Patents

Literature

13958 results about "Flame resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of improving surface flame resistnace of substrate

InactiveUS20080105276A1Improve flame retardant performanceSurface cleaningElectrostatic cleaningChemical vapor deposition coatingPlasma ignitionAtmosphere

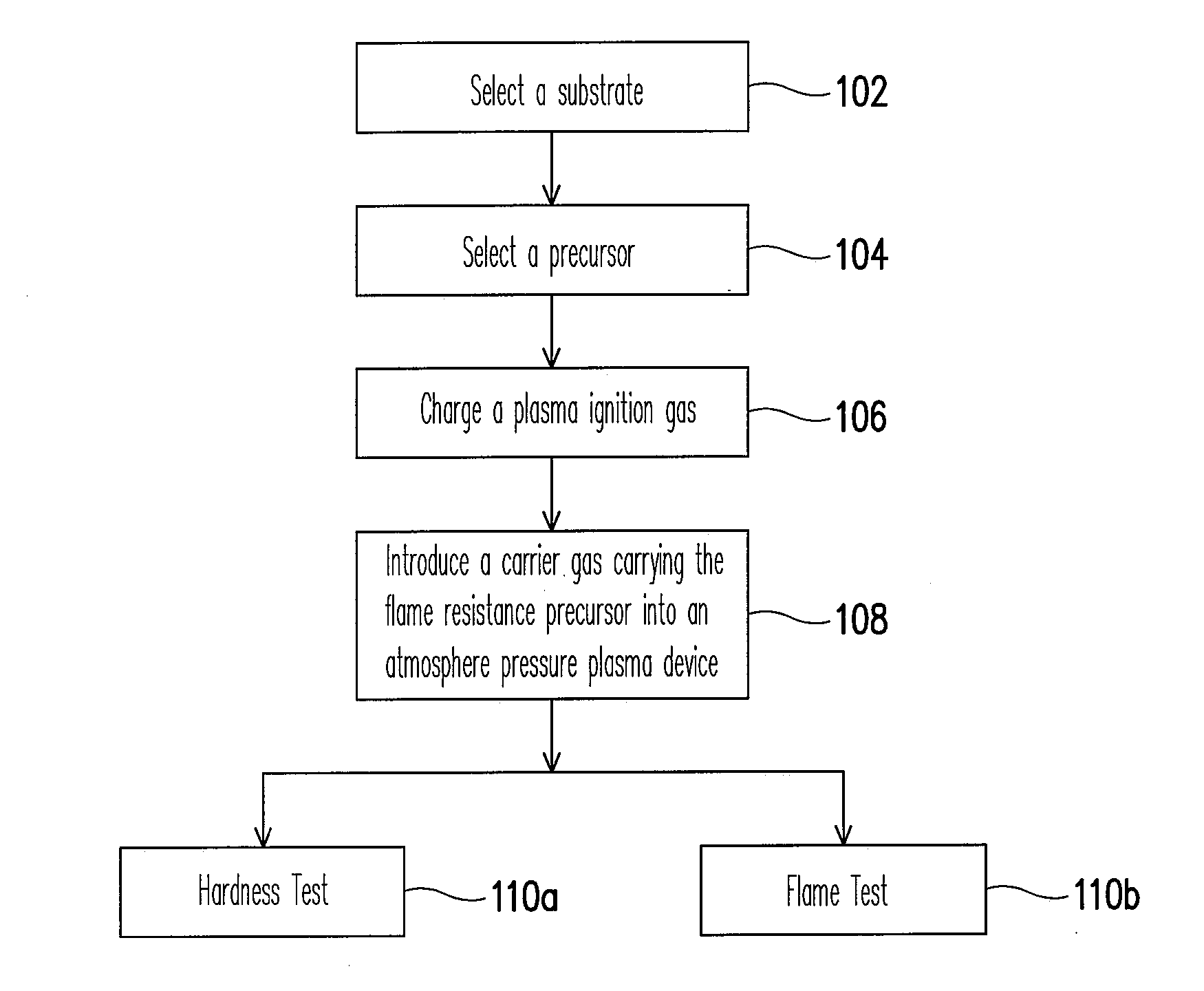

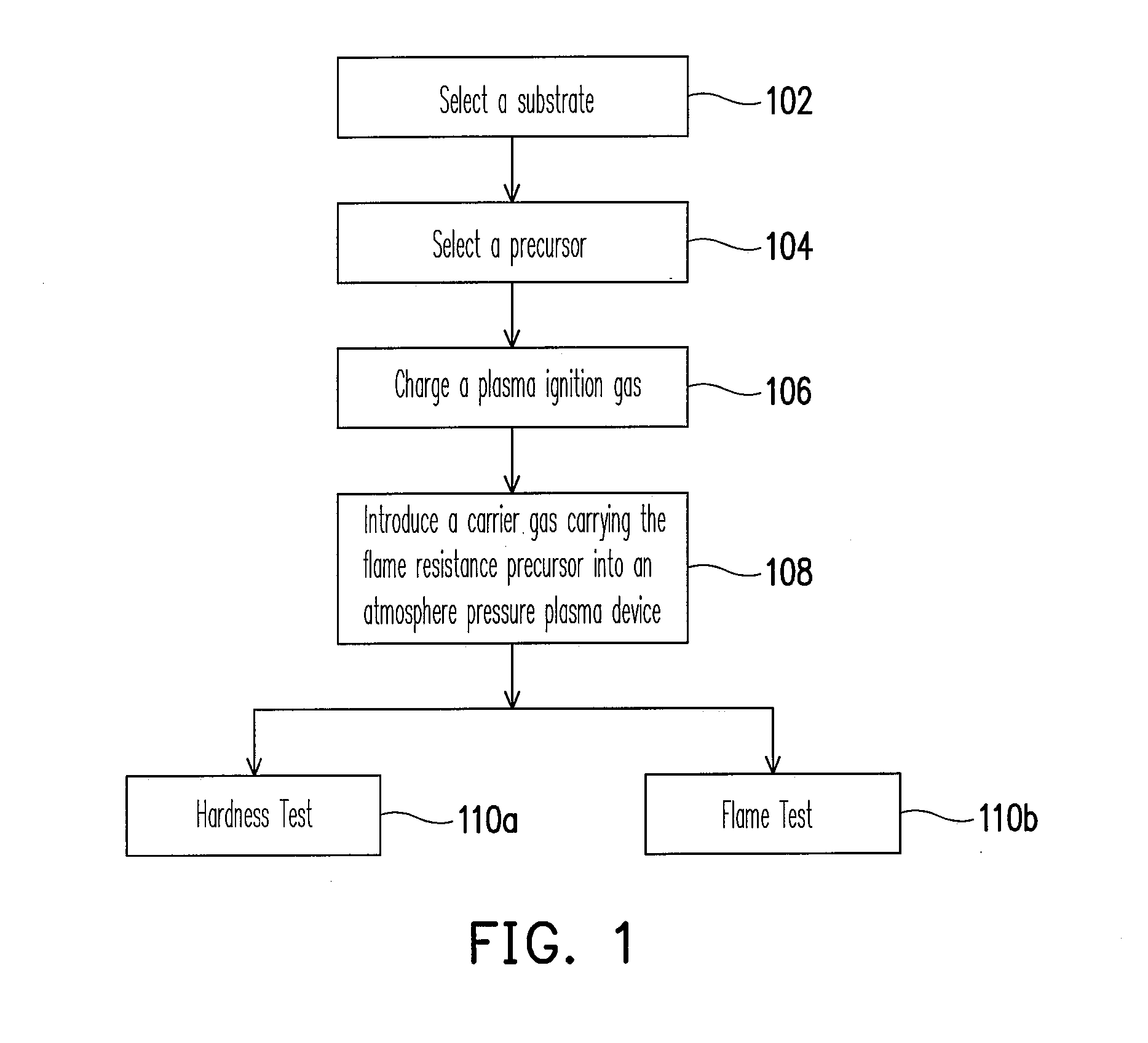

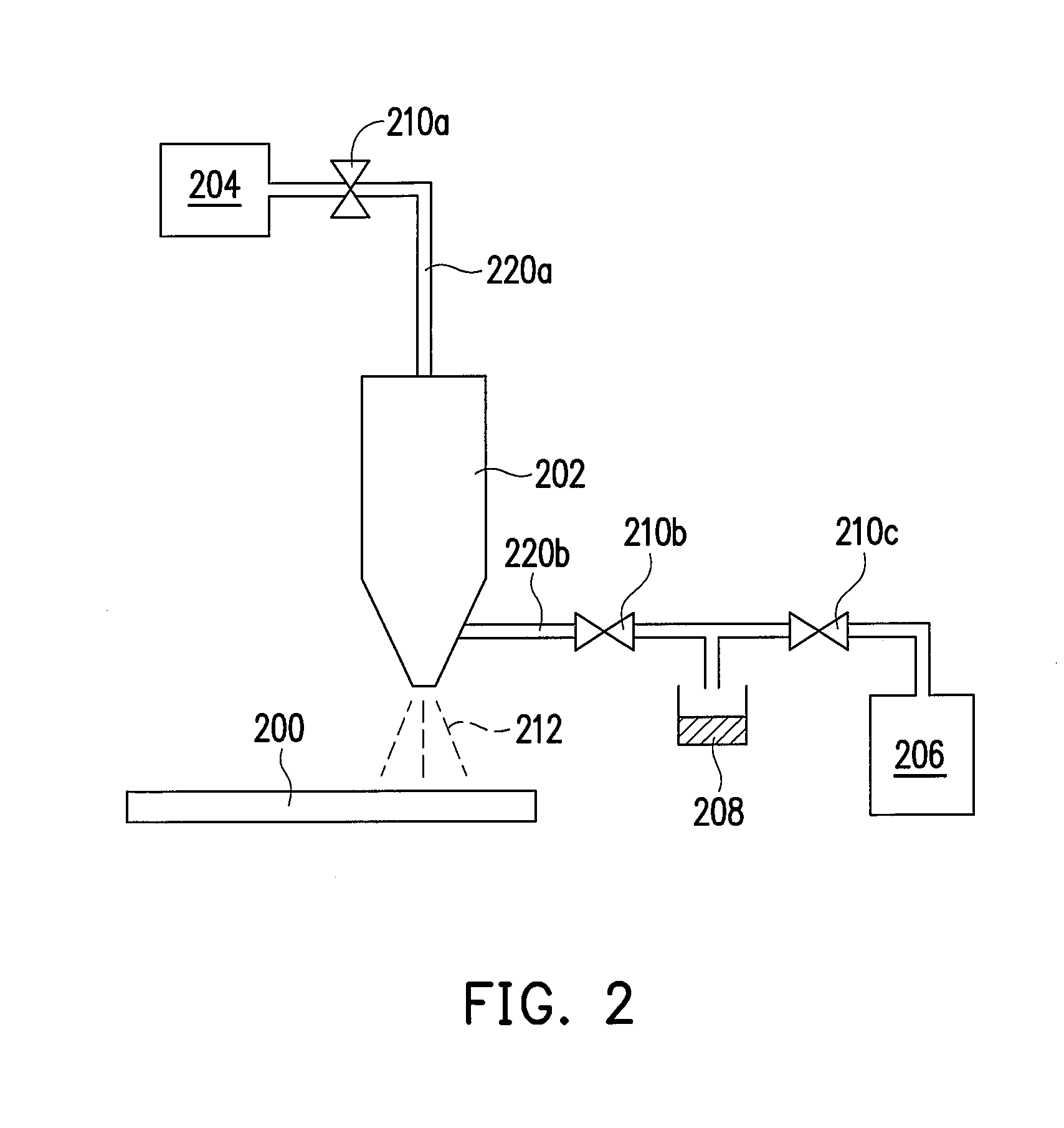

A method of improving surface flame resistance of a substrate is provided. A substrate is provided. An atmosphere pressure plasma process is performed on the surface of the substrate to form an inorganic film layer on the surface of the substrate, wherein a process gas of the atmosphere plasma process includes a flame resistance precursor, a carrier gas, and a plasma ignition gas. Particularly, the flame resistance precursor is selected from a siloxane compound, an inorganic alkoxide compound and a combination thereof. The siloxane compound has a formula of Si(OCnH2(n+1))4, n=1˜5, and the inorganic alkoxide compound has a formula of A(OCmH2m+1)4, where A represents Sn, Ti, Zr, Ce and m=2.

