Patents

Literature

1027 results about "Polytetrahydrofuran" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polytetrahydrofuran, also called poly(tetramethylene ether) glycol or poly(tetramethylene oxide), is a chemical compound with formula (C₄H₈O)ₙOH₂ or HO-(-(CH₂)₄O-)ₙ-H. It can be viewed as a polymer of tetrahydrofuran, or as the polyether derived from 1,4-butanediol.

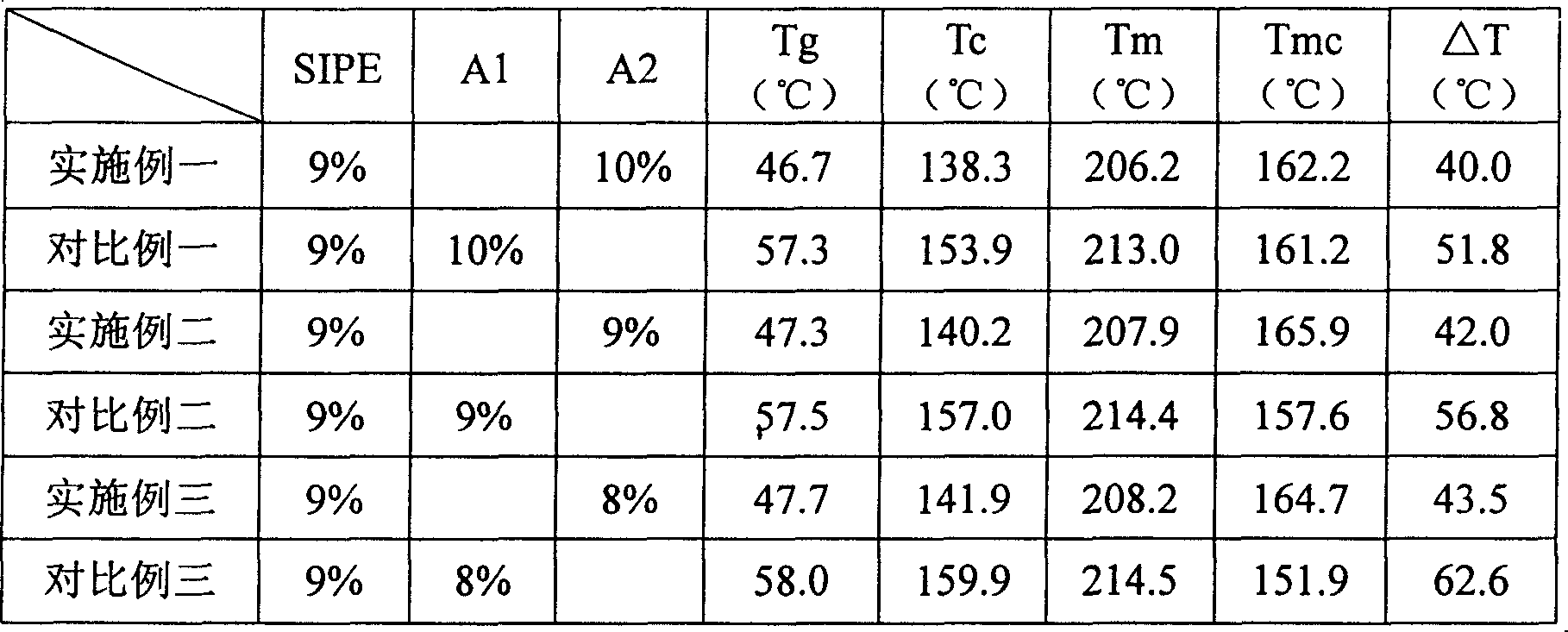

Process for preparing water-soluble copolyester

The water soluble copolyester is prepared with polytetrahydrofuran in number average molecular weight of 350-20000 as the fourth component, and metaphthalate-5-sodium sulfonate, metaphthalate dihydroxyethyl-5-sodium sulfonate, metaphthalate dimethyl-5-potassium sulfonate, or other metaphthalate type sulfonate as the third component, and through polycondensation in PTA or DMT path. Compared with the copolyester with polyglycol and other aliphatic flexible compound as the fourth component, the present invention is water soluble and has better crystallizing performance. The product produces no adhesion during drying, and may be blended with conventional polyester slice to obtain POY sea island cotton with flexible elastic process to raise the spinnability and processibility of sea island fiber.

Owner:SINOPEC YIZHENG CHEM FIBER

Preparation method of organic fluorosiloxane modified polyurethane emulsion containing short fluoroalkyl chain

ActiveCN103865026ANot easy to corrodeImprove water resistancePolyurea/polyurethane coatingsPolymer scienceSolvent

The invention relates to a preparation method of an organic fluorosiloxane modified polyurethane emulsion containing a short fluoroalkyl chain. The method comprises the following steps: by taking isophorone diisocyanate as a hard segment and a mixture of polytetrahydrofuran ether diol and hydroxyl silicone oil as a soft segment, heating to 70-110 DEG C to react for 1-8 hours; then, adding dimethylolpropionic acid and fluorine-containing diol as a chain extender for primary chain extension for 1-6 hours; cooling to 25-60 DEG C, adding a neutralizer, stirring for 0.5-1.5 hours, and transferring to a high speed disperser; adding neutralizer and a secondary chain extender, and dispersing for 0.5-3 hours at a high speed to obtain the emulsion which is uniform and stable in grain size. The prepared modified polyurethane emulsion coating not only has better temperature resistance, water resistance, solvent resistance and corrosion resistance, but also has good water repellency and oil repellency.

