Patents

Literature

1181results about "Multiple spring combinations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shock absorbing component and construction method

InactiveUS6029962AImprove the immunityGood flexibilitySolesHollow wall articlesEngineeringMechanical engineering

Owner:SKYDEX TECH +2

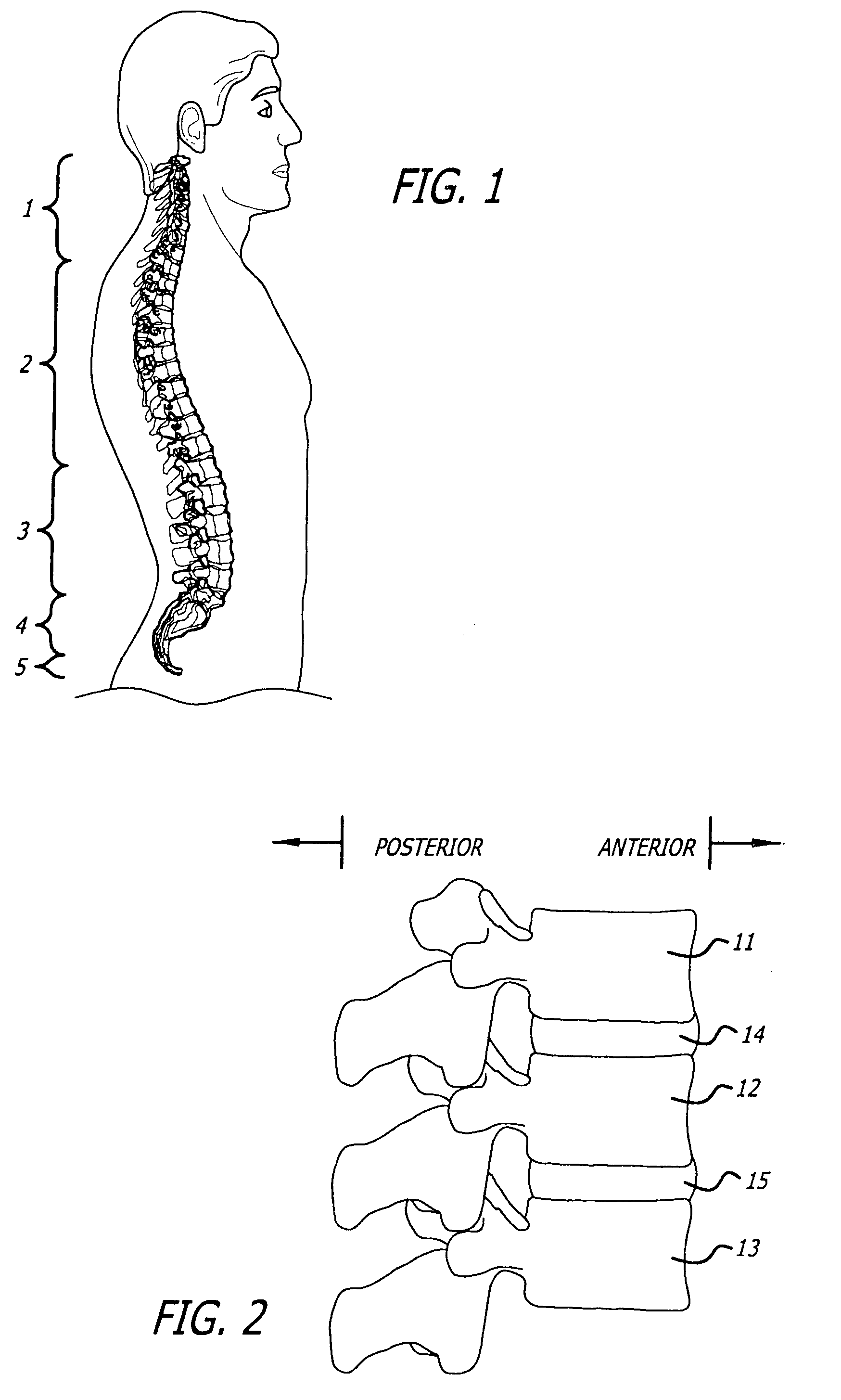

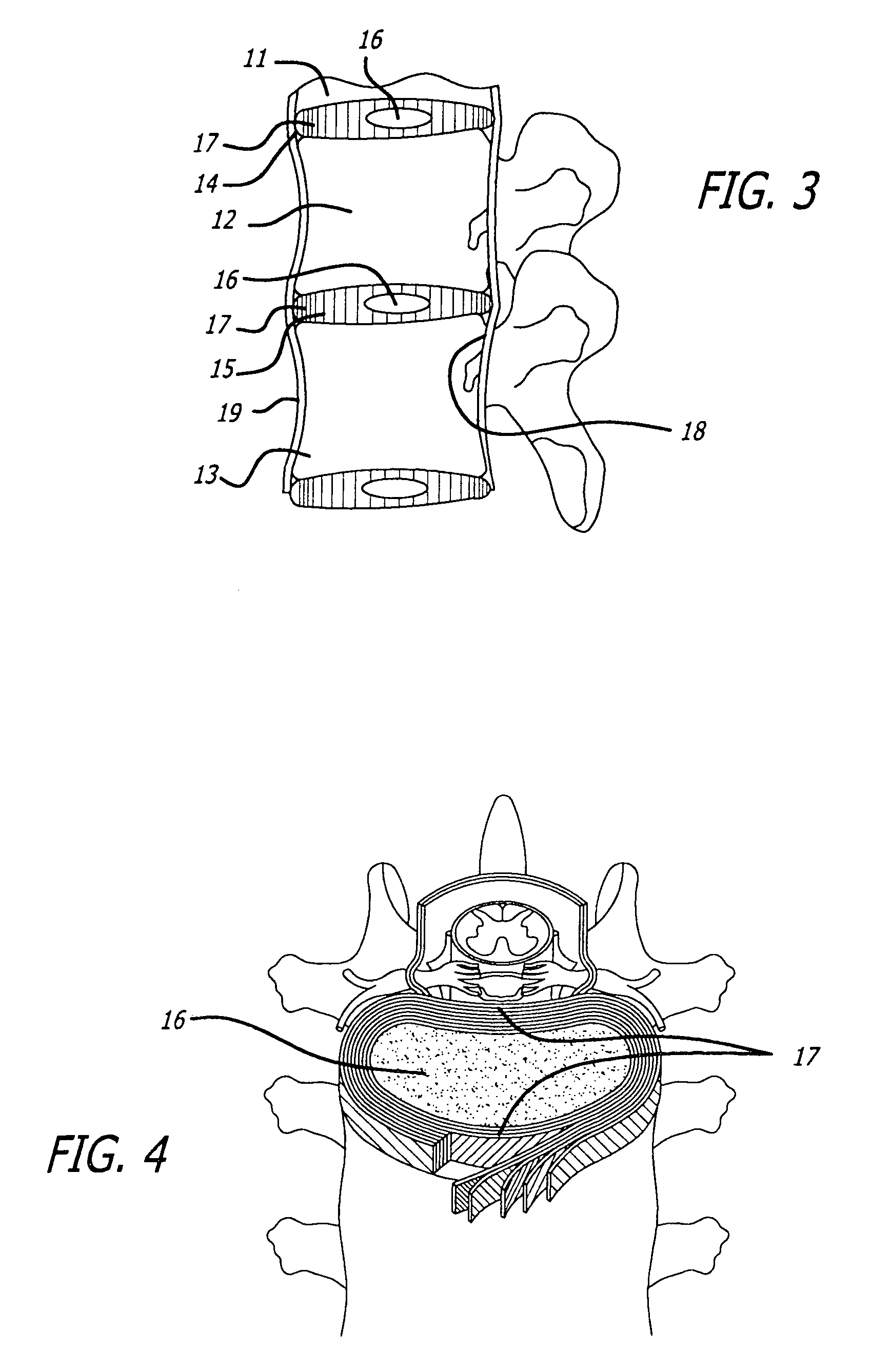

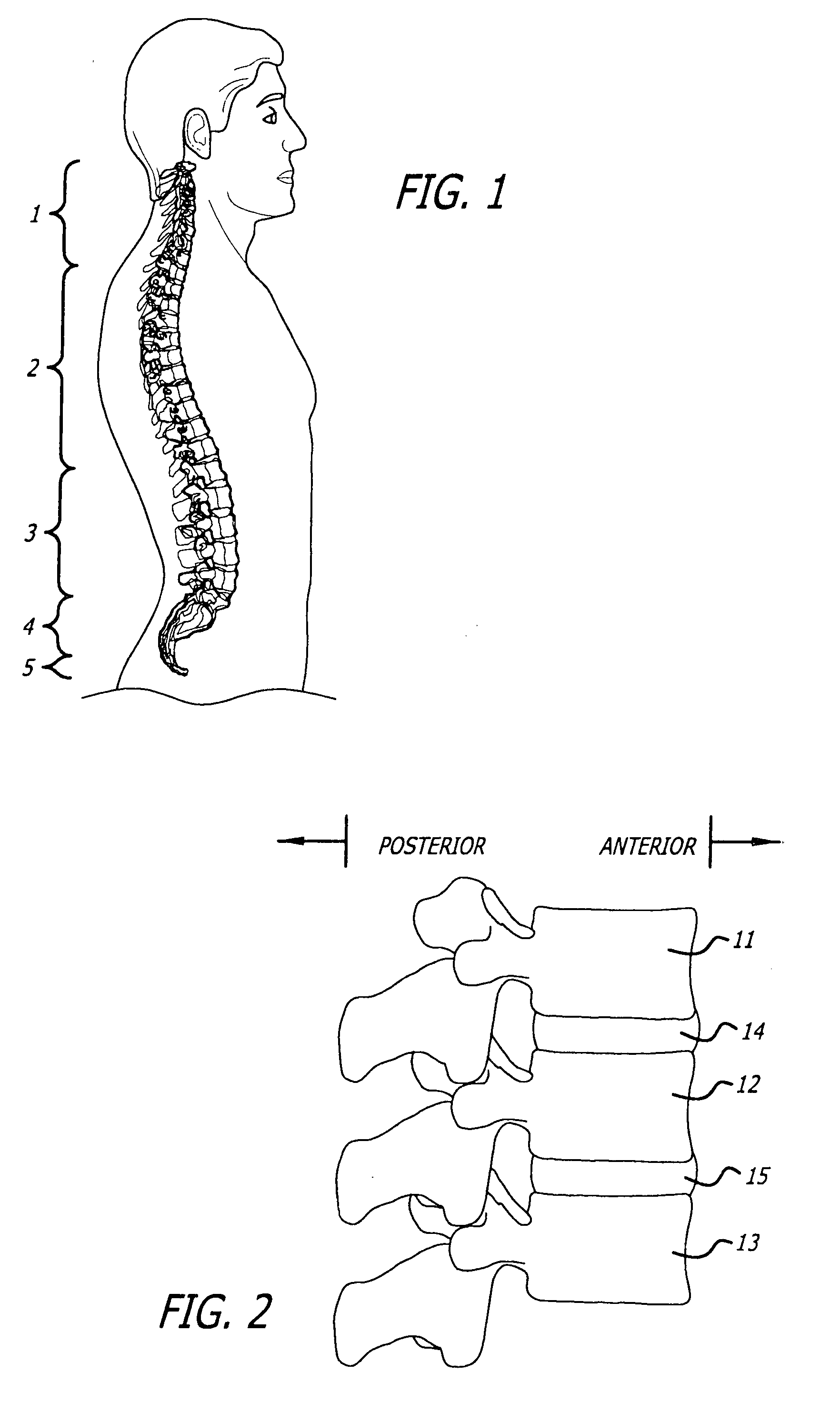

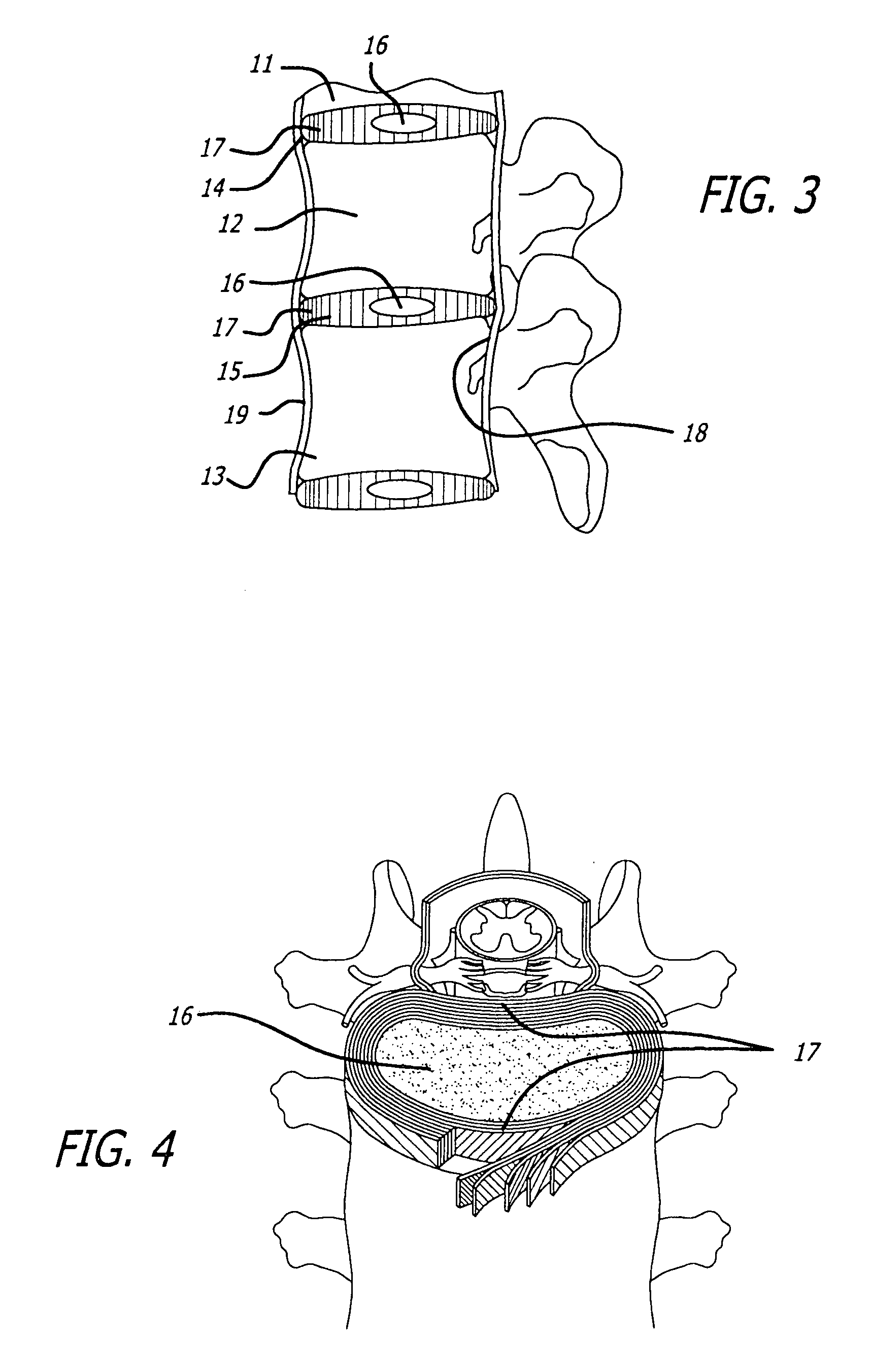

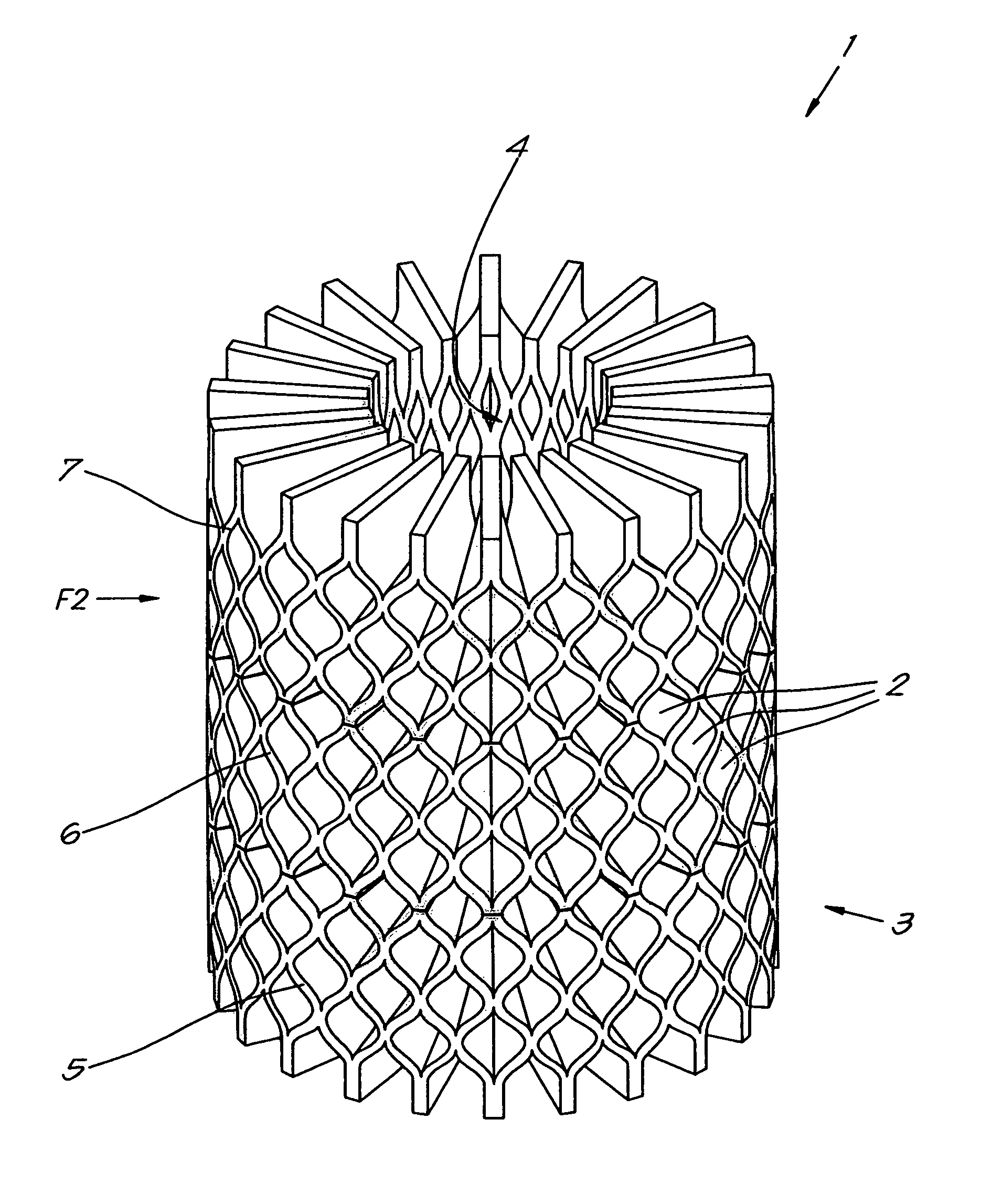

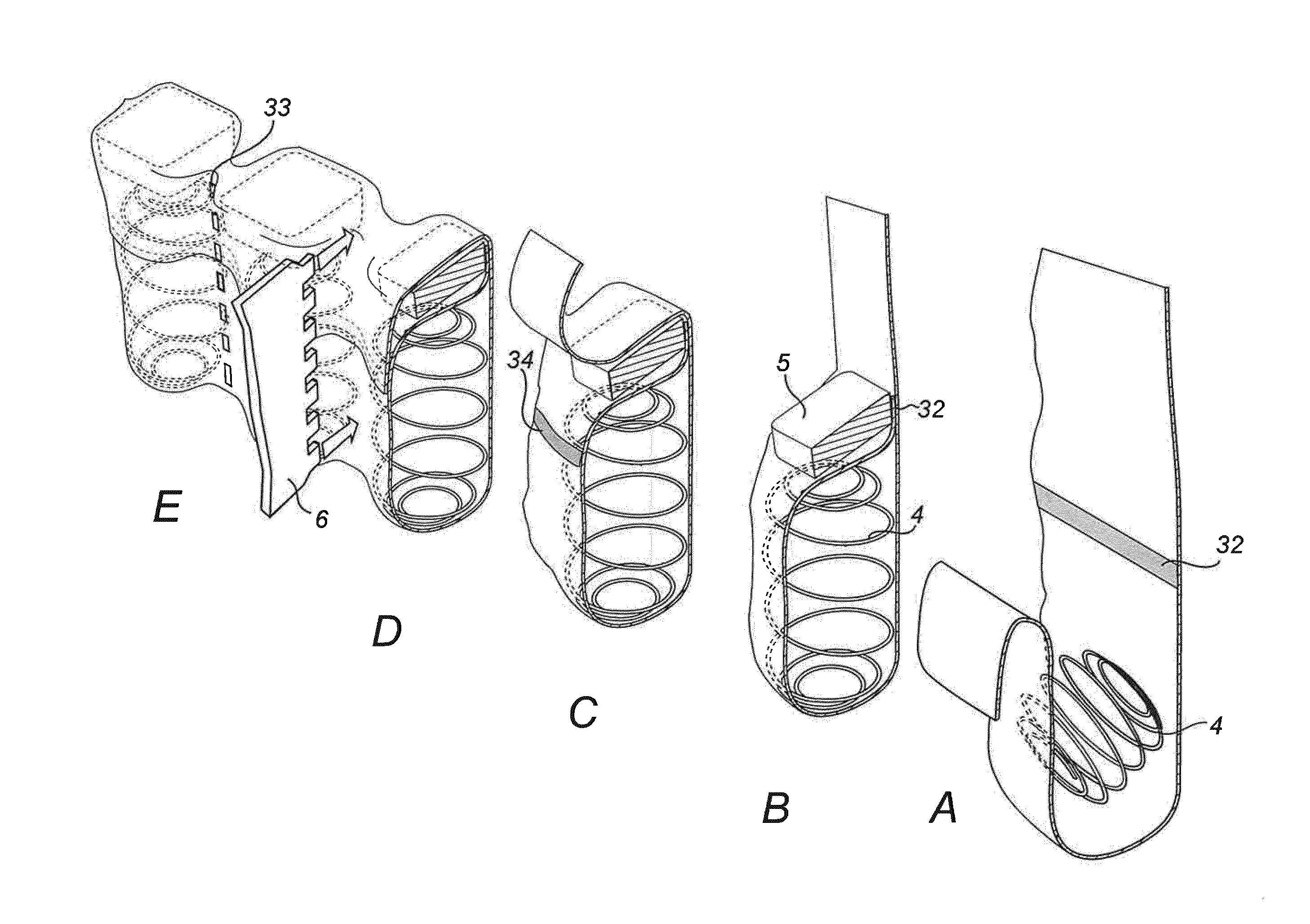

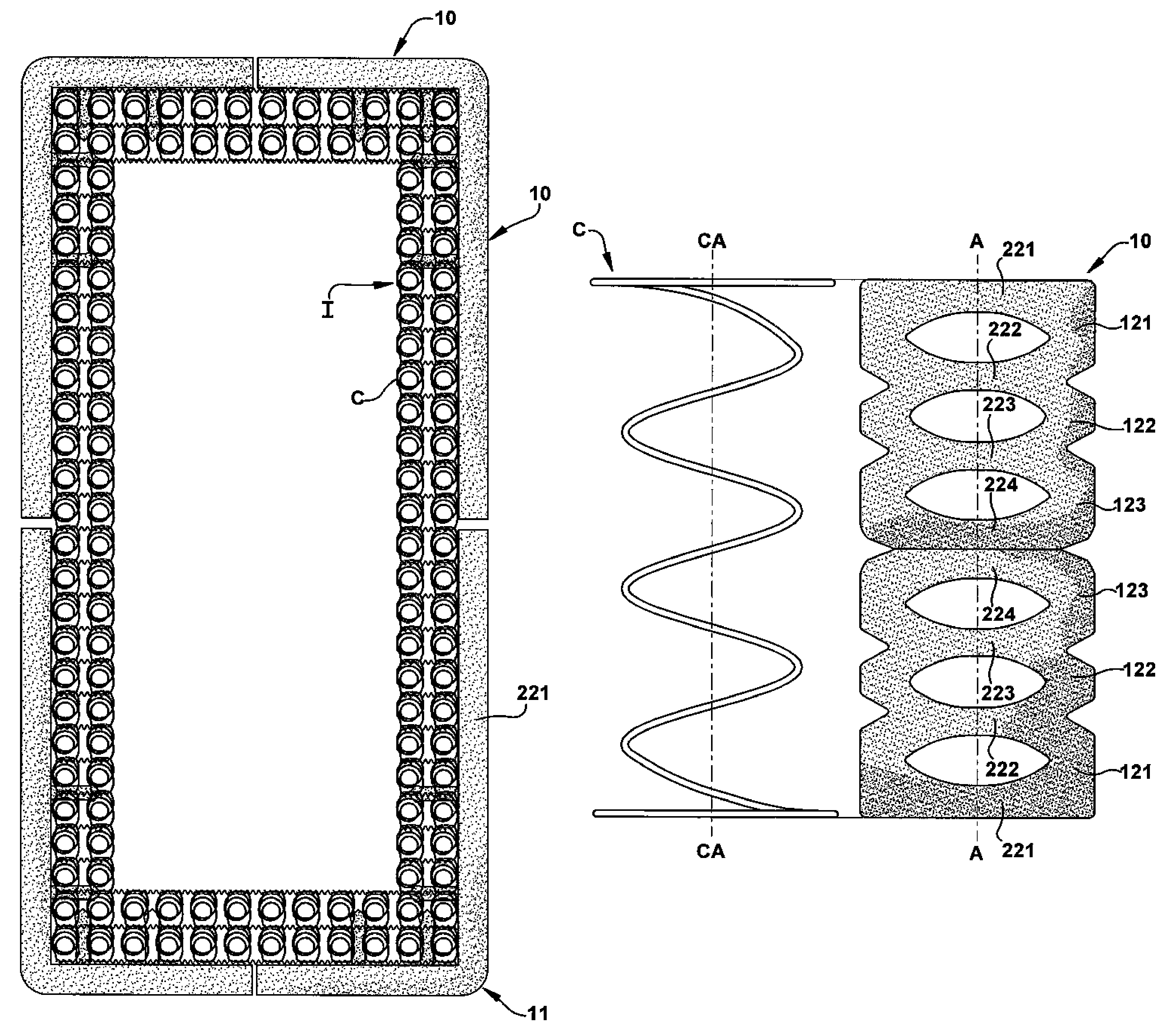

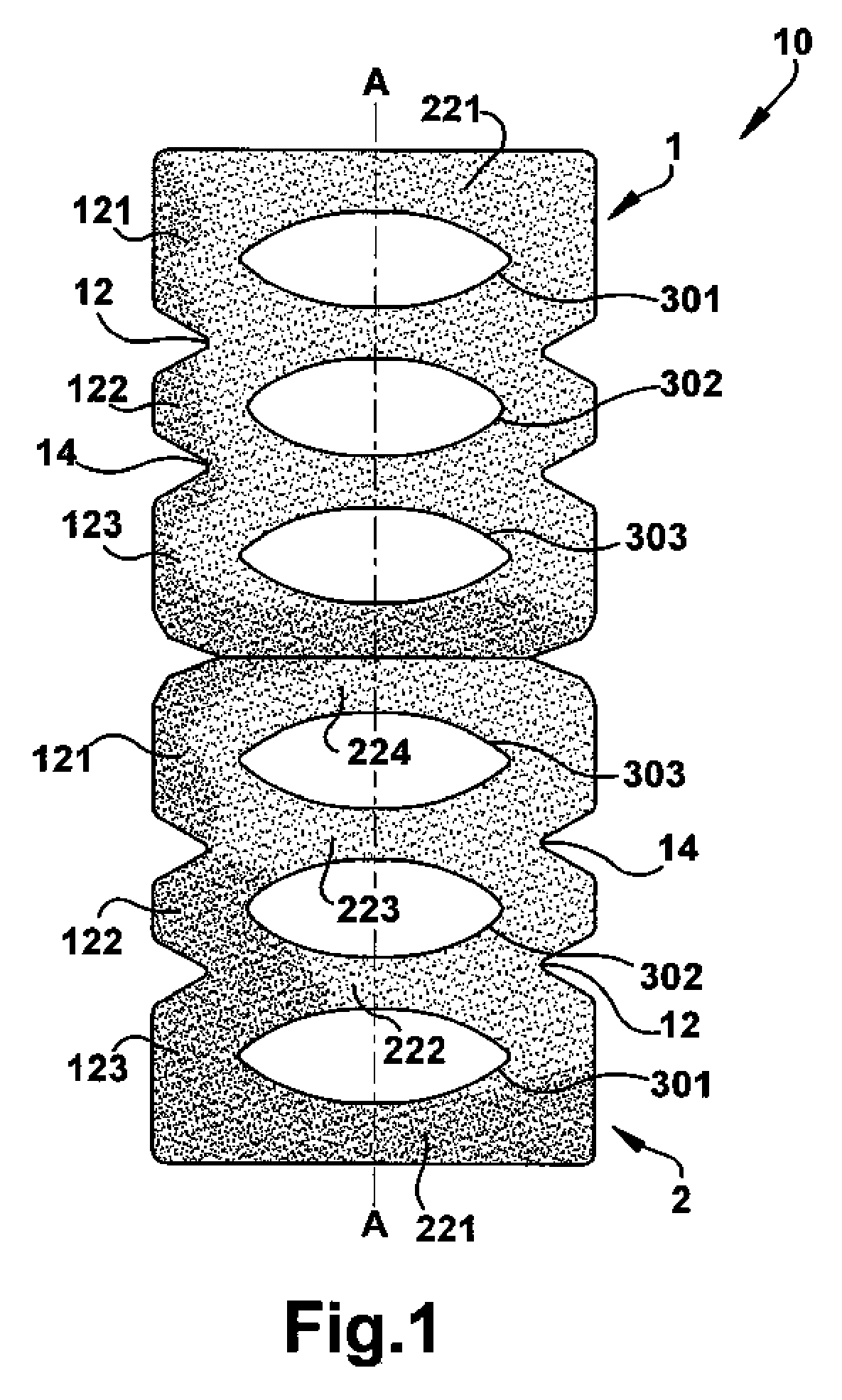

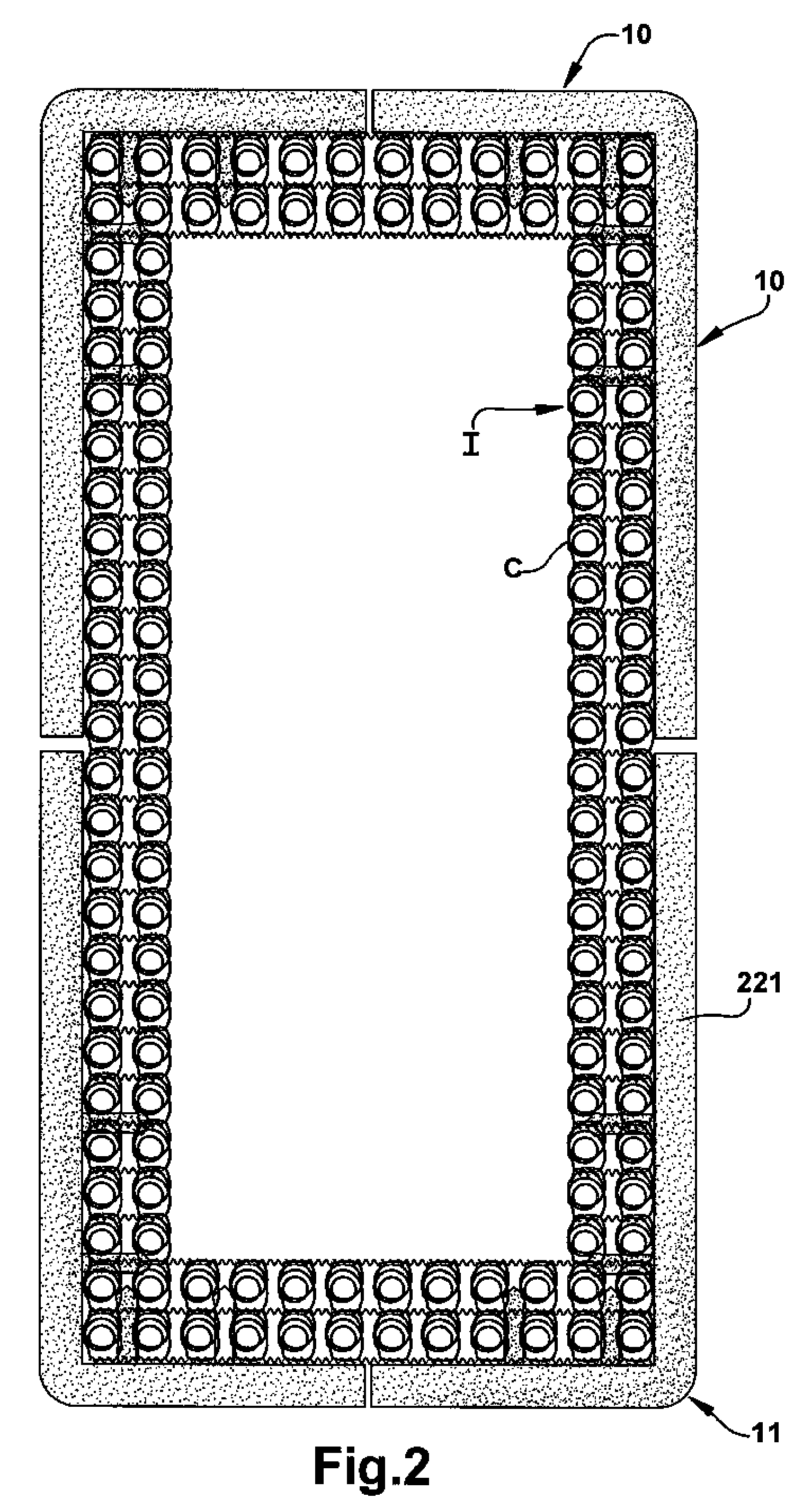

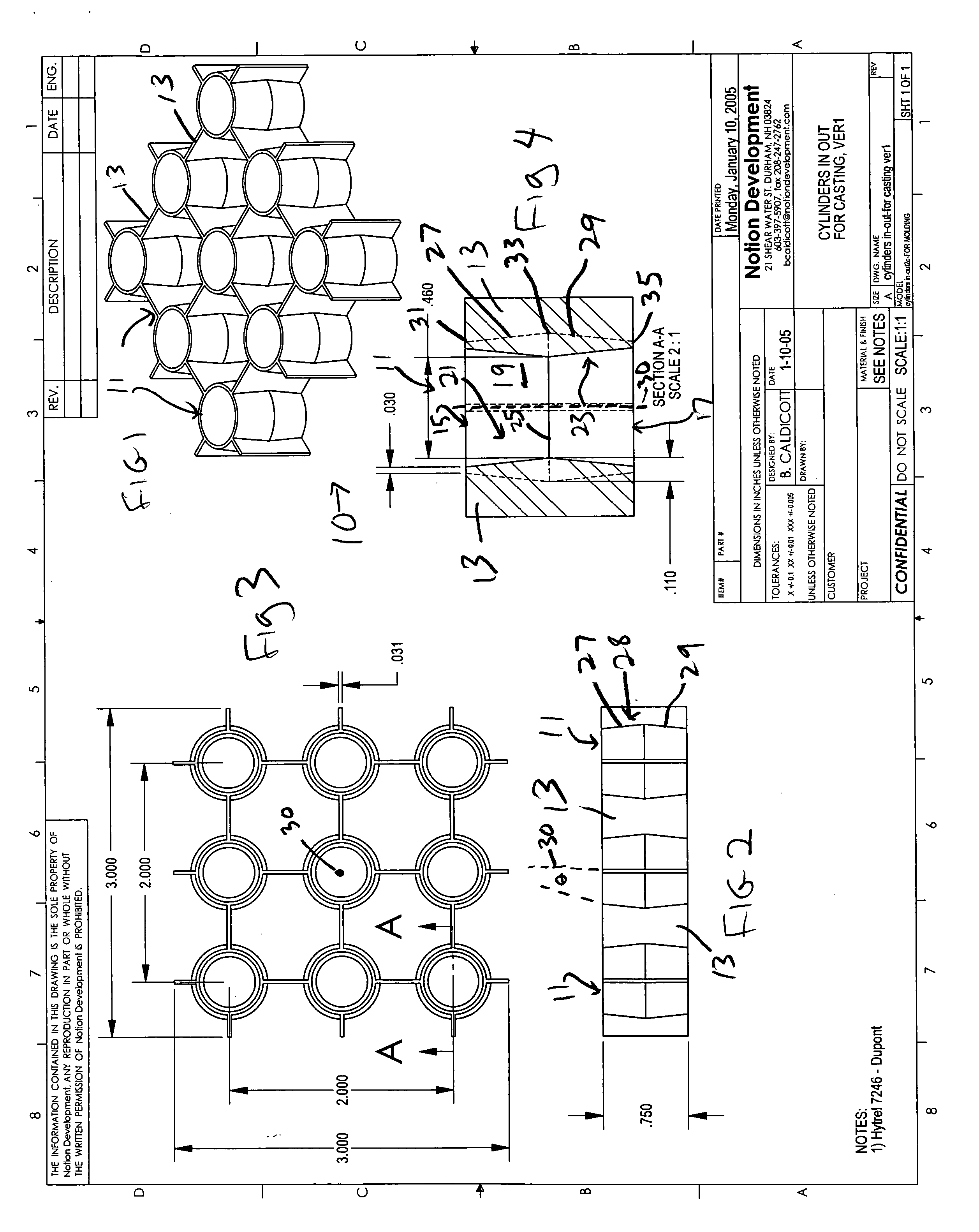

Prosthetic spinal discs

ActiveUS7309357B2Sufficient forceSmooth transitionMultiple spring combinationsSpinal implantsIntervertebral discEngineering

A prosthetic spinal disc uses a stiff spring or springs for resiliency between two plates that attach to adjacent vertebrae. When the disc has multiple springs, they may be adjacent, concentric or nested. Multiple springs may be spaced around the periphery of the plates. A foil metal bellows may surround the plates to prevent material from entering or exiting the space between the plates. Alternatively, the ends of the spring(s) may be machined with spikes to engage the vertebrae directly without plates.

