Patents

Literature

41results about How to "Solve Dimensional Accuracy Issues" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Numerically-controlled processing method of nozzle housing piece

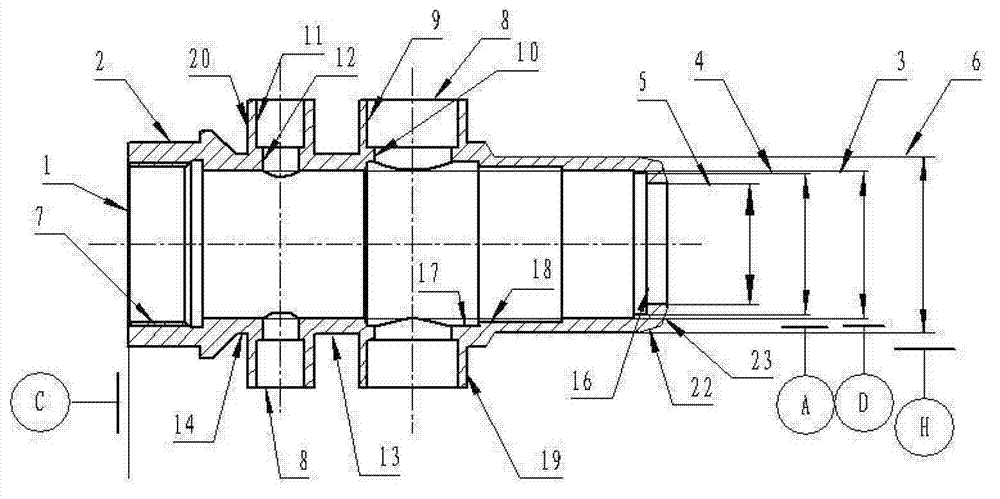

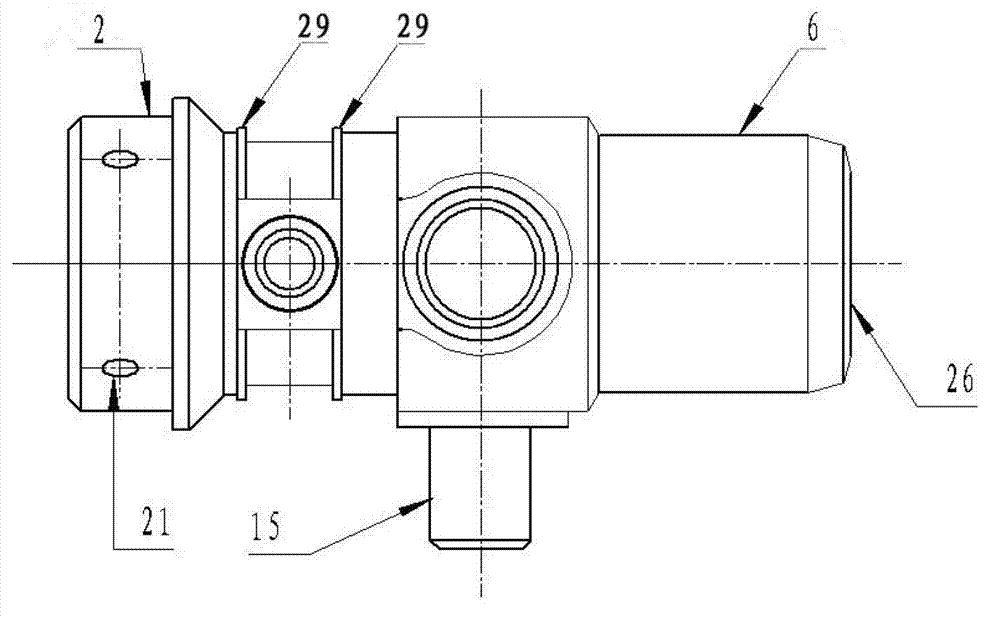

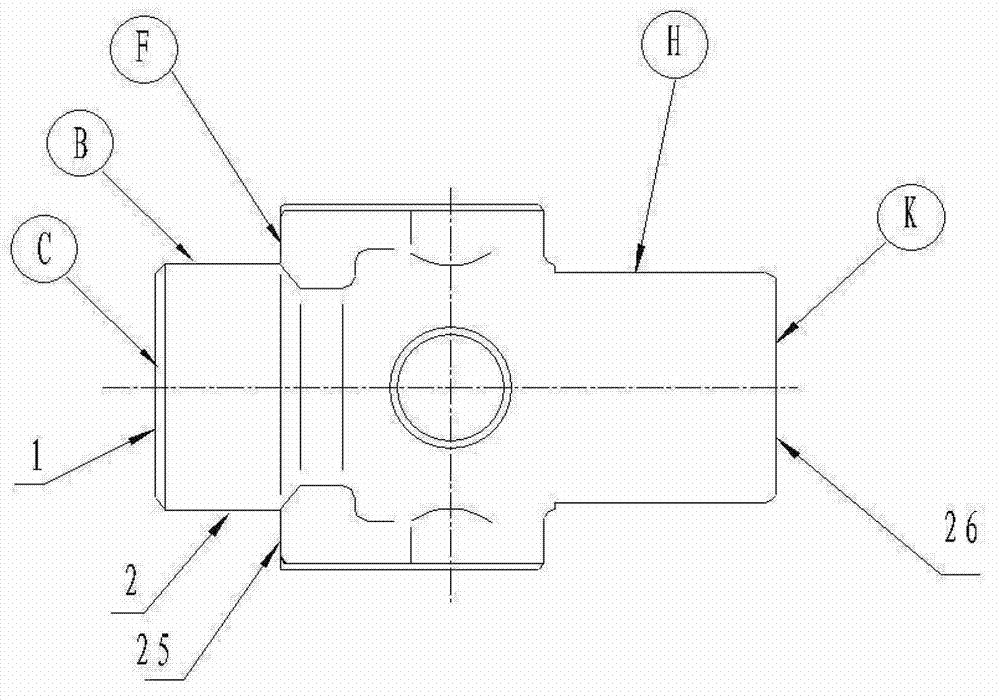

The invention discloses a numerically-controlled processing method of a nozzle housing piece. According to the method, a numerically-controlled machining / milling combined processing center is adopted and comprises two main shafts and an on-line measurement device; the workblank of the nozzle housing piece is a die-forged part, and the die-forged part is made of a nickel-based high-temperature alloy. The method comprises the following steps: designing a nozzle housing processing path; performing polishing treatment on the die-forged part to remove burrs from the die-parting face and end-face die-drawing taper; coarsely machining the tail part of the work piece; performing numerically-controlled machining / milling on the whole work piece; performing numerically-controlled fine machining of the head part of the work piece; cleaning and marking the work piece; and inspecting. The method provides the reasonable designs of processing path and processing method of the work piece as well as the processing positioning reference of the work piece, and completes the processing of the inner cavity, the outer circle, the lateral adapter, the positioning pin and other parts of the nozzle housing piece within one-step loading process. The method solves the problem that the die-forged part has a complex structure and a thin wall and has strict requirements for dimensional precision and positional precision; and overcomes the defects of long processing period, low production efficiency and poor dimensional precision and positional precision.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

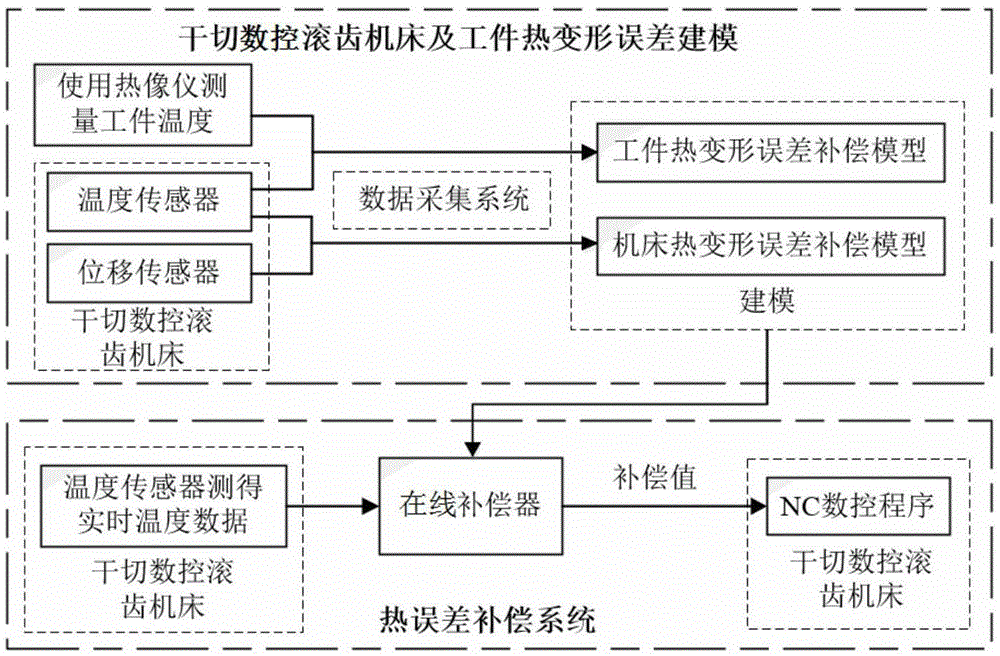

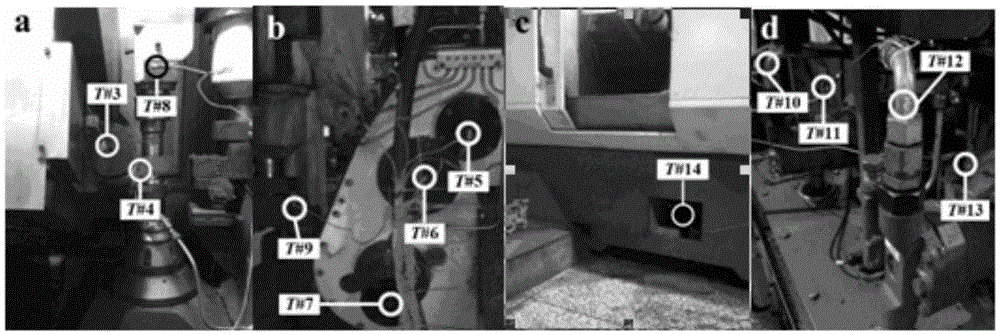

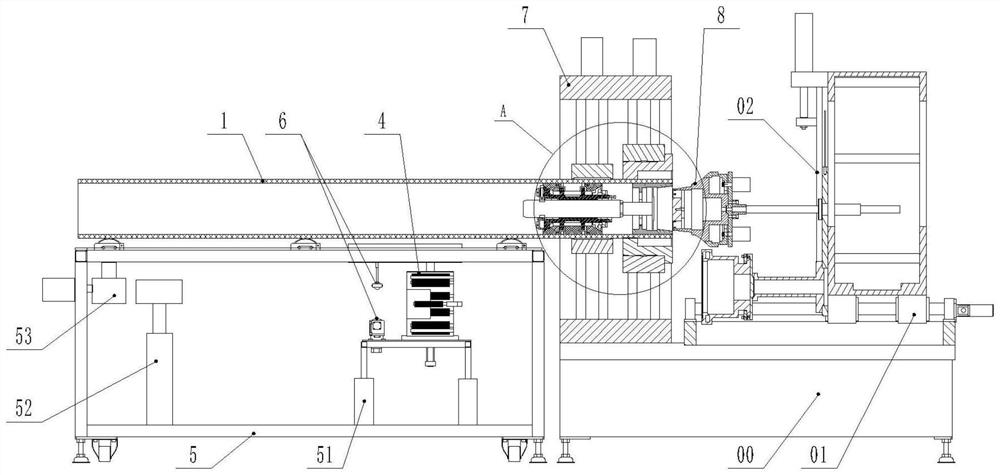

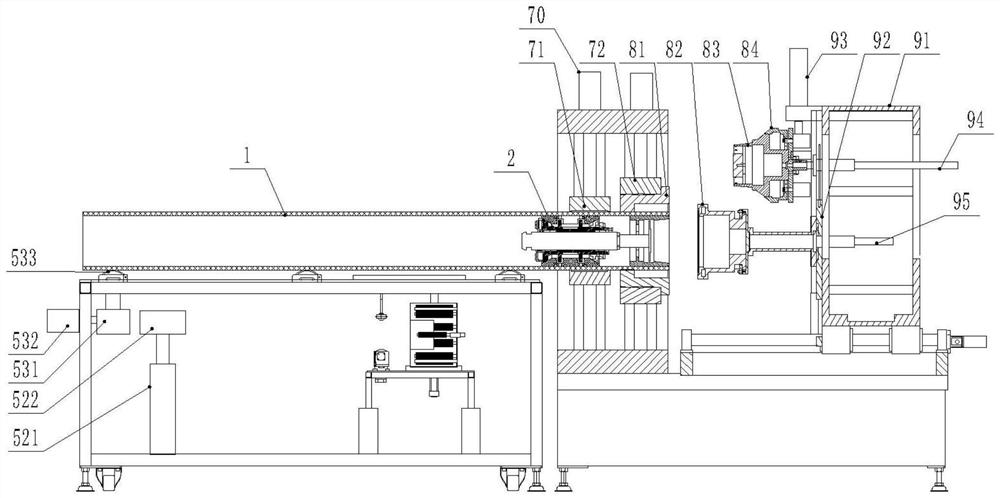

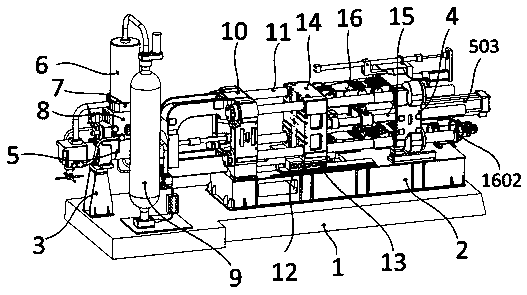

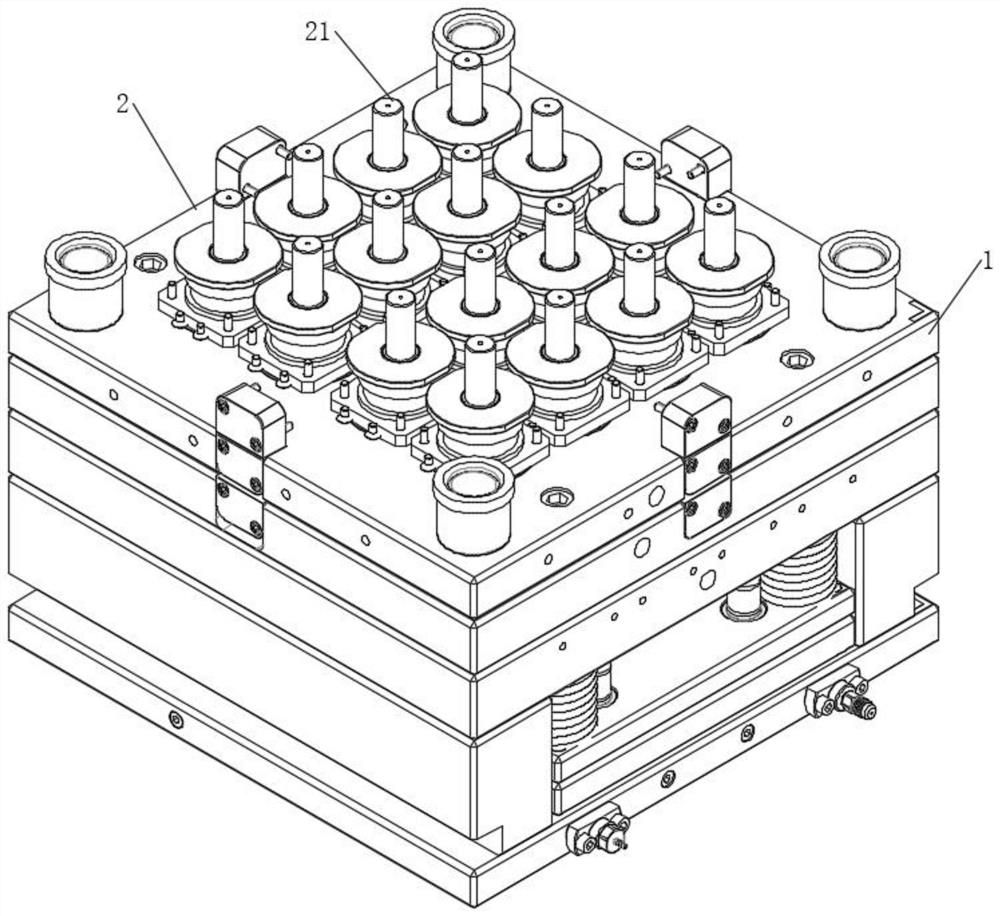

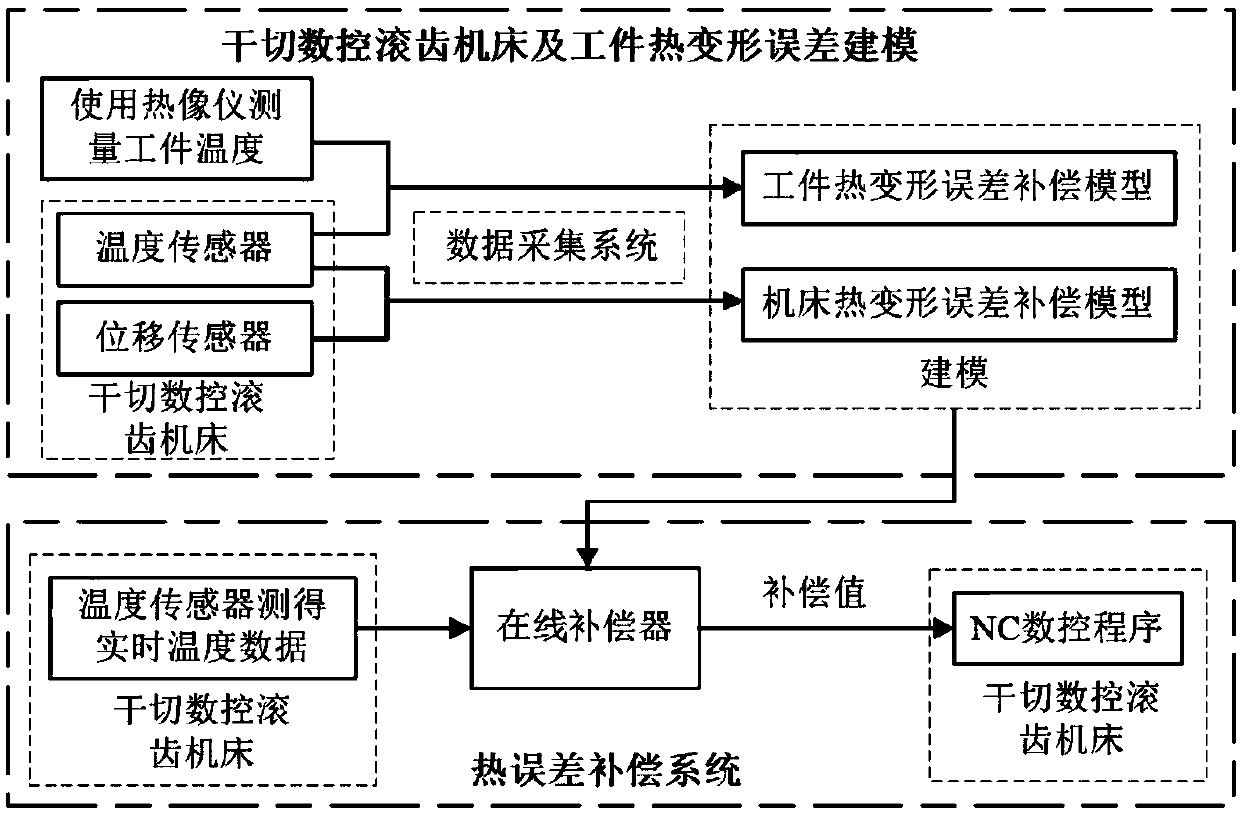

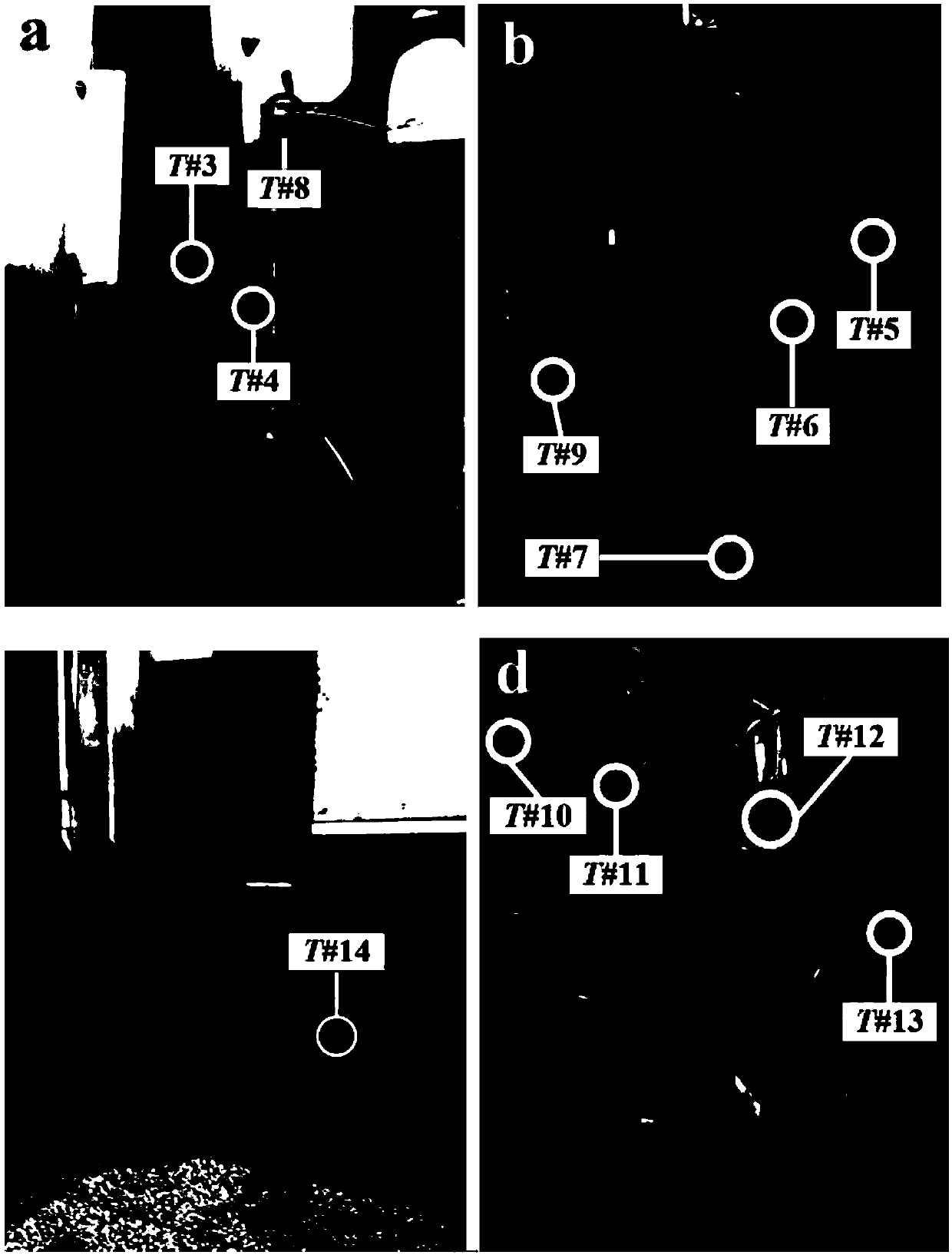

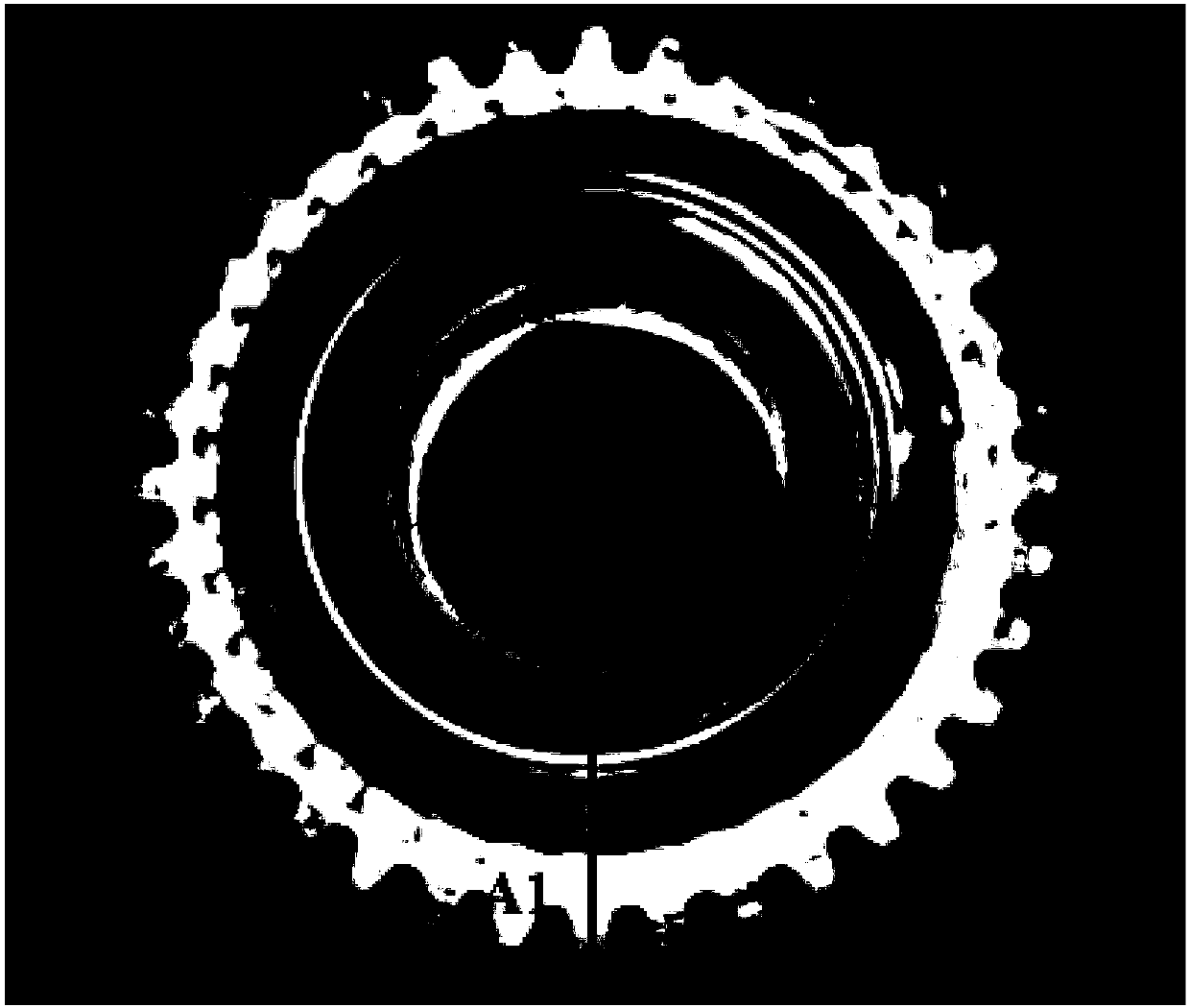

Thermal deformation error compensation method for dry-cutting numerically-controlled gear hobbing machine tool and workpieces

