Patents

Literature

105results about How to "Improve edge strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

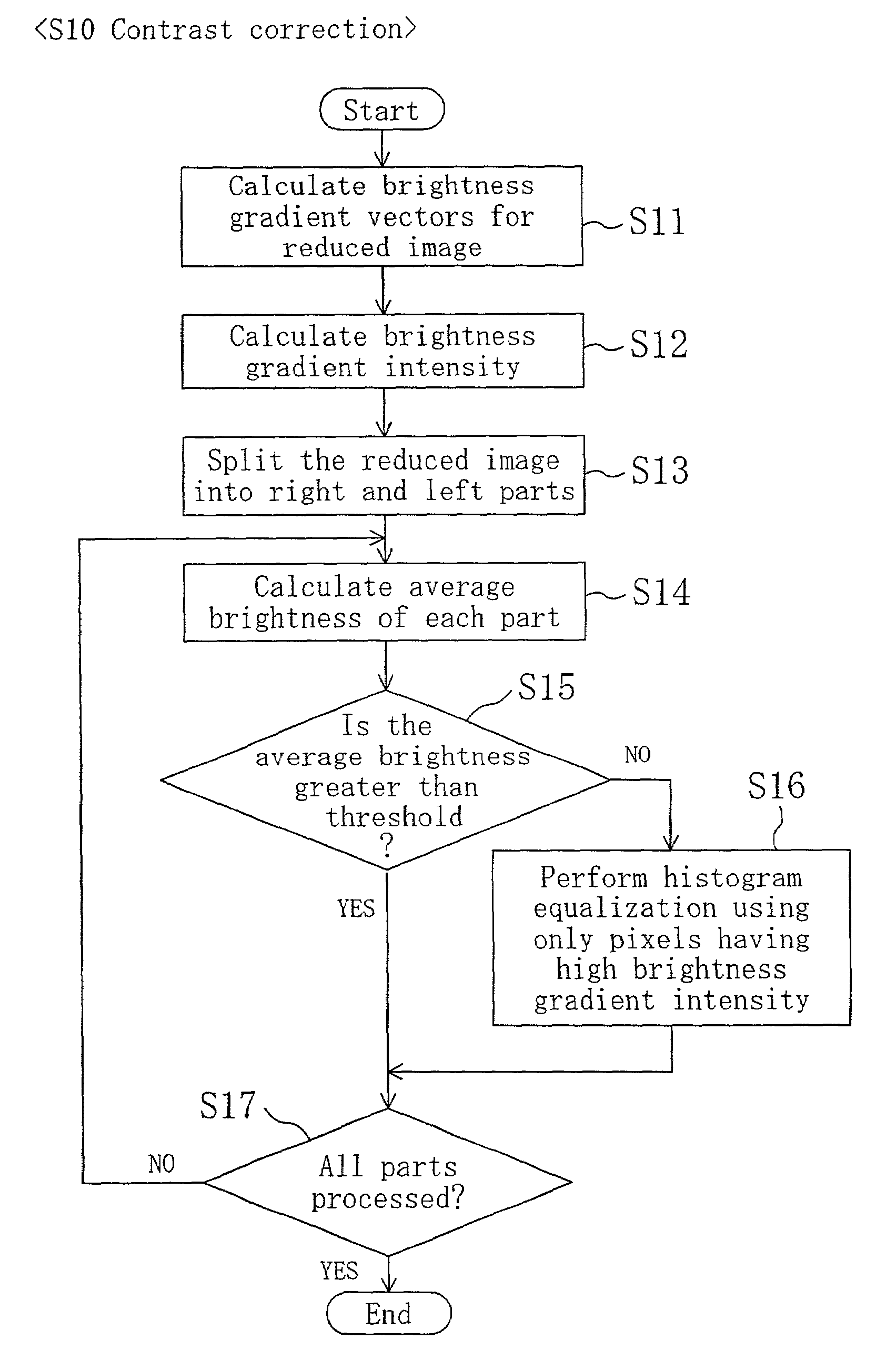

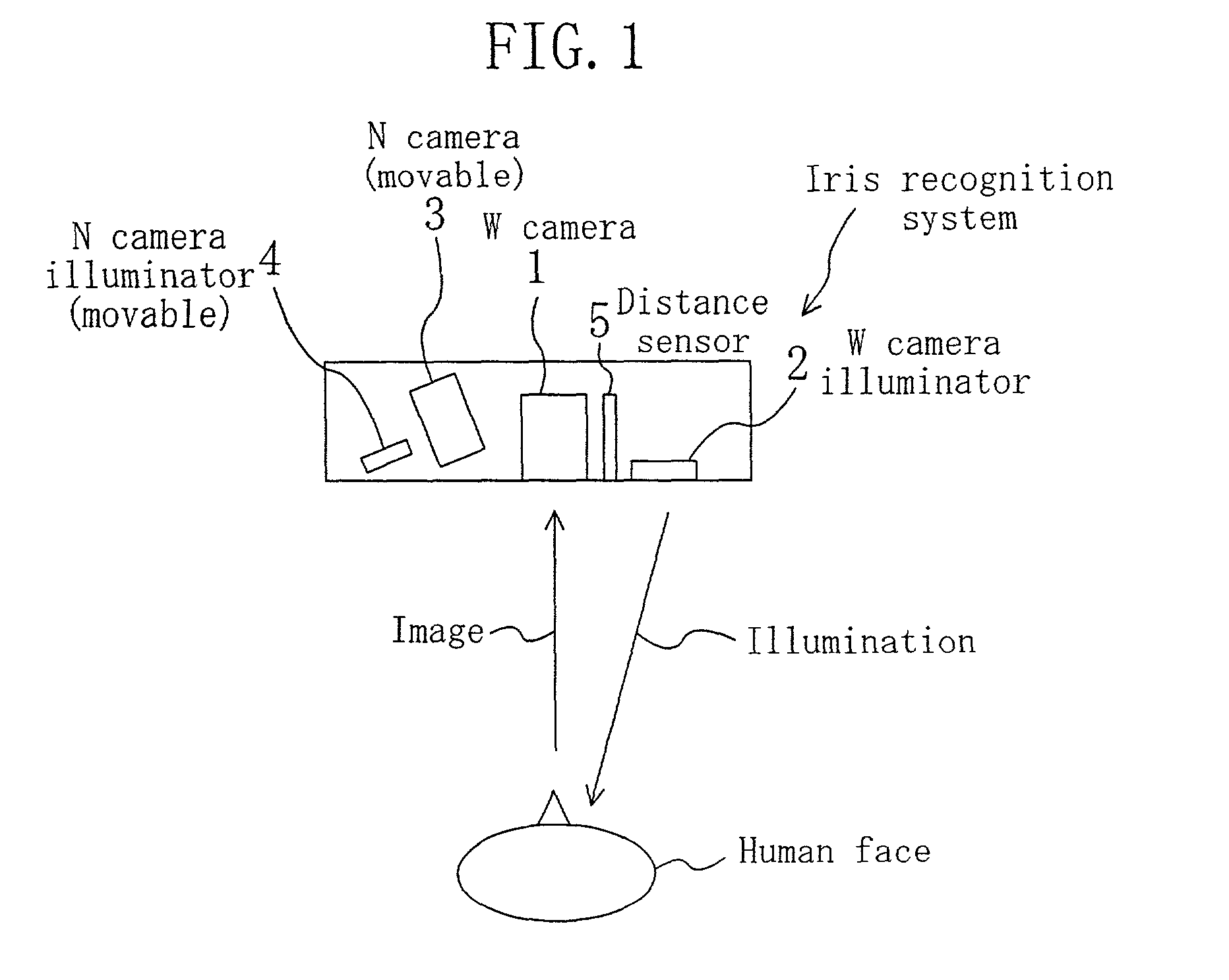

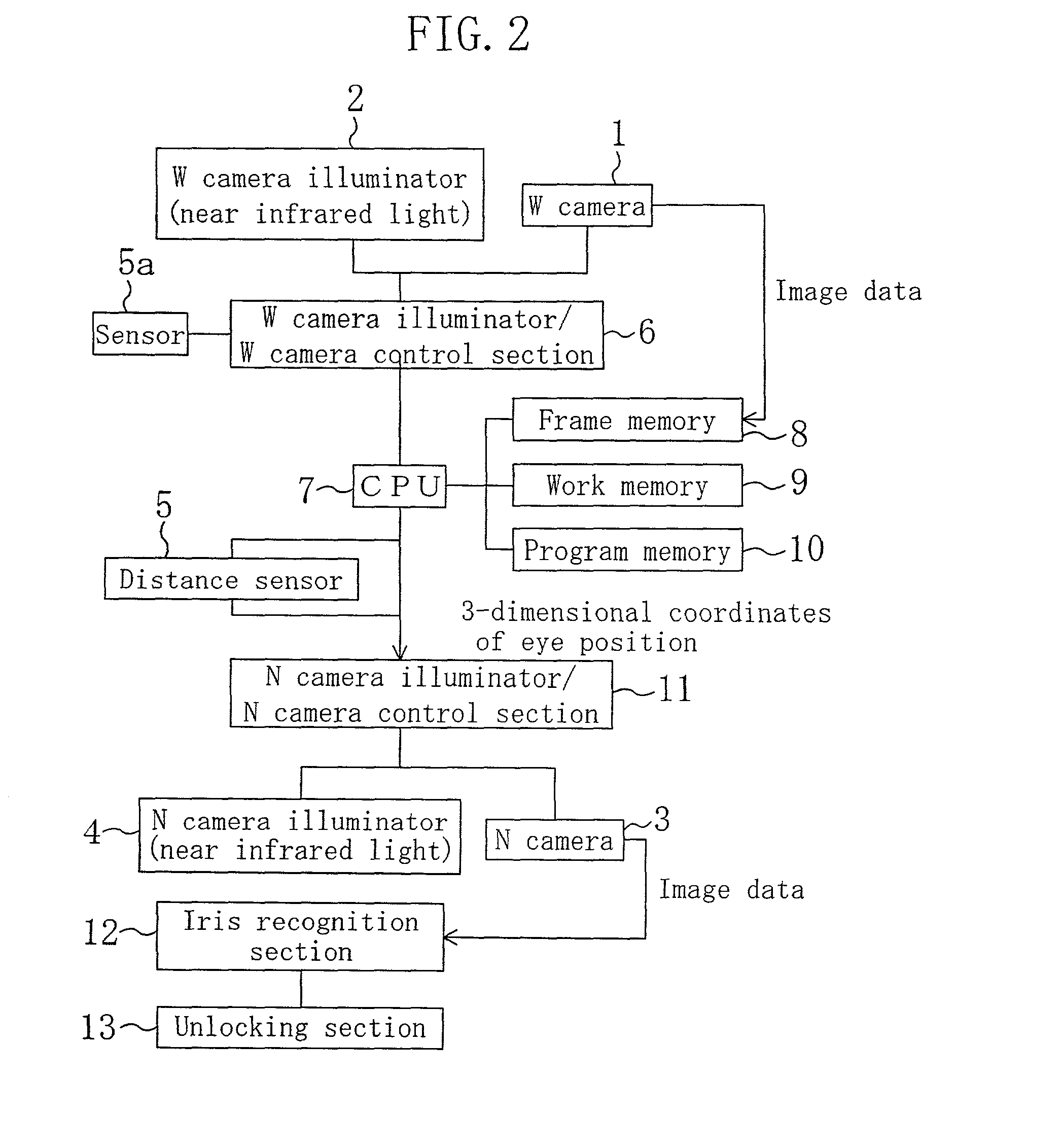

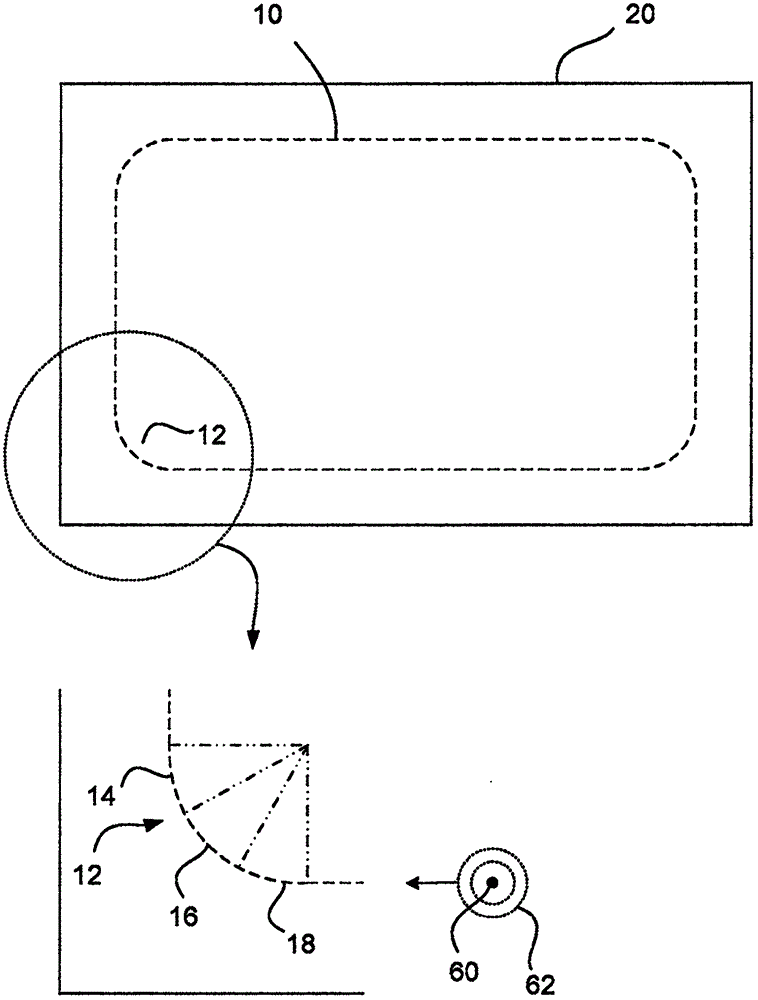

Eye position detection method and device

ActiveUS7130453B2Improve accuracyShort timeImage analysisPerson identificationPupilBrightness gradient

The position of an eye is detectable with high precision from a face image of a person taken under near infrared illumination or the like. After pre-processing, the face image is subjected to brightness correction to increase the contrast between the sclera portion and iris portion of the eye. Brightness gradient vectors are calculated for the brightness-corrected image, and matching is performed between a brightness gradient image generated using the calculated brightness gradient vectors and an eye template. Further, matching with a pupil template is performed to correct the eye center position. Final positions of both eyes are then determined.

Owner:PANASONIC CORP

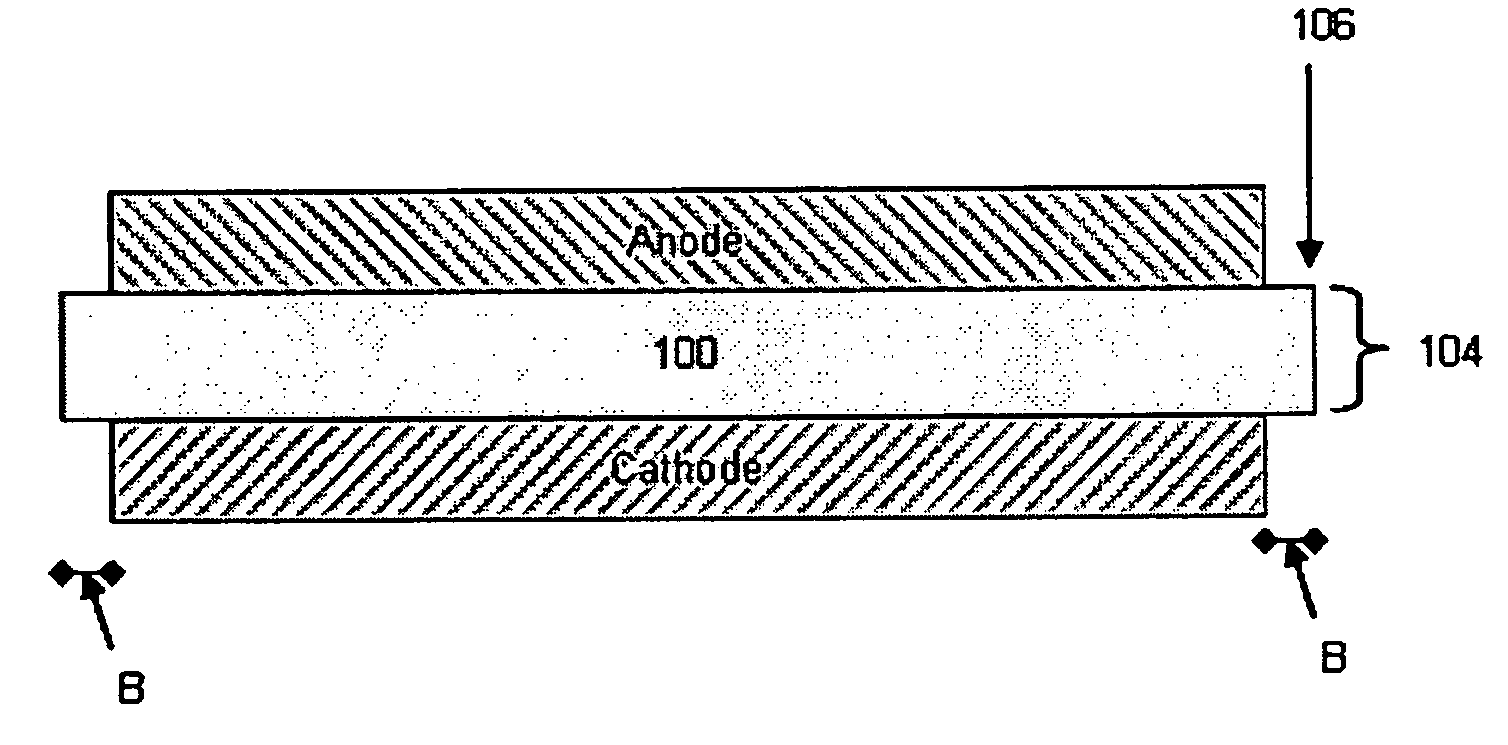

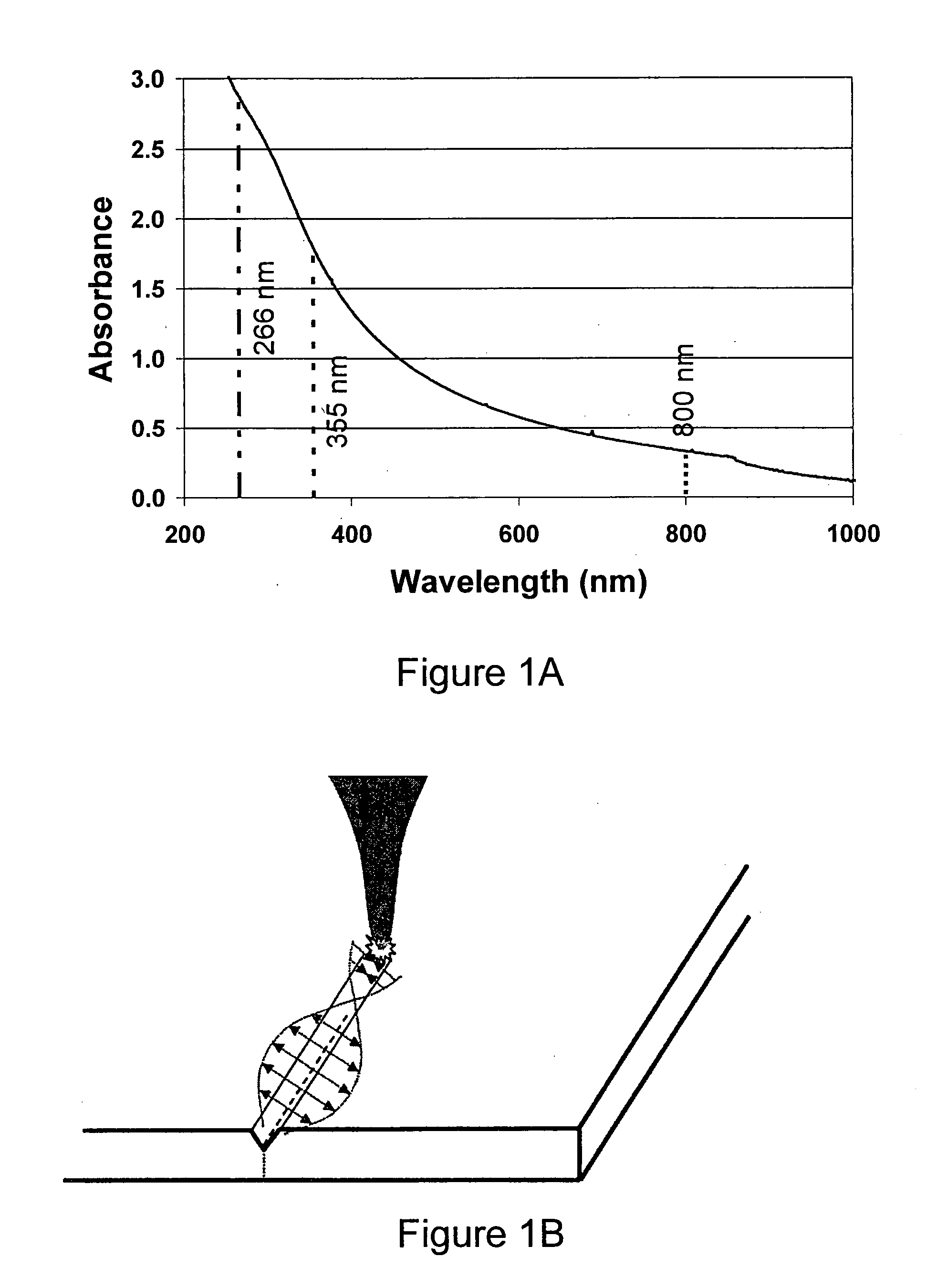

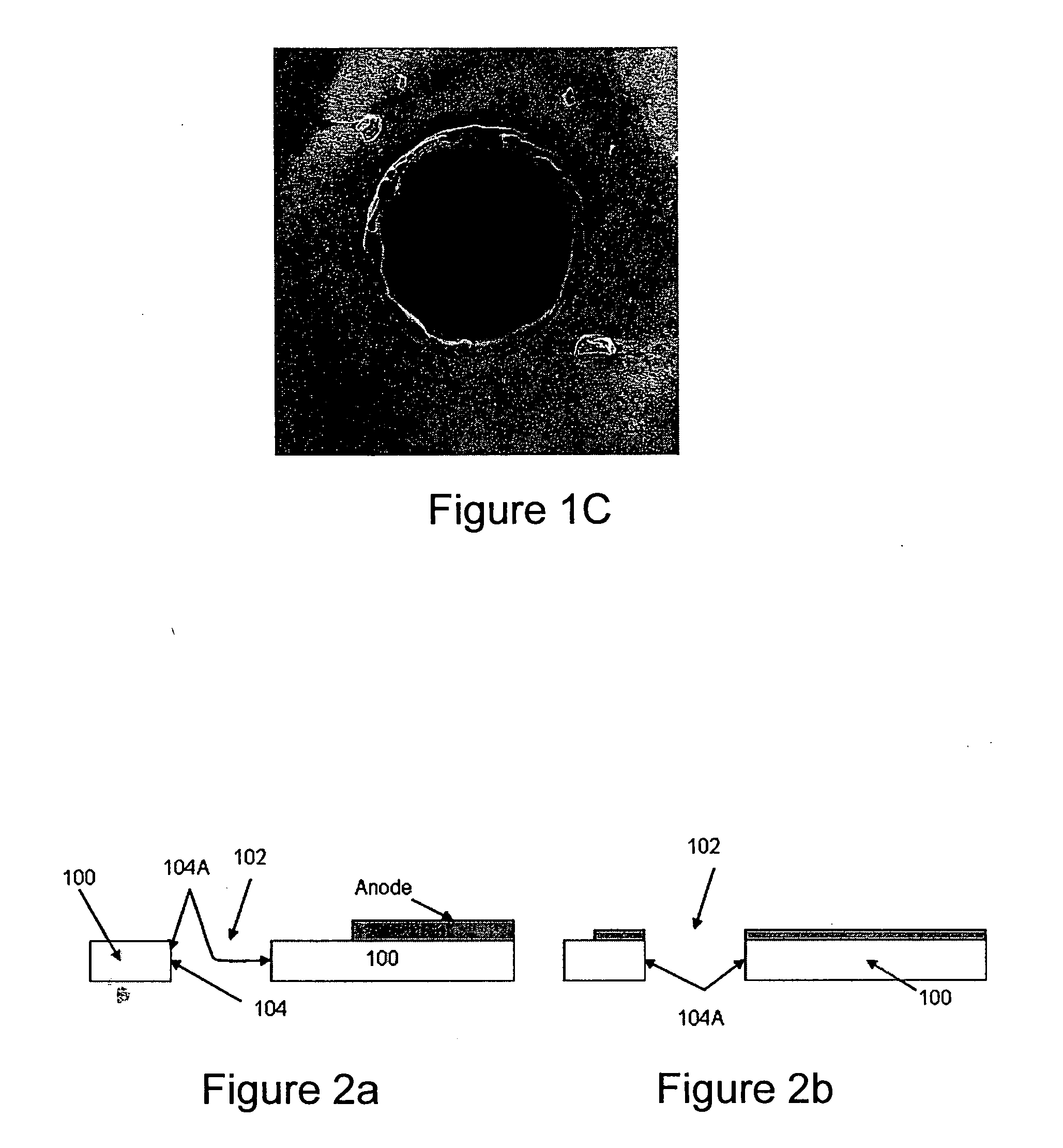

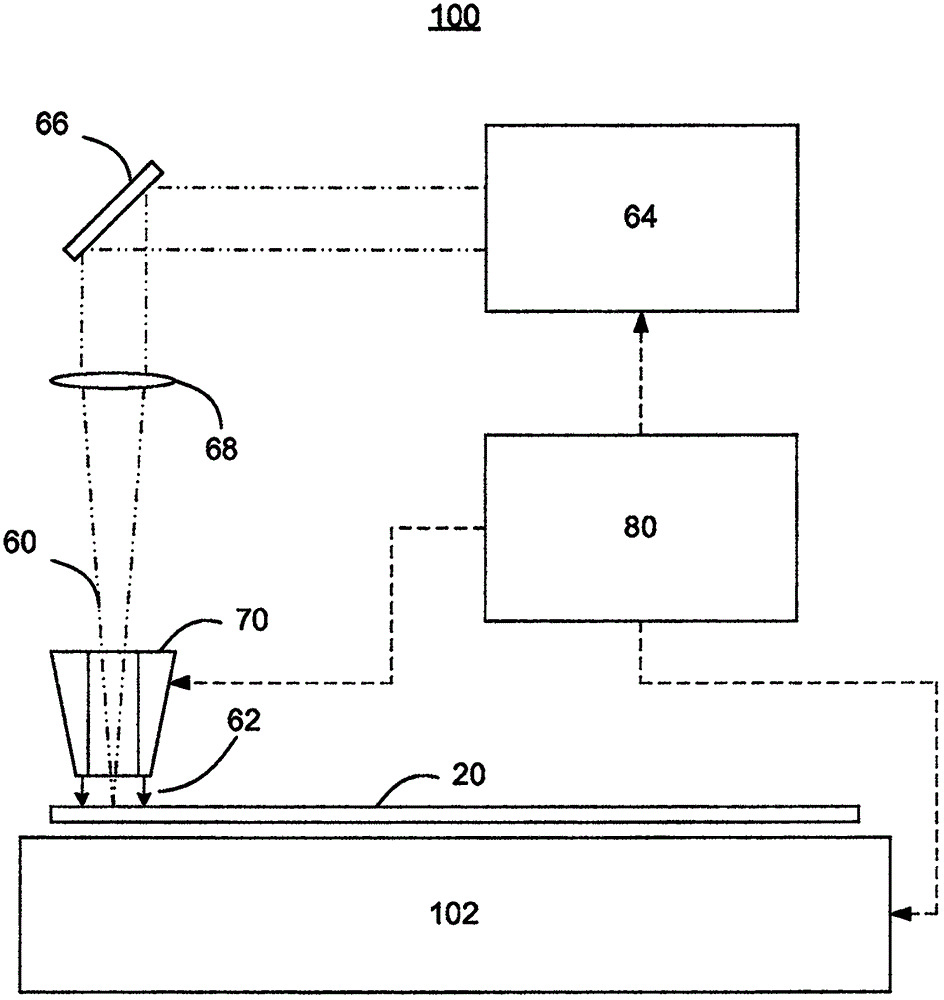

Micromachined electrolyte sheet, fuel cell devices utilizing such, and micromachining method for making fuel cell devices

InactiveUS20090081512A1Increases fabrication yieldHigh strengthFinal product manufactureDecorative surface effectsFuel cellsElectrolysis

A sintered electrolyte sheet comprising: a body of no more than 45 μm thick and laser machined features with at least one edge surface having at least 10% ablation. A method of micromachining the electrolyte sheet includes the steps of: (i) supporting a sintered electrolyte sheet; (ii) micromachining said sheet with a laser, wherein said laser has a wavelength of less than 2 μm, fluence of less than 200 Joules / cm2, repetition rate (RR) of between 30 Hz and 1 MHz, and cutting speed of preferably over 30 mm / sec.

