Patents

Literature

363results about How to "Avoid fractures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

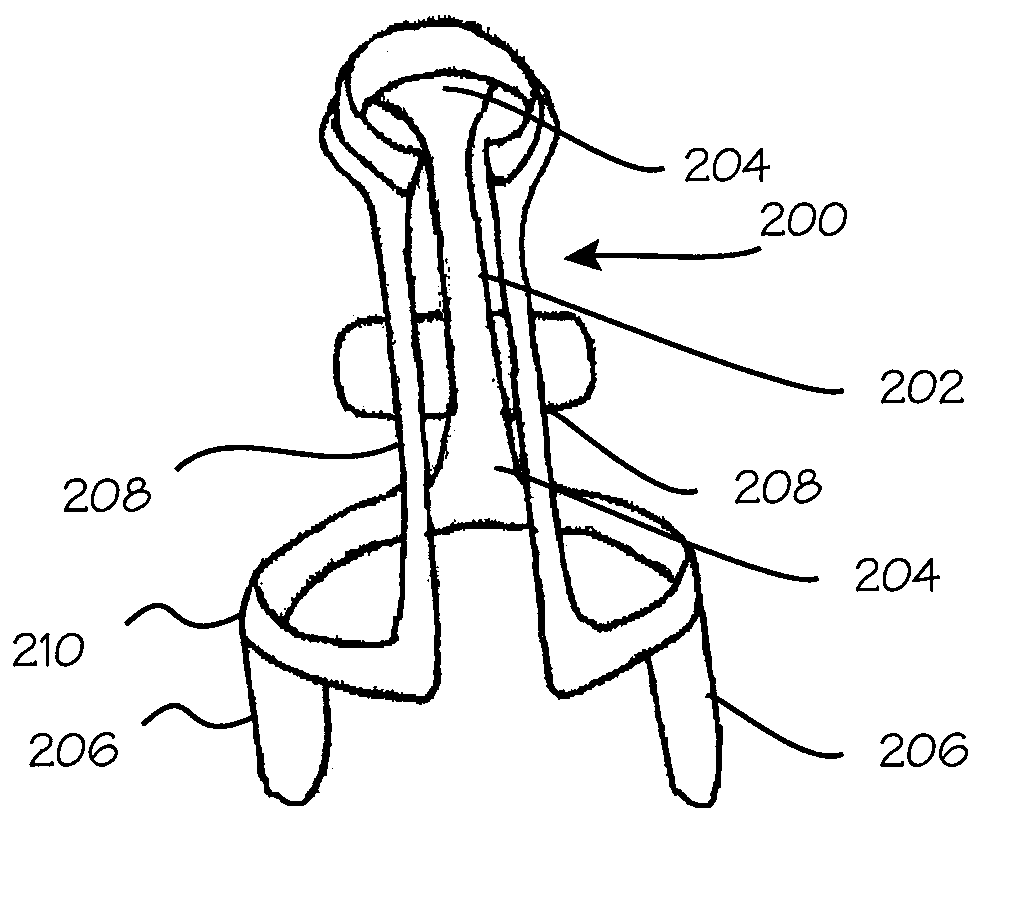

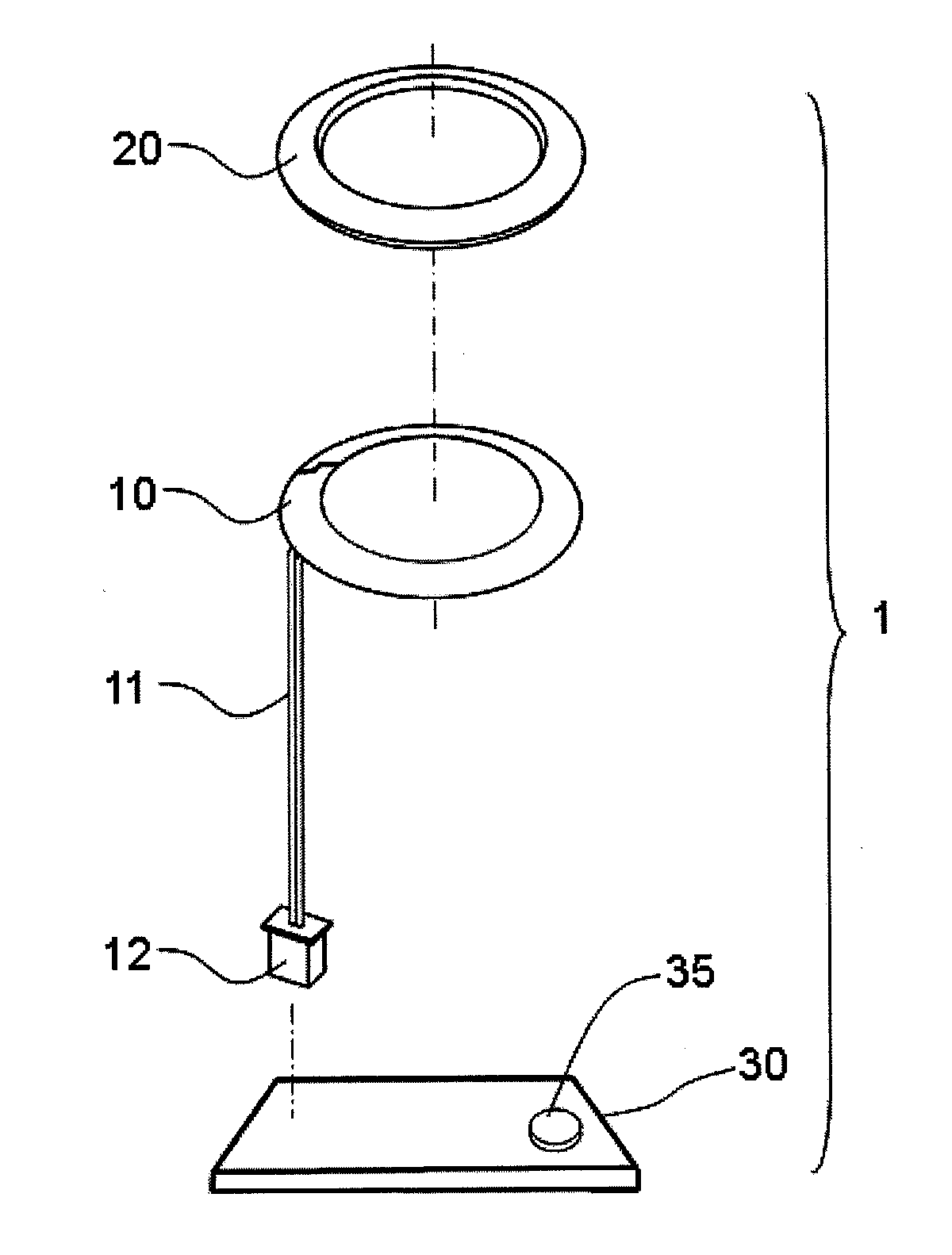

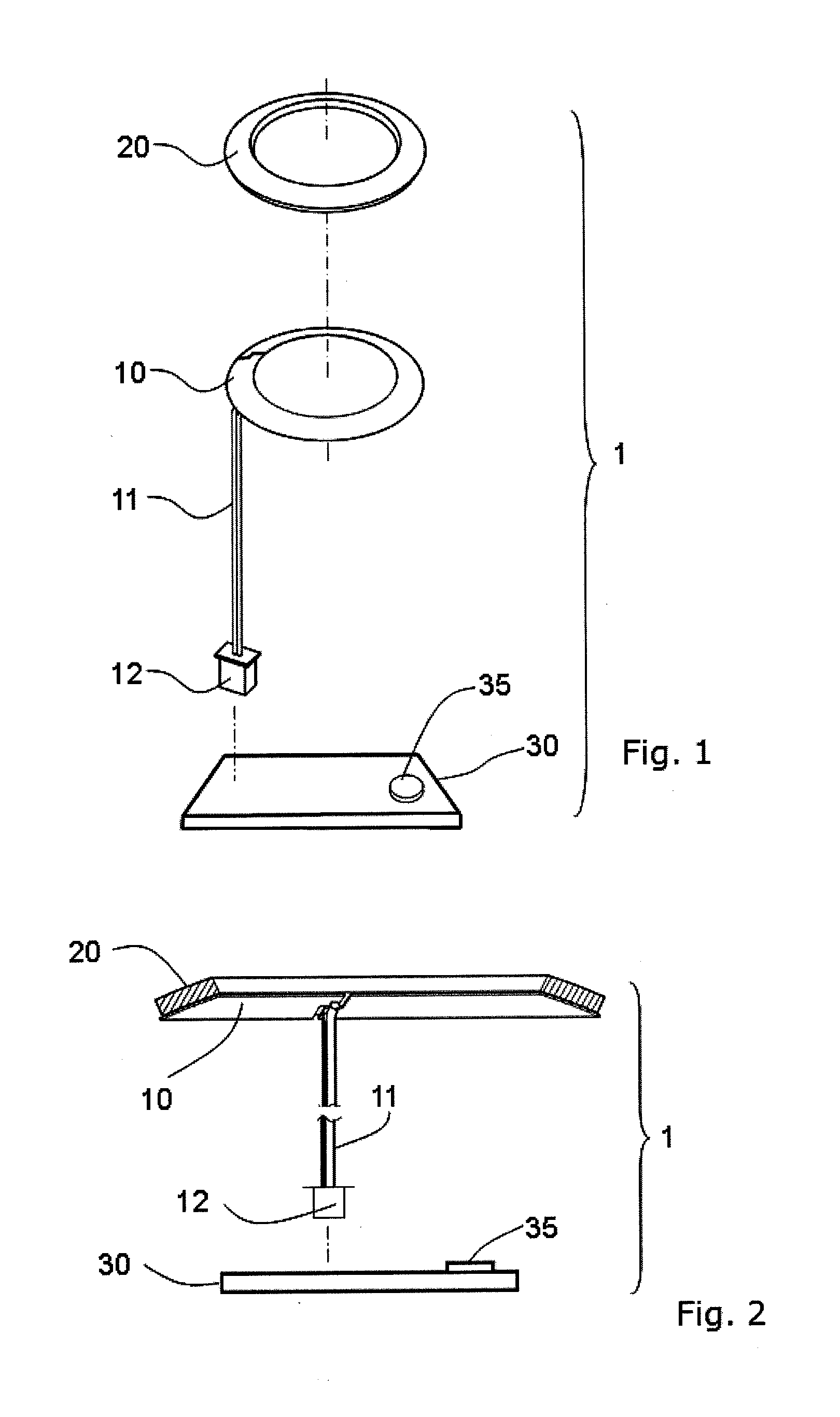

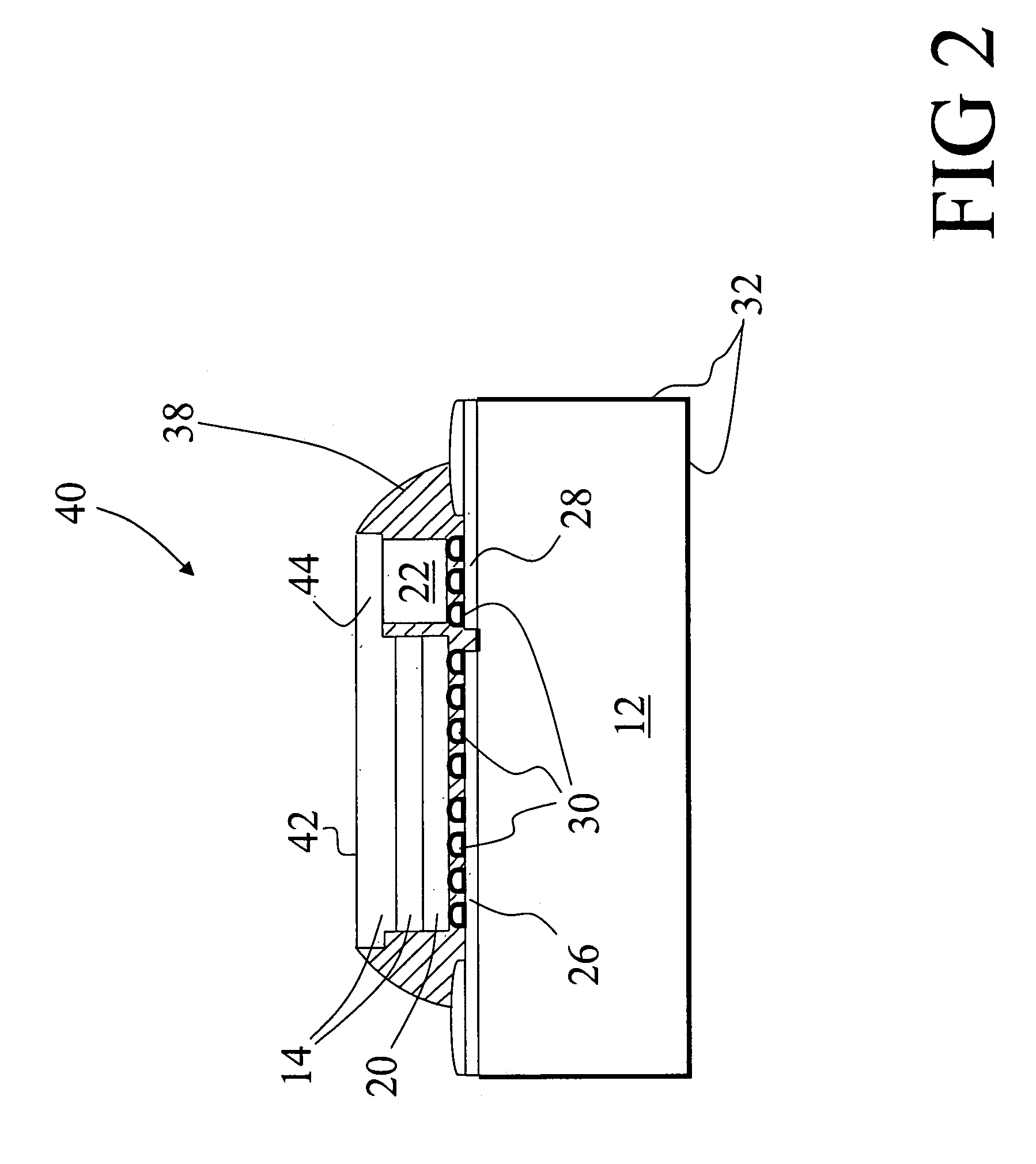

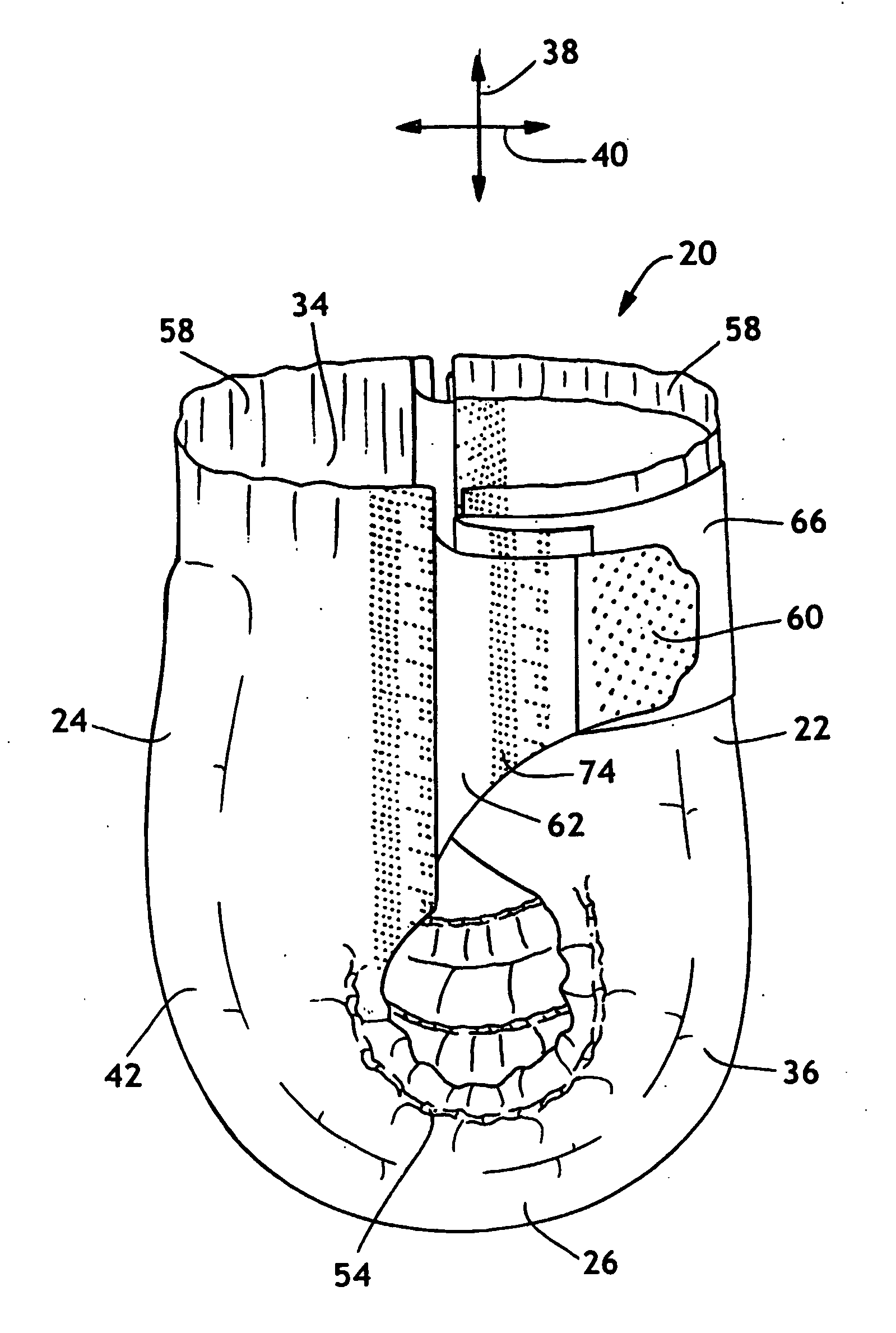

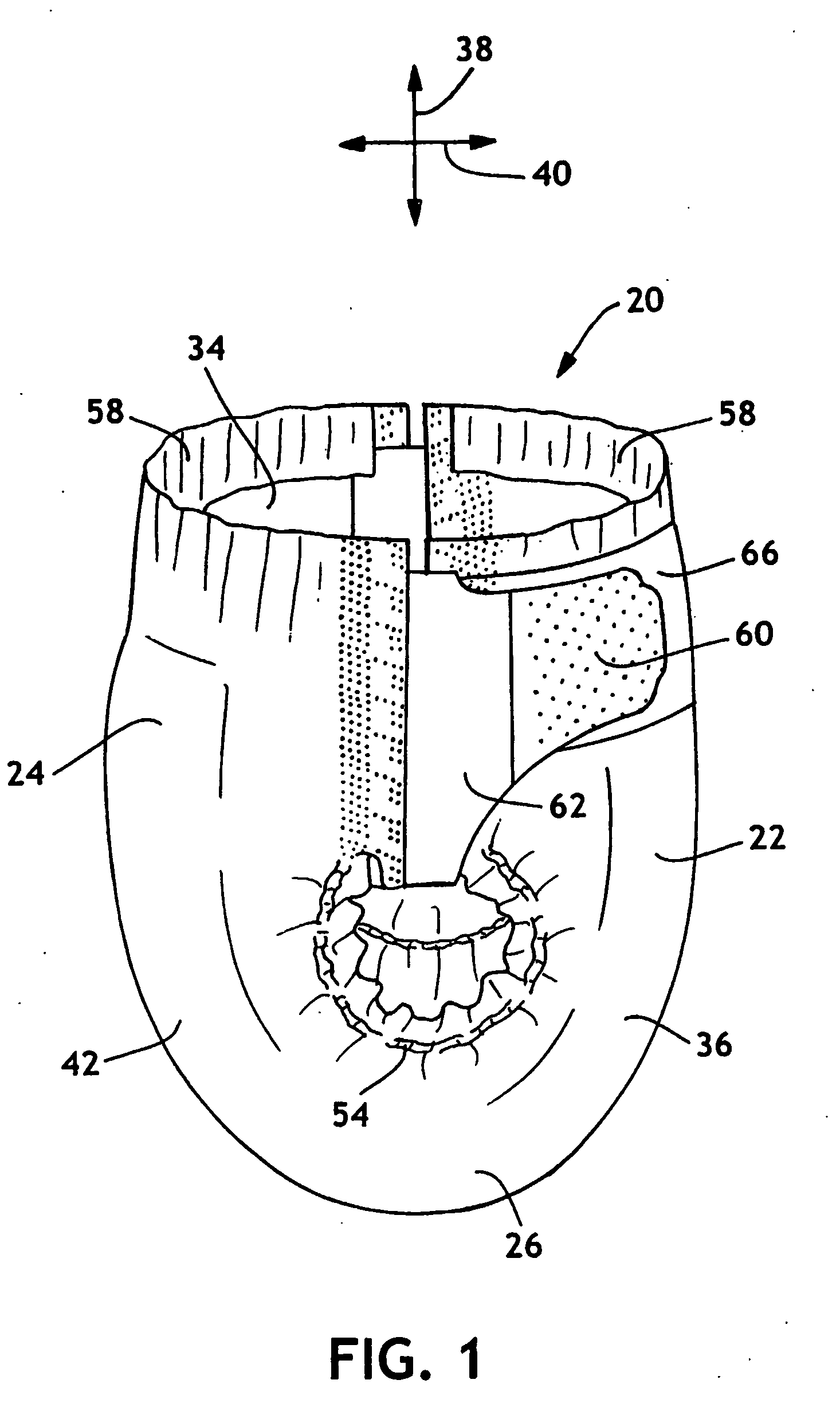

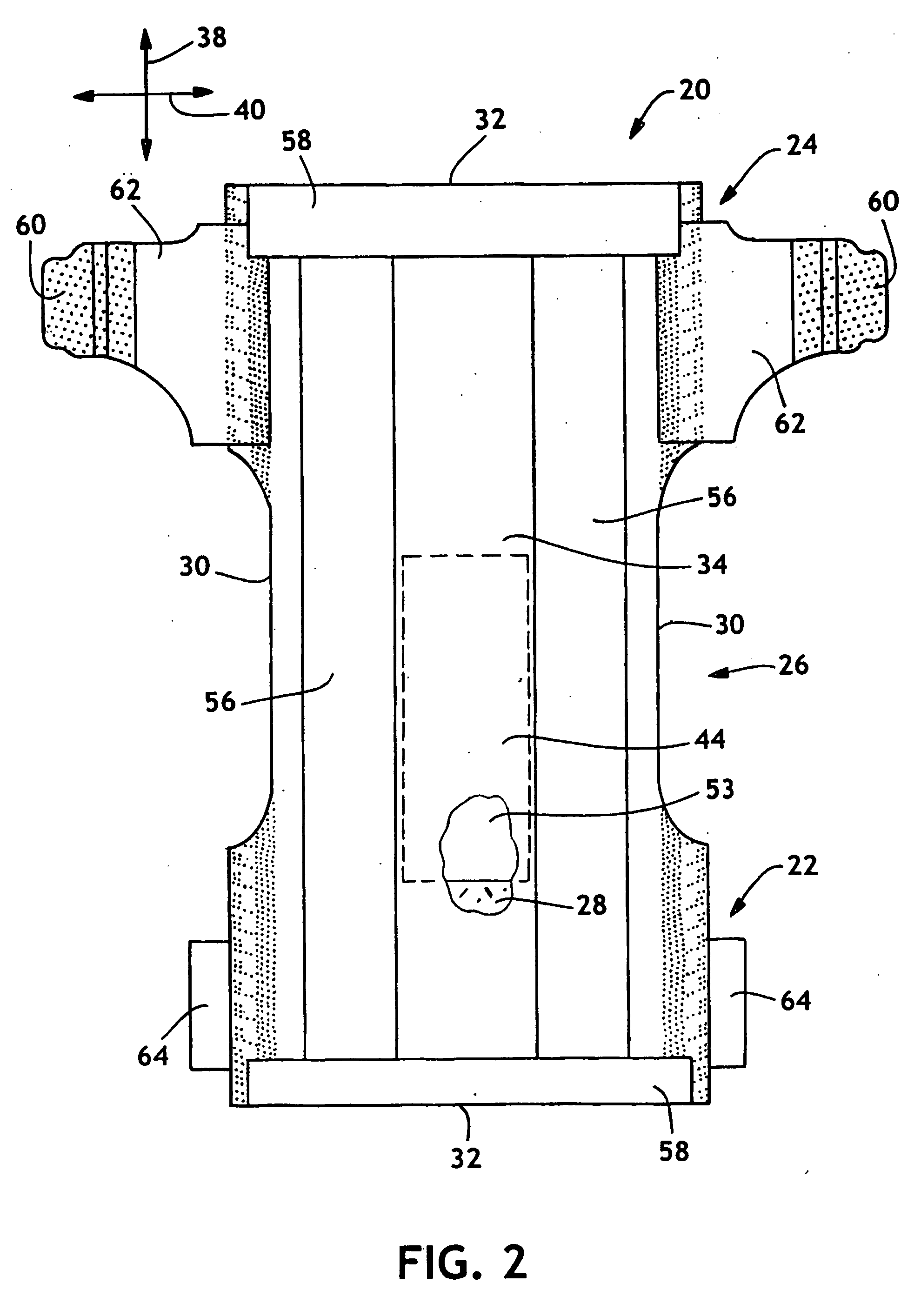

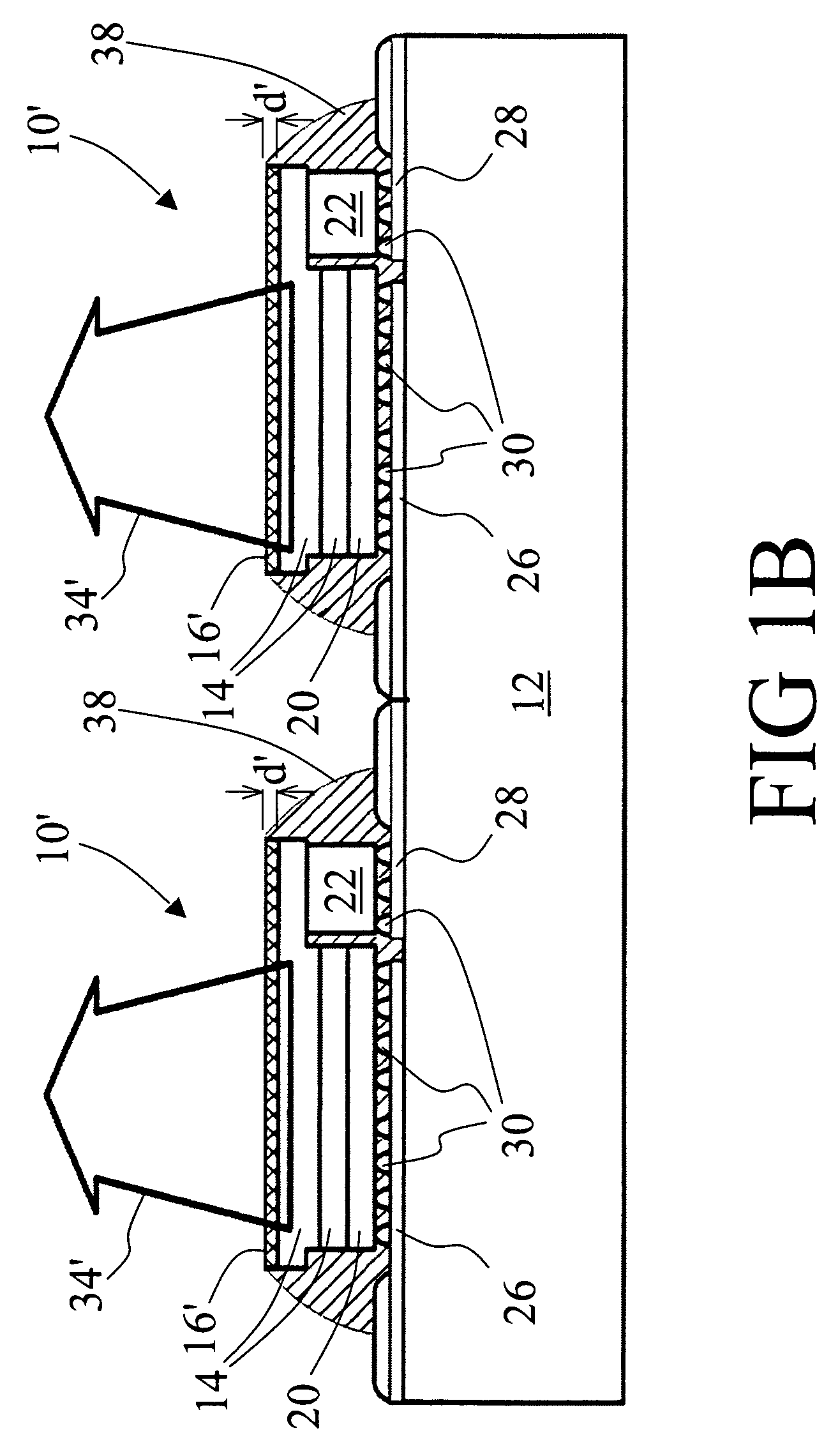

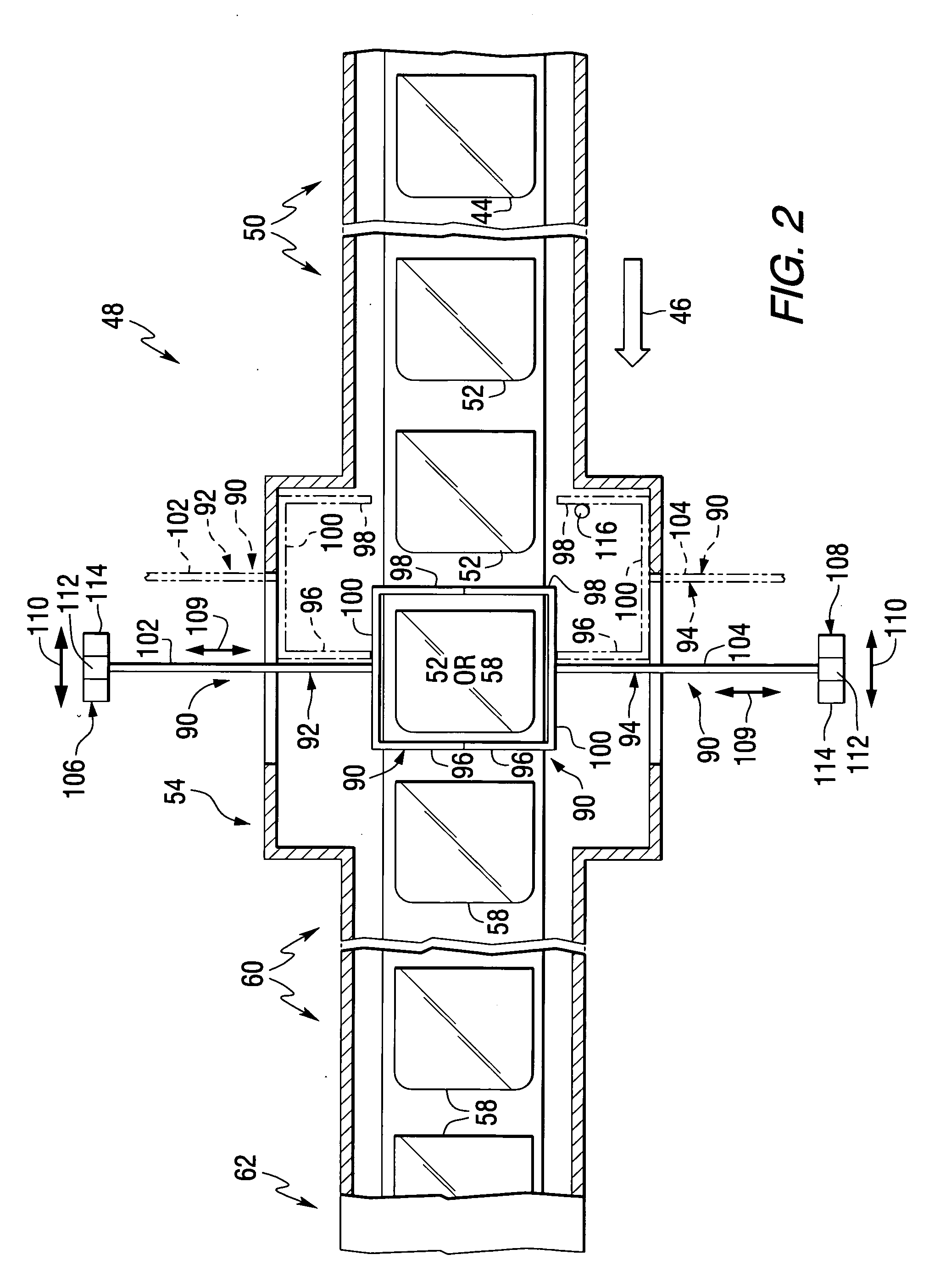

Method and Apparatus for Body Impact Protection

ActiveUS20090254003A1Maximum precisionPrevent unwanted of pressureAcceleration measurement using interia forcesPerson identificationCushioningOrgan damage

This invention relates to active protective garments which are inconspicuously worn by an individual and which activate upon certain conditions being met. Activation causes inflation of regions of the active protective garment to provide padding and impact cushioning for the wearer.The invention is an active protective garment such as pair of shorts or pants, a jacket, a vest, underwear, and the like. The garments comprise multiple layers of material that constrain pockets or regions that are inflatable by a source of compressed gas or foam. The garments also comprise sensors to detect ballistic parameters such as acceleration, distance, relative acceleration, and rotation. The sensor information is used to determine whether activation is required. Detection and activation are accomplished in a very short time period in order to offer maximal protection for the individual wearing the garment. The system comprises a computer or logic controller that monitors the sensor data in real time and coordinates the information from all sensors. The system calculates velocity, distance, and rotational velocity. A rule-based system is used to detect a complex fall in progress and discriminate said fall in progress from the events of every day life. The pockets or inflatable regions of the garment protect the individual against falls and other impacts that may cause bone fracture or organ damage.

