Supercapacitor carbon/titanium carbide core casing composite ball electrode material and preparation method thereof

A technology for supercapacitors and electrode materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc. It can solve the problems of further improvement in performance, achieve effective active reaction area, improve high rate performance, and shorten diffusion distance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

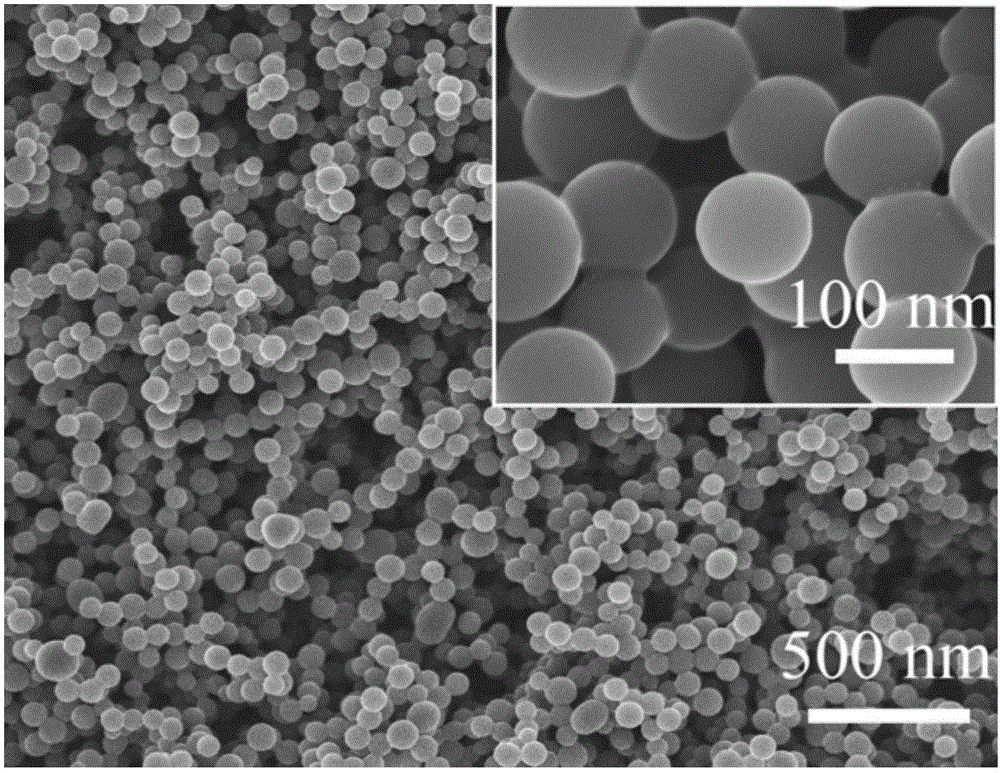

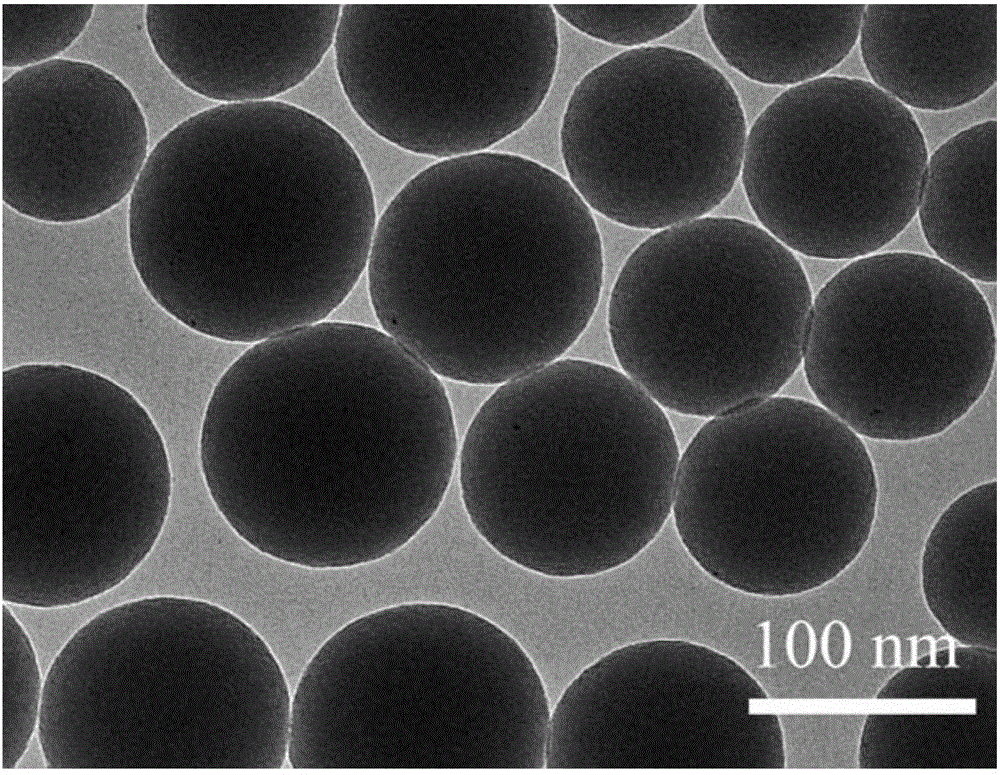

[0025] Weigh 18g of glucose and dissolve it in 1000ml of deionized water, stir until completely dissolved to form a 0.1mol / L glucose aqueous solution. Then take 80ml of glucose aqueous solution and put it into a polytetrafluoroethylene high-pressure hydrothermal tank, and put it into a foamed nickel substrate, seal the autoclave, and conduct a hydrothermal reaction at 180° C. for 2 hours. After the reaction, it was cooled to room temperature of 25°C, washed and dried with deionized water, calcined in argon at 500°C for 1 hour, and naturally cooled to room temperature of 25°C to prepare foamed nickel-supported carbon nanospheres. Scanning electron microscope (SEM) and transmission electron microscope (TEM) analysis are carried out to the obtained carbon nanosphere, such as figure 1 and 2 As shown, it can be seen that the average diameter of carbon nanospheres is 100 nm, and they are cross-linked with each other to form a porous structure.

[0026] The above-mentioned carbon n...

Embodiment 2

[0028] Weigh 90g of glucose and dissolve it in 1000ml of deionized water, stir until completely dissolved to prepare 0.5mol / L glucose aqueous solution. Then take 80ml of glucose aqueous solution and put it into a polytetrafluoroethylene high-pressure hydrothermal tank, and put