Patents

Literature

45 results about "Lead zirconium titanate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compositions and structures for chemical mechanical polishing of FeRAM capacitors and method of fabricating FeRAM capacitors using same

InactiveUS6346741B1Easy to manufactureBig advantageOther chemical processesSemiconductor/solid-state device detailsLead zirconate titanateBarium strontium titanate

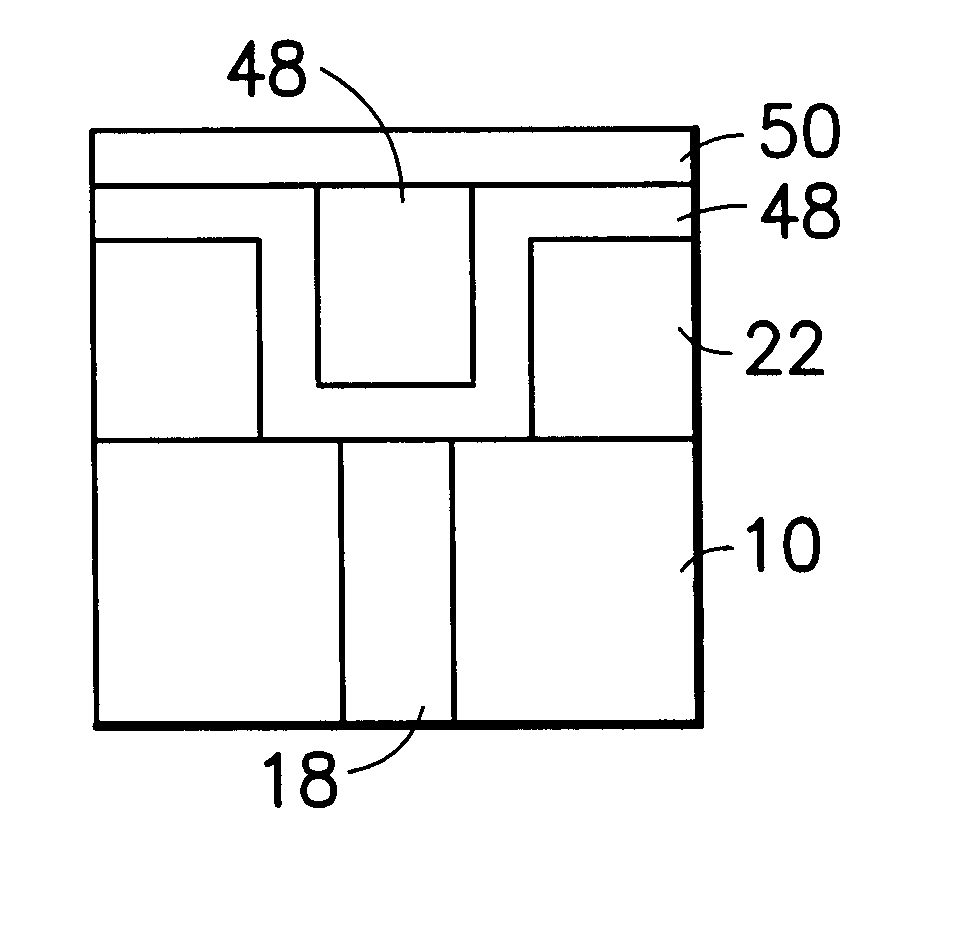

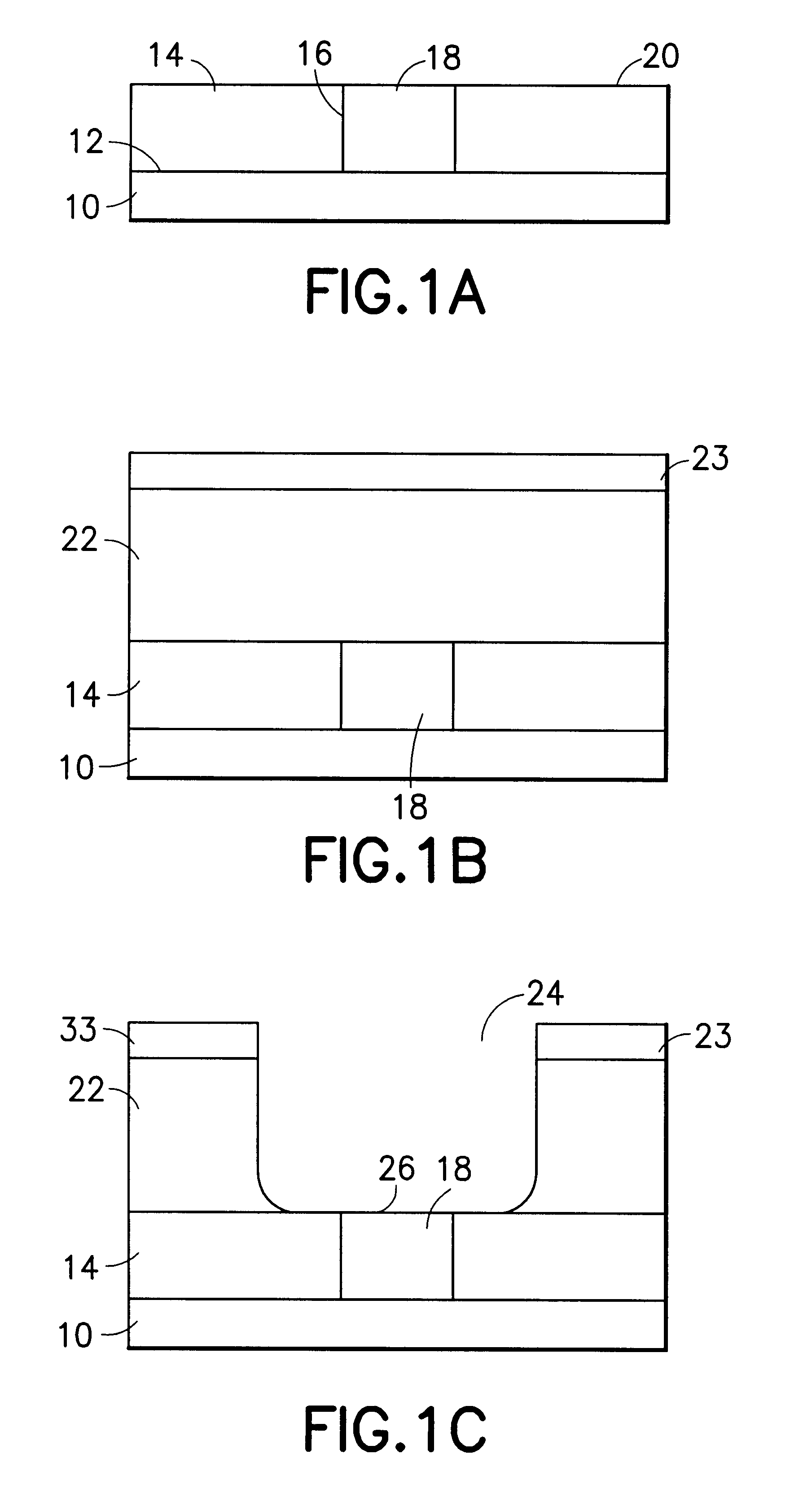

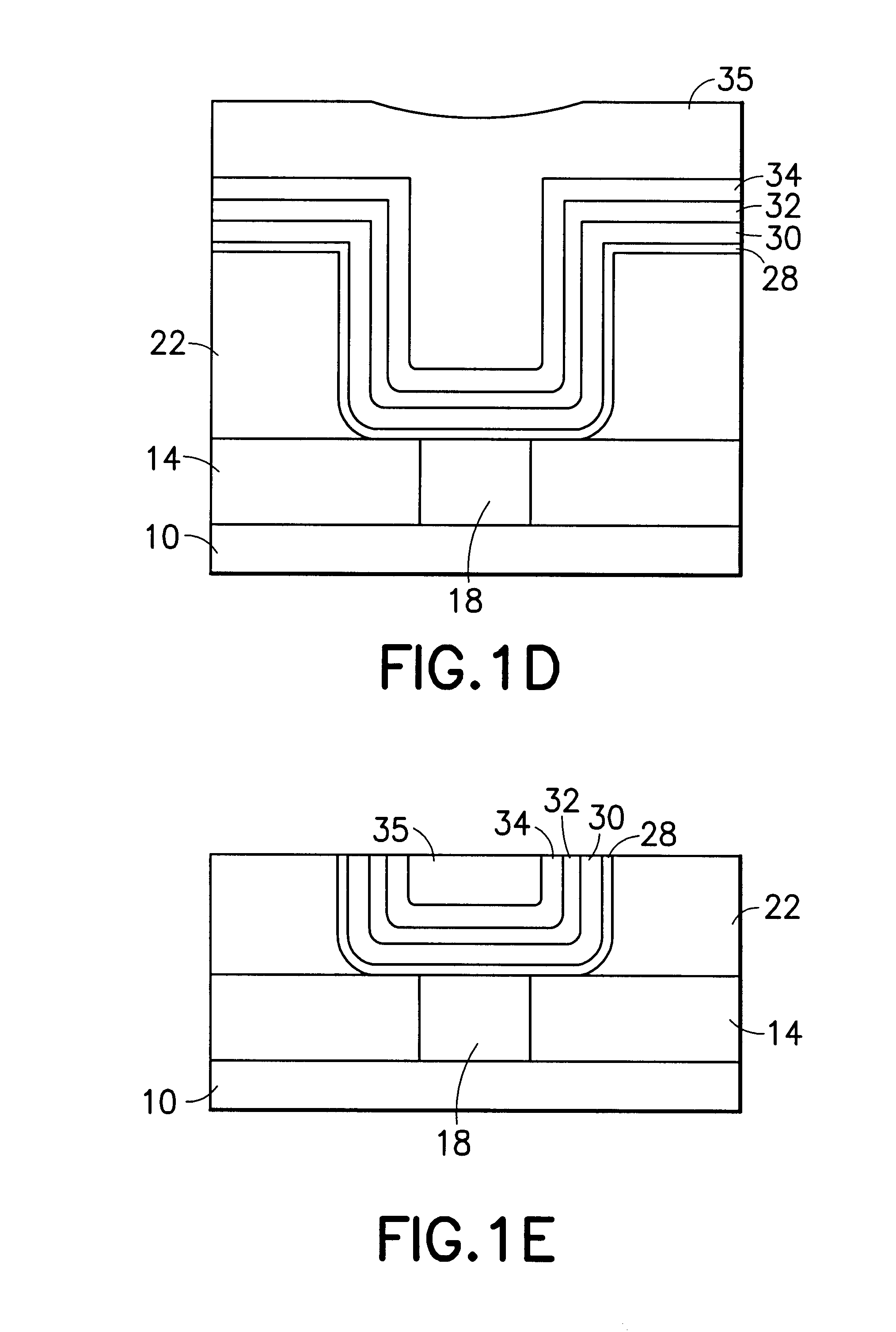

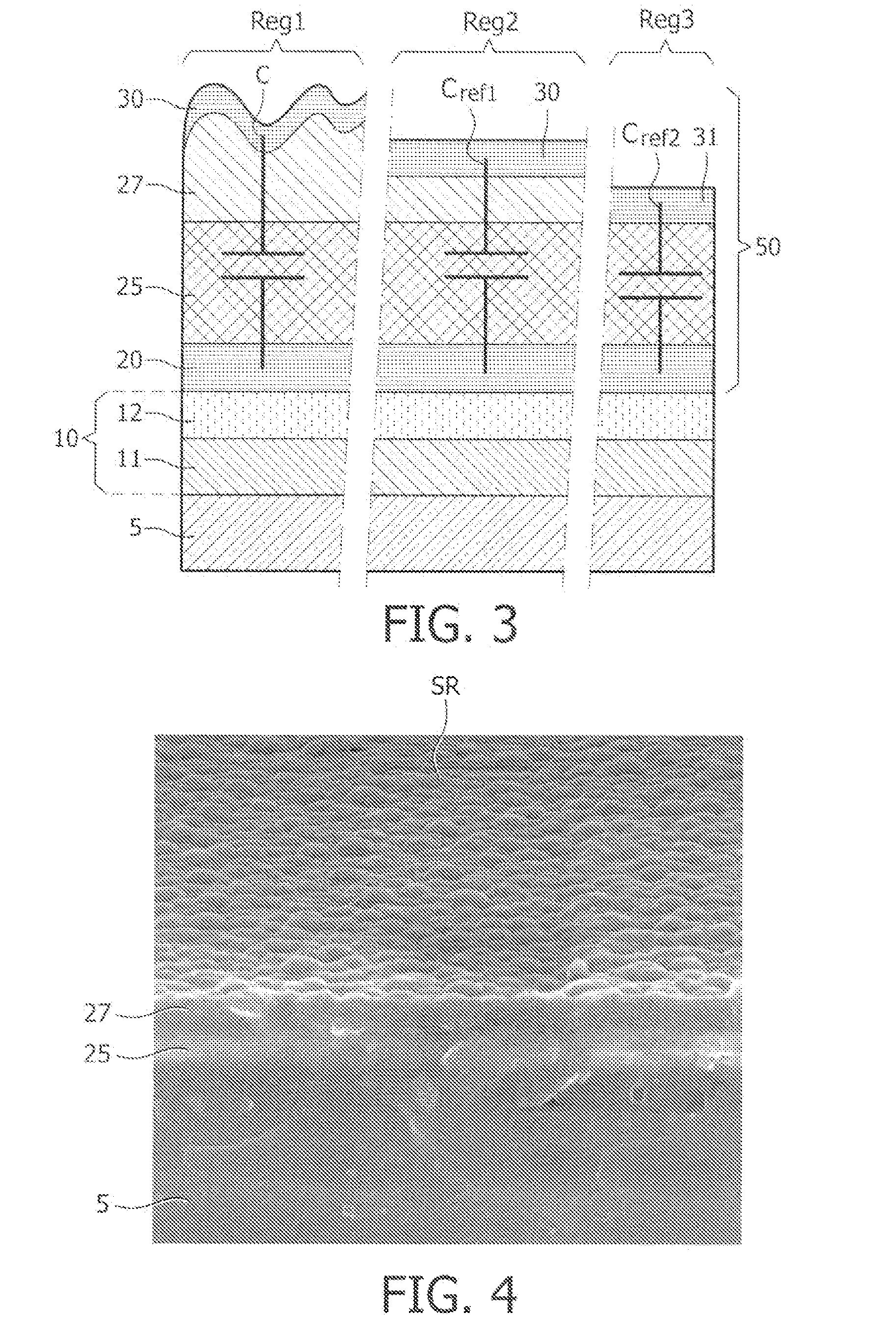

An integrated circuit structures formed by chemical mechanical polishing (CMP) process, which comprises a conductive pathway recessed in a dielectric substrate, wherein the conductive pathway comprises conductive transmission lines encapsulated in a transmission-enhancement material, and wherein the conductive pathway is filled sequentially by a first layer of the transmission-enhancement material followed by the conductive transmission line; a second layer of transmission-enhancement material encapsulating the conductive transmission line and contacting the first layer of the transmission-enhancement material, wherein the transmission-enhancement material is selected from the group consisting of high magnetic permeability material and high permittivity material. Such integrated circuit structure may comprise a device structure selected from the group consisting of capacitors, inductors, and resistors. Preferably, the transmission-enhancement material comprises MgMn ferrites, MgMnAl ferrites, barium strontium titanate, lead zirconium titanate, titanium oxide, tantalum oxide, etc.

Owner:GULA CONSULTING LLC

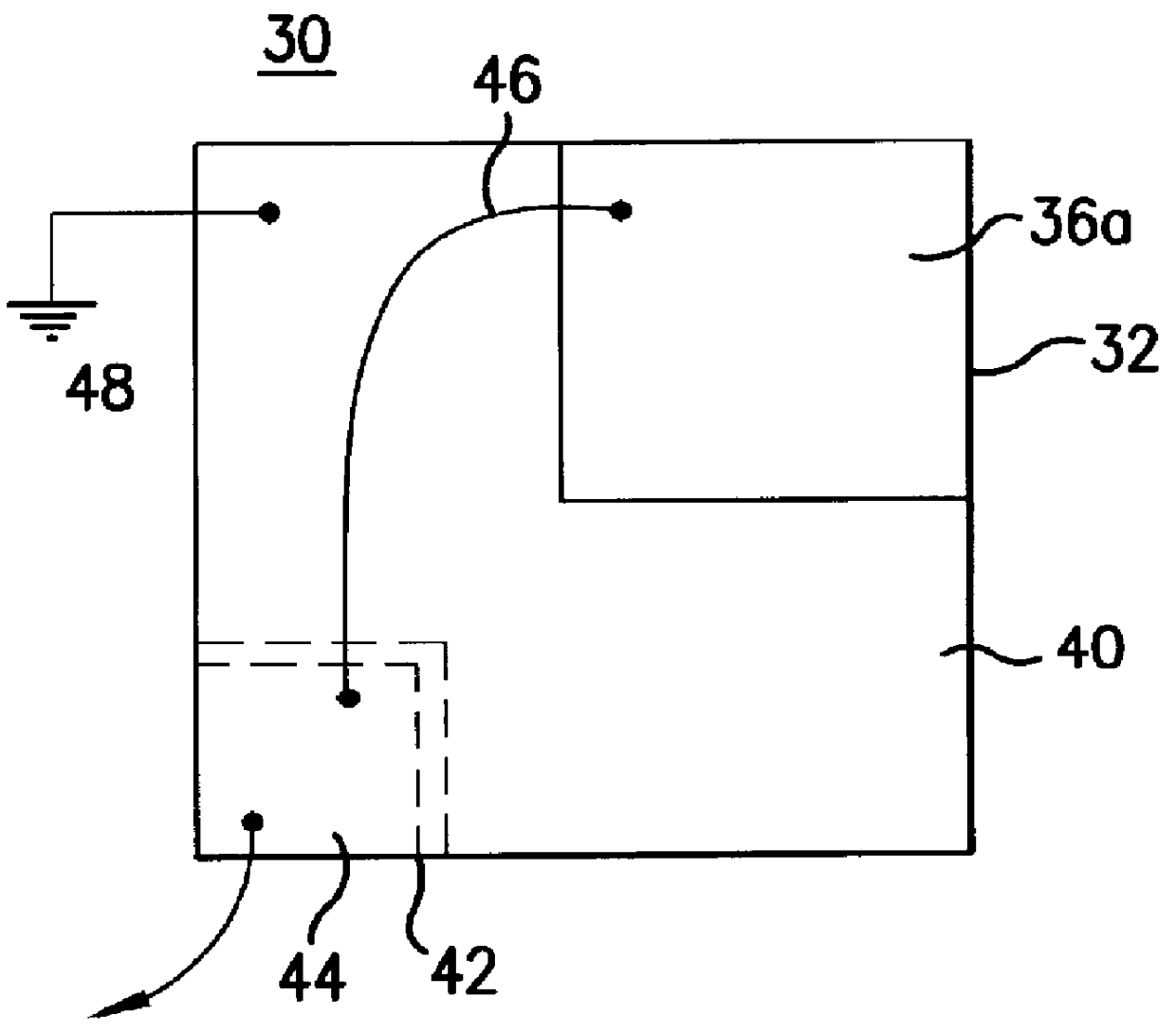

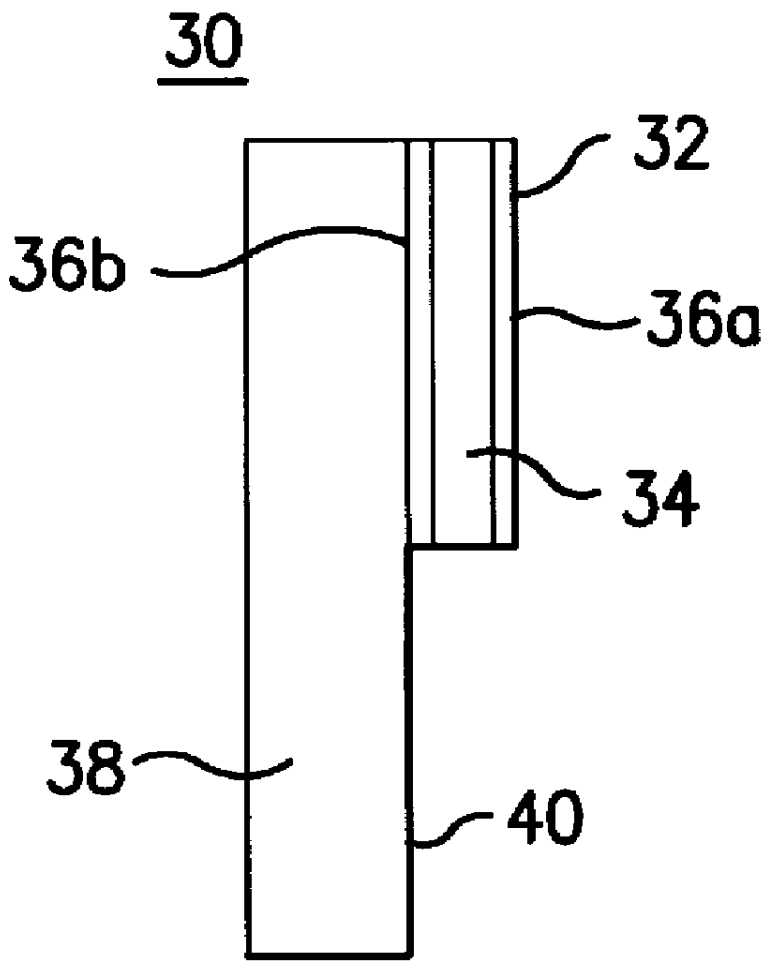

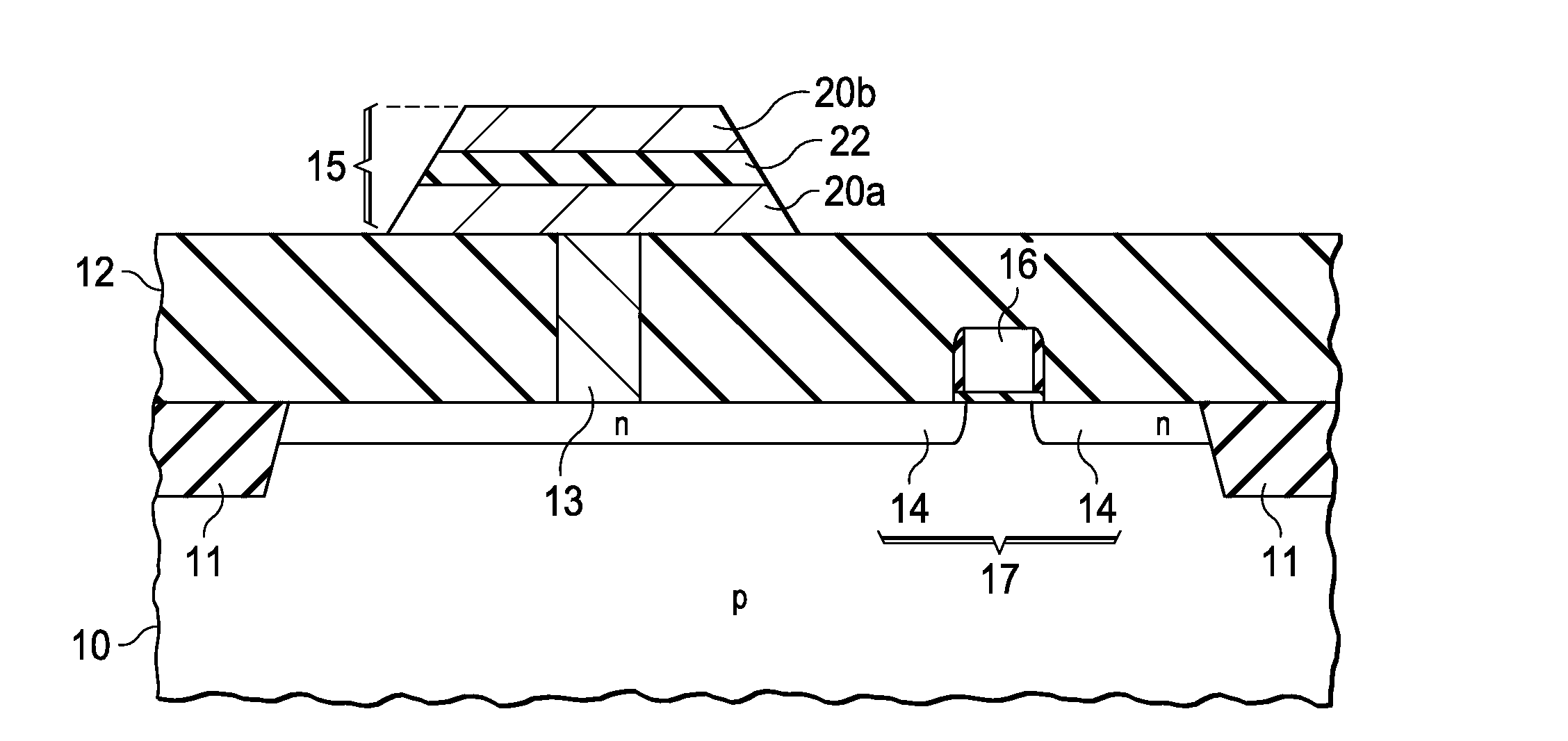

Physical structure for use in a physical unclonable

InactiveUS20110254141A1Rough surfaceConfidenceSemiconductor/solid-state device detailsSolid-state devicesCapacitancePhysical unclonable function

