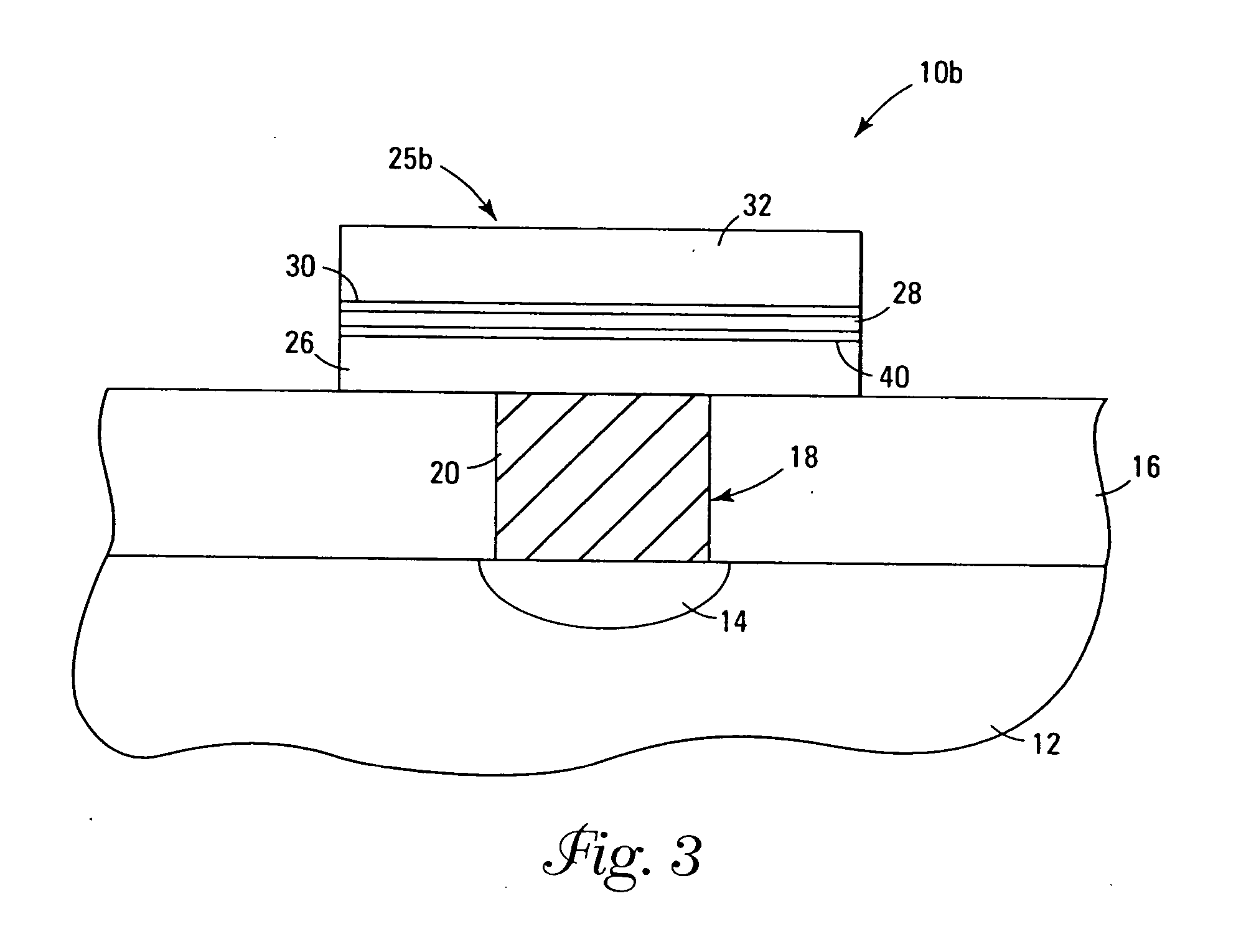

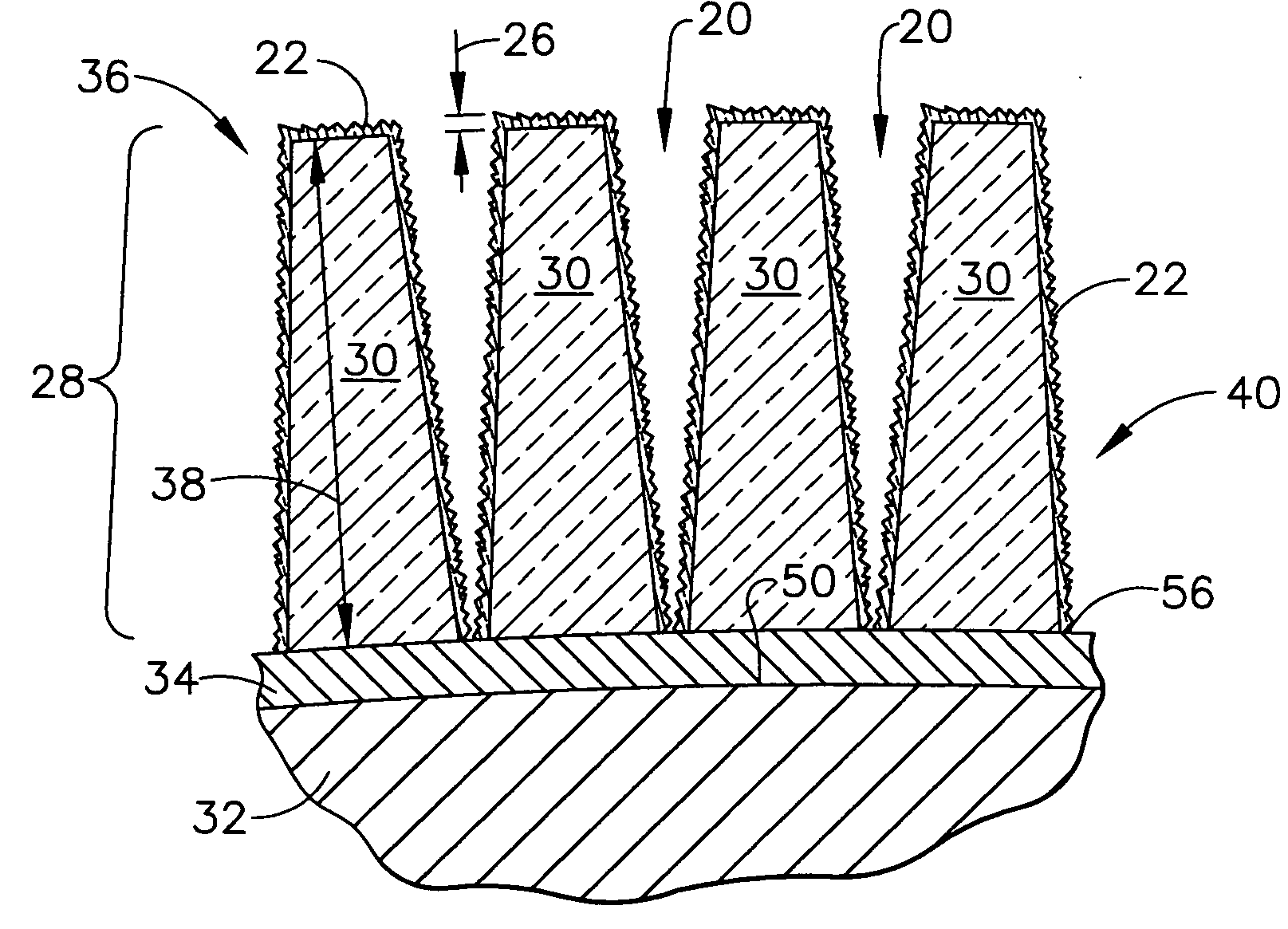

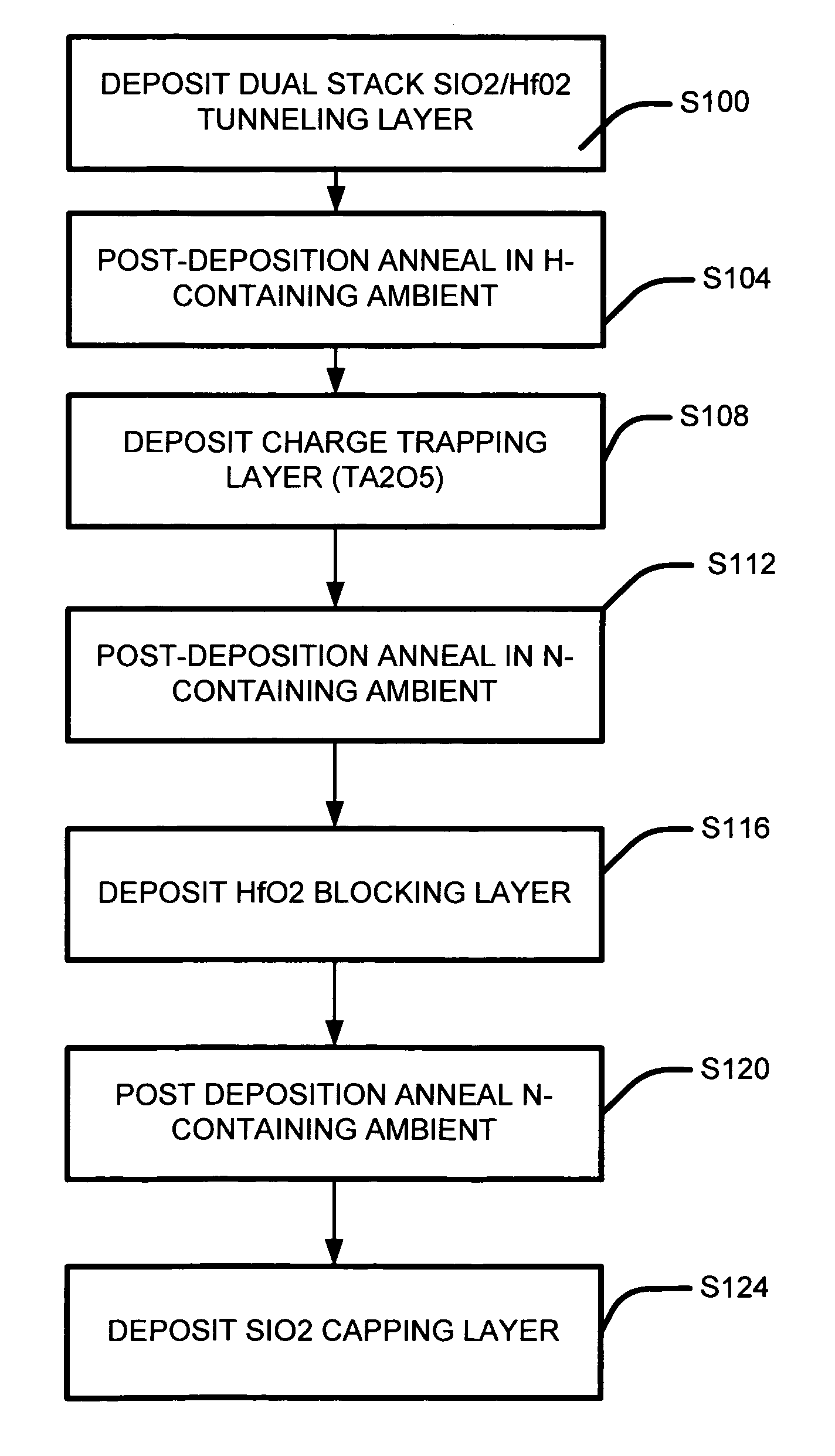

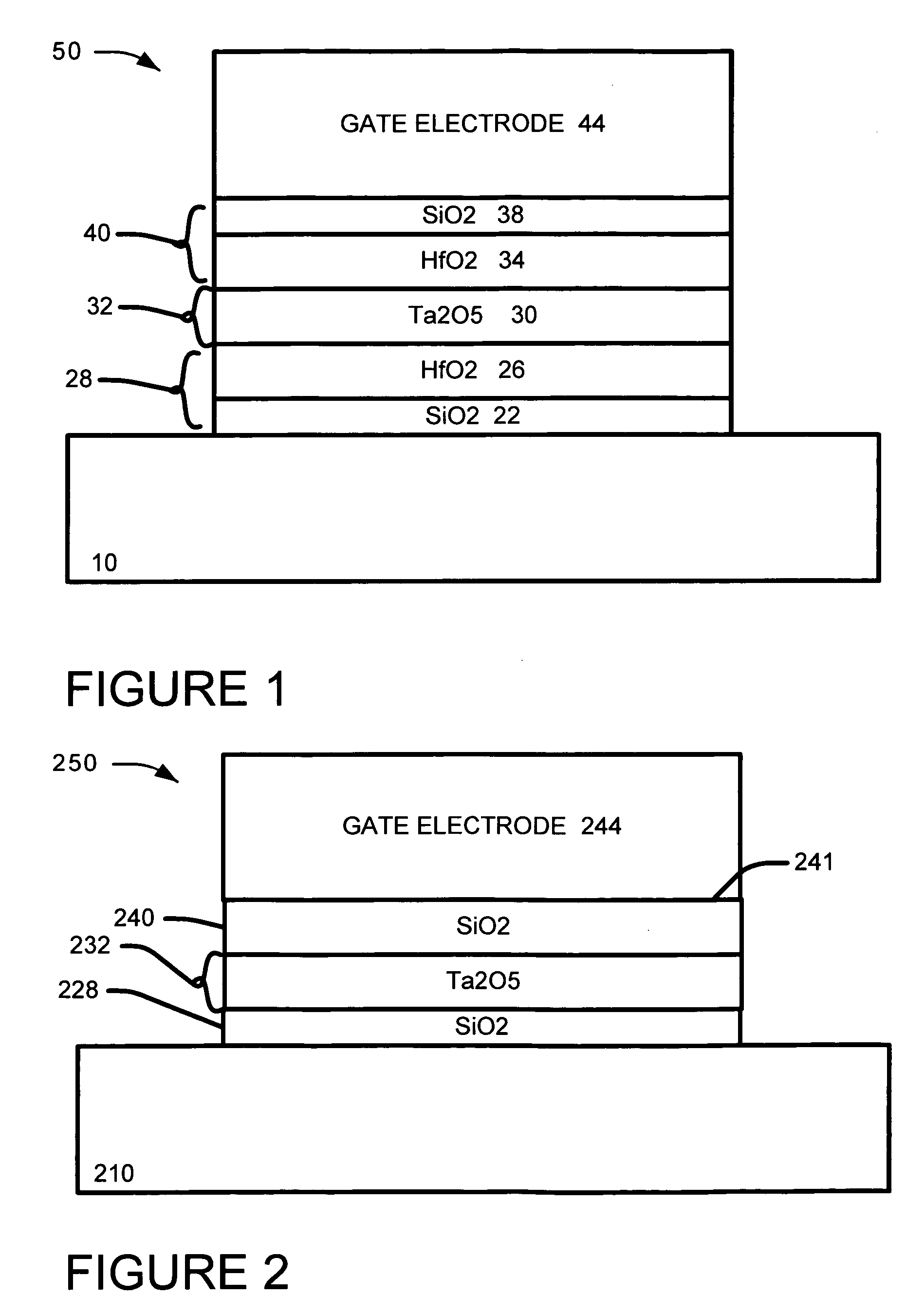

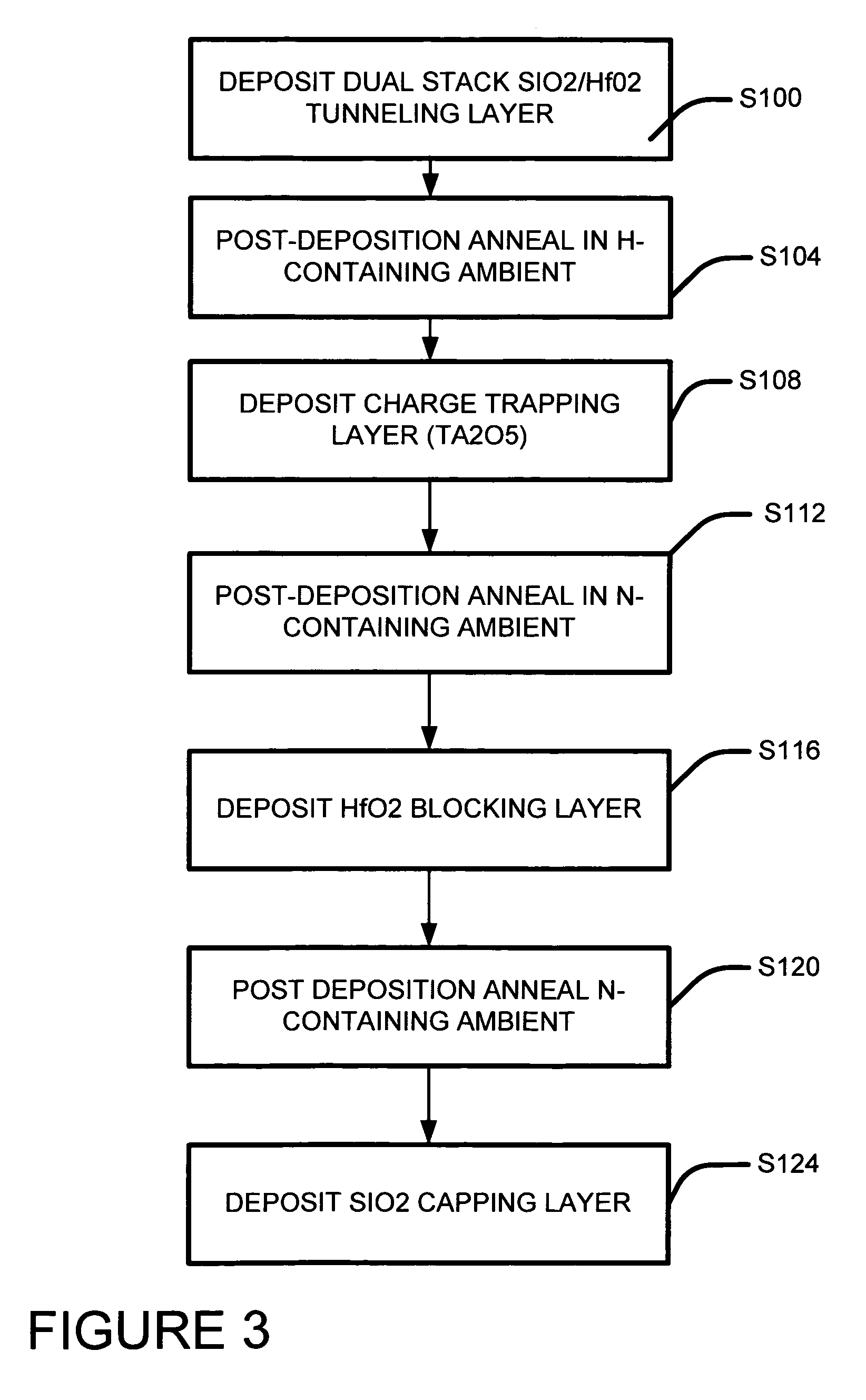

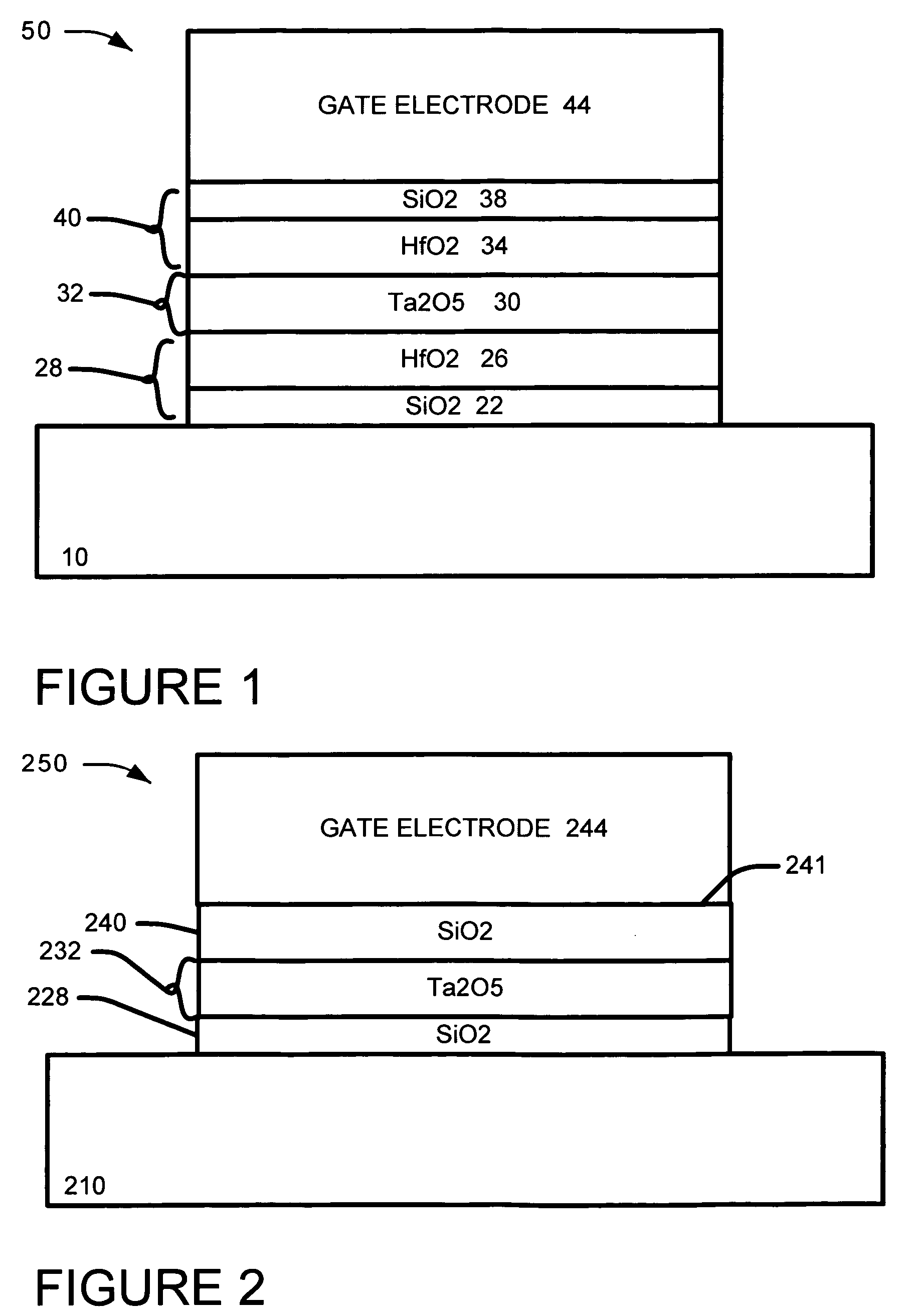

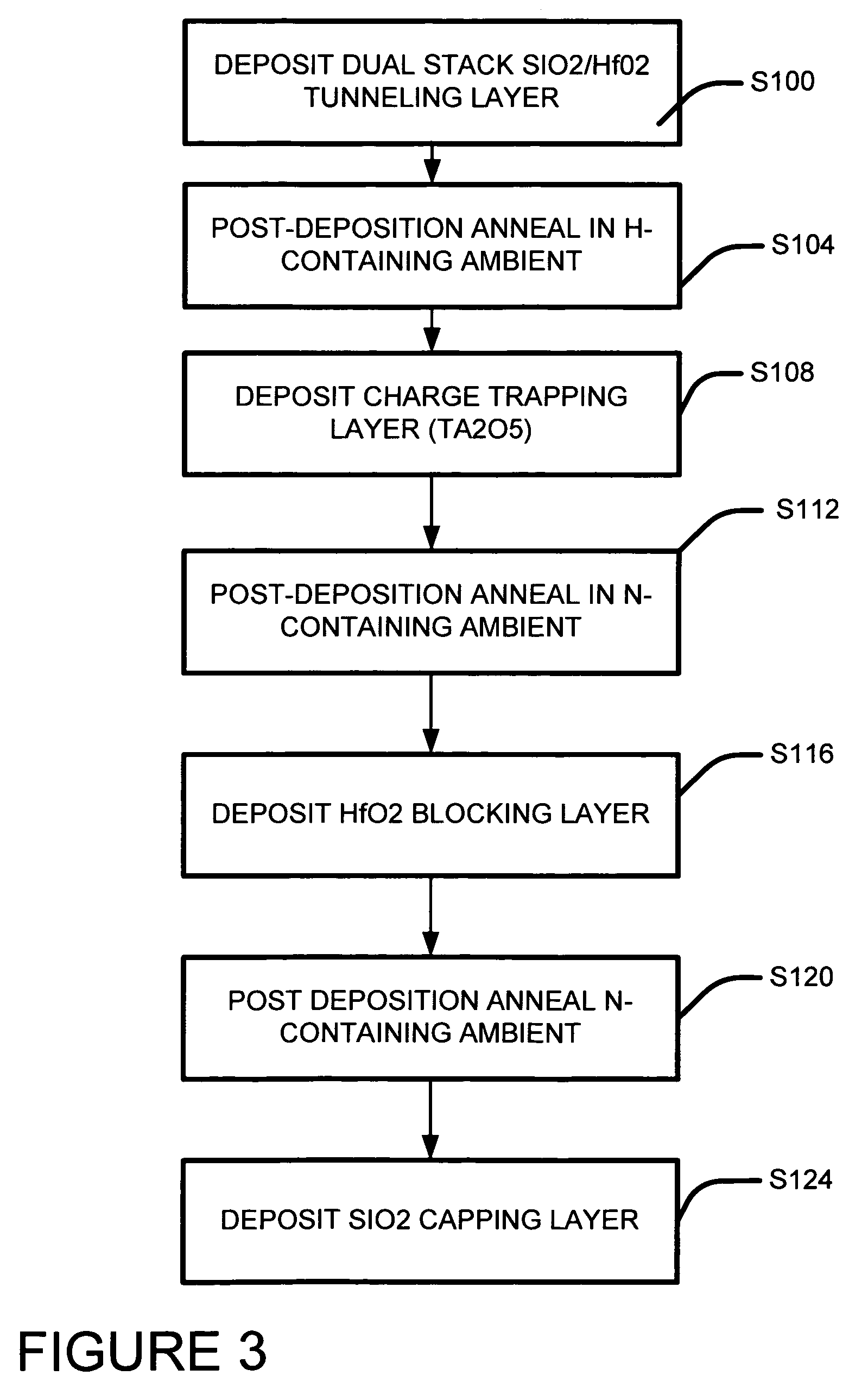

Method for forming high-K charge storage device

ActiveUS20060160303A1Reduce duplicationSemiconductor/solid-state device manufacturingSemiconductor devicesSilicon oxideBlocking layer

Structures and methods of fabricating of a floating gate non-volatile memory device. In a first example embodiment, We form a bottom tunnel layer comprised of a lower oxide tunnel layer and a upper hafnium oxide tunnel layer; a charge storage layer comprised of a tantalum oxide and a top blocking layer preferably comprised of a lower hafnium oxide storage layer and an upper oxide storage layer. We form a gate electrode over the top blocking layer. We pattern the layers to form a gate structure and form source / drain regions to complete the memory device. In a second example embodiment, we form a floating gate non-volatile memory device comprised of: a bottom tunnel layer comprised essentially of silicon oxide; a charge storage layer comprised of a tantalum oxide; a top blocking layer comprised essentially of silicon oxide; and a gate electrode. The embodiments also comprise anneals and nitridation steps.

