Patents

Literature

1510 results about "Hardenability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The hardenability of a metal alloy is the depth to which a material is hardened after putting it through a heat treatment process. It should not be confused with hardness, which is a measure of a sample's resistance to indentation or scratching. It is an important property for welding, since it is inversely proportional to weldability, that is, the ease of welding a material.

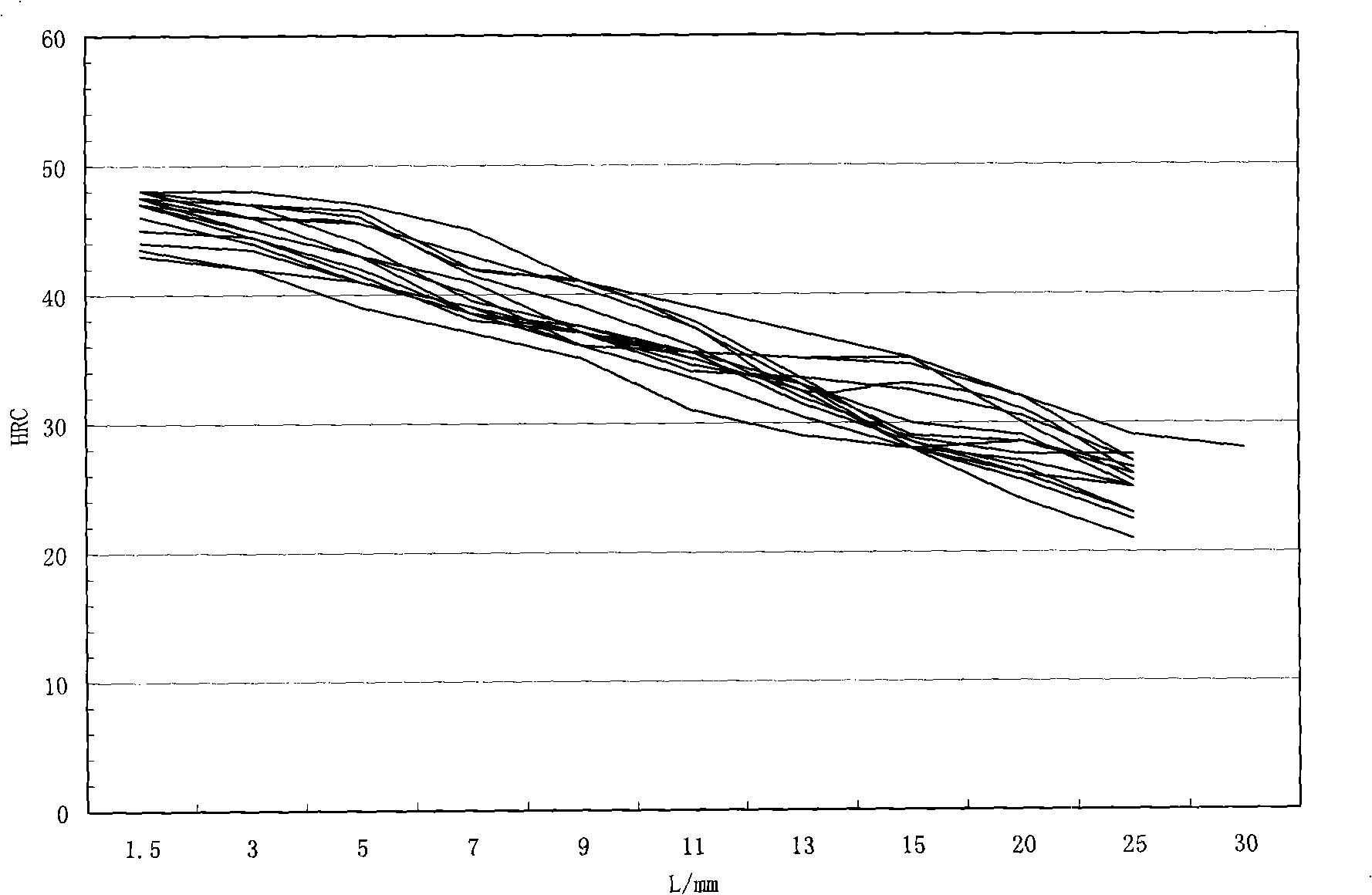

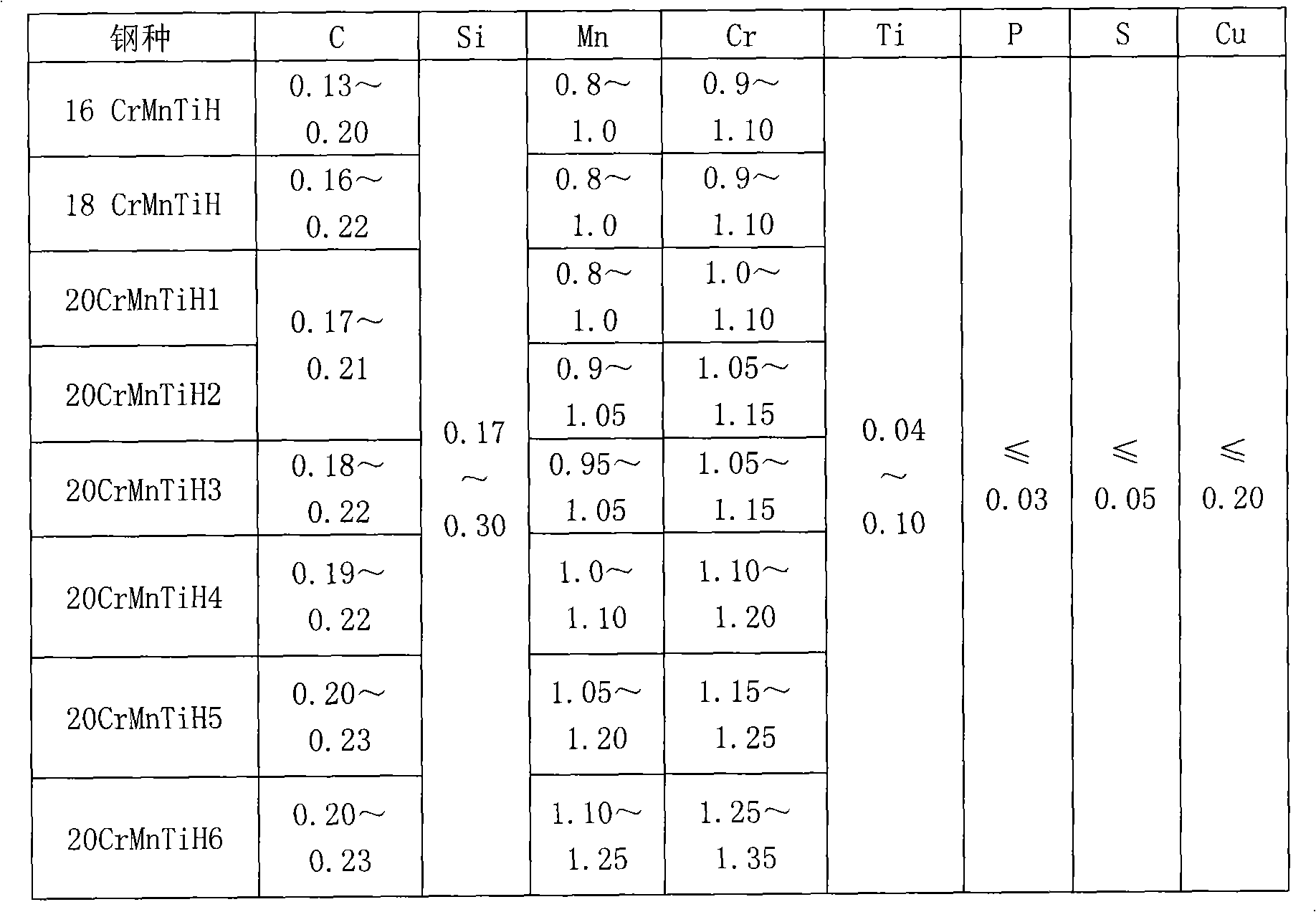

CrMnTi narrow hardenability strip pinion steels and method of manufacture

InactiveCN101289731AGuaranteed narrow hardenability band requirementsTemperature control deviceMetal rolling arrangementsChemical compositionPinion

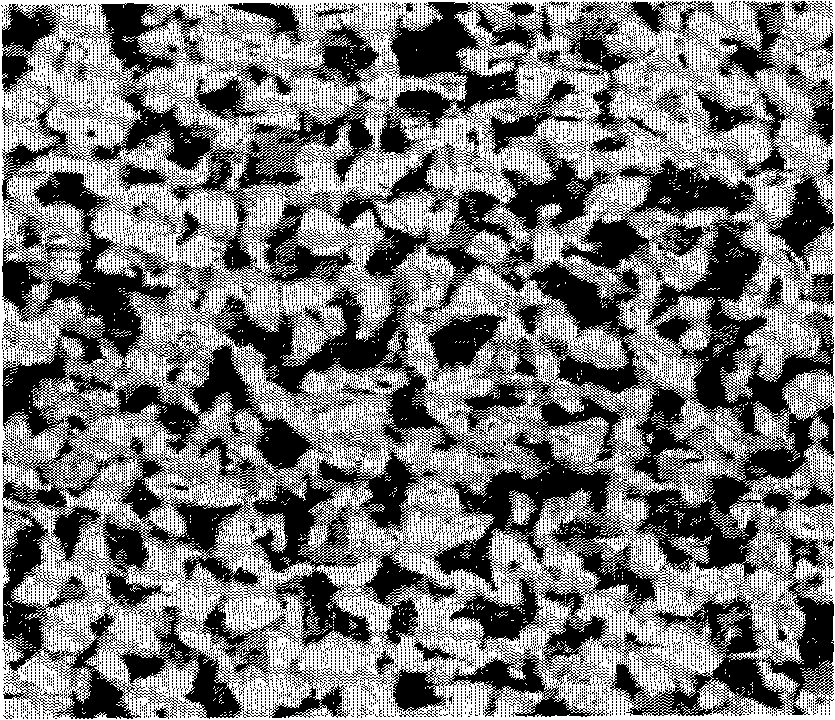

The invention relates to CrMnTi narrow-hardenability gear steel and a method for manufacturing the same, belonging to the gear steel material and the production process thereof technical field. The chemical composition in percentage by weight of the gear steel is: 0.13-0.23 percent of C, 0.17-0.30 percent of Si, 0.80-1.25 percent of Mn, 0.04-0.10 percent of Ti, 0.90-1.35 percent of Cr, less than or equal to 0.20 percent of Cu, less than or equal to 0.050 percent of S, less than or equal to 0.030 percent of P, less than or equal to 0.05 percent of Mo, less than or equal to 0.25 percent of Ni, [O] less than or equal to 20x10<-6>, [H] less than or equal to 2.5x10<-6>, and the balance being Fe and inevitable impurities. The manufacturing method comprises the following process steps of smelting, continuous casting, rolling and hot rolling, wherein in the step of continuous casting, the superheat degree of a tundish is controlled between 10 and 30 DEG C, and the casting speed is between 0.50 and 0.85 m / min; in the step of rolling, the heating temperature is between 1130 and 1280 DEG C, the start rolling temperature is more than or equal to 1100 DEG C, and the finish rolling temperature is between 850 and 980 DEG C. The gear steel and round steel in the specification between phi 30 and 160 mm can be produced by adopting the manufacturing method. By adopting narrow-composition steel grade design, electric furnace burden structure optimization, electric furnace end point control, grain-refining and banded structure control and other reasonable technological measures, the method effectively realizes hardenability narrowing and other objectives.

Owner:SHANDONG IRON & STEEL CO LTD

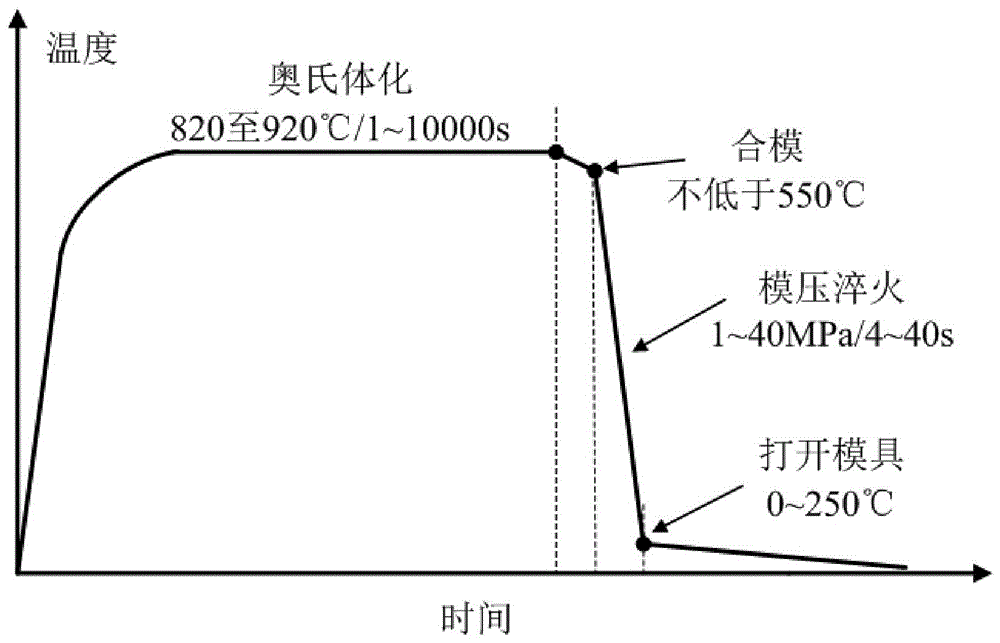

Steel plate for stamping and quenching and thermoforming method of steel plate

ActiveCN102031456ASimple compositionPlay the effect of weight reduction and energy savingHot stampingSimple component