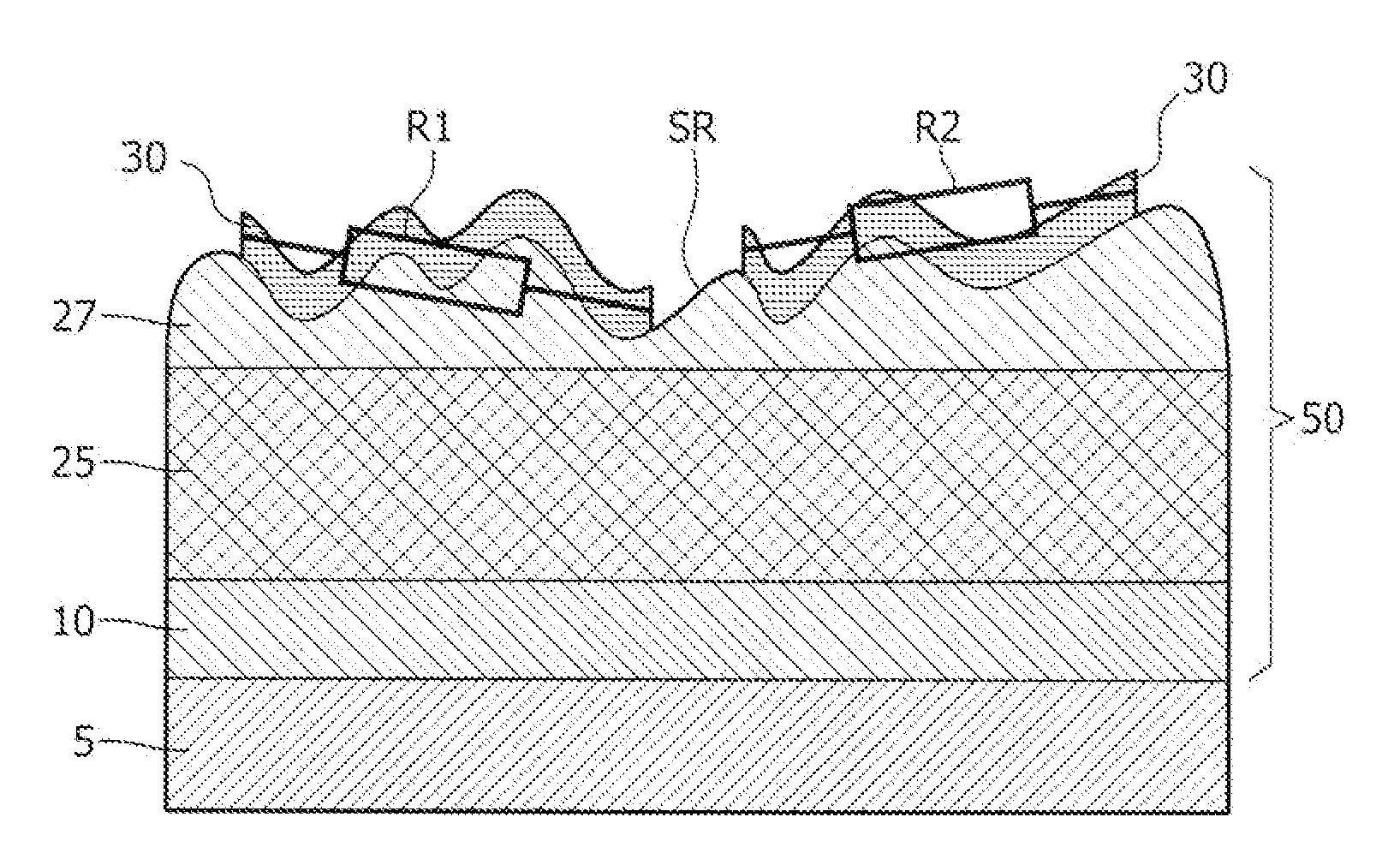

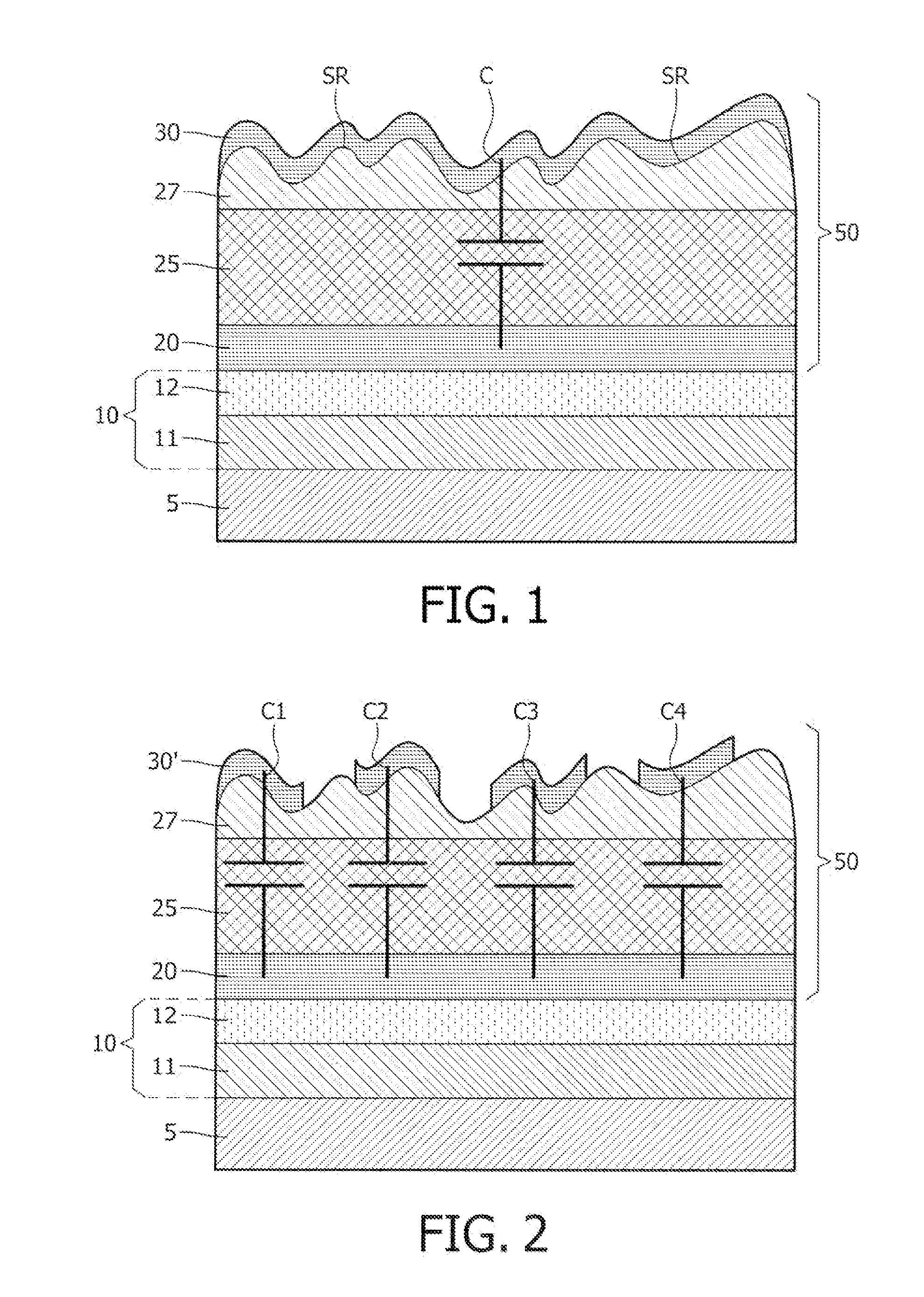

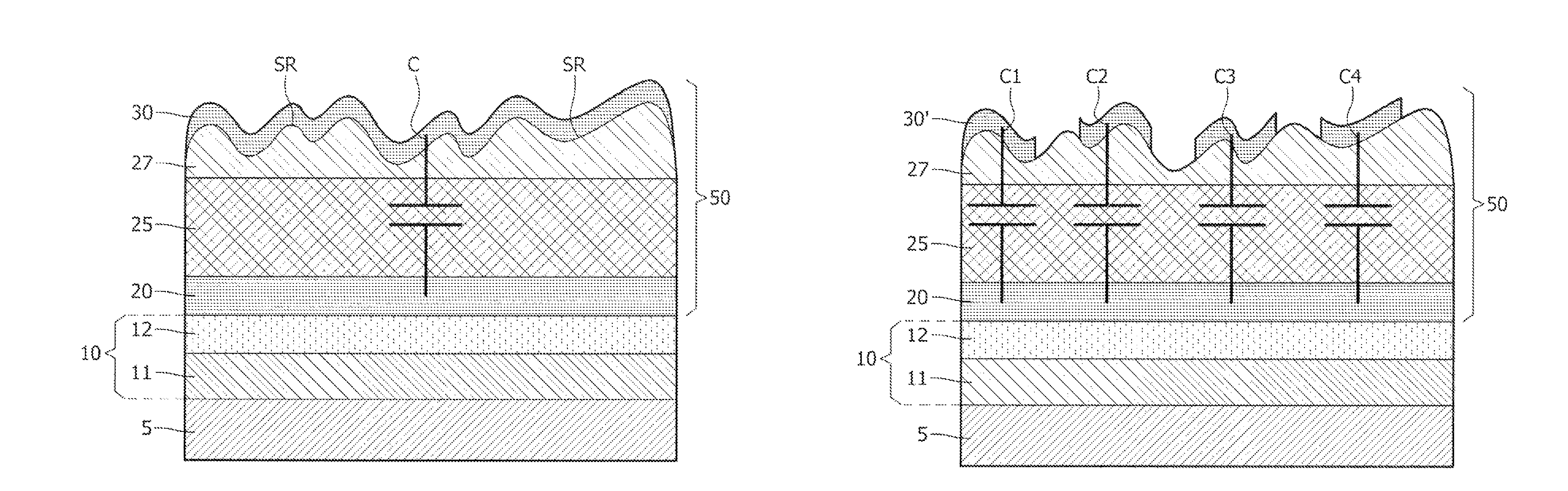

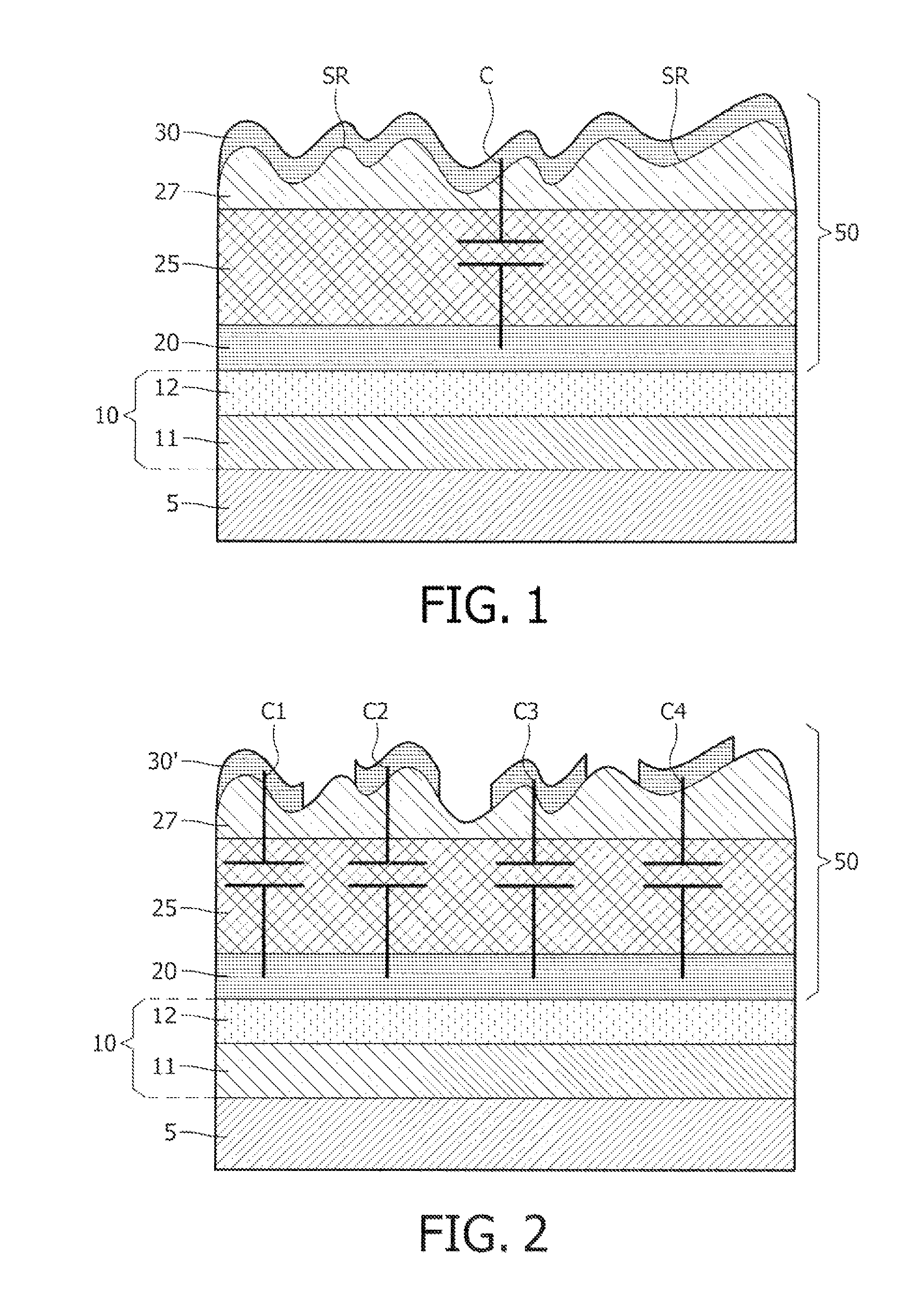

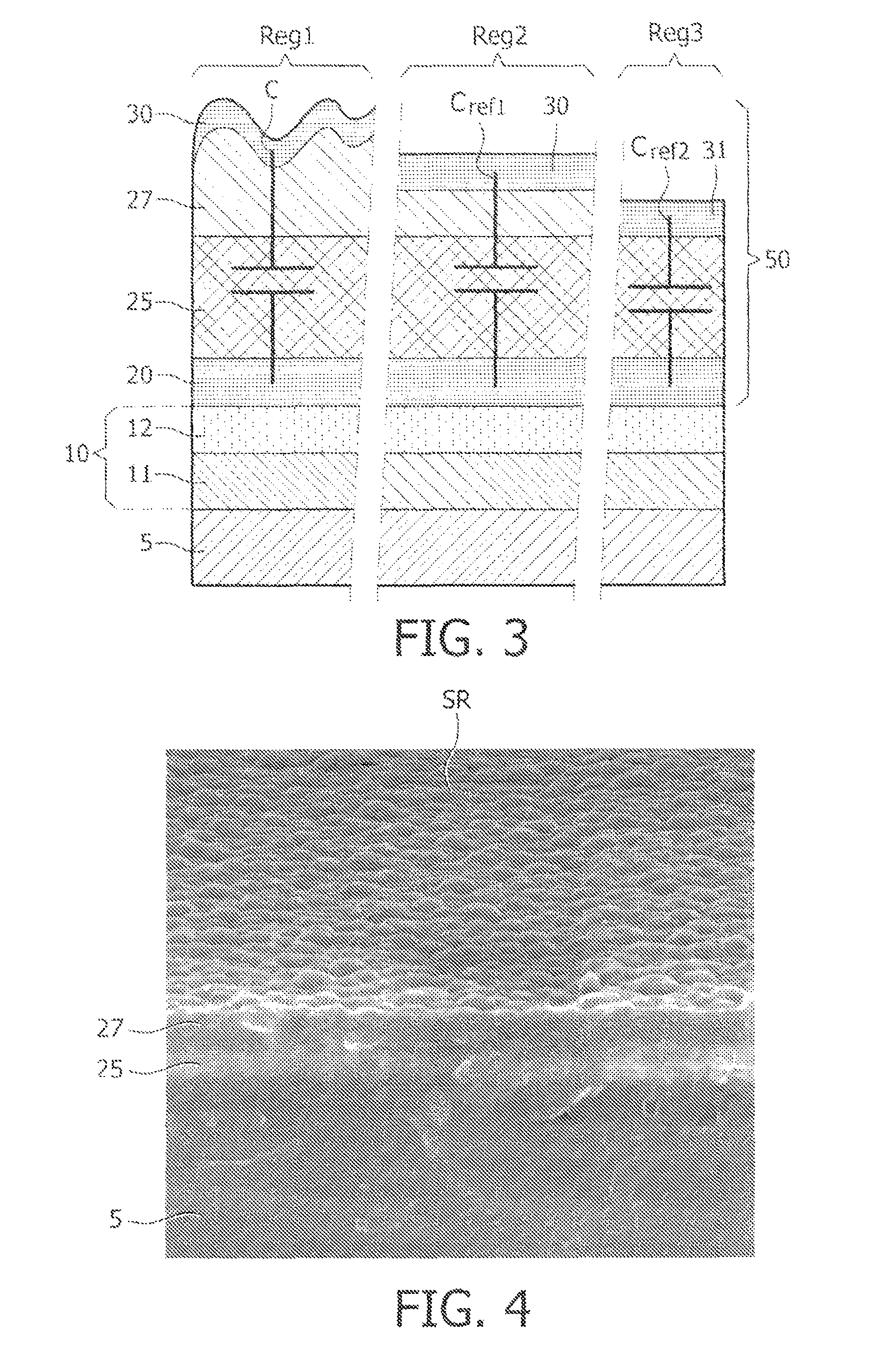

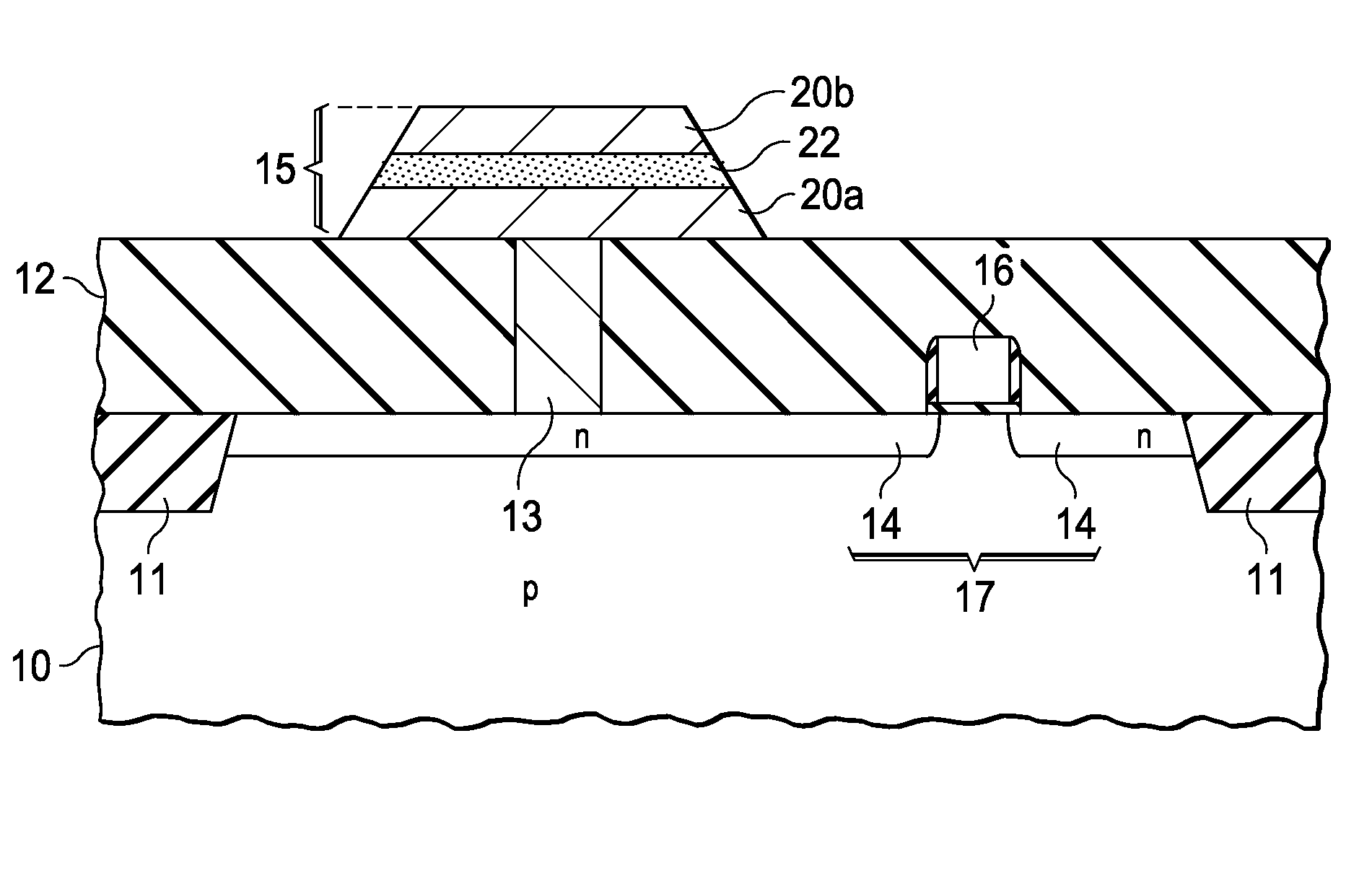

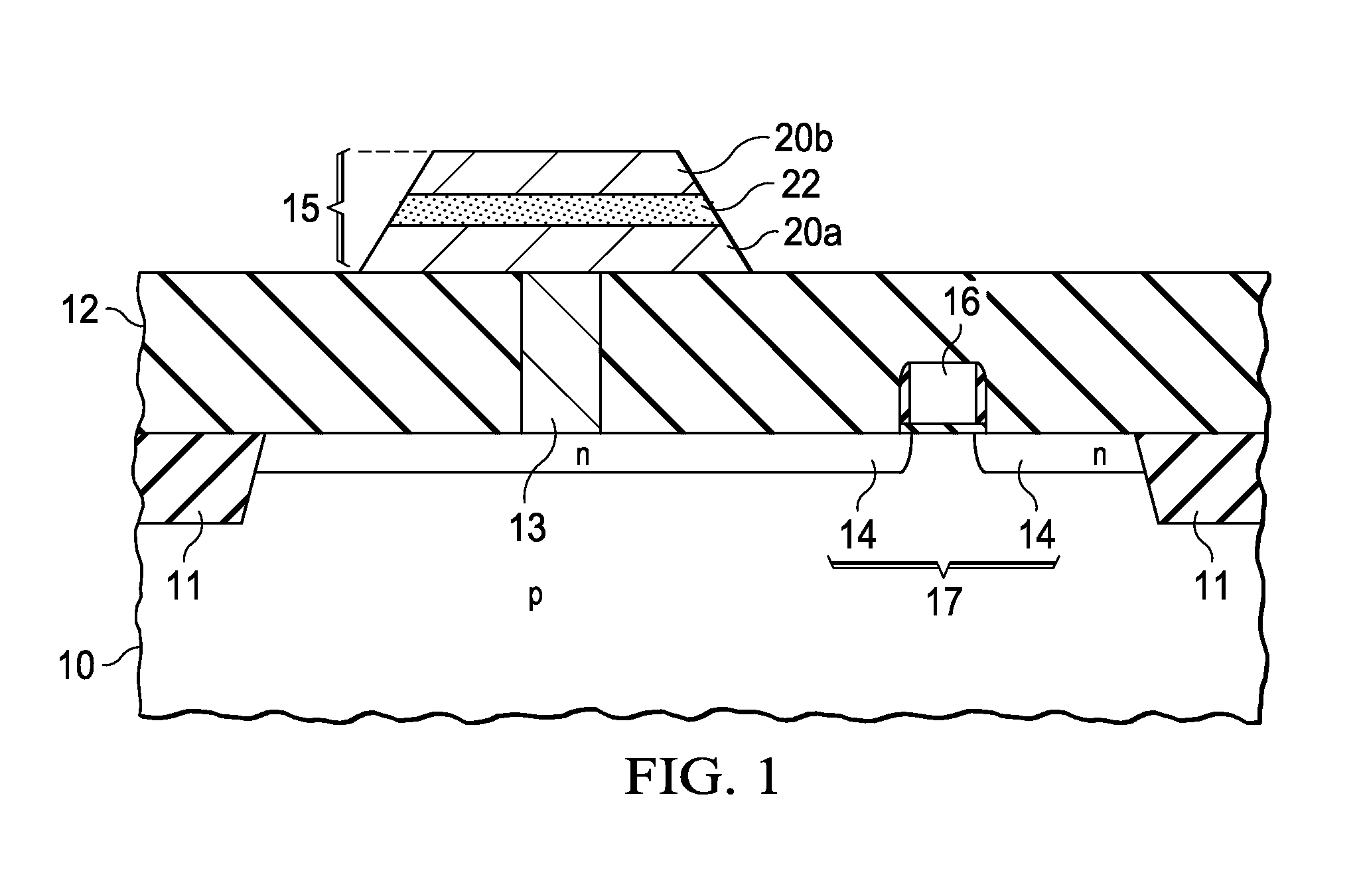

The invention relates to a semiconductor device comprising a physical structure (50) for use in a physical unclonable function, wherein the physical structure (50) comprises a lead-zirconium titanate layer (25), and a silicon-comprising dielectric layer (27) deposited on the lead-zirconium-titanate layer (25), wherein the silicon-comprising dielectric layer (27) has a rough surface (SR), the physical structure (50) further comprising a conductive layer (30) provided on the rough surface (SR) of the silicon-comprising dielectric layer (27). The invention further relates to a method of manufacturing such semiconductor device. The invention also relates to a card, such as a smartcard, and to a RFID tag comprising such semiconductor device. The inventors have found that depositing of a silicon- comprising dielectric layer (27) on a lead-zirconium titanate layer (25) using vapor deposition results in a silicon-comprising dielectric layer (27) having a rough surface (SR). This rough surface (SR) can be used in a PUF to make a resistor (R) with a variable random value by depositing a conductive layer (30) on the rough surface (SR). Alternatively, the combination of both layers (25, 27) can be used in a PUF as composite dielectric to make a capacitor (C) with a variable random capacitance value.

Owner:NXP BV

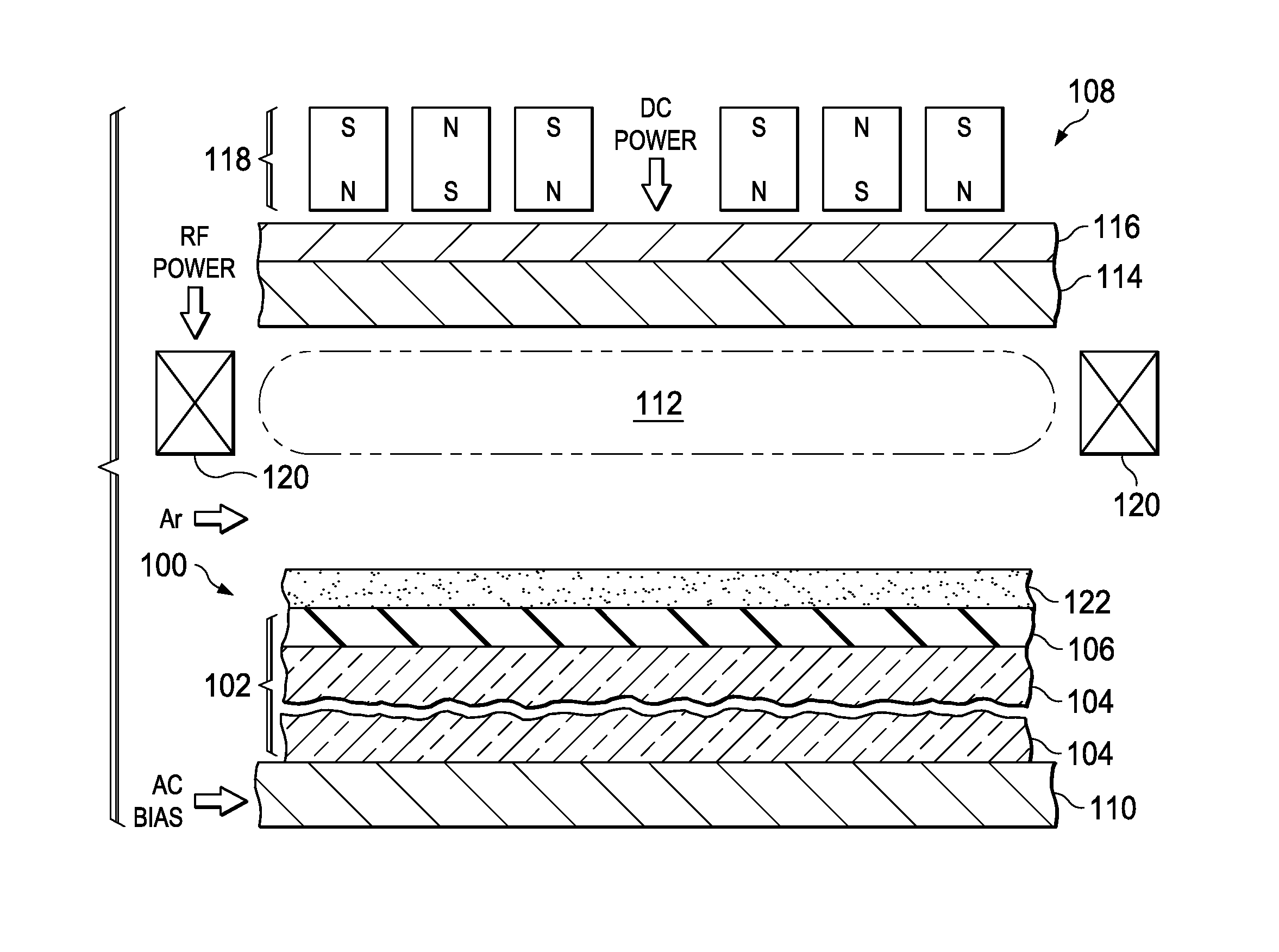

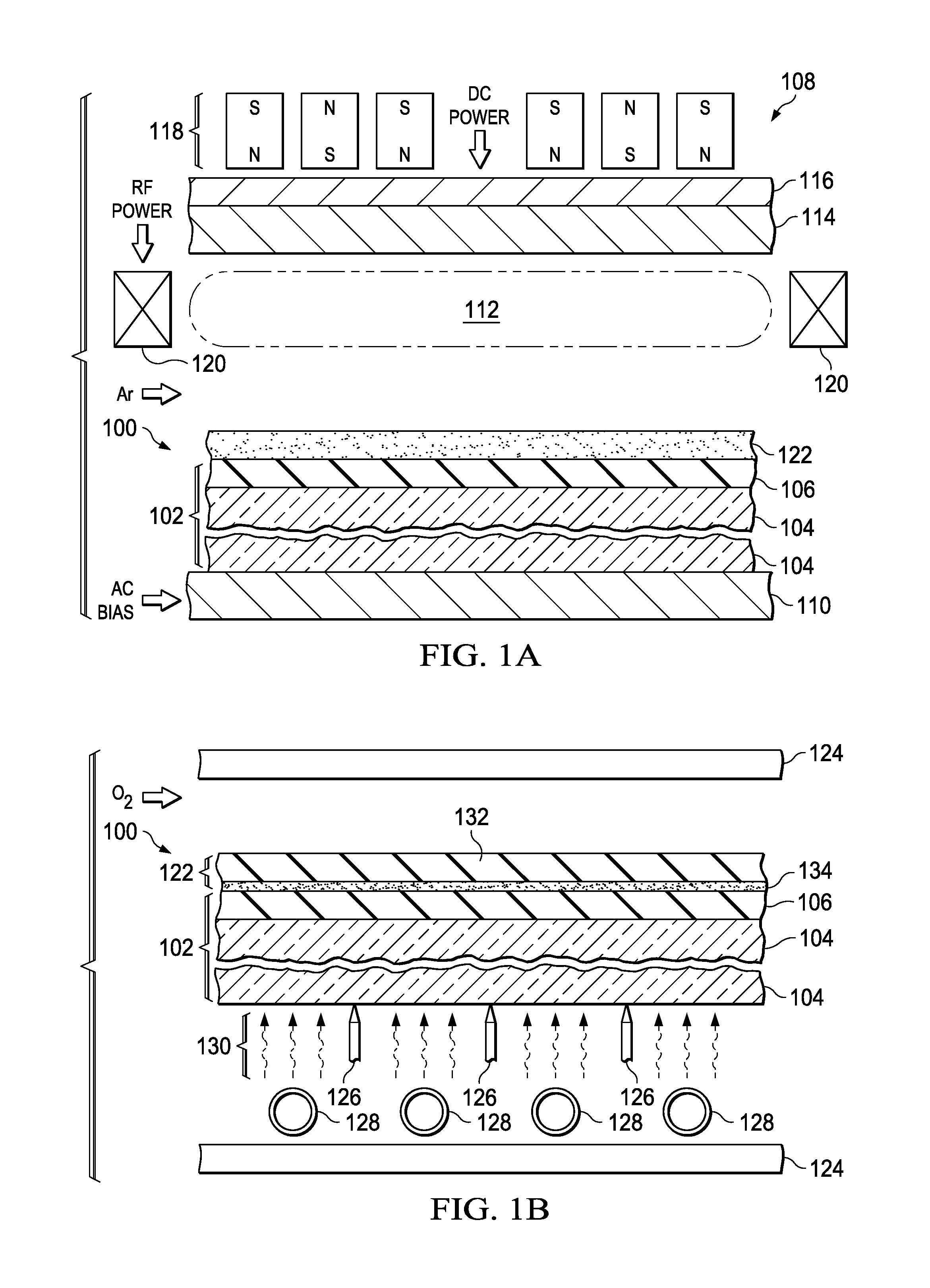

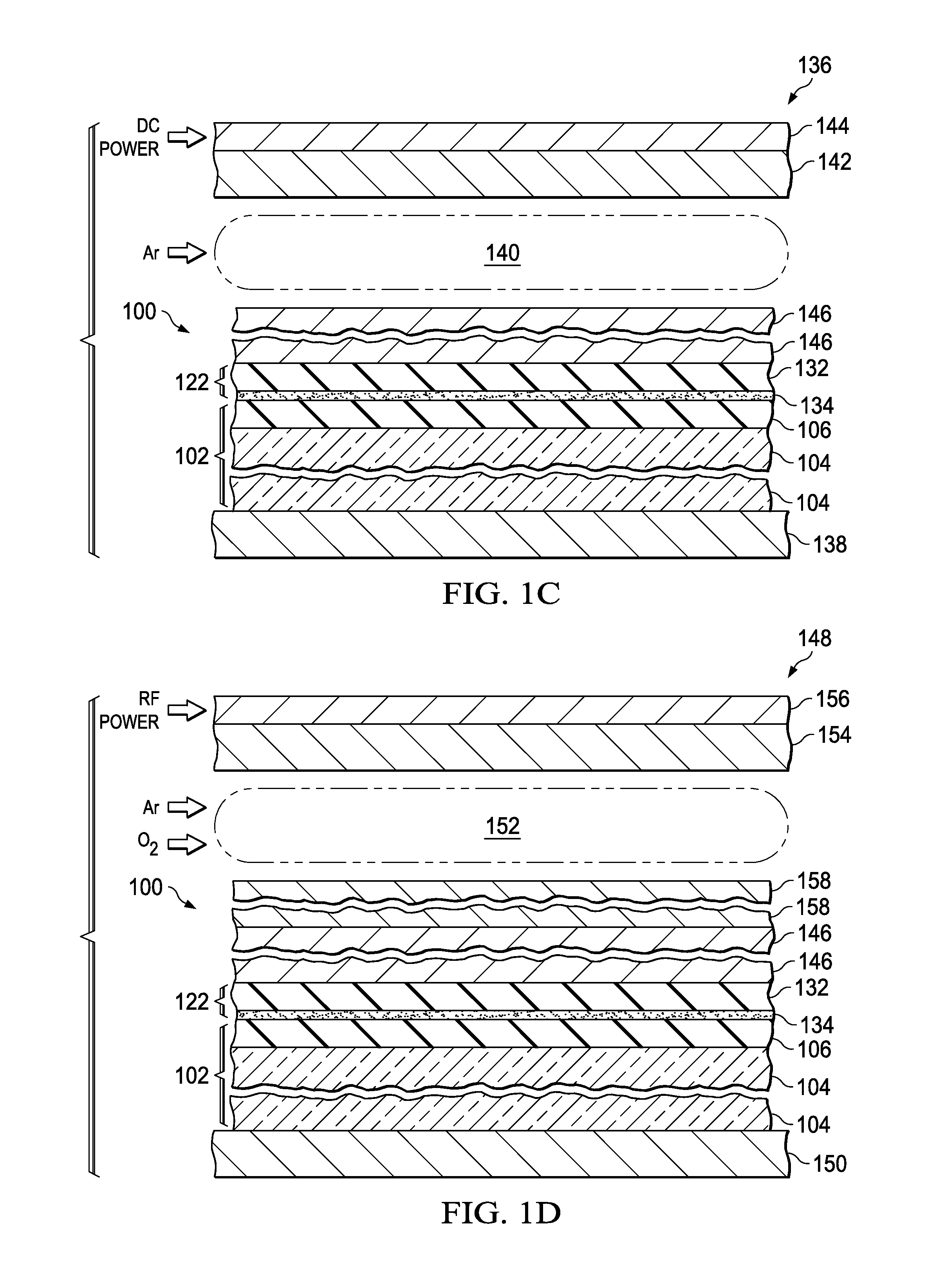

Method of patterning lead zirconium titanate and barium strontium titanate

In an embodiment of the present invention, a method is provided of patterning PZT layers or BST layers. For example, a PZT layer or a BST layer is plasma etched through a high-temperature-compatible mask such as a titanium nitride (TiN) mask, using a plasma feed gas comprising as a primary etchant boron trichloride (BCl3) or silicon tetrachloride (SiCi4). Although BCl3 or SiCl4 may be used alone as the etchant plasma source gas, it is typically used in combination with an essentially inert gas. Preferably the essentially inert gas is argon. Other potential essentially inert gases which may be used include xenon, krypton, and helium. In some instances O2 or N2, or Cl2, or a combination thereof may be added to the primary etchant to increase the etch rate of PZT or BST relative to adjacent materials, such as the high-temperature-compatible masking material. A TiN masking material can easily be removed without damaging underlying oxides. The selectivity of PZT or BST relative to TiN is very good, with the ratio of the etch rate of the PZT film to the etch rate of the TiN mask typically being better than 20:1. In addition, the etch rate for PZT using a BCl3-comprising plasma source gas is typically in excess of 2,000 Å per minute. A substrate bias power is applied to direct ions produced from the BCl3 or SiCl4 toward the surface to be etched. The bias power is controlled to avoid sputtering of a conductive layer or layers in contact with the PZT layer, so that the surface of the etched PZT is not contaminated by a conductive material, which can cause the semiconductor device which includes the patterned PZT to short out.

Owner:APPLIED MATERIALS INC

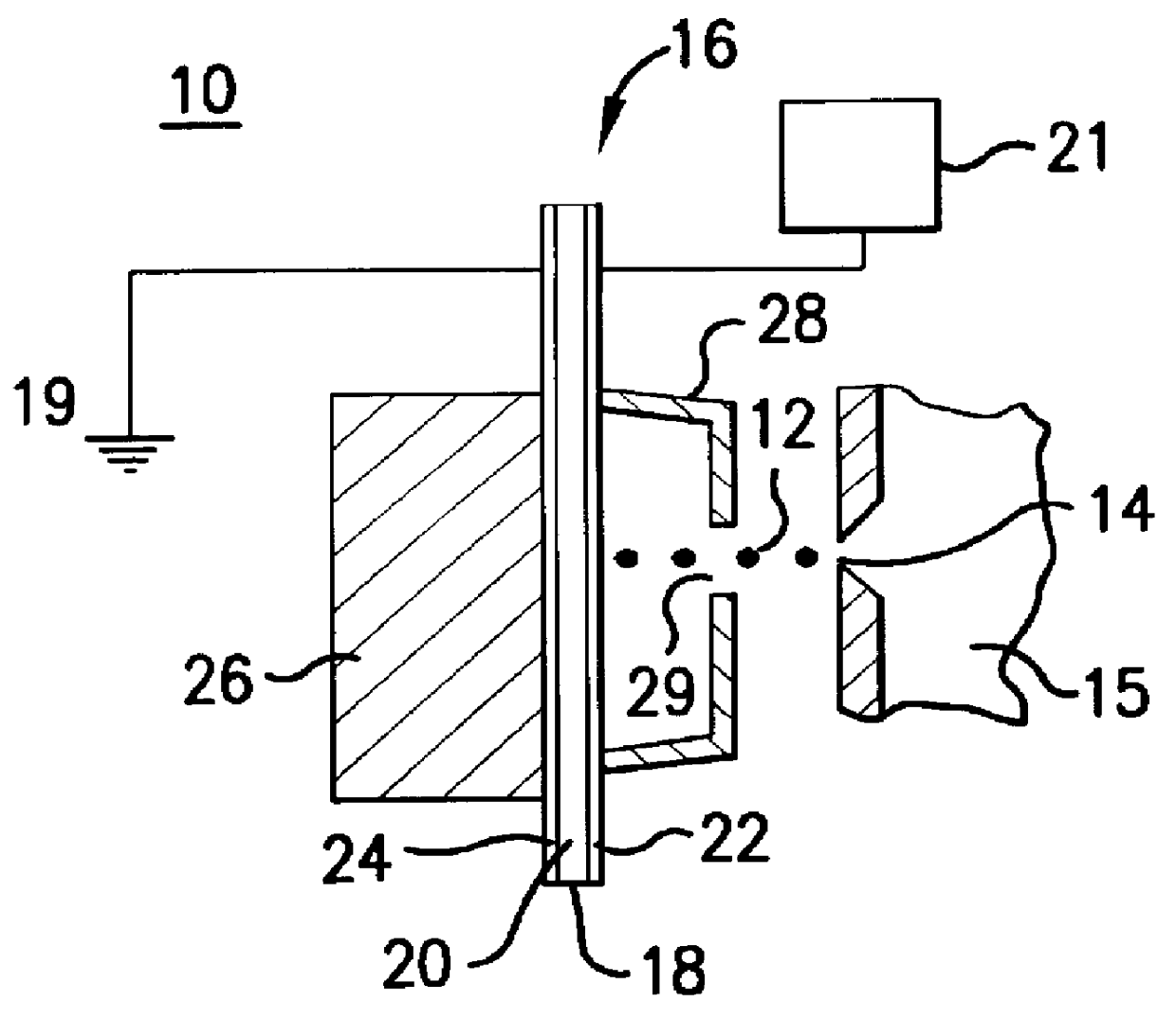

Drop detector for ink jet apparatus

InactiveUS6062668AImprove reliabilitySmall sizeThermometers using electric/magnetic elementsUsing electrical meansThermoelectric materialsEngineering

A drop detection apparatus has a thermosensitive substrate for receiving drops of ink and providing a signal representative of a change in the temperature in the thermosensitive substrate which is caused by the ink drops deposited on the thermosensitive substrate. The thermosensitive substrate is made from a pyroelectric material, such as, for example, polyvinylidene fluoride (PVDF) and lead zirconium titanate (PLZT). As a result, a drop detection apparatus has a substantially simplified structure for detecting drops of ink ejected from large numbers of jets. Furthermore, since a drop detection apparatus relies on the temperature difference between the thermosensitive substrate and the drop of ink which is substantially small in size, the drop detection apparatus can be made substantially small in size, therefore suitable for a small sized ink jet apparatus.