Owner:SHANDONG UNIV

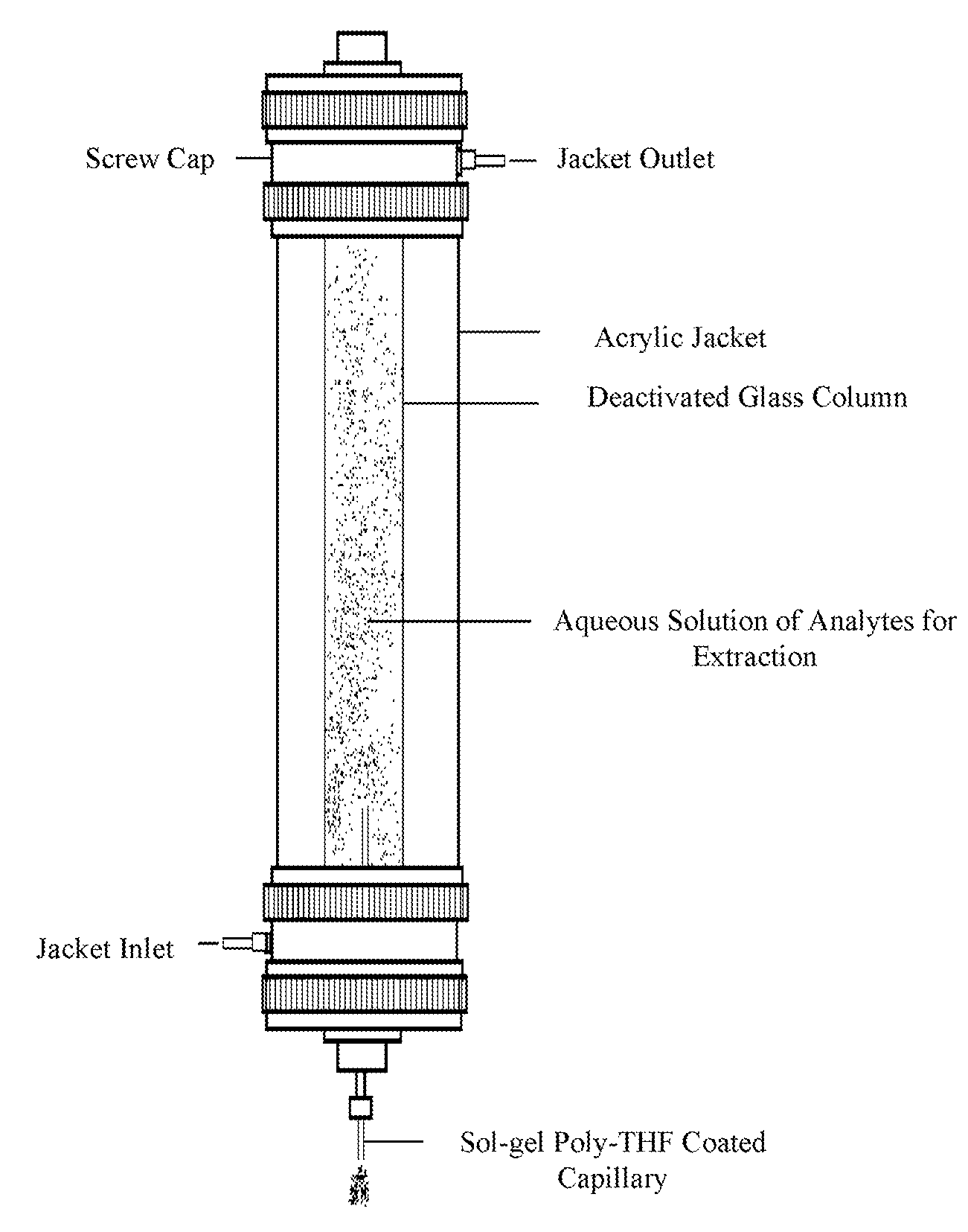

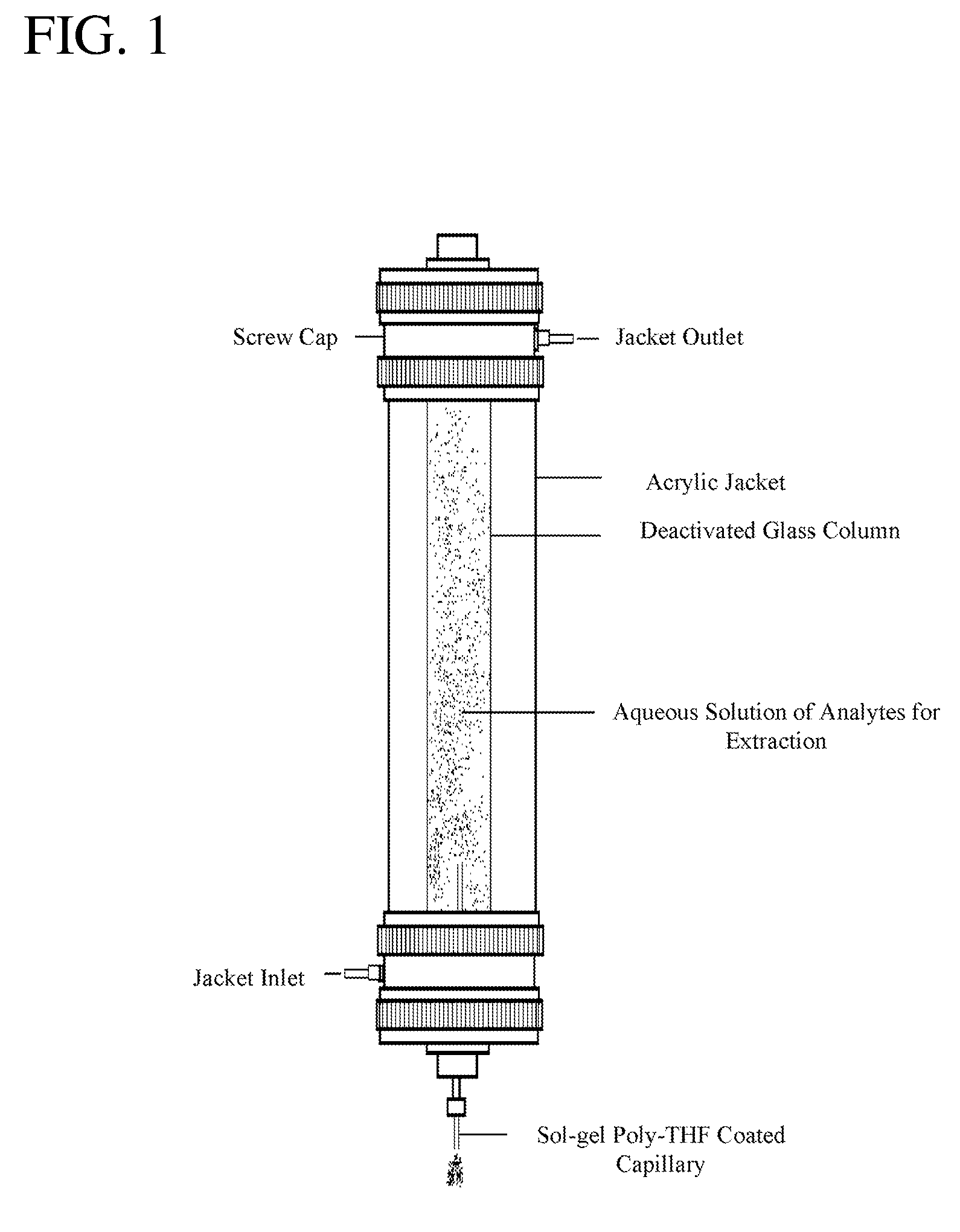

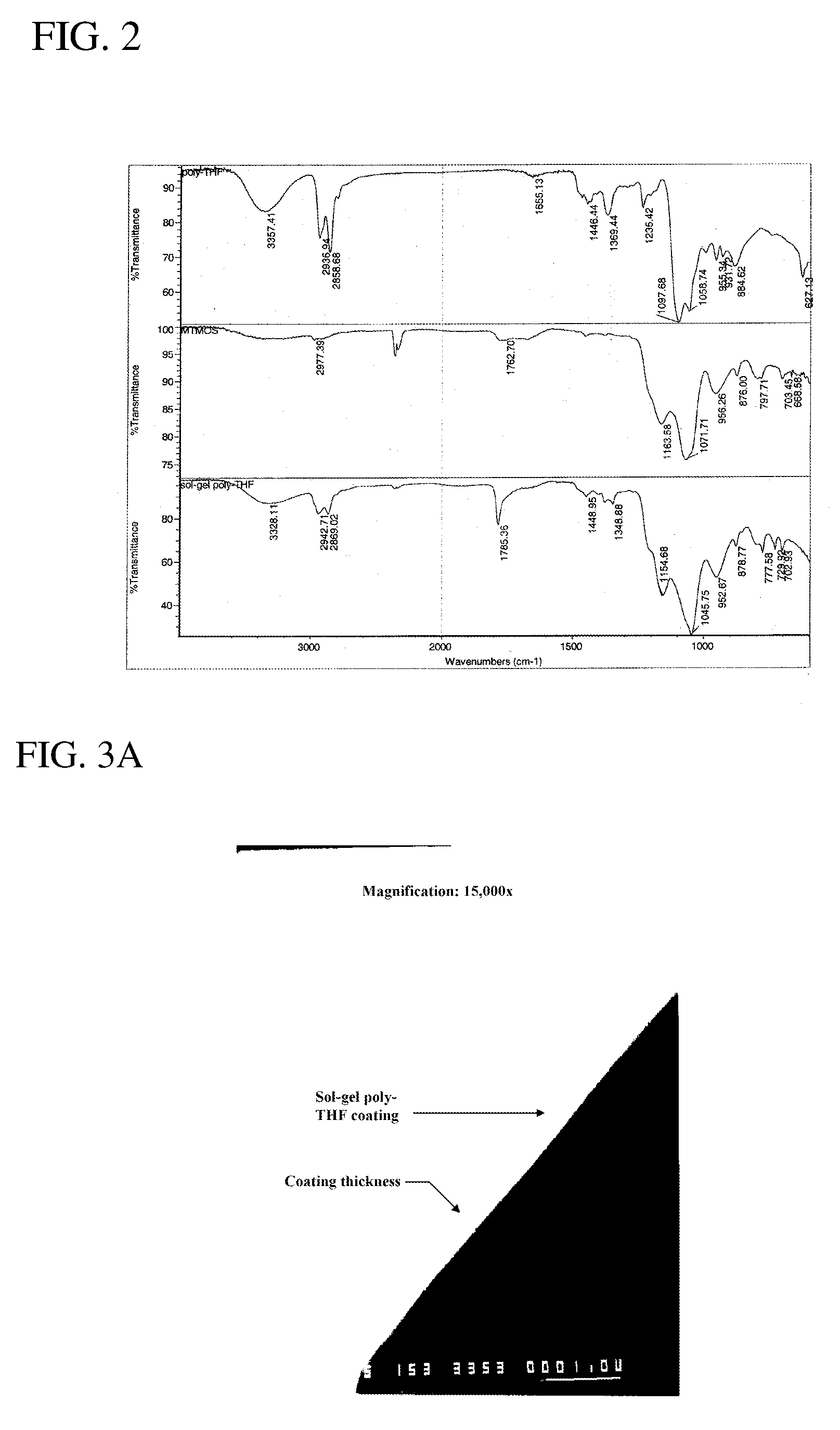

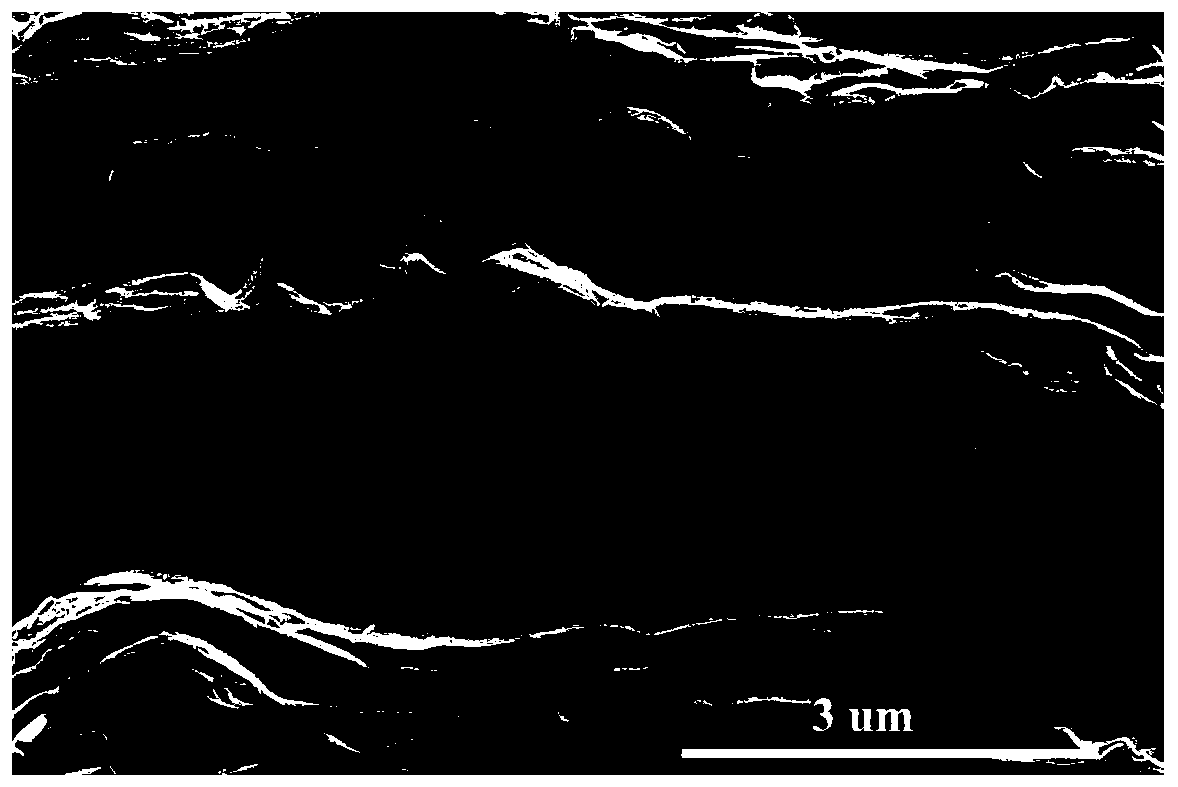

Polytetrahydrofuran-Based Coating for Capillary Microextraction

InactiveUS20060013981A1Avoid breakingLayered productsPreparing sample for investigationAnalyteGas phase

A sol-gel poly-THF coating was developed for high-performance capillary microextraction to facilitate ultra-trace analysis of polar and nonpolar organic compounds. Parts per quadrillion level detection limits were achieved using Poly-THF coated microextraction capillaries in conjunction with GC-FID. Sol-gel Poly-THF coatings showed extraordinarily high sorption efficiency for both polar and nonpolar compounds, and proved to be highly effective in providing simultaneous extraction of nonpolar, moderately polar, and highly polar analytes from aqueous media. Sol-gel poly-THF coated microextraction capillaries showed excellent thermal and solvent stability, making them very suitable for hyphenation with both gas-phase and liquid-phase separation techniques, including GC, HPLC, and CEC. In CME-HPLC and CME-CEC hyphenations, sol-gel poly-THF coated microextraction capillaries have the potential to provide new levels of detection sensitivity in liquid-phase trace analysis, and to extend the analytical scope of CME to thermally labile-, high molecular weight-, and other types of compounds that are not amenable to GC.