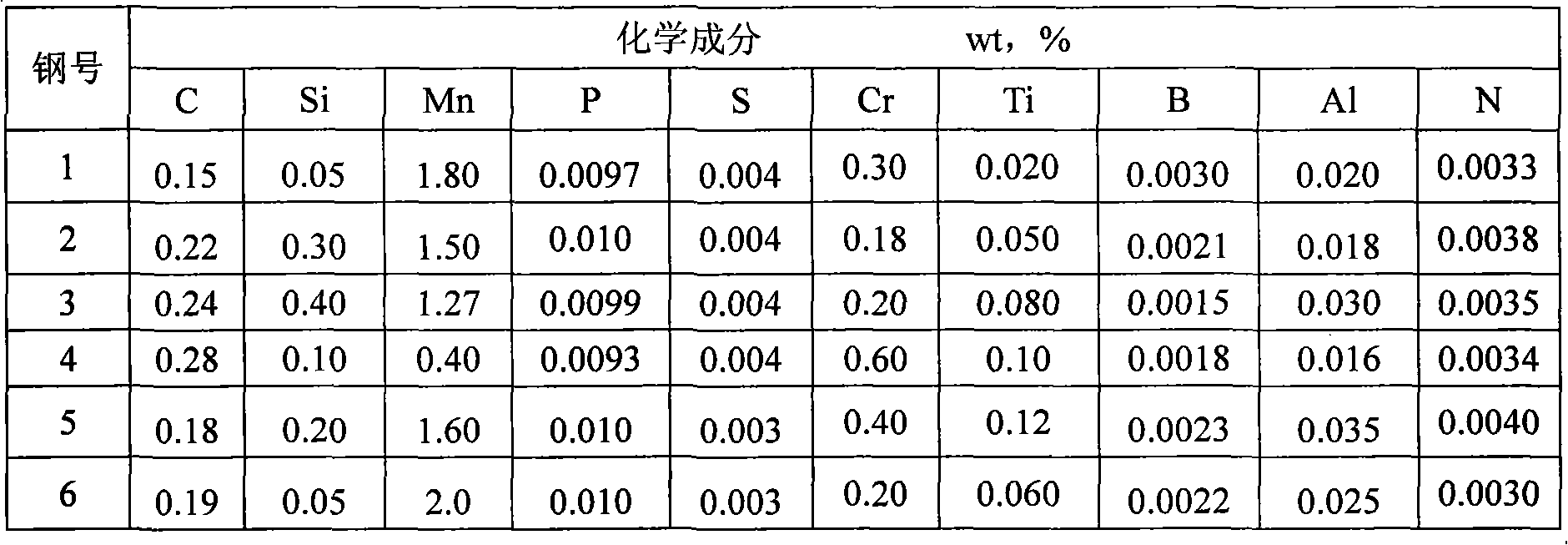

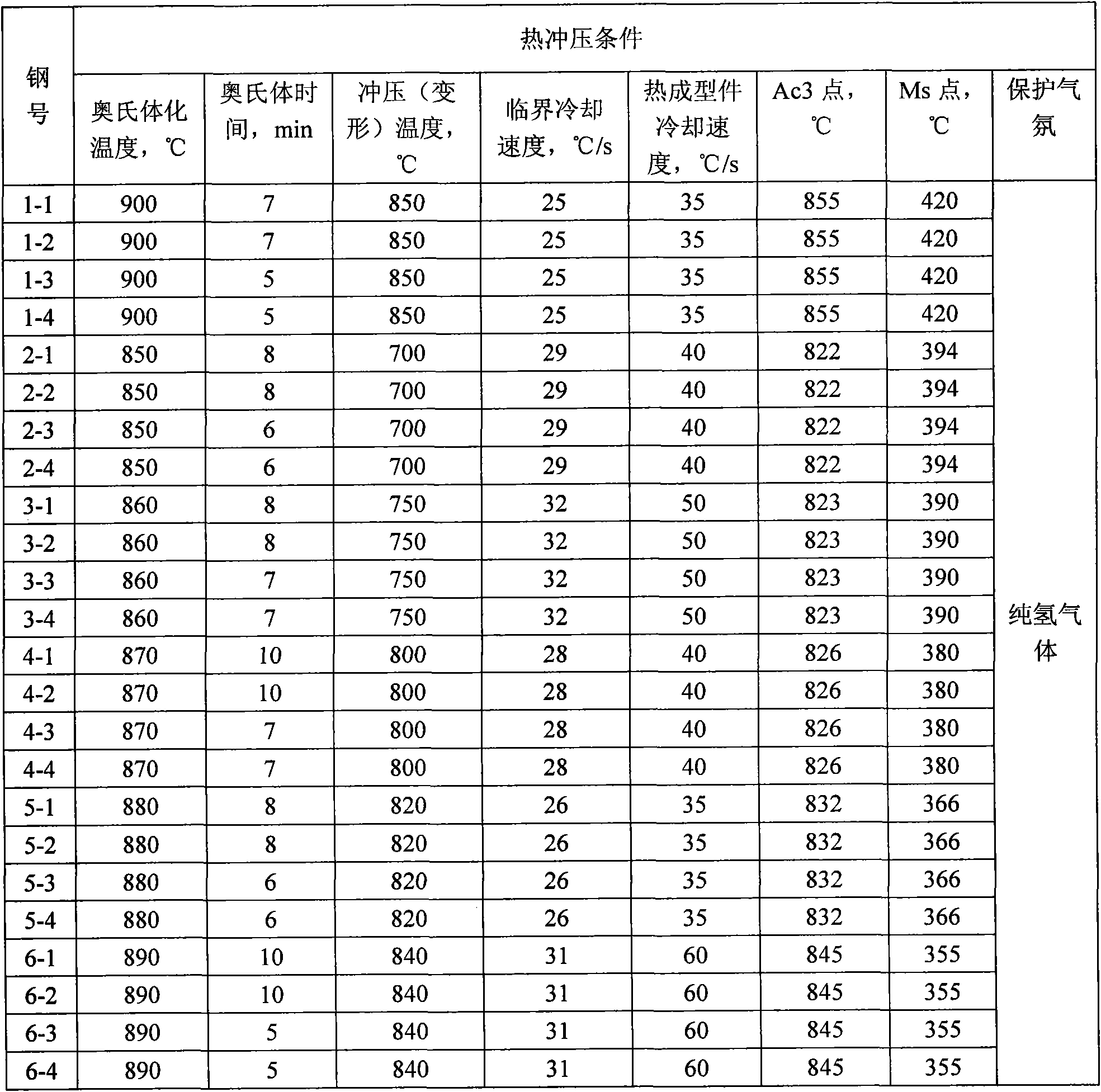

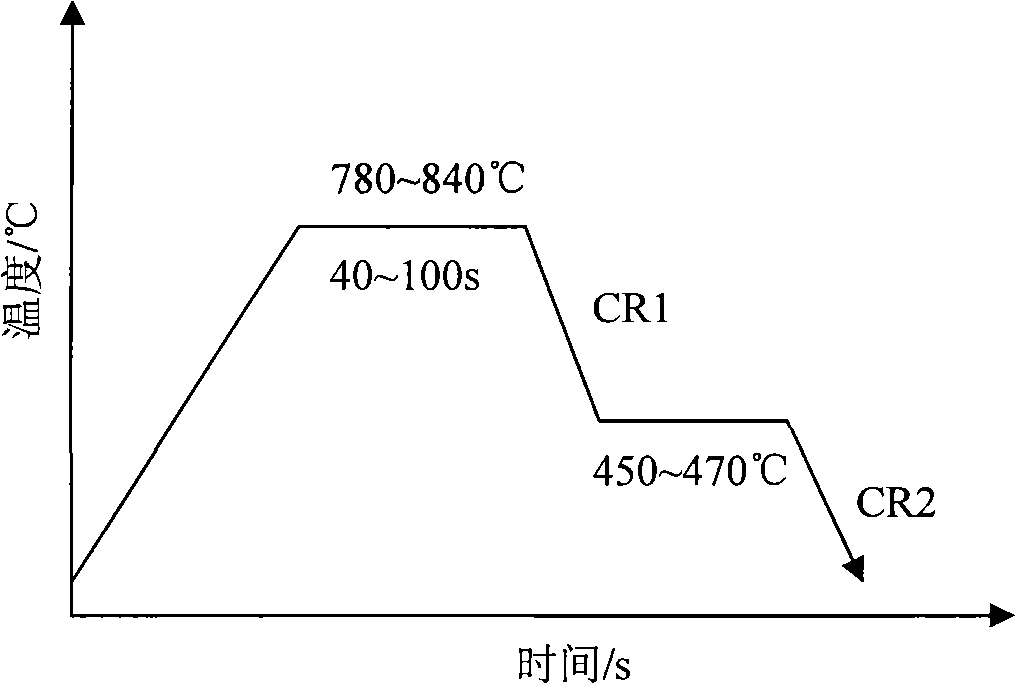

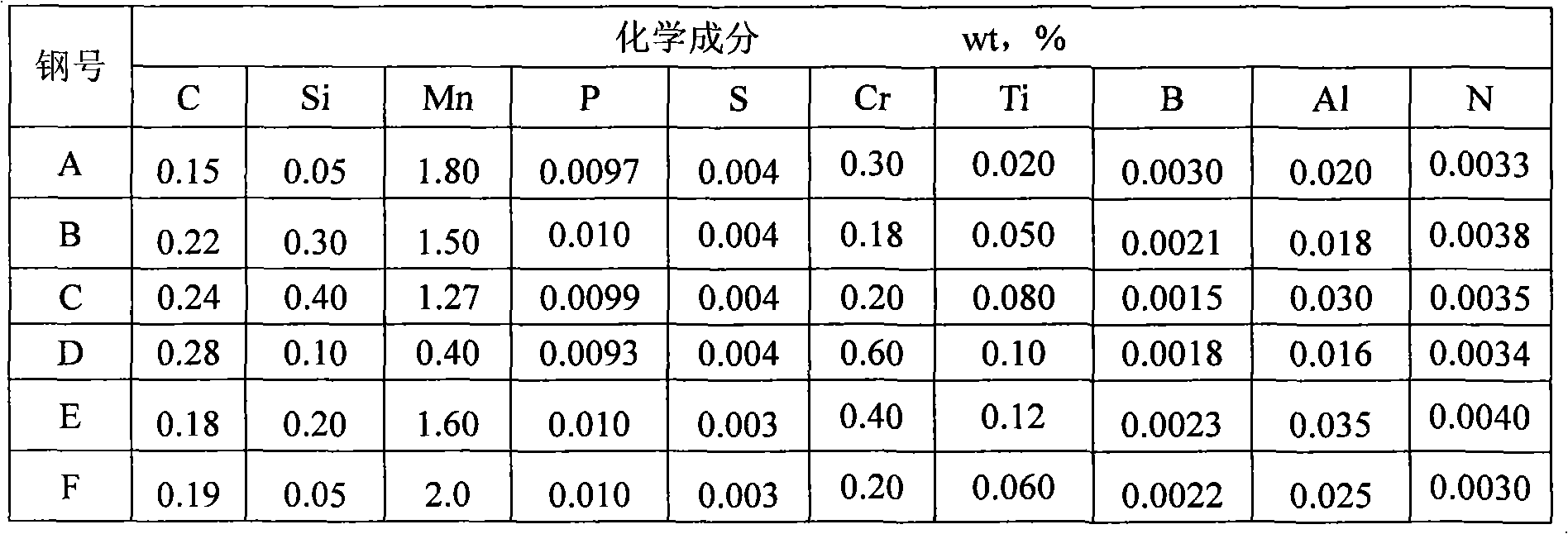

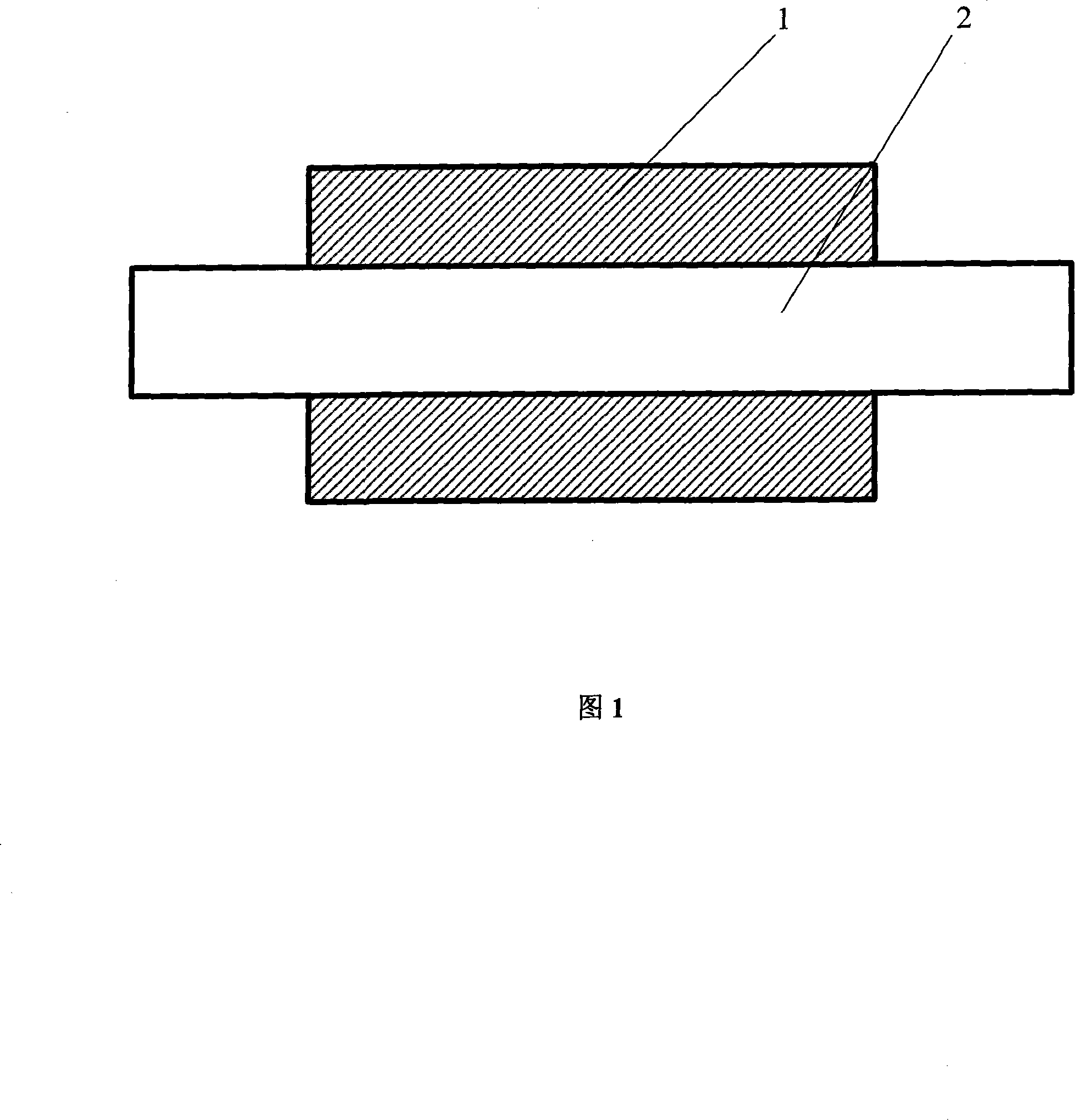

The invention discloses a steel plate for stamping and quenching and a thermoforming method of the steel plate. The steel plate comprises the following chemical components in percentage by weight: 0.14-0.28% of C, less than 0.40% of Si, 0.4-2.0% of Mn, less than or equal to 0.010% of P, less than or equal to 0.004% of S, 0.016-0.040% of Al, 0.15-0.8% of Cr, 0.015-0.12% of Ti, 0.0001-0.005% of B, less than or equal to 0.005% of N, and the balance of Fe and inevitable impurities. The thermoforming method comprises the following steps: blanking by shearing the steel plate, and heating at Ac3 to (Ac3+80) DEG C to carry out austenization; after insulating for 5-10 minutes in the heating furnace, immediately transferring the steel plate to a metal mold the inside of which is cooled by introducing water, and stamping at the high temperature of 650-850 DEG C; cooling the formed workpiece in the closed mold, and cooling the mold by water circulation in the mold, wherein the cooling rate is greater than the critical cooling rate when austenite forms martensite, and the temperature of the workpiece leaving the hot stamping production line is below 150 DEG C; and carrying out air-cooling to room temperature. The steel plate has the advantages of simple component system and favorable hardenability; and the substrate tissues, which are ferrite and pearlite, are processed by hot stamping andquenching to obtain the all martensitic structure. The tensile strength of the steel plate can be higher than 1300 N / mm<2>.

Owner:ANGANG STEEL CO LTD

1000MPa grade cold rolling hot dip galvanizing two-phase steel and manufacturing method thereof

The invention provides 1,000 MPa cold-rolled hot-dip galvanized dual-phase steel and a manufacturing method thereof, belonging to the technical field of cold-rolled hot-dip galvanized high-strength steel plates. The chemical components in mass percentage of the cold-rolled hot-dip galvanized dual-phase steel are: 0.06 to 0.18 percent of C, less than or equal to 0.1 percent of Si, 1.2 to 2.5 percent of Mn,0.05 to 0.5 percent of Mo, 0.05 to 0.6 percent of Cr, 0.005 to 0.05 percent of Al, 0.01 to 0.06 percent of Nb, 0.01 to 0.05 percent of Ti, less than or equal to 0.02 percent of P, less than or equal to 0.01 percent of S, less than or equal to 0.005 percent of N, the balance being Fe and inevitable impurities. The manufacturing method adopts Cr or Mo to replace Si, so as to enlarge an austenitic and ferritic two-phase region and improve the hardenability of the dual-phase steel, and meanwhile, the manufacturing method improves the strength of toughness of the steel by adding Nb or Ti refined grains, so as to ensure that the steel has good weldability and usability, and the strength grade of the steel can reach over 1,000 Mpa.

Owner:UNIV OF SCI & TECH BEIJING +1

Steel plate for stamping and quenching and manufacturing method thereof

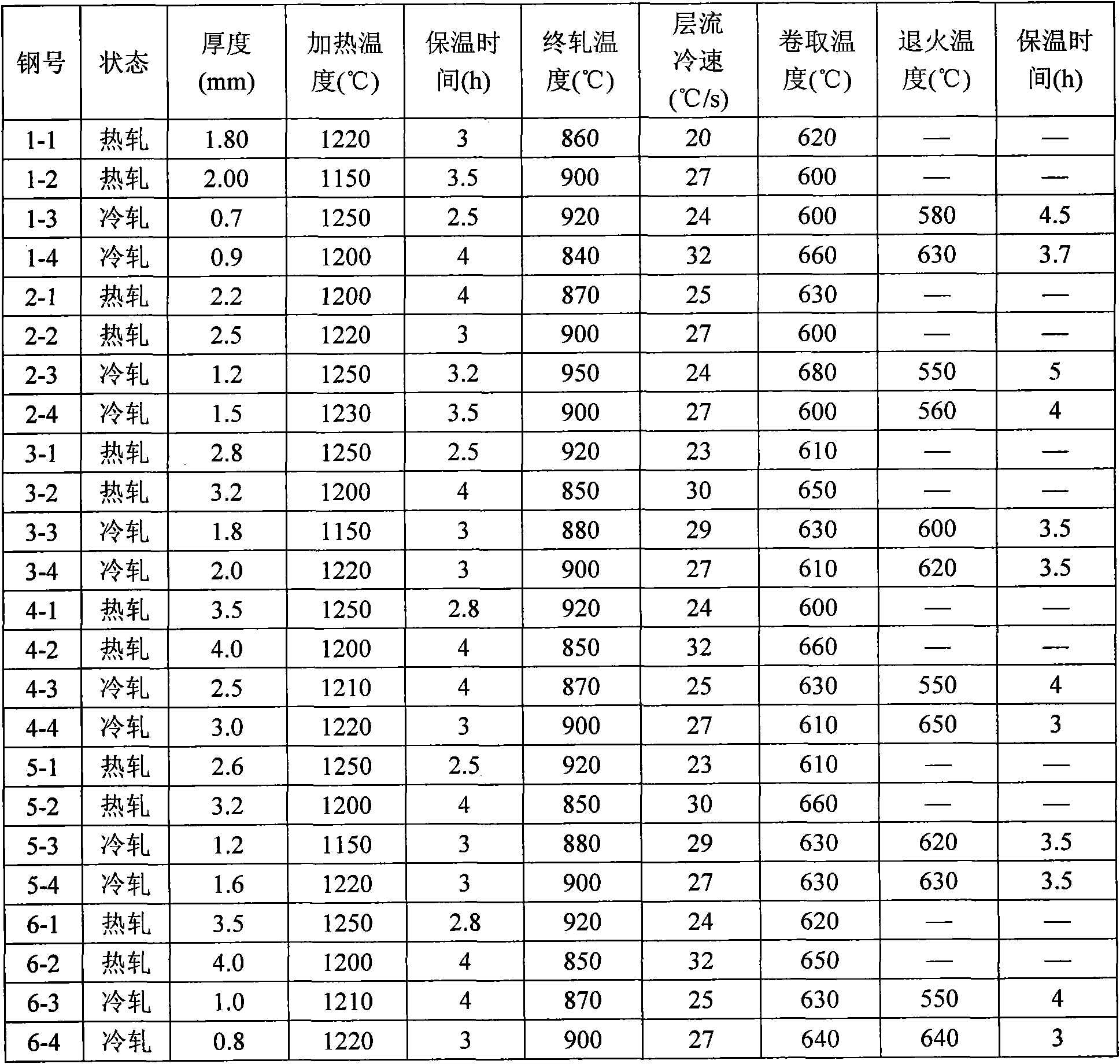

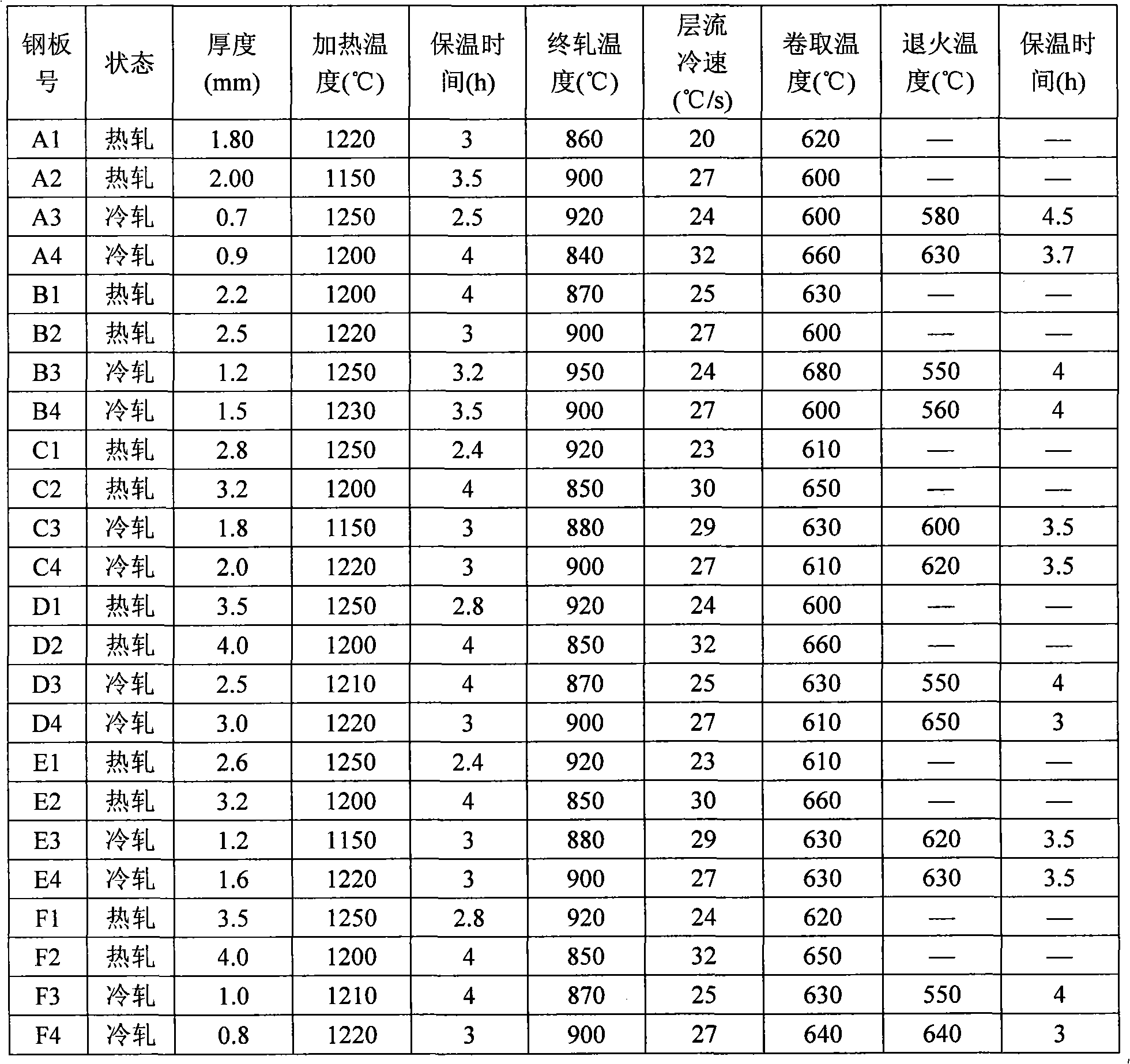

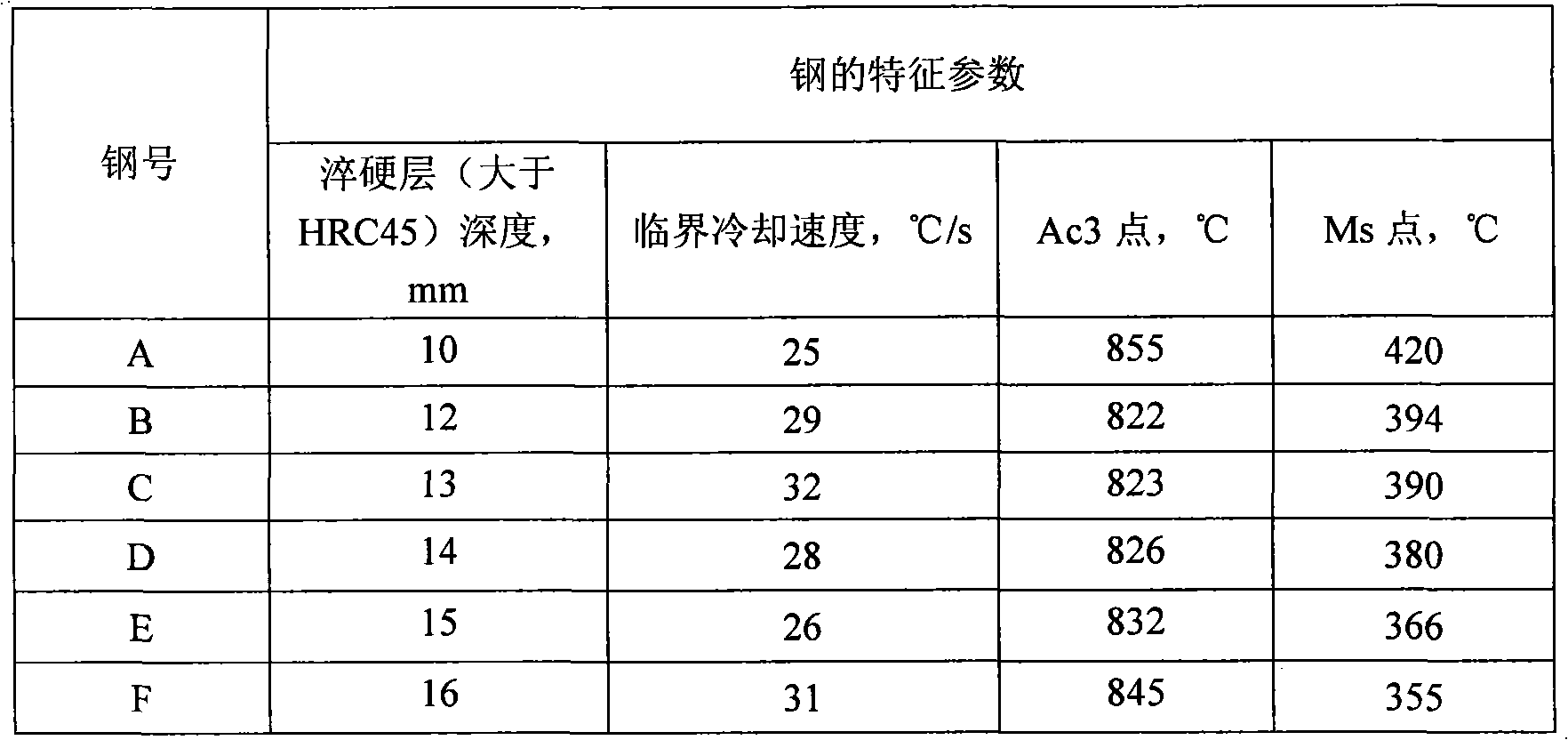

The invention discloses a steel plate for stamping and quenching and a manufacturing method thereof. The steel plate comprises the following chemical components in percentage by mass: 0.14 to 0.28 percent of C, less than 0.40 percent of Si, 0.4 to 2.0 percent of Mn, less than or equal to 0.010 percent of P, less than or equal to 0.004 percent of S, 0.016 to 0.040 percent of Al, 0.15 to 0.8 percent of Cr, 0.015 to 0.12 percent of Ti, 0.001 to 0.005 percent of B, less than or equal to 0.005 percent of N, and the balance of Fe and unavoidable impurities. The manufacturing method comprises the following steps of: heating a blank to 1,150 to 1,250 DEG C, preserving heat for 2.5 to 4 hours and performing rough rolling, and then performing finish rolling under multichannel pressure and at the final rolling temperature of between 830 and 950 DEG C, performing laminar cooling, and cooling to the rolling temperature at the cooling speed of more than 10 DEG C / s and the rolling temperature of between 600 and 680 DEG C. The cold-rolled steel plate is obtained by the following steps of: performing cold rolling on a hot rolled steel strip, annealing through a pure hydrogen gas cover furnace, and oiling and packaging. The annealing temperature is 550 to 650 DEG C and the heat preserving time is 3 to 5 hours. The steel has a simple component design and high hardenability. The depth of a hardening layer of more than HRC45 is 10 to 16mm. The steel plate consists of ferrite and pearlite. After thermal stamping and quenching, an all-martensite structure can be obtained. The tensile strength is above 1,300N / mm<2>.

