Numerically-controlled processing method of nozzle housing piece

A nozzle shell and processing method technology, applied in the field of numerical control machining of nozzle shell workpieces, can solve problems such as low production efficiency, low position accuracy, and low dimensional accuracy, and achieve the goals of increased production efficiency, stable processing process, and improved quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

[0041] In this embodiment, the CNC turning and milling compound machining center WFL M30-G with dual spindles and online measuring devices is used to process most of the surface of the nozzle housing at one time.

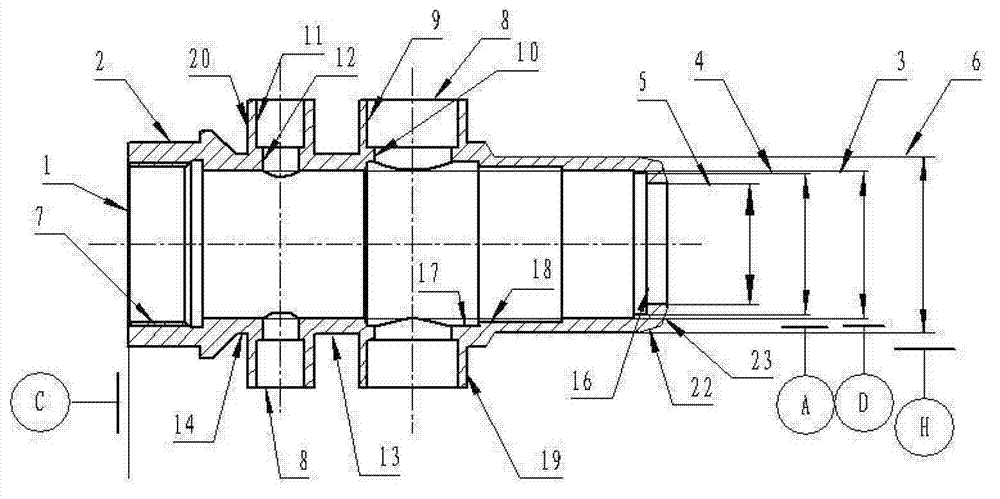

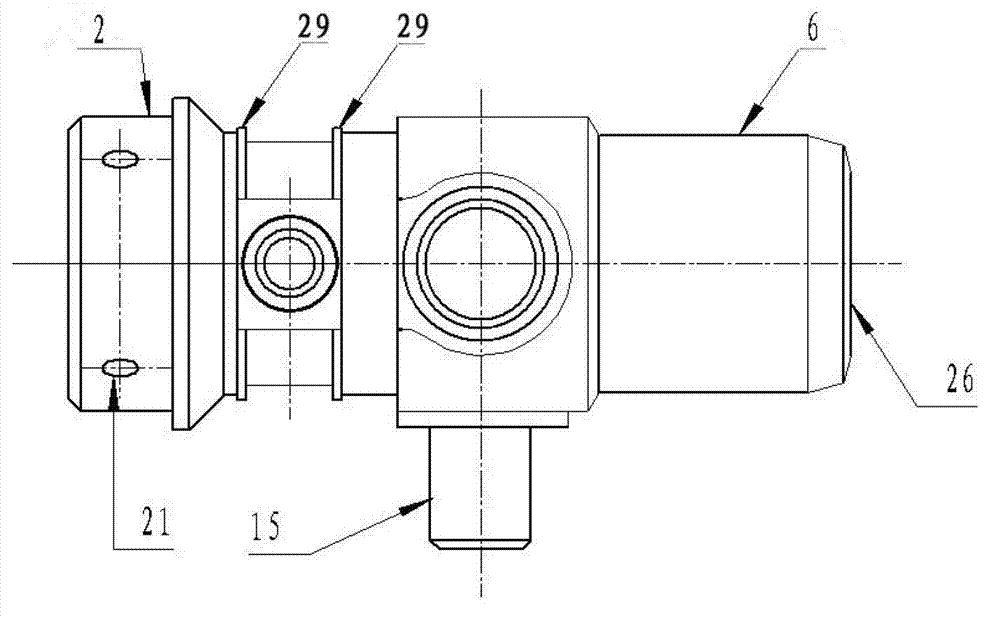

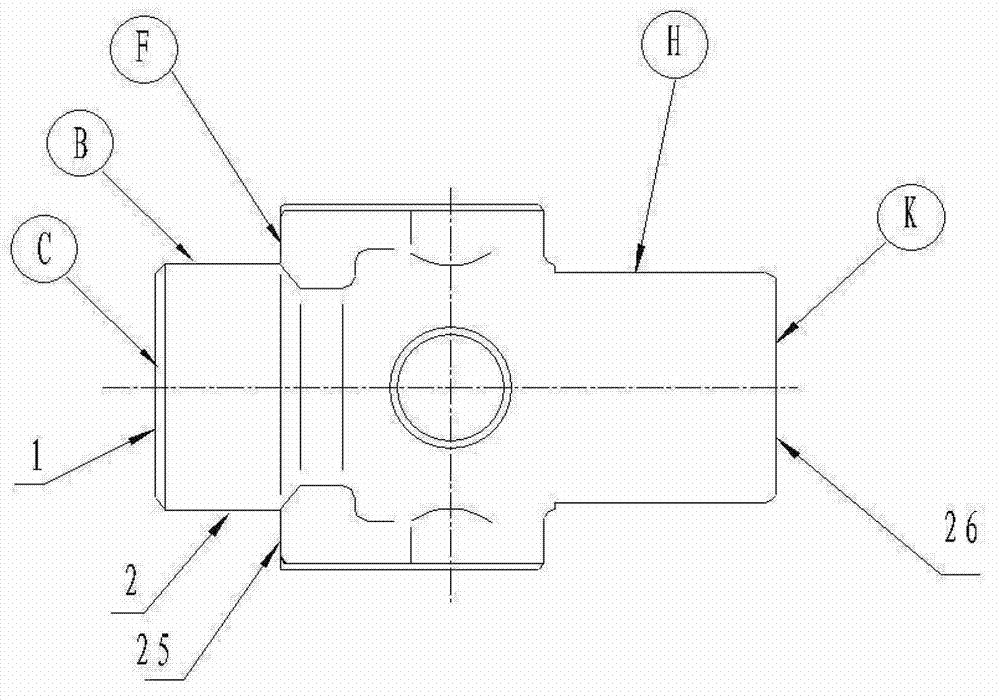

[0042] Such as figure 1 , 2 As shown, the structure of the nozzle shell is complex, and the processing size and position accuracy are high. The coaxiality requirement of the internal thread 7 to the inner hole 3 (D) of the head is not greater than φ0.03mm, and the end surface 16 of the inner hole is relatively The verticality of the hole 4 (A) is not greater than 0.02mm, the coaxiality of the inner hole 4 of the head and the small inner hole 5 of the head is not greater than φ0.03mm with respect to the reference hole 3 (D), and the inner hole of the head 3 ( D) The coaxiality with the head outer circle 6 (H) is not greater th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| verticality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com