Patents

Literature

6021 results about "Smelting process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The process of smelting uses both heat and a chemical reduction agent. This process changes the oxidation state of the ore. One of the forms of extracting metals is smelting. The purpose of the smelting process is to produce a metal from its original ore.

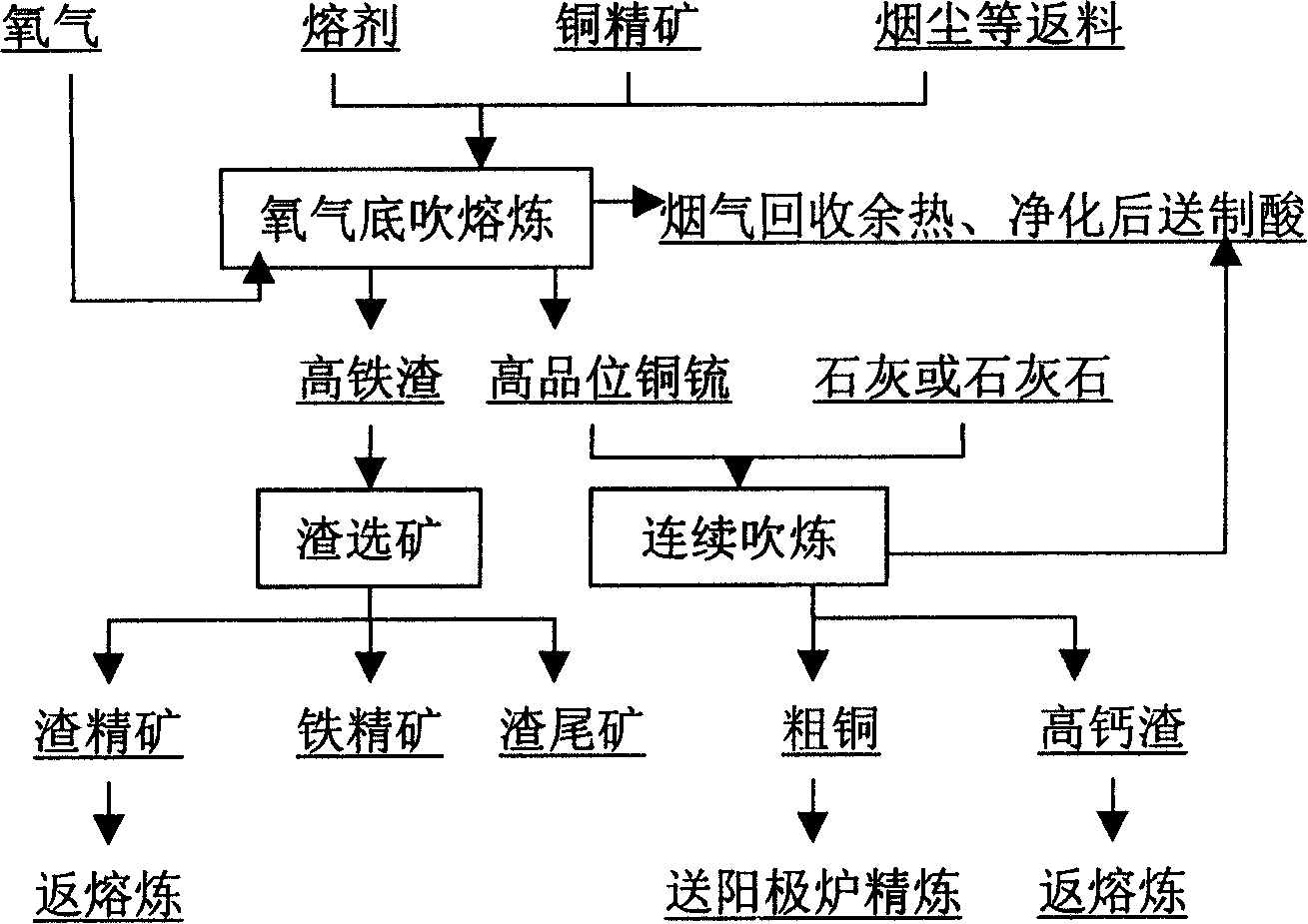

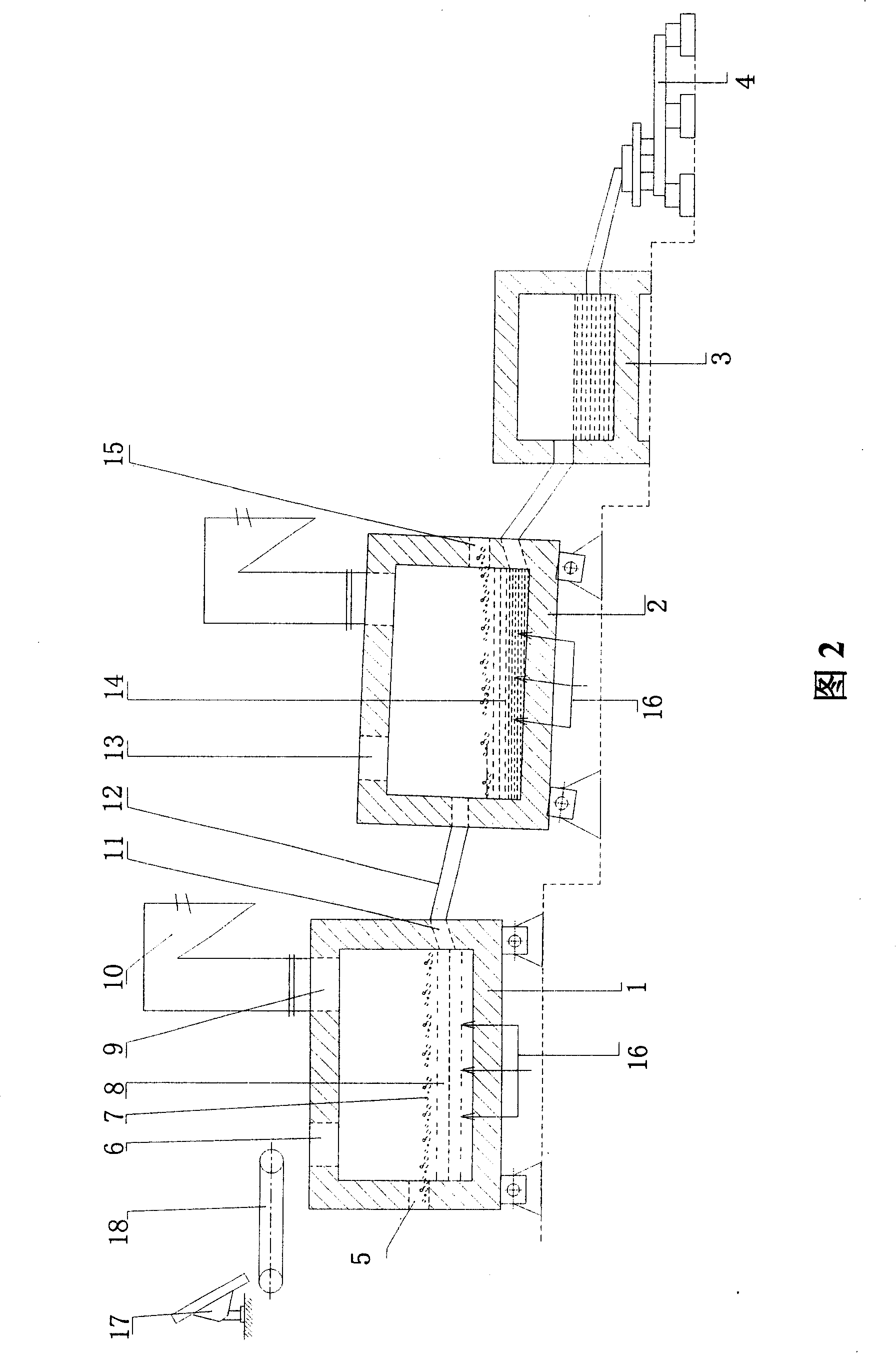

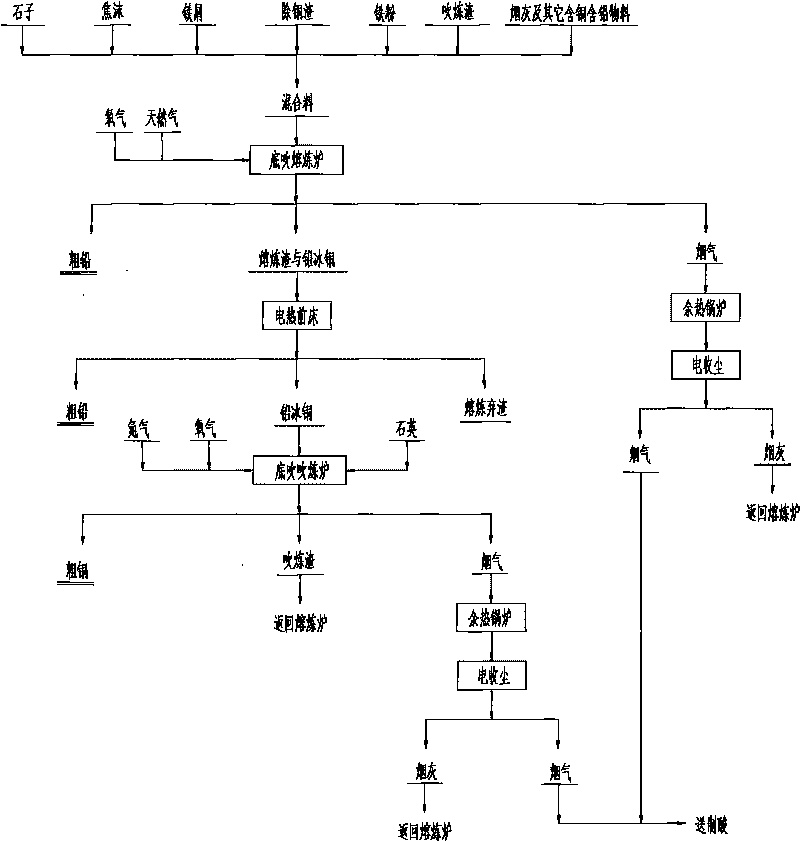

Technique for continuously smelting copper by employing oxygen bottom converter and device thereof

ActiveCN101165196AReduce loadHigh smelting yieldProcess efficiency improvementAutomatic controlSmelting process

The present invention relates to continuous copper-smelting oxygen bottom blowing furnace process and apparatus. The continuous copper-smelting process includes smelting high grade copper matte in an oxygen bottom blowing furnace, smelting coarse copper product with the high grade copper matte in one other bottom blowing furnace, producing high iron slag, dressing the furnace slag to obtain copper concentrate and returning to smelting furnace, separating out iron concentrate product and obtaining tailings. The process has short flow path, low investment, low power consumption, low cost, environment friendship and other advantages.

Owner:CHINA ENFI ENGINEERING CORPORATION

Large thickness quenched high strength steel and production method thereof

InactiveCN101363101AEquivalent lowGood welding performanceRoll mill control devicesMetal rolling arrangementsPower stationSheet steel

The invention belongs to the field of metal materials and discloses a large-thickness and high-strength quenched and tempered steel plate and a production method thereof. The steel plate mainly consists of the following chemical components by weight percentages: not more than 0.18% of C, 0.1-0.4% of Si, not more than 1.2% of Mn, 0.7-1.7% of Ni, 1.0-1.5% of Cr, 0.4-0.6% of Mo, 0.03-0.08% of V, 0.02-0.04% of Al, 0.0005-0.0020% of B, Fe and unavoidable impurities. The molten steel designed according to the components of the invention can be rolled into the large-thickness steel plate by smelting process, casting process, heating process, rolling process, water cooling process and quenching and tempering process. The steel plate has the advantages of reasonable component design, good comprehensive properties and low production cost, can be applied to off-shore oil production platform engineering, power stations, engineering scaffolds and other industries and has good application prospect.

Owner:WUYANG IRON & STEEL

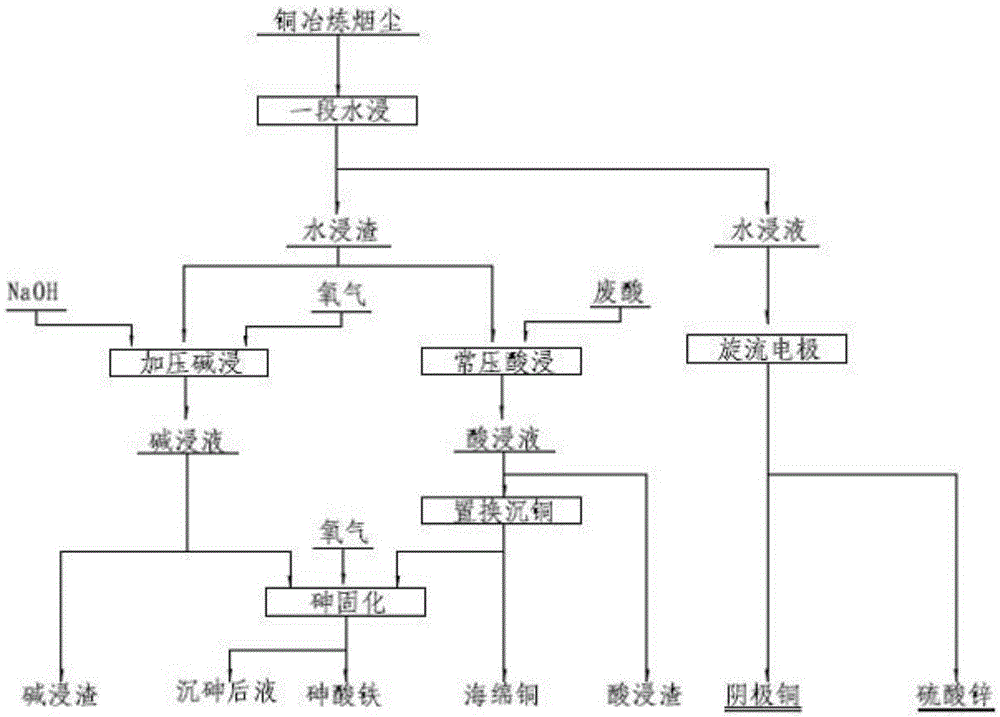

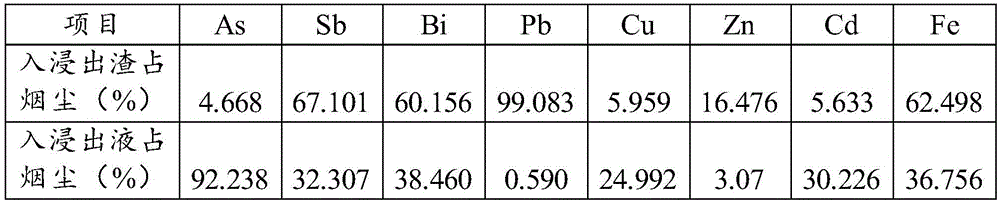

Soot treatment process in copper smelting process

ActiveCN105567983ARealize comprehensive utilizationLow arsenicProcess efficiency improvementArsenateSmelting process

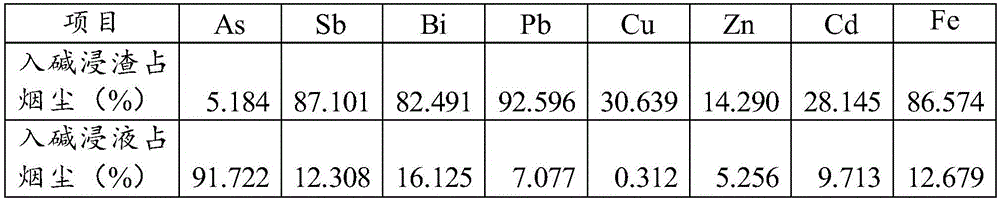

The invention provides a soot treatment process in a copper smelting process. The soot treatment process comprises the following steps: firstly carrying out water leaching on copper smelting soot to obtain a water leaching fluid and water leaching residues; then, carrying out acid leaching on one part of the water leaching residues obtained in the last step to obtain an acid leaching fluid, and carrying out alkali leaching on the other part of the water leaching residues to obtain an alkali leaching fluid; carrying out metal replacement on the acid leaching fluid obtained in the last step to precipitate copper to obtain copper-precipitated filtrate; and finally, neutralizing and oxidizing the copper-precipitated filtrate obtained in the last step and the alkali leaching fluid obtained in the last step to obtain ferric arsenate precipitates and arsenic-precipitated filtrate. The soot treatment process provided by the invention, especially the treatment process for high-arsenic high-copper soot realizes the hazard-free treatment effect of arsenic in the high-arsenic high-copper soot, and comprehensively recycles valuable metal copper, zinc and the like in the high-arsenic high-copper soot, so that gradient recycling and comprehensive utilization of soot impurities are realized.

