Patents

Literature

35results about How to "Precise ingredients" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laser smelting furnace with water cooled copper mould and method for smelting ingot

Owner:BEIHANG UNIV

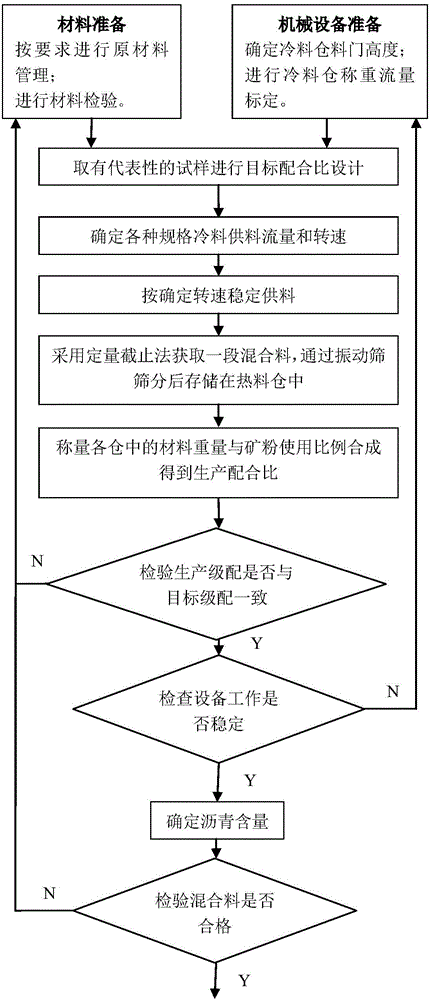

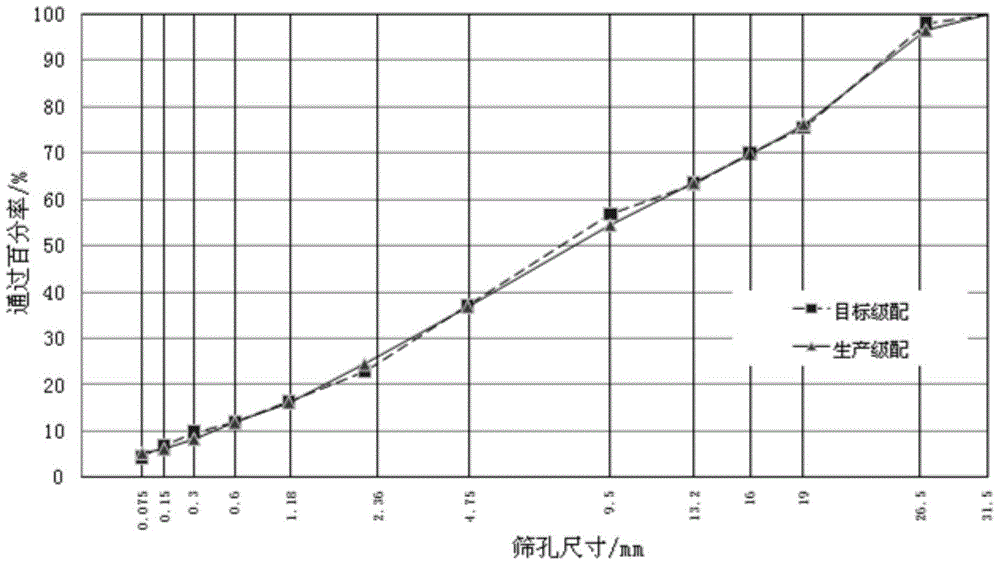

Normalized design method of production mix proportion and target mix proportion of bituminous mixture

InactiveCN104594160AGuaranteed uptimePrecise ingredientsRoads maintainenceEngineeringCalibration curve

The invention relates to a normalized design method of production mix proportion and target mix proportion of a bituminous mixture. The normalized design method comprises the following steps of calibrating a cold stock bin so as to obtain a two-dimensional calibration curve of the rotation speed of a feeding belt machine and the feeding flow rate; determining the feeding rotation speed according to the target mix proportion, intercepting the mixture by adopting a quantitative cut-off experiment method, screening by a vibration screen, and storing into a hot stock bin; weighing materials in the bins so as to obtain the proportion of hot aggregate; combining the proportion of the hot aggregate and the proportion used for mineral powder so as to obtain the production mix proportion; and combining the production grading according to the production mix proportion so as to obtain a production grading curve conforming to the target grading. The design method of the bituminous mixture is named as the normalized design method of the production mix proportion and the target mix proportion.

Owner:CHANGAN UNIV

Pre-dispersion masterbatch used as rubber ultra-fast accelerator ZDMC and preparation method of pre-dispersion masterbatch

The invention discloses a pre-dispersion masterbatch used as a rubber ultra-fast accelerator ZDMC. The pre-dispersion masterbatch used as the rubber ultra-fast accelerator ZDMC consists of the following components in parts by weight: 75-82 parts of zinc dimethyldithiocarbamate, 10-14 parts of a rubber carrier, 2-6 parts of naphthenic oil, 1 part of stearic acid, 1 part of triethanolamine, and 2-5 parts of a mixture of saturated and unsaturated fatty acid zinc soap. The zinc dimethyldithiocarbamate is prepared into the pre-dispersion masterbatch, so that the original activity of the zinc dimethyldithiocarbamate can be guaranteed effectively. The pre-dispersion masterbatch cannot be caked at room temperature, and batching is convenient and accurate, when the pre-dispersion masterbatch is used as an ultra-fast accelerator in the follow-up process, dust flying is avoided in a rubber melting process, a working environment of an operator can be improved, the use level of the accelerator is reduced, and the utilization rate of the zinc dimethyldithiocarbamate is increased; the pre-dispersion masterbatch has relatively low Mooney viscosity at the relatively low temperature of 50 DEG C, and has good dispersibility in rubber, and the quality of a rubber product can be improved.

Owner:NINGBO ACTMIX POLYMER

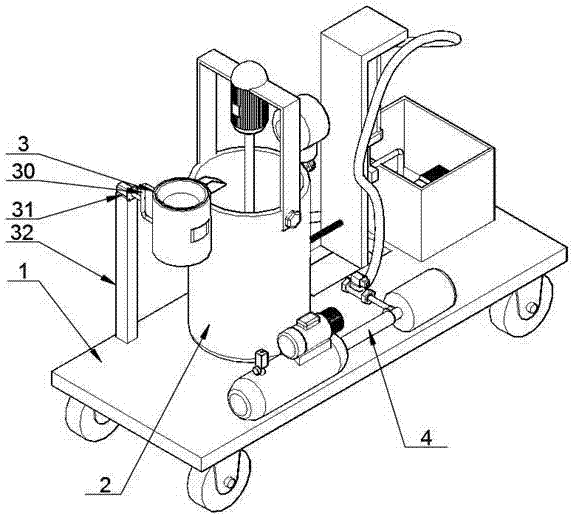

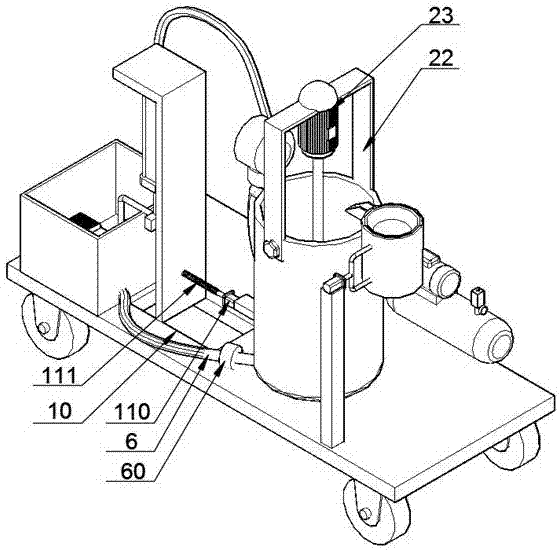

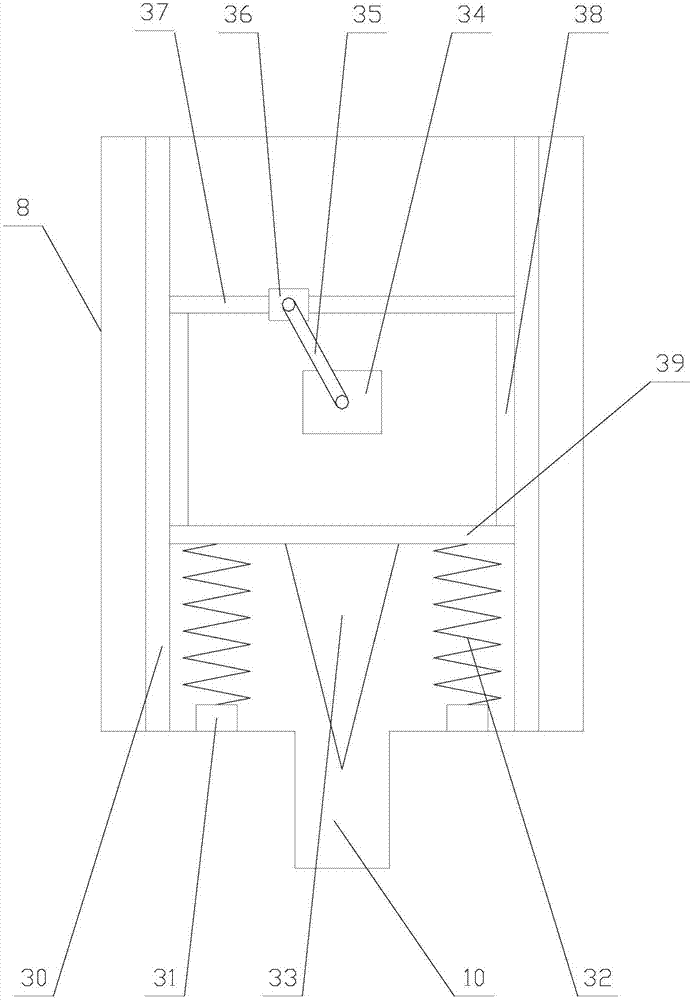

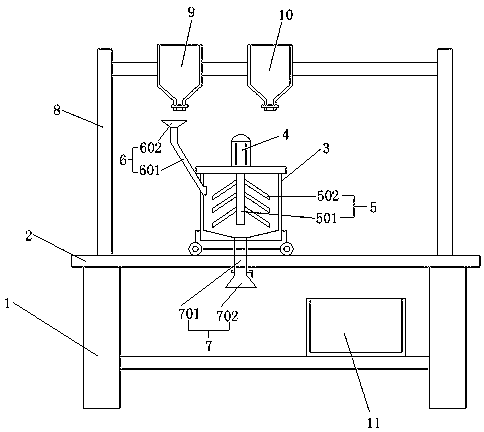

High-speed lime slurry agitator for house building coating

InactiveCN107349835APrecise ingredientsSave human effortRotary stirring mixersTransportation and packagingPistonHouse building

The invention relates to the technical field of construction machinery, in particular to a high-speed lime slurry agitator for house building coating. The high-speed lime slurry agitator comprises a rack, wherein a stirring bucket is arranged on the rack, a feeding cylinder is arranged on one side of the stirring bucket, a batching hopper is arranged on the feeding cylinder, a weighing sensor is arranged at the bottom of the batching hopper, a roll-over stand is arranged on the side face of the feeding cylinder, a second servo motor is arranged on one side of the roll-over stand, a second servo motor is fixed to the rack through a motor fixing base, an output shaft of the second servo motor is fixedly connected with the roll-over stand, a material storing pond is also arranged on the rack and is communicated with the stirring bucket through a discharging pipe, and added materials can reach the best proportional value by metering water flow and lime weight so that the agitator can agitate the best lime slurry. a wall face is automatically painted through piston motions of an air cylinder piston rod, labor is saved, painting is uniform, so that a wall face painting effect is greatly improved, and the working efficiency is greatly improved.

