Patents

Literature

531 results about "Nuclear industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

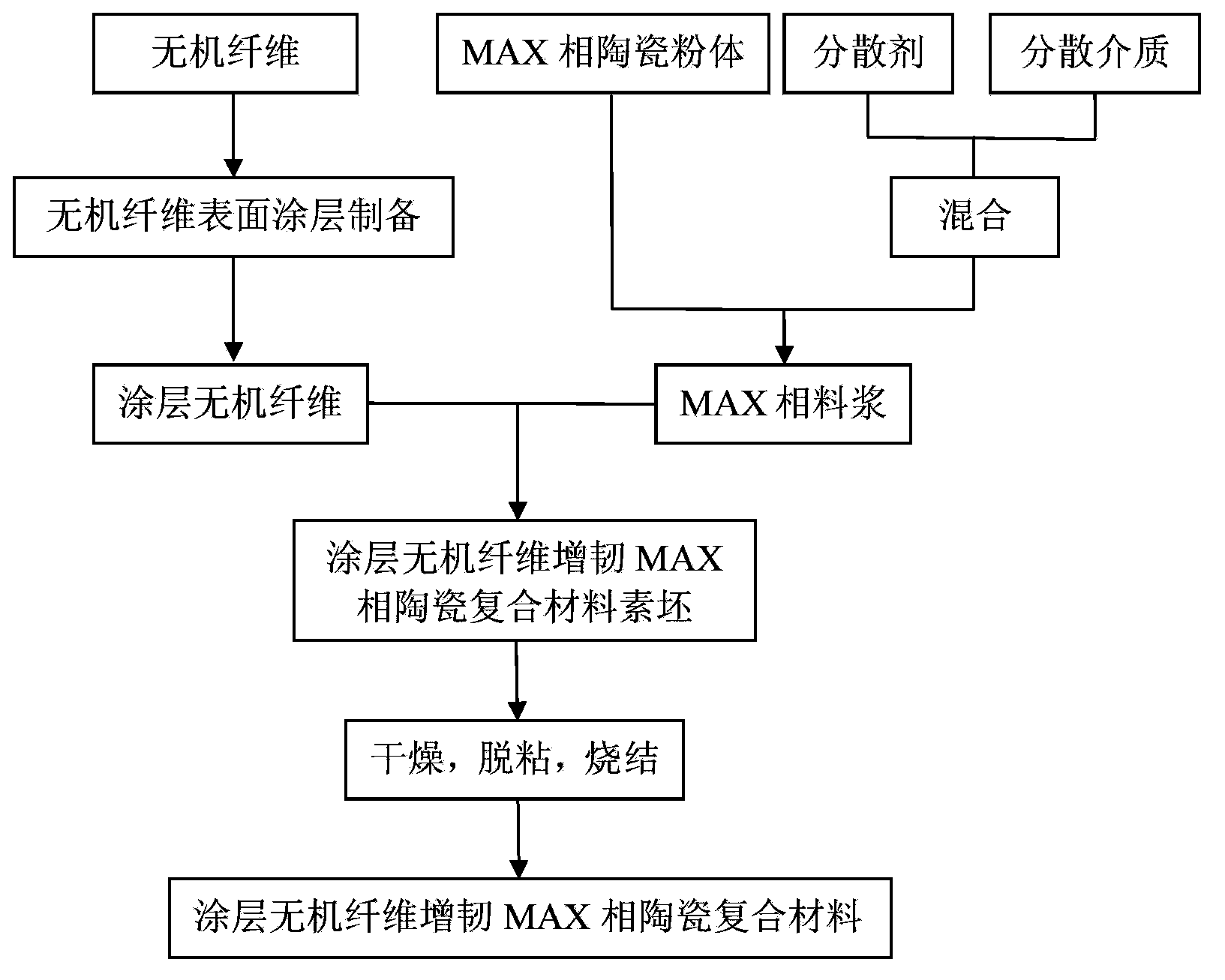

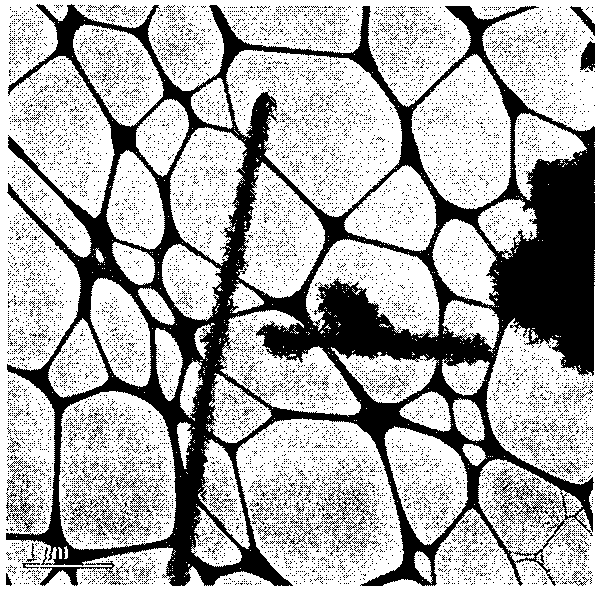

Coating inorganic fiber toughened MAX phase ceramic composite material, preparation method and uses thereof

ActiveCN103910532AAppropriate bonding interface strengthFree control of interface strengthNuclear energy generationContainmentAviationFiber

The present invention provides a coating inorganic fiber toughened MAX phase ceramic composite material and a preparation method thereof. The composite material adopts a MAX phase ceramic material as a matrix and adopts coating inorganic fibers as a toughening phase, wherein the coating inorganic fiber content is 0.5-90% (by volume), and the coating inorganic fibers are completely dispersed in the matrix and are inorganic fibers with the surface coated with the coating. Compared with the composite material in the prior art, the composite material of the present invention has the following characteristics that: the interface reaction between the inorganic fibers and the MAX phase ceramic can be effectively inhibited, the thermal expansion coefficient and elasticity modulus matching degree between the inorganic fibers and the MAX phase ceramic can be effective regulated, the effective improvement of the fracture toughness and the high temperature resistance of the MAX phase ceramic composite material can be achieved, the problems of high brittleness and insufficient use reliability of the MAX phase ceramic can be fundamentally solved, and the coating inorganic fiber toughened MAX phase ceramic composite material has potential application prospects in the high technology fields of civil use, aviation, aerospace, nuclear industry and the like, and is especially for the fission and fusion reactor nuclear power plant inner wall structure material.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

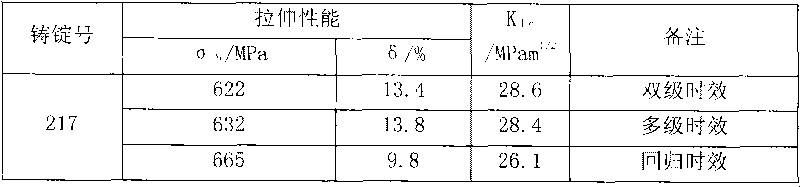

High-toughness aluminum lithium alloy and preparation method thereof

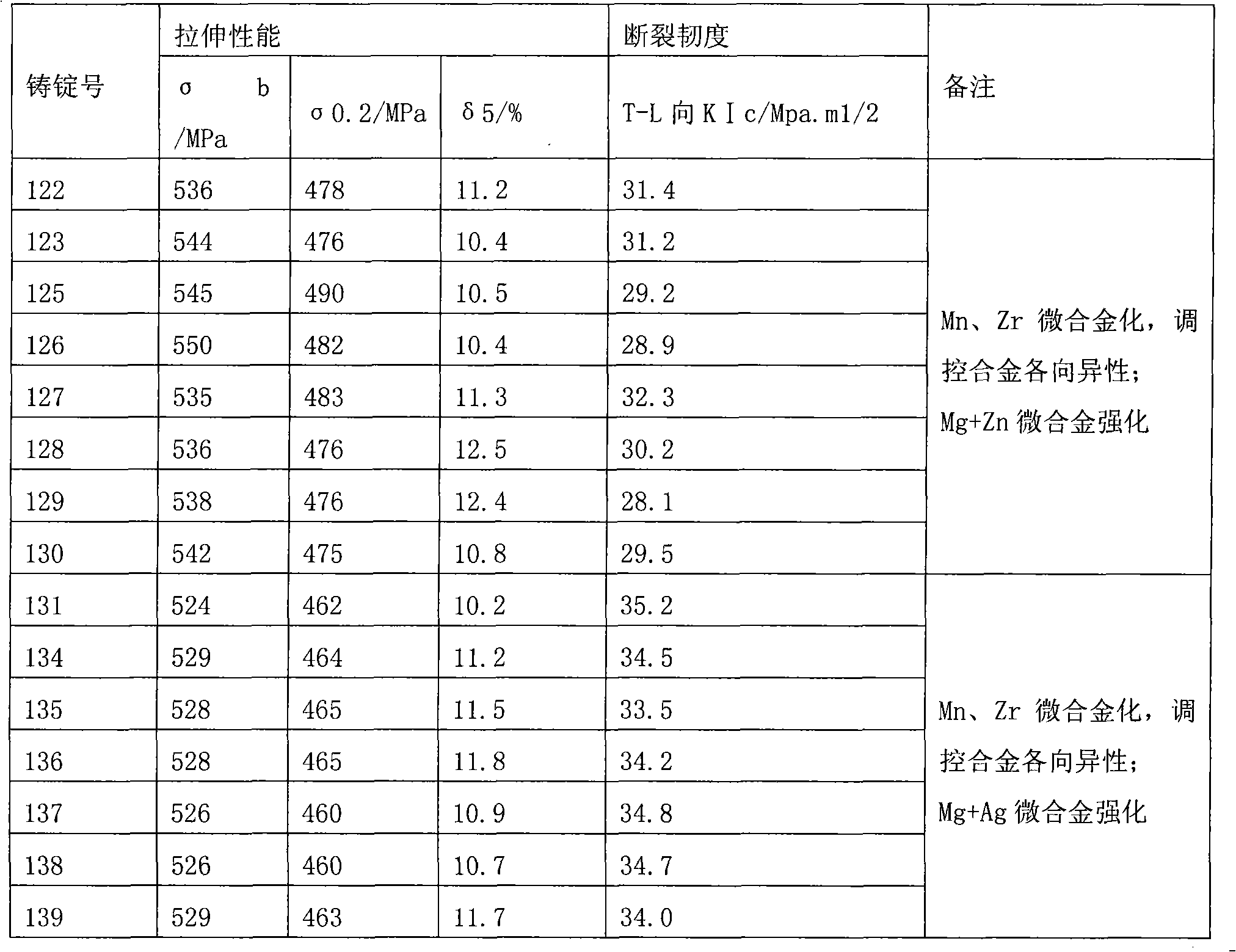

The invention discloses a high-toughness aluminum lithium alloy and a preparation method thereof. The alloy comprises the following chemical components in percentage by weight: 3.2 to 4.2 percent of Cu, 0.7 to 1.8 percent of Li, 0.20 to 0.60 percent of Mn, 0.20 to 0.60 percent of Zn, 0.06 to 0.20 percent of Zr, 0.20 to 0.80 percent of Mg, 0.2 to 0.7 percent of Ag, less than or equal to 0.10 percent of Si, less than or equal to 0.10 percent of Fe, less than or equal to 0.12 percent of Ti, less than or equal to 0.15 percent of other impurities (single impurity is less than or equal to 0.05 percent) and the balance of Al. One or five of alloy elements Mn, Zn, Mg, Ag and Zr can be selectively added. Proportioning is performed according to the alloy components, the raw materials are melted, then furnace refining and standing are performed, and alloy ingots with required specifications are cast. The alloy ingots are preferably homogenized and then molded by any process of hot extruding, hot rolling and the like, and the alloy ingots thermally treated by the preferable process can be used for processing parts. The high-toughness aluminum lithium alloy material has uniform microscopic structure and stable performance, and is suitable for manufacturing thick plates and extruded materials. The ultimate tensile strength can reach over 510MPa, and meanwhile, the elongation rate is more than 8 percent and the KIc can reach over 30MPam1 / 2. The material product can be used for structural elements of the fields of aerospace, nuclear industry, traffic and transportation, sports goods, weapons and the like.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

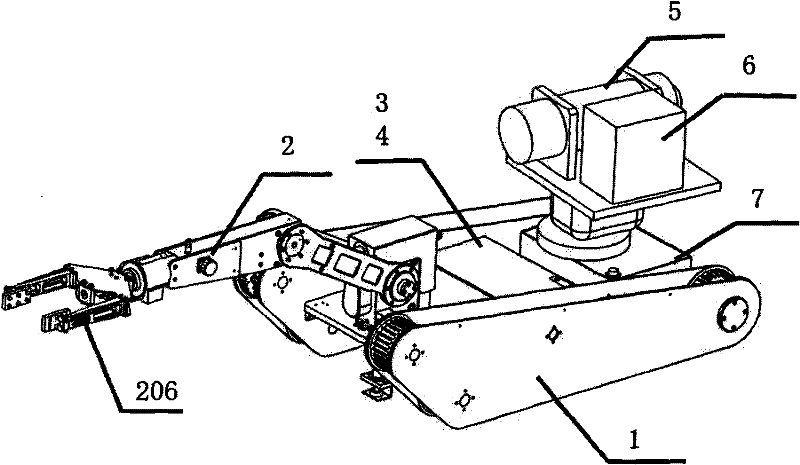

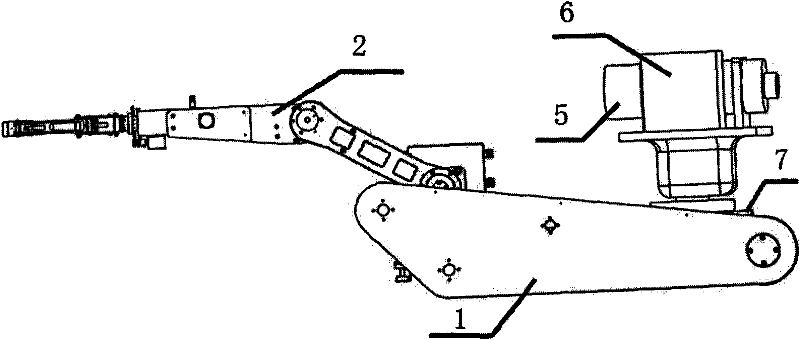

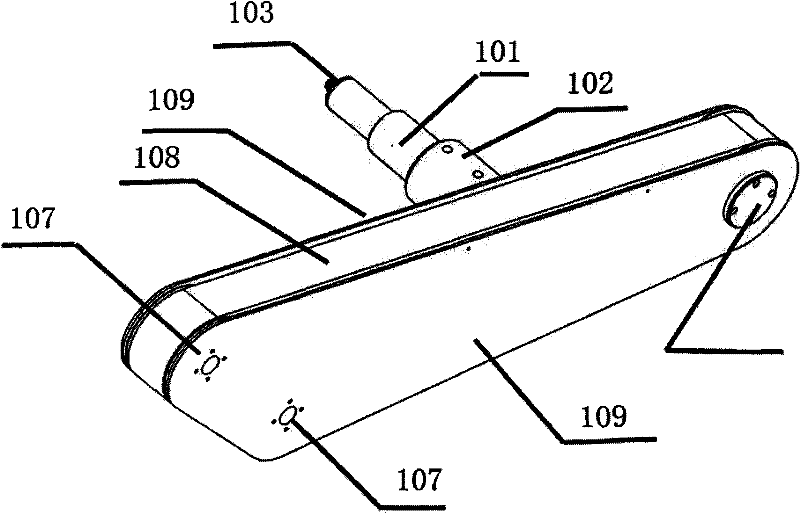

Small-sized emergency rescue and detection robot for nuclear radiation environment

InactiveCN102233575AImprove passabilityImprove stabilityProgramme-controlled manipulatorBreathing protectionRescue robotEmergency rescue

The invention belongs to the field of special equipment for nuclear industries, and in particular relates to an emergency treatment and rescue robot which can be used for a nuclear radiation environment. The robot consists of a walking base plate, a mechanical arm, a robot body motion control system, a robot redundancy navigation control system, a gamma camera, a holder, a gamma ray imaging system, a battery and a controller, wherein the walking base plate has a crawler-type structure; a motor is arranged in the middle of the base plate and is used for driving a crawler belt to operate through a chain; the mechanical arm is arranged at the front end of the base plate and has four degree of freedom; the gamma camera and the imaging system are positioned on the rear part of the robot and are arranged above the battery; and the gamma camera can be used for detecting the intensity and the direction of radiation and the robot can perform emergency treatment through the mechanical arm of the robot.

