Patents

Literature

201 results about "Tio2 coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Titanium dioxide(Tio2) is a white compound used as an important pigment in the coating industry which is quite efficient because it scatters visible light resulting in increased brightness, whiteness and opacity.

Nanoparticulate titanium dioxide coatings, and processes for the production and use thereof

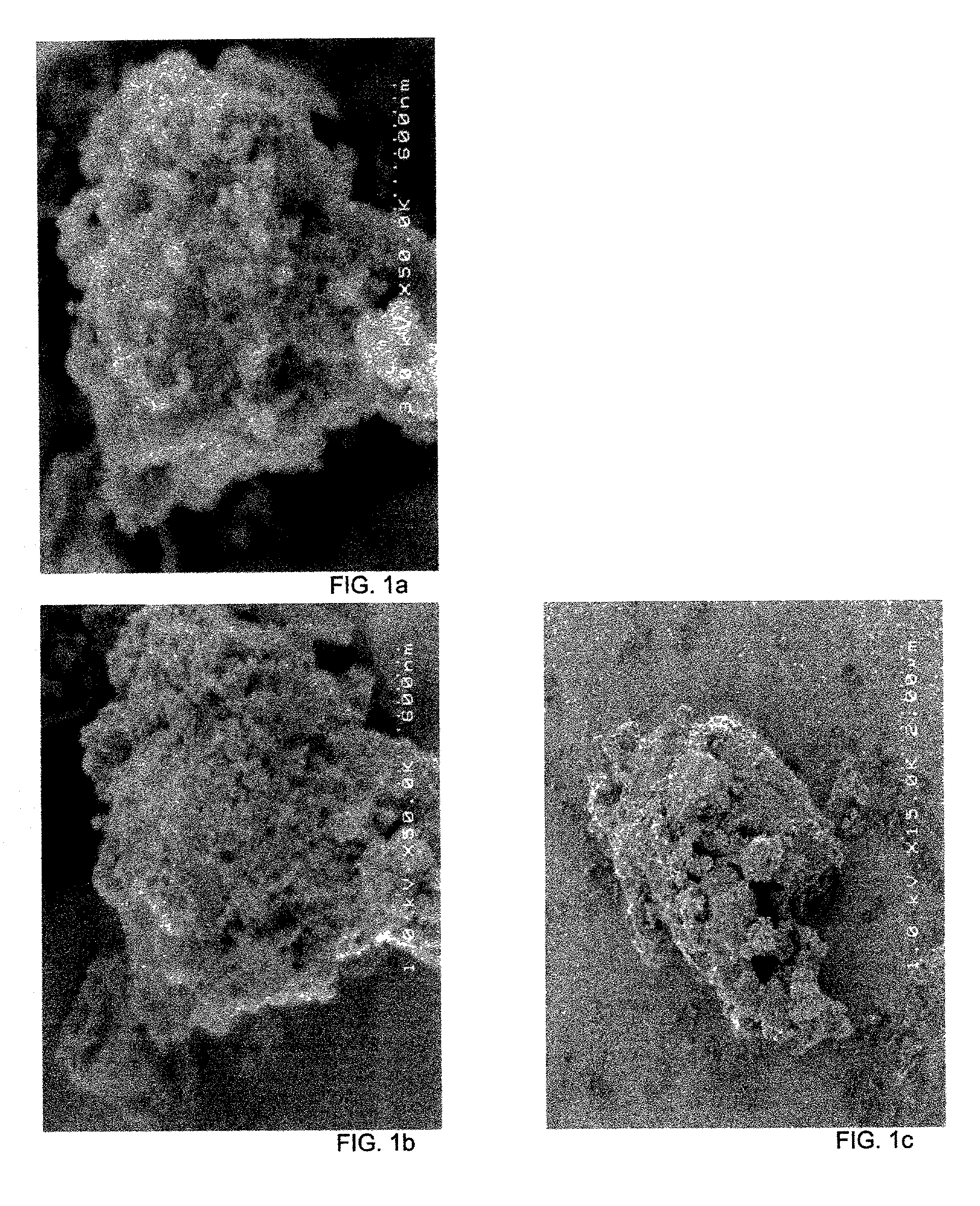

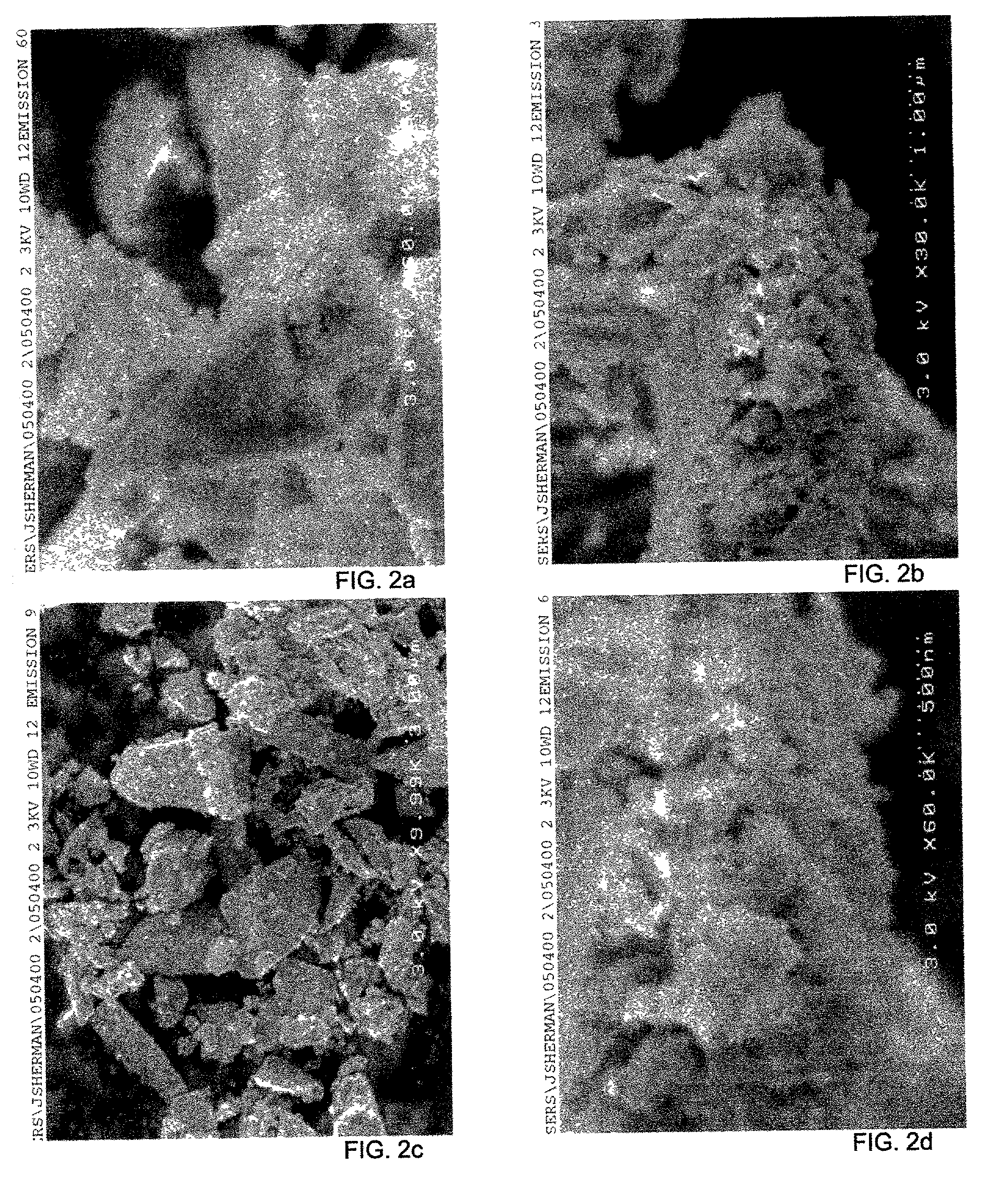

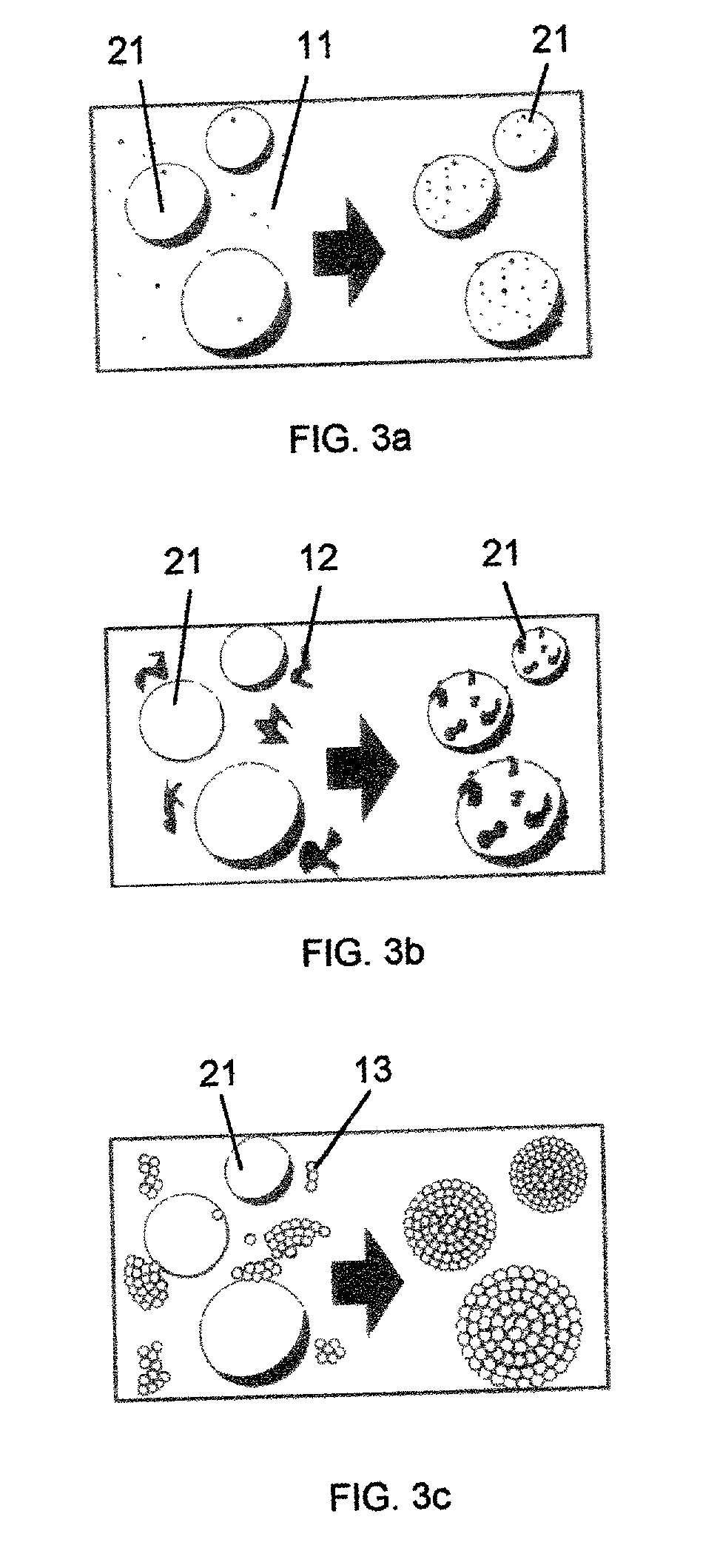

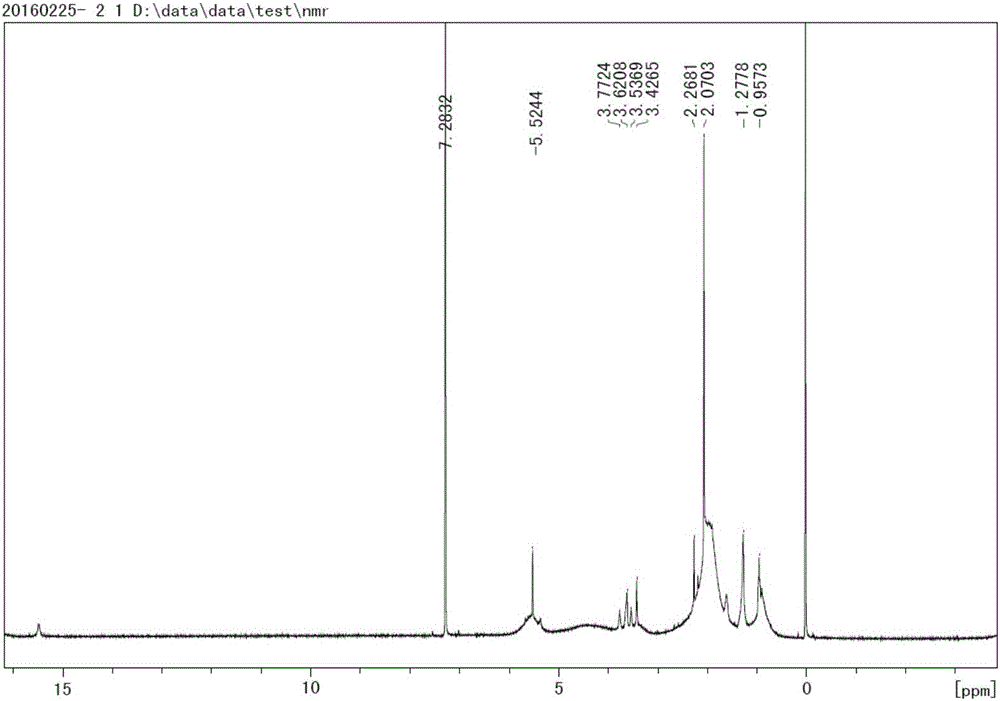

Nanoparticulate titanium dioxide coating produced by educing flocculates of titanium dioxide nanoparticles from a titanyl sulfate solution and dispersing the nanoparticles in a polar sol-forming medium to make a sol suitable as a coating usable to impart photocatalytic activity, U.V. screening properties, and fire retardency to particles and to surfaces. The photocatalytic material and activity is preferably localized in dispersed concentrated nanoparticles, spots or islands both to save costs and leverage anti-microbial effects.

Owner:SHERMAN JONATHAN

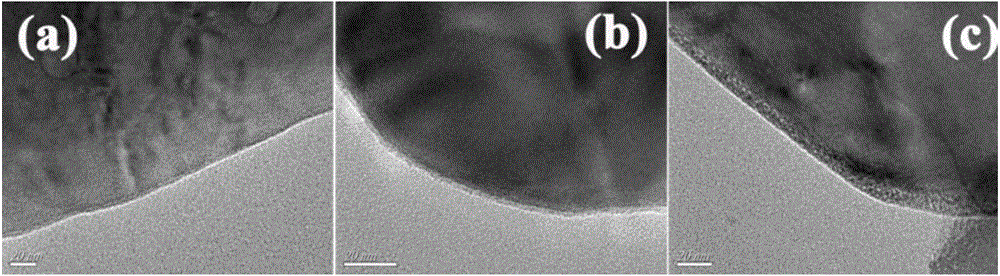

Nanometer TiO2 coating structure, preparation method and uses thereof

ActiveCN106582892AImprove bindingGuaranteed service lifeMolecular sieve catalystsCatalyst activation/preparationTitaniumPolymer solution

The present invention provides a nanometer TiO2 coating structure, which comprises a substrate and a nanometer TiO2 coating supported on the substrate surface. The invention further provides a preparation method of the nanometer TiO2 coating structure, wherein the substrate material is coated with a linear titanium oxygen polymer solution, and drying and sintering are performed to obtain the coating structure with the nanometer TiO2 loaded on the substrate material. According to the present invention, the nanometer TiO2 coating structure prepared from the linear titanium oxygen polymer has advantages of excellent photocatalytic effect and super-hydrophilic effect, such that the nanometer TiO2 coating structure has wide application prospects in the fields of air purification, water treatment, deodorization, antibacterial treatment, antifouling treatment, self-cleaning, and the like.

