Patents

Literature

292results about How to "Prevent creep" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

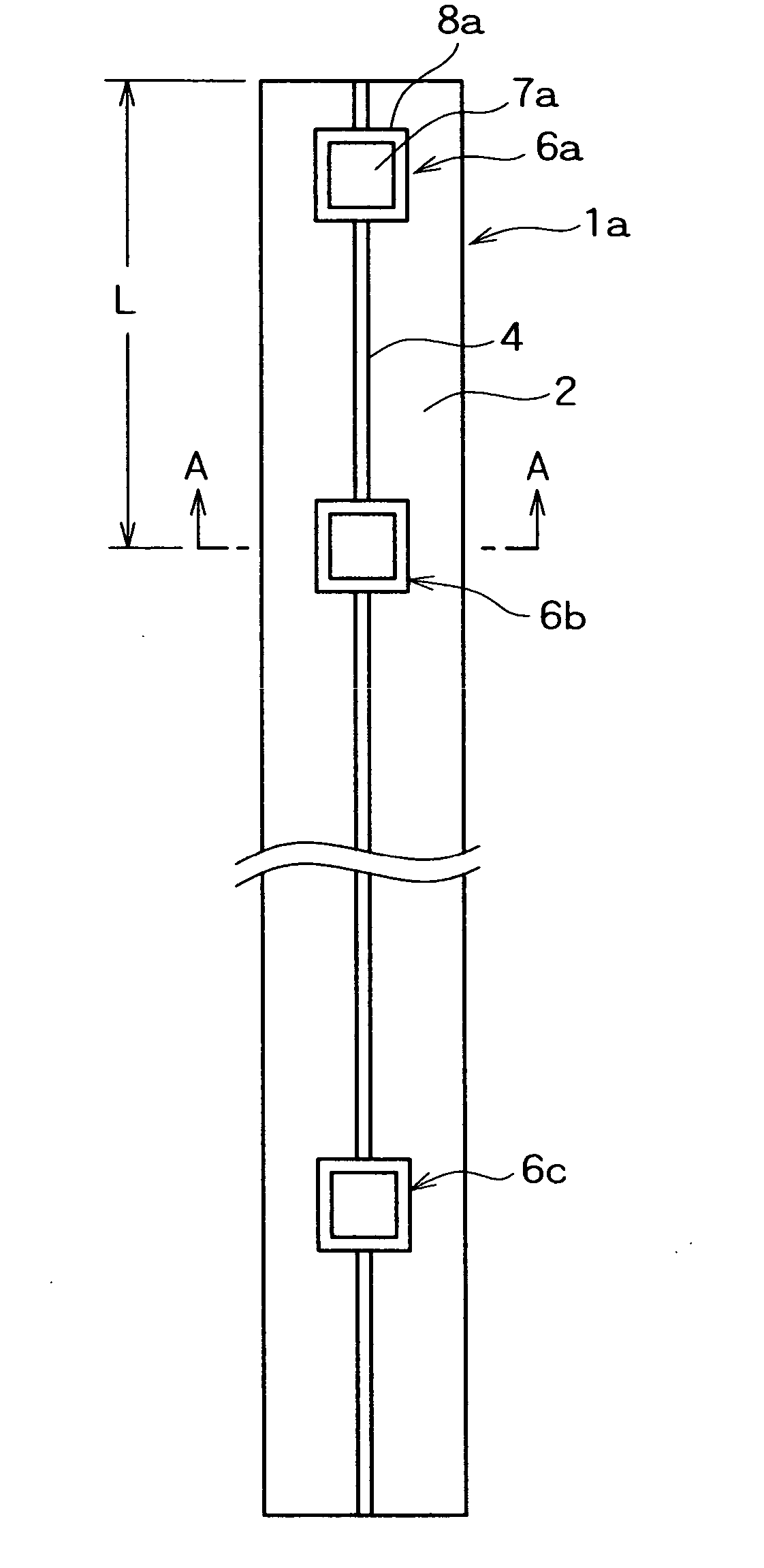

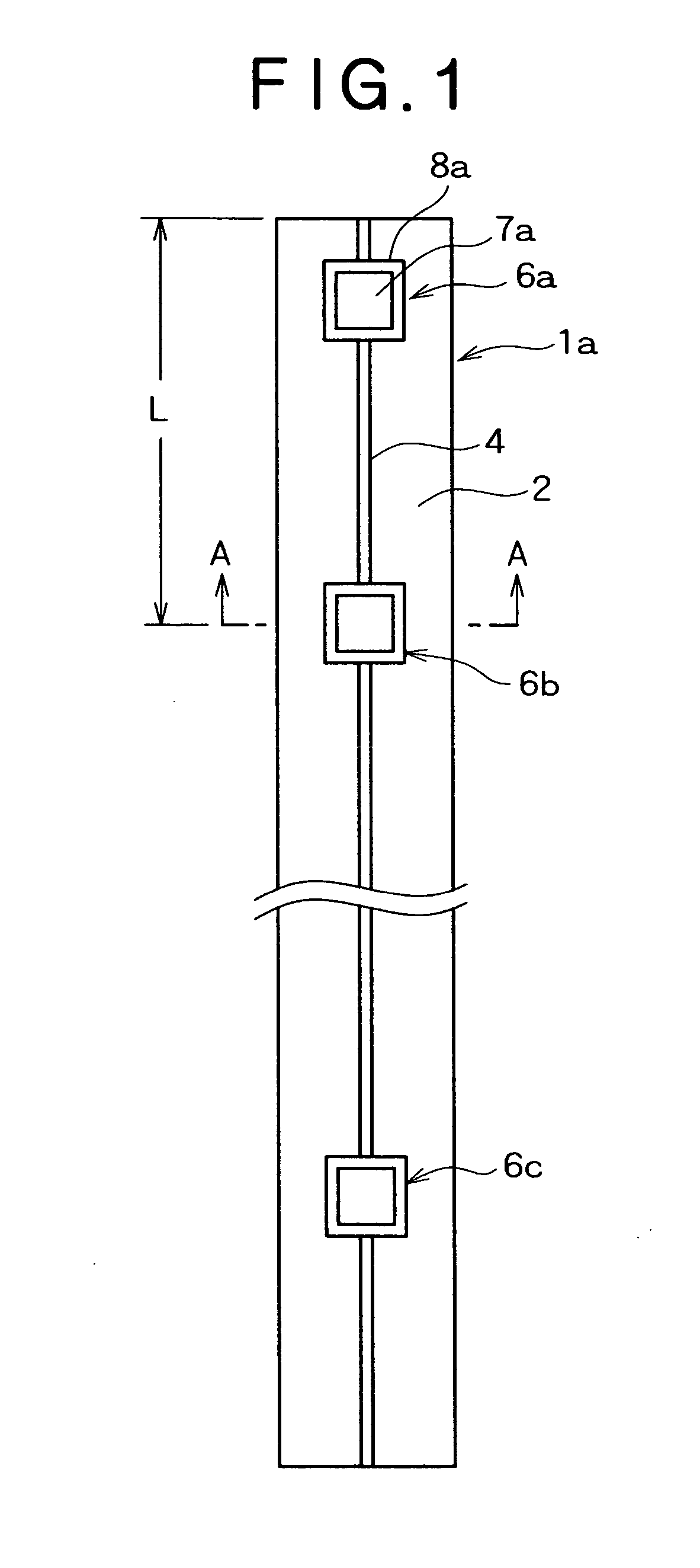

Radio lan antenna

InactiveUS20070004363A1Improve communication distanceReduce the possibilityAntenna adaptation in movable bodiesNetwork topologiesConductive materialsLayered structure

A high-frequency micro-strip line for transmitting a high-frequency wave for a wireless LAN system has a layered structure where, on a ground layer made of a conductive material, a dielectric layer made of a dielectric material and a signal line made of a conductive material are successively laid. The high-frequency micro-strip line further includes a patch antenna comprising a dielectric plate made of a dielectric material and a patch made of a conductive material, which are successively laid into a layered structure, the patch antenna being electrically connected to the signal line. A wireless-communication RF signal transmission device capable of being applied to such a line is also provided.

Owner:KOBE STEEL LTD

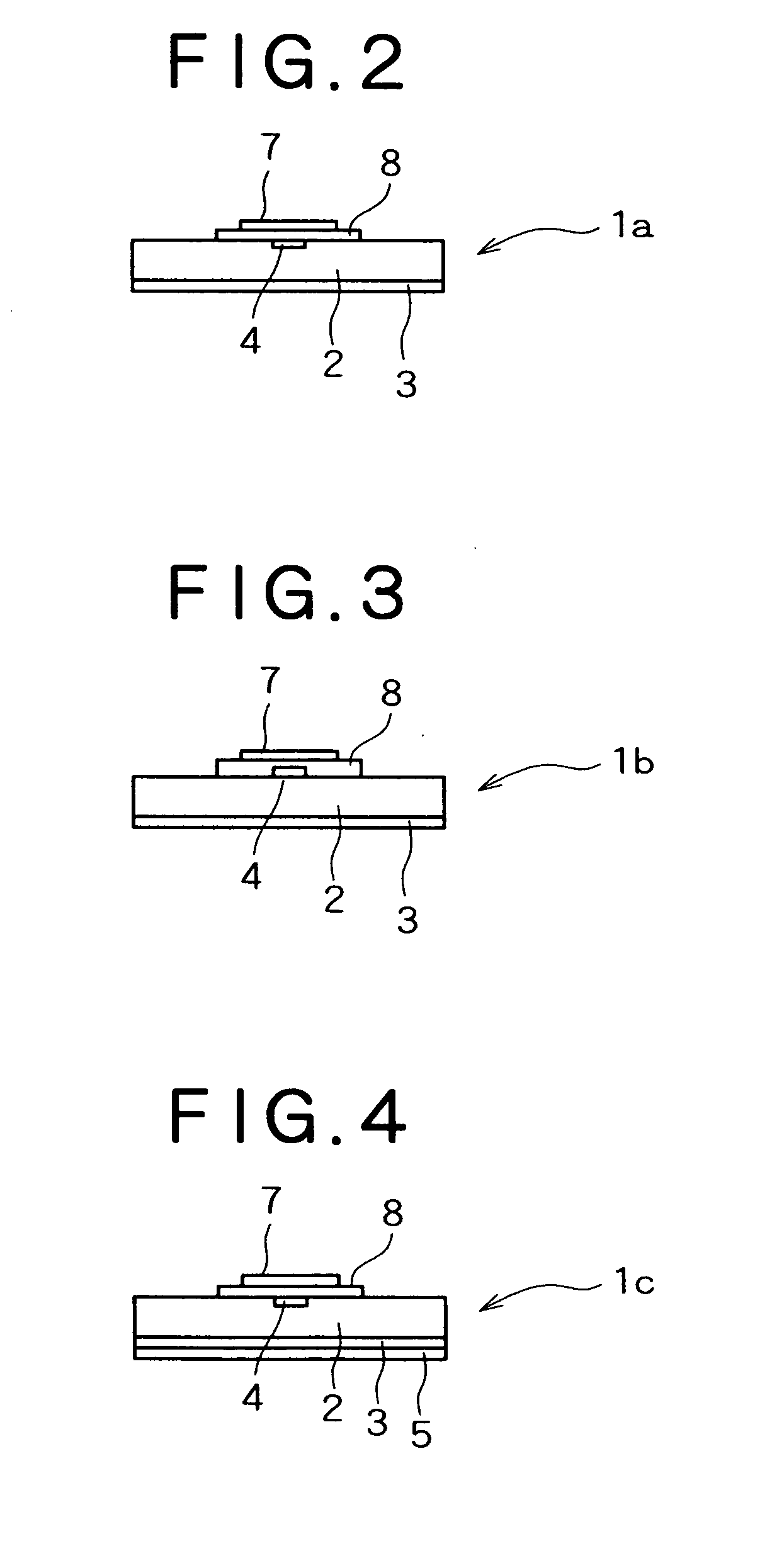

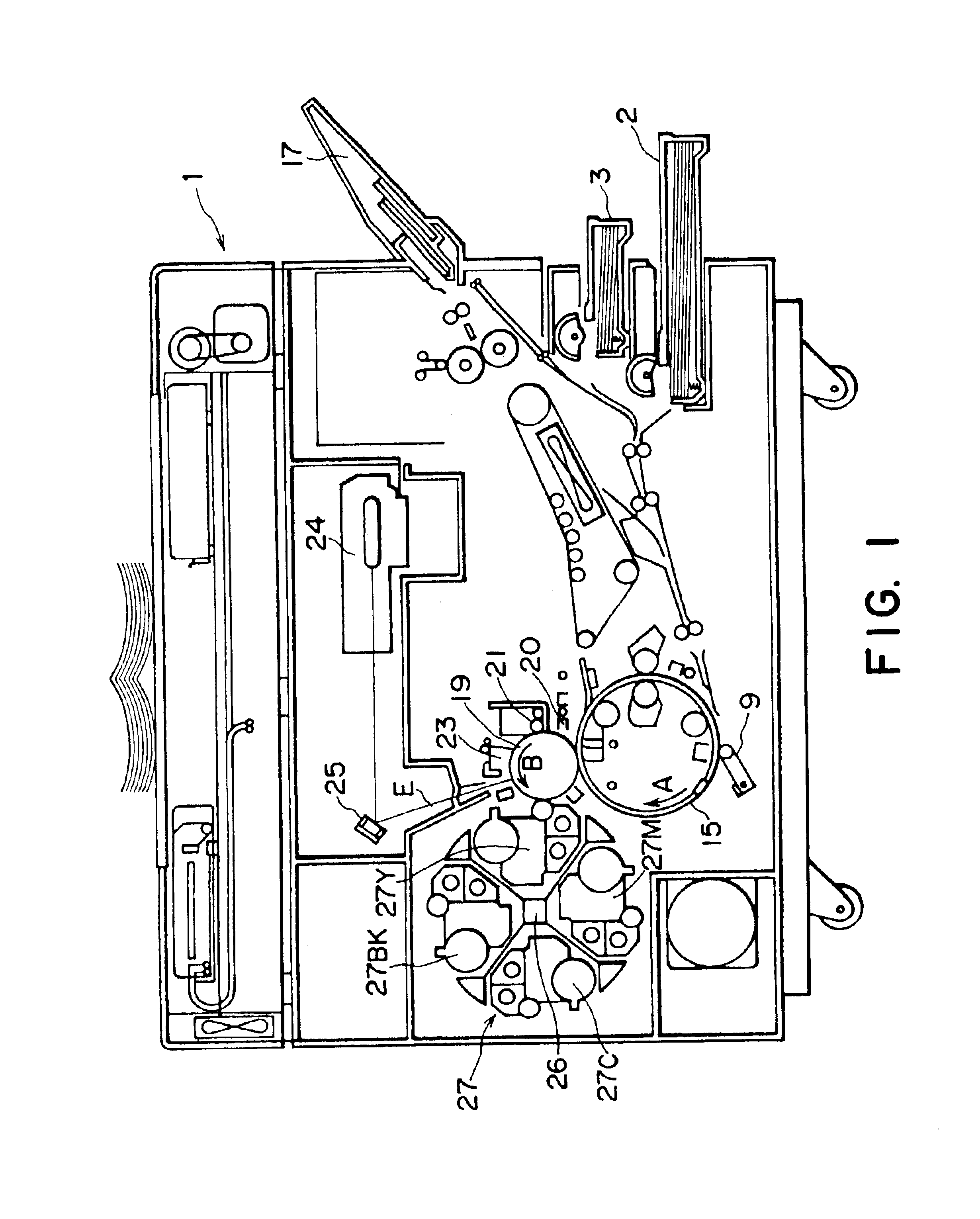

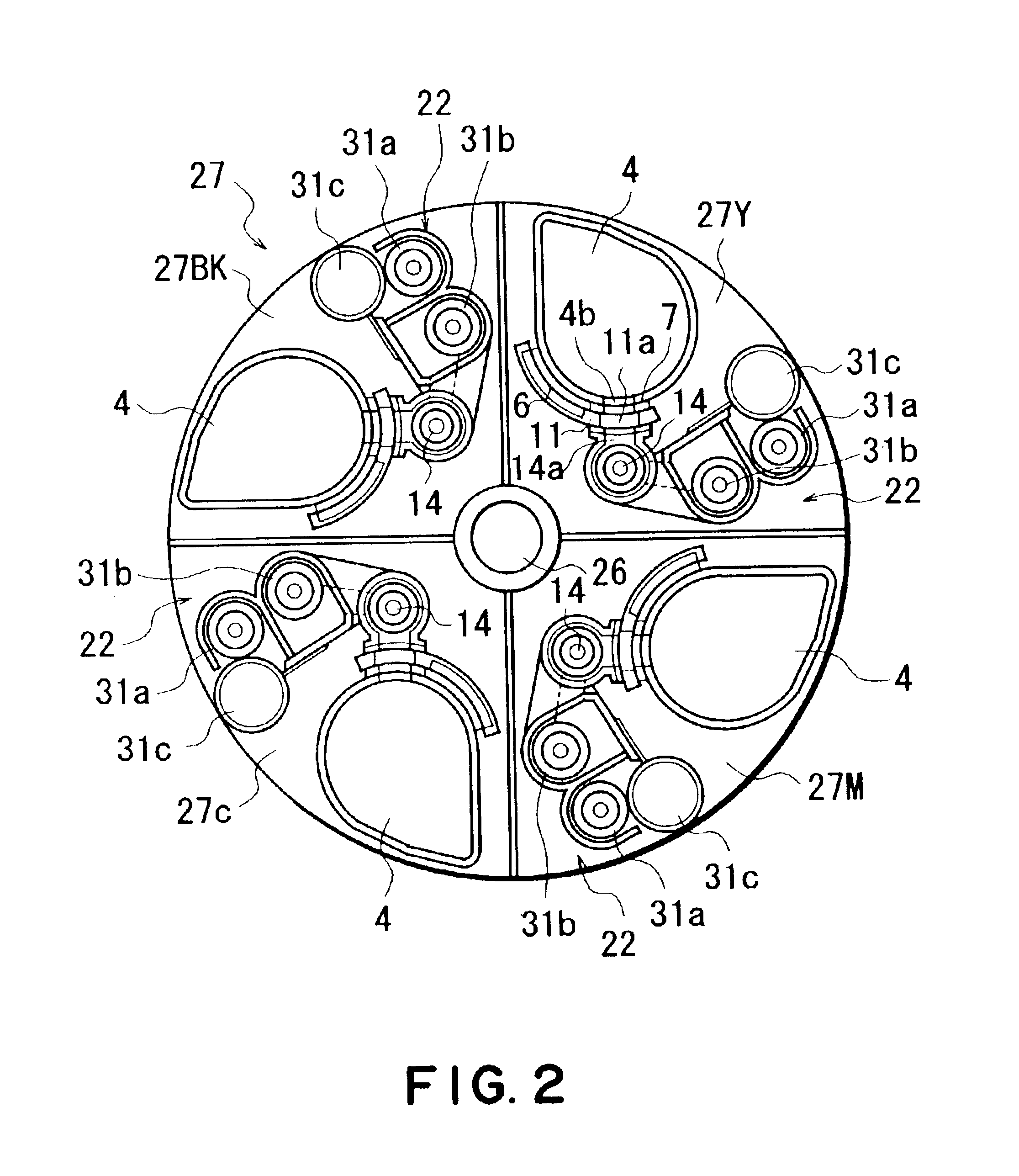

Developer supply container

InactiveUS6839533B2Simple structureLimit rotationPowdered material dispensingElectrographic process apparatusEngineeringImaging equipment

A developer supply container detachably mountable to an image forming apparatus, the developer supply container includes a main body for accommodating a developer; a discharge opening, provided in the main body, for permitting discharge of the developer; a shutter member for opening and closing the discharge opening; a rotatable member which is rotatable relative to the main body to effect opening and closing movement of the shutter member; a regulating member for limiting a rotation of the rotatable member in a direction of opening the shutter member, wherein the regulating member includes an extended portion integral with the rotatable member and extended substantially along the opening rotational direction of the rotatable member and a limiting projection, projected from the extended portion toward the main assembly, for abutment to a stopper projection of the main body, wherein the regulating member has an abutting portion for abutment to an image forming apparatus in a mounting operation of the developer supply container, and the limiting projection displaces to a position where it is incapable of abutting the stopper projection.