Owner:CHARTERED SEMICONDUCTOR MANUFACTURING

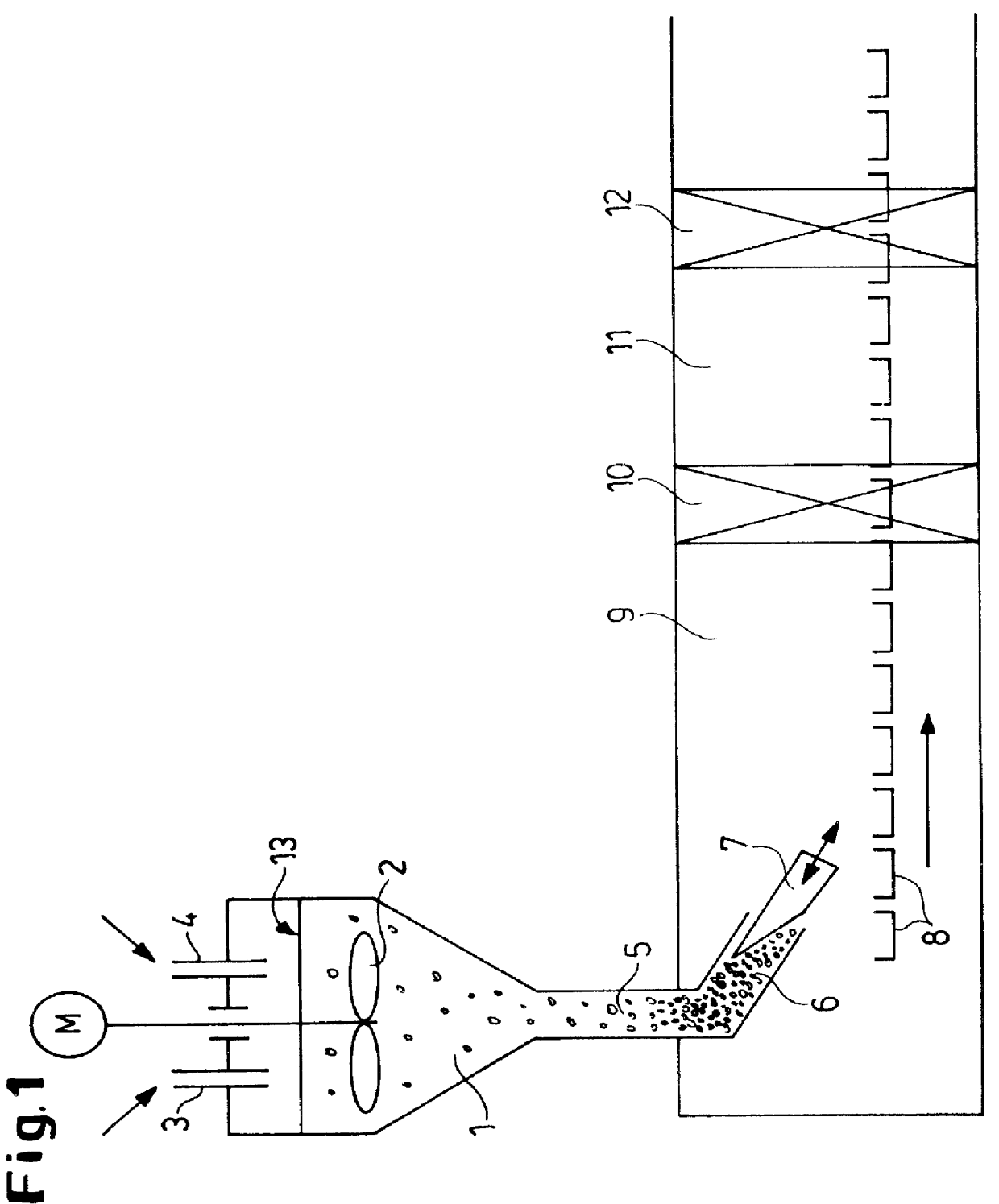

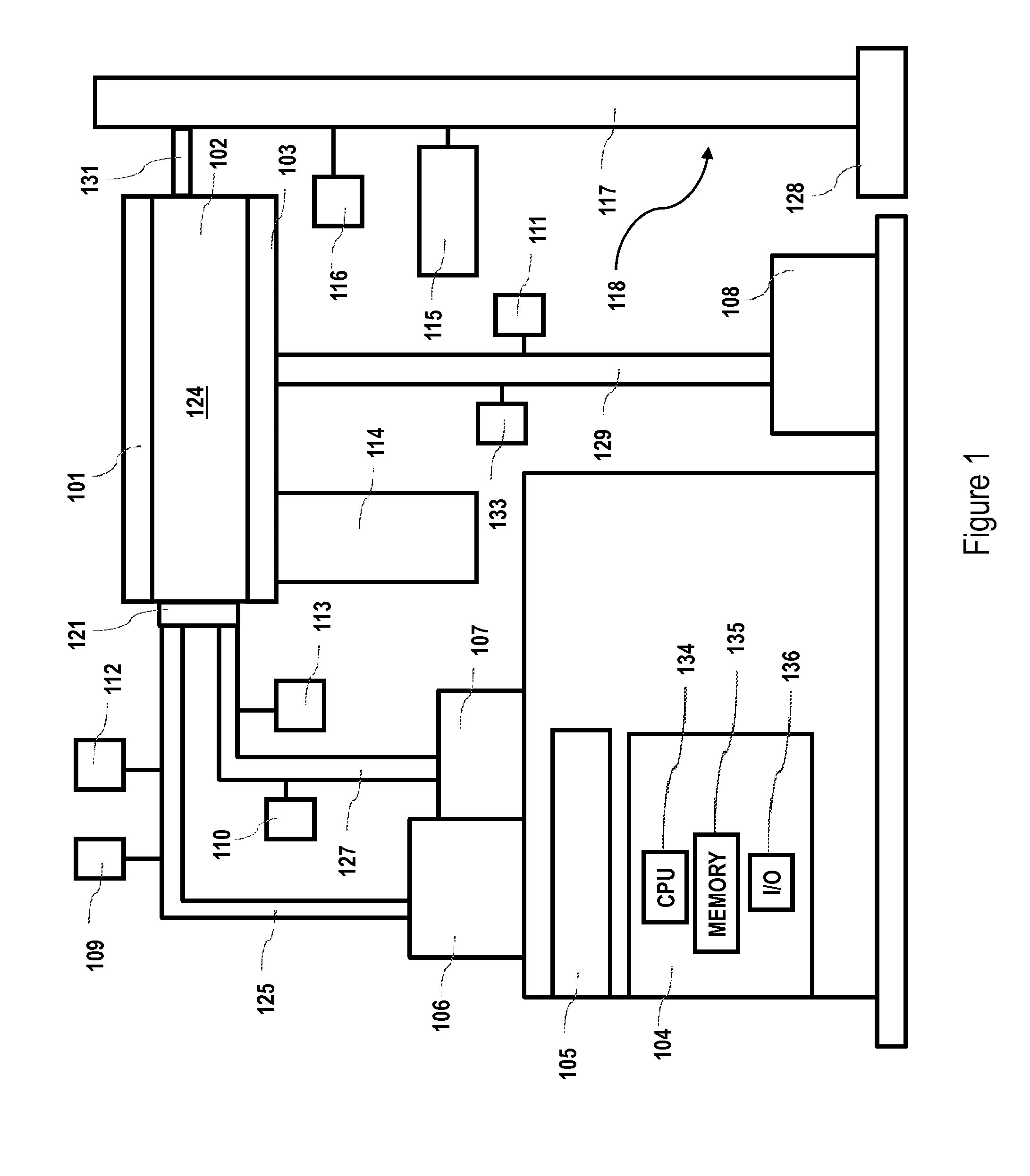

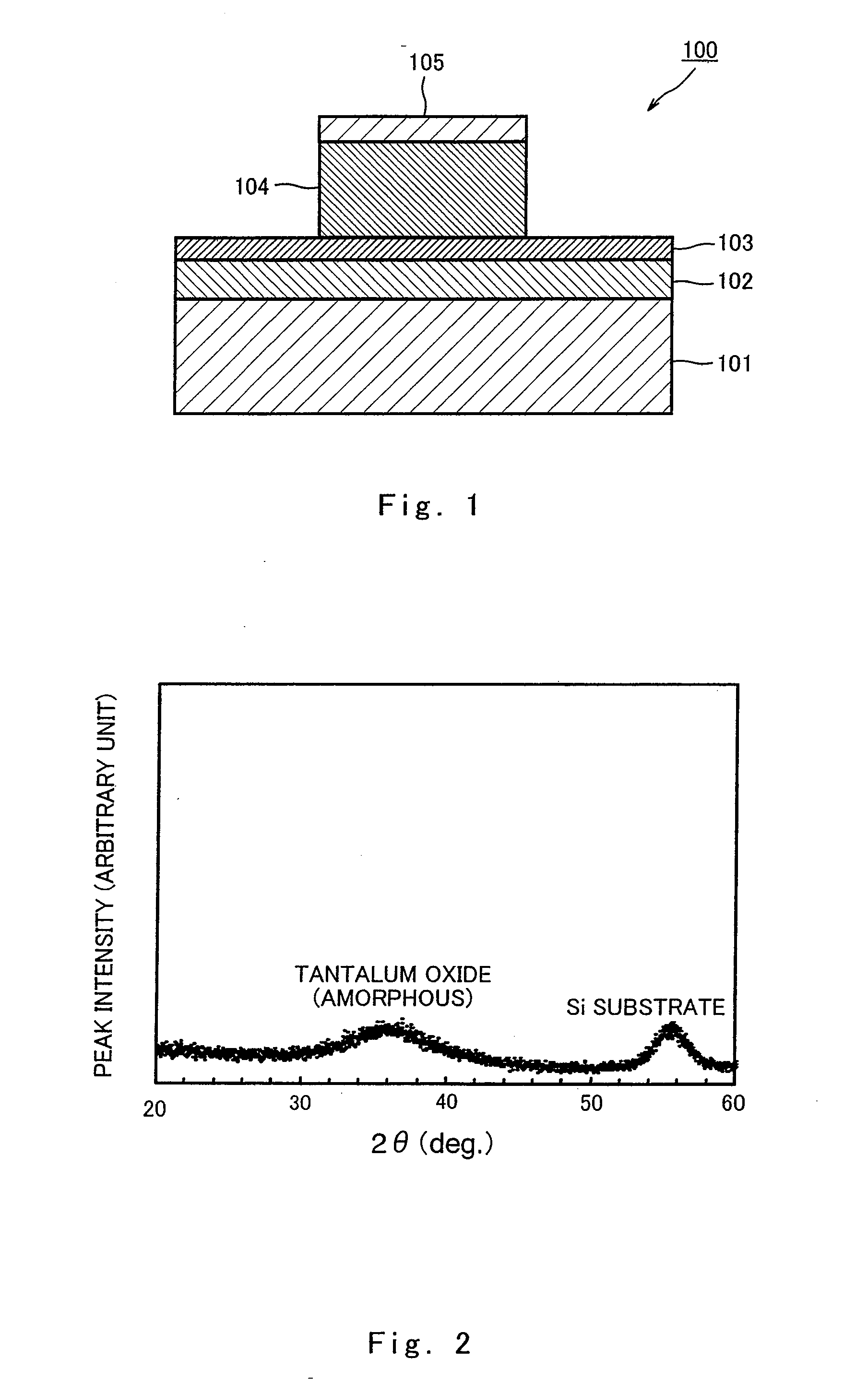

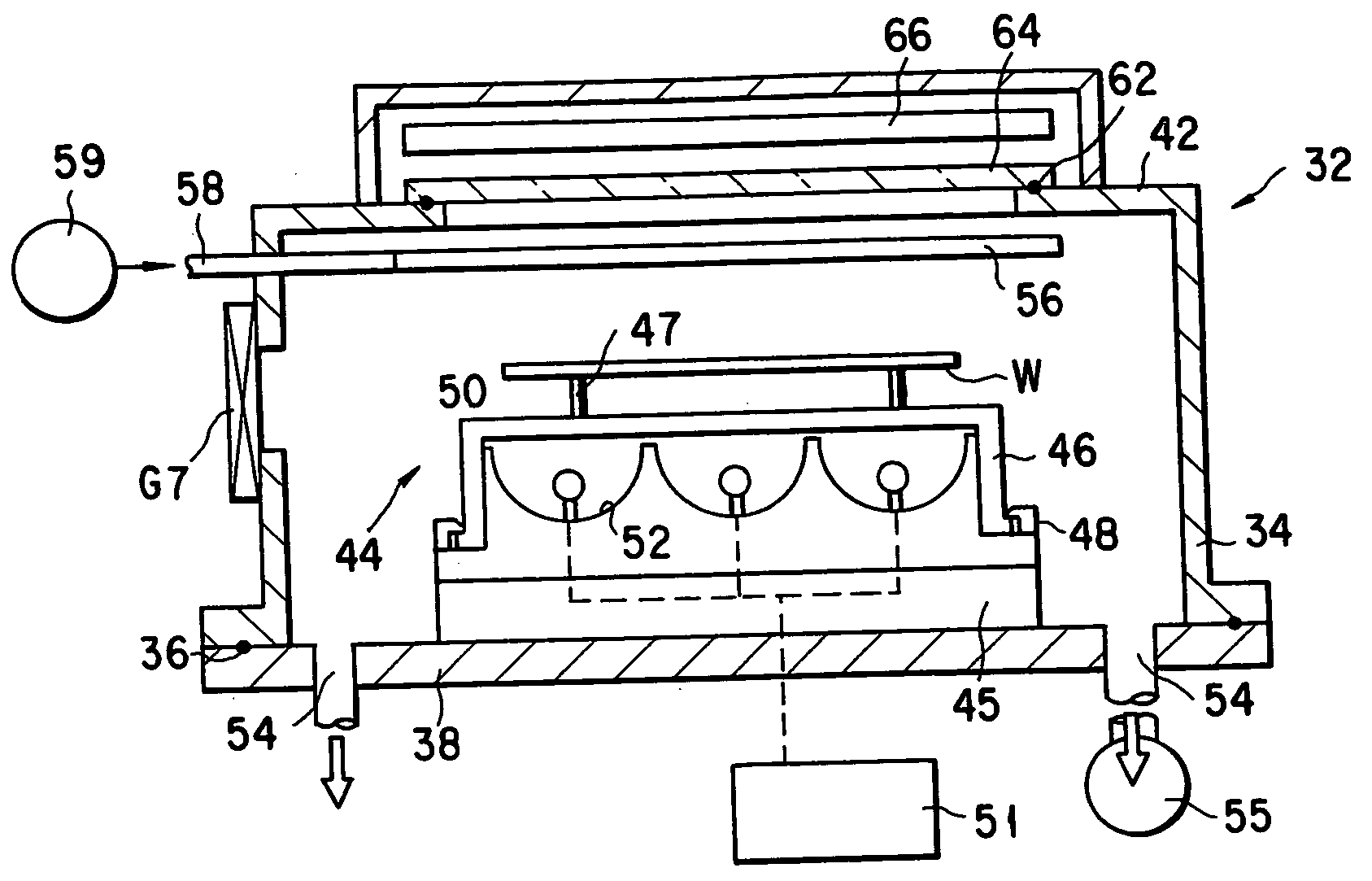

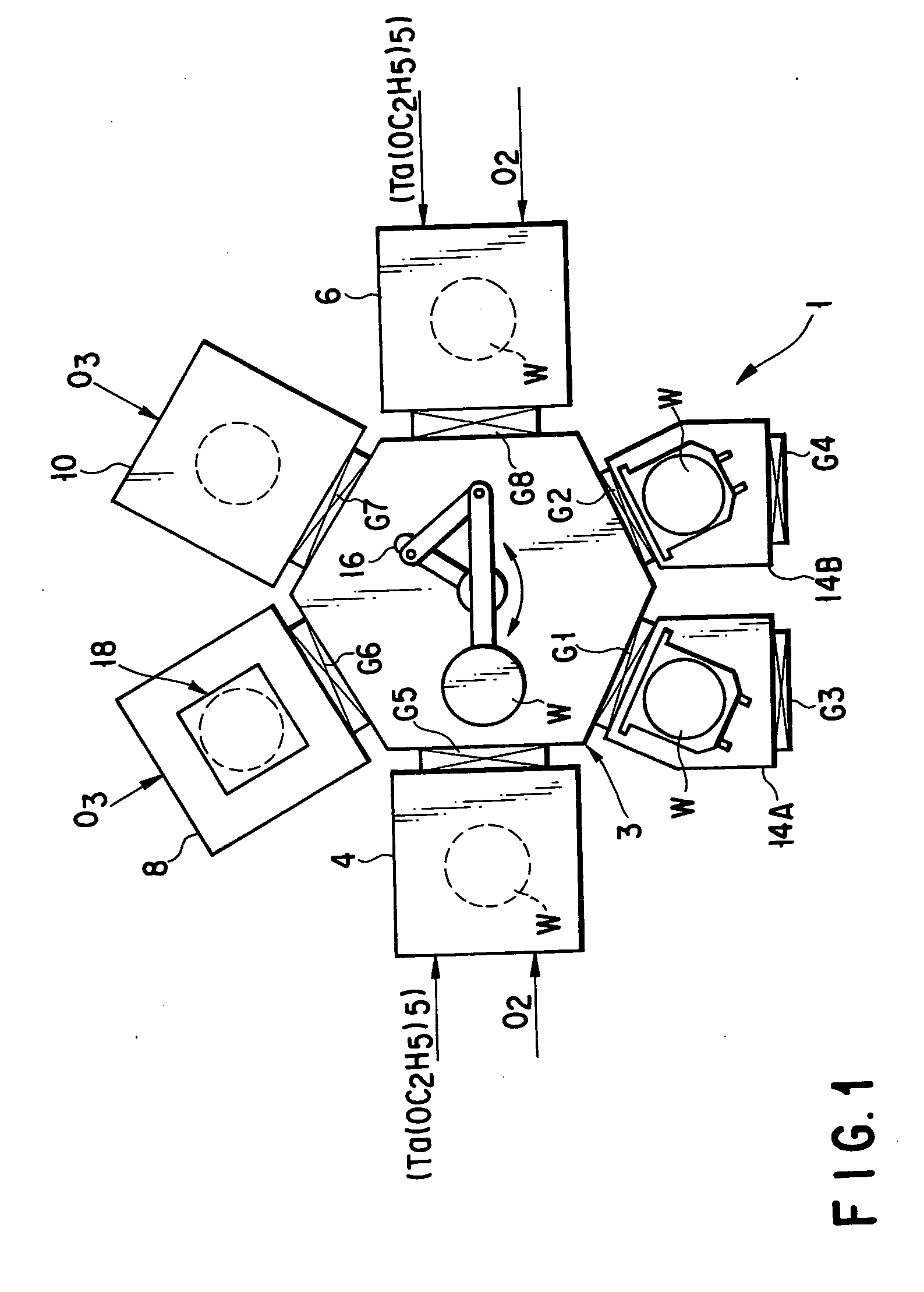

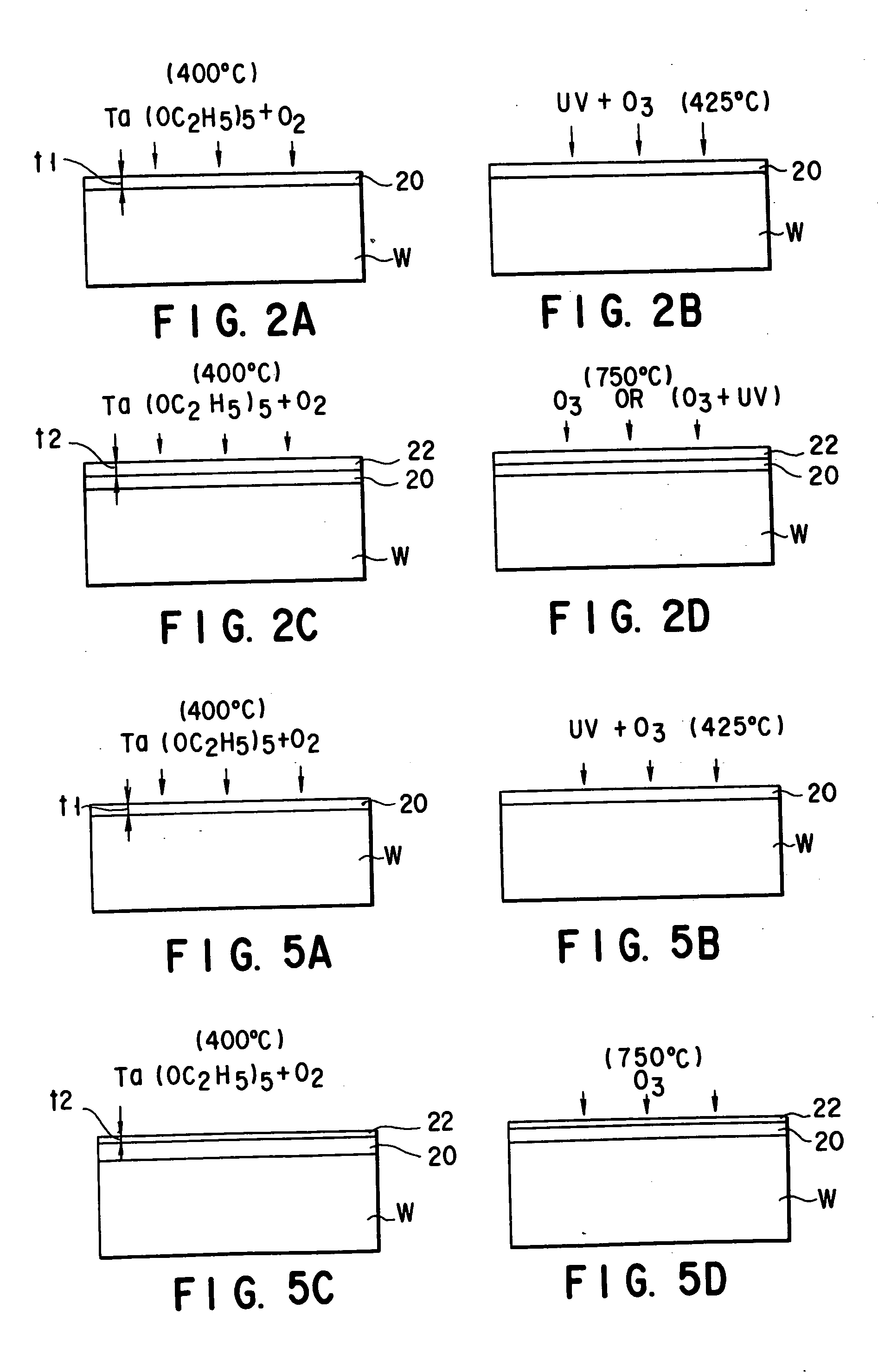

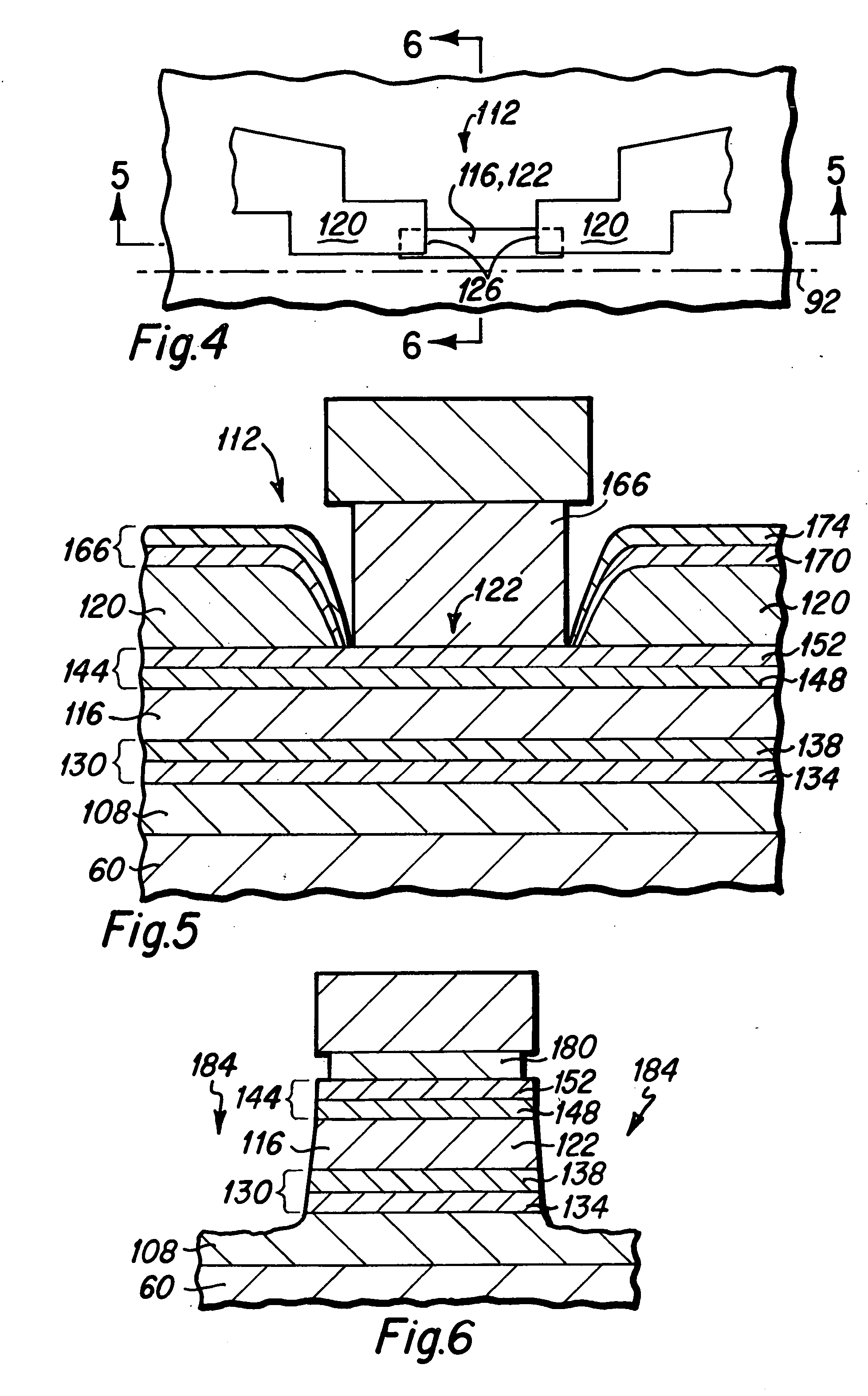

Single-substrate-heat-processing apparatus for performing reformation and crystallization

InactiveUS20050016687A1Improve throughputLow costSemiconductor/solid-state device manufacturingCapacitorsMetallurgySemiconductor

An insulating film consisting of first and second tantalum oxide layers is formed on a semiconductor wafer. First, an amorphous first layer is formed by CVD, and a reforming process for removing organic impurities contained in the first layer is carried out. Then, an amorphous second layer is formed by CVD on the first layer. Then, a reforming process for removing organic impurities contained in the second layer is carried out by supplying a process gas containing ozone into a process chamber while heating the wafer to a temperature lower than a crystallizing temperature over a certain period. Further, within the same process chamber, the wafer is successively heated to a second temperature higher than the crystallizing temperature, followed by cooling the wafer to a temperature lower than the crystallizing temperature so as to crystallize the first and second layers simultaneously.

Owner:TOKYO ELECTRON LTD

Magnetic head having multilayer heater for thermally assisted write head and method of fabrication thereof

ActiveUS20050024773A1Facilitates writing of dataLower its localized coercivityConstruction of head windingsHeads using thin filmsMetallic materialsEngineering

A magnetic head including a media heating device that is fabricated within the magnetic head structure. The media heating device is fabricated with diffusion barrier layers and / or adhesion layers beneath the heating device layers, between heating device layers and / or above the heating device layers. A diffusion barrier layer prevents the diffusion of the metal materials that comprise the heating device layers into layers that are disposed below and / or above the heating device, and adhesion layer promotes adhesion of the heating device to the magnetic head layers adjacent to the heating device. The diffusion barrier layer may be comprised of tantalum, tantalum nitride, other tantalum alloys, titanium, rhodium and ruthenium, and the adhesion layer may be comprised of tantalum, tantalum nitride, tantalum oxide, other tantalum alloys, titanium, nickel iron, chromium, platinum alloys, nickel alloys and aluminum oxide.