Owner:BEIJING HUATAI TECH CO LTD

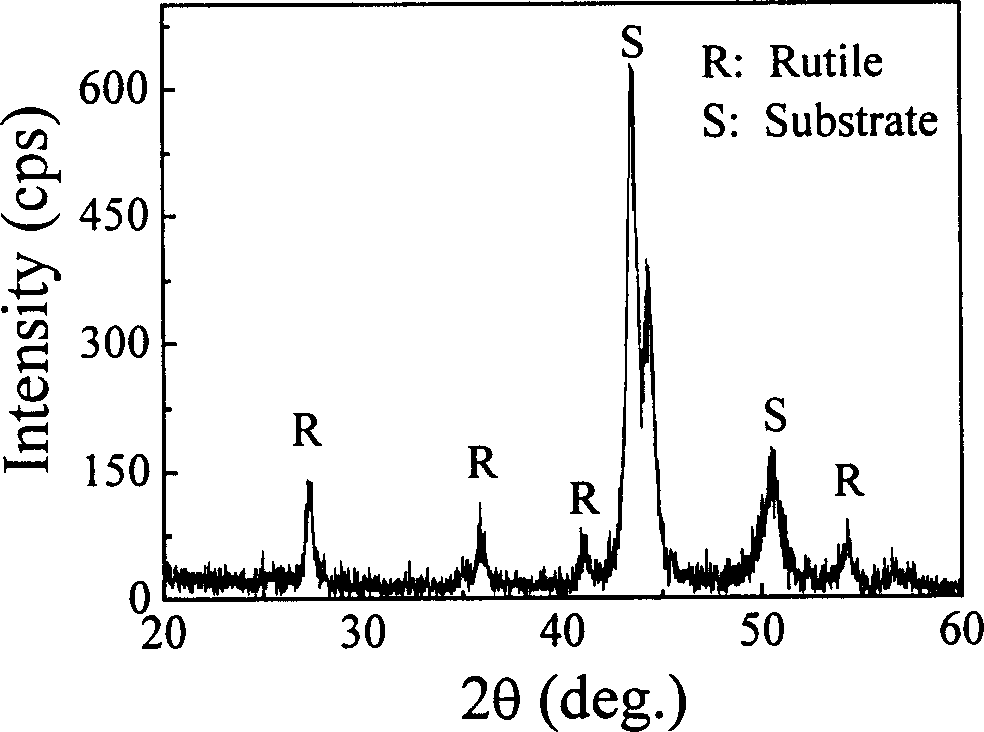

Process for preparing nano structured titanium dioxide photocatalyst coating

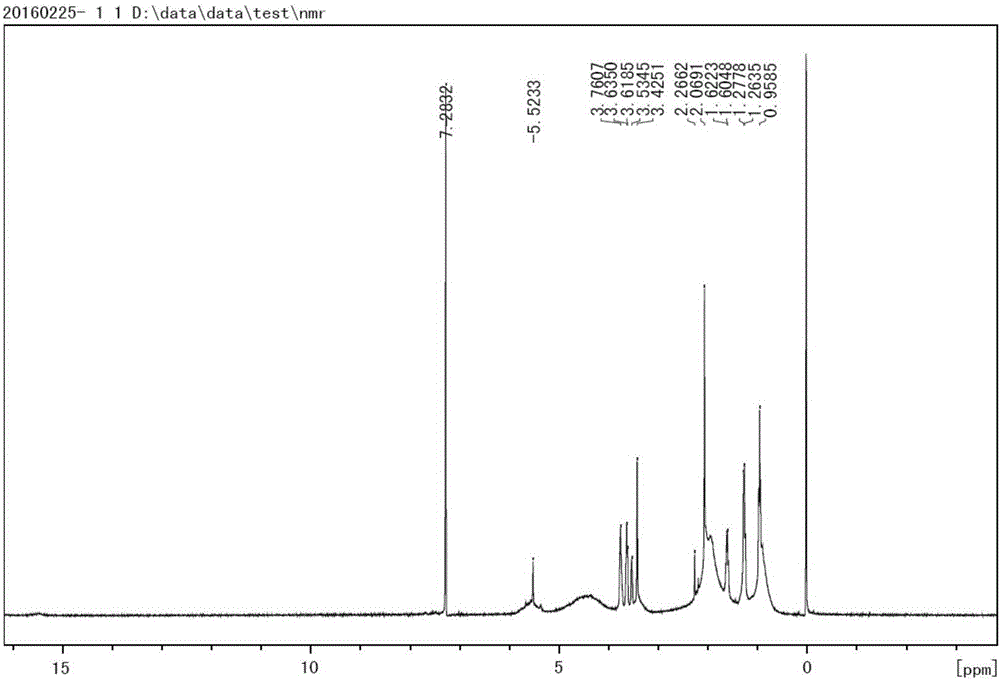

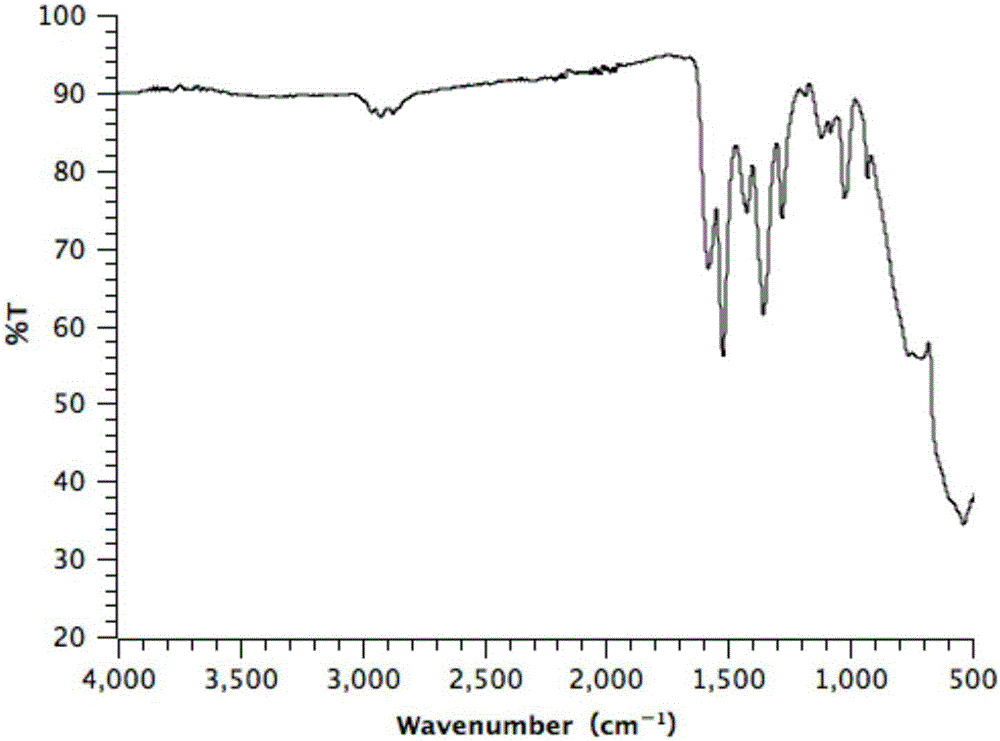

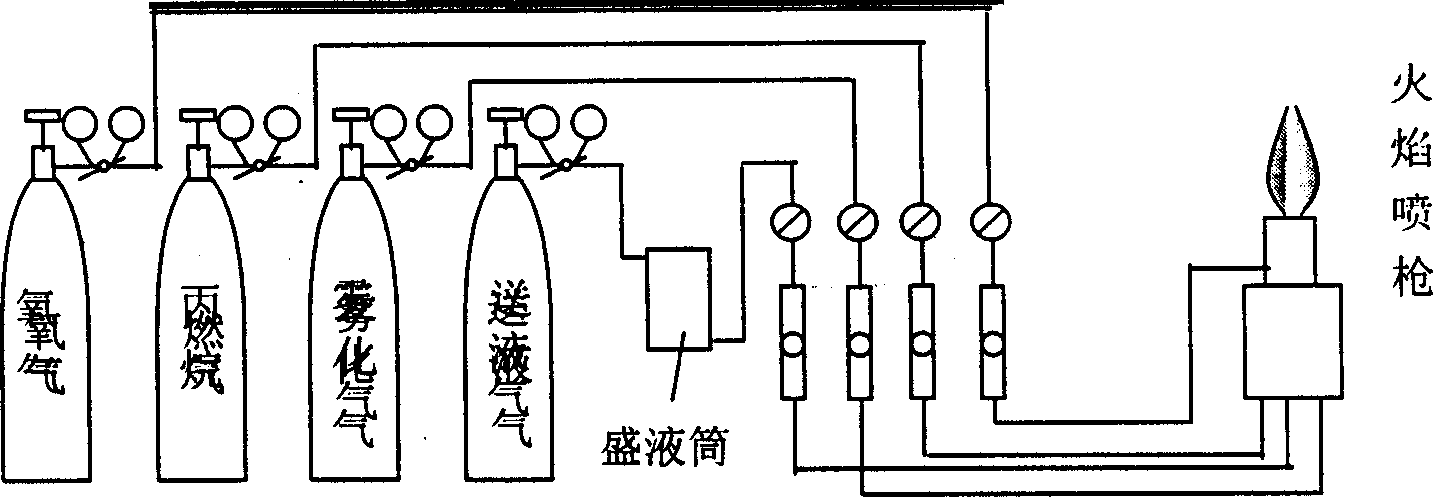

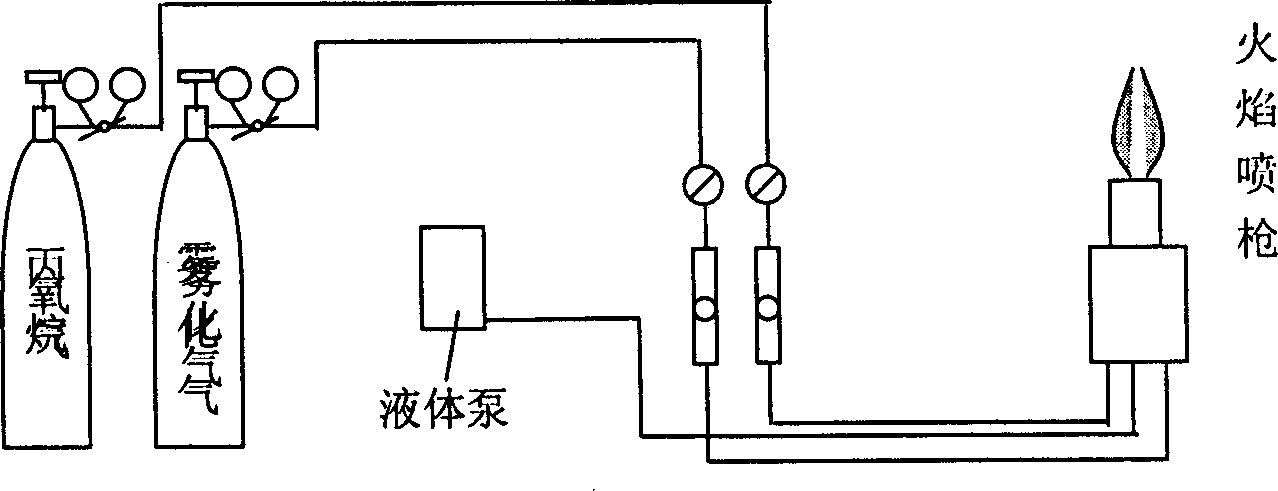

InactiveCN1450123ASimple manufacturing processReduce manufacturing costInorganic pigment treatmentInorganic saltsThermal spraying

The present invention uses organic salt containing titanium, inorganic salt, nano powder and nano amorphous titanium compound as raw material, and adopts liquid thermal spraying process to prepare TiO2 photocatalysis coating layer with nano structure on the base body. Said TiO2 coating layer has the excellent photocatalysis property, and its preparation process is simple and its production cost is low. In the liquid thermal spraying process the temp. of the base body can be controlled below 100 deg.C and it has no any undesirable affect to performance of said base body, said invention can be extensively used in the fields of chemical engineering environment and material processing technology.

Owner:XI AN JIAOTONG UNIV

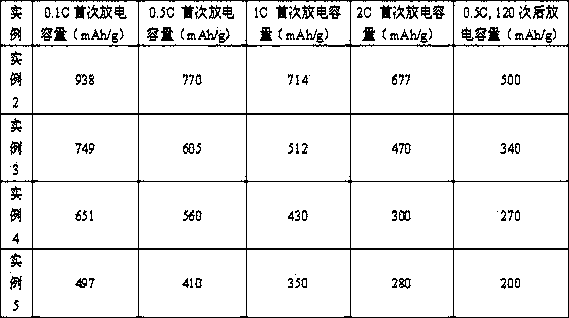

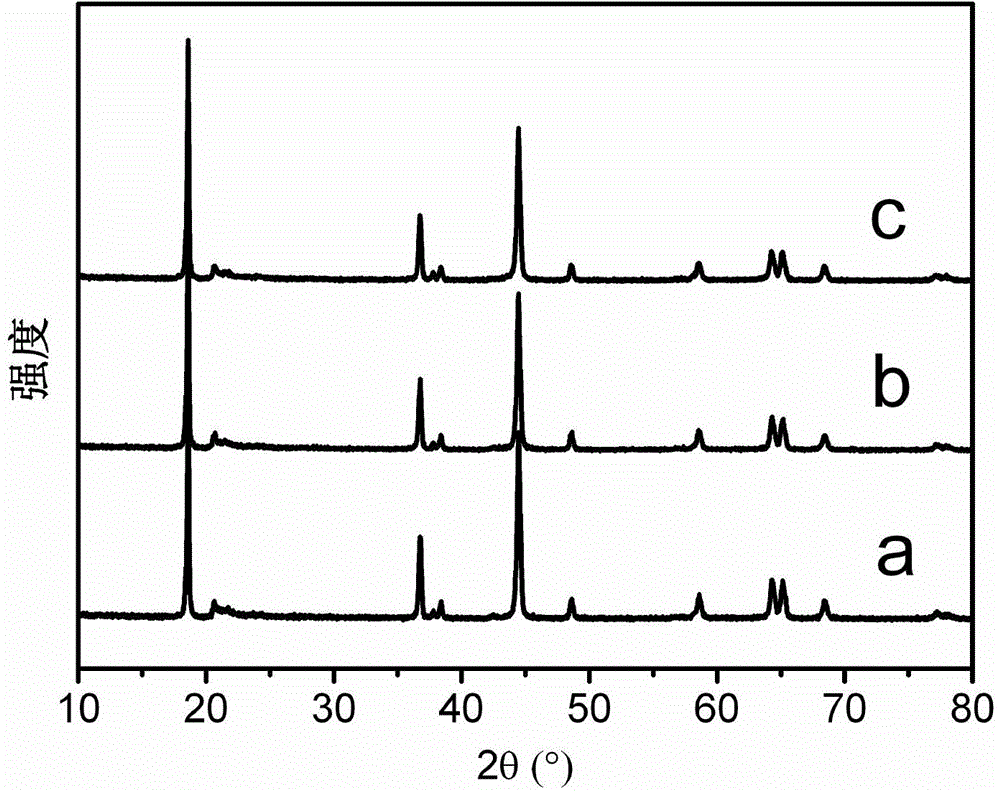

TiO2 coated sulfur/ordered mesoporous carbon composite cathode material and preparation method thereof

InactiveCN104269559ALower transmission impedanceImprove conductivityCell electrodesComposite cathodeHigh energy

The invention discloses a TiO2 coated sulfur / ordered mesoporous carbon composite cathode material and a preparation method thereof as well as the application thereof in a secondary aluminum battery. The cathode material consists of a sulfur active substance, ordered mesoporous carbon and TiO2 and is characterized in that the ordered mesoporous carbon has a highly-ordered three-dimensional pore structure, is provided with a conductive network and provides a large number of adhesion area for the active substance and a conductive channel; a TiO2 coating layer has a very effective shuttle effect of blocking polysulfide. The preparation method of the TiO2 coated sulfur / ordered mesoporous carbon composite cathode material comprises the following steps: compounding the ordered mesoporous carbon and sulfur and then TiO2 coating on an outer layer. The preparation method has the advantages of simple process, low cost, no toxic raw material used, environmental friendliness, high energy density and high sulfur utilization rate, and the rate performance and the cycle life of the secondary aluminum battery are greatly improved.

Owner:NANJING ZHONGCHU NEW ENERGY

Preparation method of self-cleaning high-transmittance dual-layer antireflection coating sol

The invention discloses a preparation method of self-cleaning high-transmittance dual-layer antireflection coating sol. The method comprises the following steps of: mixing alfol sol hydrolyzed from organic aluminum with sol obtained by co-hydrolysis of alkoxy silane and nano silicon dioxide under acidic catalysis so that the surface of the silicon diode particle is coated with a silicon-aluminum-alcohol glue; and coating a layer of TiO2 sol film layer on a solidified silicon-aluminum sol antireflection film by plating technologies, such as roller painting, spray coating and a dip-coating method. Since the TiO2 film has photocatalytic property and photo-induced super-hydrophilicity, organic pollutant adsorbed on the surface of the TiO2 film can be degraded under irradiation of sun light, and the pollutant and the dust can be washed away by rain, thus, the TiO2 coating layer has a self-cleaning function; the silicon-alcohol glue has better adhesion to the surface of substrate glass, the aluminum oxide sol is excellent in abrasion resistance; and with the dispersity of the silicon oxide particles, the coating film layer is porous, and the transmittance of the coating is improved.

Owner:CAIHONG GRP ELECTRONICS CO LTD +1

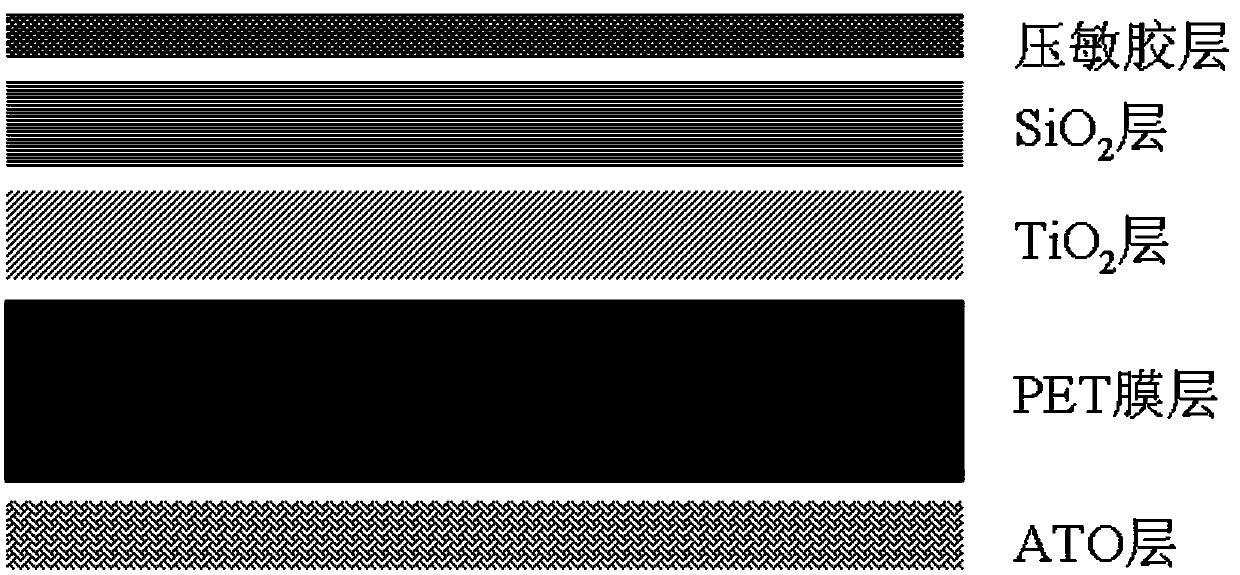

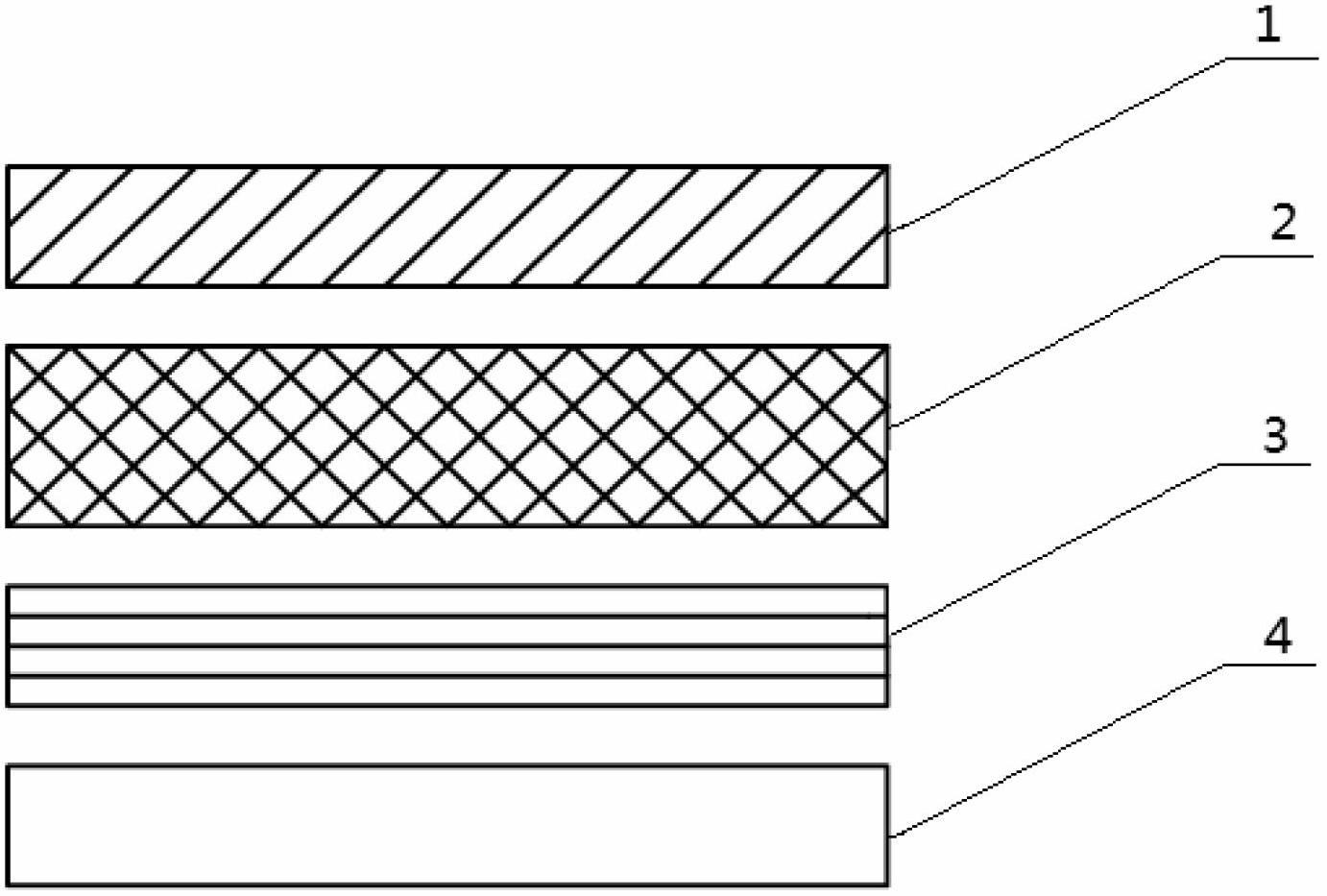

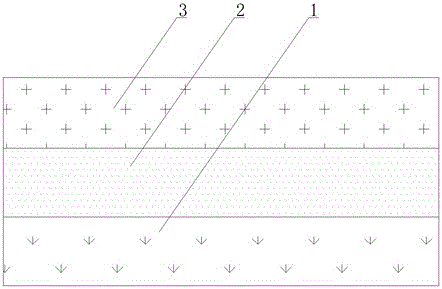

Flexible transparent nano heat-insulation film and preparation method thereof

ActiveCN104178047AImprove insulation efficiencyImprove transmittanceFilm/foil adhesivesRadiation-absorbing paintsInsulation layerThermal break

The invention discloses a flexible transparent nano heat-insulation film which comprises an organic flexible substrate, a nano antimony tin oxide layer coated on one side of the organic flexible substrate, a TiO2 layer coated on the other side of the organic flexible substrate, a SiO2 layer coated on the other side of the TiO2 layer, and a pressure-sensitive adhesive coated on the other side of the SiO2 layer. The invention also discloses a preparation method of the flexible transparent nano heat-insulation film, which comprises the following steps: 1) preparing a TiO2 coating slurry; 2) preparing a SiO2 coating slurry; 3) preparing a nano antimony tin oxide slurry; 4) coating a nano antimony tin oxide absorptive heat-insulation layer; 5) coating a SiO2 / TiO2 reflective heat-insulation layer; and 6) coating the pressure-sensitive adhesive. The method enhances the heat-insulation efficiency of the heat-insulation film, so that the indoor / outdoor temperature difference can reach 10 DEG C; the visible light transmittance of the heat-insulation film is up to 80%; the adhesive force of the coating on the flexible substrate surface reaches Grade 1; the heat-insulation layer can not easily absorb dust, and thus, can not be easily polluted; and the heat-insulation film can be easily attached to or peeled from the surface of the glass, ceramic or any other substrate.

Owner:KUNSHAN BYE MACROMOLECULE MATERIAL CO LTD

Method for preparing ceramic coating layer

InactiveCN1443871ASimple structureImprove performanceCatalyst activation/preparationPressure inorganic powder coatingCeramic coatingSpray coating

The preparation method of ceramic coating layer uses ceramic powder as raw material, specially, uses titanium oxide block body power or titanium oxide agglomeration powder as raw material, and adoptsthe cold spray-coating process to deposit titanium dioxide coating layer on the base body. The TiO2 coating layer prepared according to said ivnentino can be formed into coating layer under the condition of less than 600 deg.c, and the structure and performance of original powder can be better transferred into the coating layer, specially, in the preparation of nano structure coating and high-performance light-catalytic coating it has obvious superiority.