ActiveCN105397560AReduce machining errorsReduce scrap rateMaintainance and safety accessoriesHobbingControl system

The invention provides a thermal deformation error compensation method for a dry-cutting numerically-controlled gear hobbing machine tool and workpieces. According to the invention, while thermal deformation error compensation is carried out on the dry-cutting numerically-controlled gear hobbing machine tool by virtue of a thermal deformation error compensation system for the numerically-controlled machine tool, the thermal deformation errors of workpieces machined by the dry-cutting numerically-controlled gear hobbing machine tool are compensated by virtue of the same compensation system. The thermal deformation error compensation method comprises the following steps: firstly, establishing a thermal deformation error model for the workpieces and a thermal deformation error model for the dry-cutting numerically-controlled gear hobbing machine tool, integrating said error models in an online compensator, and during machining of the dry-cutting numerically-controlled gear hobbing machine tool, processing the temperature data obtained through measurement of temperature sensors by virtue of the online compensator to obtain error compensation values; secondly, conveying the compensation values to a machine tool numerically-controlled system; and finally, carrying out coordinate offset by virtue of the numerically-controlled system, thus realizing thermal deformation error compensation for the dry-cutting gear hobbing machine tool and the workpieces.

Owner:CHONGQING UNIV

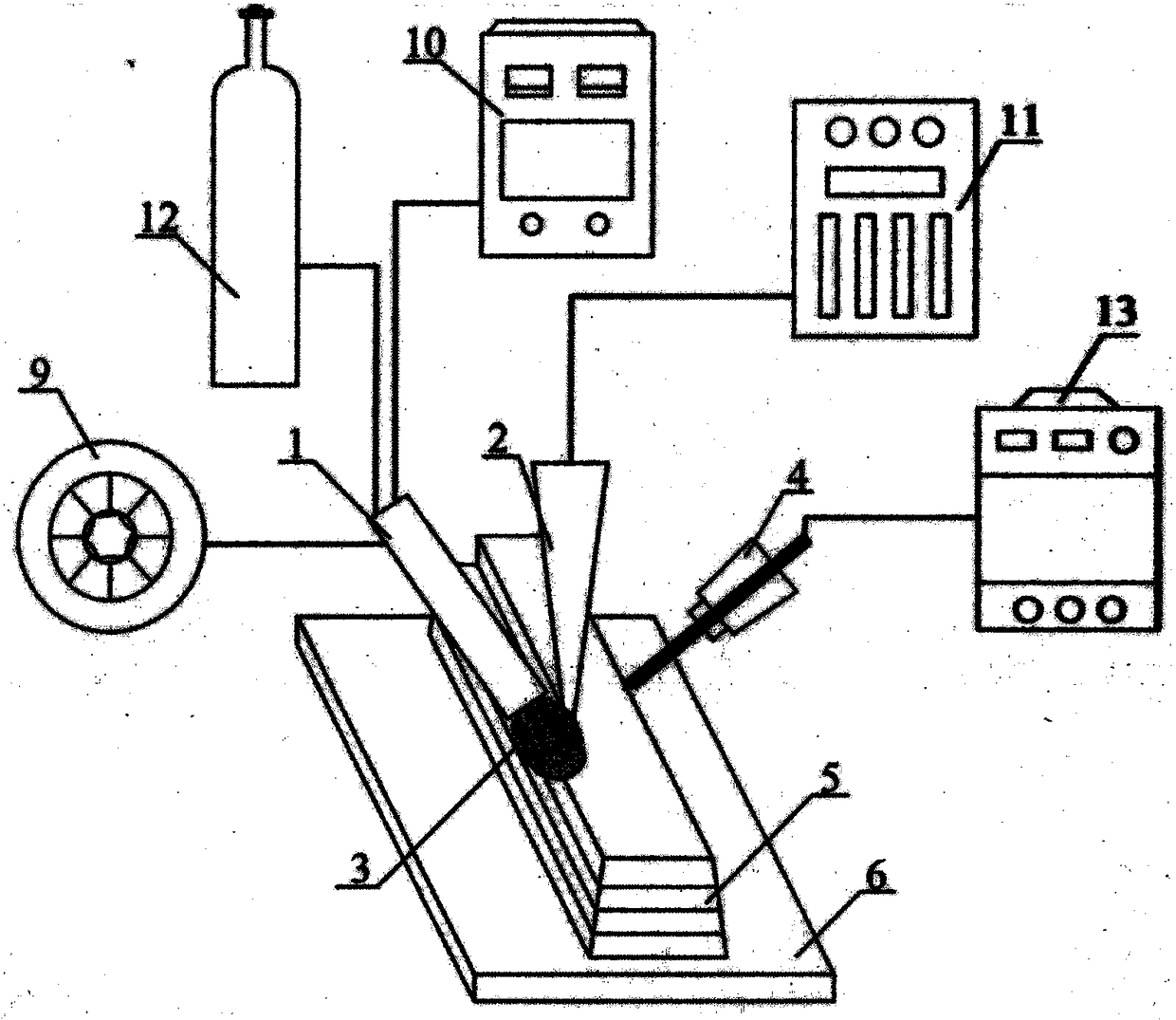

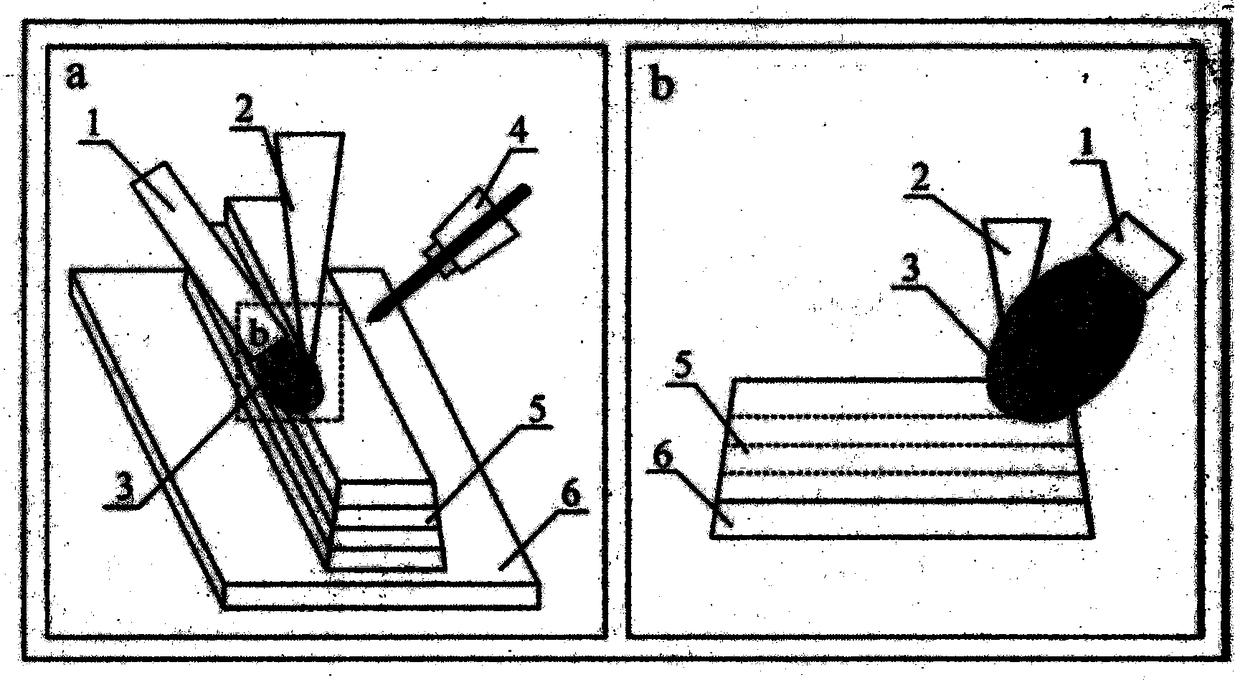

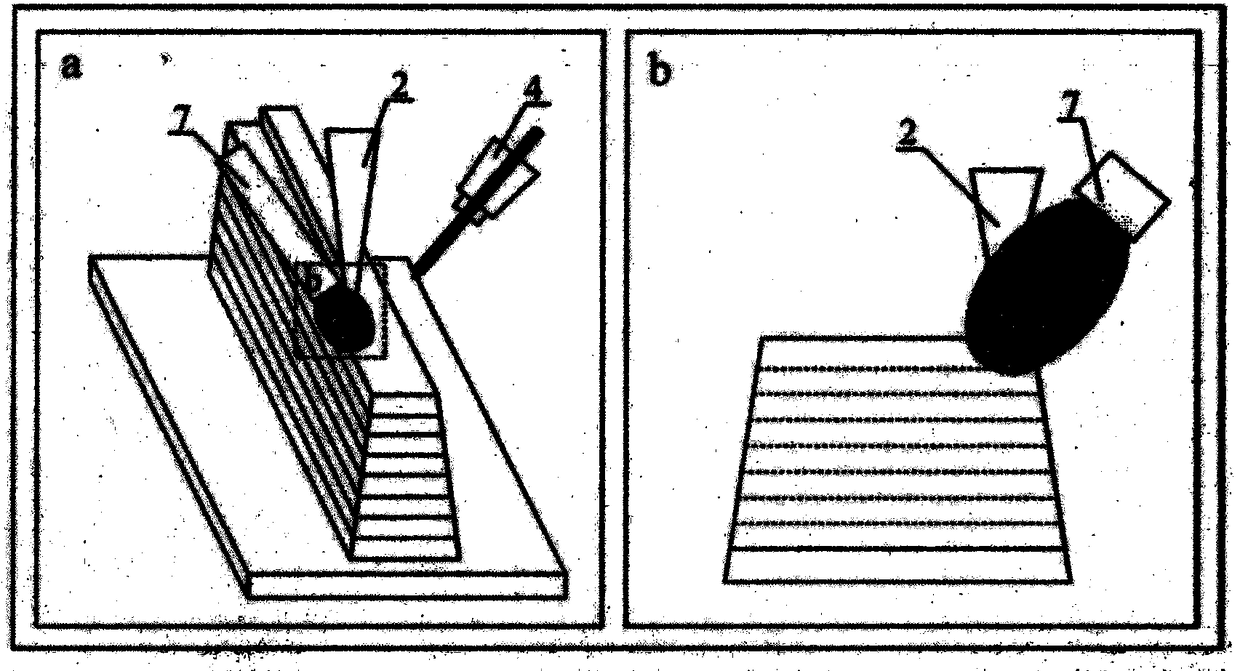

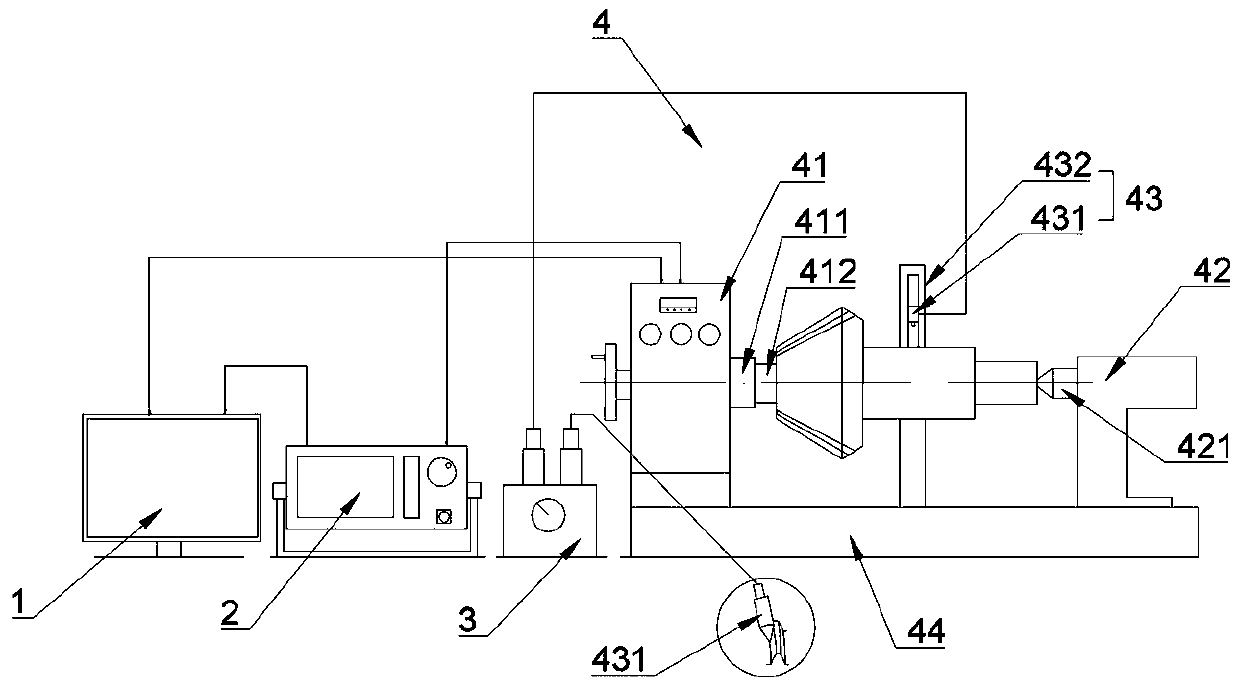

Laser-arc composite partition additive manufacturing process and device

InactiveCN108326430ASolve Dimensional Accuracy IssuesSolve quality problemsAdditive manufacturing apparatusLaser beam welding apparatusAdditive layer manufacturingSmart manufacturing

The invention relates to a laser-arc composite partition additive manufacturing process and device. According to the manufacturing process and device, the problem that during a single heat source additive manufacture, the low cost, the high production efficiency and the high forming precision cannot be simultaneously achieved is solved, and the flexible intelligent manufacturing of the part withthe complex structure is realized. The production cost is reduced, the production efficiency is improved, and meanwhile, the part with excellent performance is obtained. The additive manufacturing process comprises a forming part flexible intelligent manufacturing area division, the process of each area of the forming part is selected and determined, and finally the additive manufacturing experiment is carried out. The additive manufacturing device comprises an MIG welding machine, a TIG welding machine and a laser, wherein the central controller adjusts the heat source according to a set program, and parts which are not started to be used in the device can be lifted and placed one side by a system when the additive manufacturing experiment is carried out.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