Owner:ANGANG STEEL CO LTD

Centrifugal composite modified indefinite chilled cast iron roller and preparation method thereof

InactiveCN101177759AFine structure of roll bodyEvenly distributedRollsMetal rolling arrangementsCrazingImpurity

The invention relates to a centrifugal combined indefinite chill cast-iron roller and a preparation method thereof, pertaining to steel rolling technical field. The chemical composition of a roll barrel is (weight percent): 3.2-3.8 C, 3.8-4.5 Ni, 1.2-1.8 Cr, 0.2-0.4 Mo, 0.2-0.5Cu, 1.0-1.8 Si, <0.8Mn, 0.10-0.30 Nb, 0.05-0.20 V, 0.05-0.20 Ti, 0.04-0.07Mg, 0.02-0.05 Y, 0.01-0.03 Sb, and the rest are Fe and unavoidable microimpurity. The invention employs a electric stove to produce a roller, and the roller is moulded with centrifugal casting method; the roller is characterized by high strength and hardness, good toughness, hardness uniformity and hardenability, excellent wear resistance and oxidation resistance and the anti-cold shock and heat shock properties are also good; no phenomena like breaking, peeling, crazing and steel sticking are in the operation process; the service performance is apparently better than high nickel-chrome indefinite chill cast-iron roller; the processing technique is simple, high-heat treatment is not needed and the production cost is low. The invented roll has the advantages that: the rolling mill operating rate is significantly improved, the production cost of mill bar is reduced, the surface quality of the mill bar is improved and the economic and social benefits are good.

Owner:BEIJING UNIV OF TECH

High-hardness hypereutectic high chromium, manganese, molybdenum and tungsten alloy wear resistant steel material and use thereof

The invention discloses a high-hardness hypereutectic high Cr-Mn-Mo-tungsten alloy abrasion-resistant steel and iron material which adopts multivariant alloying and has the advantages of good hardenability, high hardness, better abrasion-resistance and wear resistance, and the like compared with the prior high-chromium cast iron especially the addition of C, Cr, Mn, Mo and tungsten, thereby enlarging the application range of materials. The invention is suitable for preparing wearing and corrosive wearing parts, in particular to parts used for impacting corrosive wearing working conditions.

Owner:JINAN UNIVERSITY

Bainitic steels with boron

InactiveUS20100319814A1Improve toughnessImprove solderabilityFurnace typesHeat treatment process controlHigh intensityTitanium

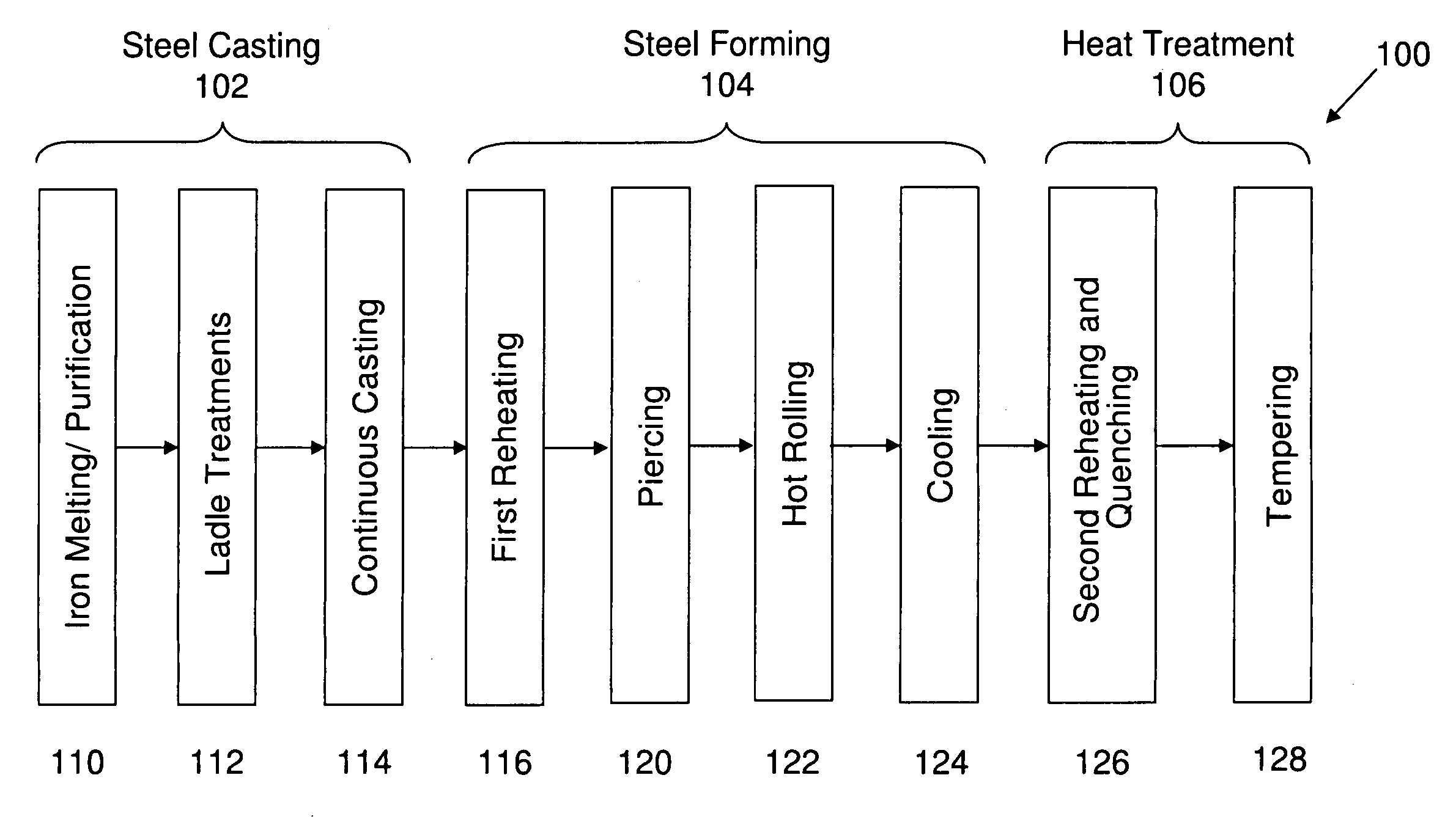

Steel compositions contain micro-alloying additions of boron and titanium, with yield strength of at least 100 ksi (690 MPa), excellent toughness and good weldability. Boron additions are used to increase hardenability. Strong nitride formers, such as titanium, may be added to the steel composition in order to prevent boron nitrides from forming. These compositions may be cooled from hot rolling in air or using accelerated cooling. After air cooling, the composition may be quenched or quenched and tempered. The compositions are suitable for high strength line pipes (for example, X100 in API 5L standard) and other applications.

Owner:TENARIS CONNECTIONS

High Strength Low Alloy Steel and Method of Manufacturing

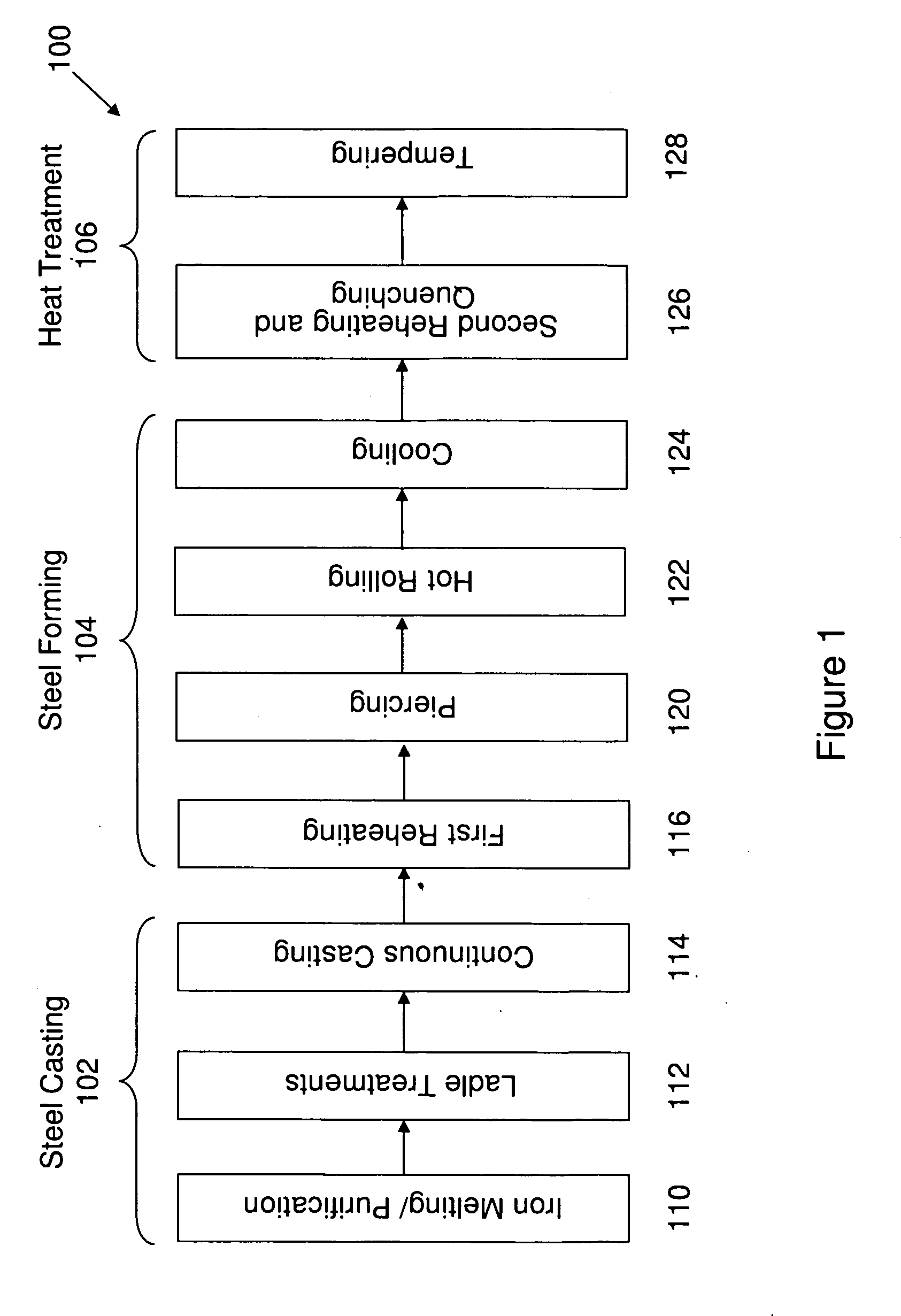

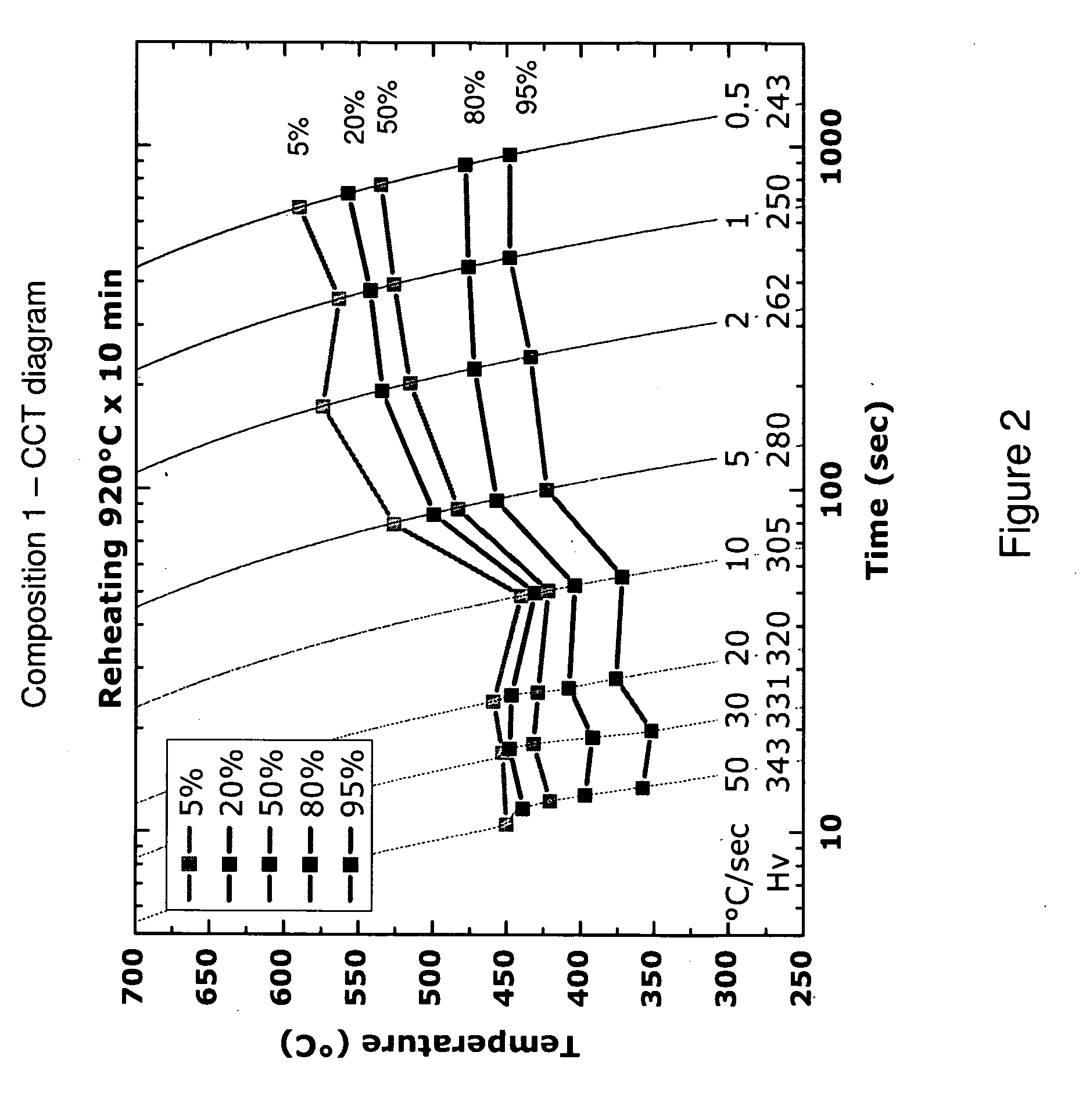

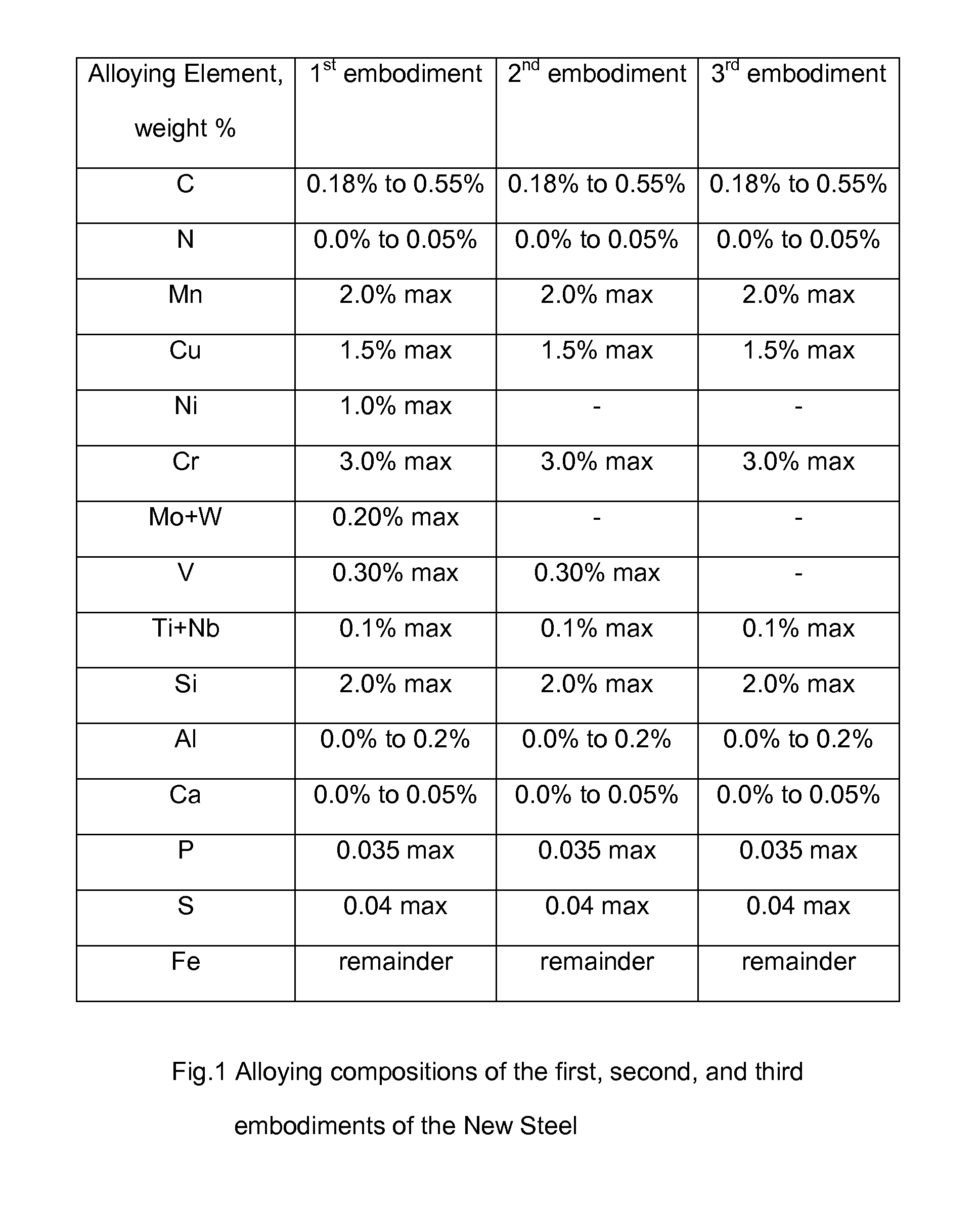

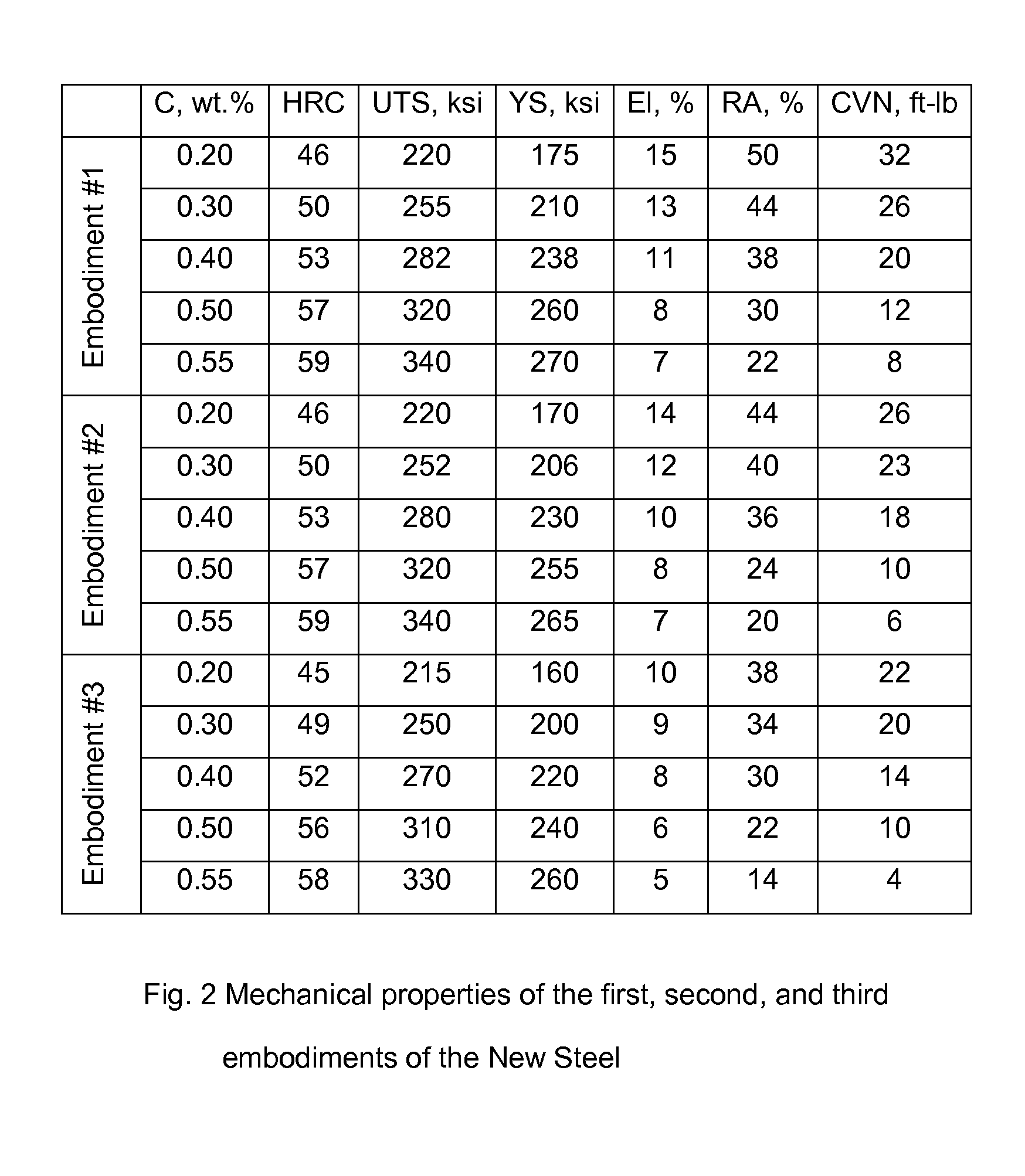

The present invention relates to a wrought, quenched and tempered, fine-grained, with deep hardenability, high strength and low alloy steel having a sum of the alloying elements: nickel, molybdenum, tungsten, vanadium, titanium, and niobium in weight percentage of 1.60% maximum in the first embodiment; vanadium, titanium, and niobium in weight percentage of 0.40% maximum in the second embodiment; titanium and niobium in weight percentage of 0.10% in the third embodiment. The air melted and hot forged steel of the first embodiment has hardness of HRC 55, an ultimate tensile strength of 300 ksi, a yield strength of 257 ksi, a total elongation of 9%, a reduction of area of 32%, and Charpy v-notch impact toughness energy of 15 ft-lb after normalizing, gas quenching, and tempering at 450° F.