Owner:ACTIVE PROTECTIVE TECH

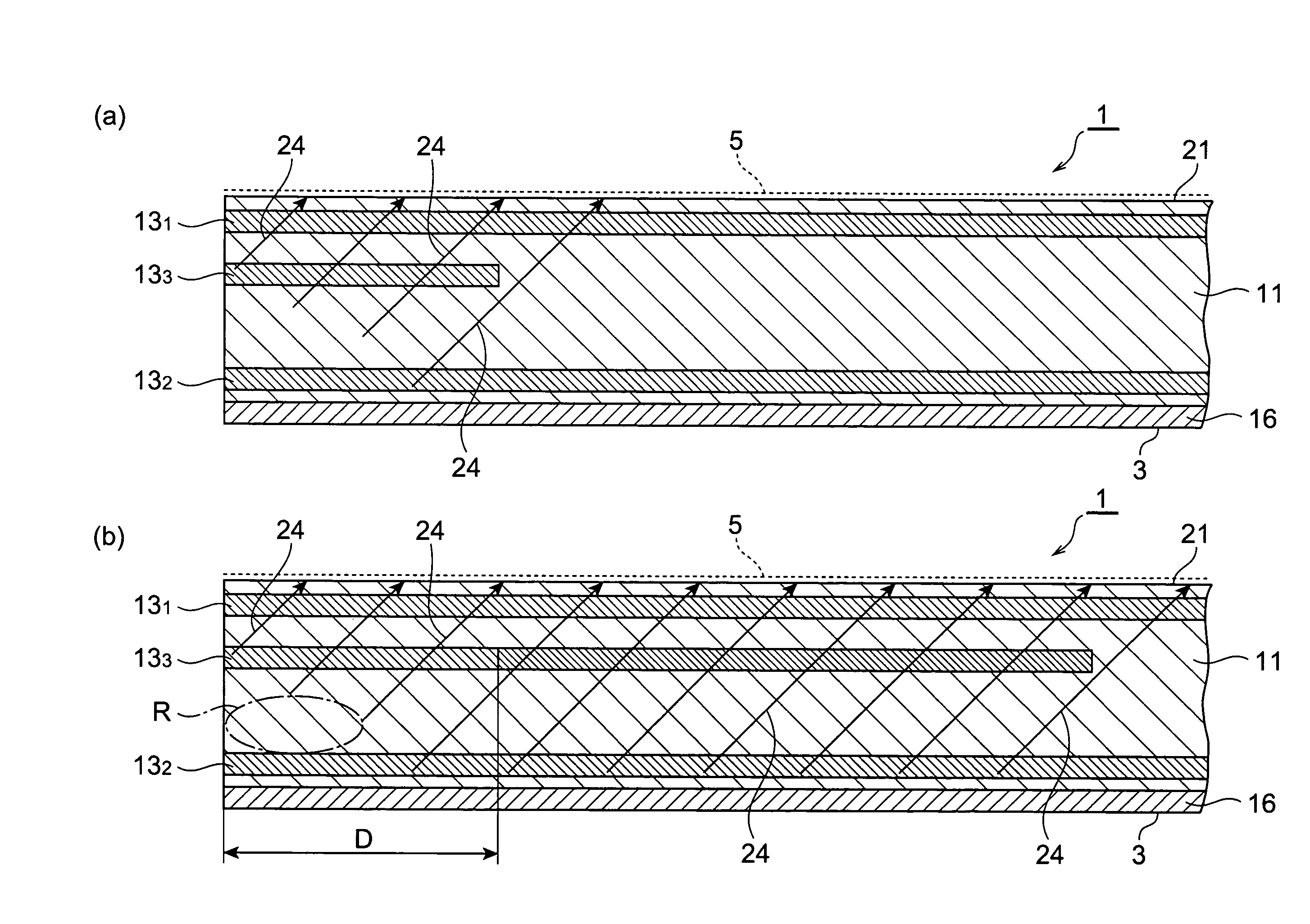

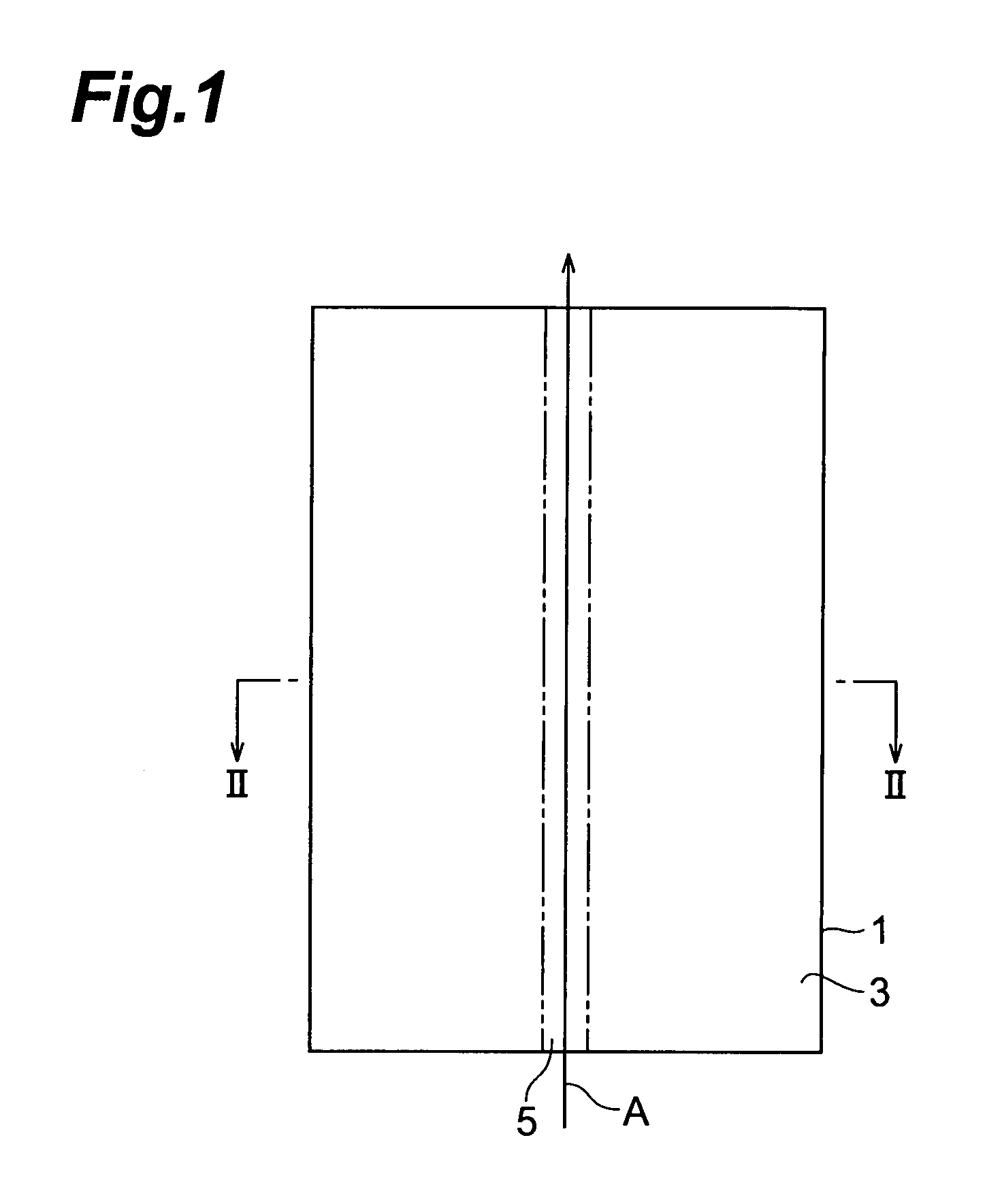

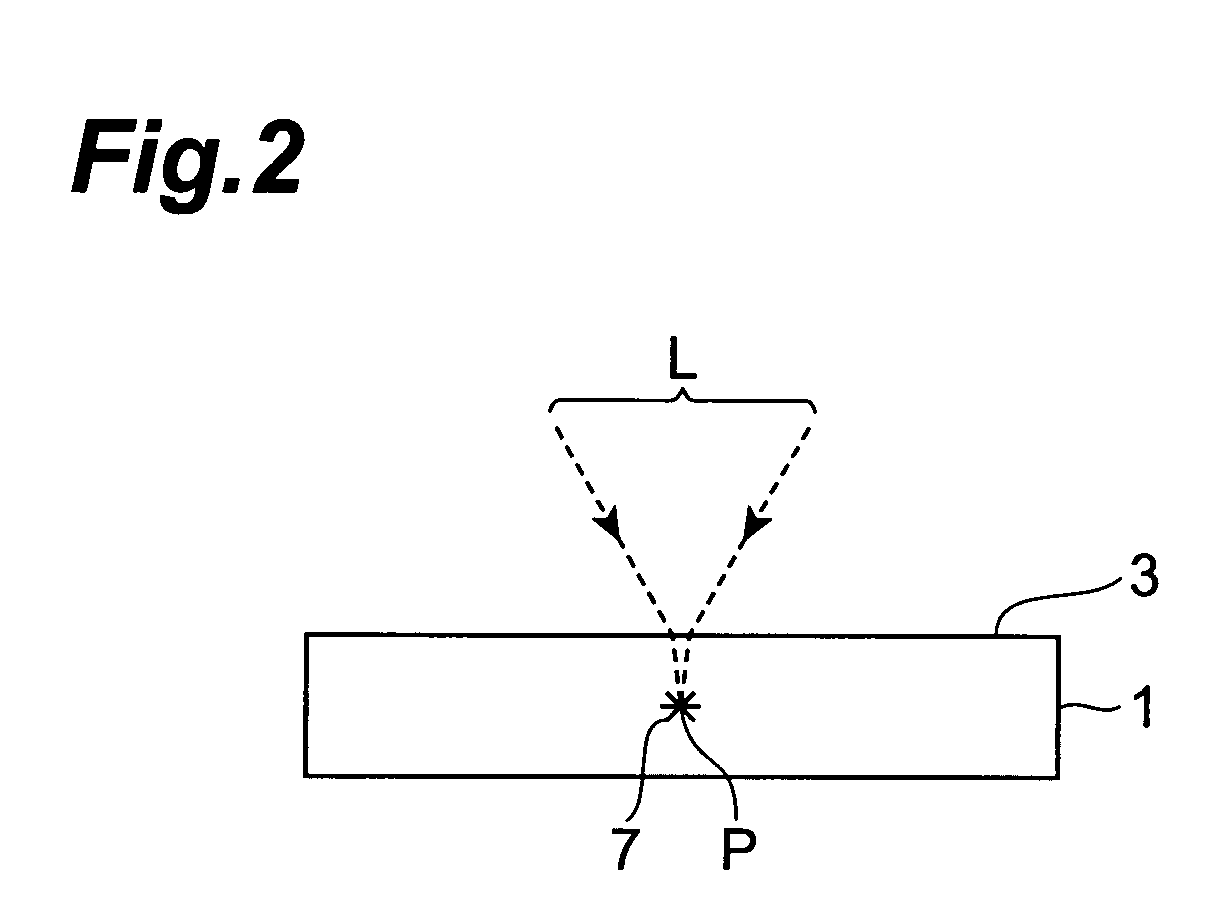

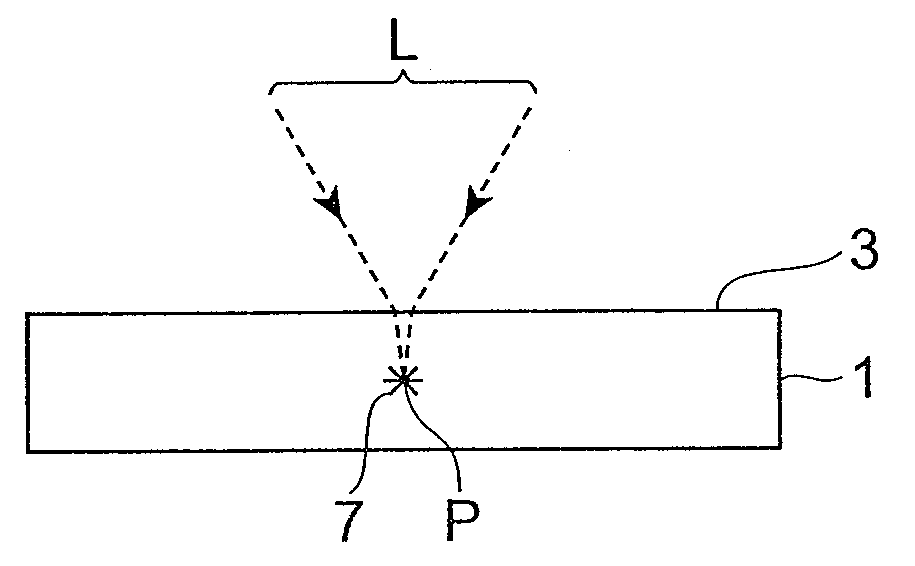

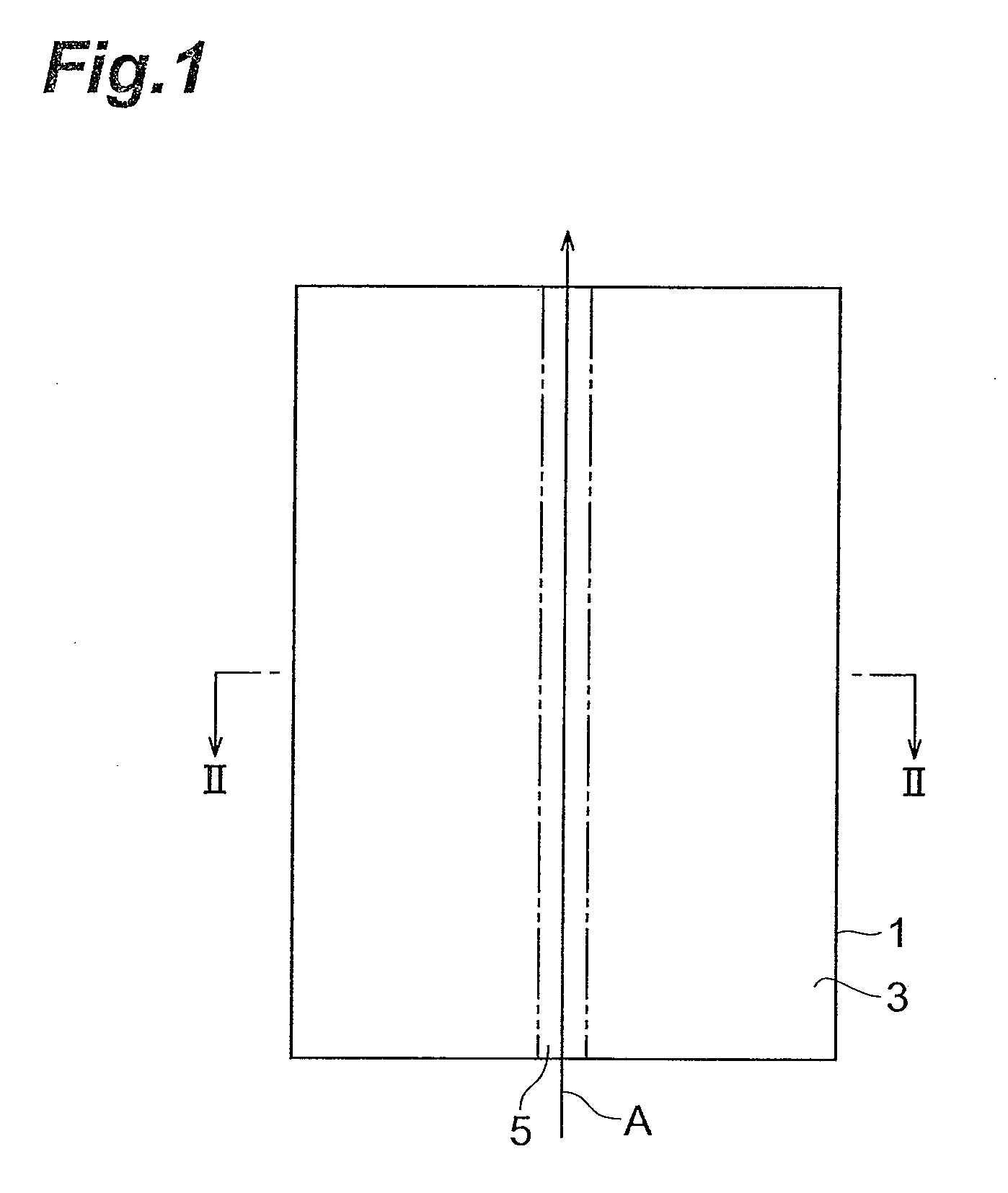

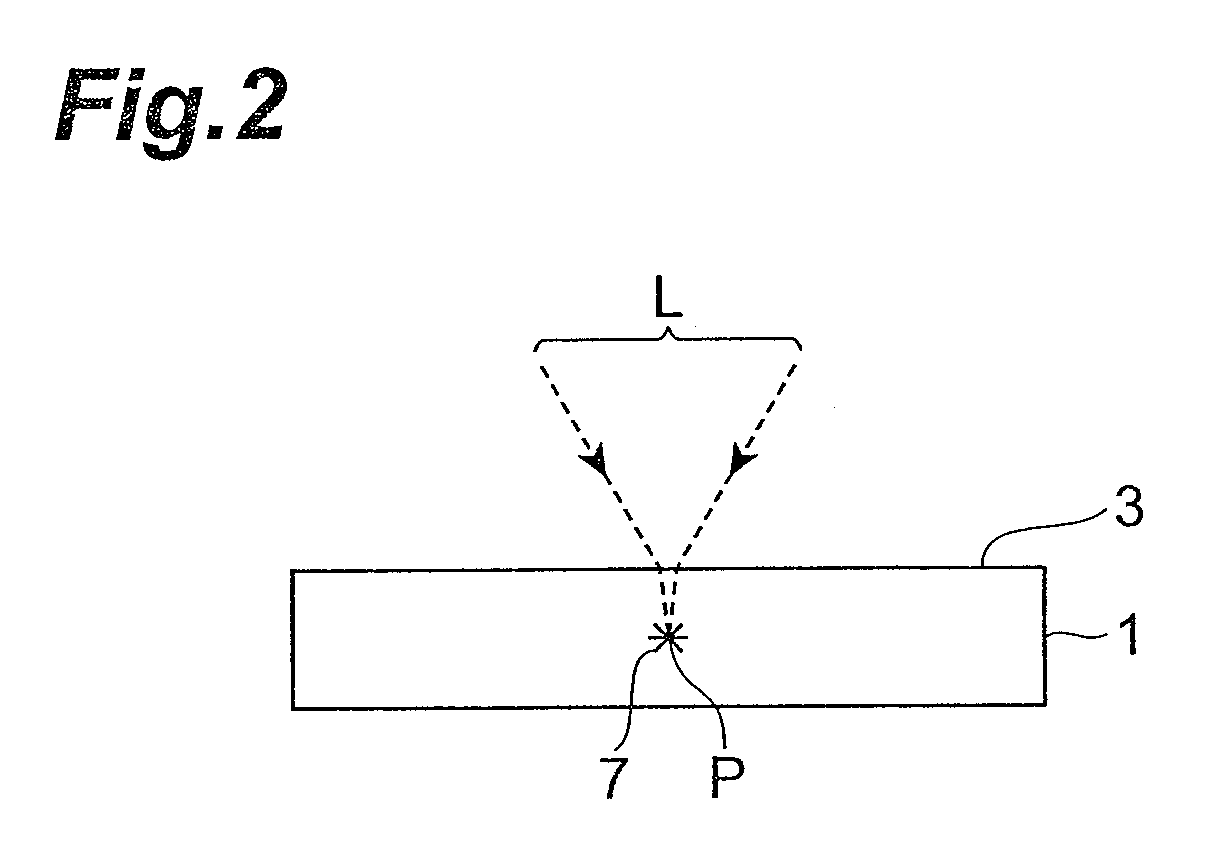

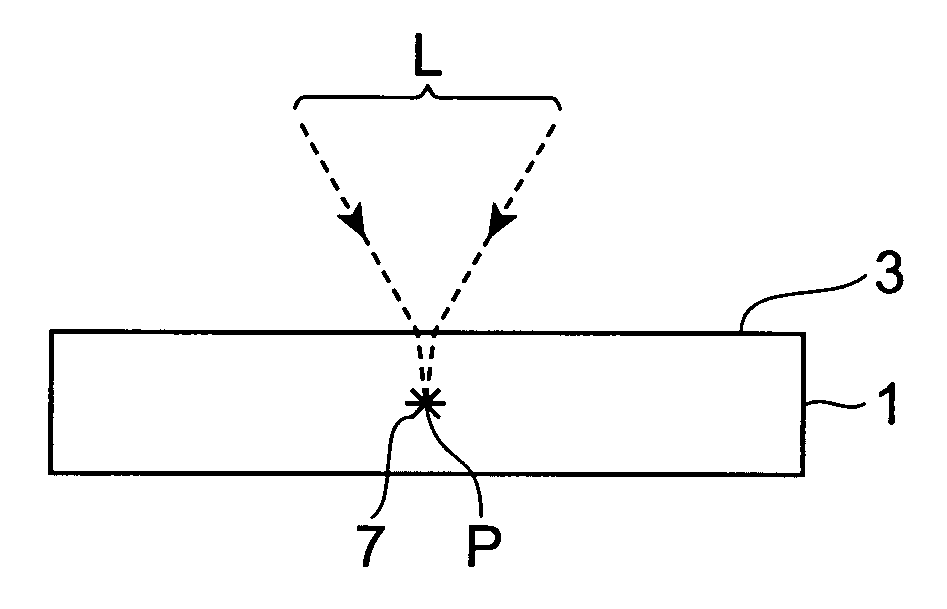

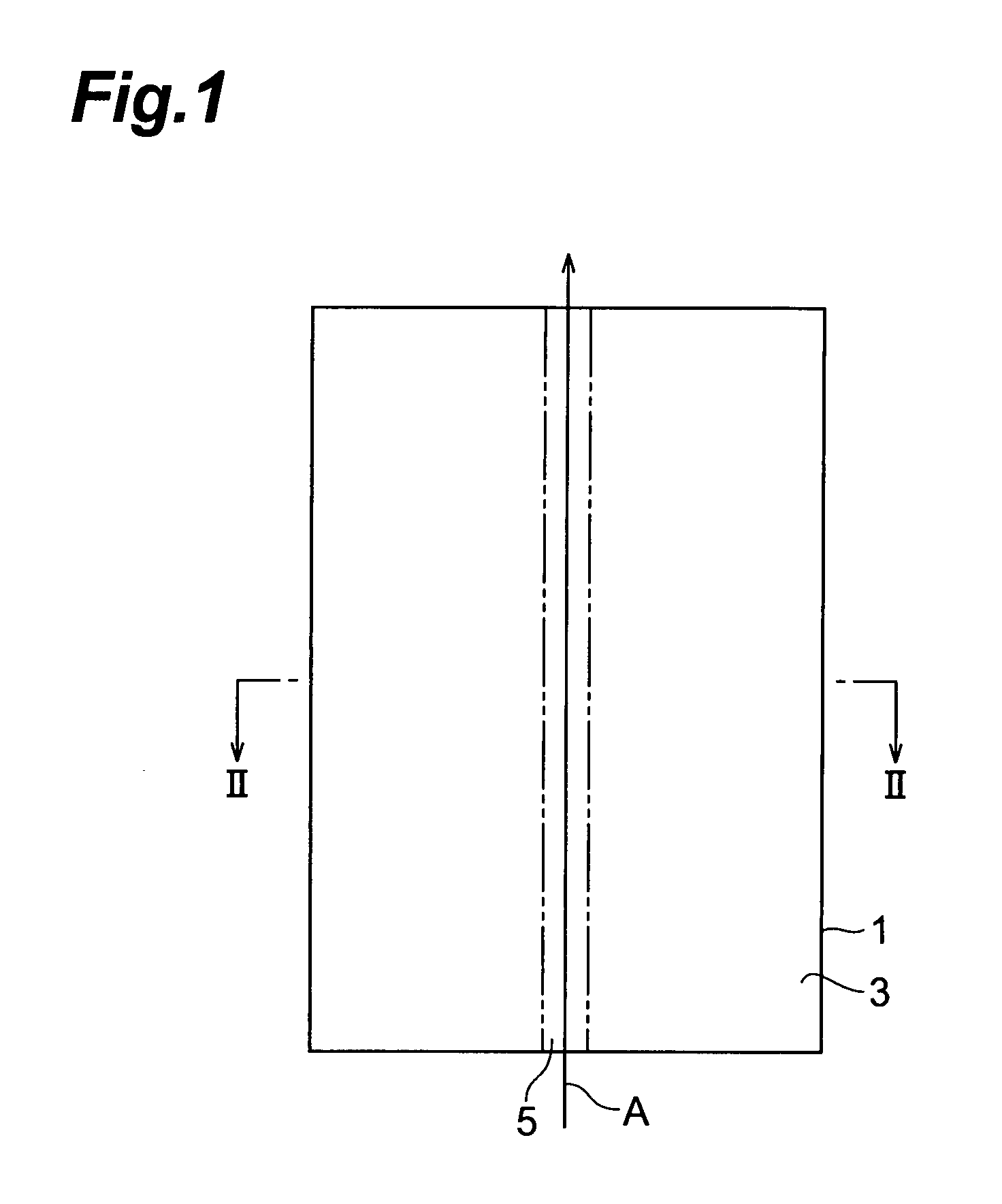

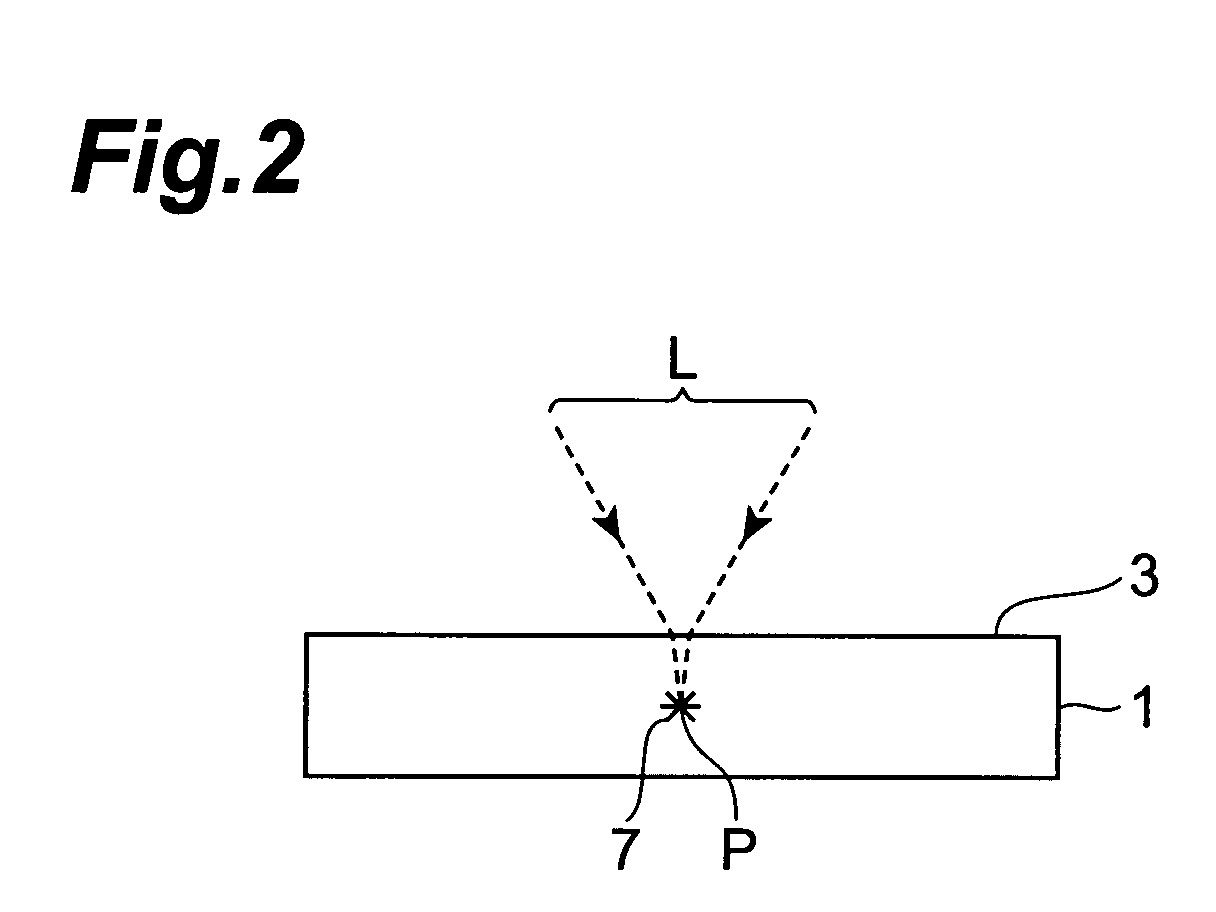

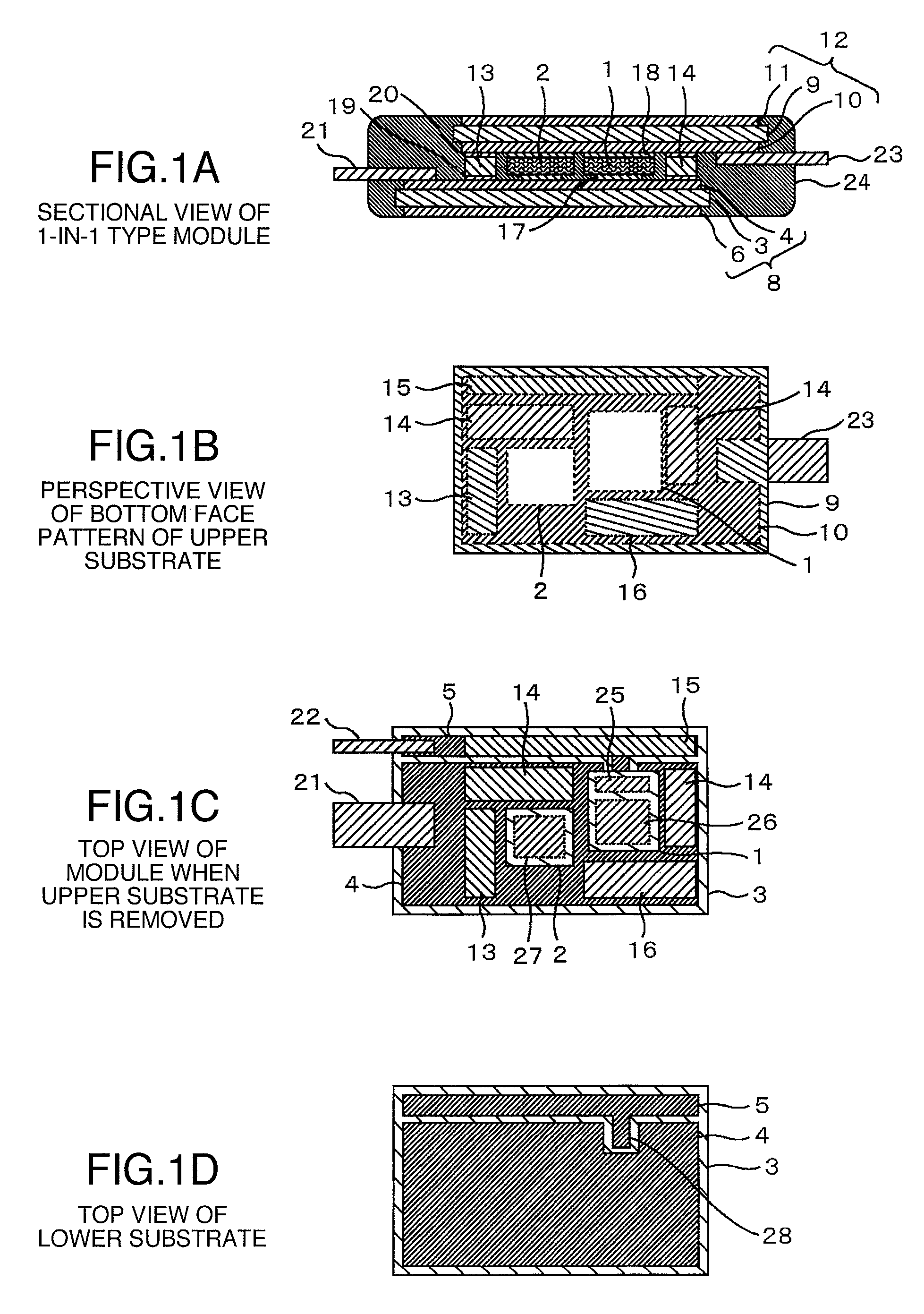

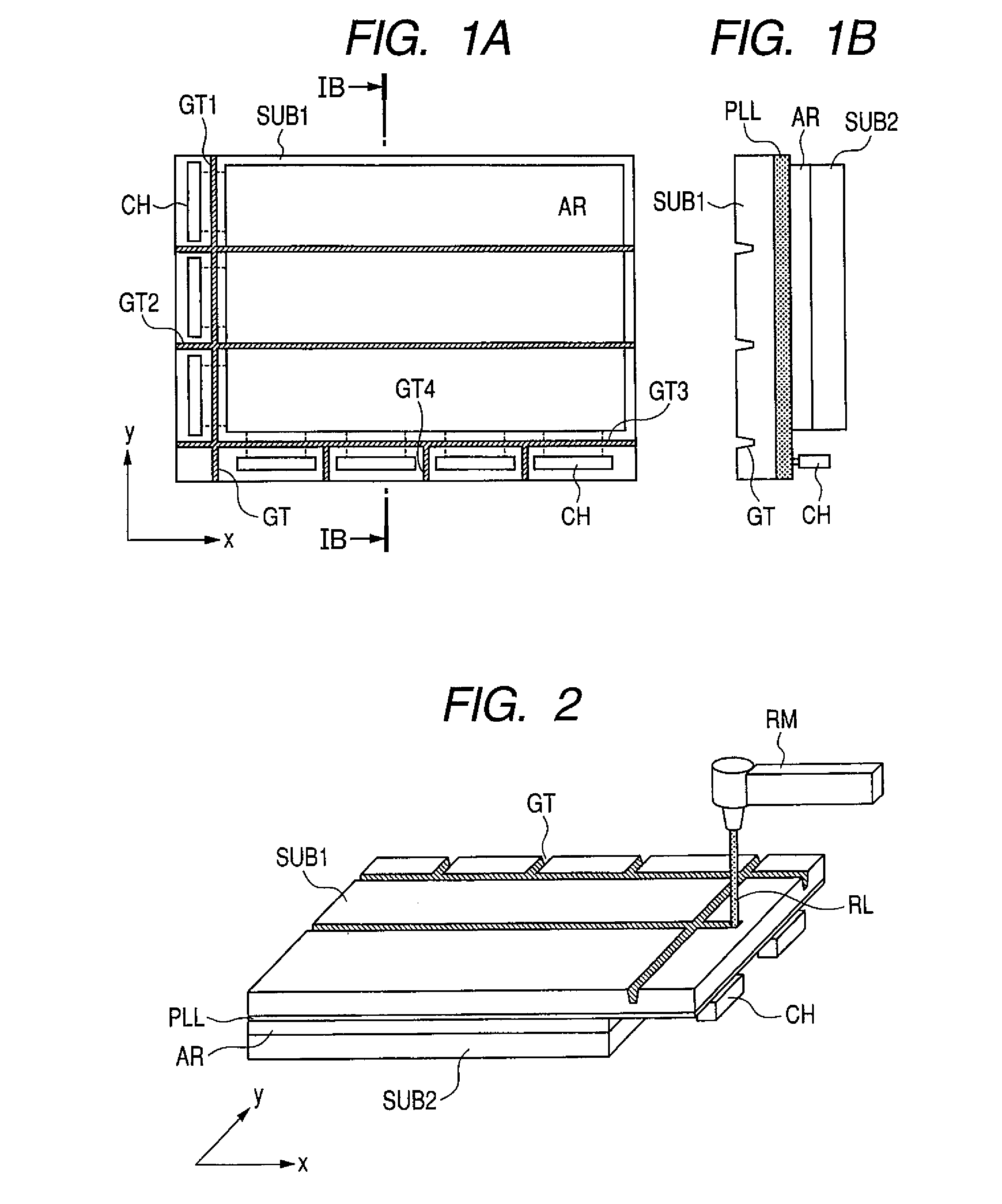

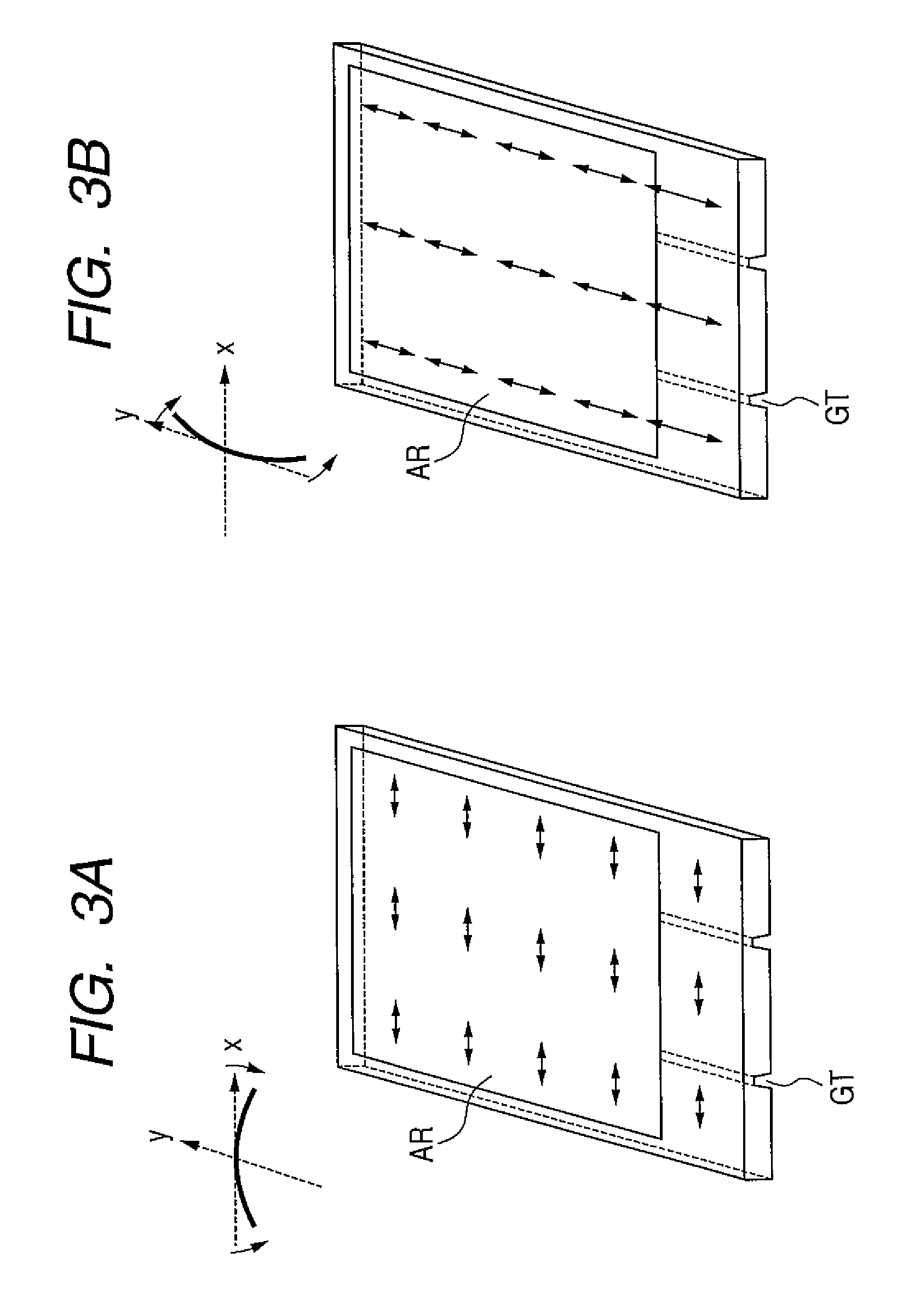

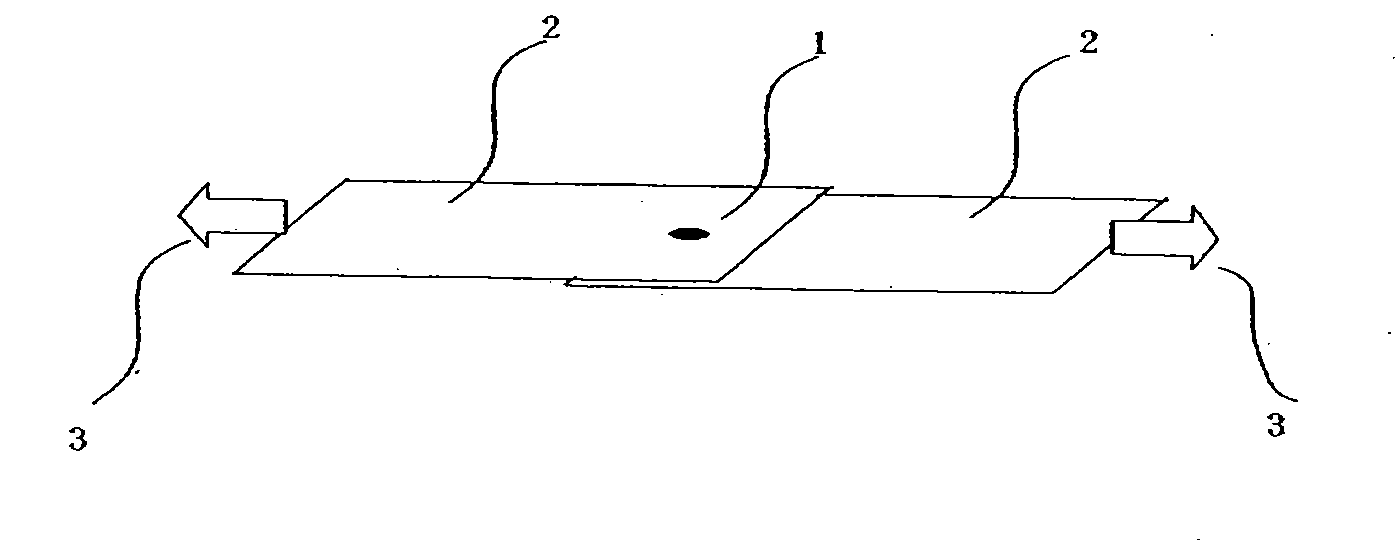

Laser processing method and chip

ActiveUS7897487B2High precision cuttingPrecise cuttingSemiconductor/solid-state device manufacturingFine working devicesLaser processingLaser light

An object to be processed can be cut highly accurately along a line to cut.An object to be processed 1 is irradiated with laser light while locating a converging point within a silicon wafer 11, and the converging point is relatively moved along a line to cut 5, so as to form modified regions M1, M2 positioned within the object 1 along the line to cut 5, and then a modified region M3 positioned between the modified regions M1, M2 within the object 1.

Owner:HAMAMATSU PHOTONICS KK

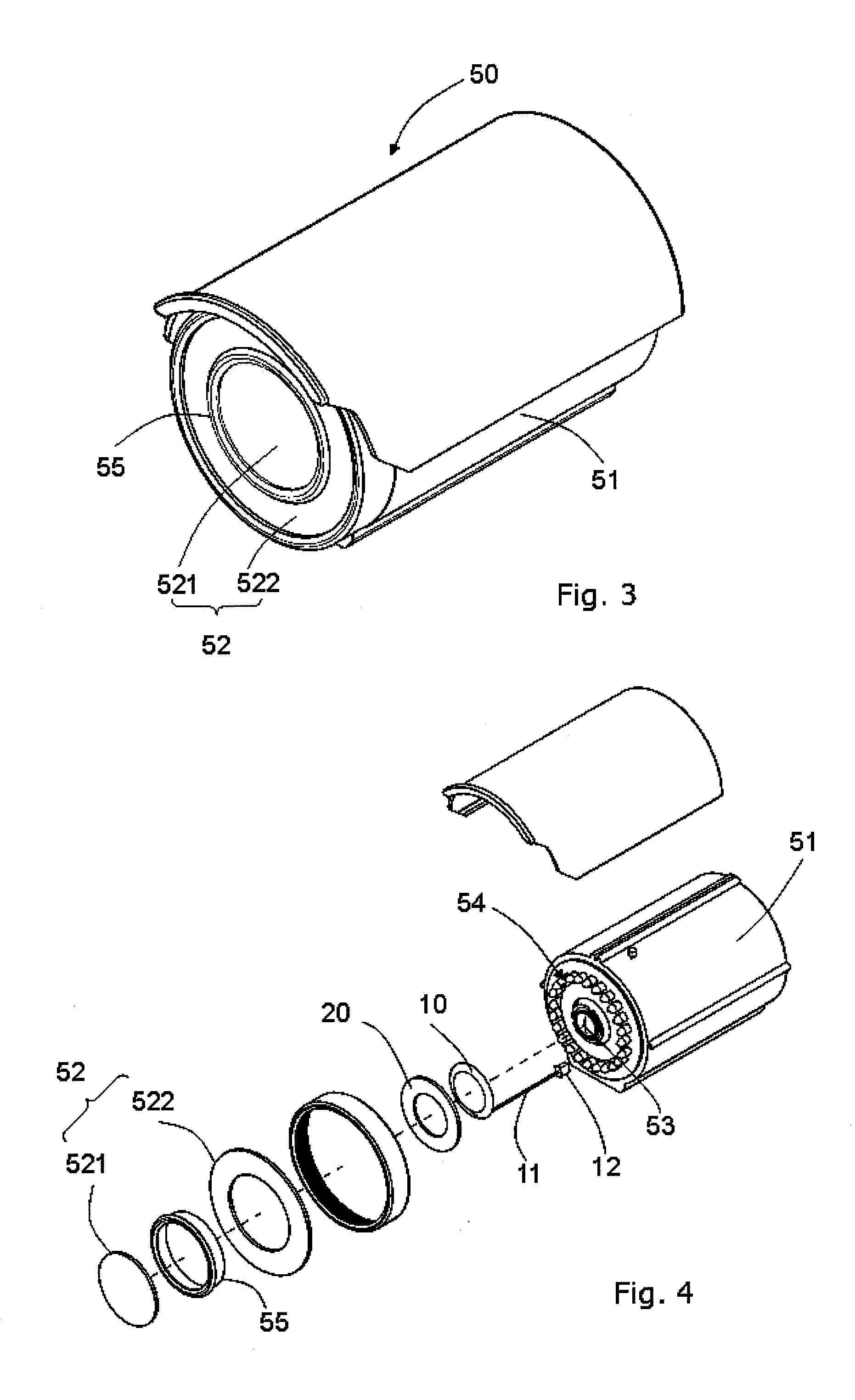

Defogging and defrosting device for protective lens of a camera

InactiveUS20120170119A1Avoid and eliminate humidificationEliminate lossCamera filtersMountingsEngineeringControl circuit

The present invention relates to a defogging and defrosting devices for the protective lens of camera, which includes a heater that is coupled to a control circuit panel, a thermal gasket that is in contact contacting with the heater, receives the heat from the heater and transmits the heat to the glass or mirror object which contacts with in order to avoid and prevent the loss of lucidity of the glass or mirror object due to humidity. The defogging and defrosting device is installed on the body of the camera instead of on the protective lens in order to avoid shading the camera view and to facilitate the removal of protective lens while adjusting the focus of the camera. It also facilitates the replacement of the protective lens of the camera.