Owner:BEIHANG UNIV

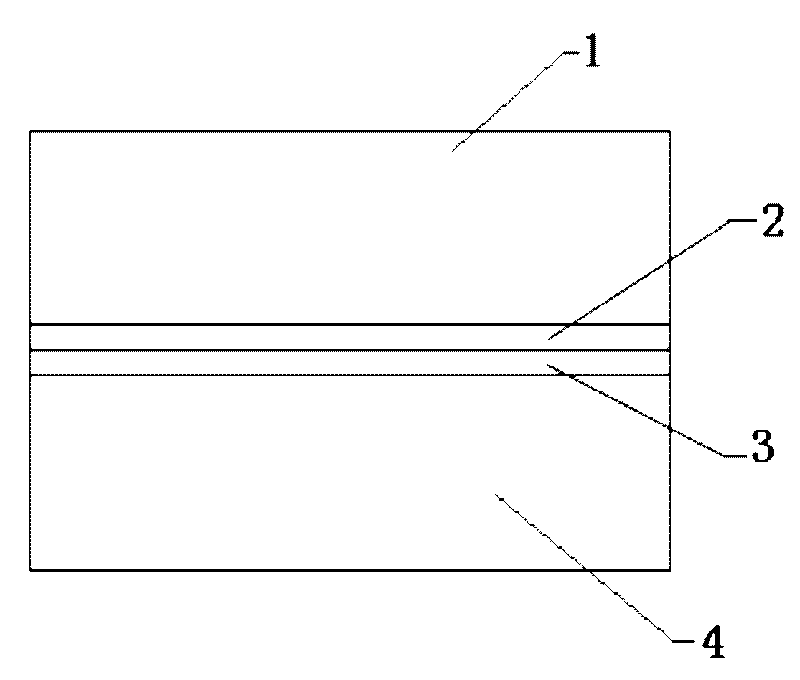

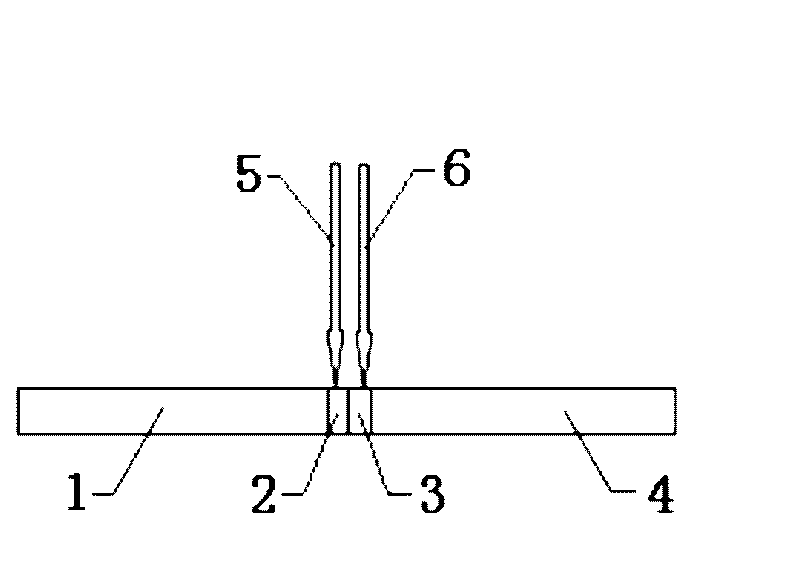

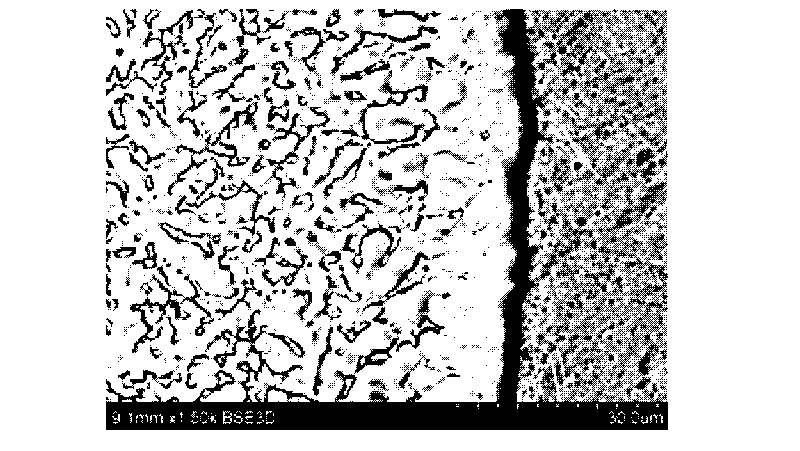

Method for controlling brittle phases of titanium and stainless steel electronic beam welding joints adopting composite intermediate layers

InactiveCN101722356AElectron beam welding apparatusWelding/soldering/cutting articlesAcid washingTitanium alloy

The invention relates to a method for controlling the brittle phases of titanium and stainless steel electronic beam welding joints adopting composite intermediate layers, belonging to the welding field of heterogeneous difficult-welding metal. The invention solves the problem that the tradition metal and stainless steel welding method can not avoid the generation of the brittle phases. The method comprises the following steps of: using pure copper and pure vanadium as the intermediate layers to form members to be welded, wherein the members to be welded consist of stainless steel, pure copper, pure vanadium and titanium, ultrasonically cleaning the members to be welded by acetone, drying the members to be welded after acid washing and water washing, and then performing secondary electronic beam welding in vacuum. The joints obtained by the method have no brittle phases, the tensile strength of the joints is greater than 299 MPa, and the yield strength is greater than 260 MPa. The method is suitable for manufacturing thrust chamber bodies of aircraft engines, nuclear fuel processing equipment in nuclear industry, and titanium / steel composite members and titanium alloy / steel composite members in chemical and medical equipment.

Owner:HARBIN INST OF TECH

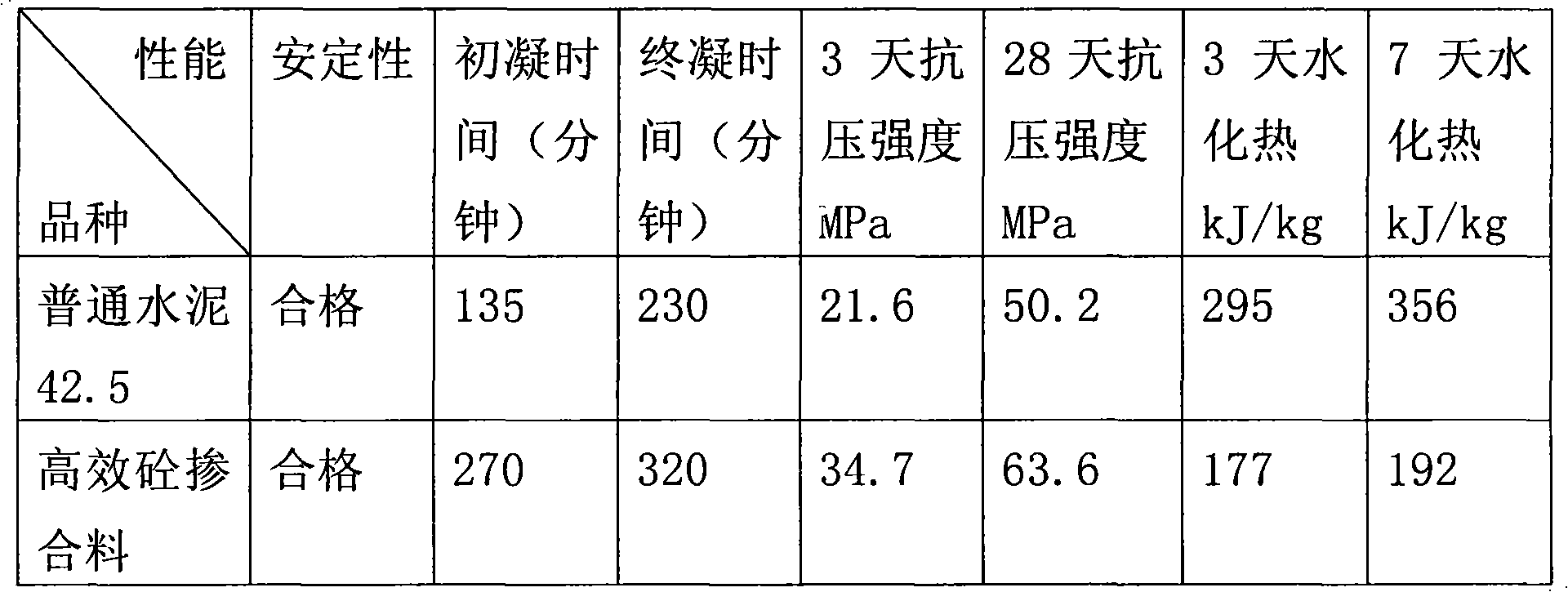

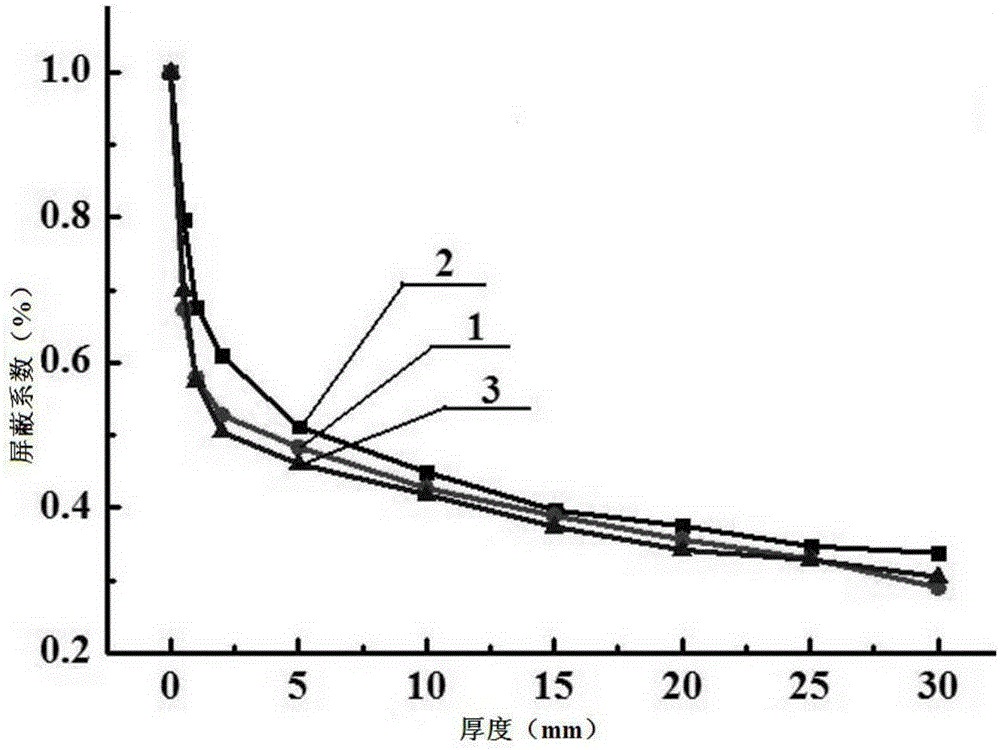

Premixed and pumped heavy concrete

InactiveCN101676239AGuaranteed homogeneityGuaranteed uniformitySolid waste managementApparent densityParticle accelerator

The invention relates to a premixed and pumped heavy concrete which comprises 80-93 parts by weight of heavy aggregate, 6-15 parts by weight of cement materials, 2-5 parts by weight of water, less than 0.4 part by weight of concrete additive and less than 0.01 part by weight of function regulator. The apparent density of the concrete is more than 3500kg / m<3>, the mixture has no phenomena of lamination and segregation, and the concrete has good cohesion and plasticity protection, thereby being applicable to long-distance pumping. The concrete selects a high-performance concrete admixture and can avoid the occurrence of cracks of the large-volume concrete caused by hydration heat of cement. The concrete is applicable to an anti-radiation heavy concrete engineering with the thickness of morethan 1500mm. The concrete can be widely used in shielding places of nuclear reactors, medical particle accelerators, customs inspection, scientific research laboratories and other applications of therelated nuclear industry and the radioactive isotope technology.

Owner:HUNAN NO 6 ENG CO LTD

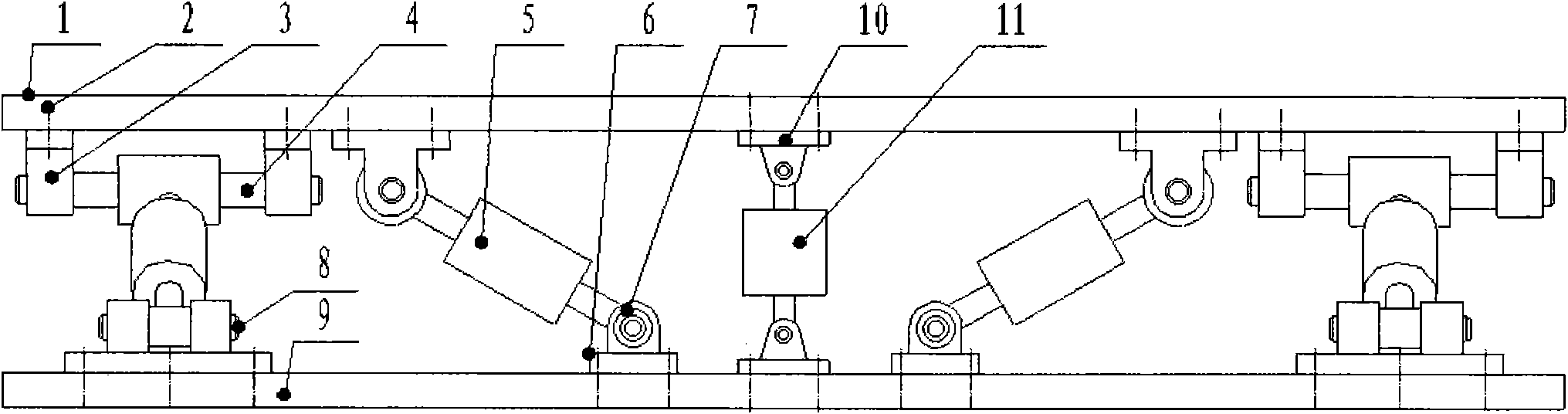

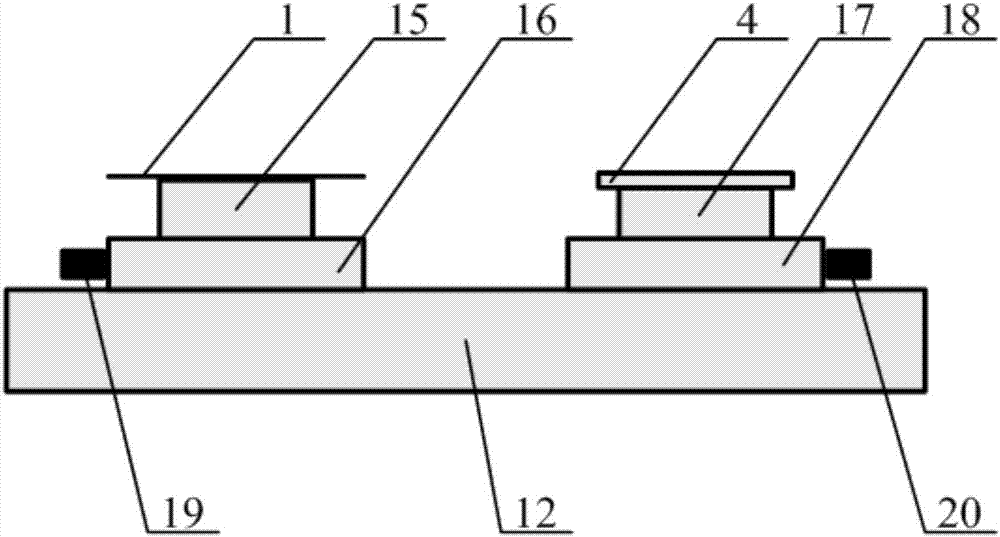

Positive and negative stiffness parallel three-translation vibration and impact isolation platform

InactiveCN101871505AImprove the dynamic environmentGuaranteed operating vibration parametersNon-rotating vibration suppressionAviationVibration control

The invention discloses a positive and negative stiffness parallel three-translation vibration and impact isolation platform, and belongs to the field of the multi-axis vibration control technology and multi-axis vibration control devices, which comprises an upper platform (1), a lower platform (9), eight elastic branched-chain structures and a silica gel magnetorheological damper (11), wherein the eight elastic branched-chain structures are fixed between the upper platform (1) and the lower platform (9) two by two in an orthogonally symmetrical four-point supporting mode; the axes of the two elastic branched-chain structures of each point are vertical mutually; and the silica gel magnetorheological damper (11) is arranged in the geometric center between the upper platform (1) and the lower platform (9). The positive and negative stiffness parallel three-translation vibration and impact isolation platform can be widely used for instruments and equipment in fields of aviation, space flight, weapons, vehicles, ships, construction, nuclear industry, mechanical industry, optical industry, semiconductor industry, photosensitive chemistry and the like, and has the advantages of large carrying capacity, high stability, small volume, low natural frequency, controlled damping, low cost of manufacturing and maintenance and the like.