Owner:UNIV OF SOUTH FLORIDA

Solvent-free environment-friendly polyurethane automobile leather surface resin as well as preparation method and application thereof

ActiveCN104086738AImprove hydrolysis resistanceGood flexibility at low temperatureSynthetic resin layered productsTextiles and paperPolymer sciencePtru catalyst

The invention provides solvent-free environment-friendly polyurethane automobile leather surface resin which is prepared by mixing a component A with a component B at a mass ratio of 2:1, wherein the component A is prepared from the following raw materials in percentage by weight: 87.6%-96.5% of polycarbonate diol, 1.0%-8.7% of liquid chain extender, 0.4%-3.0% of solid chain extender, 0.5%-1.2% of catalyst, 0.5%-2.0% of optical / thermal stabilizer, 0.1%-0.2% of defoamer and 1.0%-2.0% of solvent-free color paste; the component B is prepared from the following raw materials in percentage by weight: 5.0%-15.0% of polycarbonate diol, 36.0%-55.0% of polytetrahydrofuran diol, 39.8%-49.6% of aliphatic isocyanate, 0.05%-0.1% of catalyst and 0.1%-0.2% of H3PO4. The invention further provides a preparation method and application of the resin. The resin is environment-friendly and can be bent for 100,000 times at low temperature of minus 25 DEG C.

Owner:XUCHUAN CHEM SUZHOU

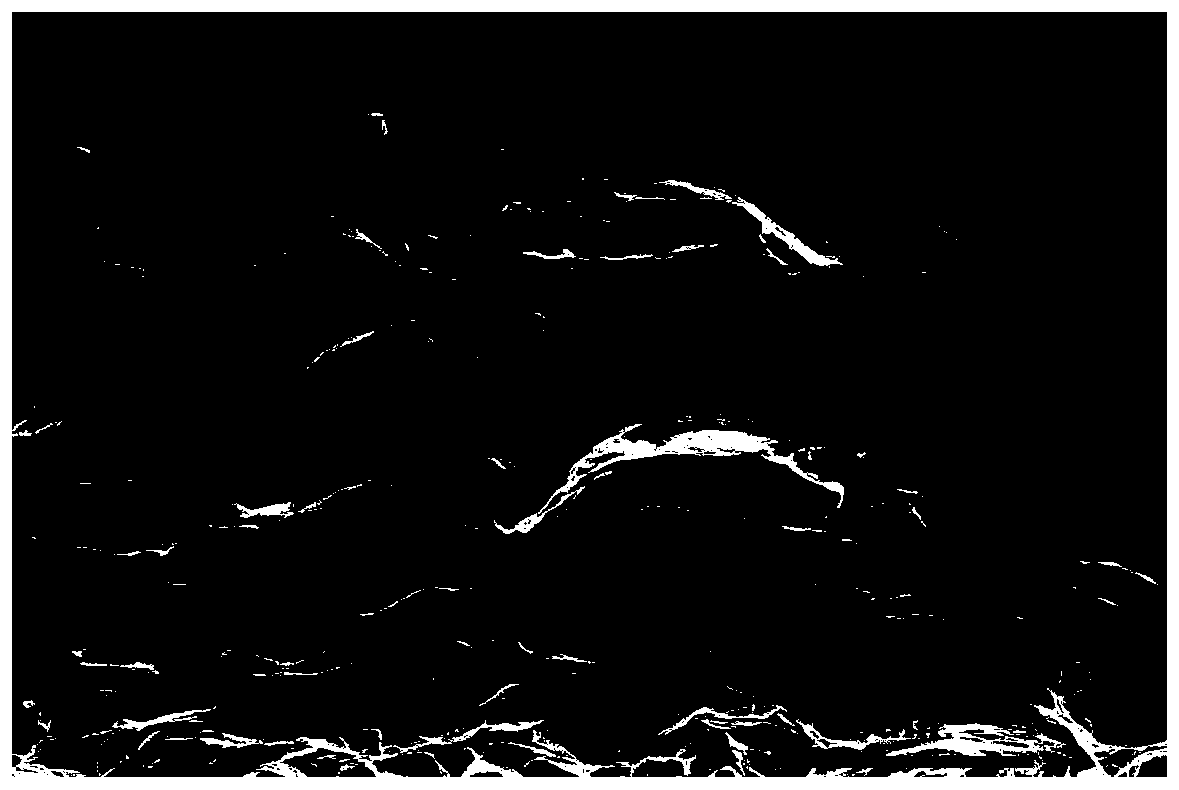

Waterborne polyurethane-MXene electromagnetic shielding bionic nanocomposite material film and preparation method

The invention relates to a waterborne polyurethane-MXene electromagnetic shielding bionic nanocomposite film and a preparation method. Through pre prepolymeriztion reaction of polytetrahydrofuran gl and diisocyanate and chain extension by a hydrophilic chain extender, then a neutralizing agent is added, subsequently, deionized water is added for emulsification dispersion to obtain a waterborne polyurethane emulsion; waterborne polyurethane and MXene are prepared into water dispersion liquid, MXene is added to the waterborne polyurethane under stirring, continuous stirring is carried out to enable waterborne polyurethane macromolecules to be fully and uniformly adsorbed on MXene nanosheets. And waterborne polyurethane-MXene composite dispersion liquid is obtained; and a series of nanocomposite films are prepared by a vacuum filtration method, a solvent evaporation method or a coating method. The prepared nanocomposite thin films have ordered "brick-wall" structures in a bionic shell layer shape on the micro and nano scales, the mechanical properties are excellent, the flexibility is good, the electromagnetic shielding effectiveness is excellent, preparation methods are diverse, thethickness is controllable, and application is wide.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Preparation method of light-resistant waterborne polyurethane

The invention discloses a preparation method of light-resistant waterborne polyurethane, which comprises the steps of mixing polytetramethylene ether glycol with diisocyanate in the presence of a dibutyltin dilaurate catalyst, stirring at 70-90 DEG C for reaction for 2-4h, obtaining a polyurethane prepolymer, adding a hydrophilic chain extender, a polyhydroxyl compound and butanone into the polyurethane prepolymer, stirring at 70-90 DEG C for reaction for 1.0-3.5 h, adding triethylamine for neutralizing, stirring for reaction for 40-60min, adding water for emulsification to form hydrophilic polyurethane, adding a nano emulsion into a hydrophilic polyurethane system, shearing and stirring for 40-60min under the condition that a pH value is 7, and obtaining light-resistant waterborne polyurethane. Prepared light-resistant waterborne polyurethane is environment-friendly and low in price, and can meet the demand of a market on a property of light-resistant polyurethane.

Owner:上海力太化学有限公司

Polyurethane resin and preparation method and application thereof

ActiveCN104004159APrevents self-crosslinking reactionsAvoid gel phenomenonFibre treatmentPolyesterPolymer science

The invention provides polyurethane resin. The polyurethane resin is mainly prepared from, by weight, 150 parts to 200 parts of polyols, 10 parts to 45 parts of chain extender, 100 parts to 150 parts of isocyanate, 0.1 part to 10 parts of antioxidant, 0.1 part to 1 part of reaction terminator, 500 parts to 800 parts of solvent and reaction activity regulator. The polyols contain 40 percent to 70 percent of PTMG, 0 to 45 percent of polyester polyol, 0 to 15 percent of polycarbonate diol, 0 to 25 percent of polycaprolactone diol and 5 percent to 10 percent of modified polydimethylsiloxane diol. The invention further provides a preparation method and application of the polyurethane resin. Tiny and even cells can be formed when the prepared polyurethane resin is used for processing superfine fiber synthetic leather, and thus the produced superfine fiber product can have fine fold lines and plump fleshy feeling.

Owner:XUCHUAN CHEM SUZHOU

Preparation method of solvent-free polyurethane interior trim leather of car

ActiveCN104963212ASimple processProcess environmental protectionTextiles and paperPolyurethane dispersionSurface layer

The invention relates to a preparation method of solvent-free polyurethane interior trim leather of a car. The preparation method comprises the following steps: (1) coating release paper with waterborne polyurethane dispersoid, placing the release paper in an environment with a temperature of 100-120 DEG C, and drying to obtain a surface layer; (b) mixing component A and component B of polyurethane foam resin, coating the surface of the surface layer with the mixture, placing into an environment with temperature of 100-120 DEG C, and drying for 1-5min, so as to form a semi-dry foaming layer; and (c) attaching base cloth to the foaming layer, placing the foaming layer into an environment with temperature of 100-120 DEG C and curing for 10-15 hours, and then separating and rolling. The component A of the polyurethane foaming resin comprises the following components in percentage by weight: 90-95% of polycarbonate diols, 1-6% of a chain extender, 2-4% of a catalyst, 0.5-2.0% of a stabilizer, 0.1-0.2% of a defoamer and 0.5-5% of an inorganic filler. The component B of the polyurethane foaming resin comprises the following components in percentage by weight; 5.0-30%of polycarbonate diols, 30.0-45% of polytetrahydrofuran diols and 39.8%-50% of aliphatic diisocyanate. In the preparation process, no solvent is used, the technology is simple and environmentally friendly.

Owner:江苏尚科聚合新材料有限公司

Water-resistant high-temperature-resistant single-component waterborne polyurethane adhesive and preparation method thereof

InactiveCN108342181AHigh strengthImprove heat resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPolyurethane adhesive

The invention discloses a water-resistant high-temperature-resistant single-component waterborne polyurethane adhesive and a preparation method thereof and relates to the technical field of polyurethane adhesives. The adhesive comprises, by weight, 30-40 parts of polytetrahydrofuran glycol, 15-22 parts of polycarbonate diol, 3-7 parts of poly-2,6-polyethylene naphthalate polyester glycol, 17-25 parts of diisocyanate, 2-5 parts of chain extender, 0.5-2 parts of silane coupling agent modified silicon dioxide nanoparticles, 0.1-0.6 part of dibutyltin dilaurate, 4-8 parts of acetone, 1-3 parts oftriethylamine, 0.05-0.1 part of sodium hydroxide and an appropriate amount of water. Polytetrahydrofuran and polycarbonate diol are adopted as oligomer polyhydric alcohols in raw materials for preparing polyurethane, and added poly-2,6-polyethylene naphthalate polyester glycol is introduced to a soft-segment part of polyurethane; by adding silane coupling agent modified silicon dioxide nanoparticles, the mechanical properties and heat resistance of the adhesive can be improved; the prepared adhesive is high in adhesive force and excellent in water resistance and high temperature resistance, and the application range of the adhesive is enlarged.