Owner:IND TECH RES INST

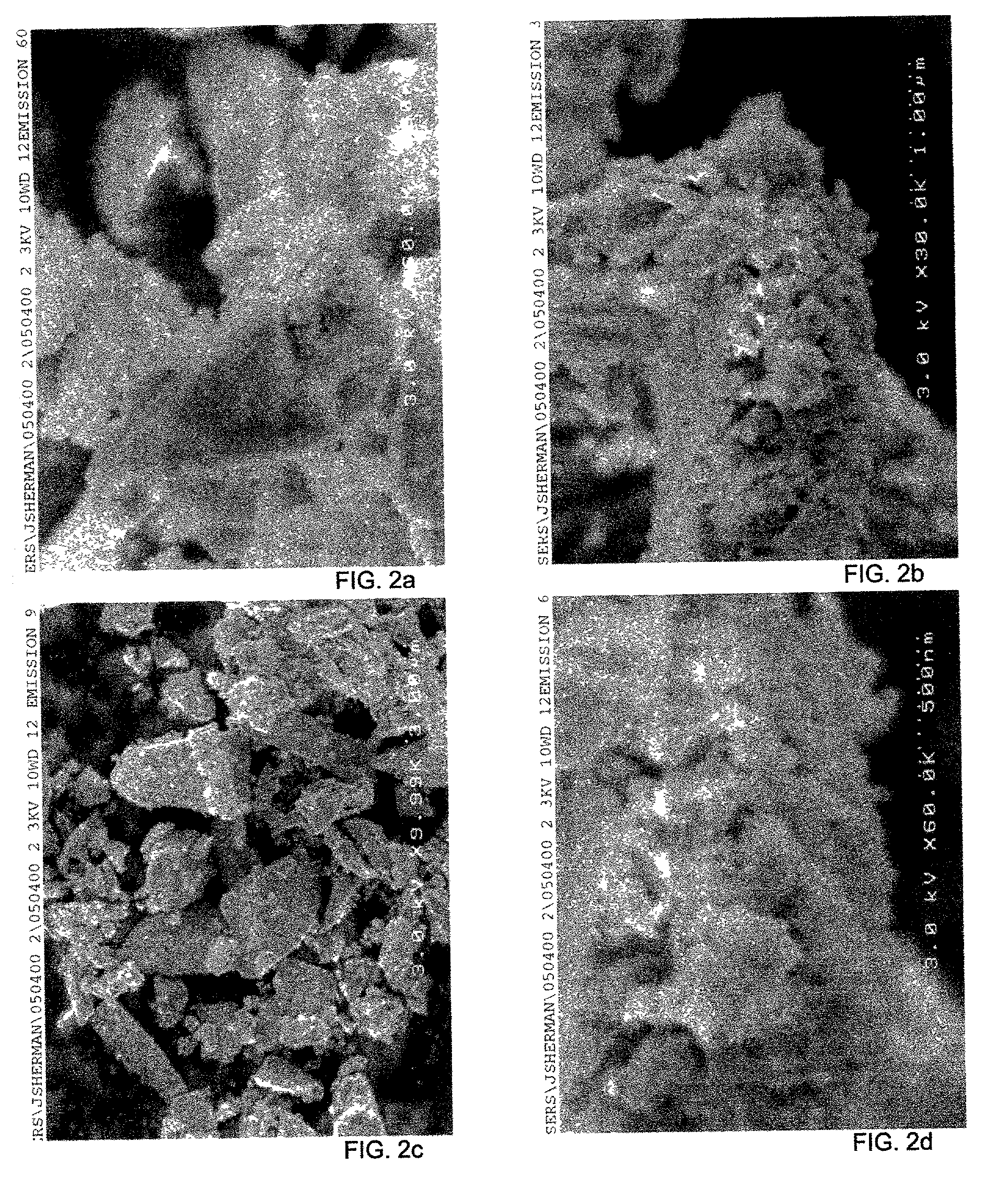

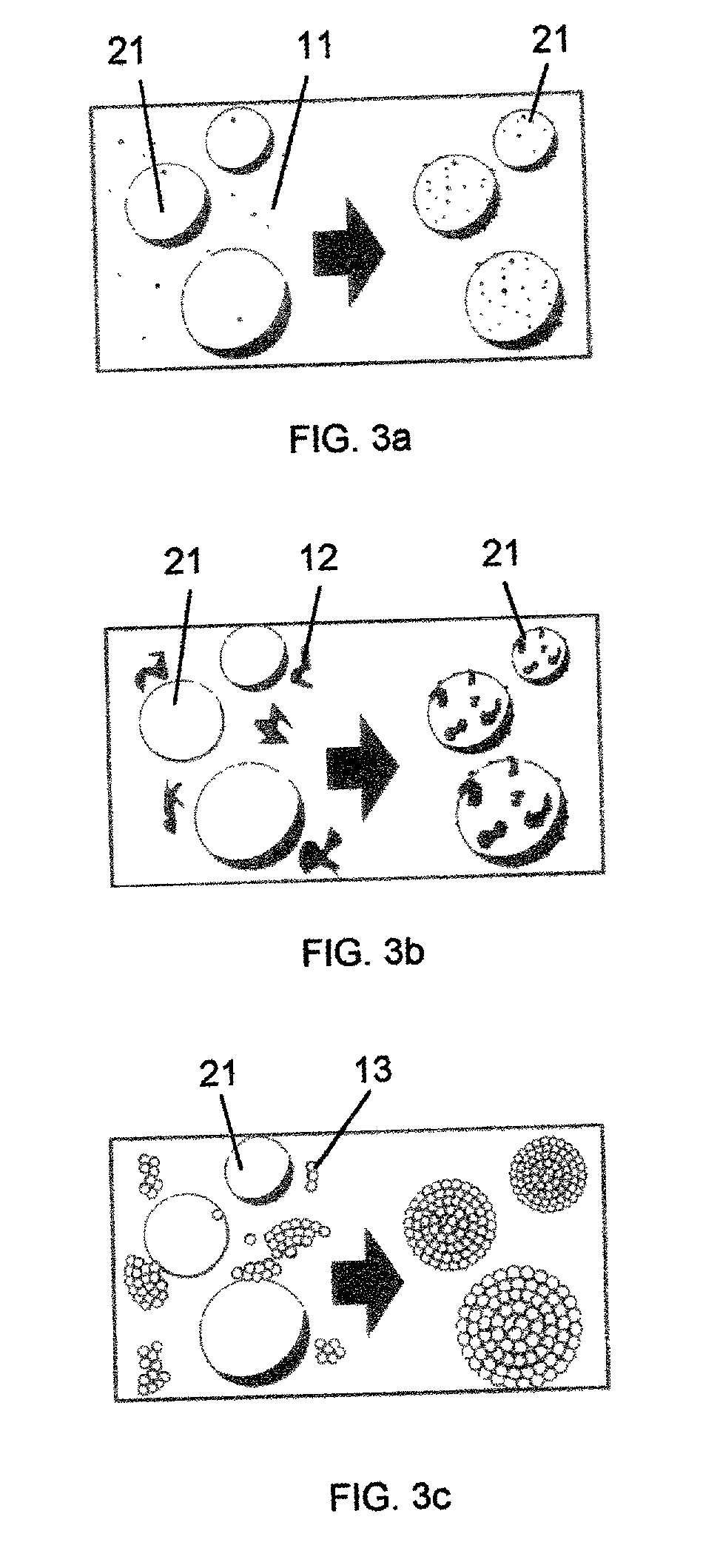

Nanoparticulate titanium dioxide coatings, and processes for the production and use thereof

Nanoparticulate titanium dioxide coating produced by educing flocculates of titanium dioxide nanoparticles from a titanyl sulfate solution and dispersing the nanoparticles in a polar sol-forming medium to make a sol suitable as a coating usable to impart photocatalytic activity, U.V. screening properties, and fire retardency to particles and to surfaces. The photocatalytic material and activity is preferably localized in dispersed concentrated nanoparticles, spots or islands both to save costs and leverage anti-microbial effects.

Owner:SHERMAN JONATHAN

Polyester compositions for calendering

Polyester compositions that provide a higher throughput in calendering processes may be prepared from a polyester having crystallization half time of at least 5 minutes, an inherent viscosity of about 0.55 to about 0.75 dL / g, a branching monomer, and a release additive. The polyester compositions show a combination of excellent melt strength with good shear response that permits higher calendering line speeds before melt fracture occurs. Also disclosed are processes for film or sheet by calendering the above compositions and the film or sheet produced therefrom. The polyester compositions, film, or sheet also may include plasticizers and / or flame retardants to increase their flexibility and enable their use in commercial applications requiring flame resistance. The film and sheet have excellent appearance and can be used in a wide range of decorative and packaging applications.

Owner:EASTMAN CHEM CO

Continuous long fiber reinforced fire-retardant thermoplastic resin and its prepn

ActiveCN1810862ASimple recipeSimple process controlLong-fiber-reinforced thermoplasticPolymer chemistry

The present invention discloses one kind of continuous long fiber reinforced fire-retardant thermoplastic resin and its preparation process. It is prepared through mixing continuous long fiber reinforced thermoplastic resin agglomerate, which has reinforcing fiber content of 30-80 wt% and agglomerate length of 3-30 mm, and fire-retardant agglomerate, which has thermoplastic resin as carrier, fire retardant in 20-60 wt%, fire-retarding synergist 5-20 wt% and other additive 0-5 wt%. The continuous long fiber reinforced fire-retardant thermoplastic resin has continuous long fiber content of 5-60 wt%. The continuous long fiber reinforced fire-retardant thermoplastic resin has excellent mechanical performance, especially impact resistance, and excellent fire-retarding performance.

Owner:KINGFA SCI & TECH CO LTD +1

Polyester blends with improved stress whitening for film and sheet applications

Disclosed are polyester blends that provide improved stress whitening behavior. The blends may be prepared from a polyester having crystallization half-time of at least 5 minutes and a polyester elastomer. The polyesters blends may be extruded or, in the presence of a release additive, calendered to produce film or sheet. Also disclosed are processes for making a film or sheet by extrusion or calendering the above blends and the film or sheet produced therefrom. The polyester blend and the film or sheet produced therefrom also may include plasticizers and / or flame retardants to increase their flexibility and enable their use in commercial applications requiring flame resistance. The film and sheet have excellent appearance and can be used in a wide range of decorative and packaging applications.

Owner:EASTMAN CHEM CO

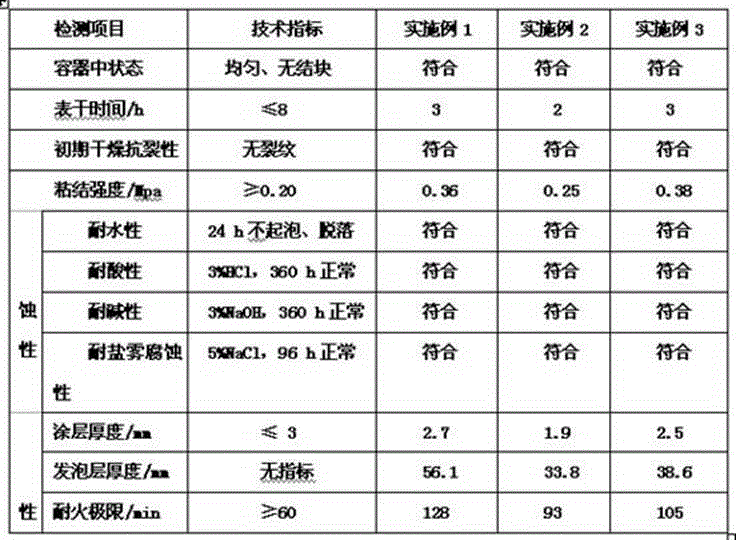

Aqueous fire-proof corrosion-proof paint for steel structure and preparation method thereof

ActiveCN104130638ATaking into account fire resistanceCompatible with anti-corrosionFireproof paintsAnti-corrosive paintsPtru catalystFoaming agent

The invention discloses aqueous fire-proof corrosion-proof paint for a steel structure and a preparation method thereof, and belongs to the technical field of paint. The aqueous fire-proof corrosion-proof paint comprises, by mass, 20-45% of a composite emulsion, 12-25% of a charring catalyst, 6-12% of a foaming agent, 8-17% of a charring agent, 5-10% of a fire retardant, 1-5% of layered double hydroxide, 8-18% of an corrosion-proof filling material, 4-12% of a strengthening filling material, 1-5% of modified nano-powder, 0.5-6% of an assistant and 10-30% of water. Through use of the composite modified emulsion as a base material, coating flame resistance, corrosion resistance and decorativeness are obtained and coating defects caused by a single emulsion as a base material are overcome. Through use of a small amount of the nano-powder, the coating is compact because of filling effects of the nano-powder, the coating corrosion caused by O2, H2O and Cl <-> is avoided, good fire-proof and corrosion-proof effects are obtained under the condition of a small addition amount and a cost is reduced. The aqueous fire-proof corrosion-proof paint has the characteristics of green environmental protection and simple preparation processes.

Owner:山东七维新材料有限公司

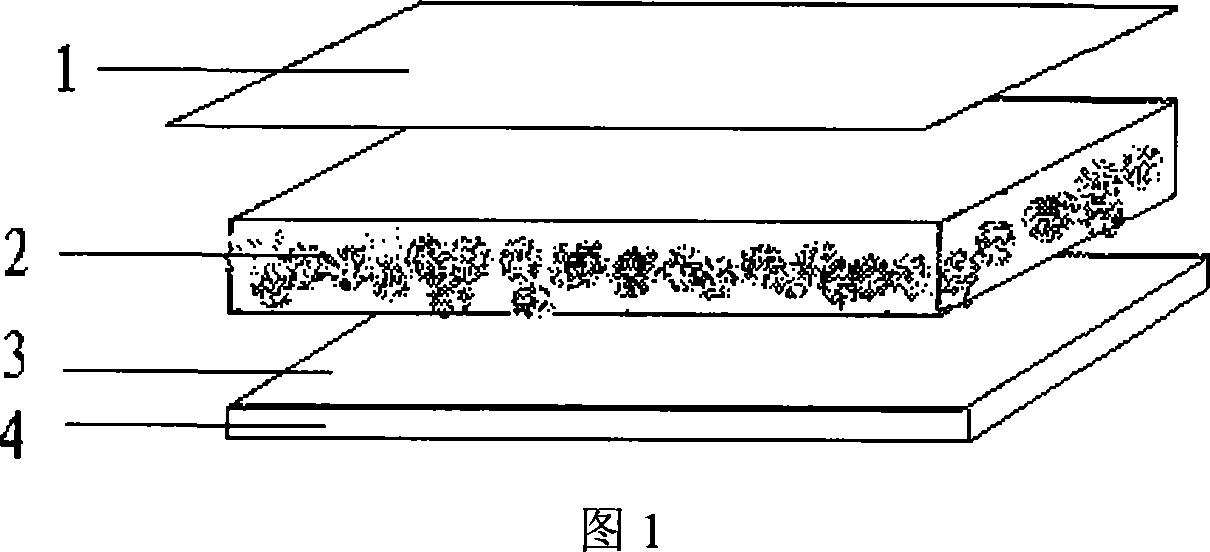

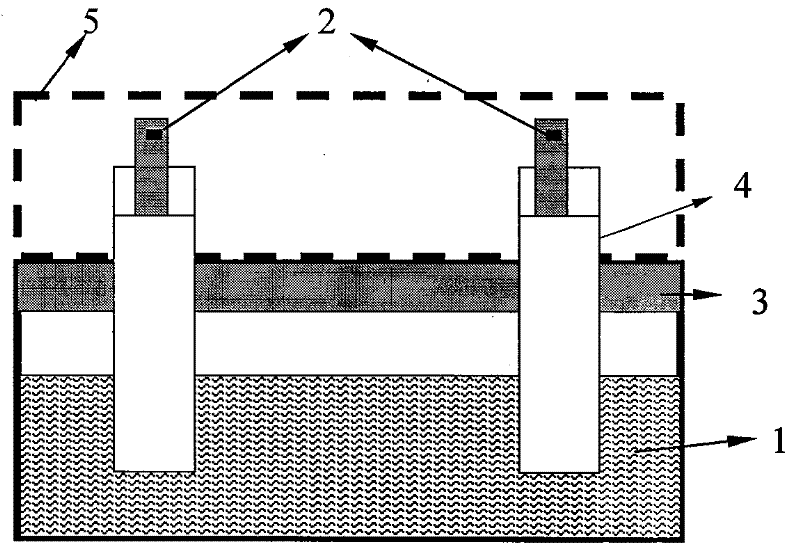

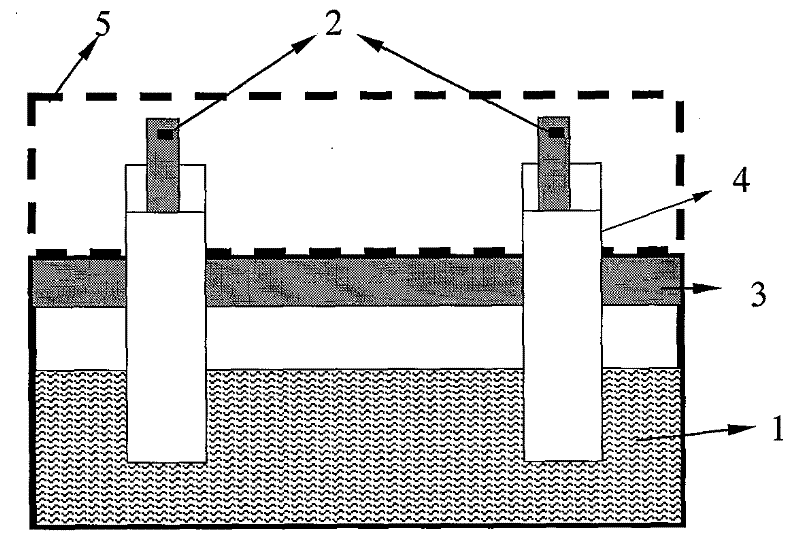

Polyurethane composite thermal insulation board, manufacturing method and application of the same

InactiveCN101220614AImprove thermal insulation performanceImprove fire and flame retardant performanceCovering/liningsLaminationProduction lineAlcohol

The invention provides a polyurethane compound heated board and a manufacturing method and application, which relates to a heated board and supplies a polyurethane compound heated board that has good heat-insulating effect, high fire-fighting and flame-retardant performance, convenient using performance and high constructing efficiency and the manufacturing method and the application. The invention includes a polyurethane rigid foam insulating layer, a bonding layer and an inorganic material composite board; the bonding layer is arranged between the polyurethane rigid foam insulating layer and the inorganic material composite board; the thickness of the polyurethane rigid foam insulating layer is 20-80mm and the thickness of the inorganic material composite plate is 3-10mm. The inorganic material composite board can be continuously produced for further use; an adhesive treatment agent is coated on the inorganic material composite board; polyhydric alcohol combination material and isocyanate combination material are added into the continuous production line for mixed foaming and curing to obtain the polyurethane compound heated board; the mass ratio of the polyhydric alcohol combination material and the isocyanate is 100:95-160.