Owner:朱文连

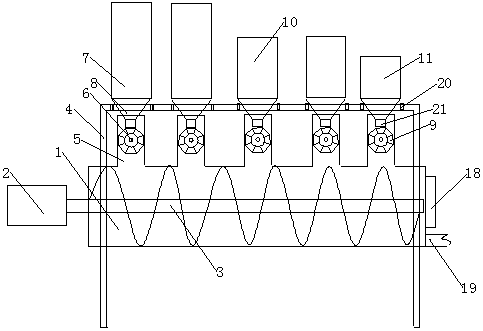

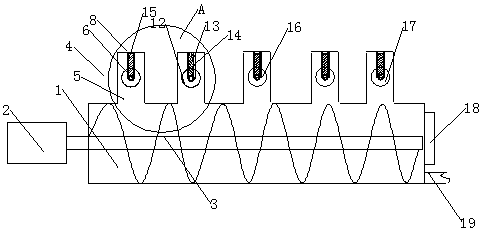

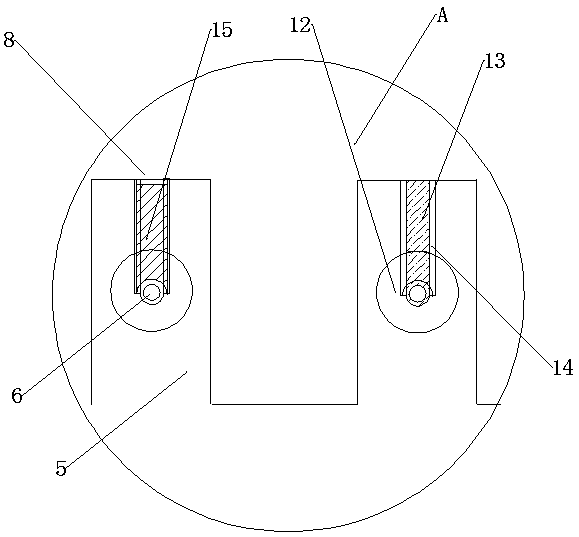

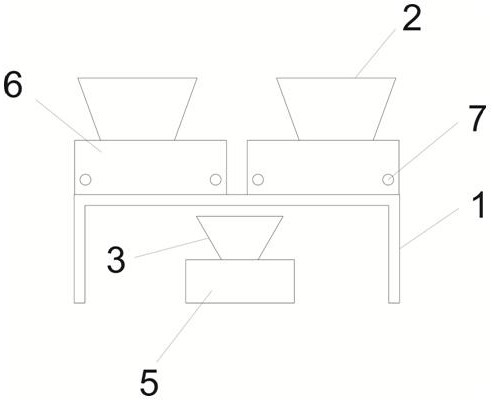

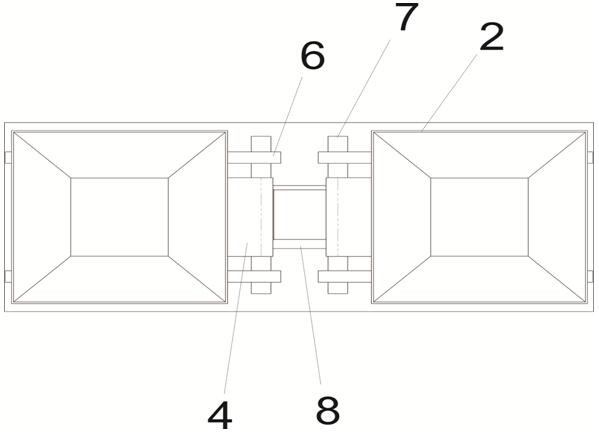

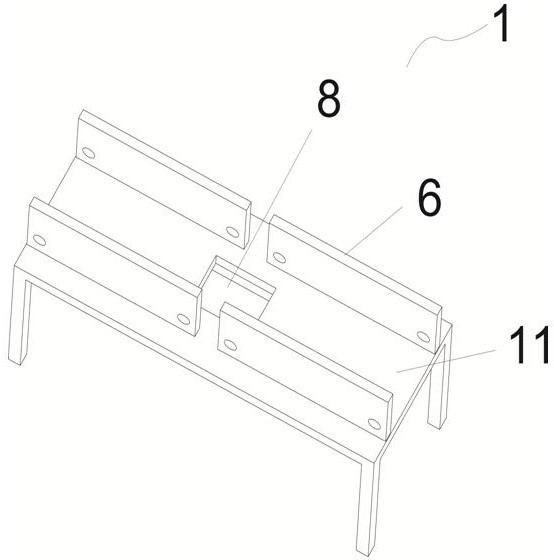

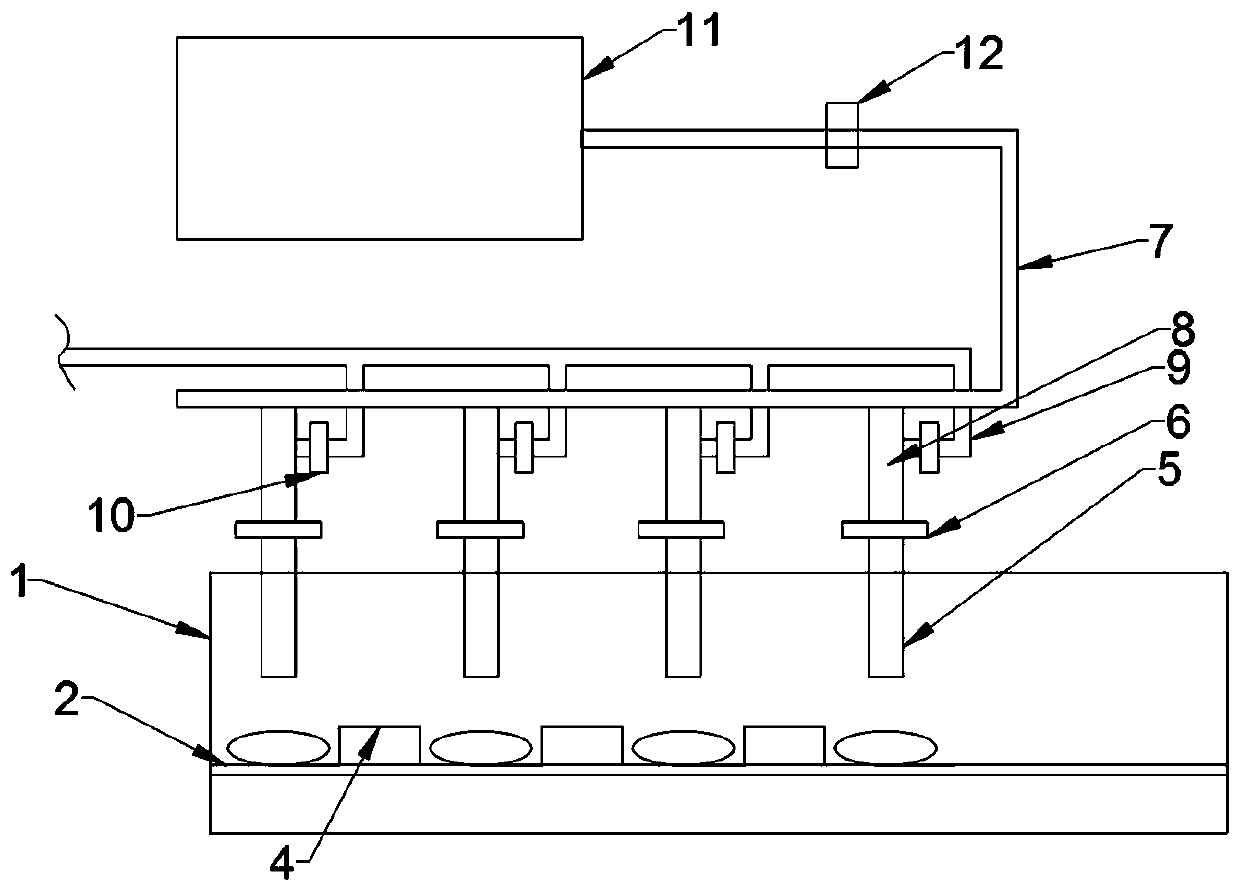

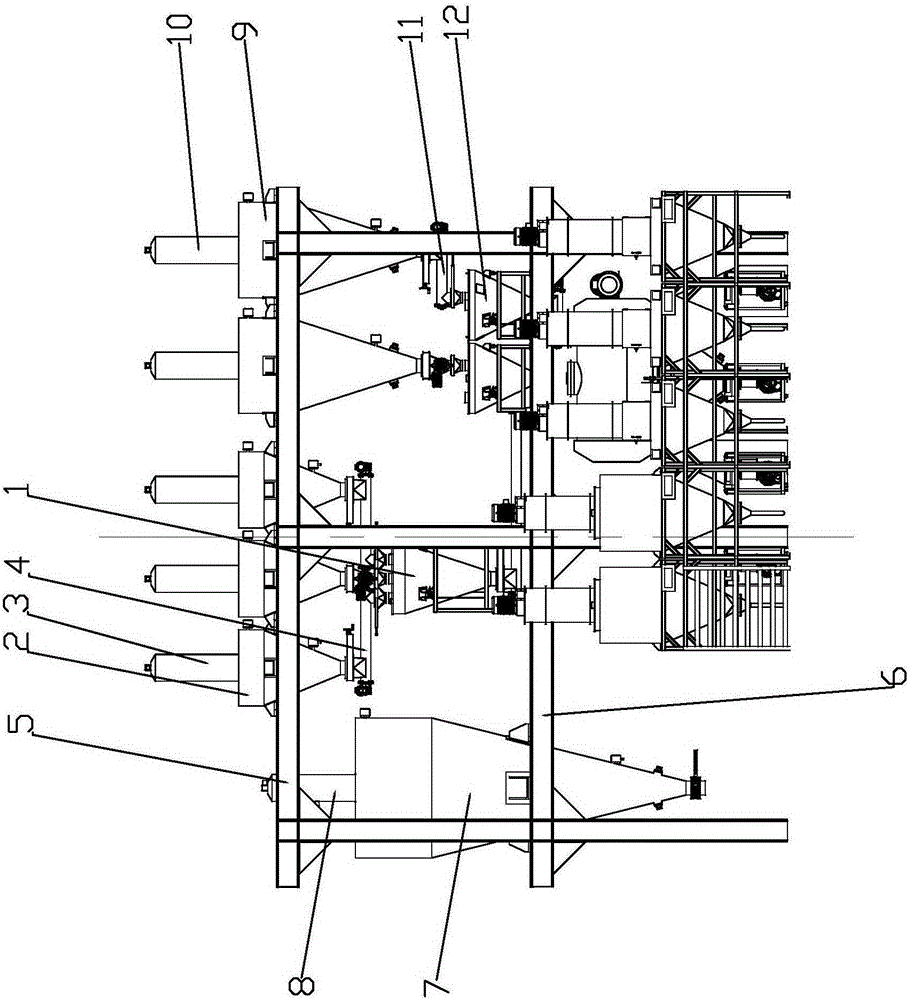

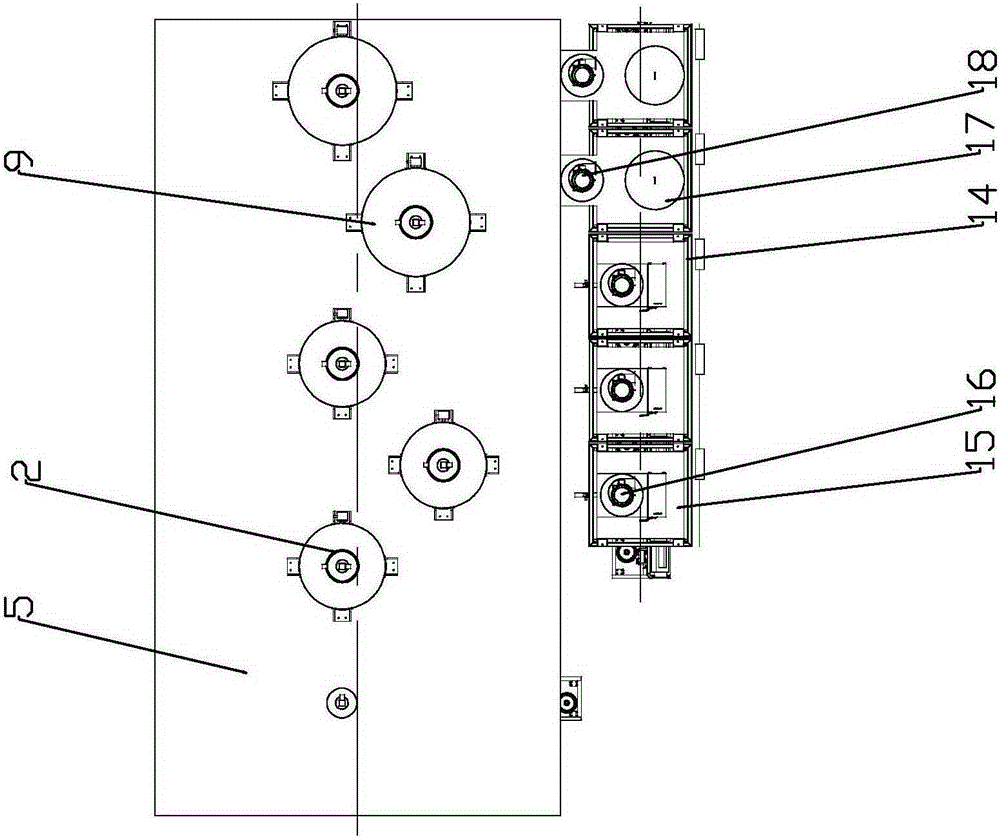

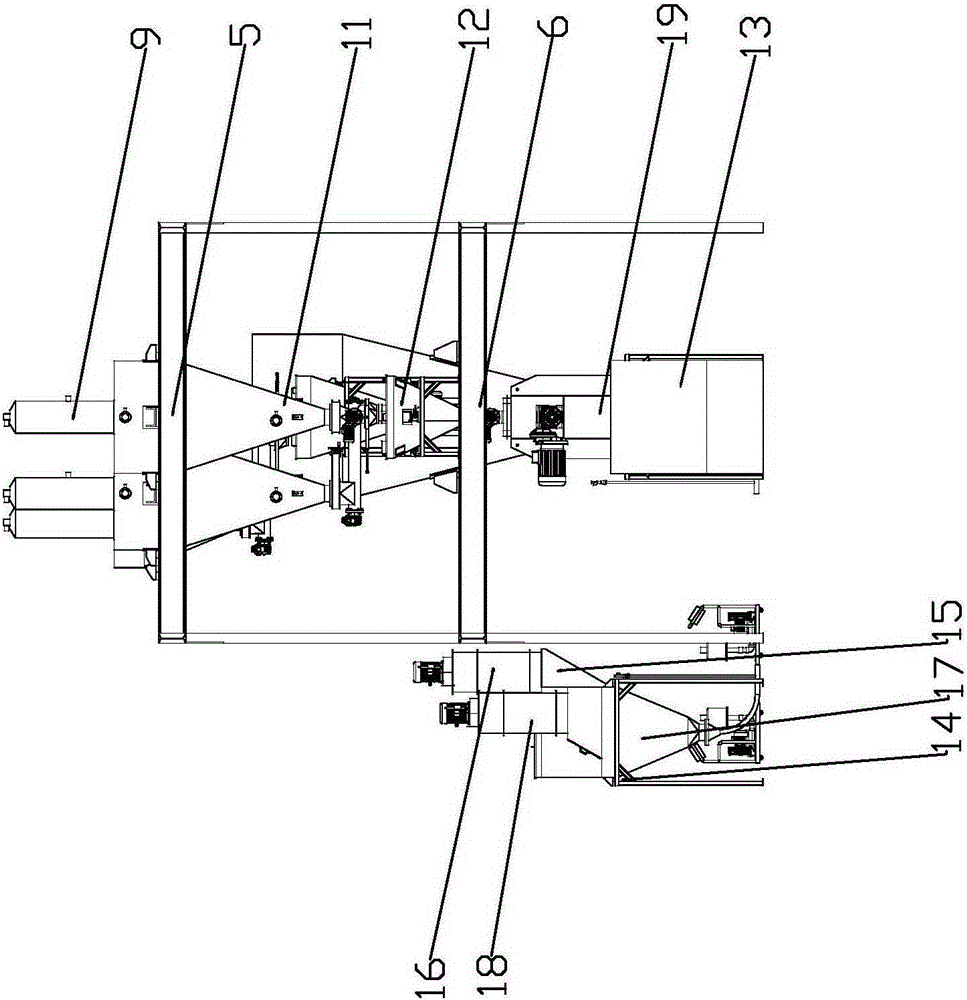

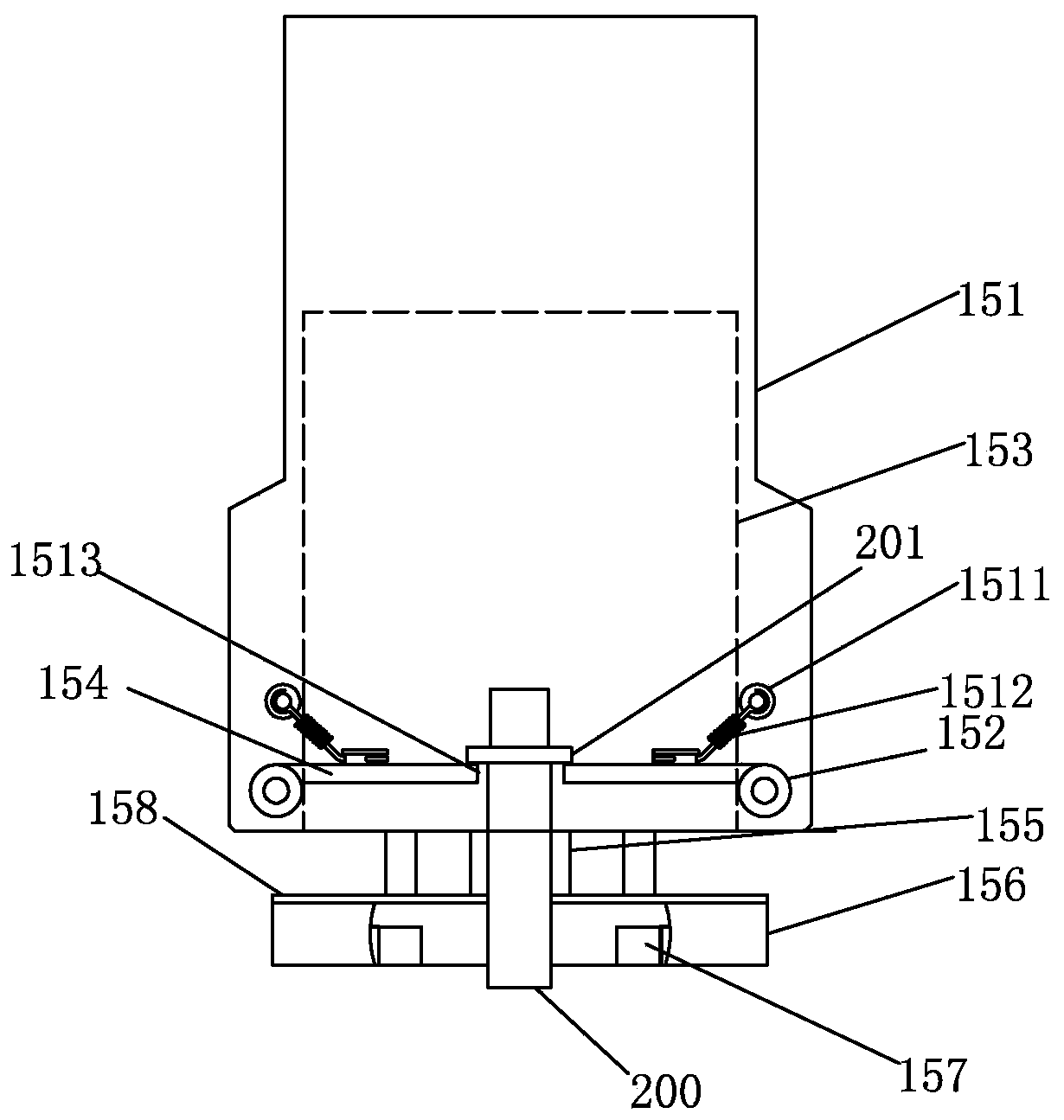

Feed proportioning and feeding system

The invention discloses a feed proportioning and feeding system. The system comprises a material proportioning device, a discharging device, a weighing device and a positioning feeding device, whereinthe material proportioning device comprises a hopper and a material mixing bin; the material mixing bin is positioned under the hopper; through the discharging device, the mixed feed in the materialmixing bin is discharged from a discharging opening; a material tube is positioned under discharged materials of the discharging device; through the weighing device, the feed in a barrel is weighed; the positioning feeding device comprises a material collecting hopper, a material feeding passage and a plurality of material feeding control baffle plates; the material collecting hopper is arranged under a material weighing base; material falling holes are formed at intervals in the material feeding passage; the quantity of the material feeding control baffle plates is identical to the quantity of the material falling holes; one material feeding control baffle plate is respectively arranged in the position of each material falling opening; by controlling the work state of the material feedingcontrol baffle plates of different material falling openings of the material feeding passage, the material feeding of the specified material falling opening can be realized. The precise proportioning, material weighing and feeding can be realized; the design is reasonable; and automation and integration degrees are high.

