High-strength room-temperature self-repairing polyurethane elastomer based on multiple dynamic reversible effects as well as preparation and application of high-strength room-temperature self-repairing polyurethane elastomer

A polyurethane elastomer, high-strength technology, applied in the field of high-strength room temperature self-healing polyurethane elastomer and its preparation, can solve the problems of less than 3MPa tensile strength of elastomer and harsh repair conditions, so as to improve self-healing performance and enhance mechanical properties. performance, the effect of accelerating energy dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

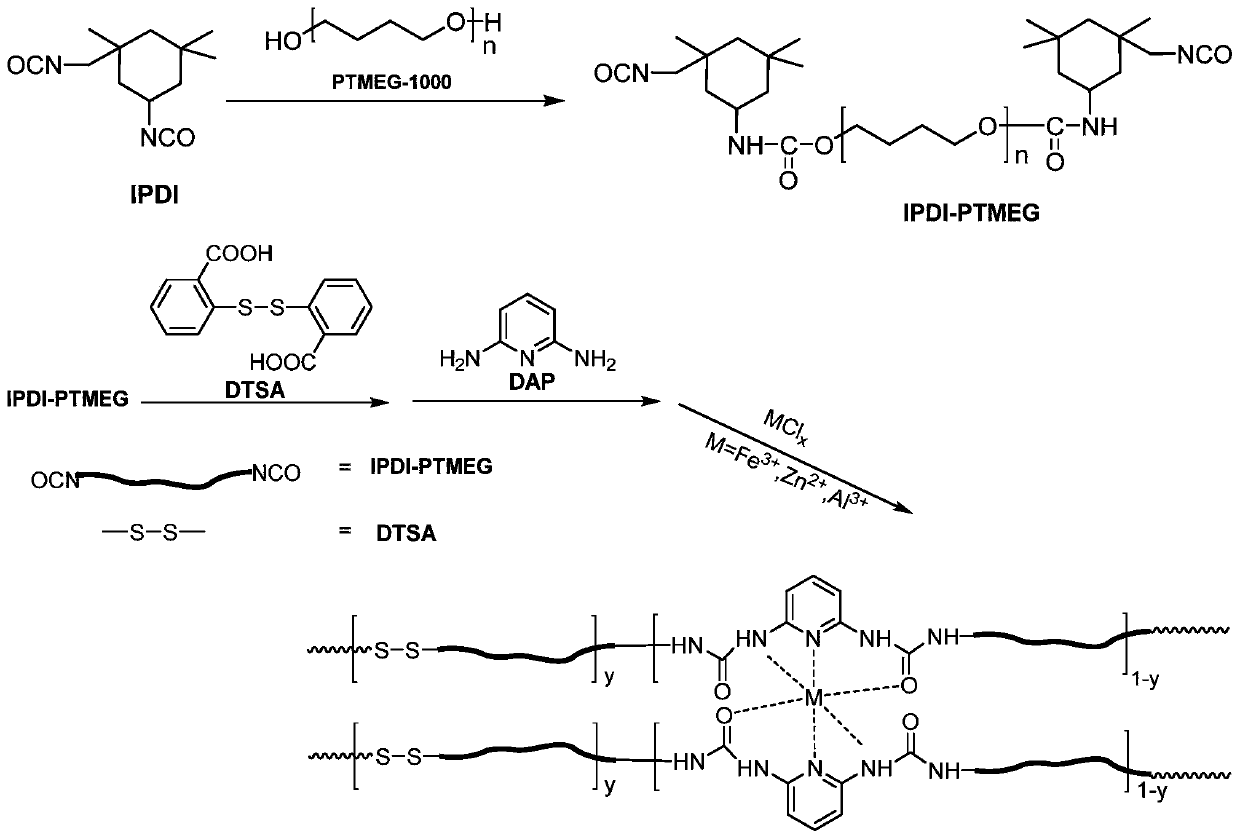

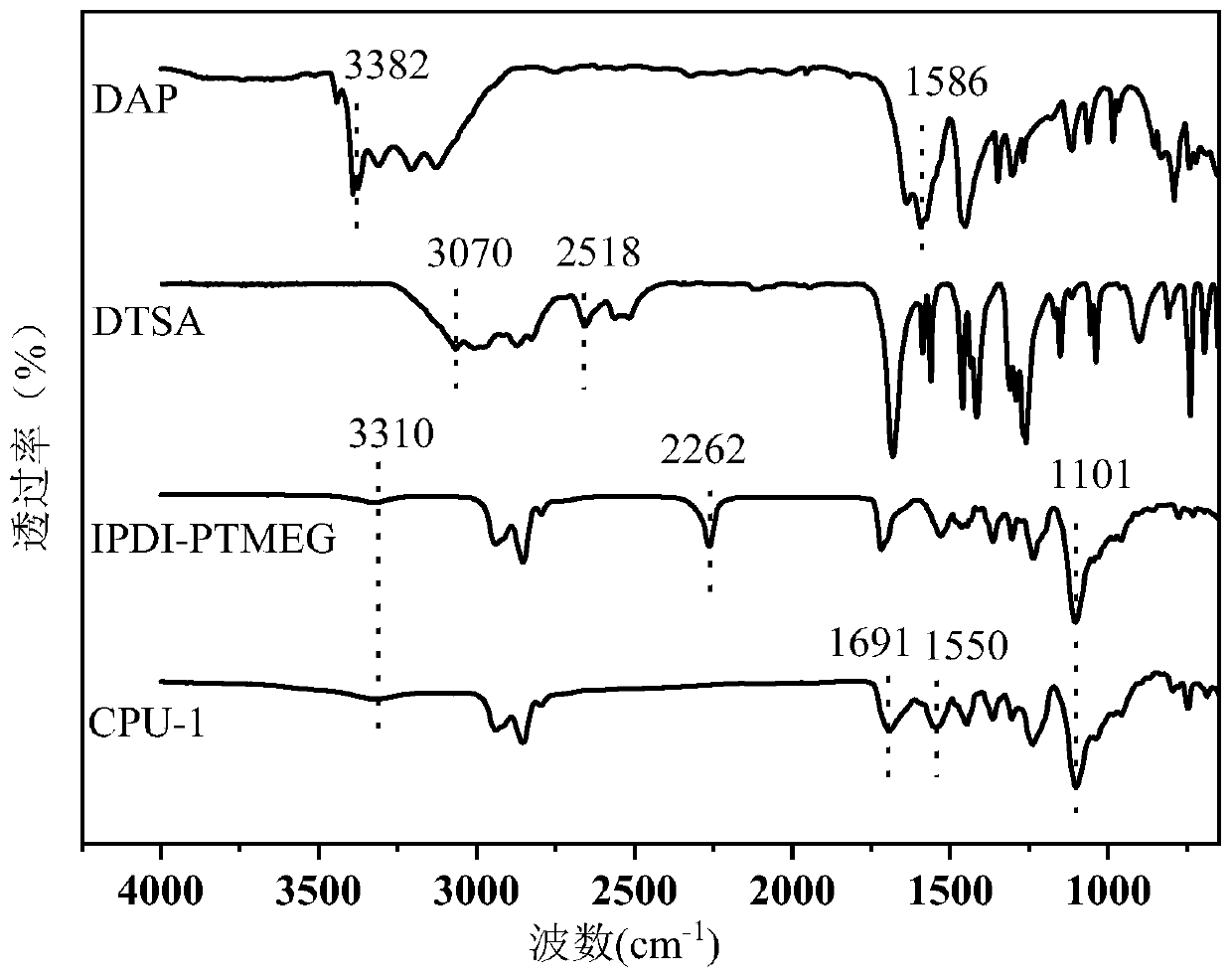

[0046] 1) Mix 100 parts of isophorone diisocyanate (IPDI) with 50 parts of polytetrahydrofuran diol (PTMEG1000) (dihydric alcohol is dehydrated before use: heat up to 105°C, and keep the vacuum degree above 0.06Mpa for dehydration 1- 2h) Mix and stir evenly, add 3 parts of dibutyltin dilaurate, and react at 80°C for 4 hours to obtain a prepolymer;

[0047] 2) Add 100 parts of N,N-dimethylacetamide diluent and 50 parts of 2,2'-dithiodibenzoic acid to the prepolymer, react at 80°C for 5 hours, then add 50 parts of 2,6 -diaminopyridine, continue to react for 1 hour to obtain a polyurethane masterbatch containing disulfide and ligand at the same time, then precipitate in methanol and dry to obtain product polyurethane;