Owner:CORNING INC

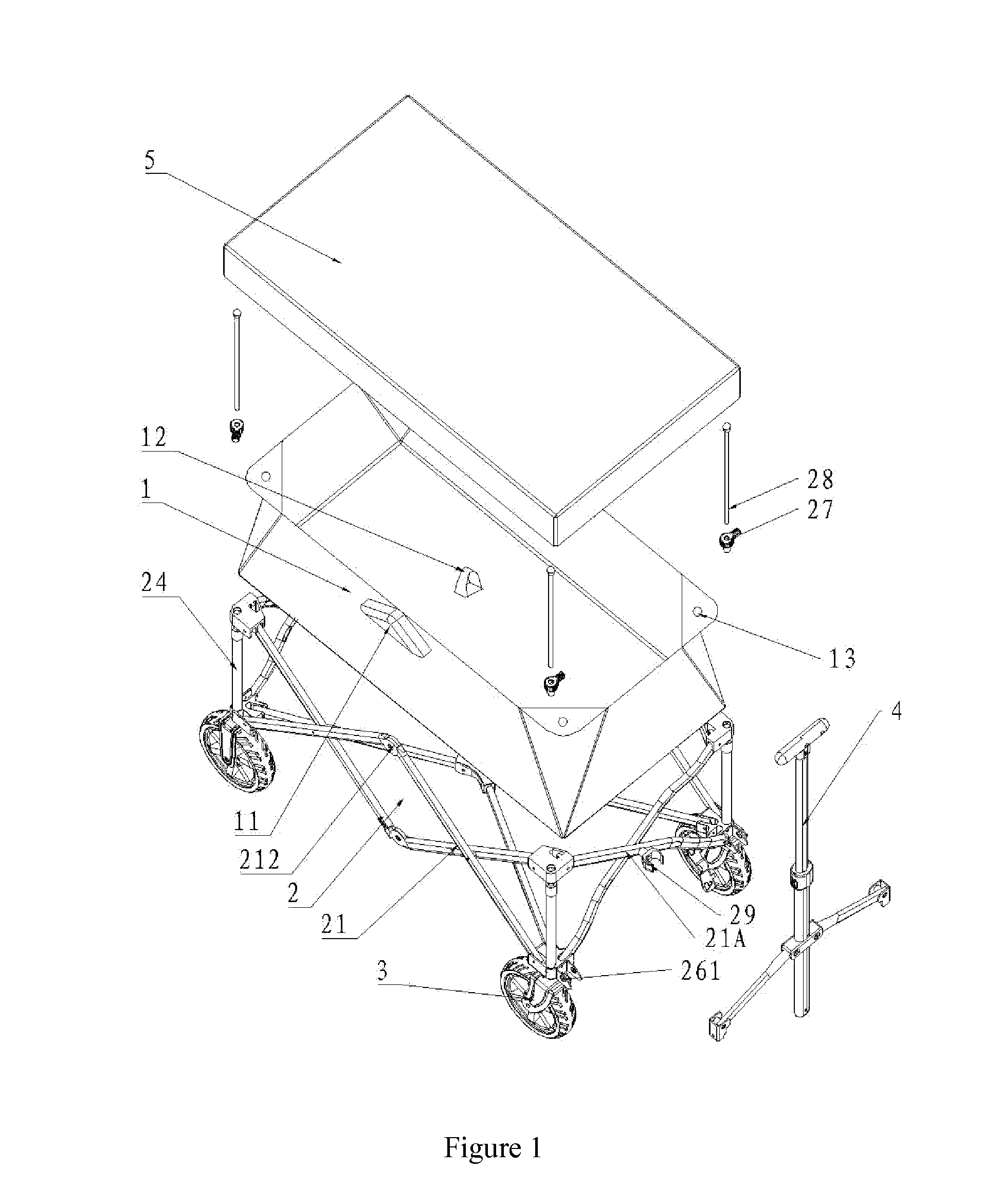

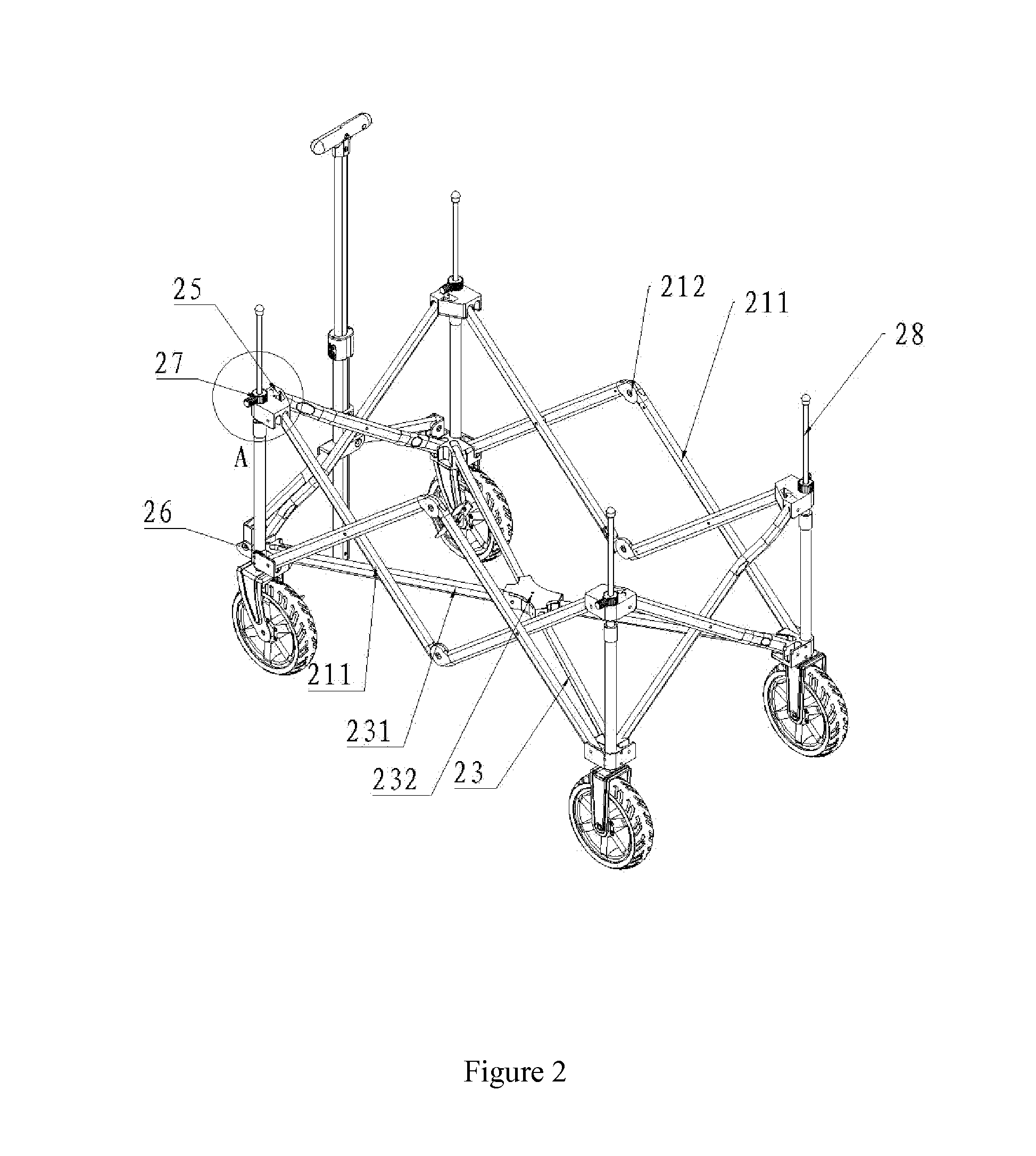

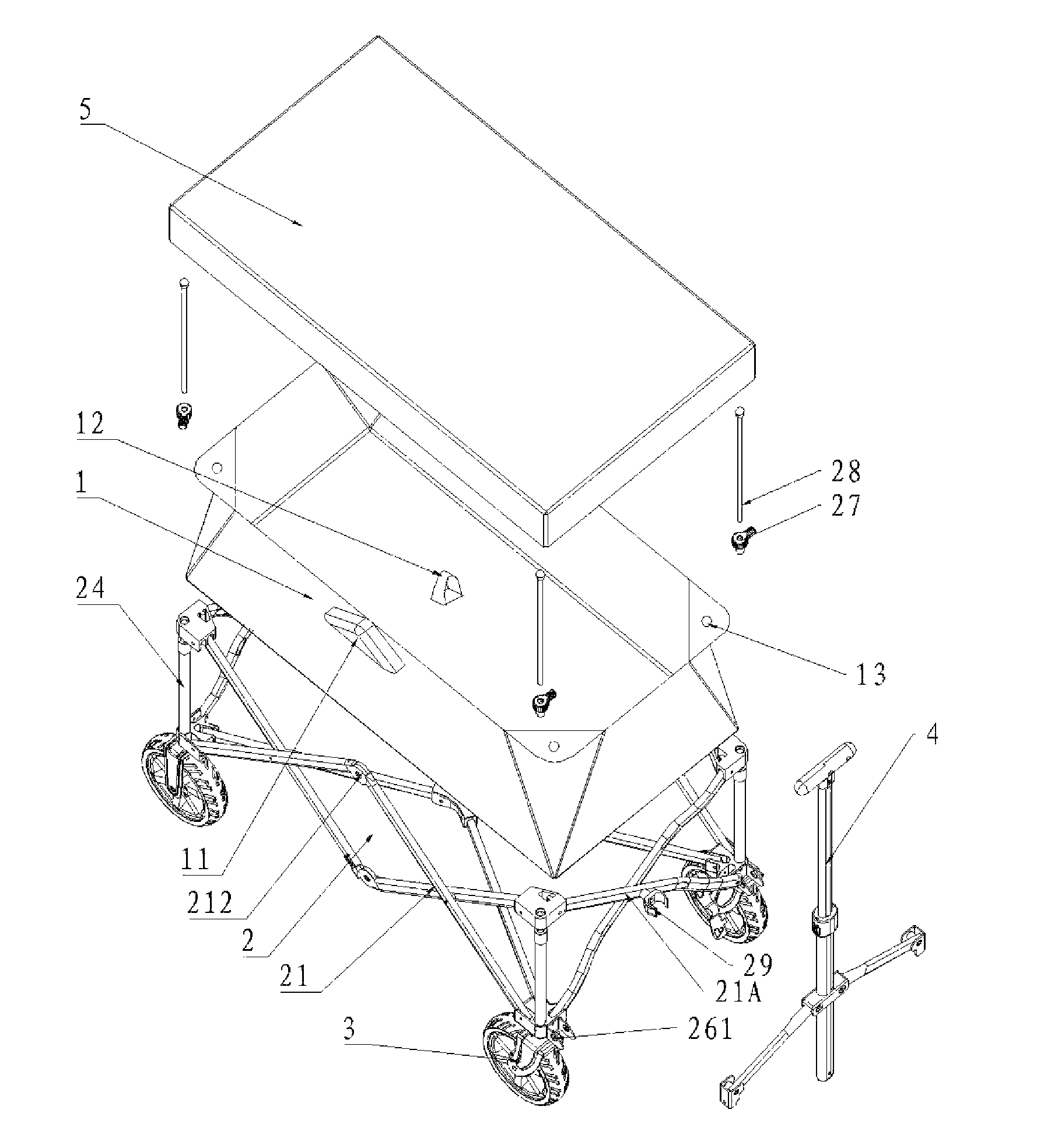

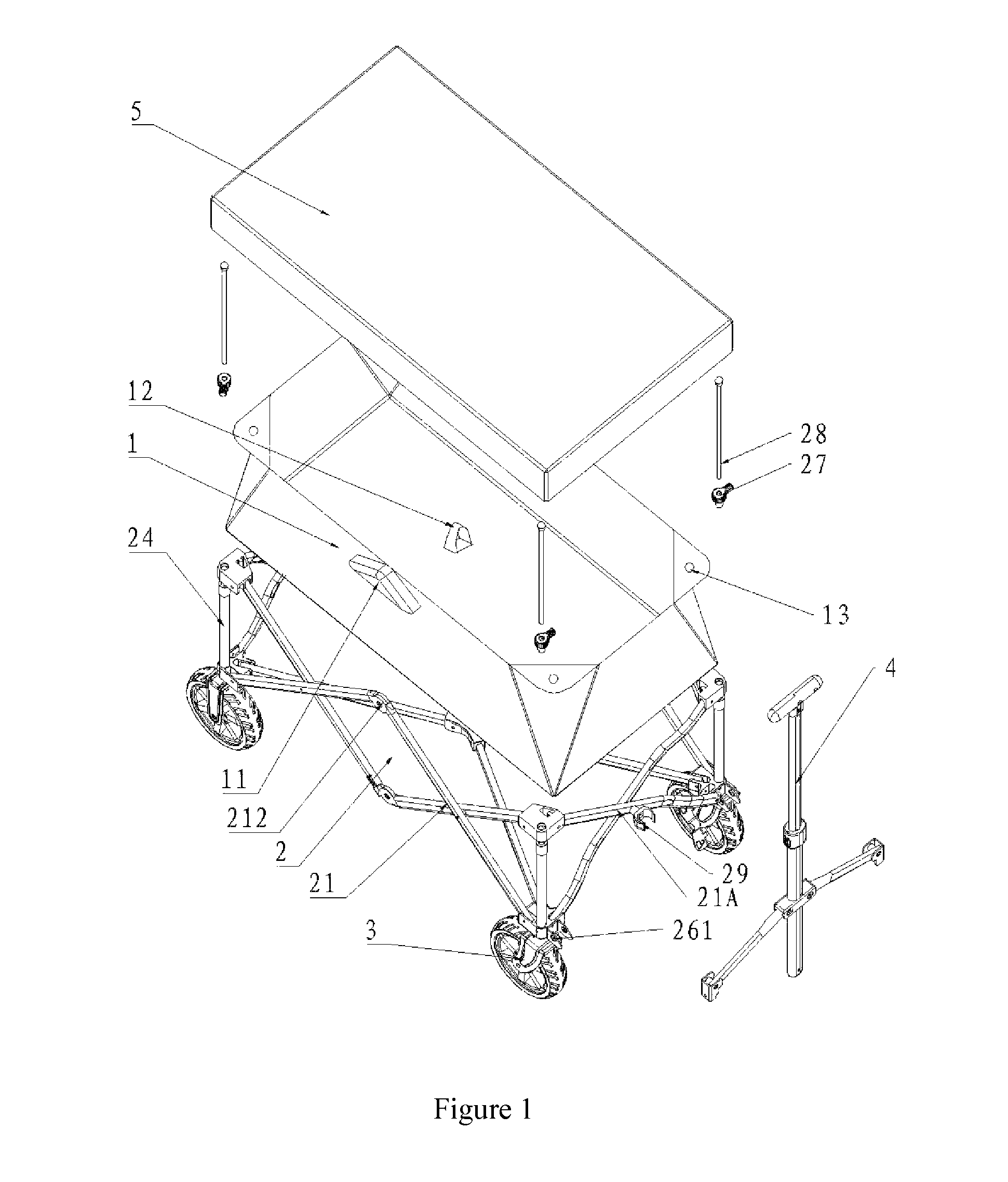

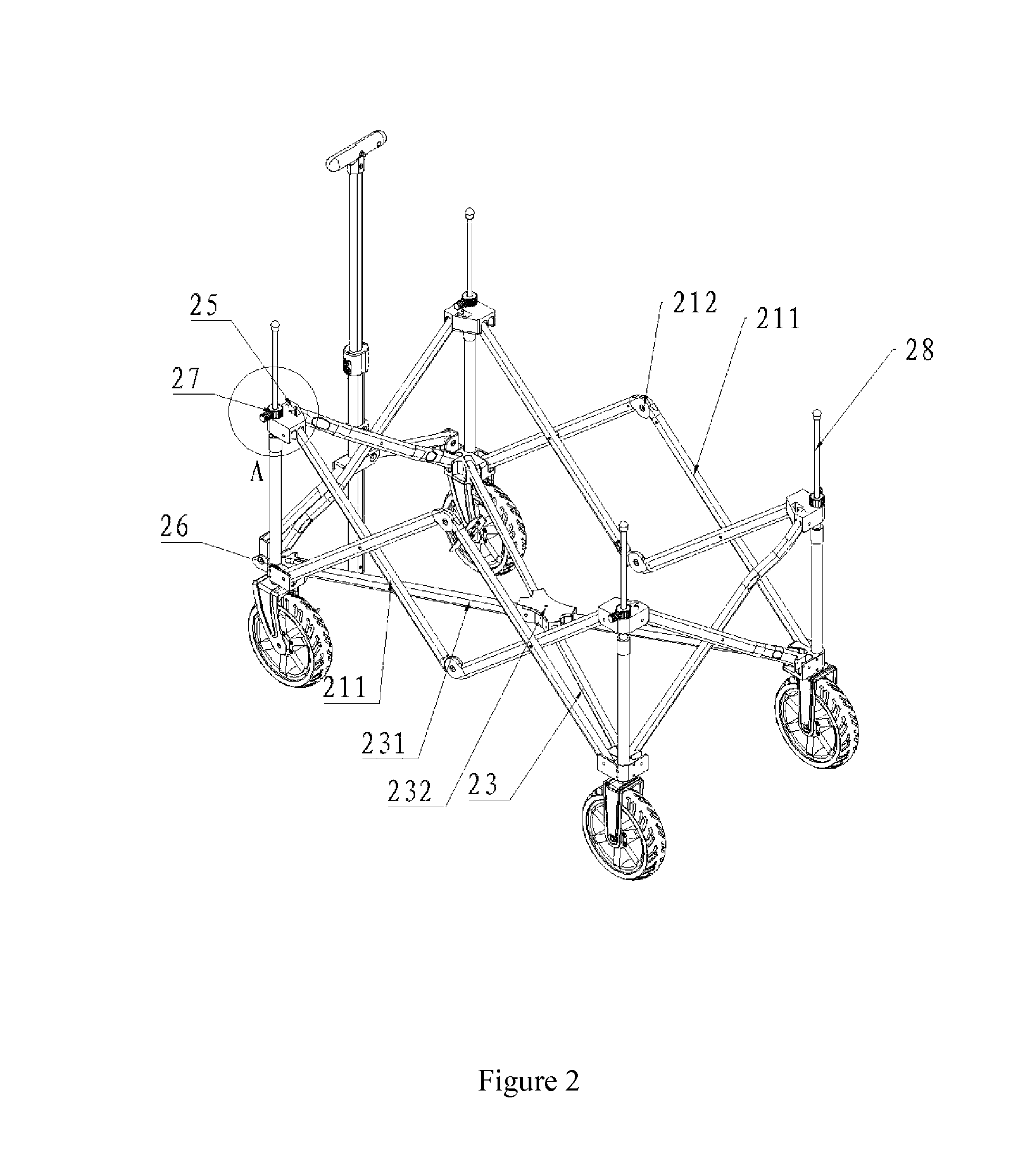

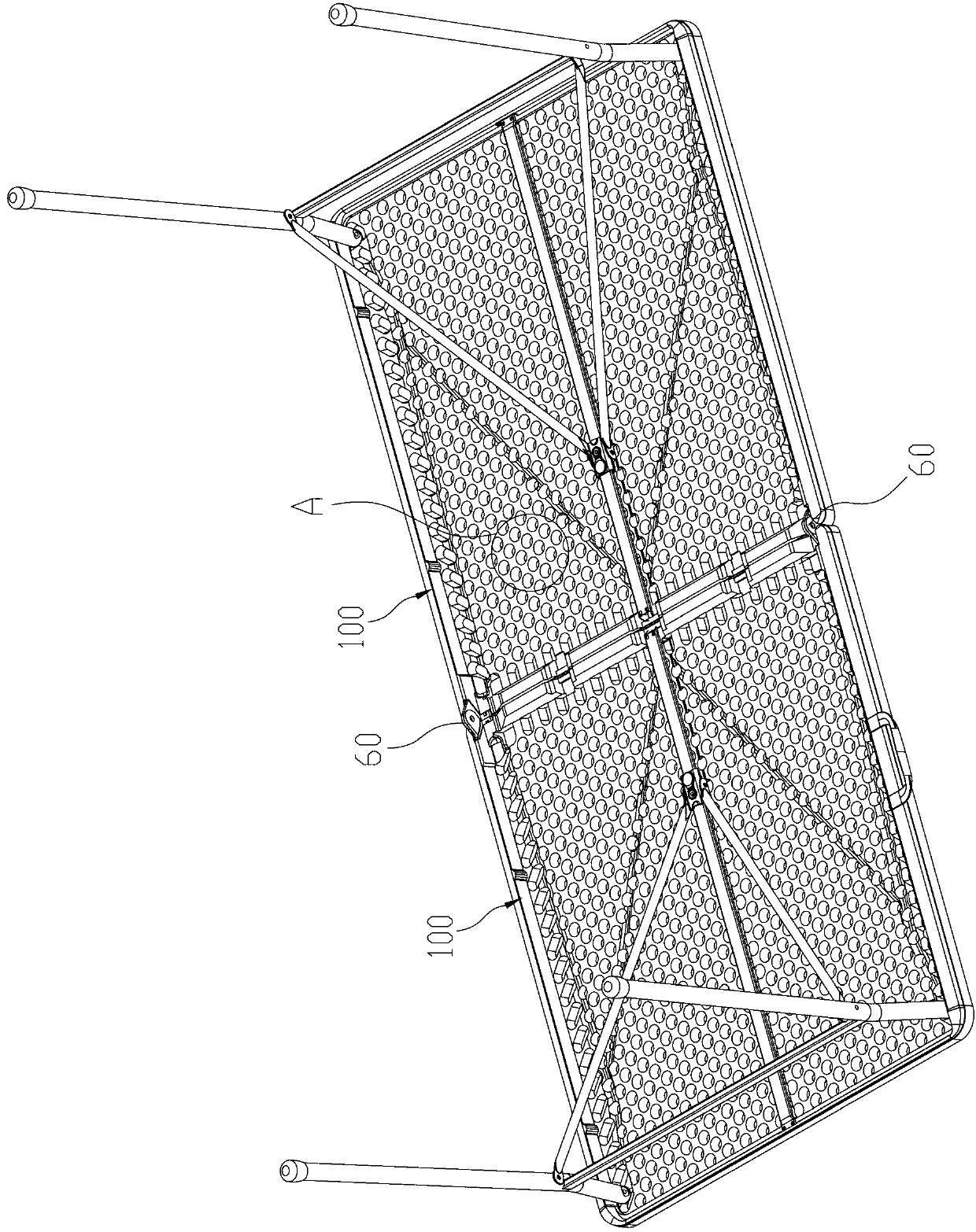

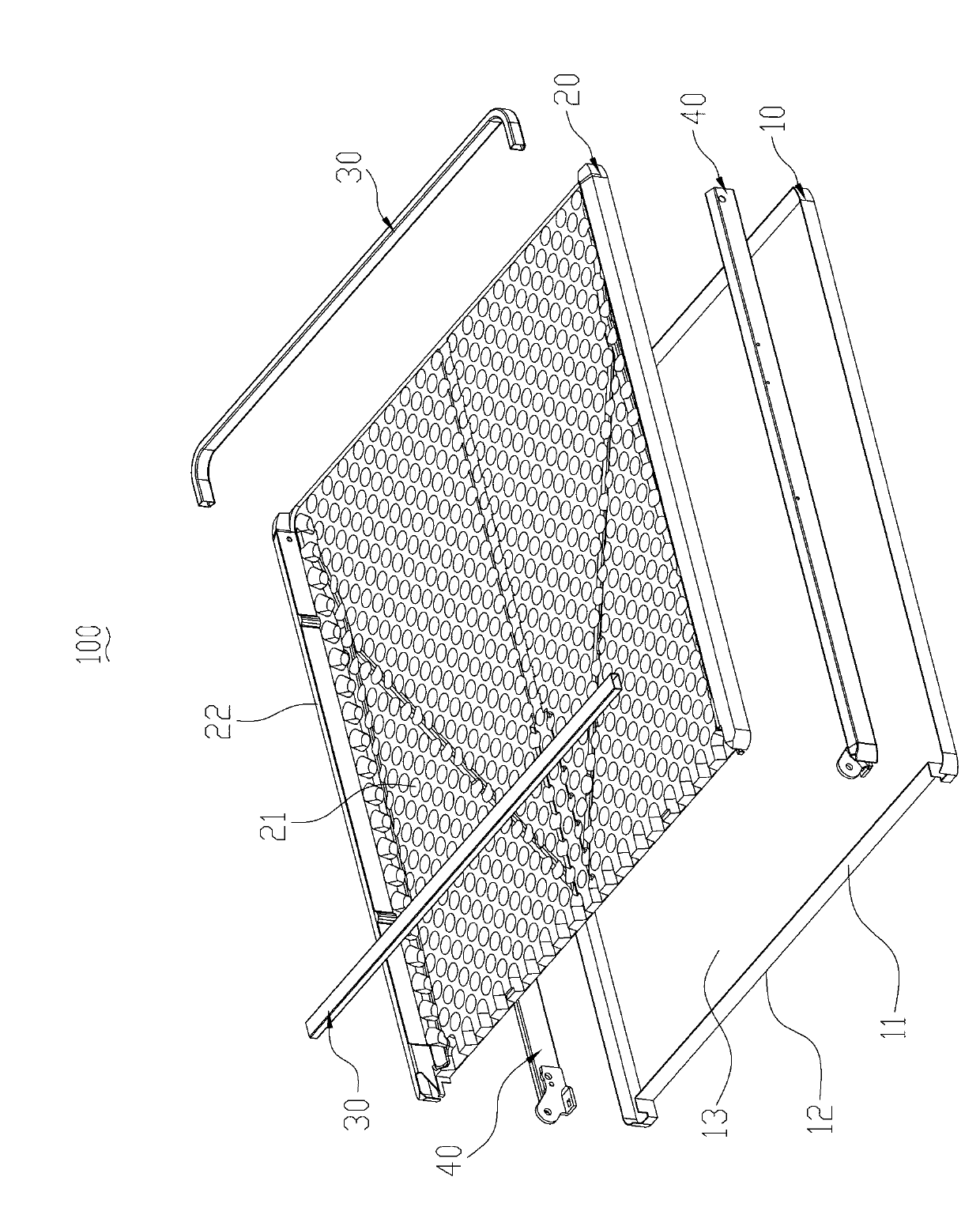

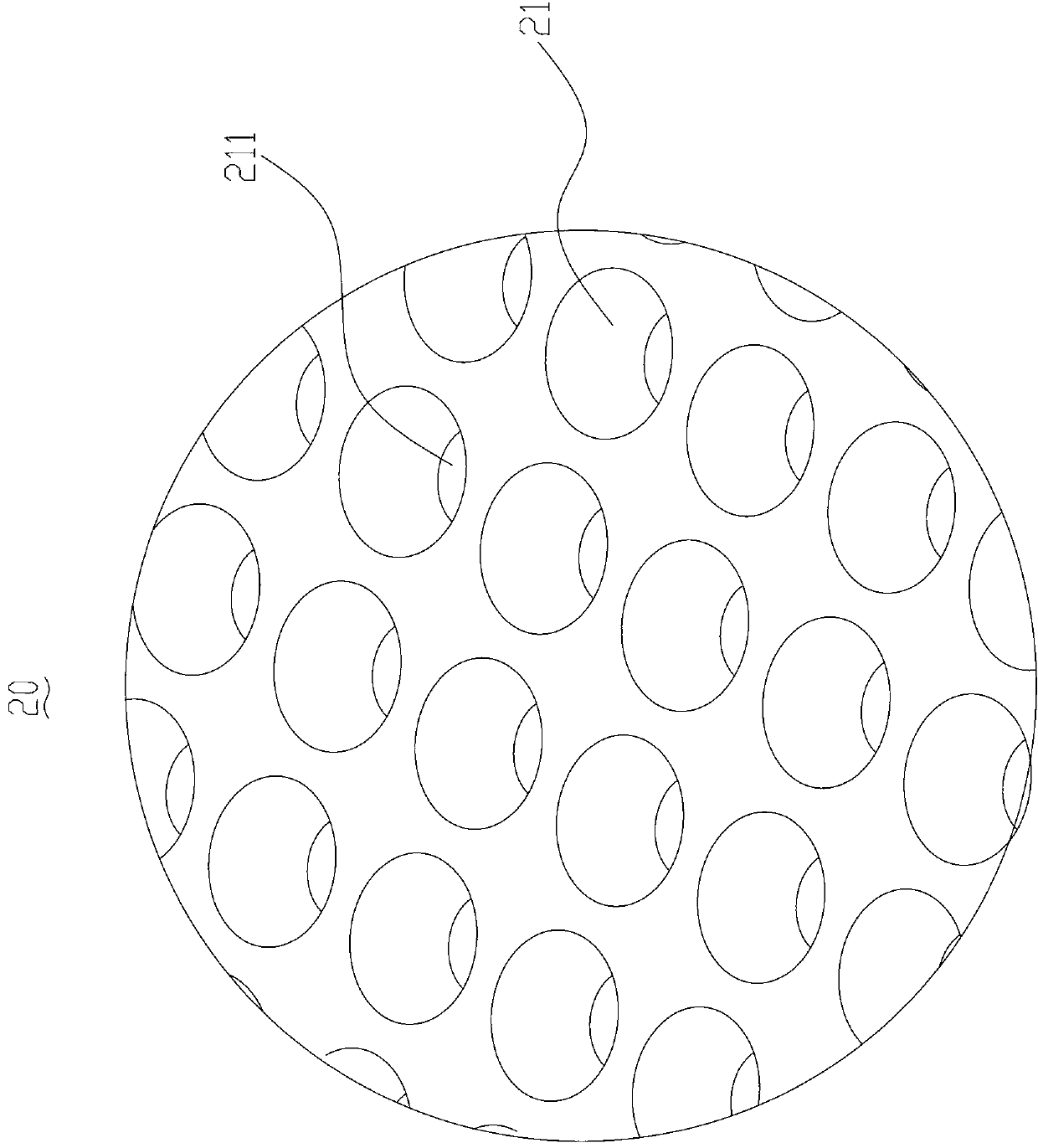

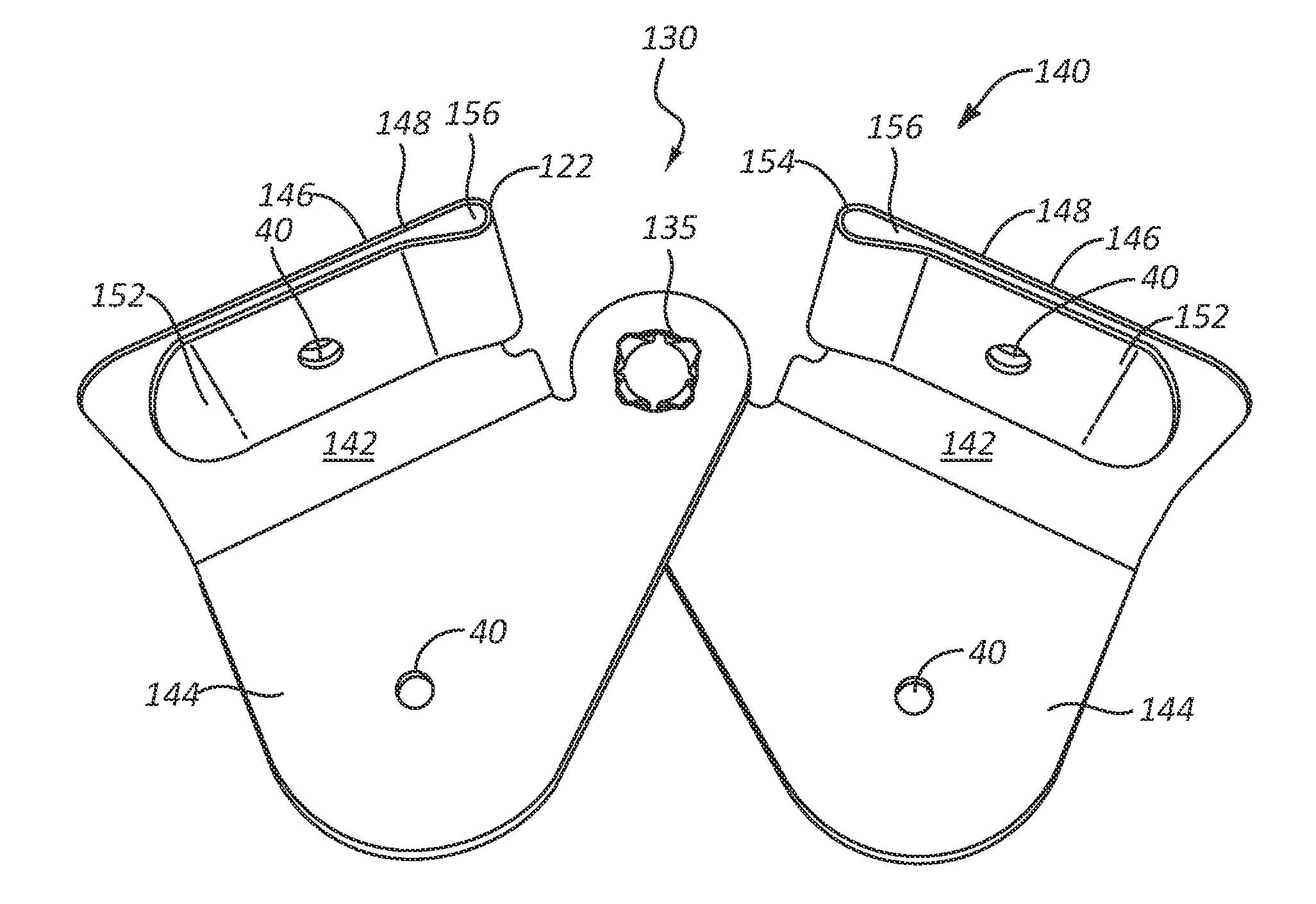

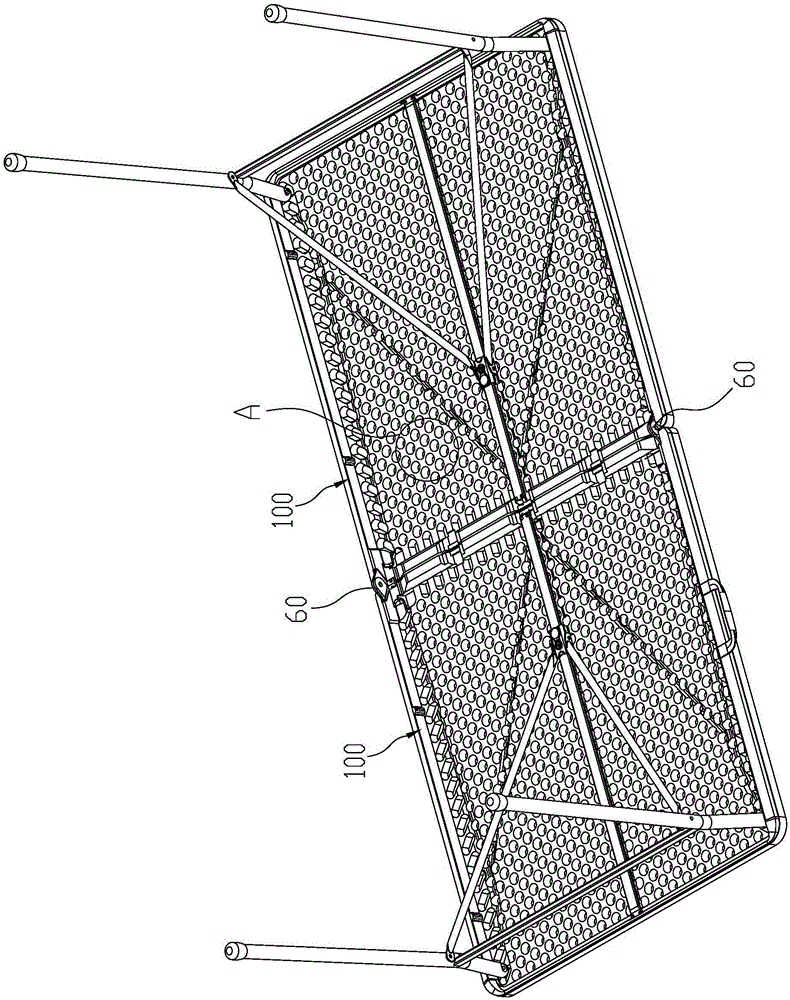

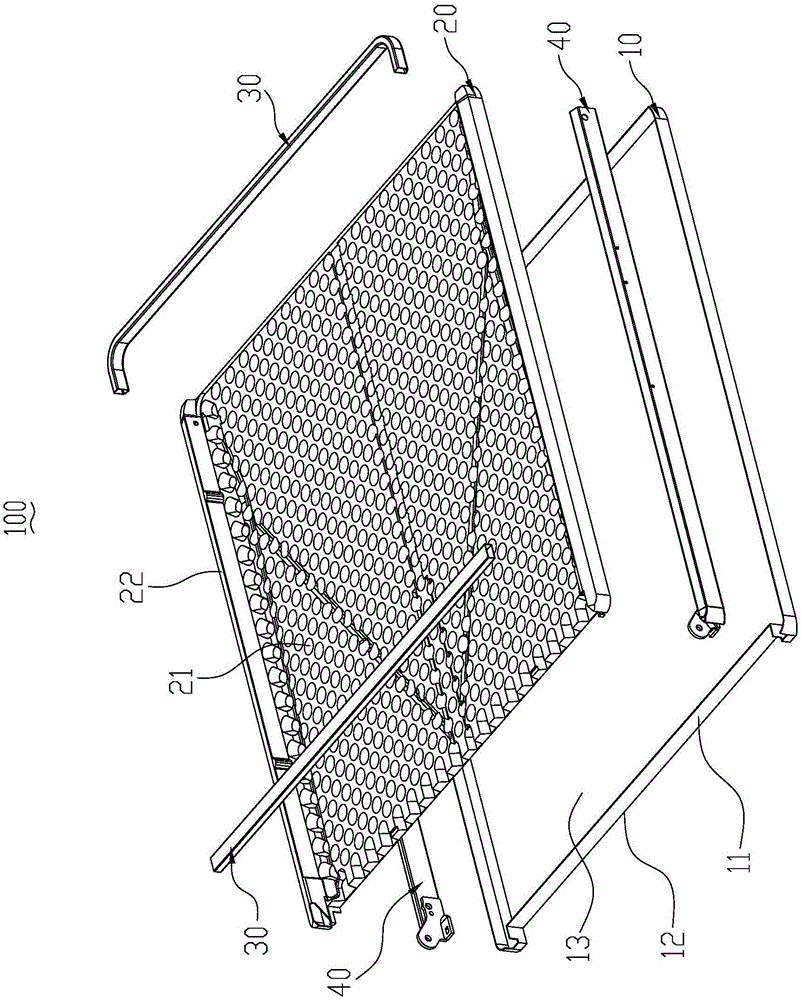

Folding trolley

InactiveUS20150151771A1Increase edge strengthLarge load capacityCarriage/perambulator accessoriesHand carts with one axisEngineeringFuselage

A folding trolley includes a folding trolley frame and a storage pocket. Said trolley frame includes side brackets and a bottom support bracket; said side bracket comprises two cross connecting rods hinged at the central point; said bottom support bracket includes bottom support rods and a central hinged seat. the side bracket is a multi-stage connecting rod structure, including at least two pairs of corresponding hinged connecting rods; the ends of the connecting rods are hinged to form pocket support ends; said storage pocket is provide with downward openings; a pulling member corresponding to the location of said central hinged seat and used for folding the trolley body is provided at the interior bottom of said storage pocket. The trolley can realize convenient fold of the whole body, increase edge strength of the storage pocket, and ease using operation for different users, and has stable structure and larger loading capacity.

