Patents

Literature

755results about How to "Guaranteed softness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

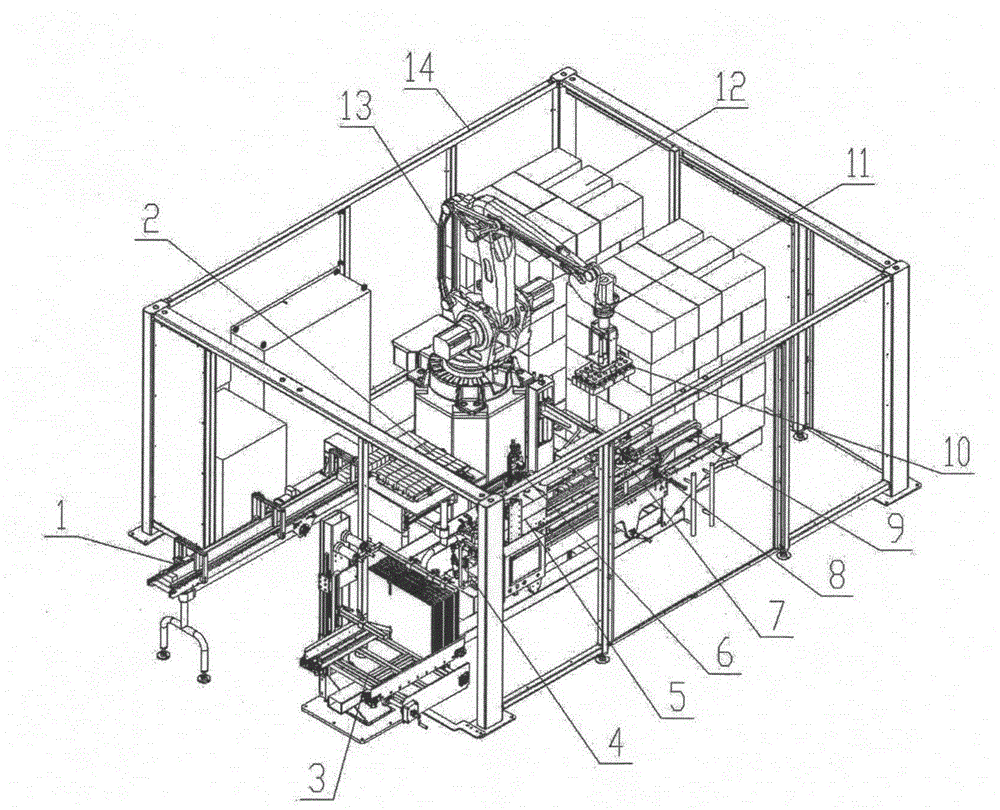

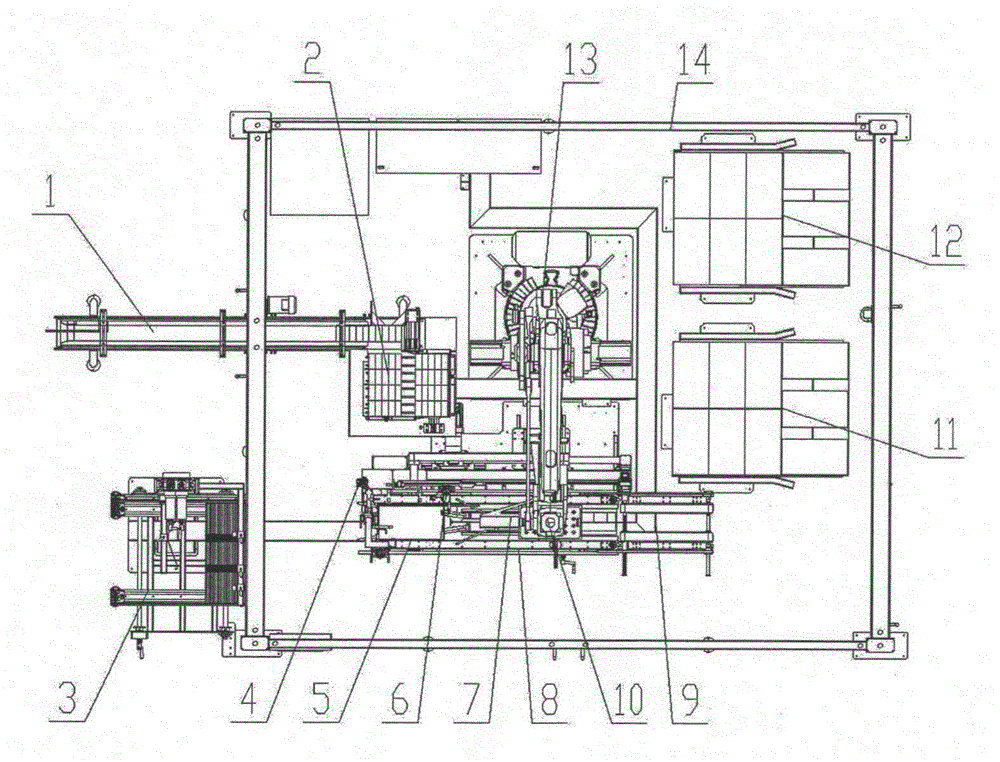

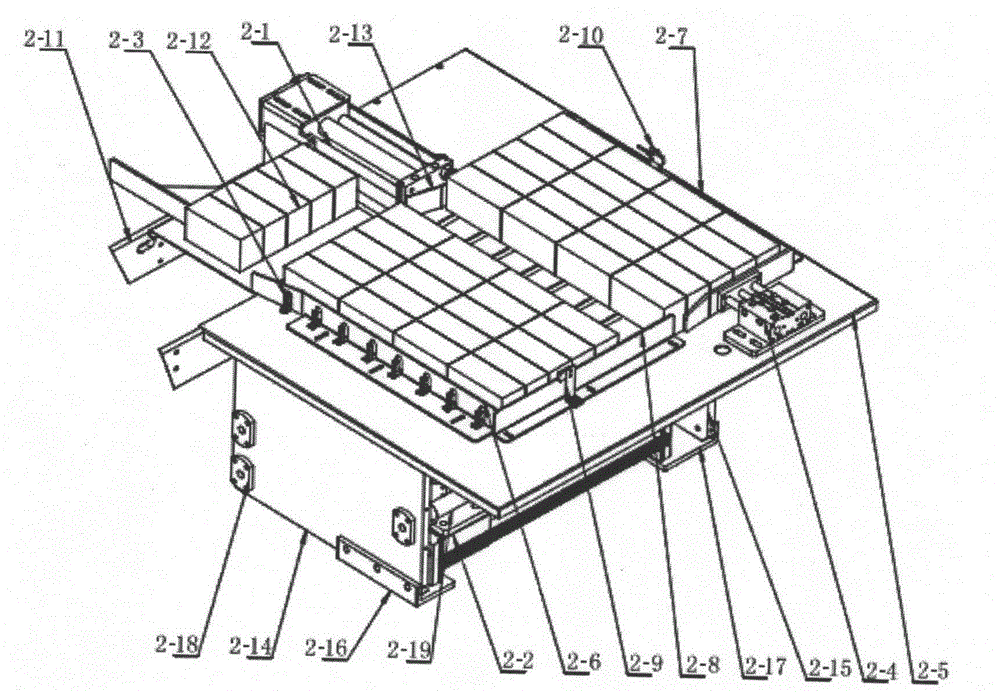

Carton filling and stacking all-in-one machine

ActiveCN104859894AReduce the difficulty of operationSmall footprintPackaging machinesCartonEngineering

The invention discloses a carton filling and stacking all-in-one machine. The carton filling and stacking all-in-one machine is characterized by comprising a carton conveying line and a storage device, wherein the head portion of the carton conveying line is connected with one side of a carton alignment device; the storage device is connected with one side of a carton filling station through an unpacking forming mechanism; the other side of the carton filling station is connected with one side of a carton strutting device; the other side of the carton alignment device is provided with a robot body; the robot body is provided with a carton filling and stacking grasp structure; a carton clamping and conveying device is arranged on the other side of the carton strutting device and connected with a carton sealing device; a carton labeling station is arranged on one side of the carton sealing device; a first tray and a second tray are arranged on one side of the carton labeling station. The functions of existing single machines are completely integrated on one machine, stations are linked tightly, the structure is compact, and operation is easy. The carton filling and stacking all-in-one machine is suitable for various specifications, stable in performance, high in efficiency and capable of greatly reducing labor cost.

Owner:SHANGHAI TOFFLON SCI & TECH CO LTD

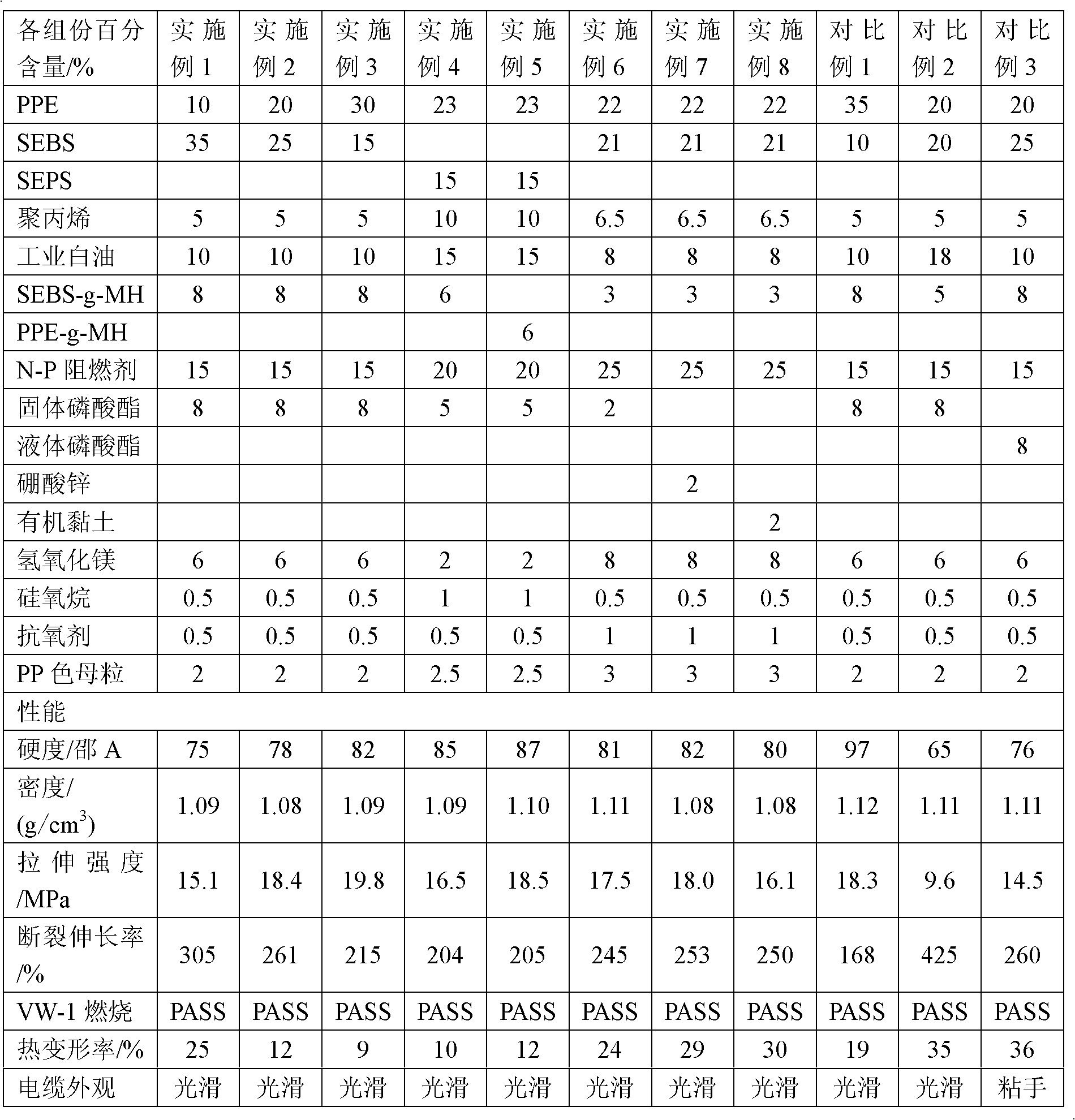

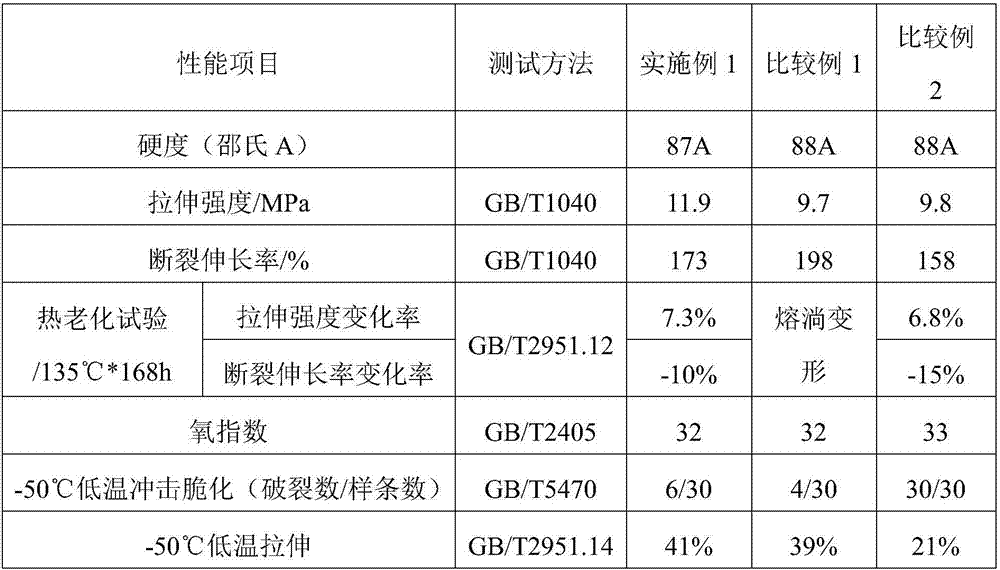

Flexible halogen-free flame-retardant polyphenyl ether electric wire cable shield material and preparation method thereof

InactiveCN102585428ANo migrationImprove flame retardant performancePlastic/resin/waxes insulatorsInsulated cablesElastomerPolyolefin

The invention relates to the field of halogen-free flame-retardant electric wire cable shield materials, in particular to a flexible halogen-free flame-retardant polyphenyl ether electric wire cable shield material and a preparation method thereof. The flexible halogen-free flame-retardant polyphenyl ether electric wire cable shield material is characterized by comprising the following raw materials in percentage: 10 to 30 percent of polyphenyl ether resin; 15 to 35 percent of styrene elastomer; 5 to 10 percent of polyolefin; 8 to 15 percent of plasticizing agent; 3 to 8 percent of compatilizer; 15 to 25 percent of main flame retardant; 2 to 8 percent of synergistic flame retardant; 2 to 8 percent of smoke suppressant; 0.5 to 1 percent of lubricant; 0.5 to 1 percent of antioxygen; and 2 to 3 percent of masterbatch. The flexible halogen-free flame-retardant polyphenyl ether electric wire cable shield material has favorable mechanical property, flexibleness, flame retardant property, heat resistance and processability.