Owner:SHANGHAI HIGHER MECHANICAL & ELECTRICAL

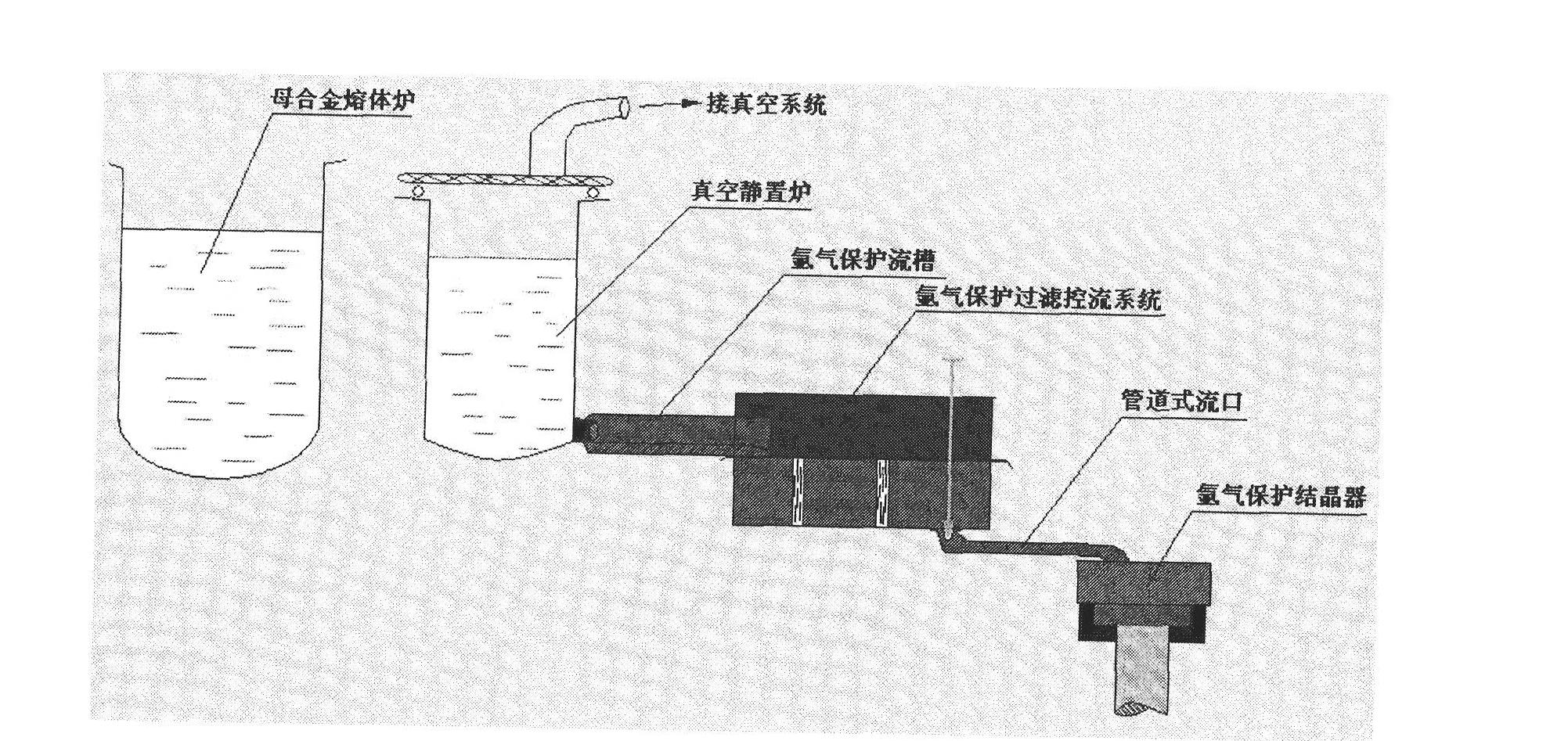

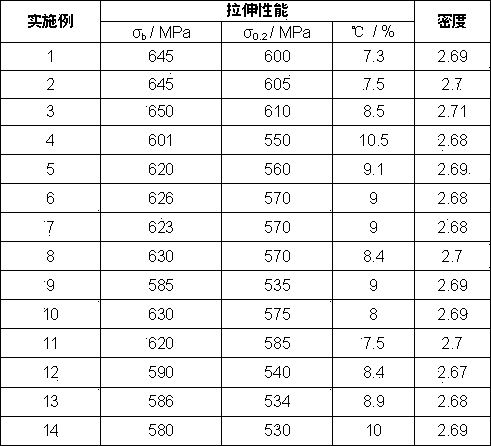

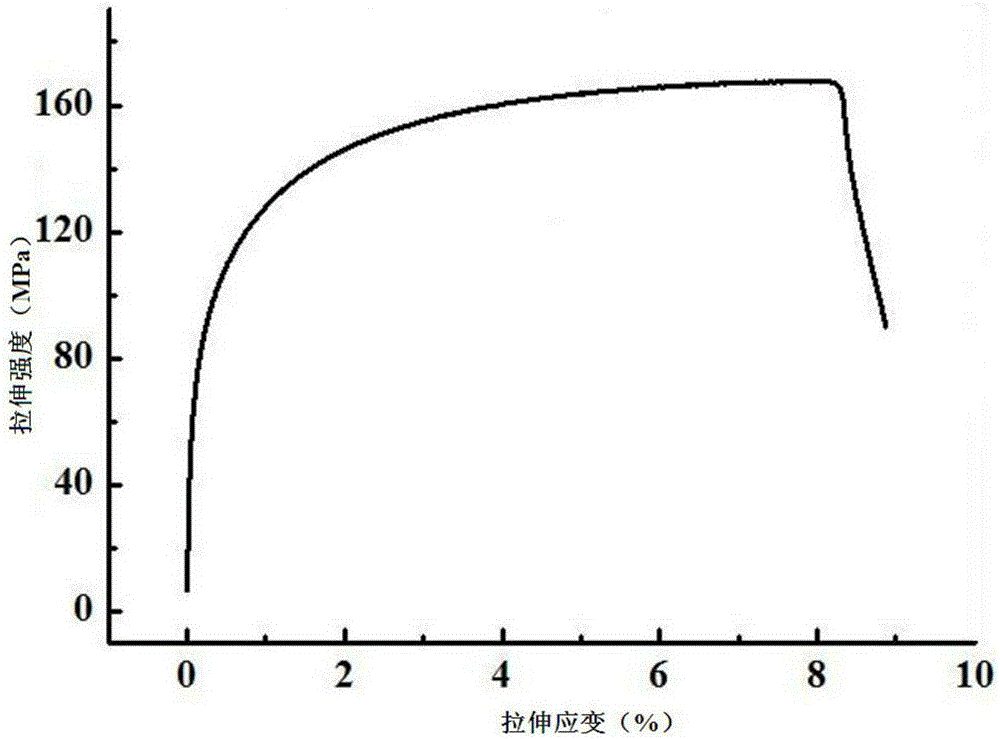

Ultrahigh strength aluminum lithium alloy and preparation method thereof

The invention discloses ultrahigh strength aluminum lithium alloy and a preparation method thereof. The ultrahigh strength aluminum lithium alloy comprises the following microelements by mass percent: 3.5 to 4.5 percent of Cu, 1.0 to 1.6 percent of Li, 0.30 to 0.70 percent of Mg, 0.2 to 0.70 percent of Ag, 0.30 to 0.80 percent of Zn, 0.20 to 0.50 percent of Mn, 0.06 to 0.16 percent of Zr, less than 0.10 percent of impurity Si, less than 0.10 percent of Fe, less than 0.05 percent of other single impurity, and the balance of Al, wherein the total amount of other impurities is less than 0.15 percent. The method comprises the steps of compounding microelements of Mg, Ag and Zn, microalloying and strengthening the microelements, performing batching according to alloy constituents, melting the raw materials, performing refining and standing on the raw material in a furnace, and casting the raw material into alloy ingots satisfying required specifications. Plates manufactured through the alloy have the advantages that the tensile strength can reach more than 580MPa, the elongation percentage is higher than 7 percent at the same time, and the plates can be applied to structural elements in fields of aerospace, nuclear industry, transportation, weapons and the like.