Owner:JIN XUGANG

Folding trolley

InactiveUS9056621B1Convenient and easy foldImprove edge strengthHand carts with multiple axesHand cart accessoriesWhole bodyEdge strength

A folding trolley includes a folding trolley frame and a storage pocket. Said trolley frame includes side brackets and a bottom support bracket; said side bracket comprises two cross connecting rods hinged at the central point; said bottom support bracket includes bottom support rods and a central hinged seat. the side bracket is a multi-stage connecting rod structure, including at least two pairs of corresponding hinged connecting rods; the ends of the connecting rods are hinged to form pocket support ends; said storage pocket is provide with downward openings; a pulling member corresponding to the location of said central hinged seat and used for folding the trolley body is provided at the interior bottom of said storage pocket. The trolley can realize convenient fold of the whole body, increase edge strength of the storage pocket, and ease using operation for different users, and has stable structure and larger loading capacity.

Owner:JIN XUGANG

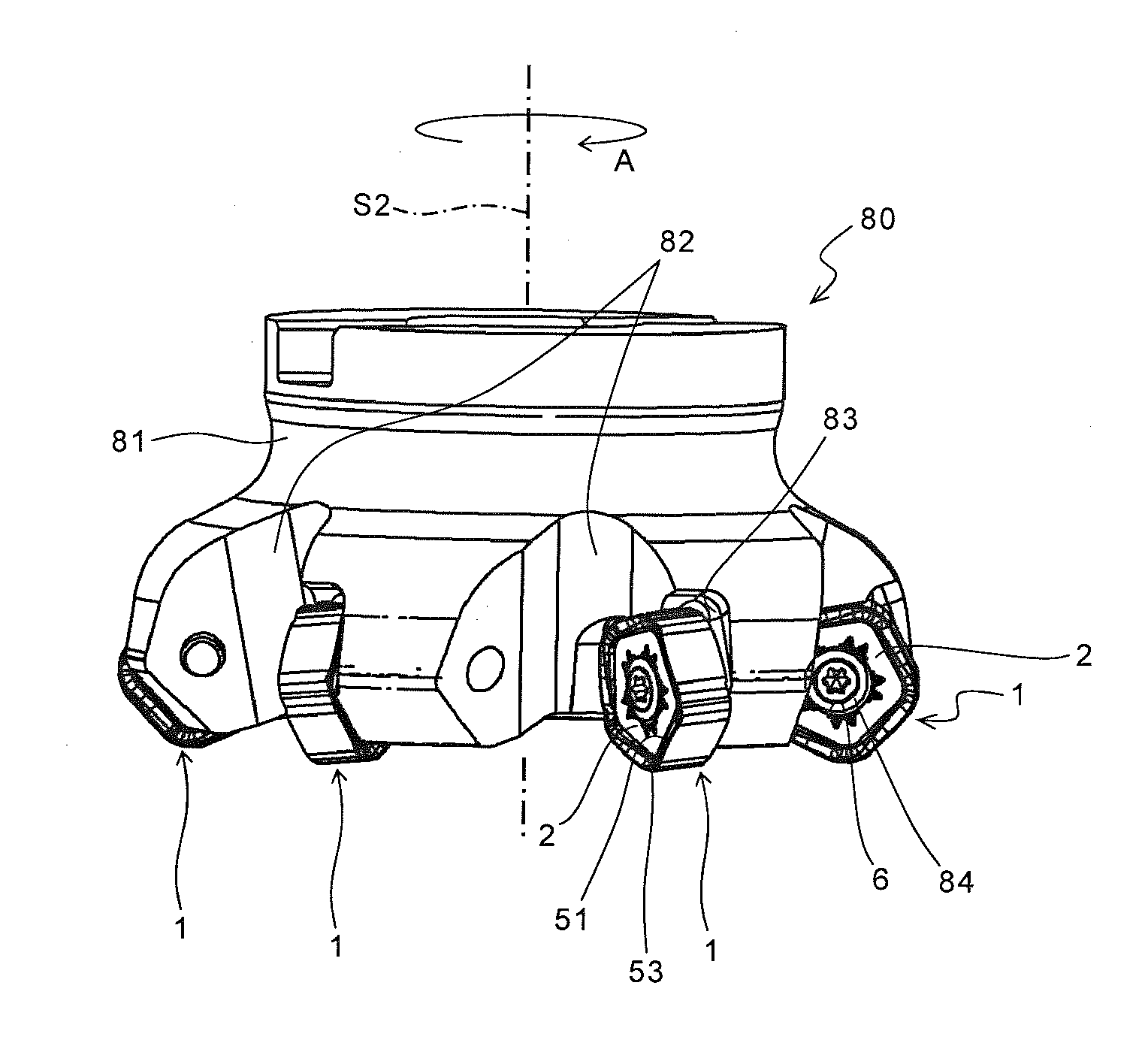

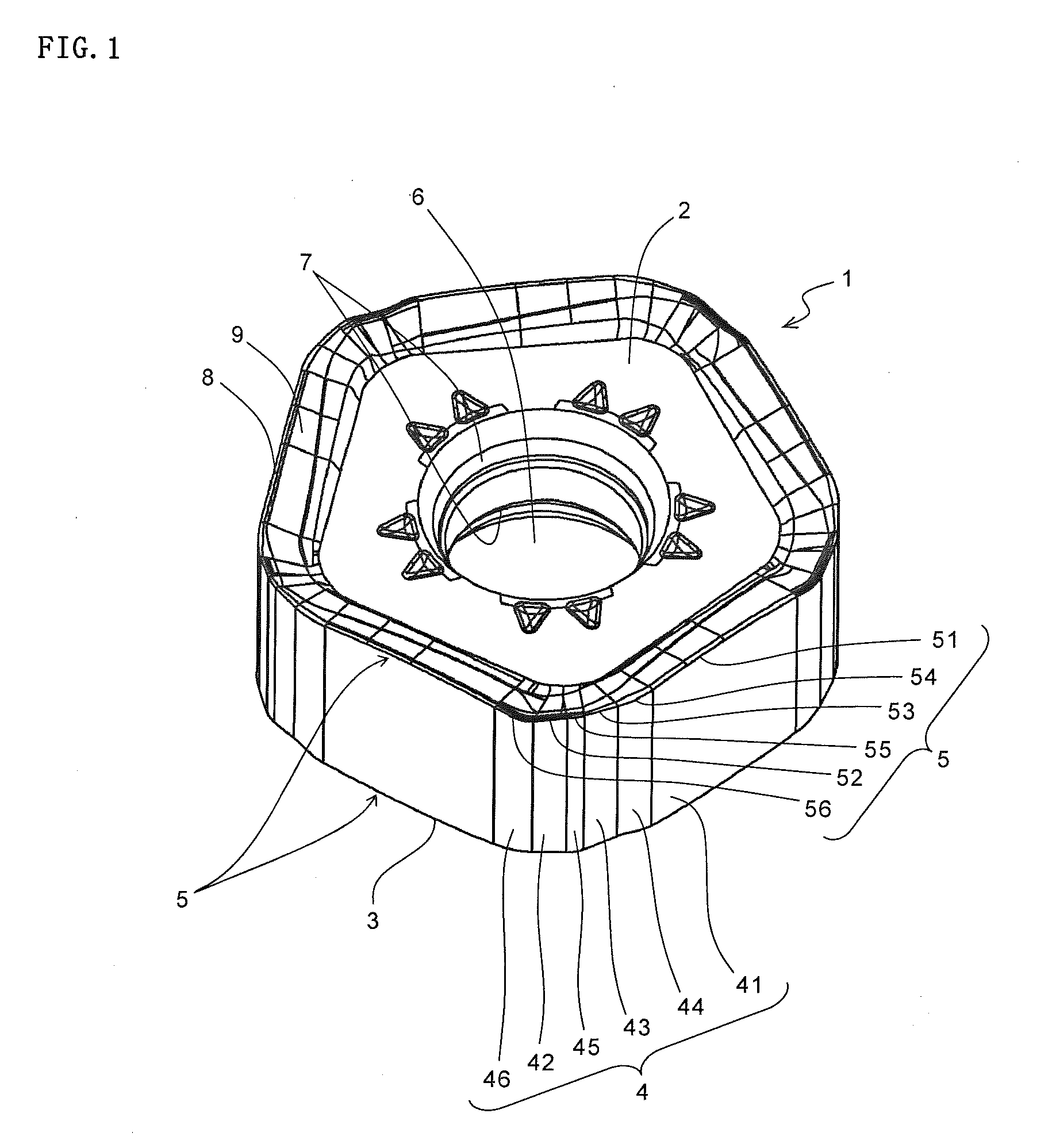

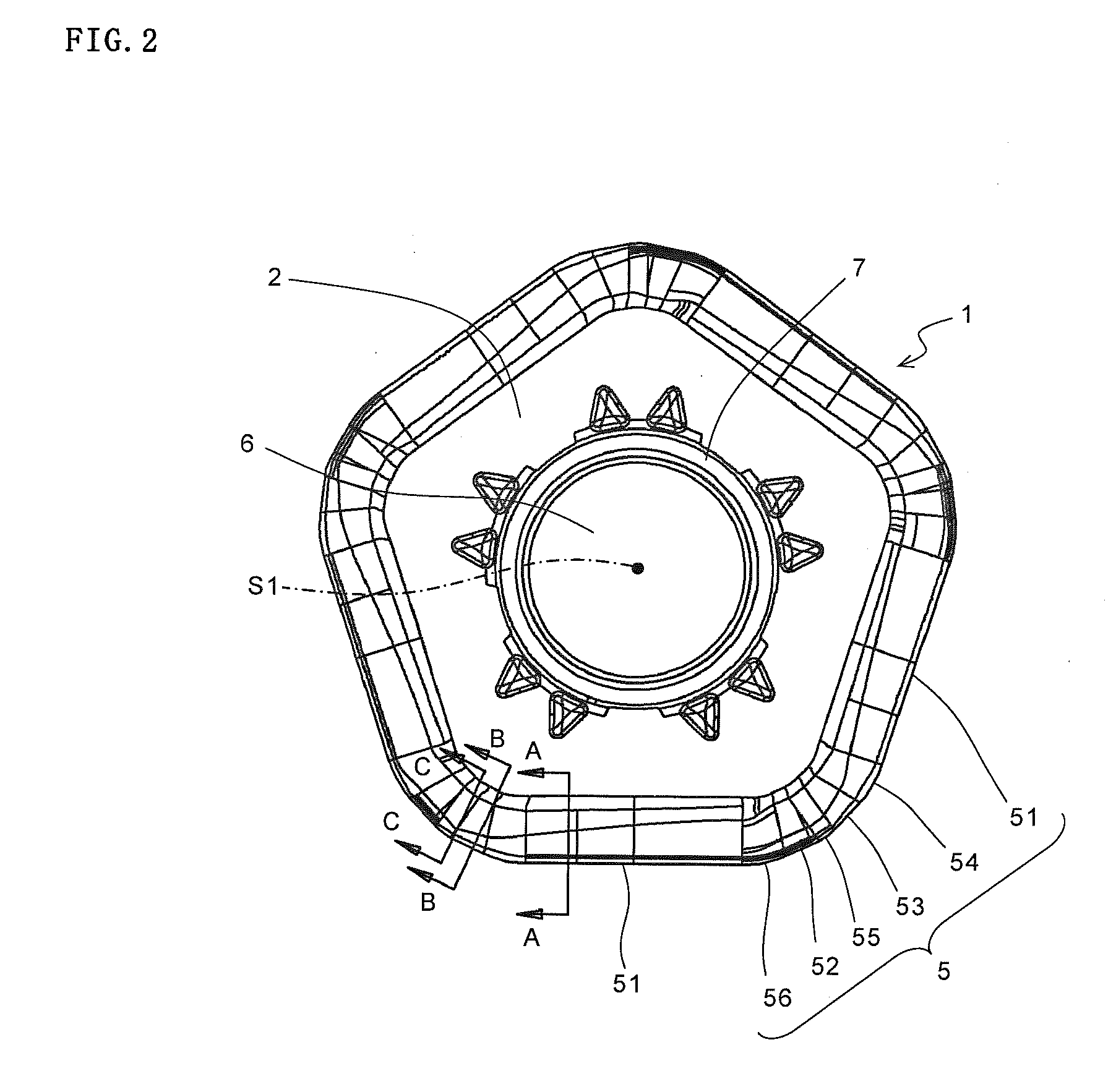

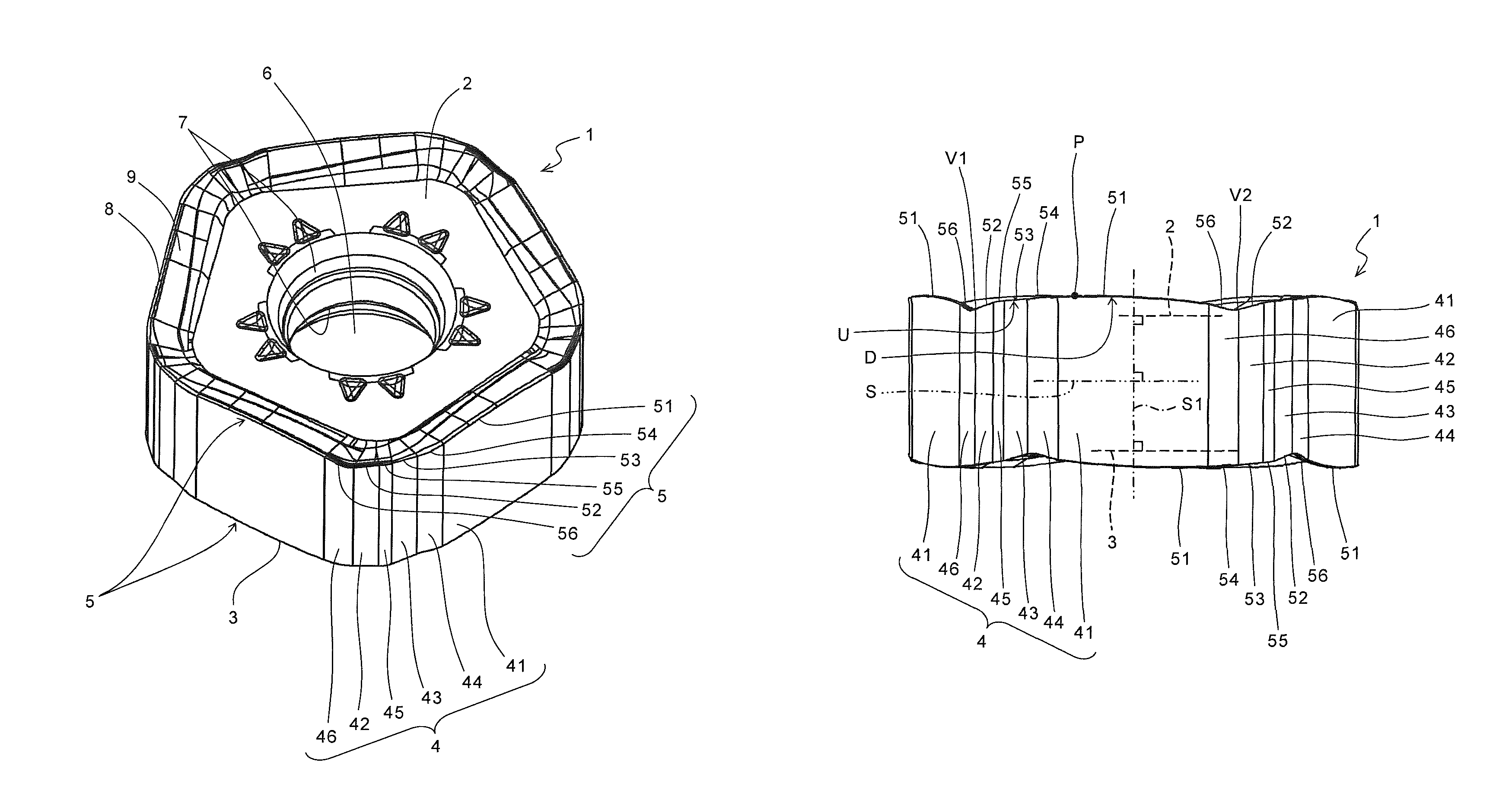

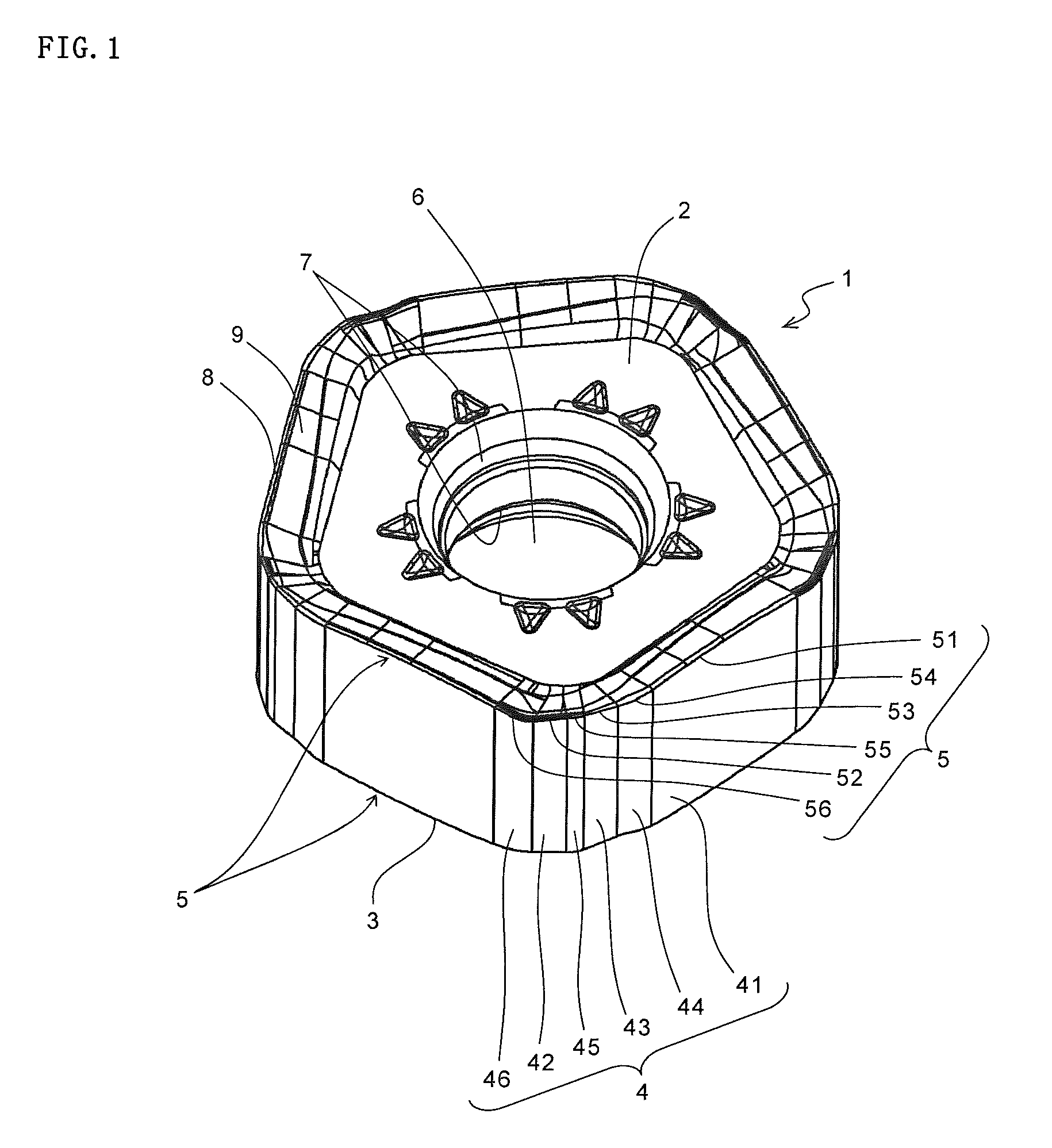

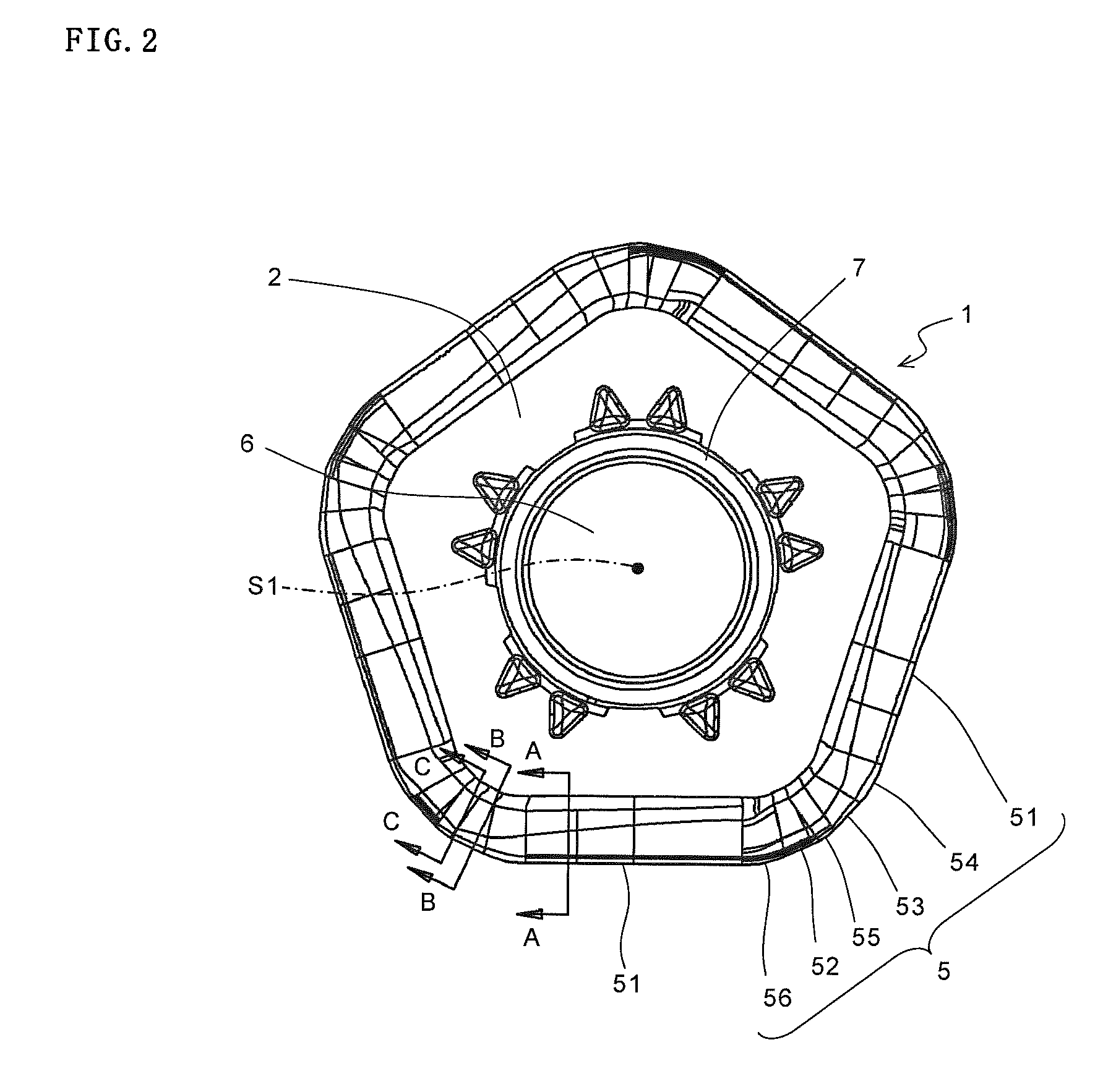

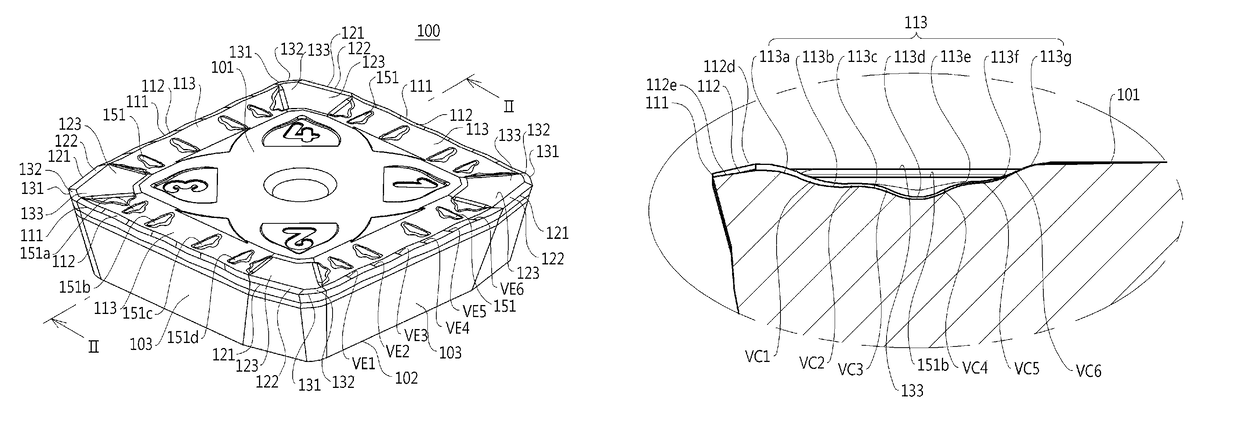

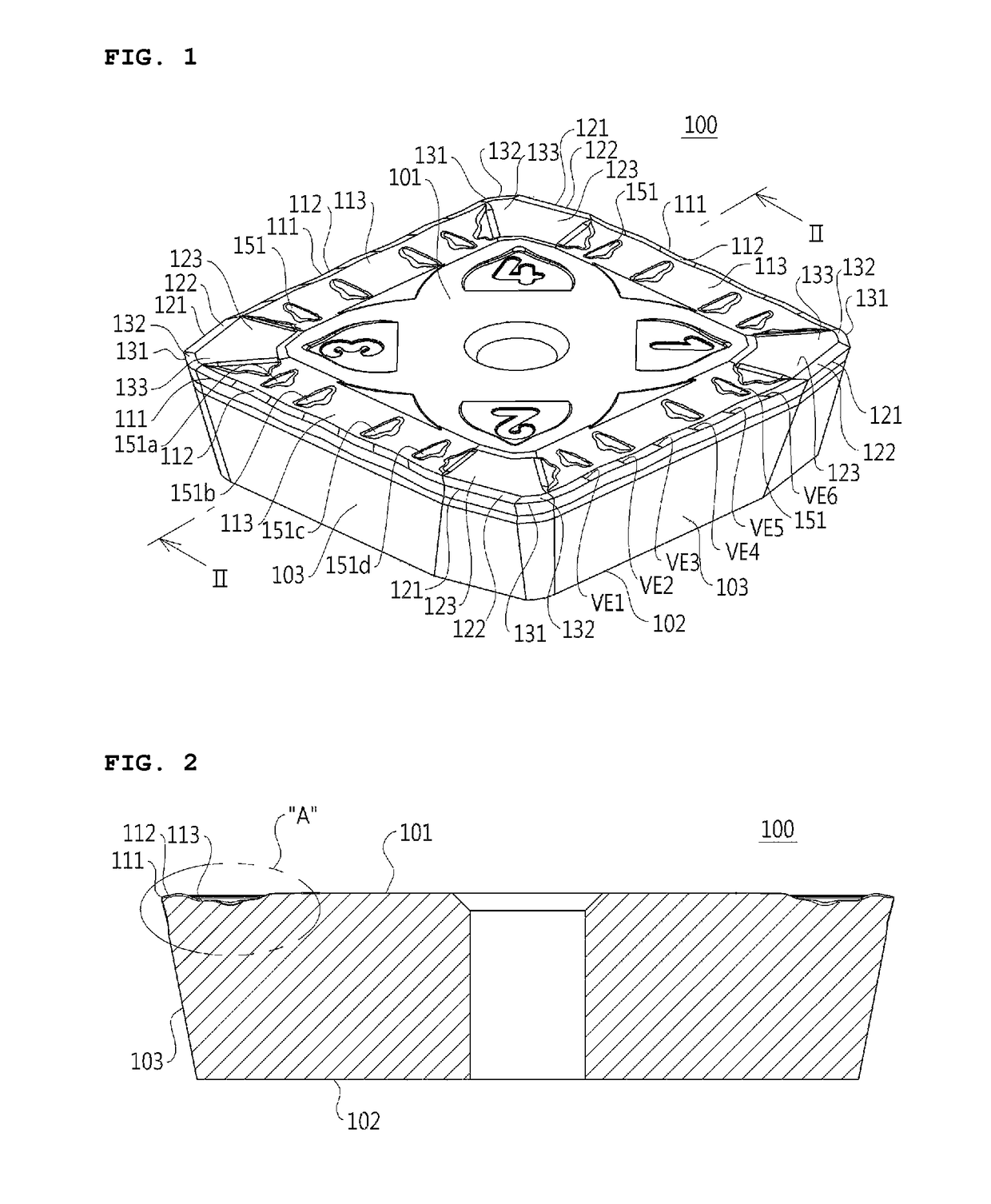

Cutting insert, cutting tool, and method of manufacturing machined product using the same

ActiveUS20120189396A1Improving cutting edge strengthReduce cutting resistanceMilling cuttersTurning toolsKnife bladesReference plane

A cutting insert according to an embodiment of the present invention includes an upper surface; a lower surface; a side surface; and a cutting edge which is located in an intersection region of the upper surface and the side surface, and includes a major cutting edge, a flat cutting edge, and a minor cutting edge located between the major cutting edge and the flat cutting edge. The cutting edge reaches a top portion thereof while being inclined upward from the flat cutting edge to the major cutting edge with respect to a reference plane perpendicular to a central axis of the cutting insert in a side view. The cutting edge is thereafter inclined downward with respect to the reference plane. A peripheral cutting edge angle of the minor cutting edge is larger than a peripheral cutting edge angle of the major cutting edge. A cutting tool including the cutting insert; and a method of manufacturing a machined product using the cutting tool are provided.