Owner:WESTERN DIGITAL TECH INC

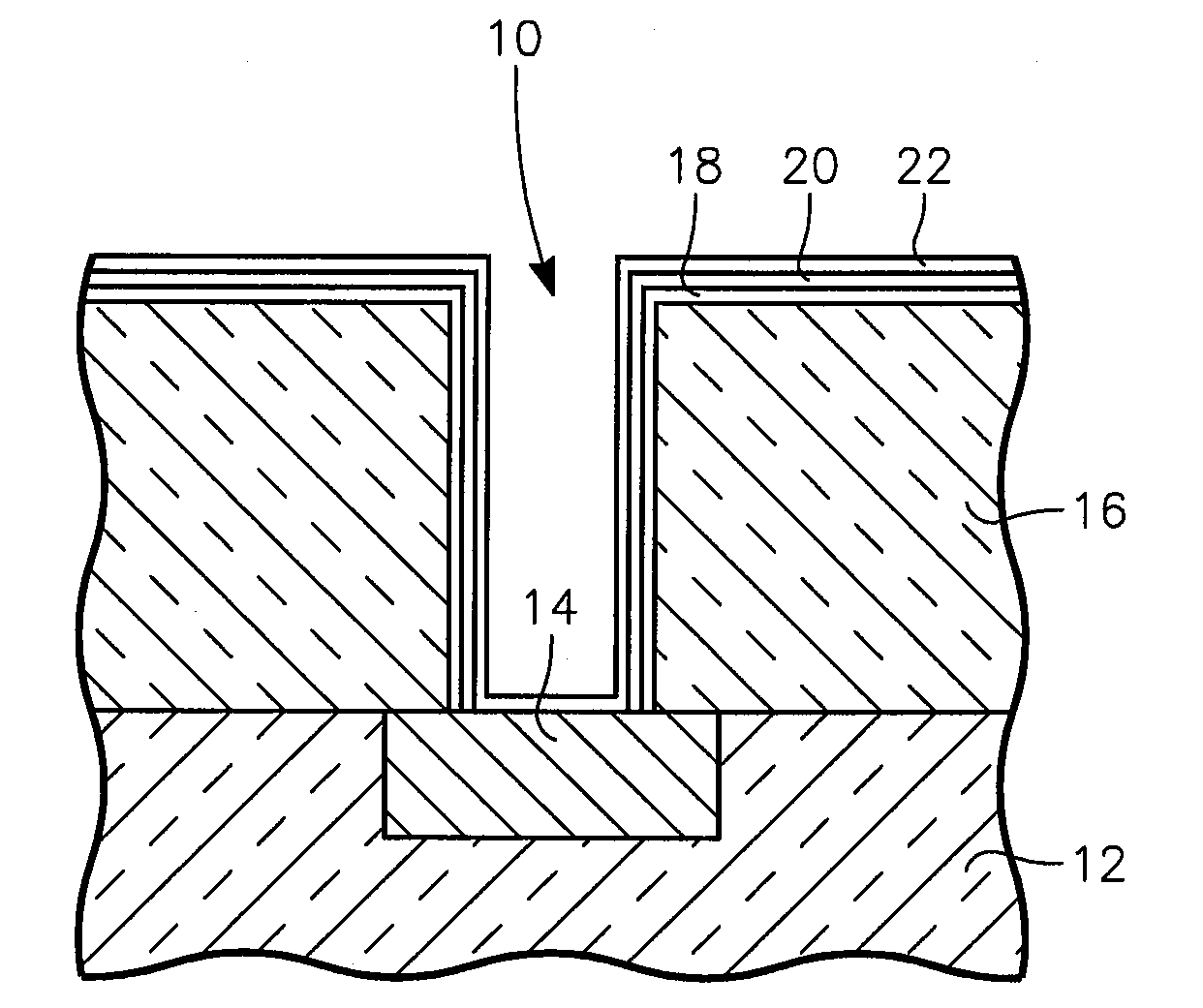

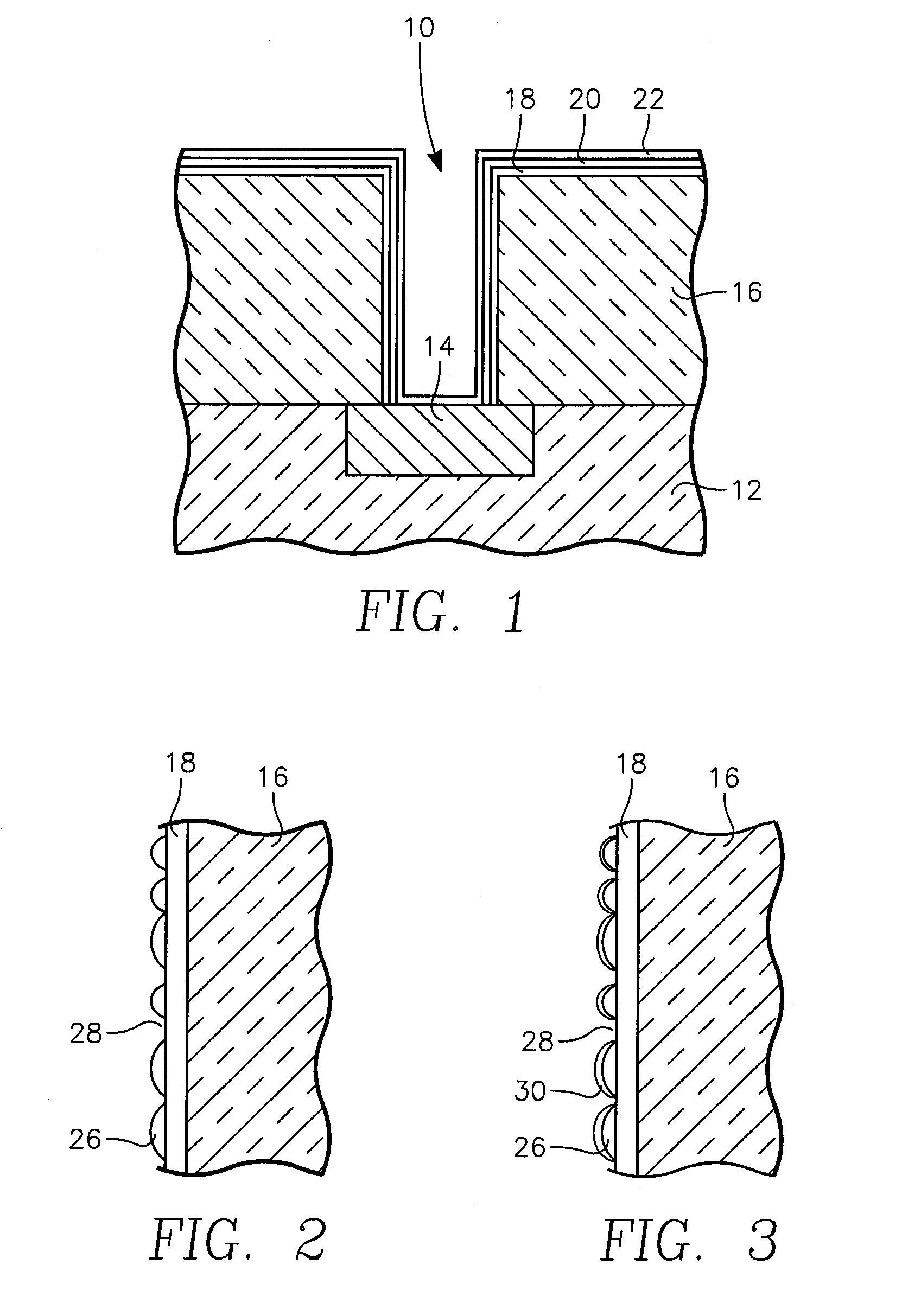

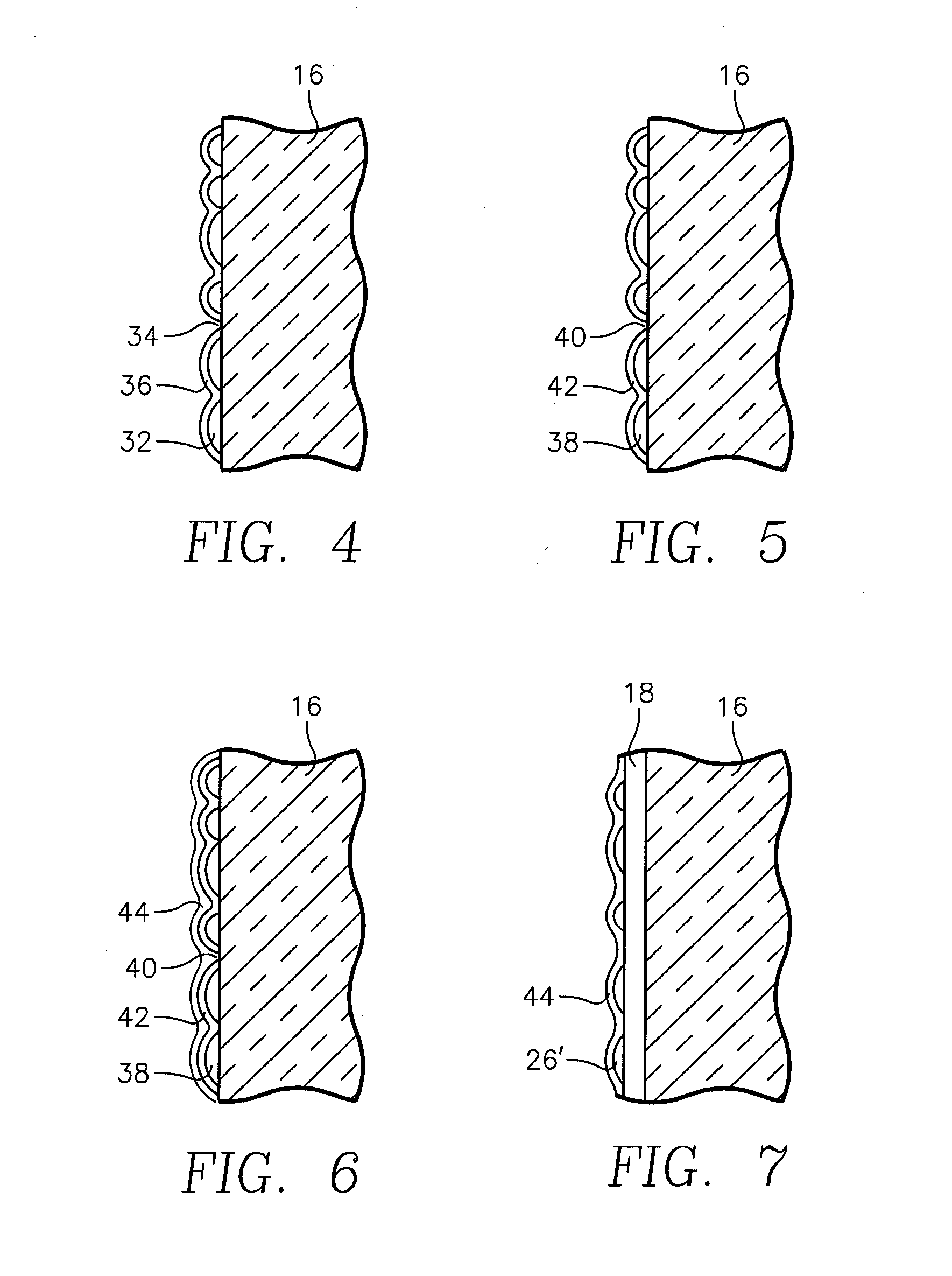

Oxidized Barrier Layer

InactiveUS20080237029A1Semiconductor/solid-state device detailsSolid-state devicesChemical physicsOxygen plasma

A method and resultant produce of forming barrier layer based on ruthenium tantalum in a via or other vertical interconnect structure through a dielectric layer in a multi-level metallization. The RuTa layer in a RuTa / RuTaN bilayer, which may form discontinuous islands, is actively oxidized, preferably in an oxygen plasma, to thereby bridge the gaps between the islands. Alternatively, ruthenium tantalum oxide is reactive sputtered onto the RuTaN or directly onto the underlying dielectric by plasma sputtering a RuTa target in the presence of oxygen.

Owner:APPLIED MATERIALS INC

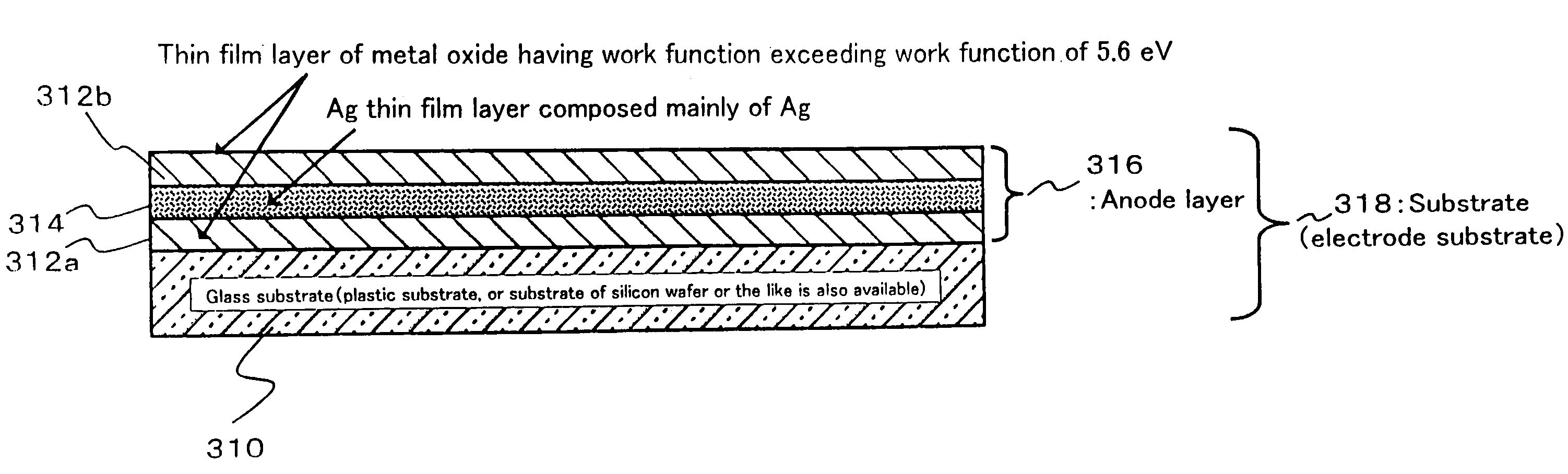

