Patents

Literature

465results about How to "Accurate ingredients" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

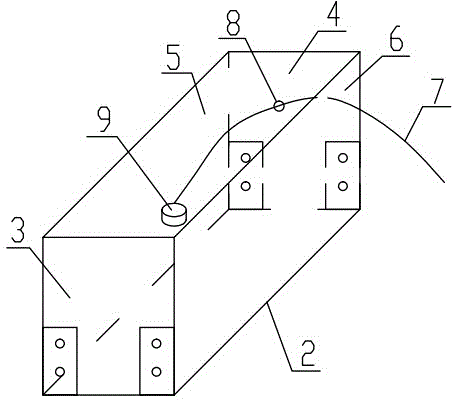

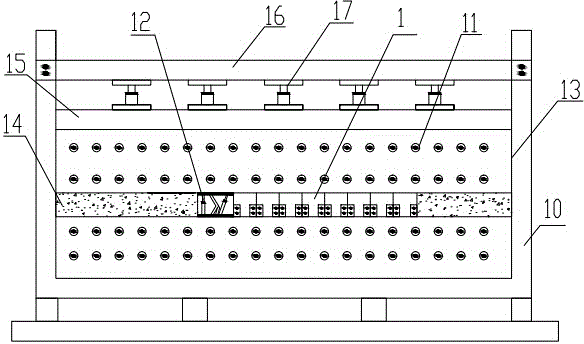

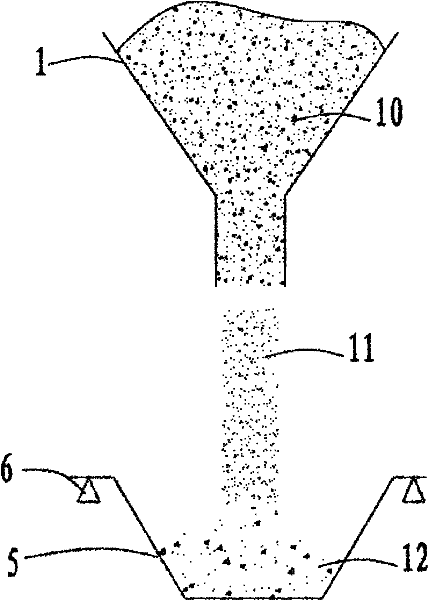

Coal mining two-dimensional physical simulation experimental device using solid filling method and experimental method

ActiveCN104568593AAccurate locationAccurate orientationMaterial strength using tensile/compressive forcesCoal miningPhysical model

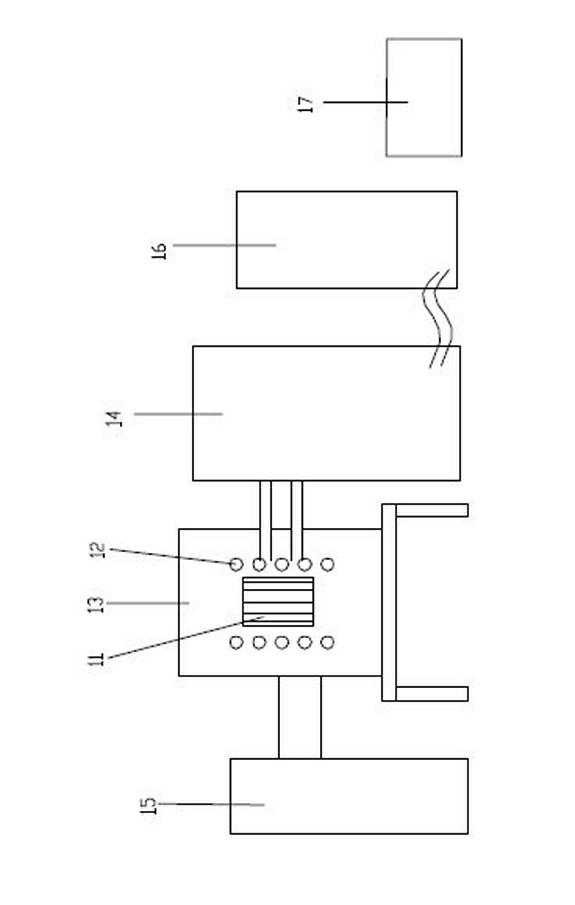

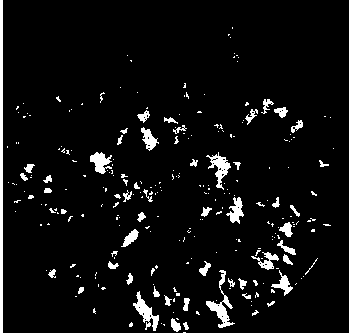

The invention discloses a coal mining two-dimensional physical simulation experimental device using a solid filling method and an experimental method, relating to the technical field of test or analysis of materials by measuring the chemical or physical properties of the materials. The experimental device comprises a two-dimensional physical simulation experimental table and multiple solid filling similar material molds, wherein rock physical models are stacked on the two-dimensional physical simulation experimental table; a simulation bracket is arranged in a coal mining layer of the rock physical models; the solid filling similar material molds are arranged in a goaf of the coal mining layer; pressure sensors are arranged on the simulation bracket and the solid filling similar material molds; and displacement monitoring points are formed in the rock physical models on the upper and lower sides of the goaf. The method is easy to operate and convenient to measure, and the compaction degree of the solid filling similar materials can be accurately set in advance.

Owner:HEBEI COAL SCI RES INST

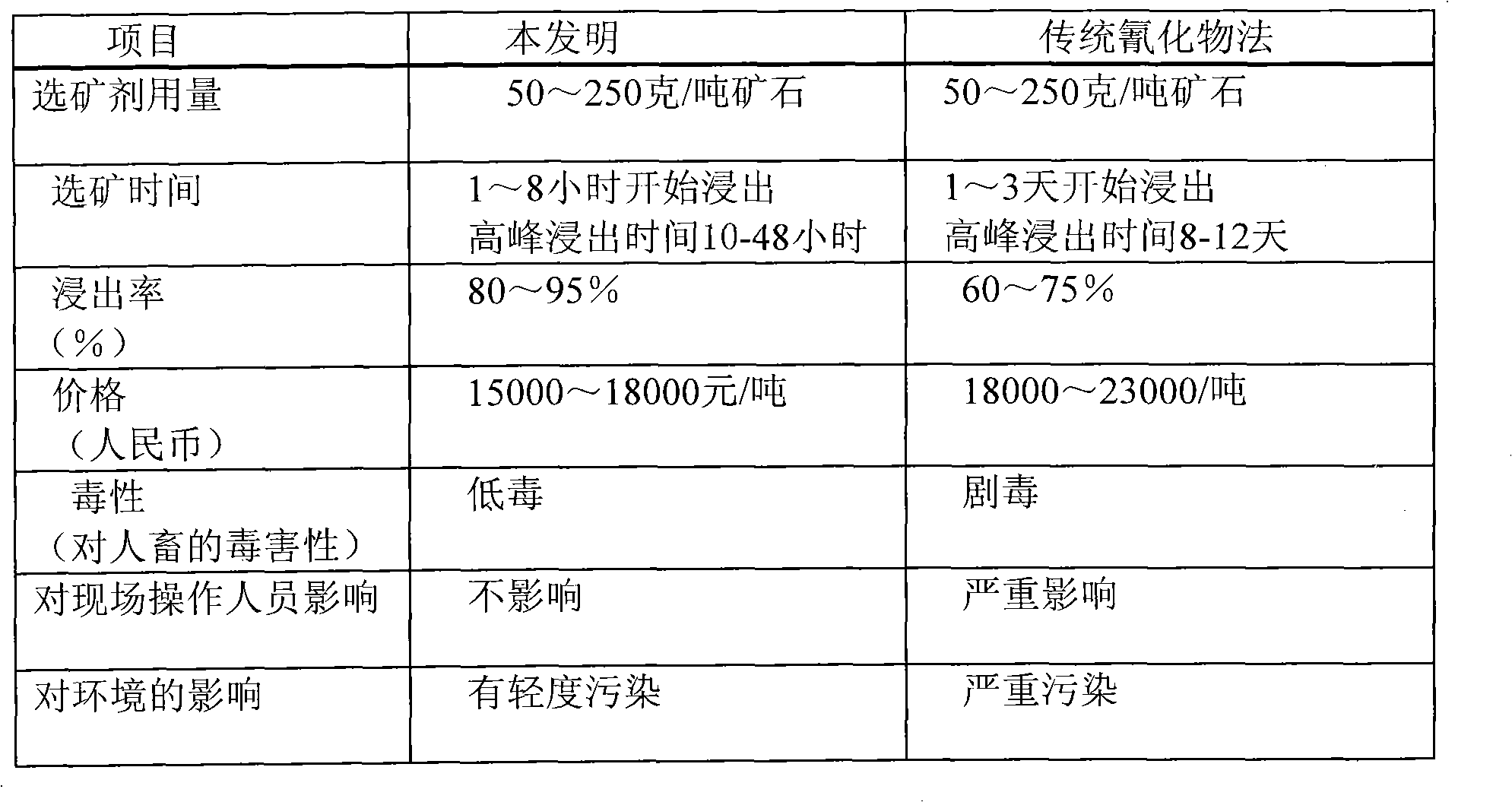

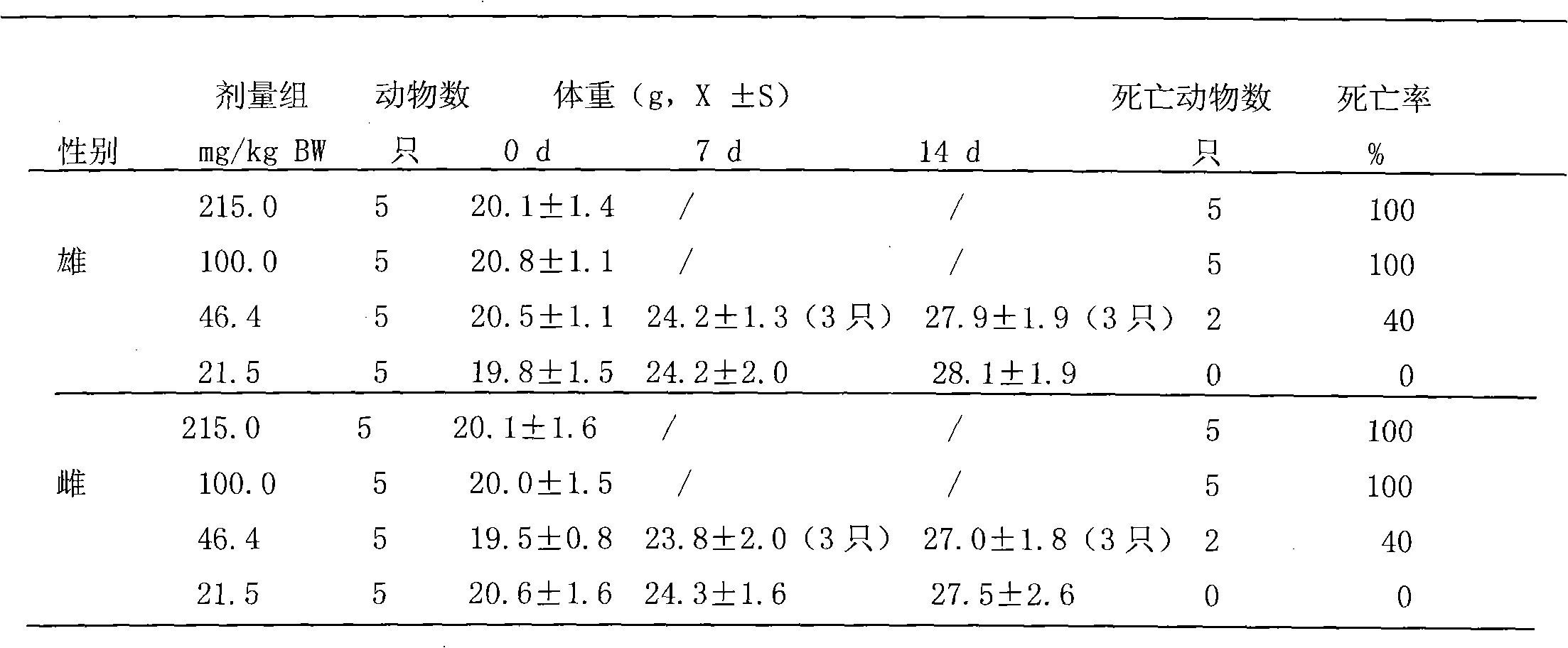

Production and using method of environmentally-friendly noble metal mineral processing reagent

ActiveCN102321807AEasy to produceAccurate ingredientsProcess efficiency improvementMolten stateCopper oxide

The invention discloses the production method of an environmentally-friendly noble metal mineral processing reagent. The method comprises the following steps: putting potassium ferrocyanide and urea after being mixed into a reactor; adding a pH regulator during the slow temperature rise process; heating to the molten state; taking a small amount of molten material detection samples, cooling and dissolving into water; measuring the pH value, enabling the molten material pH value to be 8-14; keeping the molten temperature for 5-60 minutes; and cooling to the normal temperature, thus the environmentally-friendly noble metal mineral processing reagent is obtained. The product obtained from the invention can be widely applied to the production of noble metal mine, such as the soaking, core spray of gold oxide ores, silver oxide ores and copper oxide ores, also can be used in industrial production industries such as electroplating, and used as medicaments for replacing toxic Cymag; and compared with all the other non-toxic or low-toxicity mineral processing reagents, the noble metal mineral processing reagent has the advantages of good effect, stable drug property, environmentally-friendly product, simple production method, low cost and the like.

Owner:广西地生金矿业科技有限公司 +2

Prepn process of nanometer tin oxide material with surface decorating silver

The present invention relates to the preparation process of nanometer tin oxide material with surface decorating silver, and belongs to the field of electric contact material preparing technology. The preparation process includes the following steps: adding tin oxide powder of 20-30 nm size into anhydrous ethanol and adding polyglycol as dispersant; ultrasonic stirring at room temperature and stoving; adding the treated nanometer tin oxide powder into 10-30 % concentration silver nitrate solution via electromagnetic and ultrasonic stirring for homogeneous dispersion; adding reductant hydrazine hydrate to reduce silver ion and obtain silver coated nanometer tin oxide powder and stoving at 80-120 deg.c. The present invention has the advantages of simple technological process and being suitable for industrial production, and the surface decorated nanometer tin oxide may be used in producing electric contact with excellent mechanical performance and high conductivity.

Owner:TIANJIN UNIV

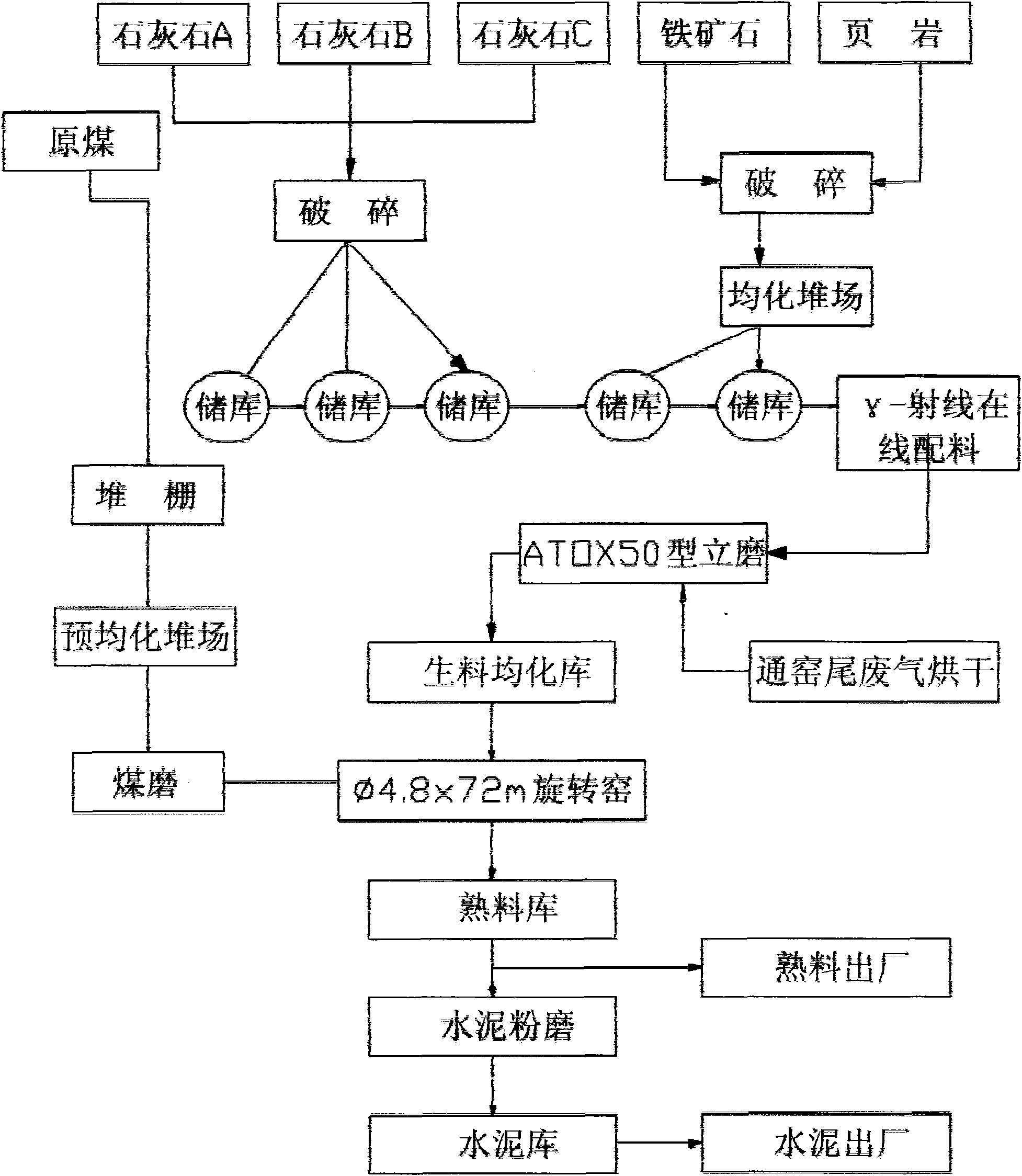

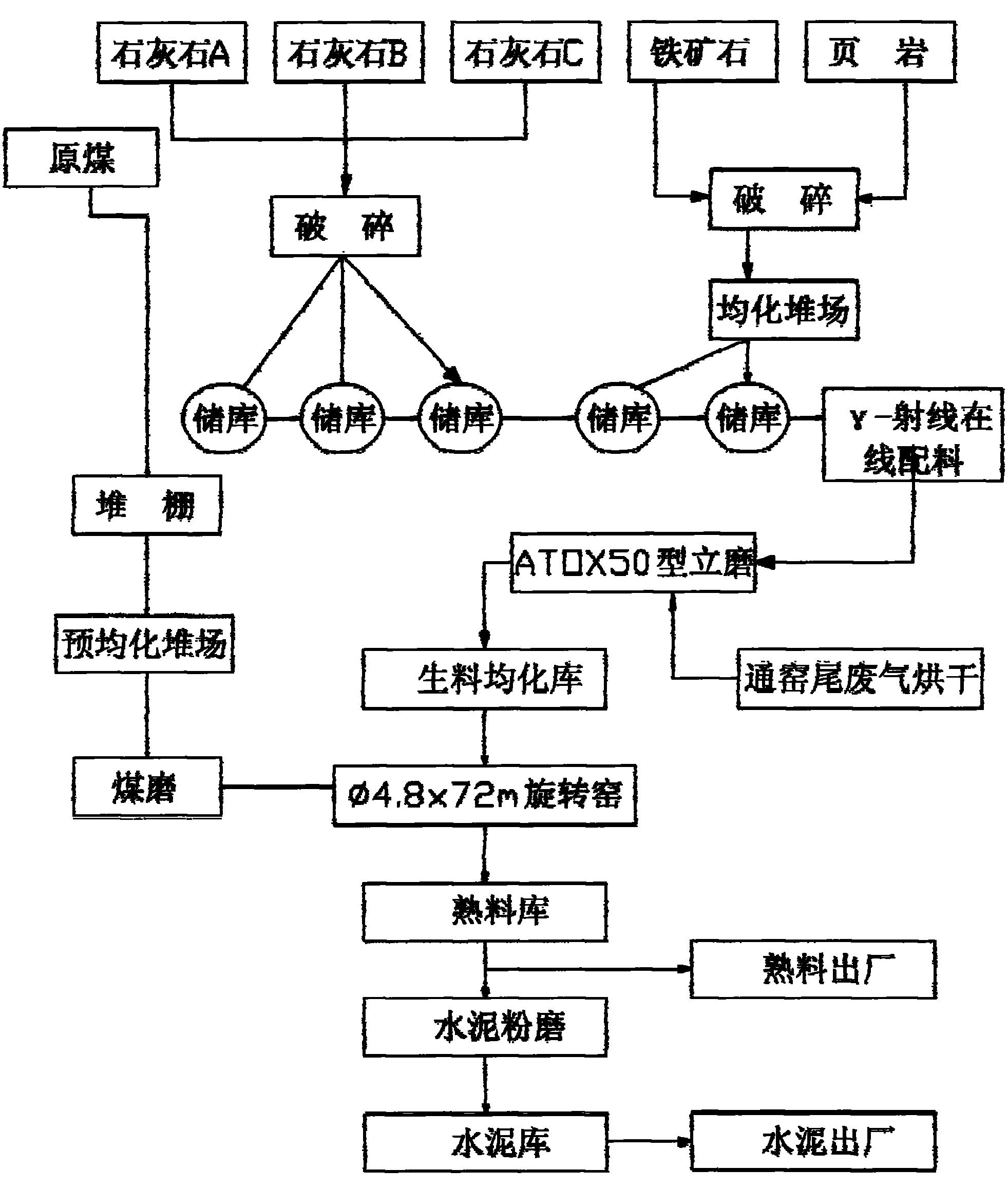

Method for producing cement by utilizing high-silicon low-calcium limestone

InactiveCN101781096AIt has the characteristics of "low calcium and high free silicon"Rich reservesIronstoneMining engineering

The invention relates to a method for producing cement by utilizing high-silicon low-calcium limestone. The cement comprises the following raw materials in percentage by weight: 48 to 50 percent of low-grade high-silicon limestone with CaO content between 42 and 45 percent and f-SiO2 content between 10 and 18 percent, 31 to 33 percent of high-magnesium limestone, 16 to 18 percent of matched limestone, 3 to 6 percent of shale and 2 to 4 percent of ironstone. The method is technology which utilizes low lime saturation ratio and ore of high silicon rate and high alumina rate and has an attribute of low silica modulus; online detection is performed on the mixture ratio of the raw materials by using a gamma ray instrument and a formula is adjusted by using one minute as a cycle; and a plate hammer counterpunch type crusher is used for crushing, a roller-type vertical grinding mill is used for grinding and waste gas at the tail of a kiln is used for drying the raw materials. The method has the advantages of capability of developing and utilizing low-grade limestone resource, accurate material burdening, timely regulation of the mixture ratio, and capability of reducing homogenization facilities and storage yard; and high quartziferous rock ore can be used in vertical milling and has high grindability. The method is suitable for utilizing high-dissociative silicon low-calcium limestone.

