Patents

Literature

2636 results about "Polyurethane elastomer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

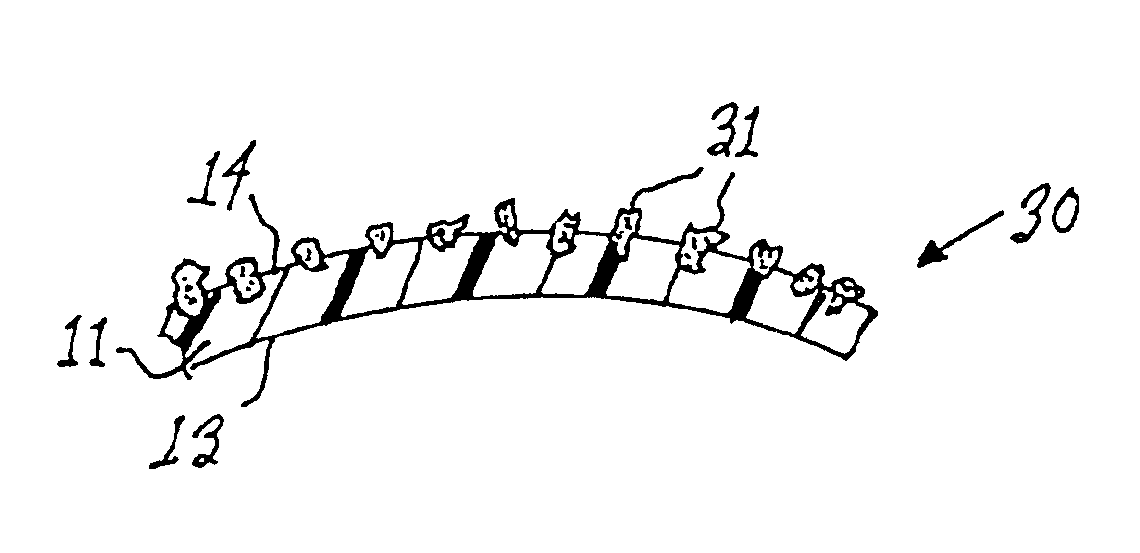

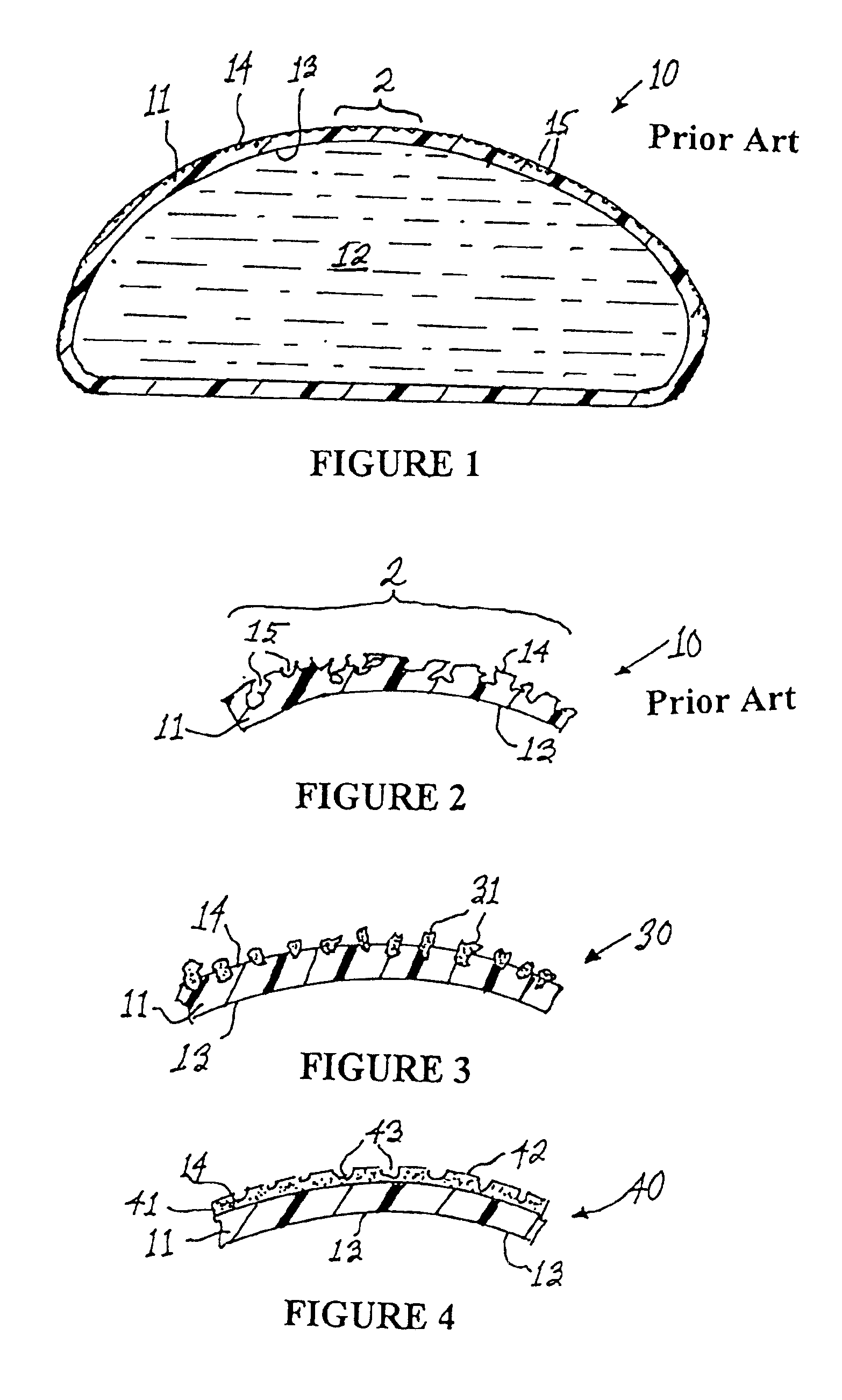

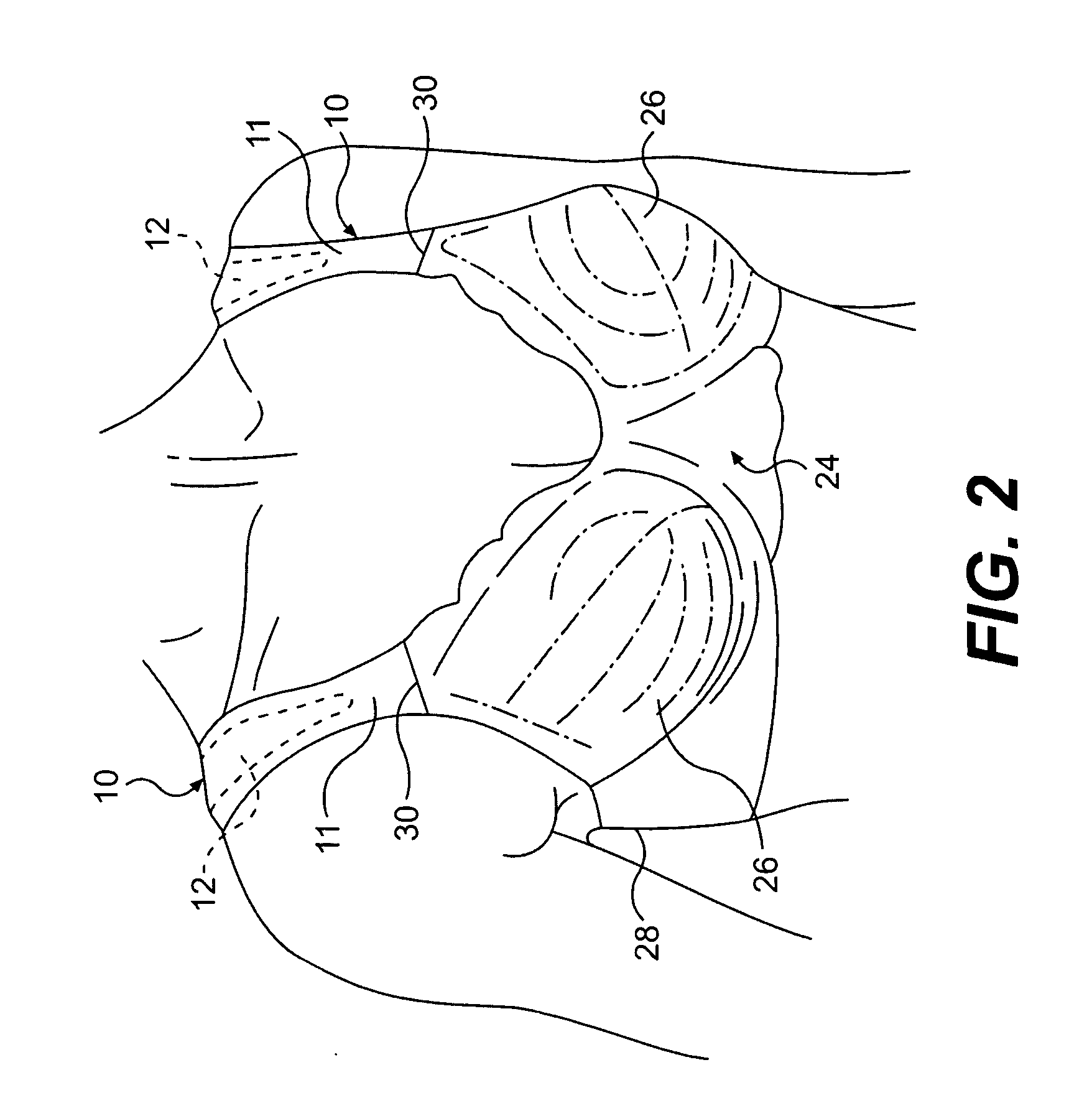

Medical implant having bioabsorbable textured surface

A hybrid medical implant having a biocompatible, nonabsorbable core portion and a bioabsorbable textured outer surface portion overlying the core portion. The hybrid implant is useful as a prosthesis for tissue augmentation and / or reconstruction. The core portion of the implant includes a body formed from a nonabsorbable, biocompatible implantable material such as silicone or urethane elastomer. The core portion may be either a solid body, a viscous gel body or a fluid-filled shell. The textured outer surface portion envelops the core portion and presents an irregular, bioabsorbable textured surface to the exterior environment. As a capsule forms around the implant following implantation, the irregular contour of the outer surface of the implant disorients structural proteins in the capsule to impede spherical contraction thereof. Either during the formation of the capsule and / or after the capsule is formed, the outer bioabsorbable surface portion of the implant is absorbed by the body of the host. After bioabsorbtion of the bioabsorbable outer surface portion, the remaining core portion of the implant remains enveloped by the capsule but unattached to capsular tissue. The outer bioabsorbable portion of the hybrid implant may include more than one biocompatible, bioabsorbable material.

Owner:WHD ELEKTRONISCHE PRUEFTECHN

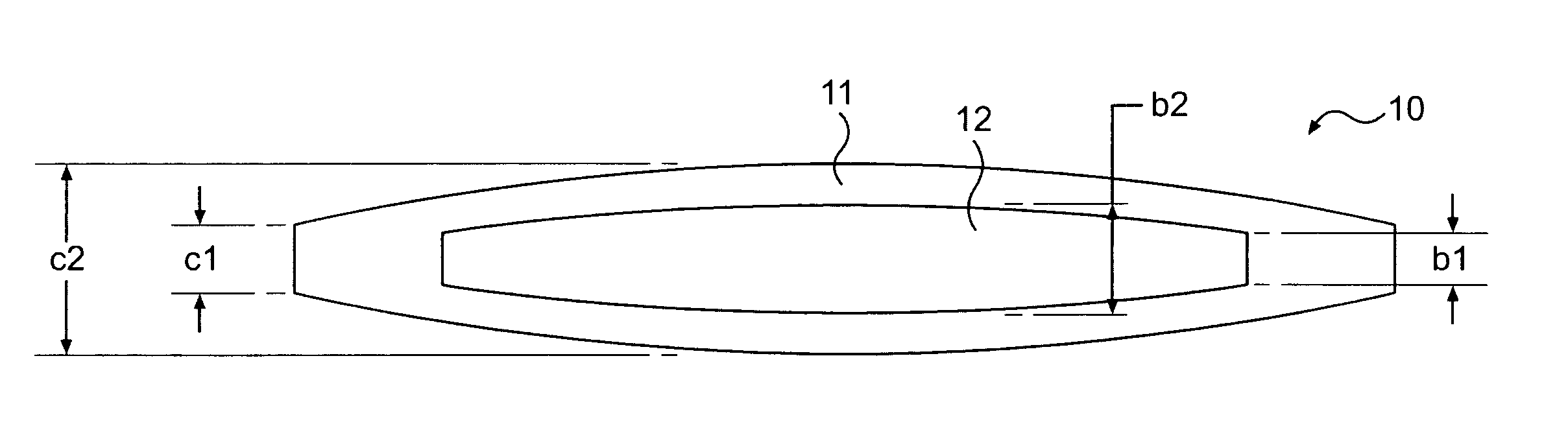

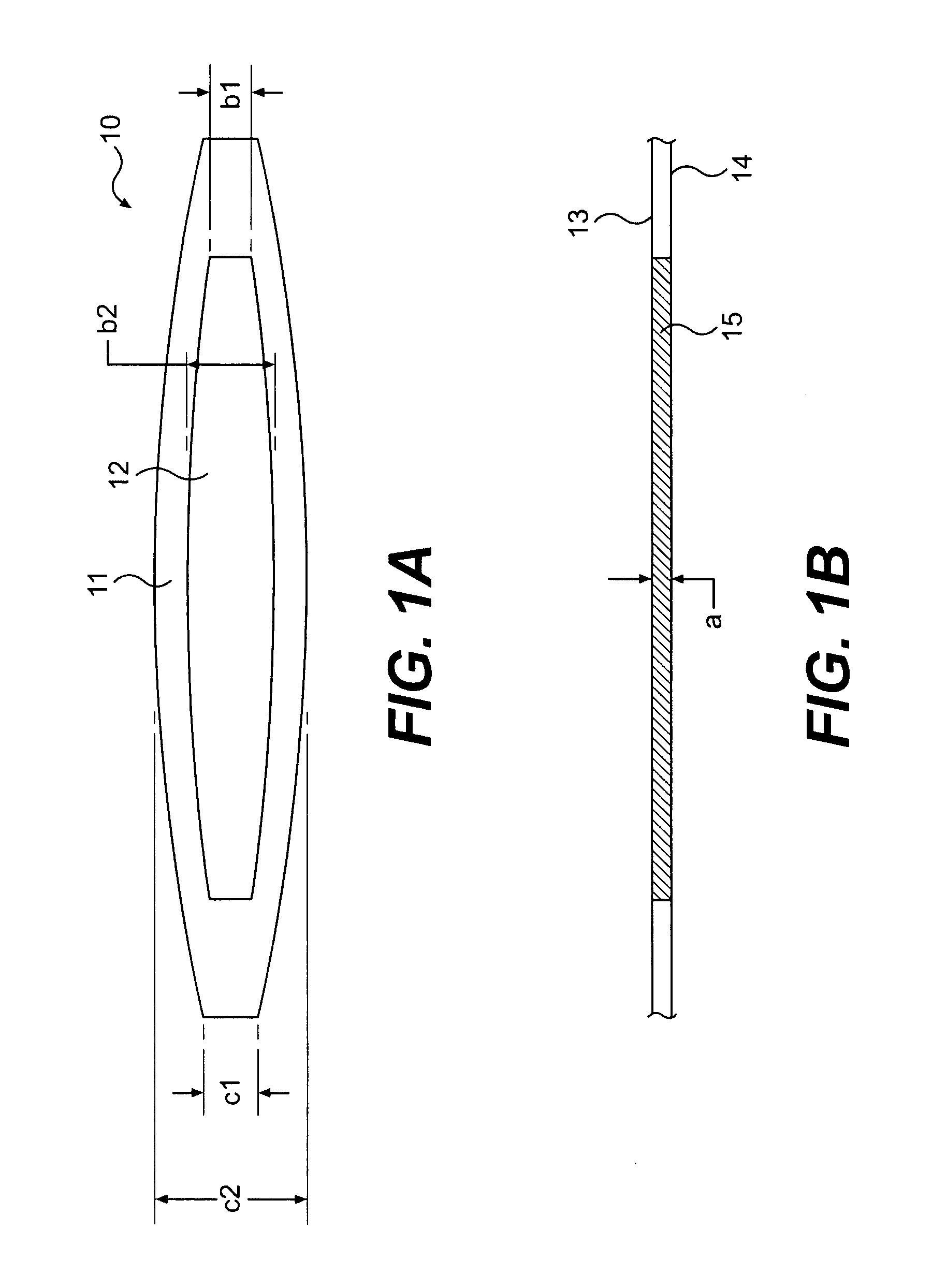

Three-piece solid golf ball

InactiveUS7160208B2Improved profileIncrease resistanceGolf ballsSolid ballsPolyurethane elastomerHardness

A three-piece solid golf ball comprising a rubber-based core inner layer, a rubber-based core outer layer, and a polyurethane elastomer-based cover, wherein the core inner layer has a JIS-C hardness of 50–85, the core outer layer has a JIS-C hardness of 70–90, the JIS-C hardness of the core outer layer at its surface minus the JIS-C hardness of the core inner layer at its center is 20–30, and the cover has a Shore D hardness of 46–55 and a gage of 1.1–2.1 mm is improved in rebound, travel distance, controllability, feel on impact and durability.