Owner:HITACHI KOKI IMAGING SOLUTIONS

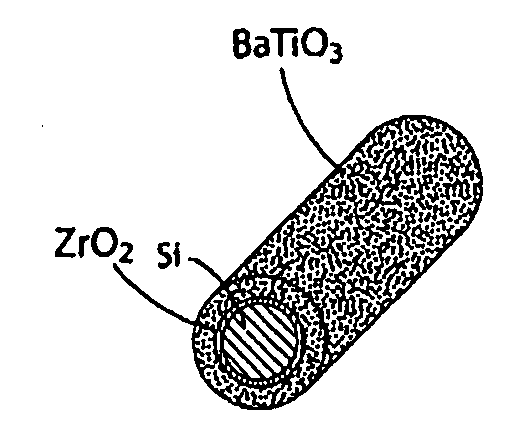

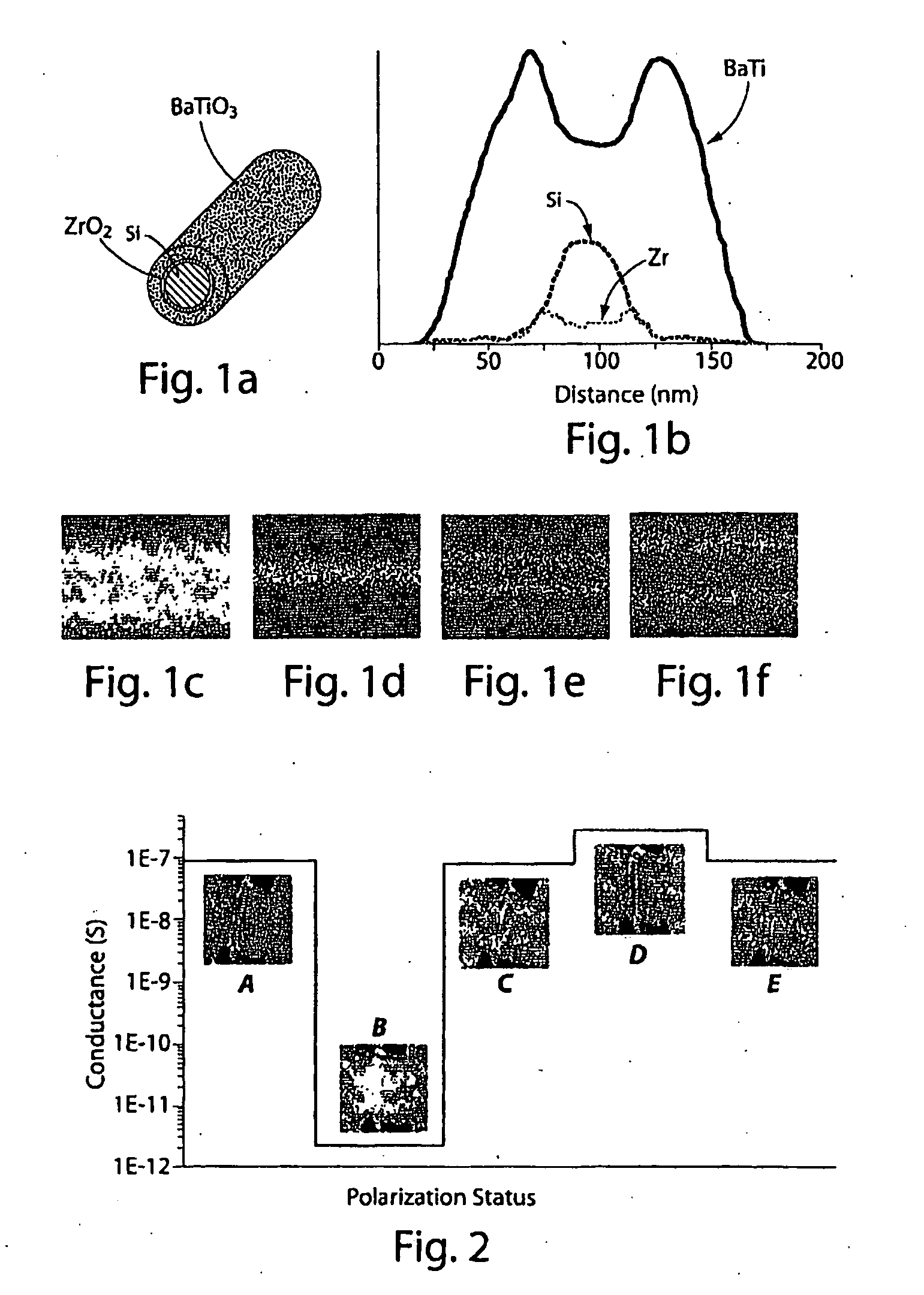

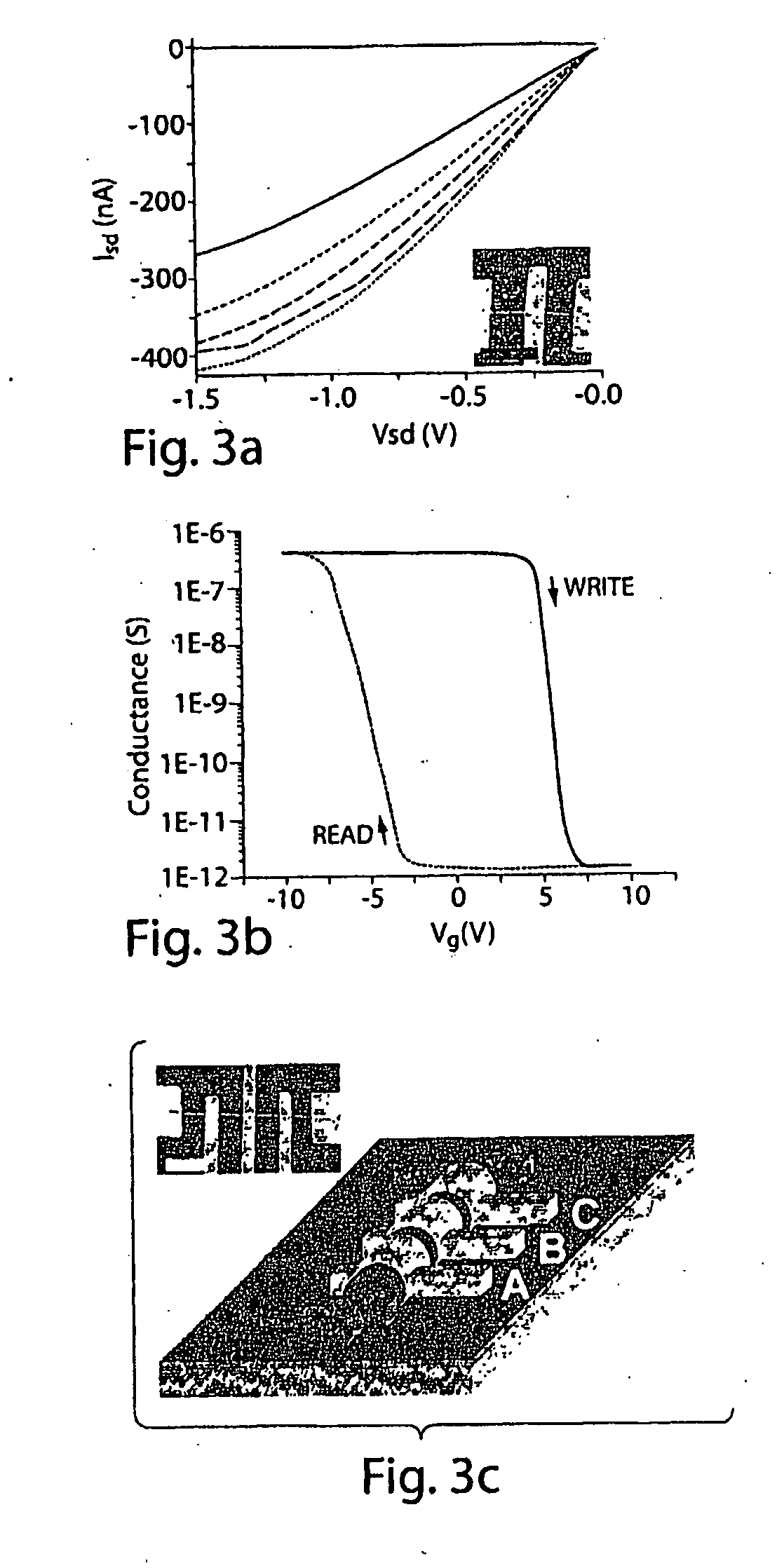

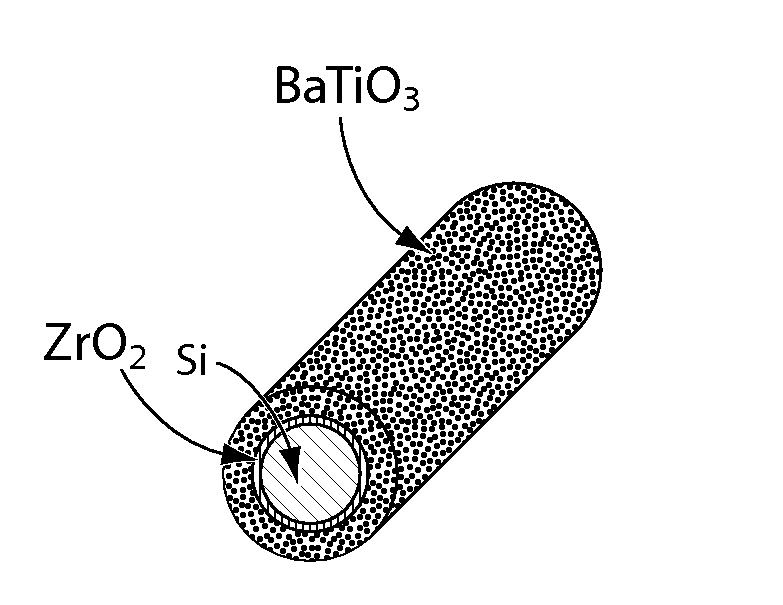

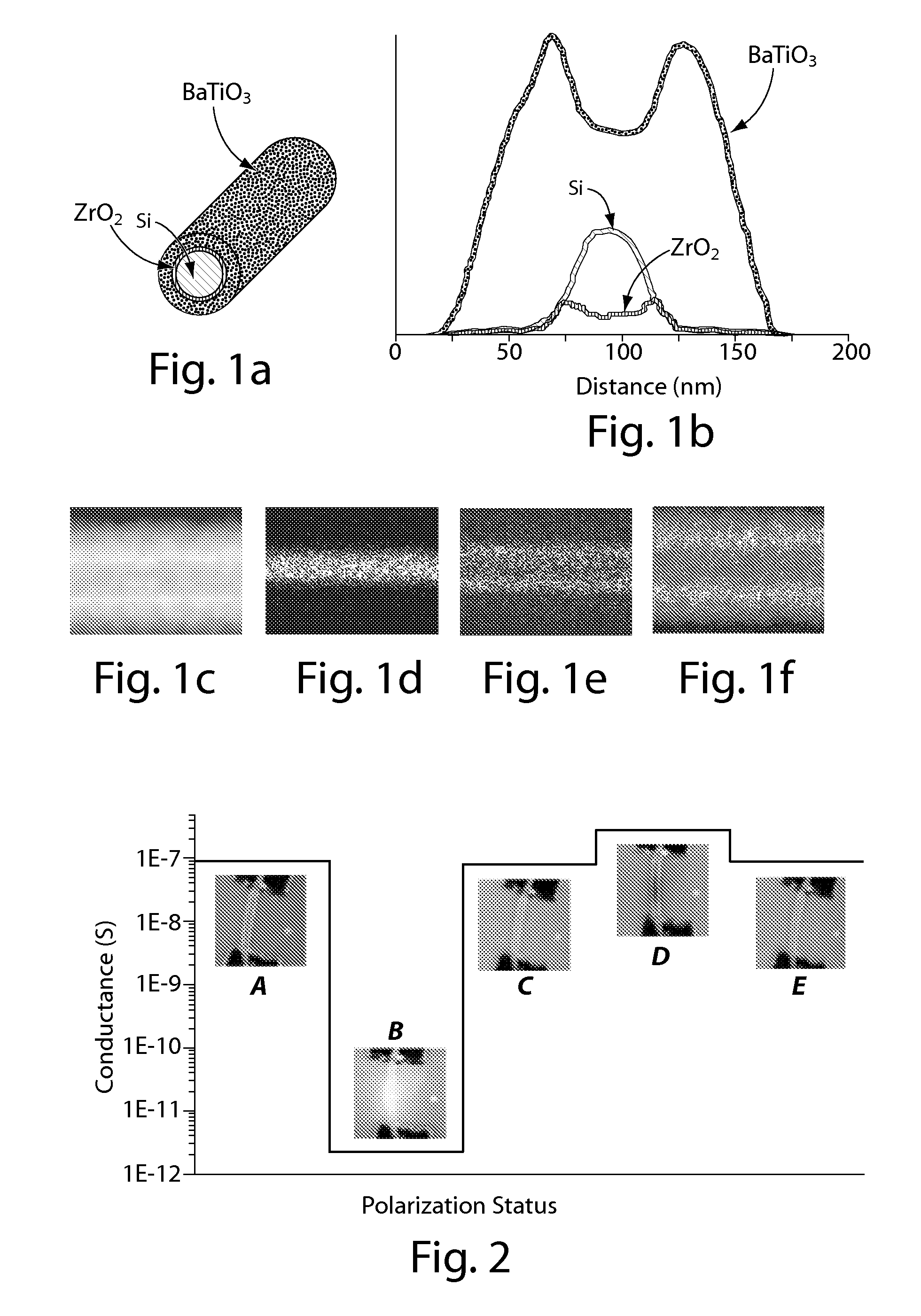

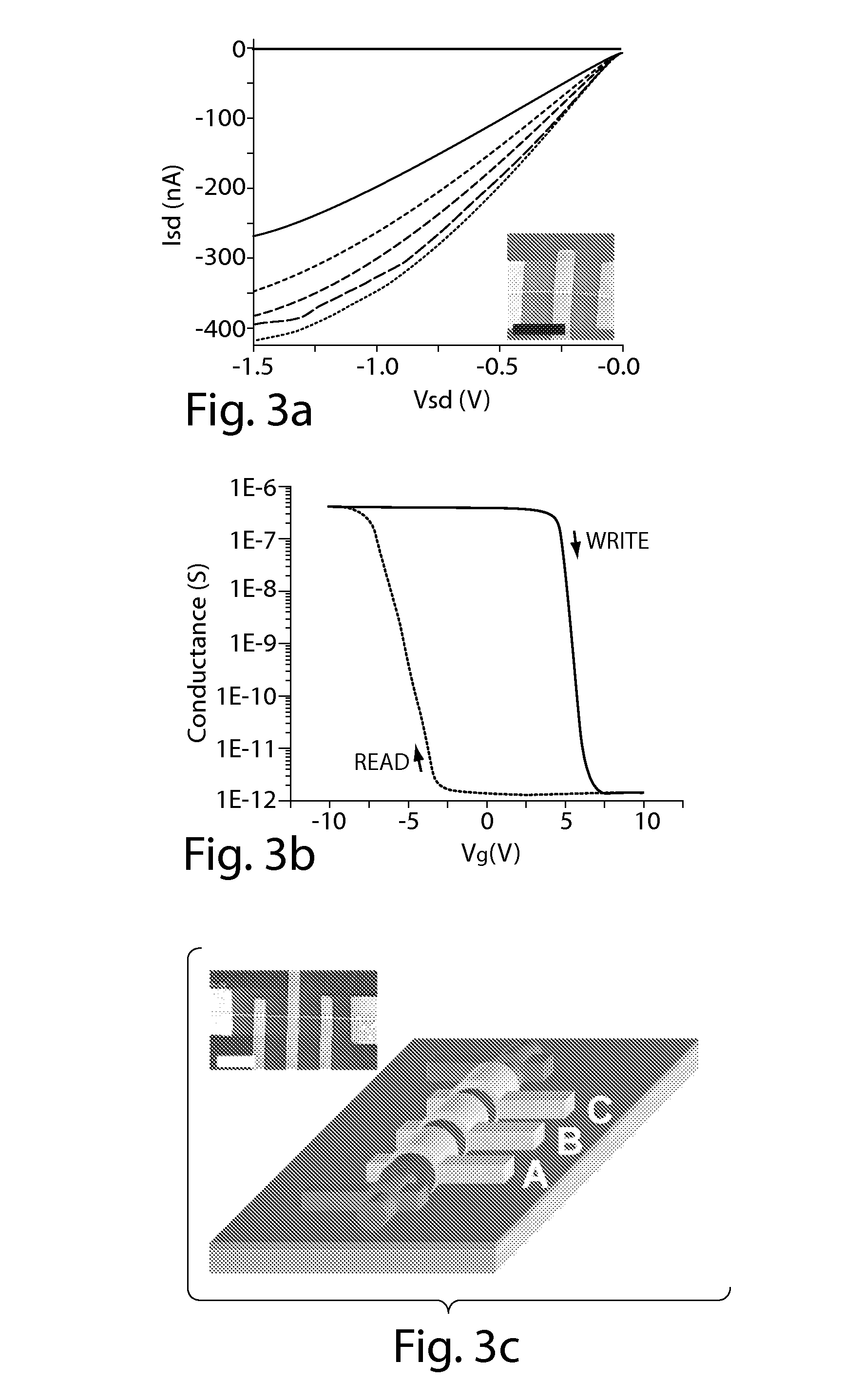

Nanoscale Wire-Based Data Storage

The present invention generally relates to nanotechnology and submicroelectronic devices that can be used in circuitry and, in some cases, to nanoscale wires and other nanostructures able to encode data. One aspect of the invention provides a nanoscale wire or other nanostructure having a region that is electrically-polarizable, for example, a nanoscale wire may comprise a core and an electrically-polarizable shell. In some cases, the electrically-polarizable region is able to retain its polarization state in the absence of an external electric field. All, or only a portion, of the electricallypolarizable region may be polarized, for example, to encode one or more bits of data. In one set of embodiments, the electrically-polarizable region comprises a functional oxide or a ferroelectric oxide material, for example, BaTiO3, lead zirconium titanate, or the like. In some embodiments, the nanoscale wire (or other nanostructure) may further comprise other materials, for example, a separation region separating the electricallypolarizable region from other regions of the nanoscale wire. For example, in a nanoscale wire, one or more intermediate shells may separate the core from the electricallypolarizable shell.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

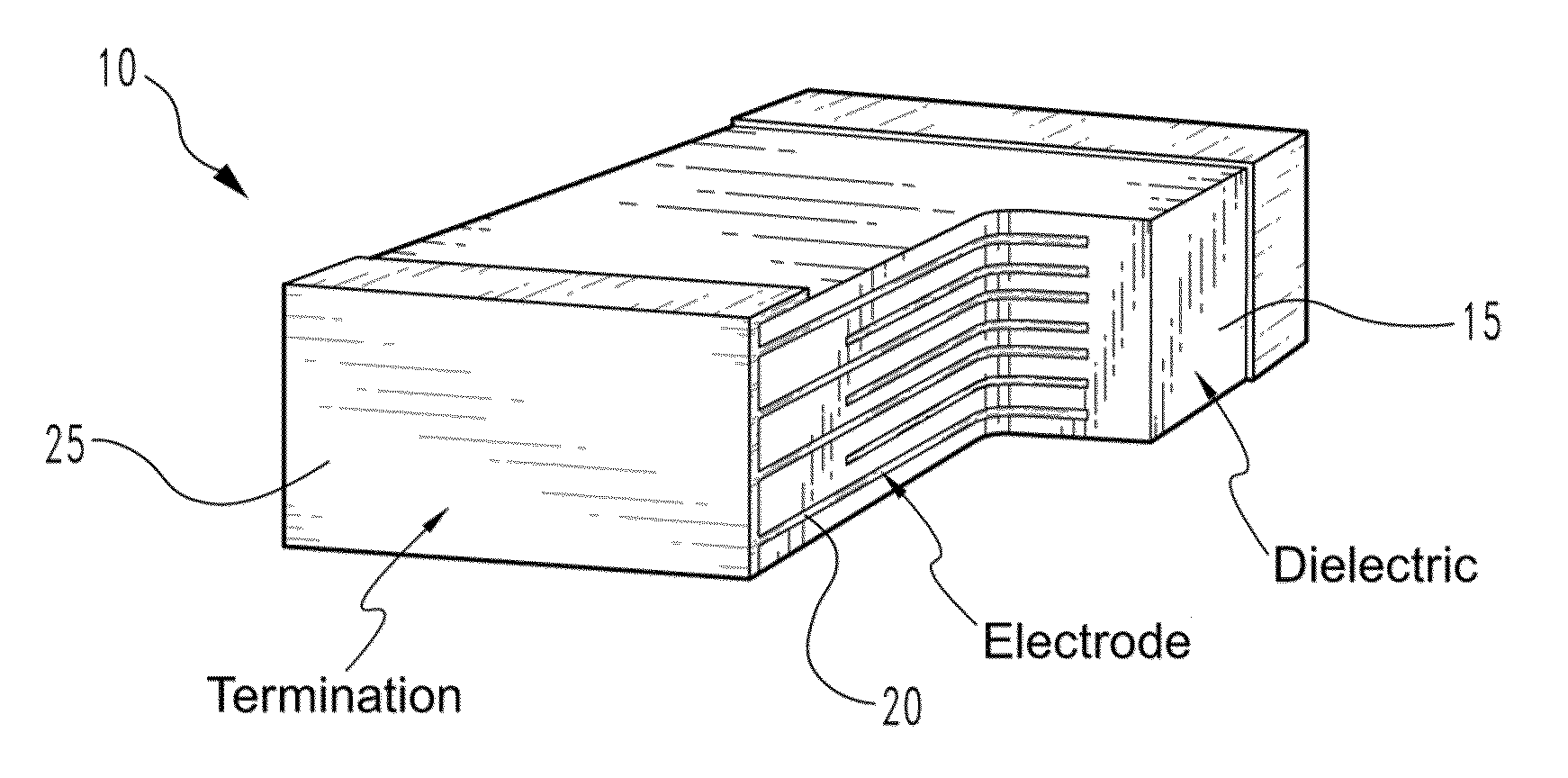

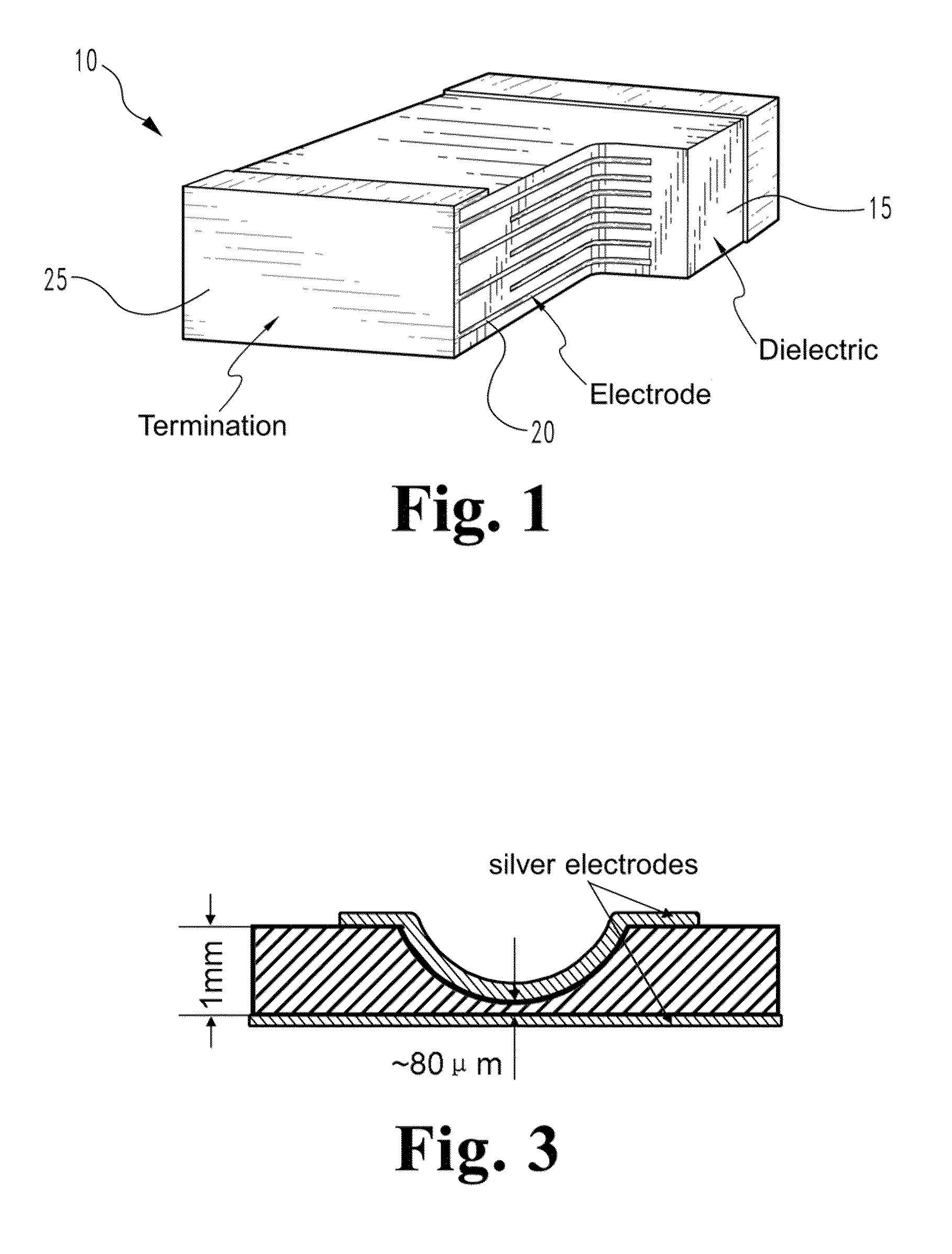

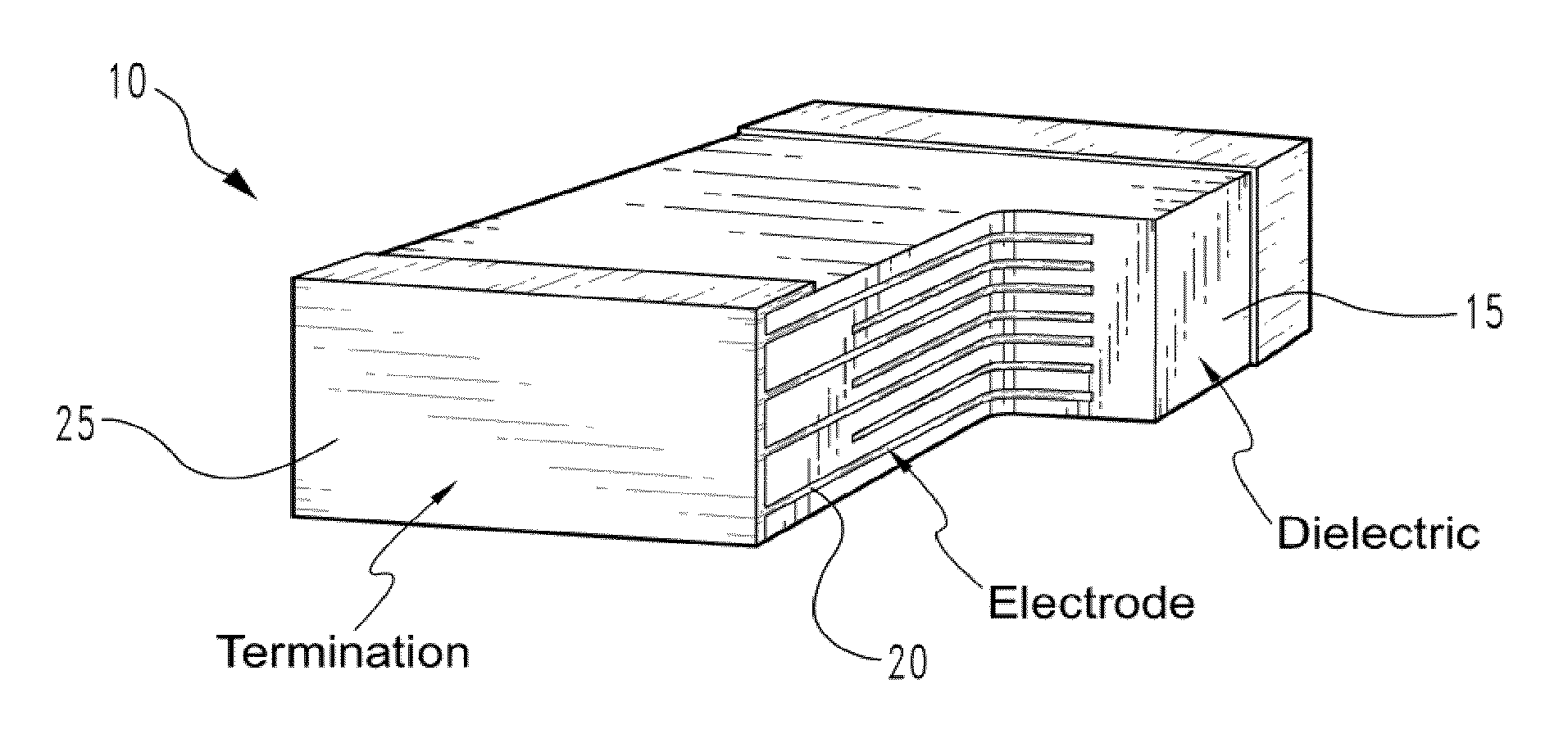

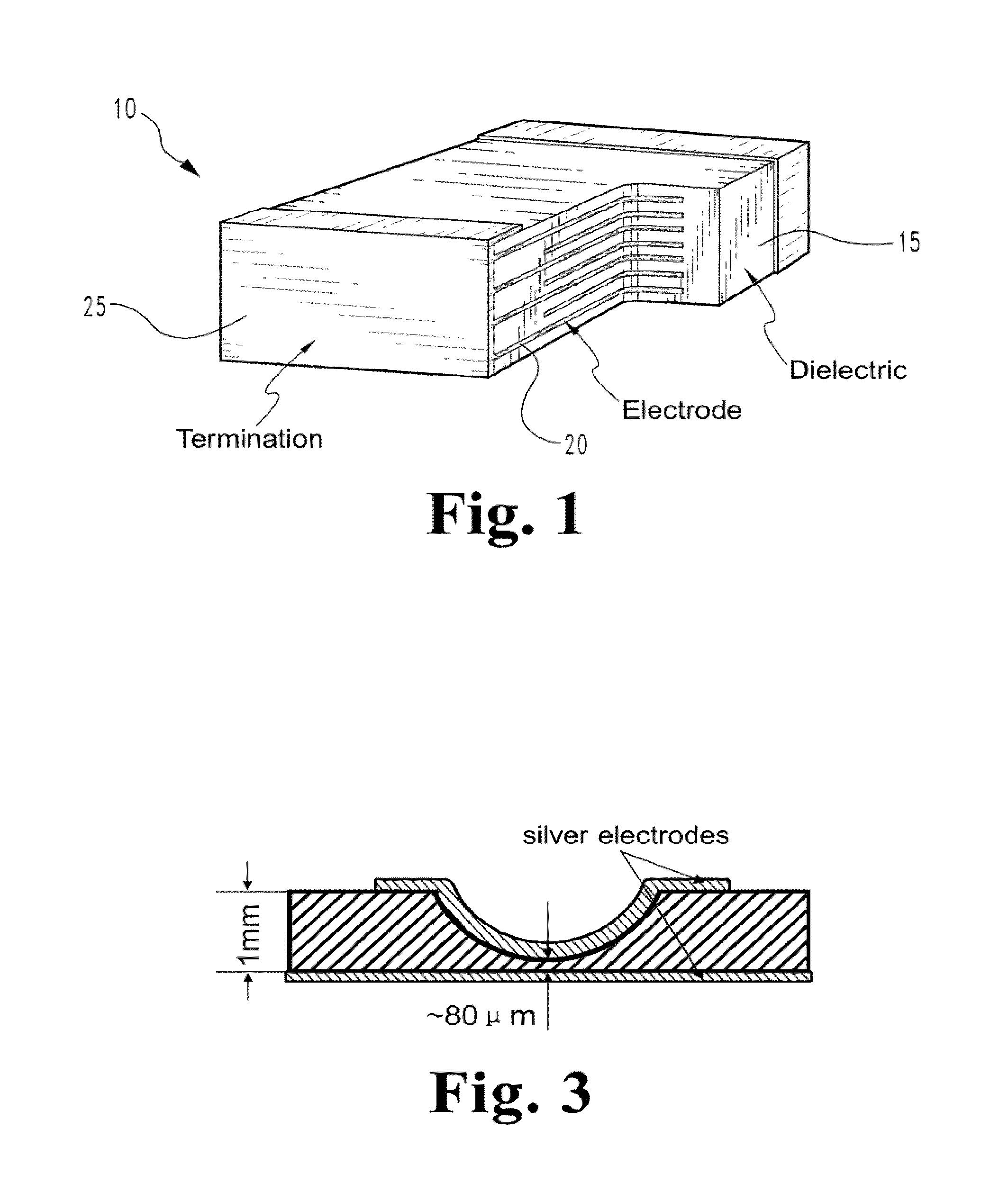

Nanostructured dielectric materials for high energy density multi layer ceramic capacitors

ActiveUS20110051315A1Increase energy densityMaterial nanotechnologyLayered productsPorosityBreakdown strength

A high energy density multilayer ceramic capacitor, having at least two electrode layers and at least one substantially dense polycrystalline dielectric layer positioned therebetween. The at polycrystalline dielectric layer has an average grain size of less than about 300 nanometers, a particle size distribution of between about 150 nanometers and about 3 micrometers, and a maximum porosity of about 1 percent. The dielectric layer is selected from the group including TiO2, BaTiO3, Al2O3, ZrO2, lead zirconium titanate, and combinations thereof and has a breakdown strength of at least about 1100 kV per centimeter.

Owner:UNIVERSITY OF MISSOURI

Highly dielectric film

InactiveUS20090306264A1Excellent in winding property (flexibility)Excellent dielectric propertiesPiezoelectric/electrostrictive device manufacture/assemblyPretreated surfacesBarium titanateFluoride

There is provided a highly dielectric film which has high dielectric property, can be formed into a think film and is excellent in winding property (flexibility). The highly dielectric film comprises (A) a vinylidene fluoride polymer, (B) barium titanate oxide particles and / or lead zirconium titanate oxide particles, and (C) an affinity improving agent, wherein the barium titanate oxide particles and / or lead zirconium titanate oxide particles (B) and the affinity improving agent (C) are contained in amounts of 10 to 500 parts by mass and 0.01 to 30 parts by mass, respectively based on 100 parts by mass of the vinylidene fluoride polymer (A).

Owner:DAIKIN IND LTD

Highly dielectric film

InactiveUS20110255211A1Excellent in winding property (flexibility)Excellent dielectric propertiesPiezoelectric/electrostrictive device manufacture/assemblyFixed capacitor dielectricLead zirconate titanateBarium titanate

There is provided a highly dielectric film which has high dielectric property, can be formed into a think film and is excellent in winding property (flexibility). The highly dielectric film comprises (A) a vinylidene fluoride polymer, (B) barium titanate oxide particles and / or lead zirconium titanate oxide particles, and (C) an affinity improving agent, wherein the barium titanate oxide particles and / or lead zirconium titanate oxide particles (B) and the affinity improving agent (C) are contained in amounts of 10 to 500 parts by mass and 0.01 to 30 parts by mass, respectively based on 100 parts by mass of the vinylidene fluoride polymer (A).