Owner:KYOCERA CORP

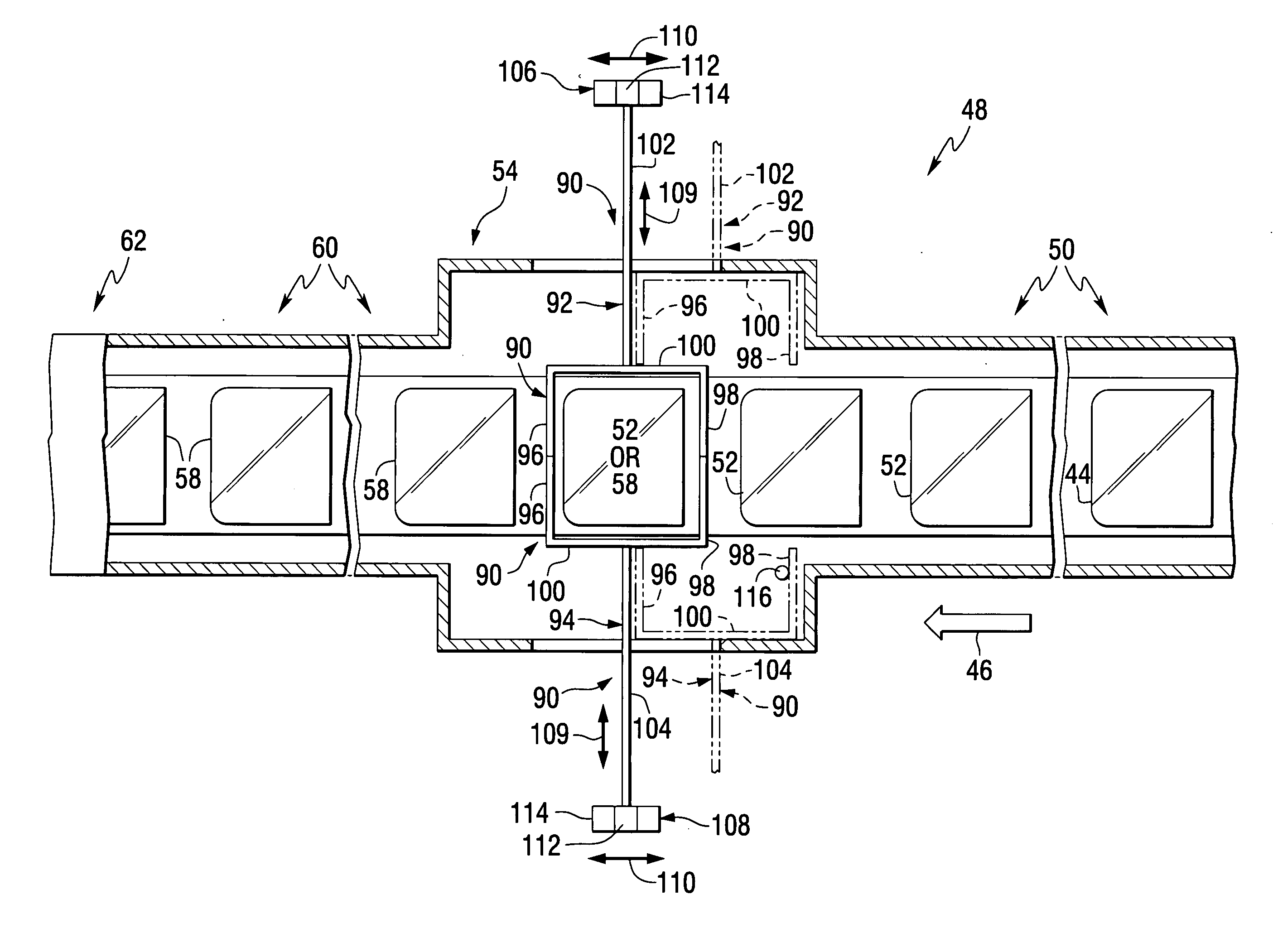

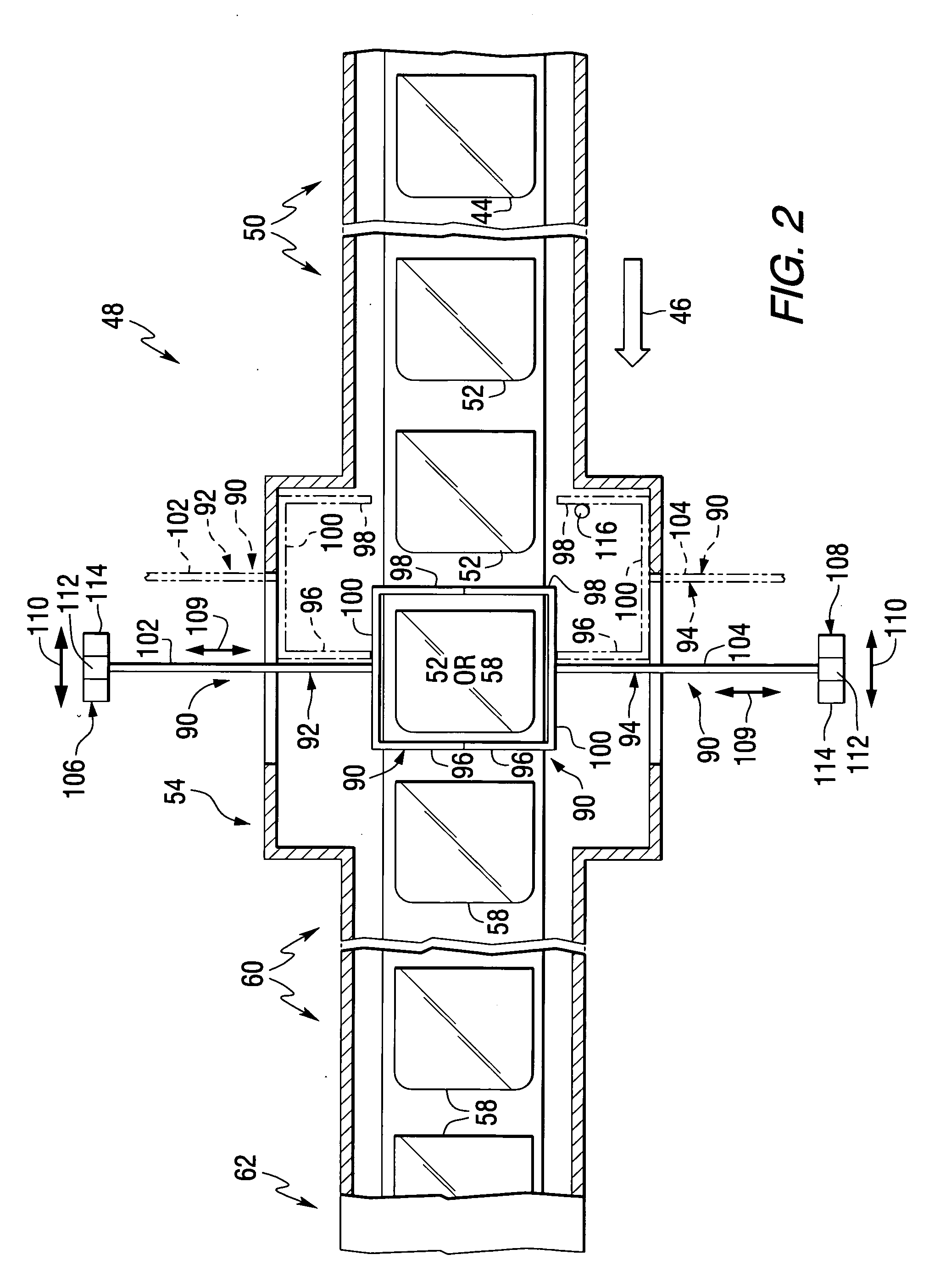

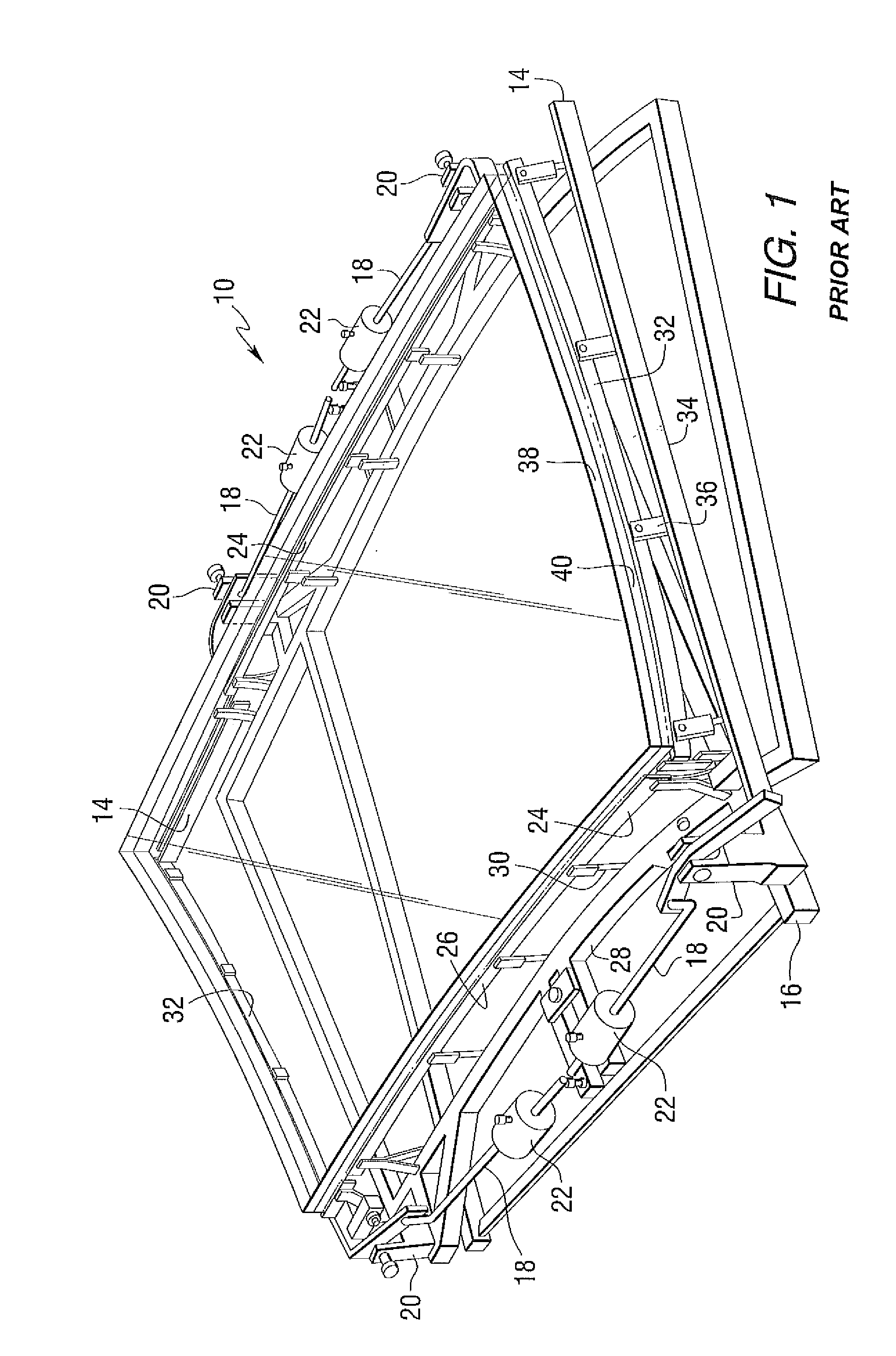

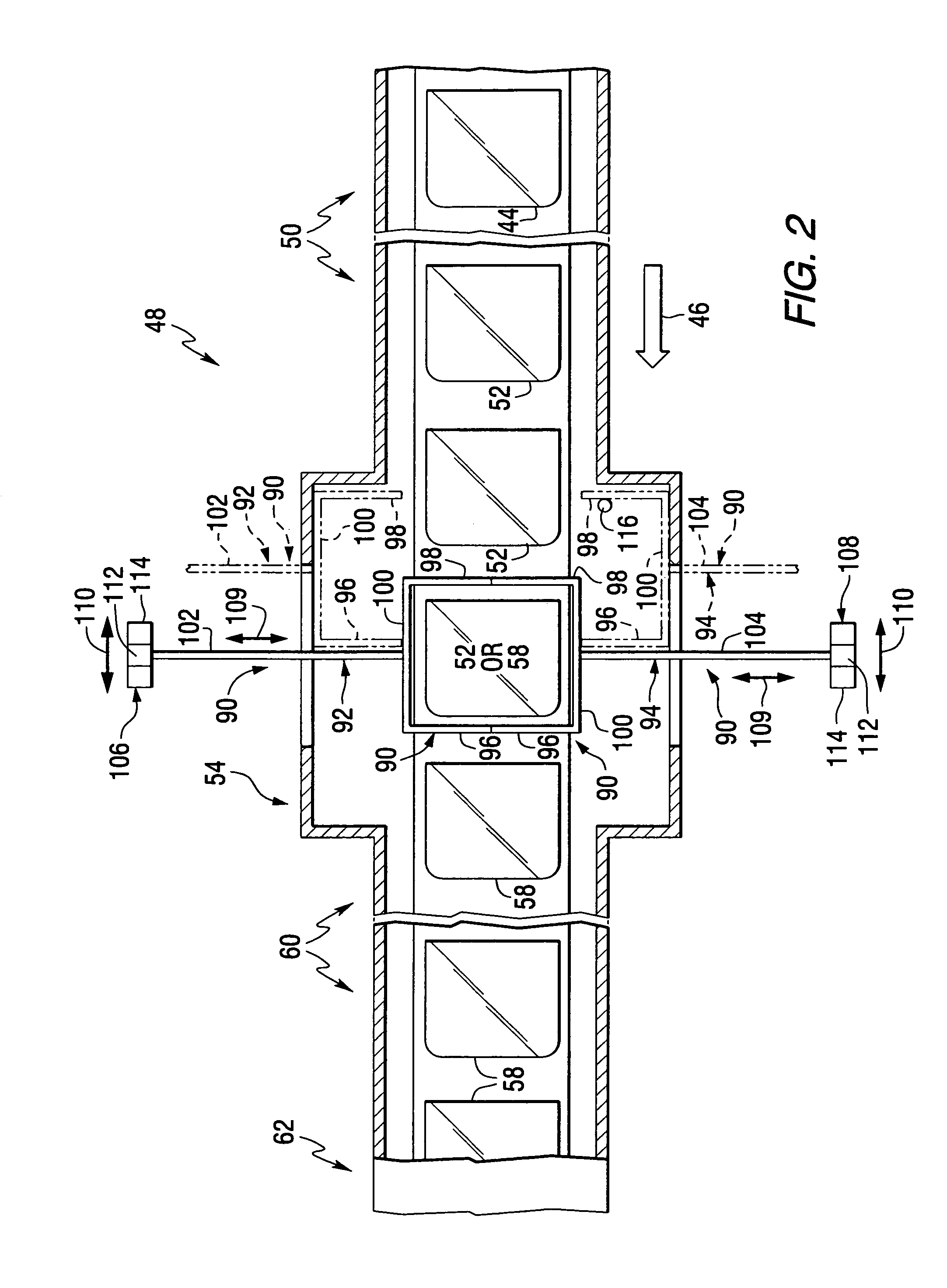

Method of and apparatus for strengthening edges of one or more glass sheets

ActiveUS20050166639A1Avoid fracturesImprove edge strengthCellulosic plastic layered productsGlass/slag layered productsGlass sheetMechanical engineering

A furnace includes a section defined as a heating section capable of attaining a predetermined temperature, the heating section having an entrance end and an exit end; a section defined as a cooling section capable of having a temperature gradient from entrance end of the cooling section to exit end of the cooling section, the entrance end of the cooling section mounted in a fixed relationship to the exit end of the heating section; a section defined as an edge cooling section between the exit end of the heating section and the entrance end of the cooling section; and an edge cooling device positioned in the edge cooling section relative to a predetermined area, and capable of cooling at least selected peripheral portions of the predetermined area at a faster rate than center portions of the predetermined area.

Owner:PITTSBURGH GLASS WORKS

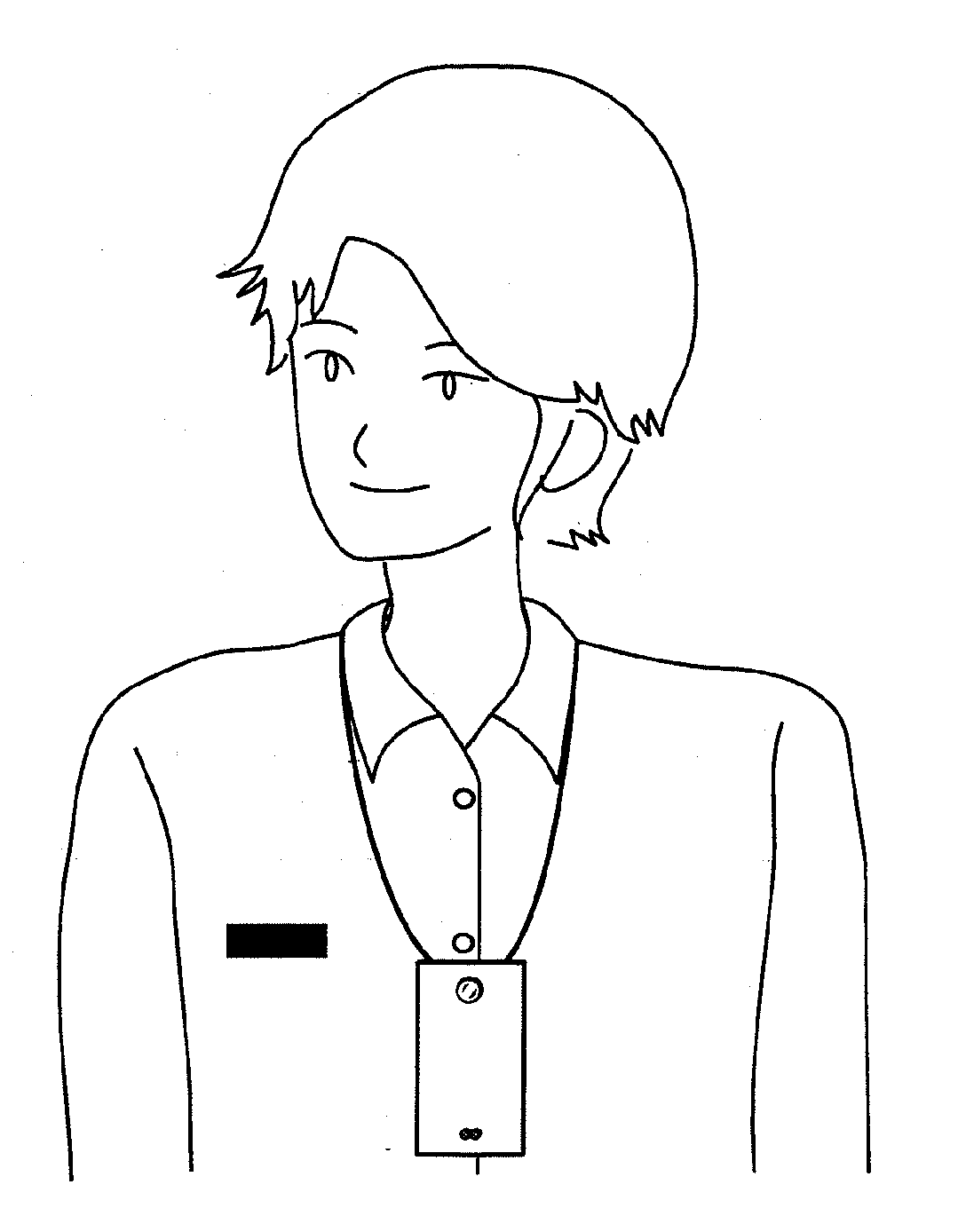

Image processing device, image processing method, image processing program, recording medium with image processing program recorded therein, and image processing processor

ActiveUS20100172598A1Improve edge strengthAccurate estimateImage enhancementTelevision system detailsImage basedImaging equipment

When an image is captured by an imaging apparatus such as a wearable terminal that is not on the premise that the image is captured in an upright state, it is not possible to estimate objects included in the captured image is like in order to correct a tilt of the captured image. Therefore, in some cases, a tilt angle of the captured image is possibly estimated based on one or more areas which are not suitable for estimating the tilt angle of the captured image, and the captured image is corrected based on the tilt angle incorrectly estimated. This deteriorates the quality of the captured image even worse.An image processing device pertaining to the present invention divides the captured image into a plurality of areas, determines a directional characteristic shown by a texture of each of the divided areas, and estimates the tilt angle of the captured image based on one or more areas whose textures have the unidirectional characteristic so as to correct the captured image with use of the estimated tilt angle.

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA +1

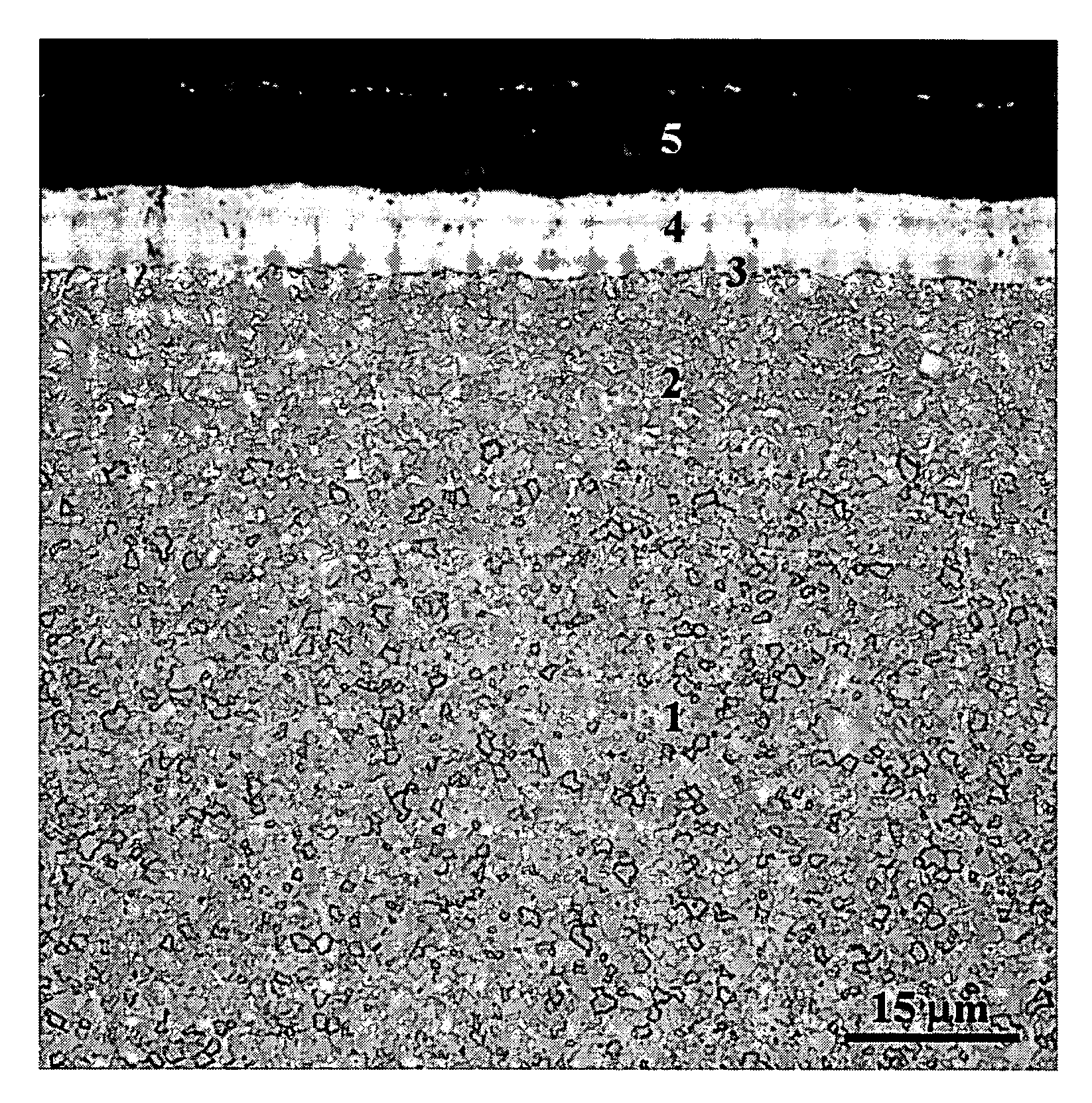

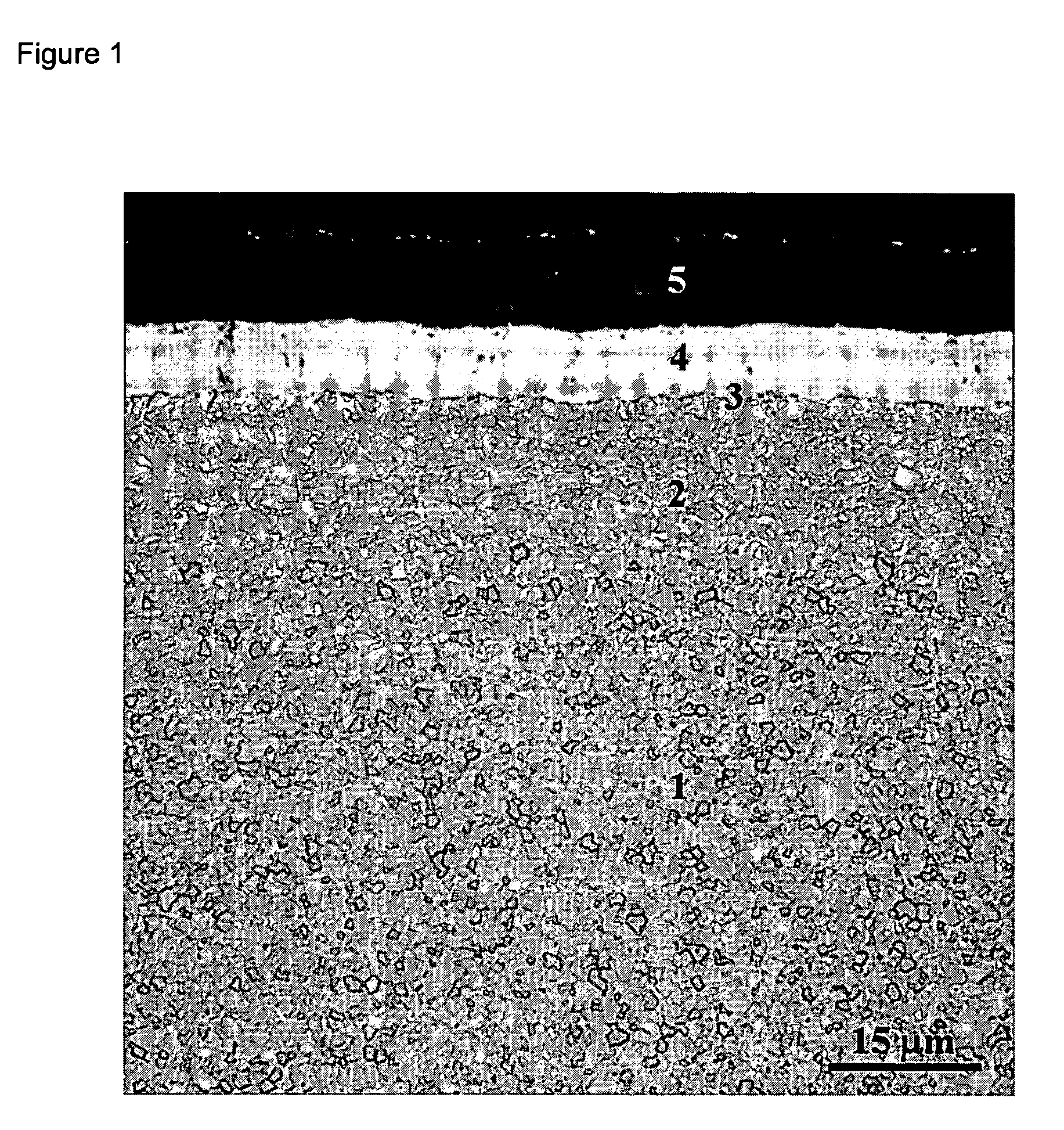

Coated cutting tool insert

InactiveUS7097901B2Improve performanceImprove edge strengthPigmenting treatmentOther chemical processesAlloyCemented carbide

The present invention relates to a coated cemented carbide cutting tool insert particularly useful for turning of cast irons but also low alloyed steels at mediate to high cutting speeds. The cutting tool insert is characterised by a cemented carbide body comprising WC, cubic carbonitrides, a W-alloyed Co binder phase, a surface zone of the cemented carbide body that is binder phase enriched and nearly free of cubic carbonitride phase, and a coating including an innermost layer of TiCxNyOz with equiaxed grains, a layer of TiCxNyOz with columnar grains and at least one layer of Al2O3.

