Patents

Literature

564results about How to "Difficult to process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

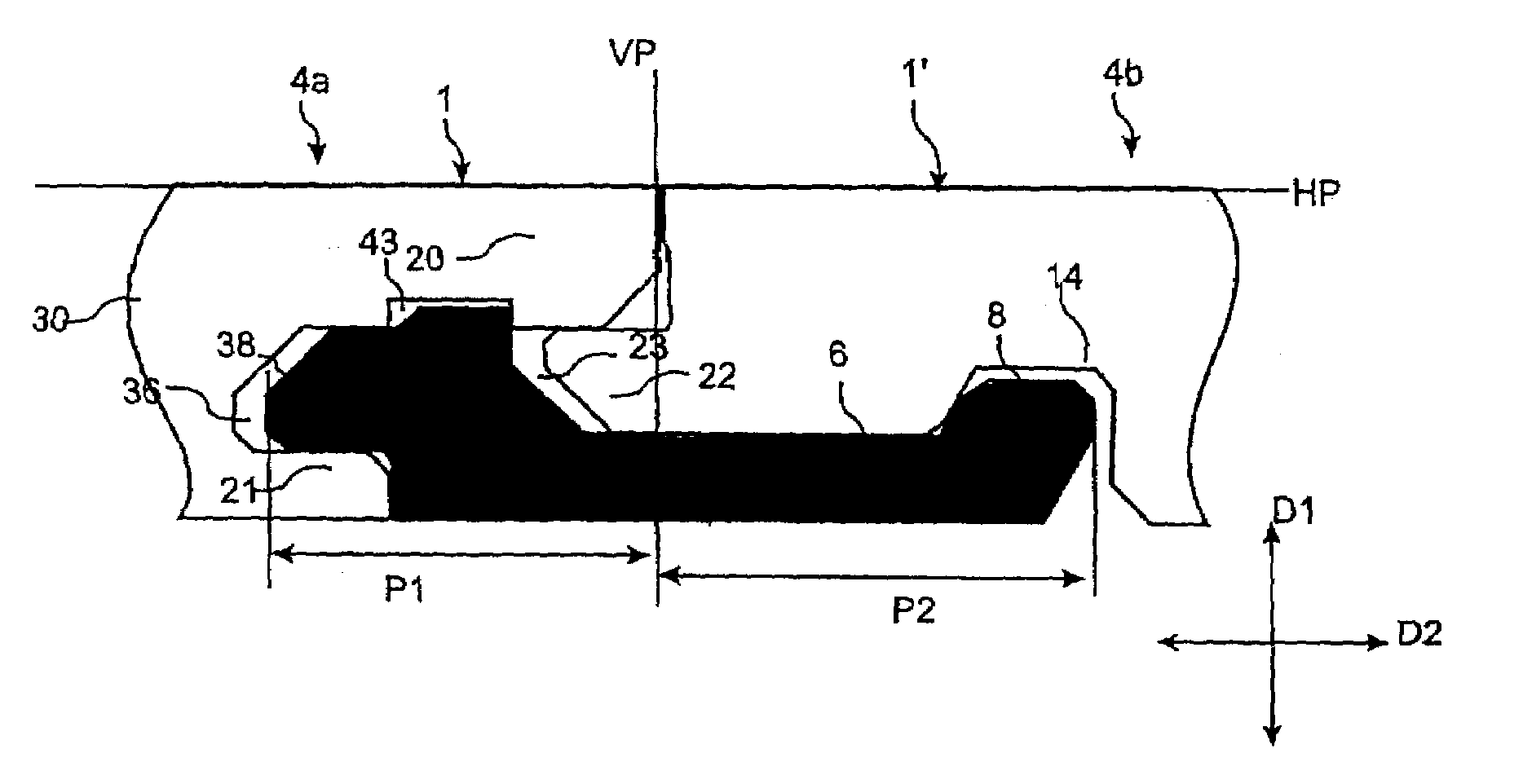

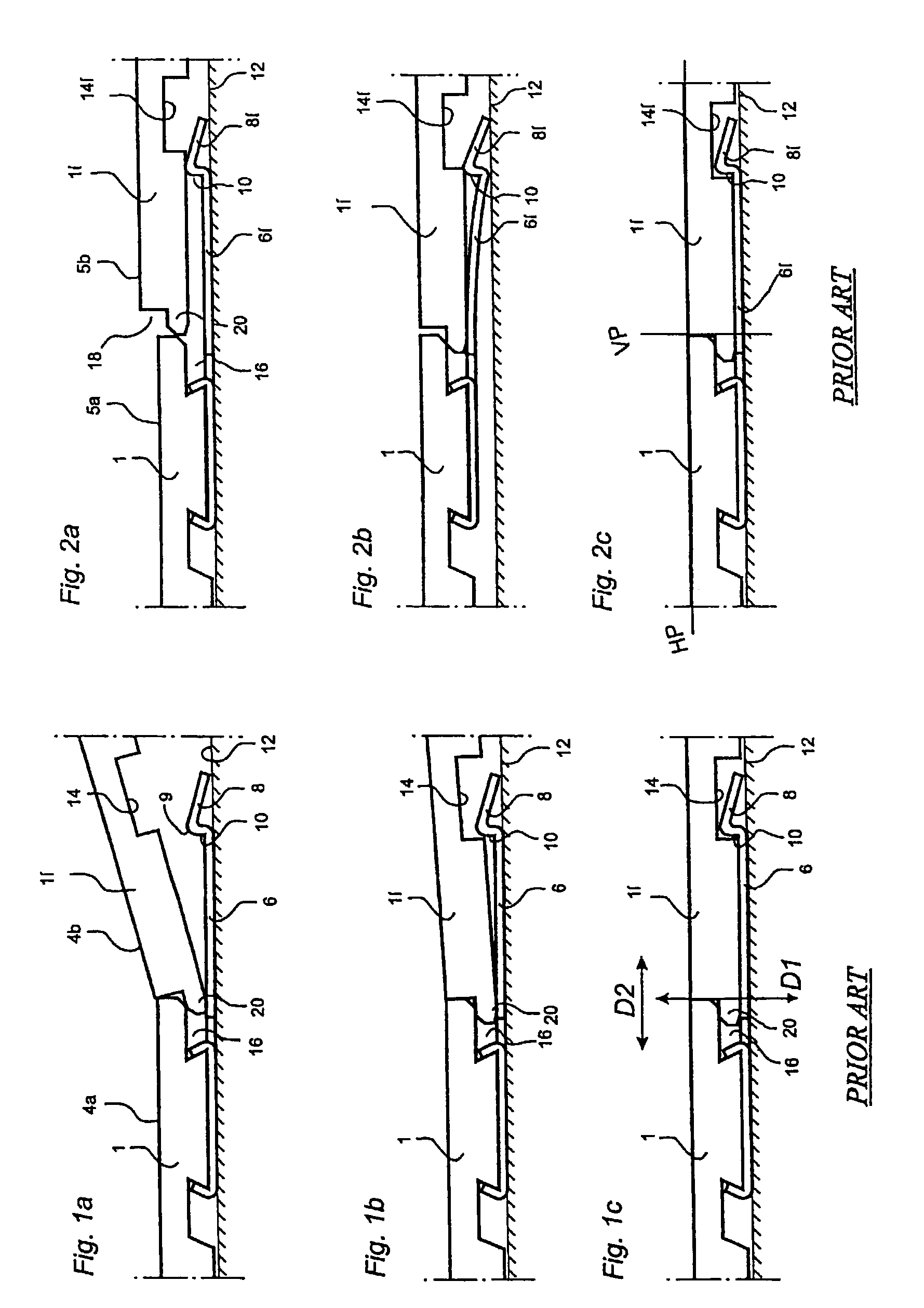

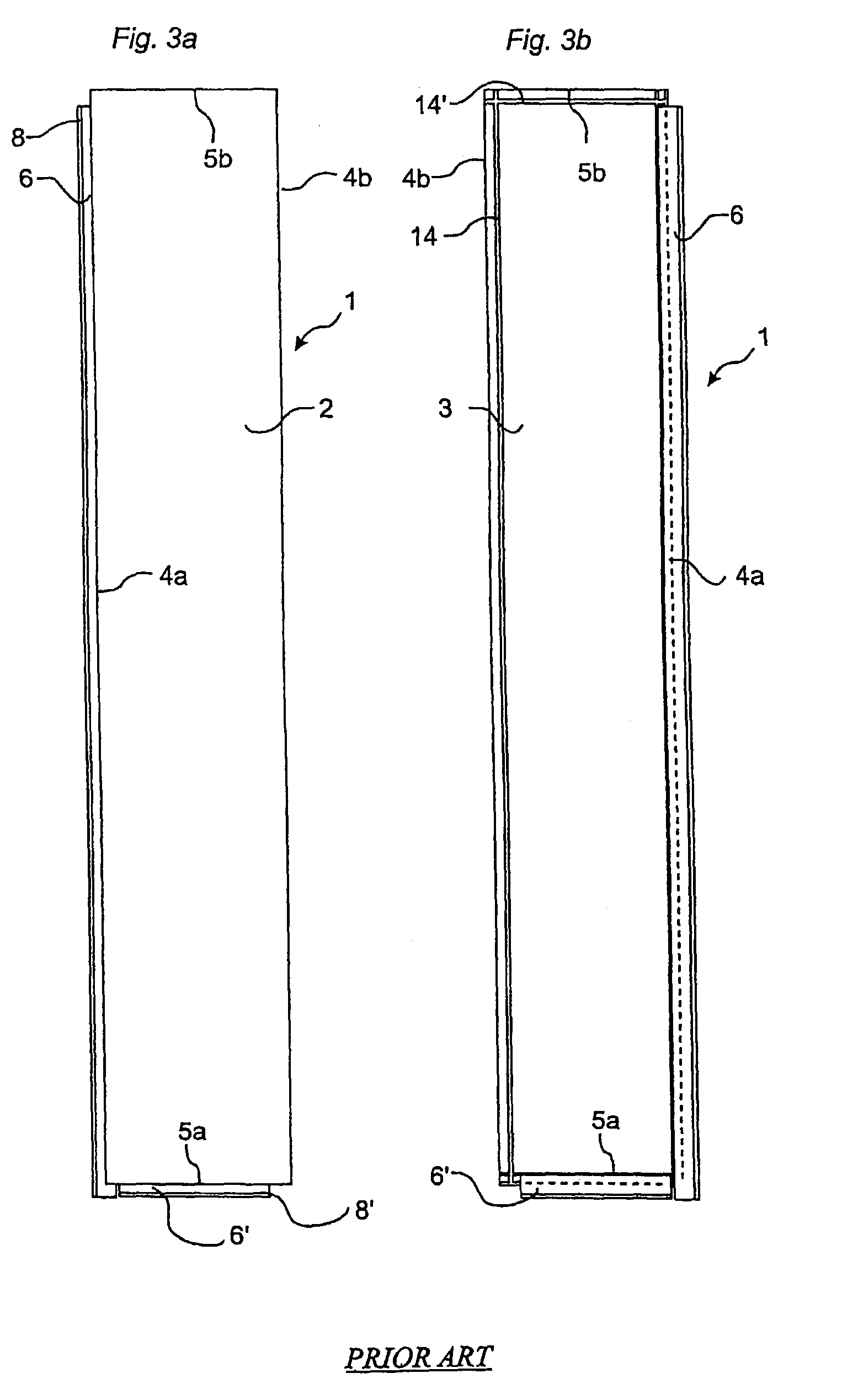

Mechanical locking system for floating floor

InactiveUS7051486B2Rational and cost-efficientReduce the amount requiredStrutsTreadsEngineeringFloating floor

Floorboards with a mechanical locking system having a separately machined strip which is mechanically joined with the floorboard.