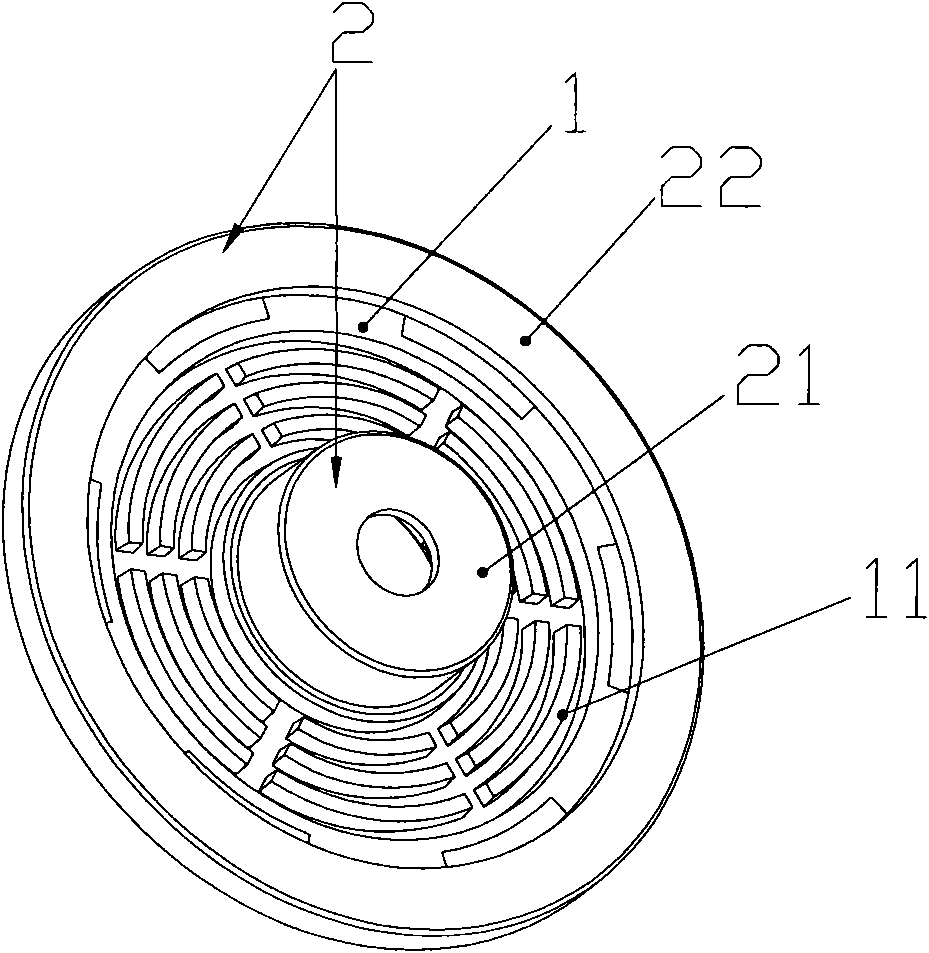

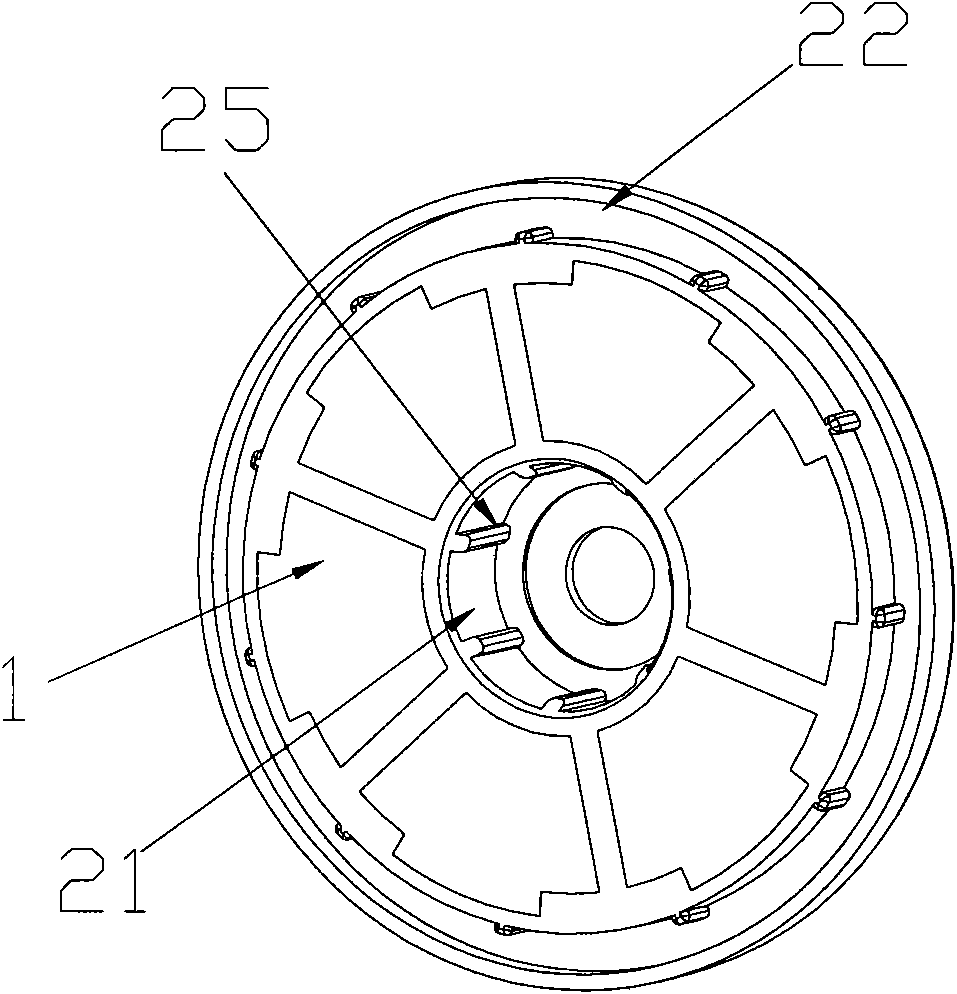

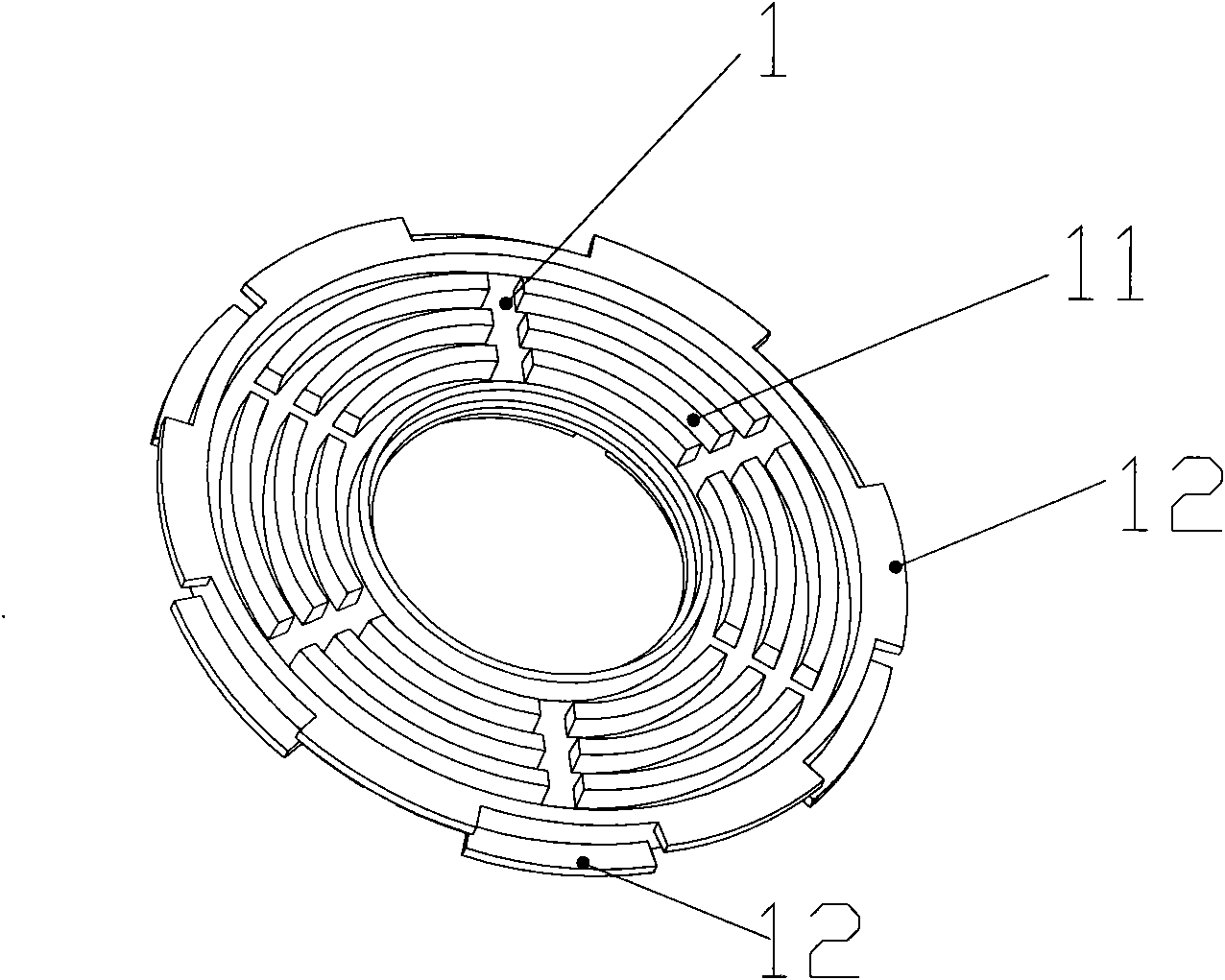

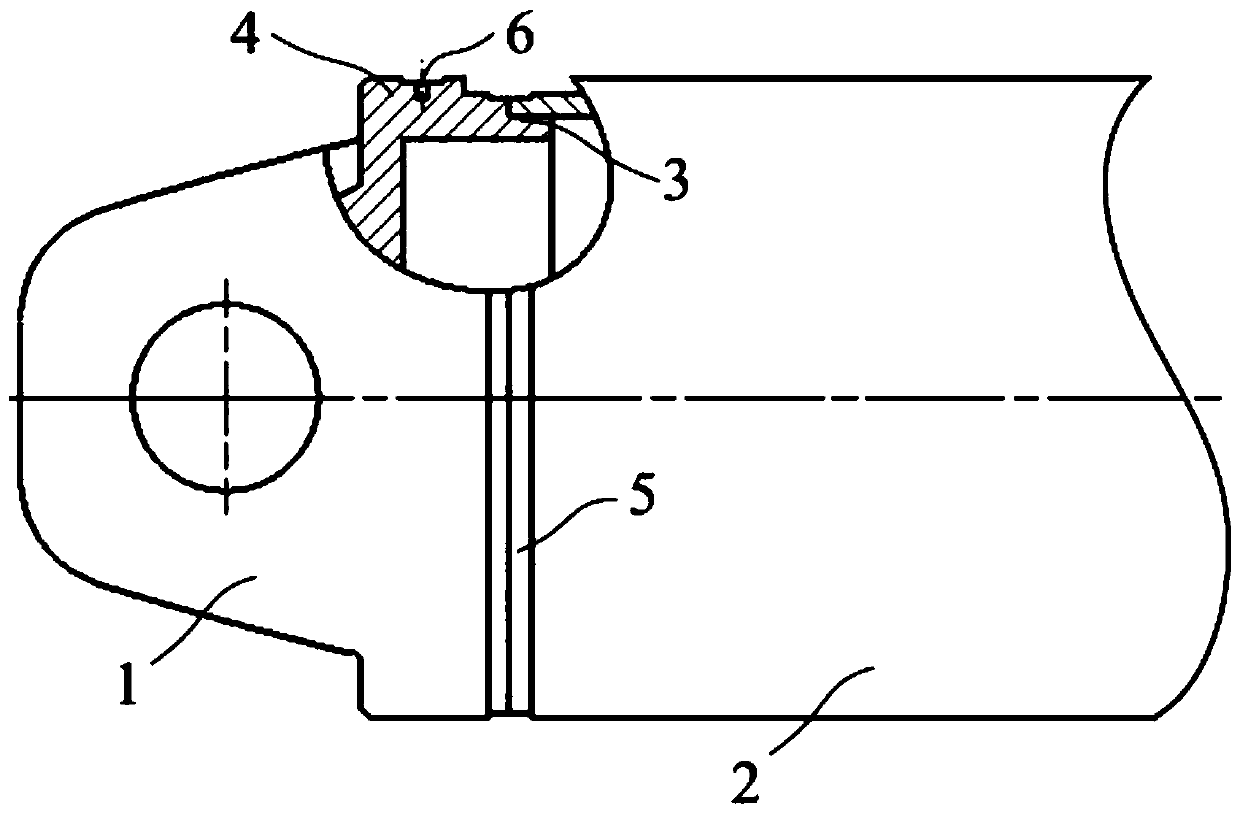

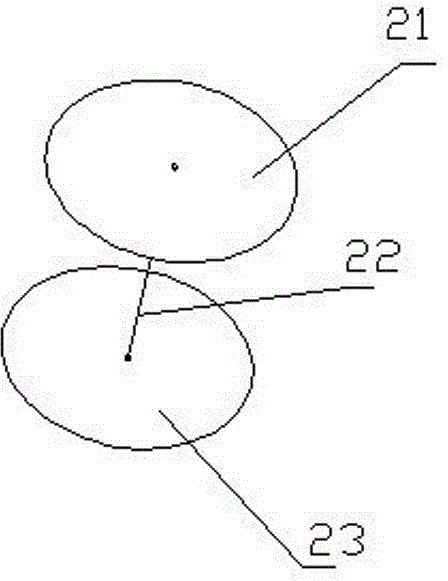

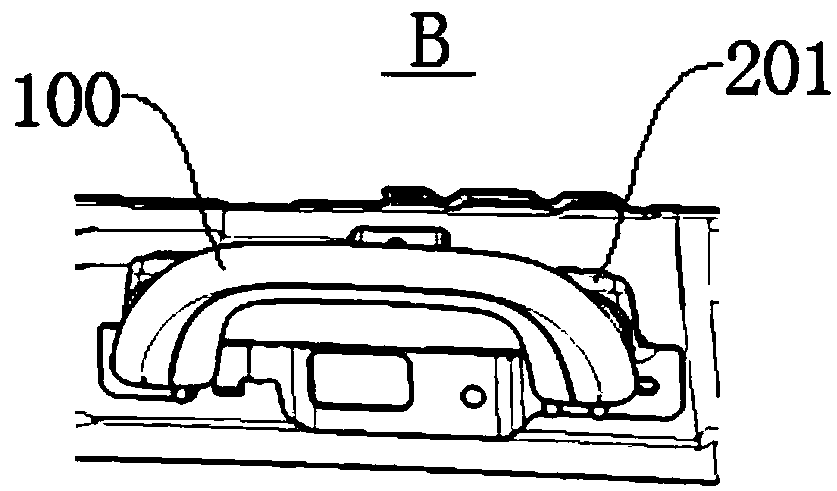

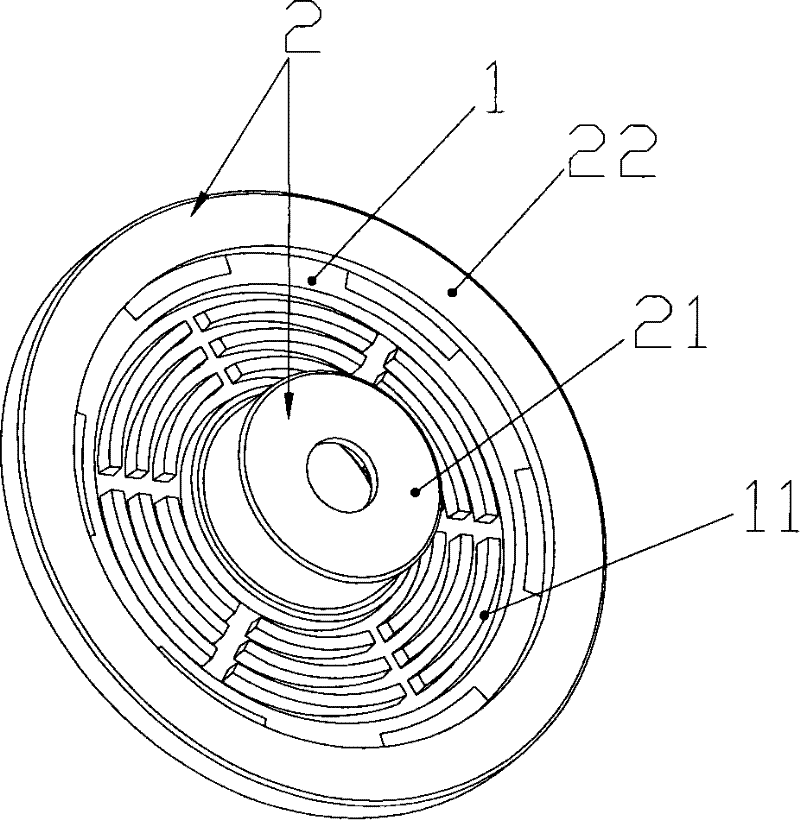

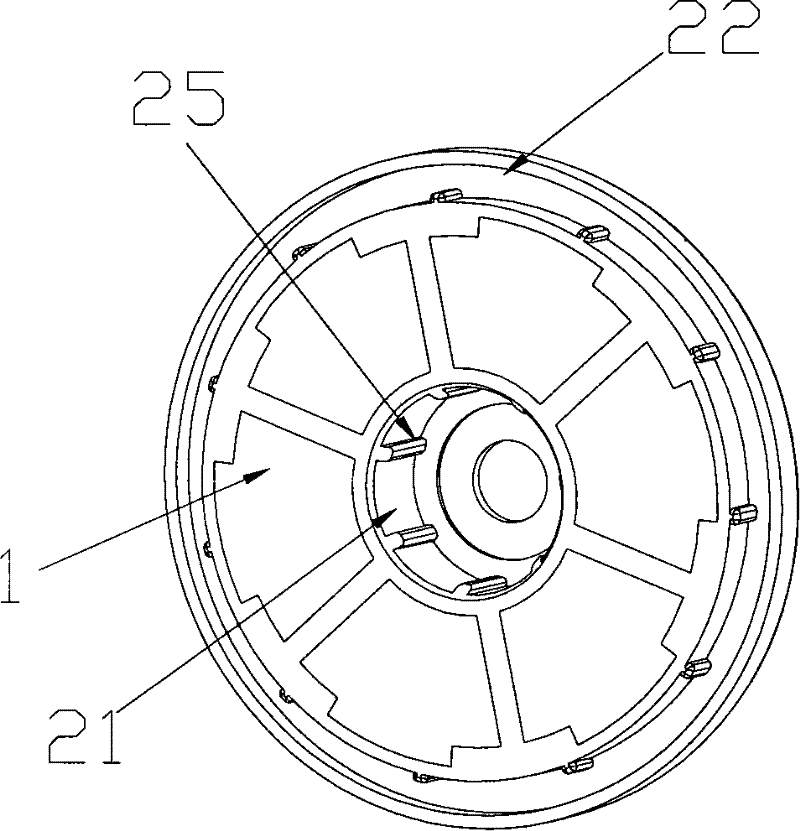

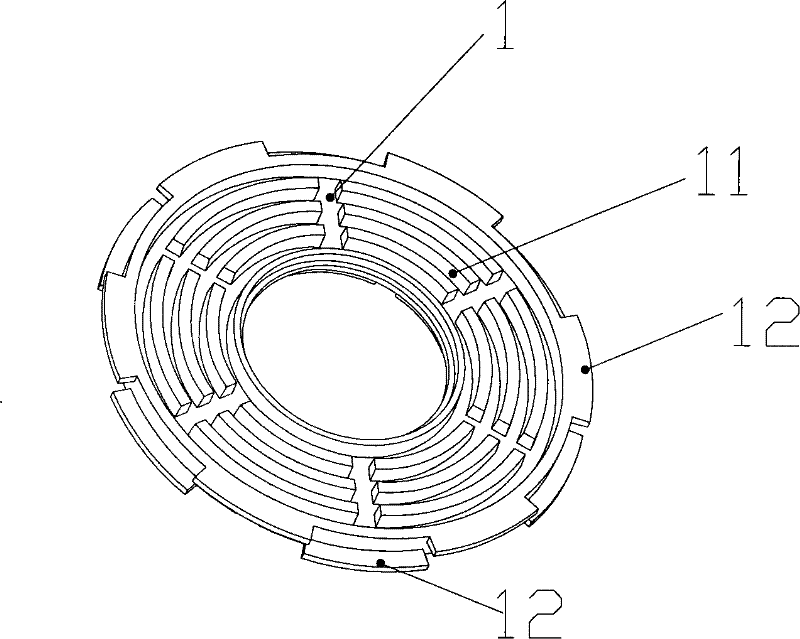

Motor end cover as well as manufacture method and applied motor thereof

ActiveCN101604878AAvoid heat differenceReduced precision requirementsManufacturing dynamo-electric machinesSupports/enclosures/casingsEngineeringInjection moulding

The invention relates to a motor end cover which comprises a metal heat dissipation piece (1) and an injection moulding piece (2), wherein the injection moulding piece comprises a bearing chamber (21) positioned at the center and a positioning clamp opening (22) positioned at the periphery; and the metal heat dissipation piece (1) is embedded between the bearing chamber (21) and the positioning clamp opening (22). The invention has the advantages of simple manufacture, lower cost, higher precision, light weight, high stability and easy heat dissipation.

Owner:ZHONGSHAN BROAD OCEAN

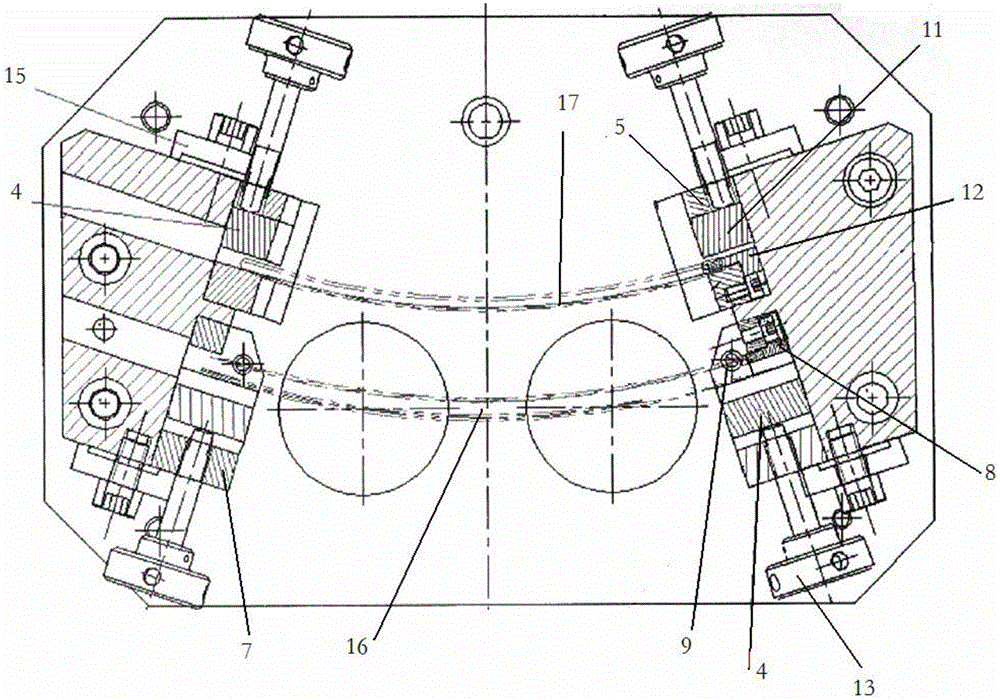

Assembly welding method of fan-shaped block welding assembly

ActiveCN106624541ASatisfy the assembly position accuracySolve Dimensional Accuracy IssuesWelding/cutting auxillary devicesAuxillary welding devicesEconomic benefitsWelding

The invention discloses an assembly welding method of a fan-shaped block welding assembly. By using a clamp positioning adjustable structure, welding deforming control is achieved, gap coping of blades and inner-and-outer templates is convenient, and specifically, the bottom face of a T-shaped plate is positioned through a T-shaped plate right positioning sliding seat, and the side faces of the T-shaped plate are positioned through a T-shaped plate side face positioning block; the T-shaped plate and the positioning sliding seats on the two sides of the T-shaped plate are stored in a fixed base body structure which is composed of a bottom plate, a left angle seat and a right angle seat, the positions are well adjusted, and pressing and fixing are conducted by using an upper face pressing plate and side face pressing plates; and the bottom face and an outer arc of a runner plate are positioned by using a runner plate right positioning sliding seat. The assembly welding method of the fan-shaped block welding assembly has the advantages that (1), machining efficiency is improved; and (2), the economic benefits are improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