Owner:DAIKIN IND LTD

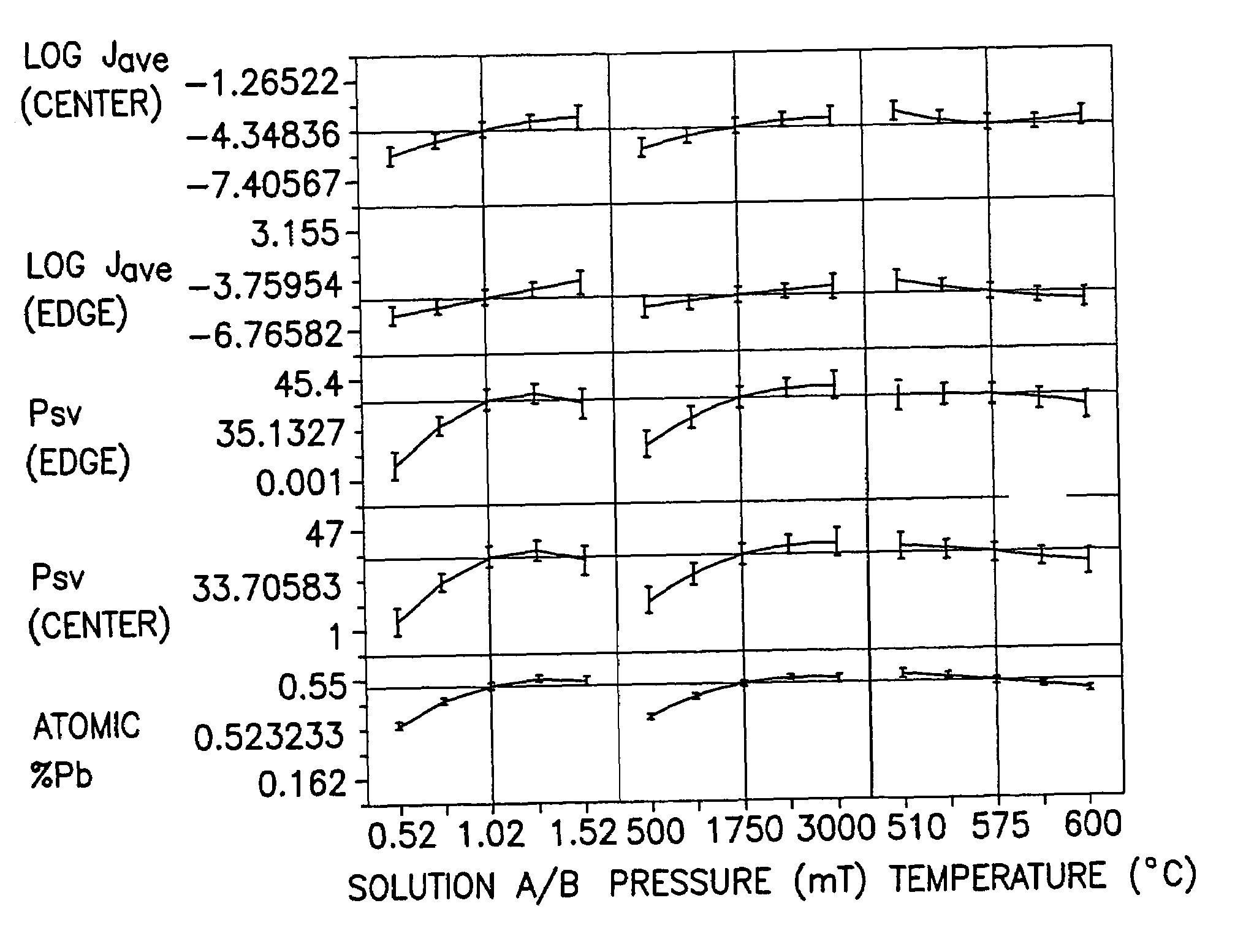

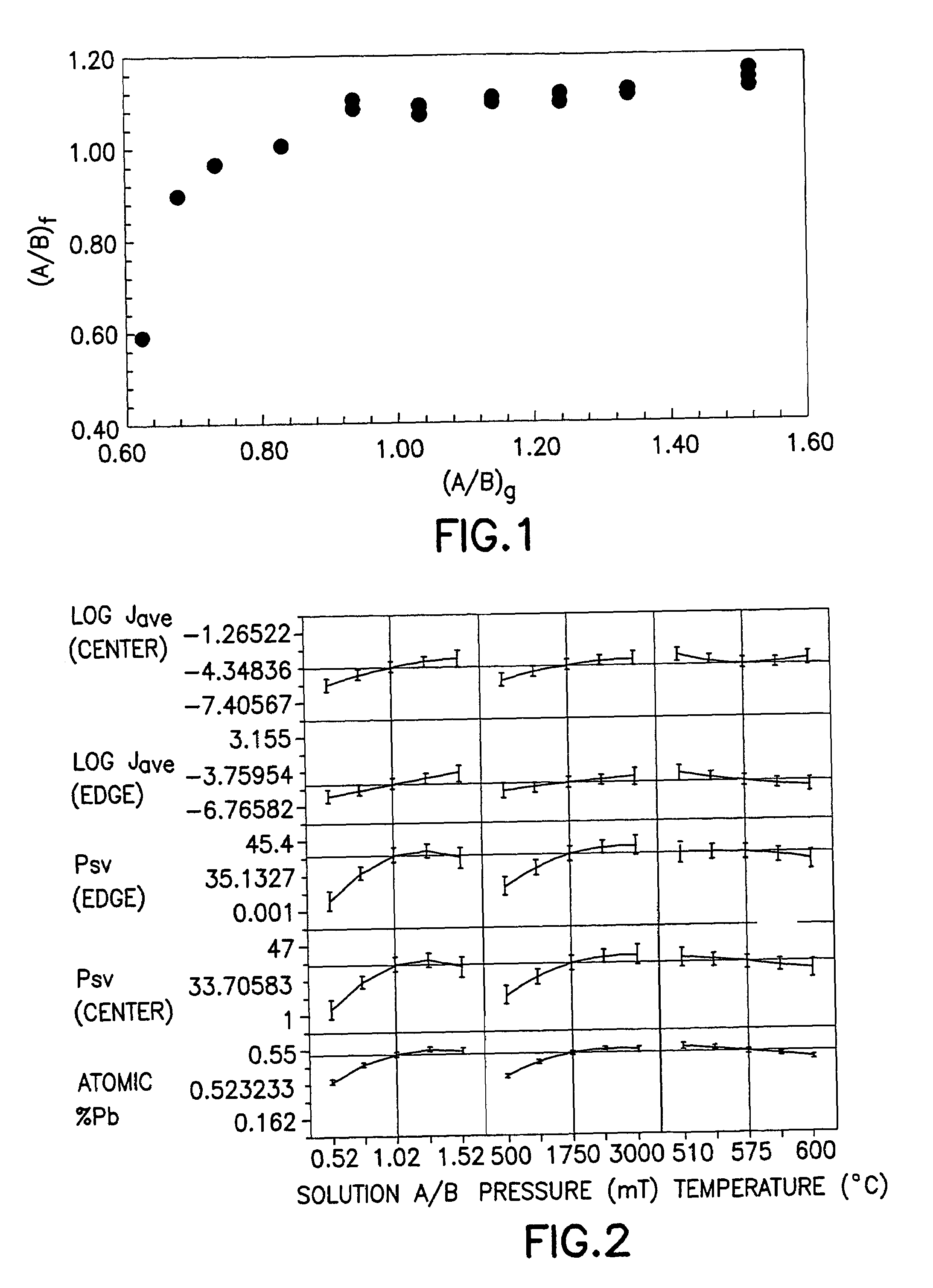

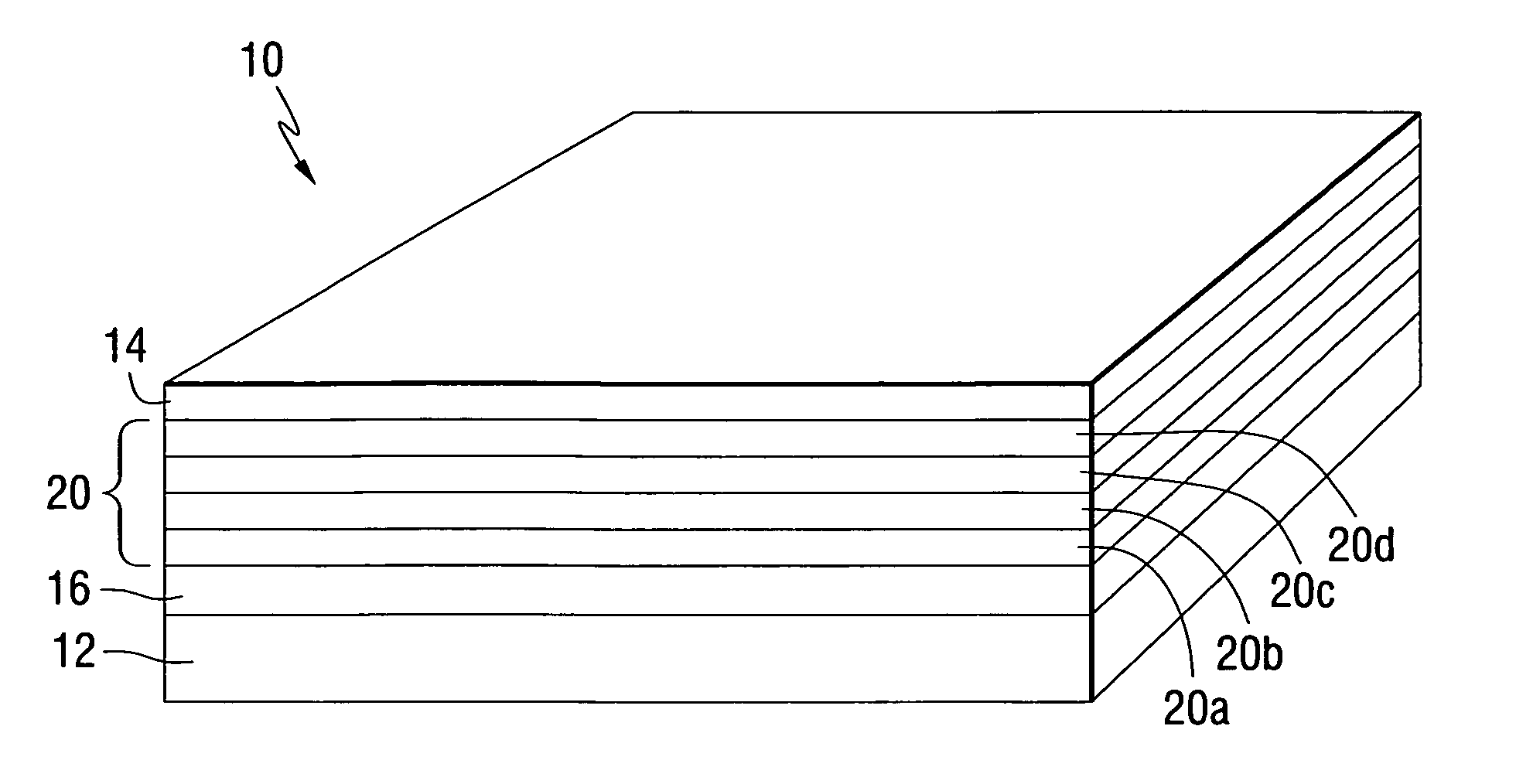

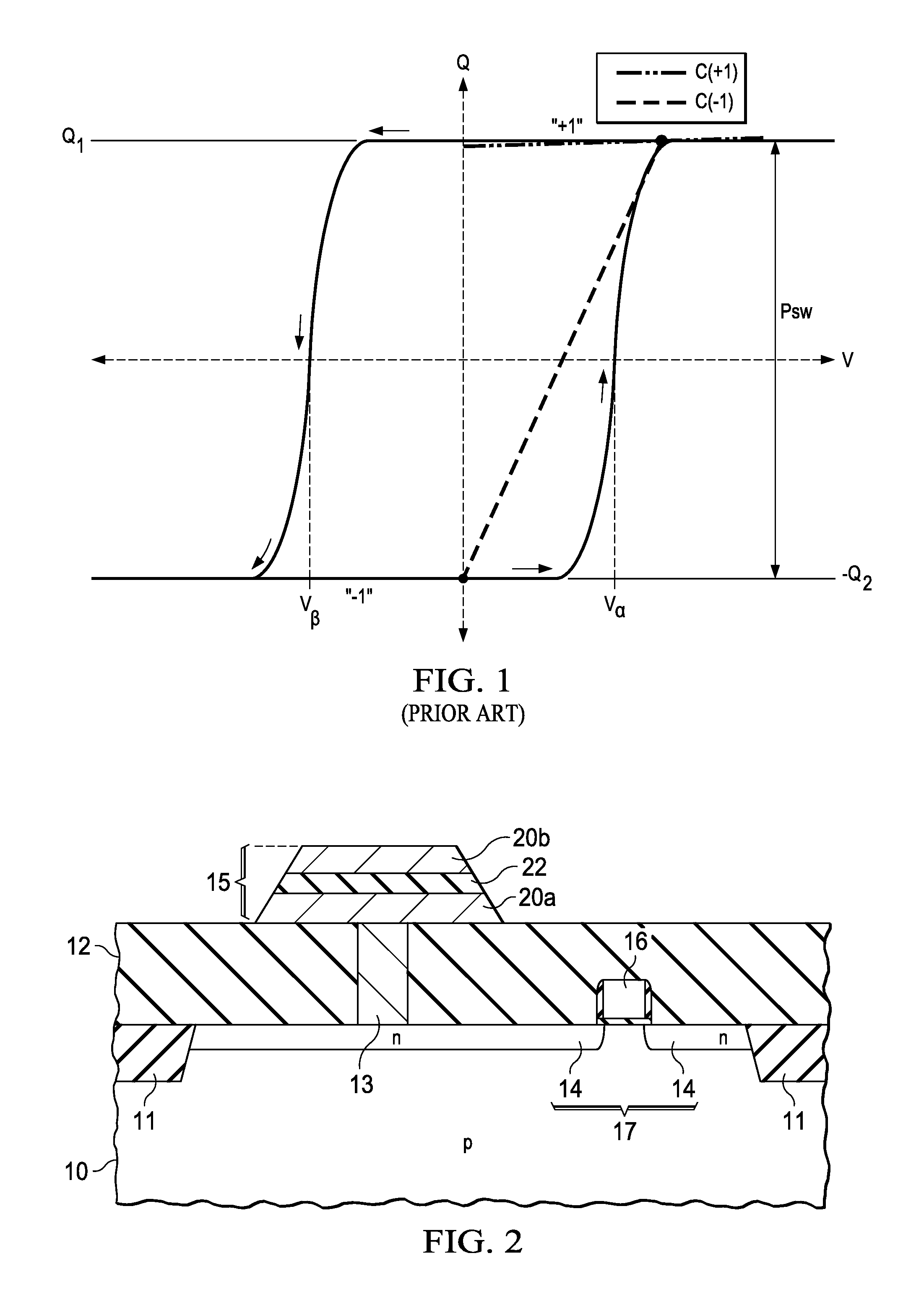

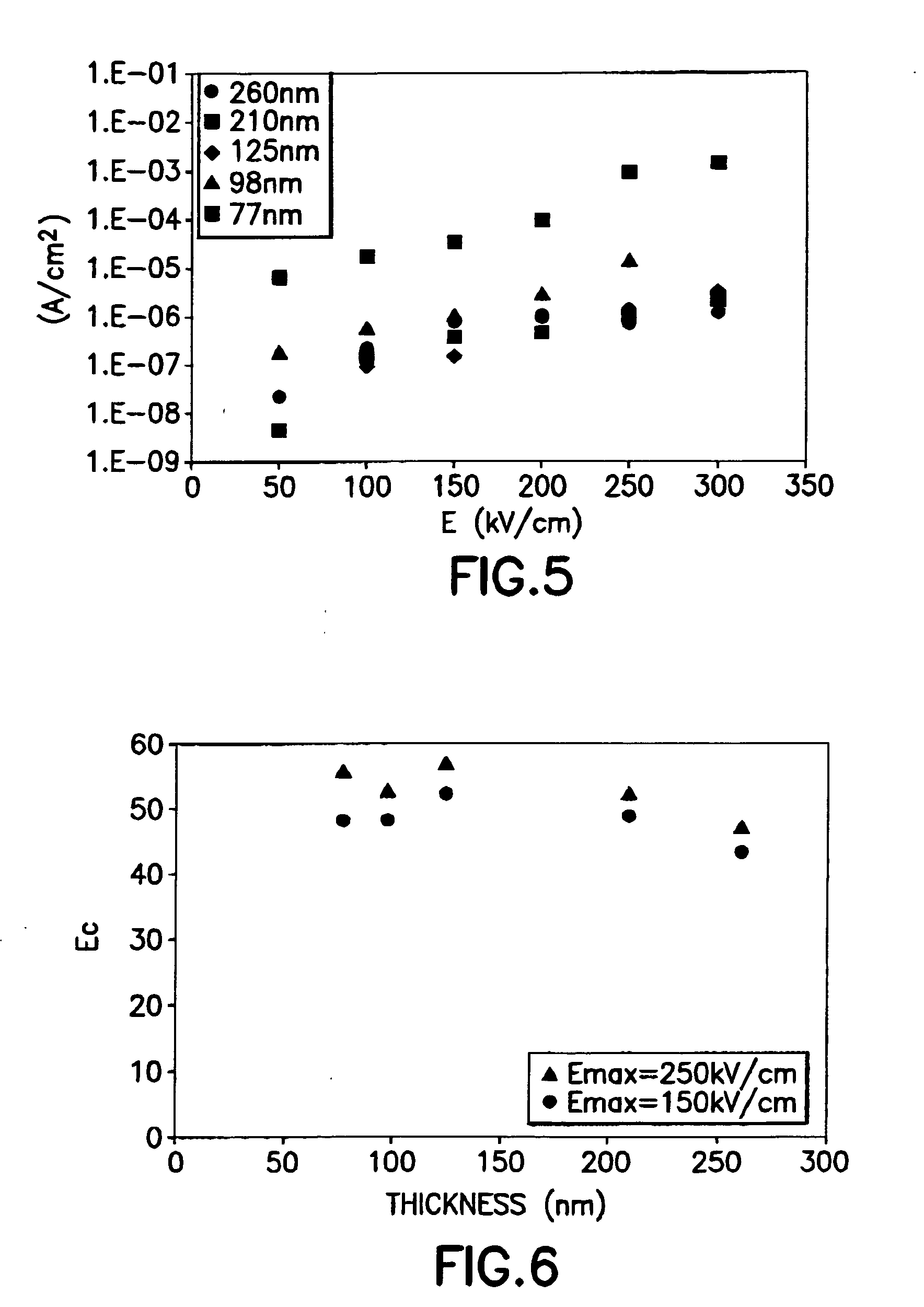

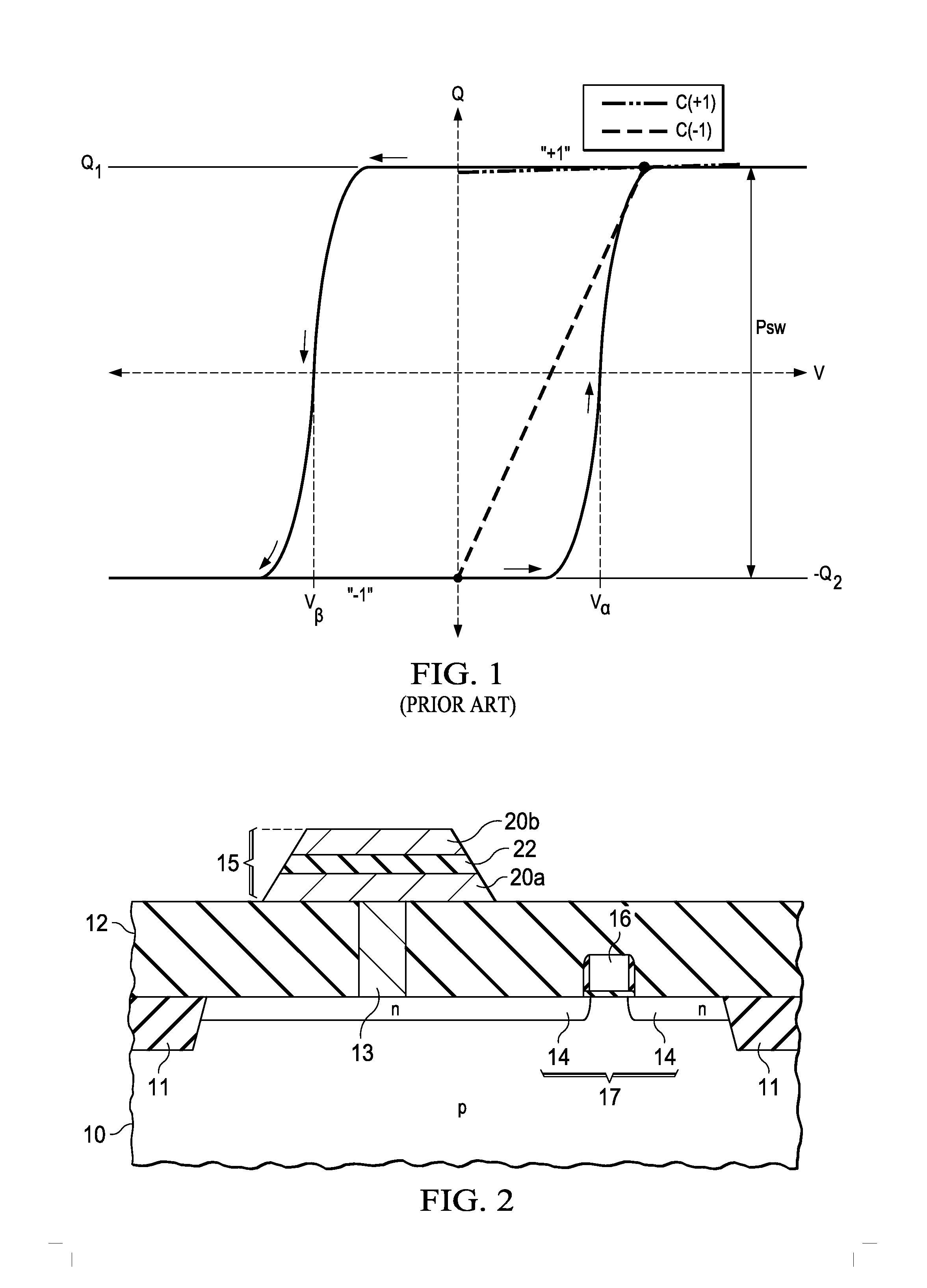

Scalable lead zirconium titanate (PZT) thin film material and deposition method, and ferroelectric memory device structures comprising such thin film material

InactiveUS6984417B2Thin/thick film capacitorGroup 4/14 organic compounds without C-metal linkagesLead zirconate titanateOptoelectronics

A novel lead zirconium titanate (PZT) material having unique properties and application for PZT thin film capacitors and ferroelectric capacitor structures, e.g., FeRAMs, employing such thin film material. The PZT material is scalable, being dimensionally scalable, pulse length scalable and / or E-field scalable in character, and is useful for ferroelectric capacitors over a wide range of thicknesses, e.g., from about 20 nanometers to about 150 nanometers, and a range of lateral dimensions extending to as low as 0.15 μm. Corresponding capacitor areas (i.e., lateral scaling) in a preferred embodiment are in the range of from about 104 to about 10−2 μm2. The scalable PZT material of the invention may be formed by liquid delivery MOCVD, without PZT film modification techniques such as acceptor doping or use of film modifiers (e.g., Nb, Ta, La, Sr, Ca and the like).

Owner:ENTEGRIS INC

Fine-particulate lead zirconium titantes zirconium titanate hydrates and zirconium titanates and method for production thereof

ActiveUS20090060831A1Easily processableEasily economically producibleMaterial nanotechnologyConductive materialLead zirconate titanateFine particulate

The invention relates to fine-particulate zirconium titanates or lead zirconium titanates and a method for production thereof by reaction of titanium dioxide particles with a zirconium compound or a lead and zirconium compound. The titanium dioxide particles have a BET surface of more than 50 m2 / g. The lead zirconium titanates can be used for the production of microelectronic components.

Owner:TRONOX PIGMENTS GMBH

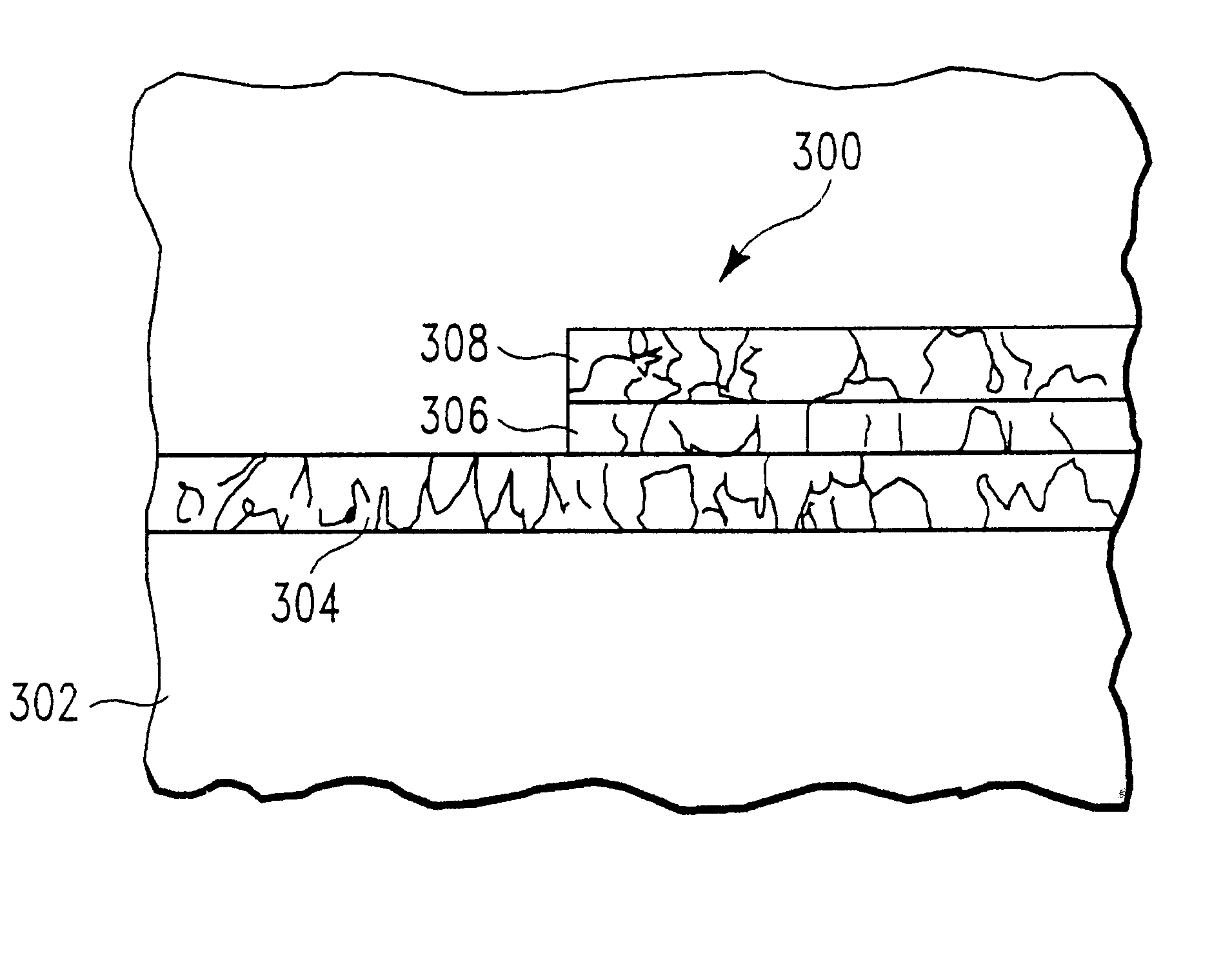

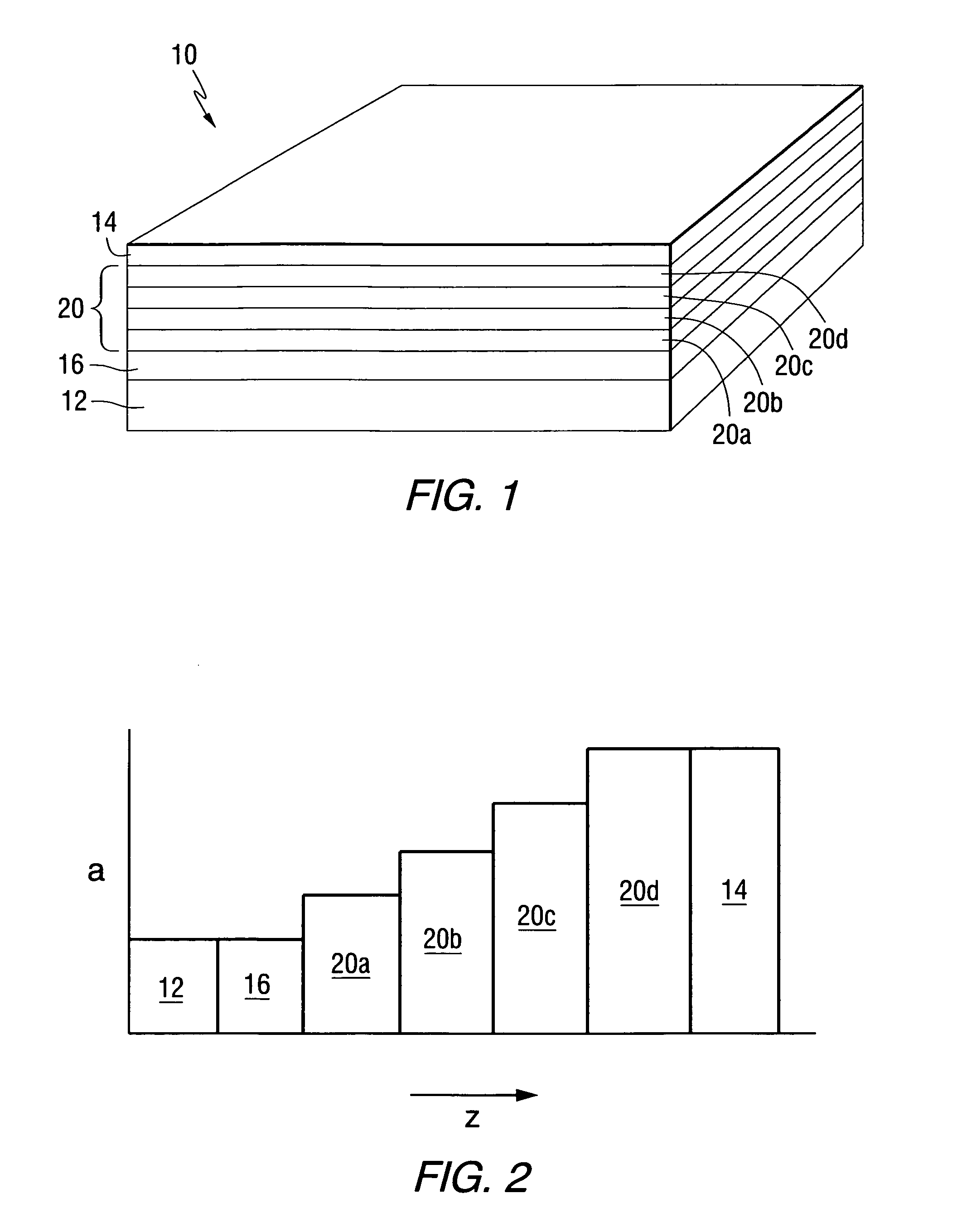

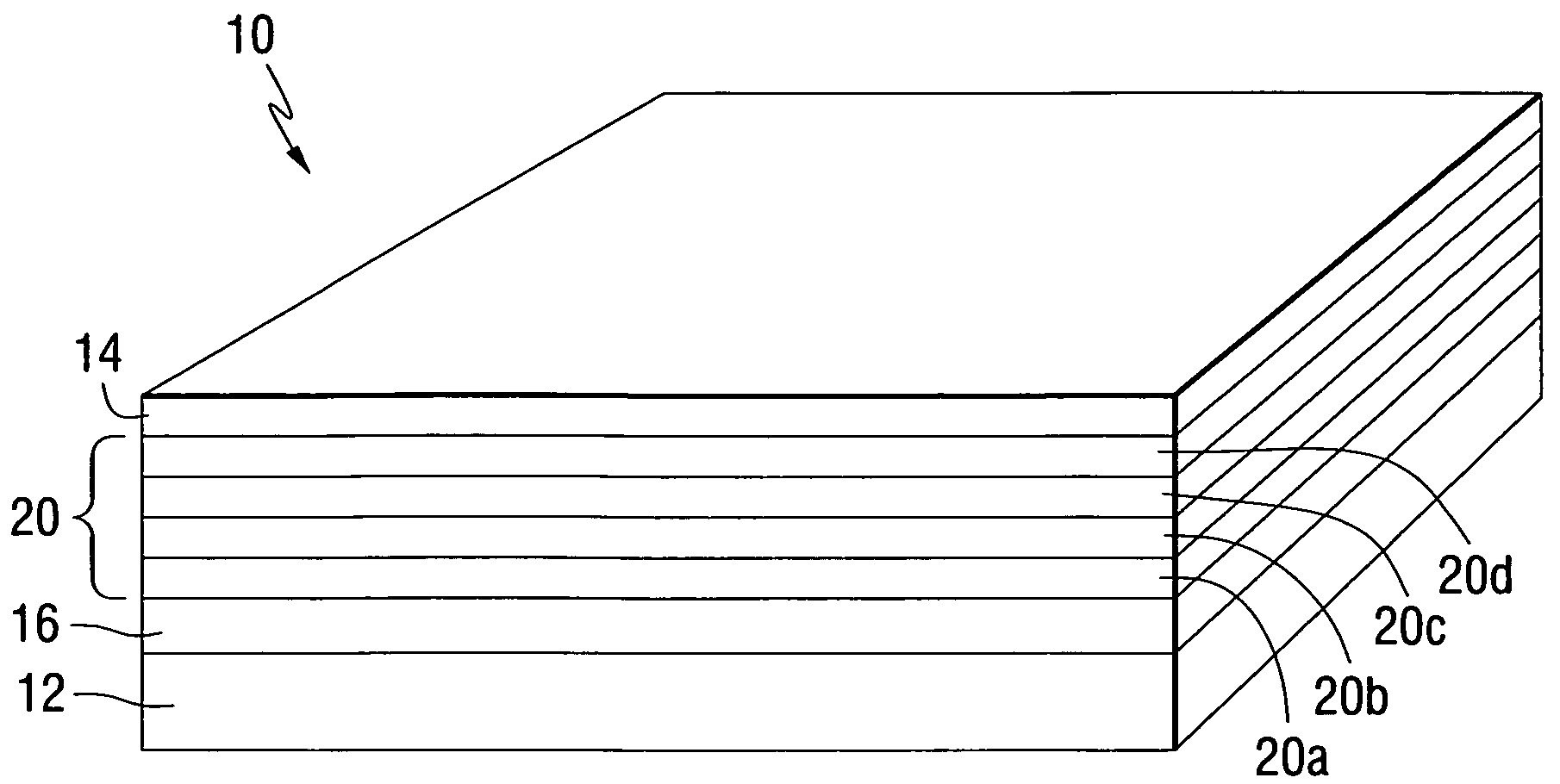

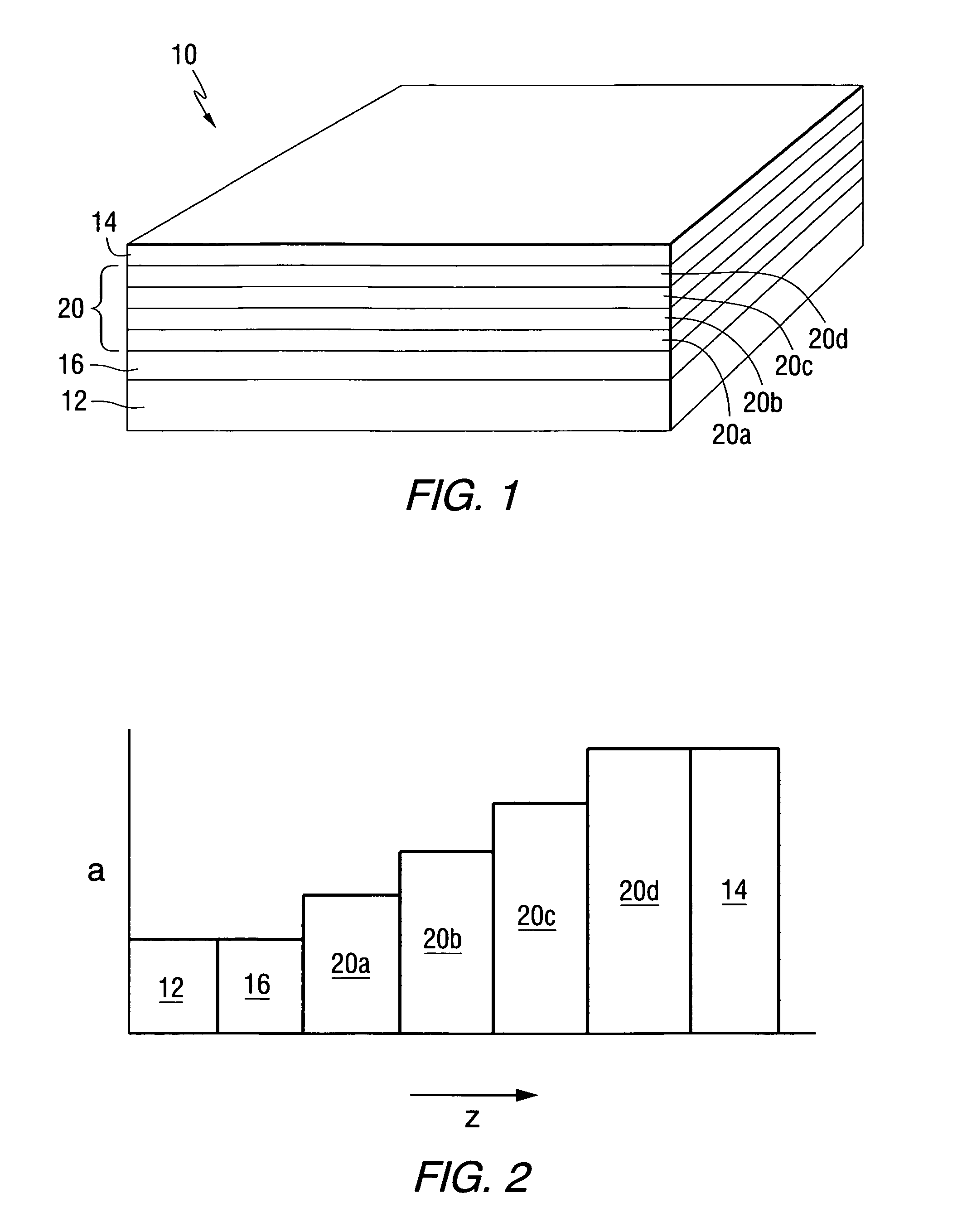

Epitaxial ferroelectric and magnetic recording structures including graded lattice matching layers

ActiveUS20080075980A1Magnetic materials for record carriersRecord information storageLead zirconate titanateMetal alloy

Epitaxial ferroelectric and magnetic recording structures having graded lattice matching layers are disclosed. A single crystal material such as Si may be used as a substrate material upon which the graded lattice matching layers are deposited. The lattice matching layers may comprise metals and metal alloys, or may comprise oxides doped with selected elements or deposited under different oxygen pressures. A recording layer, such as ferroelectric lead zirconium titanate or a magnetic Fe / Pt multilayer structure, is deposited on the graded lattice matching layers.