Owner:浙江北化阻燃材料有限公司 +1

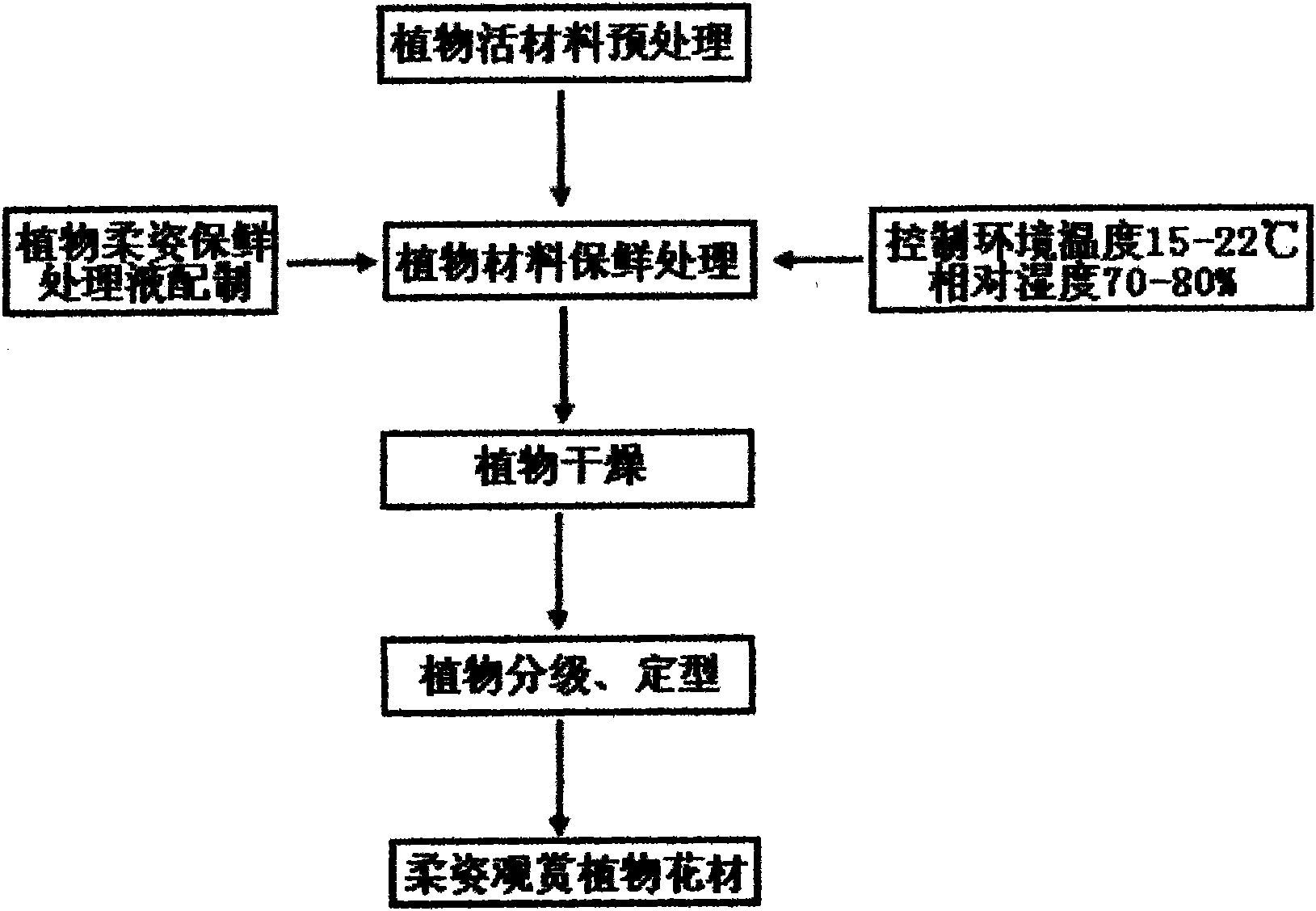

Artificial flexible-posture preserved ornamental plant and processing method thereof

ActiveCN101590780AKeep textureGuaranteed softnessDead plant preservationFloral handlingWoody plantCell metabolism

The invention discloses an artificial flexible-posture preserved ornamental plant and a processing method thereof. The artificial flexible-posture preserved ornamental plant is prepared from a naturally grown living herbaceous plant or woody plant which is harvested, kept natural posture, subjected to disinfection, fresh-keeping and coloring treatment, and then used as an ikebana material. The processing method comprises that: after pretreated, a living flowering plant material is soaked by a flexible-posture plant treating agent prepared from carbohydrate, a nourishment regulator, an antioxidant, a humectant, a preservative, edible pigment and water in a soaking container at an environmental temperature of between 15 and 22 DEG C and a relative humidity of between 70 and 80 percent untilleaves on the top of the plant are evenly dyed; and the soaked plant is aired, dried, graded and shaped into the artificial flexible-posture preserved flower material. The method utilizes the naturalmechanism of cell metabolism of flower plants, performs cellular fluid displacement and cell enclosing treatment through the flexible-posture plant treating agent, and makes the plants keep natural postures, texture and flexibleness, not influenced by spacial environment, and preserved as long as 1 to 2 years. The artificial flexible-posture preserved ornamental plant taken as a bonsai flower material does not need water dressing or daily maintenance, has stronger enjoyment property than a dry flower, and prolongs the fresh-keeping time by hundreds of times than fresh cutting plants and flowers.

Owner:云南绿荫园艺有限公司 +1

Low temperature resistant anti-crack rubber sleeve flexible cable used for wind power generation

ActiveCN101221836AMeet the torsion resistance requirementsImprove mechanical propertiesRubber insulatorsFlexible cablesPlasticizerFlexion Test

The invention relates to a low-temperature resistant and anti-crack cabtyre flexible cable for the wind power generation and is characterized in that a plasticiser inside a rubber insulation and sheath is a low-temperature resistant plasticizer and is added with 2 to 5 portions of pine tar oil and / or cylinder oil and 3 to 8 portions of coupling agent; the pitch of flexible conductor strands is intertwisted by 8 to 14 times; in the situation of a multiple-core cable, the cable pitch of insulating core is 8 to 10 times. Compared with the prior art, the invention improves the flexility at a low temperature, the anti-crack performance, the mechanical performance at a low temperature and the torsibility of the cable of the rubber insulation and sheath and can satisfy the torsibility requirements of a wind energy cable. The cable of the invention is not cracked in an impact test at a low temperature of 40 DEG C below zero and a flexion test, can maintain the flexility at a very low temperature, satisfies the requirement of the cable used at a low temperature or a maritime climate environment, and can be applicable to the use in the environmental conditions of big difference in environmental temperature, salt mist, moist heat, mould fungus, etc. In addition, an environment-friendly auxiliary material is used and the cable insulation as well as the sheath environment are good; therefore, the invention can satisfy the environment-friendly requirements of PAH such as ROHS and RAHS of the EU.

Owner:JIANGSU ZHONGMEI CABLE

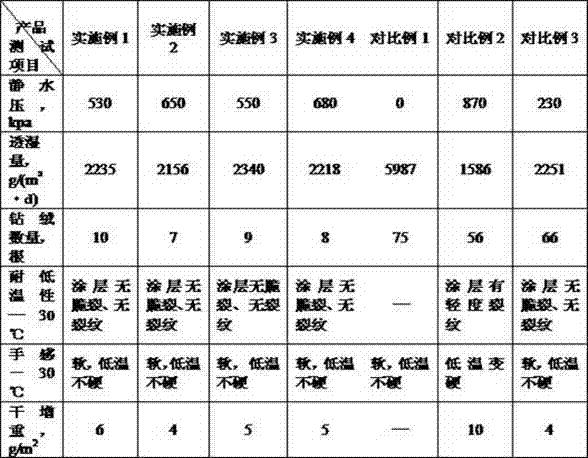

Down coat fabric treatment method for preventing down feather from escaping from needle holes

ActiveCN103614922ASolve the problem of drilling woolSolve the problem of drilling down, especially the problem of sewing needle hole drillingFibre typesPolymer scienceAdhesive

The invention discloses a down coat fabric treatment method for preventing down feather from escaping from needle holes. The down coat fabric treatment method is mainly technically characterized in that 100 parts by weight of a polyether polyurethane coating adhesive, 20-30 parts of a hydroxy terminated polydimethylsiloxane emulsion, 1-1.5 parts of an isocyanate cross-linking agent, 1.2-1.8 parts by weight of a cross-linking promoter, 3-5 parts of silicon dioxide extinction powder and 15 parts of butanone or toluene are mixed to prepare a coating adhesive, which is applied to a fabric by a floating knife coating machine, and the dry weight increase reaches 4-6 g / m<2>. The effect of preventing down feather from escaping from sewing needle holes is good, and the cold resistance, moisture permeability, washing fastness and flexibility of a fabric are ensured.

Owner:DANDONG UNIK TEXTILE

Method for preparing multi-layer composite functional surgical dressing

InactiveCN103239755AGuaranteed softnessChieve protectiveAdhesive dressingsAbsorbent padsPolyesterBiocompatibility Testing

The invention relates to a method for preparing a multi-layer composite functional surgical dressing. The method comprises the following steps: respectively and independently carding the fiber layers comprising a functional layer which is formed by mixing chitosan fiber or chitosan fiber and viscose and is directly contacted with the skin, a water-absorbing layer which is made of viscose and has high liquid absorption performance and a protective layer which is formed by mixing the viscose and polyester fiber and has the supporting and protecting functions so as to form a net, manufacturing a three-layer laminate with an upper functional layer, a middle water-absorbing layer and a lower protective layer by employing a water jet strengthening technology, coating a waterproof agent on the protective layer of the three-layer laminate to form a waterproof layer, and finally rolling to obtain the surgical dressing. The product has high biocompatibility and promotes healing, the antibacterial rate is up to 96.7 percent, the liquid absorption rate is 1259 percent, the waterproofing grade is up to level 5, and the surgical dressing can be used for clinical repair for operative incision, burn, scald, ulcer and other skin injury and is simple in production process, low in cost and environmentally-friendly.

Owner:DONGHUA UNIV +1

Polyvinyl chloride (PVC) plastic foam yoga mat and preparation method thereof

ActiveCN102000412AGood compatibilityImprove skid resistanceFibre treatmentShock absorber matsPolymer sciencePolyvinyl chloride

The invention belongs to sports equipment and preparation thereof, particularly relating to a polyvinyl chloride (PVC) plastic foam yoga mat and a preparation method thereof. The preparation method of the yoga mat has the following steps: evenly mixing PVC paste resins, plastic modified resins, EVA toughened resins, a stabilizing agent, modified nanoparticles and a foaming agent respectively at an effective amount, adding a plasticizer, and evenly stirring into a paste mixture; coating the paste mixture on a mesh by adopting a continuous blade coating method, plastifying and foaming in a foaming furnace, molding, cyclically cooling and sizing to obtain the foam mat. In the foam mat in the invention, the defects of large brittleness and poor mechanical property of the existing product are solved, especially the problems of poor skid resistance, rebound resilience and antibacterial effect are solved, and the foam mat has the advantages of obviously improved skid resistance, rebound resilience and mechanical property, good antibacterial effect and the like.

Owner:HEBEI JIAMEILE PLASTIC PRDUCTS

Preparation method of stab-resistant cut-resistant flexible material

InactiveCN108058469AReduce weightGood flexibilityLaminationLamination apparatusInorganic particleInorganic particles

The invention relates to a preparation method of a stab-resistant cut-resistant flexible material. The preparation method comprises the following steps: choosing base cloth, coating the surface of thebase cloth with a glue, then adhering one or two of an organic polymer material and an inorganic particle, obtaining a composite, and thermally pressing the composite, thereby obtaining the stab-resistant cut-resistant flexible material. The preparation method is simple, the cost is low, and the prepared stab-resistant cut-resistant flexible material is light in weight and high in flexibility, and has excellent stab-resistant cut-resistant performances.

Owner:DONGHUA UNIV

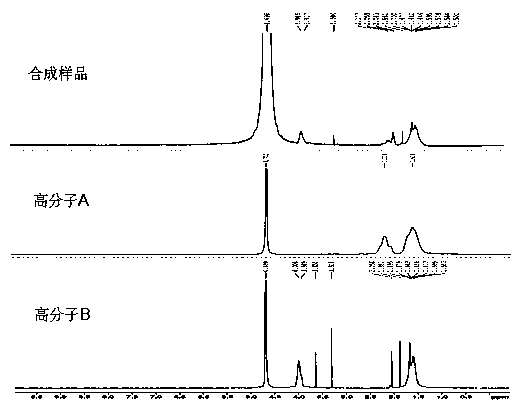

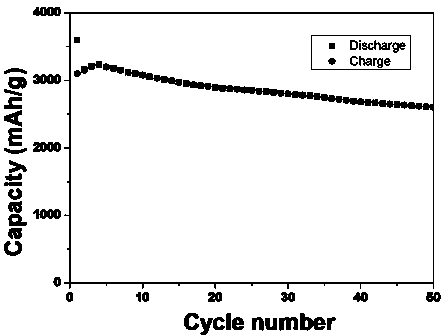

Adhesive for lithium battery and preparation method thereof

ActiveCN103427083APromote circulationImproved high-magnification performanceCell electrodesPolymer scienceAdhesive

The invention relates to adhesive for a lithium battery and a preparation method thereof. The adhesive is aqueous and is prepared through polymer A containing carboxyl functional groups and polymer B containing hydroxyl functional groups. The preparation method includes dissolving and placing the polymer A containing the carboxyl functional groups and the polymer B containing the hydroxyl functional groups in a reactor in proportion, then adding reaction initiator C to stir without a break for 10 to 12 hours at the constant temperature ranging from 40 to 70 DEG C, and cooling to the room temperature to obtain the adhesive. The adhesive has high-strength adhesion and excellent plasticity, prepared slurry can be preserved for long time without phase separation and can be mass produced, so that a battery producing process is easier and more facilitated, and consistence of battery quality can be guaranteed.