Owner:VÄLINGE INNOVATION AB

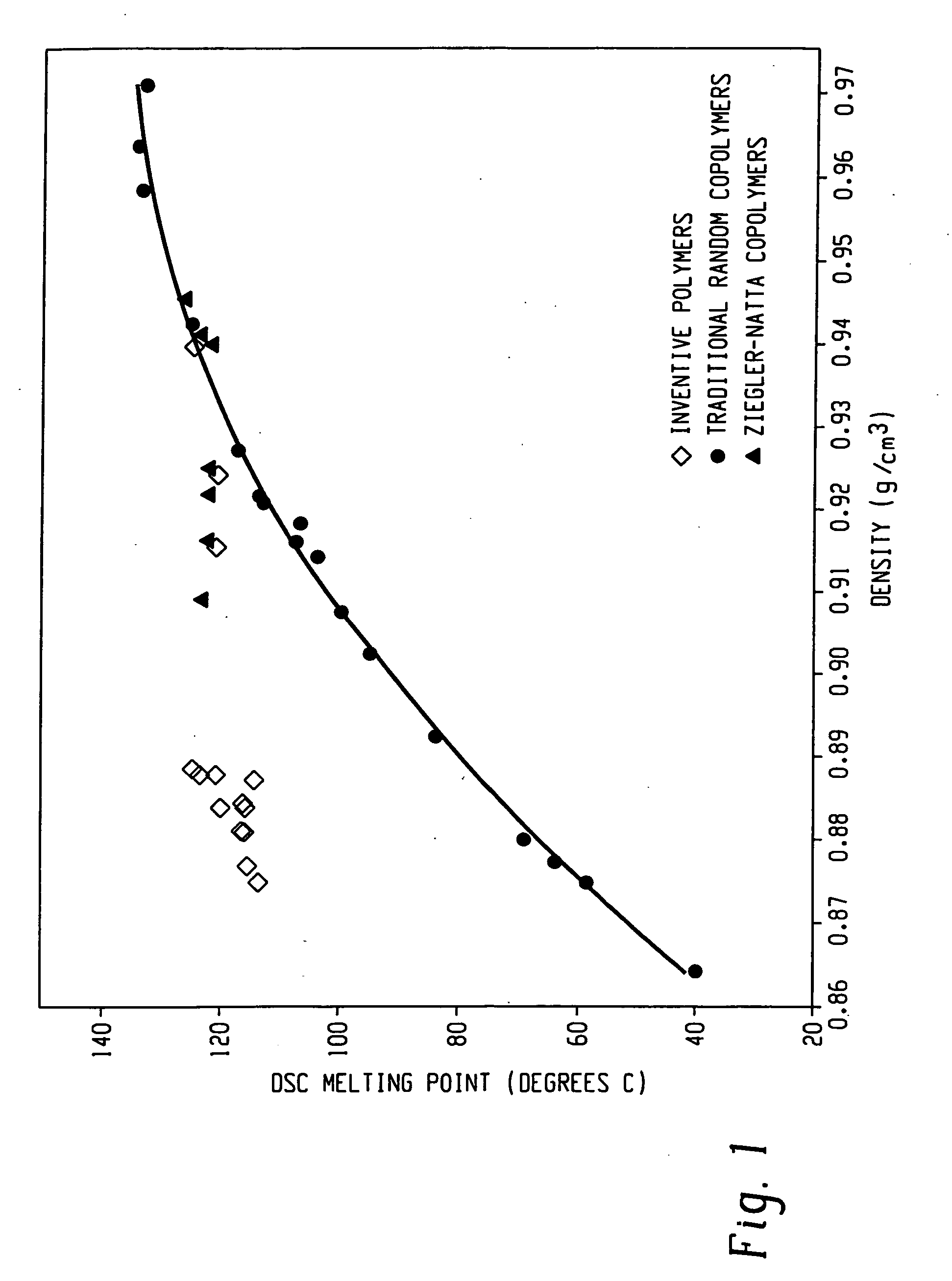

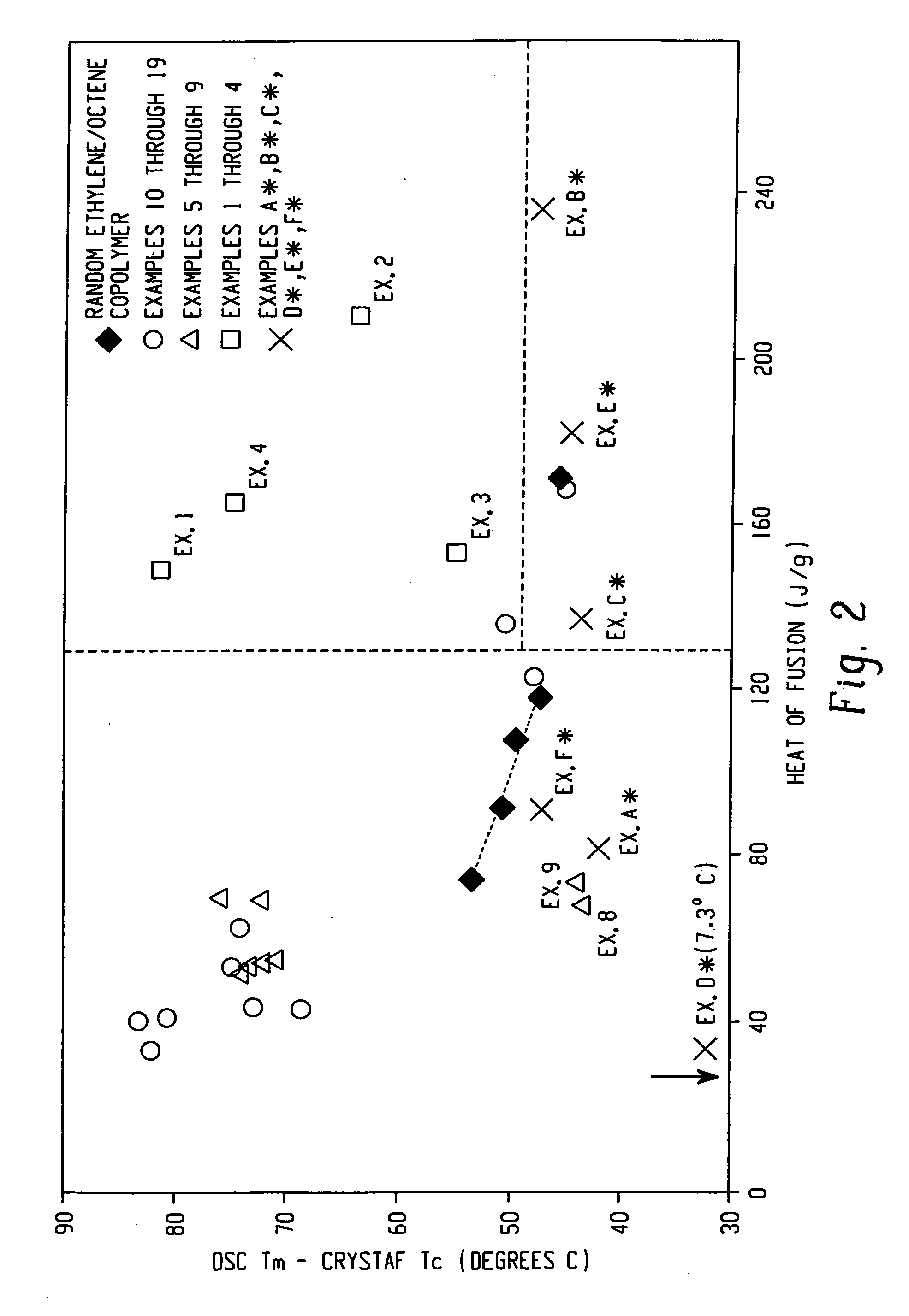

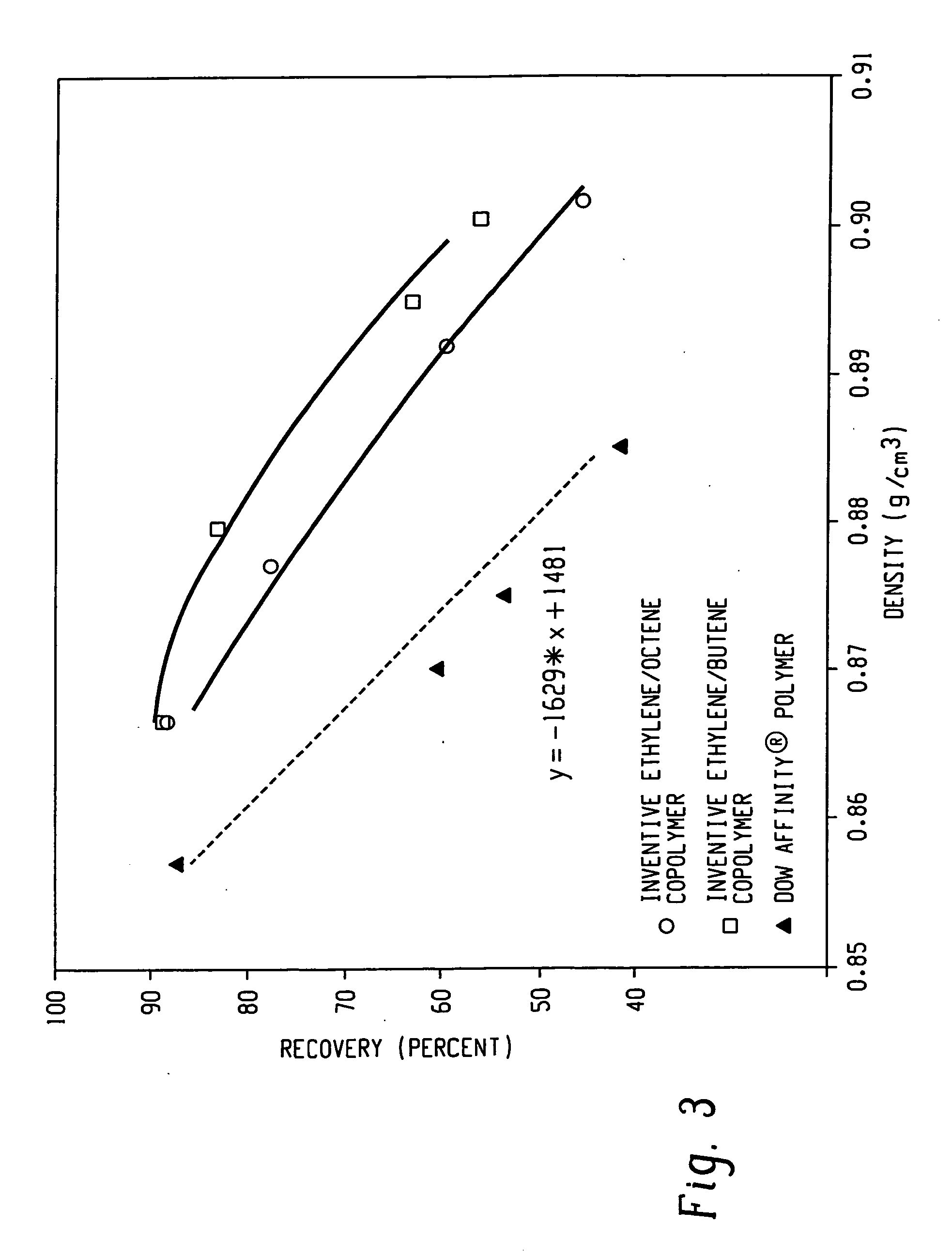

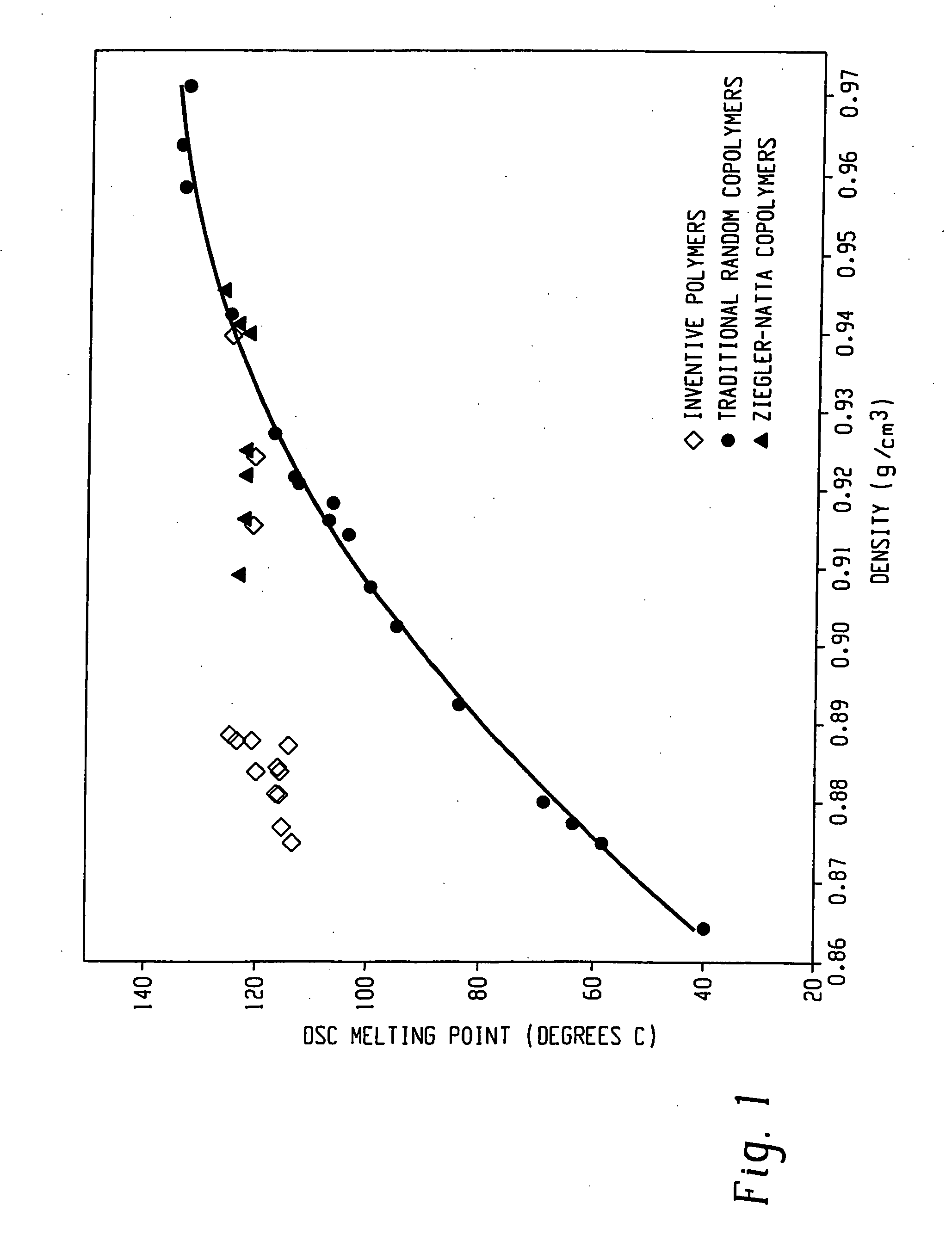

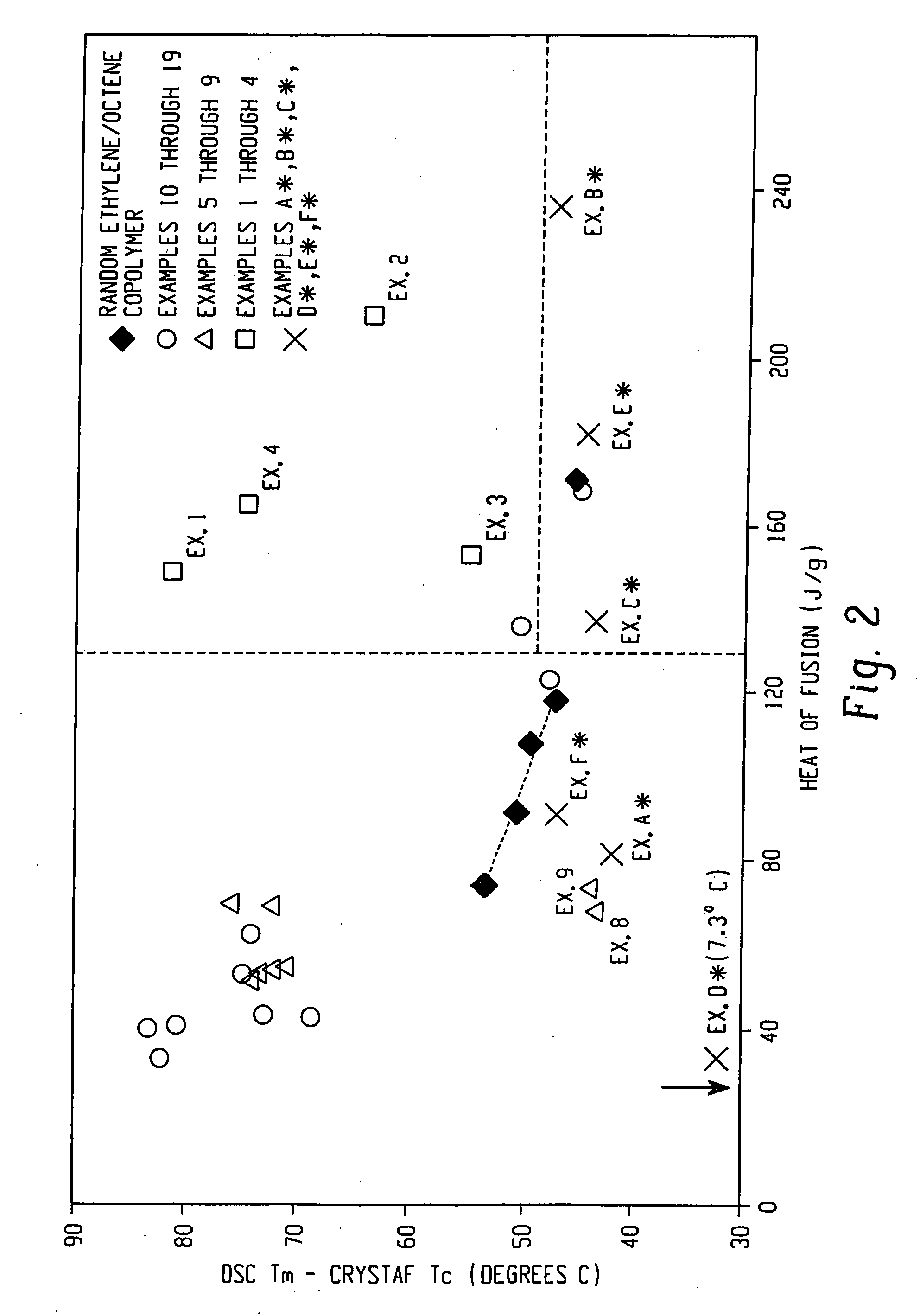

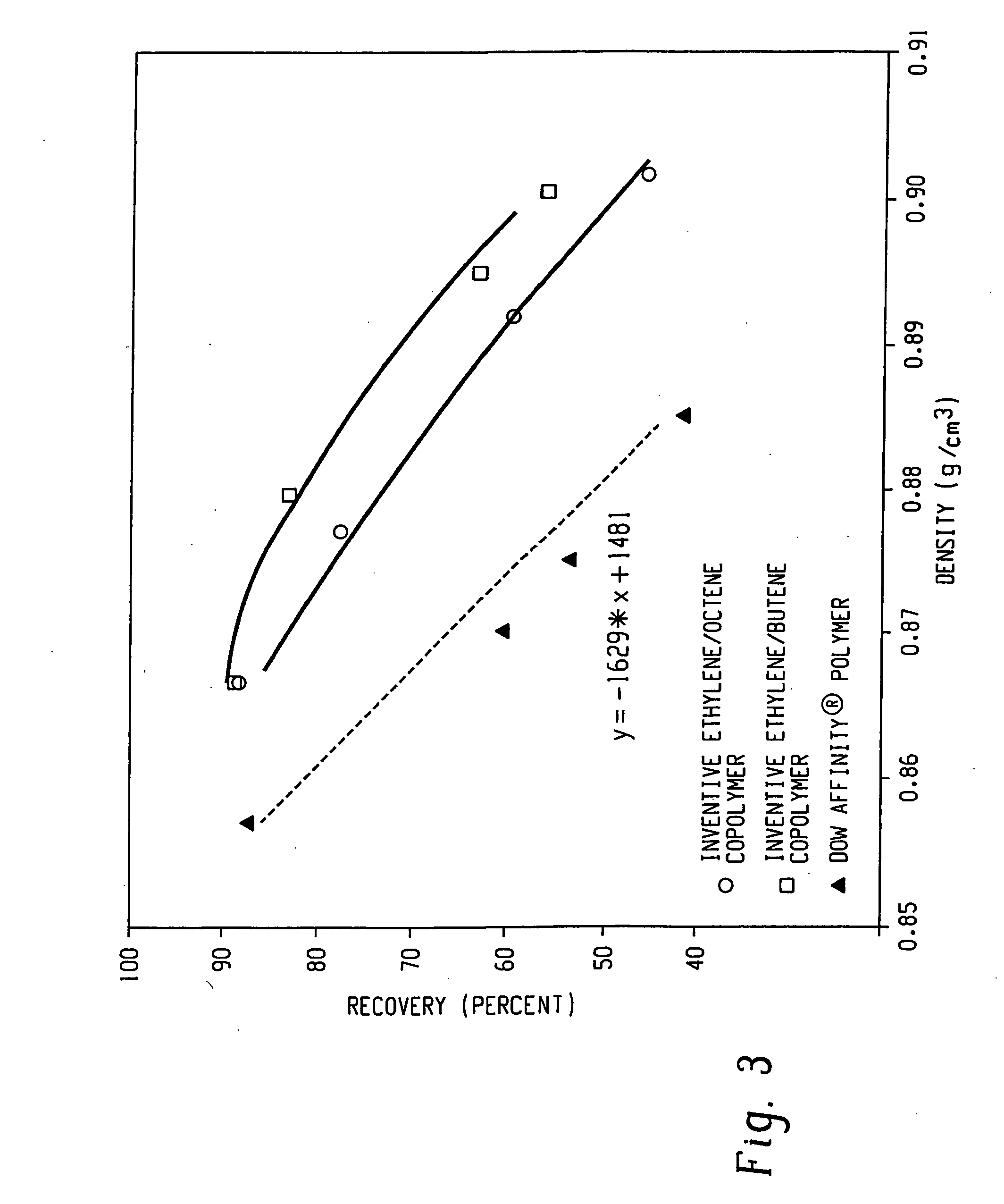

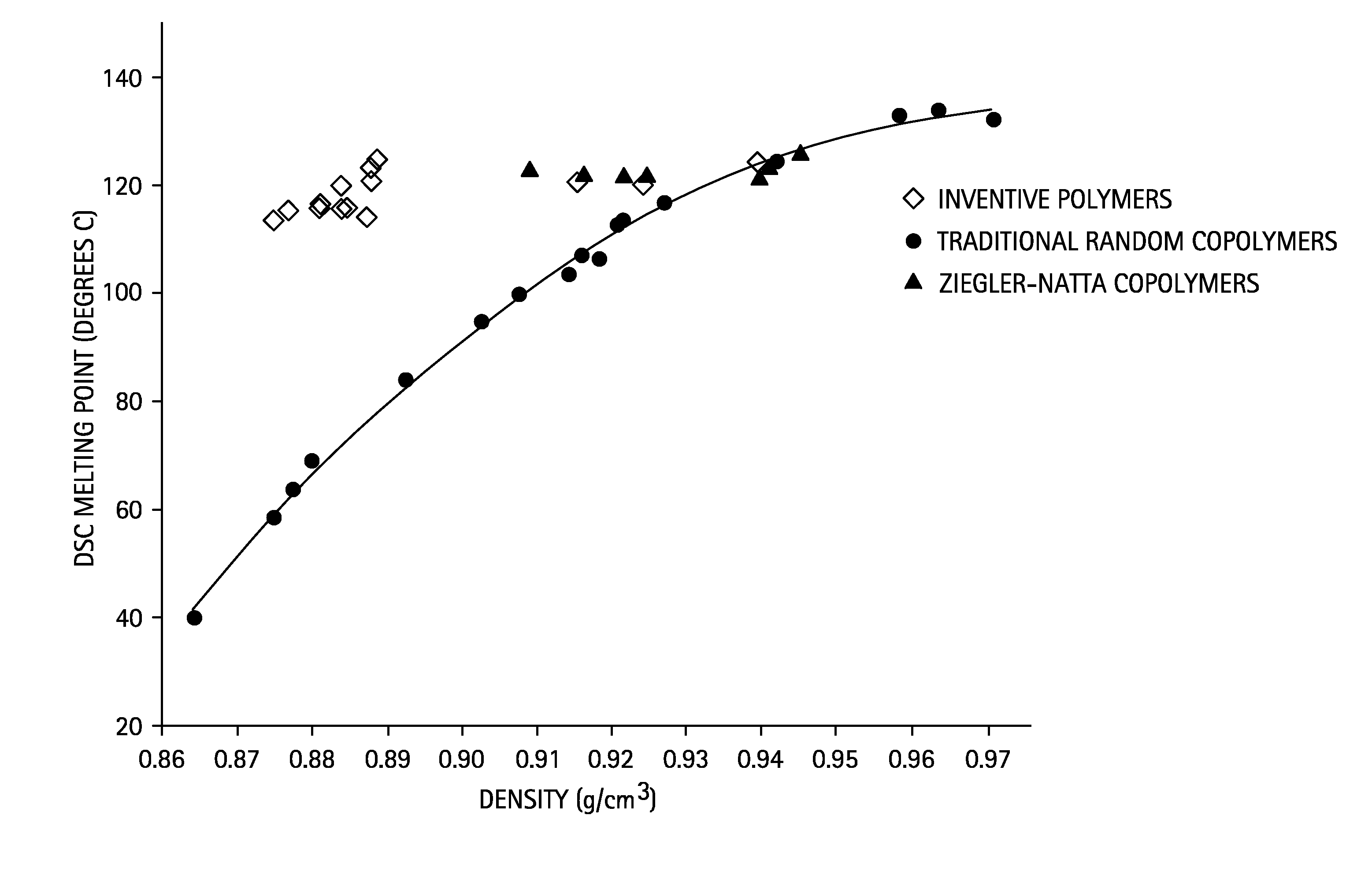

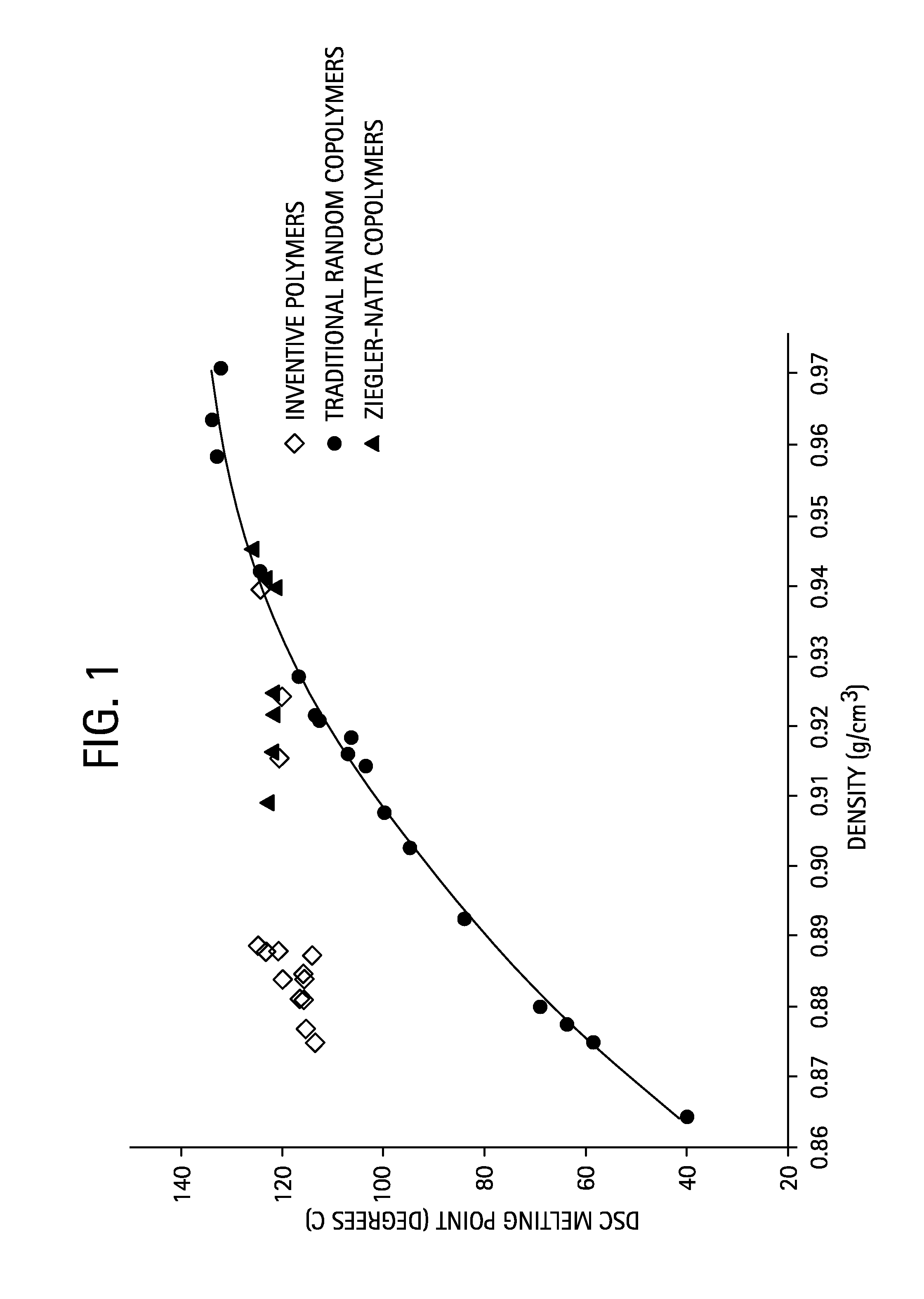

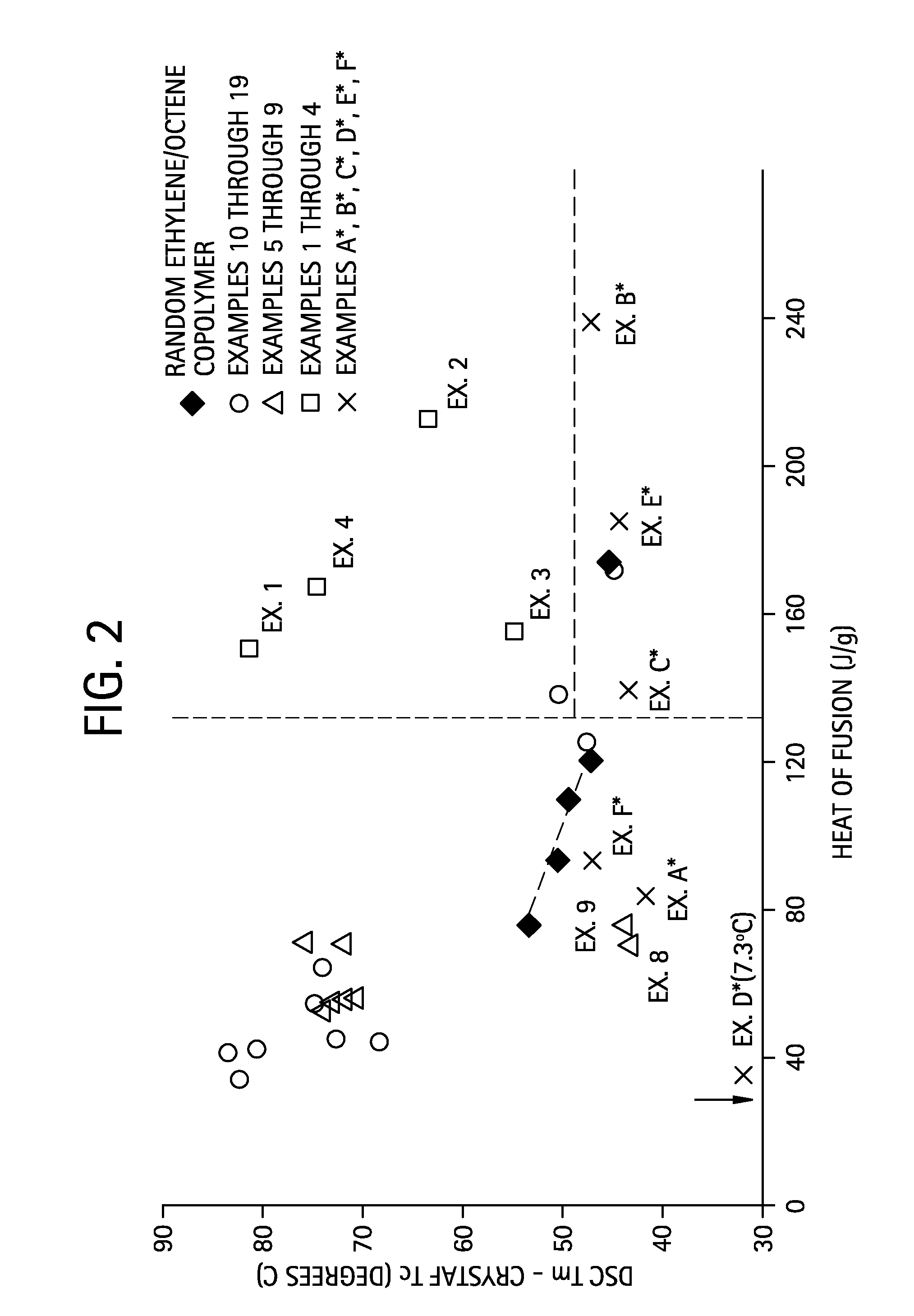

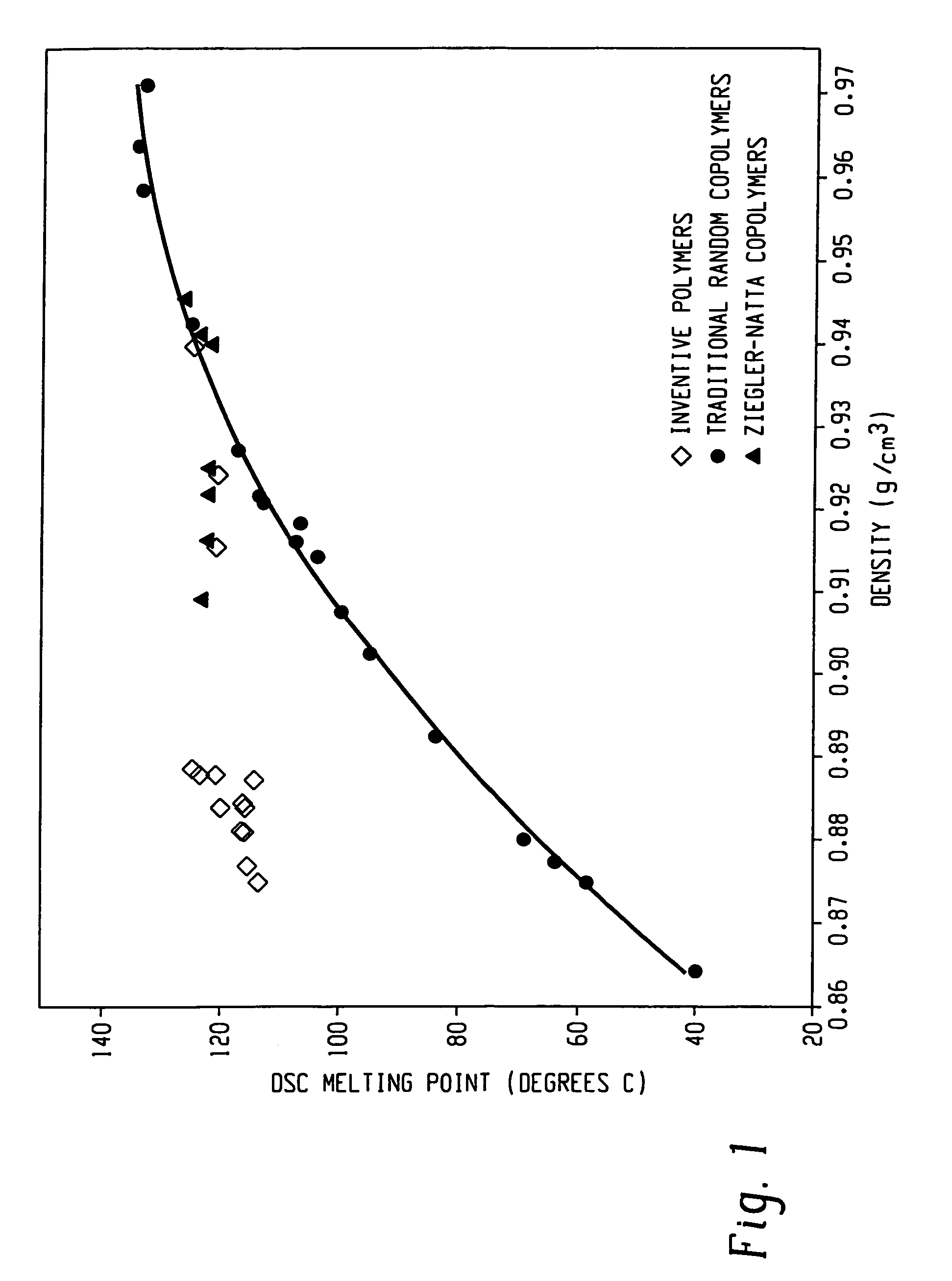

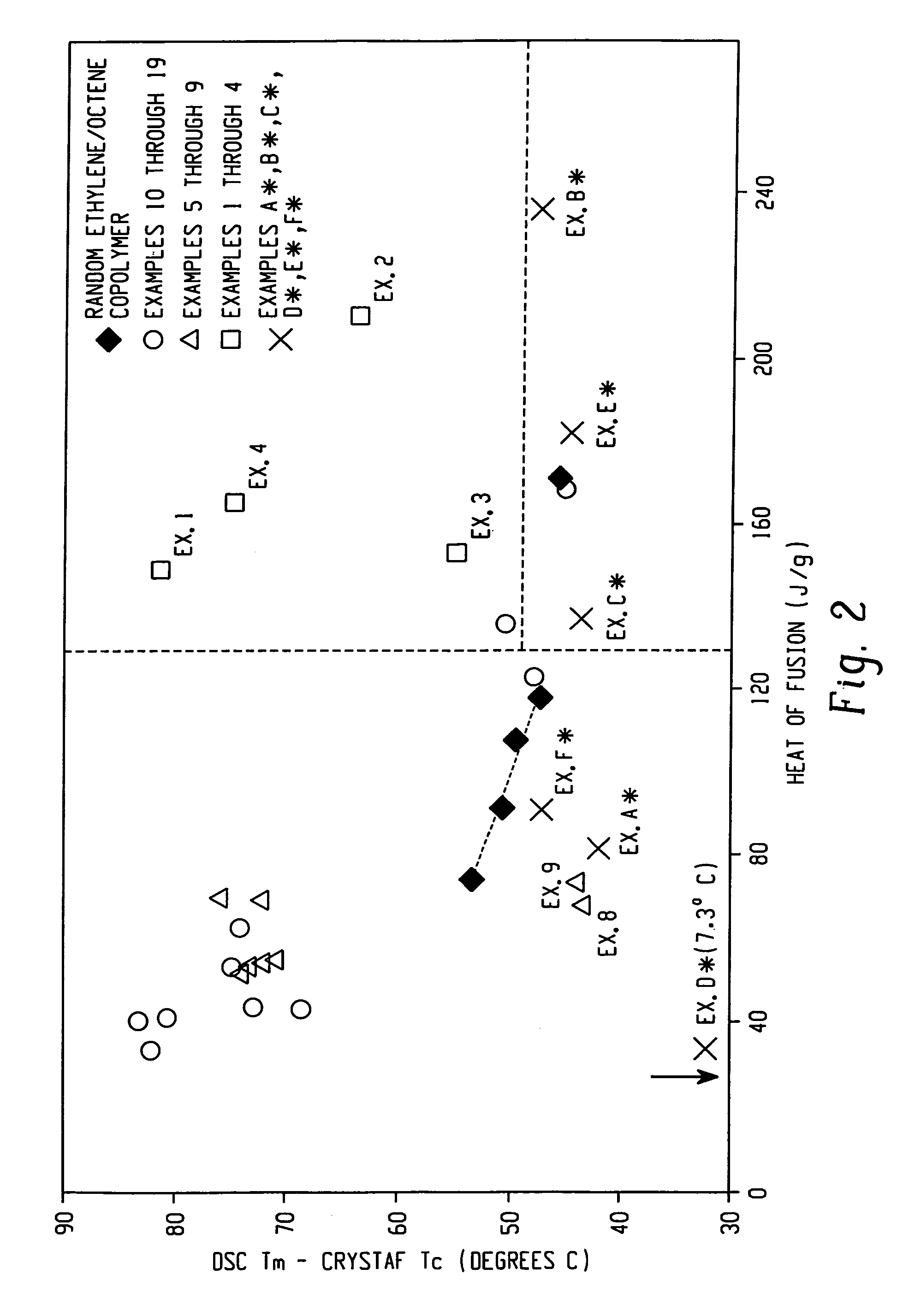

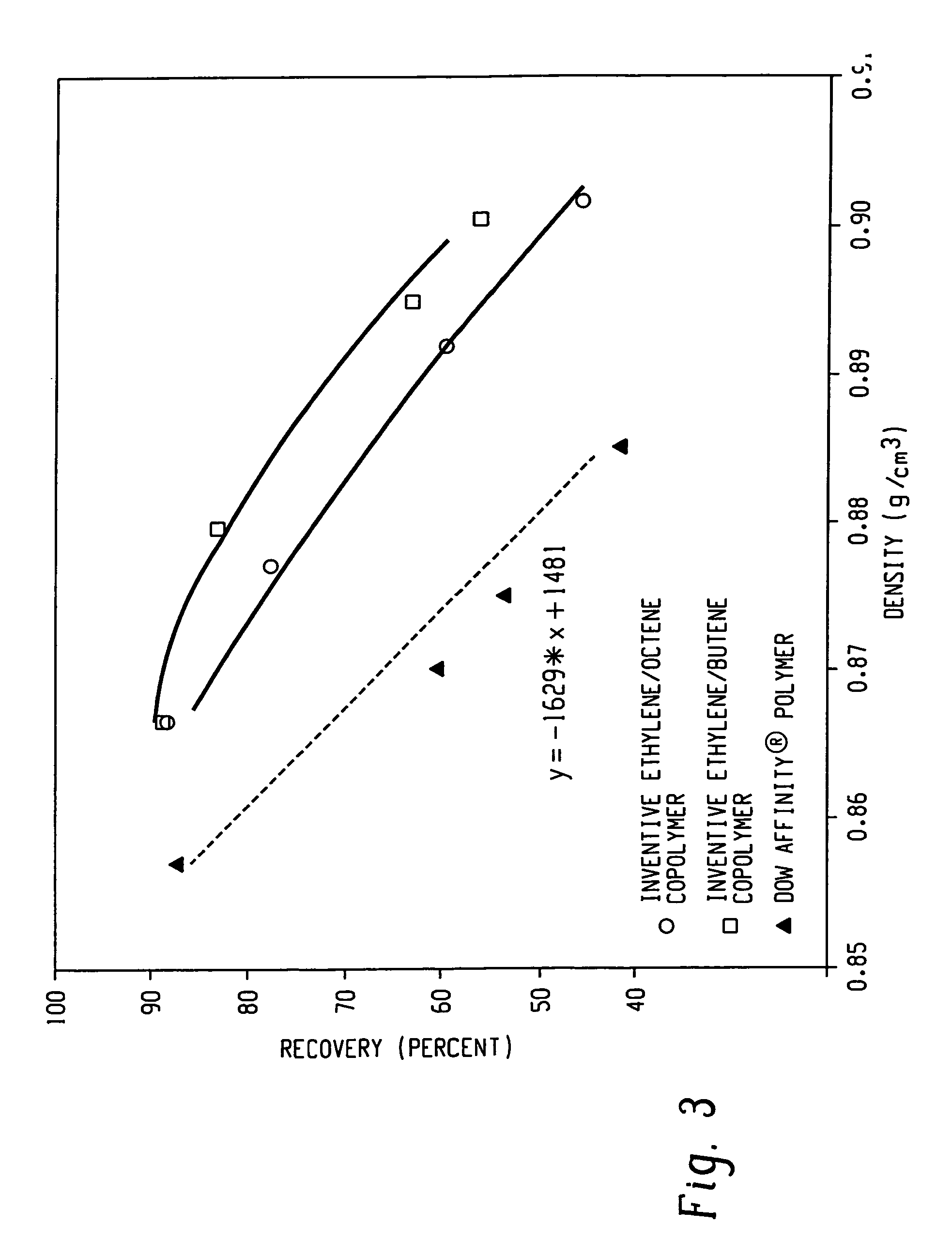

Compositions of ethylene/alpha-olefin multi-block interpolymer for elastic films and laminates

ActiveUS20070078222A1Easy to processHigh tensile strengthPersonal careSynthetic resin layered productsPolyolefinHigh pressure

This invention relates to polyolefin compositions. In particular, the invention pertains to elastic polymer compositions that can be more easily processed on cast film lines, extrusion lamination or coating lines. The compositions of the present invention preferably comprise an elastomeric polyolefin resin and a high pressure low density type resin.

Owner:DOW GLOBAL TECH LLC

Compositions of ethylene/alpha-olefin multi-block interpolymer for elastic films and laminates

ActiveUS20070155900A1Easy to processHigh tensile strengthPersonal careLayered product treatmentProduction linePolyolefin

This invention relates to polyolefin compositions. In particular, the invention pertains to elastic polymer compositions that can be more easily processed on cast film lines, extrusion lamination or coating lines. The compositions of the present invention preferably comprise an elastomeric polyolefin resin and a high pressure low density type resin.

Owner:DOW GLOBAL TECH LLC

Compositions of ethylene/alpha-olefin multi-block interpolymer for elastic films and laminates

ActiveUS20080177242A1Good physical propertiesElasticityCosmetic preparationsToilet preparationsElastomerPolyolefin

This invention relates to polyolefin compositions. In particular, the invention pertains to elastic polymer compositions that can be more easily processed on cast film lines, extrusion lamination or coating lines. The compositions of the present invention preferably comprise an elastomeric polyolefin resin and a high pressure low density type resin.

Owner:DOW GLOBAL TECH LLC

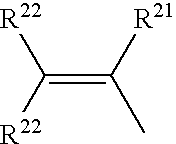

Films comprising biodegradable PHA copolymers

InactiveUS6174990B1High ratioSmall cross sectionFlexible coversWrappersBiodegradable copolymersMonomer

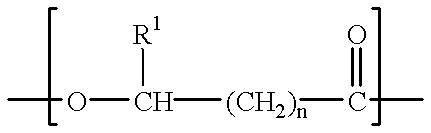

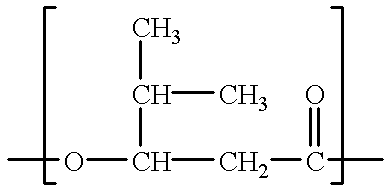

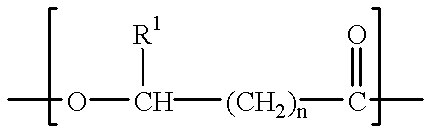

The present invention relates to biodegradable PHA copolymers comprising at least two randomly repeating monomer units. The present invention further relates to a plastic article comprising a biodegradable copolymer, wherein the biodegradable copolymer comprises at least two randomly repeating monomer units (RRMU) wherein the first RRMU has the structurewherein R1 is H, or C1 or C2 alkyl, and n is 1 or 2; the second RRMU has the structureand wherein at least 50% of the RRMUs have the structure of the first RRMU. The present invention further relates to an absorbent article comprising a liquid pervious topsheet, a liquid impervious backsheet comprising a film comprising a PHA of the present invention and an absorbent core positioned between the topsheet and the backsheet.

Owner:DANIMER IPCO LLC

Fortified confectionery delivery systems and methods of preparation thereof

InactiveUS6673380B2Great tasteImprove textureConfectioneryAnimal feeding stuffDelivery systemCarbohydrate

Chewy confectionery products, and processes for producing said products, are provided as delivery systems for minerals such as calcium. The carbohydrates of the fortified confectionery products include at least one reducing sugar and one non-reducing sugar in a weight ratio of about 1:0.2 to about 1:1 reducing sugar:non-reducing sugar. The chewy confectionery products offer a matrix for about 0.2 wt. % to 45 wt. % of a fortifying component while maintaining a smooth and soft texture.