Owner:VARTANOV GREGORY

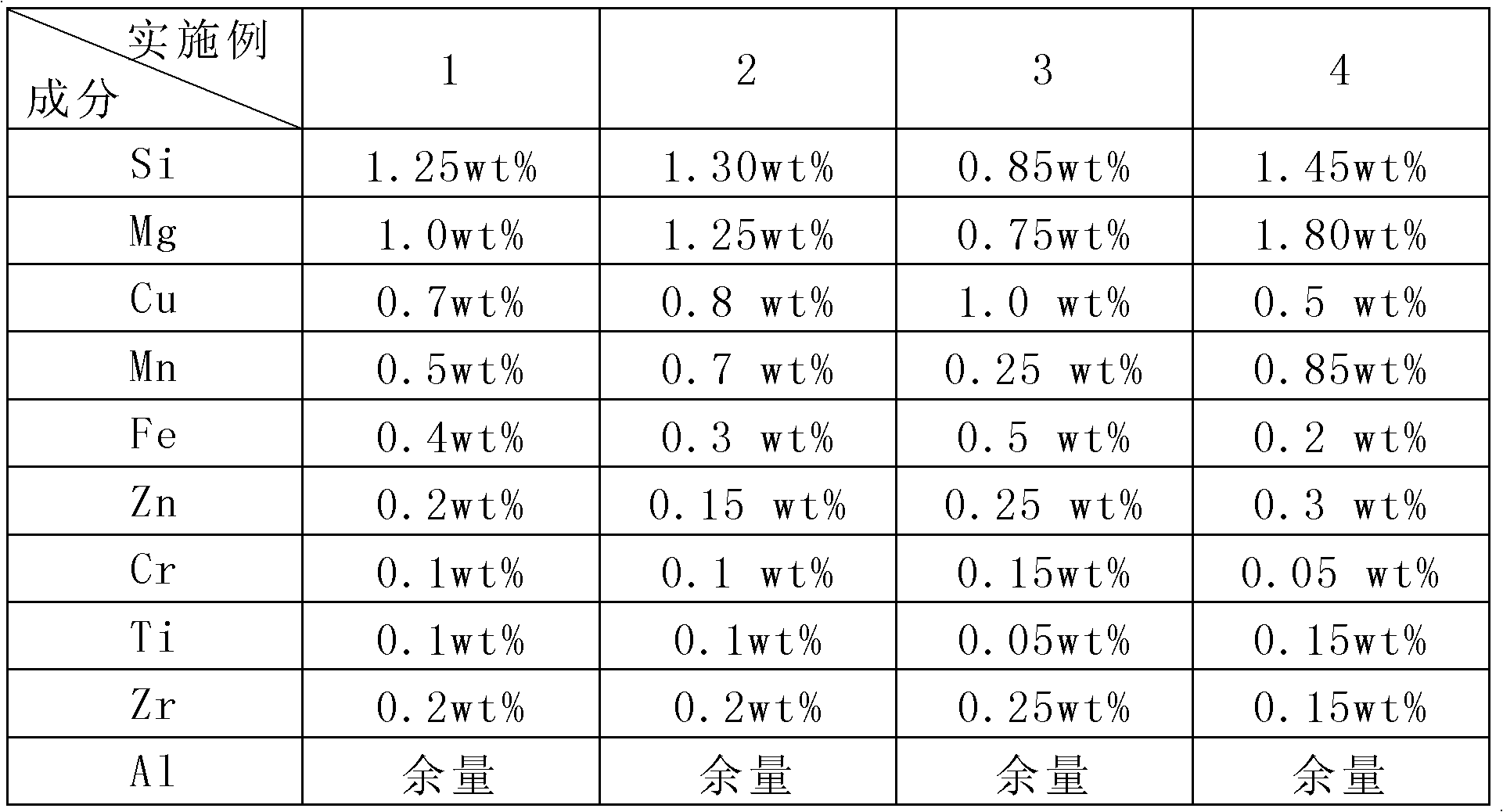

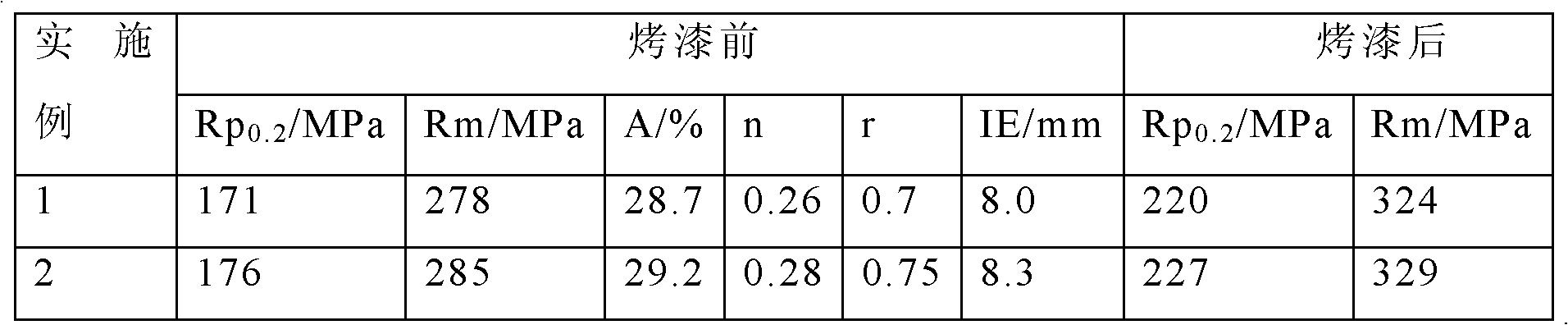

Al-Mg-Si alloys for automobile body sheets and manufacturing method thereof

ActiveCN101880805AStrong impact resistanceLower yield strengthCooking & bakingUltimate tensile strength

The invention provides Al-Mg-Si alloys for automobile body sheets and a manufacturing method thereof, belonging to the technical field of alloy materials. The invention solves the following problems: the existing 6000 series alloys have poor stamping forming performance and the strength of the alloys is possibly reduced through paint baking after stamping. The alloys comprise the following components in percentage by weight: 0.75-1.5% of Si, 0.2-0.5% of Fe, 0.2-1.0% of Cu, 0.25-1.0% of Mn, 0.75-1.85% of Mg; 0.15-0.3% of Zn, 0.05-0.15% of Cr, 0.05-0.15% of Ti, 0.05-0.35% of Zr and the balance Al. The alloys have the advantages of low yield strength, convenient stamping, high plasticity and good impact resistance and baking hardenability.

Owner:ZHEJIANG GKO IND CO LTD

High-strength high-toughness low temperature steel for ship and manufacture method thereof

ActiveCN102851591AAchieve sex changeImprove purityRoll mill control devicesProcess efficiency improvementCrack resistanceHeat-affected zone

The invention discloses high-strength high-toughness low temperature steel for ship and manufacture method thereof. The steel is composed of (by wt%) C 0.04-0.12, Si 0.20-0.55, Mn 0.8-1.4, P 0.005-0.015, S less than or equal to 0.005, Als 0.02-0.07, N less than or equal to 0.005, Cu 0.05-0.40, Ni 0.05-0.50, and Fe and unavoidable impurity in balance, with Ni / Cu of 1.2-1.5; and one or more than two of Nb 0.005-0.03, Ti 0.005-0.02, Ca 0.001-0.006, and Mg 0.0005-0.002. The steel has advantages of low compression ratio, high strength, good low temperature impact energy, good texture uniformity, and good elongation, to ensure low hardenability and cold crack resistance of repair welding heat-affected zone even if under polar climate condition.

Owner:ANGANG STEEL CO LTD

High hardness and toughness low alloy abrasion resistant steel and use thereof

The invention discloses high-hardness-ductility low alloy abrasion-resistant steel with high hardness, good ductility, high work hardening capacity, favorable comprehensive mechanical property and hardenability. In the invention, as Nb, B and rear-earth elements are added, the high-hardness-ductility low alloy abrasion-resistant steel can be ensured to have better hardenability, better ductility, high initial hardness, high work hardening capacity and better abrasion-resistant performance, thereby enlarging the application of materials. The invention is suitable for preparing wearing parts, in particular to parts used for impacting wearing working conditions.

Owner:韶关韶瑞铸钢有限公司

High strength boron-containing cold heading steel for fastener and preparation process thereof

The invention relates to high strength boron-containing cold heading steel for a fastener and a production method thereof. The cold heading steel comprises the following components in percentage by weight: 0.15-0.35% of C, less than 0.10% of Si, 0.50-1.20% of Mn, 0.08-0.50% of Cr, less than 0.035% of P, less than 0.035% of S, 0.005-0.080% of Al, 0.005-0.100% of Ti, 0.0005-0.0050% of B, and the balance of iron and impurities. The preparation process comprises the following steps of: firstly, preparing a continuous casting according to the compositions of the boron-bearing cold heading steel; secondly, sequentially heating, roughly rolling, intermediately rolling, finely rolling, and cooling the continuous casting; and finally, packaging the continuous casting in whole rolls and cooling naturally to form the finished product. The high strength boron-bearing cold heading steel for the fastener has low steel grade strength and hardness, good plasticity and excellent quenching degree, can simplify the fastener manufacture process, save the energy source and reduce the pollution. The strength of the produced large fastener is above the level 8.8. In addition, the preparation process of the high strength boron-bearing cold heading steel for the fastener has simple preparation process, easy implementation and low cost.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

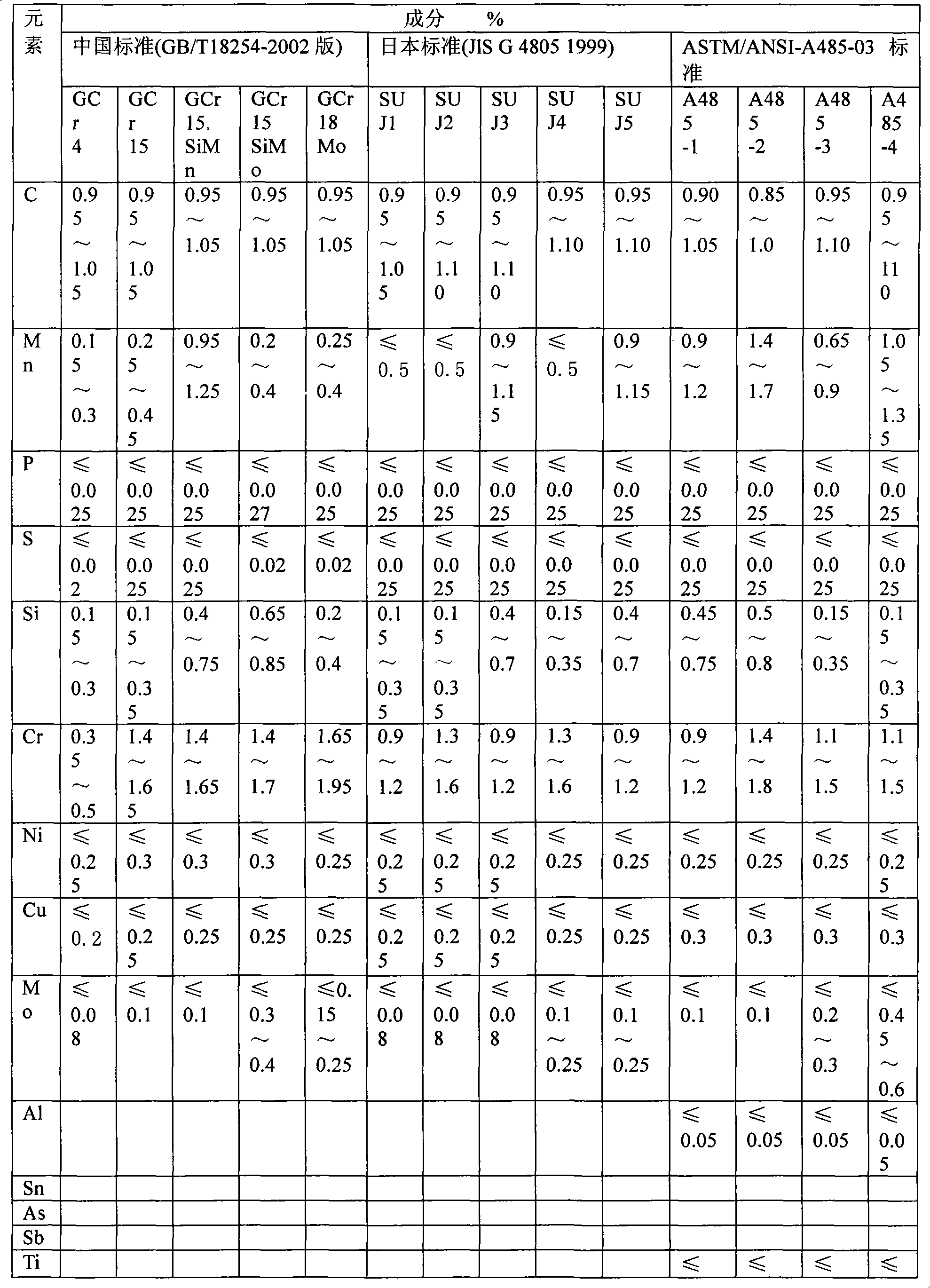

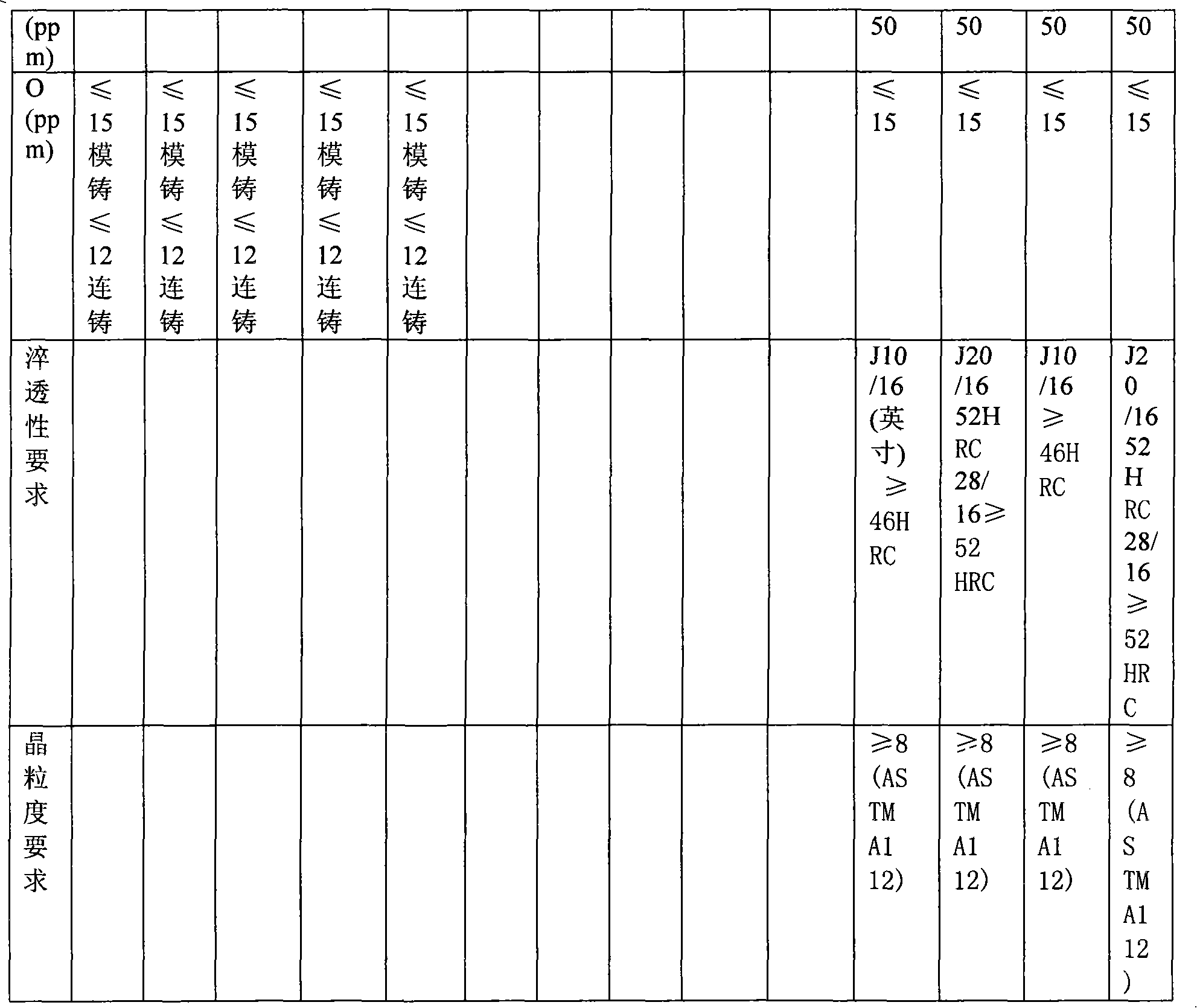

High-carbon-chromium bearing steel and manufacture method thereof

The invention discloses high-carbon-chromium bearing steel and a manufacture method thereof. The high-carbon-chromium bearing steel comprises the following chemical compositions by weight percentage: C: 0.90-1.05; Cr: 0.90-1.20; Mn: 0.90-1.25; Si: 0.45-0.75; Al: 0.02-0.04; oxygen is less than or equal to 0.0007; phosphorus is less than or equal to 0.010; sulfur is less than or equal to 0.005; titanium is less than or equal to 0.0025; copper is less than or equal to 0.15; nickel is less than or equal to 0.10; nitrogen is less than orequal to 0.0070; and the balance of unavoidable impurities and Fe. The manufacture method comprises the following steps: smelting in an electric furnace, refining in a ladle arc furnace, degassing in a vacuum furnace, pouring steel liquid into steel ingots, heating steel ingots in a heating furnace, rolling the steel ingots into square billets by a rolling mill, heating the steel ingots in a heating furnace and rolling the steel ingots into round steel by a rolling mill. Compared with the prior art, the invention has high hardenability, high crystal grain size of more than 8 grade, high commonality in technology and wide application.

Owner:BAOSHAN IRON & STEEL CO LTD

Low-carbon low-alloy steel and pipe

The present invention relates to one kind of low-carbon and low-alloy steel and produced pipe and aims at raising strength, toughness, hardness penetration and welding performance of alloy steel. The low-carbon and low-alloy steel of the present invention includes the following elements: C, Si, Mn, Al, V, Ni, B, P, S, Mo, co and Nb except Fe and impurity. The low-carbon and low-alloy steel may be used in producing conduit line pipe and other pipe of steel grade X60-X80.