Owner:XI AN JIAOTONG UNIV

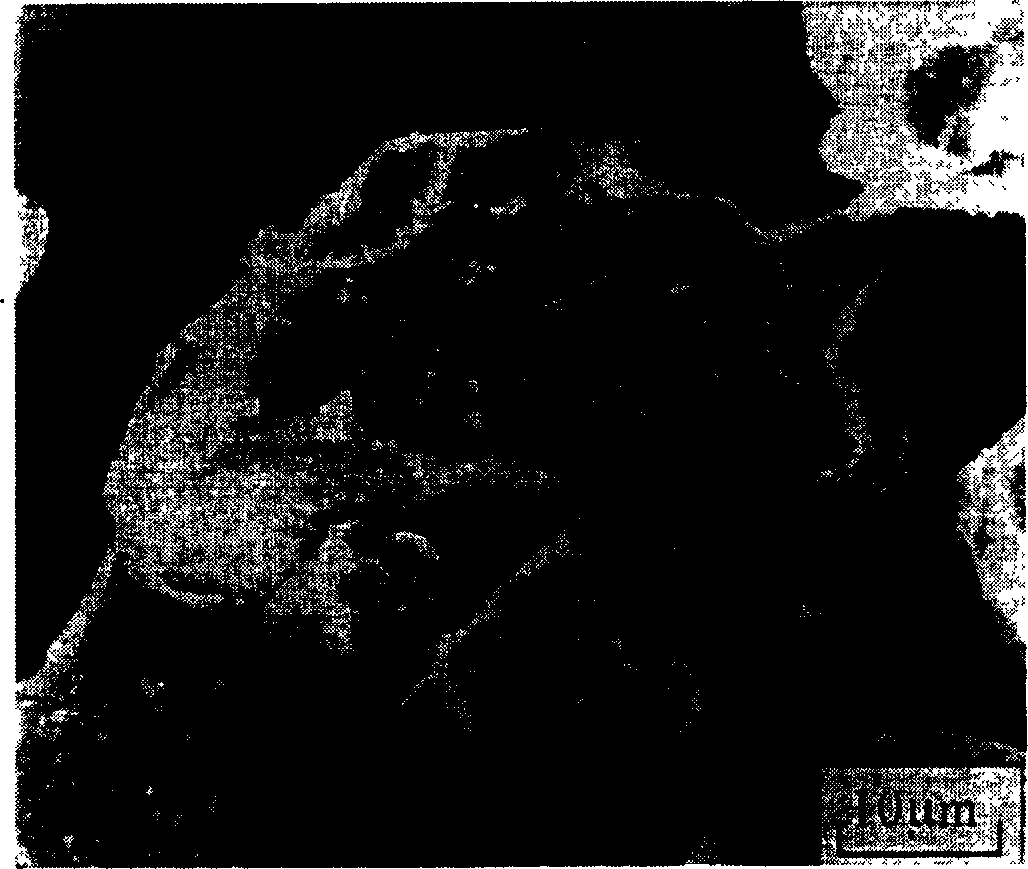

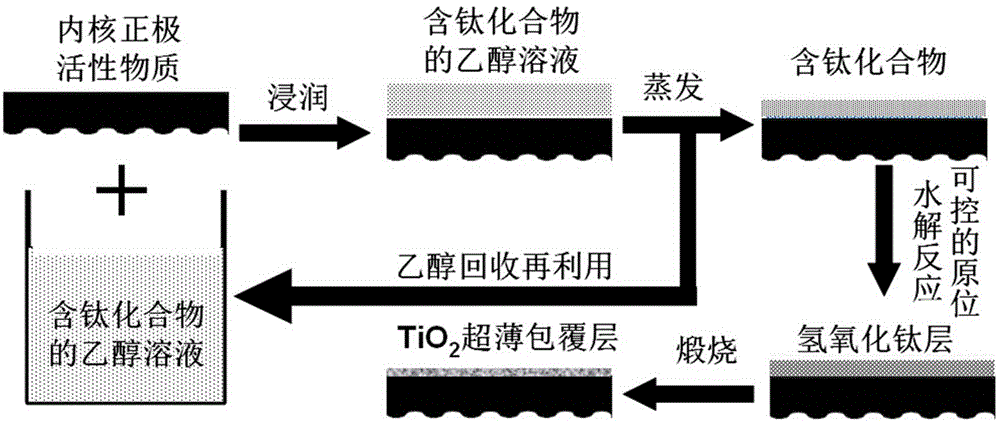

Ultrathin TiO2 coating layer of lithium battery cathode material, lithium battery cathode material and preparation method of lithium battery cathode material

ActiveCN104617267AGood conductivityLower polarization resistanceElectrode manufacturing processesSide reactionCalcination

The invention discloses an ultrathin TiO2 coating layer of a lithium battery cathode material. The coating layer is uniform and compact, and the thickness is only 0.5-20 nm. The lithium battery cathode material with a core-shell type coating structure comprises an inner-core cathode active material and the externally coated ultrathin TiO2 coating layer, wherein a mole ratio of Ti in the coating layer to a transition metal element in the inner-core cathode active material is 0.01%-3%. A preparation method of the lithium battery cathode material comprises steps as follows: a titanium contained compound is dissolved in an organic solvent; the inner-core cathode active material is added to the solution and stirred rapidly, the organic solvent is removed through heating, dry powder is obtained and is placed in dry air for standing to have in-situ hydrolysation with water molecules in air slowly and controllably, and intermediate powder is obtained and placed in an aerobic environment for calcination so as to obtain the lithium battery cathode material. The side reaction between the active material and electrolyte can be effectively inhibited, and the rate capability and the cycle performance of the lithium battery cathode material are improved.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

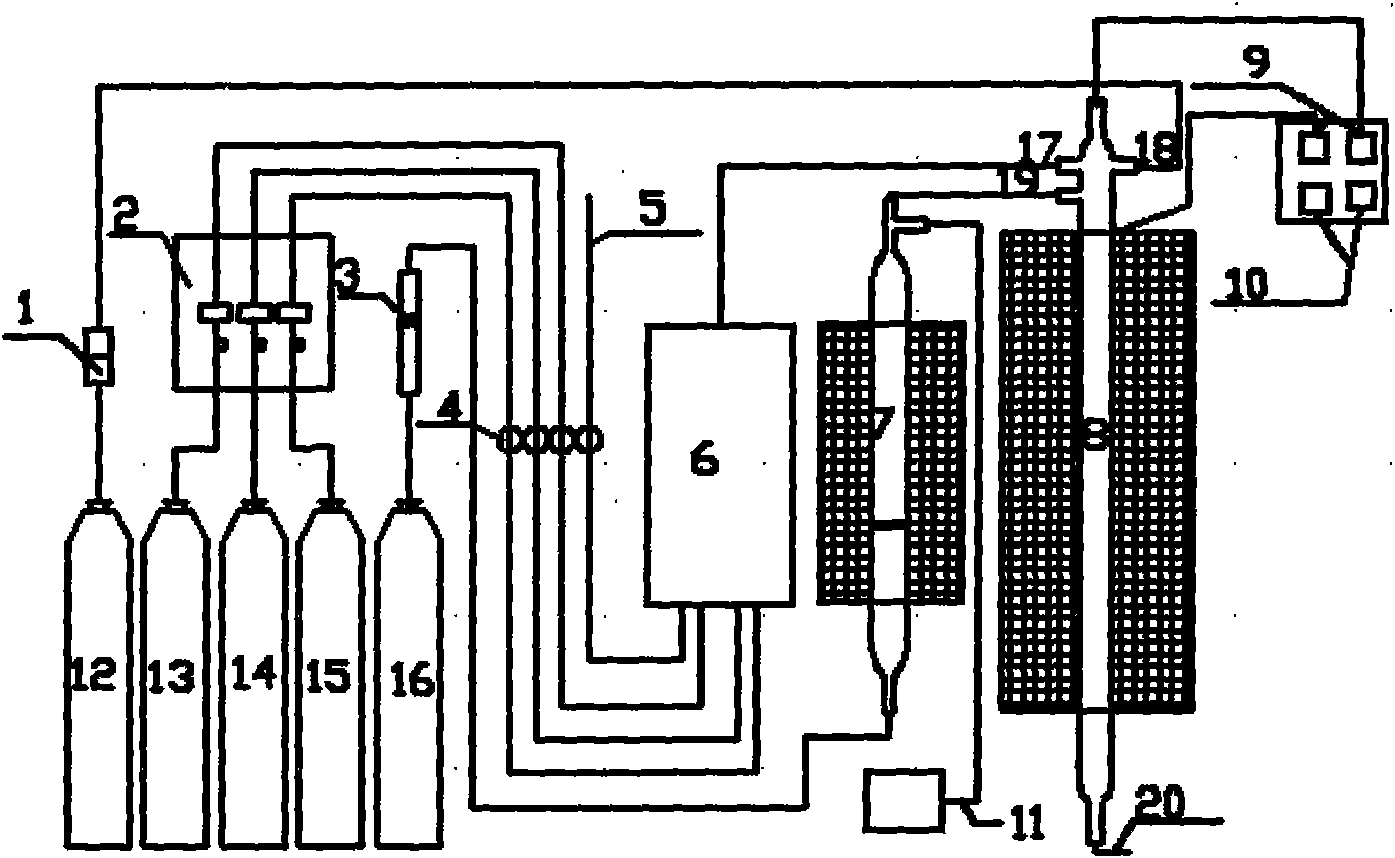

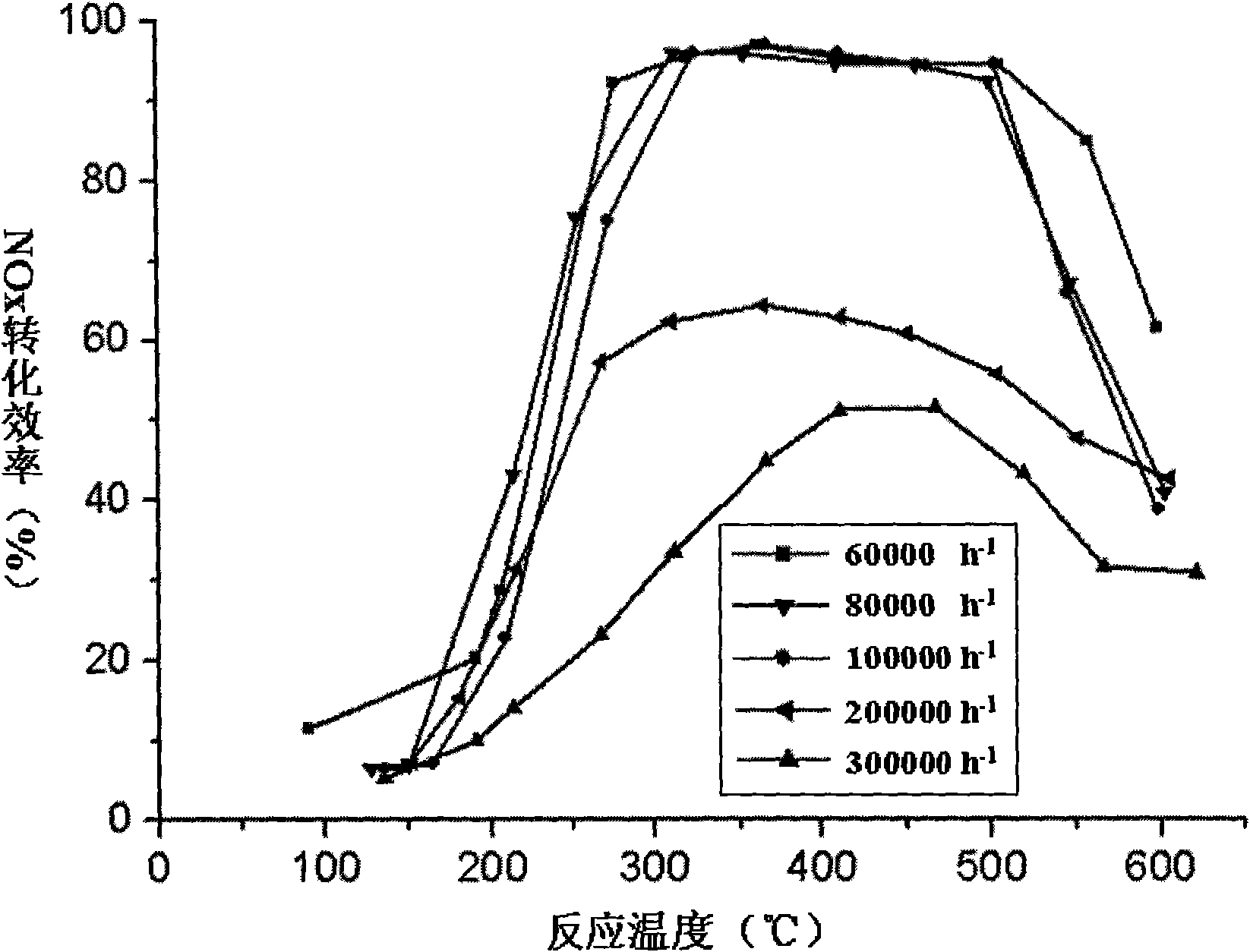

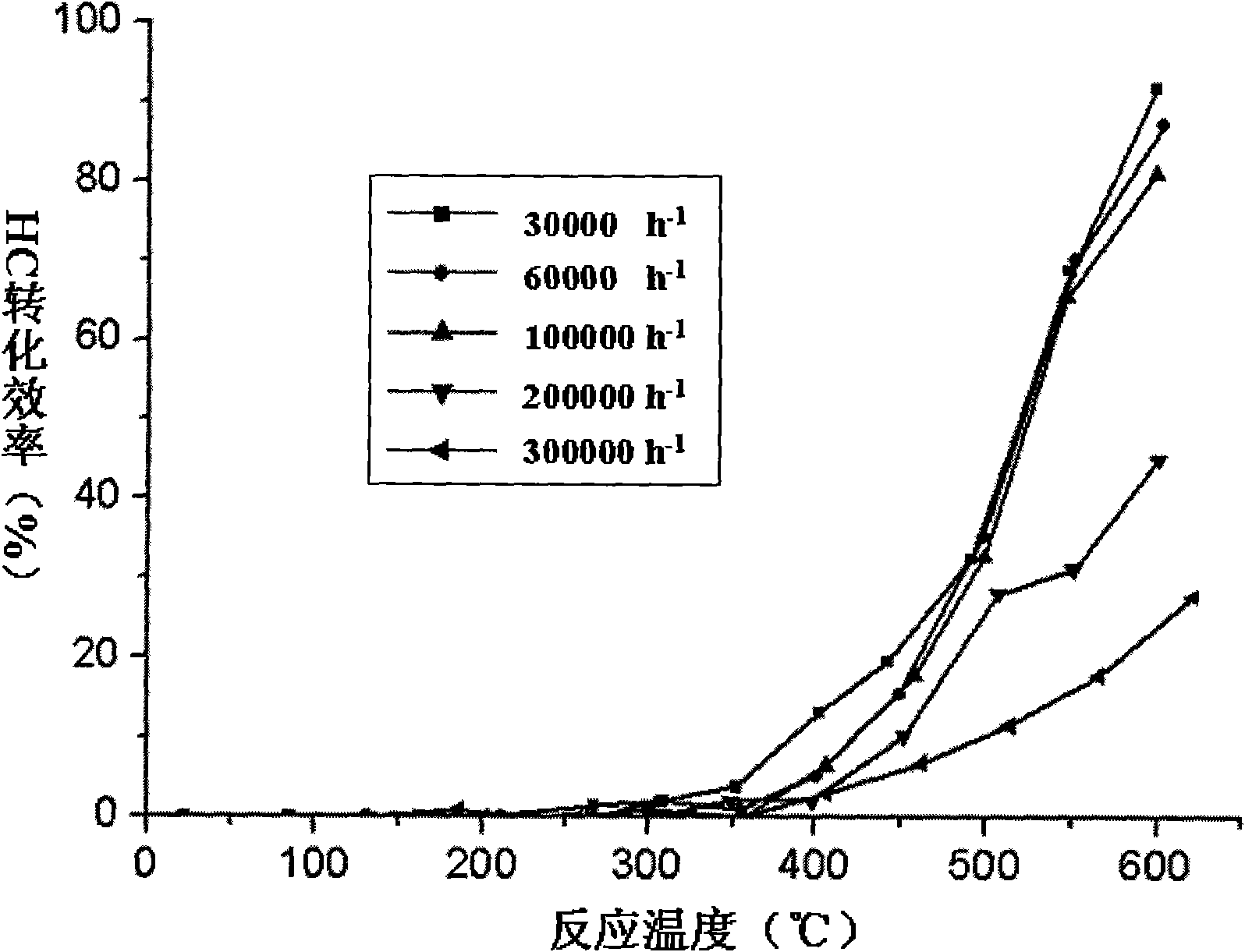

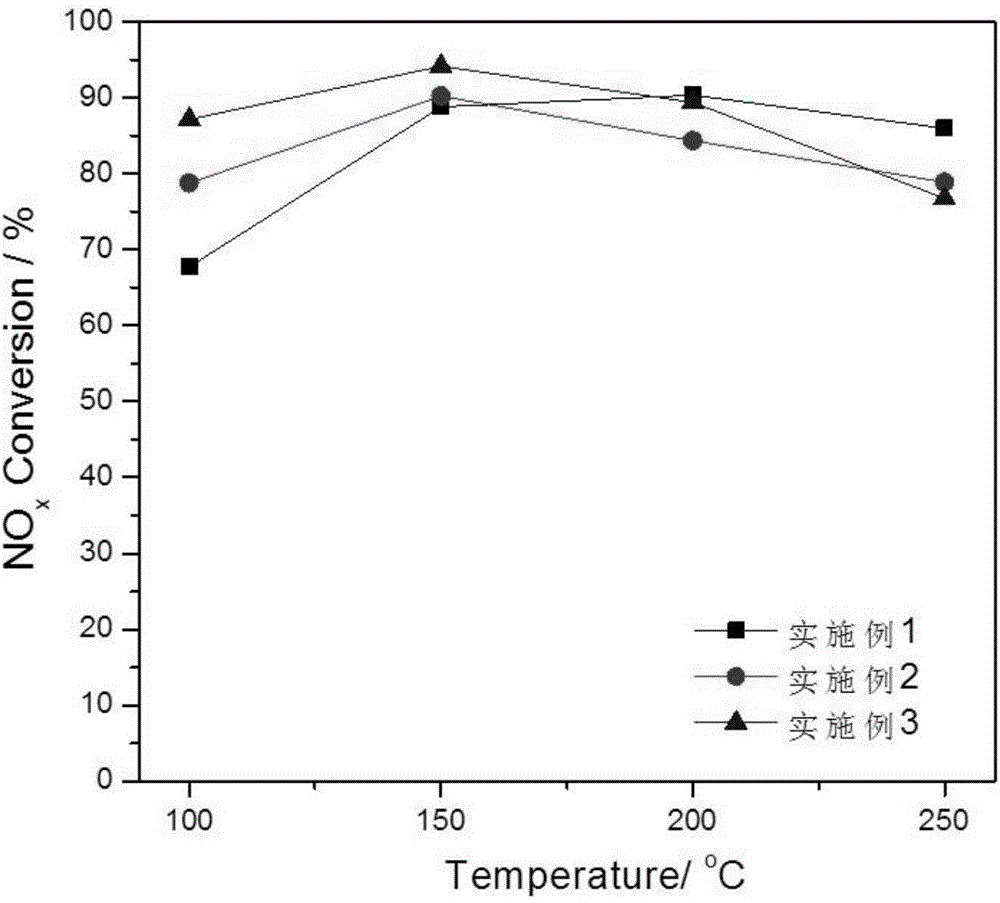

Catalyst for removing nitrogen oxide through selective catalytic reduction for Ce2O3 and V2O5 double active composition diesel truck

InactiveCN101559363ALow biological toxicityFacilitate catalytic reactionsInternal combustion piston enginesDispersed particle separationTraffic conditionsDiesel engine

The invention relates to a catalyst for removing nitrogen oxide through selective catalytic reduction for an automobile diesel engine adopting Ce2O3 and V2O5 double active compositions. The catalyst adopts scordierite honeycomb ceramics as a framework material, the Ce2O3 and the V2O5 as main active compositions, WO3 or MoO3 as an auxiliary catalyst composition, and TiO2 as a coating substrate, wherein the mass fraction of the main active compositions, namely the Ce2O3 and the V2O5, to the auxiliary catalyst composition WO3 or MoO3 to the coating substrate TiO2 is 1-3:6:12:85-93. The specific process comprises the following steps: preparing a TiO2 precursor solution; coating a TiO2 coating; coating an auxiliary catalyst; determining the loading of active compositions of oxides; and coating the main active compositions, namely the Ce2O3 and the V2O5. The catalyst replaces the V2O5 with high toxicity with the Ce2O3 with low toxicity, and reduces the environmental hazards of the catalyst, and the replaced catalyst has wider active temperature range, particularly greatly improves the low-temperature activity, and is particularly suitable for the traffic conditions of urban highways of China.

Owner:TIANJIN UNIV

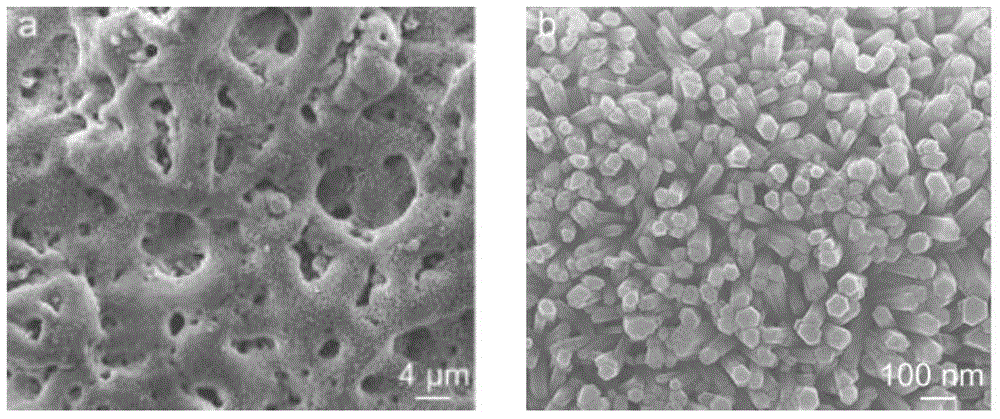

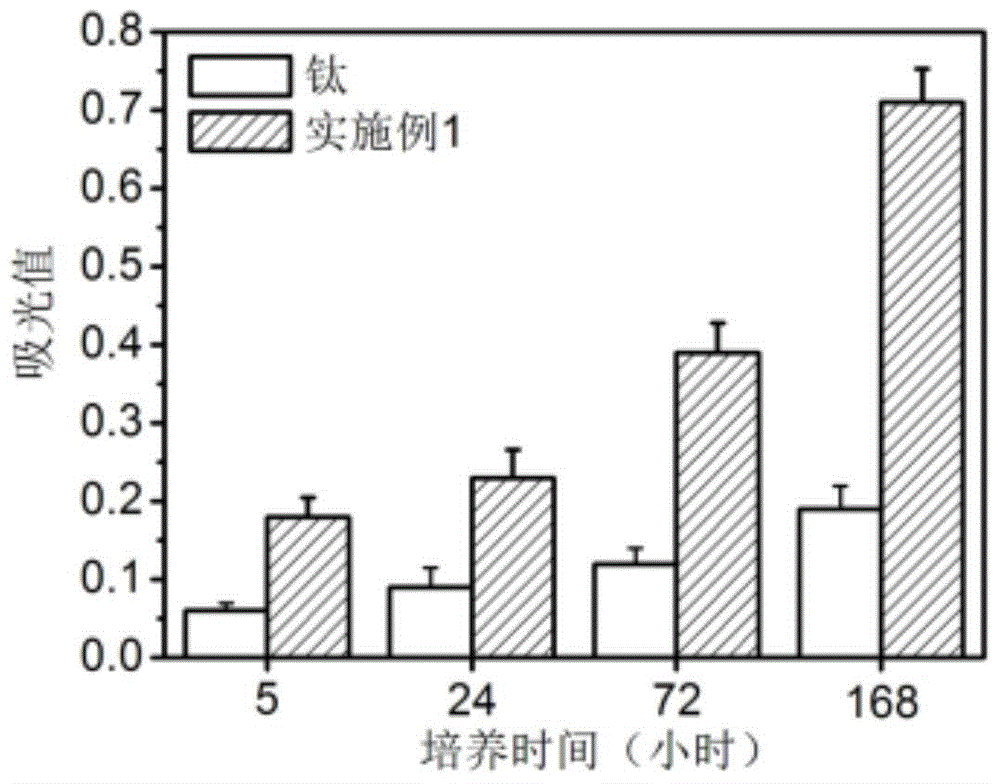

Titanium-based surface antibacterial and bone tissue regeneration induced functional coating as well as preparation method and application thereof

ActiveCN104645414AEase of mass productionSimple ingredientsSurface reaction electrolytic coatingProsthesisElectrolytic agentMicro arc oxidation

The invention provides a titanium-based surface antibacterial and bone tissue regeneration induced functional coating as well as a preparation method and application thereof. The preparation method comprises the following steps: firstly preparing an electrolyte, taking titanium or a titanium alloy as an anode and taking stainless steel as a cathode, preparing a porous TiO2 coating containing calcium, phosphorus and strontium by adopting a micro-arc oxidation technology, then sequentially performing hydro-thermal treatment by virtue of a fluorine-containing solution, and also loading human bone morphogenetic protein-2 to finally obtain a target coating disclosed by the invention, wherein the coating consists of an inner layer which is bonded on the surface of a matrix and a surface layer which is bonded on the surface of the inner layer, the inner layer is a porous TiO2 layer containing calcium, phosphorus and strontium, and the surface layer is a three-dimensional nano-fibrous hydroxyapatite layer which is loaded with human bone morphogenetic protein-2 and contains strontium and fluorine. No non-continuous interface is formed between the coating and the matrix, so that the coating provided by the invention has relatively good bonding strength and structure stability performance, also has good antibacterial and bone tissue regeneration inducing functions, and can be used for significantly promoting the osteogenic function of cells, promoting new bone formation and inhibiting the adhesion and growth of bacteria.