Owner:SINOMA TIANSHAN YUNFU CEMENT

Method for preparing Al0.5CoCrFeNi high-entropy alloy

ActiveCN106756412AReduce volatilityGuaranteed compositional uniformityHigh entropy alloysSmelting process

The invention discloses a method for preparing an Al0.5CoCrFeNi high-entropy alloy. An intermediate alloy serves as a raw material, and volatilization of a low-melting-point element Al in the smelting process is greatly reduced. Meanwhile, a vacuum induction heating device is adopted, the electromagnetic stirring effect of the induction heating device is utilized, and therefore the component uniformity of a cast ingot is guaranteed. According to the method, the melting point difference between the lowest-melting-point metal Al and the highest-melting-point metal Cr is indirectly reduced, the problem of excessive volatilization of the low-melting-point Al simple substance in the smelting process is solved, and the component uniformity of the multi-element high-entropy alloy is guaranteed through the electromagnetic stirring effect existing in induction heating. Through reasonable designing of the atmosphere, the air pressure, the die preheating temperature, the smelting temperature, the heat preservation time, the casting speed and other parameters in the smelting process, a large Al0.5CoCrFeNi high-entropy alloy cast ingot is successfully prepared.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Preparation method of flexible epitaxial ferroelectric film

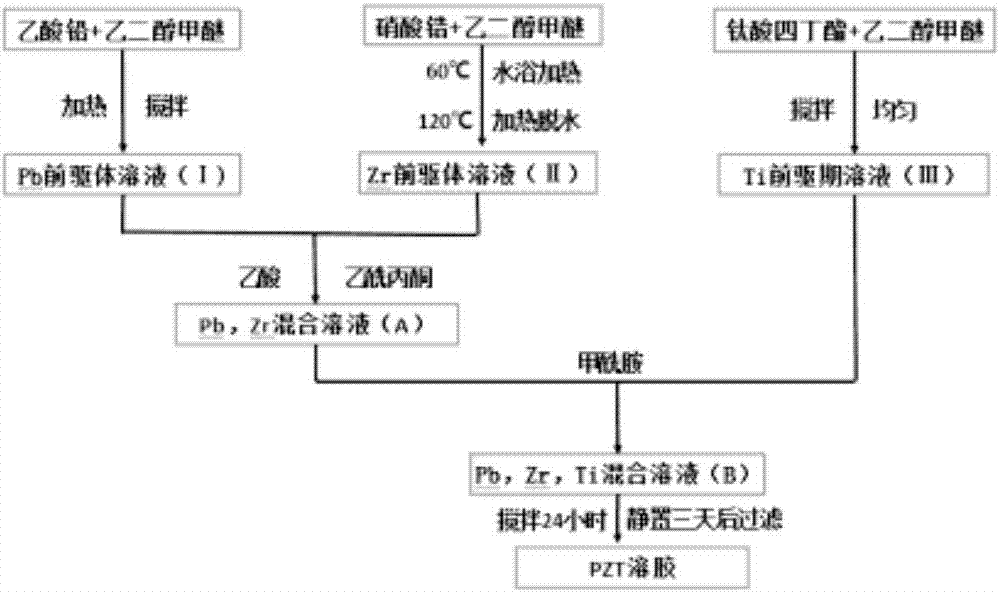

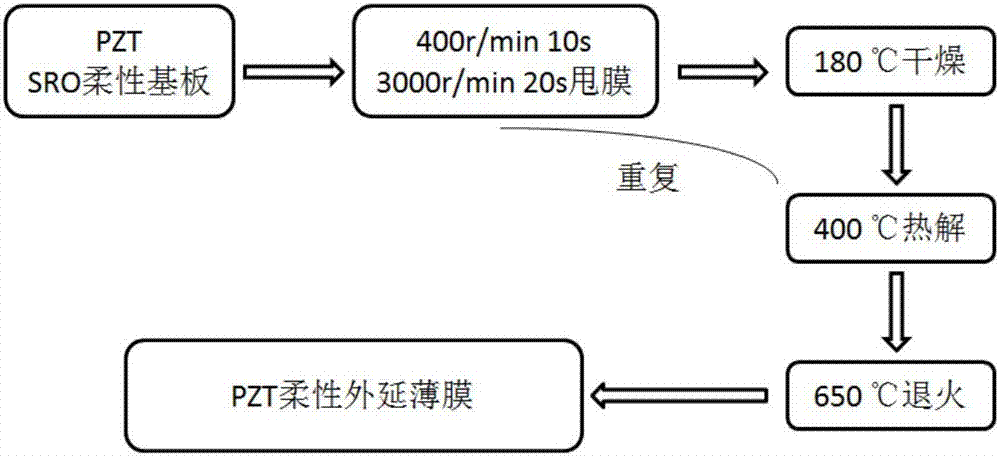

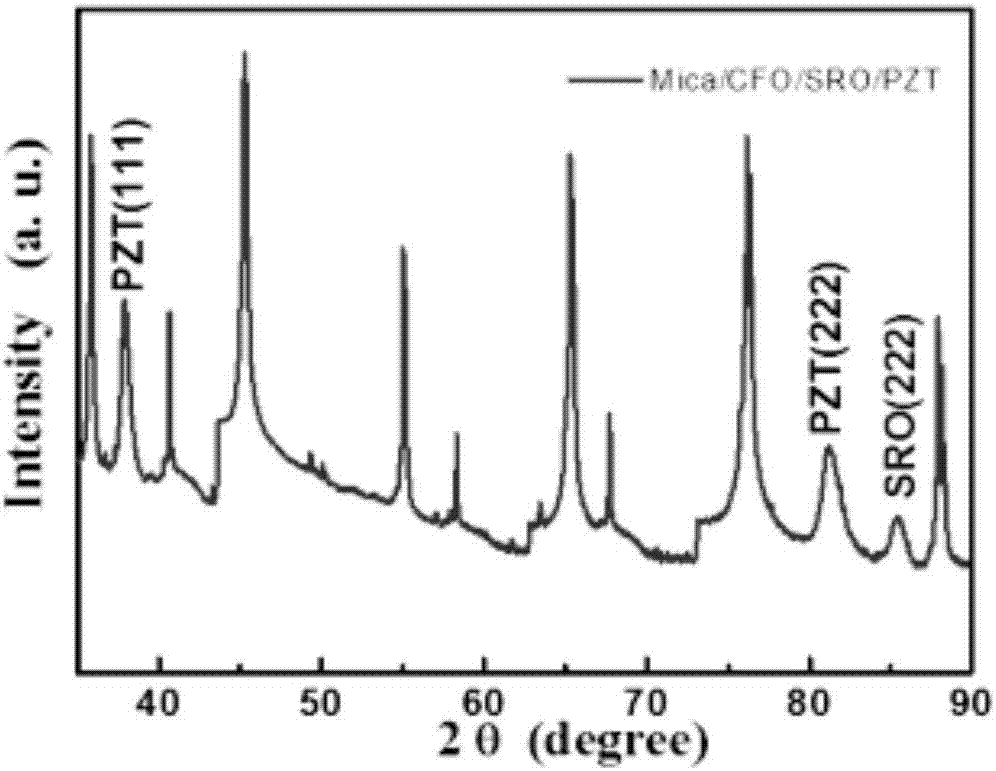

ActiveCN107256866AExcellent ferroelectric propertiesFormulation technology optimizationSolid-state devicesVacuum evaporation coatingStrontium ruthenateFilm material

The invention discloses a preparation method of a flexible epitaxial ferroelectric film. The preparation method is characterized by 1) preparing a perovskite structure oxide strontium ruthenate bottom electrode by a laser pulse deposition method; 2) preparing a precursor solution of the ferroelectric film by means of a sol-gel method, wherein the concentration of the precursor solution is 0.1-0.5mol / L, the ferroelectric film material is selected from any one of lead zirconate titanate, barium titanate or bismuth ferrite; 3) preparing the flexible epitaxial ferroelectric film, spin-coating the above-mentioned strontium ruthenate bottom electrode with the precursor solution by means of a spin coating method to obtain a uniform wet film; 4) drying, pyrolyzing and annealing the obtained uniform wet film; and (5) repeating steps 3) and 4) for 3-8 times to obtain the target flexible epitaxial ferroelectric film, and the thickness of the film is in the range of 100nm-300nm. The flexible epitaxial ferroelectric film is simple in technology and excellent in ferroelectric performance.

Owner:XIANGTAN UNIV

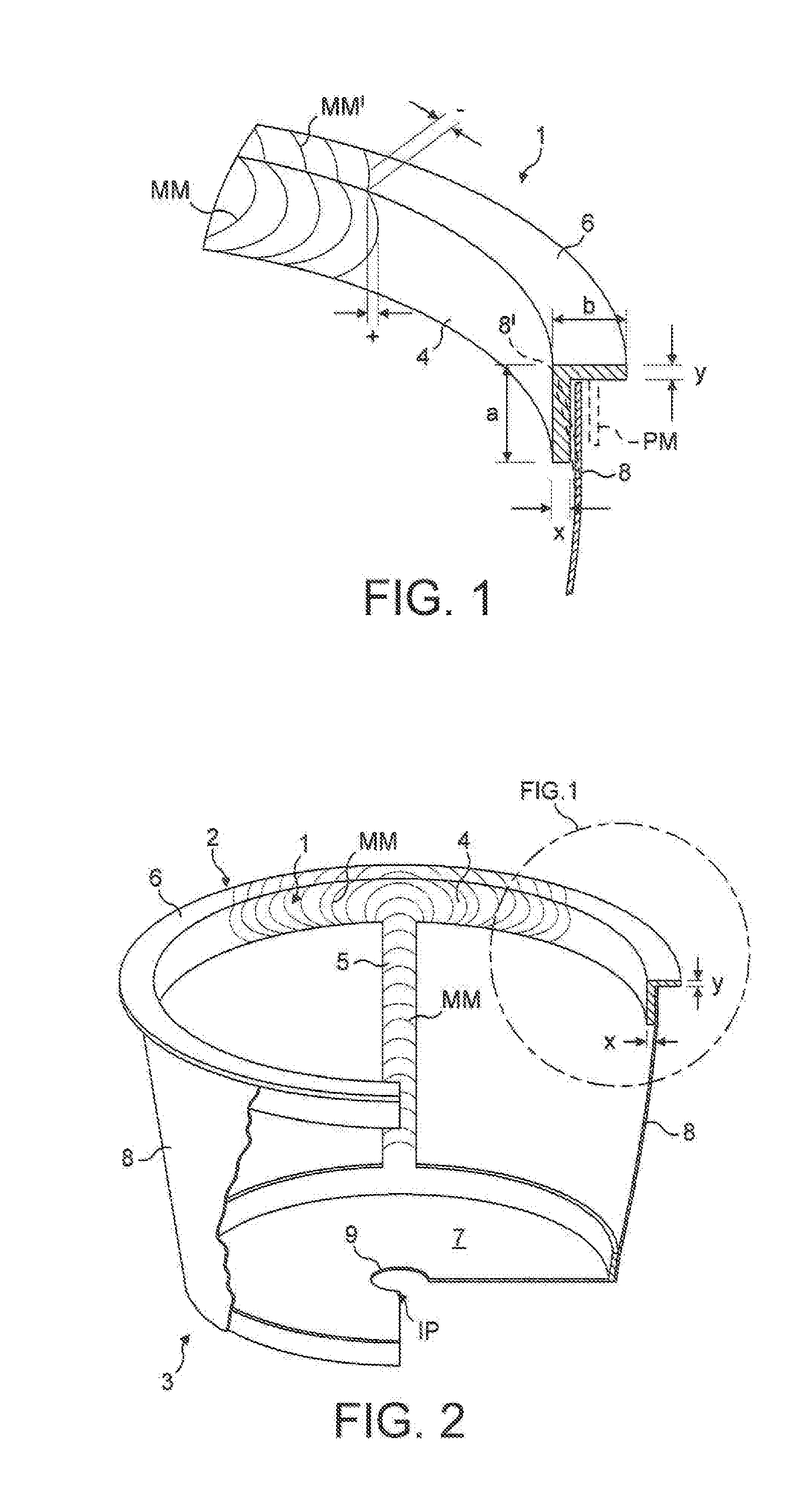

In-mould labelled container

InactiveUS20130139700A1Promote wettingEasy disposalWrappersFlexible elementsEngineeringMechanical engineering

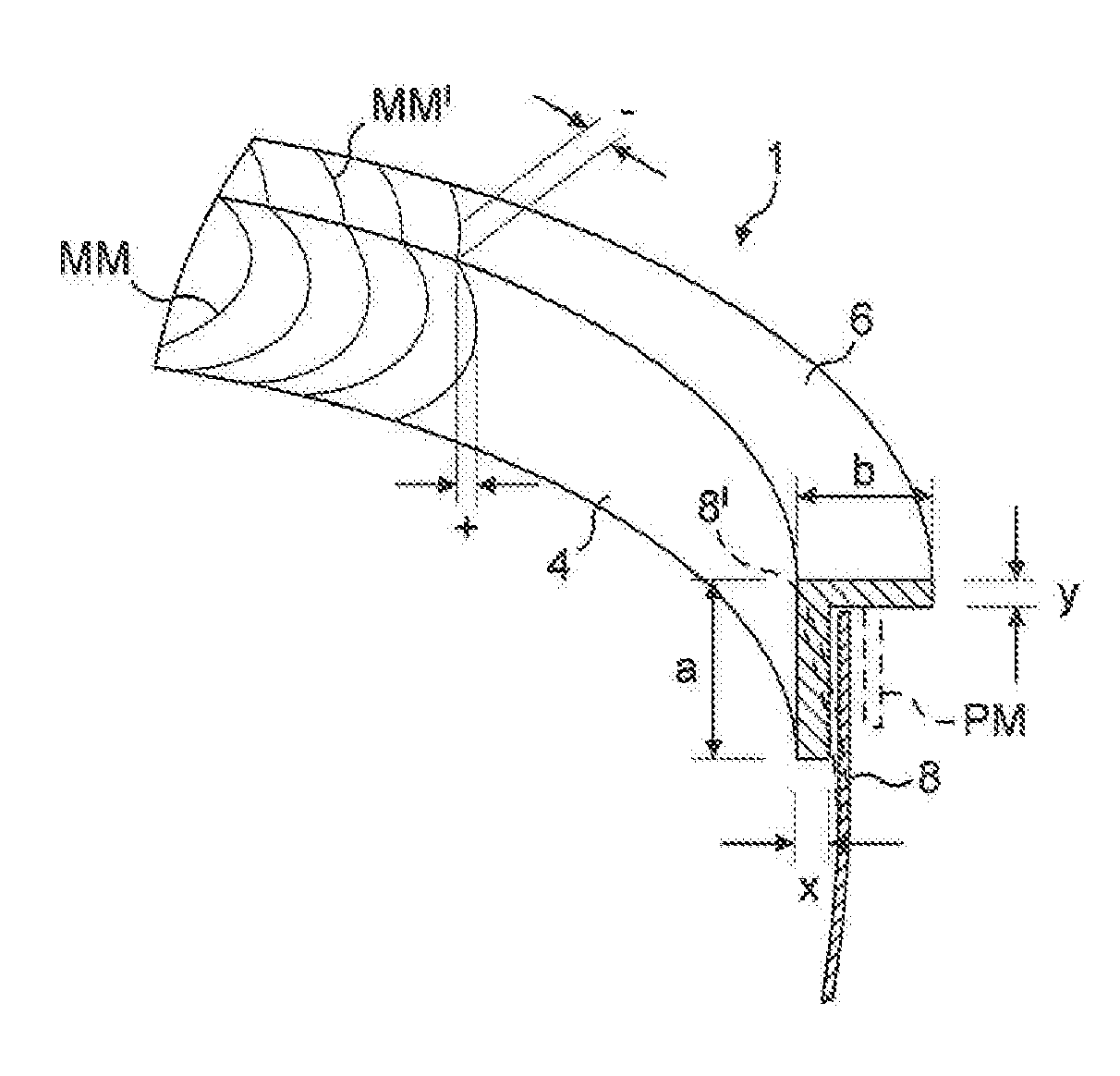

The present invention concerns a container, preferably a capsule for use in a food preparation machine, comprising: (i) a structure with a lower side, at least one substantially vertical pillar extending from the lower side, said pillar being linked to a circular upper frame, said circular upper frame having a substantially L-shaped cross-section with a first circular portion disposed vertically to which the pillar is linked, said vertical portion being linked at its upper side to a second horizontal circular portion forming a peripheral edge, said first vertical portion having a height a and a thickness x, said second horizontal portion having a width b and a thickness y, (ii) a label attached to the lower side, pillar and outer surface of the upper circular frame's vertical portion, thus forming an envelope that defines capsule side walls. According to the invention, x is superior to y, and xa is superior to yb.

Owner:NESTEC SA

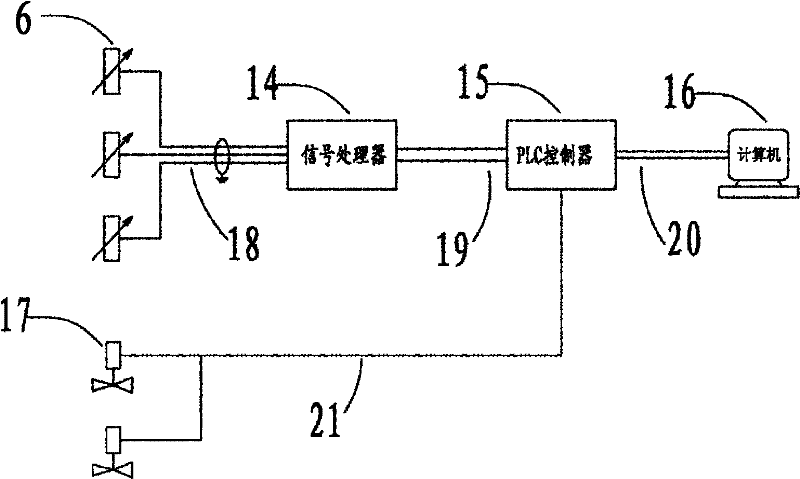

Material metering control method and material metering control device

ActiveCN102175294AOvercome the shortcomings of manual input of blanking difference to improve accuracyHigh measurement accuracyWeighing apparatus with automatic feed/dischargeProgrammable logic controllerNonlinear regression

The invention relates to a material metering control method and a material metering control device. The material metering control method comprises the following steps: starting metering: starting a material bin metering door, guiding the material in a material bin to fall onto a metering scale and starting recording the metering time (t); confirming the time of closing the material bin metering door: according to a required target material weight (mB), utilizing a PLC (programmable logic controller) to calculate and confirm the time (tA) of closing the material bin metering door and the weight (mA) of the material in the scale at the moment by utilizing a linear or nonlinear regression method; and closing the material bin metering door: closing the material bin metering door when the metering time reaches the time tA or the weight of the material in the scale is equal to mA. According to the material metering control method and material metering control device provided by the invention, the mechanical structure of the metering scale is simplified and the metering precision and metering efficiency of a metering system are efficiently increased.