Owner:TIANJIN AGRICULTURE COLLEGE

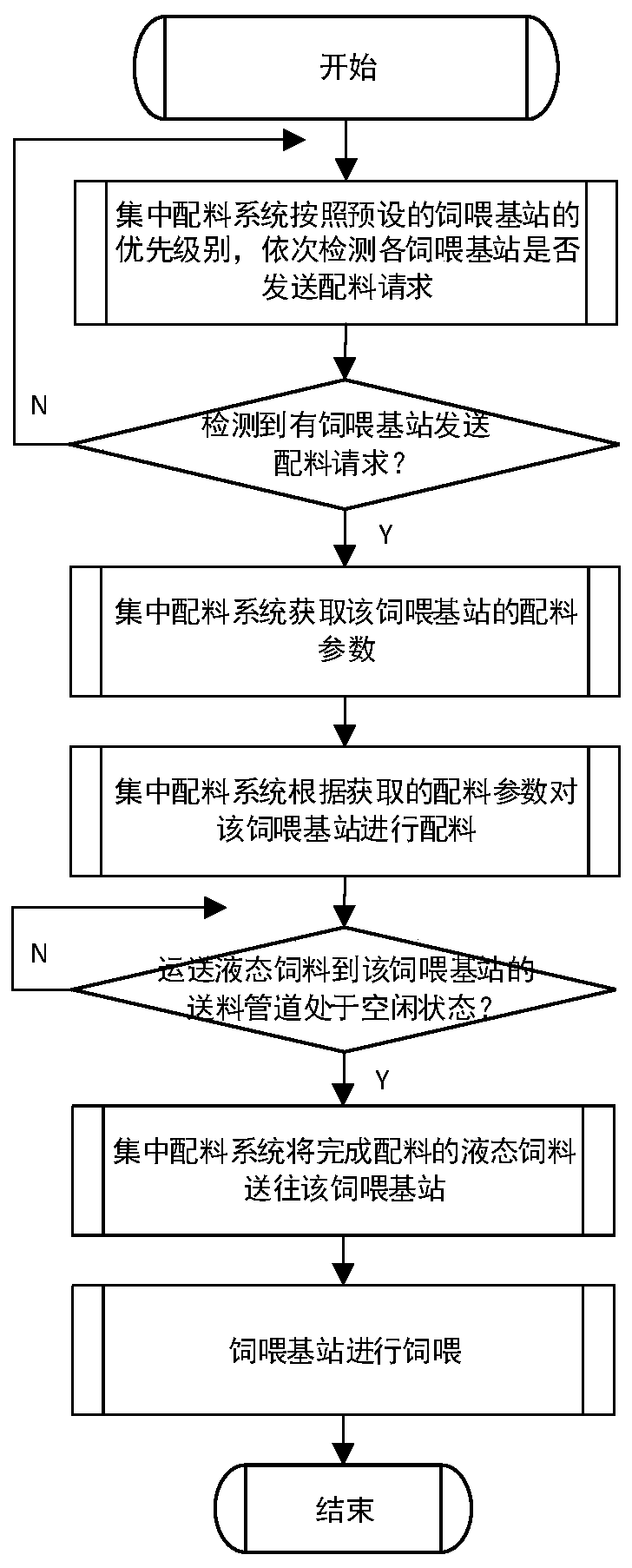

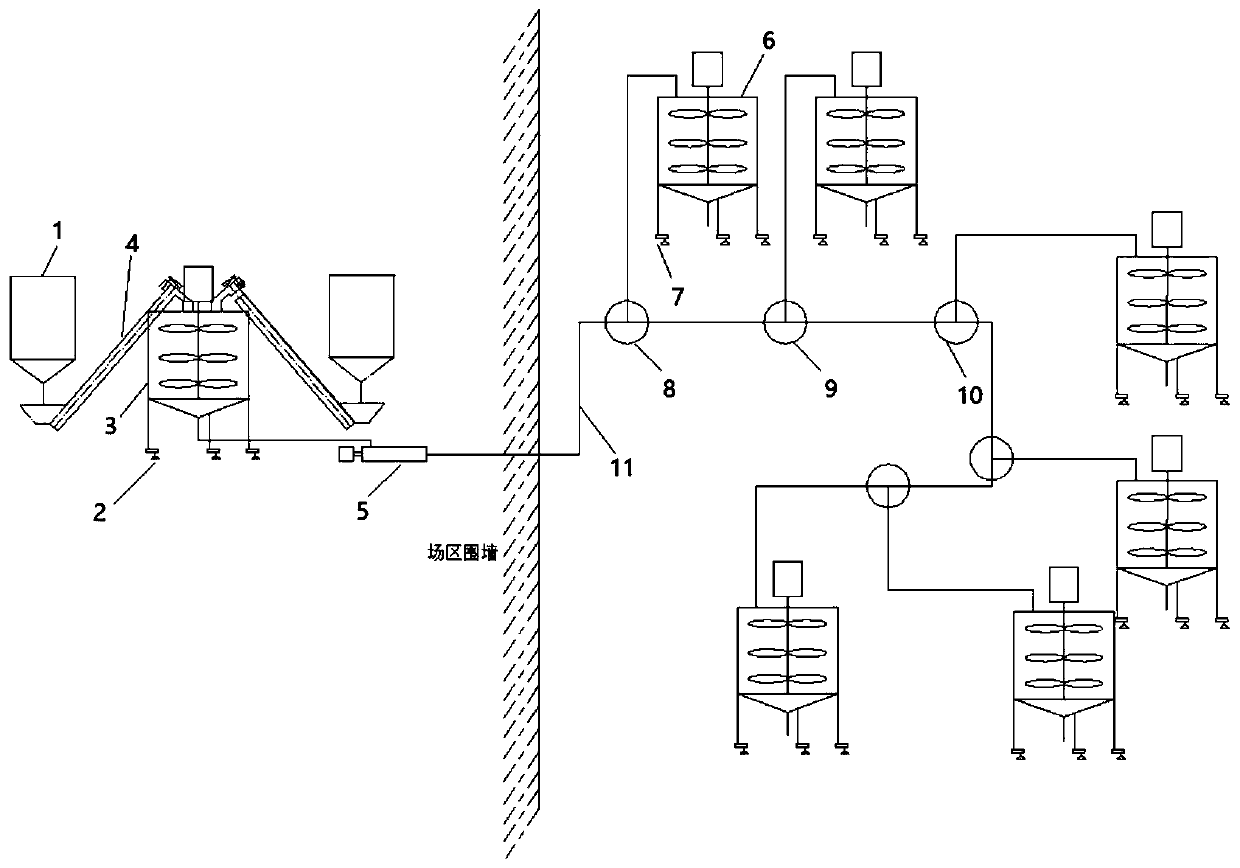

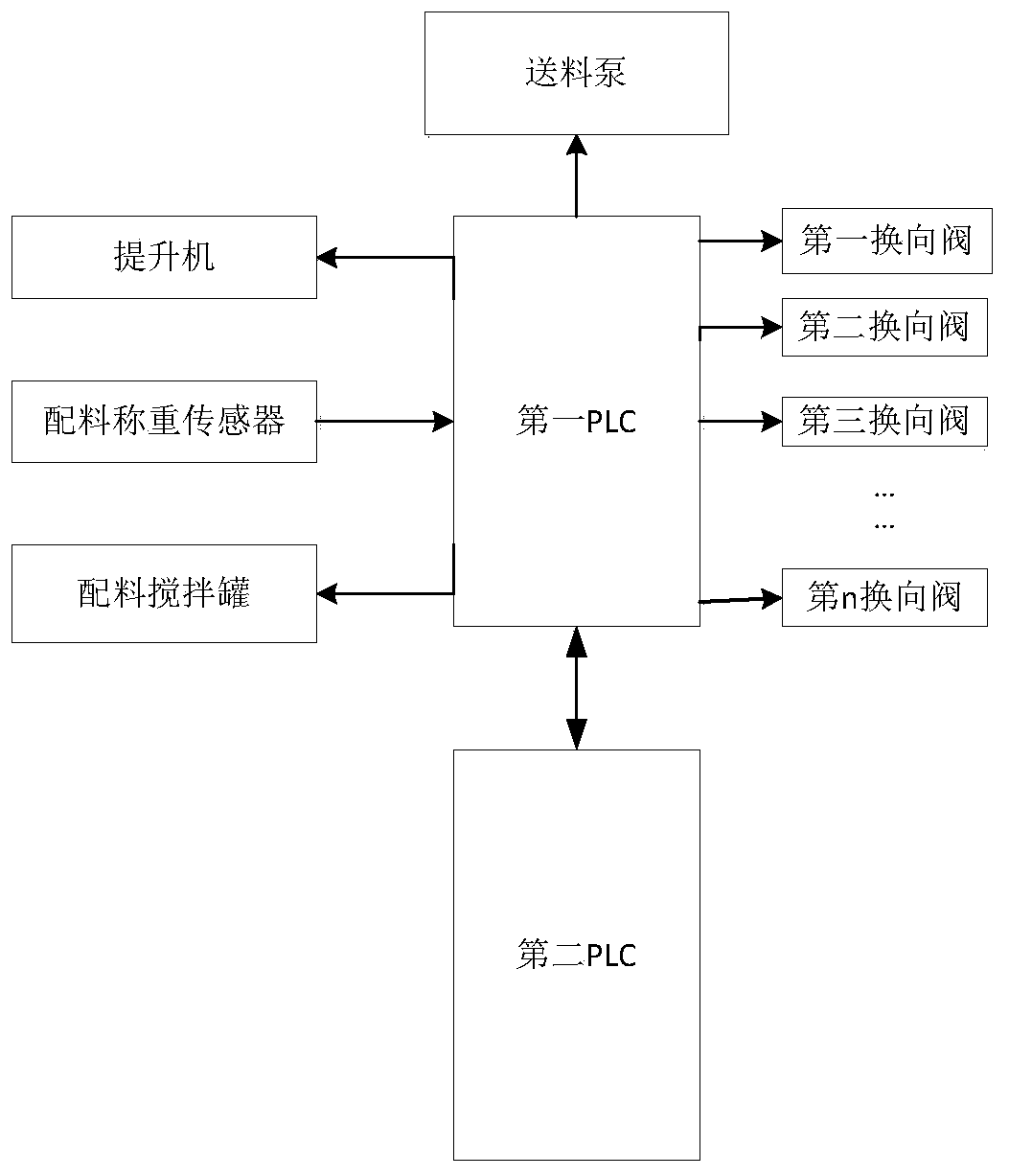

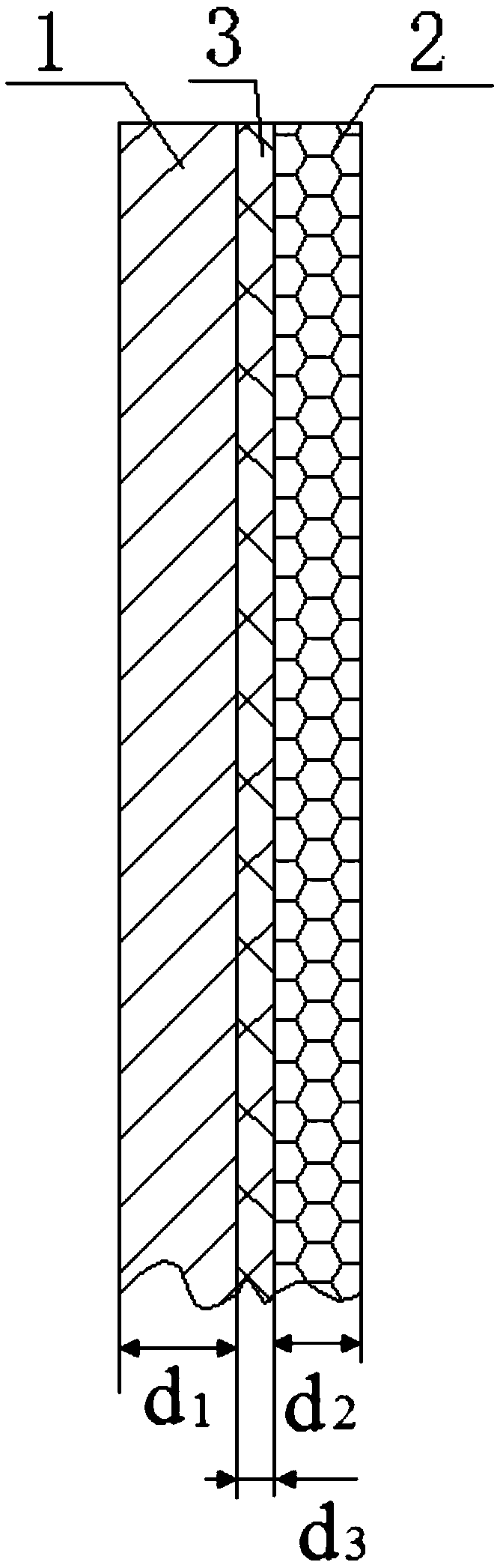

Centralized supply control method and system of liquid feeding for pig farms

ActiveCN110122354AImprove cleanlinessAvoid bringing inAnimal feeding devicesPig farmsHigh probability

The invention relates to a centralized supply control method and system of liquid feeding for pig farms. A liquid feed centralized supply zone is arranged on the periphery of a pig farm and isolated from the pig farm. Liquid feed preparation required by each feeding base station of the pig farm is completed in the centralized supply area, and the prepared liquid feed is directly conveyed to the corresponding feeding base stations through conveying pipes. By means of pipe closed feed conveying, pathogens are prevented from being carried into the pig farm along with the feed transportation link,and the risk of pig herd infection is reduced; besides, as a result of decrease of feed temporary storage equipment such as feed towers and reduction of internal road construction standards of the pig farm, the investment cost is also reduced to a great extent. The problems of pathogen transmission by transport vehicles in the feed supply process of the pig farm, large investment in feed supply equipment, high feed consumption and high probability of pollution of feed supply can be solved.

Owner:李宇晓

Electrode material for TiNiFe alloy vacuum consumable smelting and preparation thereof

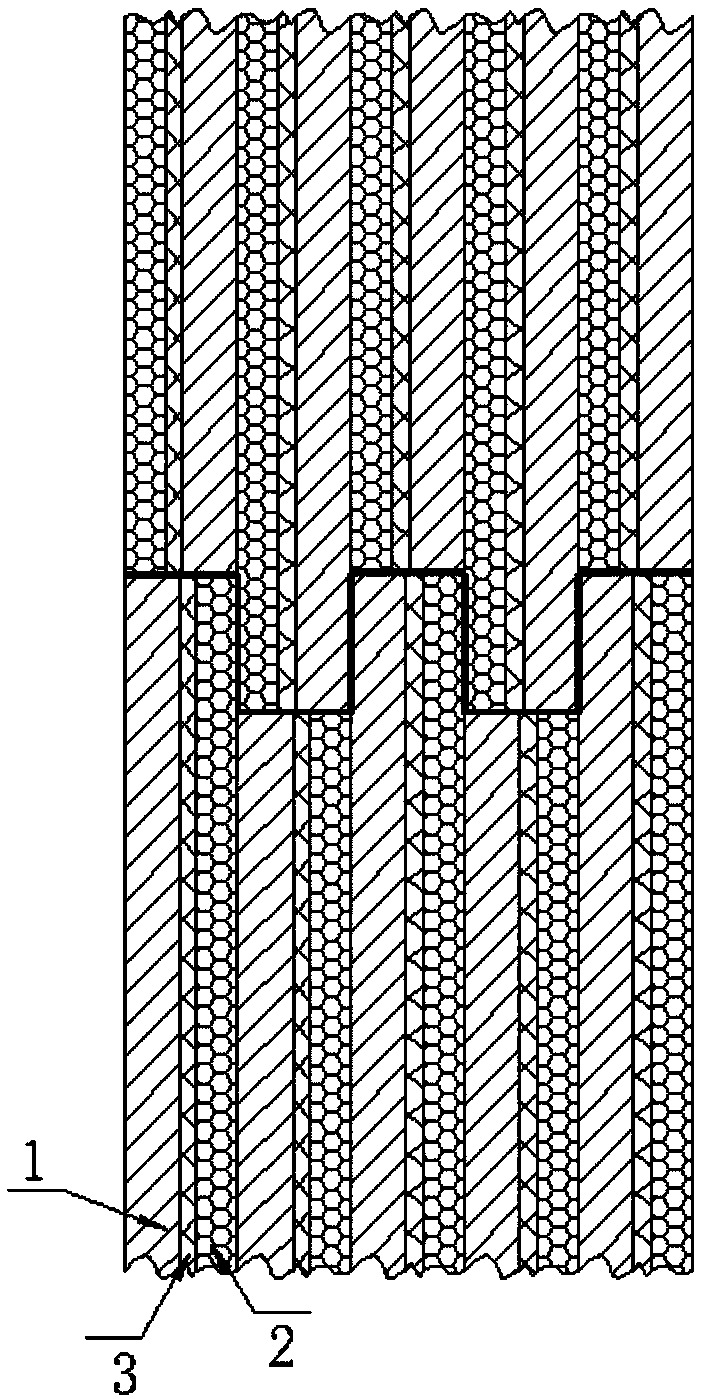

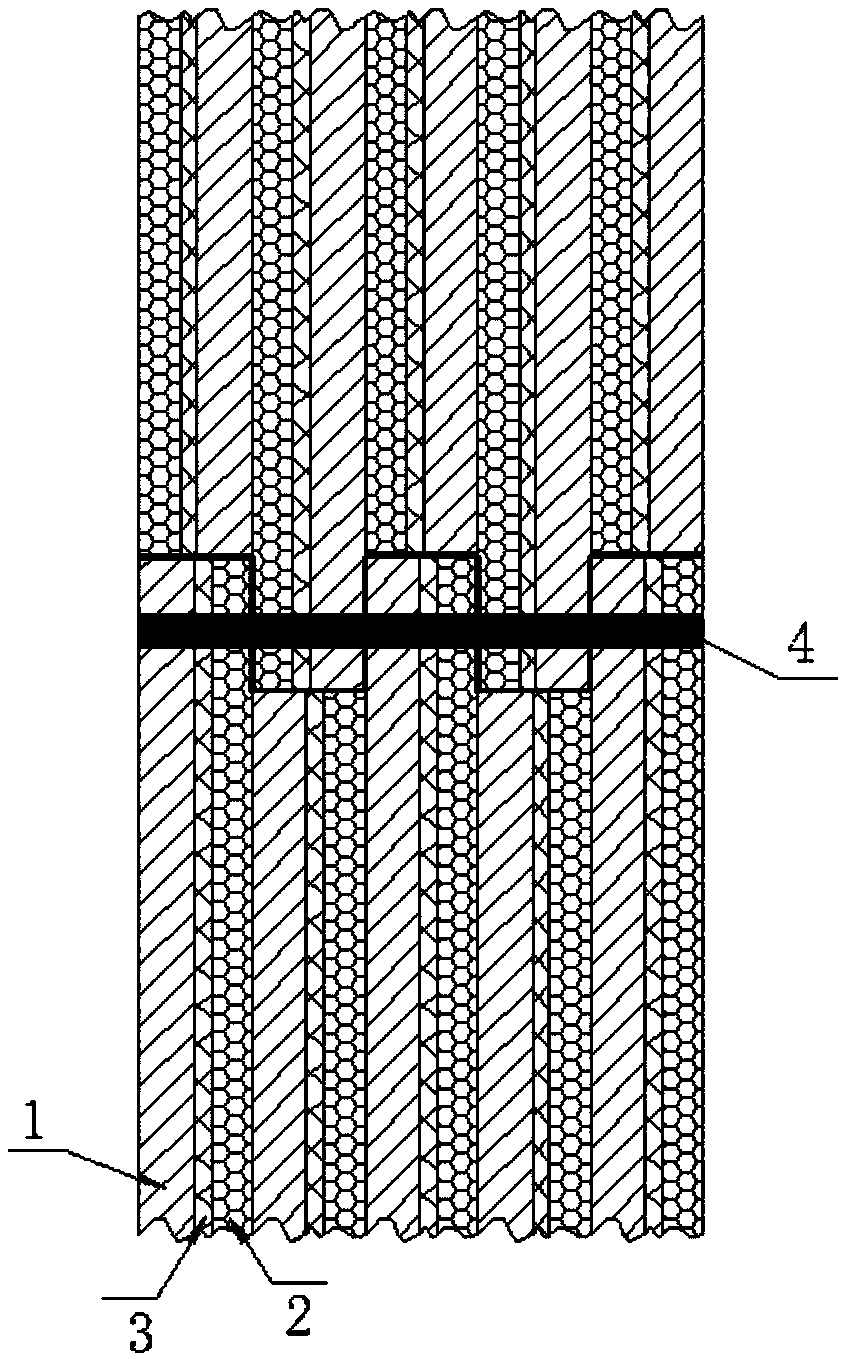

ActiveCN109355511AImprove straightnessIncrease the lengthIncreasing energy efficiencyTitaniumComposite plate

The invention discloses an electrode material for TiNiFe alloy vacuum consumable smelting and preparation thereof in the technical field of plate electrode materials. The electrode material comprisesmore than two sections of electrode plate materials, every two adjacent sections of electrode plate materials are spliced by adopting a high-low staggered mode, the electrode plate materials each comprise electrode plate material units with the same quantity, a high-purity titanium plate-high-purity iron plate-high-purity nickel plate composite plate material which is of a sandwich structure is adopted as each electrode plate material unit, and the electrode plate material units in every two adjacent sections of the electrode plate materials are spliced in a high-purity titanium plate-high-purity iron plate-high-purity nickel plate and high-purity nickel plate-high-purity iron plate-high-purity titanium plate mode aligning splicing mode. According to the electrode material for TiNiFe alloyvacuum consumable smelting, component batching is precise, the welding connection strength is high, and a foundation is laid for vacuum induction smelting of a TiNiFe alloy with the uniform components and the low impurity content; and the preparation method is simple and can be popularized to preparation of plate electrode materials for vacuum consumable smelting of other titanium alloys.