Owner:HUBEI WANRUN NEW ENERGY TECH DEV

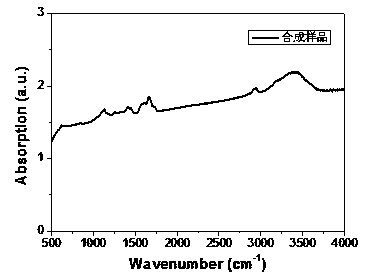

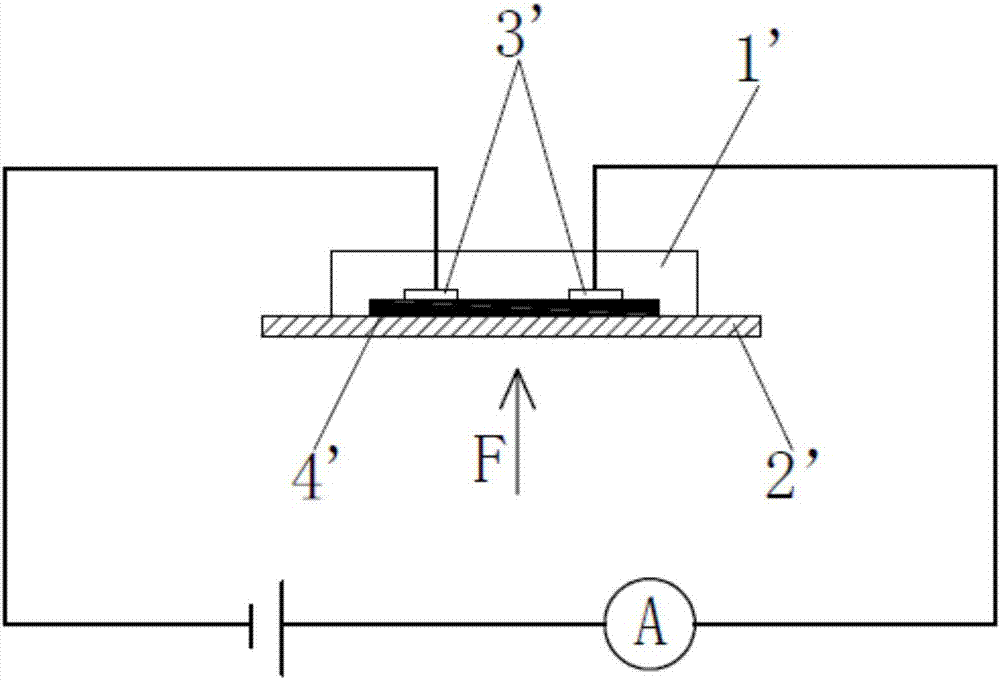

Flexible stress sensor and preparation method thereof

InactiveCN107271084ASmall sizeSolve the problem of difficult miniaturizationMaterial nanotechnologyForce measurementSemiconductor materialsMiniaturization

The present invention relates to a flexible stress sensor. The flexible stress sensor comprises two sensing assemblies; each sensing assembly includes a flexible fiber wire and a nanostructured film coating the flexible fiber wire; the flexible fiber wire is made of a conductive material or the surface of the flexible fiber wire is provided with a conductive layer; the nanostructured film is made of a conductive material or a semiconductor material; the two sensing assemblies are cross-stacked; and the nanostructured films of the two sensing assemblies contact with each other at the intersection of the two sensing assemblies. The present invention also relates to a preparation method of the flexible stress sensor. The flexible stress sensor of the invention has the advantages of small size, high resolution, high sensitivity and simple preparation, is suitable for being applied to miniaturized and integrated equipment and can be used for making wearable equipment for detecting human health.

Owner:WUYI UNIV

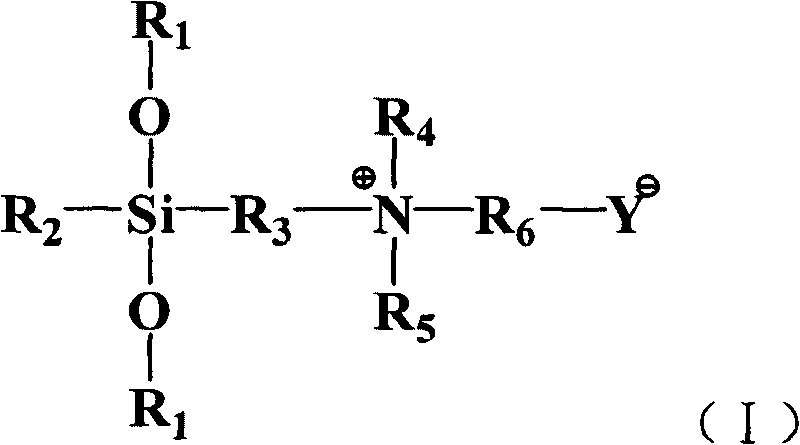

Antibiotic-mould proof textile fabric and method for preparing same

ActiveCN101760963AImprove washabilityDurable and efficient antibacterial, mildew and deodorant performanceFibre treatmentBreaking strengthBetaine

The invention discloses antibiotic-mould proof textile fabric, which is obtained by attaching organic silicon betaine onto a common antibiotic-mould proof textile fabric. The preparation method comprises the following steps of: 1, soaking the textile fabric in antibiotic finishing solution or brushing or spraying the antibiotic finishing solution on the textile fabric; 2, drying or air-drying the textile fabric processed by the step 1; and 3, washing and shaping the sample obtained by the step 2, and then drying the sample to obtain the finished product. In the antibiotic-mould proof textile fabric, the organic silicon betaine is guaranteed not to be lost in a washing process and the drug resistance in microorganisms is not generated, so that the textile fabric possesses sustained and highly efficient antibiotic, mould-proof and deodorization properties and hydrophilic property, the comfort of the textile fabric is improved, and simultaneously, and the breaking strength and the elongation at break of the textile fabric are not affected; and the preparation method is simple, easily operated and controlled and suitable for industrialized production.

Owner:HAISI MEIYU SHENZHEN TECH CO LTD

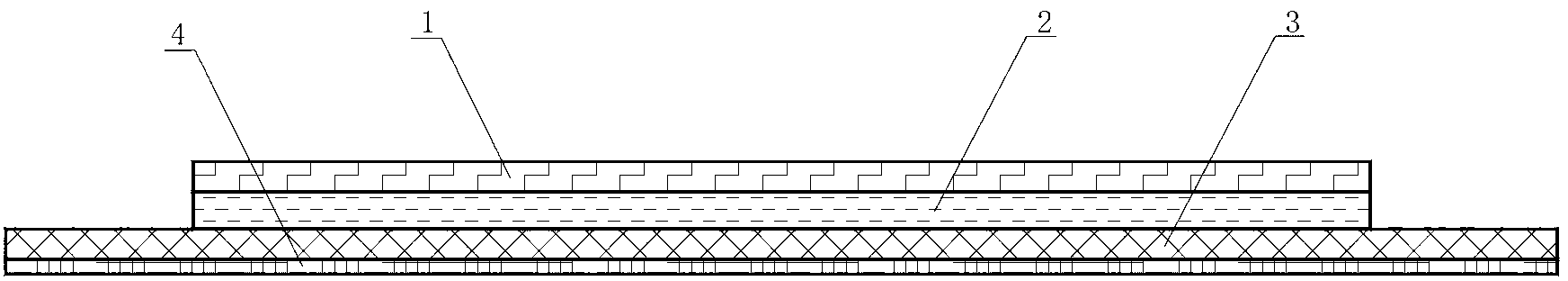

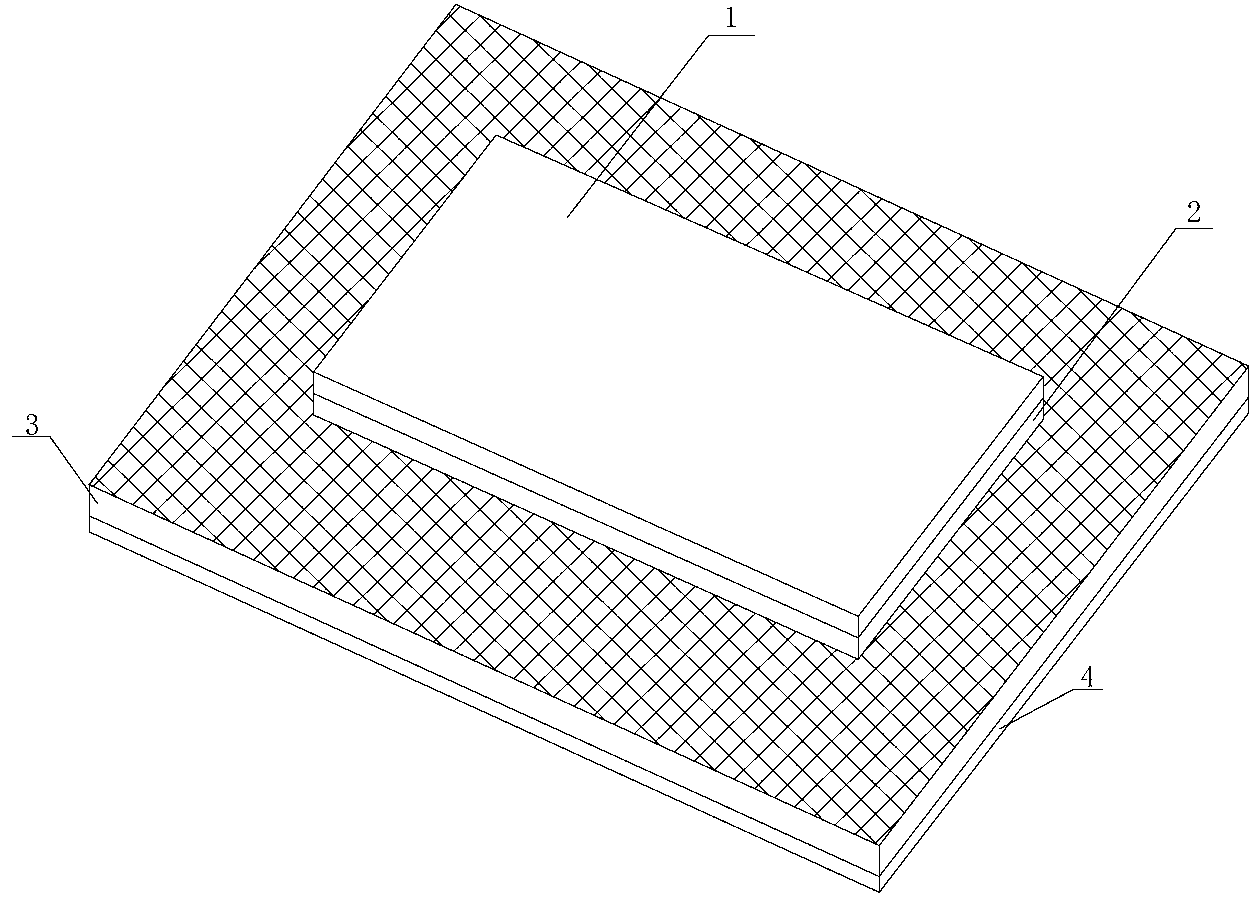

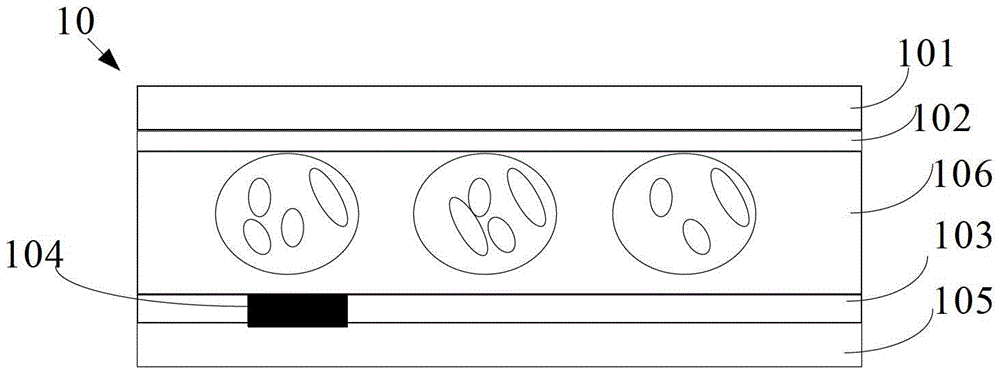

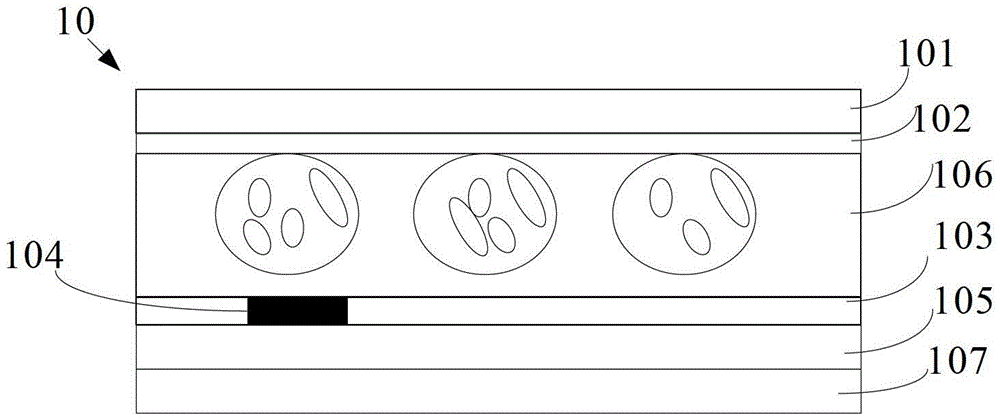

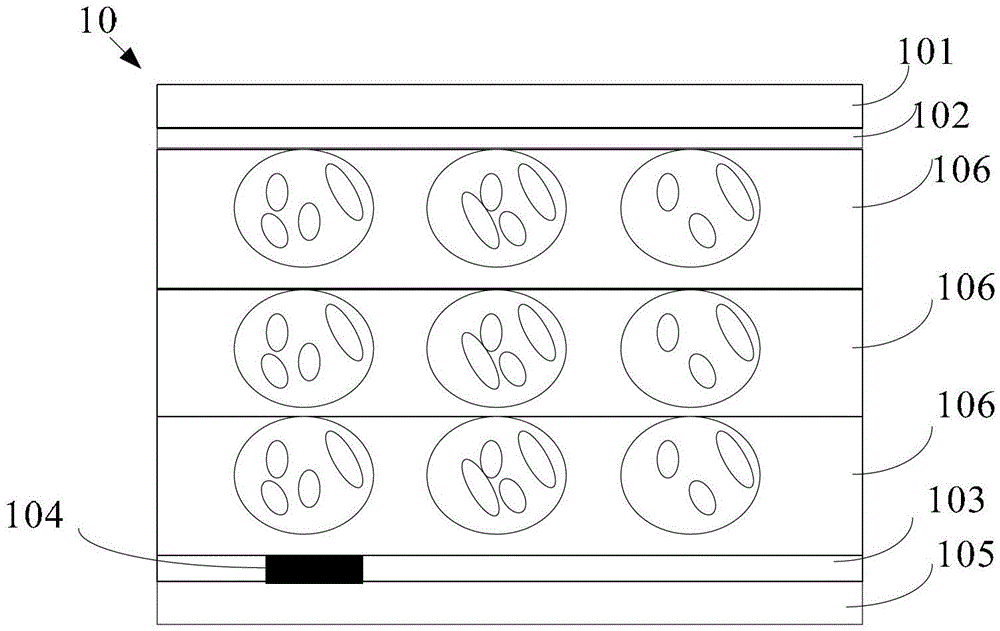

Flexible transparent LCD (Liquid Crystal Display) device and preparation method thereof

ActiveCN102749750AHigh light transmittanceGuaranteed softnessNon-linear opticsTransistor arrayLiquid-crystal display

The embodiment of the invention provides a flexible transparent LCD (Liquid Crystal Display) device and a preparation method thereof and relates to the field of manufacturing of LCD devices, and the preparation method can be used for improving the efficiency of a process for preparing the flexible transparent LCD device. The flexible transparent LCD device comprises a first flexible base plate provided with a common electrode layer, and a second flexible base plate provided with a pixel electrode and a TFFET (Thin-Film Field Effect Transistor) array, wherein at least one bistable macromolecule dispersive liquid crystal layer is formed between the first flexible base plate and the second flexible base plate. The preparation method provided by the embodiment of the invention is used for preparing the flexible transparent LCD device.