Owner:HEARTLAND CONSUMER PROD

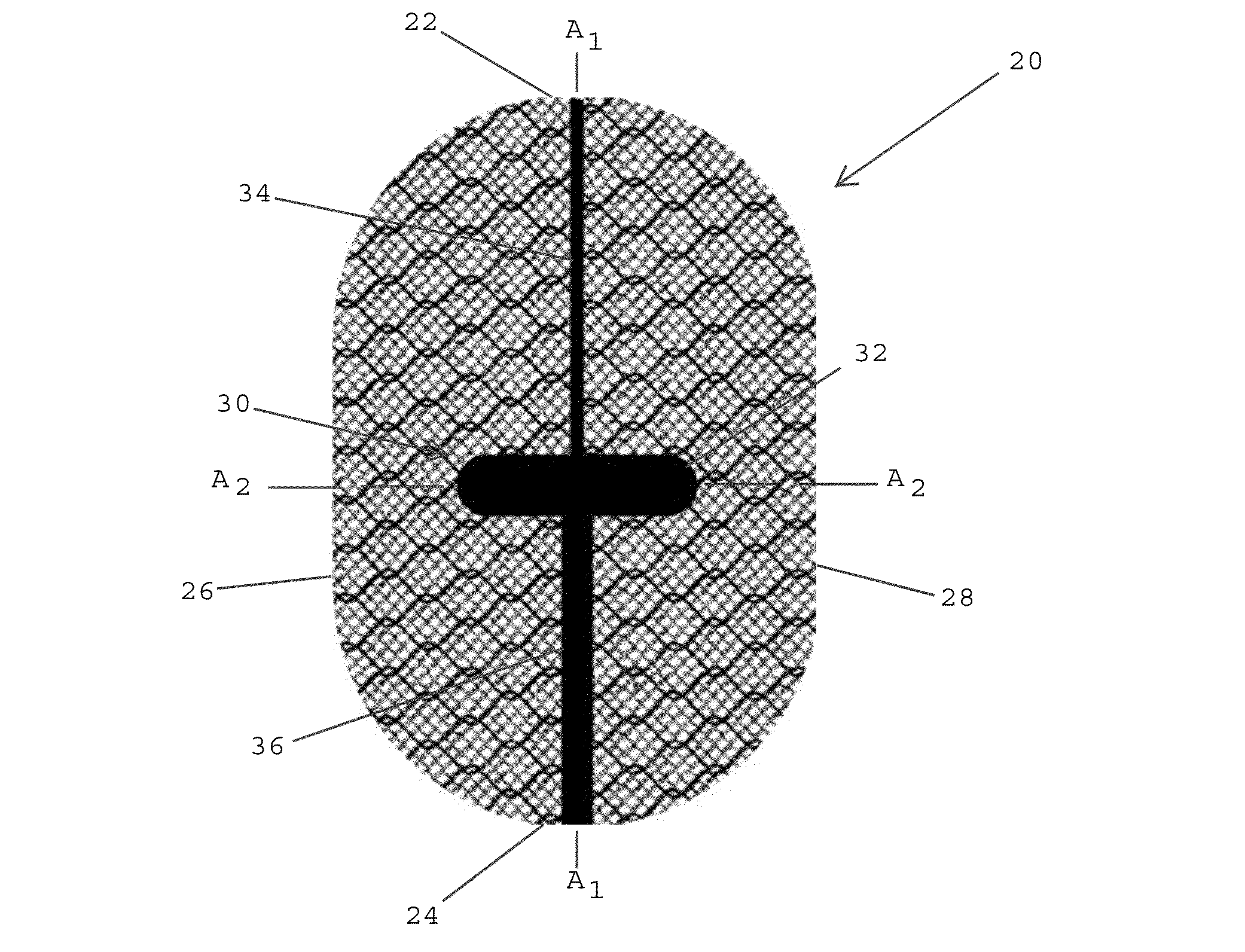

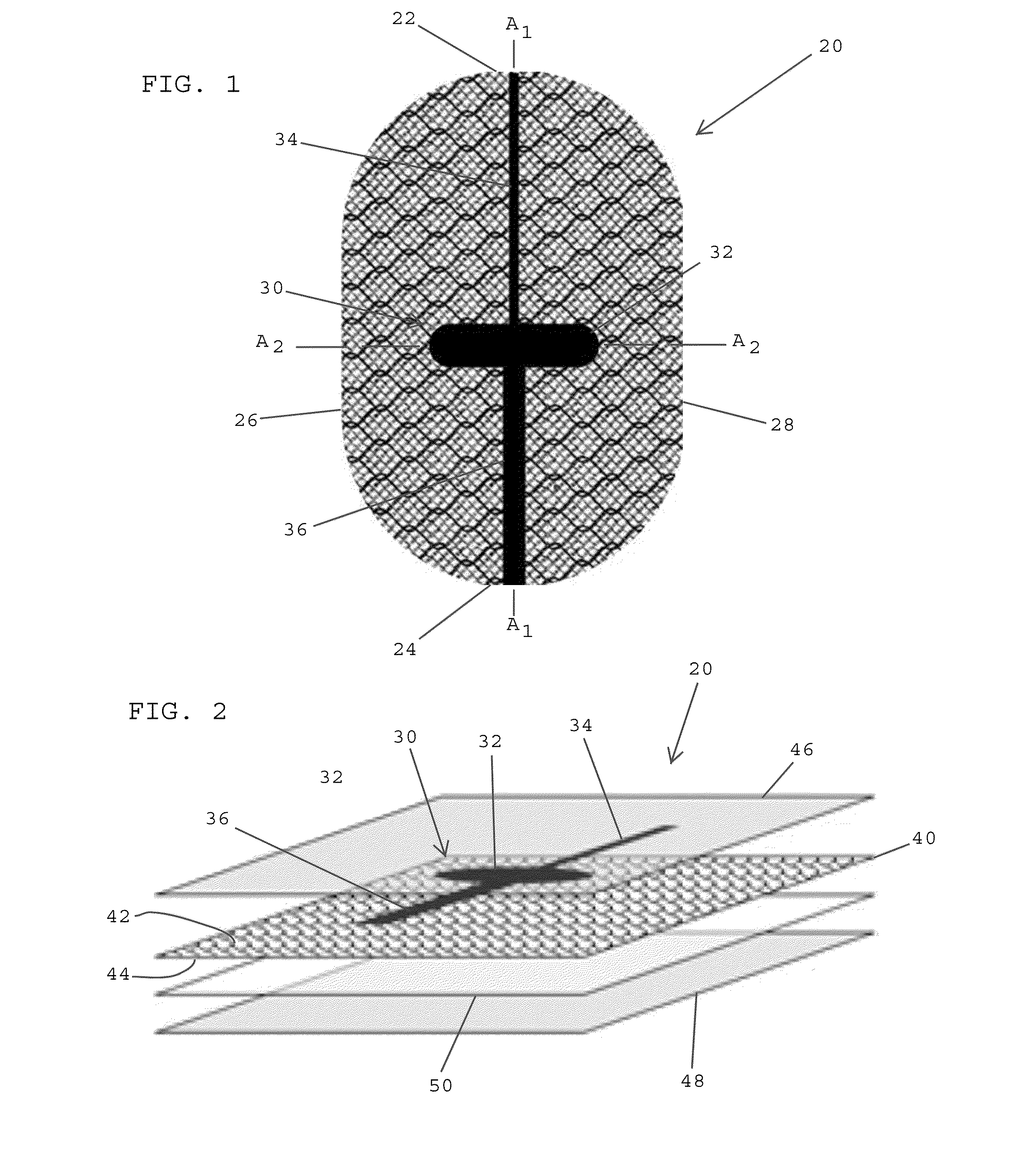

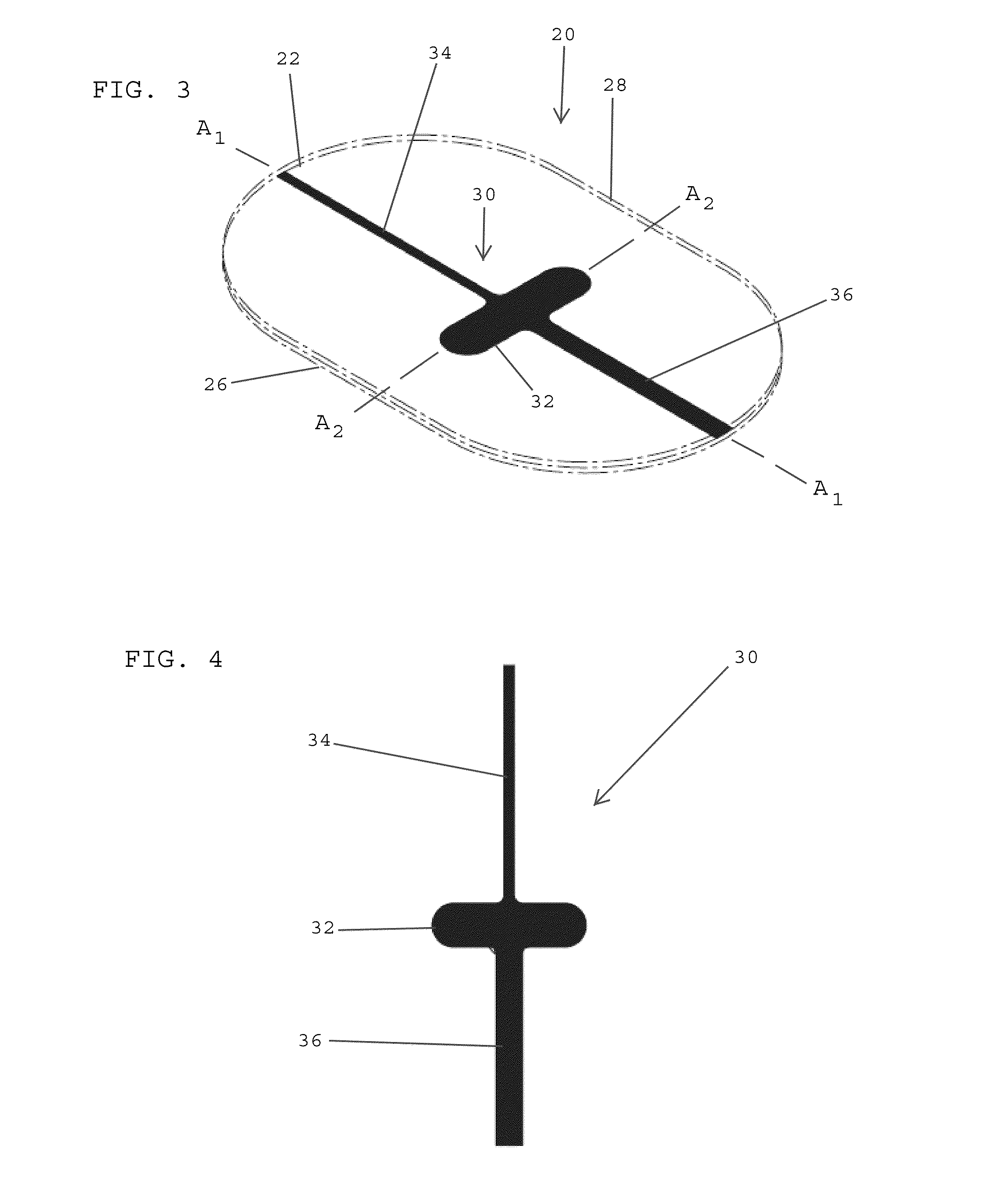

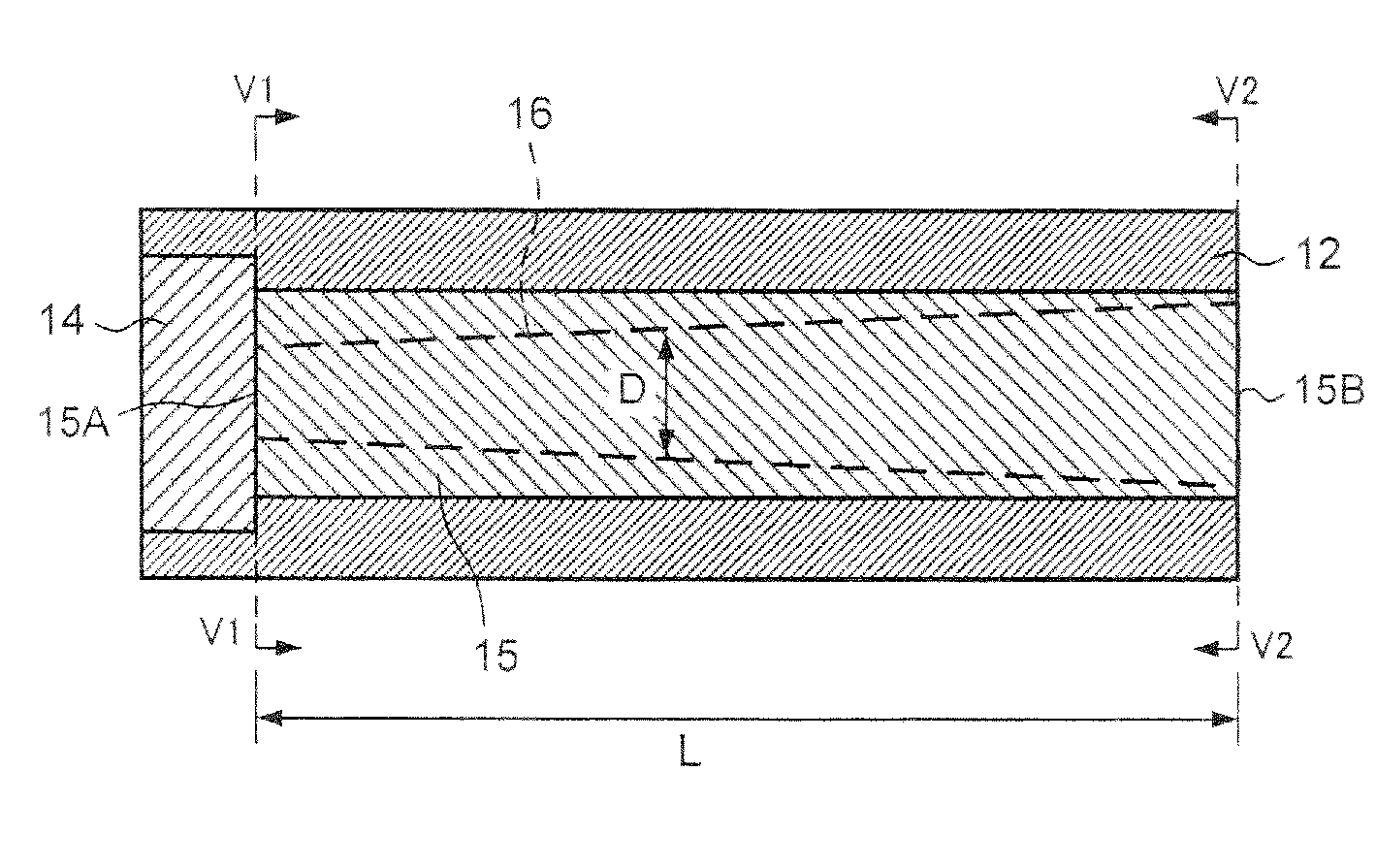

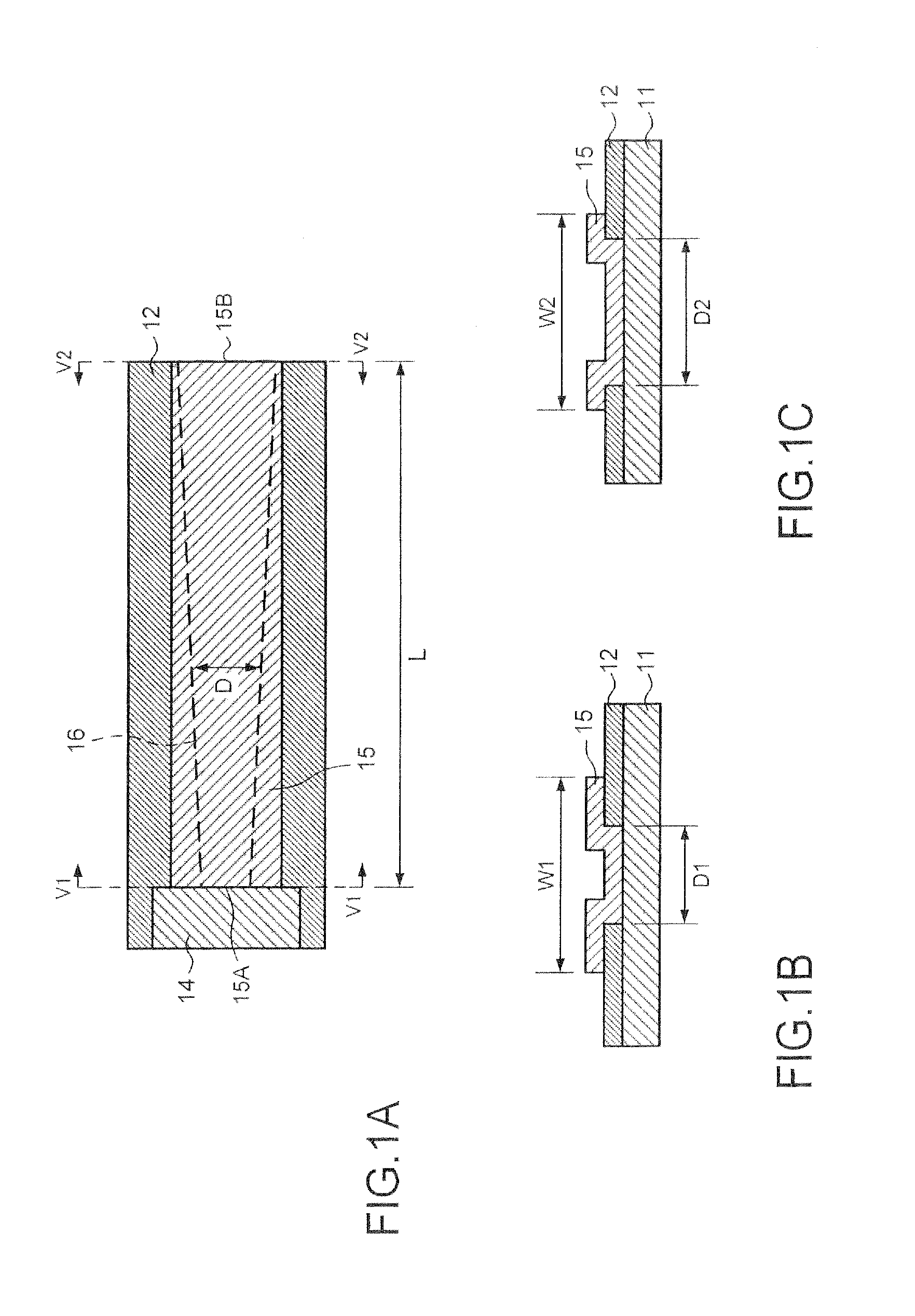

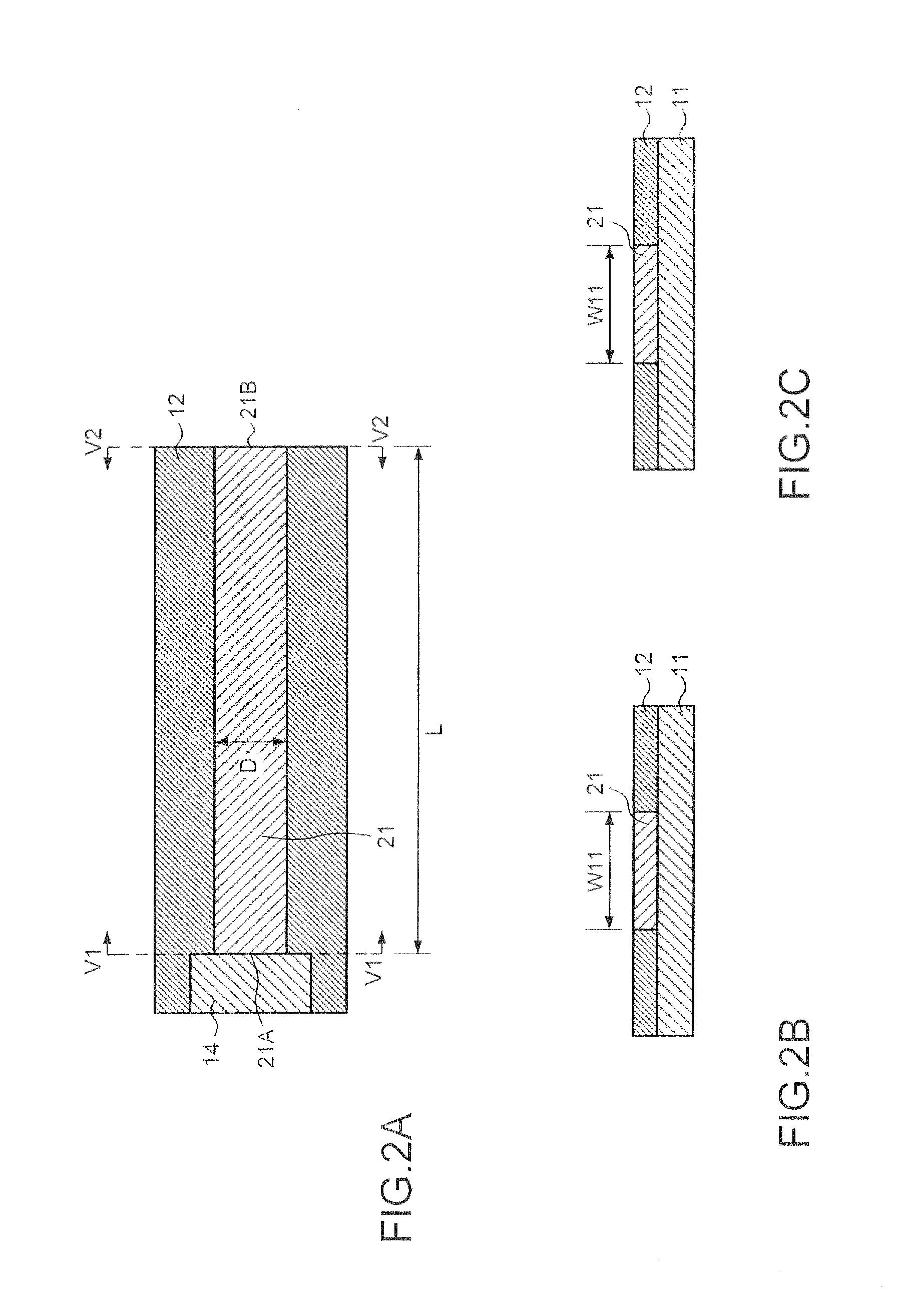

Composite anisotropic tissue reinforcing implants having alignment markers and methods of manufacturing same

ActiveUS20110307077A1Difficult to processDifferent widthLamination ancillary operationsAnti-incontinence devicesBiomedical engineeringMedicine

A composite implant includes an anisotropic surgical mesh having more stretchability along a first axis and less stretchability along a second axis that traverses the first axis, and an alignment marker overlying a first major surface of the anisotropic mesh and extending along the first axis. The implant includes a first absorbable, anti-adhesion film overlying the alignment marker and the first major surface of the anisotropic mesh, and a second absorbable, anti-adhesion film overlying the second major surface of the biocompatible mesh. The alignment marker is disposed between the first and second absorbable films and the first and second absorbable films are laminated to the anisotropic mesh.