Owner:INFINESSE CORP

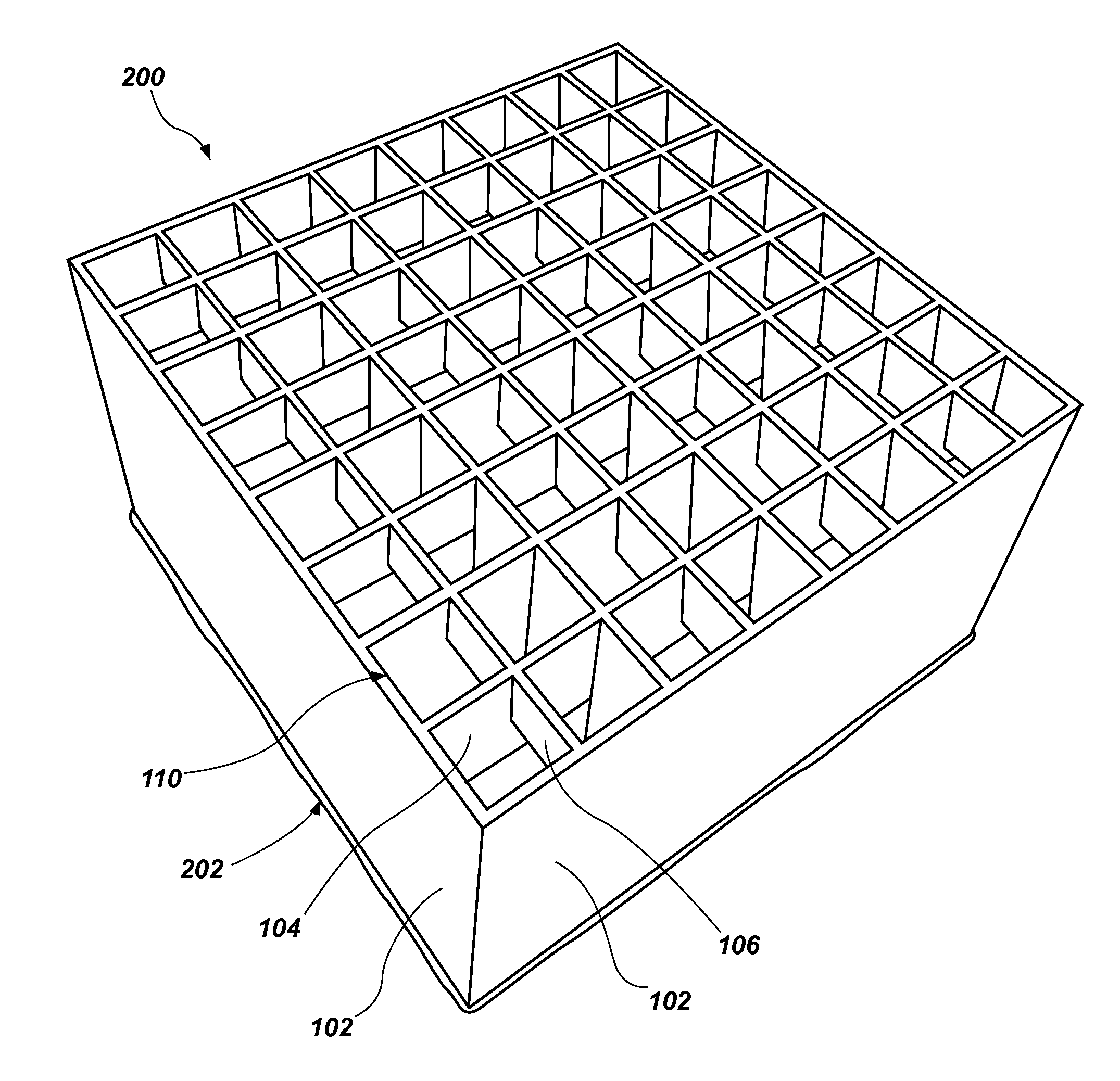

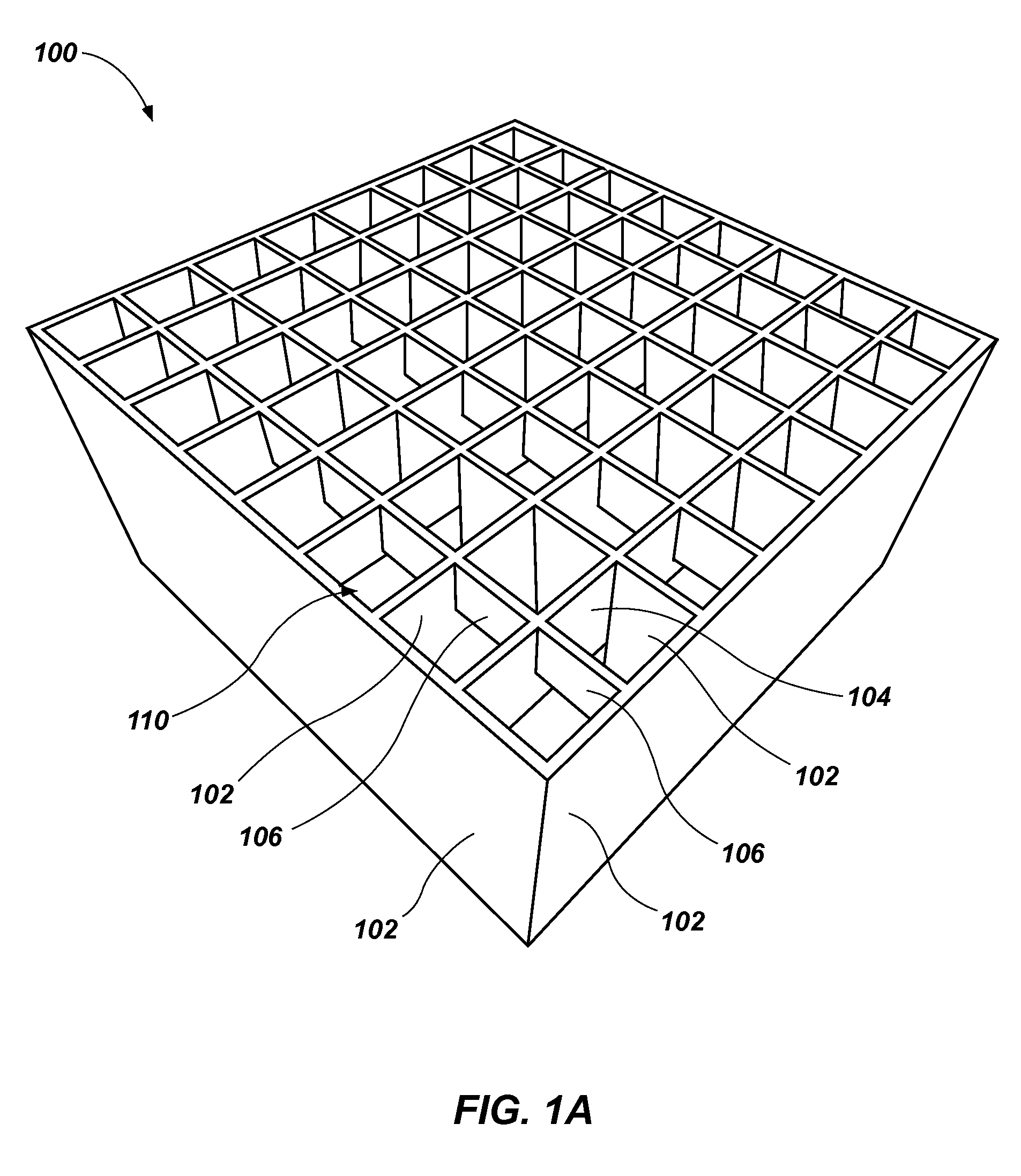

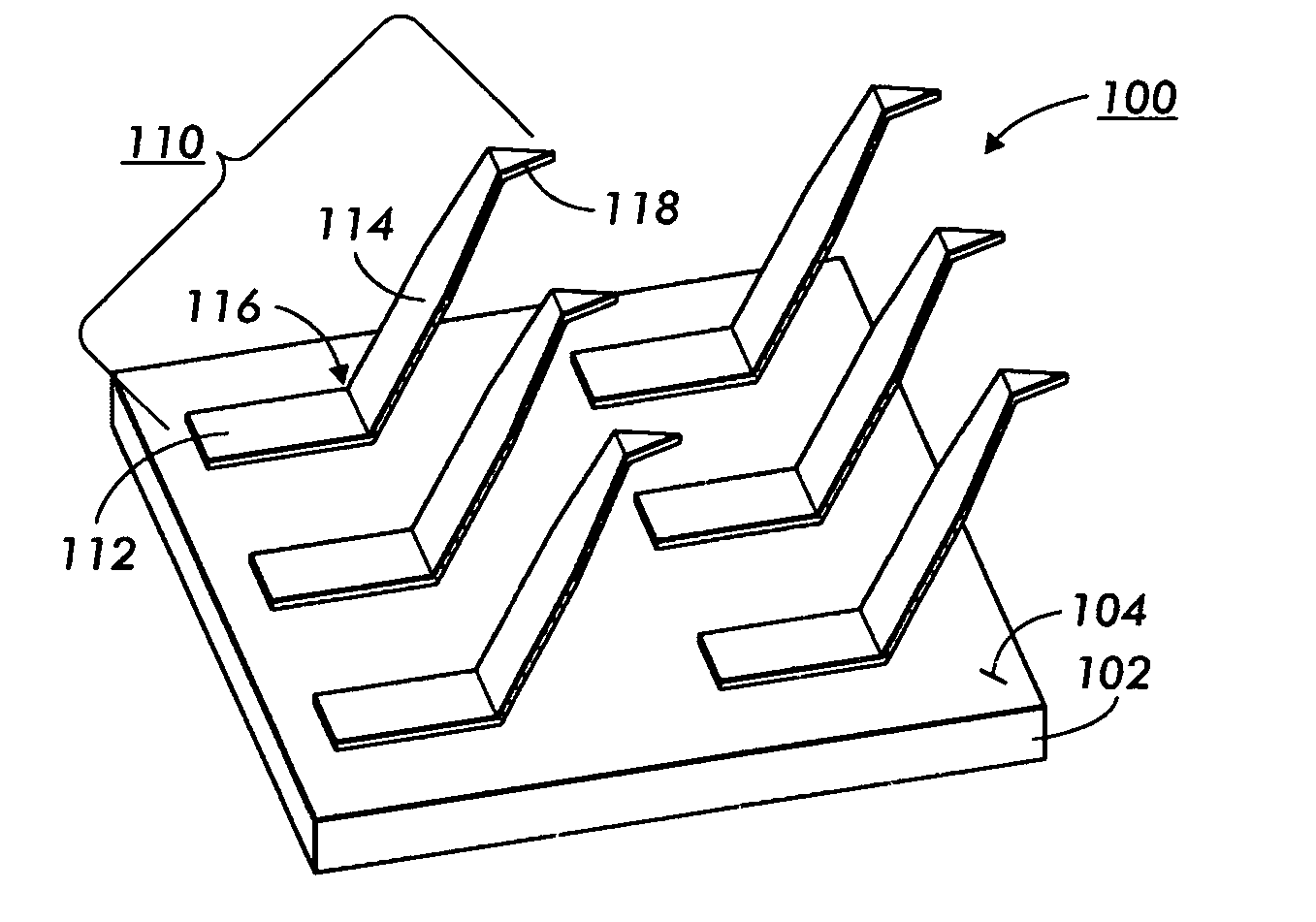

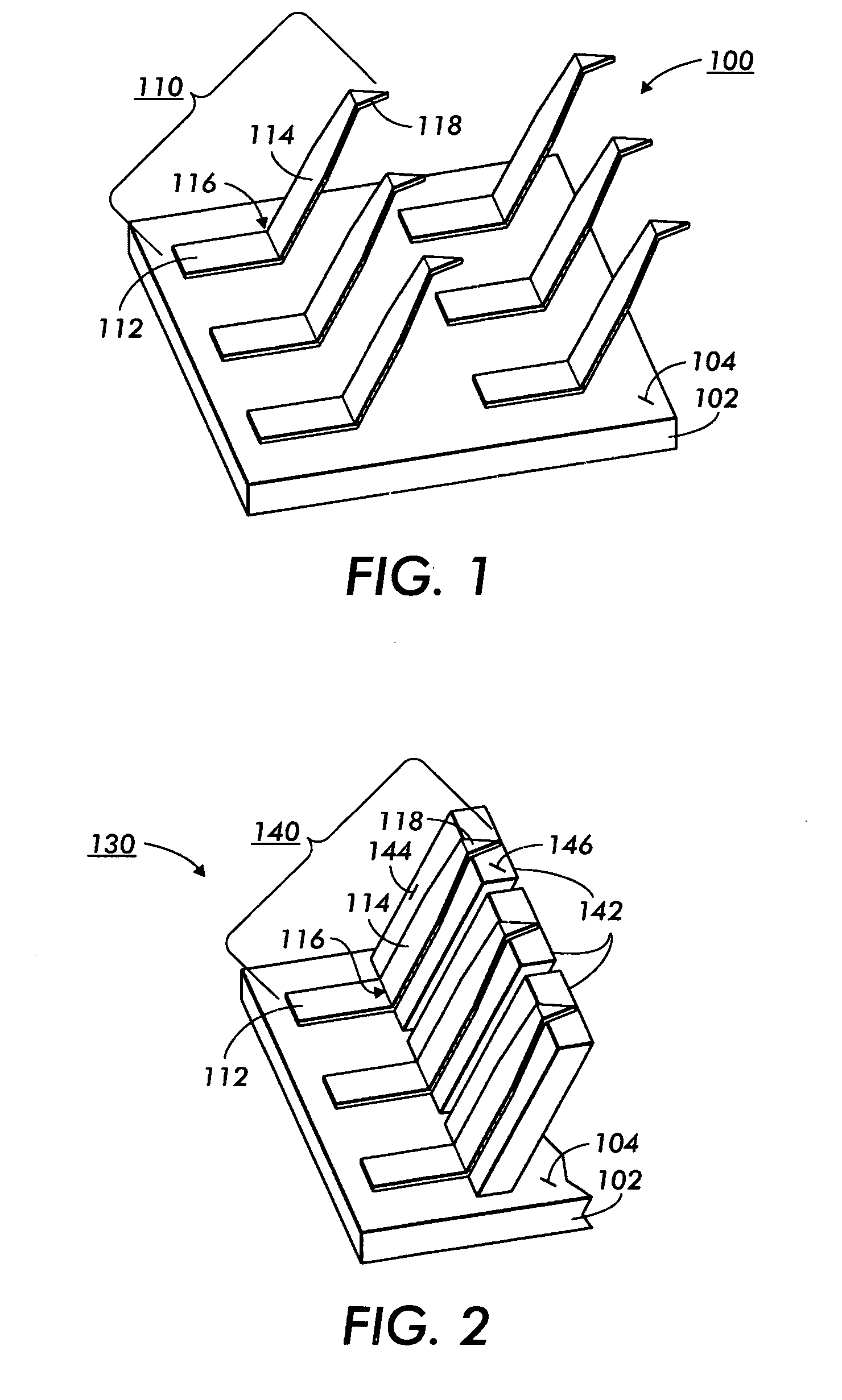

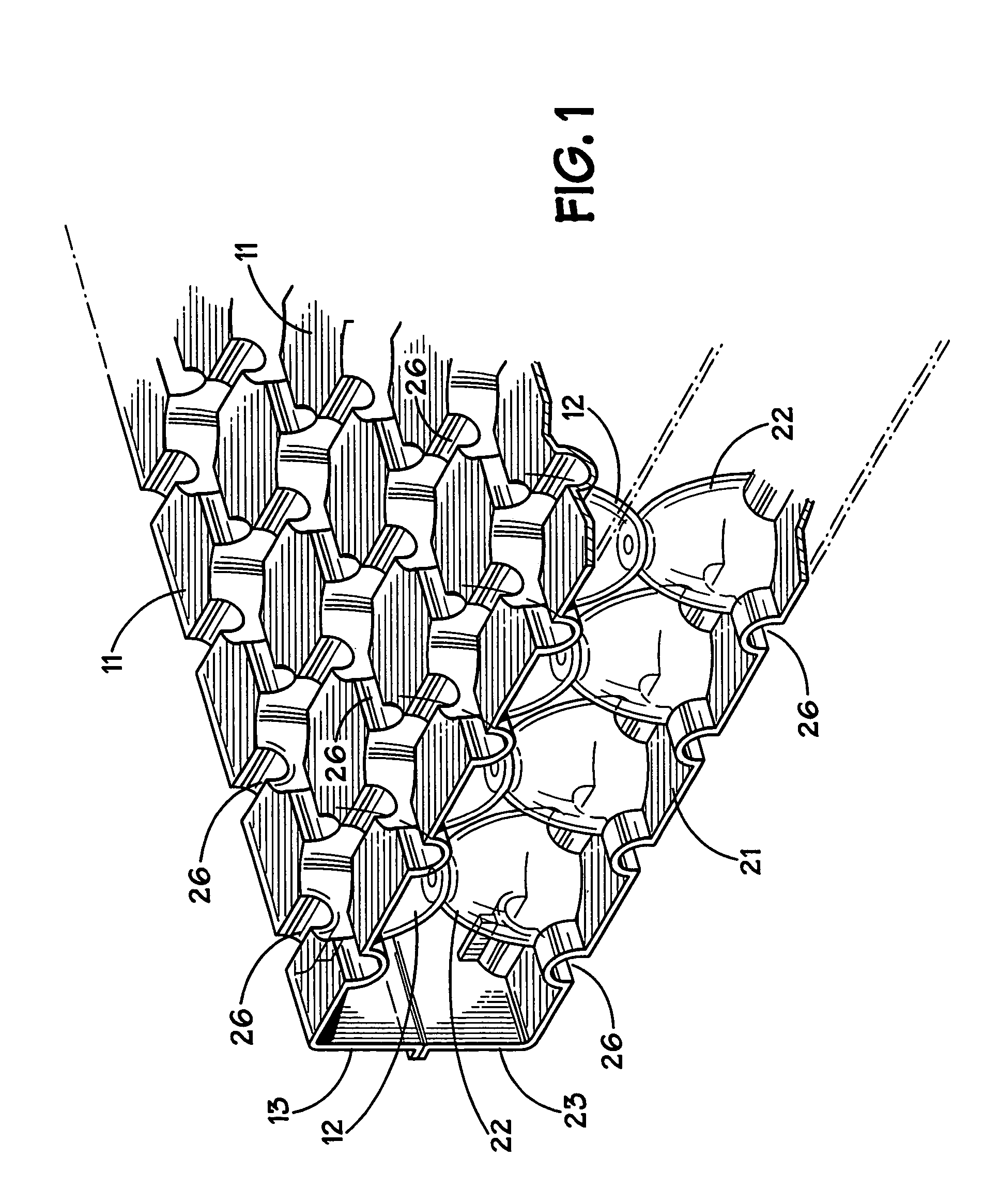

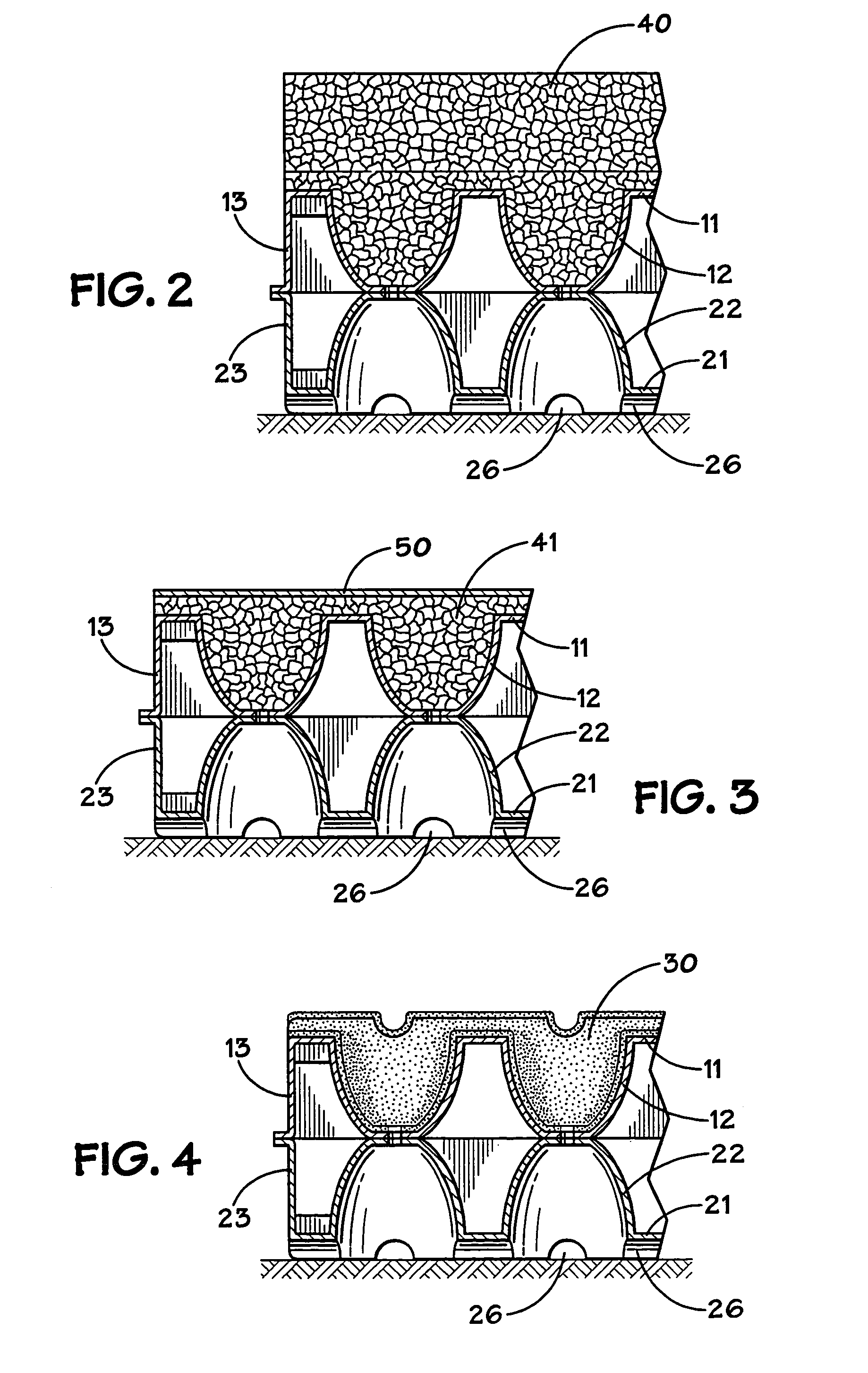

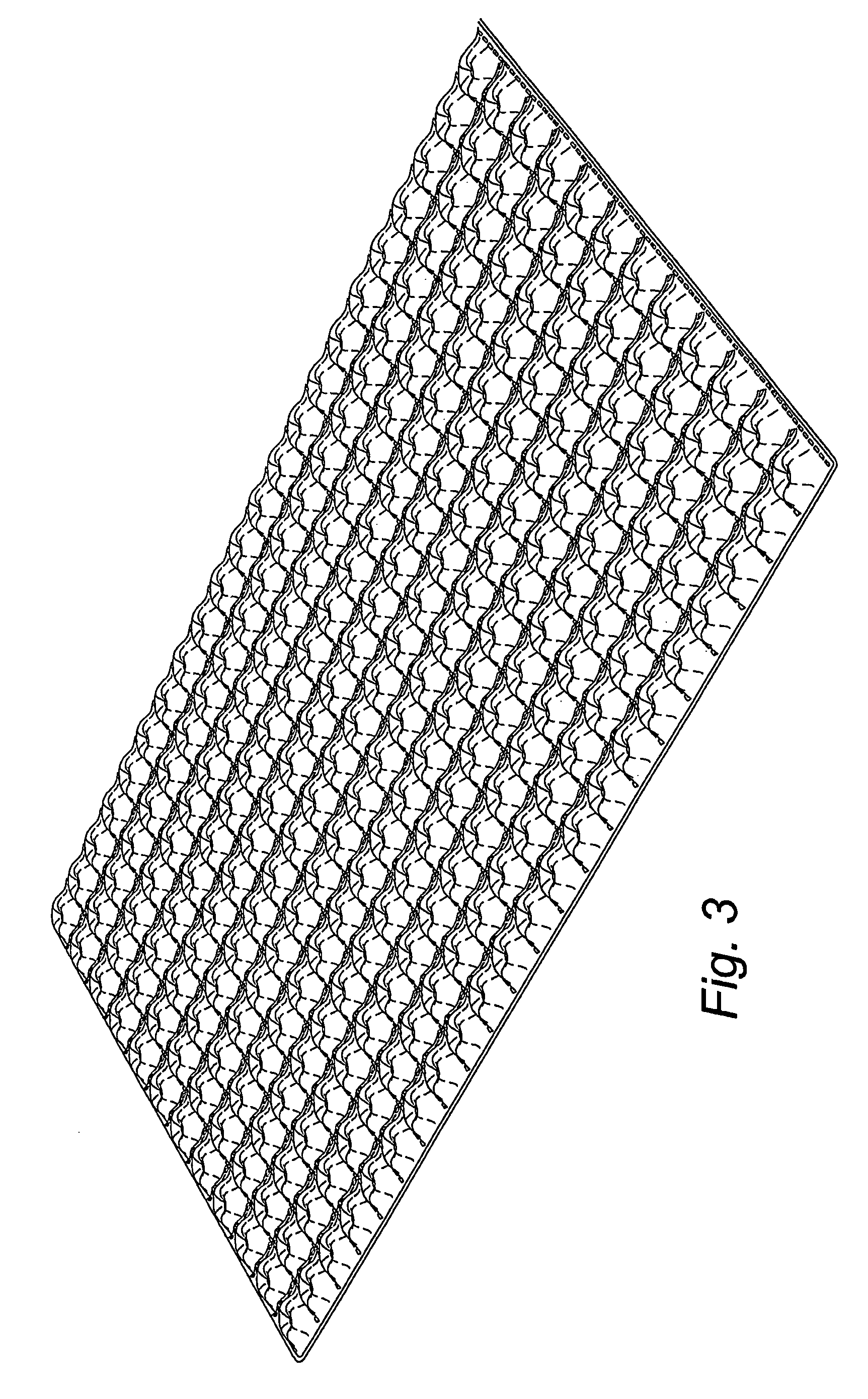

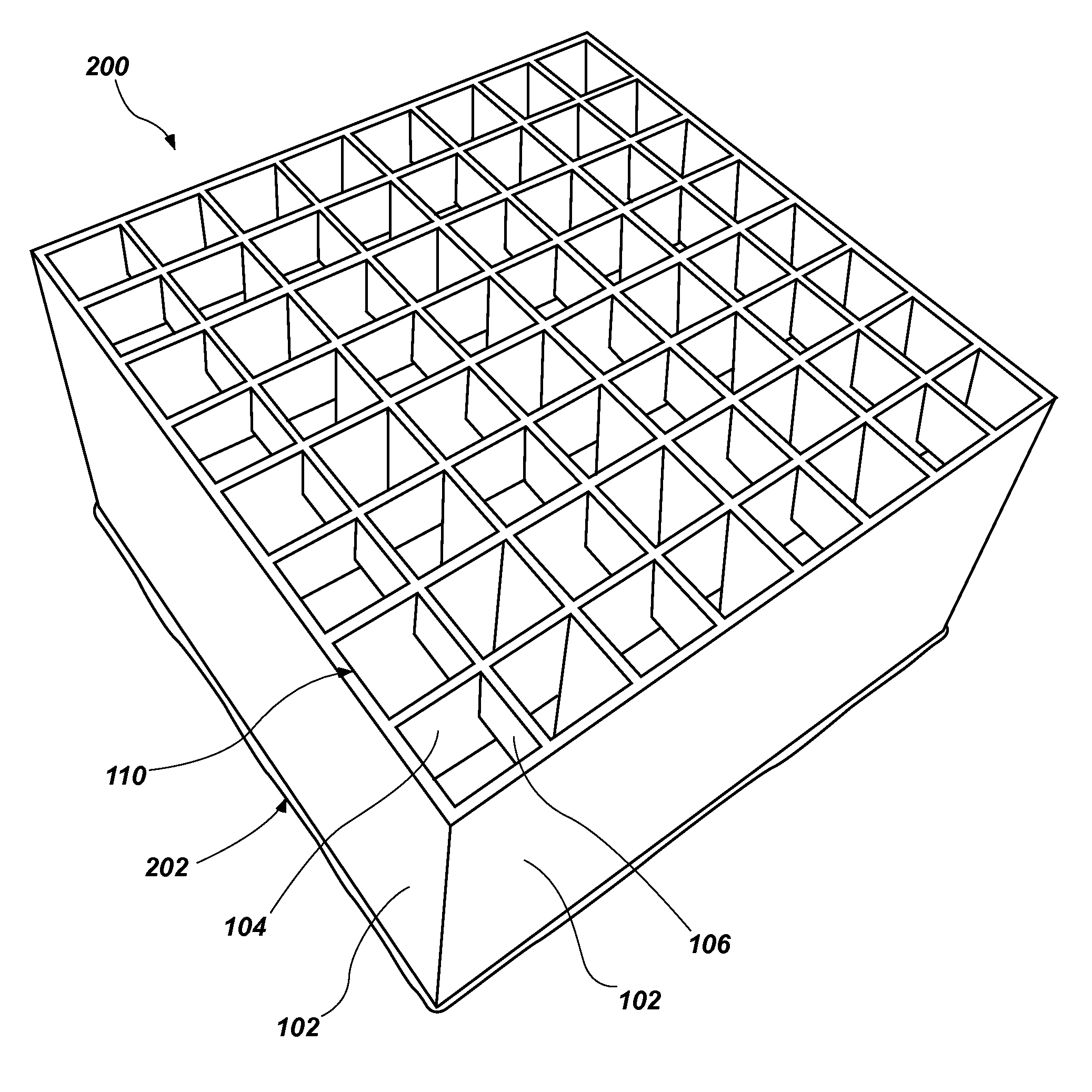

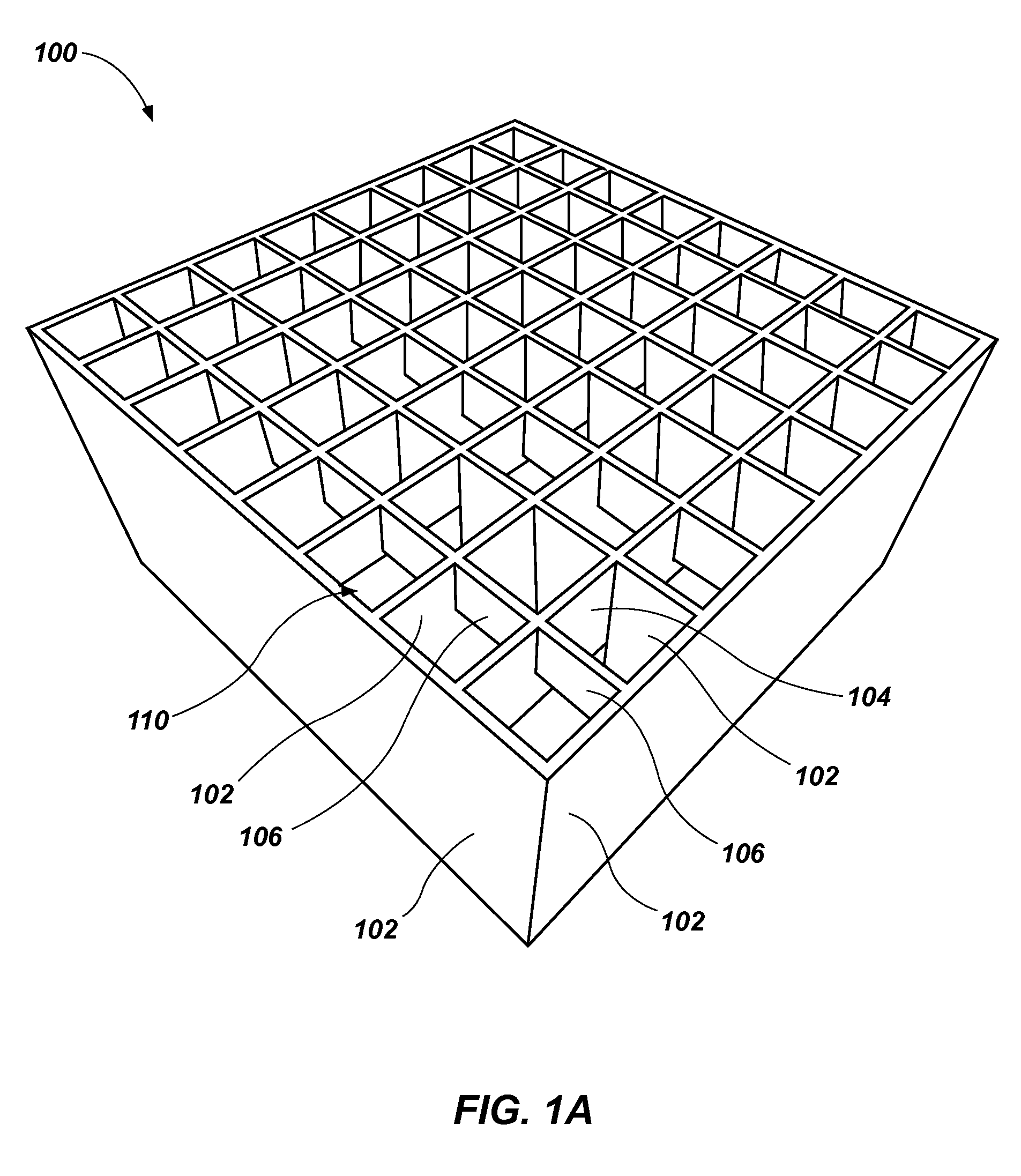

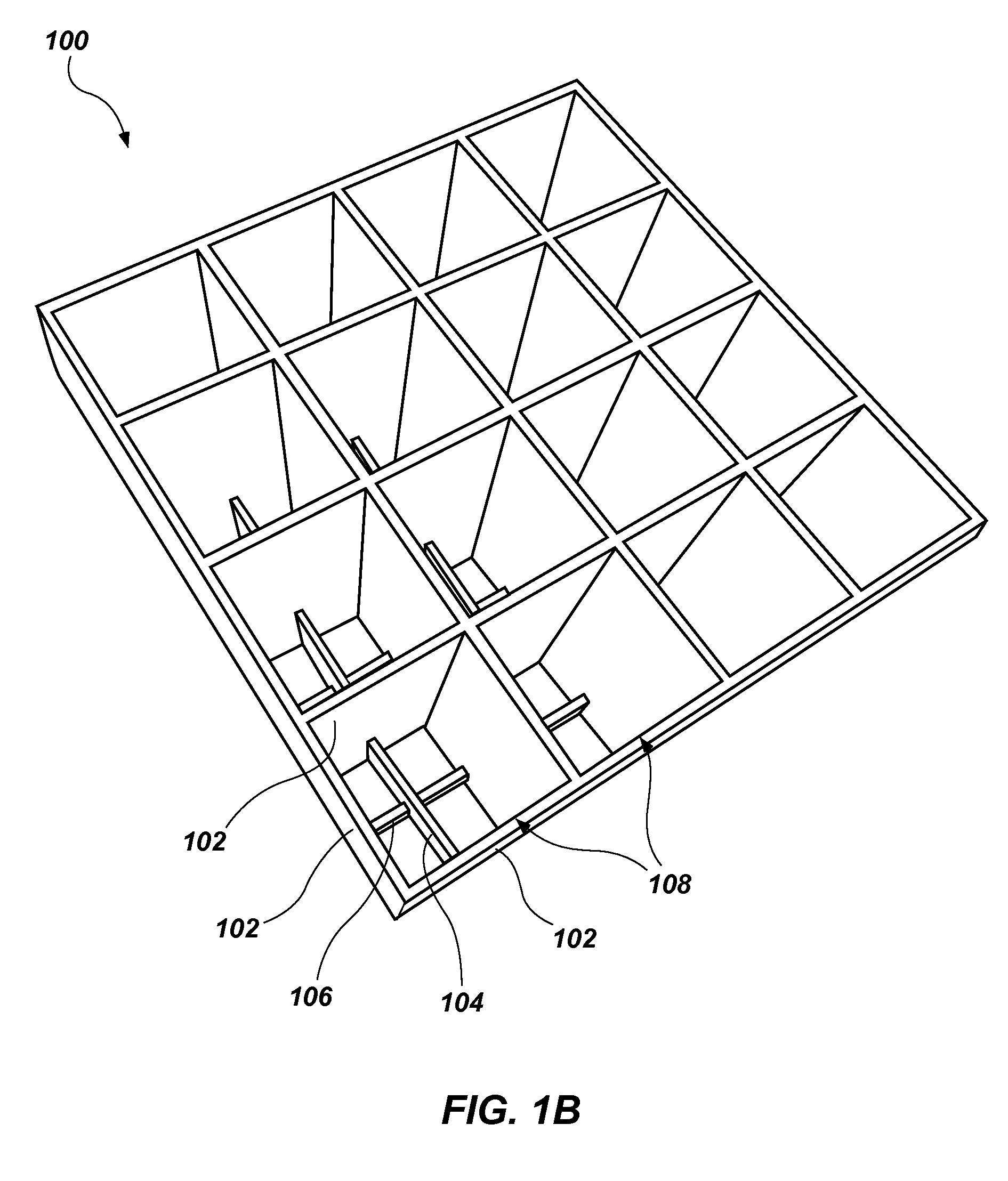

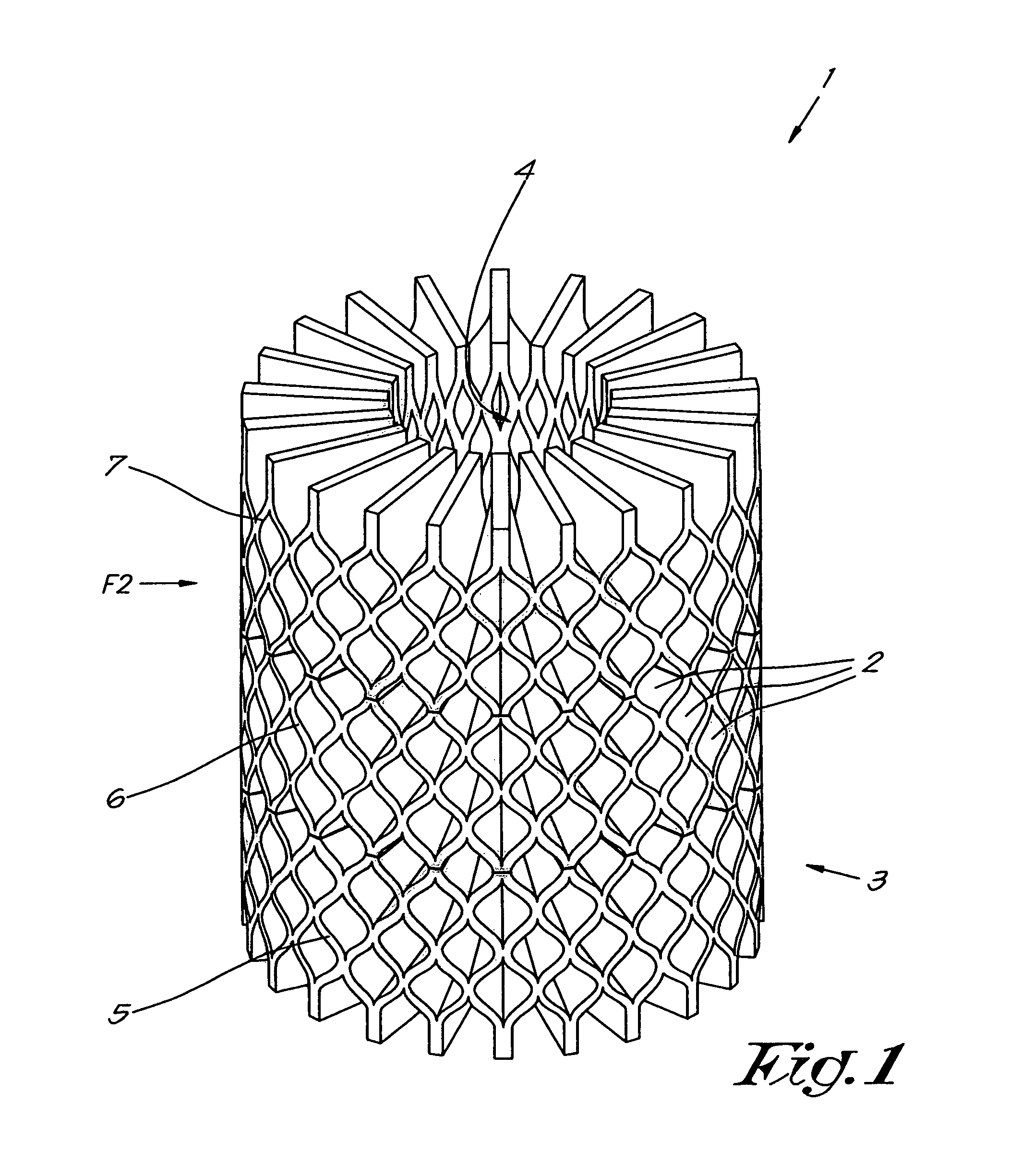

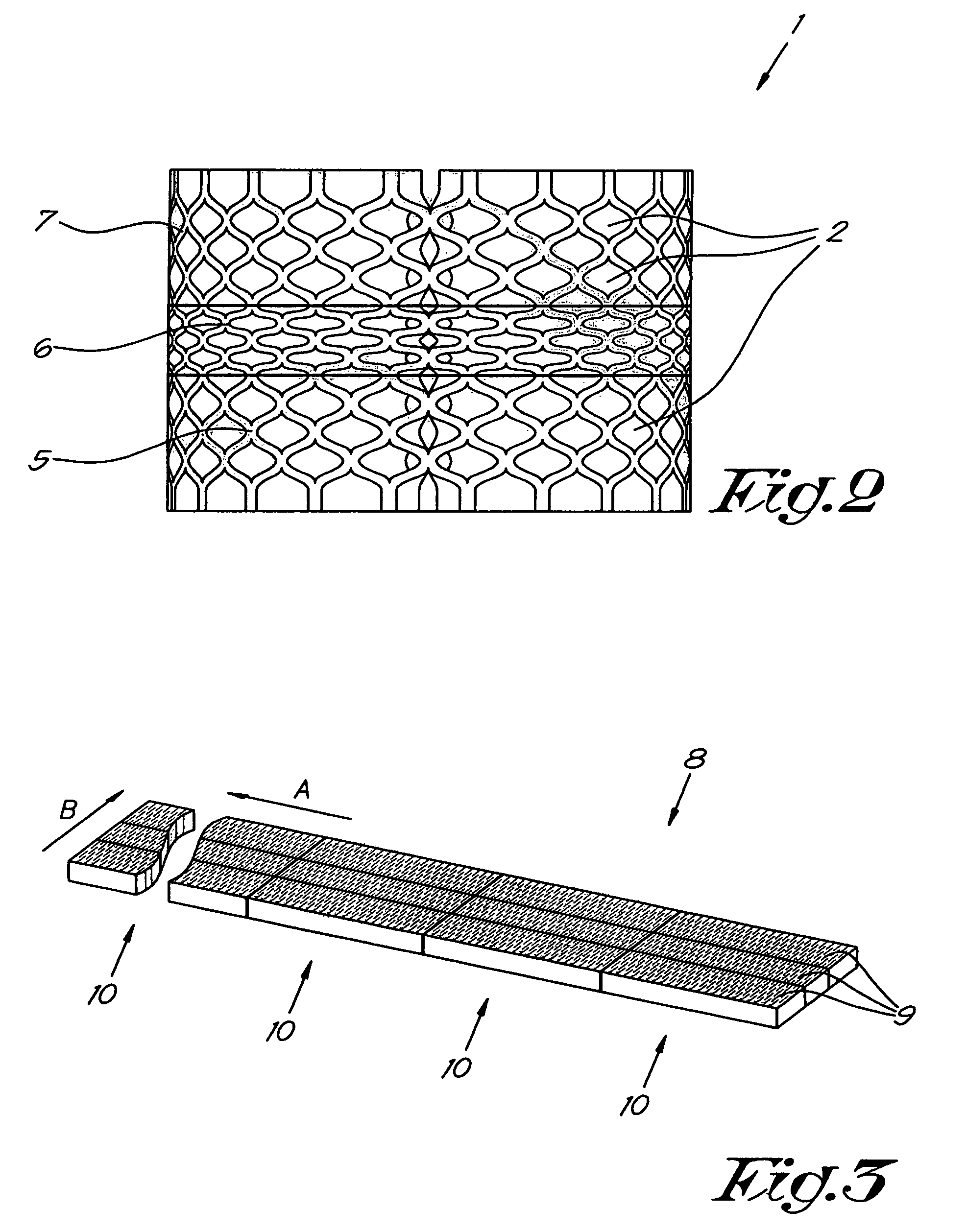

Cushioning elements comprising buckling walls and methods of forming such cushioning elements

Cushioning elements having a top cushioning surface and a bottom base surface include an elastomeric cushion member and a stabilizing material. The elastomeric cushion member includes a first plurality of interconnected buckling walls having a first mean height and a second plurality of buckling walls having a second mean height. Each buckling wall of the second plurality intersects and connects to at least two buckling walls of the first plurality. A surface of the stabilizing material on a side thereof opposite the elastomeric cushion member defines the bottom base surface of the cushioning element. The first ends of the first plurality of interconnected buckling walls and the first ends of the second plurality of buckling walls define the top cushioning surface of the cushioning element. Methods of forming cushioning elements include securing a stabilizing material to ends of the first plurality of interconnected buckling walls.