Owner:SECO TOOLS AB

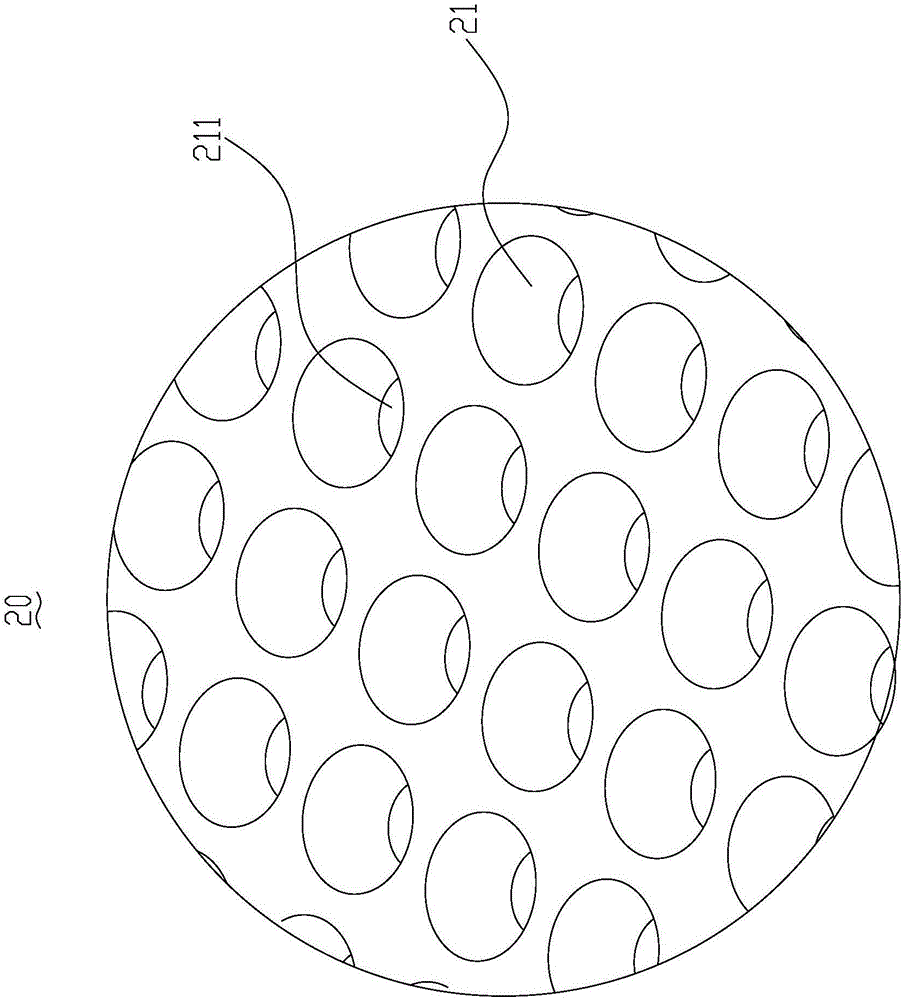

Table panel

InactiveCN103284471AImprove stress resistanceHigh strengthLayered productsFoldable tablesEngineeringSurface plate

Owner:NEW TEC INTEGRATION (XIAMEN) CO LTD

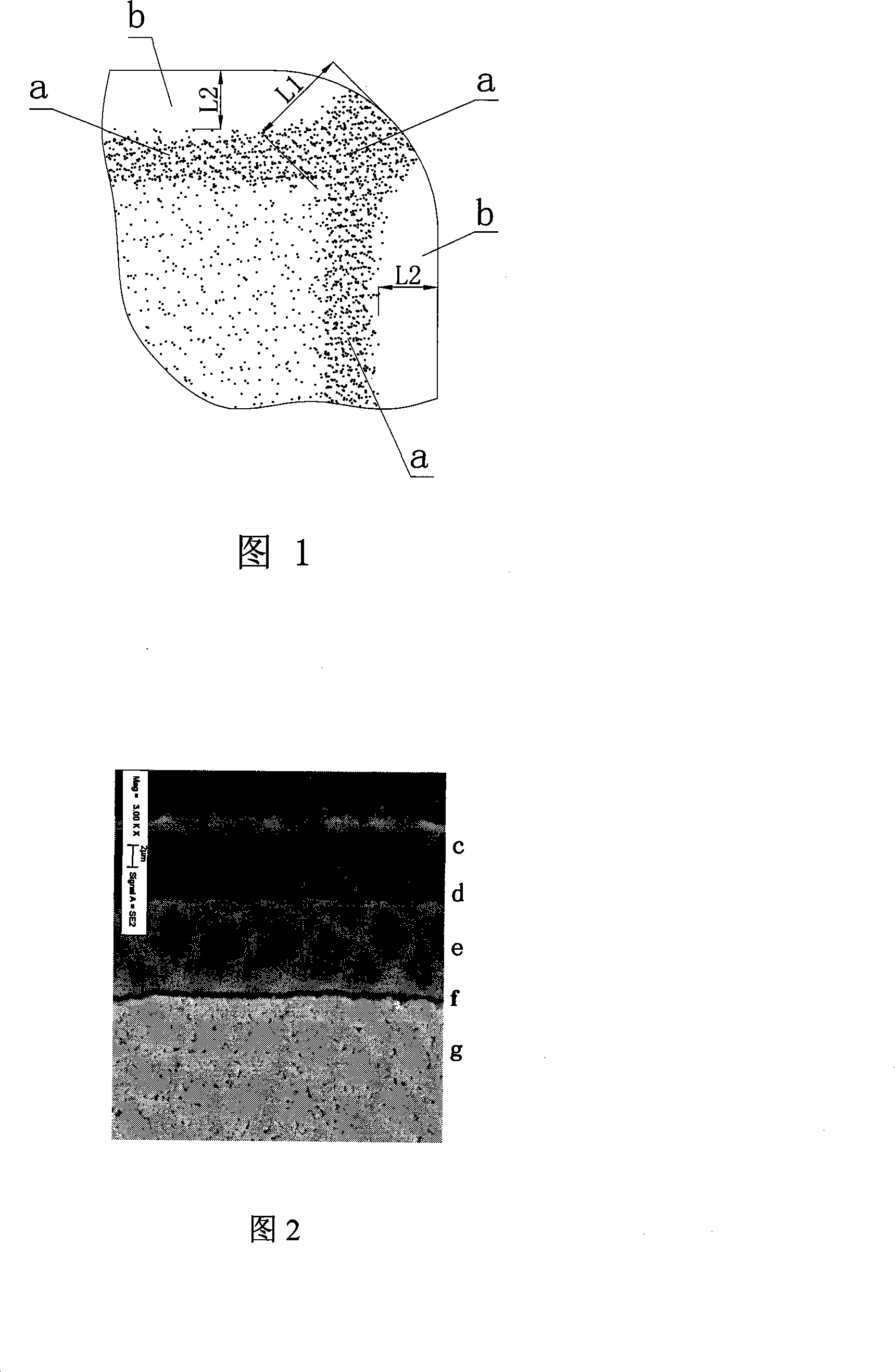

Coating blade for processing cast iron

ActiveCN101214743ADecreased strength and toughnessStrong enoughLayered productsAlloyCemented carbide

The invention discloses a coated tip used to processing cast iron, which comprises a hard alloy basal body and a coating. The invention is characterized in that the hard alloy basal body comprises 2 percent to 12 percent of cobalt by weight and 0.2 percent to 3.5 percent of cubic-structure compound of metallic elements from the families of IVb, Vb and / or VIb in the periodic table by weight. A binding phase surface enrichment area is formed on both sides of the cutting edge of the basal body. The middle pie-slice section of the binding phase surface enrichment area is a cubic structure enrichment area. The coating comprises an innermost layer of equiaxed grain TiCxNyOz, a middle layer of columnar crystal TiCxNy 2 microns to 13 microns thick, a transition layer of TiCxNyOz and an outer layer of fine crystal Alpha-Al2O3 4 microns to 12 microns thick. The tip disclosed by the invention not only has the characteristics of high wearing feature, high strength and high versatility, but also integrates the toughness and the plastic deformation resistance well. Accordingly, the invention is in particular applicable for processing cast iron.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

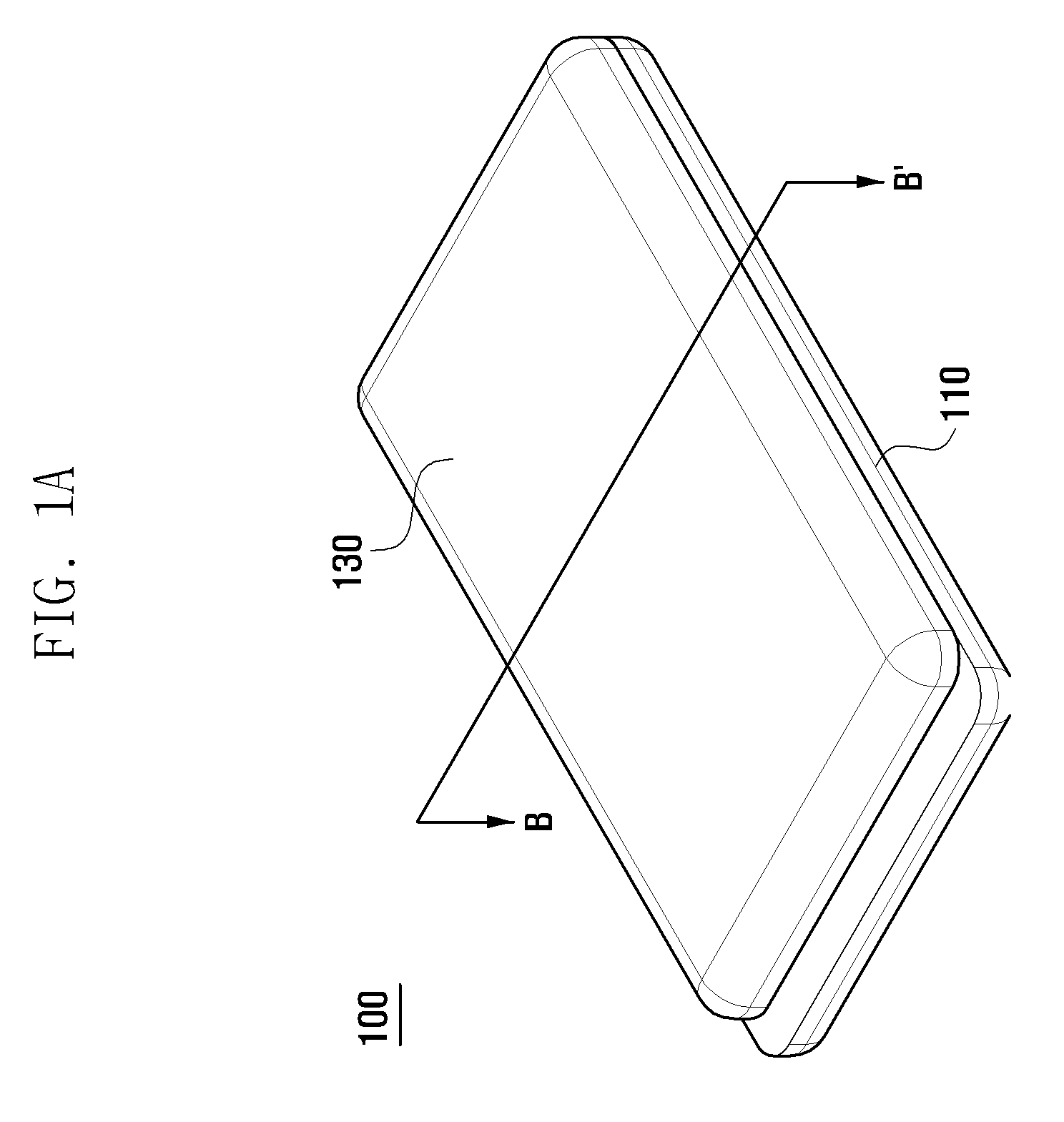

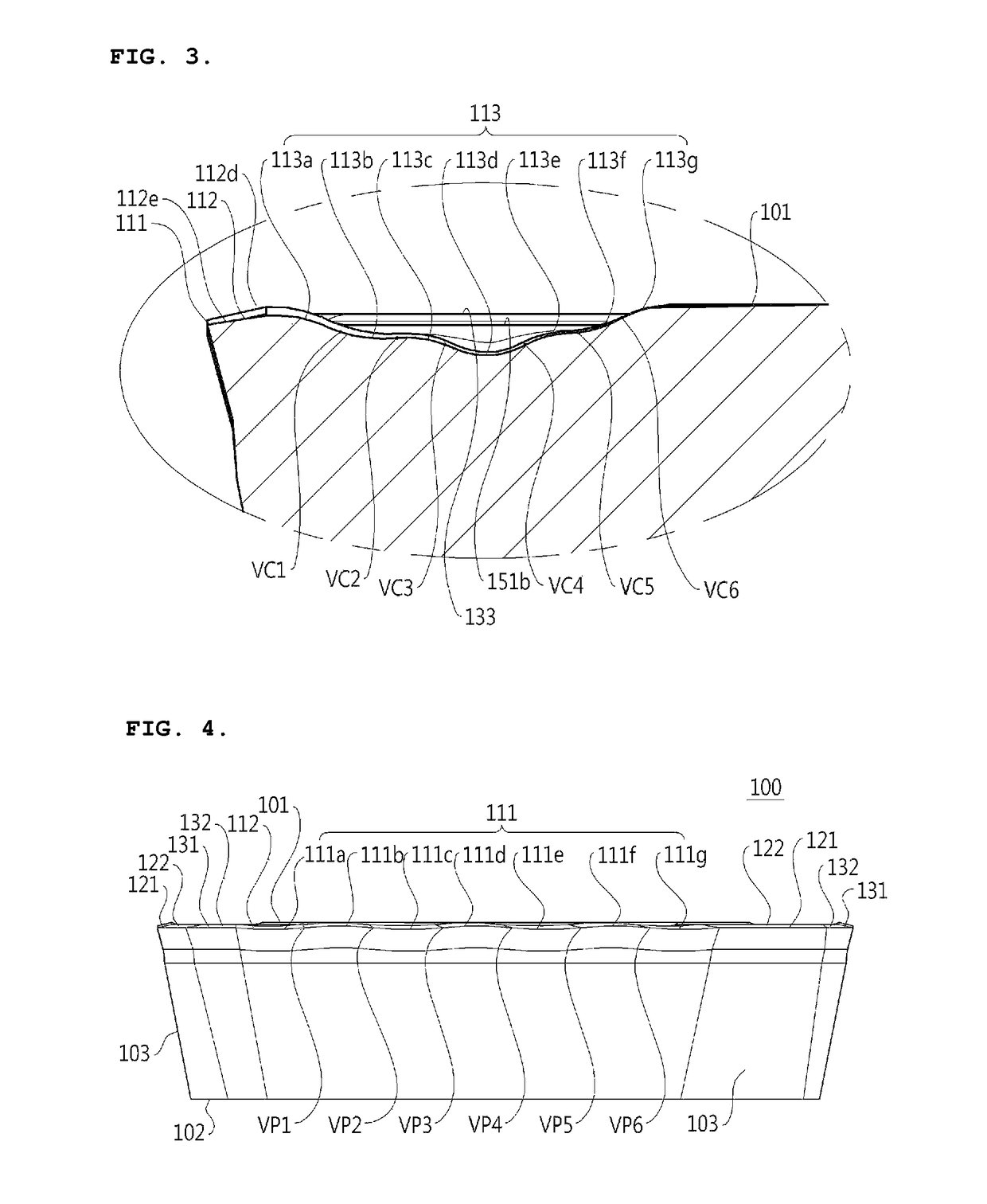

Display panel and method of manufacturing the same

InactiveUS20120075823A1Crack suppressionSuppress transitionWave amplification devicesSolid-state devicesElectrical and Electronics engineeringSurface plate

A display panel and a method of manufacturing the same are provided. The display panel includes a plurality of chip panels, each chip panel having an upper surface, a lower surface disposed parallel to the upper surface, a side surface between the upper surface and the lower surface and a connection portion between the side surface and at least one of the upper surface and the lower surface, the connection portion having a rounded configuration, and an adhesive layer interposed between the chip panels in order to vertically stack the chip panels to connect the chip panels. Therefore, in the display panel, the strength of the edge portion can be improved. Also, by forming a connection portion, a stress can be suppressed from being concentrated at the edge portion by an external mechanical stress.

Owner:SAMSUNG ELECTRONICS CO LTD

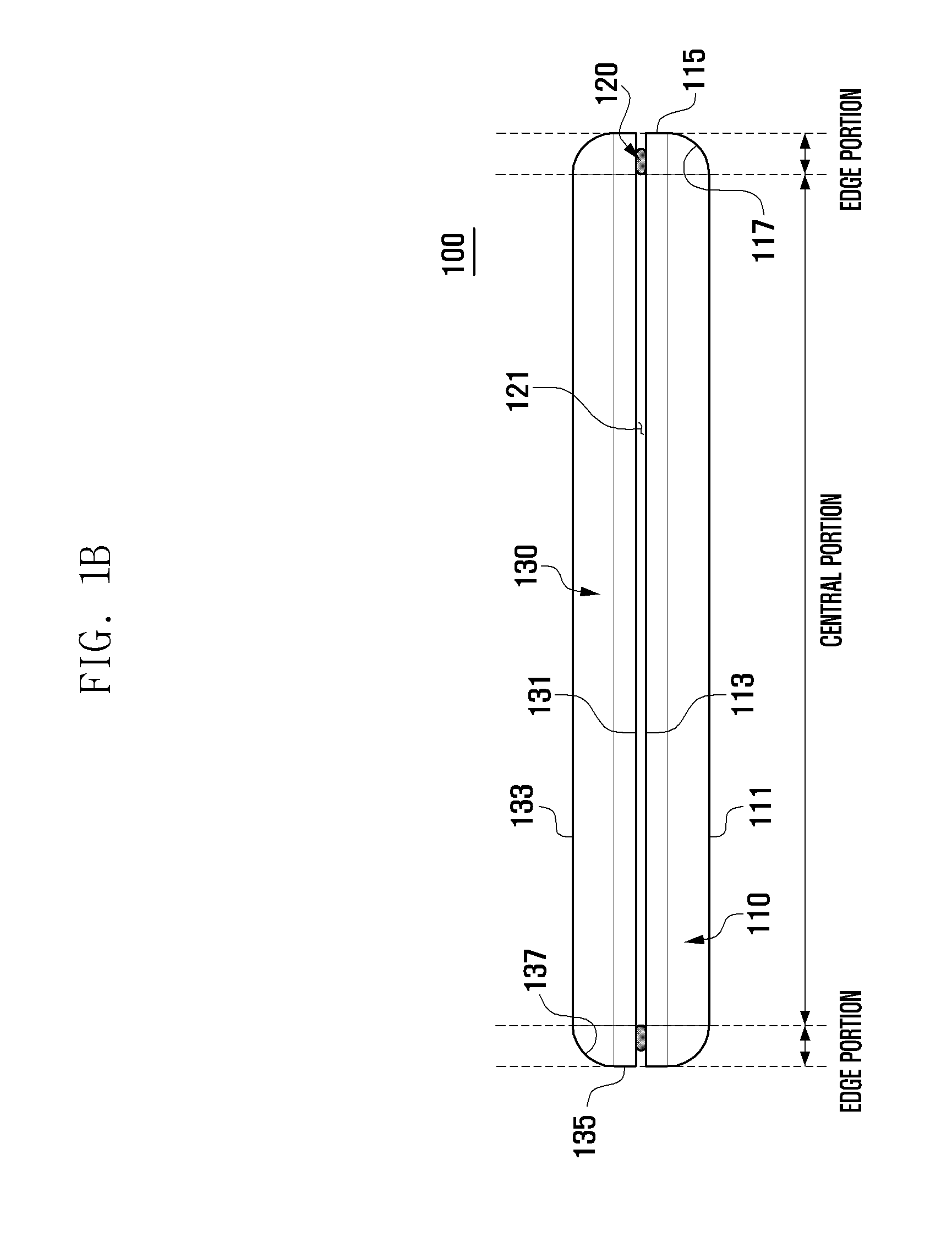

Diamond coating cutter, and preparation method and application thereof in high speed graphite processing

ActiveCN105563665AReduce cutting shock and vibrationAvoid breakingChemical vapor deposition coatingStone-like material working toolsHardnessLow friction

The invention discloses a diamond coating cutter, and a preparation method and the application thereof in high speed graphite processing. The diamond coating cutter comprises a cutter tip, a blade and a clamping cutter holder, wherein the clamping cutter holder is made of a hard alloy matrix, the cutter tip and the blade are coated with diamond coatings on matrix materials, the diamond coating cutter is characterized in that the end cutting edge front angle gamma o1 of the blade is 2 to 6 degrees, the end cutting edge rear angle alpha 1 is 5 to 13 degrees, the peripheral cutting edge front angle gamma o2 is 5 to 15 degrees, the peripheral cutting edge rear angle alpha 2 is 10 to 14 degrees, and the helical angle beta is 15 to 45 degrees. The diamond coating cutter provided by the invention has the characteristics of high hardness, wear resistance, low friction coefficient, good heat conduction and the like, is suitable for high speed graphite processing, can effectively overcome frictional wear caused by graphite dust to the surface of the cutter, and is classified as an ideal cutter for cutting graphite.

Owner:GUANGDONG UNIV OF TECH

Method of and apparatus for strengthening edges of one or more glass sheets

ActiveUS7459199B2Avoid fracturesImprove edge strengthCellulosic plastic layered productsGlass/slag layered productsEngineeringGlass sheet

A furnace includes a section defined as a heating section capable of attaining a predetermined temperature, the heating section having an entrance end and an exit end; a section defined as a cooling section capable of having a temperature gradient from entrance end of the cooling section to exit end of the cooling section, the entrance end of the cooling section mounted in a fixed relationship to the exit end of the heating section; a section defined as an edge cooling section between the exit end of the heating section and the entrance end of the cooling section; and an edge cooling device positioned in the edge cooling section relative to a predetermined area, and capable of cooling at least selected peripheral portions of the predetermined area at a faster rate than center portions of the predetermined area.

Owner:PITTSBURGH GLASS WORKS

Capacitive touch screen glass panel and manufacture method thereof

ActiveCN102508586AImprove edge strengthThe overall thickness is thinGlass/slag layered productsInput/output processes for data processingEngineeringTouchscreen

The invention is applicable to the technical field of touch screens, and provides a method for manufacturing a capacitive touch screen glass panel. The method comprises the following steps of A making a plurality of one-side or two-sided chamfers of the glass panel, and enabling the chamfers to be matched with the size of the glass panel on a glass substrate according to needed size of the glass panel; B conducting chemical strengthening treatment on the glass substrate processed by the step A; and C cutting and splitting the glass substrate processed by the step B to obtain the capacitive touch screen glass panel. The two-sided chamfers of a finished glass panel are directly made on the glass substrate during pre-manufacture of the glass substrate, the chamfers and the substrate are strengthened together to enable the chamfers to be provided with strengthening layers, so that border strength of the glass panel is fundamentally improved, and then follow-up procedures such as cutting and splitting are carried out.

Owner:CHONGQING XINJING SPECIAL GLASS CO LTD

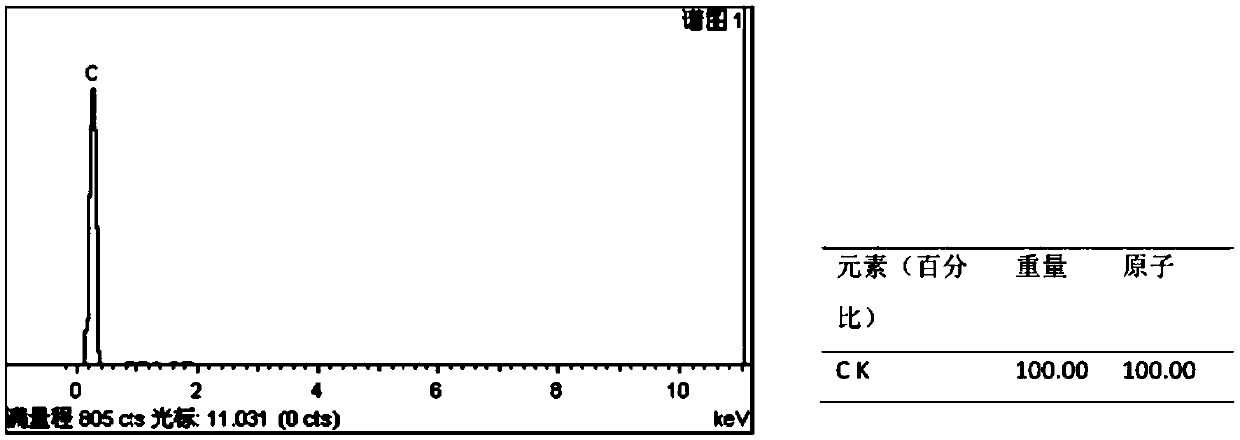

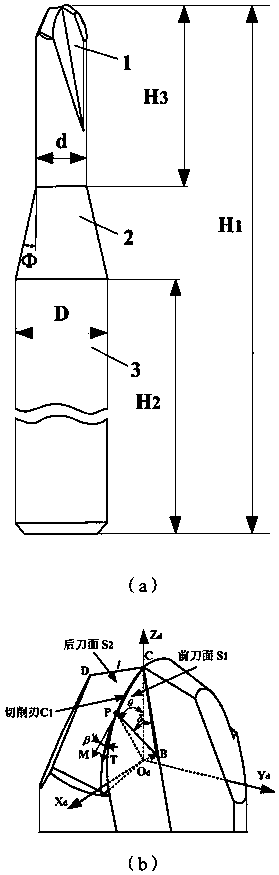

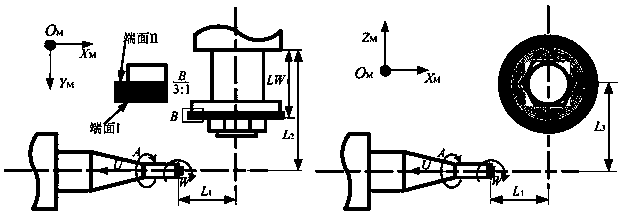

Novel micro ball end milling cutter and edge sharpening preparation technology

ActiveCN107552852ASimple structureThe geometry is easy to guaranteeMilling cuttersNumerical controlMilling cutter

The invention discloses a novel micro ball end milling cutter and an edge sharpening preparation technology of the novel micro ball end milling cutter, and belongs to the technical field of micro milling machining. The overall structure of the milling cuter is mainly composed of a cutter head part composed of a ball end and a cylinder, a conical cutter neck part and a cylindrical cutter handle part. The structure of the ball end part is designed to be a center-symmetrical two-edge structure, the front cutter face is an inclined plane, the rear cutter face is a conical face, and a cutting edgeis formed by a curve formed by crossing the inclined plane and the conical face. By means of the design method, on one hand, the cutter cutting edge strength can be improved, contact friction betweenthe cutter and a workpiece is reduced, accordingly, cutter abrasion is effectively reduced, the cutter service life is prolonged, and the dynamic unbalance value of the cutter is reduced through the symmetrical structure design; and on the other hand, a spiral edge structure of the cylinder part is omitted, the ball end part structure is simplified, the cutter preparation difficulty can be effectively lowered, and the machining quality can be improved. The edge sharpening preparation technology of the micro ball end milling cutter is designed based on a six-axis numerical control tool grinder,a cylinder grinding wheel end face is adopted for edge sharpening of the front cutter face, and meanwhile a specific-angle conical face grinding wheel conical face is adopted for edge sharpening of the rear cutter face. According to the micro ball end milling cutter, the structure is simple, the geometric structure is easy to ensure, accordingly, the machining cost is low, the manufacturing process is simple, meanwhile, the cutter edge strength is high, wear resistance is good, and the milling cutter can be widely applied to micro milling of materials difficult to machine.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