Owner:CANON KK

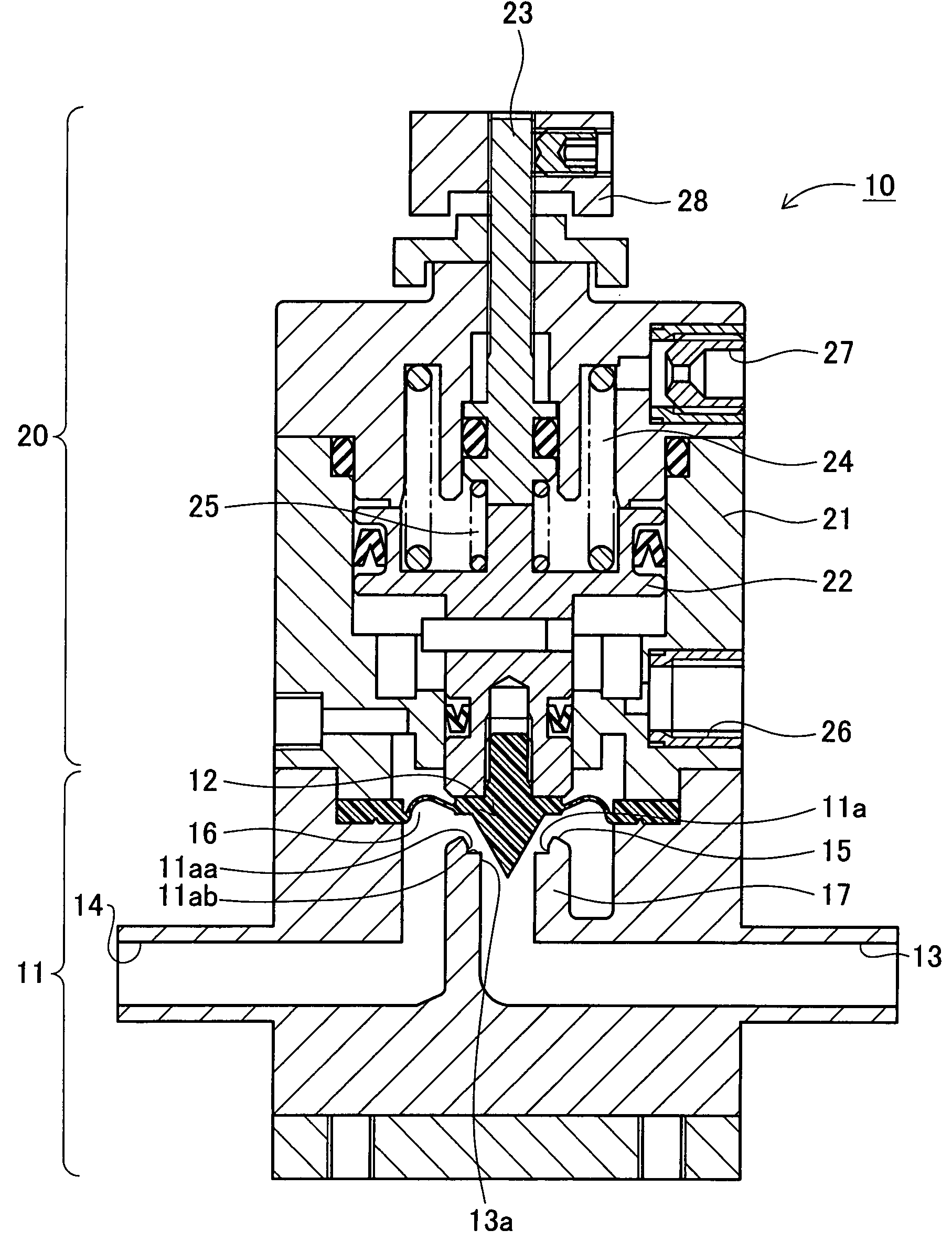

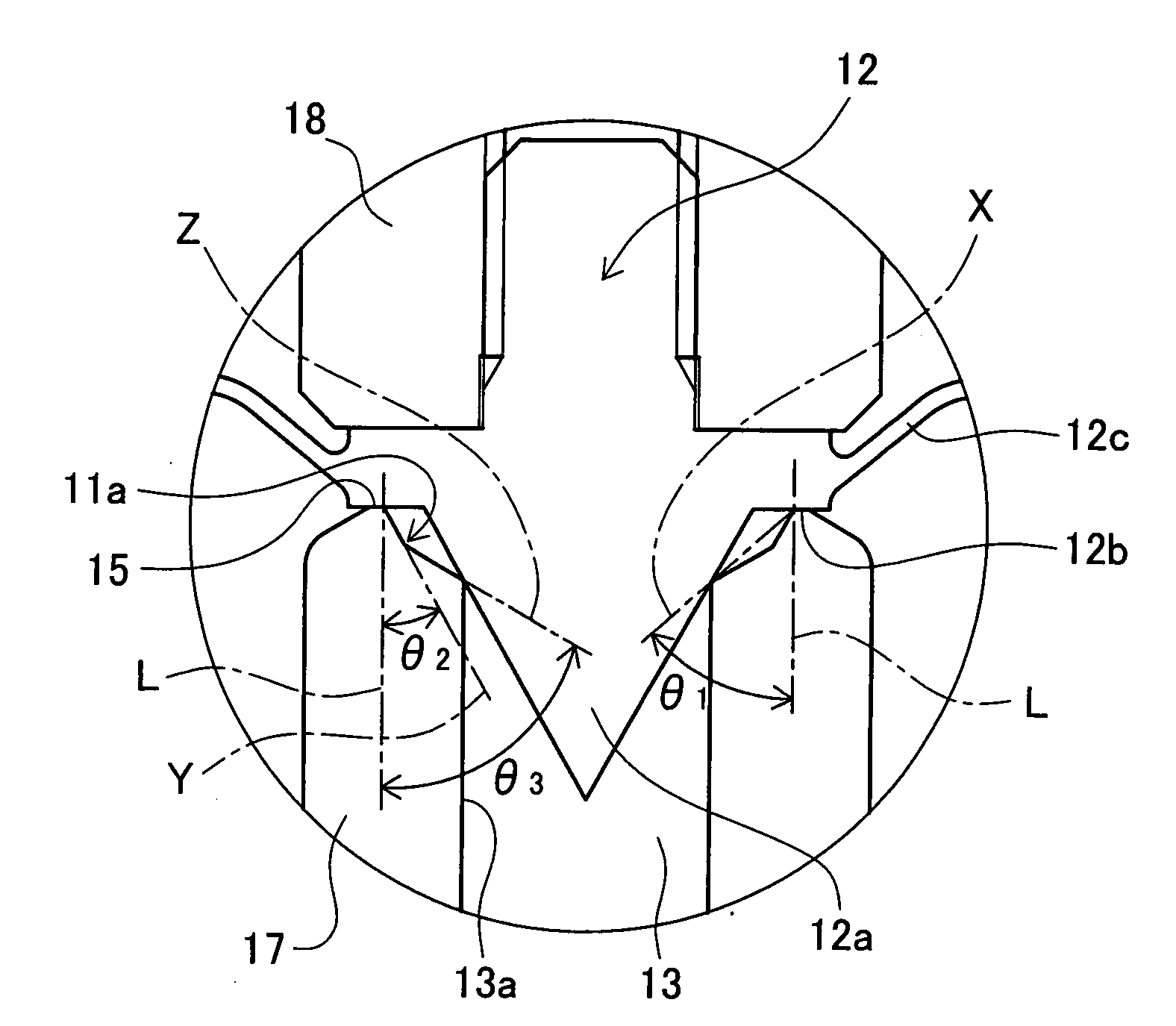

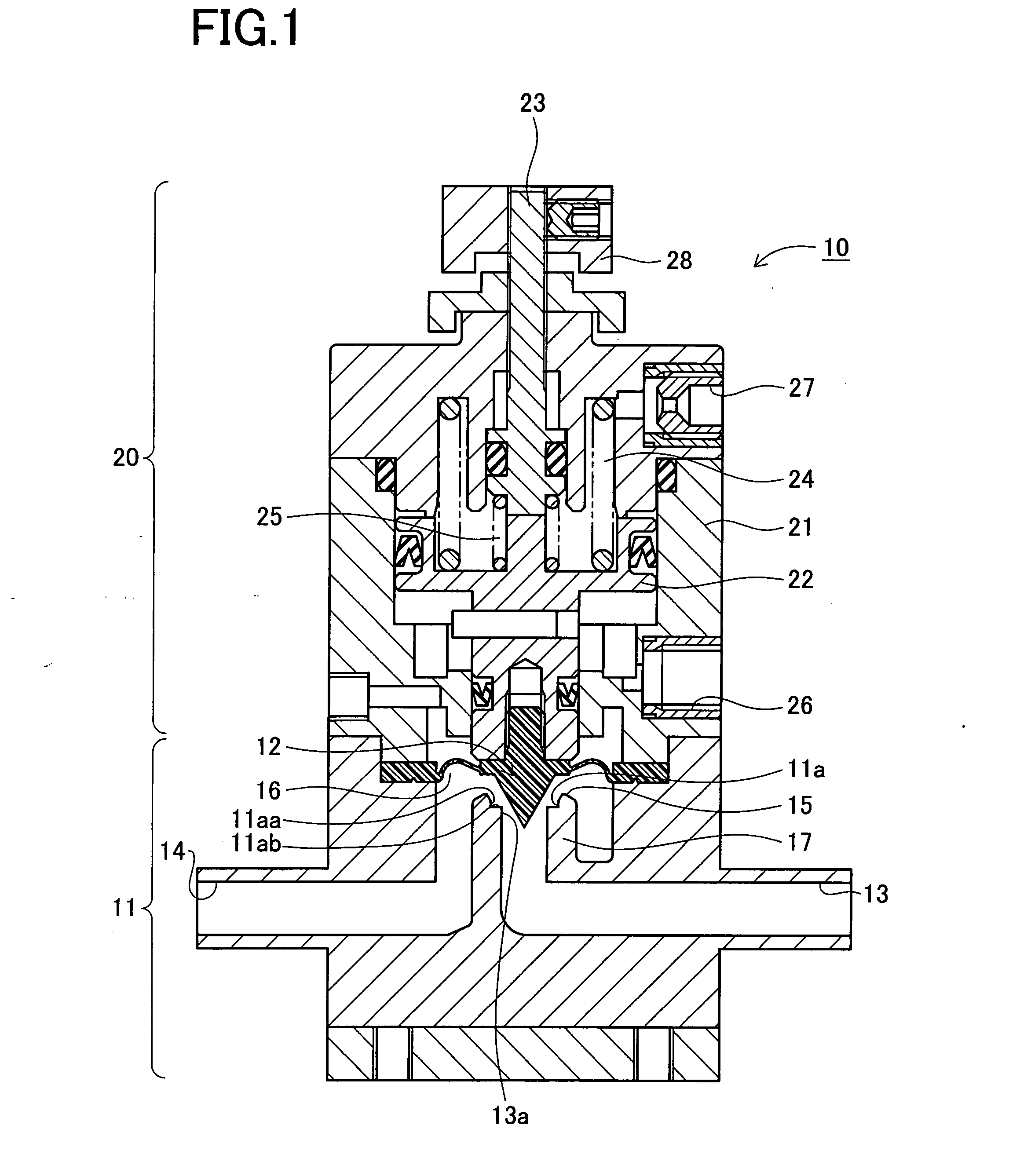

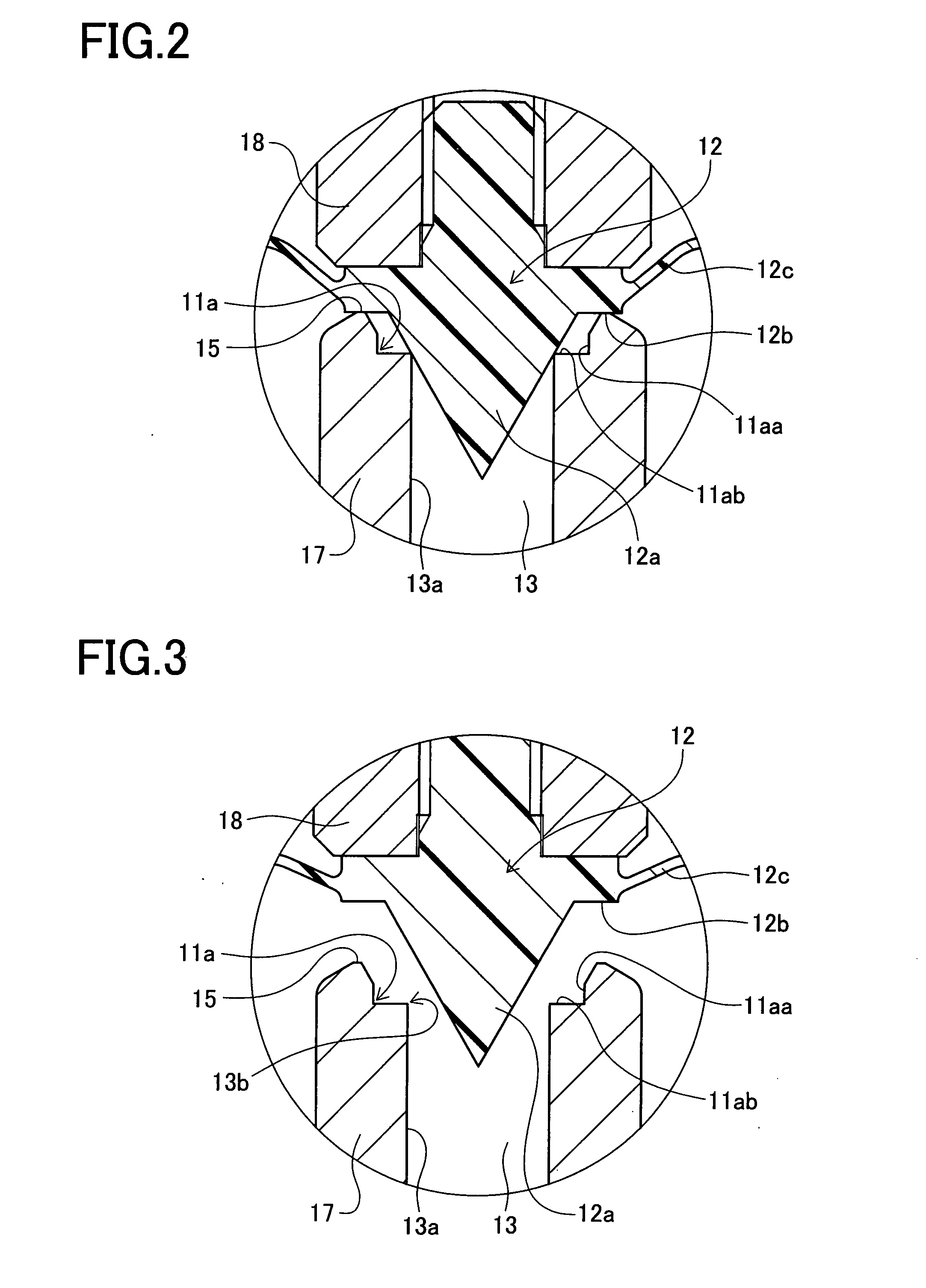

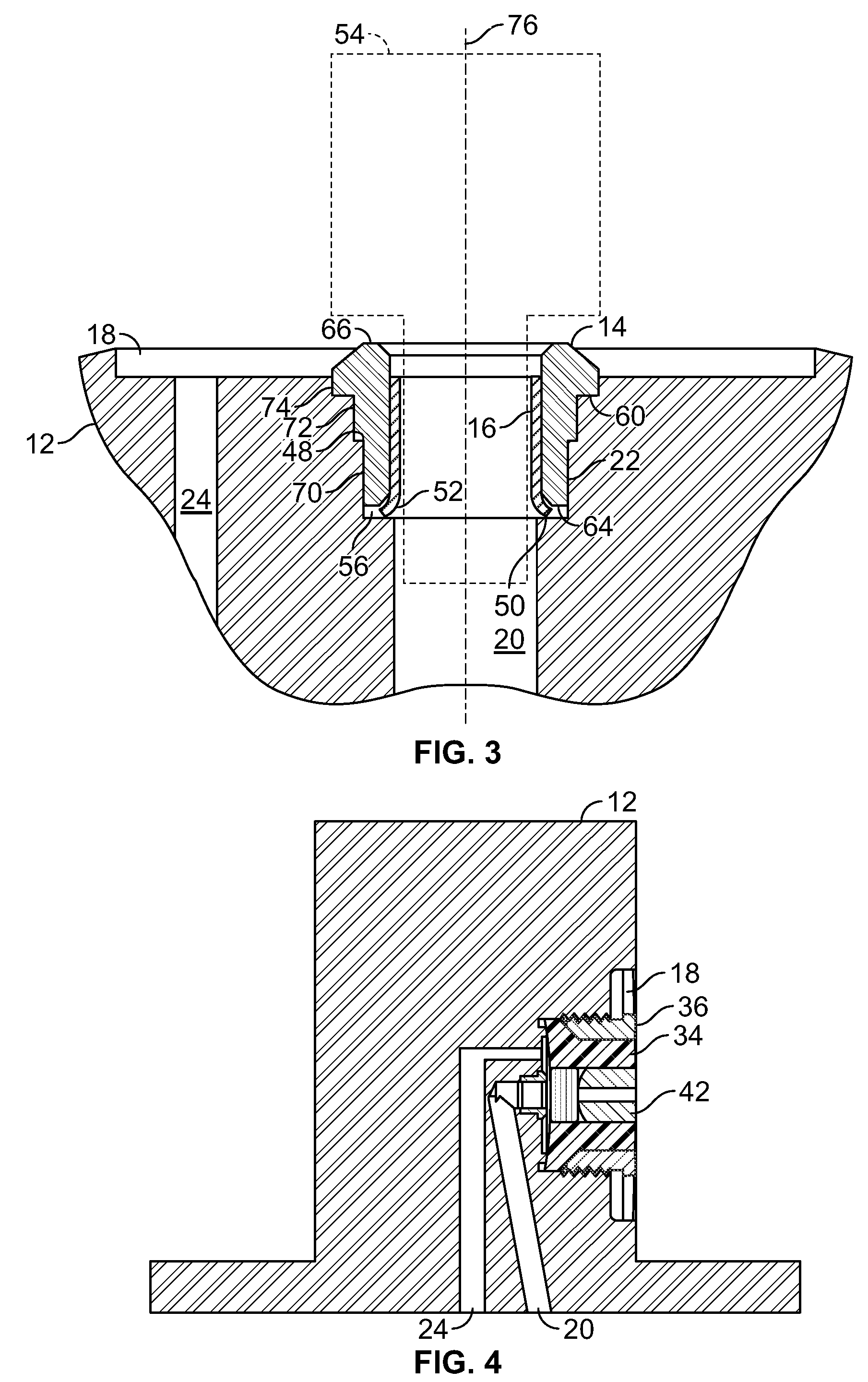

Flow control valve

InactiveUS7537194B2Improve flow stabilityPrevent radial deformationDiaphragm valvesOperating means/releasing devices for valvesEngineeringControl valves

A compact flow control valve with high flow stability is arranged to comprises: a valve body made of resin including; a first passage formed in the valve body; a valve port communicating with the first passage; and a valve seat formed around the valve port; a valve element movable into contact with and away from the valve seat; a valve chamber formed around the valve seat; a second passage communicating with the valve chamber; and a flow adjustment rod for adjusting a flow rate of a fluid allowed to flow in the valve chamber, wherein the flow adjustment rod is adjustable in position to change an opening degree of the valve element relative to the valve seat for adjusting the flow rate, and the flow control valve further comprises an annular recess formed in an inner periphery of the valve seat formed surrounding the valve port and configured to prevent radial deformation of the valve port when the valve element is moved into contact with the valve seat.

Owner:CKD

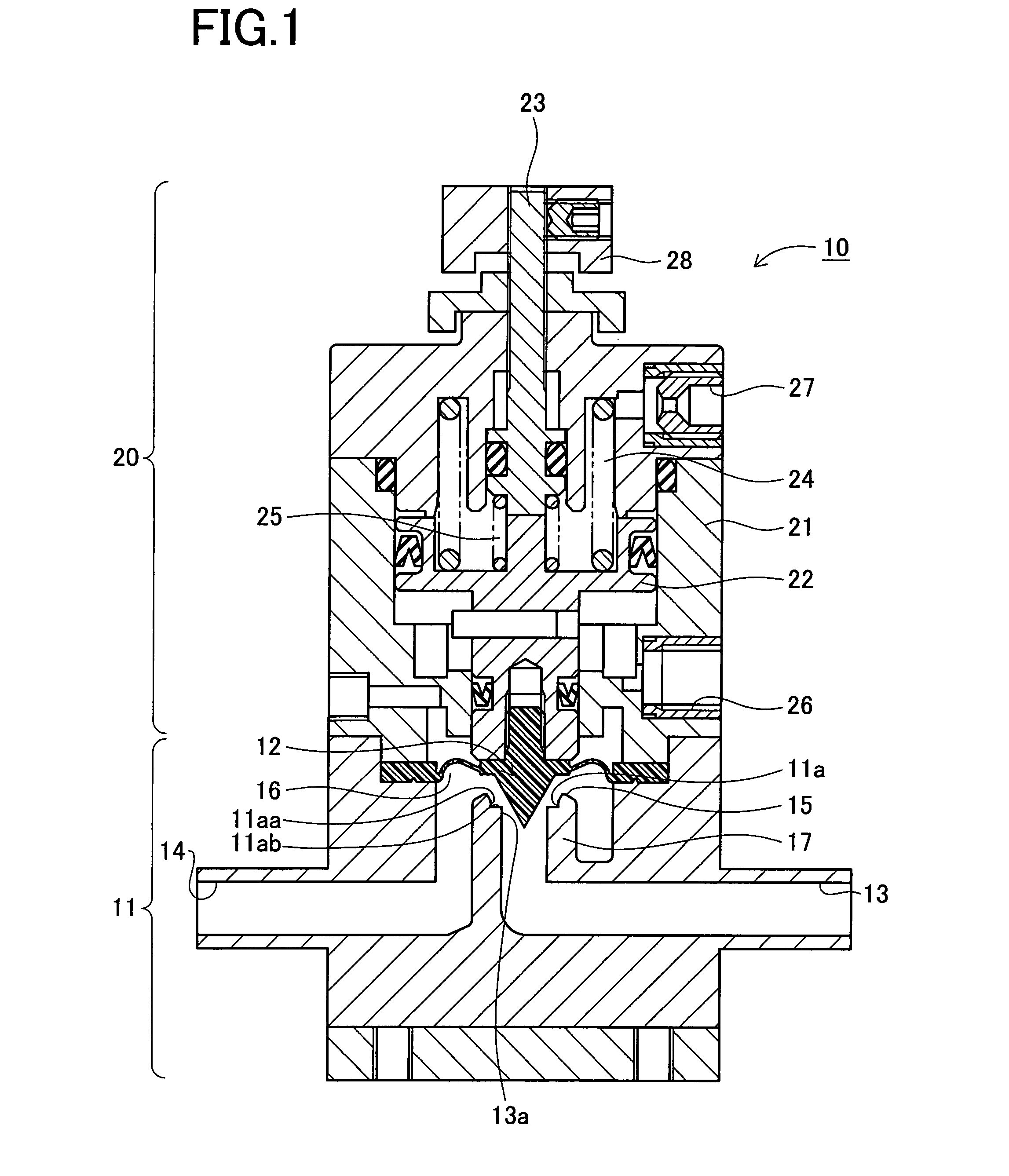

Flow control valve

InactiveUS20080001110A1Improve flow stabilityDownsizingDiaphragm valvesOperating means/releasing devices for valvesEngineeringControl valves

A compact flow control valve with high flow stability is arranged to comprises: a valve body made of resin including; a first passage formed in the valve body; a valve port communicating with the first passage; and a valve seat formed around the valve port; a valve element movable into contact with and away from the valve seat; a valve chamber formed around the valve seat; a second passage communicating with the valve chamber; and a flow adjustment rod for adjusting a flow rate of a fluid allowed to flow in the valve chamber, wherein the flow adjustment rod is adjustable in position to change an opening degree of the valve element relative to the valve seat for adjusting the flow rate, and the flow control valve further comprises an annular recess formed in an inner periphery of the valve seat formed surrounding the valve port and configured to prevent radial deformation of the valve port when the valve element is moved into contact with the valve seat.

Owner:CKD

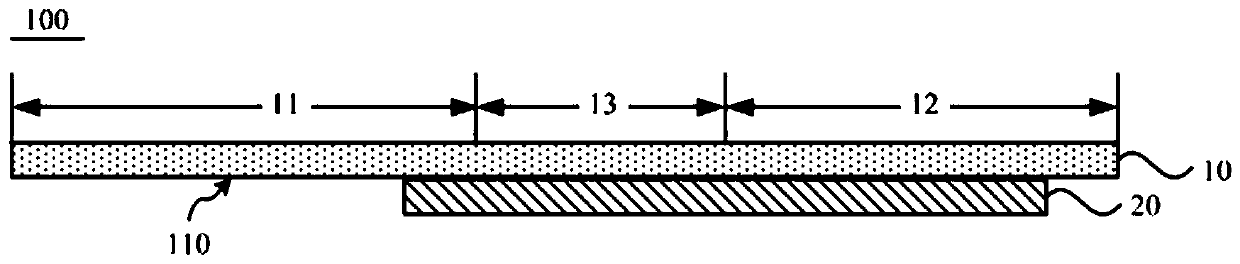

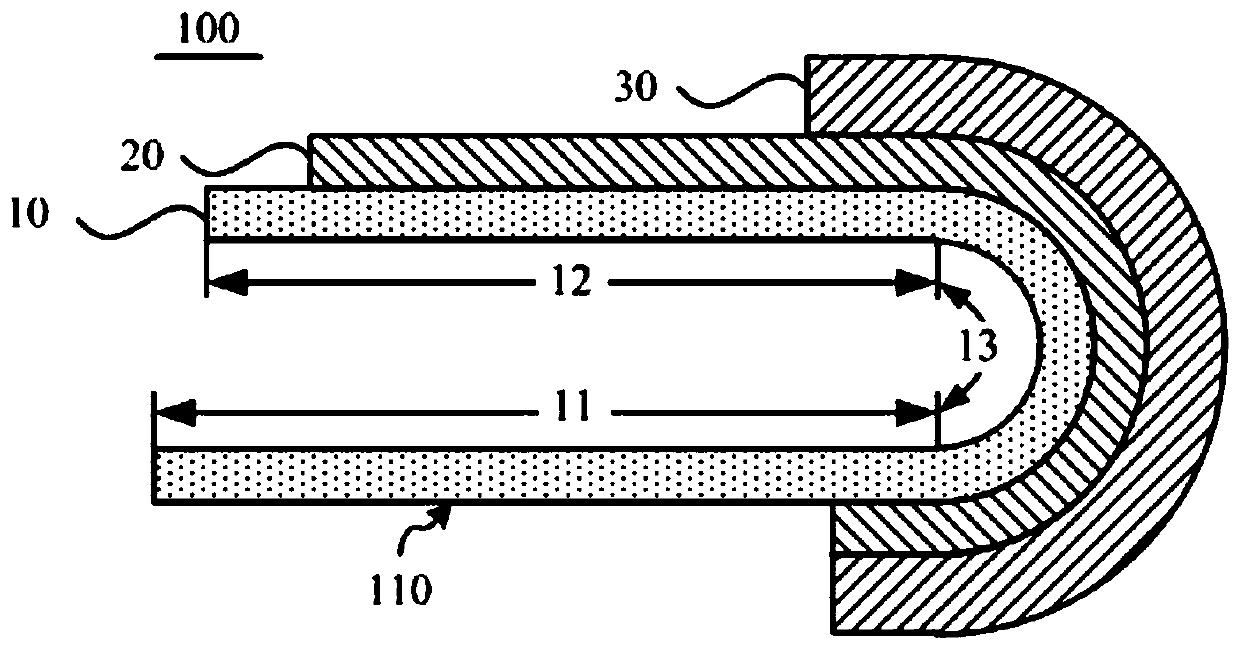

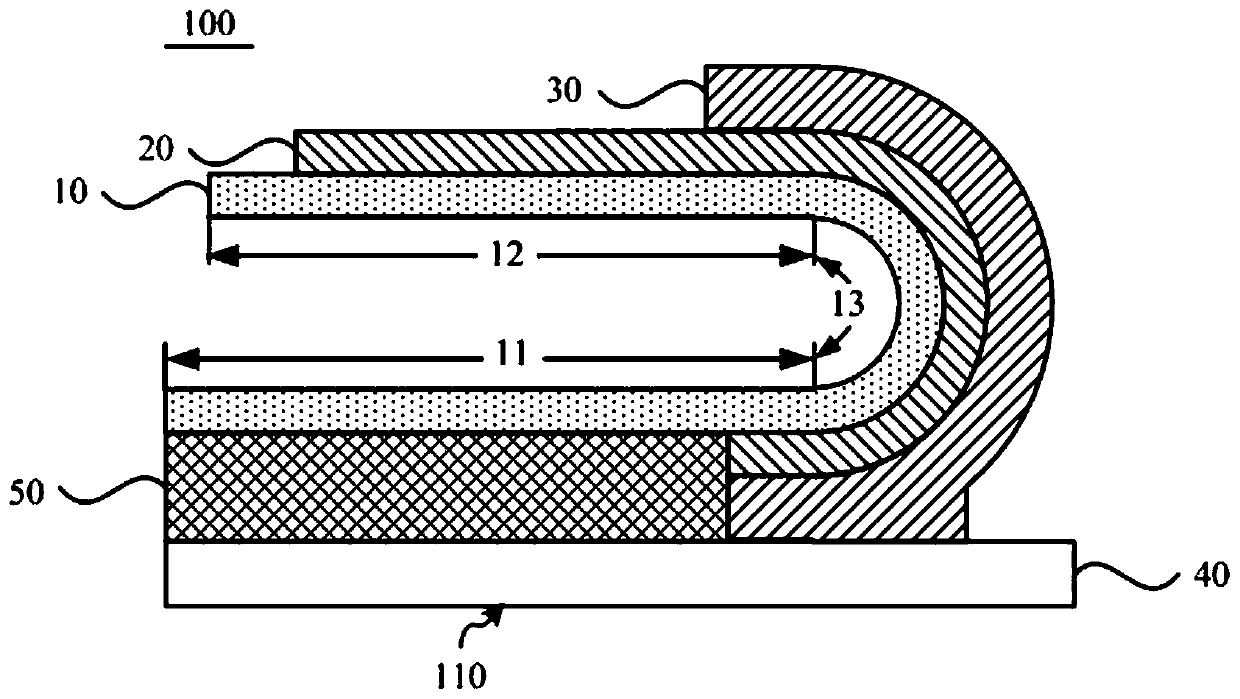

Flexible display device and preparation method thereof

ActiveCN109712530AImprove the display effectPrevent creepIdentification meansEngineeringProtection layer

The embodiment of the invention provides a flexible display device and a preparation method of the flexible display device. A flexible substrate of the flexible display device is provided with a firststraight area, a bent area and a second straight area; before bending, a first bending protecting layer is arranged in a bending area of the flexible substrate, so that the bending difficulty can bereduced, and the bending stress can be reduced; after bending, a second bending protecting layer is arranged in the bending area of the flexible substrate, so that creep occurring after the first bending protecting layer is bent can be prevented, meanwhile, a protection role can be further played on the bending area, so that the phenomenon that cracks occur on the flexible substrate and wires on the flexible substrate due to the fact that the protection capacity of a first bending protecting agent for the flexible substrate and a wiring layer arranged on the flexible substrate is reduced is avoided, and further, the display effect of the flexible display device is improved.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

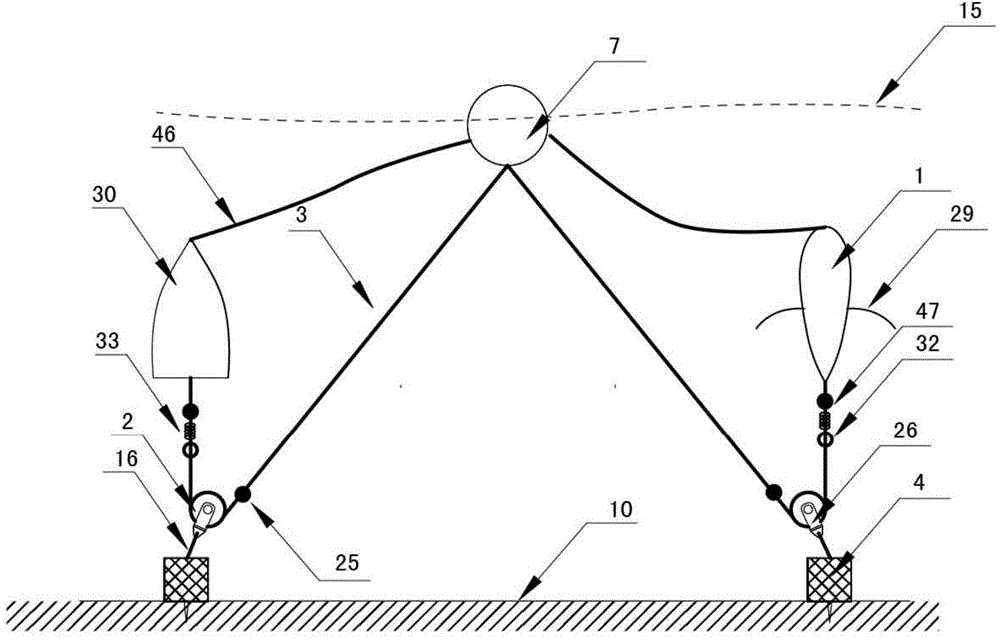

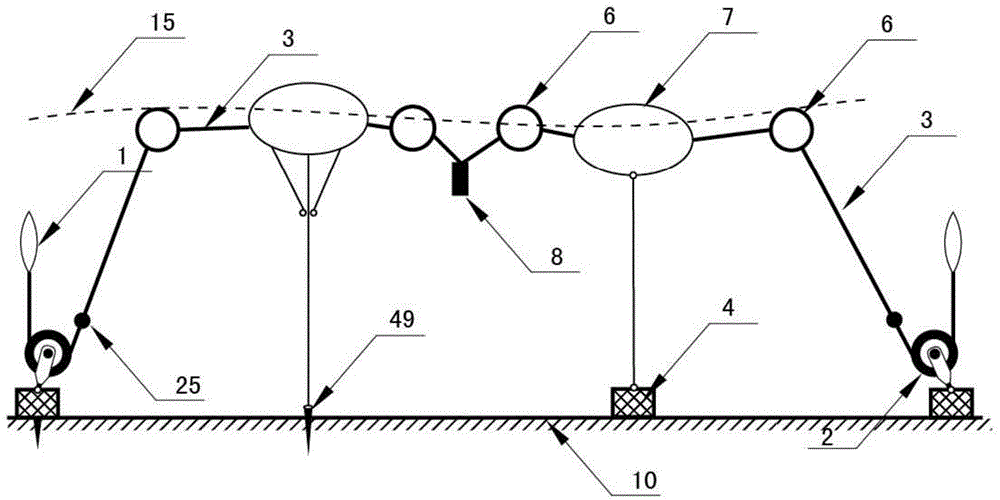

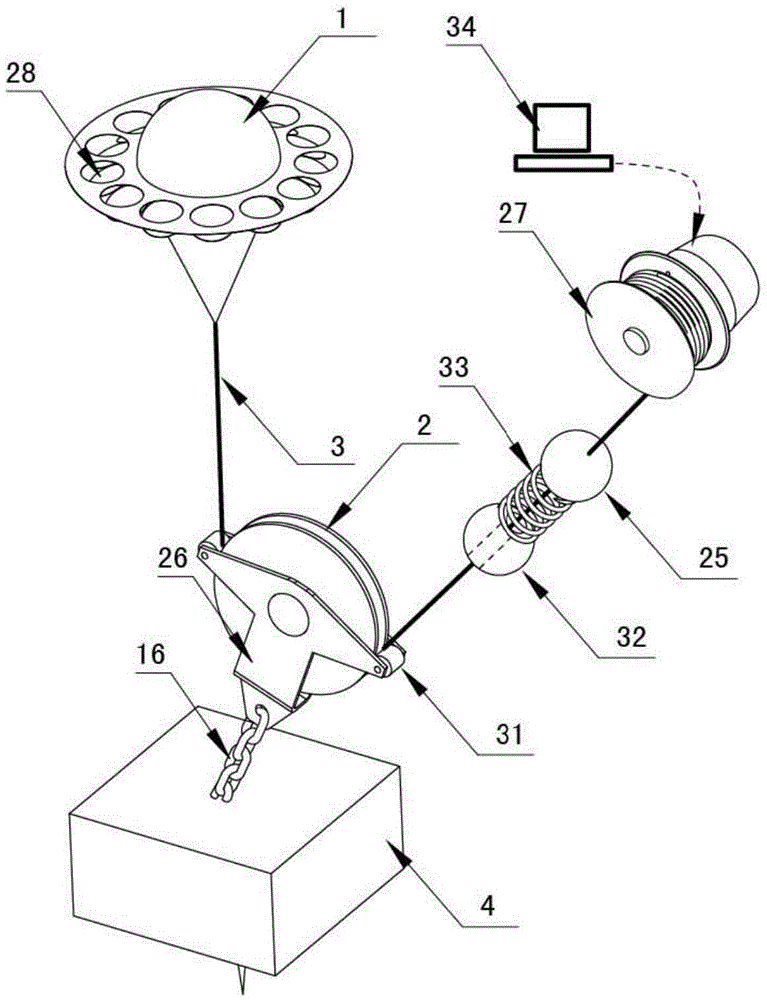

Submersible buoy pulley mooring system

The invention provides a submersible buoy pulley mooring system and relates to a mooring system. The submersible buoy pulley mooring system mainly comprises submersible buoys, pulleys, anchor bases, ropes and rope knots. The anchor bases are provided with rope chains in a tying mode. The other end of each rope chain is tied to each fixed pulley support. Each pulley is wound with a rope. One end of each rope is tied to the corresponding submersible buoy. The other end of each rope is tied to a floating body required to be moored. The positions, between the pulleys and the moored floating body and close to the pulleys, of the ropes are provided with the rope knots in a tying mode. Combination of a plurality of submersible buoy pulley anchoring units distributed on the periphery tightly pull the central floating body required to be moored jointly. By means of the submersible buoy pulley mooring system, the problems of anchor chain breakage or anchor base slippage and the like generated due to the fact that the mooring constraining force is violently increased can be avoided, so that the storm resistance capacity can be provided, and the mooring cost is lowered.

