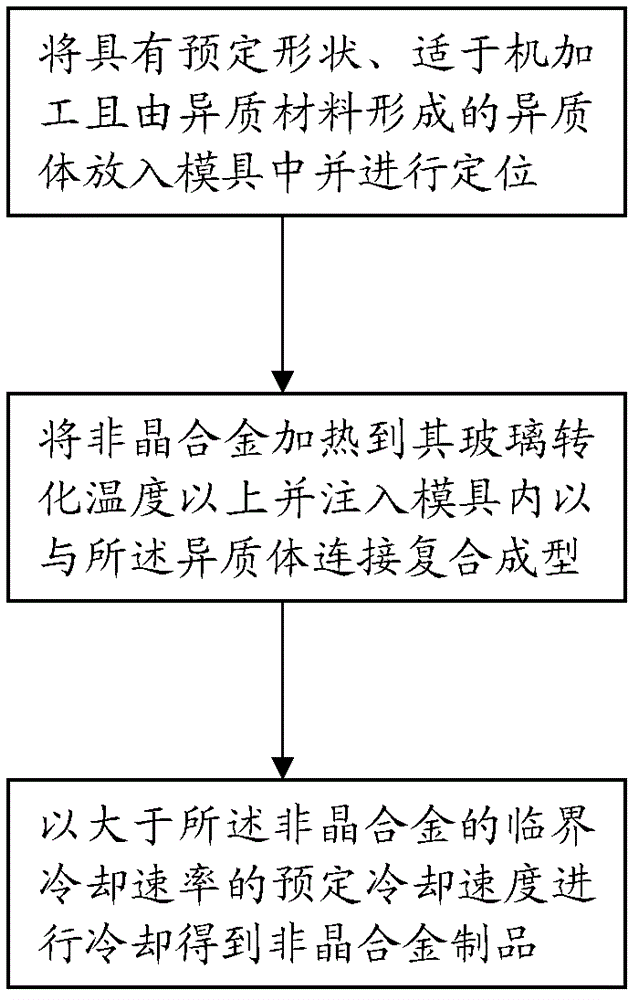

Amorphous alloy product and method for manufacturing same

A technology of amorphous alloys and manufacturing methods, applied in the field of amorphous synthetic materials, can solve problems such as difficulties, increase in physical and chemical properties of amorphous parts, and difficult accurate positioning, so as to improve processing efficiency, reduce costs, and solve positioning accuracy and Effects of Dimensional Accuracy Problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] In this embodiment, the aluminum alloy whose material is 7075 is selected as the preparation material of the heterogeneous body, and the alloy composition is Zr 52 Al 10 Cu 30 Ni 7 amorphous alloy material.

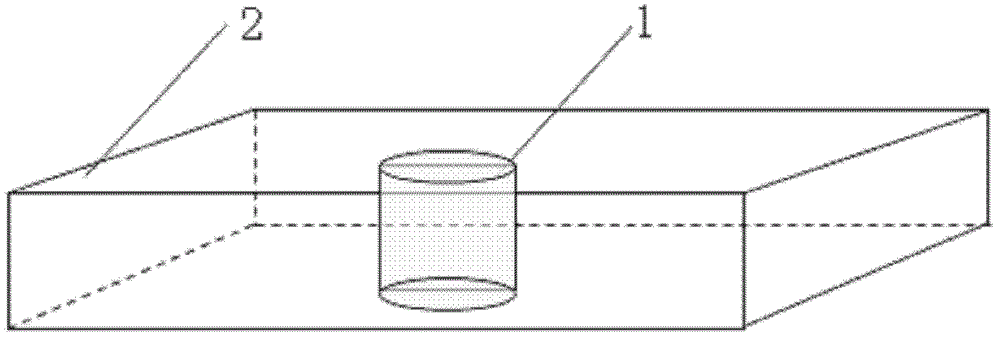

[0045] First, the aluminum alloy is processed into an aluminum alloy cylinder 1 as a heterogeneous body with a diameter of 5 mm and a length of 4 mm (such as figure 2 shown), micro-arc oxidation is performed on the surface of the aluminum alloy cylinder 1, and then the aluminum alloy cylinder 1 is put into a mold and positioned.

[0046] Thereafter, the composition will be Zr 52 Al 10 Cu 30 Ni 7 The amorphous alloy material is melted, and cast into the mold cavity with the aluminum alloy cylinder 1 positioned by die-casting equipment, so that it is combined with the aluminum alloy cylinder 1 to obtain an amorphous alloy blank.

[0047] Next, the amorphous alloy blank of composite molding is taken out from the mold, such as figure 2 As shown, an amorphous...

Embodiment 2

[0050] In this embodiment, the material is PC plastic as the preparation material of the heterogeneous body, and the alloy composition is Zr 52 Al 10 Cu 30 Ni 7 amorphous alloy material.

[0051] First, PC plastic is processed into a plastic cylinder 1 with a diameter of 5 mm and a length of 4 mm as a heterogeneous body (such as figure 2 shown), then the plastic cylinder 1 is put into the mold and positioned.

[0052] Thereafter, the composition will be Zr 52 Al 10 Cu 30 Ni 7 The amorphous alloy material is melted, and cast into a mold cavity where the plastic cylinder 1 is positioned by using a die-casting equipment, so that it is combined with the plastic cylinder 1 to obtain an amorphous alloy blank.

[0053] Next, the amorphous alloy blank of composite molding is taken out from the mold, such as figure 2 As shown, an amorphous alloy product formed of the plastic cylinder 1 and the amorphous alloy 2 as heterogeneous bodies was obtained.

[0054] Put the amorphou...

Embodiment 3

[0056] In this embodiment, the selected material is Zamak 3 zinc alloy as the preparation material of the heterogeneous body, and the selected alloy composition is Zr 52 Al 10 Cu 30 Ni 7 amorphous alloy material.

[0057] First, the zinc alloy is processed into a cylinder 1 with a diameter of 5 mm and a length of 4 mm as a heterogeneous body (such as figure 2 As shown), electroplating a nickel layer on the surface of the zinc alloy cylinder 1, and then putting the cylinder 1 into a mold and positioning it.

[0058] Thereafter, the composition will be Zr 52 Al 10 Cu 30 Ni 7 The amorphous alloy material is melted, and cast into the mold cavity with the zinc alloy cylinder 1 positioned by die-casting equipment, so that it is combined with the zinc alloy cylinder 1 to obtain an amorphous alloy blank.

[0059] Next, the amorphous alloy blank of composite molding is taken out from the mold, such as figure 2 As shown, an amorphous alloy product formed of the zinc alloy col...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com