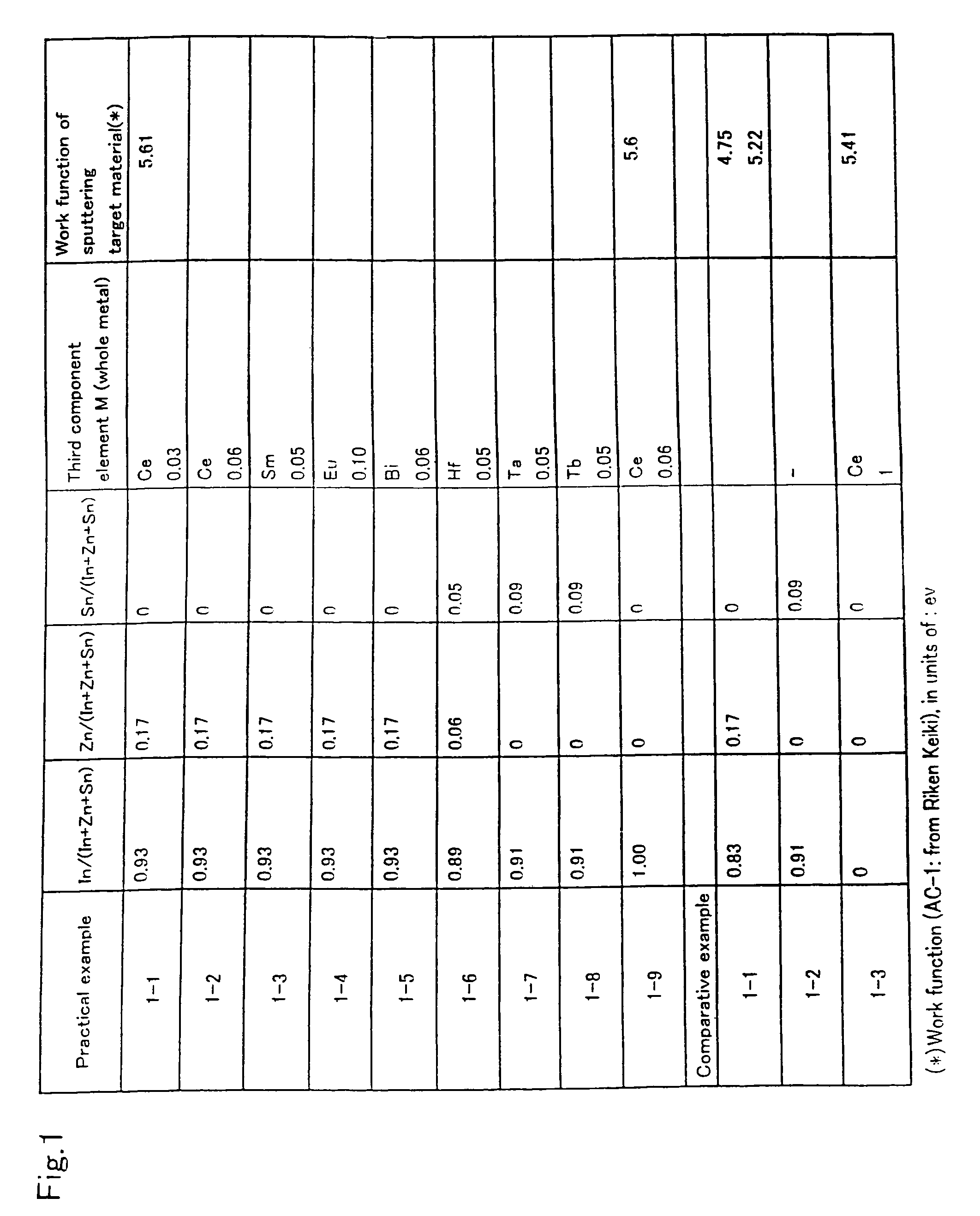

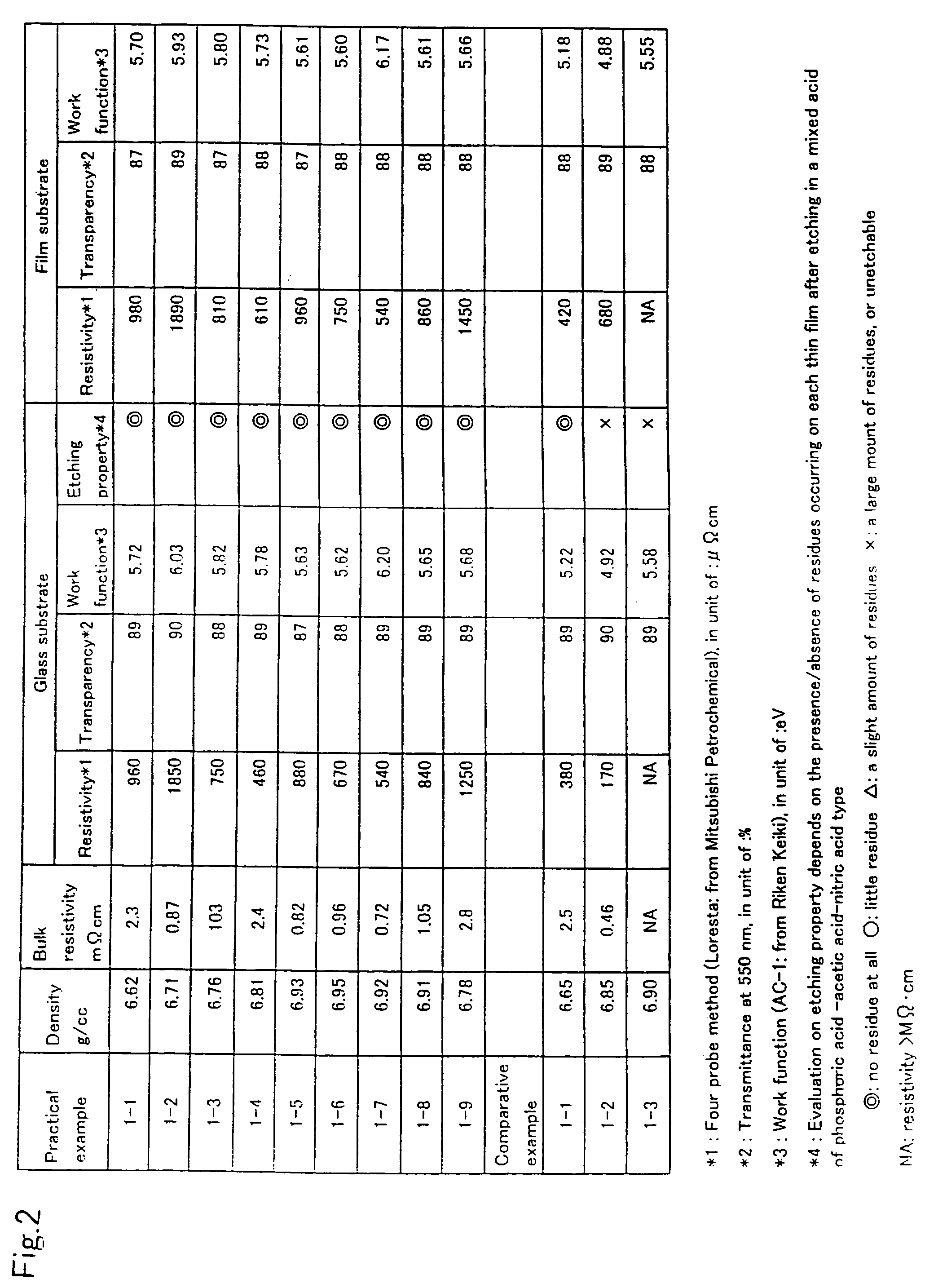

Sputtering target, sintered compact, electrically conductive film produced by using the same, and organic EL device and substrate used for the same

A sintered article is fabricated which contains one or more of indium oxide, zinc oxide, and tin oxide as a component thereof and contains any one or more types of metal out of hafnium oxide, tantalum oxide, lanthanide oxide, and bismuth oxide. A backing plate is attached to this sintered article to constitute a sputtering target. This sputtering target is used to fabricate a conductive film on a predetermined substrate by sputtering. This conductive film achieves a large work function while maintaining as much transparency as heretofore. This conductive film can be used to achieve an EL device or the like of improved hole injection efficiency.

