Patents

Literature

2165 results about "Nickel base" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anode material for nickel-base lithium ion battery and preparation method of anode material

ActiveCN104409700AEasy to operateSuitable for industrial productionCell electrodesSecondary cellsOptoelectronicsOxygen

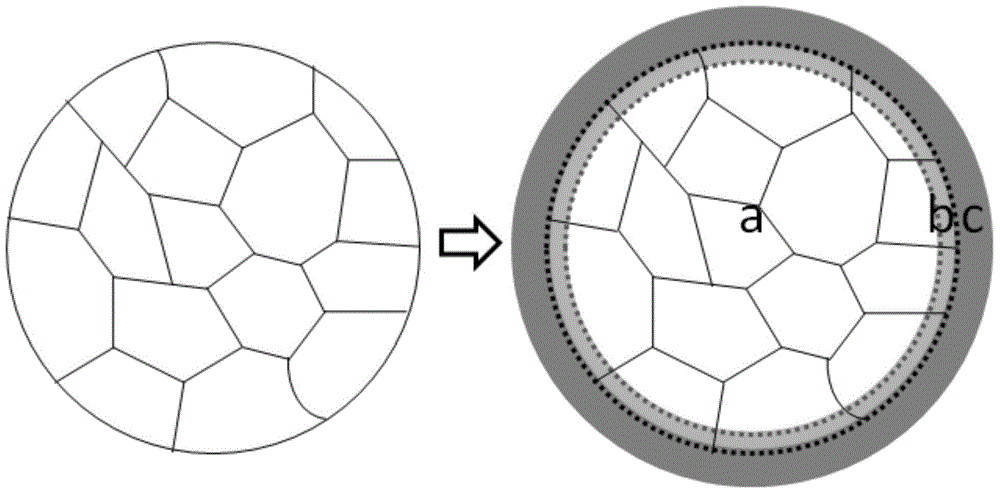

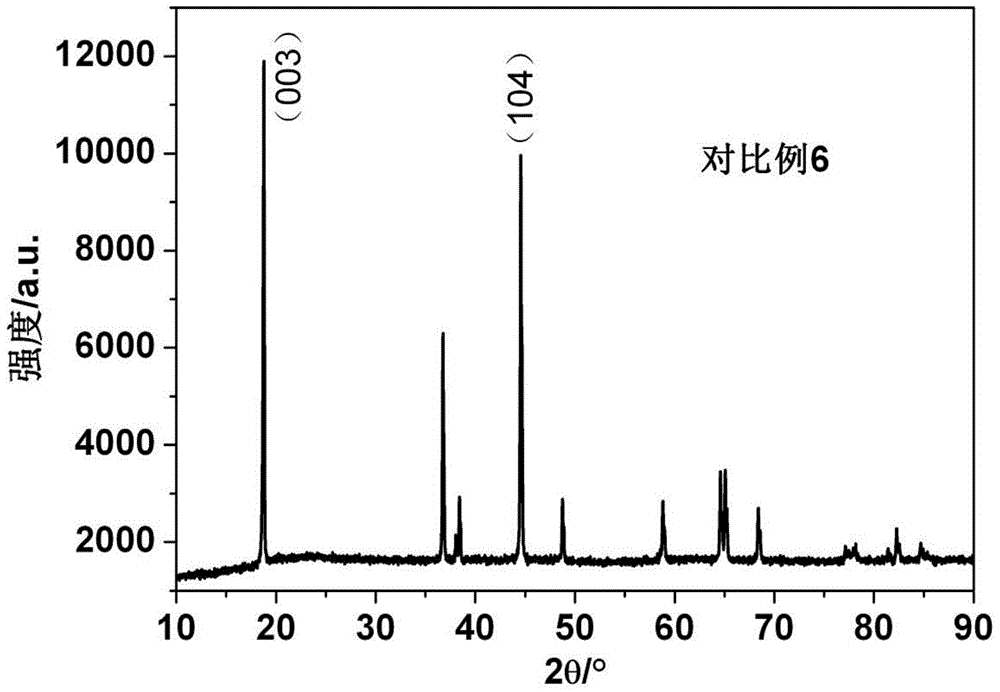

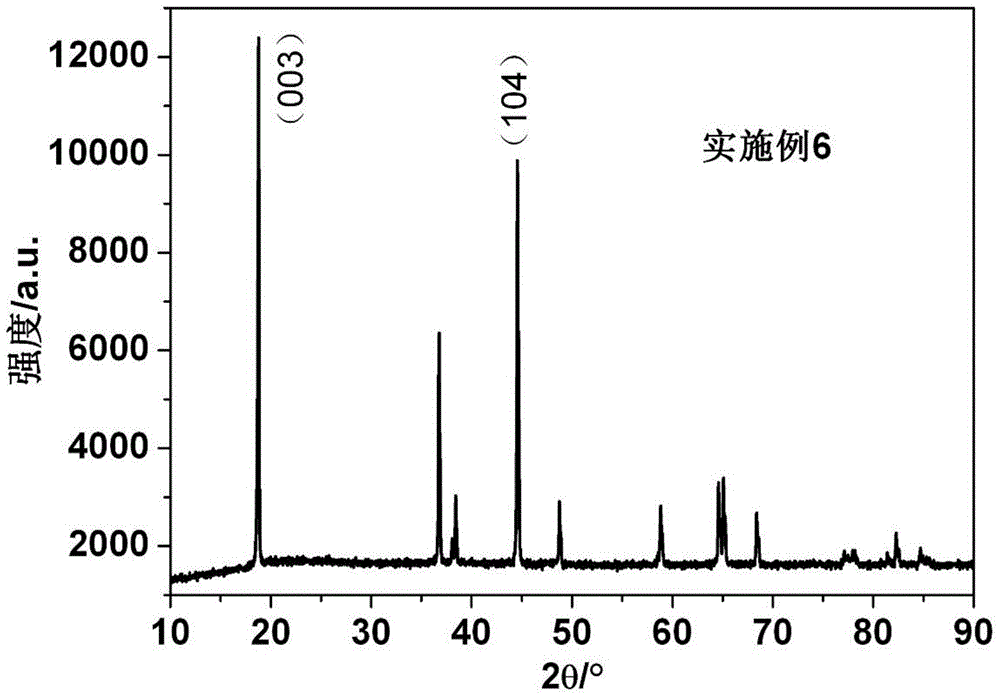

The invention provides an anode material for a nickel-base lithium ion battery and a preparation method of the anode material. The anode material comprises an inner core, a doping layer and a cladding layer, wherein the chemical formula of the inner core is LiaNixCoyMzO2; the doping layer is another inner core containing M'; at least M' and oxygen elements are contained in the cladding layer; the anode material is of a core-shell structure, and comprises the inner core, the doping layer and the cladding layer from inside to outside. The anode material for the nickel-base lithium ion battery provided by the invention is little in lithium-nickel mixing, and the cycling stability of the material is obviously improved.

Owner:BTR NEW MATERIAL GRP CO LTD

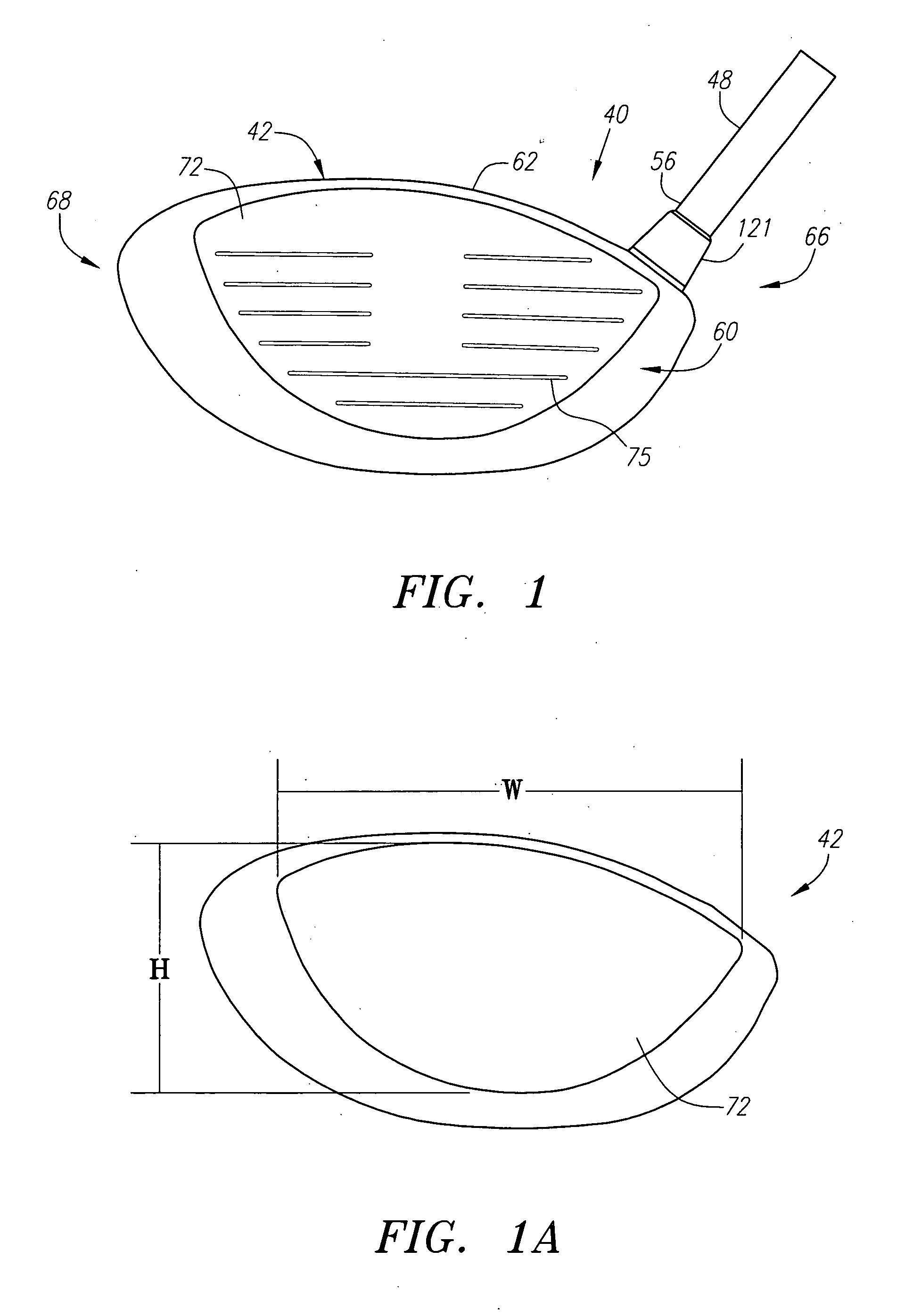

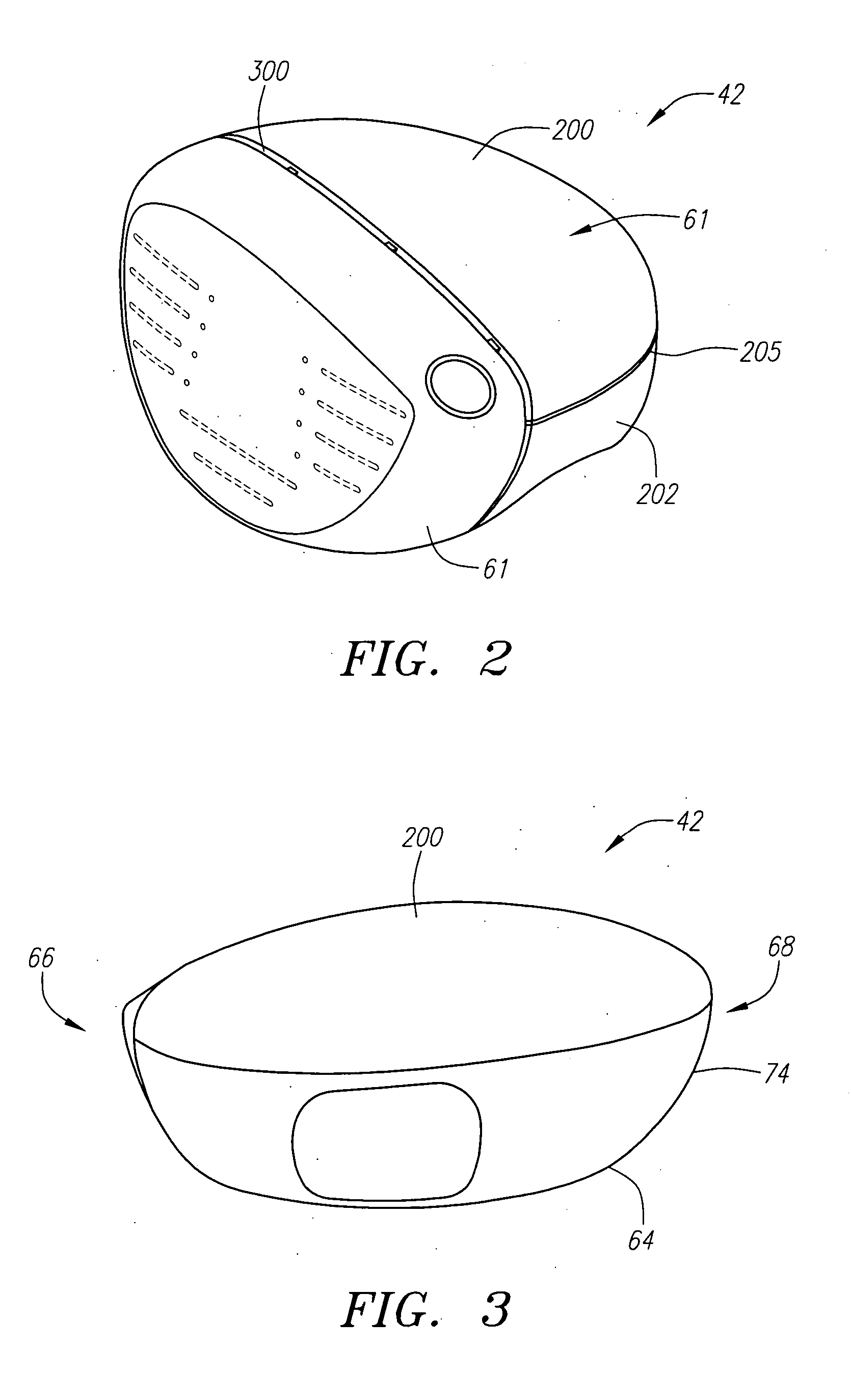

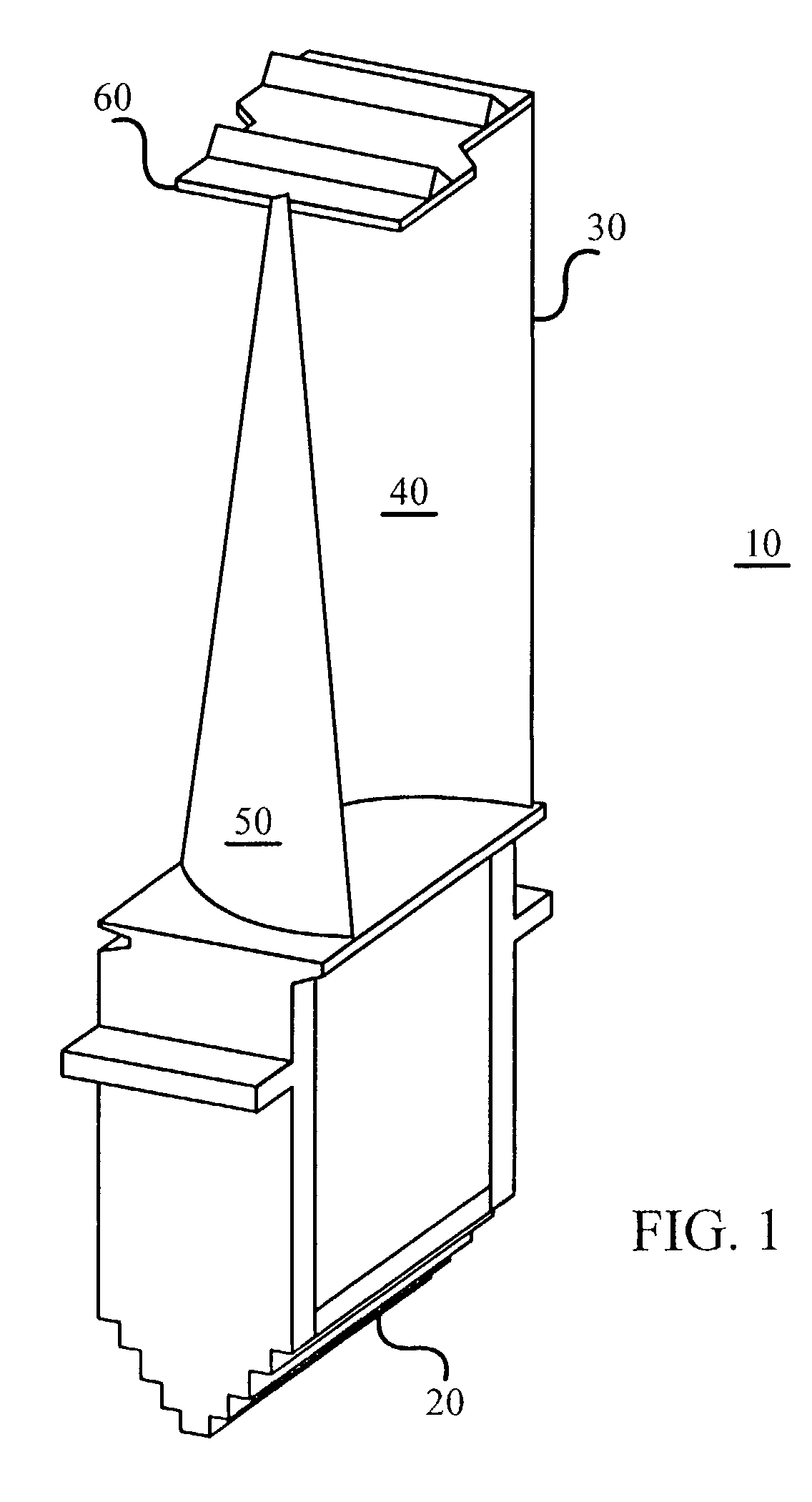

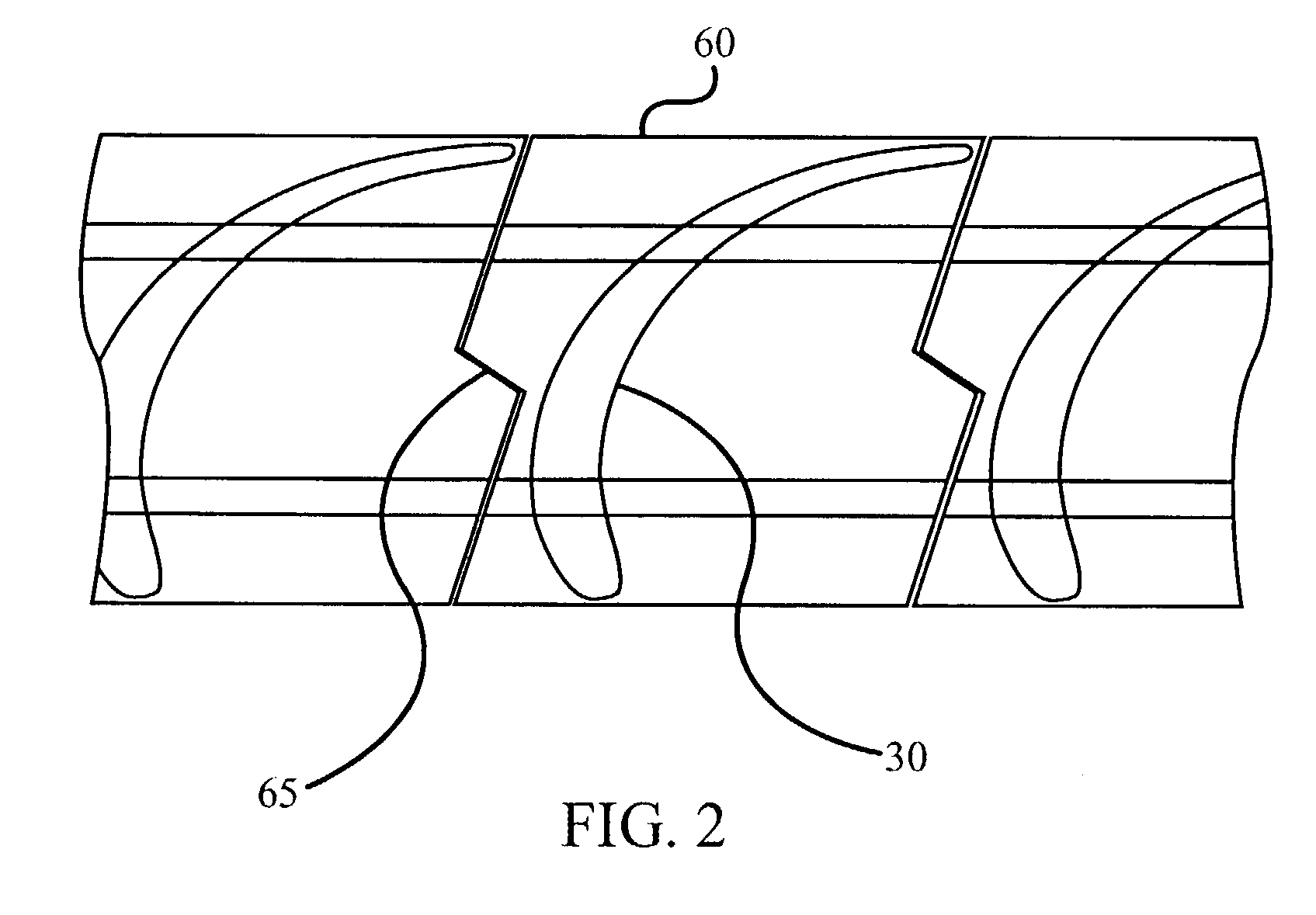

Plated magnesium golf club head

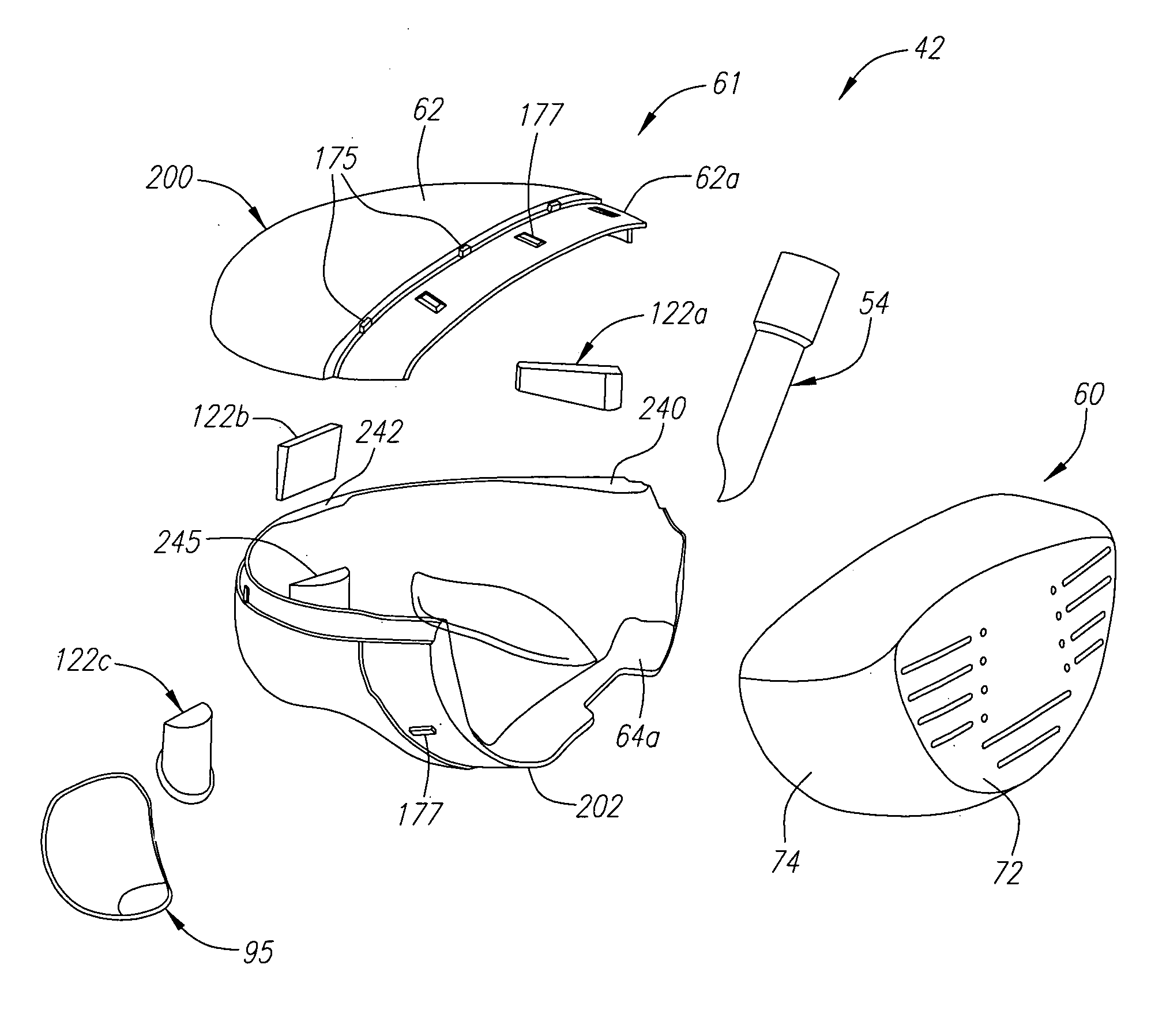

A golf club (40) having a club head (42) with a face component (60) and an aft-body (61) is disclosed herein. The face component (60) has a striking plate portion (72) and a return portion (74). The aft-body (61) is composed of a crown portion (62), a sole portion (64) and optionally a ribbon section (90). The face component (60) is composed of a metal material, and the aft-body (61) is composed of a metal material selected from the group consisting of magnesium alloys, aluminum alloys, magnesium and aluminum. A plating layer (300) is disposed on at least a portion of the aft-body (61). The plating layer (300) preferably comprises a nickel or nickel-based alloy material. The club head (42) preferably has a volume in the range of 290 cubic centimeters to 600 cubic centimeters.