Owner:PURPLE INNOVATION LLC

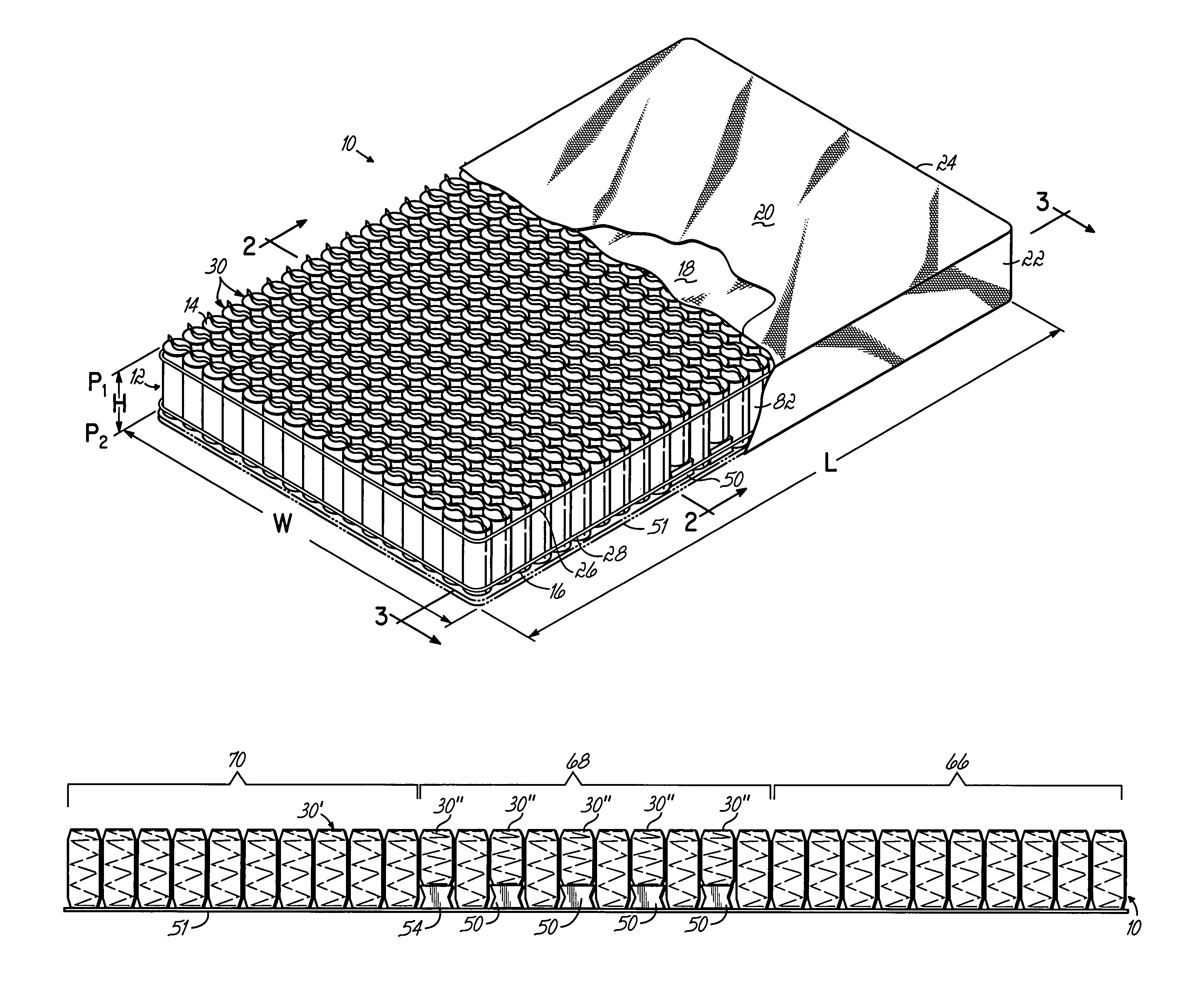

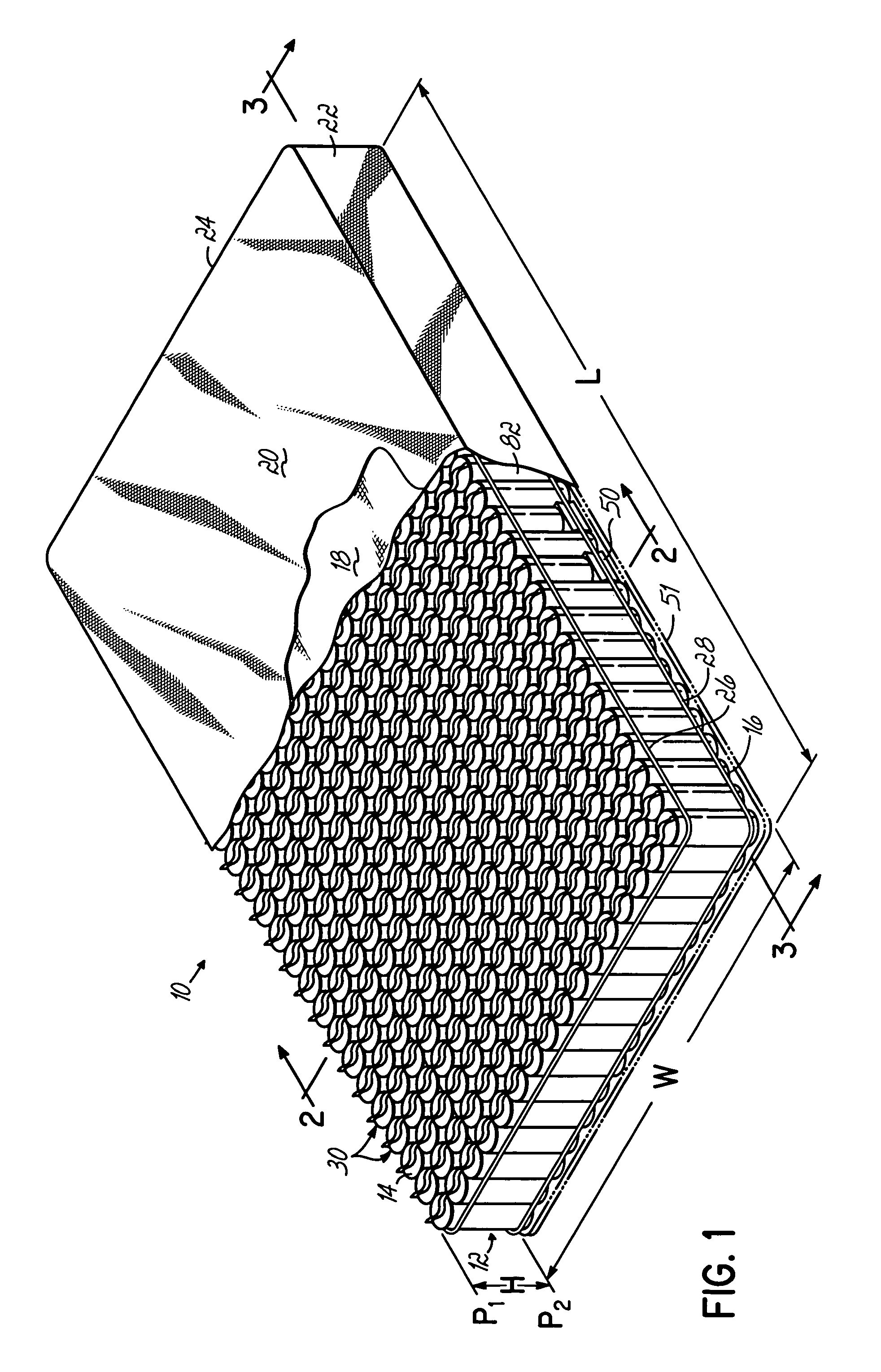

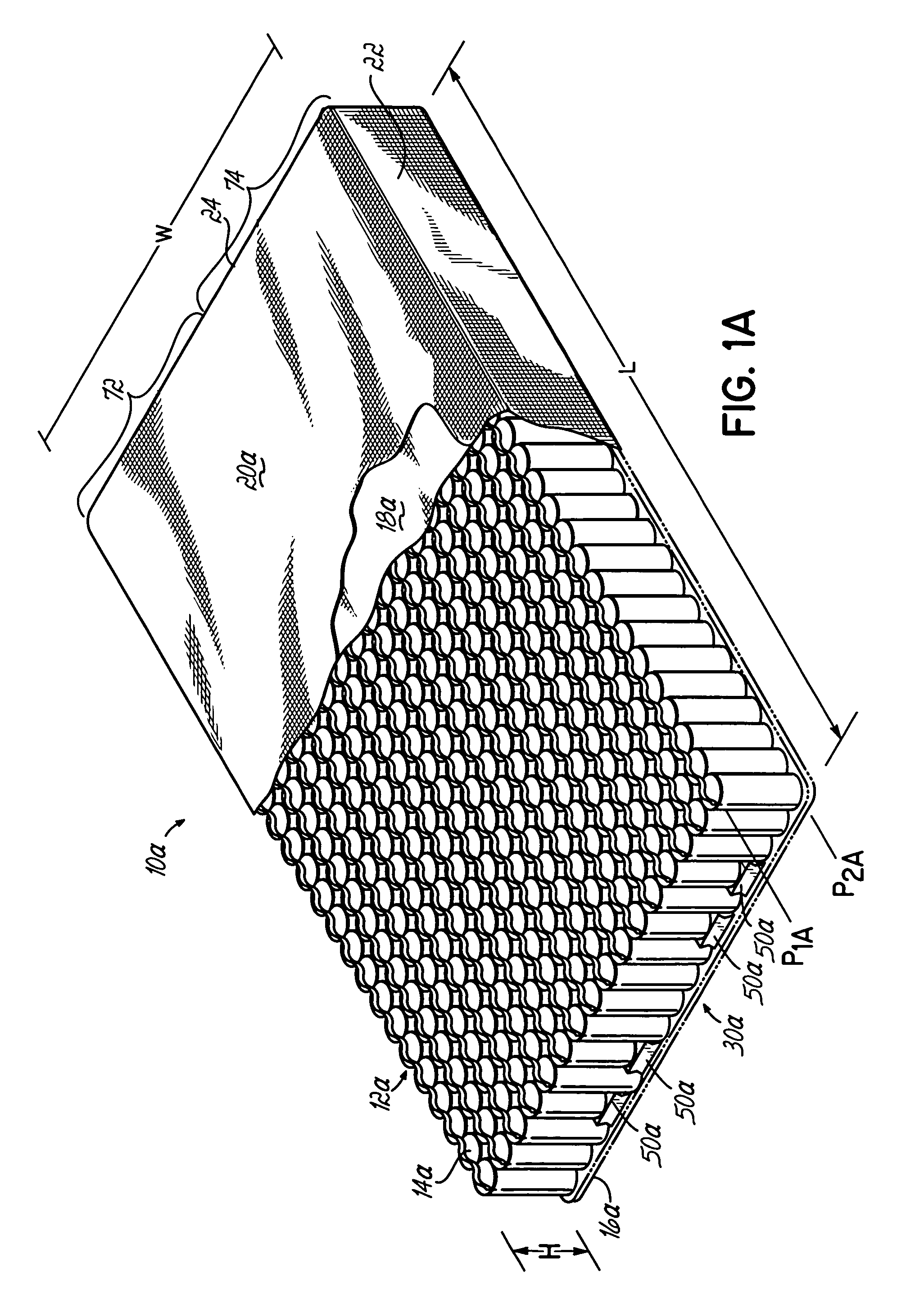

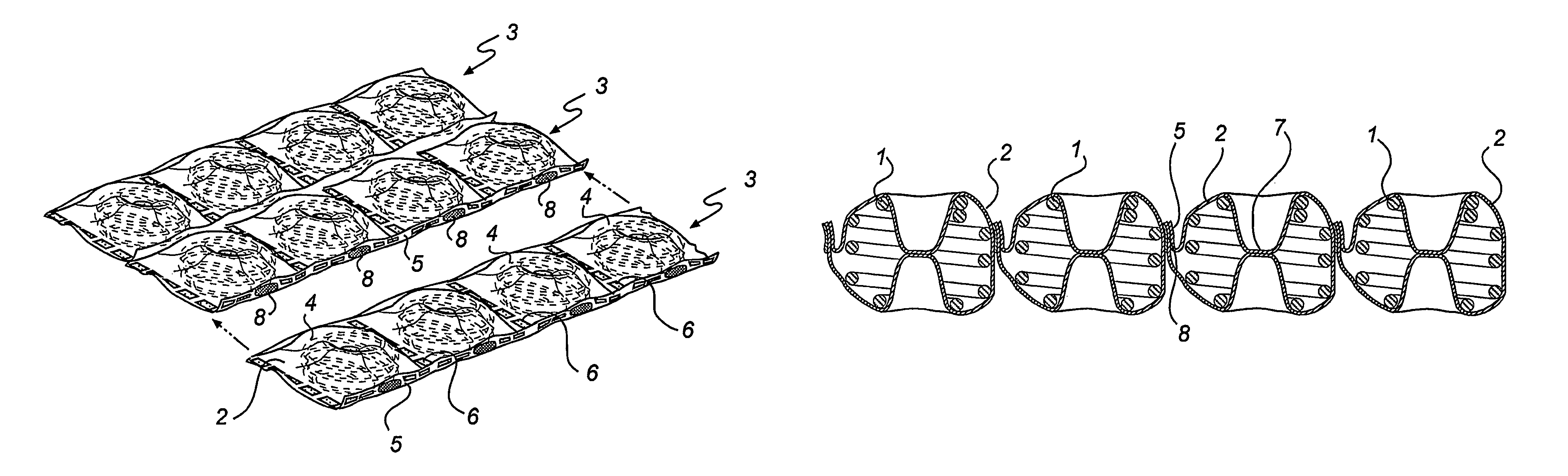

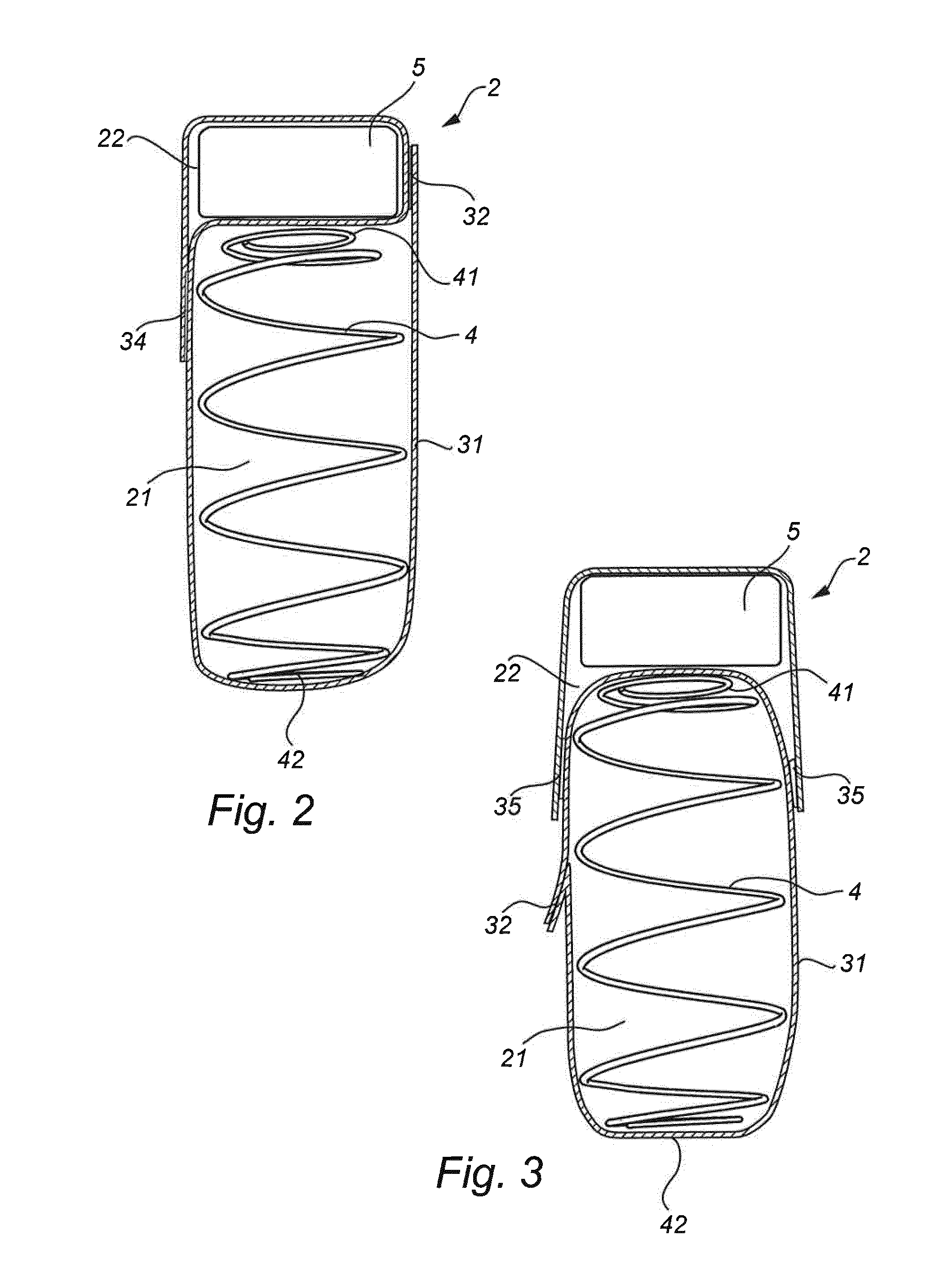

Pocketed bedding or seating product having inflatable members

ActiveUS6986182B2Improve firmnessStuffed mattressesMultiple spring combinationsEngineeringMechanical engineering

A bedding or seating product comprises a pocketed spring assembly having a plurality of parallel strings of springs joined to each other. Each of said strings of springs comprises a row of interconnected pockets, each of the pockets containing at least one spring encased in a fabric pocket. An inflatable member is sandwiched between a lower scrim sheet and some strings of springs. When inflated, the inflatable member preloads select areas of the product.