Owner:IDEMITSU KOSAN CO LTD

Method for forming high-K charge storage device

ActiveUS7479425B2Semiconductor/solid-state device manufacturingSemiconductor devicesSilicon oxideBlocking layer

Owner:CHARTERED SEMICONDUCTOR MANUFACTURING

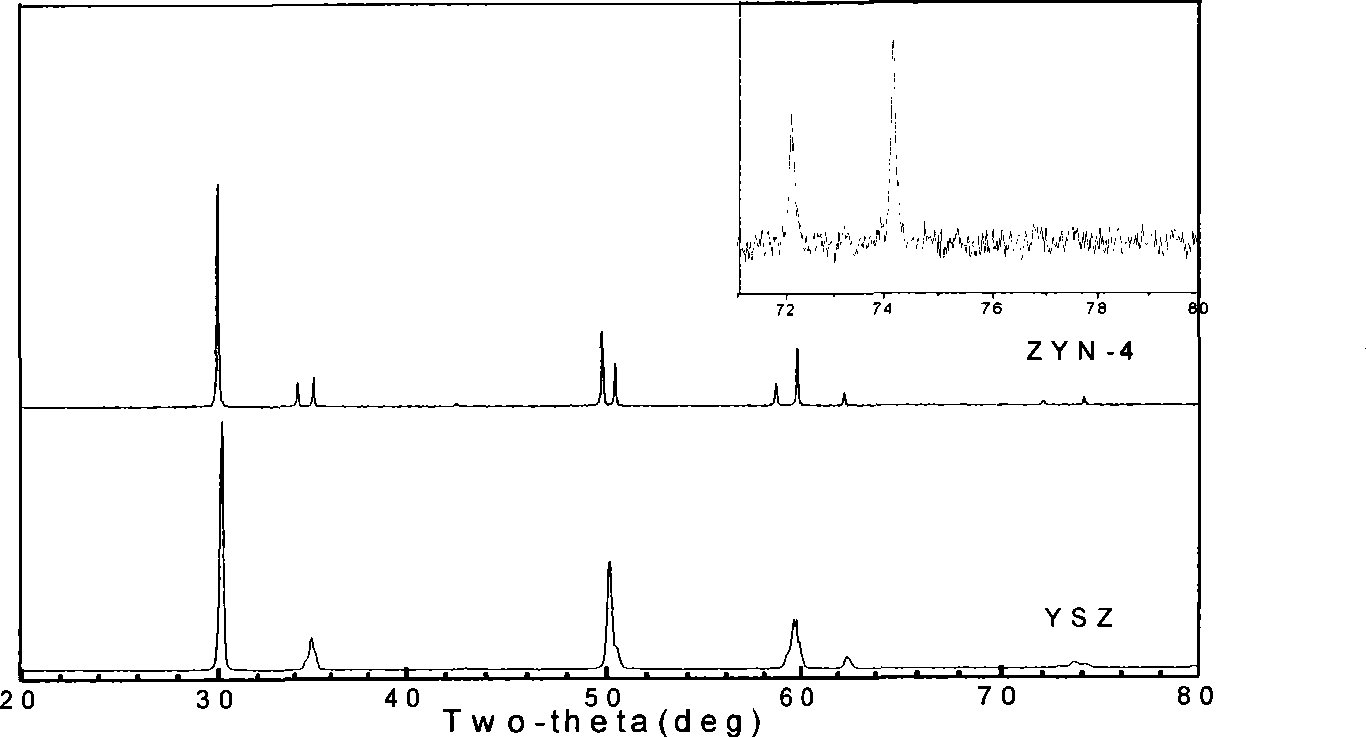

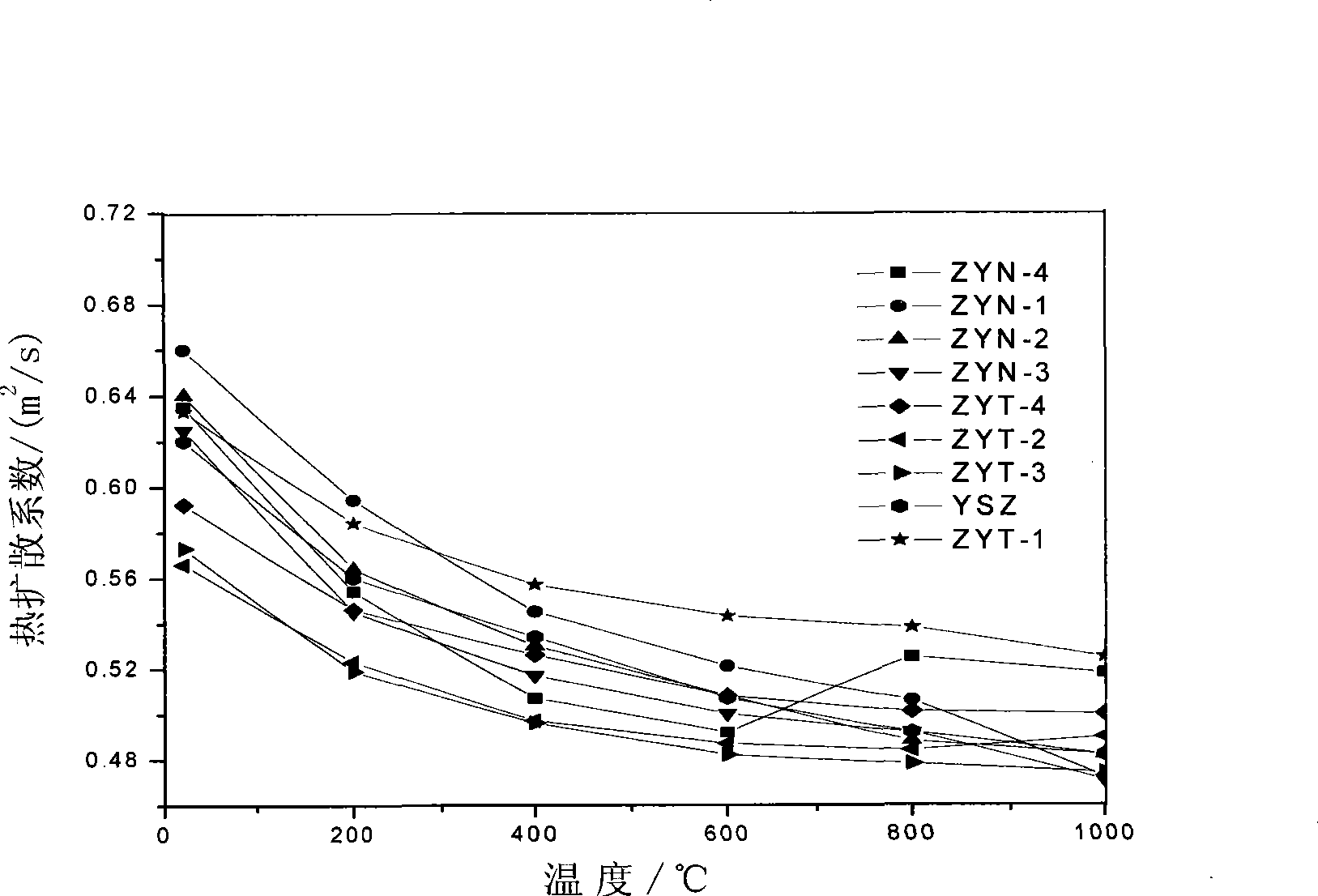

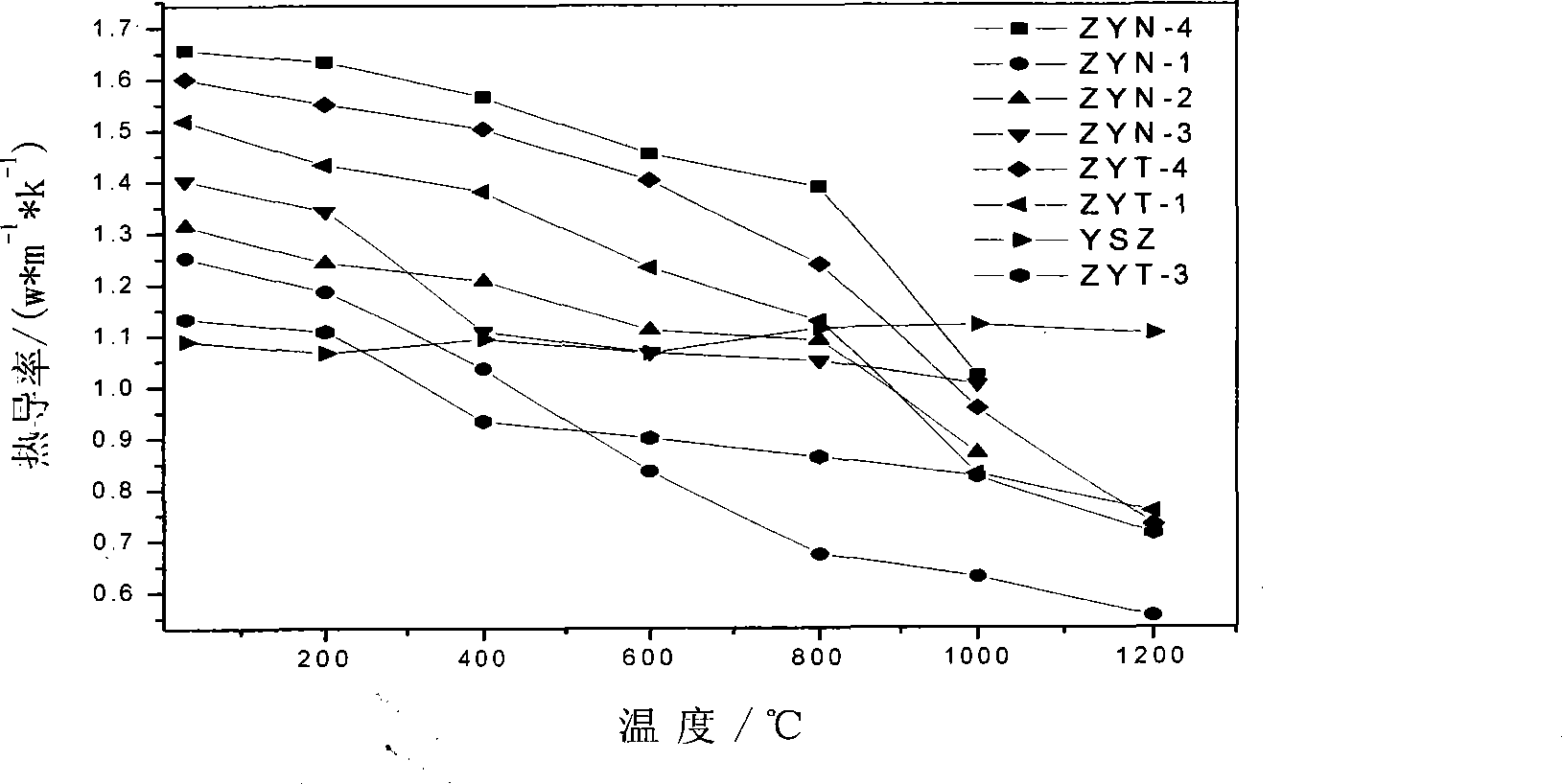

Multi-element co-stabilizing zirconia of heat barrier coat material and preparation method