Owner:ETHICON INC

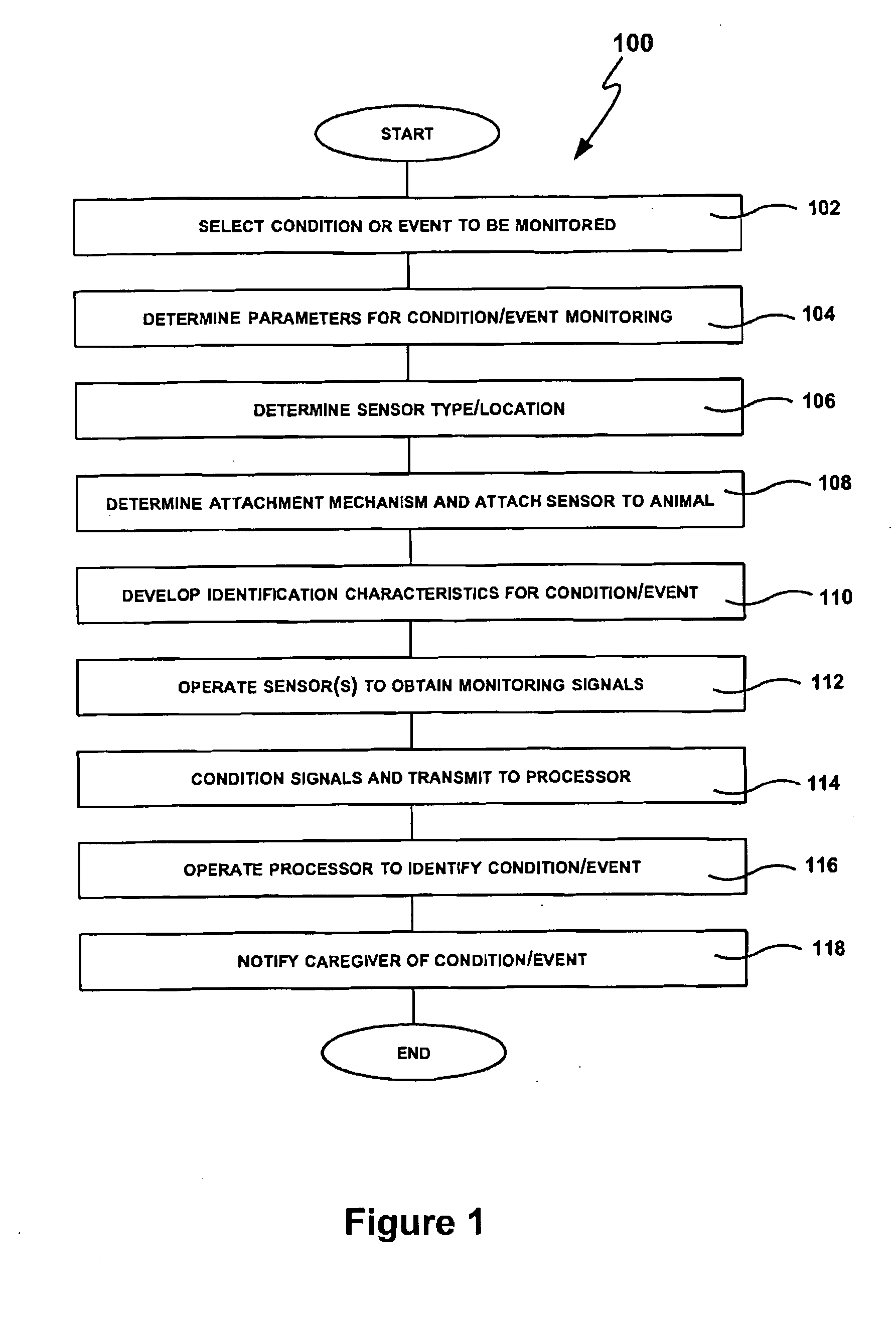

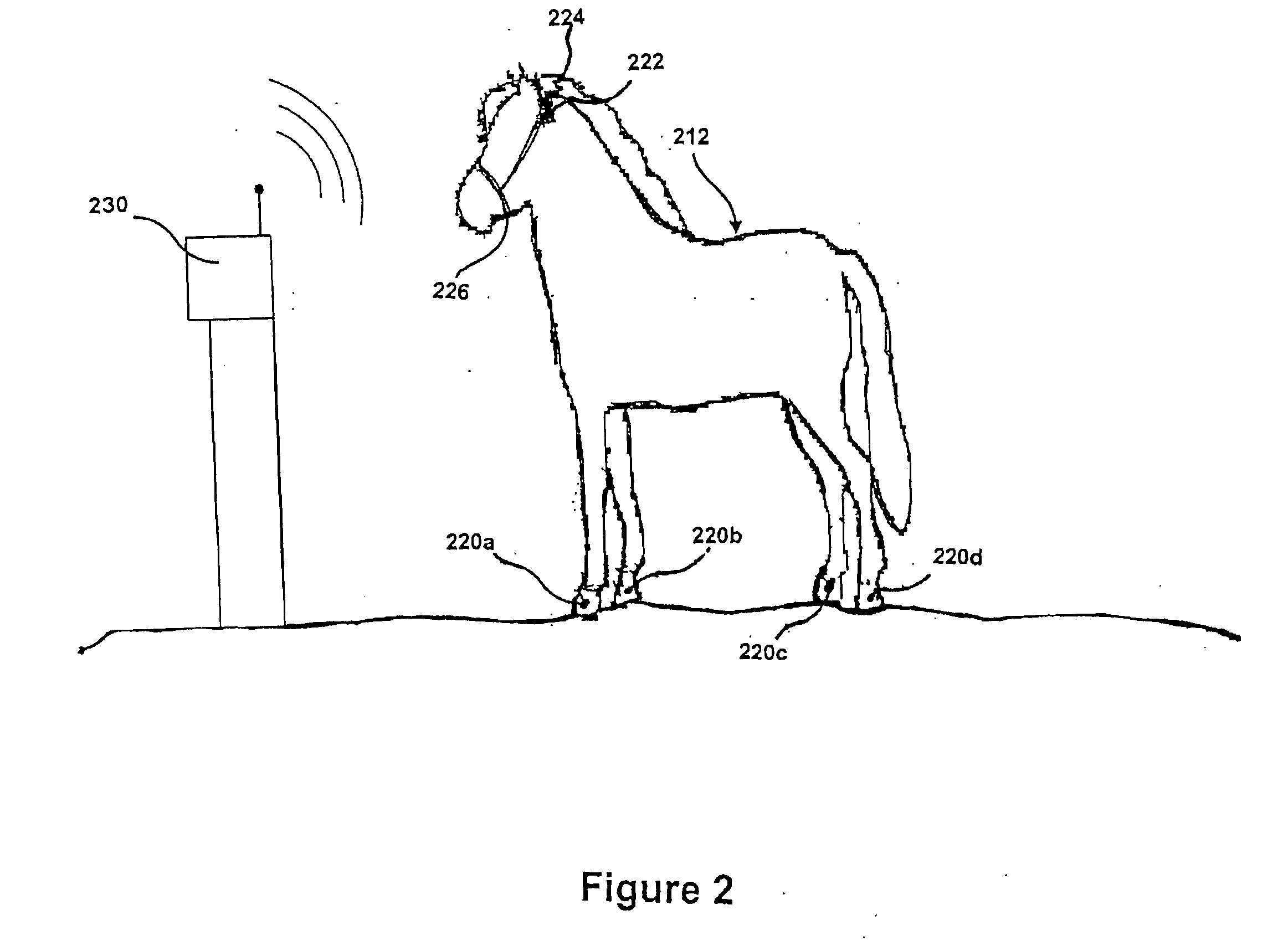

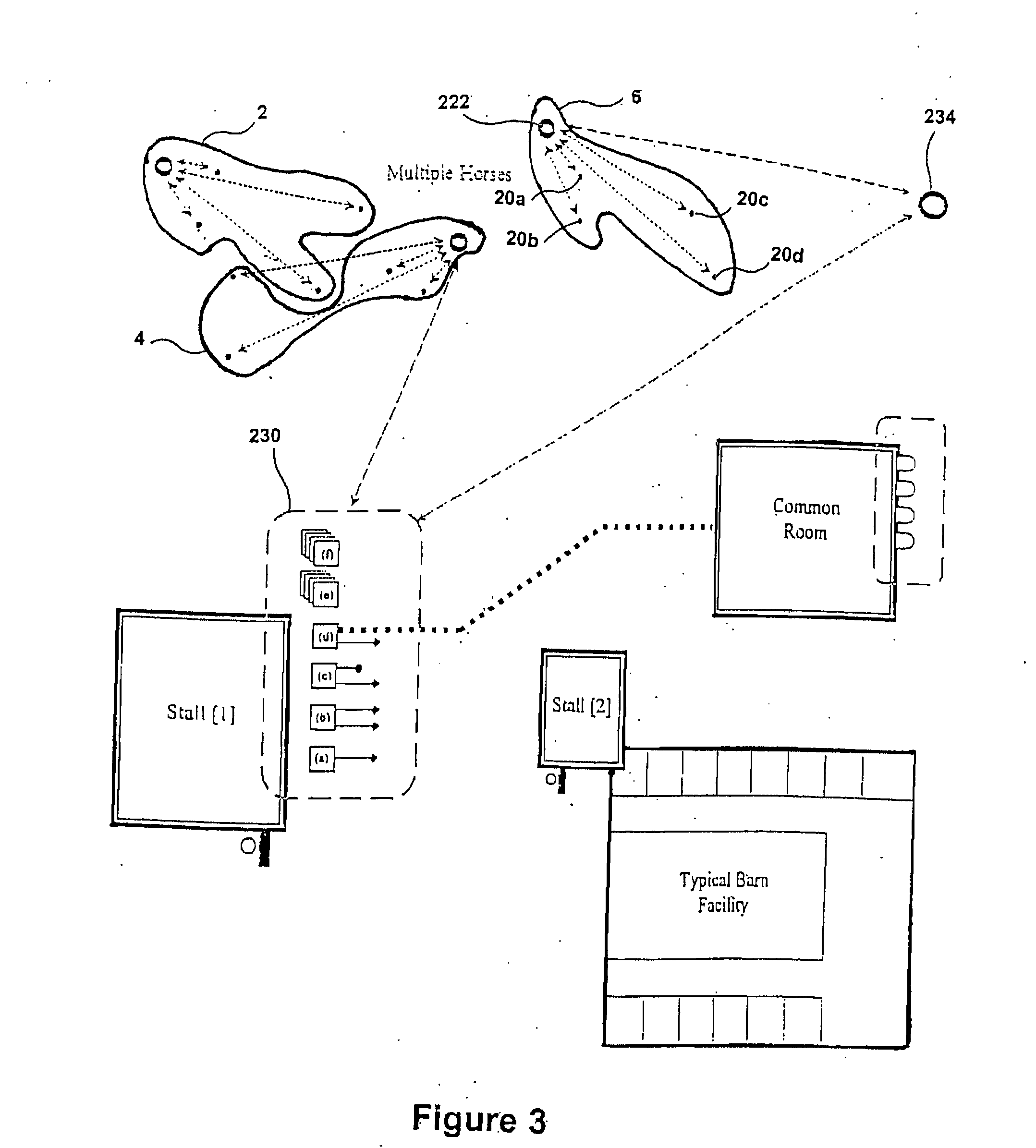

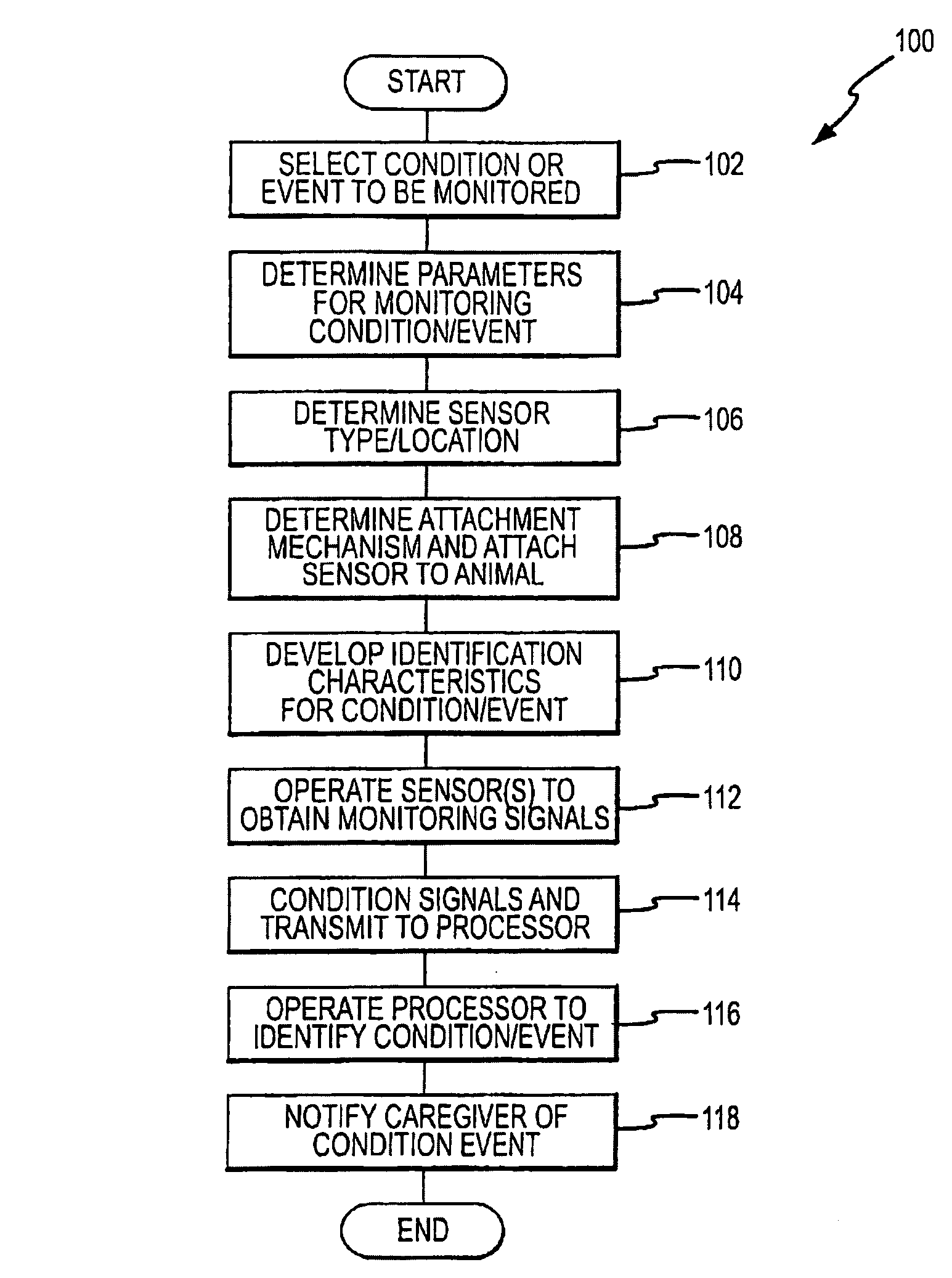

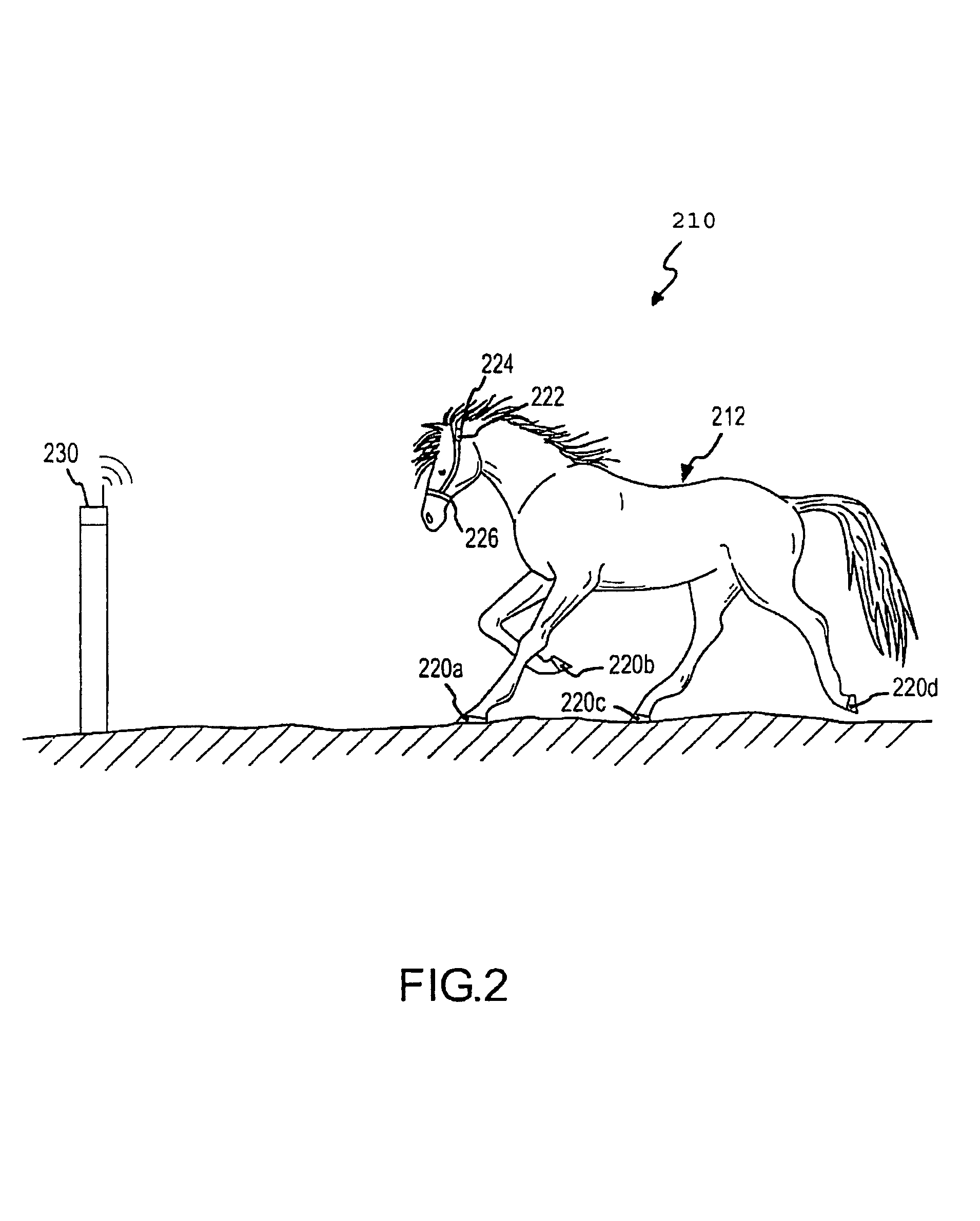

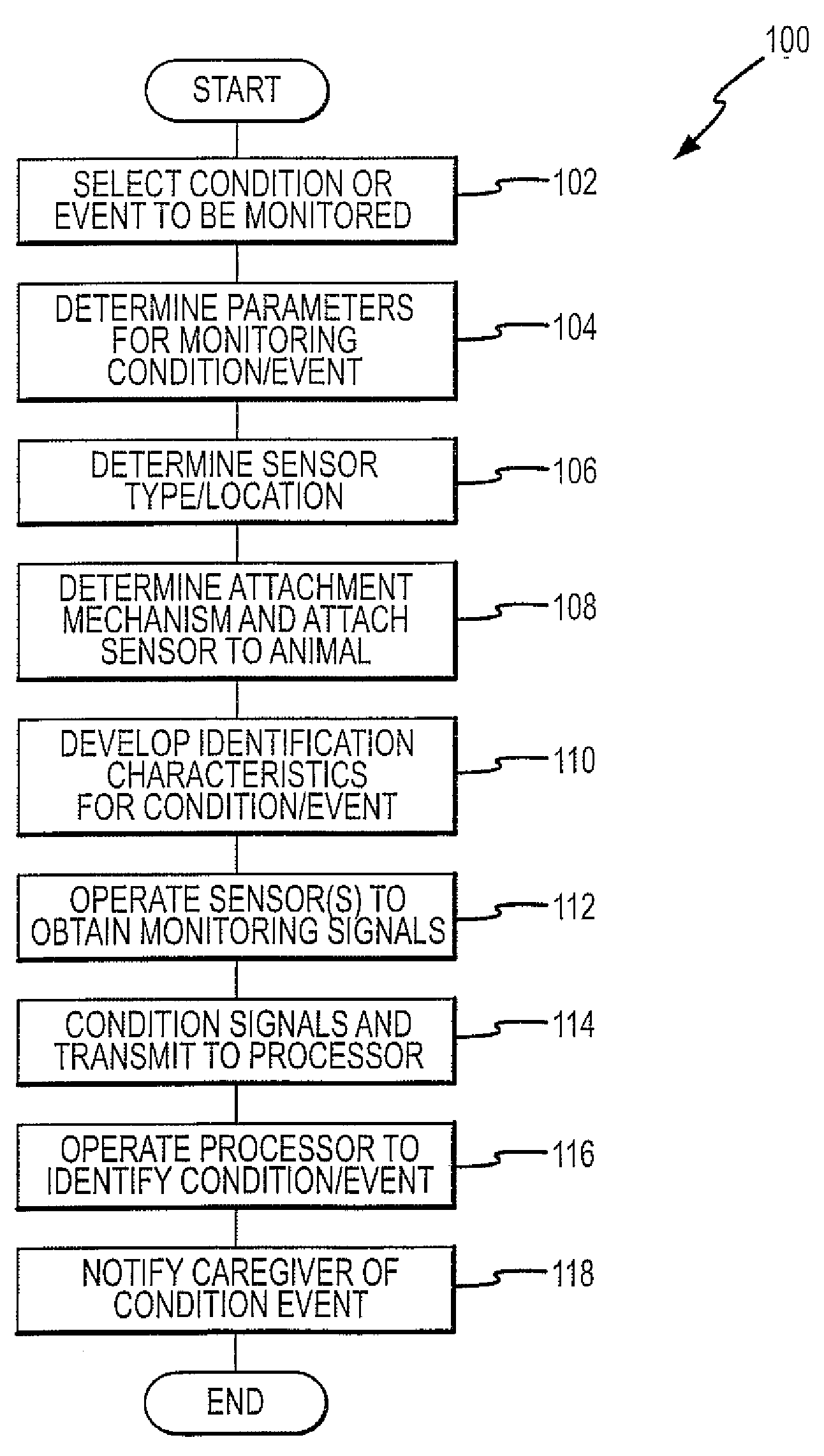

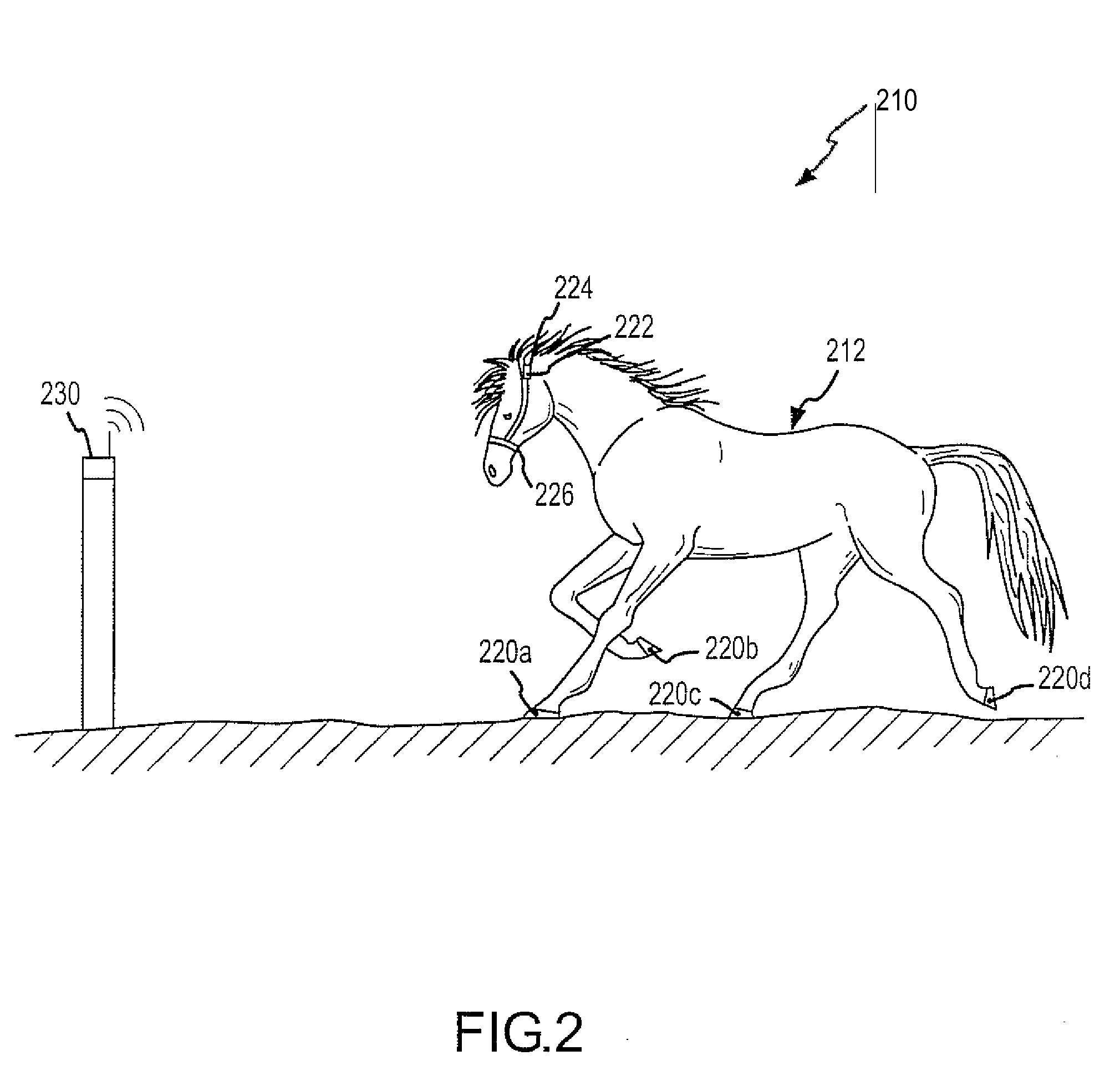

Monitoring system for animal husbandry

ActiveUS20060155172A1Safe and reliable long-term monitoringMinimize potential harmful consequenceAnimal reproductionSafety beltsPattern recognitionMonitoring system

A monitoring system (800) is operative for receiving sensor signals and analyzing the sensor signals to identify events or conditions of interest, such as colic, with respect to a monitored animal. The sensors may be animal-borne sensors such as motion related sensors. The system (800) includes a processor (802) operative to identify the conditions of interest based on a stored pattern database (806), threshold tables (808) and heuristic engines (812). Upon identification of a condition of interest, a human expert may be consulted and alerts may be generated as required.

Owner:BIO EQUIDAE LLC

Monitoring system for animal husbandry

ActiveUS7335168B2Safe and reliable long-term monitoringMinimize potential harmful consequenceAnimal reproductionSafety beltsPattern recognitionMonitoring system

Owner:BIO EQUIDAE LLC

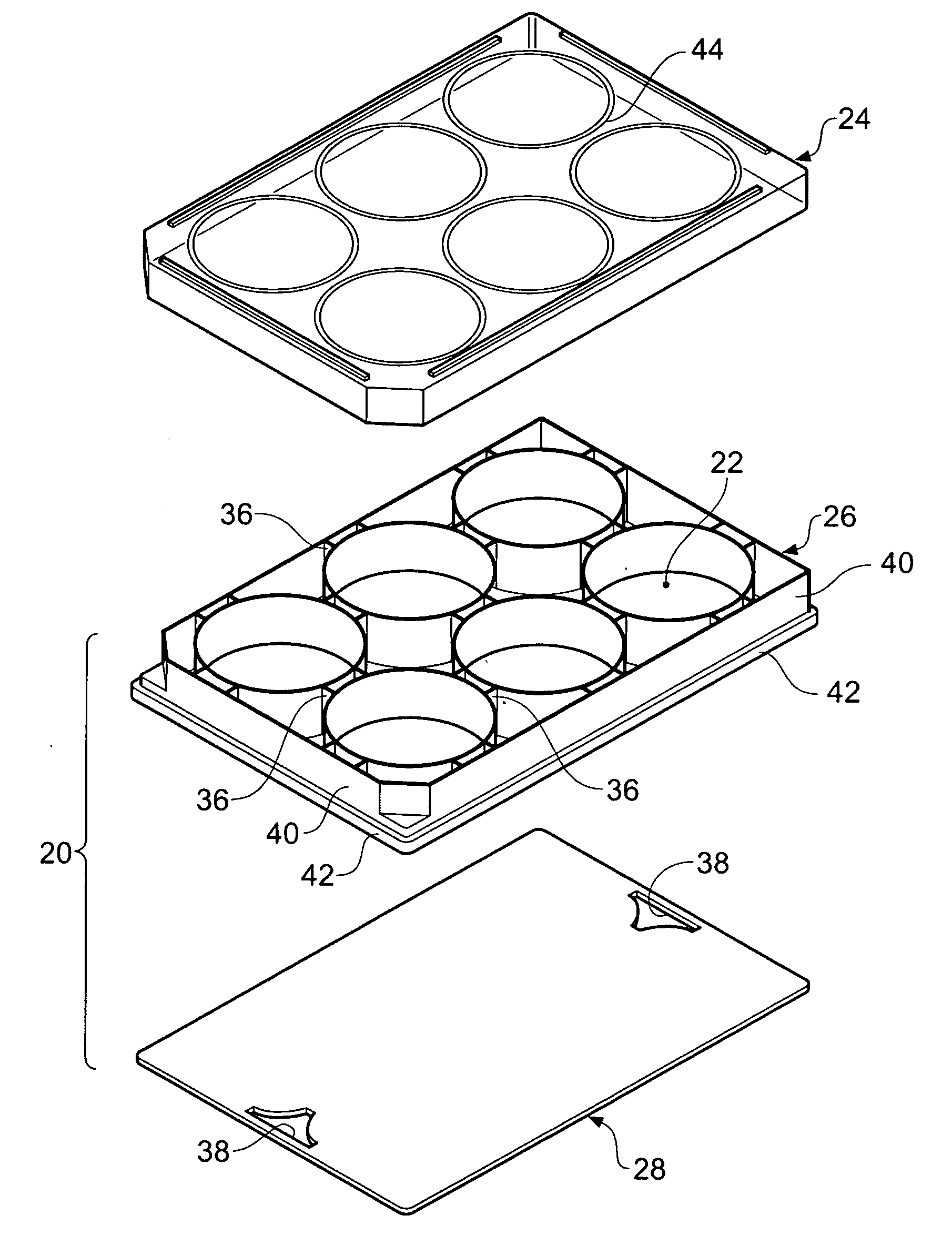

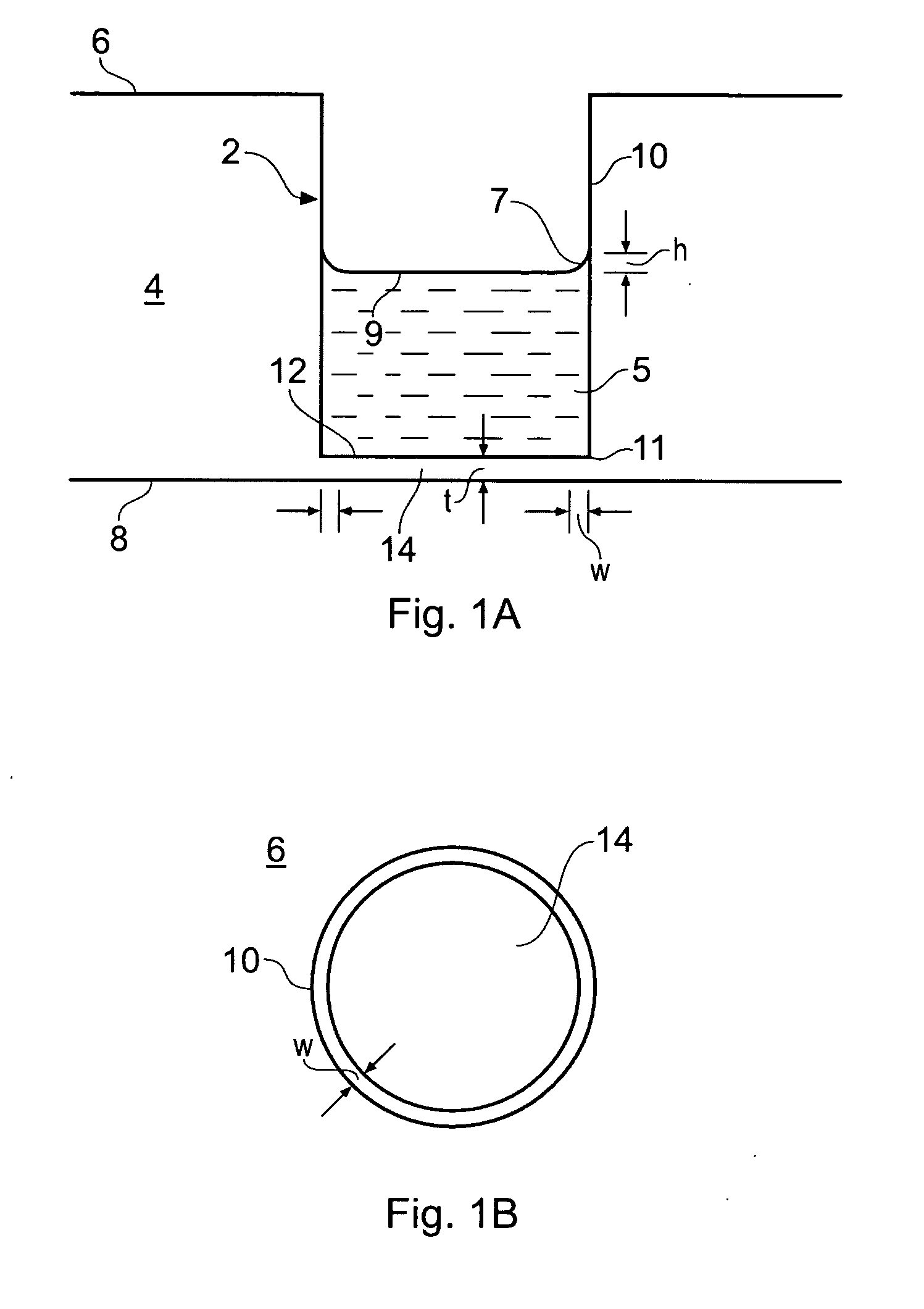

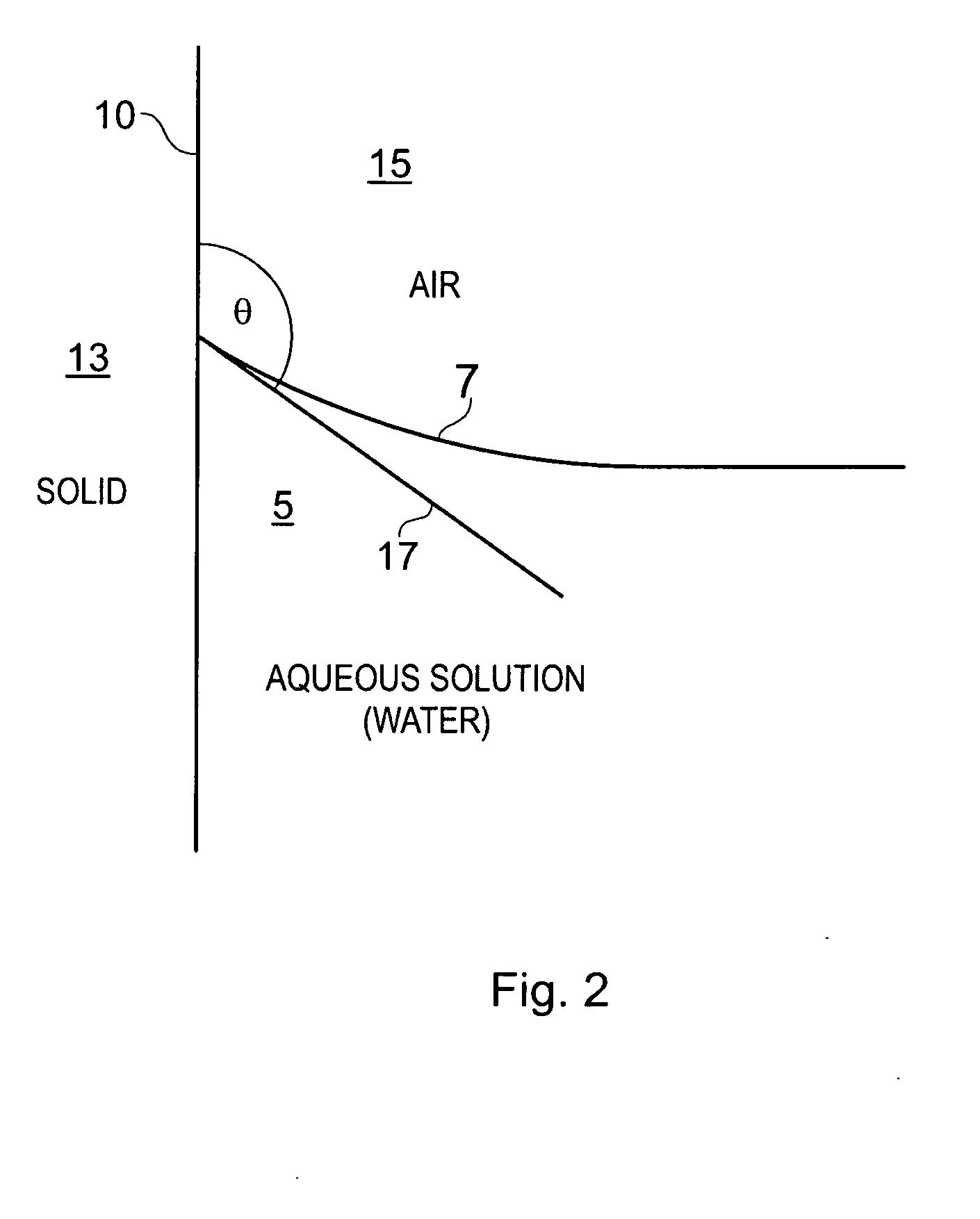

Well plate

InactiveUS20070274871A1Improve optical qualityImprove performanceAnalysis using chemical indicatorsBiochemistry apparatusPhase contrast microscopyEngineering

A well plate of non-unitary construction. The well plate is constructed from a first part of interconnected tubes that define the side walls of each well and a second part defining the well bases. The hydrophobicity of the first part is selected to suppress meniscus formation in the wells, thereby assisting optical characterization of samples in the wells, in particular by phase contrast microscopy. This can be achieved by using a natural cycloolefin copolymer (COP) which is not subjected to the usual plasma treatment to improve its wetting. The second part is formed of a single transparent sheet of hydrophilic material, such as a COP, which is bonded to the first part, for example ultrasonically.

Owner:GENETIX LTD

Compositions of ethylene/α-olefin multi-block interpolymer for elastic films and laminates

ActiveUS7737215B2Good physical propertiesElasticityPersonal careSynthetic resin layered productsPolyolefinLow density

This invention relates to polyolefin compositions. In particular, the invention pertains to elastic polymer compositions that can be more easily processed on cast film lines, extrusion lamination or coating lines. The compositions of the present invention preferably comprise an elastomeric polyolefin resin and a high pressure low density type resin.

Owner:DOW GLOBAL TECH LLC

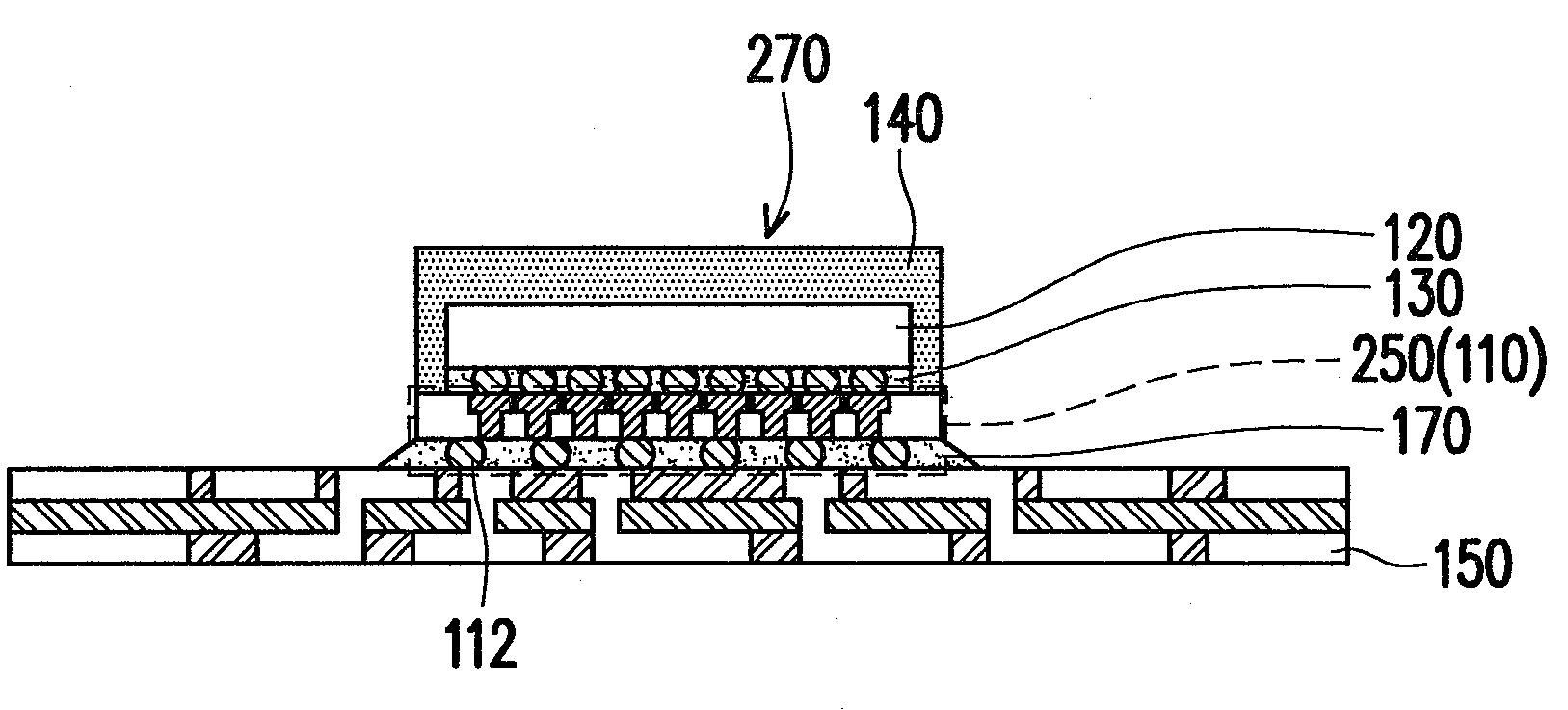

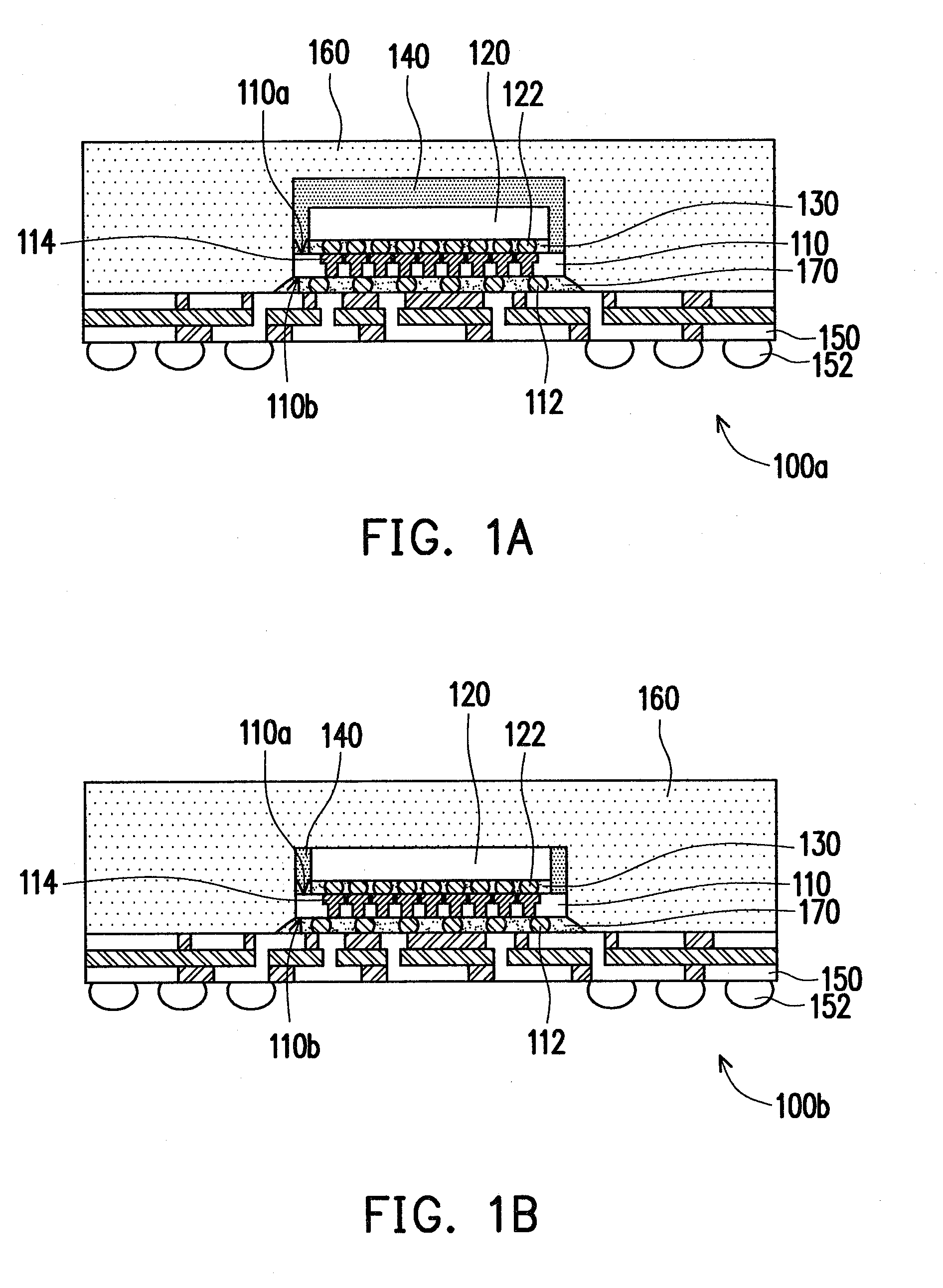

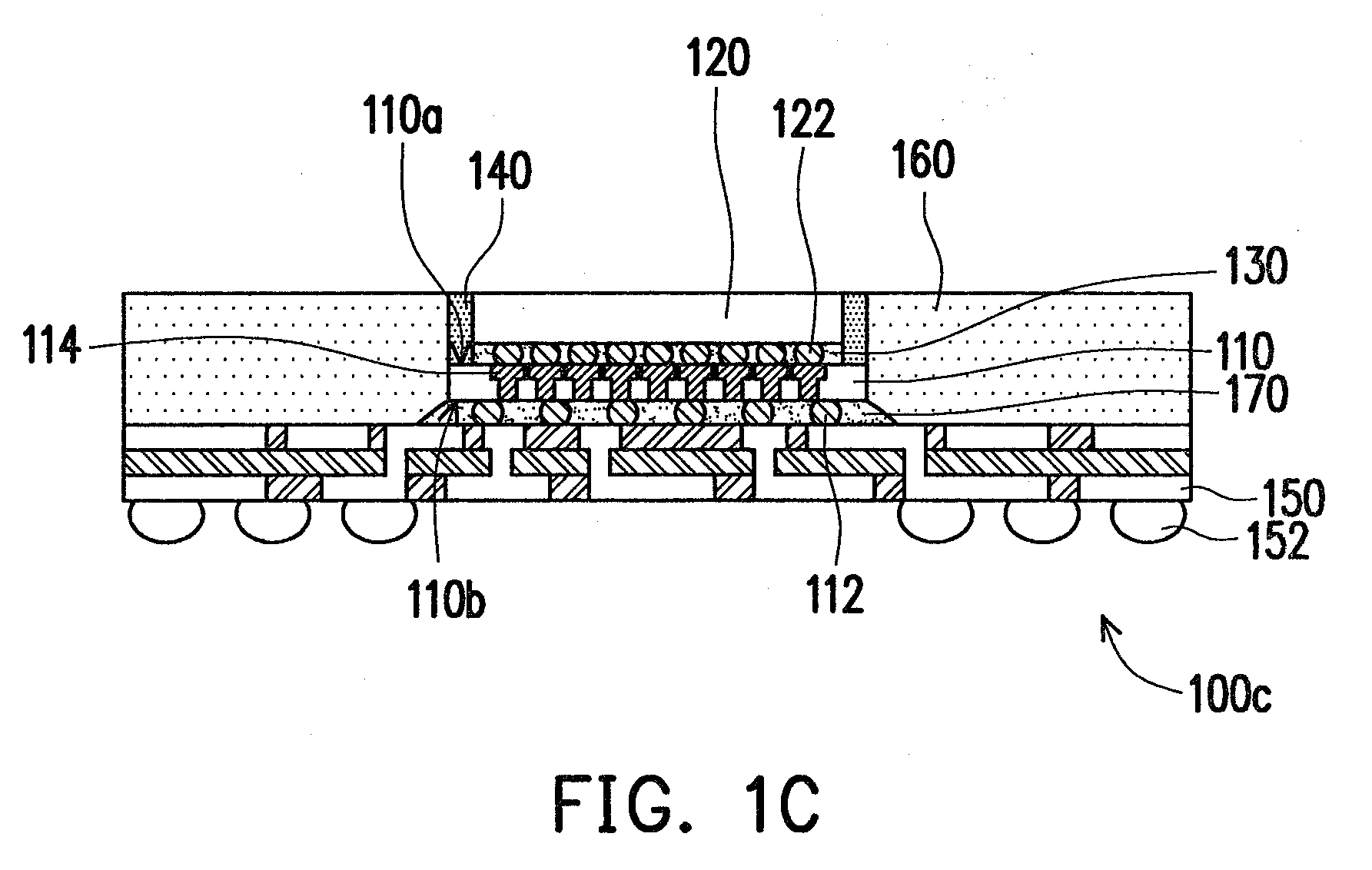

Package process and package structure

InactiveUS20100327465A1Reduce package thicknessAvoid fracturesFinal product manufactureSemiconductor/solid-state device detailsEngineeringSemiconductor

A package process is provided. First, a semiconductor substrate is disposed on a carrier, in which a surface of the carrier has an adhesive layer and the semiconductor substrate is bonded to the carrier by the adhesive layer. Next, a chip is bonded on the semiconductor substrate by flip chip technique and a first underfill is formed between the chip and the semiconductor substrate to encapsulate a plurality of first conductive bumps at the bottom of the chip. Then, a first molding compound is formed on the semiconductor substrate. The first molding compound at least encapsulates the side surface of the chip and the first underfill. Finally, the semiconductor substrate together with the chip and the first molding compound located thereon are separated from the adhesive layer of the carrier to form an array package structure.

Owner:ADVANCED SEMICON ENG INC

Semiconductor light-emitting element

ActiveUS20130161682A1Rise in element-driving voltagePatterning process difficultSemiconductor devicesInsulation layerEngineering

There is provided a semiconductor light-emitting element which has an electrode structural body including a connection electrode and a wiring electrode connected to the connection electrode, the wiring electrode stretching along a surface of a semiconductor layered body while being in partial contact with the surface of the semiconductor layered body exposed from an opening formed on the insulation layer. The area of a contact region between the wiring electrode and the semiconductor layered body increases, from a connection end which is connected to the connection electrode, along a direction in which the wiring electrode stretches.