Owner:SEAGATE TECH LLC

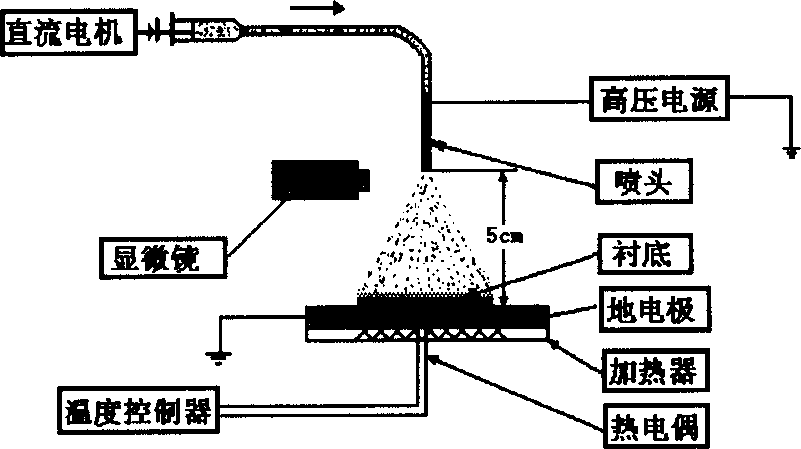

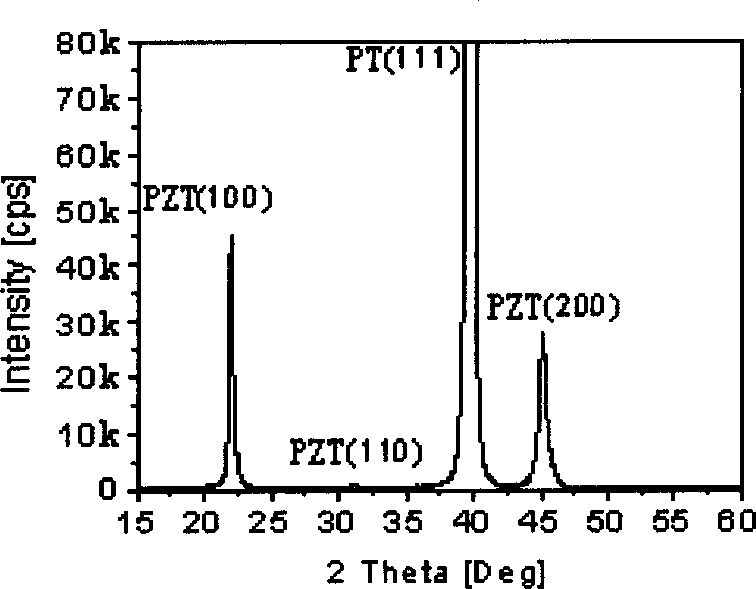

Preparation method of high performance lead zirconium titanate thin film

InactiveCN1513809AFast growthIncreasing the thicknessLead zirconate titanateMicroelectromechanical systems

A process for preparing the high-performance ferroelectric lead zirconate titanate (PZT) film includes preparing its precursor solution by sol-gel method, preparing the substrte with PZT crystal seed layer, atomizing and accelerating said precursor solution to deposit it on said substrate to become film, and heat treating. Its advantages are high growth speed, low cost, great thickness and excellent piezoelectric and dielectric performance.

Owner:UNIV OF SCI & TECH OF CHINA

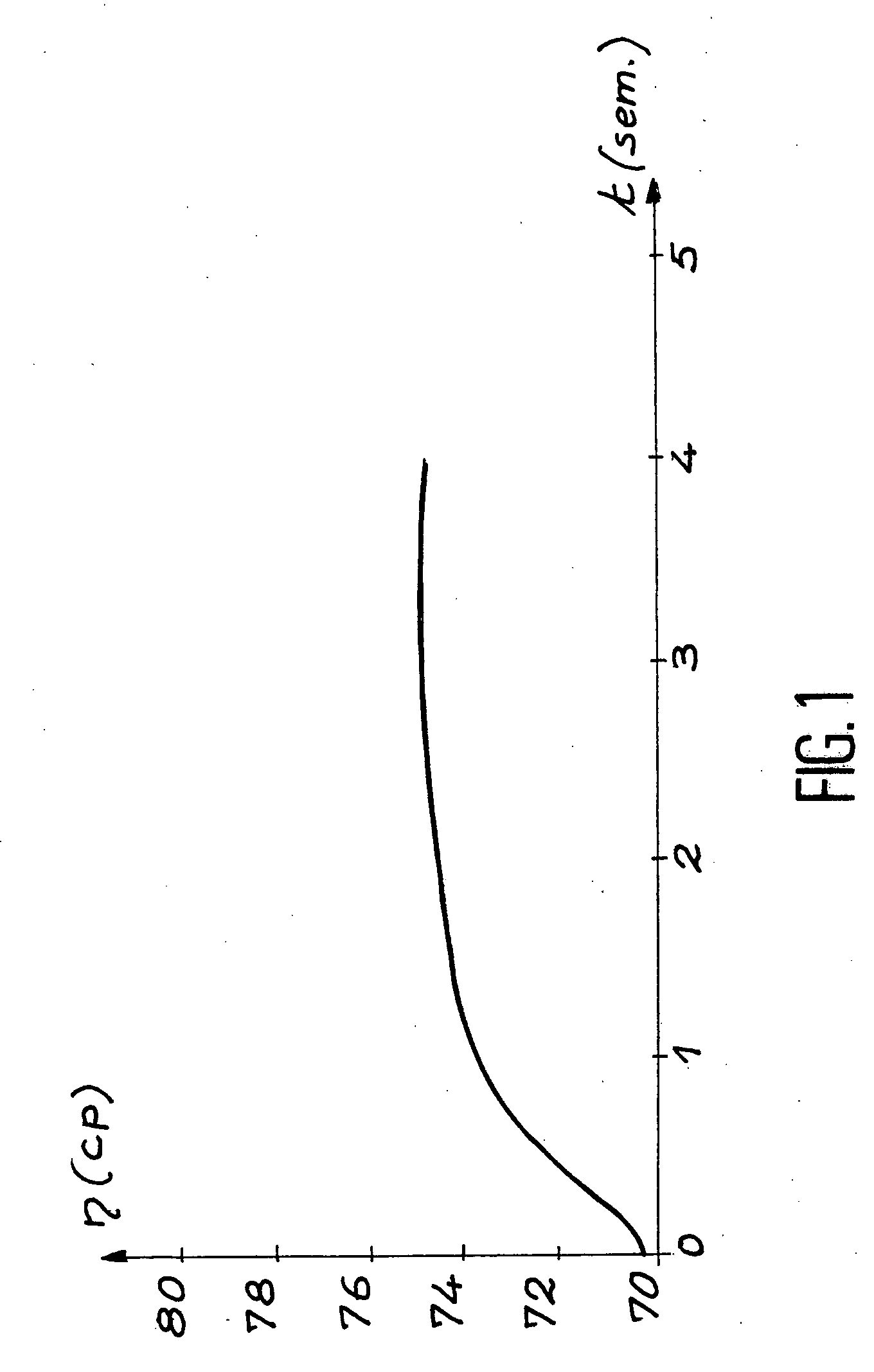

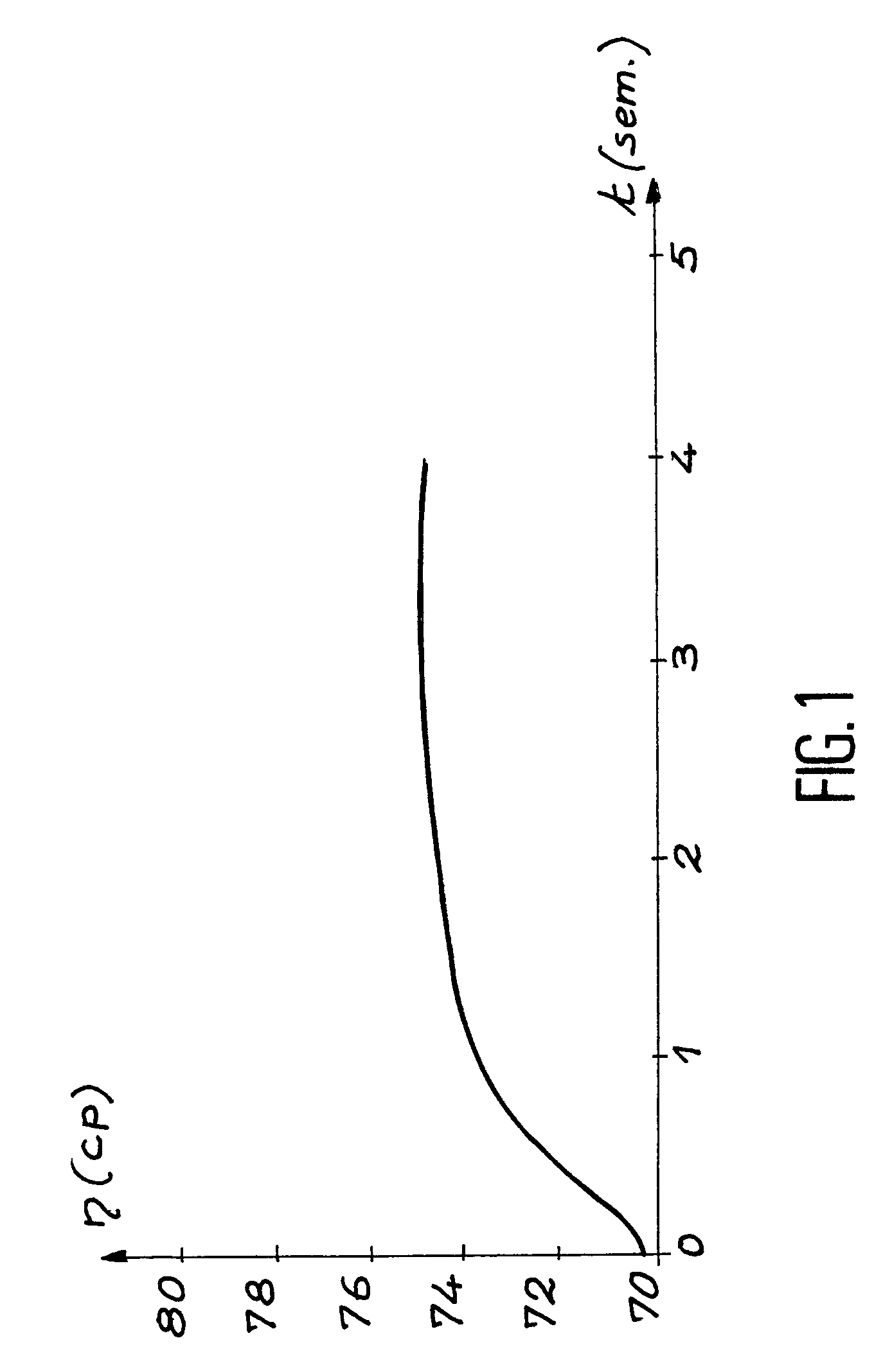

Method of preparing a stable lead zircon-titanate sol and method for preparing films based on same

InactiveUS20040014820A1Shorten the construction periodOther chemical processesZirconium compoundsLead zirconate titanateFilm base

The invention relates to a method of preparing a sol of lead zirconium titanate, known as PZT, of formula PbZrxTi(1-x)O3 with 0.45<=x<=0.7, comprising the following successive steps: (a) preparing a concentrated sol in a diol, the said sol comprising a titanium-based precursor, a zirconium-based precursor, and a lead-based precursor; (b) placing the said concentrated sol at ambient temperature without agitation, until a sol is obtained having a constant viscosity as a function of time; (c) diluting the sol obtained in (b) with a solvent compatible with the diol used in step (a). The invention likewise relates to a method of preparing PZT-based films from the said stable sol. Application of the films to the electronics field.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Nanostructured dielectric materials for high energy density multi layer ceramic capacitors

A high energy density multilayer ceramic capacitor, having at least two electrode layers and at least one substantially dense polycrystalline dielectric layer positioned therebetween. The at polycrystalline dielectric layer has an average grain size of less than about 300 nanometers, a particle size distribution of between about 150 nanometers and about 3 micrometers, and a maximum porosity of about 1 percent. The dielectric layer is selected from the group including TiO2, BaTiO3, Al2O3, ZrO2, lead zirconium titanate, and combinations thereof and has a breakdown strength of at least about 1100 kV per centimeter.

Owner:UNIVERSITY OF MISSOURI

Tunable low loss material composition and methods of manufacture and use therefore

ActiveUS20060060900A1Semiconductor/solid-state device manufacturingSemiconductor devicesBarium strontium titanateBarium titanate

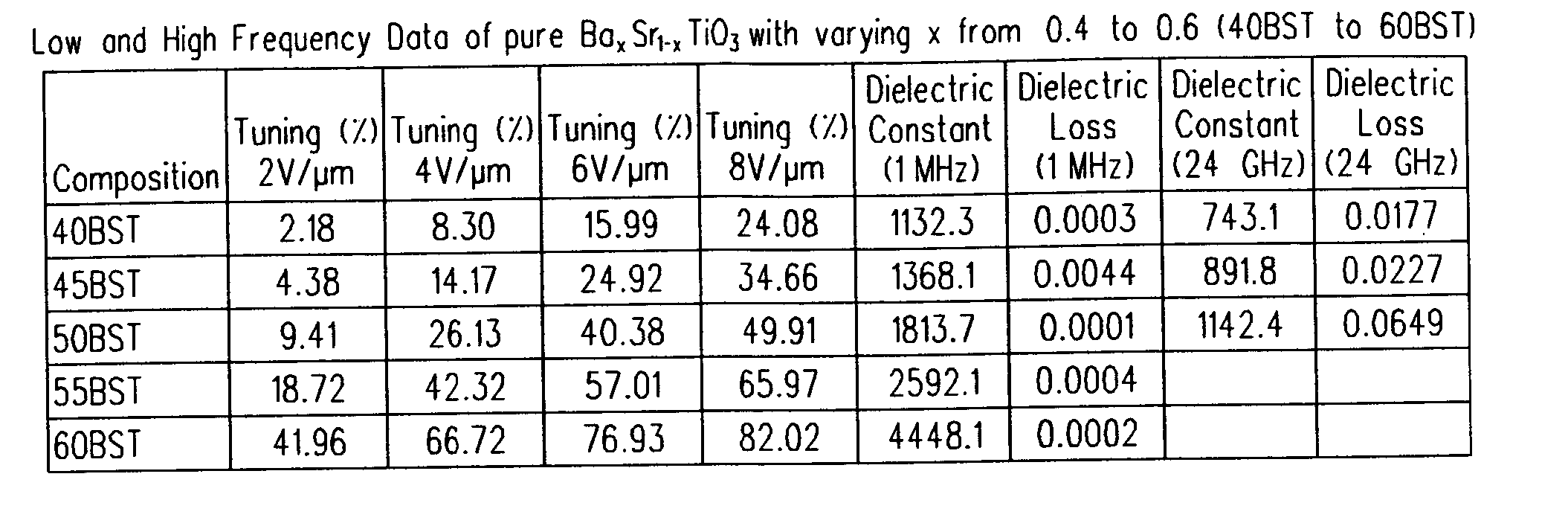

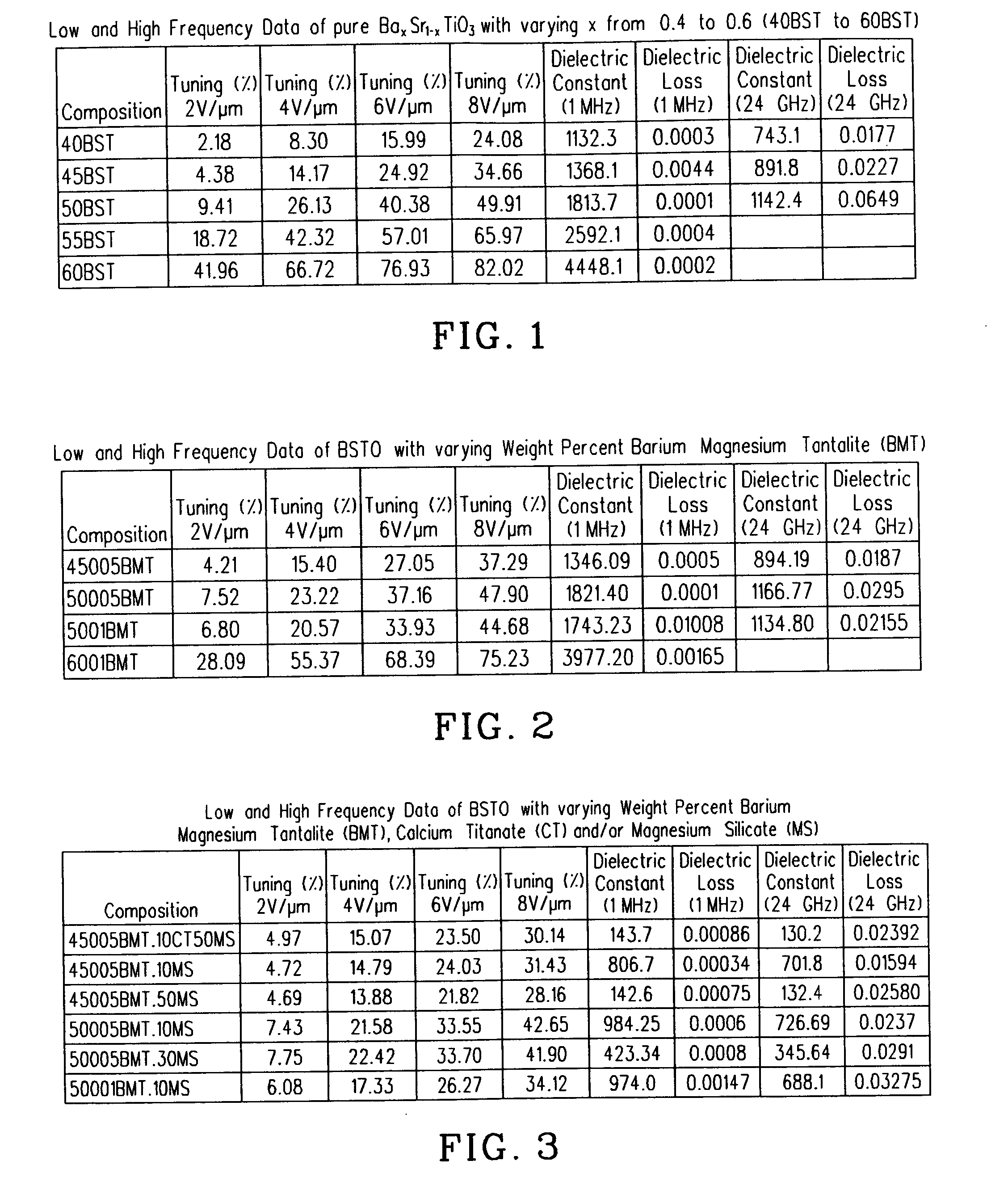

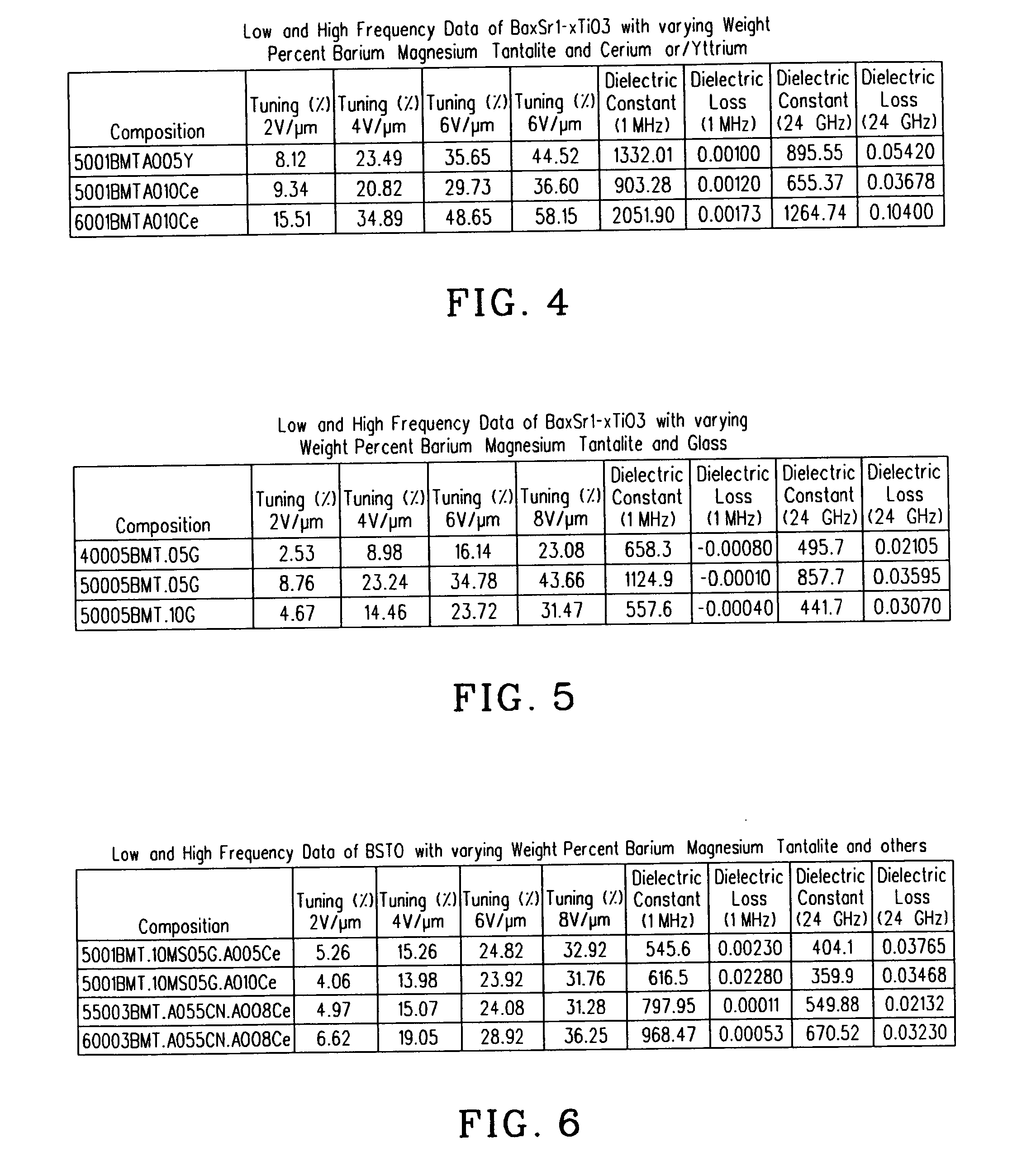

An embodiment of the present invention provides an electronically tunable dielectric material, comprising at least one electronically tunable dielectric phase and at least one compound of low loss complex perovskites. The at least one electronically tunable dielectric phase may be selected from the group consisting of barium strontium titanate, barium titanate, strontium titanate, barium calcium titanate, barium calcium zirconium titanate, lead titanate, lead zirconium titanate, lead lanthanum zirconium titanate, lead niobate, lead tantalate, potassium strontium niobate, sodium barium niobate / potassium phosphate, potassium niobate, lithium niobate, lithium tantalate, lanthanum tantalate, barium calcium zirconium titanate, sodium nitrate, and combinations thereof. Further, the barium strontium titanate may of the formula BaxSr1-xTiO3, where x is from about 0 to about 1, or more specifically, but not limited in this respect, may also be of the formula BaxSr1-xTiO3, where x may be from about 0.15 to about 0.65 or from about 0.25 to about 0.60.

Owner:NXP USA INC

Physical structure for use in a physical unclonable function

InactiveUS8659124B2Effective structureHigh voltageSemiconductor/solid-state device detailsSolid-state devicesCapacitanceDielectric