it into a foamed nickel base, seal the autoclave, and conduct a hydrothermal reaction at 225° C. for 4 hours. After the reaction, it was cooled to room temperature of 25°C, washed and dried with deionized water, calcined in argon at 650°C for 2 hours, and naturally cooled to room temperature of 25°C to prepare foamed nickel-supported carbon nanospheres.

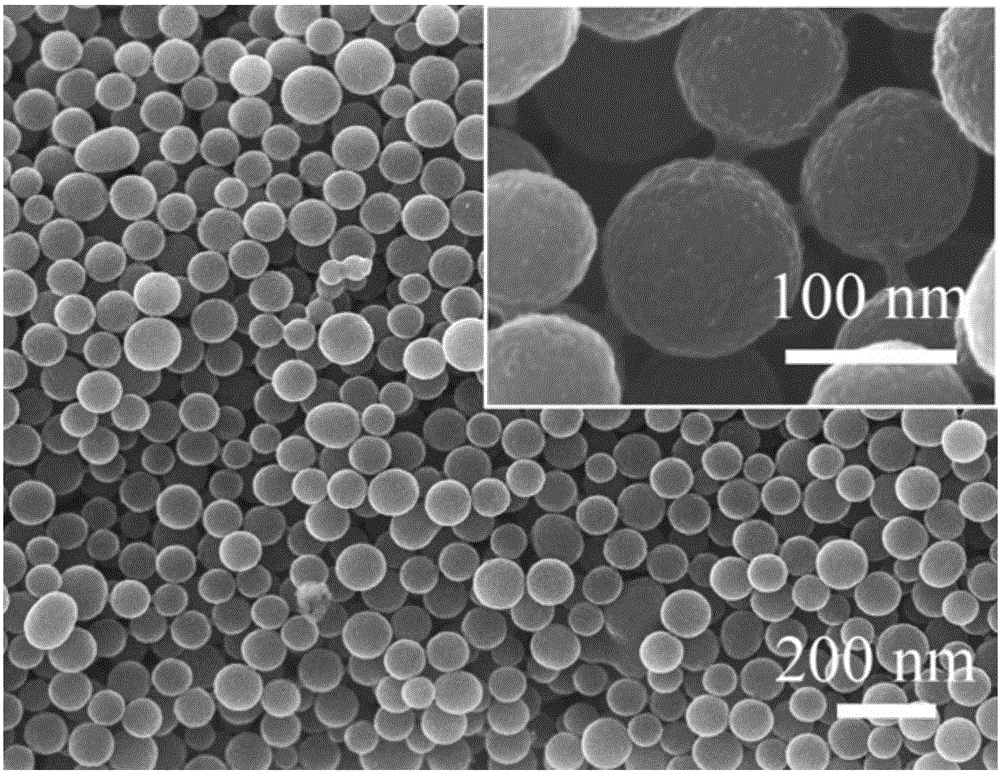

[0029] The above-mentioned carbon nanospheres supported by nickel foam were placed in an atomic layer deposition apparatus, using titanium tetrachloride and deionized water as reaction sources, and reacted for 120 deposition cycles under the condition of 150°C. After washing and drying with deionized water, calcining at 1050°C in argon for 2.5 hours, an...

Embodiment 3

[0031] Weigh 180g of glucose and dissolve it in 1000ml of deionized water, stir until completely dissolved to prepare 1mol / L glucose aqueous solution. Then take 80ml of glucose aqueous solution and put it into a polytetrafluoroethylene high-pressure hydrothermal tank, and put it into a foamed nickel base, seal the autoclave, and conduct a hydrothermal reaction at 250° C. for 6 hours. After the reaction, it was cooled to room temperature of 25°C, washed and dried with deionized water, calcined in argon at 800°C for 3 hours, and naturally cooled to room temperature of 25°C to obtain foamed nickel-supported carbon nanospheres.

[0032] The above-mentioned carbon nanospheres supported by nickel foam were placed in an atomic layer deposition apparatus, using titanium tetrachloride and deionized water as reaction sources, and reacted for 160 deposition cycles under the condition of 200°C. After washing and drying with deionized water, it was calcined at 1300°C in argon for 5 hours, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com