Owner:曲言明

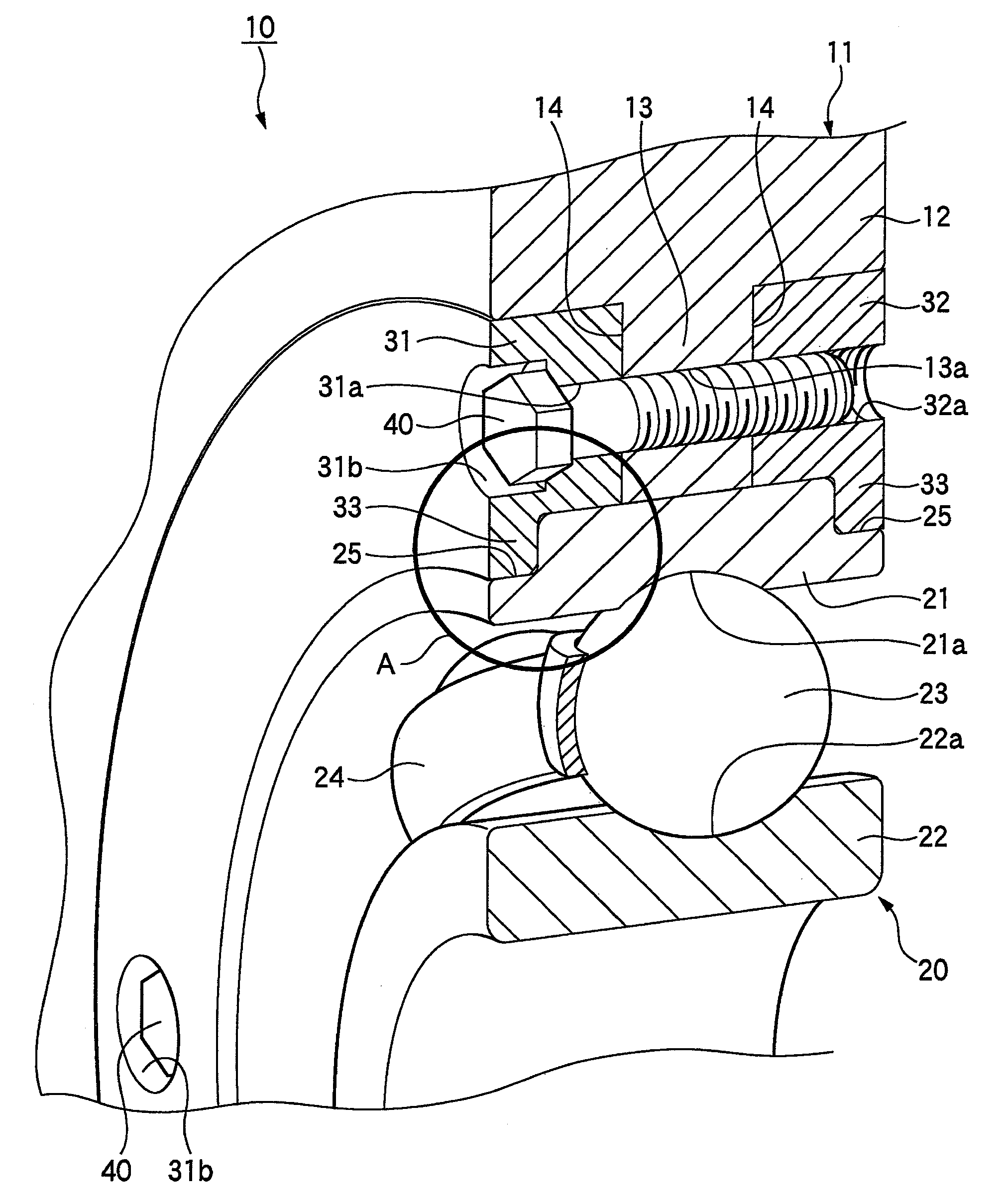

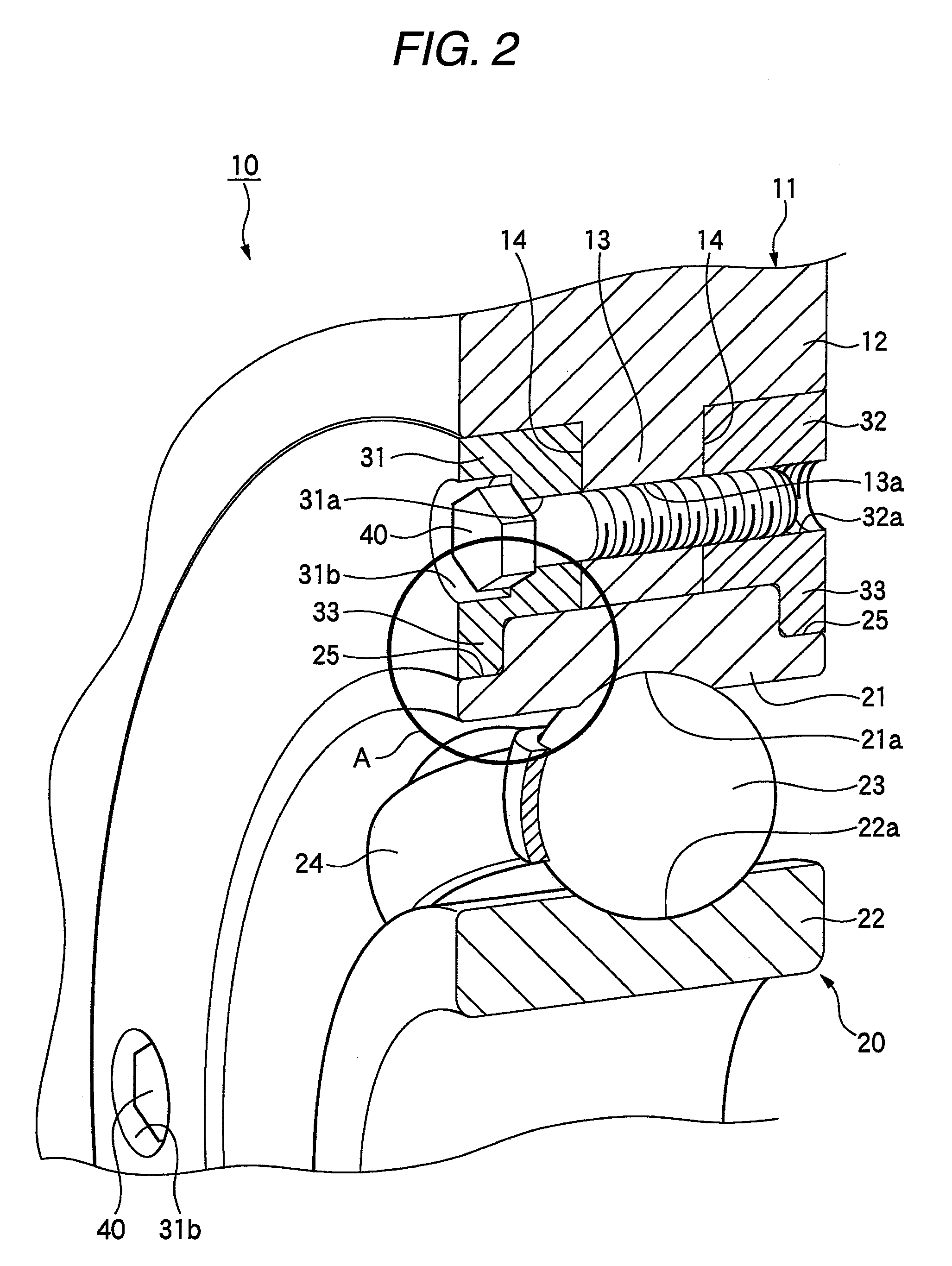

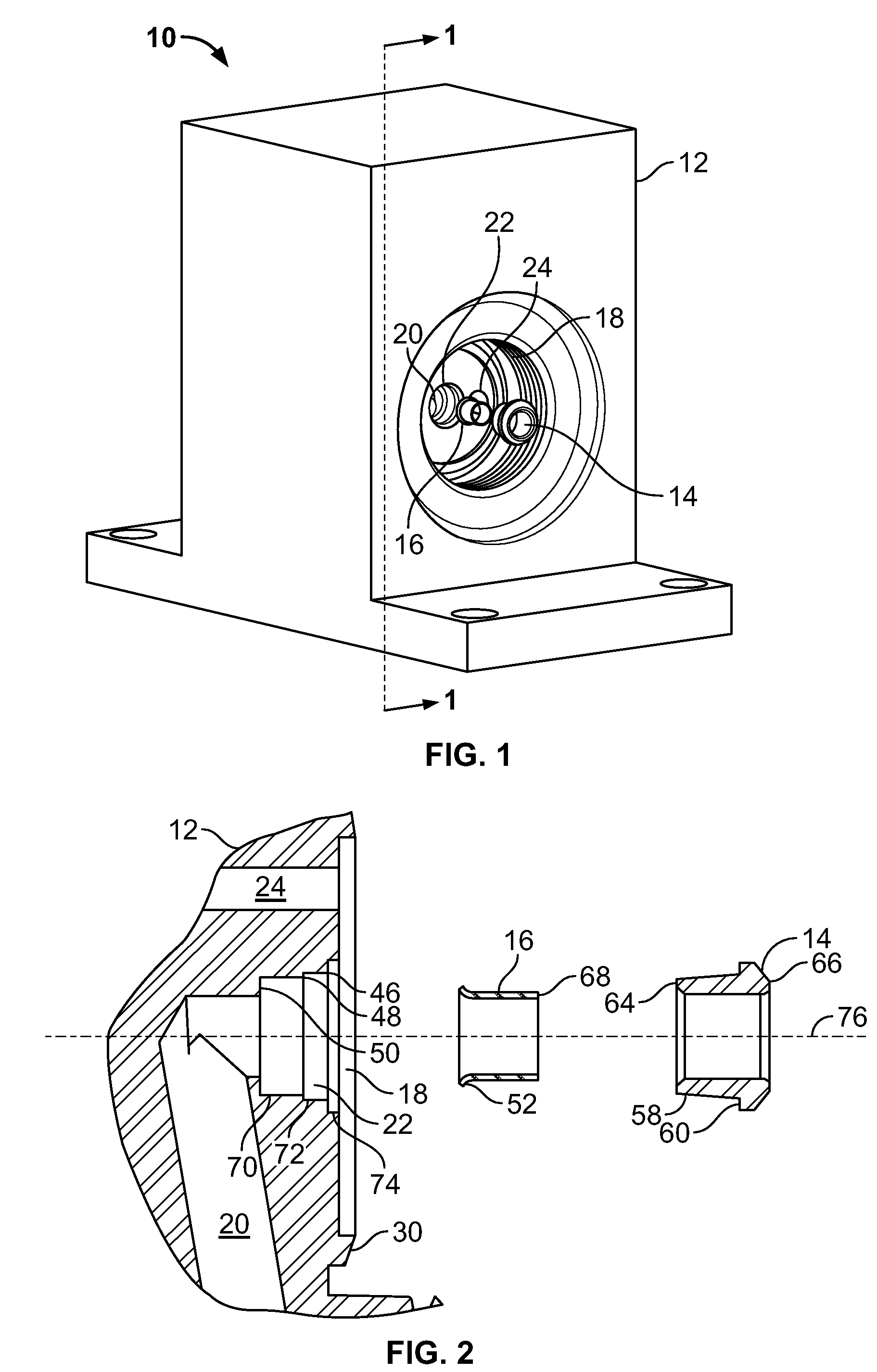

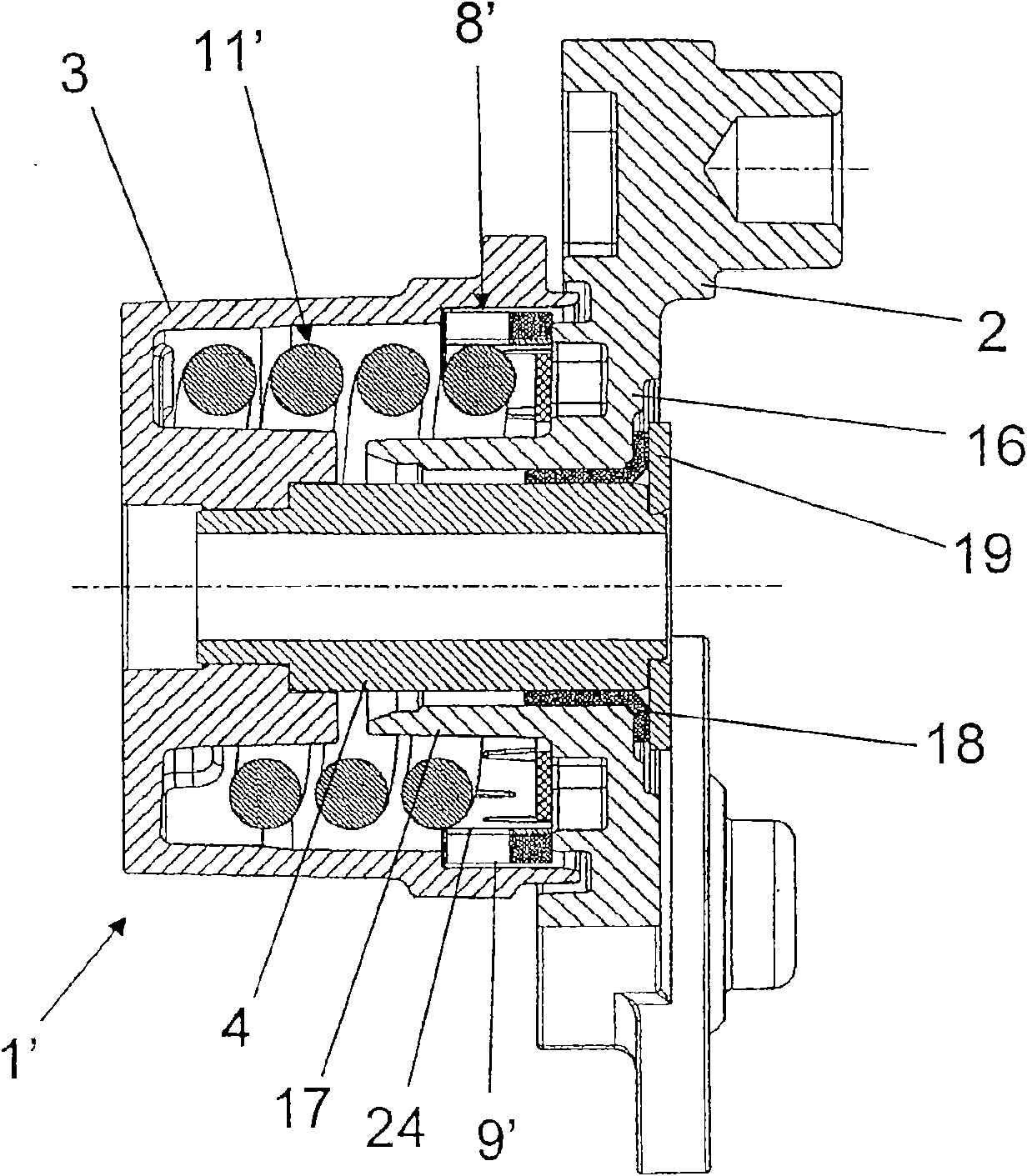

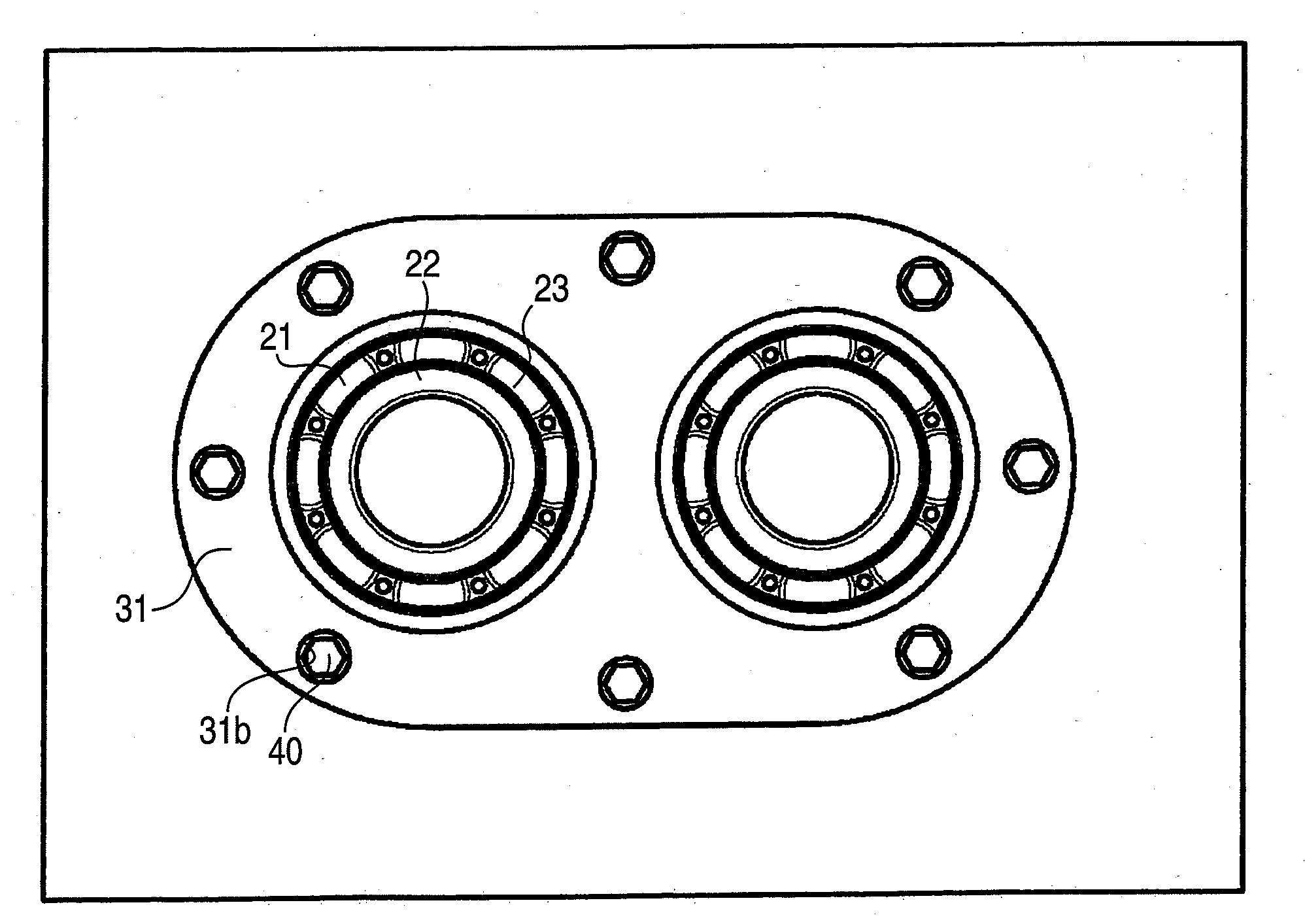

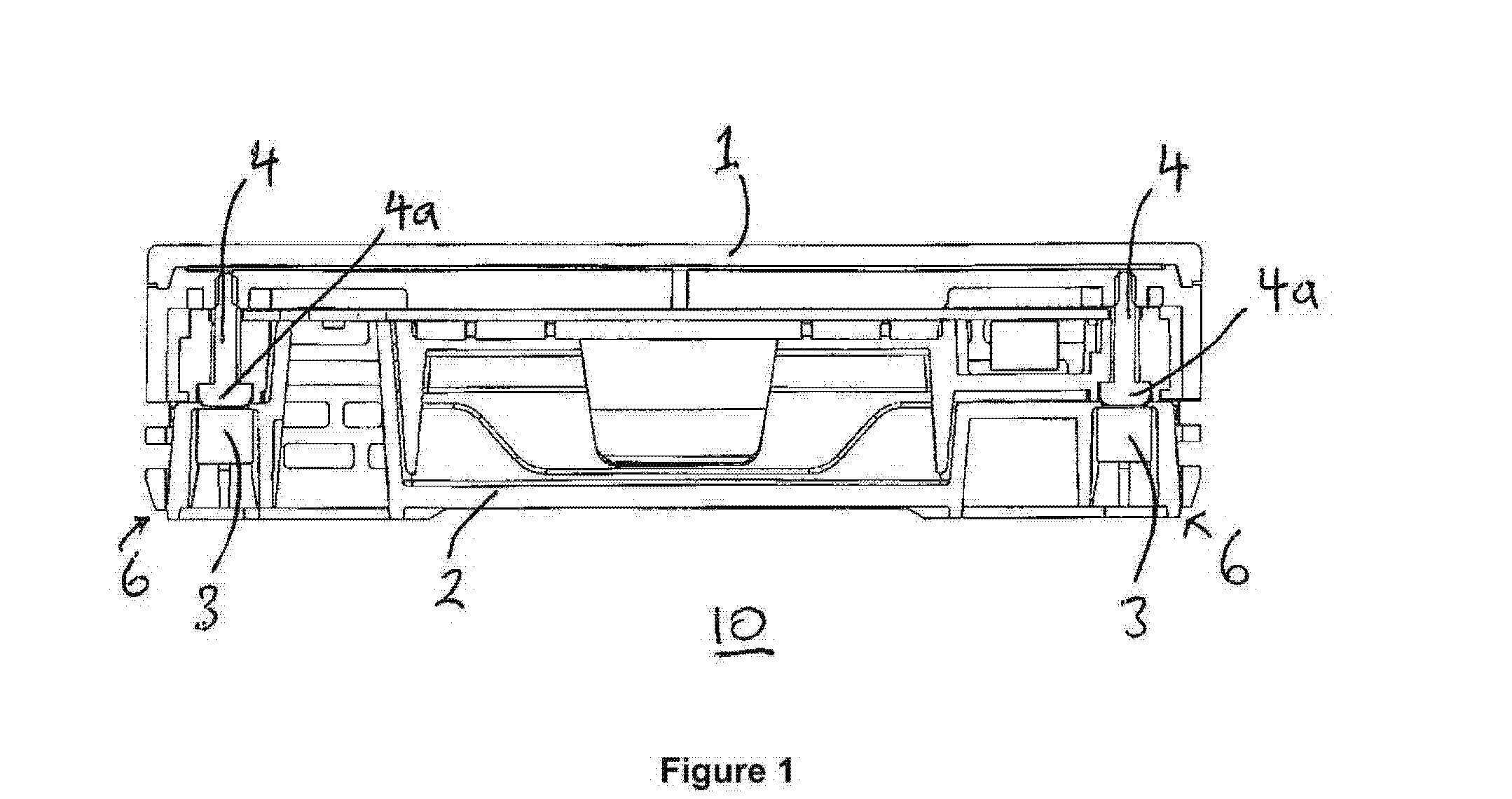

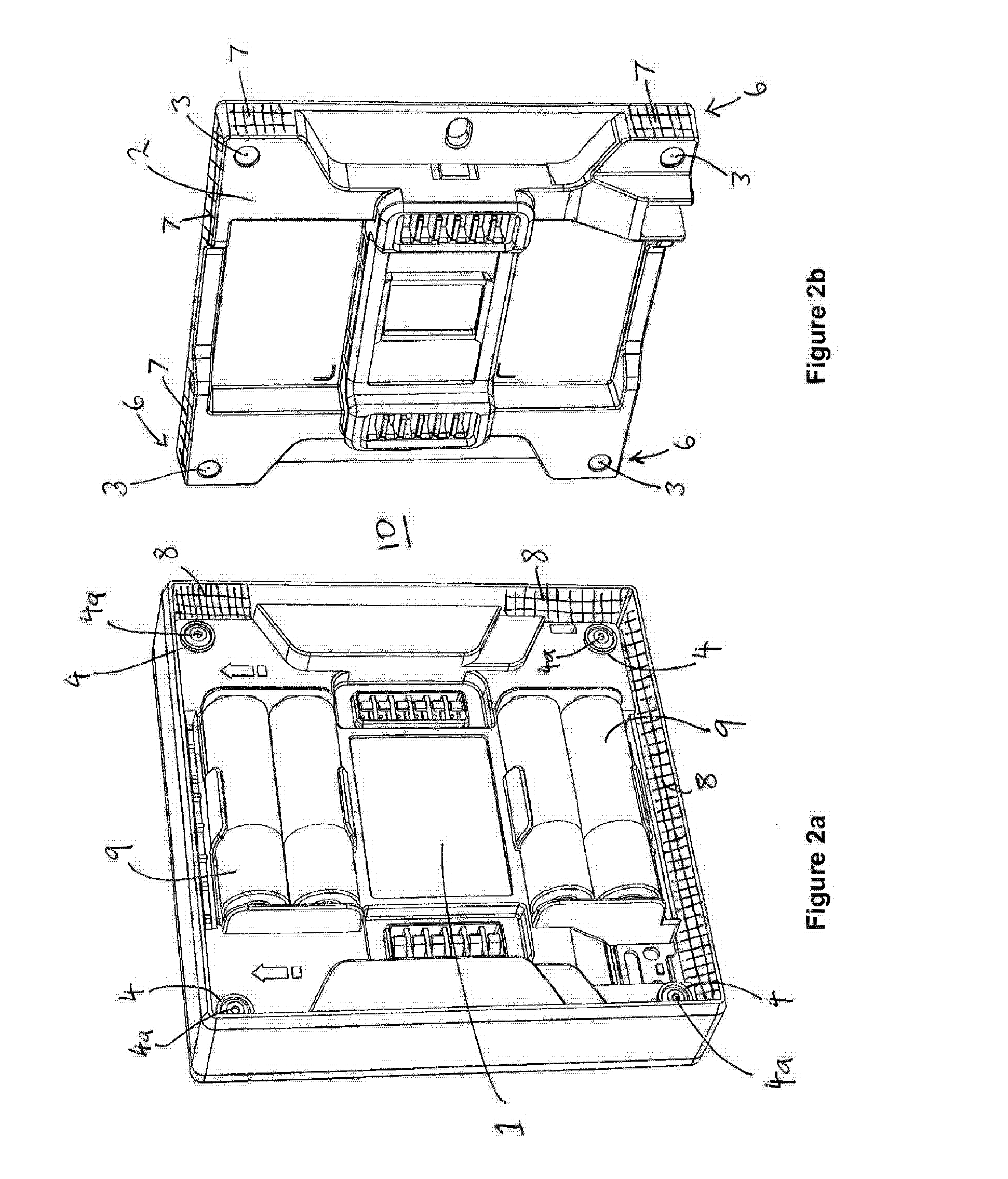

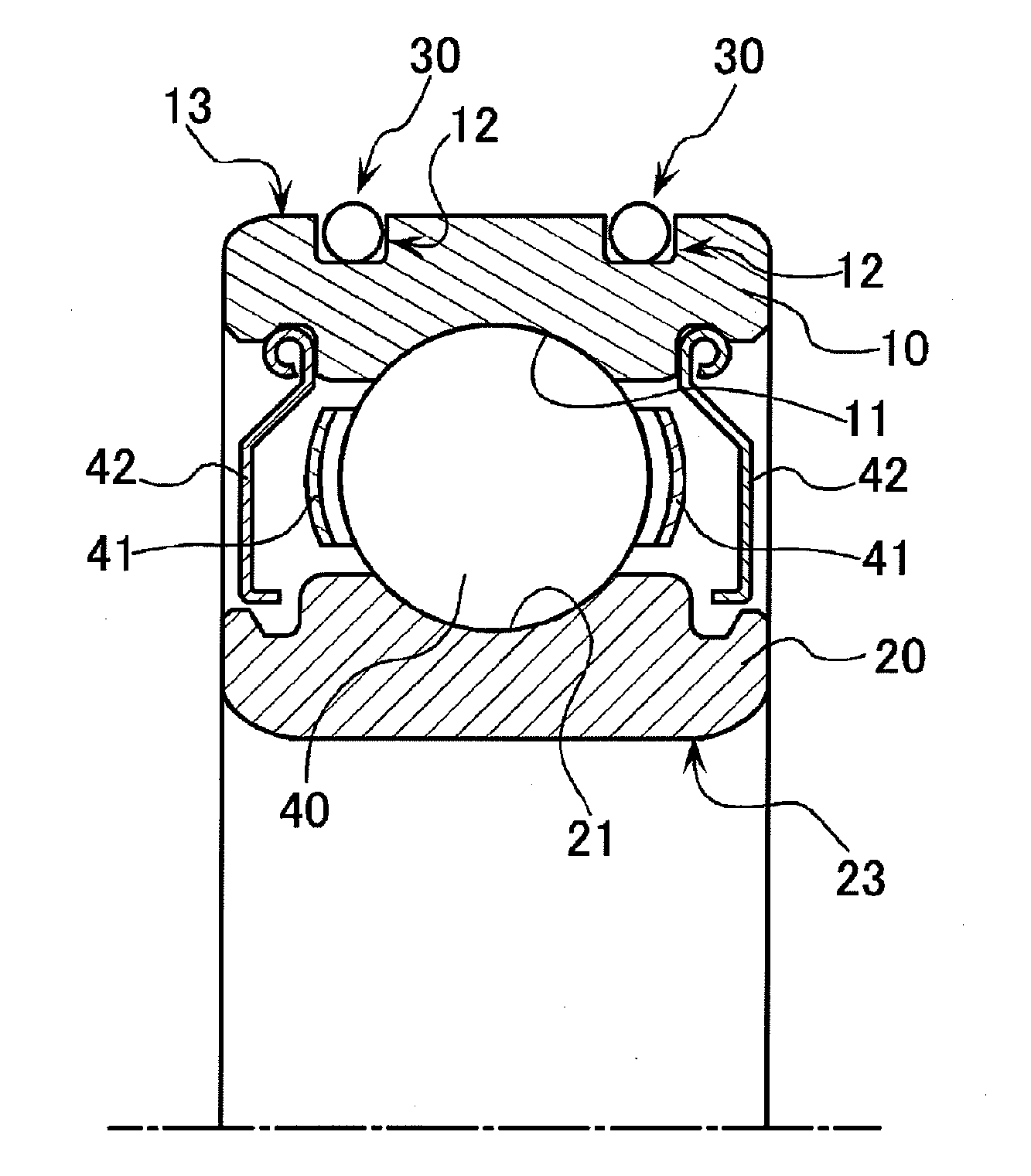

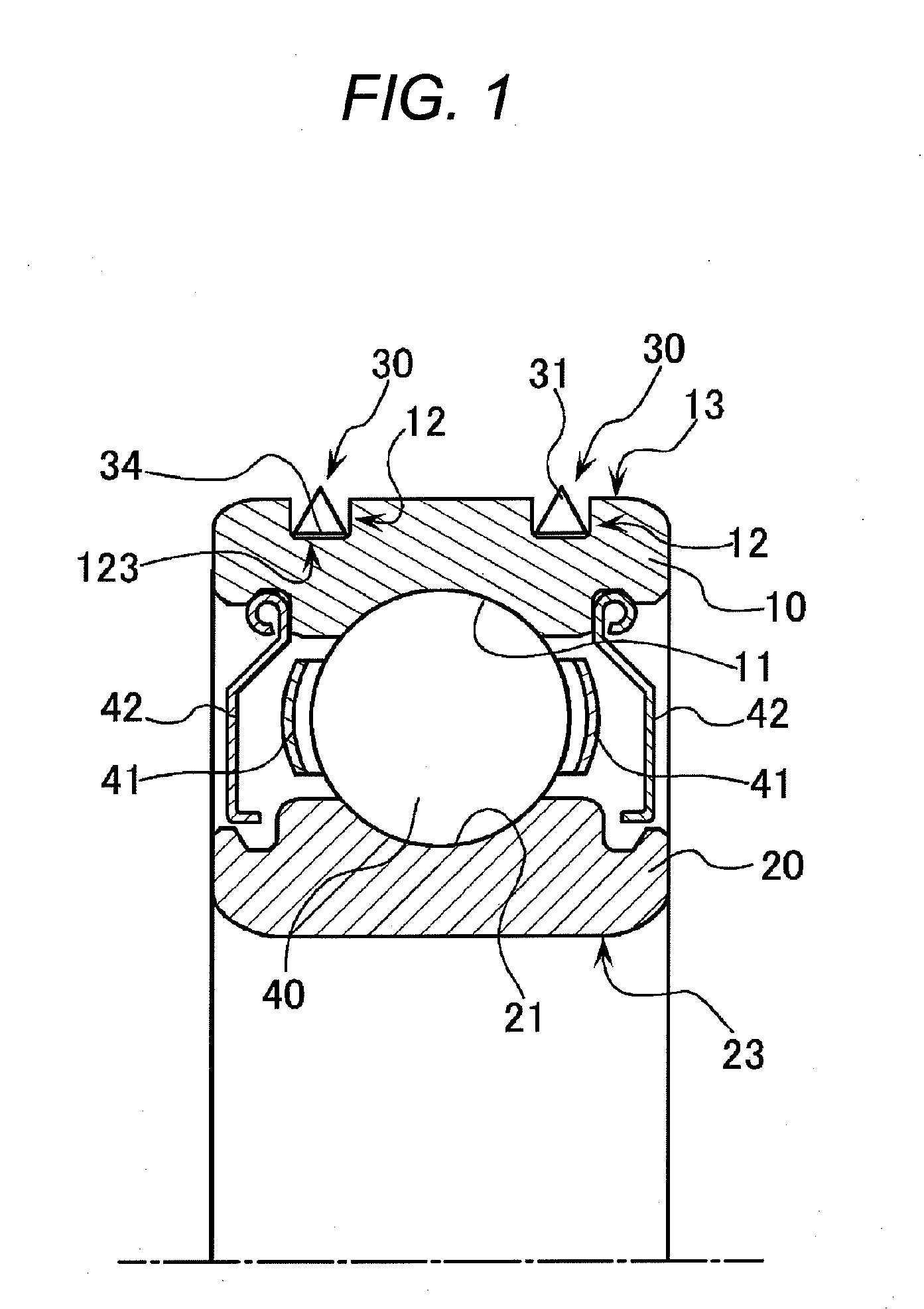

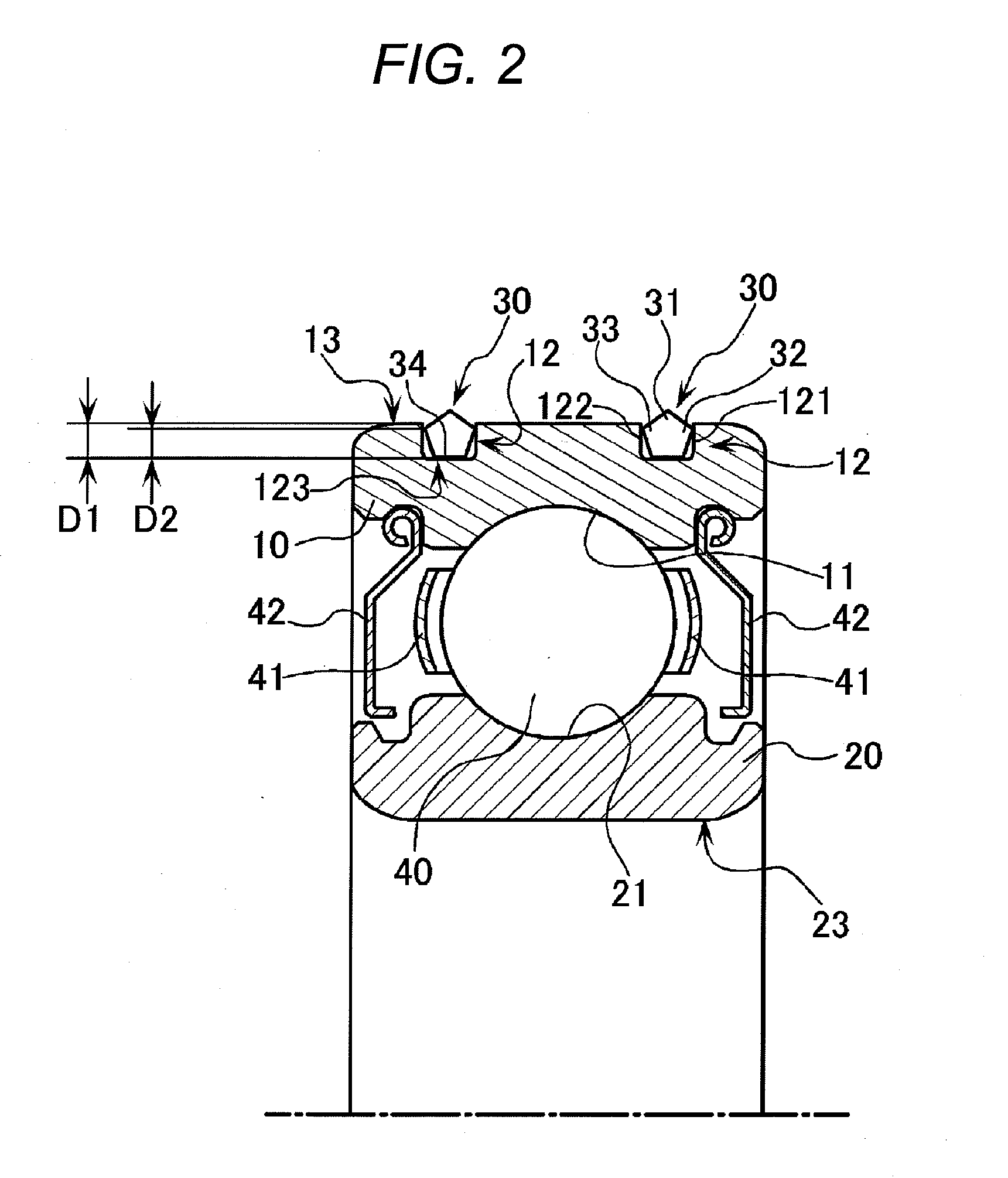

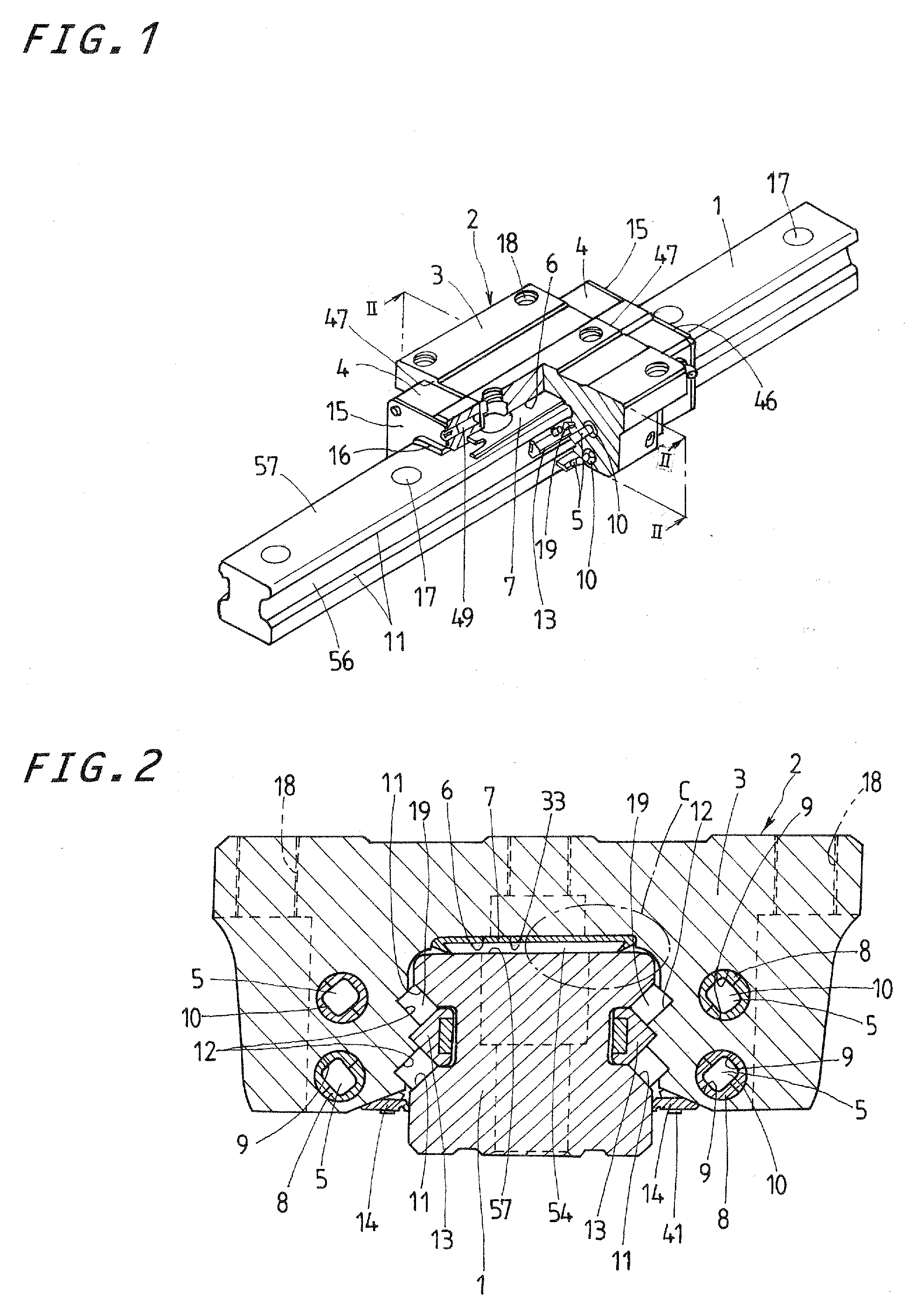

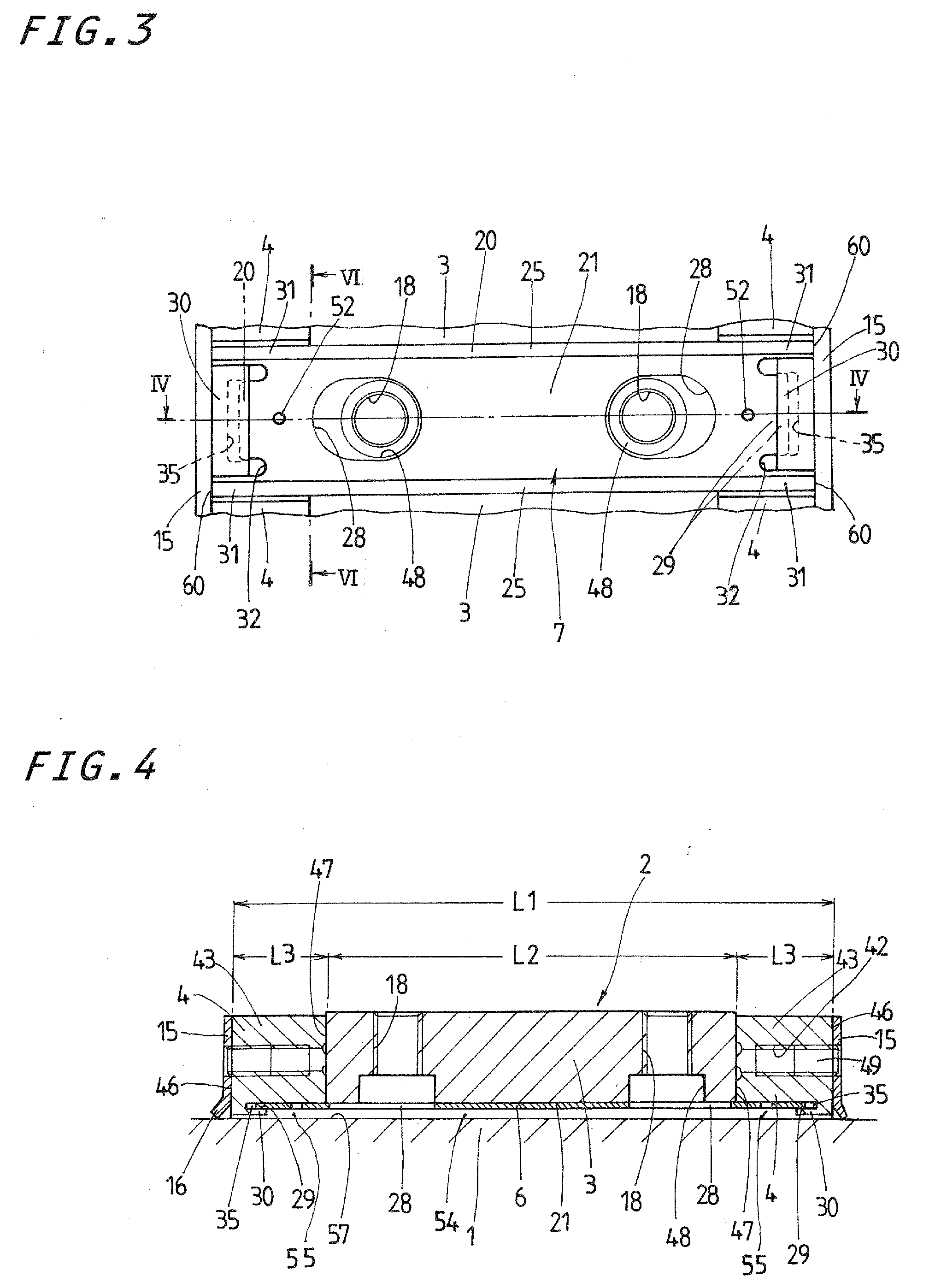

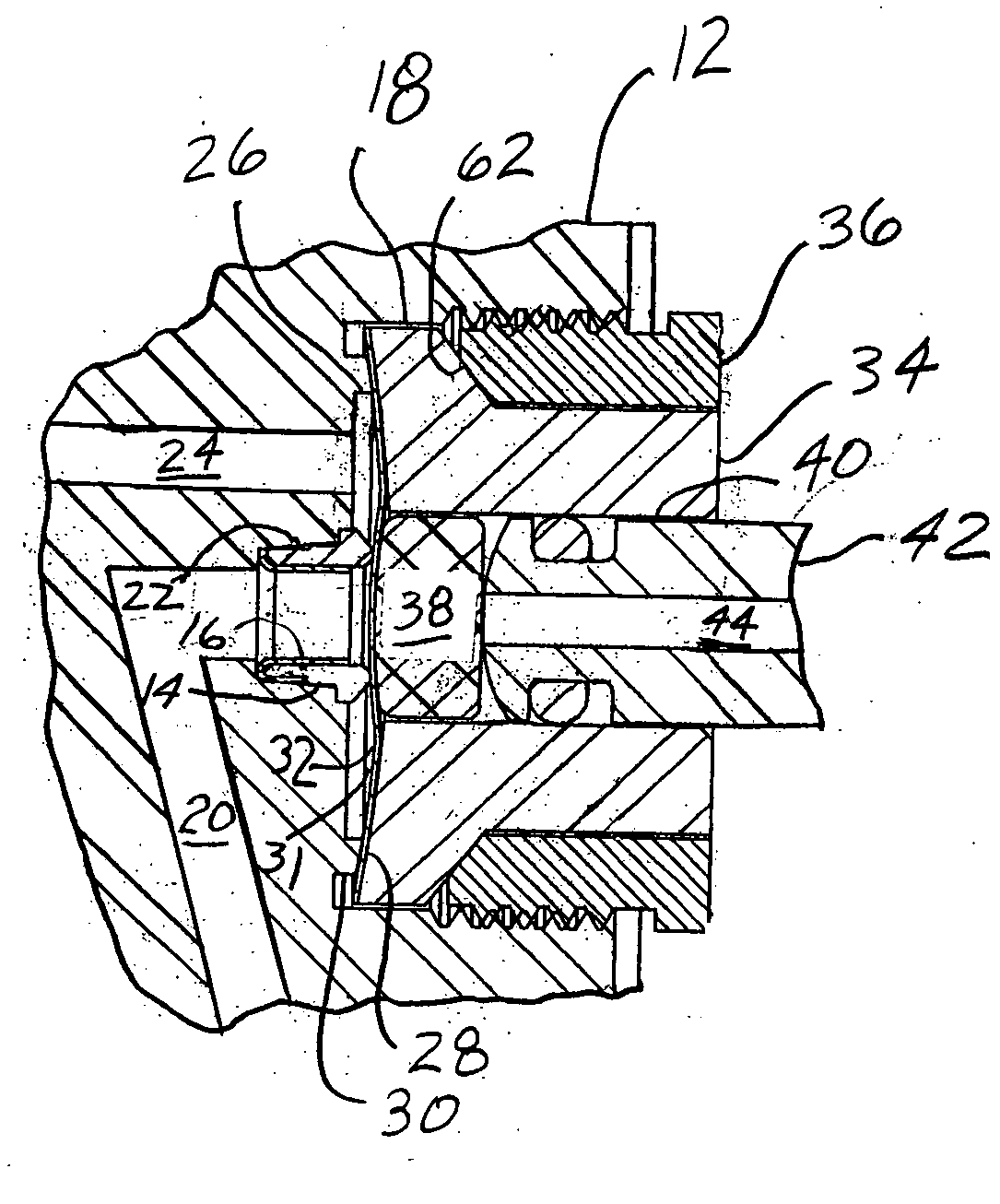

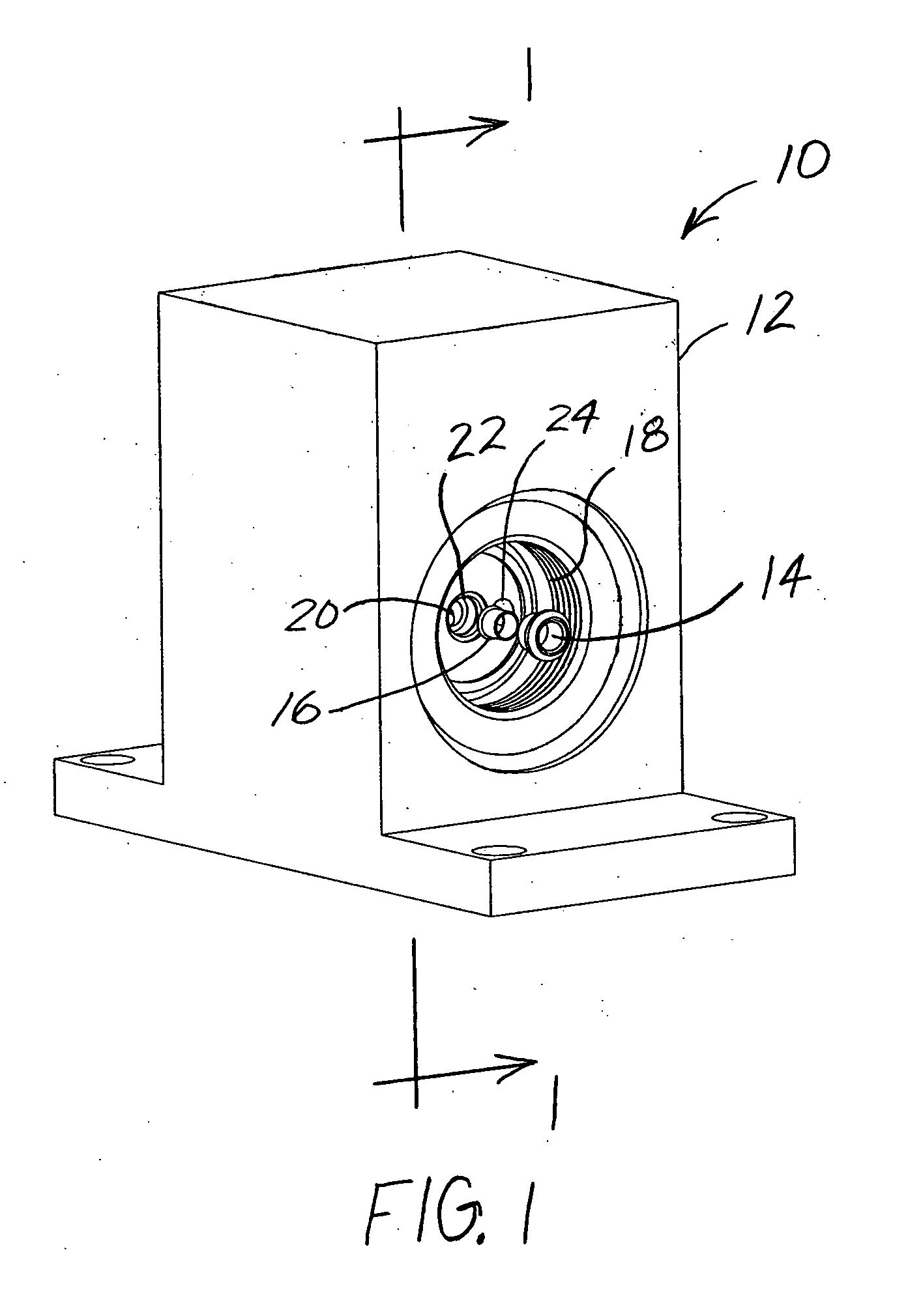

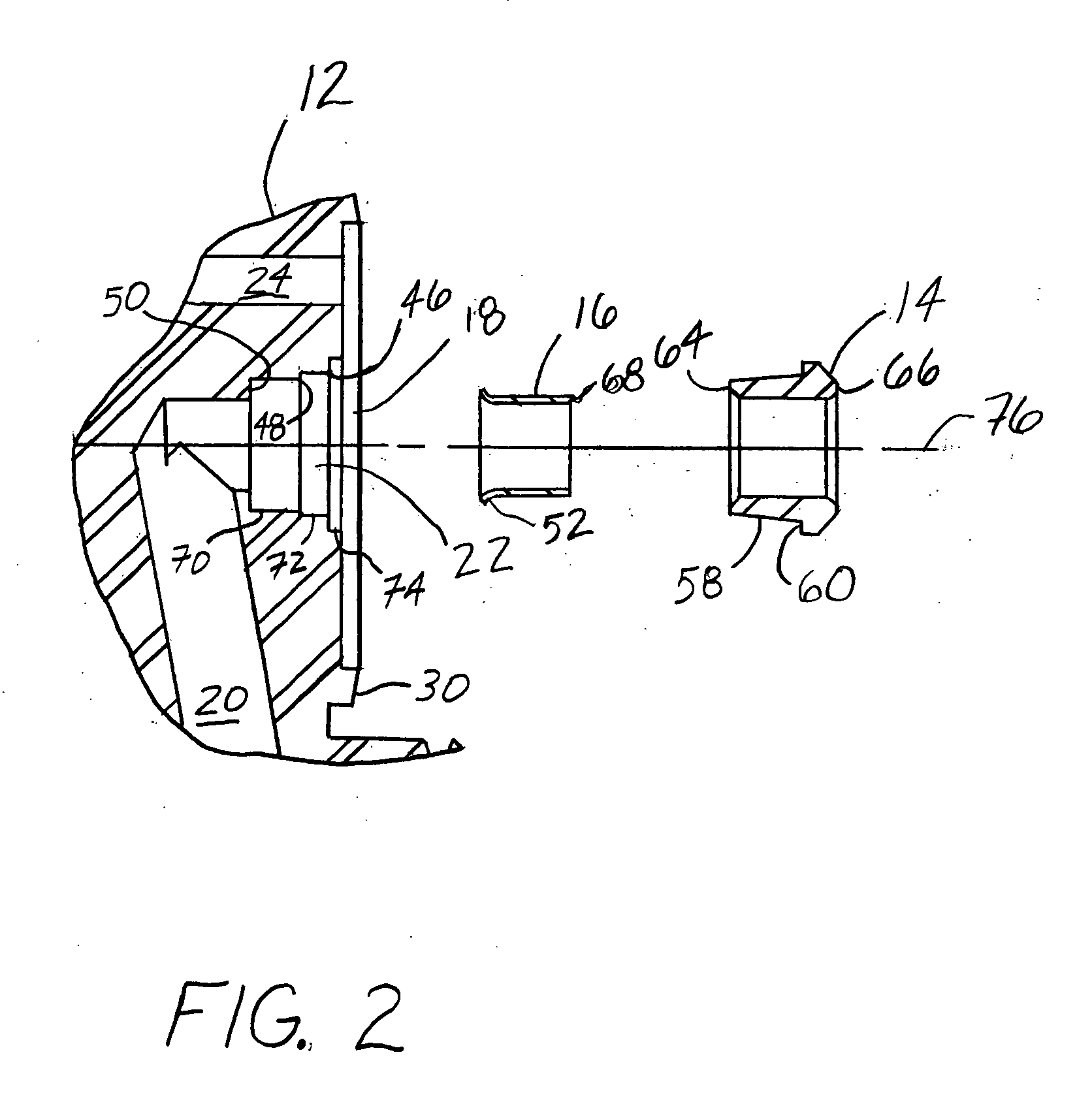

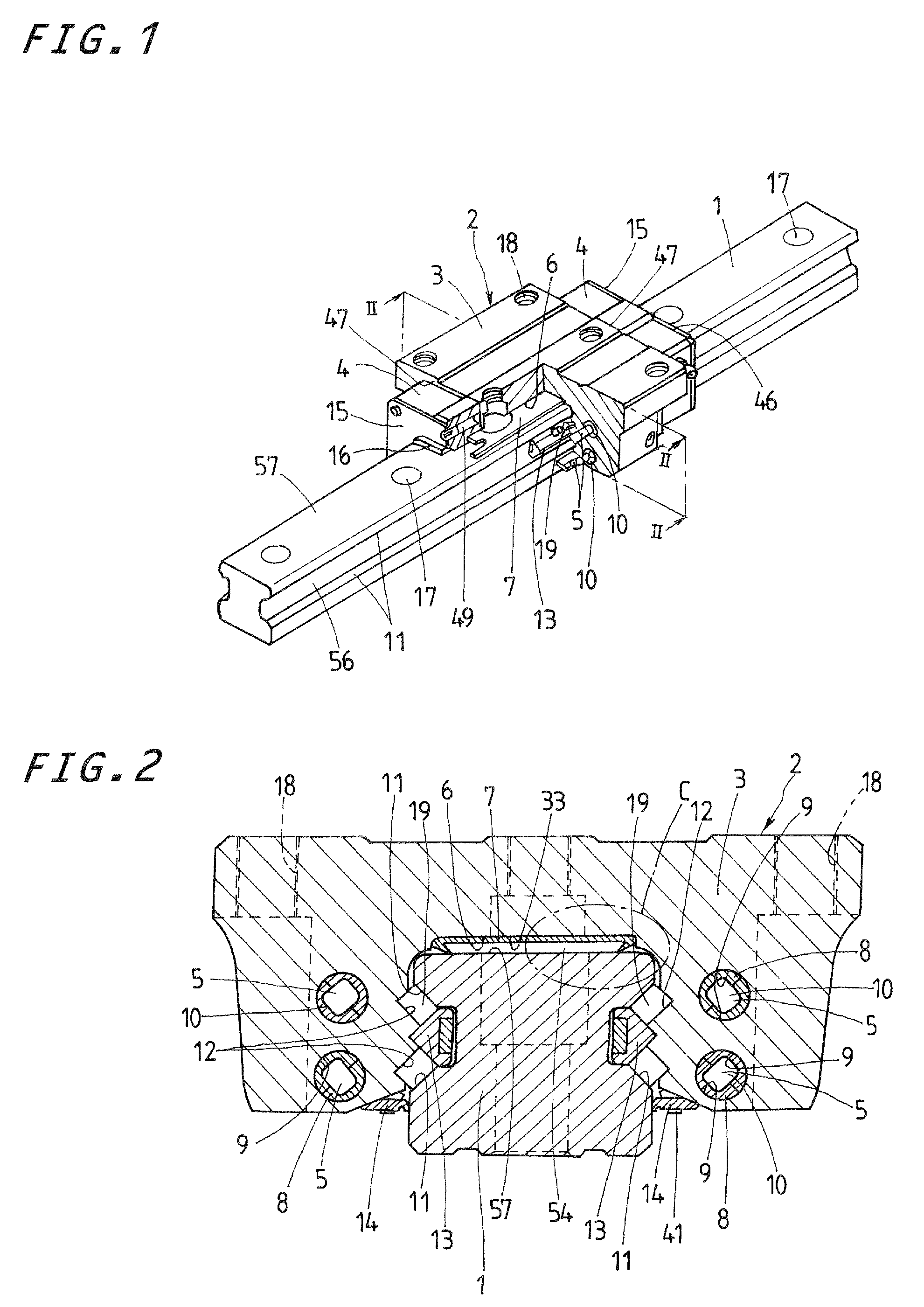

Bearing fixing device and bearing unit

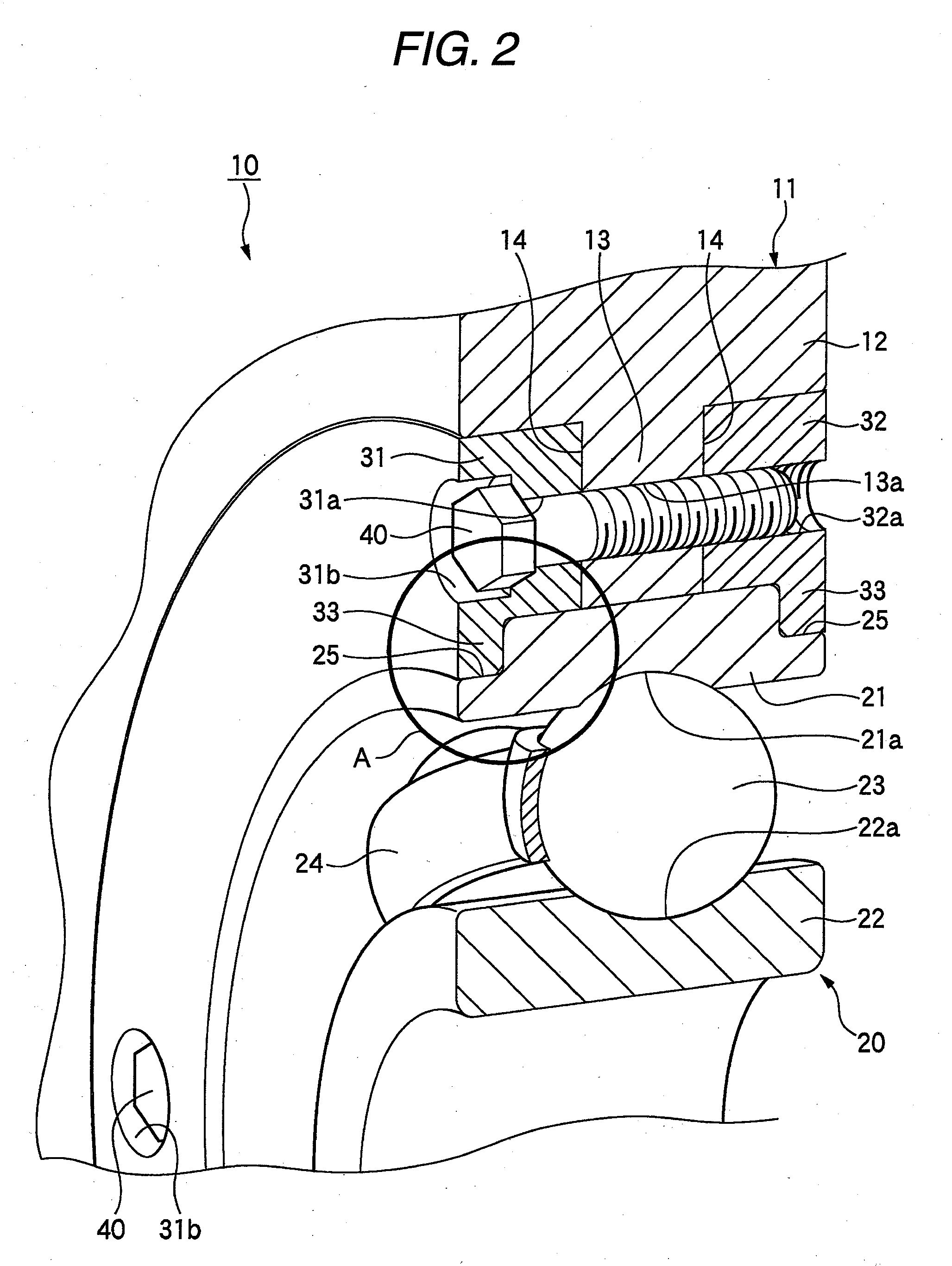

ActiveUS8052331B2Easy to assembleDownsizing of the bearingPortable framesBearing assemblyEngineeringMechanical engineering

A rolling bearing fixing device includes at least one bearing having mutually rotatable inner and outer rings, a housing having at least one fitting hole into which the bearing is fitted and a bolt insertion hole, a pair of fixing plates having at least one large-diameter hole and a bolt insertion hole; and a bolt inserted from one axial end into the bolt insertion hole of one fixing plate, the bolt insertion hole of the housing, and the bolt insertion hole of the other fixing plate, and connects the housing with the pair of fixing plates. Both axial end parts of the outer ring are held by the pair of fixing plates in the axial direction, the inner ring is positioned further inwardly of the large-diameter hole of the fixing plates in the radial direction and the inner ring is rotatable with respect to the fixing plates.