Owner:TOPVIEW OPTRONICS CORP

Laser processing method and chip

ActiveUS20100184271A1High precision cuttingPrecise cuttingSemiconductor/solid-state device manufacturingFine working devicesLaser processingLaser light

An object to be processed can be cut highly accurately along a line to cut.An object to be processed 1 is irradiated with laser light while locating a converging point within a silicon wafer 11, and the converging point is relatively moved along a line to cut 5, so as to form modified regions M1, M2 positioned within the object 1 along the line to cut 5, and then a modified region M3 positioned between the modified regions M1, M2 within the object 1.

Owner:HAMAMATSU PHOTONICS KK

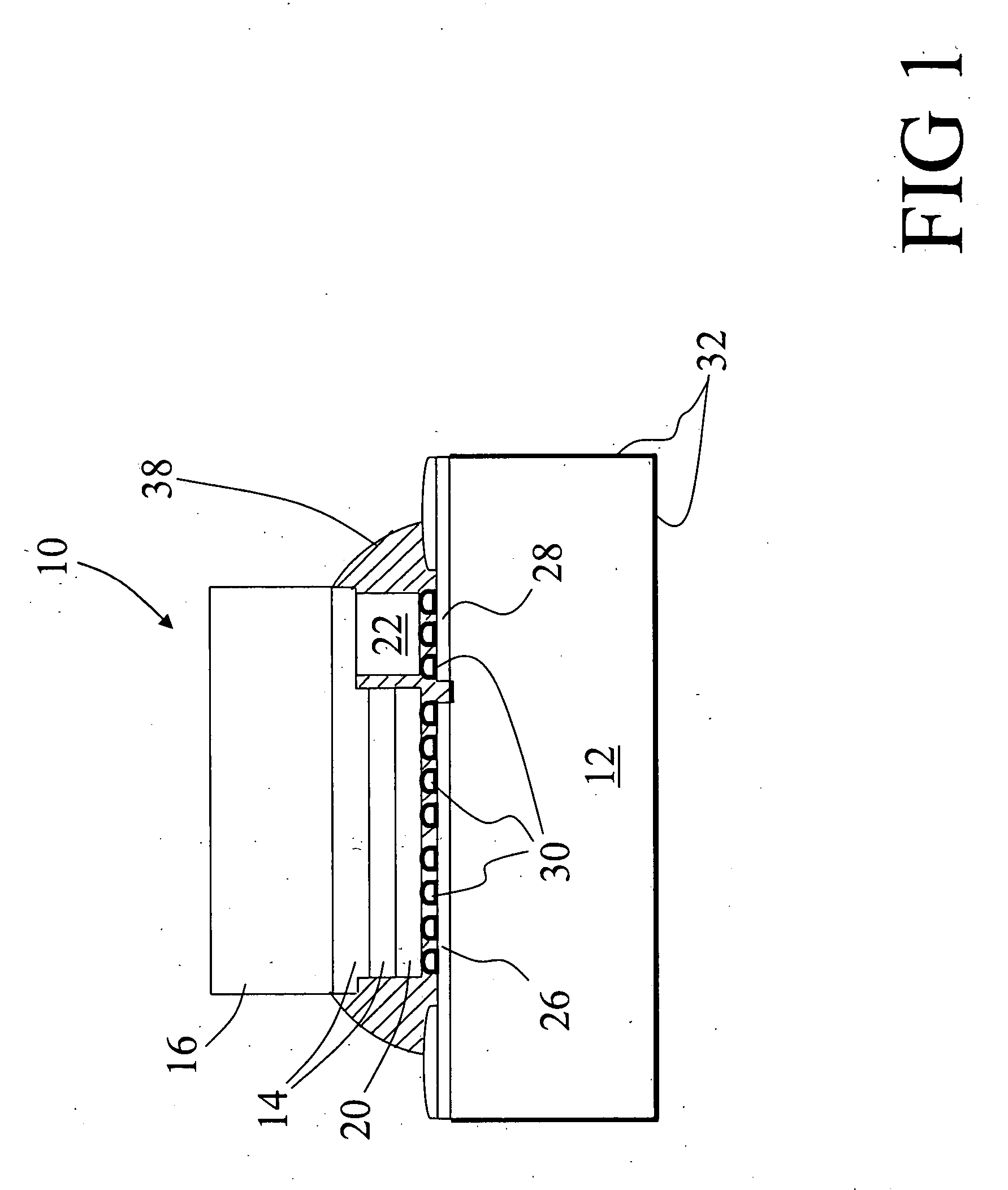

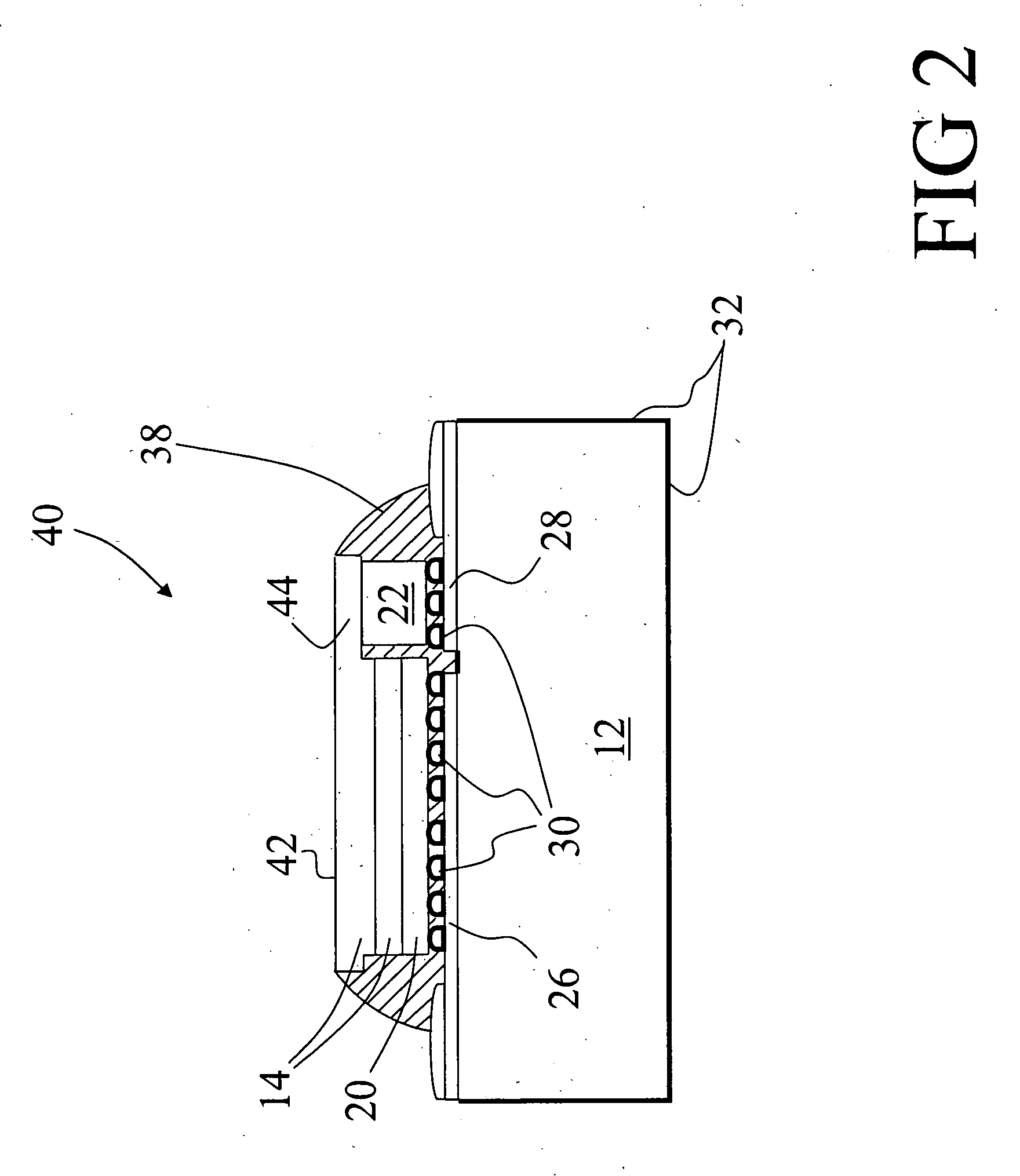

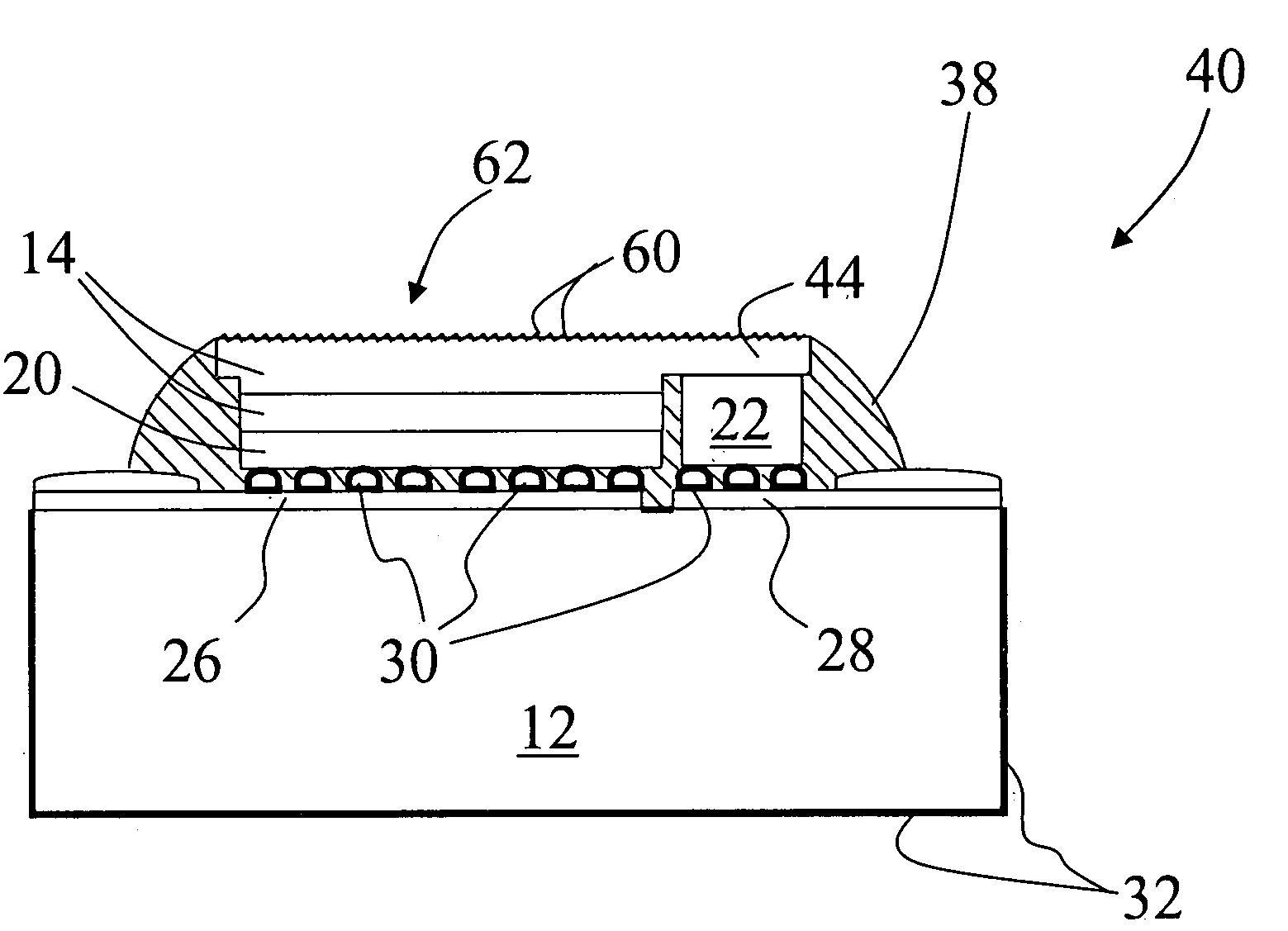

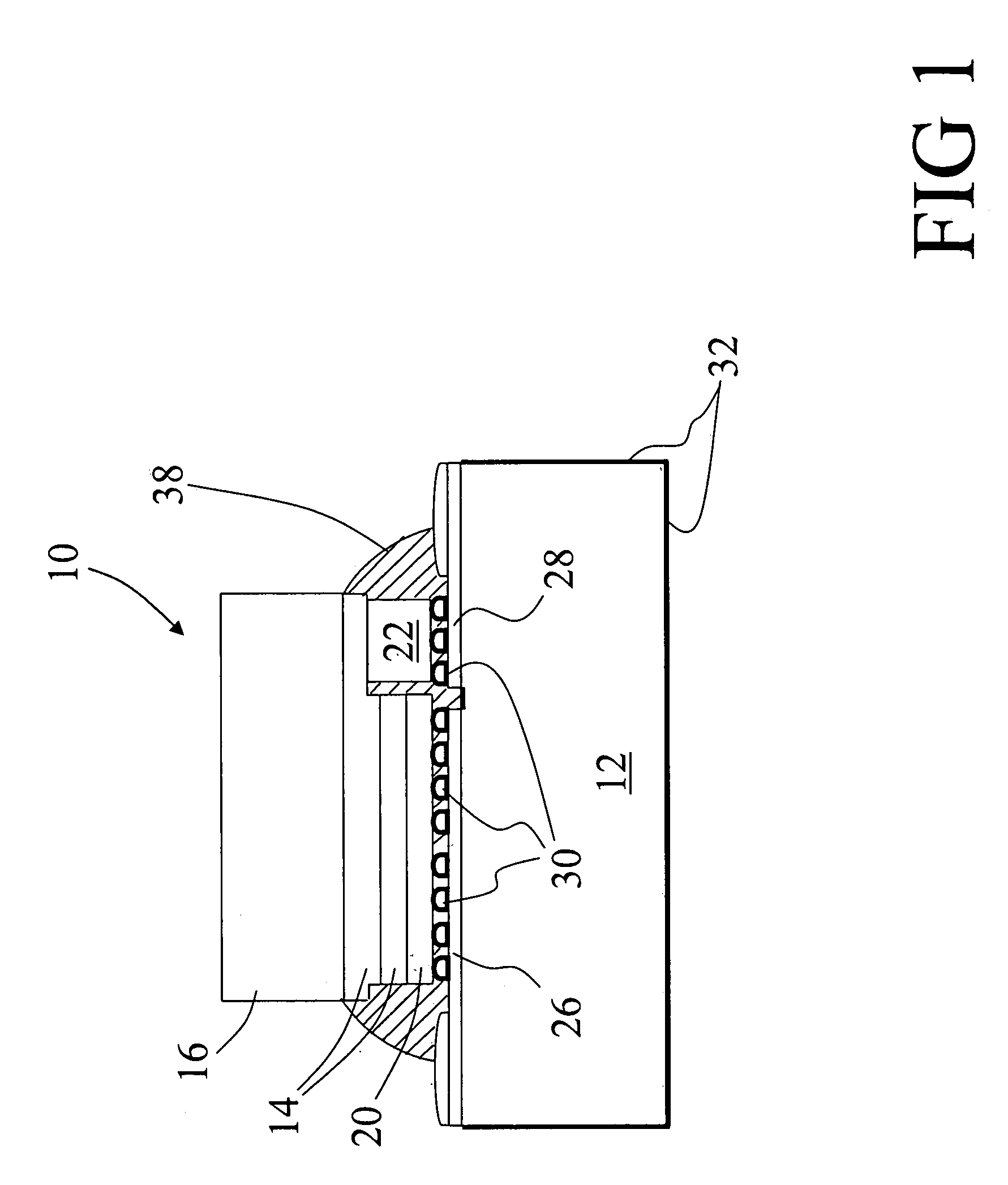

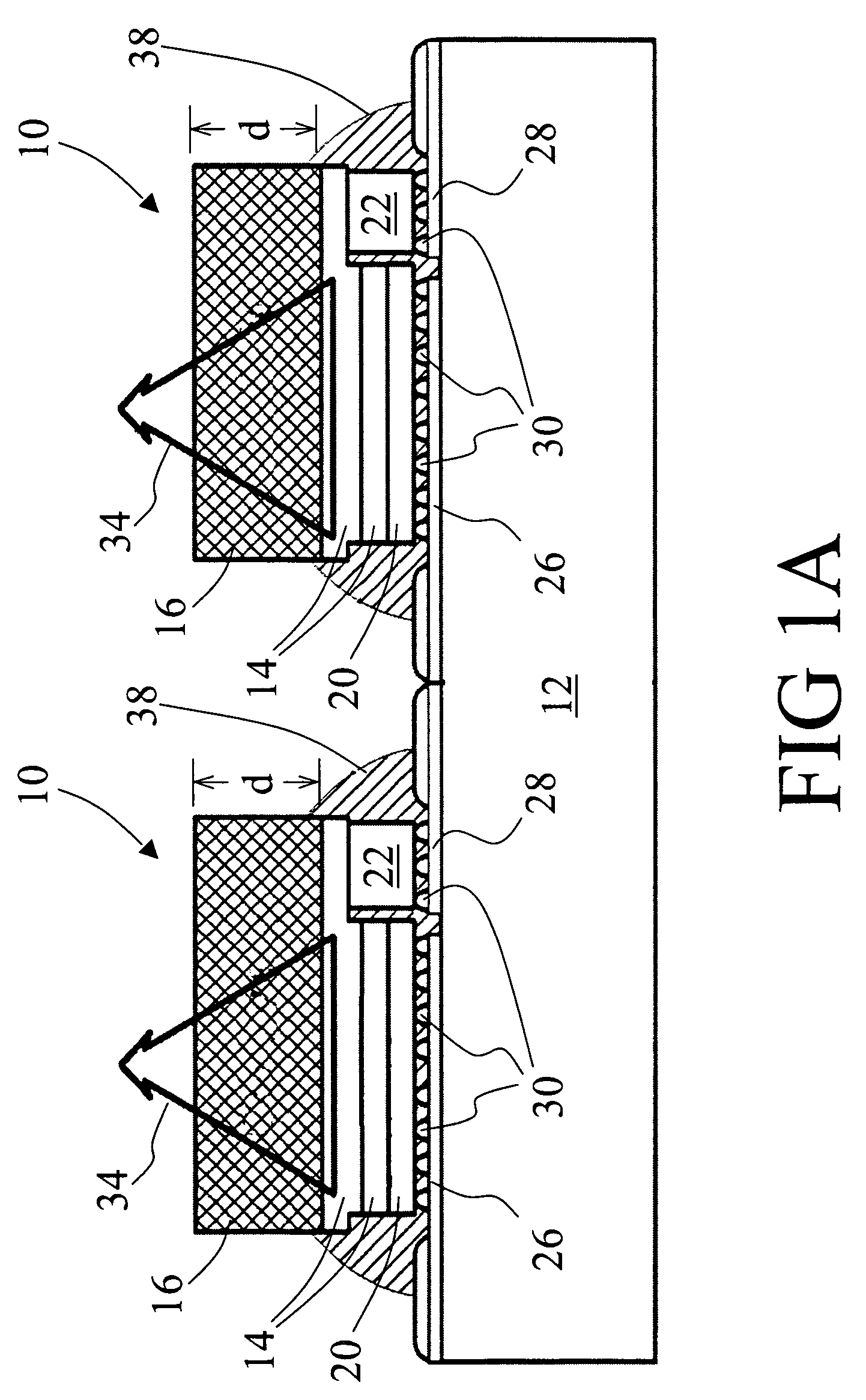

Increased light extraction from a nitride LED

InactiveUS20060202223A1Improve light extractionEasy to fixSemiconductor/solid-state device detailsSolid-state devicesWaferingFlip chip

In a method for fabricating a flip-chip light emitting diode device, a submount wafer is populated with a plurality of the light emitting diode dies. Each device die is flip-chip bonded to the submount. Subsequent to the flip-chip bonding, a growth substrate is removed. The entire submount is immersed in the etchant solution, exposed to the light for a prespecified period of time, removed from the solution, dried and diced into a plurality of LEDs., The LEDs are immediately packaged without any further processing.

Owner:GELCORE LLC (US)

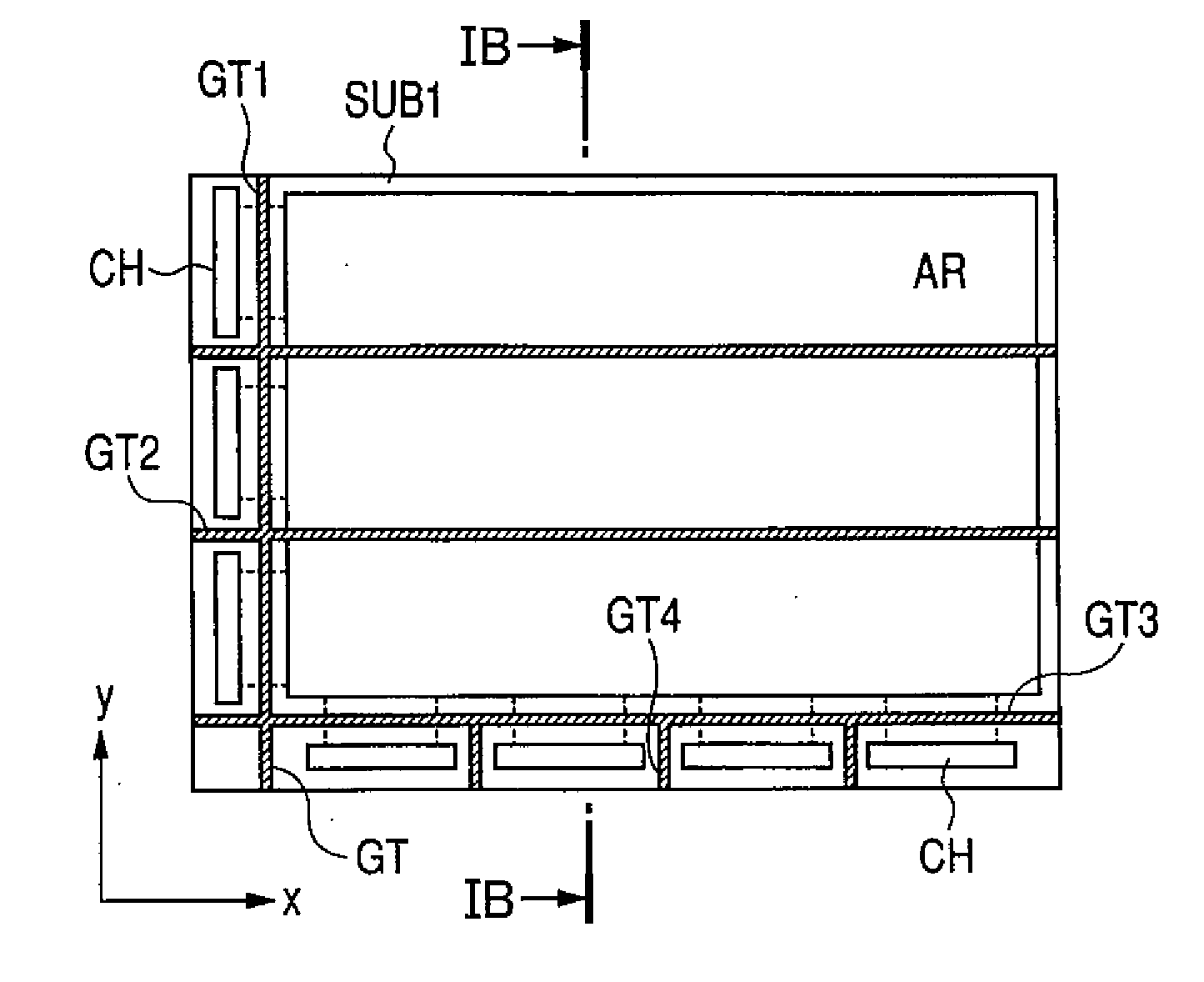

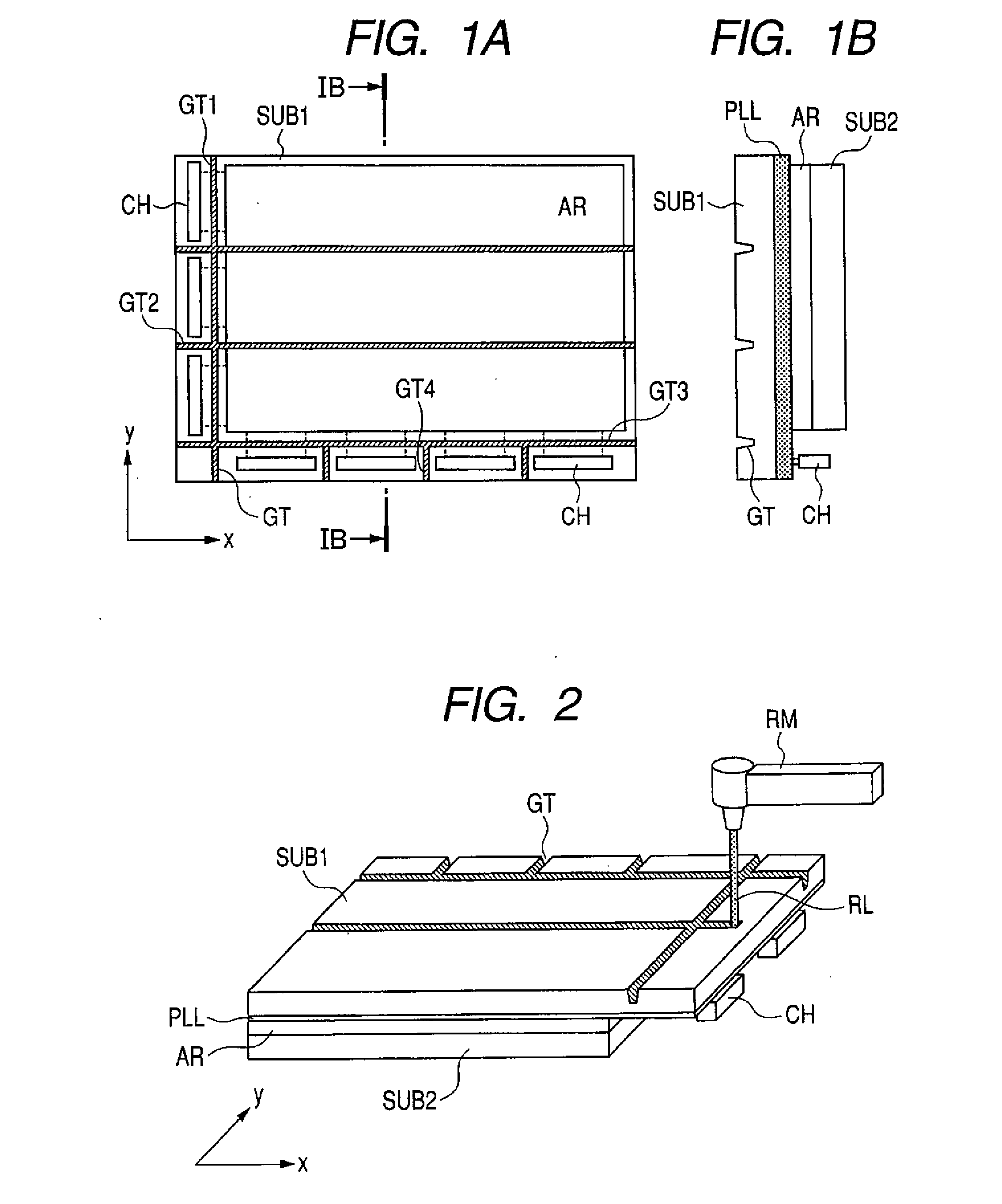

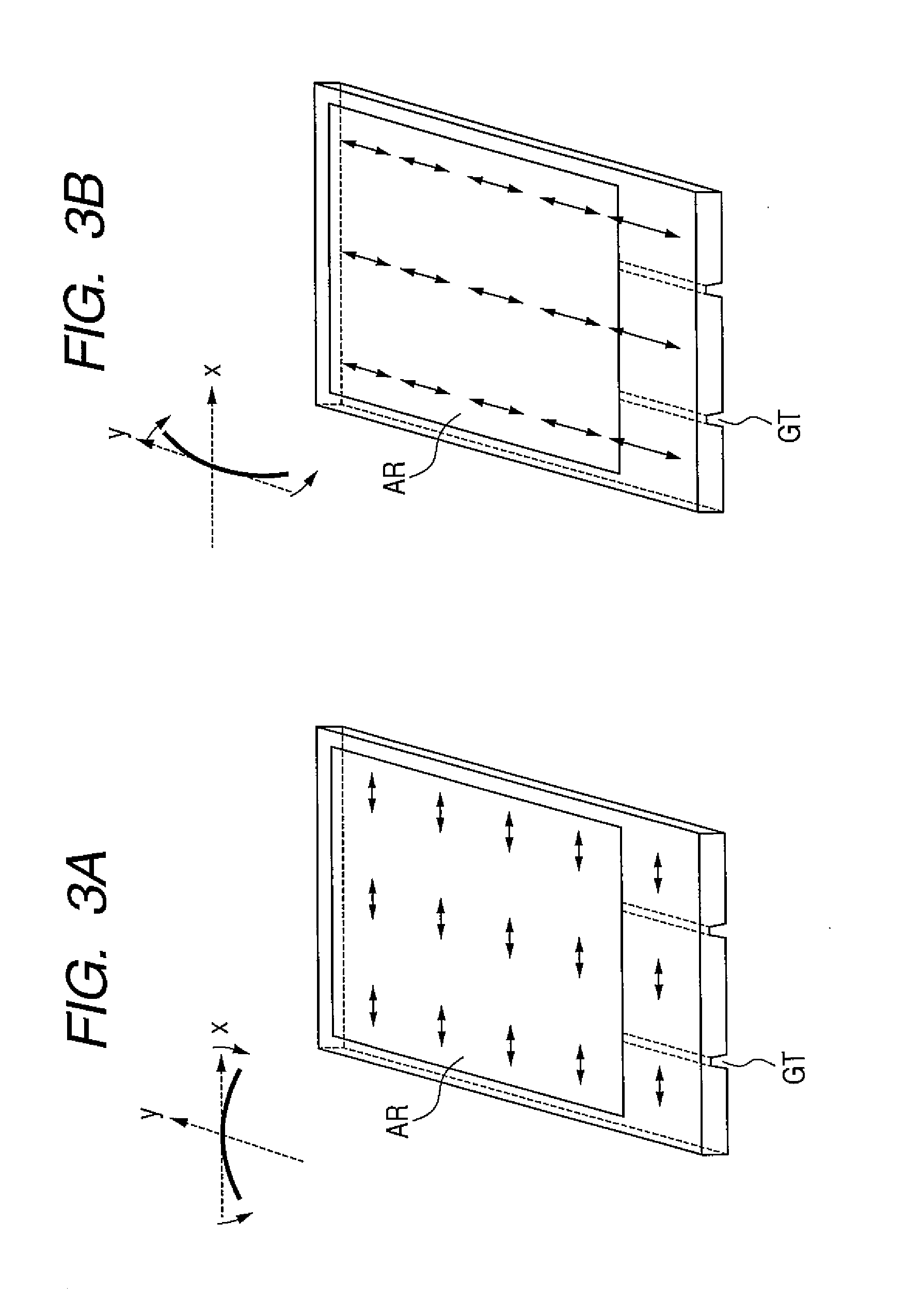

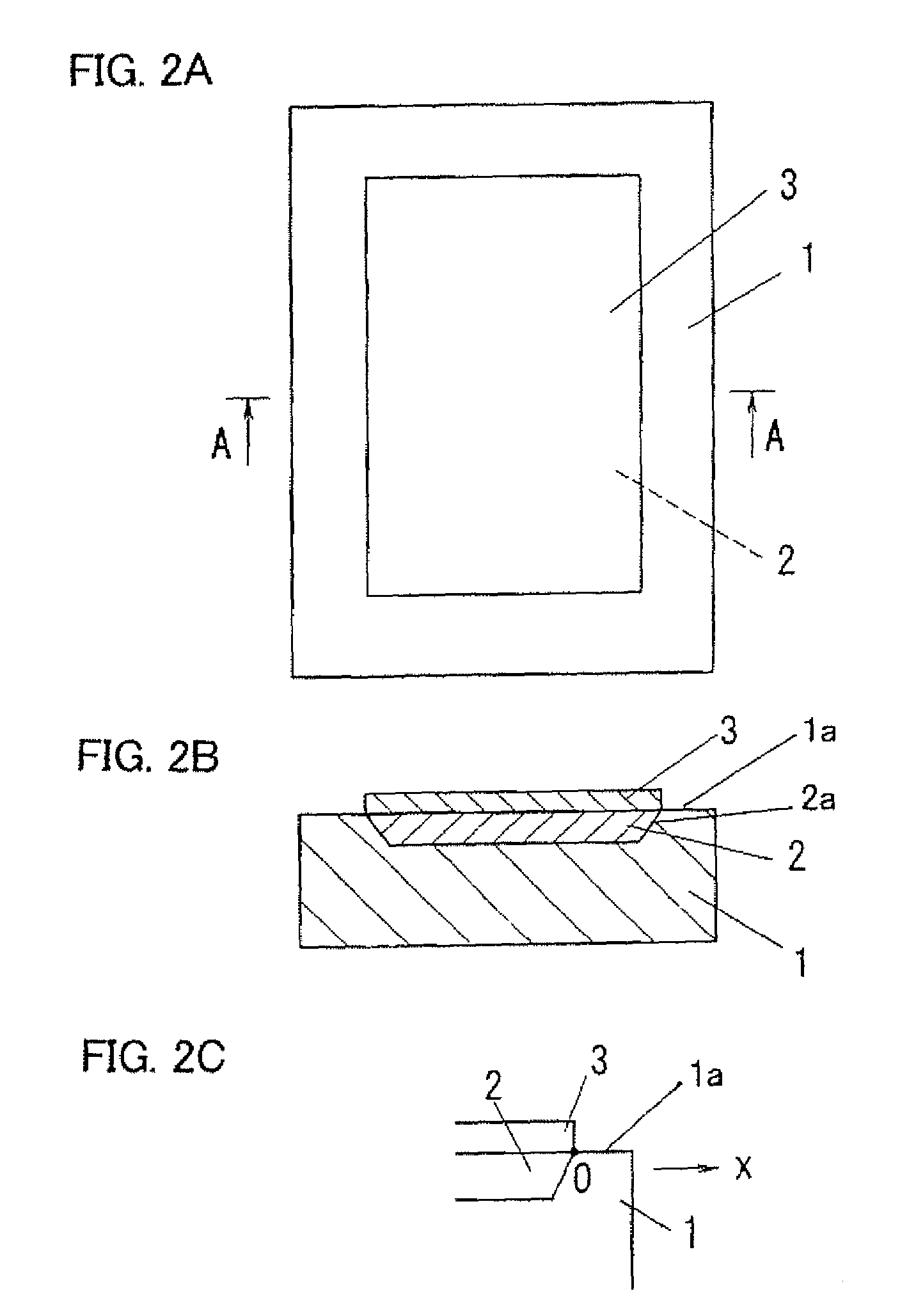

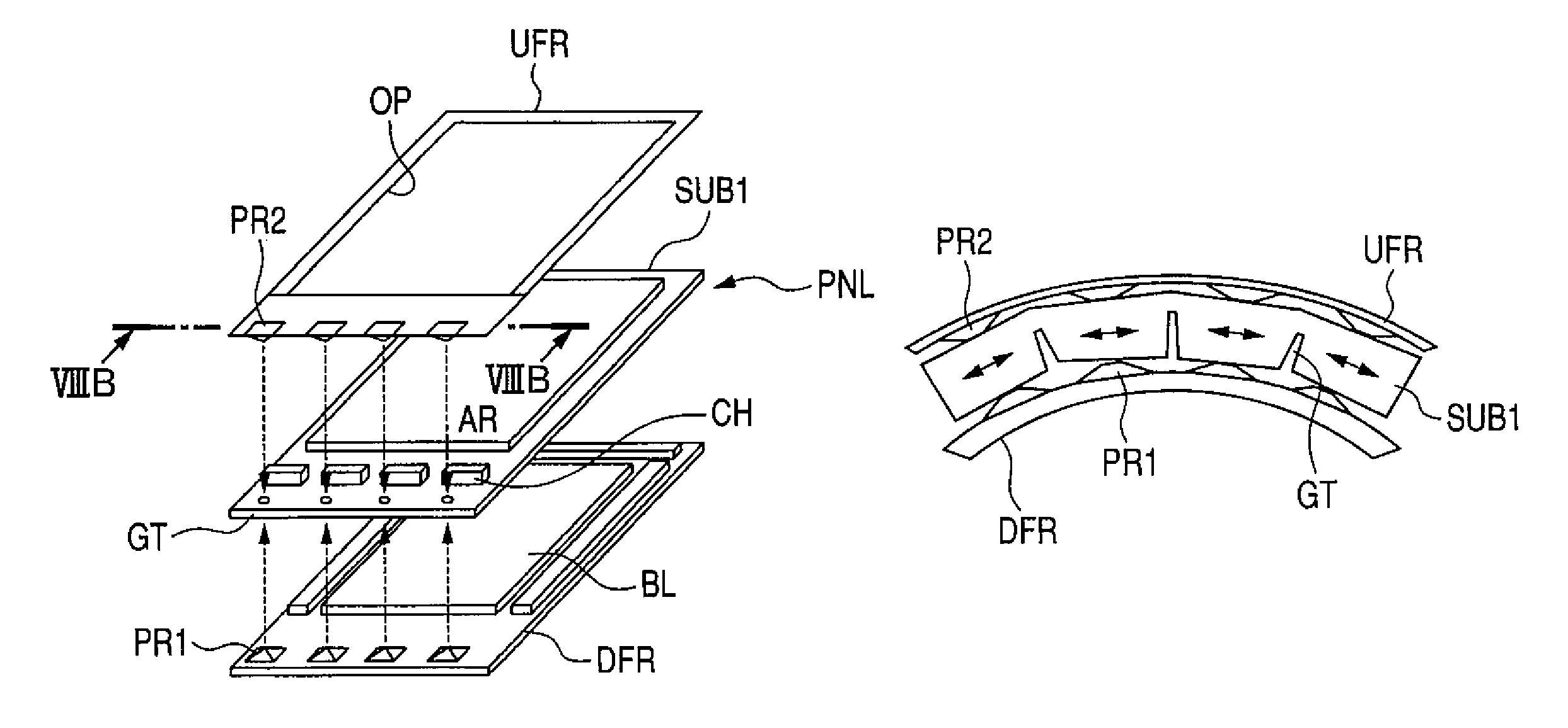

Image display

ActiveUS20100073620A1Avoid frackingAvoid fracturesDischarge tube luminescnet screensLamp detailsSemiconductor chipDisplay device

To provide an image display which is capable of preventing fracturing of a substrate which is attributable to a substrate expansion arising from heating or humidification during a manufacture process, impact in use, or distortion when curved display is conducted, a connection failure between a semiconductor chip and a wiring terminal which are mounted on the substrate, and crack occurring in the substrate in the vicinity of an area where the semiconductor chip is mounted, with no need to add members and with no limit of pulling the wiring around. An image display part is formed on one surface of a flexible substrate, and a groove with a depth not reaching a thickness of the substrate is continuously or intermittently defined in another surface of the substrate.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