Owner:GRIMAT ENG INST CO LTD

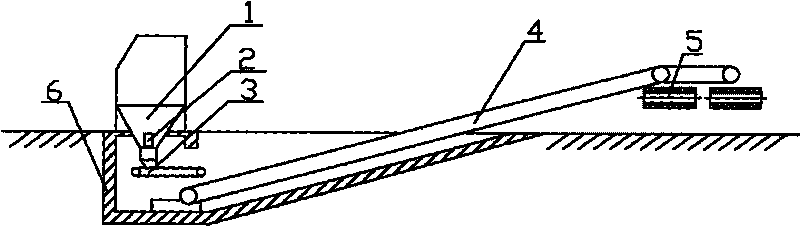

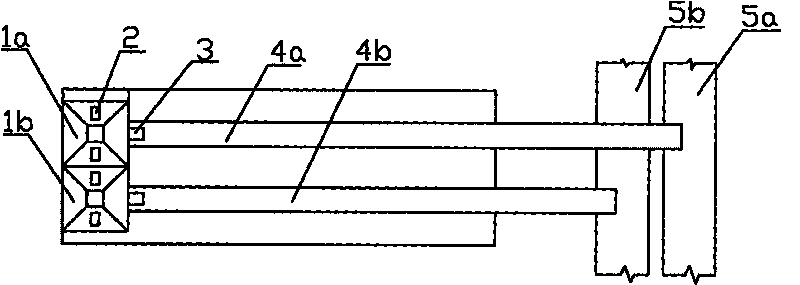

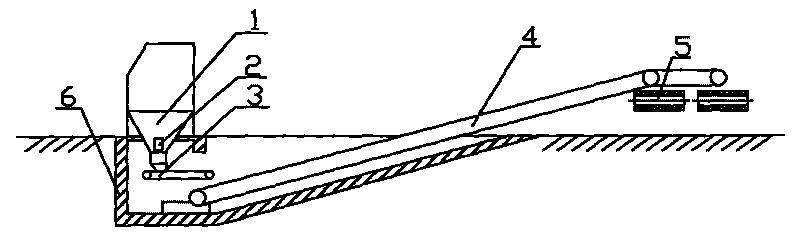

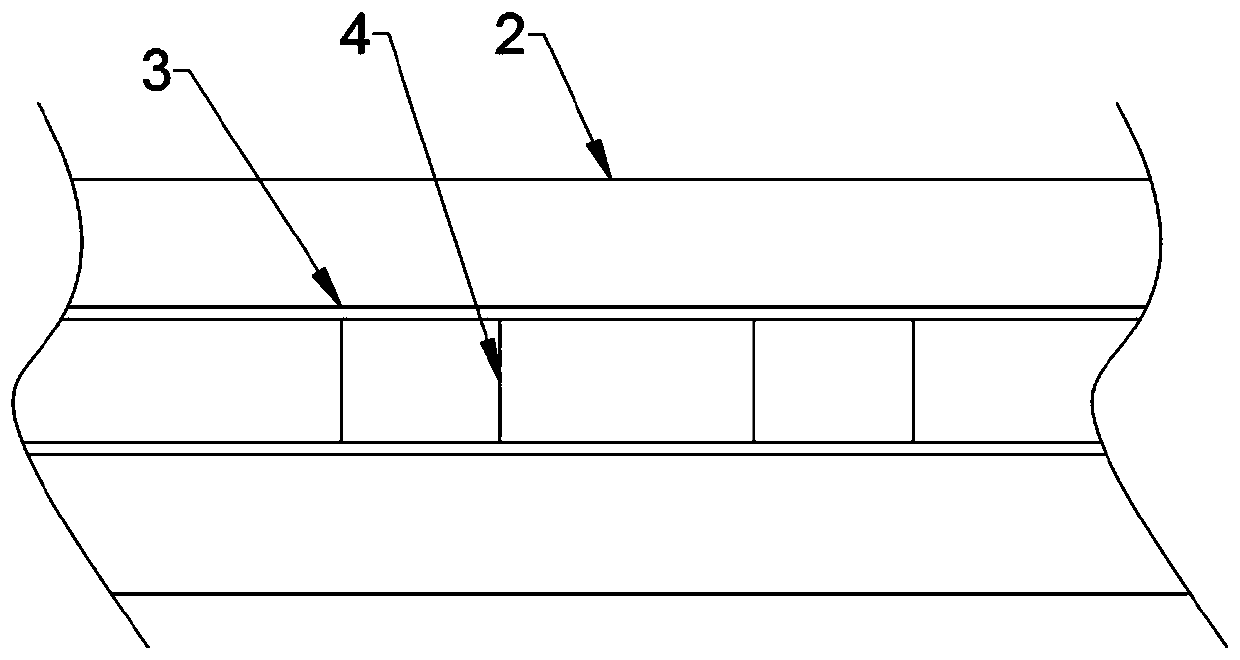

Batching apparatus of wet desulfurization gypsum

InactiveCN101693604AOvercome frictionOvercoming cohesionConveyorsConveyor partsMechanical engineeringGypsum

The invention discloses a batching apparatus of wet desulfurization gypsum, which comprises hoppers (1), a belt electronic scale (3), a climbing conveyer belt (4) and a main conveyer belt (5). A group of hoppers (1) are arranged inside a pit (6); two vibrators (2) are symmetrically arranged at a discharging port of each hopper (1); the belt electronic scale (3) is arranged below the hoppers (1); one end of the climbing conveyer belt (4), which is arranged in the pit (6), is matched with the belt electronic scale (3); and the other end of the climbing conveyer belt (4) is arranged on ground and matched with main conveyer belt (5). The batching apparatus has simple structure and can smoothly convey the wet desulfurization gypsum without processing for balling, thus saving cost and improving the working efficiency.

Owner:夏刚

Dicumyl peroxide pre-dispersion rubber master batch particles and preparation method thereof

The invention discloses dicumyl peroxide pre-dispersion rubber master batch particles. The rubber master batch particles comprise the following components in parts by weight: 30-60 parts of dicumyl peroxide, 20-70 parts of a rubber carrier, 5-30 parts of an inorganic filler and 3-9 parts of processing agents. The invention also discloses a method for preparing the dicumyl peroxide pre-dispersion rubber master batch particles. The method comprises the following steps: preheating an internal mixer to the temperature of 45-60 DEG C, internally mixing the raw materials according to the weight part requirement, uniformly internally mixing, extruding and granulating. The rubber master batch particles prepared by the method disclosed by the invention are easy to prepare and mix and are stable in properties under normal storage conditions, and the active ingredients are not separated out; and moreover, the mixture is high in liquidity, the rubber master batch particles are easy to absorb and uniform to disperse in various rubber, the loss caused by liquid drops formed by melting the dicumyl peroxide during direct mixing is effectively avoided, and the maximum activity of the active ingredient dicumyl peroxide is guaranteed.

Owner:NINGBO ACTMIX POLYMER

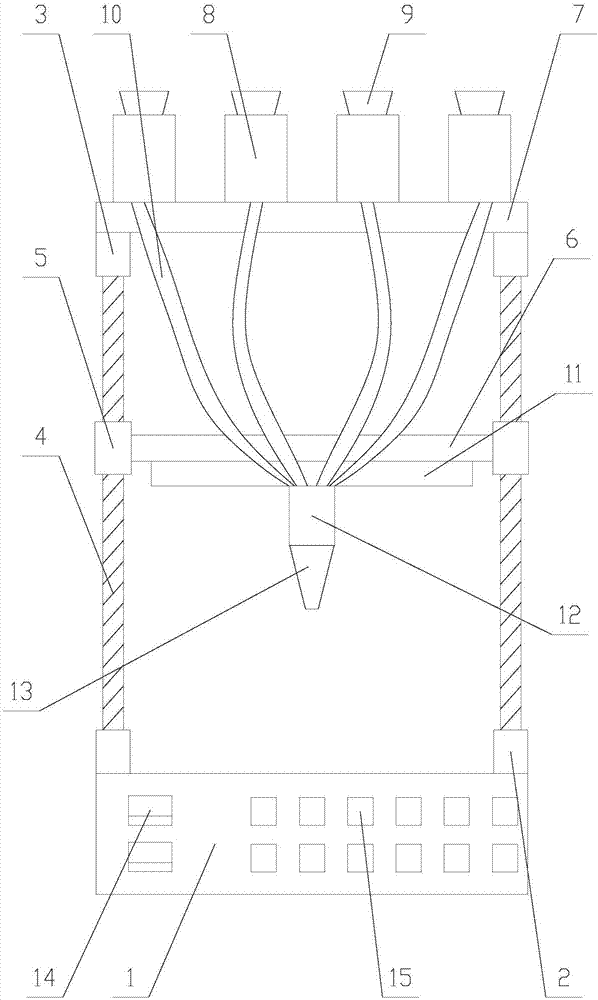

Intelligent 3D printer capable of accurately preparing materials and uniformly mixing materials

ActiveCN106891003AMove preciselyAccurate control of flow rateAdditive manufacturing apparatusIncreasing energy efficiencyProcess engineeringDrive motor

The invention relates to an intelligent 3D printer capable of accurately preparing materials and uniformly mixing materials. The intelligent 3D printer comprises a heating device and a plurality of feeding units, wherein each feeding unit comprises a raw material box; a material control mechanism is arranged in each raw material box; each material control mechanism comprises a speed adjusting block, a fourth driving motor, a third connection rod, a sliding ring, a top rod, a bottom rod and two support rods; two stirring units are arranged in the heating device; each stirring unit comprises a support plate, a fifth driving motor, a fifth driving shaft and a plurality of paddle blades. According to the intelligent 3D printer capable of accurately preparing materials and uniformly mixing materials, the height positions of the speed adjusting blocks are changed by the third driving motors in the raw material boxes; pressure data of a pressure sensor is used as feedback; the speed adjusting blocks can accurately move, so that the material circulating speeds are accurately controlled; the materials are accurately prepared; furthermore, the two stirring units in the heating device are used for fully mixing the materials entering the heating device; the materials and the quality of printed samples are ensured; meanwhile, the practicability of the equipment is further improved.

Owner:都昌西交口腔科技有限公司

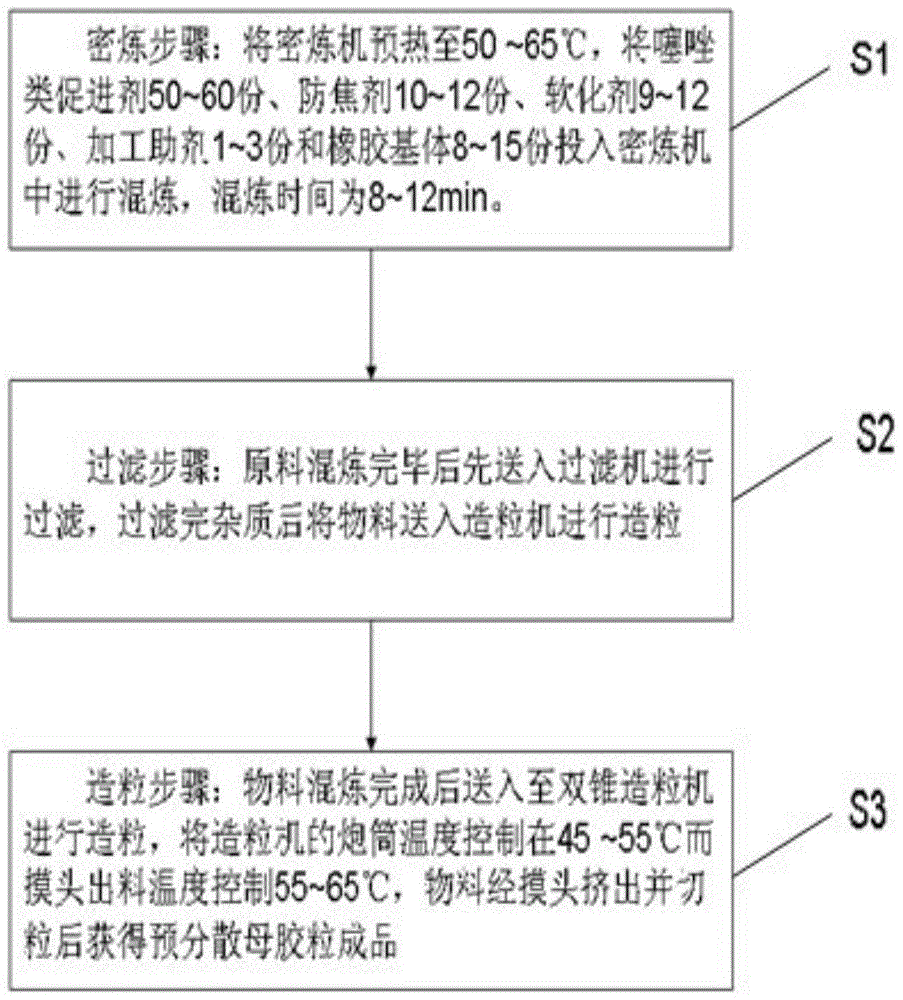

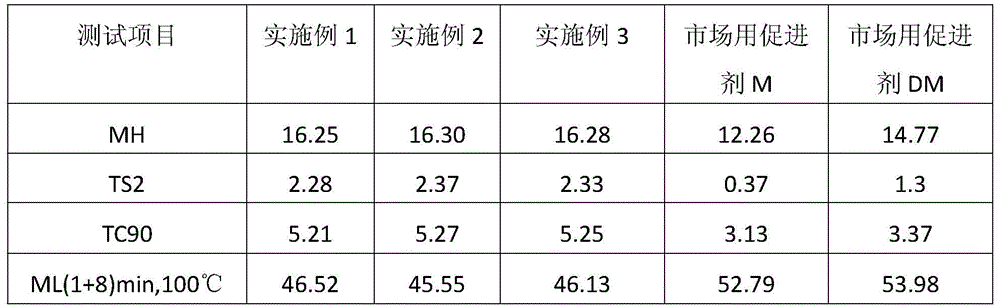

Pre-dispersed masterbatch of scorch-resistant comprehensive accelerator for rubber as well as preparation method

The invention discloses a pre-dispersed masterbatch of a scorch-resistant comprehensive accelerator for rubber. The masterbatch comprises the following components in parts by weight: 8-15 parts of a rubber matrix, 50-60 parts of a thiazole accelerator, 10-20 parts of an anti-scorching agent, 9-12 parts of a softener, and 1-3 parts of a processing auxiliary agent. A preparation method comprises the following steps: (1) a mixing step: the thiazole accelerator, the anti-scorching agent, the processing auxiliary agent and the softener are added into a mixer according to a certain ratio, mixing is carried out for about 30 seconds, the rubber matrix is added, and mixing is carried out for 8-12 minutes at 50-65 DEG C; (2) a granulation step: after mixing of materials, the materials are sent into a granulating machine for granulation. The pre-dispersed masterbatch is used for preparing rubber compounds, and has the advantages of easy dispersion, non-pollution, good processability, etc.; and the masterbatch provides good scorch-resisting effects for rubber.

Owner:GUANGDONG DUBA NEW MATERIAL CO LTD

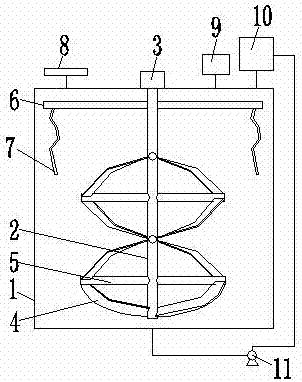

Novel stirrer

PendingCN107321218AImprove the mixing effectImprove efficiencyTransportation and packagingRotary stirring mixersBiochemical engineeringElectric machinery

The invention relates to a novel stirrer. The stirrer comprises a shell; a stirring main shaft is arranged in the middle of the shell; a motor is arranged on the upper end of the stirring main shaft; at least one set of external helical ribbons is arranged on the stirring main shaft; the external helical ribbons is fixedly connected to the stirring main shaft through a short support rod; the stirring main shaft, which is above the external helical ribbons, is provided with a long support rod; a self-rotation stirring member is arranged on the long support rod; the top of the shell of one side of the motor is provided with an automatic distributing device; the other side of the motor is provided with a monitoring device; a mixing barrel is arranged next to the monitoring device, the mixing barrel is connected to the bottom of the shell through a pipeline; and the pipeline between the mixing barrel and the shell bottom is provided with a feed pump. The stirring effect is good, the production efficiency is high, and the operation is safe and reliable.

Owner:JIANGSU AOLUNDA HIGH TECH IND

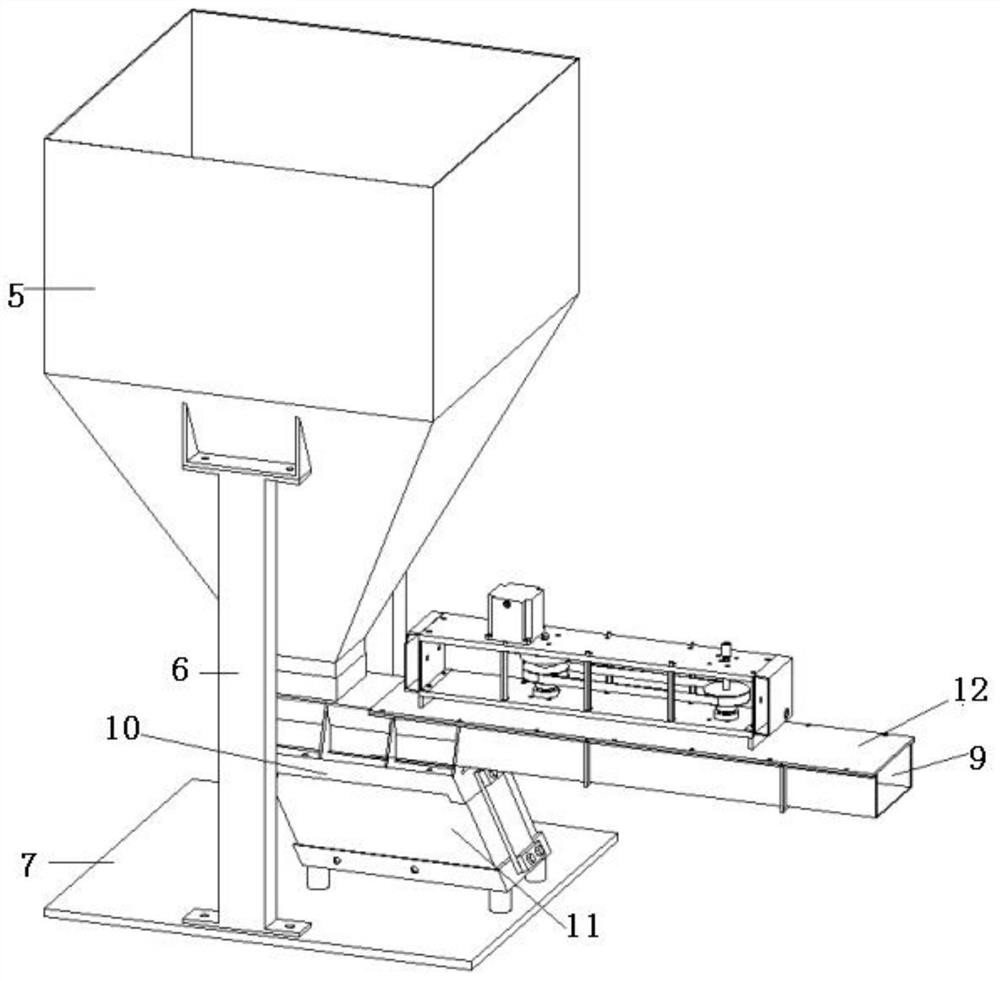

Novel precision batching device for fertilizer production

PendingCN110404440AControl the feeding speedPrecise cutting timeRotary stirring mixersTransportation and packagingSolenoid valveEngineering

The invention relates to a novel fertilizer production precision batching device. The device comprises a support frame, the support frame is provided with clamping seats, a first hopper, a second hopper and a third hopper are sequentially arranged above the clamping seats from left to right, a material guiding port is arranged below each of the first hopper, the second hopper and the third hopper,every material guiding port is provided with a solenoid valve, a batching auger is arranged below the support frame, feeding troughs corresponding to the clamping seats are arranged above the batching auger, the rear wall of every feeding trough is provided with a U-shaped groove, sliding slots are arranged at the left side and the right side of every U-shaped groove, a clamping plate is clampedand connected between the two sliding slots with facing openings, a rotating shaft is arranged in every U-shaped groove, every rotating shaft is provided with material guiding roller grooves, the rotating shafts are sequentially connected with a first motor, a second motor and a third motor from left to right, and a time relay and a material outlet are arranged at the right side of the batching auger. The device has the advantages of quickness in batching, high precision, convenience in use, and simple structure.

