Preparation method of high performance lead zirconium titanate thin film

A lead zirconate titanate, high-performance technology, applied in the field of preparation of ferroelectric functional ceramic materials, can solve the problems of difficulty in obtaining piezoelectric properties, long heat treatment time, poor preferred orientation, etc., and achieve excellent film properties and high solution utilization. , Excellent piezoelectric effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

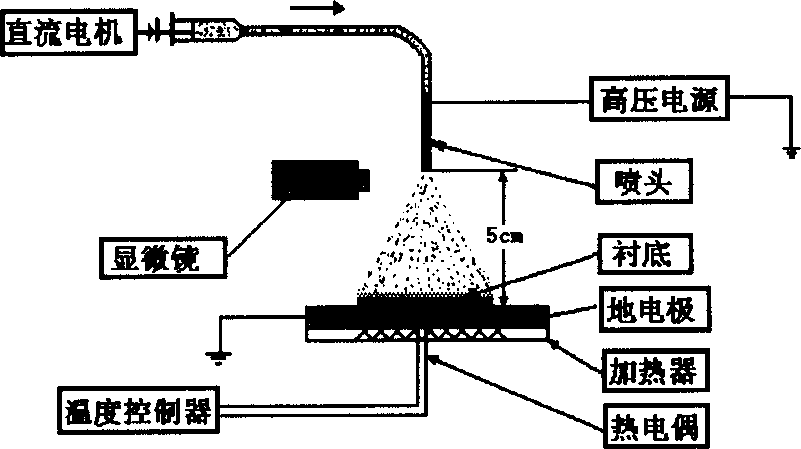

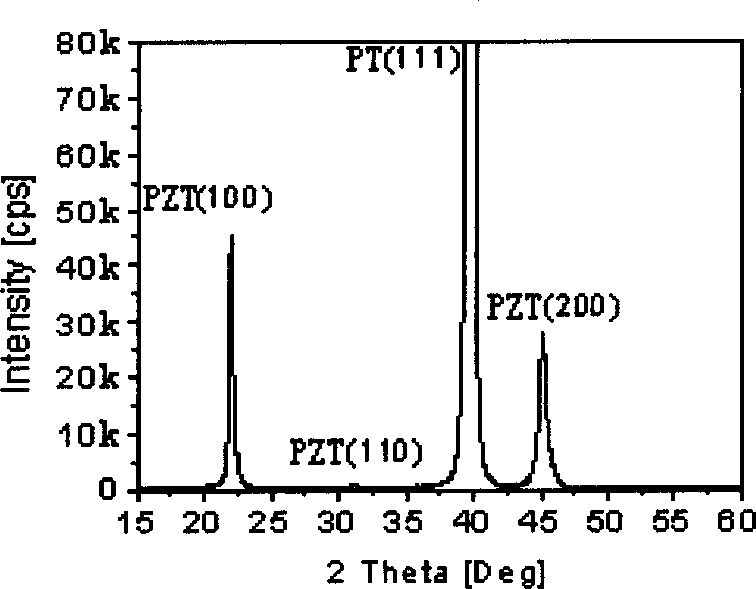

[0019] Anhydrous lead acetate is dissolved in acetic acid, and then zirconium propoxide and titanium isopropoxide are sequentially added according to the molar concentration ratio of lead, zirconium and titanium in the ratio of Pb:Zr:Ti=1:0.53:0.47. After stirring evenly with ultrasonic vibration, add a mixed solution of deionized water, acetic acid and isopropanol in a volume ratio of deionized water: acetic acid: isopropanol = 3:5:10. After being uniformly stirred by ultrasonic vibration, the solution was diluted to 0.4 mol / L with acetic acid and isopropanol. The prepared precursor solution was added to the electroatomization device, the flow rate was controlled at 0.6 ml / hour, the inner diameter of the atomization nozzle was 0.25 mm, the distance between the nozzle and the substrate was 5 cm, and a DC voltage of 4500 volts was applied. The substrate used is: SiO was prepared on a Si substrate according to the previous thermal oxidation method 2 film, sputtering method to p...

example 2

[0021] Other conditions are the same as Example 1, the control flow rate is 0.8 ml / hour, the inner diameter of the atomizing nozzle is 0.4 mm, the distance between the nozzle and the substrate is 6 cm, and a DC voltage of 4800 volts is added. The substrate temperature is set at 100°C, and the coating time is 20 minutes. For every 10 minutes of coating (about 1 micron thick), the substrate and film are placed in a resistance furnace and baked at 350°C for 40 minutes, and then baked at 600°C. Baking for 20 minutes, and then annealing the substrate and the film with the desired thickness in a PbO saturated atmosphere at 600°C for 4 hours to obtain a PZT iron with a thickness of 2 microns that is completely perovskite and strongly oriented along the (100) crystal direction. Electric film.

example 3

[0023] Other conditions are the same as Example 1, the control flow rate is 1 ml / hour, the inner diameter of the atomizing nozzle is 0.6 mm, the distance between the nozzle and the substrate is 7 cm, and a DC voltage of 5500 volts is added. The substrate temperature is set at 350°C, and the coating time is 40 minutes, among which the substrate and film are placed in a resistance furnace for 20 minutes (about 2 microns thick) and baked at 600°C for 15 minutes, and then the substrate and The film with the desired thickness was annealed in a PbO saturated atmosphere at 600° C. for 2 hours to obtain a PZT ferroelectric film with a thickness of 4 microns that was completely perovskite and preferentially oriented along the (100) crystal direction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com