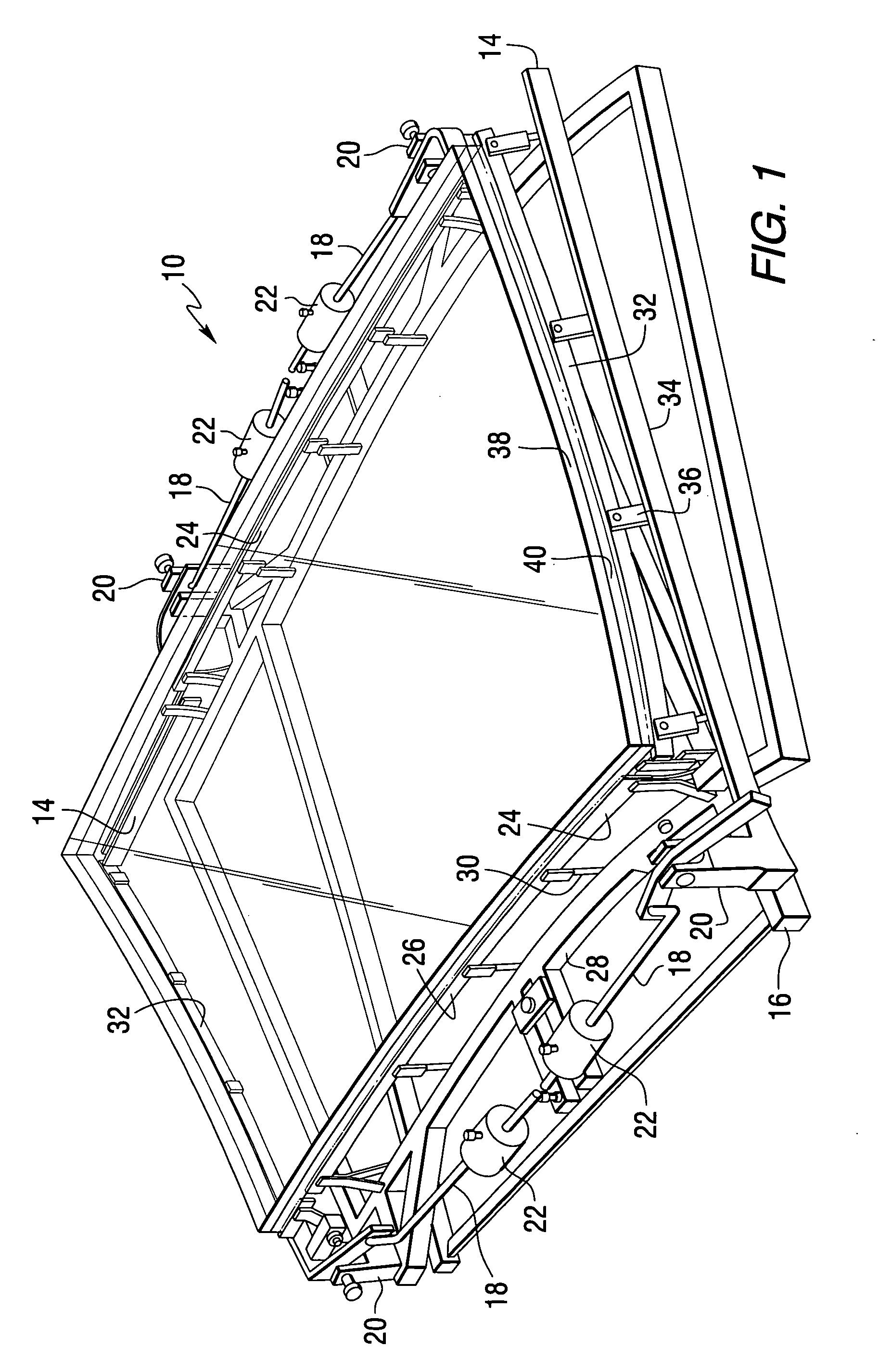

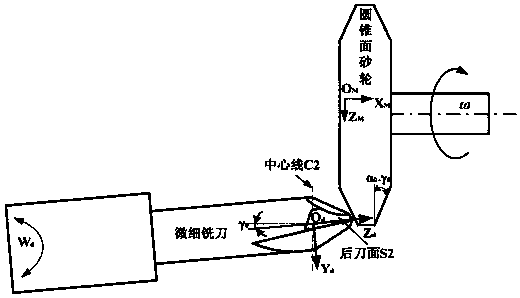

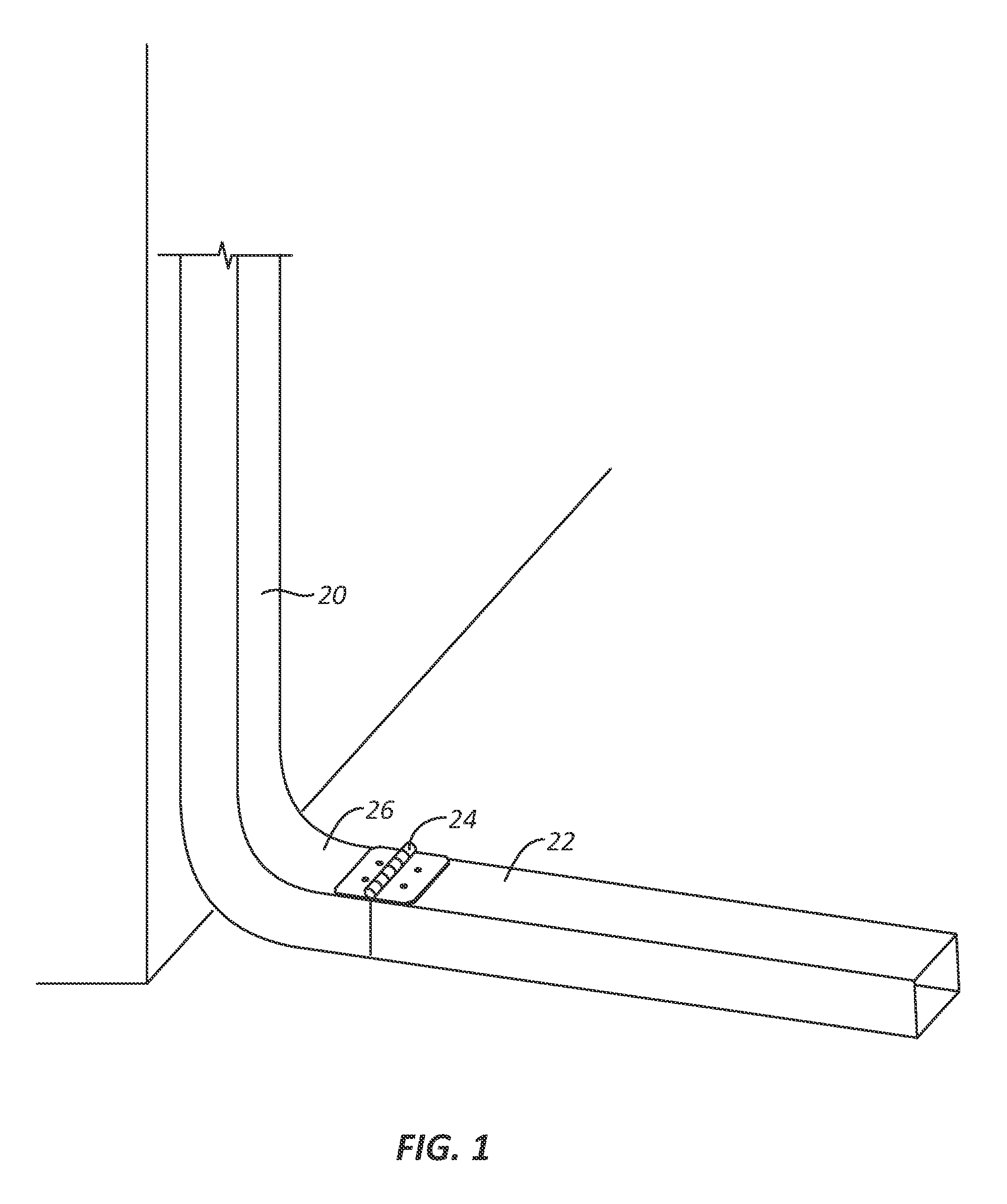

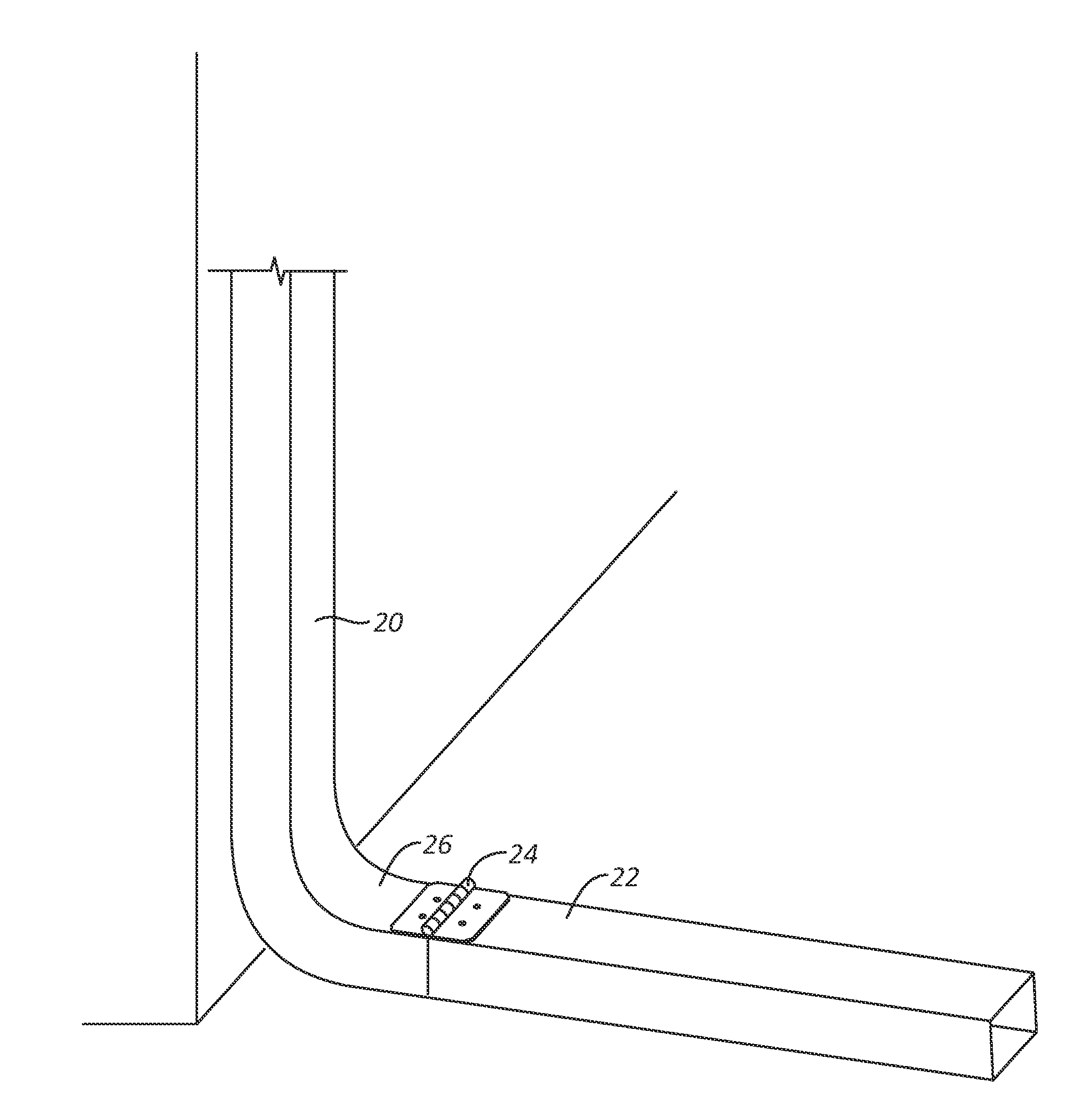

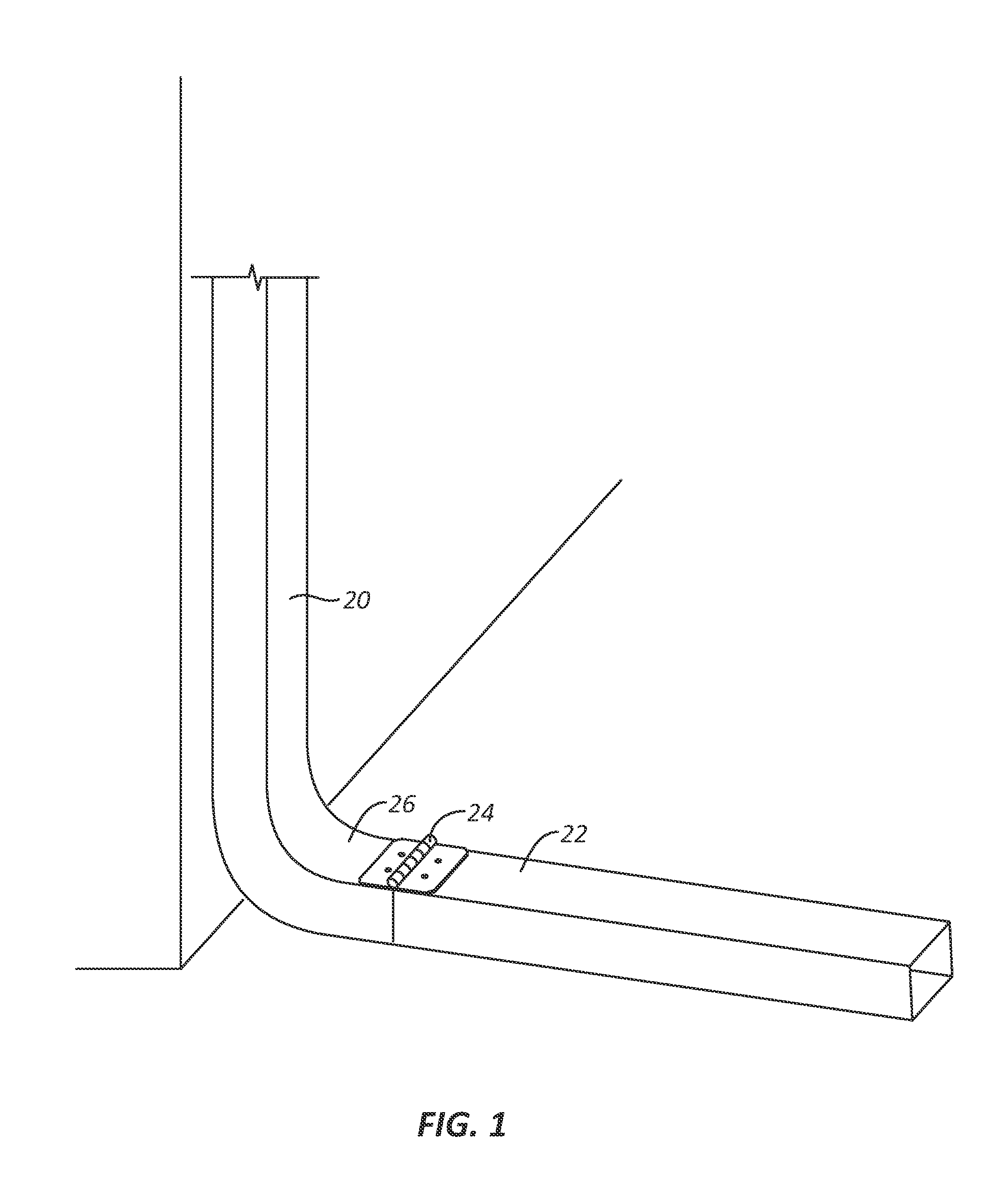

Sandwich coupling mechanism

ActiveUS8938858B2Improve edge strengthWing accessoriesAdjustable jointsEngineeringMechanical engineering

A sandwich mechanism is disclosed that has to opposing members that form a pocket into which material such as downspout sheet metal can be inserted. The opposing members clamp onto the downspout and can be secured into place using a screw that passes through the opposing members and the inserted downspout. Two sandwich mechanisms may be coupled together using a brace or a hinged member. The hinged member will permit a user to independently articulate the coupled pieces of downspout or downspout extension.

Owner:GPI HOME SOLUTIONS INC

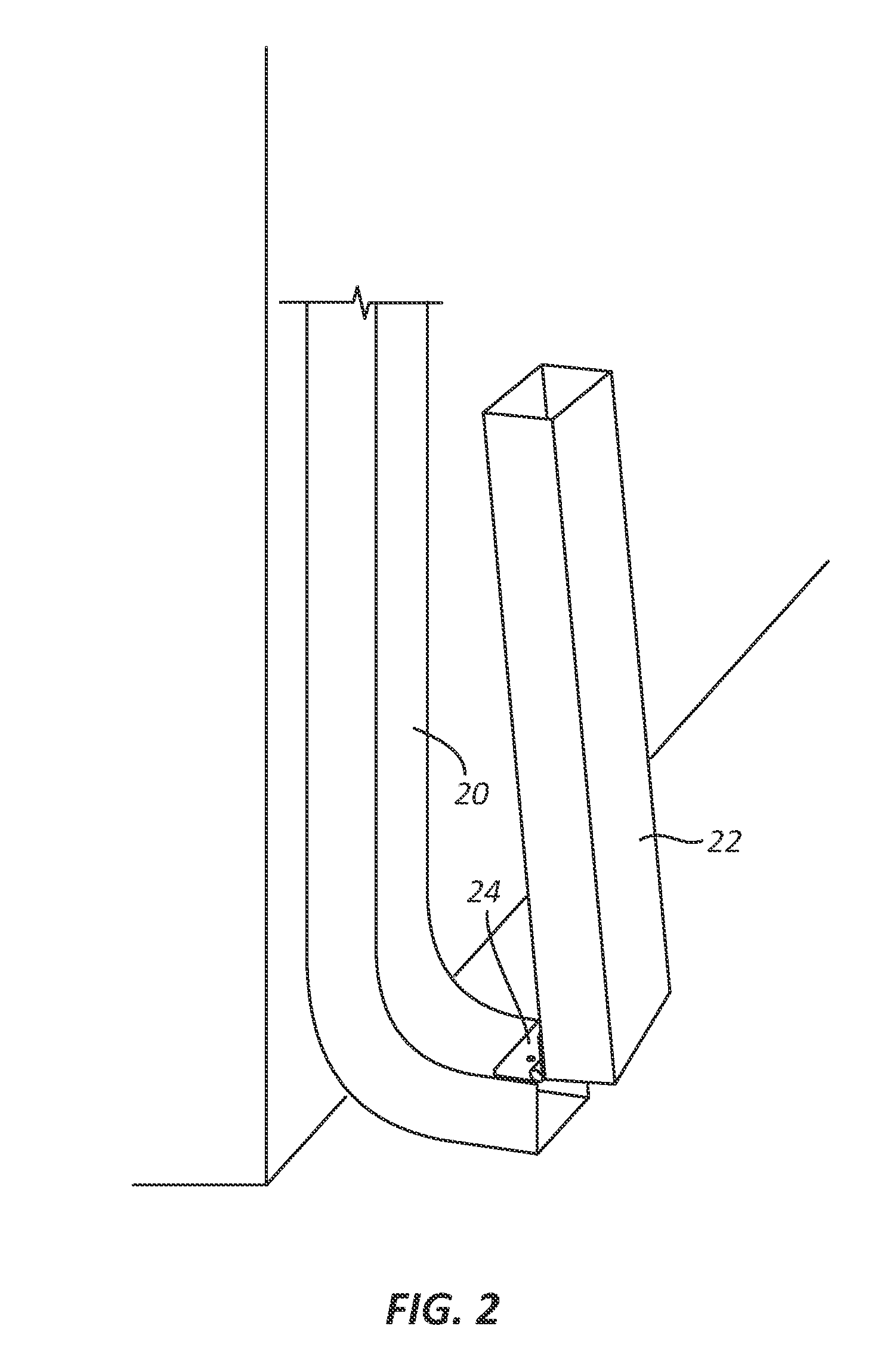

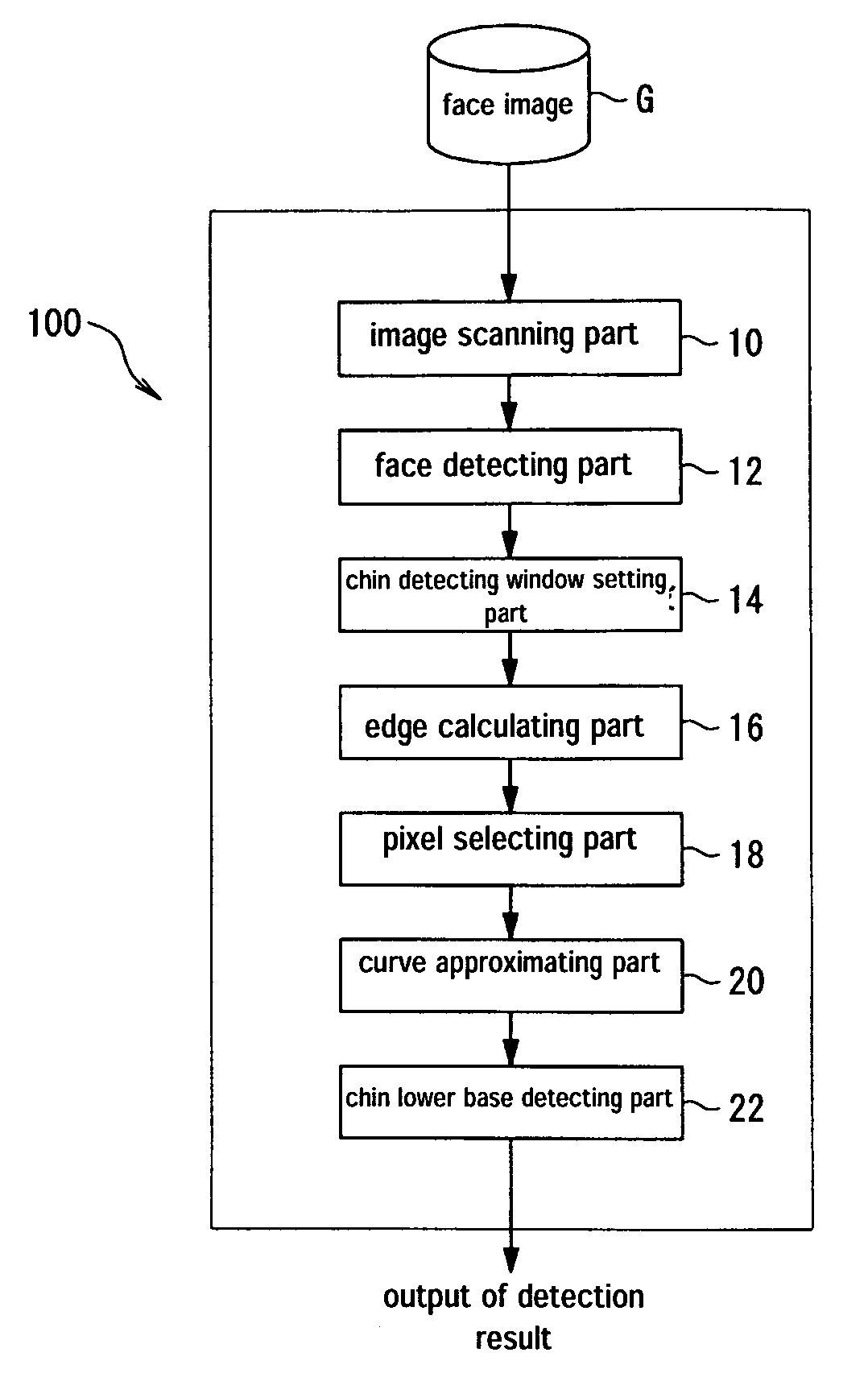

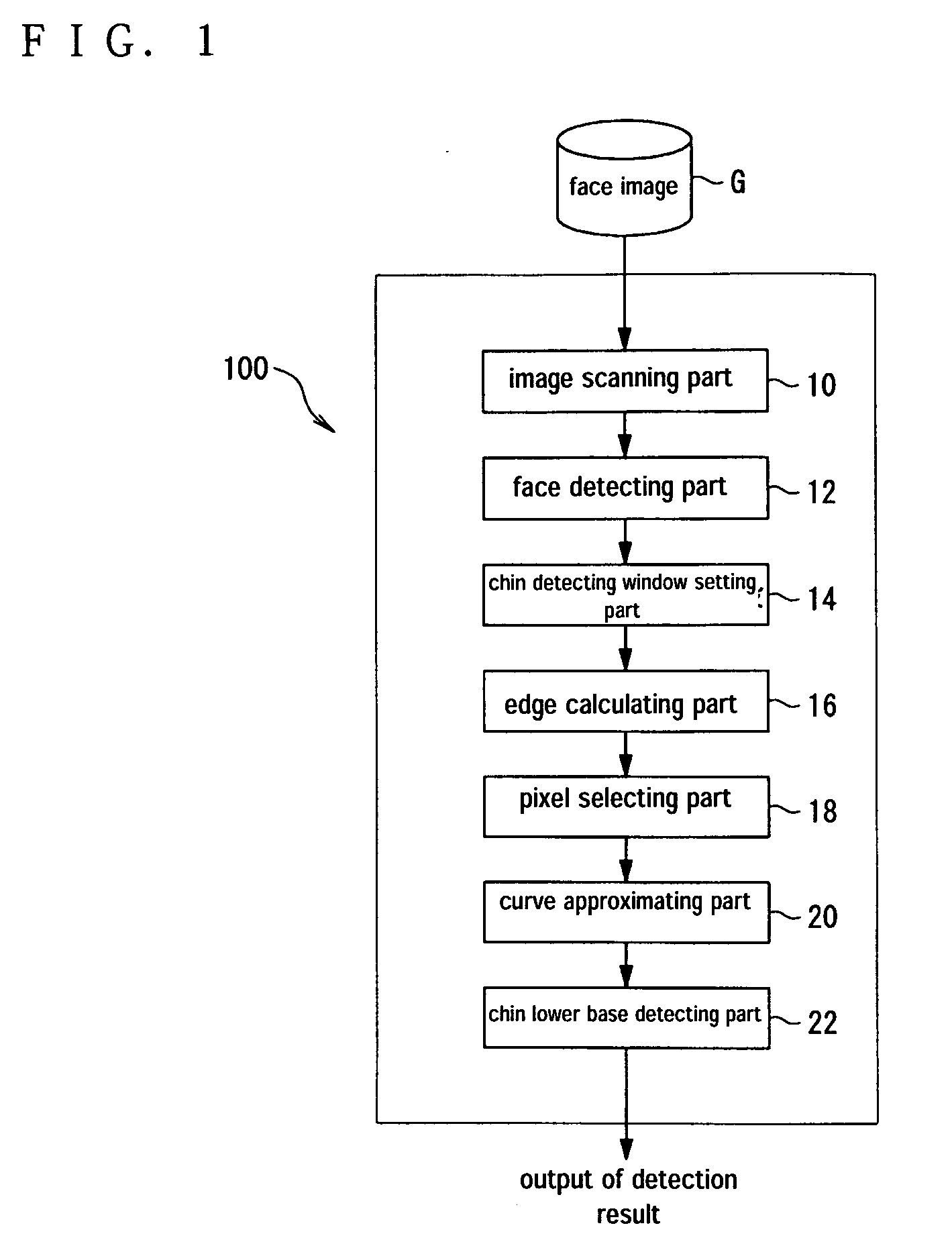

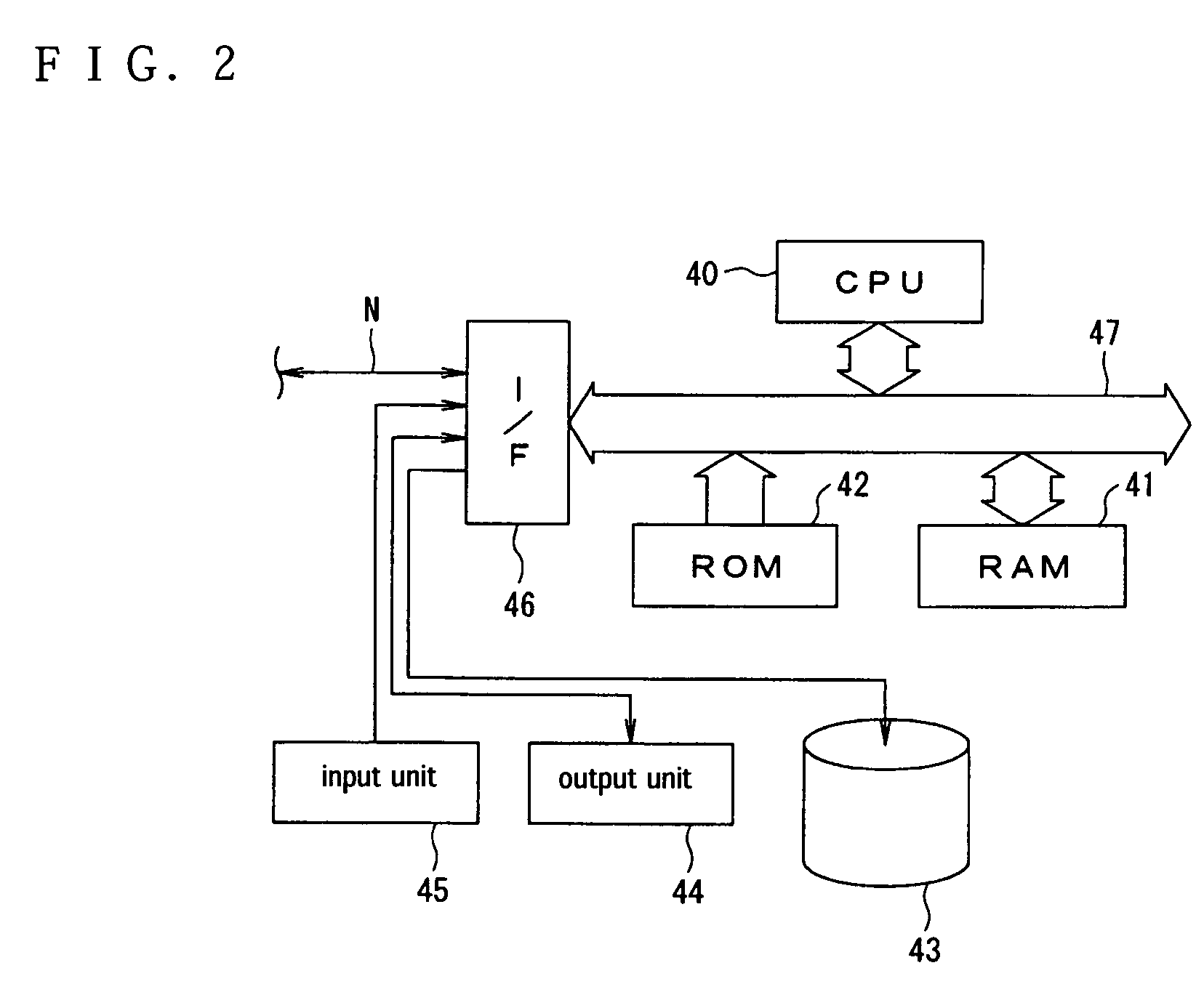

Chin detecting method, chin detecting system and chin detecting program for a chin of a human face

InactiveUS20060010582A1Improve edge strengthSimple and reliable processImage enhancementImage analysisChinEdge strength

A chin detecting method is provided. After detecting a human face and setting a chin detecting window at a lower part of the image, an edge strength distribution is calculated within the chin detecting window and pixels having an edge strength with a threshold value or more are detected based on the edge strength distribution. Then an approximated curve is obtained to most match a distribution of each of the detected pixels and a lowermost part of the approximated curve is identified as the lower base of the chin of the human face. Thereby the chin lower base of the human face can be detected automatically, accurately and quickly.

Owner:SEIKO EPSON CORP

Tabletop board

InactiveCN106617681AImprove stress resistanceHigh strengthFoldable tablesStowable tablesEngineeringUltimate tensile strength

The invention discloses a tabletop board which comprises an upper panel, a lower base plate and at least one pair of internal embedded parts. The upper panel is provided with a flat outer surface, the lower base plate is provided with a plurality of sunken parts, the sunken parts are arranged on the lower base plate in a staggered mode, and the top faces of the sunken parts abut against the inner surface of the upper panel; the internal embedded parts are arranged on the two opposite edges inside the upper panel and the lower base plate. The top faces and the side walls of the sunken parts can well bear pressure from the upper panel, so that the pressure resistance of the upper panel is improved, and the higher strength can be ensured while the wall thickness of the tabletop board is smaller. Particularly, when the total area of the sunken parts accounts for 30-70% the area of the lower base plate, the contact area between the top faces of the sunken parts and the inner surface of the upper panel is large, and the strength of the tabletop board is improved. Particularly, when the area of each sunken part is 1-15 square centimeters, the number of the sunken parts is increased, the areas of the top faces and the side walls of the sunken parts are increased, and the strength of the tabletop board is greatly improved.

Owner:NEW TEC INTEGRATION (XIAMEN) CO LTD

Cutting insert, cutting tool, and method of manufacturing machined product using the same

ActiveUS8485764B2Improve edge strengthHigh suppression characteristicsMilling cuttersMilling equipment detailsKnife bladesReference plane

Owner:KYOCERA CORP

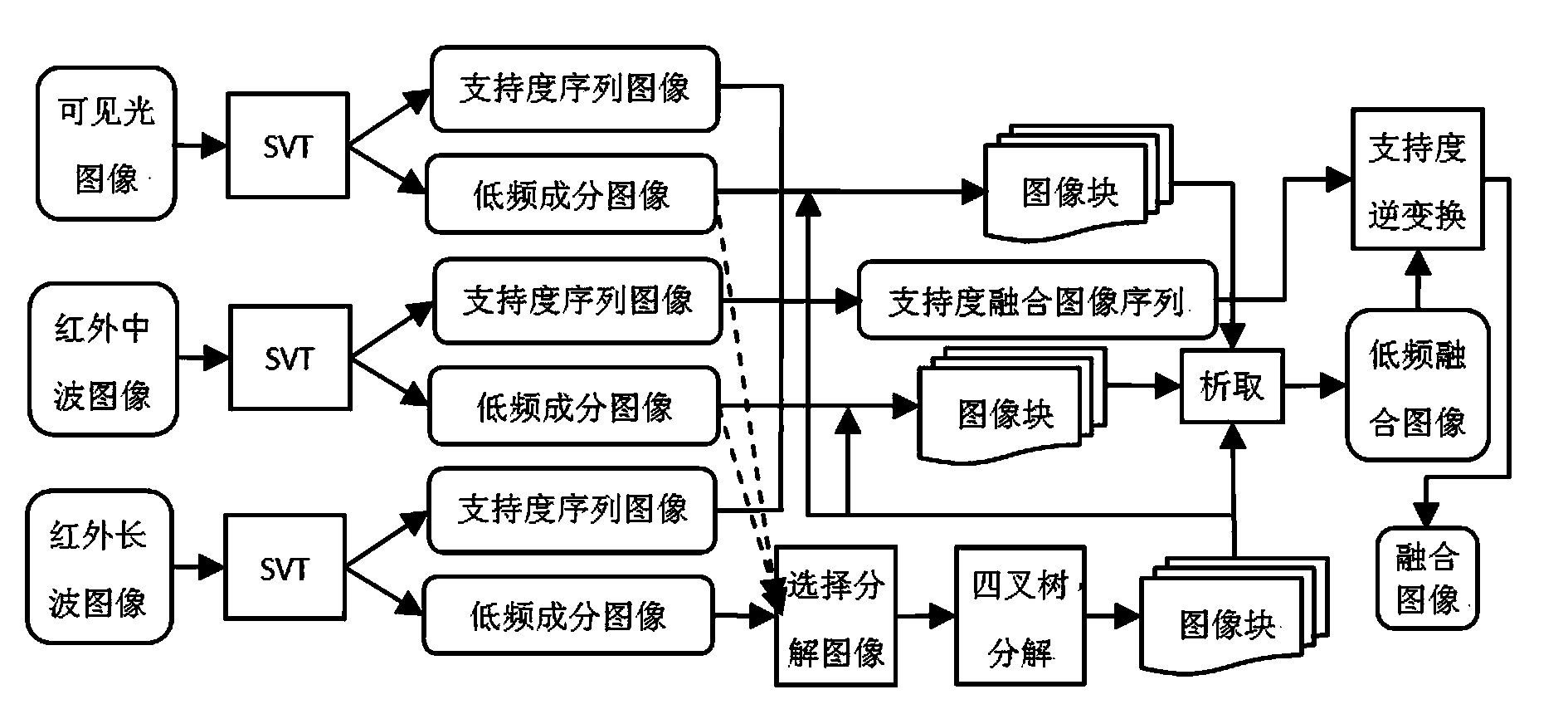

Multiband image fusion method based on multiscale transformation and possibility theory

InactiveCN103729836AImprove edge strengthIncrease contrastImage enhancementPossibility theoryRunning time

The invention relates to an image fusion method, in particular relates to a multiband image fusion method, and more particularly relates to a multiband image fusion method based on multiscale transformation and possibility theory. The method comprises the following steps of respectively carrying out support degree transformation on multiple bands of images to obtain low-frequency images and support-degree sequence images; decomposing a last layer of low-frequency component image with most scattered gray value by utilizing a quadtree method; respectively decomposing the last layer of low-frequency component image of other bands of images by adopting the quadtree decomposition result as an evidence; respectively fusing block images corresponding to multiband low-frequency components by adopting an extraction mode to obtain low-frequency fusion block images; splicing the fused block images to obtain a low-frequency fusion image; and executing the support-degree inverting transformation on the low-frequency fusion image and the support-degree sequence image synthesized by utilizing a maximal method to obtain a final synthesized image. According to the image fusion method, the marginal strength, the contrast ratio and the entropy of the synthesized image can be effectively enhanced; meanwhile, the running time is greatly shortened.