Owner:BOE TECH GRP CO LTD

Poly fleece textile using polypropylene glycol terephthalate as material and its production method

InactiveCN1730758ABeneficial to stand uprightConsistent grain sizeWeft knittingDyeing processYarnPolytrimethylene terephthalate

The present invention discloses one kind of polyester polar fleece fabric with polypropanediol terephthalate as material and its production process. The polyester polar fleece fabric has facing material of polypropanediol terephthalate yarn or filament and foundation material of other natural or synthetic fiber yarn or filament, and knitted. The polyester polar fleece fabric with polypropanediol terephthalate has soft hand feeling, high loft and elasticity, high dirt resistance, good fuzz resistance and excellent antistatic performance.

Owner:QUANZHOU HAITIAN MATERIAL TECH CORP

Ultrasoft noiseless feather prevention fabric and fabrication method thereof

InactiveCN103147205AGood anti-feather effectGuaranteed softnessWoven fabricsVegetal fibresEngineeringFilament yarn

The invention aims at disclosing ultrasoft noiseless feather prevention fabric and a fabrication method thereof. The ultrasoft noiseless feather prevention fabric is formed by interweaving warp cotton yarns and weft superfine denier polyester filament yarns in an upper two / lower one structure. Compared with the prior art, as the cotton yarns are interweaved with the superfine denier filament yarns, and windproof soft finish is adopted, a feather penetration resistance effect is improved; the fabric has a good feather prevention effect; the softness of the fabric is ensured; the fabric is soft in hand feel and noiseless; the rough hand feel and noises of the traditional feather quilt fabric are improved; and a purpose of the ultrasoft noiseless feather prevention fabric is achieved.