Owner:YANGGU XIANGGUANG COPPER

Method for harmless disposal and recycling of aluminum ash

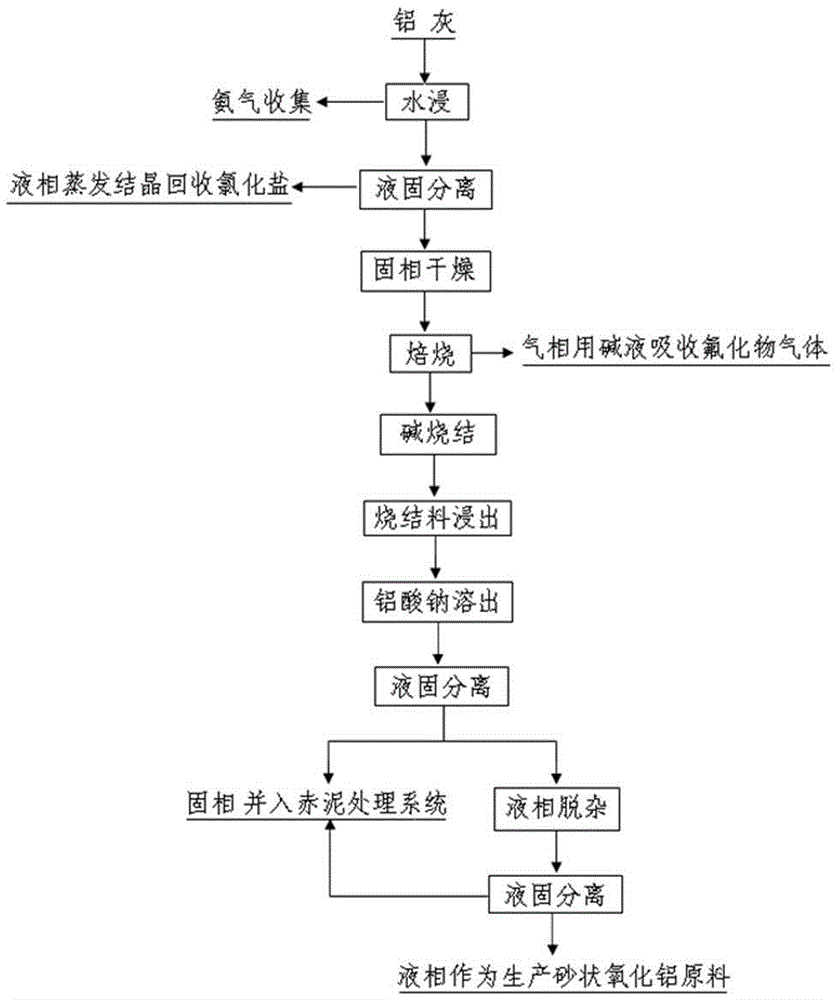

ActiveCN105271327ATo achieve the purpose of comprehensive recycling of resourcesGreat social valueAmmonia preparation/separationAluminium oxides/hydroxidesMetallic aluminumSodium aluminate

The invention discloses a method for harmless disposal and recycling of aluminum ash. The method comprises steps of raw material water immersion nitrogen and chlorine removal, calcination fluorine removal, alkali fusion sintering, sintering material dissolving-out and purifying impurity removal. Aluminum ash generated in metal aluminum smelting process is employed as a raw material, after metal aluminum is recycled through secondary processing, nitrides are removed through water immersion, fluorides are removed through calcinations, alkali fusion sintering is carried out, the sintering materials are dissolved out, impurities are removed through a sodium aluminate solution, the processed aluminum ash is employed as a raw material for producing sand-shaped aluminum oxide. Ammonia gas generated in the aluminum ash harmless disposal process can be employed as an ammonium production raw material, a chlorination liquid generated can be employed as a chlorate production raw material, and silicon fluoride gas generated in the calcination process is absorbed by an aqueous solution. The method is simple and practical, environmental protection benefits are high, the production efficiency is high, the device investment is low, and energy consumption is low. Harmless and recycling disposal of hazardous wastes can be achieved. The obtained product can be applied in practical production.

Owner:YUNNAN WENSHAN ALUMINUM

Method for melting nickel-base high temperature alloy with electro-slag furnace

The invention relates to a method for melting a nickel-base high temperature alloy with an electro-slag furnace. The method includes the following methods: loading materials, welding a high temperature alloy electrode and a false electrode to be smelted together, and placing slag materials at the bottom of a crystallizer; blowing the welded electrodes with inert gases, and closing a protection cover; protecting a smelting closing smoke exhaust valve, and feeding an Ar gas into the crystallizer and the protection cover; striking an arc and melting slag; cleaning smelting slag materials, starting a smelting period, and swinging a slag resistor for less than 0.5 m omega during the smelting process; adding oxidizing agents, and adding metal aluminum powder continuously or at intervals to serve as deoxidizing agents during an electro-slag re-melting process; adopting feeding thorough three stages, power feeding is decreased rapidly, power feeding is decreased slowly, and finally heat is preserved at constant power; and casting a die, cooling and demolding the die. According to the method for melting the nickel-base high temperature alloy with the electro-slag furnace, the surface of a nickel-base high temperature steel ingot has no slag groove defect, and the burning losses of Al and Ti are less than or equal to 5%.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

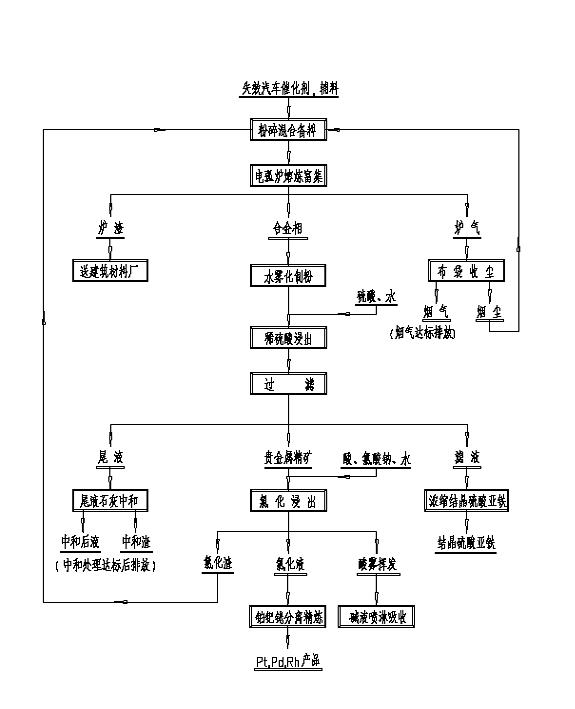

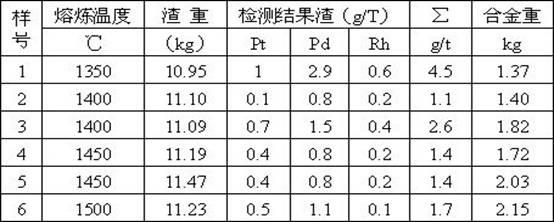

Method for extracting precious metal from spent automobile catalyst by concentration smelting-wet separation process

ActiveCN102534226AHigh recovery rateReduce lossesProcess efficiency improvementSmelting processAlloy

Owner:浙江煌盛铂业有限公司

High strength strapping steel with tensile strength over 1,100 MPa and manufacturing method thereof

The invention discloses high strength strapping steel with tensile strength over 1,100 MPa and a manufacturing method thereof. The high strength strapping steel comprises the following components in percentage by weight: 0.25 to 0.35 percent of C, 1.0 to 2.0 percent of Mn, less than or equal to 0.45 percent of Si, less than or equal to 0.04 percent of S, less than or equal to 0.04 percent of P, and the balance of Fe and inevitable impurities. The manufacturing method comprises a steel smelting process, hot rolling process, cold rolling process and ferrite-austenite two-phase region quick quenching and annealing heat treatment process for smelting pure steel while controlling the state of impurities. The method can realize the excellent combination of strength and plasticity, realizes the clean production of the high-strength strapping steel which has a tensile strength over 1,100MPa and an elongation over 10 percent, and has the advantages of easy-to-implement production operation, high production efficiency, low production cost, light environmental pollution. Thus, the method has a good application prospect.