Owner:STANLEY ELECTRIC CO LTD

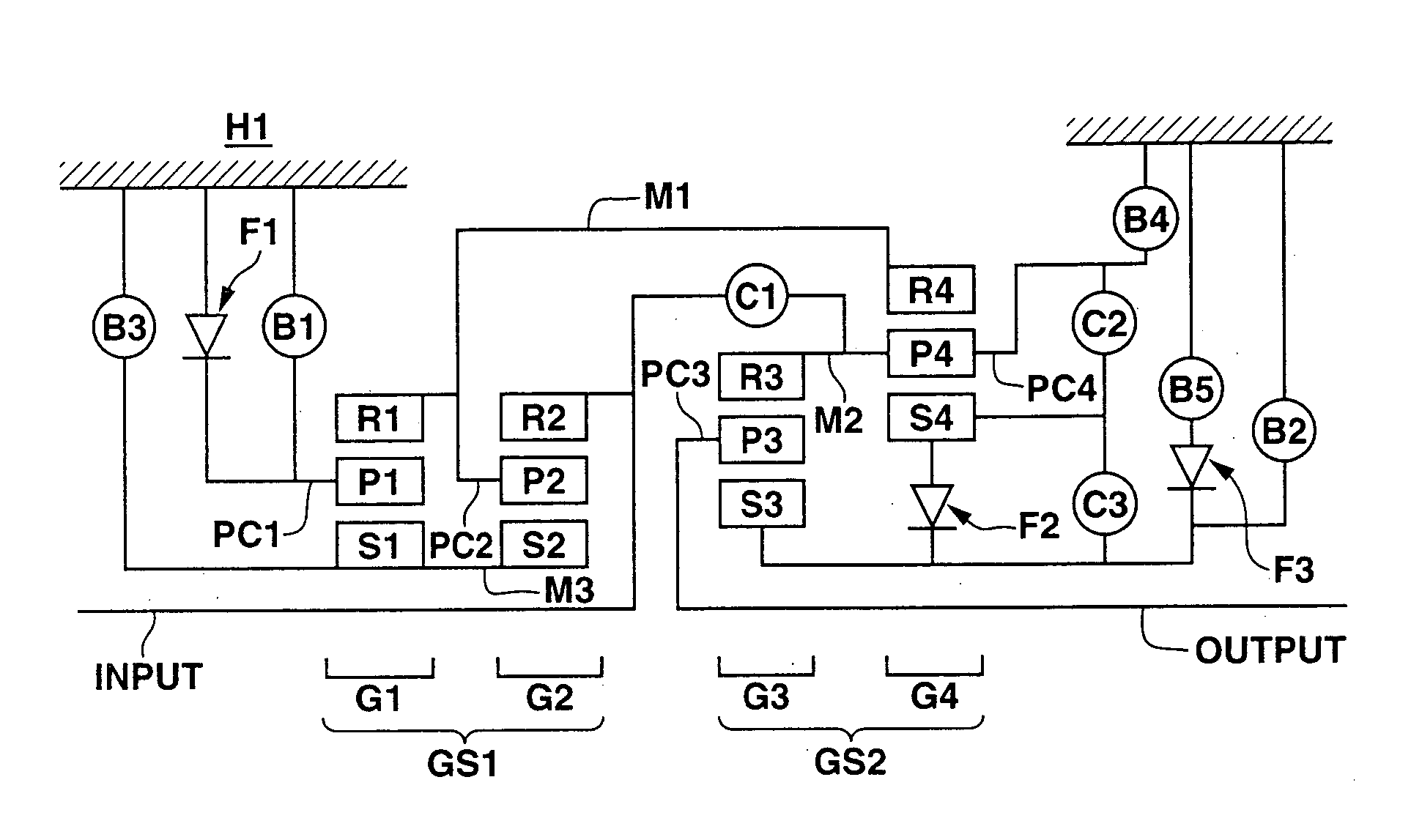

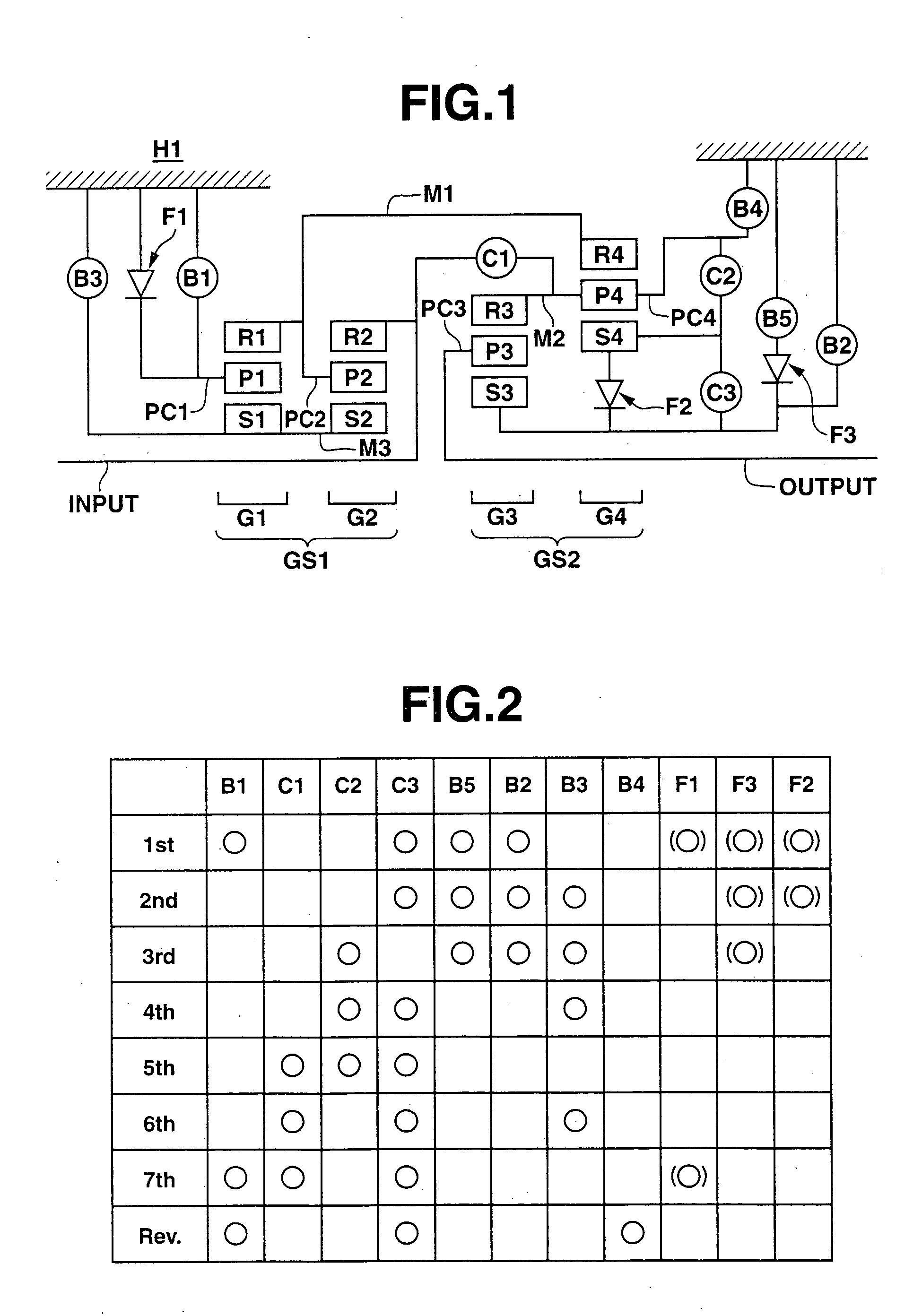

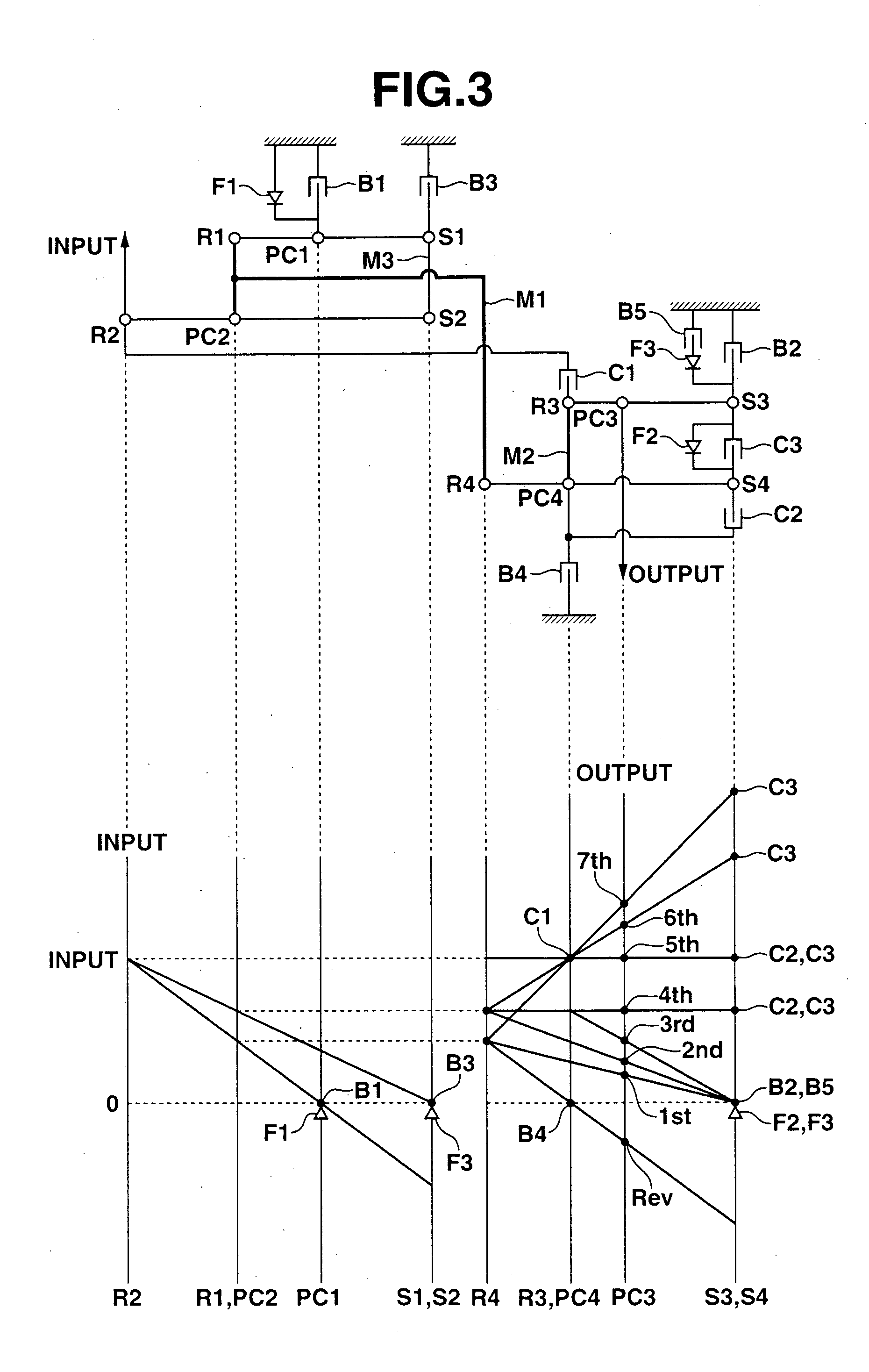

Power transmission mechanism

ActiveUS20050113205A1Difficult to processIncrease manufacturing costToothed gearingsTransmission elementsAutomatic transmissionEngineering

A power transmission mechanism for an automatic transmission, configured to establish seven or more forward speeds and one reverse speed. The power transmission mechanism includes four simple planetary gears, three connection members interconnecting two of the rotating members of the planetary gears, three clutches selectively connectable between two of the rotating members, and four brakes each operable to hold selectively against rotation one of the rotating members.

Owner:JATCO LTD

Absorbent articles comprising biodegradable PHA copolymers

InactiveUS6160199AProtect and promote and control plant growthRaise the ratioSynthetic resin layered productsBaby linensBiodegradable copolymersPolymer chemistry

The present invention relates to biodegradable PHA copolymers comprising at least two randomly repeating monomer units. The present invention further relates to a plastic article comprising a biodegradable copolymer, wherein the biodegradable copolymer comprises at least two randomly repeating monomer units (RRMU) wherein the first RRMU has the structure wherein R1 is H, or C1 or C2 alkyl, and n is 1 or 2; the second RRMU has the structure and wherein at least 50% of the RRMUs have the structure of the first RRMU. The present invention further relates to an absorbent article comprising a liquid pervious topsheet, a liquid impervious backsheet comprising a film comprising a PHA of the present invention and an absorbent core positioned between the topsheet and the backsheet.

Owner:DANIMER IPCO LLC

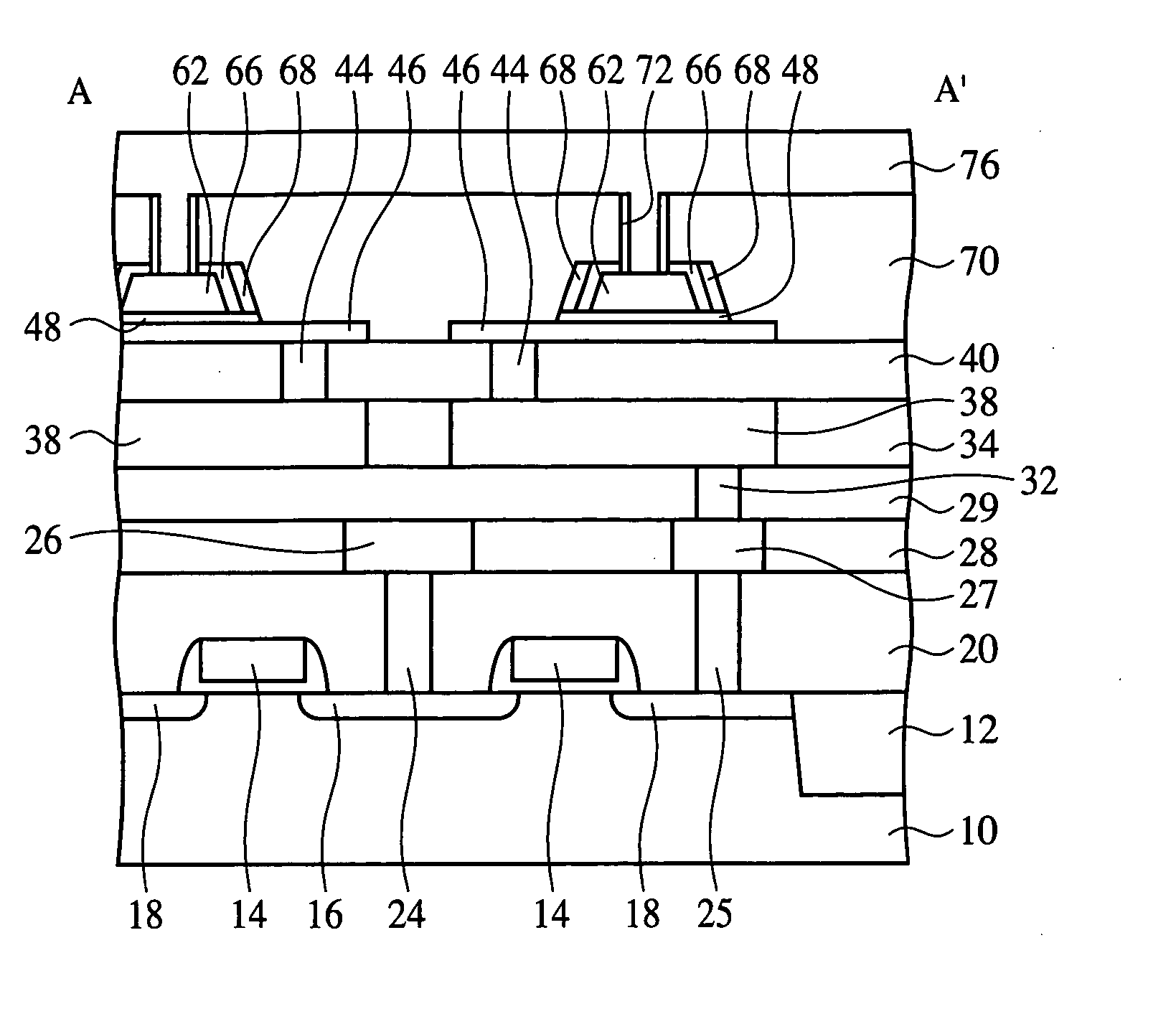

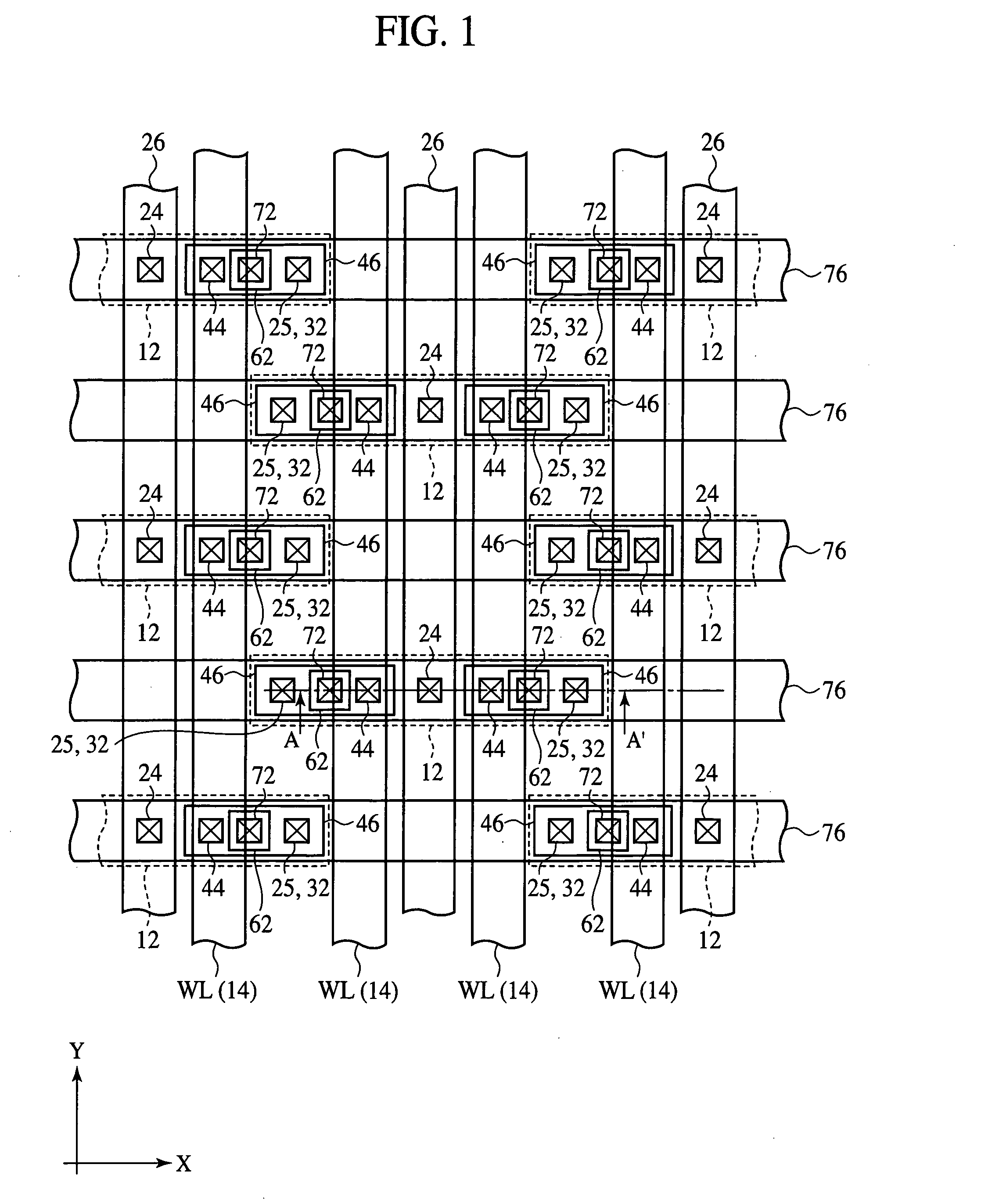

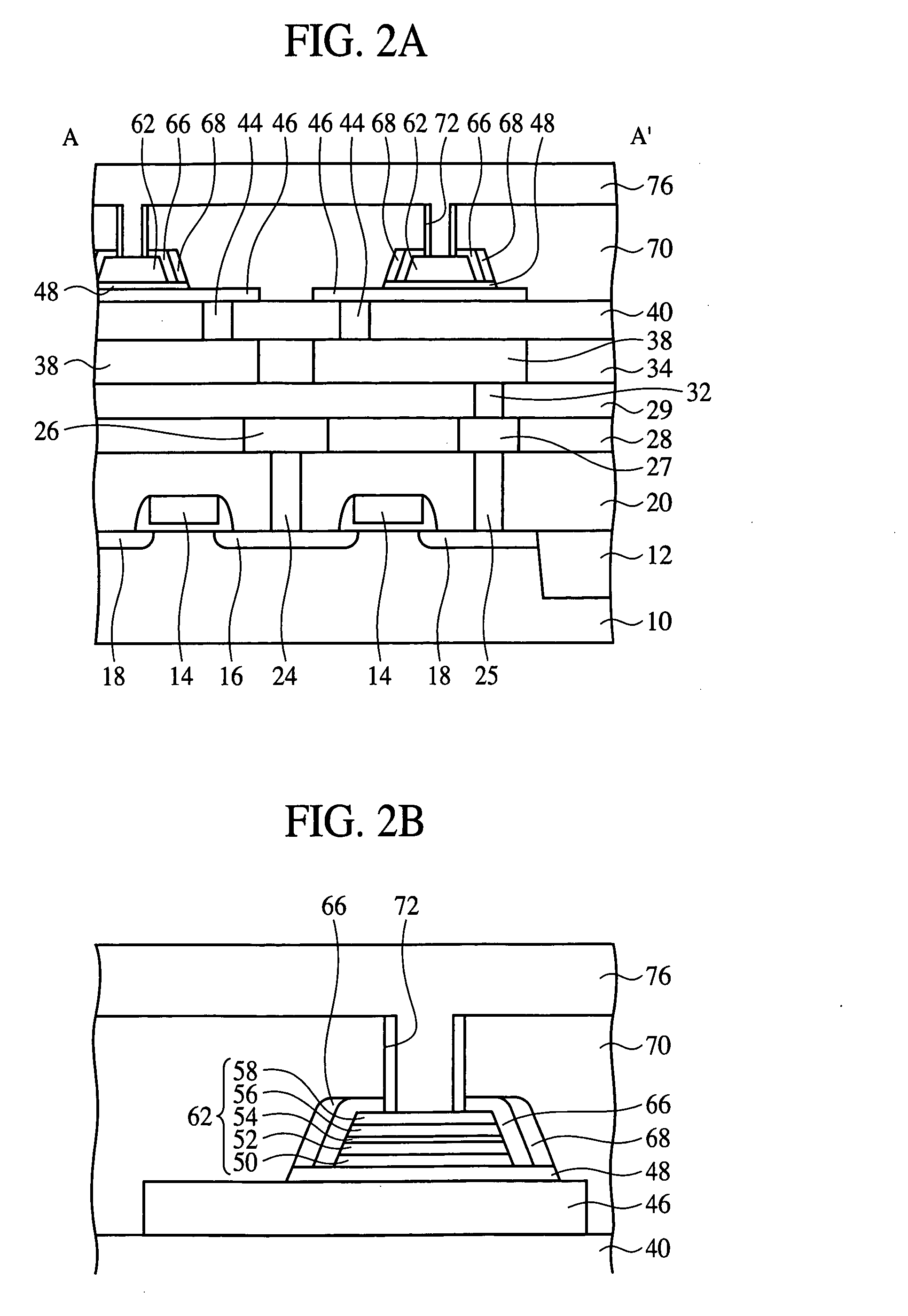

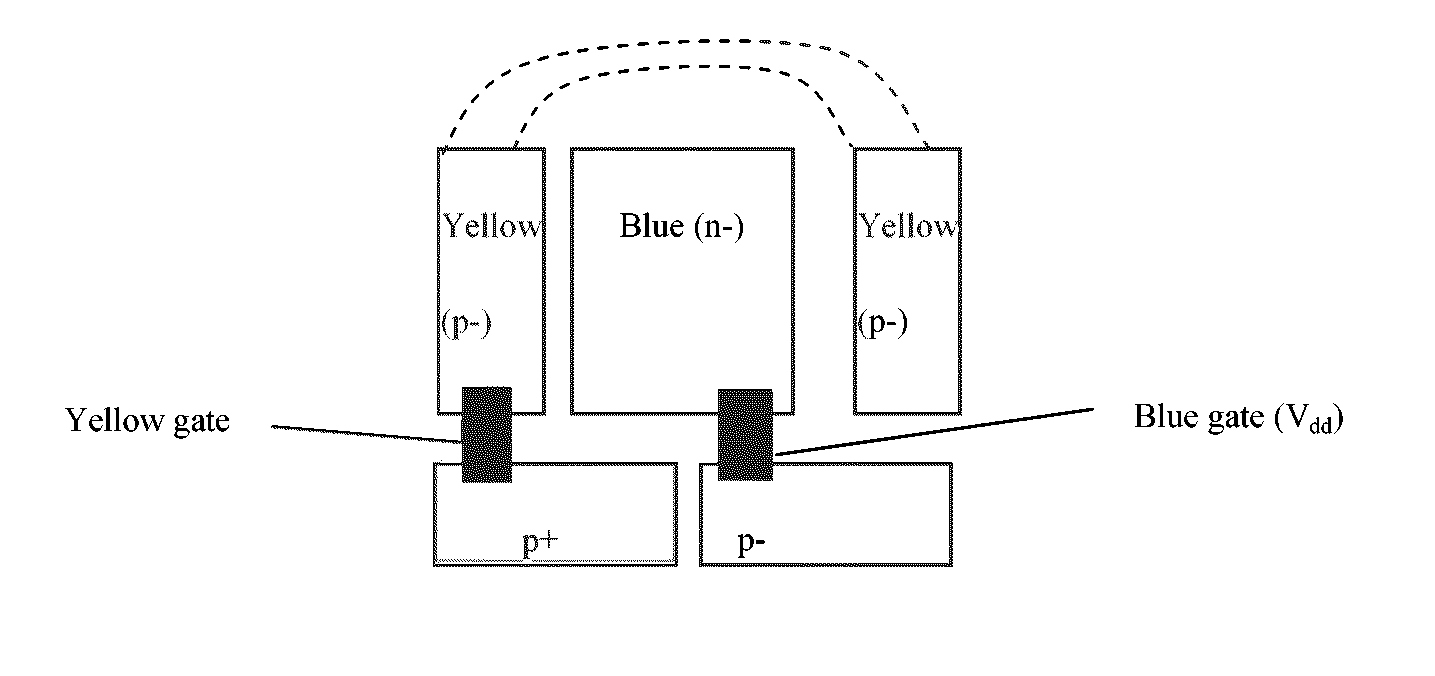

Magnetic memory device and method for fabricating the same

InactiveUS20070241410A1Fabrication processDifficult to processNanoinformaticsMagnetic-field-controlled resistorsMagnetic memoryMagnetization

The magnetic memory device includes a magnetic shield film 48, and a magnetoresistive effect element 62 formed over the magnetic shield film 48 and including a magnetic layer 52, a non-magnetic layer 54 and a magnetic layer 56, in which a magnetization direction of the first magnetic layer or the second magnetic layer is reversed by spin injection, and a second magnetic shield film 68 formed over the side wall of the magnetoresistive effect element 62. Thus, the arrival of the leakage magnetic field from the interconnection near the magnetoresistive effect element 62 can be effectively prevented.

Owner:FUJITSU LTD

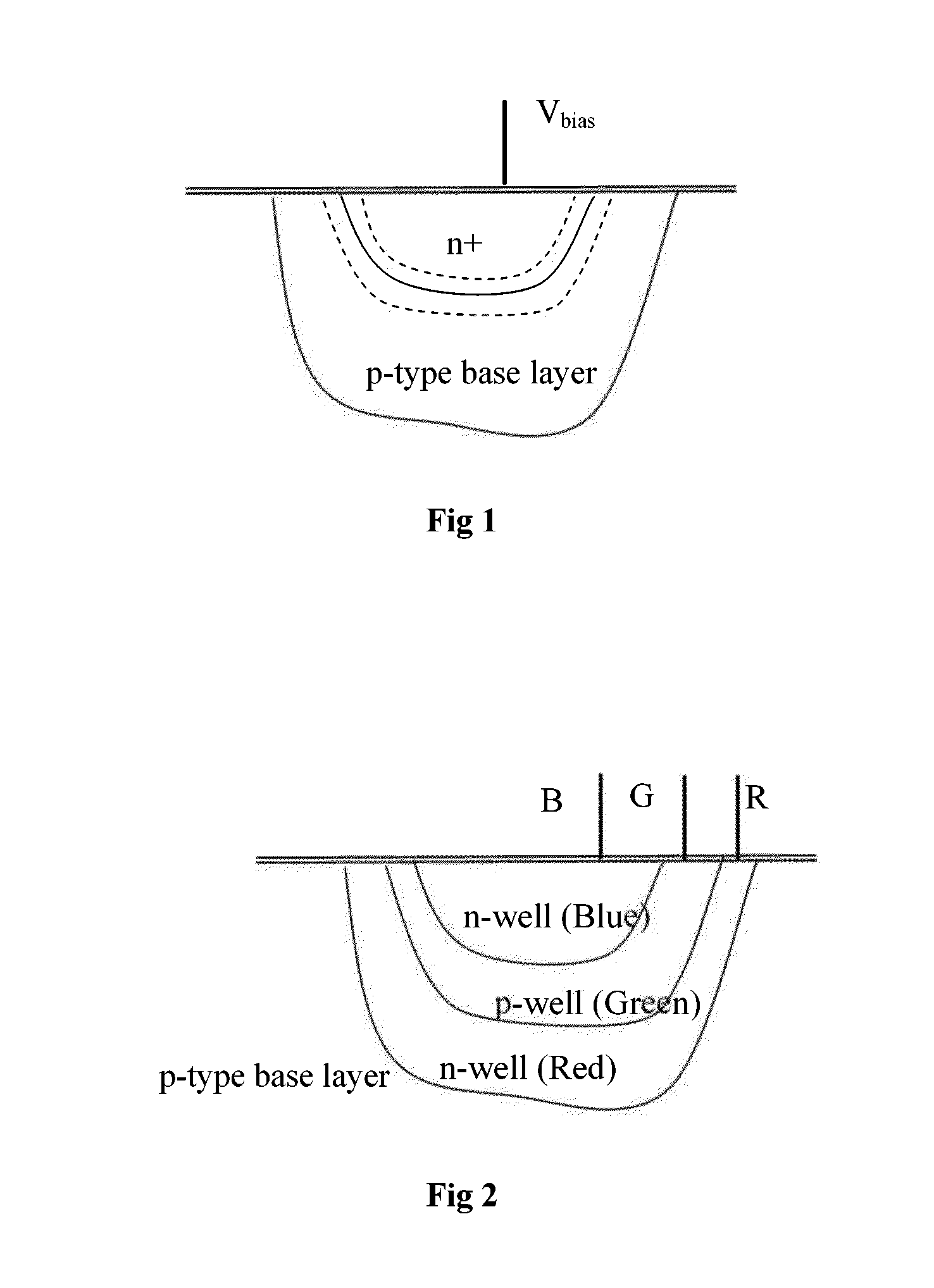

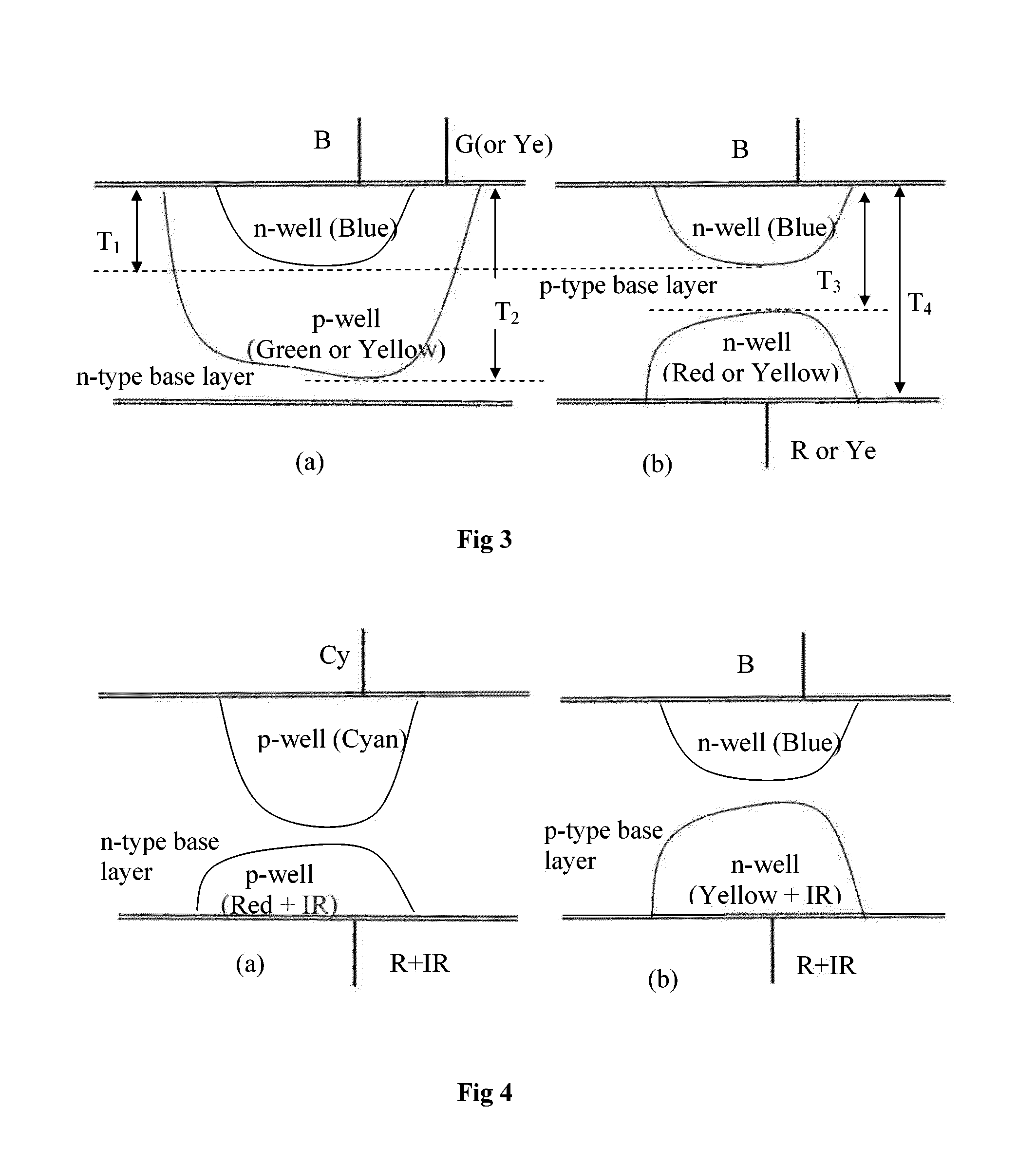

Multi-spectrum photosensitive device

ActiveUS20130062506A1Color sensing performanceGood colorSolid-state devicesMaterial analysis by optical meansN type siliconVisible spectrum

A multi-spectrum photosensitive device comprises two, three, or four composite sensing pixels arranged in layers up and down in a base layer of P-type or N-type silicon by means of single-sided processing or double-sided processing, each composite sensing pixels can sense respectively spectrum orthogonal or complementary to each other in visible light or visible and infrared light. The basic sensing pixels on different layers of the composite sensing pixels can be designed to sense different colors or spectrums, so that a multi-spectrum photosensitive chip can be achieved by repeatedly arranging the macro units consisting of more than one composite sensing pixel. The present disclosure also includes a new multi-layer sensing pixel, and examples of which used in a single-sided double-layer, or a double-sided double-layer, or a double-sided three-layer, or a double-sided four-layer, or a single-sided mixed double-layer, or a double-sided mixed with double-layer or a multi-layer multi-spectrum sensing device. A multi-spectrum photosensitive device according to the present disclosure has the advantage of better color sensing performance, integration of color sensing and infrared sensing, and a simple processing technique.