Owner:SHANGHAI SHUIXING HOME TEXTILE

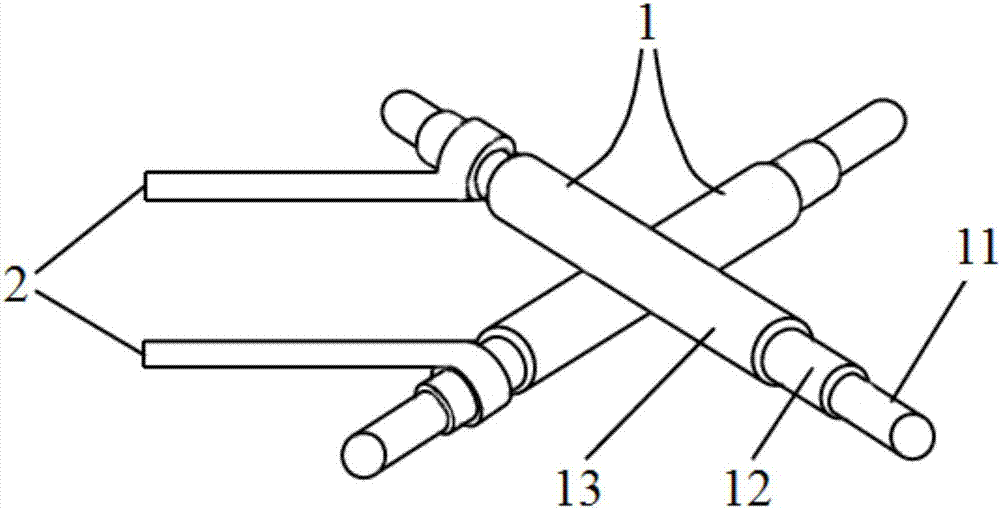

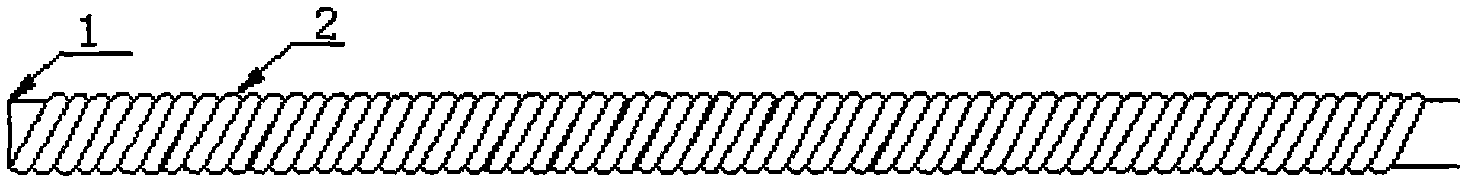

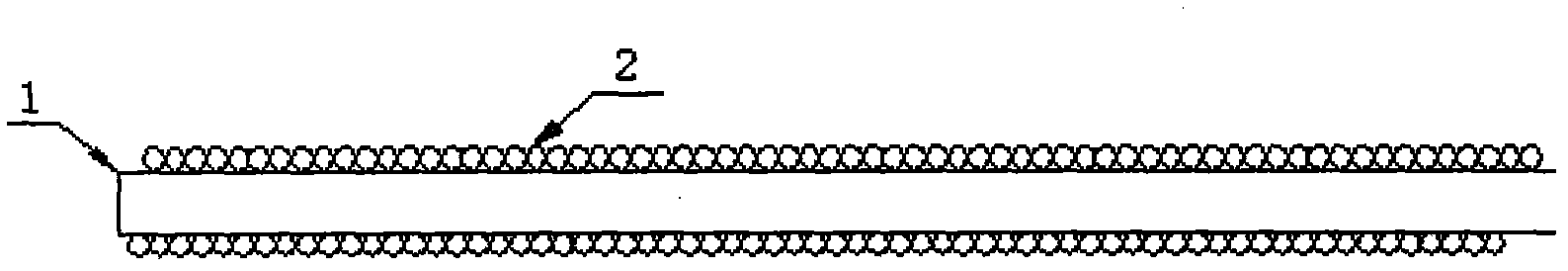

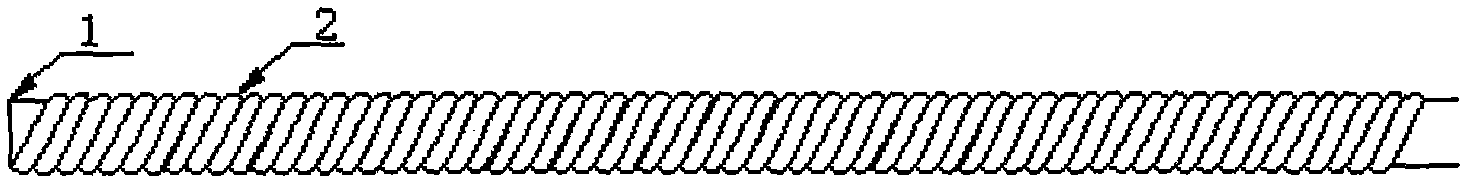

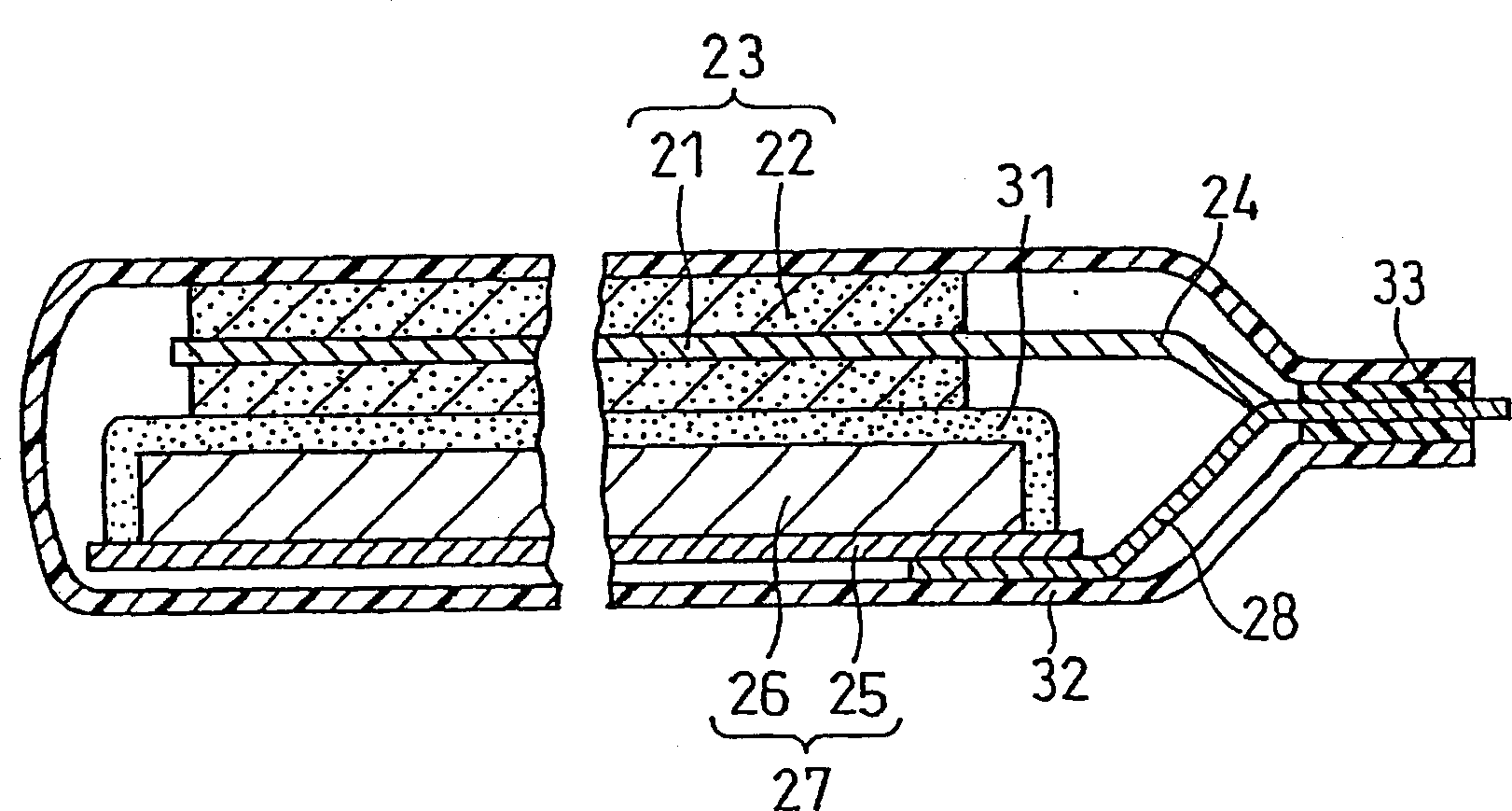

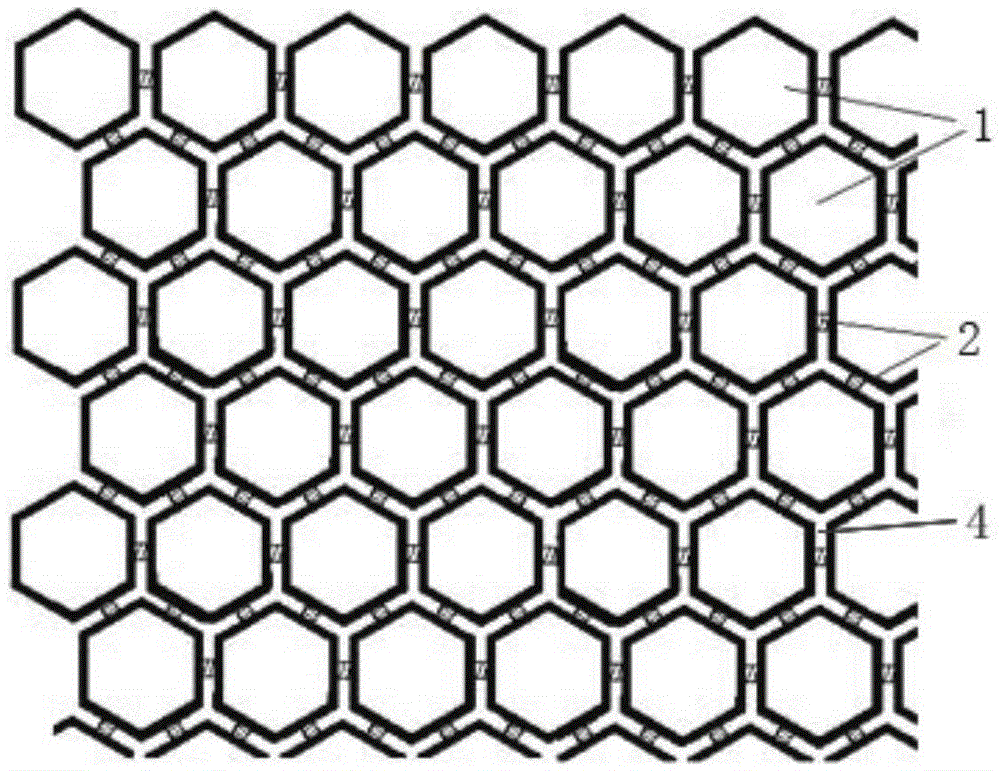

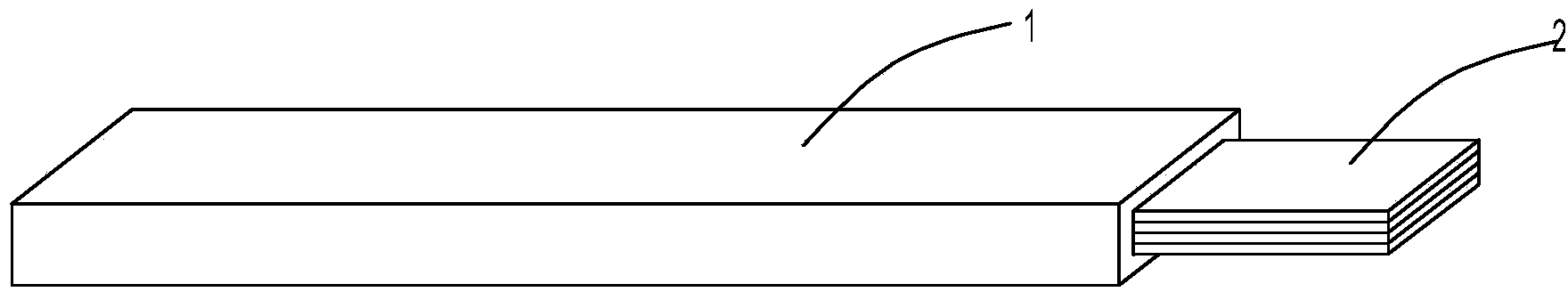

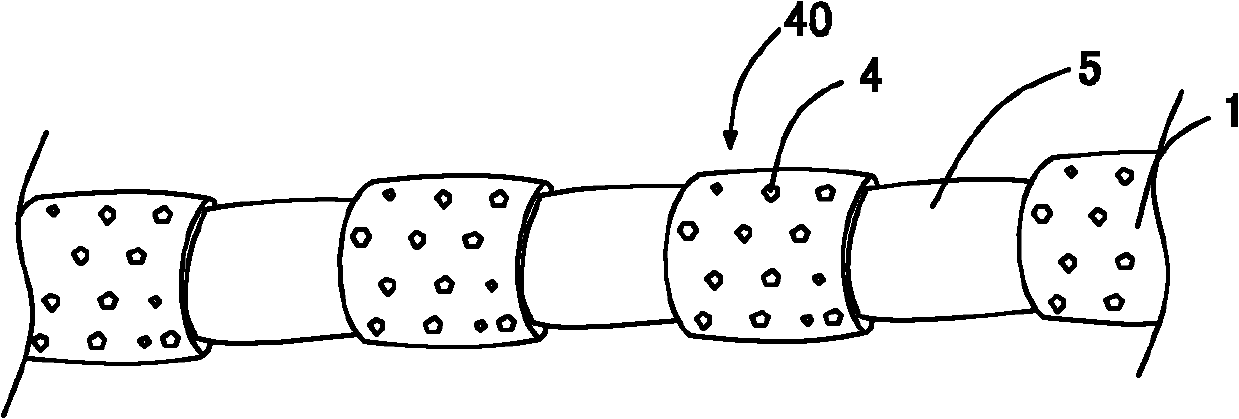

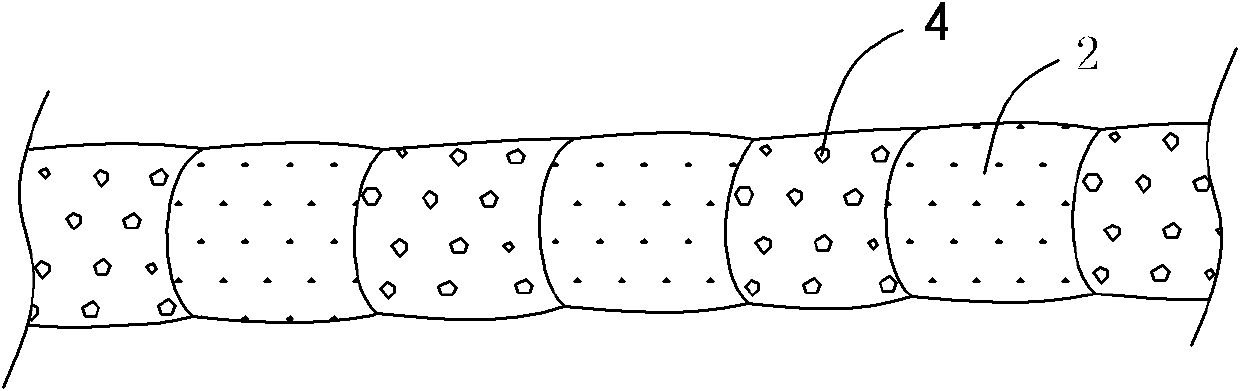

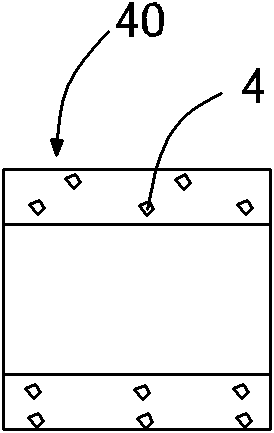

Intravascular stent with improved developing performance and method for improving developing performance of intravascular stent

ActiveCN102429750AImprove the development effectIncrease flexibilityStentsSurgeryStress distributionInsertion stent

The invention provides a method for improving the developing performance of an intravascular stent and an intravascular stent with improved developing performance, and particularly provides an intracranial vessel stent. According to the invention, at least one layer of wire (2) made of a developing material is integrally wound on a stent wave rod (1) of the stent. By adopting the stent, accurate positioning under medical image equipment during and after surgery can be ensured, and the wound developing rod (2) is positioned at an unstressed or hardly-stressed position on the stent without influencing the expansion and stress distribution of the stent, so that the service life of the stent is not shortened, and the expected application effect of the stent is not influenced.

Owner:MICROPORT NEUROTECH SHANGHAI

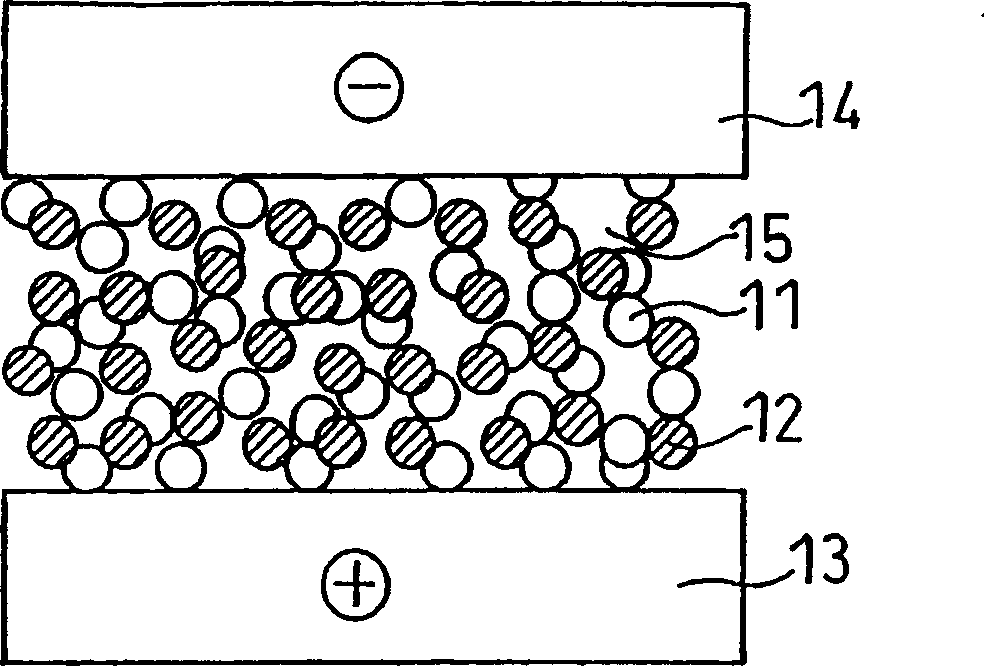

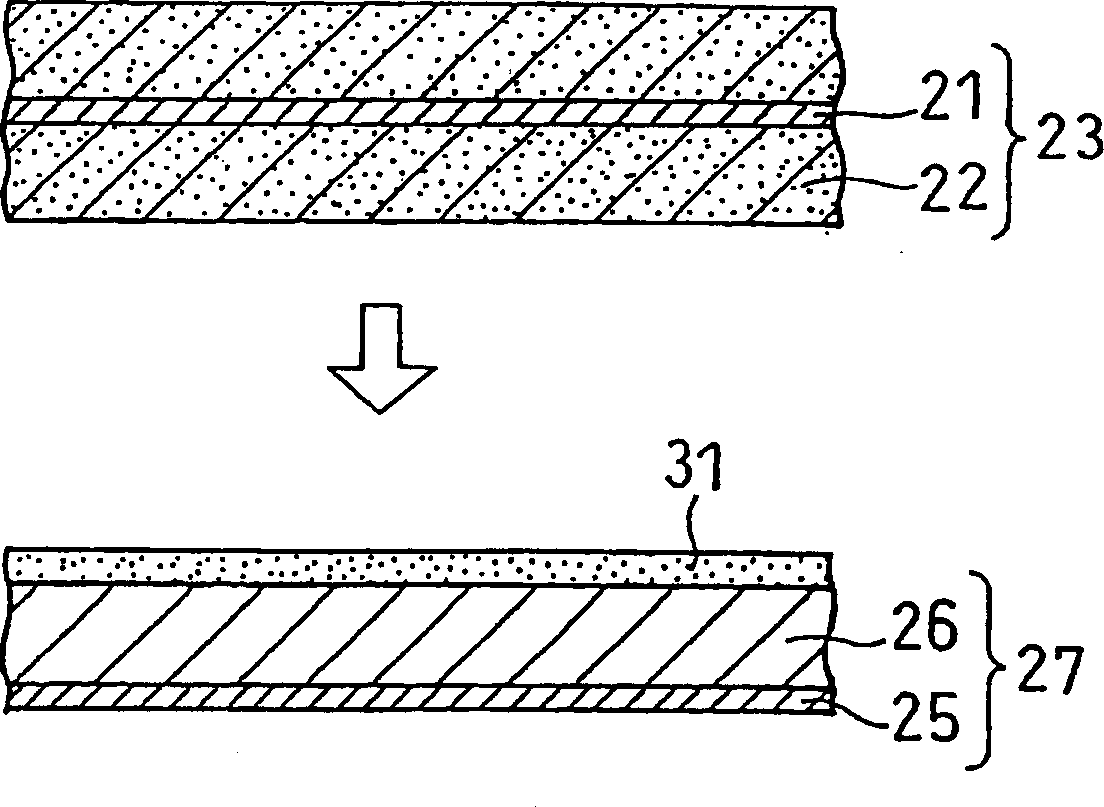

Lithium ion secondary battery

ActiveCN1795578AGuaranteed heat resistanceTake security into considerationCell seperators/membranes/diaphragms/spacersFinal product manufactureMethacrylateMaterials science

A lithium ion secondary battery includes a positive electrode capable of absorbing and desorbing lithium ion, a negative electrode capable of absorbing and desorbing lithium ion, a porous film interposed between the positive electrode and the negative electrode, and a non-aqueous electrolyte: the porous film being adhered to a surface of at least one of the positive electrode and the negative electrode; the porous film including a filler and a resin binder; the resin binder content in the porous film being 1.5 to 8 parts by weight per 100 parts by weight of the filler; and the resin binder including an acrylonitrile unit, an acrylate unit, or a methacrylate unit.

Owner:PANASONIC CORP

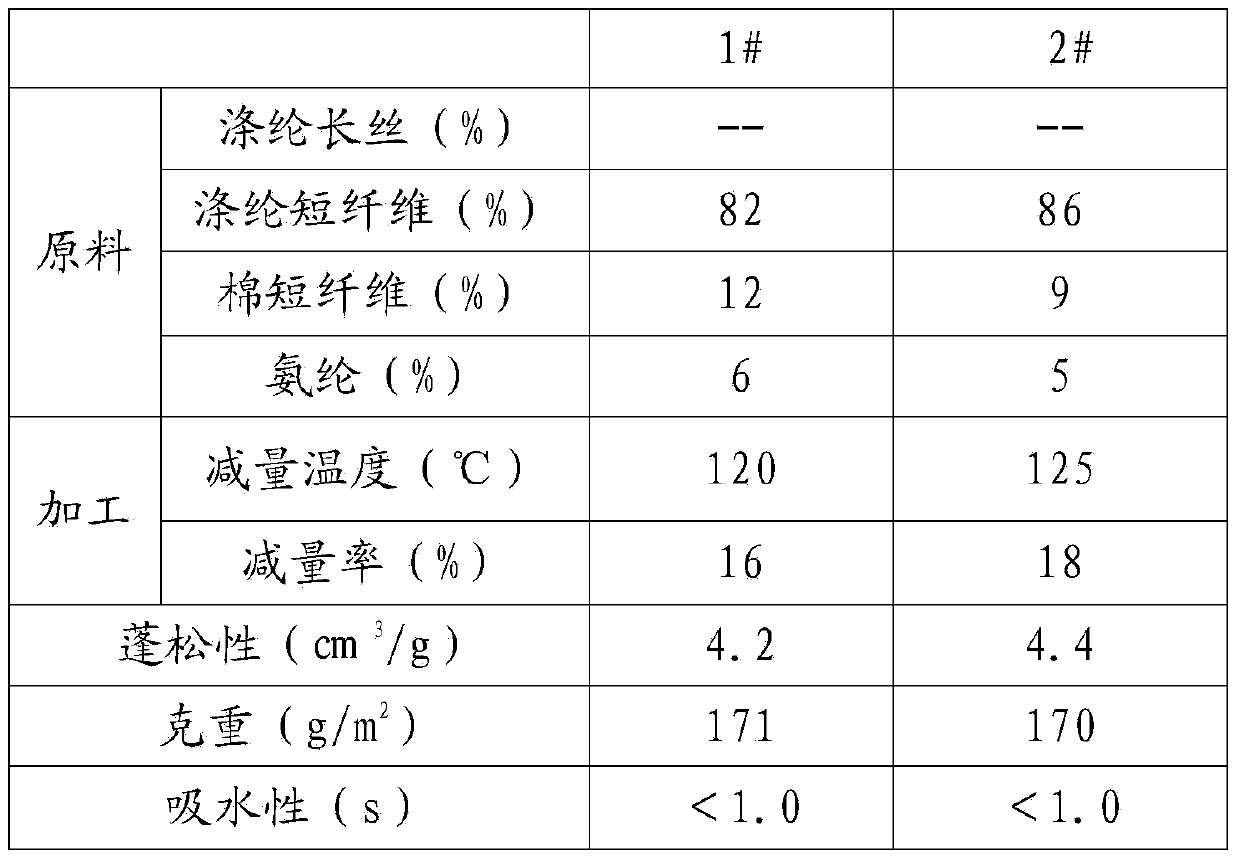

Knitted fabric and production method thereof

The invention provides knitted fabric. The knitted fabric is characterized in that the knitted fabric is composed of polyester staple fibers, cotton fibers and spandex, and the weave of the knitted fabric is fish scales and the derivative weave of the fish scales, wherein the content of the polyester staple fibers is 80% of the total mass of the fabric. In the process of knitting cloth with the knitted fabric, the temperature and the time of knitting, pre-shaping, refining, alkali peeling, dyeing, settling and shaping and other stages are limited, and therefore the elasticity, the air permeability, the comfort and the softness of the textile fabric are guaranteed.

