Aluminum alloy sheet superior in paint baking hardenability and invulnerable to room temperature aging, and method for production thereof

An aluminum alloy plate and plate thickness direction technology, which is applied in the field of aluminum alloy plate and its manufacturing, can solve the problems of reduced panel formability and bending workability, reduced edge folding workability, difficulty in production, etc., and achieves improved baking curability, The effect of improving bending workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

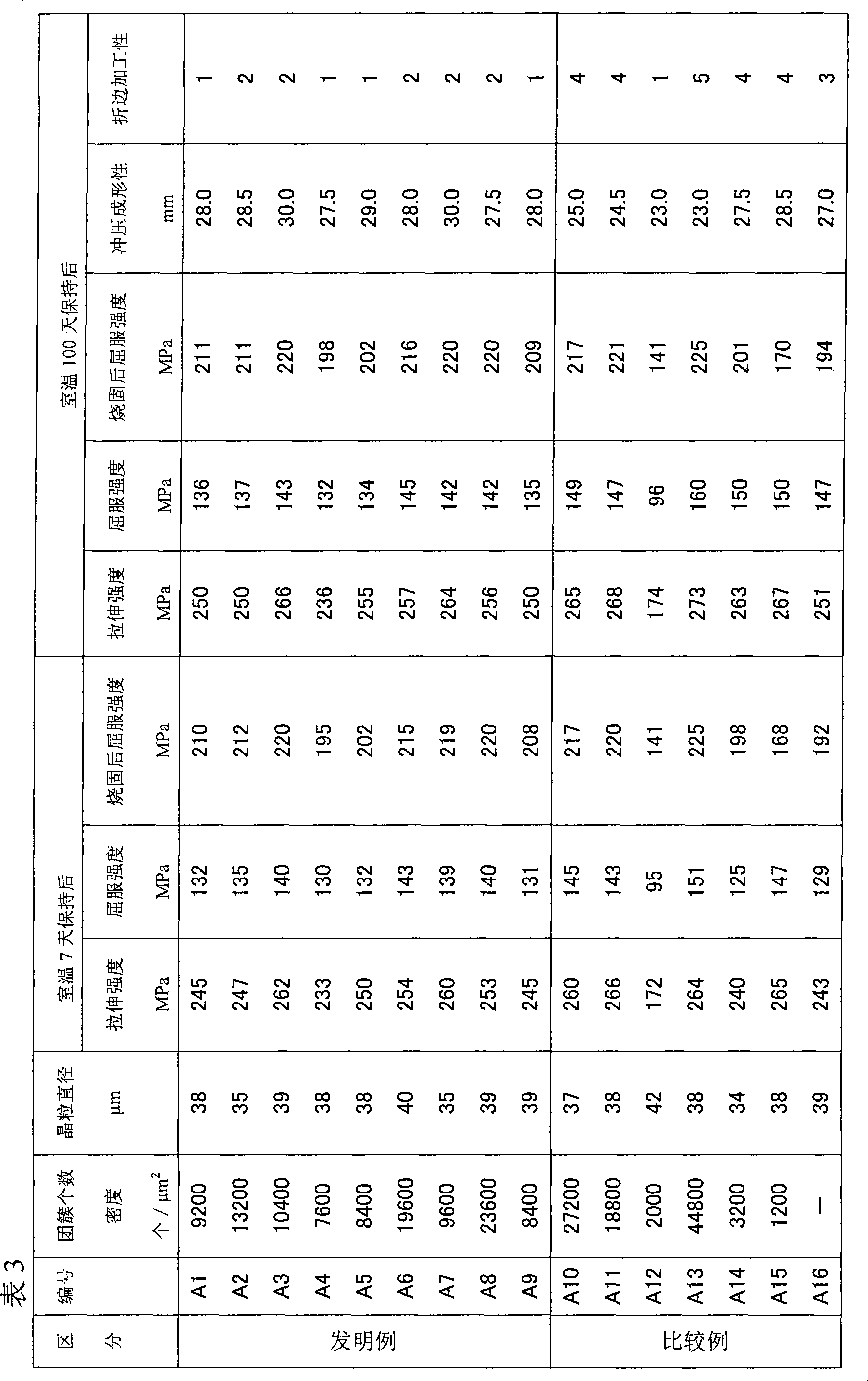

[0097] Embodiments of the present invention are described below. First, as Example 1, 6000-series aluminum alloy plates having different cluster conditions specified in the present invention were produced, and the effects (influence) of the curability of the baking varnish and the aging at room temperature were investigated.