Owner:BAOSHAN IRON & STEEL CO LTD

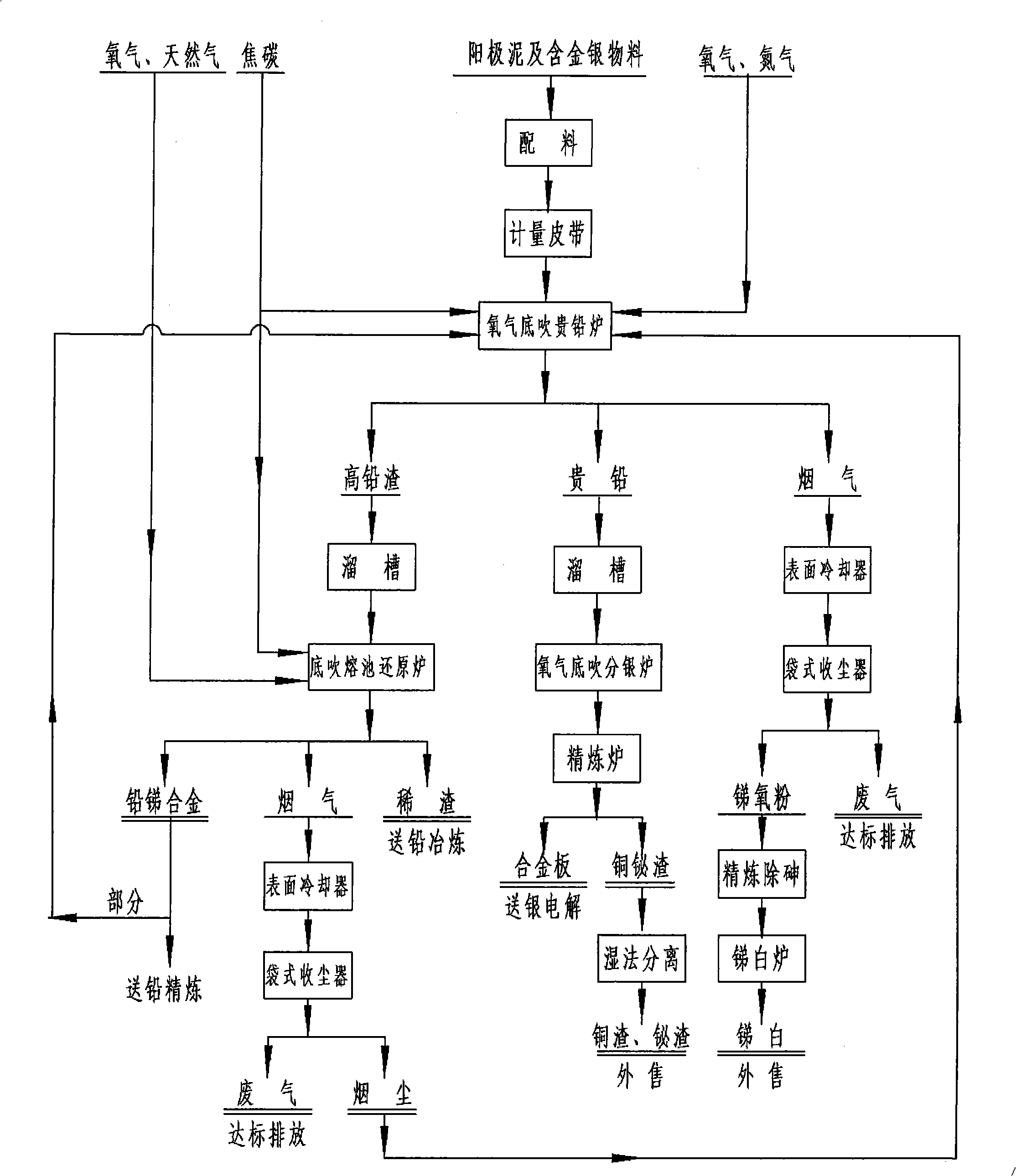

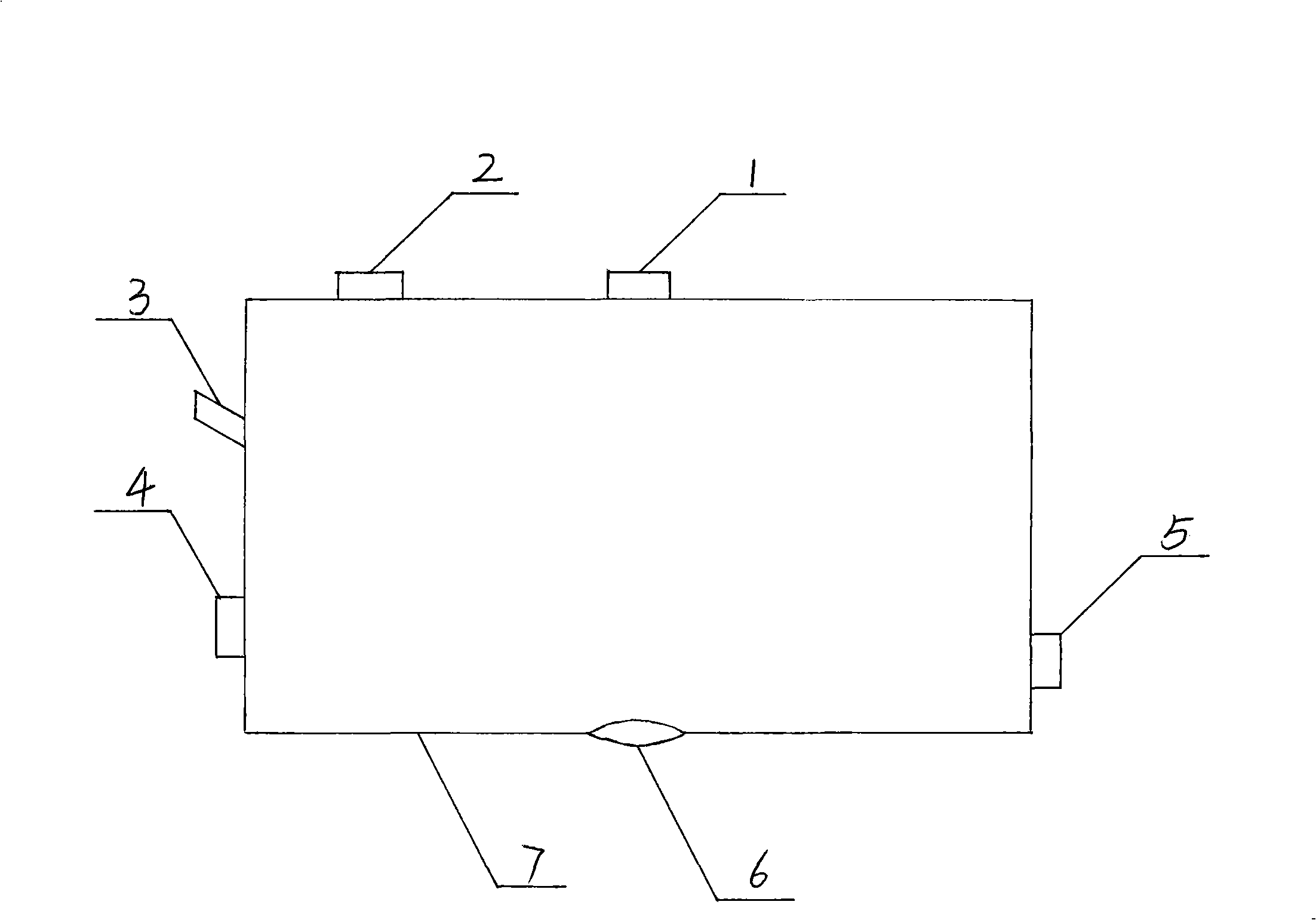

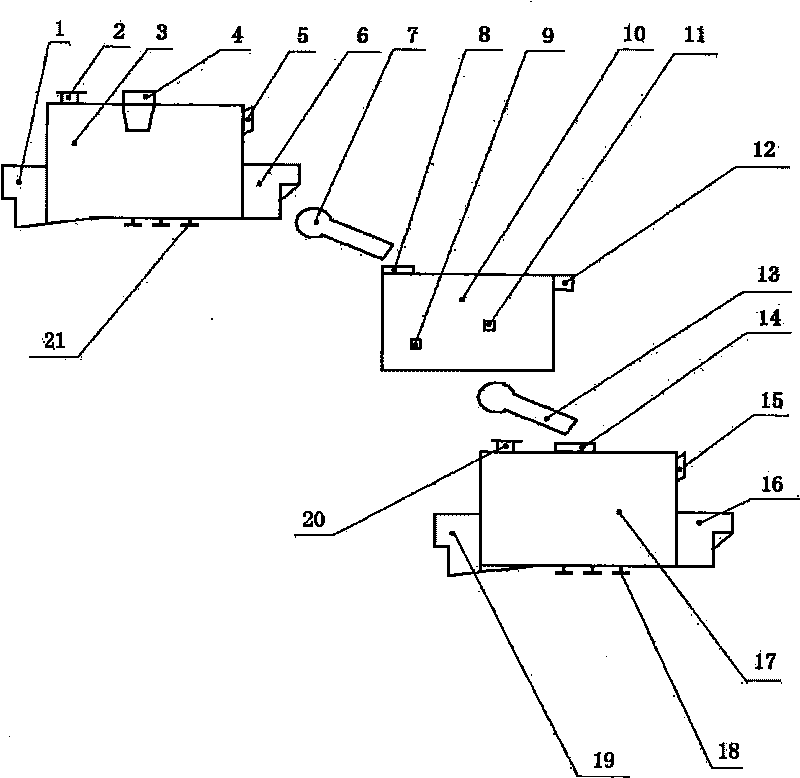

Smelting method for separating value metals from anode mud by firing process and device thereof

The present invention relates to a smelting method for separating and extracting noble and base metals during anode mud pyrogenic attack process and the device thereof, belonging to the field of nonferrous metallurgical industry. The smelting compositions only includes anode mud and nut coke, continuous oxidation-reduction smelting is carried out on the anode mud by oxygen bottom blown smelting method, gold, silver, copper and bismuth are enriched, arsenic and stibium are volatilized, silicon and lead are slagged, the smelting process is divided into two processes: one is the process of bottom oxidative slagging of oxygen and noble lead or bottom lead; the other is the process of reducing volatilization of coke on the slag surface, the two processes are two continuous combined cycle smelting processes finished in a same furnace and during the same time, the smelting process is non-alkali low-silicon high-lead-slag type, the mass ratio of the SiO2 to PbO is 0.2 to 0.5. The invention has the advantages of low cost, large handling capacity, low energy comsuption, long using period of refractory lining, high direct recovery rate of gold, silver, copper, stibium and bismuth, strong adaptability to raw materials, high automation level, etc.

Owner:HENAN YUGUANG GOLD & LEAD

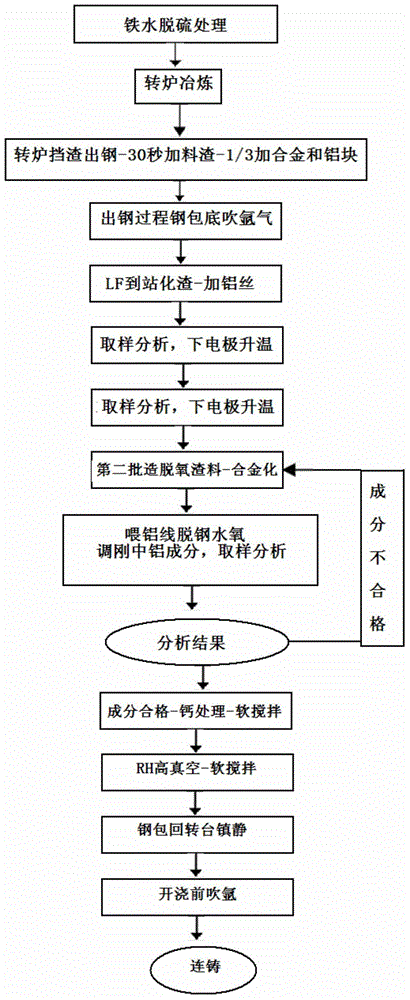

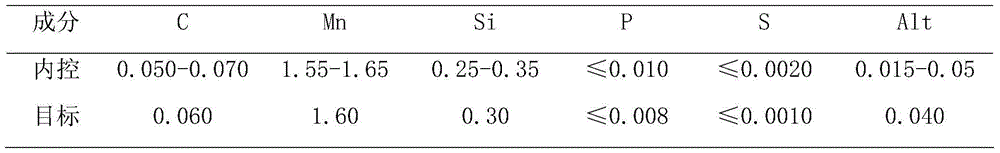

High-cleanliness pipeline steel smelting process

ActiveCN104630418ASolve the difficulty of cleanliness controlQuality improvementManufacturing convertersSulfurNon-metallic inclusions

The invention discloses a high-cleanliness pipeline steel smelting process. The process route comprises molten iron pouring, molten iron pretreatment, converter smelting, tapping, deoxidizing, alloying, LF refining furnace, treating with calcium, RH vacuum furnace and continuous casting and is characterized by comprising the following specific steps: firstly, converter smelting process; secondly, refining furnace smelting process; and thirdly, continuous casting process. The invention belongs to a steel-making process in the field of metallurgy and relates to a method for smelting and controlling a high-cleanliness pipeline steel. By molten iron desulphurization pretreatment, optimizing a converter tapping and deoxidizing system and a slagging system, LF refining furnace deep deoxygenation and reducing slag manufacturing processes, RH high-vacuum-degree degassing and inclusion removal process, the pouring is protected by the continuous casting in the whole process so that the composition of a casting billet is uniform, the contents of harmful elements such as S, P, O, N and H are low, the non-metallic inclusions are effectively controlled, the casting billet is good in internal quality and the production of high value-added ultra-low sulfur steel is ensured.

Owner:NANJING IRON & STEEL CO LTD

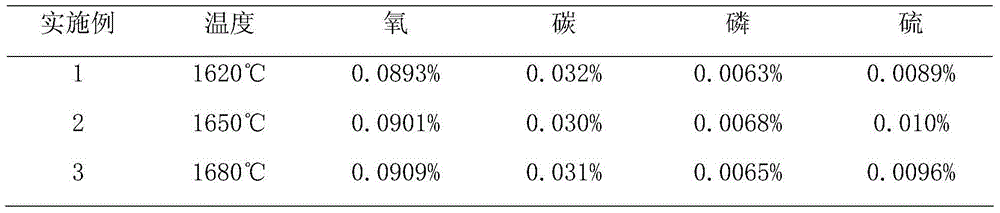

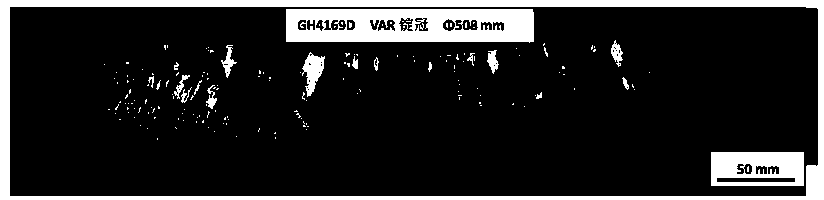

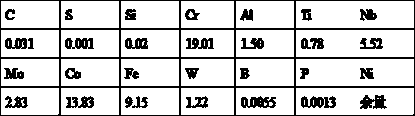

Smelting technique of novel nickel-iron-base high-temperature alloy GH4169D

The invention discloses a smelting technique of a novel nickel-iron-base high-temperature alloy GH4169D, which aims to smelt the novel high-temperature alloy GH4169D consumable ingot which has the advantages of lower raw material cost and favorable hot working properties in industrial production as well as high stability at high temperature. The scheme of the smelting technique is as follows: on the basis of the GH4169 alloy composition, the Fe content is lowered, the sum and proportion of Al and Ti are adjusted, and proper P and B are added; and by adopting a triple (VIM+PESR+VAR) smelting technique, proper slag and technological parameters are selected, and the burning loss of Al and Ti in the protective-atmosphere electroslag smelting process is controlled to obtain the precise contents of Al and Ti. The technique enhances the metallurgical quality of the high-temperature alloy, and fills up the blank of the high-temperature alloy in the aspect of the application temperature between 650 DEG C and 750 DEG C; the GH4169D alloy has the high strength, favorable hot working property and weldability of the GH4169 alloy, and has the high application temperature and other comprehensive properties of the GH4738 alloy; and the GH4169D alloy has long-term stability at 700 DEG C.

Owner:FUSHUN SPECIAL STEEL SHARES

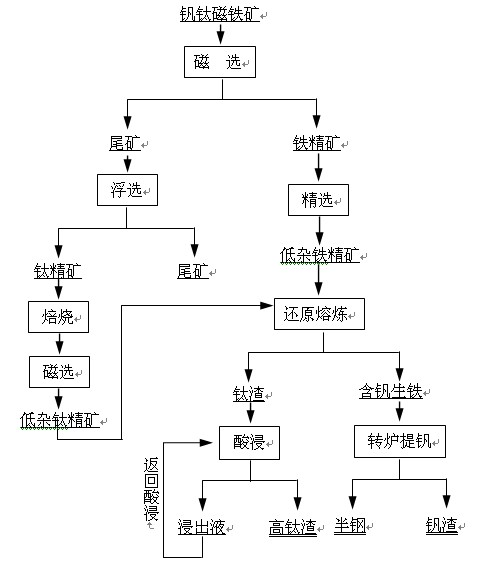

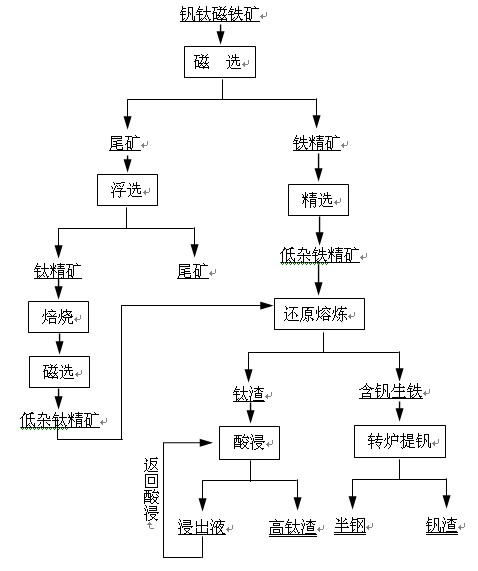

Method for separating vanadium-titanium magnetite to extract iron, vanadium and titanium

InactiveCN102179292AHigh technical difficultyIncrease processing costWet separationSmelting processMagnetite

The invention discloses a method for separating vanadium-titanium magnetite to extract iron, vanadium and titanium, comprising the following steps of: magnetically selecting raw magnetite, that is, acquiring iron-vanadium concentrate and tail magnetite after performing magnetic selection on the vanadium-titanium magnetite; sorting titanium concentrate from the tail magnetite, that is, acquiring the titanium concentrate after performing floating selection on the obtained tail magnetite; roasting and magnetically selecting the titanium concentrate, that is, performing enriched-titanium impurity-removing magnetic selection after roasting the titanium concentrate; finely selecting the iron-vanadium concentrate, that is, performing the magnetic selection and fine section again on the iron-vanadium concentrate obtained from magnetic selection; reducing and smelting, that is, mixing the titanium concentrate obtained from the impurity-removing process with the iron concentrate according to the beneficiation yield, adding in a reducer and soda ash to perform reduced iron and vanadium smelting process; purifying vanadium slag, that is, removing the impurity of the vanadium slag obtained by reducing and smelting by using the acidic dipping to obtain the high-quality titanium slag product with the content of TiO2 larger than 92%; and extracting vanadium from pig iron, that is, performing vanadium extraction by converter blowing on the vanadium-containing pig iron obtained by reducing and smelting to obtain the semi-steel and vanadium slag. The method not only improves the utilization ratio of titanium, iron and vanadium but also obtains the high-titanium slag product with the content of TiO2 larger than 92% so as to widen the application field of titanium.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

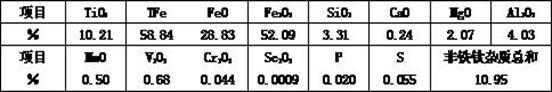

Boron steel producing converter smelting process

InactiveCN101045948ALow oxygen content in molten steelHigh yieldManufacturing convertersSmelting processMolten steel

The present invention belongs to the field of iron and steel smelting technology, and is especially boron steel producing process in a converter. The production process includes the steps of smelting in a converter, deoxidizing and refining in a ladle, and boron alloying. The boron steel producing process has low oxygen content in molten steel after refining, high boron steel yield of 69.4-91.8 %, and excellent application foreground.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

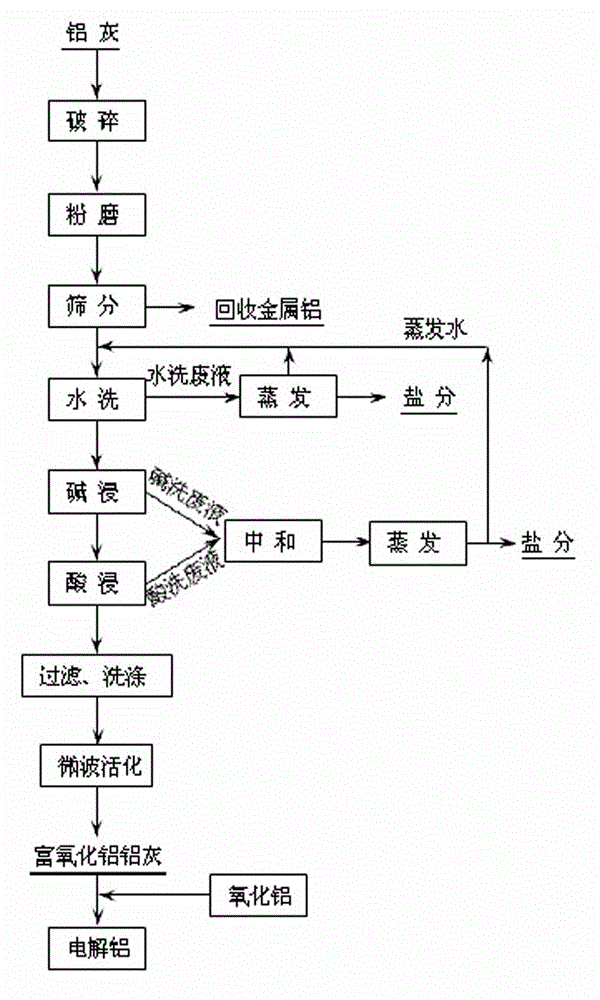

Resource utilization method of aluminum ash

ActiveCN103555955AEfficient recyclingComprehensive recyclingProcess efficiency improvementLiquid wasteMicrowave

The invention discloses a resource utilization method of aluminum ash. The method comprises the following steps: by taking primary slag and flammable dross generated in a smelting process of electrolytic aluminum, and aluminum ash such as salt slag and scum generated in a coarse aluminum refining and processing process as raw materials, recovering aluminum through process steps of crushing, grinding and vibrating screening; and then, respectively carrying out technologies such as washing, pressurized alkaline leaching and normal pressure acid leaching to obtain aluminum oxide-rich aluminum ash. The aluminum ash dried and activated by microwaves returns to an aluminum cell. After the acid-washing liquid waste and alkali-washing waste are effectively neutralized, the acid-washing liquid waste and alkali-washing waste are concentrated and evaporated to recover effective salt. The process provided by the invention can realize resource utilization of aluminum ash on the spot, and is simple and easy to operate and low in production cost, so that the environmental pollution and resource waste caused by aluminum ash are avoided.