Owner:TOPGOLF CALLAWAY BRANDS CORP

Nickel system hydrogenation catalyst, preparation method and application

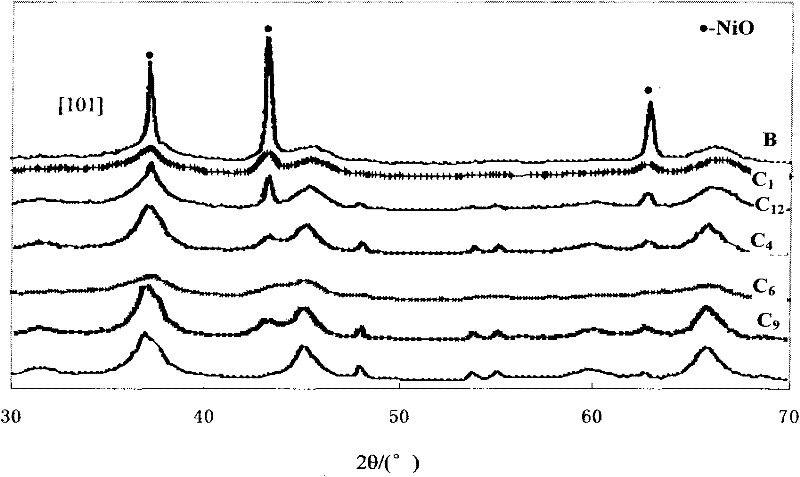

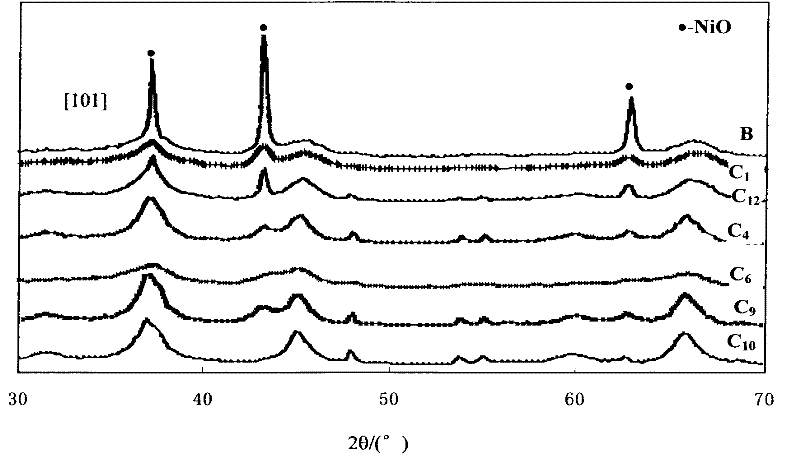

ActiveCN101037613AImprove hydrogenation activityImprove stabilityHydrocarbon by hydrogenationRefining to eliminate hetero atomsResistAdjuvant

The invention realtes to a nickel based hydrogenation catalyst, preparation and application thereof. Using alumina or and monox silica as carrier, the catalyst prepared by means of coprecipitation, main containing active component Ni, is characterized in catalyst composed by active component Ni, La, adjuvant X1 and carrier X2O. Calculated by weight of component, the catalyst including: NiO 40-70%, La2O3 2-5%, X2O 20-50%, wherein X1 is selected from one or more of Cu, Mg, Zr, X2 is selected from Al or and Si; surface area to volume ratio thereof is 80-200 m<2> / g, pore volume ratio is 0.4-0.8 ml / g. The catalyst is suit for mono olefin hydrogenation, especially for hydrogenation of pyrolysis C9 distillation, which has higher hydrogenation activity, definited sulfur poison resist and carboid resist to fit for higher require of high colloid raw material hydrogenation which of catalyst has high hydrogenation activity and good stability.

Owner:PETROCHINA CO LTD

Process for producing gasoline with a low sulphur content

InactiveUS6334948B1Treatment with hydrotreatment processesMetal/metal-oxides/metal-hydroxide catalystsGasolineMetal

A process for producing a gasoline with a low sulphur content comprises: separating a sulphur-containing gasoline into a light fraction and a heavy fraction, hydrodesulphurising the light gasoline on a nickel-based catalyst, hydrodesulphurising the heavy fraction on a catalyst comprising at least one group VIII metal and / or at least one group VIB metal, and mixing the desulphurised fractions.

Owner:INST FR DU PETROLE

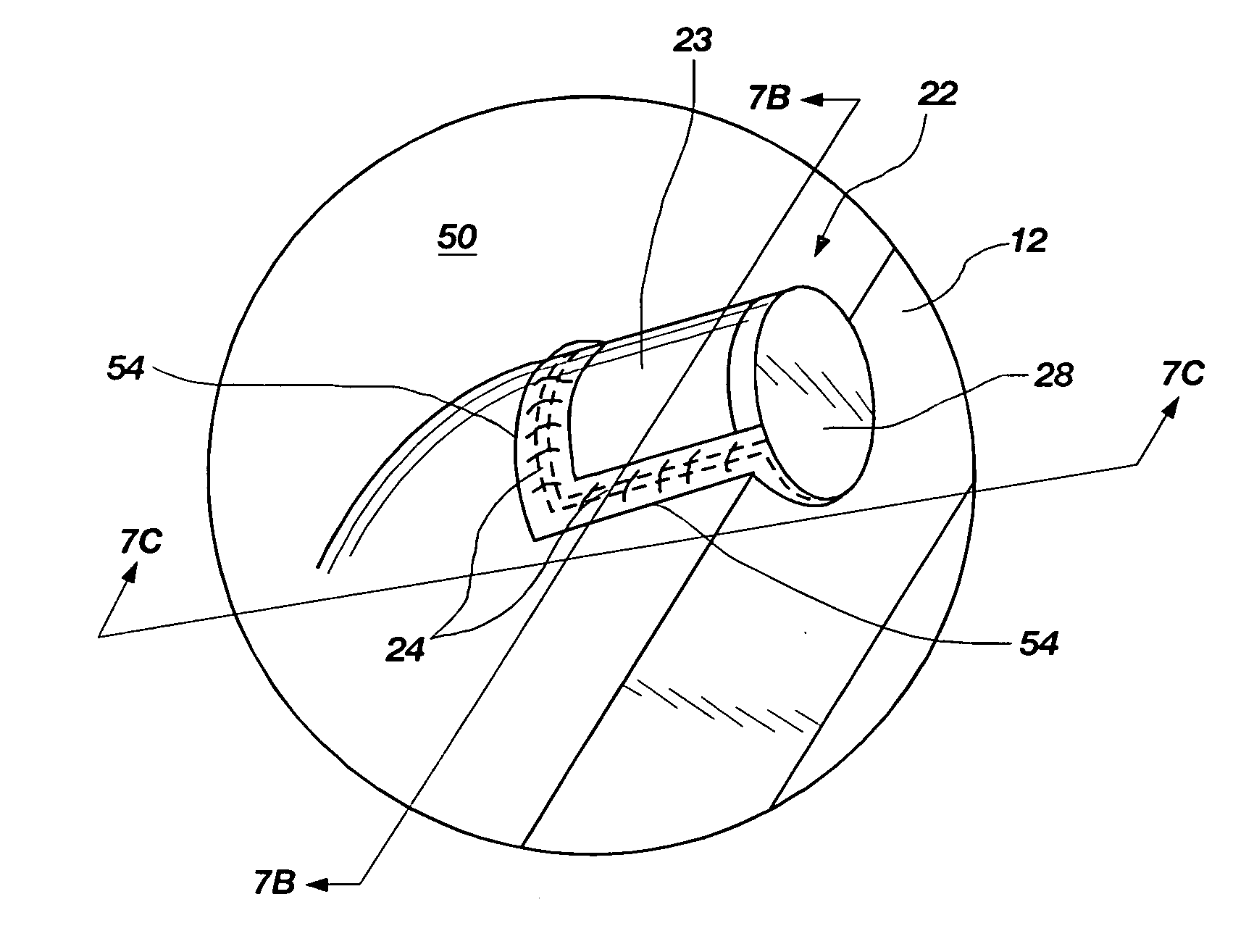

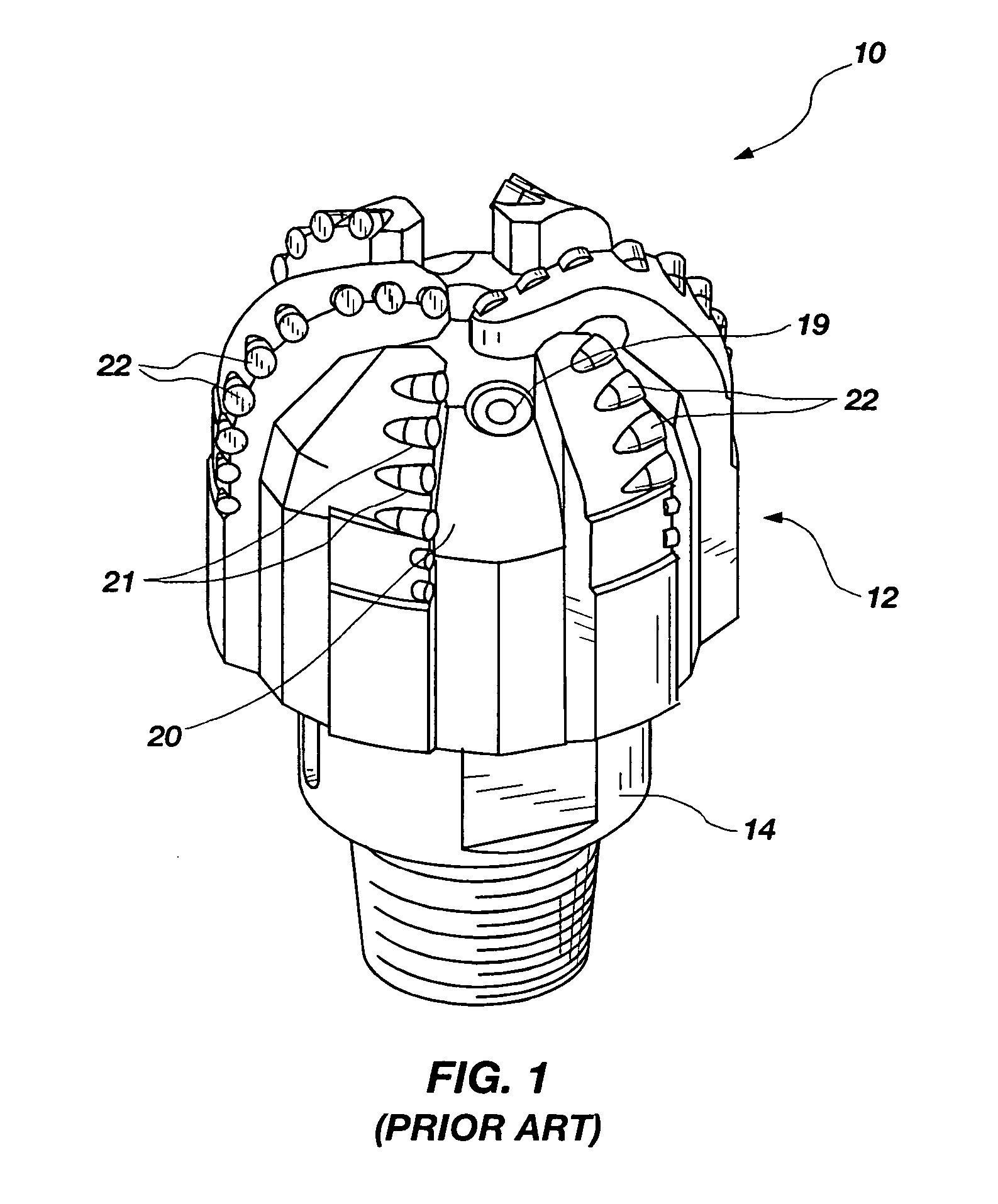

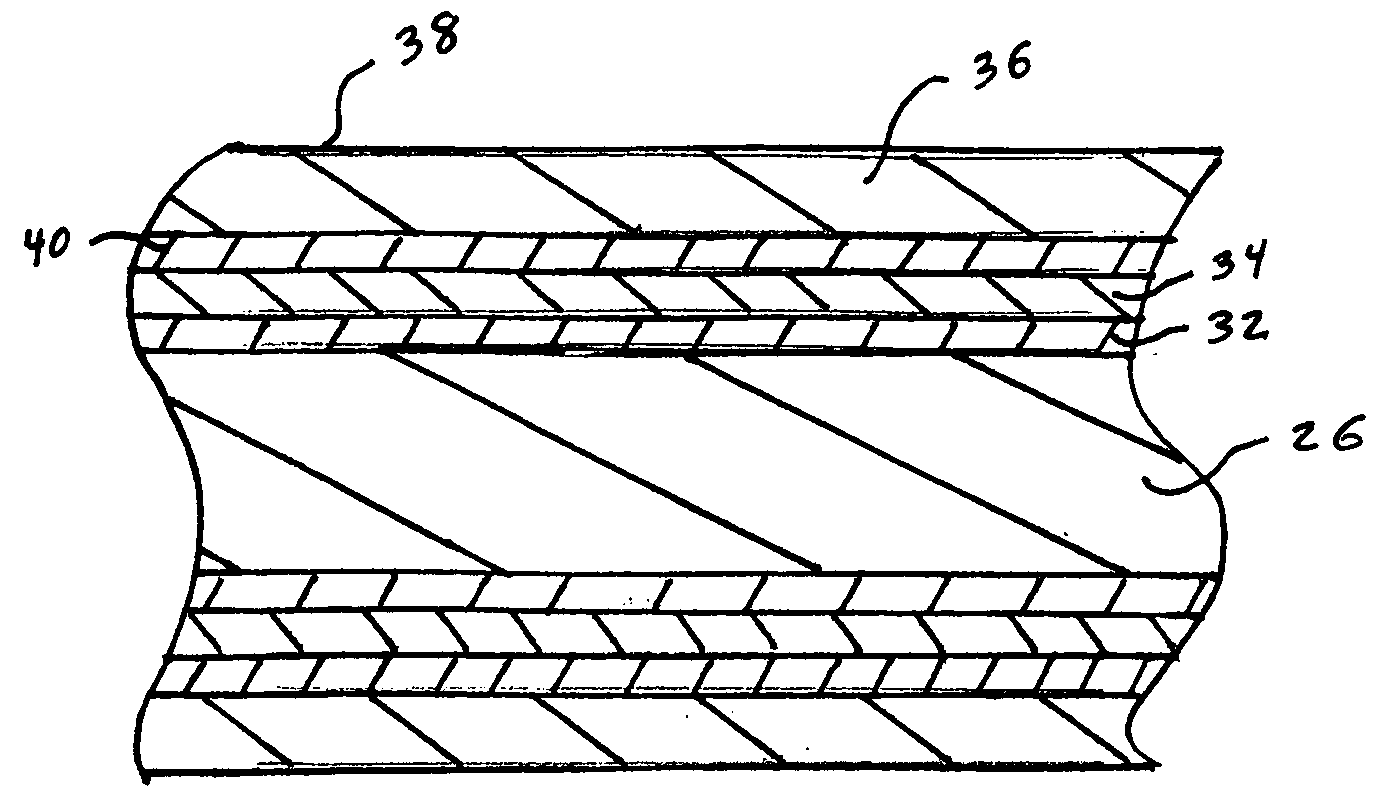

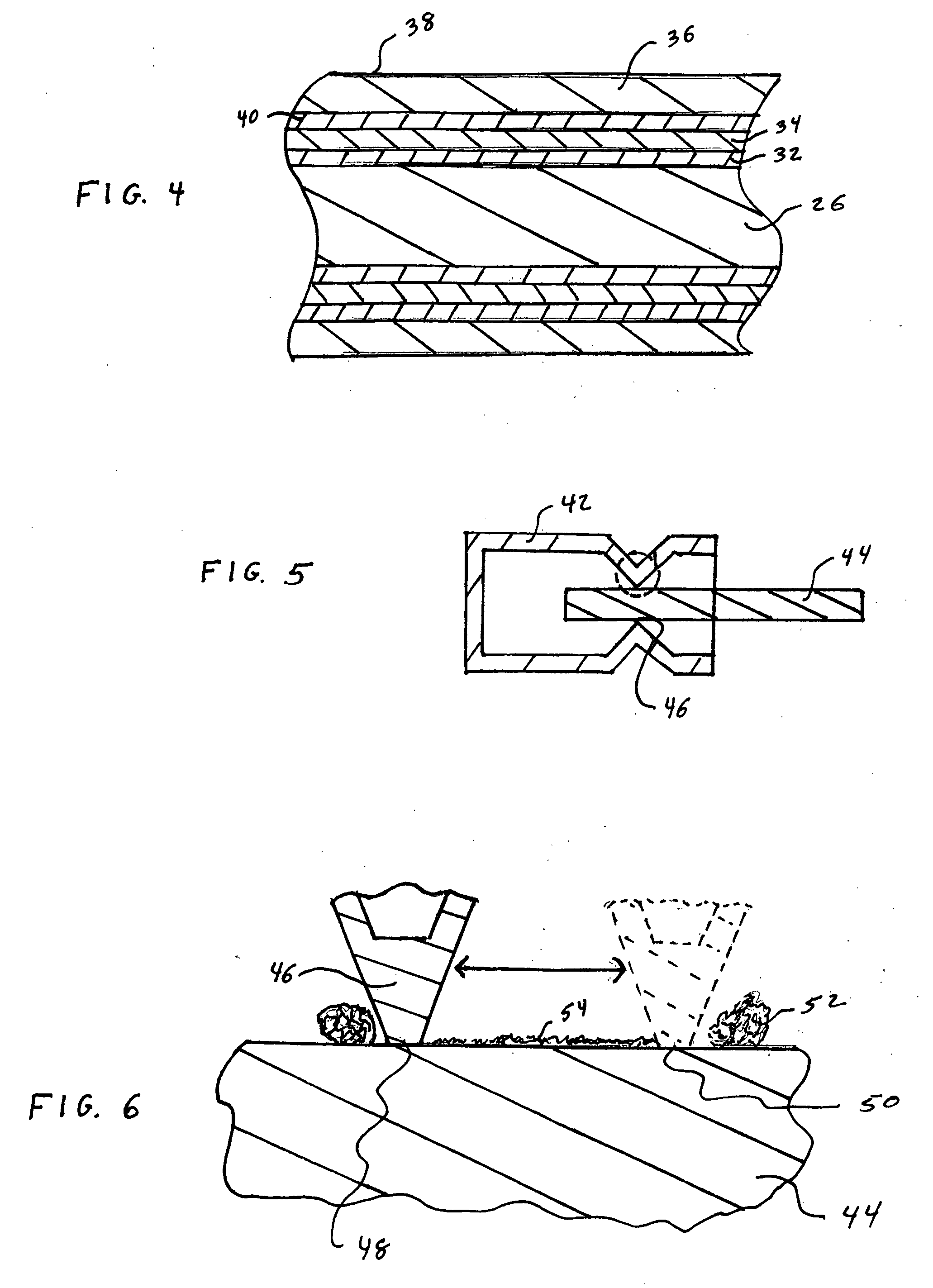

Composite materials including nickel-based matrix materials and hard particles, tools including such materials, and methods of using such materials

An abrasive wear-resistant material includes a matrix and sintered and cast tungsten carbide granules. A device for use in drilling subterranean formations includes a first structure secured to a second structure with a bonding material. An abrasive wear-resistant material covers the bonding material. The first structure may include a drill bit body and the second structure may include a cutting element. A method for applying an abrasive wear-resistant material to a drill bit includes providing a bit, mixing sintered and cast tungsten carbide granules in a matrix material to provide a pre-application material, heating the pre-application material to melt the matrix material, applying the pre-application material to the bit, and solidifying the material. A method for securing a cutting element to a bit body includes providing an abrasive wear-resistant material to a surface of a drill bit that covers a brazing alloy disposed between the cutting element and the bit body.

Owner:BAKER HUGHES INC

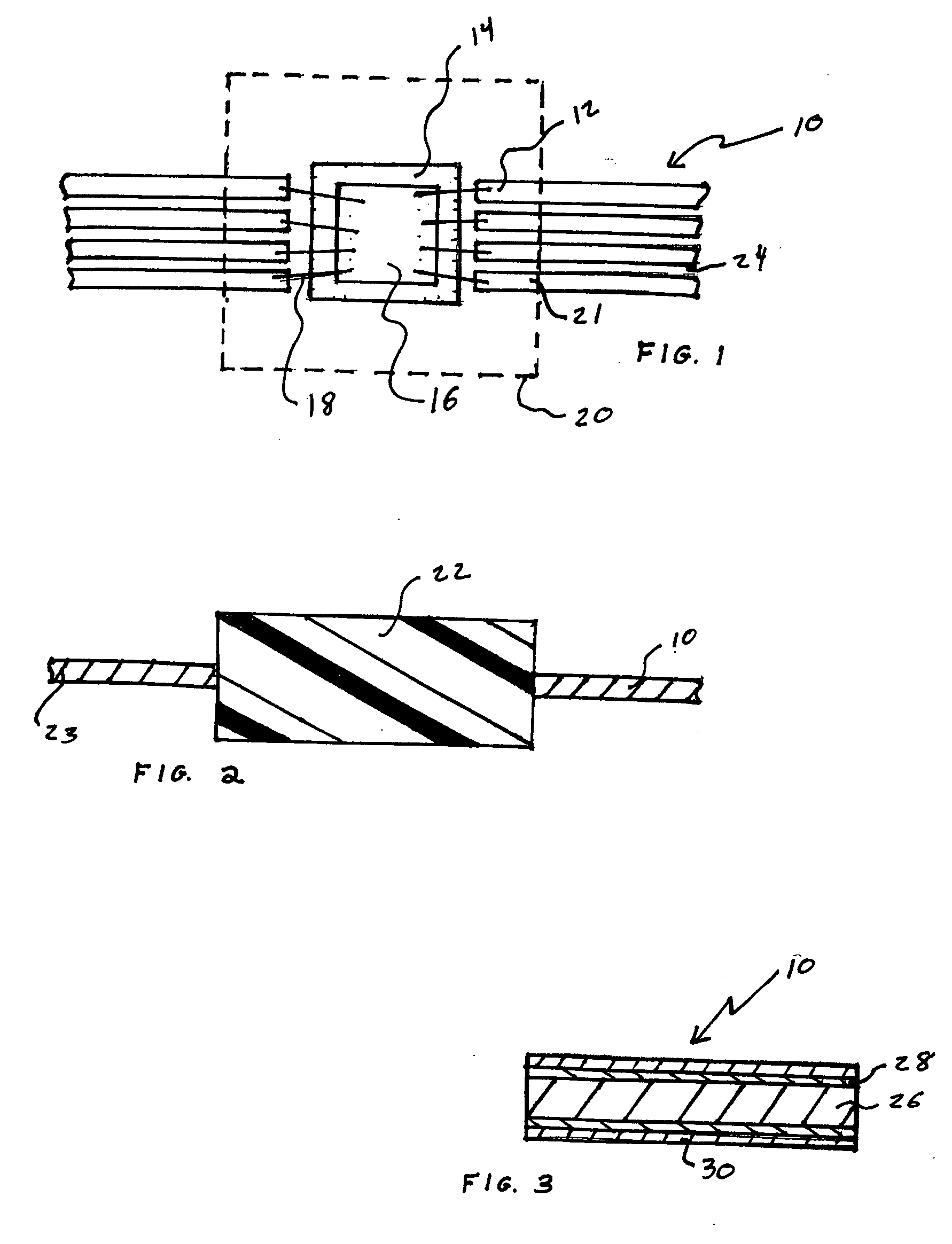

RFID transponder and method for connecting a semiconductor die to an antenna

InactiveUS20120193801A1Reduce mechanical stressSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipAlloy

An RFID transponder having a semiconductor die with a solderable contact area and an antenna made from a winding wire, wherein the winding wire is soldered to the contact area, and the solderable contact area is made from a nickel based alloy.

Owner:TEXAS INSTR INC

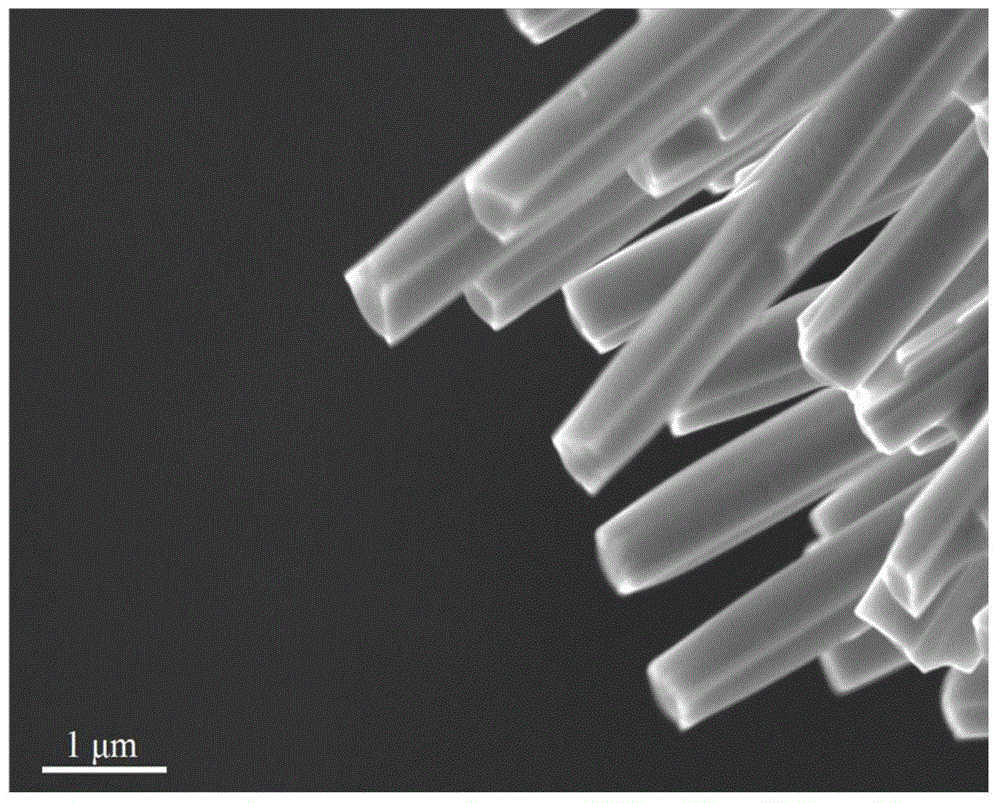

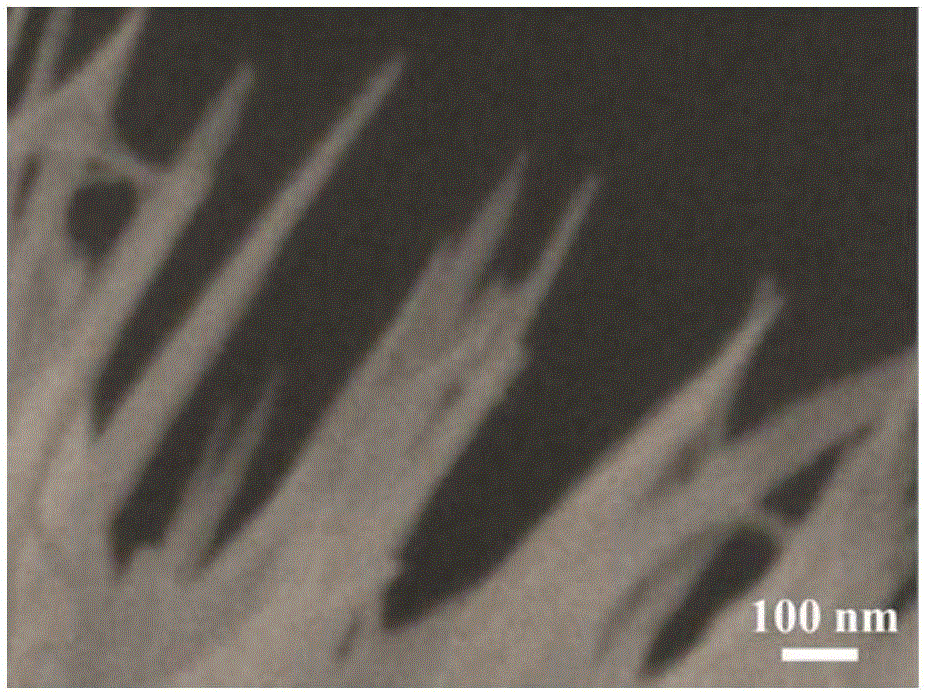

Method for preparing high-performance molybdenum-based hydrogen evolution electrode by phosphatizing molybdate precursor

The invention provides a method for preparing a high-performance molybdenum-based hydrogen evolution electrode by phosphatizing a molybdate precursor and belongs to the fields of water electrolysis and electric catalytic hydrogen evolution in the chlor-alkali industry. The method comprises the steps of pre-processing foamed nickel, growing the molybdate precursor in situ on the surface of a pre-processed foamed nickel base with the hydrothermal synthesis method, and finally placing the prepared precursor and a phosphorus source into a rube furnace together for phosphating of the molybdate precursor so that the high-performance molybdenum-based hydrogen evolution electrode can be prepared. The method is novel, the technology adopted is simple, production cost is low, the requirement for equipment is low, and the method is suitable for industrial production. Furthermore, the electrode is large in specific area, can be combined with the base firmly, has excellent hydrogen evolution activity and stability, and can be widely applied to the fields of water electrolysis and hydrogen evolution in the chlor-alkali industry.