Owner:常德市三一机械有限公司

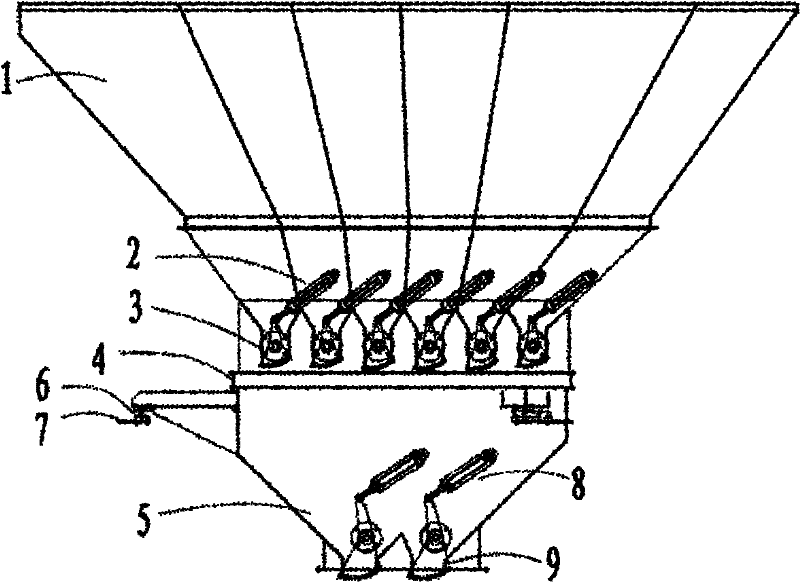

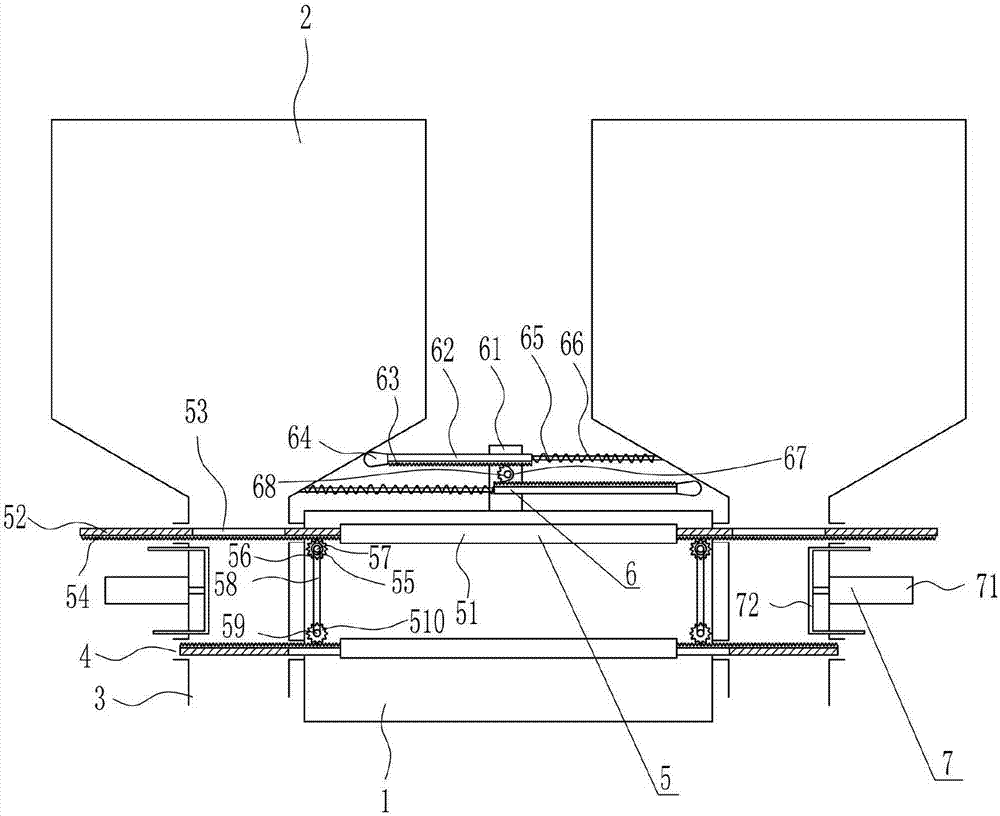

Batching device for smelting

InactiveCN107138098AAccurate ingredientsImprove batching efficiencyMixer accessoriesLoading/unloadingEngineeringSmelting

The invention relates to batching equipment, in particular to a batching device for smelting. Technically, the invention aims to provide a batching device for smelting with the characteristics of no need for manual batching, accurate batching and high batching efficiency. In order to solve the technical problem, the batching device for smelting provided by the invention comprises a mounting plate and the like. Blanking hoppers are symmetrically arranged on the left side and right side above the mounting plate, the bottoms of the blanking hoppers are connected to blanking pipes, two blanking pipes are both located on the left side and right side of the mounting plate, the upper sides and lower sides of the blanking pipes are both equipped with sliding chutes, the front side of the mounting plate is provided with a quantitation apparatus, a beat apparatus is arranged above the quantitation apparatus, and adjustment apparatuses are mounted outside the blanking pipes. The batching device for smelting provided by the invention reaches the effects of no need for manual batching, accurate batching and high batching efficiency.

Owner:雷海涛

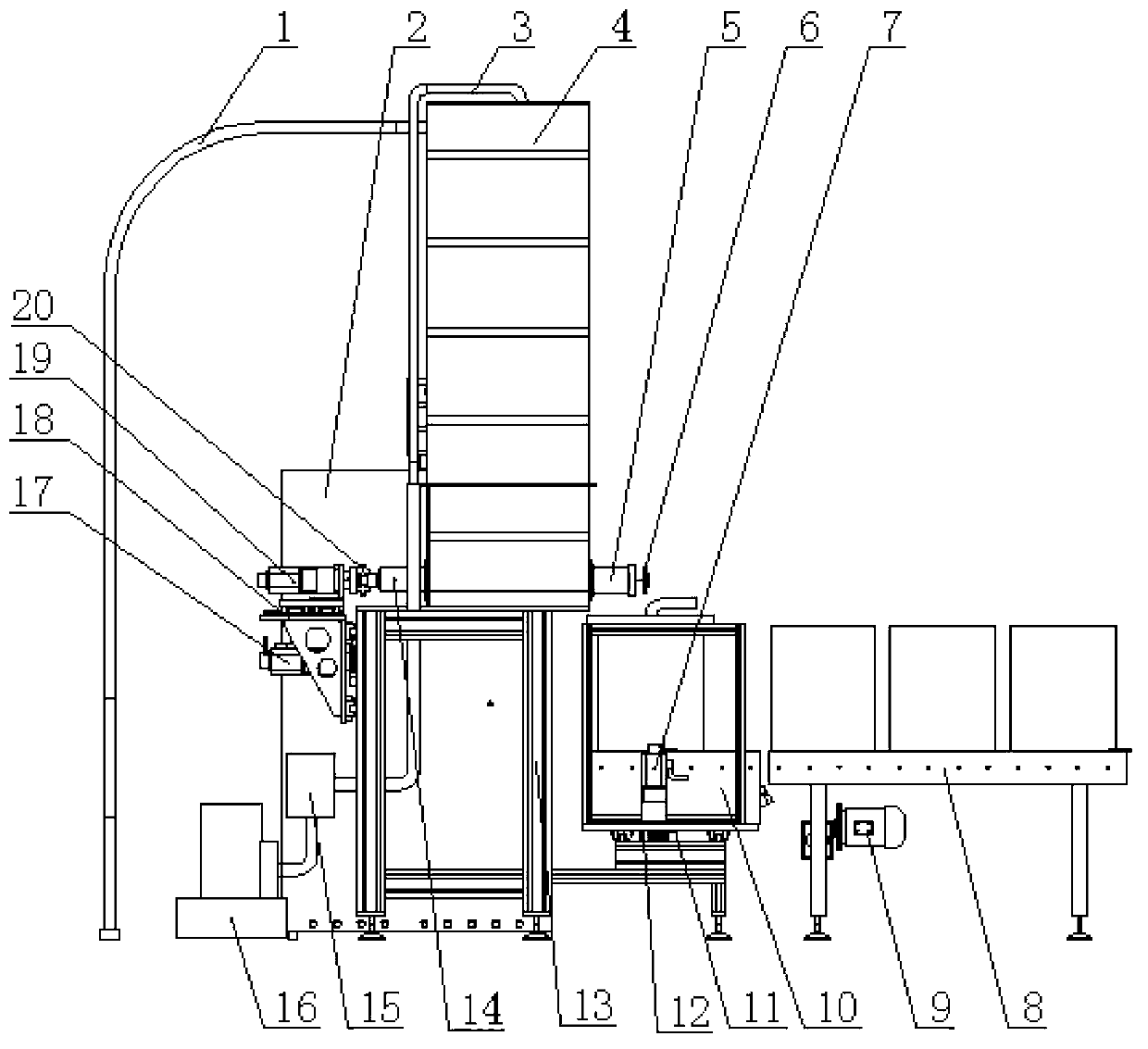

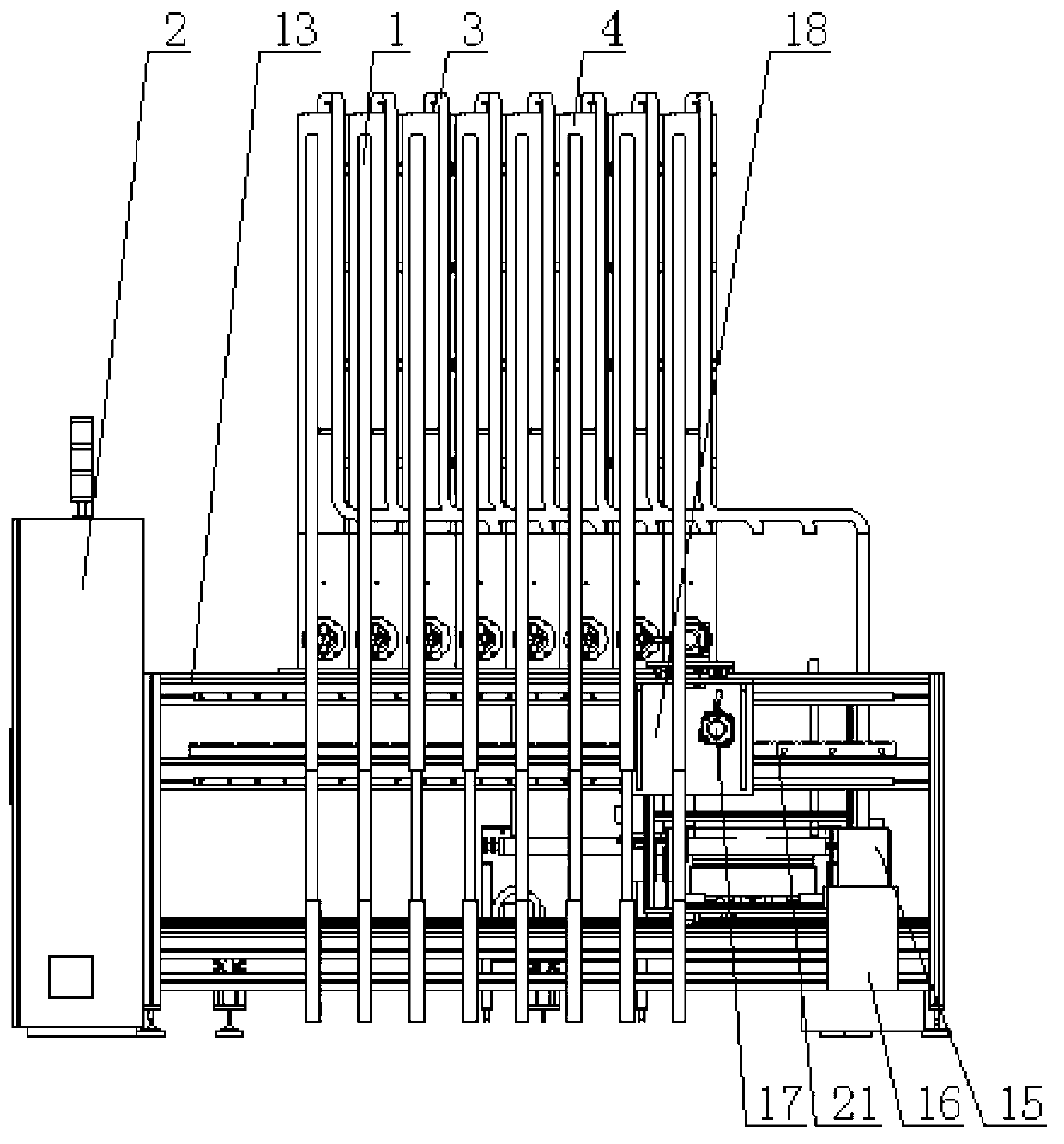

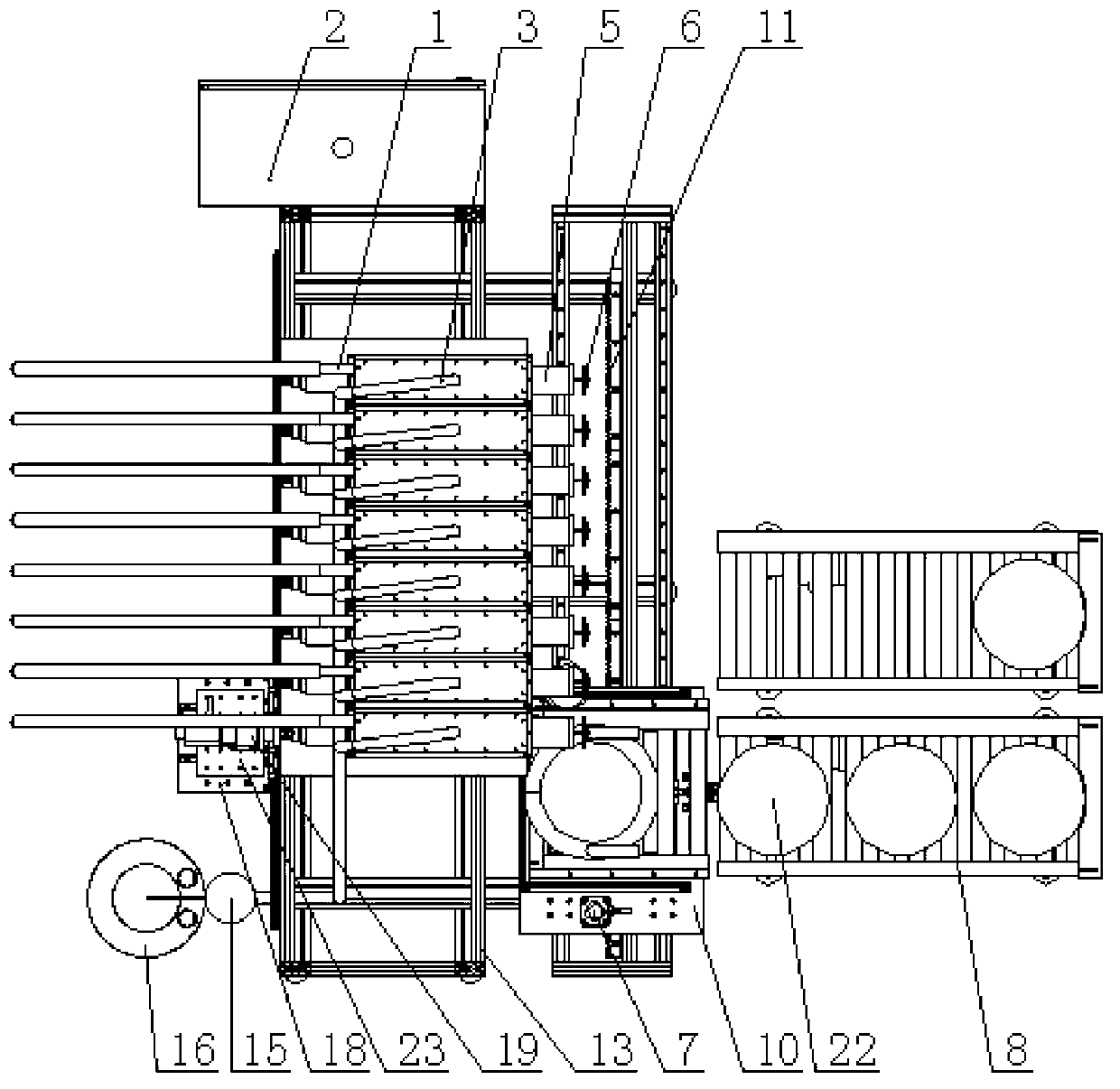

Automatic powdery dye weighing system

ActiveCN103276545AImprove weighing efficiencyAvoid pollutionTextile treatment machine partsWeighing apparatus for materials with special property/formWorking environmentEngineering

The invention relates to an automatic powdery dye weighing system. The automatic powdery dye weighing system comprises a frame, a plurality of feeding devices, a movable rotary-shifting manipulator, a movable receiving trolley and an electric control cabinet, the feeding devices are arranged on the frame side by side, the movable receiving trolley is correspondingly arranged below the front ends of the feeding devices, the movable rotary-shifting manipulator is correspondingly arranged at the rear ends of the feeding devices, the electric control cabinet is arranged on one side of the frame, each feeding device comprises a dye box and a screw feeder, each screw feeder is mounted on the lower portion of each dye box, a discharge hole is made at the front end of each screw feeder, the rear end of each screw feeder is matched with the movable rotary-shifting manipulator so as to achieve discharging, the upper portions of the dye boxes are connected with a feeding pipe and a negative pressure pipe, and the negative pressure pipe is connected with a negative pressure fan. The automatic powdery dye weighing system has the advantages that the automatic powdery dye weighing system is simple in structure, scientific and reasonable in design, capable of effectively improving dyeing recipe weighing efficiency and good in weighing repeatability, pollution of powder to working environments is avoided, labor is freed, and the working environments are improved.

Owner:杭州三拓科技有限公司

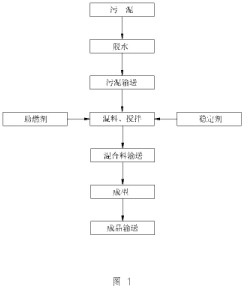

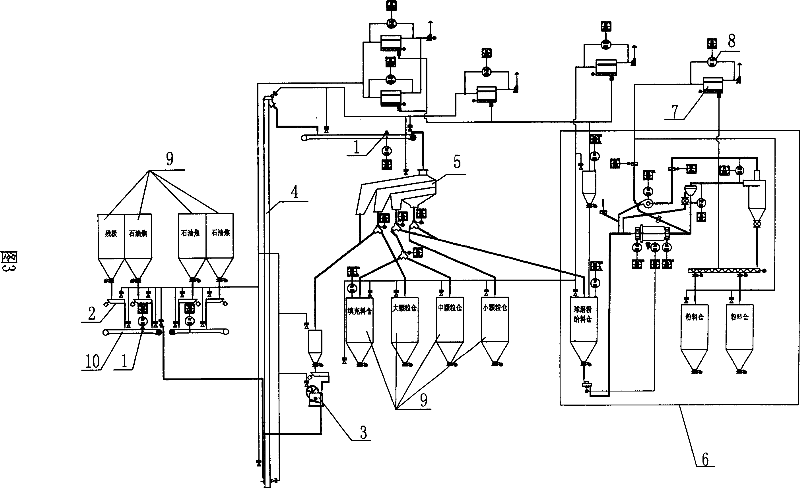

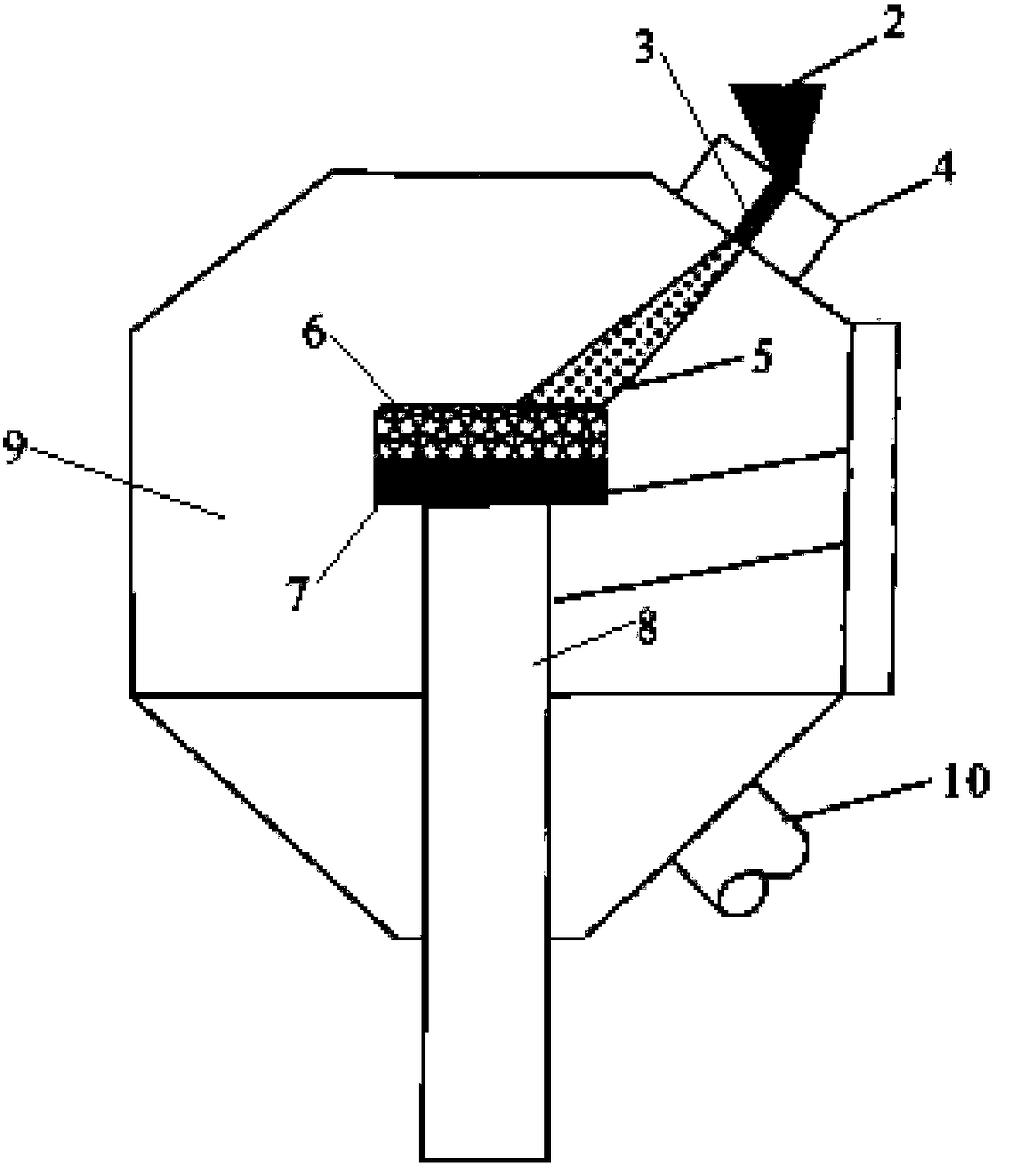

Fodder automatic batching system and production process thereof

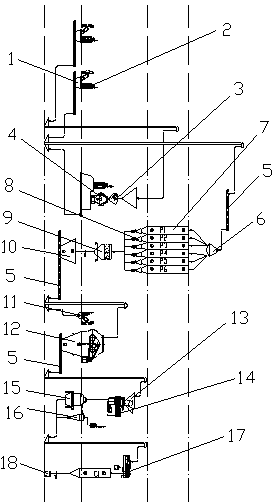

The invention relates to a fodder automatic batching system and a production process of the fodder automatic batching system. The fodder automatic batching system comprises a pulse dust removal fan, a conveyor, a distributor, a plurality of stock bins, a batching scale, a mixer, a conditioner, a granulator and a classifying screen. The pulse dust removal fan is arranged in a charging opening and connected with the distributor through the conveyor, a pulverizer is arranged between the pulse dust removal fan and the distributor, the distributor is connected with the tops of the stock bins, discharge openings in the bottoms of the stock bins are gathered into the batching scale, the batching scale is connected with the mixer through the conveyor, the mixer is connected with the conditioner, the conditioner is connected with the granulator, and the granulator is connected with the classifying screen through the conveyor. According to the fodder automatic batching system and the production process of the fodder automatic batching system, batching efficiency can be improved, batching accuracy is guaranteed, the automation degree is high, and the application range is wide.