Owner:BOLY MEDIA COMM SHENZHEN

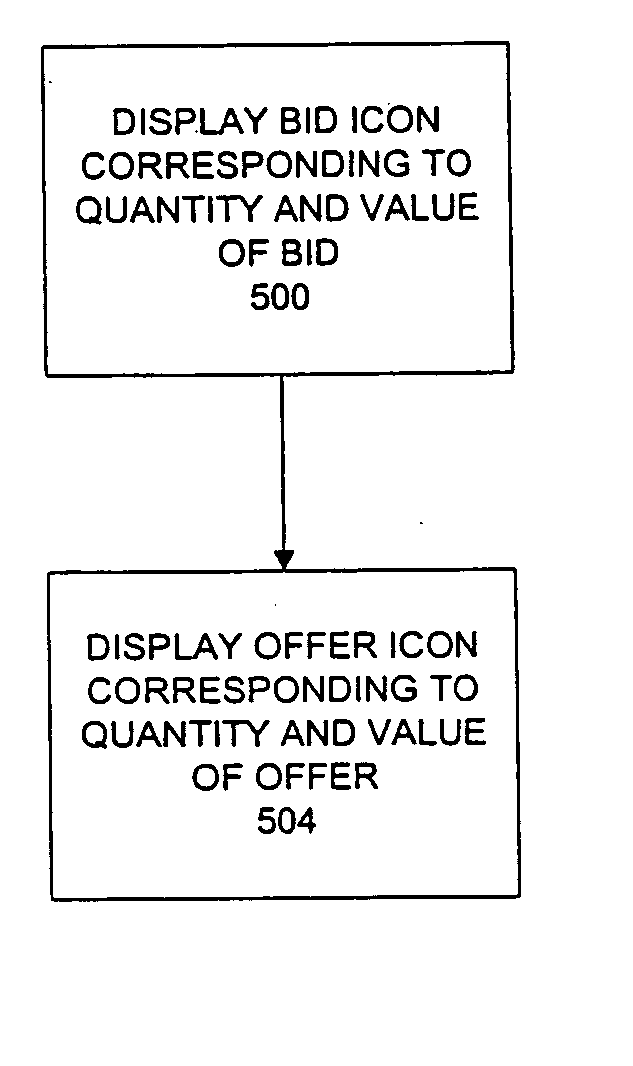

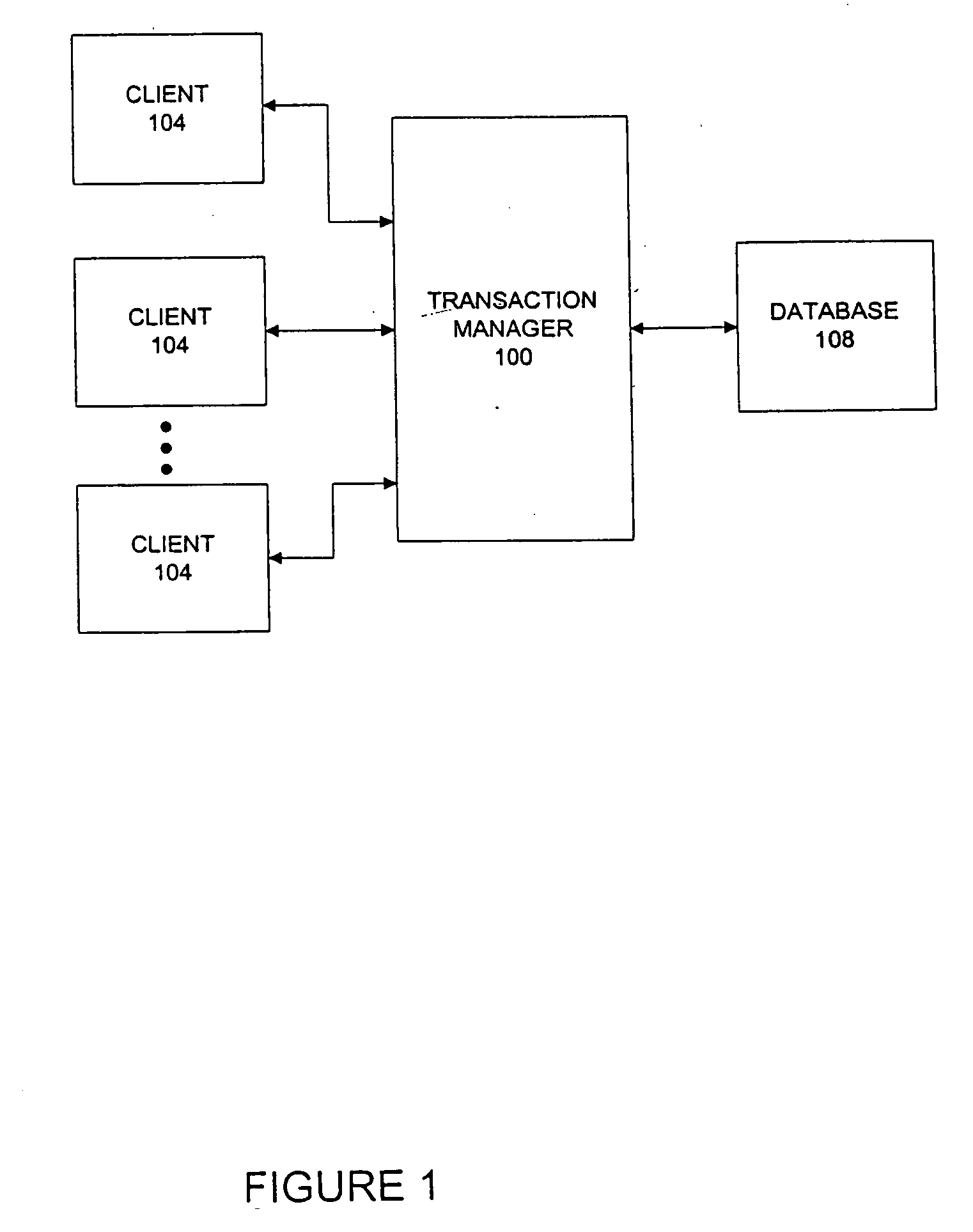

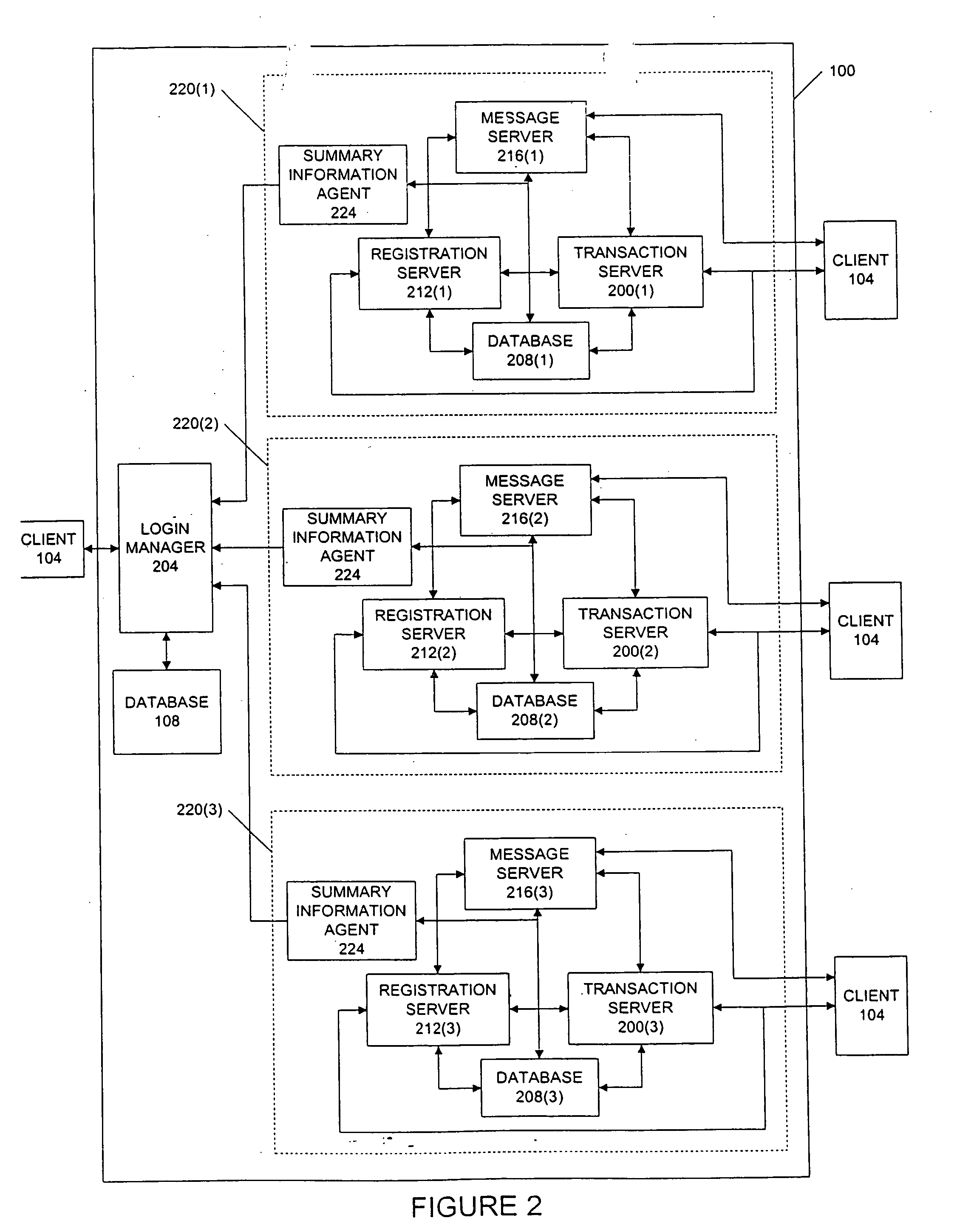

User interface for an electronic trading system

InactiveUS20060259405A1Improve abilitiesMake fastFinanceDigital computer detailsMultiple contextData source

A user interface for an electronic trading exchange is provided which allows a remote trader to view in real time bid orders, offer orders, and trades for an item, and optionally one or more sources of contextual data. Individual traders place orders on remote client terminals, and this information is routed to a transaction server. The transaction server receives order information from the remote terminals, matches a bid for an item to an offer for an item responsive to the bid corresponding with the offer, and communicates outstanding bid and offer information, and additional information (such as trades and contextual data) back to the client terminals. Each client terminal displays all of the outstanding bids and offers for an item, allowing the trader to view trends in orders for an item. A priority view is provided in which orders are displayed as tokens at locations corresponding to the values of the orders. The size of the tokens reflects the quantity of the orders. An alternate view positions order icons at a location which reflects the value and quantity of the order. Additionally, contextual data for the item is also displayed to allow the trader to consider as much information as possible while making transaction decisions. A pit panel view is also provided in which traders connected to the pit are represented by icons, and are displayed corresponding to an activity level of the trader.

Owner:TRADING TECH INT INC

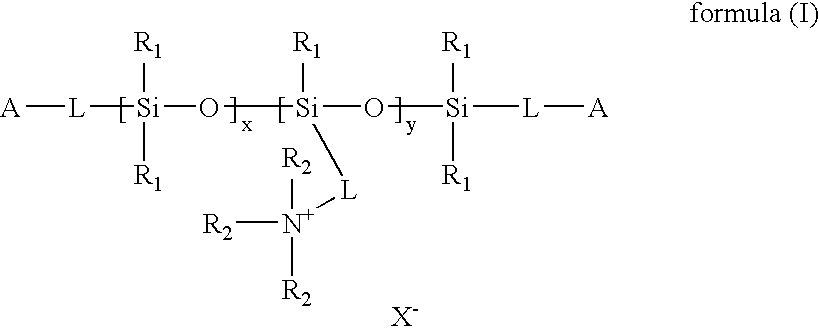

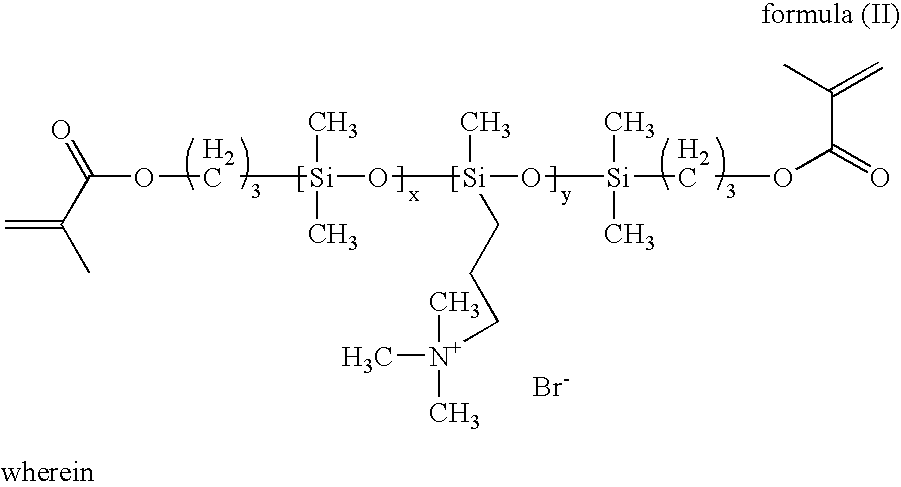

Polymerizable silicon-containing monomer bearing pendant cationic hydrophilic groups

InactiveUS20070161769A1Significant hydrophilic characterImprove solubilityOptical elementsEnd-groupSide chain

The present invention relates to polymeric compositions useful in the manufacture of biocompatible medical devices. More particularly, the present invention relates to novel siloxanyl random copolymers bearing polymerizable activated unsaturated end-groups and containing a hydrophilic, cationic substituent in the polymer chain which are capable of polymerization to form transparent polymeric compositions having high water contents; characteristics useful in the manufacture of ophthalmic devices. The polymeric compositions comprises polymerized polymerizable silicone bearing pendant cationic hydrophilic groups

Owner:BAUSCH & LOMB INC

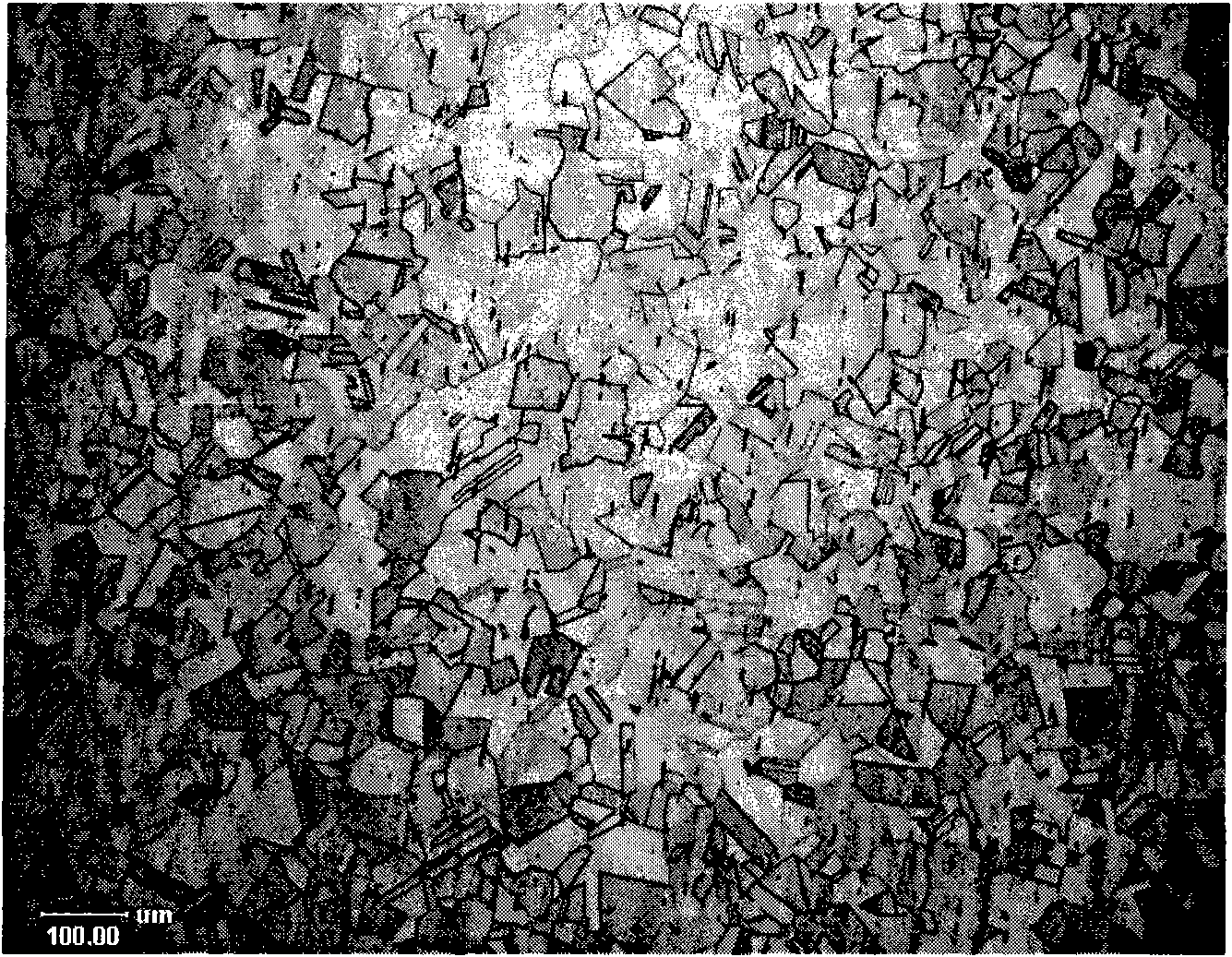

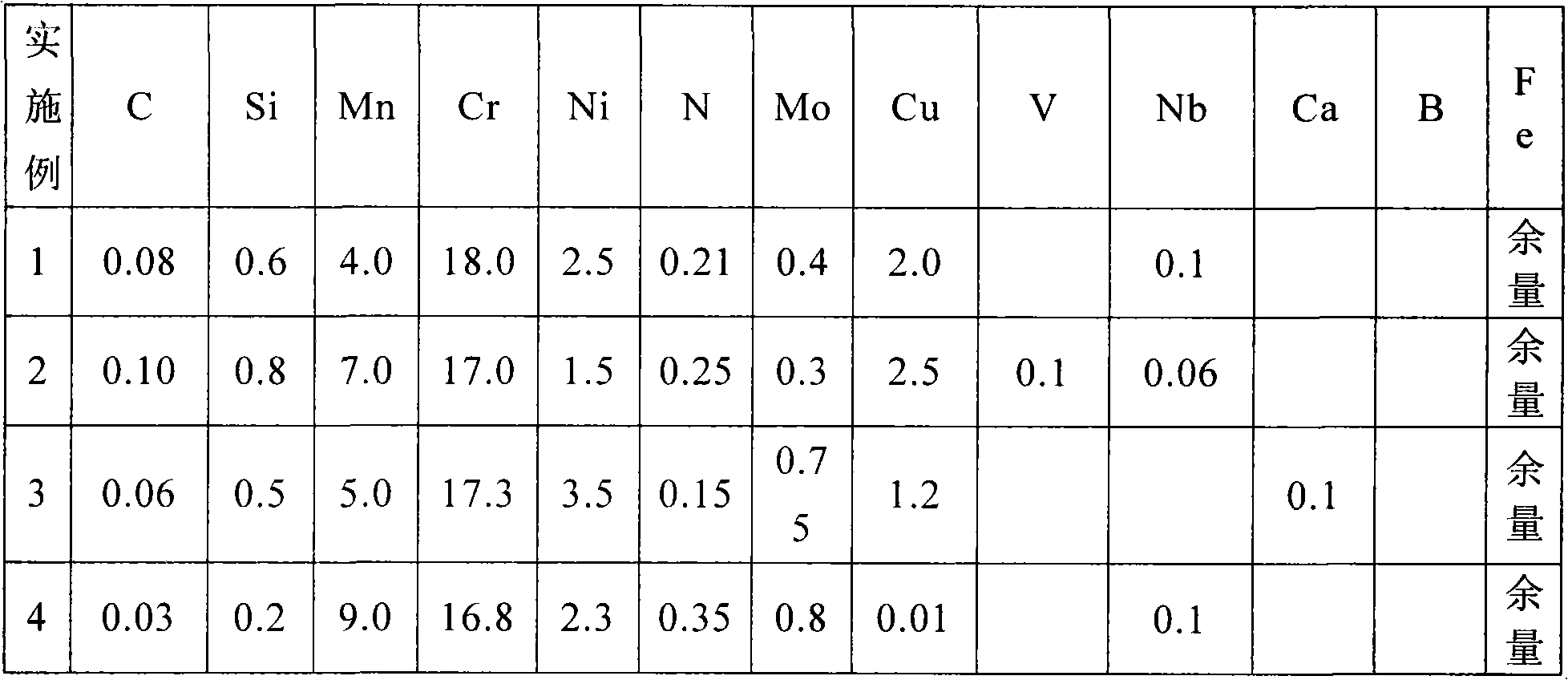

Molybdenum-containing nickel-saving austenitic stainless steel with excellent corrosion resistance and manufacturing method thereof

ActiveCN102337481ALow costReduced corrosion resistancePitting resistance equivalent numberAustenitic stainless steel

Owner:BAOSTEEL DESHENG STAINLESS STEEL

Polyvinyl chloride/chlorinated polyvinyl chloride skin foamed sheet and preparation method thereof

InactiveCN102040785AHigh surface hardnessIncrease productivityAntioxidantChlorinated polyvinyl chloride

The invention relates to a polyvinyl chloride / chlorinated polyvinyl chloride skin foamed sheet and a preparation method thereof, and the polyvinyl chloride / chlorinated polyvinyl chloride skin foamed sheet comprises the following materials in parts by weight: 60-90 parts of polyvinyl chloride, 10-40 parts of chlorinated polyvinyl chloride, 2.8-7 parts of stabilizer, 3-5 parts of foam regulator, 1-3 parts of foam nucleating agent, 0.5-2 parts of foaming agent, 0.6-1.5 parts of external lubricant, 0.5-1 part of internal lubricant, 0.5-2 parts of processing aids, 0.05-0.5 part of antioxidant and no more than 30 parts of filler. The preparation method is as follows: adding all the materials into a high-speed stirring machine, and mixing uniformly; heating to 90-120 DEG C, and carrying out heat preservation for more than 10 minutes; placing into a cold mixing machine, cooling down to 25-45 DEG C, tapping into a storage bin, extruding a foaming material through an extruder, and further carrying out vacuum shaping, cooling molding and edge trimming and finishing; and finally carrying out cutting and packaging according to the required length. The product has high surface hardness and great strength, is less prone to deformation, easy for processing, reasonable in manufacturing process, low in cost, good in quality and high in efficiency and has extensive popularization value and good economic and social benefits.

Owner:杜文军

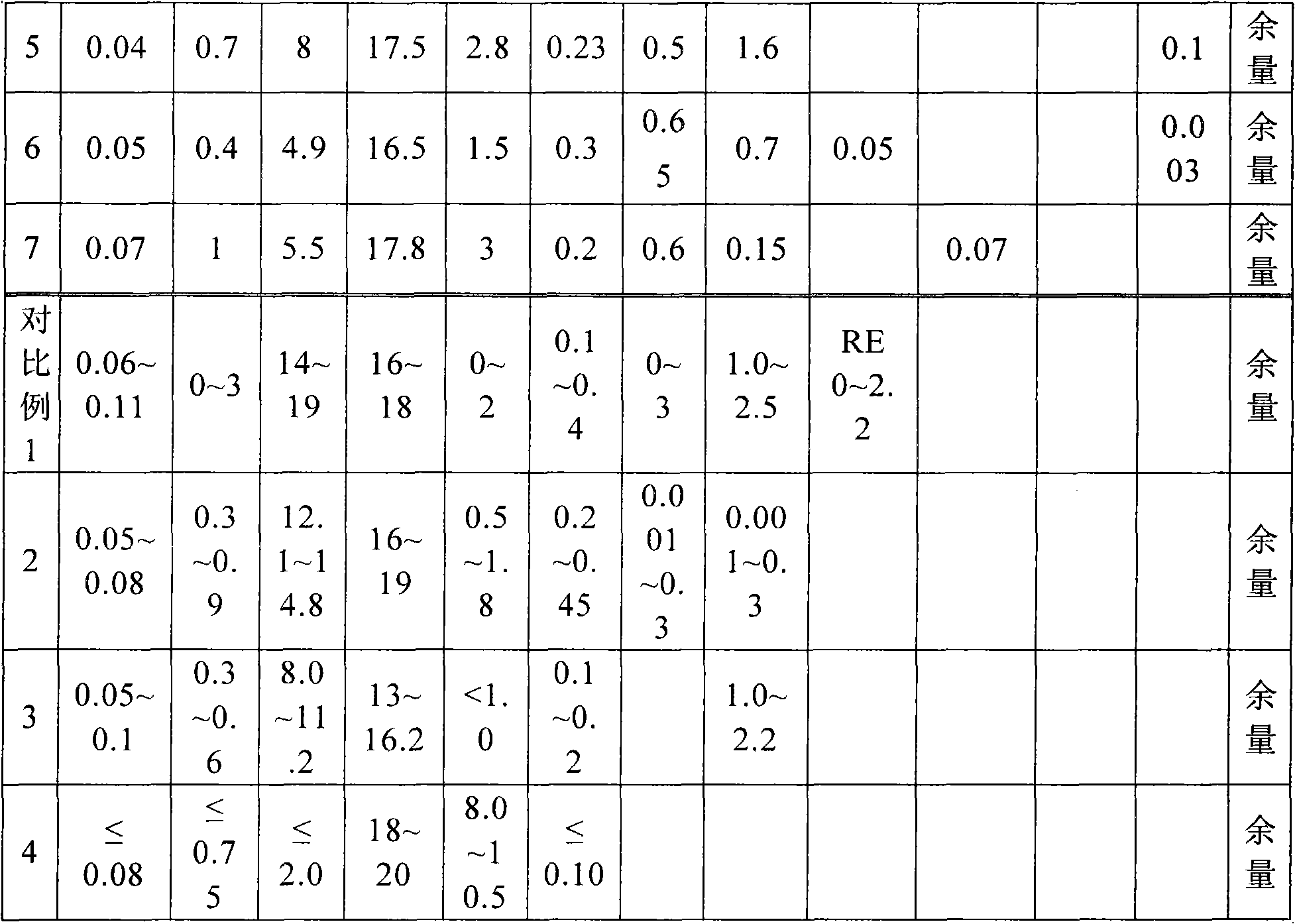

Natural acidification of frozen dairy desserts using natural plant sources

InactiveUS20160309740A1Improved texturalImproved sensorial propertyFrozen sweetsCocoaAdditive ingredientPlant Sources

The present invention relates to a frozen confection product comprising natural bean extract as acidifying agent. The present invention also relates to a method of producing a frozen confection product by adding natural bean extracts to an ingredient mix and then homogenize, pasteurize, and freeze the mix. Preferably the method uses a standard freezing step followed by low temperature freezing.

Owner:NESTEC SA

Biodegradable PHA copolymers

The present invention relates to biodegradable PHA copolymers comprising at least two randomly repeating monomer units. The present invention further relates to a plastic article comprising a biodegradable copolymer, wherein the biodegradable copolymer comprises at least two randomly repeating monomer units (RRMU) wherein the first RRMU has the structure wherein R1 is H, or C1 or C2 alkyl, and n is 1 or 2; the second RRMU has the structure and wherein at least 50% of the RRMUs have the structure of the first RRMU. The present invention further relates to an absorbent article comprising a liquid pervious topsheet, a liquid impervious backsheet comprising a film comprising a PHA of the present invention and an absorbent core positioned between the topsheet and the backsheet.