Owner:NXP BV

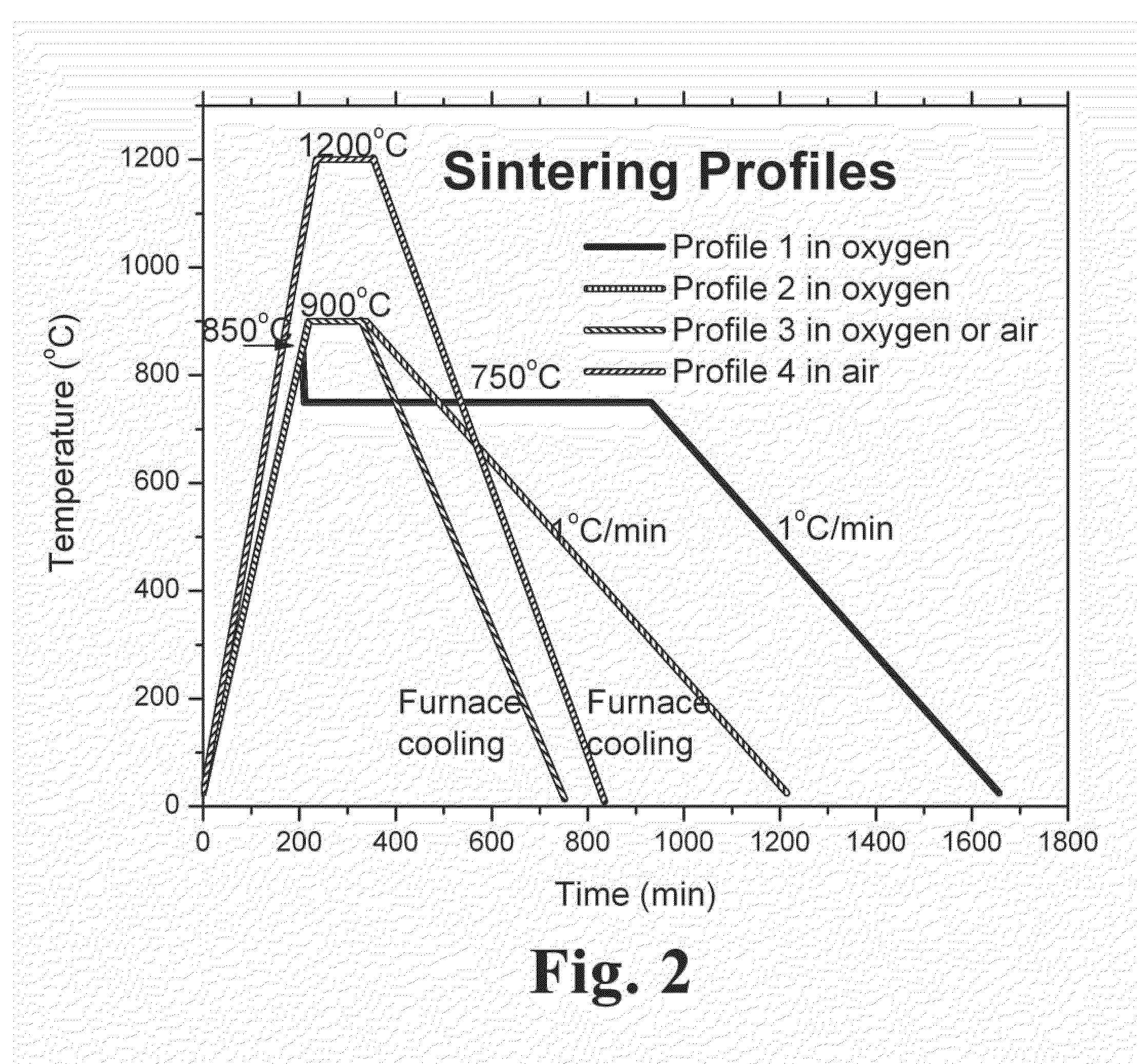

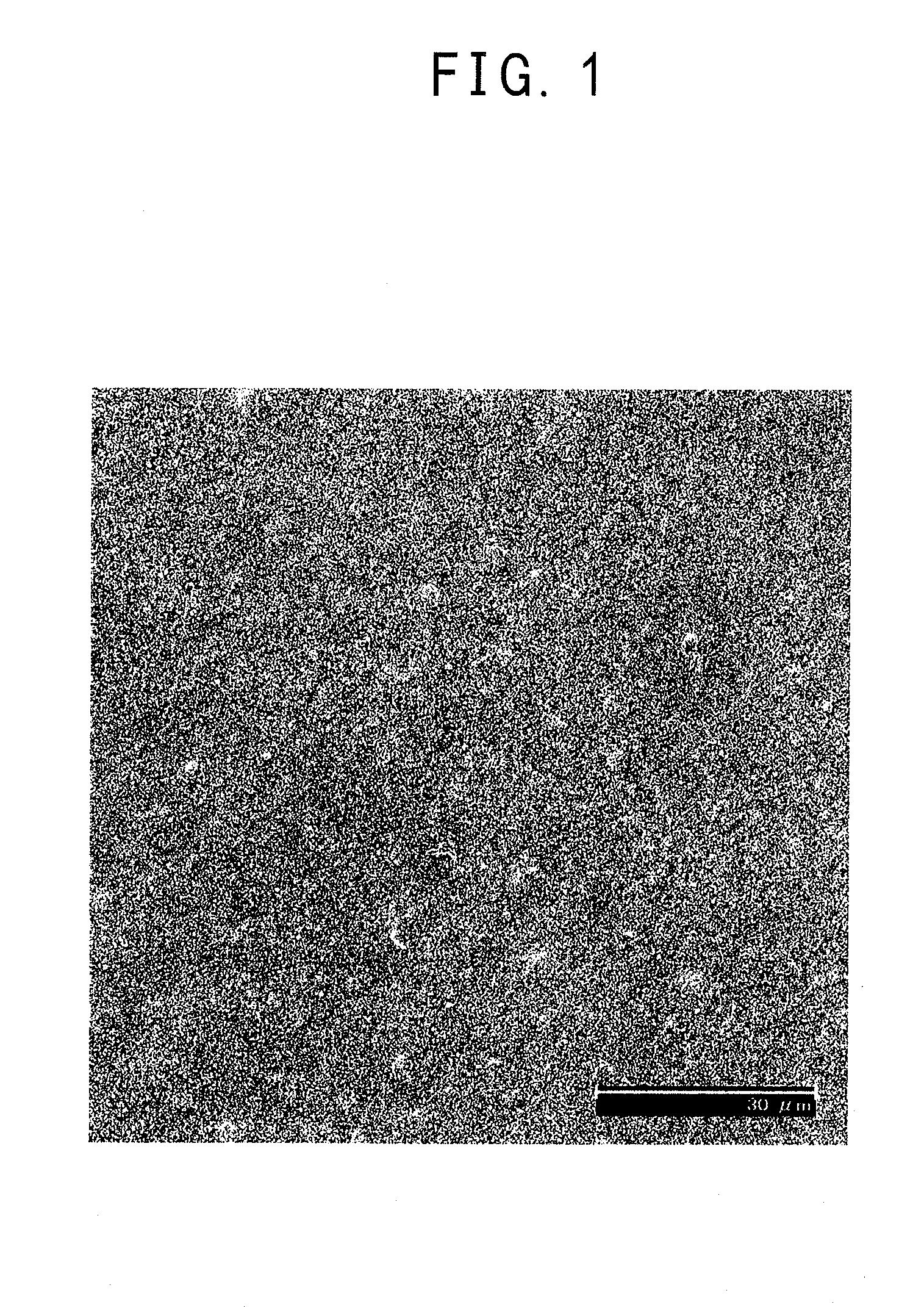

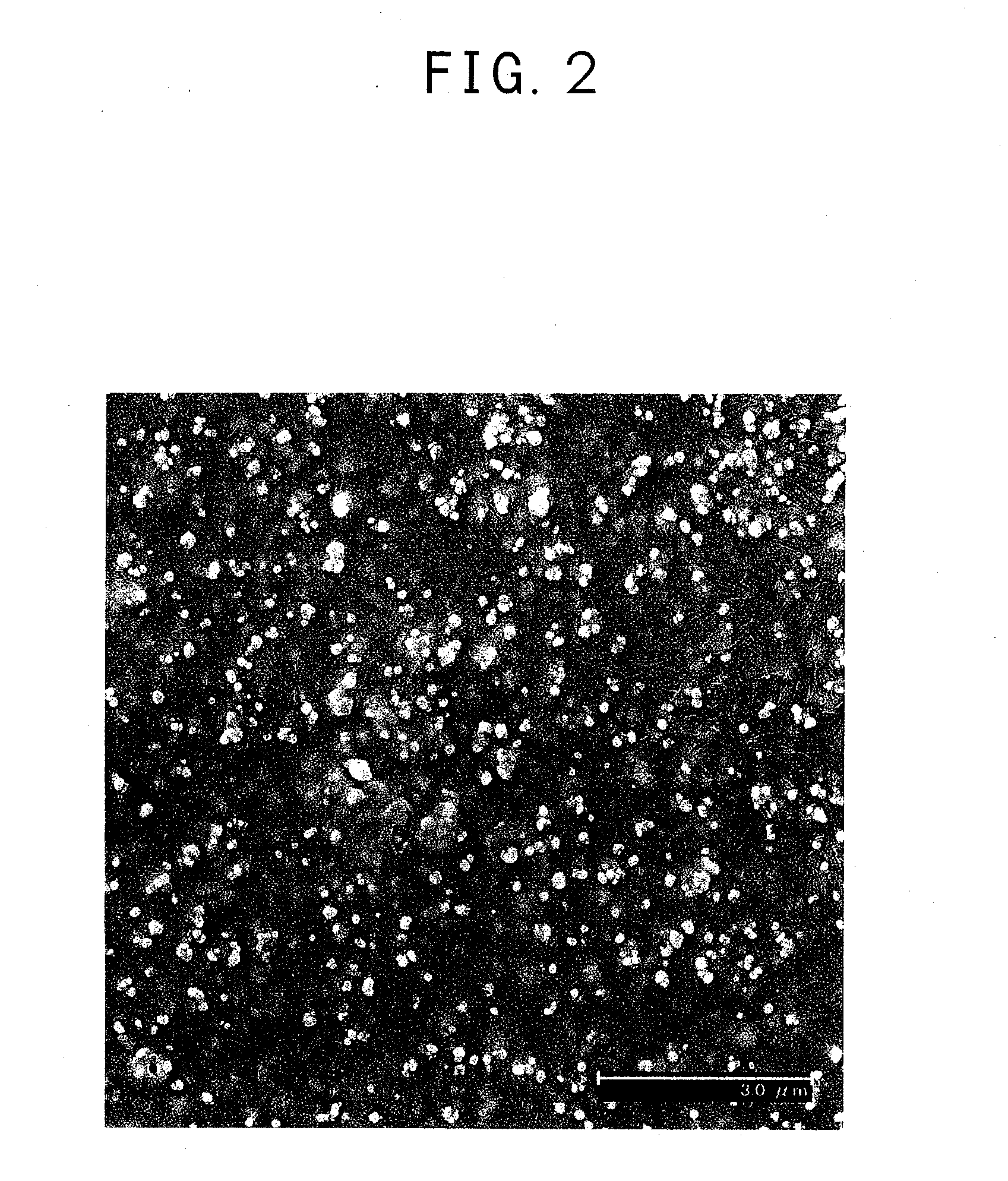

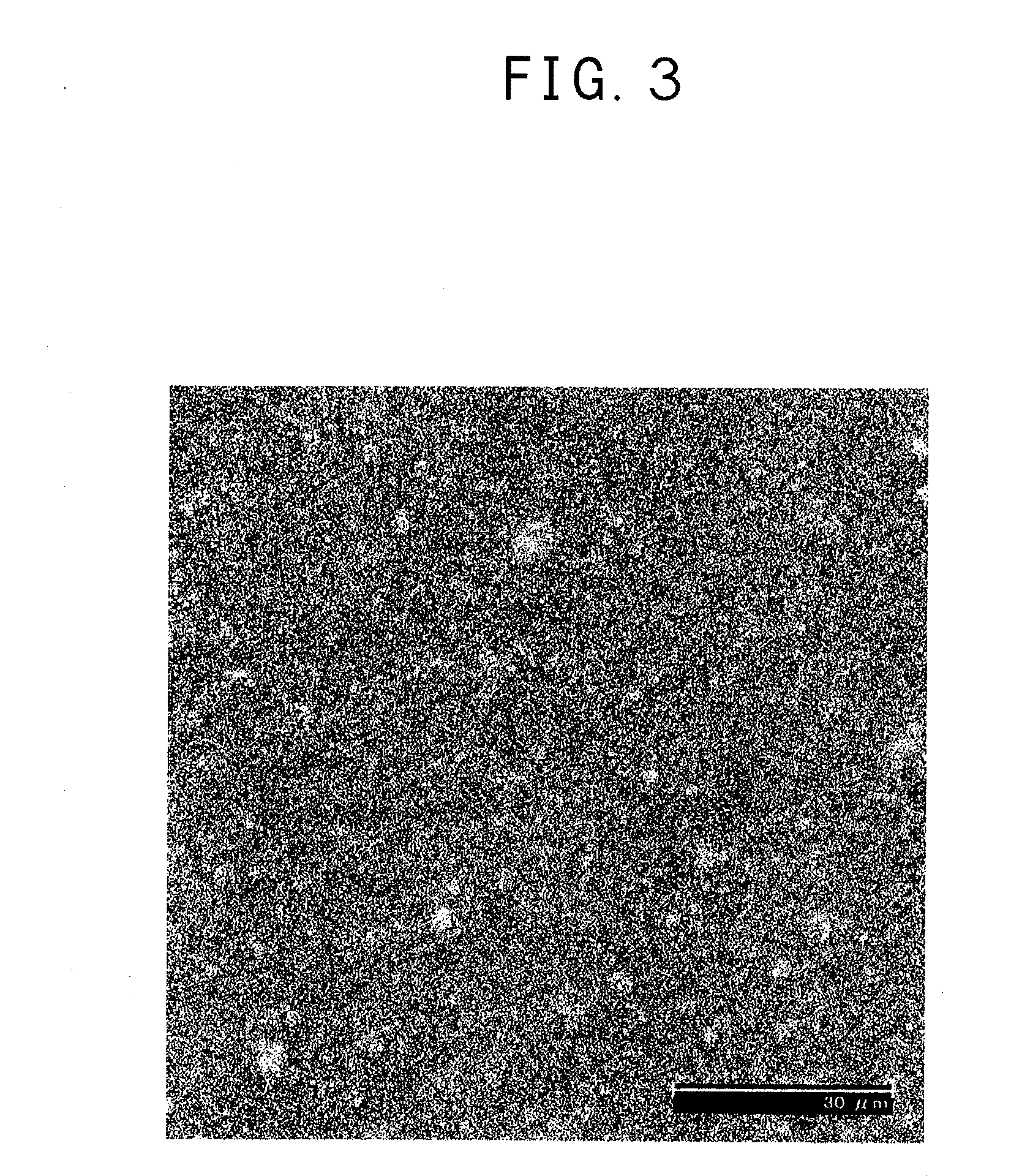

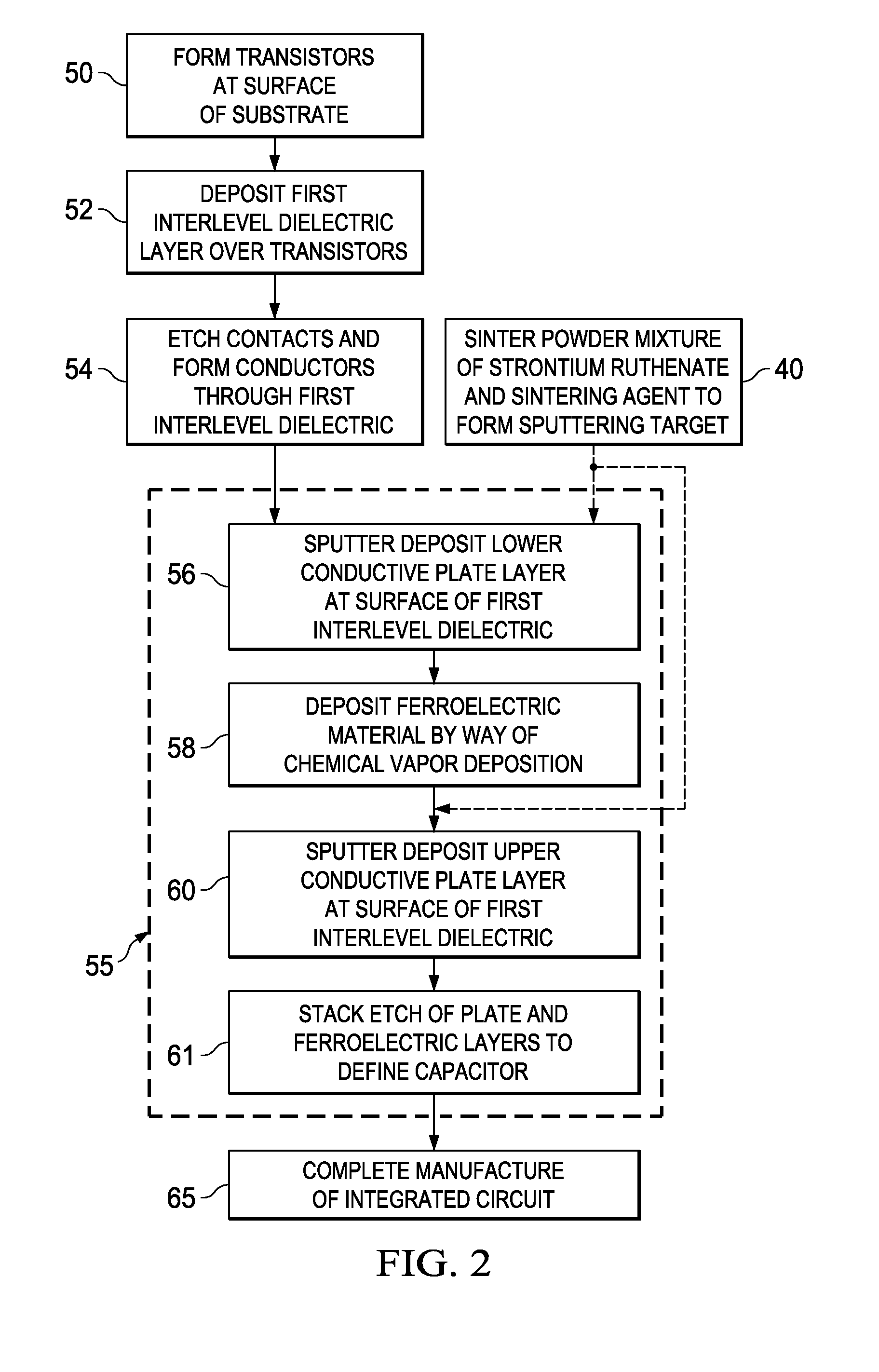

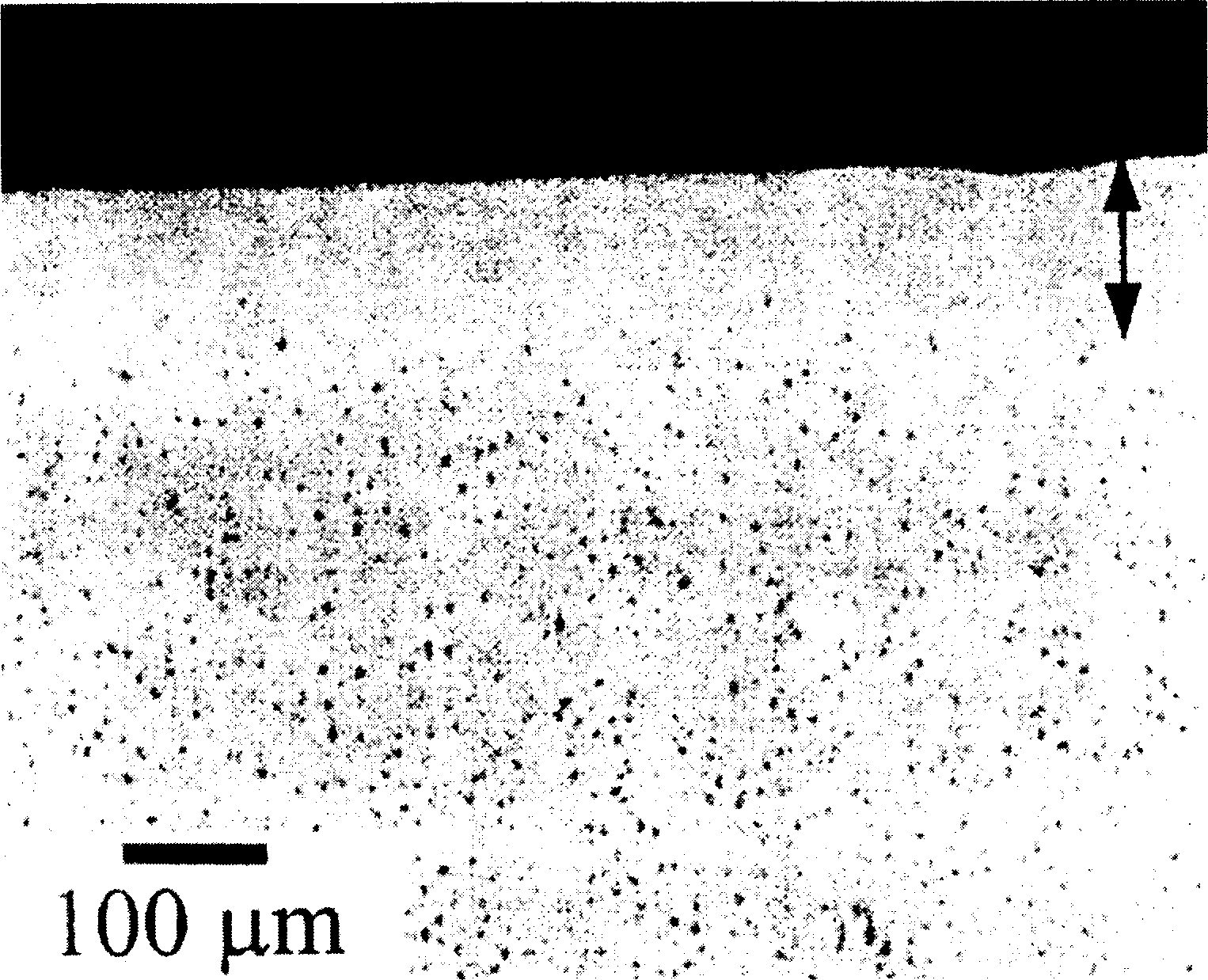

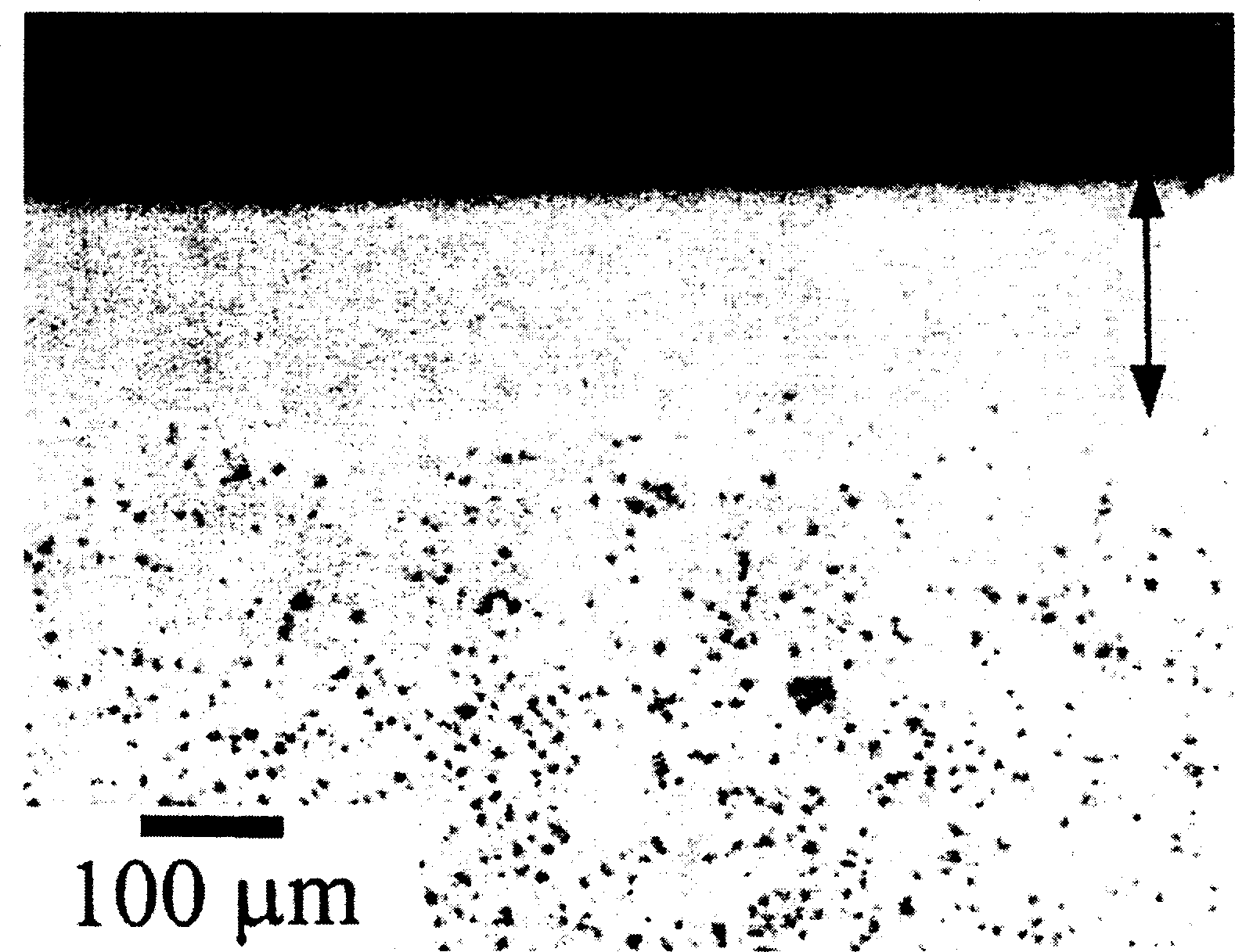

Process-compatible sputtering target for forming ferroelectric memory capacitor plates

InactiveUS20140147940A1High densityReduce porosityCellsHot-dipping/immersion processesPorosityPowder mixture

A sputtering target for a conductive oxide, such as SrRuO3, to be used for the sputter deposition of a conductive film that is to be in contact with a ferroelectric material in an integrated circuit. The sputtering target is formed by the sintering of a powder mixture of the conductive oxide with a sintering agent of an oxide of one of the constituents of the ferroelectric material. For the example of lead-zirconium-titanate (PZT) as the ferroelectric material, the sintering agent is one or more of a lead oxide, a zirconium oxide, and a titanium oxide. The resulting sputtering target is of higher density and lower porosity, resulting in an improved sputter deposited film that does not include an atomic species beyond those of the ferroelectric material deposited adjacent to that film.

Owner:TEXAS INSTR INC

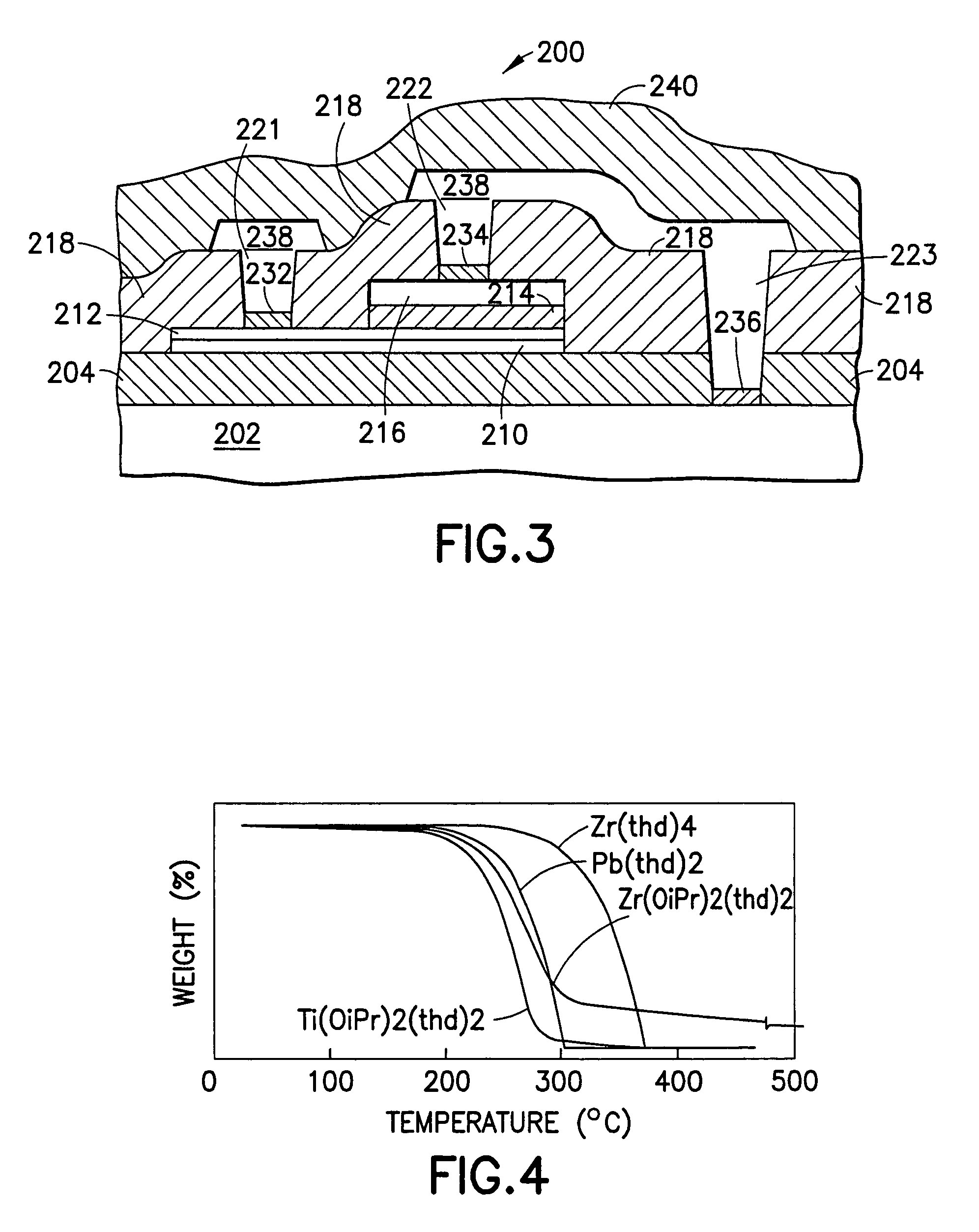

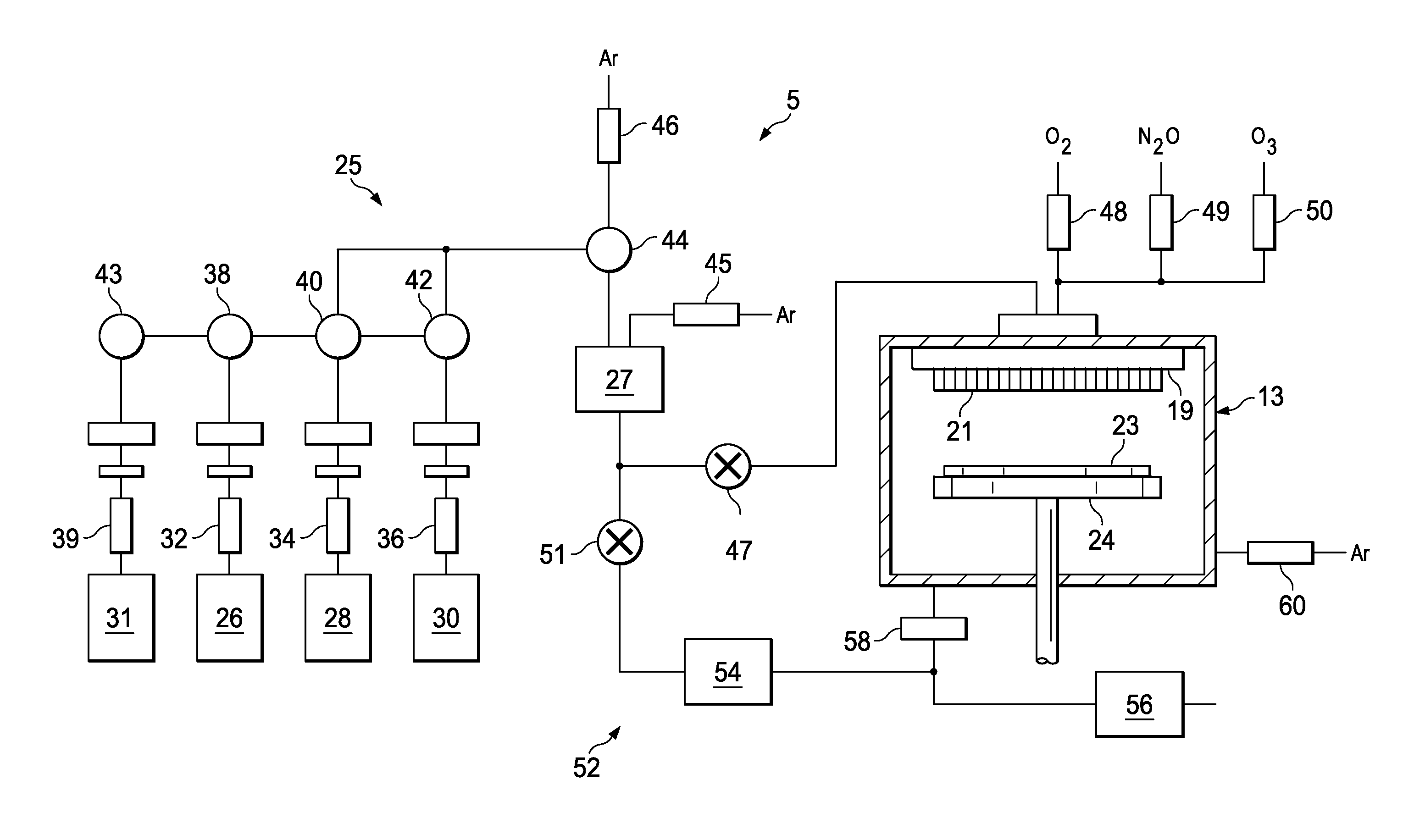

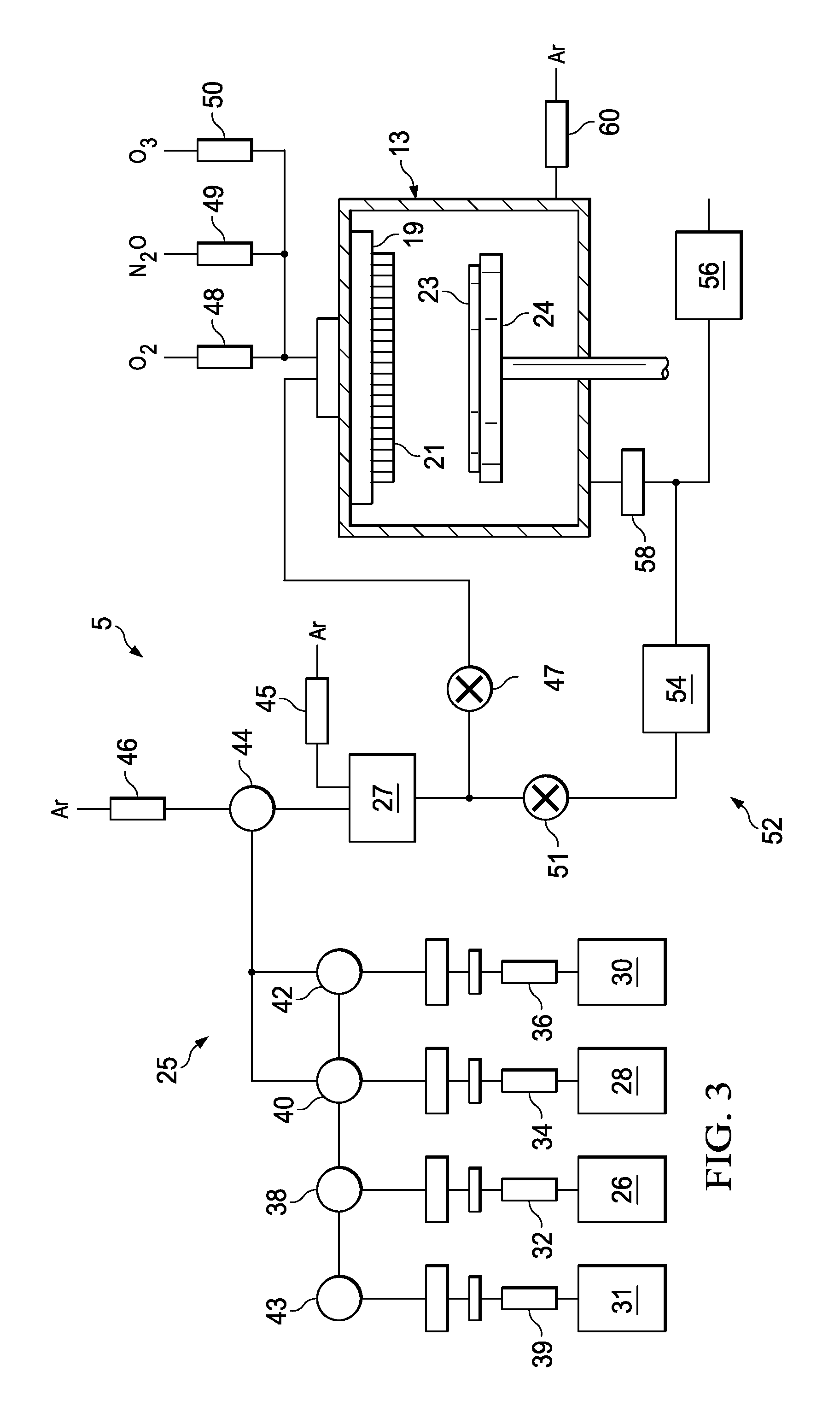

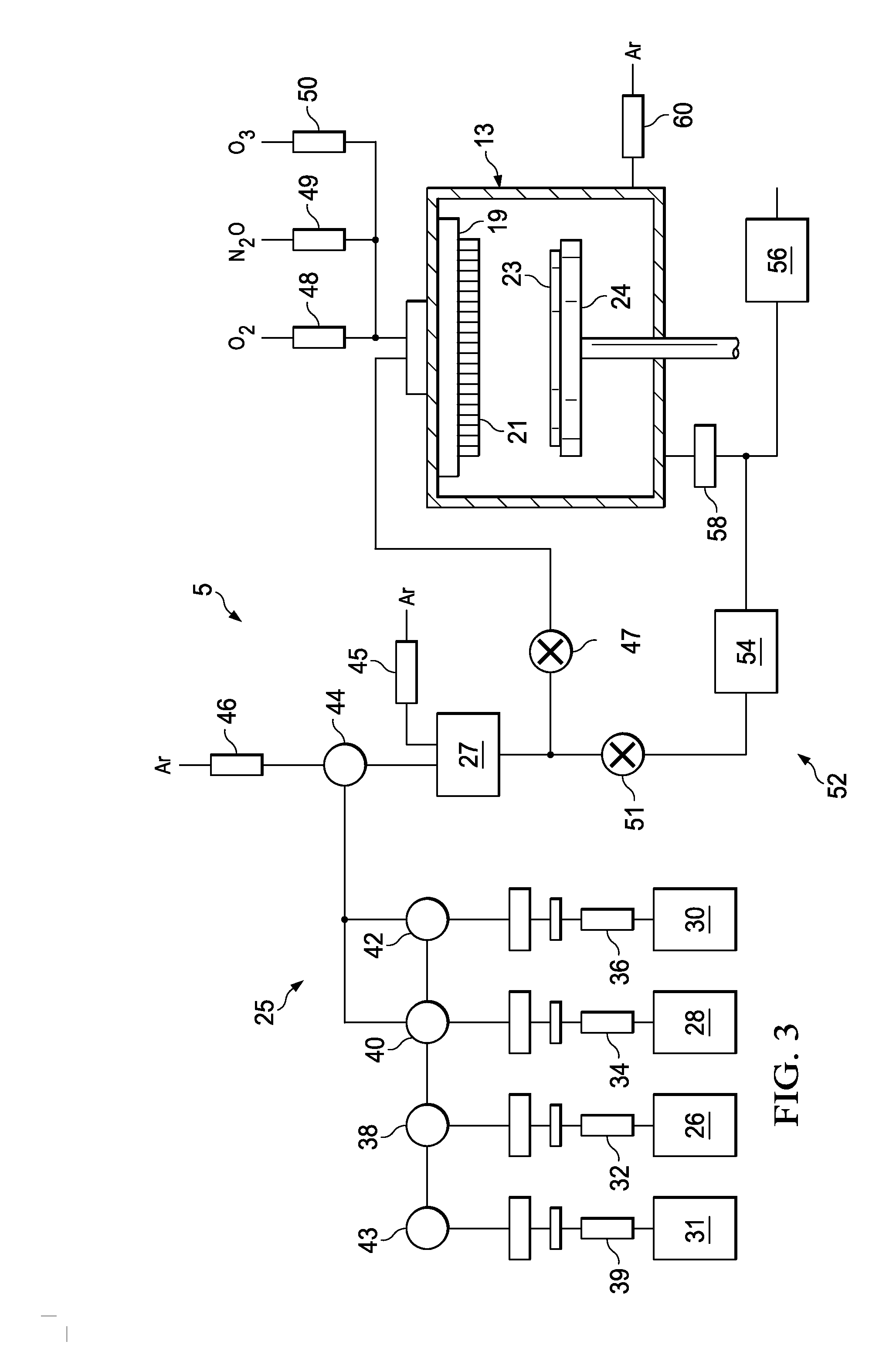

Multi-step deposition of ferroelectric dielectric material

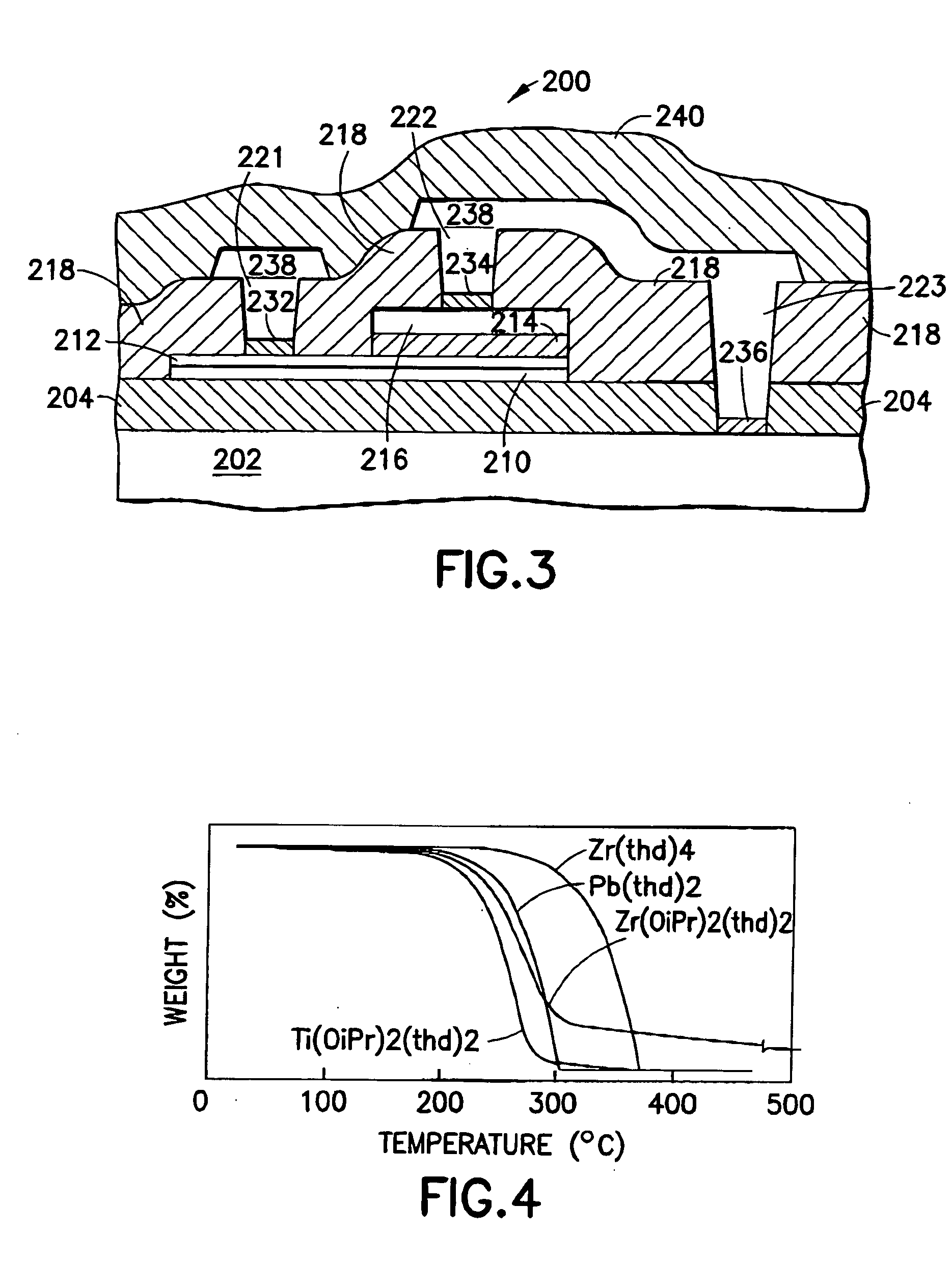

ActiveUS8962350B2Inhibition formationQuality improvementSolid-state devicesSemiconductor/solid-state device manufacturingDielectricTitanium

Multi-step deposition of lead-zirconium-titanate (PZT) ferroelectric material. An initial portion of the PZT material is deposited by metalorganic chemical vapor deposition (MOCVD) at a low deposition rate, for example at a temperature below about 640 deg C. from vaporized liquid precursors of lead, zirconium, and titanium, and a solvent at a collective flow rate below about 1.1 ml / min, in combination with an oxidizing gas. Following deposition of the PZT material at the low flow rate, the remainder of the PZT film is deposited at a high deposition rate, attained by changing one or more of precursor and solvent flow rate, oxygen concentration in the oxidizing gas, A / B ratio of the precursors, temperature, and the like.