Owner:BAOSHAN IRON & STEEL CO LTD

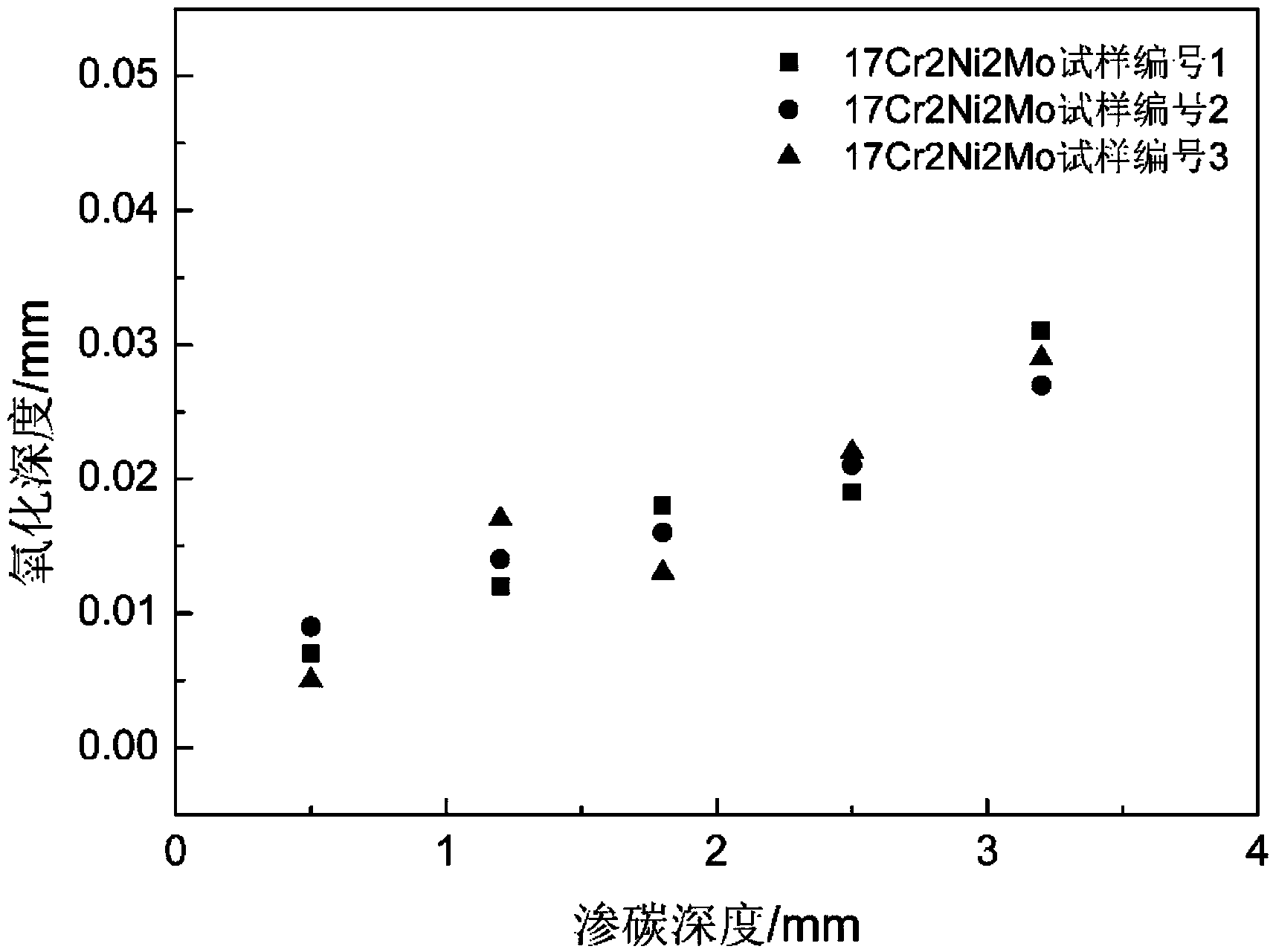

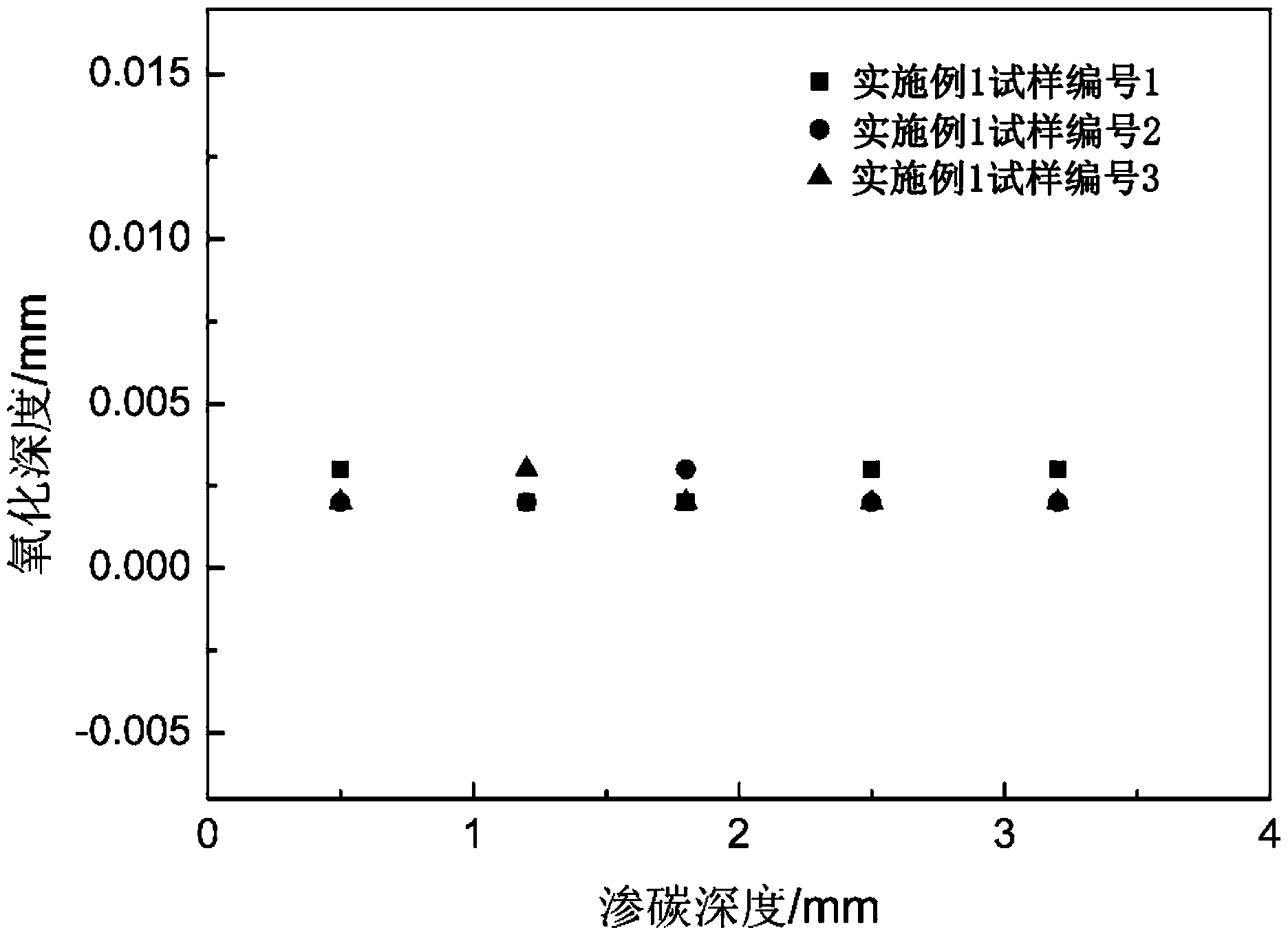

Carburizing alloy steel, and preparation method and application thereof

The invention relates to carburizing alloy steel, and a preparation method thereof. The alloy of the carburizing alloy steel comprises, by mass, 0.15%-0.25% of C, less than or equal to 0.30% of Si, 0.30%-1.20% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, 0.30%-1.50% of Cr, 2.80%-3.80% of Ni, 0.30%-1.00% of Mo, 0.01%-0.08% of Al, at least one selected from 0.05%-0.15% of V and 0.025-0.10% of Nb, and the balance being Fe and inevitable impurities. A mass percentage of V, Nb and Al meets an equation of V+Nb+Al <= 0.30%. The carburizing alloy steel provided by the invention has good anti-fatigue performance, excellent comprehensive properties, good hardenability, high yield ratio, extremely small internal oxidation and the characteristic of resisting grain growth at a high temperature, and is suitable for manufacturing heavy-duty gears.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

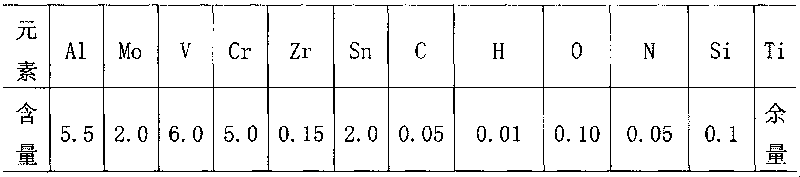

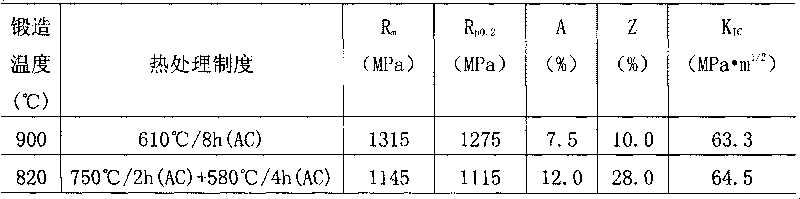

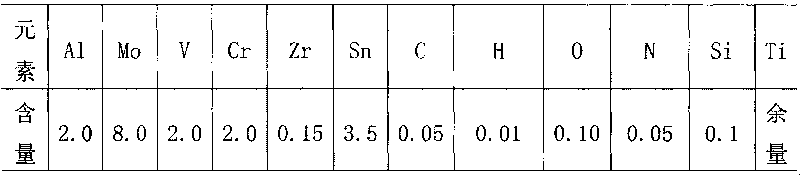

Novel high strength and toughness titanium alloy

The invention relates to a novel high strength and toughness titanium alloy which includes (by weight percent): 2.0-5.5 % of Al, 2.0-8.0 % of Mo and 2.0-6.0 % of V, wherein the ratio of Mo to V is 1 / 3-4. The titanium alloy contains 2.0-5.0 % of Cr or Cr and Fe (at most 0.9 % of Fe), the relationship k beta =CMo / 11+CV / 14.9+CCr / 6.5+CFe / 5 is satisfied and the value is 0.85-1.4. The titanium alloy also contains less than or equal to 0.10% of Si, less than or equal to 0.10% of O and less than or equal to 0.01% of H, the content of the rest components is controlled according to that of normal titanium alloy, and the allowance is Ti. The titanium alloy can also contain one or two of the neutral elements of Zr, Hf, Sn, each of which accounts for 0.15-3.5%. The titanium alloy has strong hardenability and good structure stability under high temperature, and segregation and fragile intermetallic compounds can be prevented. The titanium alloy has good pressure workability and welding property and has good tensile ductility and forgeability.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

A non-modulated production process of plastic mold steel thick plate

The invention discloses a production technology of a non-modulated plastic die steel thick plate. The production technology comprises the following steps: converter smelting and ladle furnace (LF) and Ruhrstahl Heraeus (RH) refining are adopted to pour a continuous cast billet; the heating temperature is 1150-1200 DEG C, the precision rolling temperature is 900-950 DEG C, the finish rolling temperature is 860-900 DEG C; the cooling control of the steel plate is performed after the steel plate is rolled, the phase transformation strengthening and the precipitation strengthening of the microalloyed carbon nitride are utilized to ensure that when the section of the steel plate is not modulated, the structure and performance are uniform along the section, the plastic die steel of which section hardness is 300-340 is obtained; the rolled steel plate is tempered to eliminate the stress and avoid sawing crack, the hardness of the steel plate is uniform after tempering, and the section has granular bainite structure. In the production technology, the alloy component is controlled, Ni is not added, a small amount of Mo, B and V are added and the Cr content is increased properly, thus the steel plate has higher hardenability; and the cooling control of the rolled steel plate is performed to ensure that the large-section steel plate has bainite structure. The production technology is suitable for the production of the non-modulated plastic die steel thick plate, which is prepared from the 320mm continuous cast billet and of which thickness is less than 120mm.

Owner:NANJING IRON & STEEL CO LTD

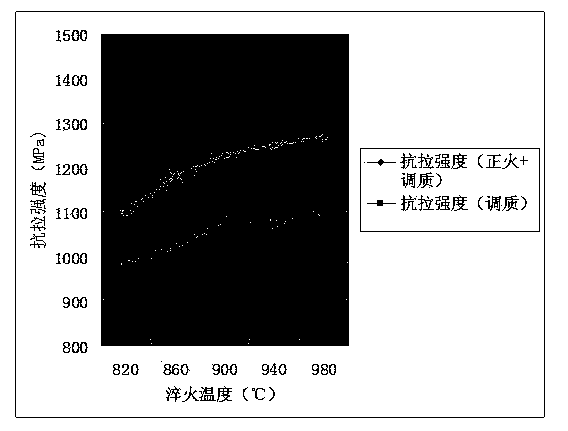

Alloy cast steel for high speed train brake disc, heat treatment method thereof and high speed train brake disc manufactured by the alloy cast steel

The invention discloses an alloy cast steel for a high speed train brake disc, a heat treatment method thereof and a high speed train brake disc manufactured by the alloy cast steel. The alloy cast steel is composed of the following components in percentage by weight: 0.18-0.26% of carbon, 0.16-0.50% of silicon, 0.55-1.40% of manganese, not larger than 0.03% of phosphorus, not larger than 0.03% of sulfur, 0.90-2.00% of chromium, 0.71-1.80% of nickel, 0.65-1.20% of molybdenum, 0.20-0.35% of vanadium, not larger than 0.30% of other components, smaller than 0.1% of tungsten and the balance of ferrum; and the heat treatment method comprises two steps of normalizing and tempering. The alloy cast steel disclosed by the invention has the beneficial effects that such alloy elements as manganese, nickel, chromium, molybdenum, vanadium, and the like, and such main components in the cast steel material as carbon, silicon and the like are reasonably mixed and are effectively thermally treated to refine the crystalline grain and improve the hardenability and heat resistant properties of the alloy cast steel material, and the normal temperature strength and the high temperature strength are greatly improved, so that the alloy cast steel material has excellent comprehensive mechanical properties. A brake disc manufactured by the alloy cast steel can meet the application requirements of high speed trains.

Owner:CRRC QISHUYAN INSTITUTE CO LTD +1

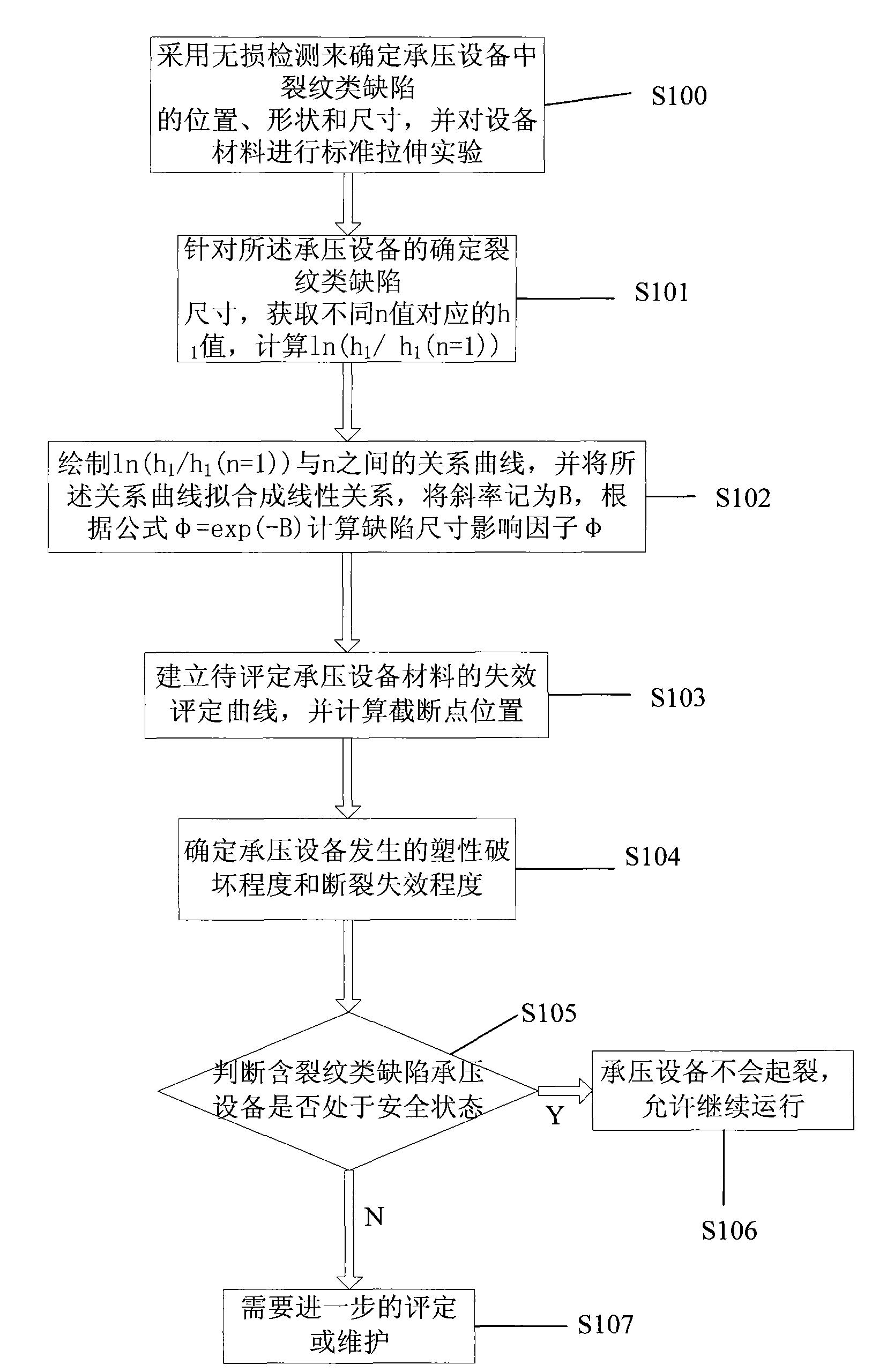

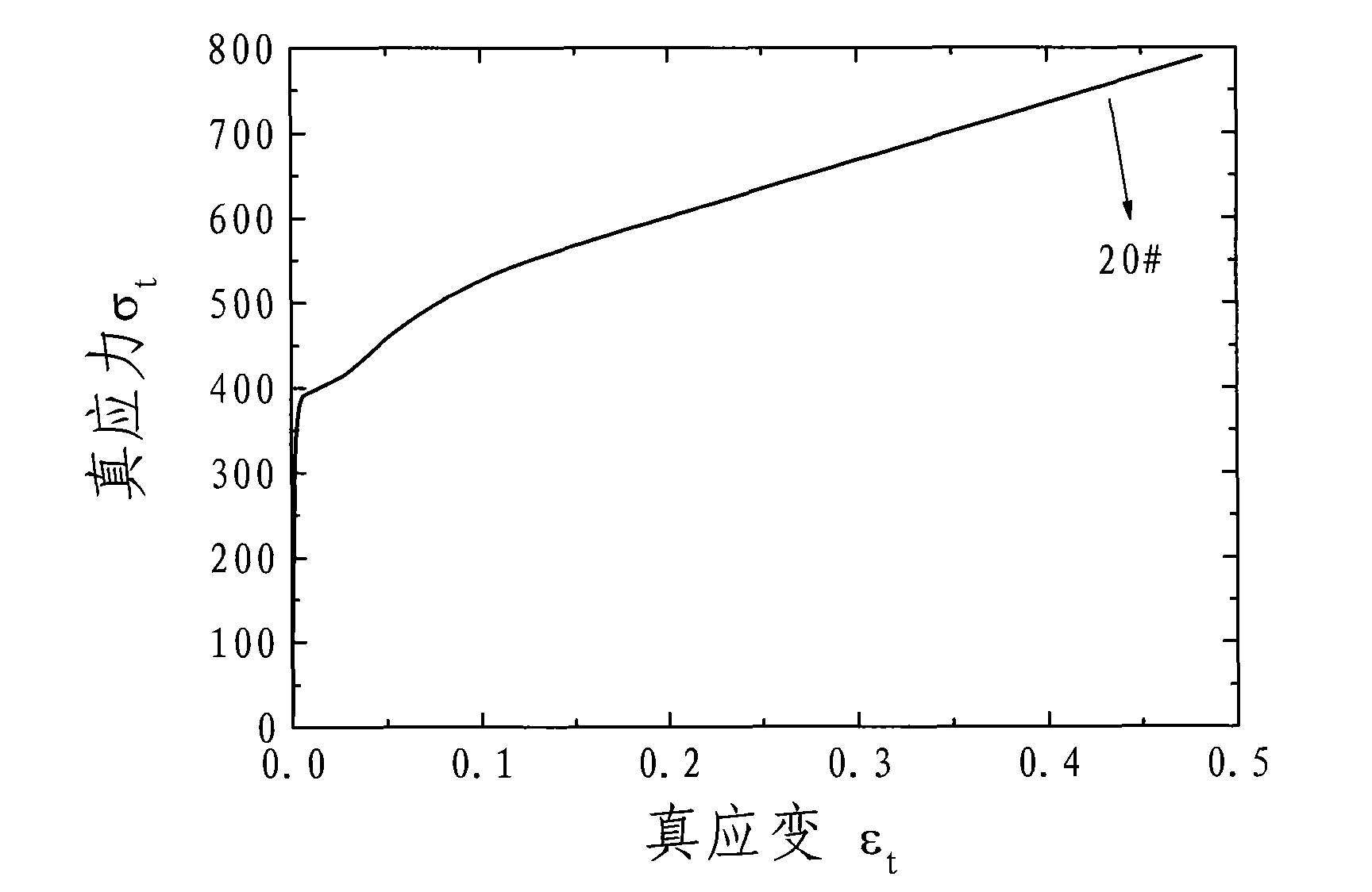

Safety evaluating method of pressure equipment containing crack defects

InactiveCN101975695AAccurately reflectAvoid mockingMaterial strength using tensile/compressive forcesDefect sizeLinear relationship

Owner:EAST CHINA UNIV OF SCI & TECH

Bainite pre-hardening plastic mold steel and preparation method and heat treatment method thereof

The invention relates to bainite pre-hardening plastic mold steel and a preparation method and a heat treatment method thereof. Chemical components of the steel are optimized on the basis of P20 steel, the content of manganese (Mn) is appropriately increased, the content of the chromium (Cr) and molybdenum (Mo) is reduced, little niobium (Nb) is added, and no nickel (Ni) and vanadium (V) in expensive price are not contained. The preparation method of the plastic mold steel comprises the following steps of: compounding, smelting and casting; carrying out the multi-directional forging heat machining; carrying out the wind cooling and the air cooling; and finally carrying out the tempering heat treatment. The plastic mold steel has characteristics of large cross section, low cost, high hardenability, good hardness uniformity and the like and also has low susceptibility of flake formation, a diffusion hydrogen annealing process is omitted, in addition the post-forging normalizing is adopted to substitute a thermal refining process, so that the production period is greatly shortened, the domestication of the plastic mold steel with large cross section, long service life, top quality and short period can stride forward for a large step, and the existing domestic manufacturing concept of energy conservation, emission reduction, sustainability and economical type can be met.

