Diamond coating cutter, and preparation method and application thereof in high speed graphite processing

A diamond coating and cutting tool technology, which is applied in the field of mechanical processing, can solve problems such as tool wear, no significant increase in service life, and difficulty in meeting complex electrode requirements for tool shapes, so as to overcome friction and wear, improve cutting performance, and ensure stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

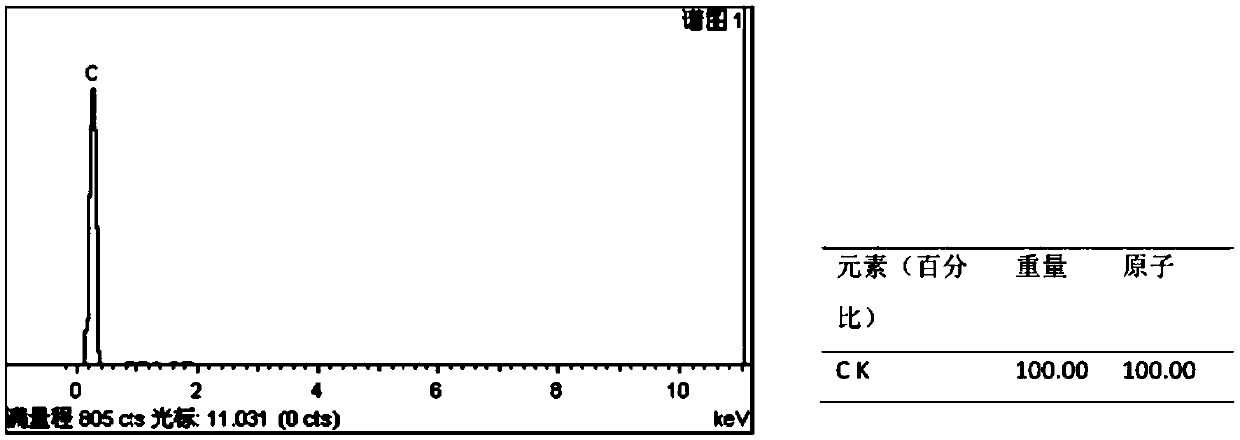

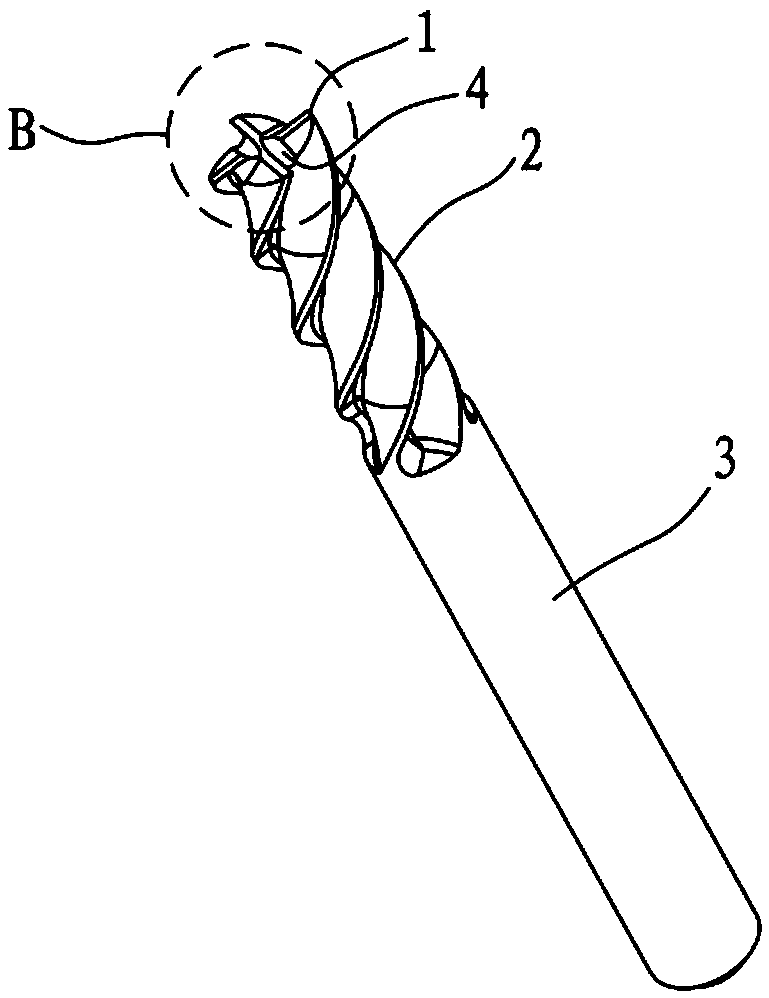

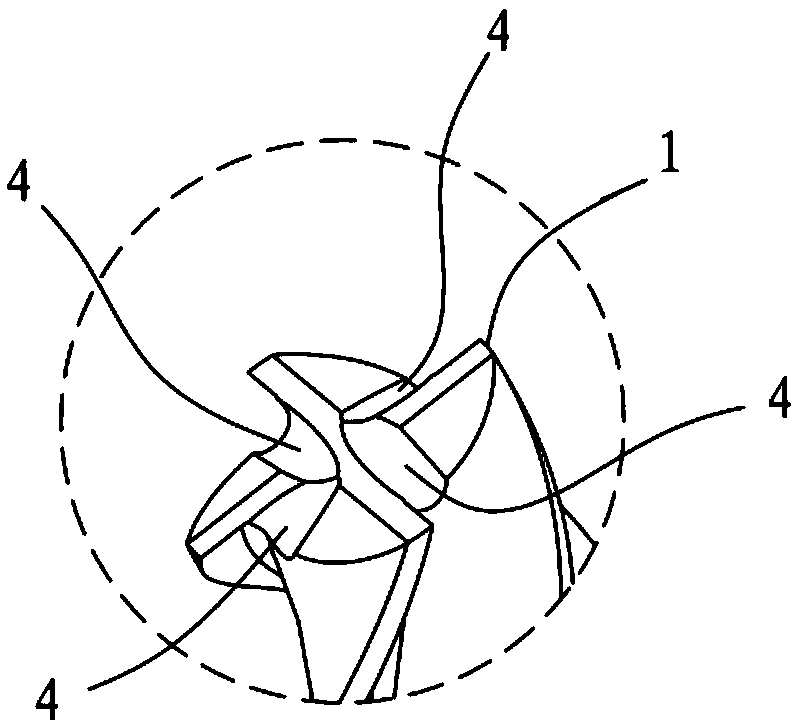

[0040] Such as figure 1 , figure 2 As shown, the present invention discloses a diamond-coated tool, comprising a cutting tip 1, a blade 2 and a clamping handle 3, the clamping handle 3 is a cemented carbide substrate, and the cutting tip 1 and the blade 2 are in the The base material is coated with a diamond coating. The matrix material of the cutting tip 1 and the cutting edge 2 is tungsten carbide cemented carbide, wherein the mass percentage of cobalt is not more than 6%; the proportion of vanadium carbide or titanium carbide or other mixtures is not higher than 1%. The thickness of the diamond coating is 7-20 μm. The cutting tip 1 is provided with a number of dust flutes 4 along the cutting direction, which facilitates the effective dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com