Owner:TEXAS INSTR INC

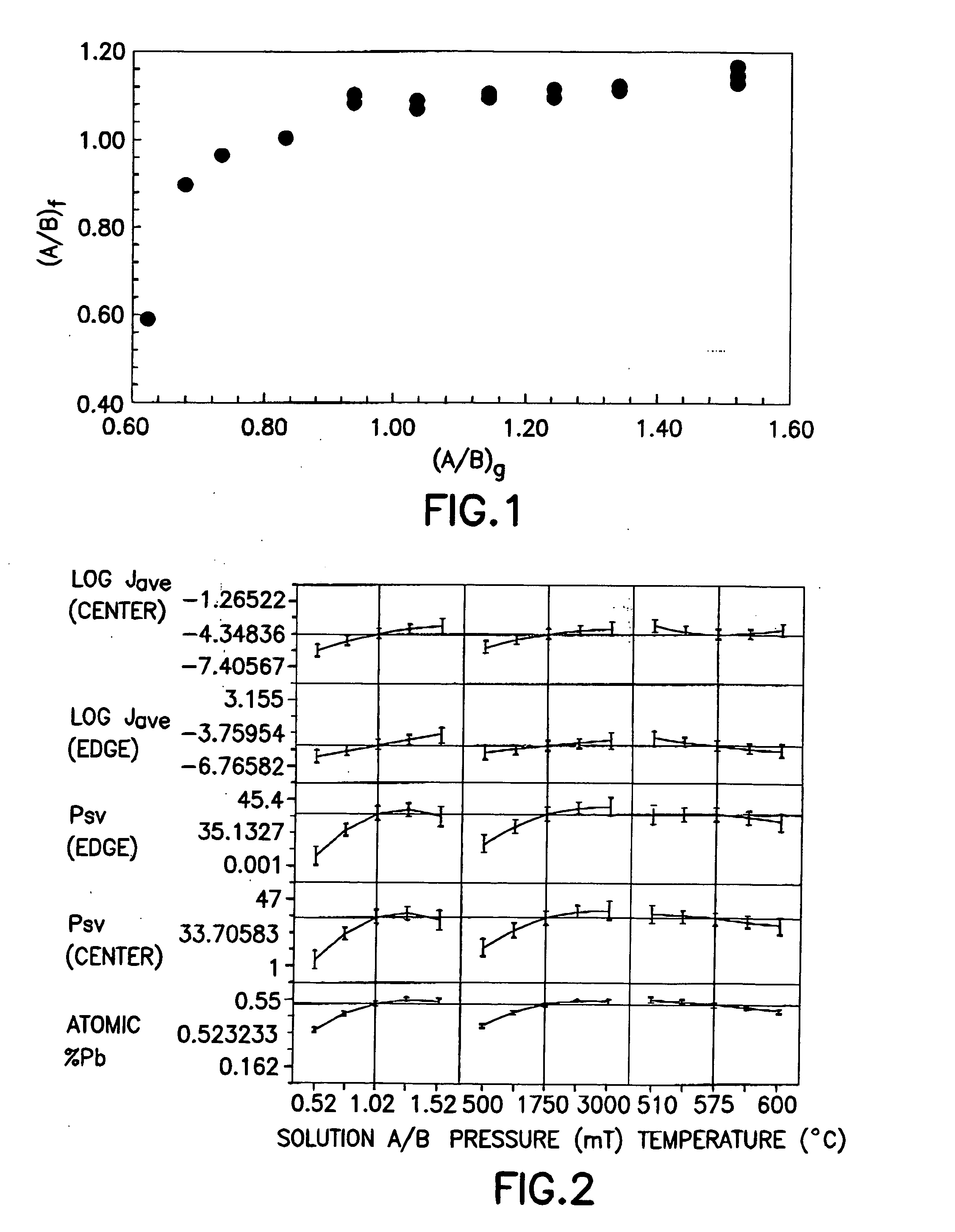

Scalable lead zirconium titanate (PZT) thin film material and deposition method, and ferroelectric memory device structures comprising such thin film material

InactiveUS20060115596A1Tin organic compoundsThin/thick film capacitorLead zirconate titanateOptoelectronics

A novel lead zirconium titanate (PZT) material having unique properties and application for PZT thin film capacitors and ferroelectric capacitor structures, e.g., FeRAMs, employing such thin film material. The PZT material is scalable, being dimensionally scalable, pulse length scalable and / or E-field scalable in character, and is useful for ferroelectric capacitors over a wide range of thicknesses, e.g., from about 20 nanometers to about 150 nanometers, and a range of lateral dimensions extending to as low as 0.15 μm. Corresponding capacitor areas (i.e., lateral scaling) in a preferred embodiment are in the range of from about 104 to about 10−2 μm2. The scalable PZT material of the invention may be formed by liquid delivery MOCVD, without PZT film modification techniques such as acceptor doping or use of film modifiers (e.g., Nb, Ta, La, Sr, Ca and the like).

Owner:ENTEGRIS INC

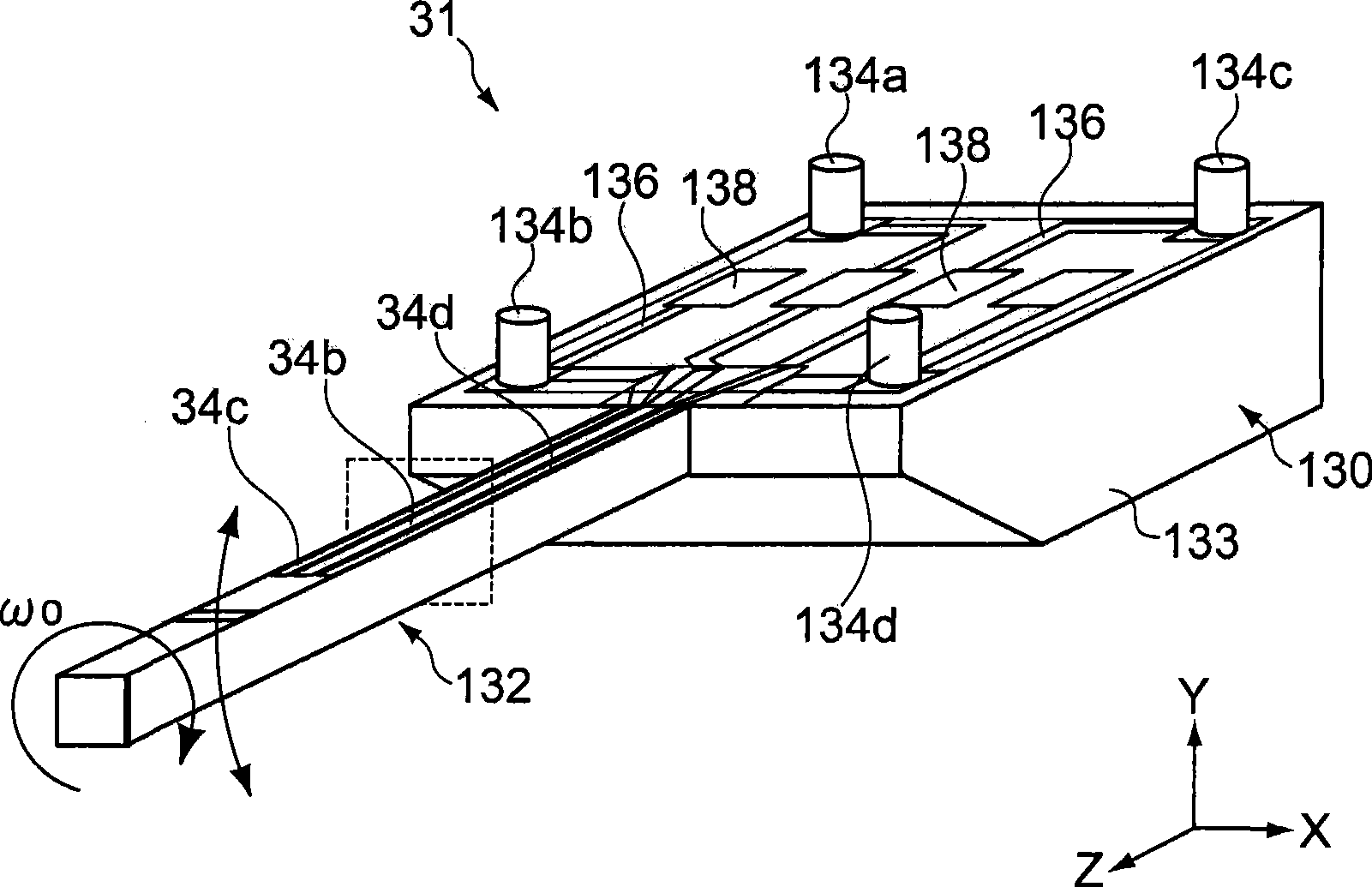

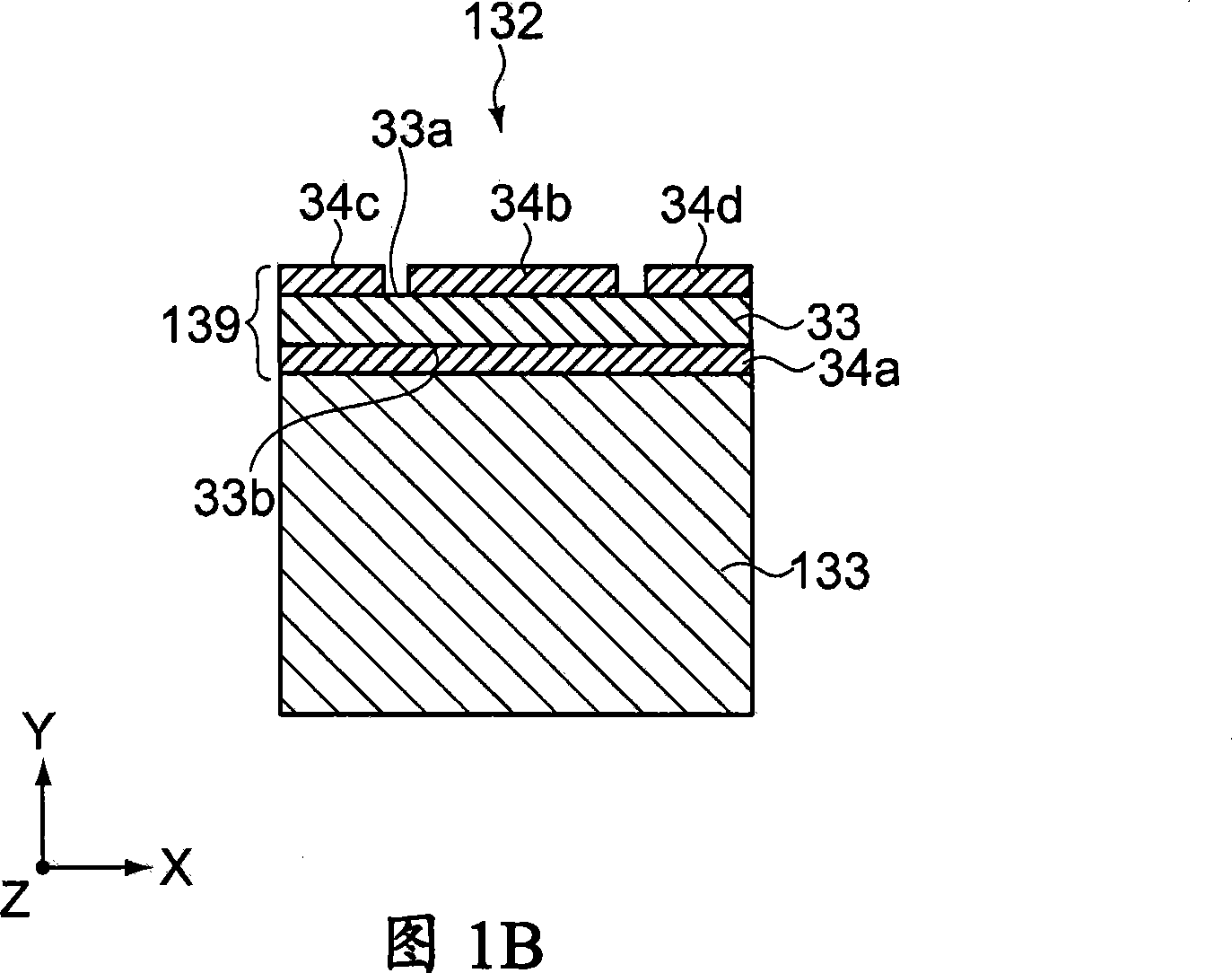

Piezoelectric device, angular velocity sensor, and method of manufacturing a piezoelectric device

ActiveCN101436642AImprove heat resistanceExcellent piezoelectric propertiesPiezoelectric/electrostrictive device manufacture/assemblySpeed measurement using gyroscopic effectsLead zirconate titanateAngular velocity

A piezoelectric device includes a piezoelectric film and an electrode film. The piezoelectric film is constituted of lead zirconium titanate represented by Pb 1+X (Zr Y Ti 1-Y )O 3+x , where X is 0 or more and 0.3 or less and Y is 0 or more and 0.55 or less, the piezoelectric film having a tension stress. The electrode film applies a voltage to the piezoelectric film.

Owner:SONY CORP

Method of preparing a stable lead zircon-titanate sol and method for preparing films based on same

InactiveUS7820723B2Shorten the construction periodOther chemical processesZirconium compoundsLead zirconate titanateFilm base

A method of preparing a sol of lead zirconium titanate, known as PZT, of formula PbZrxTi(1−x)O3 with 0.45≦x≦0.7, comprises the steps of:(a) preparing a concentrated sol in a diol, the sol comprising a titanium-based precursor, a zirconium-based precursor, and a lead-based precursor;(b) placing the concentrated sol at ambient temperature without agitation, until a sol is obtained having a constant viscosity as a function of time;(c) diluting the sol obtained in (b) with a solvent compatible with the diol used in step (a). The sol is useful for preparing PZT-based films for use in the electronics field.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Multi-Step Deposition of Ferroelectric Dielectric Material

ActiveUS20140225226A1Defect formationInhibition formationSolid-state devicesSemiconductor/solid-state device manufacturingDielectricTitanium

Multi-step deposition of lead-zirconium-titanate (PZT) ferroelectric material. An initial portion of the PZT material is deposited by metalorganic chemical vapor deposition (MOCVD) at a low deposition rate, for example at a temperature below about 640 deg C. from vaporized liquid precursors of lead, zirconium, and titanium, and a solvent at a collective flow rate below about 1.1 ml / min, in combination with an oxidizing gas. Following deposition of the PZT material at the low flow rate, the remainder of the PZT film is deposited at a high deposition rate, attained by changing one or more of precursor and solvent flow rate, oxygen concentration in the oxidizing gas, A / B ratio of the precursors, temperature, and the like.

Owner:TEXAS INSTR INC

Nanoscale wire-based data storage

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

Fine-particulate lead zirconium titantes zirconium titanate hydrates and zirconium titanates and method for production thereof

ActiveUS8080230B2Easy to processSimple and economical processMaterial nanotechnologyConductive materialZirconium compoundsPhysical chemistry

Owner:TRONOX PIGMENTS GMBH

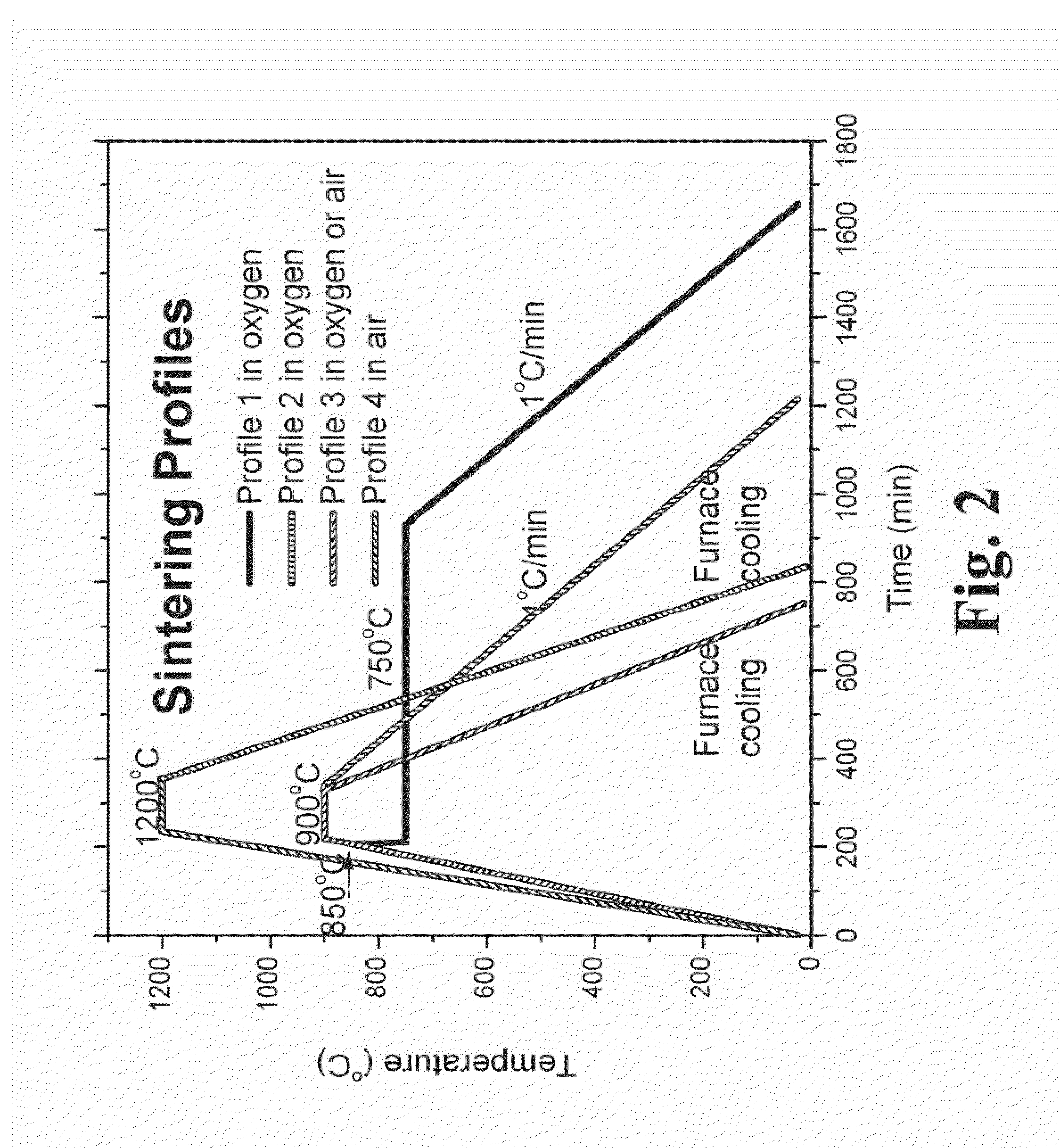

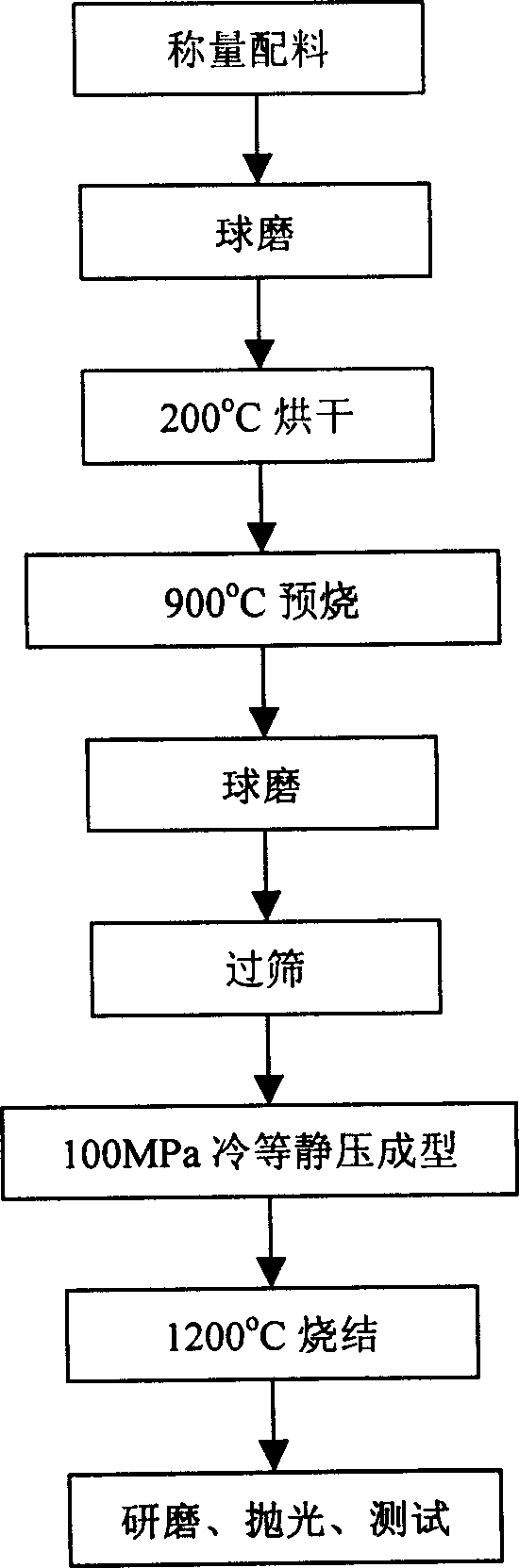

Method of preparing lanthanum lead zirconium titanate transparent photoelectric ceramic

A process for preparing the transparent photoelectric lanthanum lead zirconate titanate ceramics includes such steps as proportionally mixing lead oxide, La2O3, ZrO2 and TiO2 while adding excesive lead oxide, adding absolute alcohol, ball grinding for 4-6 hr, baking at 200 deg.C, precalcining at 900 deg.C for 2 hr, ball grinding for 18-24 hr, baking, sieving, cold isostatic pressing under 100 MPa for shaping, sintering in PbZrO3 atmosphere at 1200 deg.C for 0.5-12 hr, natural cooling, and polishing by 1-micron alumina p-type adrasive material. It has high optical transmission percentage up to 70%.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

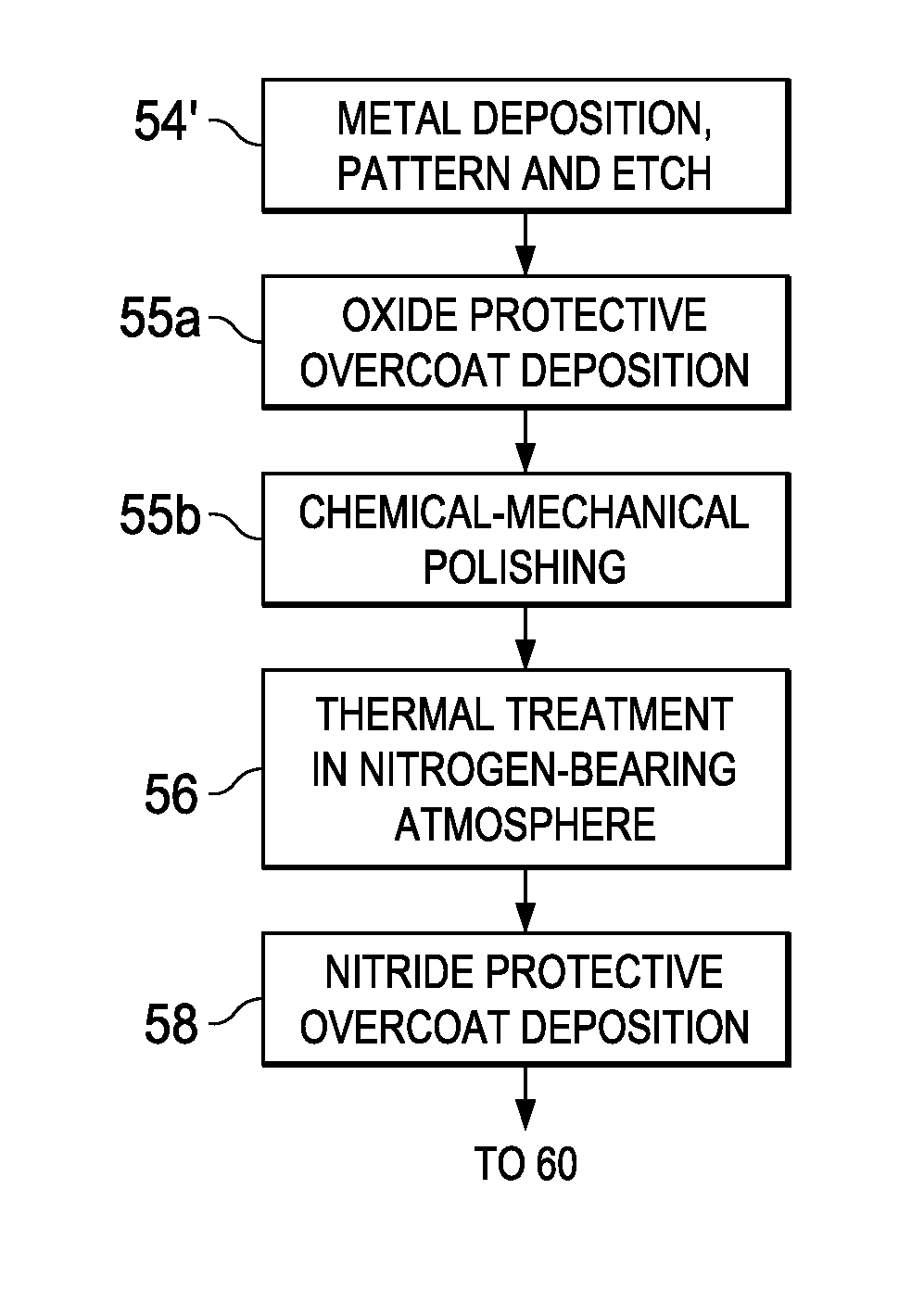

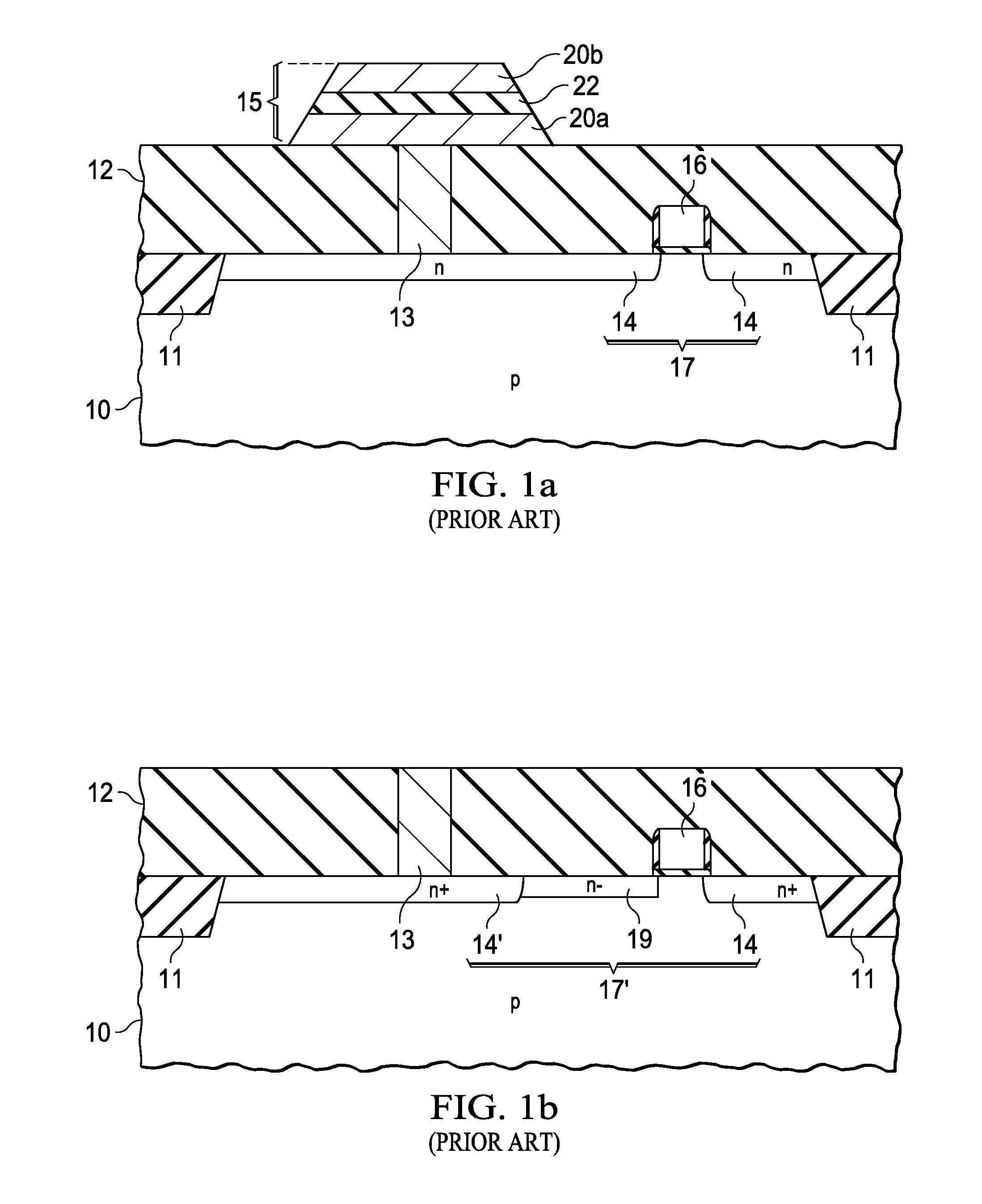

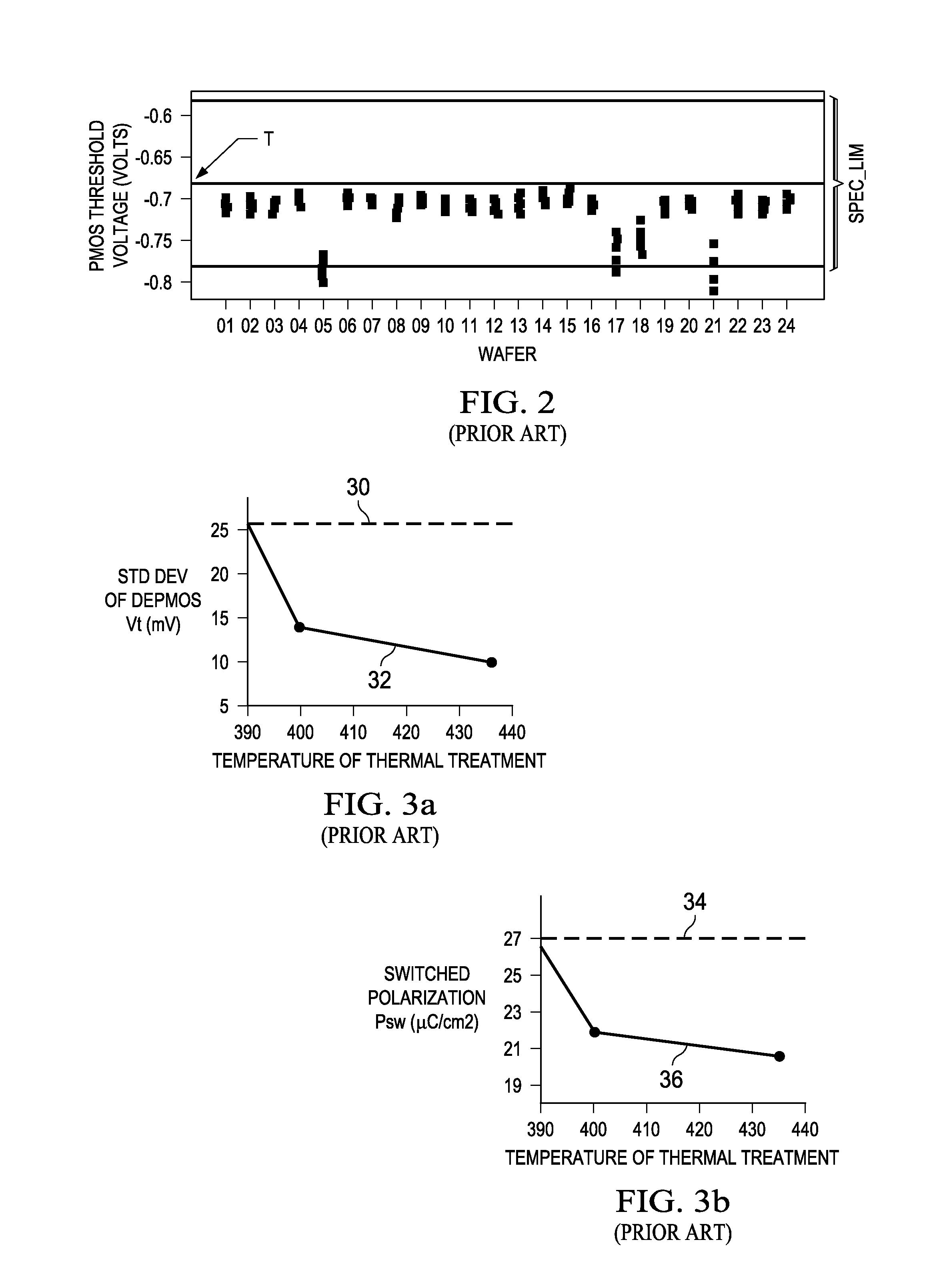

Thermal Treatment for Reducing Transistor Performance Variation in Ferroelectric Memories

ActiveUS20150079698A1Strict controlSolid-state devicesSemiconductor/solid-state device manufacturingLead zirconate titanateHydrogen

Thermal treatment of a semiconductor wafer in the fabrication of integrated circuits including MOS transistors and ferroelectric capacitors, including those using lead-zirconium-titanate (PZT) ferroelectric material, to reduce variation in the electrical characteristics of the transistors. Thermal treatment of the wafer in a nitrogen-bearing atmosphere in which hydrogen is essentially absent is performed after formation of the transistors and capacitor. An optional thermal treatment of the wafer in a hydrogen-bearing atmosphere prior to deposition of the ferroelectric treatment may be performed.