Owner:CENT SOUTH UNIV +1

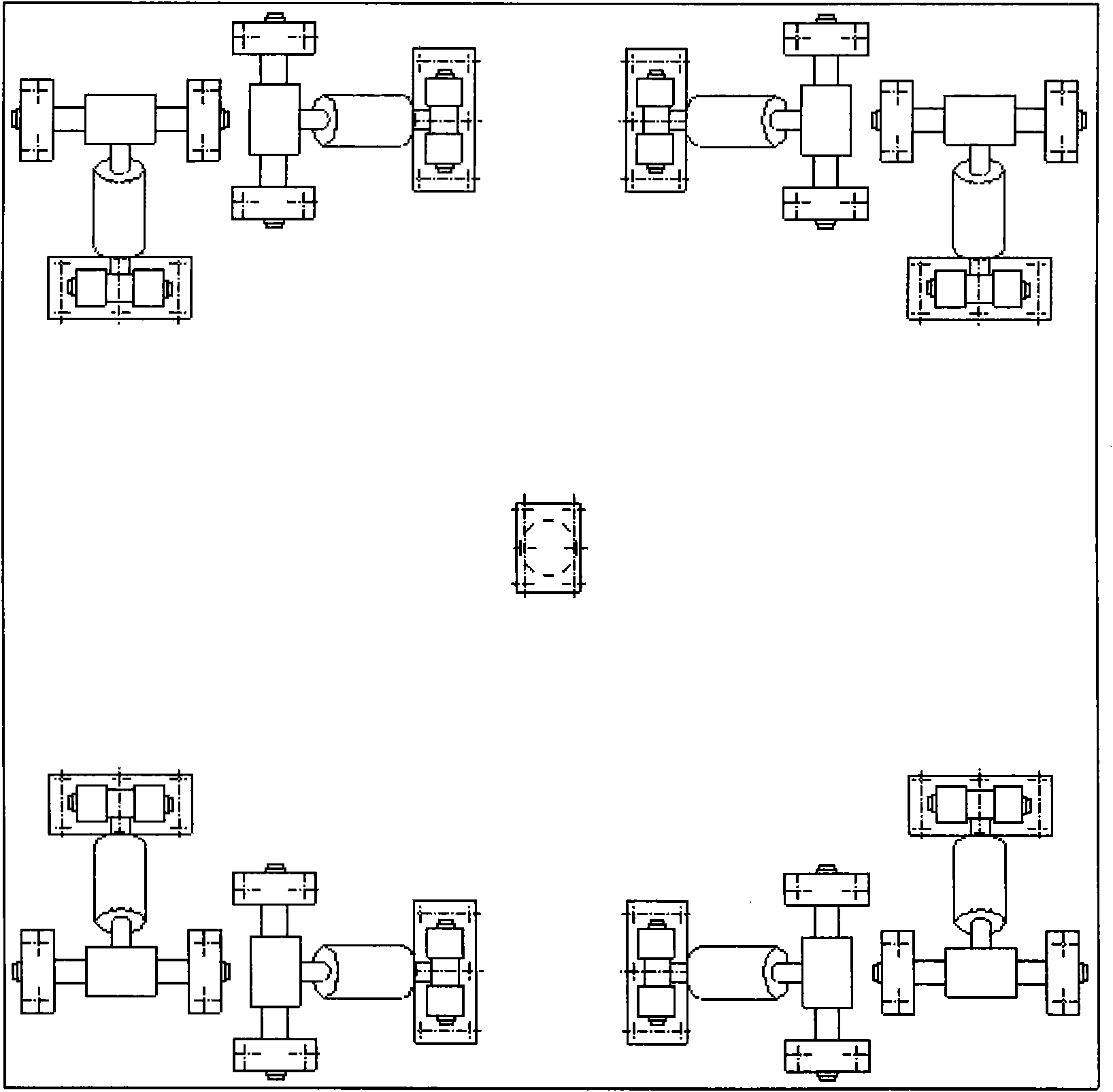

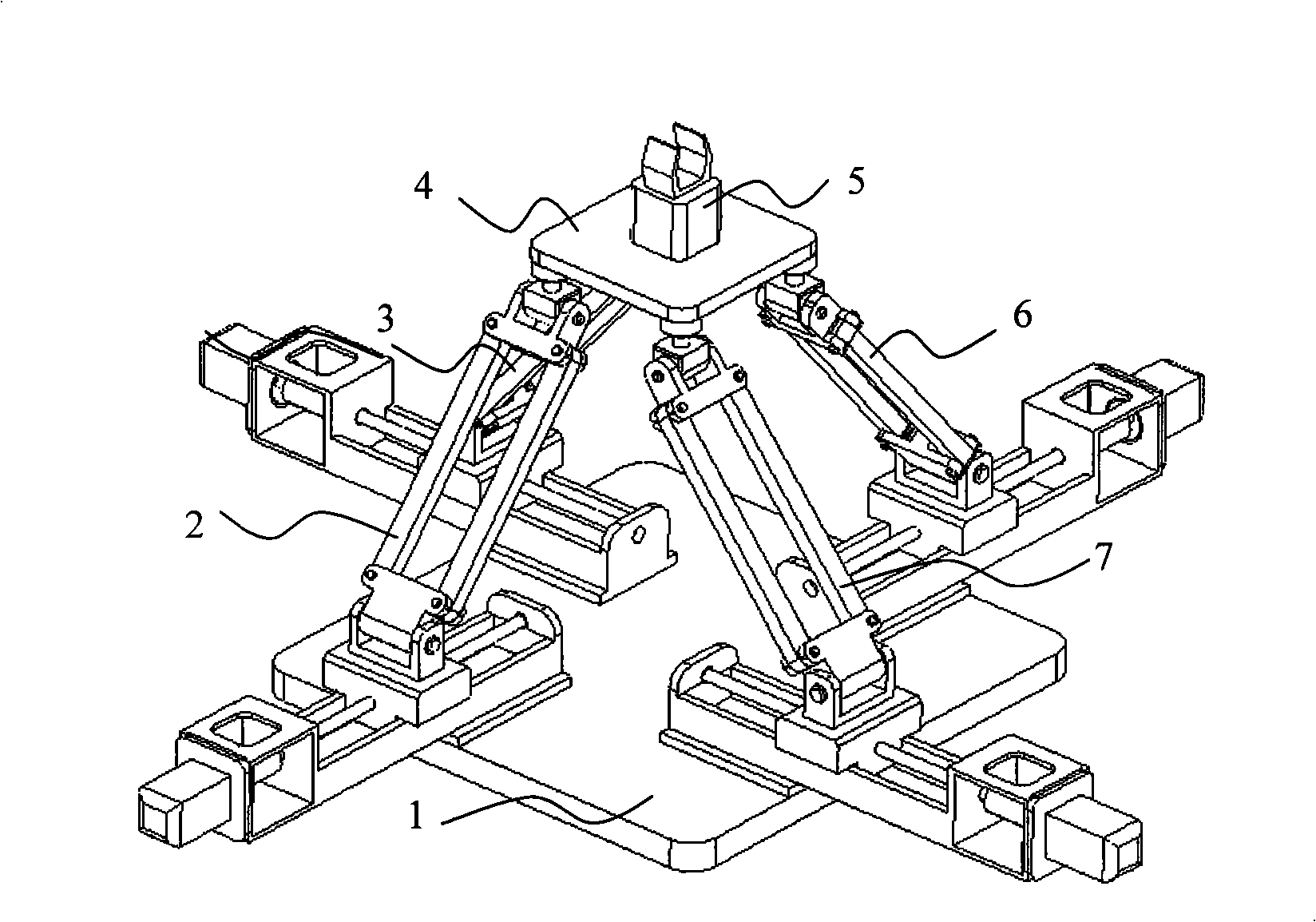

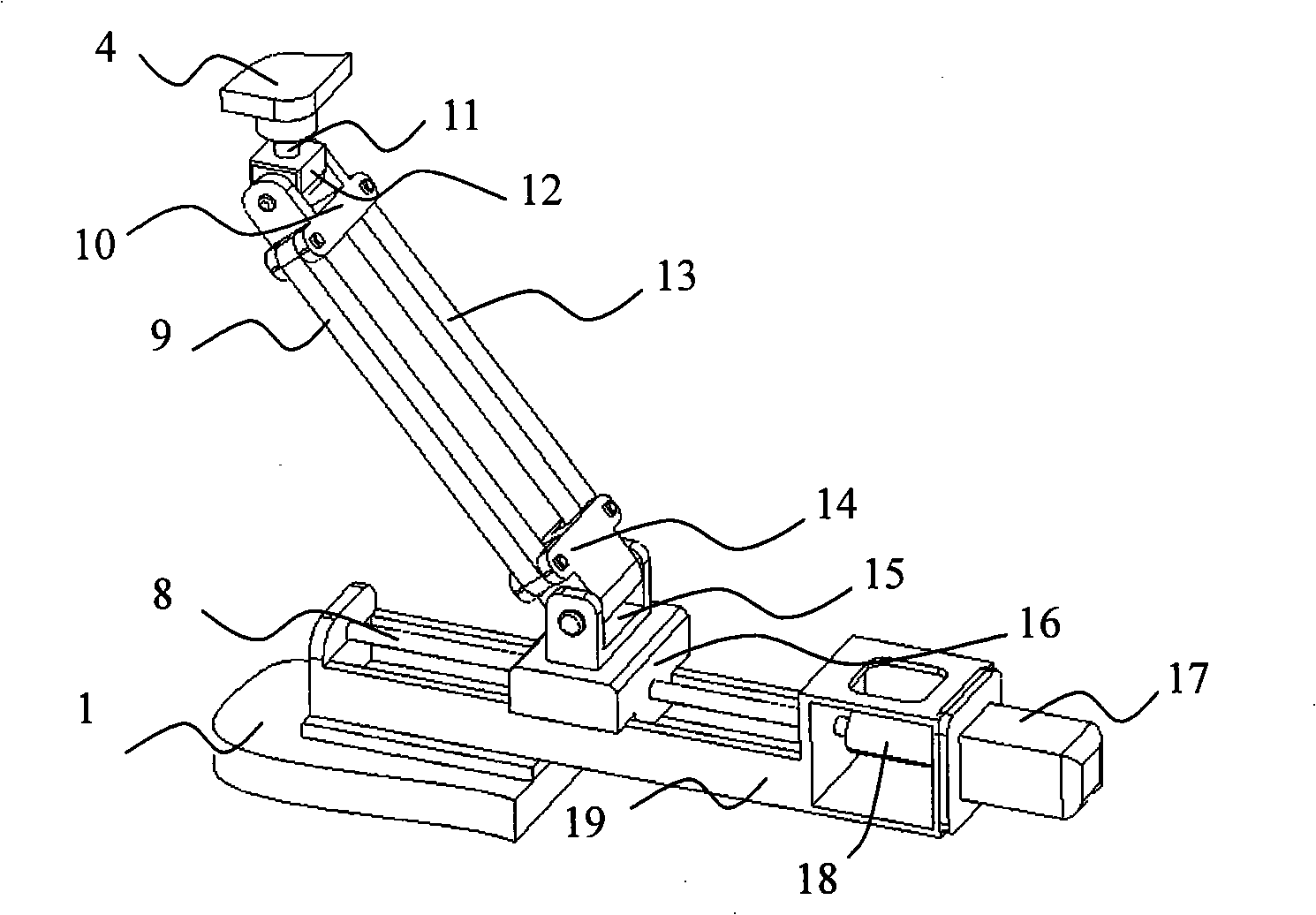

Four-freedom degree industrial robot

The invention discloses a four-DOF industrial robot, which comprises a pedestal (1), a moving platform (4), and a tool or a clamp (5), wherein the tool or the clamp (5) is arranged on the moving platform (4). The four-DOF industrial robot is characterized in that the pedestal (1) is connected with the moving platform (4) through four moving branched chains (2, 3, 6, 7) with same structures, four connecting rods (9, 10, 13, 14) in the moving branched chains are connected one another through four rotating pairs to form a parallelogram mechanism, the connecting rod (10) is connected with a rotating shaft (11) vertically arranged on the moving platform (4) through the rotating pair (12), and the connecting rod (14) is connected with a sliding table (16) through the rotating pair (15). Under the drive of four straight line movement driving units, the four-DOF industrial robot can realize the three-dimensional movement and the one-dimensional movement of the moving platform (4). The four-DOF industrial robot has the advantages of simple structure, large working space, high precision, strong bearing capacity, good manufacturability and the like, thus the four-DOF industrial robot can be applied in the modern industry fields of automobiles, electronics, nuclear industry, aerospace and the like.

Owner:YANSHAN UNIV

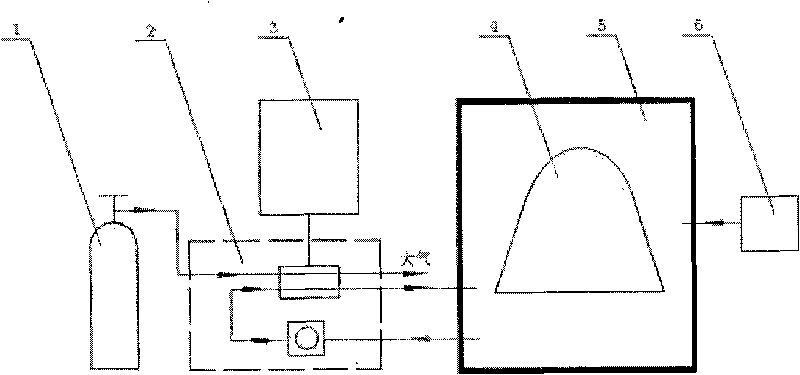

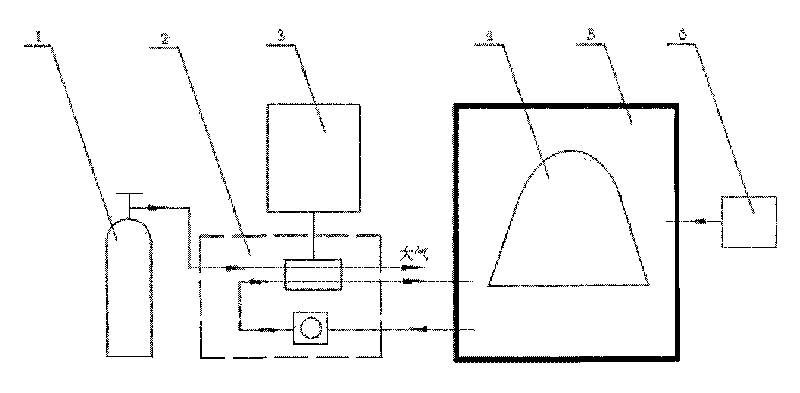

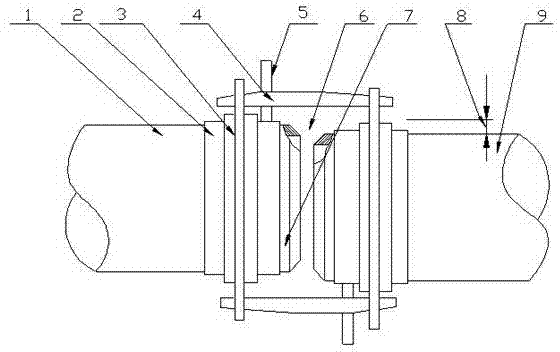

Atmosphere accumulation leak detection system and leak detection method thereof

InactiveCN101738294ACause damageOriginal designDetection of fluid at leakage pointAviationEngineering

The invention provides an atmosphere accumulation leak detection system which comprises a collector, a leak detector, an atmosphere reference gas source, a probe gas sampling system and a leak rate calibration system. The invention also provides an atmosphere accumulation leak detection method. The leak detection system and the leak detection method are suitable for the total leak rate detection of large-size workpieces of the aerospace industry, ships, vehicles, the nuclear industry, and the like, and meanwhile, the leak detection system and the leak detection method are also suitable for smaller workpieces having sealing requirements of other industries. The detection method belongs to the range of non-contact nondestructive detection, cannot do any damage to detected pieces and completely conforms to national relative standards of nondestructive detection.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

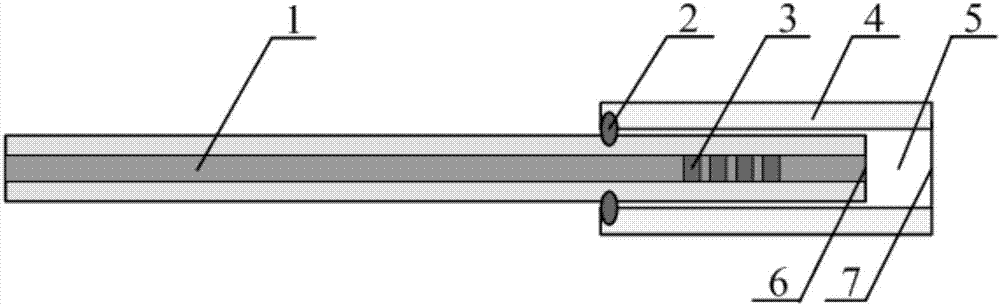

A capillary type fiber grating high-temperature sensor and a manufacturing method thereof

InactiveCN107014520ASmall structure sizeAvoid problems with large differences in thermal compatibilityThermometers using physical/chemical changesFiberGrating

The invention relates to a capillary type fiber grating high-temperature sensor and a manufacturing method thereof applicable to precision measurement of high temperatures such as structural member surface temperatures and air-flow temperatures in the fields of spaceflight, weapons, nuclear industry, etc. The invention belongs to the technical field of optical fiber sensing measurement. The sensor comprises fiber gratings as temperature measurement sensing elements and a non-metallic capillary as a package structure. A method of welding is used to achieve the integrated packaging of an optical fiber and the capillary, thereby reducing the size of a sensor structure, reducing influences by thermal mismatch between the packaging structure and the optical fiber, avoiding easy aging and creep caused by adhesive, avoiding softening and decomposition at high temperatures and improving the sensor operating temperature range as well as the long-term stability and reliability of working in high temperature and other harsh environments. The sensor and the manufacturing method thereof can be applied to precision measurement of high temperatures such as structural member surface temperatures and air-flow temperatures in the fields of aerospace, weapons, nuclear industry, etc.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

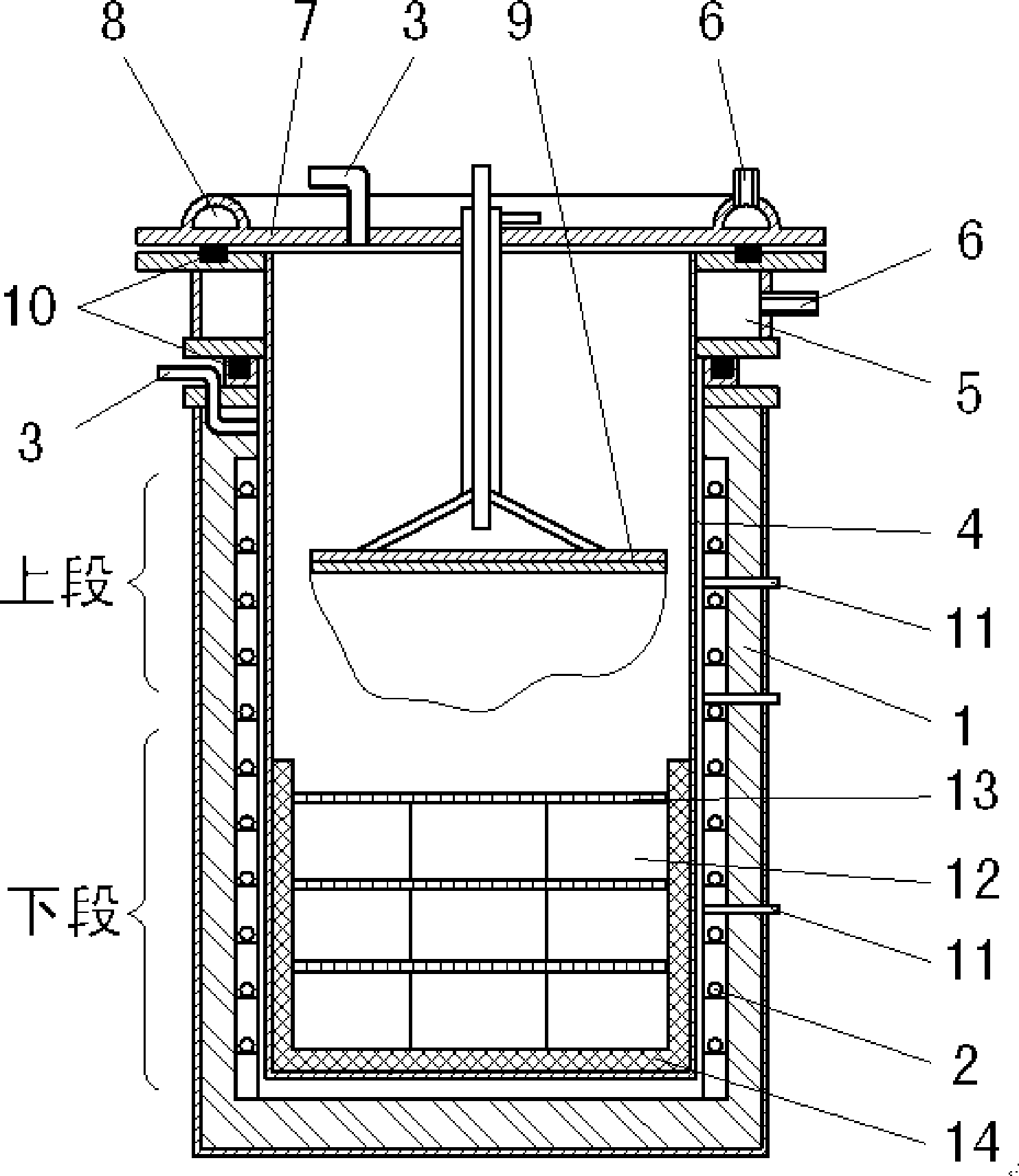

High-pure magnesium preparation method and apparatus

Owner:GUIYANG AL-MG DESIGN & RES INST

Neutron absorbing material and preparation method thereof

A neutron absorbing material and its preparation method relate to a neutron absorbing material and its preparation method. The invention aims to solve the problem that existing spent fuel shielding materials cannot ensure neutron shielding property of a composite material, and plasticity of a composite material can be enhanced. The neutron absorbing material is prepared from, by volume, 10-20% of boron carbide, 1-2% of a neutron absorber and 78-89% of aluminium or aluminium alloy. The preparation method comprises the following steps: 1, weighing; 2, drying; 3, ball-milling and mixing; and 4, cold pressing for blank-making and hot pressed sintering. The neutron absorbing material prepared in the invention has high shielding property, has good plasticity, is easy for machine-shaping, can meet requirements of densification and long-term tendency for spent fuel storage, and is an ideal spent fuel storage grid material. The neutron absorbing material of the invention is used in the field of neutron radiation shielding in nuclear industry.

Owner:HARBIN INST OF TECH

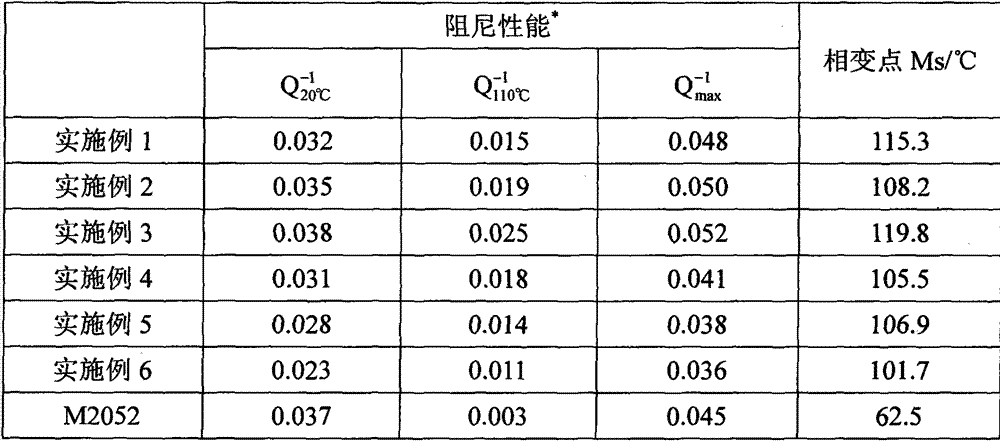

High-damping Mn-Cu damping alloy and manufacturing method thereof

ActiveCN104762540AIncrease temperatureImprove hot and cold working performanceRare earthNoise reduction

The invention provides a high-damping Mn-Cu damping alloy and a manufacturing method thereof. The alloy comprises chemical components of: 60.00-75.00 wt% of 2.00-5.00 wt% of Ni, 0.50-3.00 wt% of Al, 1.50-2.50 wt% of Fe, no more than 0.01 wt% of C, no more than 0.10 wt% of Si, less than 0.020 wt% of P, less than 0.020 wt% of S, no more than 0.050 wt% of N, no more than 0.010 wt% of O, one or more selected from Zr, Ti, La, Ce, Y and mixed rare earth (Mm), and the balance of Cu and inevitable impurities. After heat treatment, the alloy has damping performances as follows: Q<-1><max> of 0.035-0.055, Q<20 DEG C> <-1> of 0.020-0.040, and Q<110 DEG C> <-1> of 0.010-0.030. The alloy has high damping capacity, good temperature stability, wide temperature range, high strength and good processability, can be processed into sectional material and strips, is applicable to the parts requiring vibration and noise reduction in the fields of aviation and space flight, navigation, nuclear industry, automobile manufacturing, electrical equipment and precision instruments and instrumentation, and can play the roles of reducing the vibration transmission, reducing noise and prolonging the service life of structural components.