Owner:SHANGHAI UNIV

Quenched and tempered steel sheet and manufacturing method thereof

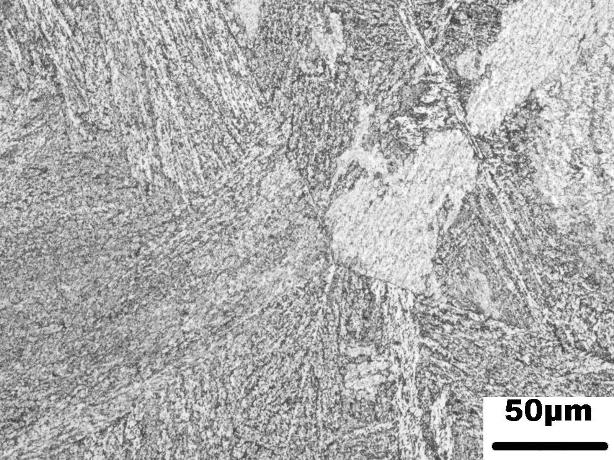

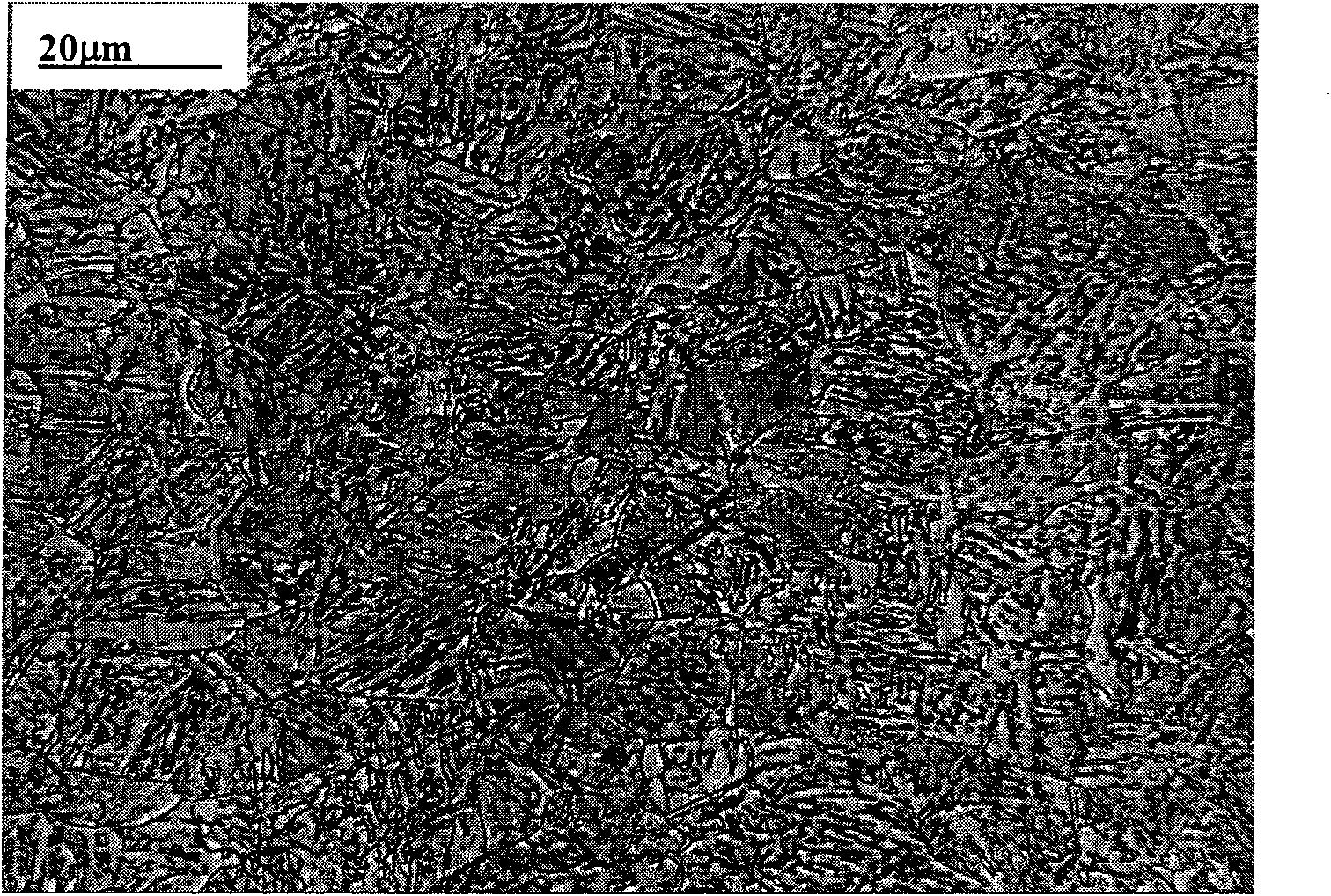

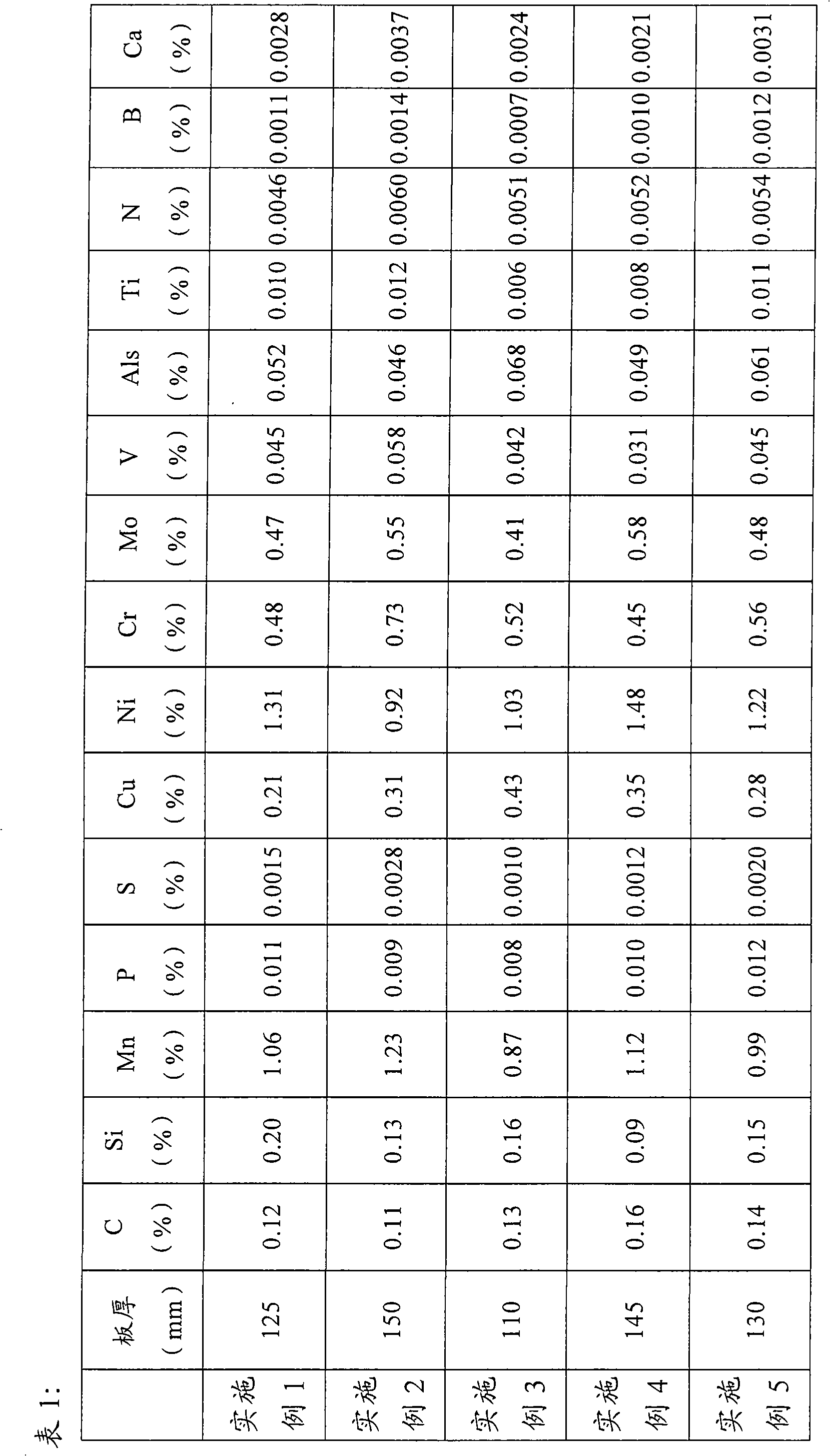

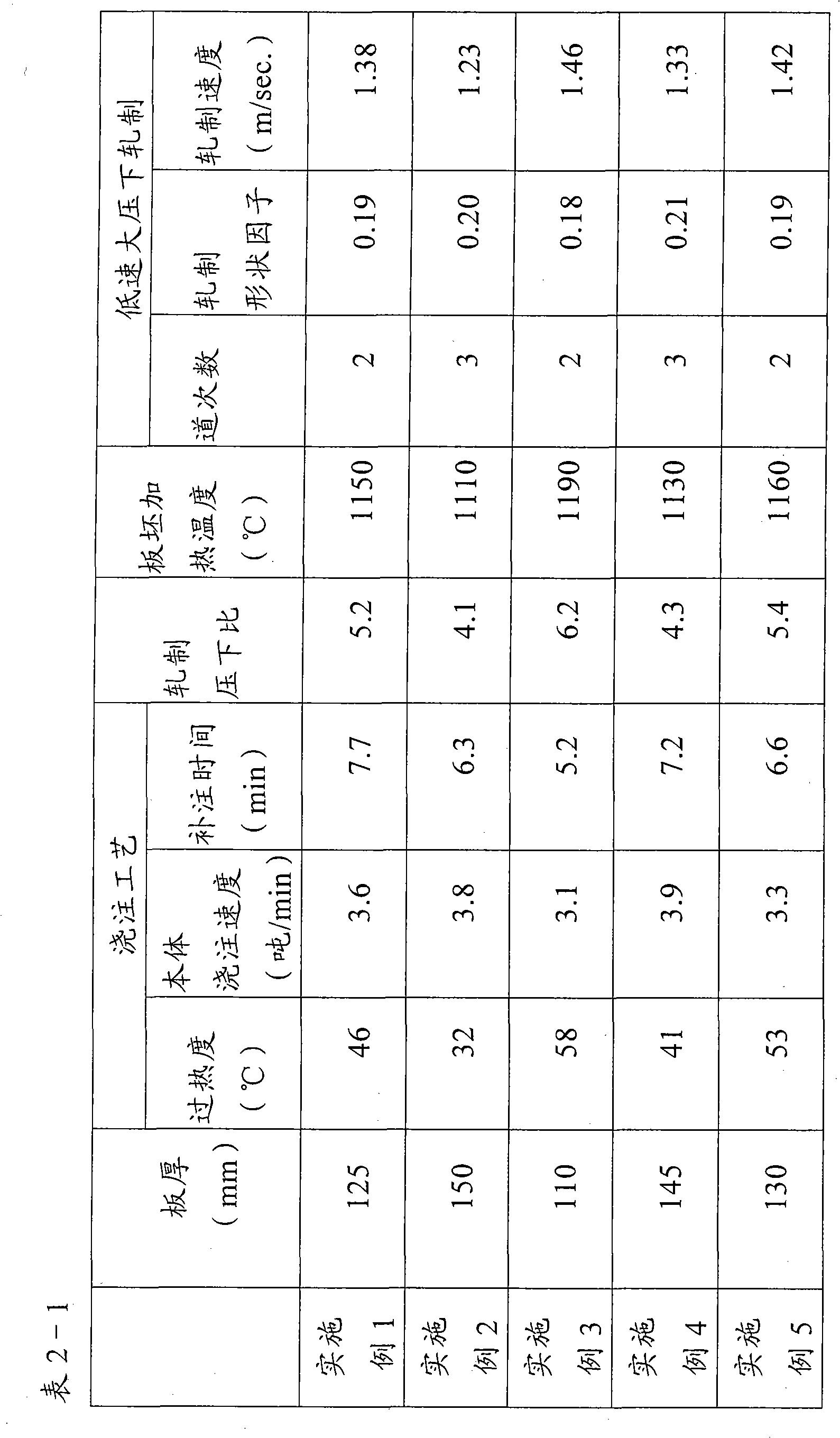

ActiveCN101962741AStrong plastic matchingSimple welding processRoll force/gap control deviceMolten metal pouring equipmentsSheet steelChemical composition

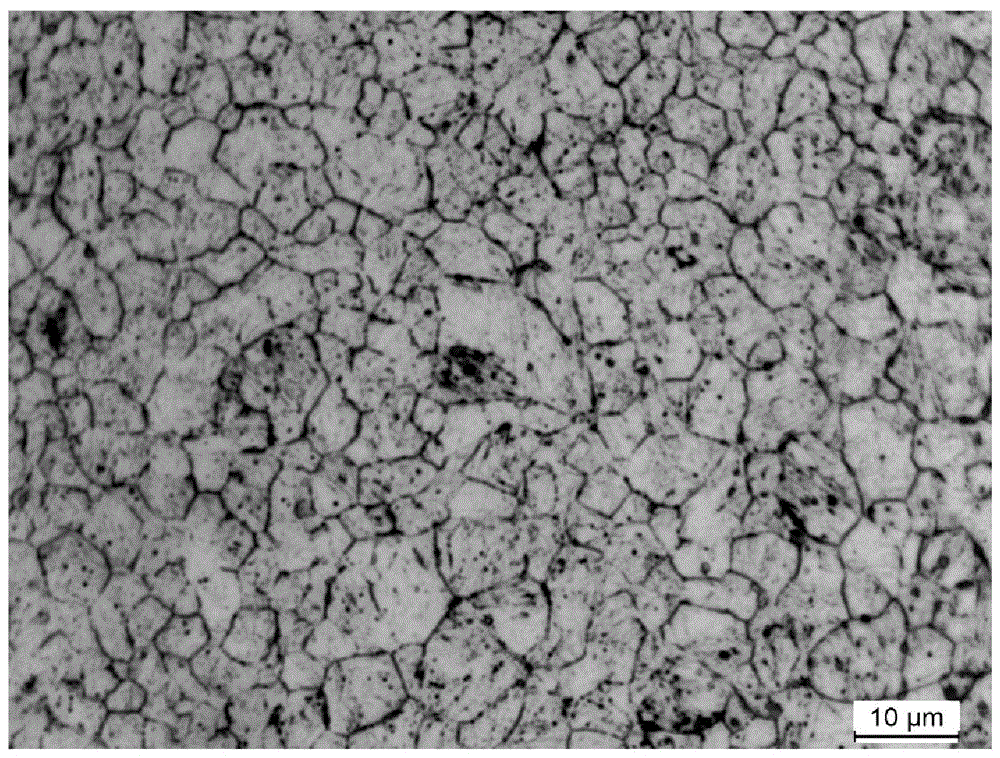

The invention provides a 80kg extra-thick quenched and tempered steel sheet. The steel sheet comprises the following chemical compositions: 0.10 to 0.16 percent of C, less than or equal to 0.20 percent of Si, 0.85 to 1.25 percent of Mn, less than or equal to 0.013 percent of P, less than or equal to 0.0030 percent of S, 0.20 to 0.45 percent of Cu, 0.90 to 1.50 percent of Ni, 0.45 to 0.75 percent of Cr, 0.40 to 0.65 percent of Mo, 0.030 to 0.060 percent of V, 0.045 to 0.070 percent of Als, 0.006 to 0.012 percent of Ti, less than or equal to 0.0060 percent of N, 0.0006 to 0.0014 percent of B, 0.001 to 0.005 percent of Ca, and the balance of iron and inevitable impurities, wherein the chemical compositions meet the following conditions that: the Mn equivalent / C is more than or equal to 10 and less than or equal to 20; the Als is more than or equal to (Mn equivalent / c)*(N-0.292Ti); the Ni equivalent is more than or equal to 1.15 percent; the Mo equivalent is more than or equal to 0.25 percent; Ca / S is more than or equal to 0.80 and less than or equal to 3.00, and (Ca)(S)0.18 is more than or equal to 5*10<-4> and less than or equal to 2.5*10<-3>; and F*DI equals to the effective hardenability index Deff and is more than or equal to 1.00*t. The invention also relates to a method for manufacturing the quenched and tempered steel sheet. The technology of optimal recrystallization controlled rolling+offline quenching and tempering is adopted to ensure that the microstructure of the finished product steel sheet is a fine tempered bainite and tempered martensite, the average colony size is less than 25mu m, and excellent obdurability / plasticity matching and uniform mechanical performance along the direction of the sheet thickness can be acquired.

Owner:BAOSHAN IRON & STEEL CO LTD

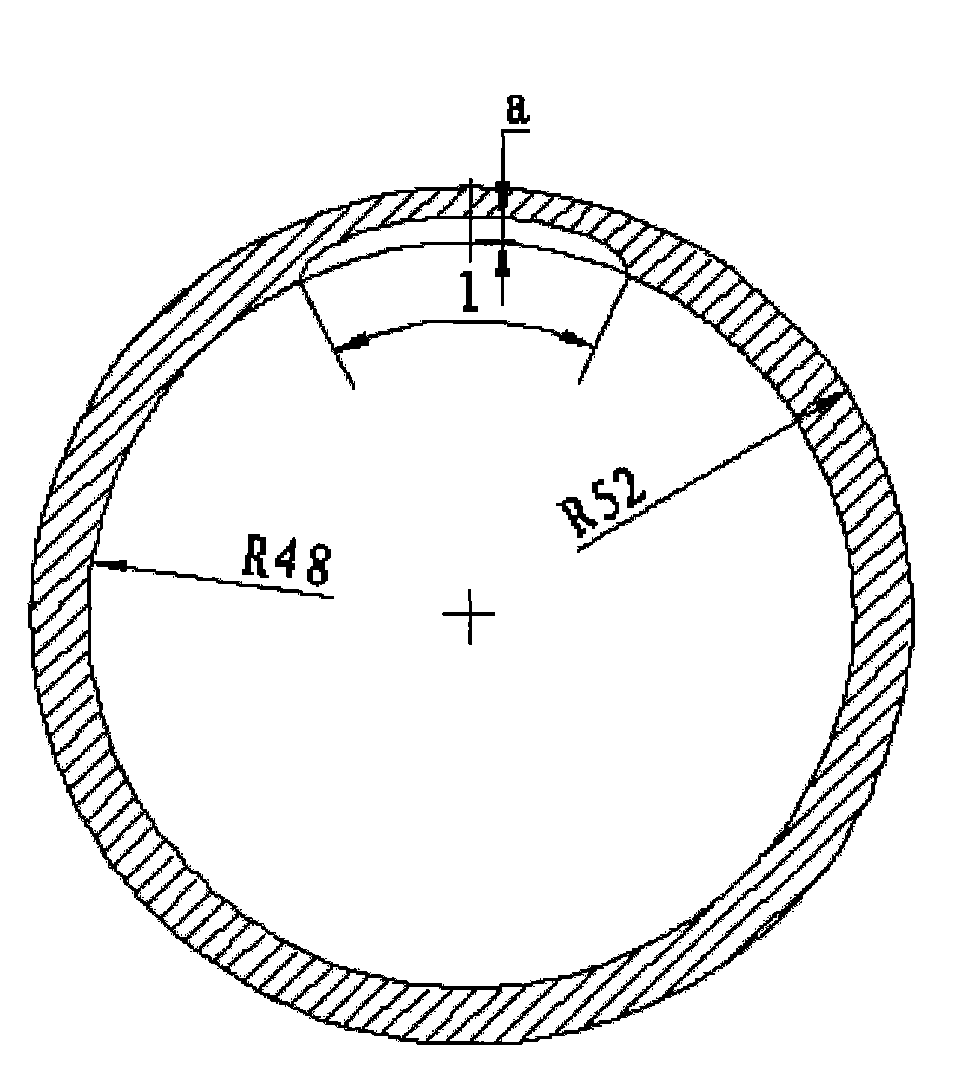

Composite roll for centrifugally casting high-chromium cast iron and a preparation method thereof

The invention relates to a composite roll for centrifugally casting high-chromium cast iron and a preparation method thereof, belonging to the technical field of the steel rolling. The composite roll comprises a roll external layer and a roll core. The chemical components of the materials of the roll external layer in terms of the percentage by weight are as below: 25-28 of alloy scrap iron of a high-nickel-chromium infinite chilled iron roll, 28-30 of carbon ferrochrome, 1.5-2.5 of mid-carbon ferromanganese, 2.5-3.5 of ferroboron, 0.5-0.8 of silicon-calcium-barium alloy, 0.2-0.4 of aluminum, 0.3-0.5 of ferrotitanium, 0.2-0.4 of rare earth ferrosilicon, 0.10-0.15 of zinc, 0.15-0.18 of magnesium and the balance of low-carbon waste steel sheet. The roll core is high-strength alloy cast iron or low-alloy ductile cast iron. The roll external layer and the roll core are formed through centrifugal composite casting. The roll has low production cost, contains a small number of impurities and has high degree of purity; the hardenability, the mechanical performance and the thermal fatigue of the roll can be improved; and the roll has long service life and low production cost.