Owner:厦门高特高新材料有限公司

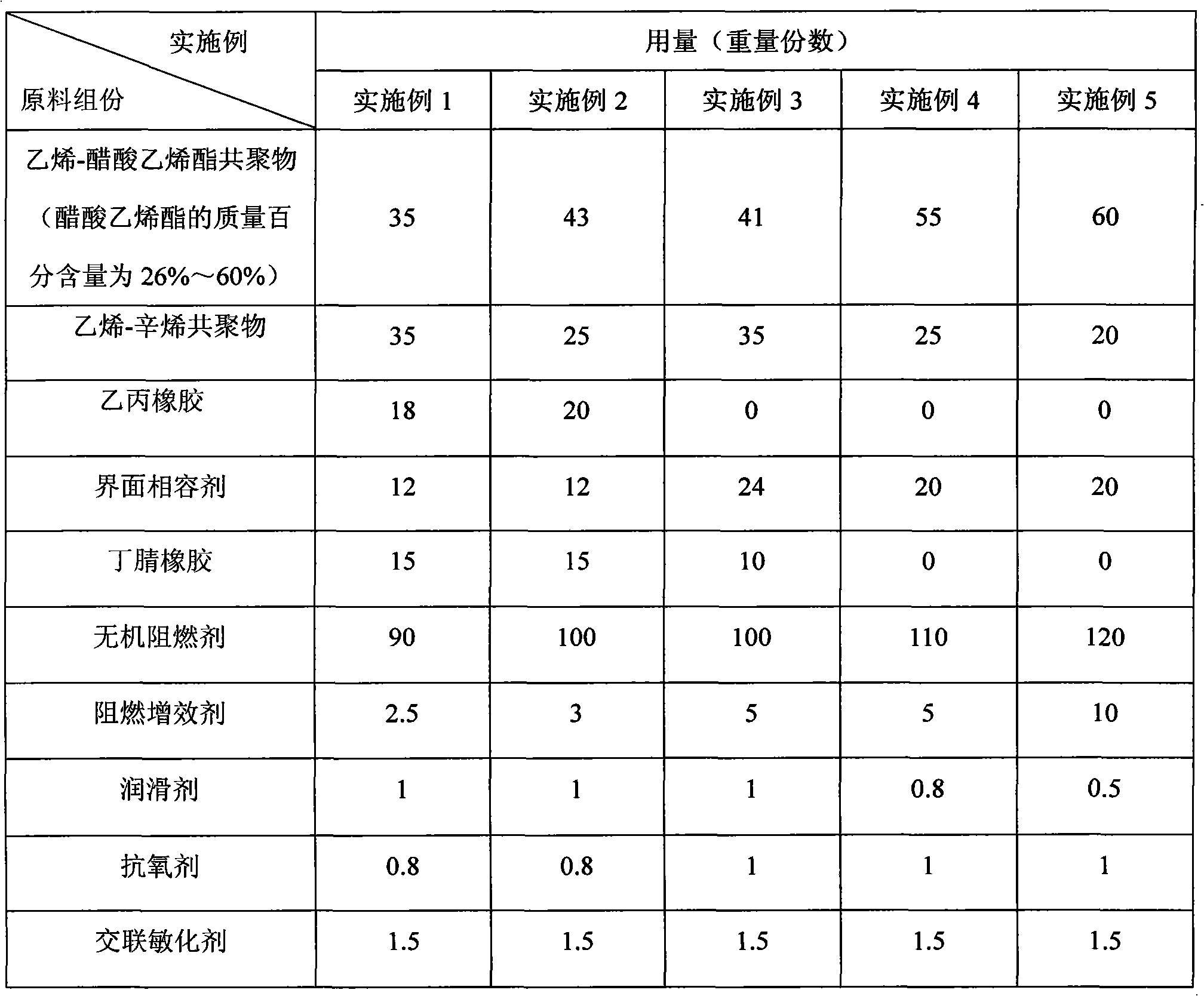

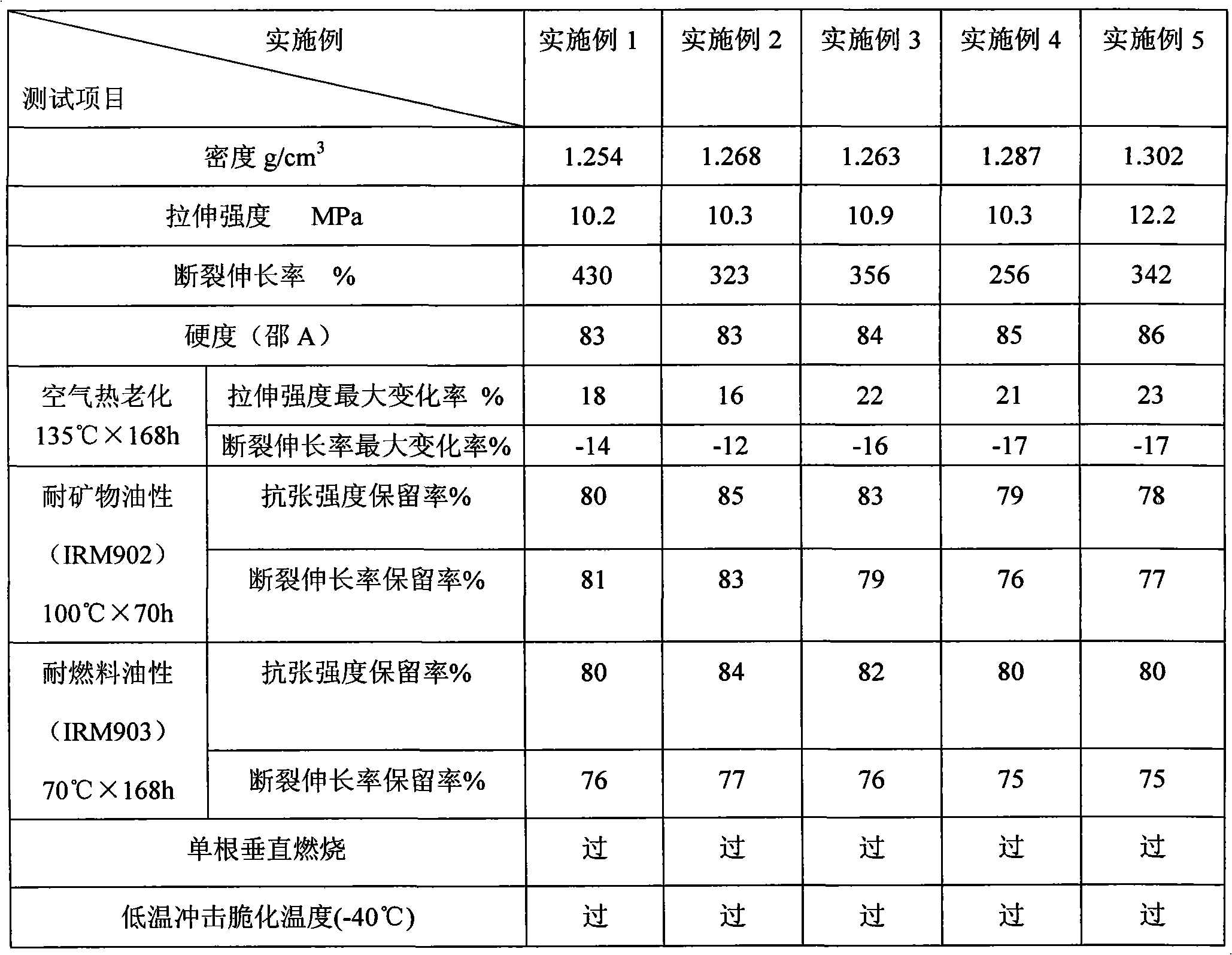

Irradiation cross-linking oil resistance type soft low smoke zero halogen flame-retardant cable material

ActiveCN102070821AGood oil resistanceGood flexibilityPlastic/resin/waxes insulatorsCross-linkSilanes

The invention provides an irradiation cross-linking oil resistance type soft low smoke zero halogen flame-retardant cable material which comprises the following components in parts by weight: 60-90 parts of ethylene-vinylacetate copolymer, ethylene-propylene-diene rubber and ethylene-octylene copolymer, 0-20 parts of nitrile rubber, 10-30 parts of interface compatilizer, 80-130 parts of flame retardant, 2-15 parts of flame-retardant synergist, 0.5-1.0 part of antioxidant, 1-2 parts of cross-linking sensitizing agent and 0.5-1.0 part of lubricant. The preparation method of the cable material in the invention mainly comprises the steps of silane surface modification treatment of the flame retardant, mixing and extruding of a double screw mixer-extruder unit or an internal mixer unit, brace water cooling or water ring particle cutting and the like. The cable material provided by the invention has the advantages of superior flame resistance (single cable can vertically burn), good mechanical properties, especially high softness, oil resistance, high-temperature resistance (the cable material can be used in a range of minus 40 DEG C-125 DEG C), low smoke, low toxicity and excellent processability.

Owner:JIANGSU DEWEI ADVANCED MATERIALS

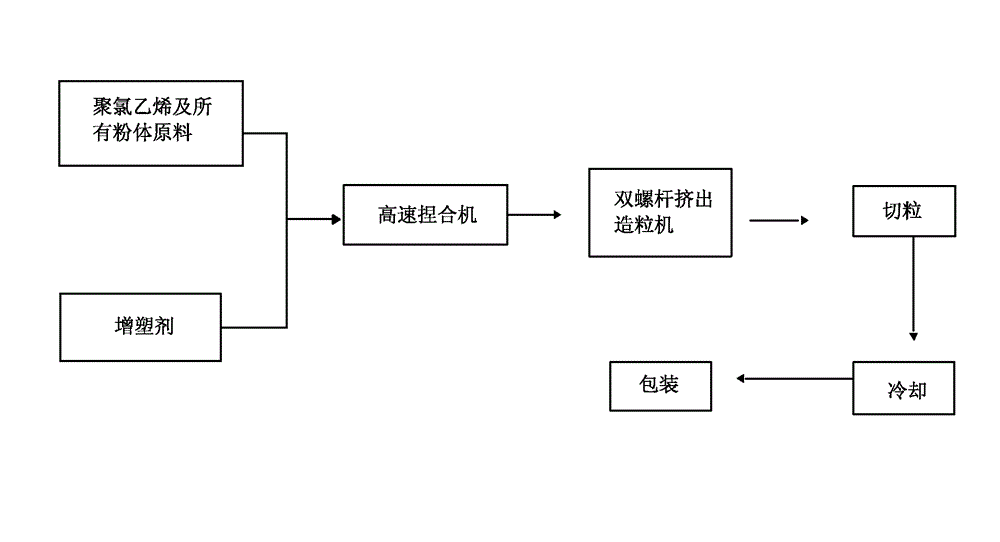

Wear-resisting flame-retardant polyvinyl chloride insulation and sheathing materials

ActiveCN102719040AImprove wear resistanceExcellent squeeze performancePlastic/resin/waxes insulatorsInsulated cablesPolymer sciencePlasticizer

The invention relates to insulation materials and sheathing materials, and in particular relates to a wear-resisting flame-retardant polyvinyl chloride insulation and sheathing material. The wear-resisting flame-retardant polyvinyl chloride insulation and sheathing material comprises the following raw materials in parts by weight: 100 parts of polyvinyl chloride resin, 40 to 60 parts of plasticizer, 6 to 30 parts of wearable modifying agent, 4 to 8 parts of stabilizing agent, 4 to 32 parts of fire retardant, 10 to 40 parts of filling agent, and 0.8 to 3 part(s) of lubricating agent. The insulating and sheathing material has good wear-resisting and flame-retardant properties, high squeezing performance, high rolling performance and high flexing performance, as well as high flexibility and processability.

Owner:SUZHOU SILVER AGE TECH CO LTD

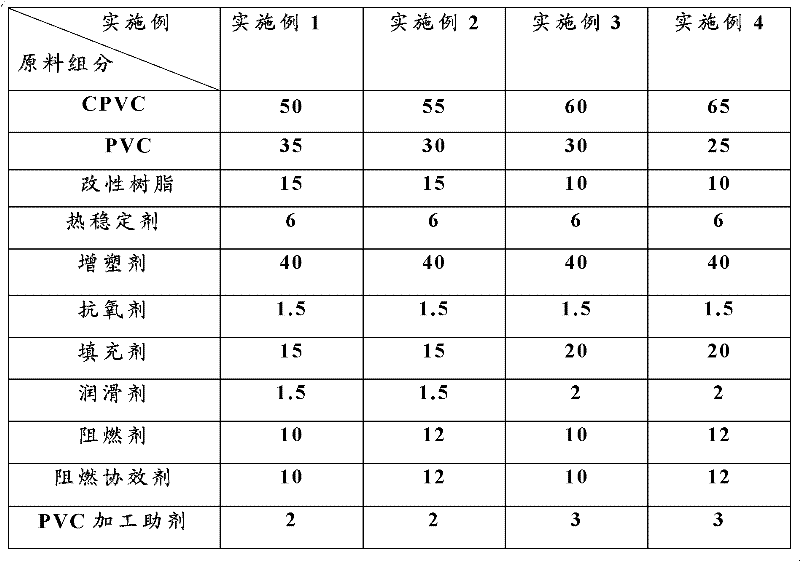

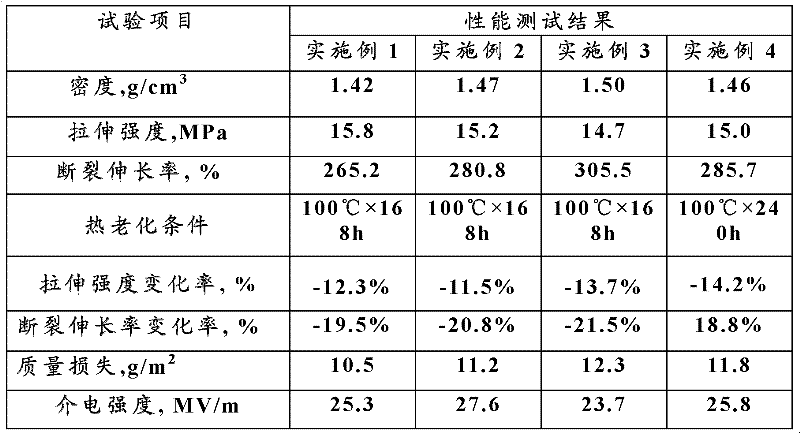

Chlorinated polrvinyl chloride modified material as well as preparation method and application thereof

ActiveCN102532763AGood physical and mechanical propertiesImprove brittlenessInsulated cablesInsulated conductorsAntioxidantShock resistance

The invention relates to a chlorinated polrvinyl chloride modified material as well as a preparation method and application thereof. The raw material formula of the chlorinated polrvinyl chloride modified material comprises the following components in parts by weight: 40-90 parts of chlorinated polrvinyl chloride, 20-70 parts of polrvinyl chloride, 5-30 parts of modified resin, 1.5-10 parts of heat stabilizing agent, 20-60 parts of plasticizer, 1-10 parts of antioxidant, 1-10 parts of lubricating agent, 5-40 parts of filling agent, 8-40 parts of fire retardant, 8-40 parts of flame retardant synergist and 1-20 parts of polrvinyl chloride processing aid. Compared with the known CPVC (chlorinated polrvinyl chloride) modified plastic, the CPVC modified plastic disclosed by the invention is more excellent in physical and mechanical properties and is relatively reduced in cost; and compared with the known CPVC modified plastic, the CPVC modified material disclosed by the invention is obviously improved in heat resistance and flame retardant property (oxygen index can reach about 45%, and simple root of CPVC modified material can be vertically burnt) besides more excellent processabilityand obviously improved material brittleness and shock resistance. Thus, the CPVC modified material disclosed by the invention is suitable for being used as a wire and cable sheath material.