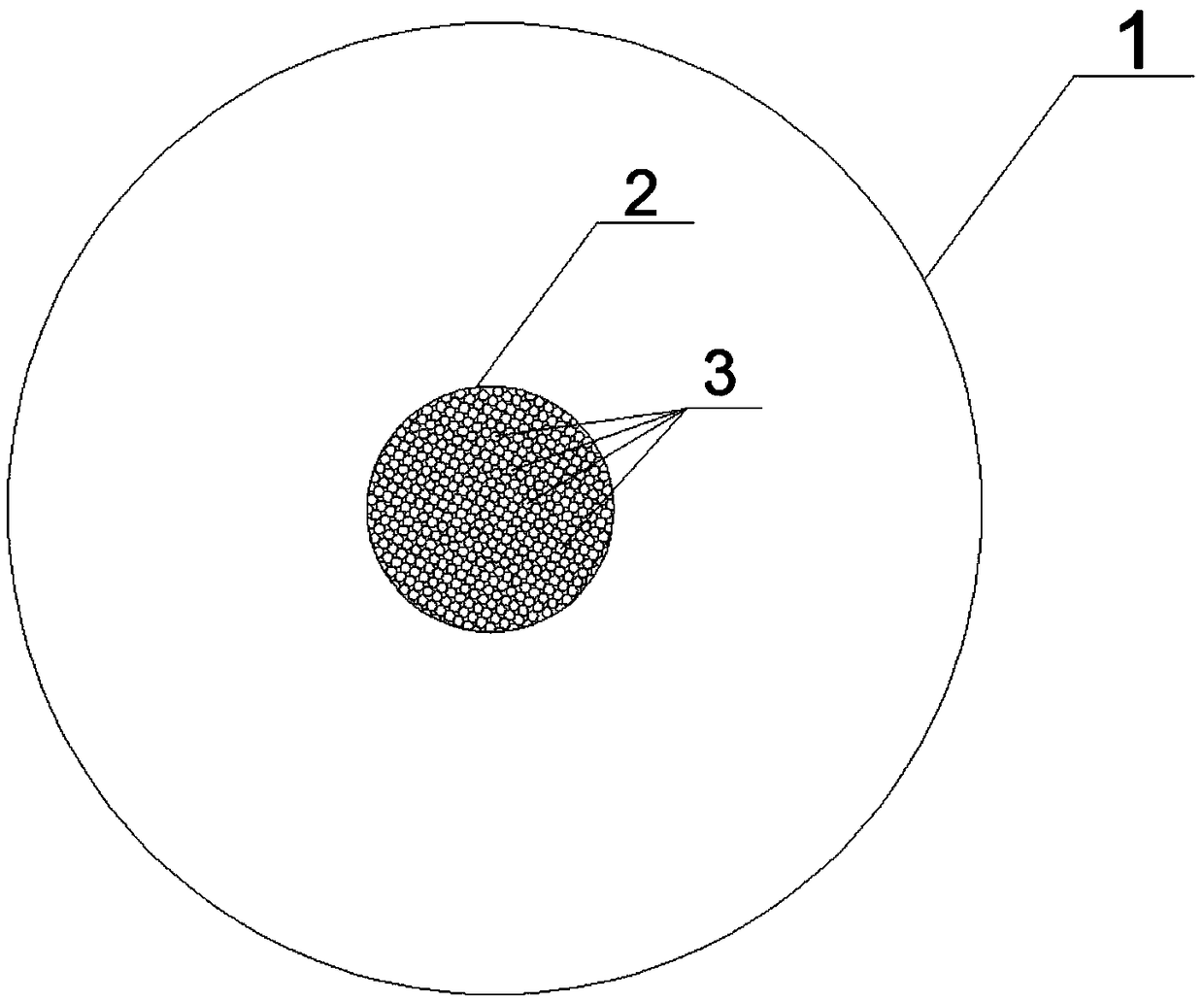

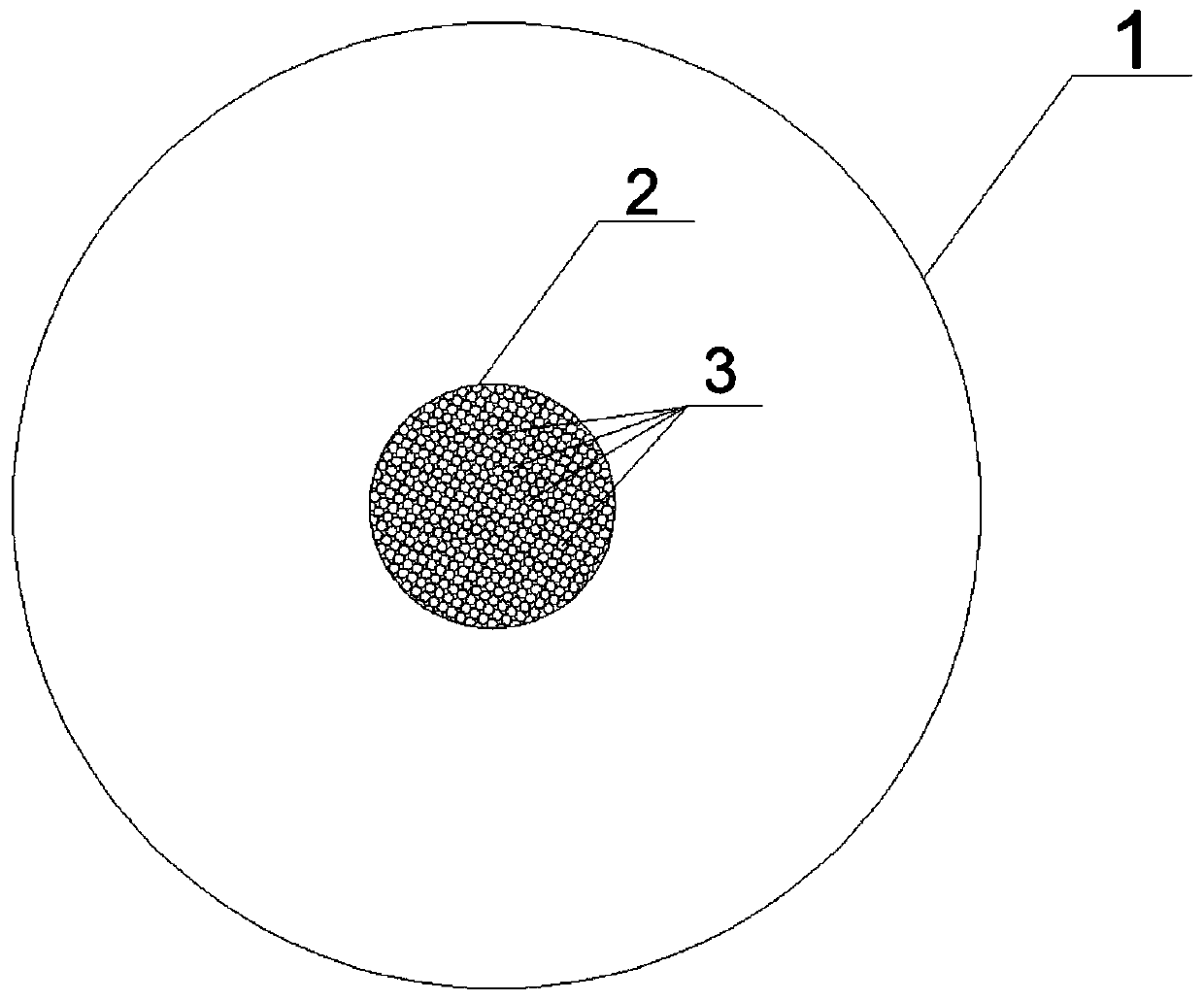

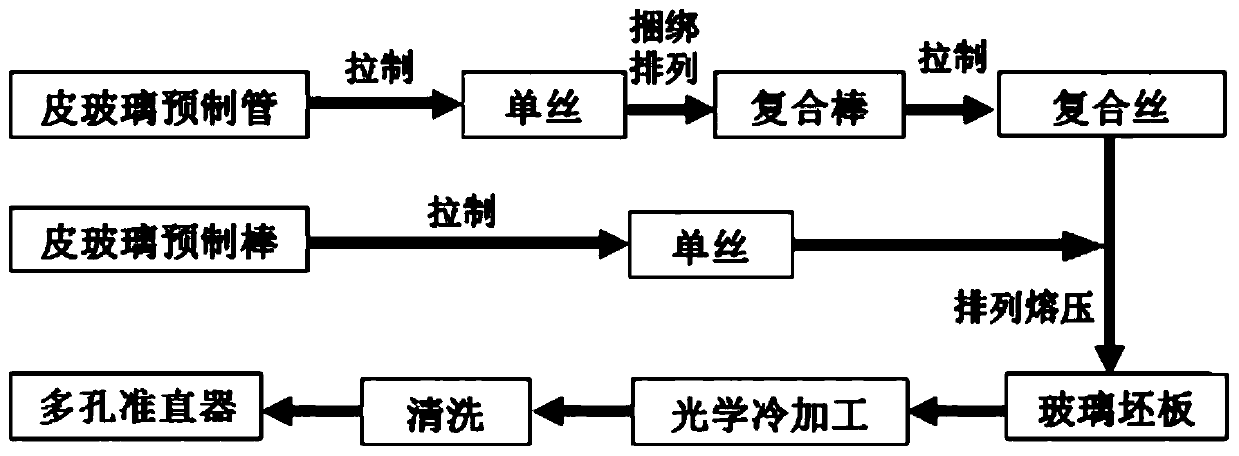

Collimator and manufacturing method

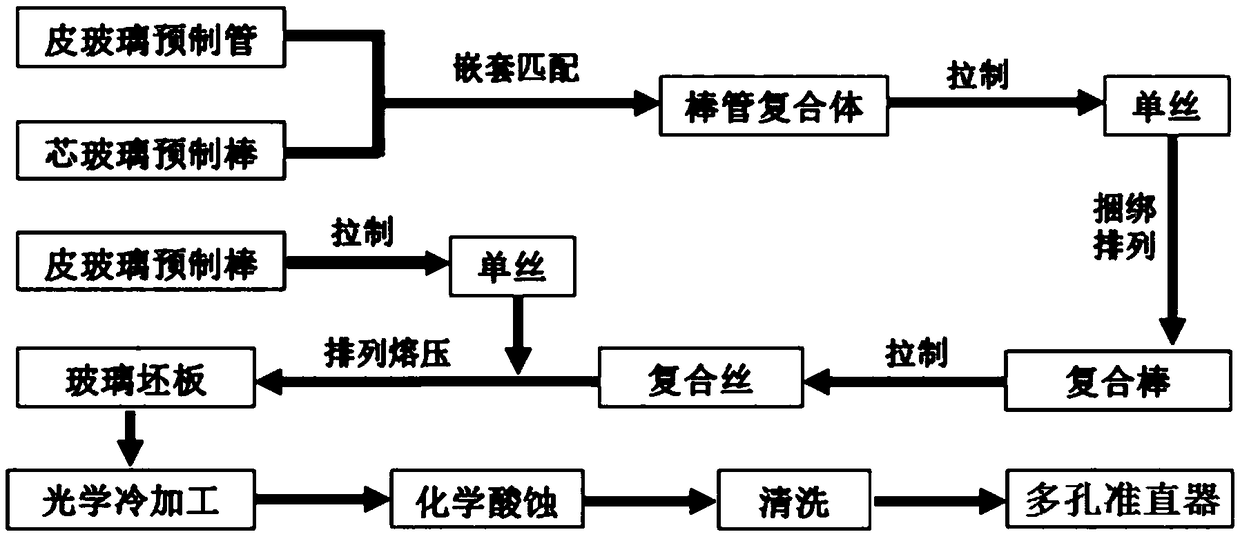

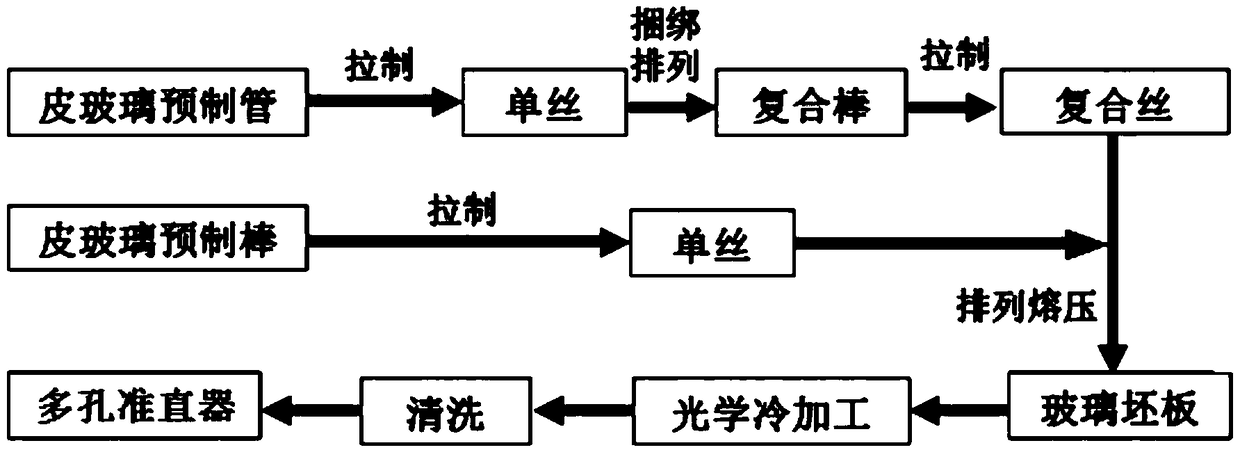

ActiveCN108922646ASolve Dimensional Accuracy IssuesUniform sizeGlass making apparatusHandling using diaphragms/collimetersAcid etchingFilling materials

The invention relates to a collimator and a manufacturing method. The collimator includes a base body of a flat plate shape, wherein the upper surface and lower surface of the base body are parallel to each other, at least a through hole which penetrates through the upper surface and the lower surface and has a pore diameter of 1-100 [mu]m is formed in the base body, and the base body is made of glass. A glass blank plate is prepared by using a glass rod tube nested drawing method, optical cold processing is conducted, and then chemical etching is performed so as to obtain the collimator. After the glass of the collimator is determined, core glass matched with the determined glass is designed, and the core glass is removed through acid etching, wherein the core glass is mainly used as a filling material of micropores during manufacture so as to ensure the roundness of the micropores. Through the collimator, the collimation efficiency of particles and stability of particle movement canbe improved effectively, the scattering angle of the particles is reduced, and conditions for high stability, high reliability and miniaturization of atomic clocks, ray cameras and other precision equipment are created.

Owner:CHINA BUILDING MATERIALS ACAD

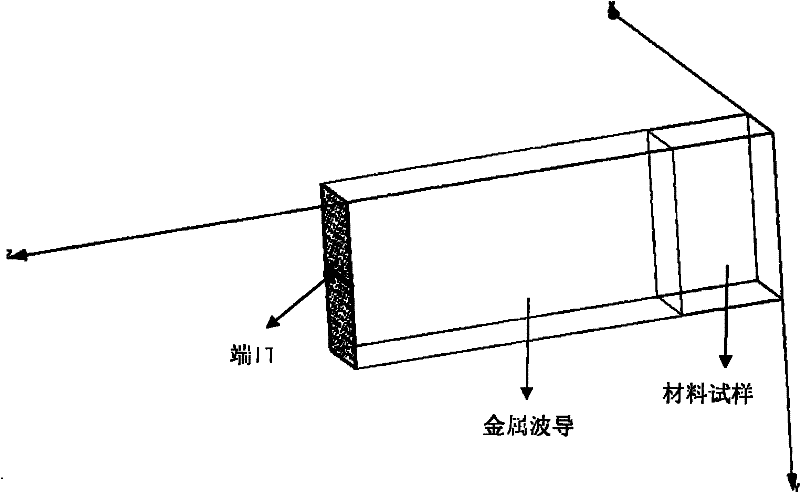

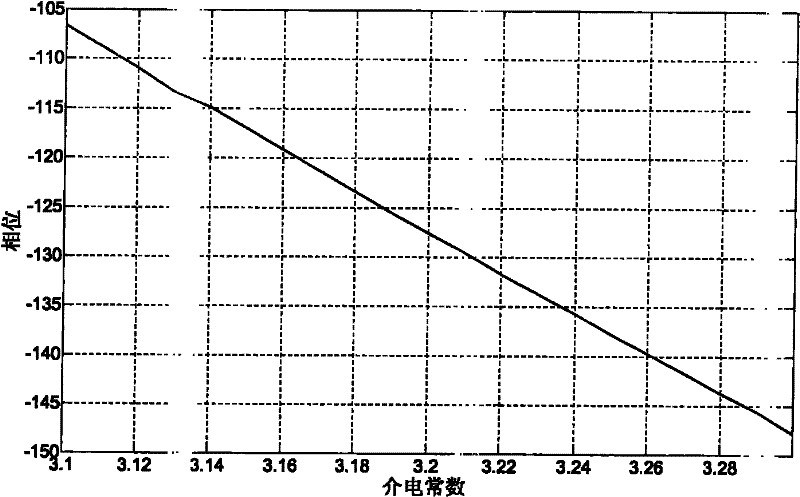

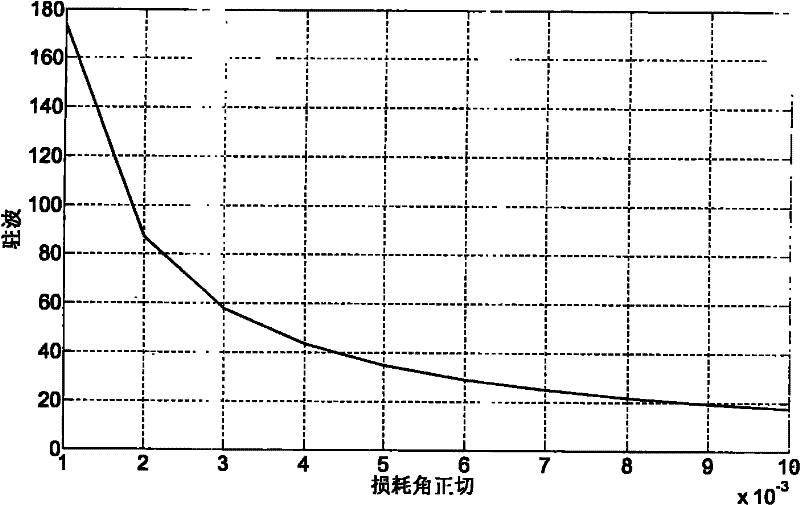

Method for testing dielectric constant and loss angle tangent parameter of antenna cap material

InactiveCN102539934ASolve Dimensional Accuracy IssuesAddressing Test AccuracyResistance/reactance/impedenceDielectricWaveguide

The invention provides a method for testing a dielectric constant and a loss angle tangent parameter of an antenna cap material. The method comprises the steps of: setting a testing waveguide length according to a testing frequency band, connecting the testing waveguide to a network analyzer, calibrating the network analyzer, testing an initial phase and a standing wave; placing a test block with wavelength of odd number times of that of a half waveguide or any length, measuring the phase and the standing wave by using the network analyzer; and scanning the dielectric constant of the material by using a parameter scanning function of an Ansoft HFSS (High Frequency Structure Simulator), setting the dielectric constant of the material to be 3.3-3.4 and the step length of the material to be 0.01, and obtaining a scanning simulation result of the phase. By adopting the invention, accurate testing of the dielectric constant and the loss angle tangent parameter of the antenna cap material is effectively improved, and the dielectric constant and the loss angle tangent (tan delta) parameter of a dielectric material can be obtained. The invention has the advantages of increasing working efficiency and reducing correlation of the testing precision and the size of a sheet to be tested.

Owner:SHANGHAI RADIO EQUIP RES INST

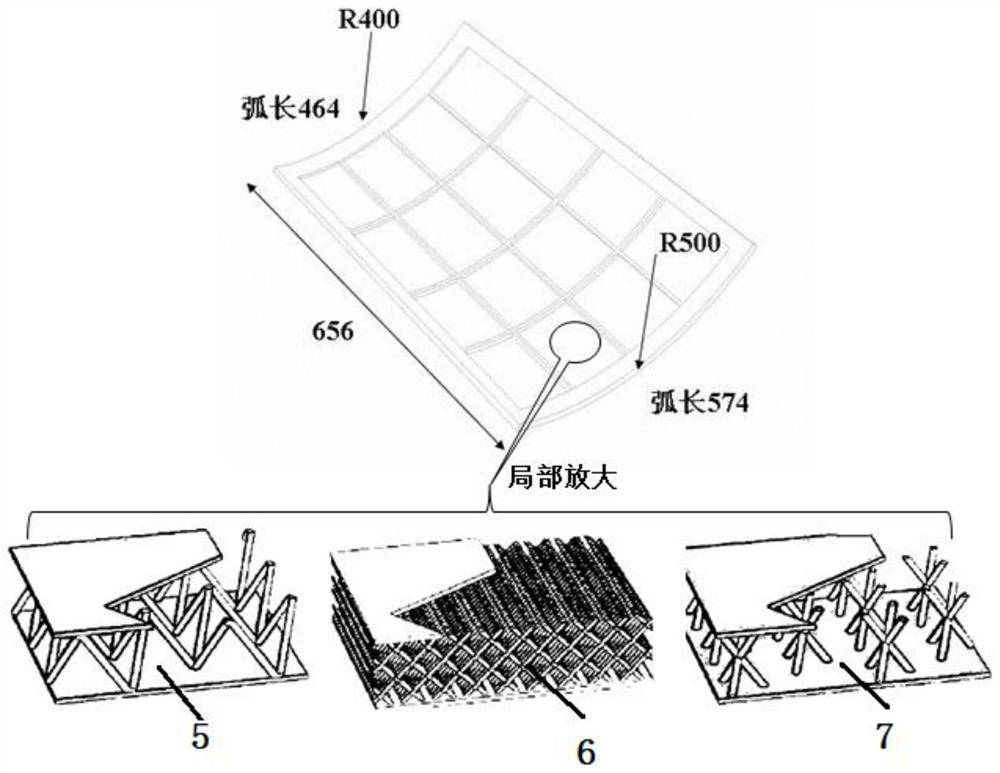

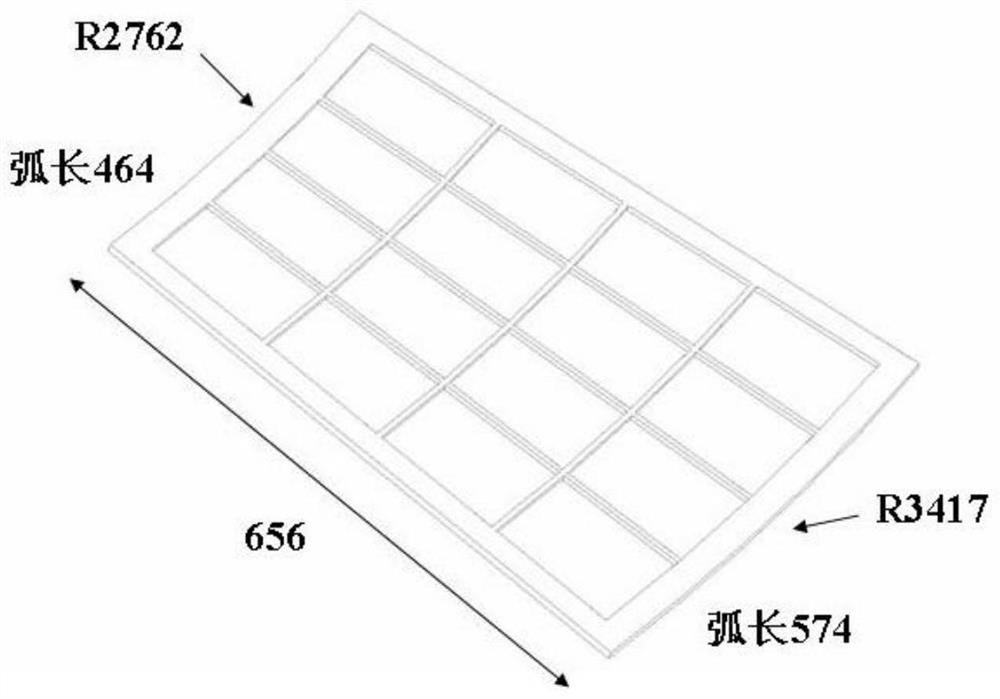

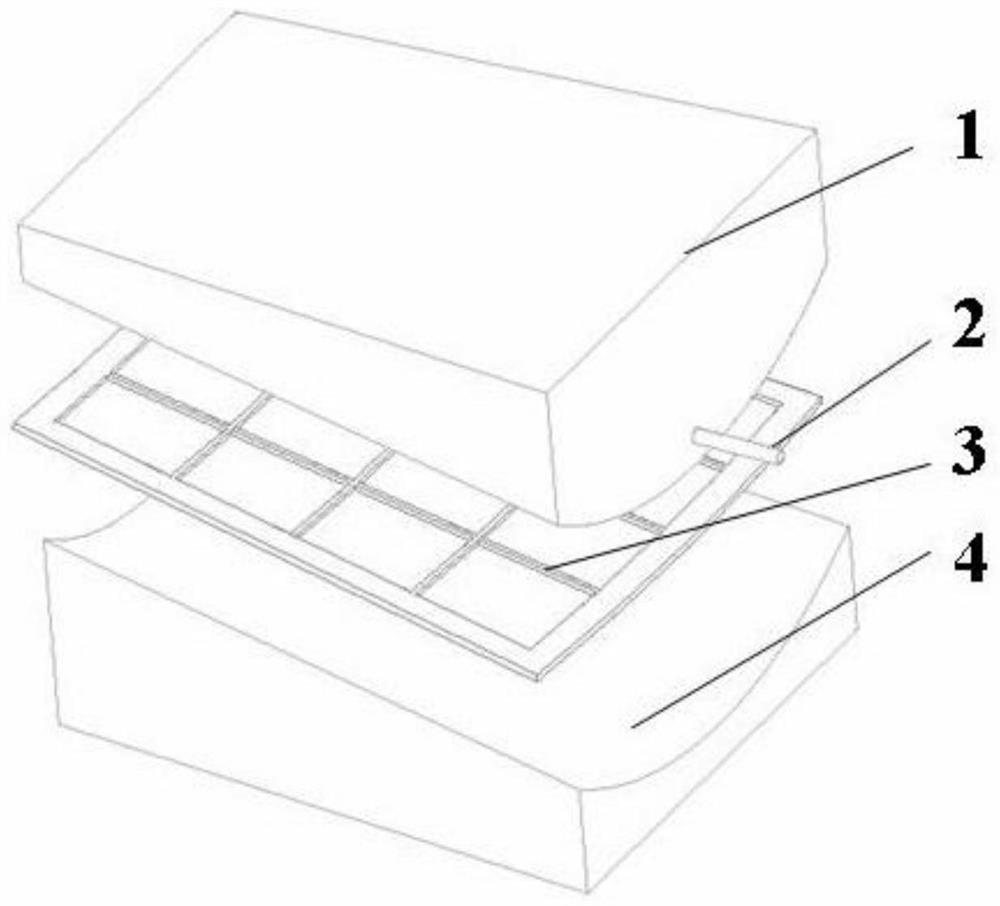

Additive hot-pressing inflatable composite forming method for topological structure wallboard

ActiveCN111744983AImprove integrityImprove surface qualityShaping toolsIncreasing energy efficiencyStructural engineeringClosed cavity

The invention discloses an additive hot-pressing inflatable composite forming method for a topological structure wallboard, belongs to the technical field of precision sheet metal processing, and solves the defects of poor integrity, difficulty in appearance precision control or higher cost in existing technical processing. The forming method comprises the following steps of step 1, determining positions of reinforcing ribs and a topological structure of a topological structure wallboard blank required by hot-pressing forming; step 2, preparing the topological structure wallboard blank by an additive; step 3, manufacturing a hot-pressing forming die of the topological structure wallboard; step 4, placing the topological structure wallboard blank in a cavity of a hot-pressing forming die, and performing hot-pressing forming on the topological structure wallboard blank; and step 5, forming a closed cavity between the topological structure wallboard blank and an upper die, communicating the closed cavity with an external gas source through a vent hole, and performing ventilation and pressurized correction on the closed cavity in order to enable a curved surface part between the reinforcing ribs of the topological structure wallboard to form a smooth curved surface. According to the method, the surface quality of parts is improved.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