Owner:ZHONGBEI UNIV

Sandwich coupling mechanism

ActiveUS20130161943A1Smooth rotationSecure couplingWing accessoriesAdjustable jointsEngineeringMechanical engineering

A sandwich mechanism is disclosed that has to opposing members that form a pocket into which material such as downspout sheet metal can be inserted. The opposing members clamp onto the downspout and can be secured into place using a screw that passes through the opposing members and the inserted downspout. Two sandwich mechanisms may be coupled together using a brace or a hinged member. The hinged member will permit a user to independently articulate the coupled pieces of downspout or downspout extension.

Owner:GPI HOME SOLUTIONS INC

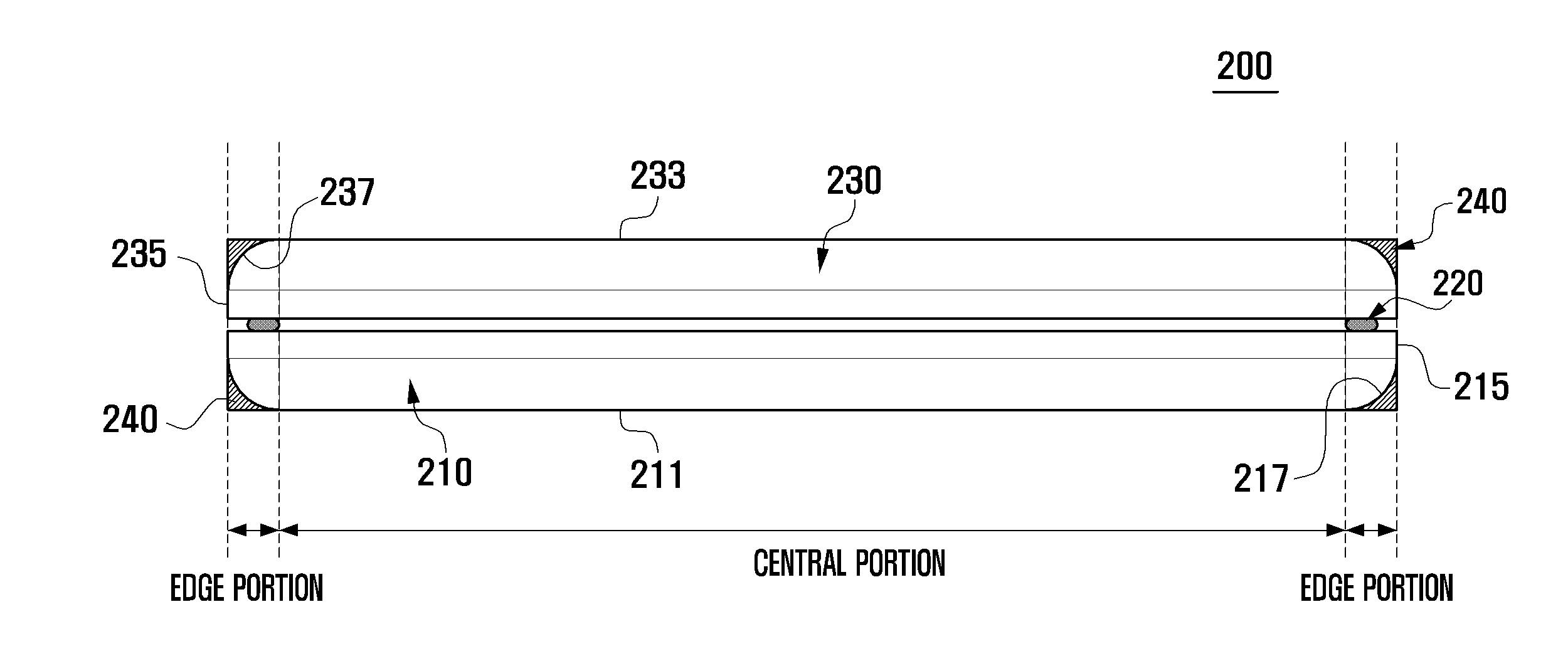

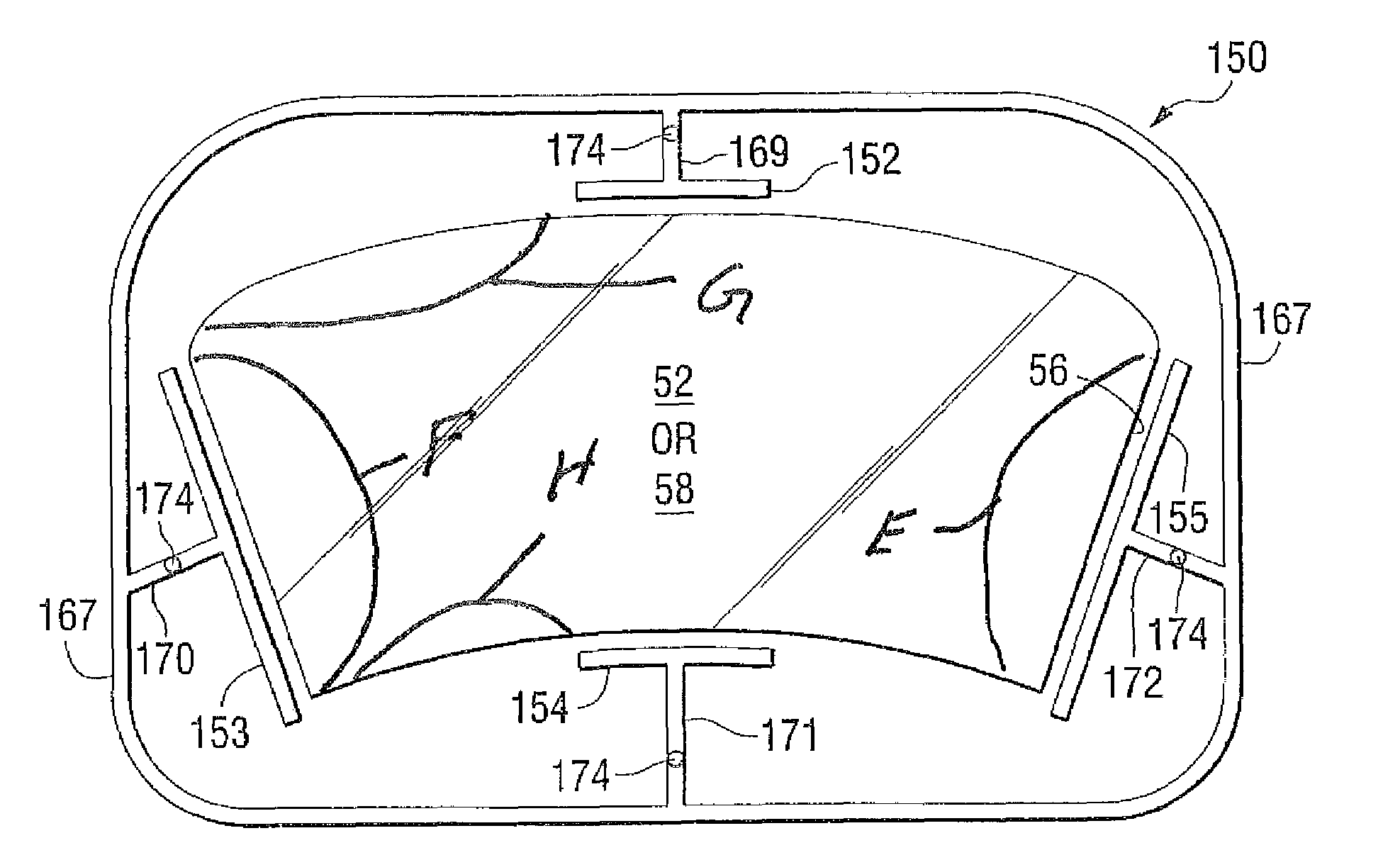

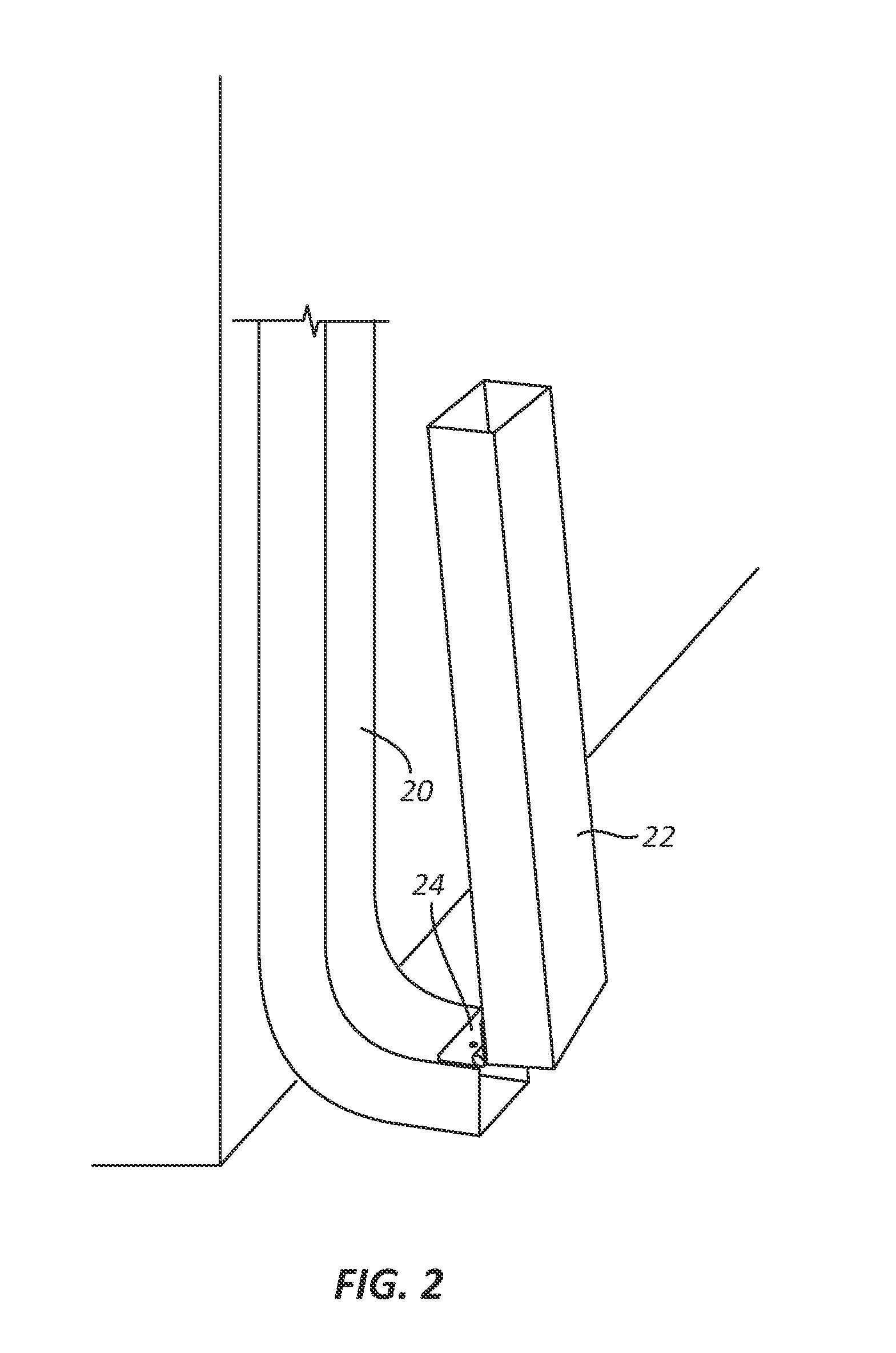

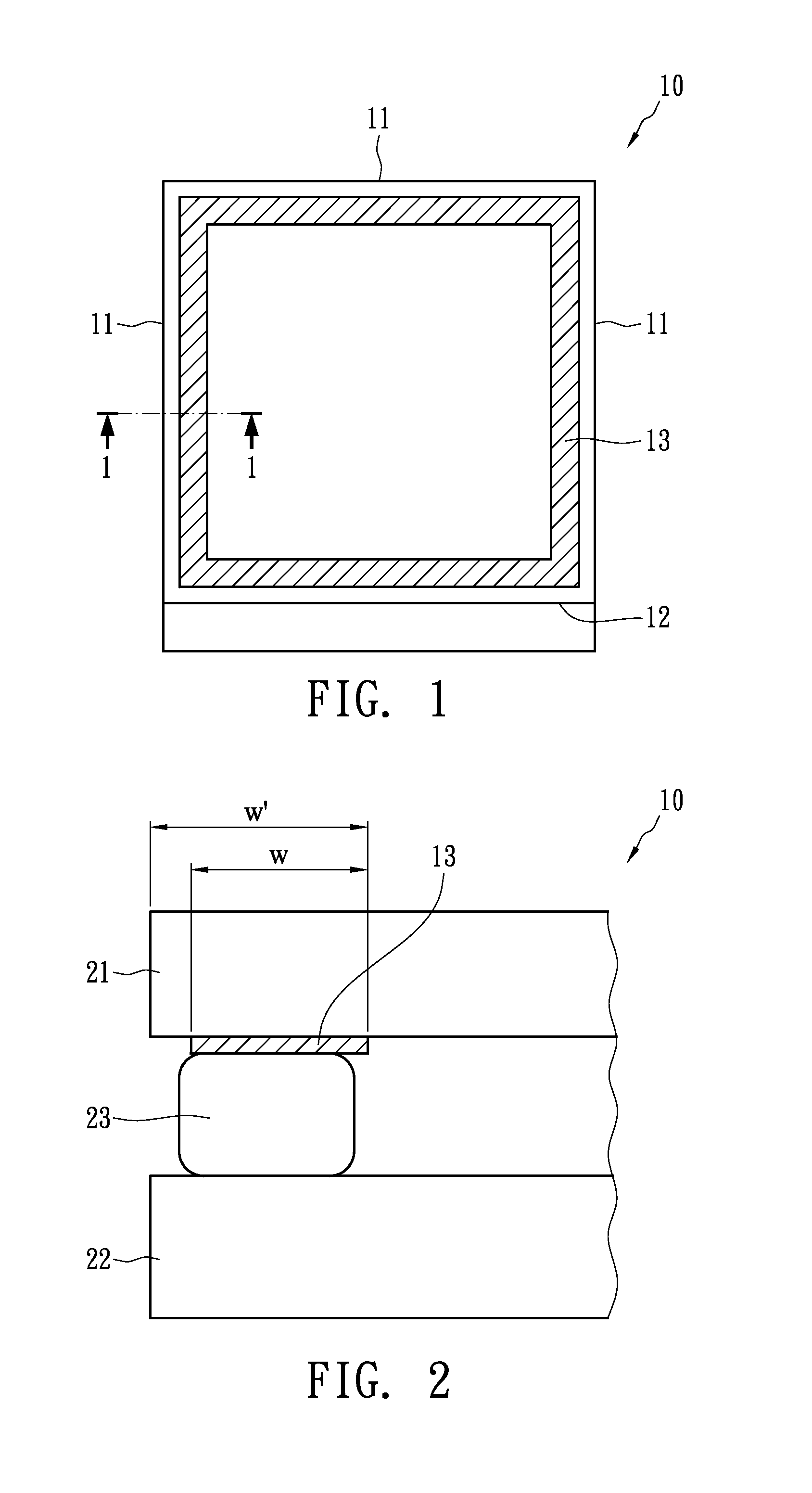

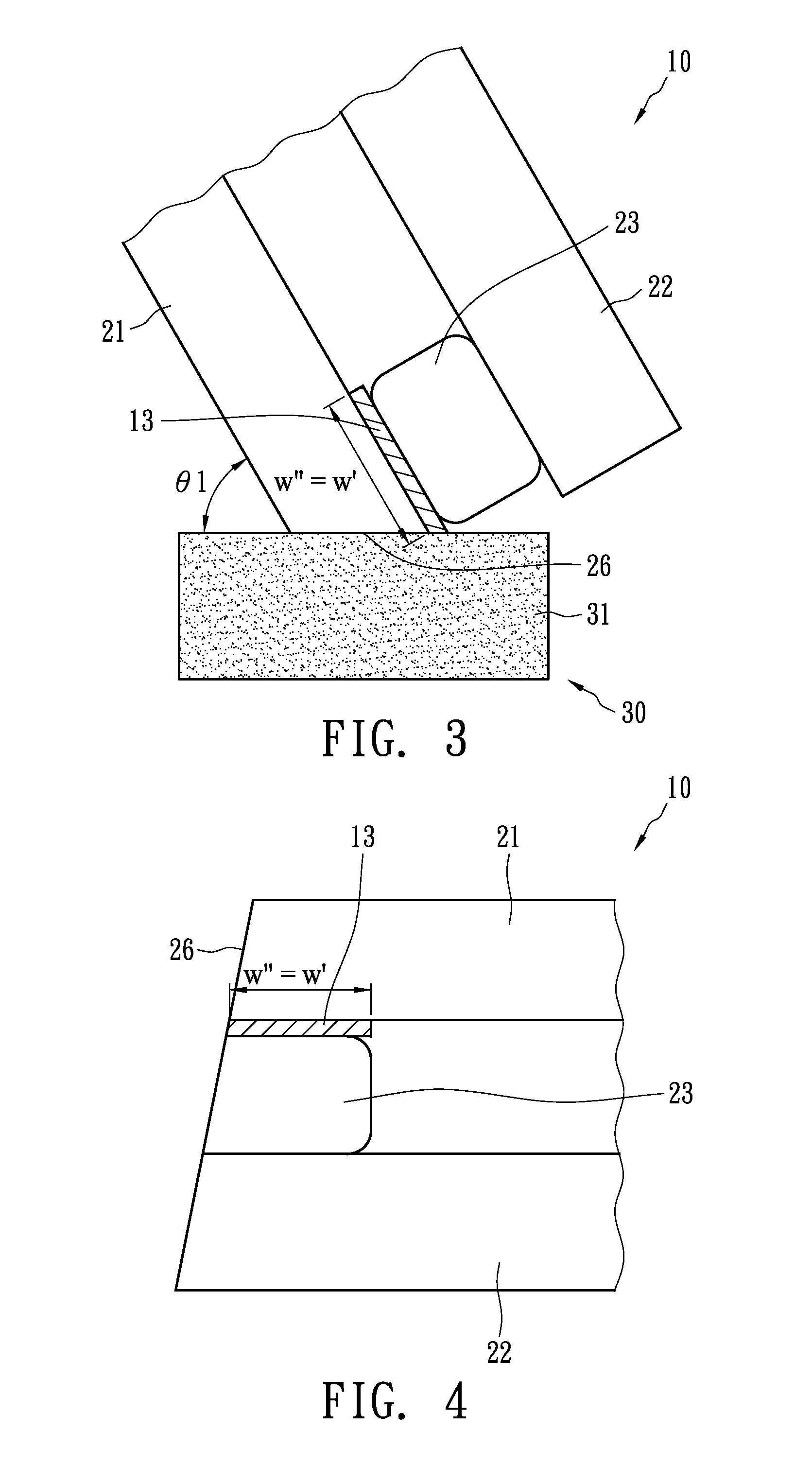

Display panel and method for narrowing edges and increasing edge strength thereof

ActiveUS8854591B2Efficiently narrowedHigh strengthEdge grinding machinesTube/lamp screens manufactureEdge strengthEngineering

An edge narrowing method for a display panel is disclosed. The display panel includes a first substrate, a second substrate, a sealant and a light-shielding area. The sealant is disposed between the first substrate and the second substrate. The light-shielding area is disposed between the first substrate and the sealant. The method includes the steps of providing the display panel, a grinding apparatus and a polishing apparatus; tilting the display panel so that the first substrate and a grinding member of the grinding apparatus have a first grinding angle therebetween; grinding the first substrate and the light-shielding area with the grinding apparatus while the display panel is tilted at the first grinding angle, thereby forming a first grinding end surface; stopping grinding of the first substrate and the light-shielding area when the width of the light-shielding area is between 0.35 and 1 mm; and polishing the first grinding end surface with the polishing apparatus to form a first end surface.

Owner:AU OPTRONICS CORP

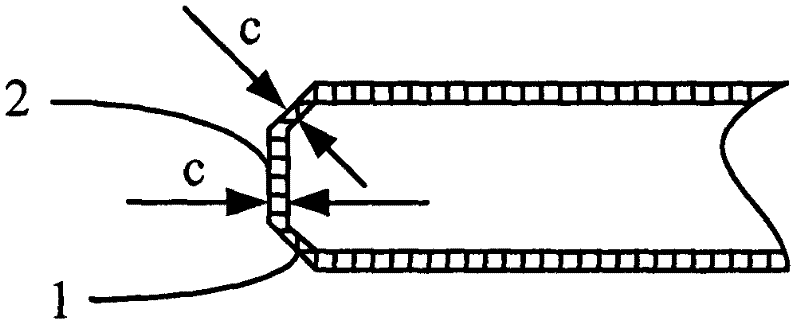

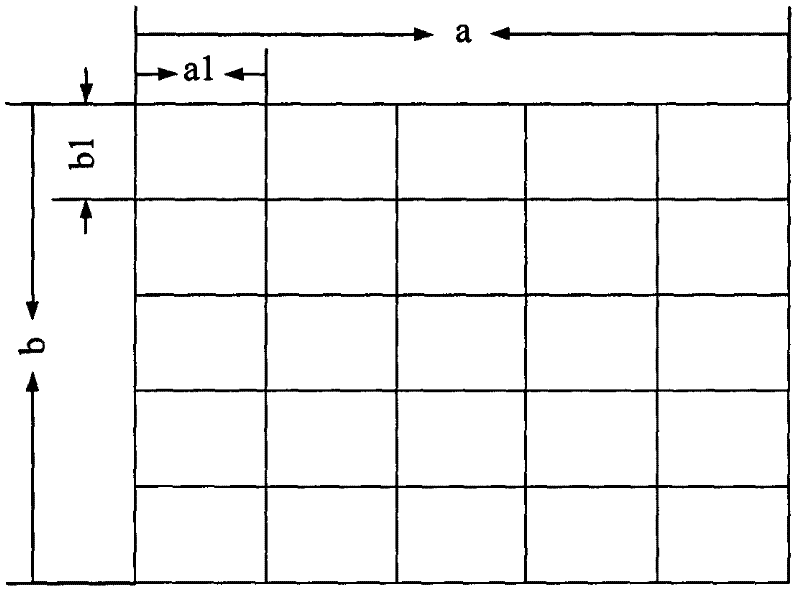

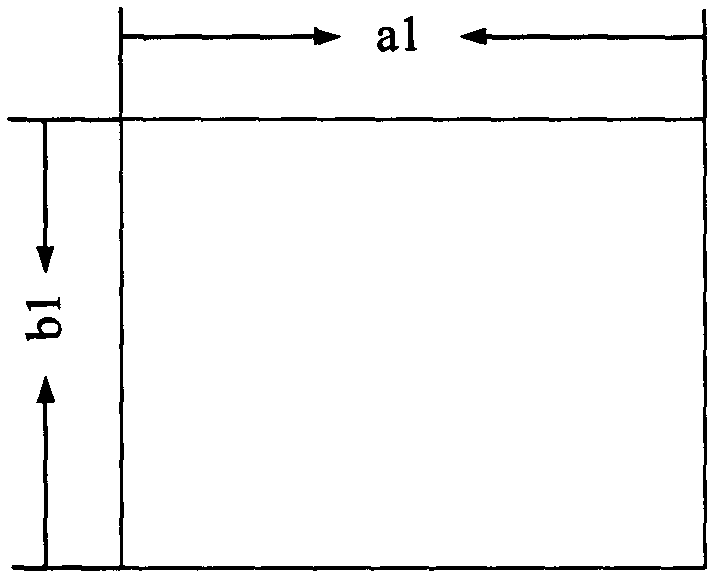

Method for sealing edge of plastic cellular sandwich board and apparatus thereof

ActiveCN107379726AWon't crushImprove side wall strengthLamination ancillary operationsSynthetic resin layered productsSandwich boardMechanical engineering

The invention relates to a method for sealing an edge of a plastic cellular sandwich board and an apparatus thereof. According to the invention, an edge sealing zone is arranged outside the contour of a product, in the edge sealing zone, a high-temperature part is inserted between an upper skin and a lower skin of the edge, honeycomb is removed through fusing, the upper skin and the lower skin are softened, and then the upper skin and the lower skin are turned to a center, so that edge sealing of the product is realized. According to the edge sealing method, the product edge is full and firm, the product edge intensity is enhanced, the problem of edge enclosing of a PPHC material is solved, and an application of the PPHC material on a spare wheel cover plate is promoted.

Owner:宁波正海汽车内饰件有限公司

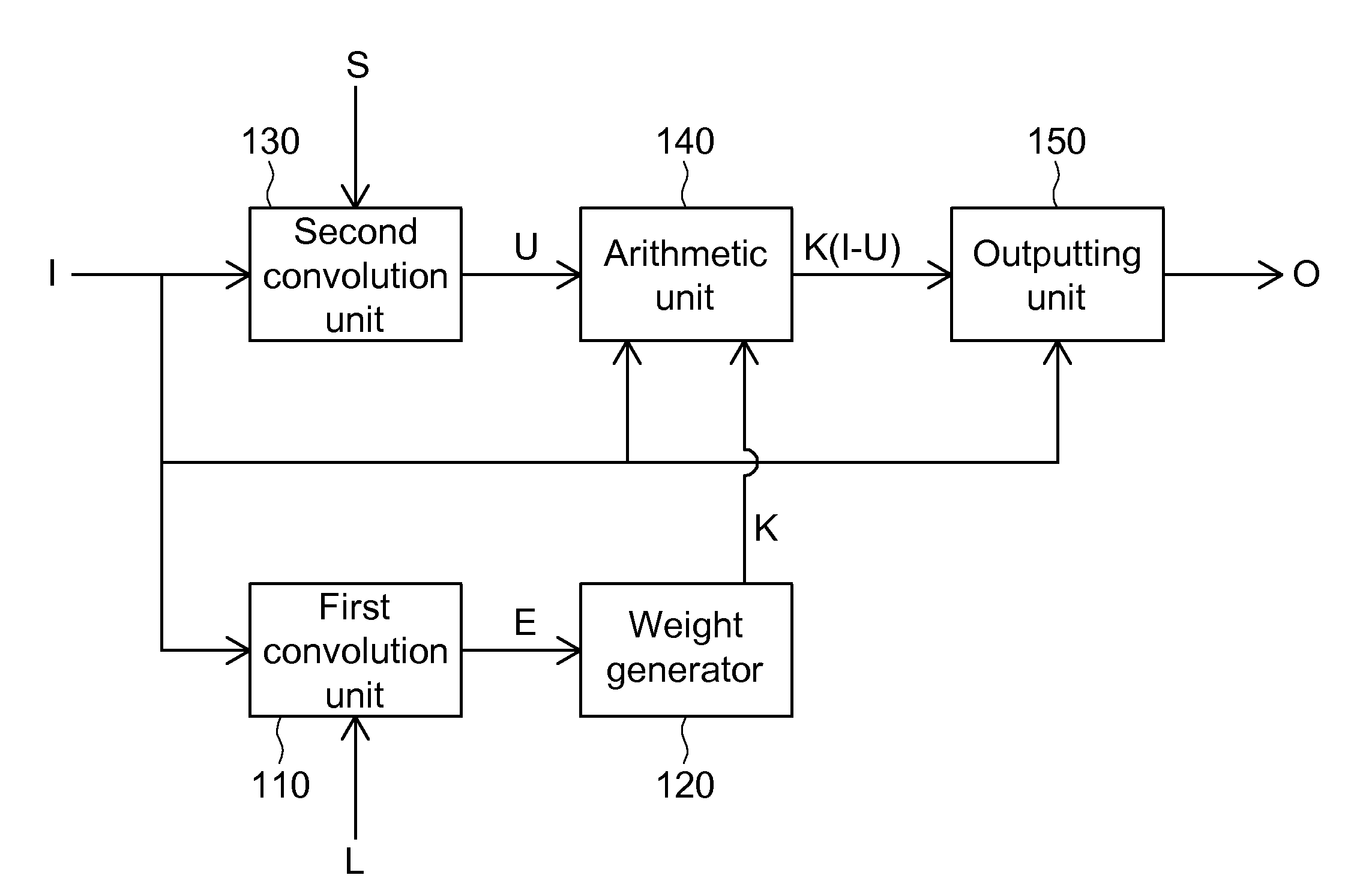

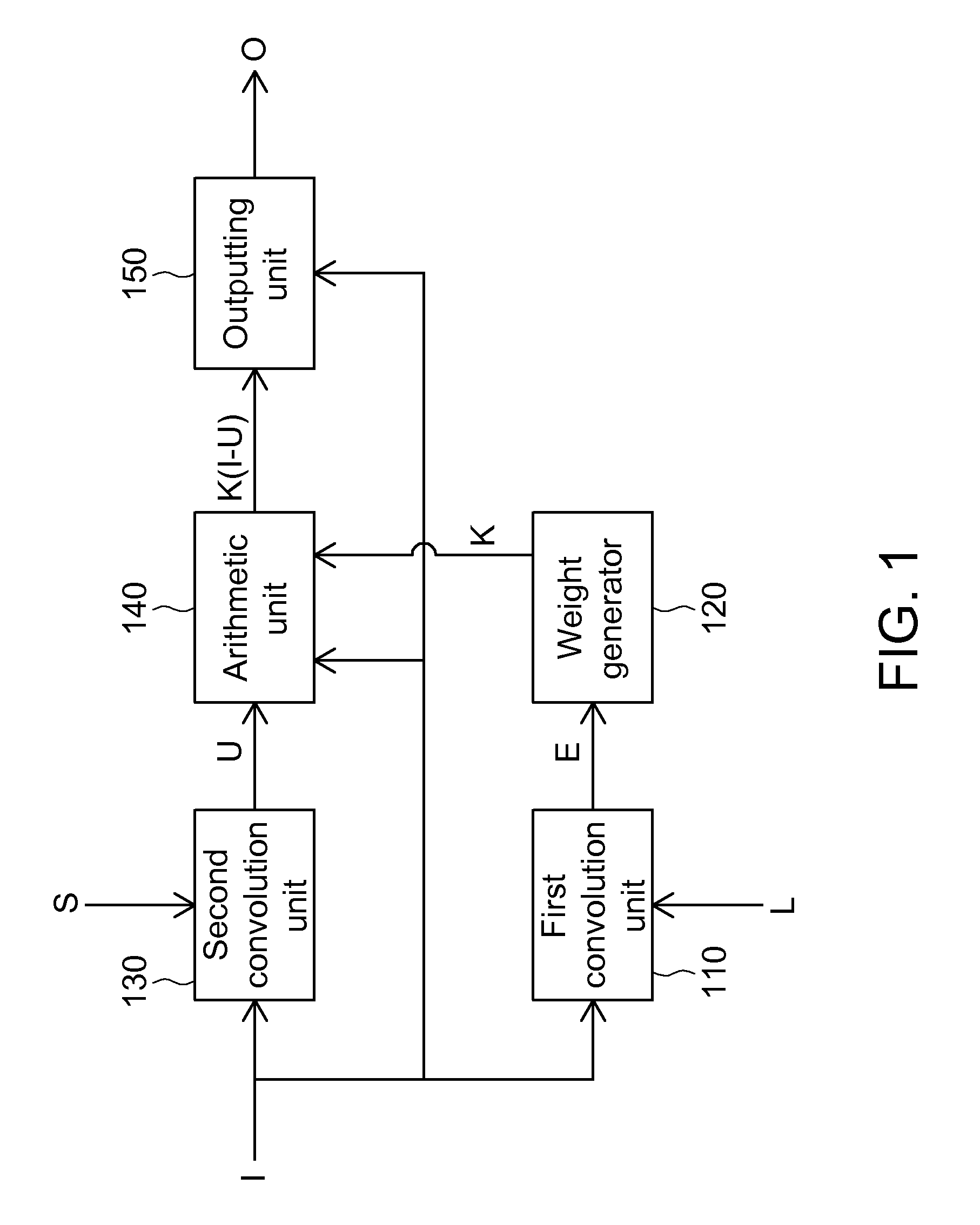

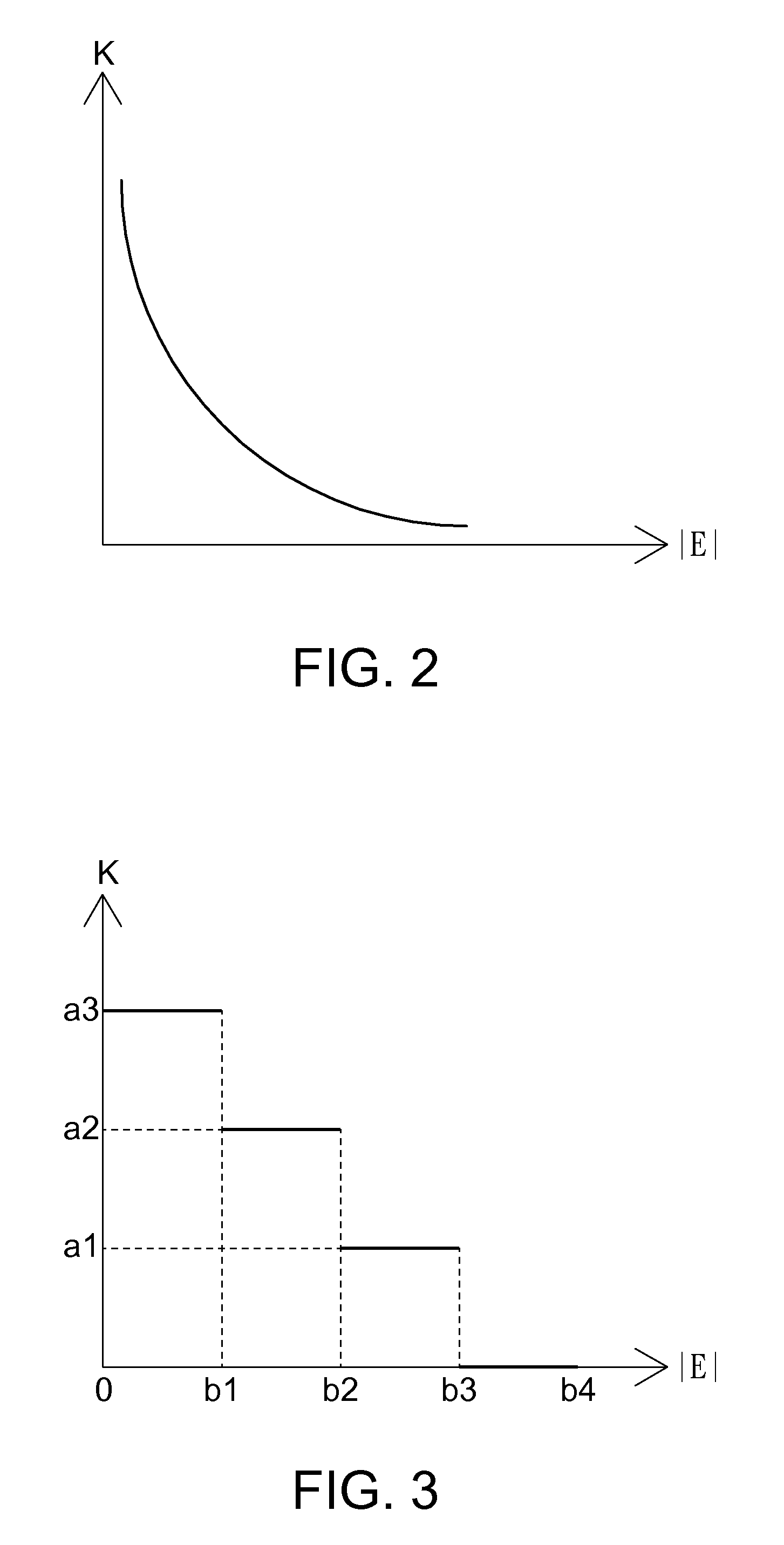

Image processing apparatus and image processing method

ActiveUS20090180707A1Improve the display effectEnlarge regionImage enhancementCharacter and pattern recognitionHigh-pass filterConvolution

An image processing apparatus and an image processing method. The image processing apparatus includes a first convolution unit, a weight generator, a second convolution unit, an arithmetic unit and an outputting unit. The first convolution unit performs a convolution to output edge strength according to an original image signal and a high pass filter mask. The weight generator chooses a weight coefficient according to the edge strength. The second convolution unit performs a convolution to output an unsharp image signal according to the original image signal and a low pass filter mask. The arithmetic unit outputs a first sharpening signal according to the original image signal, the unsharp image signal and the weight coefficient. The outputting unit outputs a processed image signal according to the original image signal and the first sharpening signal.