Owner:BEIJING BEIYE FUNCTIONAL MATERIALS CORP

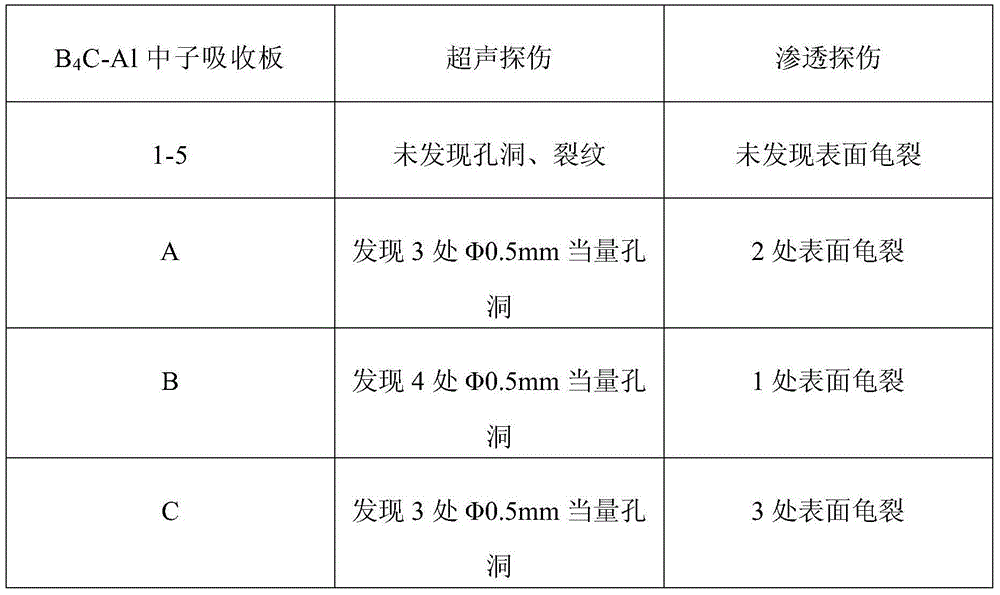

Large-dimension B4C-Al neutron absorption plate and preparation method thereof

InactiveCN104372191ANo need for sintering processOvercoming the problem of further increase in defectsShieldingNuclear reactorNuclear power

A disclosed preparation method for a large-dimension B4C-Al neutron absorption plate comprises: 1) crushing boron carbide powder, aluminium powder and silicon powder and mixing uniformly, so as to obtain a mixed powder with the particle size of 3.5-63 mu m; 2) putting the mixed powder into a can, vacuumizing at 200-350 DEG C, sealing, and then performing heat isostatic pressing processing on the sealed can under the conditions that the pressure is 80-150 MPa, the temperature is 400-600 DEG C and the time is 20 min; 3) removing the can at the outer side of the blank material, performing multiple times of rolling at 450-600 DEG C, controlling the deformation amount of each time rolling to be 10-20%, so as to obtain a plate with the needed thickness; and 4) processing the plate. The invention also discloses the dimension of the B4C-Al neutron absorption plate obtained by using the above method. The prepared B4C-Al neutron absorption plate is applicable to nuclear industry fields such as nuclear reactors, nuclear power stations and the like.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD +1

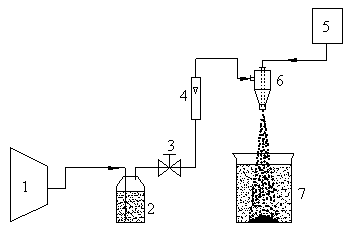

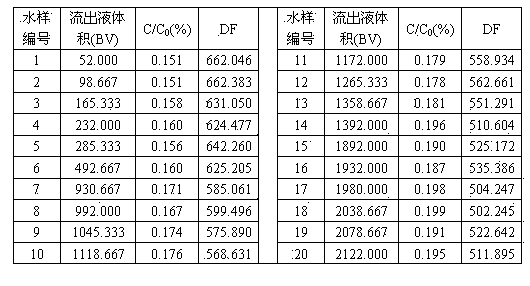

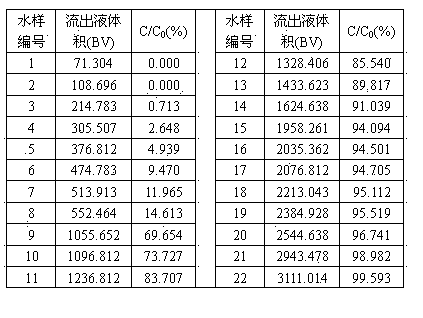

Caesium selective absorbent and preparation method thereof

ActiveCN103831090AHigh selectivitySolve problems unsuitable for fixed bed operationOther chemical processesAlkali metal oxides/hydroxidesLiquid wasteSorbent

The invention provides a caesium selective absorbent and a preparation method of the caesium selective absorbent and belongs to the fields of material preparation and radioactive liquid waste disposal. The caesium selective absorbent is in a sphere-similar particle shape and comprises the following components in parts by weight: 50-90 parts of an inorganic ion exchanging agent and 10-50 parts of polyacrylonitrile, wherein the inorganic ion exchanging agent has high selectivity to caesium. According to the sphere-similar caesium selective absorbent, the high selectivity of the inorganic ion exchanging agent to the caesium is remained, and the caesium selective absorbent is regular in shape and can be uniformly filled in a fixed bed due to the sphere-similar shape, so that the problem that a primary inorganic ion exchanging agent is not suitable for the operation of the fixed bed is solved, and the prepared absorbent can be used for processing radioactive liquid waste generated by nuclear industries and nuclear power stations through the fixed bed. The preparation method is unique and has the advantages of simplicity in operation, mild synthesis condition and the like; a granulating device utilized in the preparation method is simple, is easy to operate and is good in repeatability.

Owner:NAVAL UNIV OF ENG PLA

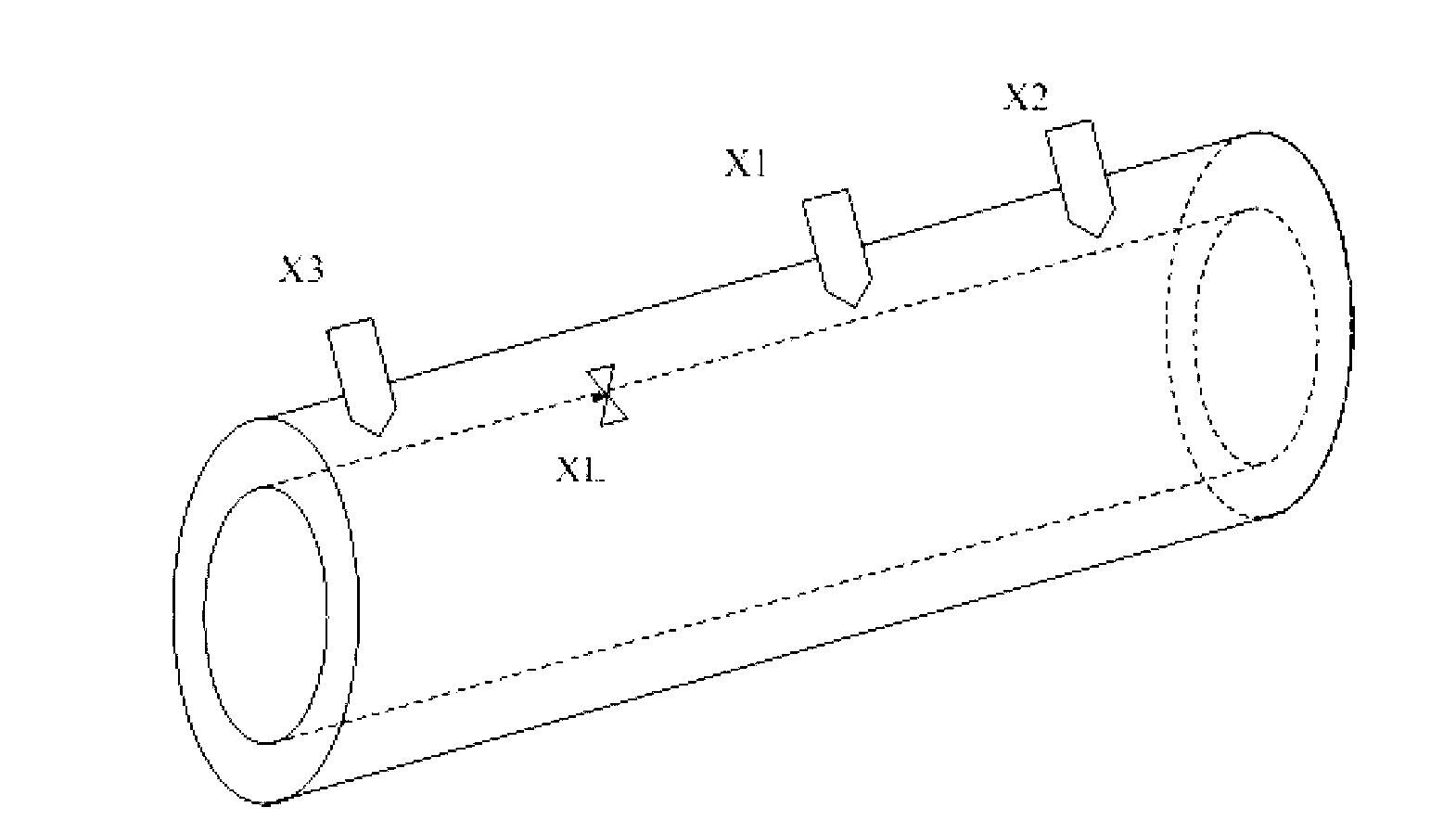

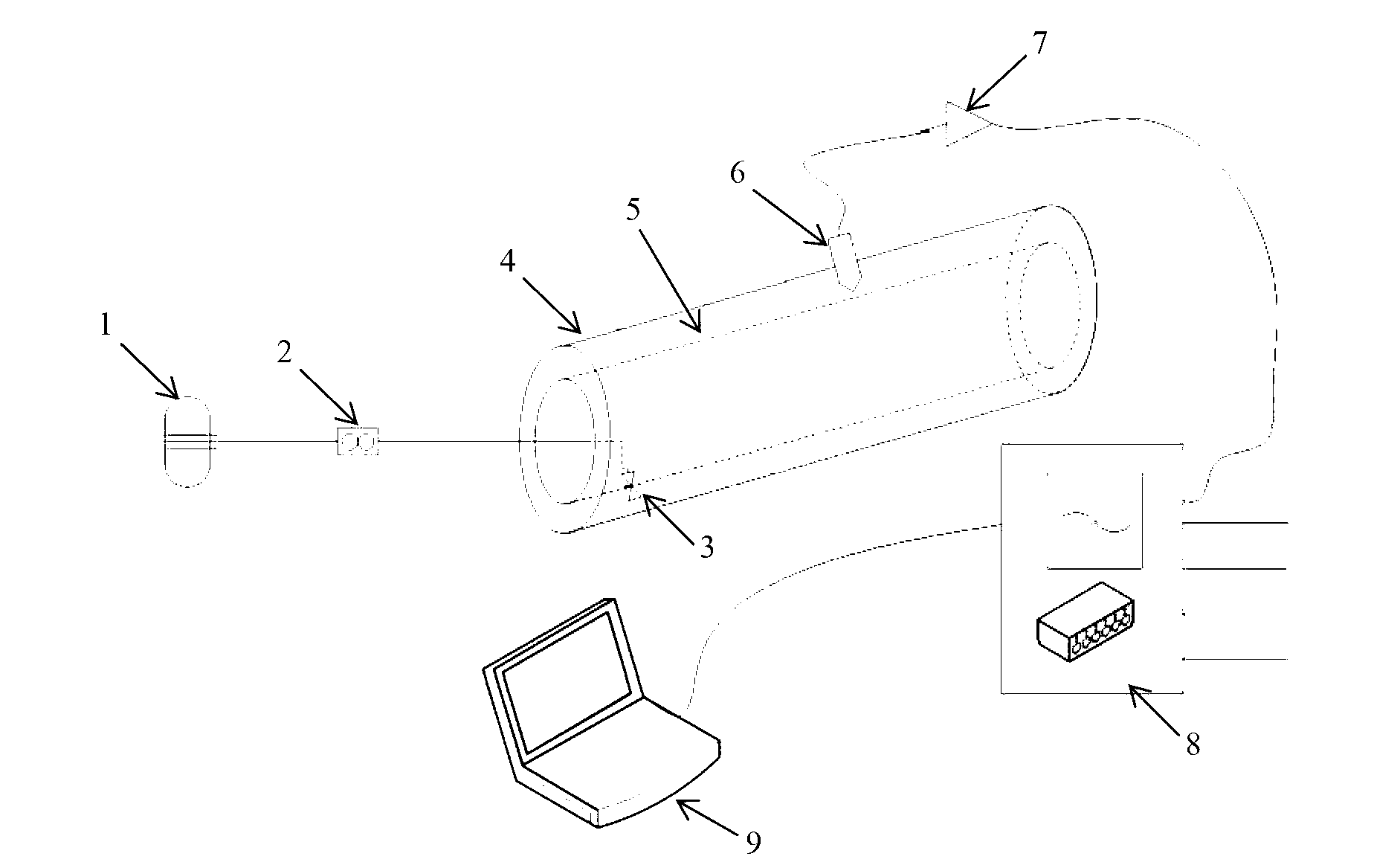

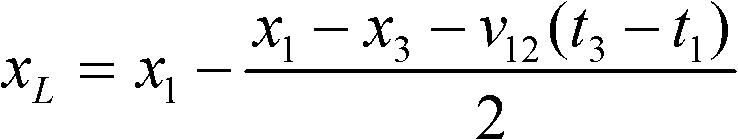

Method and system for temperature and humidity monitoring of high-energy pipeline subject to medium leakage in nuclear power plant

The invention belongs to the technical field of a measurement technique in a nuclear industry, and particularly relates to a method and a system for temperature and humidity monitoring of a high-energy pipeline subject to medium leakage in a nuclear power plant. According to the method, a plurality of temperature probes and humidity probes are added on a transmission channel between the wall of the high-energy pipeline and an insulating layer and are used for measuring changes of the absolute humidity in a channel subject to medium leakage, and the leakage position is identified according to relationships of differences of the time for different probes to receive humidity increase signals; the humidity increase is converted into the overall medium increase in the overall channel after being recorded by the humidity probes, and the leakage rate is calculated through dividing the overall medium increase by the cumulative time; the size of a leakage source is estimated through dividing the volumetric leakage rate of an actual leakage place by the leakage rate based on thermal calculation; and auxiliary judgment of pipelines leakage and leakage positions is performed by the temperature probes according to temperature rise. Risks of breakage of two ends of the high-energy pipeline can be avoided, certain unnecessary facilities can be eliminated, and the complexity and construction cost of a nuclear reactor structure can be reduced.

