Aluminum-vanadium-tin-chromium intermediate alloy and preparation method thereof

A master alloy, aluminum vanadium tin chromium technology, applied in the field of metal materials, can solve the problems of finished product segregation of titanium alloy products, high impurity content of master alloy, difficult to meet aerospace and other problems, achieve optimal performance, small component segregation, and help For the effect of homogenization of ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention also provides the preparation method of the aluminum vanadium chromium intermediate alloy described above, including the following steps:

[0035] Mix aluminum source, vanadium source and tin source, and perform aluminum thermal reaction to obtain aluminum vanadium 1-level alloy;

[0036] The aluminum vanadium primary alloy was mixed with a chromium source to perform vacuum smelting to give the aluminum vanadium chromium intermediate alloy.

[0037] The present invention mixes aluminum source, vanadium source, and tin source, and aluminum heat reactions to obtain aluminum tin 1-level alloys. The present invention first mixes aluminum source, vanadium source, and tin source, aluminum thermal reaction, can neutralize the density and melting point of vanadium and tin moniral, allowing the four yuan alloy more uniform.

[0038] In the present invention, the aluminum source, vanadium source, and tin source are mixed, and the aluminum source, vanadium source...

Embodiment 1

[0056] First, aluminum hot smelting process

[0057] (1) Aluminum powder and pentoxide, dry dry, dry temperature of 110 ° C, dry drying time;

[0058] (2) According to the mass fraction of vanadium and vanadium and tin in the nitroxide, the mass fraction of vanadium and tin in the chemical reaction, the mass ratio of aluminum hot smelting process alloy is calculated: aluminum powder and five The mass ratio of diofoxide and tin oxide is 5.260: 8.570: 1.000;

[0059] (3) Precaution of 120 r / min in the mixture in the mixture in the mixture in the mixture in the mixture in the mixture in a mixture of 120 R / min;

[0060] (4) The mixed aluminum powder and pentoxide, and tin oxide are preheated to the furnace temperature of 43 ° C, the ignition smelting, after 24 h, to obtain an aluminum vanadium 1-level alloy.

[0061] Second, the vacuum smelting process matching

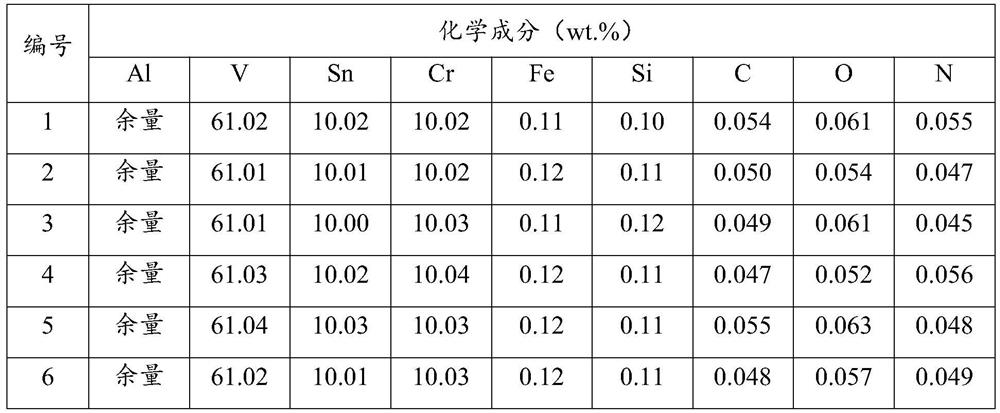

[0062] After obtaining the aluminum tin level alloy, it is refined to break and analyze the composition according to th...

Embodiment 2

[0079] First, aluminum hot smelting process

[0080] (1) Aluminum powder and pentoxide, dry dry, dry temperature of 110 ° C, dry drying time;

[0081] (2) According to the mass fraction of vanadium and vanadium and tin in the nitroxide, the mass fraction of vanadium and tin in the chemical reaction, the mass ratio of aluminum hot smelting process alloy is calculated: aluminum powder and five Dioxide, the mass ratio of tin oxide is 5.304: 7.926: 1.000;

[0082] (3) Precaution of 120 r / min in the mixture in the mixture in the mixture in the mixture in the mixture in the mixture in a mixture of 120 R / min;

[0083] (4) The mixed aluminum powder and pentoxide, and tin oxide are preheated to the furnace temperature of 43 ° C, the ignition smelting, after 24 h, to obtain an aluminum vanadium 1-level alloy.

[0084] Second, the vacuum smelting process matching

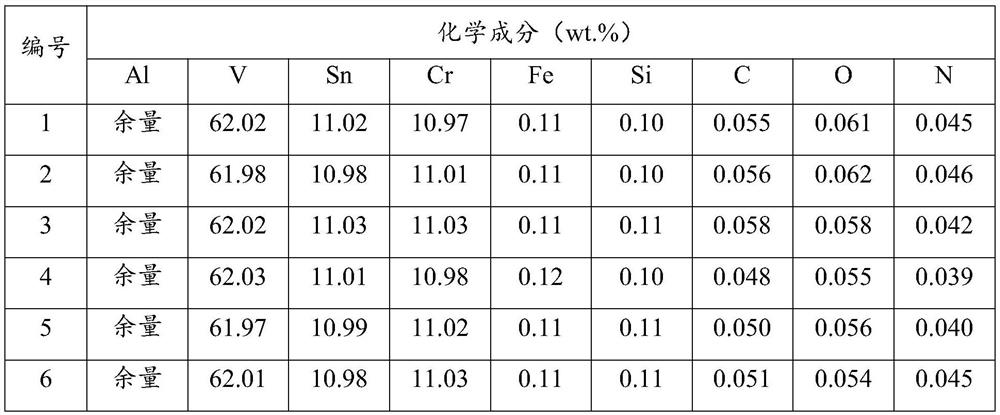

[0085] After obtaining the aluminum tin level alloy, it is finely broken, and the melting process ratio is calculated accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com