Owner:江苏环立板带轧辊有限公司

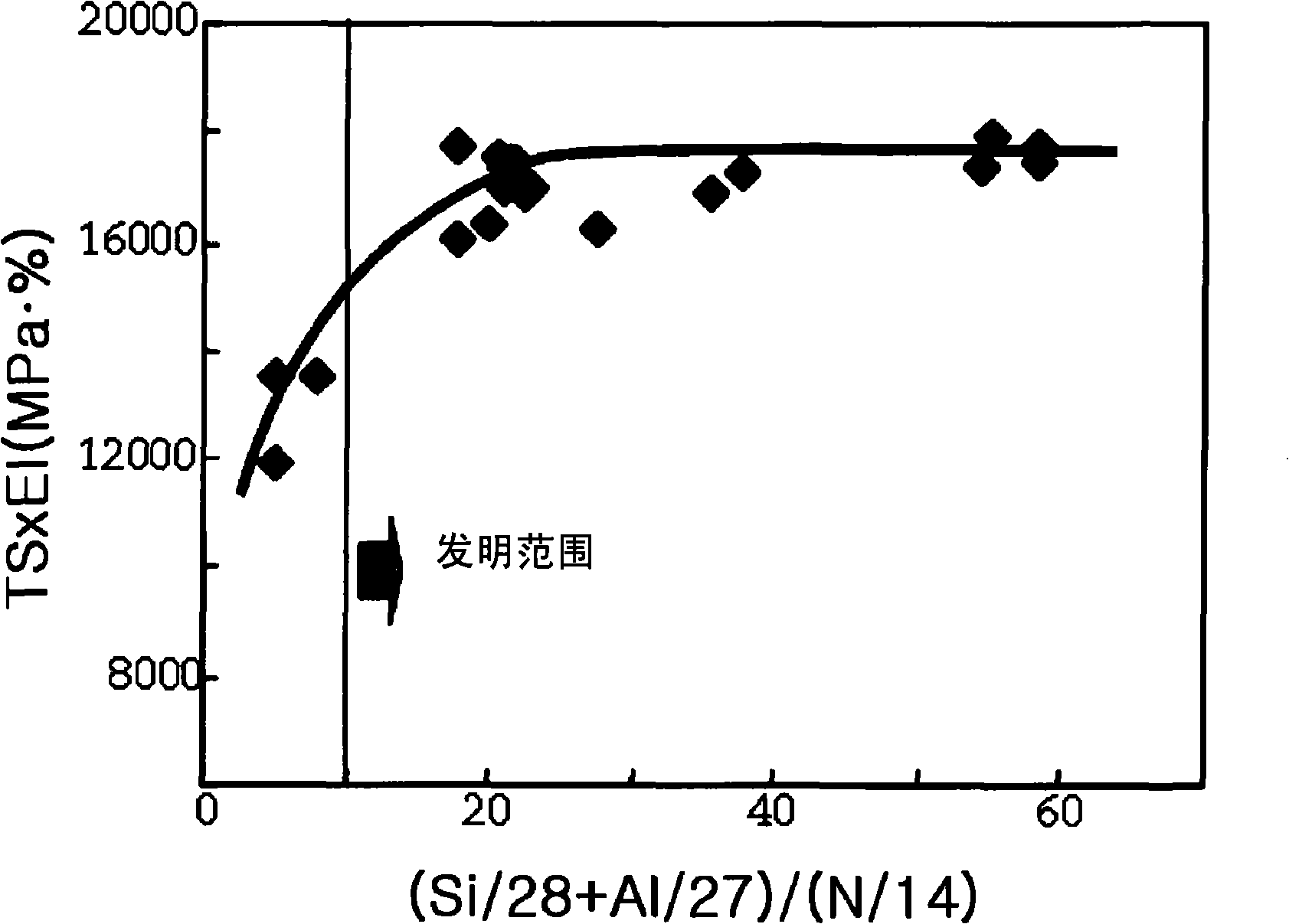

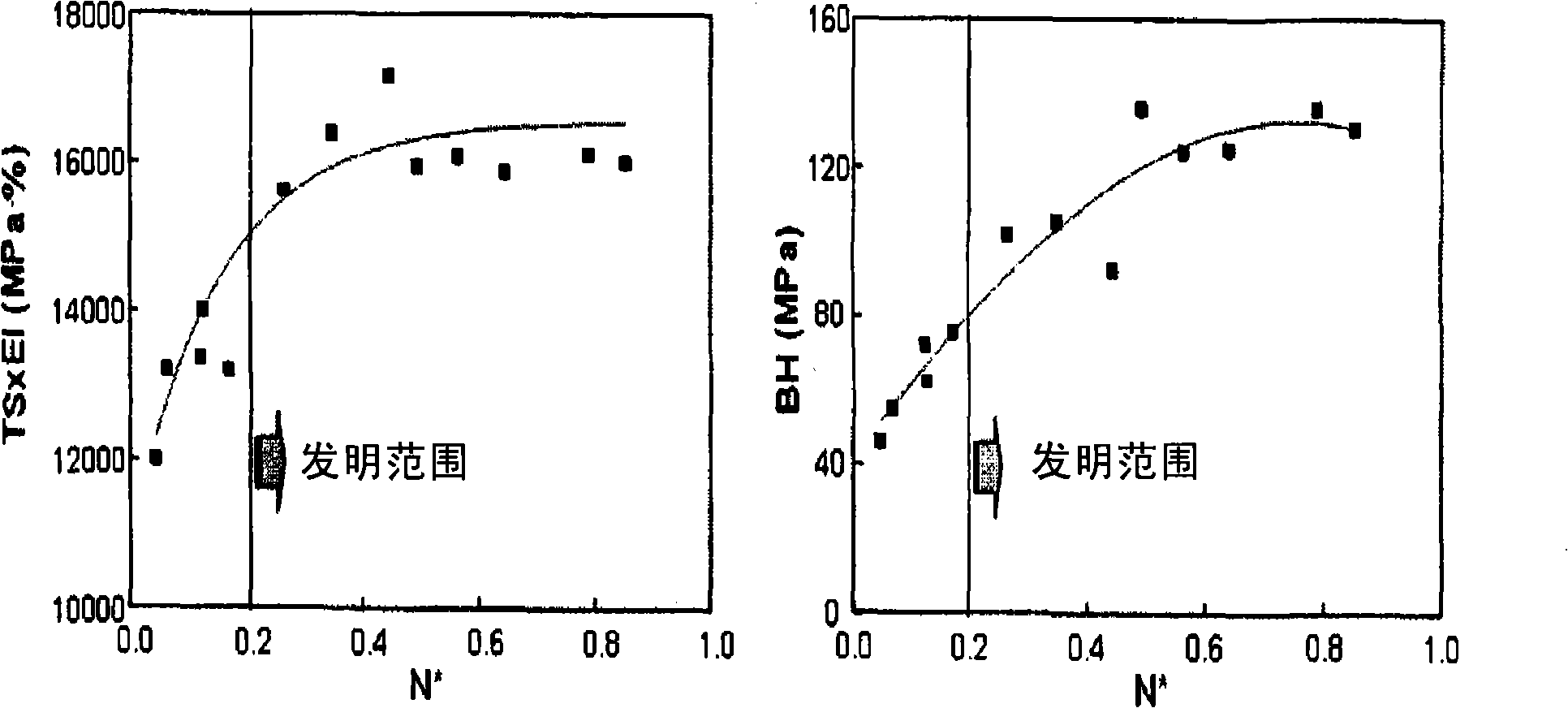

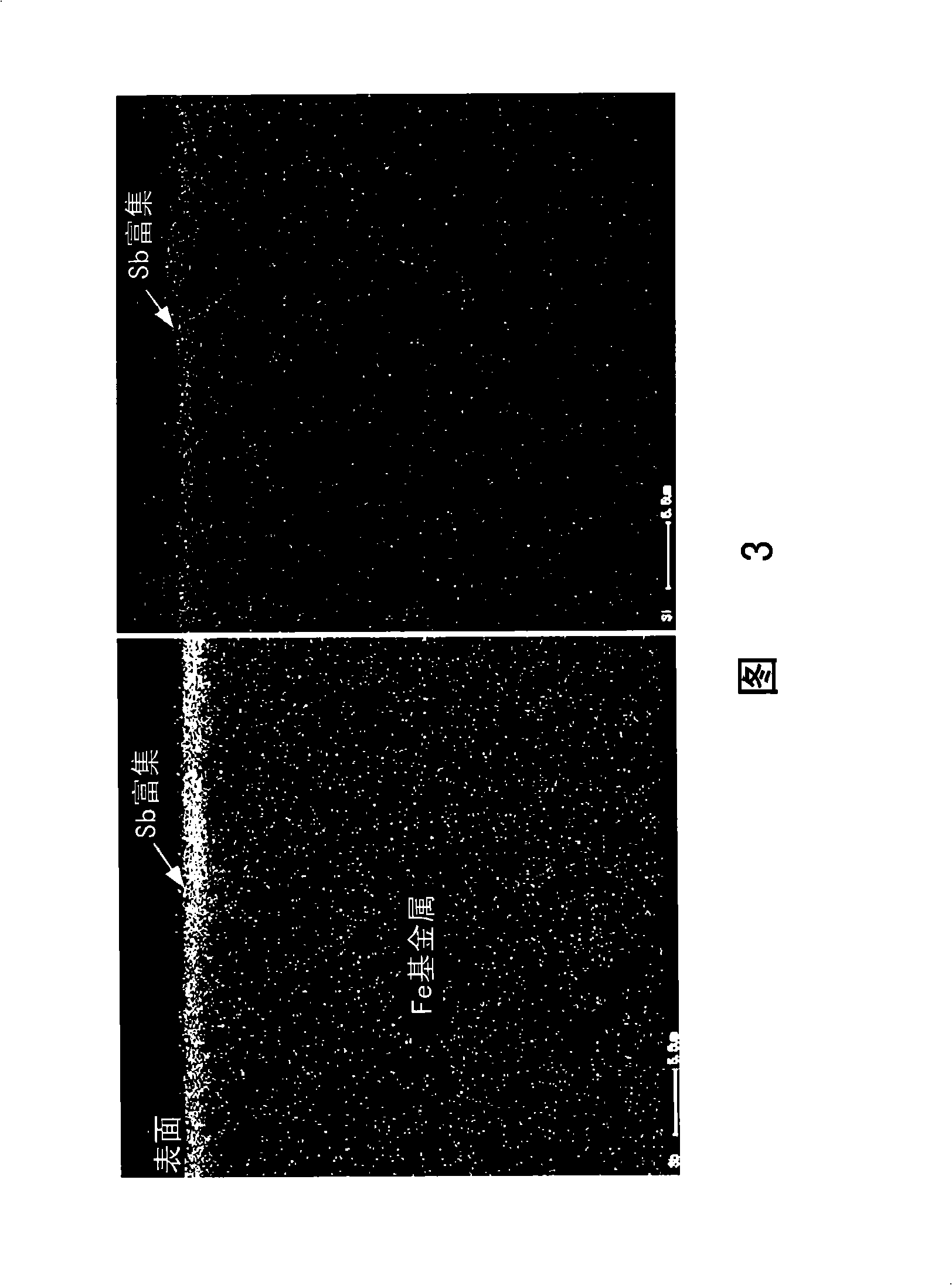

High strength cold rolled steel sheet and hot dip galvanized steel sheet having excellent formability and coating property, and the method for manufacturing thereof

The invention relates to high strength cold rolled steel sheet and high strength zinc-coated steel plate sheet mainly used as structural components and reinforcing members of a vehicle body, these steel sheets include remarkable formability and coating property and comprise: 0.01-0.2 weight percent of carbon (C), 0.01-2 weight percent of silicon (Si), 0.5-4.0 weight percent of manganese (Mn), less than 0.1 weight percent of phosphor (P), less than 0.03 weight percent of sulfur (S), less than 1.0 weight percent of soluble aluminum (Sol.Al), 0.001-0.1 weight percent of nitrogen (N), 0.005-1.0 weight percent of stibium (Sb), and remaining ferrum (FE) and inevitable impurities. The invention also relates to the zinc-coated steel plate sheet and a manufacturing method for these steel sheets. In accordance with the invention, remarkable coating property can be attained and tensile strength is more than 490 MPa. In the other hand, the formability thereof is ensured, TS*El balance thereof is more than 15,000. Furthermore, the outstanding bake hardenability of which BH value is more than 80 MPa can be attained.