Owner:CHONGQING UNIV

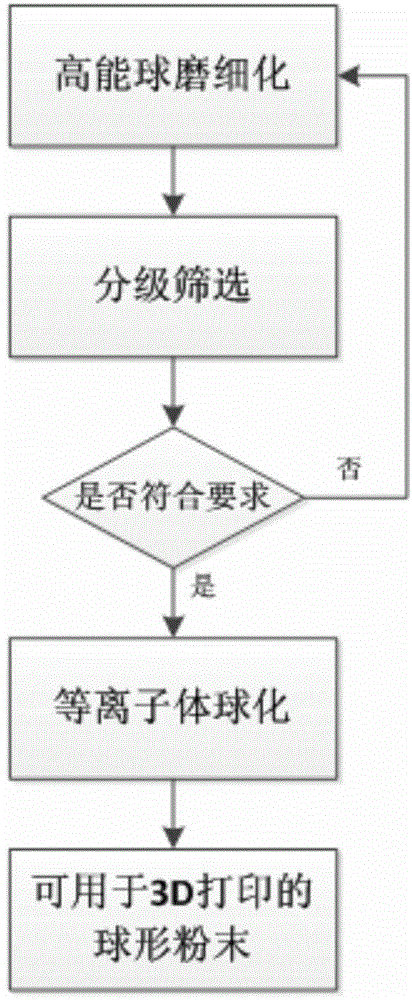

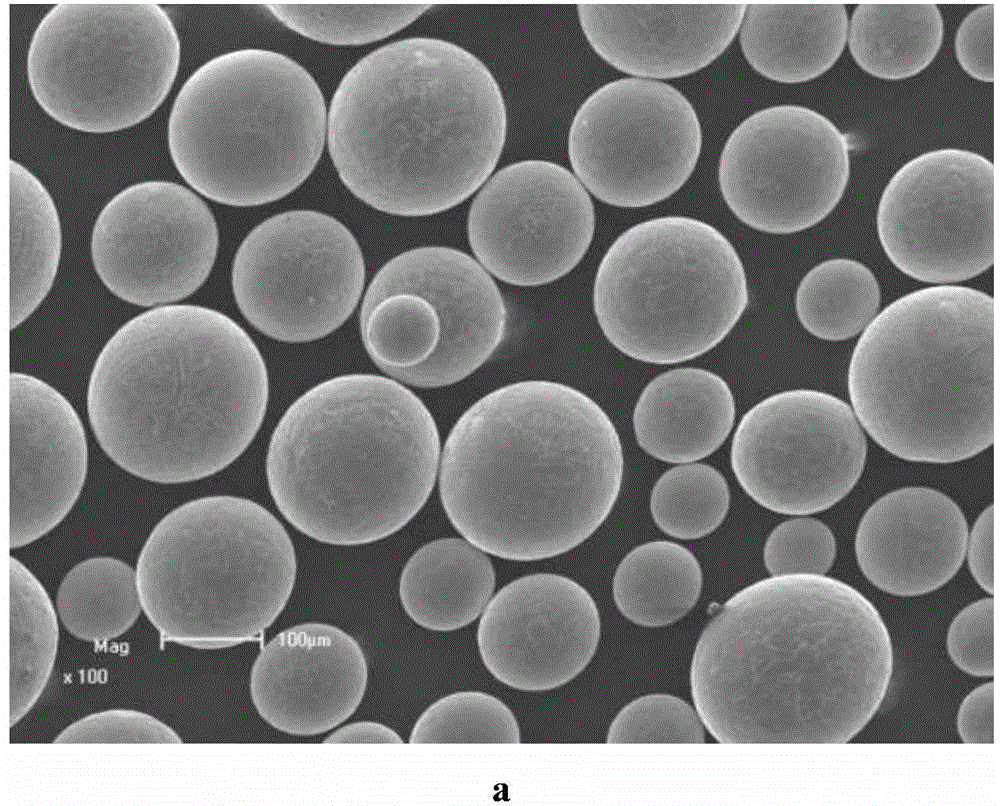

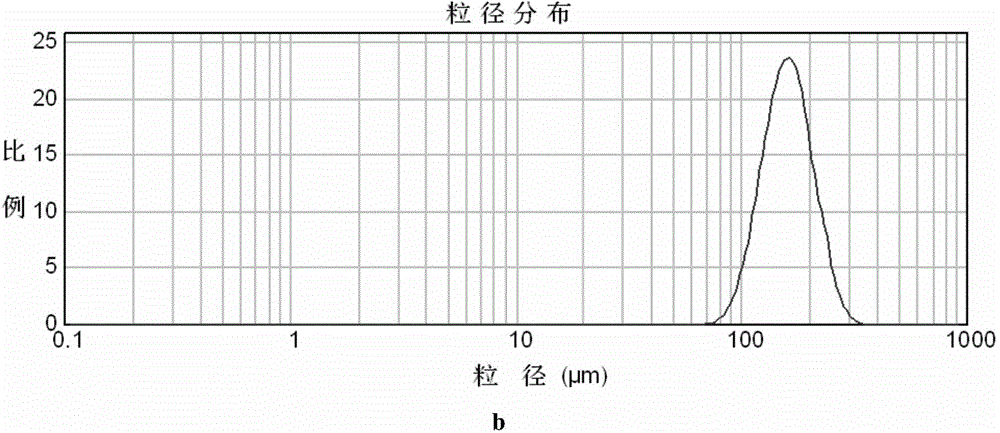

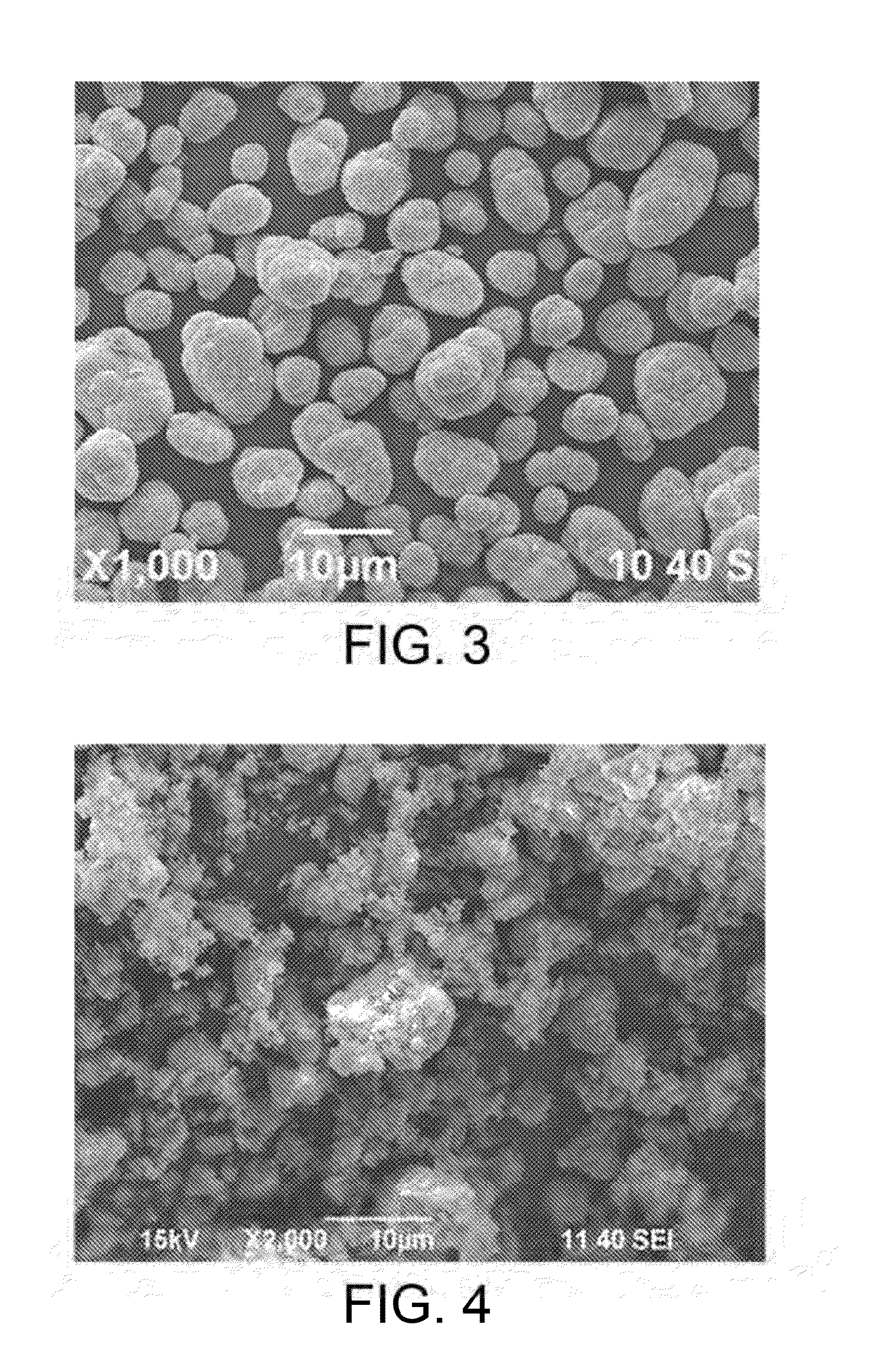

Method for preparing spherical powder material used for three-dimensional printing

The invention discloses a method for preparing a spherical powder material used for three-dimensional printing. The method includes the steps of raw material selecting, high-energy ball milling and radio-frequency plasma spherizing. Selected raw materials are metal or alloy powder in the step of raw material selecting; the step of high-energy ball milling is carried out under the argon shielding condition, petroleum ether serves as the ball milling medium, and the metal or alloy powder is aluminum alloy powder, or titanium alloy powder, or nickel-base alloy powder, or stainless steel powder or tungsten alloy powder; according to the step of radio-frequency plasma spherizing, the total gas flow is 100 L / min-200 L / min, the input power of plasma is 50 kW-100 kW, the negative pressure of a gas outlet of a system is minus 1000 Pa-minus 2000 Pa, and the powder conveying amount is 50 g / min-150 g / min. The manufactured spherical powder is high in sphericity degree, even in granularity, low in oxygen content and good in liquidity, has few defects and is suitable for three-dimensional printing. The method for preparing the spherical powder material used for three-dimensional printing has the advantage that the process is accurate and controllable.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

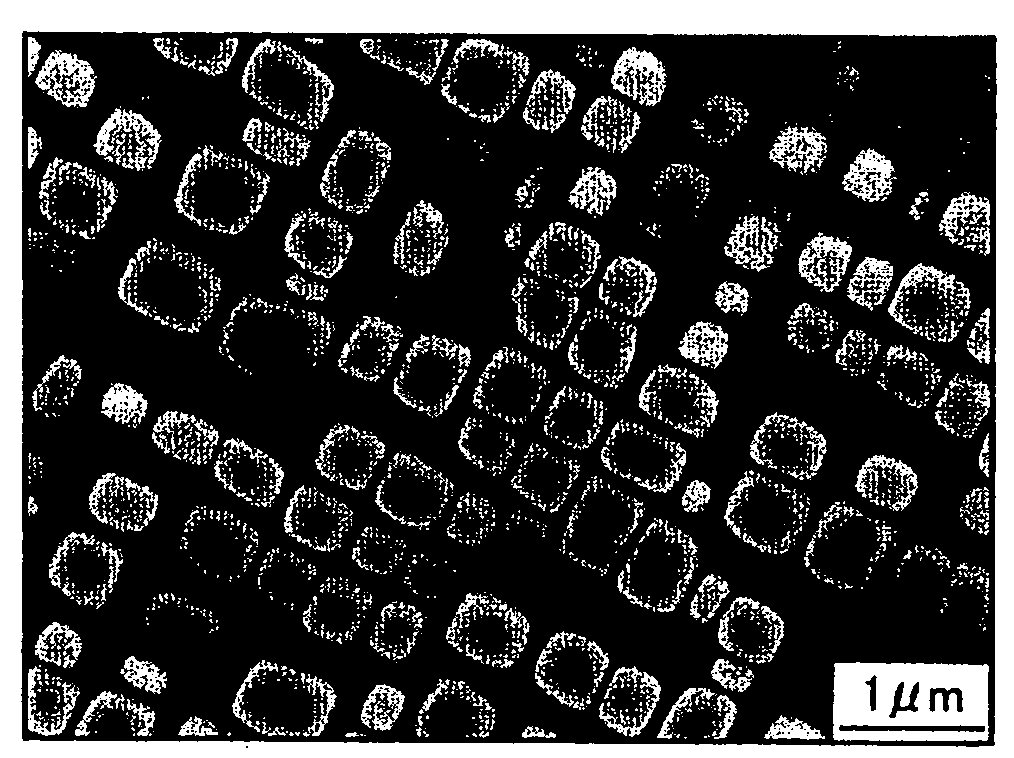

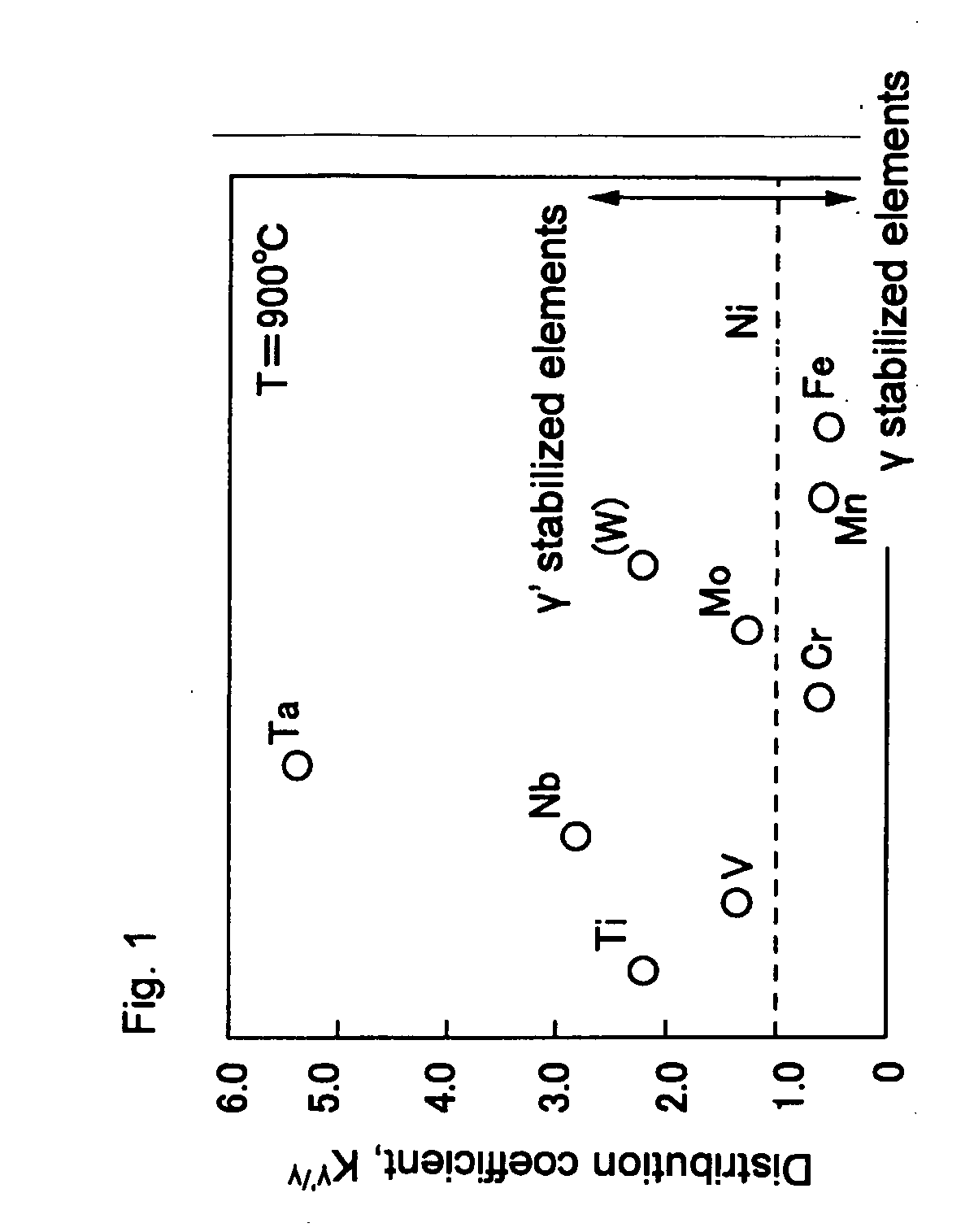

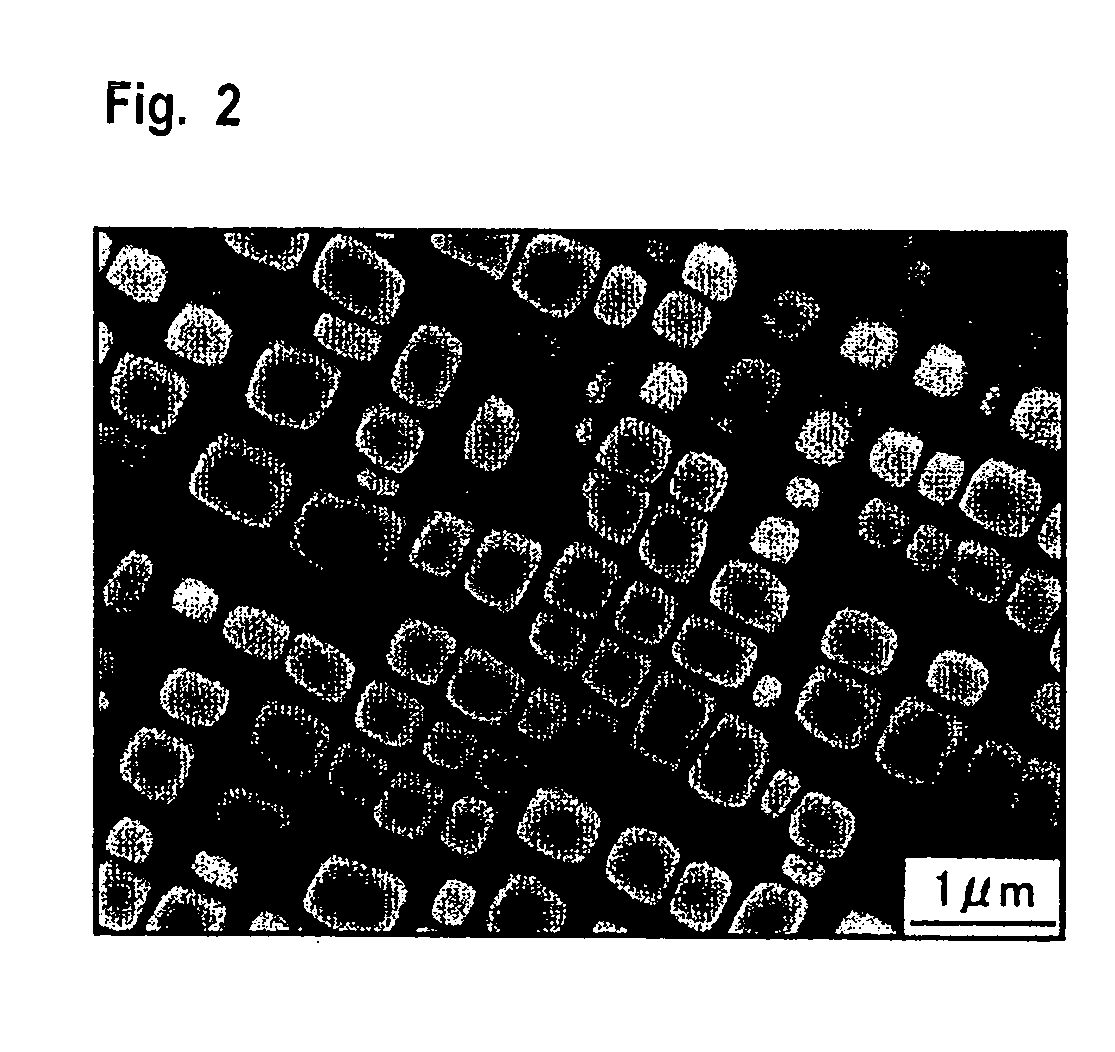

Cobalt-base alloy with high heat resistance and high strength and process for producing the same

A Co-base alloy which has a basic composition including, in terms of mass proportion, 0.1%-10% Al, 3.0-45% W, and Co as the remainder and has an intermetallic compound of the Ll2 type [Co3(Al,W)] dispersed and precipitated therein. Part of the Co may be replaced with Ni, Ir, Fe, Cr, Re, or Ru, while part of the Al and W may be replaced with Ni, Ti, Nb, Zr, V, Ta or Hf. The intermetallic compound [Co3(Al, W)] has a high melting point, and this compound and the matrix are mismatched little with respect to lattice constant. Thus, the cobalt-base alloy can have high-temperature strength equal to that of nickel-base alloys and excellent structure stability.

Owner:JAPAN SCI & TECH CORP

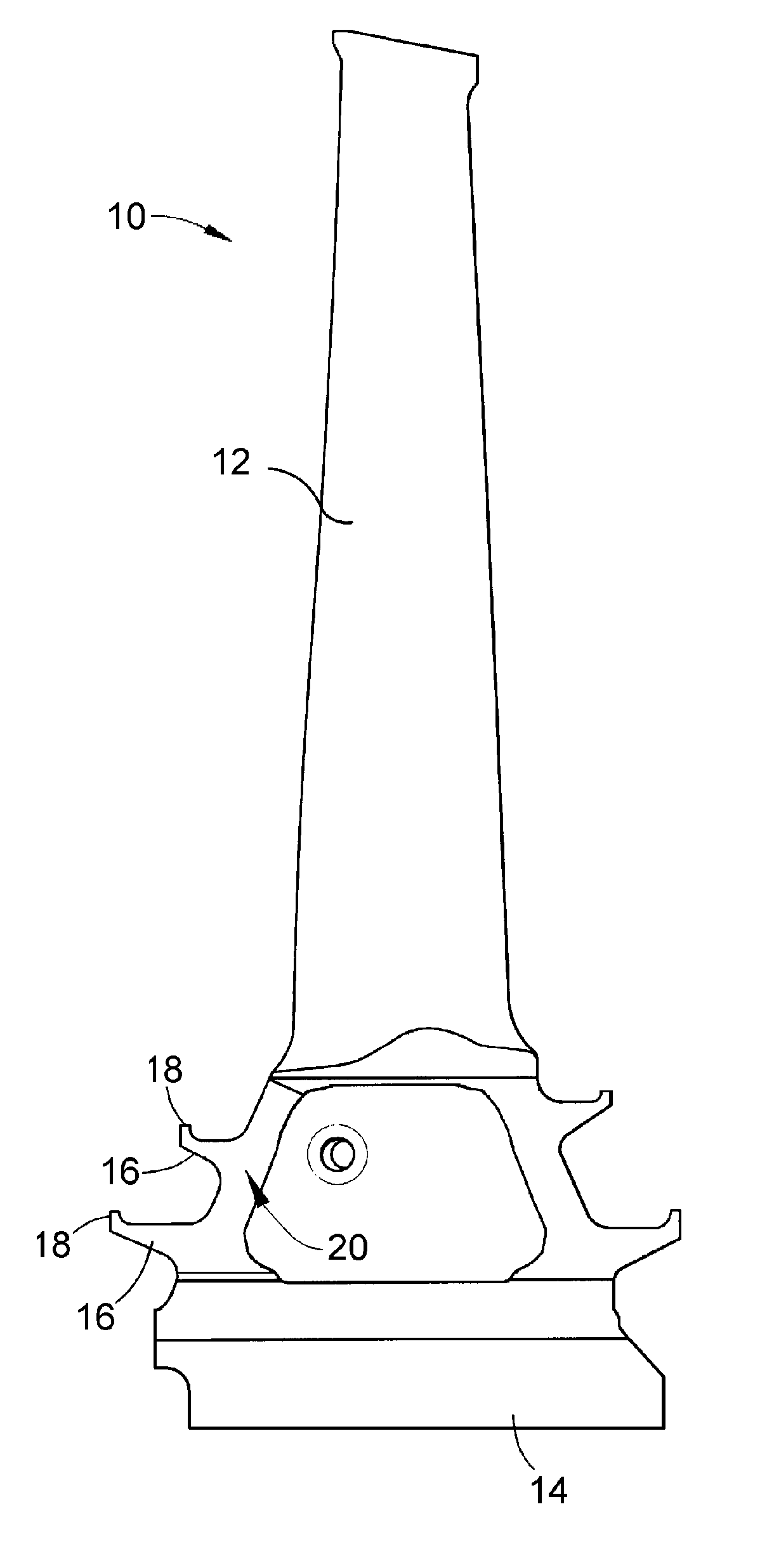

Preform and method of repairing nickel-base superalloys and components repaired thereby

InactiveUS20060134454A1Minimize distortionEasy to crackBlade accessoriesSolid state diffusion coatingPowder mixtureWear resistant

A process for repairing a turbine component of a turbomachine, as well as a sintered preform used in the process and a high gamma-prime nickel-base superalloy component repaired thereby. The sintered preform contains a sintered mixture of powders of a cobalt-base braze alloy and a cobalt-base wear-resistant alloy. The braze alloy constitutes at least about 10 up to about 35 weight percent of the sintered preform and contains a melting point depressant such as boron. The preform is formed by mixing powders of the braze and wear-resistant alloys to form a powder mixture, and then sintering the powder mixture. To use the preform, a surface portion of the turbine component is removed to expose a subsurface portion, followed by diffusion bonding of the preform to the subsurface portion to form a wear-resistant repair material containing the braze alloy dispersed in a matrix of the wear-resistant alloy.