Owner:TEXAS INSTR INC

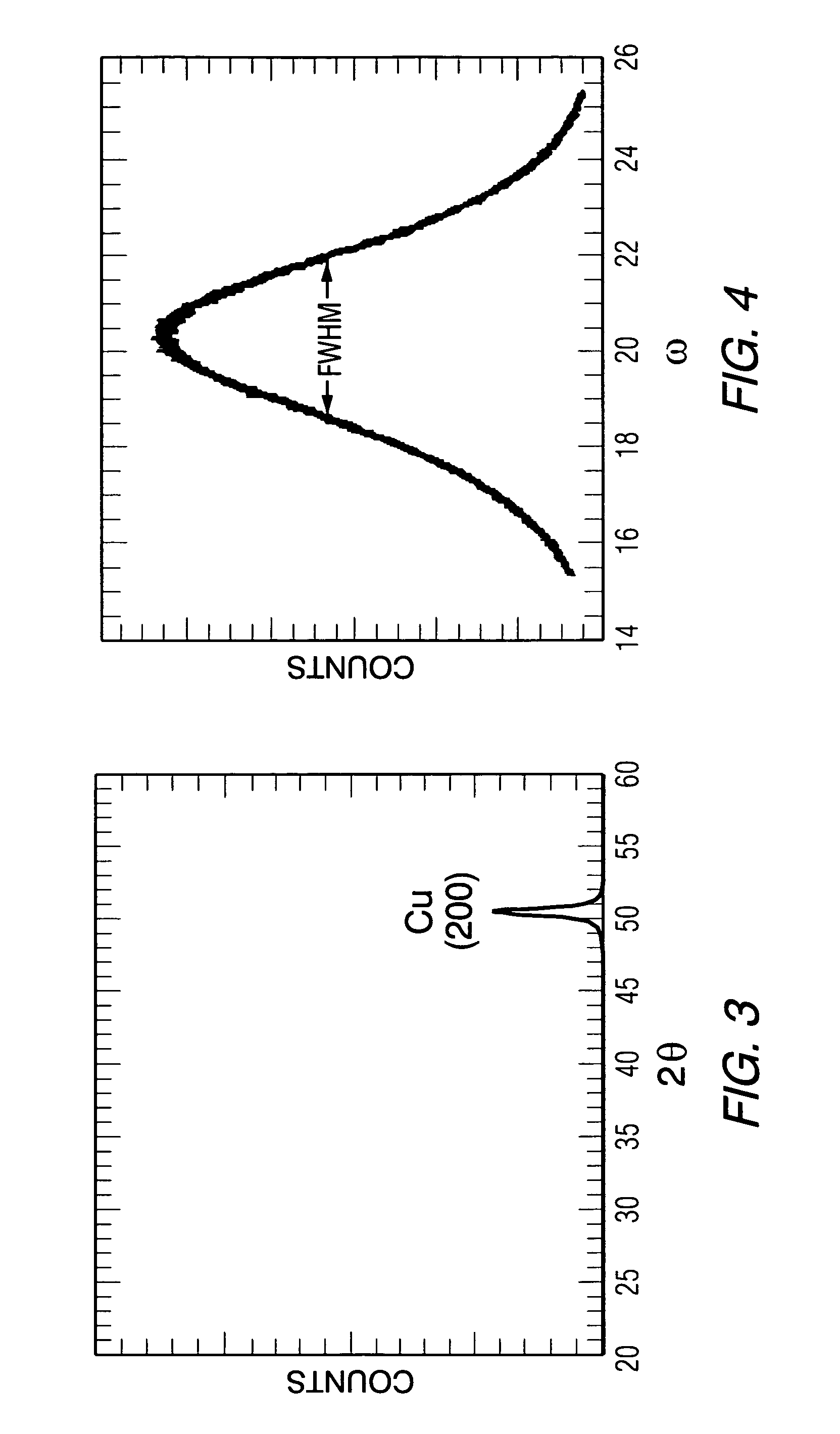

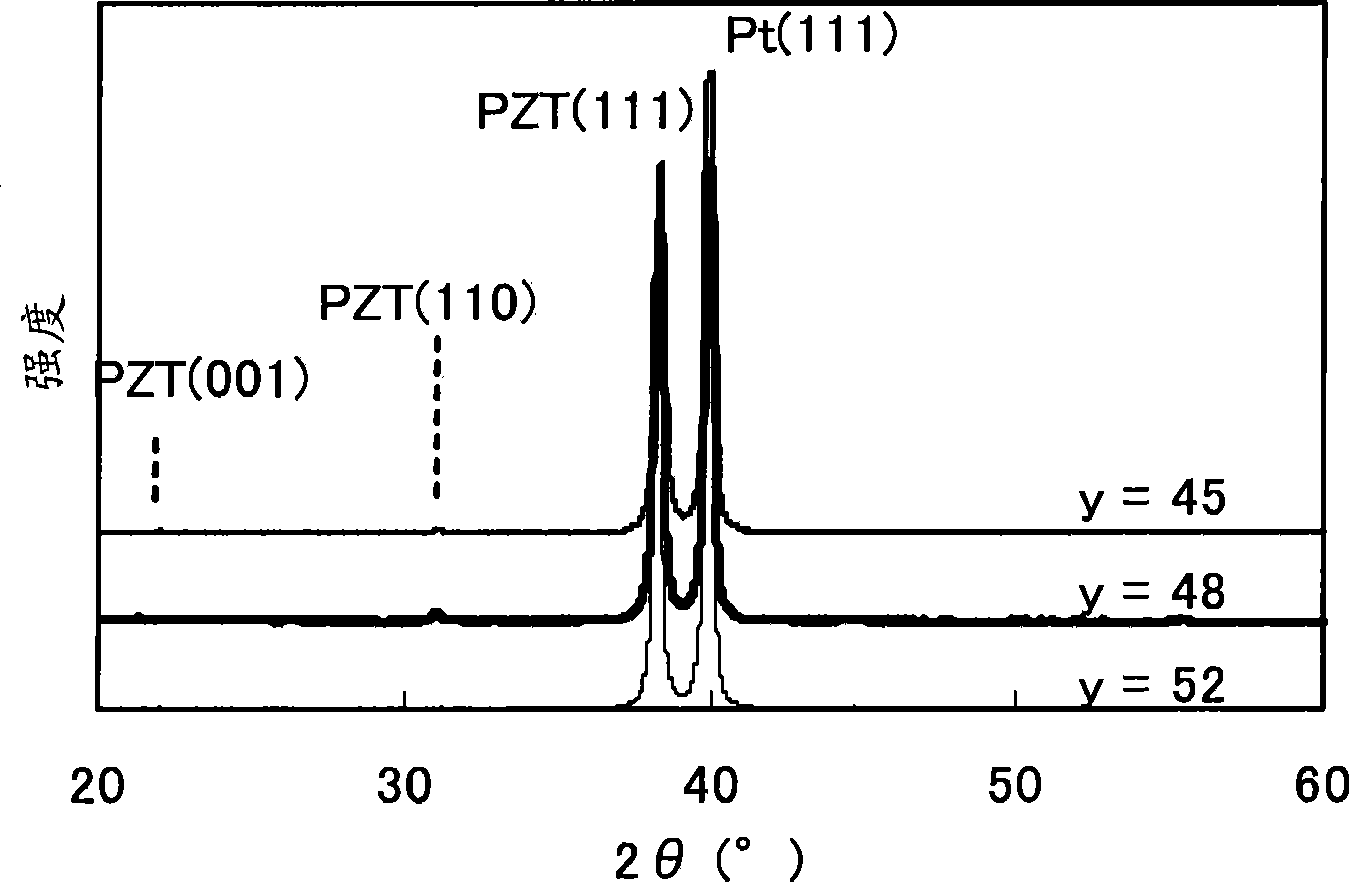

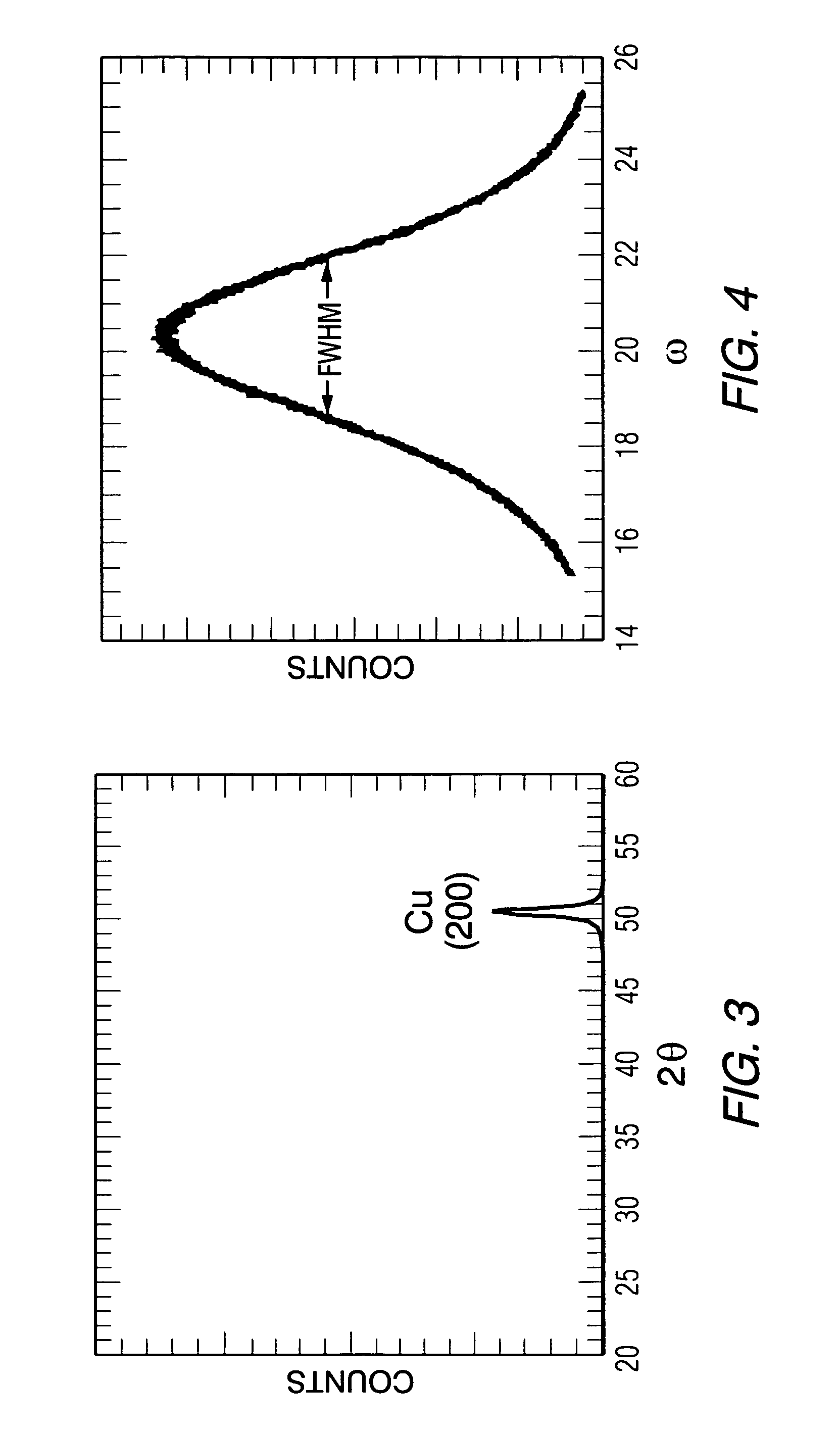

METHODS TO IMPROVE THE CRYSTALLINITY OF PbZrTiO3 AND Pt FILMS FOR MEMS APPLICATIONS

InactiveUS20150380635A1Piezoelectric/electrostriction/magnetostriction machinesVacuum evaporation coatingLead zirconate titanateRocking curve

A microelectronic device containing a piezoelectric component is formed sputtering an adhesion layer of titanium on a substrate by an ionized metal plasma (IMP) process. The adhesion layer is oxidized so that at least a portion of the titanium is converted to a layer of substantially stoichiometric titanium dioxide (TiO2) at a top surface of the adhesion layer. A layer of platinum is formed on the titanium dioxide of the adhesion layer; the layer of platinum has a (111) crystal orientation and an X-ray rocking curve FWHM value of less than 3 degrees. A layer of piezoelectric material is formed on the layer of platinum. The piezoelectric material may include lead zirconium titanate.

Owner:TEXAS INSTR INC

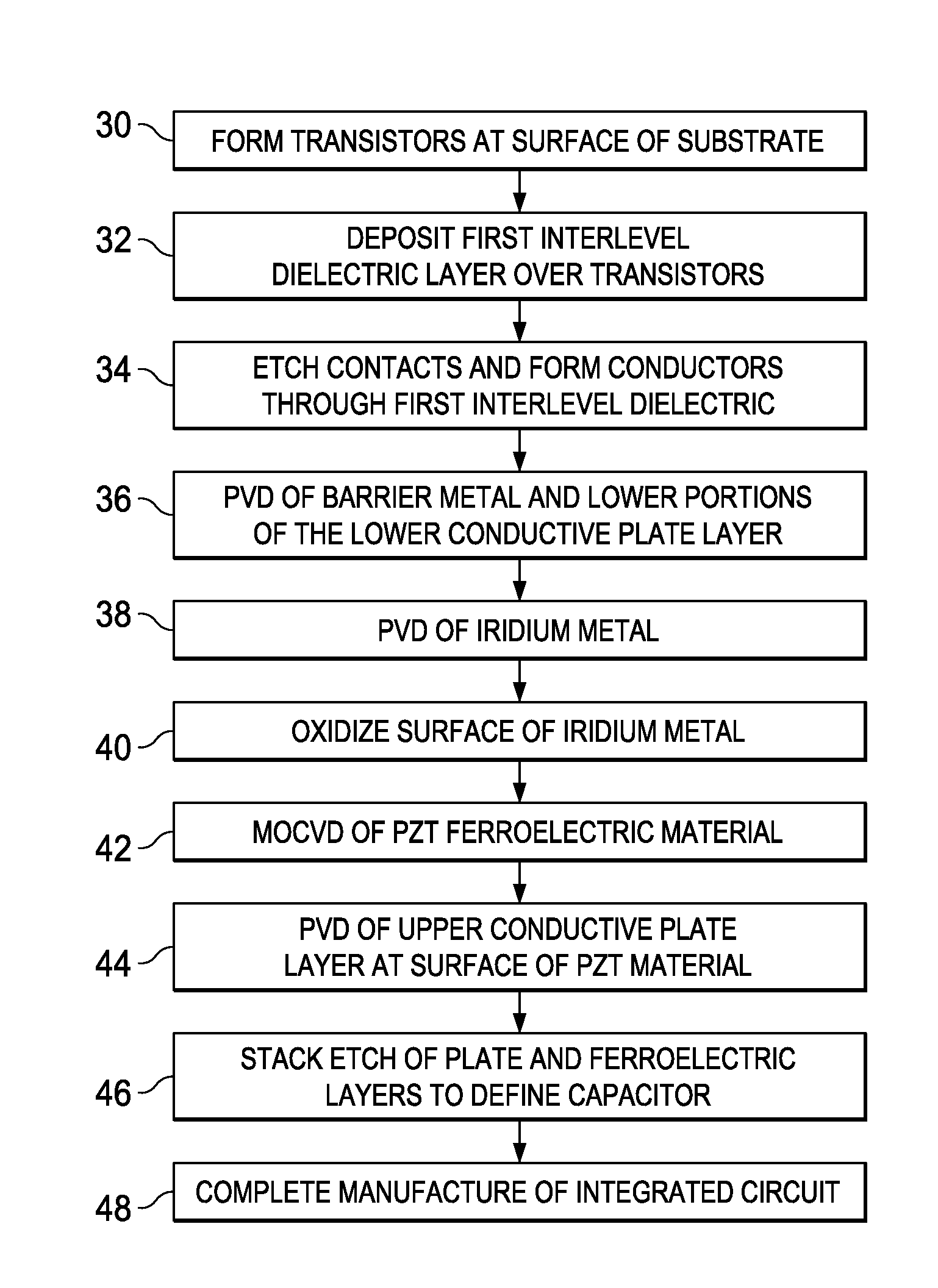

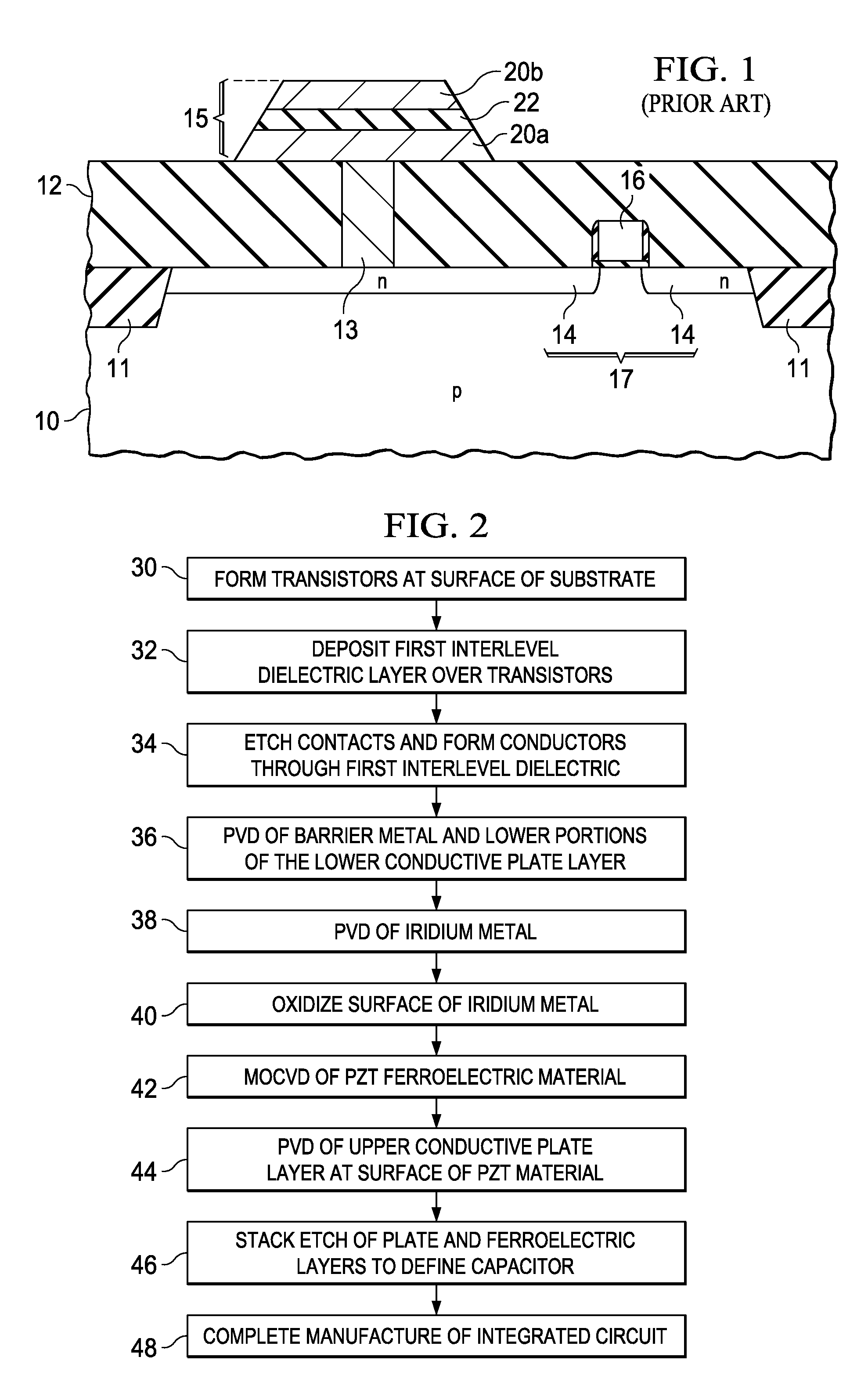

Adhesion of Ferroelectric Material to Underlying Conductive Capacitor Plate

ActiveUS20140227805A1Improve adhesionReduce sensitivitySolid-state devicesSemiconductor/solid-state device manufacturingCrystal structureMetal

Deposition of lead-zirconium-titanate (PZT) ferroelectric material over iridium metal, in the formation of a ferroelectric capacitor in an integrated circuit. The capacitor is formed by the deposition of a lower conductive plate layer having iridium metal as a top layer. The surface of the iridium metal is thermally oxidized, prior to or during the deposition of the PZT material. The resulting iridium oxide at the surface of the iridium metal is very thin, on the order of a few nanometers, which allows the deposited PZT to nucleate according to the crystalline structure of the iridium metal rather than that of iridium oxide. The iridium oxide is also of intermediate stoichiometry (IrO2-x), and reacts with the PZT material being deposited.

Owner:TEXAS INSTR INC

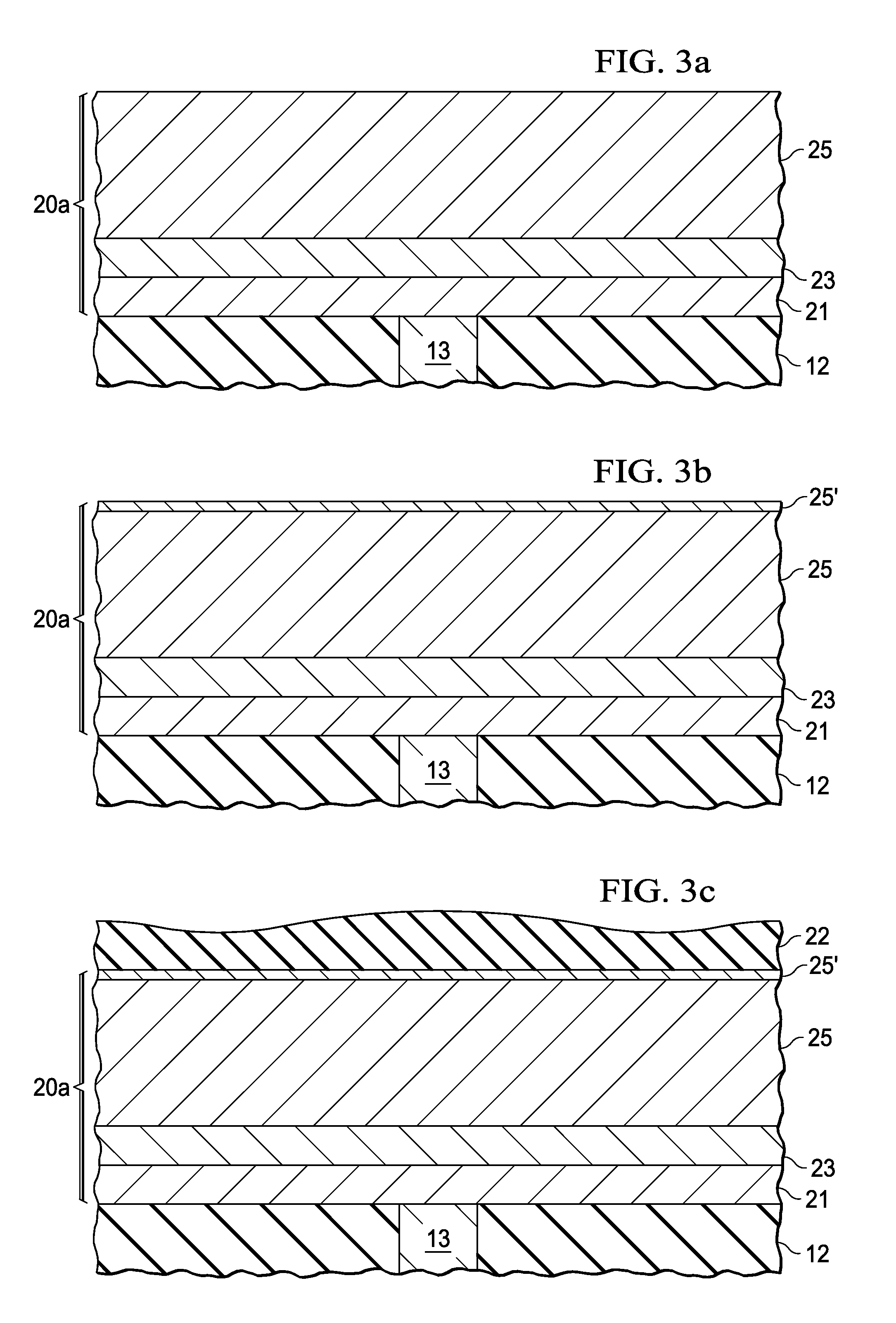

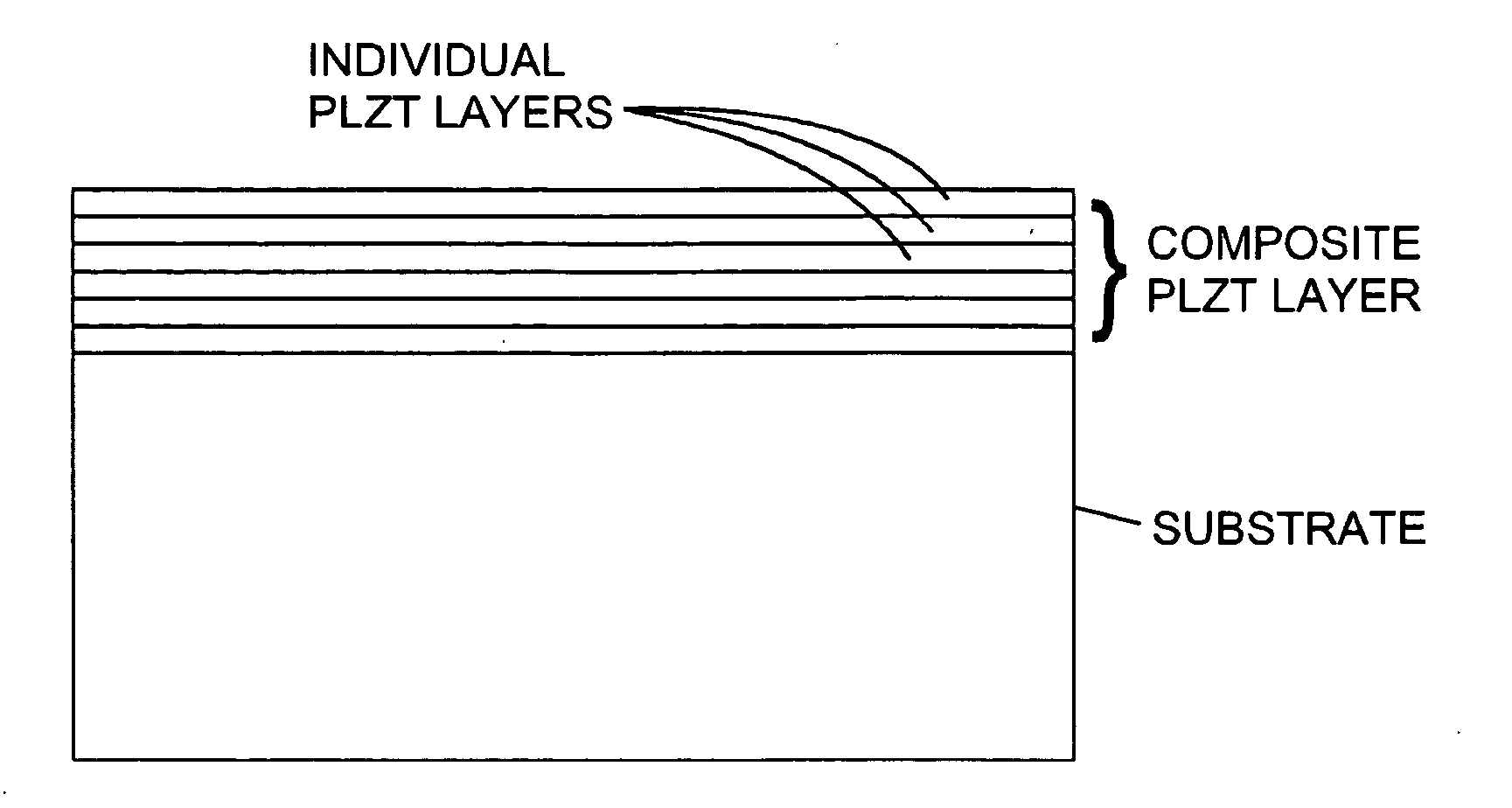

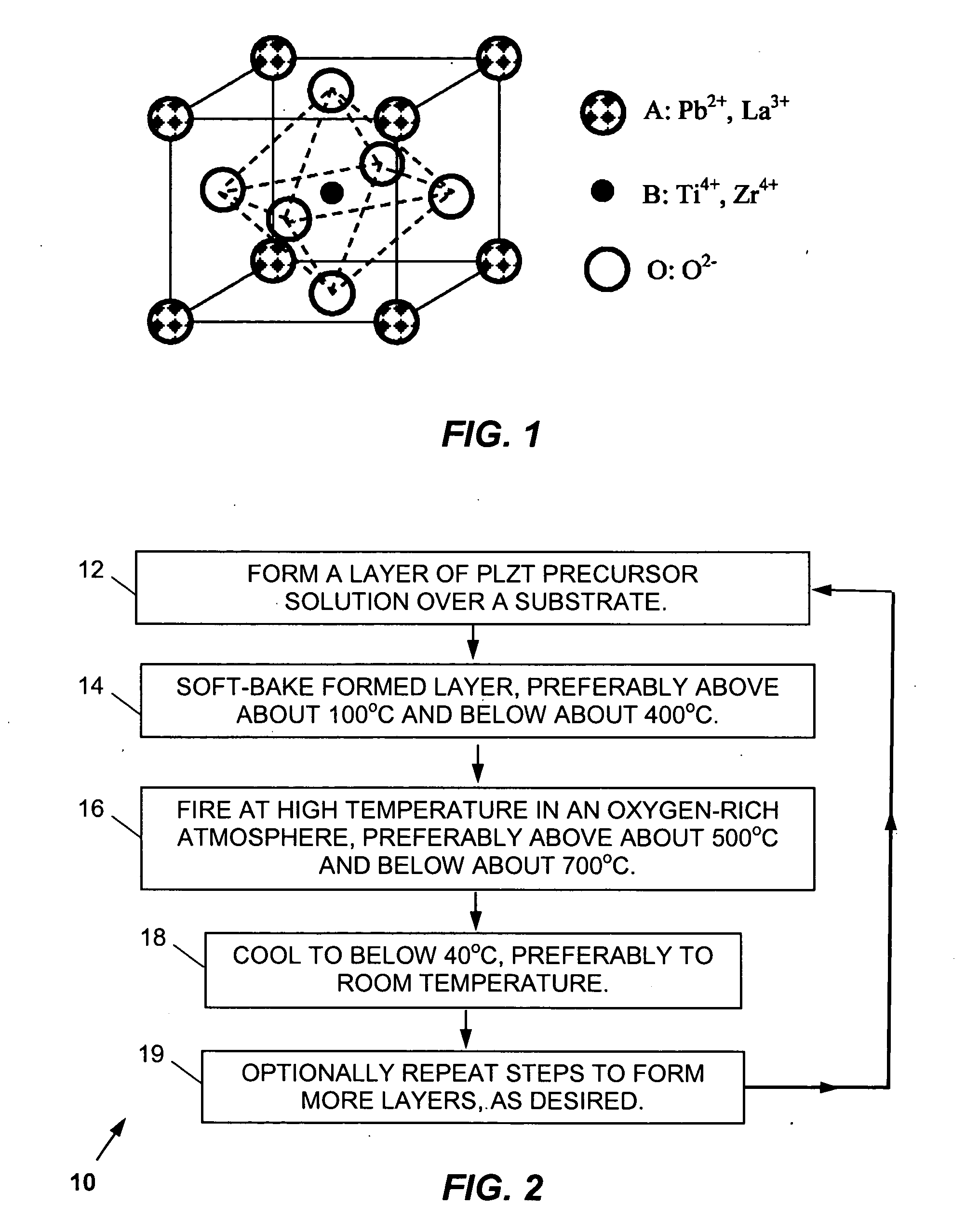

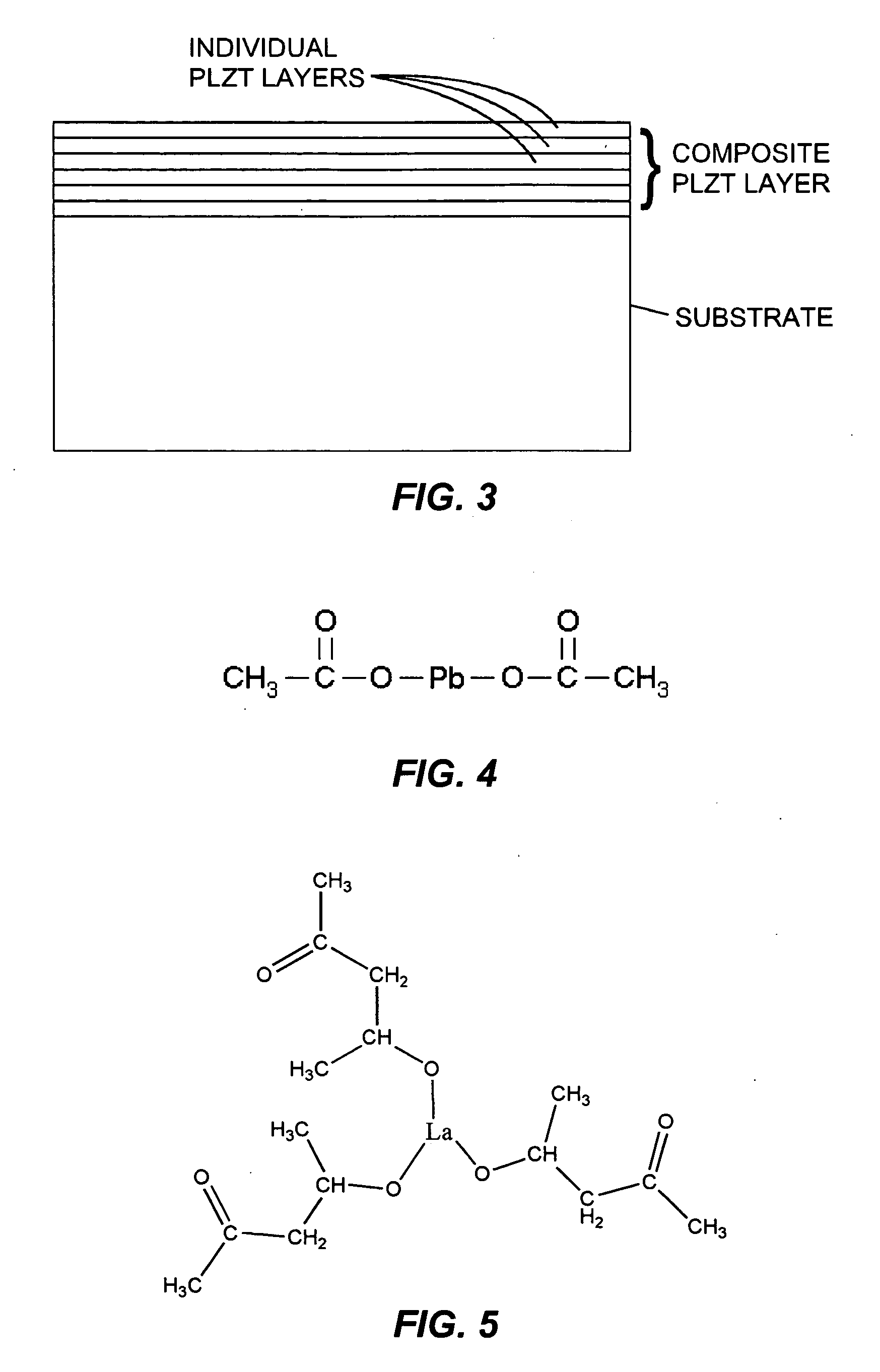

Methods of forming lanthanum-modified lead zirconium titanate (PLZT) layers, devices with PLZT layers, and precursor formation solutions

ActiveUS20050281943A1Pretreated surfacesSemiconductor/solid-state device manufacturingLead zirconate titanateLanthanum

Methods and solutions for forming lanthanum-modified lead zirconium titanate (PLZT) layers are disclosed. The PLZT layers are highly transparent to 1550 nm wavelength light, and have high crystal quality. Loss factors as low as 0.25 dB per mm are achieved. Fast and low-cost methods are disclosed for making the layers. Devices structures using the layers are also disclosed.

Owner:FUJITSU LTD

Epitaxial ferroelectric and magnetic recording structures including graded lattice matching layers

ActiveUS7541105B2Magnetic materials for record carriersRecord information storageMetal alloySingle crystal

Epitaxial ferroelectric and magnetic recording structures having graded lattice matching layers are disclosed. A single crystal material such as Si may be used as a substrate material upon which the graded lattice matching layers are deposited. The lattice matching layers may comprise metals and metal alloys, or may comprise oxides doped with selected elements or deposited under different oxygen pressures. A recording layer, such as ferroelectric lead zirconium titanate or a magnetic Fe / Pt multilayer structure, is deposited on the graded lattice matching layers.

Owner:SEAGATE TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com