Owner:JIANGSU DEWEI ADVANCED MATERIALS

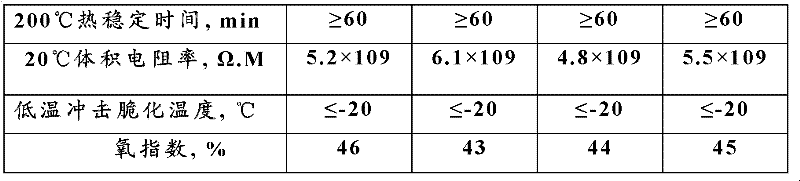

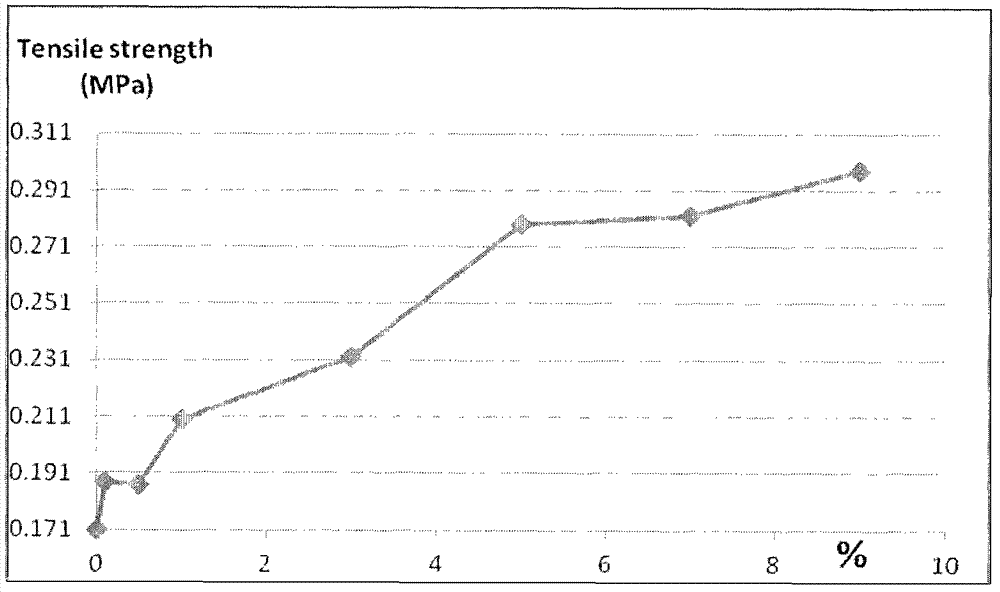

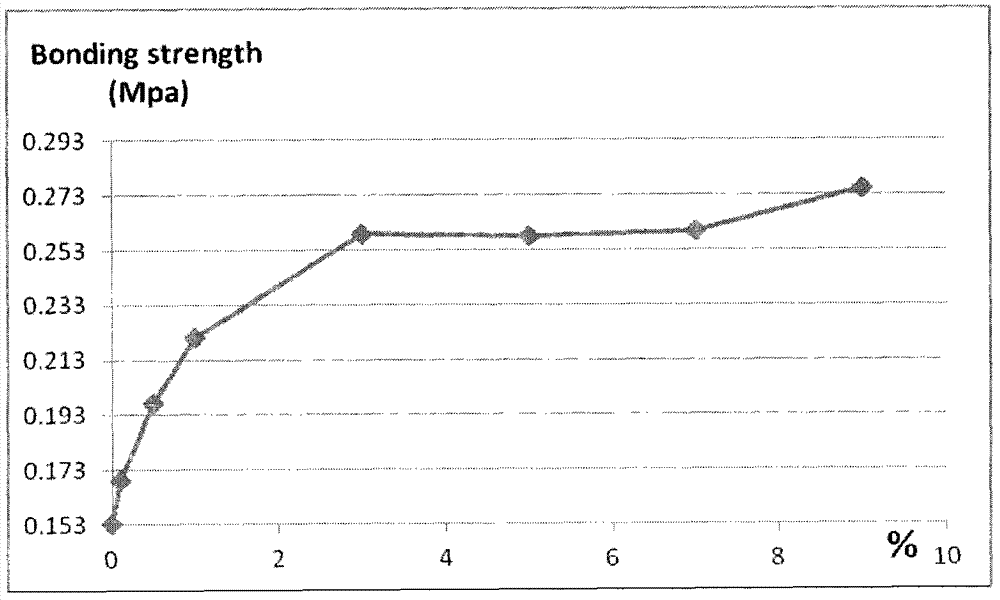

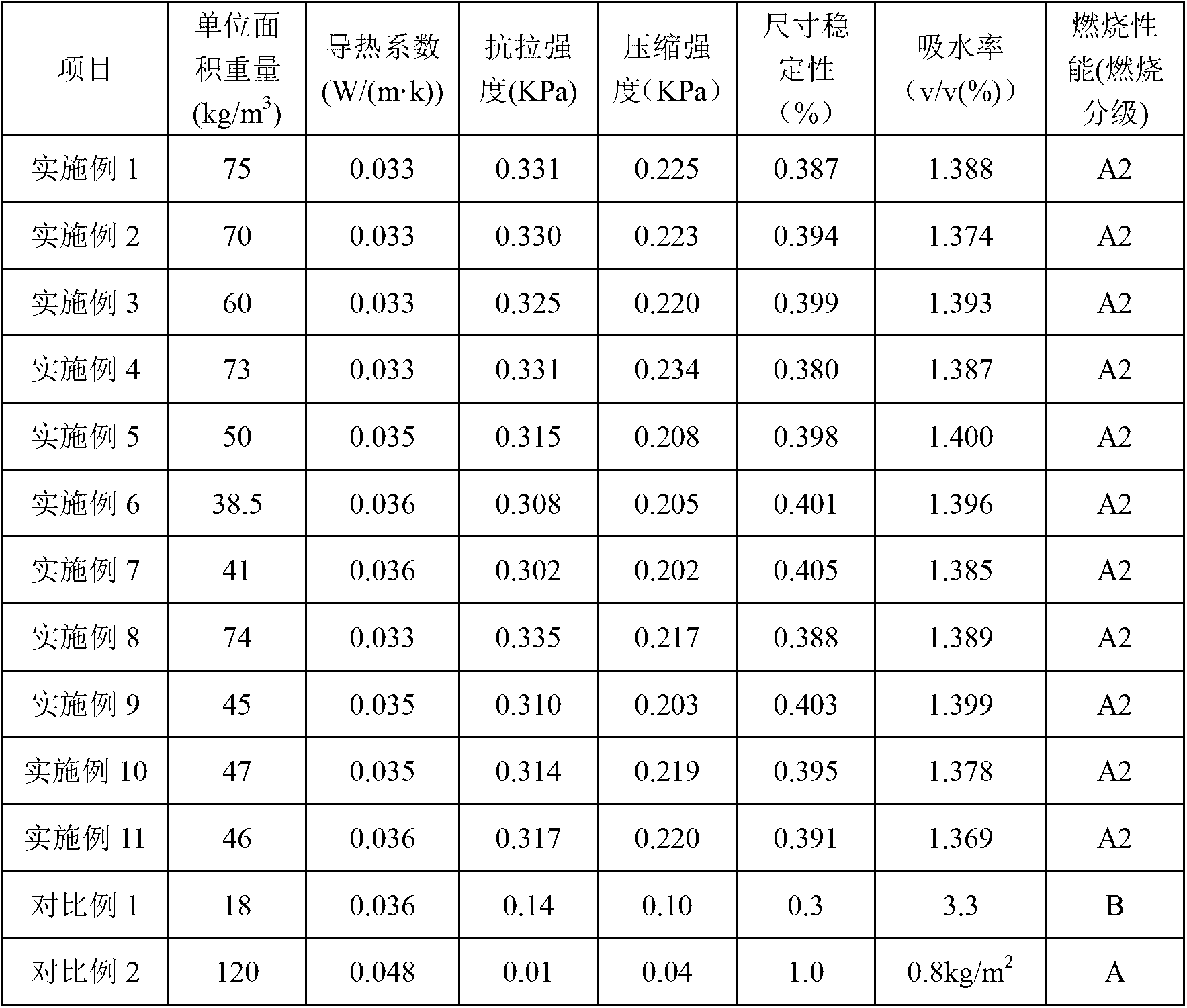

Nano-material-containing high-strength high-heat insulation exterior wall inorganic heat-retaining face brick

The invention belongs to the field of building materials, relates to a use of a nano-material in a building exterior wall heat-retaining system and provides a nano-material-containing high-strength high-heat insulation exterior wall inorganic heat-retaining face brick. The nano-material-containing high-strength high-heat insulation exterior wall inorganic heat-retaining face brick is characterized in that nano-particles are used so that compressive strength, tensile strength and bonding strength are improved. The nano-material-containing high-strength high-heat insulation exterior wall inorganic heat-retaining face brick is prepared by adding a nano-material having a nanoscale particle size into a mixed system of cement, an auxiliary gel material, a polymer binder, an inorganic light heat-retaining material, fibers and water, uniformly mixing, carrying out pressing molding of the mixture, carrying out organic polymer crosslinking and cement hydration drying, and carrying out waterproof layer coating. The nano-material-containing high-strength high-heat insulation exterior wall inorganic heat-retaining face brick has the advantages of excellent flame resistance, high compressive strength, high tensile strength, high bonding strength and good insulation effects.

Owner:平湖市法而特建筑保温科技有限公司

Organoclay/polymer compositions with flame retardant properties

InactiveUS6610770B1Cheap to makeIncrease risk of ignitionSilicon compoundsOrganoclayPolymer chemistry

The present invention is directed to polymer compositions with flame retardant properties that are made from a polymer blended using a defined process with a smectite clay that has been reacted with a specified mixture of organic materials.The inventive compositions have the property that when the organically modified clay is added to the polymer, a composite results which has flame-retardant properties and is based on the finding that degree of dispersion of a smectite organoclay in a polymer matrix will give the compositions flame-retardant properties. Further, it has been found that it is very important to proper functioning of the flame retardant polymer compositions that they have the organoclay dispersed in the polymer such that it is not completely exfoliated.

Owner:ELEMENTIS SPECIALTIES INC

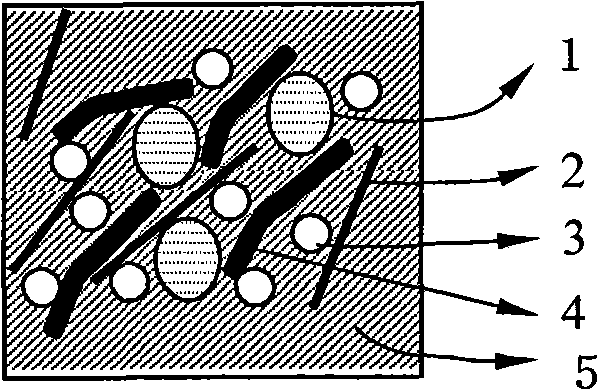

Composite polystyrene heat insulation material and preparation method of heat insulation board

InactiveCN103059435AImprove fire and flame retardant performanceLow thermal conductivityCombustionThermal insulation

The invention discloses a fireproof and flame-retardant composite polystyrene heat insulation material and a method for preparing a heat insulation board by using the material, which belongs to the technical field of the heat insulation boards. The composite heat insulation board combining an inorganic heat insulation material and an organic heat insulation material has the characteristics of fireproof property, heat insulation, flame-retardant property and low heat conductivity of the organic material, so the fireproof and flame-retardant performance of the composite heat insulation material can be improved based on unchanging the heat conductivity of the polystyrene. The method for preparing the composite heat insulation board is simple and easy to operate; each polystyrene granule is covered with a layer of a fireproof and flame-retardant material on the surface, so that each granule forms an integrated and independent unit, thereby effectively interrupting the conduction of the heat and the spread of the flame to achieve a non-combustion effect. The prepared composite polystyrene heat insulation board has the advantages of light weight, low heat conductivity, good heat insulation effect, high tensile strength, good toughness, high size stability, low moisture absorption and good flame resistance, and the combustion performance can be A2 grade (GB8624-2006).

Owner:河南铝城聚能实业有限公司

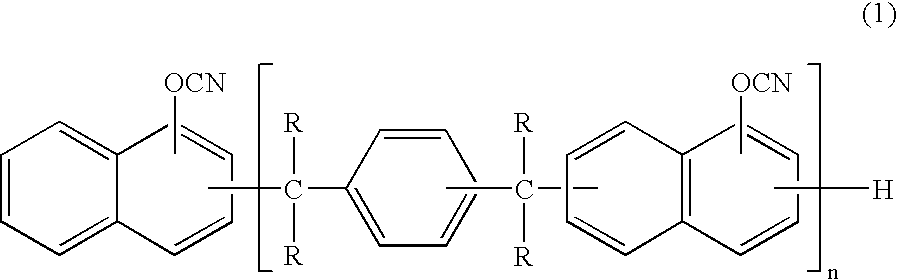

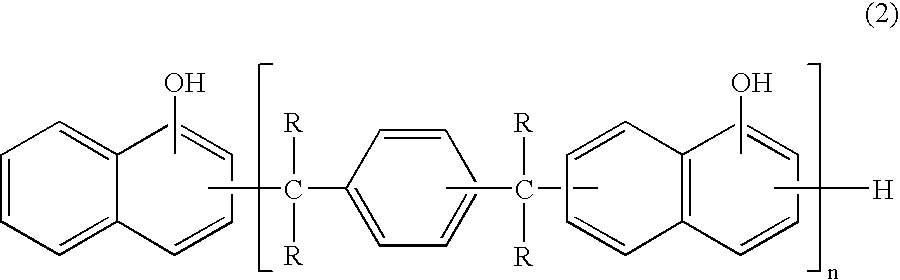

Prepreg and laminate

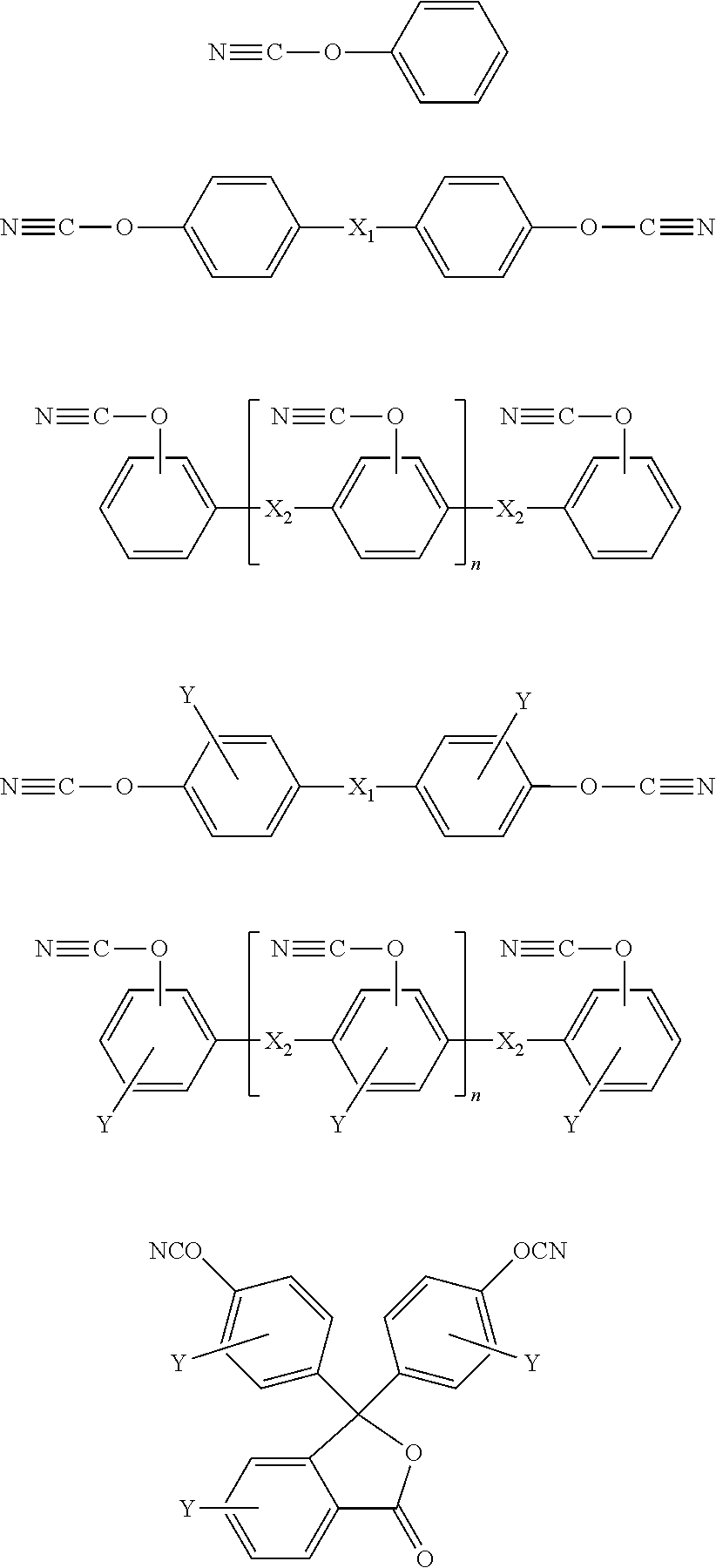

ActiveUS20090017316A1Improve flame retardant performanceImprove heat resistanceSpecial tyresElectrical equipmentThermal dilatationPolymer science

A prepreg for a printed wiring board, comprising a cyanate ester resin having a specific structure, a non-halogen epoxy resin, a silicone rubber powder as a rubber elasticity powder, an inorganic filler and a base material, which prepreg retains heat resistance owing to a stiff resin skeleton structure, has high-degree flame retardancy without the use of a halogen compound or a phosphorus compound as a flame retardant, and has a small thermal expansion coefficient in plane direction without using a large amount of inorganic filler, and a laminate comprising the above prepreg.