Owner:佛山市三水日邦化工有限公司

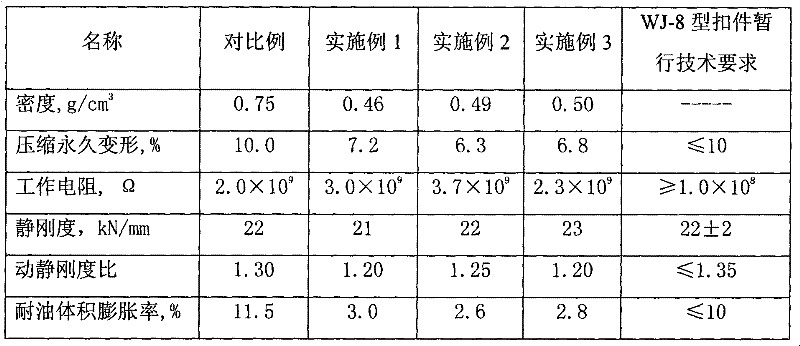

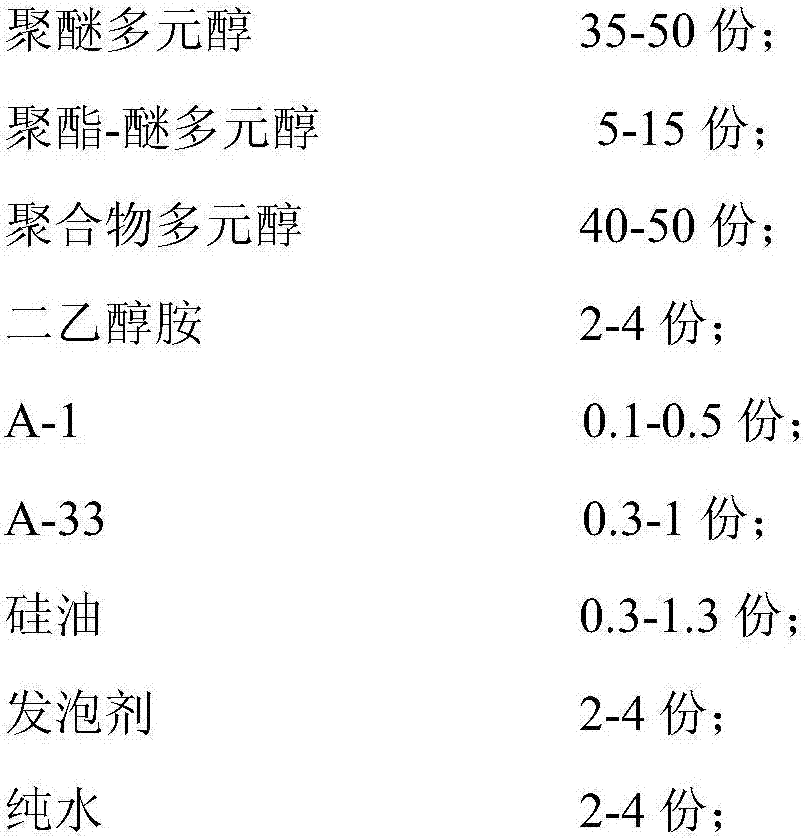

Micropore polyurethane elastomer material and preparation method and use thereof

The invention discloses a micropore polyurethane elastomer material and a preparation method and use thereof. The micropore polyurethane elastomer material is composed of two components. The A component includes polyether polyatomic alcohol P1, polyether polyatomic alcohol P2, chain extension agents, foam stabilizers, water, tertiary amine catalysts and hollow glass microspheres by weight percentage. The B component comprises methylene diphenyl diisocyanate (MDI), TODI, and polyether polyatomic alcohol P1. P1 is selected from polytetrahydrofuran polyatomic alcohol with number-average molar mass as 1000-6000 and functionality as 2-3. P2 is selected from propylene oxide polythene oxide copolyether polyatomic alcohol with number-average molar mass as 2000-6000, functionality as 3-4 and primary hydroxyl content larger than or equal to 70%. The isocyanate index number of the A component and the B component is 1.1. The A component and the B component are prepared respectively, quickly and evenly mixed according to proportion, poured in a mould and solidified to obtain the micropore polyurethane elastomer which can be used as an elastic bearing plate of high speed railways.

Owner:LIMING RES INST OF CHEM IND

Polyurethane resin

InactiveCN101381447ANo yellowing phenomenonGuaranteed softnessFibre treatmentAnti freezingOrganic solvent

The invention relates to polyurethane resin, which consists of the following components in weight percentage: 4 to 5 percent of polyethylene glycol adipate, 11 to 13 percent of polytetrahydrofuran glycol, 0.4 to 0.6 percent of ethylene glycol, 1.8 to 1.9 percent of isophorone diamine, 6 to 8 percent of isophorone diisocyanate, 0.08 to 0.1 percent of antioxidant and 73 to 80 percent of organic solvent. The polyurethane resin is applied to produce instep leather of top-grade travel shoes and has good ultraviolet ray yellow stain resistant performance; and under the sunlight, the leather color can be kept unchanged for a long time, and no yellow stain occurs; meanwhile, the polyurethane resin also has good anti freezing property, and no crack generates when the polyurethane resin is used at low temperature for a long time.

Owner:XUCHUAN CHEM KUNSHAN

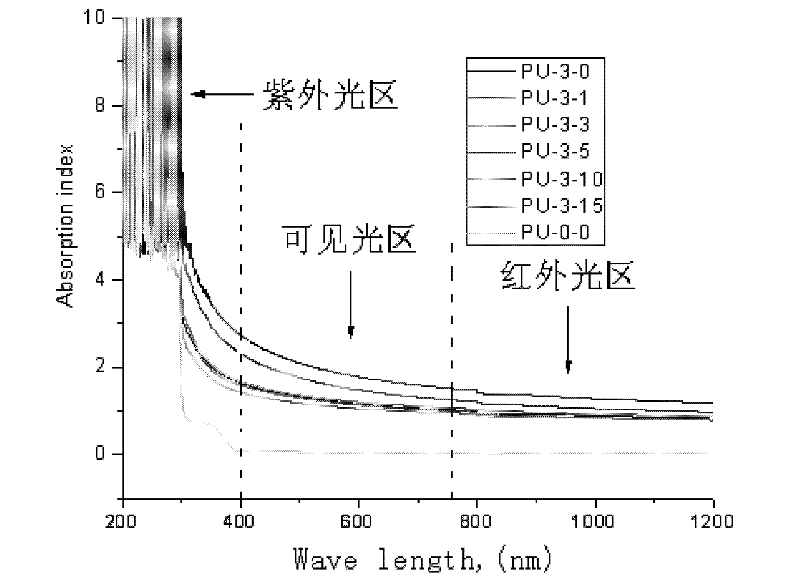

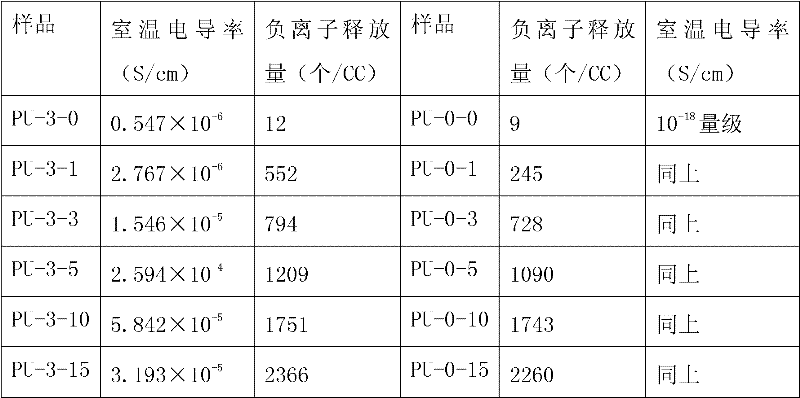

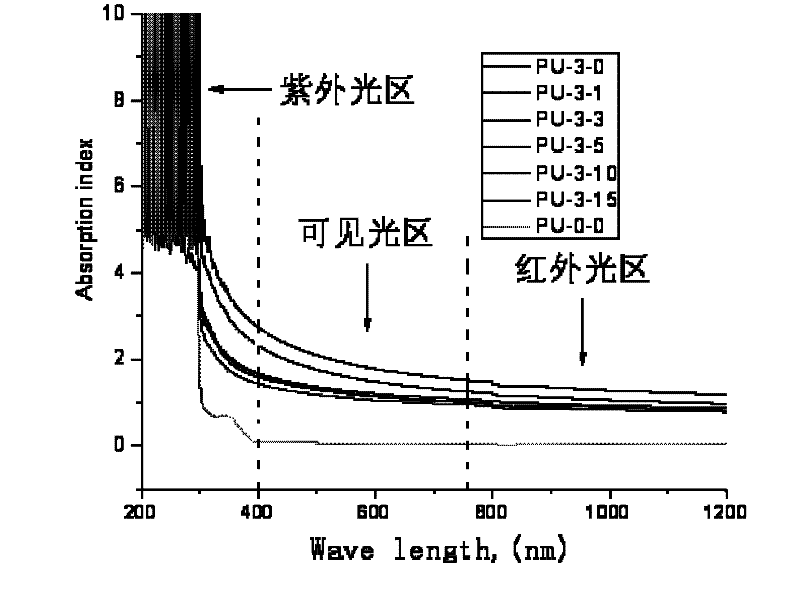

Preparation method for electroconductive polyurethane complex with anion releasing function