Owner:宝鸡卡斯特医疗科技有限公司

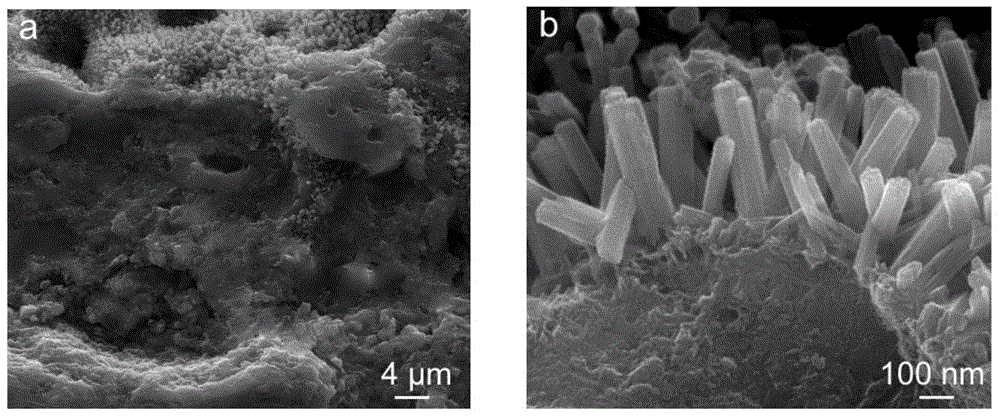

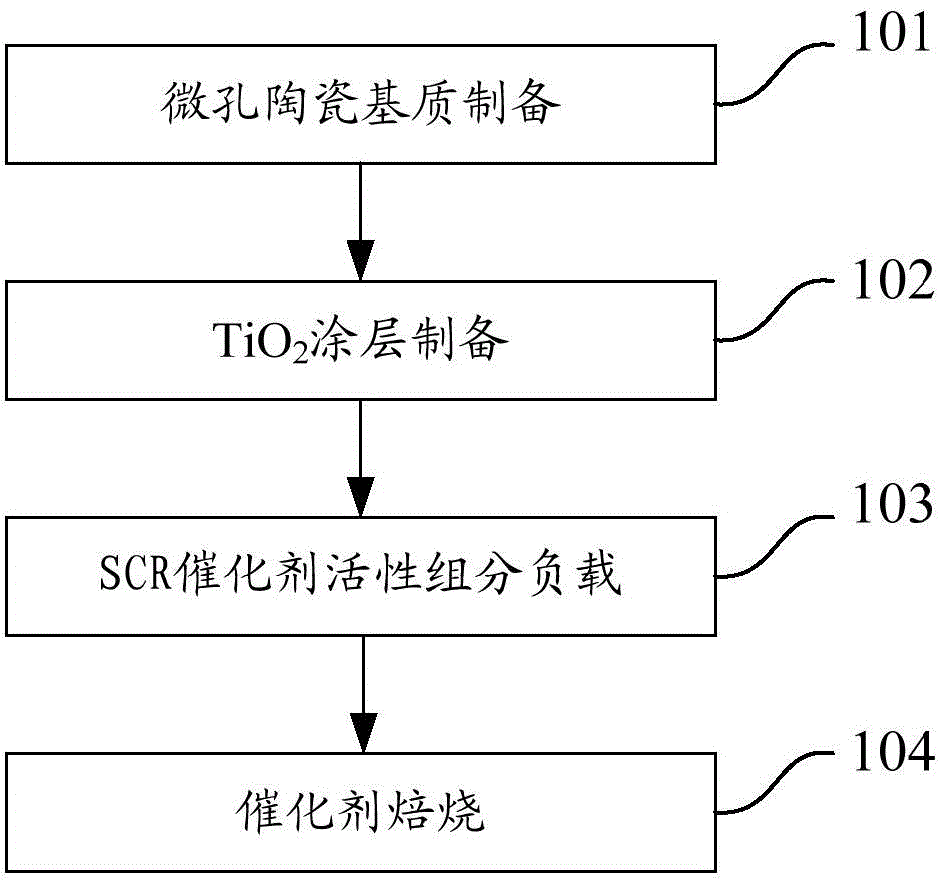

Micropore ceramic catalyst and preparation method thereof

ActiveCN104549398AEfficient removalHigh SCR catalytic activityPhysical/chemical process catalystsDispersed particle separationFlue gasActive component

The invention discloses a micropore ceramic catalyst and a preparation method thereof. The micropore ceramic catalyst takes at least one material of SiC, SiO2 and Al2O3 as an aggregate to prepare a microporous ceramic substrate, a TiO2 coating is prepared through a sol-gel method, and MnOx-CeO2 is loaded as a catalyst active component through a dipping or spraying way. The preparation method provided by the invention comprises the following steps: (1), preparing the microporous ceramic substrate; (2), preparing the TiO2 coating; (3), loading the SCR catalyst active component; (4), roasting the catalyst. The catalyst provided by the invention can be mounted behind a dirt catcher at the tail end of a cement kiln, can be used for effectively removing fine particles in flue gas, and has relatively high SCR catalytic activity.

Owner:CHINA BUILDING MATERIALS ACAD

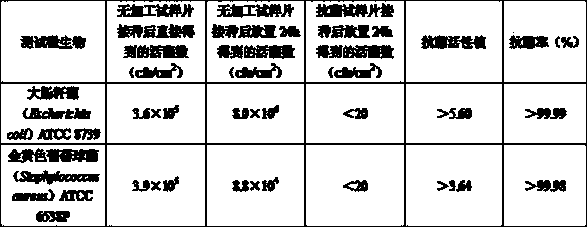

Preparation method of antimicrobial coating for metal of medical equipment

ActiveCN104194424AInhibit sheddingFor long-term storageAntifouling/underwater paintsPaints with biocidesMedical equipmentMetallic materials

The invention relates to a preparation method of an antimicrobial coating for metal of medical equipment and belongs to the technical field of plating of metal materials. The preparation method comprises the following steps: after titanate is dissolved with a solvent, adding acid, water, silicon-contained compounds, dispersing agents, silver salt and synergists in sequence in the mixing process and uniformly stirring to prepare a titanium oxide coating; upwardly and uniformly taking out the medical equipment metal immersed into the titanium oxide coating, airing, blowing or drying; then, putting the coated metal into a muffle furnace to calcine; taking out, naturally cooling to a room temperature and obtaining the antimicrobial coating on the metal of the medical equipment. According to the preparation method, as the titanium oxide coating containing silver is adopted as an antimicrobial material, and the silicon-containing compounds and the synergists are added, the preparation method has the characteristics that the preparation method is simple, the operation is convenient, the cost is low, and the antibacterial effect is good, the falling-off of coating materials can be prevented during the use, and the prepared coating can be stored for a long time.

Owner:刘军

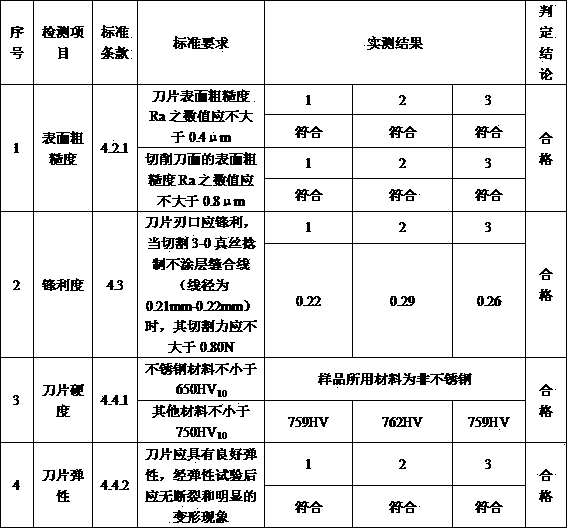

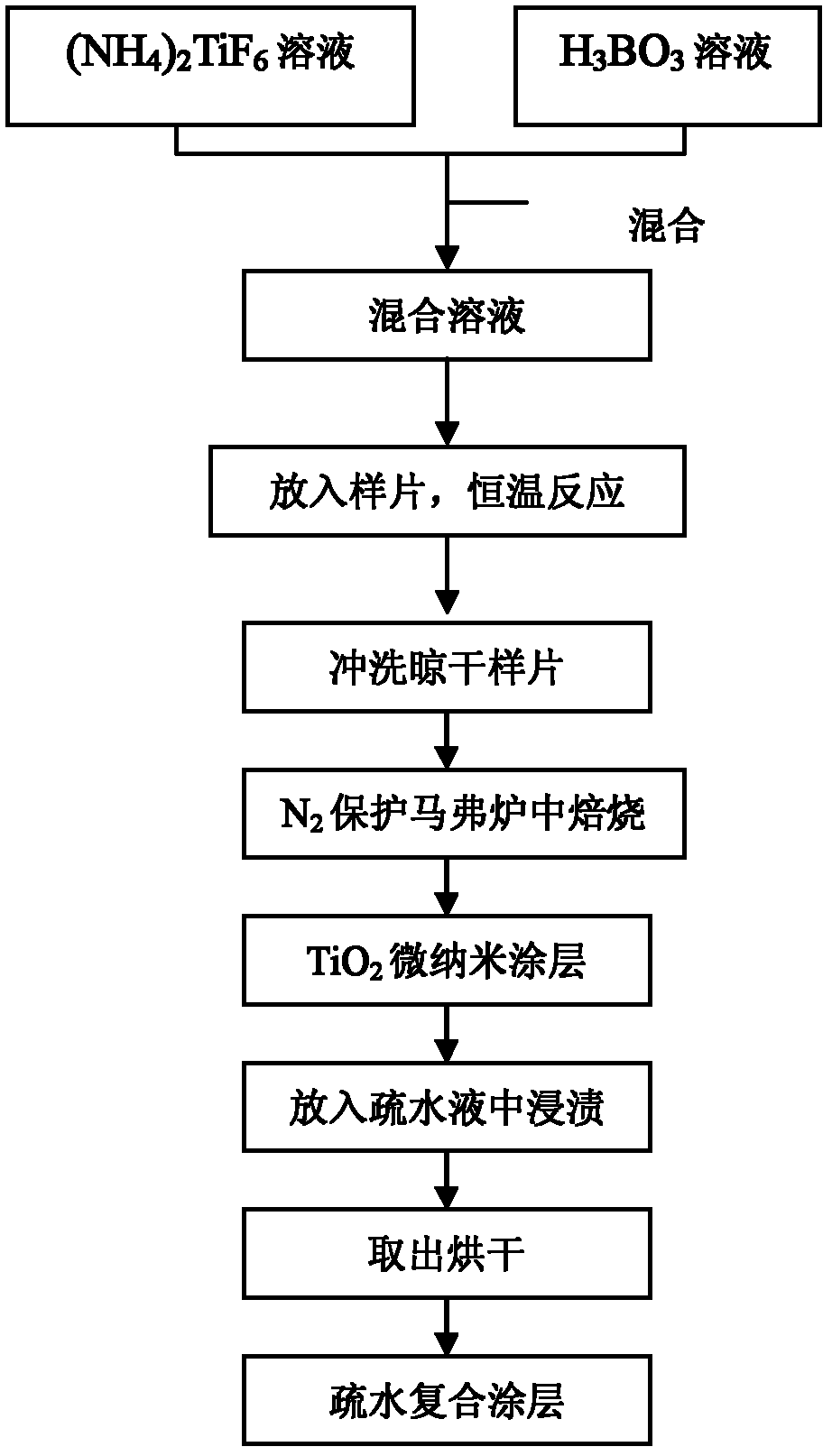

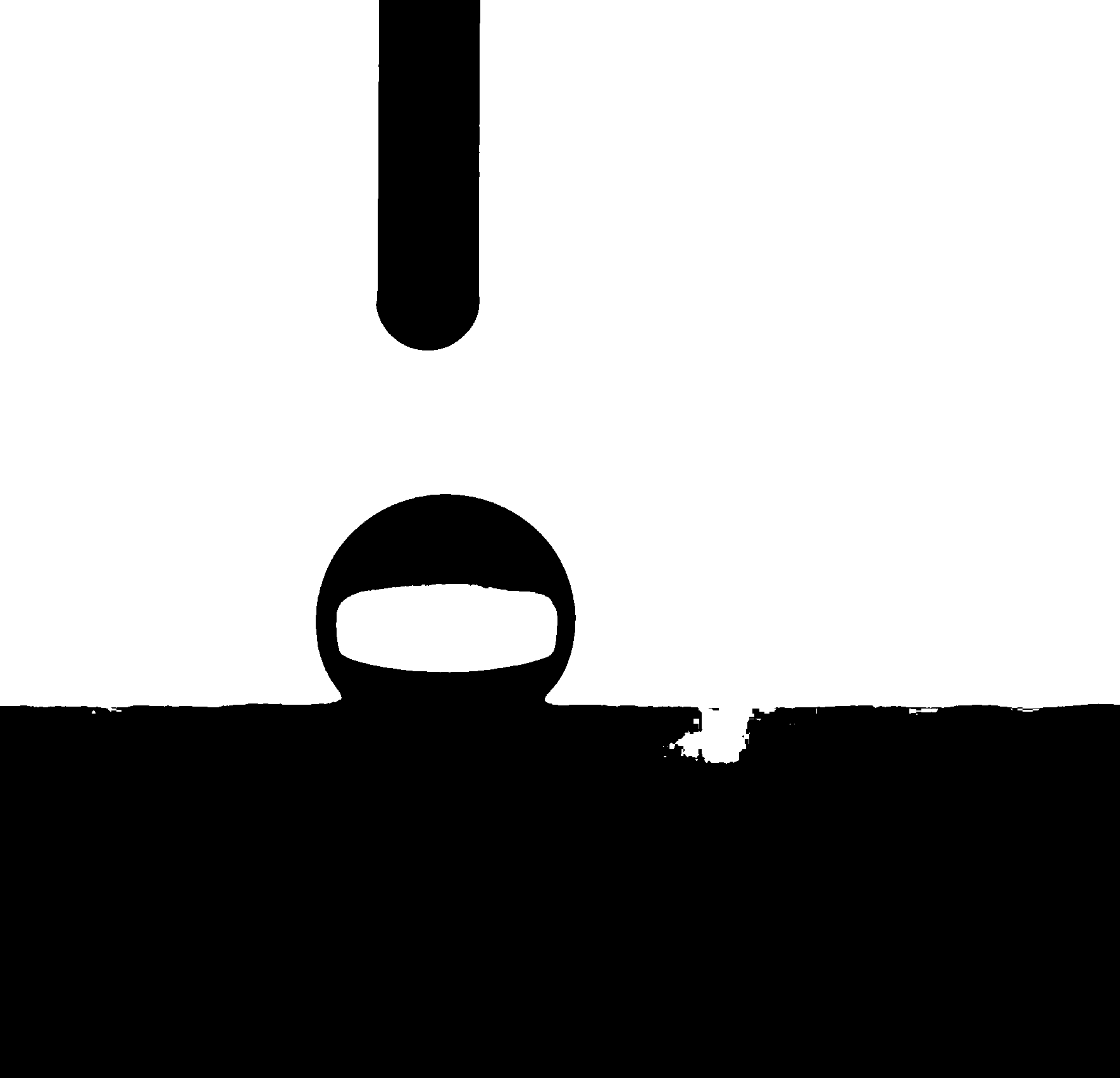

Liquid-phase deposition-impregnation preparation method of micro/nano low-surface hydrophobic composite anti-scaling coating

InactiveCN102527613AUniform and dense appearanceImprove hydrophobicityPretreated surfacesSpecial surfacesWater bathsDistilled water

The invention discloses a liquid-phase deposition-impregnation preparation method of a micro / nano low-surface hydrophobic composite anti-scaling coating, which includes the following steps of (a) grinding, polishing and cleaning a stainless steel substrate to be deposited; (b) treating the stainless steel substrate with diluted acid ultrasonically, forming a coarse structural layer on the surface of the stainless steel substrate, washing and cleaning the surface with distilled water and then drying the same at the room temperature; (c) placing the stainless steel substrate with the surface having the coarse structural layer into mixed solution in a constant-temperature water bath with the temperature ranging from 20 degrees to 80 degrees to prepare a substrate chip by means of deposition; (e) sintering the dried substrate chip in a resistance furnace under protection of N2 and taking the sintered substrate chip out of the resistance furnace after reducing the temperature of the sintered substrate chip to the normal temperature; (f) impregnating the substrate chip with a TiO2 coating into fluorosilane hydrophobic solution of the mass concentration ranging from 0.1% to3%, taking out the same and then drying in an oven with the temperature ranging from 100 DEG C to 200 DEG C. The coating prepared by the method is thin, compact, uniform and free of cracking and can be combined with the substrate firmly.