Owner:NSK LTD

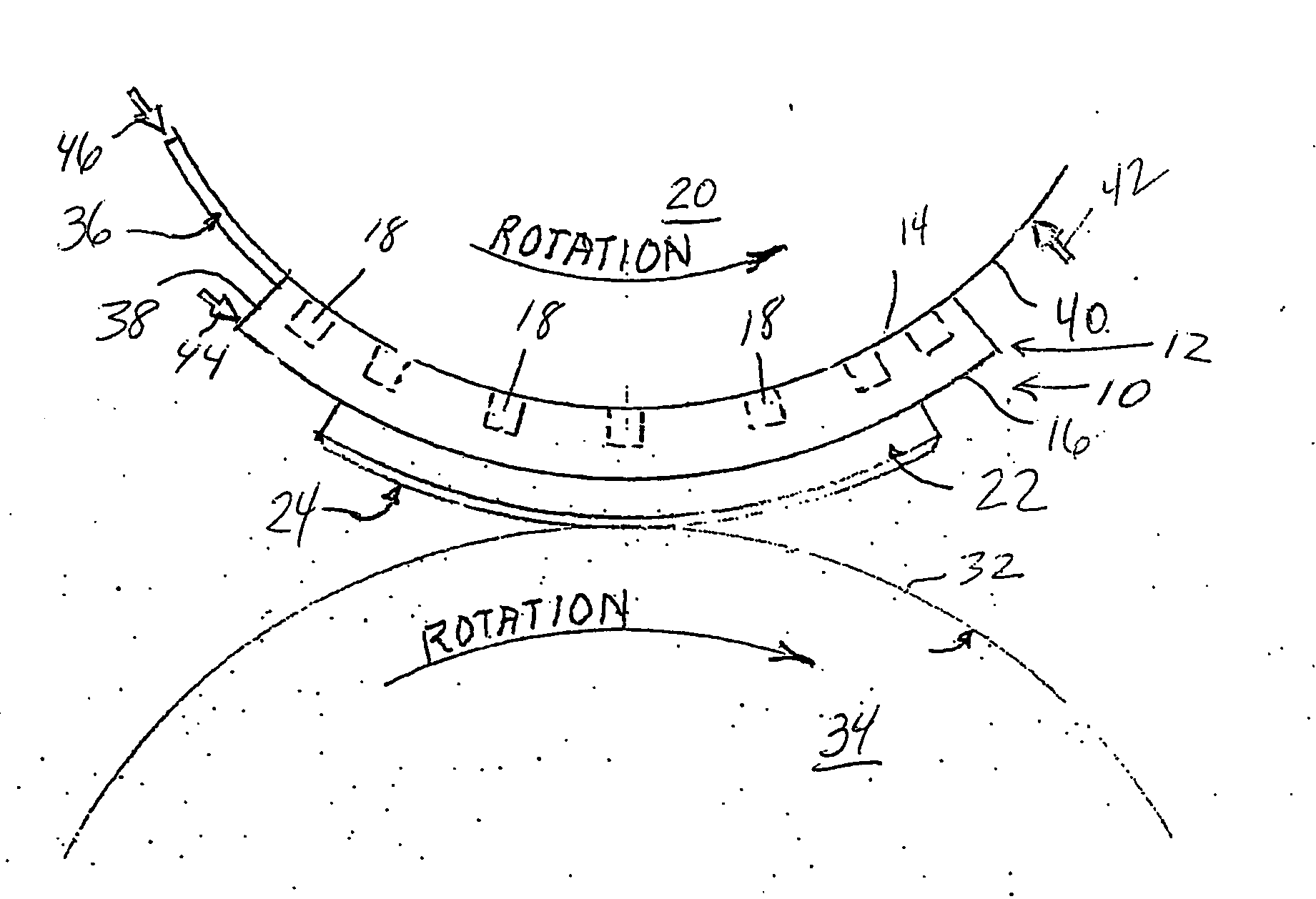

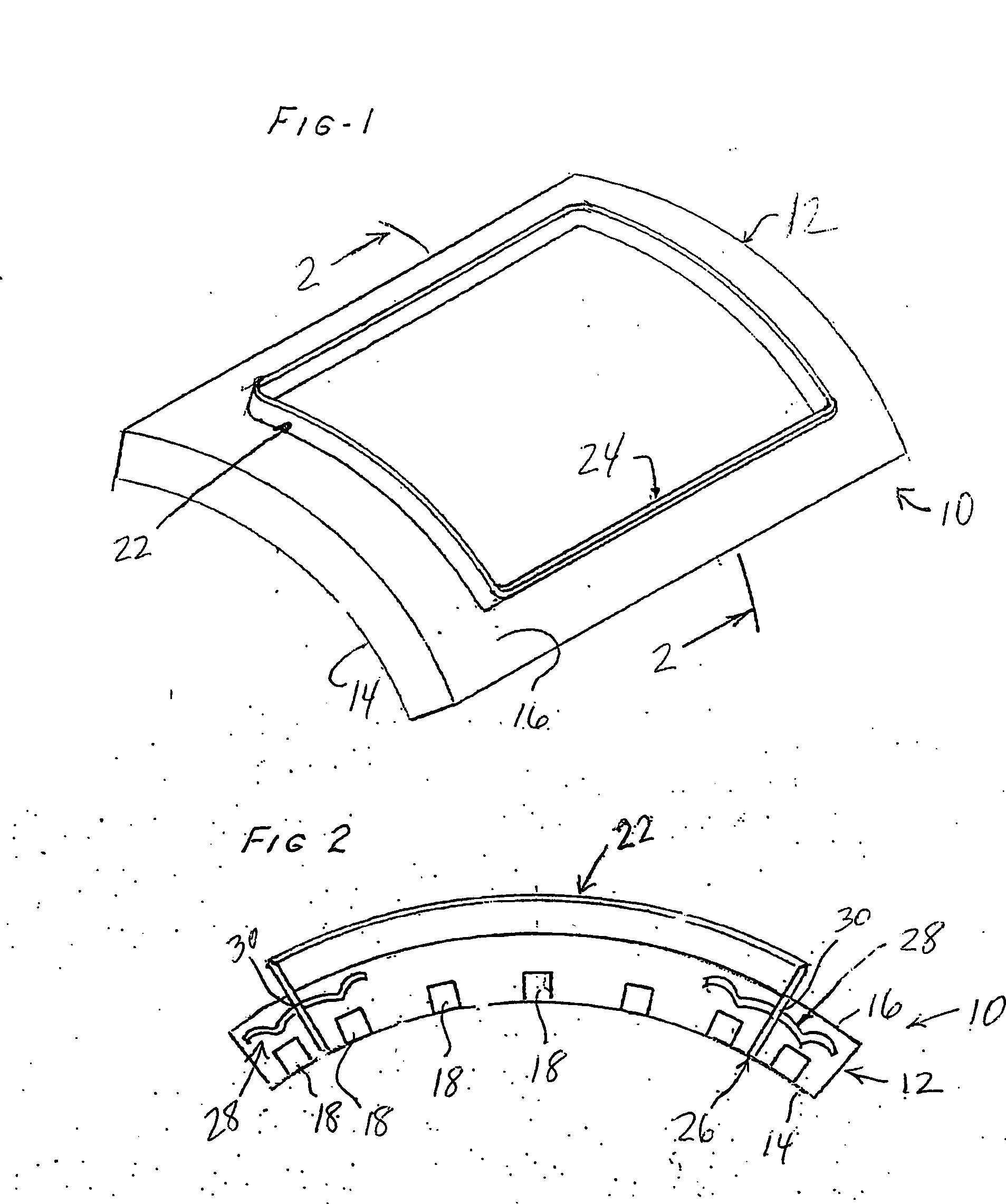

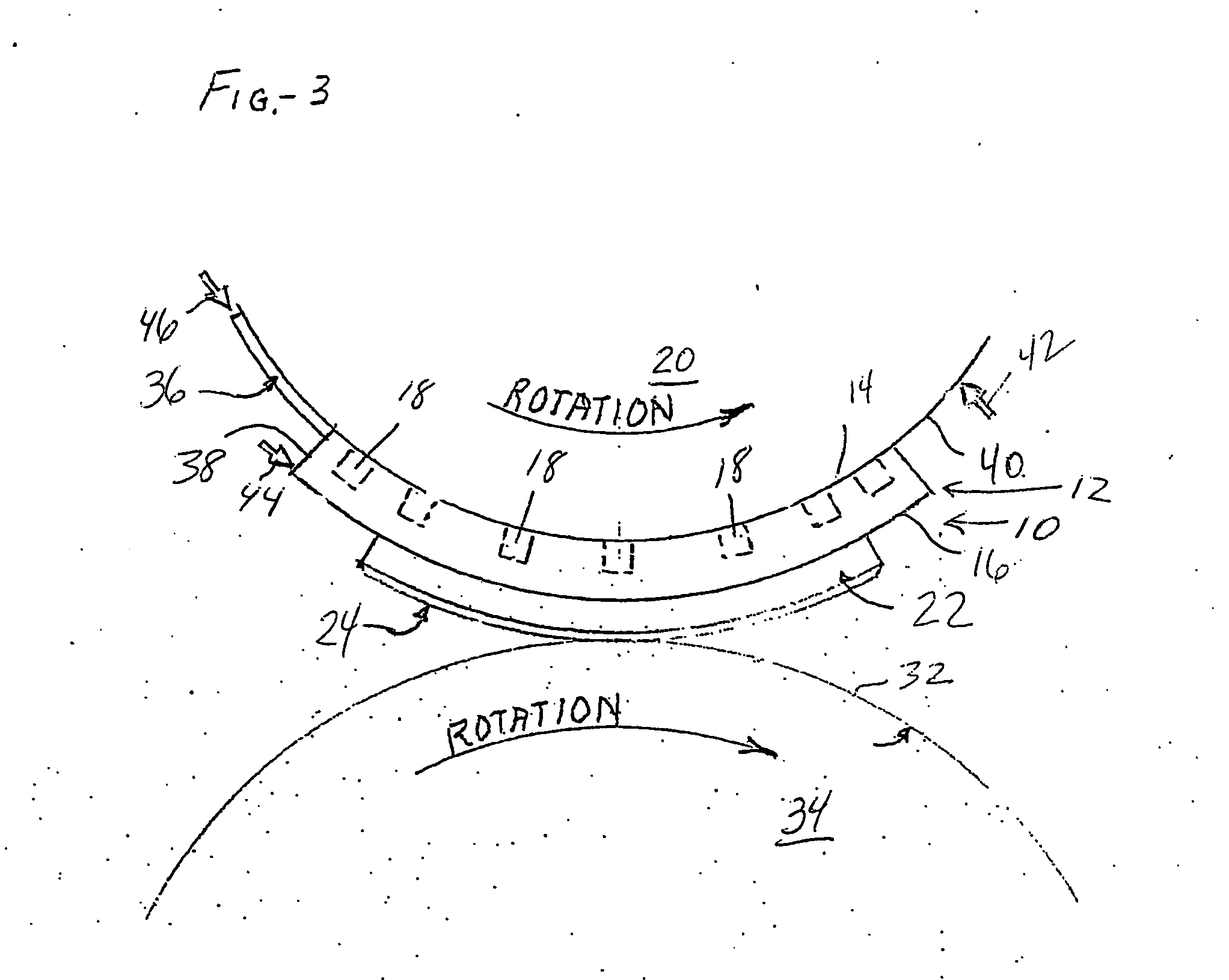

Magnetic rotary die

InactiveUS20050045005A1DifferencePrevent creepStock shearing machinesMetal working apparatusNeodymium magnetKnife blades

A rotary cutting die which is mountable on a metal cylinder. The rotary cutting die includes a rotary die plate having a concave, inner surface which is magnetically attractable and magnetically mountable on a metal cylinder. A cutting blade is mounted on a concave, outer surface of the die plate. Connectors may be engaged with the cutting blade and the die plate. A plurality of magnetic elements, such as neodymium magnets, are in the rotary die plate. The magnetic elements make the inner surface of they die plate magnetically attractable to the metal cylinder, thereby providing that the rotary cutting die is mountable on the metal cylinder without having to use screws, clamps or other mechanical holding devices. To prevent creep of the cutting die during operation, a magnetic member, such as a rubber magnet, may be magnetically mounted on the die cylinder, against the die plate.

Owner:PAPER BENDERS SUPPLY

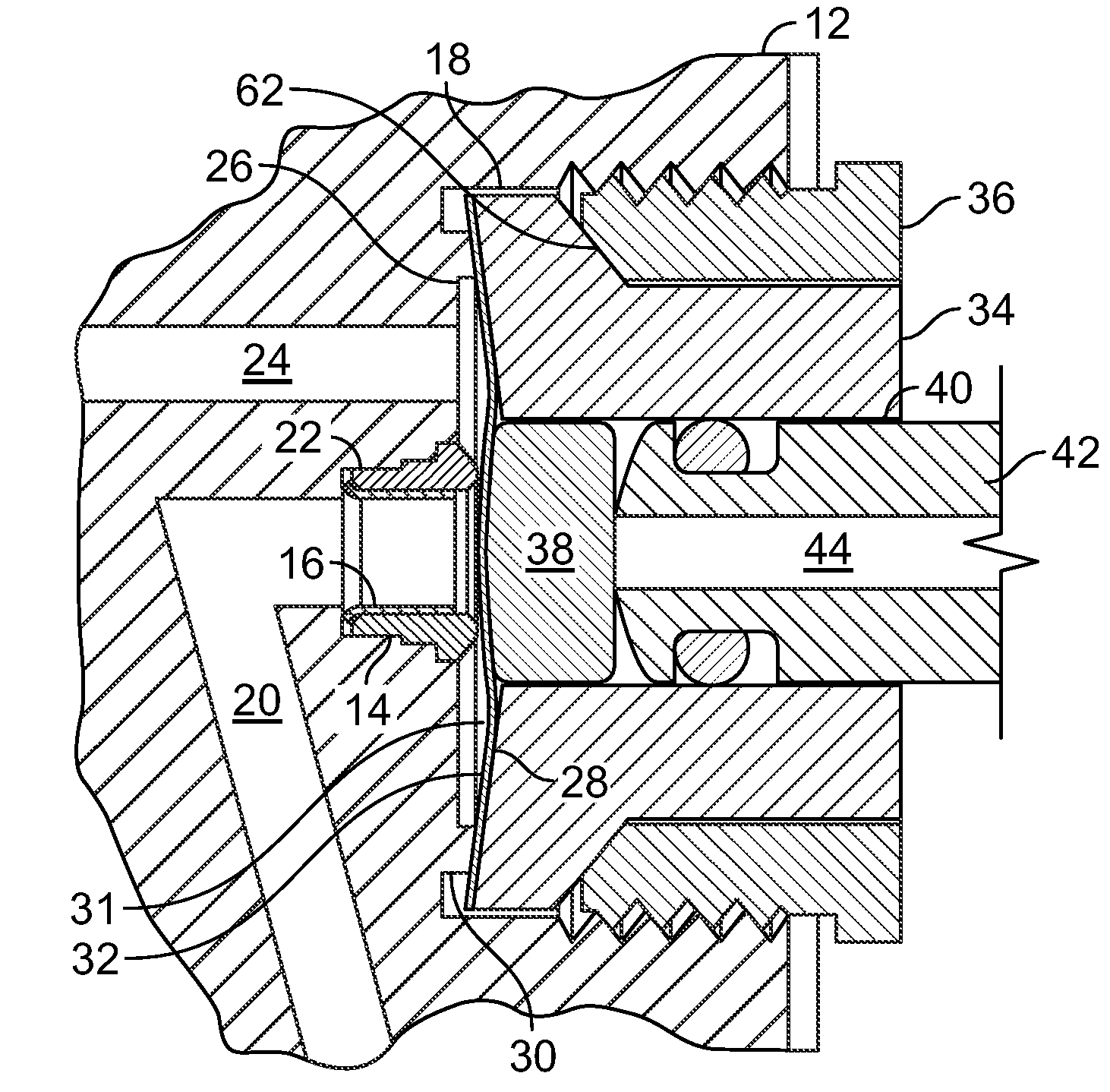

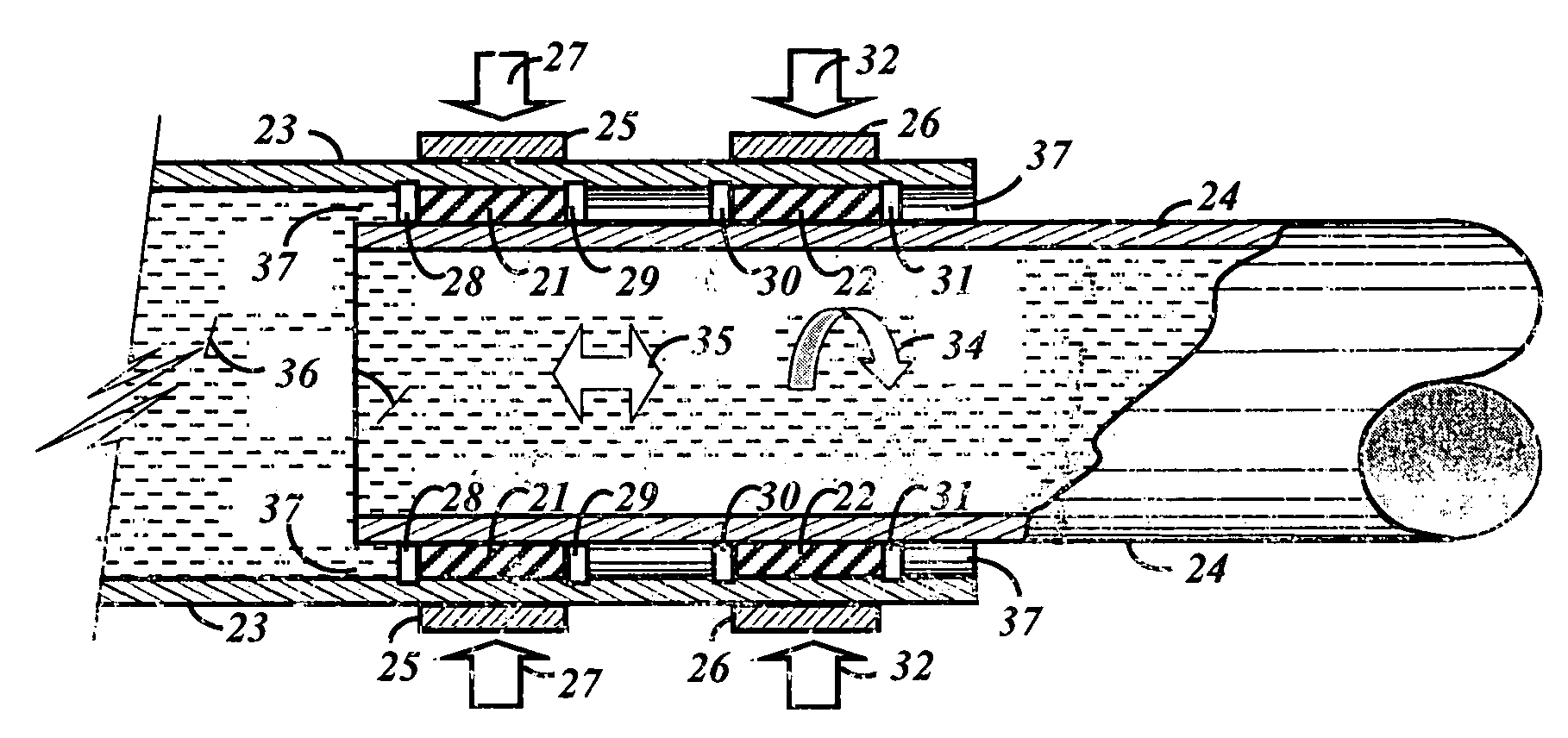

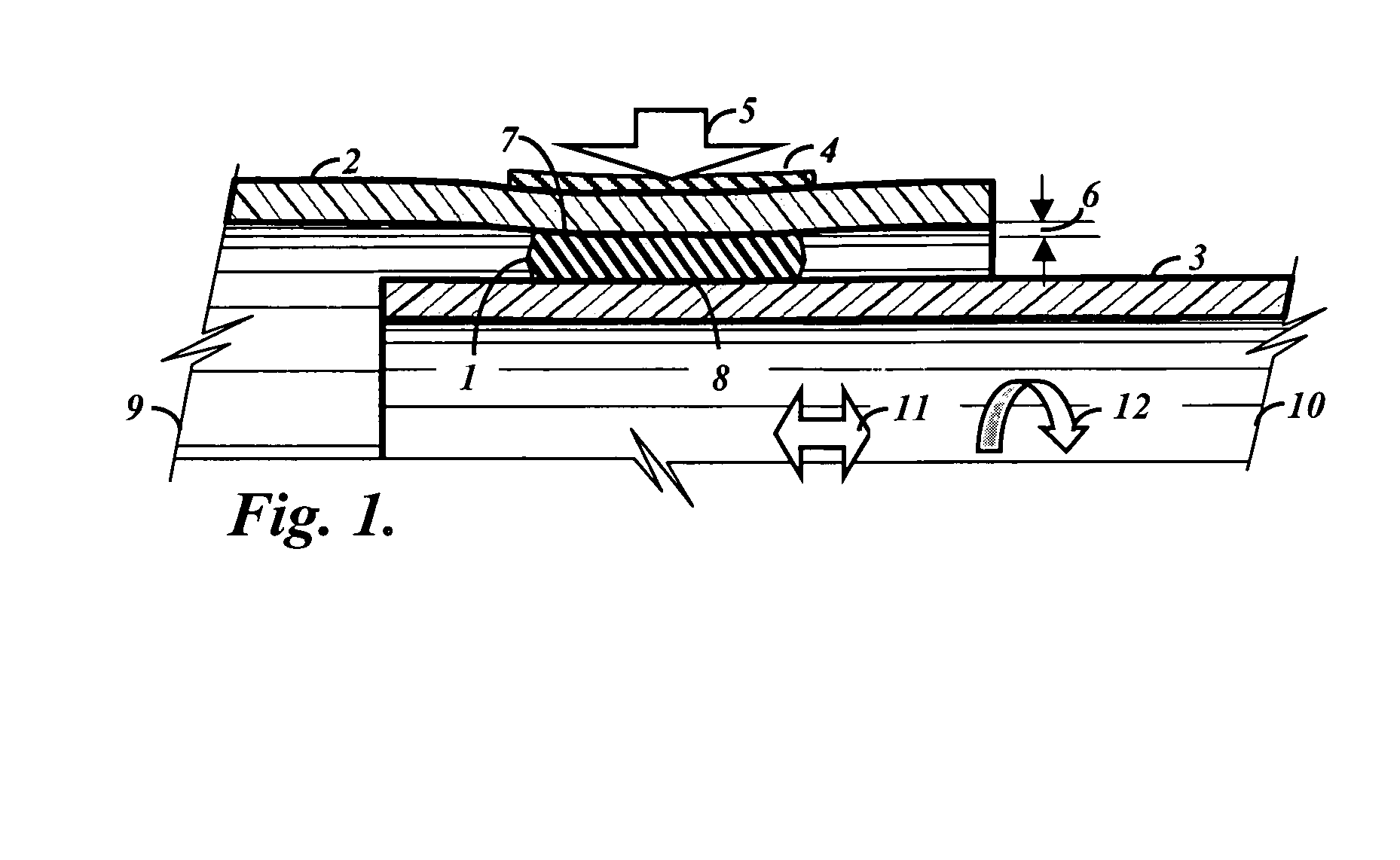

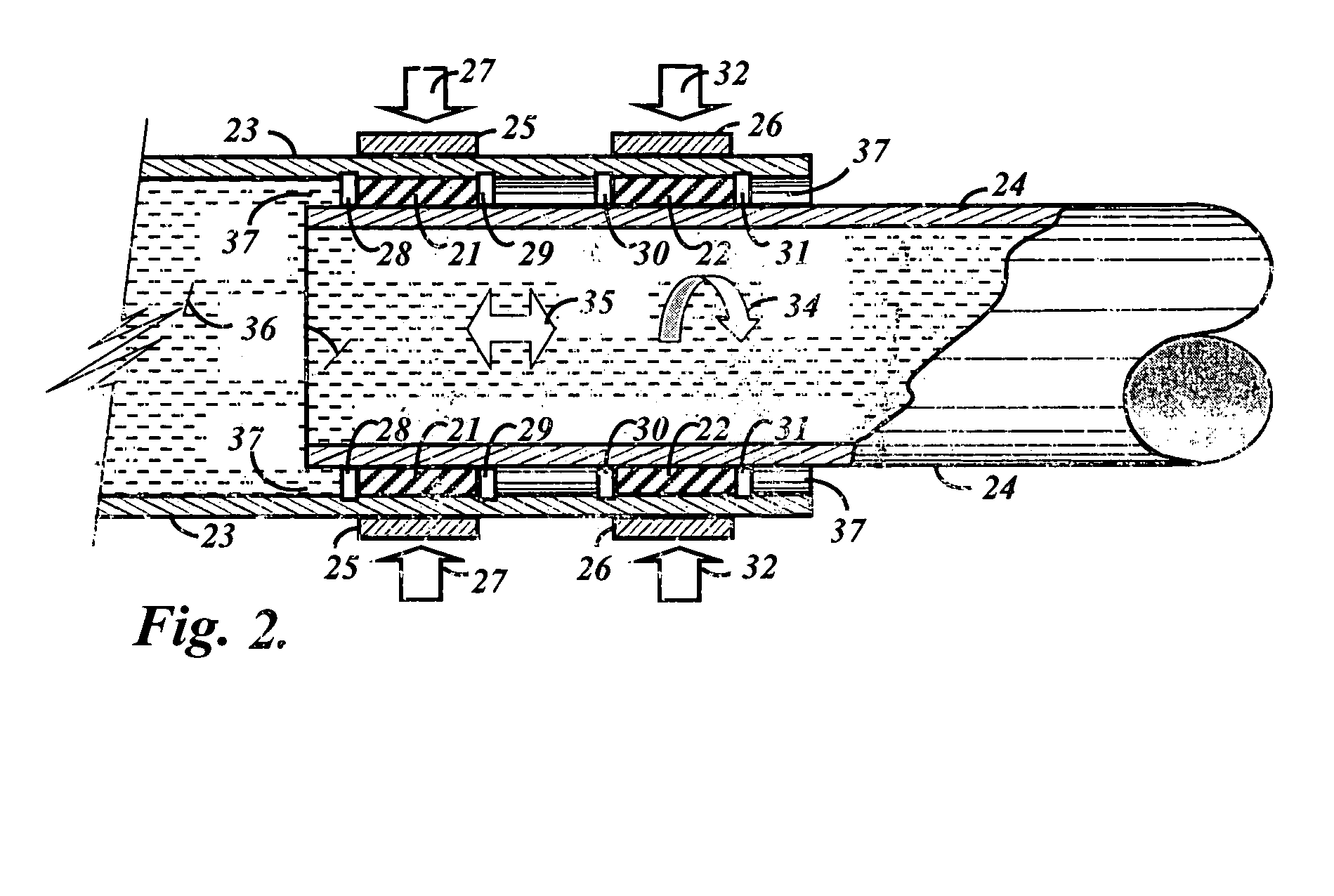

Removable valve seat member for diaphragm valve

ActiveUS7686280B2Prevent creepImprove understandingDiaphragm valvesOperating means/releasing devices for valvesDiaphragm valveValve seat

An apparatus and method for a diaphragm valve includes a valve body having a chamber in fluid communication with a first channel and a second channel. A diaphragm is disposed in the chamber, and a tapered seat member is at least partially disposed in the first channel. A sleeve is compressively disposed in the seat member between the seat member and the first channel to maintain a fluid tight seal between the seat member and the first channel. A valve member is movable to controllably urge the diaphragm into and out of engagement with the seat member to control flow of fluid between the first the first and second channel.