Owner:L & P PROPERTY MANAGEMENT CO

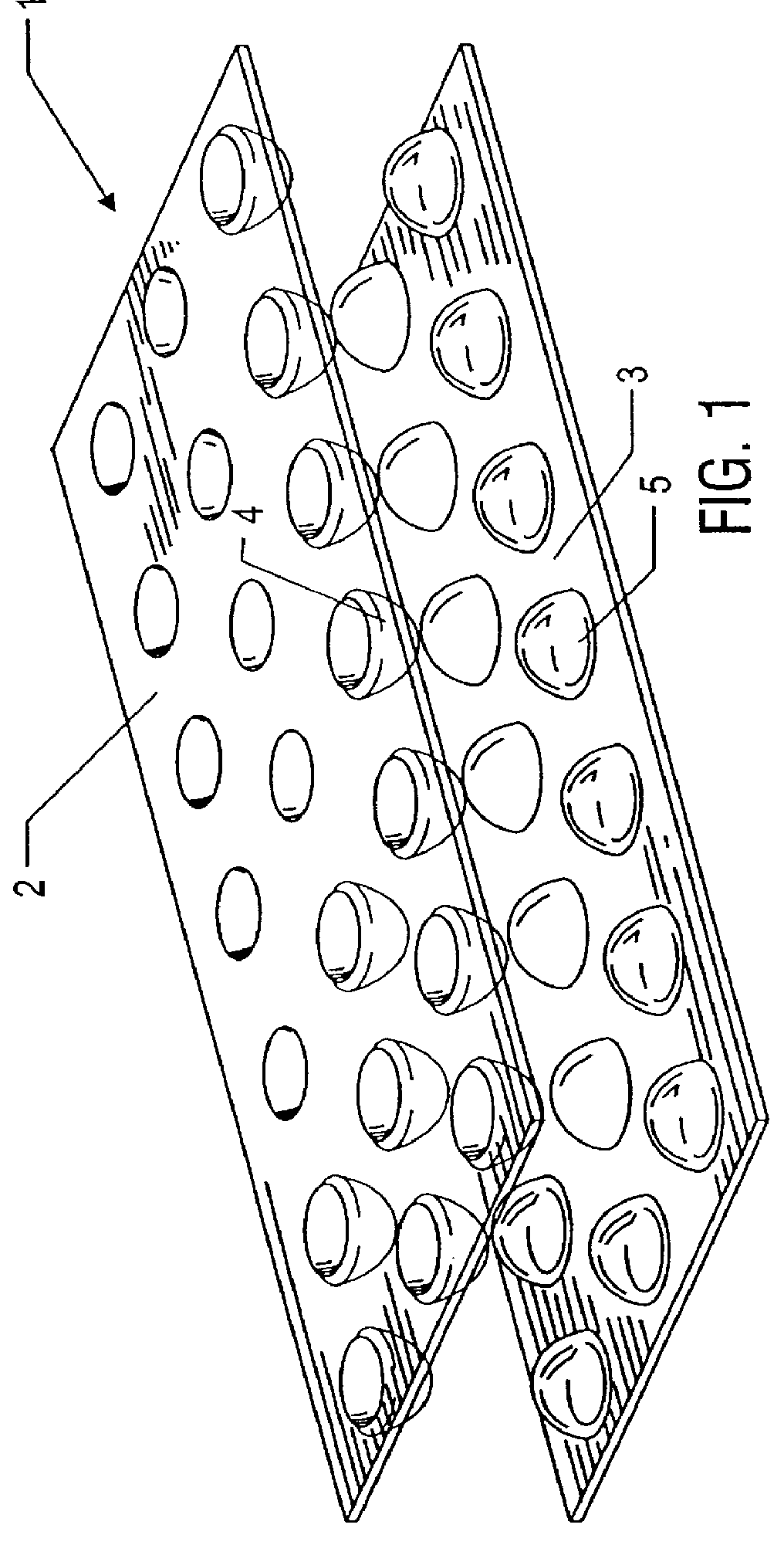

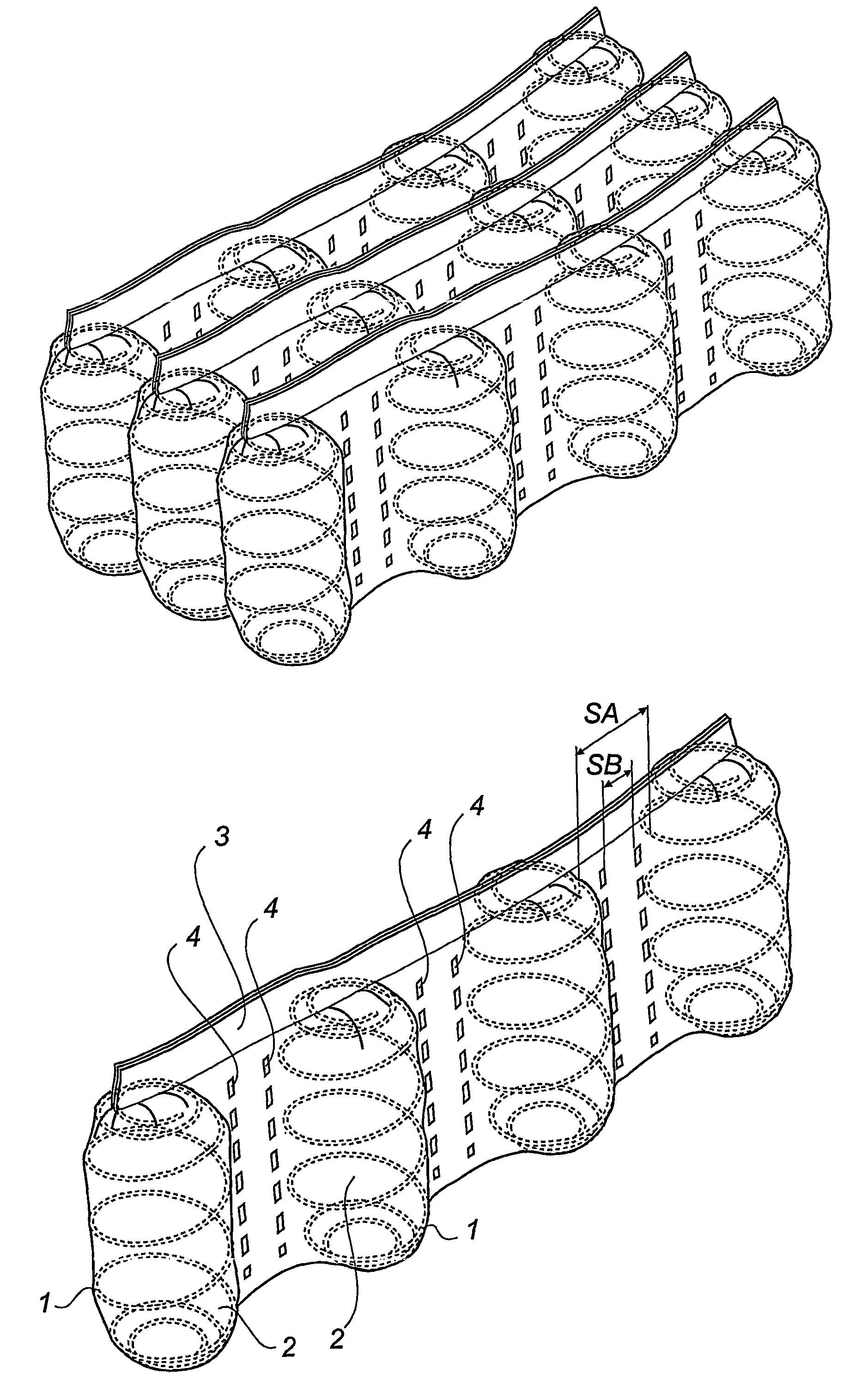

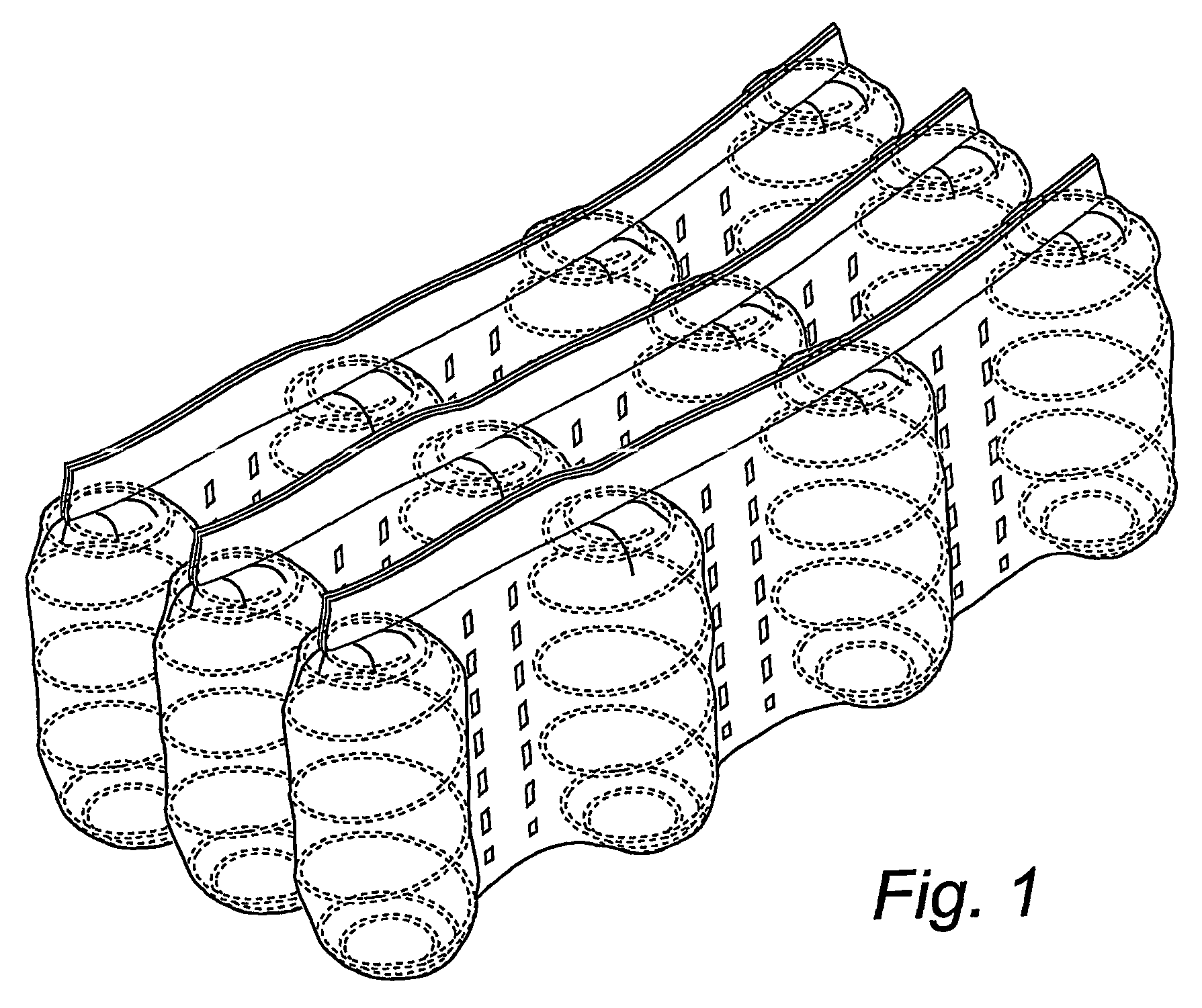

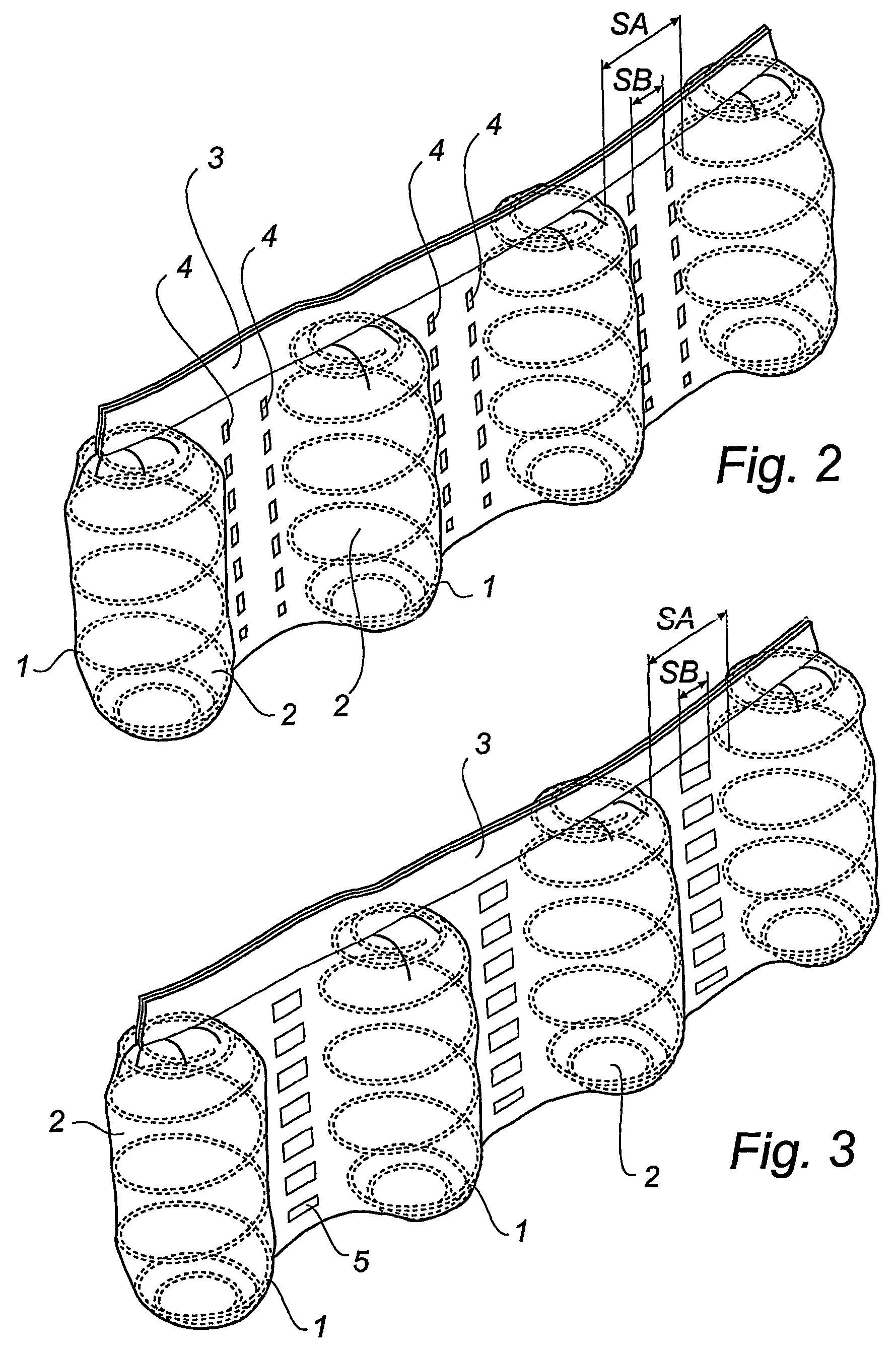

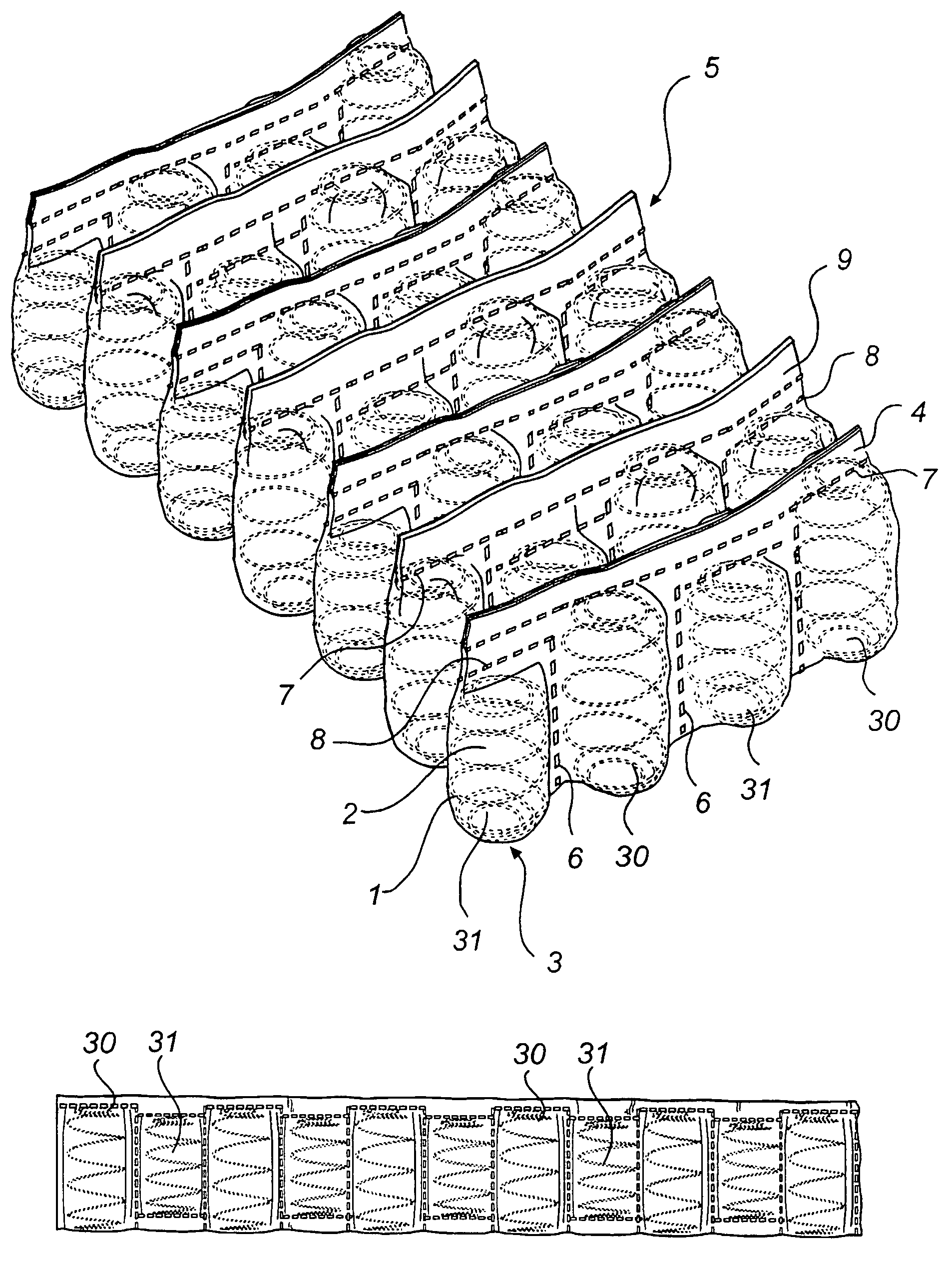

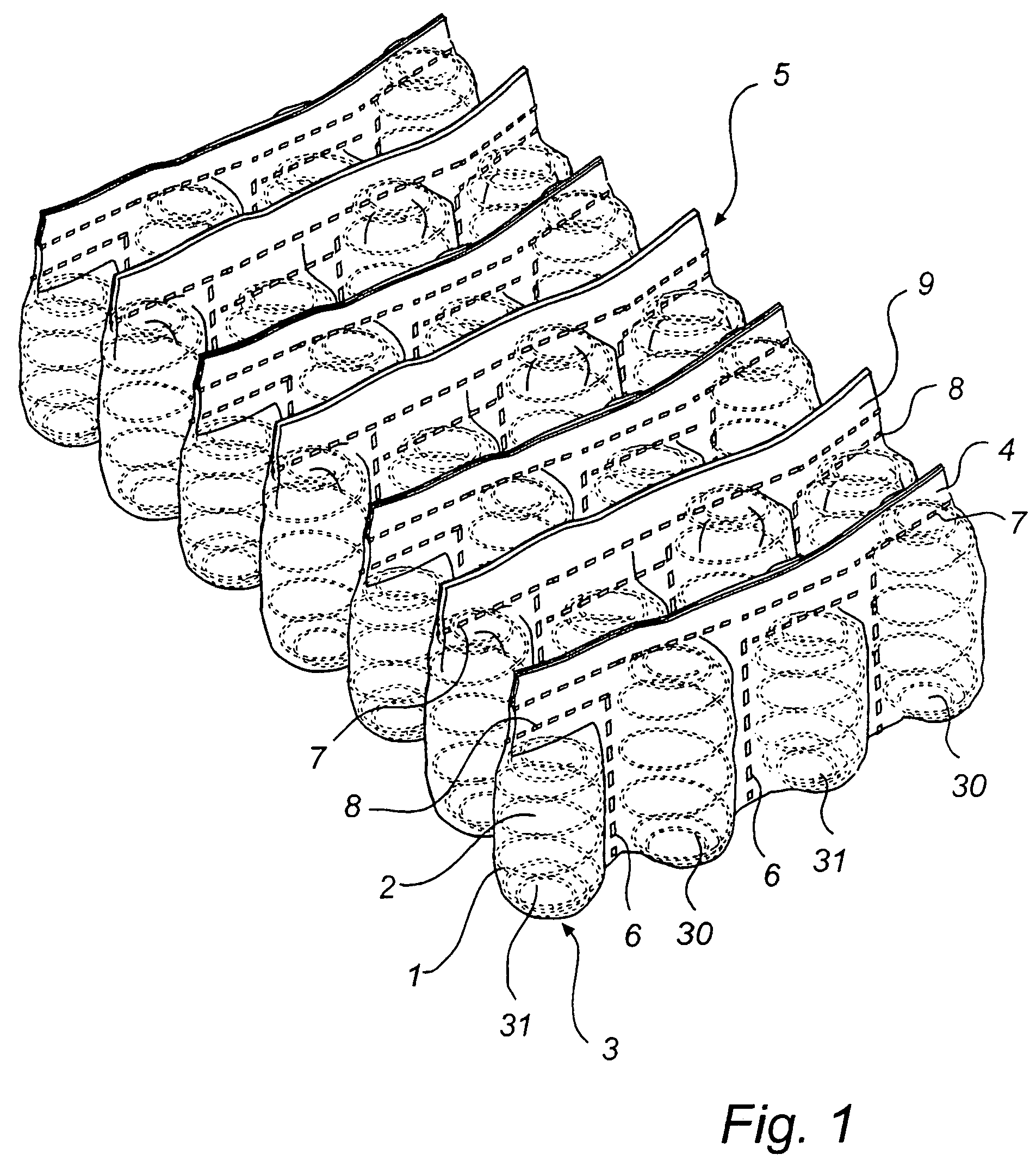

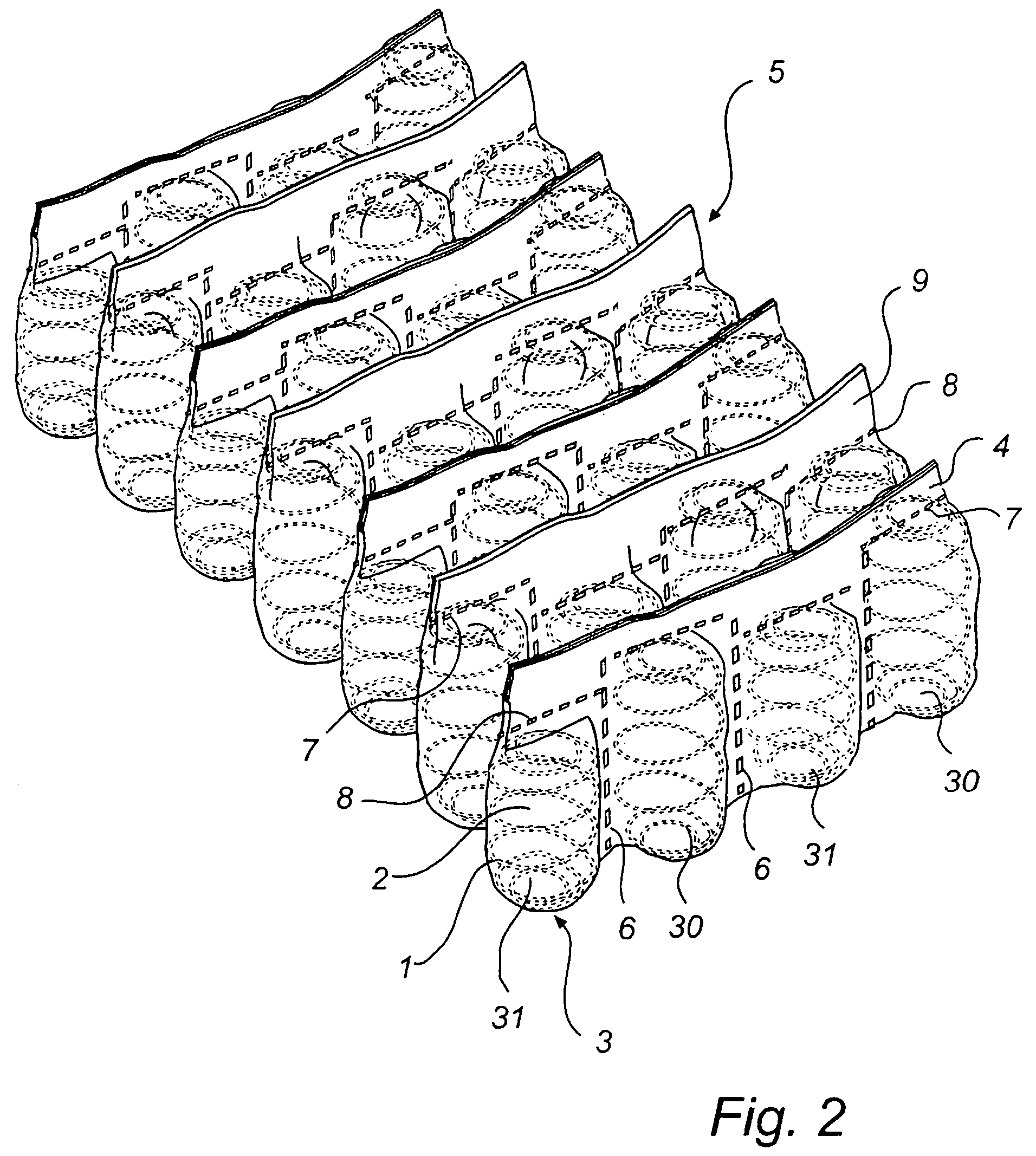

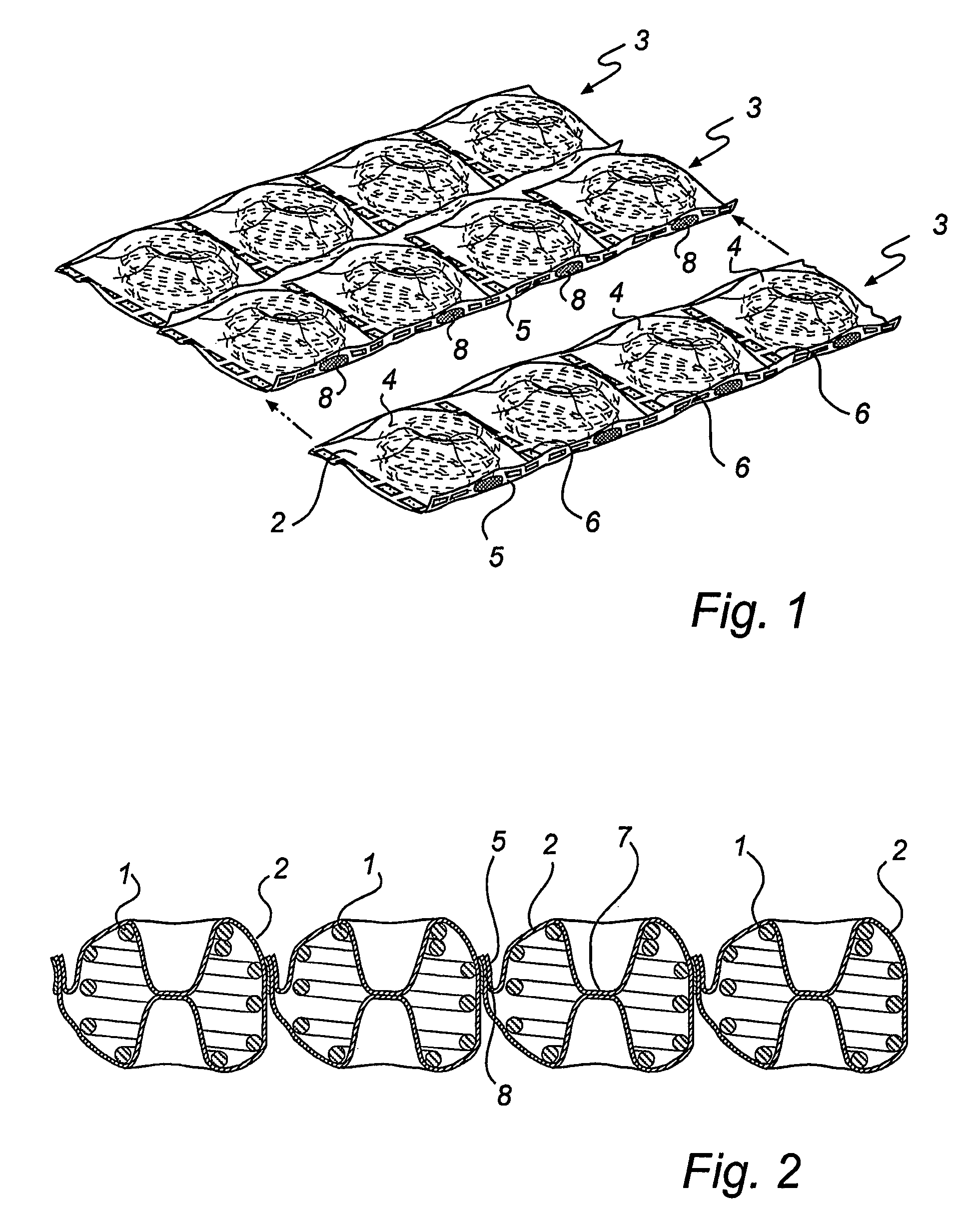

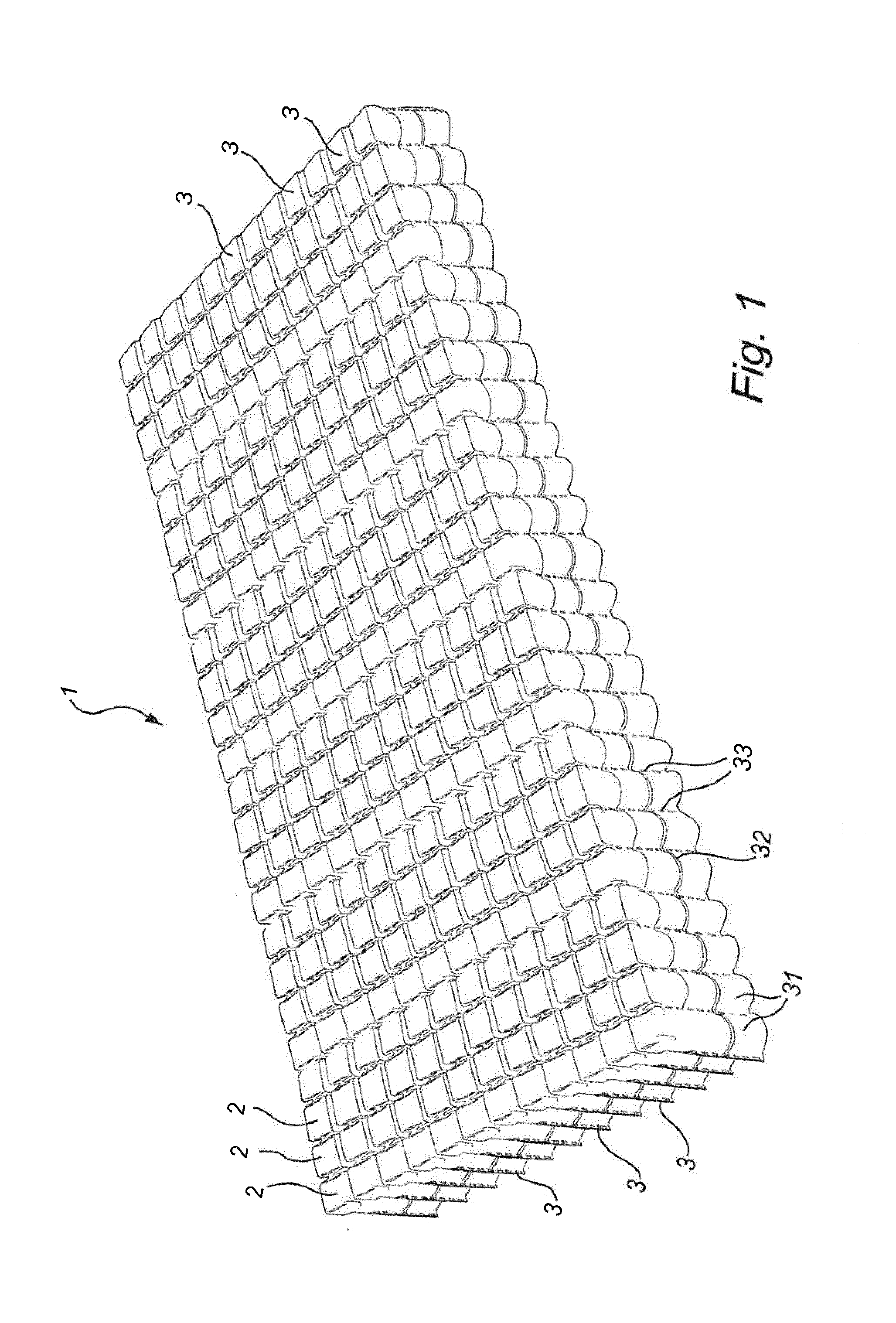

Separated pocket spring mattress

InactiveUS7048263B2Easy and less-expensive to manufactureLess compactStuffed mattressesMultiple spring combinationsCoil springBiomedical engineering

A spring mattress comprising a plurality of interconnected coil springs (1) enclosed in covers (2), known as a pocket-spring mattress, is described, wherein at least two springs that are located adjacent to one another are spaced apart by an interjacent separation distance (SA), said separation distance exceeding approximately 10% of the diameter of the largest one of the spiral turns of the adjacent springs. Also described is a method of manufacturing a corresponding mattress.

Owner:STJERNFJADRAR

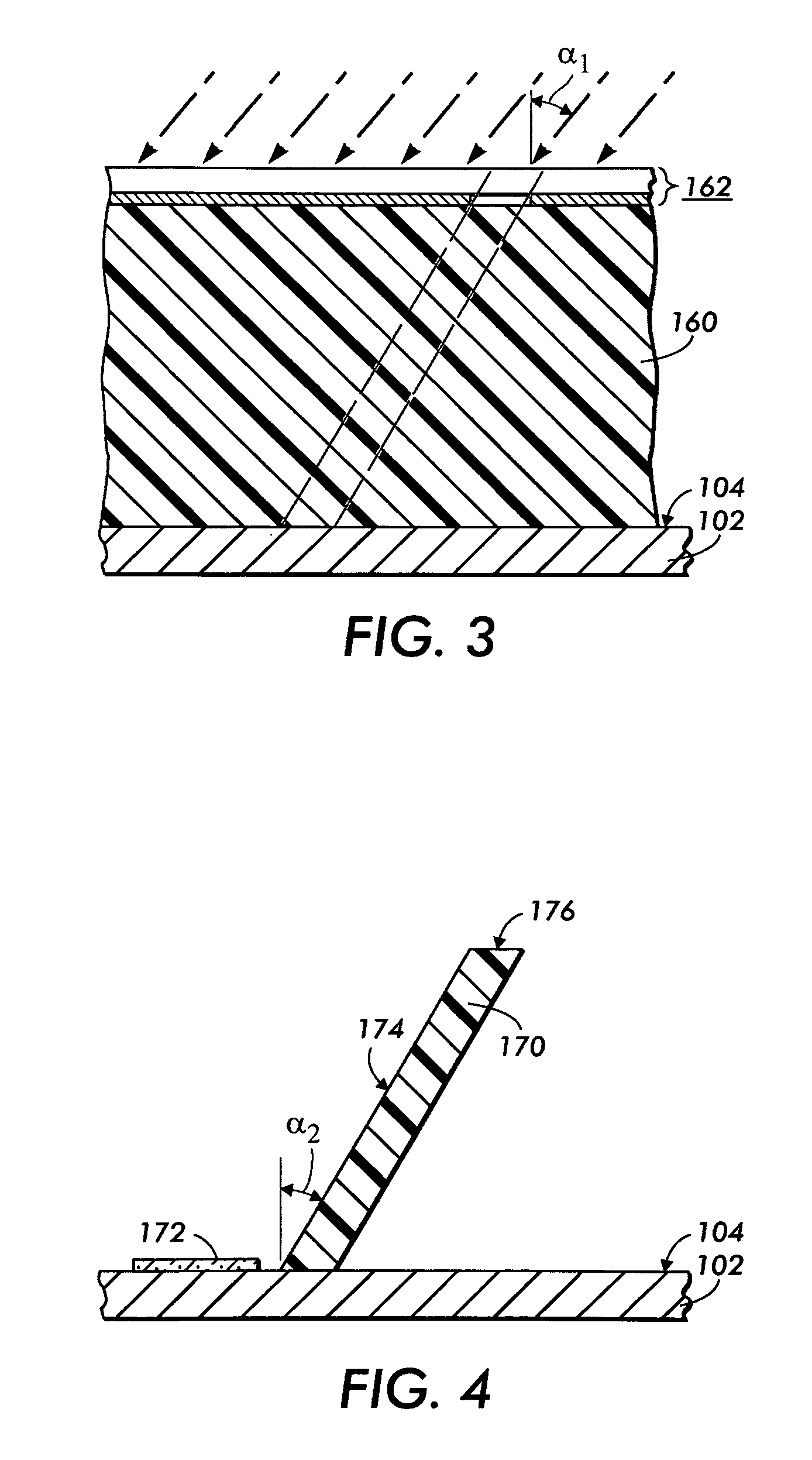

Oblique parts or surfaces

Various structures, such as microstructures and wall-like structures, can include parts or surfaces that are oblique. In some implementations, a cantilevered element includes a spring-like portion with a uniformly oblique surface or with another artifact of an oblique radiation technique. In some implementations, when a deflecting force is applied, a spring-like portion can provide deflection and spring force within required ranges. Various oblique radiation techniques can be used, such as radiation of a layer through a prism, and structures having spring-like portions with oblique radiation artifacts can be used in various applications, such as with downward or upward deflecting forces.

Owner:PALO ALTO RES CENT INC

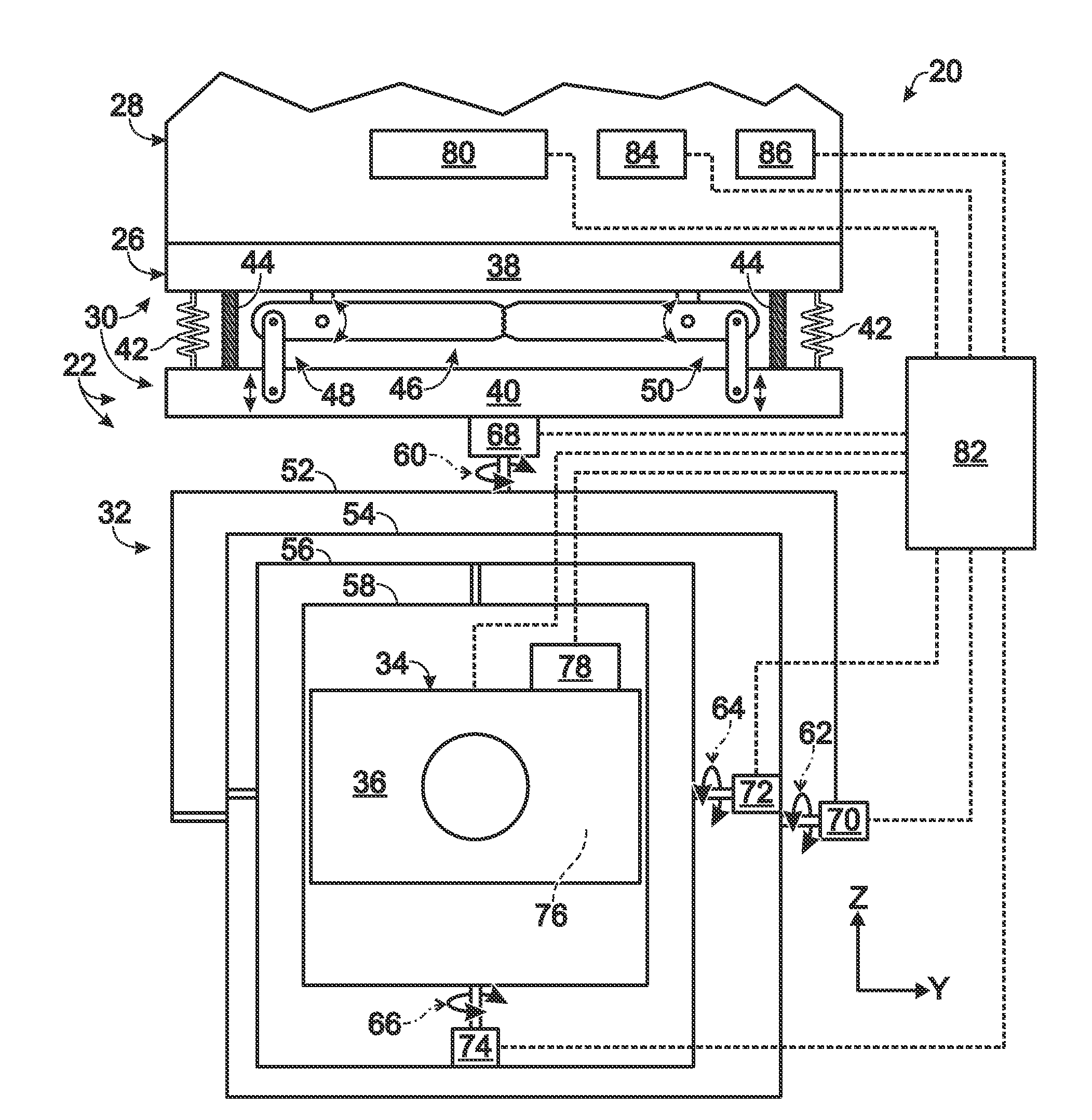

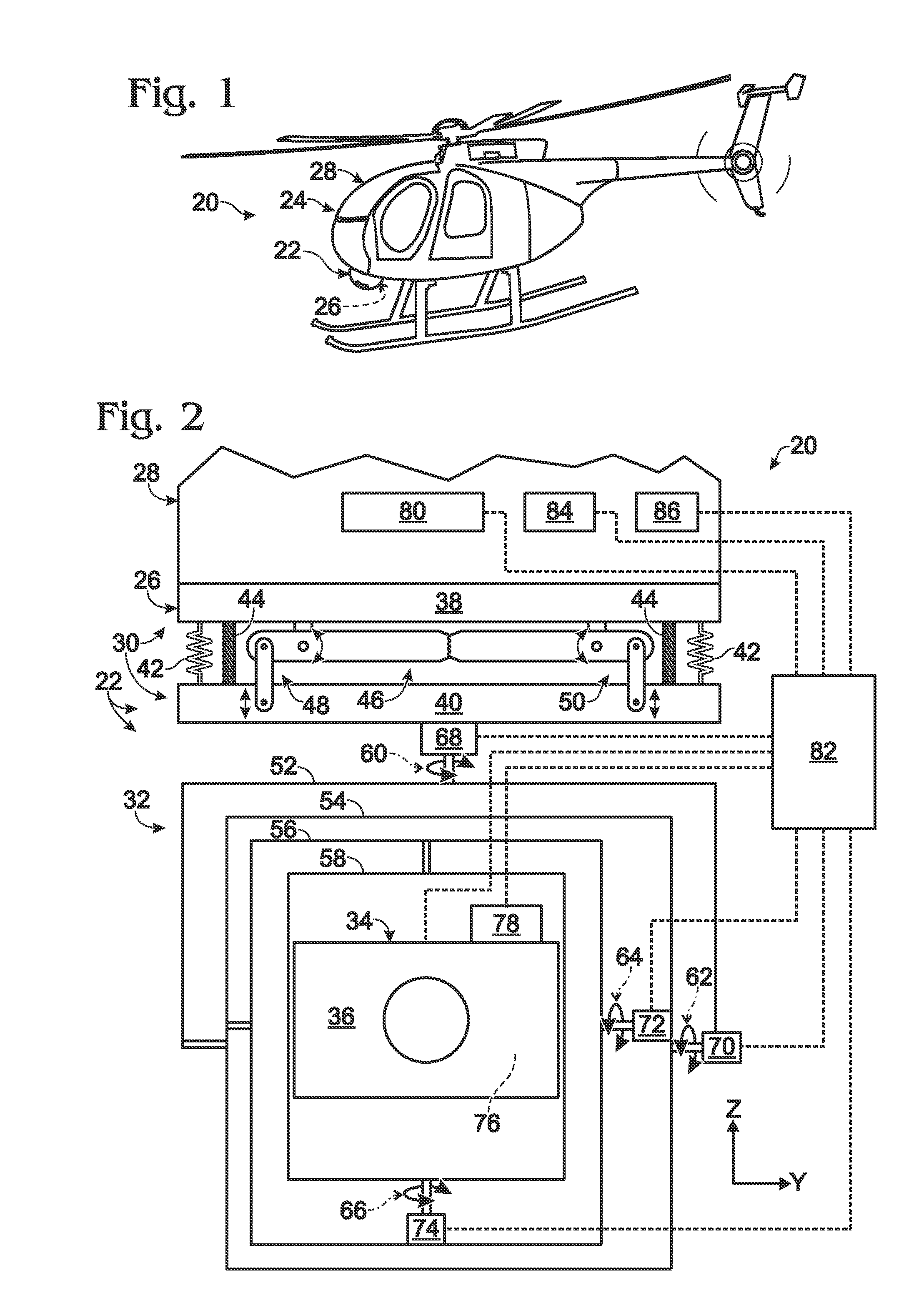

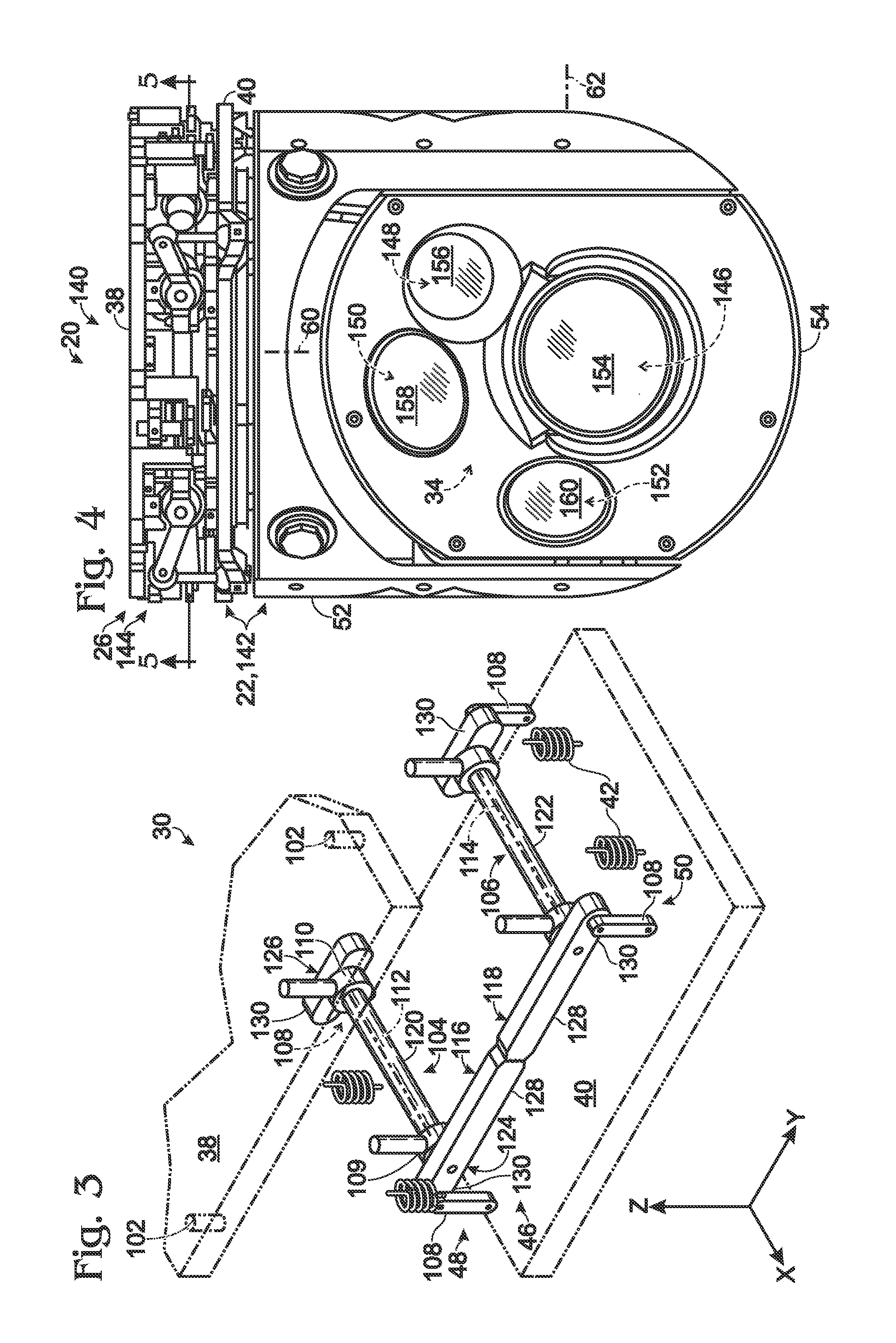

Gimbal system with linear mount

ActiveUS20120316685A1Pointing accuratelyImprove accuracyTelevision system detailsPortable framesEngineeringMechanical engineering

Owner:TELEDYNE FLIR LLC

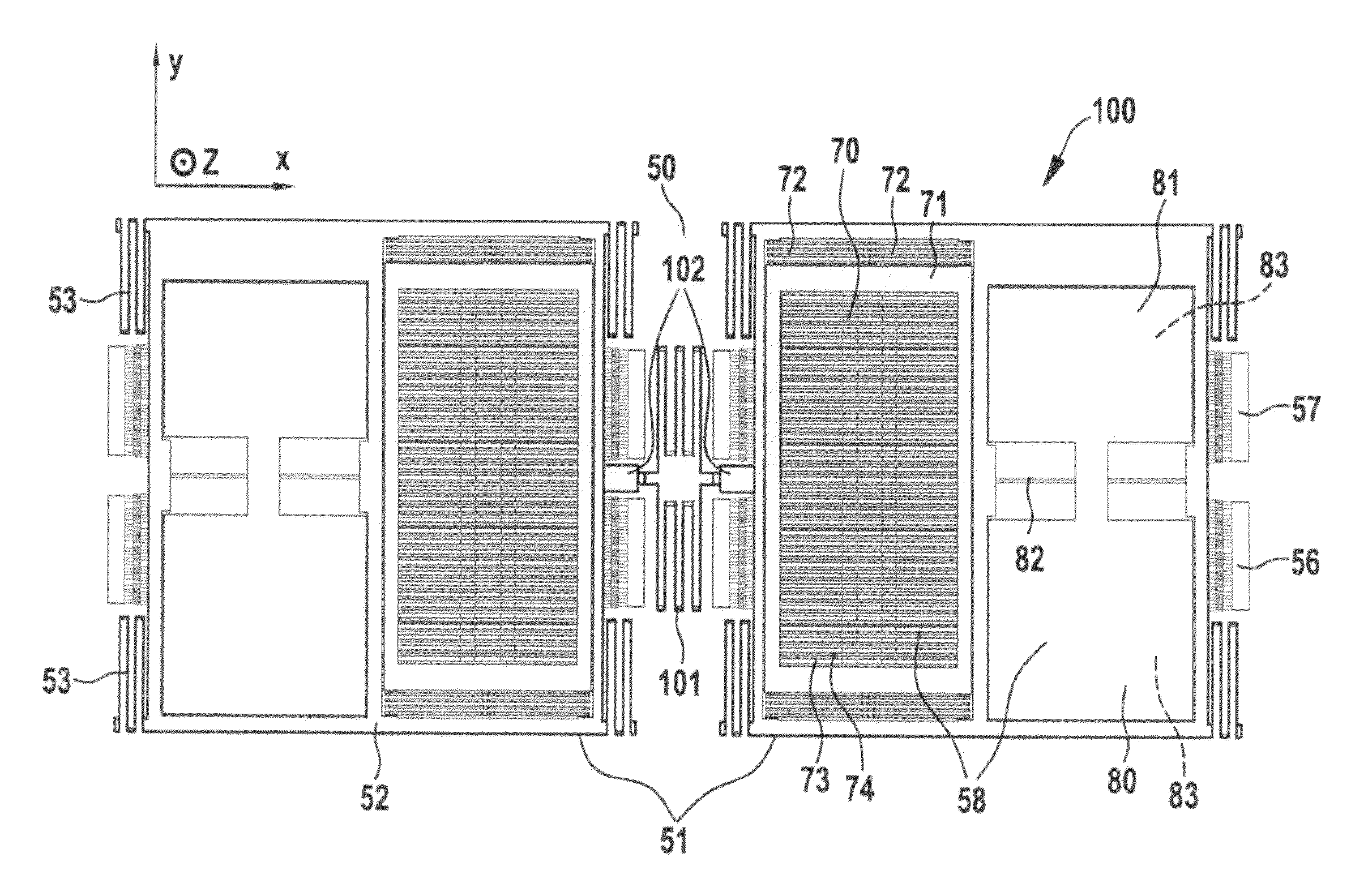

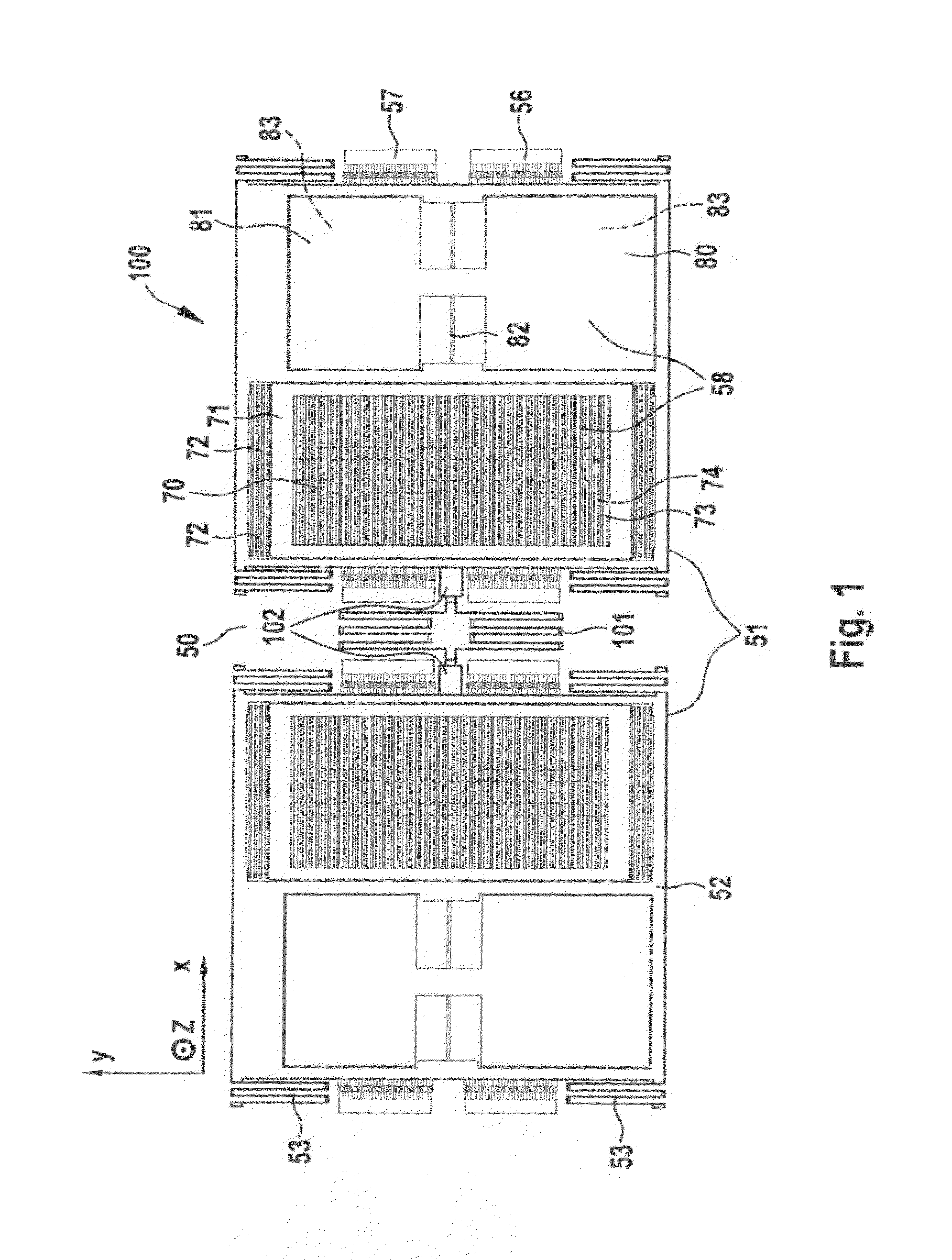

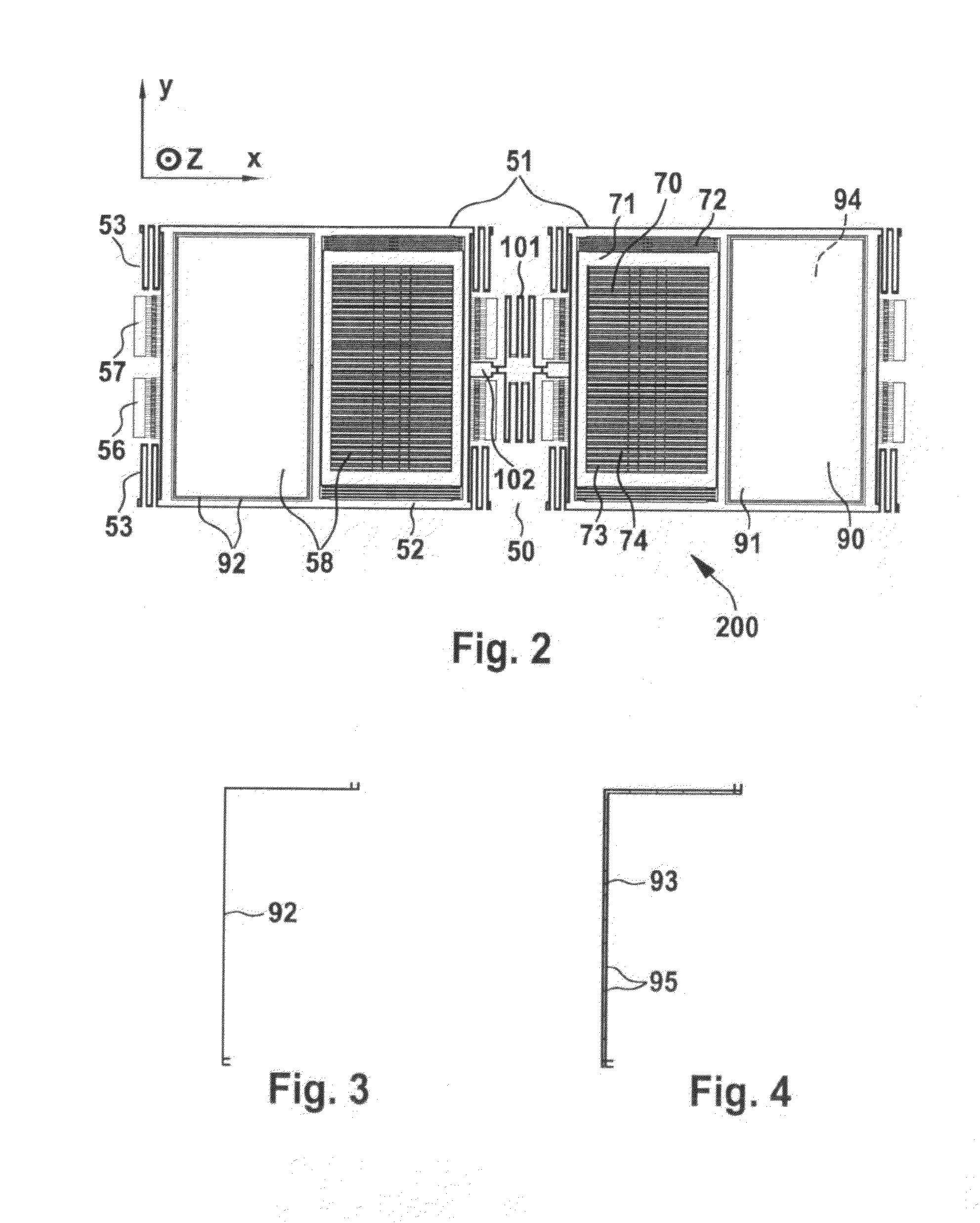

Yaw-rate sensor

ActiveUS20120060604A1Reduces space and power requirementEasy to make costAcceleration measurement using interia forcesLeaf springsEngineeringCoriolis force

A yaw-rate sensor having a substrate and a plurality of movable substructures that are mounted over a surface of the substrate, the movable substructures being coupled to a shared, in particular, central spring element, means being provided for exciting the movable substructures into a coupled oscillation in a plane that extends parallel to the surface of the substrate, the movable substructures having Coriolis elements, means being provided for detecting deflections of the Coriolis elements induced by a Coriolis force, a first Coriolis element being provided for detecting a yaw rate about a first axis, a second Coriolis element being provided for detecting a yaw rate about a second axis, the second axis being oriented perpendicularly to the first axis.