Owner:GENERAL ELECTRIC CO

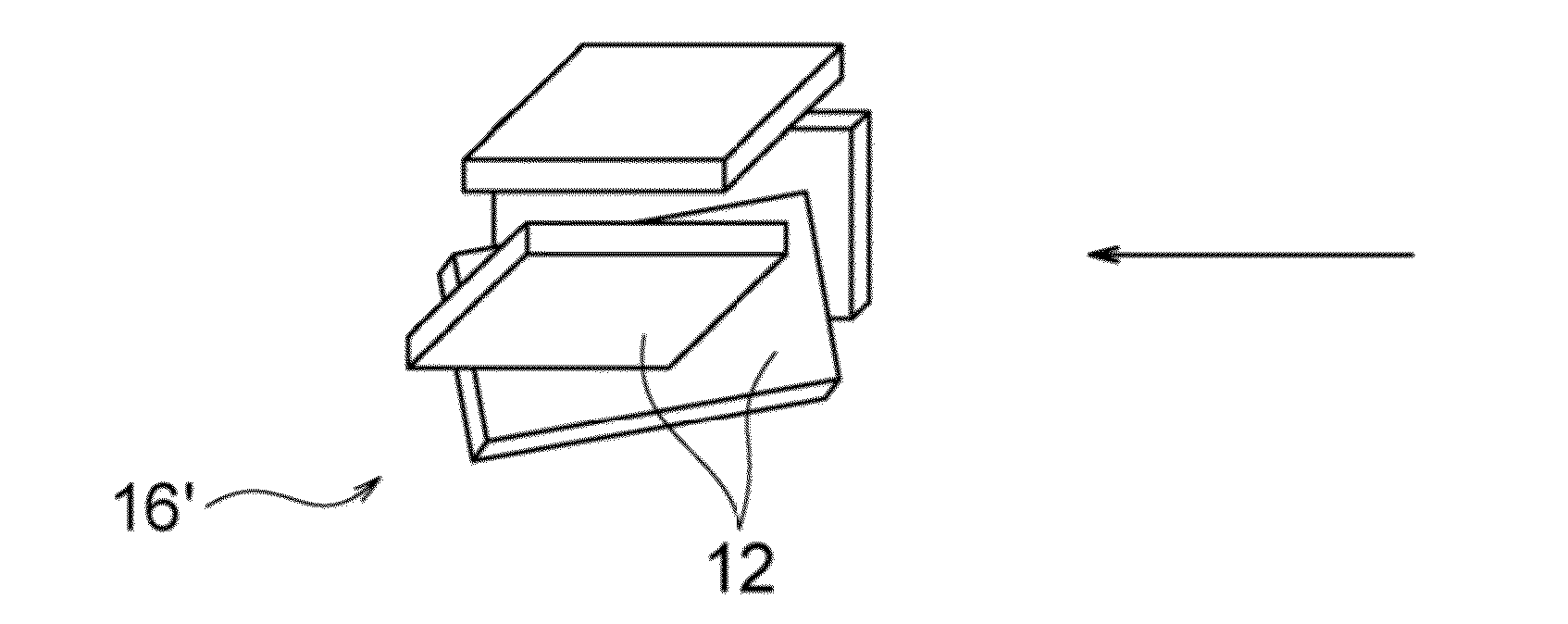

Positive electrode active material for lithium secondary battery and positive electrode including same

ActiveUS20150093580A1Increase volumetric energy densityGood rate characteristicsCell electrodesSynthetic resin layered productsLithium-ion batteryMaterials science

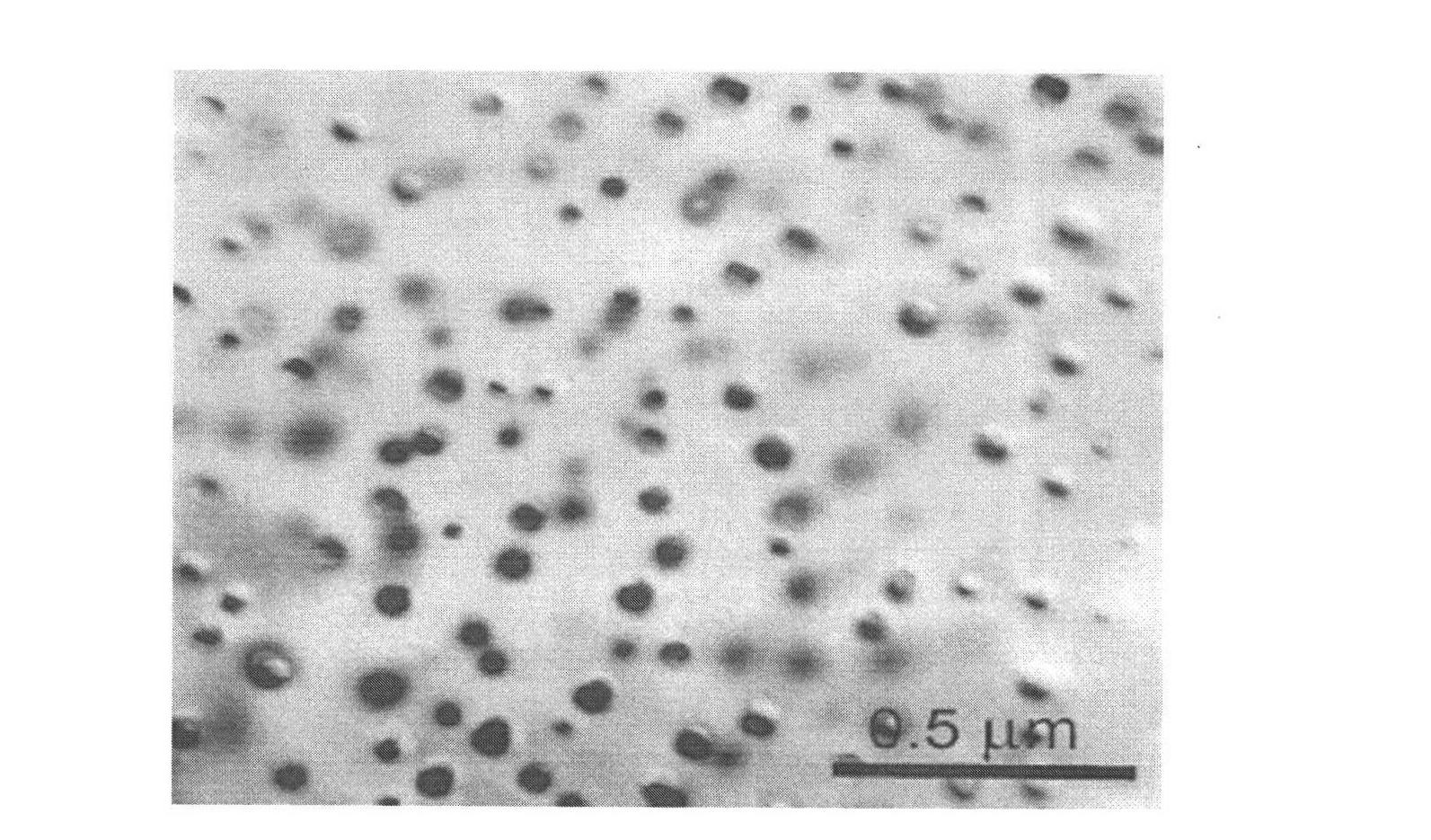

There is provided a positive electrode active material capable of achieving a high volume energy density and yet superior rate characteristics when configured as a positive electrode for lithium secondary batteries. This positive electrode active material comprises a plurality of secondary particles each comprising primary particles composed of a lithium-nickel based complex oxide having a layered rock-salt structure. The plurality of secondary particles have a volume-based average particle diameter D50 of 5 to 100 μm, and at least part of the plurality of secondary particles are coarse secondary particles having a particle diameter of 9 μm or greater. The coarse secondary particles have a voidage of 5 to 25%, and the ratio of through holes among all voids in the coarse secondary particles is 70% or greater.

Owner:NGK INSULATORS LTD

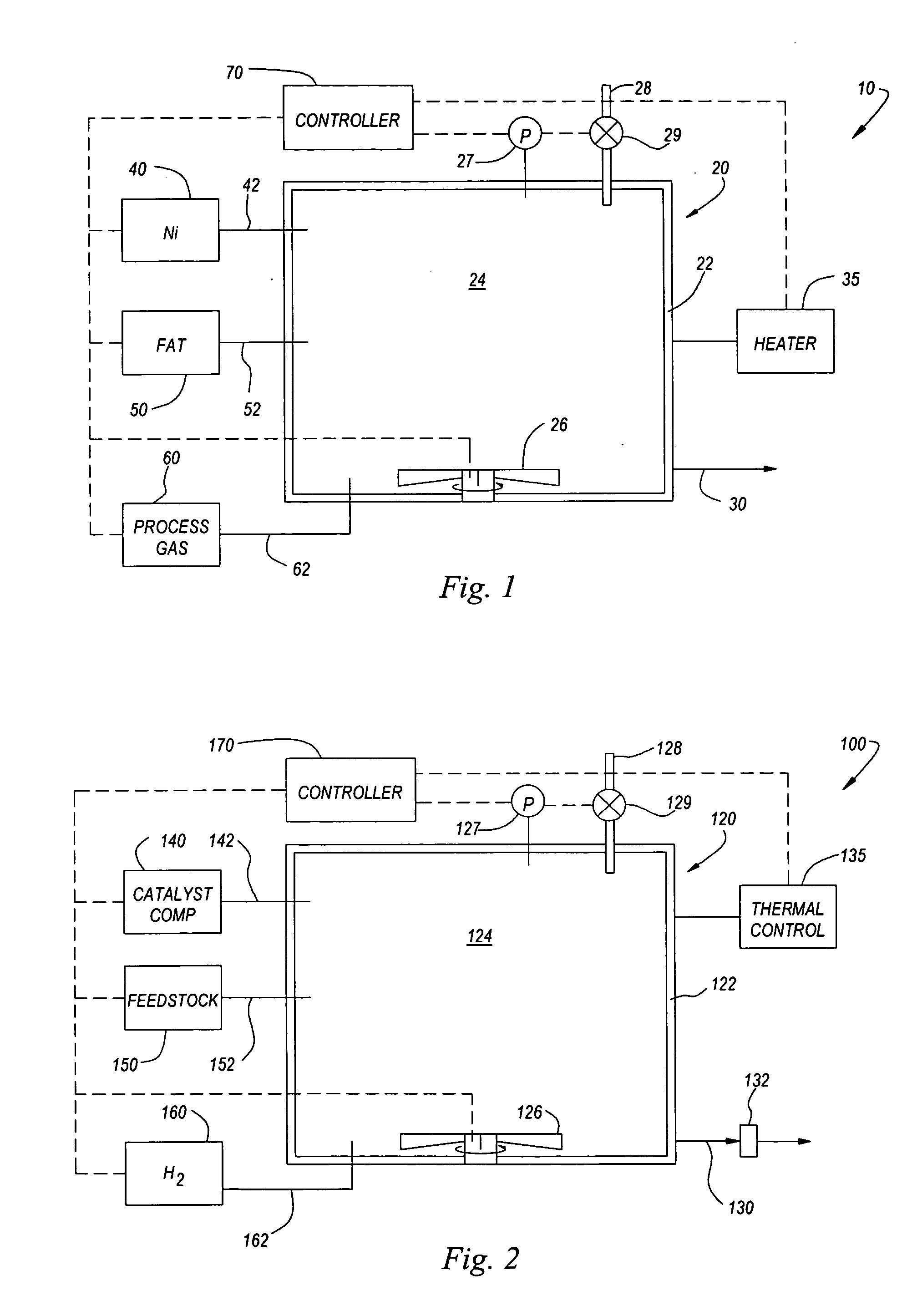

Low trans-fatty acid fat compositions; low-temperature hydrogenation, e.g., of edible oils

InactiveUS20050027136A1Fatty acid hydrogenationOrganic compound preparationPartial hydrogenationHydrogenation reaction

The present disclosure provides low trans-fatty acid fat compositions, methods of hydrogenating unsaturated feedstocks (e.g., oils), and hydrogenation catalyst compositions. One exemplary method involves producing an activated catalyst composition by heating a nickel-based catalyst to a first temperature of at least about 100° C. in the presence of hydrogen and a fat component. An unsaturated feedstock may be contacted with the activated catalyst composition and hydrogenated by sustaining a hydrogenation reaction at a second temperature of no greater than about 70° C. Some specific implementations of the invention permit the production of partially hydrogenated seed oils with low trans-fatty acid contents.

Owner:CARGILL INC

Fretting and whisker resistant coating system and method

ActiveUS20050106408A1Minimized increaseHigh resistivityAnodisationHot-dipping/immersion processesCoating systemFlexible circuits

A coated electrically conductive substrate has particular utility where there are multiple closely spaced leads and tin whiskers constitute a potential short circuit. Such substrates include leadframes, terminal pins and circuit traces such as on printed circuit boards and flexible circuits. This electrically conductive substrate has a plurality of leads separated by a distance capable of bridging by a tin whisker, a silver or silver-base alloy layer coating at least one surface of at least one of the plurality of leads, and a fine grain tin or tin-base alloy layer directly coating said silver layer. An alternative coated electrically conductive substrate has particular utility where debris from fretting wear may oxidize and increase electrical resistivity, such an in a connector assembly. This electrically conductive substrate has a barrier layer deposited on the substrate that is effective to inhibit diffusion of constituents the substrate into a plurality of subsequently deposited layers. The subsequently deposited layers include a sacrificial layer deposited on the barrier layer that is effective to form intermetallic compounds with tin, a low resistivity oxide metal layer deposited on said sacrificial layer, and an outermost layer of tin or a tin-base alloy directly deposited on the low resistivity oxide metal layer. In this alternative embodiment, the barrier layer is preferably nickel or a nickel-base alloy and the low resisitivity oxide metal layer is preferably silver or a silver-base alloy. When heated, the coated substrate of this second embodiment forms a unique structure having a copper or copper-base alloy substrate, an intervening layer formed from a mixture or metals including copper and tin, and an outermost layer which is a mixture of a copper-tin intermetallic containing phase and a silver-rich phase. It is believed that this silver-rich phase is particularly beneficial to reduce an increase in resistivity due to oxidation of fretting wear debris.

Owner:WIELAND ROLLED PROD NORTH AMERICA LLC

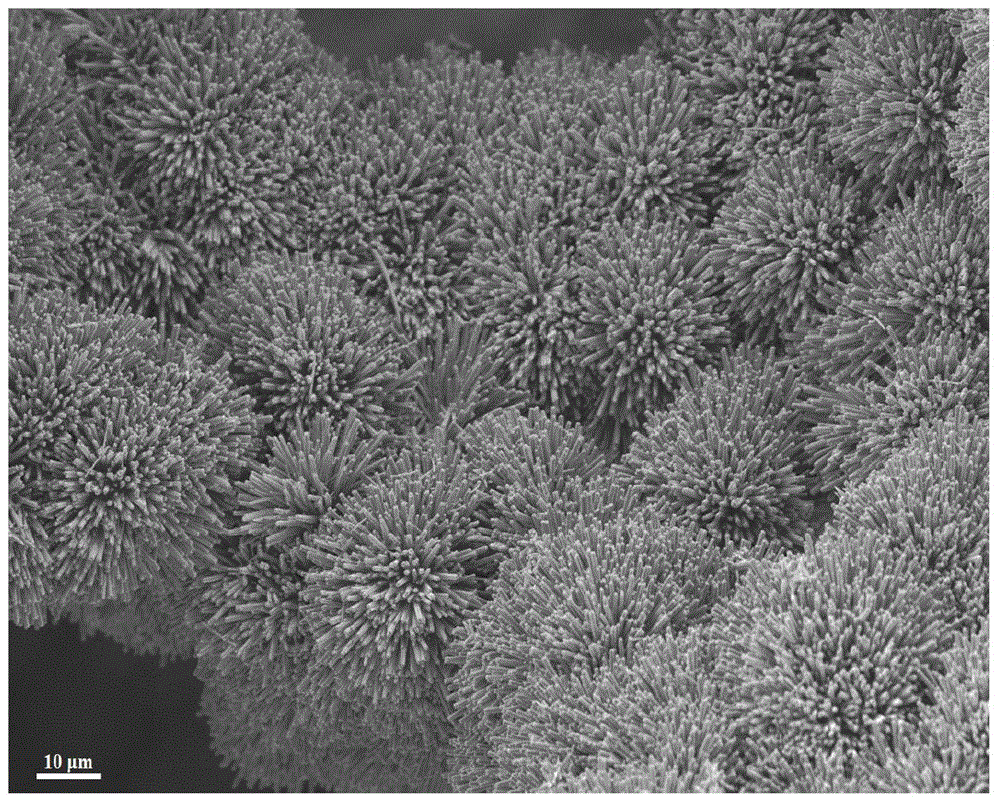

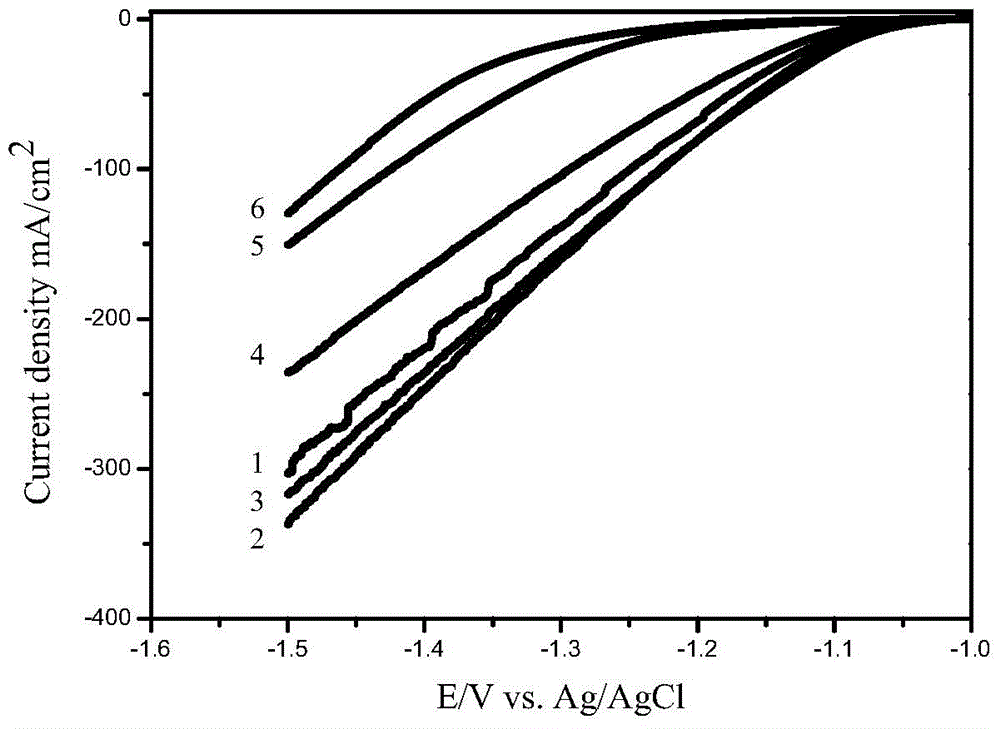

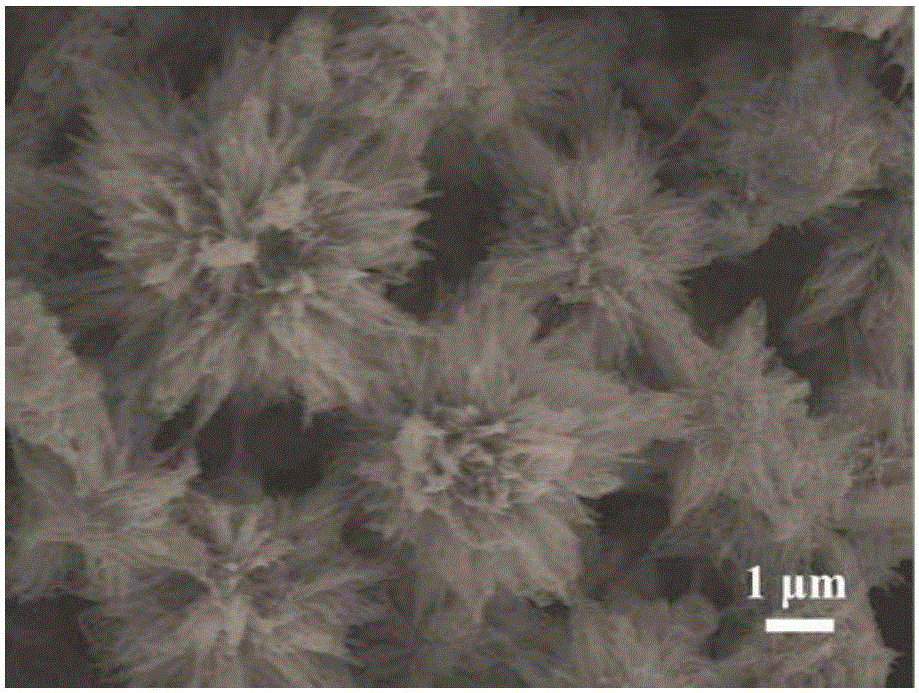

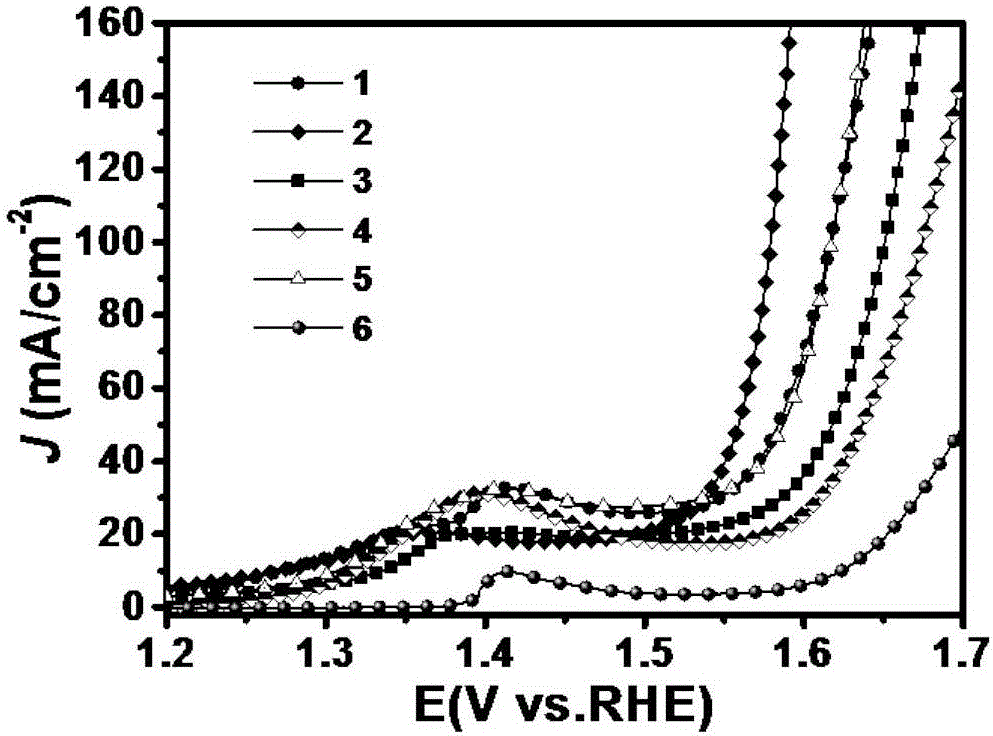

Method of partial vulcanization to improve oxygen evolution electrode performance of metal hydroxide

InactiveCN106011911AIncrease intrinsic activityImprove bindingPhysical/chemical process catalystsElectrodesVulcanizationHydrothermal synthesis

The invention provides a method of partial vulcanization to improve oxygen evolution electrode performance of metal hydroxide and belongs to the field of oxygen evolution catalyzation of electrolysis of water. The method comprises the following steps: firstly, pretreatment is carried out on nickel foam, then, special nano floriform metal hydroxide is formed on the surface of the nickel base after the pretreatment in an in-situ growth manner through the hydrothermal synthesis method, and finally, the prepared metal hydroxide and a sulphur source have hydrothermal reaction to prepare a hydroxyl metal sulfide oxygen evolution electrode. According to the invention, the method is novel, the demanded technology is simple, the production cost is low, requirements to equipment are lower, and industrial production is suitable; in addition, the prepared electrode has excellent oxygen evolution activity and stability, is large in specific surface area, firmly combines with a base, and can be applied to the field of oxygen evolution through industrial electrolysis of water.

Owner:CHONGQING UNIV

Nickel-base alloy for the electro-welding of nickel alloys and steels, welding wire and use

The alloy contains, by weight, less than 0.05% of carbon, from 0.015% to 0.5% of silicon, from 0.4% to 1.4% of manganese, from 28% to 31.5% of chromium, from 8% to 12% of iron, from 2% to 7% of molybdenum, from 0% to 0.75% of aluminium, from 0% to 0.8% of titanium, from 0.6% to 2% in total of niobium and tantalum, the ratio of percentages of niobium plus tantalum and of silicon being at least 4, less than 0.04% of nitrogen, from 0.0008% to 0.0120% of zirconium, from 0.0010% to 0.0100% of boron, less than 0.01% of sulphur, less than 0.020% of phosphorus, less than 0.30% of copper, less than 0.15% of cobalt and less than 0.10% of tungsten, the remainder of the alloy, with the exception of unavoidable impurities of which the total content is at most 0.5%, consisting of nickel. The alloy is used, in particular, for the production of wires for the electro-gas welding of units or components of nuclear reactors and, more particularly, of pressurised water-cooled nuclear reactors.