Owner:上海缀菱纺织品有限公司

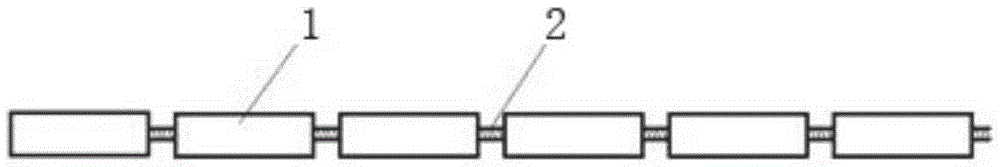

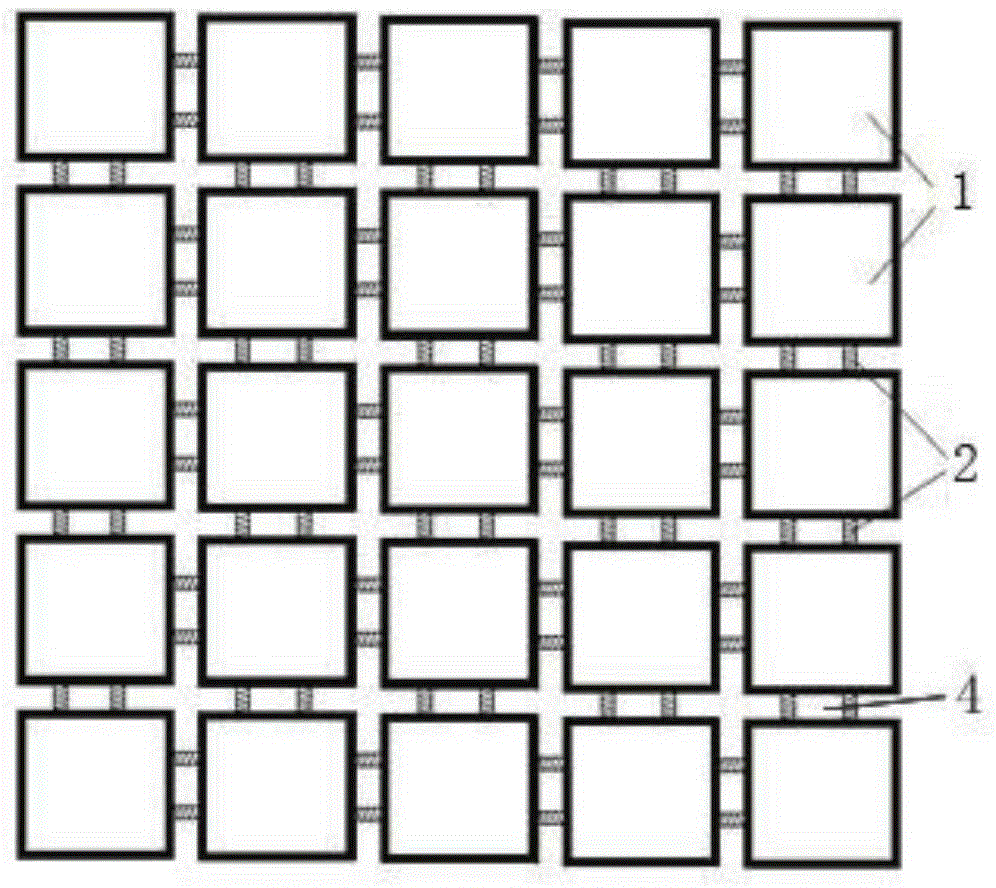

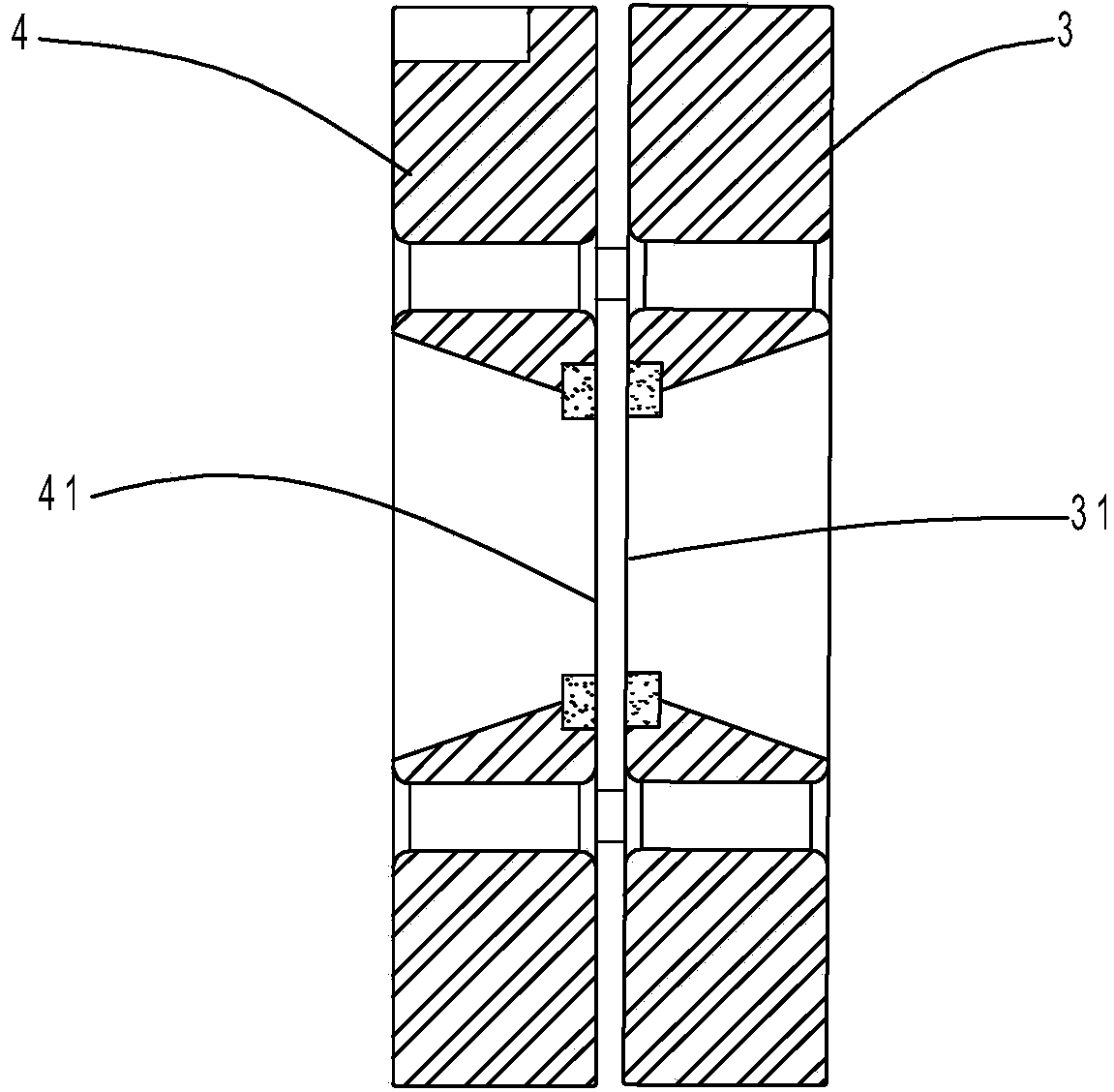

Flexible stab-resistant material and preparation method thereof

The invention discloses a flexible stab-resistant material and a preparation method thereof. The flexible stab-resistant material is composed of small protection modules and high-strength connecting members connecting the small protection modules. The high-strength connecting members are arranged among the small protection modules according to a certain order. The small protection modules are made from thermoplastic high molecular materials and high-property reinforced fiber in a combined mode, such as glass fibers, aramid fibers, chopped fibers of carbon fibers, nylon, and polycarbonate. The high-strength connecting members are made from high-strength high-modulus polyethylene, filaments, yarns or strands, and the filaments, the yarns or the strands are made from aramid fibers or carbon fiber materials. Gaps are formed among the small protection modules, so that the flexibility of the protection material is greatly improved. The invention further discloses a preparation method for forming the flexible stab-resistant material in an injection mode.

Owner:SUZHOU GAOJIA PROTECTION TECH CO LTD

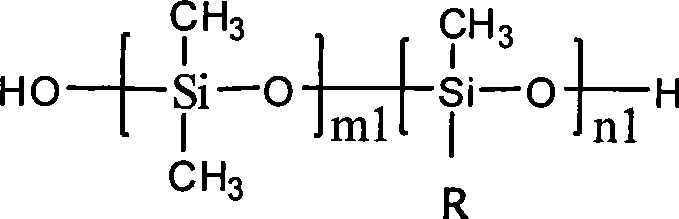

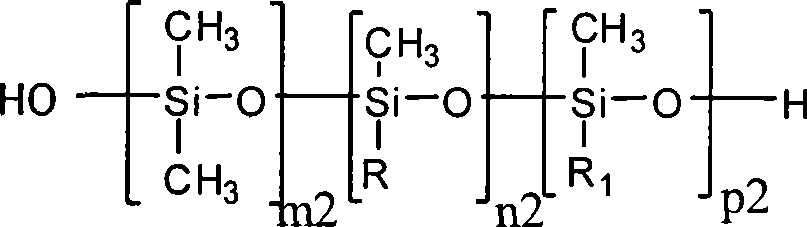

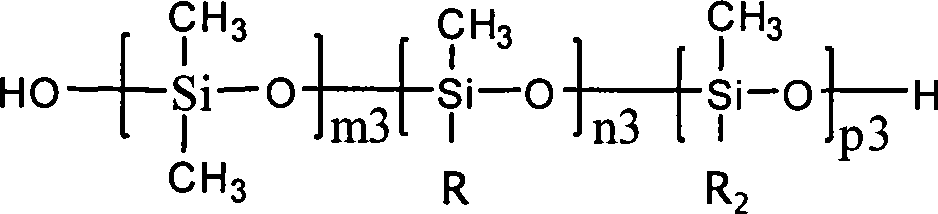

Organosilicon fluorine multifunctional fabric finishing agent and preparing method thereof

The invention discloses an organic fluosilicic multifunctional textile finishing agent. Aiming at the problem existing in the current commercially available organic silicone finishing agent, a small amount of organic fluorin radical is introduced to the organic silicone finishing agent; under the condition of not changing the original effect of the organic silicone finishing agent, the smooth property of the finishing agent is further improved, simultaneously, water-and-oil-repellent effect is increased to a certain extent; the finishing agent is innocuous and pollution-free, and has high cost performance and wide application prospect. The invention also discloses a preparation method of the organic fluosilicic multifunctional textile finishing agent which has simple technological operation, the prepared latex has strong stability and difficult emulsion breaking, delamination does not happen after the latex is placed for a long time, the use is simple, the hand-feeling of the textile is obviously improved and the additional value is increased.

Owner:ZHEJIANG RUNTU +1

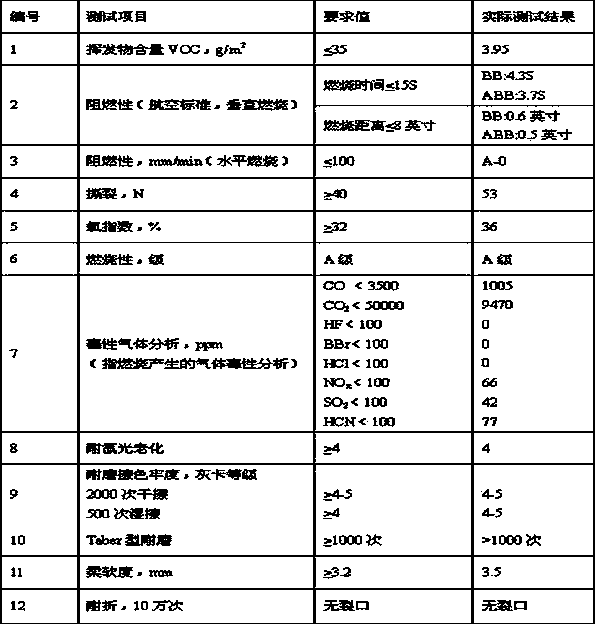

Production process of flame retardant trim cow leather

ActiveCN104032048AProper firmnessImprove uniformityTanning treatmentPolyurea/polyurethane coatingsEngineeringWear resistance

The invention relates to a production process of flame retardant trim cow leather. The production process comprises the steps of fleshing, deliming, softening, tanning, shaving, retanning, dyeing, stuffing, drying, milling and finishing, wherein the step of tanning comprises the successive procedures of salting, pickling and chrome powder tanning; and the retanning, the dyeing, the stuffing, the low-temperature airing drying and the finishing adopt characteristic processes. The flame retardant trim cow leather is compact and uniform in body, is excellent in toughness, is good in resilience and is excellent in flame retardance, and the quality can be controlled easily in the production process; after the leather is stretched in a seat or is used, the seat can be kept in an optimal form and comfort because of excellent resilience of the leather; and under the precondition of guaranteeing the softness and flame retardance, the water resistance, the sweat resistance, the color fastness to rubbing and the wear resistance of a coating layer are effectively improved.

