Boron steel producing converter smelting process

A technology of converter smelting and boron steel, applied in the manufacture of converters, etc., can solve the problems that the boron content of finished steel is lower than the steel type requirements, affect the final performance of steel, reduce the hardenability of steel, etc., achieve low oxygen content and simple steps , the effect of easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

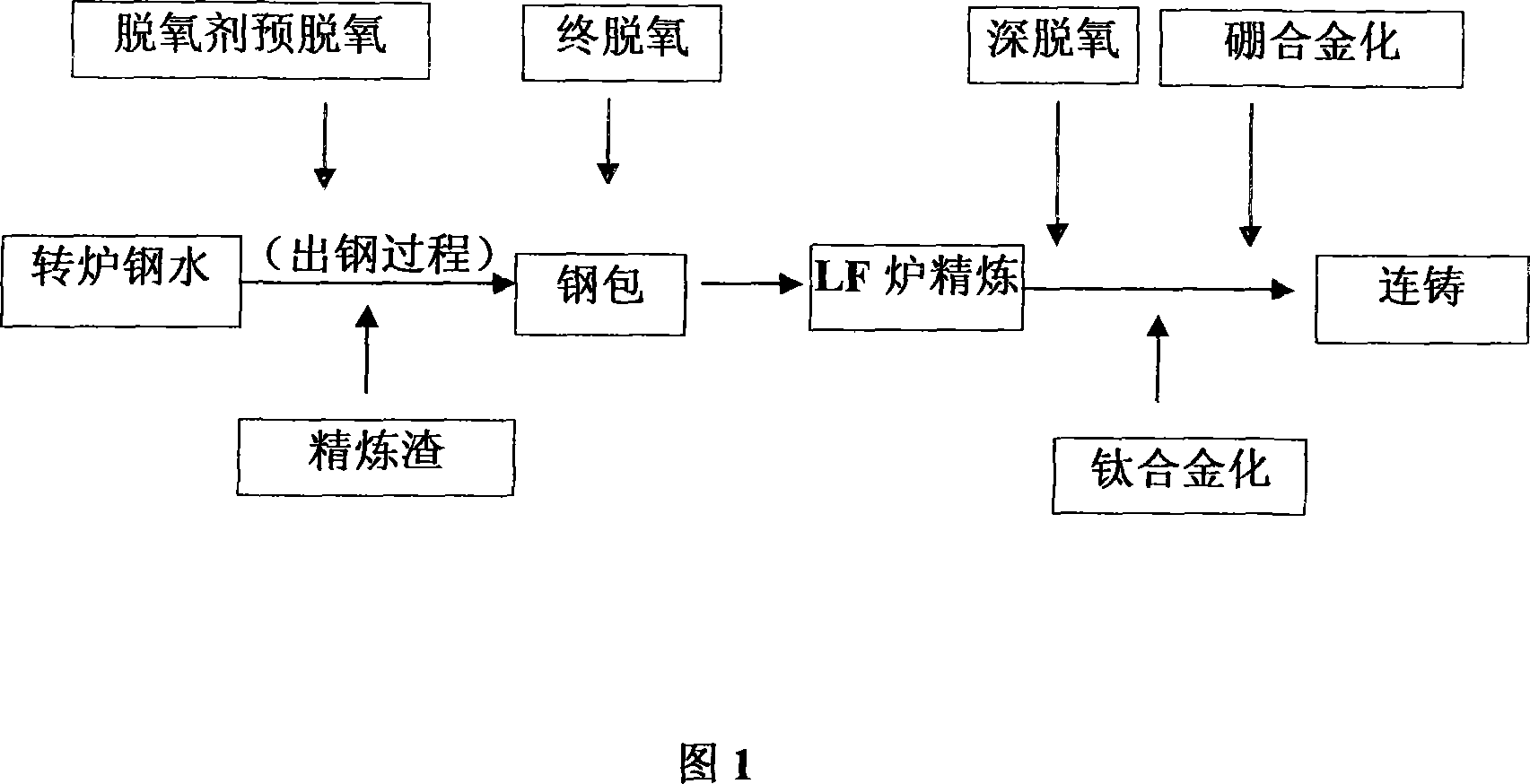

Image

Examples

Embodiment 1

[0026] Embodiment one uses the method of the present invention to smelt boron steel

[0027] Using the method of the present invention to smelt boron steel with a boron content of 0.0005% to 0.0030%:

[0028] Add 135.2 tons of molten iron into the top-bottom re-converter to initially smelt molten steel.

[0029] Converter tapping, adding 360kg of deoxidizer (about 2.7kg per ton of steel) for pre-deoxidation during the tapping process, the main component of deoxidizer is CaC 2 62.3%, Si 17.5%; 980kg of refining slag (about 7.4kg per ton of steel) is added during the tapping process, and the main physical and chemical indicators of the slag are: Al 2 o 3 43.2%, SiO 2 17.5%, gas production 240L / kg; use a wire feeder to feed aluminum wire 300m (60kg in total) for final deoxidation, and analyze the acid-soluble aluminum in molten steel to be 0.022%.

[0030] After the aluminum wire is fed, the ladle is transported to the LF furnace for refining. After refining, the slag samp...

Embodiment 2

[0032] Embodiment 2 Using the method of the present invention to smelt boron steel

[0033] Using the method of the present invention to smelt boron steel with a boron content of 0.0005% to 0.0030%:

[0034] Add 140.5 tons of molten iron into the top-bottom re-converter to initially smelt molten steel.

[0035] Converter tapping, adding 400kg of deoxidizer (about 2.8kg per ton of steel) for pre-deoxidation during the tapping process, the main component of deoxidizer is CaC 2 68.4%, Si 13.9%; 1000kg of refining slag (about 7.1kg per ton of steel) is added during the tapping process, and the main physical and chemical indicators of the slag are: Al 2 o 3 45.8%, SiO 2 16.2%, gas production 260L / kg; use a wire feeder to feed aluminum wire 300m (60kg in total) for final deoxidation, and analyze the acid-soluble aluminum in molten steel to be 0.029%.

[0036] After feeding the aluminum wire, the ladle is transported to the LF furnace for refining. After refining, the slag samples...

Embodiment 3

[0038] Embodiment 3 Using the method of the present invention to smelt boron steel

[0039] Using the method of the present invention to smelt boron steel with a boron content of 0.0005% to 0.0030%:

[0040] Add 145.0 tons of molten iron into the top-bottom re-converter to initially smelt molten steel.

[0041] Converter tapping, adding 420kg of deoxidizer (about 2.9kg per ton of steel) for pre-deoxidation during the tapping process, the main component of deoxidizer is CaC 2 65.3%, Si 14.6%; 1200kg of refining slag (about 8.2kg per ton of steel) is added to the tapping process, and the main physical and chemical indicators of the slag are: Al 2 o 3 45.4%, SiO 2 16.4%, gas production 240L / kg; use wire feeder to feed Al wire 400m (80kg in total) for final deoxidation, take steel sample for analysis of acid-soluble aluminum is 0.035%.

[0042] After feeding the aluminum wire, the ladle is transported to the LF furnace for refining. After refining, the slag samples are anal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com