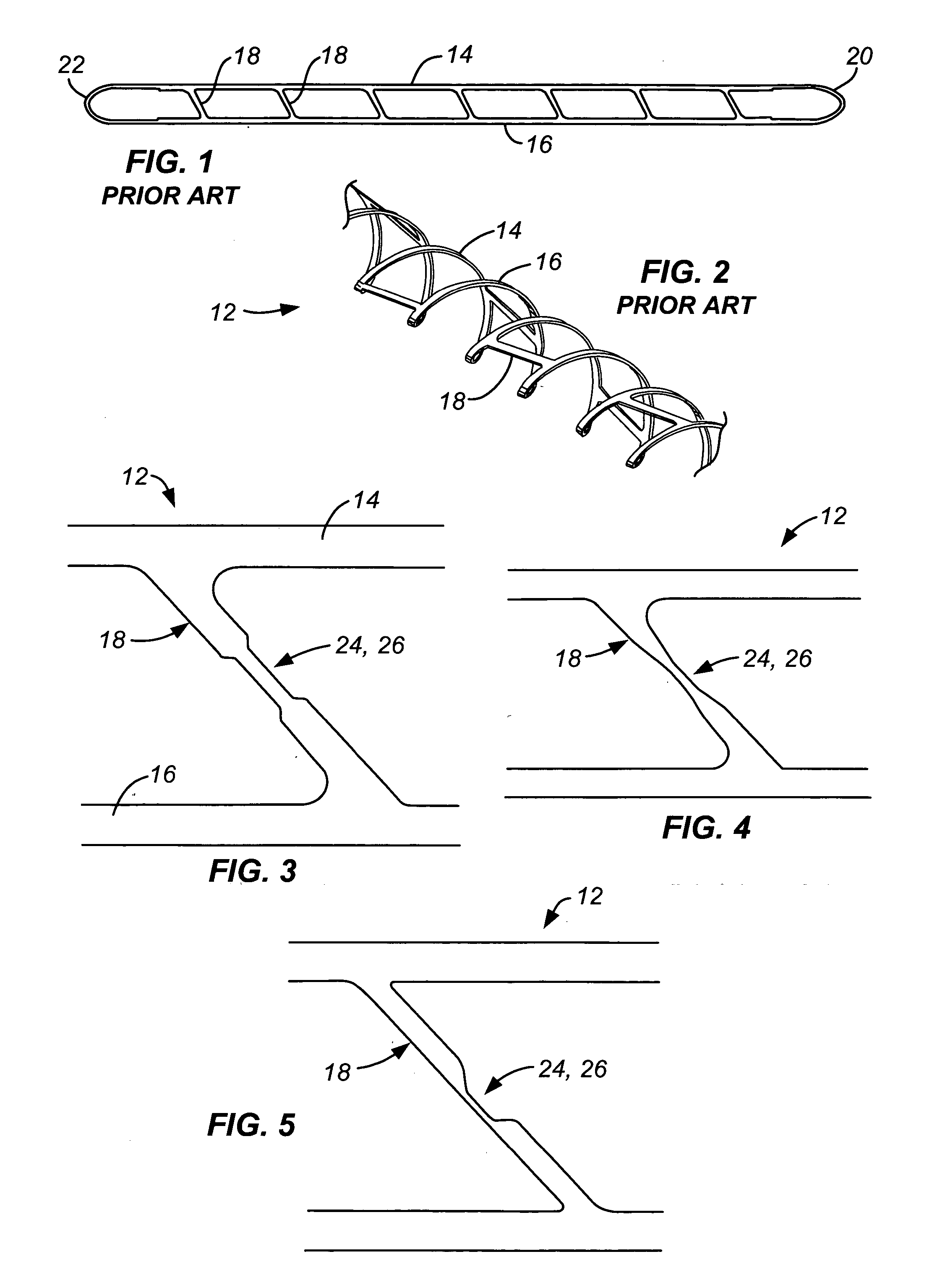

Coiled ladder stent

InactiveUS20060058869A1Reduces or minimizes any negative consequences from the rung failureAvoid fracturesStentsBlood vesselsMedicineInsertion stent

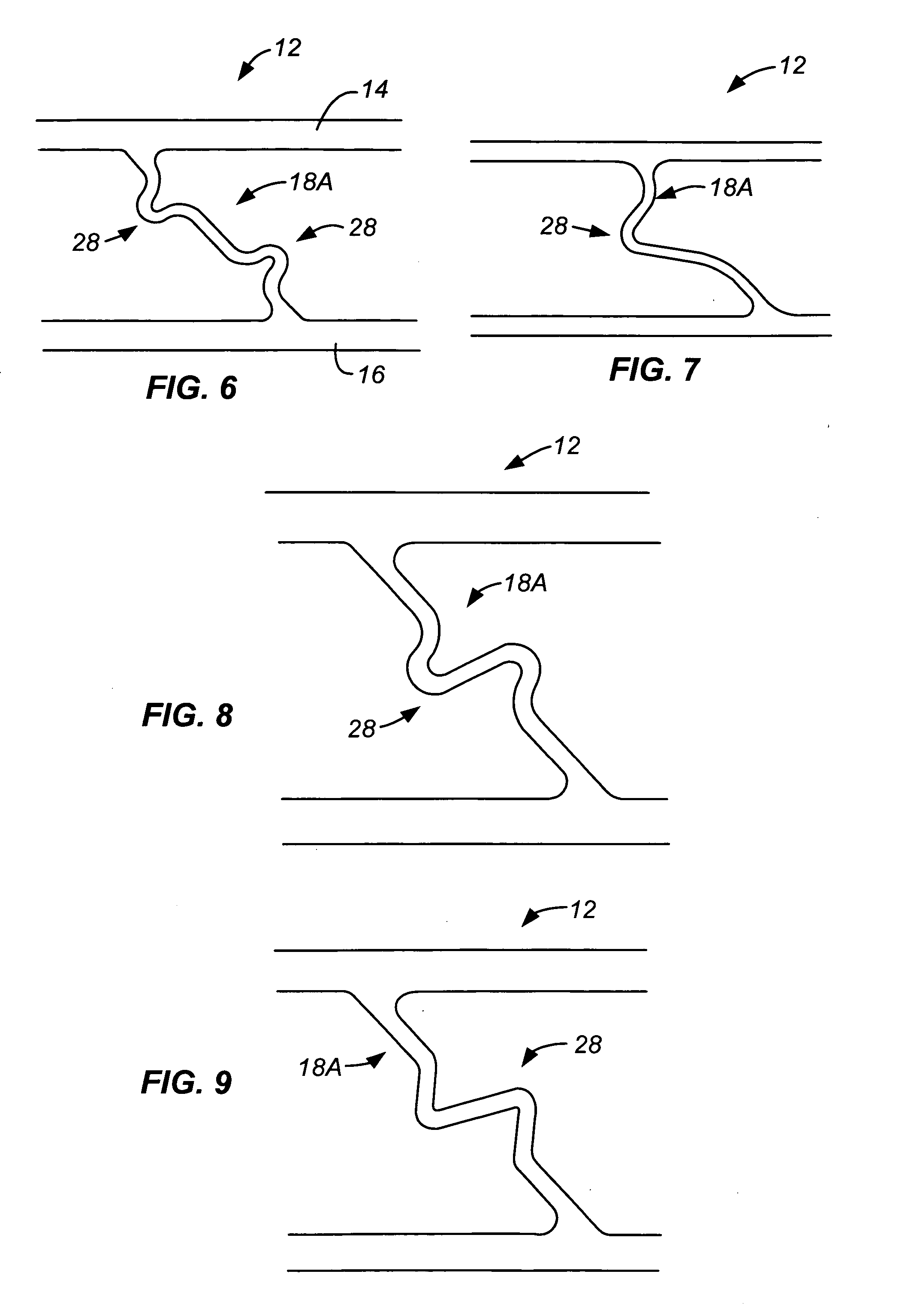

A coiled ladder stent comprises first and second rails and rungs connecting the rails. At least one rung has lower strength portion or is an enhanced flexibility rung, or both. The lower strength portion is positioned at a reduced strength fracture location along the rung so to promote any fracture of the ladder stent at the fracture location along the rung to help prevent fracture of a rail. One way to make the lower strength portion is to make the cross-sectional area of the lower strength portion less than the average cross-sectional area of the rung. The enhanced flexibility aspect helps to accommodate relative movement between the first and second rails. Doing so helps to prevent fracture of the rails and rungs. In some embodiments of the invention the enhanced flexibility rung comprises one or more nonlinear, such as generally S-shaped or generally U-shaped, portions.

Owner:LEMAITRE VASCULAR

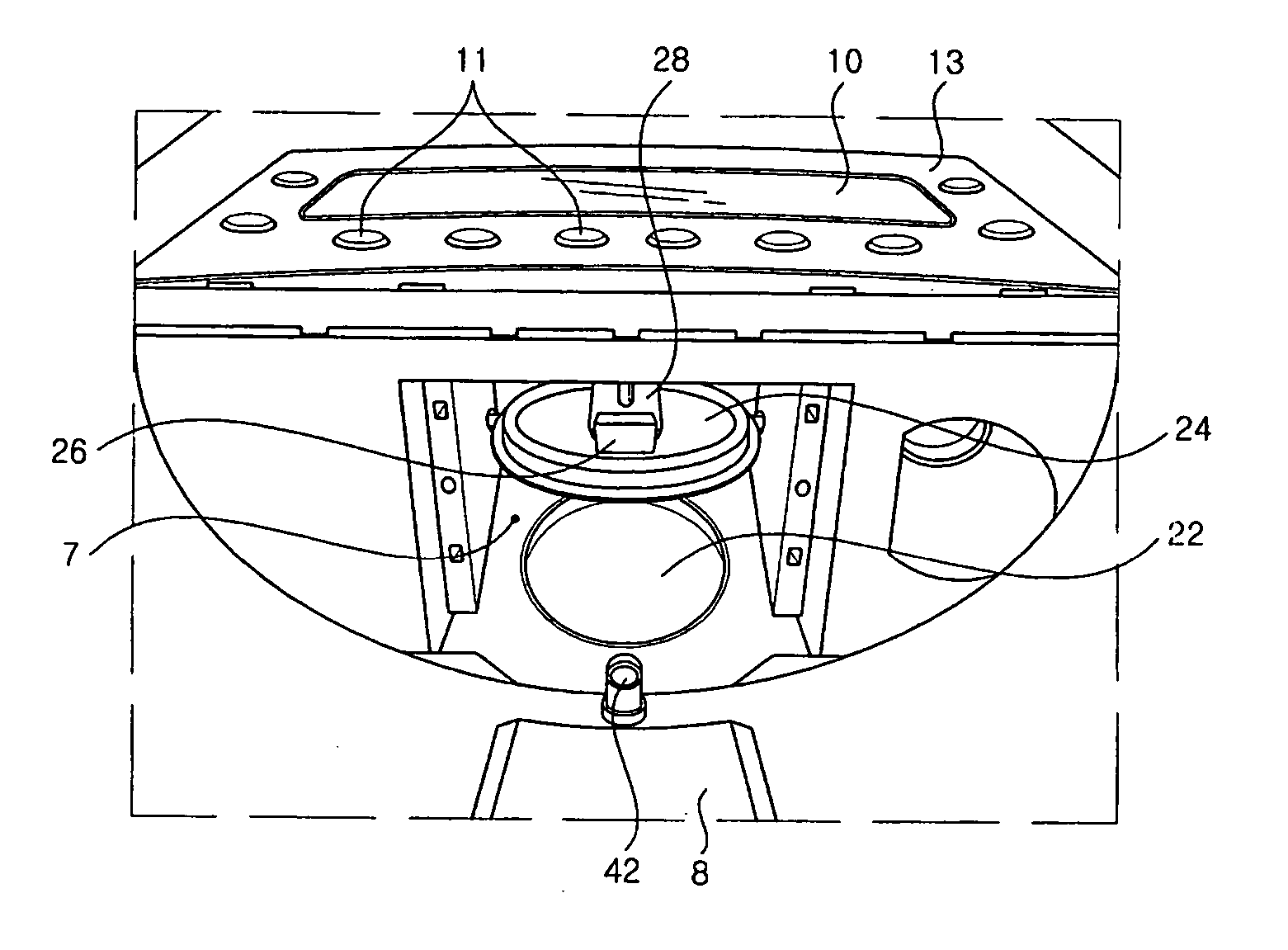

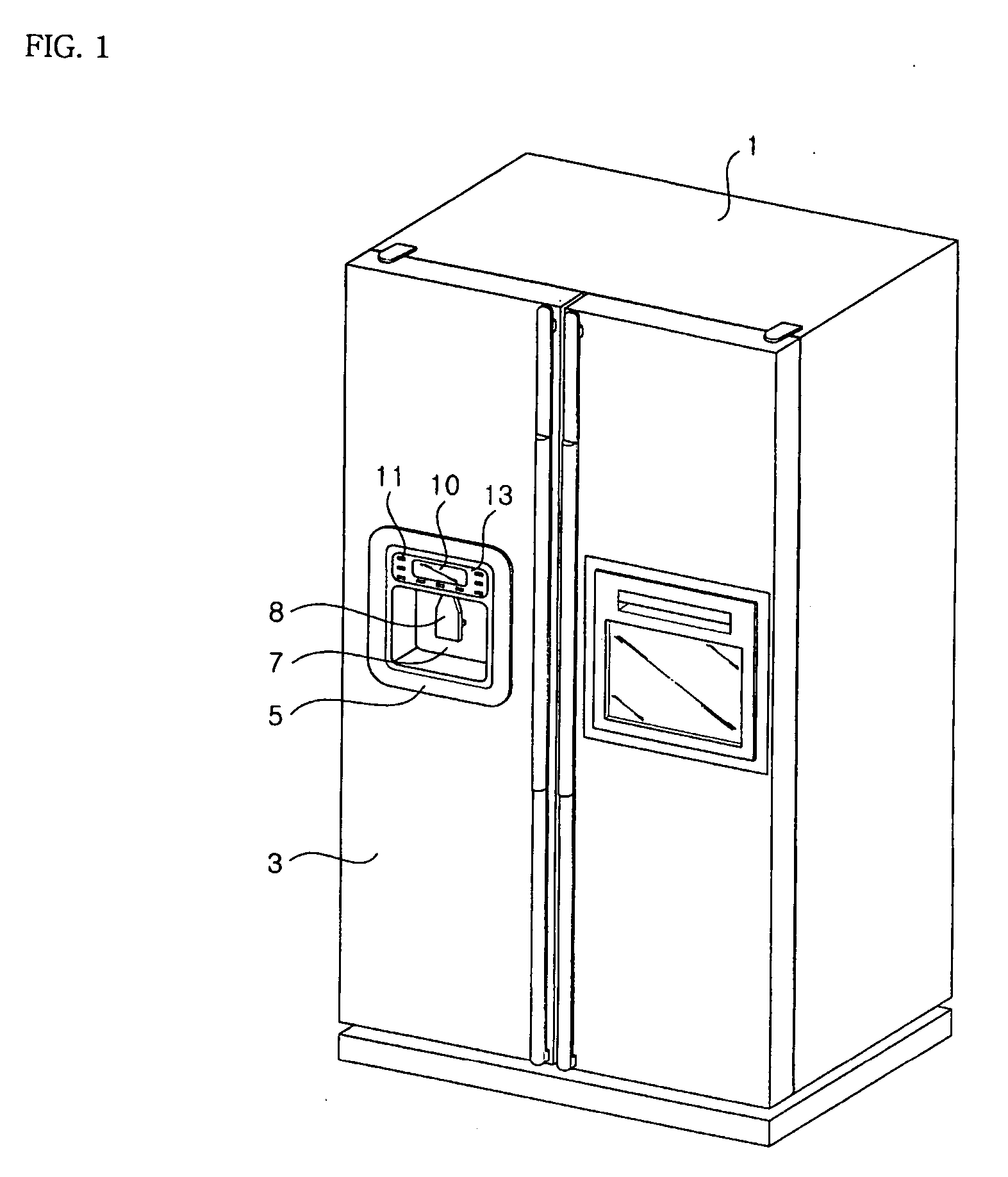

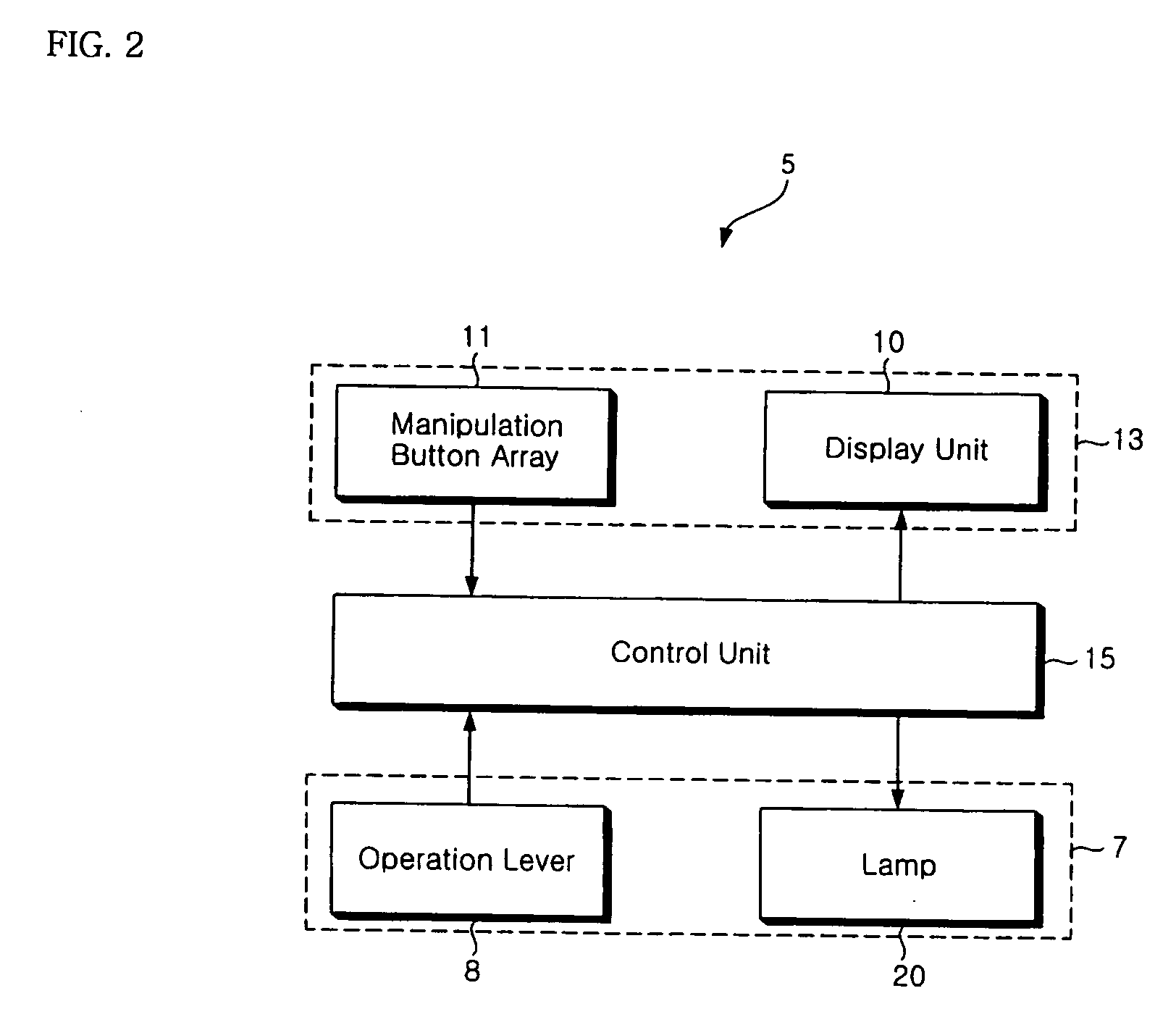

Apparatus and method for controlling lamp of refrigerator

Disclosed are an apparatus and a method for controlling lamps which are provided in a dispenser and a backlight of a manipulation button array. According to the present invention, at least one lamp is provided in the dispenser and an illumination sensor for sensing the surrounding brightness of a refrigerator or a sensor for detecting a user approaching the refrigerator is also provided. There is also provided a memory unit for previously storing a reference luminous intensity, the value of which is capable of being changed by the user. There is also provided a lamp driving unit for selectively controlling the brightness of the lamp by controlling the output signal thereof according to a driving control signal of a control unit. According to the present invention, the user can easily take ice or water from the dispenser because the lamp is turned on. In addition, because the reference luminous intensity can be changed and stored in relation to the surrounding brightness of the refrigerator, it is possible to control the condition for turning on or off the lamp according to the surrounding environment or the user's taste. Moreover, because the dispenser and the backlight are normally illuminated with the minimum brightness, it is easy to use the dispenser, and because the dispenser and the backlight are illuminated with the maximum brightness for a predetermined length of time and then the illumination is gradually returned to the minimum brightness or turned off, it is possible to efficiently use the dispenser.

Owner:LG ELECTRONICS INC

Laser processing method and chip

ActiveUS20080000884A1Avoid fracturesShorten the timeSemiconductor/solid-state device manufacturingFine working devicesLaser processingLaser light

An object to be processed can be cut highly accurately along a line to cut.An object to be processed 1 is irradiated with laser light while locating a converging point within a silicon wafer 11, and the converging point is relatively moved along a line to cut 5, so as to form modified regions M1, M2 positioned within the object 1 along the line to cut 5, and then a modified region M3 positioned between the modified regions M1, M2 within the object 1.

Owner:HAMAMATSU PHOTONICS KK

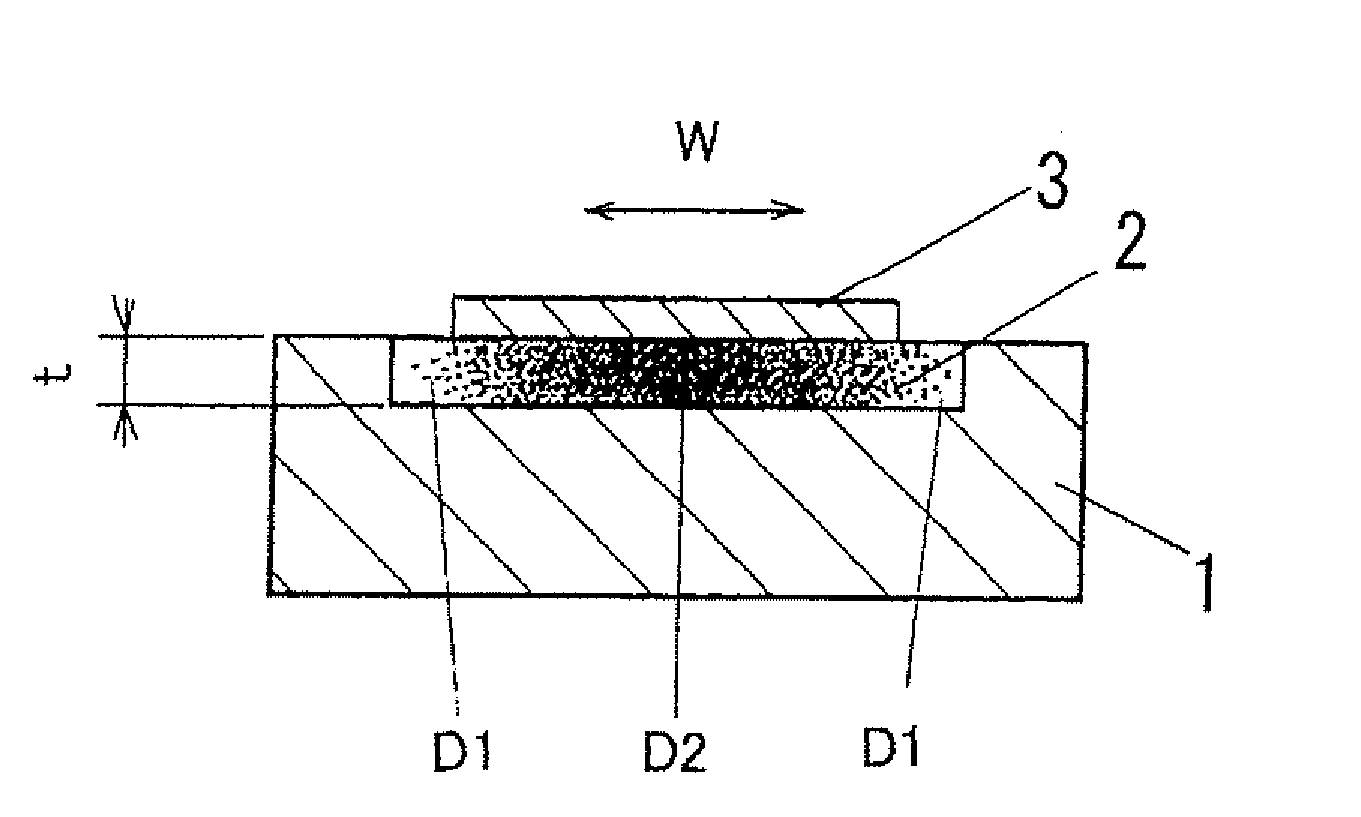

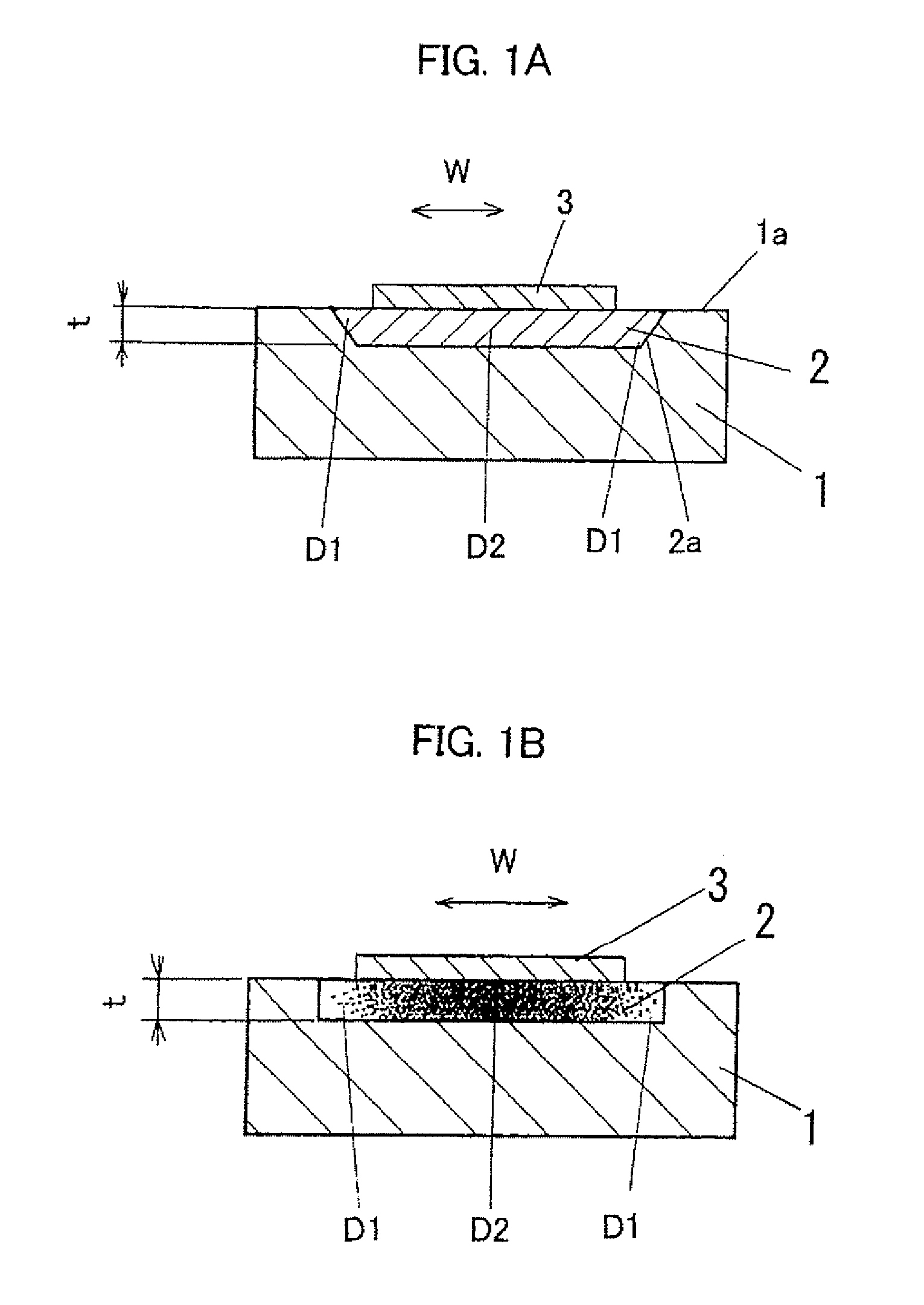

Pressure wave generator and process for manufacturing the same

InactiveUS7474590B2Reduce the likelihood of occurrenceMade smallMicrophonesElectrothermic-effect transistorPorosityElectrical conductor

Even when compression stress is generated because a volume of a thermal insulation layer 2 is expanded due to oxidized by oxygen in the air, occurrence of cracks and fractures of the thermal insulation layer and a heating conductor 3 caused by the cracks are prevented by dispersing the compression stress. A pressure wave generator comprises a substrate 1, the thermal insulation layer 2 of porous material which is formed on a surface of the substrate 1 in thickness direction, and the heating conductor 3 of thin film formed on the thermal insulation layer 2, and generates pressure waves by heat exchange between the heating conductor 3 and a medium. When a thickness at the center of the thermal insulation layer 2 in width direction W is used as a reference thickness, and it is assumed that distribution of thickness of thermal insulation layer in the width direction is averaged with the reference thickness, porosity in an outer peripheral portion of the thermal insulation layer is made smaller than porosity in the center portion. By making the porosity in the outer peripheral portion of the thermal insulation layer 2 smaller, a number of immovable points on the outer periphery of the thermal insulation layer 2 restricted by the substrate 1 is increased and the positions of them are dispersed, so that the compression stress compressed in the outer peripheral portion of the thermal insulation layer 2 can be dispersed.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Increased light extraction from a nitride LED

InactiveUS7125734B2Improve light extractionEasy to fixSemiconductor/solid-state device detailsSolid-state devicesWaferingLight-emitting diode

In a method for fabricating a flip-chip light emitting diode device, a submount wafer is populated with a plurality of the light emitting diode dies. Each device die is flip-chip bonded to the submount. Subsequent to the flip-chip bonding, a growth substrate is removed. The entire submount is immersed in the etchant solution, exposed to the light for a prespecified period of time, removed from the solution, dried and diced into a plurality of LEDs. The LEDs are immediately packaged without any further processing.

Owner:GELCORE LLC (US)

Plasticized Grafts and Methods of Making and Using Same

InactiveUS20100030340A1Avoid fracturesReduce the temperatureTissue regenerationFemurPlasticizerDiseases transmission

The invention provides a plasticized tissue or organ that does not require special conditions of storage, for example refrigeration or freezing, exhibits materials properties that approximate those properties present in natural tissue, is not brittle, does not necessitate rehydration prior to clinical implantation and is not a potential source for disease transmission. Replacement of the chemical plasticizers by water prior to implantation is not required and thus, the plasticized bone or soft tissue product can be placed directly into an implant site without significant preparation in the operating room.