Owner:浙江富邦汽车内饰科技有限公司

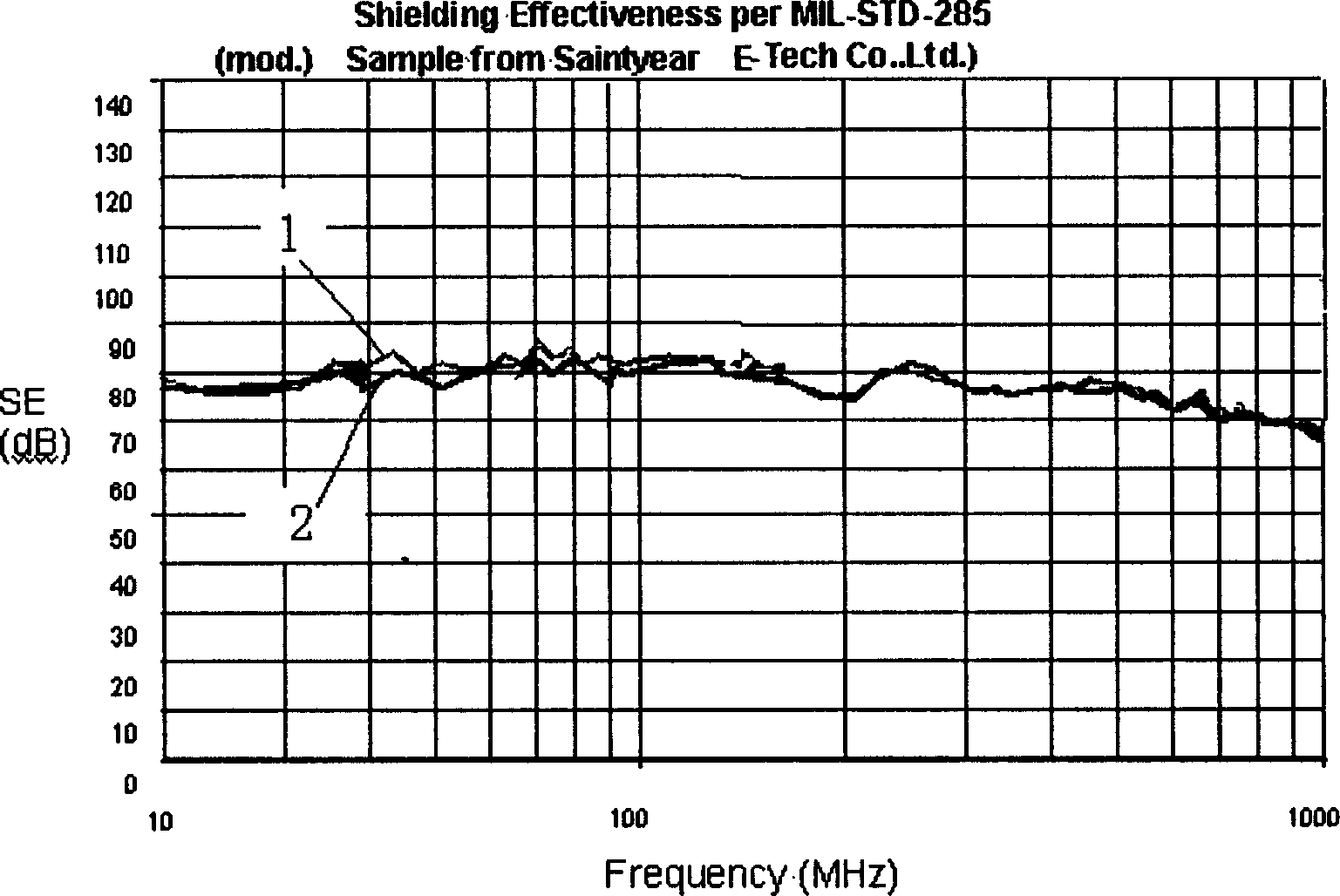

Copper-in-tin electromagnetic screen textile and method for preparing same

ActiveCN1621603AImprove conductivityEasy to brazeMagnetic/electric field screeningFibre treatmentCopper platingSulfur

The present invention is one kind of copper-in-tin electromagnetic shielding fabric and its preparation process. Onto the surface of non-metal fabric base fiber, metal copper is first plated chemically and tin is then electroplated to form composite conducting copper-tin film to obtain electromagnetic shielding fabric. The base fiber may be nylon, Dacron or orlon. The electromagnetic shielding fabric has high conducting performance, is weldble, flexible and ventilative, and can isolates sulfur in insulating material.

Owner:DONGHUA UNIV

Antibacterial deodorant and anti-wrinkle finishing process

ActiveCN105648771ATidy up steps simplifiedSave time organizingBiochemical fibre treatmentSingeingCooking & bakingHazardous substance

The invention provides an antibacterial deodorant and anti-wrinkle finishing process of cotton / silk blended fabric. The finishing process includes steps: (a), singeing; (b), performing one-bath desizing, scouring and bleaching; (c), performing antibacterial deodorant and anti-wrinkle finishing; (d), pre-baking; (e), baking; (f), washing with water; (9), drying. An antibacterial deodorant anti-wrinkle finishing agent is formed by reasonably proportioning components like citric acid, polyethylene glycol, waterborne polyurethane and beta-cyclodextrin, and is environment-friendly, free of releasing toxic and harmful substances like formaldehyde, safe and secure. By adding a softener into the finishing agent, the cotton / silk blended fabric of cotton fabric can be further ensured to be maintained soft without deforming, and practicability is improved.

Owner:深圳市歌中歌服饰有限公司

Novel cable used in electromobile and preparation method of cable

InactiveCN104112508AIncrease the areaLarge carrying capacityPower cablesFlat/ribbon cablesTemperature resistancePolyolefin

The invention provides a novel cable used in an electromobile and a preparation method of the cable. The cable comprises an insulator and a cladding conductor. The cable is characterized in that the conductor is formed by stacking a plurality of flat square copper strips; and the insulator is a crosslinked polyolefin insulator. With the cable in the structure above, the current-carrying capacity is large, heat radiation is achieved favorably, temperature resistance level is high, and the cable can be normally used at environment temperature of 150 DED C and the bellow. The cable is good in mechanical strength, softer and convenient to install and wire, convenient to produce and high in practicality; and the installation space is saved.

Owner:惠州市以泰克电线工业有限公司

Processing method of down-proof fabric

InactiveCN102433743AGuaranteed softnessGuaranteed cold resistanceFibre treatmentTextile shapingPolymer scienceTear resistance

The invention discloses a processing method of down-proof fabric. The invention belongs to the technical field of textile fabric processing. The method comprises a post-finishing step. The post finishing step comprises a water repelling step, a calendaring step, and a drying step. During the water repelling step, the fabric is delivered through a repelling tank containing a solution of a functional auxiliary agent; during the calendaring step, the surface of the fabric delivered through the repelling tank and processed by using a rolling liquid is calendared; during the drying step, the calendared fabric is dried by baking, such that the down-proof fabric is obtained. The method is characterized in that: the functional auxiliary agent comprises raw materials of, by weight: 5.5-6.5 parts of a water repelling agent, 0.8-1.2 parts of a bridging agent, 0.8-1.2 parts of resin, 0.08-0.12 parts of a promoting medium; the pH value of the functional auxiliary agent is 4-5; the pressure and the temperature of a calendaring roller of a calendaring machine, and the moving speed of the fabric are controlled during the calendaring step; and the temperature of a baking oven, and the moving speed of the fabric are controlled during the drying step. With the method, the down-proof effect is good, and the soft effect, the cold-resistance and the tearing resistance of the fabric can be ensured.

Owner:常熟华懋纺织有限公司

Diamond wire saw and manufacturing method thereof

ActiveCN101905491APrevent infiltrationGuaranteed softnessGrinding devicesFine working devicesDiamond wire sawPlastic materials

The invention discloses a diamond wire saw and a preparation method thereof. The diamond wire saw comprises a bending-resistant flexible multi-strand rope. The preparation method comprises the following steps: a, removing oil from the surface of the flexible multi-strand rope and coating high-temperature resistant inorganic glue onto the flexible multi-strand rope at intervals, so as to form an isolated coating layer after the glue is cured; b, adding metal soldering materials into the organic glue to prepare a pastry mixture; c, coating or impregnating the pastry metal soldering materials onto the spaced parts of the flexible multi-strand rope, and then spreading diamond abrasive particles onto the rope; spraying or cold-pressing a layer of metal soldering materials onto the surface of the rope after the organic glue is cured; d, putting the obtained flexible multi-strand rope into a vacuum brazing furnace for sintering, taking the rope out of the furnace and then removing the inorganic glue; after heat treatment, coating a layer of rubber-plastic material protection layer onto the spaced parts of the flexible multi-strand rope; after the glue is cured, obtaining the diamond wire saw. The diamond wire saw can effectively prevent a braze-welding material from entering into gaps of the flexible multi-strand rope so as to solve the problem that the conventional diamond wire saw manufactured by taking the flexible multi-strand rope as a centre line is too inflexible and is entirely unusable.

Owner:XIAMEN ZL DIAMOND TECH CO LTD

Konjac glucomannan edible tableware and preparation method thereof

InactiveCN102010526AImprove quality stabilityHigh tensile strengthPlatesWater resistantUltimate tensile strength

A preparation method of konjac glucomannan edible tableware comprises preparing esterification modified products, preparing composite gel, heating, centrifugally degassing, shaping tableware, samming and easing back, and sterilizing. The viscosity, film formation temperature and gel strength of konjac glucomannan sol-gel are easy to control, thereby greatly improving the performance and stability of industrial production. The konjac glucomannan edible tableware makes up the defect in the aspect of quality control of products; and the sensory quality of the konjac glucomannan edible tableware is greatly improved. Furthermore, the main raw material konjac glucomannan adopted in the invention is low in price, thereby not only improving the safety of tatableware but also greatly reducing the production cost of products. The konjac glucomannan edible tableware is a water-resistant and high-temperature resistant edible tableware.

Owner:FUJIAN AGRI & FORESTRY UNIV

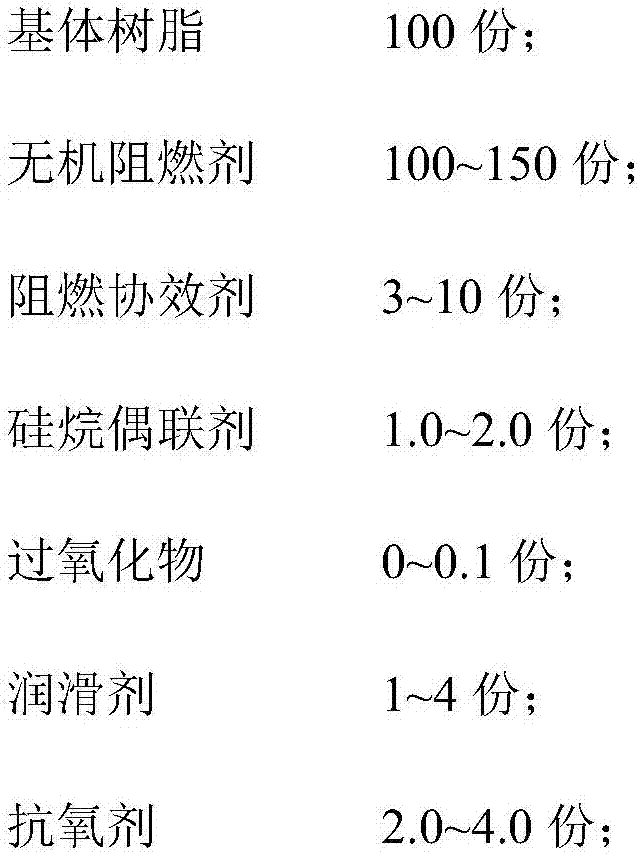

High-temperature-resistant soft thermoplastic low-smoke halogen-free flame-retardant polyolefin cable material

ActiveCN106867090AGuaranteed flame retardant performanceGood heat resistancePlastic/resin/waxes insulatorsOxideMaterial hardness

The invention discloses a high-temperature-resistant soft thermoplastic low-smoke halogen-free flame-retardant polyolefin cable material, and belongs to the technical field of cable sheath or insulation high-molecular material. The high-temperature-resistant soft thermoplastic low-smoke halogen-free flame-retardant polyolefin cable material is composed of 100 parts of a matrix resin, 100 to 150 parts of inorganic fire retardant, 3 to 10 parts of a flame-retardant synergistic agent, 1.0 to 2.0 parts of a silane coupling agent, 0 to 0.1 part of a peroxide, 1 to 4 parts of a lubricant, and 2.0 to 4.0 parts of an anti-oxidant; the matrix resin is composed of, by weight, 25 to 60 parts of an ethylene copolymer, 20 to 55 parts of an alkene segmented copolymer, and 10 to 25 parts of a compatilizer. The flame resistance and softness of the high-temperature-resistant soft thermoplastic low-smoke halogen-free flame-retardant polyolefin cable material are ensured; the high-temperature-resistant soft thermoplastic low-smoke halogen-free flame-retardant polyolefin cable material prepared via blending possesses excellent heat resistance and low temperature performance; material mechanical performance is ensured; and material hardness is reduced.

Owner:CHANGSHU ZHONGLIAN PHOTOELECTRICITY NEW STUFF

Artificial soft posture preserved ornamental plant treating agent

The invention discloses an artificial soft posture preserved ornamental plant treating agent. The treating agent comprises carbohydrates, a nutrition regulator, an antioxidant, a humectant, an antiseptic and food color, and is prepared from 30 to 45g of carbohydrates, 30 to 45g of nutrition regulator, 20 to 35g of antioxidant, 20 to 35g of humectant, and 12 to 25g of food color which are dissolved in 1 liter of water and uniformly mixed. The treating agent can perform cell sap replacement and cell sealing treatment by utilizing the natural mechanism of the cell metabolism of flowers and plants, so that the plants can keep natural postures, texture and softness, are not affected by space and environment, and can be kept fresh as long as 1 to 2 years; the plants, treated by the treating agent and used as bonsai flowers, are unnecessary to water and maintained daily; the ornamental characteristics of the plants are greatly enhanced compared with dry flowers; and the preservation period is prolonged by hundreds of times compared with that of fresh cut plants and flowers.

Owner:云南绿荫园艺有限公司 +1

Positive pole of Li-ion battery and the Li-ion battery

InactiveCN101212053AHigh specific capacityImproved magnification performanceCell electrodesSecondary cellsMethacrylatePhysical chemistry

The invention relates to an anode of a lithium ion battery, which comprises a current collector and an anode material on the current collector. The anode material contains an anode active material and a binding agent, wherein the binding agent comprises a first polymer and a second polymer. The first polymer contains fluorine with a functional group, and the second polymer contains at least a cell of acrylonitrile cell, a methylacrylonitrile cell, an acrylic acid ester cell and a methacrylic acid ester cell. The invention also provides the lithium ion battery containing the anode. The anode of the lithium ion battery provided by the invention can improve the specific capacity, rate performance and cycle performance of the battery.