The invention relates to a multivariant co-stable zirconia thermal barrier coating material and a preparation method which belong to the field of materials. The multivariant co-stable zirconia thermal barrier coating material is characterized by consisting of the following materials according to mole fractions: zirconia, yttria, niobium oxide or tantalum oxide and rare earth oxide. The preparation method comprises the following steps: a zirconia ball is ground by wet process, dried and molded; a pre-burnt block is obtained by pre-burning; the pre-burnt block is smashed and further carried out with the wet ball milling to obtain slurry; the slurry is dried, granulated and mould pressed to obtain a green body, the green body is sintered to obtain the multivariant co-stable zirconia thermal barrier coating material; the ceramic material can be used as a target material for preparing a thermal barrier coating by using the EB-PVD method. A third phase of Nb2O5 / Ta2O5 is introduced in YSZ to develop the stable existence interval of t-ZrO2 to further obtain non-transition t'-ZrO2, and the rare earth oxide is added to increase the defects to further improve the phonon or photon scattering on the basis, thereby improving the using temperature of the ZrO2 thermal barrier coating and reducing the thermal conductivity of the material.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

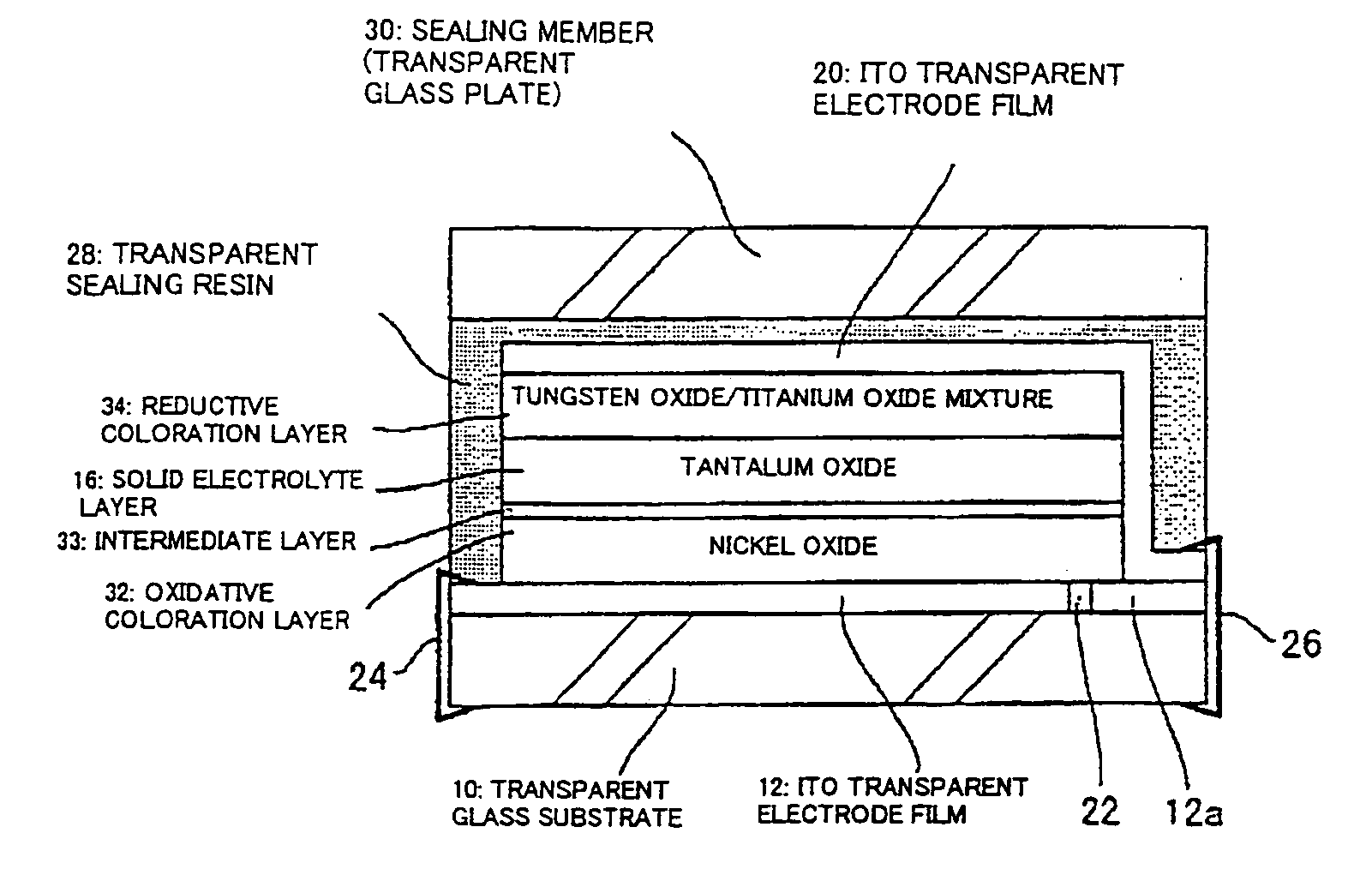

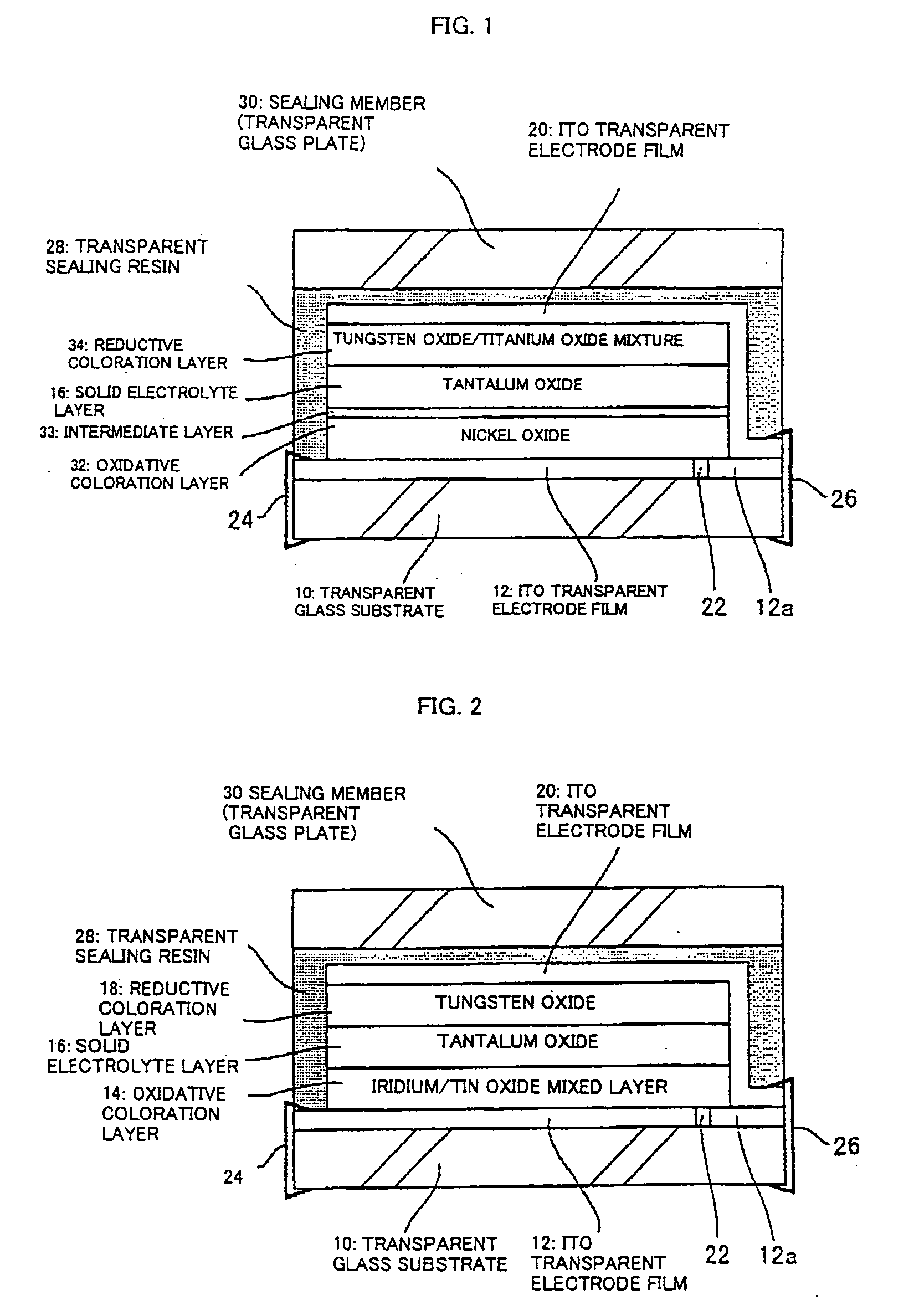

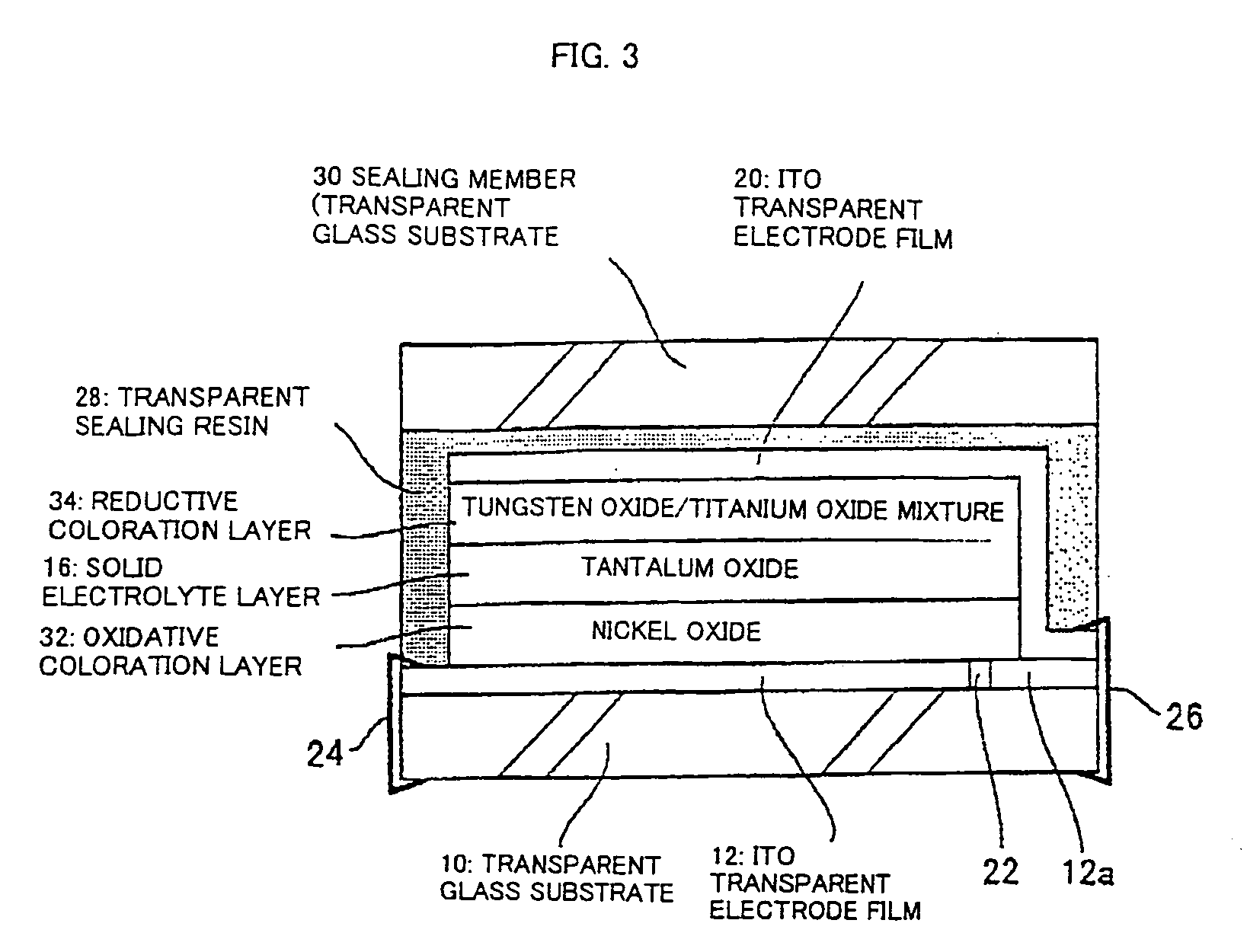

Electrochromic element

InactiveUS20050248824A1Suppresses characteristic deteriorationInhibit transparencyNon-linear opticsInter layerOptoelectronics

Deterioration of characteristics due to repeated cycles of coloration and discoloration in an electrochromic element comprising an oxidative coloration layer composed of a nickel oxide and a electrolyte composed of a solid electrolyte is suppressed. A lower ITO transparent electrode film 12 is formed on a transparent substrate 10. A nickel oxide film 32 making up an oxidative coloration layer, an intermediate layer 33, a tantalum oxide film making up a solid electrolyte layer, a mixed film comprising a tungsten oxide and a titanium oxide making up a reductive coloration layer, and an upper ITO transparent electrode film 20 making up an upper electrode film are formed on the lower ITO transparent electrode film 12 on this order. The intermediate layer 33 is a transparent film comprising a metal oxide such as SnO2, a metal such as Al, or a composite of the metal oxide and the metal.

Owner:MURAKAMI CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com