Owner:LIFENET HEALTH

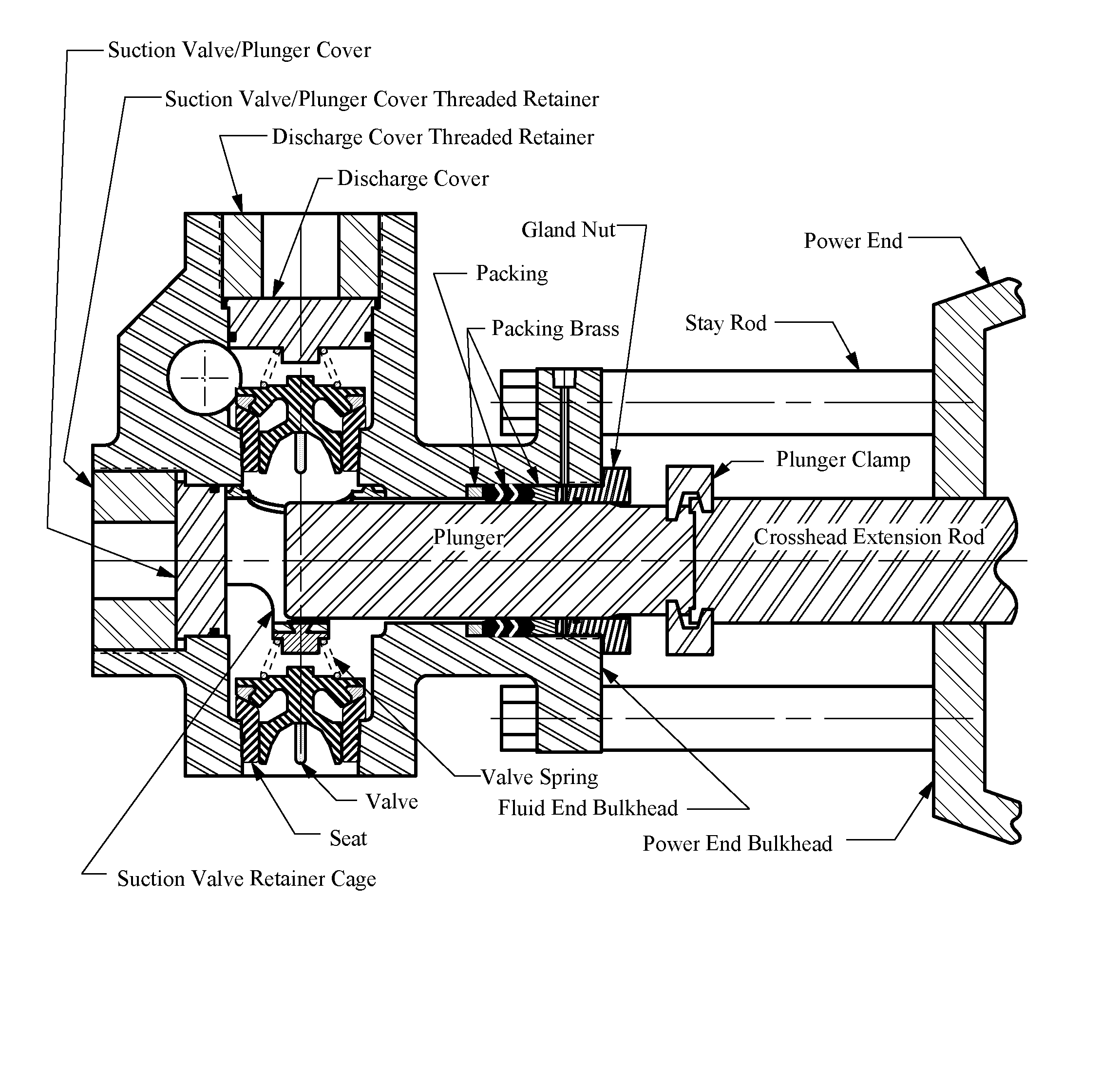

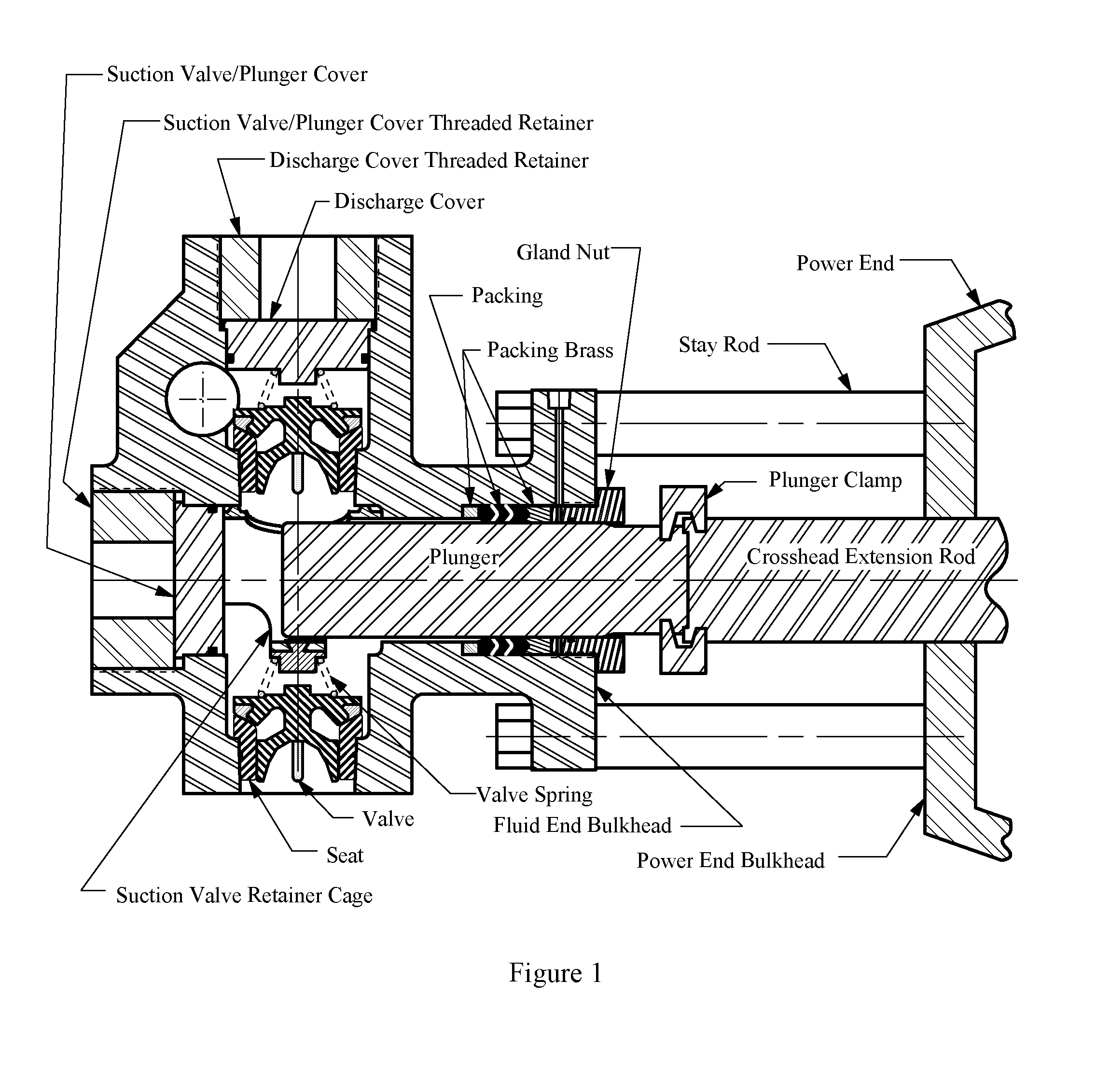

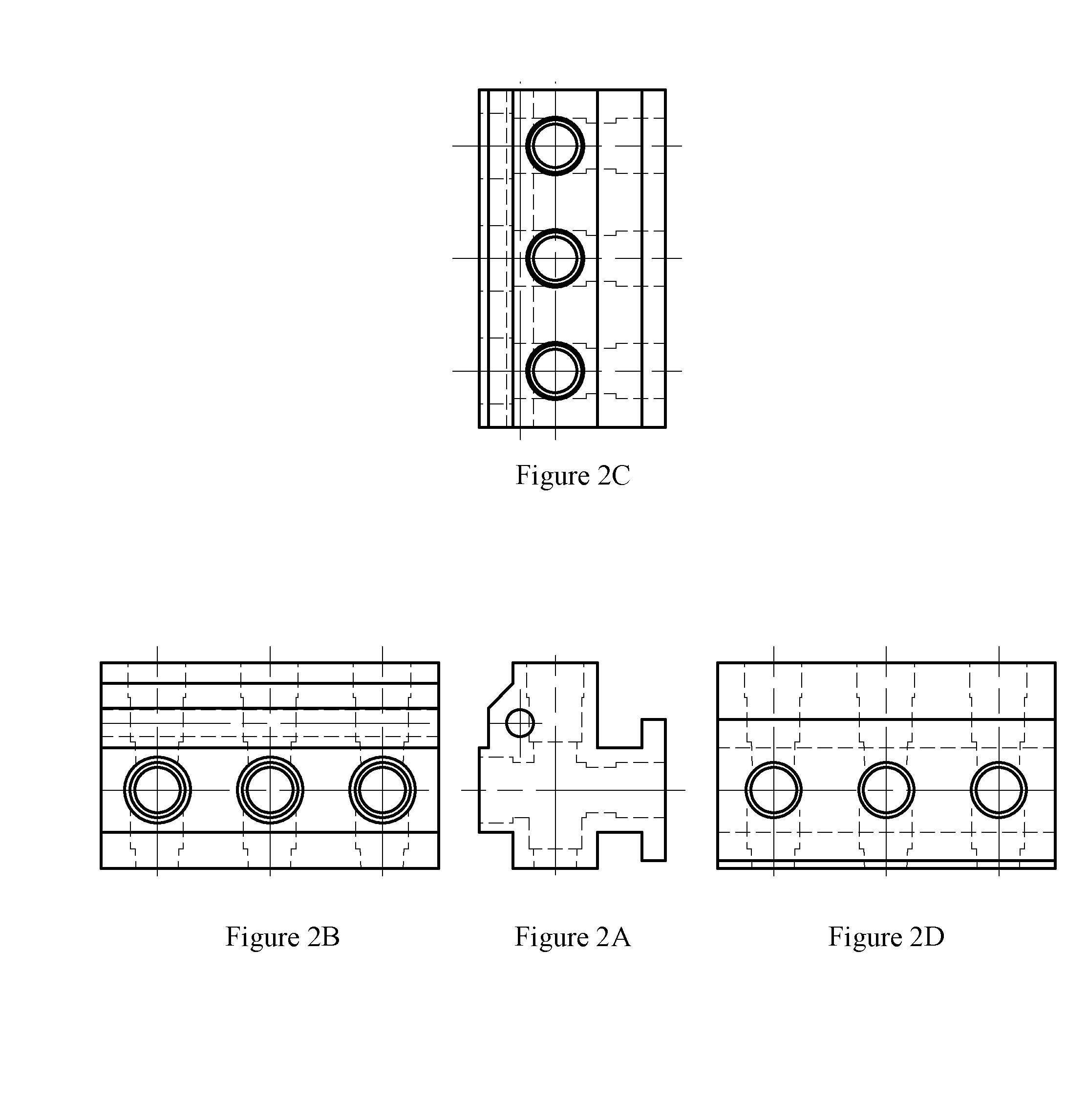

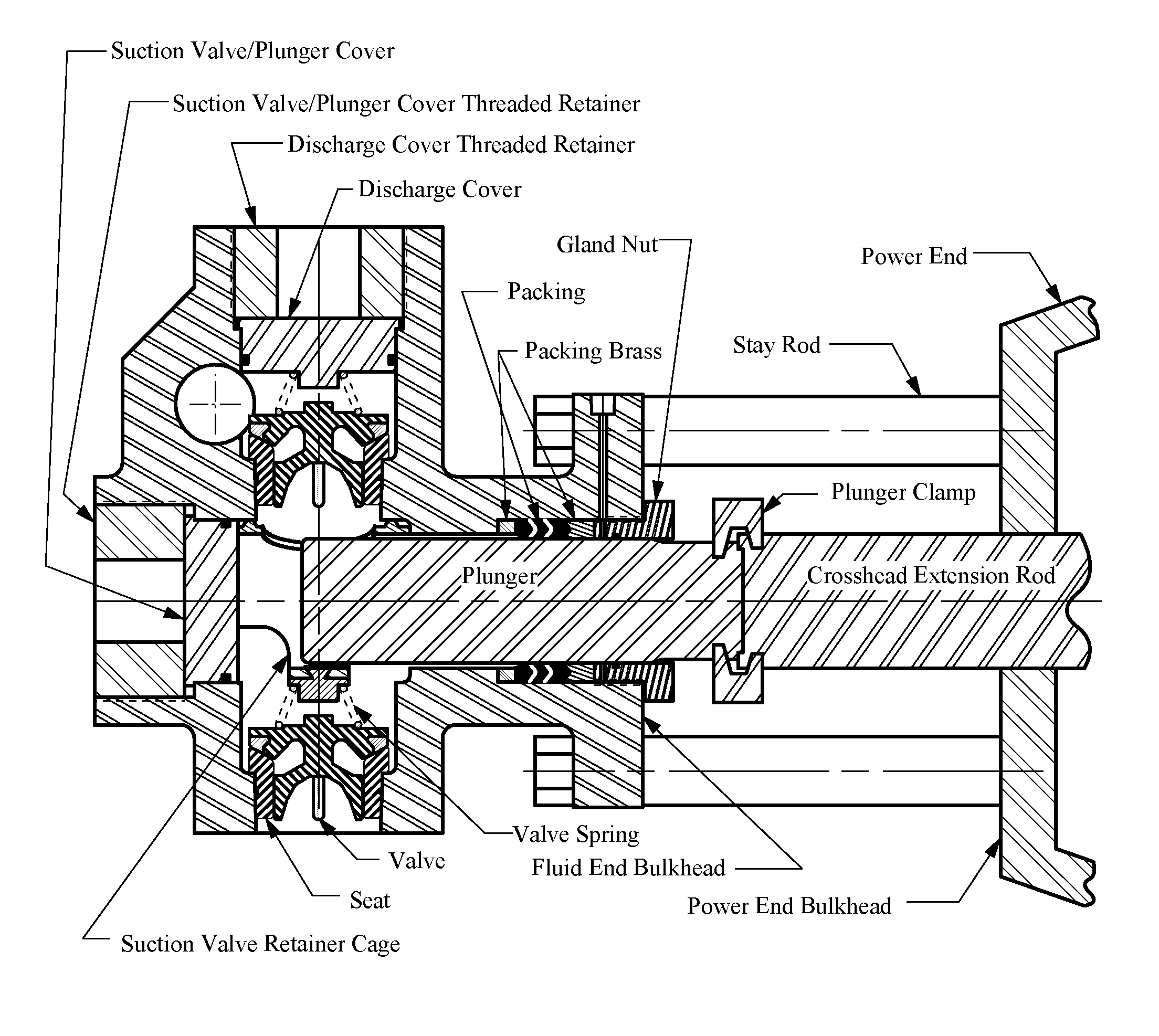

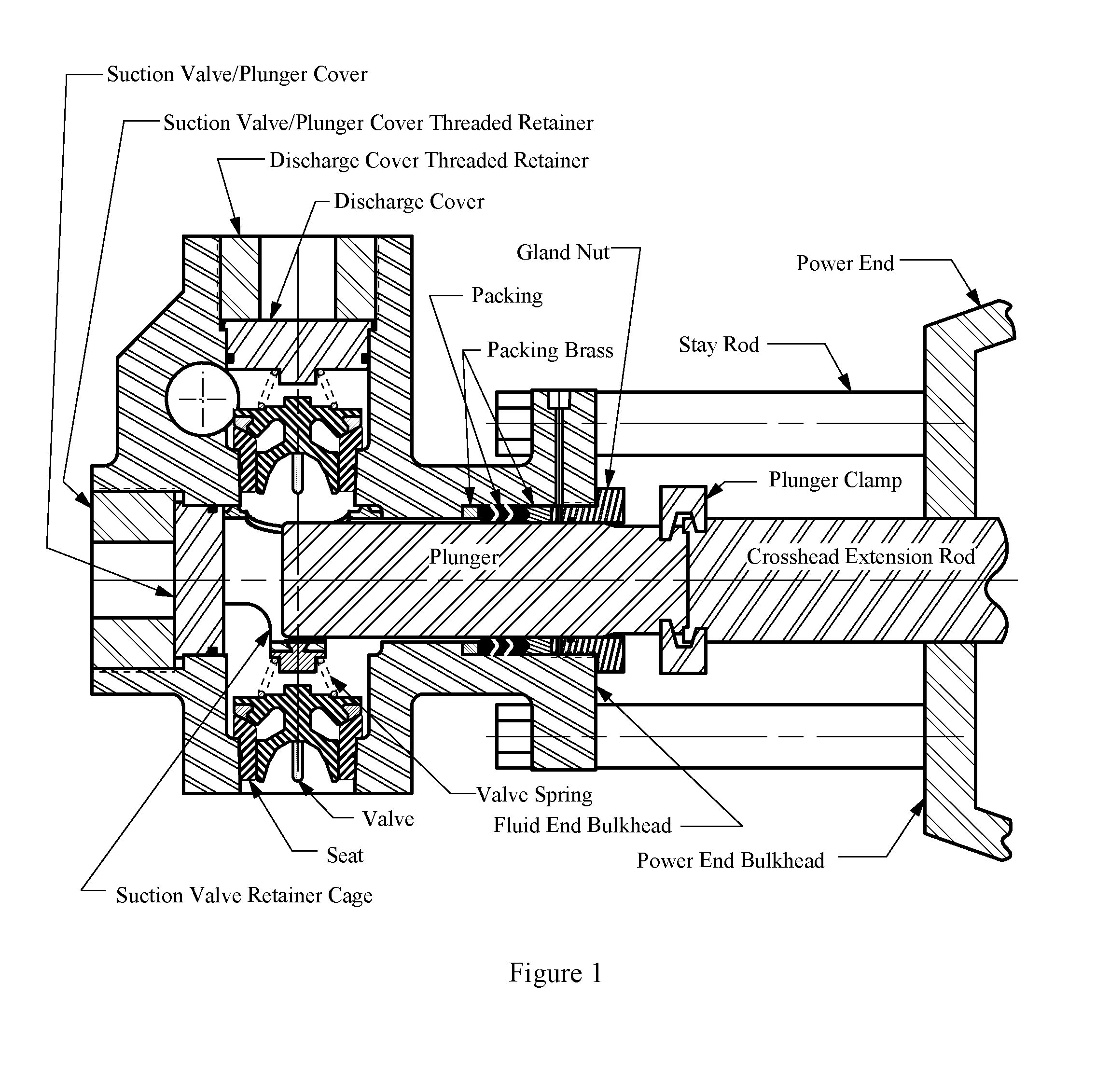

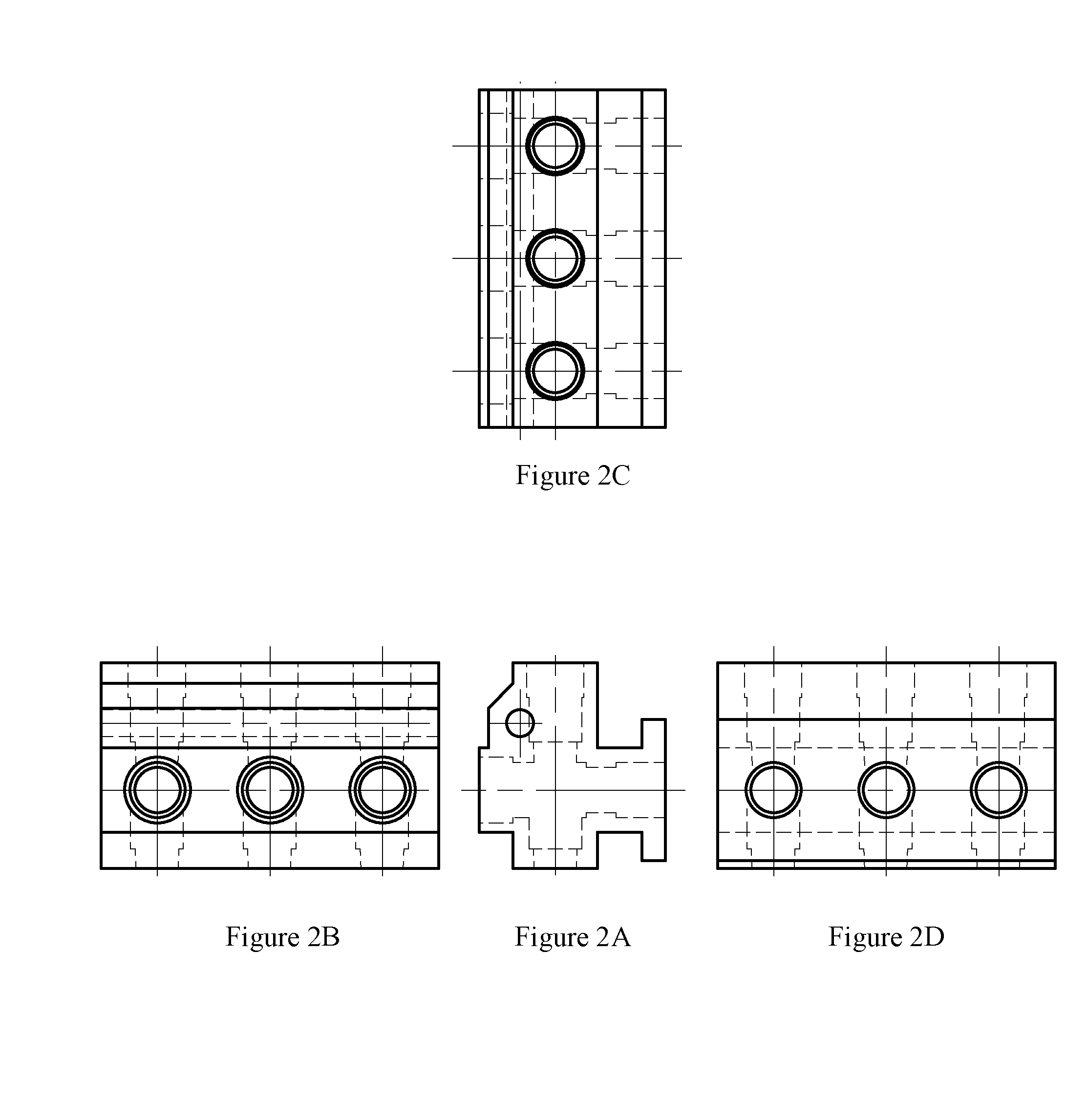

Fluid end with carbide valve seat and adhesive dampening interface

ActiveUS9435454B2Avoid fracturesApply evenlyPositive displacement pump componentsCheck valvesInterference fitCarbide

Owner:ALTIS INVESTMENTS LLC

Absorbent article having dual pattern bonding

InactiveUS20060089616A1Easy to joinImprove integrityBaby linensTamponsElectrical and Electronics engineeringChassis

The present invention relates to improvements in bonding patterns for the attachment of components of disposable absorbent articles. For example, in order to provide attachment of an ear portion to a longitudinal side of the chassis of an article, there may be an attachment area. The attachment area may include an overlapping area of chassis material(s) (outer cover and / or liner materials) and ear portion material. The overlapping areas of chassis material and ear portion material are bonded together in such a way as to include a variegated bond pattern and a uniform bond pattern. The bonding patterns of the invention may also be used to form the side seams and passive side bonds for articles that are donned as pants.

Owner:KIMBERLY-CLARK WORLDWIDE INC

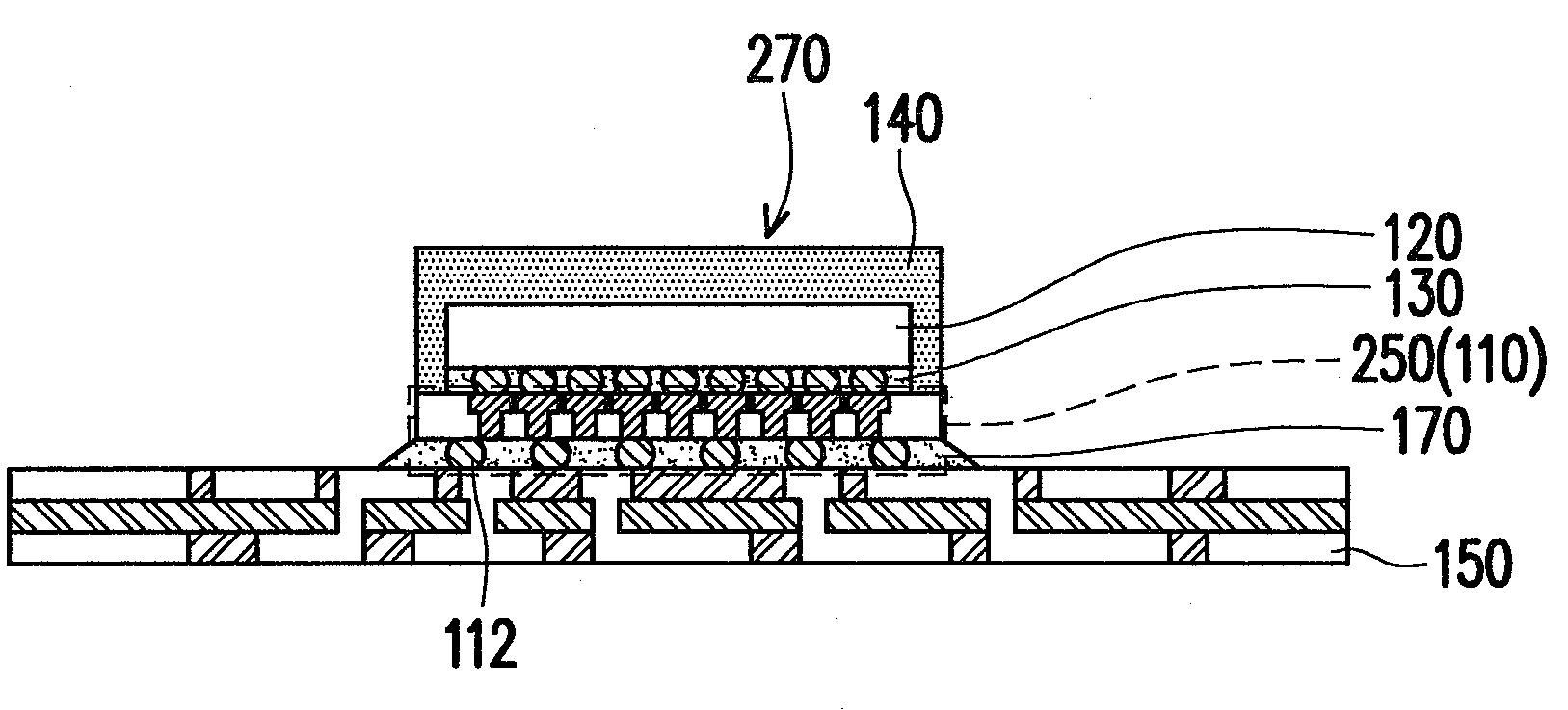

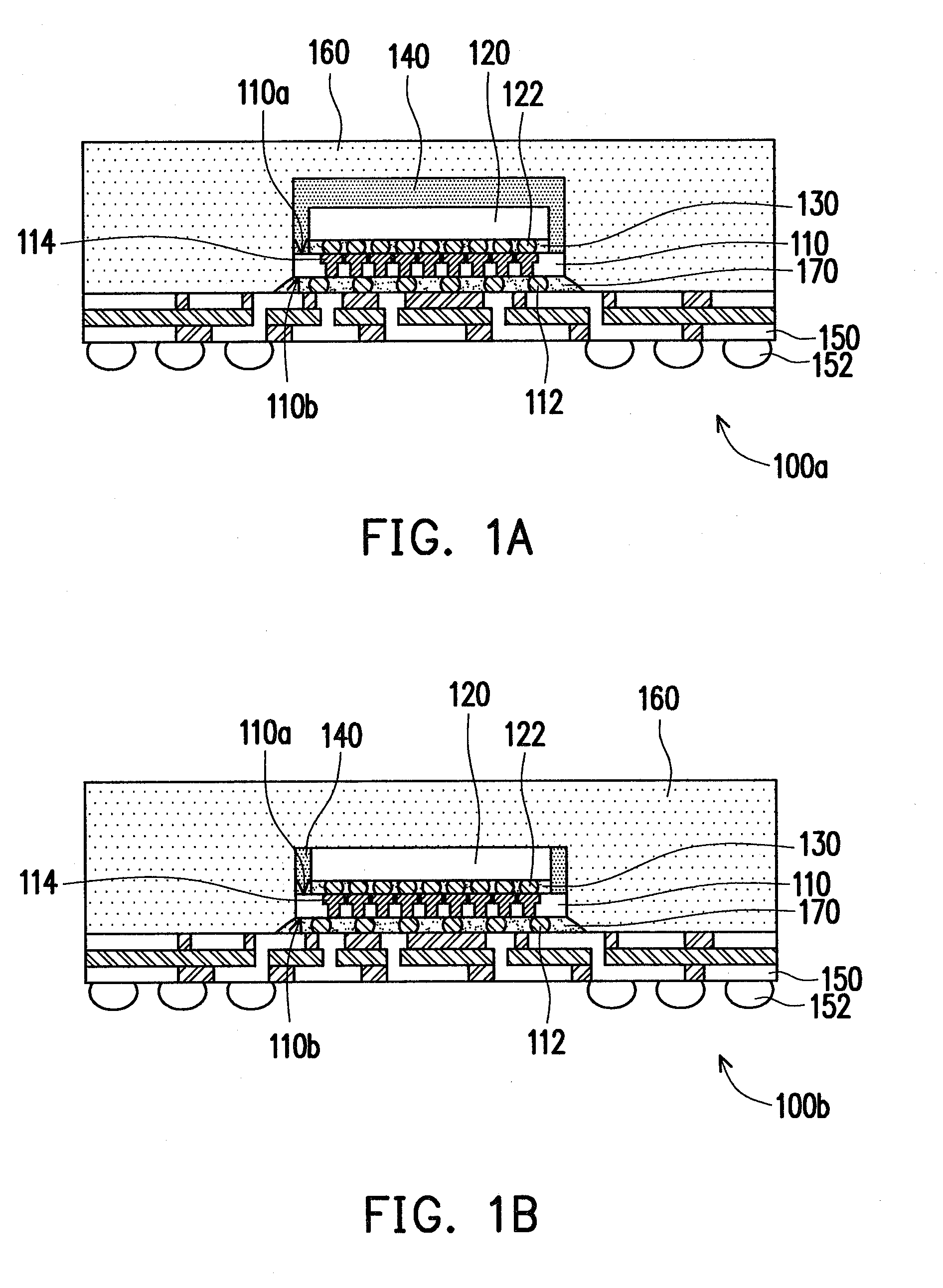

Package process and package structure

InactiveUS20100327465A1Reduce package thicknessAvoid fracturesFinal product manufactureSemiconductor/solid-state device detailsEngineeringSemiconductor

A package process is provided. First, a semiconductor substrate is disposed on a carrier, in which a surface of the carrier has an adhesive layer and the semiconductor substrate is bonded to the carrier by the adhesive layer. Next, a chip is bonded on the semiconductor substrate by flip chip technique and a first underfill is formed between the chip and the semiconductor substrate to encapsulate a plurality of first conductive bumps at the bottom of the chip. Then, a first molding compound is formed on the semiconductor substrate. The first molding compound at least encapsulates the side surface of the chip and the first underfill. Finally, the semiconductor substrate together with the chip and the first molding compound located thereon are separated from the adhesive layer of the carrier to form an array package structure.

Owner:ADVANCED SEMICON ENG INC

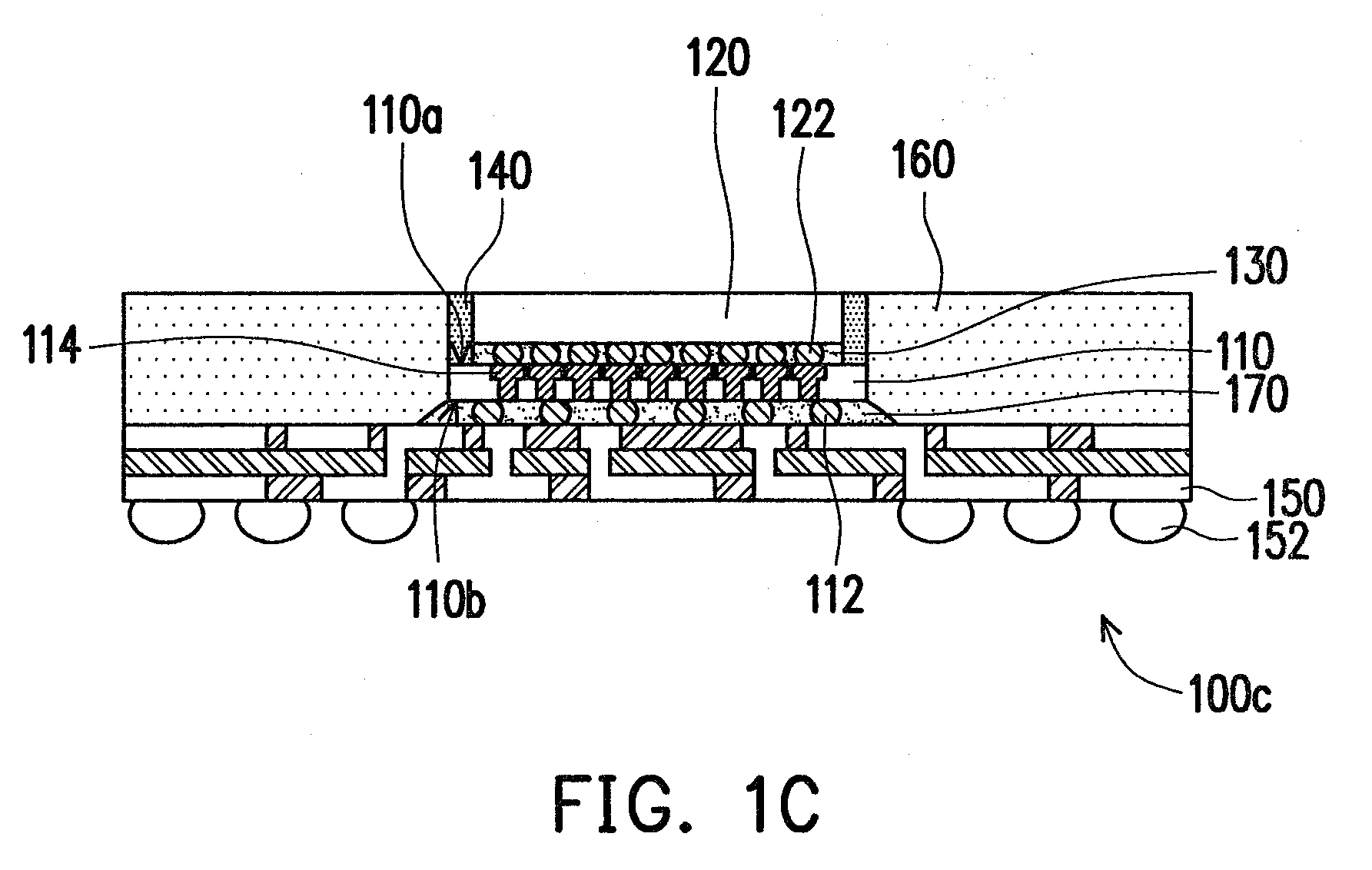

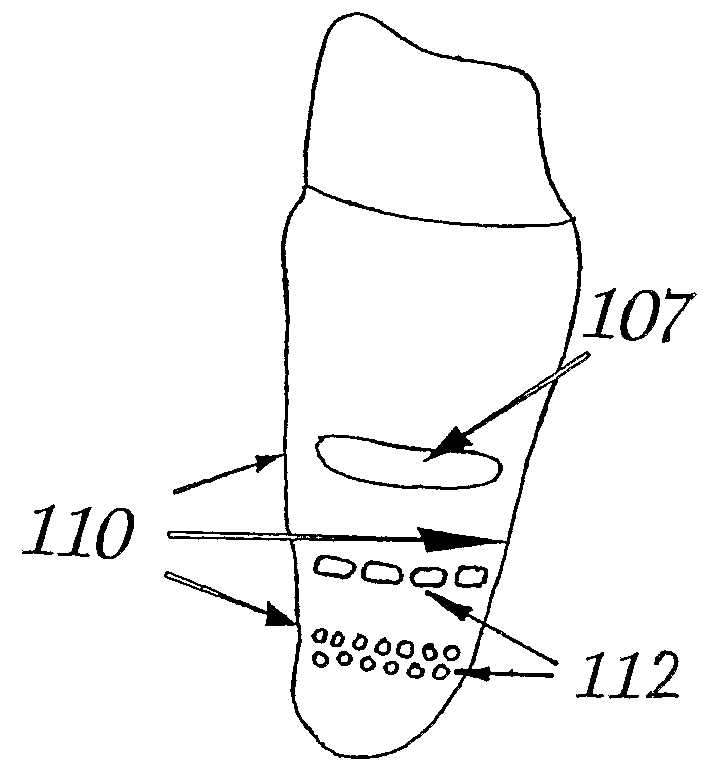

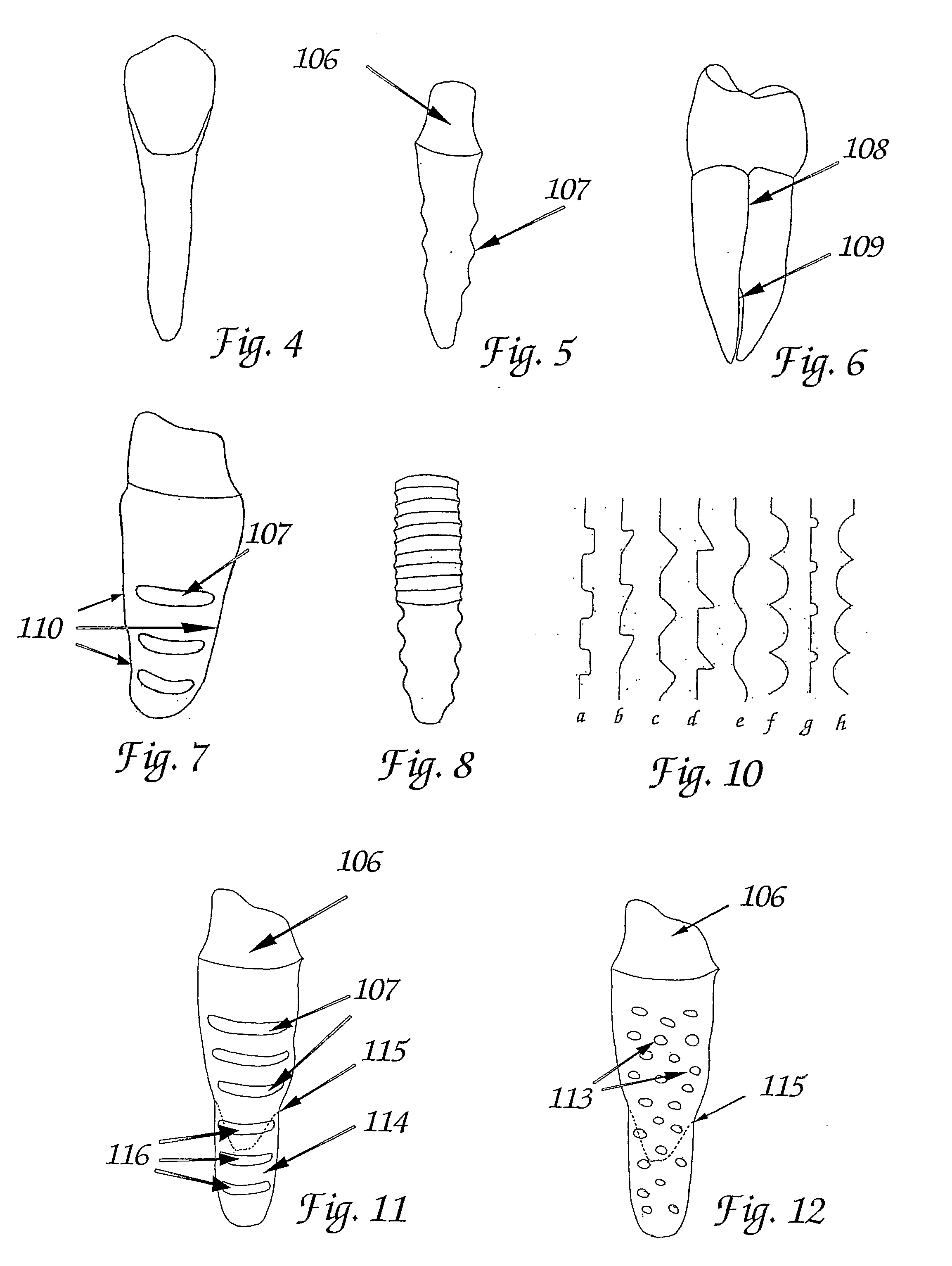

Tooth Implant

ActiveUS20090092944A1Short maintenance periodMinimal traumaDental implantsExtract toothThin cortical bone

The invention concerns a non rotation-symmetric but root-analogue or tooth socket-analogue dental implant of the same size and shape as the root of the extracted tooth with macro retentions protruding from the implant surface (107, 113, 116).Macro retentions (107, 113, 116) are strictly limited to surface areas of the implant in the interdental space next to spongy and thick bone and in case of the last molar, facing the bone at the end of the tooth row. The diameter of the dental implant in transverse direction next to the thin cortical bone buccal and lingual / palatinal is identical to the alveolar bone or preferably stands back to avoid any pressure induced resorption and fracture of the thin cortical bone layer, respectively, at any cost.

Owner:PIRKER WOLFGANG

Fluid End with Carbide Valve Seat and Adhesive Dampening Interface

ActiveUS20140070127A1Avoid fracturesApply evenlyPositive displacement pump componentsCheck valvesEngineeringHigh pressure

A tungsten carbide seat for high-pressure oilfield well service pumps is disclosed. A bonding agent, in conjunction with an interference tapered fit between the valve seat and fluid end housing eliminates stresses created in prior art interference fits. Three interface embodiments are disclosed: a shallow taper combined with a shoulder, a steep taper without a shoulder, and a compound surface in which the seat has an external concave surface and the housing surface that mates with the seat has a convex surface.

Owner:ALTIS INVESTMENTS LLC

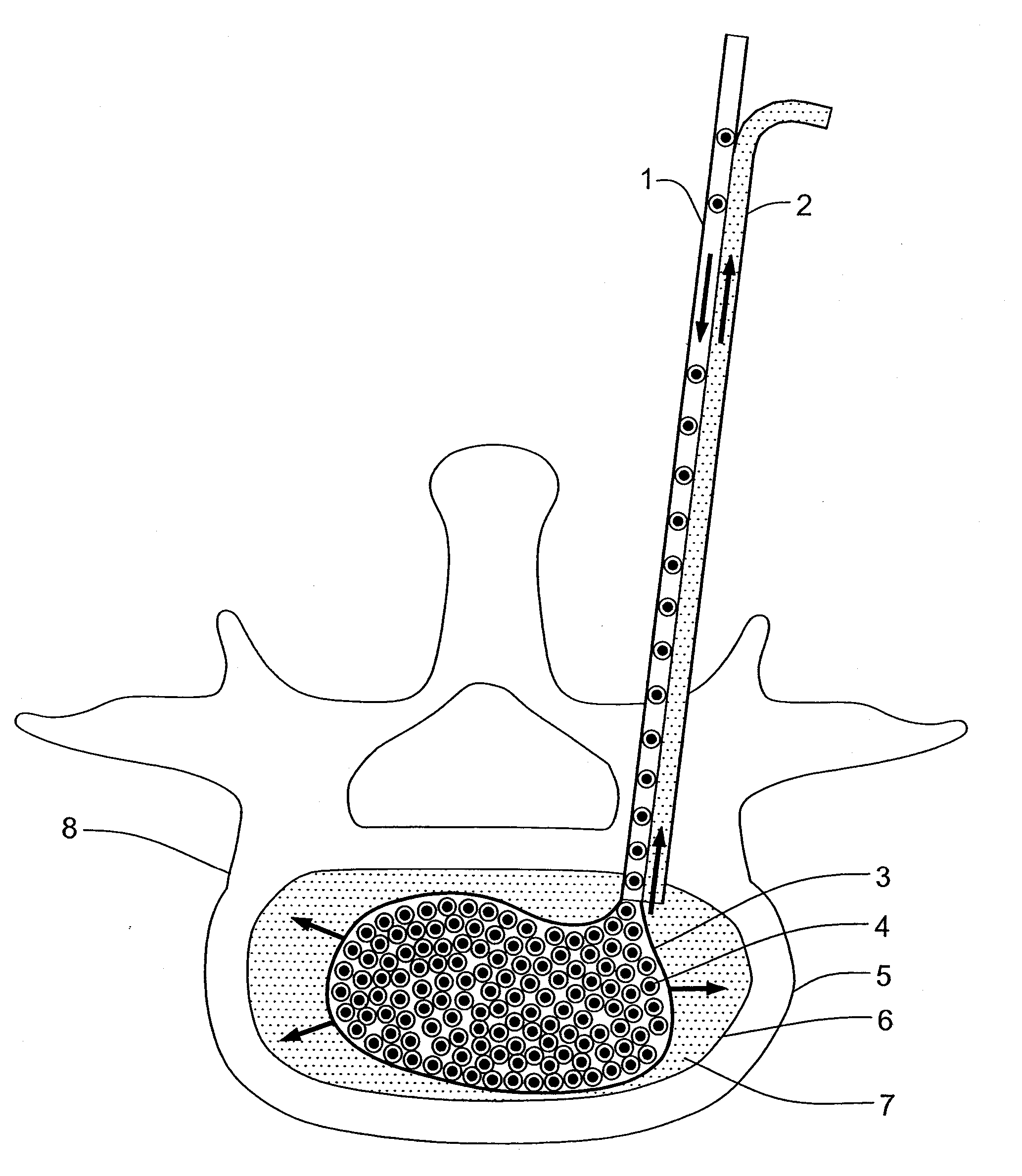

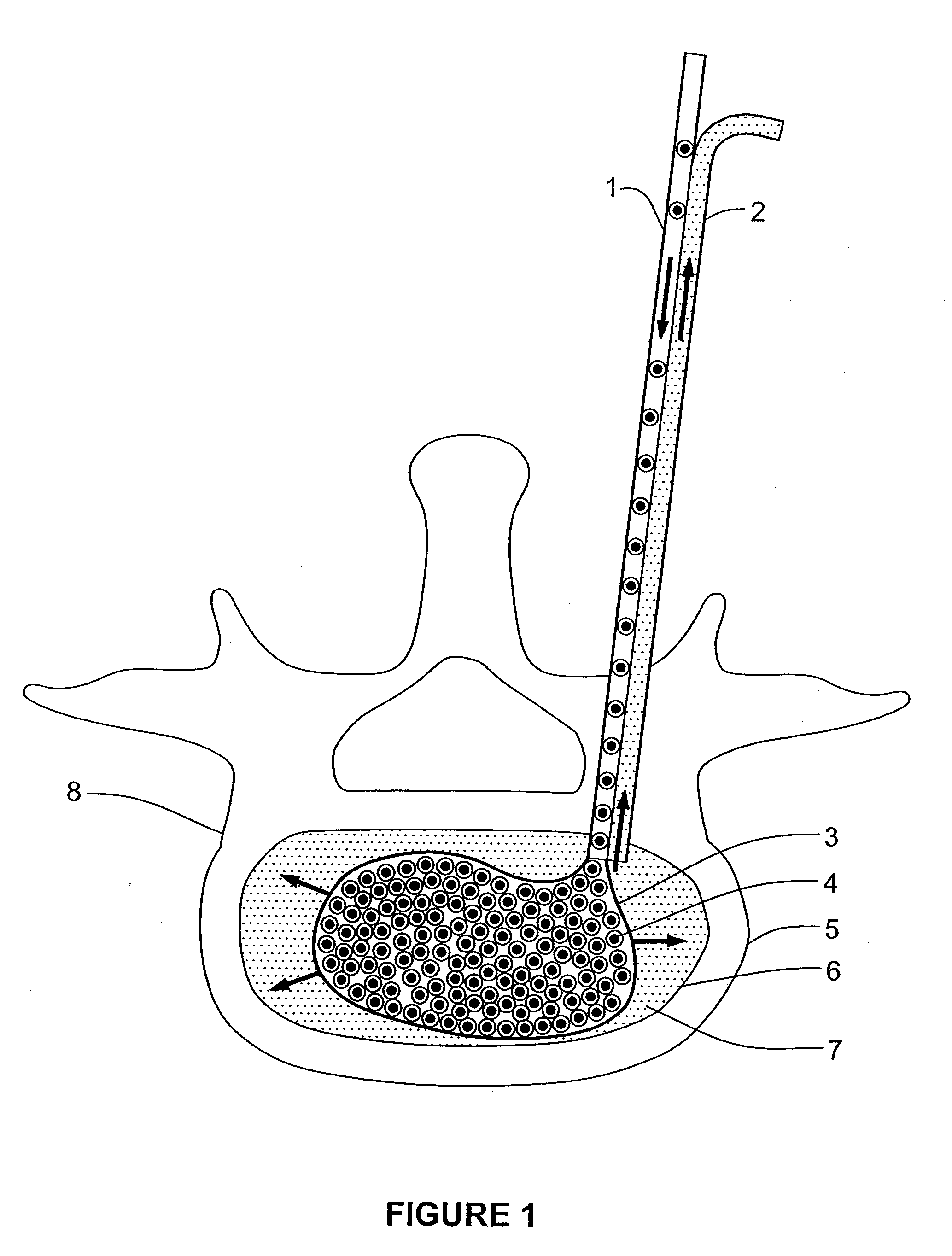

Method and device for reducing susceptibility to fractures in vertebral bodies

InactiveUS20080051800A1Reduce sensitivityIncrease bone densityInternal osteosythesisPeptide/protein ingredientsBone growthUltimate tensile strength

The invention provides a method and a device for administering bone matrix with or without additional bone growth enhancing agents, or administering one or more bone growth enhancing agents to the interior surface of an unfractured vertebral body to enhance bone growth and strength, thus reducing susceptibility of the vertebral body to subsequent fracture.