Owner:CRANE INSTR & SAMPLING INC

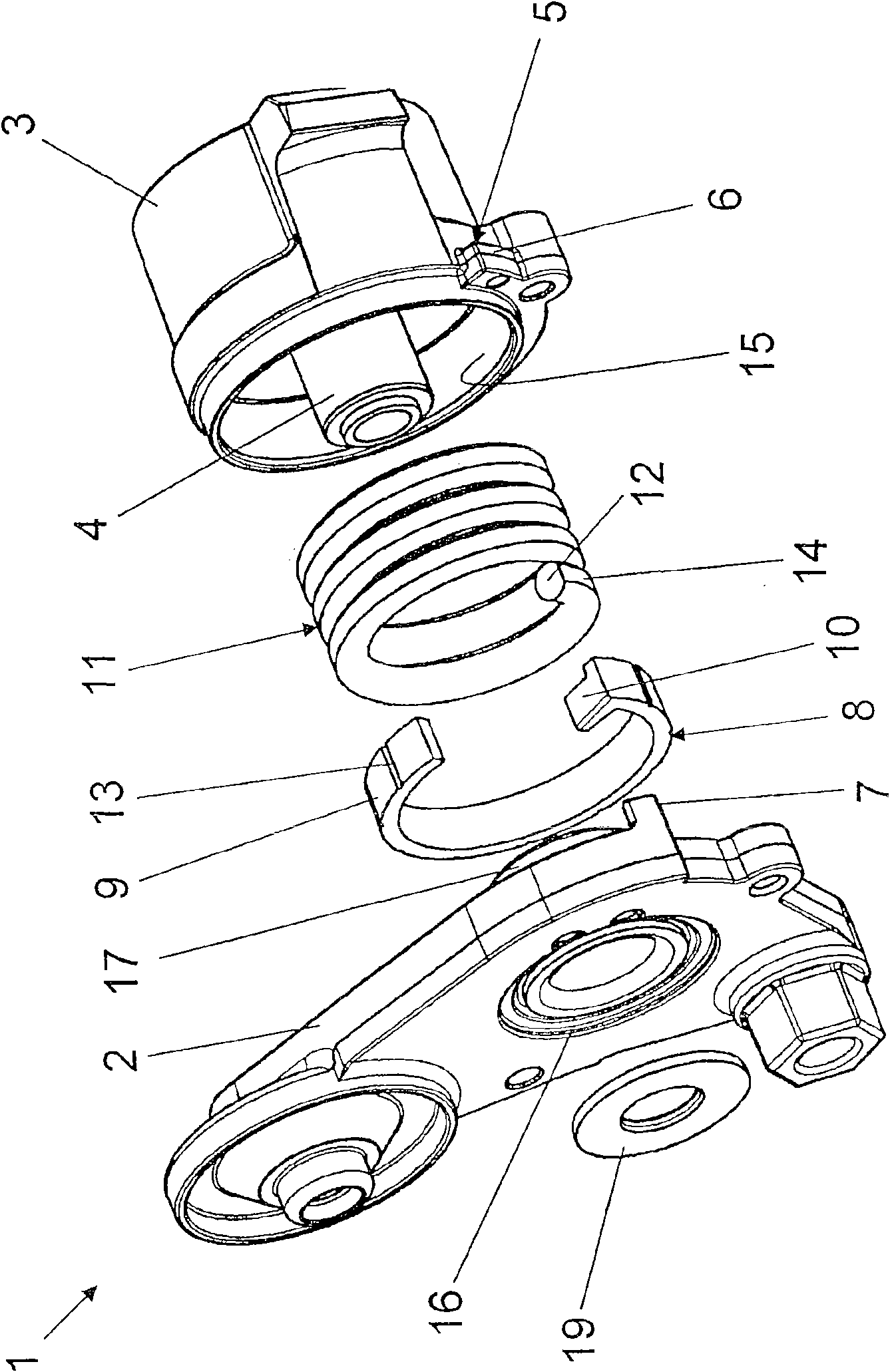

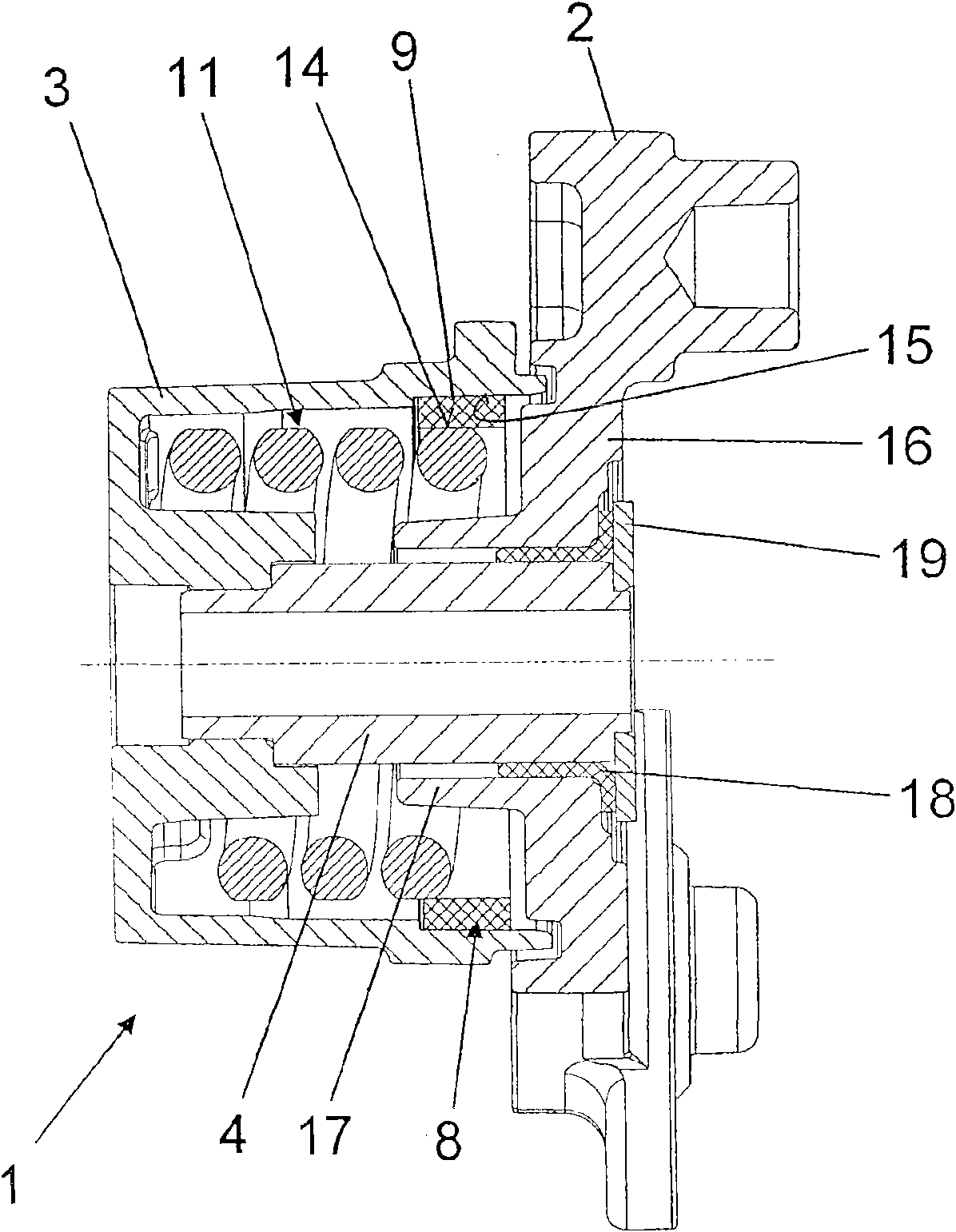

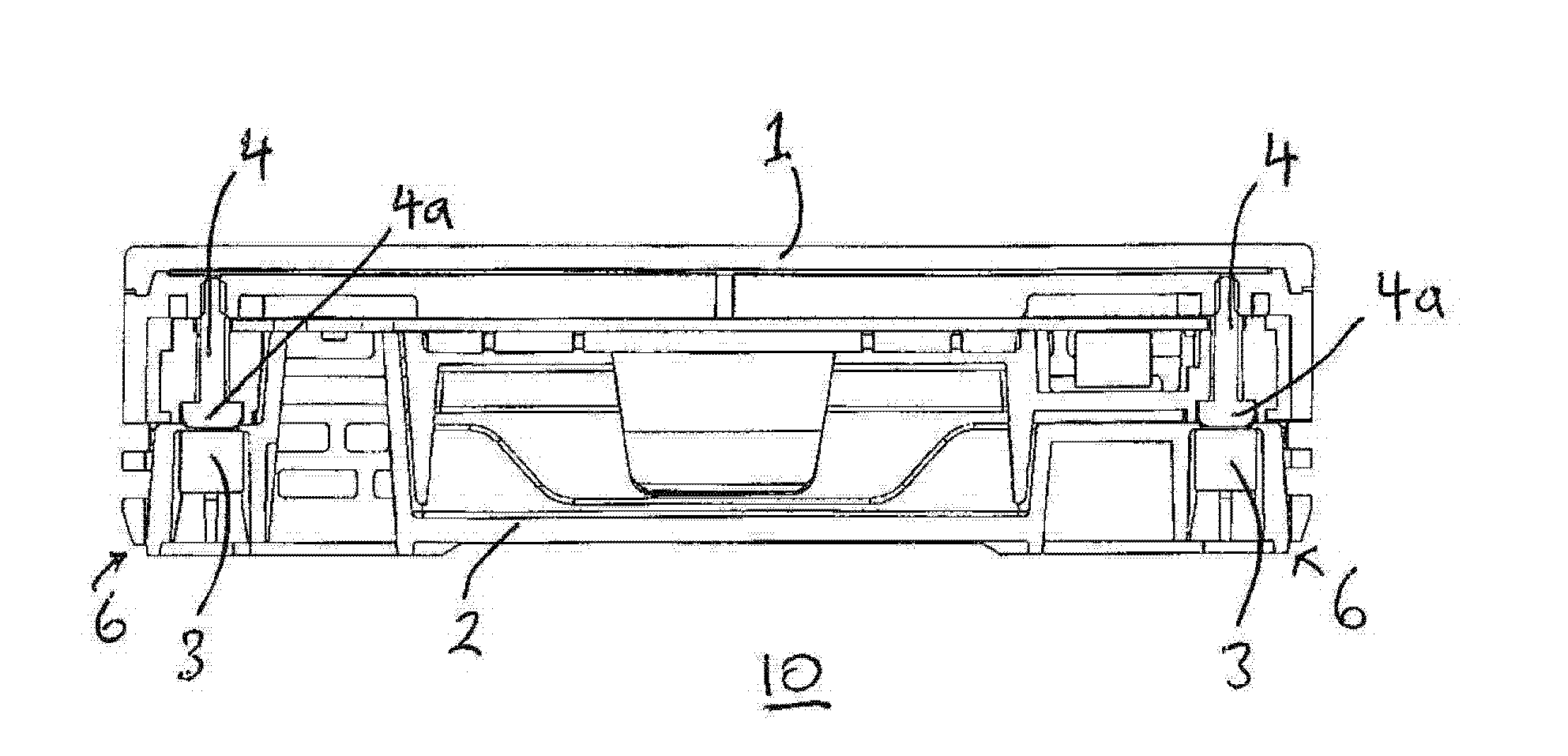

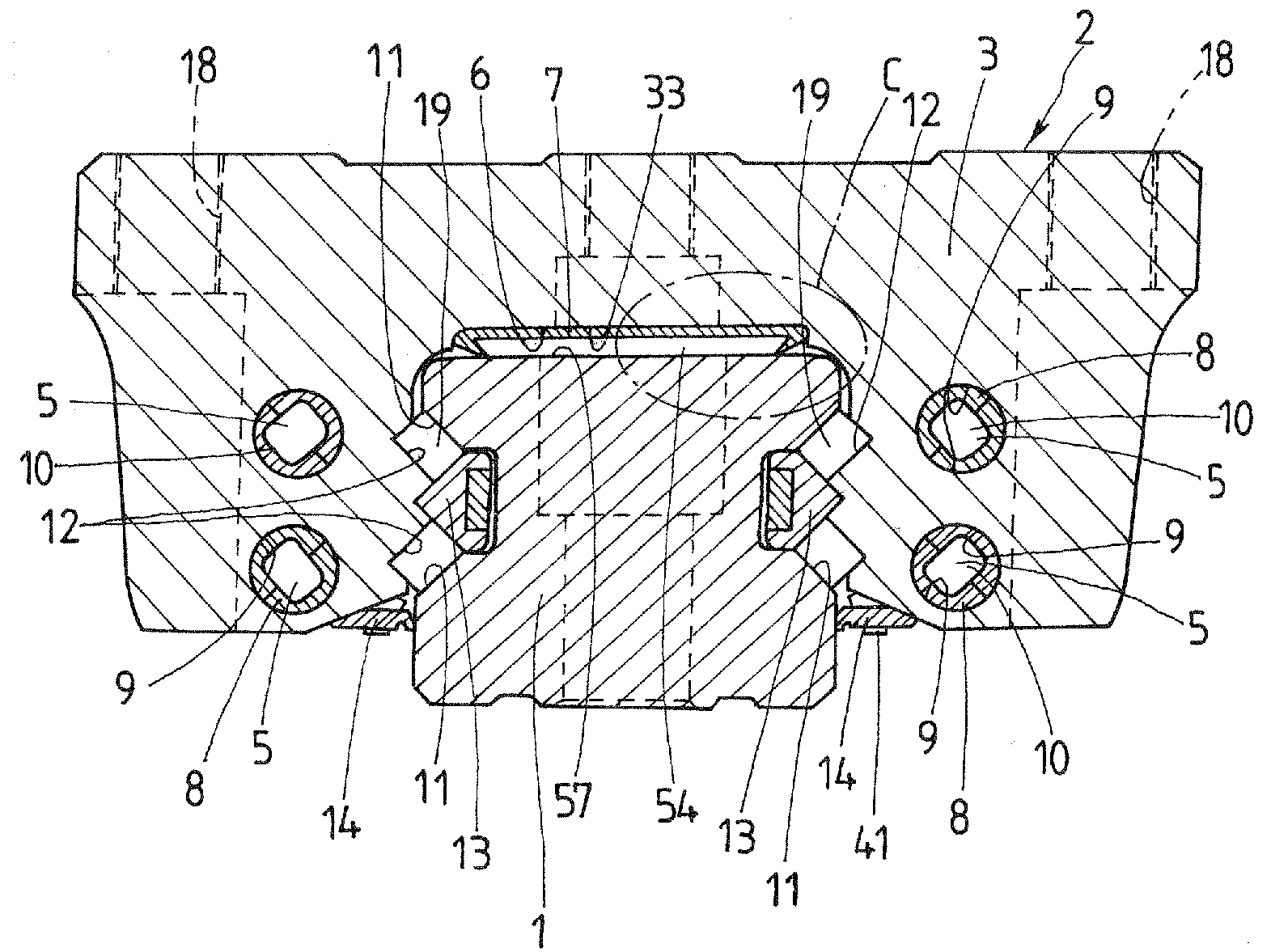

Damping device of a mechanical tensioning system for a traction mechanism drive

The invention relates to a damping device of a mechanical tensioning system (1, 1') for a traction mechanism drive, for example of a motor vehicle, for damping pivoting movements of a tensioning arm (2) which is supported at one end via a tensioning roller on a traction mechanism and which is rotatably mounted at the other end on a positionally fixed housing part (3), having an annular friction element (8, 8'), the periphery of which is formed as a friction lining (9, 9') which, to generate a friction torque, interacts with a friction surface (15) of the housing part (3) which surrounds the friction element (8, 8'), wherein a torsional spring (11, 11') which connects the housing part (3) and the tensioning arm (2) in terms of rotational force, which is embodied as a coil spring and by means of which the tensioning arm (2) can be acted on with a torsional moment so as to generate a continuous preload of the traction mechanism is supported on the friction element (8, 8') and exerts a radially outwardly acting force on the friction lining (9, 9'). In order that the damping device has a high level of operational reliability and load capacity and a long service life and is neverthelessof structurally simple and cost-effective design, surface contact means (14, 24) which act on the friction lining (9, 9') are provided for the transmission of the radial force between the torsional spring (11, 11') and the friction lining (9, 9').

Owner:SCHAEFFLER TECH AG & CO KG

Bearing fixing device and bearing unit

ActiveUS20090001245A1DownsizingEasy to assemblePortable framesBearing assemblyRolling-element bearingMechanical engineering

A rolling bearing fixing device includes at least one bearing having mutually rotatable inner and outer rings, a housing having at least one fitting hole into which the bearing is fitted and a bolt insertion hole, a pair of fixing plates having at least one large-diameter hole and a bolt insertion hole; and a bolt inserted from one axial end into the bolt insertion hole of one fixing plate, the bolt insertion hole of the housing, and the bolt insertion hole of the other fixing plate, and connects the housing with the pair of fixing plates. Both axial end parts of the outer ring are held by the pair of fixing plates in the axial direction, the inner ring is positioned further inwardly of the large-diameter hole of the fixing plates in the radial direction and the inner ring is rotatable with respect to the fixing plates.

Owner:NSK LTD

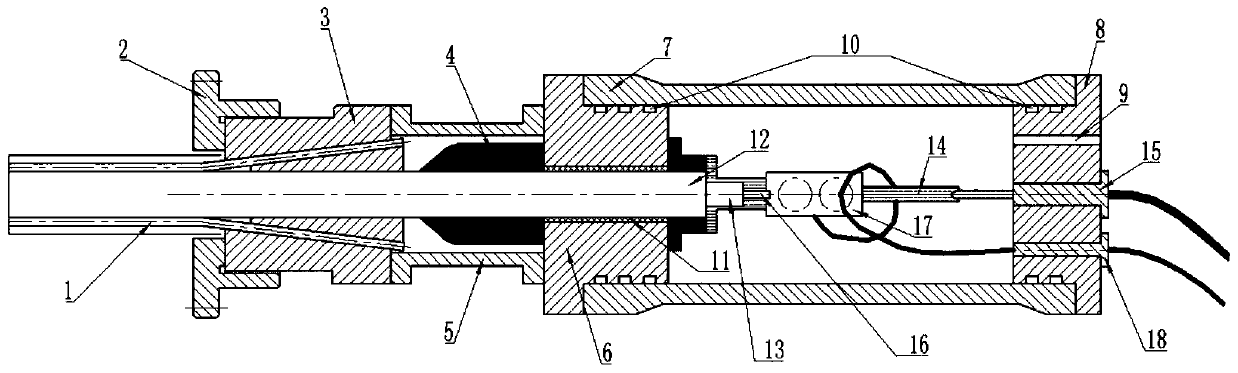

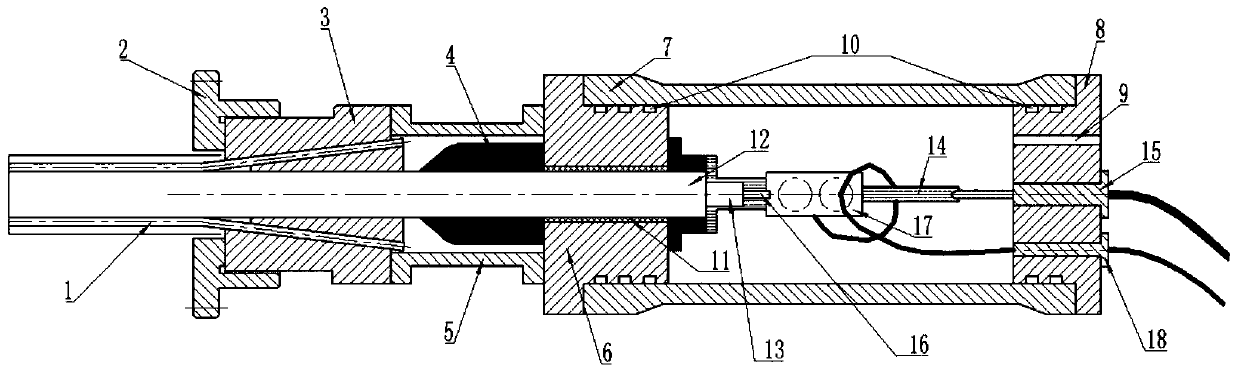

Pressure-balanced photoelectric separation device for main submarine base stations

InactiveCN109842085AImprove reliabilityPrevent creepCable fittings in presence of gas/oilCopper conductorFiber

The invention relates to the technical field of submarine observation equipment, in particular to a pressure-balanced photoelectric separation device for main submarine base stations. The device includes a submarine cable, an armored steel wire fixing mechanism, a cable core sealing protection mechanism and an oil-filled tank body mechanism. The submarine cable includes an armored steel wire (1) and a submarine cable core (12). The submarine cable core (12) is wrapped with a PE insulating layer, and a copper conductor (13) and an optical fiber unit (16) are arranged inside the submarine cablecore (12). The armored steel wire fixing mechanism is in butt joint with the cable core sealing protection mechanism, and the cable core sealing protection mechanism is in butt joint with the oil-filled tank body mechanism. The submarine cable is inserted into the armored steel wire fixing mechanism, and passes through the cable core sealing protection mechanism to the inside of the oil-filled tank body mechanism. The copper conductor (13) is connected through electrical leading with an electrical cable cabin-penetrating part (15) arranged at the end of the oil-filled tank body mechanism. Theoptical fiber unit (16) is directly welded to an optical cable cabin-penetrating part (18). The problem that a submarine cable core creeps into a photoelectric separation cabin under the pressure of deep water is solved.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

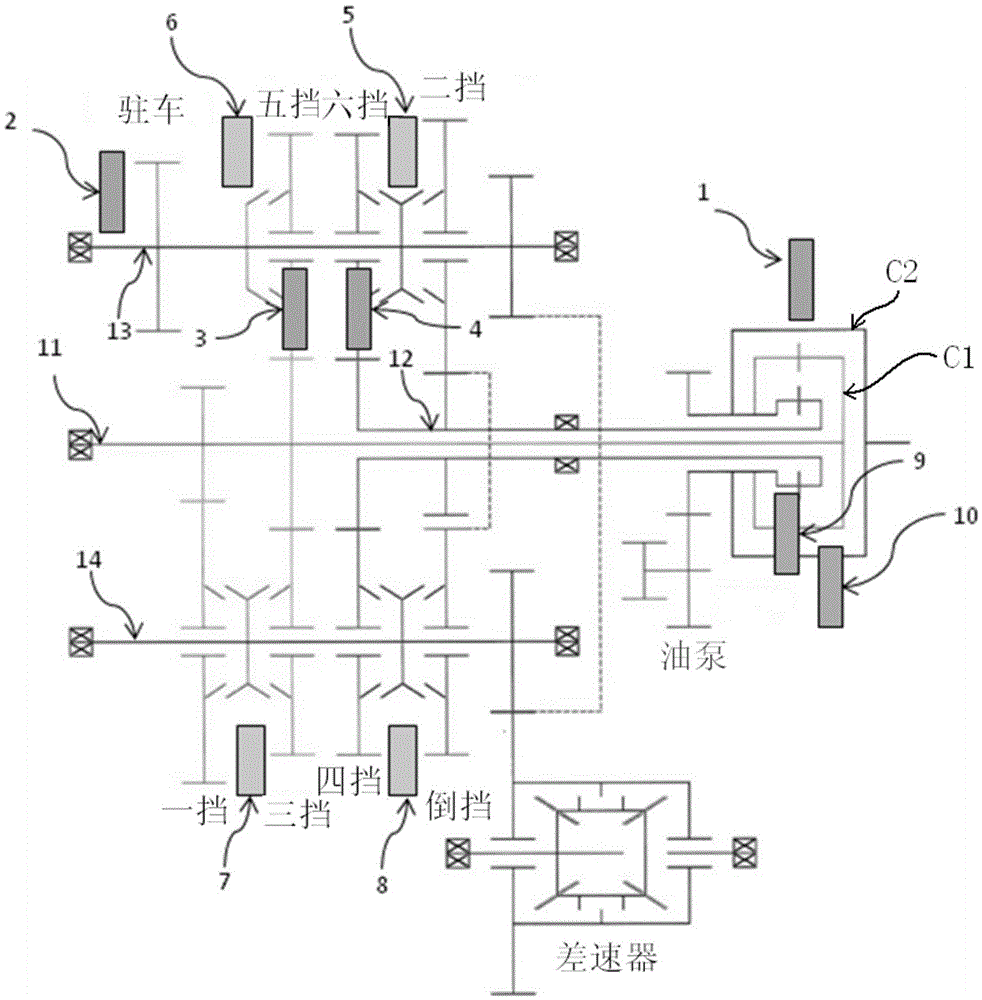

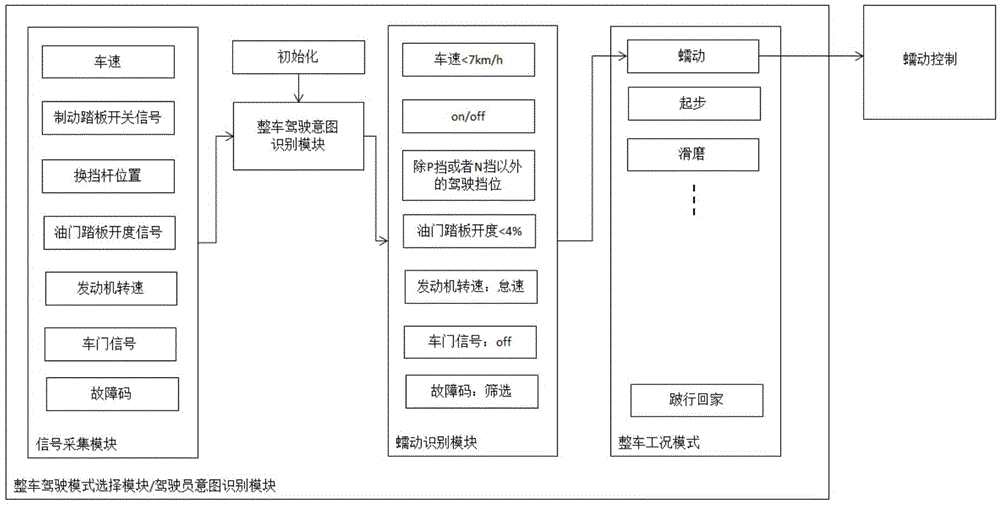

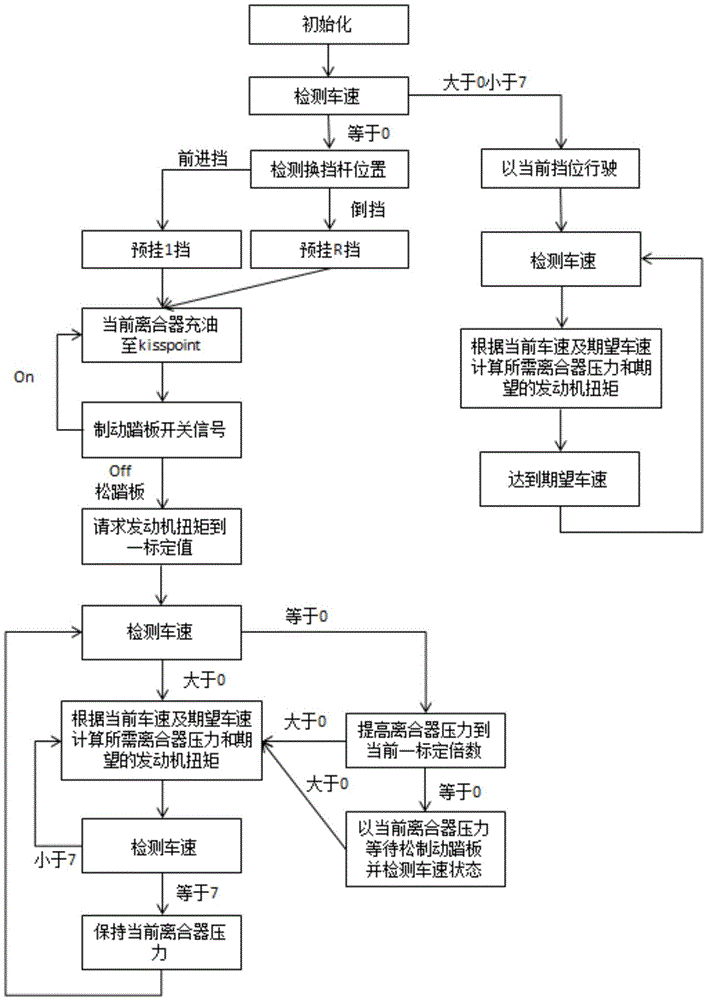

Double-clutch automatic transmission creeping control method

ActiveCN105644562AAchieve peristalsisAvoid vehicle function lossDriver input parametersAutomatic transmissionSwitching signal

The invention provides a double-clutch automatic transmission creeping control method. Under the condition that only a brake pedal switch signal is provided and no brake pressure signal is provided, the following control steps are executed, wherein the steps include that the vehicle speed is detected, and when the vehicle speed is 0, the position of a shifting lever is detected; and if the shifting lever is located at a forward gear or a reverse gear, pre-gear-engagement is conducted, and oil is injected in a current clutch to the kiss point. By the adoption of the method, it can be guaranteed that the whole vehicle creeping function can still be maintained when the brake pressure signal fails.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

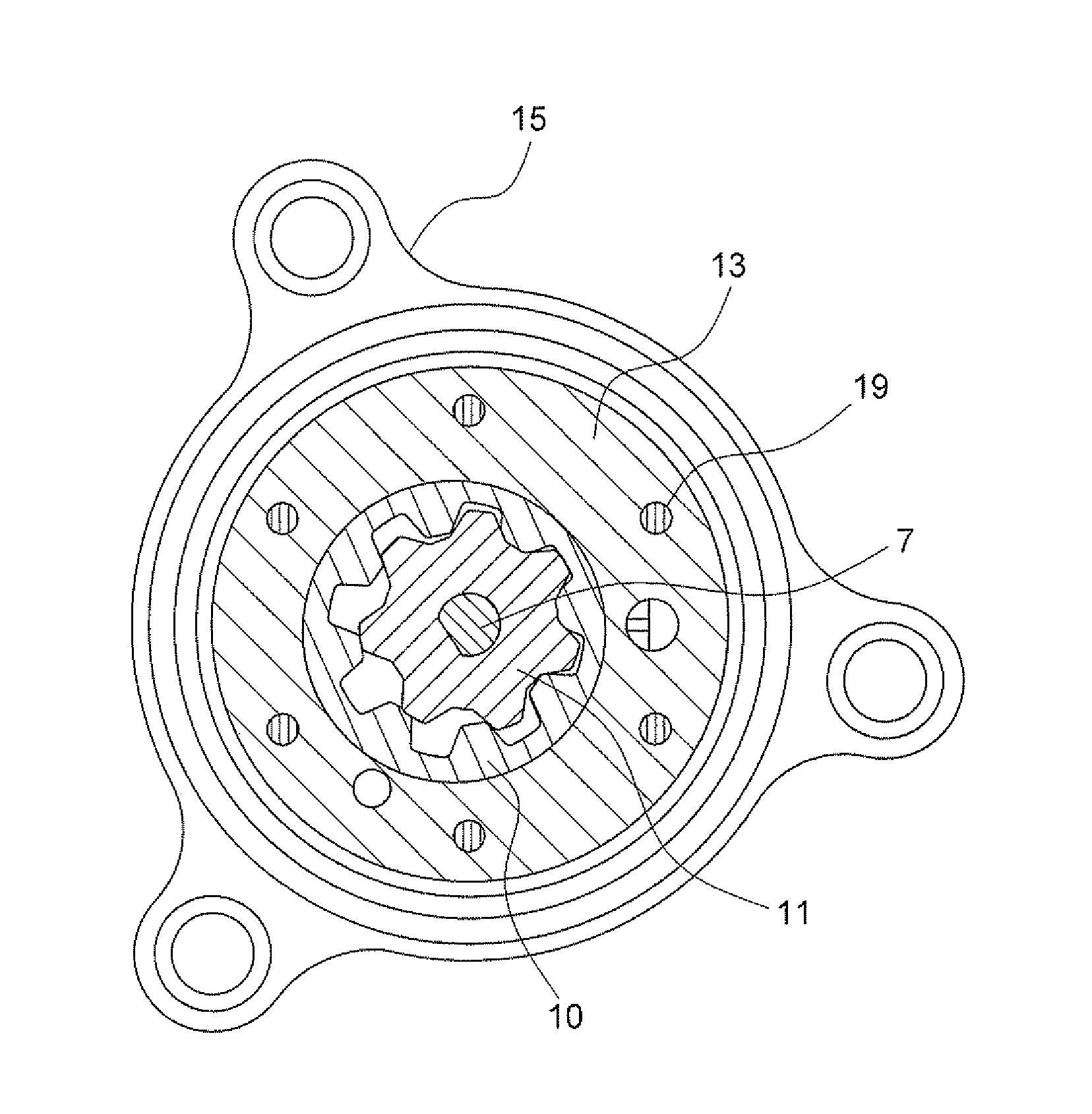

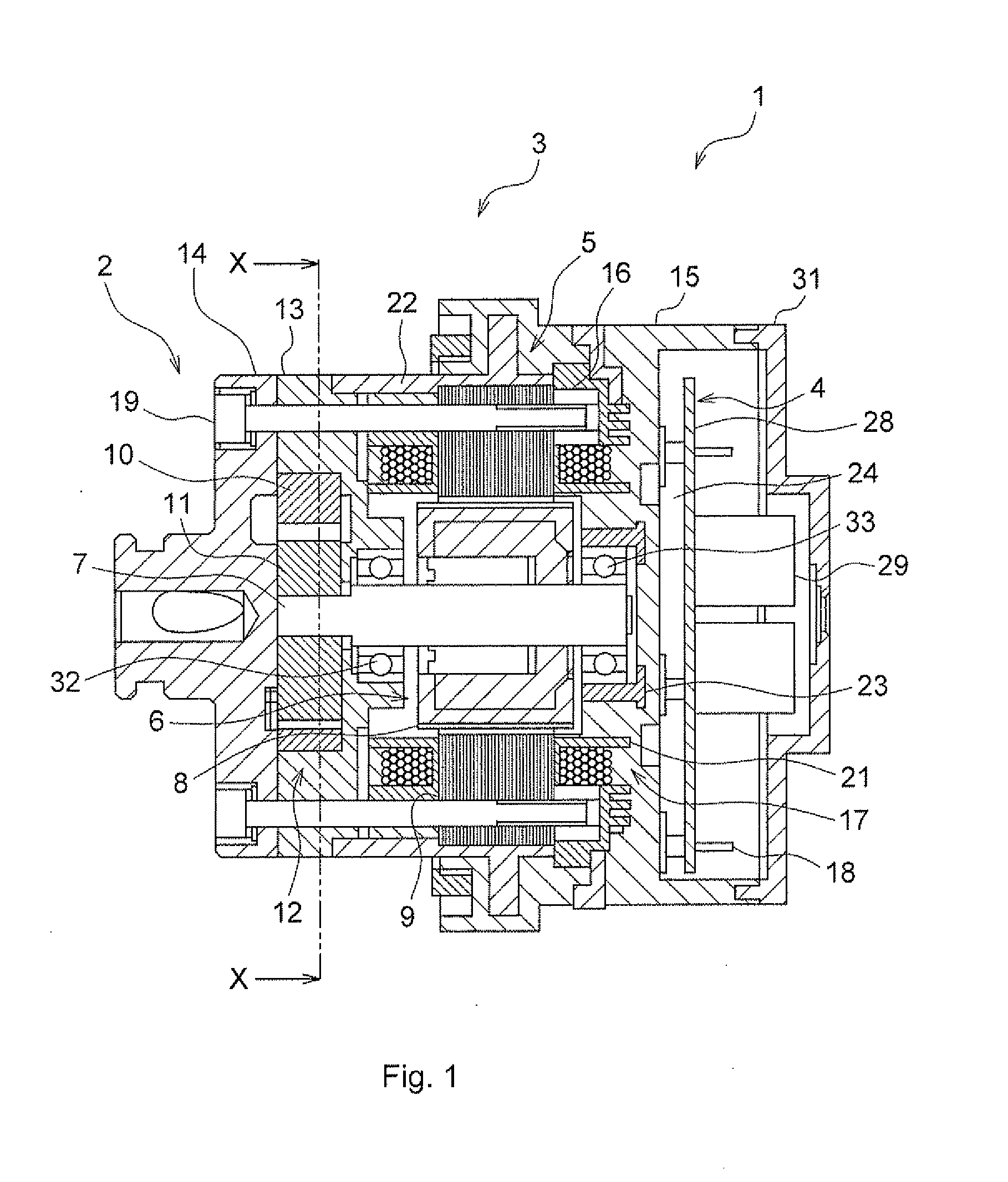

Electric oil pump system

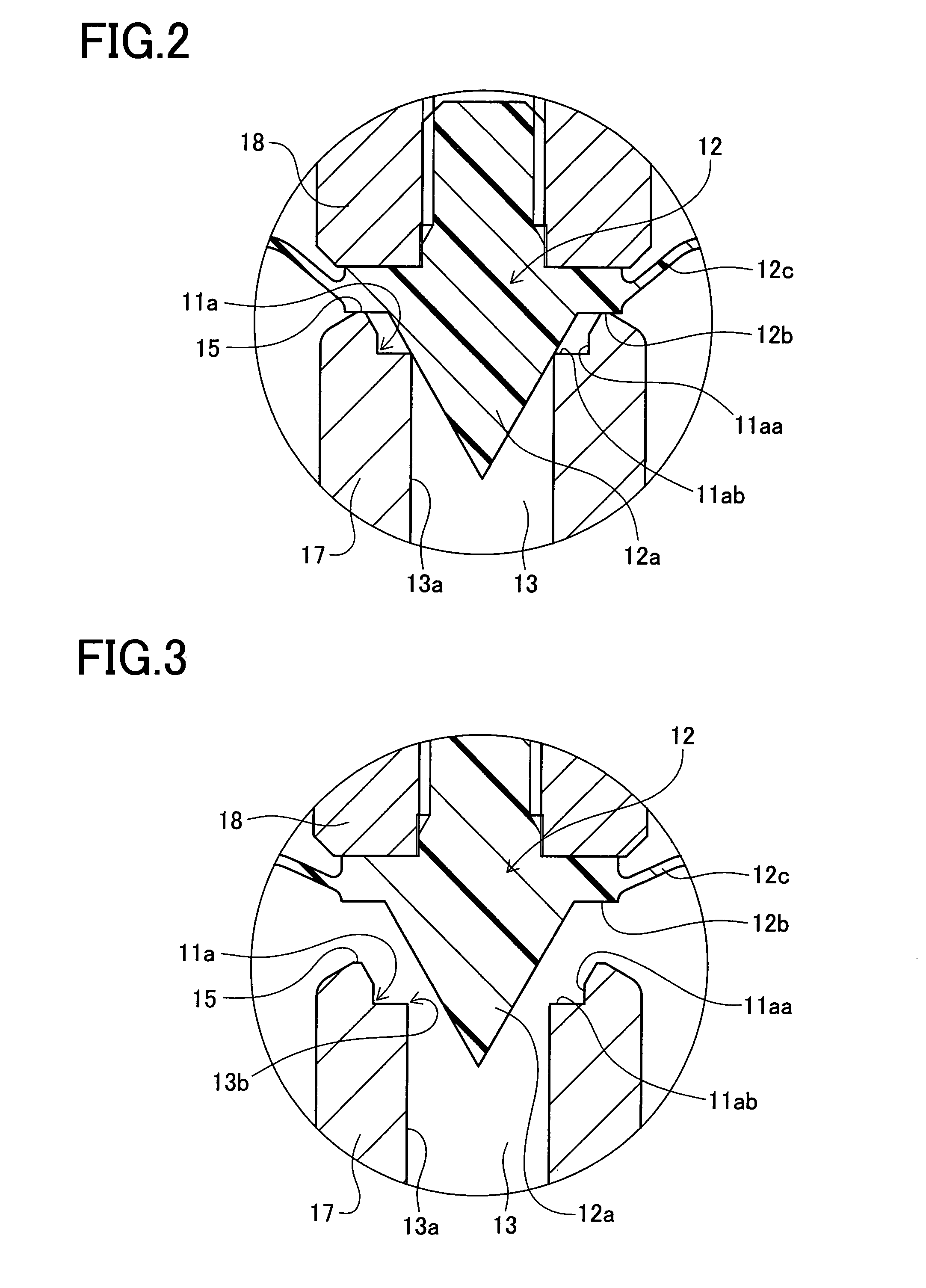

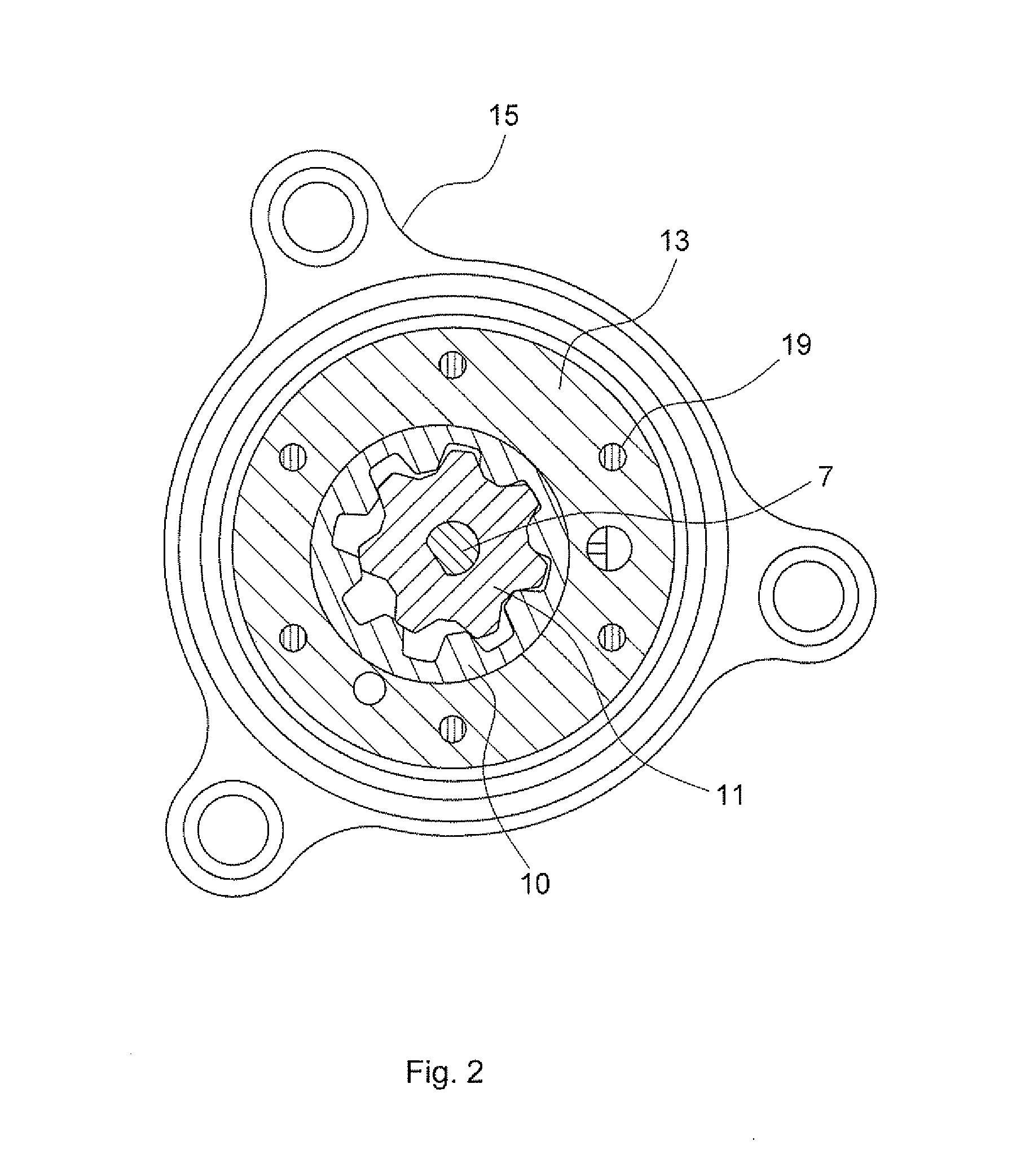

ActiveUS20130202464A1Creep deformationPrevent creepRotary piston pumpsRotary/oscillating piston combinationsThin metalBrushless motors

A stator is fixedly fastened at its outer periphery by a cylindrical and thin metal collar. One end of the collar is engaged with a pump housing. Multiple metal nuts are embedded in insulators fitted to stator cores through insert molding. The stator of a brushless motor is fixed by screwing bolts passed through the pump housing from a pump plate, to nuts embedded in the insulators.