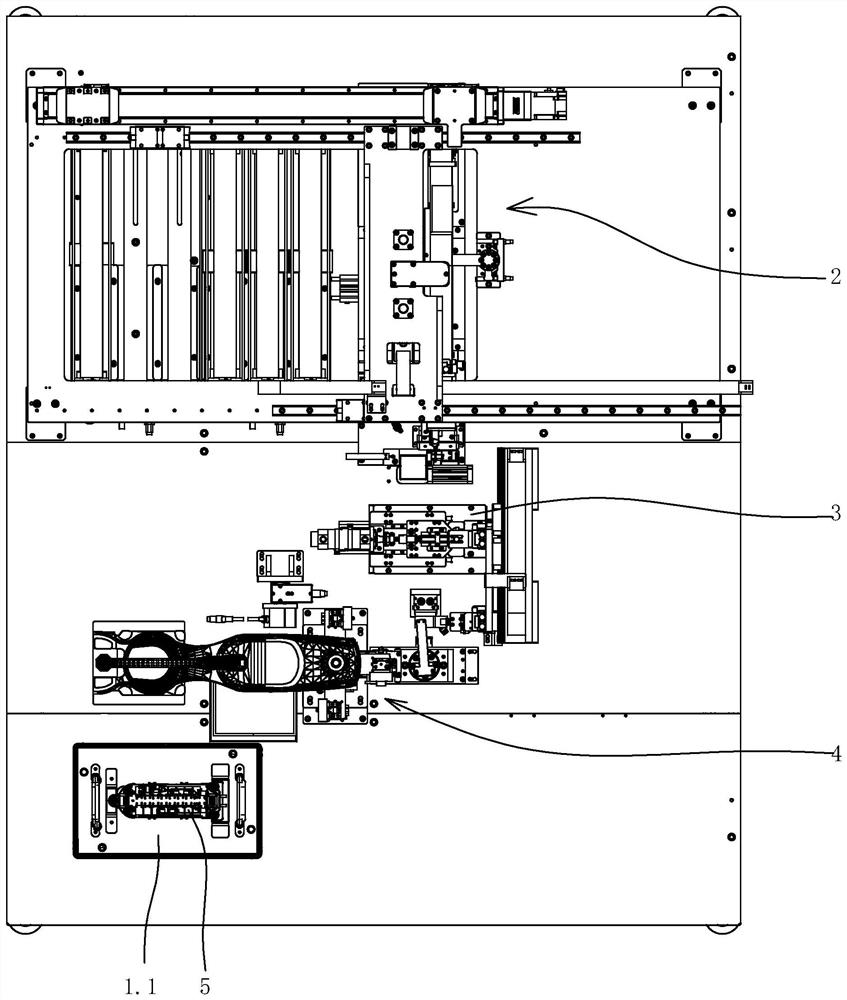

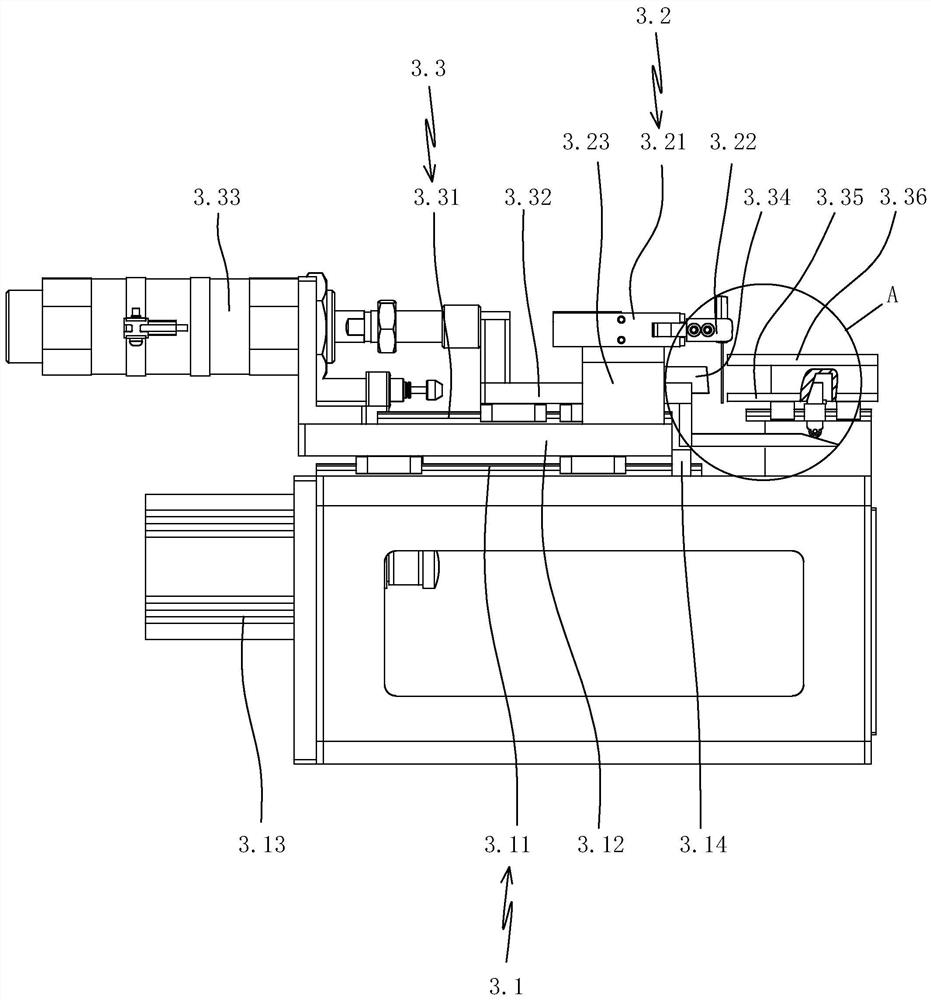

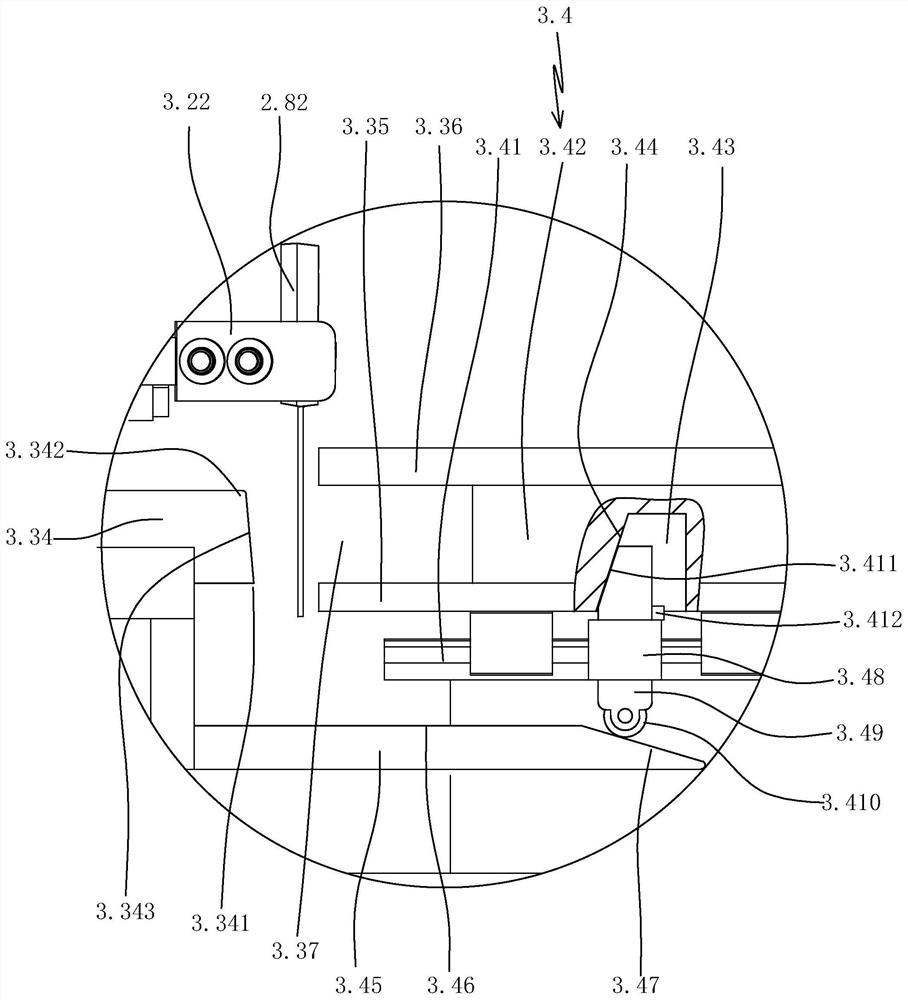

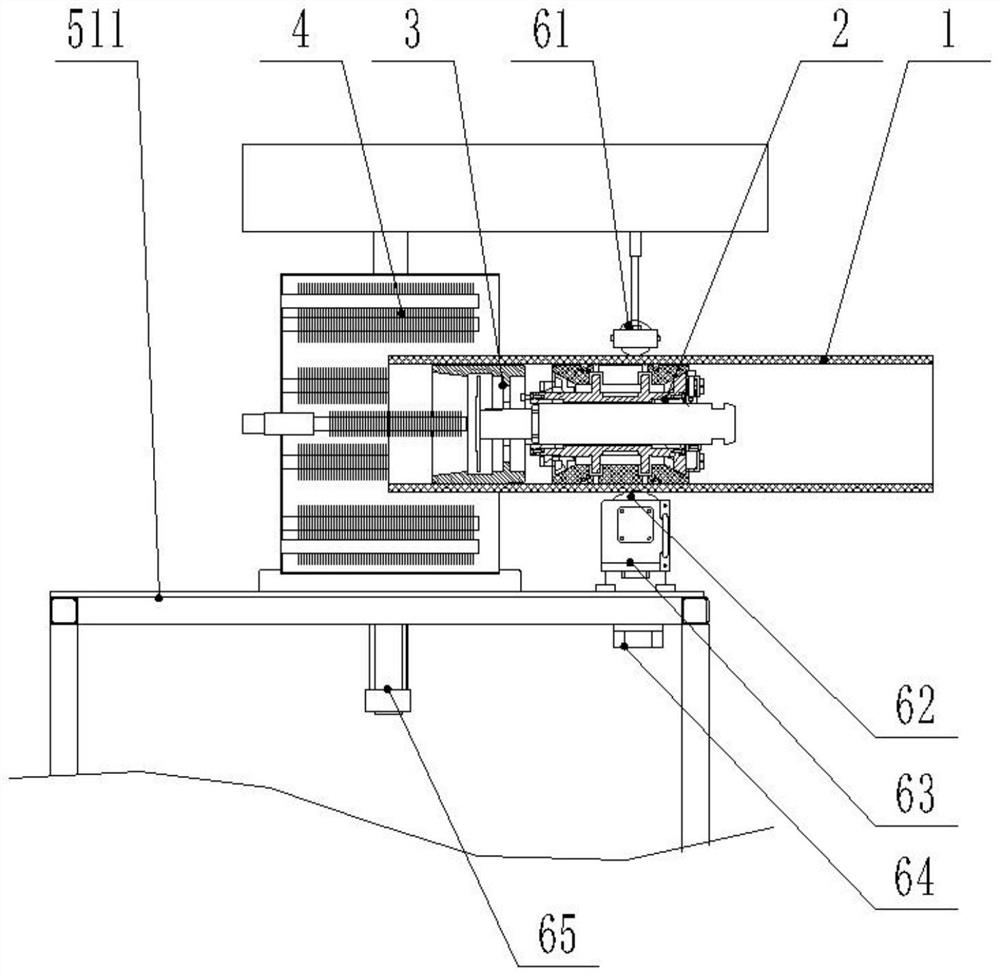

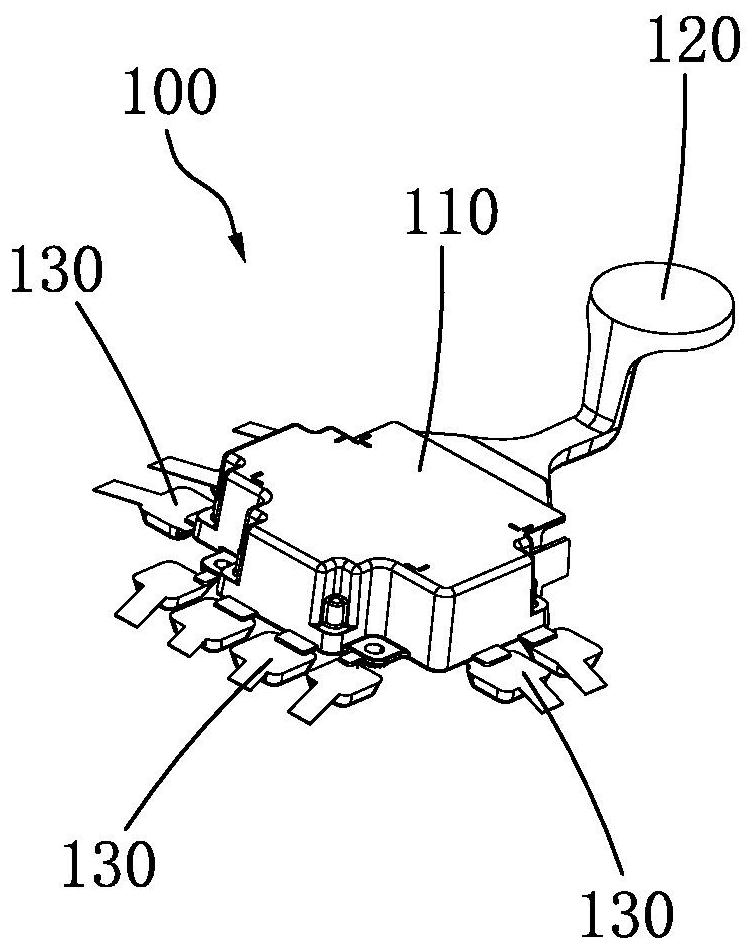

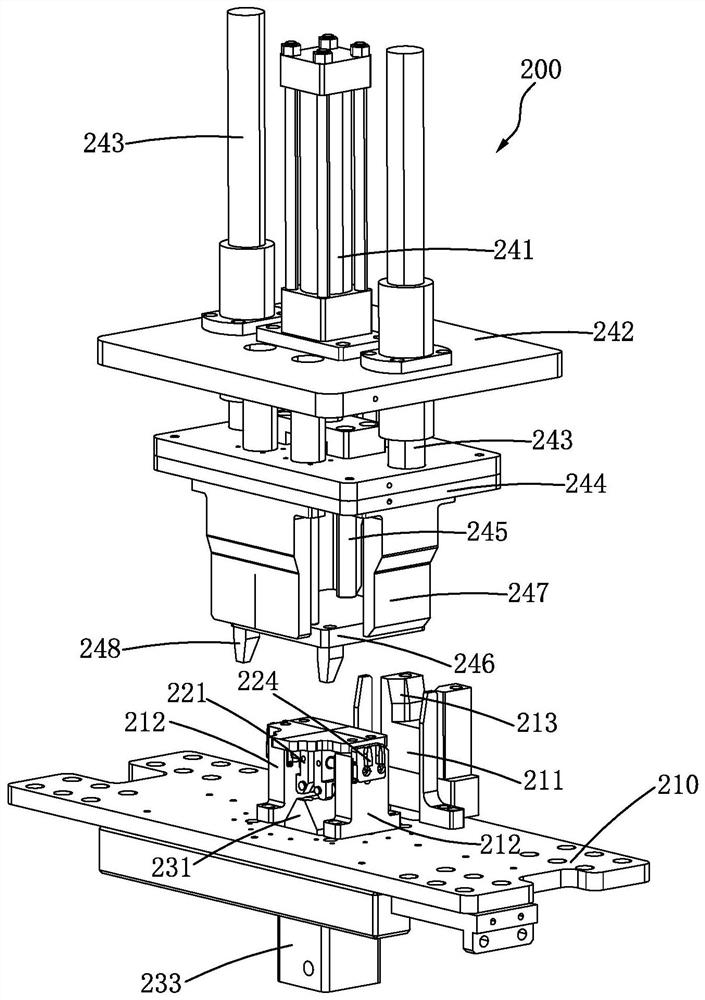

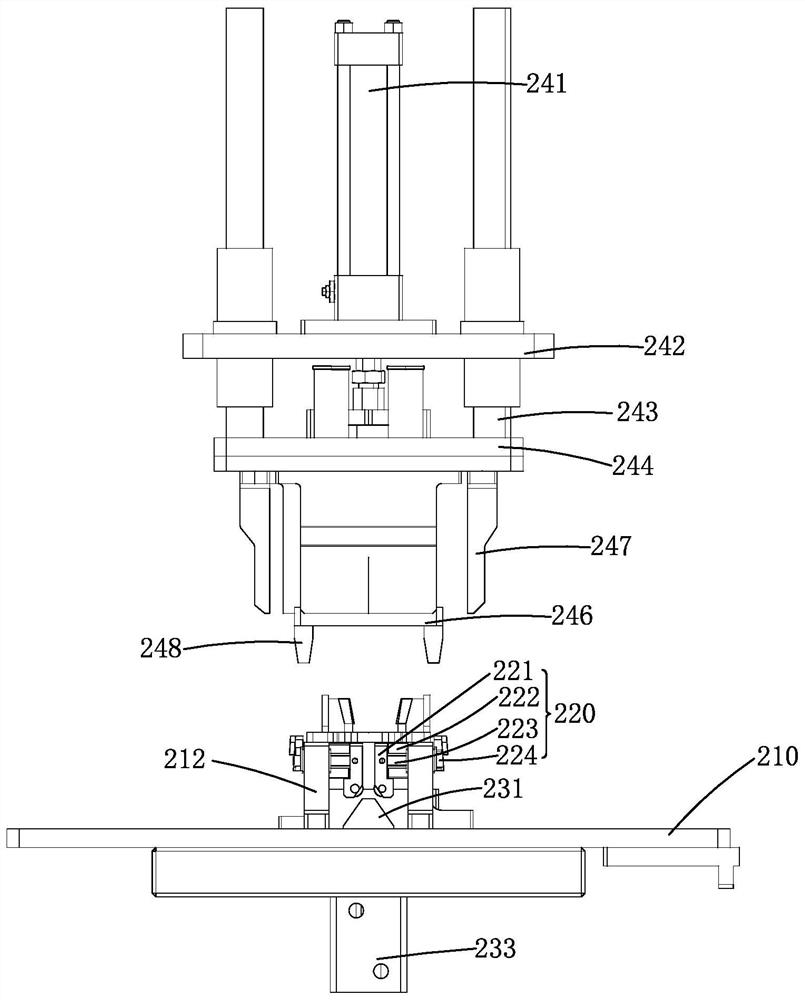

Automatic loading, unloading, shaping and installing integrated robot for IGBT chip

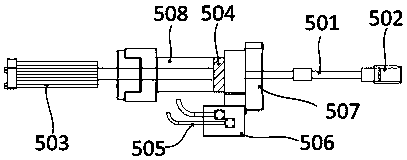

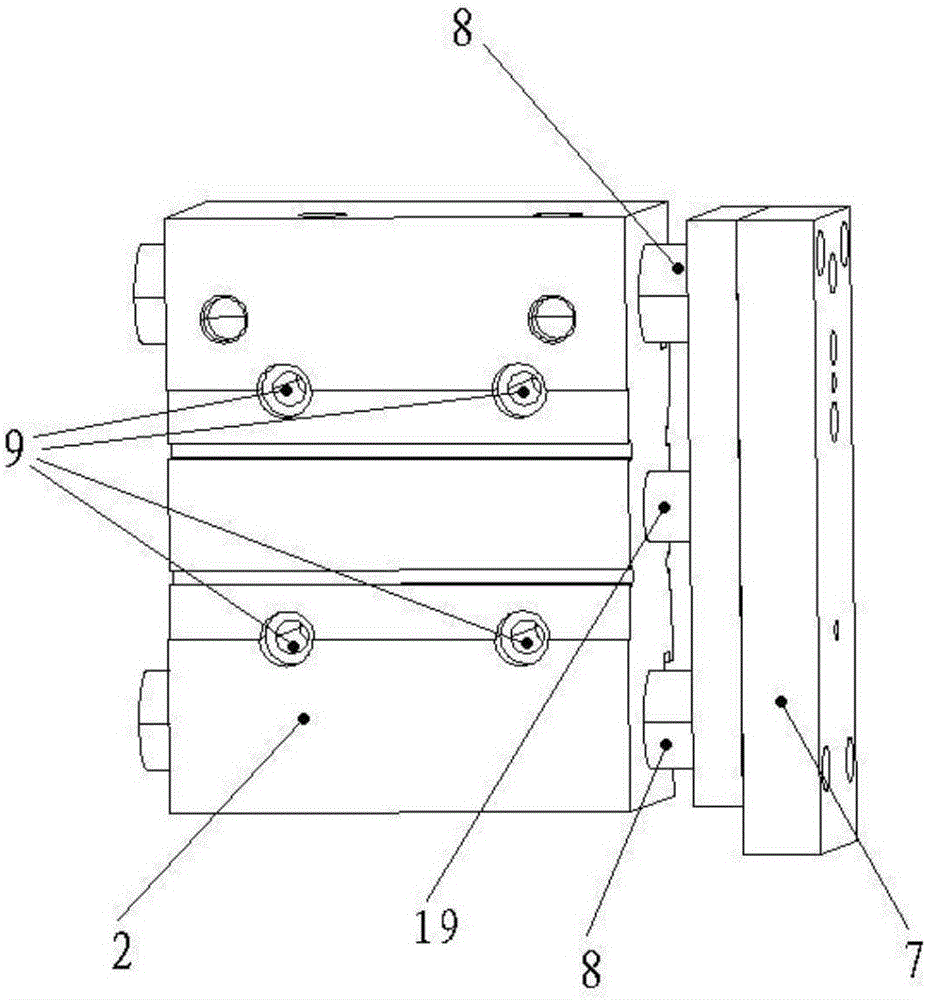

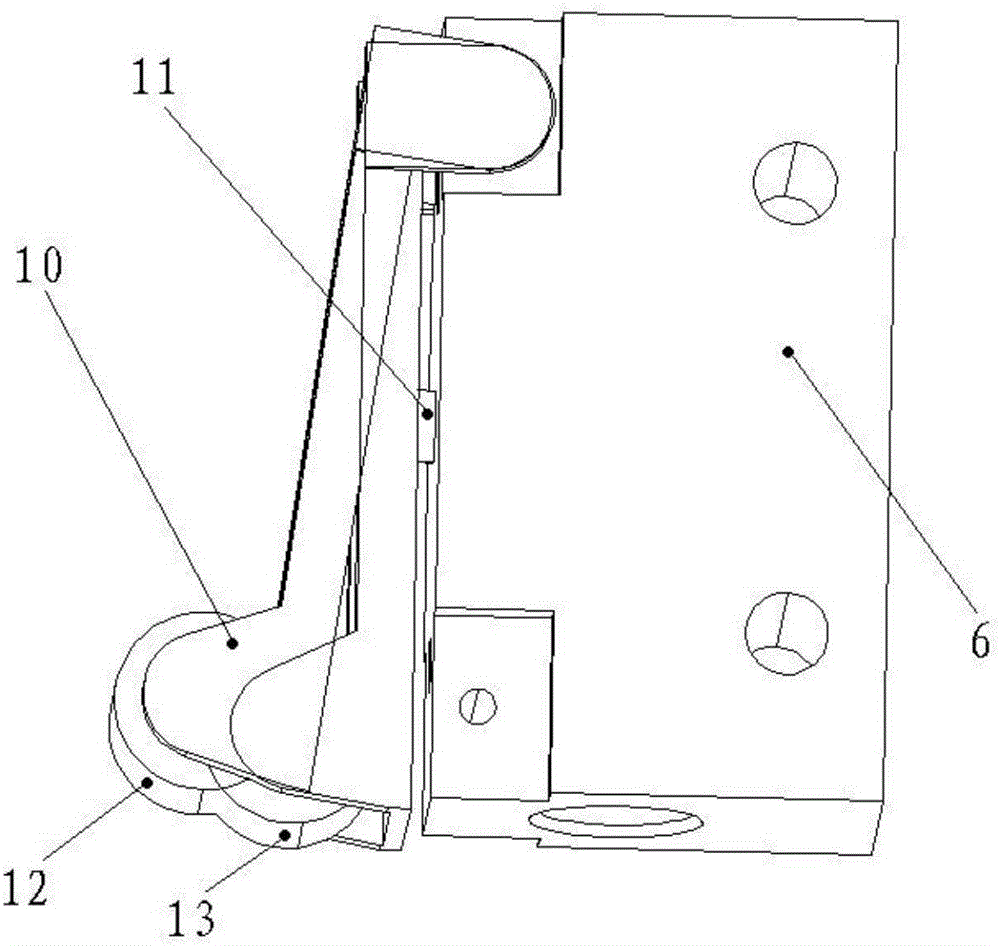

PendingCN113140496AImplement automatic installationSolve Dimensional Accuracy IssuesSemiconductor/solid-state device manufacturingConveyor partsStructural engineeringMachine

The invention discloses an automatic loading, unloading, shaping and installing integrated robot for an IGBT chip. The automatic loading, unloading, shaping and mounting integrated robot can realize automatic mounting of the IGBT chip, can effectively solve the problem that the size precision of the chip after pin shearing, bending and forming is affected due to chip positioning errors of two machining procedures of pin shearing and bending. The robot comprises a rack, a tray used for placing an IGBT module; an automatic chip discharging machine used for outputting the chips in the chip material pipe one by one; a chip shaping station comprising a chip pin shearing and bending device, wherein the chip pin shearing and bending device is used for carrying out pin shearing and bending on the pins of the chips so as to realize pin shearing and bending of the pins of the chips; and a chip mounting station used for carrying the chip which passes through the chip shaping station and is subjected to pin cutting and bending of the chip pins to the IGBT module on the tray.