Owner:KUNMING METALLURGY INST

Method for adding rare earth metal into steel to improve performance

The invention relates to the field of manufacturing of high-quality metal materials, in particular to a method for adding rare earth metal into steel to improve the performance. In the smelting process of molten steel, the degree of purity of the molten steel and the degree of purity of the high-purity rare earth metal are strictly controlled; the high-purity rare earth metal is added into a steel ladle; the content of sulfur in the molten steel is below 200 ppm and the total oxygen content is below 40 ppm before the high-purity rare earth metal is added; and the total oxygen content of the added high-purity rare earth metal is below 200 ppm. The method is applicable to the processes such as a converter BOF-ladle refining LF-vacuum degassing RH or VD-continuous casting CC / mold casting MC flow, an electric arc furnace EAF-ladle refining LF-vacuum degassing RH or VD-continuous casting CC / mold casting MC flow and a converter BOF / intermediate frequency furnace GOR / AOD(-ladle refining LF)-continuous casting CC / mold casting MC flow, prepares high-quality carbon structural steel, low alloy steel, medium-high alloy steel, tool and mould steel, bearing steel, spring steel, stainless steel and electrical steel, and solves the bottleneck problems that due to a conventional rare earth adding process, the performance of rolled steel is not stable and a water gap is blocked in the production process.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Dephosphorization method of semi-steel

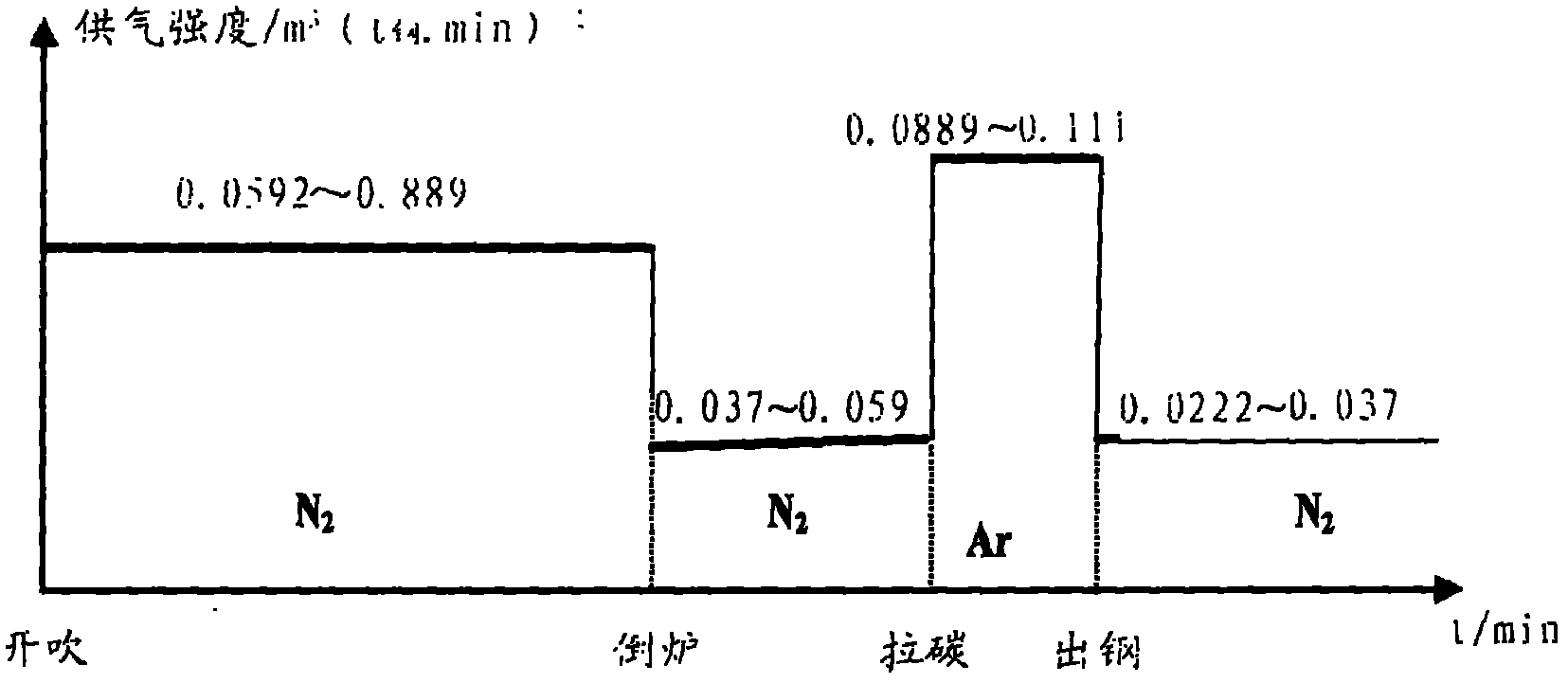

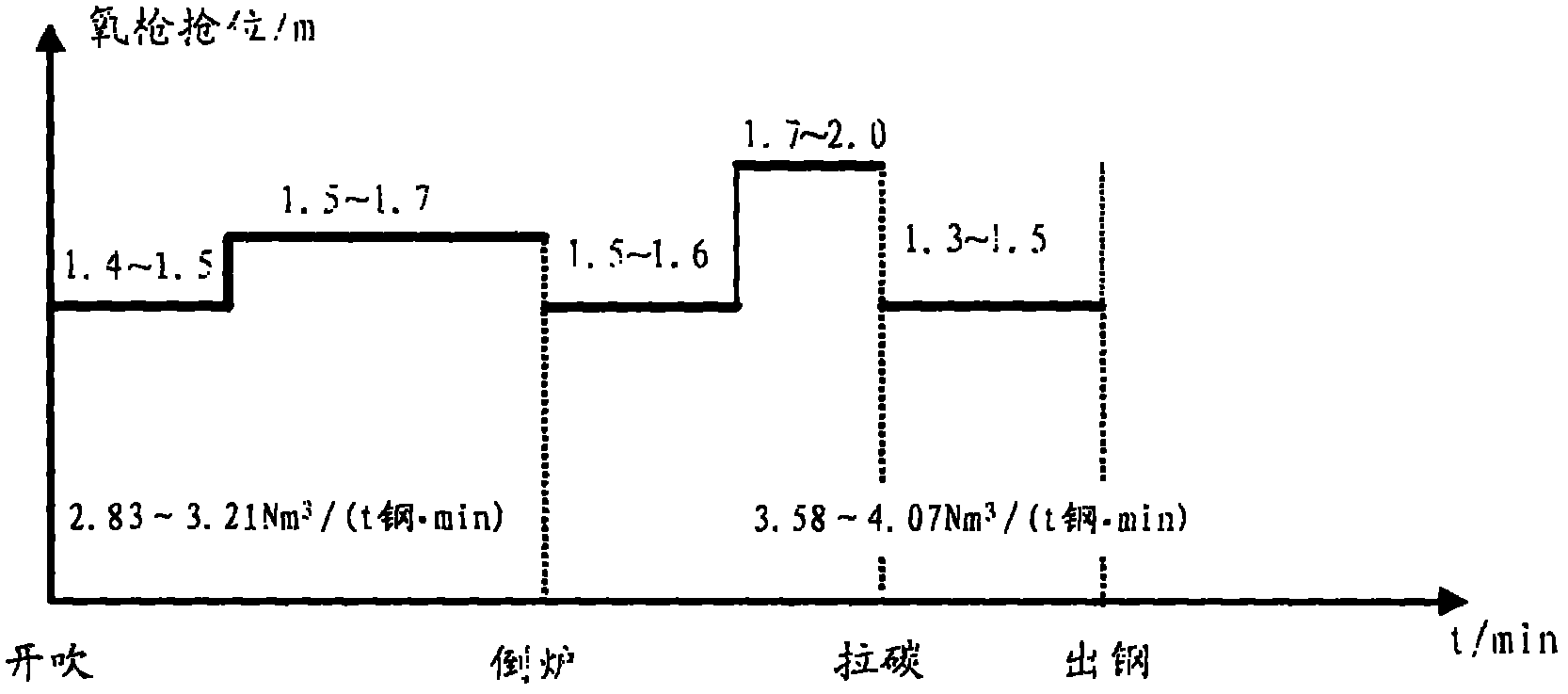

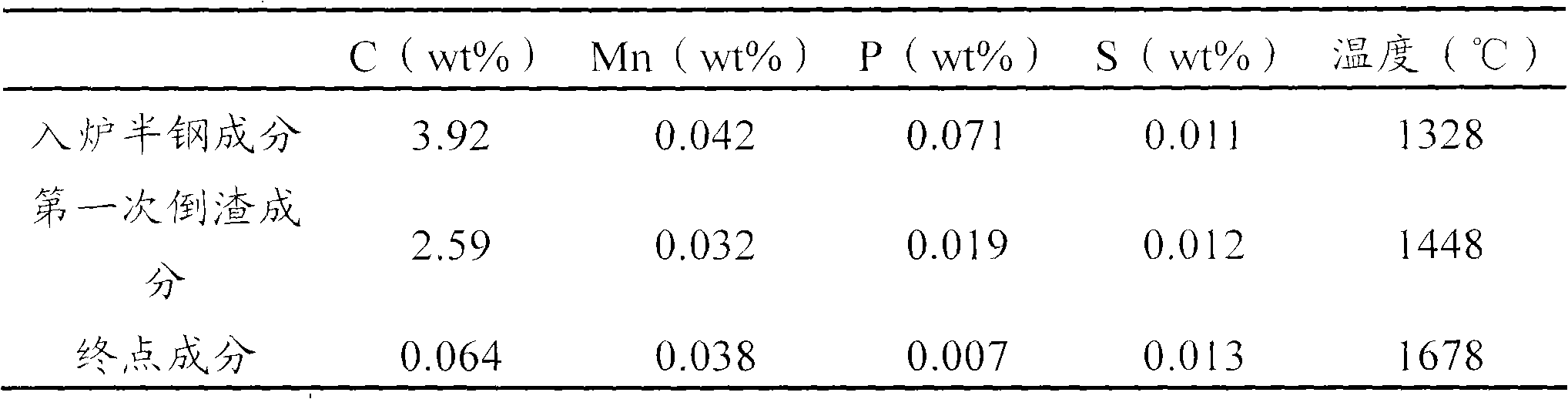

The invention provides a dephosphorization method of semi-steel. The method comprises the following steps: adopting a six-hole oxygen gun to perform sectional smelting through a way of adjusting the oxygen supply strength of the oxygen gun, namely first dephosphorization smelting, adding a first batch of slag-making materials, controlling the oxygen supply strength of a top-blowing oxygen gun at 2.83-3.21Nm3 / (t steel. min), simultaneously bottom-blowing nitrogen, smelting and deslagging; performing second dephosphorization smelting, adding a second batch of the slag-making materials, controlling the oxygen supply strength of the top-blowing oxygen gun at 3.58-4.07Nm3 / (t steel. min), bottom-blowing the nitrogen during the time period from the beginning of the second dephosphorization smelting to carbon catching, bottom-blowing argon during the time period from the carbon catching to the terminal point of converting, smelting, stopping slag, tapping for getting molten steel with the content of a phosphorus element, which is not more than 0.008% by weight percentage, and performing the operation of remaining the slag after the tapping. By adopting the method, the dephosphorization effect is good, the dephosphorization efficiency is high, the smooth operation of the smelting process of a converter can be ensured, the steel-making production cost can be reduced and the semi-steel can be adopted for producing low-phosphorus steel with high grade and high added value.

Owner:PANZHIHUA IRON AND STEEL +2

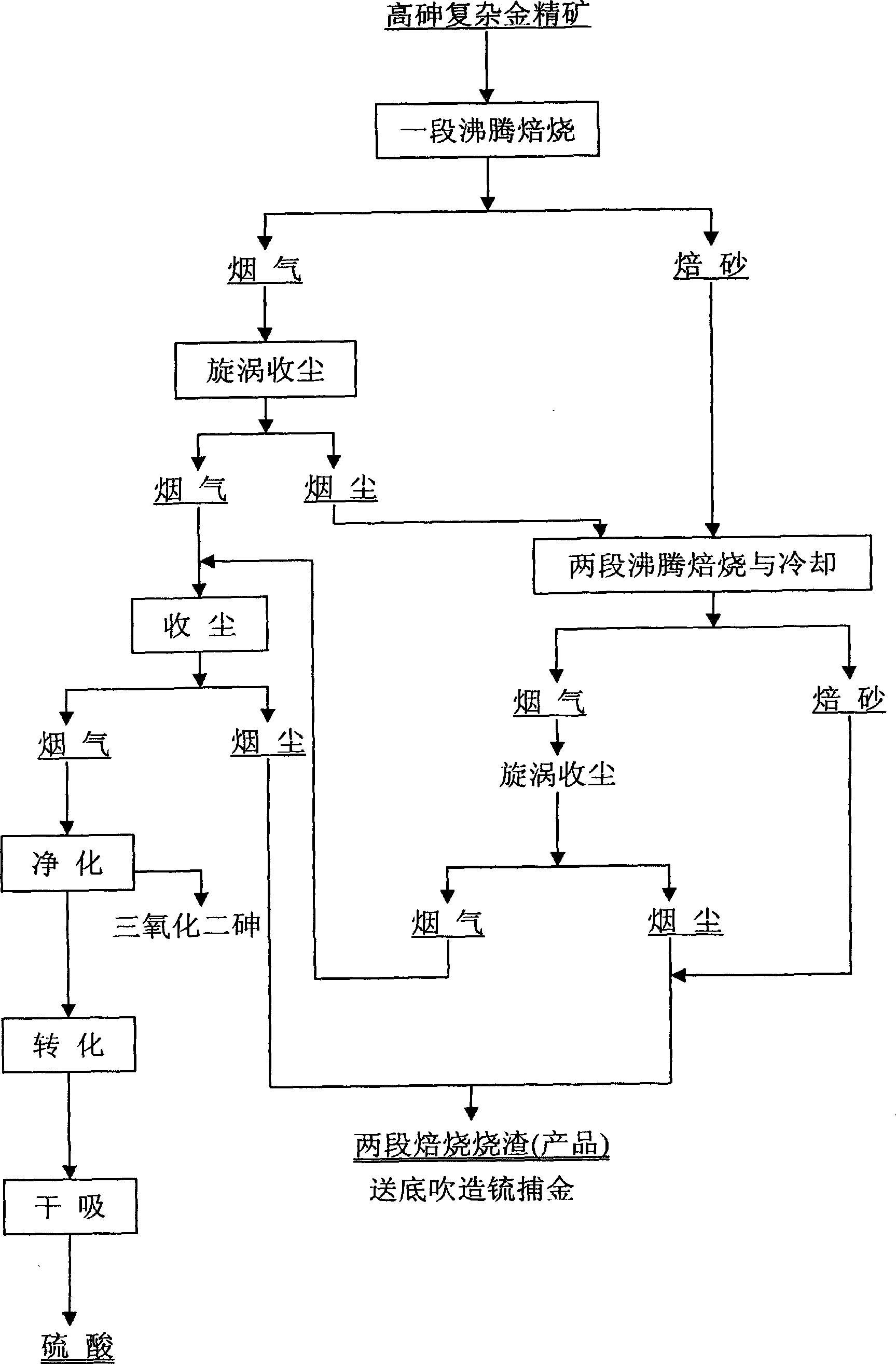

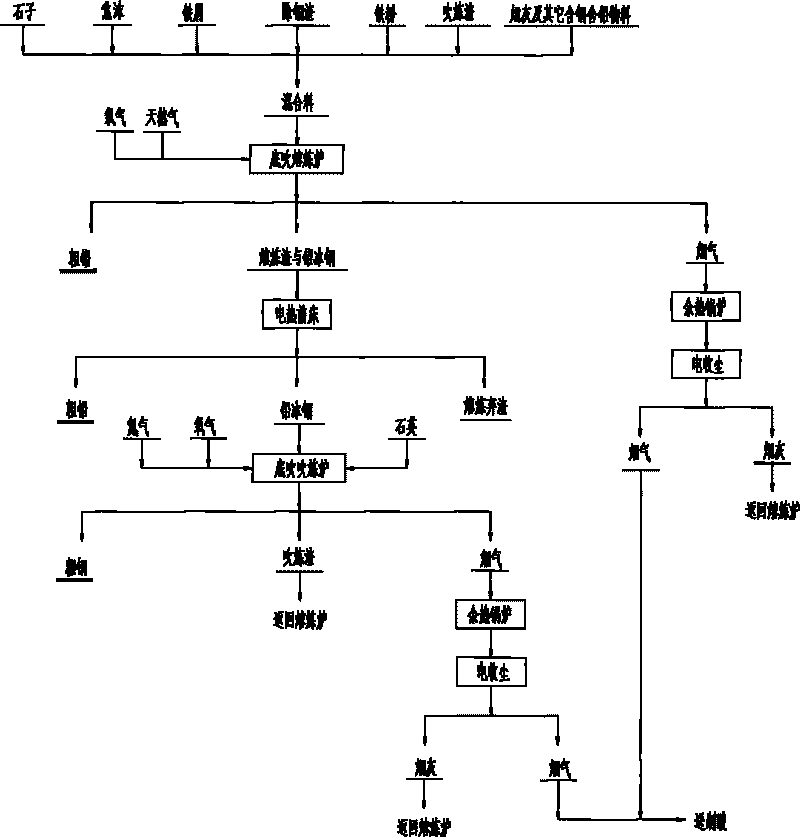

Method for extracting high arsenic complicated golden ore concentrate multielement