Owner:JTEKT CORP

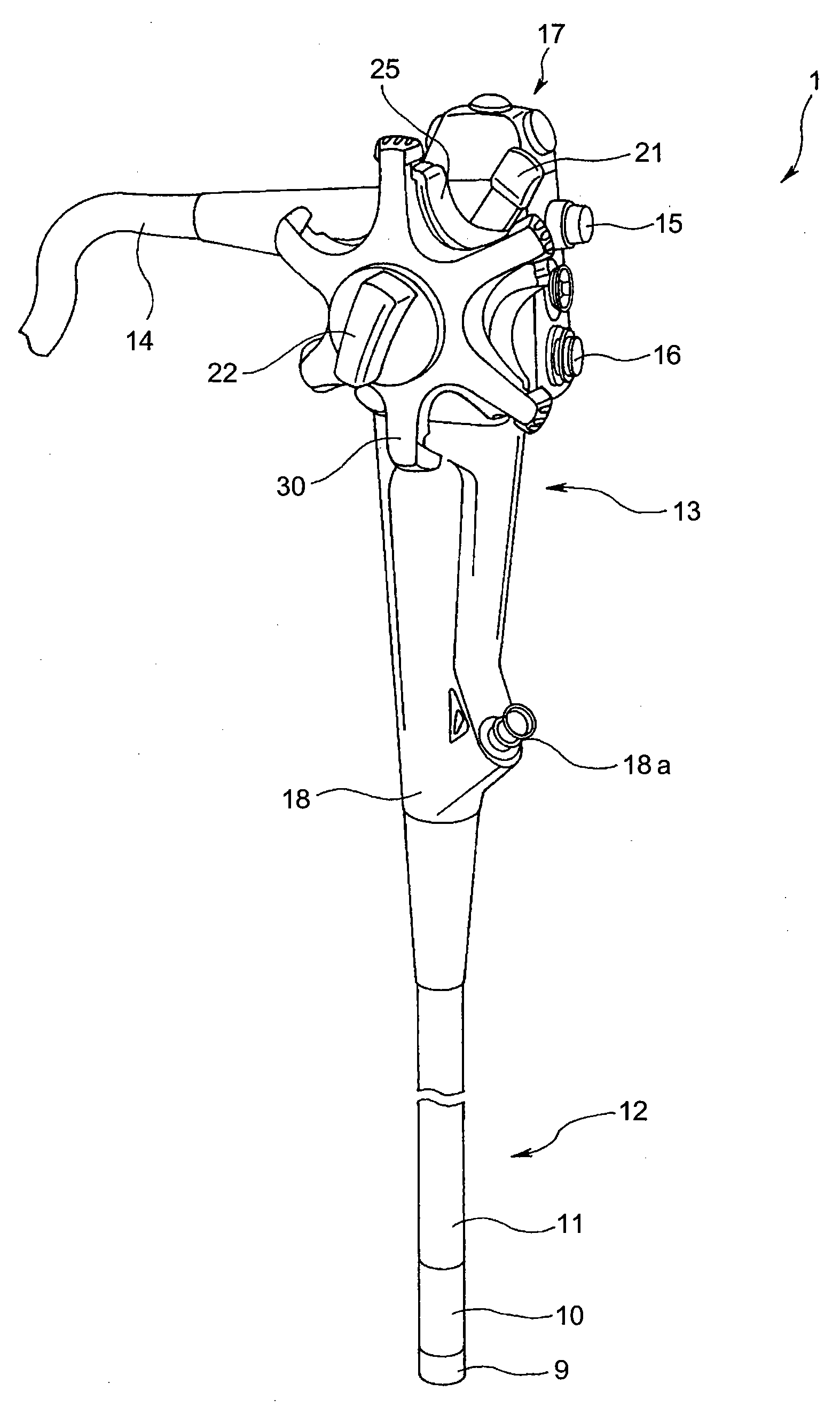

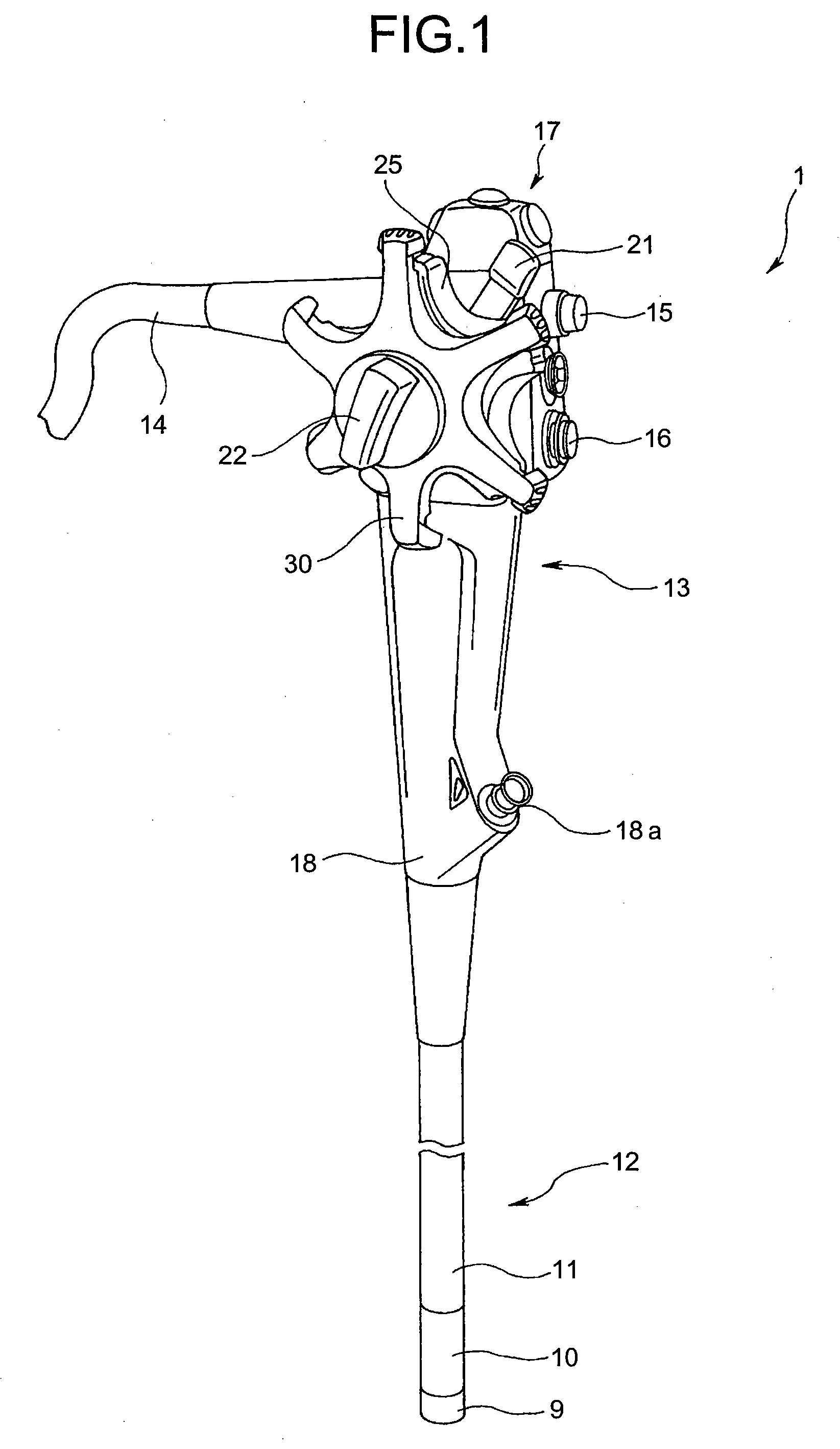

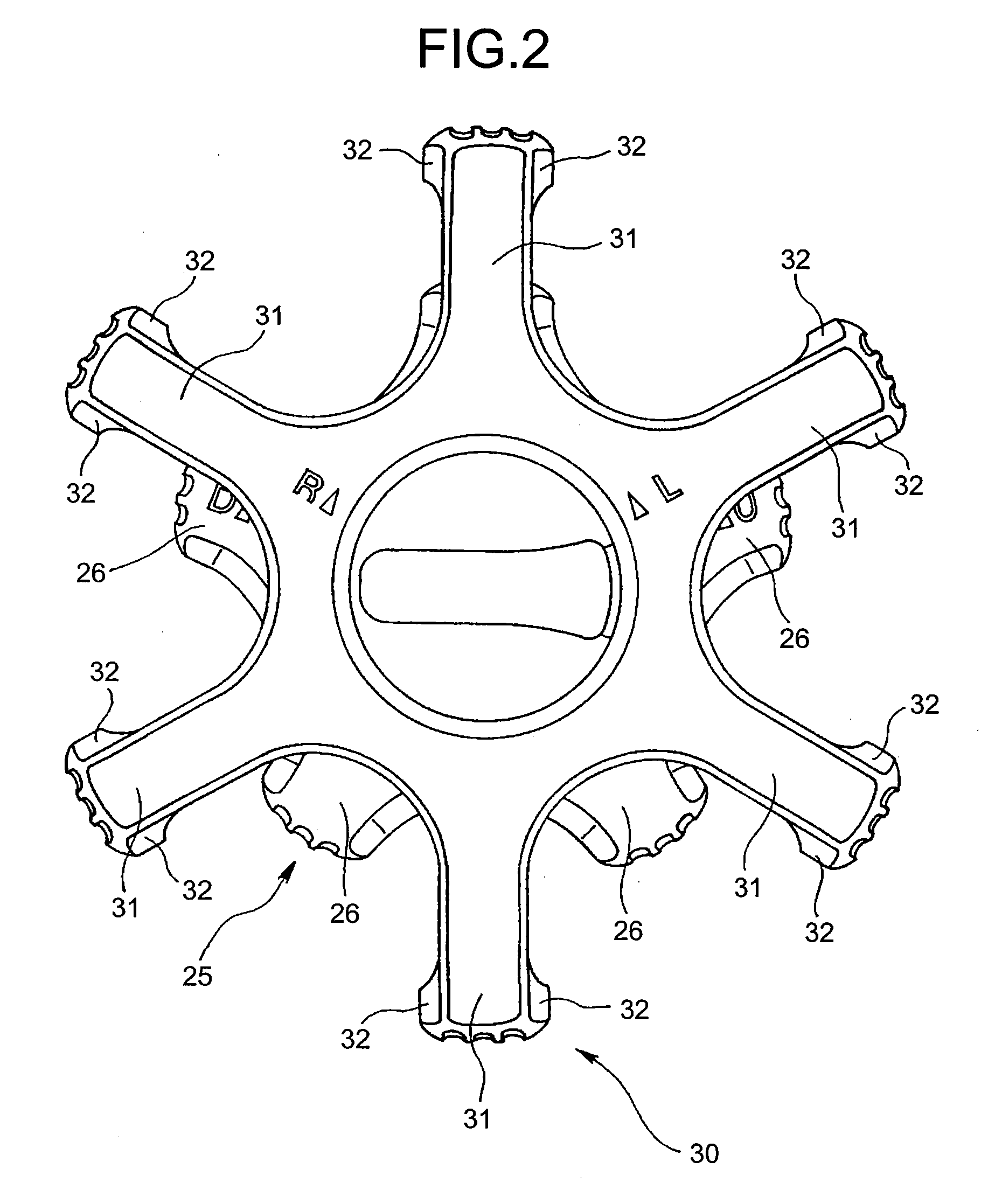

Endoscope And Supportive Member For Bending Operation Of The Same

An endoscope includes an insertion portion having a bendable portion; an operation portion from which the insertion portion extends; a first bending operation knob arranged on a surface of the operation portion and including depressions and first protrusions, to bend the bendable portion in a first direction when rotated; and a second bending operation knob arranged over the first bending operation knob and including depressions and second protrusions, to bend the bendable portion in a second direction when rotated. A length of the second protrusion from a center of rotation to a tip portion is longer than a length of the first protrusion from the center of rotation to tip portions of the first protrusions, and the second protrusion has a depression near a projection of a circular orbit of rotation of each tip portion of the first protrusions onto a surface facing the first bending operation knob.

Owner:OLYMPUS CORP

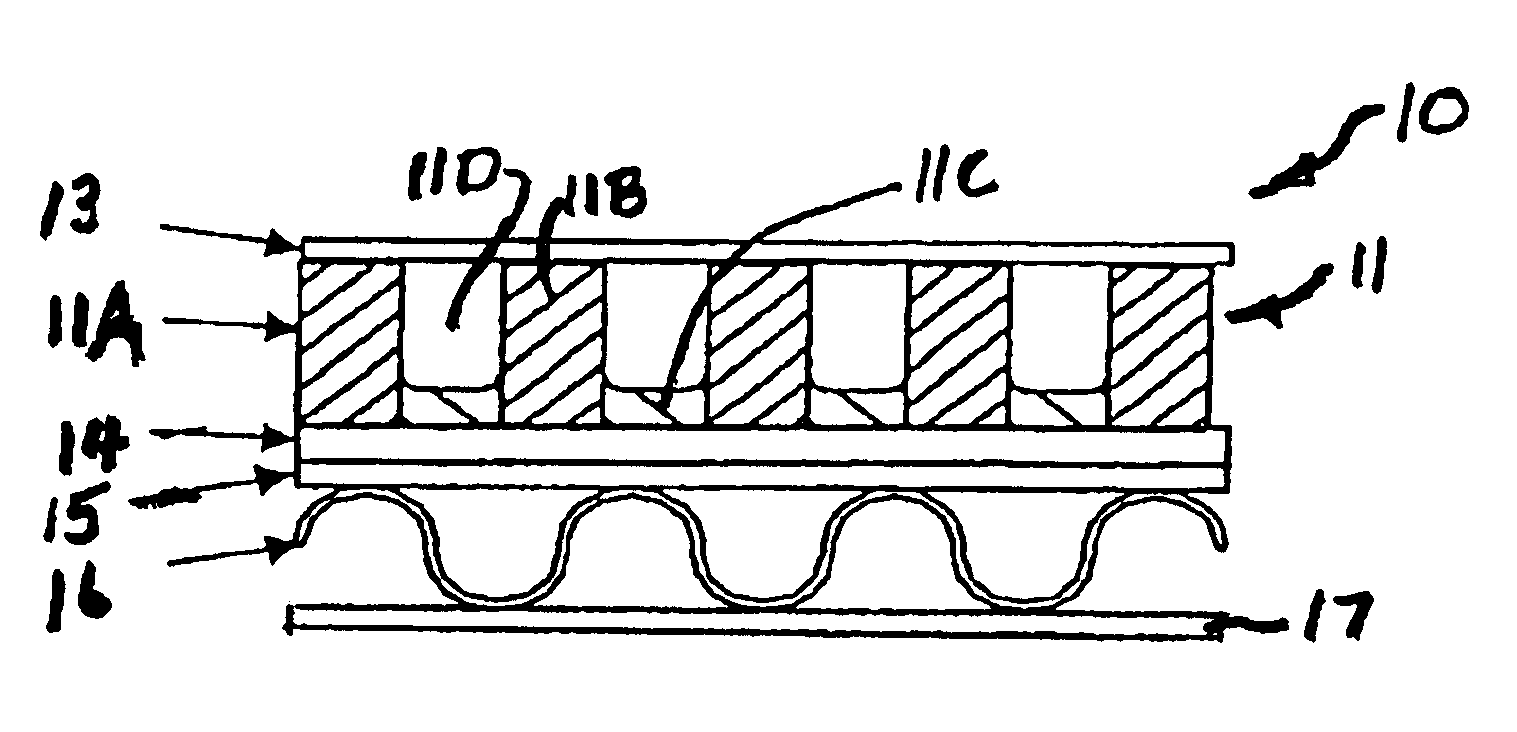

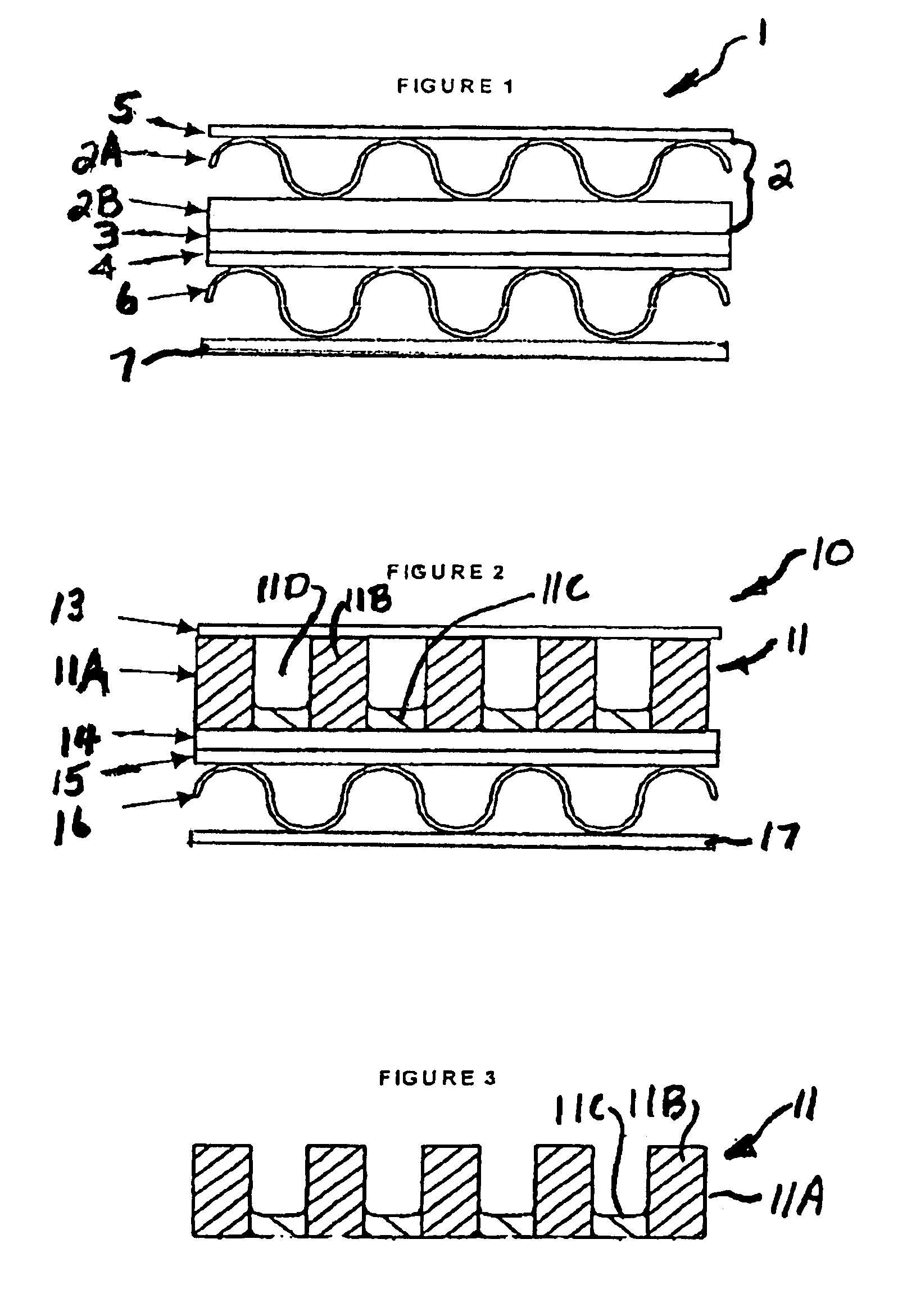

Dual-porosity ribbed fuel cell cathode

InactiveUS6890679B2Increasing the thicknessLess porosityFuel cells groupingElectrode carriers/collectorsPorosityFuel cells

Owner:FUELCELL ENERGY INC

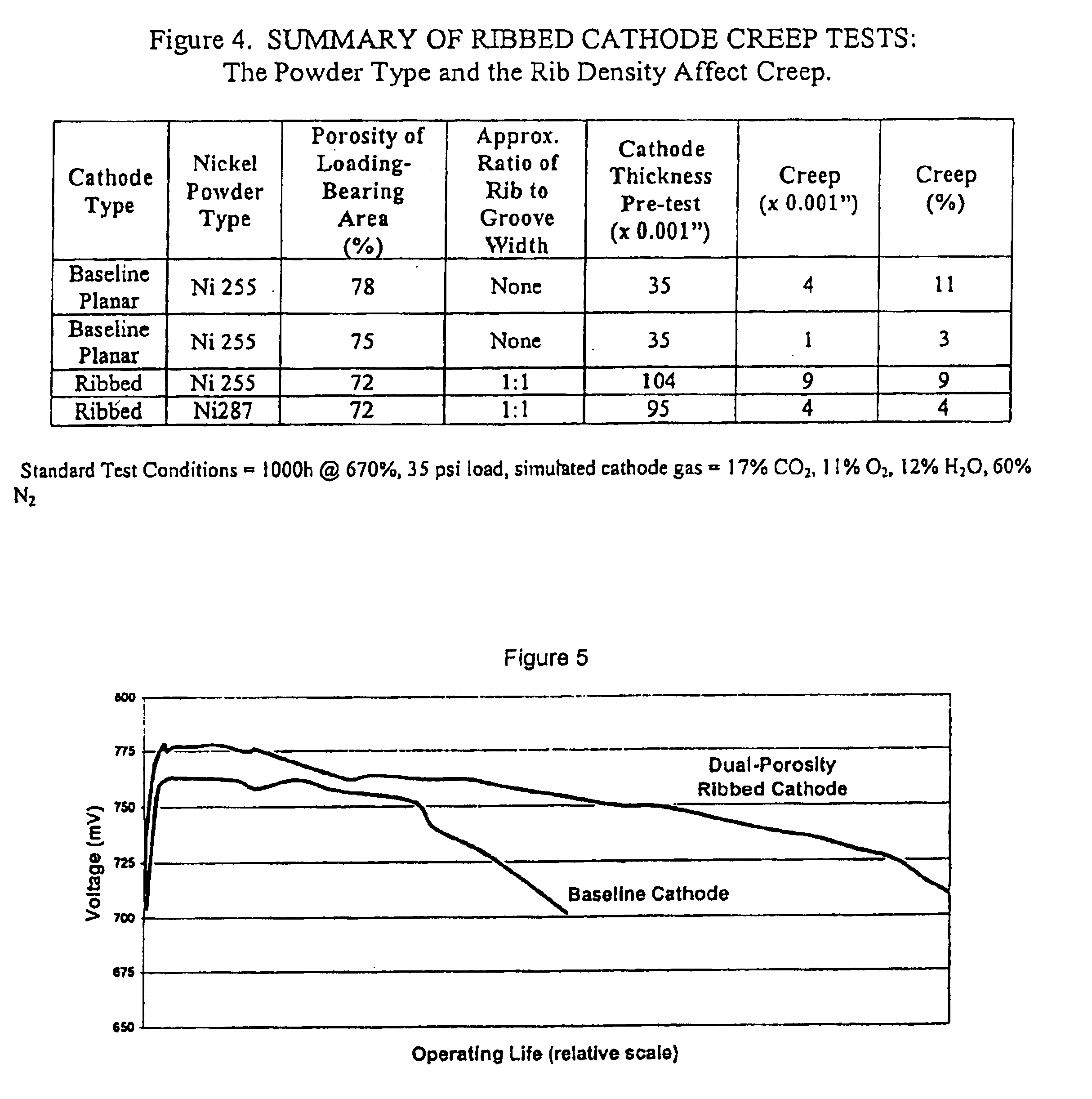

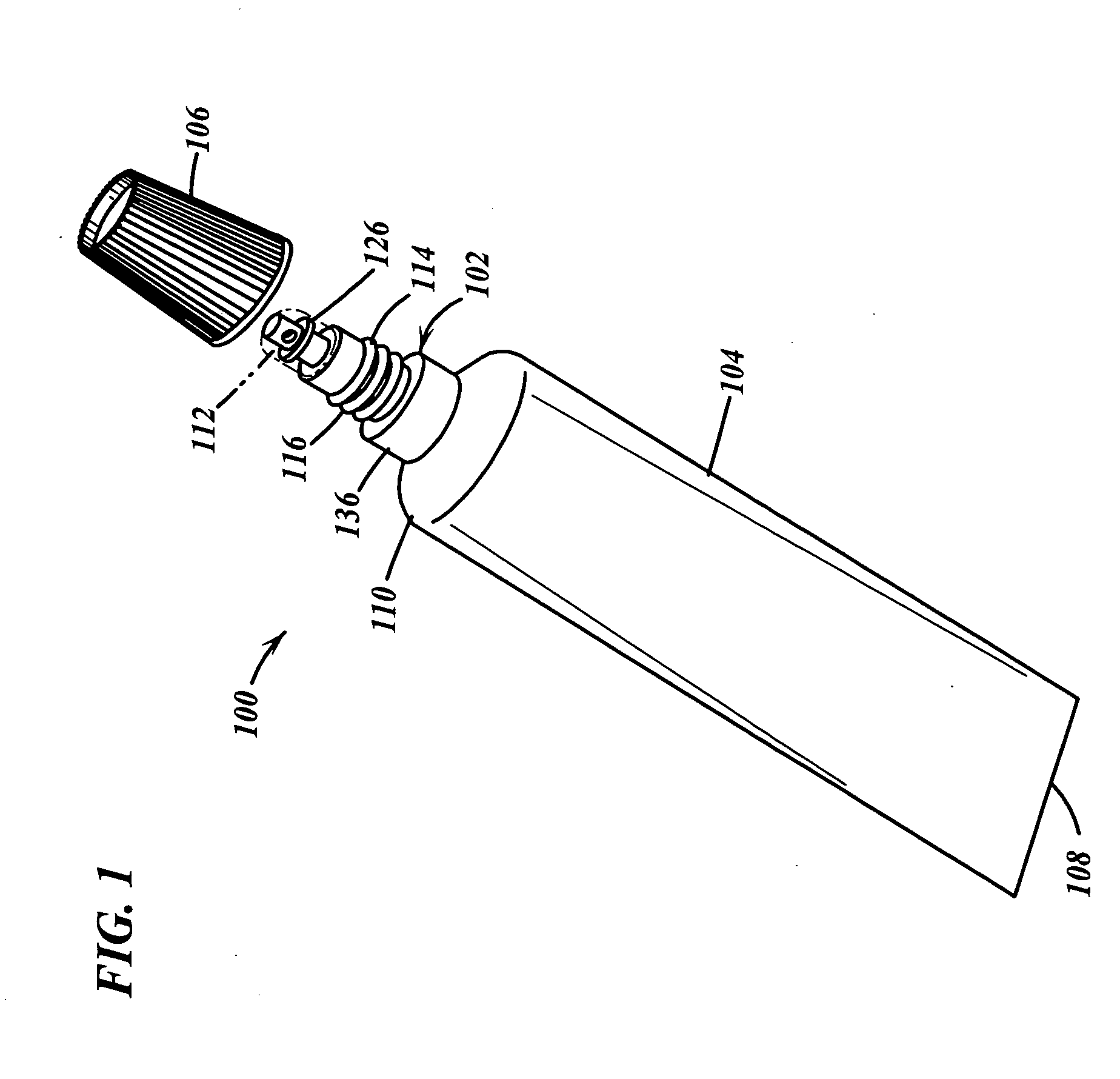

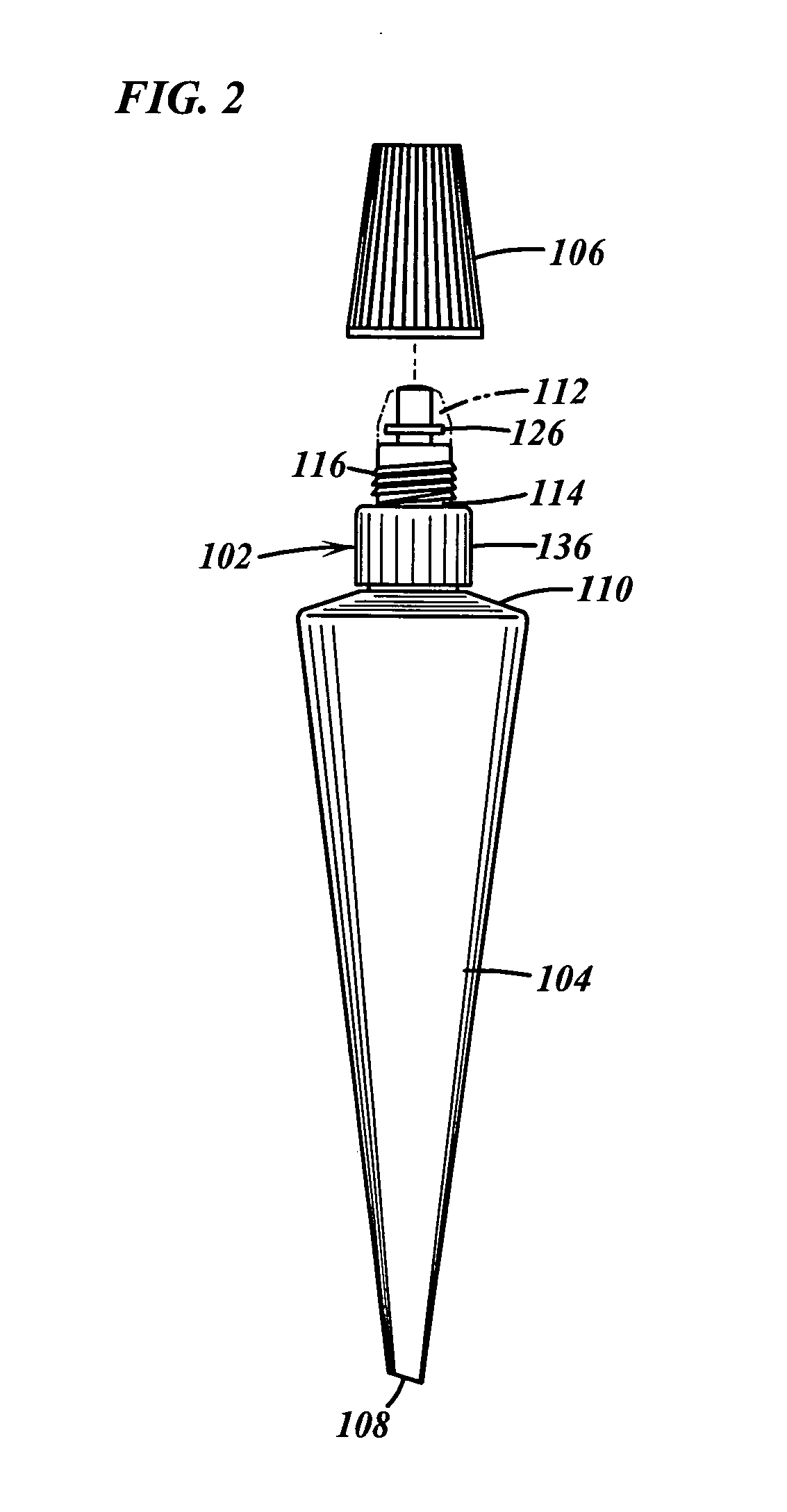

Container and valve assembly for storing and dispensing substances, and related method

InactiveUS20050155987A1Avoid enteringLow pressureClosuresDispensing apparatusIndustrial engineeringVALVE PORT

Owner:MEDICAL INSTILL TECH

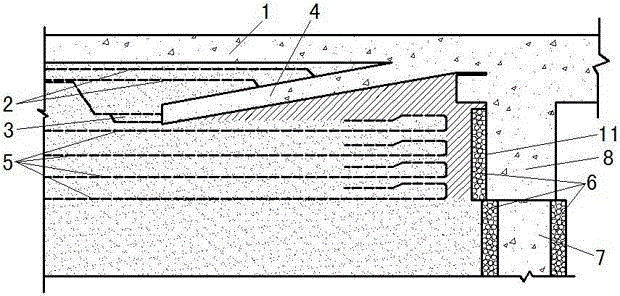

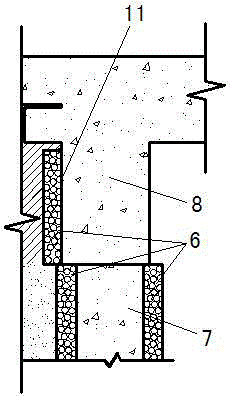

Structure and method for controlling jointless abutment back subsidence and pavement cracking by using reinforcement geotextile

InactiveCN103981802AImprove integrityIncrease stiffnessPaving detailsBridge structural detailsAbutmentRoad surface

The invention relates to a structure and a method for controlling jointless abutment back subsidence and pavement cracking by using reinforcement geotextile. The bridge abutment of a jointless bridge is connected with an access board, backfill reinforced by multilayer reinforcement geotextile is arranged above the access board, backfill reinforced by multilayer reinforcement geotextile is also arranged under the access board, spacing is formed between the backfill reinforced by multilayer reinforcement geotextile and under the access board, and the wall body of the bridge abutment, an elastic material layer in the spacing is wrapped on the abutment back of the abutment, the wall body of the abutment is supported on a single rank of piles, the periphery of the single rank of piles is also wrapped by an elastic material layer, and the access board is obliquely arranged, and a discrete material layer is arranged at the tail end of the access board. With the reinforcement principle of the reinforcement geotextile and ingenious structural arrangement, a flexible structural layer with good overall integrity and higher rigidity is formed, so that the abutment back subsidence and pavement cracking of the jointless bridge are effectively controlled, the rigid-and-flexible stable transition of the road and bridge transition section is realized, and the structure and method are particularly applicable to jointless bridges with integral type abutments.