Owner:HANGZHOU WOLEI INTELLIGENT TECH

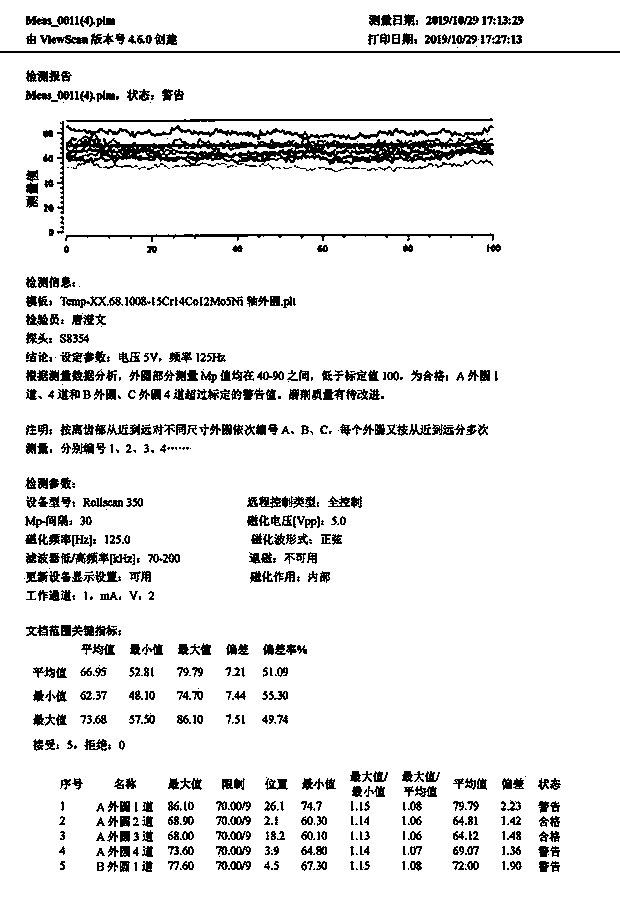

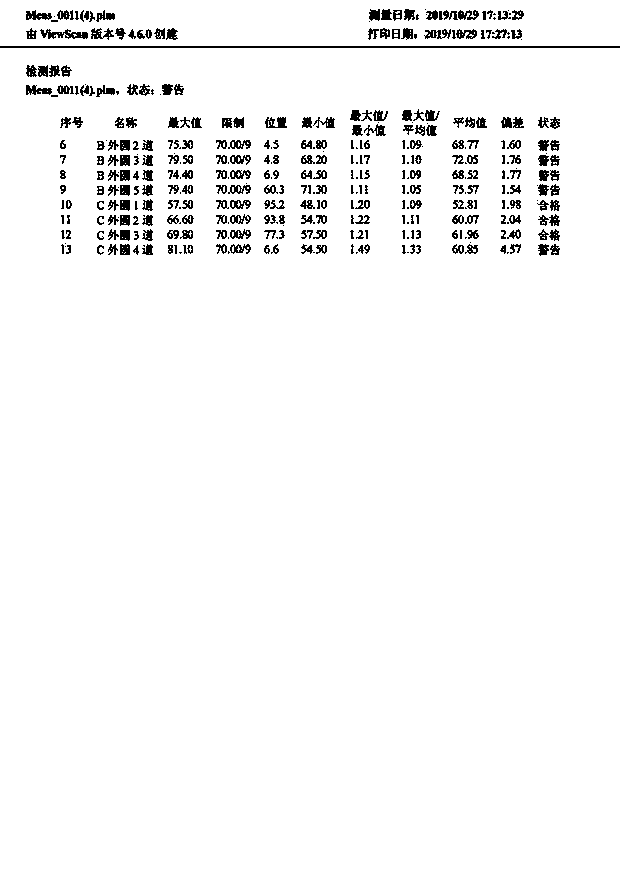

Magnetoelastic grinding burn detection method for acid-corrosion-resistant steel gear

InactiveCN110836806ASolve the problem that the resolution of defects is not as good as that of conventional steel gearsSolve Dimensional Accuracy IssuesPreparing sample for investigationMaterial magnetic variablesManufacturing engineeringAcid corrosion

The invention discloses a magnetoelastic grinding burn detection method for an acid-corrosion-resistant steel gear to solve the problems that acid corrosion detection influences the size precision androughness of a gear and the defect distinguishing degree of acid corrosion detection of an existing acid-corrosion-resistant steel gear is not the same as that of a conventional steel gear. Before ato-be-detected gear part is detected, an acceptance standard calibration value and a warning value are determined according to a contrast gear part and a gear defect part, a detector is directly adopted to detect the grinding burn defect without damage during the subsequent detection of the to-be-detected gear part, and the to-be-detected gear part does not need to be subjected to acid corrosion.

Owner:ZHONGNAN TRANSMISSION MACHINERY FACTORY CHANGSHAAVIATION IND

Integral type flanged flange production equipment and method

ActiveCN114192643AHeating evenlyGuaranteed dimensional accuracyShaping toolsMetal-working feeding devicesForming processesFlange

The invention discloses integral type flanged flange production equipment and method. A conveying device is arranged at the top of a bracket, a lifting mechanism is arranged at the bottom of the bracket, a heating device is arranged on a lifting table of the lifting mechanism, a flange forming device is arranged at the discharging end of the conveying device, and the flange forming device comprises a pre-expanding mold and a forming mold which are arranged on a base; according to the forming device, a flange structure can be directly formed on a pipeline port part, the pipeline size is supported and corrected through the inner supporting device and the inner sleeve in the forming process, and the size precision of the pipeline is guaranteed; the flange structures formed at the ends of the pipelines needing to be connected are connected through bolts. According to the connecting mode, the pressure resistance degree of pipeline connection is ensured, the problems of unreliable weld joints and large difficulty coefficient of a welding connecting mode are solved, rapid and reliable connection of the pipelines on a construction site is achieved, and the connecting mode is suitable for the technical field of pipeline connection.

Owner:HUACHUANG TIANYUAN IND DEVING

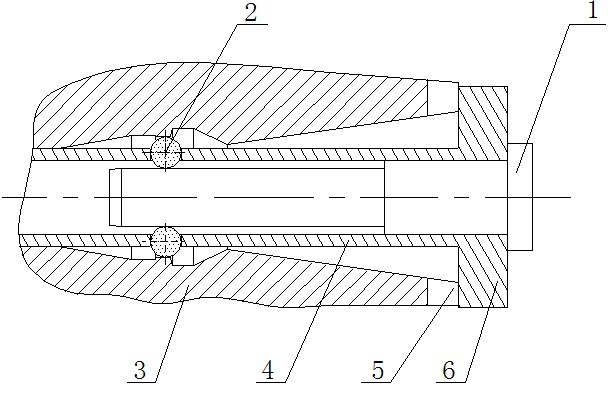

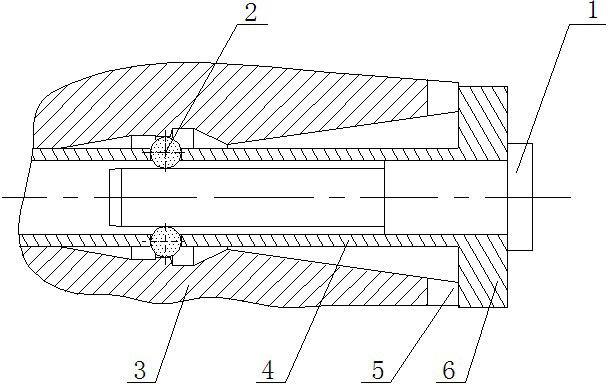

Processing center spindle inner bore checking fixture

InactiveCN102589380ASimple structureImprove machining accuracyMechanical diameter measurementsEngineeringMechanical engineering

The invention provides a processing center spindle inner bore checking fixture. The checking fixture comprises a checking sleeve and a go / no-go gauge matched with the checking sleeve, wherein the front end of the checking sleeve extends into the spindle inner bore; an outer edge is arranged at the rear end of the checking sleeve; a through hole is arranged on the side wall of the checking sleeve; and a ball is mounted in the through hole. The checking fixture provided by the invention has a simple structure, can accurately and quickly check whether the processed center spindle inner bore is qualified, and improve the processing precision of the center spindle inner bore.

Owner:SHANDONG BEST PRECISION

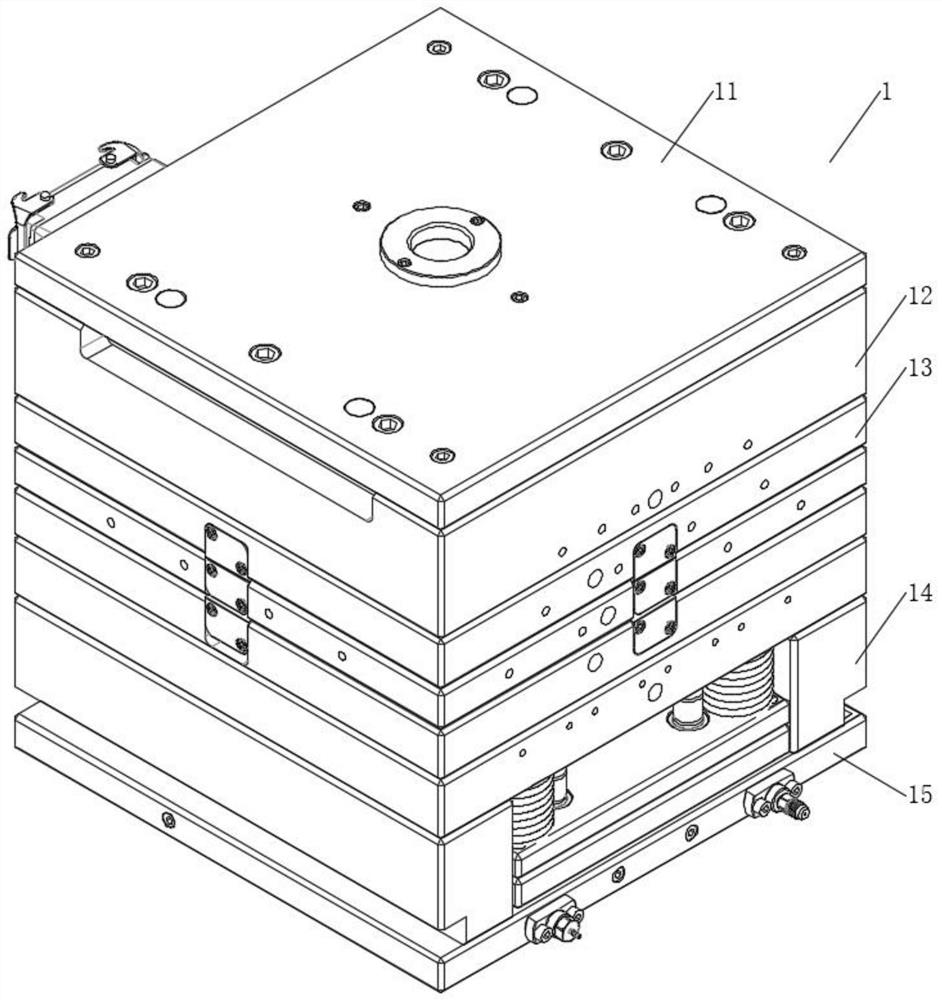

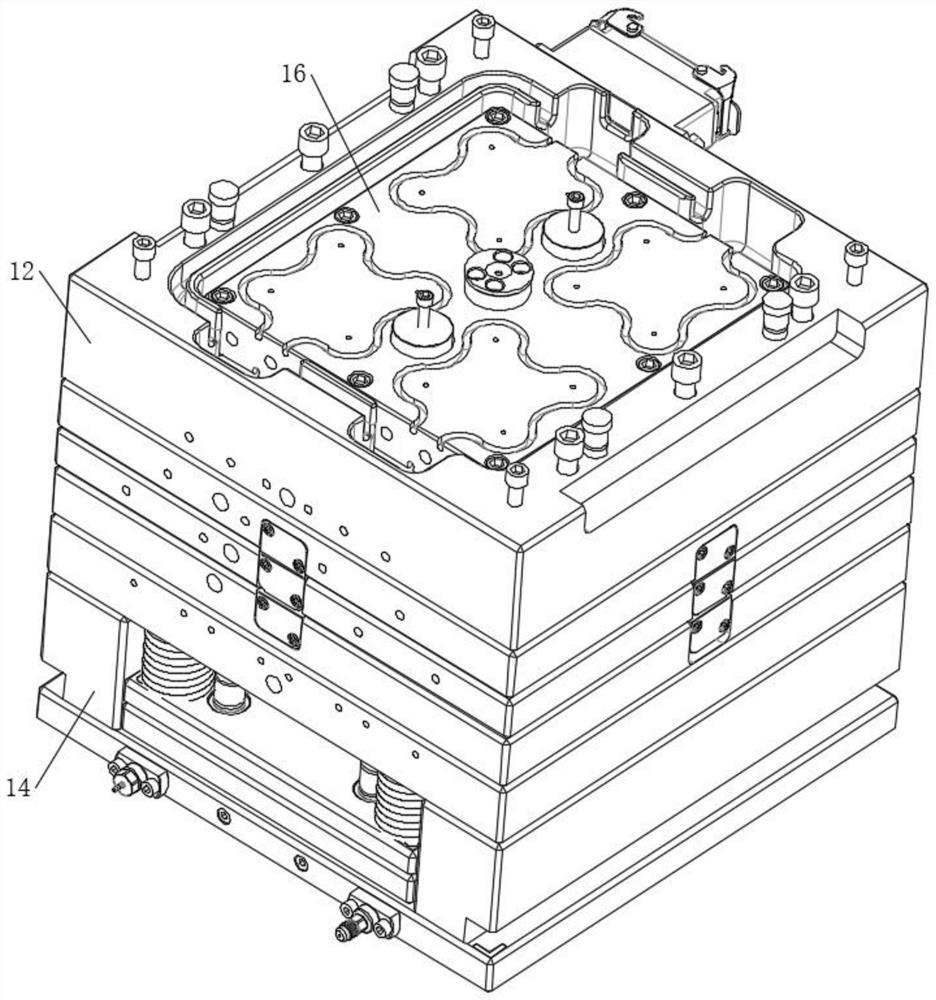

Vertical compression type horizontal die-casting machine and die-casting method thereof

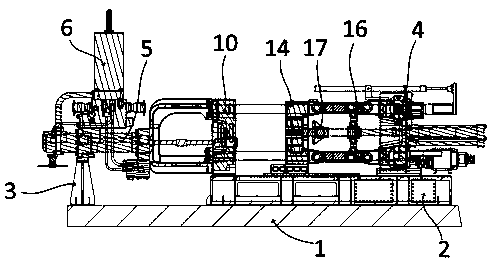

The invention discloses a vertical compression type horizontal die-casting machine and a die-casting method thereof and belongs to the field of metal die-casting. The vertical compression type horizontal die-casting machine comprises a supporting mechanism, an injection mechanism and a die locking mechanism, wherein the die locking mechanism comprises a movable die base, a fixed mounting plate, head plates arranged on the fixed mounting plates, tail plates arranged on the movable die base, pull rods hinged between the head plates and the tail plates and crankshaft rods connected with the pullrods and the head plates. When the movable die base instantly retreats and the included angle between the two pull rods is approximately horizontal, the vertical compression type horizontal die-casting machine transmits original backward push force of the movable die base to the T-shaped crankshaft rods, torque is greatly reduced, and the rebound effect is further reduced further through pressurestabilization of a gas resistor. A one-way valve is arranged at a feed port, and the vertical compression type horizontal die-casting machine conducts accurate feeding to prevent the situation of non-uniformity of the solution injection amount. The problems that a movable die base is likely to instantly retreat and the size precision of die cast parts is affected in the die-casting process of an existing die-casting machine are solved.

Owner:南京斯庄森金属材料有限公司

Novel transmission shaft and friction stir welding process thereof

InactiveCN111059135ASolving Welded Joint Weakness ProblemsSolve the weakening problemShaftsNon-electric welding apparatusDrive shaftEngineering

The invention discloses a novel transmission shaft and a friction stir welding process thereof. The novel transmission shaft comprises an aluminum alloy shaft fork (or a steel shaft fork) and an aluminum alloy shaft pipe, wherein the shaft fork and the shaft pipe are connected in a friction stir welding manner; and a lap step is arranged at the end, connected with the shaft pipe, of the shaft fork, the part, near the lap step, of the excircle of the shaft fork is provided with a small tangential boss, and the shaft pipe is arranged on the lap step of the shaft fork in a sleeving mode. In orderto realize the welding of the same type materials of the aluminum alloy shaft fork and the aluminum alloy shaft pipe or the welding of the different materials of the steel shaft fork and the aluminumalloy shaft pipe, the small boss for ending the friction stir welding process is designed on the shaft fork, so that the adverse effect, from friction stir welding ending pin holes, on the welding quality of the transmission shaft is avoided. The novel aluminum alloy (or steel / aluminum) transmission shaft which is high in connection strength, high in coaxiality, stable in quality, and large in diameter-to-thickness ratio and the friction stir welding process thereof are suitable for the market requirements of vehicle lightening and cost reducing.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