Owner:ROBERT BOSCH GMBH

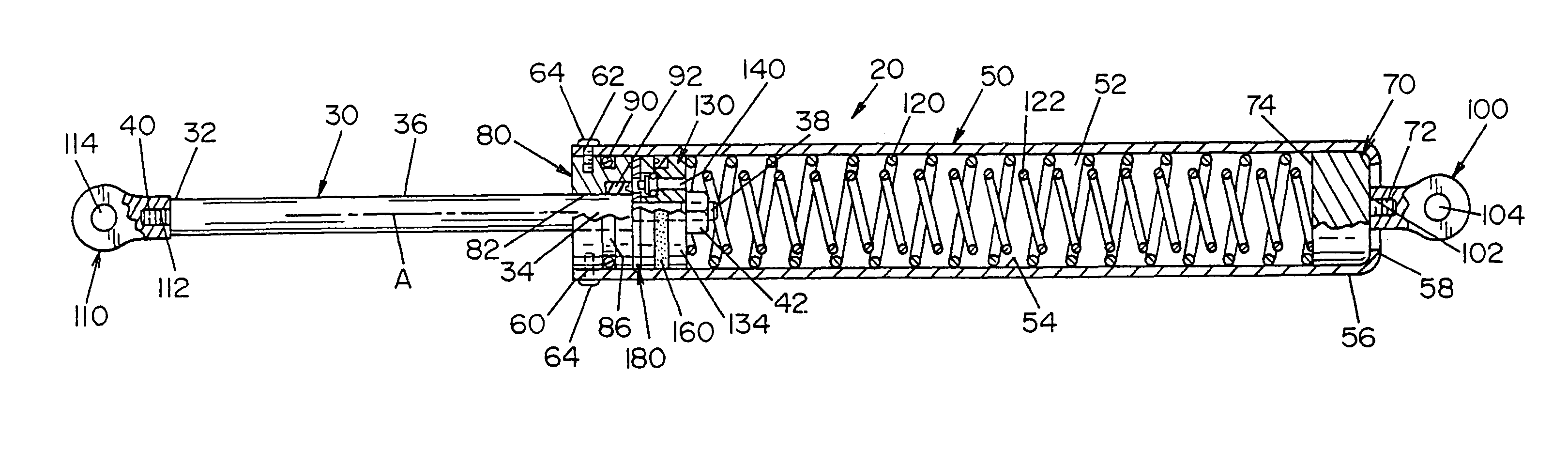

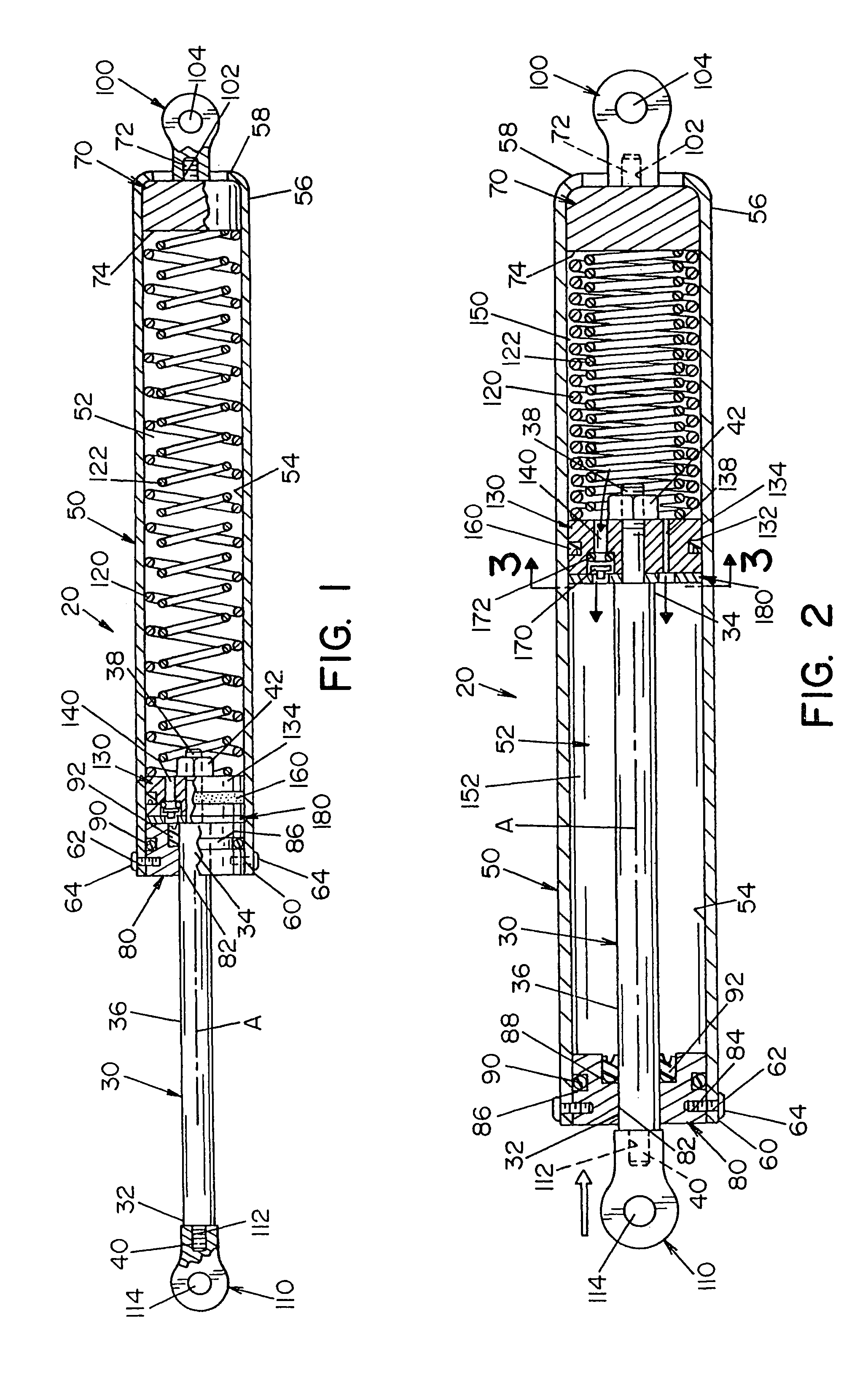

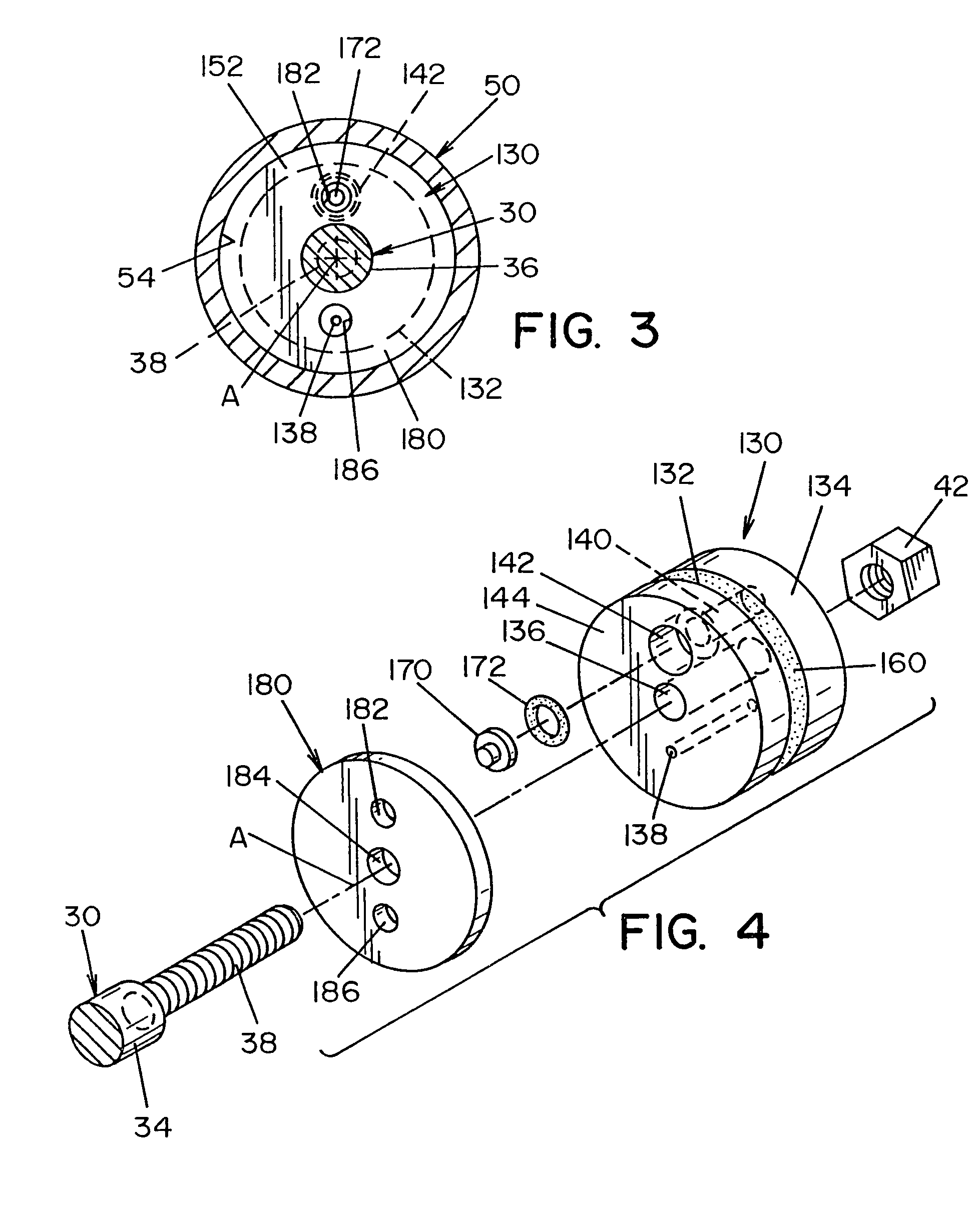

Dampened compression spring rod

ActiveUS8292274B2Reduce probabilityReduce loadMultiple spring combinationsResilient suspensionsEngineeringLinear rate

A spring system for relatively displacing elements attached to end mounts of the rod assembly comprises a housing having a rod member movable between extended and retracted positions relative thereto, and a first compression spring in the housing surrounded by a second compression spring for biasing the rod member to one of an extended or retracted position relative to the housing. The two springs are oppositely wound whereby, from a compressed condition, the spring rod exerts an expansion force which increases at a linear rate. The spring system includes a valve arrangement to control the rate at which the spring rod moves from a retracted position to an extended position.

Owner:BARNES GROUP

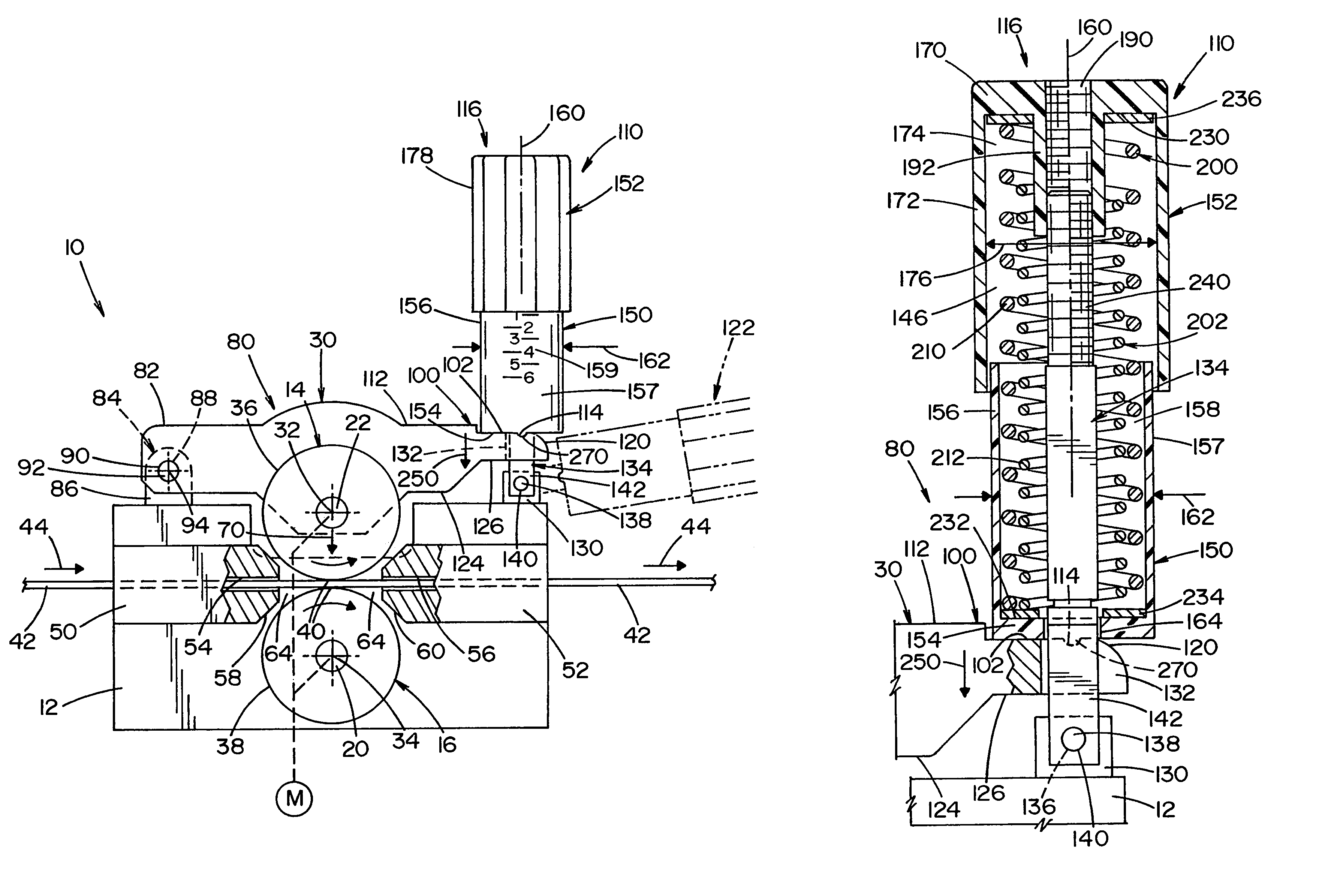

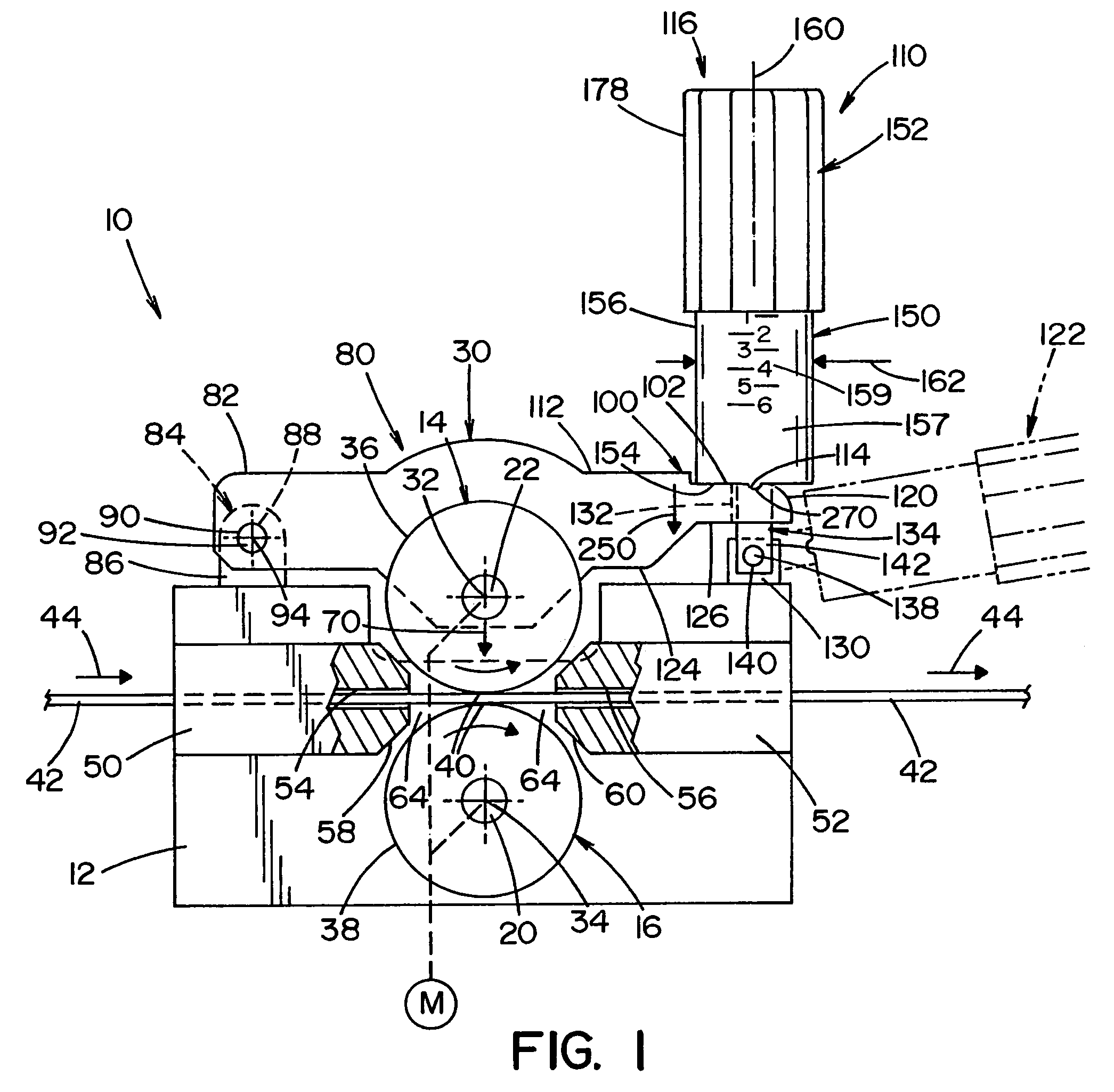

Wire gripper for a drive unit of a wire feeder

A gripping device for a set of pinch rollers used in a wire feeder that supplies a welding operation with a consumable welding wire. The welding wire passes between the pinch rollers whereby the pinch rollers engage the wire with a gripping force and incrementally rotate to control the outflow of the wire to the welding operation. The gripping device has a first member which is displaceable relative to a second member and a spring mechanism extending between the first and second members which has at least a first and a second spring modulus. The spring mechanism produces the gripping force as the first and the second members are displaced toward one another. The gripper urges one roller of the set of pinch rollers toward the other roller of the set to engage the wire and to apply the gripping force. By including a spring with a first and second spring modulus, the gripper can apply a first range of gripping forces with the force produced by the first spring modulus and a second range of gripping forces with the force produced by the second spring modulus.

Owner:LINCOLN GLOBAL INC

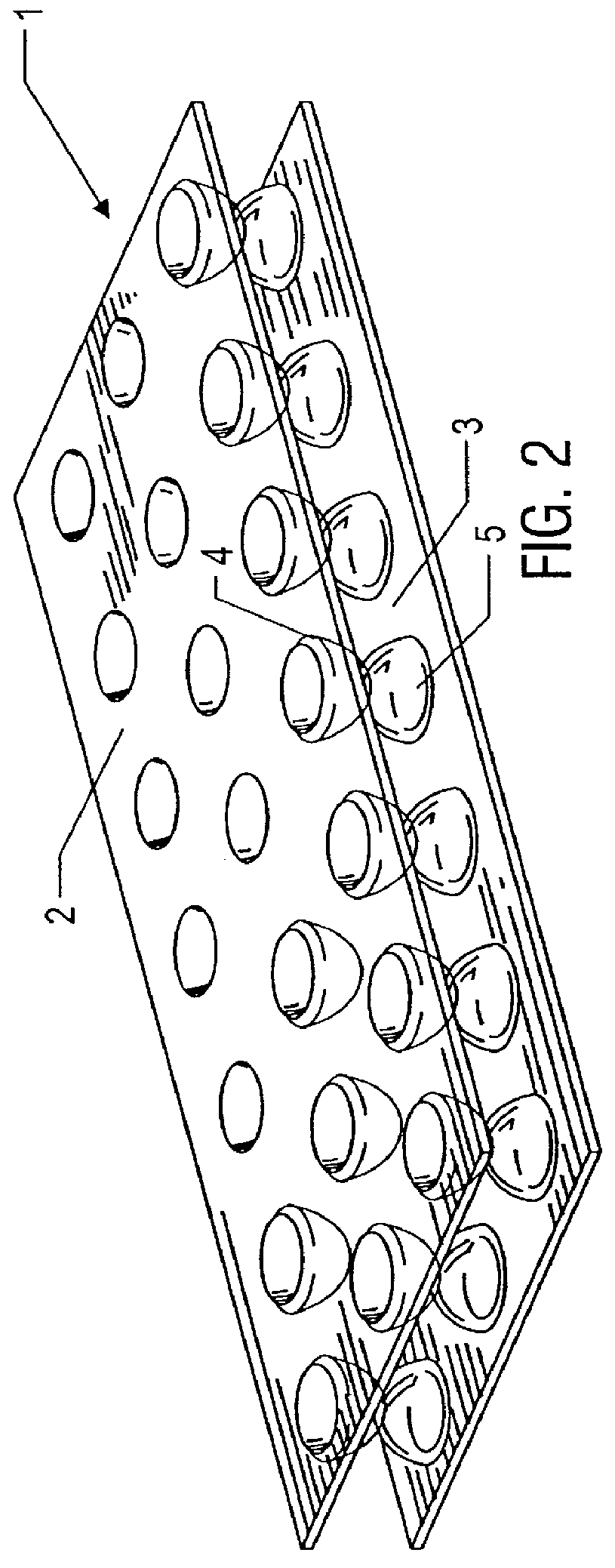

Pocket mattress with varying height

ActiveUS7194777B2Easy to provideSoft layerStuffed mattressesMultiple spring combinationsCoil springBiomedical engineering

Owner:STJERNFJADRAR

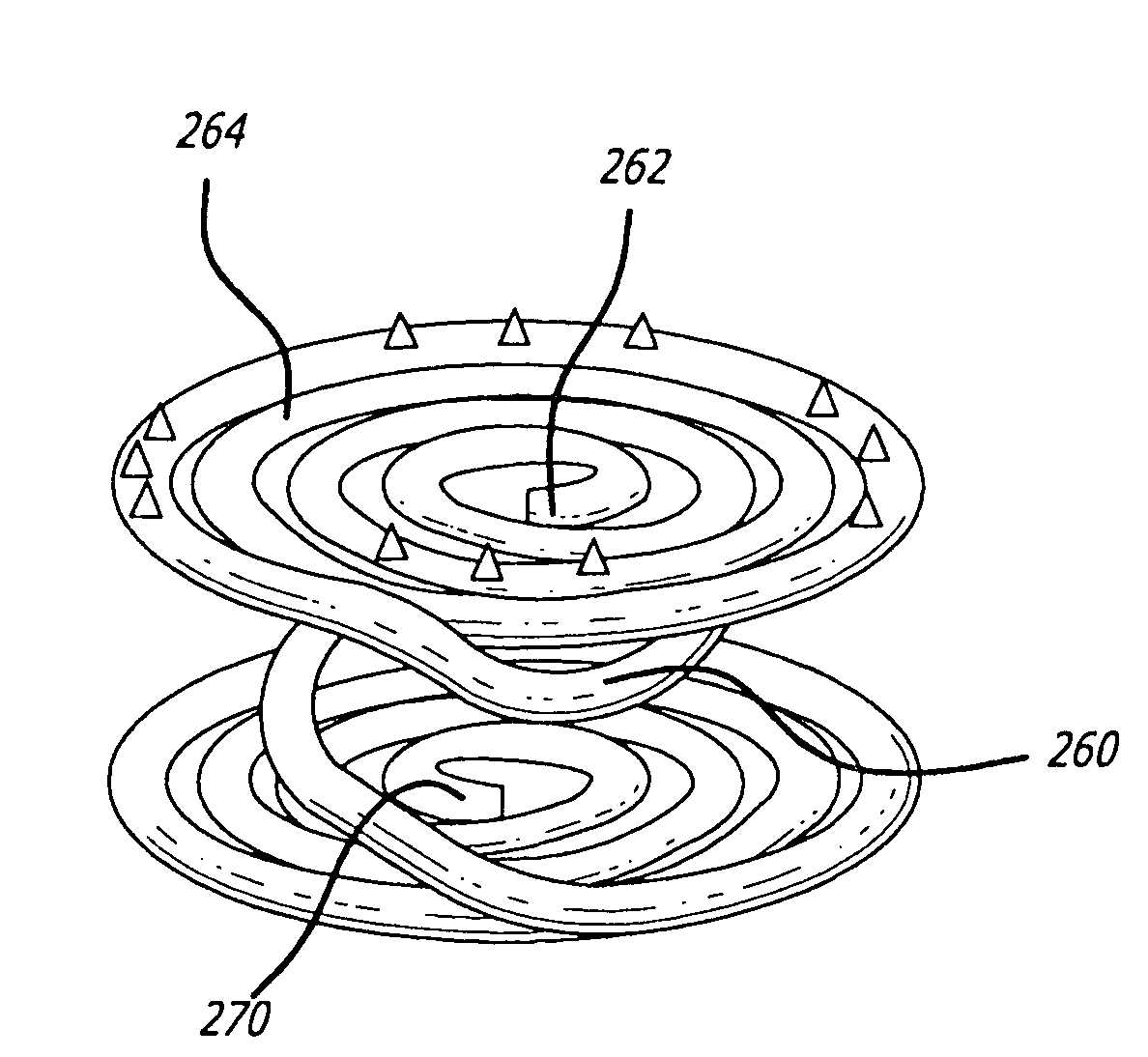

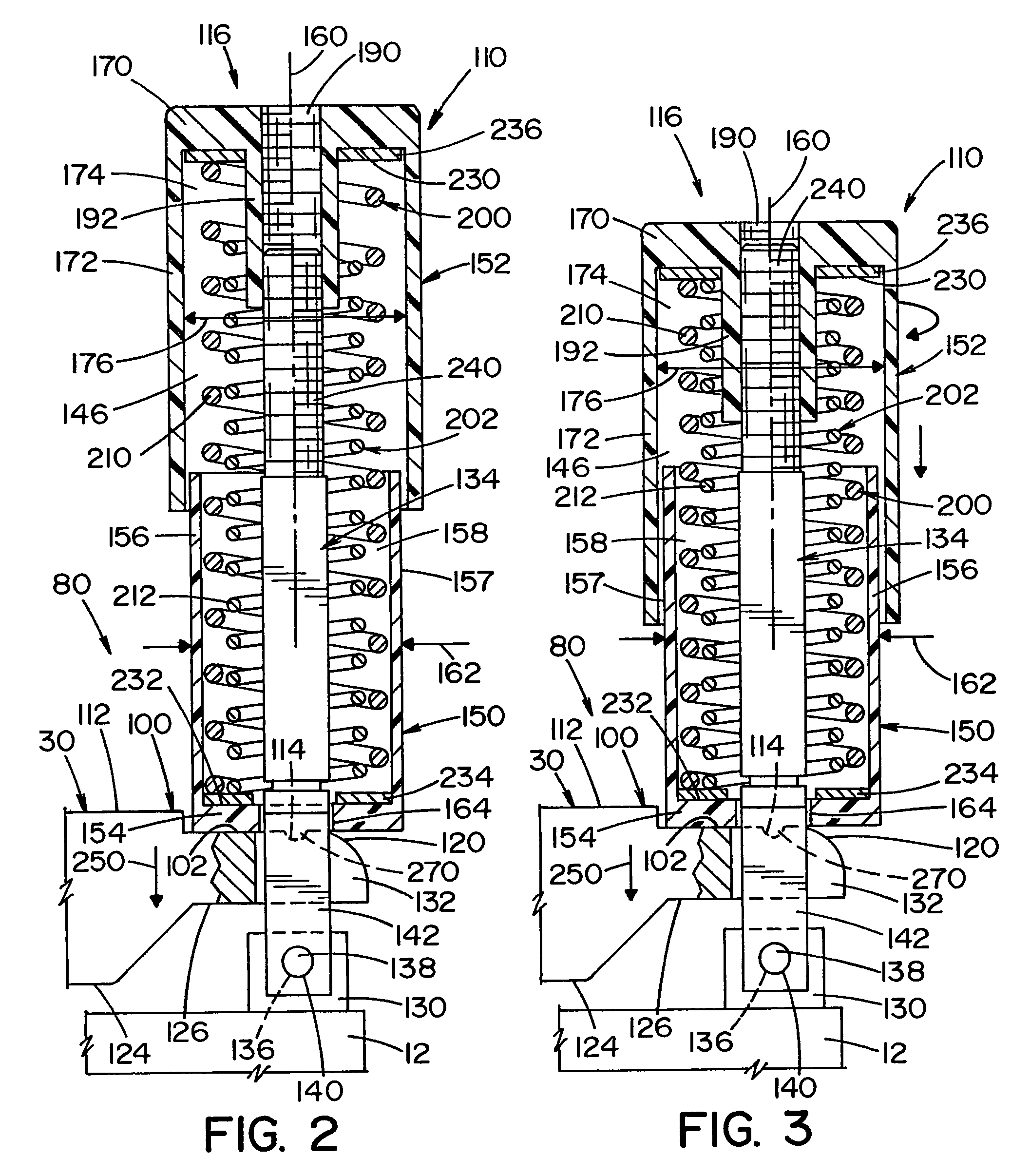

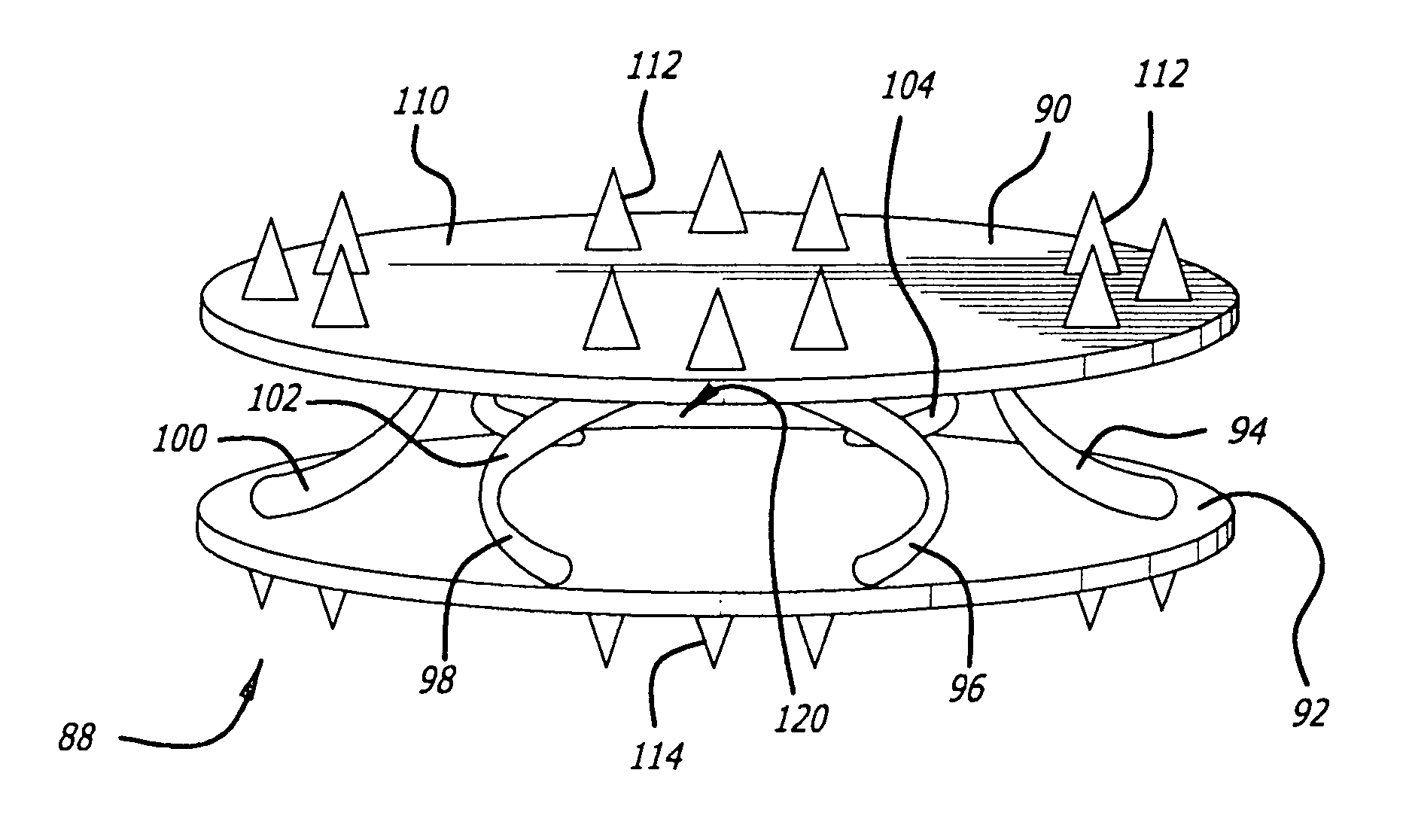

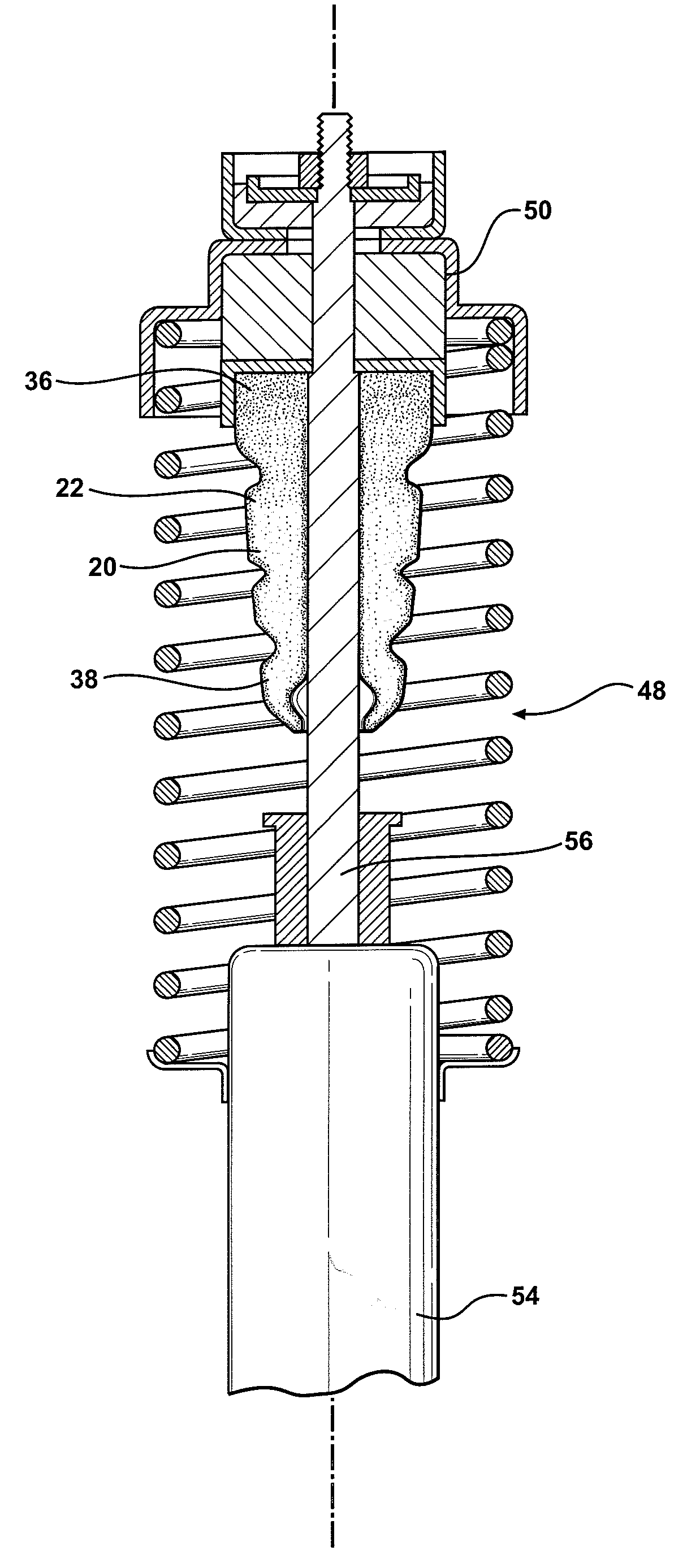

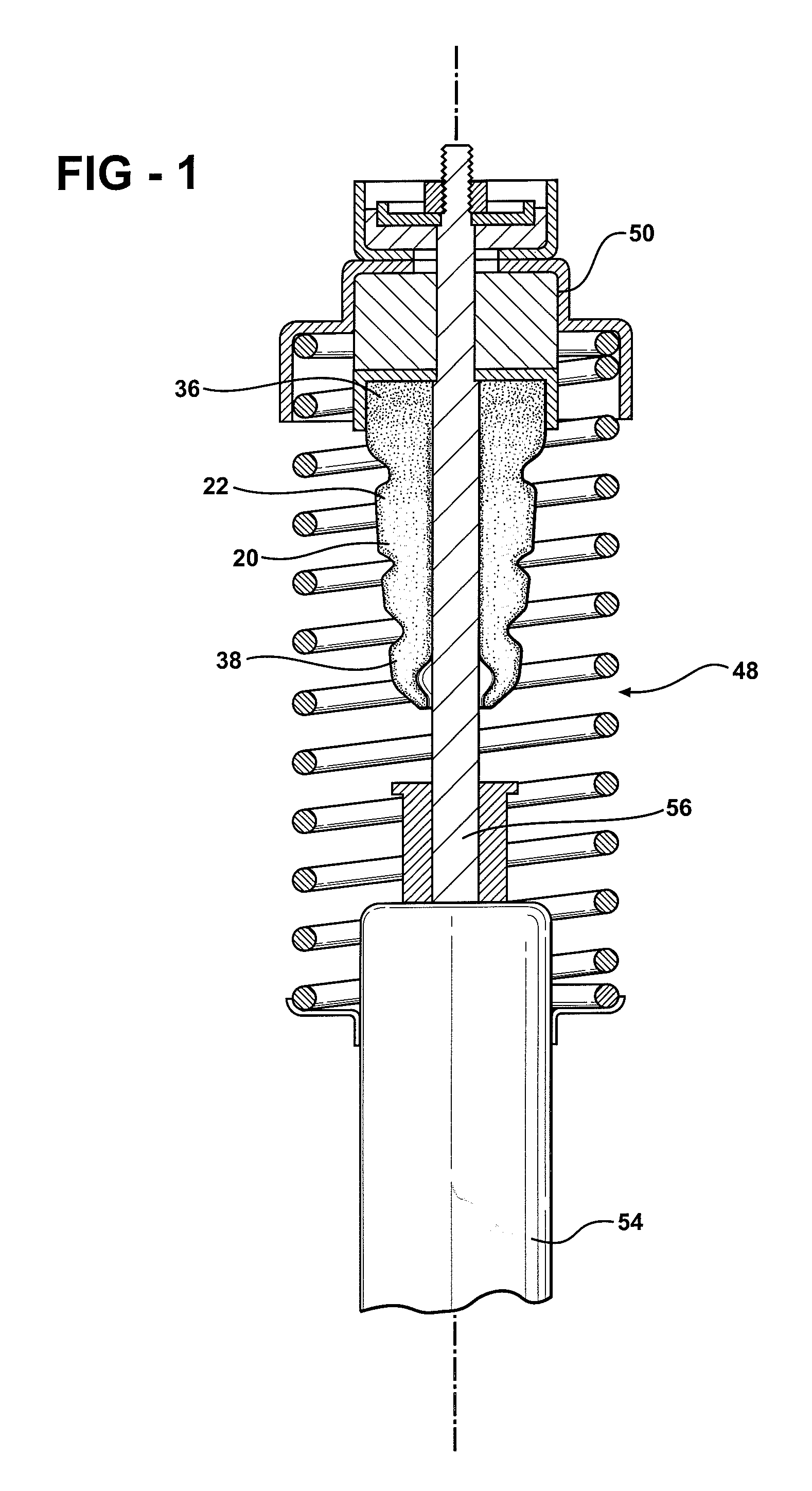

Prosthetic spinal discs

ActiveUS20060149381A1Minimizing localized stressIncrease contact areaMultiple spring combinationsSpinal implantsPhysical medicine and rehabilitationIntervertebral disc

A prosthetic spinal disc uses a stiff spring or springs for resiliency between two plates that attach to adjacent vertebrae. When the disc has multiple springs, they may be adjacent, concentric or nested. Multiple springs may be spaced around the periphery of the plates. A foil metal bellows may surround the plates to prevent material from entering or exiting the space between the plates. Alternatively, the ends of the spring(s) may be machined with spikes to engage the vertebrae directly without plates.