Owner:CHINA NUCLEAR POWER ENG CO LTD

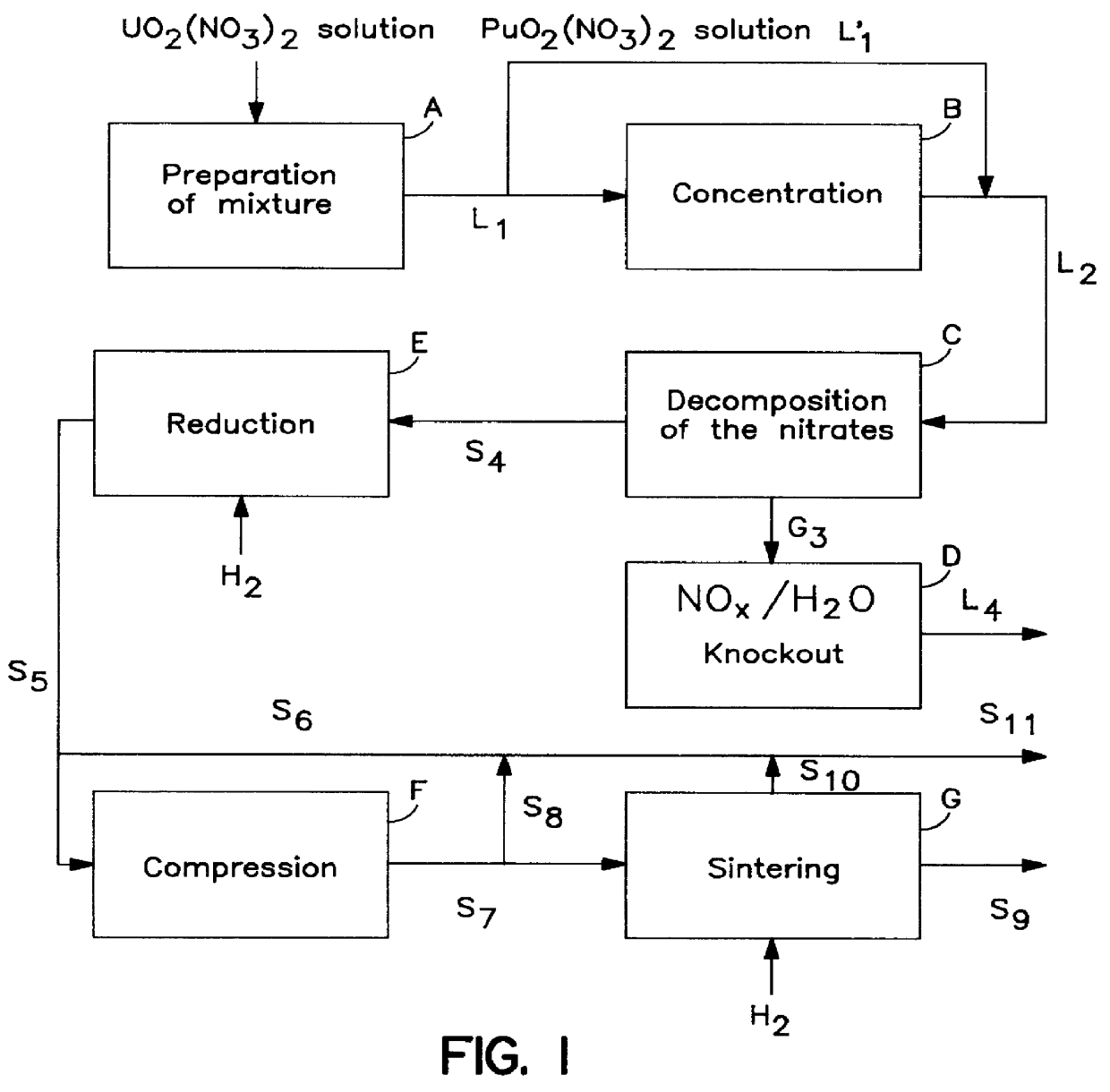

Method for preparing a mixture of powdered metal oxides from nitrates thereof in the nuclear industry

InactiveUS6110437AEasy to recycleImprove responseOxygen/ozone/oxide/hydroxideTransuranic element compoundsPowder mixtureNitrate

PCT No. PCT / FR96 / 01993 Sec. 371 Date Mar. 2, 1999 Sec. 102(e) Date Mar. 2, 1999 PCT Filed Dec. 12, 1996 PCT Pub. No. WO97 / 21629 PCT Pub. Date Jun. 19, 1997A thermal decomposition method useful in the nuclear industry for preparing a powdered mixture of metal oxides having suitable reactivity from nitrates thereof in the form of an aqueous solution or a mixture of solids. According to the method, the solution or the mixture of solids is thermomechanically contacted with a gaseous fluid in the contact area of a reaction chamber, said gaseous fluid being fed into the reaction chamber at the same time as the solution or mixture at a temperature no lower than the decomposition temperature of the nitrates, and having a mechanical energy high enough to generate a fine spray of the solution or a fine dispersion of the solid mixture, and instantly decompose the nitrates. The resulting oxide mixtures may be used to prepare nuclear fuels.

Owner:COMURHEX

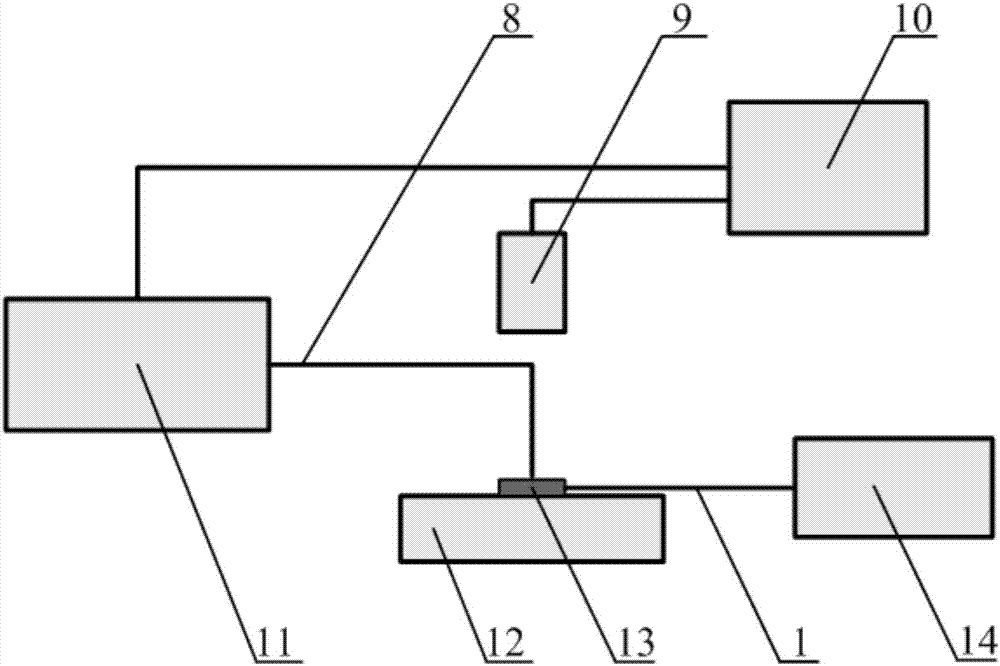

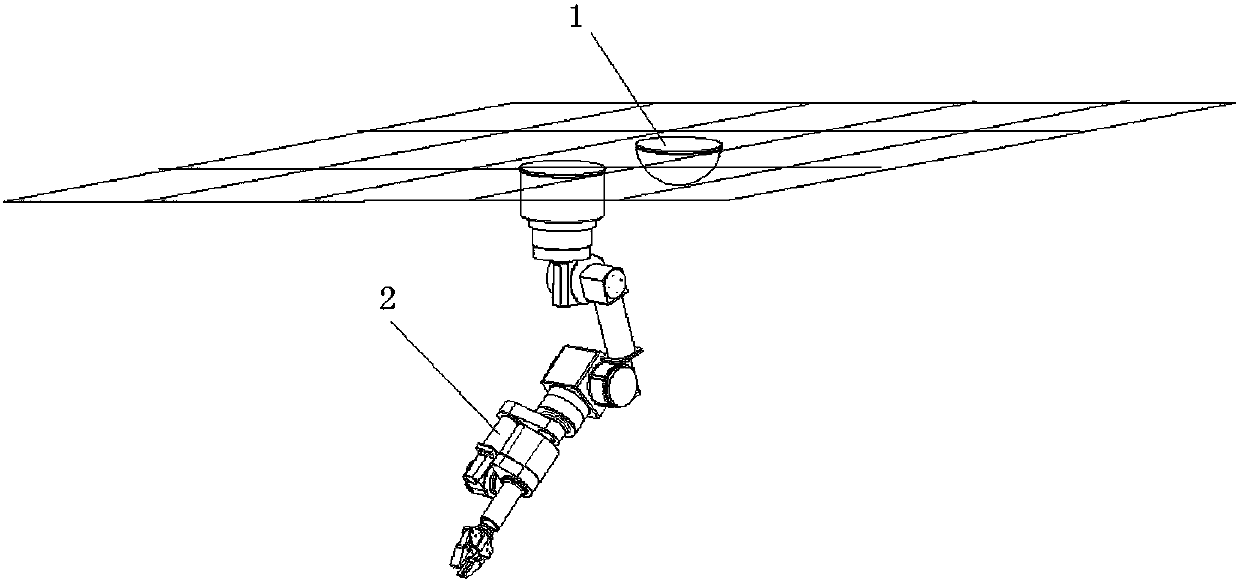

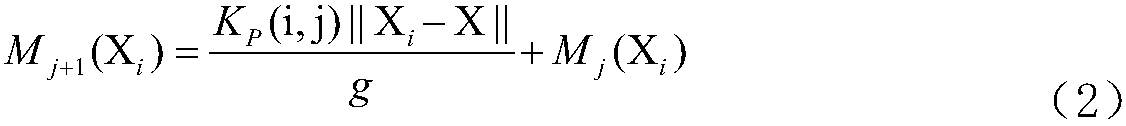

Master-slaver heterogeneous teleoperation control system and method of robot arm with telepresence

InactiveCN107662195AEasy to operateIncrease exerciseProgramme-controlled manipulatorProgramme controlControl systemNuclear power

The invention discloses a positioning method of a master-slaver heterogeneous teleoperation control system of a robot arm with the telepresence. The master-slaver heterogeneous teleoperation control system comprises a global environment monitoring camera, an end monitoring camera, a central controller with a display screen and the robot arm with a master manipulator at the front end. By defining the tree-dimensional coordinate systems of the cameras, the master manipulator and the robot arm, the pose data in the coordinate systems is converted through a rotation transformation matrix to obtainthe data of the real-time pose which the robot arm in the robot arm coordinate system needs to reach in equal proportion according to the movement pose of the master manipulator, the data serves as acontrol signal to control the robot arm to move in place, and the teleoperation control over a multi-degree-of-freedom anti-radiation robot in nuclear decommission, nuclear waste treatment, nuclear power station maintenance and other nuclear industry fields.

Owner:中国东方电气集团有限公司

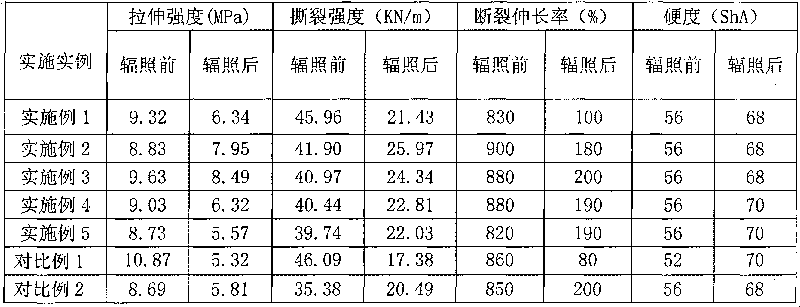

Peroxidated heat-vulcanized silicone rubber resistant to irradiation and preparation method thereof

ActiveCN101717581AImprove radiation resistanceImprove mechanical propertiesChemical industryPolymer science

The invention discloses a peroxidated heat-vulcanized silicone rubber resistant to irradiation and a preparation method thereof. The peroxidated heat-vulcanized silicone rubber comprises 100 parts of silicon rubber, 10-60 parts of anti-irradiation agent, 40-70 parts of gaseous white carbon black, 2-7 parts of concentrated crosslinker and 0.5-2.5 parts of vulcanizing agent according to parts by weight. The peroxidated heat-vulcanized silicone rubber resistant to irradiation is prepared from a main material of methyl vinyl silicon rubber by modification; the rubber has strong environmental suitability, and the stretch strength reaches more than 6MPa and the tear strength reaches more than 20KN / m after 500KGy of irradiation; the rubber can be used for producing various rubber products resistant to irradiation such as rubber cushions, sealing parts, buffer elements, distance sleeves, diaphragms, and can be widely applied to the conditions abundant in high-energy irradiation such as aerospace, nuclear industry, electronic communication, chemical industry, medicine and ship; thus, the rubber has very good economic benefit and promotional value.

Owner:SHANDONG UNIV

Process for manufacturing end socket for nuclear industry

The invention relates to a process for manufacturing an end socket for a nuclear industry. The process comprises the following steps of: material purchasing, acceptance of materials, cutting, welding, heat treatment, swell pressing, hot spinning and heat treatment. The invention discloses the process for manufacturing the end socket for the nuclear power, which is autonomously developed in China, and the process for manufacturing the end socket for the nuclear power is controlled strictly according to the nuclear power specification; the end socket manufactured in a hot stamping or hot spinning mode completely meets the nuclear specifications; and compared with the like products in foreign countries, the end socket reduces the total manufacturing cost of a nuclear power station under the condition of the same quality.

Owner:CHANGZHOU KUANGDA WEIDE MACHINERY

Novel high-strength/tenacity aluminum alloy and preparation method thereof

The invention relates to a novel high-strength / tenacity aluminum alloy and a preparation method thereof. The alloy comprises the following components in term of weight percent: 9.0-10.0% of Zn, 1.2-2.4% of Mg, 1.3-2.6% of Cu, 0.06-0.2% of Zr, 0.10-0.30% of Cr, 0.1-0.5% of V, not more than 0.08% of Si, not more than 0.10% of Fe, not more than 0.1% of Ti, not more than 0.05% of each of other impurities, not more than 0.15% of the total content and the balance Al, wherein the alloy elements Zr, Cr and V can be added selectively or simultaneously. The preparation method comprises the following steps: mixing the alloy components, smelting the raw materials, refining in a furnace and standing and then pouring to prepare an alloy ingot with the required specification, after carrying out preferential homogenization on the alloy ingot, machining and shaping the alloy ingot through forging, after preferential hot treatment, using the shaped blank for machining parts. The aluminum alloy of the invention has uniform microstructure and stable property, the ultimate tensile strength of the aluminum alloy can reach over 600MPa, simultaneously the elongation is higher than 10% and KIc in the T-L direction can reach over 28MPam1 / 2. The aluminum alloy can be applied to the structural elements in such fields as aerospace, nuclear industry, transportation, sports goods and weapons, etc.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

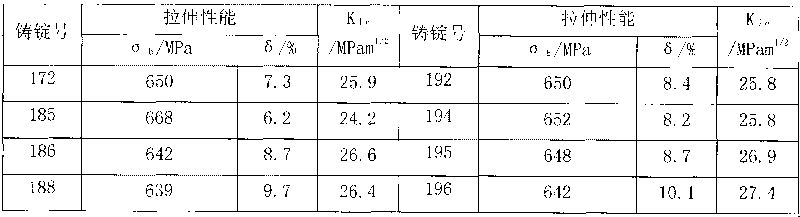

Steel-based multifunctional ceramic composite coating and preparation method thereof

InactiveCN101579958AImproved thermal shock stabilityIntegrity guaranteedMolten spray coatingCeramic layered productsChemical industryCeramic composite

The invention discloses a steel-based multifunctional ceramic composite coating and a preparation method thereof, comprising an iron and aluminum alloy layer, an alumina coating, a silicon dioxide coating and a silicon carbide coating which are adhered on the surface of alloy steel. The invention provides a method which takes iron and aluminium powder, alumina powder, silicon dioxide (quartz) powder, and silicon carbide powder as raw materials, utilizes the vacuum plasma spraying technology to prepare the composite coating on the surface of the base material of the alloy steel, and finally utilizes the hot isostatic pressing technology to carry out densification treatment to the composite coating so as to ultimately obtain the novel alumina / silicon dioxide / silicon carbide multi-functionalceramic composite coating. The method has concise procedures, is convenient for large-scale production, is not only applicable to fusion reactor with rigorous requirement and other nuclear industry fields, but also applicable to the fields of chemical industry, daily furniture industry, electrical appliance industry, manufacturing industry, boiler and high temperature resistant material and the like.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