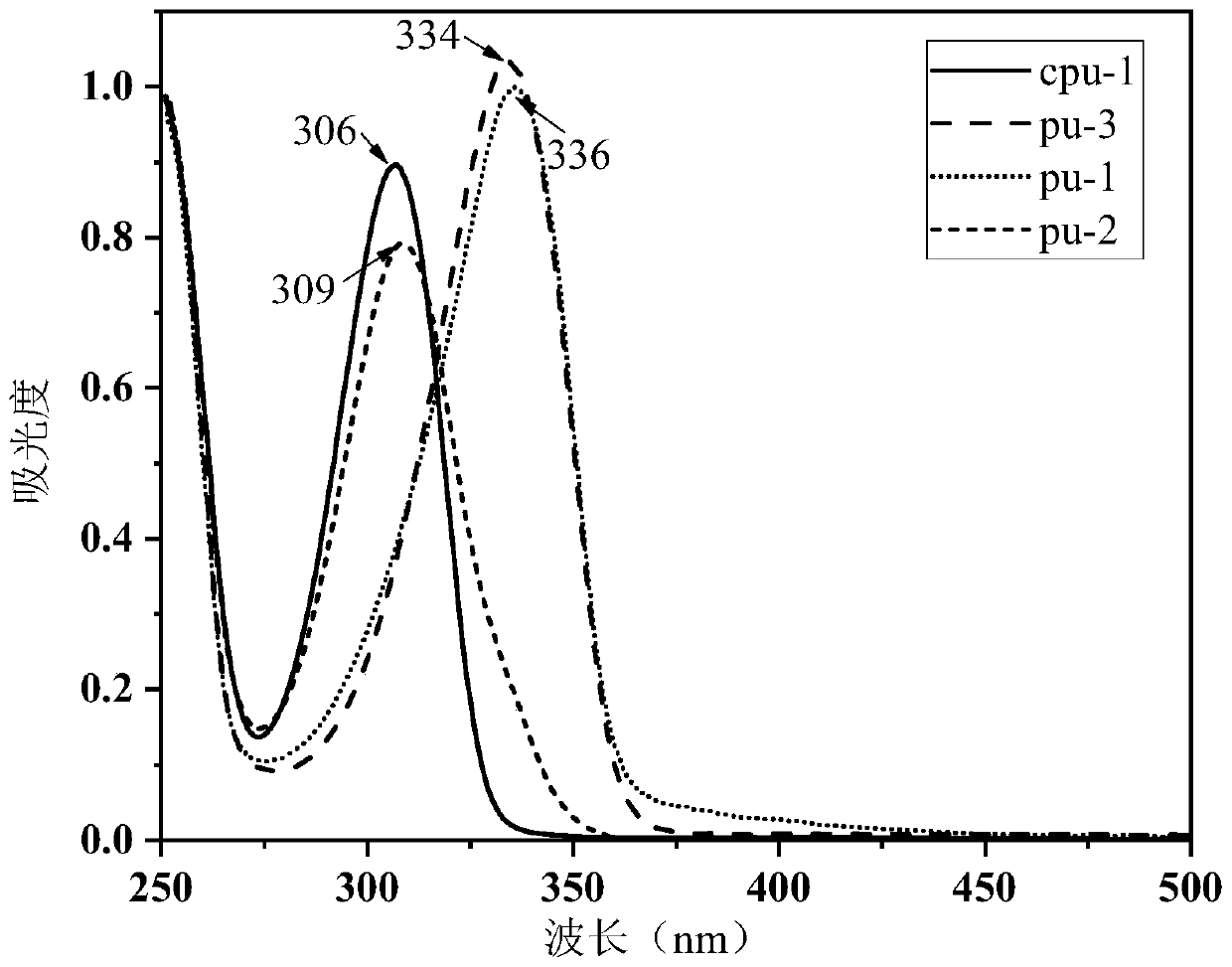

[0048] 3) Dissolve the above product in 1000 parts of chloroform, add 20 parts of ferric chloride, stir at 60°C for 12 hours (condensation and reflux), pour into a mold for molding, and slowly evaporate the solvent at room temperature to obtain a high-strength roo...

Embodiment 2

[0050] 1) Mix and stir 100 parts of isophorone diisocyanate (IPDI) and 50 parts of polytetrahydrofuran diol (PTMEG 1000) evenly, add 3 parts of dibutyltin dilaurate, and react at 80°C for 4 hours to obtain a prepolymer;

[0051] 2) Add 100 parts of N,N-dimethylacetamide dilution and 50 parts of 2,2'-dithiodibenzoic acid to the prepolymer, add 50 parts of 2,6-diamino after reacting at 80°C for 5 hours Pyridine, and then continue to react for 1 hour to obtain a polyurethane masterbatch containing both disulfide and ligand, and then precipitate in methanol and dry to obtain the product polyurethane;

[0052] 3) Dissolve the above product in 1000 parts of chloroform, add 20 parts of zinc chloride, stir at 60°C for 12 hours, pour into a mold at room temperature and slowly evaporate the solvent to obtain a high-strength room temperature self-healing polyurethane material PU-2.

Embodiment 3

[0054] 1) Mix and stir 100 parts of isophorone diisocyanate (IPDI) and 50 parts of polytetrahydrofuran diol (PTMEG1000) evenly, add 3 parts of dibutyltin dilaurate, and react at 80°C for 4 hours to obtain a prepolymer;

[0055] 2) Add 100 parts of N,N-dimethylacetamide dilution and 50 parts of 2,2'-dithiodibenzoic acid to the prepolymer, add 50 parts of 2,6-diamino after reacting at 80°C for 5 hours Pyridine, and then continue to react for 1 hour to obtain a polyurethane masterbatch containing both disulfide and ligand, and then precipitate in methanol and dry to obtain the product polyurethane;

[0056] 3) Dissolve the above product in 1000 parts of chloroform, add 20 parts of aluminum chloride, stir at 60°C for 12 hours, pour into a mold at room temperature and slowly evaporate the solvent to obtain a high-strength room temperature self-healing polyurethane material PU-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com