Owner:INFINESSE CORP

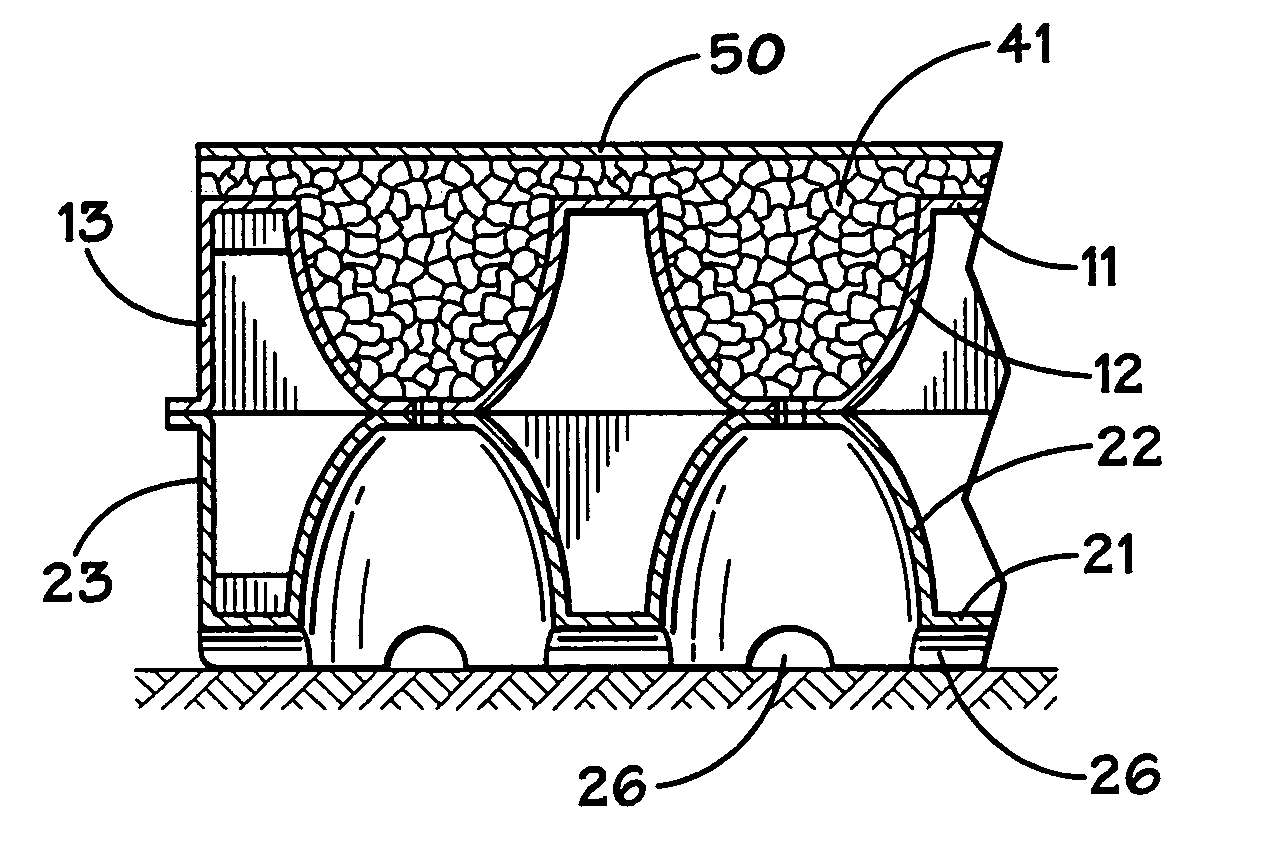

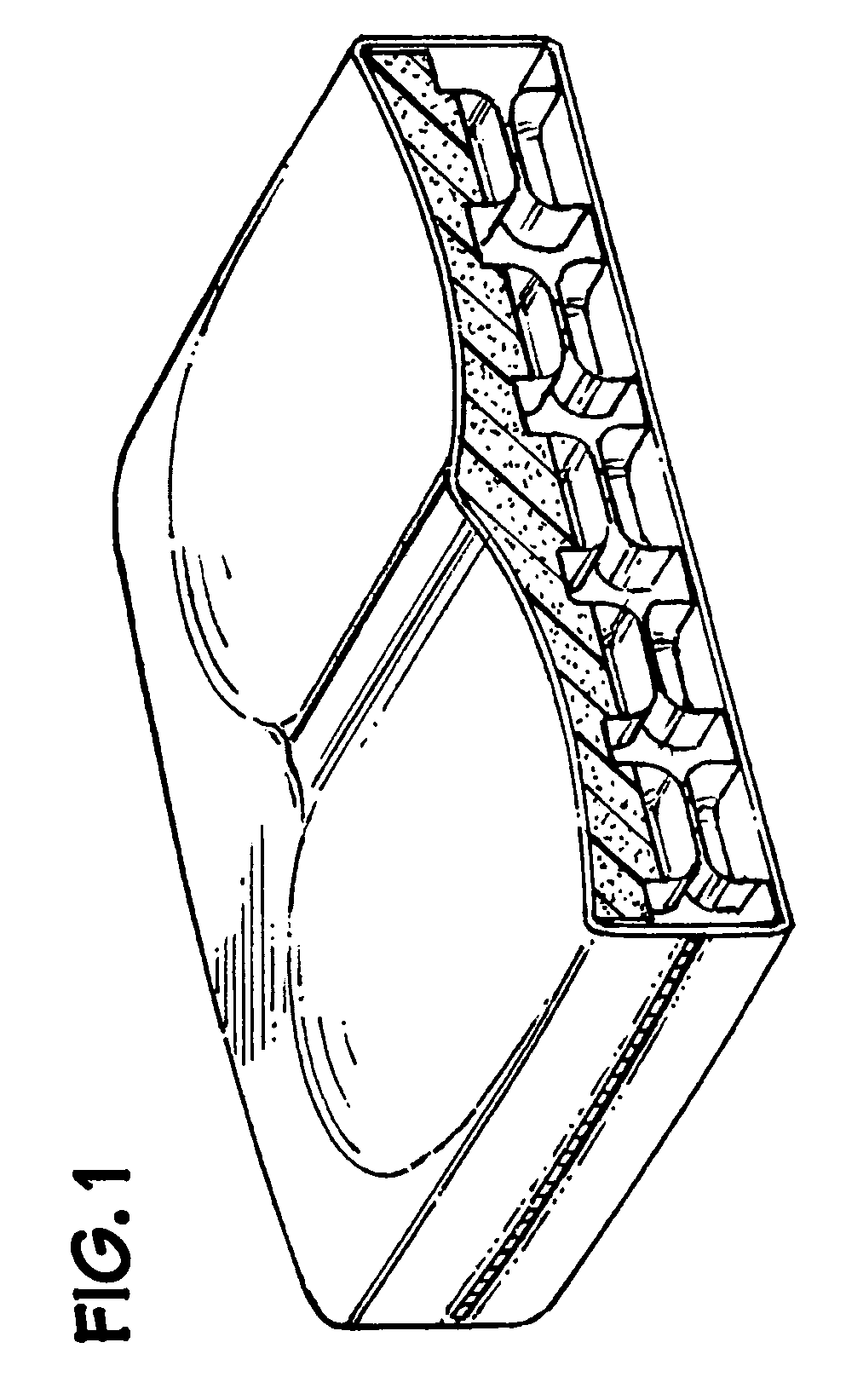

Cushioning structure for floor and ground surfaces

InactiveUS7033666B2Less laborImprove buffering effectLayered productsMultiple spring combinationsThermoplasticParticulates

Owner:SKYDEX TECH INC

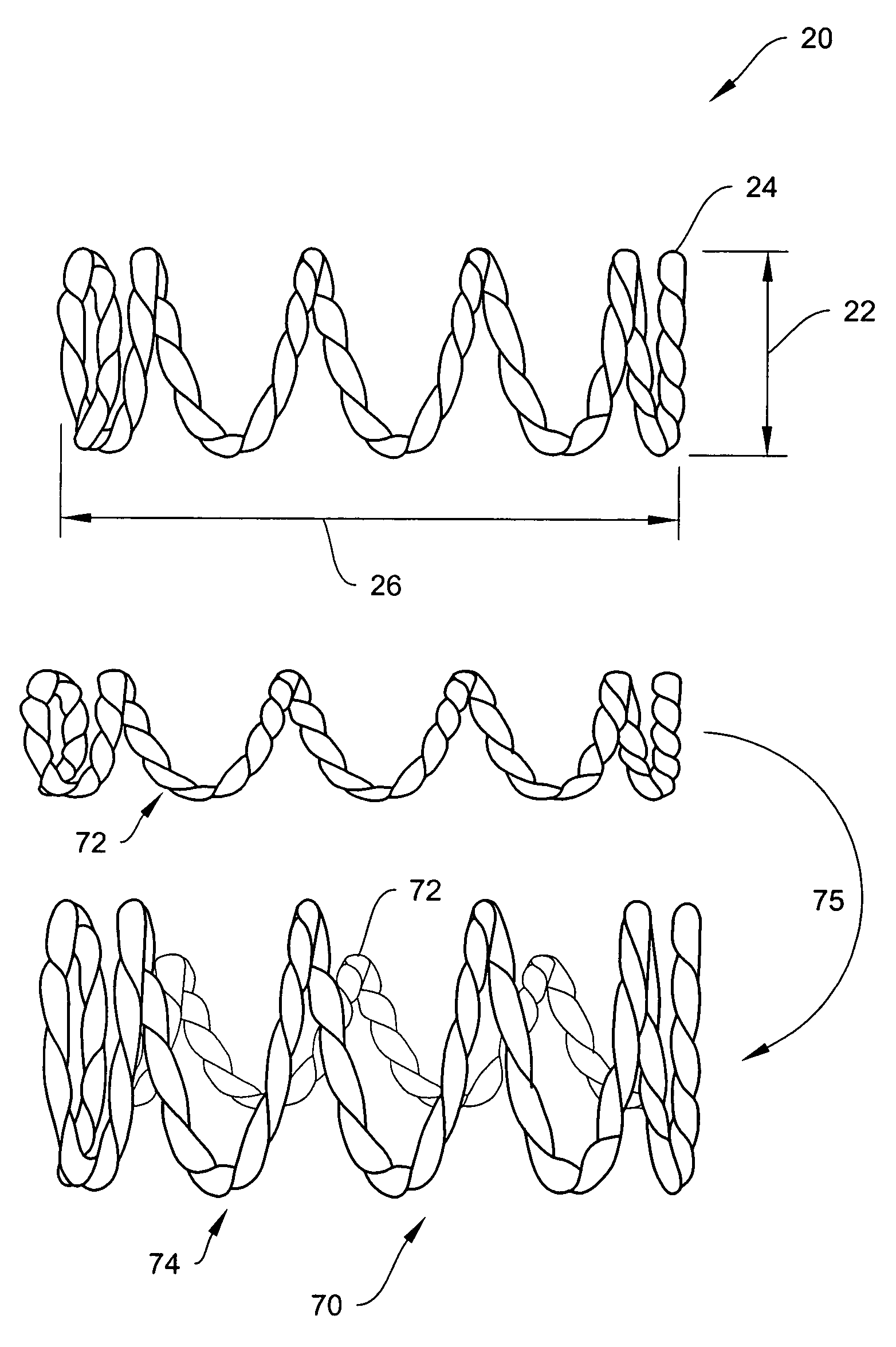

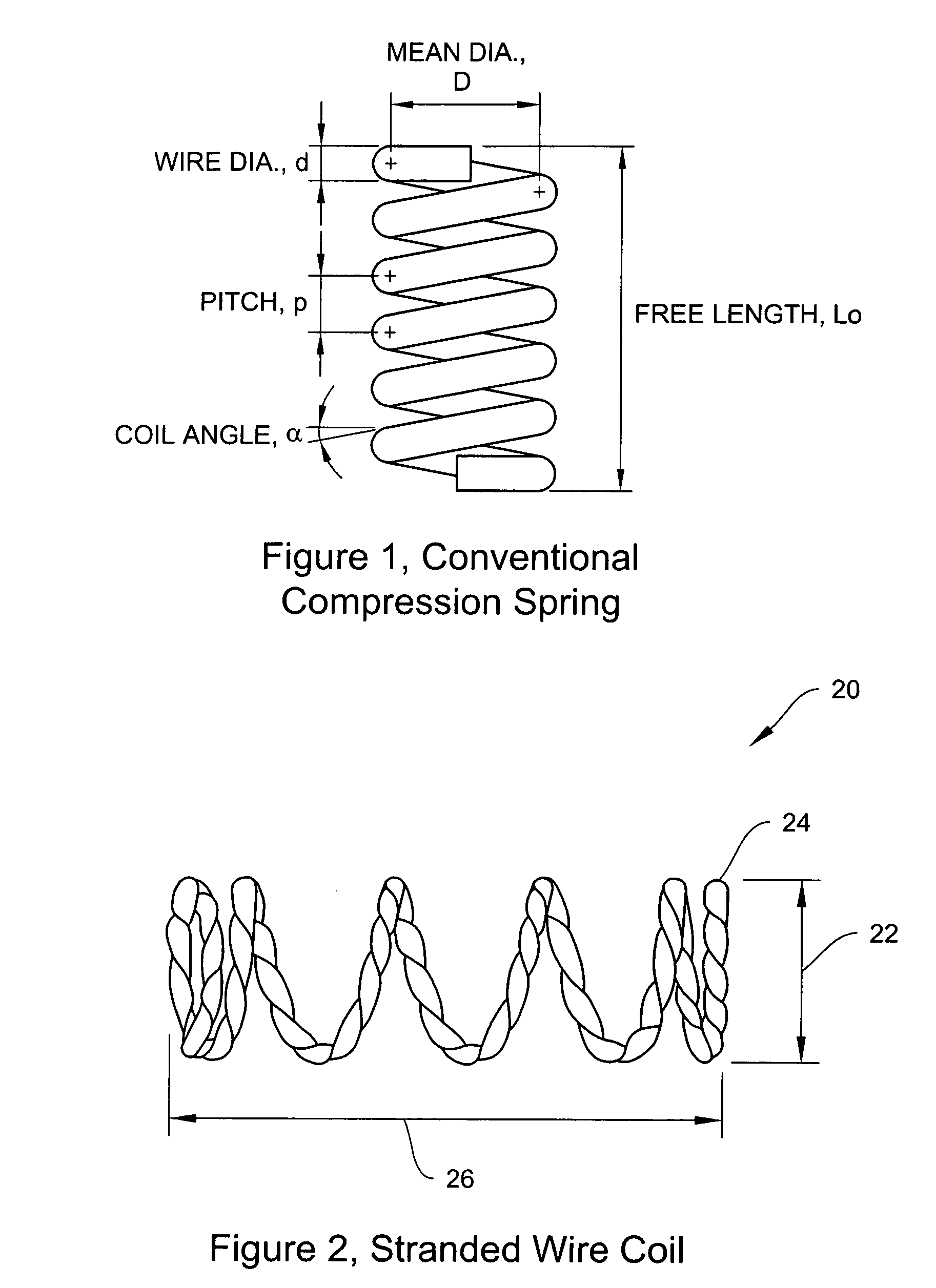

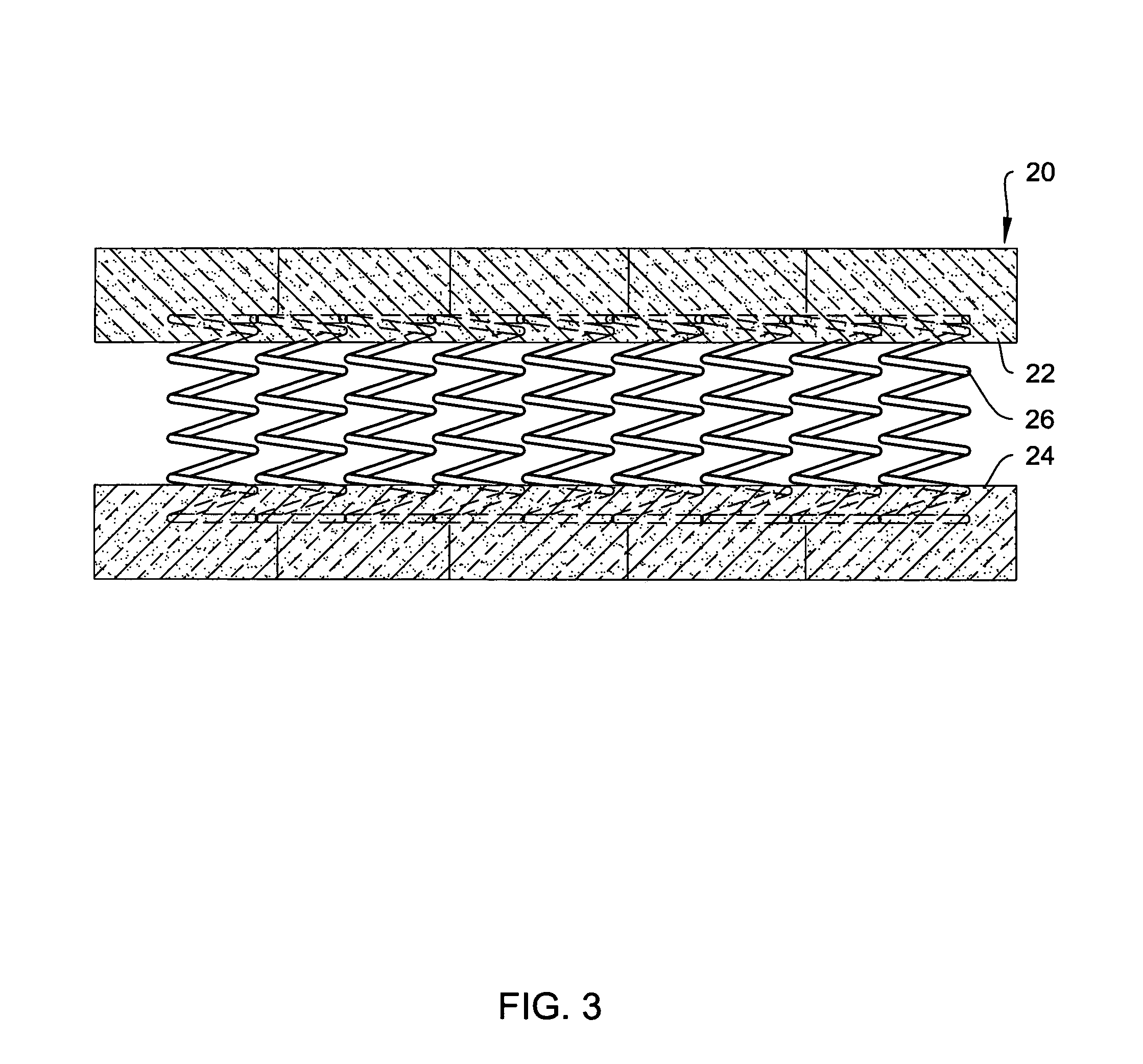

Multi-stranded coil spring

InactiveUS7168117B2Reduce adverse effectsStuffed mattressesMultiple spring combinationsCoil springHelical coil

Owner:SIMMONS CO +1

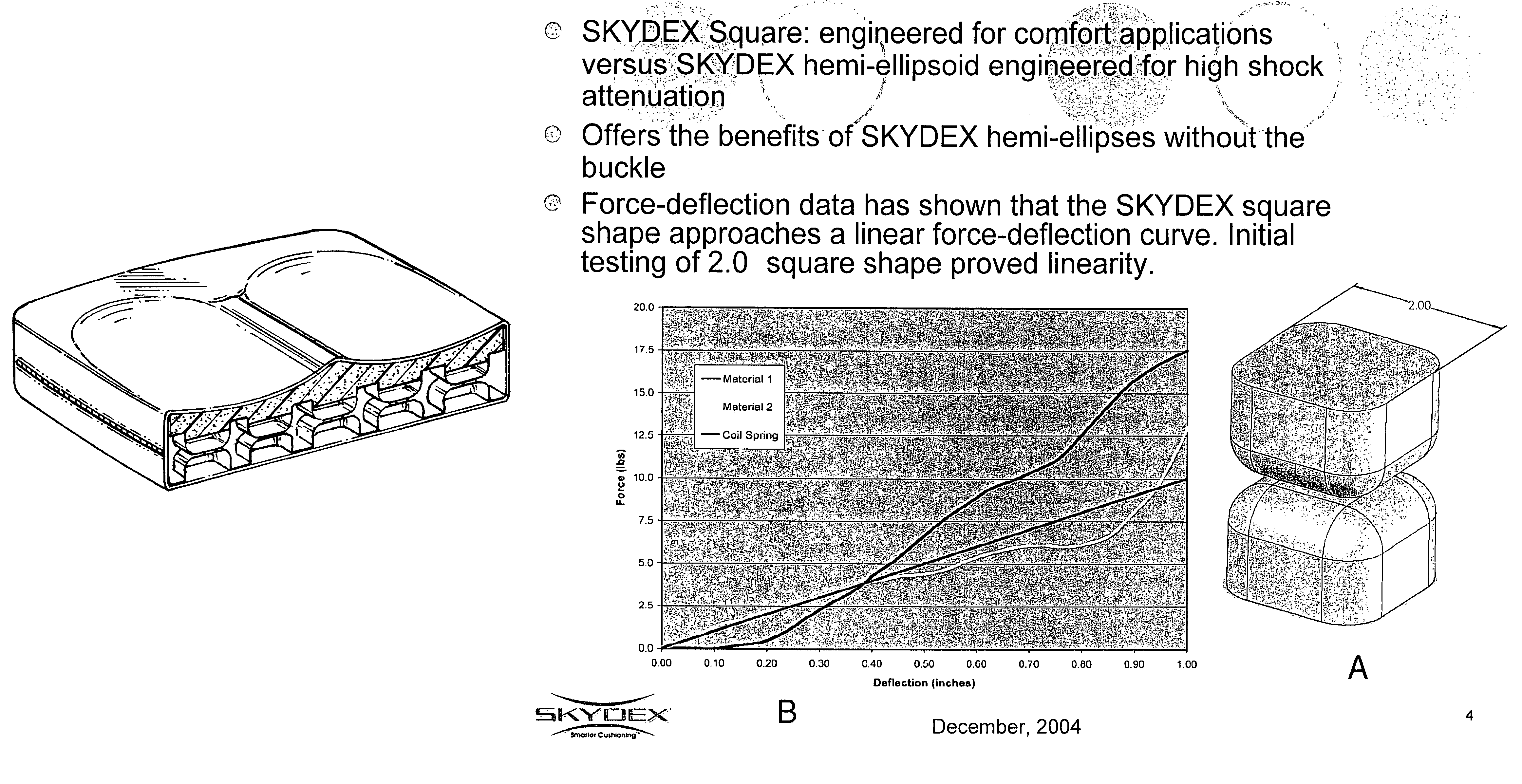

Cushioning system with parallel sheets having opposing indentions for linear deflection under load

ActiveUS7574760B2Resistant to tear and punctureEasy to cleanStuffed mattressesLeaf springsEngineeringBiomedical engineering

A cushion comprises a first surface made of flexible high polymer resin; a second surface made of flexible high polymer resin, in at least partially coextensive relation to the first surface to define a cavity therebetween, the coextensive relation defining opposing corresponding portions of the first and second surfaces; a plurality of support members comprising inwardly directed indentations in both of the first and second surfaces extending into the cavity, a plurality of the indentations in each of the first and second surfaces having a square shape and an outwardly facing recess, a plurality of the indentations in the first surface abutting the indentations in the second surface; a layer of viscoelastic foam substantially overlying the first surface; and, a fabric enclosure surrounding the first surface, the second surface and the foam layer.

Owner:SKYDEX TECH INC

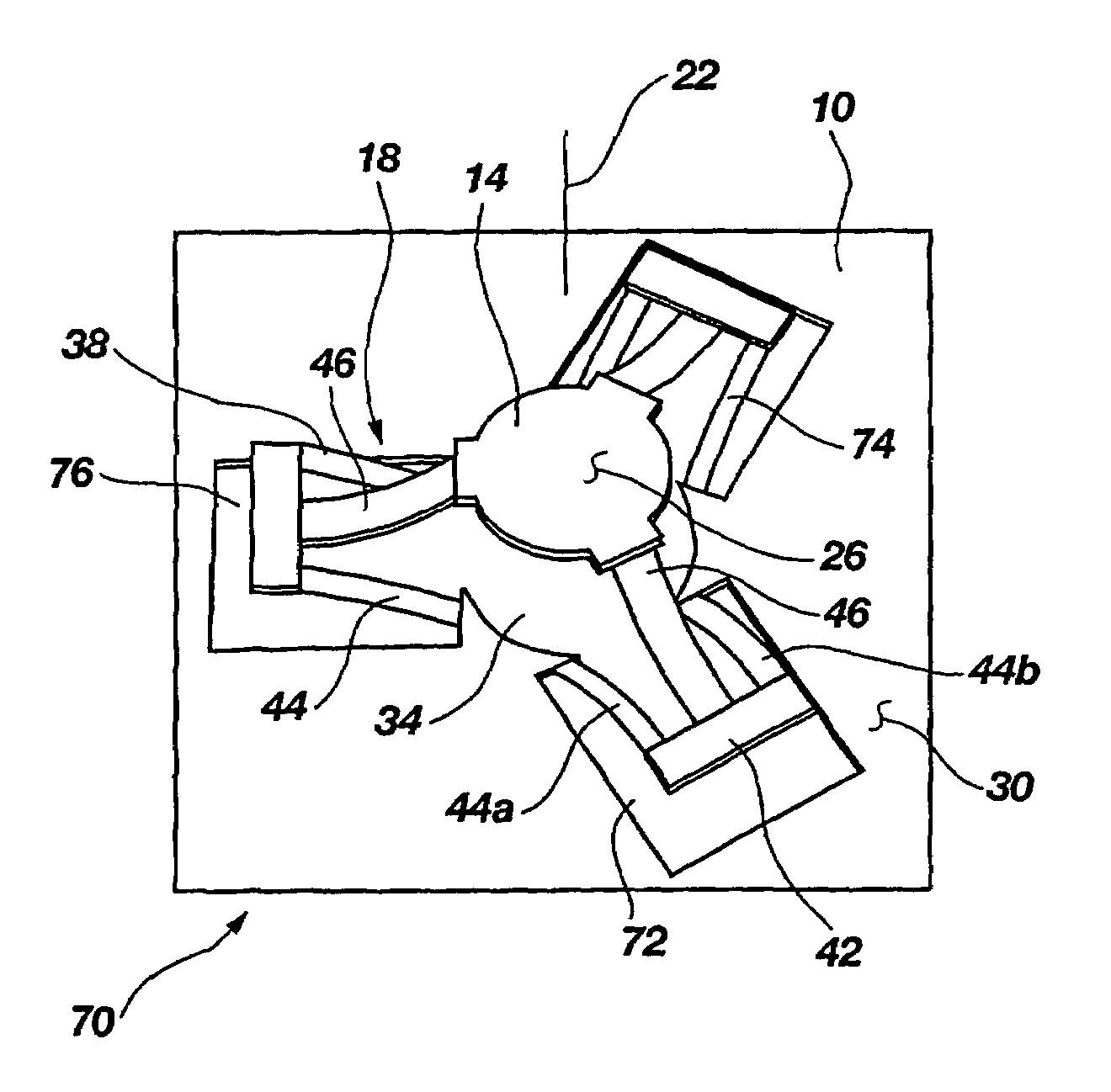

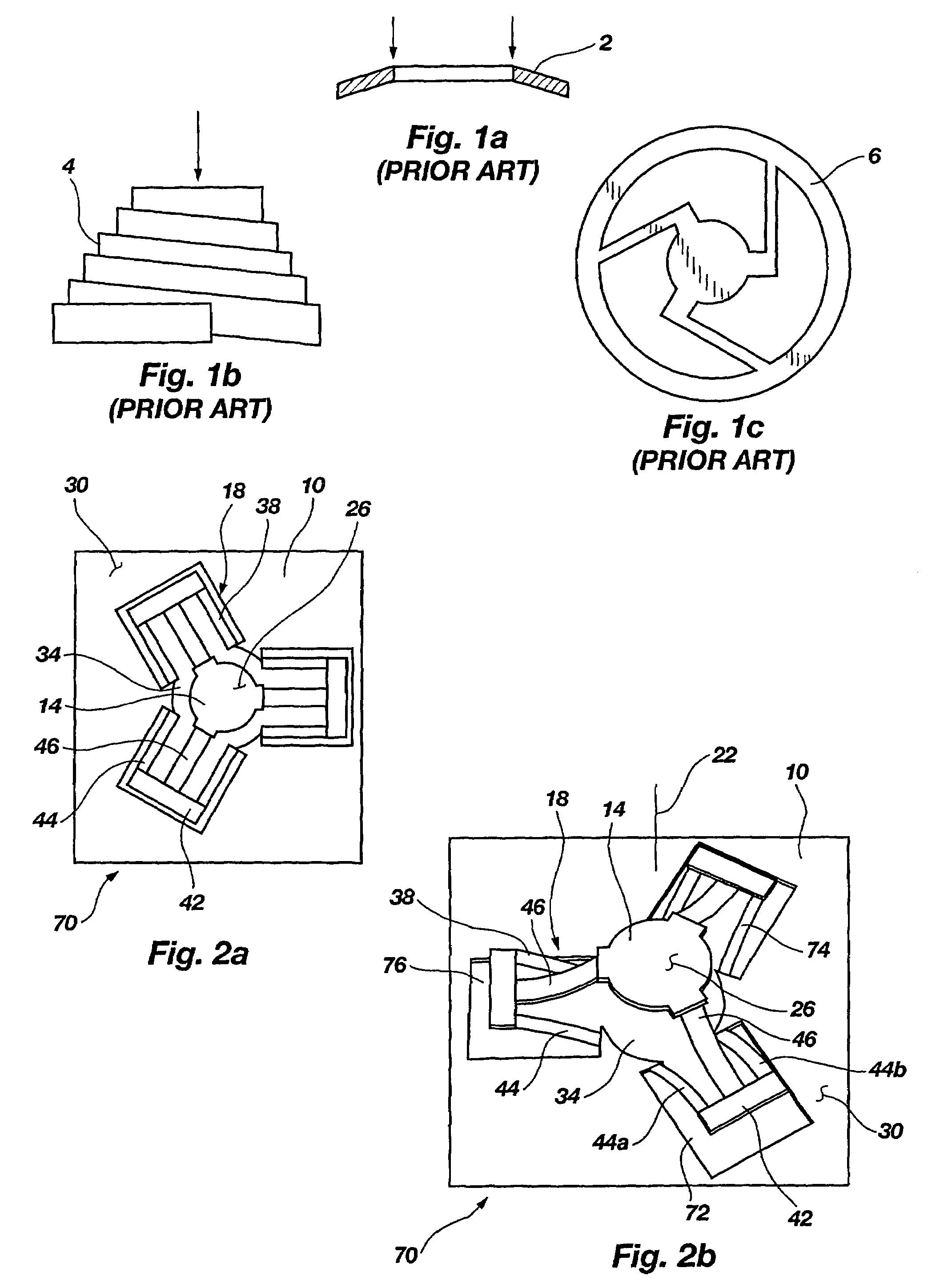

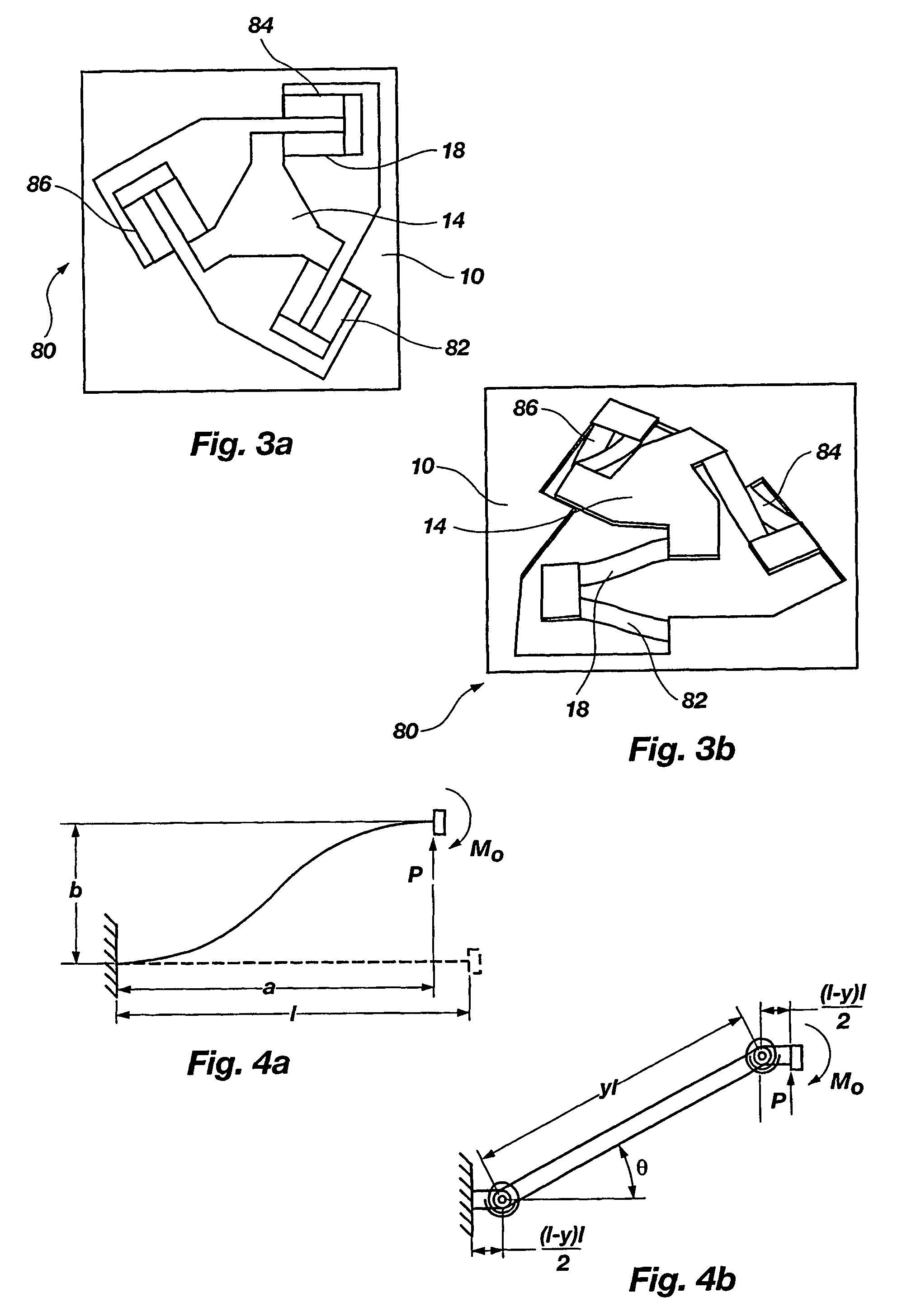

Compliant, ortho-planar, linear motion spring

An ortho-planar spring has a platform movably coupled to a base and being movable linearly with respect to the base along at least a portion of an axial direction perpendicular to both a base surface and a platform surface. A resilient and flexible connecting structure is connected to and between the base and platform. The connecting structure is bendable to develop (i) an axial force along the axial direction to bias the platform in a stable position with respect to the base, and (ii) non-axial forces which substantially sum to zero to preserve the orientation of the platform with respect to the base. Thus, the spring is very compact and does not have rotation between the deflecting ends. The spring may be associated with a valve opening, and a button for restricting flow through the valve opening, to bias the button at a position with respect to the valve opening.

Owner:BRIGHAM YOUNG UNIV

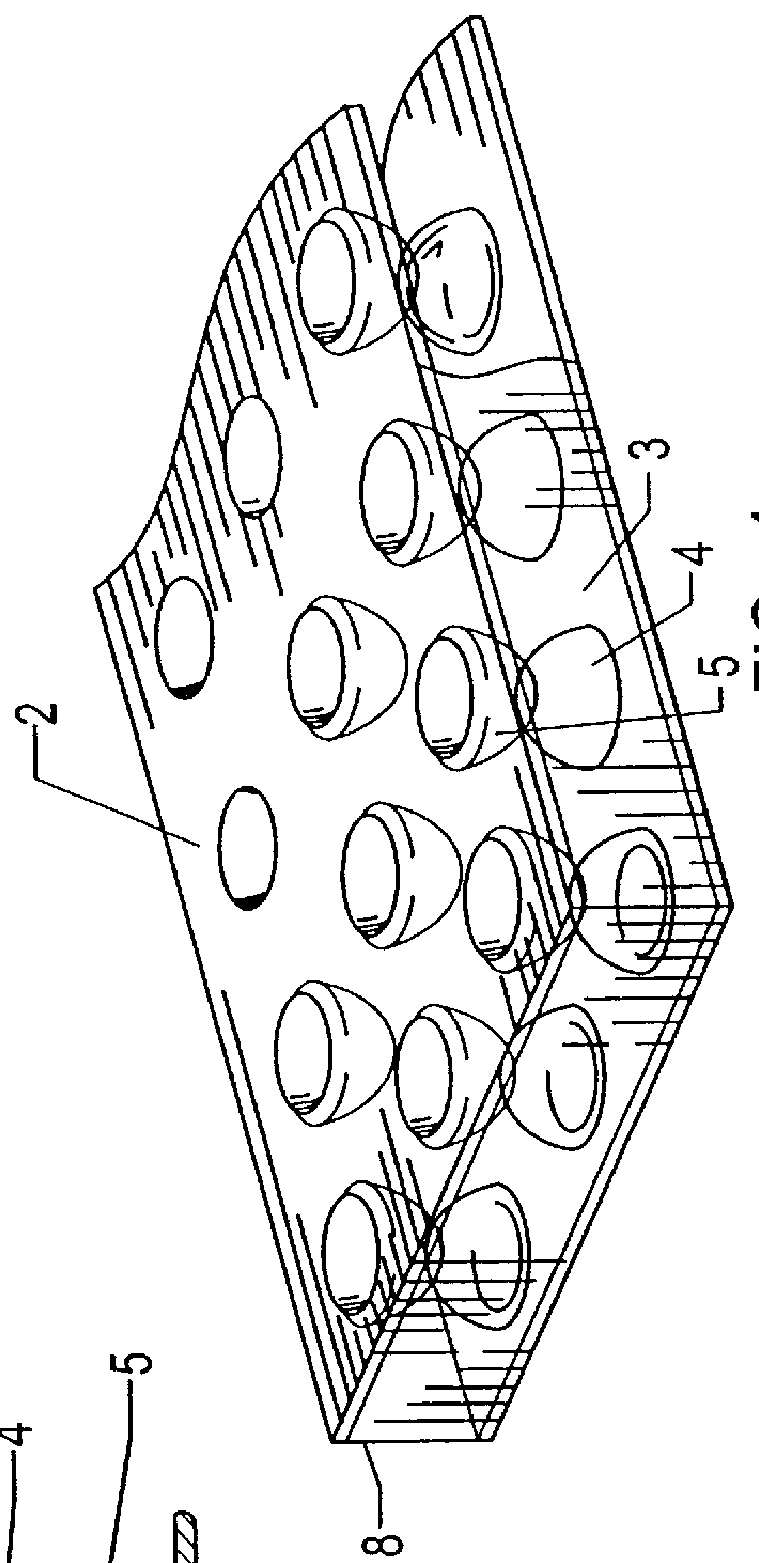

Thin pocket mattress, and method and device for its manufacturing

ActiveUS8087114B2Cost-effective manufacturingReduce the amount requiredStuffed mattressesMultiple spring combinationsCoil springEngineering