Owner:CHANGZHOU MIMORI ELECTROMECHANICAL TECH

Laser smelting furnace with water cooled copper mould and method for smelting ingot

Owner:BEIHANG UNIV

Manufacturing method for pre-alloying gold-tin pre-forming soldering lug

The invention provides a manufacturing method for a pre-alloying gold-tin pre-forming soldering lug. The process of the method mainly comprises five steps such as raw material preparation, pre-alloying, hot rolling, annealing and blanking forming. Due to the fact that N2+H2 mixed protective gas is injected into a vacuum melting protective system to conduct the pre-alloying, gold-tin alloy is not prone to be oxidized in melting process. Due to adoption of the hot rolling and annealing blanking of gold-tin materials after the pre-alloying, a machined gold-tin soldering lug is accurate in composition, complete and precise in shape and excellent in soldering using performance. Meanwhile, the manufacturing method for the pre-alloying gold-tin pre-forming soldering lug has the advantages of being simple in technology and process, reasonable in production cost and high in production efficiency.

Owner:GUANGZHOU XIANYI ELECTRONICS TECH

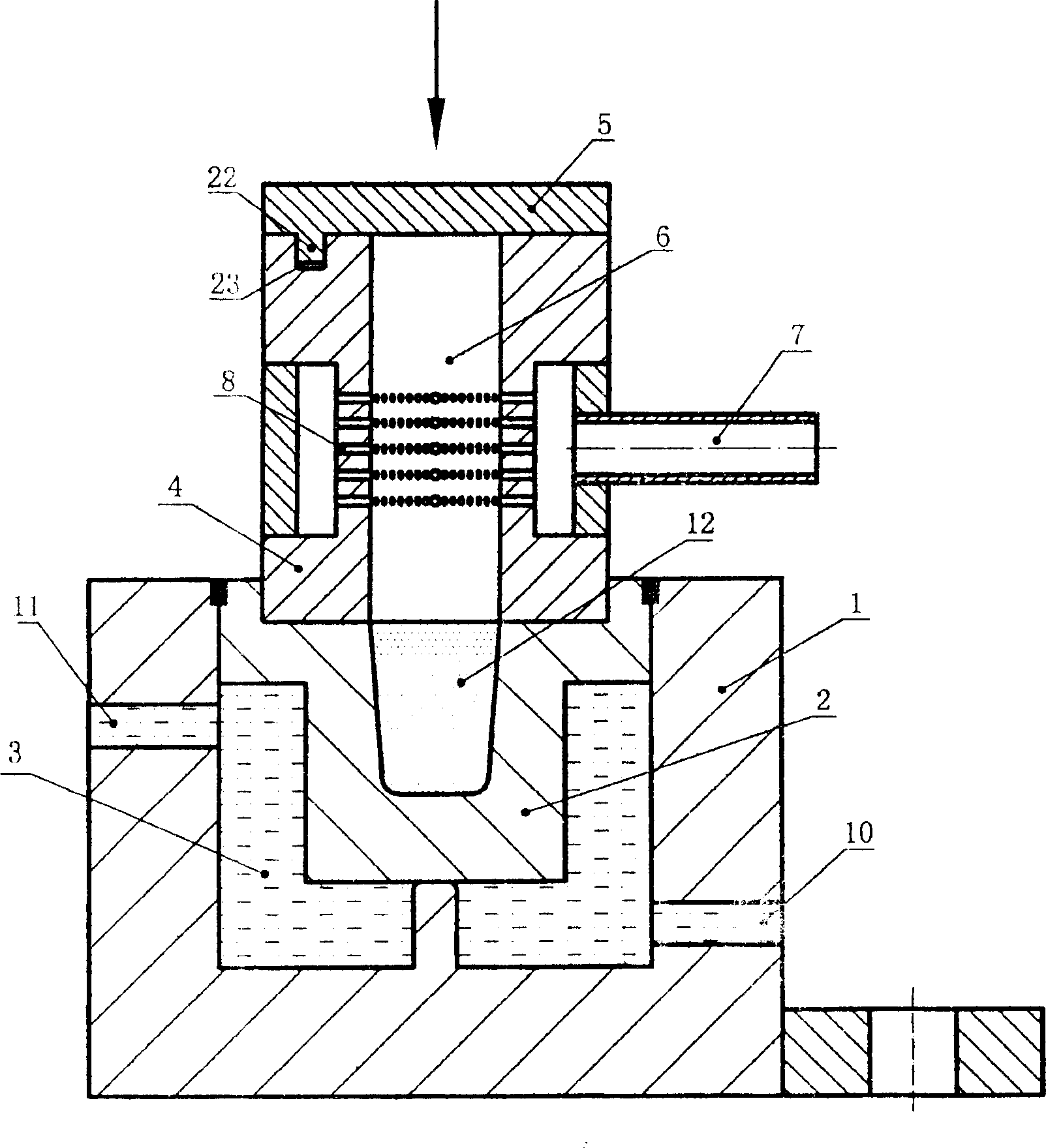

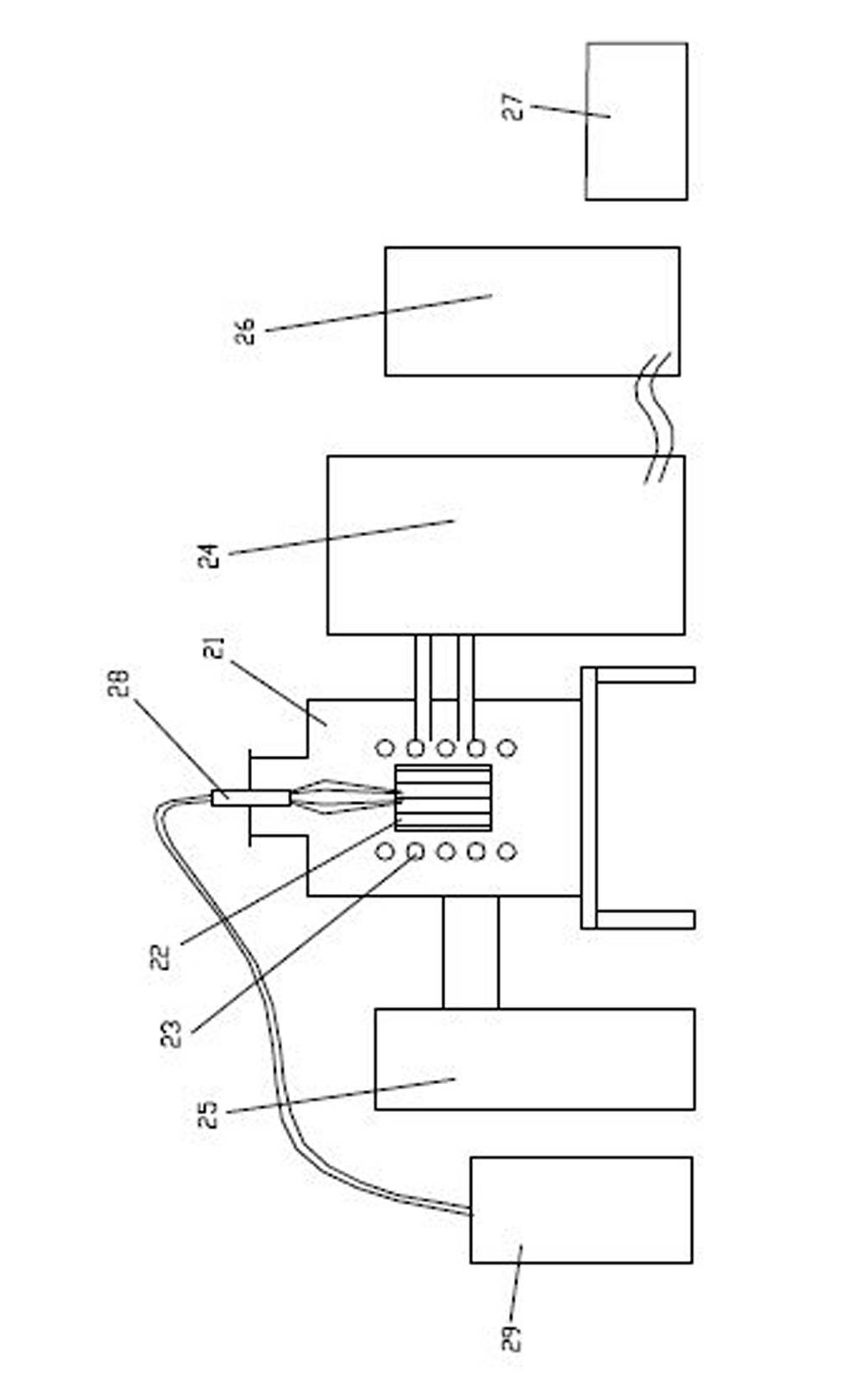

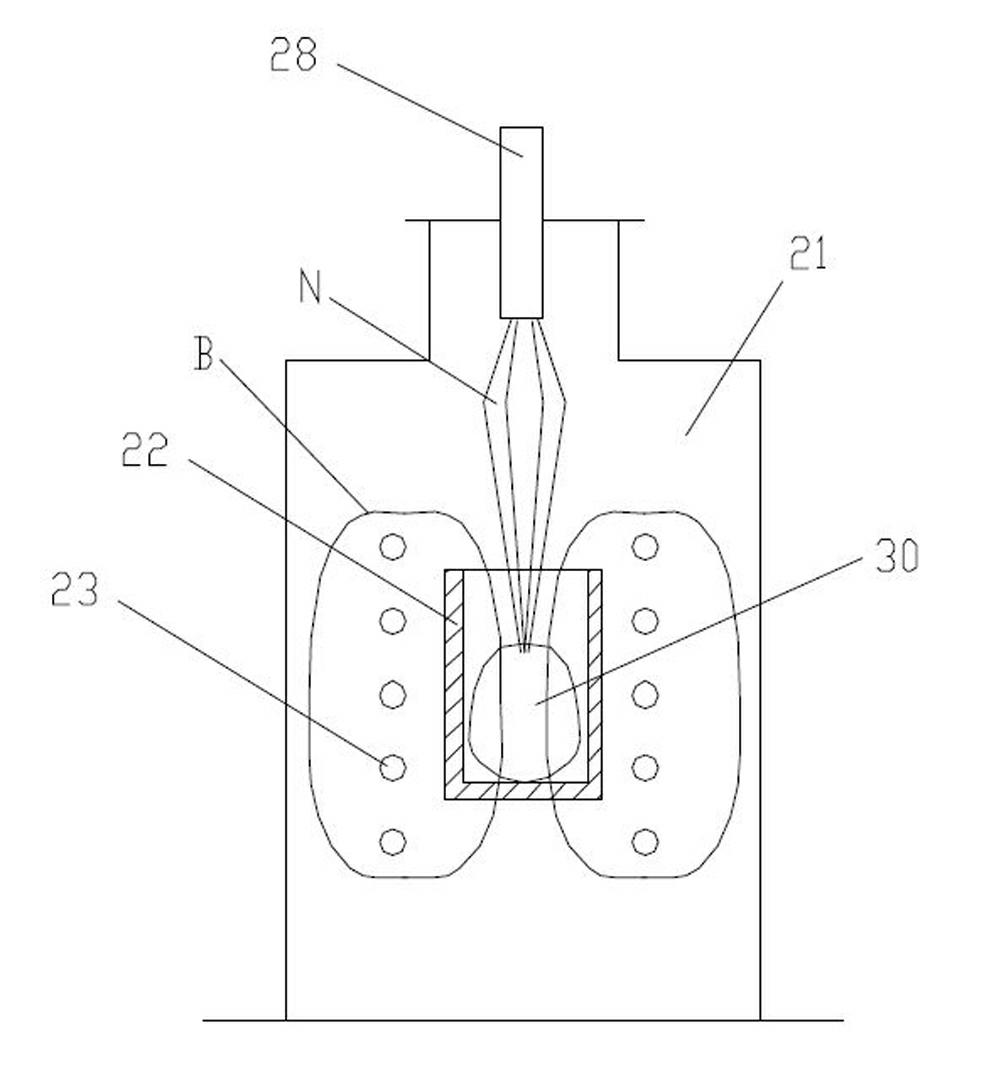

Cold crucible vacuum inductive smelting device having energy beam auxiliary heat source

InactiveCN102183144AUniform compositionAccurate ingredientsCrucible furnacesIntermediate frequencyEngineering

The invention relates to a cold crucible vacuum inductive smelting device having an energy beam auxiliary heat source, which comprises a vacuum chamber, a cold crucible, an induction coil, a high frequency / intermediate frequency induction power supply used for supplying electric power to the induction coil, a vacuum argon-filling system, a control cabinet, a cooling system used for cooling the cold crucible, an energy beam launching head and an energy beam generator, wherein the cold crucible is arranged in the vacuum chamber; the induction coil is arranged in the vacuum chamber; the induction coil is encircled on the exterior of the cold crucible; the energy beam launching head is arranged on the top of the vacuum chamber and is positioned above the cold crucible; the energy beam generator is connected to the energy beam launching head; and the energy beam generator is used for generating an energy beam and transmitting the energy beam to the energy beam launching head. The device provided by the invention can be used for preparing the refractory metal and alloy which are characterized by accurate and uniform components, consistent tissues and compact materials.

Owner:张森

Refinement modifier for hypoeutectic aluminum-silicon cast alloy, and preparation method and application thereof

The invention discloses a refinement modifier for hypoeutectic aluminum-silicon cast alloy, and a preparation method and the application thereof. The refinement modifier for hypoeutectic aluminum-silicon cast alloy is characterized by comprising the chemical ingredients of Al-1Ti-3B-10RE which are, by weight, 0.9% to 1.1% of Ti, 2.8% to 3.2% of B, 10% to 12% of RE, and the balance Al. The RE comprises the ingredients of 40% of mixed light rare earth rich in La, and 60% of Y. The problem of (Al and Ti)B2 and AlB2 agglomeration in a refinement modifier is solved due to the active roles of rare earth elements in cooperation with fusion magnetic blending and quick solidification. Compared with the widely used refinement modifier Al-5Ti-1B and the widely used refinement modifier Al-10Sr, the refinement modifier for hypoeutectic aluminum-silicon cast alloy has the function of integrating refinement and modification, and is easy to apply; andthe titanium silicide poisoning refinement effect or the phenomenon that air intake of alloy melt is intensified by Sr or the phenomenon that Sr and B poison each other does not exist, and the effect of refining alpha-Al and the mechanical property ofalloy can be obviously improved.

Owner:JIANGXI ZHONGYAN METAL TECH CO LTD

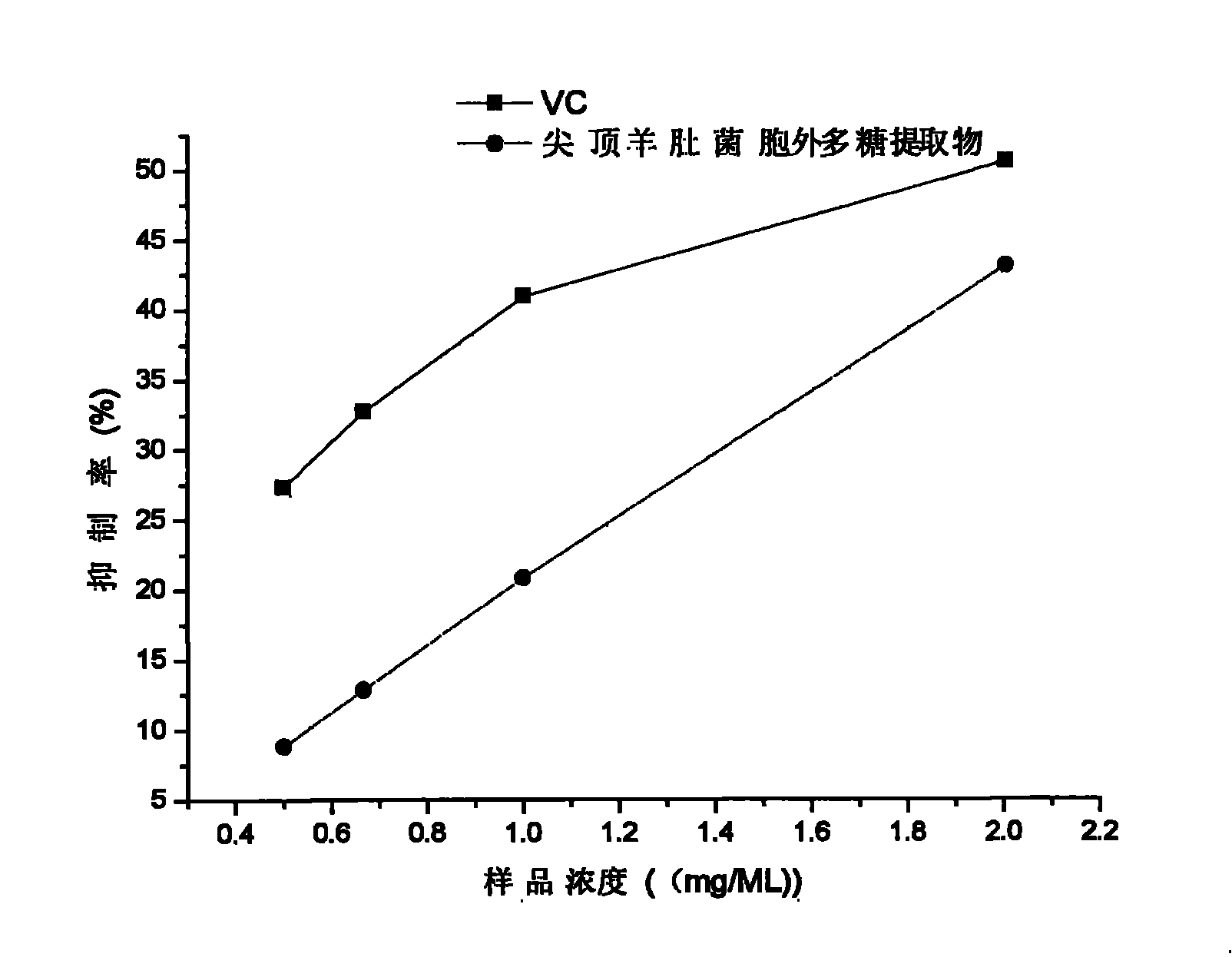

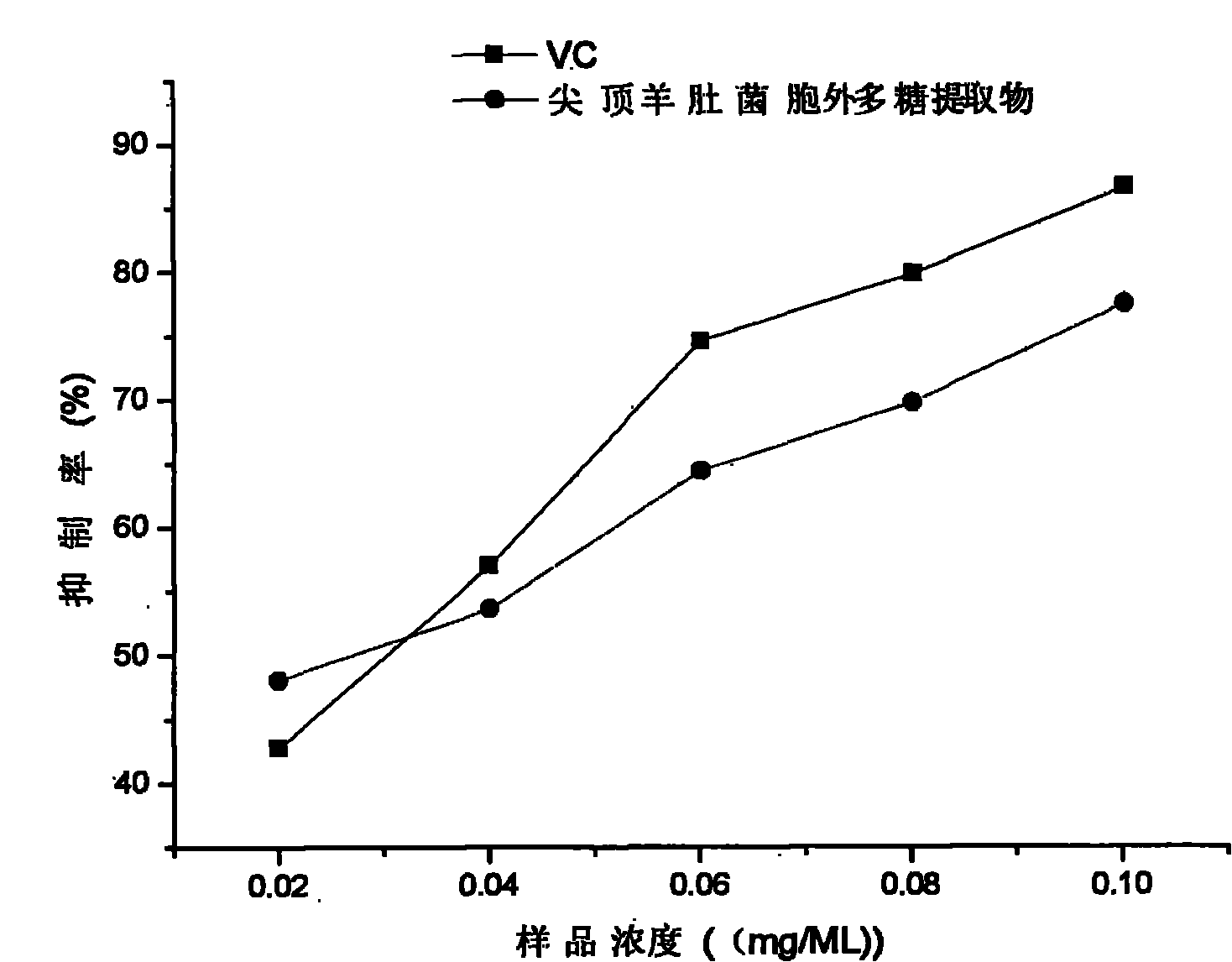

Morchellaconica extracellular polysaccharide extractive and preparation method and application thereof

InactiveCN101870740AAntioxidant is goodLife-prolonging and anti-aging effectsOrganic active ingredientsAntinoxious agentsFiltrationCentrifugation

The invention belongs to the biological technical field, which discloses a morchellaconica extracellular polysaccharide extractive and a preparation method and application thereof. The extractive is liquid fermentation liquor which is obtained by fermenting and culturing morchellaconica liquid and separating mycelium through centrifugation and vacuum filtration. The liquid fermentation liquor is concentrated to 1 / 3 to 1 / 6 of the original bulk to obtain concentrated solution and the concentration temperature is 50 to 70 degrees centigrade. The protein of the concentrated solution is removed and the concentrated solution is centrifuged. Activated extract is obtained. Polysaccharide in the concentrated solution is dialyzed and settled in 95 percent of ethanol at 0 to 10 degrees centigrade for 12 to 25 hours, the bulk of which is once to 5 times larger than the bulk of the activated extract. The pH value is 4 to 8. Flocculent white substance is precipitated after still placement. White sedimentation is obtained after centrifugation separation, which is frozen and dried to obtain the morchellaconica extracellular polysaccharide extractive. The invention has simple preparation process and allows mass production. The extractive has no harm on human body and good antioxidant and anti-aging action and can be used for preparing antioxidant and anti-aging medicine or health care food.