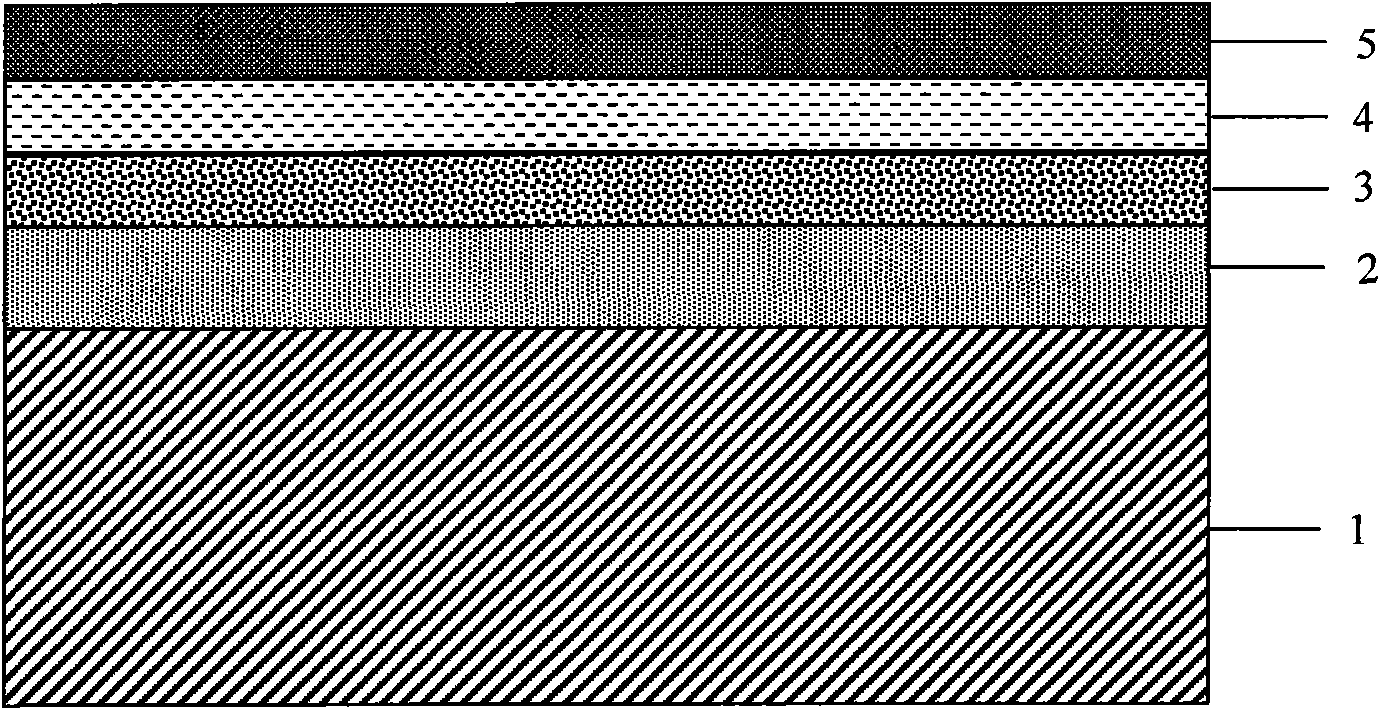

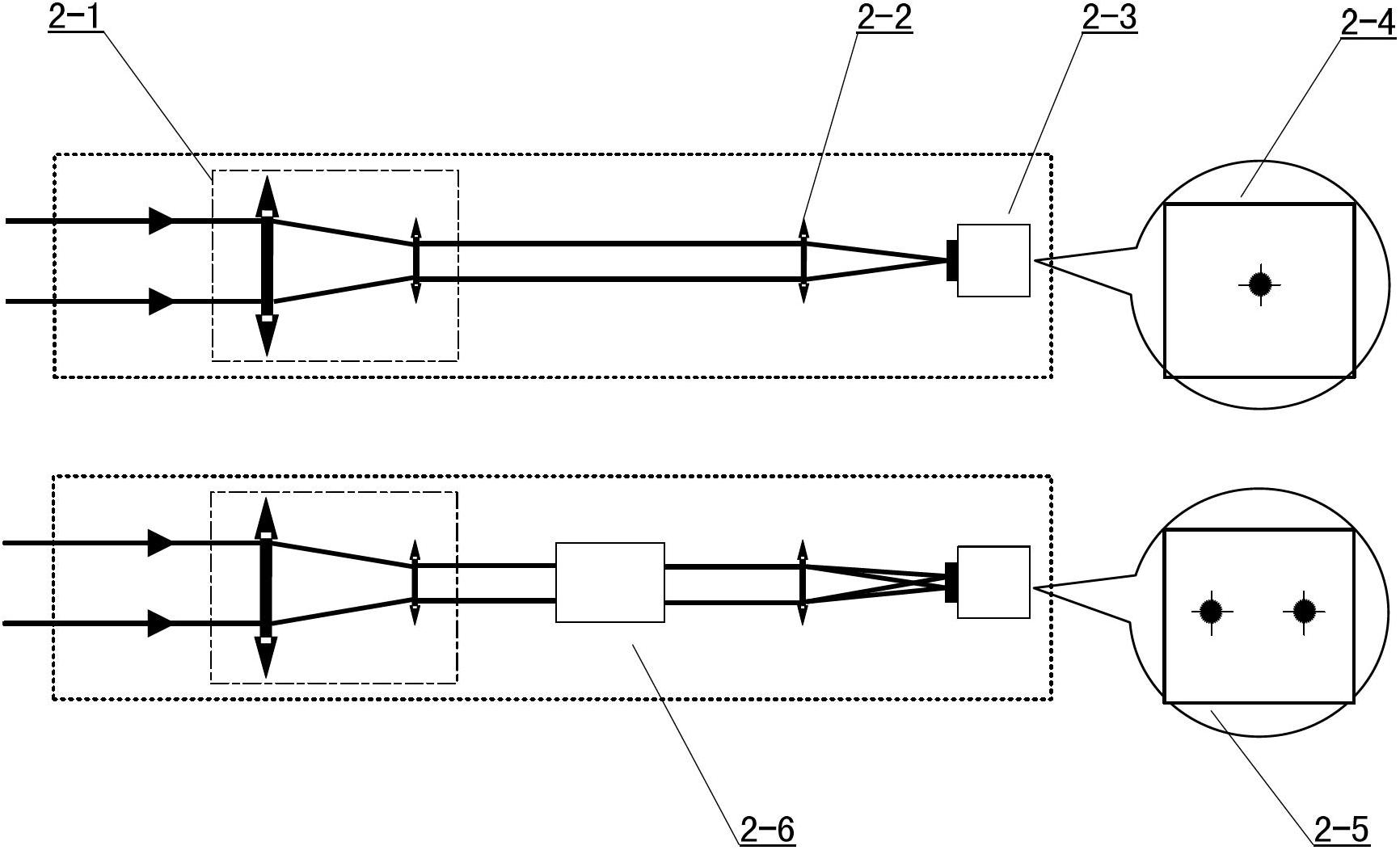

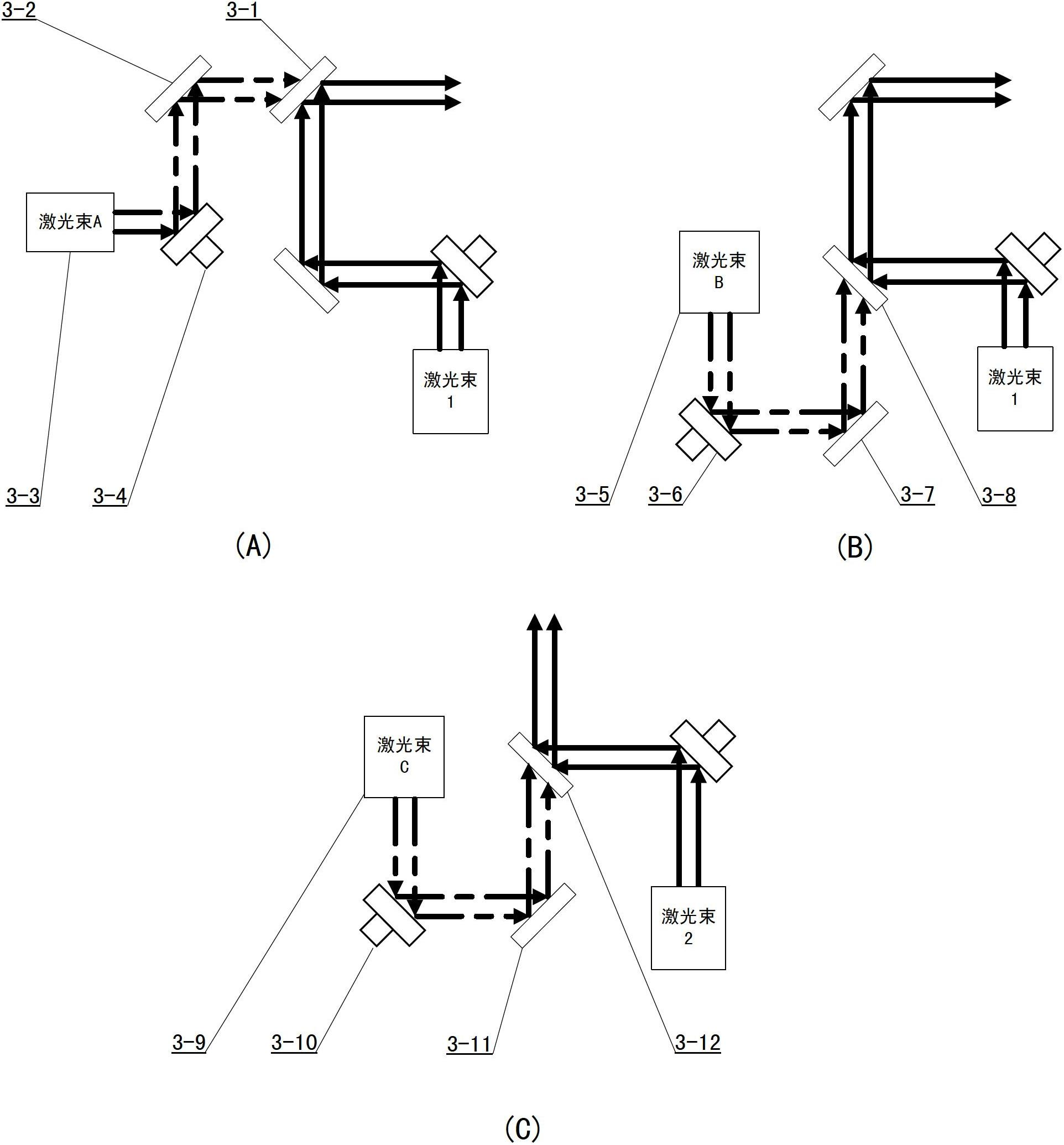

Laser beam common aperture power synthesizing system based on light beam stable closed-loop control

ActiveCN102662241AReal-time correction of pointing errorsAchieve coaxial launchOptical elementsLoop controlBeam splitting

The invention provides a laser beam common aperture power synthesizing system based on light beam stable closed-loop control. Aiming to solve the technical problems, light beam high-precision synthesis is carried out by a light beam stable closed-loop control method aiming to two paths of laser beams with different wavelengths. Two paths of laser respectively pass through respective tilting mirrors and transmission mirrors and the light beam coupling is realized on a synthesizing mirror; meanwhile, appointed error information of each path of the light beam is detected by a synthesizing sensor through a manner of beam splitting and imaging of a dispersion element; the appointed error information of the light beam is converted into driving voltage through calculation and treatment to drive the tilting mirror to carry out angle deflection to eliminate an appointed error of the light beam; finally, high-speed and high-precision synthesis of a plurality of paths of the light beams is realized and the power density of a target point is improved; and the path quantity of the synthesizing light beams can be expanded according to actual requirements. The laser beam common aperture power synthesizing system based on the light beam stable closed-loop control, can be used for fields of material science, nuclear industry, machining, scientific researches and the like, has the advantages of good continuity, high stability and strong anti-interference capability, and is suitable for high-precision incoherent synthesis of a plurality of paths of the light beams under long-time continuous working conditions.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Preparation method of three-dimensional woven carbon fiber-reinforced magnesium-based composite material

The invention relates to a preparation method of a three-dimensional woven carbon fiber-reinforced magnesium-based composite material. The method comprises the following steps of: (1) removing an organic adhesive layer from the surface of three-dimensional woven carbon fiber; (2) coating a layer of silicon dioxide coating on the surface of the three-dimensional woven carbon fiber with a sol-gel method, wherein the thickness of the silicon dioxide coating is greater than 0.2 micro; and (3) preparing the prepared three-dimensional woven carbon fiber coated with the silicon dioxide coating on the surface into the three-dimensional woven carbon fiber-reinforced magnesium-based composite material with a powder metallurgy method. The three-dimensional woven carbon fiber-reinforced magnesium-based composite material prepared with the method has low density, high specific strength, high plasticity, high toughness and high processing performance; and moreover, the preparation method is simple and practical, has low cost, and can be widely applied to the fields of aerospace, nuclear industry, military equipment, various transport facilities, heavy industry, mechanical industry, light industry and the like.

Owner:常熟市星源金属涂层厂

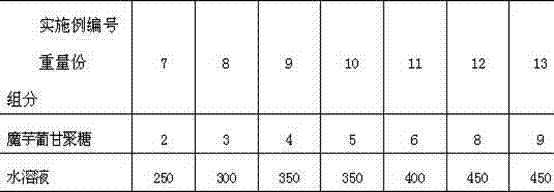

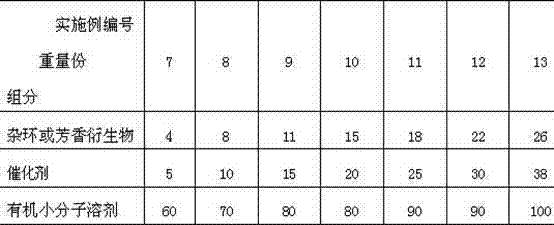

Method for preparing absorbing material based on modified konjac glucomannan

InactiveCN102161711AWith adsorptionImprove complexation abilityOther chemical processesWater/sewage treatment by sorptionLone electron pairFiltration

The invention discloses a method for preparing an absorbing material based on modified konjac glucomannan. The method is characterized by comprising the following steps of: soaking konjac glucomannan in mixed solution of an organic small molecular swelling solvent and water, swelling for 2 to 24 hours, performing vacuum filtration, and washing a solid by using an organic small molecular solvent to remove residual moisture; and adding the swollen konjac glucomannan into a heterocyclic or aromatic derivative which is dissolved by the organic small molecular solvent and has lone electron pairs or / and free electrons, stirring and reacting for 1 to 72 hours in the presence of a catalyst at the temperature of between 50 and 120 DEG C, precipitating a material obtained after the reaction by using a precipitation solvent, filtering, and washing and drying a solid to obtain modified konjac glucomannan powder. In the method, the modified konjac glucomannan has the characteristic of absorbing heavy metal ions; and the absorbing material can be widely used for treating heavy metal ions, radioactive nuclide wastewater and the like produced by mining industry, chemical industry, nuclear industry and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Welding method for assembly of stainless steel tube

InactiveCN102922209AAvoid damageBlock hot melt splashWelding/cutting auxillary devicesArc welding apparatusPetrochemicalSewage treatment

The invention relates to a welding method for assembly of a stainless steel tube, which is aimed at solving the problems of poor quality, low construction efficiency and environment pollution of the conventional welding assembly of the stainless steel tube, and belongs to the technical field of stainless steel tube welding engineering. The method comprises the following steps of: assembling a pad on the outer wall of the stainless steel tube; fastening the pad on the outer wall of the stainless steel tube; installing an assembly tool on the outer wall of the stainless steel tube; correcting the stainless steel tube by the assembly tool; and welding the stainless steel tube. The welding method is applied to the industrial fields of petroleum and natural gas, petrochemical engineering, fertilizers, nuclear industry, sewage treatment and the like.