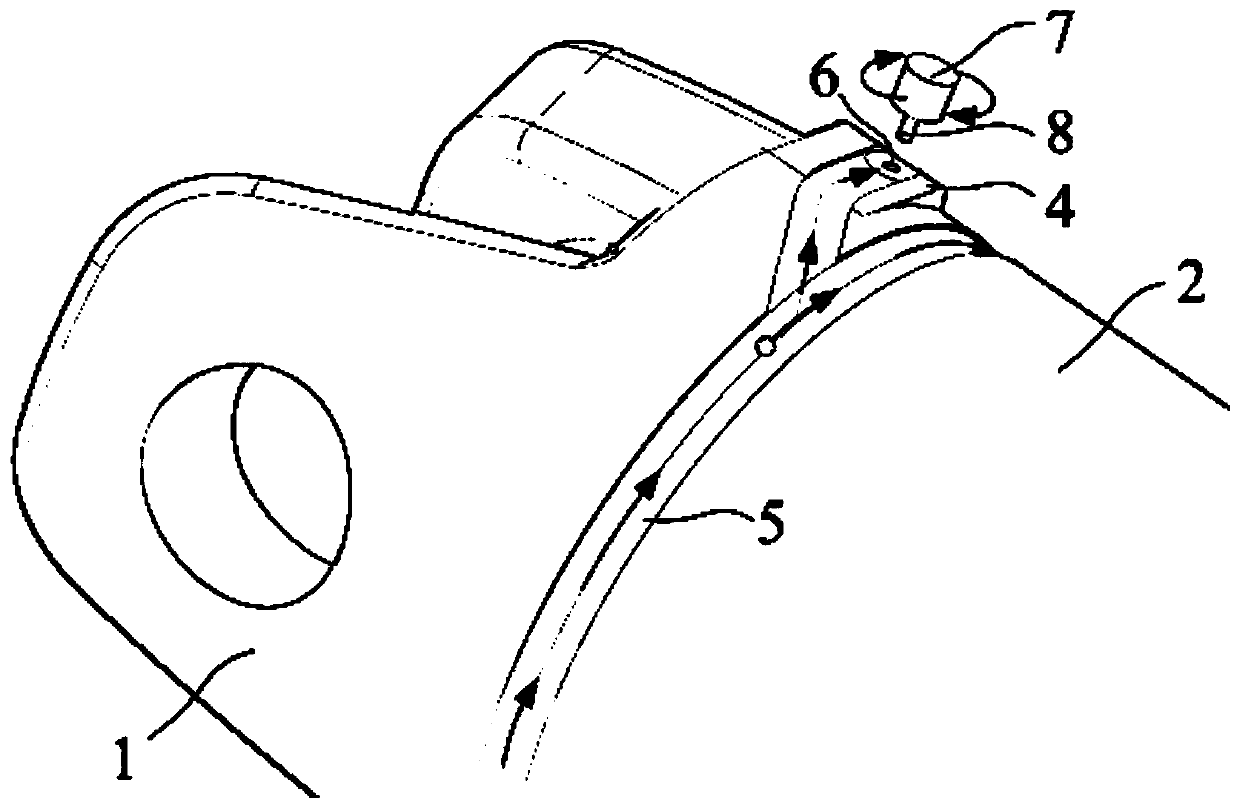

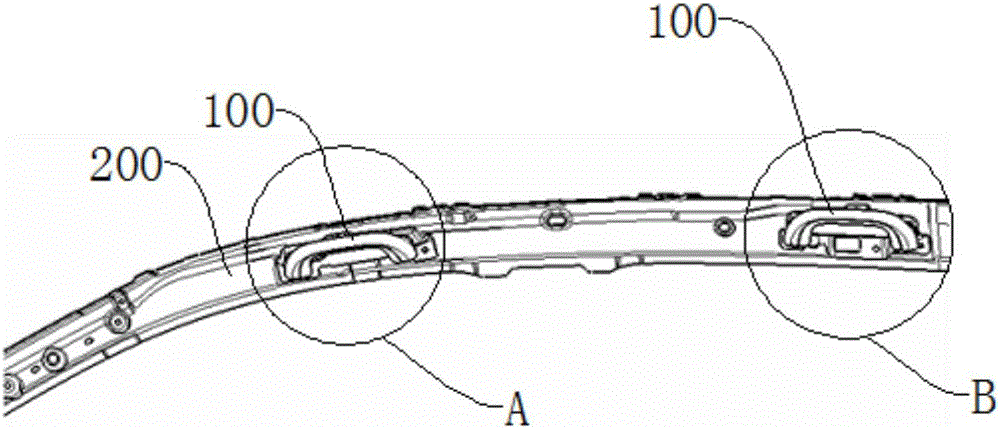

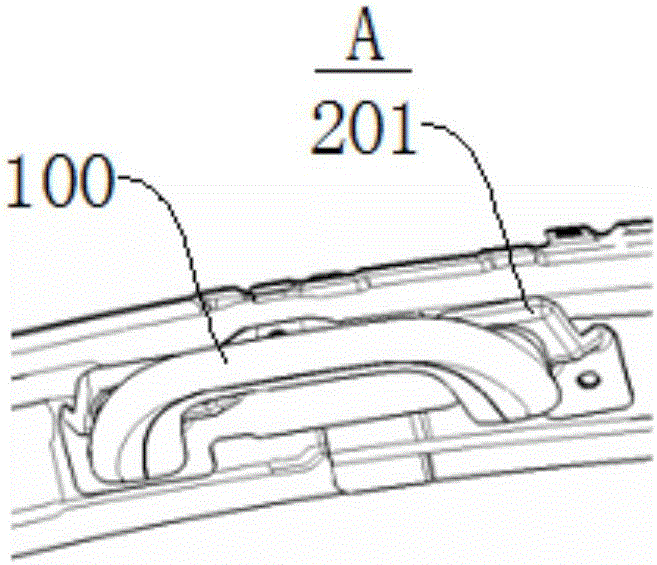

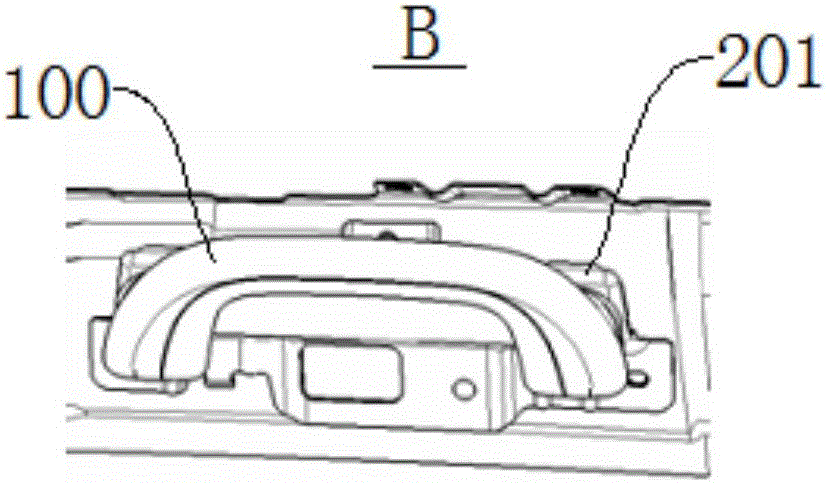

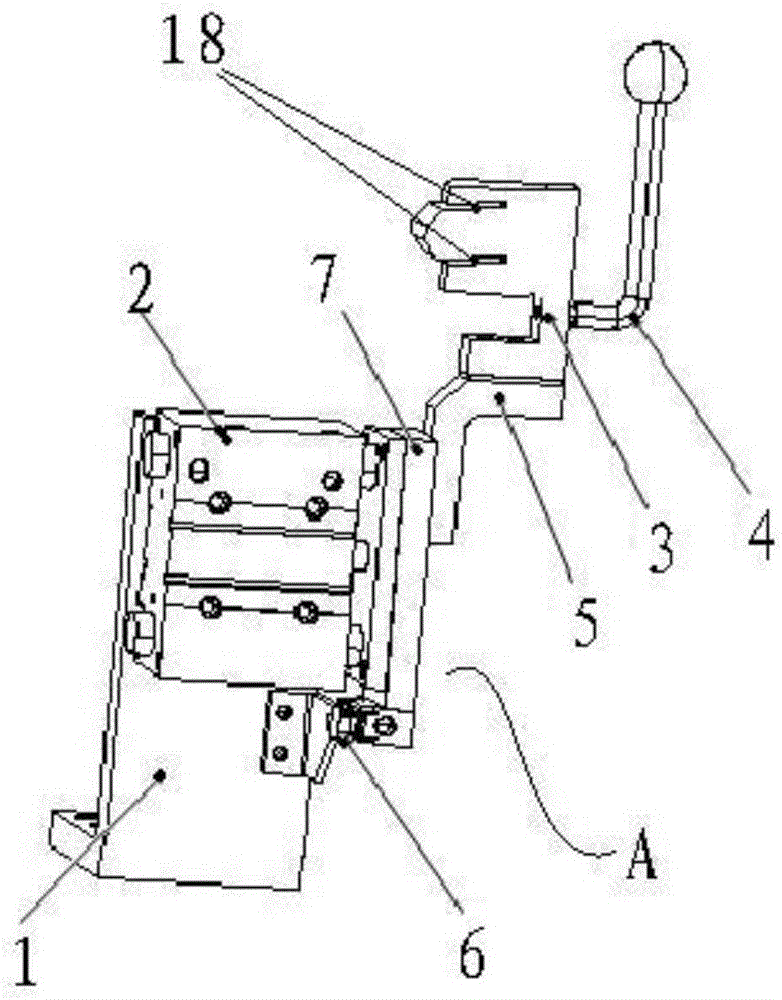

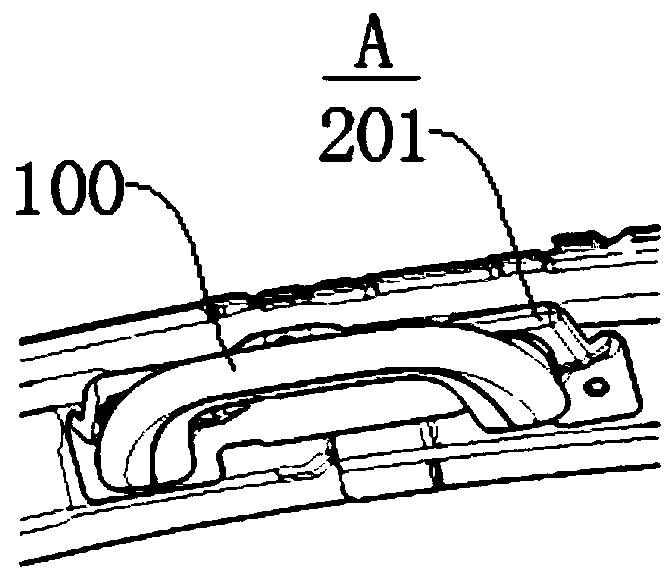

Vehicle, handrail for vehicle and control method for handrail

ActiveCN106379212AGuaranteed stabilityAdjustable return forceVehicle arrangementsHandrailAutomotive engineering

The invention discloses a vehicle, a handrail for the vehicle and a control method for the handrail. The handrail comprises a base, a body which is arranged on the base and can rotate when collected between a first position close to the roof of the vehicle and a second position for holding, and a hydraulic energy storage assembly which is arranged on the base and is connected with the body, wherein when the body rotates from the first position to the second position under holding force, the hydraulic energy storage assembly can supply damping force to prevent the body from rotating from the first position to the second position; and when the body rotates from the second position to the first position, the hydraulic energy storage assembly can supply resetting force to drive the body to return to the first position. According to the handrail disclosed by the invention, the body can be closely fitted to the roof of the vehicle under a condition that the handrail is not used, and the phenomenon that the body cannot be reset can be avoided; and furthermore, the steadiness of rotation of the body between the first position and the second position can be also guaranteed, and the phenomenon that the body is collided with the roof is avoided.

Owner:BAIC MOTOR CORP LTD

Automobile door glass guiding groove sizing device and clamp tool

InactiveCN106475719AEffective control of lifting forceSolve Dimensional Accuracy IssuesWelding/cutting auxillary devicesAuxillary welding devicesSizingElectrical and Electronics engineering

The invention relates to an automobile door glass guiding groove sizing device and a clamp tool. The automobile door glass guiding groove sizing device comprises a fixing base, a driving unit with guiding mechanisms, and a clamping groove mechanism used for sizing of an automobile door glass guiding groove, wherein the driving unit comprises a mounting plate connected with the guiding mechanisms and telescopic rods of the driving unit, and the driving unit is mounted on the fixing base; notches matched with the automobile door glass guiding groove in shape are formed in one side of the clamping groove mechanism; the notches face the direction parallel to the movement direction of the telescopic rods; and the clamping groove mechanism is connected with the mounting plate. Through the automobile door glass guiding groove sizing device, the automobile door glass guiding groove can be sized, and the problem that the precision of the automobile door glass guiding groove is low due to other factors in the assembling process of an automobile door is solved, so that lifting force of automobile door glass is increased. The invention further relates to the clamp tool comprising the automobile door glass guiding groove sizing device.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

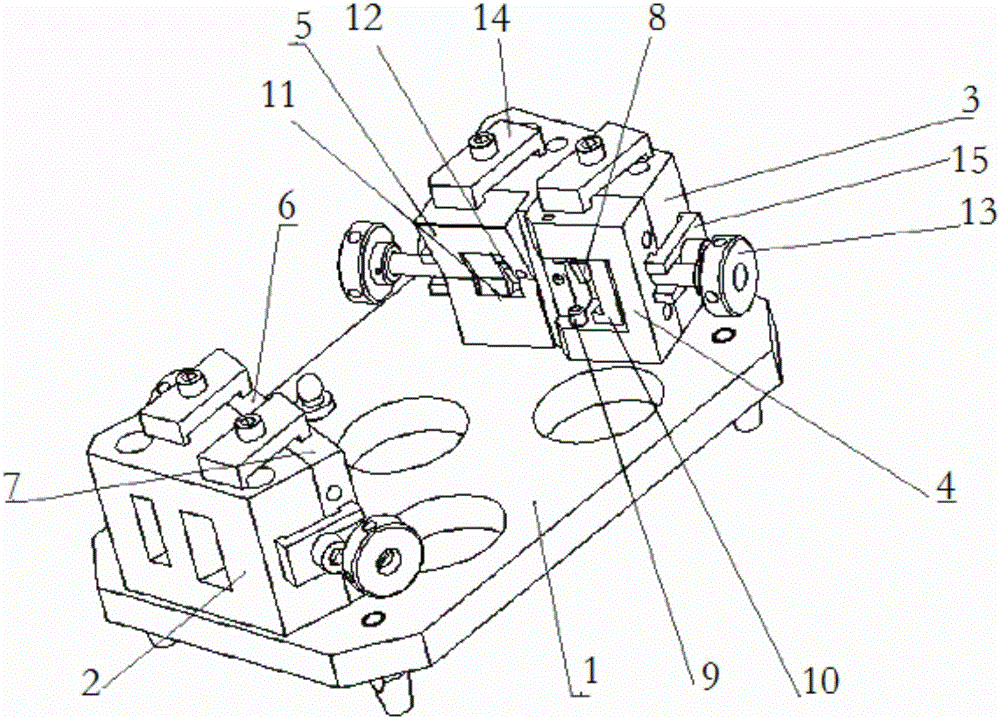

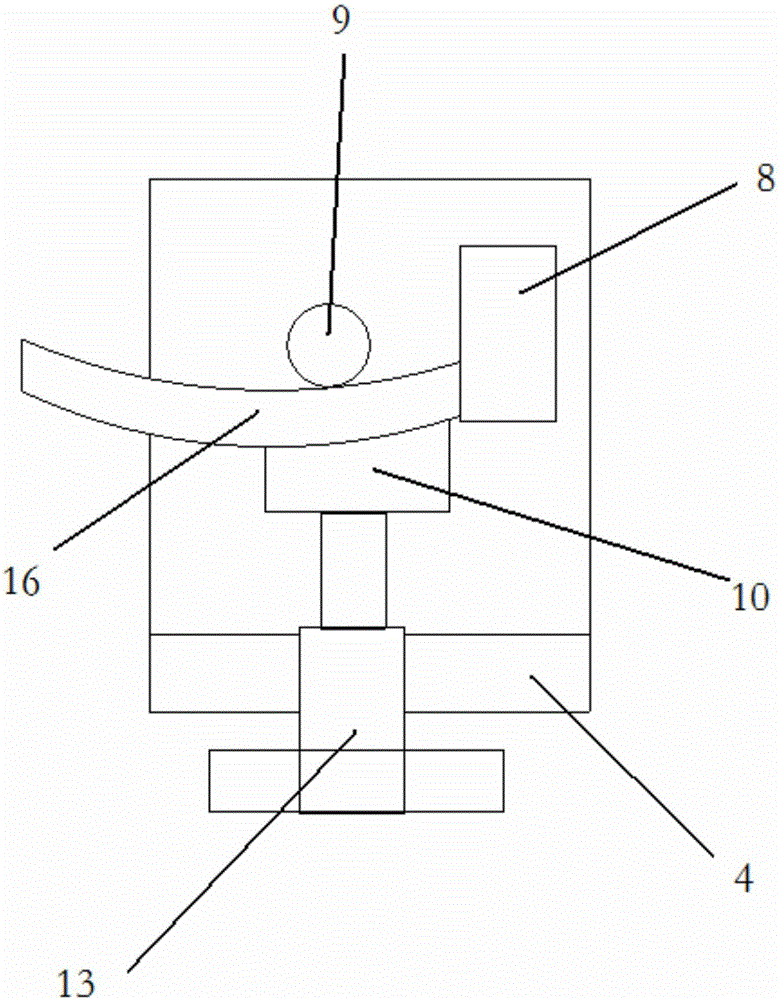

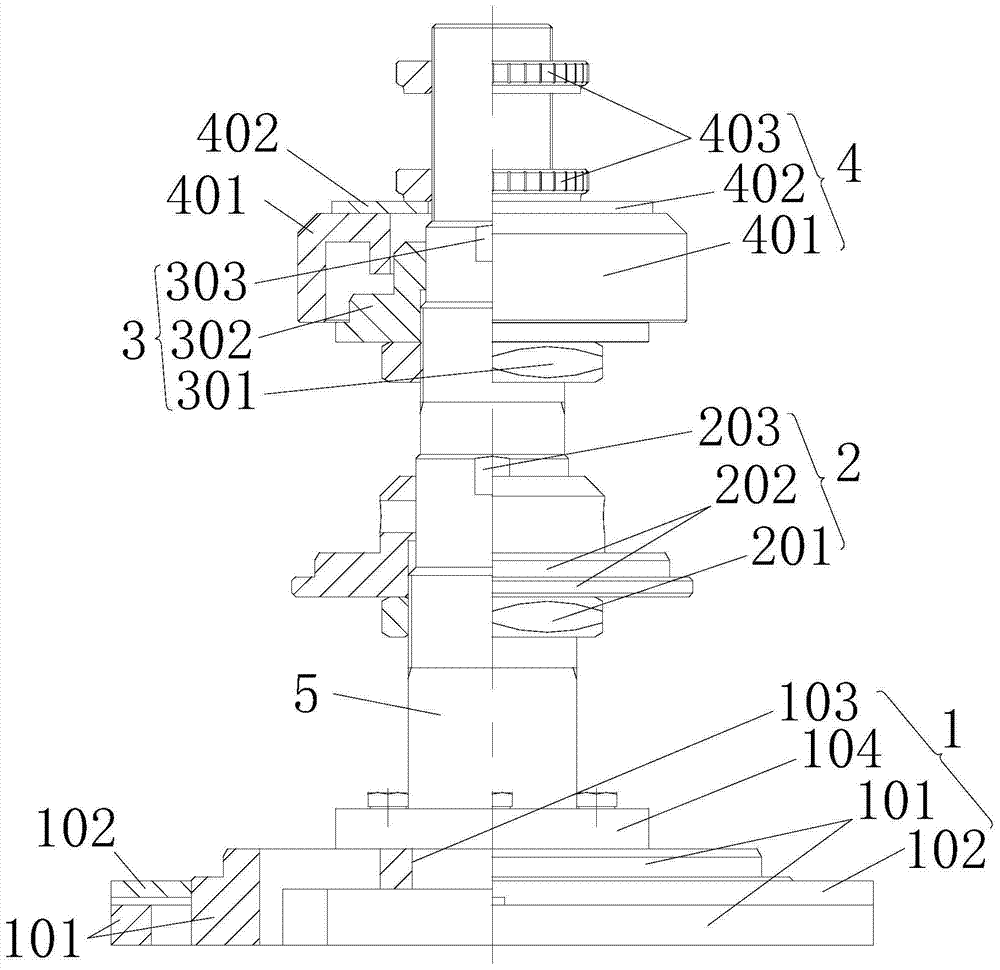

Wax mold assembling fixture and assembling method for welding and assembling rotary wax mold parts

The invention discloses a wax pattern assembly clamp and method for welding and assembling a rotary body wax pattern part. The wax pattern assembly clamp for welding and assembling the rotary body wax pattern part comprises a bottom positioning mechanism used for supporting a bottom unit body of the rotary body wax pattern part from the bottom and positioning the bottom unit body, a middle positioning mechanism used for positioning a middle unit body of the rotary body wax pattern part, a top positioning mechanism used for positioning a top unit body of the rotary body wax pattern part, and a pressing mechanism pressing the top unit body from the upper portion of the top unit body. The bottom positioning mechanism, the middle positioning mechanism, the top positioning mechanism and the pressing mechanism are coaxially arranged. The relative position between the bottom positioning mechanism and the middle positioning mechanism is adjustable. The relative position between the middle positioning mechanism and the top positioning mechanism is adjustable. The problems of misalignment, fash and the like produced by pressing of all the wax pattern unit bodies and the size precision of combined wax patterns are solved.

Owner:CHINA HANGFA SOUTH IND CO LTD

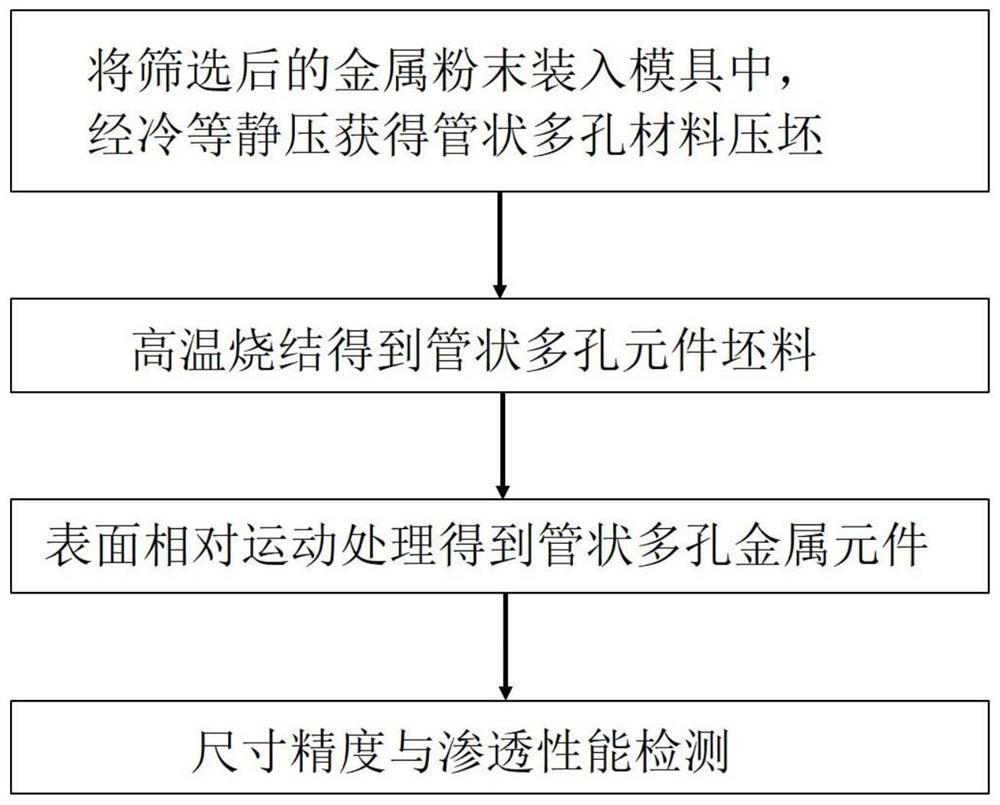

Preparation method of tubular porous metal element with tiny permeation flux

ActiveCN113714502ASolve Dimensional Accuracy IssuesNo harmNuclear energy generationMetallic materialsRelative motion

The invention discloses a preparation method of a tubular porous metal element with tiny permeation flux. The method comprises the following steps of 1, preparing a tubular porous material pressed blank by using metal powder as a raw material and adopting a cold isostatic pressing method; 2, performing high-temperature sintering on a tubular porous material pressed blank to obtain a tubular porous element blank; and 3, carrying out relative movement treatment on the surface of the tubular porous element blank through a hard tool, and a tubular porous metal element is obtained. According to the method, the hard tool is adopted for carrying out forced relative movement treatment on the surface of the tubular porous element blank prepared through a powder sintering method, so that part of the porous material is stripped and falls off collectively, by controlling the condition technological parameters of the relative movement treatment, precise control over the size precision and the permeation amount of the tubular porous metal element is achieved at the same time, and the requirements of the modern industry on the porous metal material with small permeation flux are met.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

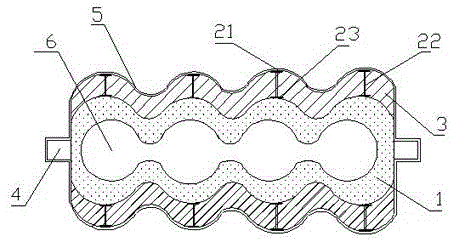

Engine dry cylinder liner machine body foam model and manufacturing method thereof

InactiveCN104668457AAvoid driftingSolve Dimensional Accuracy IssuesFoundry mouldsFoundry coresPulp and paper industryEvanescent mode

The invention discloses an engine dry cylinder liner machine body foam model. A water jacket sand core is arranged at a water jacket part between an engine cylinder liner and a machine body; and multiple fixed support clamps are arranged in a machine body foam model at the outer side of the water jacket sand core. The invention further discloses a manufacturing method of the engine dry cylinder liner machine body foam model; the fixed support clamps are put in corresponding positions in a mold for preparing the foam model; magnets are put at the outer side of the mold for sucking the fixed support clamps; and a foam material is added for preparing. When an evanescent mode is used for casting a dry cylinder liner machine body of an engine, the fixed support clamps are inlaid in the foam model, so that the phenomenon of shifting the sand core in the casting can be effectively prevented, and the product pass percent is improved.