The invention discloses a preparation method for an electroconductive polyurethane complex with an anion releasing function, and the method comprises the following steps: firstly vacuum-drying polytetrahydrofuran glycol, carbon nanotubes and tourmaline powder; separately mixing the dried carbon nanotubes and tourmaline powder with polytetrahydrofuran glycol, sealing in containers, standing at a certain temperature for several hours to obtain surface-modified carbon nanotubes and tourmaline powder, adding the surface-modified carbon nanotubes and the tourmaline powder into a solvent so as to be uniformly dispersed, adding polyurethane and reacting under a certain condition to obtain the polyurethane complex based on a complex system of the carbon nanotubes and the tourmaline powder. The obtained modified complex system of the carbon nanotubes and the tourmaline powder has the advantages of the carbon nanotubes and the tourmaline powder, so that the polyurethane complex has higher anionreleasing capability and electrical conductivity because of the synergistic effect of the carbon nanotubes and the tourmaline powder, and simultaneously has excellent ultraviolet and electromagnetic absorption properties and mechanical properties.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Breathable polyurethane synthetic leather preparation method

InactiveCN106087451AImprove breathabilityComfortable to wearTextiles and paperPolymer scienceGluconacetobacter

The invention belongs to the technical field of synthetic leather preparation and relates to a breathable polyurethane synthetic leather preparation method. The method includes: subjecting octamethyl cyclotetrasiloxane and gamma-aminoethyl aminopropyl trimethoxysilane to ring opening and polymerization to obtain amino modified silicon oil; reacting with polytetrahydrofuran glycol to obtain polyether modified amino silicon oil; reacting with isophorone diisocyanate to obtain a prepolymer; reacting with 2,2-dimethylolpropionic acid and the like, and carrying out operations such as neutralizing to obtain polyether amino silicon oil modified polyurethane; fermenting gluconacetobacter and polyether amino silicon oil modified polyurethane to obtain bacterial cellulose; mixing with part of polyether amino silicon oil modified polyurethane, adding additives, stirring, coating, and performing operations of solidifying, washing, drying and the like to obtain breathable polyurethane synthetic leather. The breathable polyurethane synthetic leather prepared according to the method is higher than 720mL / cm<2>.h in air permeability and light and comfortable to wear and is excellent in water permeability which is higher than 952g / m<2>.24h.

Owner:周荣

Polyurethane resin for solvent-free crease-free microfiber mirror-surface synthetic leather and preparation method and application of polyurethane resin

The invention discloses a polyurethane resin for solvent-free crease-free microfiber mirror-surface synthetic leather. The polyurethane resin is prepared from a component A and a component B in a mass ratio of 2:1-1:2 by means of stirring and mixing, wherein the component A comprises 80-95 parts of polytetrahydrofuran glycol, 5-15 parts of chain extenders, 0.01-0.5 part of catalysts, 0.5-2.0 parts of light / heat stabilizers, 0.01-0.2 part of defoaming agents and 0.1-2.0 parts of solvent-free color paste, and the component B comprises 40-50 parts of polytetrahydrofuran glycol, 50-60 parts of isocyanate, 0.001-0.1 part of phosphoric acid and 0.01-05 part of catalysts. The invention further provides a preparation method and application of the polyurethane resin. The solvent-free crease-free microfiber mirror-surface synthetic leather prepared by the preparation method is capable of resisting normal-temperature flexing for 100 thousand times in terms of physical performance and resistant to the temperature as low as -10 DEG C and remains uncracked for 80 thousand times at -10 DEG C.

Owner:HEFEI ANLI POLYURETHANE NEW MATERIAL

Preparation method for waterborne polyurethane with improved fire resistance by virtue of nano materials

The invention discloses a preparation method for waterborne polyurethane with improved fire resistance by virtue of nano materials. Under the condition that a dibutyltin dilaurate catalyst exists, PTMG and IPDI (isophorone diisocyanate) are mixed for reaction at the temperature of 75-95 DEG C for 1.5-3.5 hours, so that polyurethane prepolymer can be obtained; a hydrophilic chain extender, of which the weight of carboxyl groups is 1.2-3.2 % of that of the polyurethane prepolymer, and an acetone solvent, of which the weight is 12-25% of that of the polyurethane prepolymer, are added into the polyurethane prepolymer for reaction at 65-85 DEG C for 1.5-3.5 hours, then, triethylamine is added for neutralization reaction for 30-50 minutes, and water is added for emulsification, so that polyurethane emulsion A can be formed; nano material emulsion, with the weight being 5-10% of that of the polyurethane emulsion A, is added into the polyurethane emulsion A, and the mixture of the nano material emulsion and the polyurethane emulsion A is subject to shear agitation for 20-50 minutes under the condition that the pH value is 7, as a result, the fire resistance waterborne polyurethane can be obtained. The prepared fire resistance polyurethane is environment-friendly and low is price, and can meet the low cost requirement on fire resistance leather products by the market.

Owner:STATE GRID CORP OF CHINA +3

High-gloss polyurethane resins and application thereof

InactiveCN101831048AIncrease brightnessImprove heat resistanceFibre treatmentLeather surface finishingPolymer scienceButanediol

High-gloss polyurethane resins are prepared by polymerizing poly(adipate1,4-butanediol ester), polytetrahydrofuran, castor oil, diphenyl-methane diisocyanate, toluene diisocynate, ethylene glycol, 1,4-butanediol, trimethylopropane, 2,2-dimethyl-1,3-propanediol and other molecules through a body; the prepared resin has narrow molecular chain distribution. After dimethyl silicone oil and butanone are added, the resins can be used as a leather processing agent, has better leveling property on the leather and artificial leather and high luminosity. In addition, the resins have stronger adhesive force and are remarkably superior to common like products.

Owner:ZHEJIANG LUOXING IND CO LTD

PTMG (polyoxytetramethylene glycol) modifying moisture curing polyurethane melt adhesive and preparation method thereof

ActiveCN104449537AImprove hydrolysis resistanceReduced flexibilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesSilanesAntioxidant

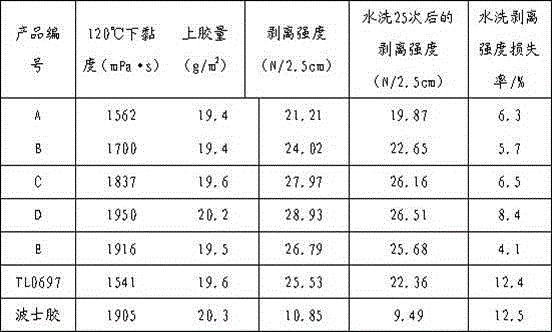

The invention discloses a PTMG (polyoxytetramethylene glycol) modifying moisture curing polyurethane melt adhesive and a preparation method thereof. The melt adhesive product comprises the following raw materials in parts by weight: 18-35 parts of polypropylene glycol, 15-30 parts of polytetrahydrofuran glycol, 8 parts of poly adipic acid-1, 6 hexanediol esterdiol, 0.5 part of an antioxidant, 15-20 parts of tackifying resin, 24-25 parts of 4, 4'- ditan diisocyanate, 0.01 part of a catalyst, 0-0.5 part of a chain extender, 0-2 parts of a silane coupler, and 0-0.5 part of white carbon black. The PTMG modifying moisture curing polyurethane melt adhesive prepared by the preparation method disclosed by the invention has the advantages of high stripping strength, good washing resistant performance, good flexibility, environmental protection and the like.

Owner:SHANGHAI TIANYANG HOT MELT ADHESIVE CO LTD +2

Preparation method of heat resistant spandex fiber

ActiveCN102220653AImprove heat resistanceGood lifting effectMonocomponent synthetic polymer artificial filamentFiberPolymer science

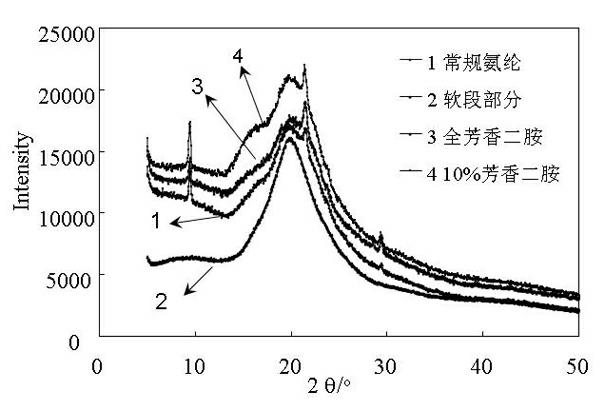

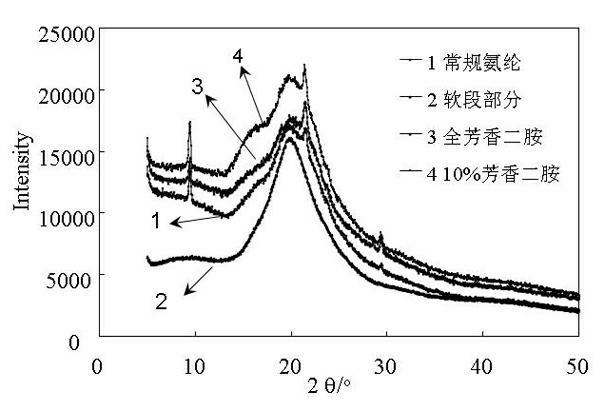

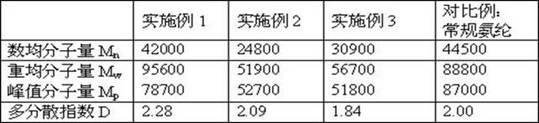

The invention discloses a preparation method of heat resistant spandex fiber, belonging to the technical field of polymer textile material and preparation thereof; the preparation method comprises the following steps of: (1) mixing polyoxytetramethylene and 4,4'-methylenebis(phenyl isocyanate) according to a mole ratio of 1 / 1.4 to 1 / 2.5 for reaction to obtain a prepolymer; (2) adding non-protonicpolar solvent to the prepolymer prepared in the step (1) so that the prepolymer is dissolved in the non-protonic polar solvent to obtain prepolymer solution; (3) adding a chain extender in the prepolymer solution obtained in the step (2) to obtain spandex spinning fluid with a molecular weight of 20-300 thousands after polymerization reaction, wherein the chain extender is aromatic diamine or themixture of aromatic diamine and aliphatic diamine; (4) using the spandex spinning fluid prepared in the step (3) to obtain the heat resistant spandex fiber with a solution spinning method. Compared with conventional spandex, the product has obviously improved resistance to heat; moreover, the viscosity stability of the polymer is good.

Owner:ZHEJIANG KAIPUTE SPANDEX +1

Depolymerization of polytetrahydrofuran derivatives

The invention discloses a method for depolymerization of a mixture containing polytetrahydrofuran derivatives, including heating the mixture comprising polytetrahydrofuran derivatives at 100-250° C. in the presence of a beta-zeolite catalyst to obtain tetrahydrofuran, whereby the tetrahydrofuran monomer can be recovered from the waste materials in the preparation of polytetramethylene ether glycols.