Owner:FRAMSTOME ANP

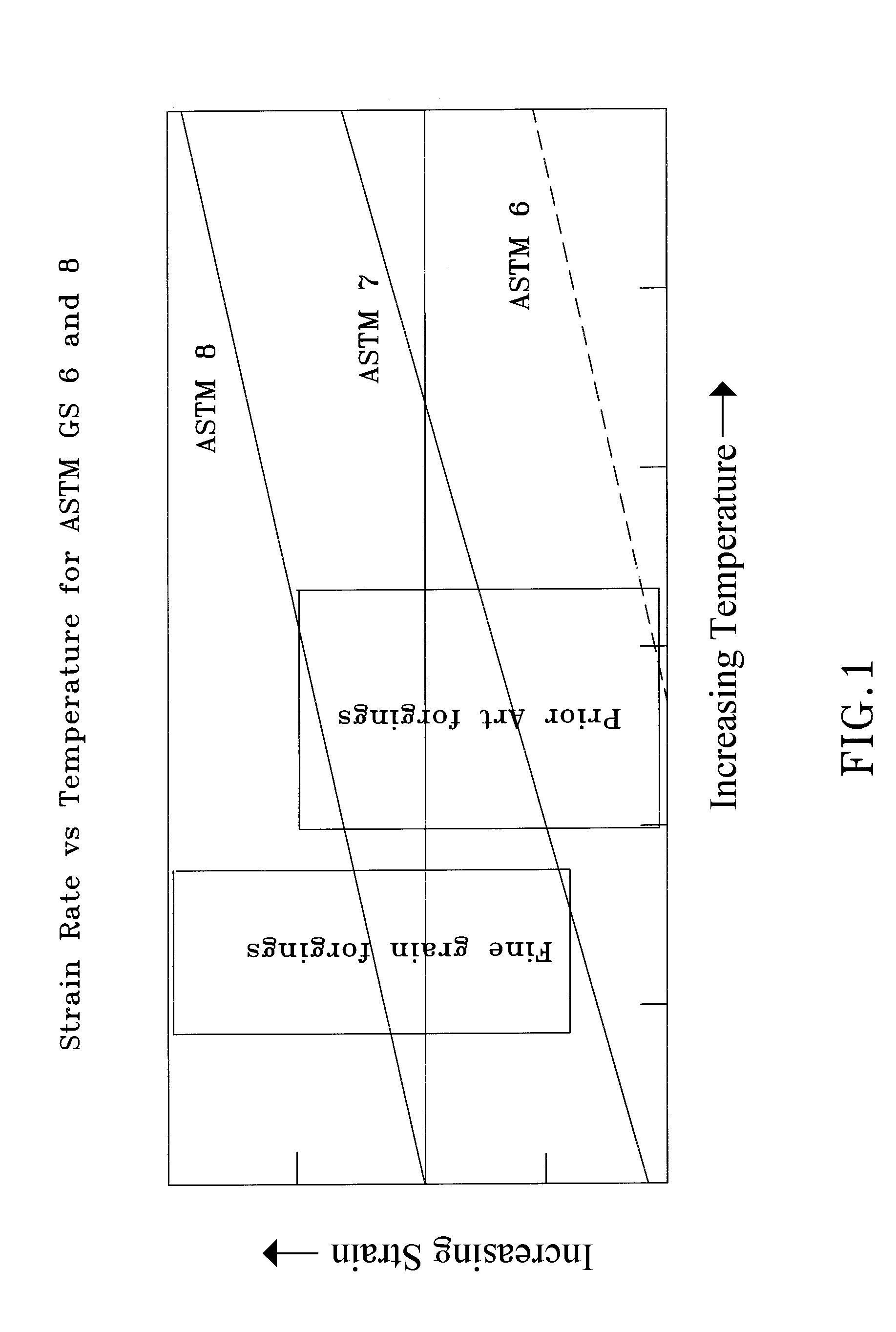

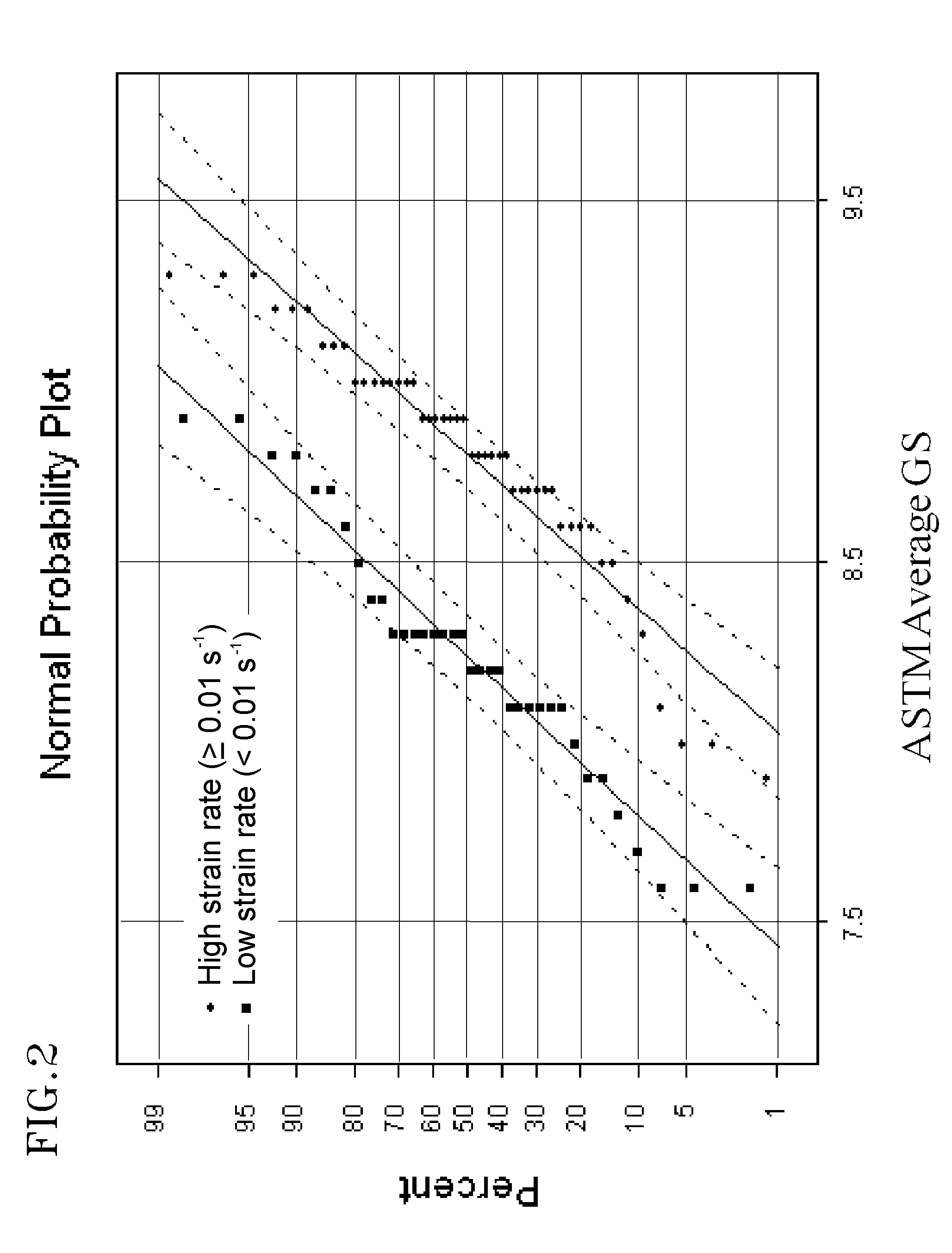

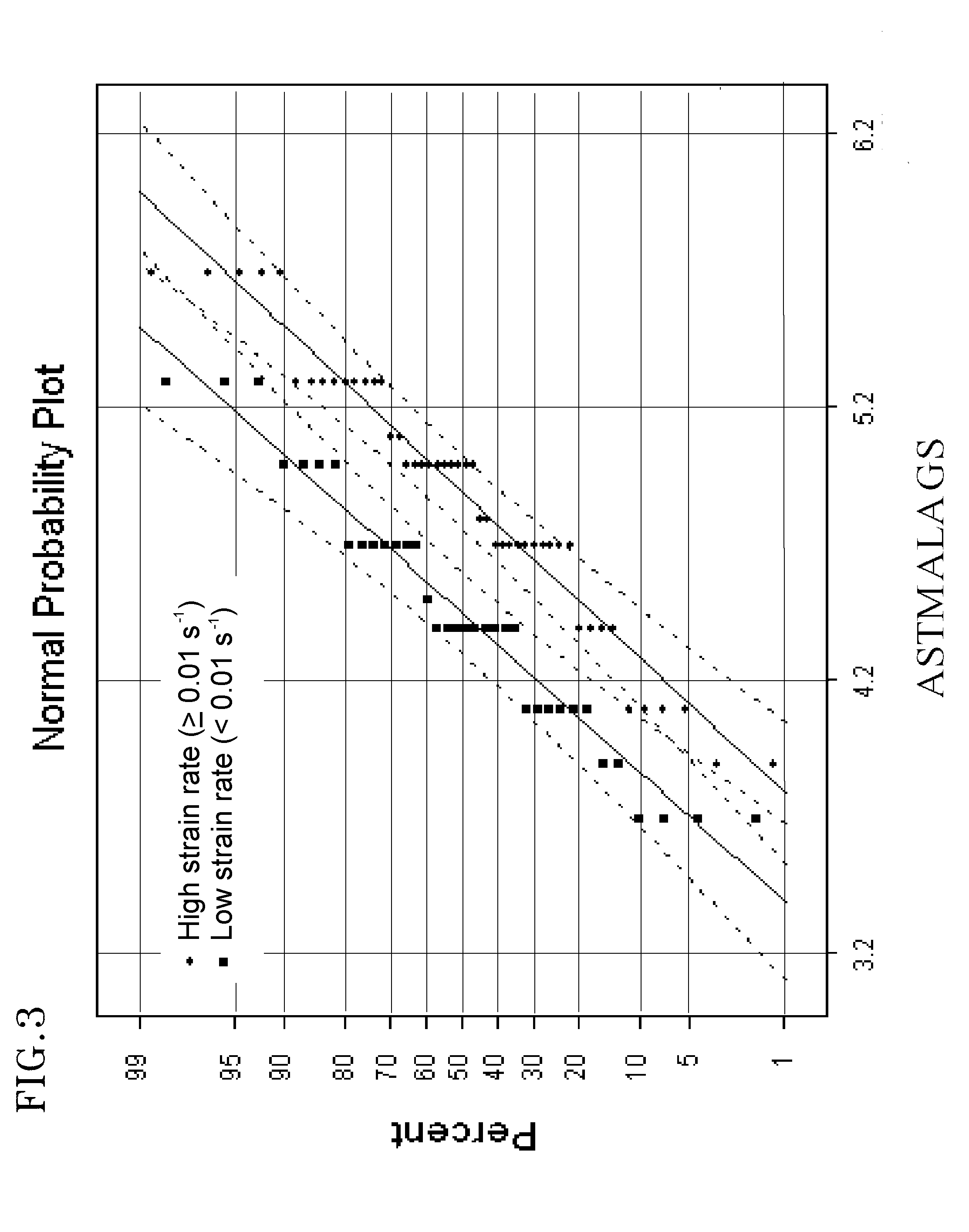

Method of controlling and refining final grain size in supersolvus heat treated nickel-base superalloys

InactiveUS20090000706A1High strain rateAvoiding necessity to forge superplasticallyHigh carbonHeat treated

A method of forming a component from a gamma prime precipitation-strengthened nickel-base superalloy. The method entails formulating the superalloy to have a sufficiently high carbon content and forging the superalloy at sufficiently high local strain rates so that, following a supersolvus heat treatment, the component is characterized by a fine and substantially uniform grain size distribution, preferably finer than ASTM 7 and more preferably in a range of about ASTM 8 to 10.

Owner:GENERAL ELECTRIC CO

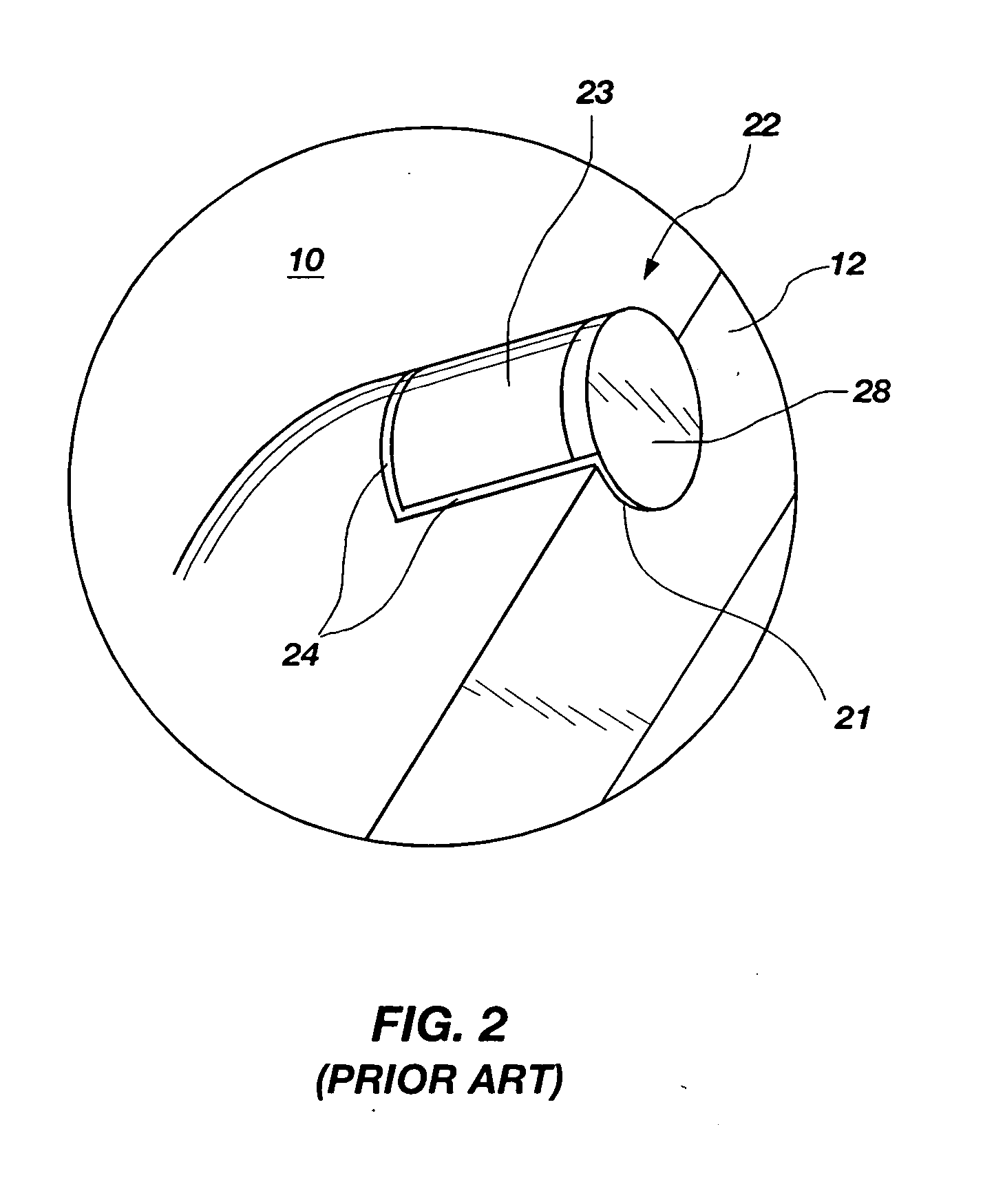

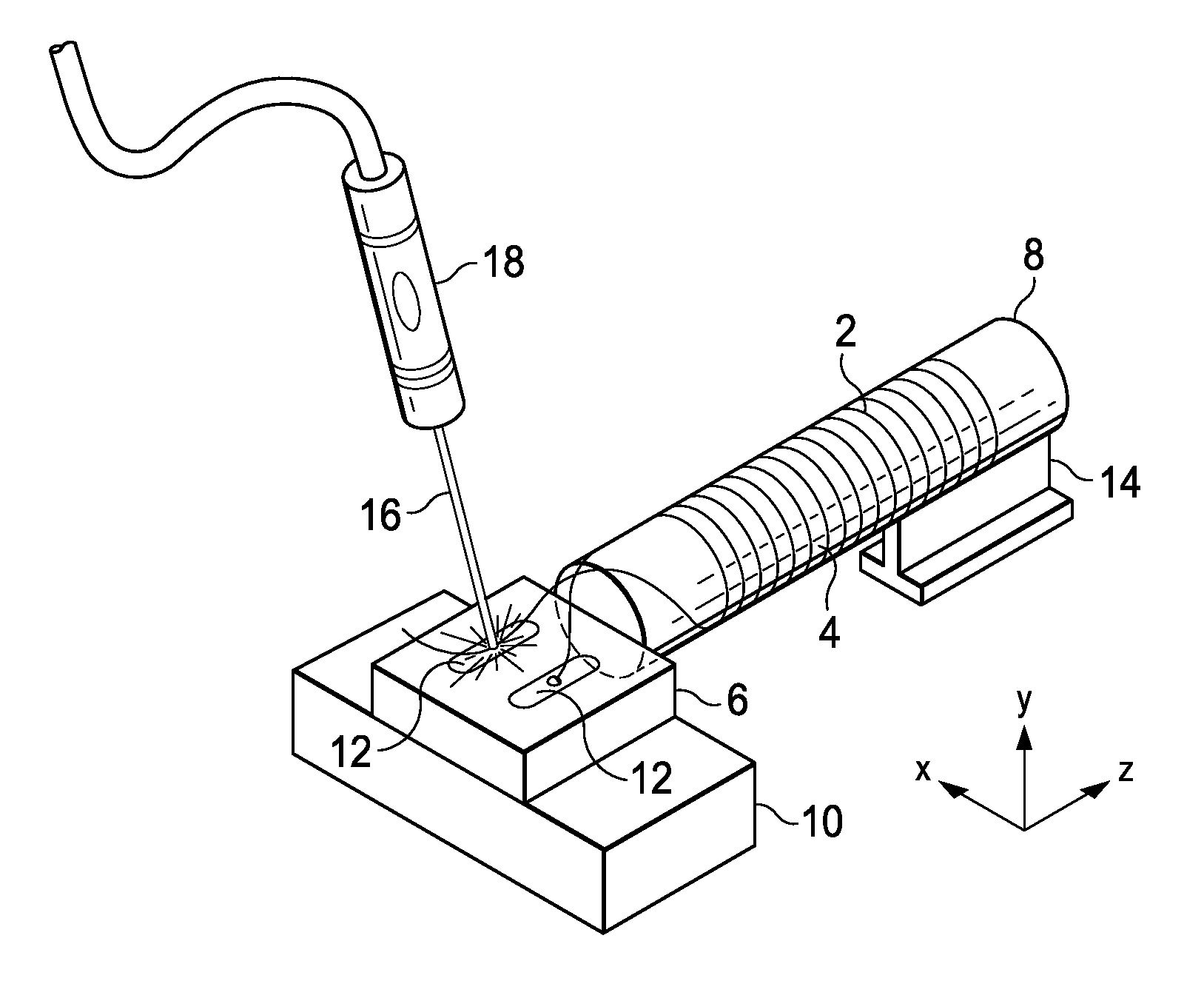

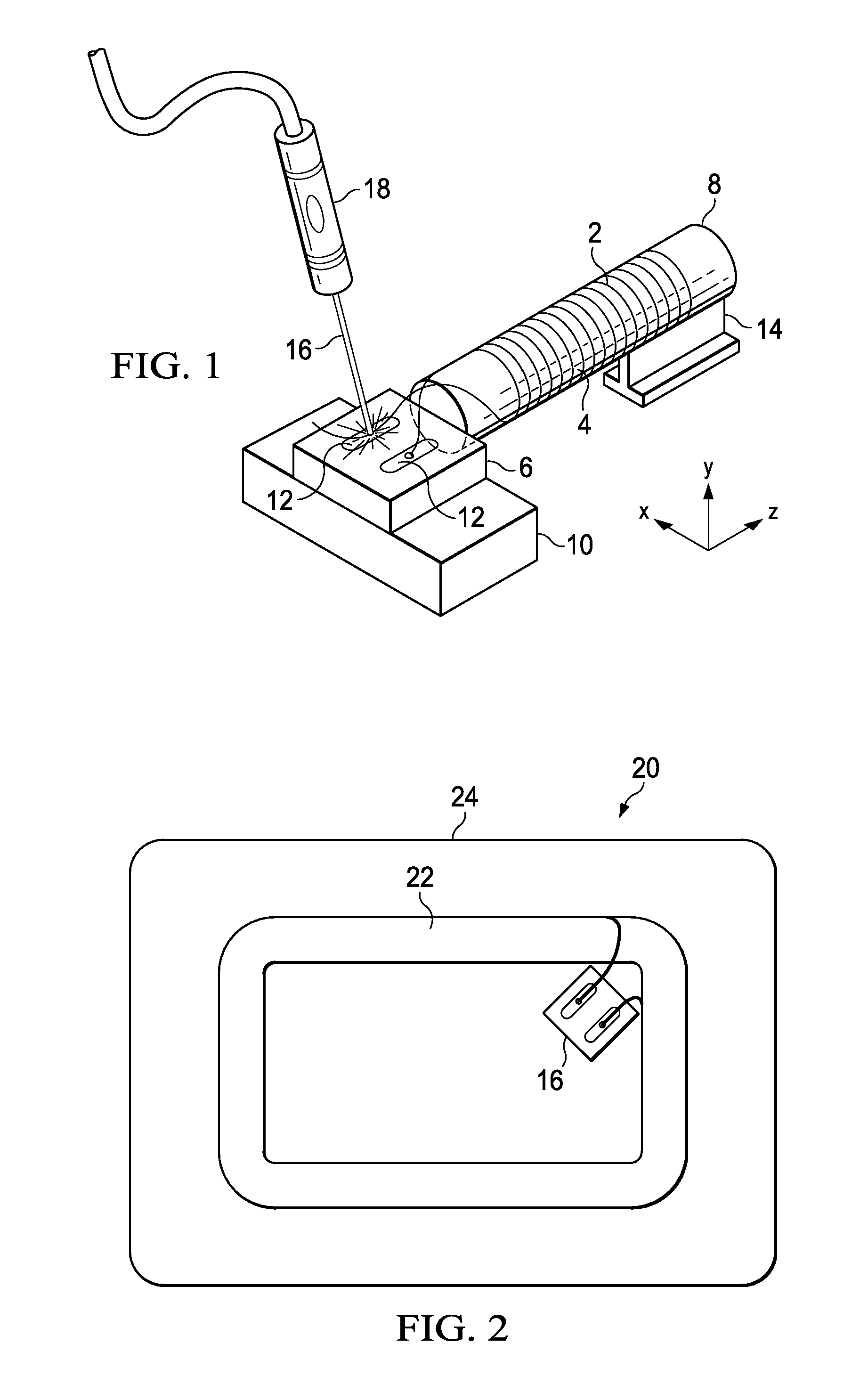

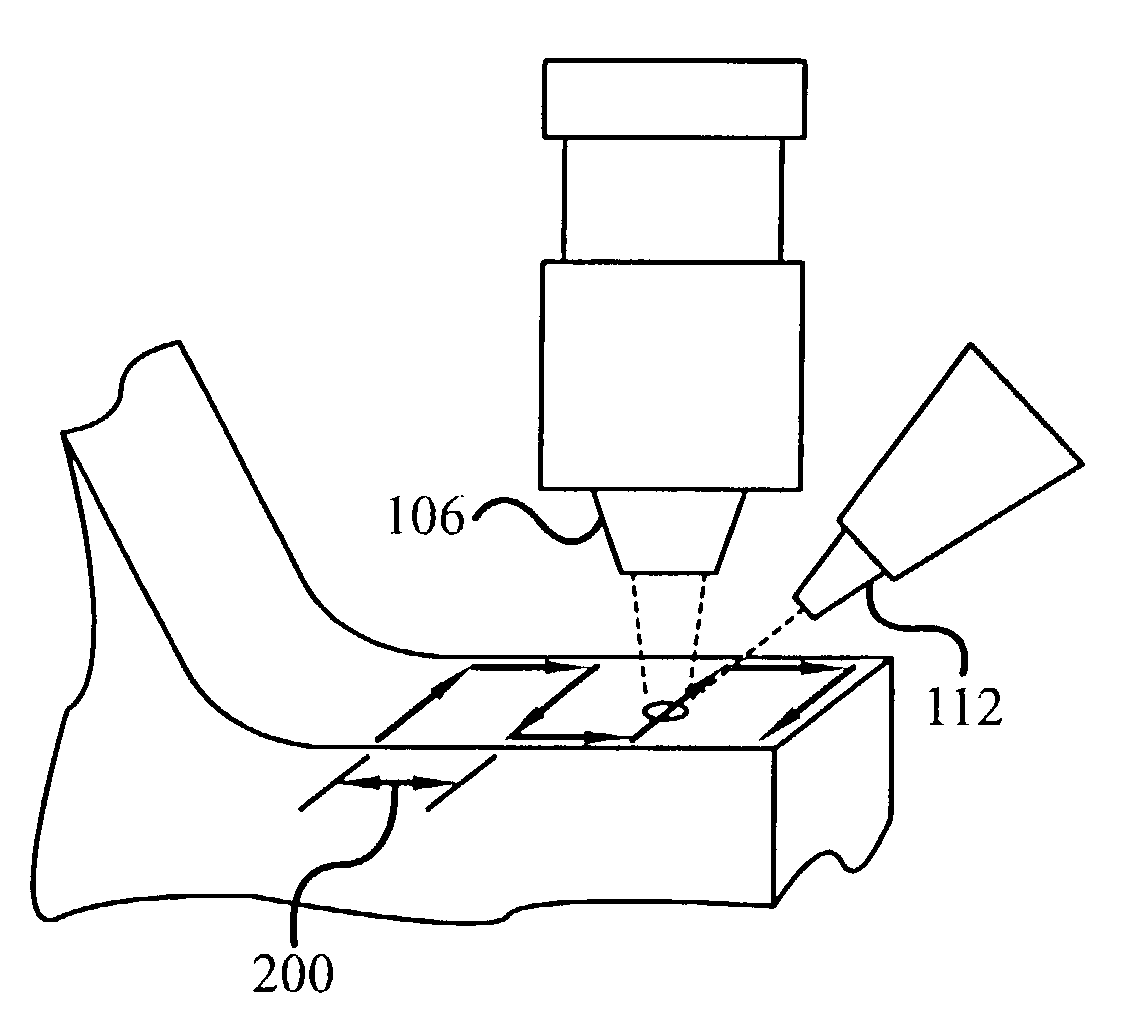

Laser powder fusion repair of Z-notches with nickel based superalloy powder

A method is provided for repairing Z-notch wear surfaces on low pressure gas turbine engine turbine blades. The method is directed to turbine blades made of superalloy Inconel 713. Powdered Inconel 713 is welded to the Z-notch wear surface by directing an Nd:YAG laser beam upon the material. The laser beam is focused and traverses the wear surface in a stich-like pattern. The method allows Inconel 713 turbine blades to be repaired with the same material in a manner that does not generate cracking in the matrix material.