Owner:SOUTH CHINA NORMAL UNIVERSITY

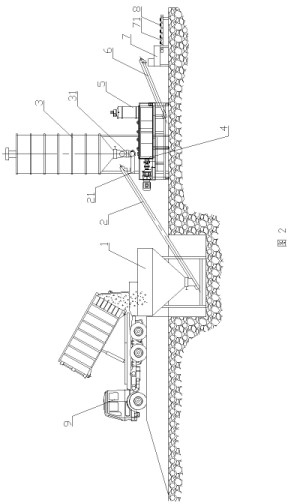

Method and device for producing bunker coal with sludge

InactiveCN102517115ASave resources and costsReduce dosageBiofuelsSolid fuelsBriquetteProcess engineering

The invention discloses a method and a device for producing bunker coal with sludge. The method comprises the following steps: dewatering the sludge through a dewaterer to ensure that the water content of the sludge is 40 to 55 wt percent after treatment; delivering the dewatered sludge through a sludge delivering device; adding a combustion improver and a stabilizing agent to the dewatered sludge, wherein the weight of the combustion improver is 20 to 30 percent that of the dewatered sludge, and the weight of the stabilizing agent is 8 to 15 percent that of the dewatered sludge; uniformly stirring the sludge mixed with the combustion improver and the stabilizing agent through a mixer; connecting a mixture delivering device with a formation device to mold the mixture; connecting the formation device with a finished product delivering device for delivering, drying and processing molded coal; connecting the feed end of the stirrer with a combustion improver quantificationally adding device and a stabilizing agent quantificationally adding device; and arranging a sludge meter between the sludge transportation device and the stirrer. The invention has the advantages that the structure of the device is simple; the fuel value can be more than 5000 kilocalorie; the burning performance is improved; the device is easy to operate and convenient to apply; the dose of pulverized coal is small; the coal saving effect is good; the cost is low; and the resource utilization of sludge is enhanced.

Owner:青州市圣洁环保设备科技有限公司

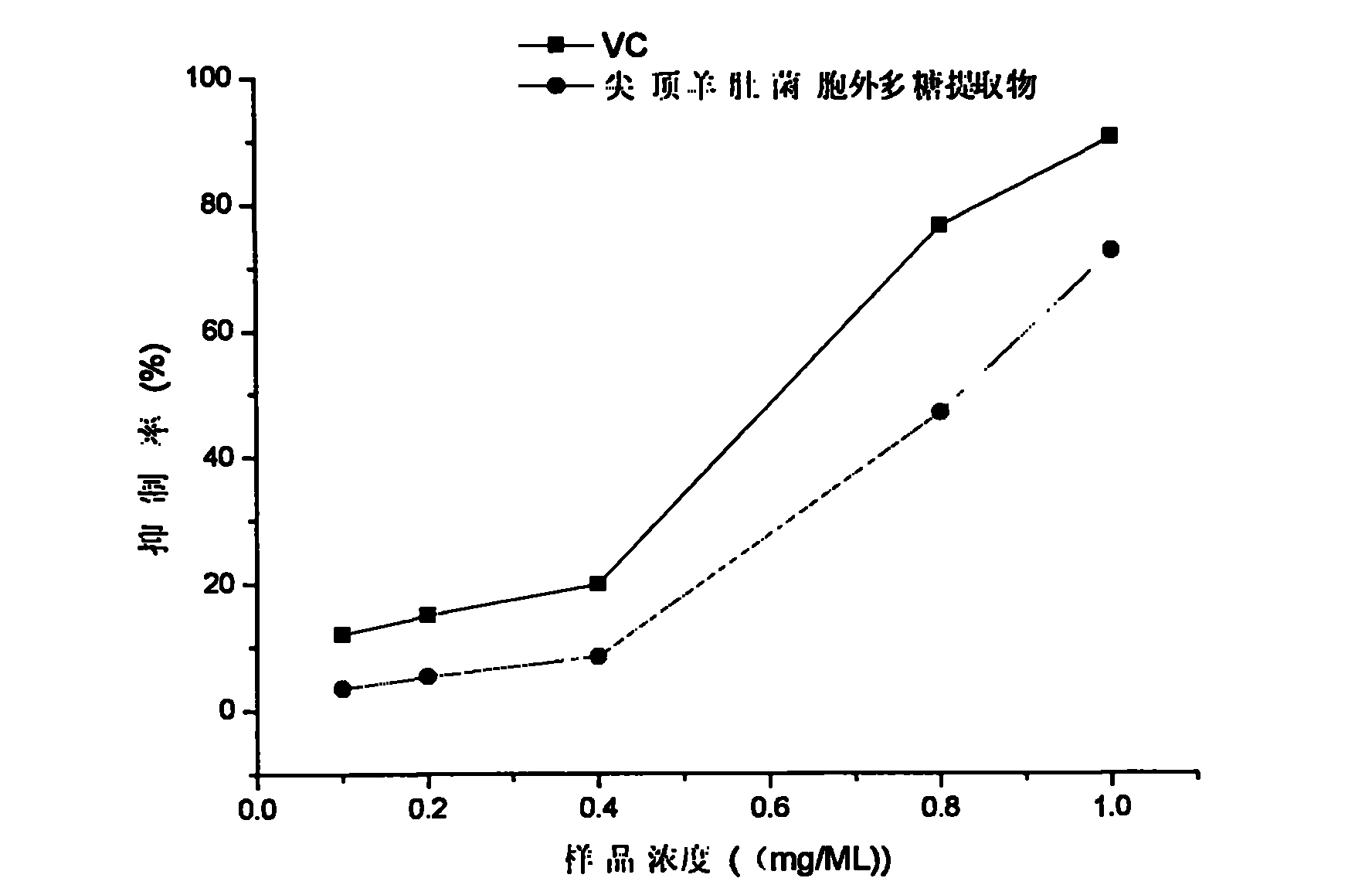

Polysaccharide extract of Chinese caterpillar fungi as well as preparation method and application of polysaccharide extract

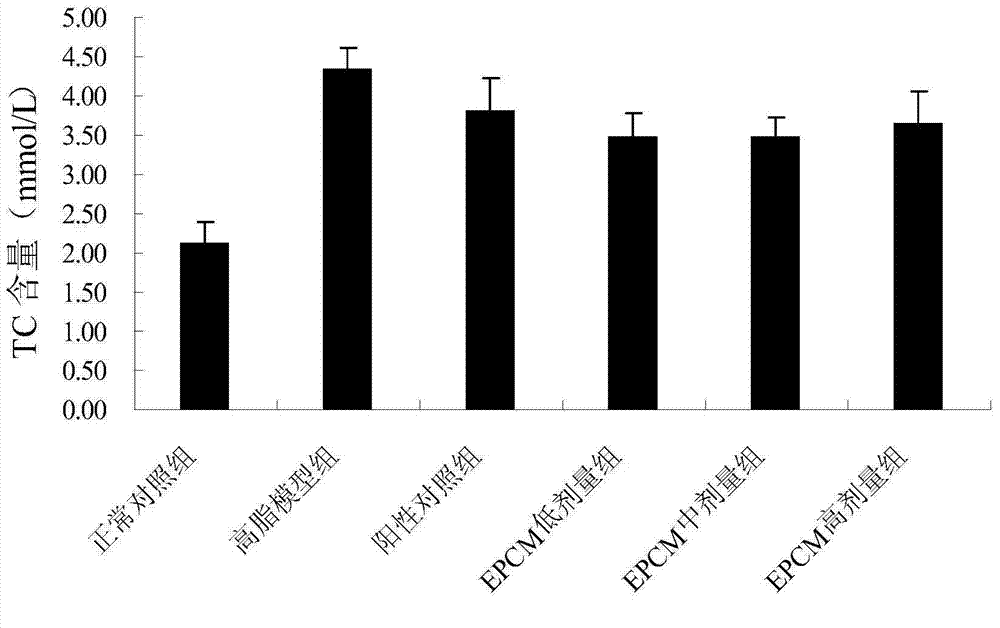

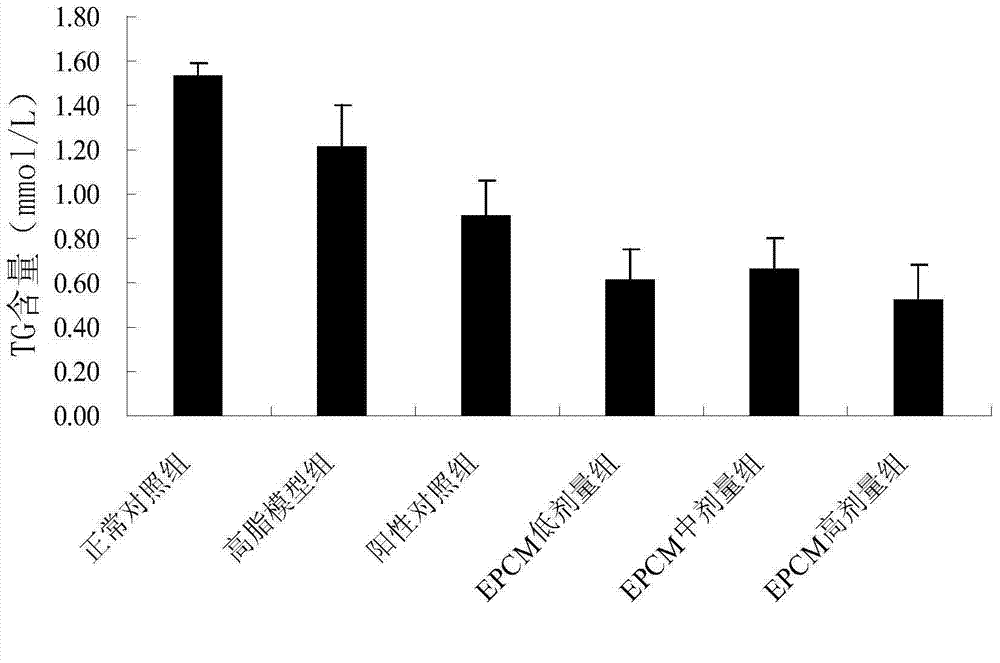

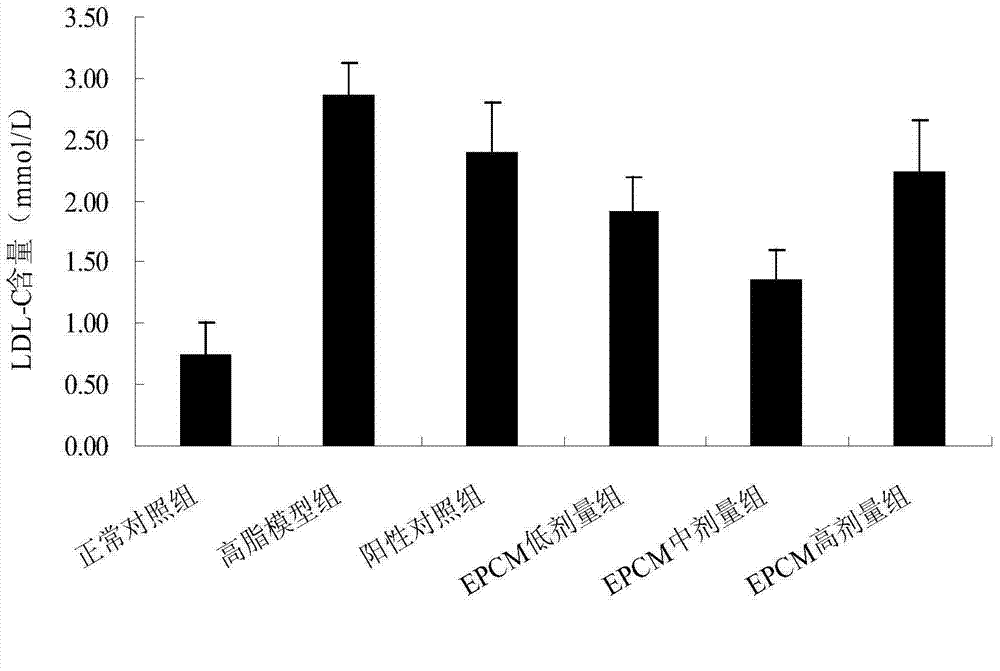

ActiveCN104497160AGood hypolipidemic effectEasy to makeOrganic active ingredientsMetabolism disorderBiotechnologyUltrafiltration

The invention belongs to the field of biotechnology and in particular relates to a polysaccharide extract of Chinese caterpillar fungi as well as a preparation method and application of the polysaccharide extract. The preparation method of the polysaccharide extract of the Chinese caterpillar fungi comprises the following steps: after submerged fermentation culture of mycelium of the Chinese caterpillar fungi, removing the mycelium of a fermented product by virtue of centrifugal separation to obtain a fermentation broth; after removing small molecule substances of the fermentation broth by virtue of ultrafiltration, concentrating the fermentation broth; and carrying out treatments of protein removal, ethanol precipitation, decoloring by hydrogen peroxide, dialysis and vacuum freeze-drying on the concentrated fermentation broth to prepare the polysaccharide extract of the Chinese caterpillar fungi. The preparation method is simple in process and is capable of carrying out efficient mass production with high quality. The prepared polysaccharide extract of the Chinese caterpillar fungi is nonhazardous to a human body, has good physiological function of reducing blood fat and can be used for developing a medicament or health food with the capability of reducing blood fat.

Owner:SOUTH CHINA NORMAL UNIVERSITY

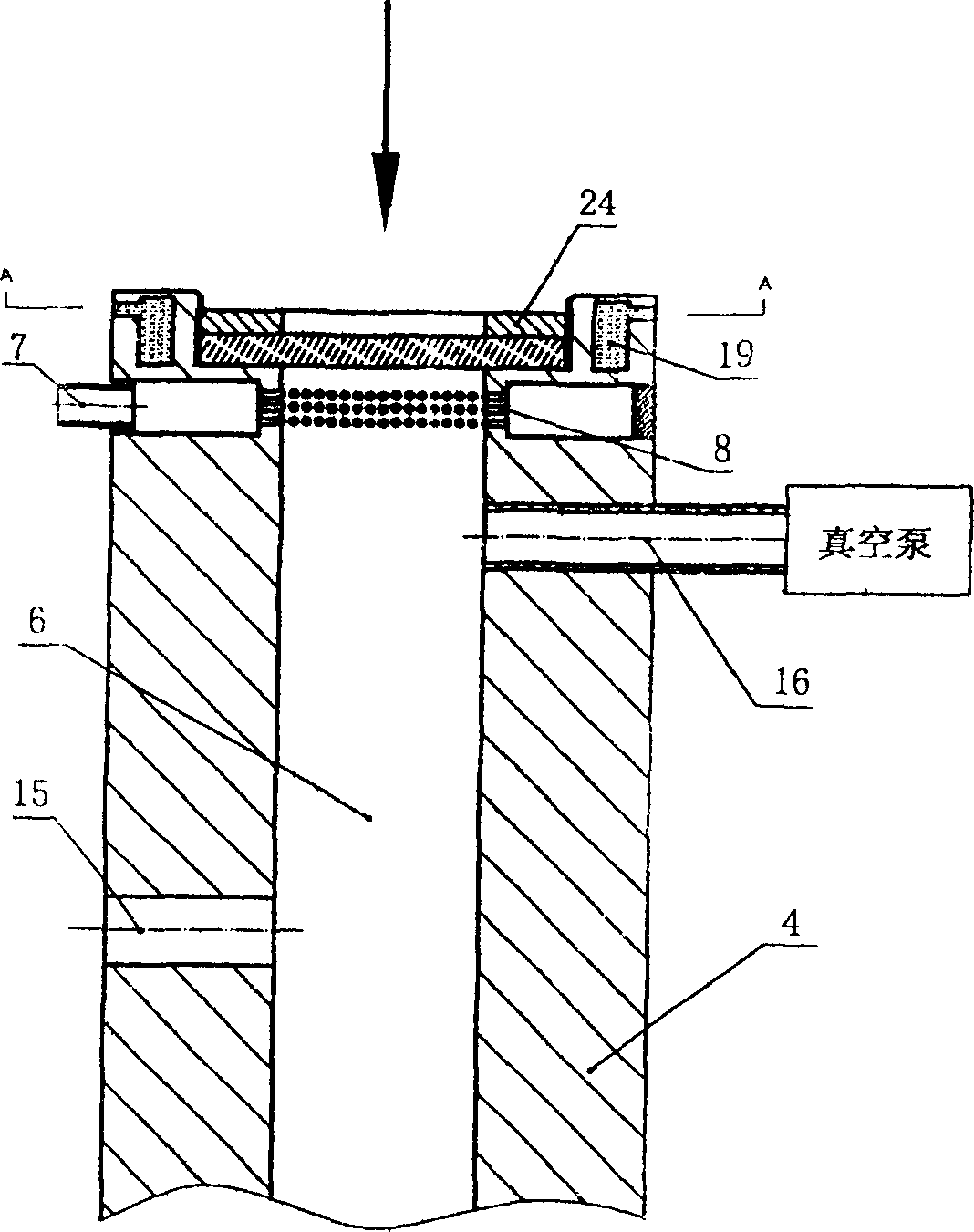

Method for preparing amorphous nano-sheets

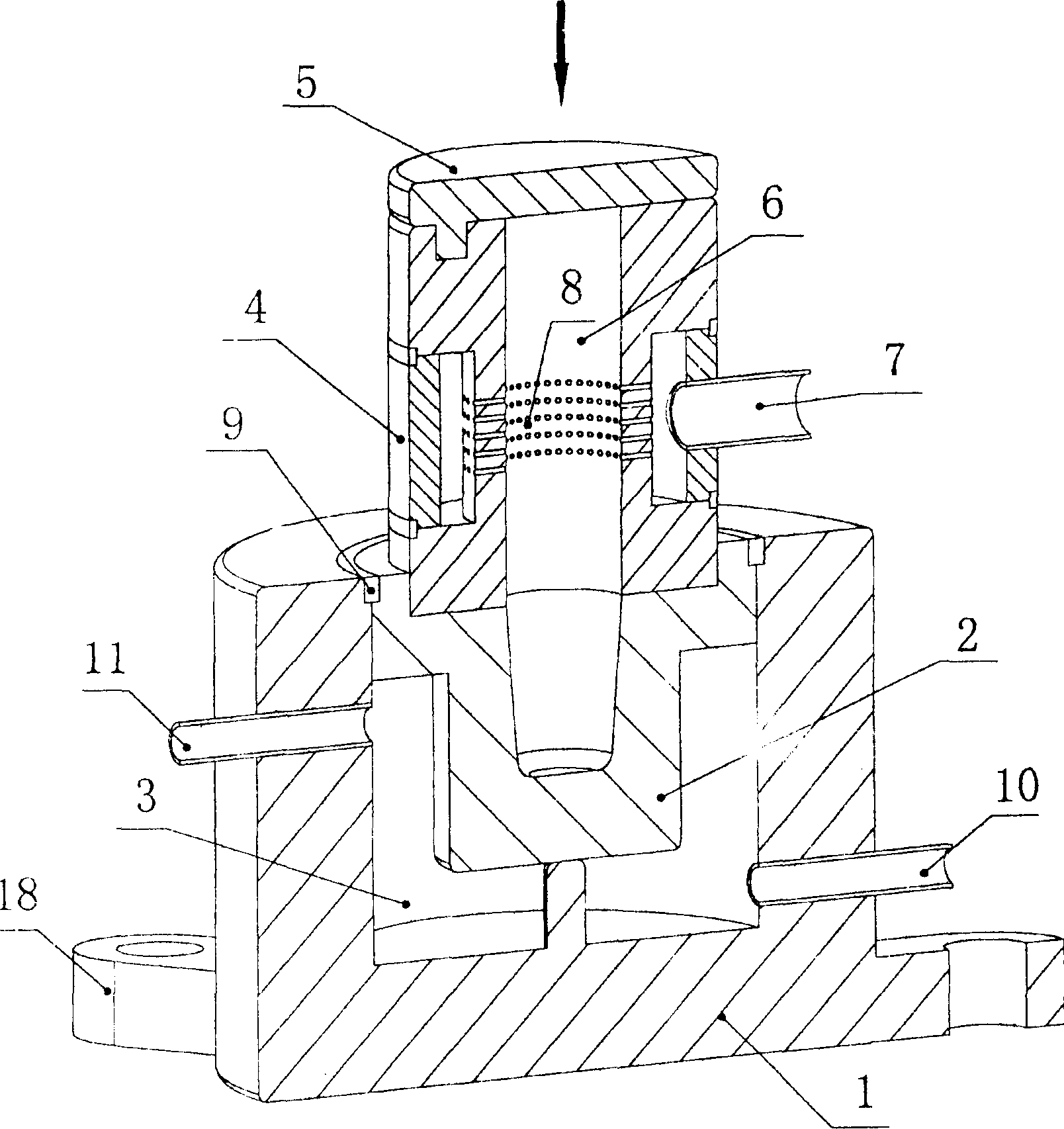

InactiveCN101570313ANo pollution in the processAccurate ingredientsNanostructure manufactureVacuum pumpingAlcohol