Owner:MITSUBISHI GAS CHEM CO INC

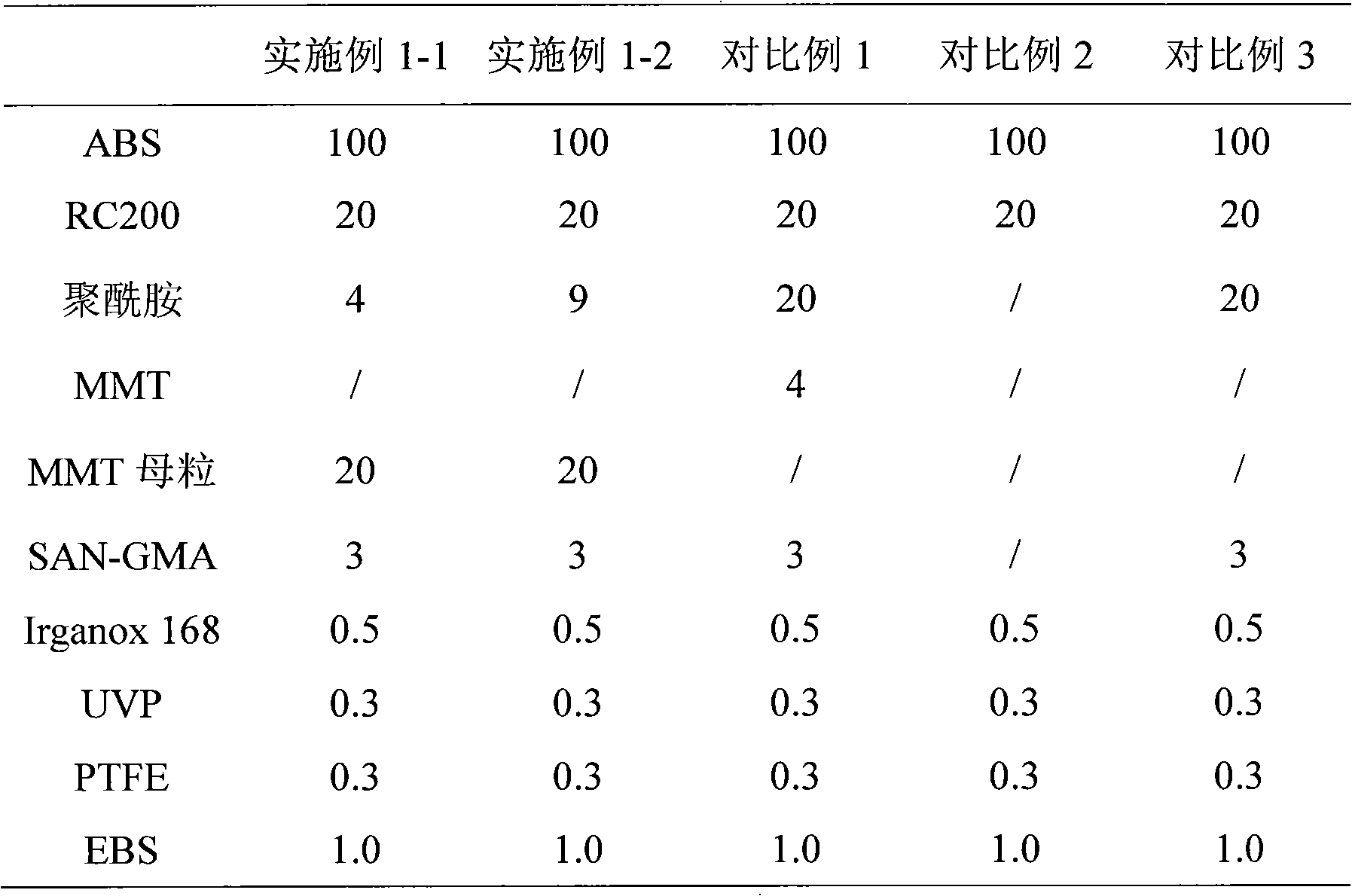

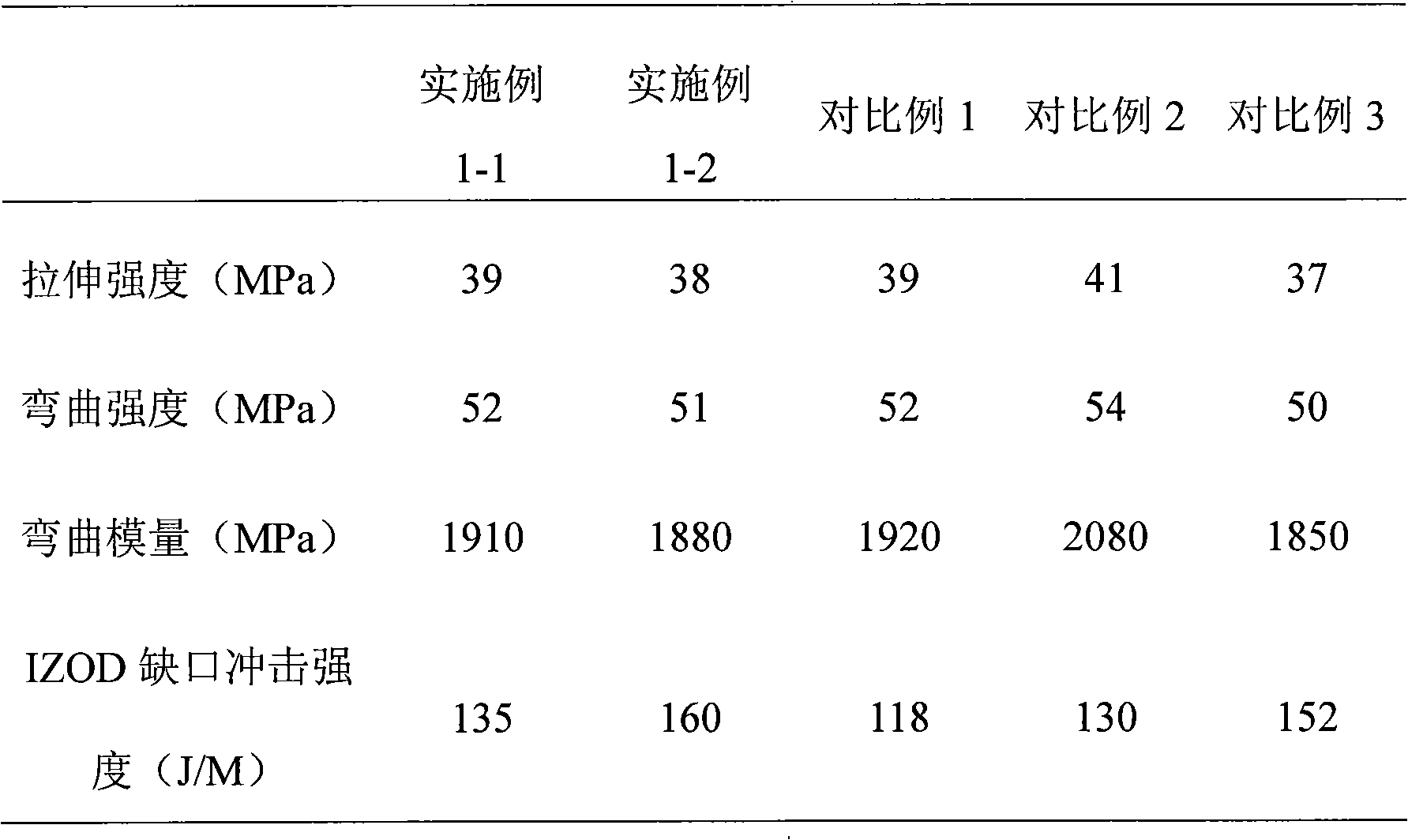

High-performance halogen-free flame retardant ABS modified resin and preparation method thereof

The invention relates to a high-performance halogen-free flame retardant ABS modified resin and a preparation method thereof. The resin comprises the following components with the content (in parts by weight): 100 ABS resin, 4-30 polyamide, 5-25 phosphate fire retardant, 0.1-0.5 anti-drippage agent, 5-10 toughening agent, 1-5 nano filler, 1-5 compatilizer, 0.2-1 antioxidant, 0.1-0.5 light stabilizer and 1-5 processing agent. Compared with the prior art, the invention has reasonable technique, and overcomes the defects of poor flame retardant property and low impact strength of the existing halogen-free flame retardant ABS; and the invention adopts a novel high-efficiency halogen-free flame retardant compounding synergism technology, a novel polyamide coal-forming agent, the high-efficiency synergism between organic and inorganic fire retardants, and the master batch method processing technique, thus endowing the resin with high fire resistance on the basis of improving the original good performances (especially the impact performance) of the ABS resin, and having wide application prospect.

Owner:SHANGHAI KUMHO SUNNY PLASTICS +1

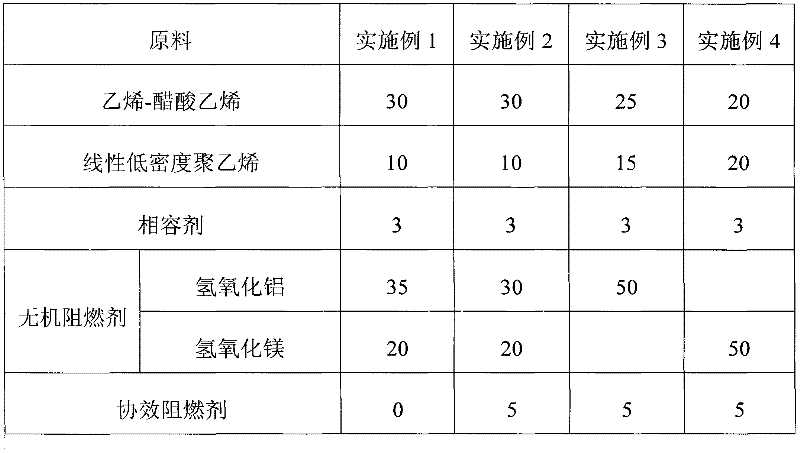

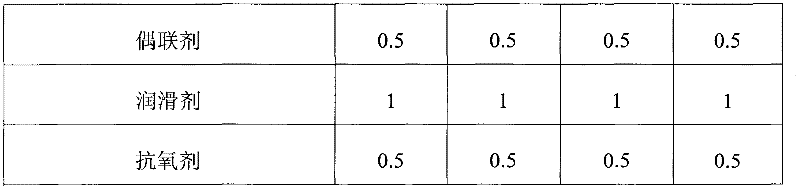

Synergistic flame-retardant low-smoke halogen-free polyolefin cable material and preparation method thereof

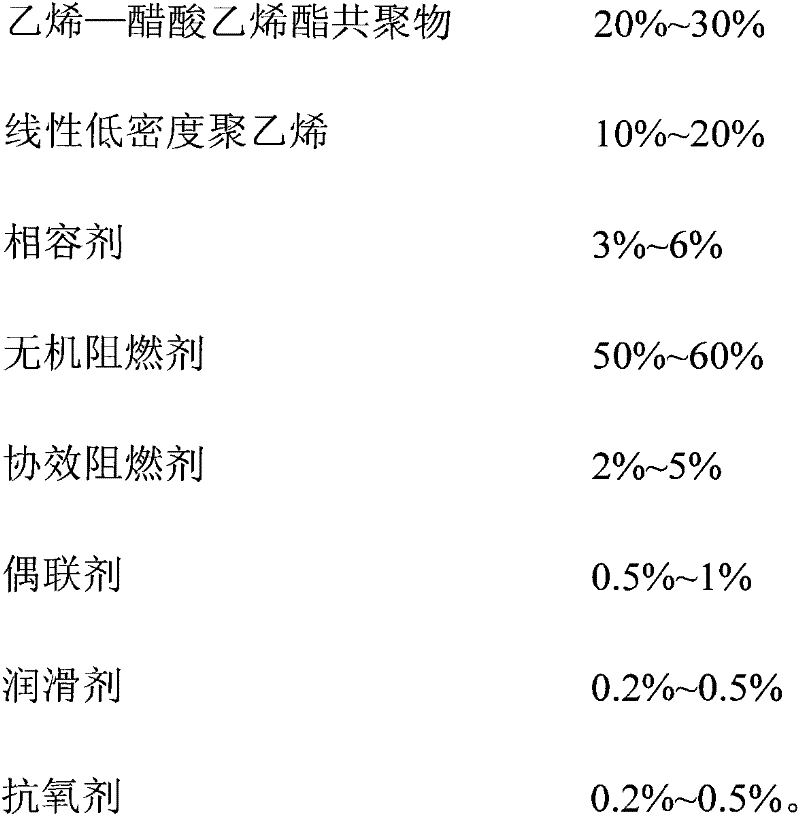

ActiveCN102250409AImprove flame retardant performanceImprove uniformityPlastic/resin/waxes insulatorsLow-density polyethylenePolymer science

The invention discloses a low-smoke halogen-free flame-retardant polyolefin cable material and a preparation method thereof. The formula of the cable material comprises the following raw materials in percentage by weight: 20-30% of ethylene-vinyl acetate copolymer, 10-20% of linear low-density polyethylene, 3-6% of compatilizer, 50-60% of inorganic flame retardant, 2-5% of synergistic flame retardant, 0.5-1% of coupling agent, 0.2-0.5% of lubricant and 0.2-0.5% of antioxidant. The preparation method of the cable material comprises surface treatment of the inorganic flame retardant, burdening,mixing, milling, extrusion and granulation and other process steps. Compared with the prior art, the cable material disclosed by the invention has the advantages of superior flame retardancy, low smoke, low toxicity, no droplets, good processing performance, good dispersion of the inorganic flame retardant, and better uniformity and surface finish degree.

Owner:ZHEJIANG JAVA SPECIALTY CHEM CO LTD

Silicone rubber for composite insulator and preparation method thereof

The invention discloses a silicone rubber for a composite insulator, wherein the silicone rubber comprises the following raw materials in parts by weight: 30-50 parts of methyl vinyl silicone rubber A, 50-70 parts of methyl vinyl silicone rubber B, 25-50 parts of fumed silica, 100-130 parts of aluminium hydroxide, 1-6 parts of silane coupling agent, 0.2-2 parts of ultraviolet absorber, 2-6 parts of zinc oxide, 0.5-3 parts of triethanolamine, 0.2-1 parts of stearic acid, 0.5-2 parts of hydrogen-containing silicone oil, 0.2-1 parts of vinyl silicone oil, 0.5-3 parts of color masterbatch rubber, 2-6 parts of hydroxyl silicone oil and 0.5-1 parts of vulcanizing agent. The silicone rubber provided by the invention can achieve the following performances: the tensile strength is larger than 4 MPa; the breaking elongation is larger than 350%; the peel strength is larger than or equal to 12 KN.m<-1>; the shore hardness is 60+ / -5 degrees; the thermal aging tensile strength retention is larger than or equal to 90%; the anti-creep track passes a grade of 1A4.5; the flame retardance reaches a grade of FV-0; the average static contact angle is larger than 105 degrees; the electrical surface resistivity is larger than 2*10<15> omega; the dielectric constant is smaller than 3.8; and the dielectric loss angle tangent is smaller than 0.01.

Owner:PINGGAO GRP +2

Halogen-free resin composition and copper clad laminate and printed circuit board using same

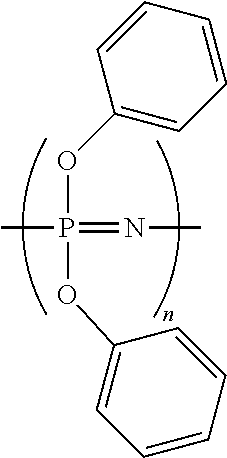

ActiveUS20130075138A1Low dissipation factorHigh heat resistancePrinted circuit aspectsSynthetic resin layered productsLow dissipationStyrene maleic anhydride

The halogen-free resin composition comprises (A)100 parts by weight of cyanate ester resin; (B) 5 to 50 parts by weight of styrene-maleic anhydride; (C) 5 to 100 parts by weight of polyphenylene oxide resin; (D) 5 to 100 parts by weight of maleimide; (E) 10 to 150 parts by weight of phosphazene; and (F) 10 to 1000 parts by weight of inorganic filler. By using specific components at specific proportions, the halogen-free resin composition of the invention offers the features of low dielectric constant, low dissipation factor, high heat resistance and high flame retardancy, and can be made into prepreg or resin film, and thereby used in copper clad laminate or printed circuit board.

Owner:ELITE MATERIAL

Halogen-free expansion type flame-retardant and preparation thereof

The invention relates to a halogen-free intumescent flame-retardant polypropylene composite and a preparation method thereof. Calculated by weight percentage, the composite comprises 35 to 80 percent of polypropylene, 5 to 30 percent of coated poly-ammonium phosphate, 1 to 20 percent of melamine and the derivatives, 1 to 15 percent of halogen-free macromolecular char forming flame retardant, 0.1 to 5 percent of flame retardant synergist, 1 to 20 percent of rigid inorganic particle, 0.05 to 5 percent of coupling agent, 0.1 to 10 percent of compatilizer, 1 to 20 percent of toughening agent and 0.01 to 4 percent of antioxidant. Compared with the prior art, the material of the invention has good toughness, high strength and environment-protecting flame retardance, and the composite can be widely applied in the fields such as automobile and electronic appliances.

Owner:SHANGHAI RES INST OF CHEM IND +1

Polyamide composition with flame retardance and thermoplasticity

The invention discloses a polyamide composition with flame retardance and thermoplasticity. The polyamide composition with flame retardance and thermoplasticity comprises the following components in percentage by weight: 30-90% of thermoplastic polyamide resin, 5-40% of a brominated flame retardant, 0.5-15% of a flame-retardant synergist and 0-50% of a reinforcing material. According to the polyamide composition, the brominated flame retardant, the high-efficiency flame-retardant synergist (namely zinc borate) and organic silicon are added in polyamide resin, on the one hand, the polyamide composition can replace antimony trioxide which is a rare material and is limited to be exploited by the nation at present, limited strategic resources of the nation can be saved, and the cost is lowered; and on the other hand, the flame retardance, a CTI (comparative tracking index) value and GWIT (glow wire ignition temperature) of the polyamide composition can be improved greatly, and the safety guarantee is provided for the use of the flame-retardant polyamide product on electronic appliances with high requirements.