Owner:HONEYWELL INT INC

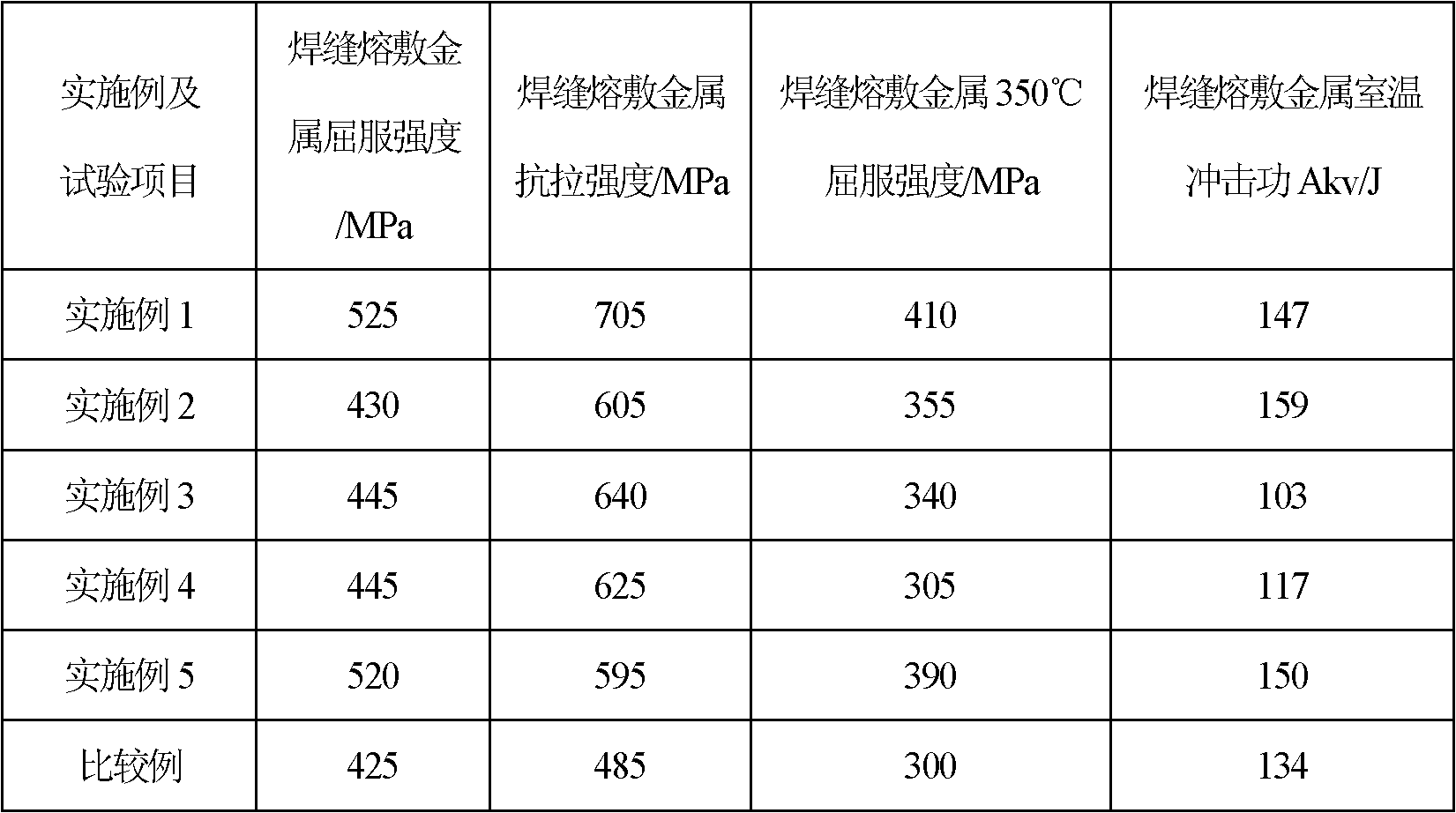

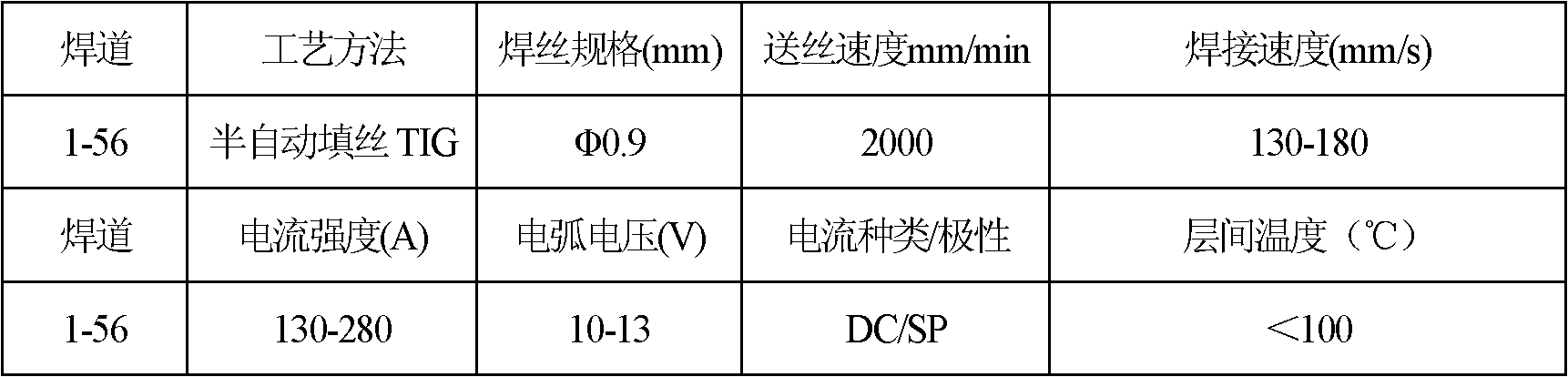

Nickel-based welding electrode for welding nickel-chromium-molybdenum alloy

ActiveCN102430876AExcellent heat crack resistanceEasy to useWelding/cutting media/materialsSoldering mediaCrack resistanceNiobium

The invention relates to a nickel-based welding electrode which comprises the following component by weight percent (wt%): 50.0-68.0% of Ni, 18.0-23.0% of Cr, 6.0-11.0% of Mo, 3.0-6.0% of Nb, 2.50-9.00% of Fe, 0.01-0.1% of C, 0.10-1.00% of Mn, 0.010-0.10% of Si, 0.015% of S or less, 0.015% of P or less, 0.01-0.10% of Cu, 0.003-0.010% of Co and the balance of impurities. The coat of the nickel-based welding electrode comprises the following components by weight percent of the welding core: 12-18% of marble, 10-15% of fluorite, 12-18% of barium carbonate, 5.0-6.4% of rutile, 3.5-5.0% of ferroniobium, 3.3-4.5 of chromium metal powder, 0.45-0.65% of sodium carbonate, 0.45-0.65% of electrolytic manganese and 1.3-1.8% of zircon sand, and the adhesion agent is 10-20% of the total weight of the power. The nickel-based welding electrode is prepared by mixing, wrapping mixture on the welding core and baking at low and high temperature. The nickel-based welding electrode disclosed by the invention is used for nickel-chromium-molybdenum alloy steel welding, ensures that the excellent mechanical properties, the excellent corrosion resistance, the excellent thermal crack resistance and the hightensile strength of the welding seam match with those of the base material, has good welding process performance, guarantees attractive molding and can be used for the welding of the steel (with 9% of Ni) working at low temperature.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

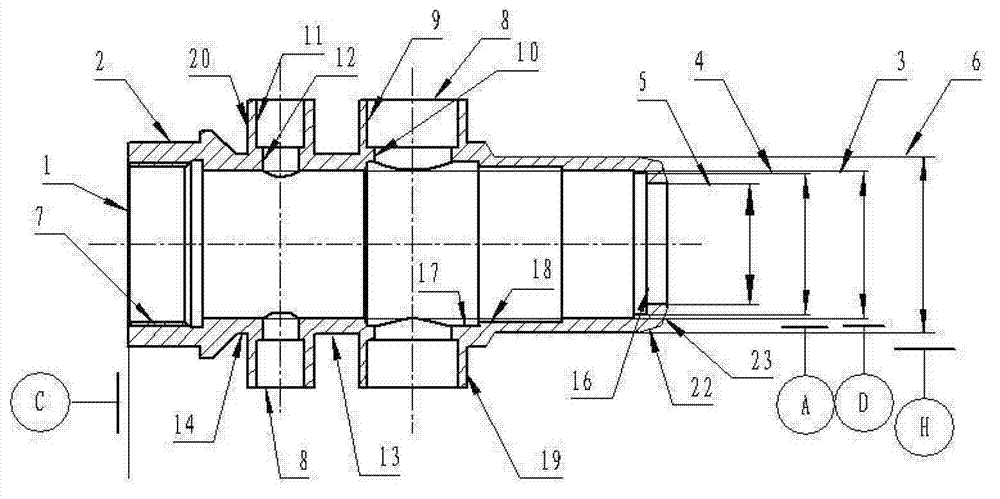

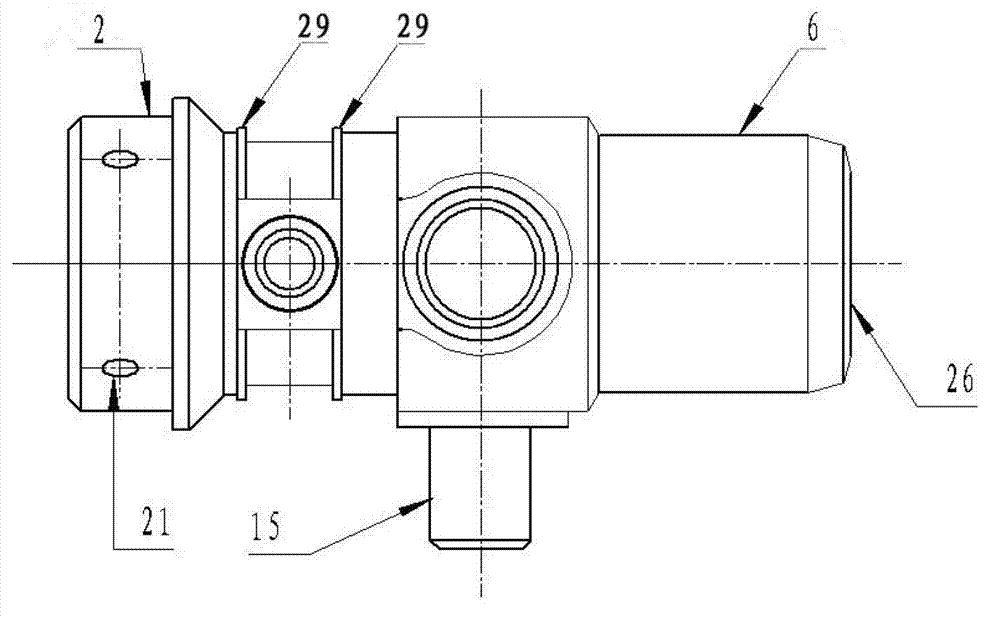

Numerically-controlled processing method of nozzle housing piece

The invention discloses a numerically-controlled processing method of a nozzle housing piece. According to the method, a numerically-controlled machining / milling combined processing center is adopted and comprises two main shafts and an on-line measurement device; the workblank of the nozzle housing piece is a die-forged part, and the die-forged part is made of a nickel-based high-temperature alloy. The method comprises the following steps: designing a nozzle housing processing path; performing polishing treatment on the die-forged part to remove burrs from the die-parting face and end-face die-drawing taper; coarsely machining the tail part of the work piece; performing numerically-controlled machining / milling on the whole work piece; performing numerically-controlled fine machining of the head part of the work piece; cleaning and marking the work piece; and inspecting. The method provides the reasonable designs of processing path and processing method of the work piece as well as the processing positioning reference of the work piece, and completes the processing of the inner cavity, the outer circle, the lateral adapter, the positioning pin and other parts of the nozzle housing piece within one-step loading process. The method solves the problem that the die-forged part has a complex structure and a thin wall and has strict requirements for dimensional precision and positional precision; and overcomes the defects of long processing period, low production efficiency and poor dimensional precision and positional precision.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

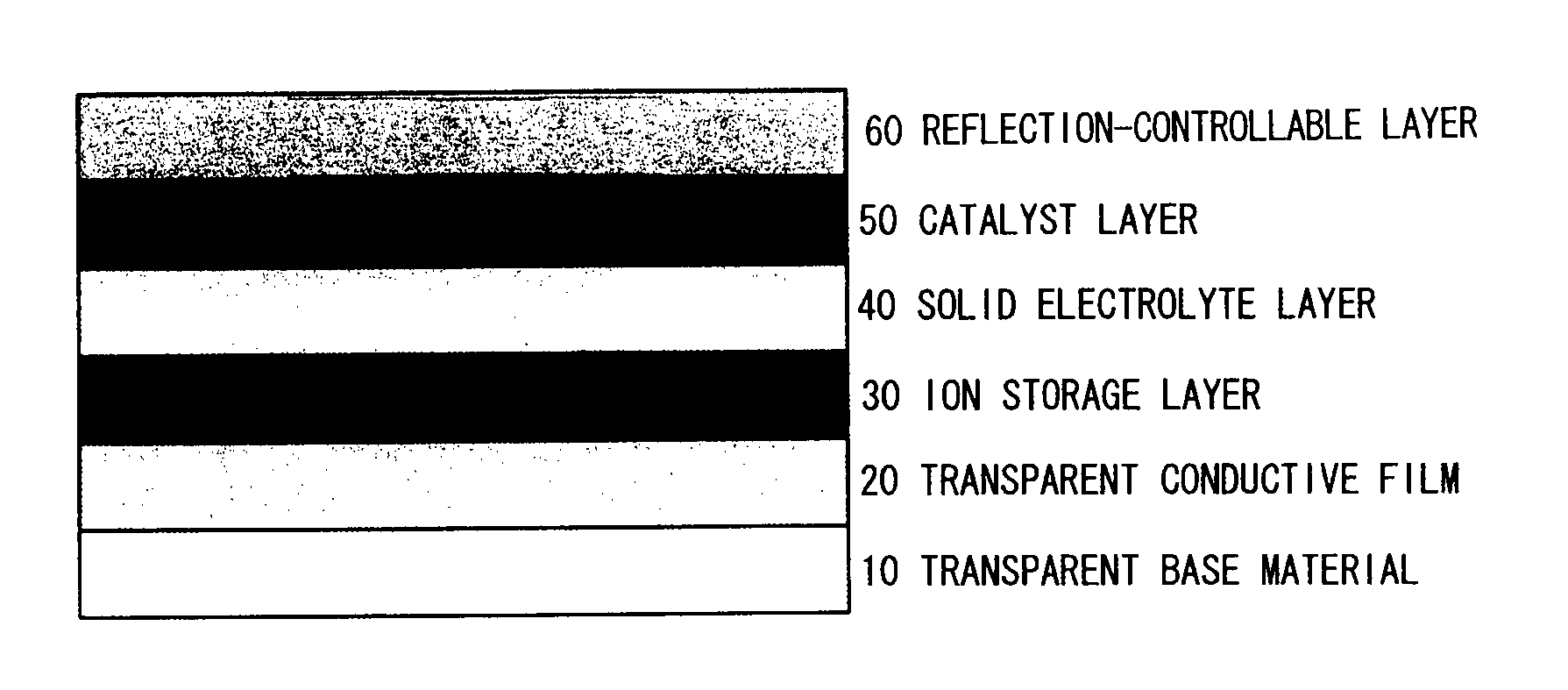

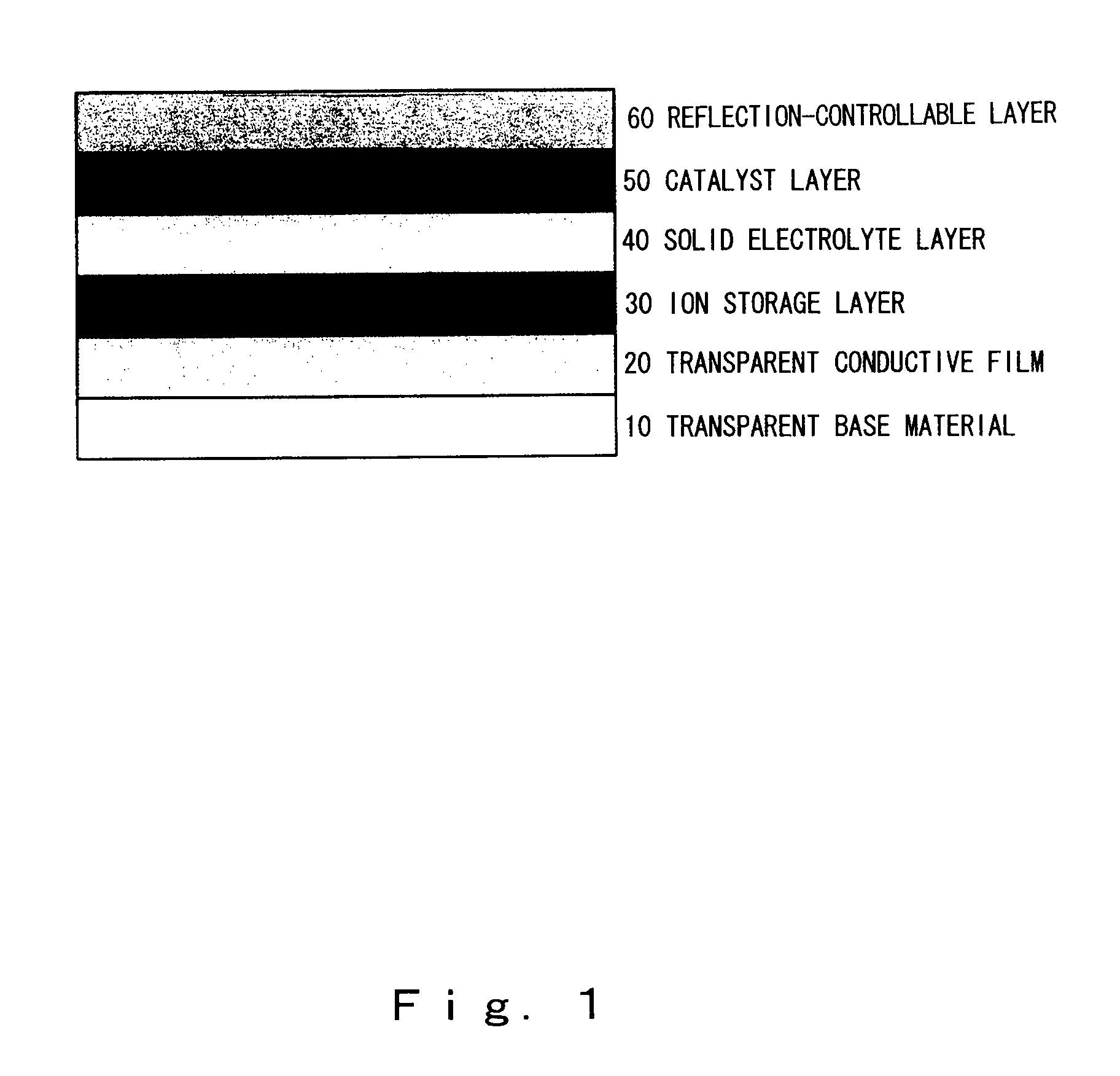

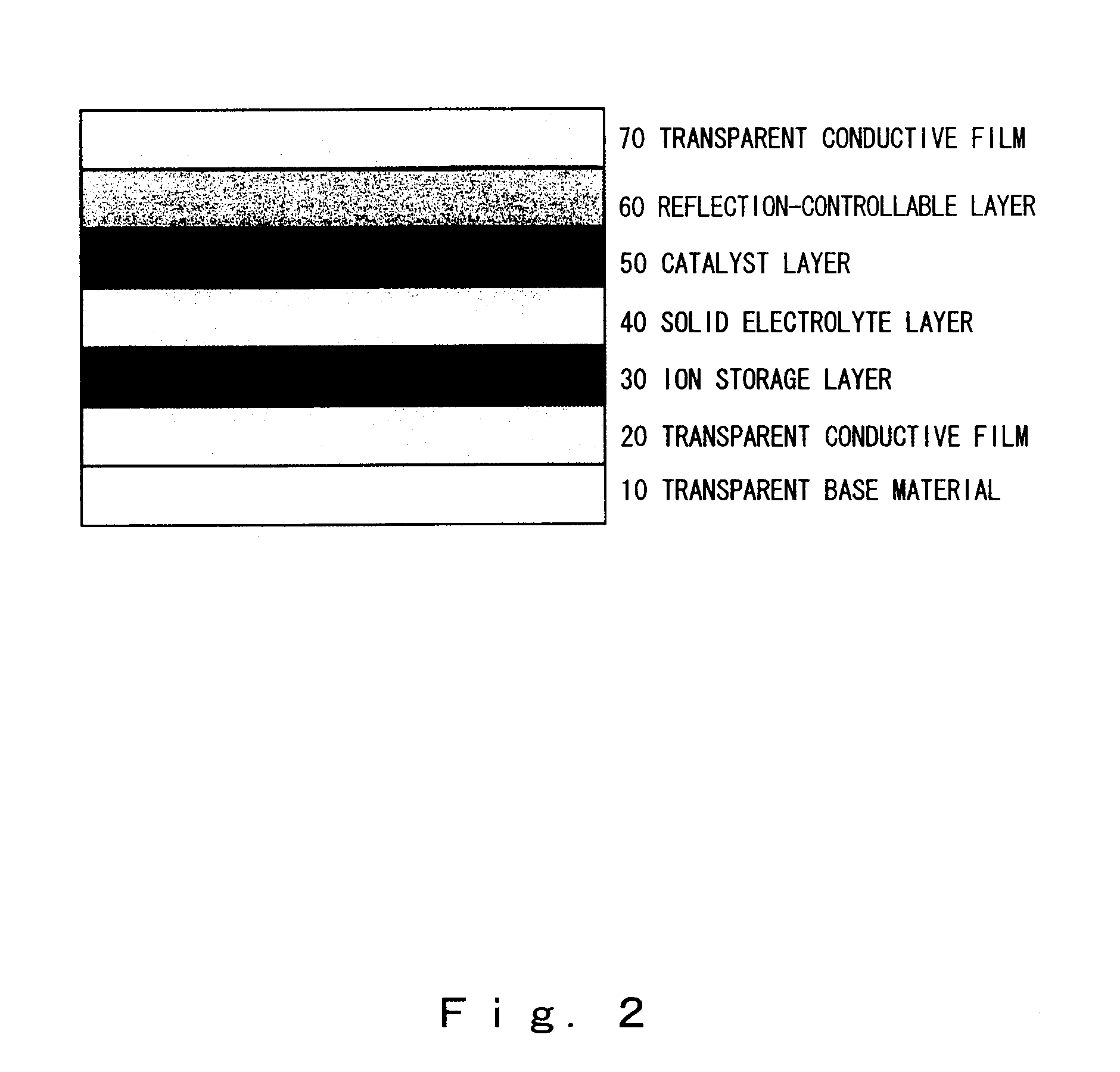

All-solid-state reflection-controllable electrochromic device and optical switchable component using it

InactiveUS7545551B2High light transmittanceShort of areaNon-linear opticsAll solid stateAlloy thin film

The present invention provides an all-solid-state reflection-controllable electrochromic device and a reflection-controllable member using that device, and the present invention relates to the all-solid-state reflection-controllable electrochromic device, which is a reflection-controllable device in which a multilayer thin film is formed on a transparent base material, wherein, at least a transparent conductive film layer, an ion storage layer, a solid electrolyte layer, a catalyst layer and a reflection-controllable layer using a magnesium-nickel based alloy thin film are formed on the base material; and, a reflection-controllable member incorporating this reflection-controllable electrochromic device, and it is possible to provide a reflection-controllable electrochromic device, having a novel multilayer structure with high transmissivity when transparent and capable of switching in a short period of time over a large surface area, and a reflection-controllable member incorporating this device.

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

Preparation method of nickel-based hydrogenation catalyst

ActiveCN102451691AUniform precipitationEvenly dispersedMetal/metal-oxides/metal-hydroxide catalystsPetroleum resinSilicon oxide

The invention discloses a preparation method of a nickel-based hydrogenation catalyst. The preparation method comprises the following steps that carrier alumina and / or silicon oxide, an active metal ingredient and an auxiliary agent ingredient are prepared into slurry; the slurry and a precipitator are added into a reactor in a parallel flow way and are prepared into a catalyst precursor; and the catalyst precursor, a peptizing agent and water are mixed, kneaded, molded, dried and calcined to form the nickel-based hydrogenation catalyst. Through the preparation method, the active metal ingredient can uniformly precipitate on the carrier so that high-uniformity uniformity of the active metal ingredient on the carrier is guaranteed. Through the parallel flow way for precipitation, a uniform precipitation environment in precipitation is obtained so precipitates having the same shape and size are obtained. The nickel-based hydrogenation catalyst obtained by the preparation method can be utilized for hydrogenation decoloration of C5 petroleum resin, C9 petroleum resin and C5-C9 mixed petroleum resin.

Owner:CHINA PETROLEUM & CHEM CORP +1

Nickel-base alloy

Owner:ATI PROPERTIES

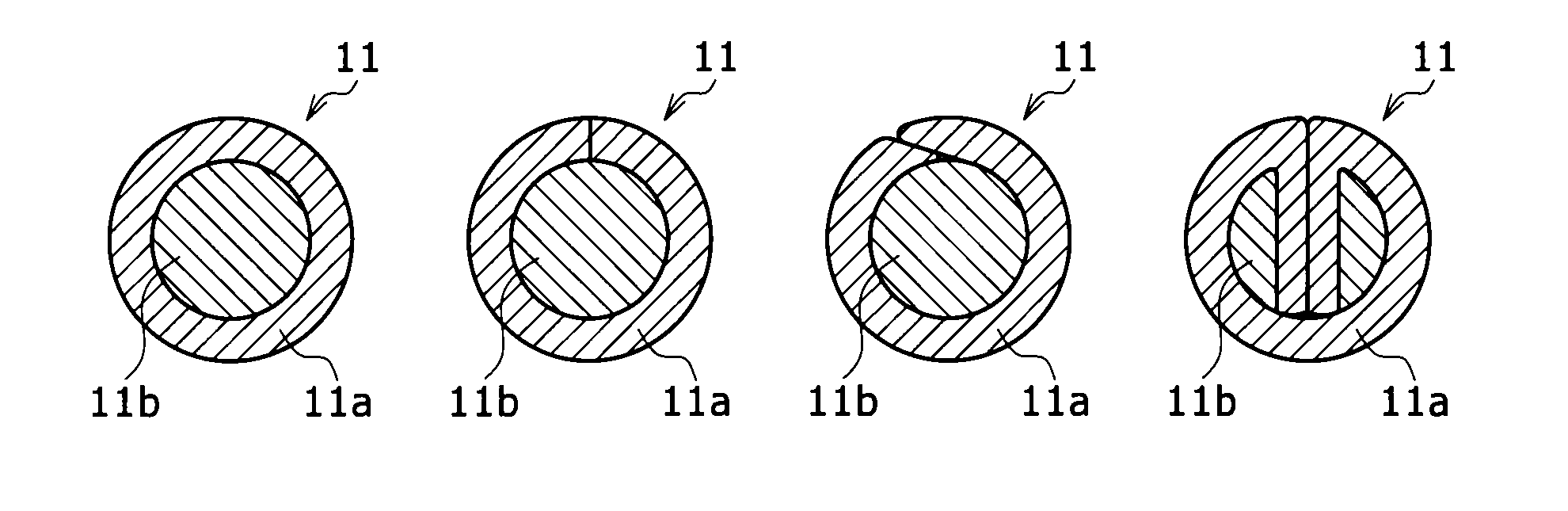

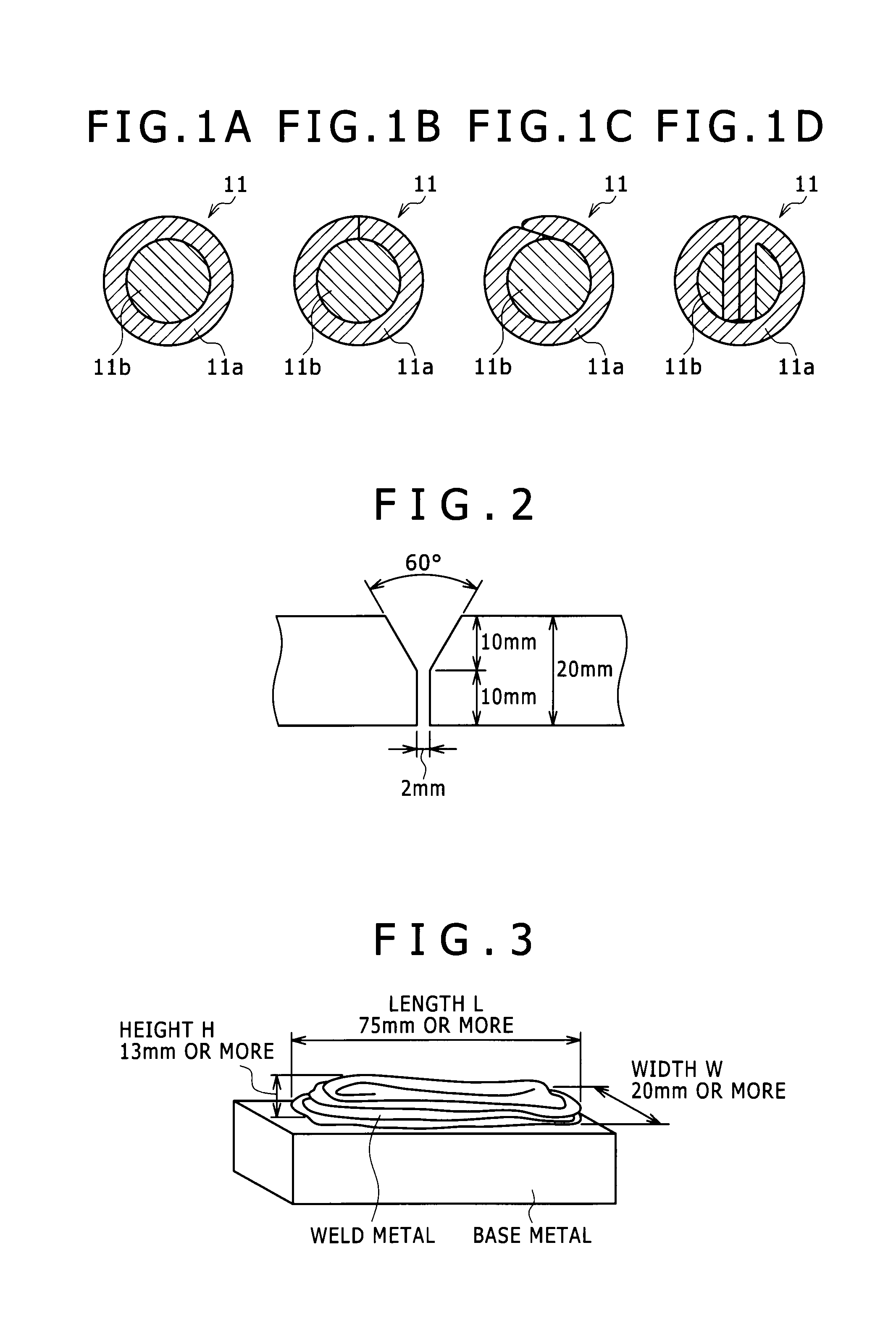

Flux-cored nickel-based alloy wire

InactiveUS20110171485A1Improve solderabilityImprove pitting resistanceWelding/cutting media/materialsThin material handlingPotassiumLithium compound

A flux-cored nickel-based alloy wire contains, based on the total mass of the wire, 3 to 11 percent by mass of TiO2, 0.2 to 1.3 percent by mass of SiO2, 1 to 3 percent by mass of ZrO2, and 0.3 to 1.0 percent by mass of manganese oxides in terms of MnO2, contains of a total of 0.2 to 1.0 percent by mass in terms of Na, K and Li of sodium compounds, potassium compounds, and lithium compounds. The flux has a ratio (([TiO2]+[ZrO2]) / [SiO2]) of the total of the TiO2 and ZrO2 contents to the SiO2 content of 5.0 to 14.5, in which [TiO2], [SiO2] and [ZrO2] represent TiO2, SiO2 and ZrO2 contents. The wire shows excellent weldability in welding of all positions typically on 9% nickel steels and nickel-based alloy steels and gives a weld metal having good pitting resistance, bead appearance, and resistance to hot cracking.