Owner:赛富肥业有限公司

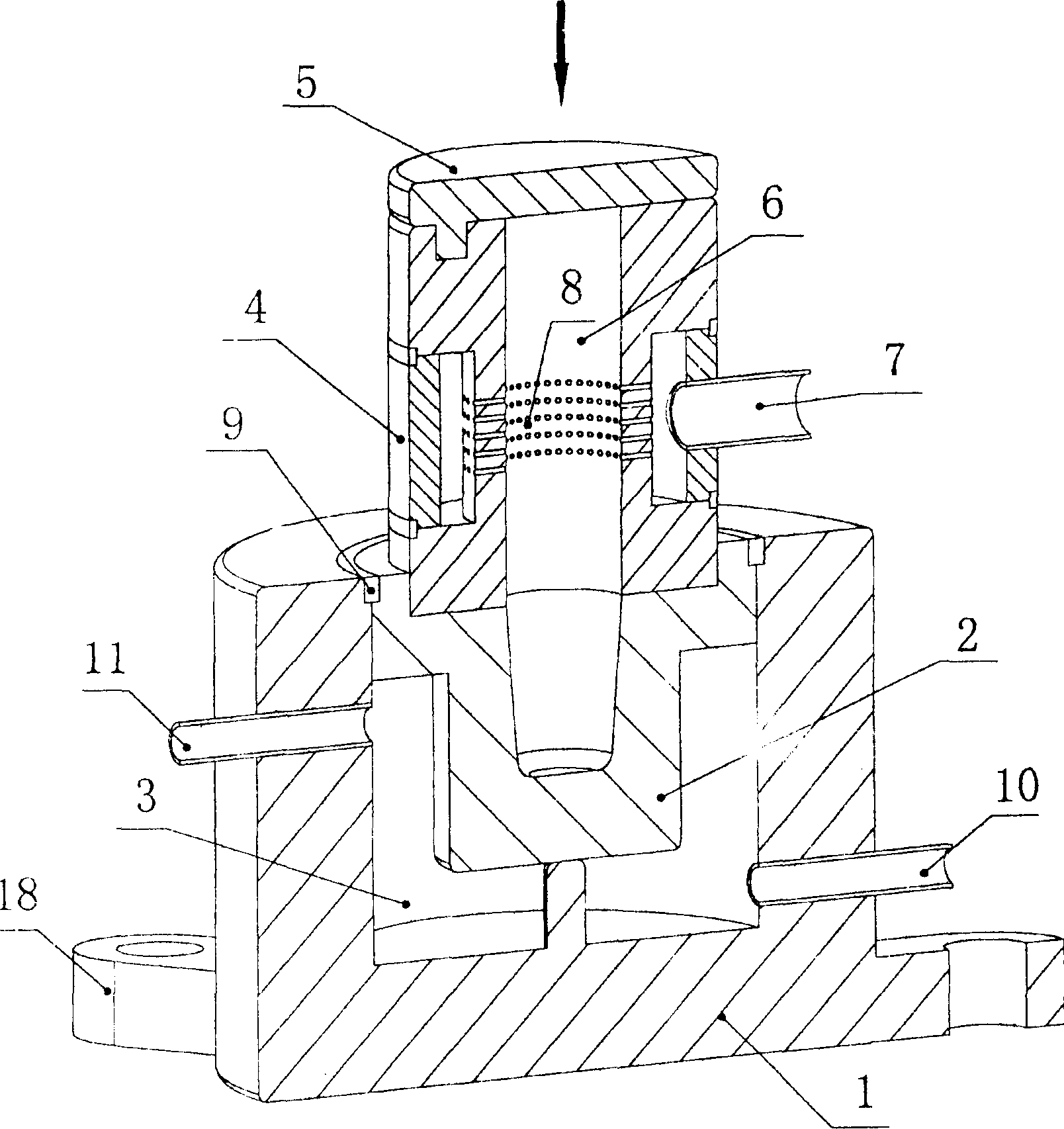

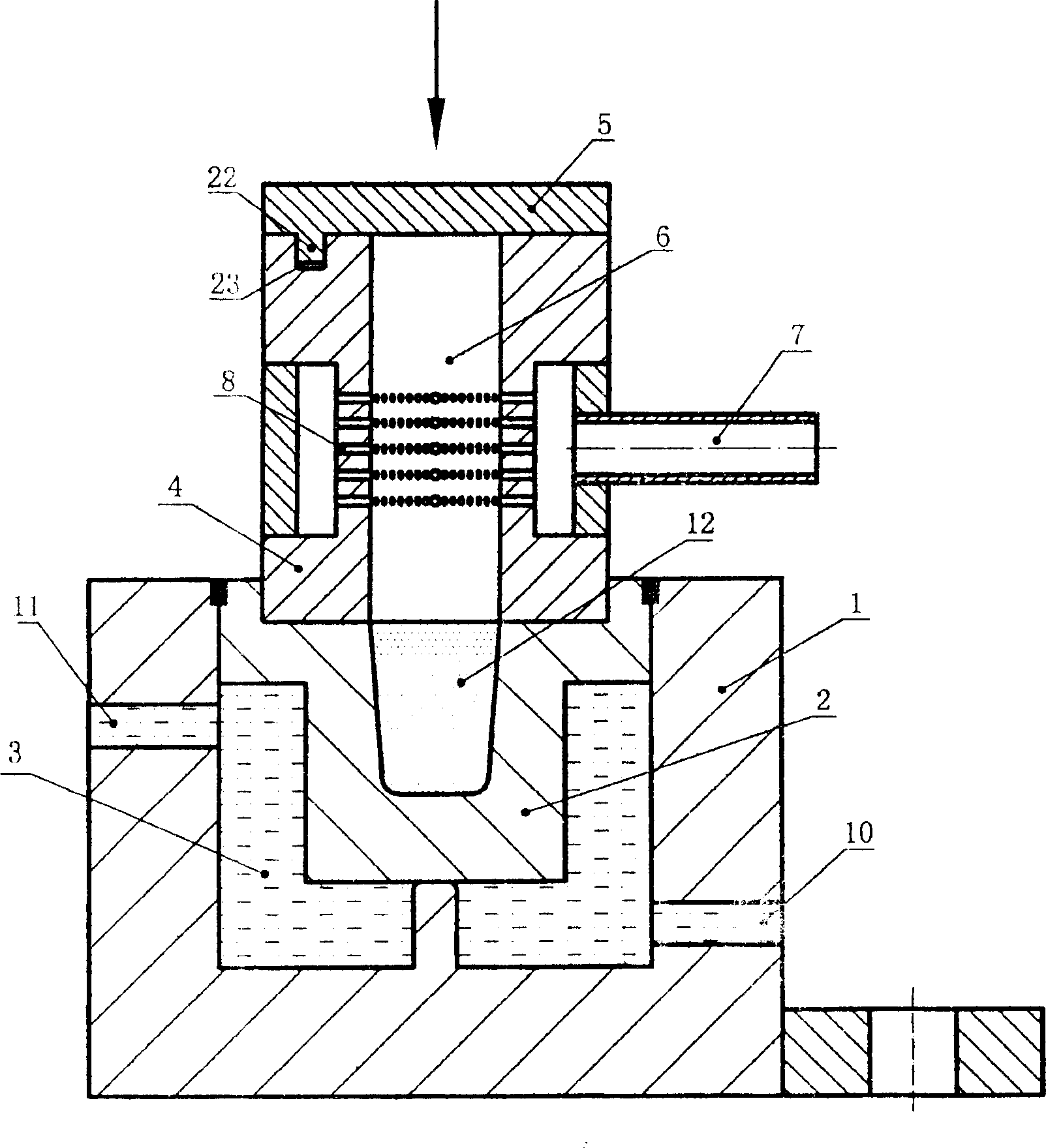

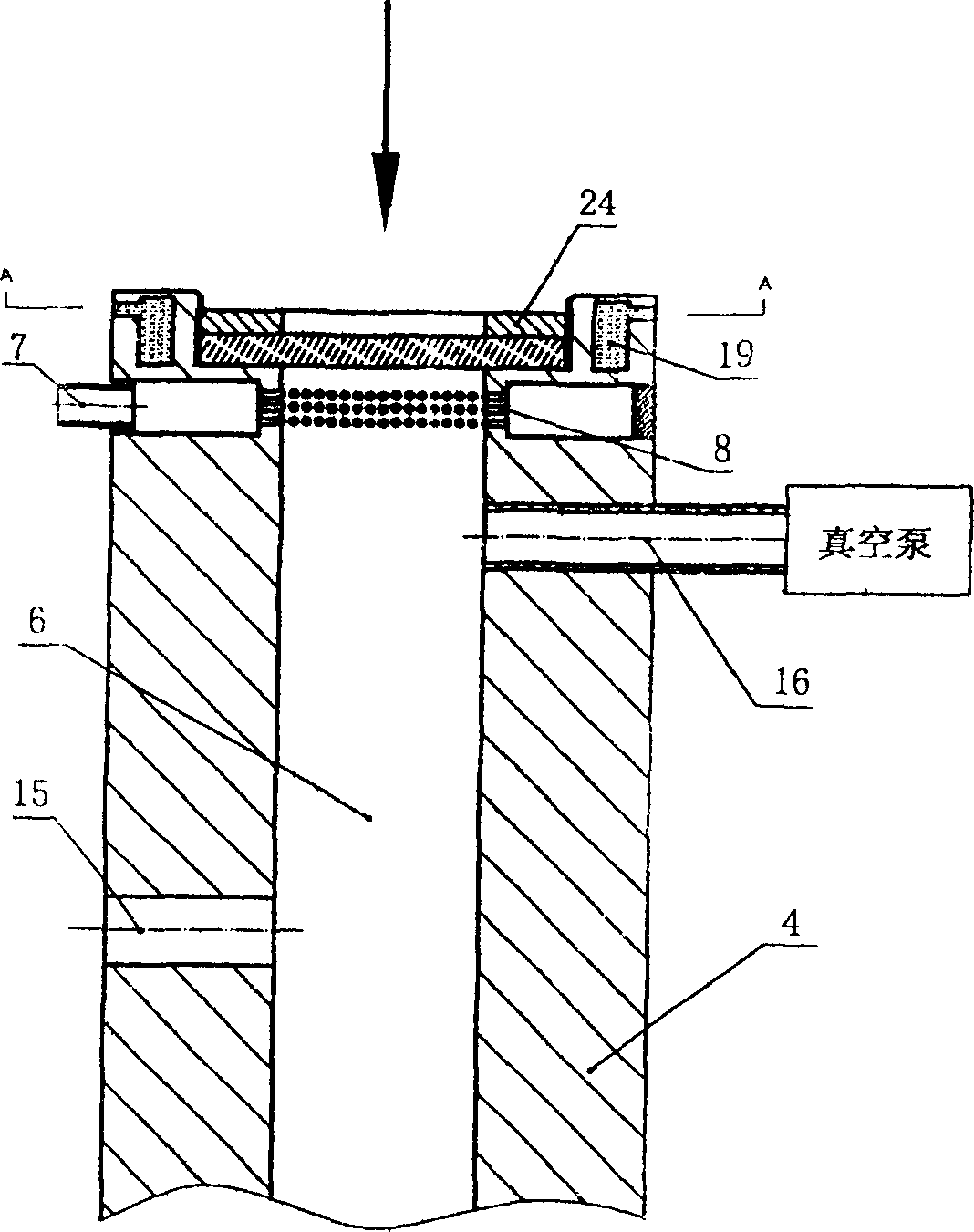

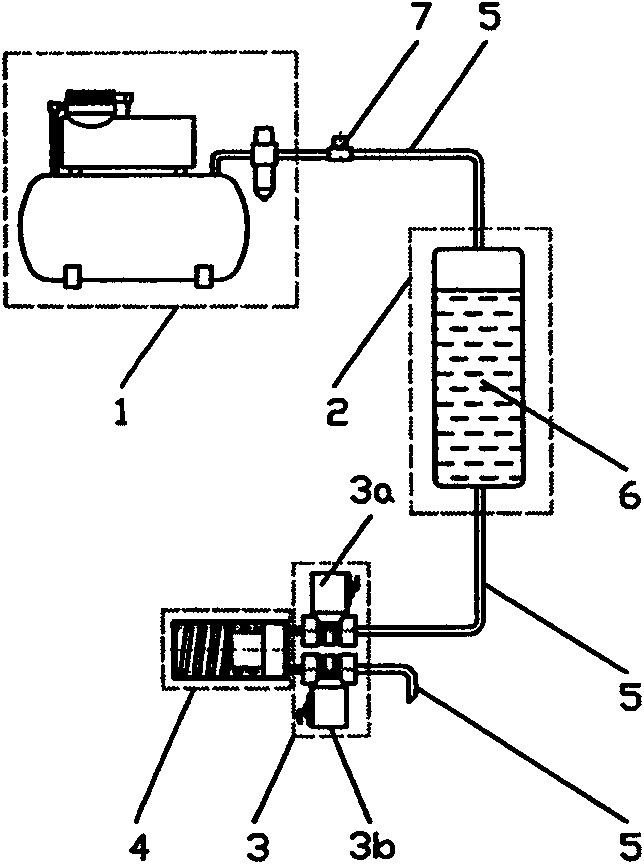

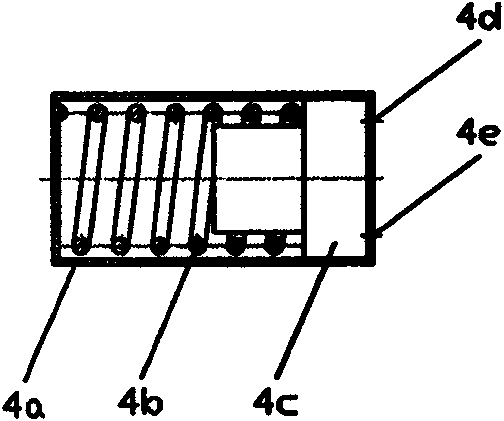

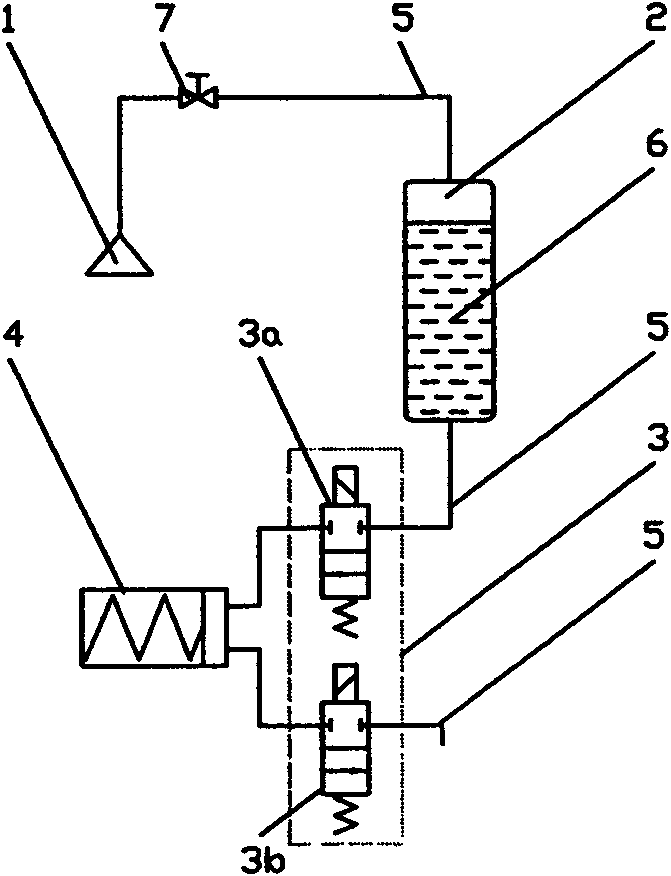

Quick metering and dispensing device and method thereof for liquid spices

InactiveCN101629839AImprove batching accuracyPrecise ingredientsMovable measuring chambersLiquid storage tankExhaust valve

The invention belongs to the field of liquid metering, and particularly relates to a quick metering and dispensing device and a method thereof for liquid spices. The quick metering and dispensing device for liquid spices is characterized in that an air exhaust opening of a compressed air source (1) is connected with an air inlet of a liquid storage tank (2) through a pipeline; a liquid exhaust opening of the liquid storage tank (2) is communicated with a liquid inlet of a liquid inlet valve (3a) of a control valve (3); a liquid exhaust opening of the liquid inlet valve (3a) is communicated with a liquid inlet (4d) of a metering cavity (4); a liquid exhaust opening (4e) of the metering cavity (4) is communicated with a liquid inlet of a liquid exhaust valve (3b) of the control valve (3); and a liquid exhaust opening of the liquid exhaust valve (3b) is communicated with outside through a pipeline.