Owner:DIAZ ROBERT +1

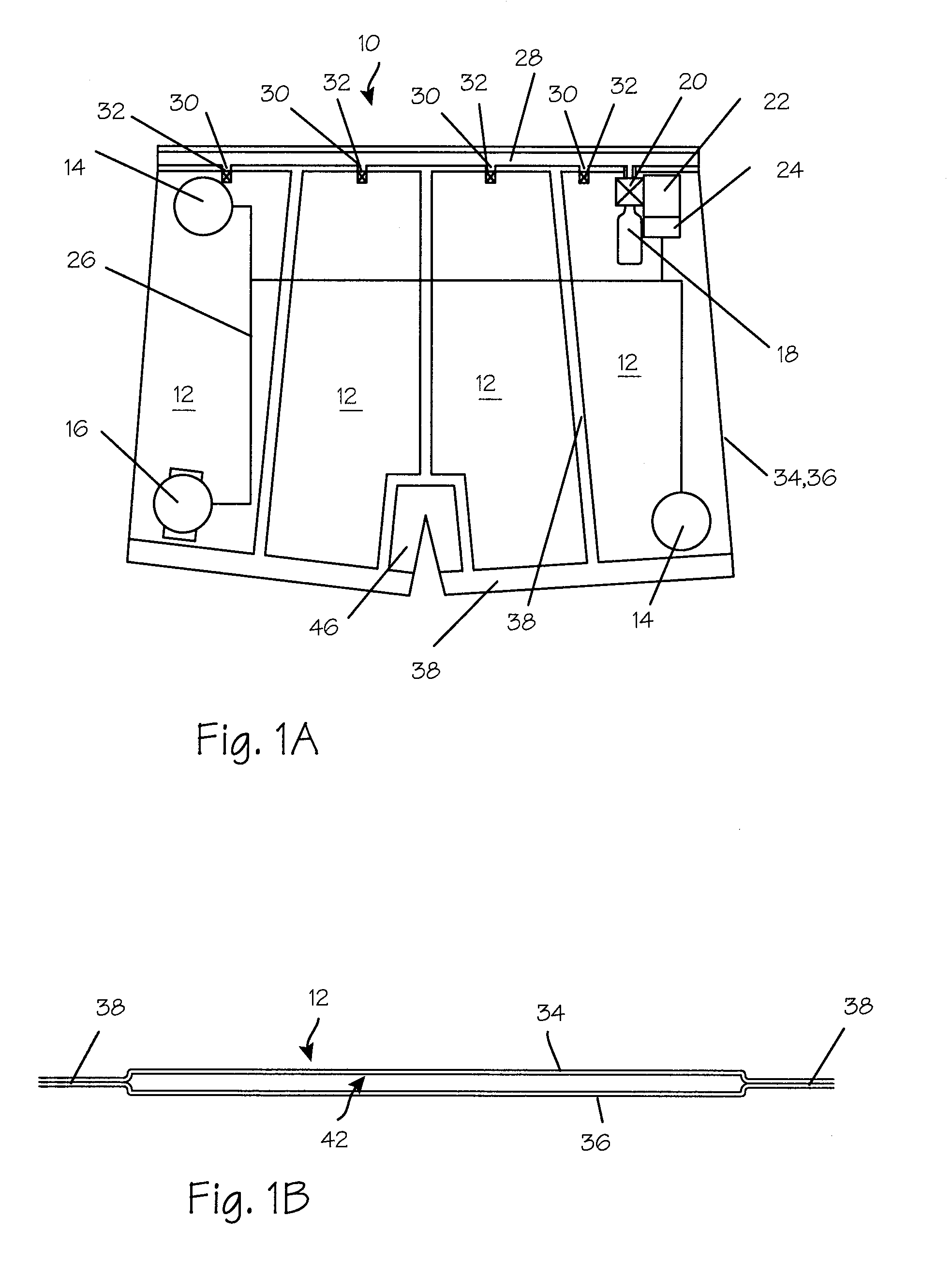

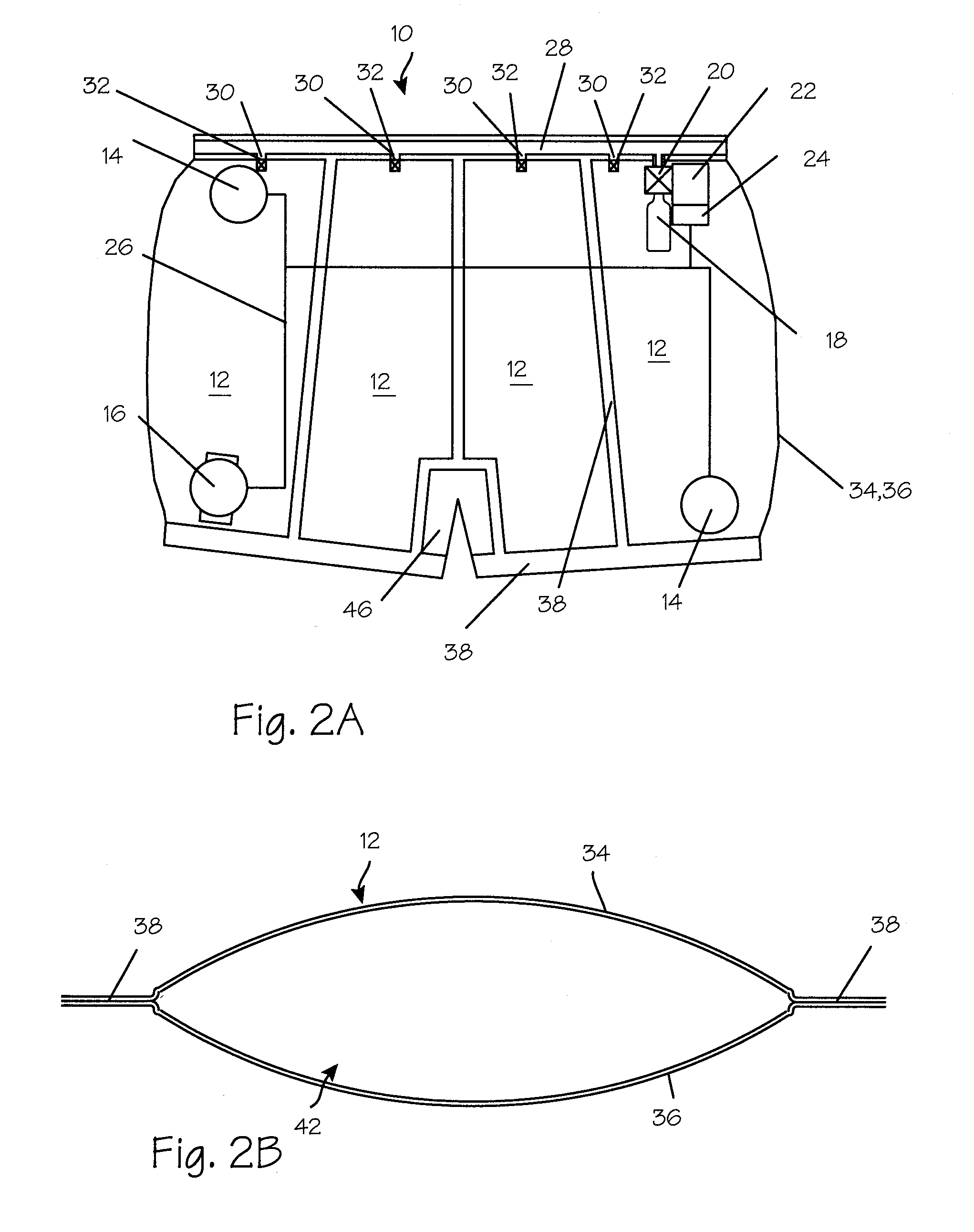

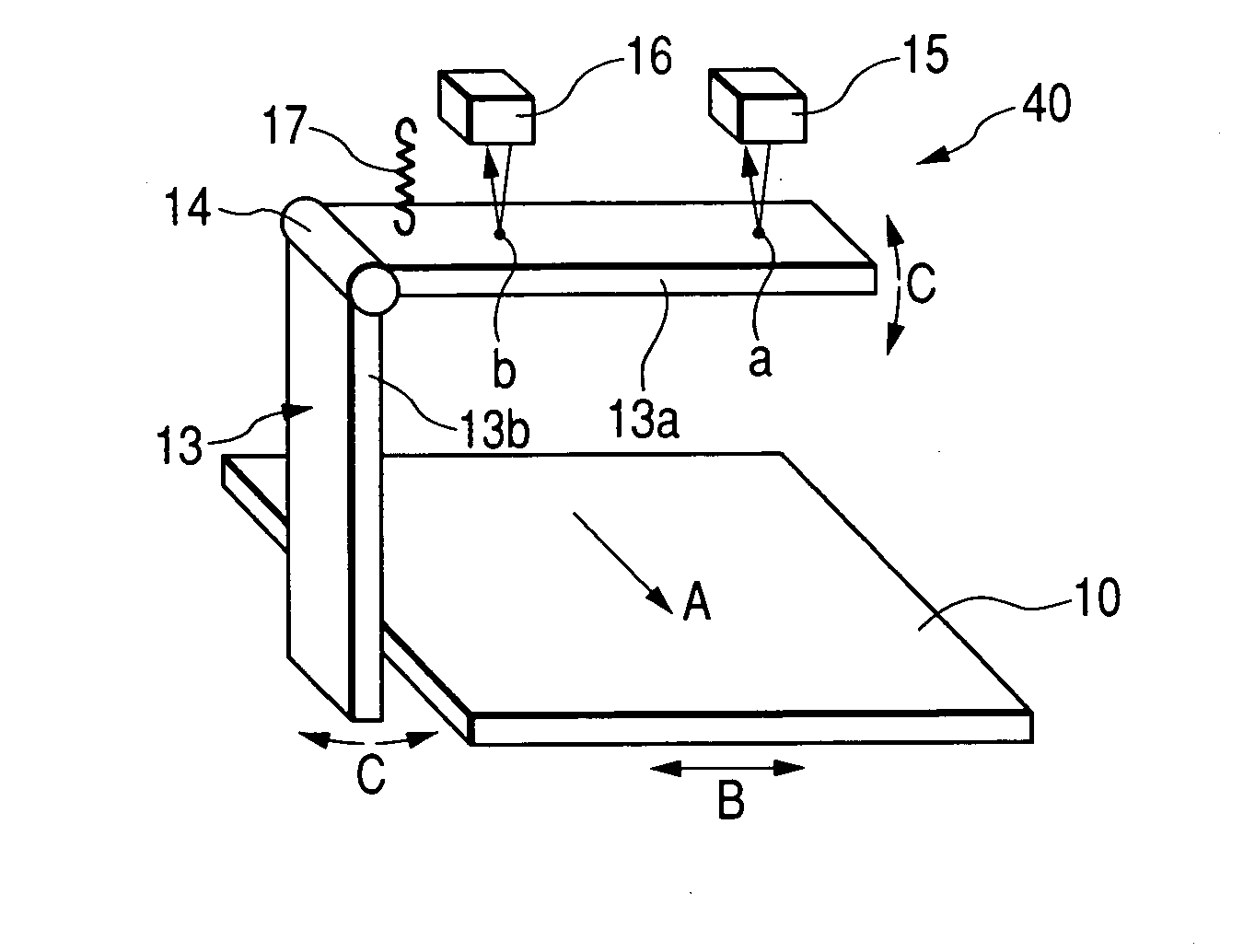

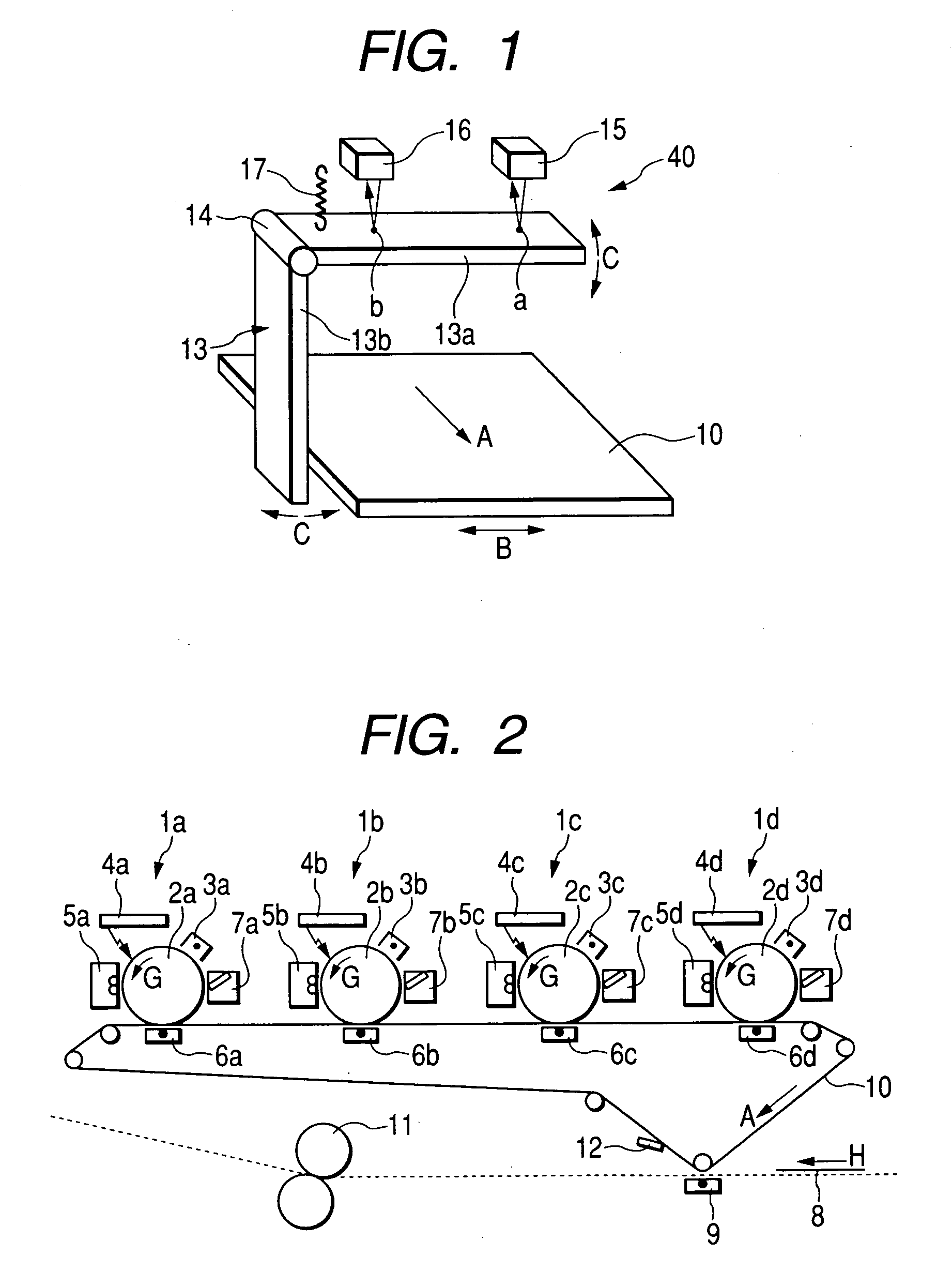

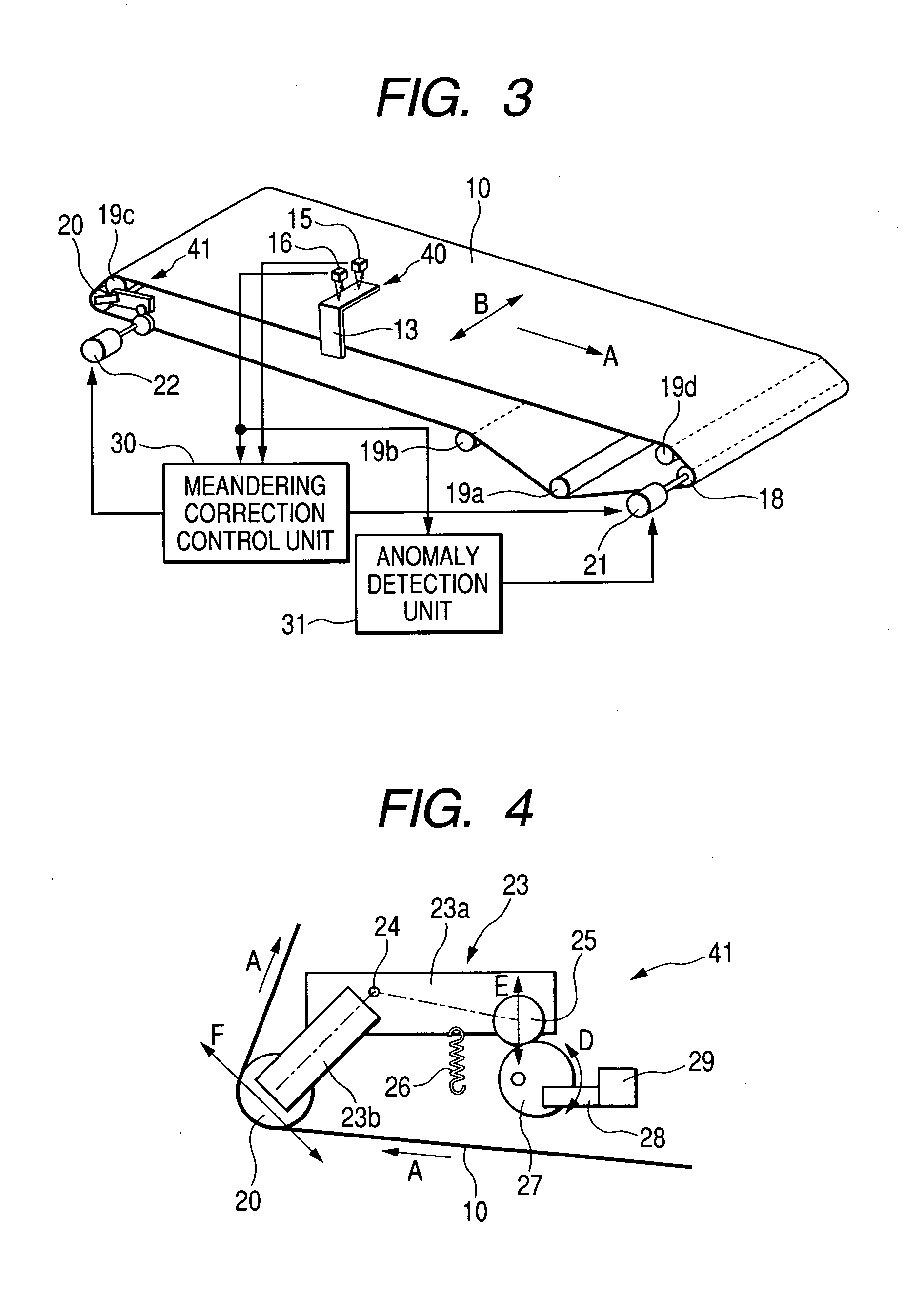

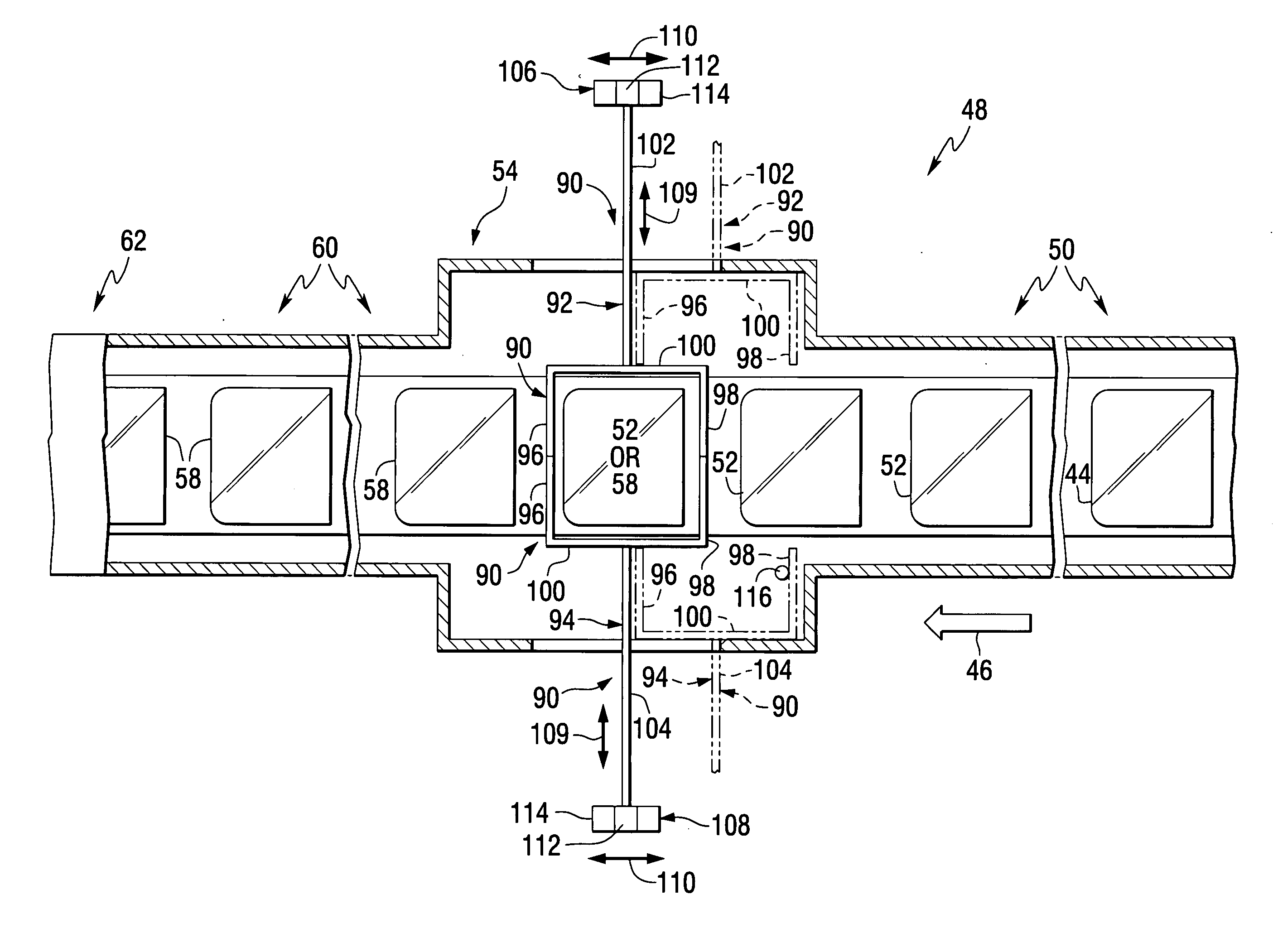

Belt conveyor and image forming apparatus using the same

InactiveUS20060289280A1Improve accuracyImprove picture qualityElectrographic process apparatusRollersImage formationBelt conveyor

A belt conveyor includes: an endless belt that is looped over a plurality of rollers, the plurality of rollers including a drive roller and a meandering correction roller; a drive unit that rotates the drive roller to drive the endless belt; a meandering correction unit that adjusts an inclination of the meandering correction roller to correct meandering of the endless belt in a width direction thereof; a plurality of position detection units that detect positions of the endless belt in the width direction thereof and output detection signals; and a meandering correction control unit that selectively uses the detection signals from the plurality of detection units to control the meandering correction unit.

Owner:RICOH KK

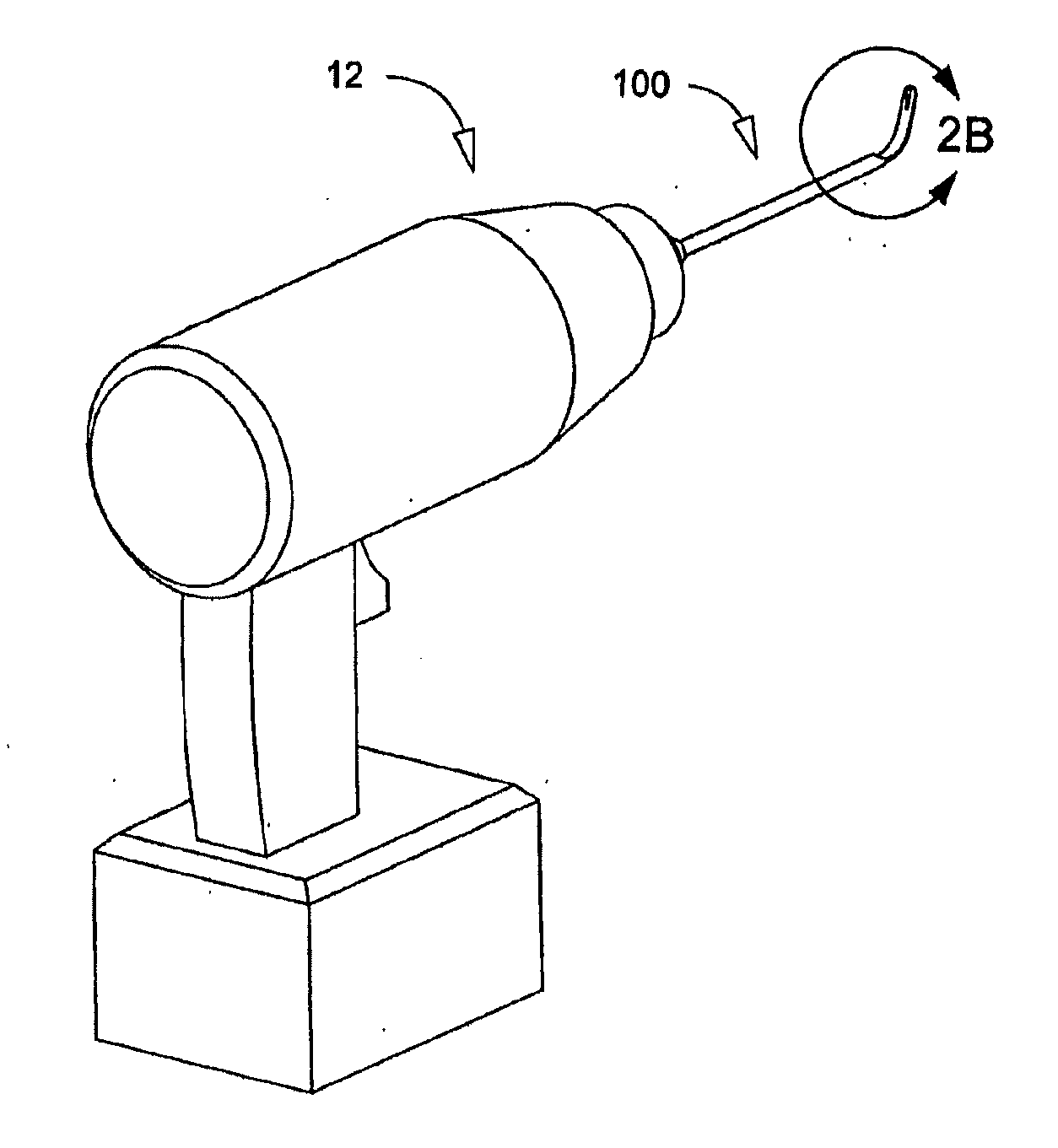

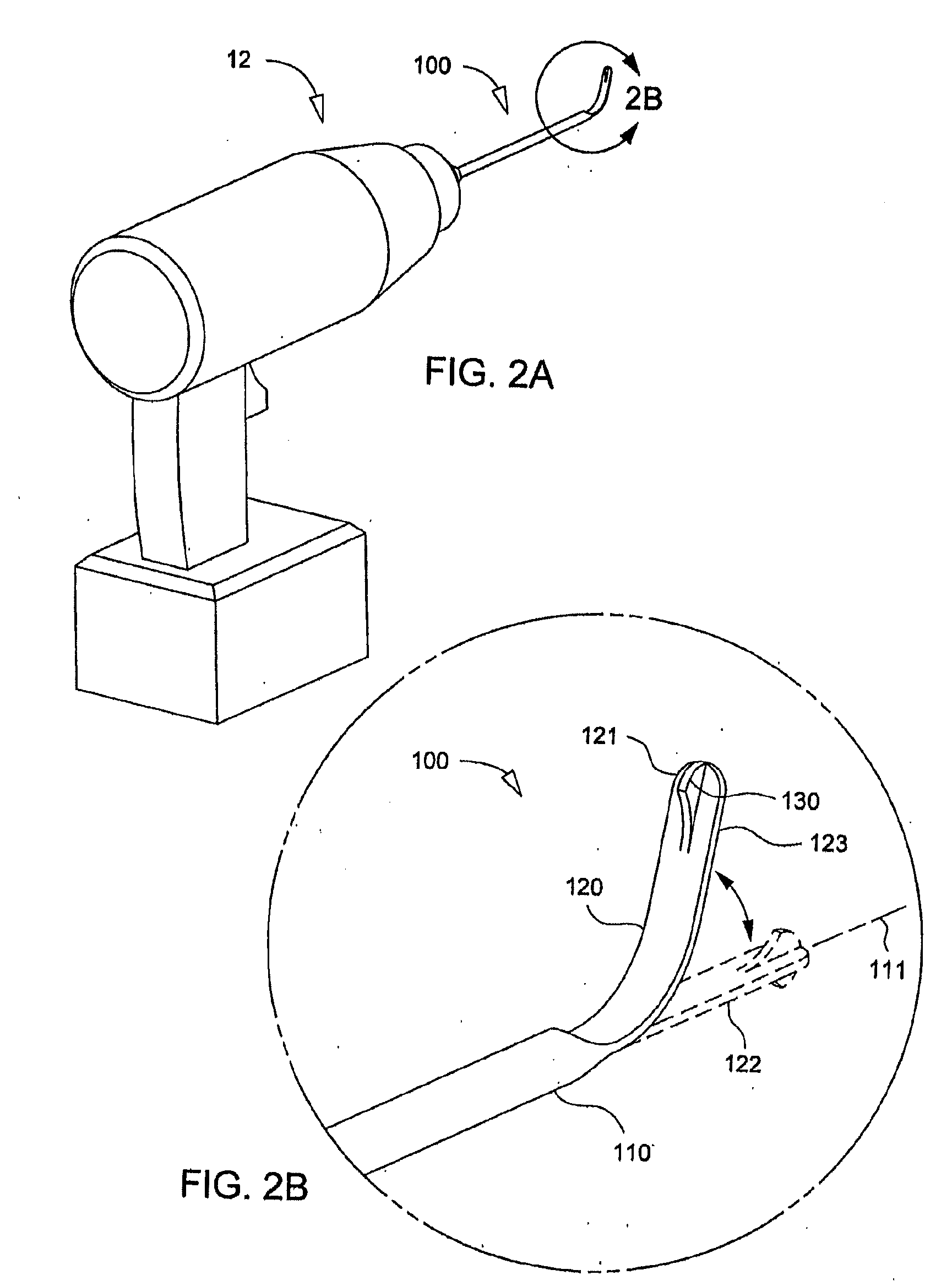

Tissue Cavitation Device and Method

InactiveUS20100241123A1Small entrancePromote healing of a bony deficitProsthesisOsteosynthesis devicesCavitationMinimally invasive procedures

A percutaneous surgical device and method for creating a cavity within tissue during a minimally invasive procedure. A cavitation device includes a shaft interconnected to a flexible cutting element. A flexible cutting element has a first shape suitable for minimally invasive passage into tissue. The flexible cutting element has a means to move toward a second shape suitable for forming a cavity in tissue. When used in bone, the resulting cavity is usually filled with bone cement or suitable bone replacement material that is injectable and hardens in situ. The disclosed cavitation device and methods can be used for the following applications: (1) treatment or prevention of bone fracture, (2) joint fusion, (3) implant fixation, (4) tissue harvesting (especially bone), (5) removal of diseased tissue (hard or soft tissue), and (6) general tissue removal (hard or soft tissue).

Owner:MIDDLETON LANCE +1

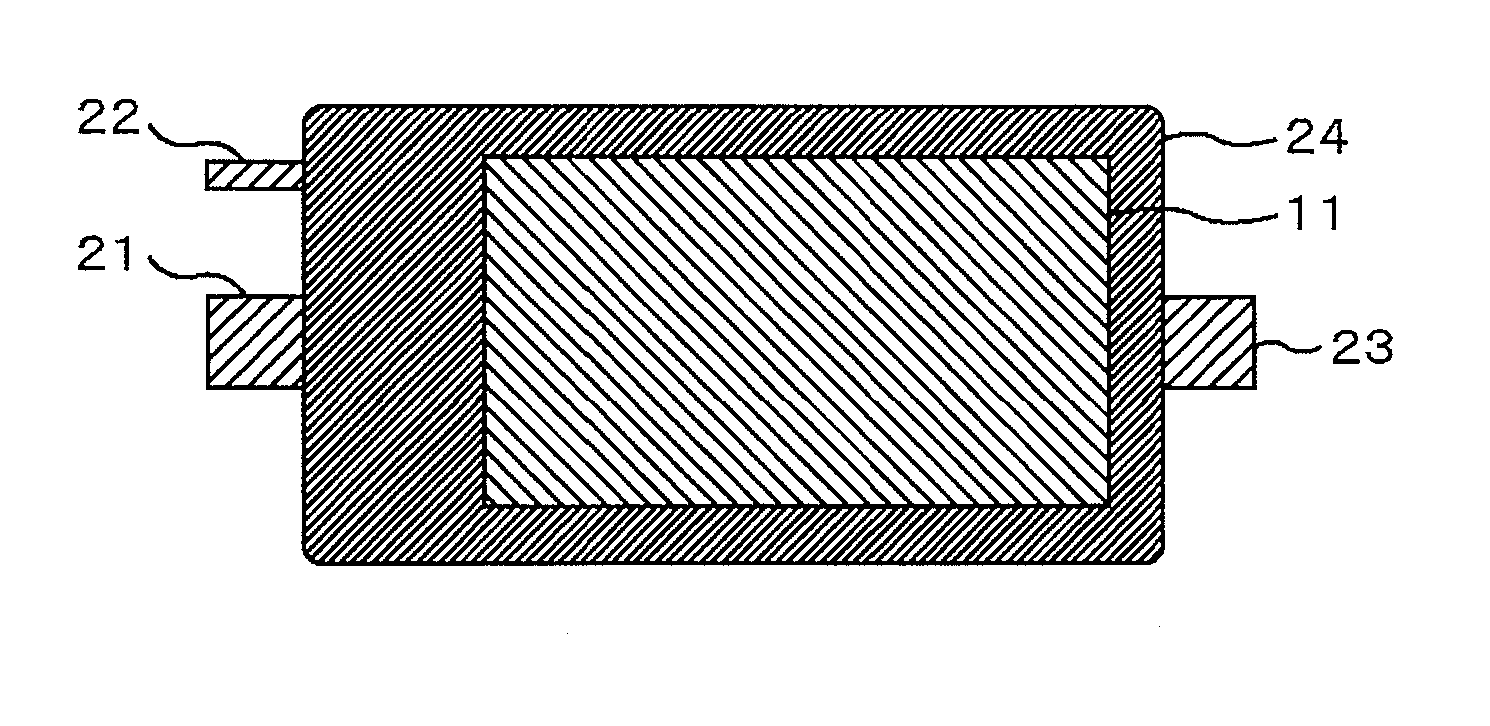

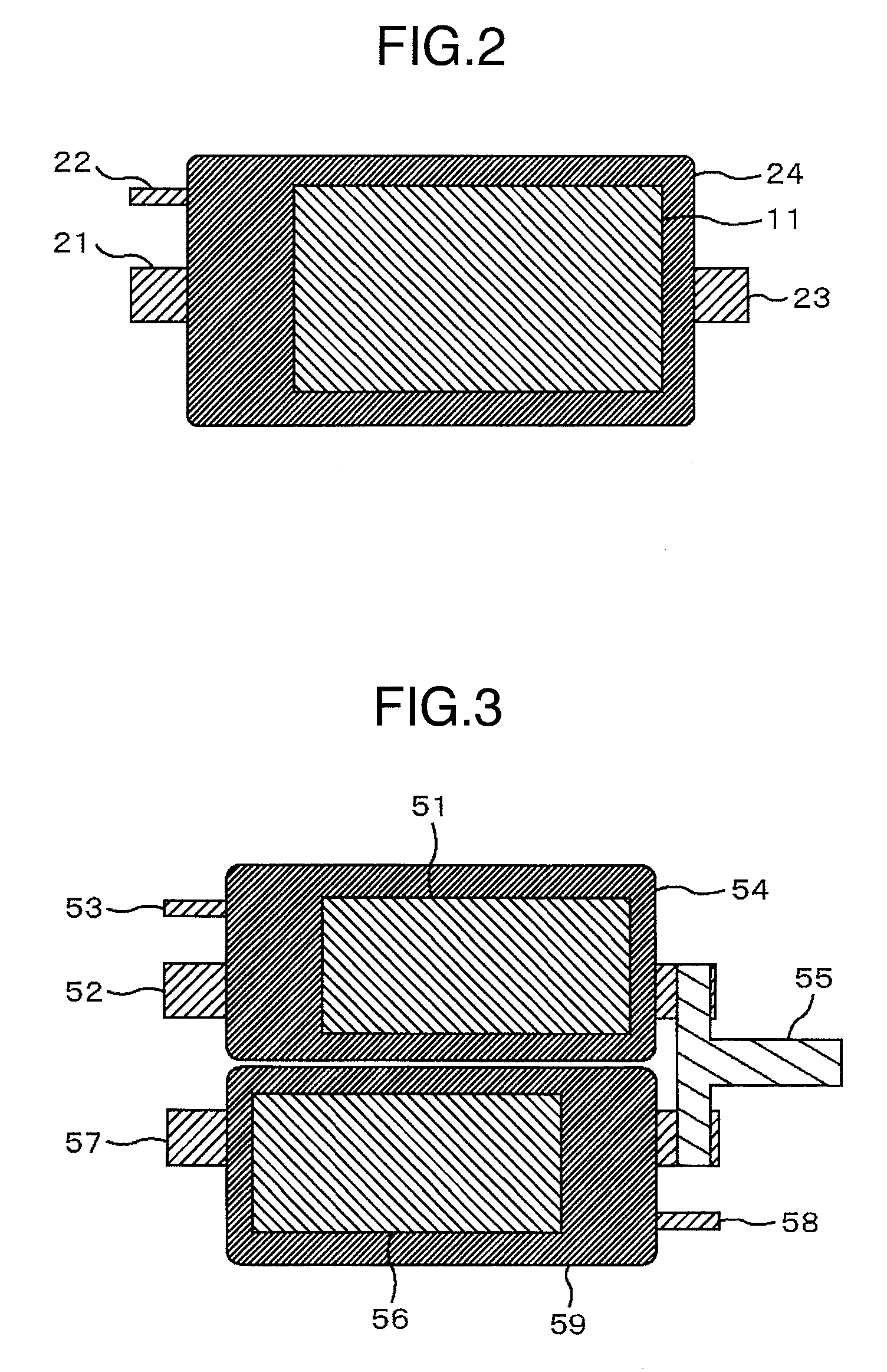

Power Semiconductor Module

InactiveUS20070267739A1Possibility of damageAvoid fracturesSemiconductor/solid-state device detailsLaminating printed circuit boardsThermal expansionInorganic materials

A power semiconductor module and an inverter apparatus in which a device or a joining part is not mechanically damaged even when the temperature in use becomes a high temperature in the range of 175 to 250° C., resulting in excellent reliability at high temperature retaining test and thermal cycling test. Low thermal expansion ceramic substrates are disposed above and below the device. A material having a coefficient of thermal expansion of 10 ppm / K or less is disposed between the ceramic substrates. In addition, an inorganic material having a coefficient of thermal expansion in the range of 2 to 6 ppm / K or less is disposed around the device.