Owner:SHANGHAI BYD

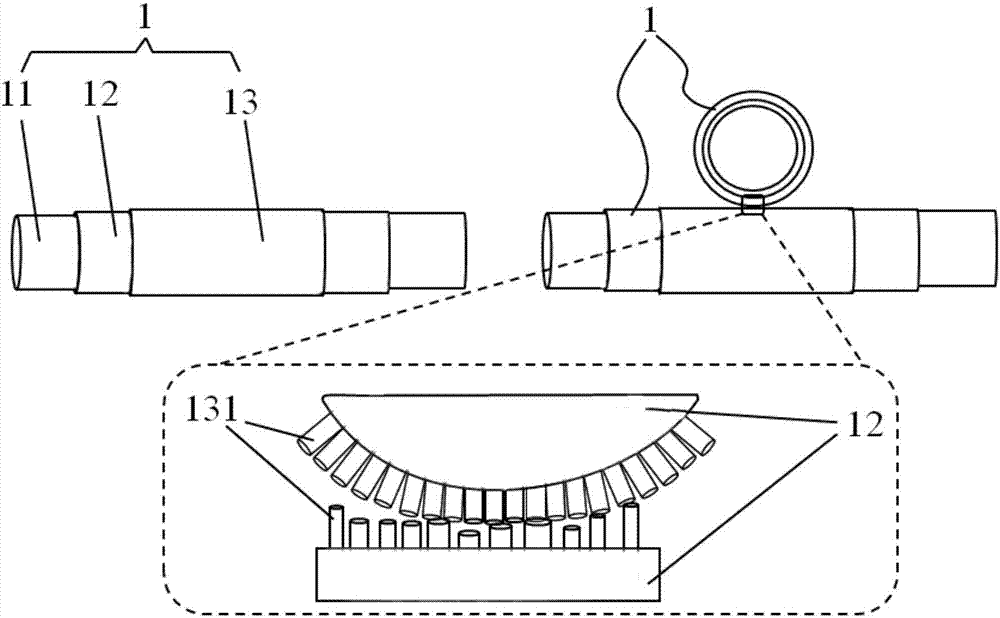

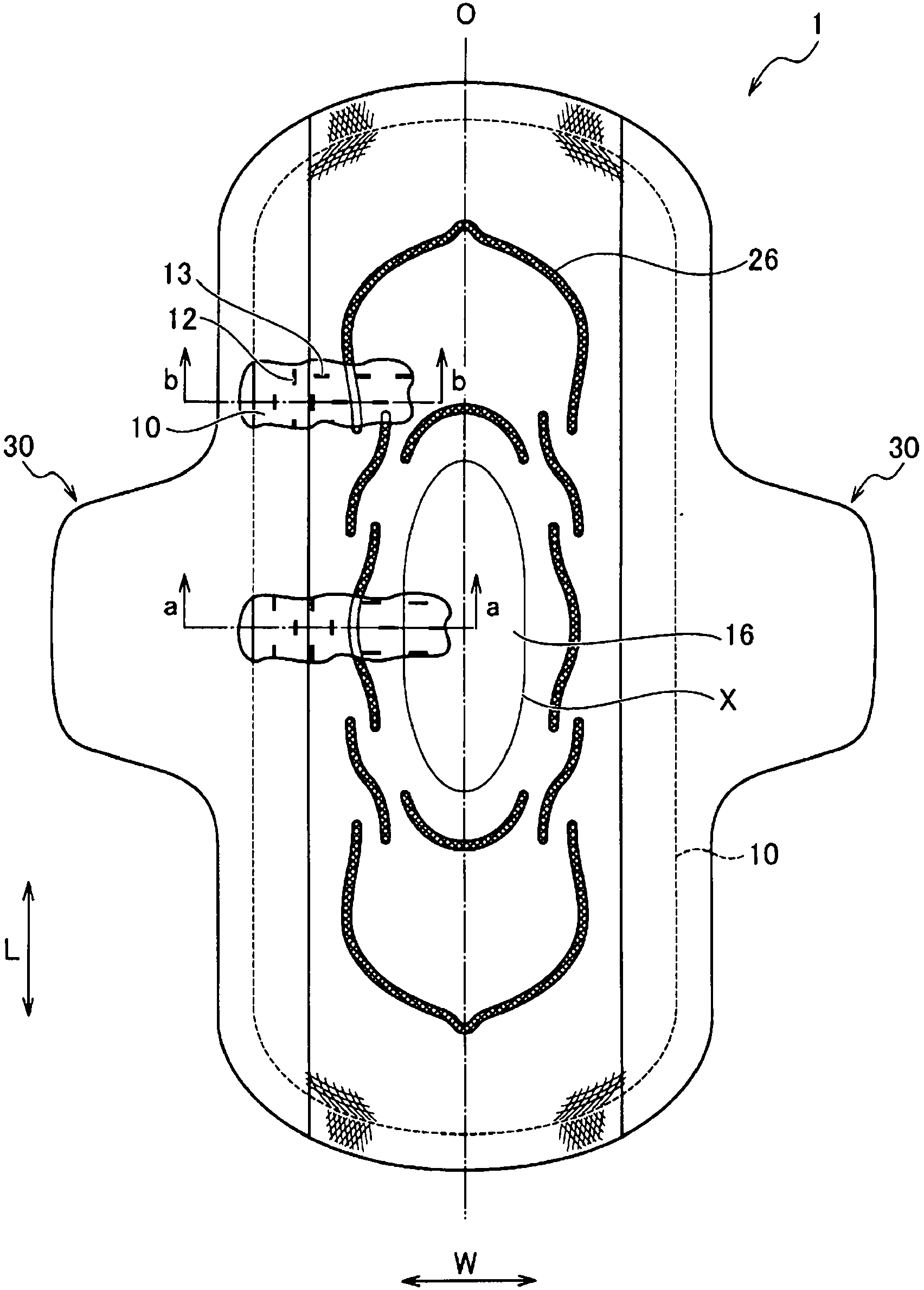

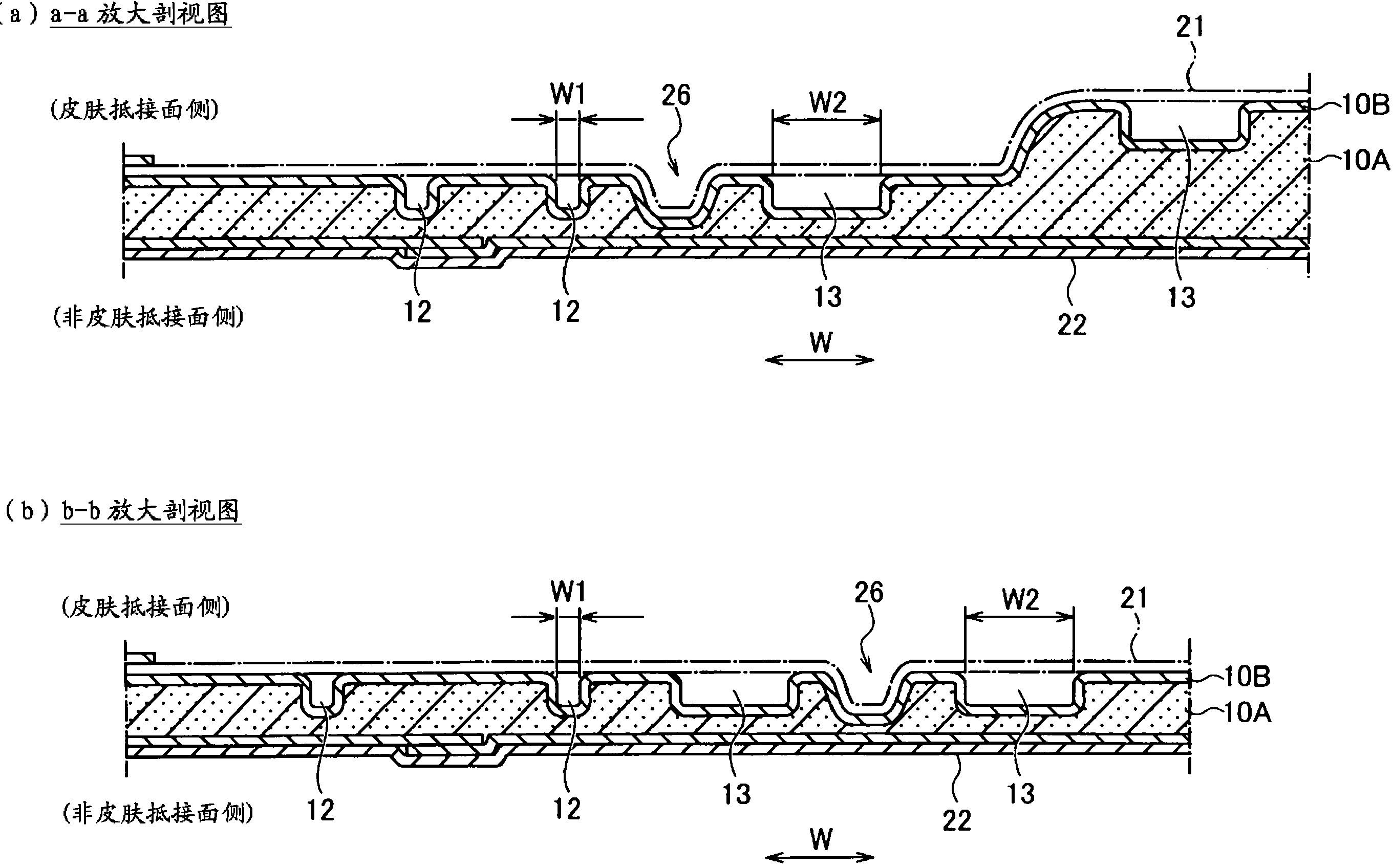

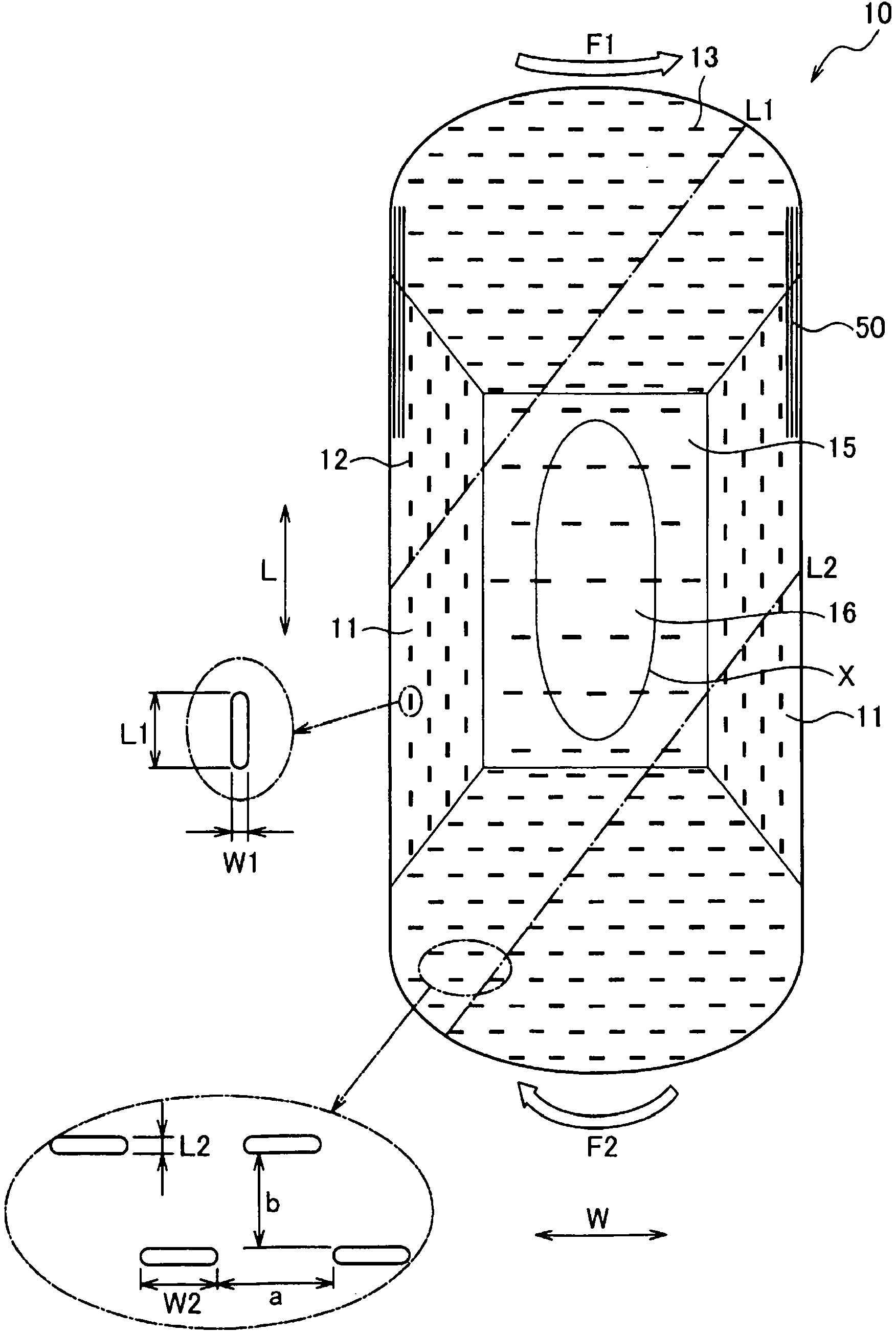

Absorbent article

In this absorbent article (1) which has been made thinner overall while maintaining flexibility and hindering twisting, both edges of the excretion orifice-facing region (15) of the absorber (10) is provided with a plurality of first stamped parts (12) that are provided with spaces therebetween. Over all of the areas of the absorber (10) other than the regions (11) where the first stamped parts (12) are provided, a plurality of second stamped parts (13) are provided with spaces therebetween. The plan view shape of the first stamped parts (12) is configured so that the dimension (L1) along the longitudinal direction of the absorbent article (1) is longer than the dimension (W1) along the width direction of the absorbent article (1). The plan view shape of the second stamped parts (13) is configured so that the dimension (W2) along the width direction of the absorbent article (1) is longer than the dimension (L2) along the longitudinal direction of the absorbent article (1).

Owner:UNI CHARM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com