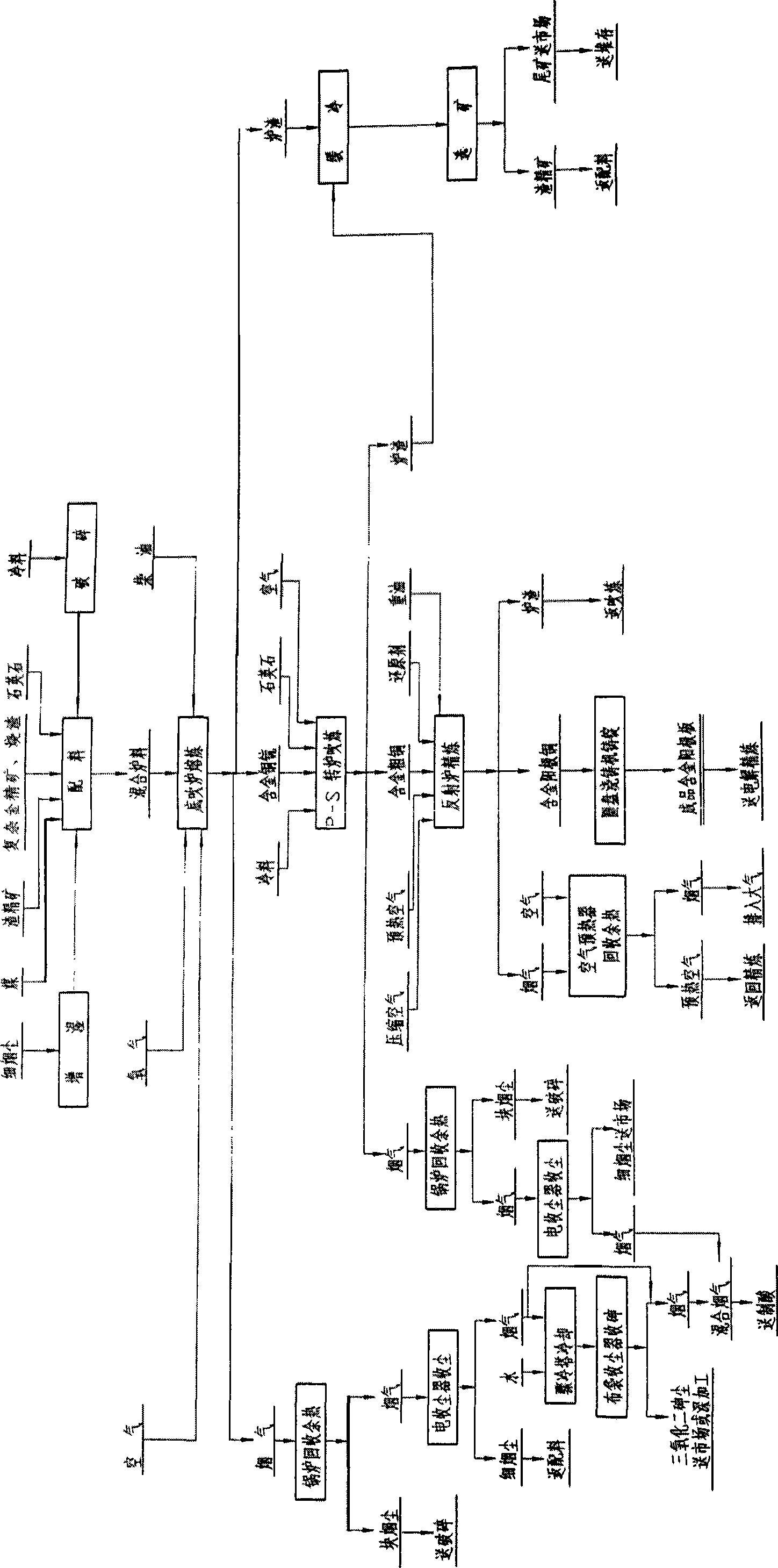

ActiveCN101519731AImprove recycling efficiencyReduce low altitude pollutionPhotography auxillary processesReverberatory furnaceElectrolysisMaterials science

The invention discloses a method for extracting high arsenic complicated golden ore concentrate multielement. The method comprises the following steps that: the multielement complicated golden ore concentrate with extra-high arsenic is subjected to the roast dearsenification technique treatment, part of sulfur in the multielement high arsenic golden ore concentrate converted into sulfur dioxide and the arsenic converted into arsenic trioxide enter flue gas which is subjected to dust and arsenic collection, and then enter an acid making system to produce sulphuric acid; the multielement smelting slag and multielement low arsenic golden ore concentrate obtained by roast dearsenification, return products and flux are mixed to obtain copper matte regulus, and the like by adopting oxygen enrichment bottom blowing matte smelting gold collecting process to carry out the smelting process; the copper matte regulus is subjected to converting and refining to cast an anode plate which is sent to an electrolysis system to obtain an electrolytic copper product by refining; anode mud generated through electrolysis is sent to a noble metal refine system to produce gold and sliver, and the like; smelting slag and converting slag are subjected to floatation treatment to obtain copper and iron ore concentrate; and the generated gangue belongs to harmless slag and can be used. The method has the characteristics of wide range of the raw material application, high synthesized recovery efficiency of valuable element, and obvious economic and environment benefits.