Owner:HITACHI LTD

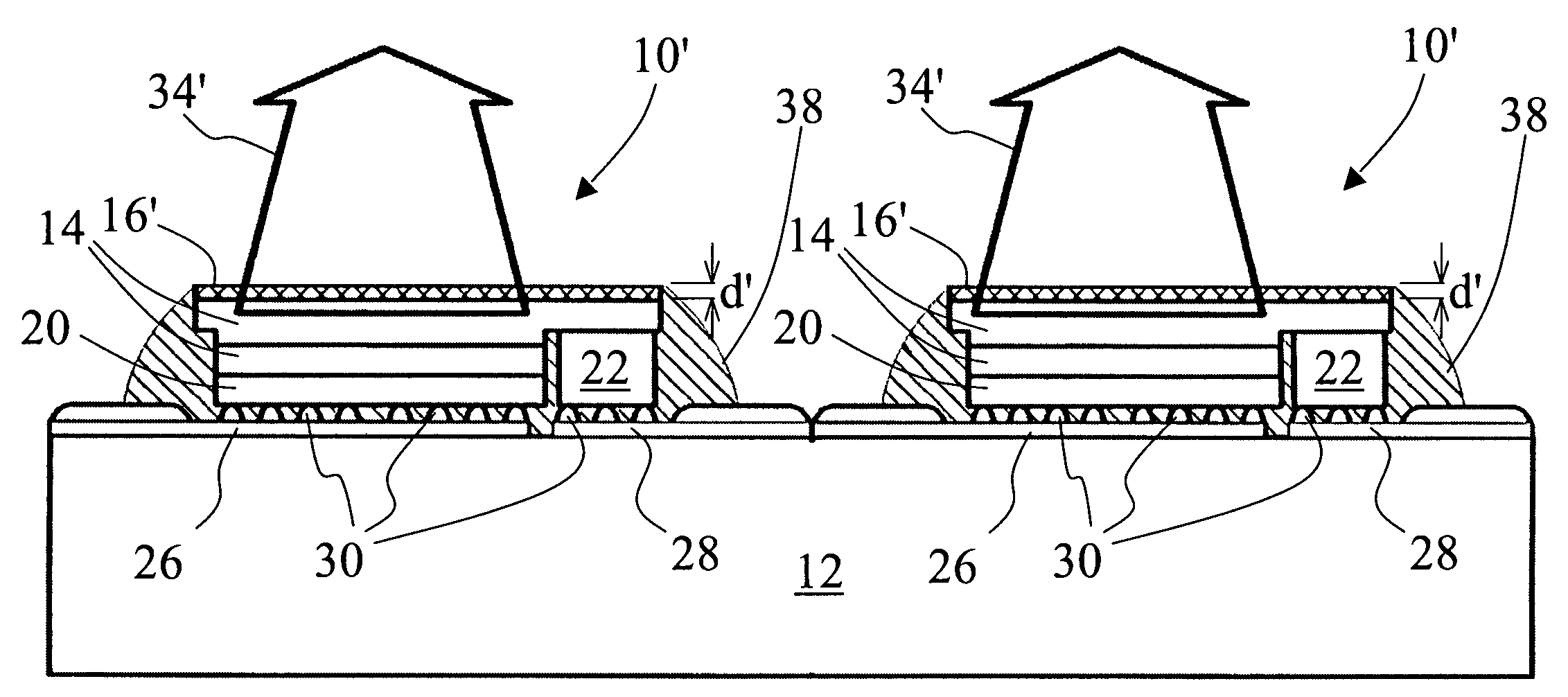

Image display

ActiveUS8294869B2Avoid fracturesAvoid spreadingDischarge tube luminescnet screensLamp detailsDisplay deviceSemiconductor chip

To provide an image display which is capable of preventing fracturing of a substrate which is attributable to a substrate expansion arising from heating or humidification during a manufacture process, impact in use, or distortion when curved display is conducted, a connection failure between a semiconductor chip and a wiring terminal which are mounted on the substrate, and crack occurring in the substrate in the vicinity of an area where the semiconductor chip is mounted, with no need to add members and with no limit of pulling the wiring around. An image display part is formed on one surface of a flexible substrate, and a groove with a depth not reaching a thickness of the substrate is continuously or intermittently defined in another surface of the substrate.

Owner:JAPAN DISPLAY INC +1

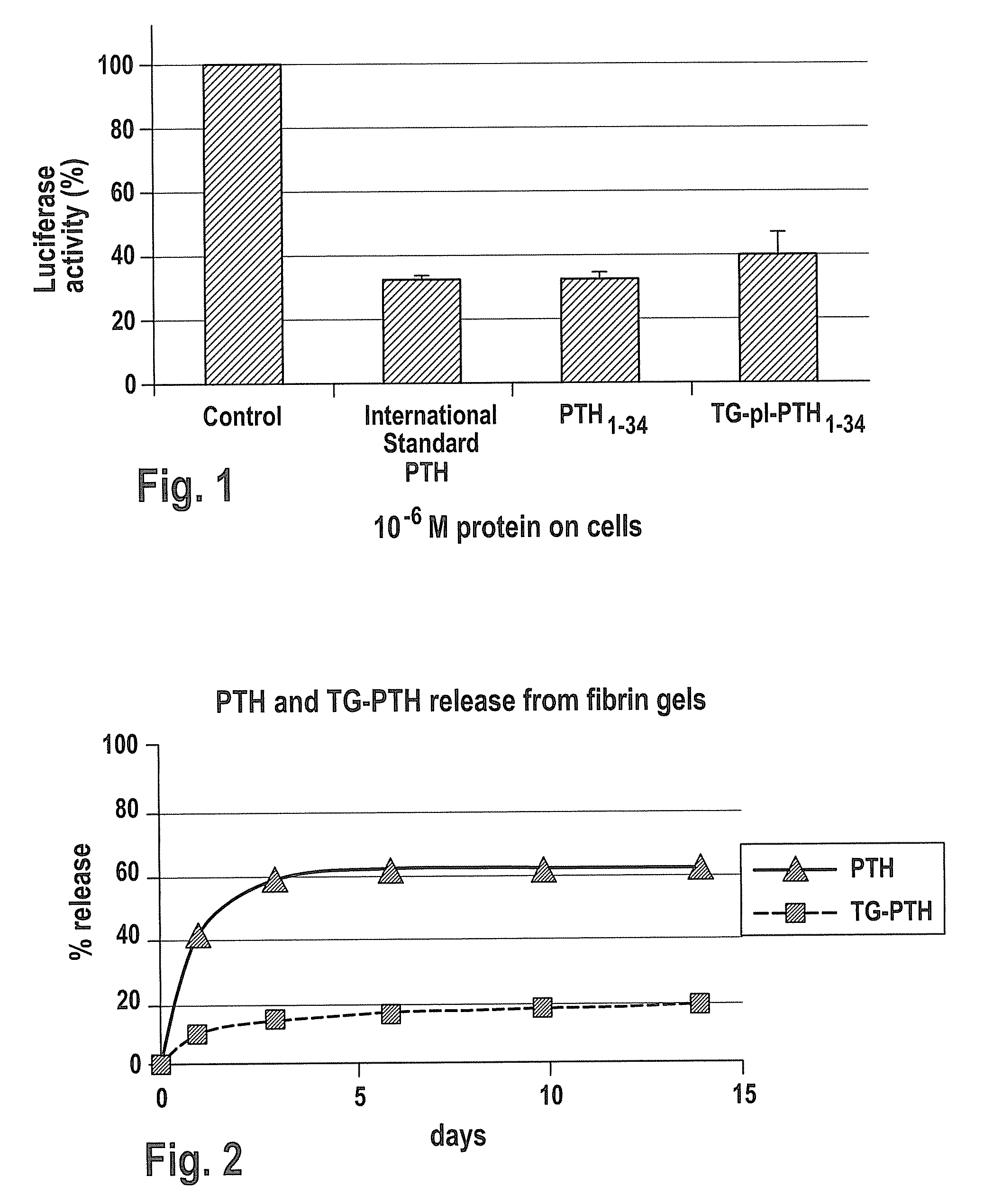

Local treatment of bone defects

ActiveUS20070010440A1Reduce the chance of fractureRestore integrityFibrinogenPeptide/protein ingredientsAneurysmal bone cystTopical treatment

A method of local treatment of specific bone defects such as osteoporosis or bone cysts comprises the step of local administration of a formulation comprising a fusion peptide containing a first domain comprising PTH or BMP 2 or BMP 7, and a second domain comprising a covalently crosslinkable substrate domain; and a material suitable of forming a biodegradable matrix suitable for cellular growth or in-growth, wherein the fusion peptide is covalently linked to the matrix. In one embodiment, the matrix contains one or more contrast agents, and is preferably formed in the absence of a growth factor. The matrix may be used in the treatment of fluid-filled cysts such as Tarlov cysts, ovarian cysts, arachnoid cysts, aneurysmal bone cysts or hepatic cysts.

Owner:KUROS BIOSURGERY AG

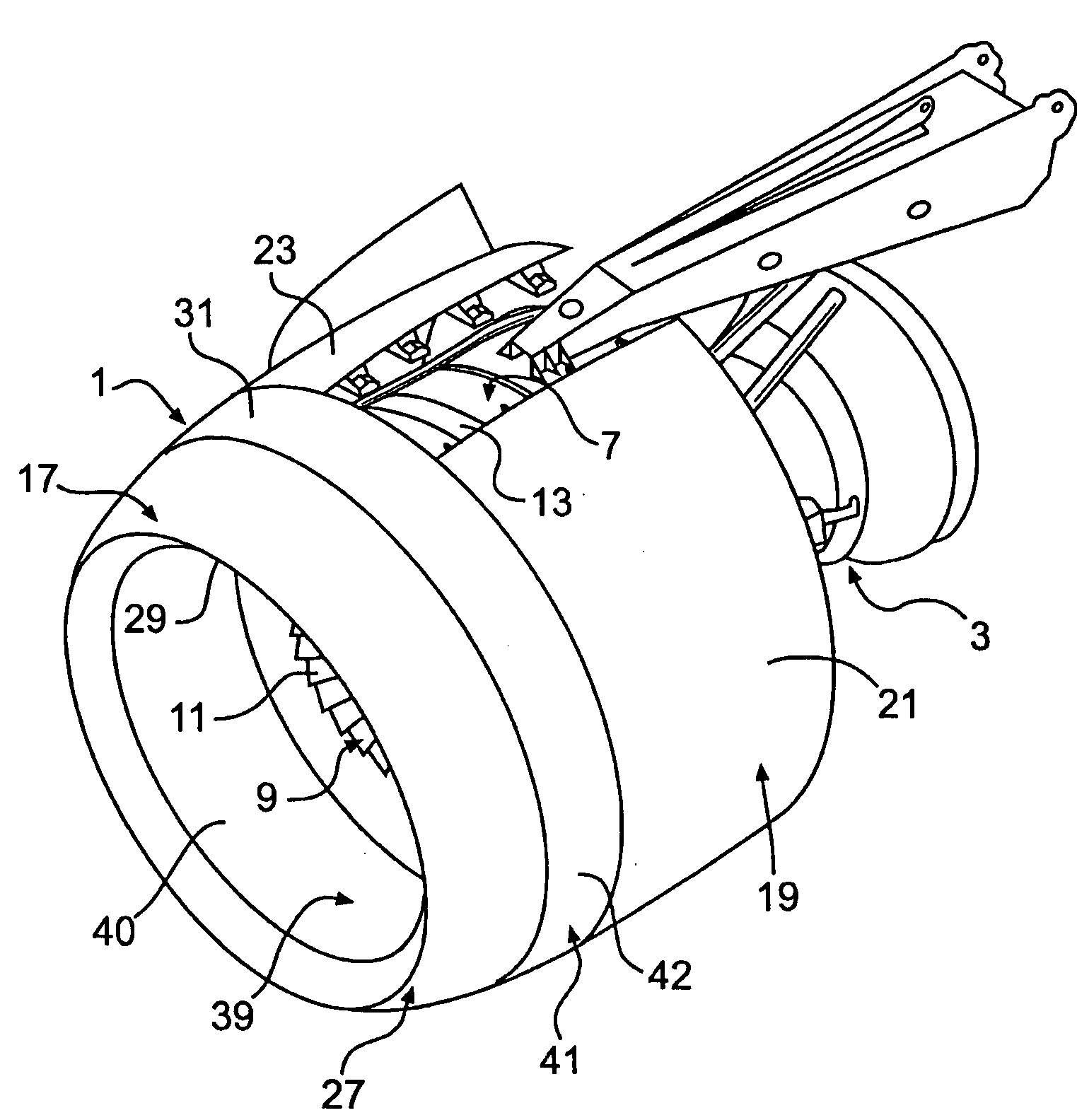

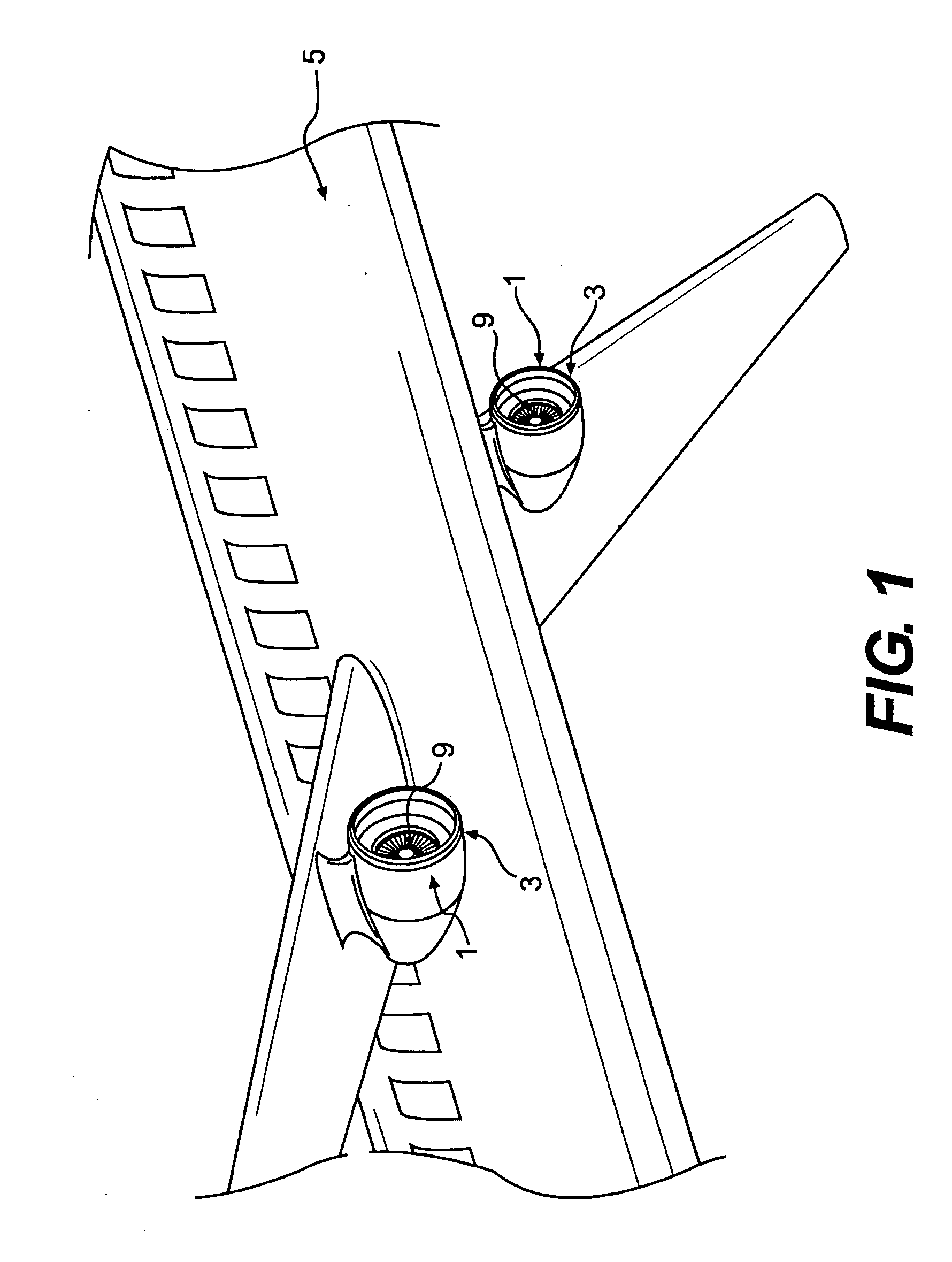

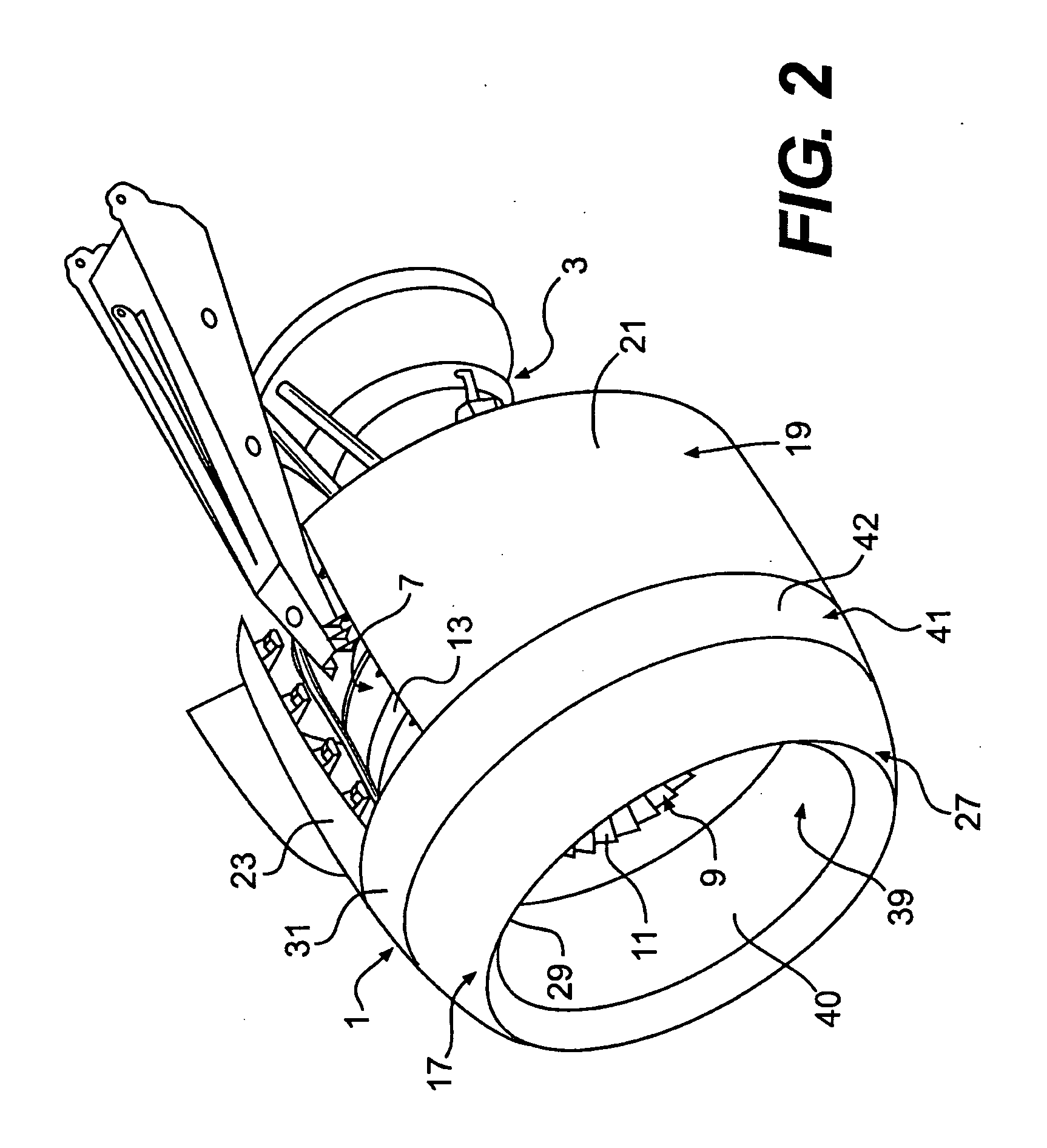

Aircraft engine inlet having zone of deformation

An inlet assembly for an aircraft engine nacelle includes an inner barrel, an outer barrel radially spaced from the inner barrel, and a rear support for supporting the outer barrel relative to the inner barrel. The rear support includes at least one radially extending stiffener and at least one energy absorber defining a zone of deformation adjacent the inner barrel. The rear support is deformable in the zone of deformation in response to forces applied during a fan blade-out event to prevent fracture of the rear support.

Owner:ROHR INC

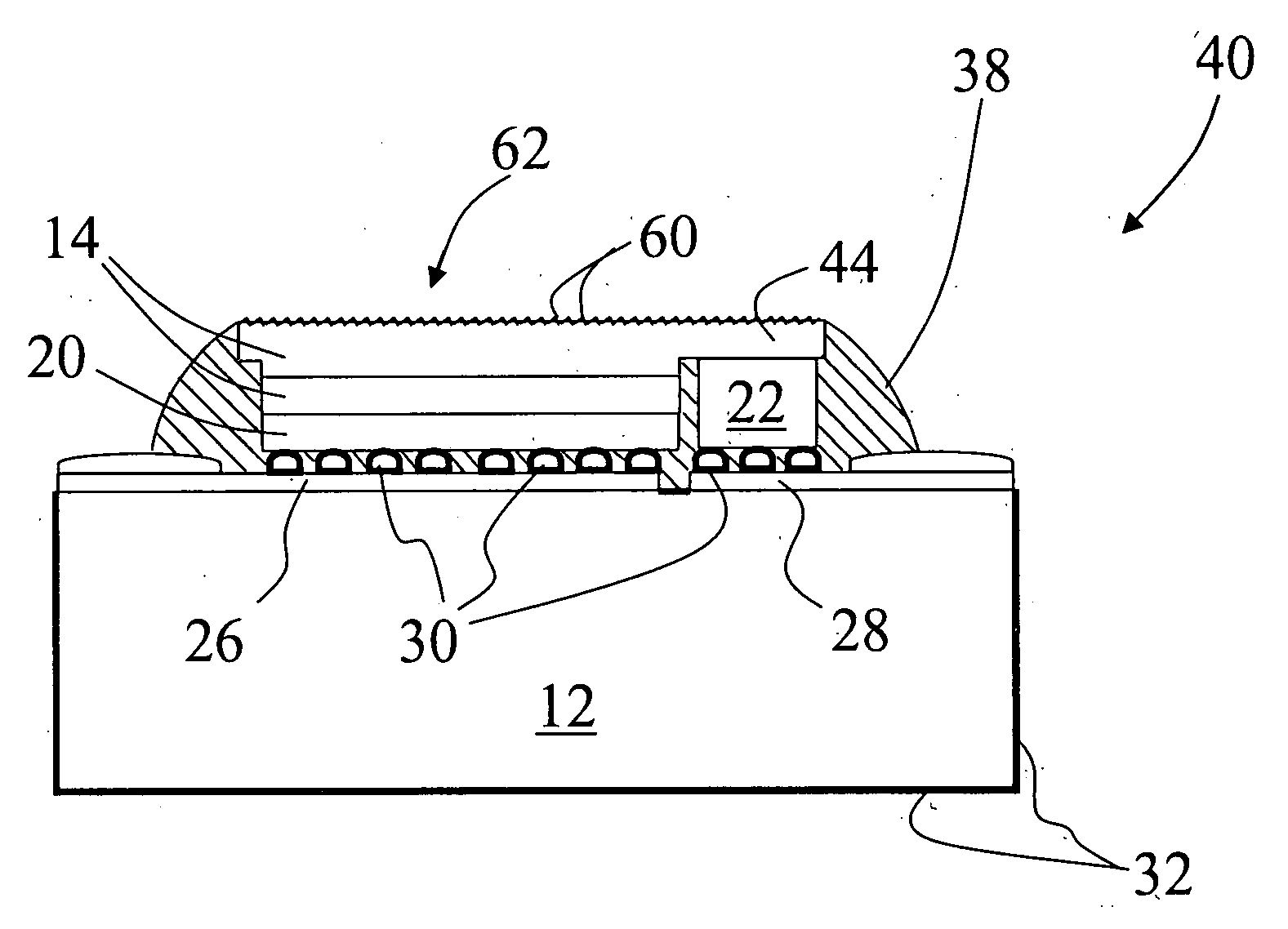

Flip chip light emitting diode devices having thinned or removed substrates

ActiveUS7456035B2Reduce thicknessConvenient lightingSemiconductor/solid-state device detailsSolid-state devicesLight-emitting diodeDiode

Owner:GE LIGHTING SOLUTIONS LLC

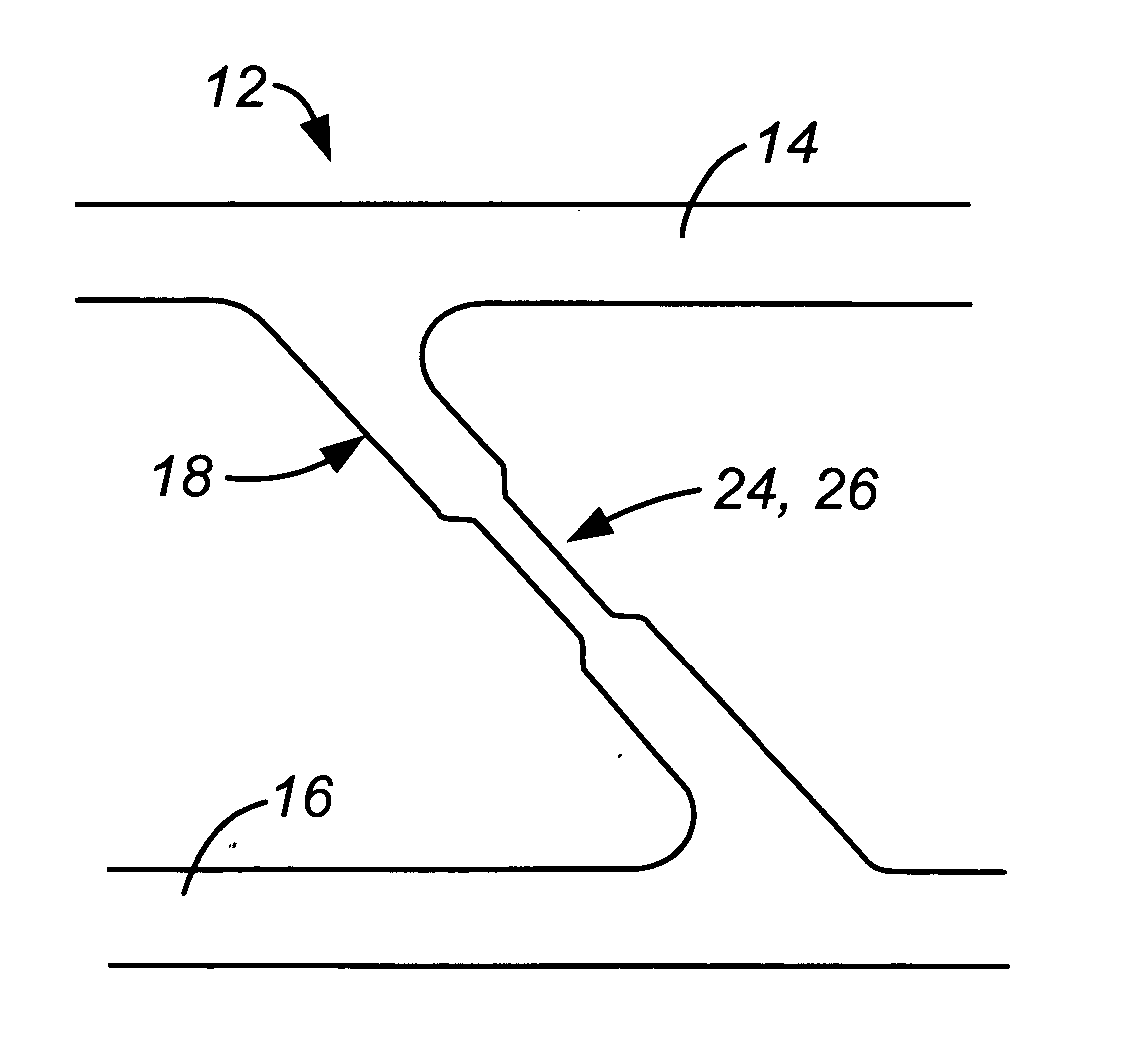

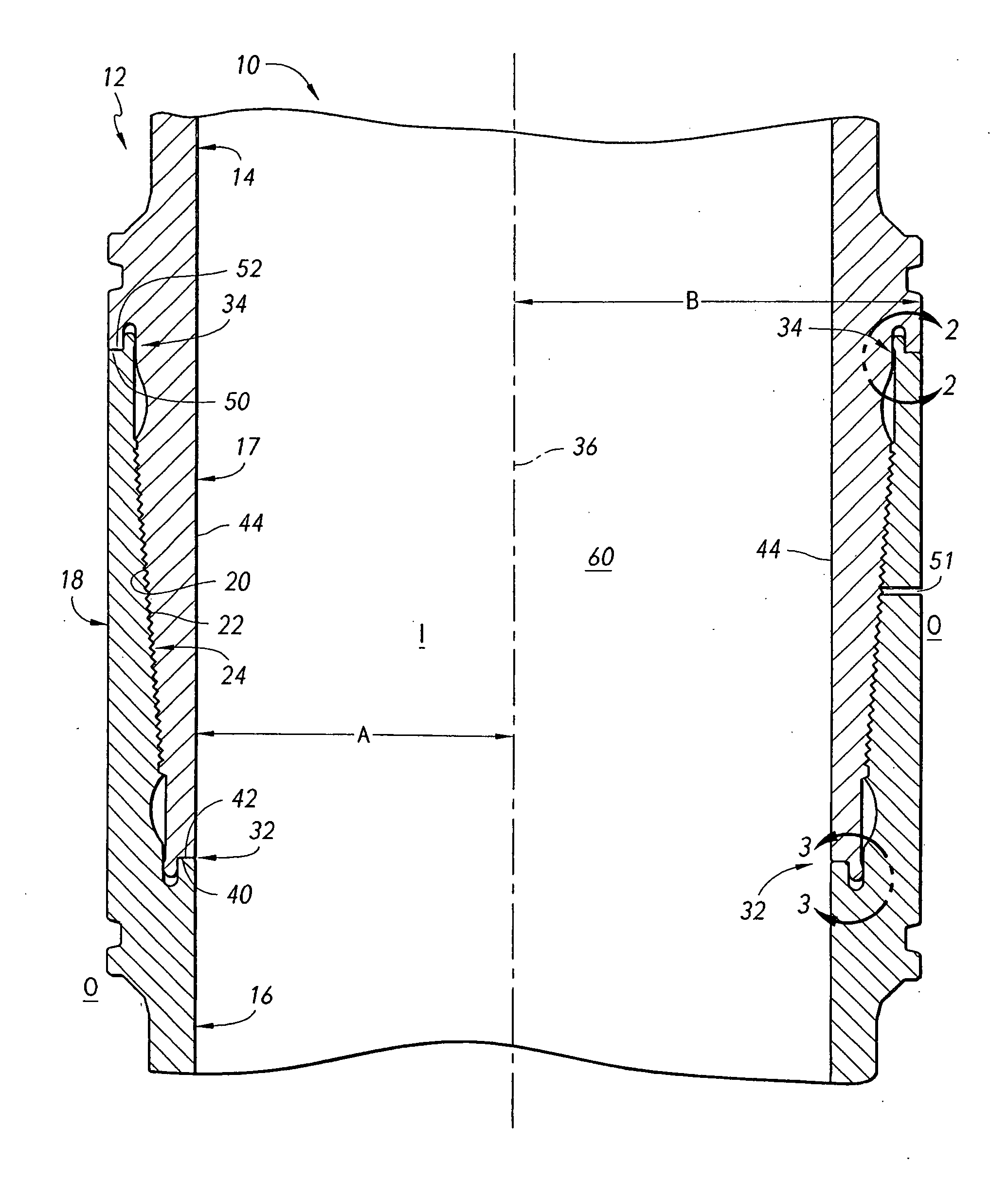

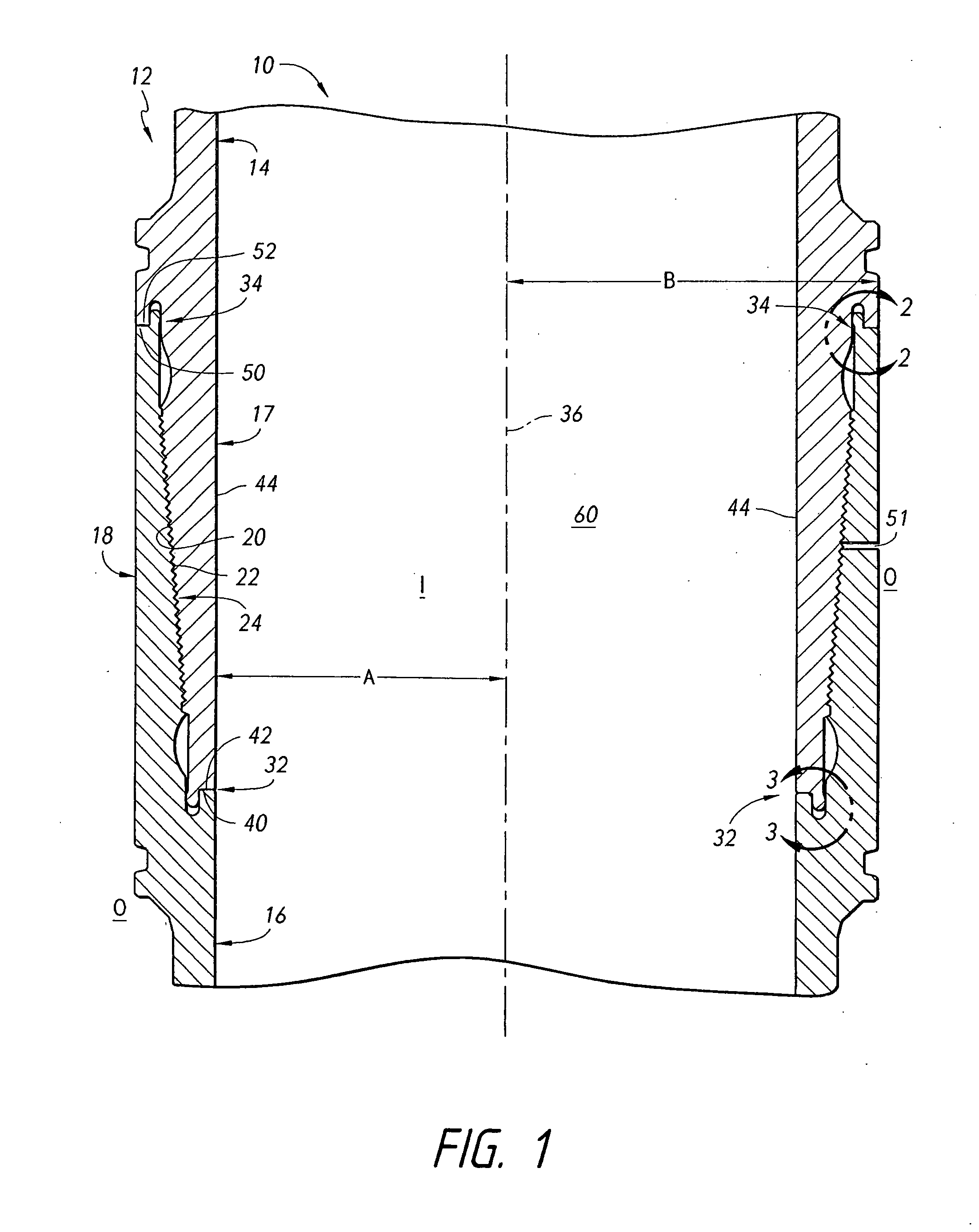

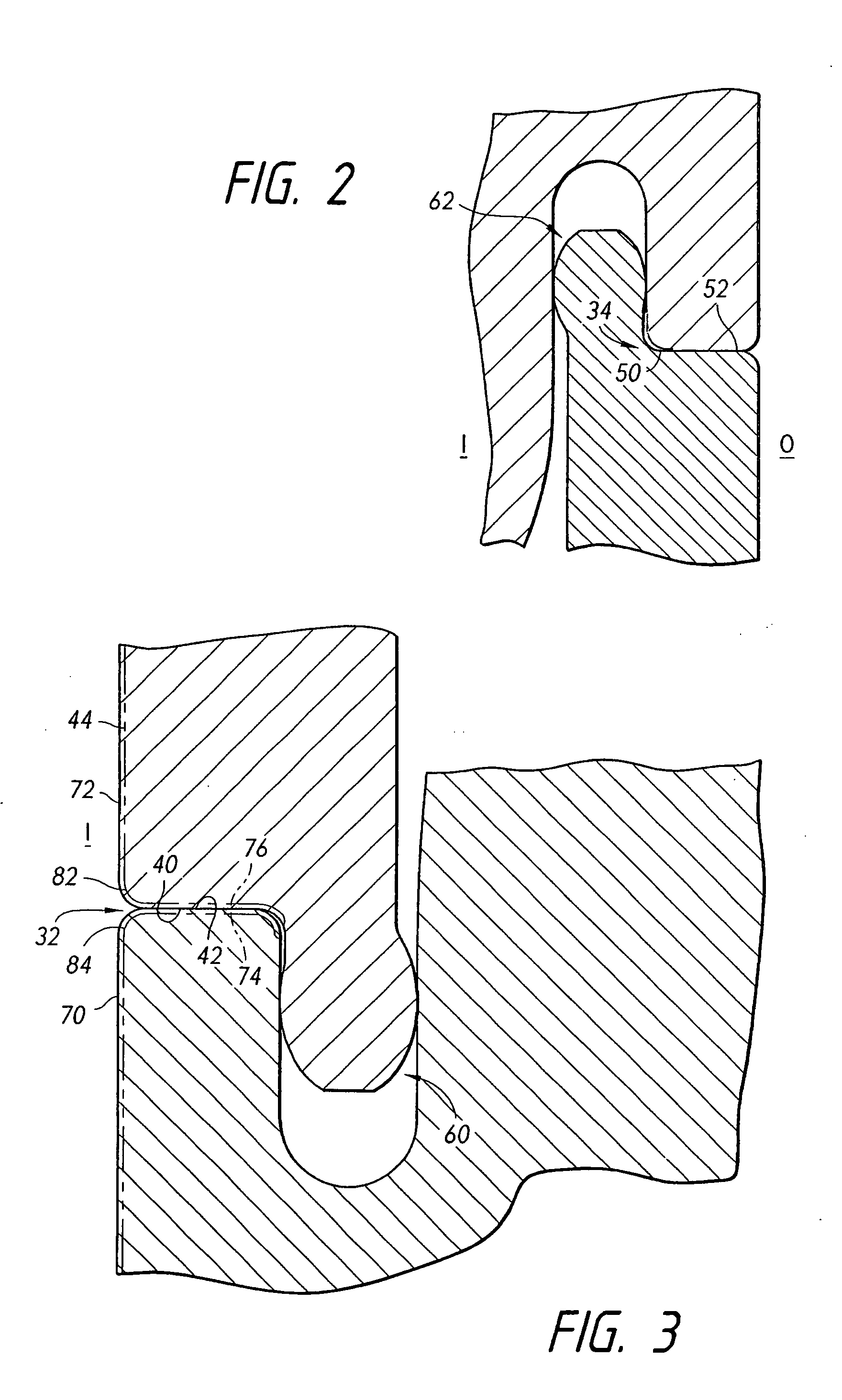

Sealed pipe joint

InactiveUS20110227338A1Stress resistantAvoid fracturesDrilling rodsFluid pressure sealed jointsCorrosion resistantEngineering

In a pipe joint where two pipe sections (14, 16) have threadably engaged end portions (17, 18), joint ends (32, 34) are substantially sealed to each other by a sealing surface (40, 50) on one pipe section that substantially abuts a sealing surface (42, 52) on the other pipe section. In one joint, a ring-shaped cutout (121, FIG. 7) is formed in a first pipe section and a ring-shaped spacer (120) is located in the cutout. The spacer is chosen from several that have slightly different lengths so the spacer end contacts the corresponding sealing surface (130). In a pipe string used to carry corrosive fluid, the inner surface (44) of adjacent pipe sections is covered with a corrosion resistant coating (70, 72). Where the sealing surface is connected to a rounded corner (82, 84), the coating extends to and along the sealing surfaces (40, 42). Where there are sharp corners (80) at the intersection of the inside surface (40) with the sealing surface (40B, 42B), the coating does not extend along the sealing surfaces.