Owner:KOBE STEEL LTD

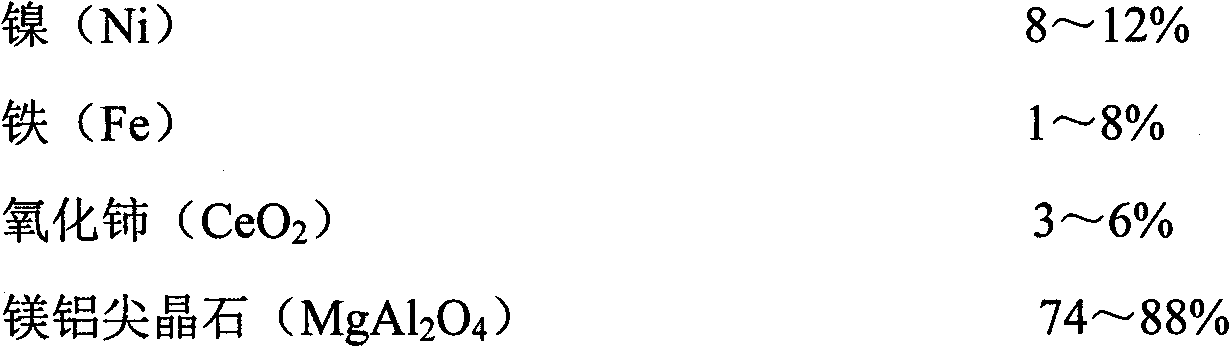

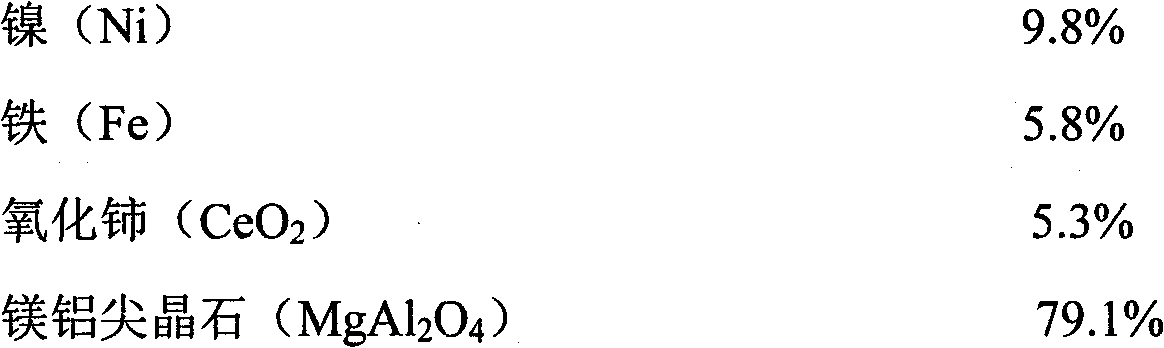

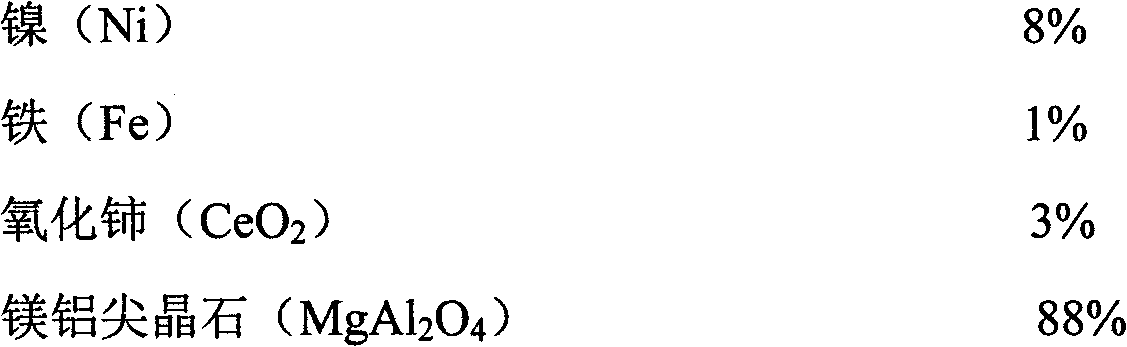

Catalyst for preparing synthesis gases through dry methane reforming (DMR) and preparation method thereof

ActiveCN102416328AImprove conversion rateImprove anti-coking performanceHydrogenMetal/metal-oxides/metal-hydroxide catalystsSpinelNon precious metal

The invention provides a catalyst for preparing synthesis gases through dry methane reforming (DMR) and a preparation method thereof, belonging to the technical field of catalysts for preparing synthesis gases through DMR. The catalyst is formed by nickel, iron, cerium oxide and magnesia-alumina spinel. The method comprises the following steps of: firstly preparing a mesoporous MgAl2O4 spinel carrier, then preparing a nickel-based catalyst suspension and finally preparing the finished product through such simple processes as filtering, washing, drying and roasting. The catalyst and the preparation method have the following beneficial effects that: as such non-precious metal raw materials as nickel and iron are adopted and the raw material sources are wide, the cost is low; the process is simple, the equipment is simple and the production cost is low; the prepared product has high catalytic activity; the conversion rates of methane and carbon dioxide are high; and the carbon depositionresistance and stability are good. The catalyst can be widely used for preparing synthesis gases through DMR.

Owner:XUZHOU FENGTONG INFORMATION TECH CO LTD

Nickel-based welding wire for main equipment of nuclear island of nuclear power station

ActiveCN102581513AProcess stabilityReduce defectsArc welding apparatusWelding/cutting media/materialsChemical compositionNuclear power

The invention belongs to the technical field of welding materials, and particularly discloses a nickel-based welding wire for main equipment of a nuclear island of an AP1000 nuclear power station. The method is applicable to welding pressure containers of reactors (including welding of driving tube seats, safe seats of connecting tubes and supporting blocks of reactor cores) and welding of steam generators (including build-up welding of tube plates and welding of tubes and the tube plates), and solves problems that welding wires of the kind in the prior art are always imported, cost is high and the like. Basic chemical components of the nickel-based welding wire include, by weight ratio, from 28.0 to 31.5% of Cr, from 7.0 to 11.0% of Fe, from 0.4 to 1.0% of Ti, from 0.25 to 1.10% of Al, from 0.90 to 1.5% of Al+Ti, lower than or equal to 1.0% of Mn, lower than or equal to 0.02% of Nb, lower than 0.04% of C, lower than or equal to 0.15% of Si, lower than 0.005% of P, lower than 0.005% of S, lower than 0.001% of B, lower than 0.02% of Zr, lower than 0.005% of Ca, lower than 0.005% of Mg, lower than 0.02% of Ta, lower than 0.02% of Cu, lower than 0.05% of Co, lower than 0.5% of Mo and the balance Ni. By the aid of the welding wire, microalloying of weld joints can be realized, the weld joints meet standard requirements, and the welding wire can replace imported welding wires.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

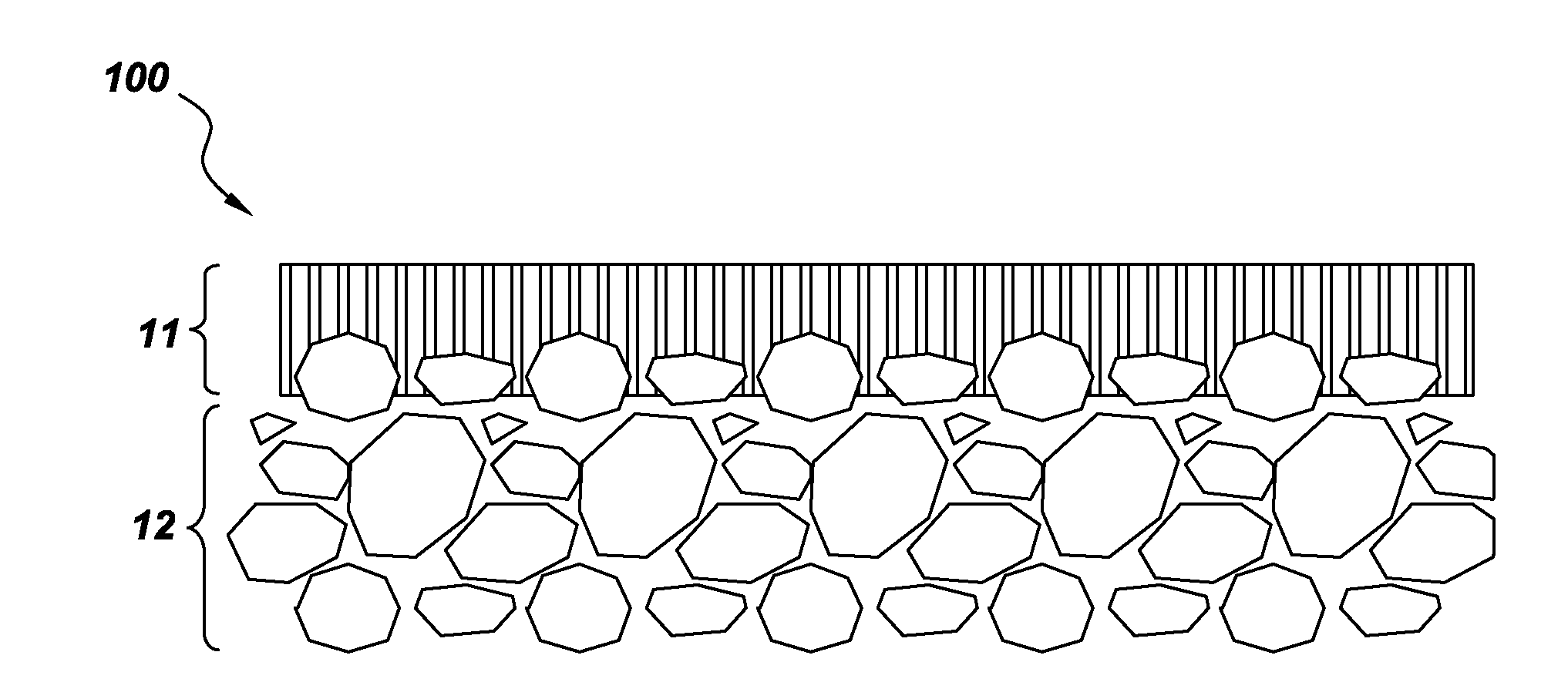

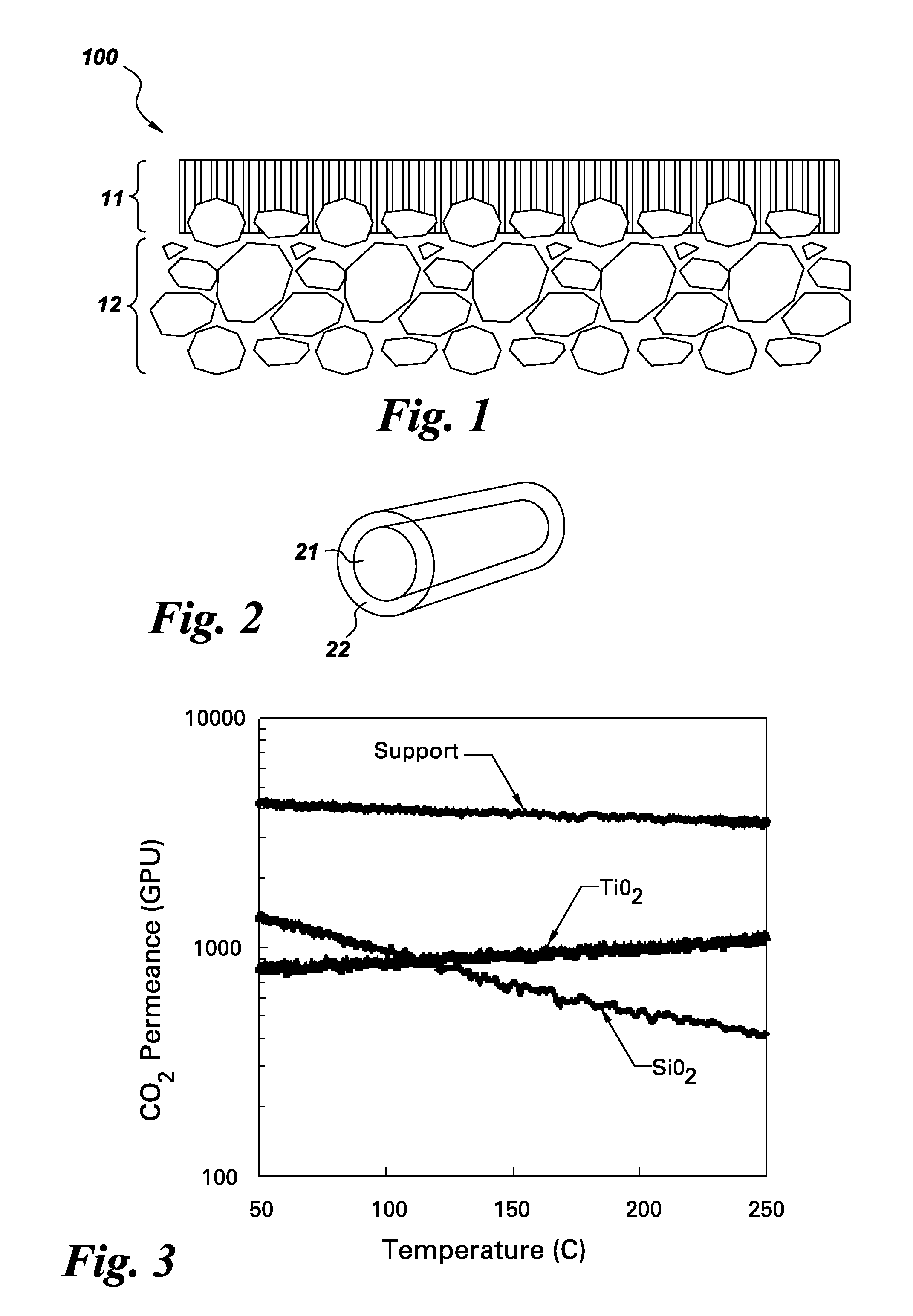

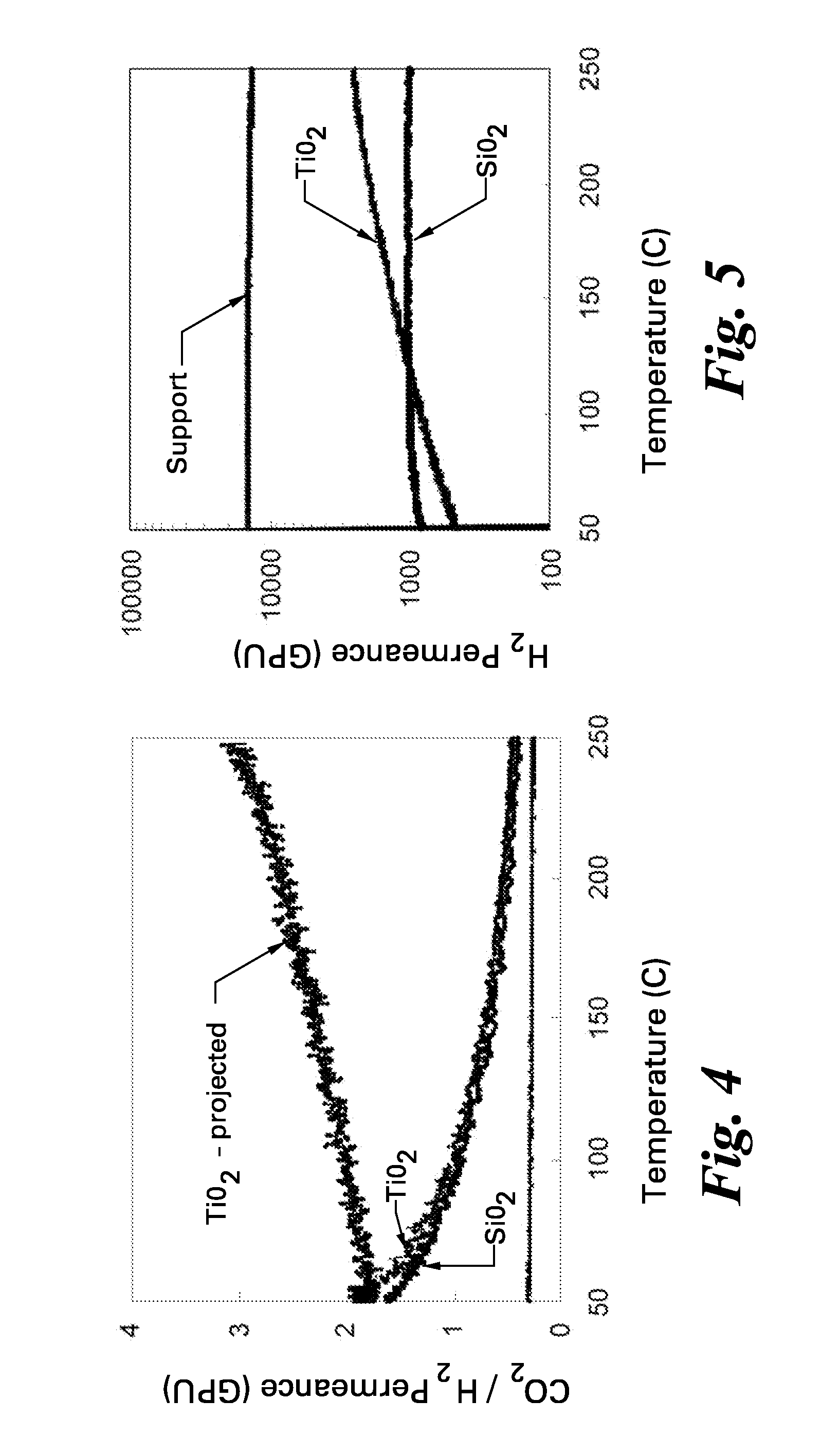

Membranes for separation of carbon dioxide

Methods for separating carbon dioxide from a fluid stream at a temperature higher than about 200° C. with selectivity higher than Knudsen diffusion selectivity include contacting a porous membrane with the fluid stream to preferentially transport carbon dioxide. The porous membrane includes a porous support and a continuous porous separation layer disposed on a surface of the porous support and extending between the fluid stream and the porous support layer. The porous support comprises alumina, silica, zirconia, stabilized zirconia, stainless steel, titanium, nickel-based alloys, aluminum-based alloys, zirconium-based alloys or a combination thereof. Median pore size of the porous separation layer is less than about 10 nm, and the porous separation layer comprises titania, MgO, CaO, SrO, BaO, La2O3, CeO2, HfO2, Y2O3, VOz, NbOz, TaOz, ATiO3, AZrO3, AAl2O4, A1FeO3, A1MnO3, A1CoO3, A1NiO3, A2HfO3, A3 CeO3, Li2ZrO3, Li2SiO3, Li2TiO3, Li2HfO3, A4N1yOz, YxN1yOz, LaxN1yOz, HfN2yOz, or a combination thereof;whereinA is La, Mg, Ca, Sr or Ba;A1 is La, Ca, Sr or Ba;A2 is Ca, Sr or Ba;A3 is Sr or Ba;A4 is Mg, Ca, Sr, Ba, Ti or Zr;N1 is V, Nb, Ta, Cr, Mo, W, Mn, Si or Ge;N2 is V, Mo, W or Si;x is 1 or 2;y ranges from 1 to 3; andz ranges from 2 to 7.

Owner:AIR PROD & CHEM INC

Electric power generator, steam turbine rotor spindle repaired by laser and repairing method thereof

InactiveCN1674408AMeet working conditionsHigh creep limitMagnetic circuit rotating partsPump componentsOptoelectronicsCobalt

The present invention provides a laser repaired power generator and turbine rotor shaft, on its matrix surface on alloy covering layer which can be mutually merged with matrix surface and is different from matrix completely in components is formed, and on the surface where the matrix and alloy layer are connected a micromolten layer whose thickness is 0.05-0.1 mm is formed, and said alloy covering layer is nickel base, cobalt base or iron base alloy. Said invention also provides a laser repairing method of the described power generator and turbine rotor shaft. It adopts a pre-set laser melt-covering mode, and its technological parameters are: laser power 1200-2000 W, spot diameter 2-6 mm and spot moving speed 2-20 mm / s.