The invention discloses a method for preparing amorphous nano-sheets. The method is characterized by comprising the following steps: (1) proportioning block-shaped Cu, Zr and Ti with the purity over 99.9 percent by weight according to the atomicity percentage of Cu being 55 to 65, Zr being 35 to 25 and Ti being 10; (2) putting the proportioned materials into a crucible of an electric arc furnace for melting; (3) melting alloy 3 to 5 times to smash master alloy into power with the diameter between 30 and 50 microns; (4) putting the powder into a stainless steel ball-milling pot and pouring alcohol or acetone into the pot to completely cover the powder and milling balls; and (5) performing ball-milling for 60 to 184 hours at a ball-milling speed between 300 and 500 r / min to obtain nano-scale flaky amorphous alloy powder. The method for preparing the amorphous nano-sheets has the advantages of no pollution, precise components, no need for vacuum pumping in a ball-milling process, simple equipment and low cost.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

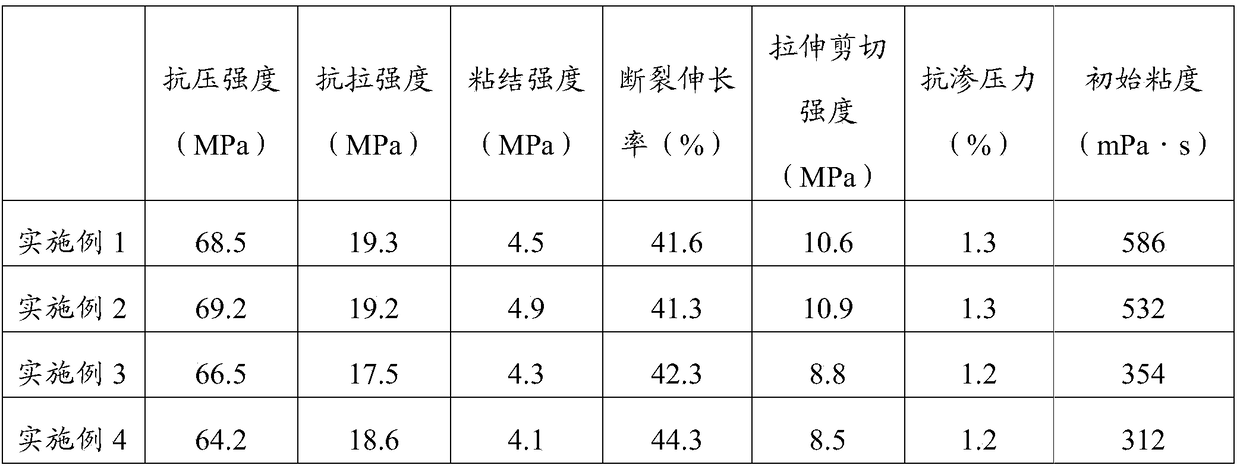

1:1 type plugging epoxy grouting material as well as preparation method and application thereof

The invention relates to a 1:1 type plugging epoxy grouting material as well as a preparation method and application thereof. The epoxy grouting material is prepared from a component A and a componentB, wherein the component A is mainly prepared from the following raw materials in parts by mass: 50-100 parts of bisphenol A type epoxy resin, 10-20 parts of liquid phenolic epoxy resin and 5-33 parts of additives; the component B is mainly prepared from the following raw materials in parts by mass: 50-100 parts of an amine curing agent, 5-15 parts of a viscosity diluent, 10-200 parts of a modifying agent, 0-3 parts of an accelerant and 0-3 parts of a silane coupling agent, wherein the modifying agent is at least one of glycidyl ether and epoxy resin. According to the preparation method, theglycidyl ether and / or the epoxy resin are / is enabled to react with active hydrogen of the amine curing agent for modifying, so that the curing agent is endowed with better toughness and good water resistance, and the brittleness of a consolidated body is also correspondingly reduced; therefore, the problems that the epoxy resin consolidated body is high in brittleness when being used as a groutingmaterial and easily cracks for the second time when a crack is enlarged or contracted, and the curing effect of the amine curing agent in water is poor are solved.

Owner:广东铁科灌浆科技有限公司

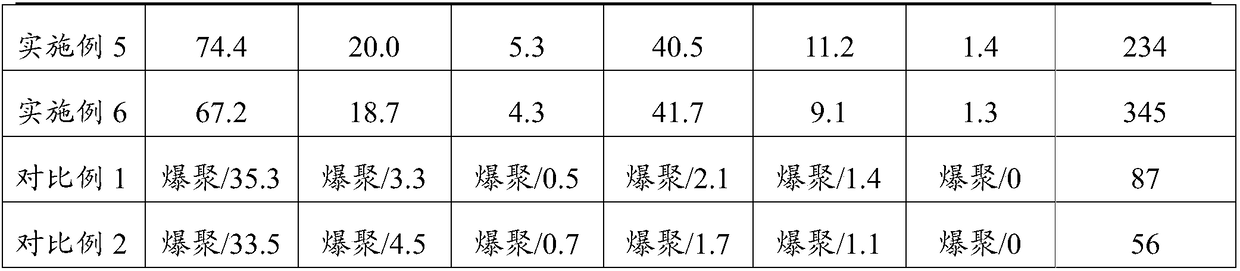

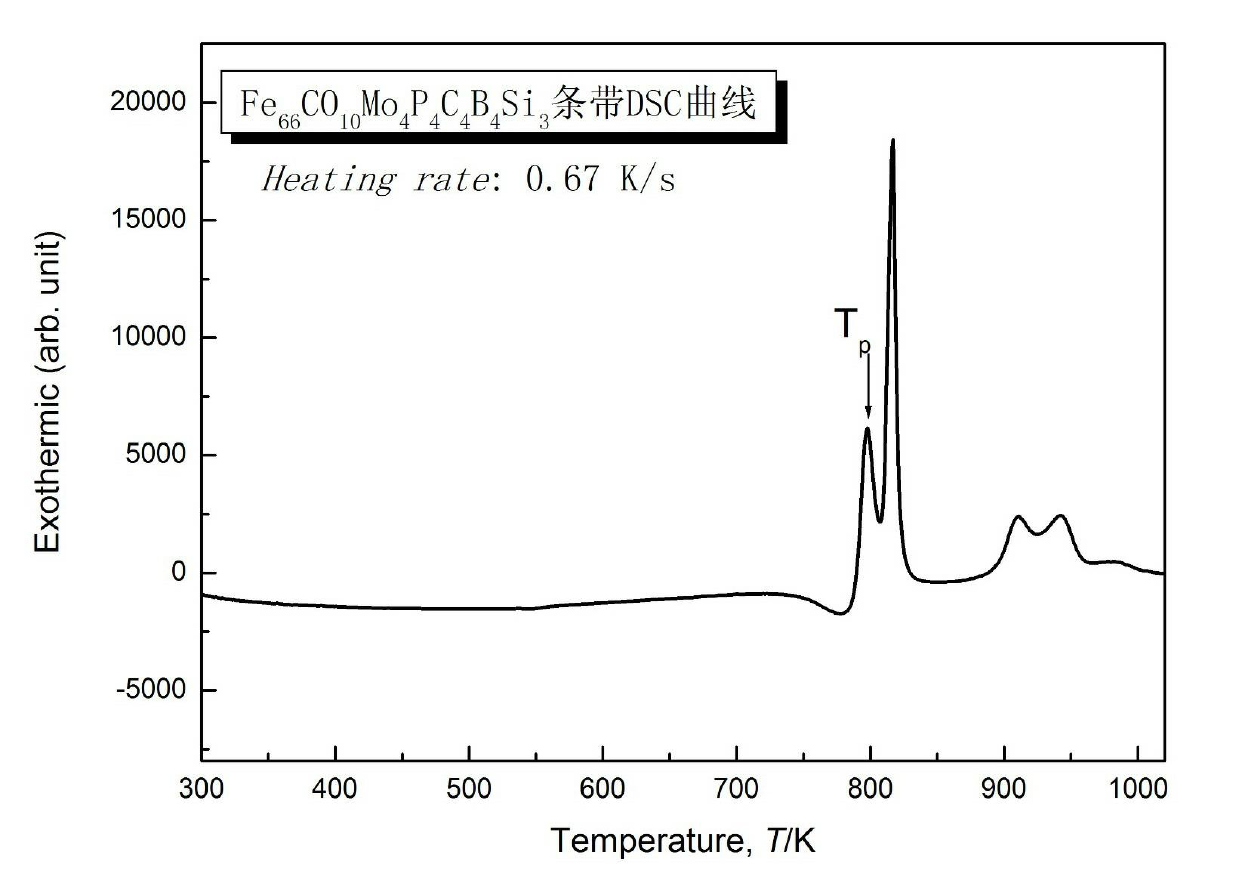

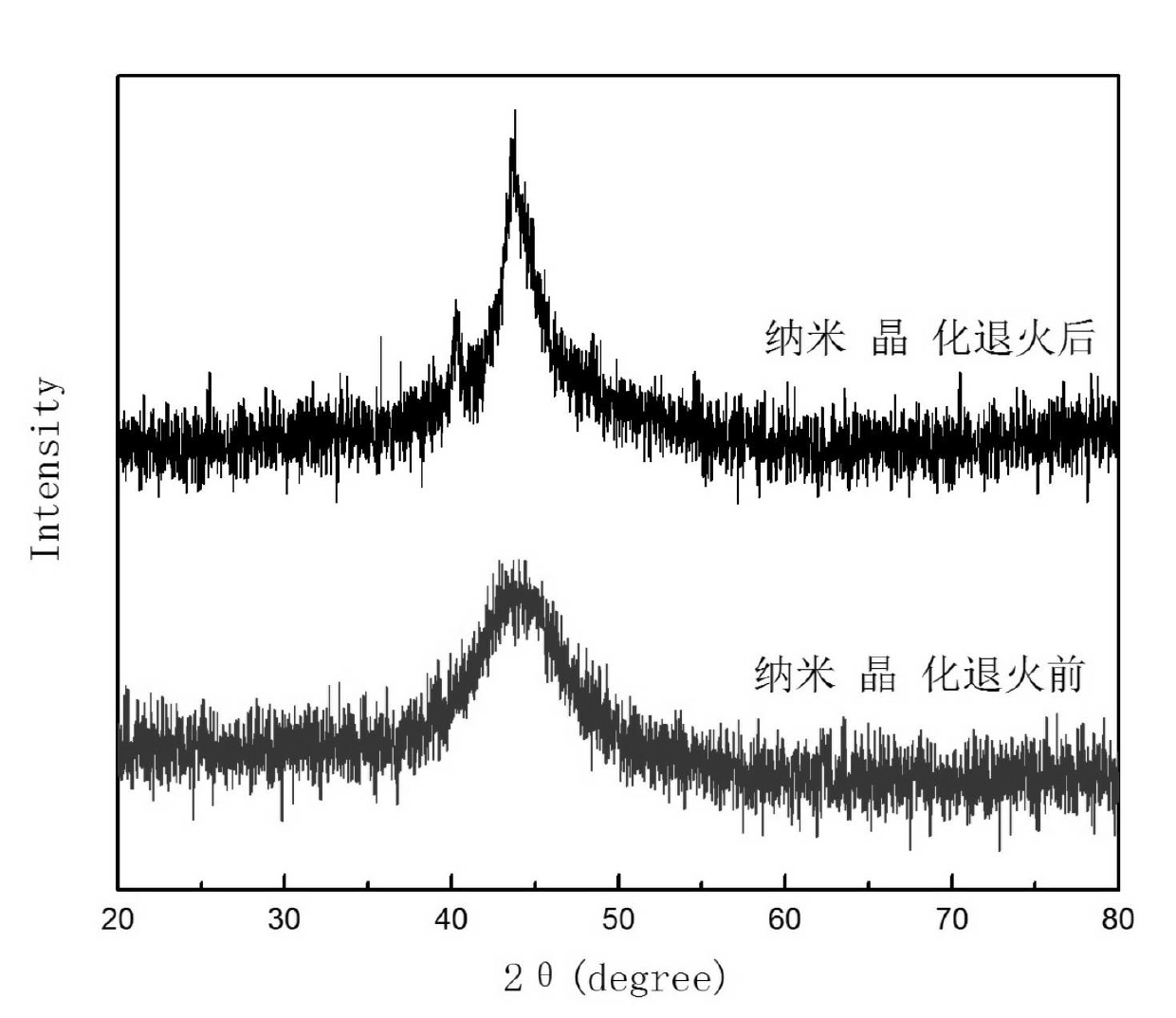

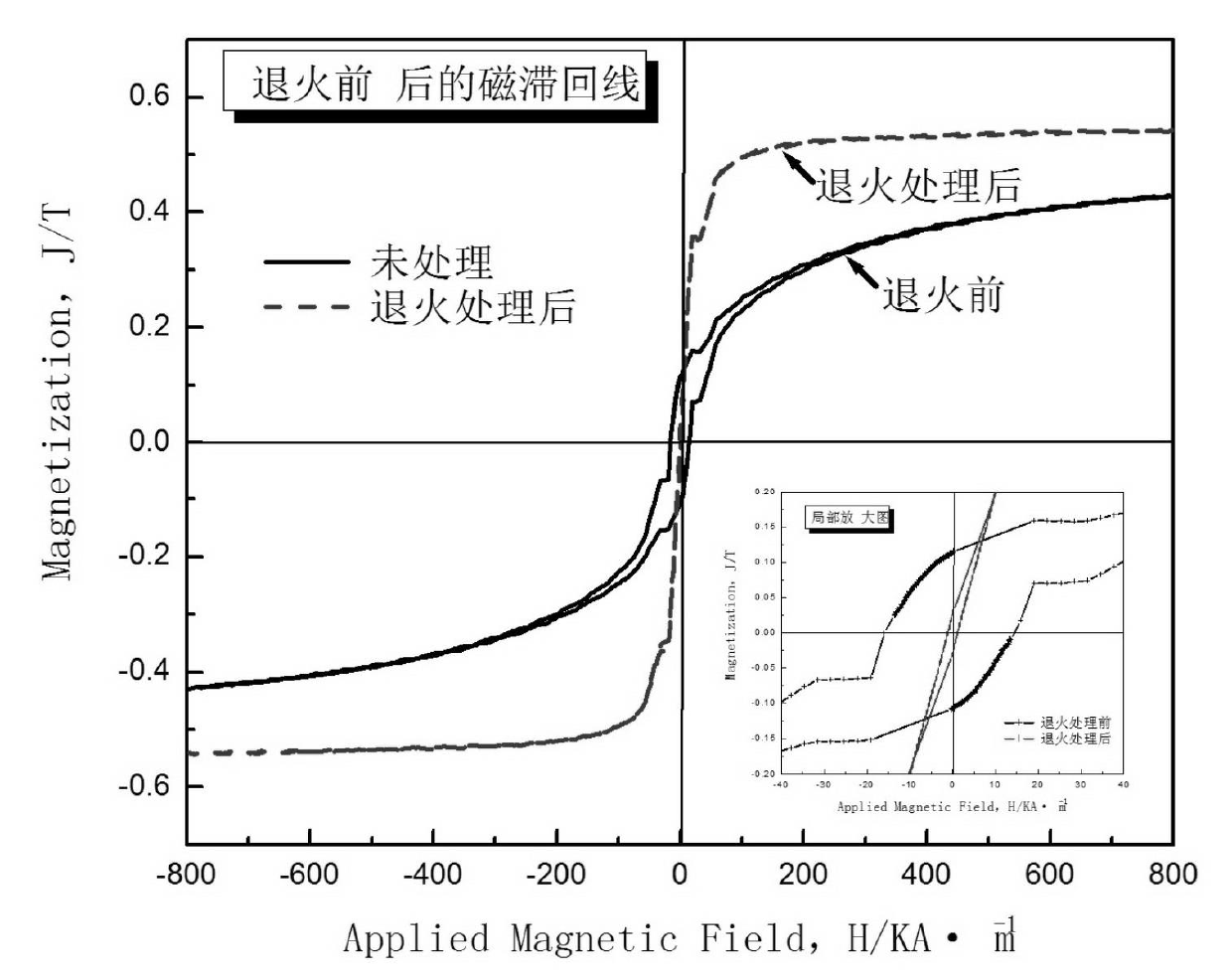

Preparation method of Fe66Co10Mo4P4C4B4Si3 block soft-magnetic nanocrystalline/amorphous composite material

The invention relates to a preparation method of a Fe66Co10Mo4P4C4B4Si3 block soft-magnetic nanocrystalline / amorphous composite material, comprising the following steps: annealing a Fe66Co10Mo4P4C4B4Si3 block amorphous alloy in vacuum at a first crystallization peak temperature Tp and preserving heat for a specific time, after annealing, putting the annealed alloy in a cooling medium to fast coolto room temperature. According to the invention, nanocrystallization of the Fe base block amorphous alloy can be realized, and the soft magnetic property can be improved obviously. The method provides a novel technological process of the Fe66Co10Mo4P4C4B4Si3 block soft-magnetic nanocrystalline / amorphous composite material.