Owner:KINGFA SCI & TECH CO LTD +1

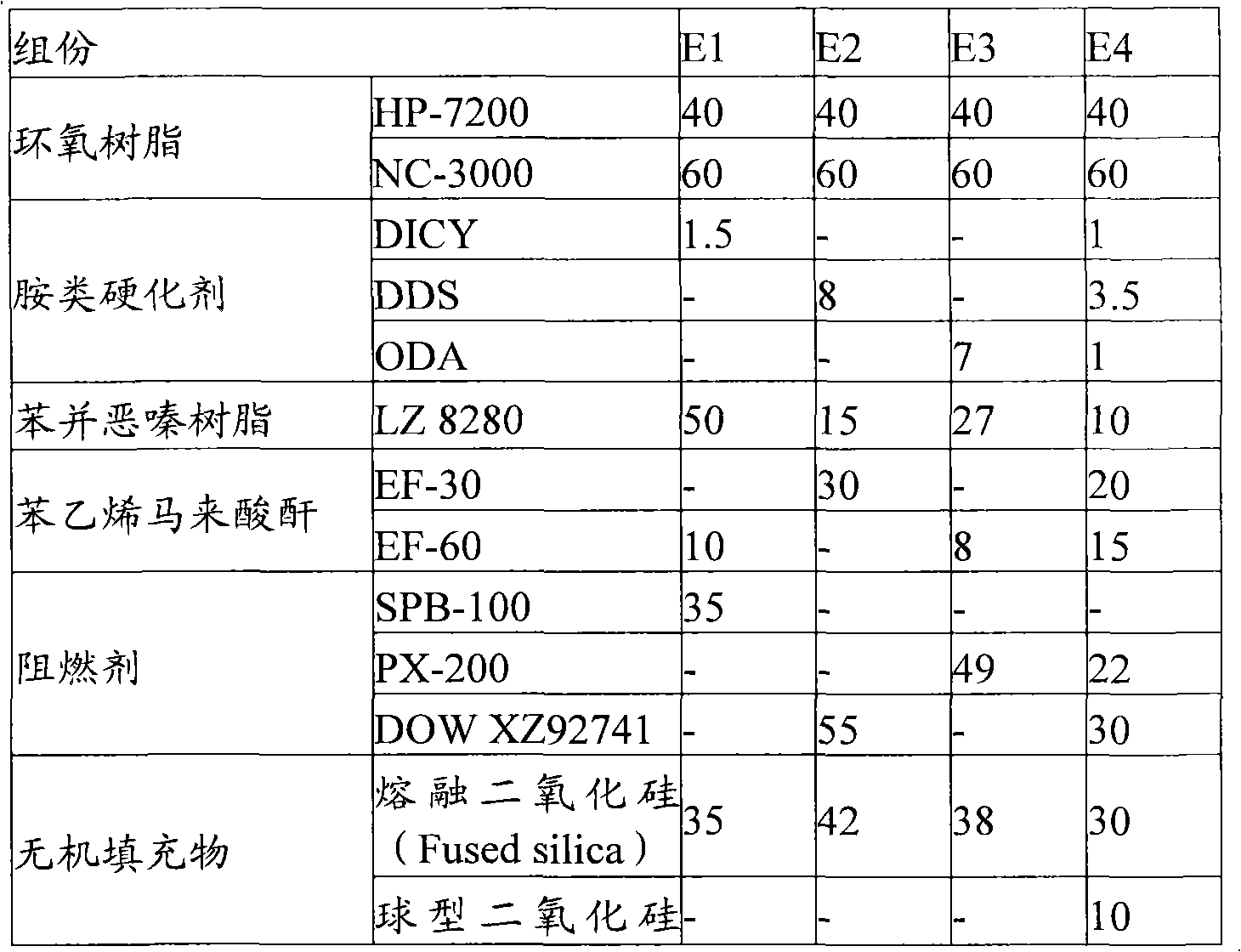

Halogen-free resin composition and copper clad laminate and printed circuit board applying the same

ActiveCN103131131ALow dielectric propertiesLow heat resistanceCircuit susbtrate materialsEpoxySheet film

The invention provides halogen-free resin composition, and a copper clad laminate and a printed circuit board applying the halogen-free resin composition. The halogen-free resin composition comprises, by weight, (A) 100 parts of epoxy resin, (B) 1 part -100 parts of benzoxazine resin, (C) 1part -100 parts of styrene maleic anhydride, (D) 0.5 part -30 parts of amine curing agents, and (E) 5-150 parts of halogen-free flame retardants. By means of the specified constituents and ration, the halogen-free resin composition achieves the purposes of low dielectric constant, low dielectric loss, high heat resistance, and high flame resistance, can be manufactured into semi-solidified rubber pieces or resin films, and then achieves the purposes of being applied to the copper clad laminate and the printed circuit board.

Owner:ELITE MATERIAL

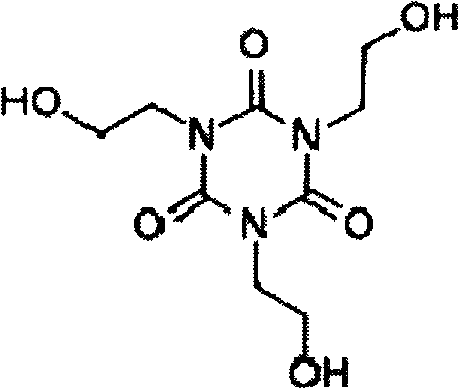

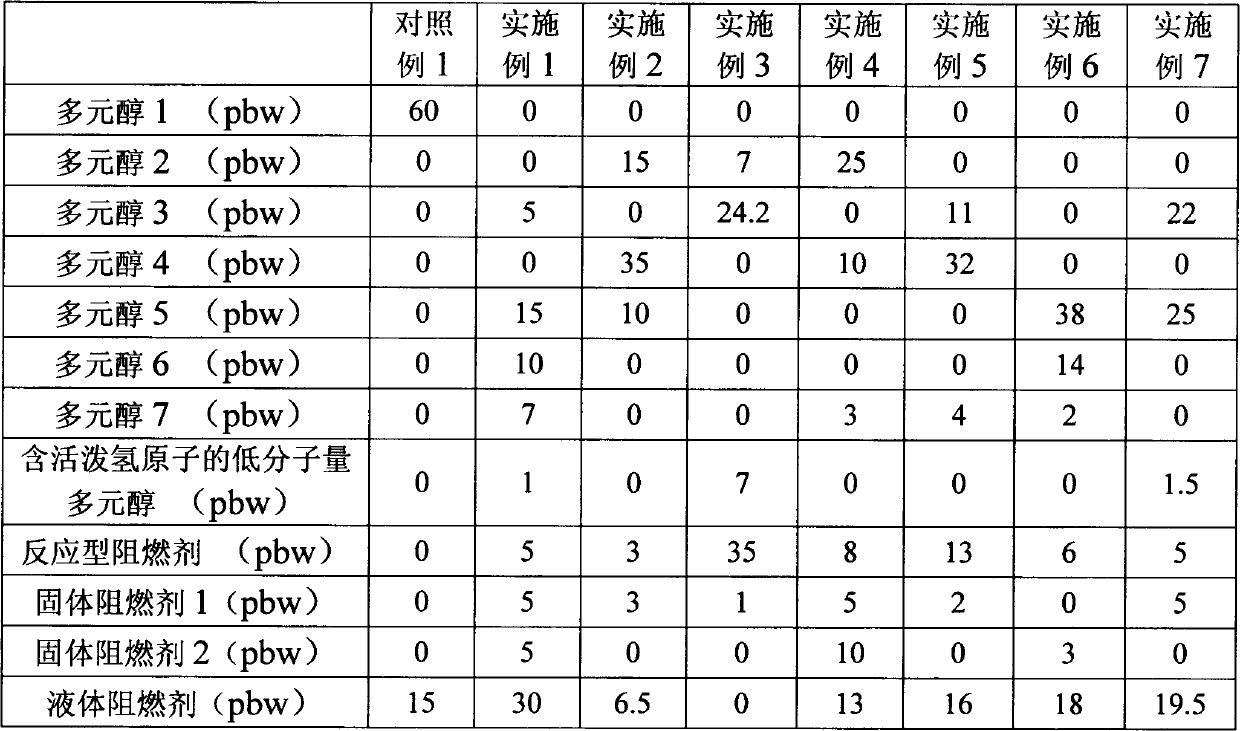

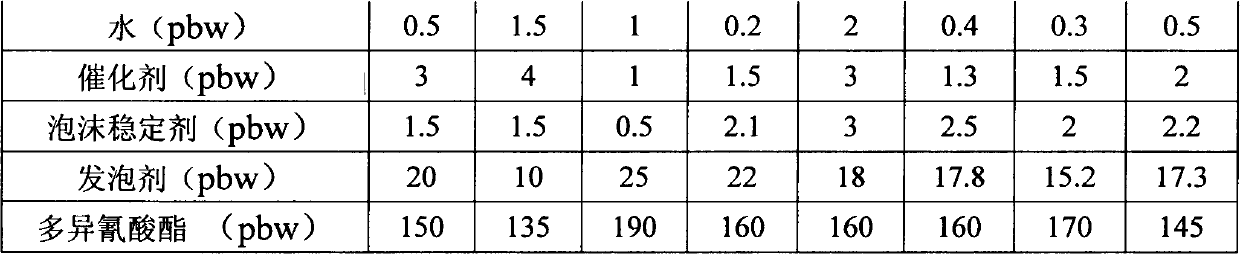

Composition for preparing highly fire-resistant polyisocyanurate foam

The invention discloses a composition for preparing highly fire-resistant polyisocyanurate foam. Based on the total quantity of the composition, the composition comprises the following components in percentage by weight: 30-60 percent of polyester polyol and / or polylol containing tri-(2-ethoxyl) isocyanurate units, 0-7 percent of polyether polyol, 0-7 percent of low molecular weight polylol or polyamine containing active hydrogen atoms, 3-35 percent of reactive flame retardant, 1-15 percent of solid flame retardant, 0-30 percent of liquid organic flame retardant, 0.2-2 percent of water, 1-4 percent of catalyst, 0.5-3 percent of foam stabilizer and 10-25 percent of physical foaming agent. Compared with a conventional PIR (Polyisocyanurate) composition, the composition system has the advantages of stability in material foaming rise, good cohesiveness of foam with plane materials, and the like. Compared with conventional polyurethane foam and PIR foam, foam prepared from the composition system has the advantages of excellent flame resistance and good compressive strength and dimensional stability.

Owner:WANHUA CHEM NINGBO RONGWEI POLYURETHANE

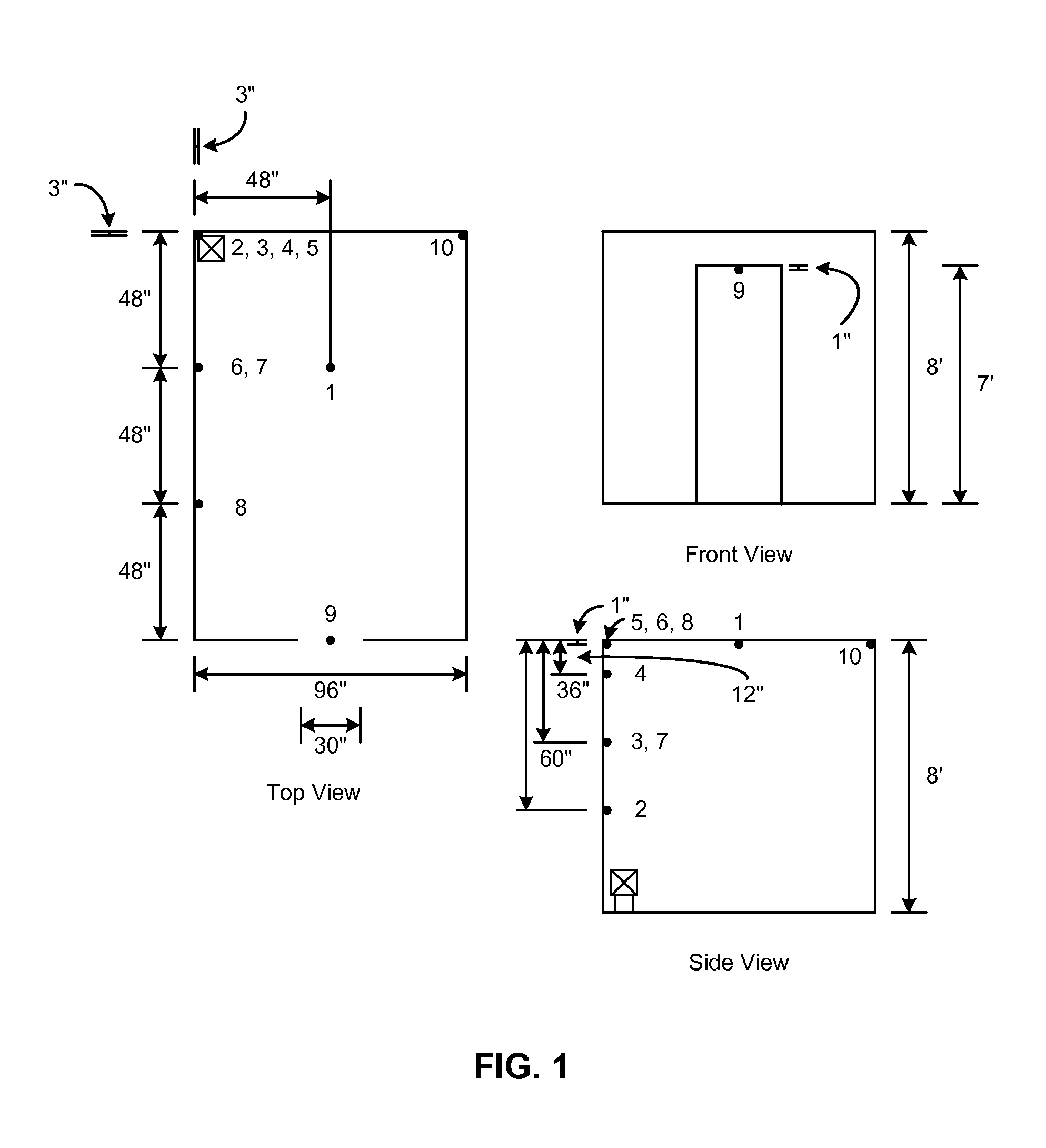

Polyurethane foam compositions and process for making same

ActiveUS20120022176A1Increased and improved fire-retardant propertyCoatingsPolymer chemistryFire retardant

The present invention generally relates to polyurethane foam composition. In one embodiment, the present invention relates to polyurethane foam compositions that have increased and / or improved fire-retardant properties due to the inclusion of one or more liquid and / or solid fire-retardants. In another embodiment, the present invention relates to polyurethane foam compositions that have increased and / or improved fire-retardant properties due to the inclusion of one or more intumescent materials (e.g., expandable graphite (EG)). In still another embodiment, the present invention relates to polyurethane foam compositions that have increased and / or improved fire-retardant properties due to the inclusion of expandable graphite.