Owner:BRIDGESTONE SPORTS

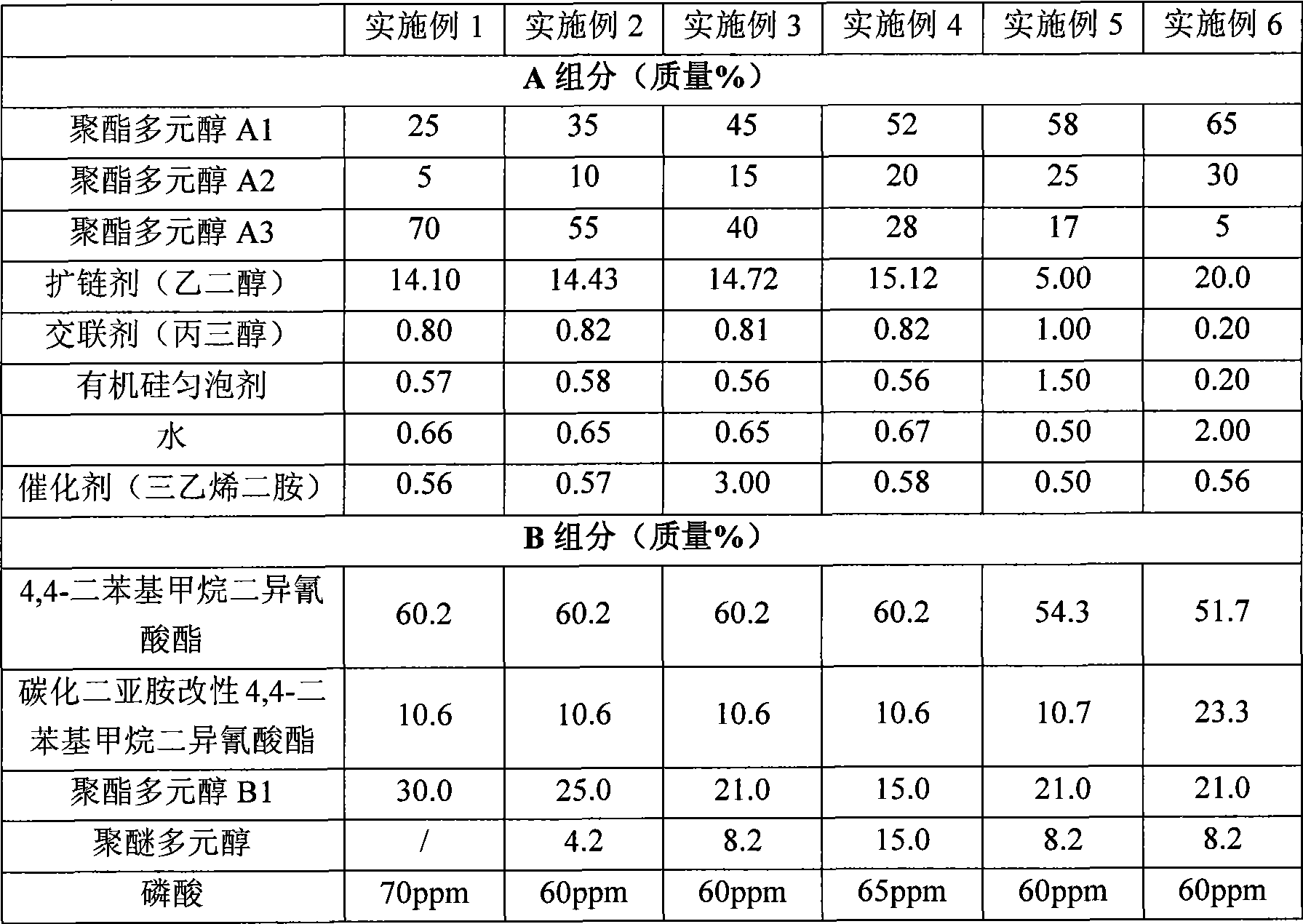

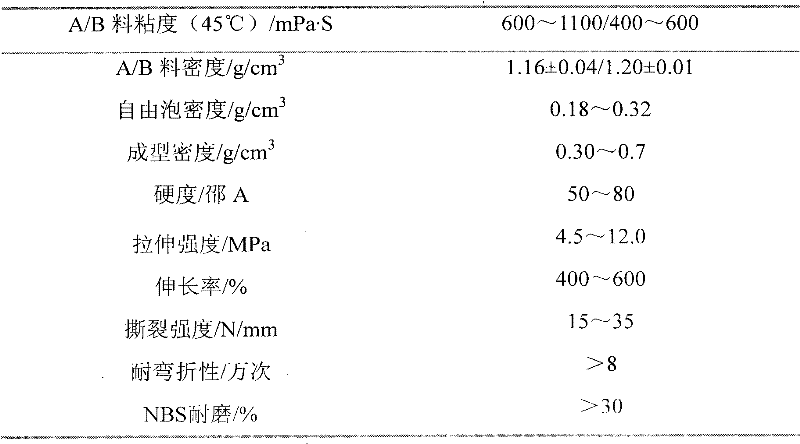

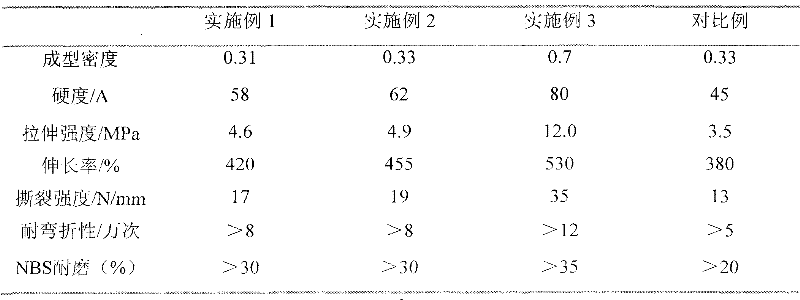

Low density high hardness polyurethane micropore elastomer and preparation thereof

The invention discloses a low-density high-hardness microporous polyurethane elastomer and a preparation method thereof; polyester polyol A1, polyester polyol A2, polyester polyol A3, Diol chain extender, crosslinking agent, tertiary amine or organic metal catalysts, organosilicone foam homogenizing agent and water foaming agent are placed in a reactor and then mixed for obtaining a component A; isocyanate, polyester polyol B1, polyether polyol, and side effect inhibitor are placed in the reactor and then reacted for preparing a component B; later, the two components are completely mixed and injected into a mold for being reacted and molded so as to obtain the microporous polyurethane elastomer. The microporous polyurethane elastomer which is produced by the method has the advantages of low density, high hardness, low product shrinkage rate and the like, and can be widely used in production of sole materials such as middle sole, large sole, and the like.

Owner:ZHEJIANG HUAFON NEW MATERIALS CO LTD

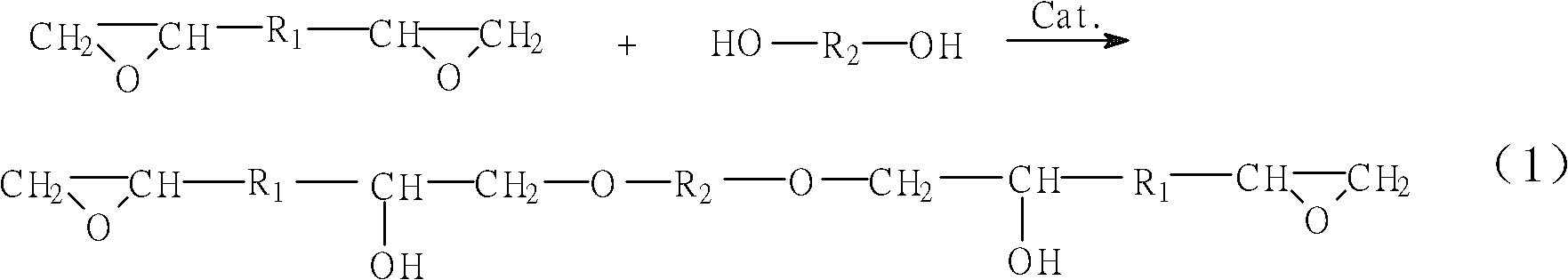

Polymerized thylene carbonate urethane elastomer and its preparation method

ActiveCN1865311AMolecular chain softRoom temperature and good flexibilityCross-linkMedical equipment

The invention discloses a polyethylene carbonate polyurethane elastomer and making method, which produces polycarbonate polyhydric alcohol through carbon dioxide and oxirane with 20-60 percent diisocyanate, 0.05-2 percent polymerization inhibitor, 2.4-17 percent chain-extending agent and or cross linking agent and 0-0.4 percent catalyst. The method possesses better mechanic property, plasticity, anti-oxidizing property and water weakened-durability, which can be applied in the liner, screen, sealing ring and medical equipments.

Owner:JIANGSU ZHONGKE JINLONG CHEM

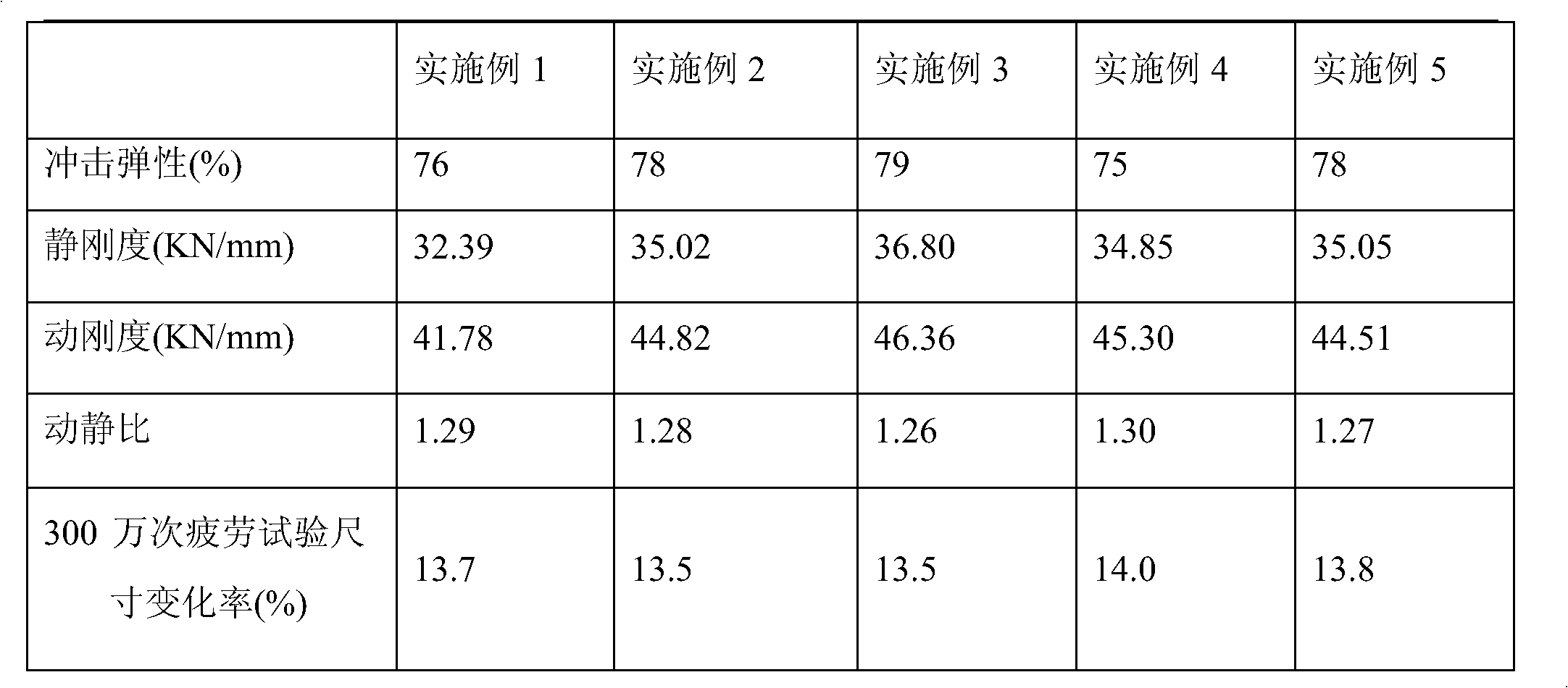

Microporous polyurethane elastomer compound with excellent dynamic performance and preparation method thereof

The invention belongs to the field of polyurethane elastomer synthesis, and particularly relates to a preparation method of a microporous polyurethane elastomer compound with excellent dynamic performance. The compound is characterized in that the compound consists of a polyol mixture component and a modified isocyanate component. The preparation method has the advantages as follows: (1) a quasi-prepolymer method is adopted to process microporous polyurethane elastomer material, the two components has similar viscosity and similar mass mixing ratios, the material mixing temperature is low, the materials are easy to mix evenly, the process control condition is simple, and the operation is easy; and (2) the microporous polyurethane elastomer material prepared by using the compound disclosed by the invention has the advantages that a ratio of dynamic stiffness to static stiffness is smaller than or equal to 1.35, the impact elasticity is larger than or equal to 75 percent, the appearance is not damaged after 3,000,000 times of fatigue tests and the dimensional change rate is smaller than or equal to 20 percent, so that the compound can be used for preparing high-performance products such as damping cushion blocks of high-speed railways and damping elements of automobiles.