Owner:STJERNFJADRAR

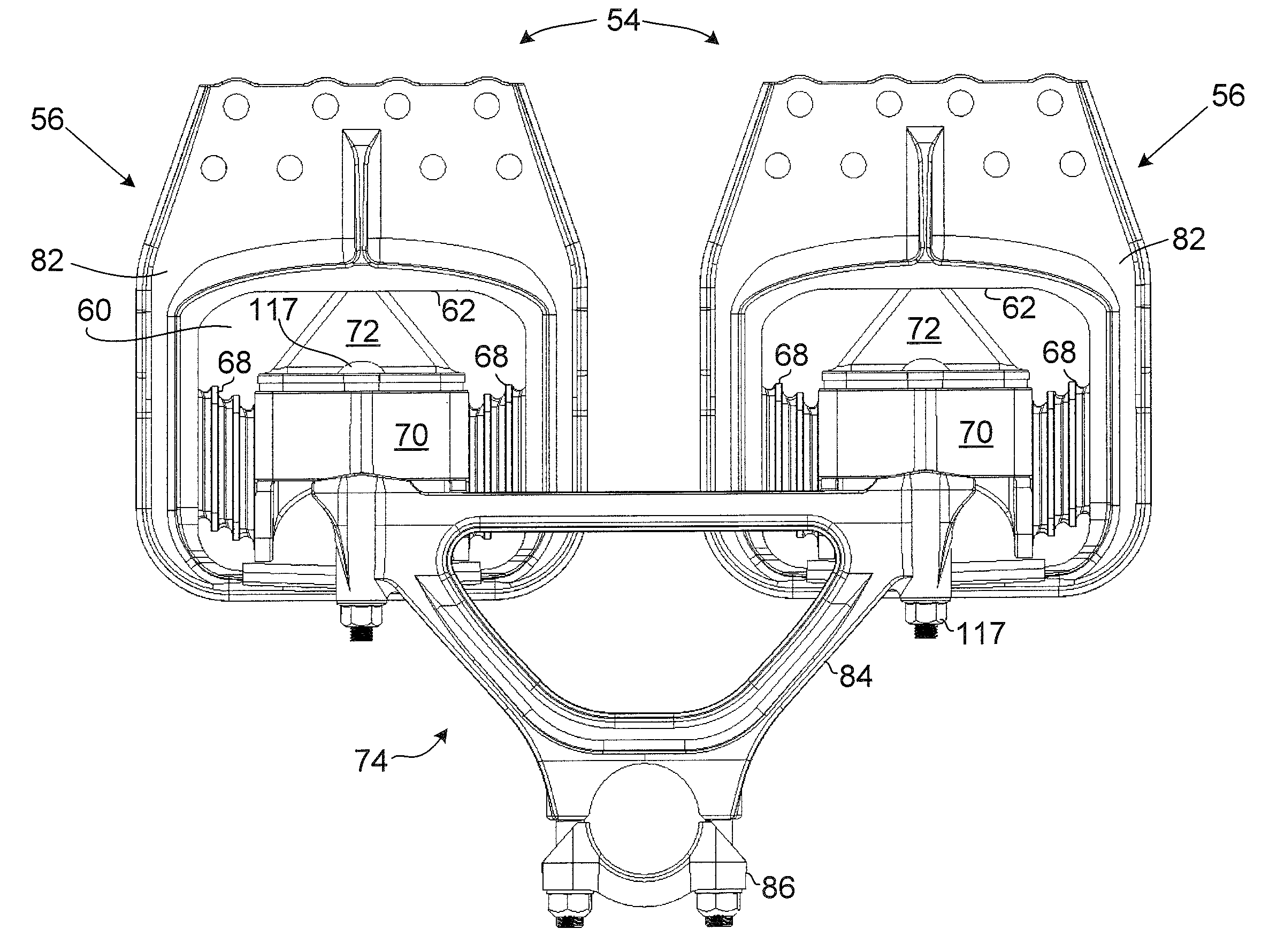

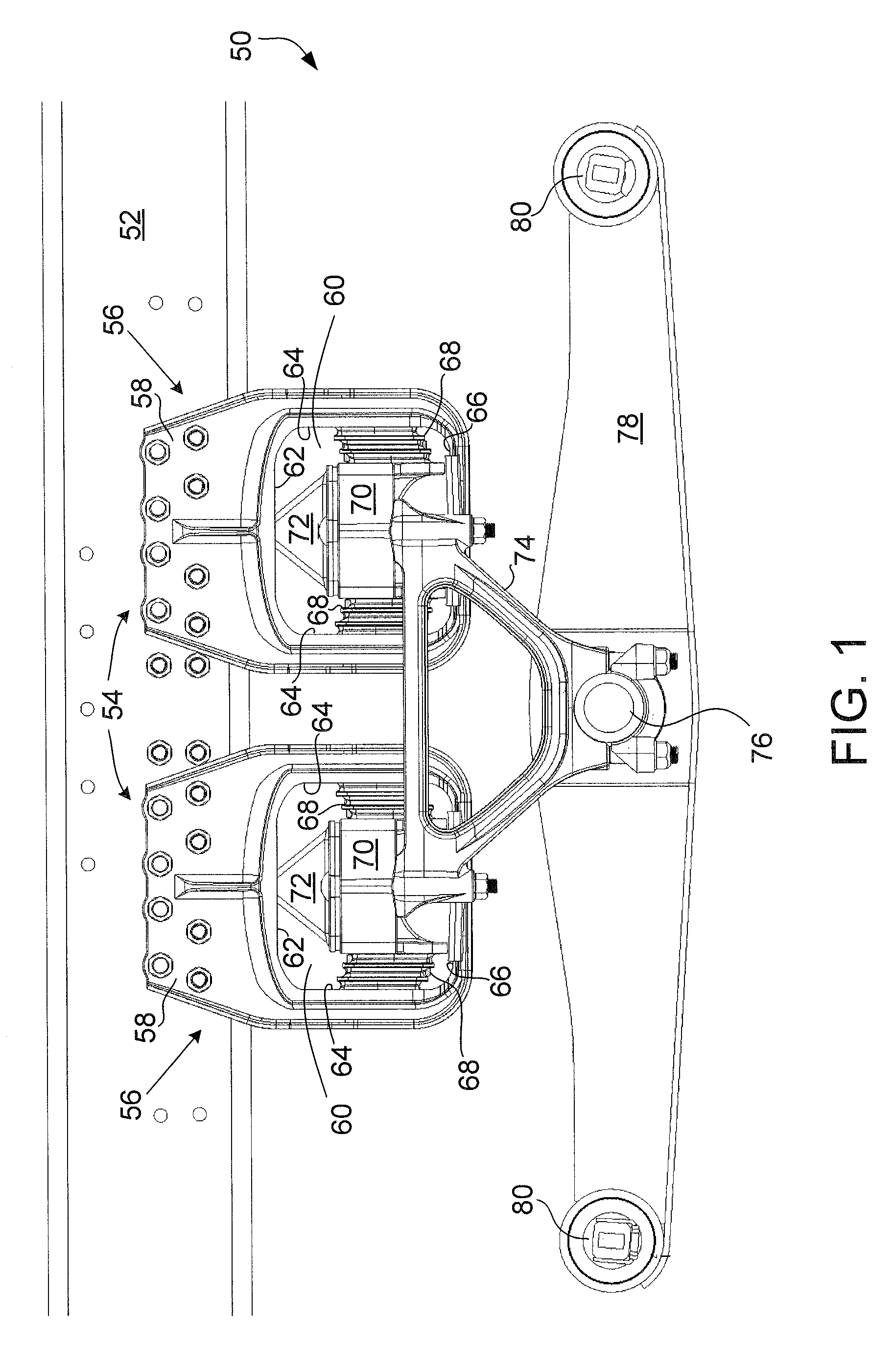

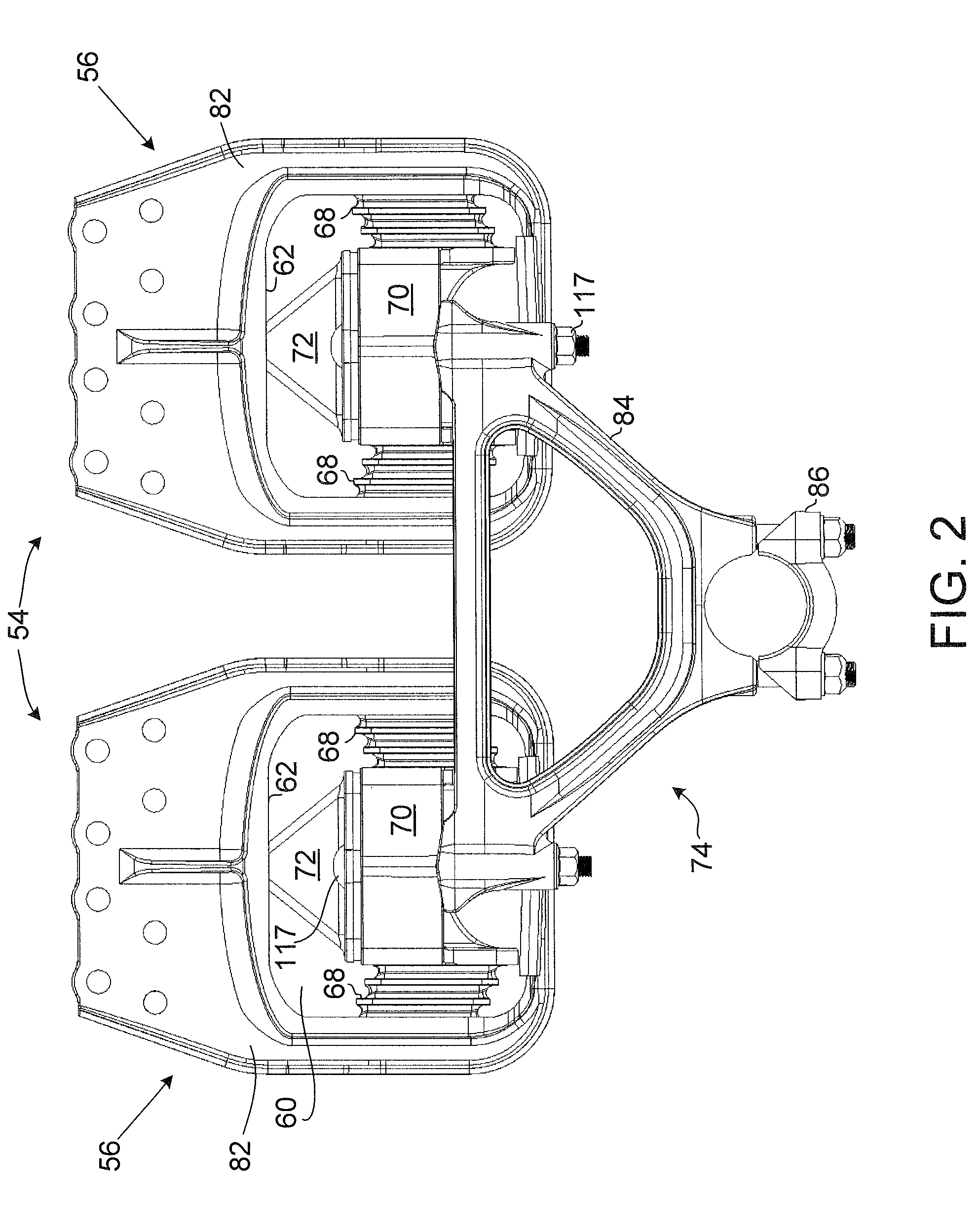

Elastomeric spring vehicle suspension

An elastomeric spring suspension is described for supporting a longitudinally extending vehicle frame rail above first and second axles forming a tandem axle configuration. The suspension includes a frame hanger assembly mounted to the vehicle frame rail. The frame hanger assembly has two full spring modules, each of which includes two elastomeric shear springs, an elastomeric progressive spring rate load cushion having a pyramidal shape with a flattened top surface and a spring mount for mounting the springs. A saddle assembly is connected to the spring mount, and an equalizing beam is connected to the saddle assembly and further connected to the axles. The spring rate for the suspension increases almost linearly as a function of sprung load, resembling a pneumatic suspension. Accordingly, the suspension exhibits excellent ride quality, without sacrificing roll stability.

Owner:HENDRICKSON USA L L C

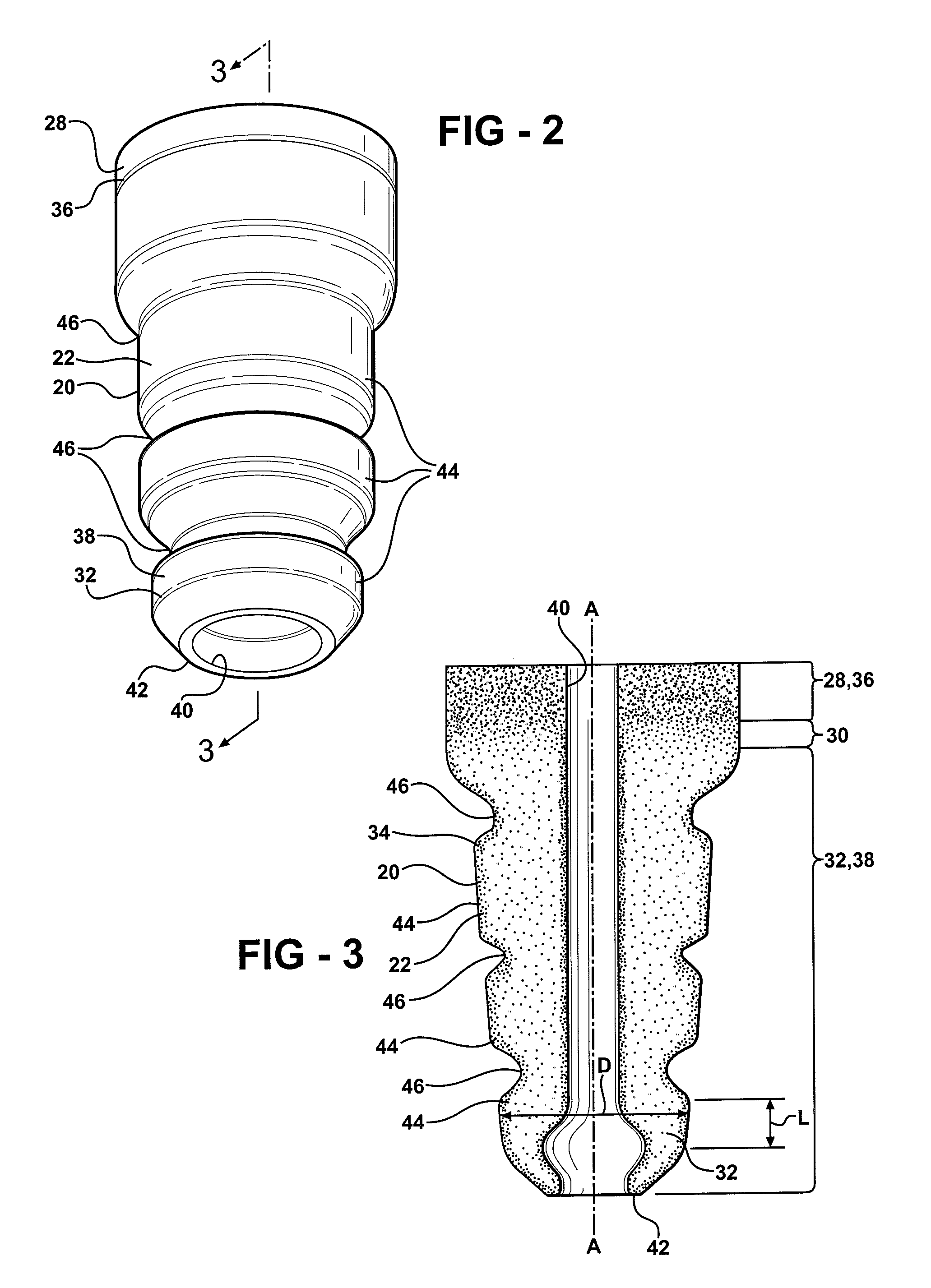

One-piece microcellular polyurethane insulator having different densities

InactiveUS20080012188A1Inhibition heightLow costPortable framesMultiple spring combinationsCoil springVolumetric Mass Density

An insulator for a vehicle includes a first portion extending along an axis, an intermediate portion extending from the first portion along the axis, and a second portion extending from the intermediate portion along the axis. The first portion defines a first density and the second portion defines a second density different from the first density. Preferably, the first density is greater than the second density such that the second portion is more compressible than the first portion. The first portion, the intermediate portion, and the second portion are integrally formed of a common homogeneous microcellular polyurethane material for defining a one-piece insulator having different densities. In exemplary embodiments, the insulator is further defined as a jounce bumper or a coil spring isolator for disposition in a wheel suspension system, and a body insulator for disposition in a mount assembly of a vehicle.

Owner:BASF CORP

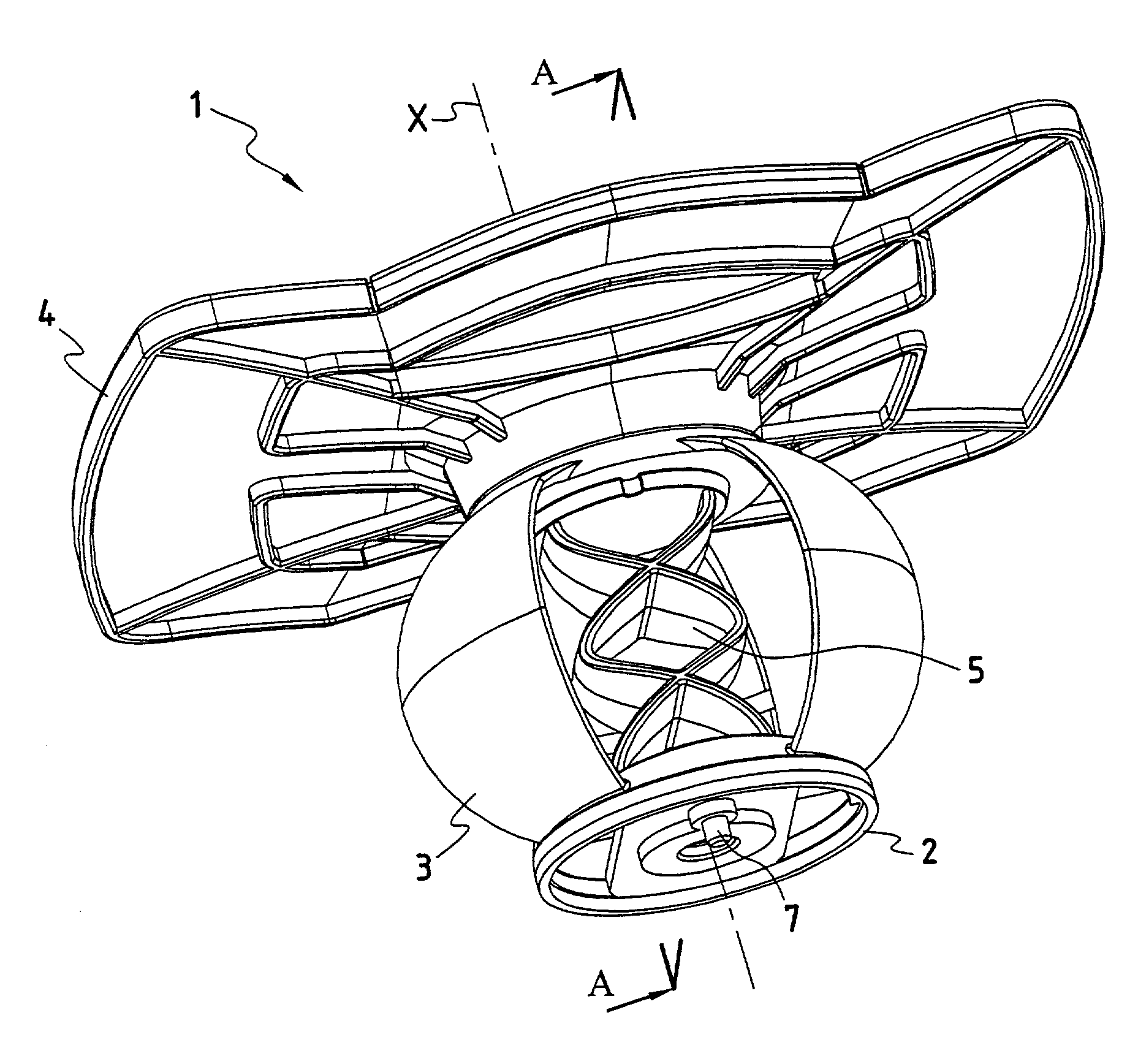

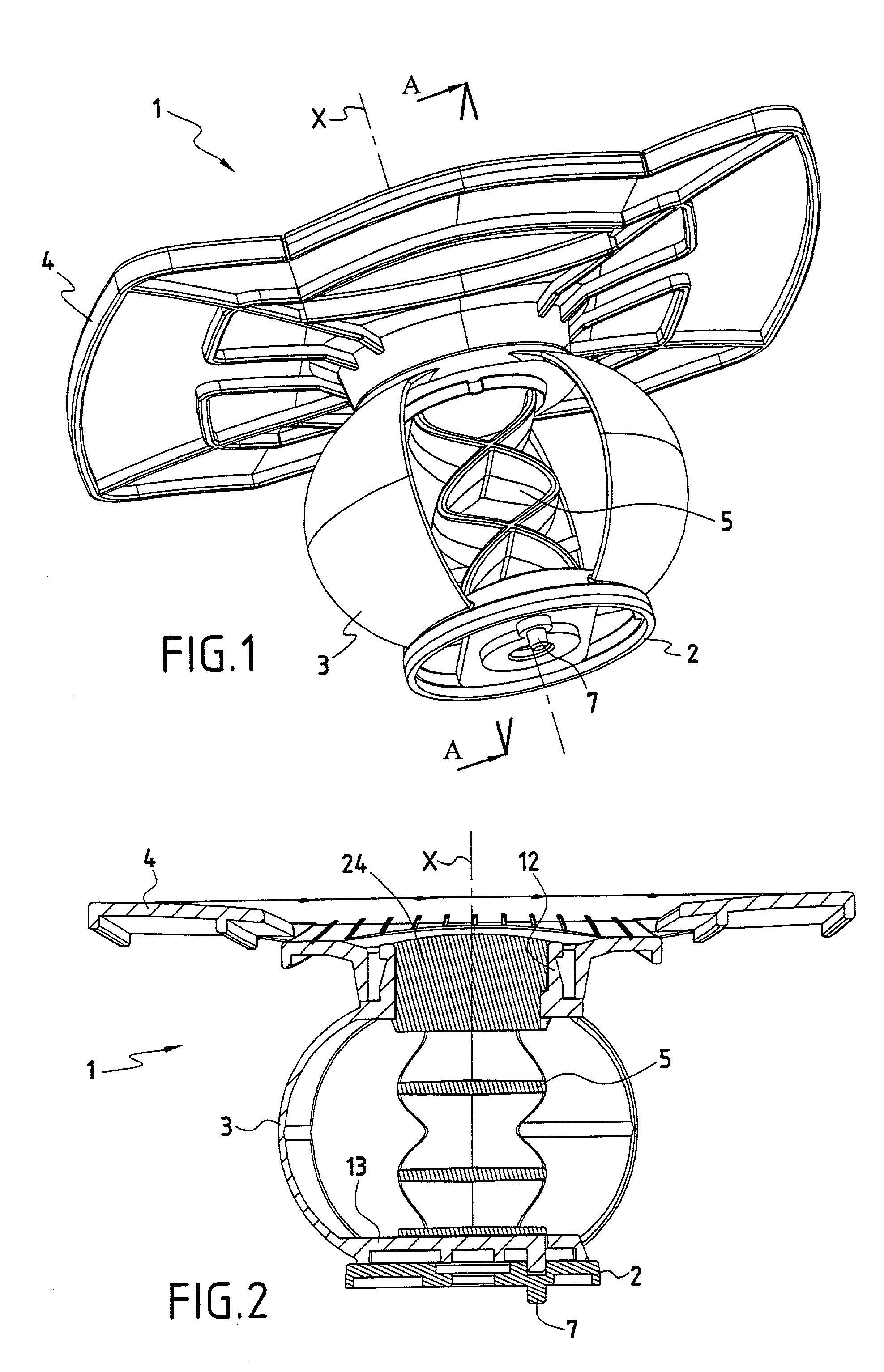

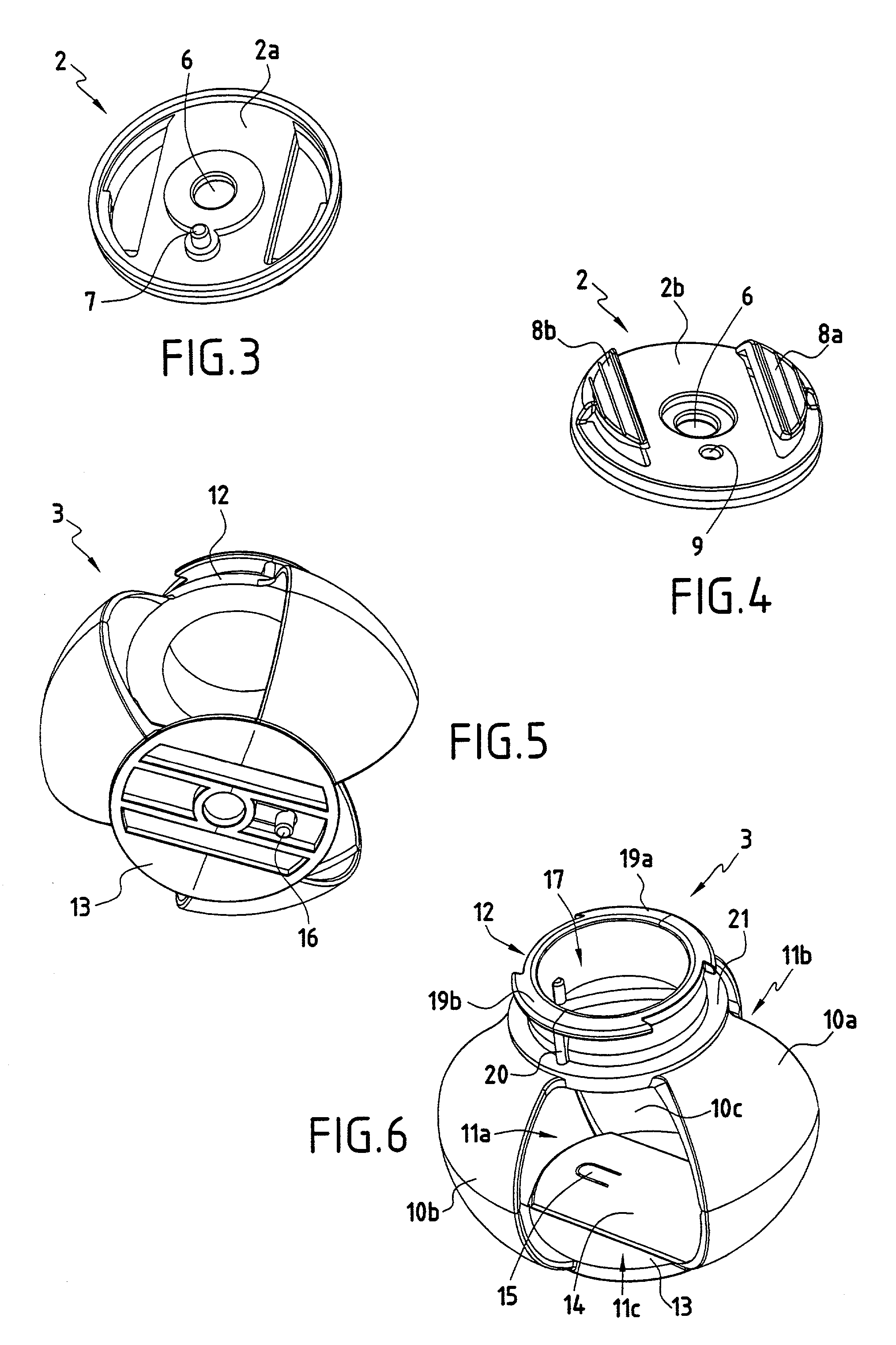

Suspension device for a bed or seat base of the multielement type

InactiveUS20020163114A1Precise positioningStuffed mattressesLeaf springsSynthetic materialsEngineering

The invention provides an individual suspension device for a bed or seat base of the multi-element type, the device being for interposing between a platform determining a support surface and a padding element such as a mattress, and comprising a foot for fixing to an element of the platform, a suspension structure fixed to the foot, and a top plate carried by the suspension structure and serving as a support for the padding element, said suspension structure being circularly symmetrical about a vertical axis, wherein the suspension structure is a single hollow piece and is made of a flexible synthetic material or a vulcanized rubber having hardness lying in the range 40 on the Shore A scale to 70 on the Shore D scale.

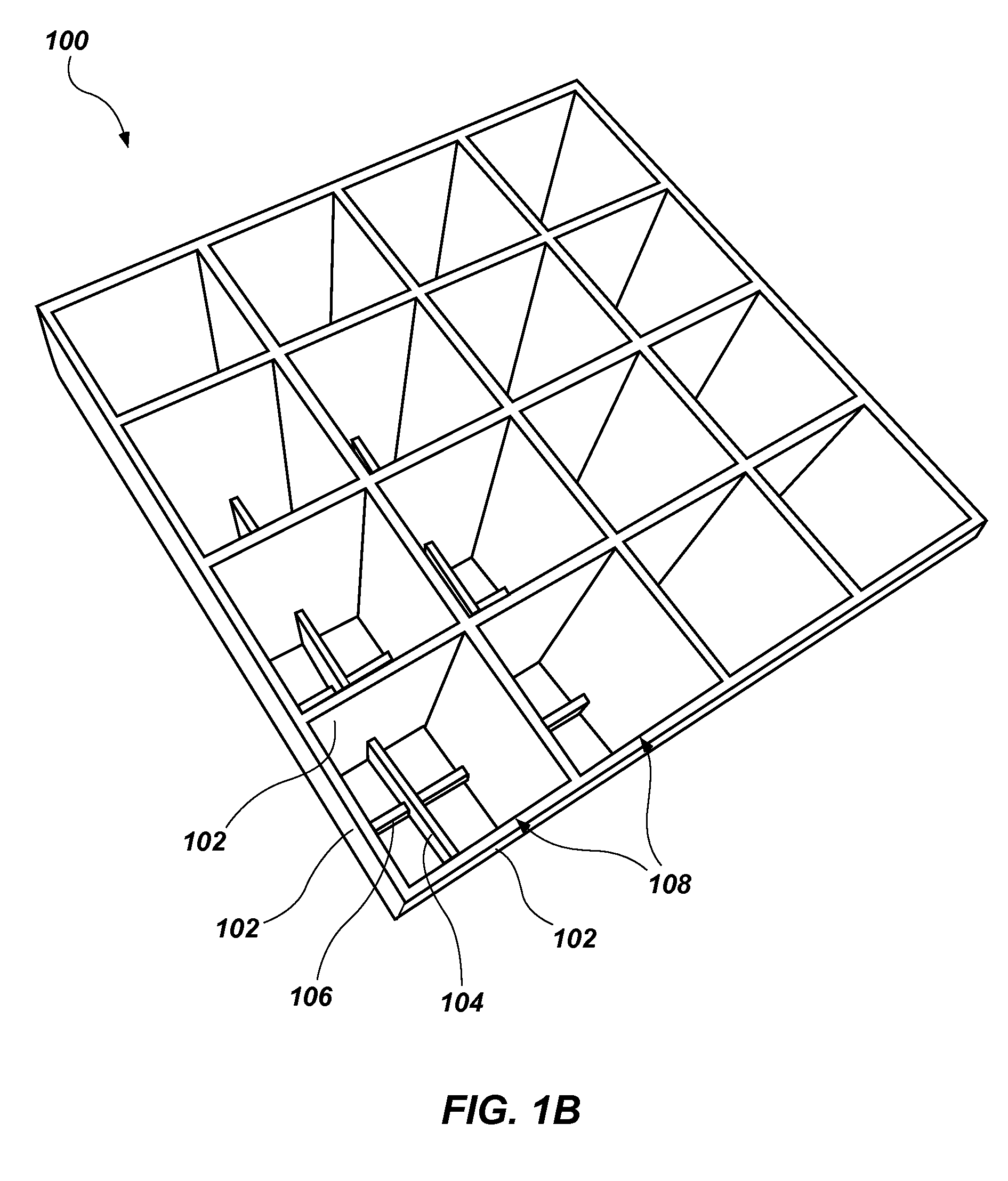

Cushioning elements comprising buckling walls and methods of forming such cushioning elements

Cushioning elements having a top cushioning surface and a bottom base surface include an elastomeric cushion member and a stabilizing material. The elastomeric cushion member includes a first plurality of interconnected buckling walls having a first mean height and a second plurality of buckling walls having a second mean height. Each buckling wall of the second plurality intersects and connects to at least two buckling walls of the first plurality. A surface of the stabilizing material on a side thereof opposite the elastomeric cushion member defines the bottom base surface of the cushioning element. The first ends of the first plurality of interconnected buckling walls and the first ends of the second plurality of buckling walls define the top cushioning surface of the cushioning element. Methods of forming cushioning elements include securing a stabilizing material to ends of the first plurality of interconnected buckling walls.

Owner:PURPLE INNOVATION LLC

Foam spring for pillows, cushions, mattresses or the like and method for manufacturing such a foam spring

ActiveUS8746662B2Improved propertyEasy to compressStuffed mattressesMultiple spring combinationsEngineeringCushion

Owner:IMHOLD

Individually pocketed coil springs with cushoning pads, and pocket spring mattresses with such pocketed coil springs

An individually pocketed coil spring for use in a bedding or seating product, is disclosed, as well as pocket spring mattresses including such pocketed coil springs. The individually pocketed coil spring include: a coil spring having an upper end and a lower end; a casing forming a pocket enclosing said coil spring; and a cushioning pad located above said upper end of the coil spring. The casing provides a first compartment enclosing the coil spring, and a second compartment enclosing the cushioning pad. The first and second compartments are separated from each other.

Owner:STARSPRINGS AB +1

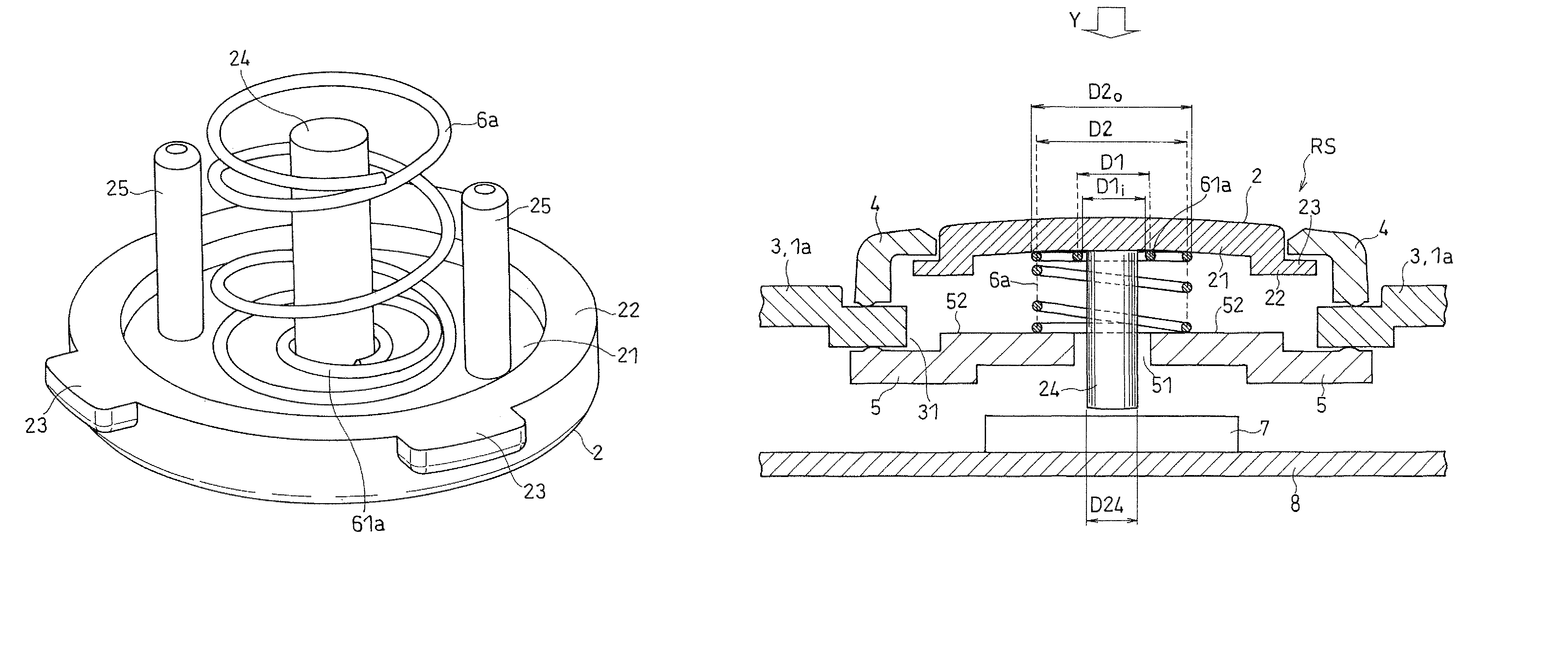

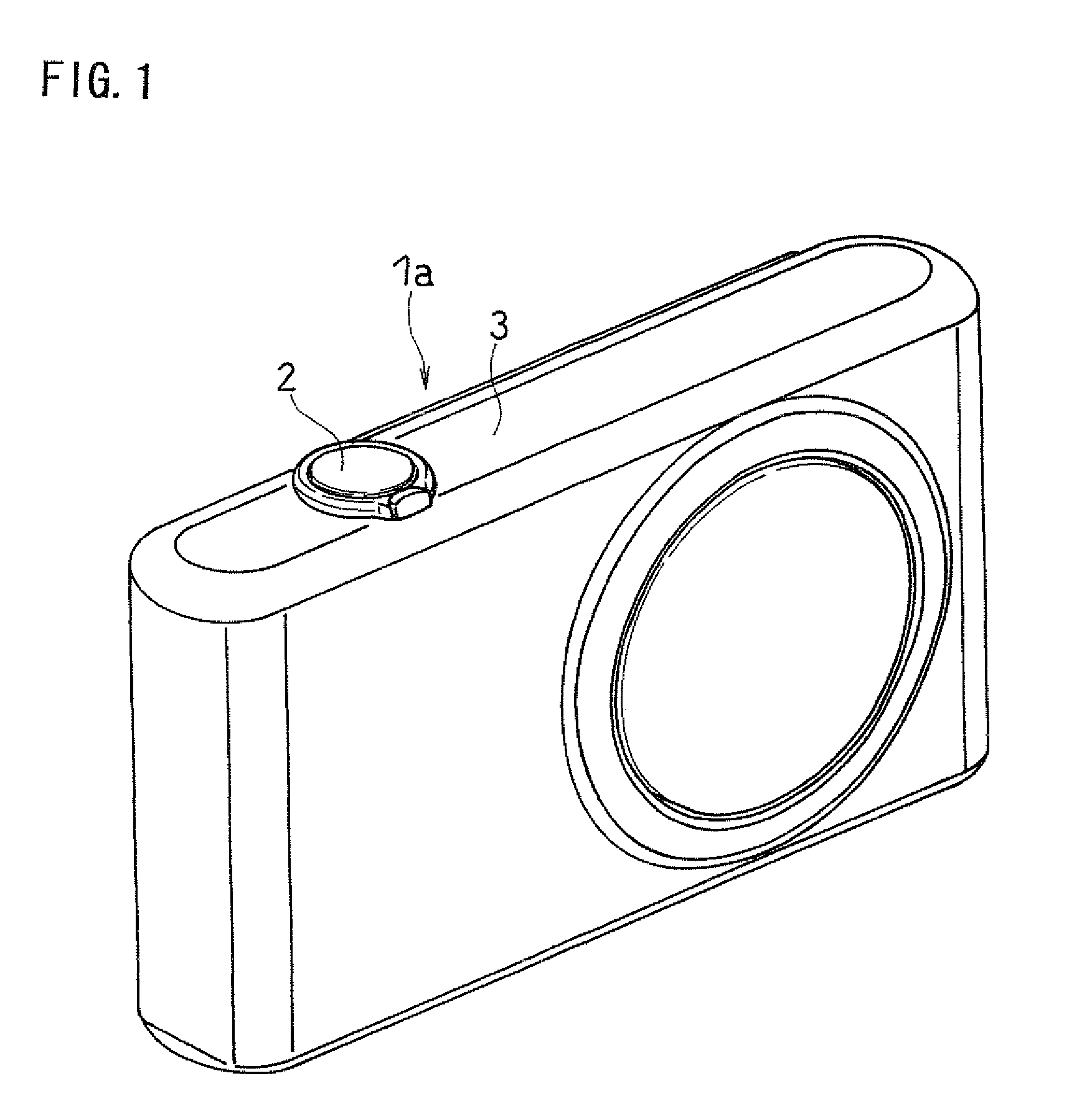

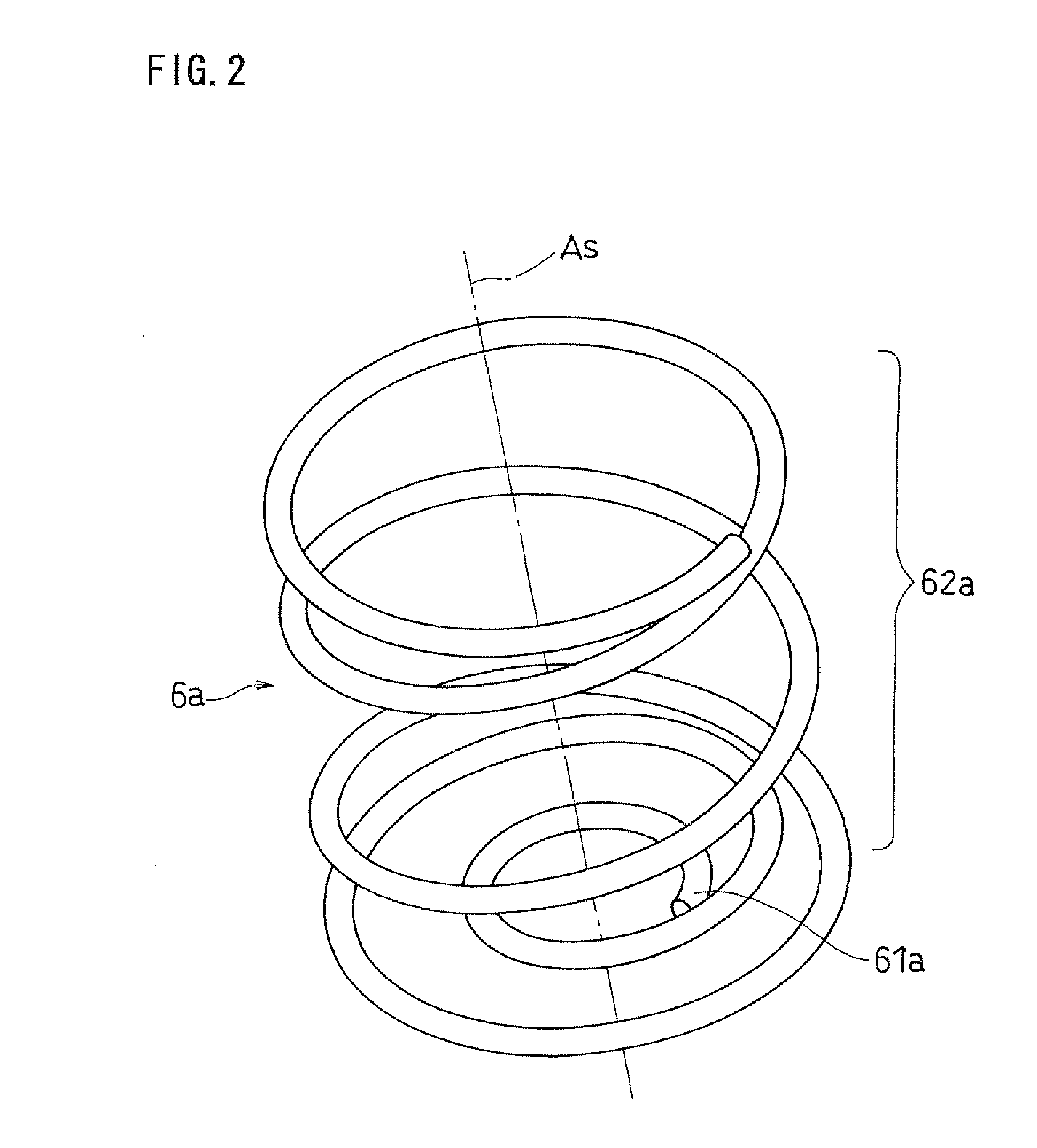

Coil spring structure of shutter button camera device and button structure of electronic device

InactiveUS7929859B2Press evenlyThe method is simple and reliableMultiple spring combinationsCamera body detailsCoil springElectronic equipment

In a camera device 1a with a shutter button 2 for transmitting an externally-applied pressing force to a switch 7, a boss 24 has a first end attached to the shutter button 2, and a second end opposed to the switch 7, a coil spring 6a has a first winding portion 61a and a second winding portion 62a, which are respectively wound into first and second shapes about a common central axis As, the second shape includes the first winding portion 61a, and the second end of the boss 24 is inserted into the first winding portion 61a.