Owner:SHANDONG HUMON SMELTING

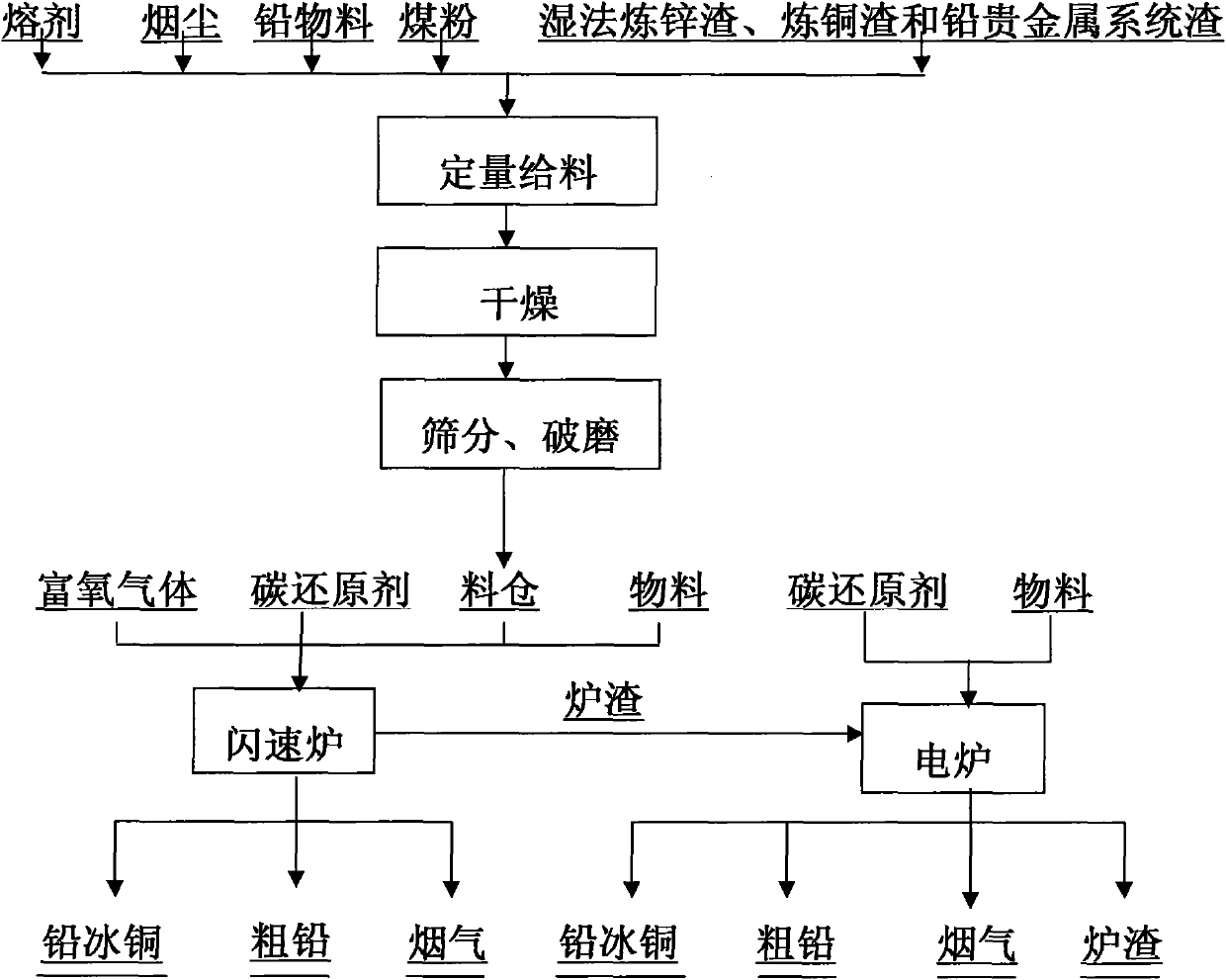

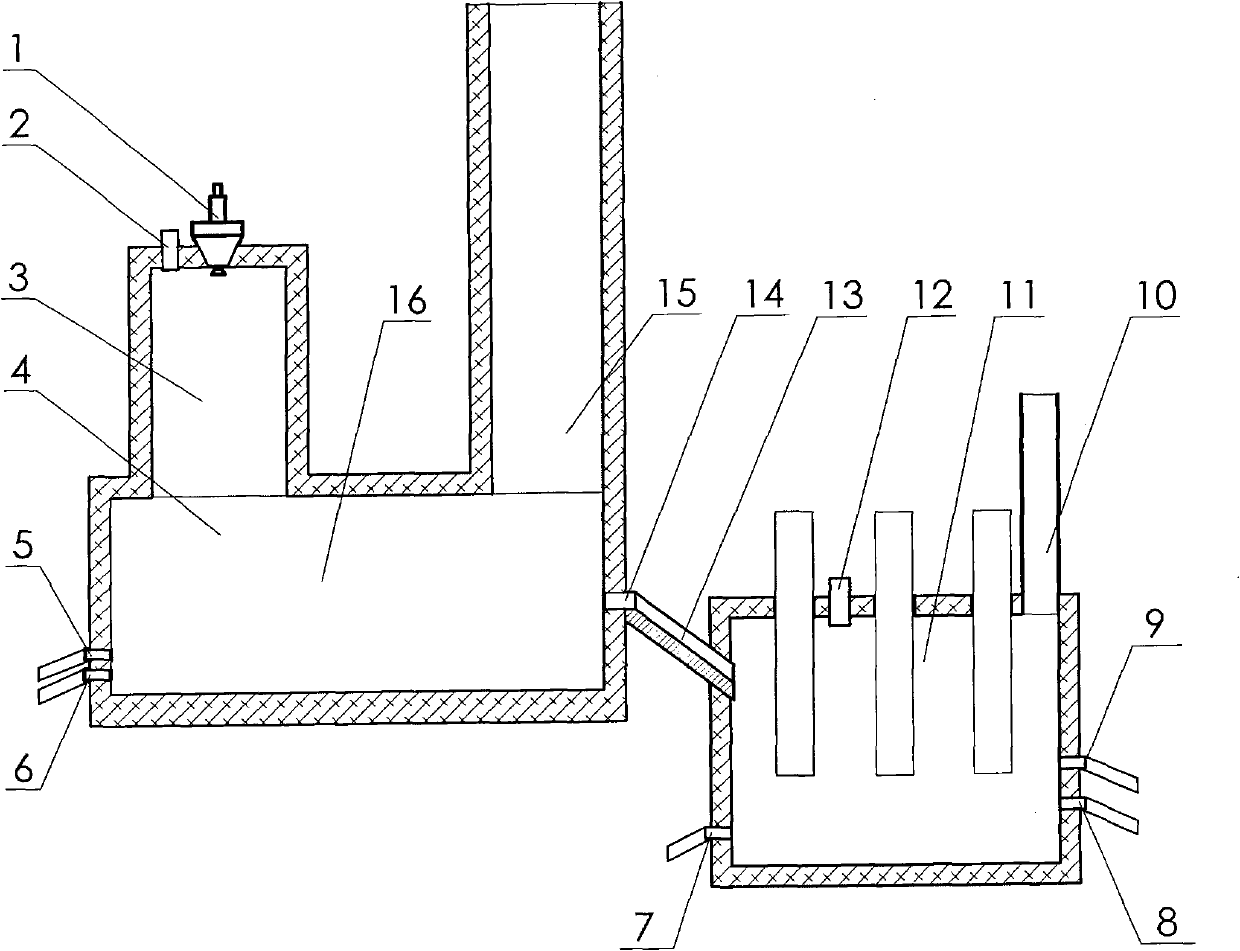

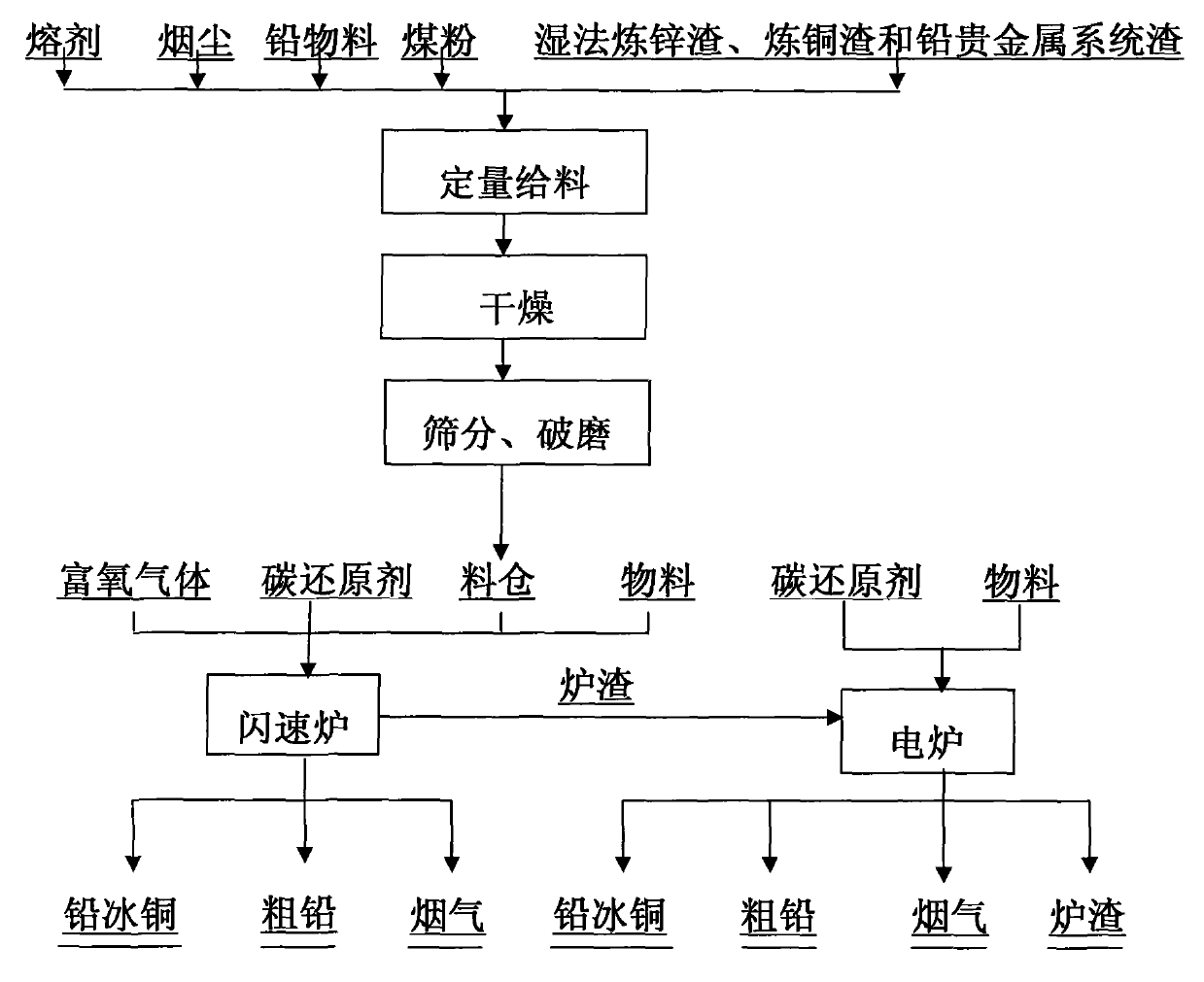

Method for smelting lead-containing material

InactiveCN101768670ANo explosion hazardAdaptableProcess efficiency improvementLead smeltingSmelting process

The invention discloses a method for smelting a lead-containing material, relating to the technological process for processing complex lead materials by utilizing a smelting method. The method is characterized in that a flash furnace and a depletion furnace are combined for smelting during the smelting process. The method of the invention has the advantages of short and continuous flow, energy saving, large capacity, efficient source utilization, environment protection, good safety and good industrial hygiene, no danger of foam slag exploration and safe production. The lead smelting process with high smelting strength and various advantages realizes single-step lead smelting, and has stronger adaptability on materials. The process is not only suitable for treating lead ore with complex components, but also suitable for treating wet smelting zinc slag, wet smelting copper slag and lead noble metal system slag, can do complementation of lead, zinc and copper and has more advantages over lead, zinc and copper jointed enterprises. The recovery rates of lead and concomitant valuable metals of copper, zinc and noble metals are higher.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

High-strength and heat-resistant magnesium alloy containing two rare earths and preparation method thereof

ActiveCN103820689AImprove mechanical properties at room temperatureStable high temperature mechanical propertiesRare-earth elementSmelting process

The invention discloses a high-strength and heat-resistant magnesium alloy containing two rare earths. The high-strength and heat-resistant magnesium alloy containing the two rare earths comprises the components as follows: 14.0-17.0wt% of Y rare earth, namely Gd, Y and Er, 0.5-2.5wt% of Ce rare earth, namely one or several of La, Ce, Pr, Nd and Sm, 0.3-1.0wt% of Zr, impurities and the balance of Mg, wherein Gd is 11.0-15.0wt%, Y is 0.5-4.0wt% and Er is 0.5-2.0wt%; the content of Nd and Sm elements is 0.2wt% or less of the total amount of the magnesium alloy, or 0; the impurities including Fe, Si, Mn and a small amount of chloride; Fe is less than or equal to 0.002wt %, Si is less than or equal to 0.04wt%, Mn is less than or equal to 0.02wt%, and chloride is less than or equal to 0.002wt%; the impurity content is more than 0; Er in the Y rare earth can be replaced by one or several of Tb, Dy, Ho, Yb and Tm. The magnesium alloy has relatively high mechanical properties at room temperature and relatively stable high temperature creep resistance, and has relatively high yield rate of rare earth elements in the smelting process.

Owner:GRIMAT ENG INST CO LTD

Smelting method for improving phosphorus removal rate of converter

ActiveCN103060508ALower oxygen pressureFoamy splash preventionManufacturing convertersSmelting processOxygen pressure

The invention discloses a smelting method for improving the phosphorus removal rate of a converter. The method comprises the following steps of: at the later stage when steel splashing slag is emptied in the converter, adding 500 to 800 kilograms of lime, slightly stirring, pre-heating, adding waste steel, and blending molten iron; adding a bath of slag forming material such as lime, lightly burnt magnesium blocks, ores and the like when blowing to 45 to 60 seconds, lifting an oxygen lance by 200 millimeters when blowing for 4.5 minutes, continuously adding 4 to 5 batches of ores, and uniformly controlling the heating speed of a molten pool to increase the FeO content of slag; when blowing to 7 minutes, properly lowering the lance for 50 to 100 millimeters, meanwhile, reducing the oxygen pressure to 0.80MPa, and continuously adding 2 to 3 batches of rest lime; and keeping the position of the final point pressure lance at 1,000 millimeters for 1 minute. By adopting the method, full-process slag smelting can be realized, the slag is not re-dried, a good phosphorus removal effect is obtained, the phosphorus removal rate is improved by 10 percent compared with the conventional smelting process, and the requirement for smelting the molten iron with a high content of phosphorus can be met.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

Smelting method for low-silicon ultralow-sulphur steel

ActiveCN102134629ARealize the purpose of deep desulfurizationReduce the amount of siliconAlkalinitySmelting process

A smelting method for a low-silicon ultralow-sulphur steel belongs to the metallurgy technical field. The smelting process for producing low-silicon ultralow-sulphur steel comprises: molten iron 'complete-three-removal' pretreatment, decarburization converter smelting, and LF refining process. In order to ensure that silicon increase in molten steel during deep desulphurization is prevented, the sulphur content in molten steel for refining pull-in is firstly decreased by KR molten iron desulphurization pretreatment, and the pressure for LF deep desulphurization is reduced; then the silicon content in molten iron in a decarburization converter is decreased by desilication pretreatment in a dephosphorization converter to ensure the alkalinity of the slag in the decarburization converter is more than 4.0. The advantages are that the problem of the easy increase of silicon during the LF refining desulphurization process in the prior art is solved; the refining time is shortened; and the production efficiency is improved.

Owner:SHOUGANG CORPORATION

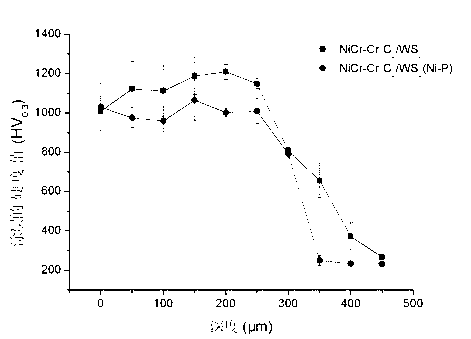

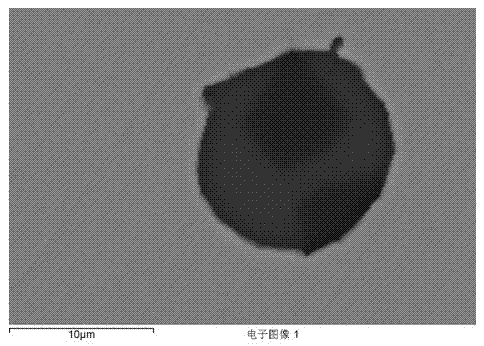

Solid lubricating high-temperature anti-wearing powder composition and preparation method of compound coating of composition

InactiveCN102836996ASignificant progressImprove high temperature wear resistance and friction reduction performanceLiquid/solution decomposition chemical coatingDecompositionEvaporation

The invention relates to a solid lubricating high-temperature anti-wearing powder composition and a preparation method of a compound coating of the composition. The powder composition comprises the following components in percentage by mass: 14-17.5% of nickel, 3-3.5% of chromium, 49-52.5% of chromium carbide and 25-30% of tungsten disulfide with a surface coated by an alloy-phosphorus alloy. A solid self-lubricating high-temperature anti-wearing compound coating is prepared by the powder composition through utilizing a laser smelting technology. According to the invention, NiCr-Cr3C2 compound powder is used as a metal substrate and the compound coating is formed by a ceramic anti-wearing phase and a metal toughening phase; WS2 is a solid lubricating phase and one layer of a micron-grade Ni-P alloy is coated on the surface of a WS2 powder grain by utilizing a chemical plating method, so that the thermal stability and the chemical stability of WS2 are increased, the decomposition and evaporation of the WS2 in a laser smelting process are effectively inhibited and the compatibility of the WS2 and the metal substrate is increased; and the compound material coating has the characteristic of high-temperature self-lubricating wearing resistance.

Owner:SUZHOU UNIV

Smelting process of high-carbon bearing steel

The invention discloses a smelting process of high-carbon bearing steel. High-alkalinity refining slag with the alkalinity value of 6-9 is obtained through adding conditioned slag and a deoxidizing agent, so that relatively good desulfuration and deoxidization effects are achieved, the content of S can be reduced to about 0.002%, and the content of O can be reduced to be less than 7ppm. Meanwhile, in order to avoid brittle impurity generation caused by overhigh alkalinity of refining slag, the content Al of the molten steel is strictly controlled in a smelting process, enough aluminum blocks for deoxidizing are added at one step in a tapping process, and no aluminum is replenished in the subsequent process, so that a deoxidized product is prevented from being floated; the content of Al in the refining slag is controlled at about 0.010%, so that secondary oxidation caused in a pouring process is reduced. On the other hand, the value of CaO / Al2O3 in the refining slag is controlled at about 1.7, so that the melting point of slag is relatively low, the flowability of the slag is relatively good, the steel slag is easy to separate, and the slag rolling and reduction reaction of molten steel in a vacuumizing process are reduced. Therefore, D-type inclusions in the bearing steel are effectively prevented from being increased, and the rating standards of inclusions in the bearing steel are reached.

Owner:ZENITH STEEL GROUP CORP +1

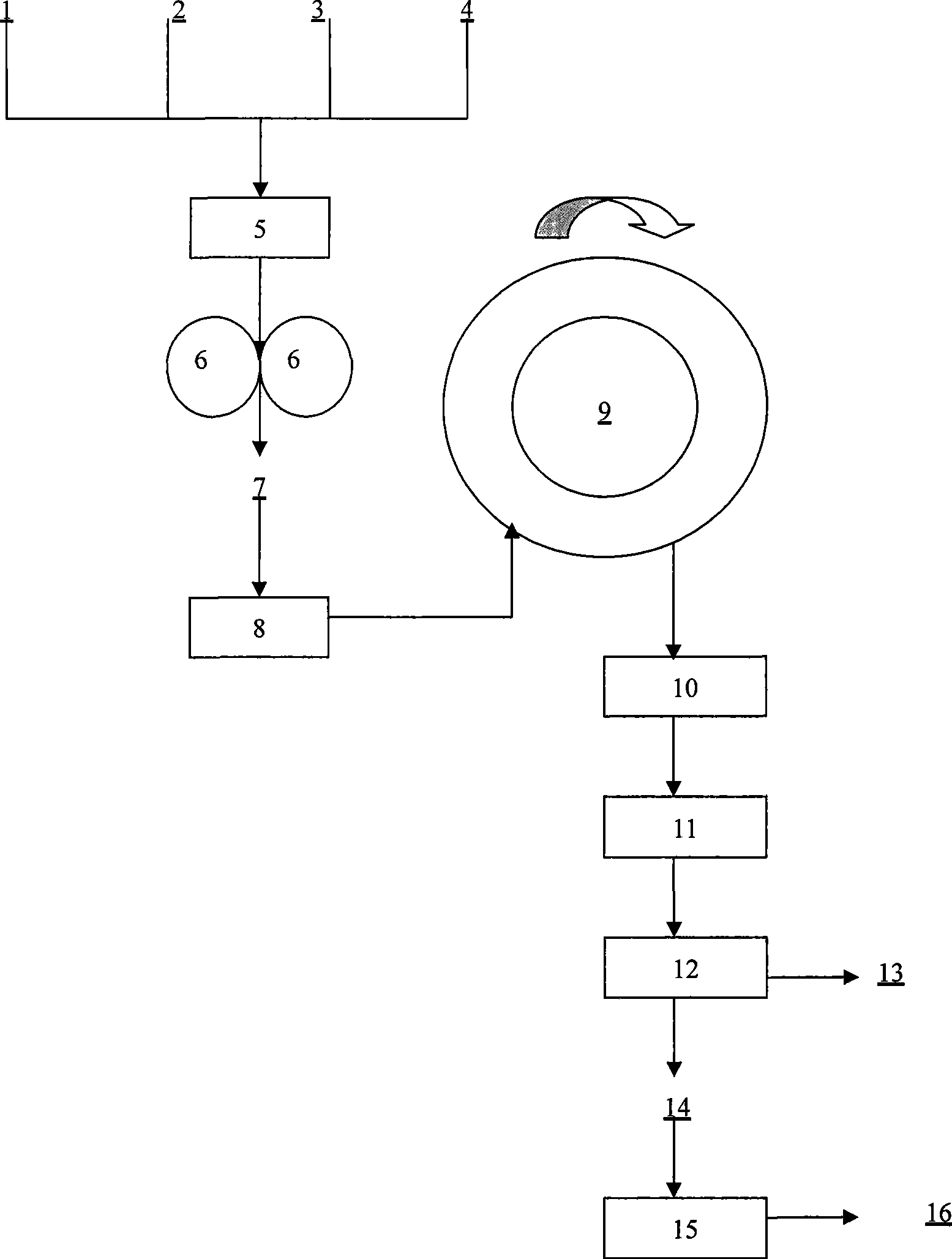

High-performance uniformity aluminium alloy ingot and production method thereof

ActiveCN101921934AImprove sorting efficiencyImprove sorting qualityProcess efficiency improvementTrace elementSmelting process

The invention discloses a high-performance uniformity aluminium alloy ingot and a production method thereof. The high-performance uniformity aluminium alloy ingot comprises the following components in percentage by weight: 2.1-3.8 percent of Cu, 7.6-9.3 percent of Si, 0-0.28 percent of Mg, 0-0.9 percent of Zn, 0-0.8 percent of Fe, 0-0.48 percent of Mn, 0-0.48 percent of Ni, 0-0.1 percent of Ti, 0-0.1 percent of Pb, 0-0.1 percent of Sn, 0-0.25 percent of other trace element sum and the balance of Al. The invention also provides the production method of the high-performance uniformity aluminium alloy ingot. The high-performance uniformity aluminium alloy ingot has even alloying components, effectively controls the problem of component segregation and has good mechanical property and good processing property. The production method of the high-performance uniformity aluminium alloy ingot can effectively remove nonmetal materials in waste aluminium materials and reduces slag generated in a smelting process.