Owner:TIANJIN UNIV

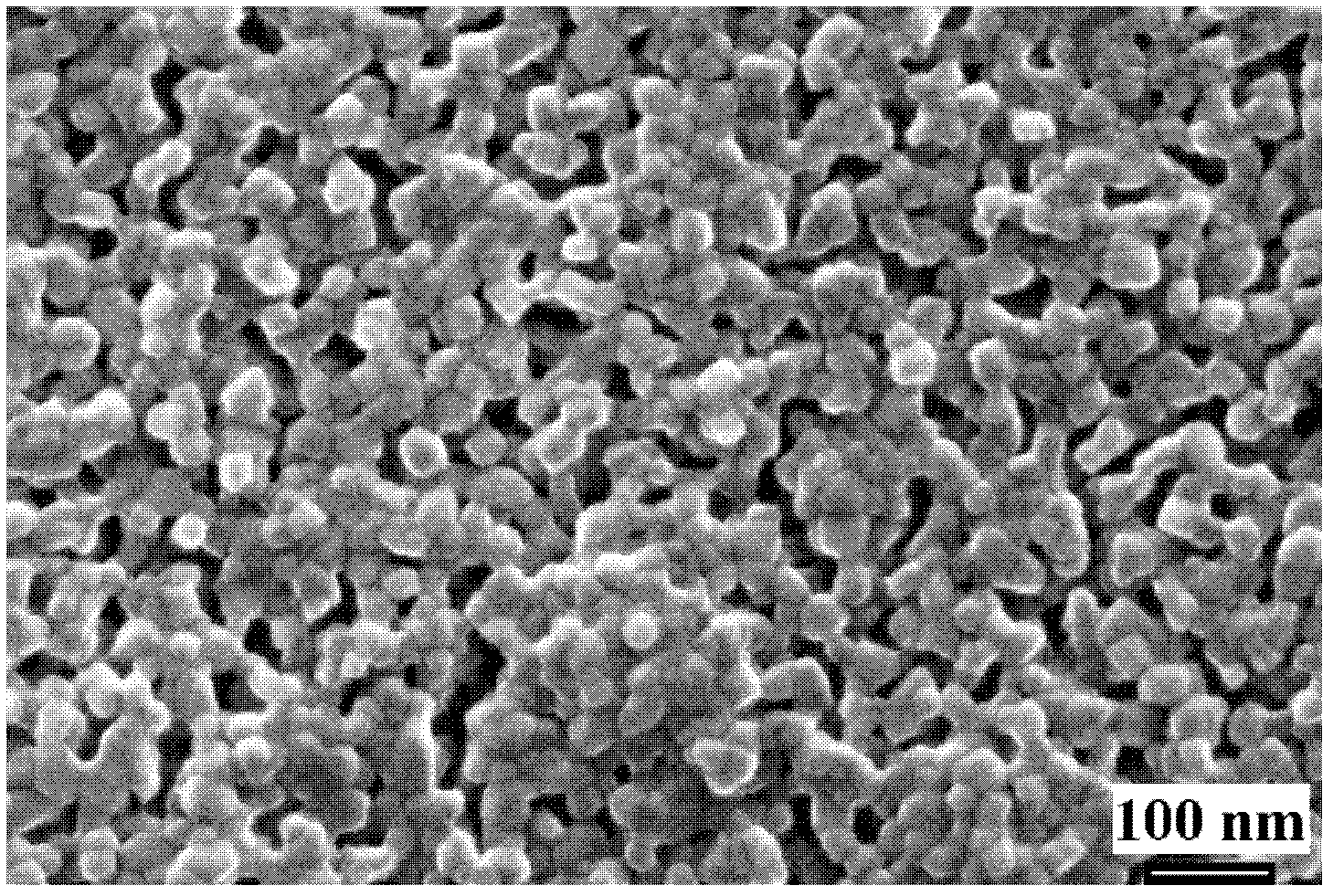

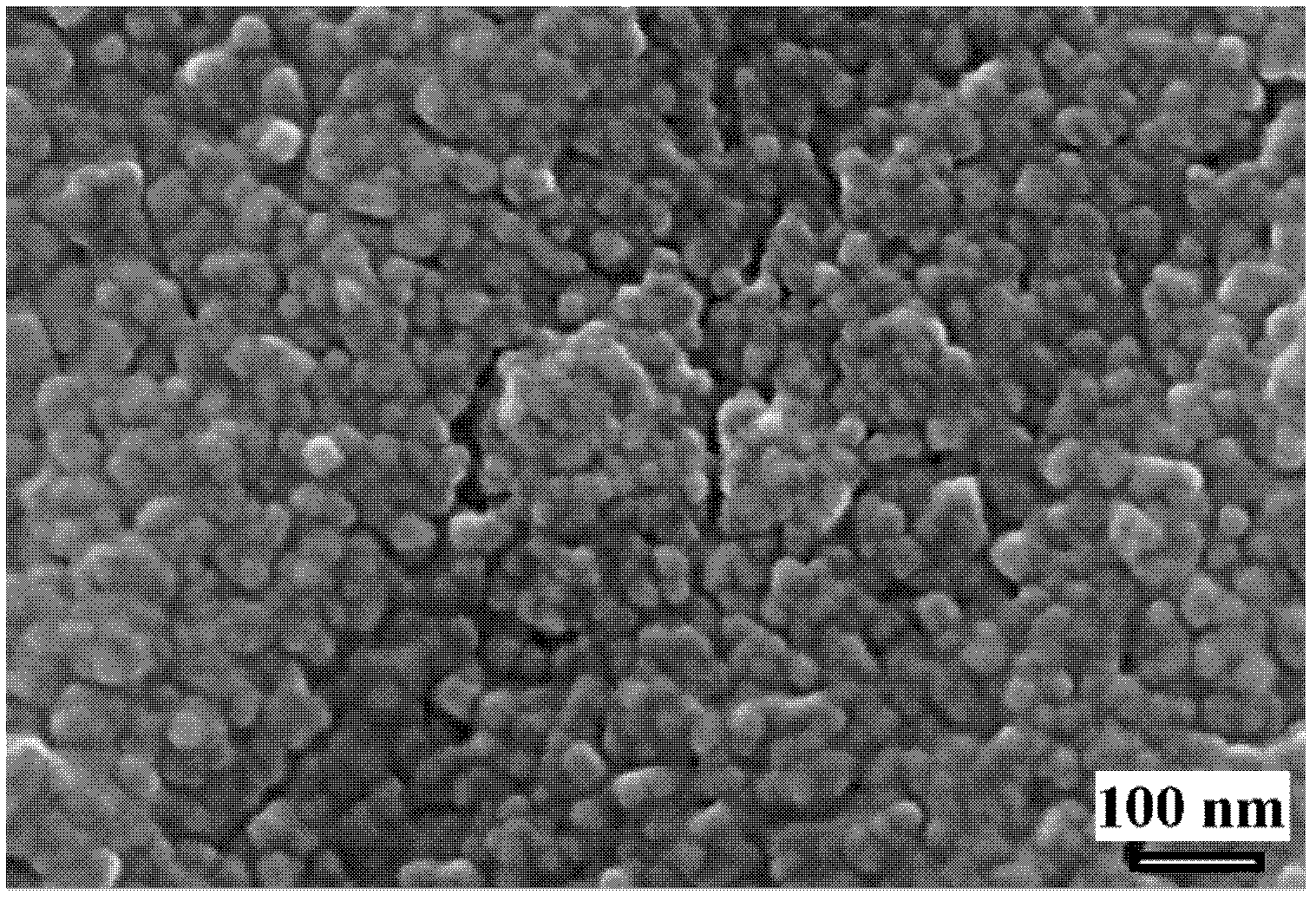

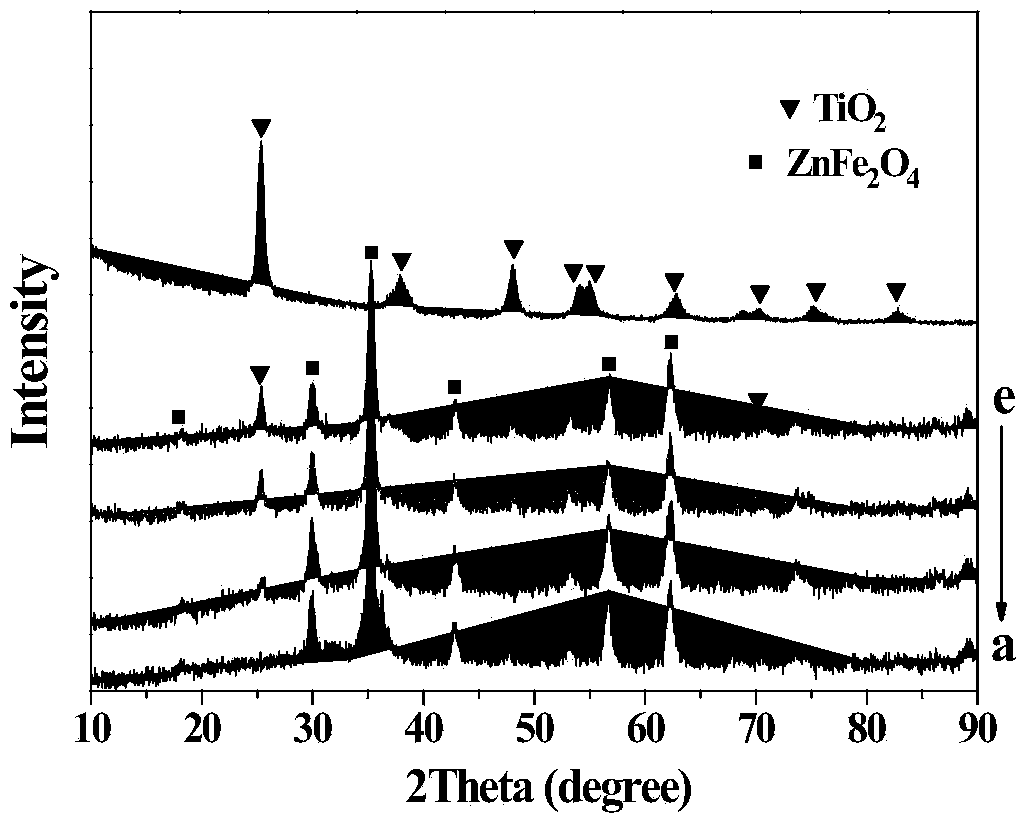

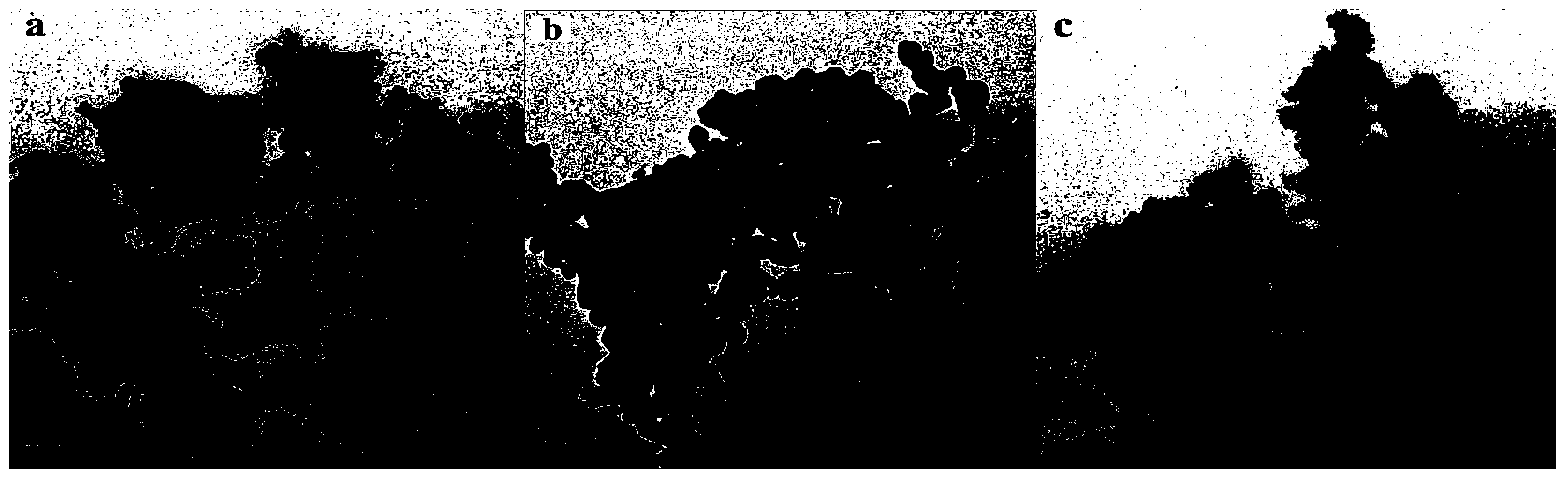

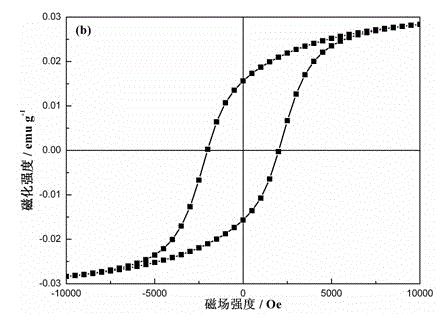

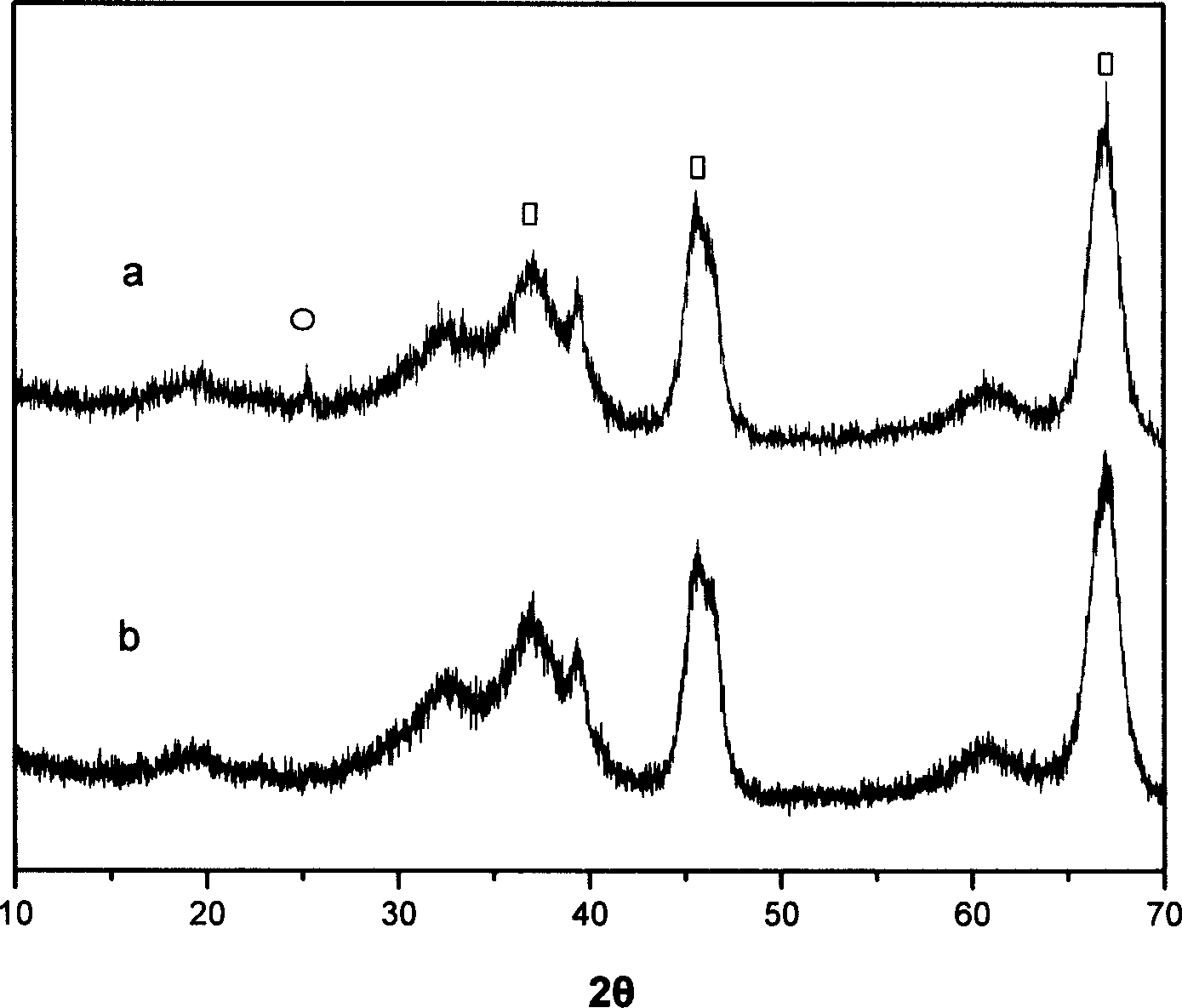

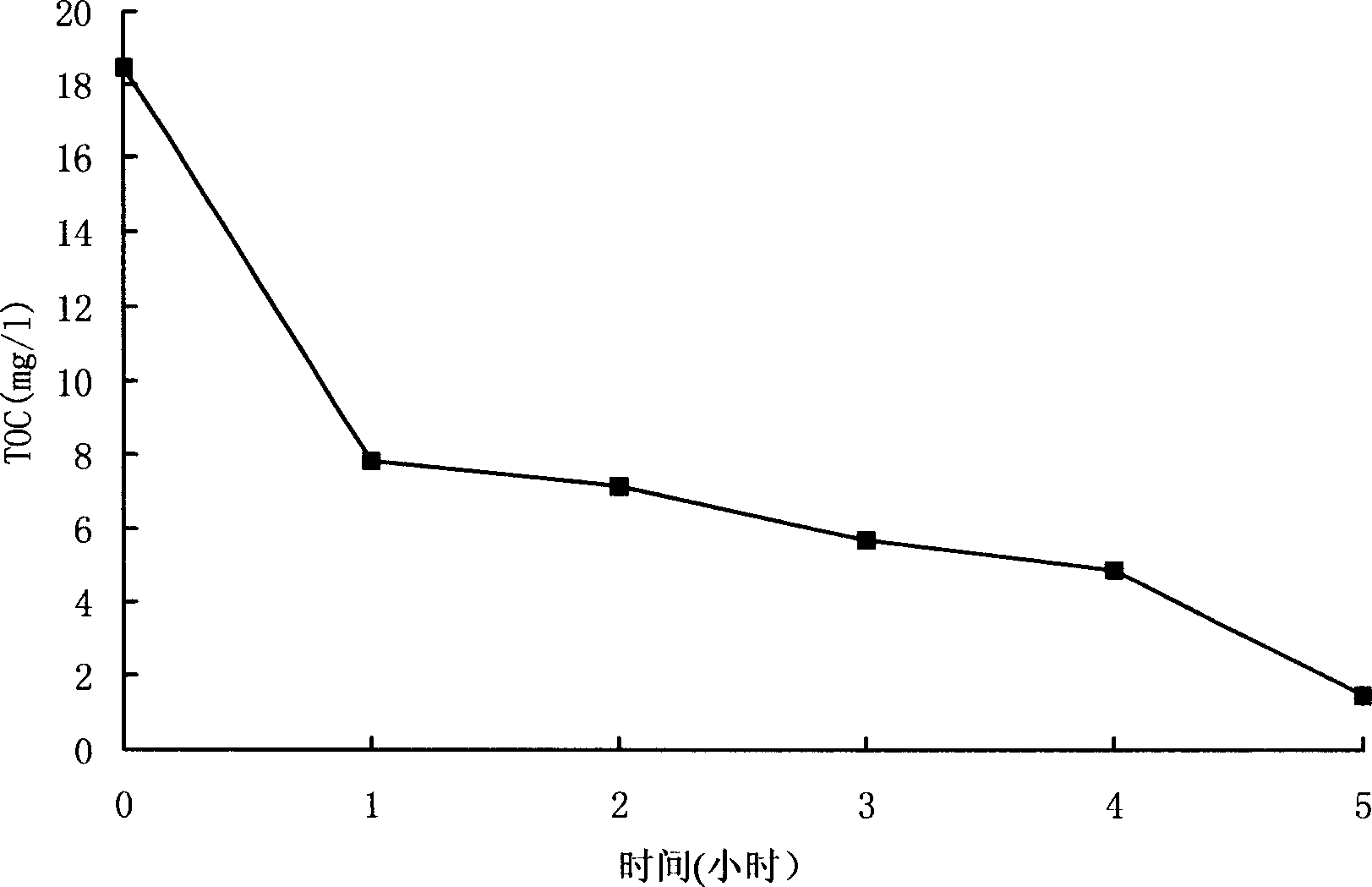

Preparation and application of novel wastewater treatment agent, ZnFe2O4/TiO2 compound

InactiveCN103949259AOvercome CorrosivityOvercoming the disadvantages of difficult recyclingWater/sewage treatment by irradiationWater/sewage treatment by magnetic/electric fieldsMicrosphereOmega

The invention belongs to the technical fields of magnetic materials and wastewater treatment, and particularly relates to a preparation method of a group of magnetically separable wastewater treatment agent, namely a zinc ferrite / titanium dioxide (ZnFe2O4 / TiO2) compound, and a process for processing wastewater by the compound. The method comprises the following steps: dispersing a template of carbon microspheres prepared from glucose into a mixed solution of a zinc salt and a ferric salt with certain concentration; refluxing, stirring, aging and drying at constant temperature to obtain a dark brown solid; carrying out high-temperature calcination to obtain hollow ZnFe2O4 powder; hydrolyzing Ti(OBu)4 under a certain condition to generate TiO2 coating the surface of hollow ZnFe2O4; sintering at high temperature to obtain the ZnFe2O4 / TiO2 compound with different TiO2 mass fractions (omega TiO2). The treatment agent is directly prepared by an ultrasonic-precipitation-hydrolysis-high temperature calcination technology. Compared with a traditional process for preparing a compound material by a calcination technology, the process provided by the invention is simpler, and has a better energy-saving effect; the prepared wastewater treatment agent can be conveniently recovered, activated, regenerated and recycled, and has the advantages of having a time-saving effect and being safe, efficient, cheap and environmentally friendly.

Owner:ZHEJIANG NORMAL UNIVERSITY

High temperature resistance anti-ultraviolet hydrophobic coating material and preparation method thereof

InactiveCN103265882AImproves UV resistanceImprove hydrophobicityCoatingsTio2 coatingUltraviolet resistance

The present invention provides a high temperature resistance anti-ultraviolet hydrophobic coating material and a preparation method thereof. The preparation method comprises: preparing a coating material: adding 2-20% by mass of nanometer titanium dioxide and a dispersant to dehydrated alcohol, dispersing to obtain a nanometer titanium dioxide dispersion, and mixing with an organosilicon resin and a curing agent to prepare a coating material; and carrying out spin coating: carrying out spin coating of a layer of an organosilicon / titanium dioxide coating material on a substrate, and carrying out spin coating of a layer of a titanium dioxide dispersion after the surface is dried, wherein the prepared coating has characteristics of good ultraviolet resistance and good hydrophobicity, and can maintain constant performances at a high temperature of 450 DEG C. The method has characteristics of wide raw material source, simple equipment and process, easy operation and low cost, and is suitable for industrial production. The coating material can be used in high temperature, anti-ultraviolet, water resistance and other fields.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Composite white pigment and preparation method thereof

InactiveCN102993787AEvenly dispersedCoated evenlyPigment physical treatmentSodium silicateTio2 coating

The invention discloses a composite white pigment and a preparation method thereof. The composite white pigment uses filter residue generated in the production of sodium silicate as a core, and crystal TiO2 as coating powder, wherein the filter residue mainly comprises quartz powder; the TiO2 is coated on the surface of the filter residue in a wet-process superfine grinding system through mechanical-chemical action, so that the composite powder has the properties of the pigment titanium dioxide. The composite powder disclosed by the invention has the characteristics such as uniform TiO2 coating, firm combination, strong covering power, high whiteness, simple preparation process, low cost and the like. The filter residue / TiO2 composite pigment has covering power and whiteness similar to those of titanium dioxide, can partially substitute titanium dioxide to be applied to the fields such as paint, plastic, printing link and the like for improving the product performance and reducing the cost.