Owner:杨斌

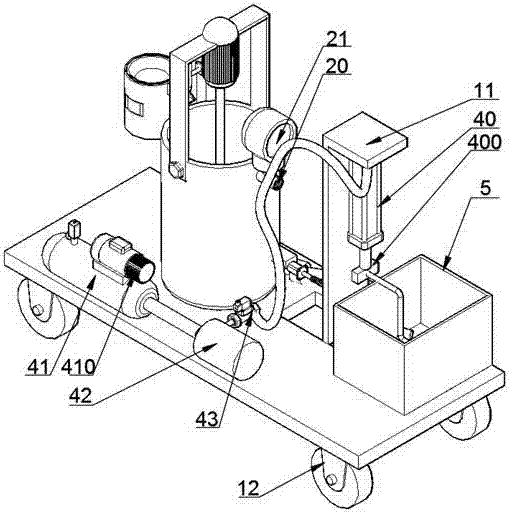

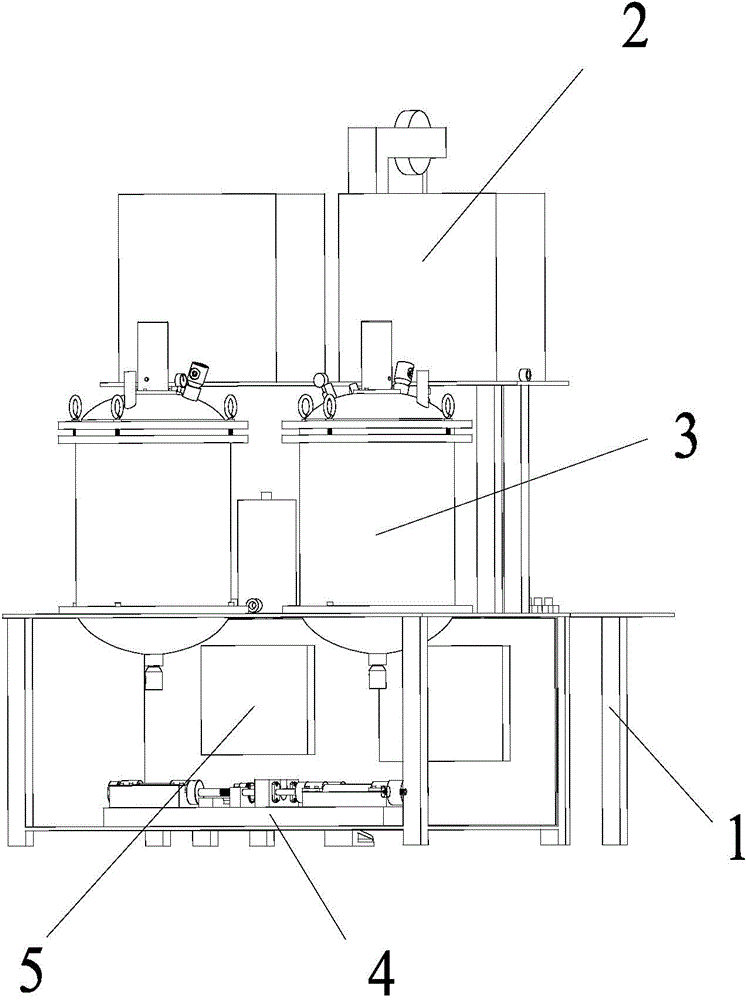

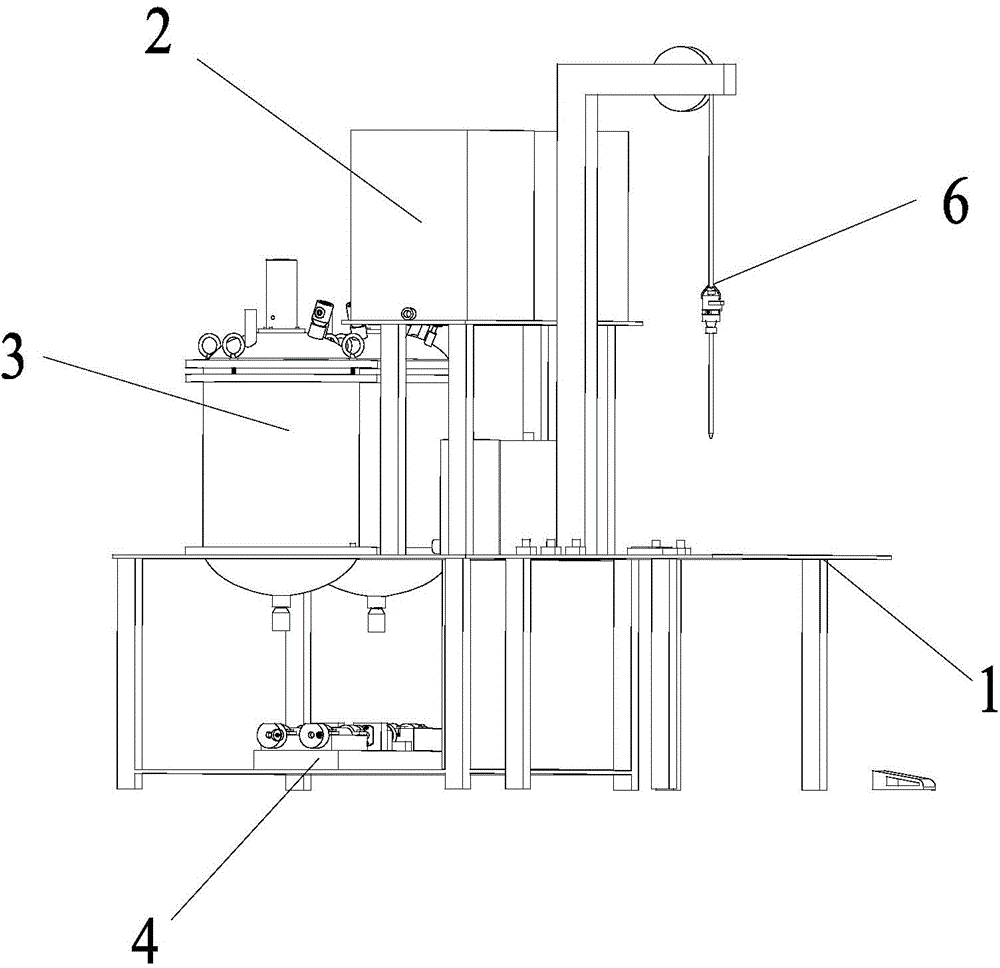

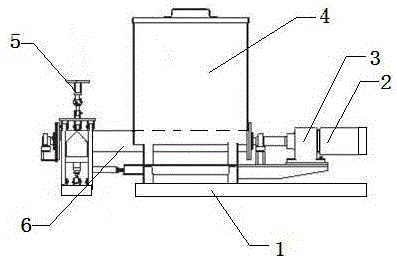

Novel polycomponent liquid material blending machine

The invention discloses a novel polycomponent liquid material blending machine. The novel polycomponent liquid material blending machine comprises a machine frame (1), a material feeding barrel (2), a material standing device (3), a material proportioning platform (4) and a discharging device (6), wherein the material feeding barrel (2), the material standing device (3), the material proportioning platform (4) and the discharging device (6) are arranged on the machine frame (1); and a power device (41), a metering device (42) and a ratio fixing device (43) which are sequentially connected are arranged on the material proportioning platform (4), the ratio fixing device (43) is connected with the material standing device (3) and the discharging device (6) respectively through a charging pipe and a discharging pipe, and the power device (41) is electrically connected with a control system (5). The liquid material blending machine provided by the invention is simple in structure, accurate in discharging and high in durability.

Owner:SUZHOU UNIV

Spicy dried tofu and making process thereof

InactiveCN105123986AWell organizedSimple preparation processCheese manufactureFood scienceAfter treatmentSugar

Provided is spicy dried tofu. Dried tofu is the raw material, added auxiliary materials comprise, by weight, 15-23 parts of soybean oil, 5-10 parts of fermented soy sauce, 12-18 parts of material water, 0.3-1 part of salt, 1-3 parts of white granulated sugar, 0.05-1.5 parts of aginomoto, 1-3 parts of chilli powder, 0.5-1.5 parts of paprika powder, 0.3-1 part of white sesame and 0.1-0.6 part of green Chinese onion sections. The making process comprises the steps of freezing, unfreezing, strip cutting, rinsing, frying and after-treatment. The spicy dried tofu is spicy, sweet and fragrant, layer of tissue is good, juiciness and chewing resistance are achieved, and the spicy dried tofu is a necessary good product for home-based leisure, travel and the like; the making process is simple, dosing is accurate, the quantitation is easy, the process is stable, the product quality is stable, and the operation is easy and convenient.

Owner:TANGSHAN XIANGMAMA FOOD CO LTD

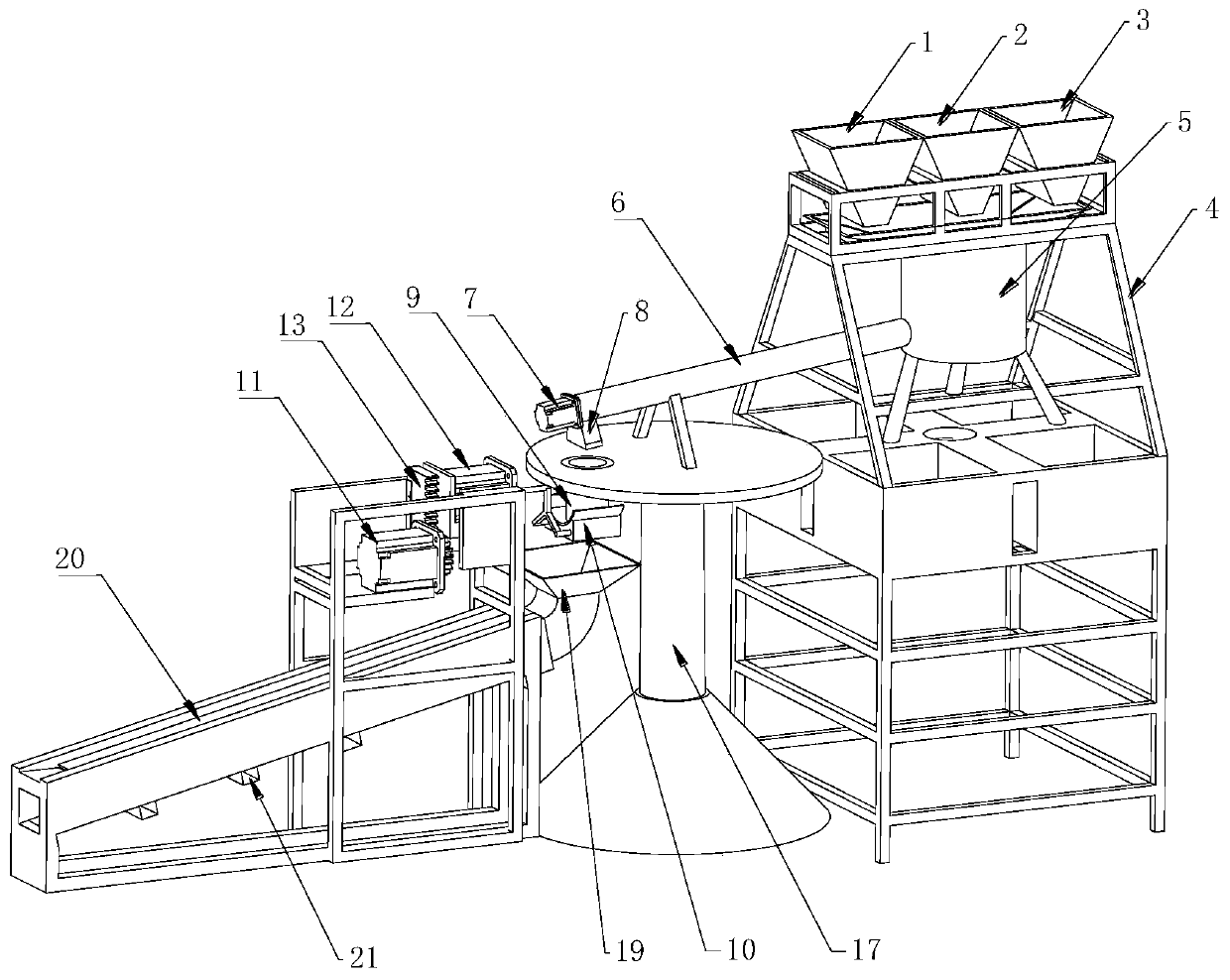

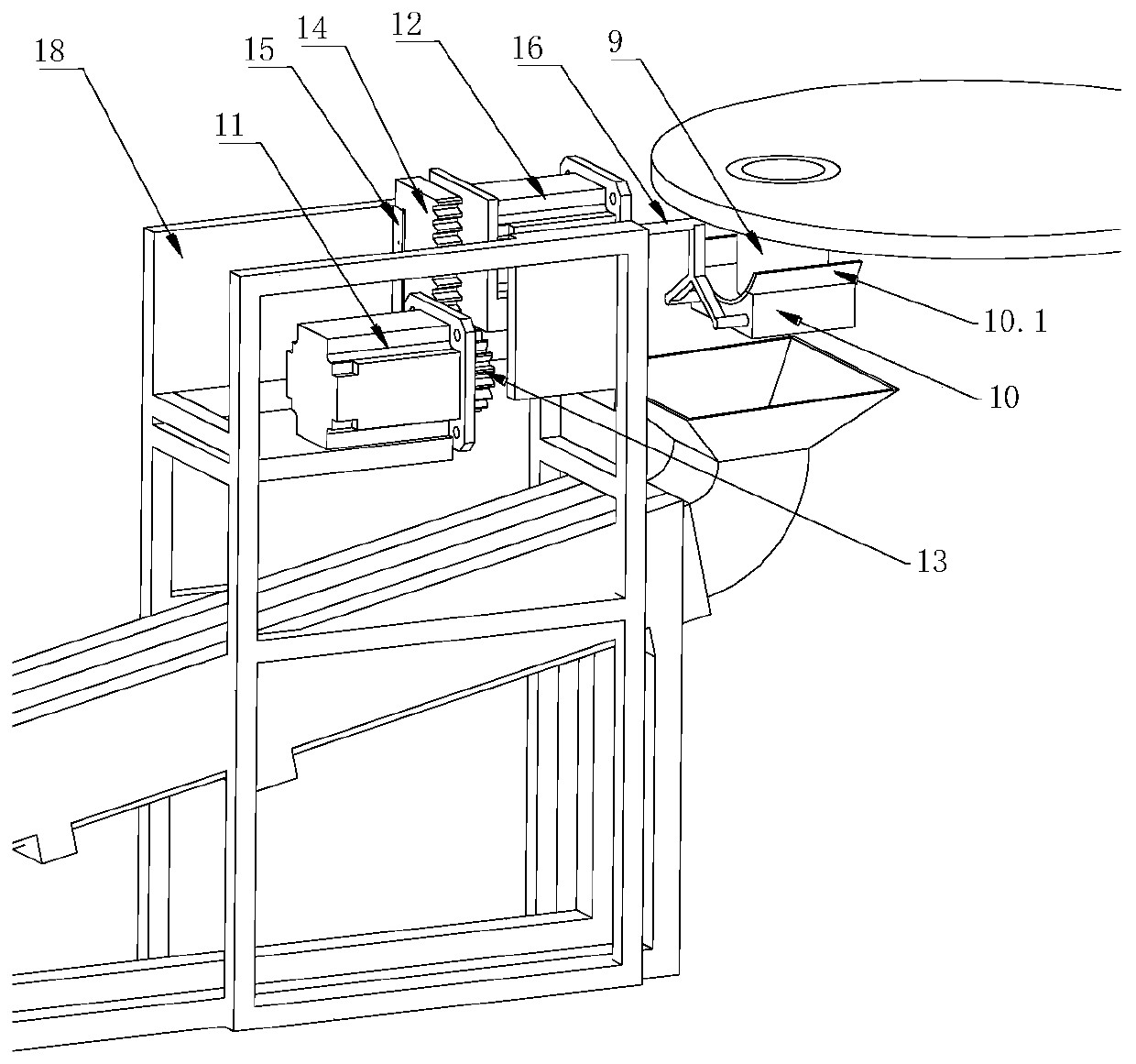

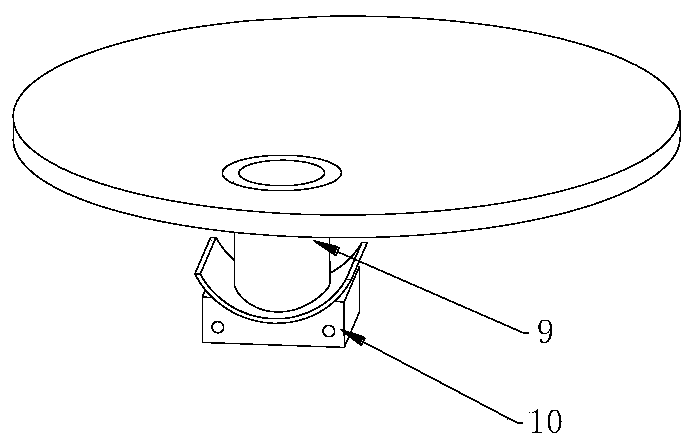

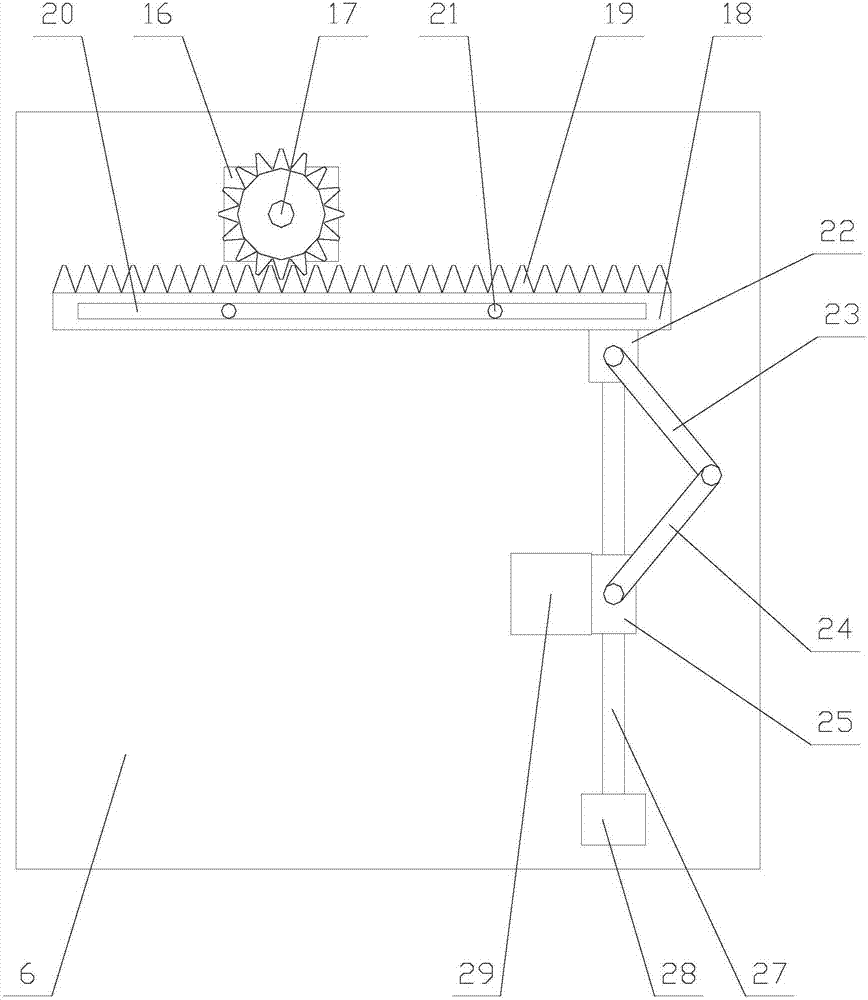

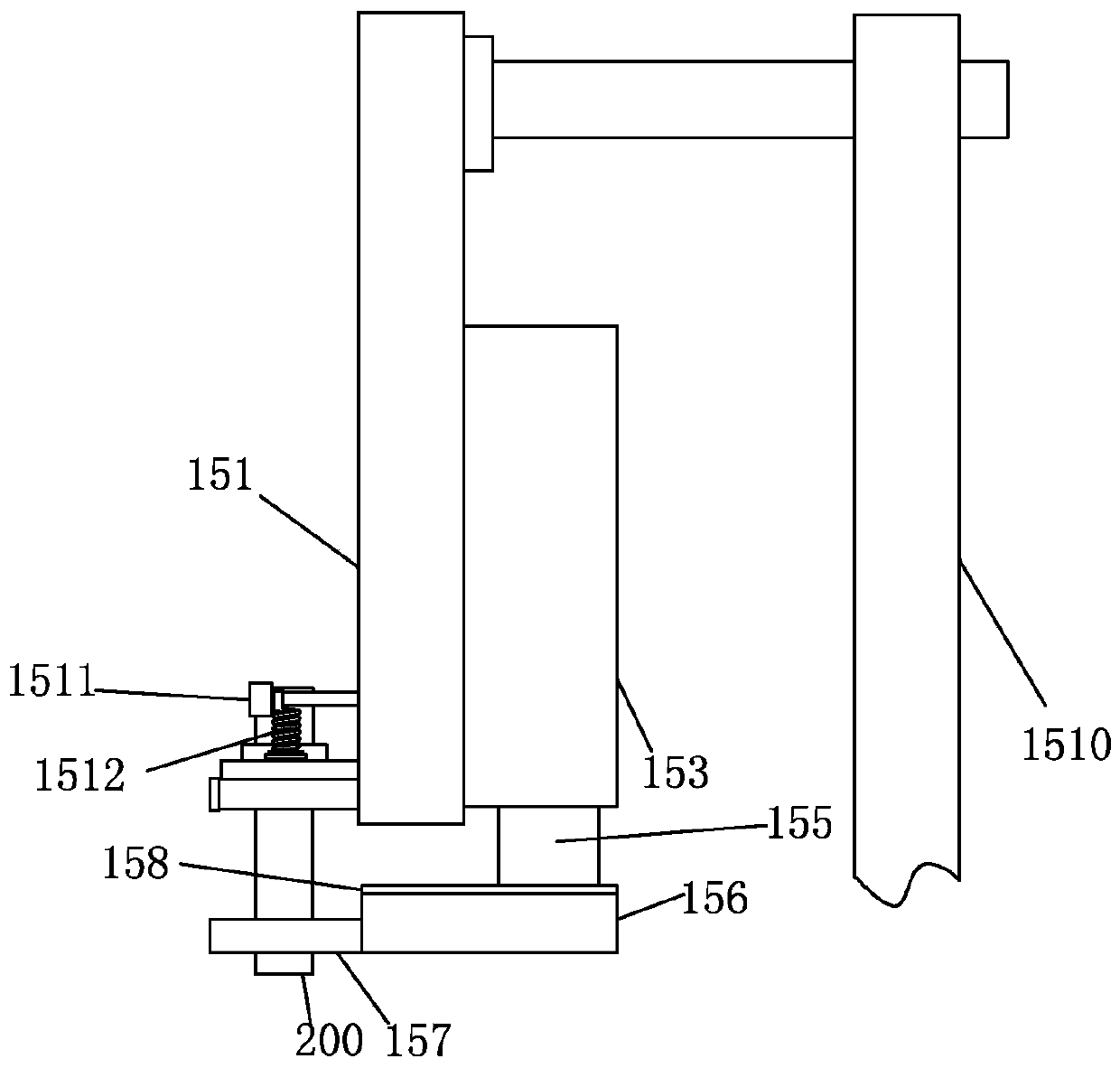

Sectional proportioning apparatus of brake pad raw material

PendingCN109046092ANo manual mixingRaw materials are accurateRotary stirring mixersTransportation and packagingMechanical engineeringBrake pad

The invention discloses a sectional proportioning apparatus of a brake pad raw material. The sectional proportioning apparatus comprises a base, a slide rail fixedly arranged on the base, and a stirring drum connected with the slide rail in a rolling manner; and the stirring drum is in a cylindrical hollow thin-wall shape, a cover of the stirring drum is fixedly provided with a motor, a rotating shaft of the motor is provided with a stirring apparatus arranged in the stirring drum, the side wall of the stirring drum is also provided with a receiving apparatus, the lower end of the stirring drum is provided with a discharging apparatus, a proportioning supporting frame is also arranged above the base, the proportioning supporting frame is provided with a first raw material drum and a secondraw material drum in a hanging manner, the base is also provided with a proportioning drum, and the proportioning drum is located below the slide rail. The movable stirring apparatus performs the sectional feeding operation among different raw material drums, so that the manual stirring is not required, time and labor can be saved, precision in proportioning can be achieved, and the production efficiency is high.