Owner:YE CHIU METAL RECYCLINGCHINALTD

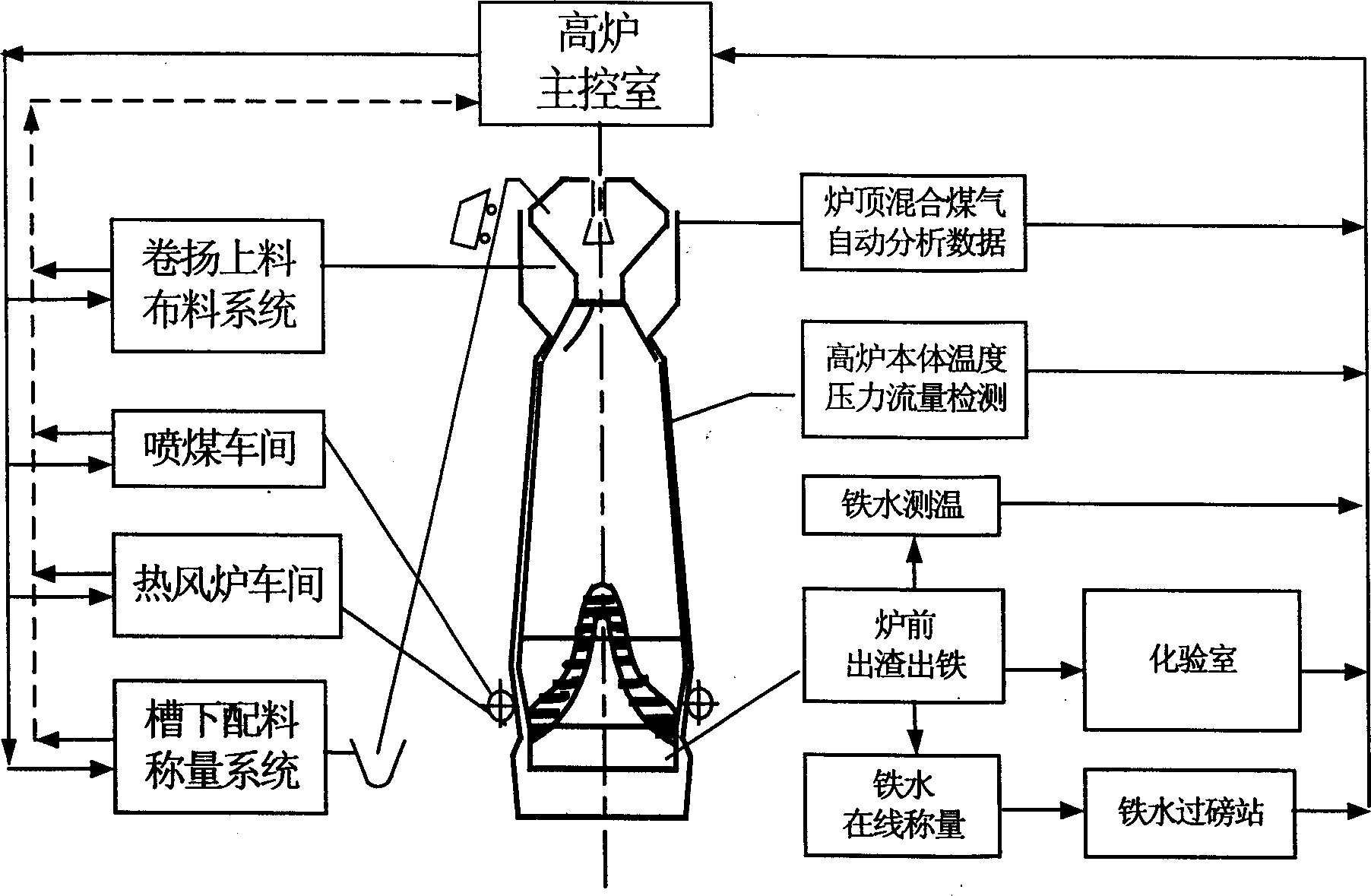

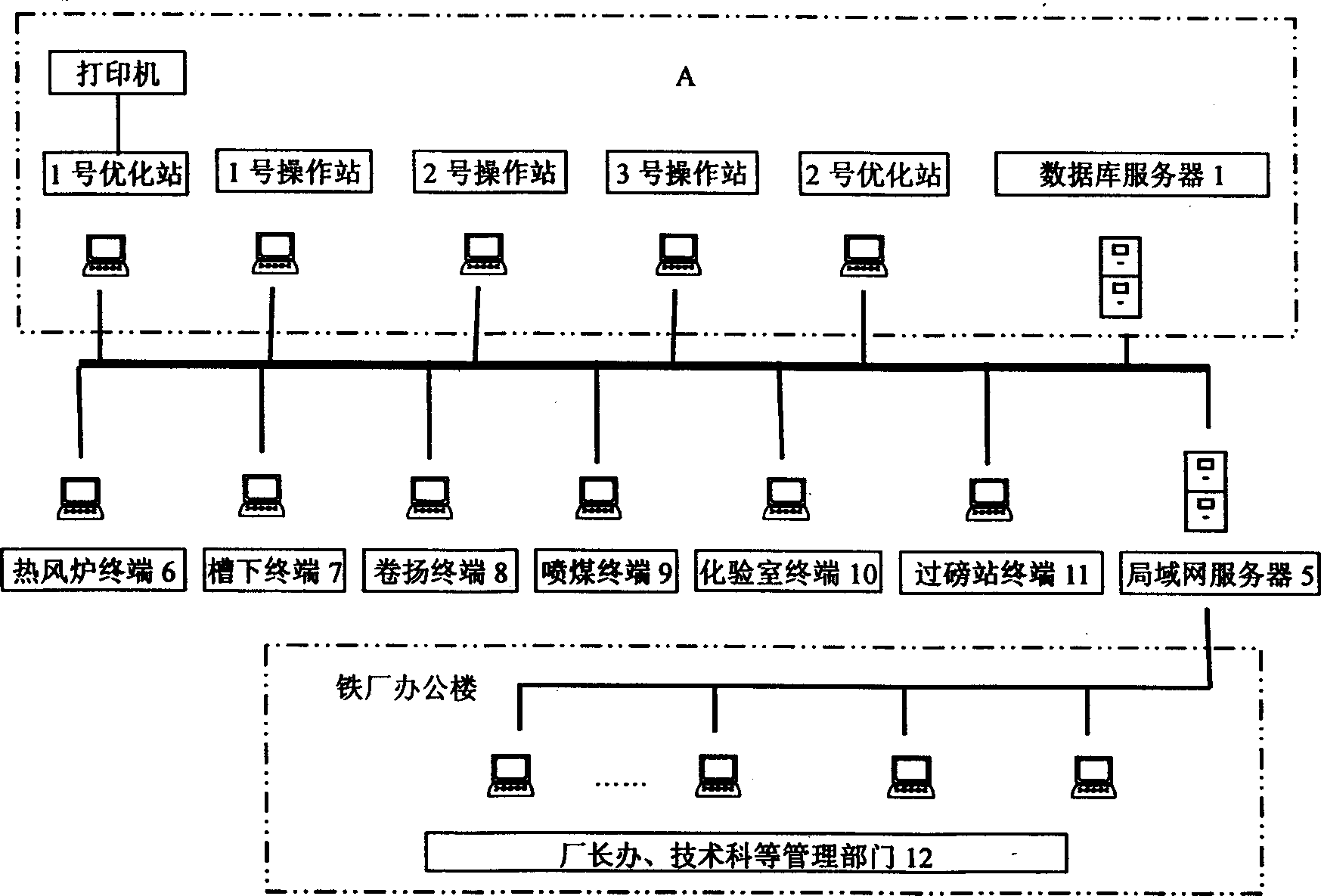

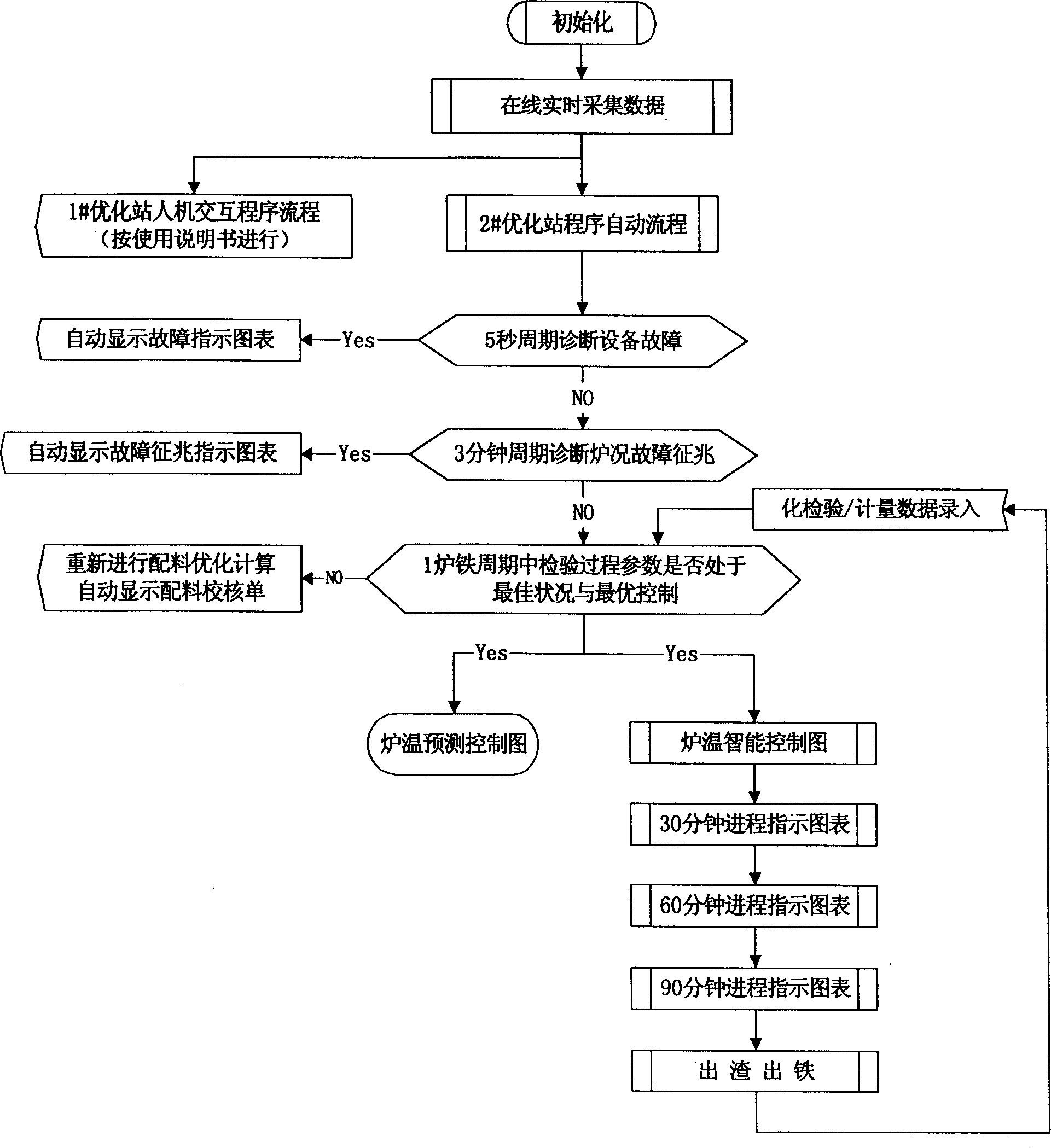

Blast furnace smelt controlling method with intelligent control system

InactiveCN1403593AGuaranteed uptimeRun to keep the blast furnace at optimumBlast furnace detailsMicrocomputerSmelting process

The intelligent control system for blast furnace smelting includes the first and the second optimizing stations in the main control room and several operation stations to constitute microcomputer LAN; and server in the iron smeltery connected to various control step terminals to constitute iron smeltery LAN; and the iron smeltery LAN is connected with the main control room LAN to constitute one network system for real-time acquiring and automatic transmitting of process information. The first optimizing station is provided with intelligent control software module and the second with automatic display module. During operation, the intelligent control software module traces the smelting process via real-time data acquisition and operates automatically according to the data from the LAN, and the operation results are output in man-computer dialogue and simple graphic display mode.

Owner:ZHEJIANG UNIV

Ultrahigh-strength and high-toughness welded cast steel

InactiveCN101074472AGood effectImprove hardenabilityHeat treatment process controlSmelting processUltimate tensile strength

A high-strength and high-toughness welding cast steel consists of C 0.12-0.17 wt%, Si 0.10-0.50 wt%, Mn 0.8-1.2 wt%, S+P<=0.025 wt%, Ni 4.00-4.50 wt%, Cr 0.7-1.2 wt%, Mo 0.40-0.50 wt%, V 0.04-0.08 wt%, Cu 0.20-0.40 wt% and iron residue. The process is carried out by selecting electric furnace + AOD duplex smelting process, pouring and heating to obtain final product. The yield strength reaches above 800 MPa, V-shaped notch impact reaches above 55J at -20 degree. It can be used for ship, ocean and petrochemical industries.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Smelting process for production of super-low sulphur steel

InactiveCN102534120AStable controlFast and stable controlManufacturing convertersSteelmakingAlkalinity

A smelting process for the production of super-low sulphur steel belongs to the technical field of steelmaking, and adopts the process route of molten iron magnesium jetting desulfuration pretreatment-converter smelting-ladle dusting-LF Furnace refining-RH refining-continuous casting. The smelting process is characterized in that the molten iron pretreatment adopts magnesium particle jetting for desulfuration; the converter smelting adopts high-grade steel scrap and lime; during tapping, ferro-aluminum is used for strong deoxygenation and slag surface deoxygenation is conducted; the ladle dusting is used for controlling reasonable jetting speed and dust consumption; the LF Furnace refining is used for controlling the feeding quantity of high-alkalinity refining slag and the bottom jetting flow rate of a ladle; and after refining, the oxidizing property and the alkalinity of steel slag are guaranteed. The invention has the advantages that super-low sulphur steel making can be realized fast on the condition that the sulphur content at the end point of the converter cannot be controlled stably; the dusting desulfuration jetting of the ladle lasts for 10 to 15 min; the desulfuration during the LF Furnace refining lasts for 15 to 30 min; the content of sulphur in steel can be controlled within 0.0010 percent fast and stably; and the batch stable control of super-low sulphur steel can be realized.

