A capillary type fiber grating high-temperature sensor and a manufacturing method thereof

A temperature sensor, fiber grating technology, applied in thermometers, thermometers with physical/chemical changes, instruments, etc., can solve the problems of large metallized packaging structure, low temperature resistance of organic adhesives, and large thermal mismatch. , to achieve the effect of improving long-term stability and reliability, reducing structural size, and expanding operating temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

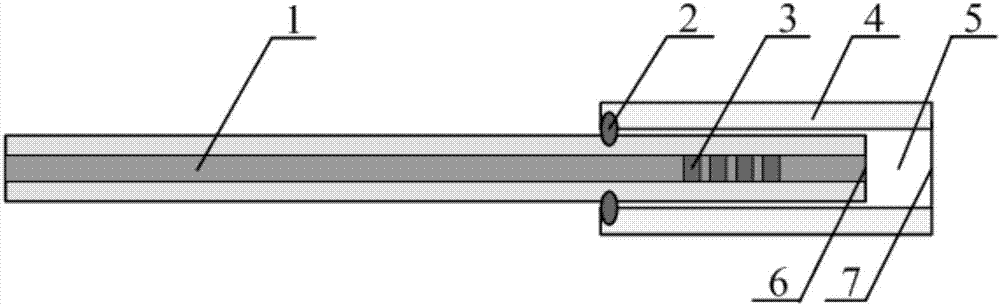

[0038] like figure 1 As shown, a capillary fiber grating high-temperature temperature sensor includes: a fiber grating 3 as a temperature measurement sensitive element, a non-metallic capillary 4 as a packaging structure, an optical fiber 1 and a cavity 5, wherein the optical fiber grating 3 is engraved on the optical fiber 1 . The connection relationship is: insert the optical fiber 1 engraved with the fiber grating 3 into the non-metallic capillary 4, and there is a certain distance between the end face 6 of the fiber and the end face 7 of the capillary as the cavity 5, and the size of the cavity 5 is designed to ensure the freedom of the fiber grating 3. Stretches to isolate strain for temperature measurement.

[0039] The manufacturing method of the sensor will be described in detail below by taking a quartz optical fiber, a fiber grating sensitive element carved by an excimer laser, and a quartz glass capillary with double-ended openings as examples.

[0040] A kind of ...

Embodiment 2

[0052] like figure 1 As shown, a capillary fiber grating high-temperature temperature sensor includes: a fiber grating 3 as a temperature measurement sensitive element, a non-metallic capillary 4 as a packaging structure, an optical fiber 1 and a cavity 5, wherein the optical fiber grating 3 is engraved on the optical fiber 1 . The connection relationship is: insert the optical fiber 1 engraved with the fiber grating 3 into the non-metallic capillary 4, and there is a certain distance between the end face 6 of the fiber and the end face 7 of the capillary as the cavity 5, and the size of the cavity 5 is designed to ensure the freedom of the fiber grating 3. Stretches to isolate strain for temperature measurement.

[0053] The fabrication method of the sensor will be described in detail below by taking a quartz optical fiber, a fiber grating sensitive element engraved by a femtosecond laser, and a single-end closed sapphire crystal capillary as examples.

[0054] A kind of ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com