Owner:TCC CHEM CORP

Preparation method of antibacterial polyurethane

InactiveCN101880371AImprove the bactericidal effectStrong anti-mold and anti-moth propertiesDiphenylmethaneManufacturing technology

The invention relates to a preparation method of antibacterial polyurethane, which belongs to the technical field of manufacture of organic polymer materials with antibacterial function. The preparation method comprises the pre-polymerization reaction, the chain extension reaction and the termination reaction, diphenylmethane-4,4'-diisocyanate and polytetrahydrofuran are taken as basic raw materials, and the preparation method is characterized by adding 500-10000ppm of quaternary ammonium salt with antibacterial activity in the pre-polymerization reaction stage. The preparation method has the advantages of wide sources of the raw materials, easy control of reaction conditions and low cost, and the produced antibacterial polyurethane has the advantages of good antibacterial effect and long-term keeping of the antibacterial activity.

Owner:LUDONG UNIVERSITY +1

Preparation method of polyether amine

ActiveCN102604072AAchieve synthesisLess side effectsPolyethylene oxideTert-Butyloxycarbonyl protecting group

The invention relates to a preparation method of polyether amine. In the structure of polyether amine, the main chain is polypropylene oxide, polyethylene oxide, polytetrahydrofuran or a copolymer of polypropylene oxide, polyethylene oxide and polytetrahydrofuran; and one end of the main chain is hydroxyl, and the other end of the main chain is an alcohol amine compound terminated end having a H2N-R-O-H structure. Polyether amine is prepared by the following steps: (1) protecting the amino of the alcohol amine compound by using BOC (tertbutyloxycarbonyl) and maintaining hydroxyl to obtain BOC-NH-R-OH; (2) in the catalysis of strong base or double-metal cyanide, by using BOC-NH-R-OH, initiating polyethylene oxide, polypropylene oxide, tetrahydrofuran or the mixture of polyethylene oxide, polypropylene oxide and tetrahydrofuran to react for ring opening polymerization; and (3) under the acidic condition, carrying out BOC deprotection reaction to obtain polyether amine. According to the invention, polyether main chains having different hydrophilic properties can be obtained by regulating the ratio of polypropylene oxide to polyethylene oxide to polytetrahydrofuran in the polyether chain; and one end of the polyether chain contains the amino, thus the amino can provide strong hydrophilic property after acidification. Polyether amine prepared by using the method can be applied to the fields of a surfactant, a flocculant, textile dyeing and finishing auxiliary, electrophoretic paint and the like.

Owner:WUXI ACRYL TECH

Preparation method and application method of solvent-free moisture-curable resin for synthetic leather

The invention provides a preparation method and an application method of a solvent-free moisture-curable resin for synthetic leather. The preparation method is as below: adding polytetrahydrofuran glycol, isophorone diisocyanate and bismuth octoate to the reactor, heating to 75-80 DEG C, polymerizing for 1-1.5 h to obtain the solvent-free moisture-curable resin for synthetic leather. The application method is as below: mixing and stirring the solvent-free moisture-curable resin for synthetic leather and bis-N,N'-(methyl-butyl methylene)-diethylenetriamine, coating the mixed material on the synthetic leather surface by a roller coating method, curing at the temperature of 85-95 DEG C, then drying at 120-135 DEG C, and finally cooling and rolling. The solvent-free moisture-curable resin for synthetic leather obtained by the invention is used for surface moisture solidification process for synthetic leather, so as to obtain brightening surface with high brightness, water resistance and wear resistance. The application process does not produce contamination, and can solve the solvent pollution problem in synthetic leather moisture curing process.