Owner:SHENYANG DALU LASER TECH

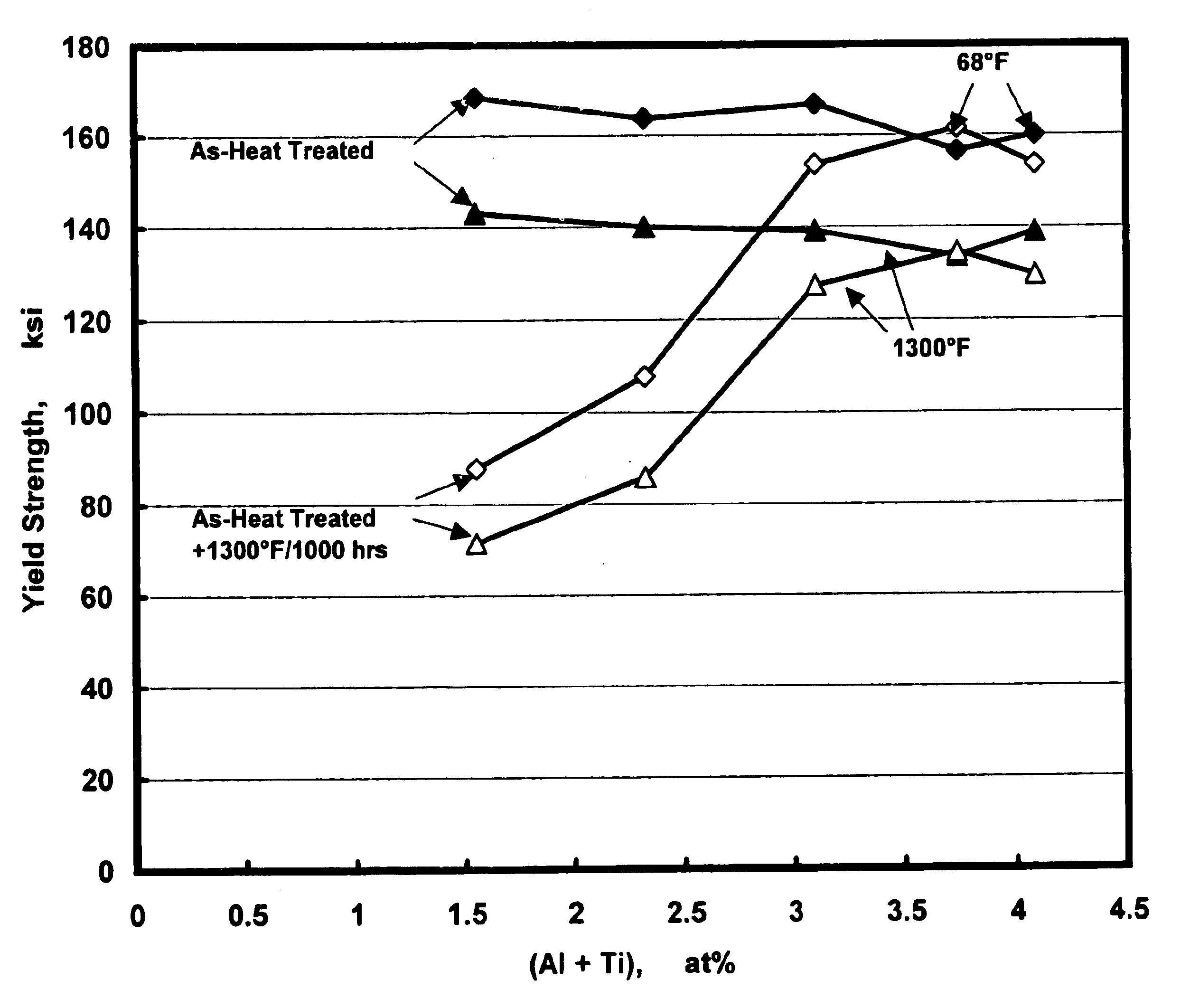

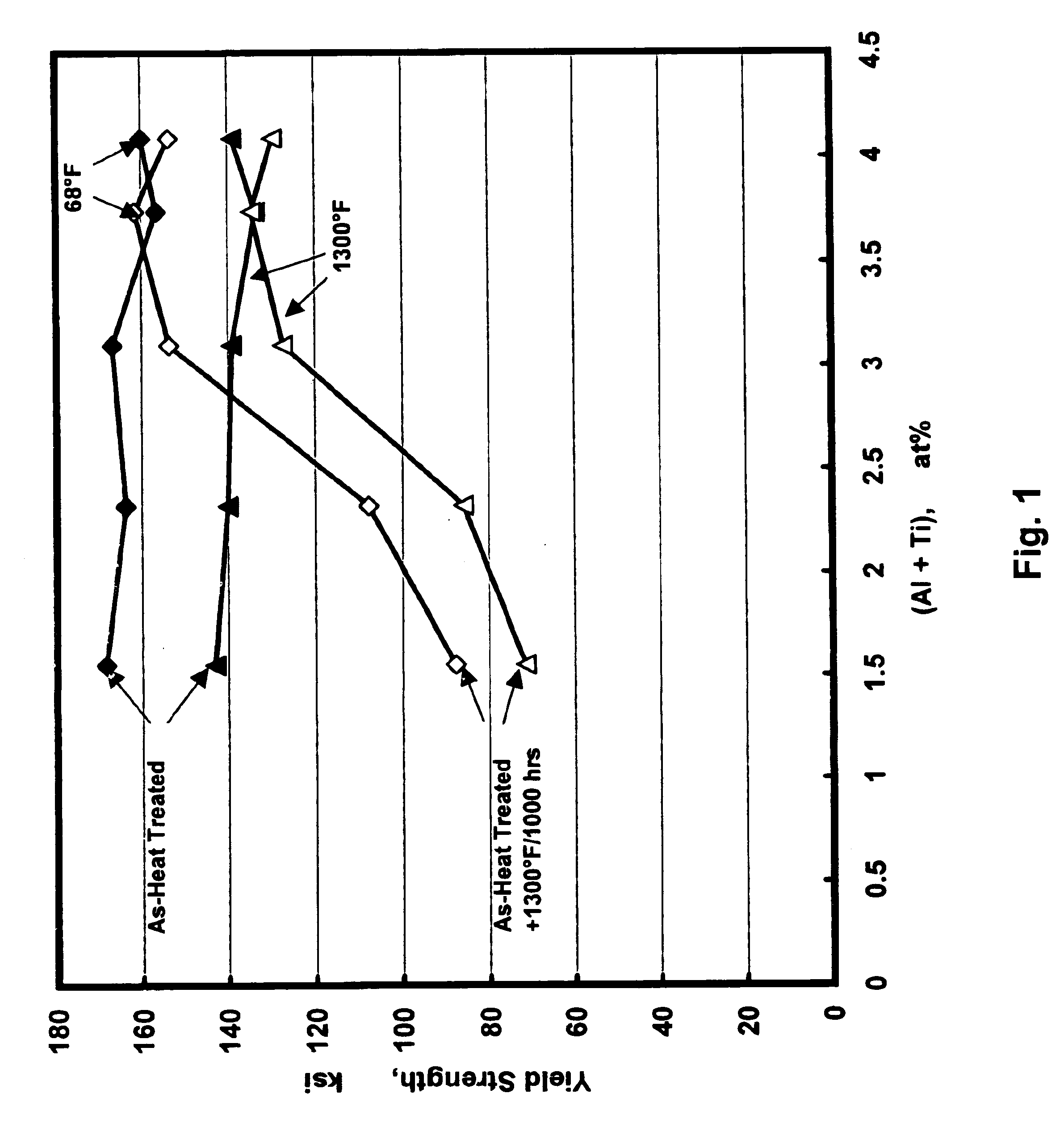

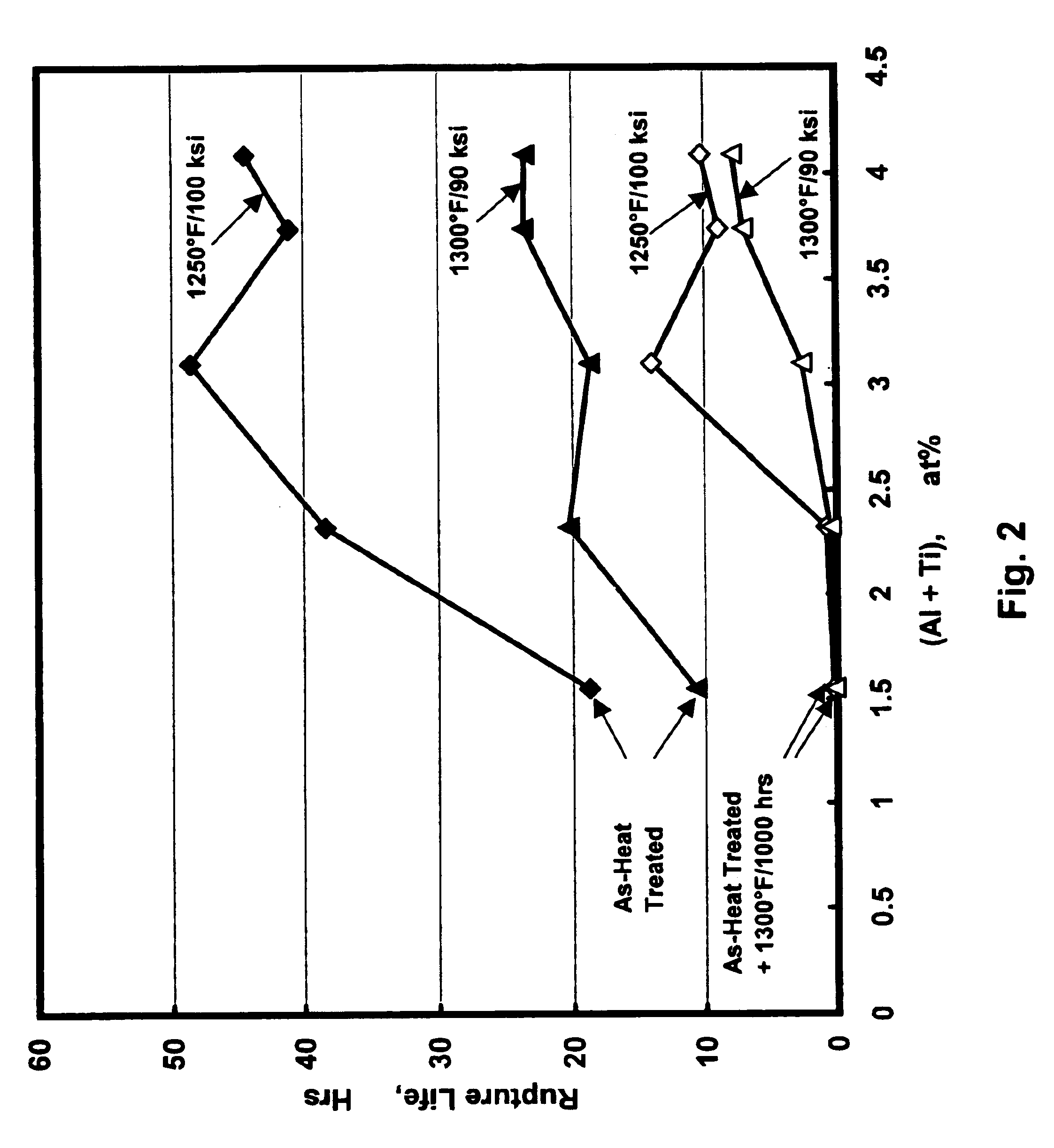

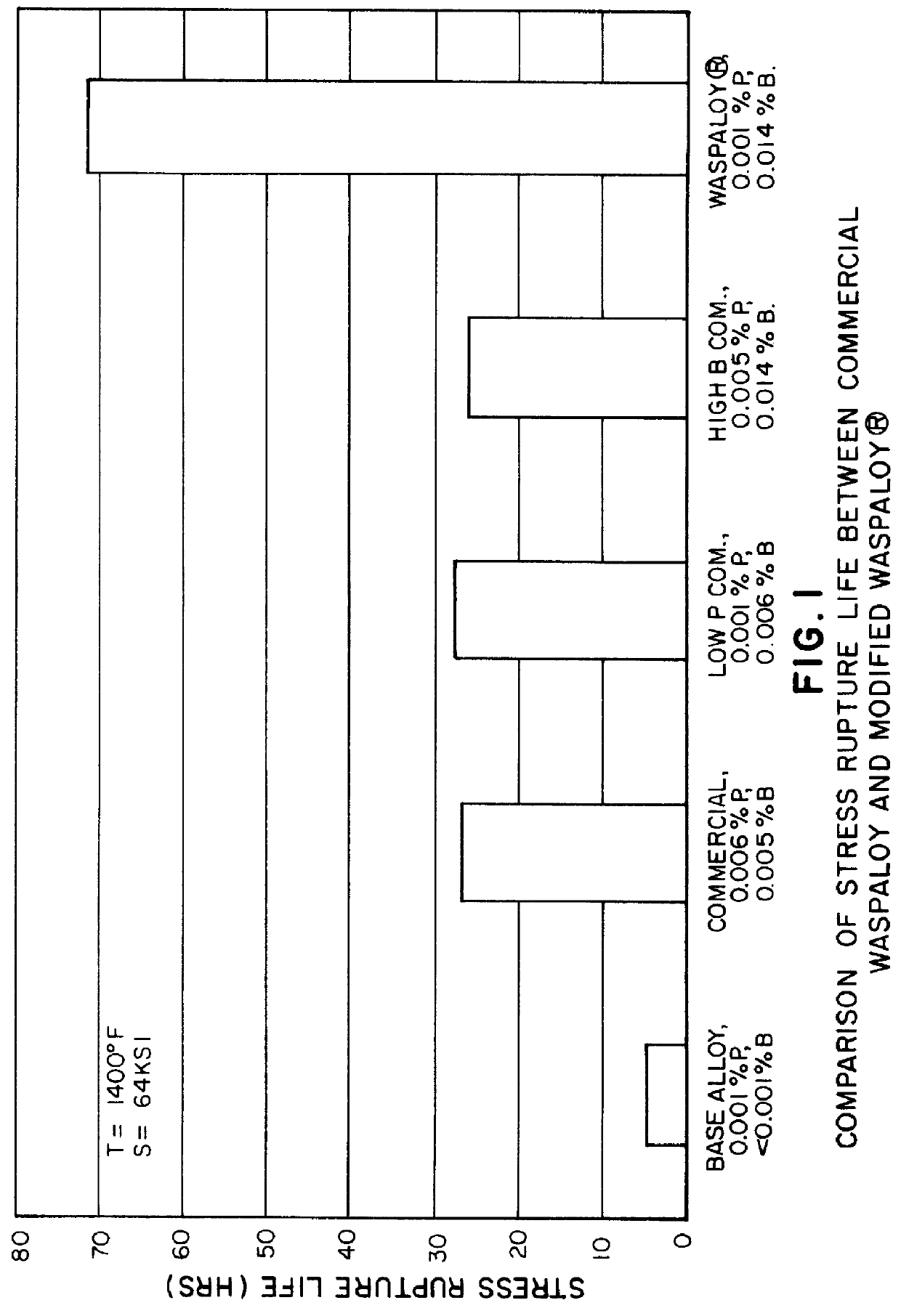

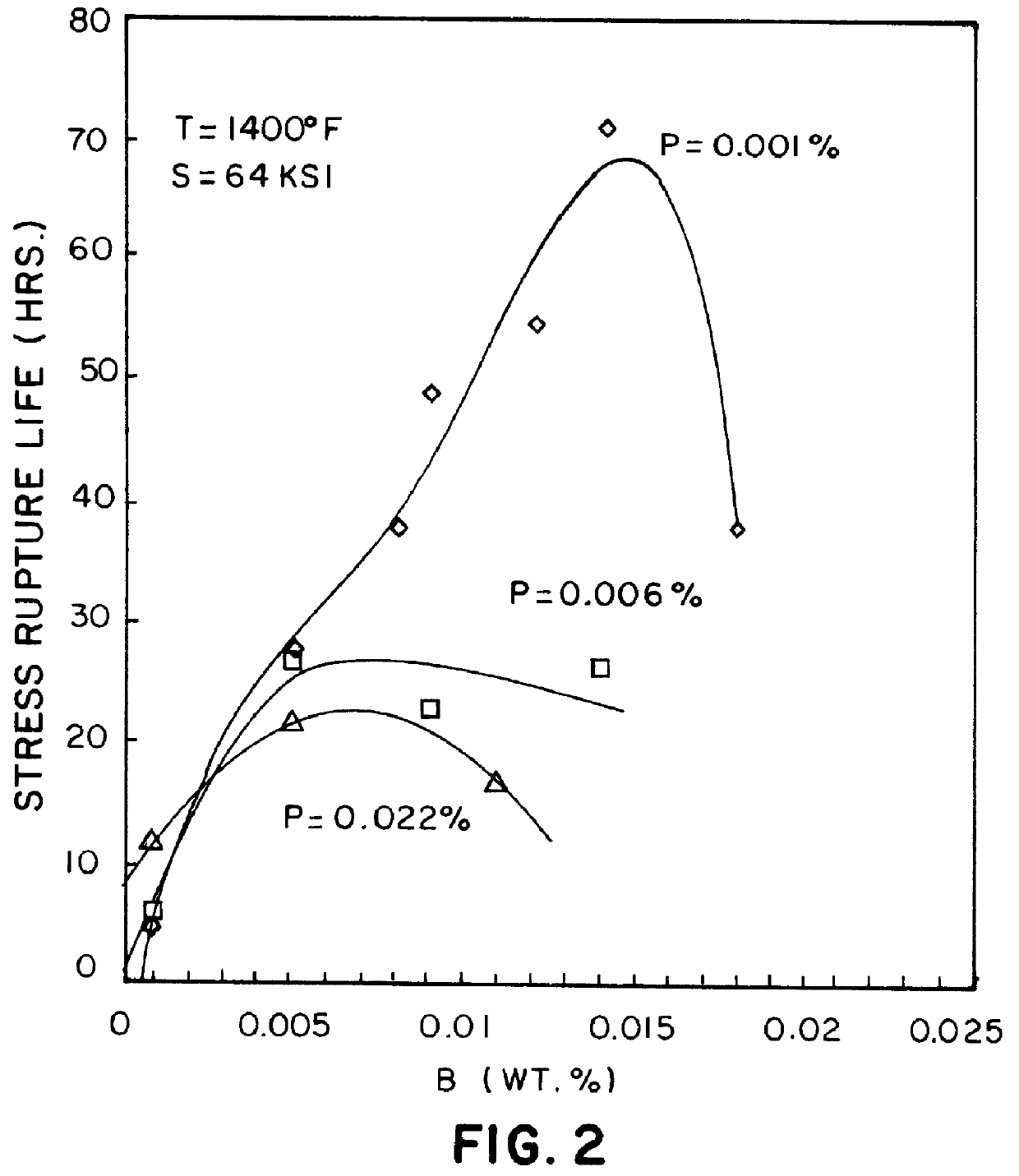

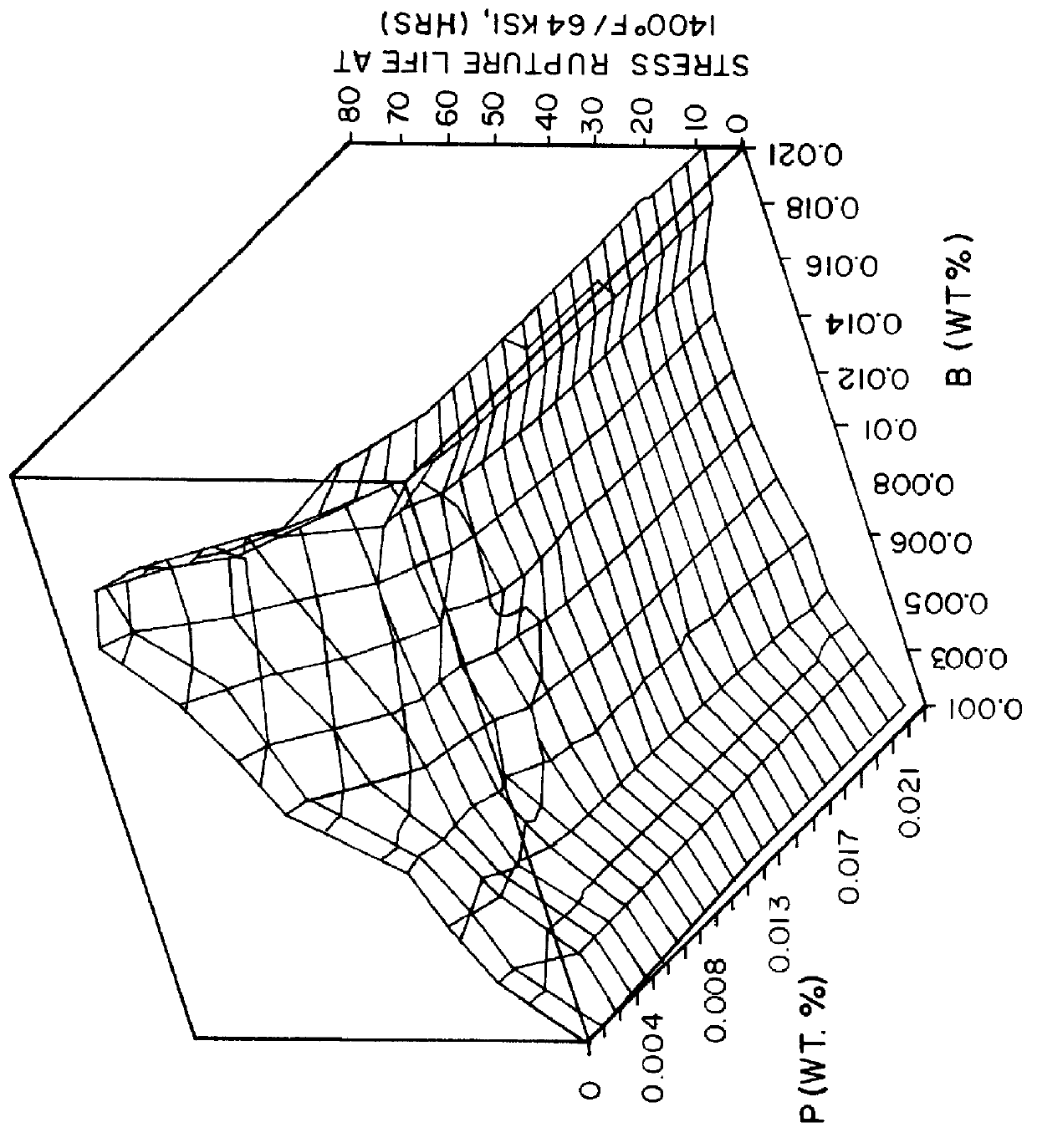

Stress rupture properties of nickel-chromium-cobalt alloys by adjustment of the levels of phosphorus and boron

Nickel-base alloys with improved elevated temperature creep and stress rupture lives are disclosed which are particularly useful for components in gas turbine engines exposed to high temperatures and stresses for long periods of time. The alloys are nickel-based consisting essentially of 0.005 to 0.15% C, 0.10 to 11% Mo, 0.10 to 4.25% W, from 12 to 31% Cr, 0.25 to 21% Co, up to 5% Fe, 0.10 to 3.75% Nb, 0.10 to 1.25% Ta, 0.01 to 0.10% Zr, 0.10 to 0.50% Mn, 0.10 to 1% V, l.8-4.75% Ti, 0.5 to 5.25% Al, less than 0.003% P, and 0.004 to 0.025% B. Key to the improvement of creep and stress rupture lives is the extremely low P content in conjunction with high B contents.

Owner:TELEDYNE INDS

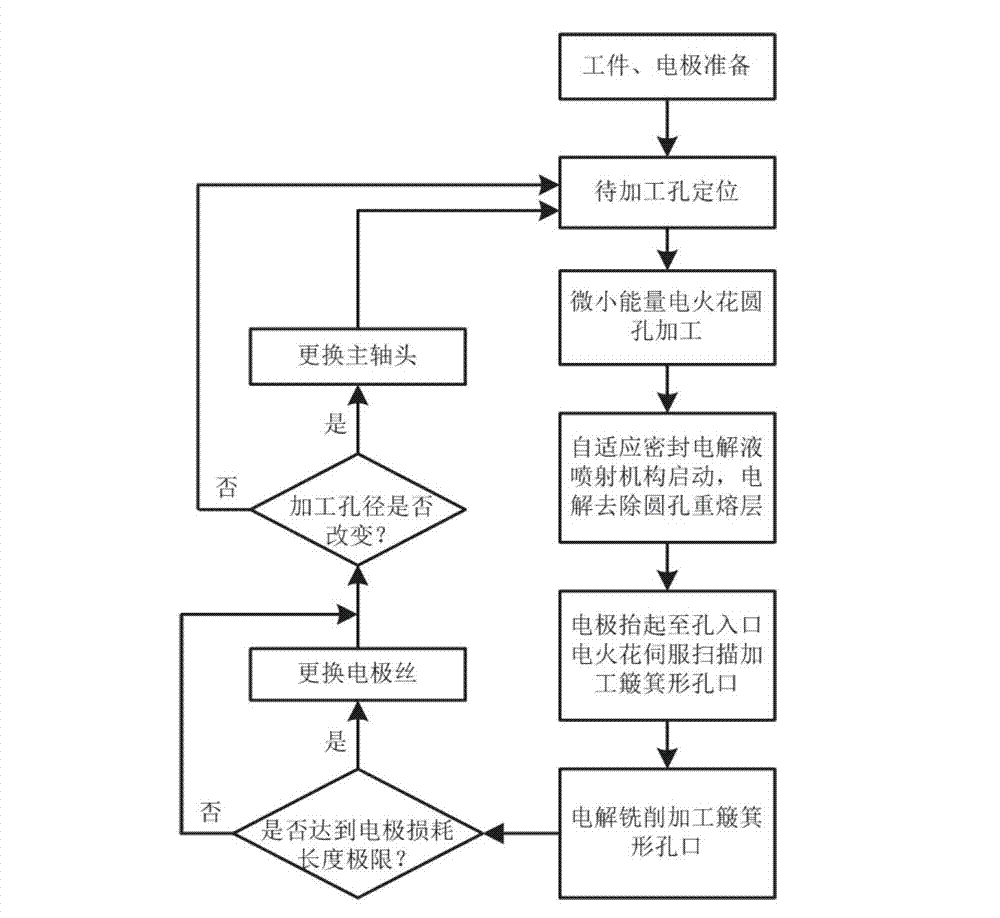

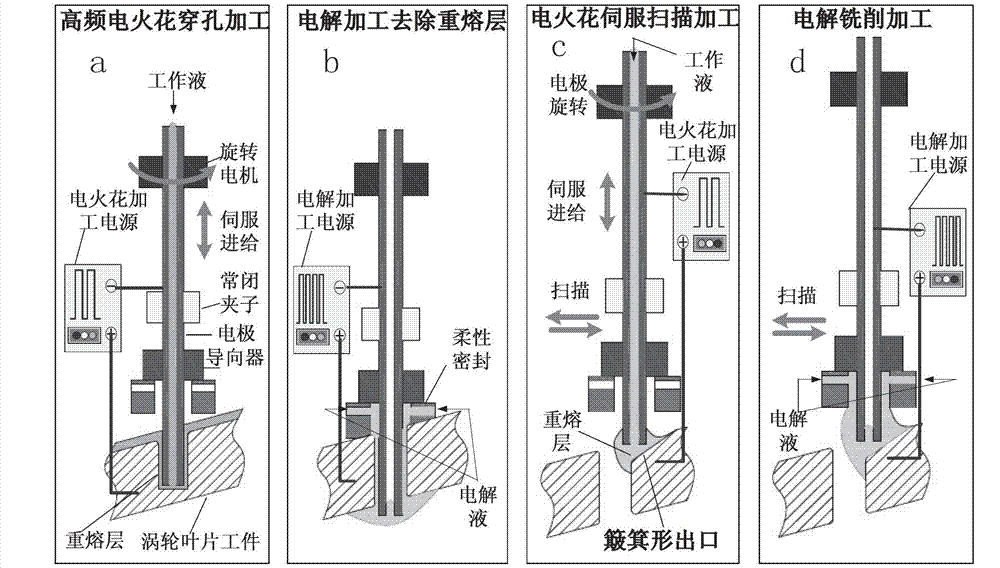

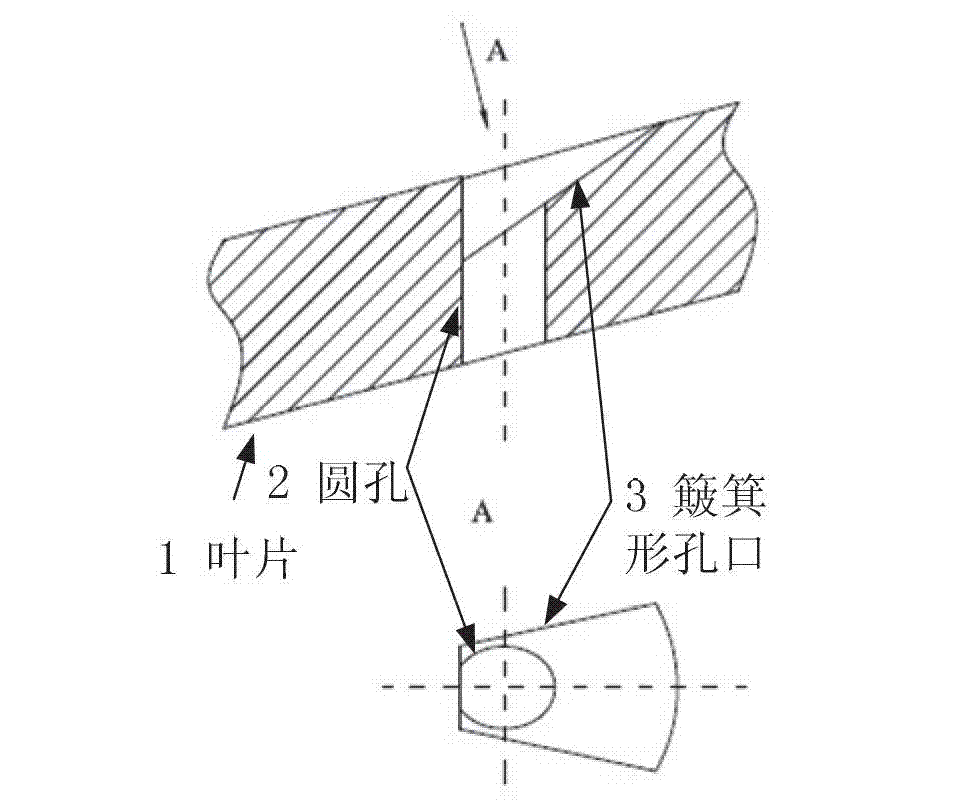

Machining method of gravity-free smelting layer air membrane hole of aviation engine turbine blade

InactiveCN102861956AReduce manufacturing difficultyShorten the manufacturing cycleAviationEngineering

The invention belongs to the technical field of small hole electric machining and particularly relates to a machining method of a gravity-free smelting layer air membrane hole of an aviation engine turbine blade. The machining method comprises four steps: firstly, machine a circular hole with a needed size a nickel-based high-temperature alloy blade on a gas turbine by utilizing washing liquid electric sparks in a hollow electrode according to a design requirement; then utilizing the same electrode to electrolyze the machined circular hole in an electrolyte environment of an outer washing solution to remove a re-smelted layer; then, raising the electrode and utilizing an electric spark servo scanning and milling and machining process to machine a dustpan-shaped hole opening of the air membrane hole; and finally, utilizing the end part of the electrode to carry out electrolytic milling machining on the dustpan-shaped hole opening to remove the re-smelted layer of the hole opening so as to improve the surface quality. According to the machining method disclosed by the invention, the problem of a residual re-smelted layer and small cracks of the air membrane hole machined by the electric sparks can be solved, a secondary clamping and positioning error is avoided and the machining efficiency is improved.

Owner:TSINGHUA UNIV

High-strength corrosion-resisting nickel base alloy and manufacturing method thereof

InactiveCN102628127AWill not affect the comprehensive application performanceNo destabilizationRare-earth elementNiobium

The invention relates to a high-strength corrosion-resisting nickel base alloy and a manufacturing method thereof. The high-strength corrosion-resisting nickel base alloy comprises the following chemical components by weight percent: not more than 0.04% of carbon (C), about 20.0%-26.0% of chromium (Cr), about 6.0%-10.0% of cobalt (Co), about 4.0%-8.0% of tungsten (W), not more than 1.0% of molybdenum (Mo), not more than 1.0% of Ferrum (Fe), not more than 0.5% of silicon (Si), not more than 0.5% of manganese (Mn), about 0.8%-1.3% of niobium (Nb), about 0.3%-0.7% of titanium (Ti), about 0.6%-1.0% of aluminum (Al), about 0.1%-0.4% of zirconium (Zr), not more than 0.003% of boron (B), tiny lanthanum (La) or rare-earth element (Re), and the balance of nickel (Ni) and inevitable impurity element. Vacuum melting and electroslag remelting are adopted, and then solution treatment and ageing treatment are performed.

Owner:丹阳恒庆复合材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com