Owner:ZHENGZHOU UNIV

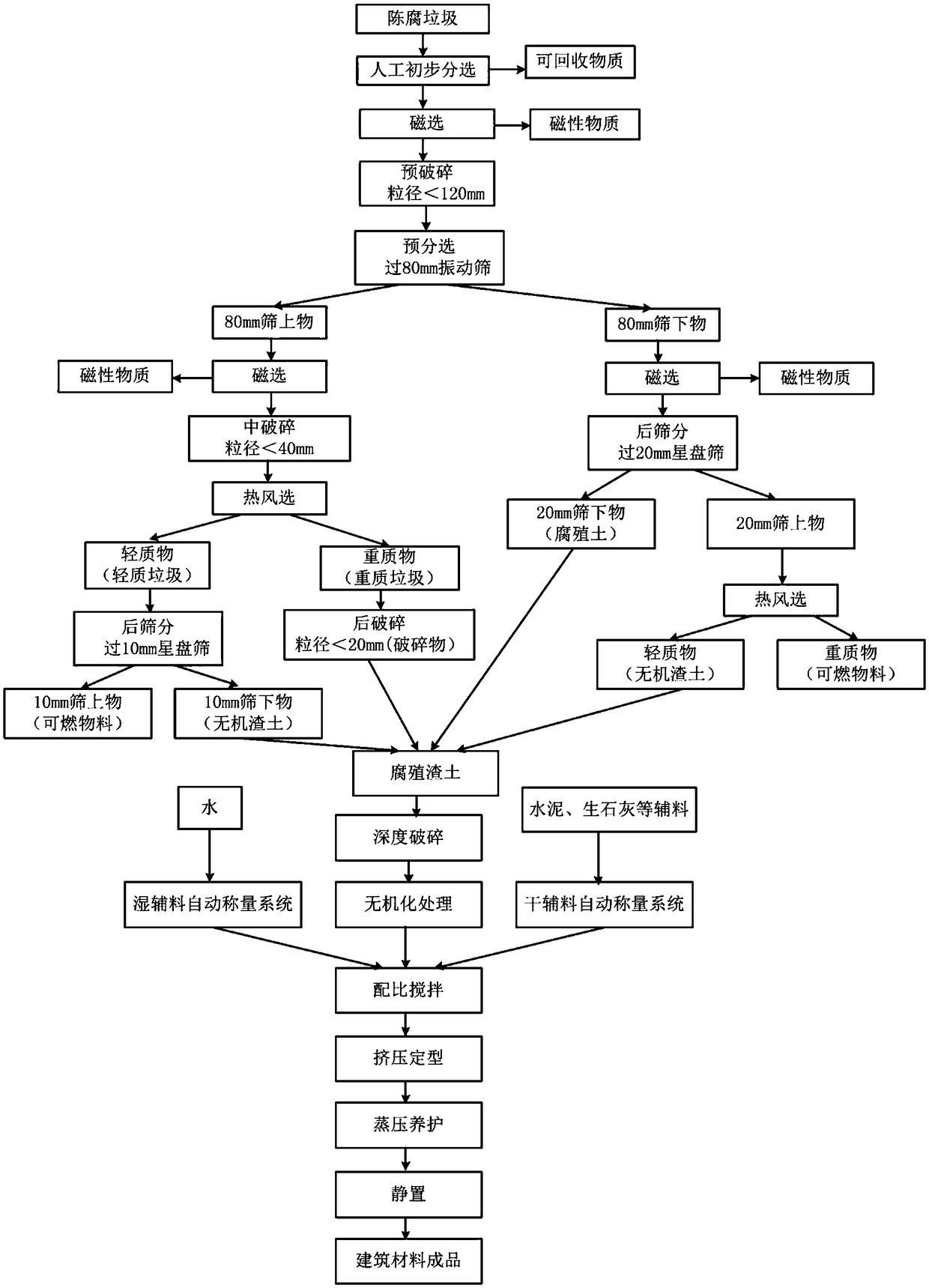

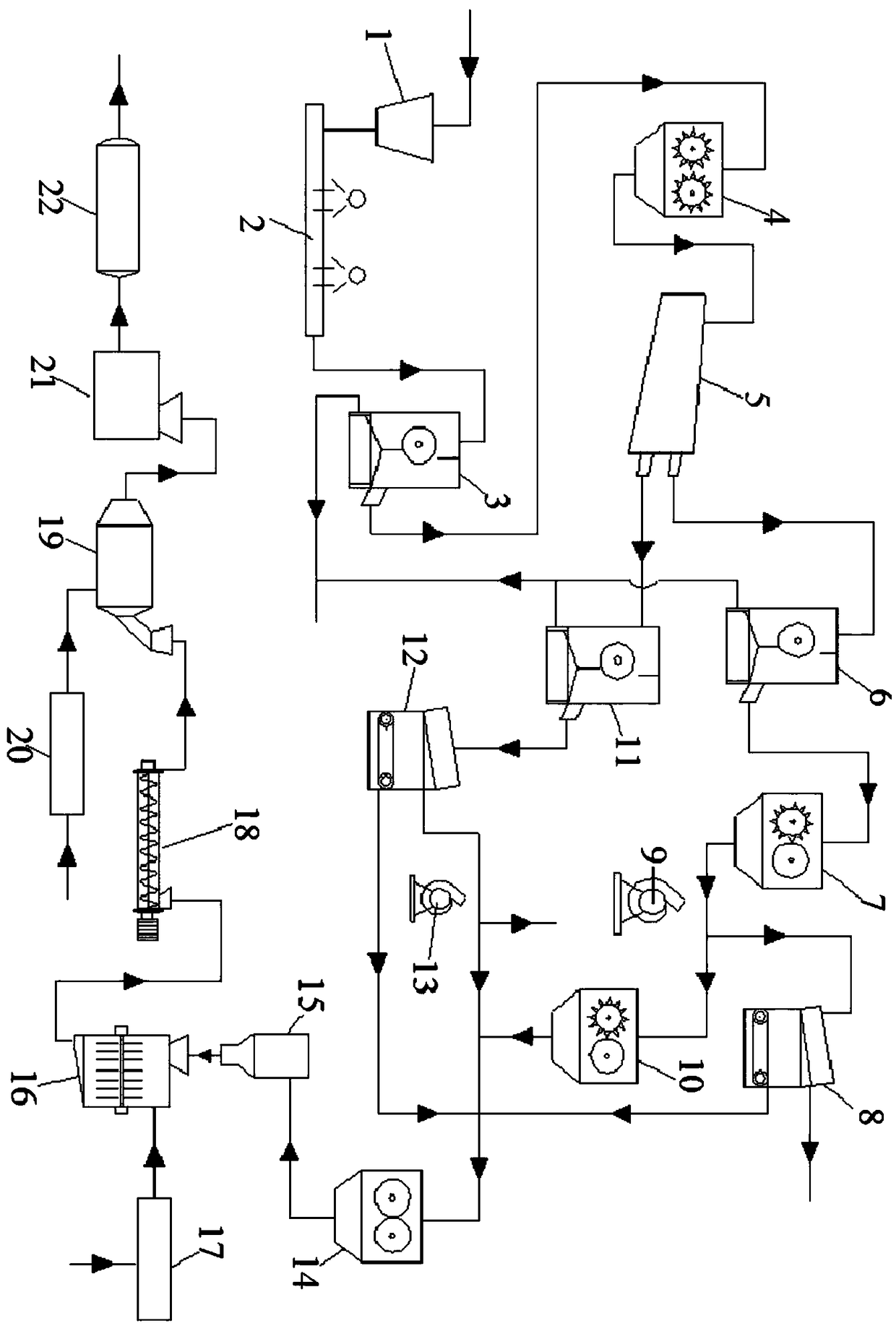

Method and system for manufacturing building materials by using stale garbage

ActiveCN108746152AEfficient separationAccurate sortingSolid waste disposalEnvironmental resistanceSocial benefits

The invention discloses a method and a system for manufacturing building materials by using stale garbage. According to the method, the building material is prepared by taking humic muck screened outfrom the stale garbage as a raw material, and compared with sorting of different components of the stale garbage in the prior art, the method has the advantage that the accuracy is higher so that theresidual value of available resources in the garbage can be fully played; according to the system, manual sorting, magnetic separation, hot air separation, screening and crushing devices are combined, the process is well-organized, high-efficiency separation of magnetic substances, combustibles, the humic muck, large plastic blocks, large rubber blocks and other recyclable objects in the stale garbage can be achieved, so that accurate sorting and highly recovery of recyclable resources in the stale garbage can be realized; and meanwhile, due to the fact that the content of the humic muck in the stale garbage is extremely high, the muck is regenerated into the building material, a large amount of soil taking land can be saved every year, and the extremely good environmental protection benefit and social benefit are achieved.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

Method for preparing flexible hafnium oxide-based ferroelectric film

InactiveCN108039408AWon't crackImprove ferroelectric propertiesSemiconductor/solid-state device manufacturingGalvano-magnetic device manufacture/treatmentSingle crystalPulsed laser deposition

The invention discloses a method for preparing a flexible hafnium oxide-based ferroelectric film. The method comprises the following steps: 1) preparing a TiN bottom electrode on a monocrystalline flexible mica sheet by adopting magnetron sputtering or preparing a perovskite structure oxide SRO bottom electrode by adopting a pulsed laser deposition method; 2) preparing a precursor solution of theferroelectric film by adopting a sol-gel method, wherein the concentration of the precursor solution is 0.01-0.05mol / L, and the ferroelectric film material is selected from any one of zirconium-dopedhafnium oxide and yttrium-doped hafnium oxide; 3) preparing the hafnium oxide-based ferroelectric film, namely performing spin-coating on the precursor solution on the SRO or TiN bottom electrode by adopting a spin-coating method so as to obtain a uniform wet film; 4) performing drying, pyrolysis and annealing treatment on the prepared uniform wet film; and 5) repeating the steps 3) to 4) for several times, thereby obtaining the target flexible hafnium oxide-based ferroelectric film.

Owner:XIANGTAN UNIV

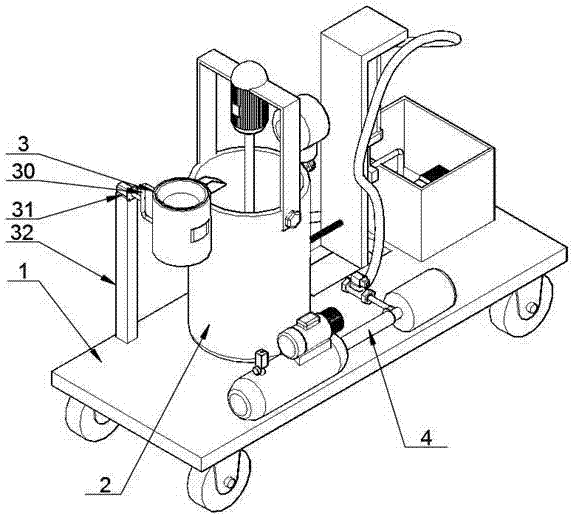

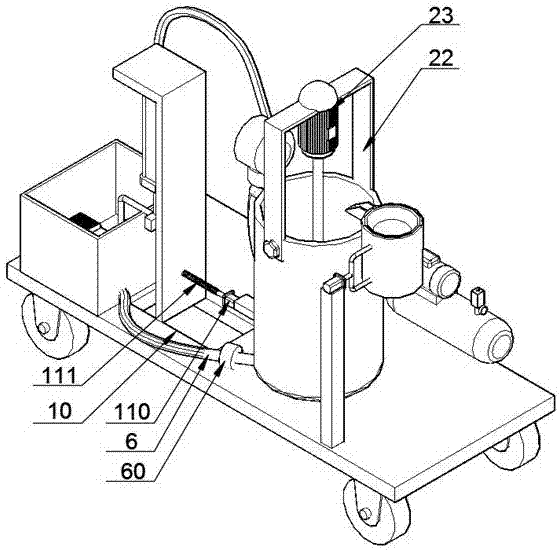

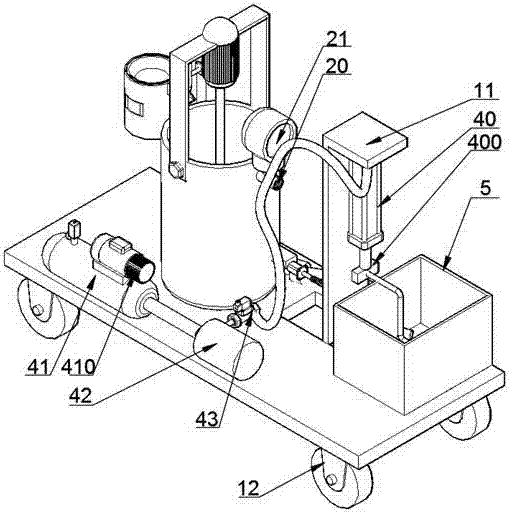

High-speed lime slurry agitator for house building coating

InactiveCN107349835APrecise ingredientsSave human effortRotary stirring mixersTransportation and packagingPistonHouse building

The invention relates to the technical field of construction machinery, in particular to a high-speed lime slurry agitator for house building coating. The high-speed lime slurry agitator comprises a rack, wherein a stirring bucket is arranged on the rack, a feeding cylinder is arranged on one side of the stirring bucket, a batching hopper is arranged on the feeding cylinder, a weighing sensor is arranged at the bottom of the batching hopper, a roll-over stand is arranged on the side face of the feeding cylinder, a second servo motor is arranged on one side of the roll-over stand, a second servo motor is fixed to the rack through a motor fixing base, an output shaft of the second servo motor is fixedly connected with the roll-over stand, a material storing pond is also arranged on the rack and is communicated with the stirring bucket through a discharging pipe, and added materials can reach the best proportional value by metering water flow and lime weight so that the agitator can agitate the best lime slurry. a wall face is automatically painted through piston motions of an air cylinder piston rod, labor is saved, painting is uniform, so that a wall face painting effect is greatly improved, and the working efficiency is greatly improved.

Owner:朱文连

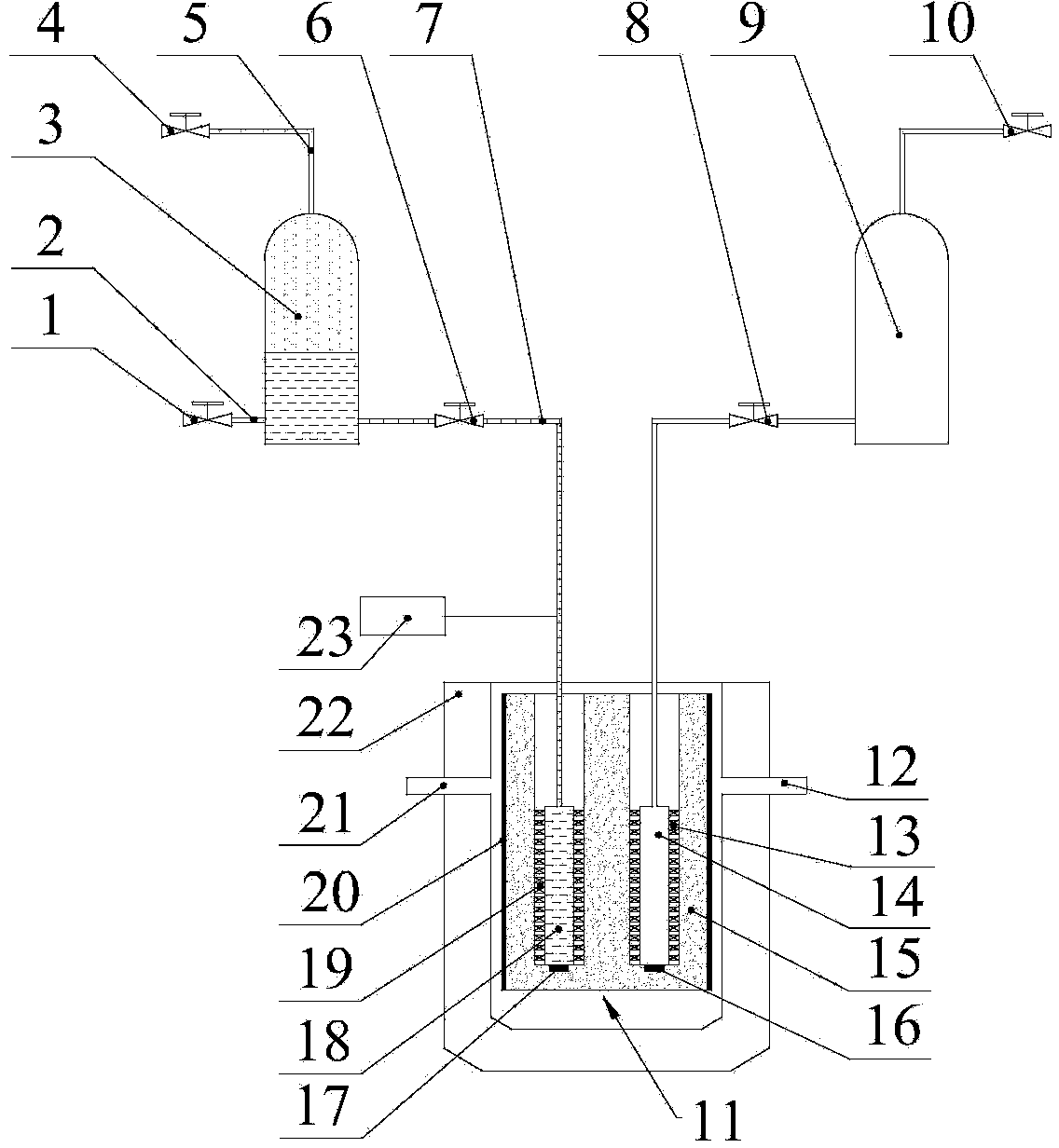

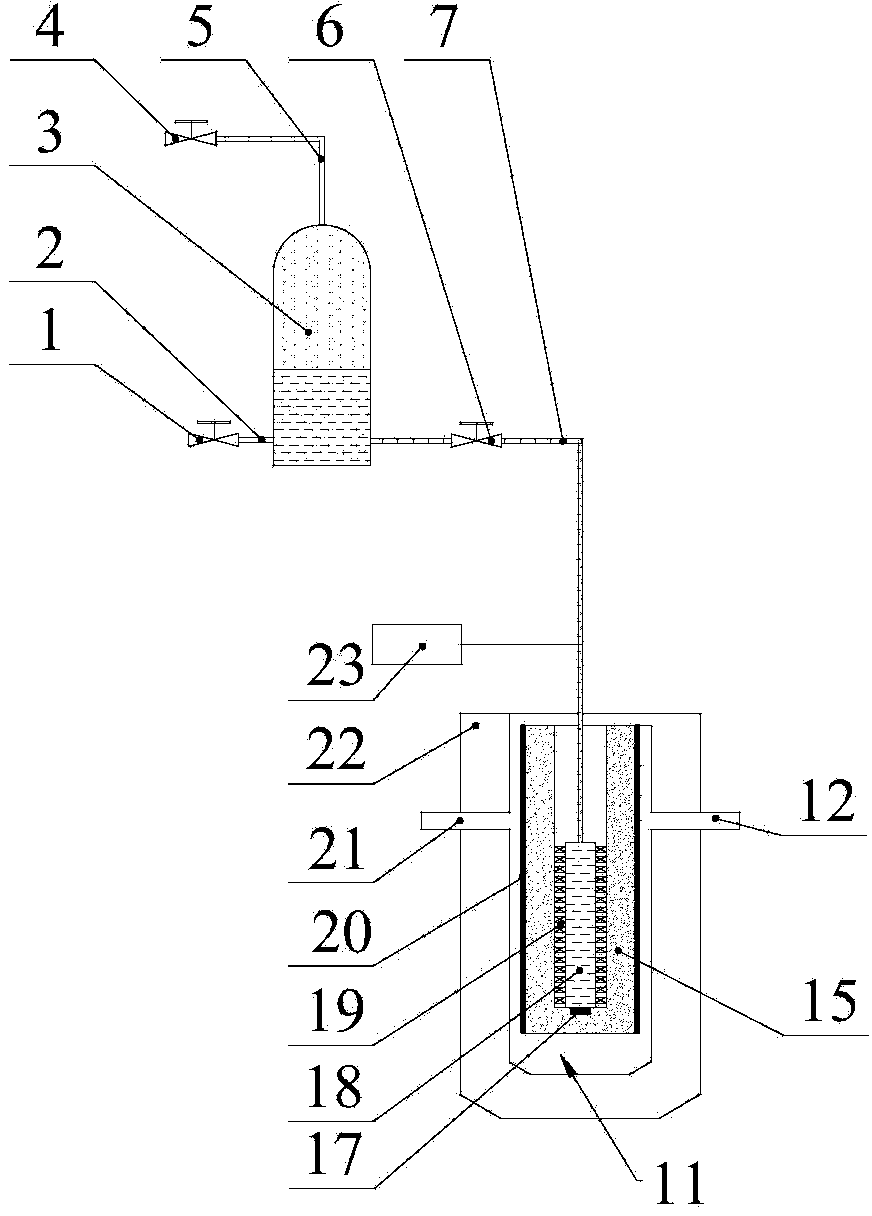

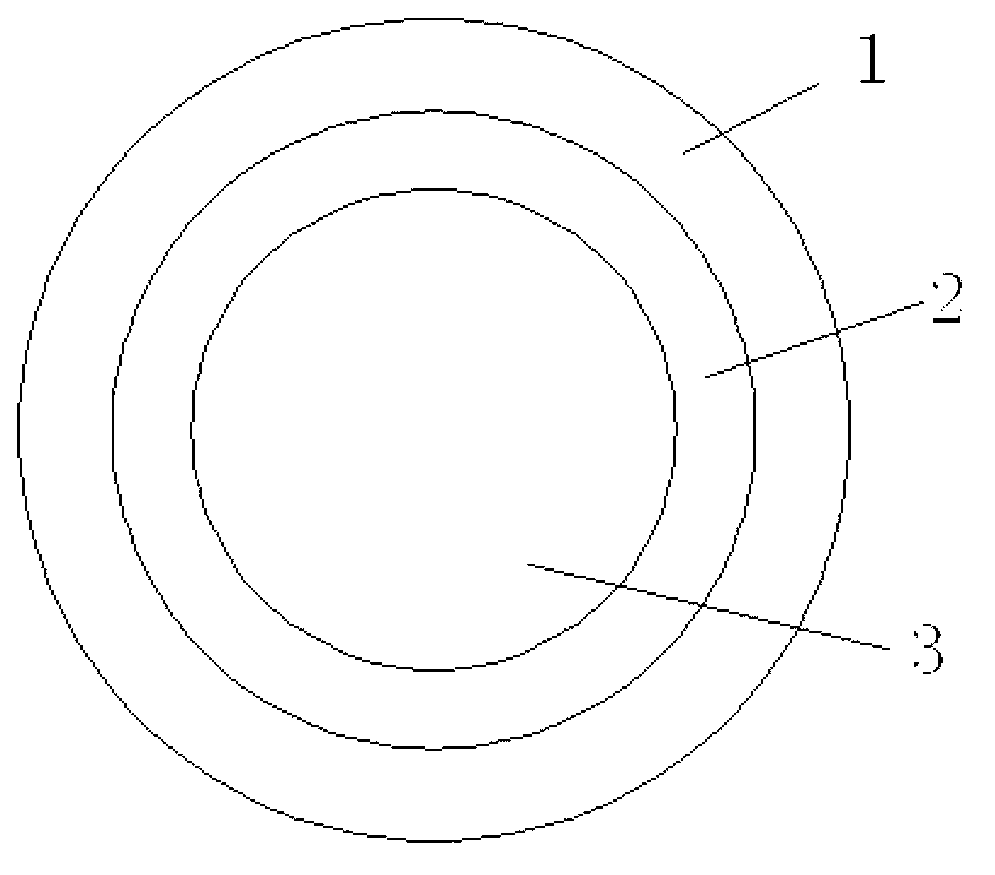

Liquid specific heat capacity measuring device capable of realizing self-balanced pressurization and measuring method

InactiveCN103837567AEasy to adjustUnaffected by thermal expansionMaterial heat developmentSuper coolingHeat flow

The invention discloses a liquid specific heat capacity measuring device capable of realizing self-balanced pressurization and a measuring method. The device comprises a pressure balancing mechanism and a measuring mechanism which are communicated to each other, wherein the pressure balancing mechanism comprises a liquid storage tank, a liquid inlet pipe with a first valve and a liquid outlet pipe with a second valve; one end of the liquid outlet pipe is fixed with the liquid storage tank and the other end of the liquid outlet pipe is fixed with the measuring mechanism. The liquid specific heat capacity measuring device capable of realizing self-balanced pressurization and the measuring method, which are disclosed by the invention, have the advantages that to-be-measured liquid is always in a super-cooling region through a method of pressurizing the to-be-measured liquid by balance gas; the volume of the liquid storage tank is far greater than that of a measuring pool, so that the pressure of the liquid is hardly influenced by the heating expansion of liquid in the measuring pool; the measuring pool is always full of the to-be-measured liquid, so that the influence of bubble generation and liquid evaporation on the heat flow is avoided, the gas-liquid interface is always in the liquid storage tank far away from the measuring pool and the measuring accuracy is high; specific heat capacity experimental data of the whole heating region under the same pressure can be obtained through one heating experiment, so that the experimental time is shortened.

Owner:ZHEJIANG UNIV

Preparation method of broadband gradient LED (Light-emitting Diode) fluorescent film

InactiveCN103243318AImprove performanceUniform color temperatureSolid/suspension decomposition chemical coatingLuminescent compositionsChemistryBroadband

The invention provides a preparation method of a broadband gradient LED (Light-emitting Diode) fluorescent film. The preparation method is characterized in that broadband gradient LED fluorescent powder serves as a raw material; a uniform multicolour (red, green, blue and the like) fluorescent material film is deposited on an LED device or an LED lampshade gasket by a suspension method or a sol-gel method; and the broadband gradient LED fluorescent film prepared by the method has uniform isotropic color temperatures. The preparation method can be used for manufacturing and massively producing high-performance white LEDs with same performance, and can be used for preparing white LED devices, which can emit light approximating to sunlight, with high photoelectric conversion rates and high color rendering indexes. The broadband gradient LED fluorescent powder has a special structure and composition, and is good in dispersity, high in stacking density, great in scattering intensity and high in light-emitting efficiency.