Owner:STAHL JOHN A +1

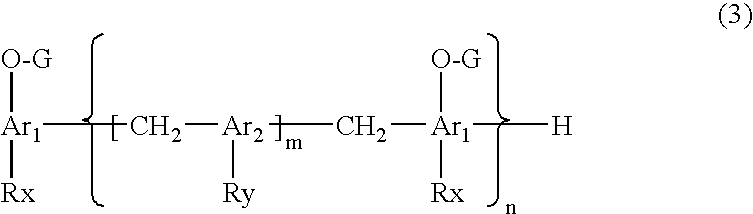

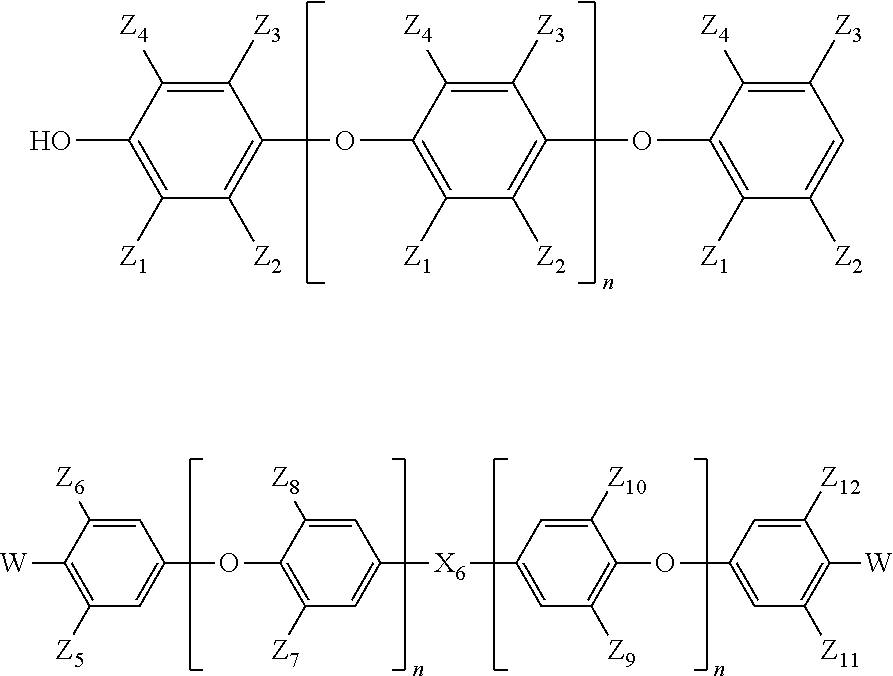

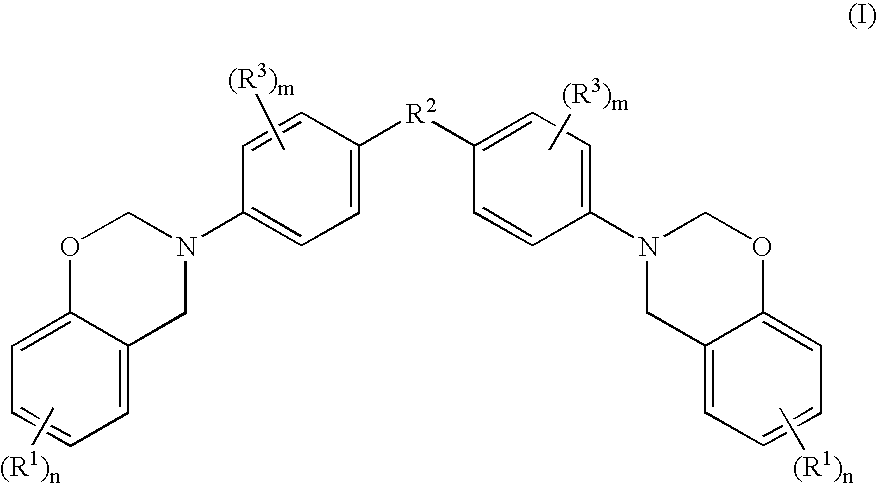

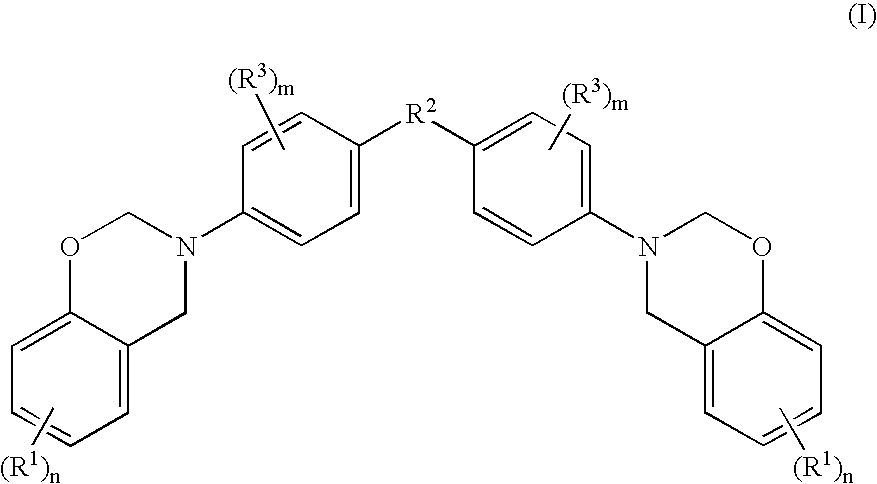

Halogen-free resin composition

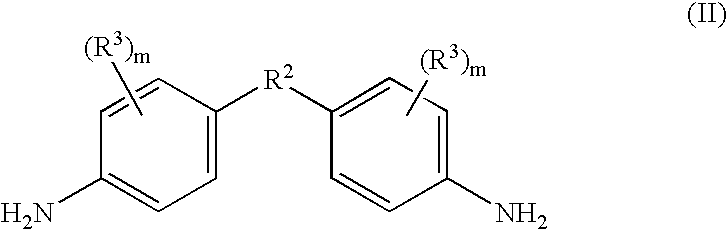

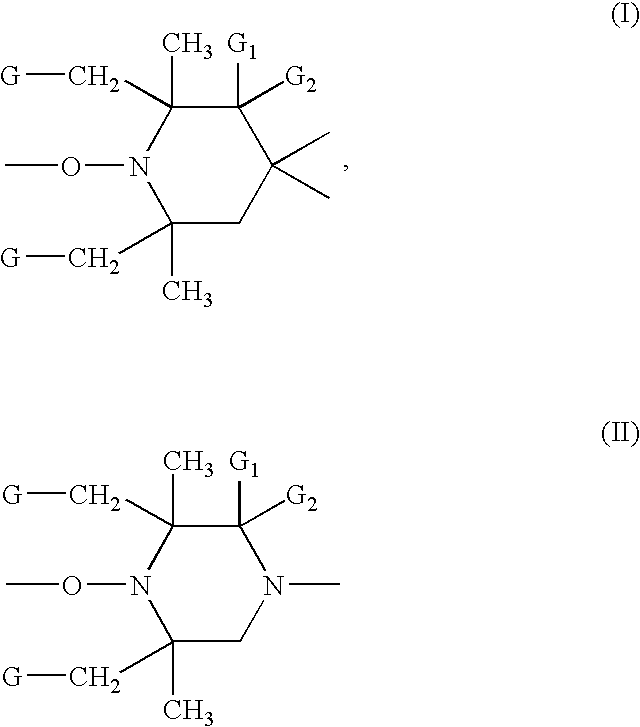

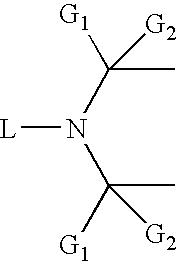

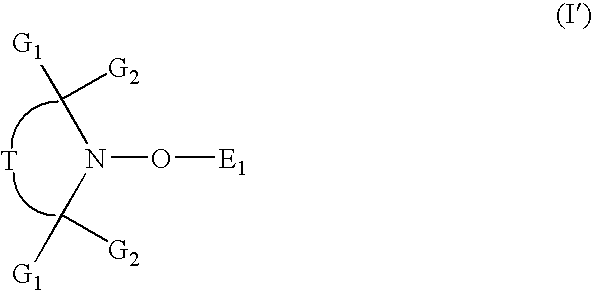

Disclosed is a halogen-free resin composition comprising: (A) one or more phosphorus-containing epoxy resins; (B) a hardener; (C) a hardening accelerator; (D) a polyphenylene oxide resin; and (E) a filling material, wherein the hardener of component B has the structure represented by the following formula (I): wherein each symbol is as defined above. The halogen-free resin composition of the present invention without adding halogen has excellent heat resistance and flame retardant property, and excellent dielectric property. The halogen-free resin composition of the present invention is particularly useful in the application of bonding sheets, composite materials, laminated plates, printed circuit boards, copper foil adhesives, inks used for build-up process, semiconductor packaging materials and the like.

Owner:CHANG CHUN PLASTICS CO LTD

Anti-oil and fire-retardant chlorinated polyethylene sheath material with good weather resistance and preparation method thereof

ActiveCN101597410AGood oil resistanceReach high temperaturePlastic/resin/waxes insulatorsClimate change adaptationPolymer scienceUltra fine

The invention relates to an anti-oil and fire-retardant chlorinated polyethylene sheath material with good weather resistance and a preparation method thereof. The sheath material uses chlorinated polyethylene rubber as main raw material and adds chlorosulfonated polyethylene rubber, triallyl isocyanurate, 1,3-bis (tert-butyl peroxide isopropyl) benzene, trioctyl trimellitate, carbon black, antioxidant 1010, ultra-fine talc powder, antimony trioxide, and high-activity magnesium oxide R-150 according to ratios; the preparation method is as follows: at first, mixing part of the auxiliary agents, then mediating, internal mixing, open mixing, granulating and extruding are carried out on the mixture to form cables, thus the cables are obtained. In the formula, high temperature resistant plasticizer is utilized, various auxiliary agents with appropriate proportions are added into the formula, so that chlorinated polyethylene rubber cable material can reach a high temperature of 105 DEG C, and can be used at the lowest temperature of minus 50 DEG C. The sheath material has the advantages of good anti-aging property, excellent electrical insulation and mechanical property, environmental protection and high flame resistance, thereby being suitable for cold and oil-contaminated severe environment and transmission and distribution circuits of which the current-carrying capacities are large and the rated voltages are at or below 450 / 750V. Meanwhile, compared with traditional chloroprene rubber cable material, the sheath material has the characteristics of low cost, fast extruding speed and high output benefit.

Owner:NINGBO WELL ELECTRIC APPLANCE CO LTD

A high flame retardant high thermal conductivity composite material component and its manufacturing method

InactiveCN102260413AImprove thermal conductivityImprove flame retardant performancePolymer sciencePhenol formaldehyde resin

The invention relates to a high-molecular composite material having performances of high heat conduction and high flame retardation, the invention is characterized in that the composite material does not contain any halogen or a non environmentally-friendly heavy metal fire retardant, the flame resistance is capable of reaching a UL94 V0 standard, simultaneously, the composite material has good heat conducting performance, the heat conduction coefficient is more than 0.5 W / m. DEG C. The composite material provided in the invention has good injection moulding performance, extruding performance and hot pressing performance. The composite material comprises the following basic components: 1) one or a plurality of metal hydroxides, such as aluminum hydroxide, magnesium hydroxide, zinc hydroxide and the like, wherein the weight content is 10-70%, 2) about 0.2%-60% of the weight content of expandable graphite flaky powder, the lamina size is more than 10 um, and the expandable coefficient is more than or equal to 20 times; 3) 15%-70% of the weight content of matrix resins, such as epoxy resin, organic silicone resin, phenolic resin, thermosetting polyester resin and thermoplastic resins of nylon 6, nylon 66, PBT, PP, HDP and the like. The composite material component of the invention can be directly used for radiators such as LED, electric appliances and electronic components, the heat can be radiated into colder environment so that the operating temperature of the electronic device can be reduced.

Owner:HEFU NEW MATERIAL TECH WUXI

Flame retardant composition with improved fluidity, flame retardant resin composition and molded products

ActiveUS20070176154A1Improve flame retardant performanceImproved powder property and hygroscopic propertyDyeing processMelamine phosphateAdditive ingredient

The invention provides a flame retardant composition comprising 1-99 weight parts of a salt of piperazine and an inorganic compound selected from among piperazine phosphate, piperazine pyrophosphate and piperazine polyphosphate, or a mixture of two or more of these piperazine salts (ingredient (A)), 99-1 weight parts of a salt of melamine and an inorganic compound selected from among melamine phosphate, melamine pyrophosphate and melamine polyphosphate, or a mixture of two or more of these melamine salts (ingredient (B) ) (wherein, the sum of ingredient (A) and ingredient (B) is 100 weight parts), 0-50 weight parts of an arbitrary ingredient (ingredient (C)), and 0.01-20 weight parts of a silicone oil having a viscosity at 25° C. of 5000 mm2 / s (ingredient (D)) which is added thereto. This flame retardant not only has superior flame retarding properties, but also has enhanced powder properties and anti-hygroscopic properties, and when it is added to a resin, there is little change of electrical resistance.