Owner:POHANG IRON & STEEL CO LTD

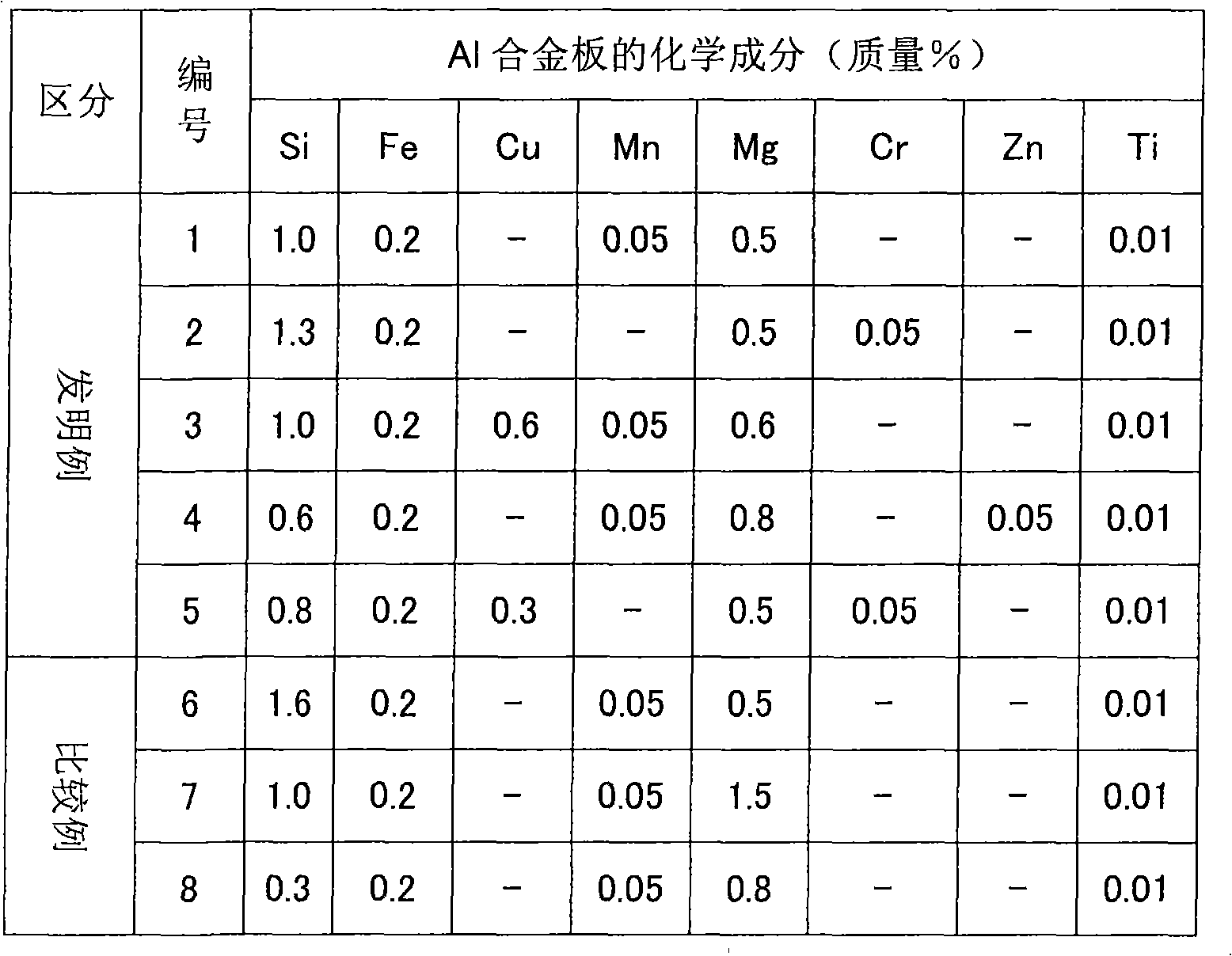

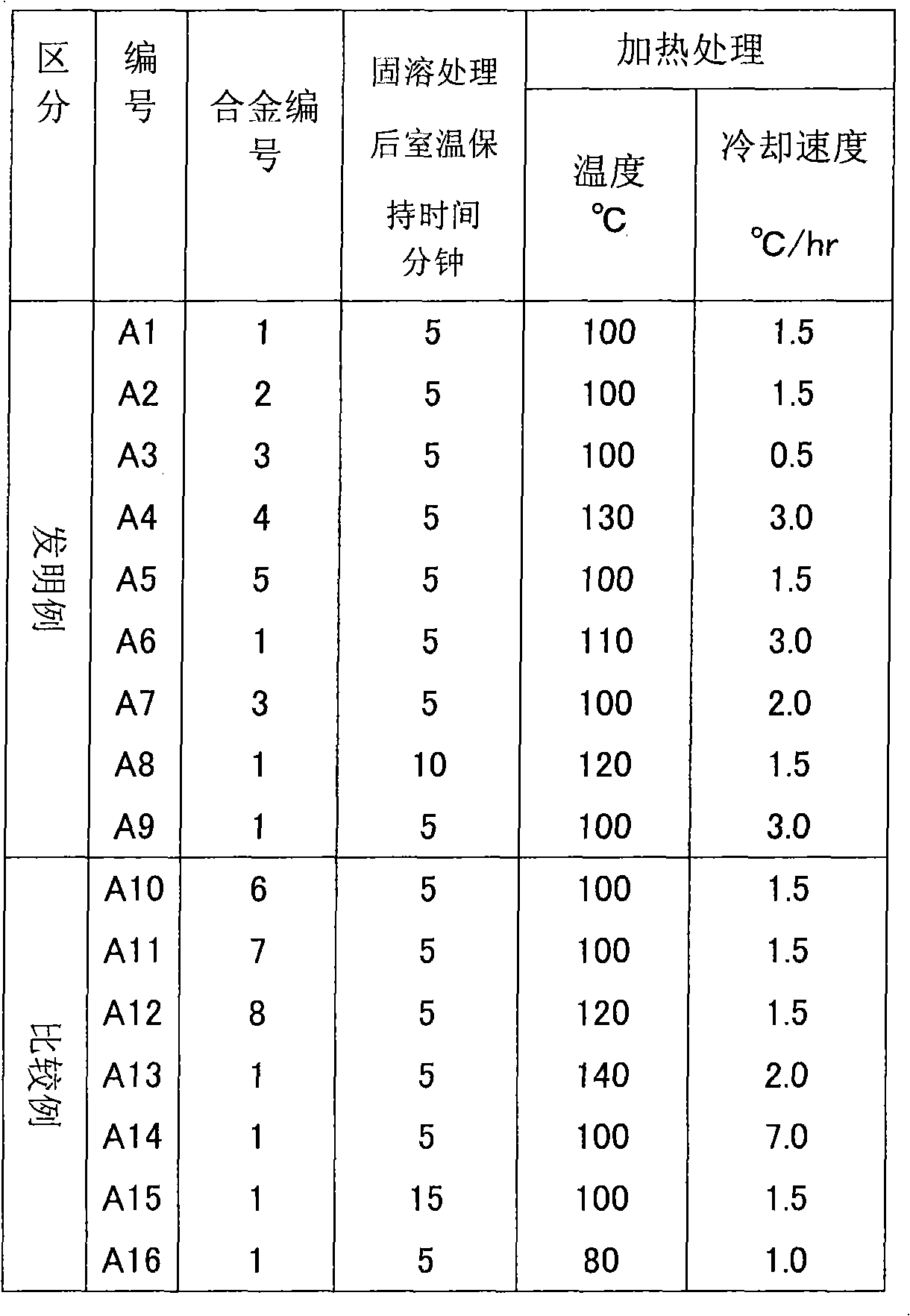

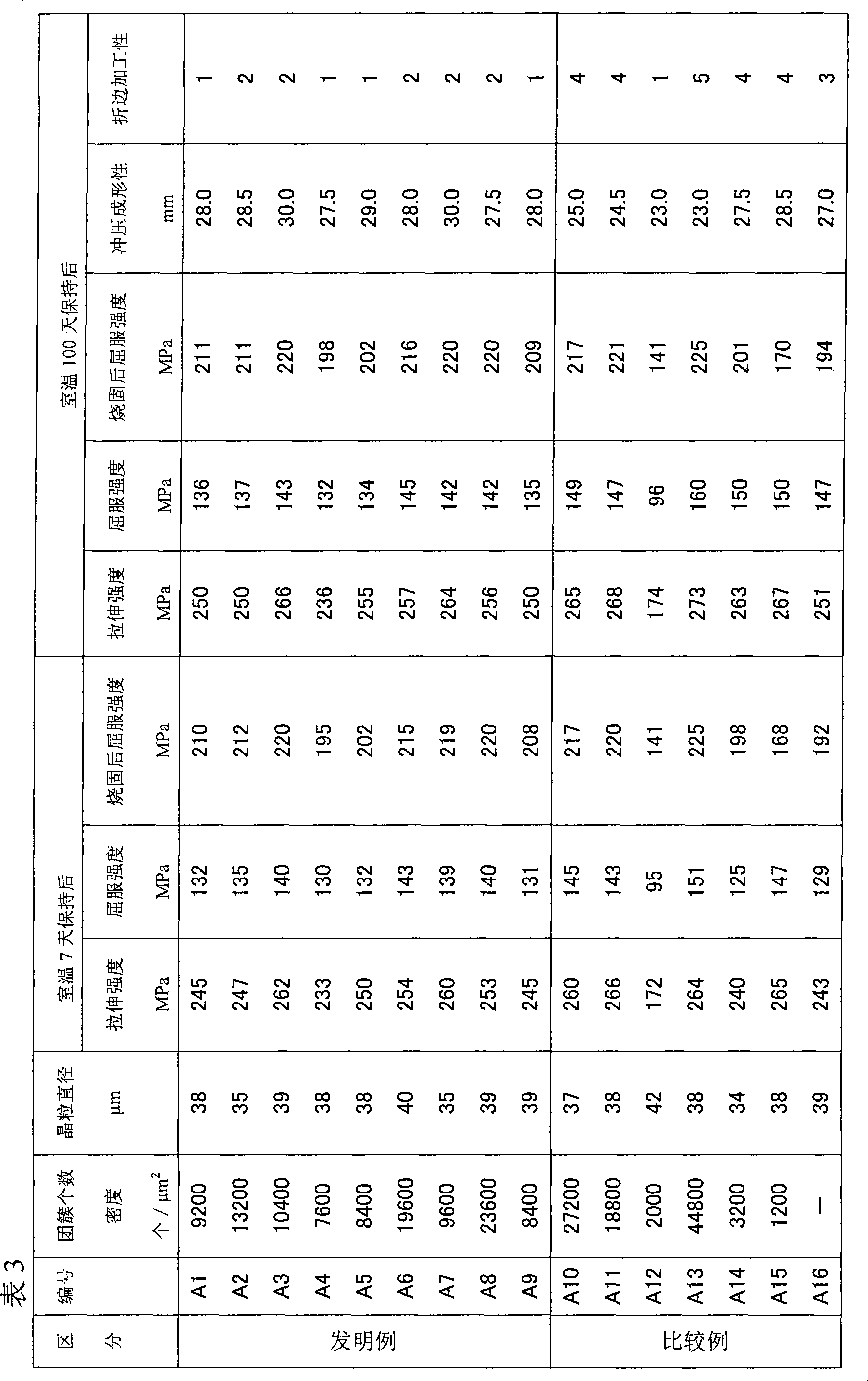

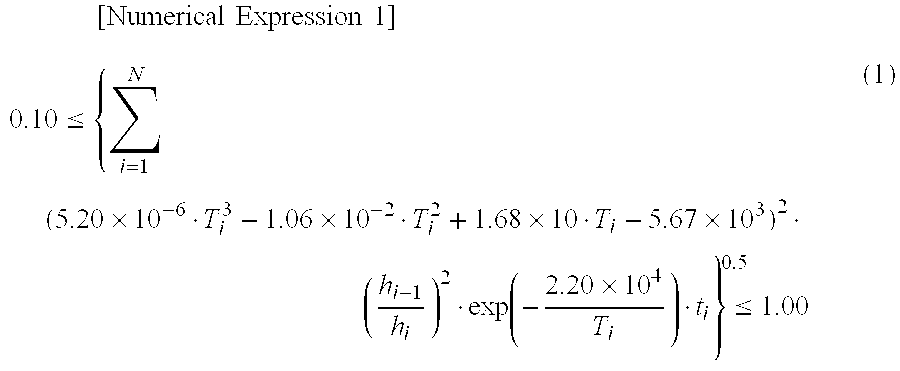

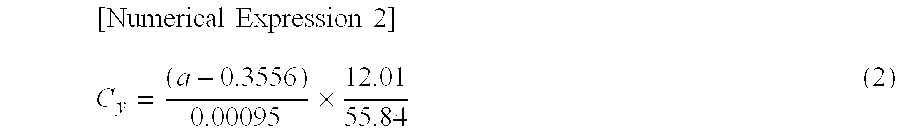

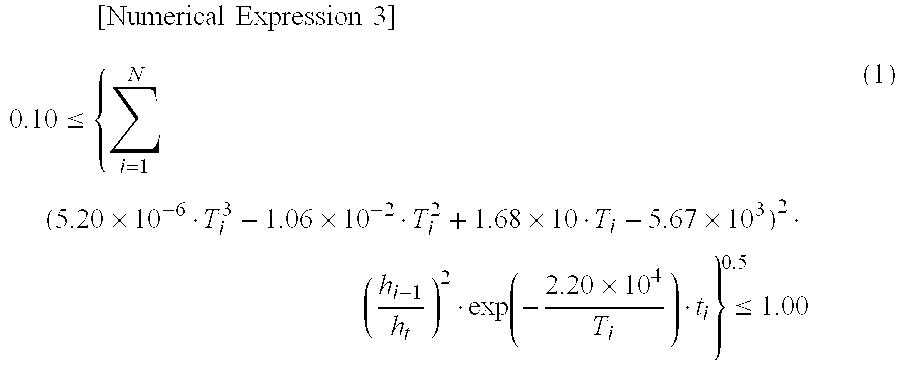

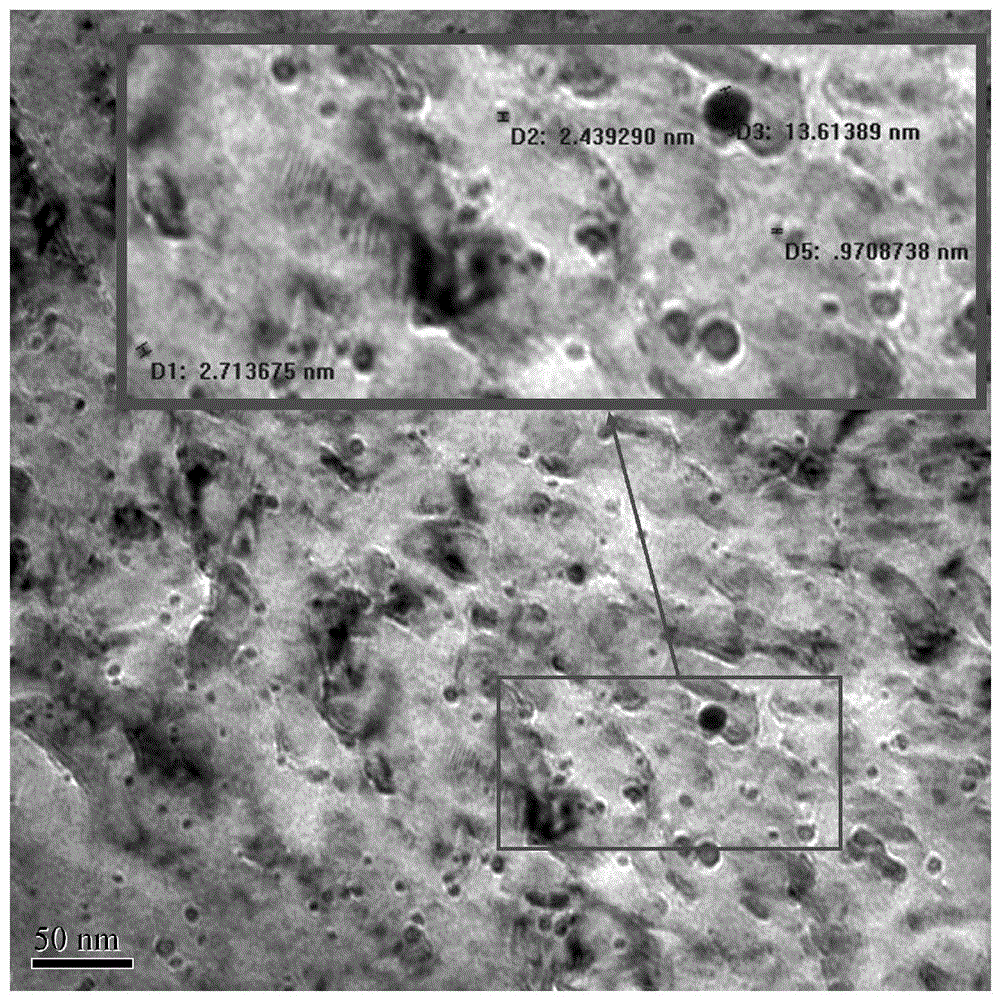

Aluminum alloy sheet superior in paint baking hardenability and invulnerable to room temperature aging, and method for production thereof

An aluminum alloy sheet of specific Al-Mg-Si composition, which, owing to preliminary aging treatment under adequate conditions, has a specific metallographic structure in which there are a large number of clusters of specific size (each being an aggregate of atoms) expressed in terms of number density, which, when observed under a transmission electron microscope of 1,000,000 magnifications, appear as dark contrast in the bright field image. It is superior in paint baking hardenability and is invulnerable to room temperature aging during storage for a comparatively long period of 1 to 4 months.

Owner:KOBE STEEL LTD

High-strength hot-dip galvanized steel sheet, high-strength alloyed hot-dip galvanized steel sheet excellent in bake hardenability, and manufacturing method thereof

ActiveUS20140234660A1UnstableEnlarge bake hardening amountHot-dipping/immersion processesFurnace typesUltimate tensile strengthAustenite

Steel contains each of C, Si, Mn, P, S, Al, N, O, at a range from ⅛ thickness centered around a ¼ sheet thickness from a surface to ⅜ thickness centered around the ¼ sheet thickness from the surface at a base steel sheet, a structure of the base steel sheet contains, in volume fraction, 3% or more of a retained austenite phase, 50% or less of a ferrite phase, and 40% or more of a hard phase, average dislocation density is 5×1013 / m2 or more, solid-solution C amount contained in the retained austenite phase is in mass % 0.70 to 1.00%, X-ray random intensity ratio of FCC iron in an texture of the retained austenite phase is 3.0 or less, ratio between a grain diameter relative to a rolling direction and a grain diameter relative to a sheet width direction of the retained austenite phase is 0.75 to 1.33.

Owner:NIPPON STEEL CORP

Steel for hot stamping forming, hot stamping forming process and hot stamping forming component

ActiveCN106399837AReach yield strengthReach tensile strengthHot-dipping/immersion processesUnderstructuresHot stampingUltra fine

The invention relates to steel which is provided with ultra-fine grains and used for hot stamping forming, a manufacturing process of the steel, a hot stamping forming process and a hot stamping forming component. The steel comprises, by weight, 0.27%-0.40% of C, 0.2%-3.0% of Mn, 0.11%-0.4% of V, 0-0.8% of Si, 0-0.5% of Al, 0-2% of Cr, 0-0.15% of Ti, 0-0.15% of Nb, 0-0.004% of B, less than 2% of the total content of Mo, Ni, Cu and other alloy elements beneficial to improve the hardenability of the steel and other impurity elements.

Owner:NORTHEASTERN UNIV +1

Carbon-manganese composite microalloyed steel for engineering machinery and preparation method thereof

InactiveCN101654761AHigh hardenability and stabilityEasy to controlTemperature control deviceElectric furnaceMechanical componentsChemical composition

The invention relates to a carbon-manganese composite microalloyed steel for engineering machinery and a preparation method thereof. The steel comprises the following chemical compositions by weight percent: 0.32-0.37% of C, 0.15-0.30% of Si, 1.20-1.40% of Mn, 0.030% or less of P, 0.030% or less of S, 0.0005-0.0030% of B, 0.10-0.60% of Cr, 0.01-0.07% of Al and the balance Fe and trace impurities,wherein the content of available boron in the steel is not less than 95%. The invention also provides a preparation method of the composite microalloyed steel and the method controls the ratio of Ti to N to be 3-6 and the acid soluble aluminium content to be 0.030-0.050% so as to ensure that boron in the steel is almost available boron. The preparation method of the invention controls the contentof trace element boron and ensures the hardenability of steel so that the steel is suitable to be used for the preparation of important mechanical parts.

Owner:SHANDONG IRON & STEEL CO LTD

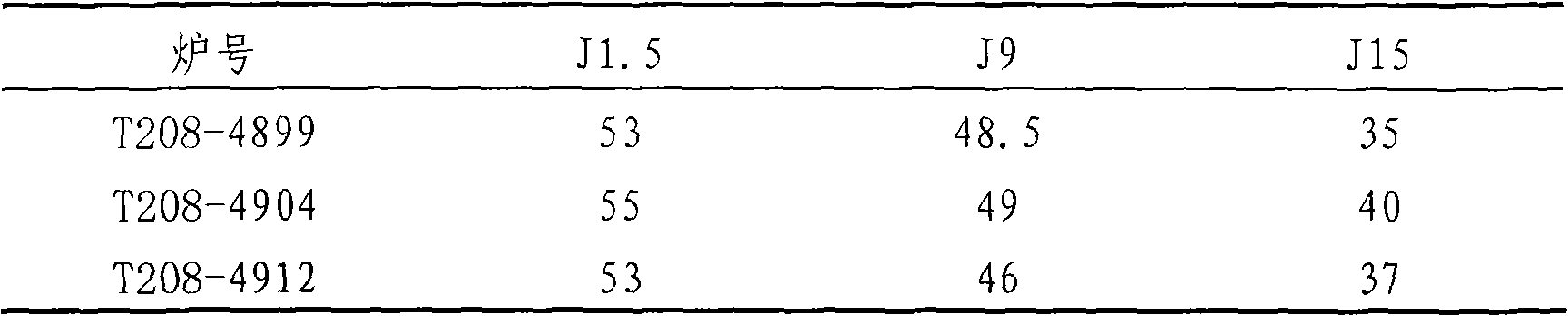

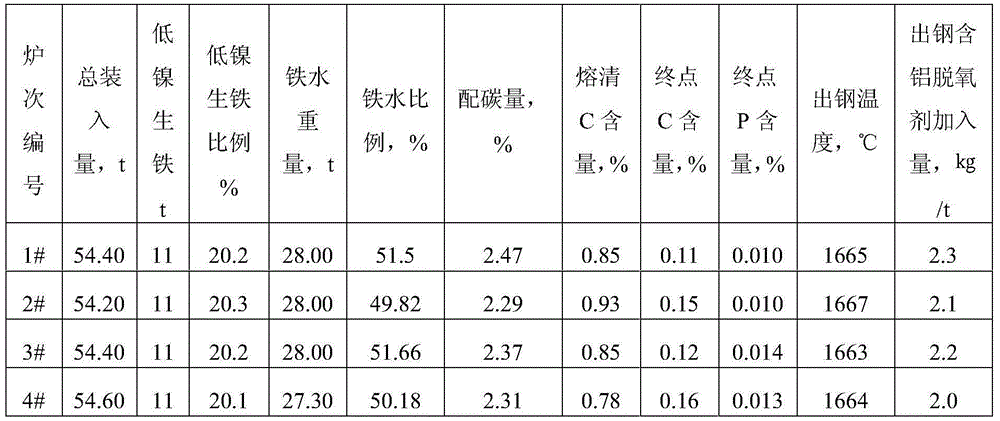

Production method of Mn-Cr high-performance gear steel

The invention belongs to the technical field of alloy steel, and in particular, relates to a manufacturing method of Mn-Cr gear steel. The gear steel comprises the following components: 0.17-0.22% of C, 0.15-0.25% of Si, 1.10-1.40% of Mn, 1.00-1.30% of Cr, Mo not more than 0.08%, B not more than 0.0005%, Cu not more than 0.02%, Ni not more than 0.02%, 0.025-0.055% of Al, P not more than 0.015%, 0.020-0.035% of S, N not more than 130 ppm, and the balance of iron. The method improves the cleanness of molten steel through optimizing the refining process and the slag system control, performs the nitrogen adding treatment through a wire feeding procedure to effectively refine grains of the aluminum deoxidation gear steel, realizes precise control of hardenability alloy elements, solves the deoxidation and sulfur maintaining contradiction, and guarantees excellent pouring performance of the molten steel and excellent cutting performance of the gear steel.

Owner:ZENITH STEEL GROUP CORP +1

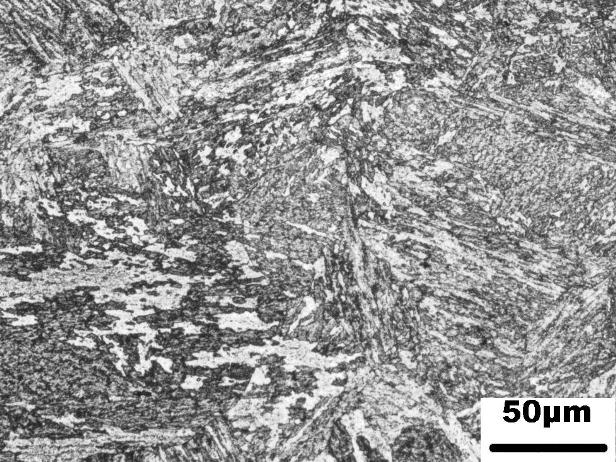

Rolling method of low-banded structure gear steel

ActiveCN103194580AImprove fatigue lifeReduce manufacturing costRoll mill control devicesMetal rolling arrangementsOperabilityHigh pressure water

The invention discloses a rolling method of low-banded structure gear steel. The method comprises the following steps of: (1) heating a steel blank within a three-section type heating furnace; (2) carrying out dephosphorization on the heated steel blank by high-pressure water, and sequentially carrying out rough rolling, intermediate rolling, water cooling, and finish rolling; (3) water-cooling and air-cooling the finish-rolled steel blank sequentially; and (4) slowly cooling the cooled round bar steel to be lower than 200DEG C after shearing. Due to the use of the rolling method, the production technology difficulty that the level of the high-end hardenability carburized gear steel banded structure is hard to lower due to the conventional rolling technology can be overcome, so that that the level of the banded structure of the gear steel is lowered to be lower than 1.0 grade from 3.0 grade of the conventional rolling technology, and therefore, the aim of prolonging the fatigue life of the gear can be achieved. The rolling method further has the characteristics of being simple in technical route, low in production cost, high in operability and the like.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

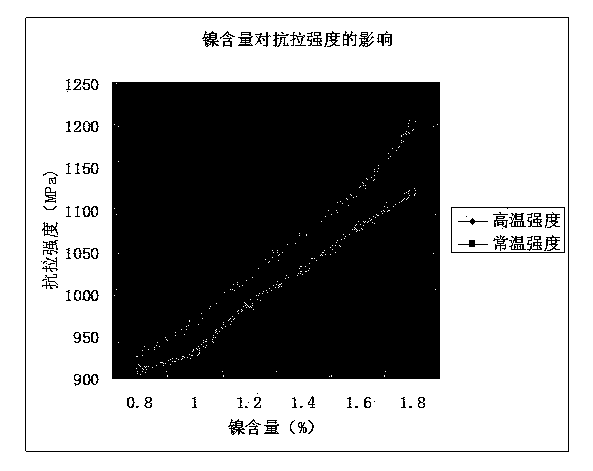

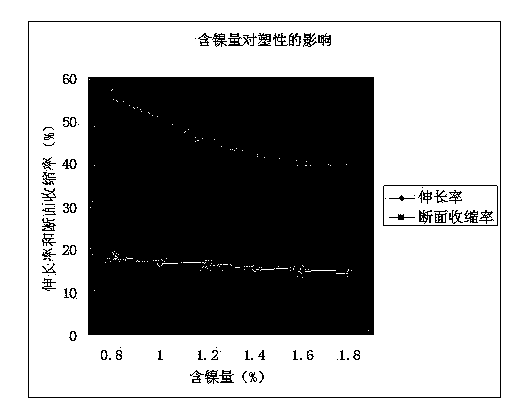

CrNiMo high-strength pinion steel and preparation method thereof

ActiveCN104372258AImprove heat treatment effectGuaranteed mechanical propertiesProcess efficiency improvementPinionUltimate tensile strength

The invention relates to a CrNiMo high-strength pinion steel and a preparation method thereof. The pinion steel comprises the following chemical components in percentage by mass: 0.19%-0.25% of C, 0.17%-0.37% of Si, 0.70%-1.00% of Mn, at most 0.030% of P, at most 0.030% of S, 0.85%-1.25% of Cr, 0.40%-0.70% of Ni, 0.30%-0.40% of Mo, 0.015%-0.050% of Al, at most 2.5*10<-4>% of H, 30*10<-4>%-80*10<-4>% of N, at most 15*10<-4>% of T.O, and the balance of Fe and inevitable impurities. The invention also provides a preparation method of the pinion steel. The nickel molybdenum alloy is added to improve the heat treatability of the material, thereby ensuring the mechanical properties of the material. The hardenability of the material is enhanced, and the material satisfies the performance requirements for large module pinions.

Owner:SHANDONG IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com