Owner:SHANDONG INOV POLYURETHANE

Anti-tack spandex fibers containing antimicrobial agents therein and fabrics made therefrom

InactiveUS6479144B2Easy to processImprove cohesionMonocomponent polyurethanes artificial filamentBiocideYarnFiber

Polyurethane elastomer yams (particularly spandex) containing certain silver-based antimicrobial formulations therein are provided. This invention relates to polyurethane elastomer yams (particularly spandex) containing certain silver-based antimicrobial formulations therein. Such formulations comprise antimicrobial compounds, such as, preferably, triclosan and / or silver-containing ion-exchange resins, such as zirconium phosphate, glass, and / or zeolite compounds. The inventive spandex yarns exhibit excellent antimicrobial qualities as well as surprisingly good anti-tack / frictional characteristics. As a result, antimicrobial spandex yams are provided which exhibit ease in processing, particularly in further knitting, weaving, etc., to produce fabrics therefrom. Such fabrics are also encompassed within this invention.

Owner:MILLIKEN & CO

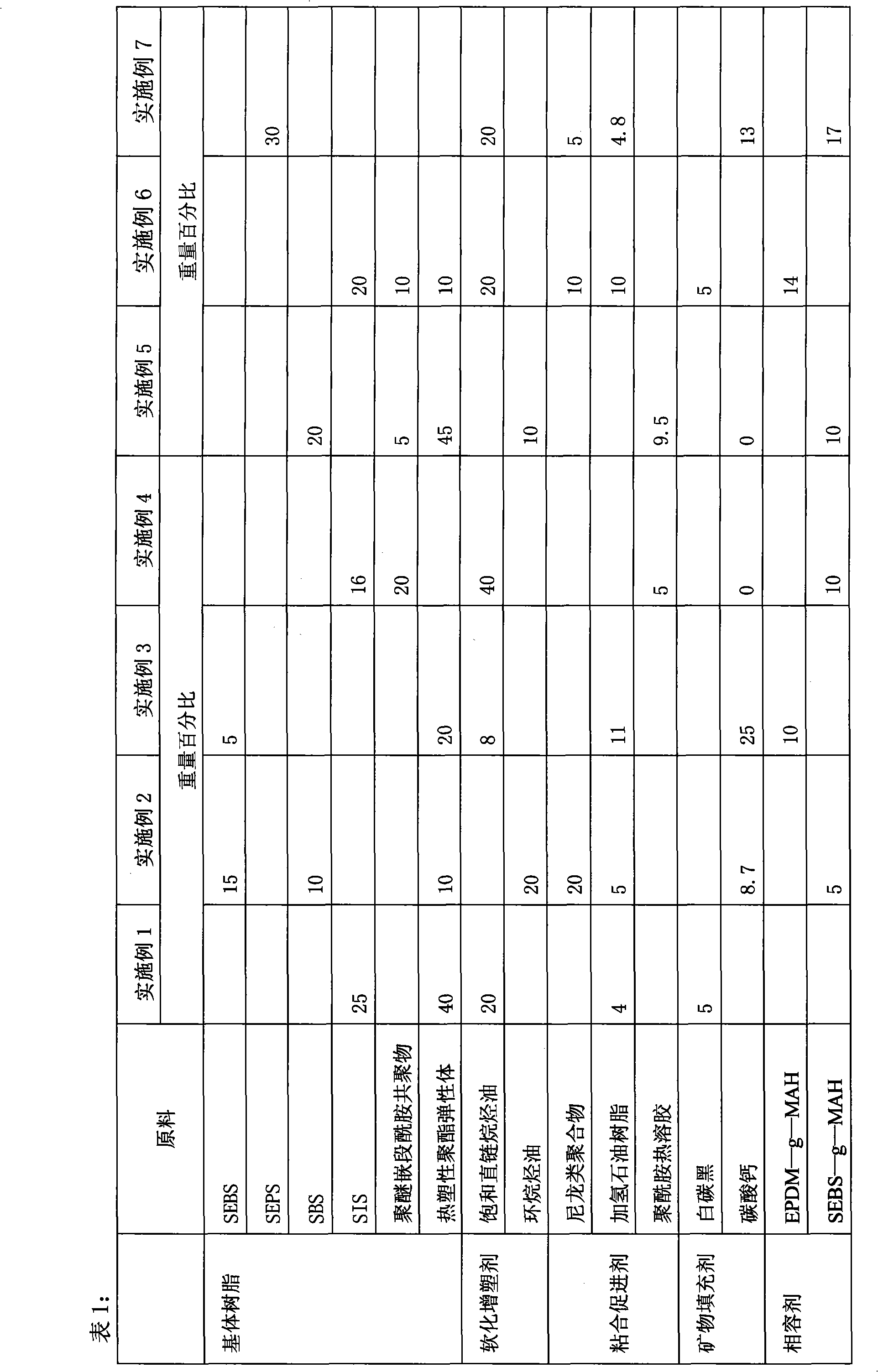

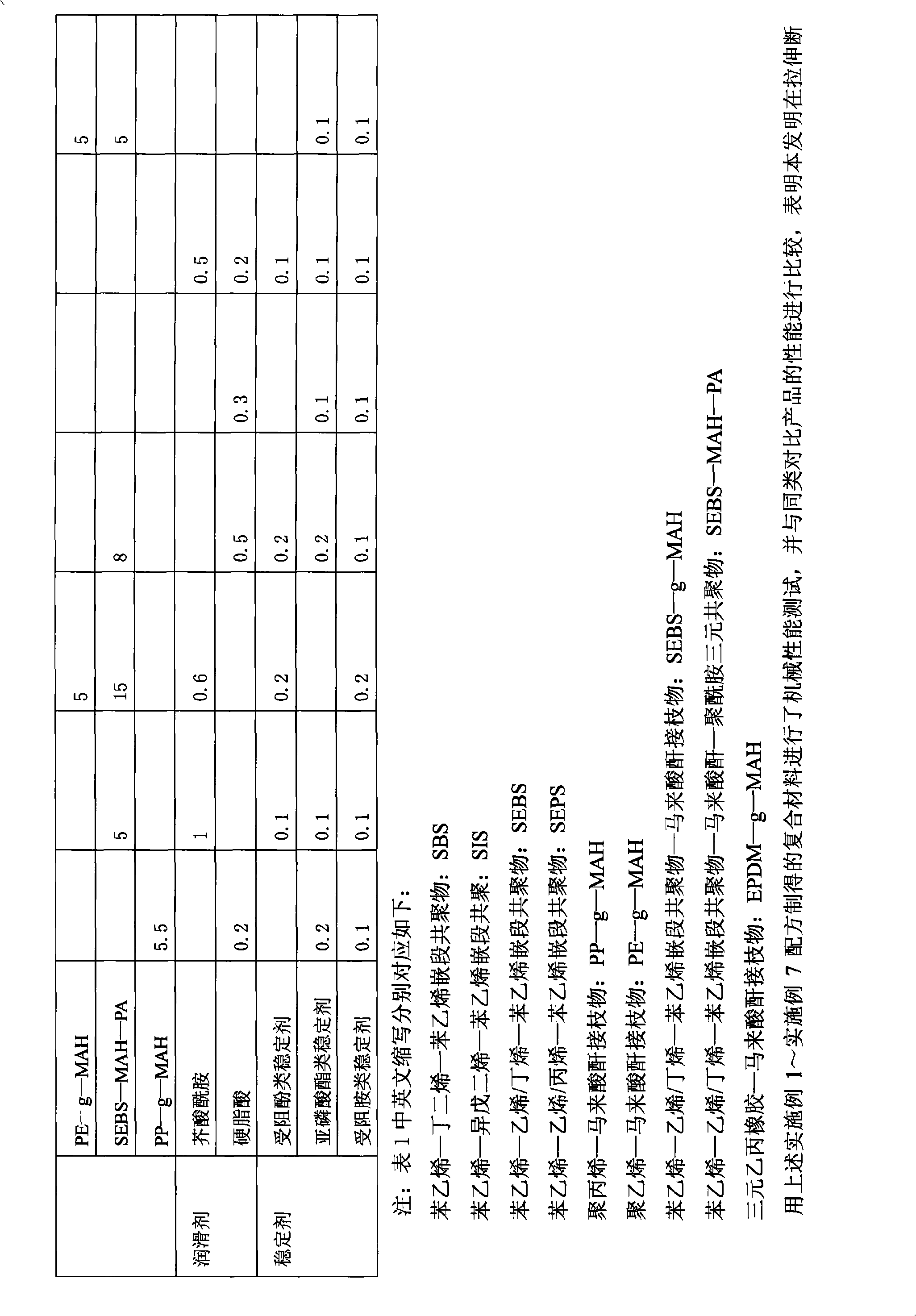

Thermoplastic elastomer capable of coating and bonding with nylon

The invention provides a thermoplastic elastomer coated and bonded by nylon, comprising matrix resin, softened plasticizer, adhesion promotor, mineral filler, lubricant and stabilizer, wherein the weight percentage of the material is as follow: resin 20-75%, softened plasticizer 5-45%, adhesion promoter1-30%, mineral filler 0-3%, compatiblizing agent 5-35%, lubricant 0-2%, stabilizer 0-2%. The matrix resin also comprises: thermoplasticity polyurethane elastomer or polymerized silica block amide copolymer, which makes the thermoplastic elastomer with good physical property, in addition a great variety of compatiblizing agents are used, therefore each component fully and mutually dissolves with each other to reduce the occurence of delamination, and the solubility of the composite material to the other engineering plastics, so that the thermoplastic elastomer is firmly adhesive on the surface of the nylon material without any bonding agent by twice injection of plastic jetting-moulding machine or extruder, and coating adhesive on the material such as ABC, PC. The market prospect is increased.

Owner:NINGBO SHIP PLASTIC CO LTD

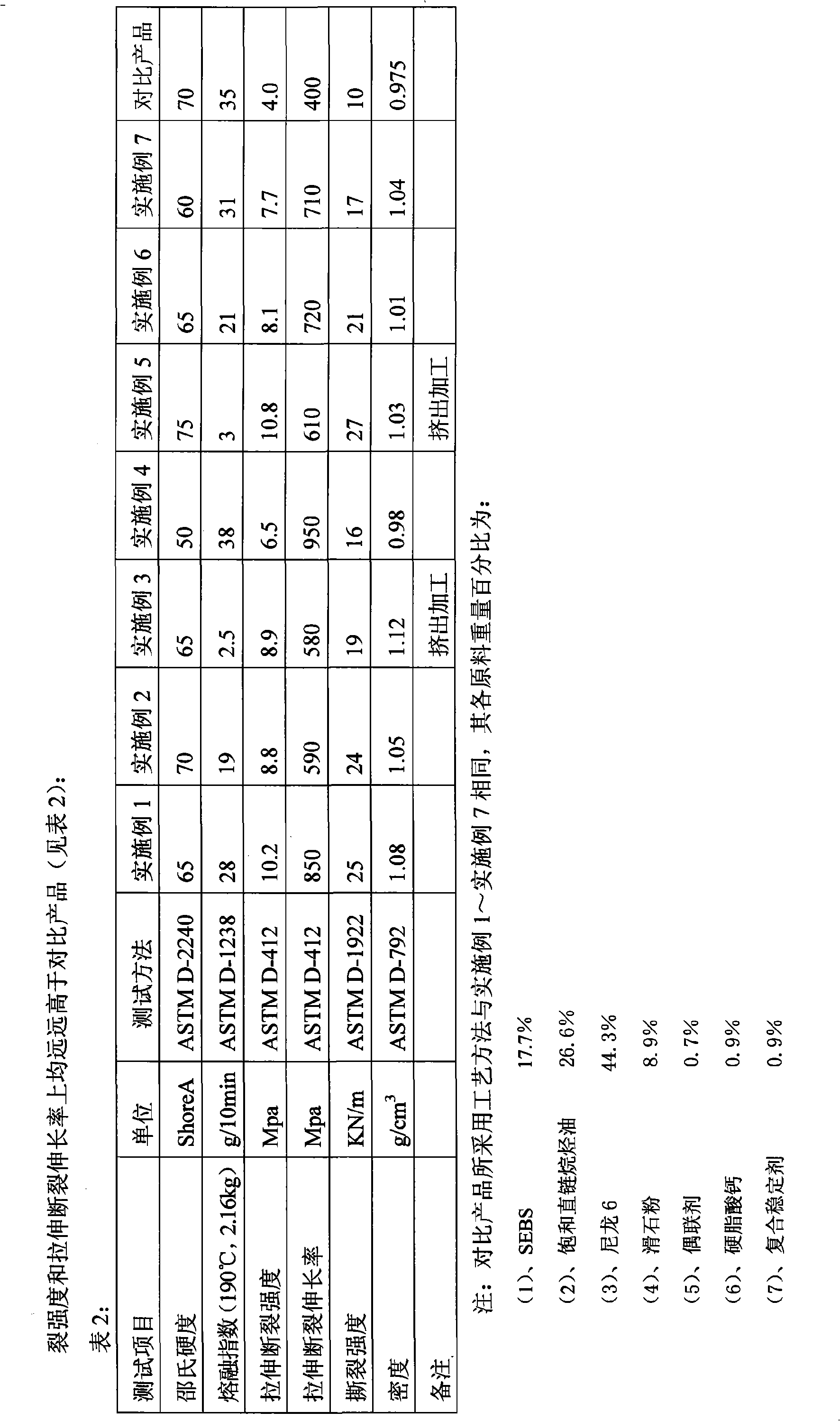

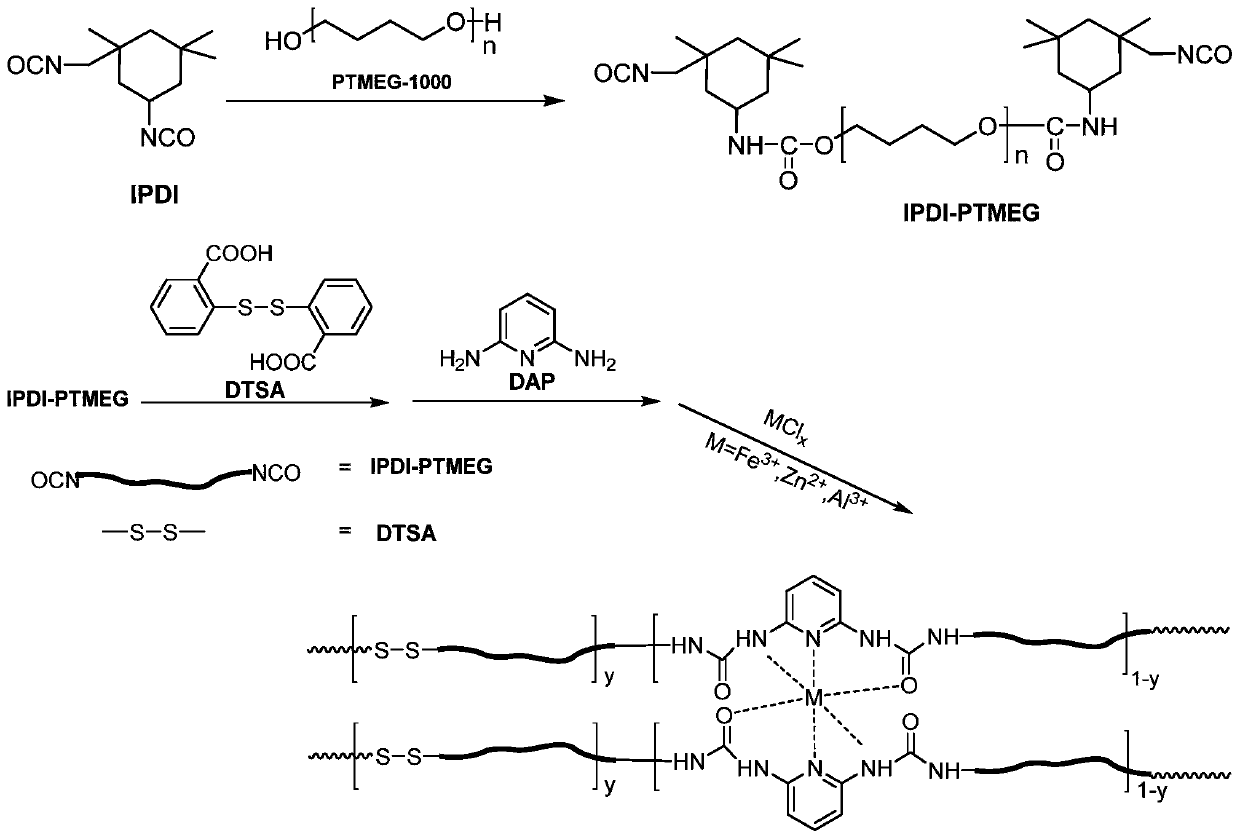

High-strength room-temperature self-repairing polyurethane elastomer based on multiple dynamic reversible effects as well as preparation and application of high-strength room-temperature self-repairing polyurethane elastomer