Owner:SHAANXI UNIV OF SCI & TECH

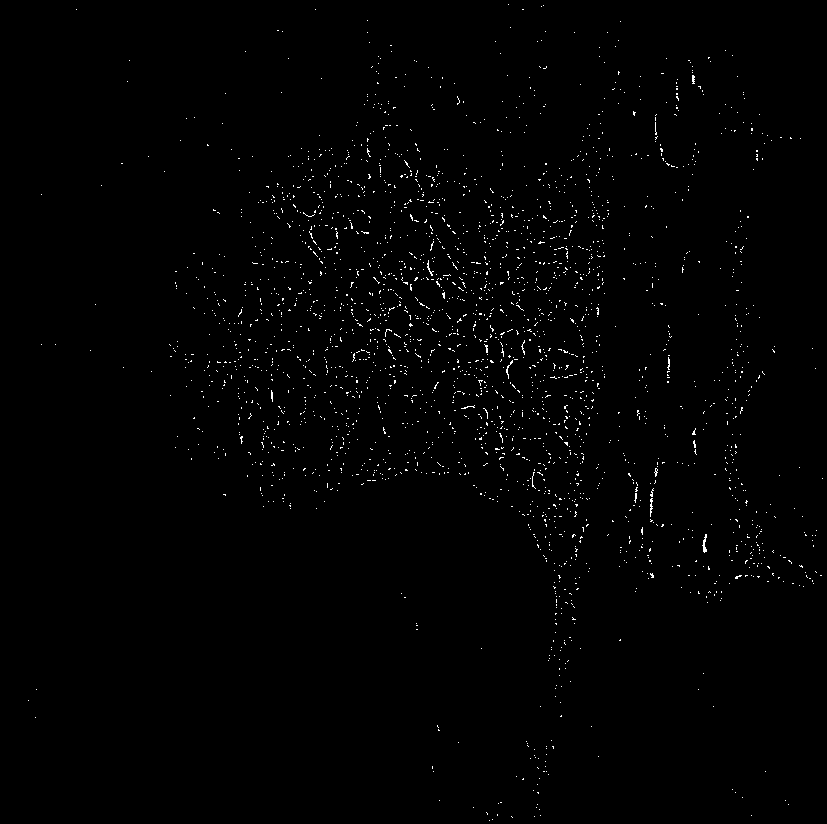

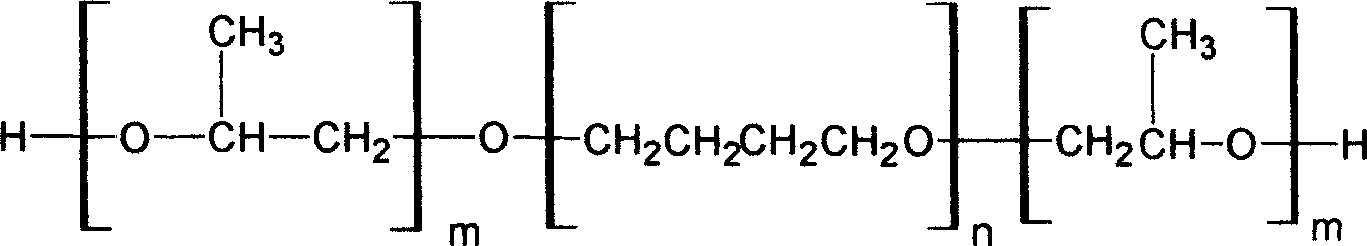

Bimetallic cyanide catalyst for epoxide ring-opening polymerization

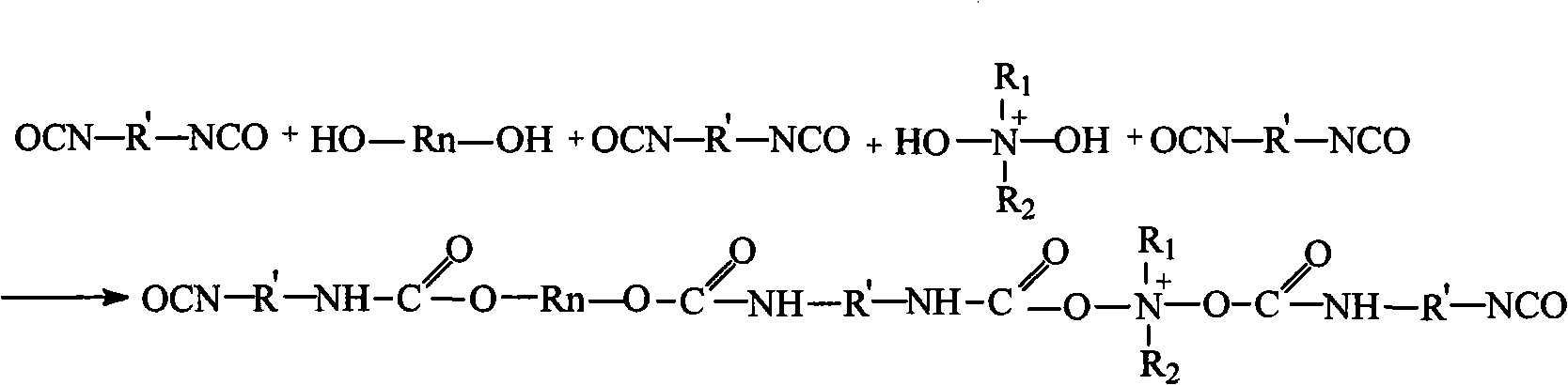

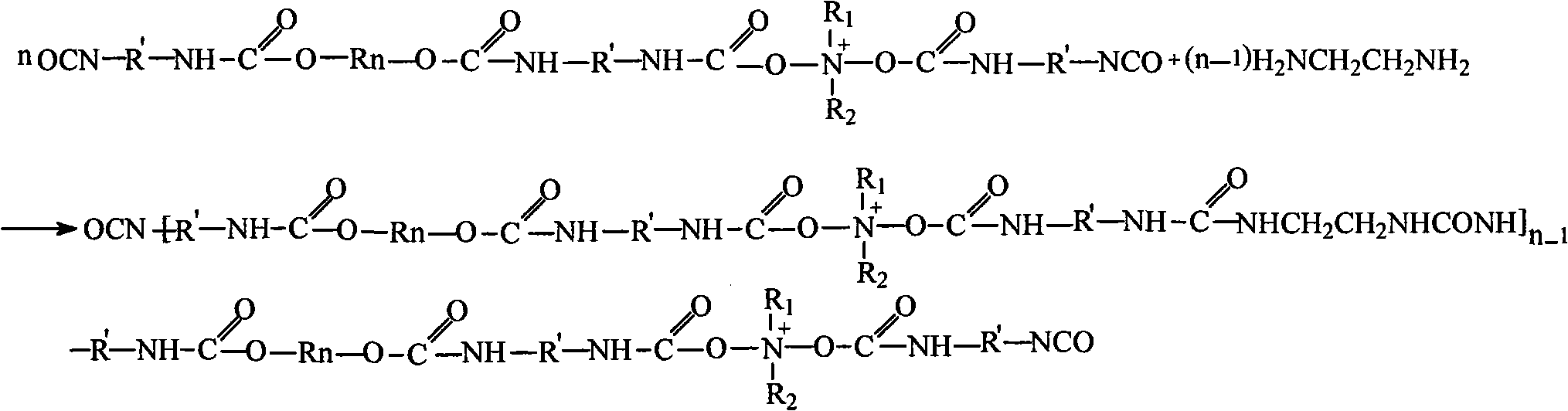

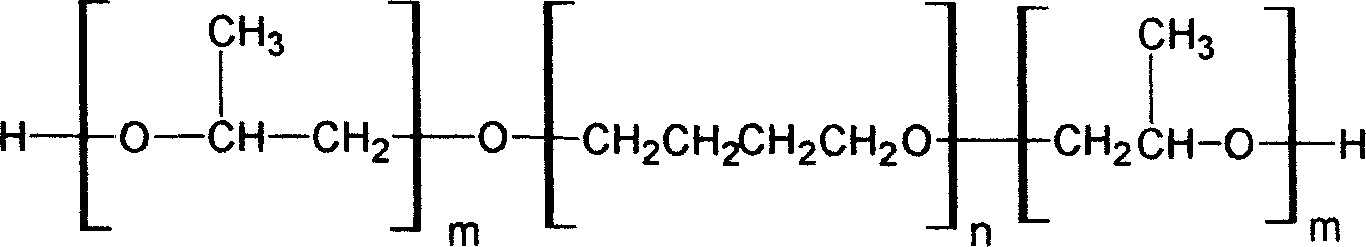

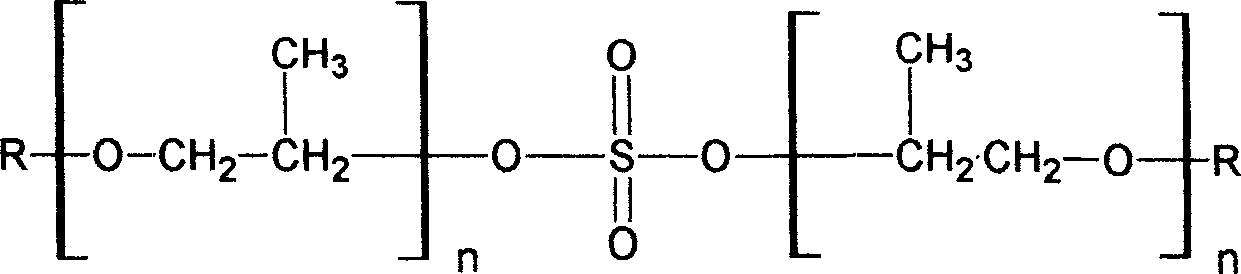

The present invention discloses one kind of bimetallic cyanide catalyst for the ring-opening polymerization of epoxide. The catalyst has the chemical general expression of Ma1[M2(CN)b]d.xM3(X)c.wH2O.yT.jL1.zL2, where, L1 is polytetrahydrofuran oxyprpopyl olefin blocked polyether and L2 is polyether ester sulfate in the structure as shown. The present invention is used for the ring-opening polymerization of alkylene oxide and has high activity and other excellent performance.

Owner:HUAIAN BUD POLYURETHANE SCI & TECH CO LTD

Low-temperature resistant high-strength universal polyurethane elastomer pouring material for ground laying and preparing method thereof

A low temp-resistant high-strength universal pouring material of polyurethane elastomer laid on the ground surface is disclosed. During its preparing process, the new monomers, polytetrahydrofuran diol and tetrafuran-epoxy propane copolymer diol, are used to react on diisocyanate, and the cross-linking agent, filler and catalyst are newly designed. Its advantages are high versatility, high strength and high resistance to low temp.

Owner:孙贤育

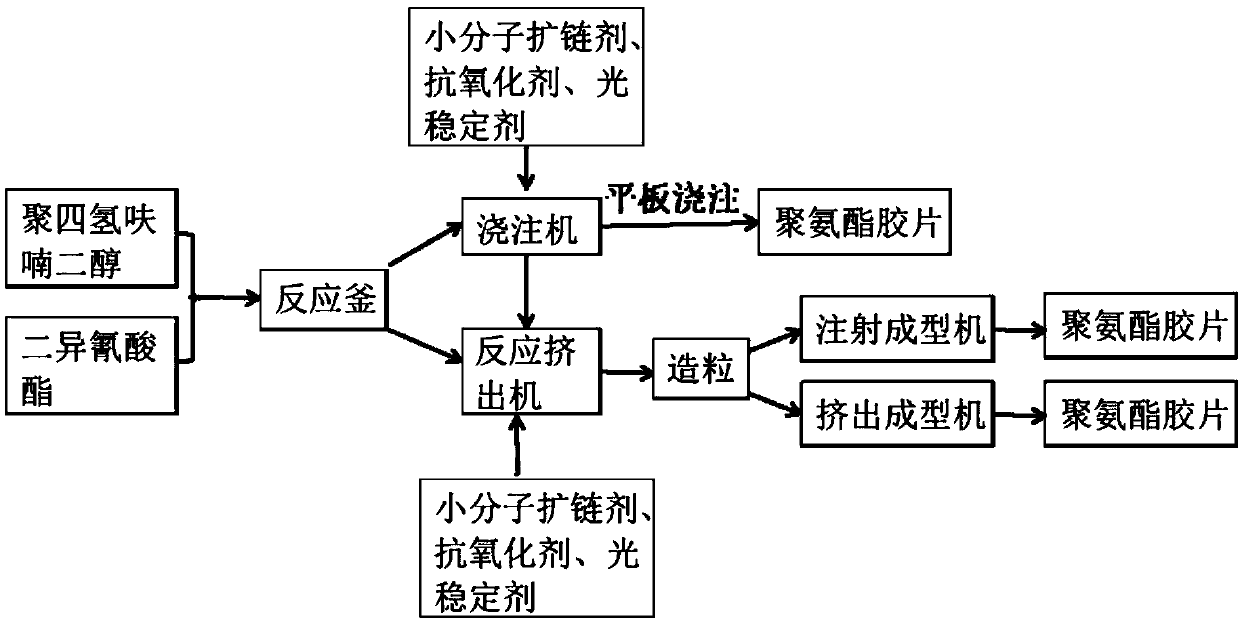

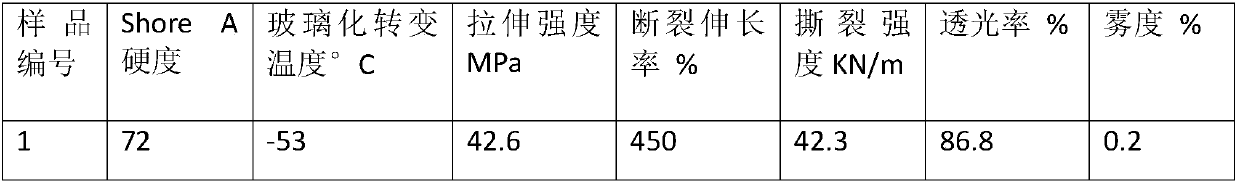

Optically thermoplastic polyurethane elastomer and preparation method thereof

InactiveCN108047415ASimple processWide performance adjustable rangePolyureas/polyurethane adhesivesSolubilityAntioxidant

The invention belongs to the technical field of optical polyurethane elastomers used for composite structure safe glass, and relates to an optically thermoplastic polyurethane elastomer and a preparation method thereof. The elastomer comprises the following components in parts by weight: 60.00% to 80.00% of polyether glycol, 3.00% to 8.00% of a polyhydric alcohol micromolecular chain extender, 10%to 30% of aliphatic diisocyanate, 0.01% to 0.05% of an organic tin catalyst, 0.50% to 1.50% of an oil-solubility antioxidant and 1.00% to 2.00% of a light stabilizer, wherein polytetrahydrofuran withthe molecular weight of 600 to 2000 is selected as the polyether glycol. The polyurethane elastomer material is synthesized and prepared by using a two-step method of a reaction kettle, after the synthesized polyurethane material is pelletized and heated for curing, optical polyurethane elastomer films with different thicknesses can be prepared through the method such as direct flat plate pouringor extrusion pelletizing and then injection forming and extrusion forming. The optically thermoplastic polyurethane elastomer has a high mechanical property, optical performance and tearing strength;the tensile strength is 30 to 45 MPa, the elongation at break is 400% to 700%, the tearing strength is 30 to 50 KN / m, and the light transmittance after being compounded with 2 mm glass is 85% to 87%.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

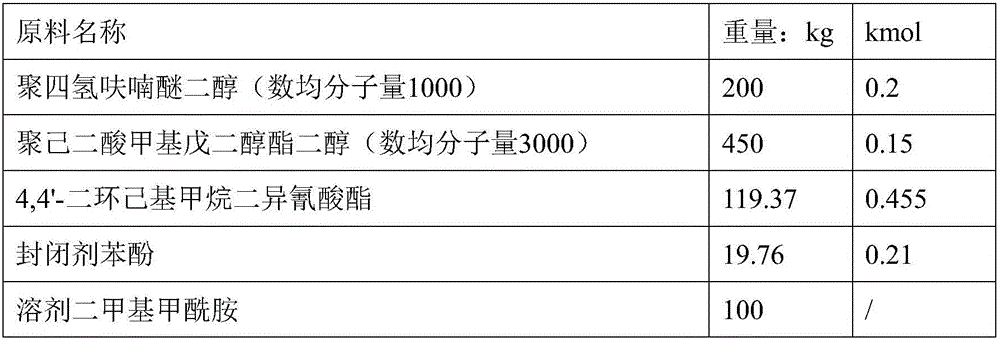

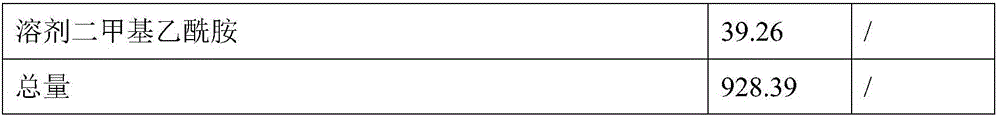

High solid content two-liquid type adhesive layer polyurethane resin and preparation method thereof

InactiveCN106750084AReduce usageReduce negative impactPolyureas/polyurethane adhesivesPolymer scienceSolvent

The invention discloses high solid content two-liquid type adhesive layer polyurethane resin and a preparation method thereof. The high solid content two-liquid type adhesive layer polyurethane resin is prepared from the following raw materials: polyhydric alcohols, diisocyanate, a sealing agent and a solvent, wherein the polyhydric alcohols comprise a polyhydric alcohol A and a polyhydric alcohol B; the polyhydric alcohol A is selected from polyadipic acid ethylene glycol and butanediol copolyester diol, polyadipic acid diglycol ethylene glycol copolyester diol and polytetrahydrofuranether diol or polytetrahydrofuran ethylene oxide copolyether diol; the polyhydric alcohol B is a polyhydric alcohol which contains a side group and is liquid at 20 DEG C. By using part of polyhydric alcohols which are liquid at normal temperature, polyurethane resin with the solid content of 80-90% is obtained, and the use amount of the solvent is reduced; when synthetic leather is prepared, by adding a marketed polyfunctionality compound which can be reacted with a isocyanate group as a crosslinking agent (such as triethylene tetramine) into the resin, smooth kink marks of the synthesized leather can be realized without changing the existing process.