Owner:盐城加申汽车制动部件有限公司

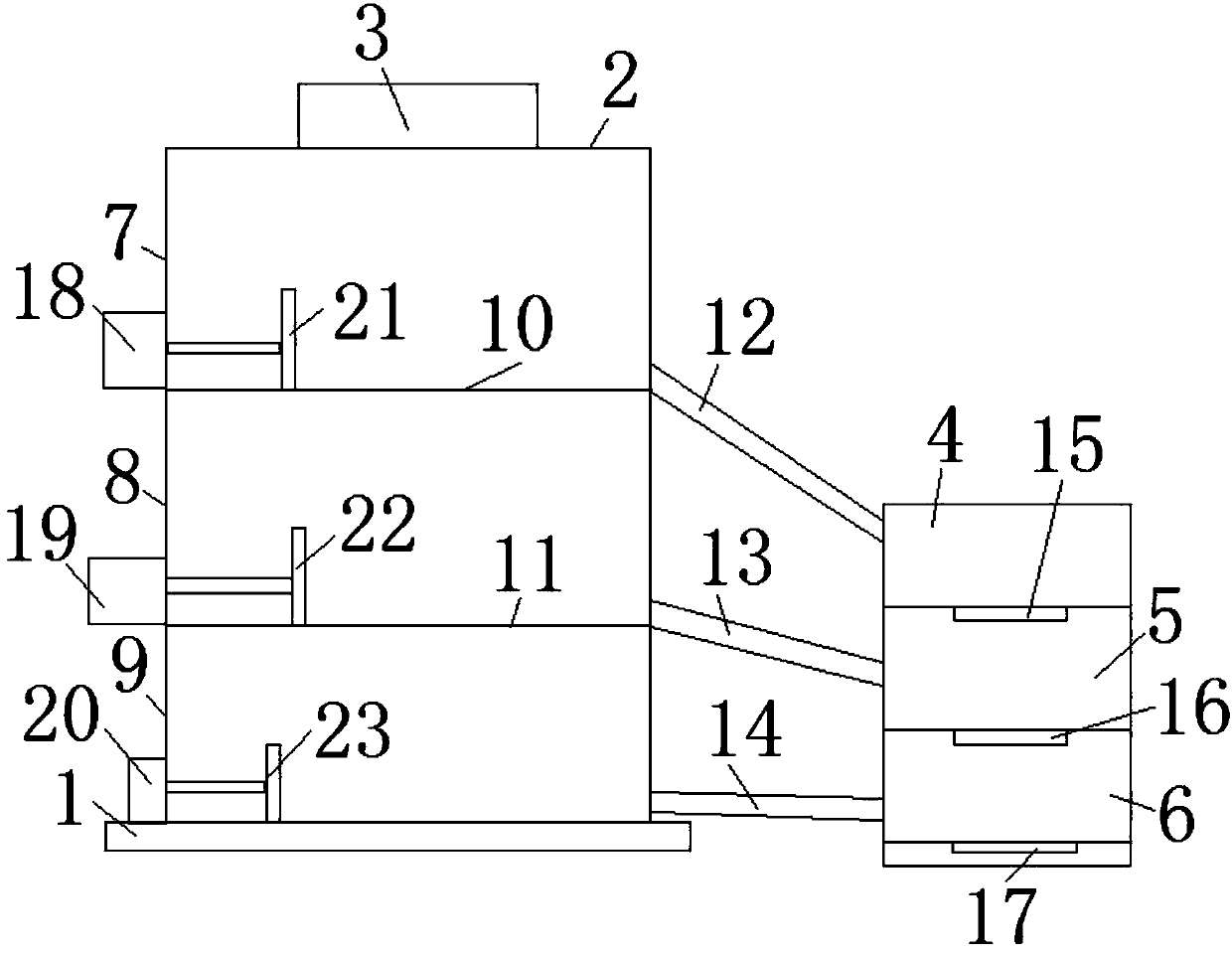

Recycling and discharging device

InactiveCN111085419AReduce problemsPrecise ingredientsSievingScreeningWaste productProcess engineering

The invention provides a recycling and discharging device, and relates to the technical field of machining. The recycling and discharging device comprises a base and a machine body arranged at the upper end of the base, and a recycling opening communicating with the interior of the machine body is formed in the upper end of the machine body. The recycling and discharging device further comprises weighing boxes, wherein the weighing boxes comprise the first weighing box, the second weighing box and the third weighing box which are sequentially arranged from top to bottom; and the machine body comprises a first box body, a second box body and a third box body which are sequentially arranged from top to bottom. The recycling and discharging device further comprises a sieve plate structure, and the sieve plate structure comprises a first sieve plate and a second sieve plate; the first sieve plate is arranged between the first box body and the second box body, and the second sieve plate isarranged between the second box body and the third box body; and the first box body communicates with the first weighing box through a first pipeline, the second box body communicates with the secondweighing box through a second pipeline, and the third box body communicates with the third weighing box through a third pipeline. According to the recycling and discharging device, burdening can be more accurate, errors are reduced, produced products reach the standard, and waste products are reduced.

Owner:抚顺市东方碳素有限公司

Silane coupling agent (gamma-aminopropyltriethoxysilane) pre-dispersed master batch and preparation method thereof

ActiveCN105694241ASolve the problem of slow mixingStable in natureBULK ACTIVE INGREDIENTDust pollution

The invention discloses a silane coupling agent (gamma-aminopropyltriethoxysilane) pre-dispersed master batch, which can solve the problem of low speed of mixing due to polarity difference between liquid-state gamma-aminopropyltriethoxysilane and rubber during direct mixing. On a normal storage condition, the master batch has stable performance without separation of activated components; at a room temperature, the master batch is free of adhesion so that blending is facilitated, blending accuracy is increased, and blending error is reduced; the master batch has good flow characteristic after being mixed with rubber, has high loading capacity, can be bonded with rubber closely in time even when polarity thereof is different from polarity of rubber, keeps good dispersibility under action of different shear force, further can improve dispersibility and flow characteristic of active ingredients of rubber, shorten cycle of mixing with rubber, improve mixing effect and rubber production efficiency, reduce dust pollution and improve work environment for workers, and also has effect of reducing rejection rate of rubber products.

Owner:NINGBO ACTMIX POLYMER

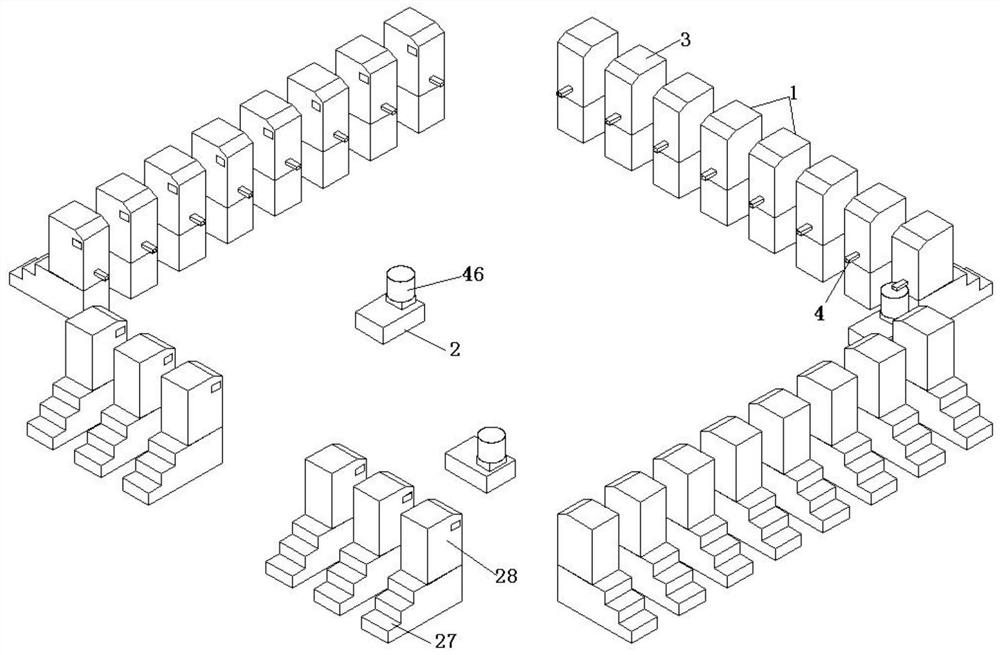

AGV integrated full-intelligent batching control system

PendingCN113800212AFully automatedPrecise ingredientsControl devices for conveyorsMechanical conveyorsControl systemControl engineering

The invention discloses an AGV integral full-intelligent batching control system which comprises a plurality of batching units and a batching AGV, each batching unit comprises a protective shell, a material flow control device and a controller are arranged in the protective shell, the material flow control device is connected with the controller, an output end of the material flow control device is connected with a discharging port, the discharging port is fixed to the protective shell, the controller is in telecommunication connection with an upper computer control center, and the batching AGV is in telecommunication connection with the upper computer control center. According to the system, the upper computer control center can control different batching units to carry out automatic batching according to setting, the batching is accurate, and manual misoperation errors are avoided; and according to the system, automation of batching and transportation is achieved, the labor cost is reduced, and the production efficiency is improved.

Owner:道专(上海)智能技术发展有限公司

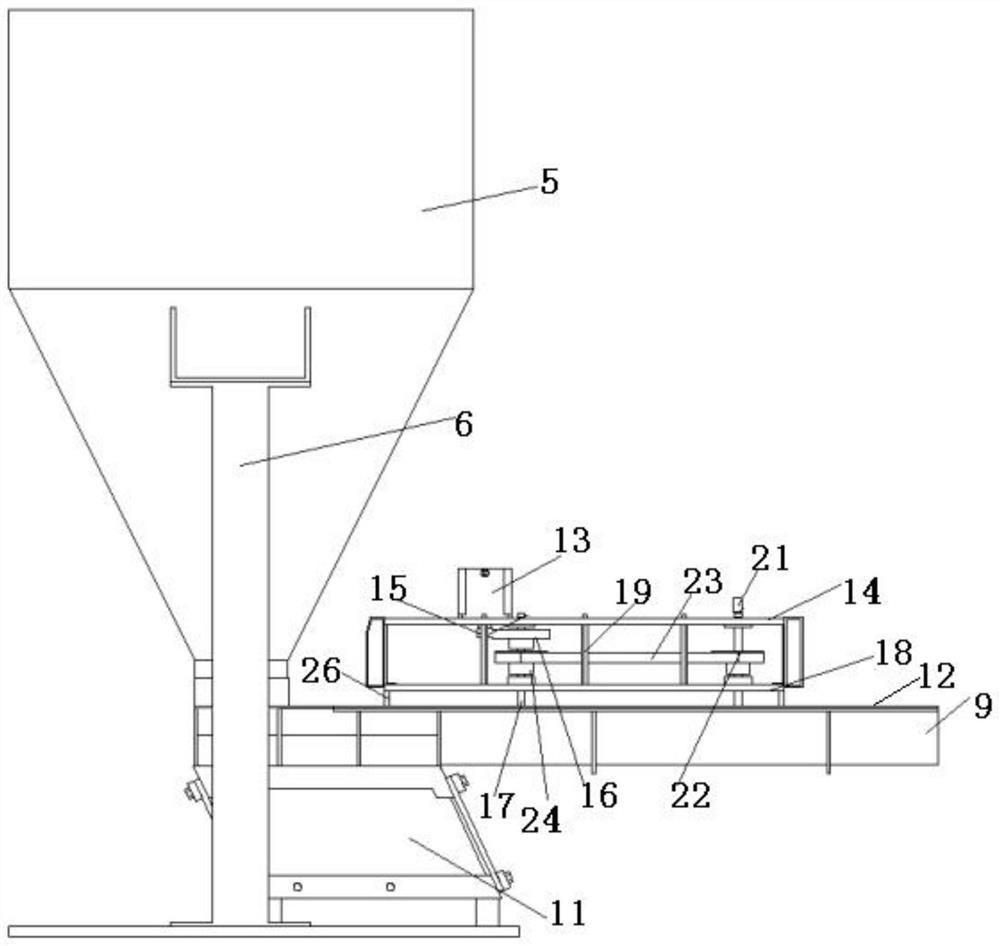

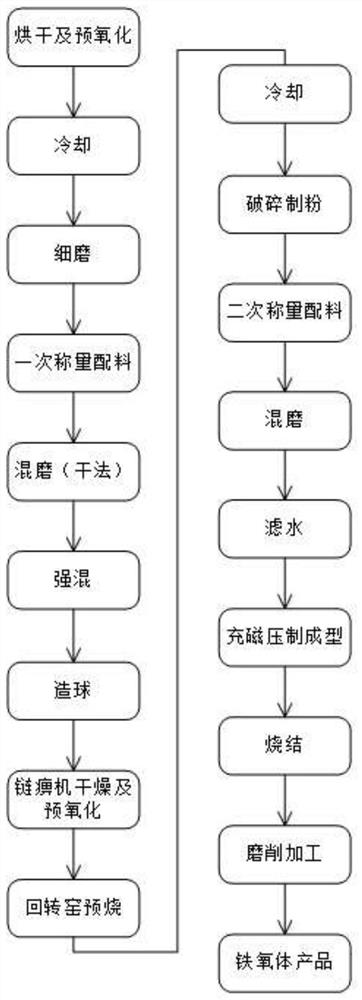

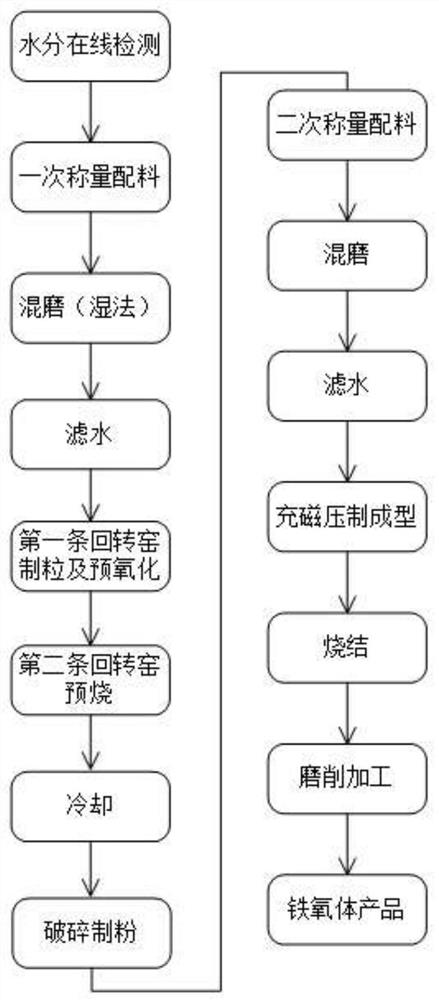

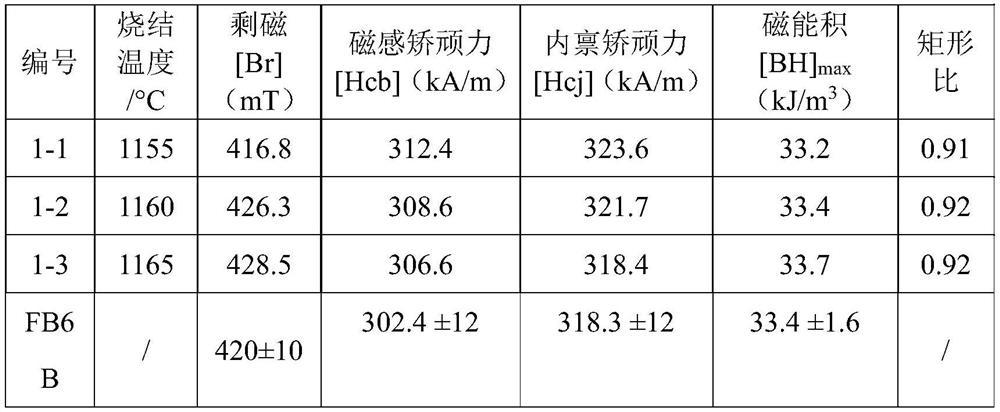

Process for preparing permanent magnetic ferrite in short process

InactiveCN113620700AEfficient and smooth productionRealize short process preparationInorganic material magnetismStrontium carbonateCompression molding

The invention relates to a process for preparing permanent magnetic ferrite in a short process. The process comprises the following steps: proportioning ultra-pure magnetite concentrate and strontium carbonate according to the molar ratio of SrO.nFe2O3 (n is more than 5.6 and less than 6.1), and then carrying out wet-process mixed grinding and water filtration; feeding the slurry subjected to water filtration into a first rotary kiln for drying, granulating and pre-oxidizing, and then feeding the slurry into a second rotary kiln for pre-sintering; and crushing the pre-sintered material, adding an additive to carry out secondary batching, and then carrying out wet-process mixed grinding, water filtering, magnetizing compression molding, sintering and grinding to obtain the permanent magnetic ferrite. In the preparation process of the permanent magnetic ferrite, a two-stage rotary kiln process is innovatively provided, drying, granulation and pre-oxidation of a pre-sintering material are carried out in the first rotary kiln, and a pre-sintering reaction is completed in the second rotary kiln, so that the oxidation of the ultra-pure magnetite concentrate is closely linked with the solid-phase sintering reaction process of iron strontium oxide, the links of drying, cooling, pelletizing, strong mixing and chain numbness machine pre-oxidation in the prior art are omitted, and the production is more efficient and smoother.