The invention belongs to the technical field of self-repairing elastomer materials, and discloses a high-strength room-temperature self-repairing polyurethane elastomer based on multiple dynamic reversible effects as well as preparation and application thereof. A preparation method comprises the following steps: 1) reacting a dihydric alcohol with a diisocyanate under the action of a catalyst to obtain a prepolymer; wherein the dihydric alcohol is a mixture of more than one from a polyether glycol and a polysiloxane glycol; 2) reacting a dicarboxylic acid chain extender with the prepolymer toobtain an oligomer; adding a diamine chain extender, continuously reacting, and carrying out subsequent treatment to obtain polyurethane; wherein the dicarboxylic acid chain extender and the diamine chain extender are collectively called as chain extenders, and the chain extenders contain disulfide bonds and pyridine groups; 3) in an organic solvent, reacting polyurethane with a metal salt cross-linking agent, and removing the solvent to obtain the high-strength room-temperature self-repairing polyurethane elastomer. The preparation method is simple and mild in condition, and the prepared polyurethane elastomer is excellent in mechanical property and high in self-repairing efficiency and is applied to a flexible substrate materials, wearable equipment and intelligent protective coating.

Owner:SOUTH CHINA UNIV OF TECH

A kind of thermoplastic polyurethane elastomer and preparation method thereof

The invention relates to a thermoplastic polyurethane elastomer and a preparation method thereof. The preparation method comprises the following steps of: mixing polyester polyol, polyether polyol or a mixture of polyester polyol and polyether polyol, organic diisocyanate and micromolecular diol, inputting into a twin-screw premixing unit, shearing and dispersing in axial and radial directions ata high speed for 1 to 2 minutes to make the polymer have certain viscosity and molecular weight, pressing into a co-rotating reactive twin-screw extruder at the temperature of between 180 and 240DEG C, reacting for 2 to 3 minutes, and performing underwater granulation by using a granulator to obtain thermoplastic polyurethane elastomer particles. Compared with the prior art, the invention has a series of advantages that: production equipment investment is small, the process is simple, the process is controlled stably, and the prepared polyurethane elastomer has a few gel points, good appearance and color, good physical and mechanical properties, uniform molecular weight distribution and wide application prospect.

Owner:SHANGHAI HENGAN POLYURETHANE CO LTD

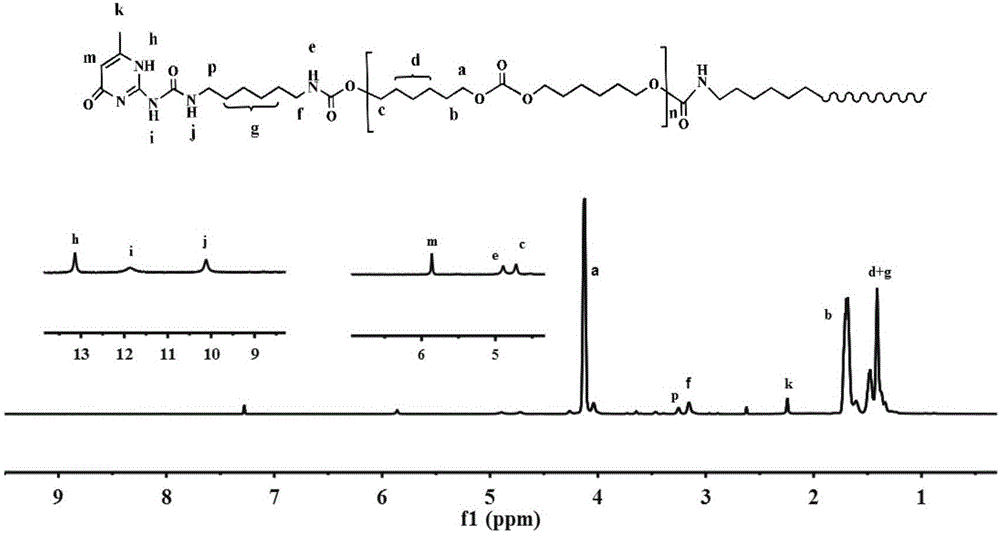

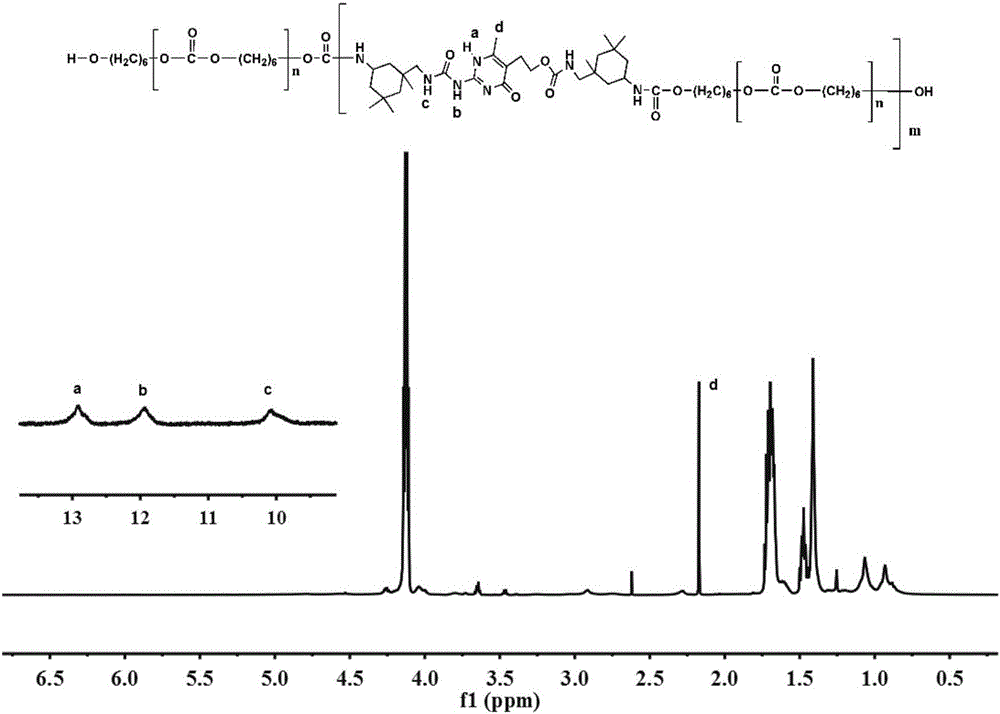

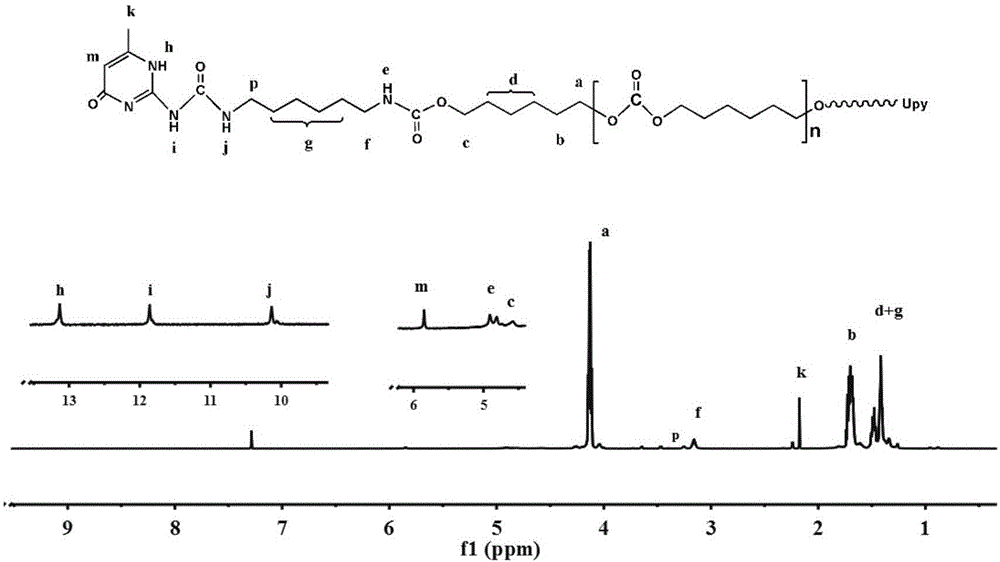

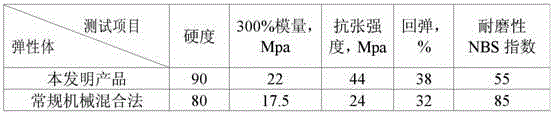

Preparing method of thermally-driven self-repairing elastomer based on hydrogen-bond interaction

The invention provides a preparing method of thermally-driven self-repairing elastomer based on hydrogen-bond interaction. The method comprises the steps that firstly, ureido pyrimidone type mono-isocyanate molecules are prepared, then diisocyanate is used for carrying out chain extension on low polymer glycol to prepare a hydroxyl-terminated polyurethane low polymer, and finally, Upy-terminated type thermally-driven self-repairing elastomer is prepared by terminating the hydroxyl-terminated polyurethane low polymer with UPY-NCO; secondly, ureido pyrimidone type diisocyanate is prepared, then ureido pyrimidone type diisocyanate and the low polymer glycol are subjected to addition polymerization, and the hydrogen bond network type thermally-driven self-repairing elastomer with Upy units in a main chain controllable is prepared. Compared with a traditional foreign-aid type self-preparing material (a micro capsule type, a micro vessel type and the like), the thermally-driven self-repairing material is a thermoplastic material and can be repeatedly processed and used, and theoretically multi-time repairing capability can be achieved at the same position.