Owner:HUAFON MICROFIBER SHANGHAI

High pertormance thermoplastic polyether ester elastomer with low degree of hardness and high melting point

A low-hardness, high-smelting-point and high-performance thermoplastic polyether ester contains the hard short-chain polyester segment consisting of bicarboxylic acid and binary alcohol and the soft polyether ester segment consisting of bicarboxylic acid and oplyalkyleneether diol. In its synthesis the polytetrahydrofuran ether diol and composite antoxidizing agent are used.

Owner:SINOTEX INVESTMENT & DEV CO LTD

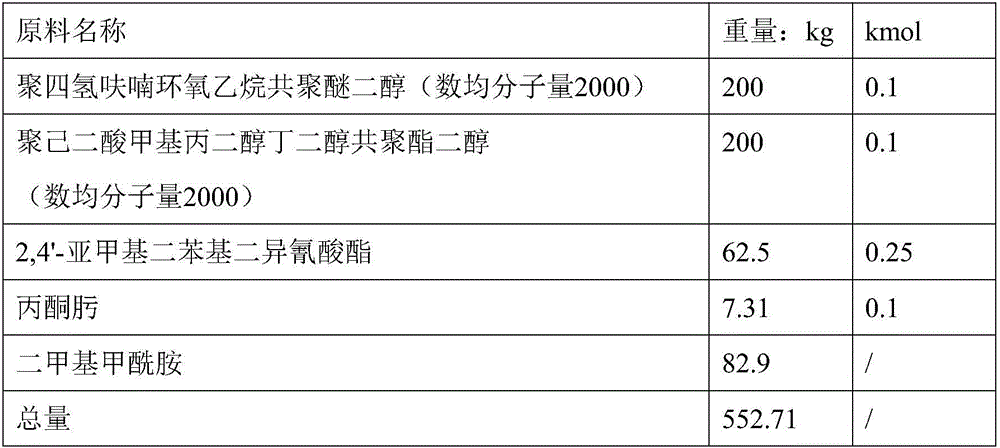

Polyester-polyether polyol, preparation method thereof as well as prepared high-resilience polyurethane foamed plastic and preparation method thereof

The invention belongs to the technical field of polymer synthesis and particularly relates to polyester-polyether polyol, a preparation method thereof as well as prepared high-resilience polyurethane foamed plastic and a preparation method thereof. The polyester-polyether polyol is a copolymer of a mixture, as an initiator, of polyester polyol or polyether polyol and polytetrahydrofuran glycol and alkylene oxide and has a hydroxyl value being 30-75mgKOH / g; the alkylene oxide is ethylene oxide and propylene oxide; and the polyester polyol is prepared by adopting adipic acid, neopentyl glycol, diethylene glycol and epsilon-caprolactone. The polyester-polyether polyol is colorless and transparent and has the characteristics of low content of residual catalyst and stable properties; and the prepared high-resilience polyurethane foamed plastic has the characteristics of good formula latitude, excellent mechanical property and good weatherability.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

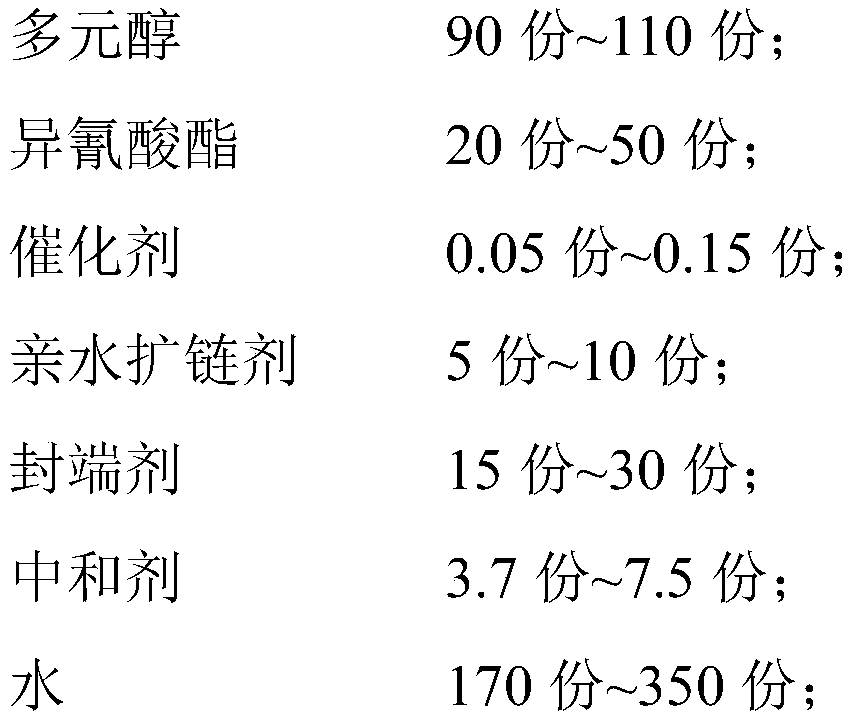

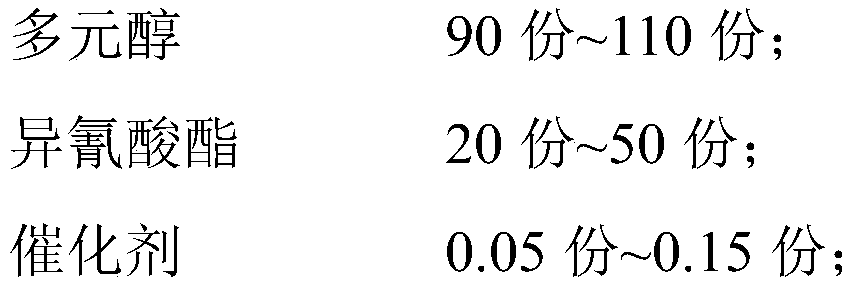

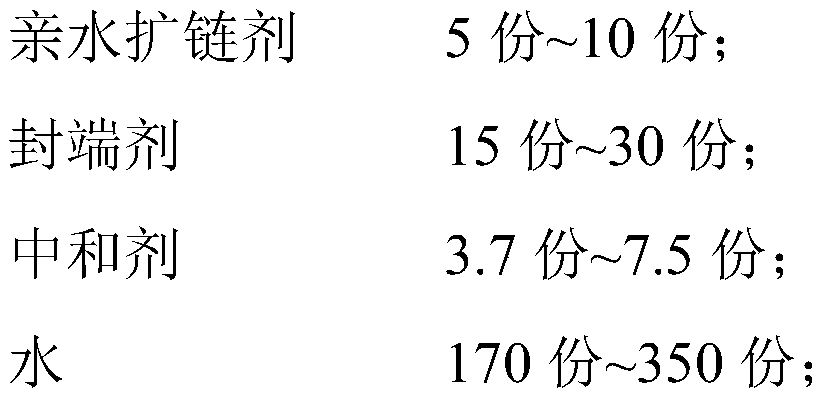

Waterborne polyurethane emulsion, coating and preparation method and application of waterborne polyurethane emulsion

The invention relates to a waterborne polyurethane emulsion, a coating and a preparation method and application of the waterborne polyurethane emulsion. The waterborne polyurethane emulsion is mainlyprepared from the following components (by mass): polyols, isocyanate, a catalyst, a hydrophilic chain extender, an end-capping reagent, a neutralizer and water, wherein the polyols comprise a polyolA and a polyol B; the polyol A is carbon dioxide copolymer polyol, and the polyol B is at least one of polycarbonate diol, polybutylene adipate diol and polytetrahydrofuran diol. The preparation method comprises the following steps: mixing polyol A and polyol B for use; and matching isocyanate, a catalyst, a hydrophilic chain extender, an end-capping reagent, a neutralizer and water and controlling the mass parts of all the components. Thereby, the microphase separation of the waterborne polyurethane emulsion and the interaction between hydrogen bonds can be improved, and the waterborne polyurethane has good stability, water resistance and chemical reagent corrosion resistance.

Owner:广州康狄夫环保科技有限公司

Nano silicon dioxide modified polyurethane composite material

The invention discloses a nano silicon dioxide modified polyurethane composite material comprising the raw materials: polytetrahydrofuran glycol, hydroxyl-terminated polyepichlorohydrin, isocyanate, epoxy resin, a chain extender, 1H,1H,8H,8H-dodecafluoro-1,8-octanediol, a catalyst, polypropylene, a maleic anhydride grafted ethylene-octene copolymer, an acrylonitrile-styrene-butadiene copolymer, ethylene-propylene-diene rubber, organic modified nano silicon dioxide, tetrapod-like zinc oxide whiskers, graphene oxide, carbon nanotubes, expanded graphite, tris(2-chloroethyl) phosphate, triphenyl phosphite, tris(2,4-di-tert-butylphenyl)phosphite, di(octane phenol polyoxyethylene)phosphate, polythiazole, and a silane coupling agent. The nano silicon dioxide modified polyurethane composite material provided by the invention has the advantages of excellent heat resistance, good flame retardancy, good water resistance, and high strength.

Owner:CHUZHOU GLOBAL POLYURETHANE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com