Owner:PANASONIC CORP

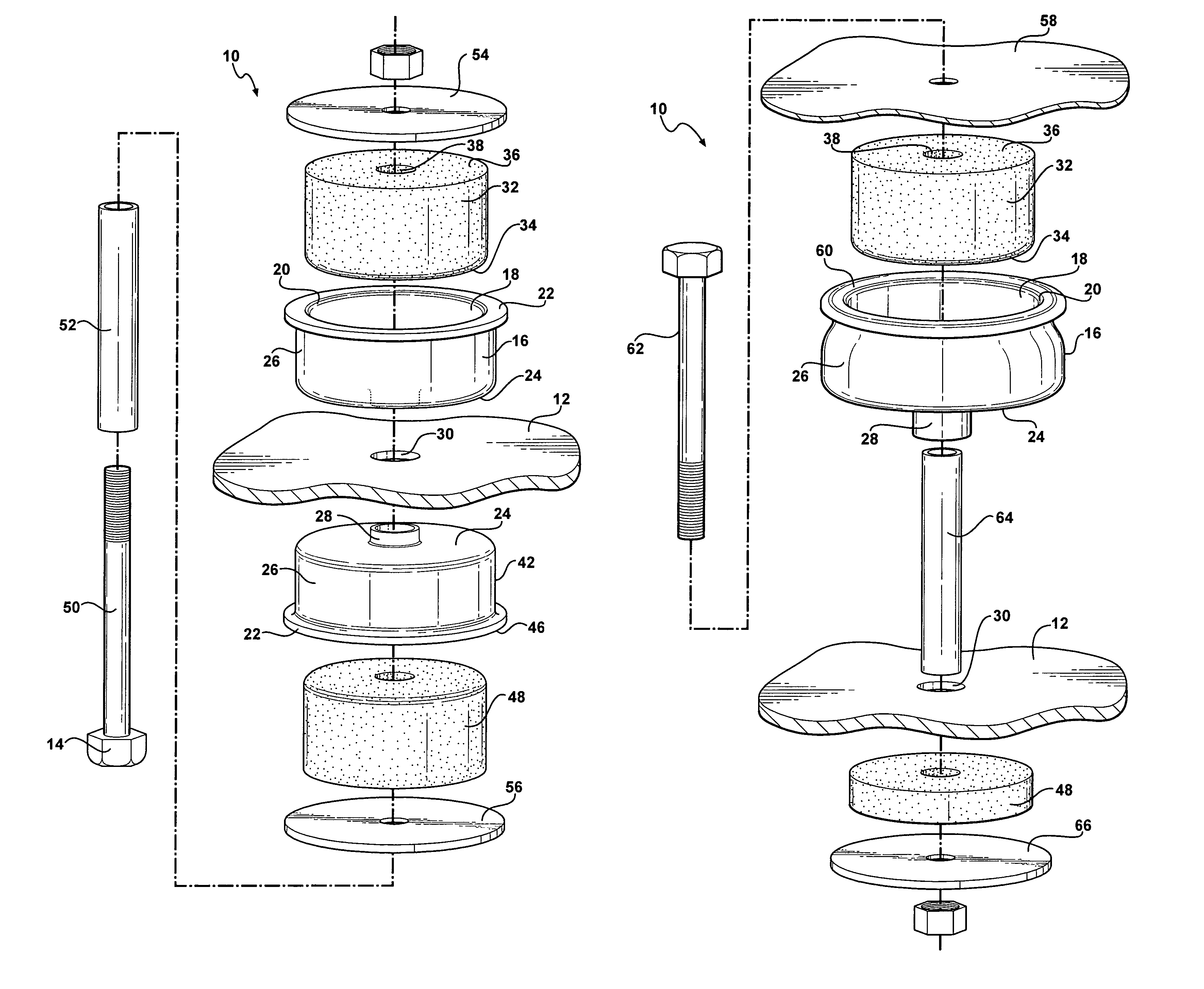

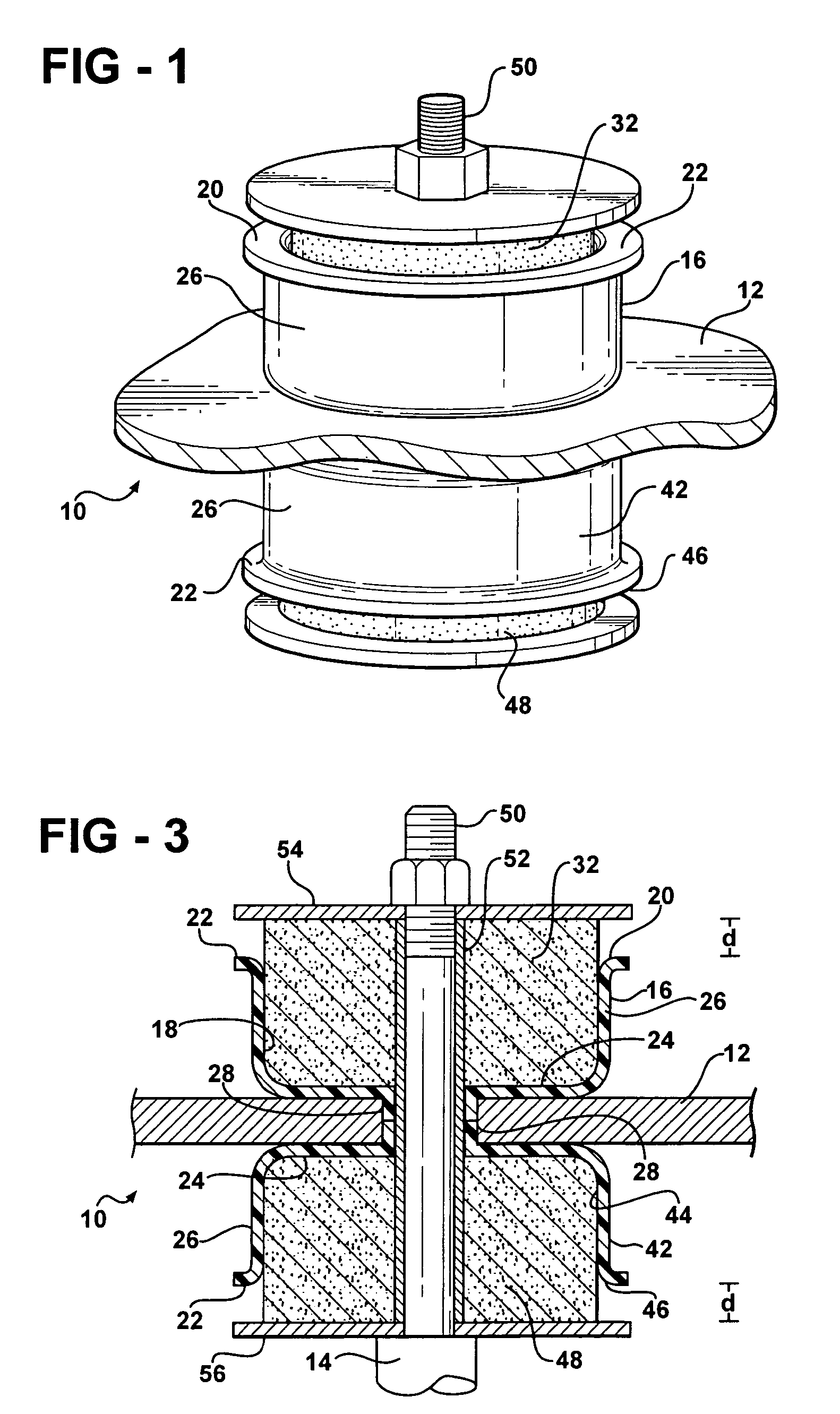

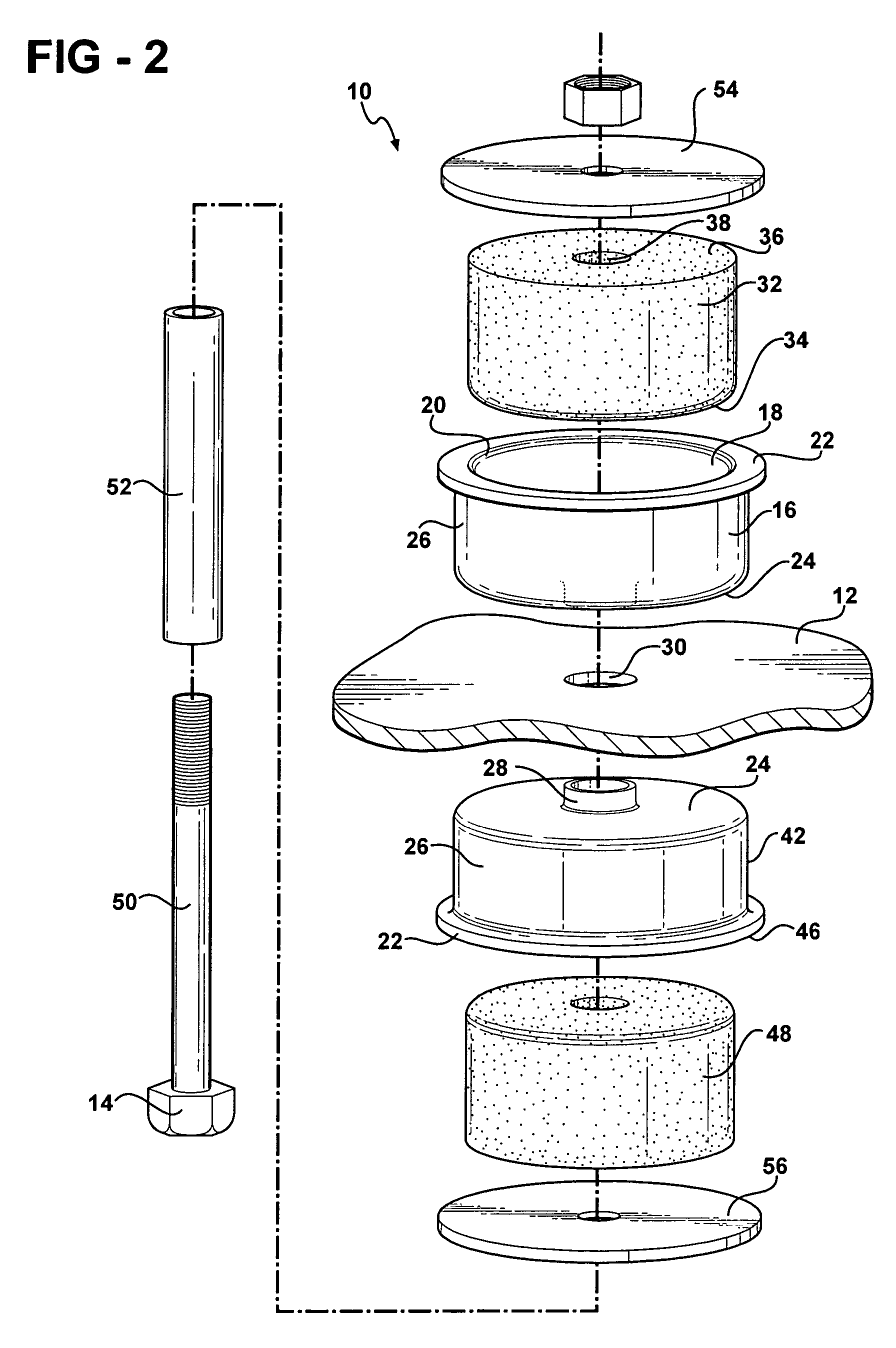

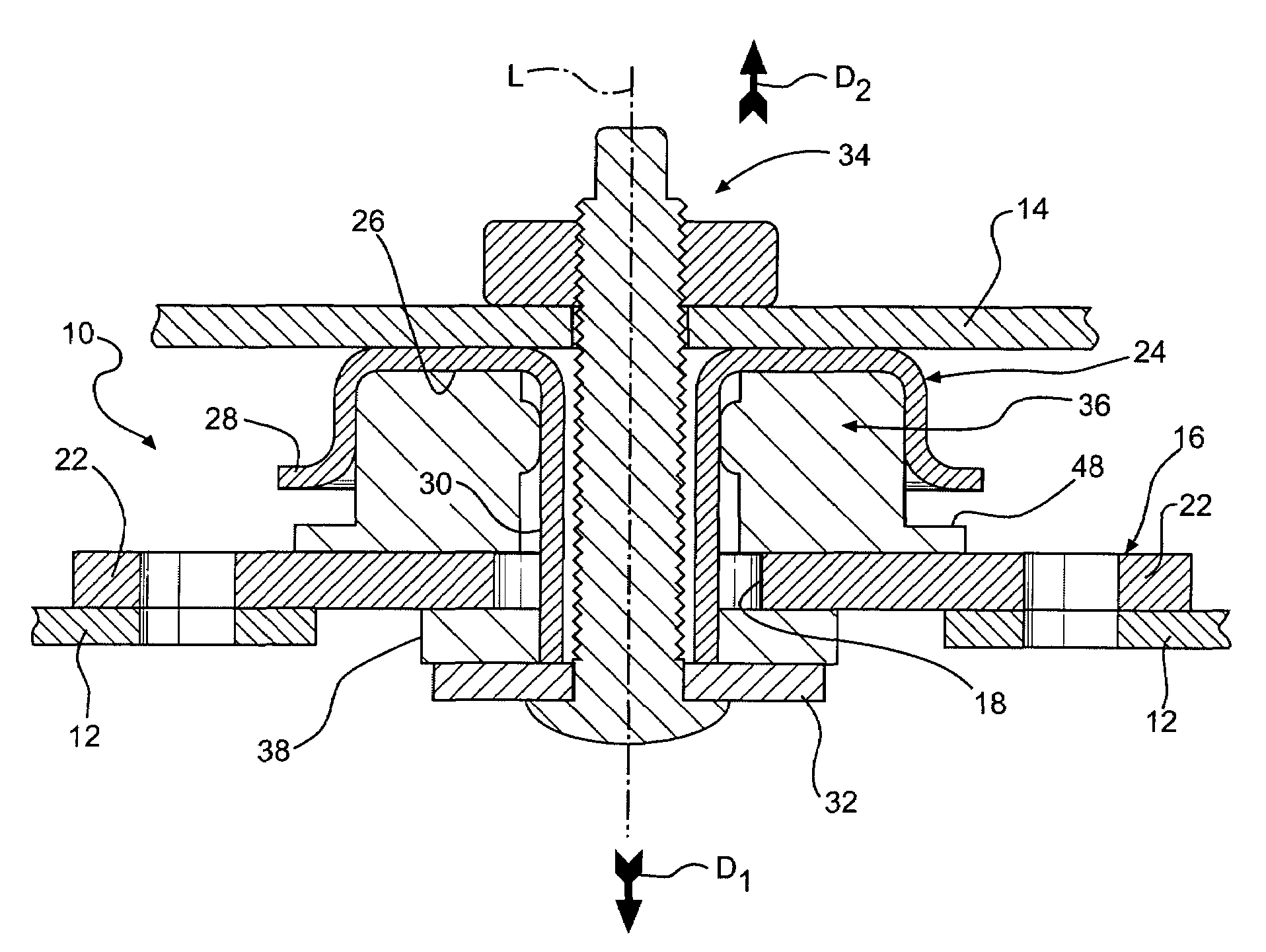

Mount assembly

InactiveUS7070157B2Vehicle body-frame connectionsMultiple spring combinationsPolyurethane elastomerHigh frequency vibration

A mount assembly for use in an automotive suspension system, body mount, cradle mount, or other like device. The mount assembly includes a polyurethane elastomer carrier mounted to a frame and having a peripheral outer rim. A microcellular polyurethane insulator is coupled to the frame and extends beyond the peripheral outer rim. The polyurethane elastomer of the carrier has a first modulus of elasticity. The microcellular polyurethane of the insulator has a second modulus of elasticity that is less than the first modulus of elasticity of the carrier such that the mount assembly can provide two distinct rates of elasticity, or stiffness, for adequately isolating both low amplitude, high frequency vibrations and high amplitude, low frequency impacts.

Owner:BASF CORP

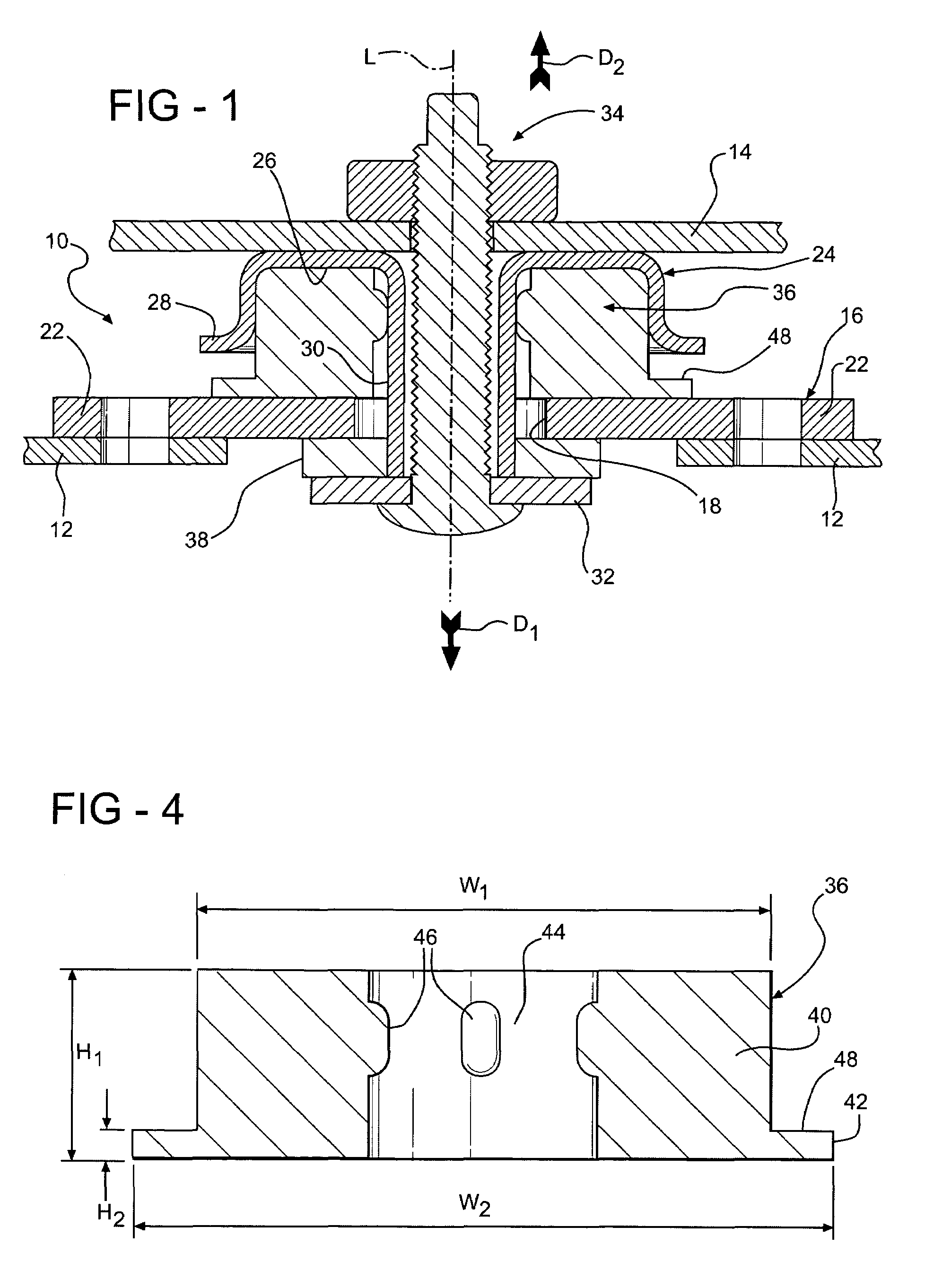

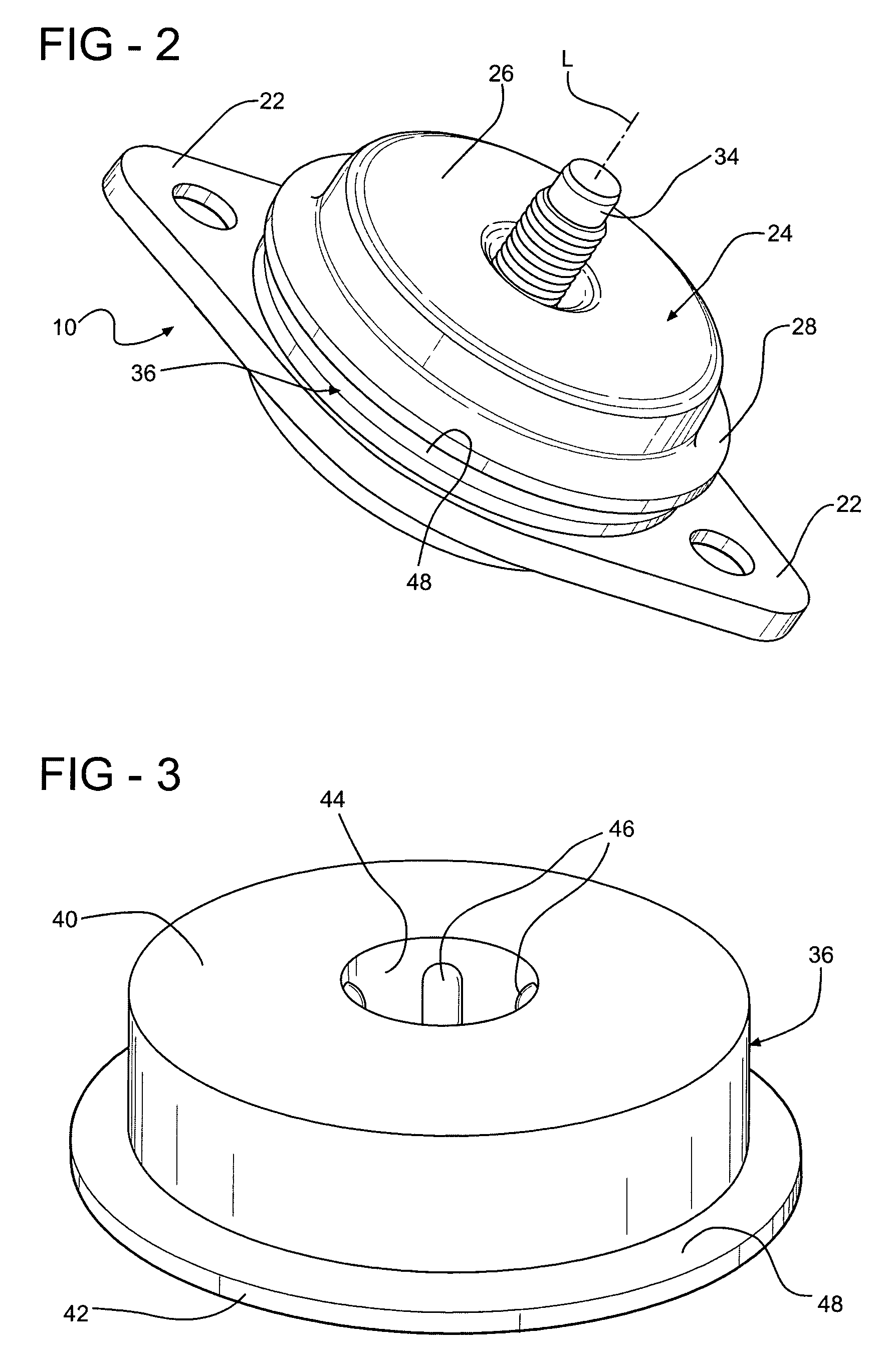

Two stage isolation mount assembly

InactiveUS7048265B2Increase amplitudeEffectively control maxiumum displacementMultiple spring combinationsResilient suspensionsElectrical resistance and conductanceEngineering

A mount assembly having a support structure mounted to a frame of a vehicle and a carrier mounted to a vehicle body. The support structure is displaceable relative to the carrier along a line of travel. An insulator is disposed between the support structure and the carrier for coupling the carrier to the support structure. The insulator has a first portion defining a first resistance for isolating the vibrations of the support structure during an application of a first force along a line of travel. The insulator also has a second portion defining a second resistance with the second resistance being greater than the first resistance for controlling the maxiumum displacement of the support structure after the application of the first force and during an application of a second force along the line of travel wherein the second force is greater than the first force. The insulator also provides for tunability of the nature and location of the transition between the first resistance and the second resistance.

Owner:BASF CORP

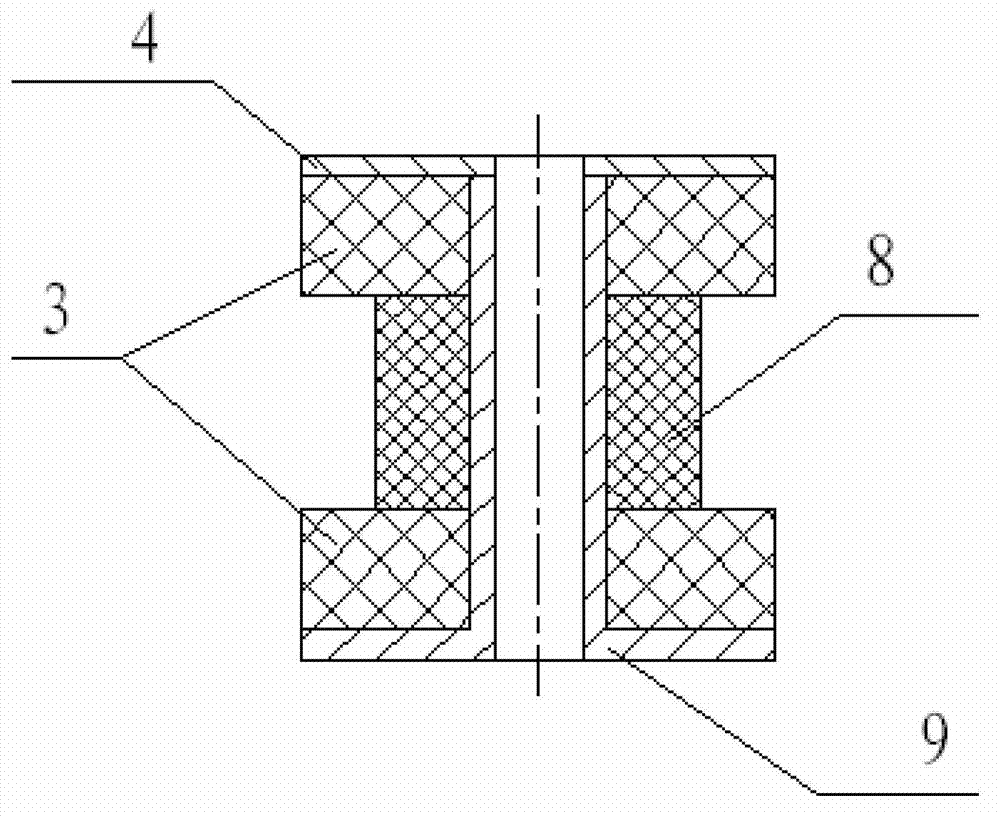

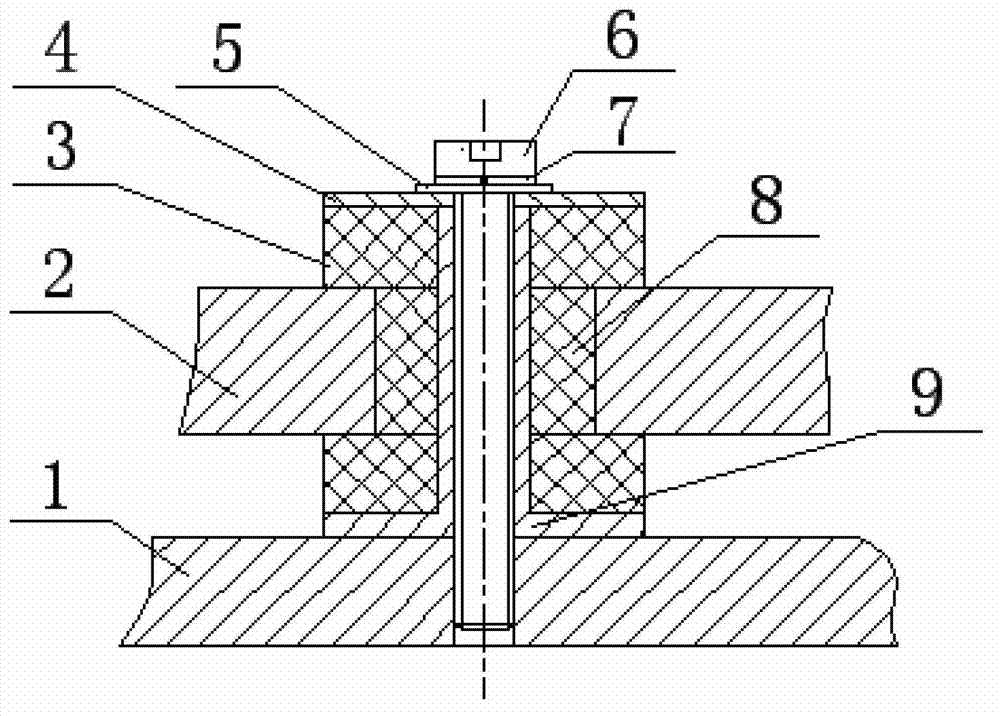

Combined type rubber shock absorber

ActiveCN103115100AImprove reliabilityStrong designabilityMultiple spring combinationsRubber materialEngineering

The invention relates to a combined type rubber shock absorber and belongs to the technical field of rubber vibration isolators. The combined type rubber shock absorber is mainly used for vibration and buffering processing of electronic equipment or instruments. The combined type rubber shock absorber comprises a rubber anti-vibration pad, a rubber anti-vibration column, a metal limiting lining and a metal limiting gasket. According to the combined type rubber shock absorber, vibration and impact energy is translated into heat energy and deformation energy of rubber materials through the deformation of rubber parts by means of a combined shock absorber structure, the rubber anti-vibration pad is capable of reducing dynamic energy of an instrument with vibration to be isolated in the axial direction, the rubber anti-vibration column is capable of reducing dynamic energy of the instrument with the vibration to be isolated in the radial direction, the metal limiting lining and the metal limiting gasket are used in a matching mode, dynamic displacement of the shock absorber is limited due to the fact that the shock absorber is installed on a base plate of the instrument through bolts, and then an installation function and a limiting function are achieved.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

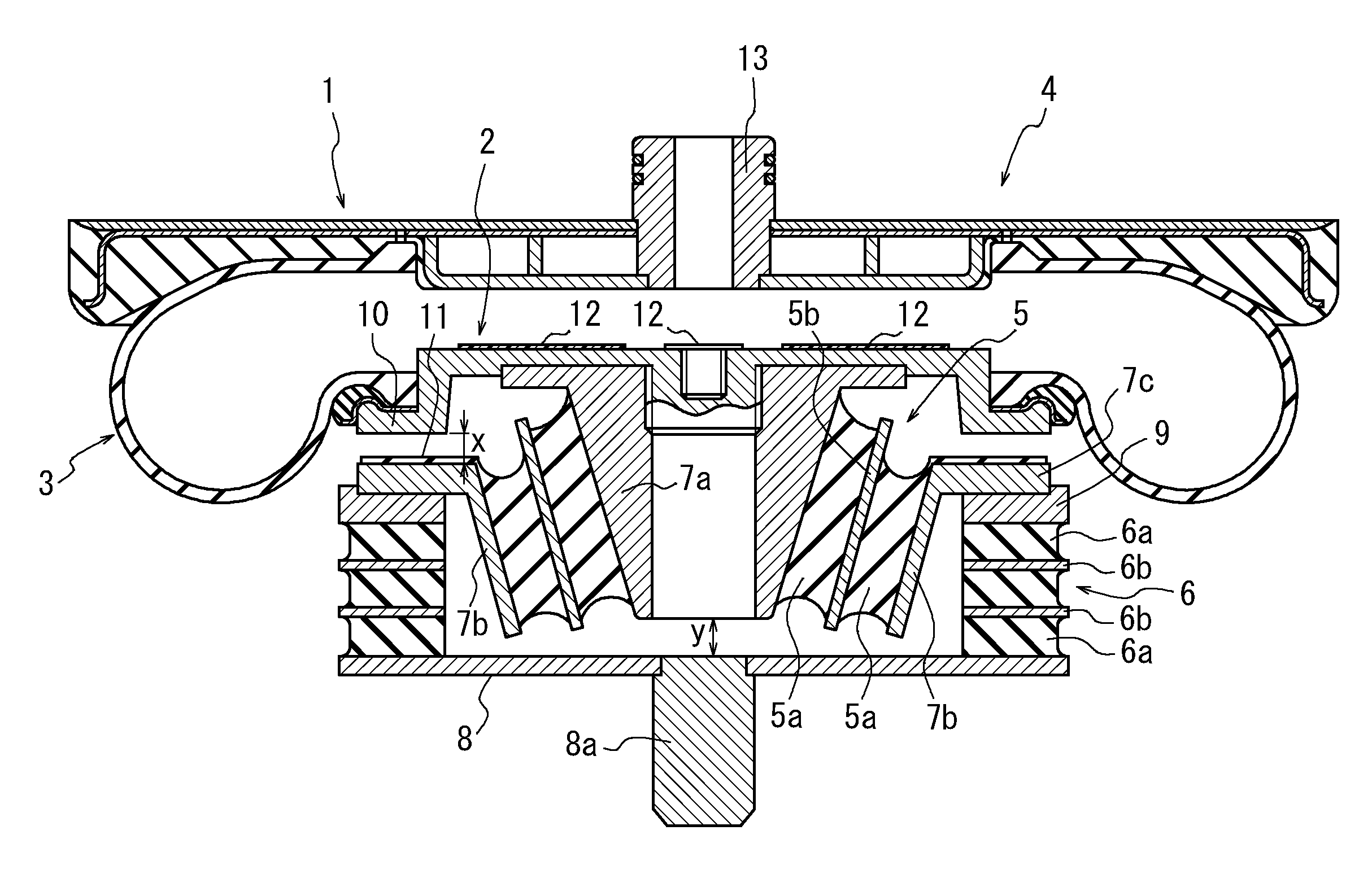

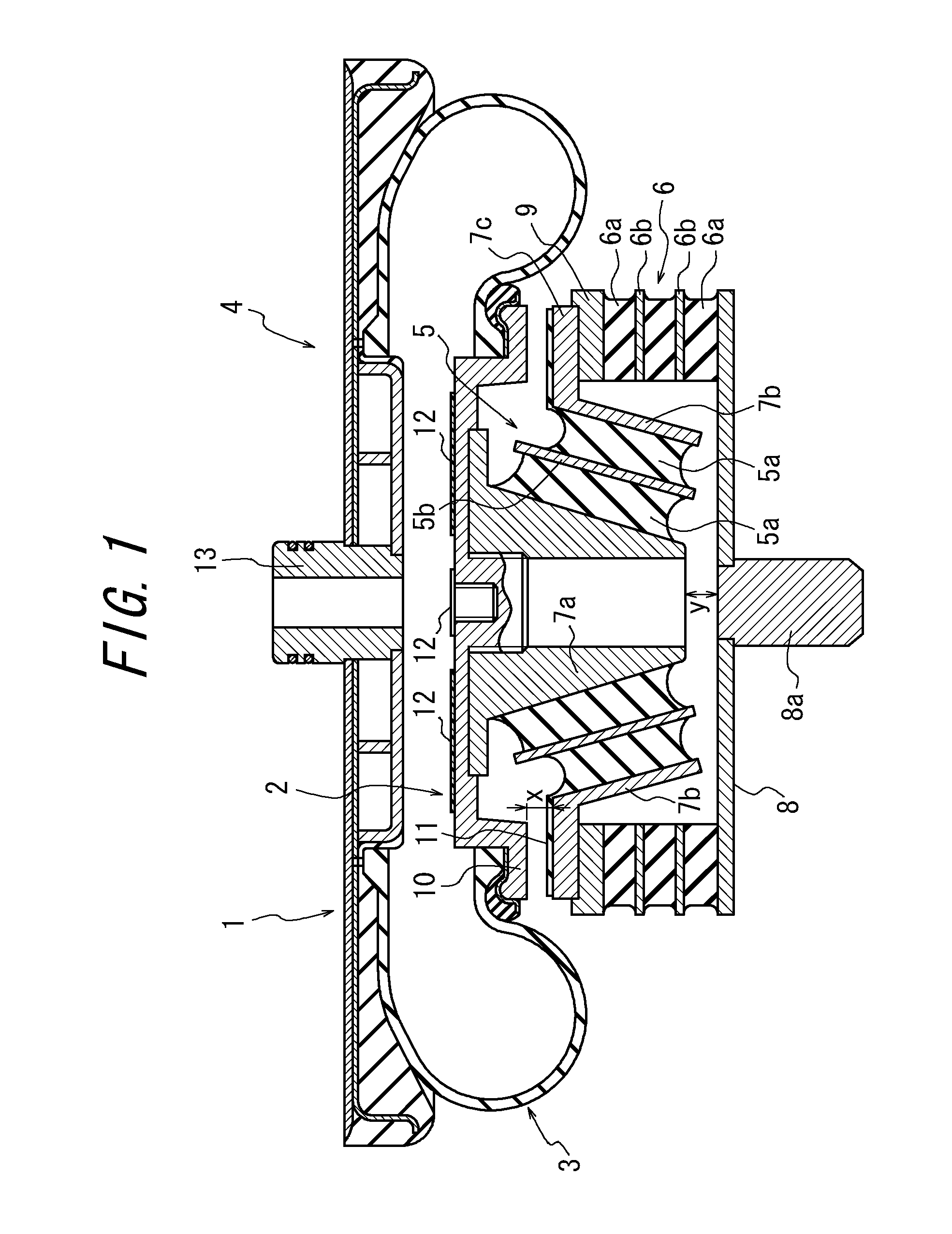

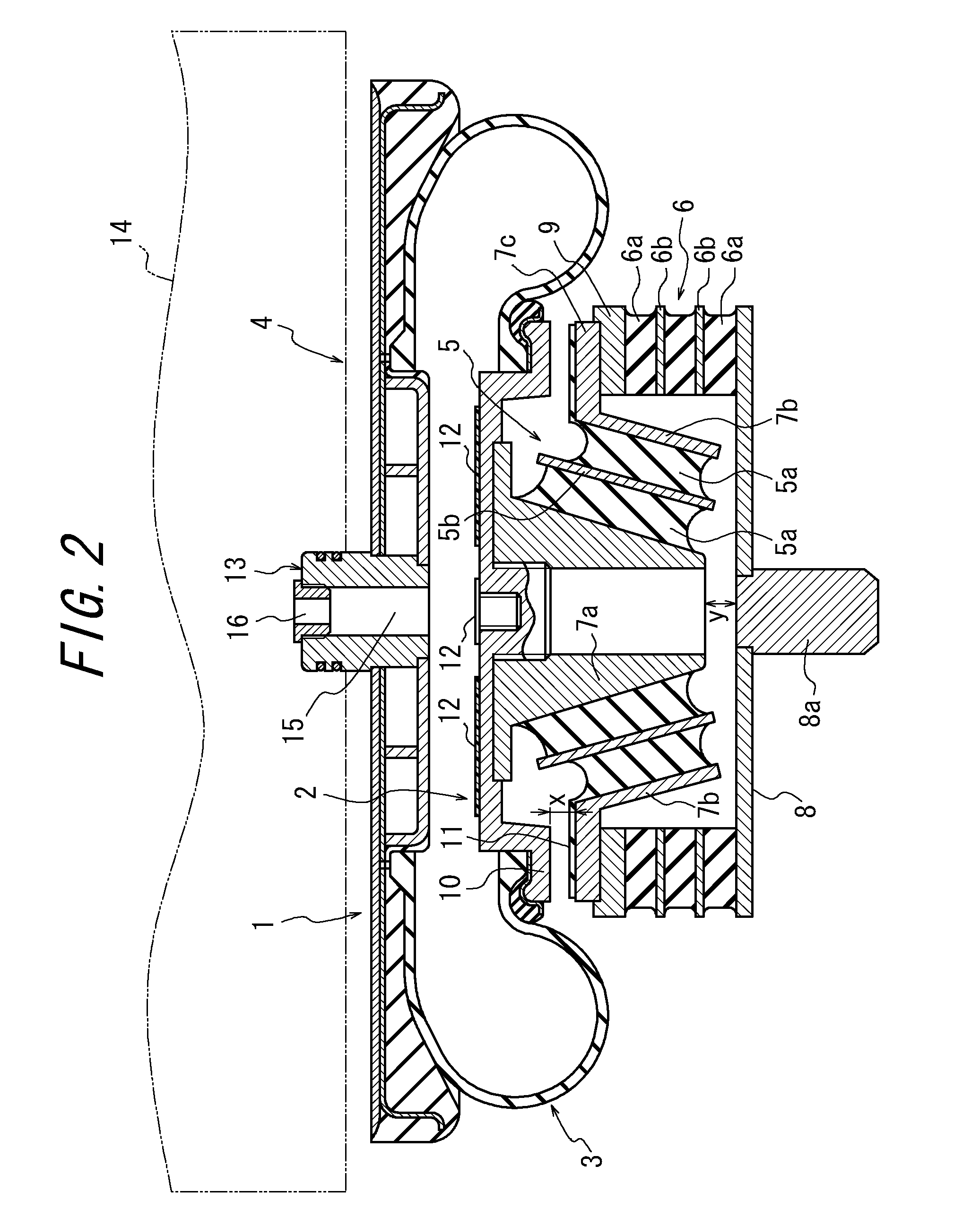

Air spring device

InactiveUS20110031662A1Stiff constantSimple structureNon-rotating vibration suppressionMultiple spring combinationsRubber materialAir spring

An air spring device includes an air spring (4) wherein gas is filled in an interior defined by an upper face plate (1), a lower face plate (2), as well as a cylindrical flexible diaphragm body (3) having opposite ends gas-tightly connected to the upper and lower face plates (1, 2), respectively. Between the lower face plate (2) and a lower supporting plate (8) spaced downward therefrom, a shear spring means (5) and a compression spring means (6) are series-connected, which are made mainly of rubber material. When a vertical load is applied to the air spring device, the shear spring means (5) and the compression spring means (6) are subjected mainly to shearing deformation and compressive deformation, respectively. The air spring device further includes an abutment member (10) allowing the compression spring means (6) to support the load in place of the shear spring means (5), after the deformation amount of the shear spring means (5) reaches a predetermined level.

Owner:BRIDGESTONE CORP

Foam springs and innerspring combinations for mattresses

Owner:SEALY TECH LLC

Lateral displacement shock absorbing material

ActiveUS20070083965A1Improve energy absorptionImprove ventilationEye treatmentHatsThermoplasticLateral displacement

A lateral displacement shock absorbing material includes a material consisting of a plurality of elongated tubular impact absorbing members, each having an axis of elongation. The axes of elongation of the respective tubular members are parallel to one another. The tubular members are retained with their axes in parallel relation by virtue of webbing, laterally extending from the sides of each tubular member, and interconnecting them together. Each of the tubular members consists of an outer surface made up of two frustoconical surfaces with their larger diameter ends abutting one another and their smaller diameter ends facing away from one another. Each tubular member includes a passageway defined by two frustoconical shapes with the smaller diameter ends abutting one another, and the larger diameter ends facing away from one another and defining the openings of each passageway. The material may be made of thermoplastics including polypropylene, urethanes, and rubber. In operation, upon impact, the side walls of the tubular members bulge or displace laterally to absorb impacts. The taper of the walls and the open space within the tubular members allow the energy absorbing material to displace laterally allowing a greater range of travel.

Owner:CASCADE MAVERIK LACROSSE LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com