Owner:SOUTH CHINA UNIV OF TECH

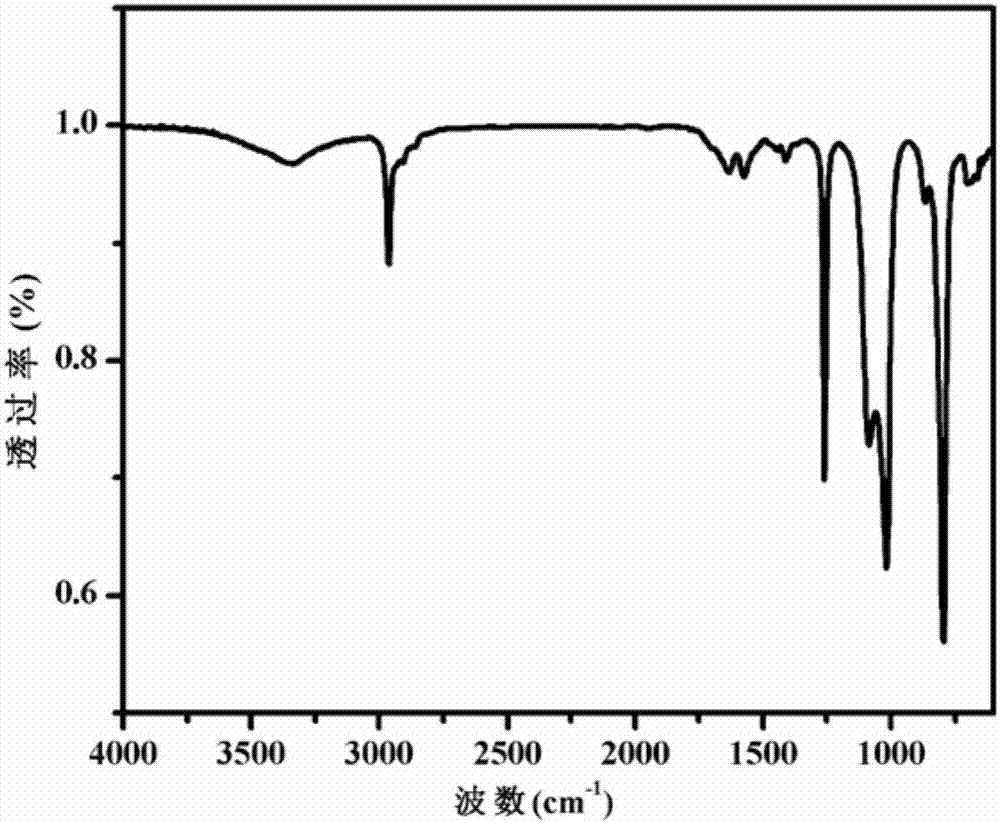

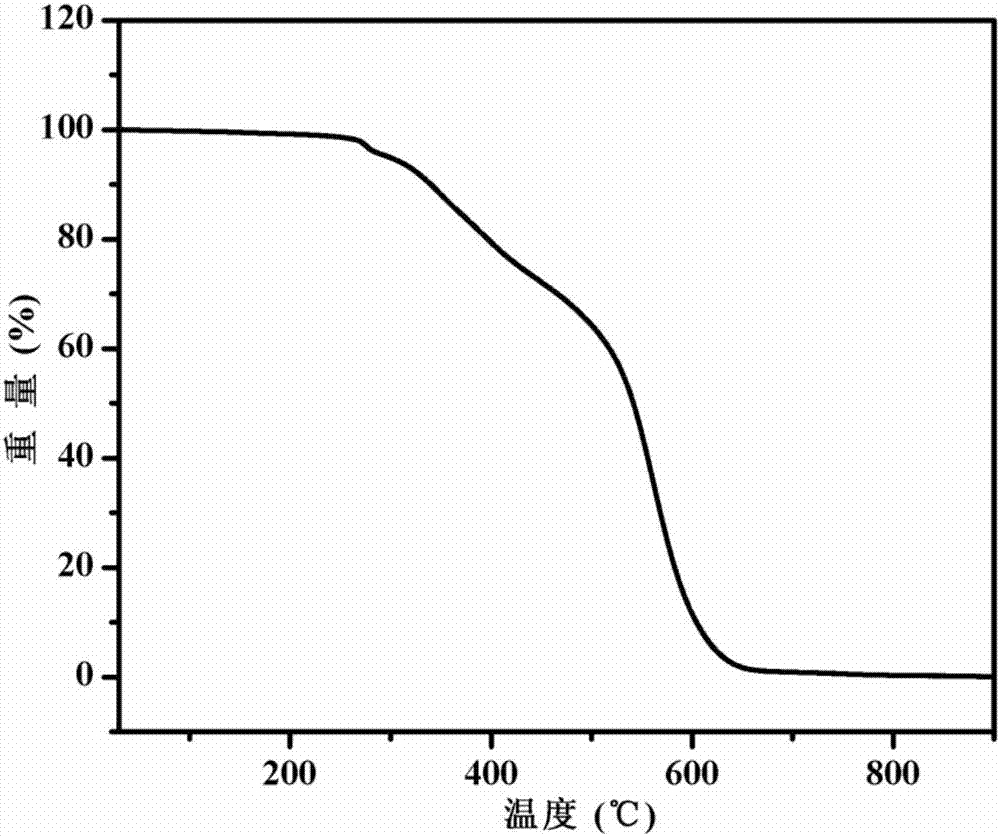

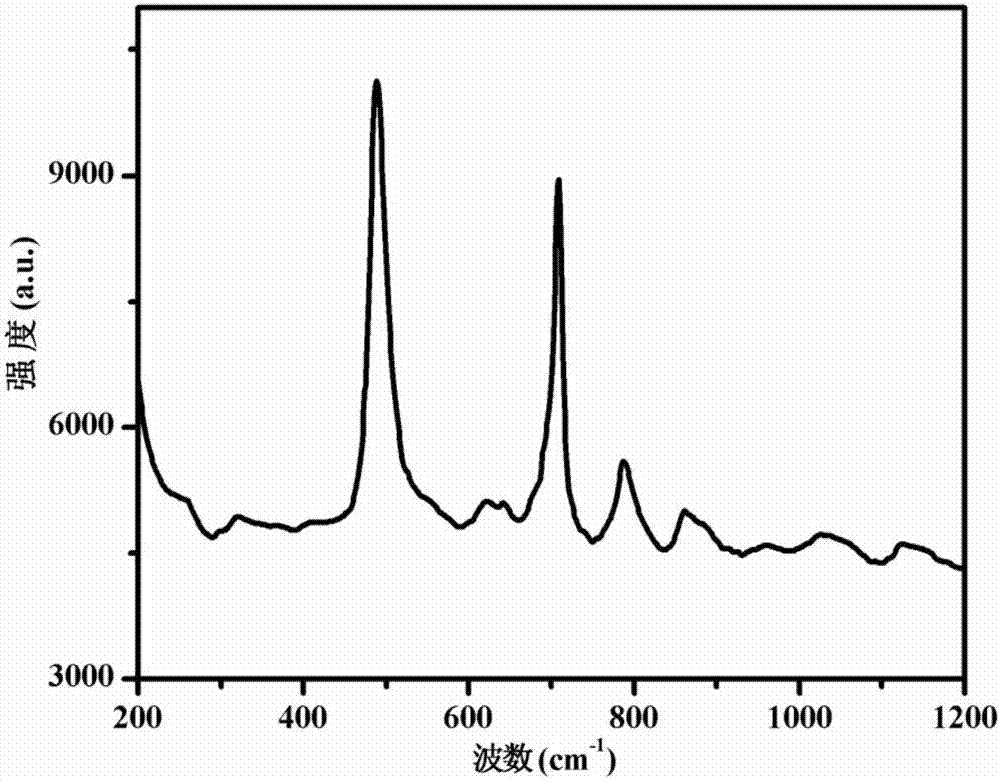

Nanosilicon dioxide modified polyurethane elastomer and preparation method thereof

The invention discloses a nanosilicon dioxide modified polyurethane elastomer and a preparation method thereof. The preparation method comprises the steps of enabling polyether glycol, isocyanate and micromolecular dihydroxy alcohol to be subjected to addition polymerization reaction to prepare a polyurethane prepolymer as a component A; uniformly mixing a chain extender, ethyl silicate and a silane coupling agent, carrying out in-situ hydrolysis on ethyl silicate to form nanosilicon dioxide particles, performing surface hydrophobicity modification on the nanosilicon dioxide particles by using the silane coupling agent, and removing a solvent in the mixture to obtain a component B; uniformly mixing the component A and the component B according to a certain ratio, degassing, pouring and carrying out vulcanization molding to obtain the nano-modified polyurethane elastomer. By using the preparation method, the uniform dispersion of silicon dioxide particles in polyurethane is realized, the enhancement effect of nanoparticles is sufficiently taken, the prepared polyurethane elastomer is obtained by crosslinking the nanosilicon dioxide particles, and the heat resistance and chemical stability of the polyurethane elastomer can be remarkably improved; in addition, the nanosilicon dioxide modified polyurethane elastomer can meet the requirements of a sealing element for mechanical strength, wear resistance, high elasticity and oil resistance and has a wide market prospect.

Owner:安徽嘉明新材料科技有限公司

Dihydric alcohol containing acylhydrazone bond, dihydric alcohol containing acylhydrazone bond and disulfide bond, self-repairing polyurethane elastomer and preparation method thereof

ActiveCN106117486AAchieve self-healingGood physical and mechanical propertiesHydrazone preparationHydropoly/poly sulfide preparationPolyesterMechanical property

The invention provides dihydric alcohol containing an acylhydrazone bond, dihydric alcohol containing an acylhydrazone bond and a disulfide bond, a self-repairing polyurethane elastomer and a preparation method thereof. The polyurethane elastomer is prepared from the dihydric alcohol containing the acylhydrazone bond or the dihydric alcohol containing the acylhydrazone bond and the disulfide bond and a polyurethane prepolymer. The dihydric alcohol containing the acylhydrazone bond is prepared from a dihydrazide monomer and hydroxy aldehyde. The dihydric alcohol containing the acylhydrazone bond and the disulfide bond is prepared from a dithio lipid monomer, hydrazine hydrate and hydroxy aldehyde. The polyurethane prepolymer is prepared from a polyester or polyether polyol monomer and diisocyanate. After the self-repairing polyurethane elastomer is mechanically damaged, the acylhydrazone bond or the disulfide bond on a crosslinked polymer molecular chain achieves material self-repairing through dynamic exchange reaction. The self-repairing crosslinked polyurethane elastomer material is simple in preparation, can achieve self repairing at room temperature, is high in repairing capability, short in repairing time and capable achieving many times of self repairing and has better mechanical properties.

Owner:QINGDAO UNIV OF SCI & TECH +1

Permanent gas blown microcellular polyurethane elastomers

Microcellular polyurethane elastomers having sharply reduced or virtually no urea linkages may be prepared without resort to organic physical blowing agents by frothing a frothable mixture containing isocyanate reactive polyols and chain extenders, and a frothable isocyanate component. The isocyanate component is derived by reacting a stoichiometric excess of a di- or polyisocyanate with a polyol component containing an ultra-low unsaturation polyol. The froth-produced elastomers surprisingly exhibit greatly improved tear strengths, compression set, and other physical properties as compared to all water-blown microcellular elastomers of the same density.

Owner:ARCO CHEM TECH INC

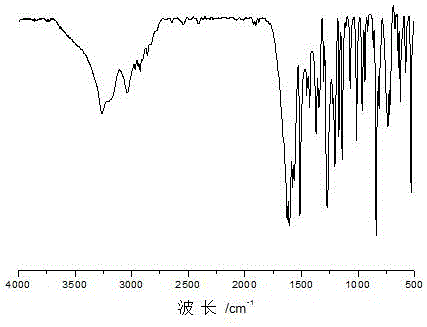

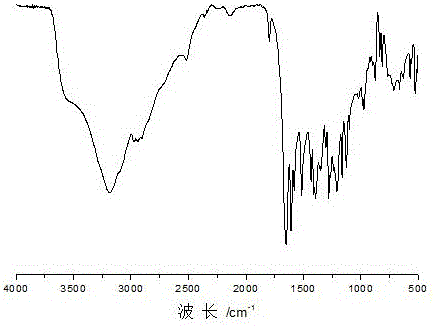

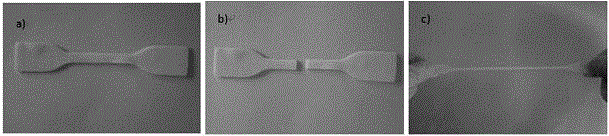

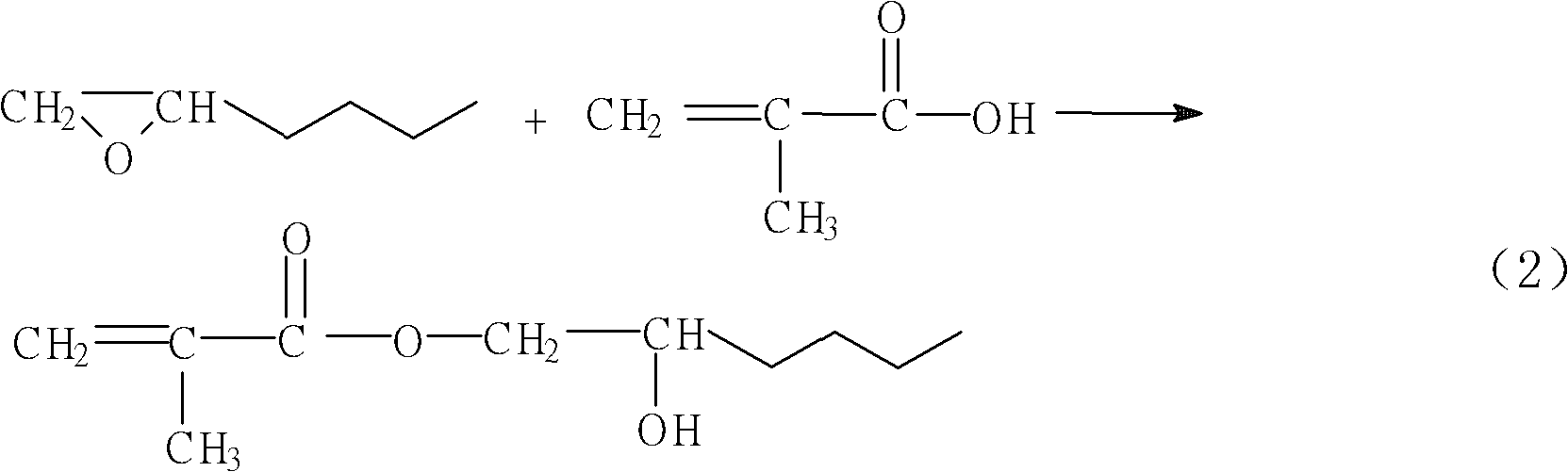

Synthesis and application of light-cured polyurethane-acrylic acid-epoxy resin adhesive

The invention relates to a novel polyurethane-acrylic acid-epoxy resin photosensitive pre-polymer, a synthesis method of the pre-polymer, a high-performance ultraviolet (UV) cured polyurethane modified acrylic acid epoxy resin adhesive prepared from the pre-polymer and application of the UV cured adhesive to bonding of a nylon membrane material and a polyurethane or modified polyurethane elastic body. A method for preparing the photosensitive pre-polymer comprises the following steps of: 1, synthesizing a lower-viscosity epoxy acrylic ester pre-polymer; 2, preparing a pre-polymer of urethane acrylate resin; and 3, mixing or reacting the two pre-polymers in a certain ratio so as to obtain the polyurethane-acrylic acid-epoxy resin photosensitive pre-polymer. A polyurethane-acrylic acid-epoxy resin UV cured adhesive is further prepared by adding a photoinitiator, a photosensitive diluent, a light curing crosslinking agent, other necessary aids and the like.

Owner:BEIHANG UNIV

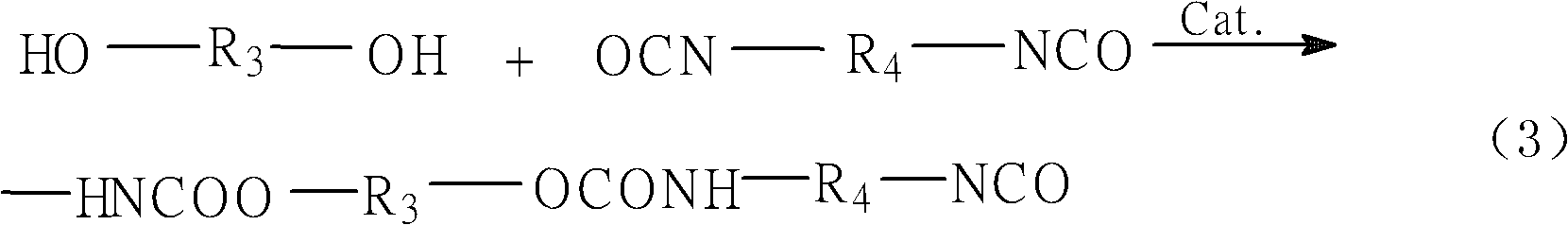

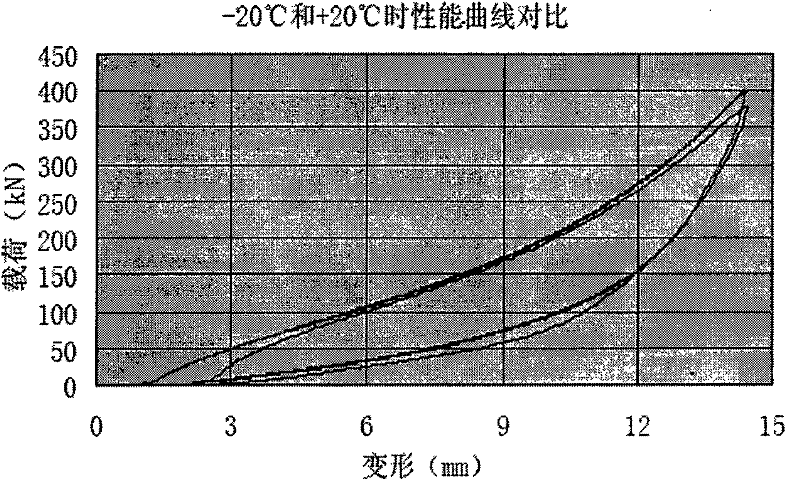

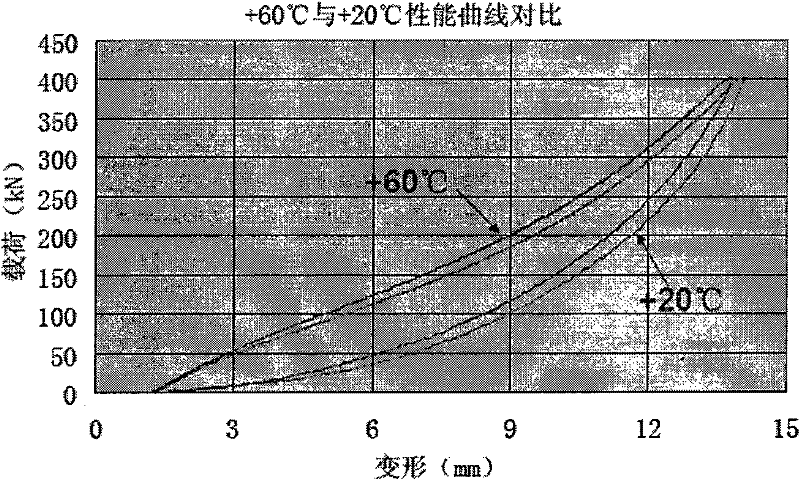

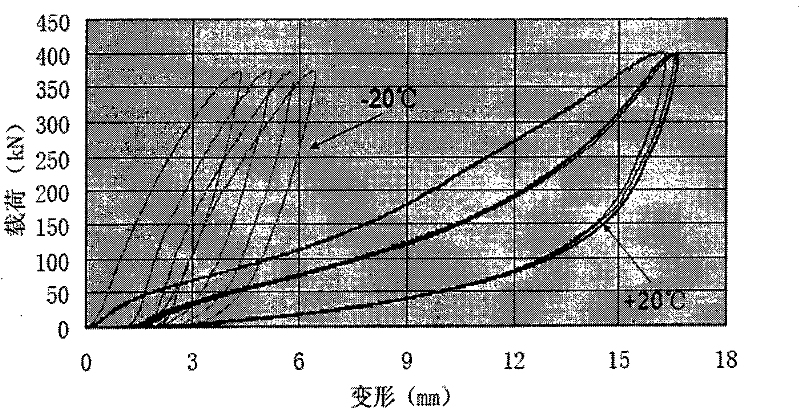

A kind of polyurethane elastomer shock absorber material and preparation method

The invention relates to a polyurethane elastomer shock absorber material and a preparation method. The present invention is formed from the following three components (A), (B) and (C) through a two-step polymerization reaction. This elastomer material has excellent mechanical properties and extremely stable stiffness maintenance over the operating temperature range. Among them (A) polymer polyol, (B) polyisocyanate, (C) low molecular polyol, ammonia chain extension cross-linking agent, (A) uses an optimized combination of polyether and polyester, and the present invention is used for The application of elastomer buffering and shock absorption can greatly reduce the volume and weight of equipment shock absorption system components, and solve the problem of large changes in the stiffness of polyurethane elastomer materials despite temperature. At the same time, the invented material has high rebound, low pressure change, hydrolysis resistance and Biodegradability, thereby expanding the application scope of polyurethane materials in elastomer shock absorption.