Owner:MEREDIAN

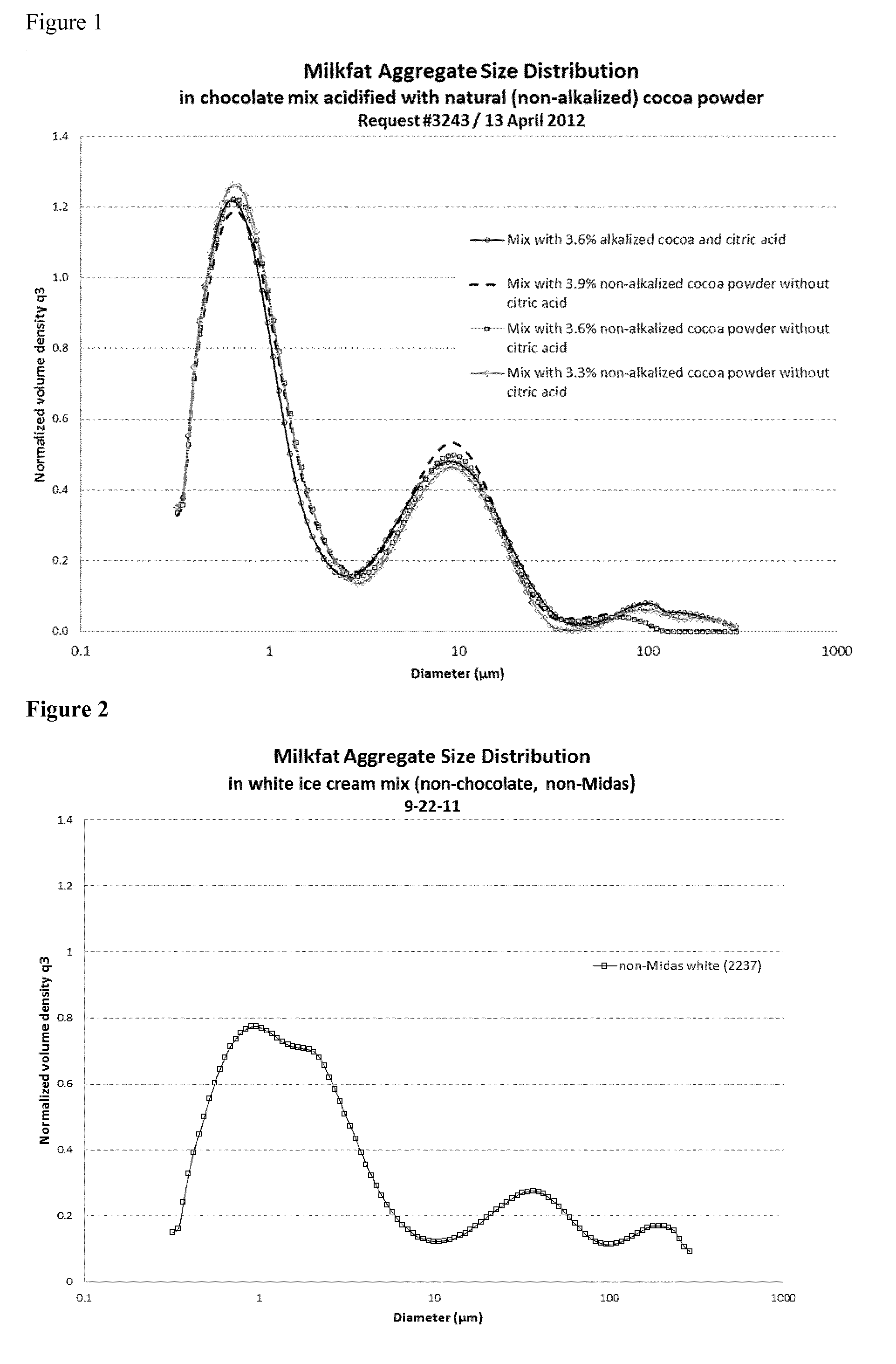

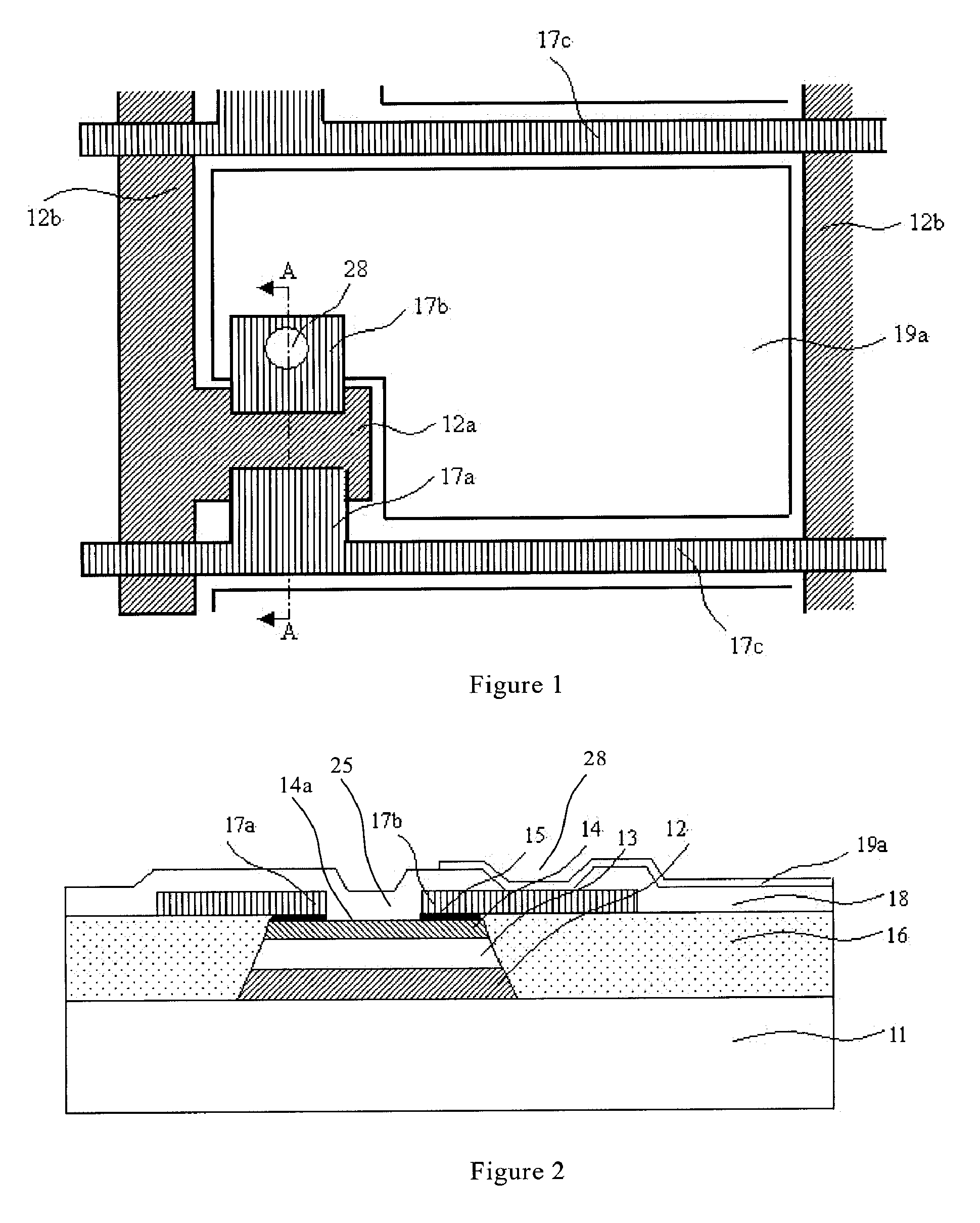

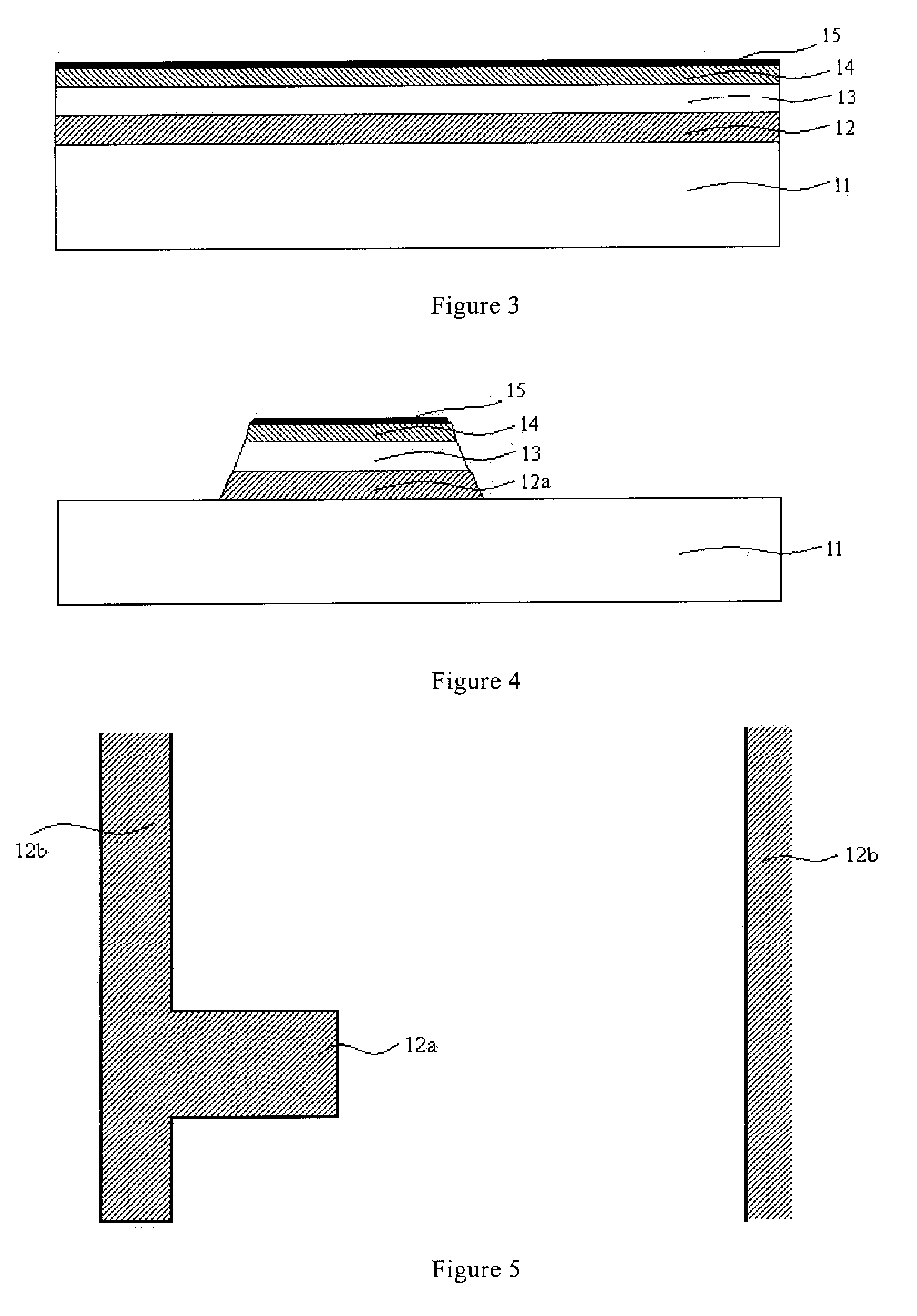

TFT array substrate and manufacturing method thereof

ActiveUS20080164470A1Difficulty costDifficult to processSolid-state devicesSemiconductor/solid-state device manufacturingOhmic contactEngineering

A TFT array substrate and a manufacturing method thereof, where the TFT array substrate includes a substrate; a gate line and a gate electrode integrated therewith, which are covered by a gate insulating layer, a semiconductor layer, and a ohmic contact layer sequentially. An insulating layer is formed on the resulting substrate and on both sides of the gate line and the gate electrode, the gate insulating layer, the semiconductor layer, and the ohmic contact layer. A trench is then formed in the ohmic contact layer to divide the ohmic contact layer over the semiconductor layer. A data line and first and second source / drain electrodes are then formed on the insulating layer and the ohmic contact layer.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD +1

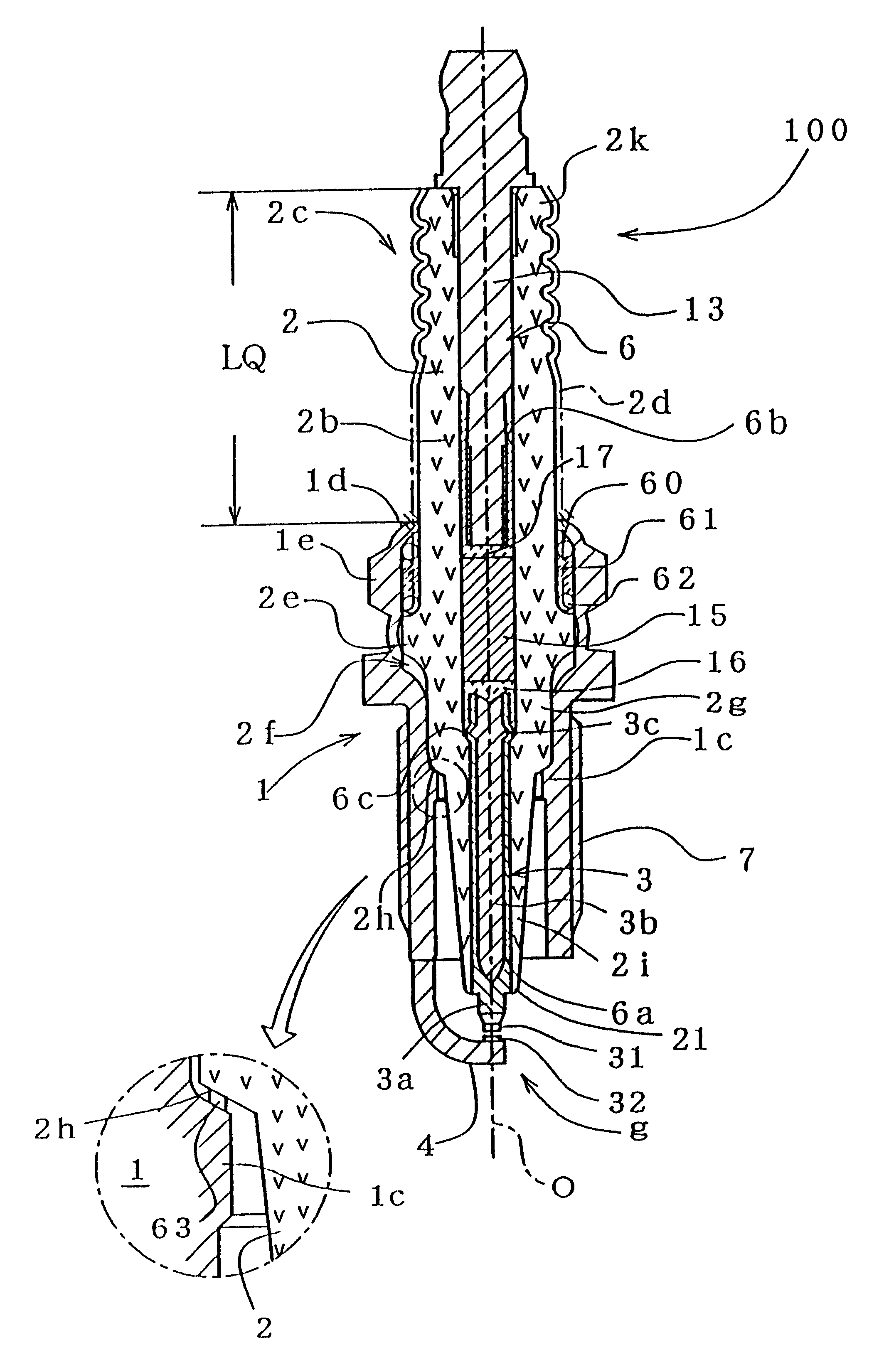

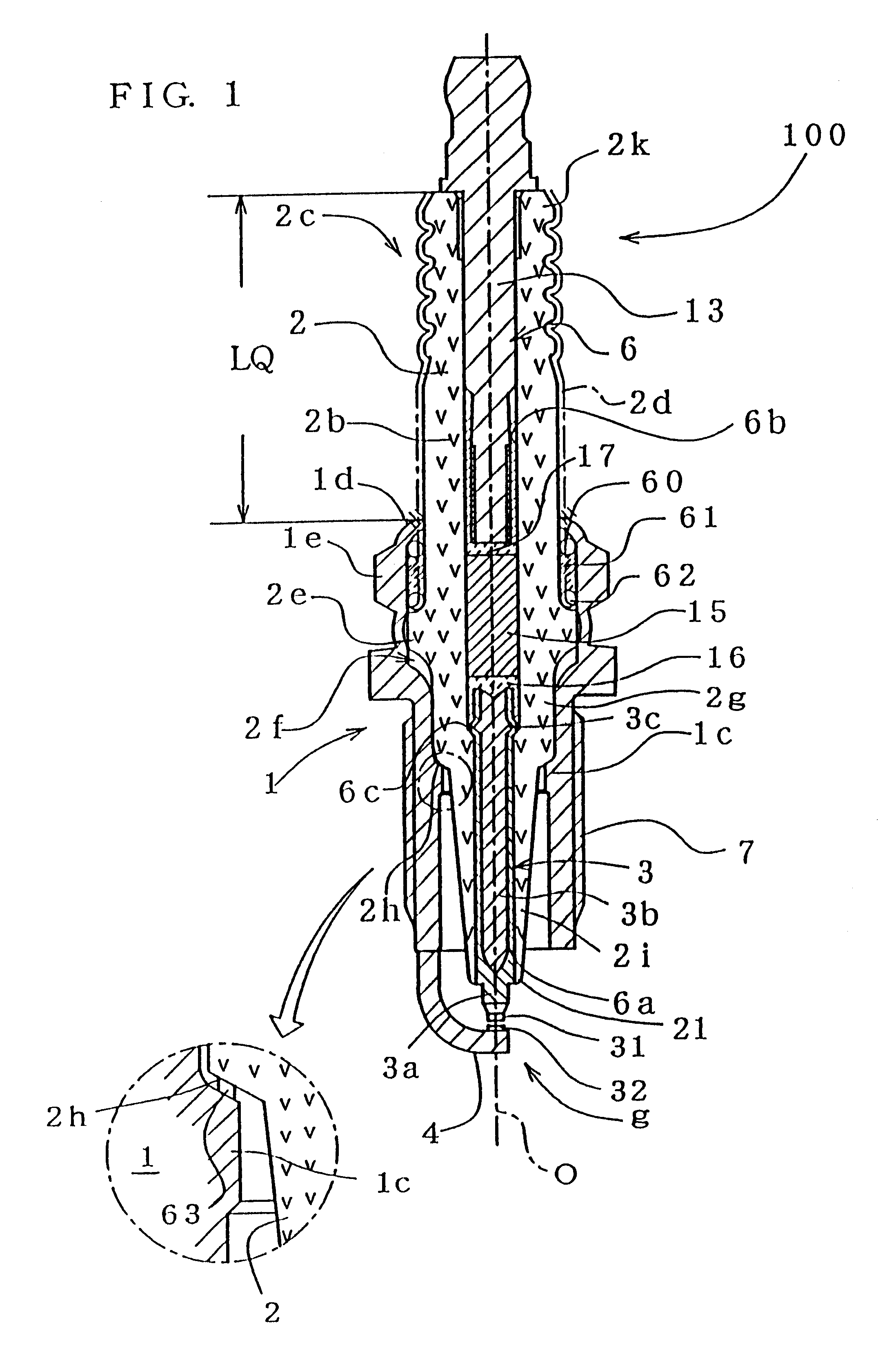

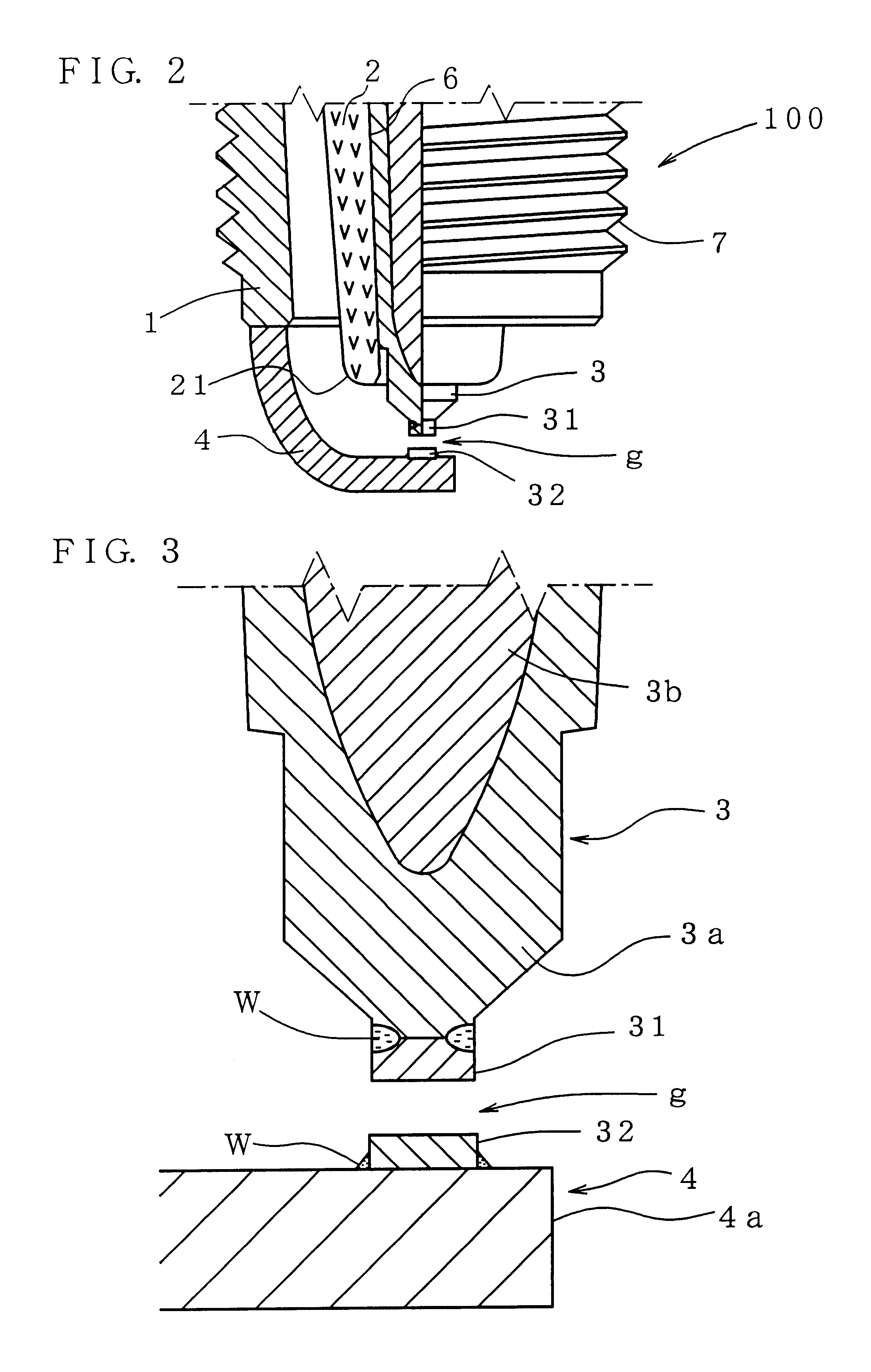

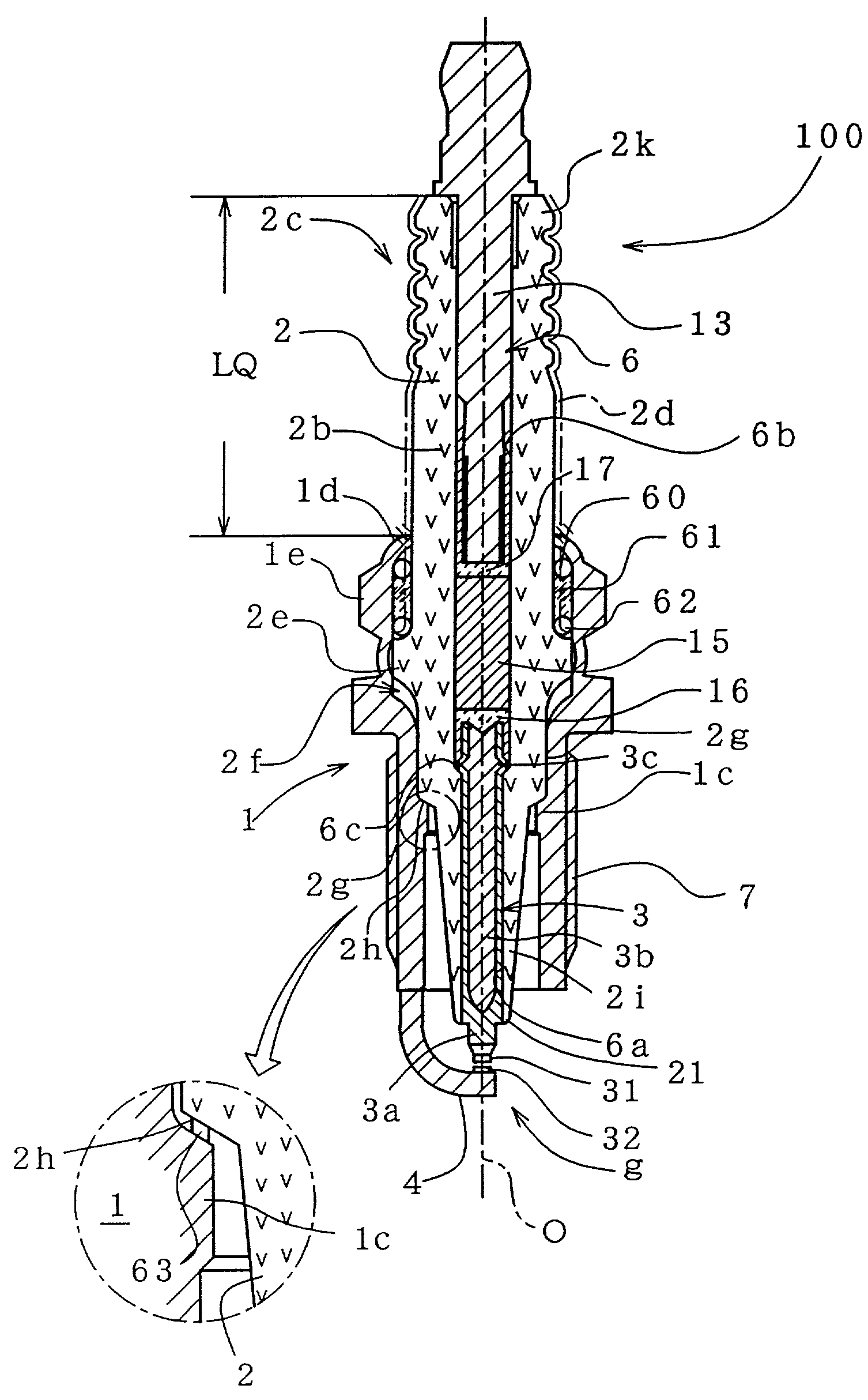

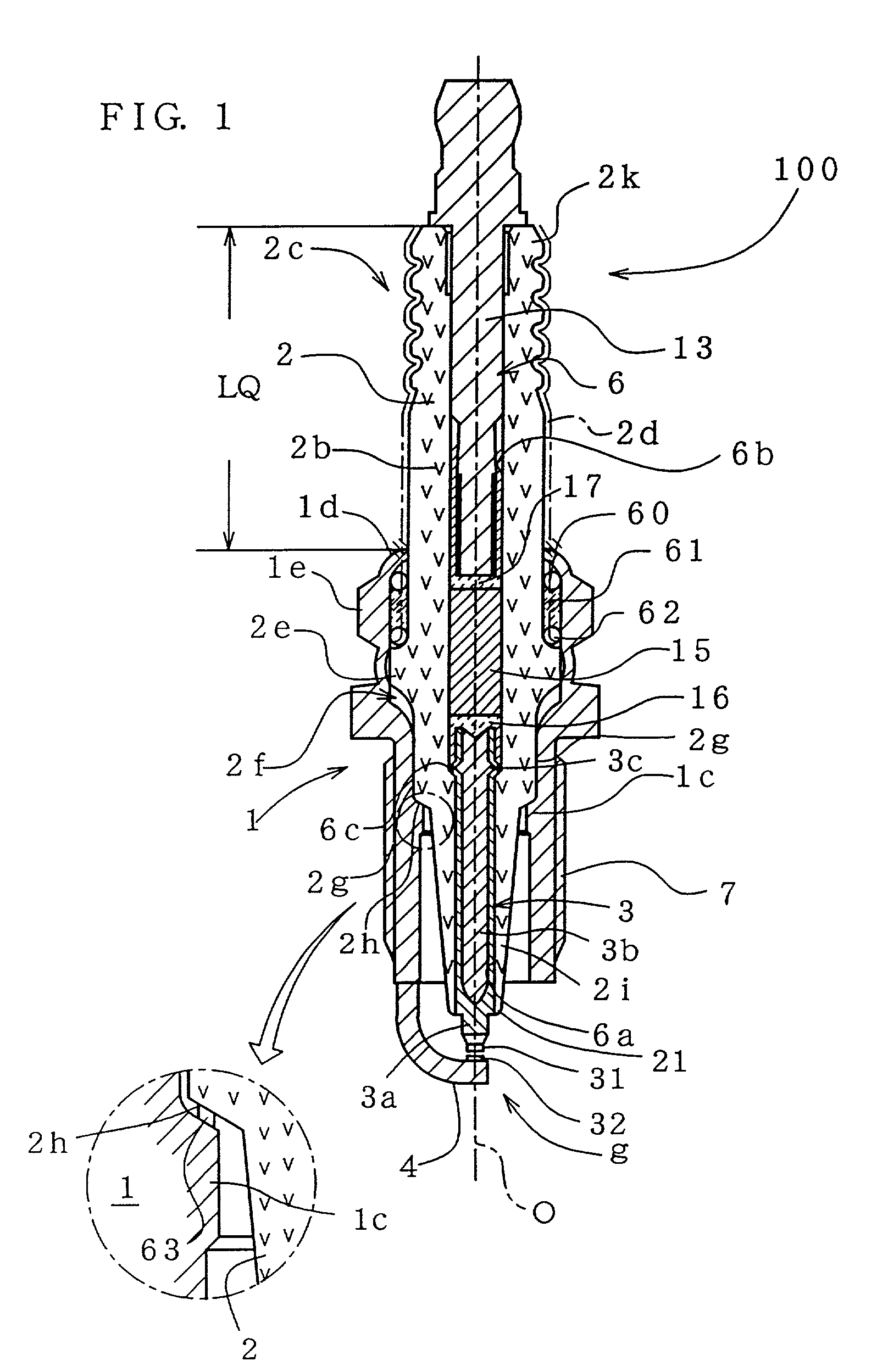

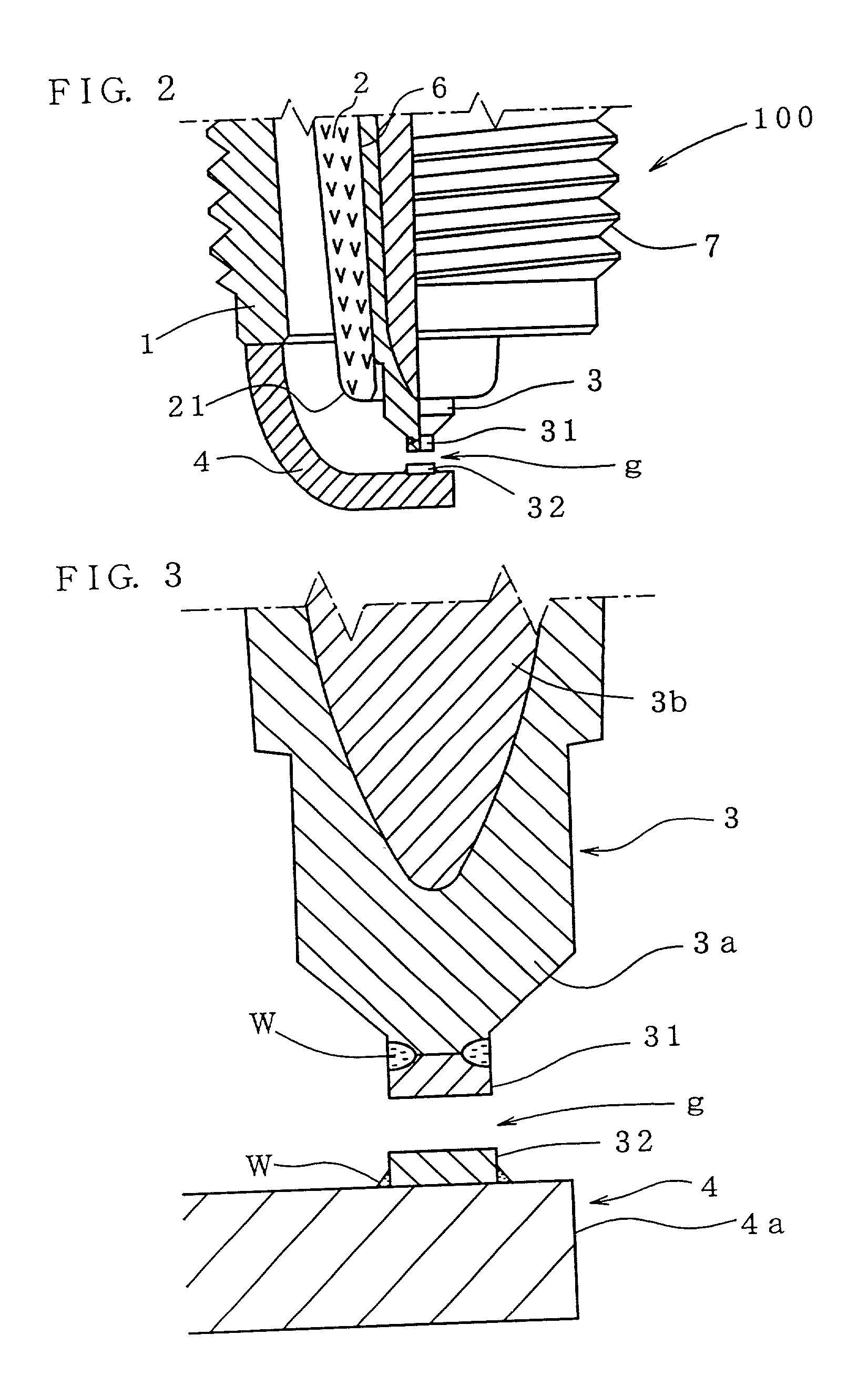

Spark plug, alumina insulator for spark plug, and method of manufacturing the same

InactiveUS6407487B1Low costLow production costSpark gapsCeramic shaping apparatusElectrical resistance and conductanceUltimate tensile strength

In insulator including alumina as a main component, a Na component in the insulator is set in the range of 0.07 to 0.5 wt % as Na2O. While the Na component content is as high as to have conventionally been regarded to be beyond the common sense, with this range of the Na component content, insulation resistance, mechanical strength and the like at high temperature are unexpectedly not reduced and an insulator with performances comparable to those of an insulator from conventional low soda alumina lower in Na component content than the above described range can be obtained. As a result, medium soda alumina and regular soda alumina that are much lower in cost than conventionally used low soda alumina can be used instead of the low soda alumina, so that dramatic reduction in production costs of insulator 2 for a spark plug 100 and in addition, of the spark plug 100 using the insulator 2 are realized.