Owner:SHOUGANG CORPORATION

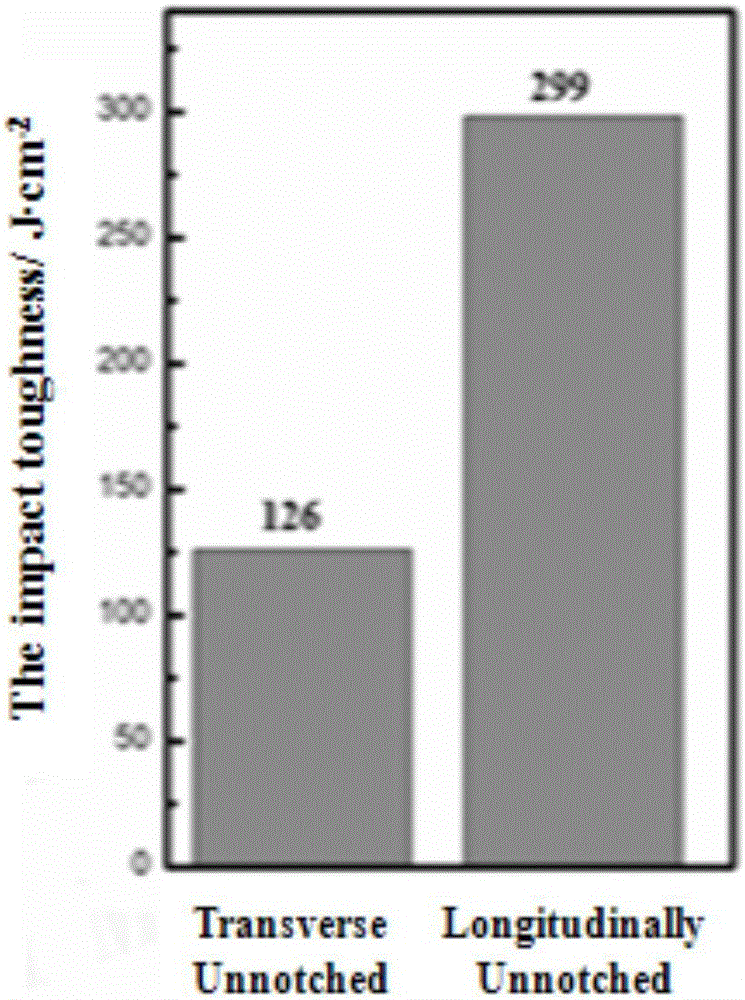

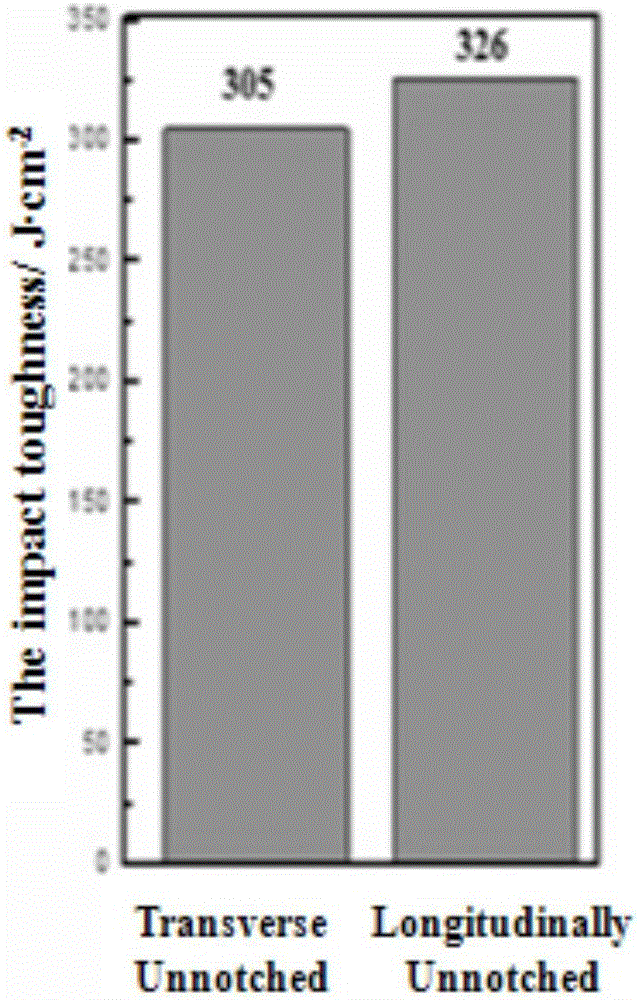

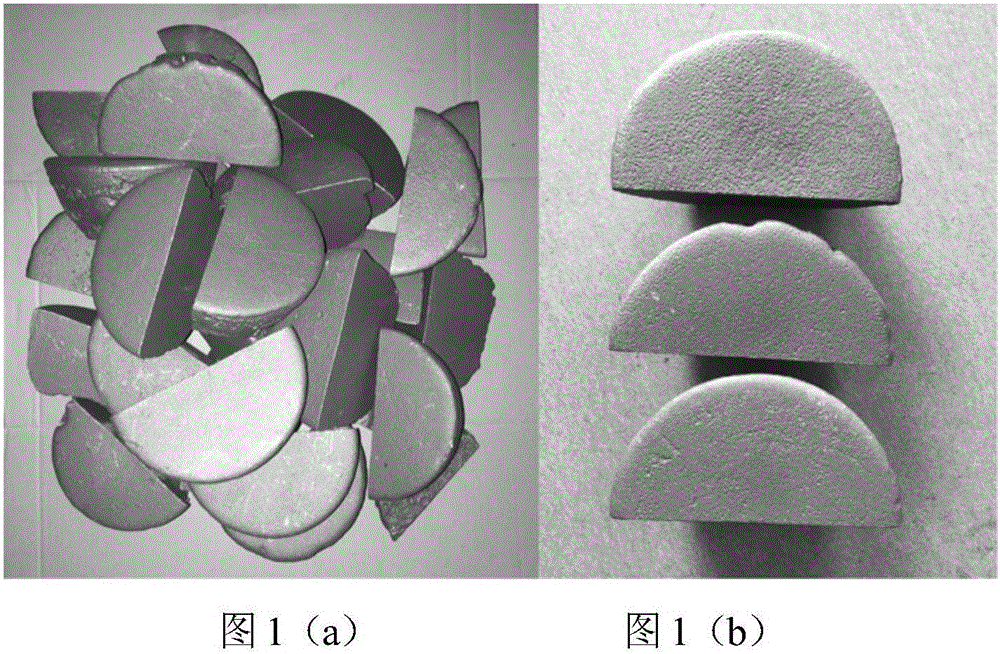

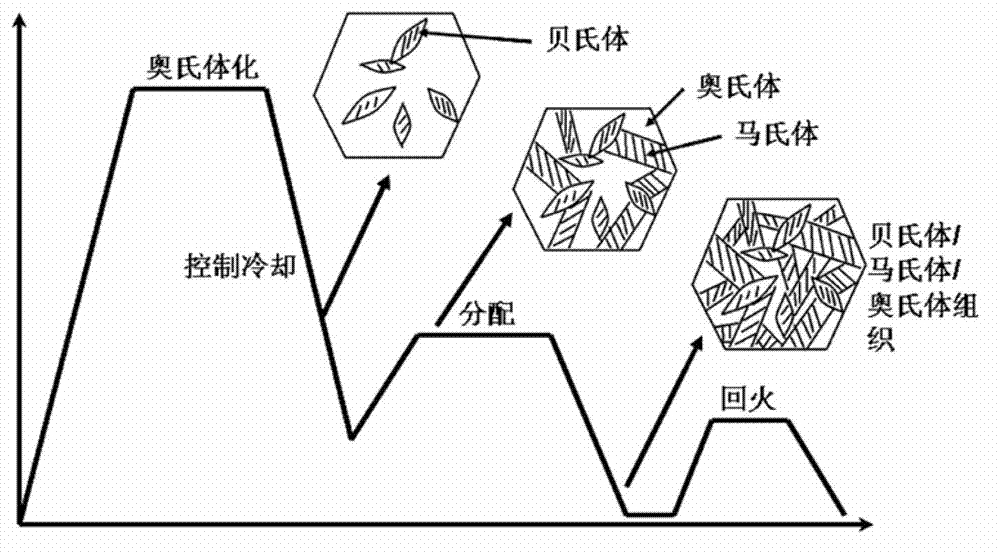

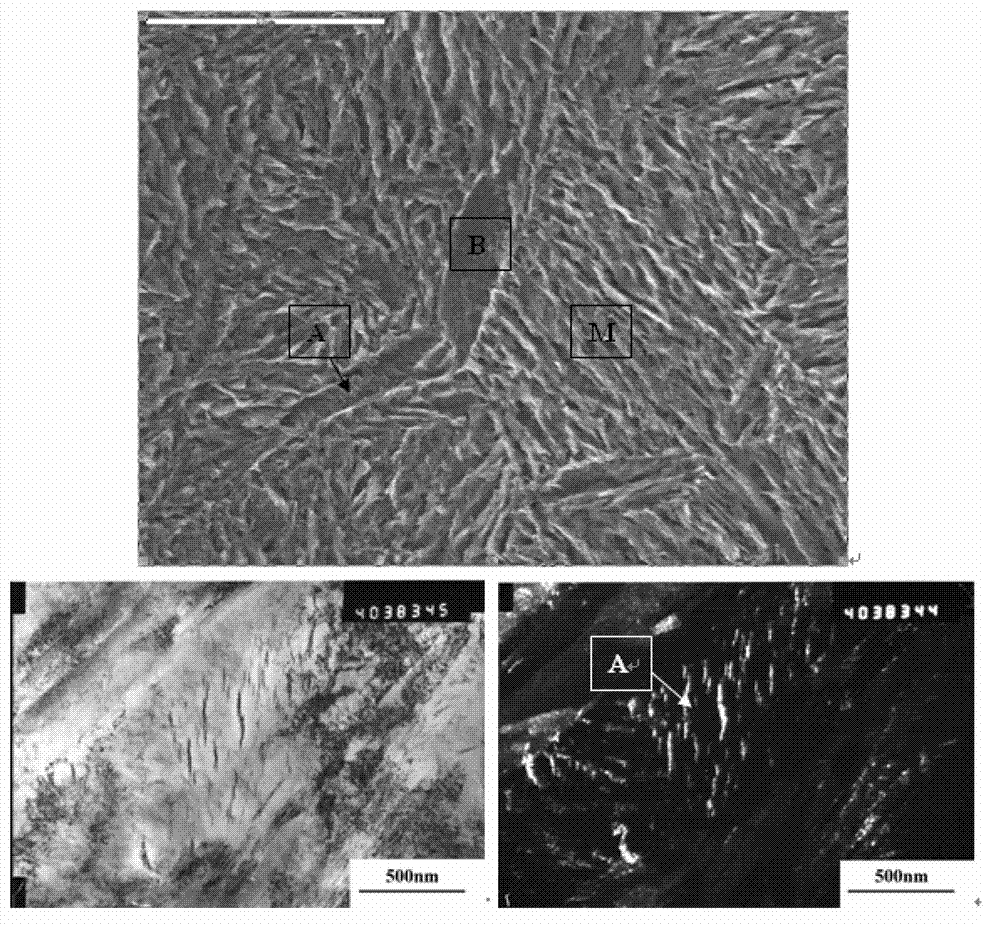

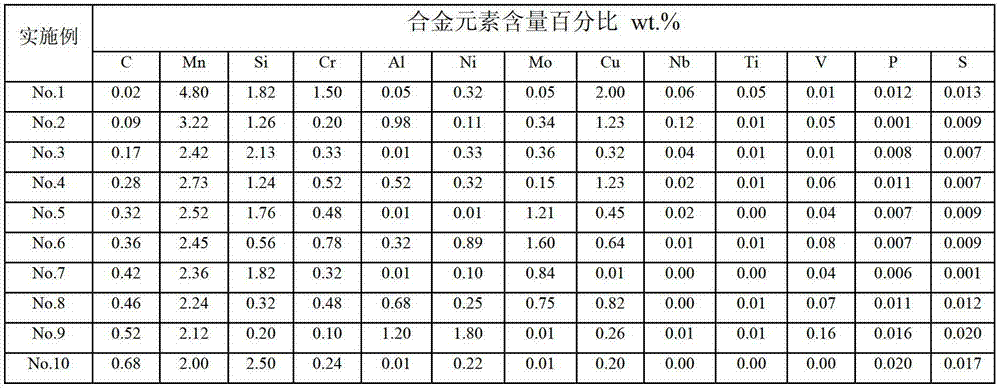

Preparation method of bainite/martensite/austenite composite high-strength steel

InactiveCN103243275AImprove stabilityOvercome the disadvantage of high costHeat treatment process controlSmelting processThick wall

The invention discloses a preparation method of bainite / martensite / austenite composite high-strength steel, belonging to the field of low-alloy high-strength steel. According to the composite high-strength steel, C, Mn, Si and Cr are used as main alloy elements, Al, Ni, Mo, Cu, Nb, Ti, V and the like are added, and the balance is Fe. The preparation method comprises the following steps: smelting, casting, forging or rolling to prepare rails, thick-wall pipes, large-section bars or thick pipes and the like by adopting a conventional steel-smelting process; carrying out austenitizing; controlling cooling by adopting different cooling media to obtain a part of bainite tissue in the cooling process; instantly carrying out distribution treatment and low-temperature tempering treatment so as to finally obtain a bainite / martensite / austenite composite tissue which is good in strong plasticity and toughness coordination, wherein the distribution time is 30-360 minutes. For a component which is large in size and easy to crack in quenching, the bainite / martensite / austenite composite high-strength steel has wide application prospect.

Owner:BEIJING JIAOTONG UNIV

Process and device for treating decopperized slag by adopting bottom-blowing molten pool to produce wet lead and raw copper

ActiveCN101705368ALow melting pointImprove liquidityProcess efficiency improvementMelting tankAutomatic control

The invention belongs to the field of nonferrous metal, in particular to a process and a device for treating decopperized slag by adopting a bottom-blowing molten pool to produce wet lead and raw copper. A bottom-blowing smelter hearth is utilized to smelt decopperized slag to produce wet lead, furnace slag and lead copper matte, ferrum-silico-calcium slag is produced in the smelting process, the furnace slag serves as building material factory raw materials after meeting the disposal slag requirements, and a bottom-blowing converting furnace is utilized to convert the lead copper matte to produce raw copper. The process has low energy consumption, long service life of the furnace, high metal recovery efficiency, low product cost, high smelting environment protectiveness , easy realization of automatic control of process, and high labour productivity; the disposal slag contains low-grade valuable metal, and therefore, the disposal slag can be comprehensively utilized as raw materials in building material industry, which accords with the recycling economy principle.

Owner:JIYUAN YUGUANG NONFERROUS METALLURGY DESIGN & RES INST CO LTD

Method for smelting nickel-iron alloy from laterite nickel oxide ore

ActiveCN101481753ALow SiLess slagProcess efficiency improvementMagnetic separationSmelting processAlloy

A method for smelting ferronickel alloy from laterite nickel oxide ore belongs to the ferronickel alloy smelting technical field. A direct reduction technique of carbon-bearing pellets in a rotary hearth furnace is adopted to reduce the nickel oxide in nickel ores to iron and nickel; then iron and nickel are smelted; the solid solutions of nickel and iron are agglomerated, cooled, shattered and subjected to magnetic selection, so that the granular ferronickel alloy with high sulfur content is obtained; and the ferronickel alloy is melted and desulphurized, so that the purified ferronickel alloy is obtained. The invention has the advantages that compared with the traditional process without separation in advance, the follow-up smelting process of the method can save a great amount of energy source for the greatly reduced quantity of slag; and the crude ferronickel obtained through smelting contains relatively low Si content.

Owner:SHOUGANG CORPORATION

Smelting method of HIC (Hydrogen Induced Crack)/SSCC (Sulfide Stress Corrosion Cracking)-preventing steel

ActiveCN103540833AImprove dynamic conditionsAchieve transformationManufacturing convertersProcess efficiency improvementOxygenStress corrosion cracking

The invention discloses a converter smelting and external refining control method of HIC (Hydrogen Induced Crack) / SSCC (Sulfide Stress Corrosion Cracking)-preventing steel. A smelting process route of converter-CAS (Control Automatic System) station-LF (Low Frequency) refining-VD (Vacuum Distillation) / RH (Relative Humidity) vacuum-calcium treatment-soft blowing-continuous casting is adopted. Low-phosphor requirements of the HIC / SSCC-preventing steel are obtained through controlling the converter smelting process route; and meanwhile, part of deoxidation type inclusions are removed by carrying out strong deoxidation, alloying as well as residue washing in a converter steel-tapping process, and over 60% of sulfur in molten steel is removed by sufficient stirring of the residue washing. In the LF refining process, refining furnace slag which is high in alkalinity, high in Al2O3 and strong in reducibility is obtained by regulating components of the refining furnace slag, and the inclusions are transformed and removed towards a low melting point by virtue of balance of the furnace slag-molten steel-inclusions. Proper vacuum treatment time and vacuum degree are kept at a vacuum treatment furnace so as to remove part of gas and inclusions, excessive calcium line is fed into the molten steel after being broken in air, and then the molten steel is softly blown and stirred for over 20 minutes to obtain the molten steel with ultralow oxygen and ultralow sulfur.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com