Owner:NORTHWEST RUBBER & PLASTIC RES & DESIGN INST CO LTD

Preparation method of thermoplastic polyurethane elastomer

InactiveCN103059554AImprove mechanical propertiesImprove heat resistancePolyethylene glycolHydrolysis

Owner:DONGGUAN JIXIN POLYMER SCI & TECH

Polyurethane elastomers having improved physical properties and a process for the production thereof

InactiveUS7045650B2Excellent characteristicsMaintain good propertiesUrea derivatives preparationIsocyanic acid derivatives preparationPolyurethane elastomerPolyol

A polyol composition having a number average molecular weight of from about 1,000 to about 3,000 Daltons is made up of (1) at least 60% by weight of a low monol polyoxypropylene polyol having a number average molecular weight of from about 2,000 to 12,000 Da and a degree of unsaturation less than or equal to 0.02 meq / g and (2) no more than 40% by weight of a polyol having a number average molecular weight of from about 400 to about 1,000 Da and a polydispersity index greater than 1.1. This polyol composition is reacted with a diisocyanate, a polyisocyanate, an isocyanate-terminated prepolymer or an isocyanate-terminated quasi-prepolymer to produce polyurethane elastomers having good physical and mechanical properties. Any of the known processes for producing polyurethane elastomers, including one-shot processes, may be used to produce elastomers in accordance with the present invention.

Owner:COVESTRO LLC

Core-shell type ammonium polyphosphate synergetic flame-retardant polyurethane elastic composite material and preparation method thereof

ActiveCN101608060AHigh flame retardant efficiencyImprove efficiencyPolyurethane elastomerFire protection

The invention discloses a core-shell type ammonium polyphosphate synergetic flame-retardant polyurethane elastic composite material and a preparation method thereof, which is characterized in that the polyurethane elastic composite material containing core-shell type ammonium polyphosphate can be obtained by melting and co-mixing 75-94.9% of polyurethane, 5-25% of core-shell type ammonium polyphosphate and 0.1-5% of synergistic agent at the temperature of 160-220 DEG C for 5-30 minutes by weight percentage. The composite material can ensure that the adding amount of flame retardant is reduced while ensuring the flame retardance effect, and the composite material has good resistance of melt drip, simultaneously improves the shortcoming of poor water resistance of the flame-retardant composite material containing the ammonium polyphosphate, enhances the compatibility of the flame retardant and a polyurethane elastomer and improves the mechanical properties of the material, such as tensile strength, fracture strength and flame retardance performance, thereby meeting the requirements of fire protection safety and engineering applications.

Owner:UNIV OF SCI & TECH OF CHINA

Self-repaired organic silicon modified polyurethane elastomer and preparation method thereof

The invention provides a self-repaired organic silicon modified polyurethane elastomer based on disulfide bonds, and a preparation method thereof. The preparation method comprises the following steps: enabling a monomer containing a diisocyanate group to react with active group capped polydimethylsiloxane so as to obtain a polyurethane prepolymer; and further performing reaction with a monomer containing the disulfide bonds, and synthesizing, thereby obtaining the self-repaired organic silicon modified polyurethane elastomer based on the disulfide bonds. The self-repaired organic silicon modified polyurethane elastomer which is modified with organic silicon has improved thermal resistance, water resistance and flexibility, and has high self-repairing efficiency as the disulfide bonds are introduced into a main polymer chain.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

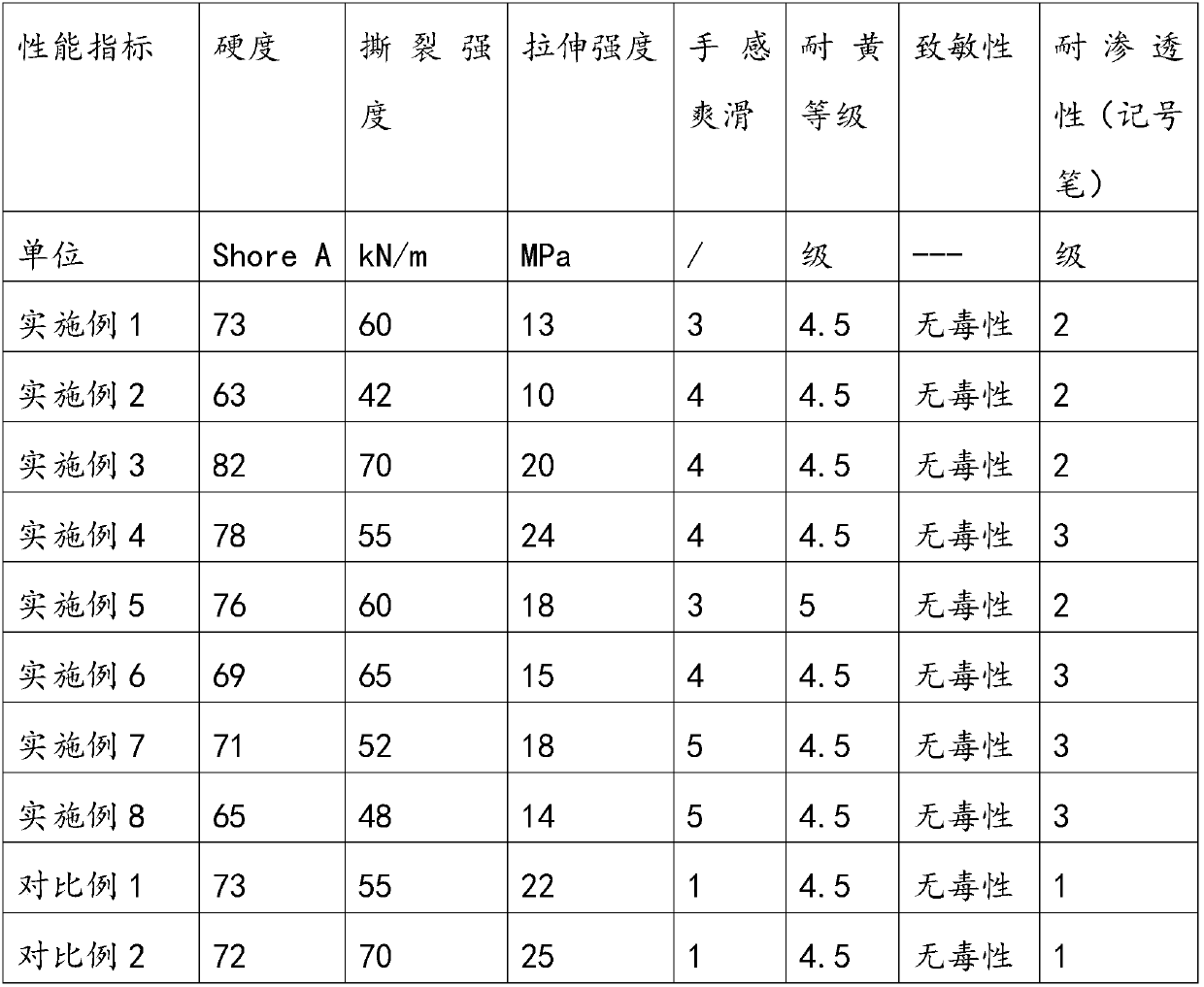

Polyurethane elastomer composition and preparation method thereof

The invention discloses a polyurethane elastomer and a preparation method thereof. The method comprises the following steps: evenly mixing polyurethane prepolymer with curing agent, removing foam, casting and curing to obtain the polyurethane elastomer, wherein the curing agent is composed of at least one of chain extender and cross-linking agent, catalyst and other additives. The Shaw hardness Aof the polyurethane elastomer prepared by the invention is 70-90A, the tensile strength thereof is not less than 14MPa, and the elongation at break thereof is not less than 360%; and the polyurethaneelastomer can resist hydrolysis, meets performance requirements for the spiral strake material in the deep-sea riser vortex-excited oscillation suppression device, and has important application value.