Owner:QINGDAO DAYUN MACHINERY

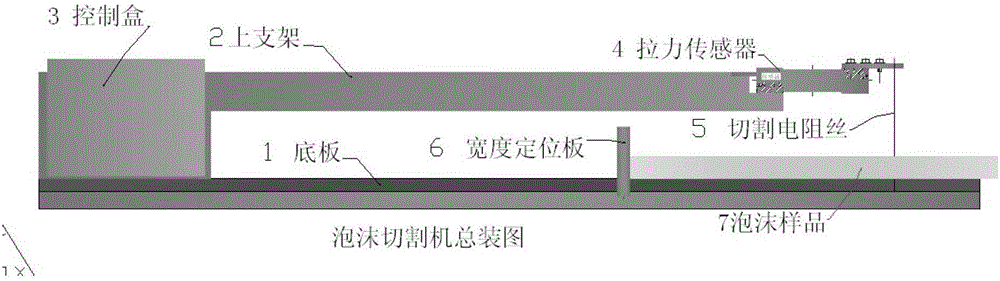

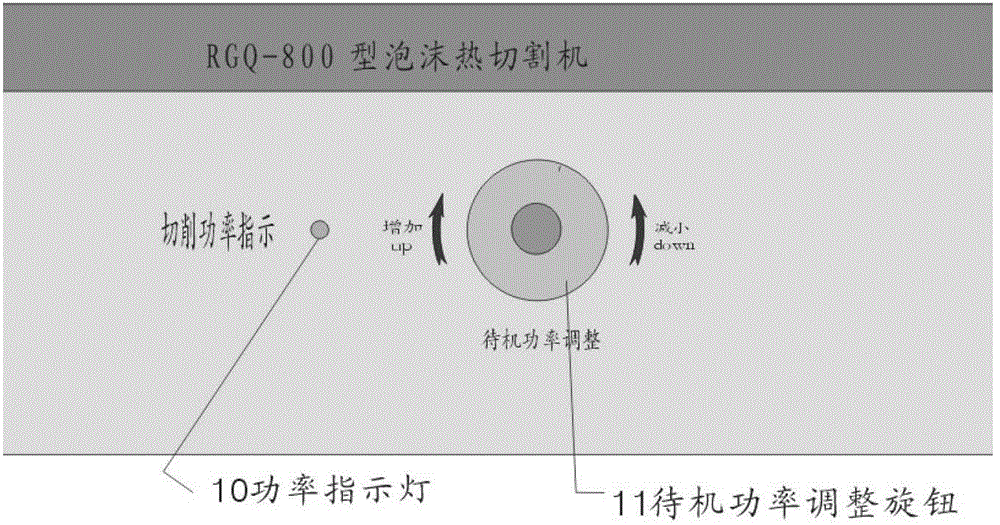

Working method for foam cutting machine using thermal cutting technology

InactiveCN103331781AQuick cutSolve Dimensional Accuracy IssuesMetal working apparatusEngineeringLED lamp

Owner:SUZHOU VOCATIONAL UNIV

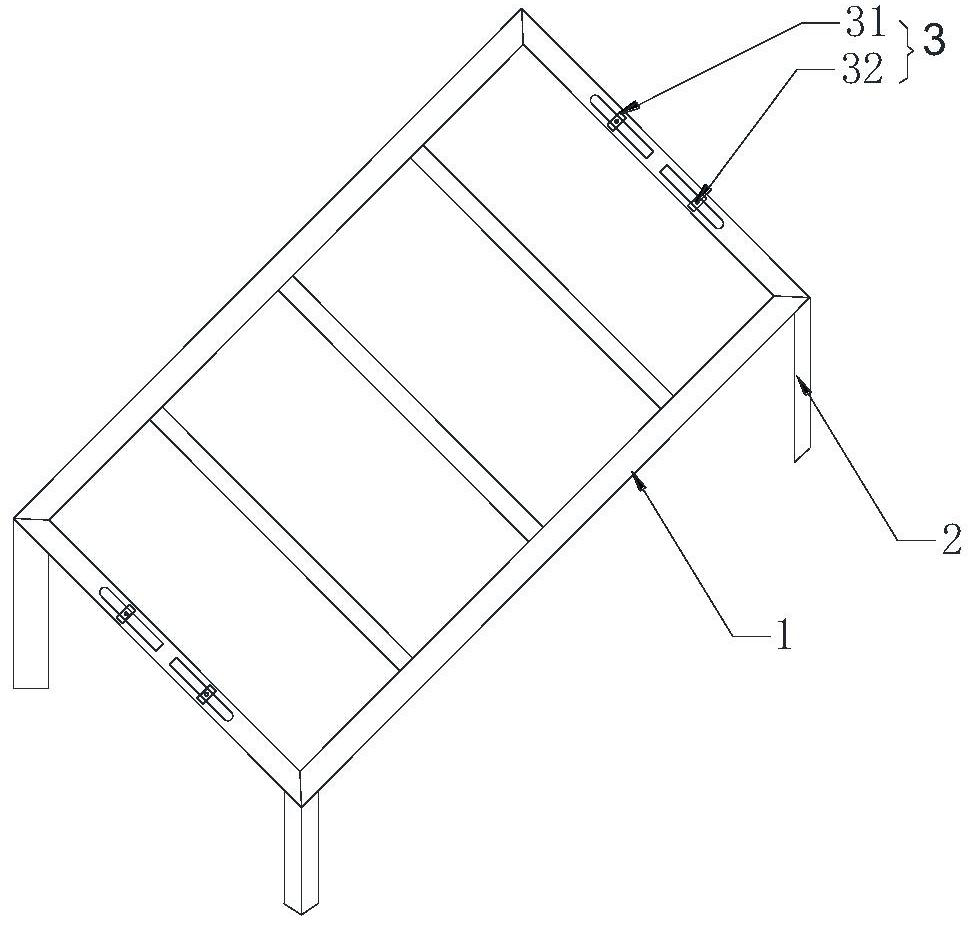

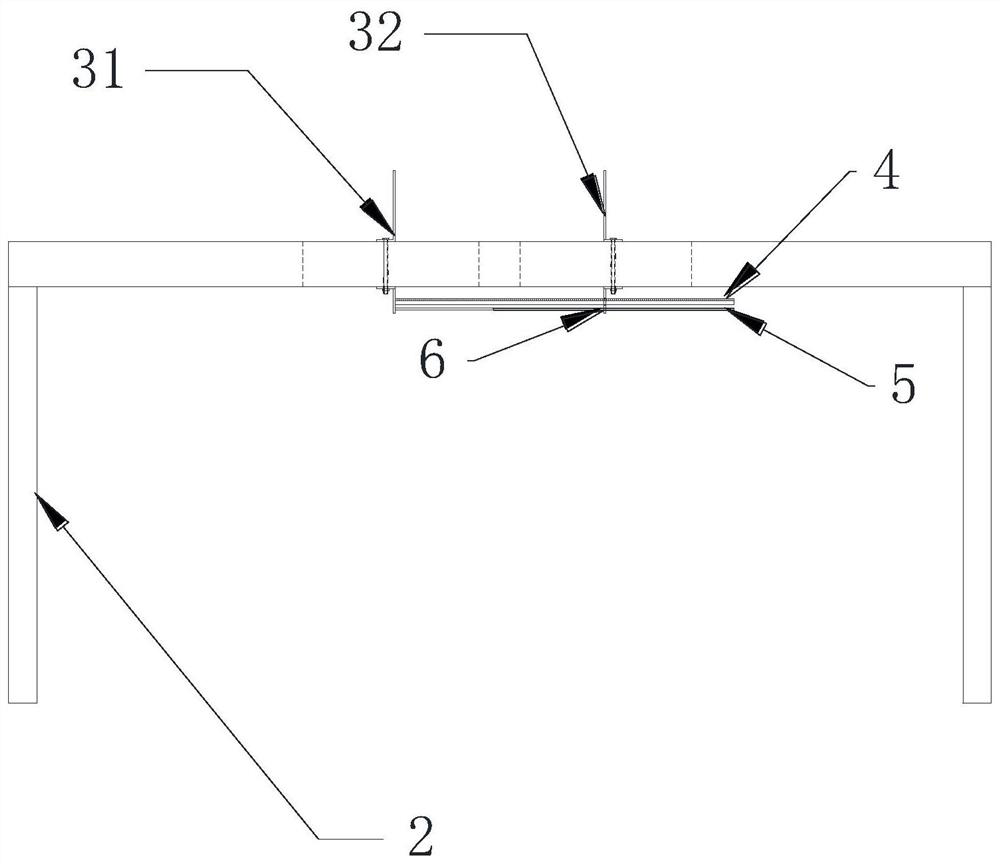

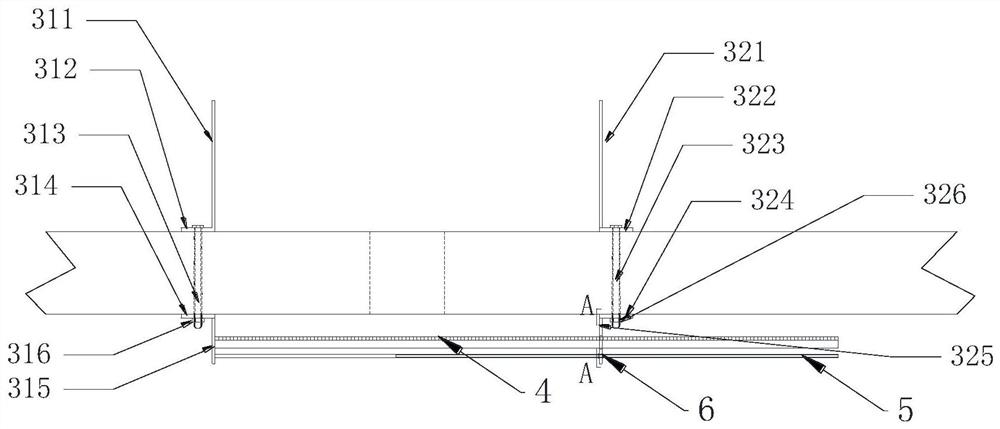

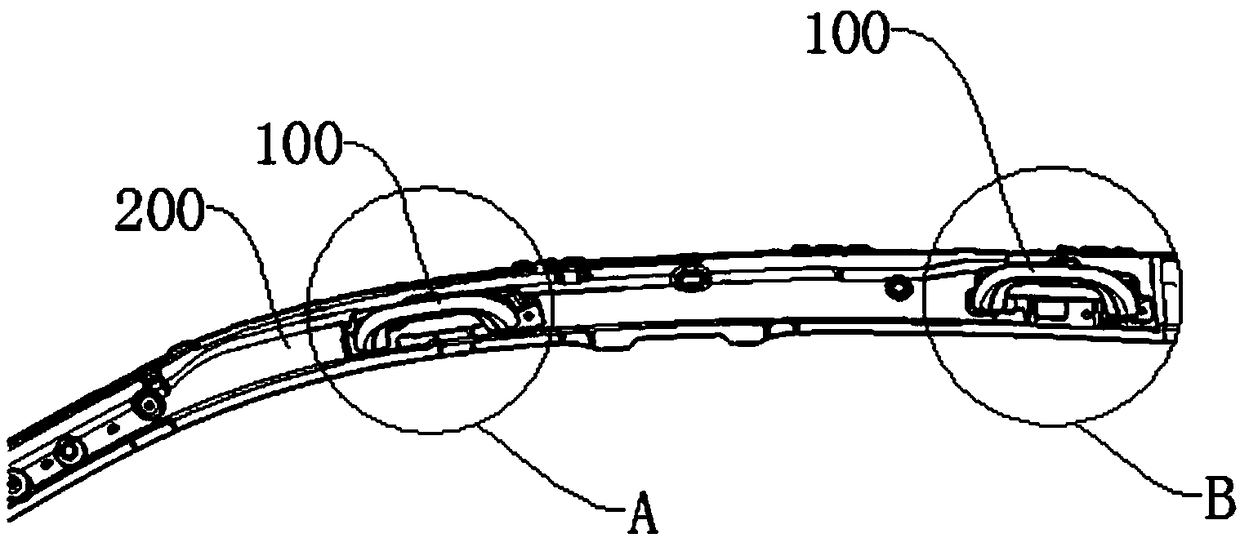

Jig frame for welding steel structure members

PendingCN111673323ASolve Dimensional Accuracy IssuesConvenient welding workWelding/cutting auxillary devicesAuxillary welding devicesDimensional precisionStructural element

The invention relates to the technical field of building construction, in particular to a jig frame for welding steel structure members. Two sides of a rectangular frame platform are respectively provided with sliding grooves; and the sliding groove on either side of the frame platform is respectively provided with a limiting device comprising a first limiting piece and a second limiting piece, and the first limiting piece and the second limiting piece are movably located in the sliding groove through matching of bolts and nuts and are oppositely arranged; and a scale is horizontally arrangedbelow each sliding groove and used for measuring the distance between the first limiting piece and the second limiting piece, so that when the steel structure members with different sizes are welded,the distance between the first limiting piece and the second limiting piece only needs to be adjusted according to the scale without welding limiting members, and then the problems of steel waste anddimensional precision of the limiting members are solved while the welding operation is convenient.

Owner:MCC5 GROUP CORP SHANGHAI

Vehicle, armrest for vehicle, and control method for armrest

ActiveCN106379212BSmooth, smooth and quiet workAdjustable return forceVehicle arrangementsEngineeringEnergy storage

The invention discloses a vehicle, a handrail for the vehicle and a control method for the handrail. The handrail comprises a base, a body which is arranged on the base and can rotate when collected between a first position close to the roof of the vehicle and a second position for holding, and a hydraulic energy storage assembly which is arranged on the base and is connected with the body, wherein when the body rotates from the first position to the second position under holding force, the hydraulic energy storage assembly can supply damping force to prevent the body from rotating from the first position to the second position; and when the body rotates from the second position to the first position, the hydraulic energy storage assembly can supply resetting force to drive the body to return to the first position. According to the handrail disclosed by the invention, the body can be closely fitted to the roof of the vehicle under a condition that the handrail is not used, and the phenomenon that the body cannot be reset can be avoided; and furthermore, the steadiness of rotation of the body between the first position and the second position can be also guaranteed, and the phenomenon that the body is collided with the roof is avoided.

Owner:BAIC MOTOR CORP LTD

Collimator and preparation method

ActiveCN108922646BSolve Dimensional Accuracy IssuesUniform sizeGlass making apparatusHandling using diaphragms/collimetersAcid etchingFilling materials

The invention relates to a collimator and a manufacturing method. The collimator includes a base body of a flat plate shape, wherein the upper surface and lower surface of the base body are parallel to each other, at least a through hole which penetrates through the upper surface and the lower surface and has a pore diameter of 1-100 [mu]m is formed in the base body, and the base body is made of glass. A glass blank plate is prepared by using a glass rod tube nested drawing method, optical cold processing is conducted, and then chemical etching is performed so as to obtain the collimator. After the glass of the collimator is determined, core glass matched with the determined glass is designed, and the core glass is removed through acid etching, wherein the core glass is mainly used as a filling material of micropores during manufacture so as to ensure the roundness of the micropores. Through the collimator, the collimation efficiency of particles and stability of particle movement canbe improved effectively, the scattering angle of the particles is reduced, and conditions for high stability, high reliability and miniaturization of atomic clocks, ray cameras and other precision equipment are created.

Owner:CHINA BUILDING MATERIALS ACAD

Preparation method of wear-resistant steel plate

InactiveCN106825578ASolve Dimensional Accuracy IssuesSolve production efficiencySheet steelWear resistant

The invention discloses a preparation method of a wear-resistant steel plate. The preparation method comprises the following steps: 1) mixing, 2) sintering, and 3) casting heating and crystallization. Compared with the prior art, the preparation method has the following advantages: with the adoption of a special raw material ratio, the produced wear-resistant steel plate is high in performance index, good in glossiness and stability, and high in overall density and surface density, and is not prone to break, and the dimensional precision, production efficiency, die life and cost problems of the existing precision protection steel plate are solved.

Owner:HECHI TECH DEV CENT

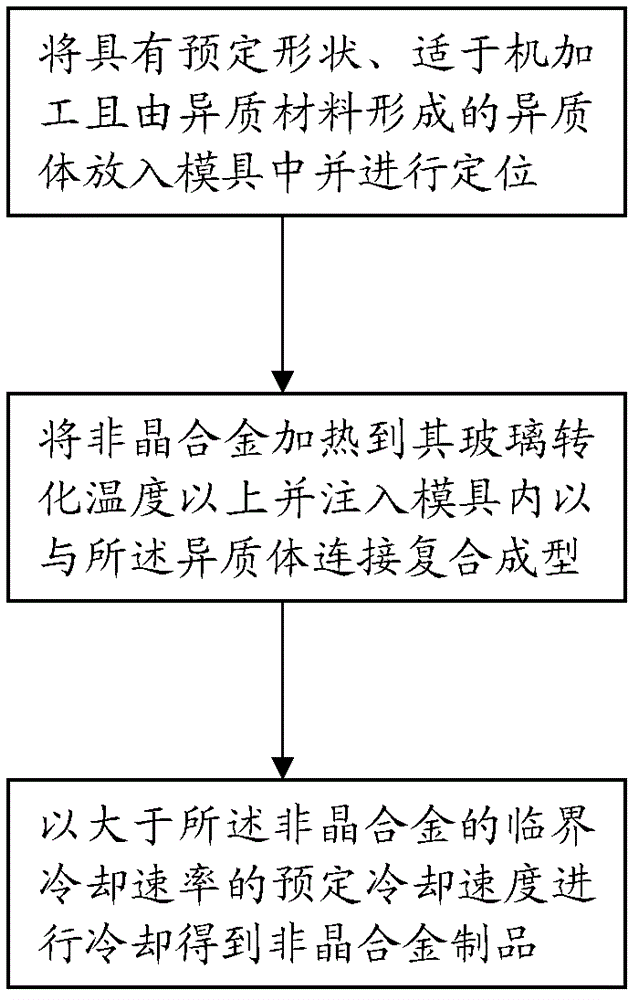

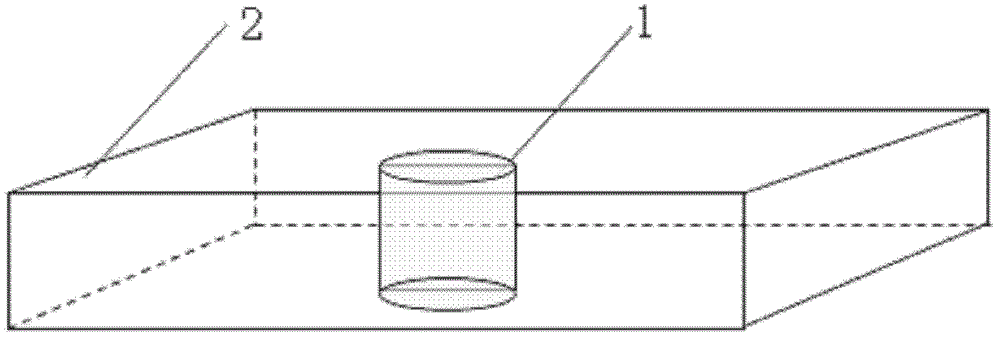

Amorphous alloy product and method for manufacturing same

ActiveCN102529191BDifficult to processSolve the positioning accuracyLayered productsThermal deformationAlloy

The invention discloses an amorphous alloy product which comprises a matrix and a heteroplasmon. The matrix is made from amorphous alloy, and the heteroplasmon is made from a heterogeneous material. The matrix is connected with the heteroplasmon, and one part of the heteroplasmon is exposed outside the matrix. The heteroplasmon is hard and is suitable for machining. The invention further discloses a method for manufacturing the amorphous alloy product, comprising the following steps: putting the heteroplasmon which is in a preset shape, is suitable for machining and is made from the heterogeneous material into a mould, and positioning the heteroplasmon; heating the amorphous alloy to above the glass transition temperature thereof, and injecting the amorphous alloy into the mould so that the amorphous alloy is connected and compounded with the heteroplasmon, wherein one part of the heteroplasmon is exposed outside the amorphous alloy; and cooling at the preset cooling speed which is higher than the critical cooling speed of the amorphous alloy to obtain the amorphous alloy product. The machining cost of the amorphous alloy product disclosed by the embodiment of the invention can be greatly reduced, and the problems that the amorphous alloy is hard to process and the heteroplasmon is subjected to thermal deformation when being compounded with the amorphous alloy are solved. The amorphous alloy product has wide application prospect.

Owner:BYD CO LTD

Punching head structure

PendingCN112536466ASolve Dimensional Accuracy IssuesSolve for shape accuracyShearing machinesShearing machine accessoriesPunchingControl cell

A punching head structure comprises a fixed plate, two clamping structures, an ejection structure, a punching structure and a control unit, wherein a through hole is formed in the middle of the fixedplate, and a first supporting piece and two second supporting pieces are arranged on the two sides of the through hole respectively; each clamping structure comprises an inner support block, a plurality of sliding rods, a first elastic element and a clamping block; the ejection structure comprises an ejection block, an ejection rod and a first pushing mechanism; the punching structure comprises asecond pushing structure, a guide sliding plate, two guide sliding shafts, a pushing plate, a plurality of second elastic elements, a pressing plate and a plurality of punching blades; and the controlunit is connected with the first pushing mechanism and the second pushing structure and controls the opening and closing of the first pushing mechanism and the second pushing structure. By utilizingthe punching head structure, the problem that at the present stage, a metal part is extremely prone to deformation due to clamping by a chuck of a lathe, and consequently the size precision, shape precision and position precision of a workpiece are affected is solved.

Owner:SUZHOU MITAC PRECISION TECH

Method for accurately and efficiently forming front sleeve type plastic part

PendingCN114012987AAvoid high temperatureSolve Dimensional Accuracy IssuesMetal working apparatusHot runnerMolten state

The invention discloses a method for accurately and efficiently forming a front sleeve type plastic part. The method comprises the following steps: S1, injecting a material in a molten state into a mold body, enabling the material to flow into a forming device along the top of the mold body, and carrying out injection molding in the forming device; S2, injecting cooling liquid into the mold body to form a double-spiral cooling water channel for rapid and uniform cooling; and S3, through upward jacking of a material jacking device, providing driving force to realize and in-mold hot cutting in the forming device. The forming device used in step S1 comprises a sprue bush, a shaping upper mold and a cooling mechanism. A hot runner plate and the sprue bush are combined to solve the problems that the mold temperature is too high, and one-mold multi-cavity forming cannot be achieved, the problems of key position coaxiality and size precision are solved by adopting a three-plate matched machining and four-wall buckling method, and the problems that a disc type sprue is not easy to cut off and manual cutting is high in cost and long in period are solved by adopting in-mold hot cutting.

Owner:张光亮 +1

A dry cutting CNC gear hobbing machine tool and a method for compensating thermal deformation errors of workpieces

ActiveCN105397560BReduce machining errorsReduce scrap rateMaintainance and safety accessoriesNumerical controlHobbing

The invention provides a thermal deformation error compensation method for a dry-cutting numerically-controlled gear hobbing machine tool and workpieces. According to the invention, while thermal deformation error compensation is carried out on the dry-cutting numerically-controlled gear hobbing machine tool by virtue of a thermal deformation error compensation system for the numerically-controlled machine tool, the thermal deformation errors of workpieces machined by the dry-cutting numerically-controlled gear hobbing machine tool are compensated by virtue of the same compensation system. The thermal deformation error compensation method comprises the following steps: firstly, establishing a thermal deformation error model for the workpieces and a thermal deformation error model for the dry-cutting numerically-controlled gear hobbing machine tool, integrating said error models in an online compensator, and during machining of the dry-cutting numerically-controlled gear hobbing machine tool, processing the temperature data obtained through measurement of temperature sensors by virtue of the online compensator to obtain error compensation values; secondly, conveying the compensation values to a machine tool numerically-controlled system; and finally, carrying out coordinate offset by virtue of the numerically-controlled system, thus realizing thermal deformation error compensation for the dry-cutting gear hobbing machine tool and the workpieces.

Owner:CHONGQING UNIV

Motor end cover and applied motor thereof

ActiveCN101604878BAvoid heat differenceReduced precision requirementsManufacturing dynamo-electric machinesSupports/enclosures/casingsEngineeringInjection moulding

Owner:ZHONGSHAN BROAD OCEAN

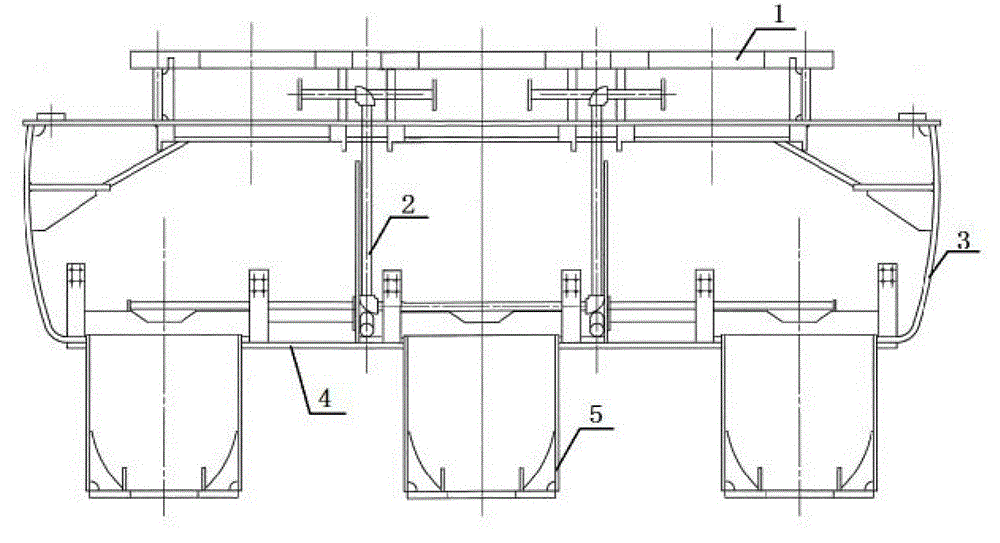

1200mw Class Nuclear Power Half-speed Turbo Generator Assembly and Welding Process for Outlet Boxes

ActiveCN103394874BSolve molding difficultiesSolve Dimensional Accuracy IssuesWelding apparatusNuclear powerEngineering

The invention relates to an assembling and welding technique of a nuclear-power turbo generator outlet box made of 06Cr19Ni10. An end socket is made of an austenitic stainless steel plate 06Cr19Ni10 which is molded through hot pressing by a press machine. Molding margins are removed by a plasma cutting machine, and cutting surfaces are processed by a machine tool. A shell is made of an austenitic stainless steel plate 06Cr19Ni10, the plasma cutting machine blanks, and 10mm molding margins are reserved in a molding direction. The shell is molded through rolling by a plate roller at a room temperature, and the shape of the shell is fixed through rib pulling after molding of the shell. The end socket and the shell are assembled and welded. A wire outlet cylinder and a flange plate are assembled and welded individually. Assembling and welding of a baseplate are completed according to air seal requirements, and the baseplate is planished after being welded and is subjected to PT flaw detection. The baseplate is individually assembled and welded with a vertical plate and a rib plate, and welding is performed according to the air seal requirements. The baseplate is subjected to shape modification by the press machine. After welding, all weld seams are ensured to have no penetrability defects and pass water pressure tests, air pressure tests and PT flaw detection.

Owner:HARBIN ELECTRIC MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com