Owner:WINTEK CORP

Edge covering method and device of plastic honeycomb sandwich panel

InactiveCN107443855ASmooth foldSimple processLamination ancillary operationsLaminationHoneycombEdge strength

The invention relates to an edge covering method and device of a plastic honeycomb sandwich panel. An edge sealing region is arranged outside a product outline; an upper surface skin is removed in the edge sealing region; a high-temperature part is used for smelting from top to bottom to remove a honeycomb and soften a lower surface skin; then the softened lower surface skin is folded over to realize edge covering of a product. By adopting an edge covering manner, the edge of the product is full and straight and the edge strength of the product is increased; the edge sealing difficulty of a PPHC (Polypropylene Honeycomb) material is solved and application of a PPHC to a spare tire cover plate is propelled.

Owner:YANTAI ZHENGHAI HIGH TECH

Methods and apparatus for cutting radii in flexible thin glass

ActiveCN106458693AReduce generationHigh strengthGlass severing apparatusWelding/soldering/cutting articlesLaser beamsCooling fluid

Methods and apparatus provide for: cutting a thin glass sheet along a curved cutting line, where the curve is divided into a plurality of line segments; applying a laser beam and continuously moving the laser beam along the cutting line; applying a cooling fluid simultaneously with the application of the laser beam in order to propagate a fracture in the glass sheet along the cutting line; and varying one or more cutting parameters as the laser beam moves from one of the plurality of line segments to a next one of the plurality of line segments, wherein the one or more cutting parameters include at least one of: (i) a power of the laser beam, (ii) a speed of the movement, (iii) a pressure of the cooling fluid, and (iv) a flow rate of the cooling fluid.

Owner:CORNING INC

Cutting insert

InactiveUS9623486B2Reduce frictionIncrease the areaTransportation and packagingMilling cuttersStructural engineering

The purpose of the present invention is to provide a cutting insert which can minimize friction with a chip and maximize heat-radiating performance. To this end, the present invention provides a cutting insert comprising: an upper surface; a lower surface; a plurality of lateral surfaces for connecting the upper surface with the lower surface; a main cutting edge formed between the lateral surface and the upper surface; and a main cutting edge land and a main cutting edge incline formed in series between the main cutting edge and the upper surface, wherein the main cutting edge incline has a first wavy shape in which two or more incline convex parts and two or more incline concave parts are repeated from the main cutting edge land toward the upper surface.

Owner:KORLOY

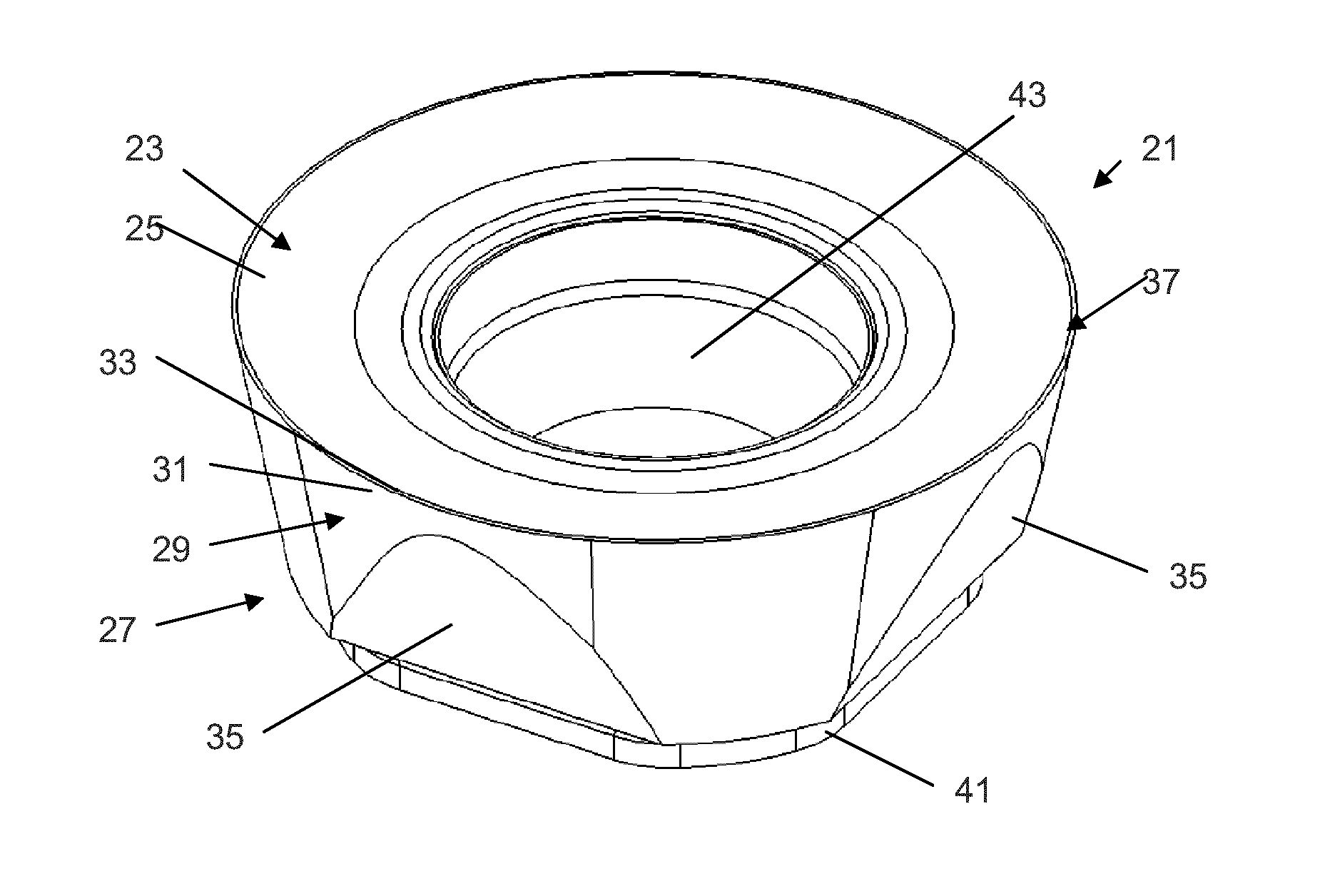

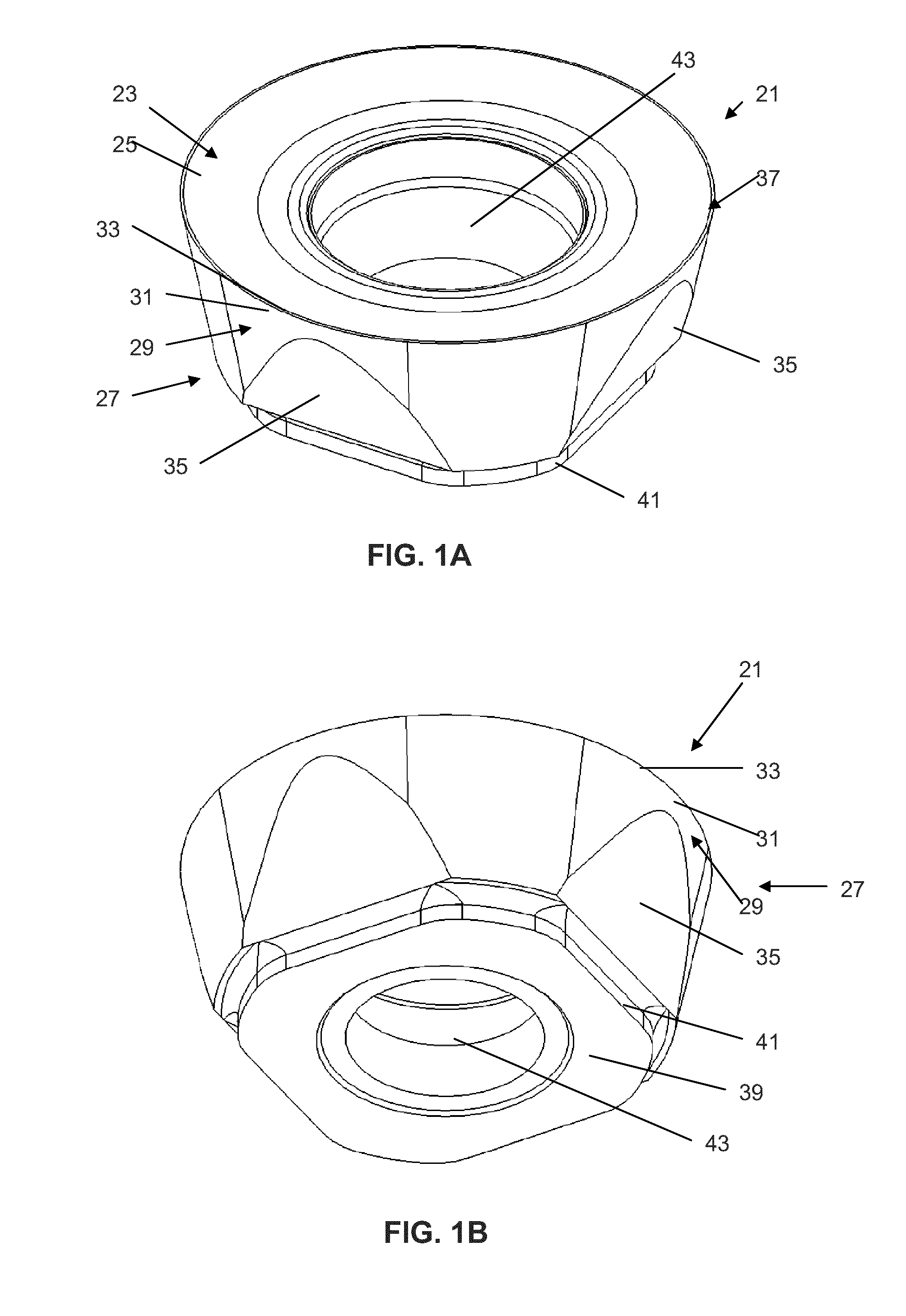

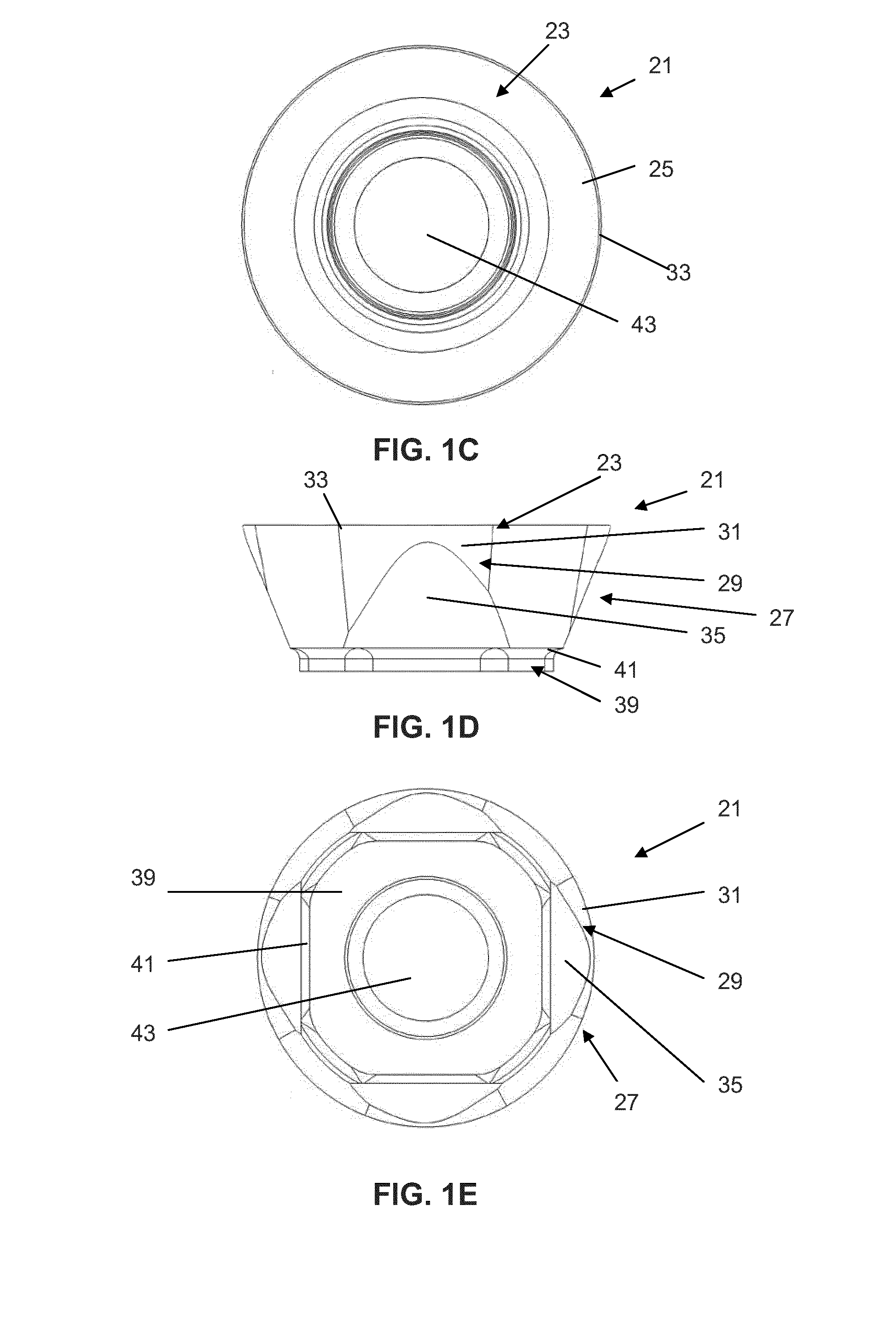

Cutting insert with evolutive wedge or clearance angle and toolholder using such a cutting insert

ActiveUS20140003874A1Easy to cutImprove edge strengthMilling cuttersMetal working apparatusWedge angleKnife holder

A circular cutting insert includes a top surface having a top edge portion, a side surface having a clearance surface and a clearance edge portion. A cutting edge is formed between the clearance edge portion and the top edge portion. The clearance edge portion and the top edge portion form a wedge angle. The wedge angle varies as a function of circumferential position about a central axis of the insert relative to a point on the cutting edge.

Owner:SECO TOOLS AB

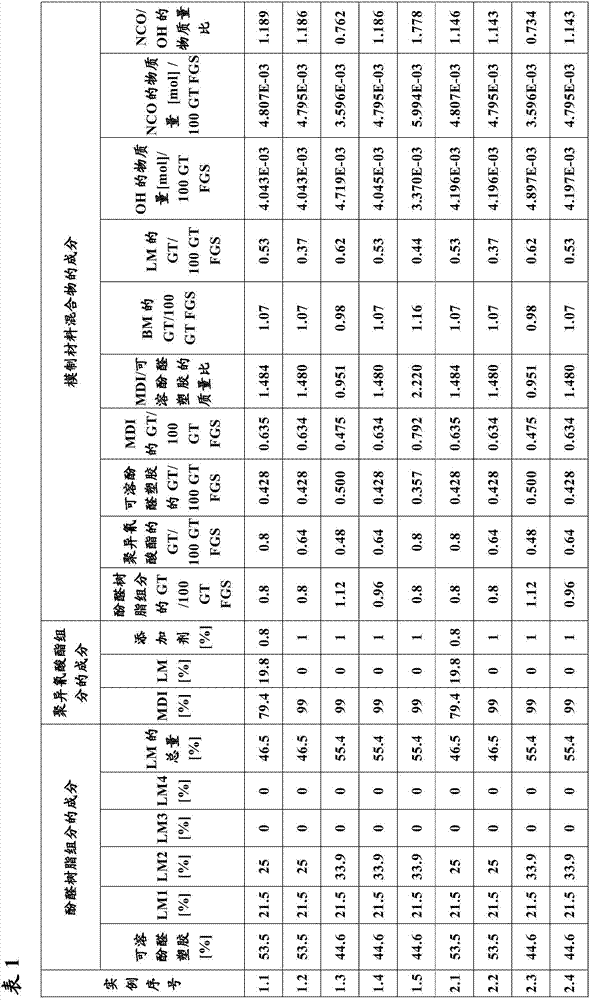

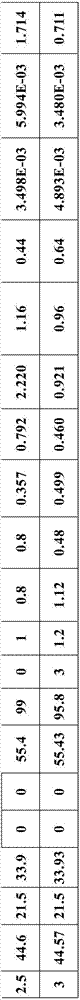

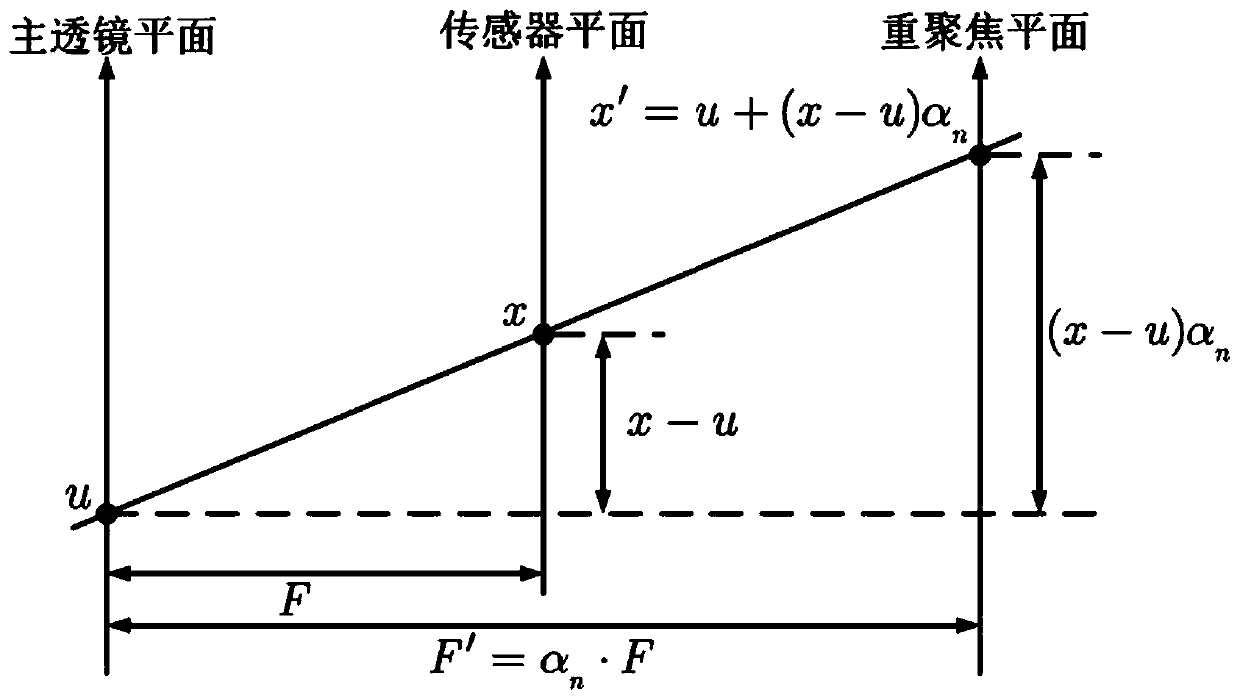

Two-component binder system for the polyurethane cold-box process

ActiveCN107073559ALow adhesion tendencyImprove liquidityFoundry mouldsFoundry coresFoundrySheet moulding compound

A description is given of a two-component binder system, in particular for use in the polyurethane cold-box process, a mixture for curing by contact with a tertiary amine, a method for producing a feeder, a foundry mould or a foundry core and feeders, foundry moulds and foundry cores that can be produced by this method, and the use of a two-component binder system according to the invention or a mixture according to the invention for binding a basic moulding compound or a mixture of basic moulding compounds, in particular in the polyurethane cold-box process.

Owner:HUTTENES ALBERTUS CHEM WERKE

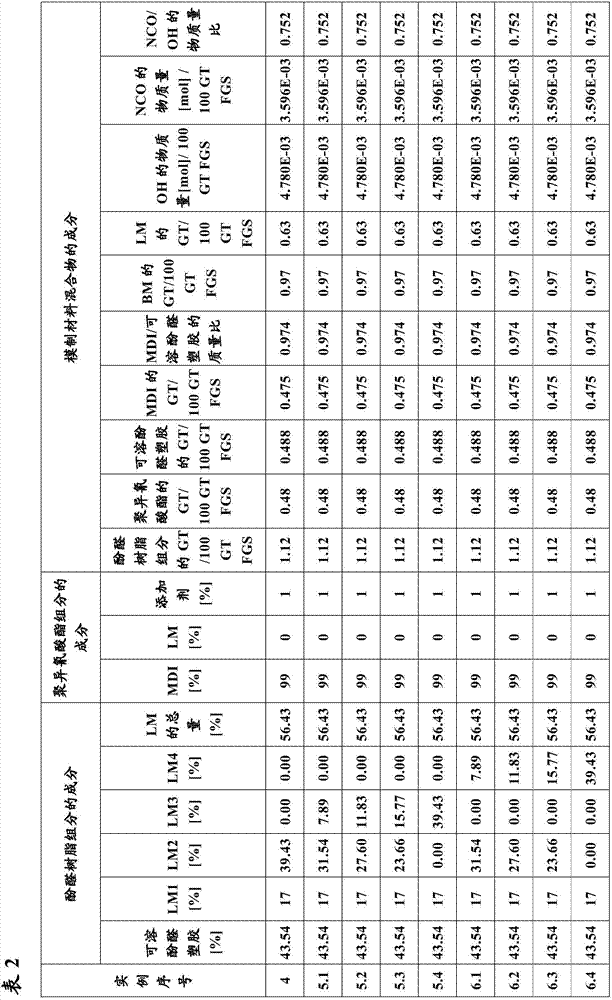

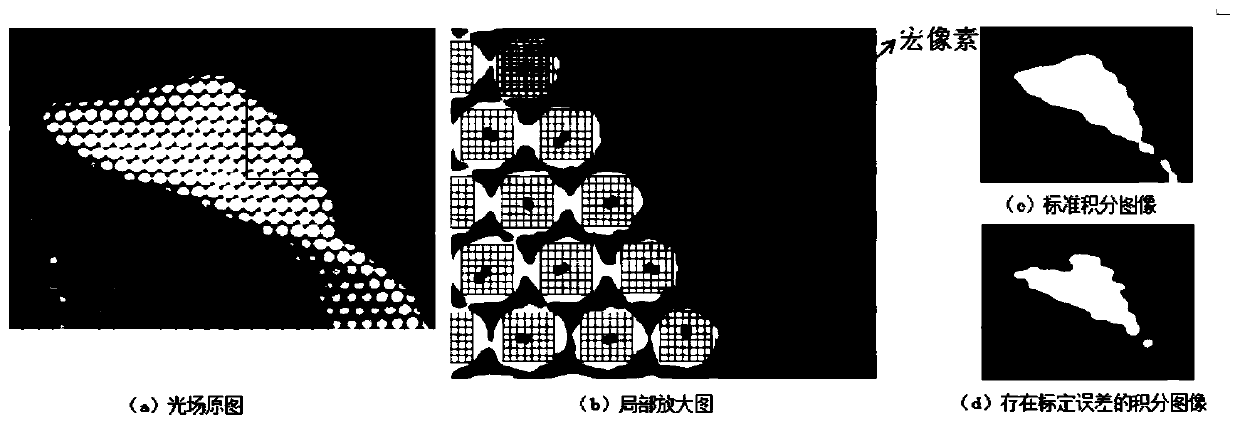

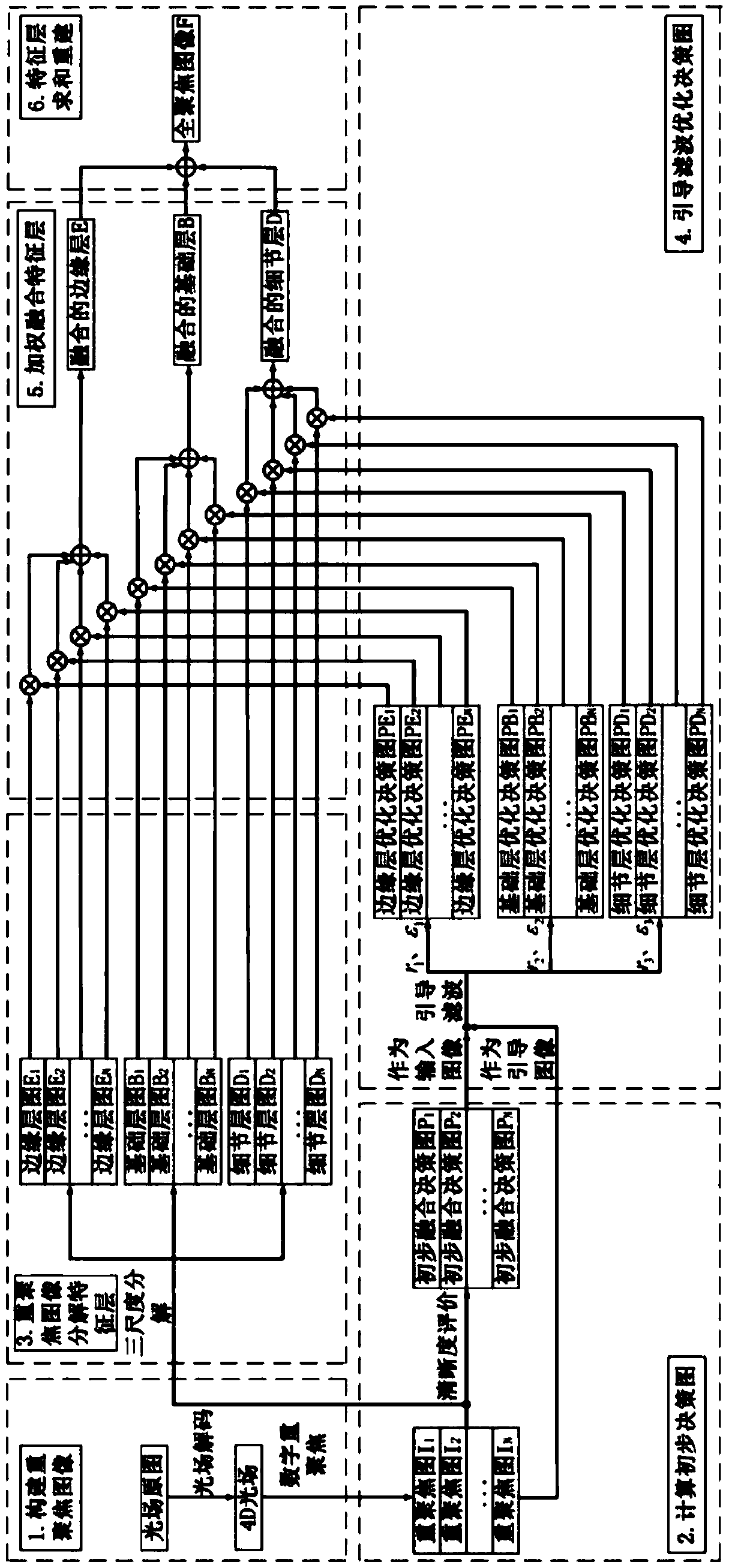

Light field full-focus image fusion method based on edge enhancement guided filtering

ActiveCN110648302AImprove edge strengthImprove clarityImage enhancementImage analysisPhysicsImage evaluation

The invention belongs to the technical field of image processing. According to the specific technical scheme, the method comprises the steps that aplurality of refocusing images obtained through digital refocusing of a light field is subjected to multi-scale decomposition, and a feature layer decision diagram guides filtering optimization to obtain a final full-focusing image. Edge information loss caused by 4D light field calibration errors is compensated; in a refocusing image multi-scale decomposition process, extraction of an edge layer is added to realize image high-frequency informationenhancement. A multi-scale image evaluation model is established to achieve edge layer guided filtering parameter optimization, a light field full-focus image with higher quality can be obtained, andon the premise that the similarity between the full-focus image and an original image is not obviously reduced, the method can enable the image perception definition of the full-focus image to be averagely improved by 18.4%.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com