Owner:CHINA NAT OFFSHORE OIL CORP +2

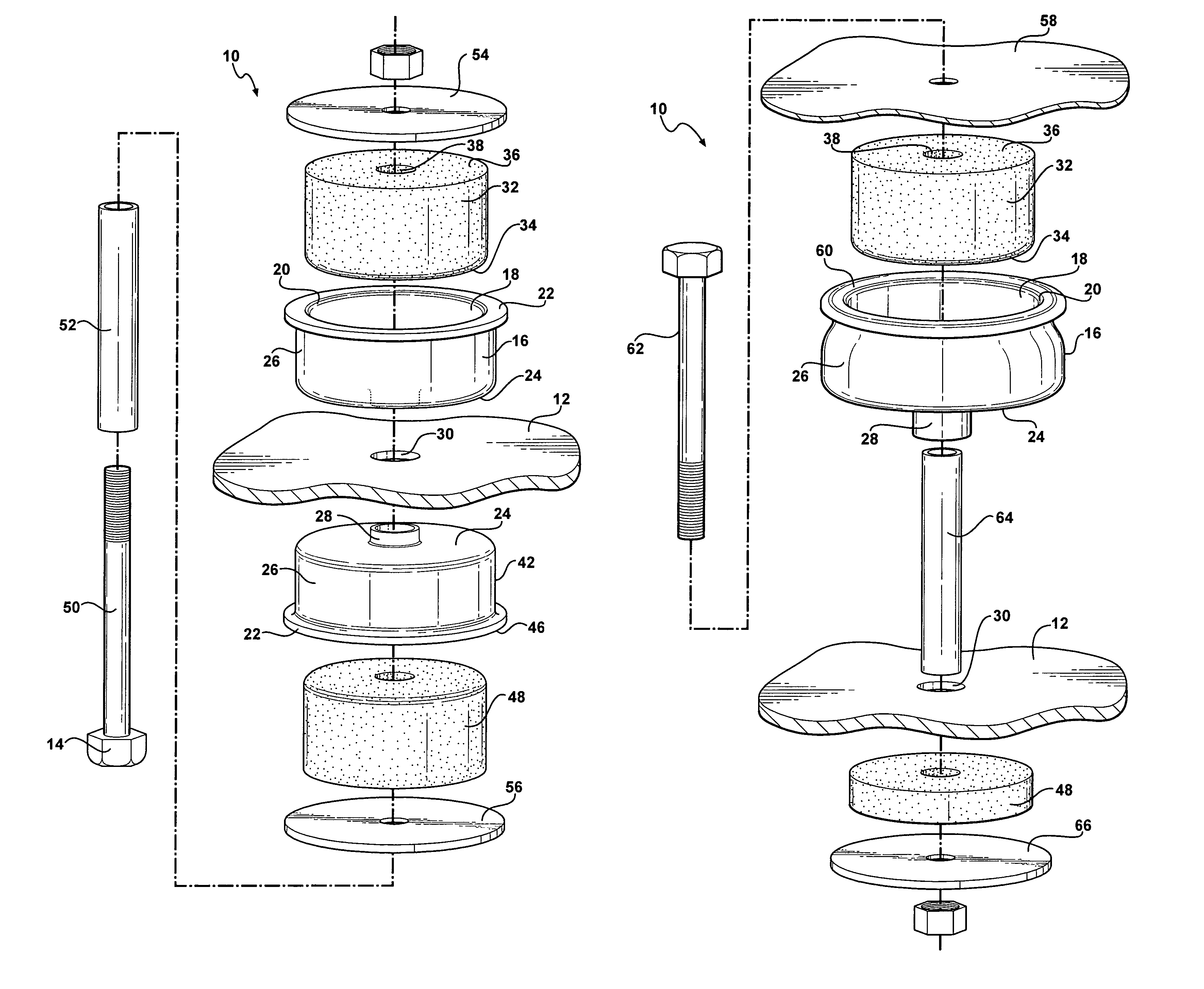

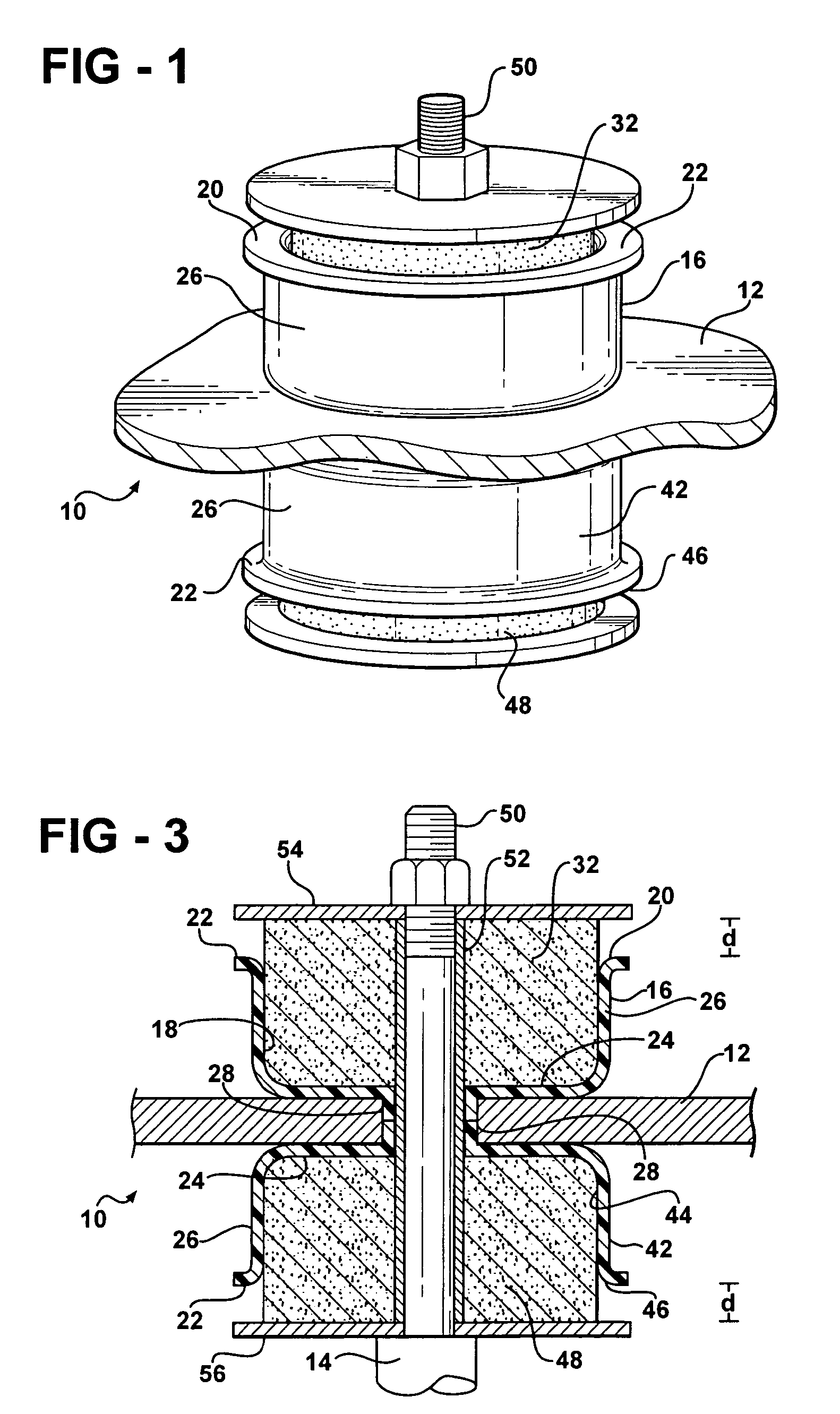

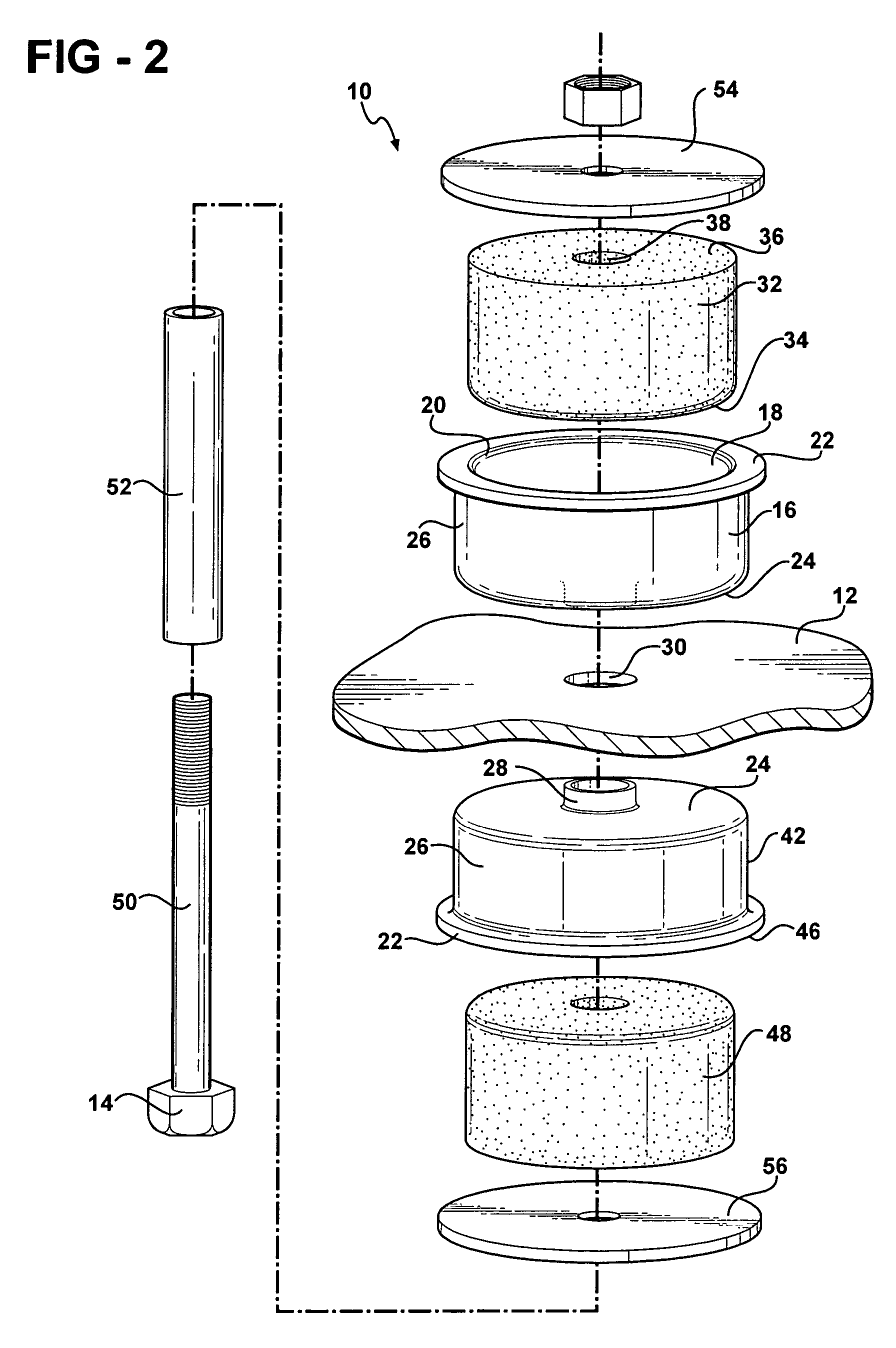

Mount assembly

InactiveUS7070157B2Vehicle body-frame connectionsMultiple spring combinationsPolyurethane elastomerHigh frequency vibration

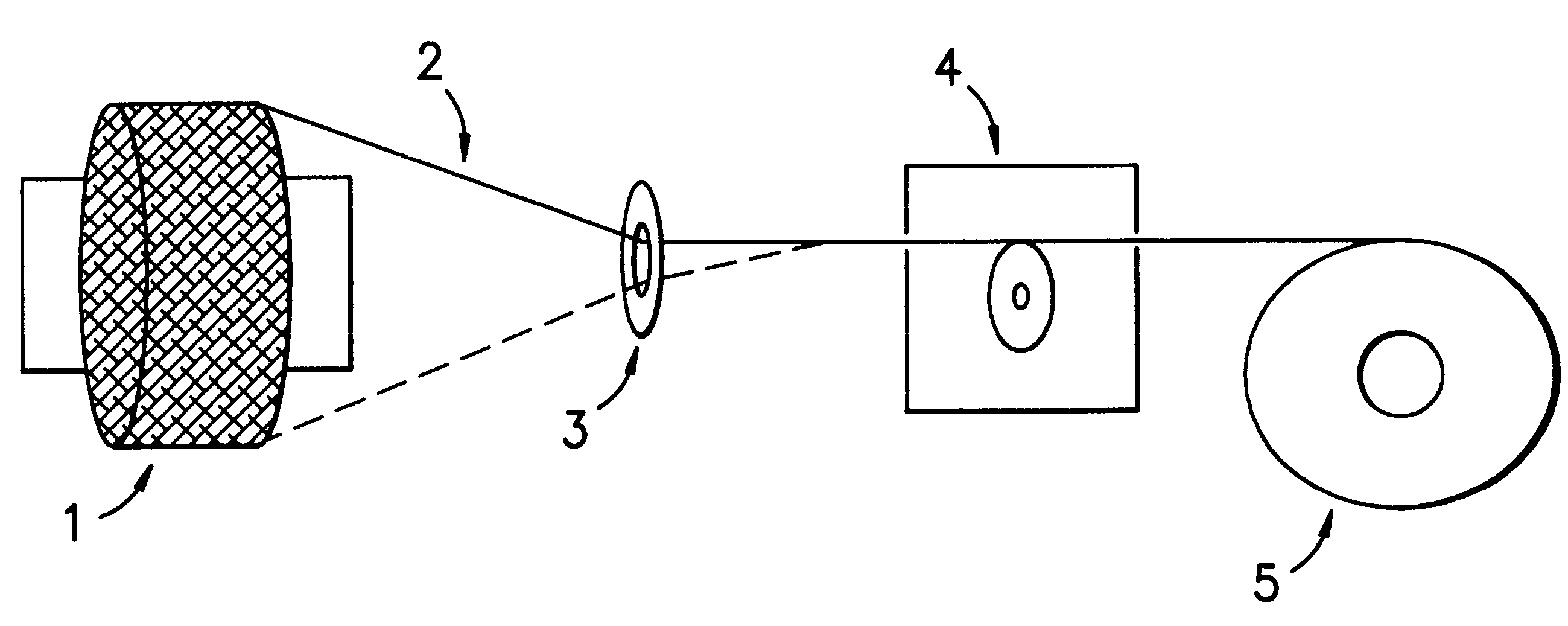

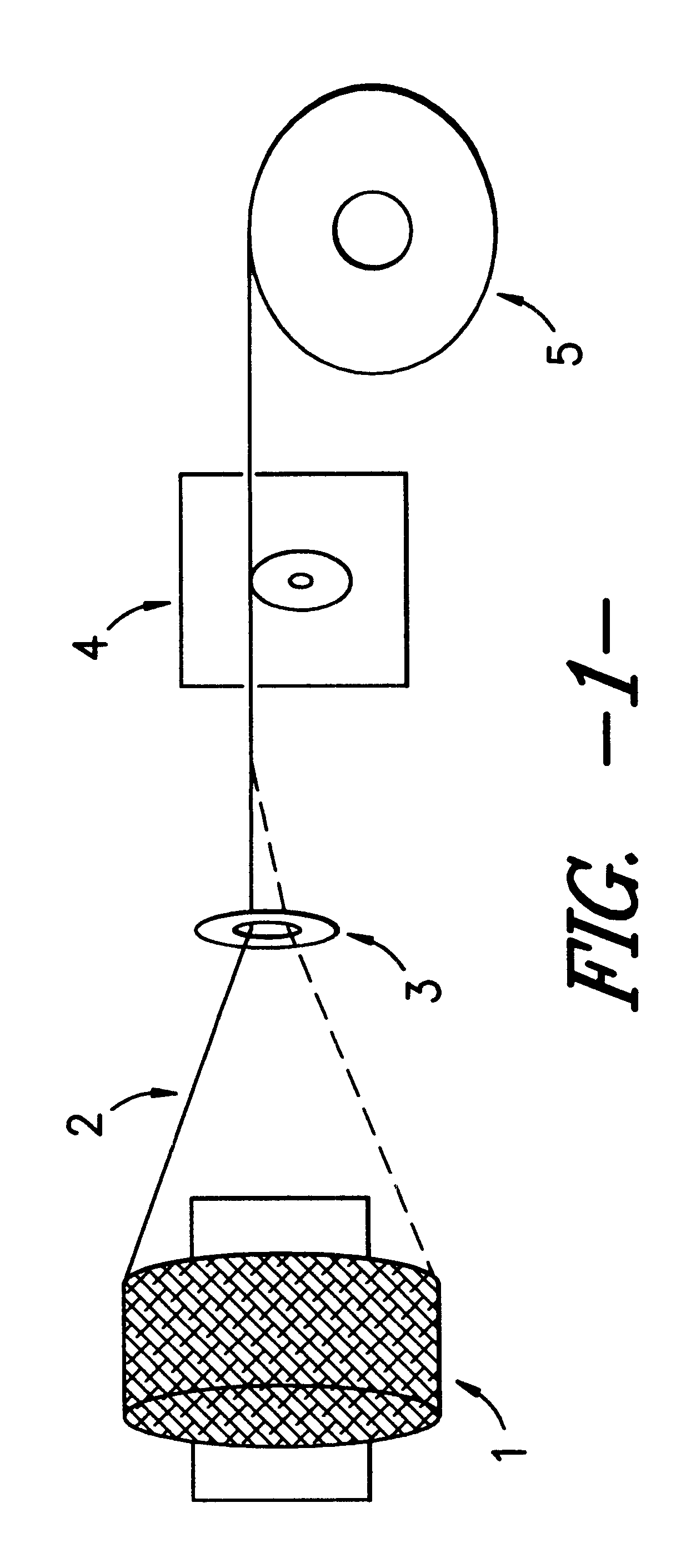

A mount assembly for use in an automotive suspension system, body mount, cradle mount, or other like device. The mount assembly includes a polyurethane elastomer carrier mounted to a frame and having a peripheral outer rim. A microcellular polyurethane insulator is coupled to the frame and extends beyond the peripheral outer rim. The polyurethane elastomer of the carrier has a first modulus of elasticity. The microcellular polyurethane of the insulator has a second modulus of elasticity that is less than the first modulus of elasticity of the carrier such that the mount assembly can provide two distinct rates of elasticity, or stiffness, for adequately isolating both low amplitude, high frequency vibrations and high amplitude, low frequency impacts.

Owner:BASF CORP

Method for producing urethane elastomer and application

ActiveCN101148494AGood spinning stabilityIncrease elasticityMonocomponent polyurethanes artificial filamentPolyesterPolyurethane elastomer

The process of producing polyurethane elastomer with the material including one component A of polyether glycol and / or polyester polyol, one component B of organic diisocyanate and one component C of small molecular diol as the chain expanding agent, includes the following steps: melting the components while adding organic tin catalyst in 0.001-0.05 wt% to the component A, metering precisely with one metering system, and mixing and bulk polymerizing in a double screw extruder with precise temperature control system at 180-260 deg.c for 3-15 min to obtain the polyurethane elastomer. The polyurethane elastomer is applied in melt spinning to produce elastic polyurethane fiber. The production process is simple, easy in control and low in cost, and elastic polyurethane fiber produced with the polyurethane elastomer has high quality.

Owner:SHANGHAI YITAN NEW MATERIAL CO LTD

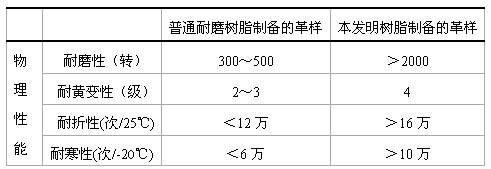

Cold-resistant high-wear-resistant polyurethane resin for synthetic leather

ActiveCN102060973AImprove wear resistanceGood yellowing resistanceFibre treatmentPolyurethane elastomerAlcohol

The invention belongs to polyurethane elastomeric materials, and particularly relates to a cold-resistant high-wear-resistant polyurethane resin for synthetic leather. The technical scheme is as follows: the cold-resistant high-wear-resistant polyurethane resin for synthetic leather is characterized by mainly comprising isocyanate, polyalcohol compound, reactive silicone oil, alcohol chain extender of which the molecular weight is lower than 150, and solvent. By using the scheme, the invention overcomes the defects in the prior art, and provides a novel cold-resistant high-wear-resistant polyurethane resin for synthetic leather.

Owner:ZHEJIANG HUAFON SYNTHETIC RESIN

Polyurethane polymer systems

InactiveUS20110098417A1Good chemical resistancePolyurea/polyurethane coatingsPolyurethane elastomerPolyol

The present invention is to the preparation and application of isocyanate based polymers, particularly polyurethane and polyurea elastomeric polymers. By incorporating polybutadiene with a polyether polyol in a polyurethane system, the produced elastomer have improved chemical resistance as compared to conventional polyurethane elastomers. For polyurea elastomer, the incorporation of high functional polyols or crosslinkers with polybutadiene gives elastomer with improved chemical resistance as compared to conventional polyurea elastomers.

Owner:DOW GLOBAL TECH LLC

Polyurethane elastomer and method for its production

The present invention provides a method for producing a thermoplastic polyurethane elastomer having excellent heat resistance and mechanical properties, and capable of obtaining one having a low hardness without using a plasticizer. A method for producing a polyurethane elastomer, which comprises reacting a polyol compound and a polyisocyanate compound, characterized by using, as all or part of the above polyol compound, a polyester ether polyol (A) obtainable by ring-opening polymerization of a mixture of an alkylene oxide and a lactone monomer with an initiator.