Owner:FUJIAN NORMAL UNIV +1

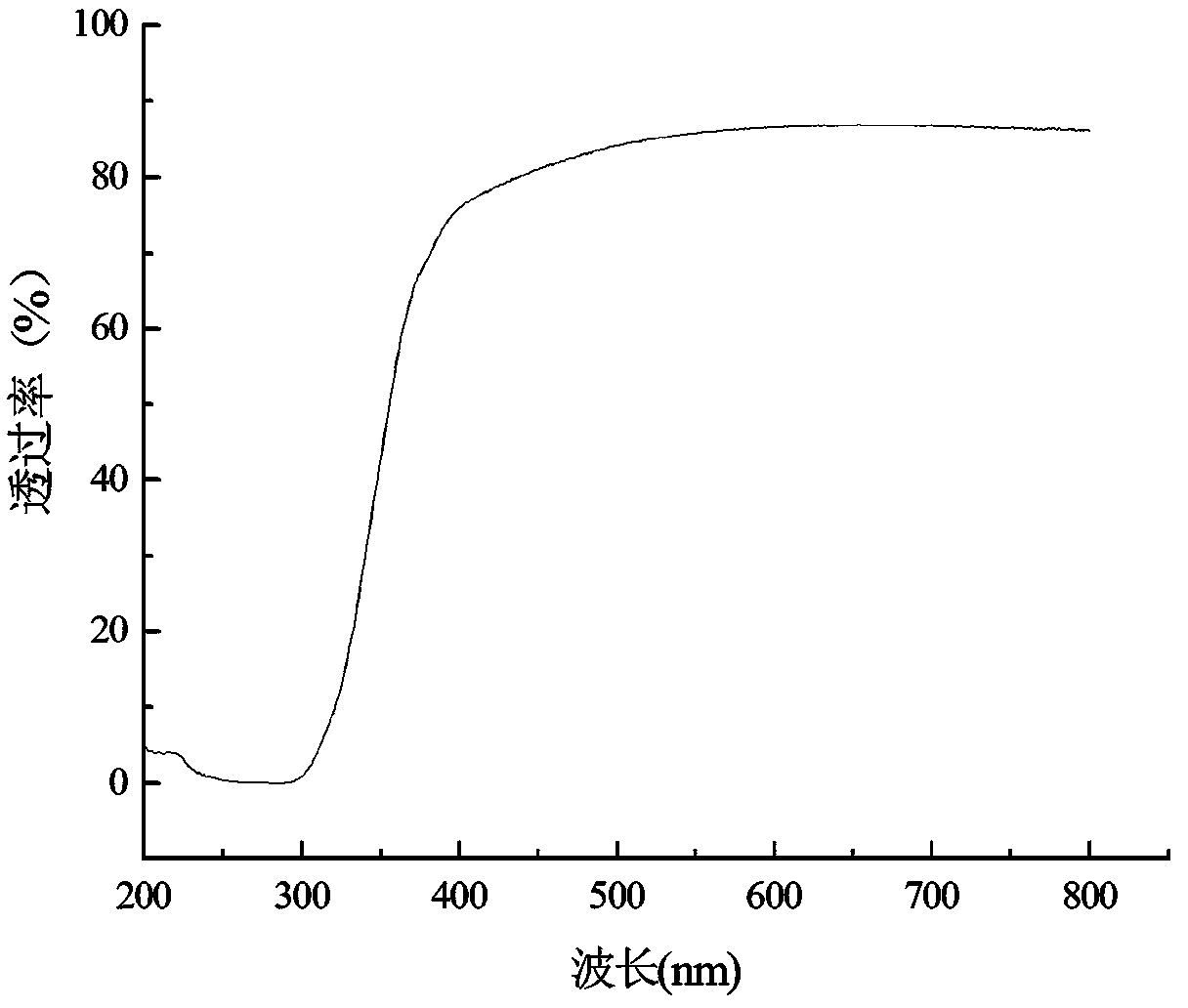

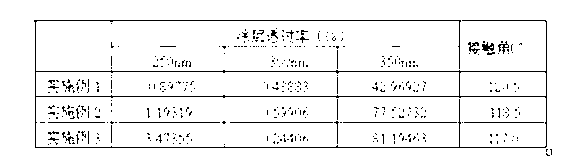

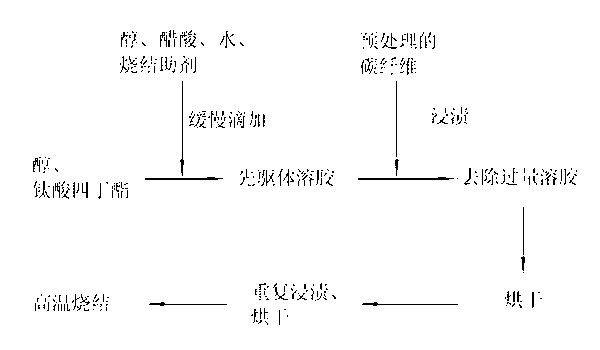

Method for preparing carbon fiber surface densified sintering TiO2 coating

InactiveCN103184687AStay flexibleImprove high temperature oxidation resistanceCarbon fibresFiberCarbon fibers

The invention discloses a method for preparing carbon fiber surface densified sintering TiO2 coating. The method takes titanate as a titanium source, an alcohol solution as a solvent, low melting point salt as an sintering aid, and organic acid as an chelating agent and a pH value regulator, and comprises the following steps: firstly, a precursor solution containing the sintering aid is obtained through hydrolysis, and then carbon fibers are dipped, dried, and sintered to obtain densified carbon fiber surface TiO2 coating. The method uses the low melting point salt as a fluxing agent which is converted into a liquid phase wet solid, penetrates between solid particles, dissolves sintering keys, and induces titanium dioxide particles to be rearranged, thereby achieving the effect of densifying the coating. The densified sintering TiO2 coating carbon fiber prepared by the method has the flexibility and stitchability of carbon fibers, simultaneously improves the high-temperature oxidation resistance performance of the carbon fibers, and avoids the interface reaction between the carbon fibers and a composite material matrix.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

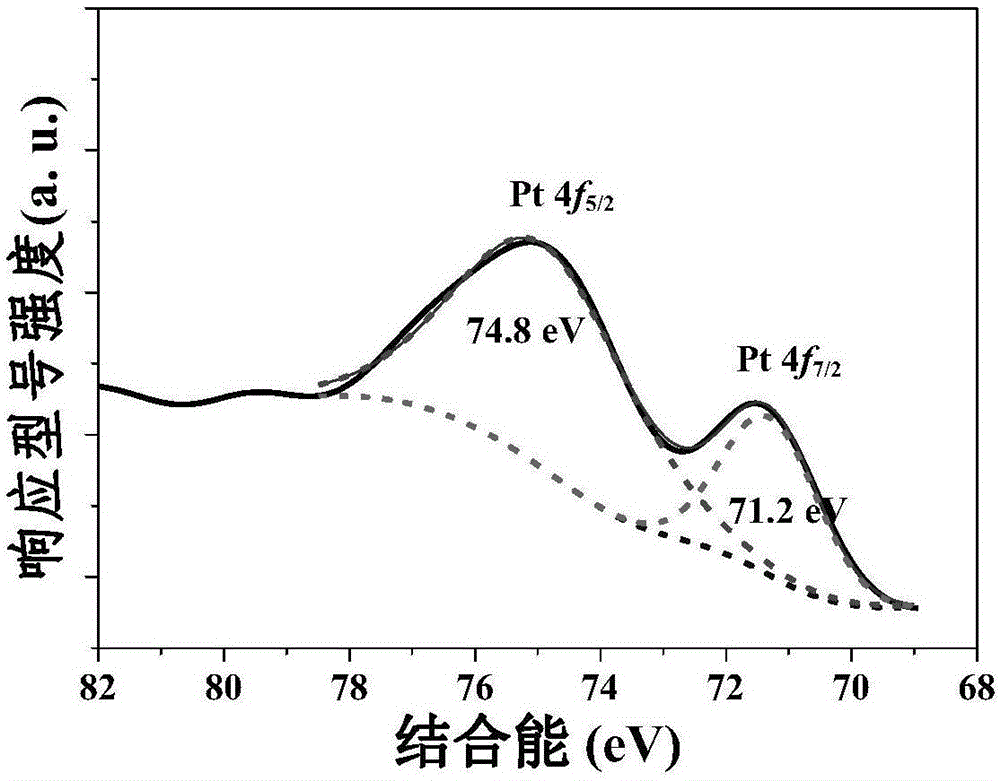

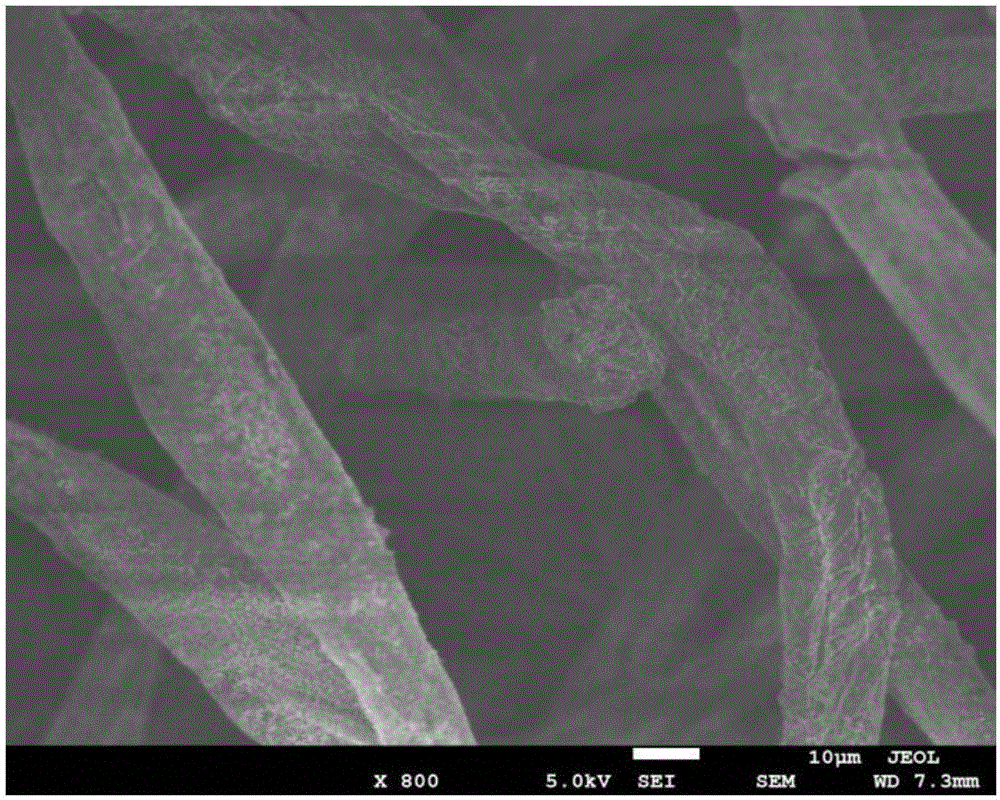

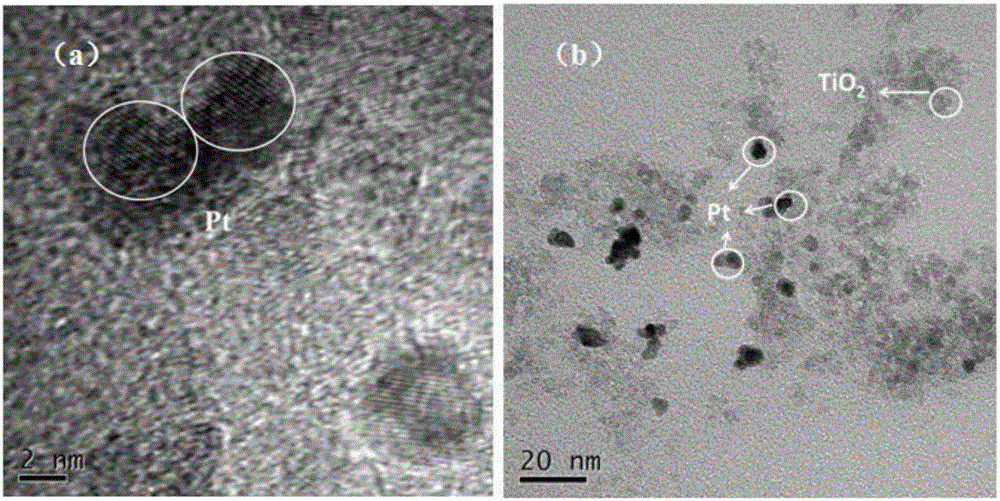

Flexible platinum formaldehyde room-temperature oxidation catalyst and preparation method thereof

ActiveCN106807451AAvoid the problem of easy sheddingAvoid breakingGas treatmentOrganic-compounds/hydrides/coordination-complexes catalystsFiberDispersity

The invention relates to a flexible platinum formaldehyde room-temperature oxidation catalyst and a preparation method thereof, in particular to a Pt / TiO2 / cotton fiber flexible composite formaldehyde room-temperature oxidation catalyst and a preparation method thereof. The catalyst comprises a degreased cotton fiber carrier, a nano TiO2 surface coating and Pt active ingredients dispersed on the surface of the TiO2 coating, wherein the Pt active ingredients exist in a zero-valence form, grain size ranges from 1nm to 10nm, and loading capacity is 0.05-2wt%. The Pt / TiO2 / cotton fiber flexible composite formaldehyde room-temperature oxidation catalyst has the advantages of hierarchical mesoporous-macroporous structure, light weight and flexibility, Pt is combined firmly with the TiO2 coating and carrier cotton fiber, elemental Pt of the active ingredients is high in dispersity on the surface of the TiO2 coating and small in grain size and can catalytically decompose formaldehyde efficiently at room temperature, noble metal Pt is low in consumption and air resistance, and the catalyst is suitable for using used in various air purifiers.

Owner:HUBEI UNIV OF TECH

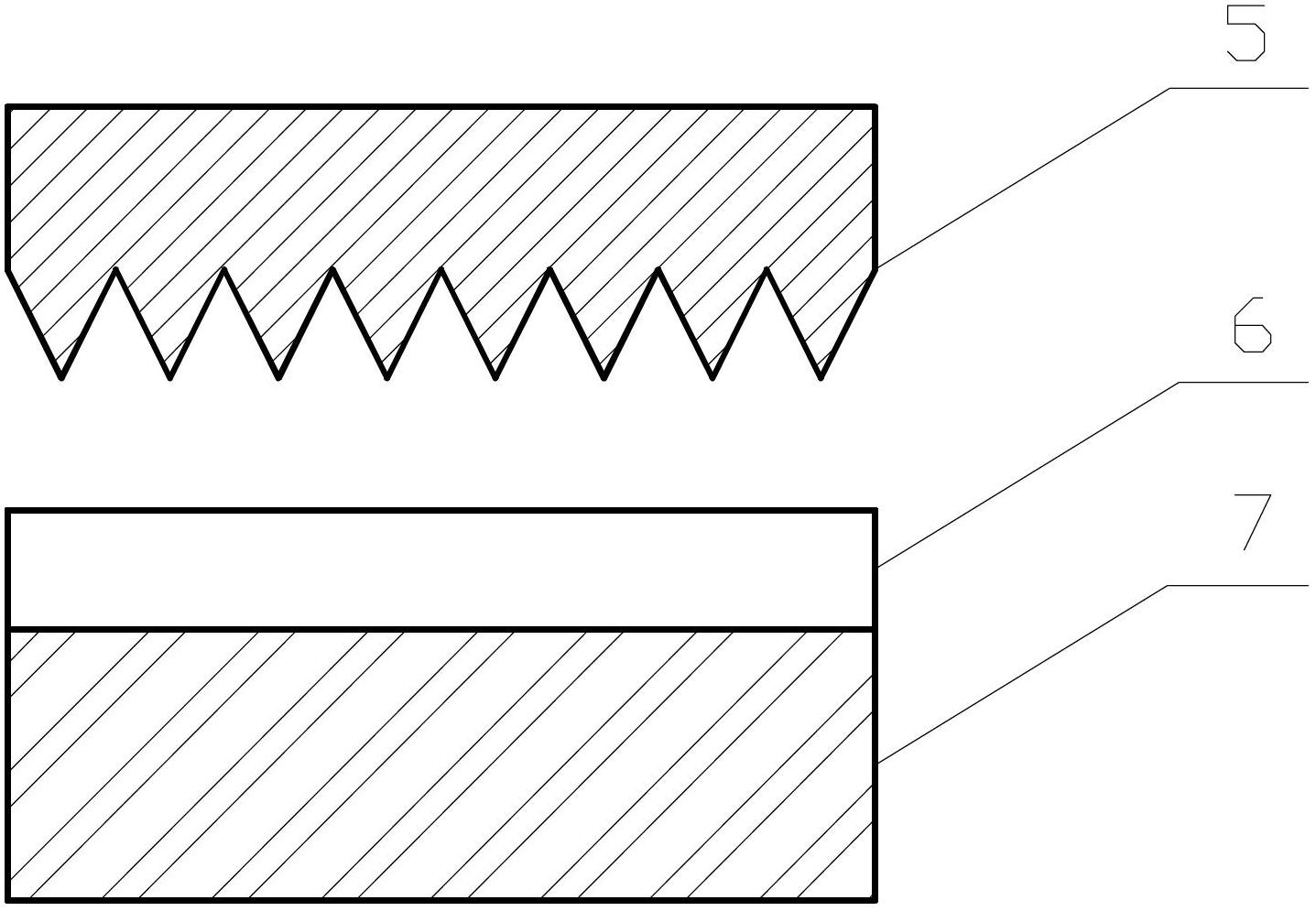

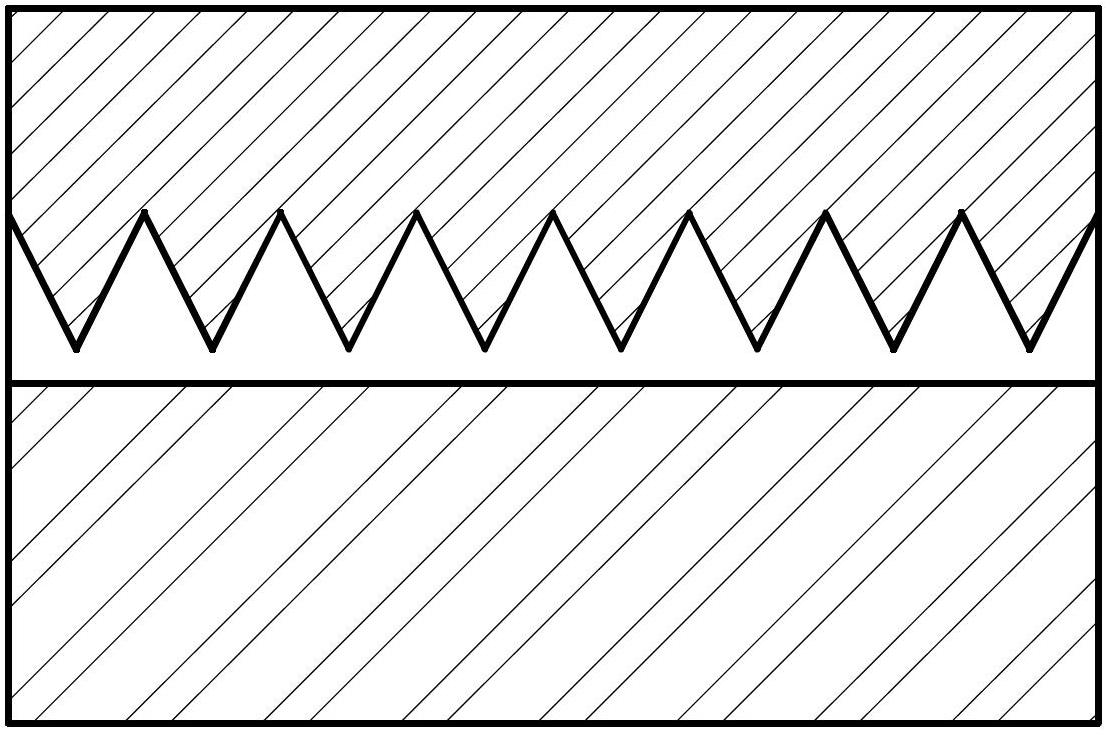

Preparation method of TiO2 plated type PU (polyurethane) or TPU (thermoplastic polyurethane) film anti-drag micro groove for airship skin

InactiveCN102658694ALow retractionReduce crackingLaminationLamination apparatusWeather resistanceLow load

The invention discloses a preparation method of a TiO2 plated type PU (polyurethane) or TPU (thermoplastic polyurethane) film anti-drag micro groove for an airship skin, relating to a preparation method of an airship skin material. The invention solves the problems of poor weather fastness, large resistance, poor thermal insulation, low load and large volume of the traditional stratosphere airship skin. The preparation method comprises the steps of: preparing a TiO2 sol precursor solution; preparing an Al template, cleaning the template, and coating a release agent; ultrasonically cleaning a film, impressing under the conditions of 135-140 DEG C and 15-20kg / cm<2>, and preserving the pressure for 2-3h; and coating a TiO2 coating on the impressed film. The prepared TiO2 plated type PU or TPU film anti-drag micro groove has the advantages of remarkable grooves, good regularity and remarkable anti-drag effects, and plays important roles in reducing the volume of an airship, increasing the load and prolonging the air residing time; and the TiO2 coating has the function of more strongly absorbing ultraviolet, and can shield elemental oxygen, so that damage of the ultraviolet to the film is reduced, and the weather resistance is increased. The preparation method is used for preparing the airship skin material.

Owner:HARBIN INST OF TECH

Modified TiO2 coating and preparation method thereof

ActiveCN103977826AImprove photocatalytic activityExert photocatalytic activityMetal/metal-oxides/metal-hydroxide catalystsPhosphateSilicon dioxide

The invention discloses a modified TiO2 coating and a preparation method thereof. The modified TiO2 coating comprises the following components in parts by weight: 60 to 100 parts of deionized water, 5 to 30 parts of titanium dioxide and 10 to 20 parts of an inorganic binder, as well as a nanometer precious metal solution, wherein the nanometer precious metal solution contains 3 wt% to 5wt% of nanometer precious metal and accounts for 0.01% to 3% of the weight of titanium dioxide based on nanometer precious metal; the inorganic binder is selected from any one of alkali metal silicates, aluminosilicate, phosphate or silicon dioxide sol. According to the modified TiO2 coating and the preparation method thereof, TiO2 is modified through the inorganic binder and the precious metal, the modified TiO2 film coating can be firmly bound on the surface of a carrier, and thus high stability is ensured, the catalyzing activity of TiO2 is improved, and a TiO2 catalyst can be recycled well; in addition, the preparation process is simple, the cost is low, the yield can reach 100%, and industrial mass production can be carried out easily.