Owner:SINGLE BUOY MOORINGS INC

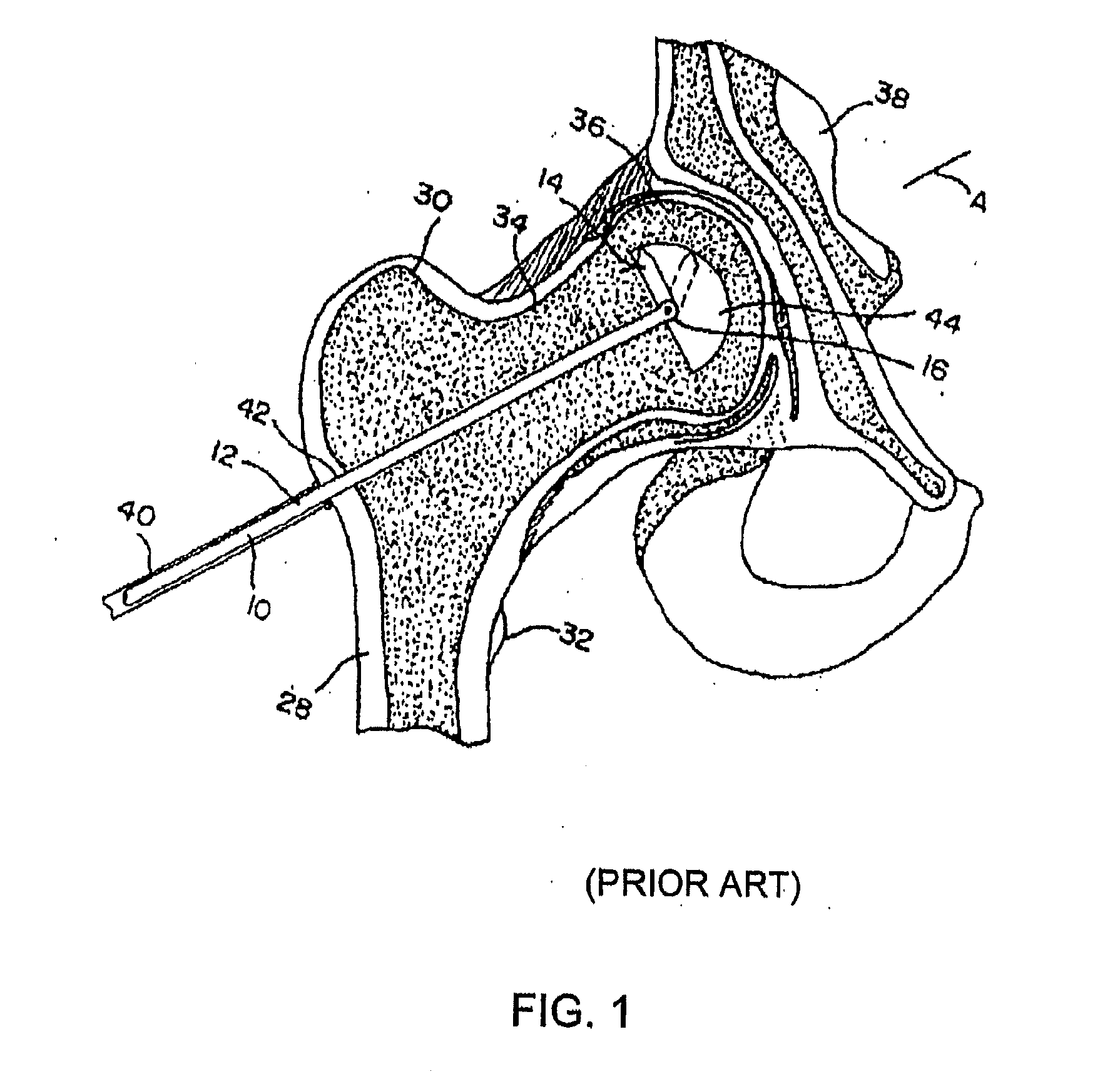

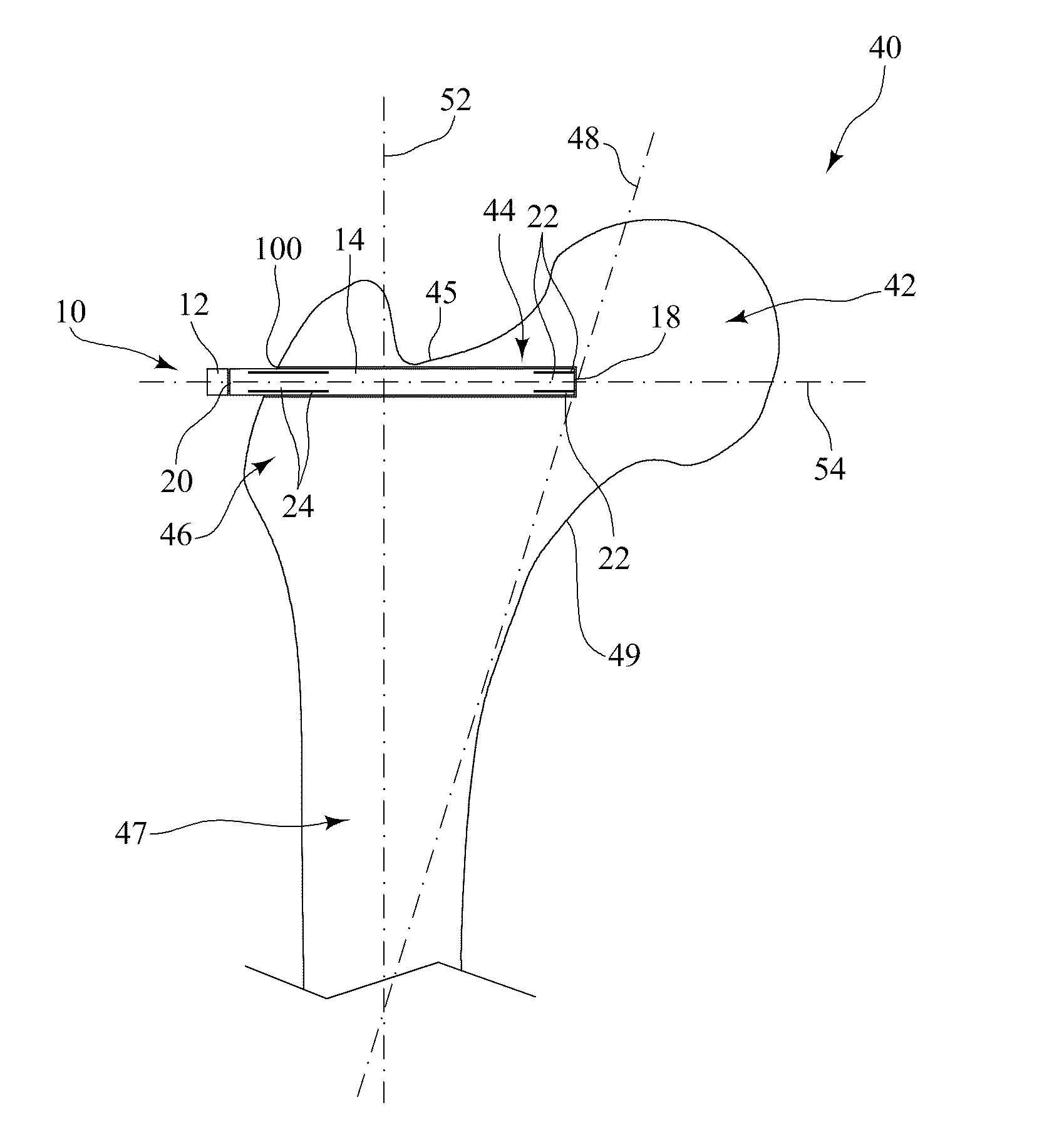

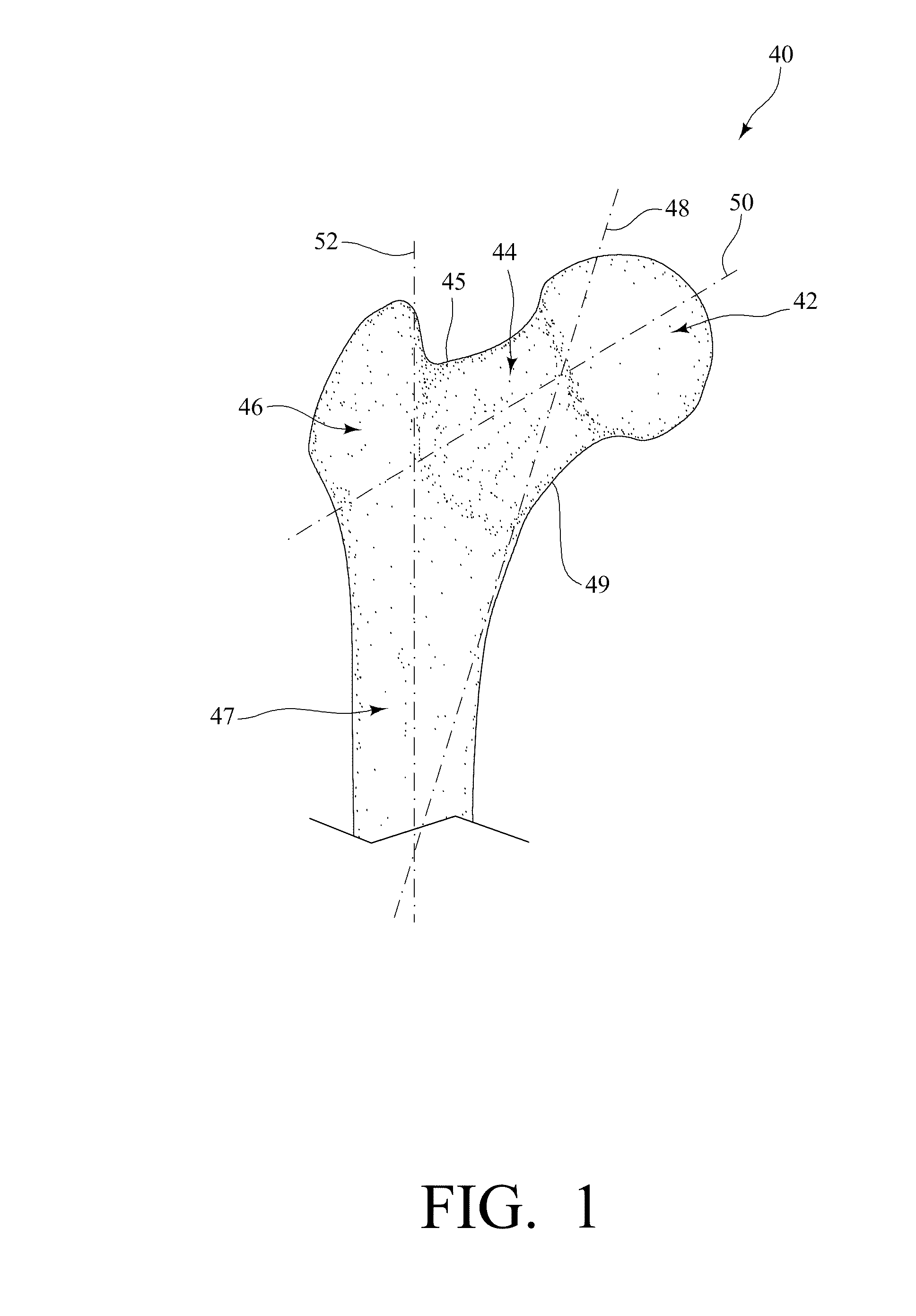

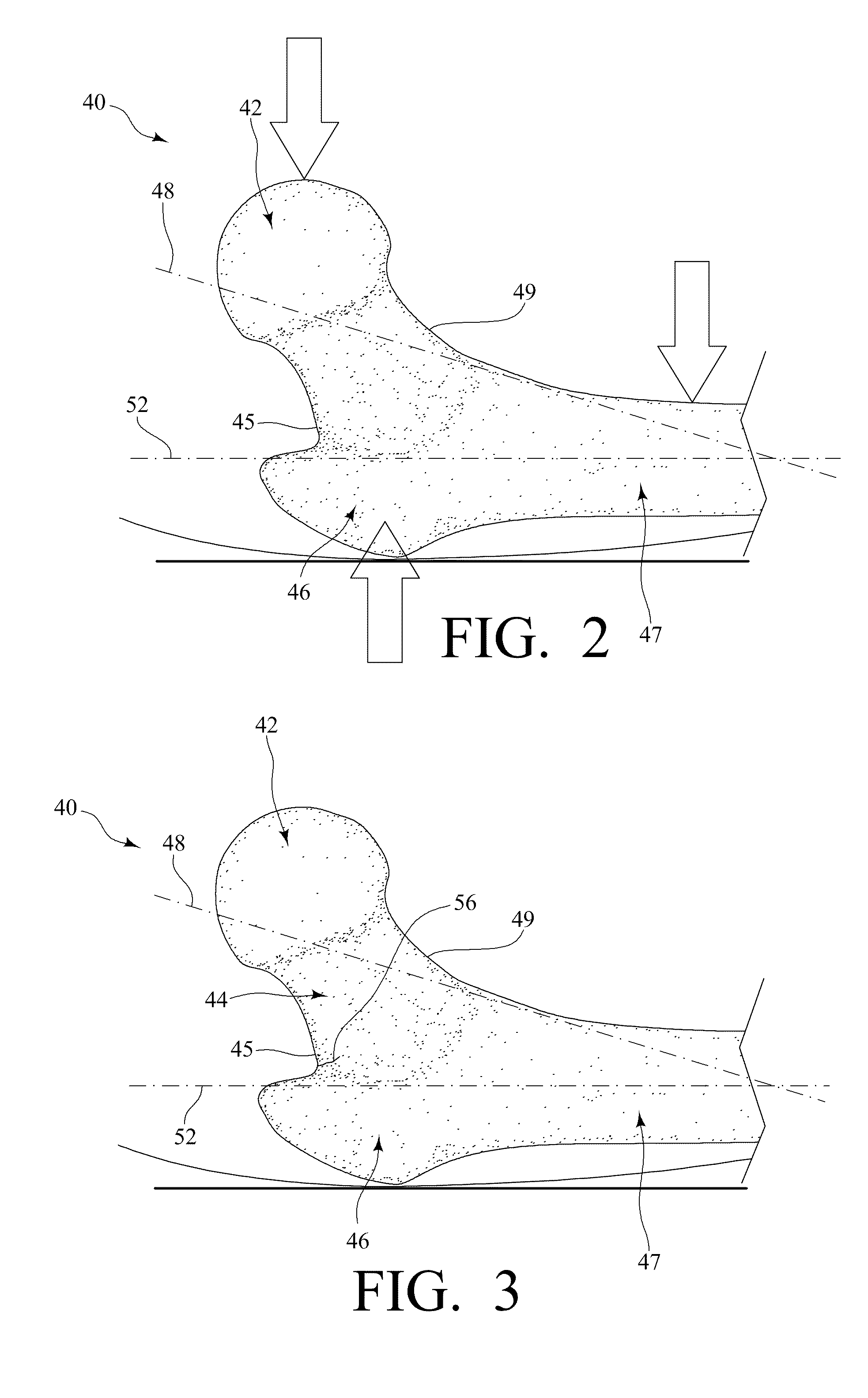

Device and method to prevent hip fractures

ActiveUS20100023012A1Prevent hip fracturesAvoid fracturesInternal osteosythesisJoint implantsRight femoral headHip fracture

A device for preventing a hip fracture includes: a shaft having a first end and a second end and an expanding means for engaging the femoral head at the first end. The shaft is positioned in a hole of a predetermined depth in a femur. The hole extends from the greater trochanter to the femoral head of the femur, such that the first end is positioned in the femoral head and the second end is positioned in the greater trochanter. The device is oriented substantially perpendicular to the long axis of the femoral shaft.

Owner:UNIV OF LOUISVILLE RES FOUND INC

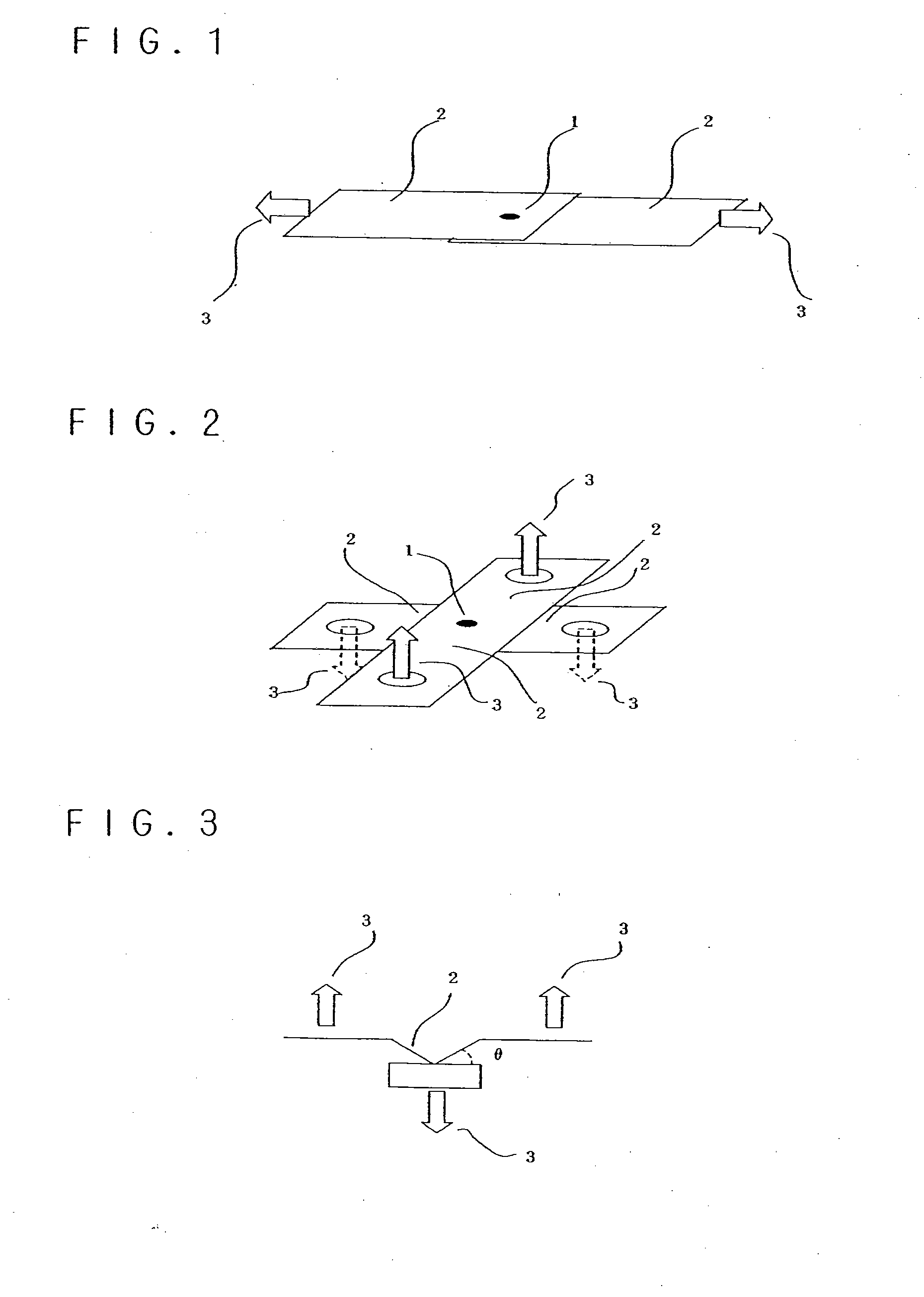

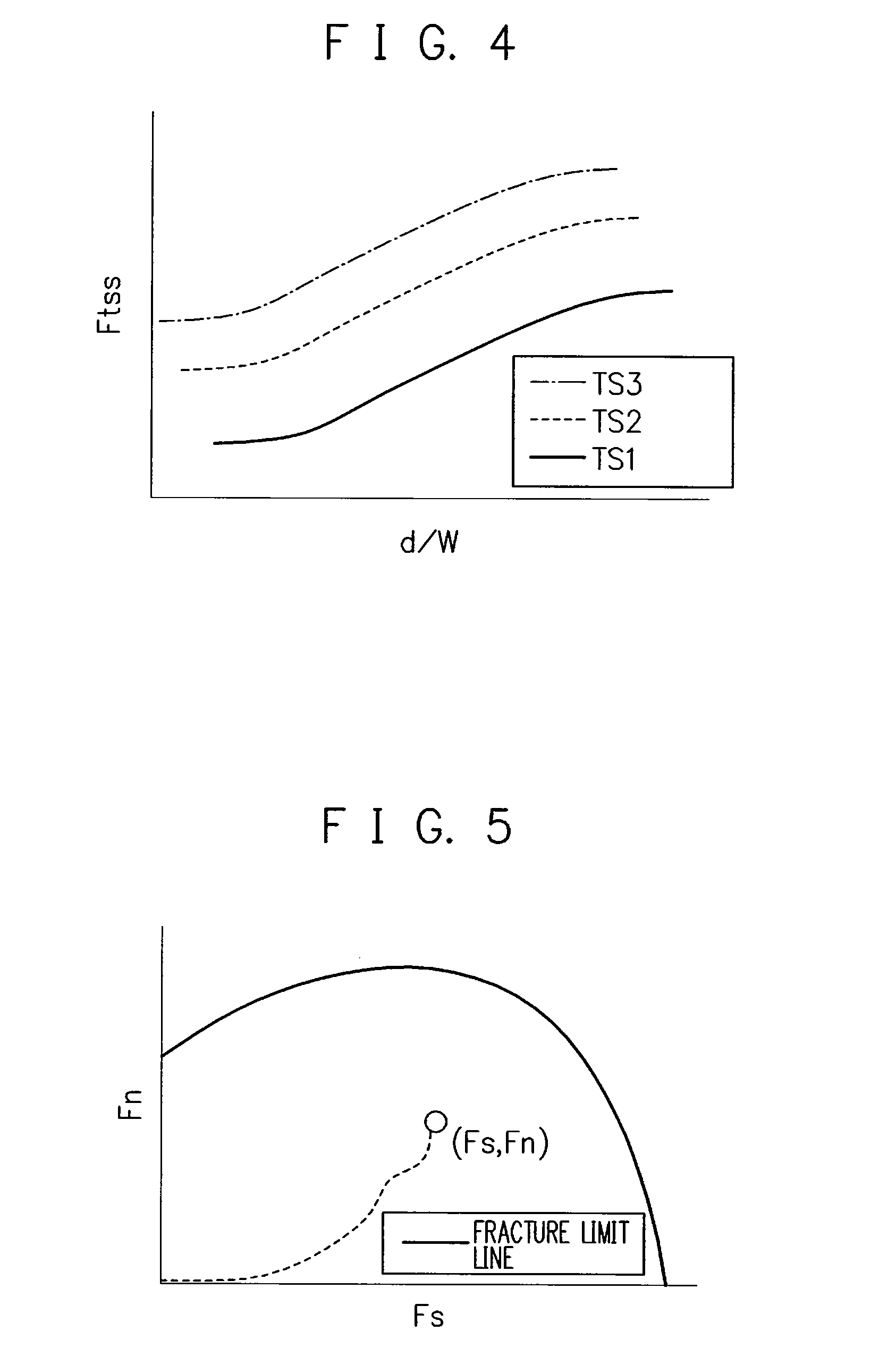

Fracture Prediction Device For Spot Welded Portion, Method Of The Same, Computer Program, And Computer Readable Recording Medium

ActiveUS20070199924A1Improve absorbed energy of crashReduce usageMaterial strength using tensile/compressive forcesArc welding apparatusEngineeringSpot welding

According to exemplary embodiments of the present invention, a fracture prediction device for a spot welded portion can be provided. For example, the device may include an input arrangement configured to input all or some of a material strength, a plate thickness, a nugget diameter of a spot welding, a plate width of a joint, and a rotation angle of the joint in a tension test, based on a cross tension test and / or a shear tension test at a spot welded joint. The device can also include a first calculation arrangement configured to calculate a fracture strength parameter of the spot welded portion from all or any of the material strength, the plate thickness, the nugget diameter of the spot welding, the plate width of the joint, and the rotation angle of the joint in the tension test. A parameter storage arrangement may also be provided which can be configured to store the fracture strength parameter by each steel type. Further, the device may further have a second calculation arrangement configured to determine a fracture of the spot welded portion by installing the fracture strength parameter stored in the parameter storage arrangement into a fracture prediction formula in which a deformation at a periphery of the spot welding is modeled by a finite element procedure. Exemplary embodiments of the method software arrangement and computer accessible medium performing similar procedures can also be provided.

Owner:NIPPON STEEL CORP

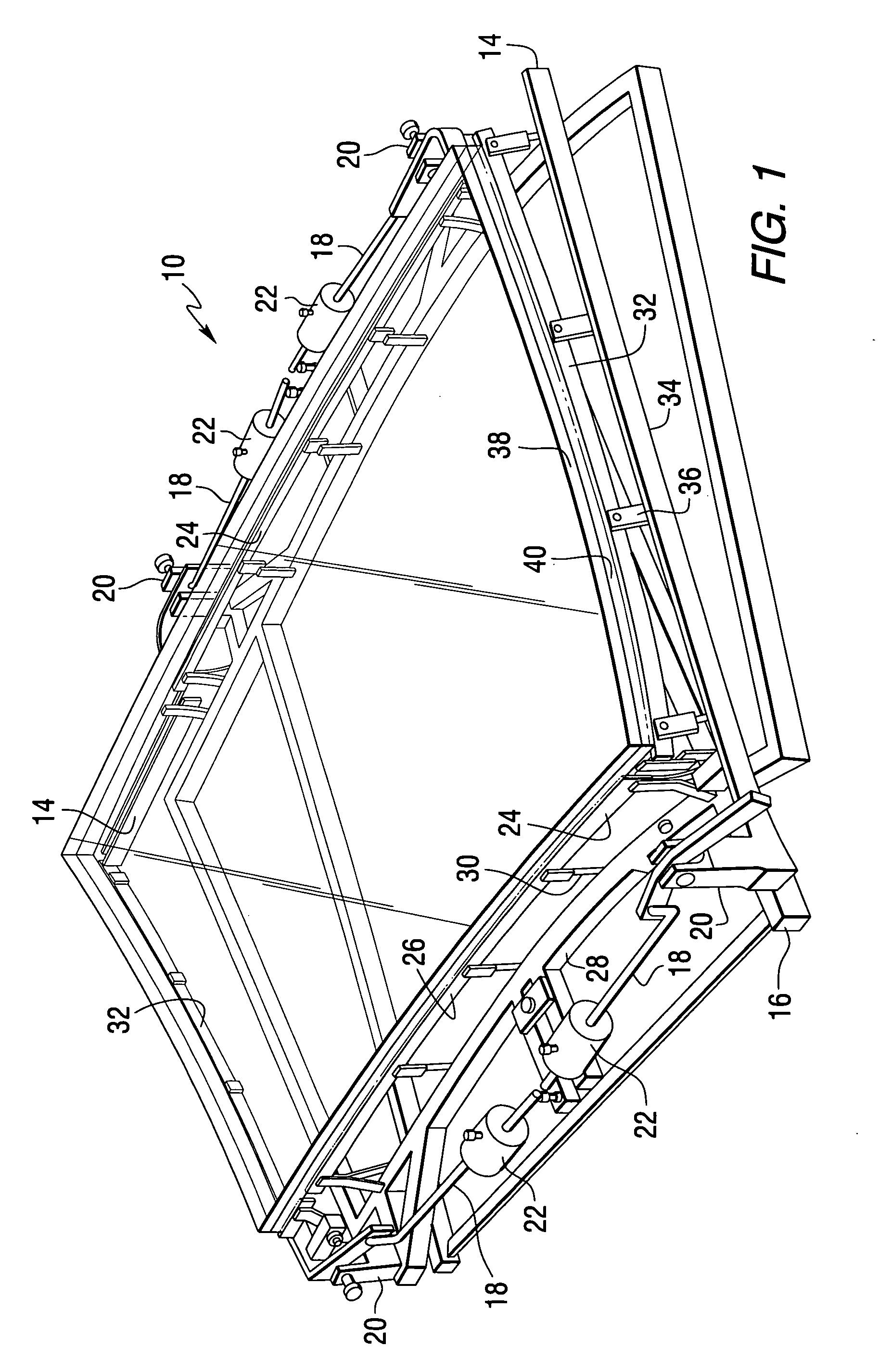

Method of and apparatus for strengthening edges of one or more glass sheets

ActiveUS20050166639A1Avoid fracturesImprove edge strengthCellulosic plastic layered productsGlass/slag layered productsGlass sheetMechanical engineering

A furnace includes a section defined as a heating section capable of attaining a predetermined temperature, the heating section having an entrance end and an exit end; a section defined as a cooling section capable of having a temperature gradient from entrance end of the cooling section to exit end of the cooling section, the entrance end of the cooling section mounted in a fixed relationship to the exit end of the heating section; a section defined as an edge cooling section between the exit end of the heating section and the entrance end of the cooling section; and an edge cooling device positioned in the edge cooling section relative to a predetermined area, and capable of cooling at least selected peripheral portions of the predetermined area at a faster rate than center portions of the predetermined area.

Owner:PITTSBURGH GLASS WORKS

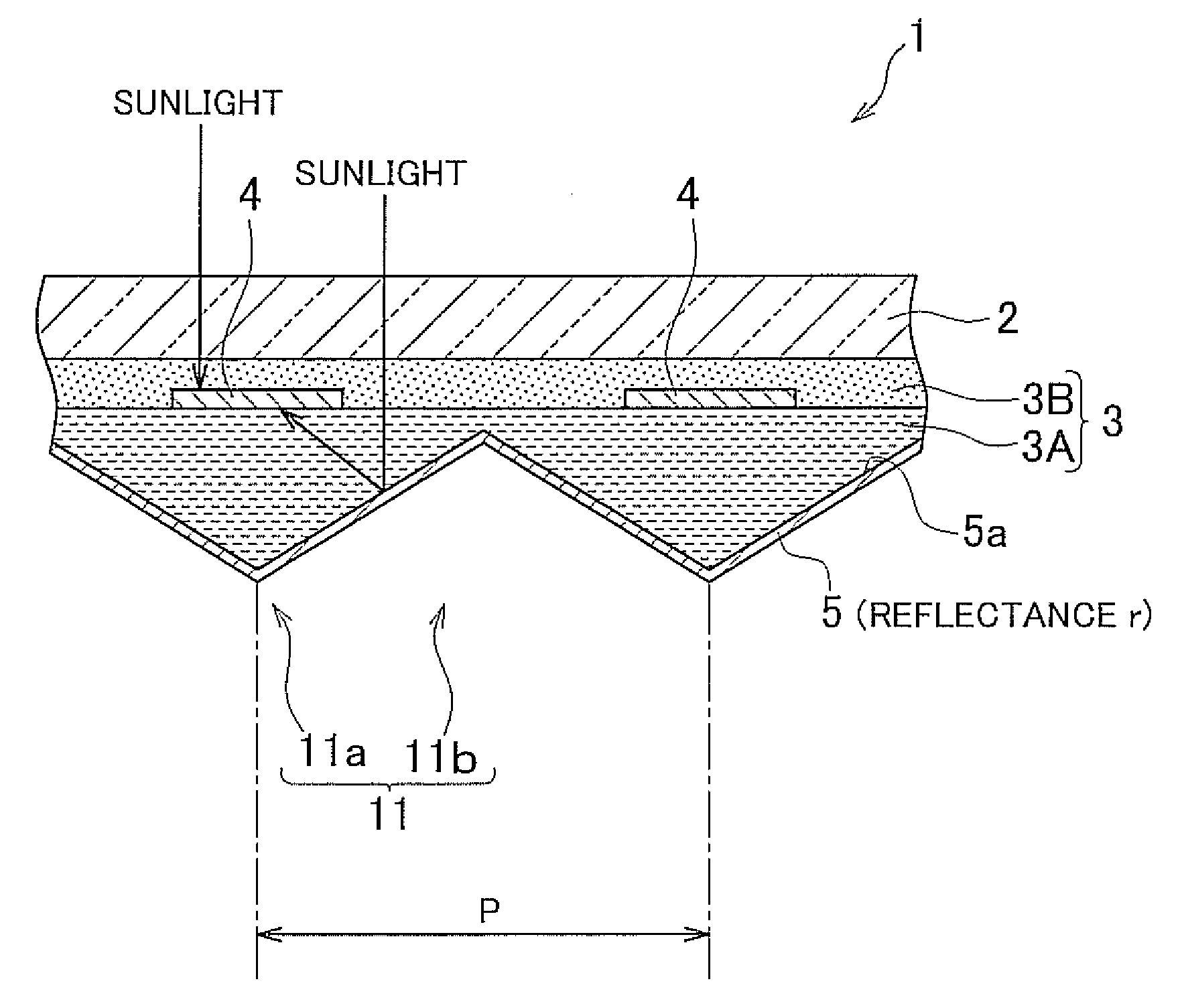

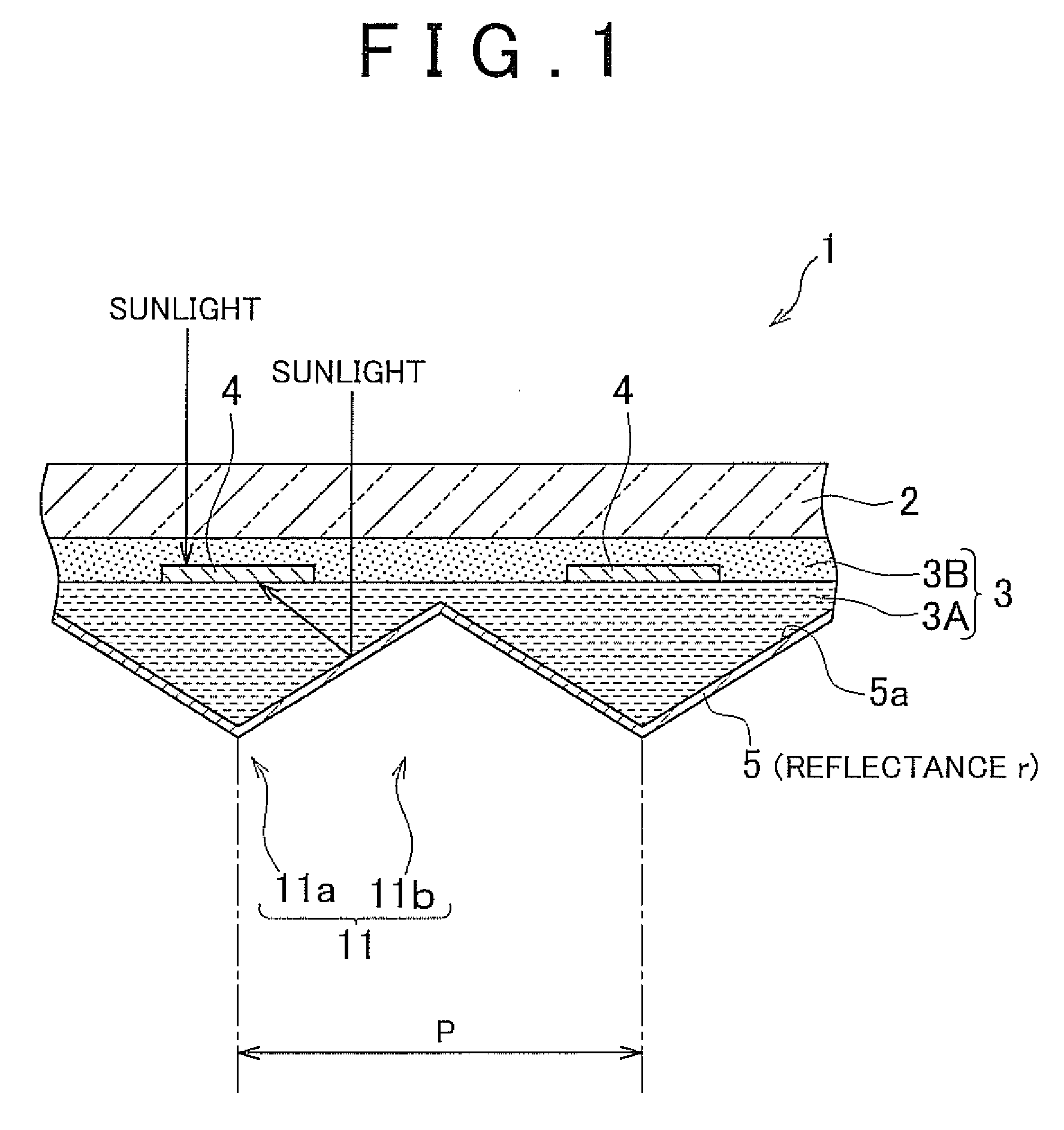

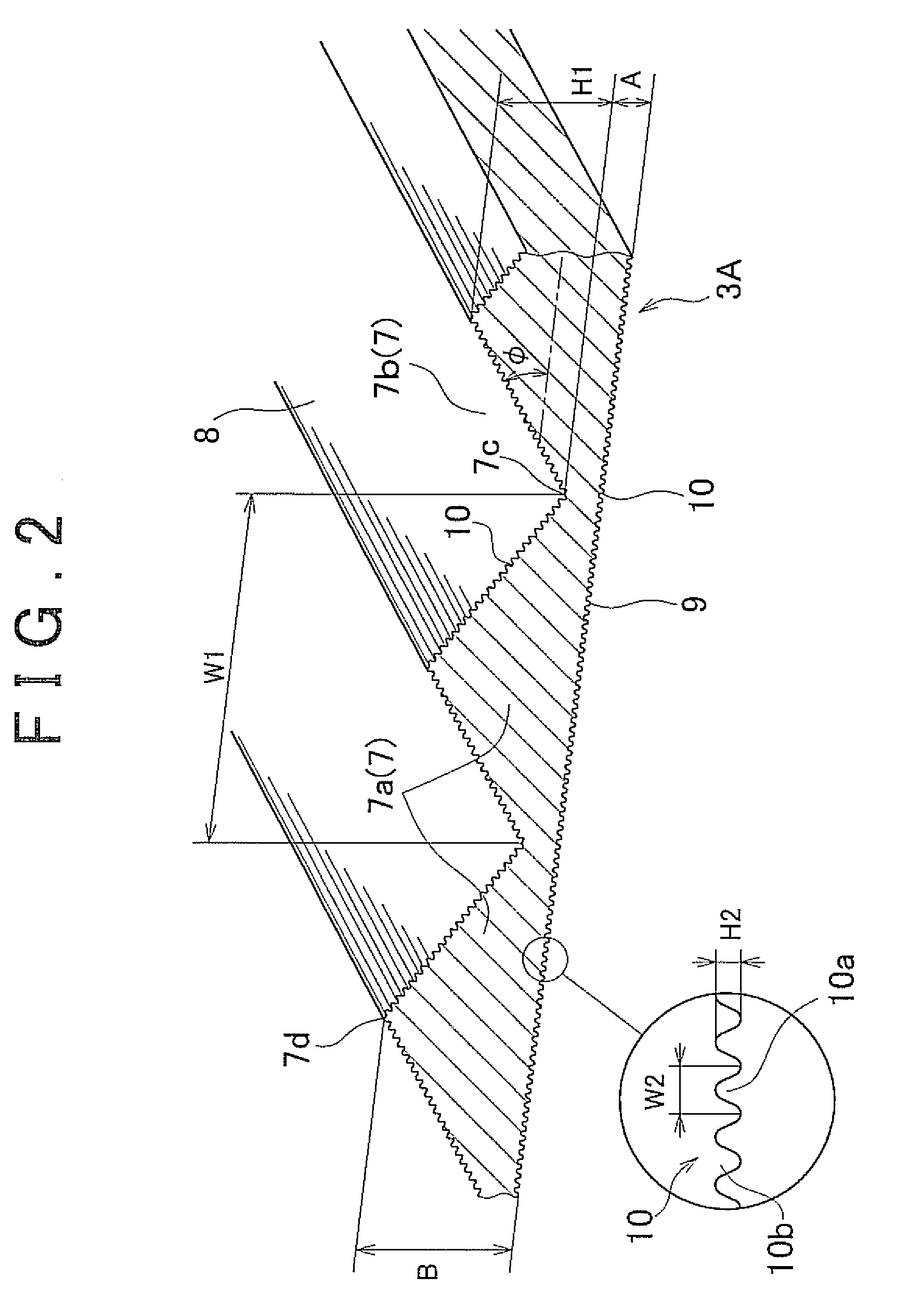

Solar cell module

InactiveUS20100252107A1Maintaining long-term reliabilityReduce lossesPhotovoltaic supportsPhotovoltaic energy generationEngineeringSolar cell

A solar cell module includes: a reflector; a encapsulant that includes a first corrugated portion that corresponds to a corrugated shape of the reflector; and a solar cell that is encapsulated in the encapsulant, wherein the encapsulant is fixed to the reflector and the solar cell; and at least one of a surface of the encapsulant fixed to the reflector and a surface of the encapsulant fixed to the solar cell is provided with a second corrugated portion that has a smaller protrusion than a protrusion of the first corrugated portion.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com