Owner:HUNAN SCI & TECH RES & DEV CENT

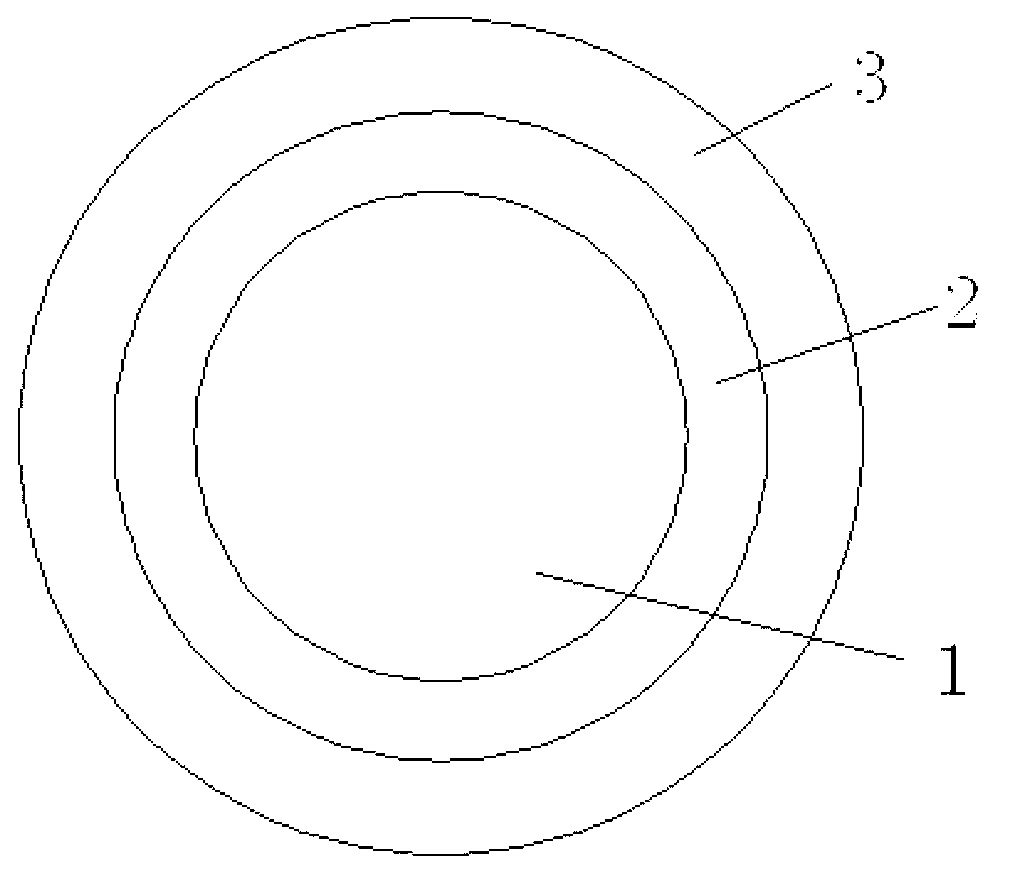

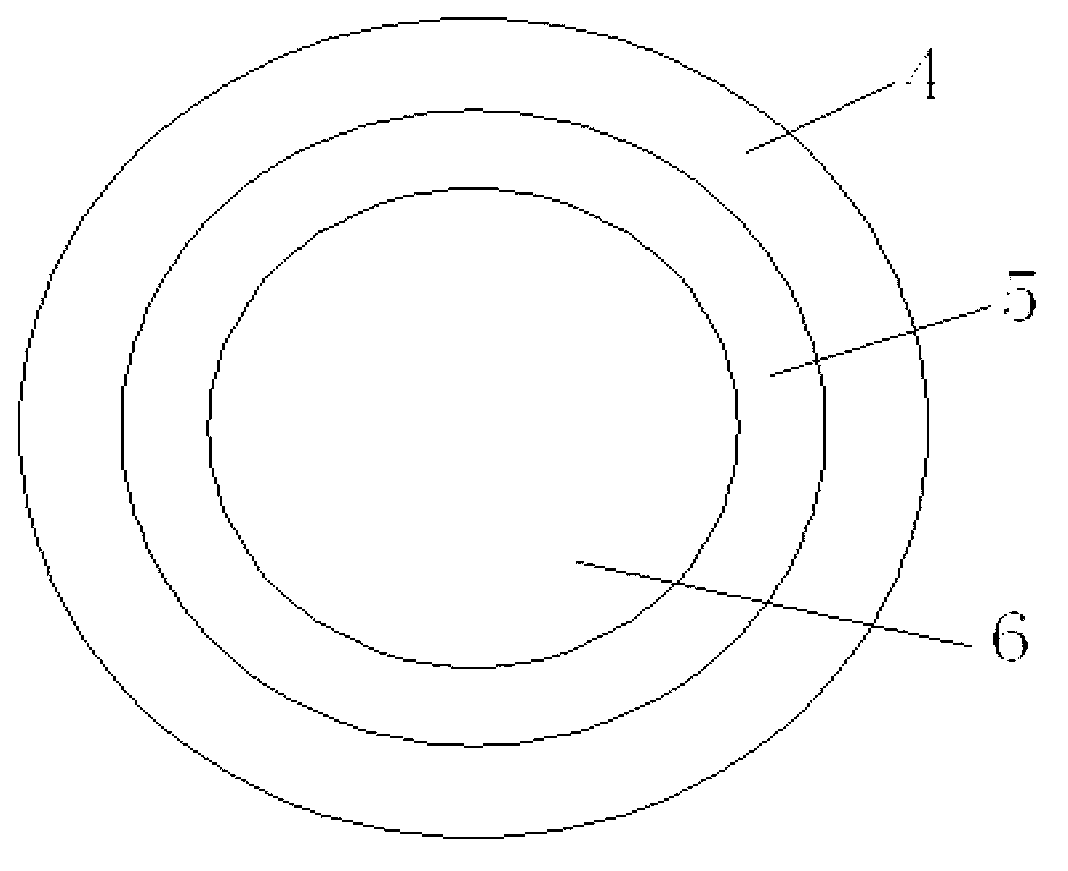

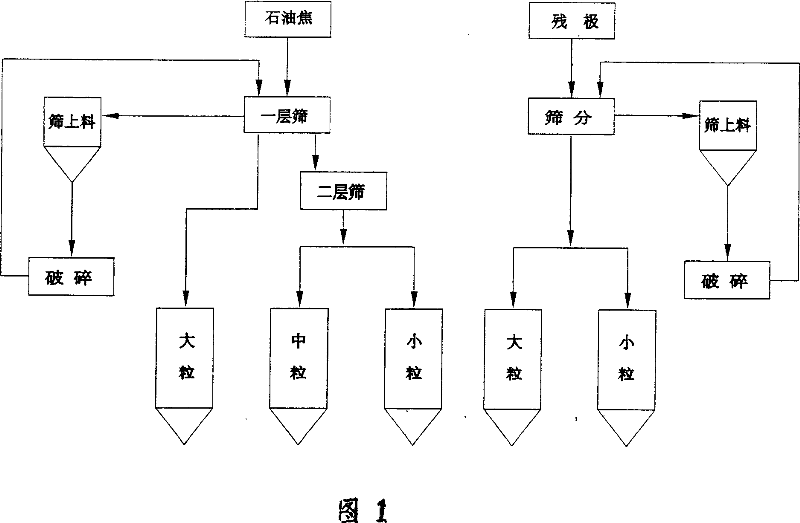

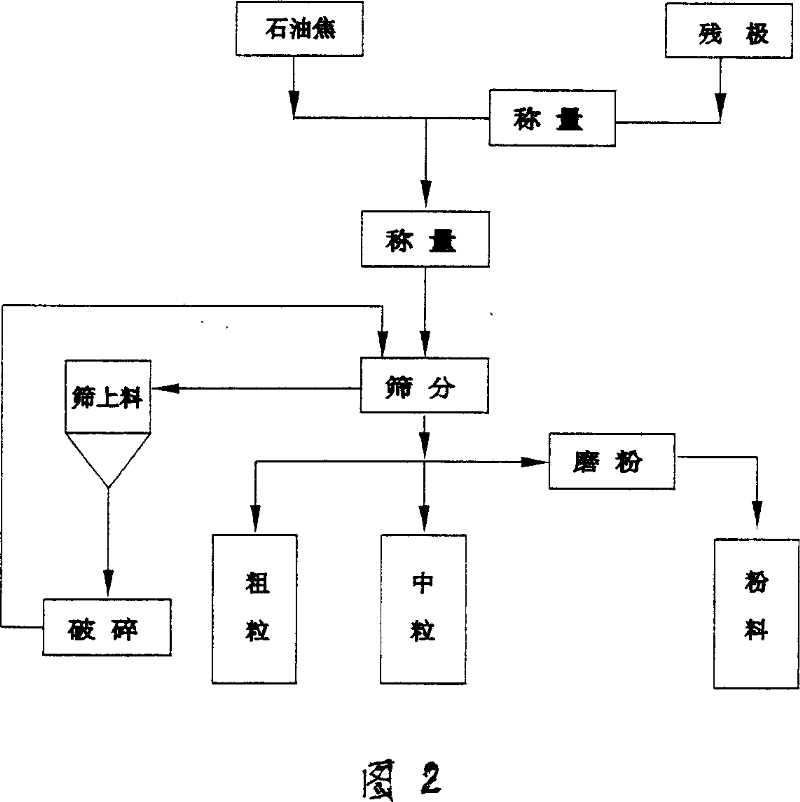

Green anode skeletal material monosystem manufacturing technique

InactiveCN101037776AAdvantages of preparation processSimple calculationGrain distributionPetroleum coke

The invention provides a process for preparing raw anode aggregate single system, including the processes of: roasting coke, crushing stub, screening, dosing amd mixing, characterized in that: petroleum coke and stub are mixed, based on the proportion, then crushing, screening, and grinding downstream. The proportion is, based on weight percent, 75-85:15-25, wherein preferably 85-80:15-20. The invention also provides the grain distribution and preferable grain distribution of the material after crashing. Accordingly, a method for implementing the said process and apparatus is provided, too. Not only the invest is saved, and labour condition and environment are improved, using and popularizing the inventive process for preparing single system, but also the cost of production is reduced anf the quality of product is improved, with prominent social and economical benefit.

Owner:NORTHEASTERN UNIV ENG & RES INST CO LTD

Aluminum lithium alloy for spaceflight and method for preparing proximate matter through aluminum lithium alloy

The invention relates to an aluminum lithium alloy for spaceflight and an aluminum lithium alloy proximate matter preparing method, and relates to the aluminum lithium alloy and the aluminum lithium alloy proximate matter preparing method. The aim is to solve the problems that the production difficulty of the aluminum lithium alloy is large, and the aluminum lithium alloy strength is low. The aluminum lithium alloy is composed of Mg, Li, Ti, Zr and Al, the Mg accounts for 5.5%-6.5%, the Li accounts for 2.2%-2.5%, the Ti accounts for 0.03%-0.12%, the Zr accounts for 0.15%-0.20%, the Zr+Ti is smaller than or equal to 0.25%, and the balance is the Al. The method includes the steps of raw material weighing, aluminum alloy molten liquid preparing, refining, spray forming, short bar cutting, blind die extrusion, heat extrusion, quenching, tension leveling and aging treatment. According to the aluminum lithium alloy and the aluminum lithium alloy proximate matter preparing method, through spray forming, the problems that the aluminum lithium alloy production difficulty is large, and the quality is poor are solved, the strength of extension reaches 485 Mpa, the ruled non-proportional extending strength reaches 345 Mpa, the percentage elongation after fracture reaches 10.0%, and blind die extrusion enables a casting ingot to be more compact.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Preparation method for high-coercivity sintered neodymium-iron-boron

ActiveCN103956244AAccurate ingredientsExtend the life cycleInorganic material magnetismDehydrogenationNitrogen gas

The invention discloses a preparation method for high-coercivity sintered neodymium-iron-boron. The method specifically comprises the following steps: batching raw materials proportionally, and preparing a thin alloy sheet by using a medium-frequency vacuum rapid-hardening melt-spinning furnace; performing normal-temperature hydrogen absorption and heating dehydrogenation on the thin alloy sheet in a reaction kettle of a hydrogen decrepitating furnace to prepare coarse particles of which the particle size is 60-80 meshes; milling hydrogen-decrepitated coarse powder by using a jet mill to form fine powder of which the average particle size is 2.0-4.0 mu m; adding one or more rare-earth nano additives into the powder by using a jet method, and performing uniform mixing in the atmosphere of argon shielding; performing oriented molding and isostatic pressing on the mixed powder under the argon shielding through a 1.8-3.0T magnetic field; filling a green neodymium-iron-boron body into a vacuum sintering furnace in a closed glove box full of nitrogen, continuously sintering the green neodymium-iron-boron body for three times, quickly cooling the green neodymium-iron-boron body, and finally, aging the green neodymium-iron-boron body twice to prepare a corresponding neodymium-iron-boron magnet of which the performance meets the national standard. The method is low in cost, simple in process, energy-saving, environmentally-friendly, and high in rare-earth utilization rate.

Owner:SHENYANG SHENGSHI WUHUAN TECH CO LTD

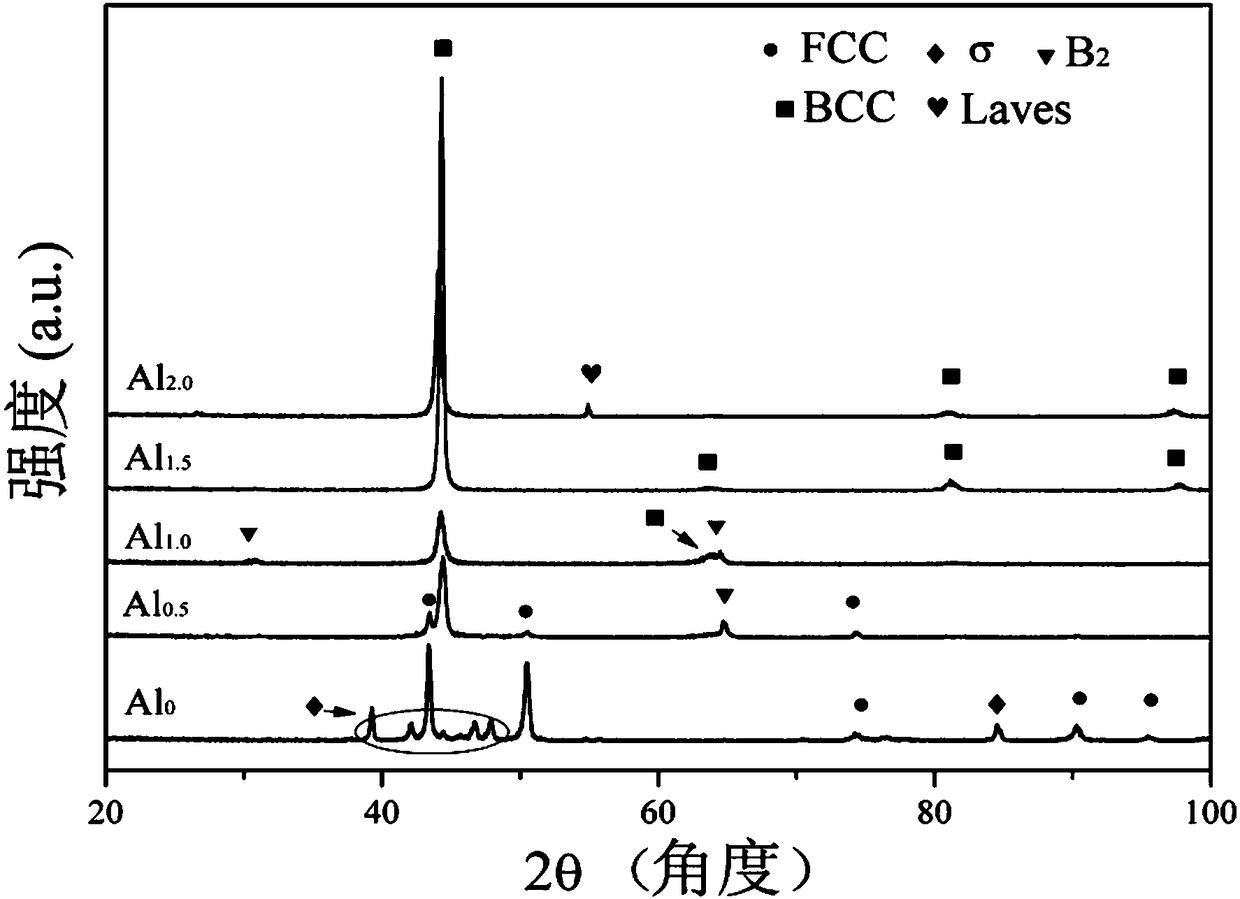

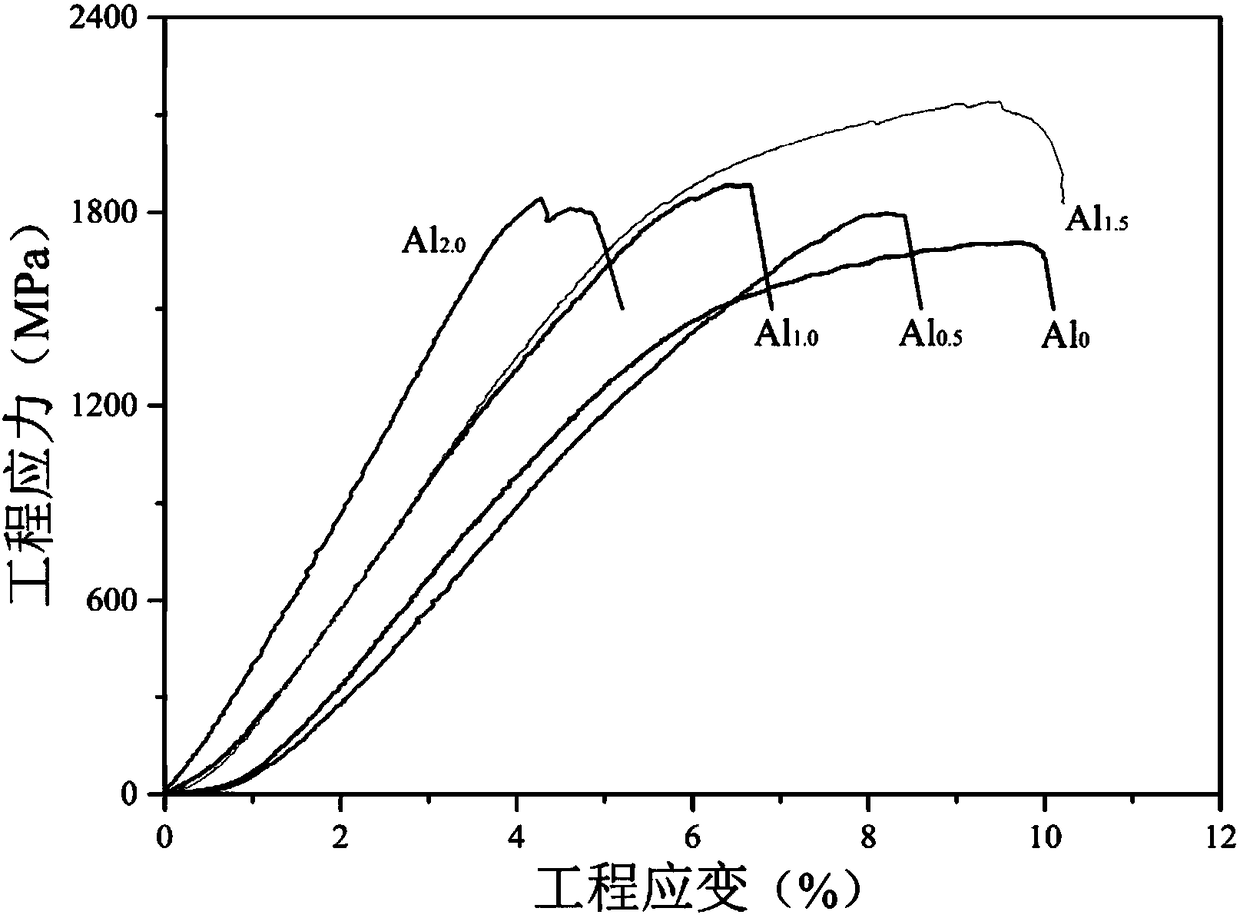

High-strength refractory six-element high-entropy alloy CoCrFeNiVAlx and preparation method thereof

The invention discloses a high-strength refractory six-element high-entropy alloy CoCrFeNiVAlx and a preparation method thereof. The high-strength refractory six-element high-entropy alloy is composedof cobalt, chromium, iron, nickel, vanadium and aluminum which all have the purity of at least 99.9%; and all the elements are calculated according to the atomic percent, specifically, Co is 14-20 at%, Cr is 14-20 at%, Fe is 14-20 at%, Ni is 14-20 at%, V is 14-20 at%, and Al is 0-30 at%. The alloy is prepared through an intermediate alloying method, and the preparation steps include that Co, Ni,Fe and Al which are low in melting point are mixed and molten, Cr and V which are high in melting point are mixed and molten, smelting is performed repeatedly for several times, then two intermediatealloys are smelted, and smelting is performed repeatedly for several times so as to guarantee the uniformity. By means of the high-entropy alloy CoCrFeNiVAlx obtained through the method, the problemsthat Al is prone to being damaged by burning and multi-element alloy smelting is non-uniform can be solved excellently, the strength, hardness and plasticity are high, and the high-strength refractorysix-element high-entropy alloy CoCrFeNiVAlx and the preparation method thereof can be applied to the fields of aerospace, mechanical heavy industries and the like.

Owner:GUANGXI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com