Owner:SHANGHAI MASTECK ENVIRONMENTAL

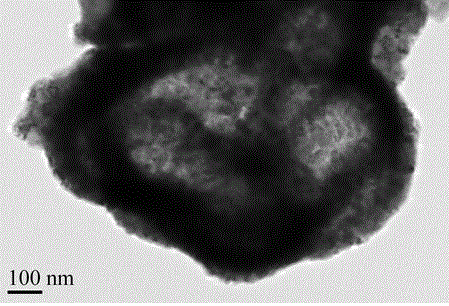

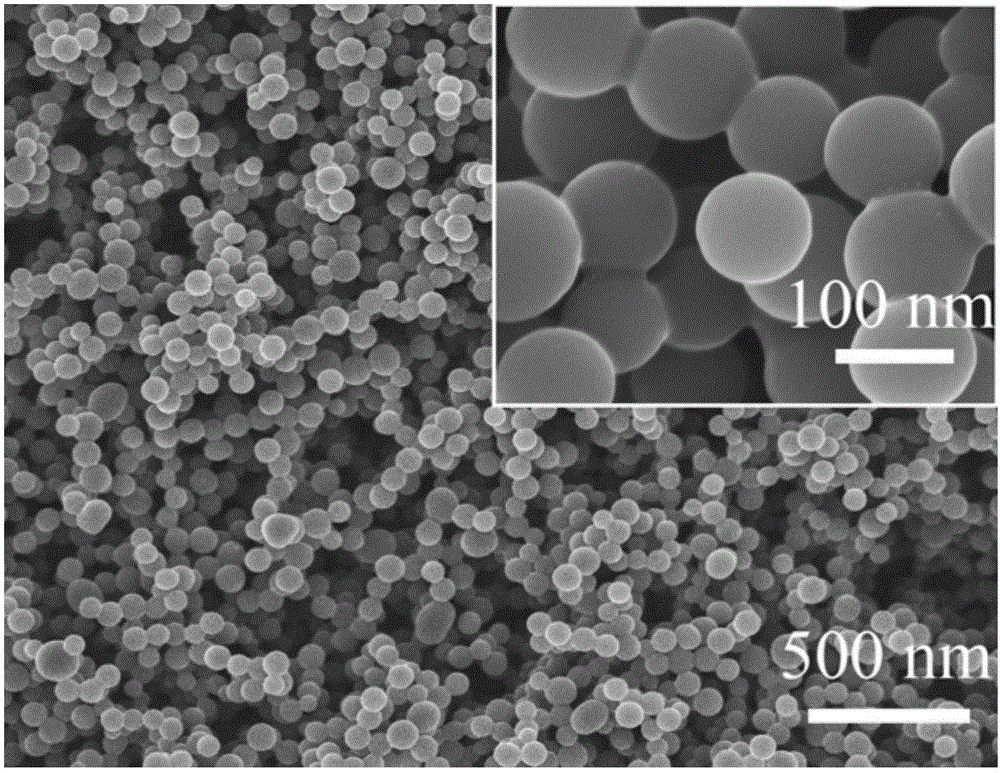

Magnetic recyclable hollow TiO2-SiO2-CoFe2O4 nano photocatalytic material and preparation method thereof

InactiveCN103143359ANot easy to fall offReduce interactionMetal/metal-oxides/metal-hydroxide catalystsMicrosphereUltraviolet lights

The invention discloses a magnetic recyclable hollow TiO2-SiO2-CoFe2O4 nano photocatalytic material and a preparation method thereof. The material is of a hollow structure, magnetic particles are wrapped by SiO2, and an outmost layer is a TiO2 coating. The method comprises the following steps of: hydro-thermally synthesizing nanocarbon spheres by utilizing glucose; precipitating SiO2 on the prepared magnetic particle surfaces through the reaction of a silicon source; based on the carbon spheres as a formwork material, loading magnetic SiO2 nano particles on carbon sphere surfaces under the action of adsorption, and thus preparing the SiO2-CoFe2O4-carbon sphere compound SCC; and loading TiO2 on the SCC surface by adopting a sol-gel method, and calcining to obtain the material. The material has the characteristics of good photocatalytic property under ultraviolet lights, controllable magnetic property, adjustable size, no physiological toxicity and the like; and moreover, due to the hollow structure, the compound microspheres also have the advantages of low density, high specific surface area and the like.

Owner:NANJING UNIV

Micro-nanostructure composite coating and preparation method thereof

InactiveCN105908117AImprove corrosion resistanceIncrease roughnessMolten spray coatingSuperimposed coating processPtru catalystPhoto catalytic

Owner:SHAOXING SPRAY MICRONANO TECH

Surface activation method of dental implant

InactiveCN101773412AEvenly distributedPromote ingrowthDental implantsArtificial teethActivation methodTitanium alloy

A surface activation method of a dental implant comprises: putting a titanium implant in 1-3M of H2SO4 liquid, using the titanium or titanium alloy of the titanium implant as an anode and using a Pt material as a cathode to carry out anode oxidation by using an anode oxidation method, preparing an oxidation film with a three-dimensional spherical pore microstructure on a surface, and existing round pits in different sizes and with apertures of 100-200nm in local areas; and putting the titanium implant with the oxidized anode in 3-5M of NaOH alkali solution for processing and forming a titanium gel on the surface, wherein the enriched Ti-OH groups induce the generation of calcium phosphate crystal nucleuses to form a bone-like apatite layer. The invention uses the combination of the anode oxidation method and an alkali process method for preparing an active TiO2 coating layer on the surface of the titanium alloy, the implant processed by the anode oxidation method has good compatibility with bone, and bonding strength and bone sediment yield are both obviously higher than that of the unprocessed titanium, thereby greatly improving the clinic success ratio of the dental implant.

Owner:沈阳天贺新材料开发有限公司

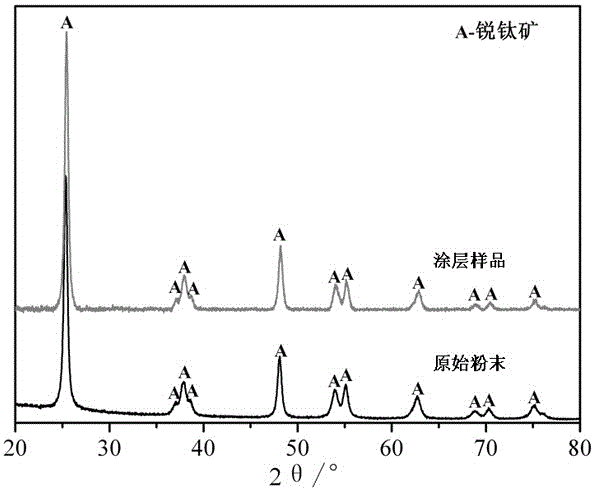

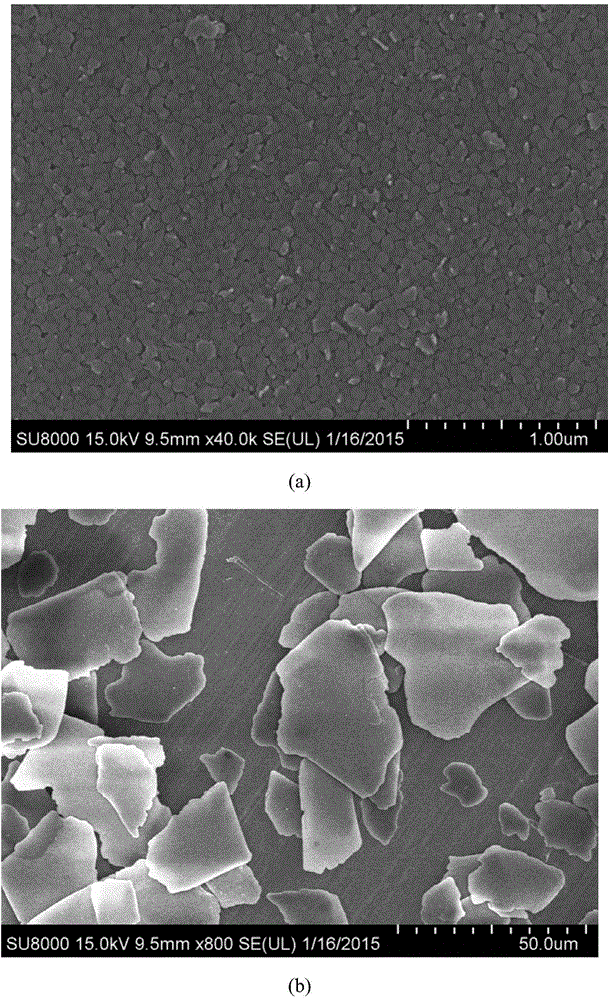

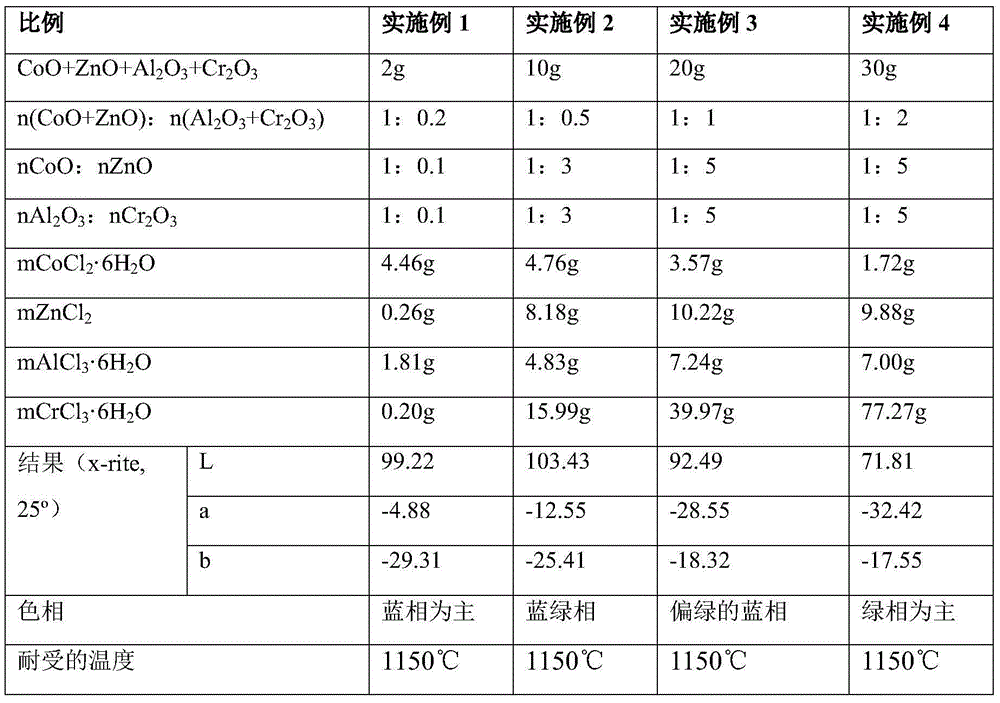

Blue-green series pigment with pearlescent effect and preparation method of pigment

ActiveCN104804475AStrong Optical Interference EffectAdd colorful effectInorganic pigment treatmentCoatingsCobalt blueTio2 coating

Blue-green series pearlescent pigment comprises the following components: 1), a substrate; 2), a SnO2 and TiO2 coating layer deposited on the substrate; and 3) a chromium, zinc and cobalt blue pigment coating layer deposited on the SnO2 and TiO2 coating layer, wherein the chromium, zinc and cobalt blue pigment coating layer comprises chromium oxide, zinc oxide, cobalt oxide and aluminum oxide or mainly comprises chromium oxide, zinc oxide, cobalt oxide and aluminum oxide. The invention further provides a method for preparing the blue-green series pearlescent pigment and an application of the blue-green series pearlescent pigment.

Owner:GUANGXI CHESIR PEARL MATERIAL CO LTD

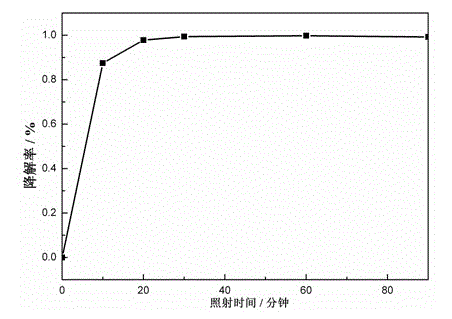

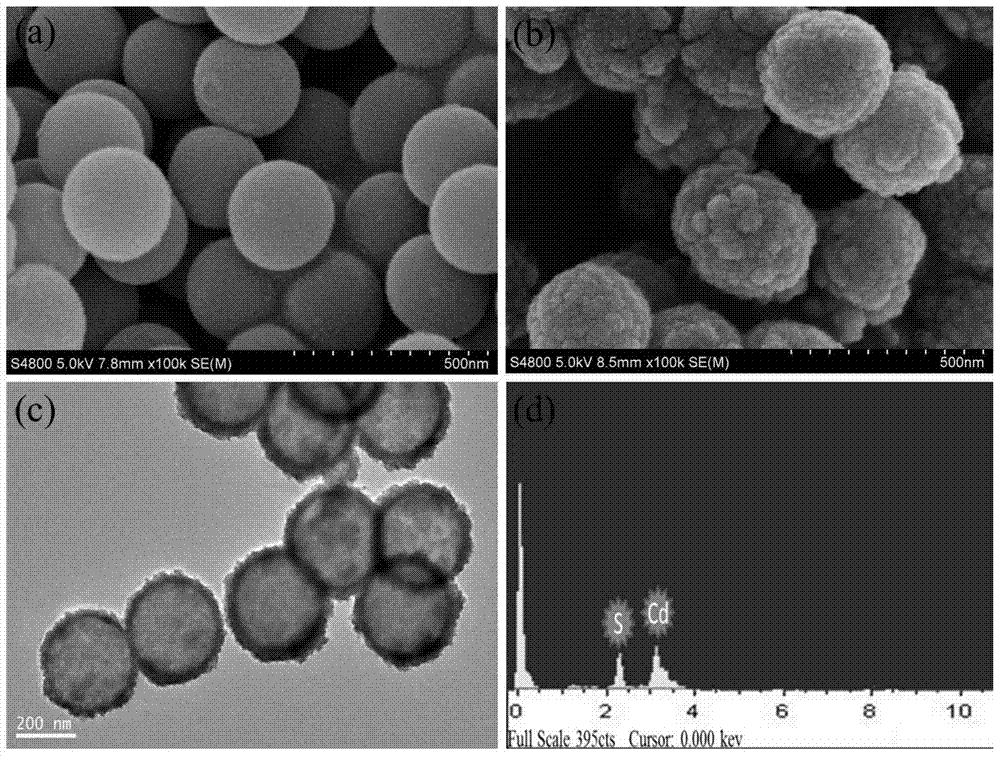

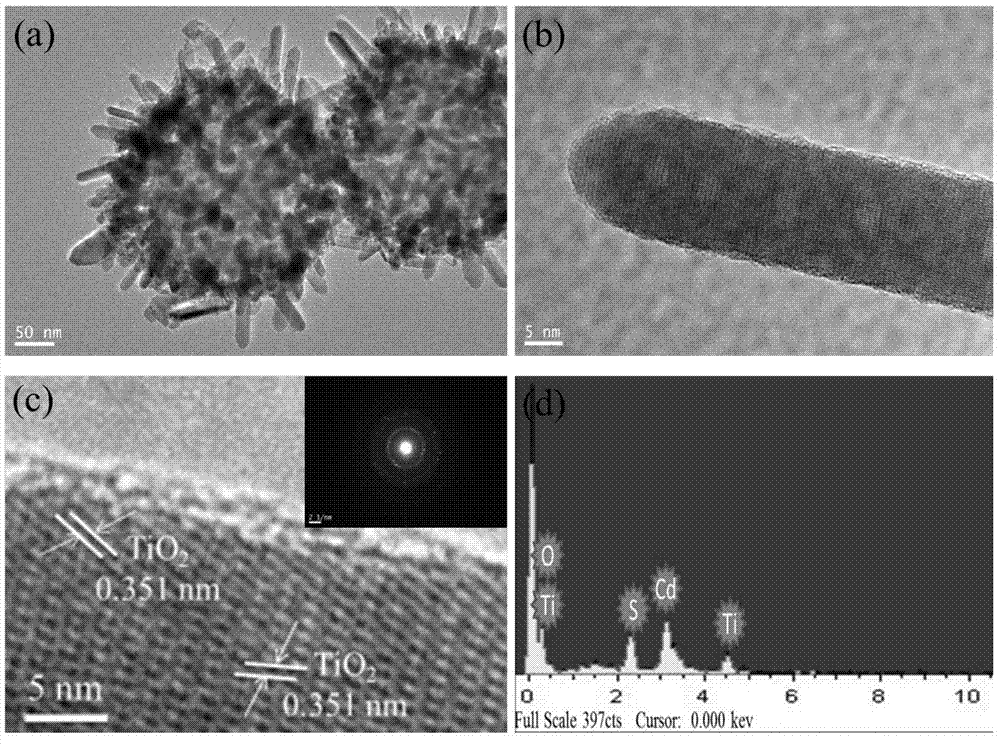

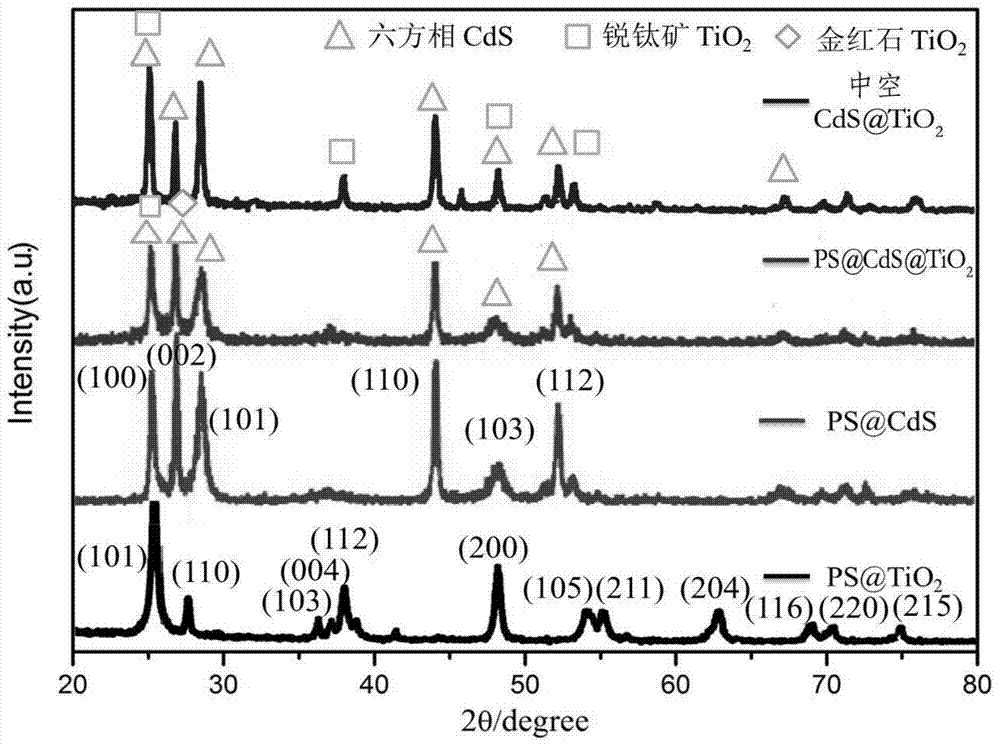

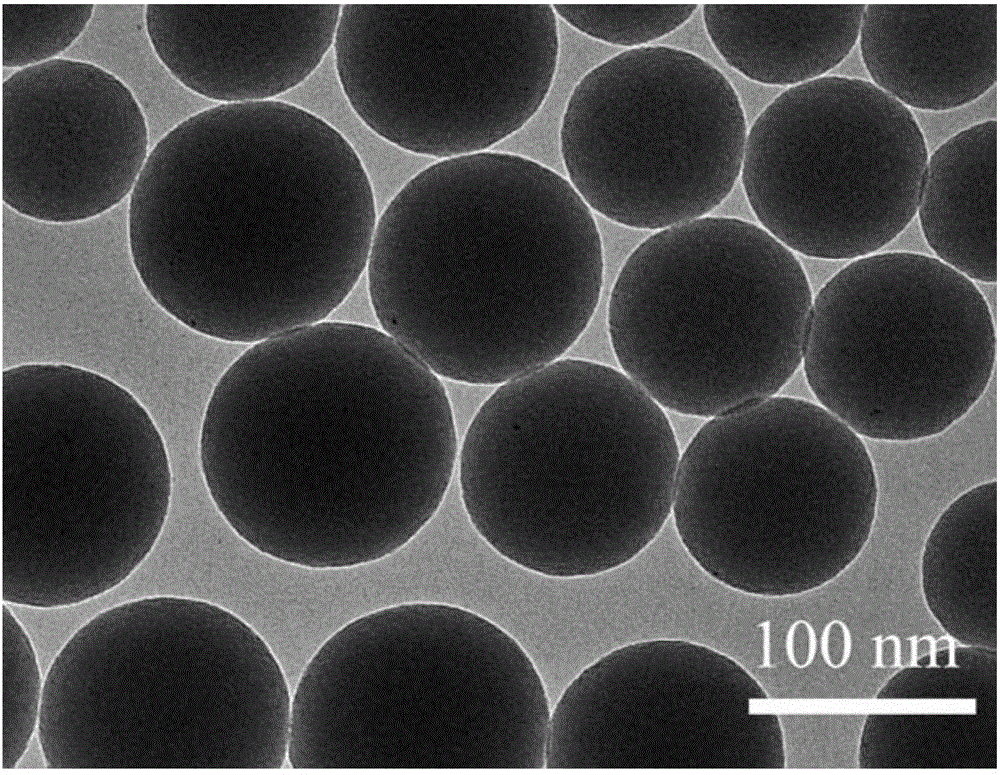

Preparation and application of dendriform TiO2-coating CdS hollow double-shell material

ActiveCN103920504AStop lossImprove stabilityPhysical/chemical process catalystsWater/sewage treatment by irradiationPolystyreneDyeing wastewater