Owner:NGK SPARK PLUG CO LTD

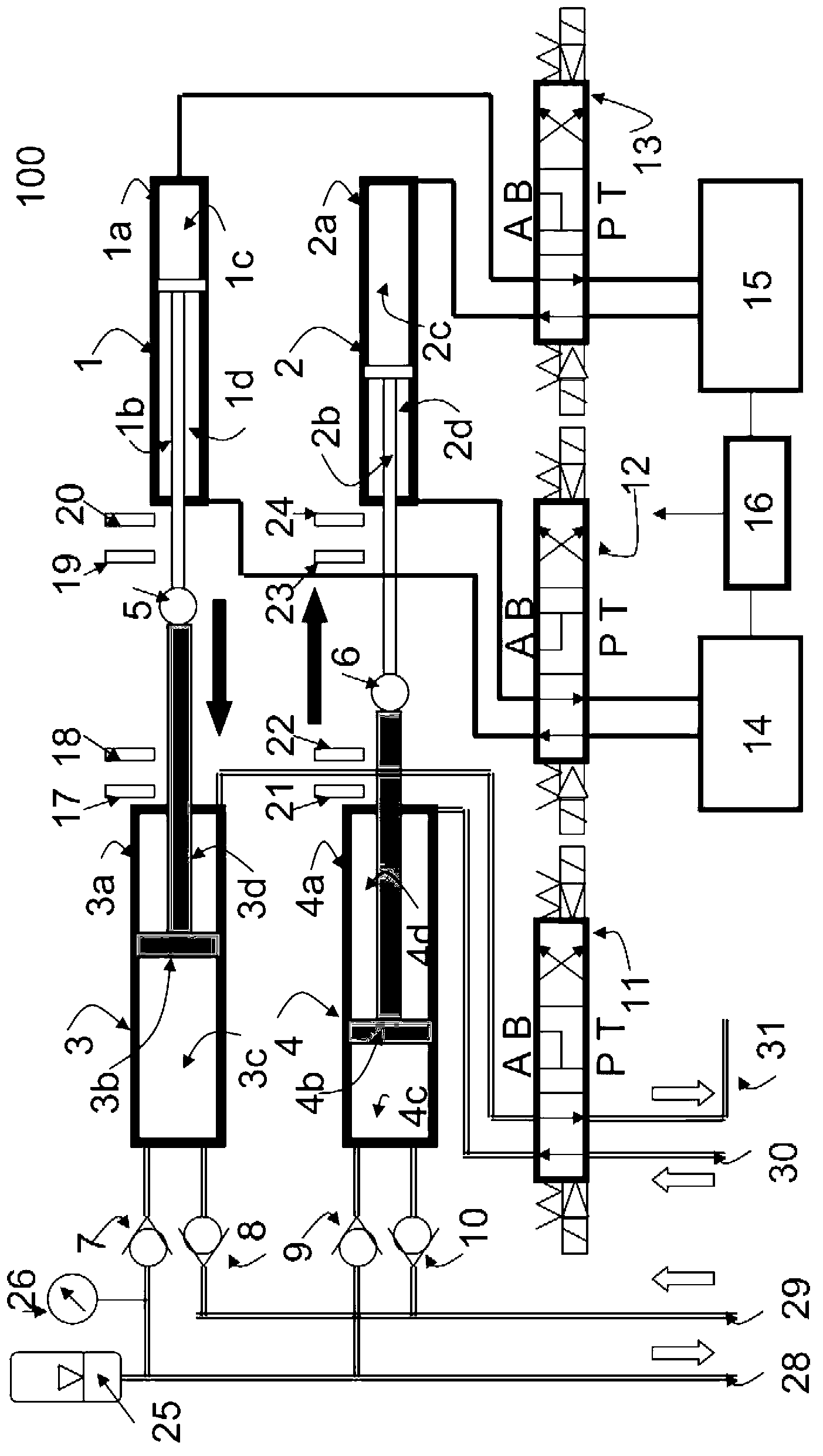

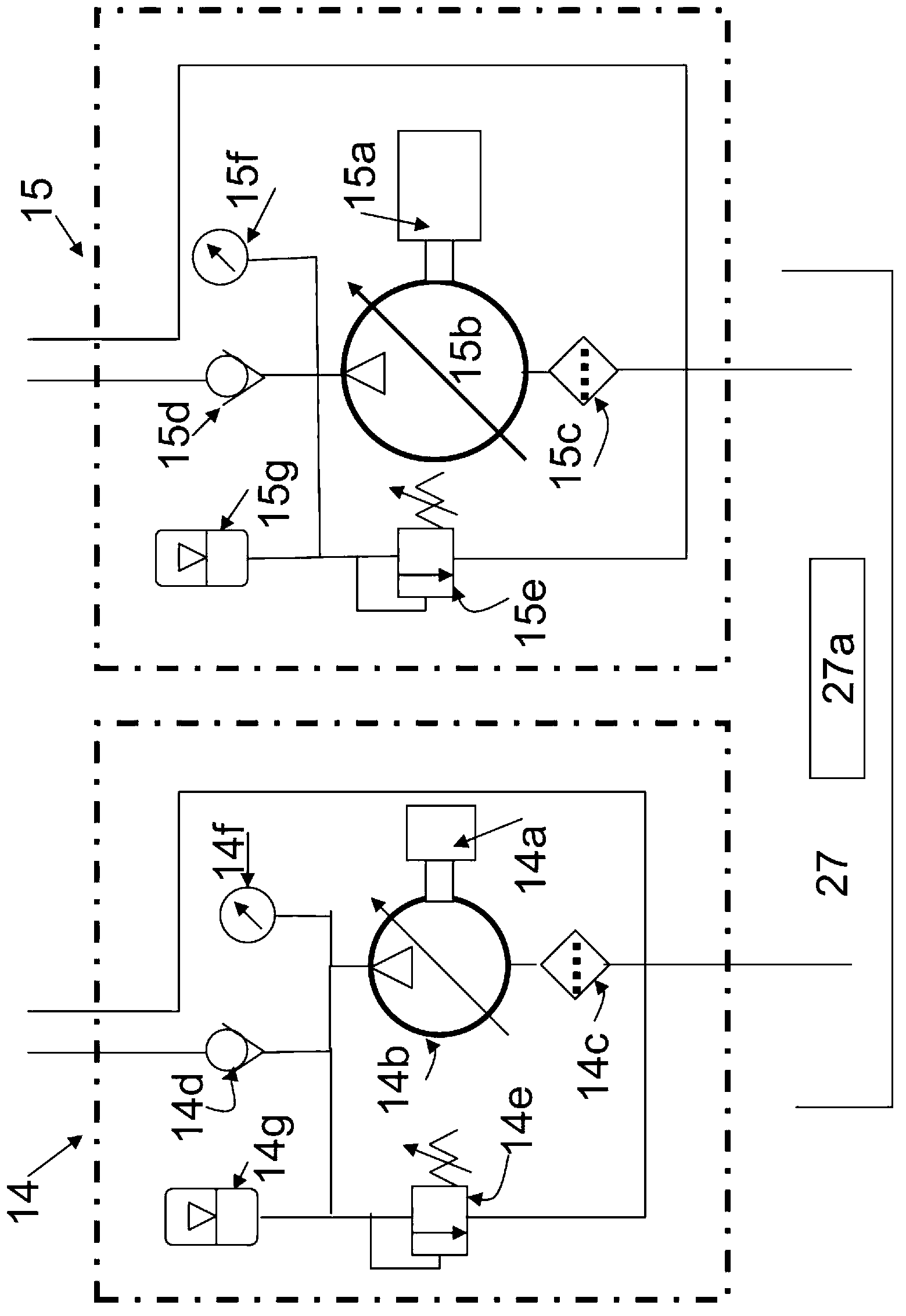

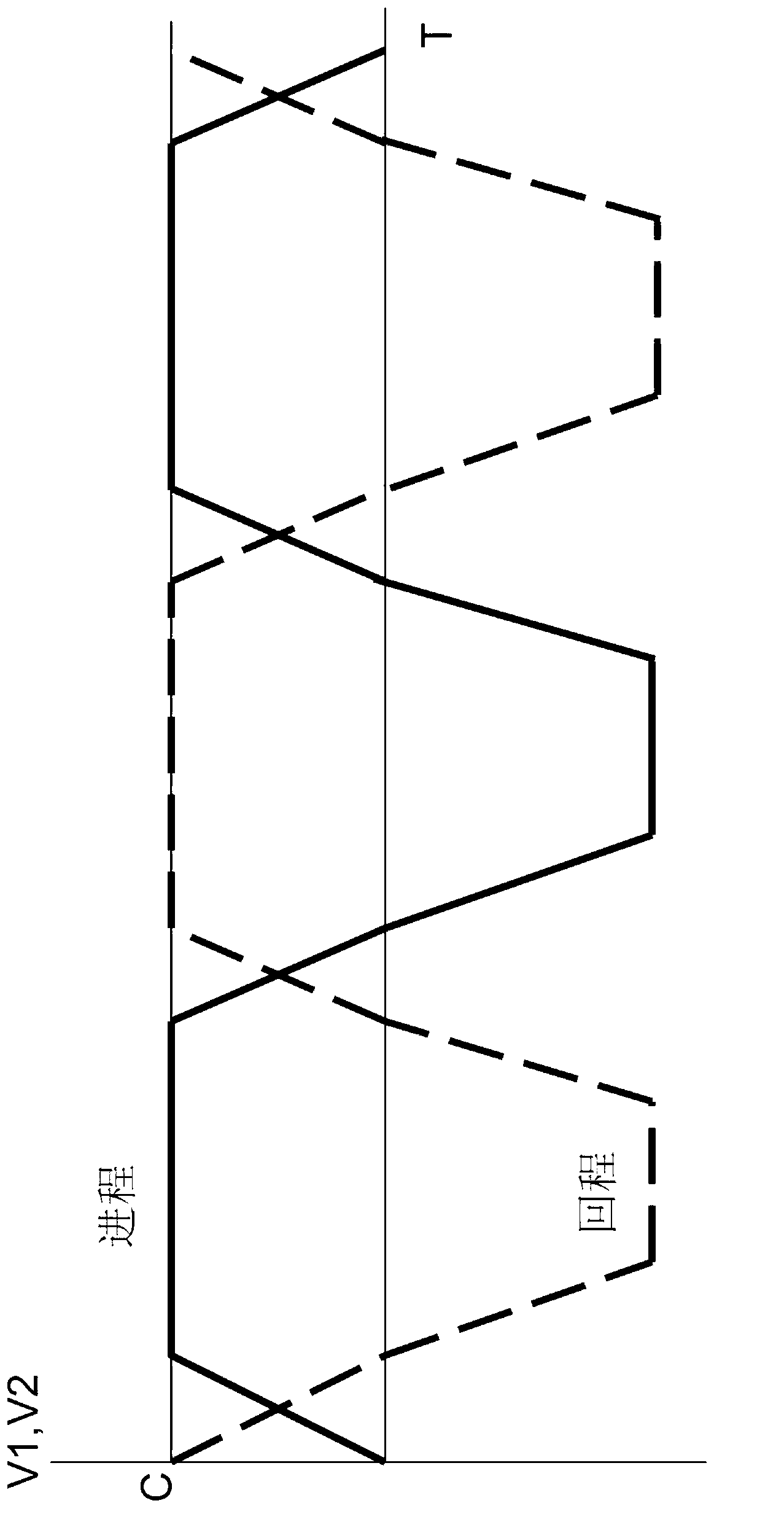

Membrane seawater desalination pressurization and energy recovery integrated method and device

ActiveCN102838186AReduce initial investment costHigh priceMembranesWater treatment parameter controlEngineeringEnergy recovery

The invention relates to a membrane seawater desalination pressurization and energy recovery integrated method and a membrane seawater desalination pressurization and energy recovery integrated device. Piston rods of single-rod seawater cylinders are connected with single-rod oil cylinders to form two or more working combined bodies which operate alternately; the oil cylinders drive the seawater cylinders to move back and forth; one piston cavities of the seawater cylinders suck high pressure strong brine in the process of moving forward and drain the high pressure strong brine in the returning process; and the other piston cavities of the seawater cylinders suck raw seawater in the returning process, pressurize the raw seawater in the process of moving forward and continuously and stably output the pressurized high pressure raw seawater to a reverse osmosis membrane modulus.

Owner:北京赛美环能科技有限公司

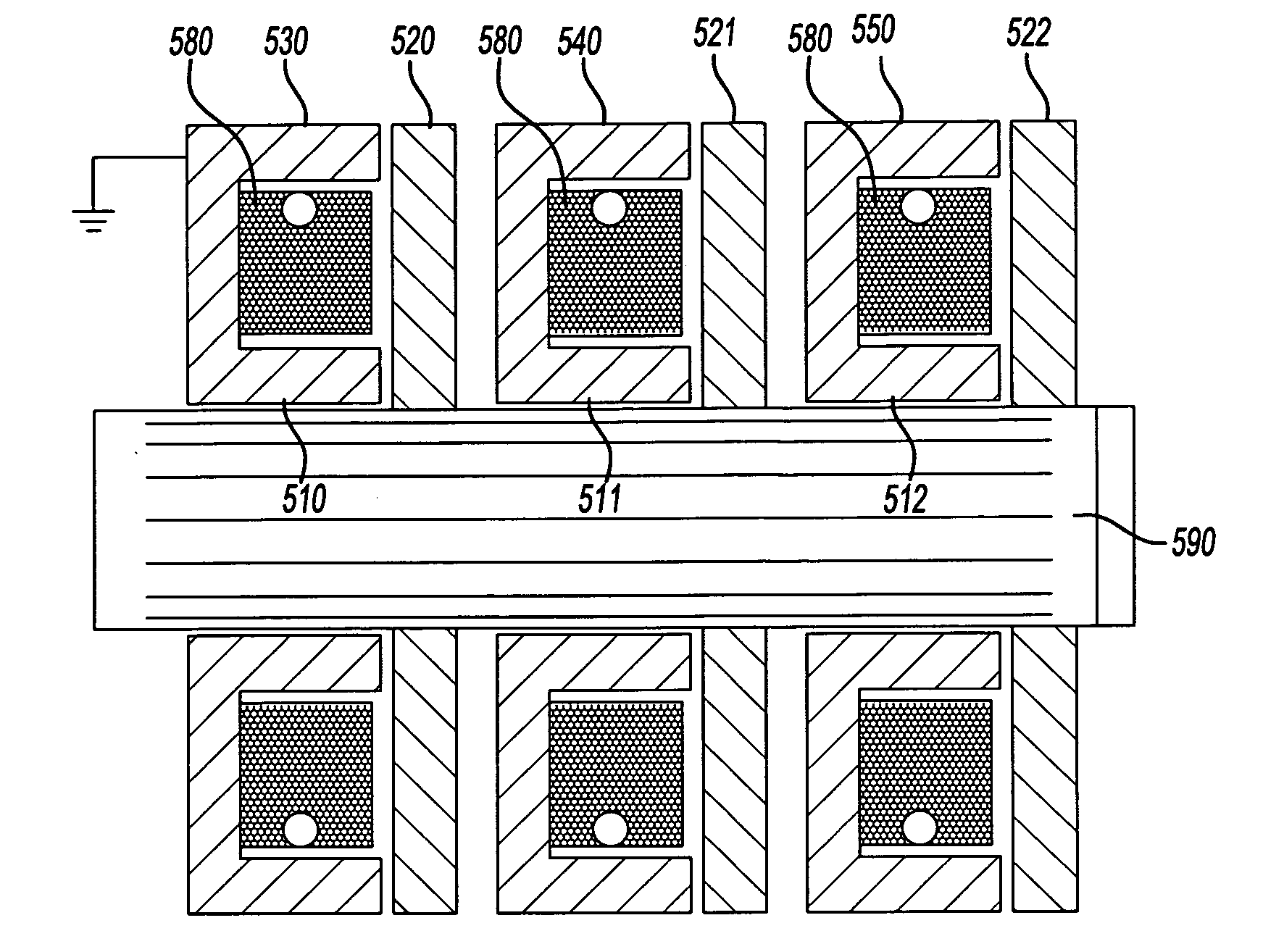

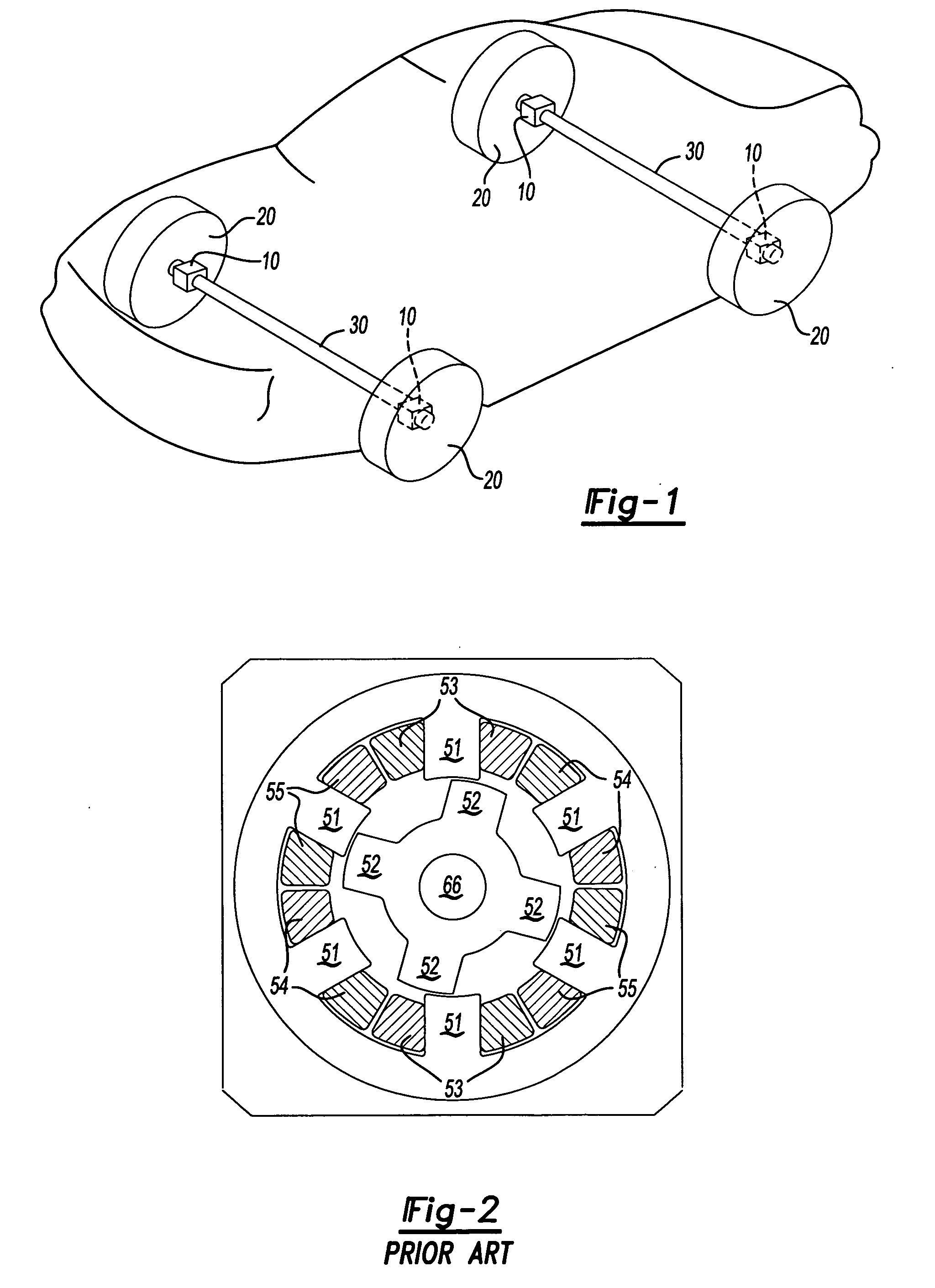

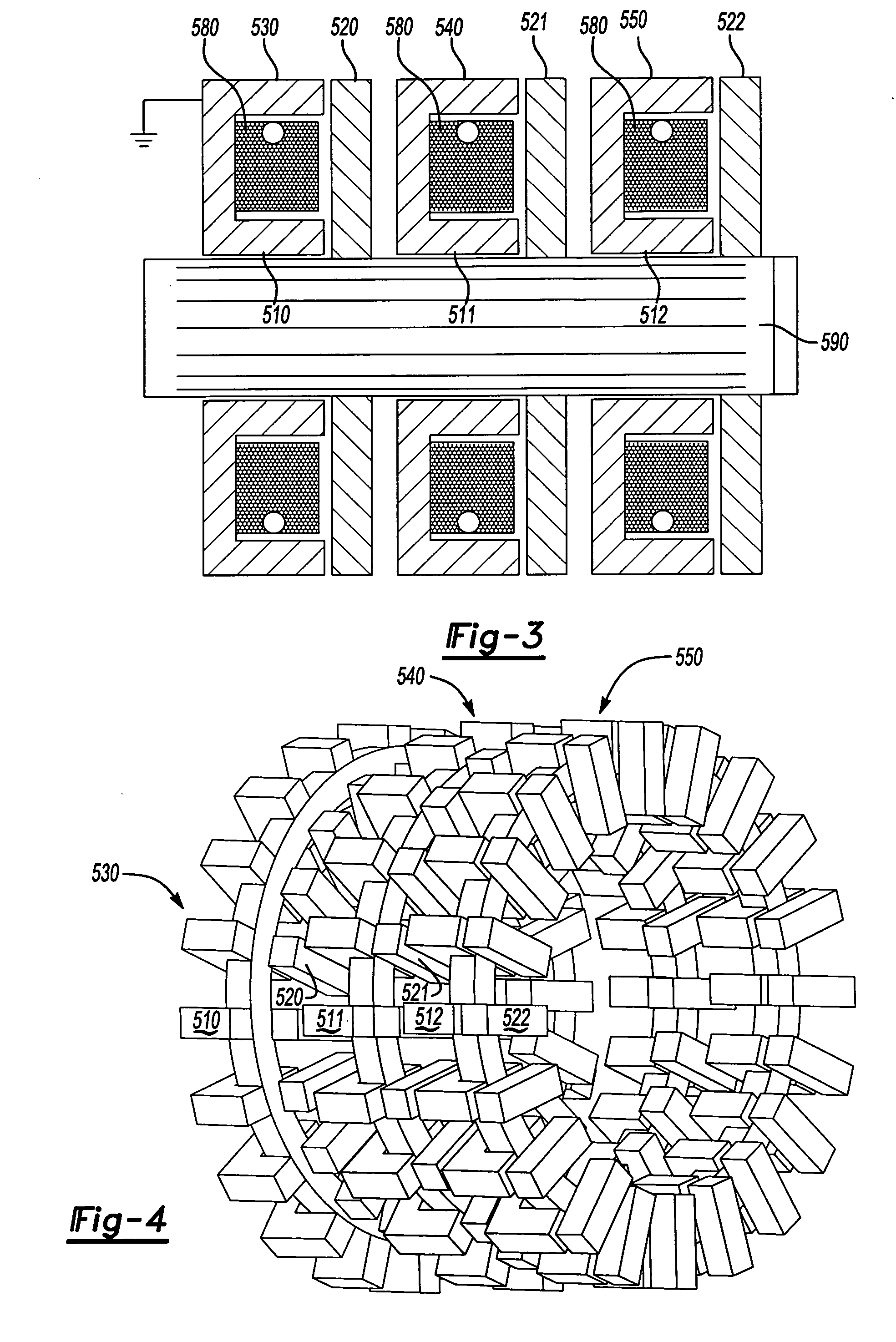

Transverse flux, switched reluctance, traction motor with bobbin wound coil, with integral liquid cooling loop

InactiveUS20080179982A1Light weightIncrease torqueAsynchronous induction motorsMechanical energy handlingTransverse fluxBobbin

The present invention deals with a transverse flux machine of the switched reluctance variety. The transverse flux machine consists of multiple phases where each phase is spaced axially along the shaft. Axial spacing provides many benefits including a decreased weight and a capability to use simple wound bobbin coils for the windings. An embedded cooling loop is provided within the coils themselves. This cooling loop provides internal temperature regulation for the windings and allows for a higher efficiency among other benefits.

Owner:ARVINMERITOR TECH

Spark plug, alumina based insulator for spark plug and production process for same insulator

InactiveUS20020024160A1Facilitate spark consumptionIncrease contentCeramic shaping apparatusSparking plugs manufactureElectrical resistance and conductanceUltimate tensile strength

In insulator including alumina as a main component, a Na component in the insulator is set in the range of 0.07 to 0.5 wt % as Na2O. While the Na component content is as high as to have conventionally been regarded to be beyond the common sense, with this range of the Na component content, insulation resistance, mechanical strength and the like at high temperature are unexpectedly not reduced and an insulator with performances comparable to those of an insulator from conventional low soda alumina lower in Na component content than the above described range can be obtained. As a result, medium soda alumina and regular soda alumina that are much lower in cost than conventionally used low soda alumina can be used instead of the low soda alumina, so that dramatic reduction in production costs of insulator 2 for a spark plug 100 and in addition, of the spark plug 100 using the insulator 2 are realized.

Owner:NGK SPARK PLUG CO LTD

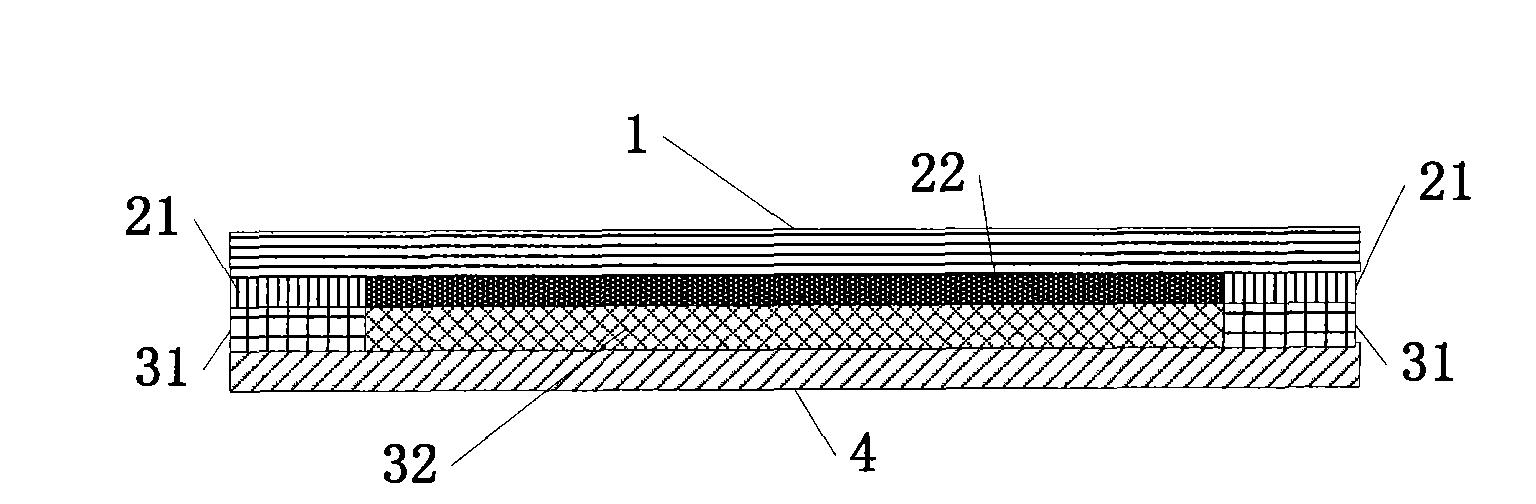

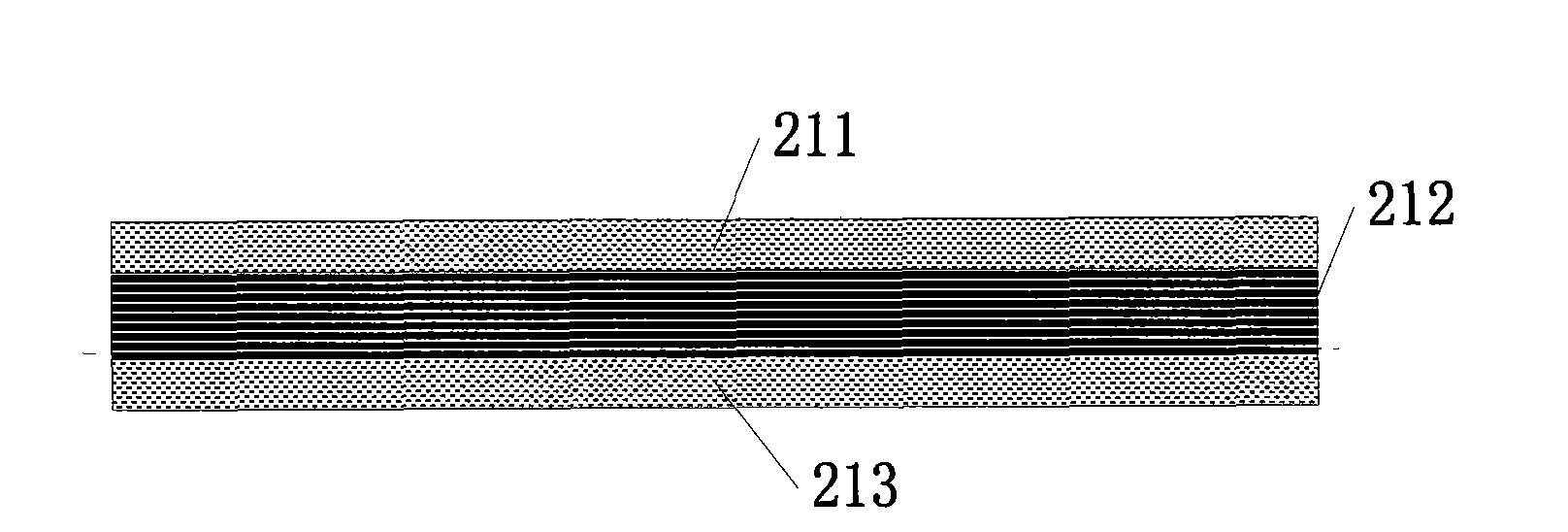

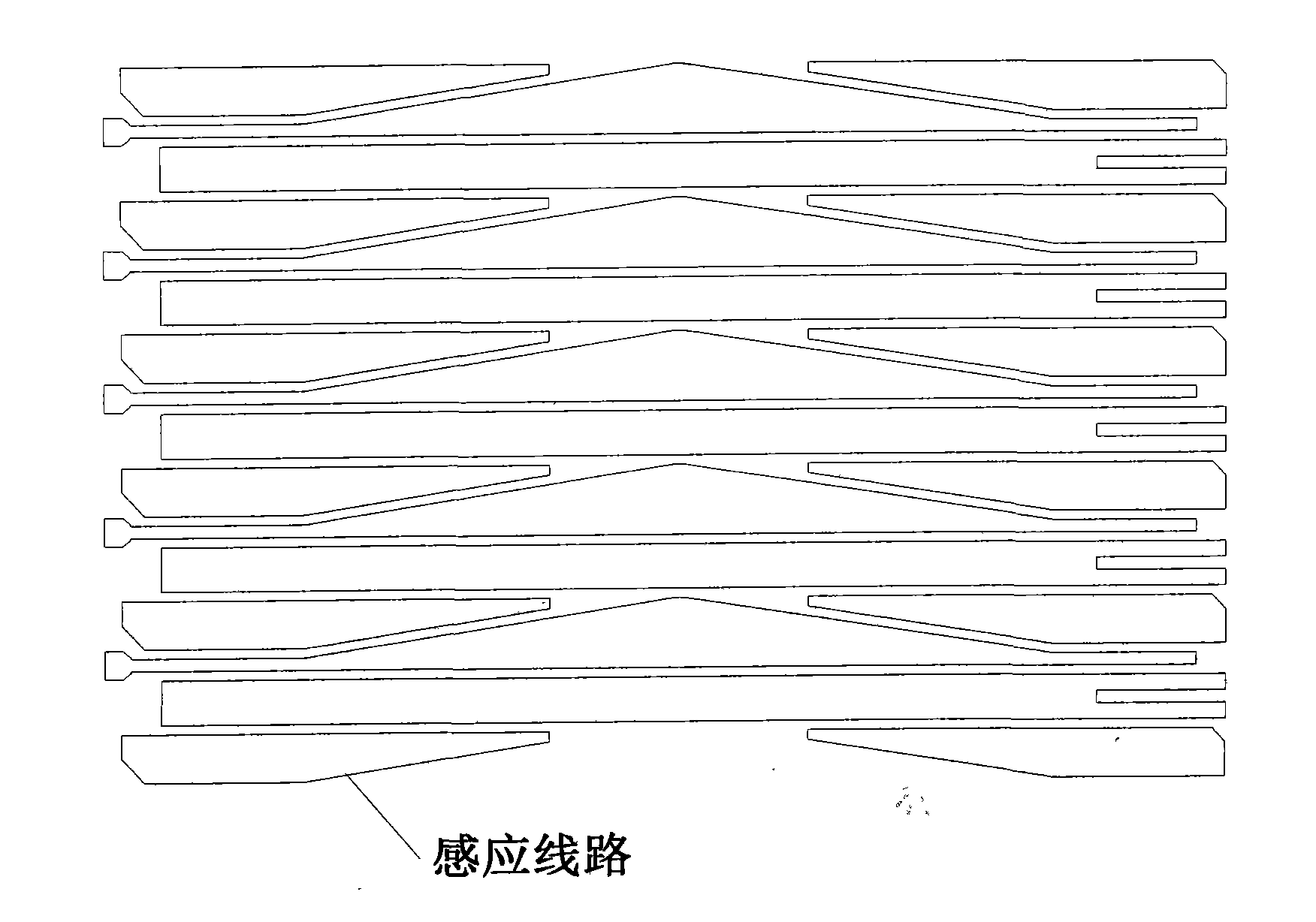

Hardening structure touch panel and manufacturing method thereof

InactiveCN101976149ASimple and safe structureReduce manufacturing costInput/output processes for data processingCapacitancePolyethylene terephthalate

The invention discloses a hardening structure touch panel and a manufacturing method thereof, and belongs to the technical field of composite layer structures of capacitive touch panels and manufacturing processes thereof. In the hardening structure touch panel, a window operating area is increased by adopting single-layer indium tin oxide (ITO) line setting on the surface of a hardened polyethylene terephthalate (PET) substrate and combining a lapped narrow line width design. The touch panel has a safe and simple structure and low production cost, reduces the thickness and the weight of the panel, improves the light transmittance of an overall sensor body, and fulfills the aims that the touch panel is not easy to damage and is easy to process, the product cost is low, the thickness of a panel body is reduced and the rate of good products is high.

Owner:牧东光电科技有限公司

Monitoring System for Animal Husbandry

InactiveUS20080202445A1Safe and reliable long-term monitoringMinimize potential harmful consequenceAnimal reproductionSurgeryPattern recognitionMonitoring system

A monitoring system (800) is operative for receiving sensor signals and analyzing the sensor signals to identify events or conditions of interest, such as Birthing, with respect to a monitored animal. The sensors may be animal-borne sensors such as motion related sensors. The system (800) includes a processor (802) operative to identify the conditions of interest based on a stored pattern database (806), threshold tables (808) and heuristic engines (812). Upon identification of a condition of interest, a human expert may be consulted and alerts may be generated as required.

Owner:BIO EQUIDAE LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com