Owner:CENT SOUTH UNIV

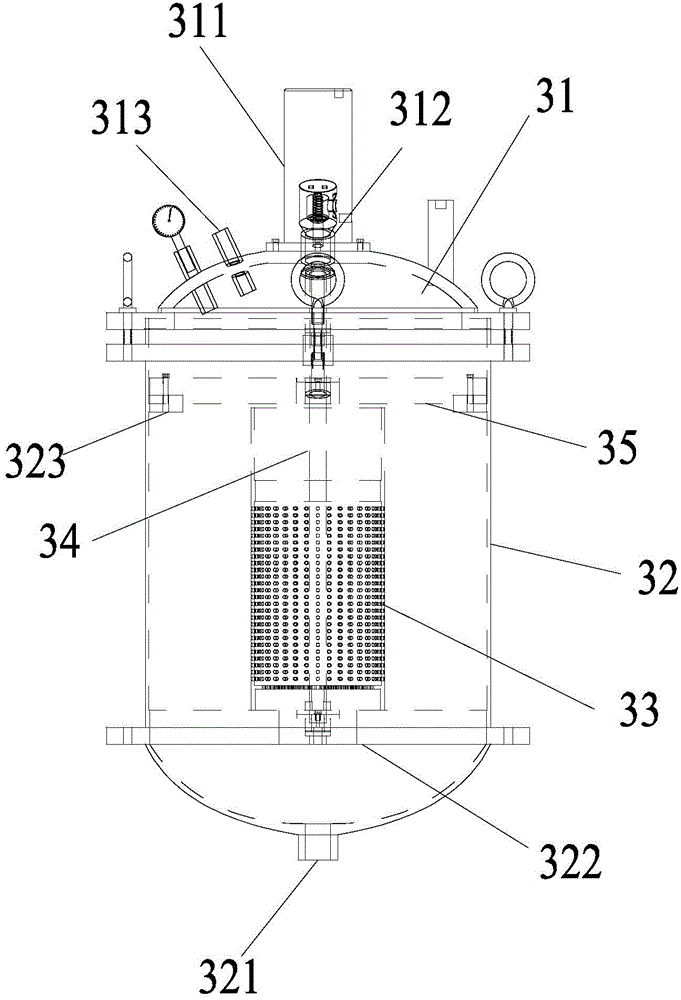

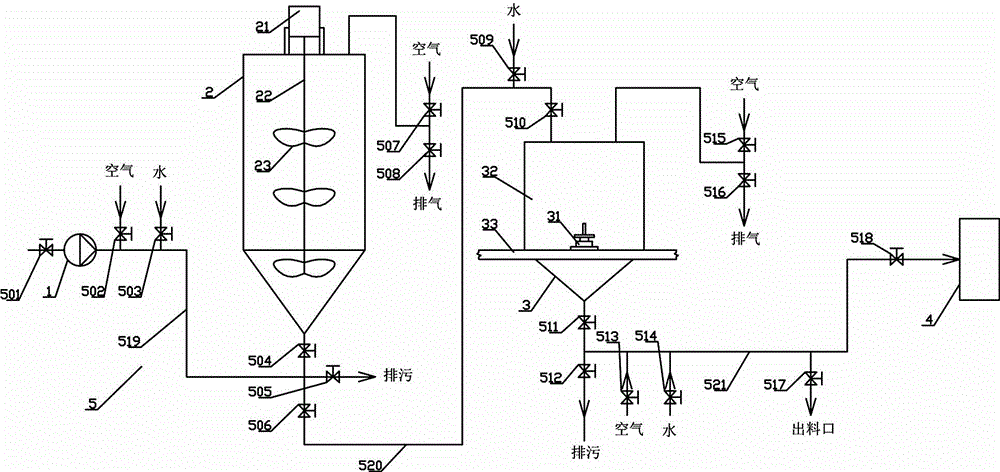

Automatic supply device and method of corn steep liquor in production of microbial fermentation

ActiveCN104531516AAutomatic and accurate batchingEasy to transportBioreactor/fermenter combinationsBiological substance pretreatmentsAgricultural engineeringCorn steep liquor

The invention relates to an automatic supply device and method of corn steep liquor in production of microbial fermentation. The automatic supply device is characterized in that a pump is connected with a storage tank through a feed pipeline, and the storage tank is connected with a weighing tank through a weighing pipeline; the weighing tank is connected with a mixing tank through a mixing pipeline, and the storage tank and the weighing tank are of sealing structures; air intake pipes are arranged on the storage tank and the weighing tank, and a plurality of valves are arranged on the feed pipeline, the weighing pipeline, the mixing pipeline and the air intake pipes. The method for mixing by the devices comprises the following steps: firstly, sending the corn steep liquor to the storage tank by the pump; secondly, introducing compressed air through the air intake pipe of the storage tank, and sending the corn steep liquor to the weighing tank; thirdly, after precisely weighing, introducing the compressed air through the air intake pipe of the weighing tank, and sending the corn steep liquor to the mixing tank. The automatic supply of the corn steep liquor in production of microbial fermentation is realized by the steps. The corn steep liquor can be automatically and precisely mixed by the device. After a batch of corn steep liquor is conveyed, the pipelines are conveniently cleaned, so that rancidity or infestation of residual corn steep liquor is avoided.

Owner:YICHANG SANXIA PHARMA

Method for maintaining dry and wet material ratio of blended ore uniform

InactiveCN108897981APrecise ingredientsGuarantee the quality of sinterData processing applicationsSpecial data processing applicationsMaterial consumptionMaterials science

The invention provides a method for maintaining the dry and wet material ratio of blended ore uniform. The method is characterized by including the steps that A, according to the hourly wet material consumption of a sintering machine, the set consumption of wet materials every day, the set total quantity of each pile of wet materials, the set total quantity of each pile of dry materials and the set piling quantity of each pile of wet materials are calculated; B, according to the total quantity of dry materials to be piled, different grades of various raw mineral materials participating in piling and the grade requirement of final sintered ore, the ratio of each kind of materials and the dry material quantity set value are calculated; C, each kind of materials participating in piling are sampled, and the actual water content is detected; the feeding quantity of the wet materials is obtained finally. By utilizing the actual water content detected in time, the actual wet material ratio isstill consistent with a set dry material ratio after the actual water content is deducted, accurate blending is achieved, and the quality of the sintered ore is guranateed.

Owner:WUKUN STEEL +1

Concrete batching device

InactiveCN112060349APrecise ingredientsImprovement ingredientsMixing operation control apparatusIngredients weighing apparatusStructural engineeringRaw material

The invention discloses a concrete batching device. The concrete batching device comprises a support, raw material hoppers, a material receiving hopper, conveying belts, a driving device, a sensor anda weighing device, wherein a working panel is arranged on the support, a through hole is formed in the working panel, the raw material hoppers are arranged on the working panel, the conveying belts are installed between the raw material hoppers and the working panel, materials in the raw material hoppers fall onto the conveying belt, and conveyed to the through hole position by the conveying belt, the material receiving hopper is arranged under the through hole, and the weighing device is arranged under the material receiving hopper. The concrete batching device can make batching of concretemore accurate, so that the production quality of the concrete is improved, and the quality of constructional engineering is guaranteed.

Owner:湖南创一机械有限公司

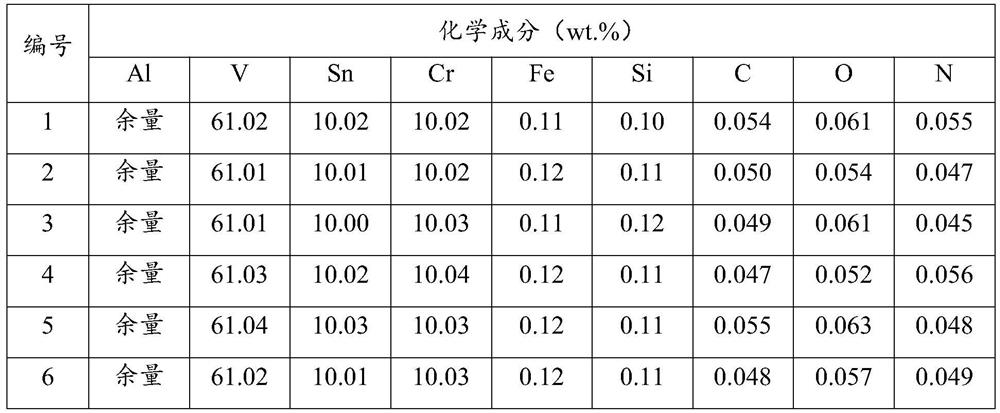

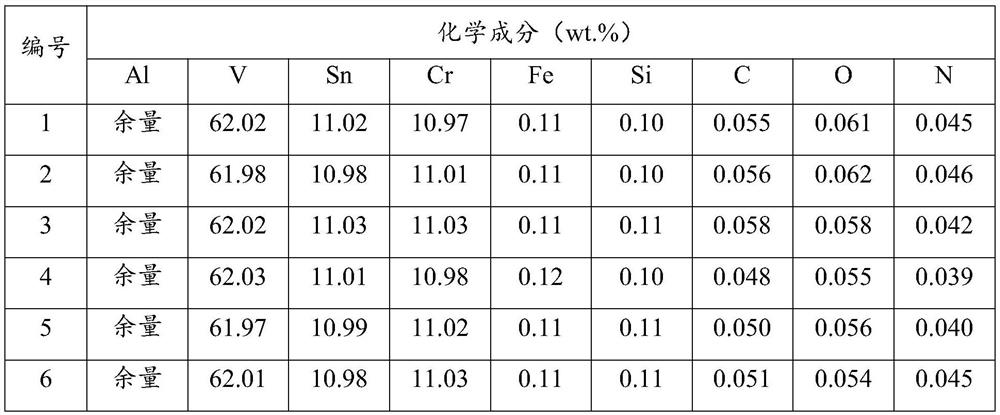

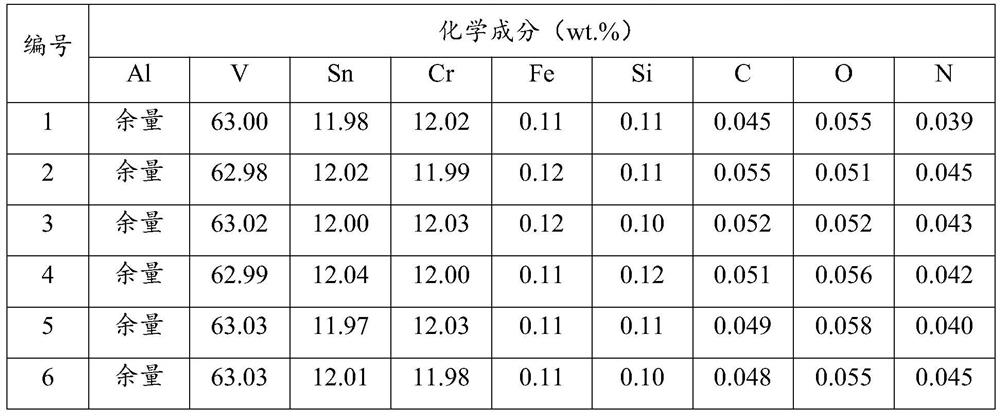

Aluminum-vanadium-tin-chromium intermediate alloy and preparation method thereof

The invention provides an aluminum-vanadium-tin-chromium intermediate alloy and a preparation method thereof, and relates to the technical field of metal materials. The invention provides an aluminum-vanadium-tin-chromium intermediate alloy. The alloy comprises the following components in percentage by mass: 61.0 to 65.0 percent of V, 10.0 to 14.0 percent of Sn, 10.0 to 14.0 percent of Cr, less than or equal to 0.15 percent of Fe, less than or equal to 0.15 percent of Si, less than or equal to 0.06 percent of C, less than or equal to 0.08 percent of O, less than or equal to 0.08 percent of N and the balance being Al. According to the invention, by controlling element composition and content, content of impurities in the aluminum-vanadium-tin-chromium intermediate alloy is low, components are uniform, segregation is small, homogenization of components of a titanium alloy is facilitated when the titanium alloy is smelted, and metallurgical defects of component segregation and inclusion are prevented.

Owner:CHENGDE TIANDA VANADIUM IND

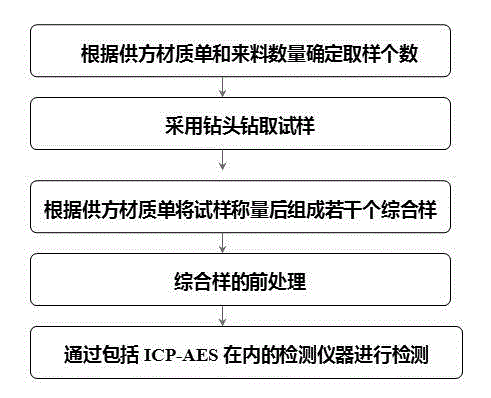

Multi-component rare earth raw material sampling method

InactiveCN104316345AReliable resultsPrecise ingredientsWithdrawing sample devicesAnalysis by thermal excitationRare-earth elementSlag

The invention discloses a multi-component rare earth raw material sampling method. The rare earth raw materials comprise lanthanum-cerium alloy, cell-grade mixed rare earth and a multi-component rare earth alloy composed of two or more rare earth elements. The rare earth raw materials are metals in as-cast state, have clean surfaces and no obvious oxide layers and form metal alloy ingots without obvious included slag. The multi-component rare earth raw material sampling method comprises determining sampling number according to a material detail form provided by a supplier and the number of one batch of fed materials, taking samples by a drill bit, weighing the samples according to the material detail form provided by the supplier, combining the samples to form an integrated sample, pre-treating the integrated sample and detecting ingredients of the multi-component rare earth alloy. The multi-component rare earth raw material sampling method has the advantages that the taken sample is representative, the detection result is real and reliable and production burdening is accurate.

Owner:JIANGXI RARE EARTH & RARE METALS TUNGSTEN GRP

Huangzangyu mushroom chicken

The invention discloses a Huangzangyu mushroom chicken. The Huangzangyu mushroom chicken is prepared through the following steps: material selection, raw material treatment, stir-frying, bagging, sterilization and storage. The local flavor is popularized to various places; meanwhile, by adoption of a dressed chicken pretreatment device and a full-automatic stir-frying device, fully-automatic operation is realized; chicken meat is beaten to be loose by adopting the dressed chicken pretreatment device; meanwhile, an overturning mechanism is matched; thus, the whole chicken is beaten; the purposethat the meat quality of the dressed chicken becomes better is achieved; the chicken meat is more tasty; the property of the chicken meat is improved; a product is easier to be popularized; and highsocial value and economic value are achieved.

Owner:宿州市符离集刘老二烧鸡有限公司

Aluminum powder precise distribution device

InactiveCN106696092AReasonable structural designSmall footprintMixing operation control apparatusIngredients weighing apparatusReducerEngineering

The invention discloses an aluminum powder precise distribution device. The aluminum powder precise distribution device is characterized by comprising a base, a driving mechanism, a speed reducer, a hopper, a weighing scale and a feeding cylinder, wherein an aluminum powder feeding device is fixedly mounted on the base; the feeding device includes the hopper, and the feeding cylinder arranged below the hopper; the feeding cylinder is driven through the driving mechanism; the hopper is mounted on a bracket of the base; the weighing scale is arranged at an output end of the feeding cylinder; and the driving mechanism can be a cylinder or a servo motor. The aluminum powder precise distribution device has the advantages of: reasonable structure design, less occupied space, change of a traditional process of manual metering, capability of realizing quantitative feeding, accurate metering, uniform stirring, good distribution effect, high automation degree and satisfaction of the modern production requirements.

Owner:刘勤卓

Refractory matter batching equipment

InactiveCN105269687AReduce labor intensityImprove working environmentMixing operation control apparatusMixing operation plantWorking environmentRefractory

The invention relates to batching equipment, in particular to refractory matter batching equipment, and belongs to the technical field of batching equipment. The refractory matter batching equipment comprises a first measuring hopper, first bins, first spiral conveyors, an upper platform, a middle platform, a storage bin, second bins, second spiral conveyors, a second measuring hopper, a spiral bin conveyor, a feeding platform, ton bag feeding bins, small bag feeding bins and a mixing machine. The upper platform and the middle platform are vertically connected into a whole, and the first bins are fixed to the upper platform. The first spiral conveyors are arranged at the discharging ends of the first bins respectively. The outlet ends of the first spiral conveyors connected with the lower ends of the first bins are connected with the first measuring hopper together, and the first measuring hopper is fixed to the middle platform. The refractory matter batching equipment is accurate in batching, the labor intensity of workers can be lowered, the working environment of the workers can be improved, and production efficiency is high. Meanwhile, mounting and debugging are convenient, the system is stable, performance is reliable, and maintenance cost is low.

Owner:WUXI SHAN CHUAN ENVIRONMENTAL PROTECTION MACHINERY CO LTD

Grabbing and releasing mechanical arm for automobile electronic rod-shaped components

InactiveCN110919675AHigh degree of automationPrecise ingredientsGripping headsEngineeringAutonomation

The invention discloses a grabbing and releasing mechanical arm for automobile electronic rod-shaped components. The mechanical arm comprises a mechanical arm support, an inserting rod taking clampingjaw, a pneumatic finger air cylinder and an inserting rod taking telescopic air cylinder. The mechanical arm is characterized in that two movable plates are hinged to the bottom of the mechanical armsupport; the two movable plates are oppositely arranged; a reset spring is mounted on one movable plate; a finger cylinder mounting plate is horizontally arranged under the movable plate; the pneumatic finger air cylinder is fixed to the bottom of the finger cylinder mounting plate; the inserting rod taking clamping jaw is arranged at the end of the pneumatic finger air cylinder; the inserting rod taking telescopic air cylinder is arranged on the rear portion of the mechanical arm support in the vertical direction; and an air cylinder push rod of the inserting rod taking telescopic air cylinder is connected with the top of the finger air cylinder mounting plate. The mechanical arm is high in automation degree, can automatically pick up, grab and release the inserting rods and the like, isaccurate in batching, improves the production efficiency and reduces the production cost.

Owner:仙桃市诚宇汽车电器股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com