Owner:SICHUAN GASOLINEEUM CONSTR ENG

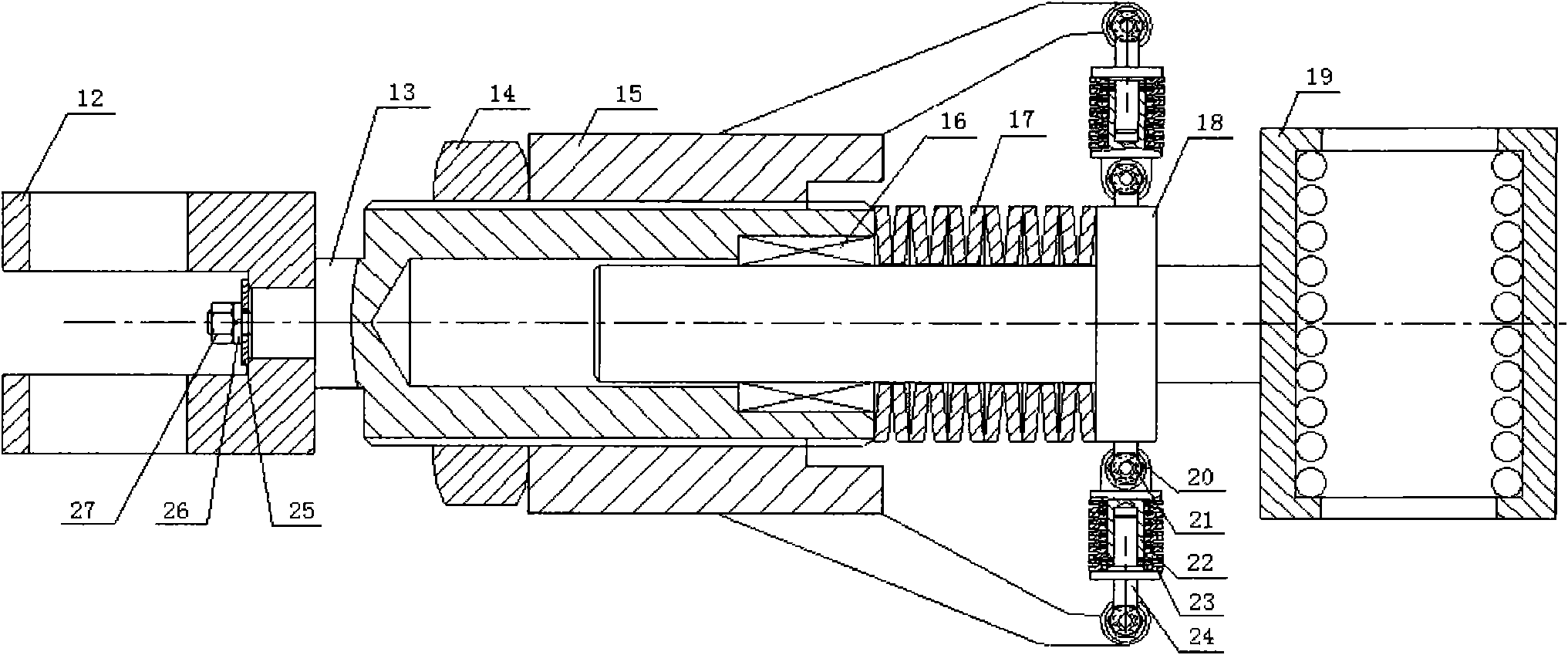

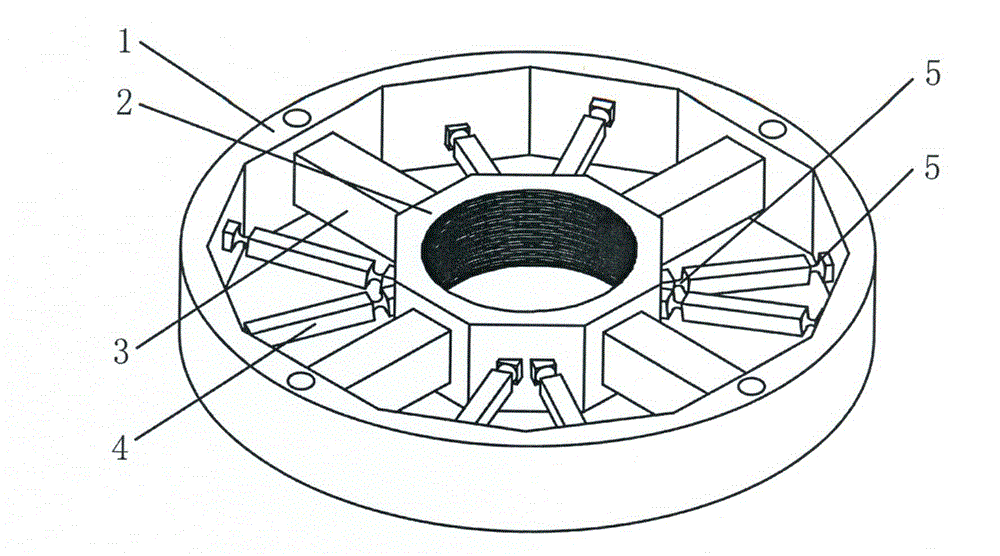

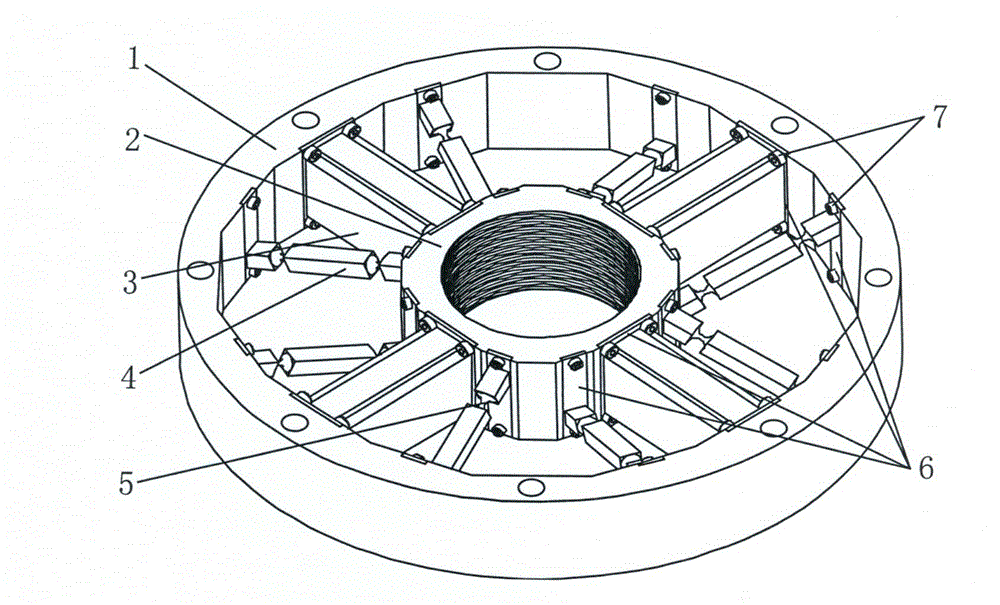

Fault-tolerant wide-range parallel six-axis force sensor

InactiveCN102865947AIncrease stiffnessImprove information utilizationForce measurementForce/torque/work measurement apparatus calibration/testingFault toleranceHigh stiffness

The invention discloses a fault-tolerant wide-range parallel six-axis force sensor, which mainly comprises an outer fixing ring, an inner proving ring, more than six detection branches and three or four bearing branches, wherein an annular polyhedron is formed by enveloping the inner proving ring and the outer fixing ring with a plane which is vertical to a branch axis; the inner surface of the inner proving ring is provided with a screw thread; the upper surface of the outer fixing ring is provided with a plurality of through holes, and can be connected with the outside through a bolt; the bearing branches are high-stiffness beams; the two ends of the high-stiffness beams are fixedly connected with the outer side of inner proving ring and the inner side of the outer fixing ring respectively; the detection branches are arranged pairwise among the bearing branches; the two ends of the detection branches are connected with the outer side of the inner proving ring and the inner side of the outer fixing ring through elastic spherical hinges; and a strain foil is attached to the middle part of each detection branch. The sensor can have an integral or assembled structure. The fault-tolerant wide-range parallel six-axis force sensor is reliable in structure, has high rigidity, a wide range and fault tolerance performance, and can be widely applied to the six-axis force measuring environment of a plurality of sensors requiring wide ranges and high reliability such as six-axis force measurement of aerospace, military, nuclear industry, robots, automobiles and the like.

Owner:YANSHAN UNIV

Method for preparing biological composite nano-water-purifying materials for removing radioactive substances in water

InactiveCN101700925AEfficient removalImprove the ability of adsorption and decontaminationWater/sewage treatment by sorptionBiological water/sewage treatmentFiberRadioactive agent

The invention belongs to the environment protection field, not only belonging to the treatment methods for controlling sewage disposal in the nuke industry and the radiochemistry industry but also belonging to the methods for eliminating radioactive isotopes in the nature water. The invention in particular relates to a method for preparing a series of biological composite nano-water-purifying materials which take mildews with different features as the matrices and various metallic nano materials (such as oxides and hydroxides of titanium, aluminum and iron, etc.) in different nano shapes (nano particles, nano fibers and nano tubes) as the modified materials and can effectively remove the radioactive substances in the water. The method fully utilizes the adsorption effect of the microbes on the surrounding substances to attach the nano materials on the surfaces of the microbial cells, thus obviously improving the capabilities of the nano materials in adsorption and dirt removal; therefore, the nano materials can effectively remove the radioactive substances in the water.

Owner:JILIN UNIV

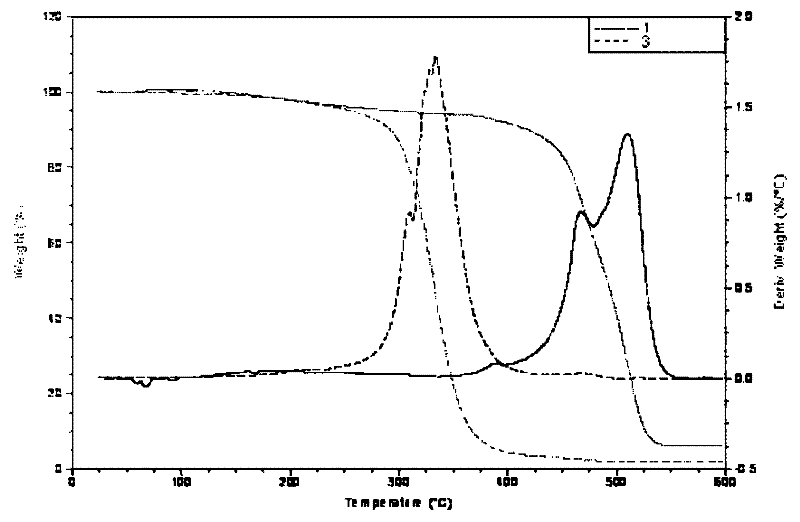

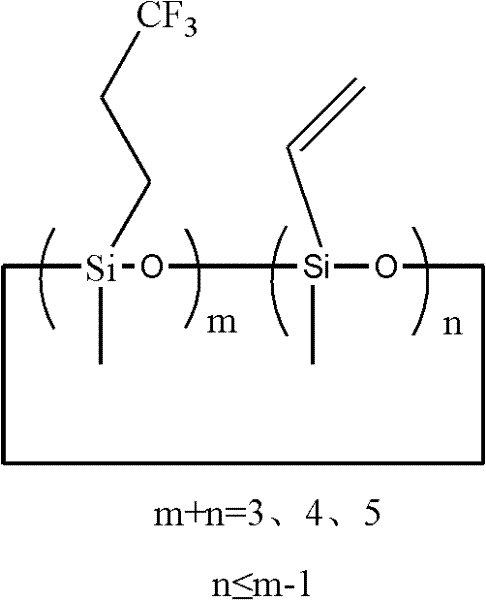

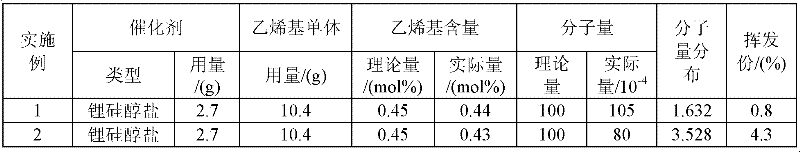

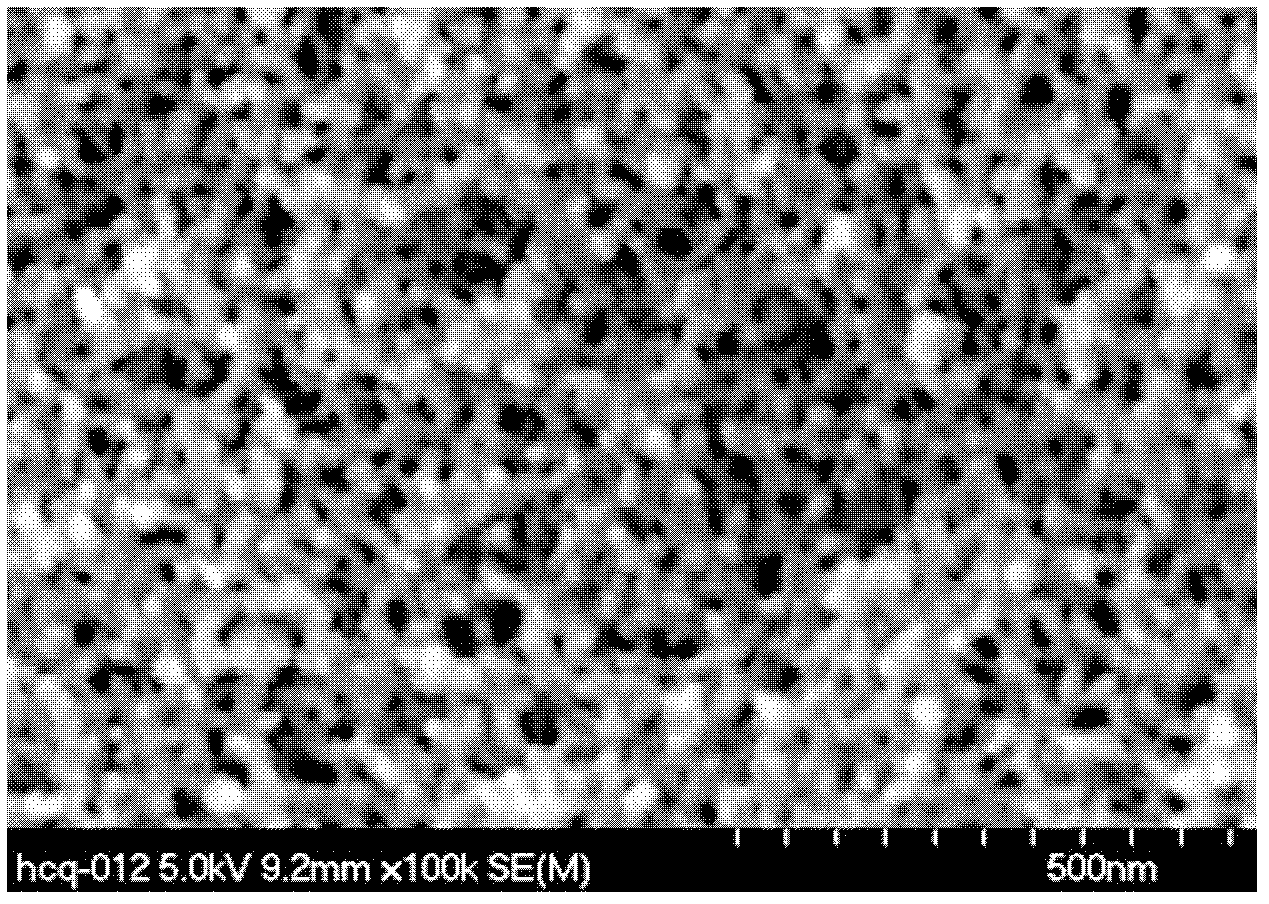

Preparation method of raw fluorinated silicone rubber with high molecular weight

The invention relates to a preparation method of raw fluorinated silicone rubber with a high molecular weight. The preparation method comprises the following steps: adding D3F in a polymerization reaction kettle for dehydration; after dehydration, and then adding fluorine-containing methyl-vinyl-cyclosiloxan and a silicone alcohol lithium salt catalyst; and continuously introducing nitrogen at normal pressure and stirring for polymerization reaction so as to prepare the raw rubber, wherein the polymerization temperature is 110-150 DEG C, the polymerization time is 0.5-3 hours, and the stirring speed is controlled at 1-50r / min. In the method, the fluorine-containing methyl-vinyl-cyclosiloxan with a high ring opening rate is used, thereby solving the problem that vinyl is not distributed on the main chain of the polymer; and the non-balanced silicone alcohol lithium salt is used as a catalytic system and a simple polymerization process and equipment are adopted, thereby solving the heat transfer and mass transfer problems in the polymerization process. Thus, the raw fluorinated silicone rubber with the high molecular weight and high temperature stability is prepared, is more suitable for industrial amplification production, can be widely applied to the environments in the fields of aviation and aerospace, nuclear industry, electronic communication, chemical engineering, medicine, ship and the like, and has good economic benefits and popularization value.

Owner:SHANDONG UNIV

Inorganic nanometer gas condensation sand insulation material and preparation method thereof

The invention relates to an inorganic nanometer gas condensation sand insulation material which is formed by carrying out catalytic combination on an inorganic porous material and silica aerogel to realize the in-pore structure nanocrystallization of the inorganic porous material. The invention also relates to a preparation method of the inorganic nanometer gas condensation sand insulation material. The preparation method comprises the steps of mixing the raw material, namely the silica aerogel, with acid to prepare a raw material in a sol state, mixing the raw material in the sol state with the inorganic porous material, catalyzing the mixed raw material in a microwave environment to ensure that the inorganic porous material is fully expanded and the raw material in the sol state enters into the pore passages of the expanded inorganic porous material to be subjected to gelatination, and drying the mixed material to obtain inorganic nanometer gas condensation sand. The obtained inorganic nanometer gas condensation sand is good in thermal insulation and hydrophobicity, is relatively reasonable in cost, and can be widely applied to buildings, petroleum, chemicals, thermal power generation, oil pipelines, nuclear industries and other high-temperature industries and fields.

Owner:马炼峰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com