Owner:ADEKA CORP

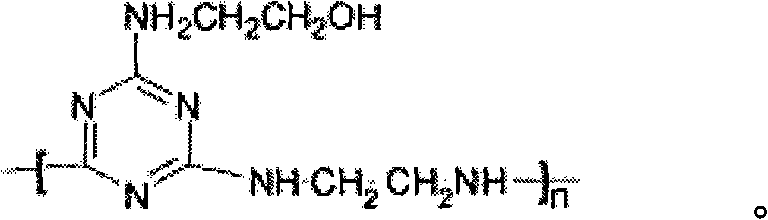

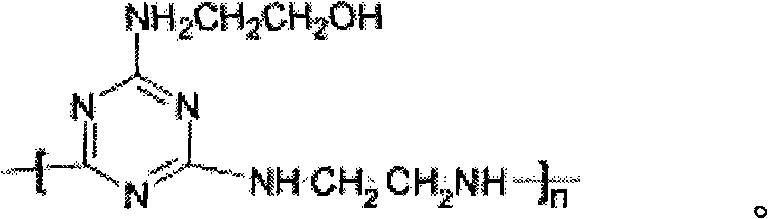

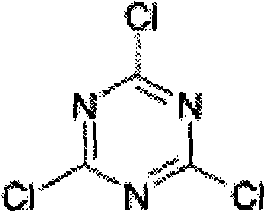

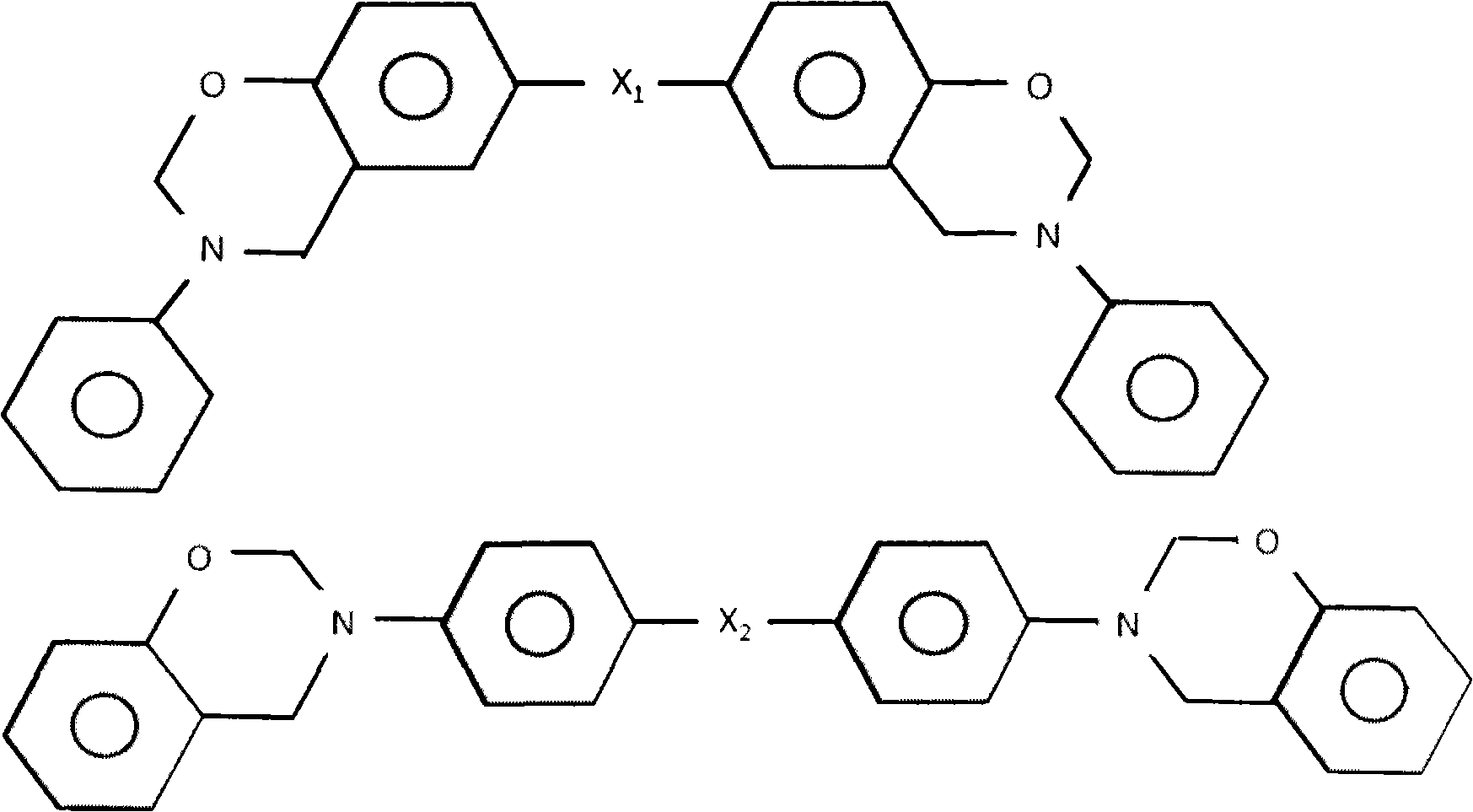

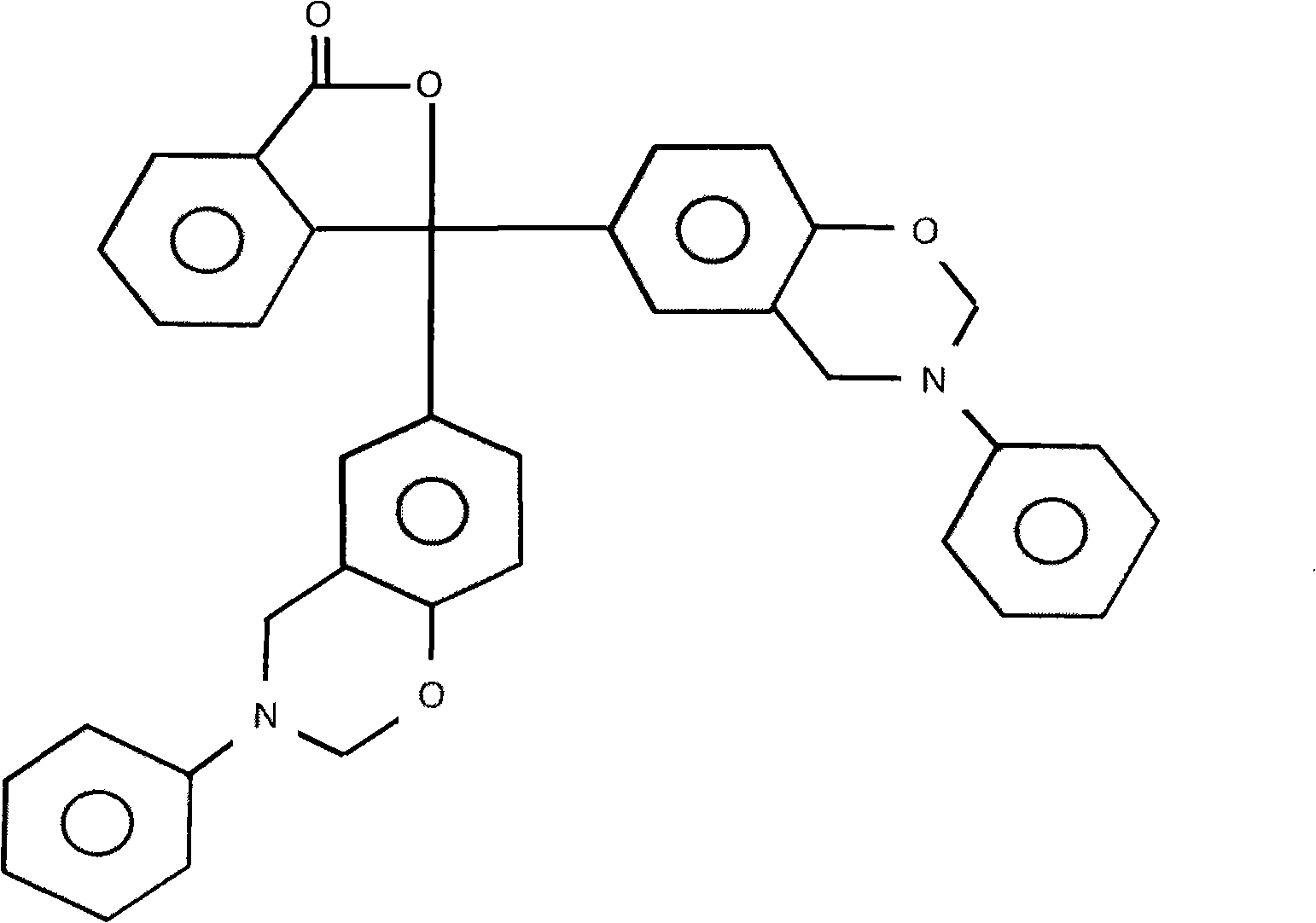

Phosphaphenanthrene flame-retardant compound containing s-triazine structure, and preparation and use thereof

ActiveCN101376665AReduce energy consumptionEasy to operateGroup 5/15 element organic compoundsEpoxyPolymer science

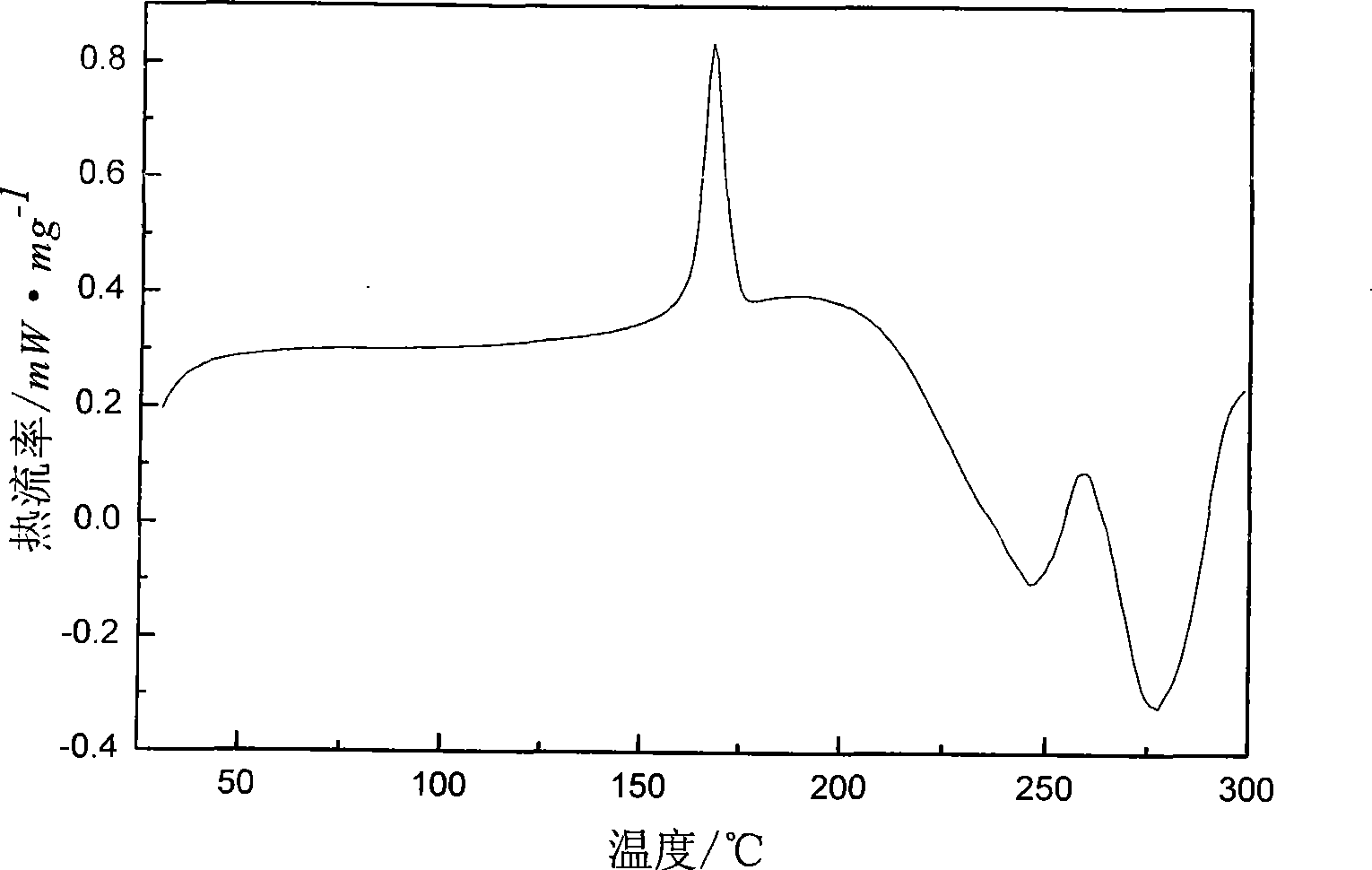

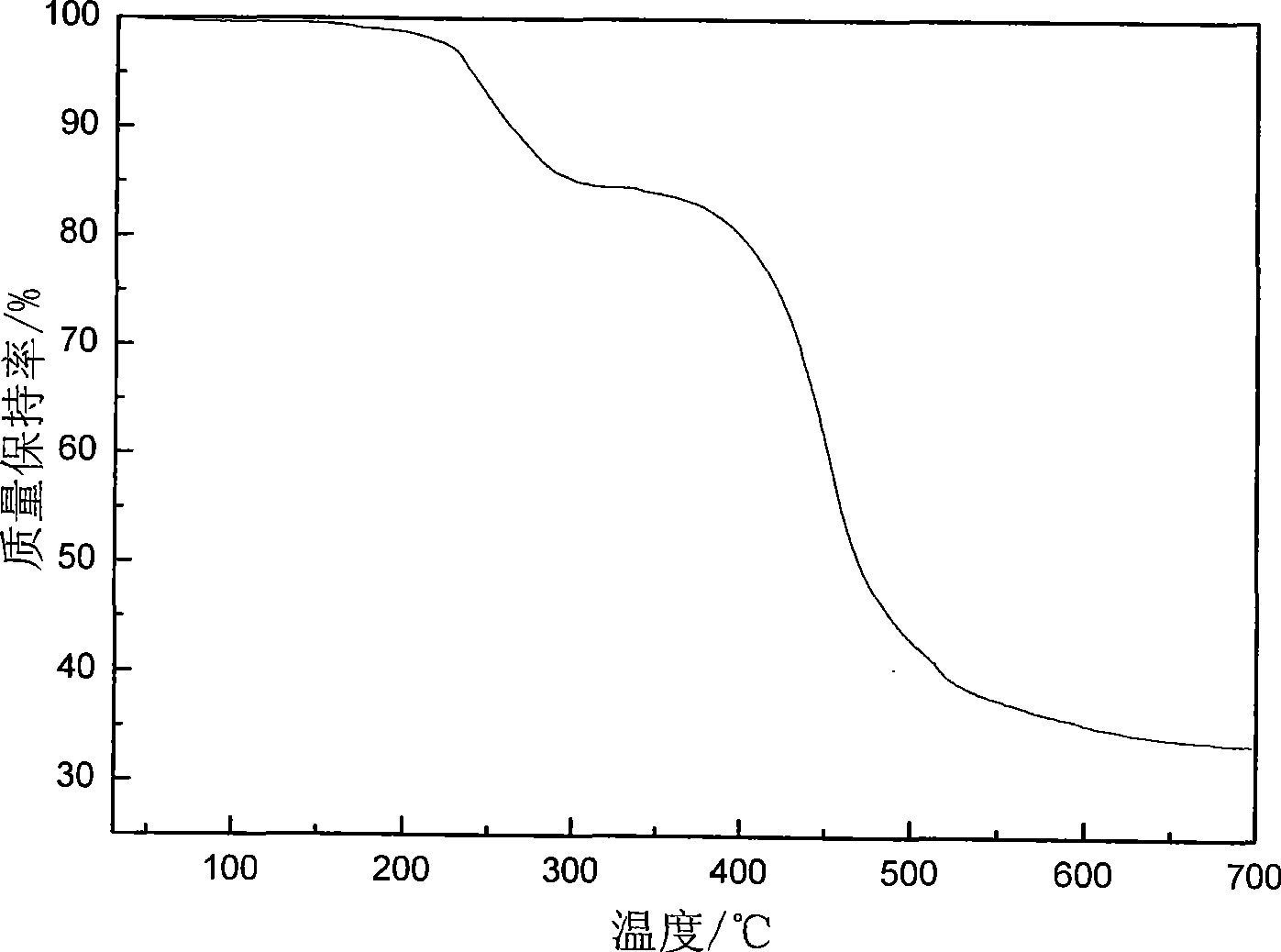

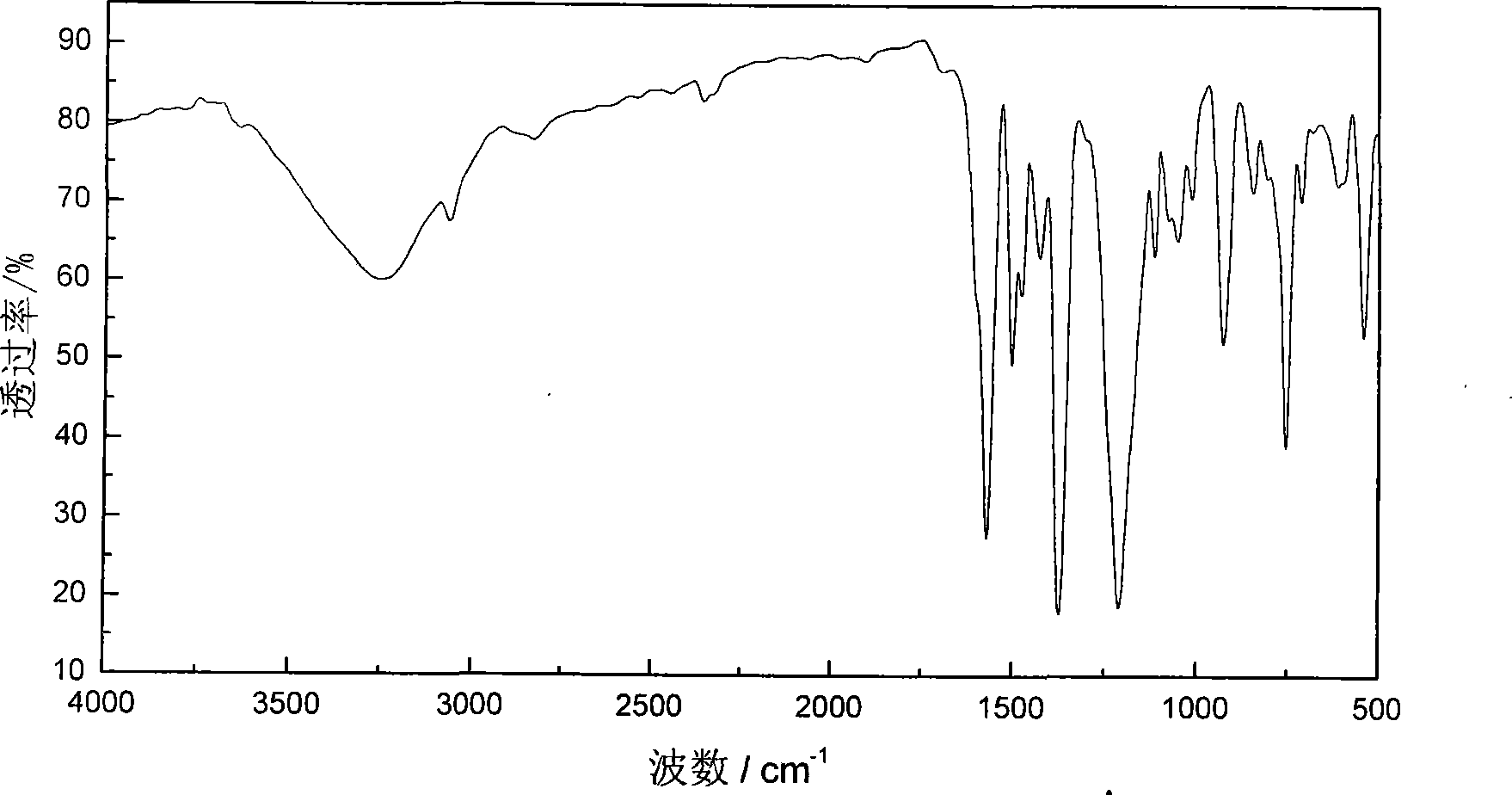

The invention discloses an oxa-phosphaphenanthrene flame retardant compound containing the sym-triazine structure and a preparation method thereof. The method is characterized in that an intermediate is synthesized from 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide(DOPO) and p-hydroxybenzaldehyde as raw material by the solution method, and then reacts with cyanuric chloride in the presence of phase transfer catalyst to obtain a 2,4,6-tri(4-(10-methenyl hydroxy-9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide)phenoxy)-1,3,5-triazine product. The compound is white crystal, and has a melting point of 166 to 169 DEG C, good thermal stability and high flame retardation efficiency, and can be adopted as a reactive flame retardant for the flame retardation of thermosetting resins such as epoxy resin, polyurethane and the like, and also as an additive flame retardant for the flame retardation of engineering plastics such as ABS, nylon and the like.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

Flame retardant compositions

Organic polymeric substrates, for example polyolefins such as polypropylene, can be made flame retardant by the incorporation of a synergistic mixture of (i.) a sterically hindered amine of the nitroxyl, hydroxylamine, alkoxyamine or hydroxyalkoxyamine class, and (ii.) a fluorinated polyolefin. Advantageously, a further flame retardant may be added, without the need of adding an antimony synergist. The compositions of the invention combine good flame retardant properties with light stability and good mechanical properties.

Owner:CIBA SPECIALTY CHEM CORP

Resin composition

InactiveUS20050107497A1Improve barrier propertiesImprove moisture resistanceSpecial tyresRecord information storagePolymer scienceAdhesive belt

A resin composition, substrate material, sheet, laminated board, resin-bearing copper foil, copper-clad laminate, TAB tape, printed board, prepreg and adhesive sheet are provided which exhibit improved mechanical properties, dimensional stability, heat resistance and flame retardance, particularly high-temperature physical properties. A resin composition containing 100 parts by weight of a thermosetting resin and 0.1-65 parts by weight of an inorganic compound, the resin composition having a mean linear expansion coefficient (α2) of up to 17×10−3 [° C.−1] over the temperature range from a temperature 10° C. higher than a glass transition temperature of the resin composition to a temperature 50° C. higher than the glass transition temperature of the resin composition.

Owner:SEKISUI CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com