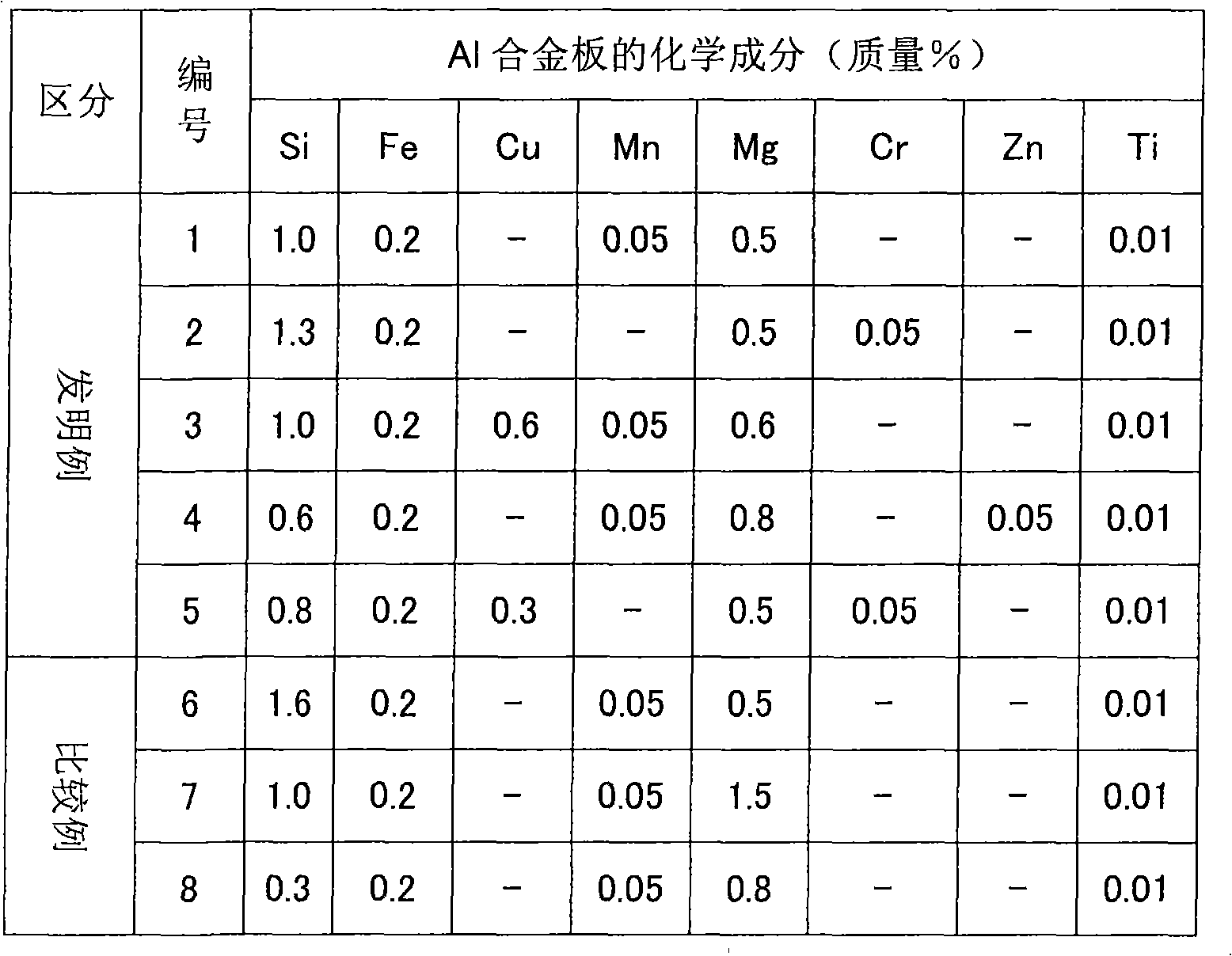

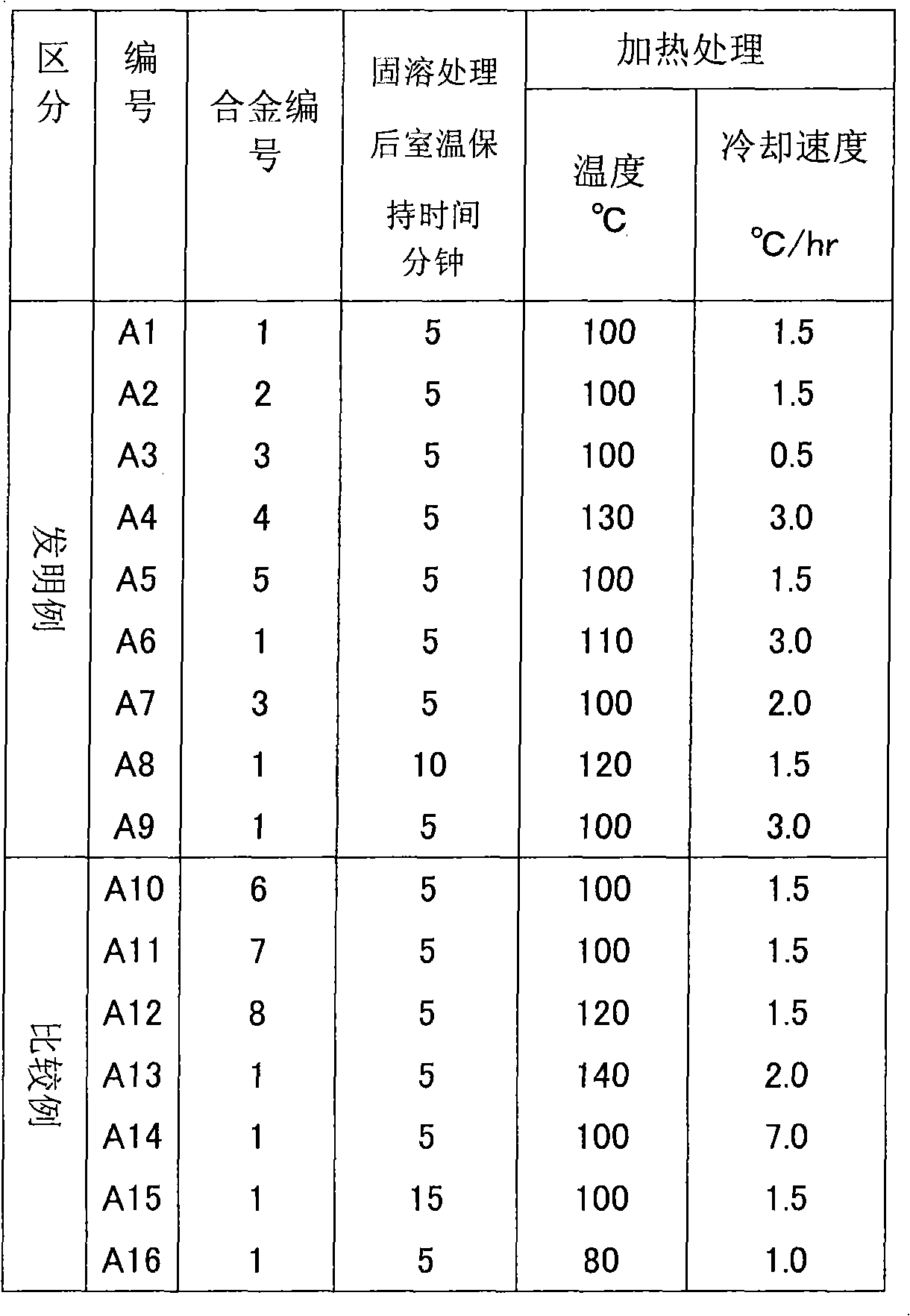

[0098] The 6000 series aluminum alloy plate shown in Table 1 is subjected to homogenization heat treatment (abbreviated as soaking treatment) and hot rolling treatment (abbreviated as hot rolling) according to the conditions shown in Table 2, and then cold rolled to perform solid solution and quenching treatment. In addition, in the expression of the content of each element in Table 1, "-" shows that it is below a detection limit.

[0099] More specific production conditions of the aluminum alloy plate are as follows. Ingots of the respective compositions shown in Table 1 were melted by using the DC casting method. At this time, the average cooling ra...

Embodiment 2

[0125] Then, as Example 2, 6000-series aluminum alloy plates were produced in which the cluster conditions specified in the present invention and the preferred requirements, that is, the average crystal grain diameter and the Mg-Si compound conditions for miniaturization were different, and The effect (influence) of the curability of the baking varnish and the aging at room temperature was investigated. Here, although the press formability and hemming workability tests were performed as in Example 1, the formability test simulated the forming of the outer panel under stricter forming conditions than in Example 1, making these test conditions more severe .

[0126] A 6000-series aluminum alloy ingot with the same composition as shown in Table 1 was melted, homogenized heat treatment and hot rolling were carried out under the conditions shown in Table 4, and cold rolling was also carried out to produce Cold-rolled sheet (coil) with a thickness of 1.0mm. Furthermore, each embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com