The invention discloses preparation and application of a dendriform TiO2-coating CdS hollow double-shell material. The preparation comprises the following steps: preparing a CdS-coating polystyrene core-shell material (PS@CdS) by adopting an ultrasonic wave assistance method, introducing CTAC, coating a TiO2 shell through a wet chemistry method to prepare the dendriform outer morphology (dendriform PS@CdS@TiO2), and sintering to remove polystyrene to obtain the target material, namely the dendriform hollow CdS@TiO2, wherein the dendriform hollow CdS@TiO2 has efficient light degradation performance for organic wastewater, especially RhB printing and dyeing wastewater under condition with visible light. The preparation conditions are mild, the method is novel, the operation process is simple, the treatment is rapid, the hollow double-shell material has good stability, photocorrosion generated by CdS is effectively avoided, the degradation capability during the recycling process is basically kept stable, the preparation and the application are economical and environmentally friendly, and the hollow double-shell material can be widely applied to degradation and recycling of other organic wastewater, especially deep degradation of organic wastewater with low concentration.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

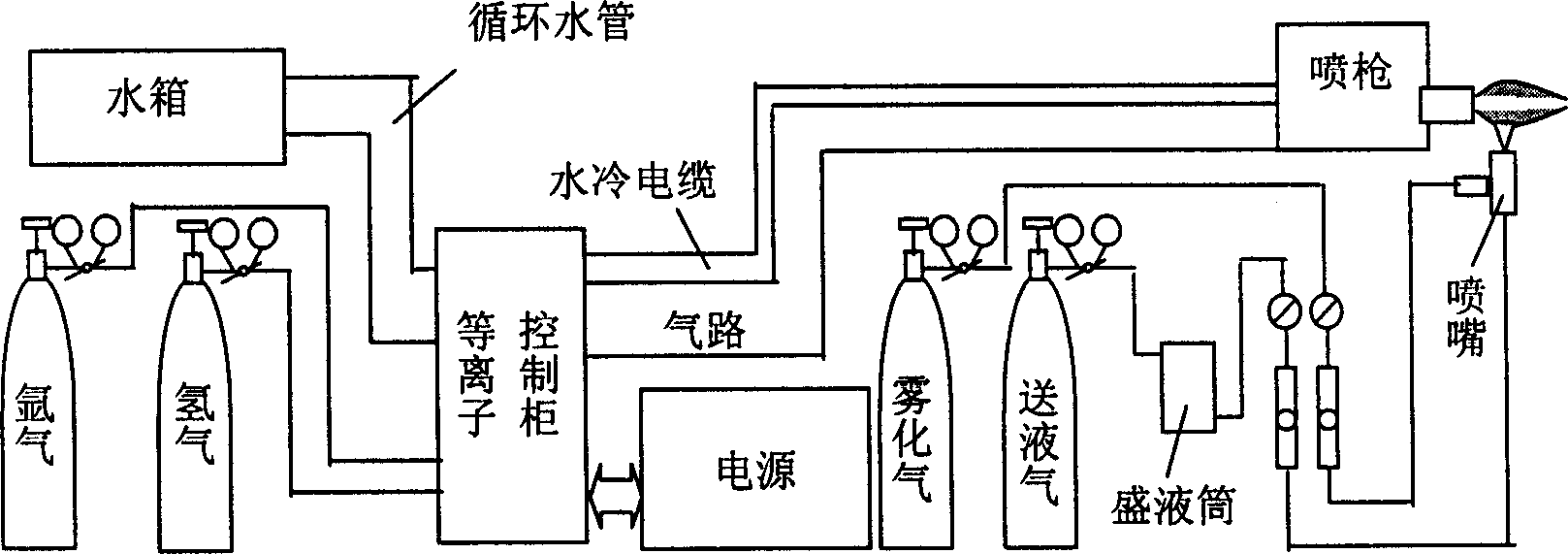

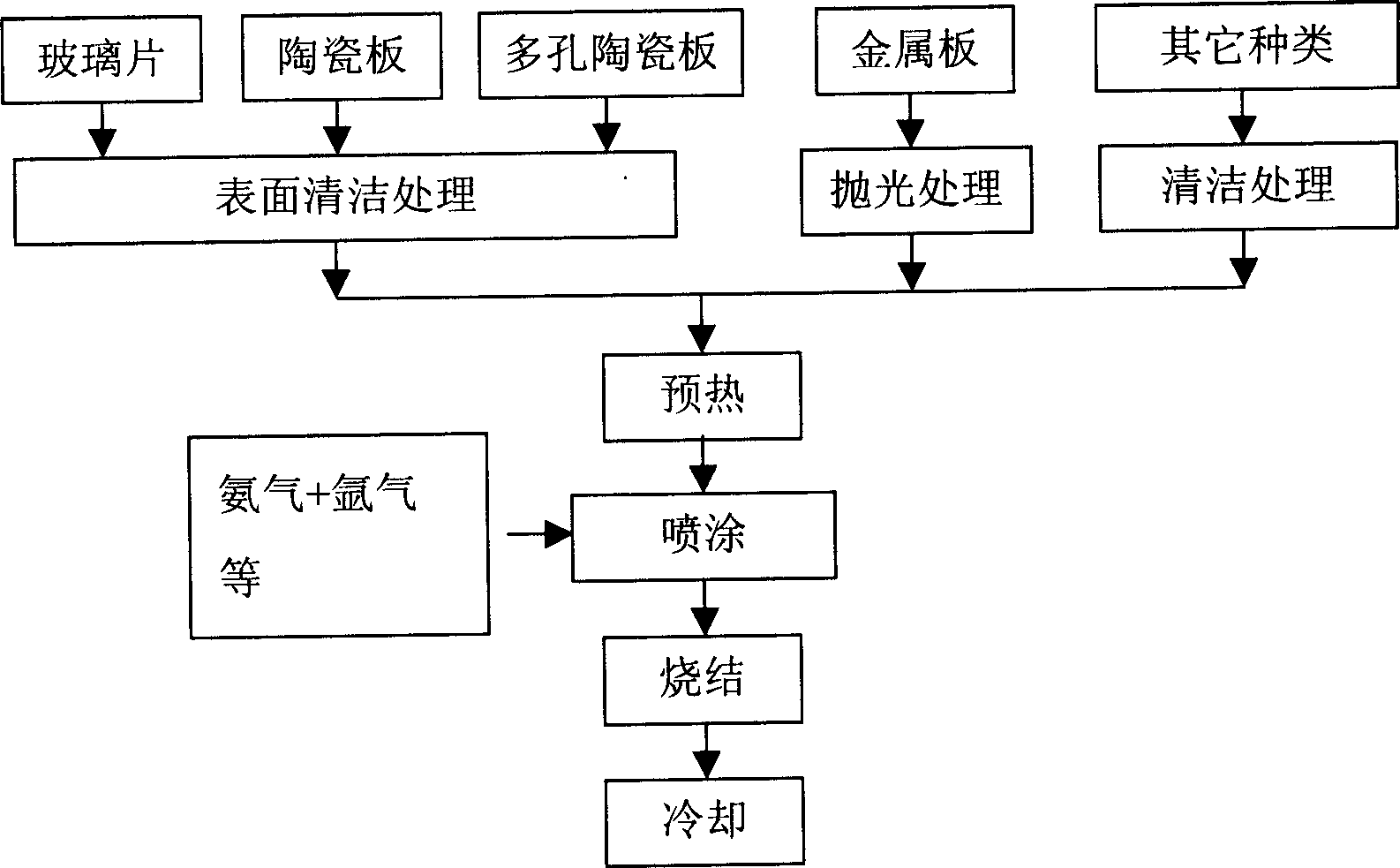

Method for forming heteronitrogen nano TiO2 light catalytic activity coating on substrate

InactiveCN1492070AImprove photocatalytic activityThe method is simpleMolten spray coatingCatalyst activation/preparationProduct gasNitrogen gas

The present invention belongs to the field of painting technology, and is especially the process of forming nitrogen doped photocatalytic TiO2 coating on sustrate. The process includes the following steps: adopting N2, Ar, Kr or their mixture as powder feeding gas; and NH3 / Ar mixture or N2 / Ar mixture as work gas; cleaning and / or polishing metal plate or other substrate, preheating at 200-600 deg.c, spraying nano TiO2 powder to the substrate surface with a plasma spray equipment while doping N element to form the N doped TiO2 film on the substrate surface; and sintering at 500-600 deg.c to cure the N doped TiO2 film completely and to form the N doped TiO2 coating.

Owner:INST OF CHEM CHINESE ACAD OF SCI

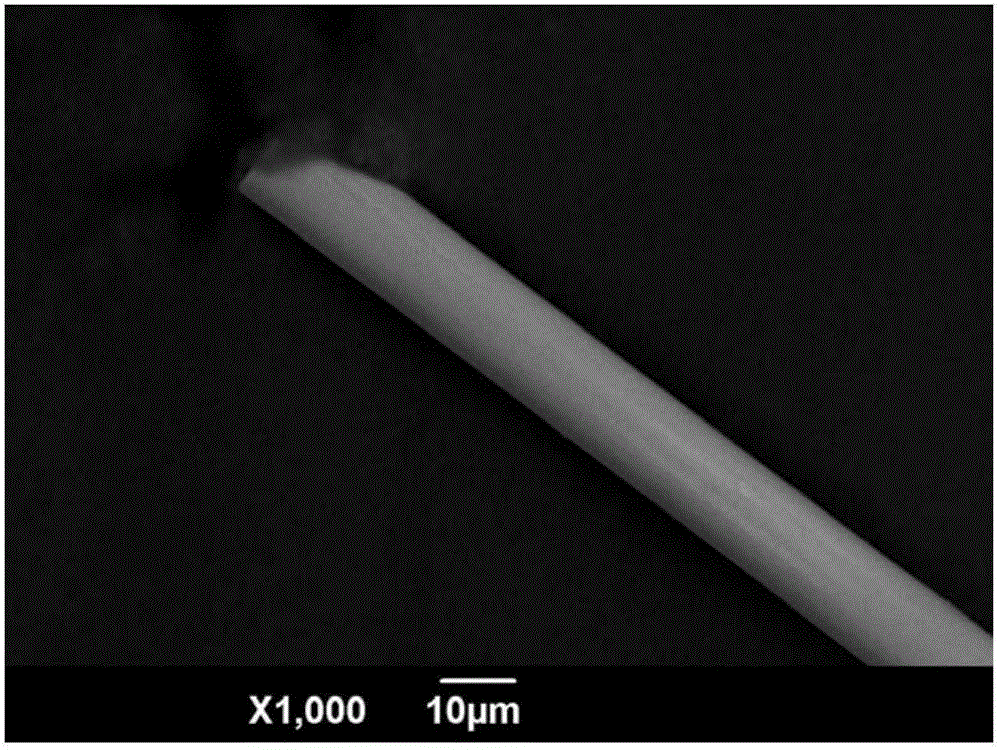

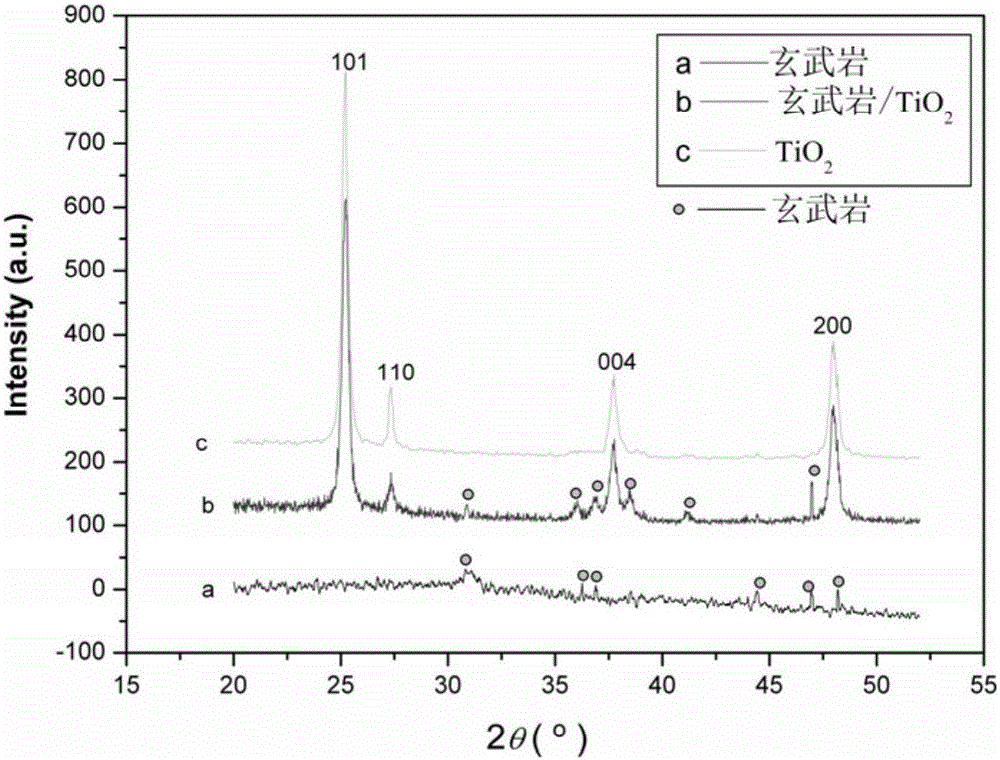

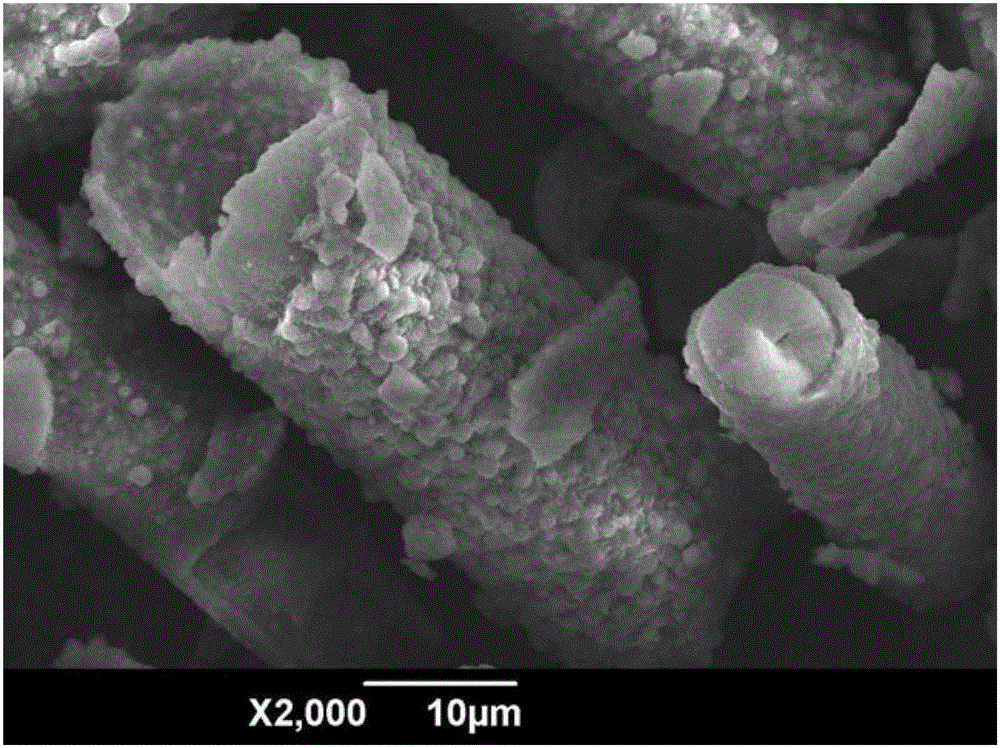

Preparation method and application of basalt fiber-TiO2 composite material

ActiveCN105195119AImprove flexibilityHigh strengthPhysical/chemical process catalystsWater/sewage treatment by irradiationEcological environmentHigh pressure

The invention relates to a preparation method of a basalt fiber-TiO2 composite material. The method comprises steps as follows: a certain amount of nano TiO2 is dissolved in deionized water, TiO2 nano-sol is prepared, chopped basalt fibers are added to a NaOH solution with certain concentration, then the TiO2 nano-sol and the solution are mixed and subjected to intense magnetic stirring, a precursor of the basalt fiber-TiO2 composite material is obtained, the prepared precursor is added to a stainless steel high-pressure hydrothermal reaction kettle provided with a polytetrafluoroethylene lining, and the basalt fiber-TiO2 composite photocatalytic material is prepared through one step by the aid of the hydrothermal reaction. The hydrothermal reaction method which is simple to operate is adopted, particulate TiO2 coatings evenly coat surfaces of the basalt fibers, and the TiO2-loaded basalt fiber composite material adopting the core-shell structure is prepared. The composite material is environment-friendly, long in service life and recyclable and is an efficient and cheap ecological environment material.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Supported nanometer crystalline titania photocatalyst and its prepn process

InactiveCN1846851AShort preparation timeLow pricePhysical/chemical process catalystsHigh volume manufacturingTio2 coating

The present invention relates to titania catalyst, and is supported nanometer crystalline titania photocatalyst and its preparation process. The supported nanometer crystalline titania photocatalyst consists of alumina pellet carrier of specific weight 0.5-5.0 g / cu cm and grain size 0.5-2.0 mm and nanometer crystalline TiO2 coating. The preparation process includes the following steps: preparing carrier, preparing precursor solution; and supporting. The alumina pellet carrier of the present invention has different pore sizes, low cost and high strength, and is suitable for industrial application.

Owner:TIANJIN GUARD T & D

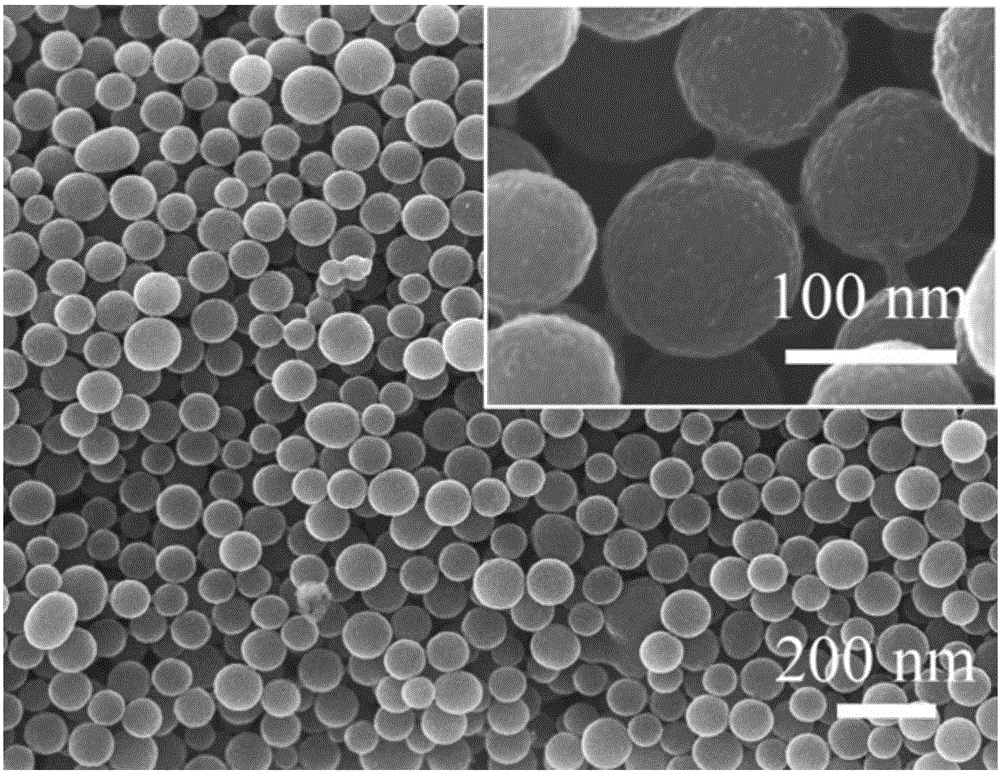

Supercapacitor carbon/titanium carbide core casing composite ball electrode material and preparation method thereof

ActiveCN106024402AEasy to controlHigh magnificationHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceHigh energy

The invention discloses a supercapacitor carbon / titanium carbide core casing composite ball electrode material and a preparation method thereof. After glucose water heat carbonation, the first step of heat treatment is carried out to produce a crosslinked carbon nanosphere loaded with nickel foam. An atomic layer deposition method is used and titanium tetrachloride and deionized water are used as a reaction source to acquire a TiO2 coating layer. A second step of heat treatment is carried out. The carbon nanosphere and the TiO2 coating layer form a supercapacitor carbon sphere and the titanium carbide composite sphere electrode material through carbon thermal reaction. The electrode material comprises a substrate, the carbon nanosphere arranged on the substrate and a titanium carbide nano-layer coating the carbon nanosphere. The diameter of the carbon nanosphere is from 100 to 500nm. The thickness of the nano titanium carbide layer is from 10 to 50nm. The electrode material provided by the invention has the advantages of high specific capacitance, high cycle service life, high energy and high power density, and has a wide application prospect in mobile communication, electric vehicles, aerospace and other fields.

Owner:ZHEJIANG UNIV

Method for preparing modified TiO2 coatings by sol-gel method

InactiveCN102463130AAvoid reunionVisible light catalyticCatalyst activation/preparationSolventDip-coating

The invention discloses a method for preparing modified TiO2 coatings by a sol-gel method, which comprises the following steps that: (1) chemical pure tetrabutyl orthotitanate Ti(OC4O9)4 is used as raw materials, ethanol is used as solvents, acetylacetone (CH3CO)2CH2 is adopted as complexing agents for preparing light yellow TiO2 sol, and the TiO2 sol is subjected to still sanding and aging for use; (2) five layers of coatings are coated on the aged TiO2 sol by a dip coating method; (3) five-layer coating samples are placed into a vacuum plating instrument (ionization N2 atmosphere), the temperature is raised to the required temperature by a certain procedure, the heat insulation is carried out for 2 hours, then, the materials are cooled along with a furnace, the doping process of carbon and nitrogen is completed, and the carbon and nitrogen doping TiO2 coatings (TNC) are prepared; and (4) the prepared carbon and nitrogen doping TiO2 coatings are placed into a muffle furnace to be annealed for 2 hours at 450 DEG C, and the annealed carbon and nitrogen doping TiO2 coatings (TTNC) are prepared. The modified TiO2 coatings are prepared through novel ion doping by the sol-gel method, the light-catalysed activity of the TiO2 is improved, and simultaneously, the coatings have better thermal stability.

Owner:BEIJING JIASHENG CENTURY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com