Owner:ASAHI GLASS CO LTD

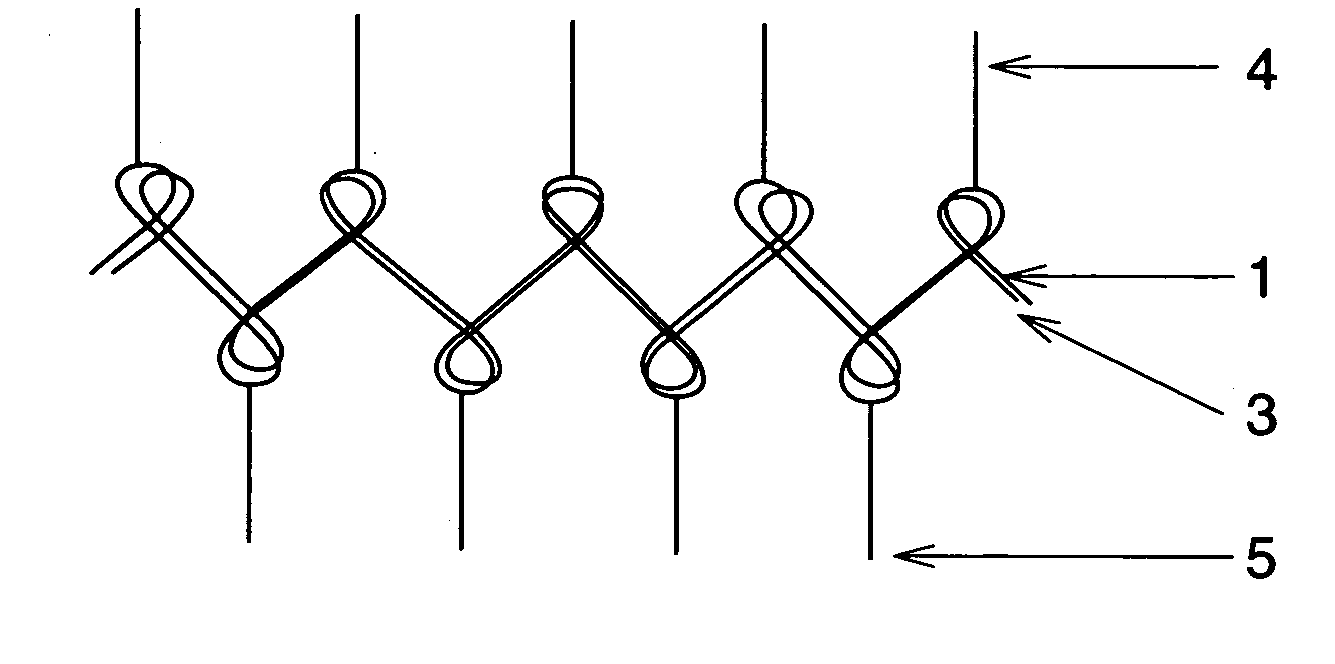

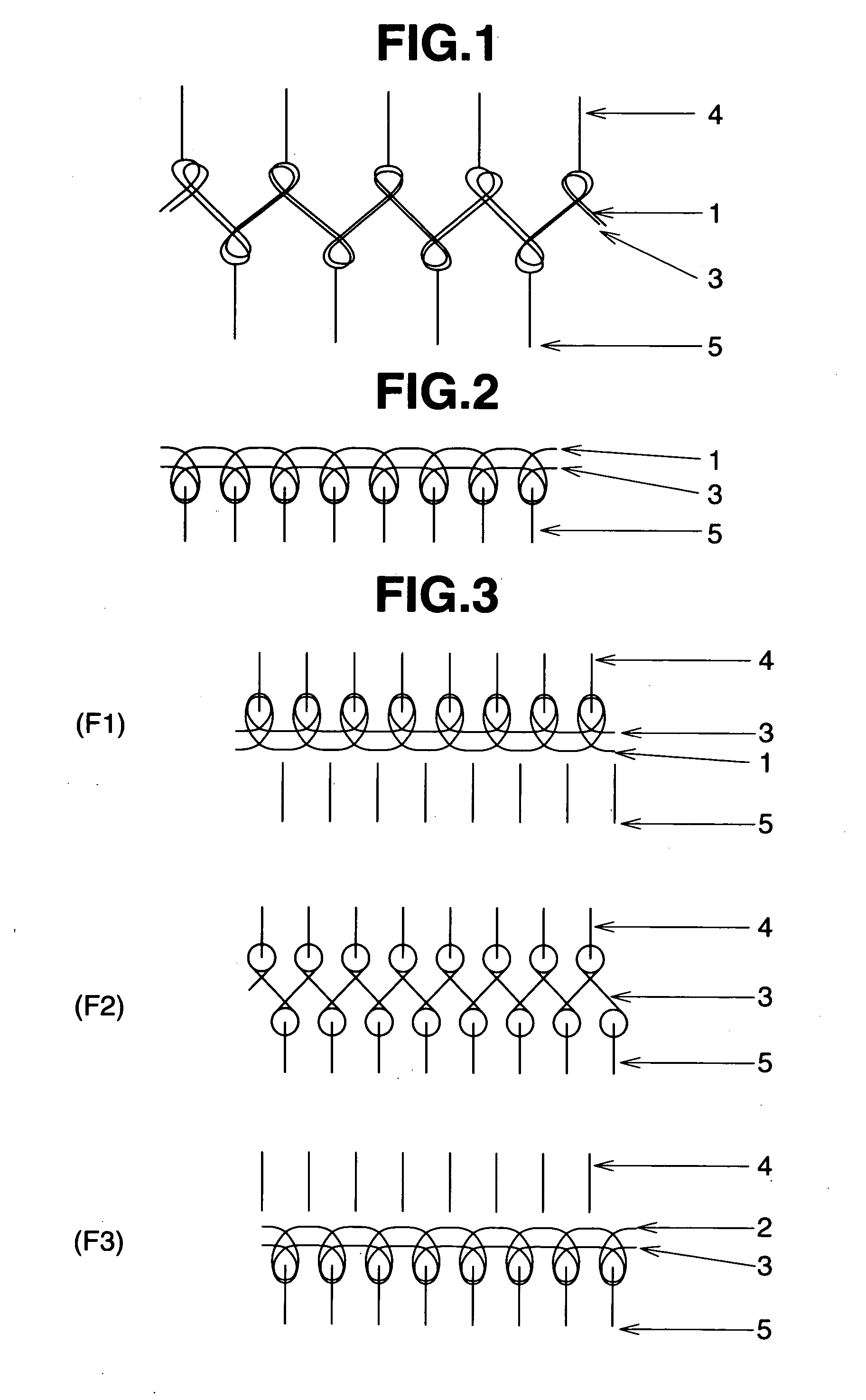

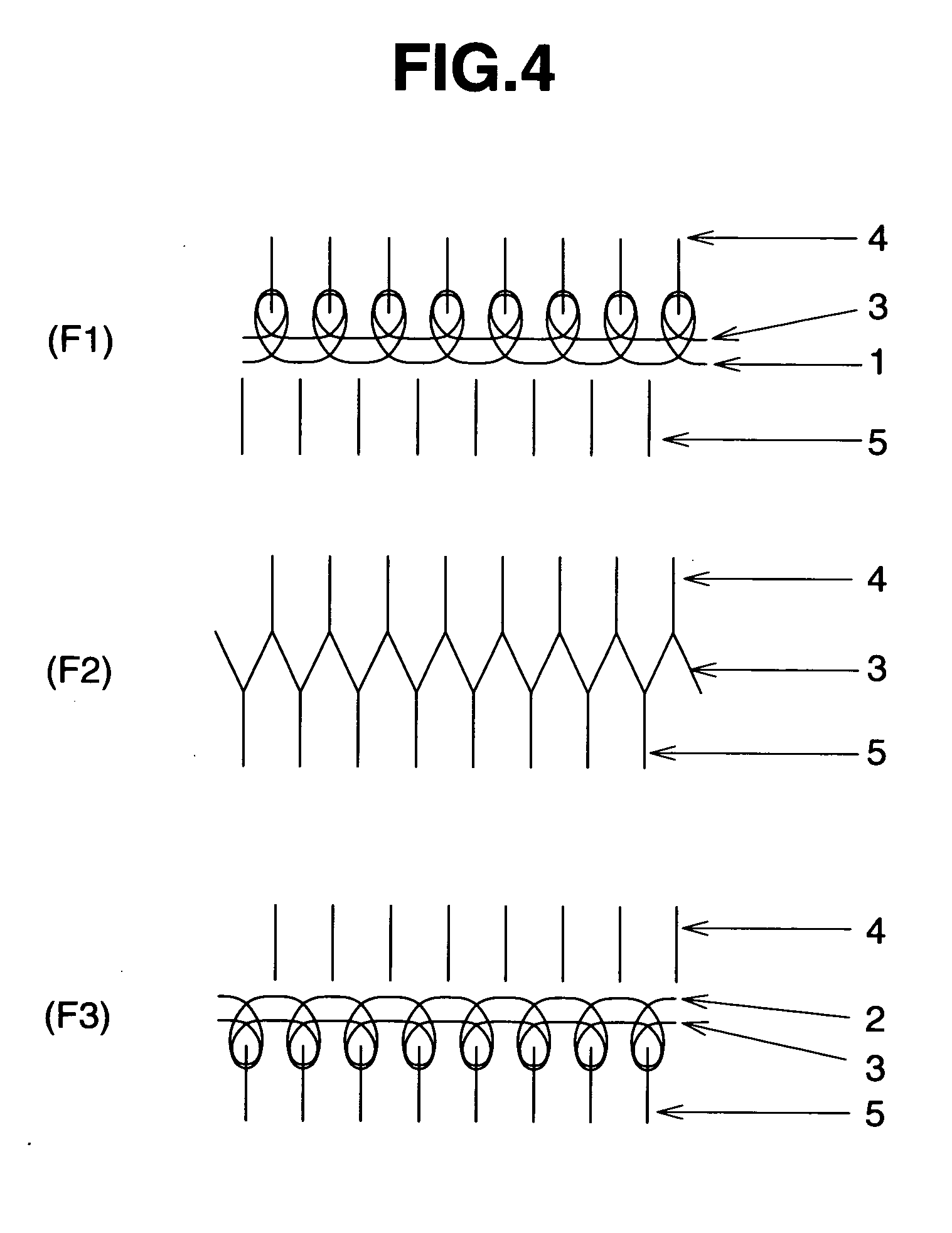

Weft Knitted Fabric Including Polyurethane Elastomer Fiber and Process for Producing the Same

ActiveUS20080032580A1Good extensibilityPromote recoveryOrnamental textile articlesWarp knittingYarnPolyurethane elastomer

A polyurethane elastomeric filament-containing weft knit fabric is obtained by plating a bare yarn of highly fusible, alkali-resistant polyurethane elastomeric filament having at least 50% retention of tenacity following dry heat treatment under 100% extension at 150° C. for 45 seconds, a melting point of 180° C. or below, and at least 60% retention of tenacity following treatment in a 2 g / L aqueous sodium hydroxide solution under 100% extension at 100° C. for 60 minutes at every loop of a weft knit fabric having a 1×1 rib. knit structure or a center yarn-containing reversible knit structure composed of at least one type of non-elastomeric yarn, then heat setting the plated structure so as to thermally fuse the highly fusible, alkali-resistant polyurethane elastomeric filaments to each other or to the non-elastomeric yarns at crossover points therebetween.

Owner:NISSHINBO TEXTILE INC +1

Thermoplastic organic silicon polyurethane elastomer and preparation method thereof

Owner:MIRACLL CHEM

Polyurethane elastomers, a process for the preparation thereof and the use thereof

InactiveUS20060293486A1Improve mechanical propertiesIncrease gas productionLithiumPolyurethane elastomer

The invention relates to polyurethane elastomers, a process for the preparation of these polyurethane elastomers and a the preparation of elastomeric molded parts comprising these polyurethane elastomers. These elastomers comprise the reaction product of a polyol component, chain extenders and / or crosslinking agents, one or more amine catalysts, a catalyst mixture which contains at least one organic titanium compound and at least one organic zinc compound, and optionally an organic lithium carboxylate and / or an organic bismuth carboxylate; with a polyisocyanate component.

Owner:BAYER MATERIALSCIENCE AG

Cushioning laminate insert for a garment shoulder strap, and method for making the same

InactiveUS20050097658A1Less discomfortReduce depressionShoulder strapGarmentsCushioningPolyurethane elastomer

The present invention relates to a cushioning laminate insert for a garment shoulder strap, such as a brassiere strap. The cushioning laminate insert of the invention includes: (1) a first outer fabric layer; (2) a central cushioning area of cured polyurethane elastomer cushioning material; and (3) a second outer fabric layer. One surface of the first and second outer fabric layers is laminated with a thermoplastic urethane (“TPU”) film. The laminated surface of the first outer fabric layer is covalently bonded to a first lateral surface of the central cushioning area, and the opposite lateral surface of the central cushioning area is self-adhered to the laminated surface of the second outer fabric layer in an open-sandwich configuration to thereby form the cushioning laminate insert. Garment shoulder straps including the cushioning laminate insert of the invention, as well as methods for making the cushioning laminate insert are also provided.

Owner:LYONS JUSTINA MAZZA +1

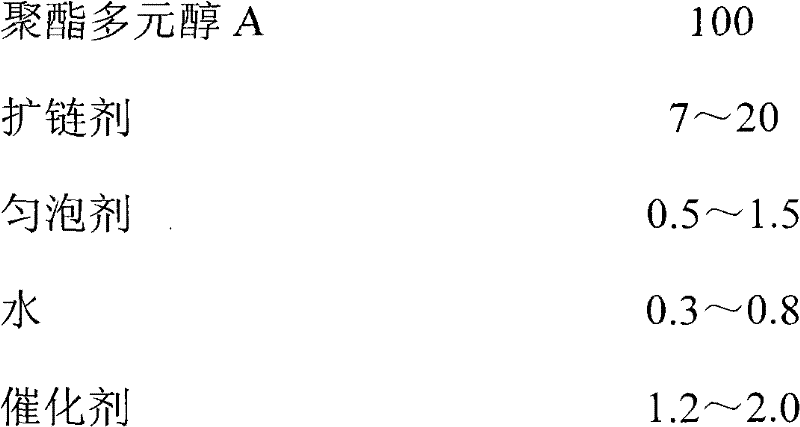

Microcellular polyurethane elastomer and preparation method thereof

The invention discloses a microcellular polyurethane elastomer and a preparation method thereof. The elastomer contains two components, i.e., a polyol component and a prepolymer component, wherein the polyol component comprises polyester polyol, a chain extender, a foam stabilizer, water, a catalyst and the like; and the prepolymer component comprises polyester polyol, isocyanate and the like. The polyester polyol in the polyol component is prepared from a mixture of aromatic dibasic acid and aliphatic diacid and a mixture of diethylene glycol and other dihydric alcohols by means of polycondensation reaction. Compared with common microcellular polyester-type elastomers, the prepared elastomer has higher hardness and mechanical properties as well as better abrasive and bending resistances, besides, the flowability of materials is good. The material can be used in the fields like soles, solid tires, buffer blocks and the like. The preparation method is simple and feasible.

Owner:LIMING RES INST OF CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com