Fodder automatic batching system and production process thereof

A technology for automatic batching and feed, applied in the fields of feed, food science, application, etc., can solve the problems of poor quality of feed products, poor automation, limited processing range, etc., and achieve the effect of excellent product quality, less impurities and saving processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

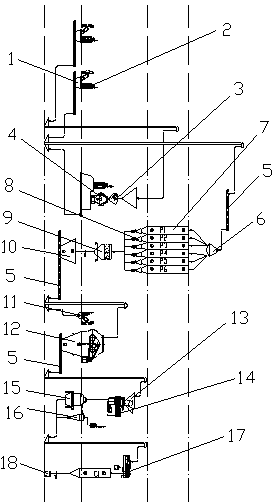

[0030] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0031] Such as figure 1 As shown, an automatic feed batching system includes a pulse dust removal fan 2, a conveying device 5, a distributor 6, several silos 7, a batching scale 9, a mixer 12, a conditioner 14, a granulator 15 and a grading screen 17 , there are multiple feeding ports 1, which are used to input different materials. The pulse dust removal fan 2 is arranged in the feeding port 1, and the input materials are dedusted by the pulse dust removal fan 2, and the pulse dust removal fan 2 passes through the conveying device 5 and the distributor 6 connected, the dust-removed material is sent to the distributor 6 through the conveying device 5, a pulver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com