Owner:FUZHOU UNIV

Consumer Product System

InactiveUS20160363143A1Retention strength can be reducedPrevent creepProgramme controlSpace heating and ventilation safety systemsProduct systemHuman–computer interaction

A user interface with a display region having an array of configurable button elements operatively connected to a processor adapted to operate in accordance with a predetermined instruction set to activate a predetermined set of the button elements corresponding to a matching set of device nodes to be in operative connection for a user to control via the user interface. There is also a method of releasably retaining a first portion with a second portion of a mounted electronic device, the method including the steps of: locating the first portion in non-contacting proximity to the second portion of the electronic device such that at least one magnet located in one of the first or second portions exerts attractive force on at least one ferrous component of the other of the first or second portions such that the magnetic force guides the first portion into self-aligning contact with the second portion.

Owner:ZEN ECOSYST IP PTY LTD

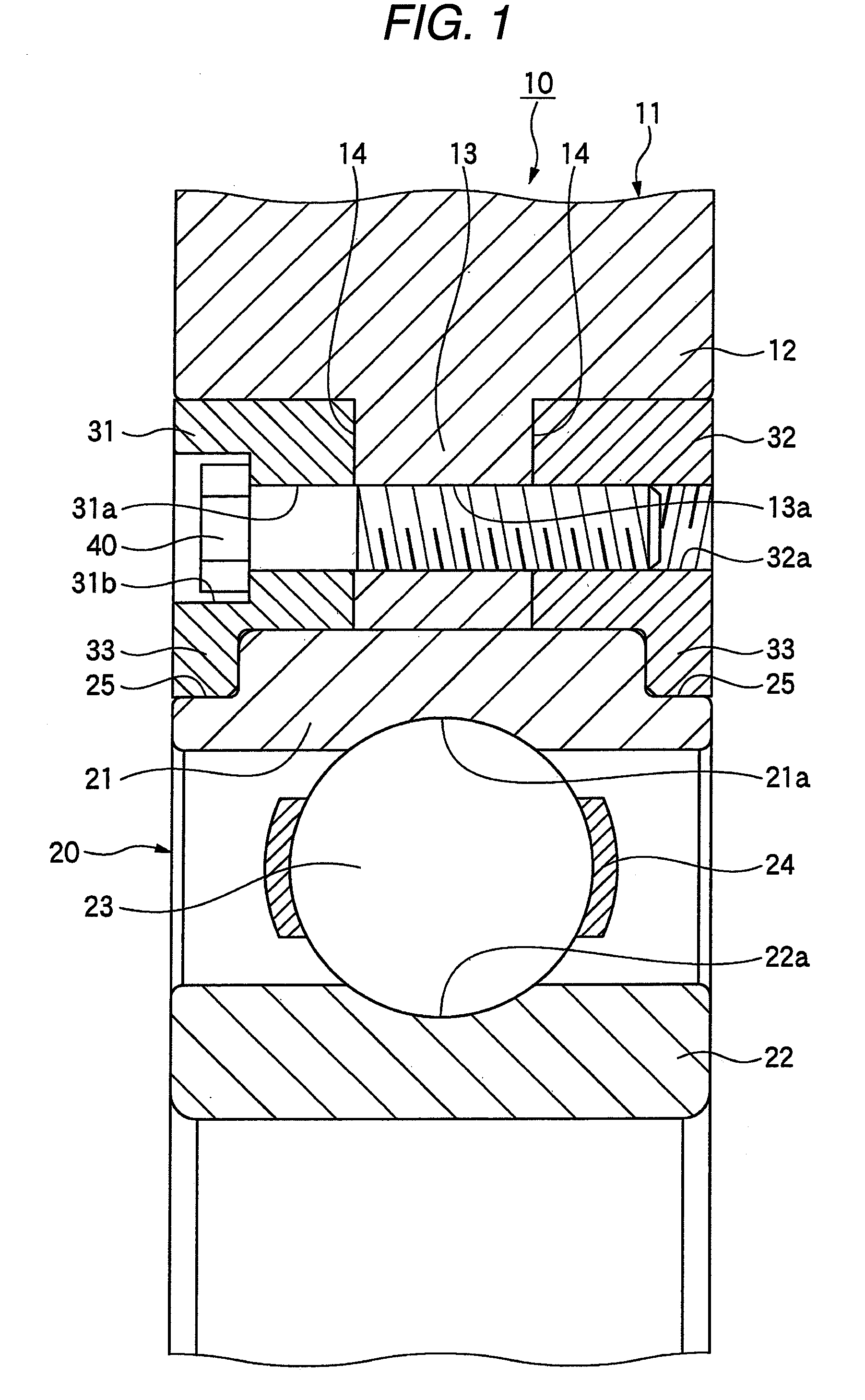

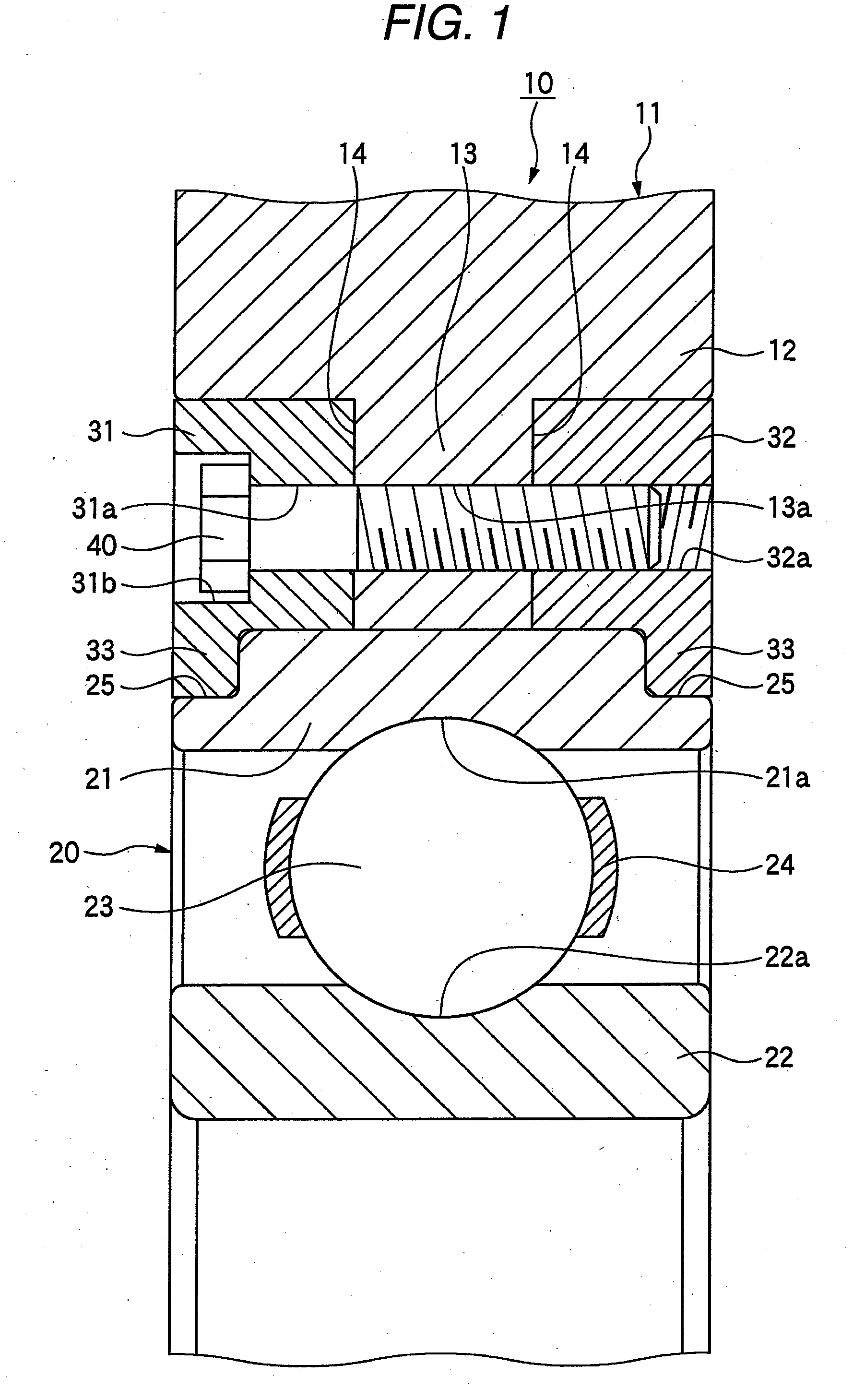

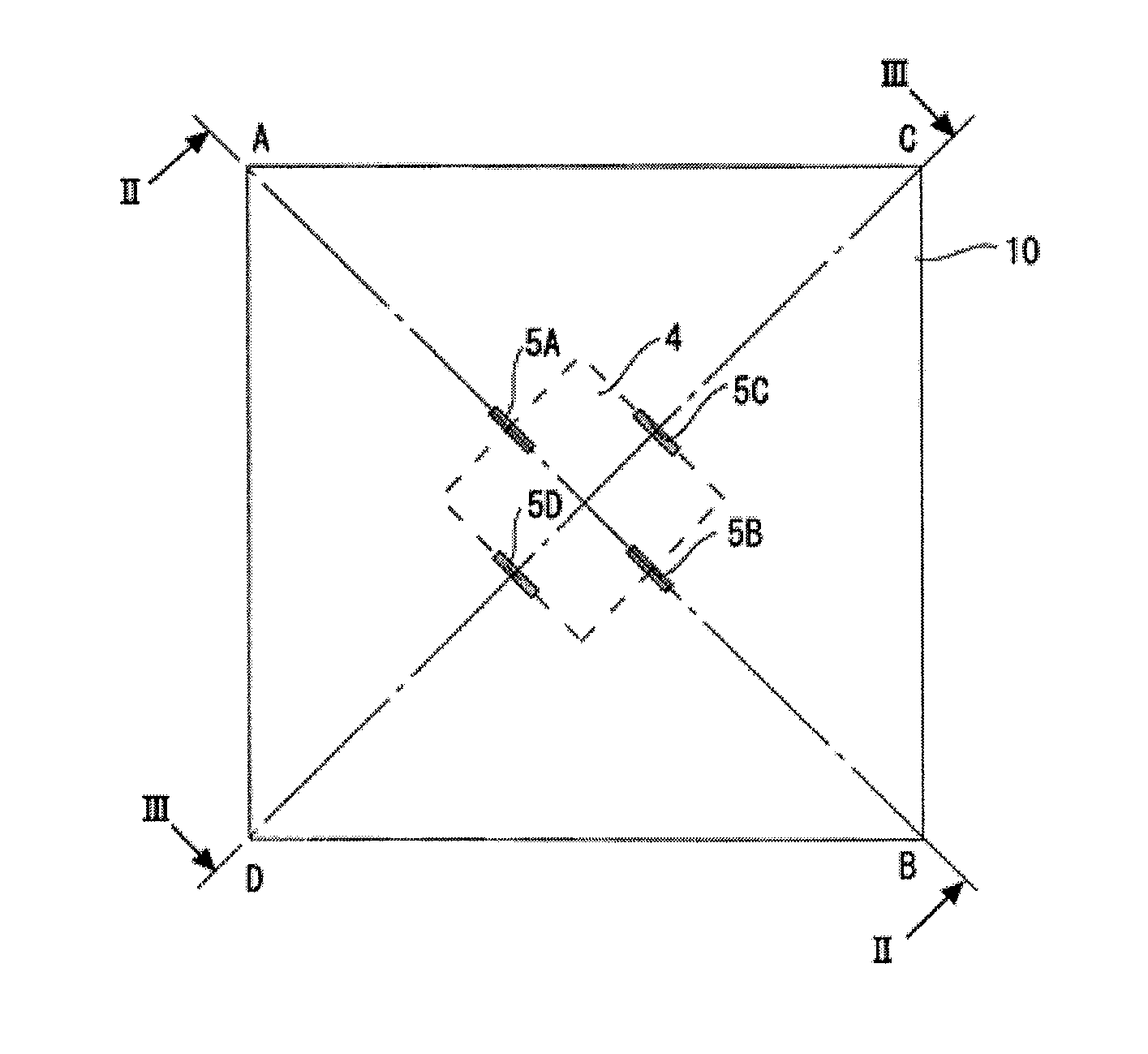

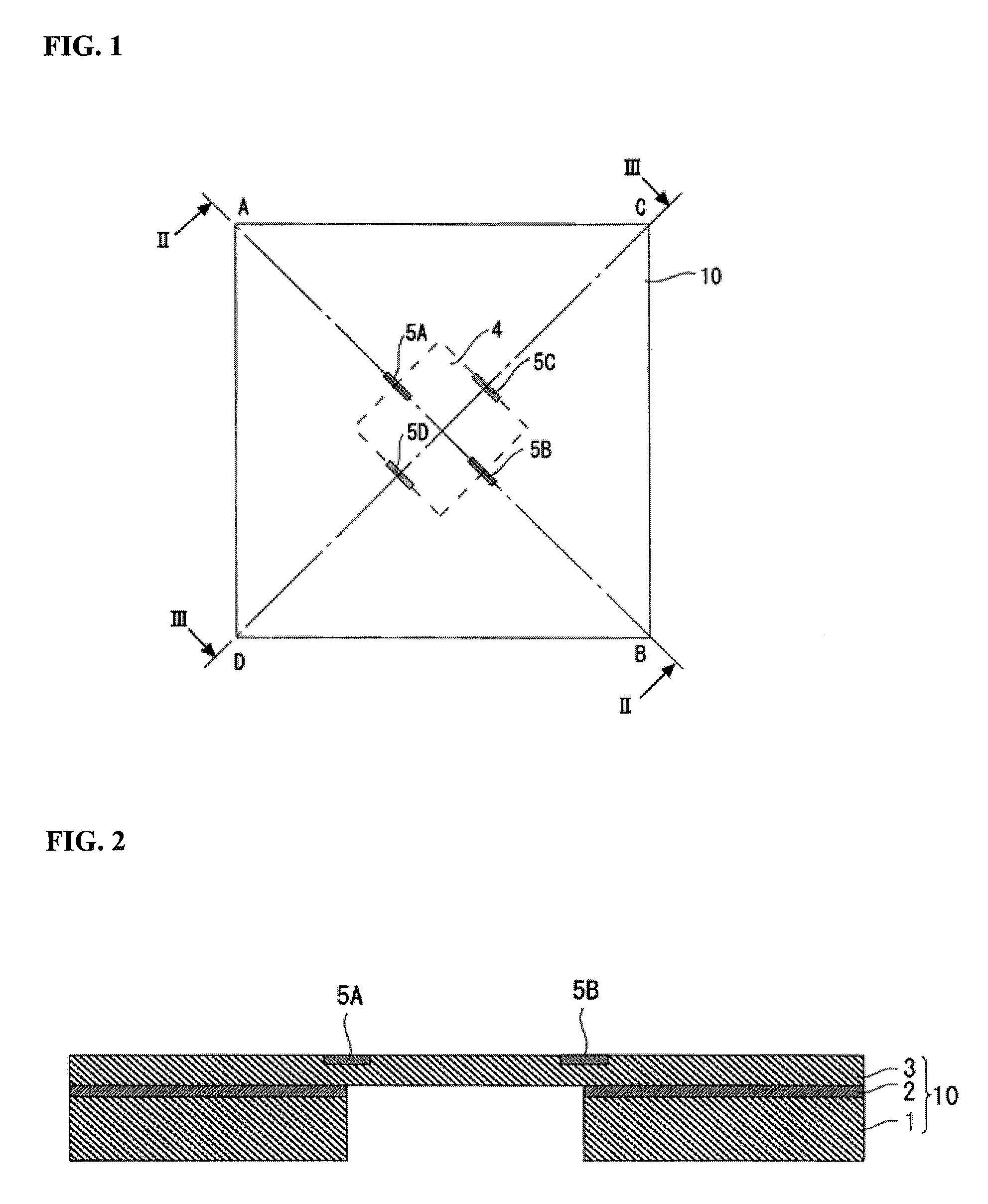

Rolling bearing

InactiveUS20100014794A1Reduce creep torqueInhibitionEngine sealsBearing assemblyRolling-element bearingEngineering

There is provided a rolling bearing which comprises at least: an outer ring 10 and an inner ring 20 disposed rotatable relative to each other; and plurality of rolling elements 40 respectively interposed rollably between the outer and inner rings. The outer ring is fitted into a housing (not shown) and the inner ring is fitted with a shaft (not shown), whereby the rolling bearing supports rotation between the shaft and housing. Between the fitting surface (not shown) of the housing and the outer circumferential surface 13 of the outer ring and / or between the fitting surface of the shaft and the inner circumferential surface 23 of the inner ring, there is interposed an O-ring 30 made of an elastic member having a reduced friction coefficient between the fitting surface of the housing and the outer circumferential surface of the outer ring or between the fitting surface of the shaft and the inner circumferential surface of the inner ring.

Owner:NSK LTD

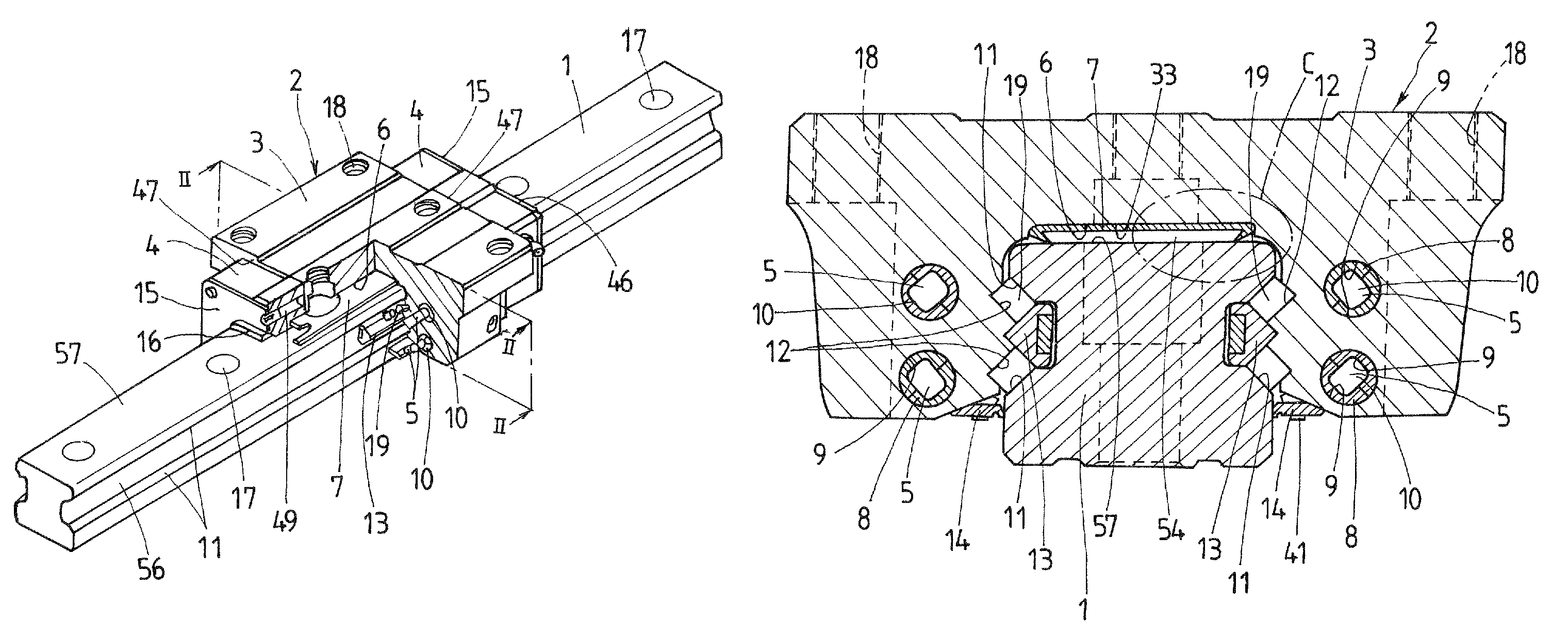

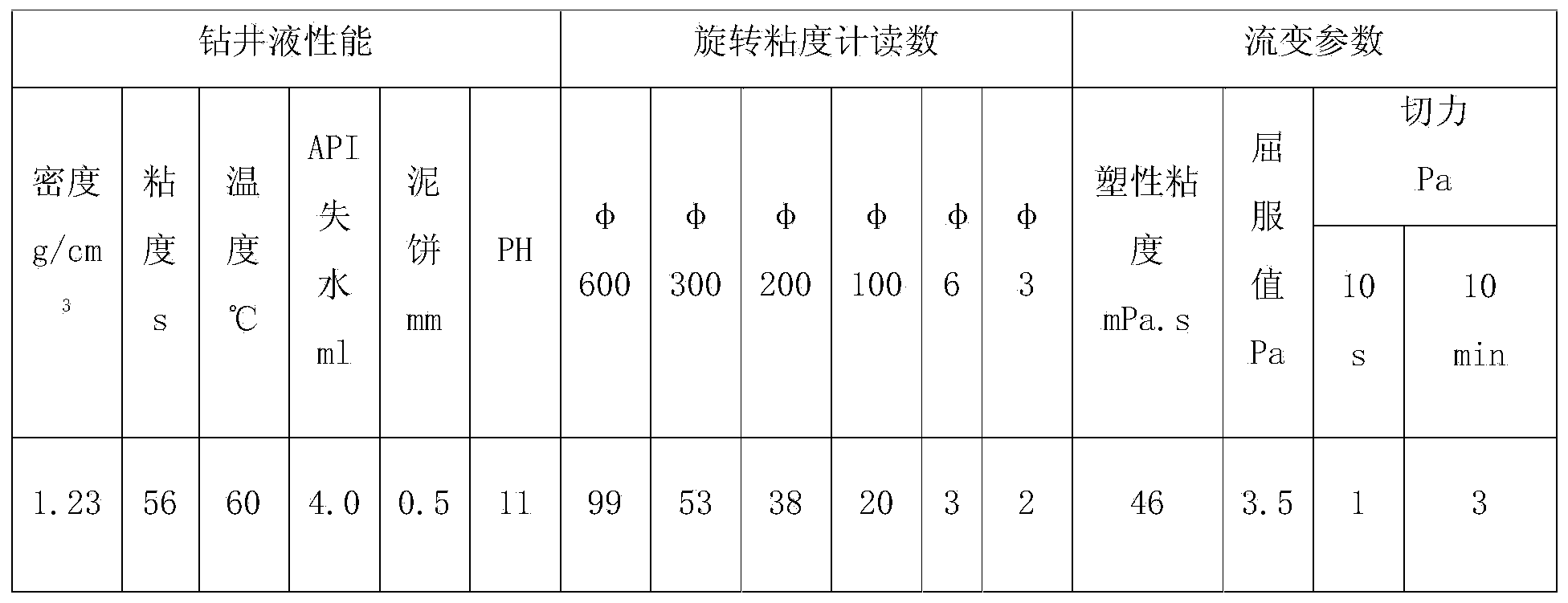

Linear motion guide unit with inside seal

ActiveUS20080279489A1Easy to installCheap productionLinear bearingsBearing componentsLinear motionForeign matter

A linear motion guide unit makes sure of smooth sliding movement of a slider over a guide rail even under harsh working environment in which much foreign materials or contaminants may occur. Load-carrying races are kept free of foreign materials that have already creped into the inside of the slider. An inside seal is installed in a recess open downward in the slider. The inside seal is composed of a metallic core and a sealing member that includes a joint portion secured to the metallic core and a major portion integral with the joint portion. The joint portion has a mating surface to come into engagement with a downward surface deep inside the recess cut in a carriage while the major portion includes a first lip to come into sliding engagement with a top surface of the guide rail, a second lip come into abutment against an inward sidewall of the recess, and third lip to come into abutment against a downward surface deep inside a recess cut in an end cap.

Owner:NIPPON THOMPSON

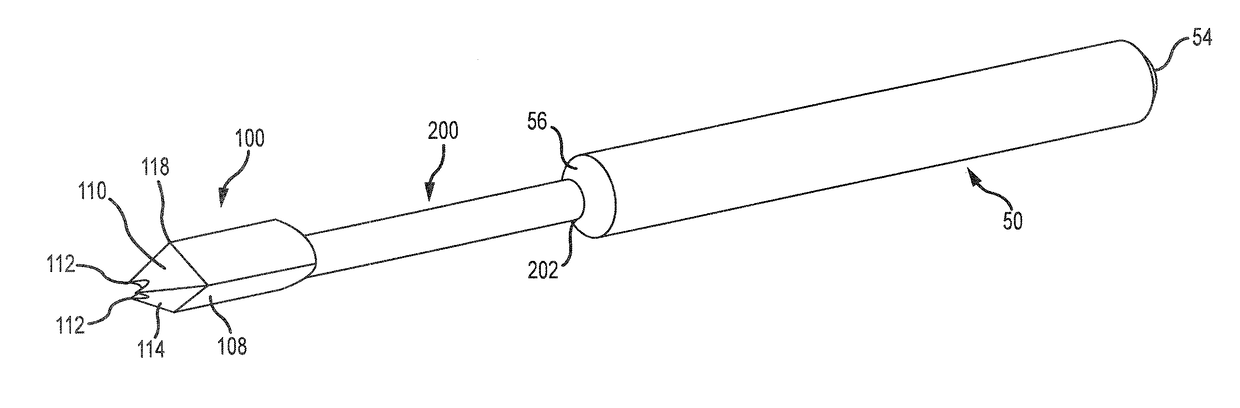

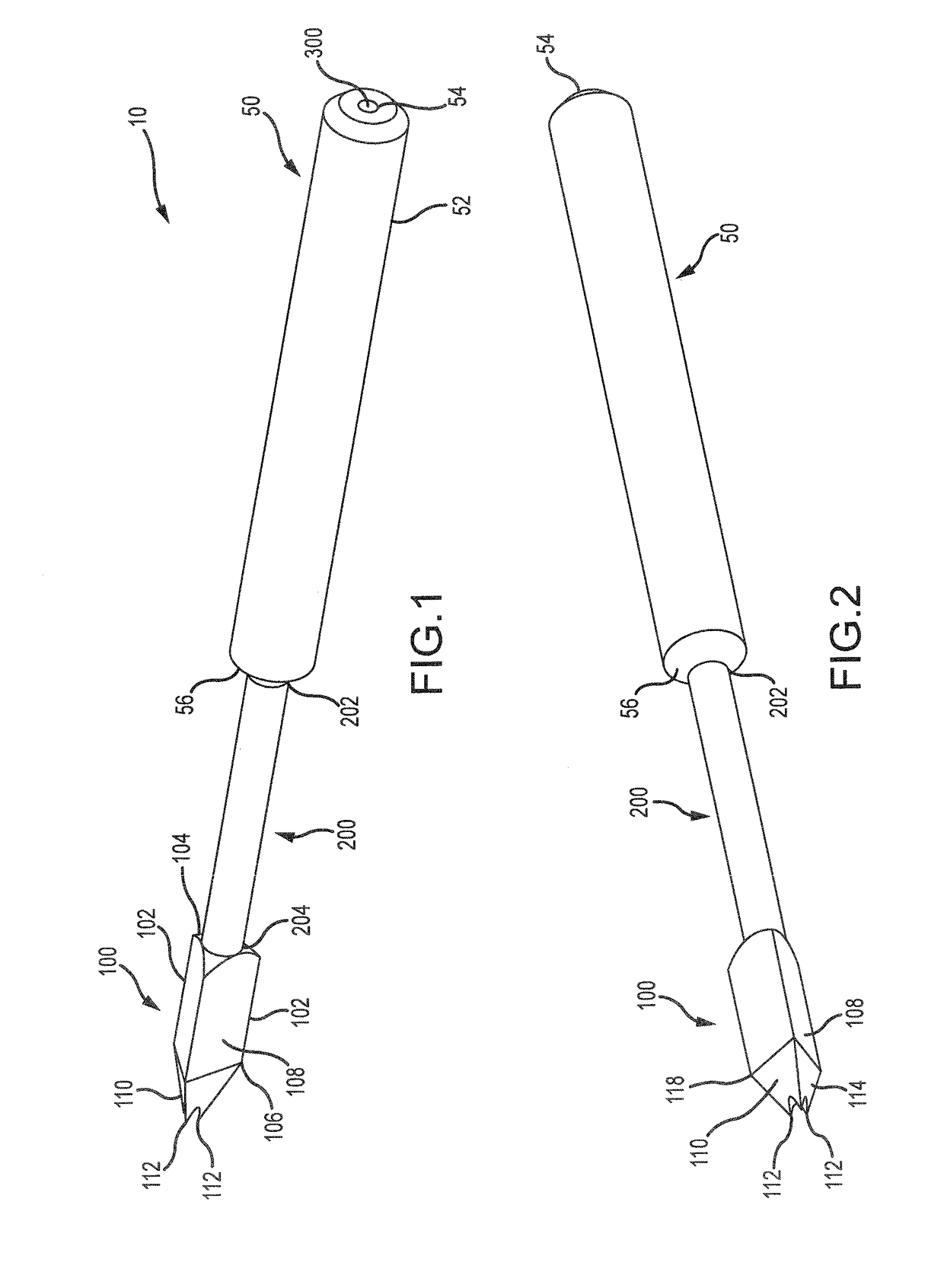

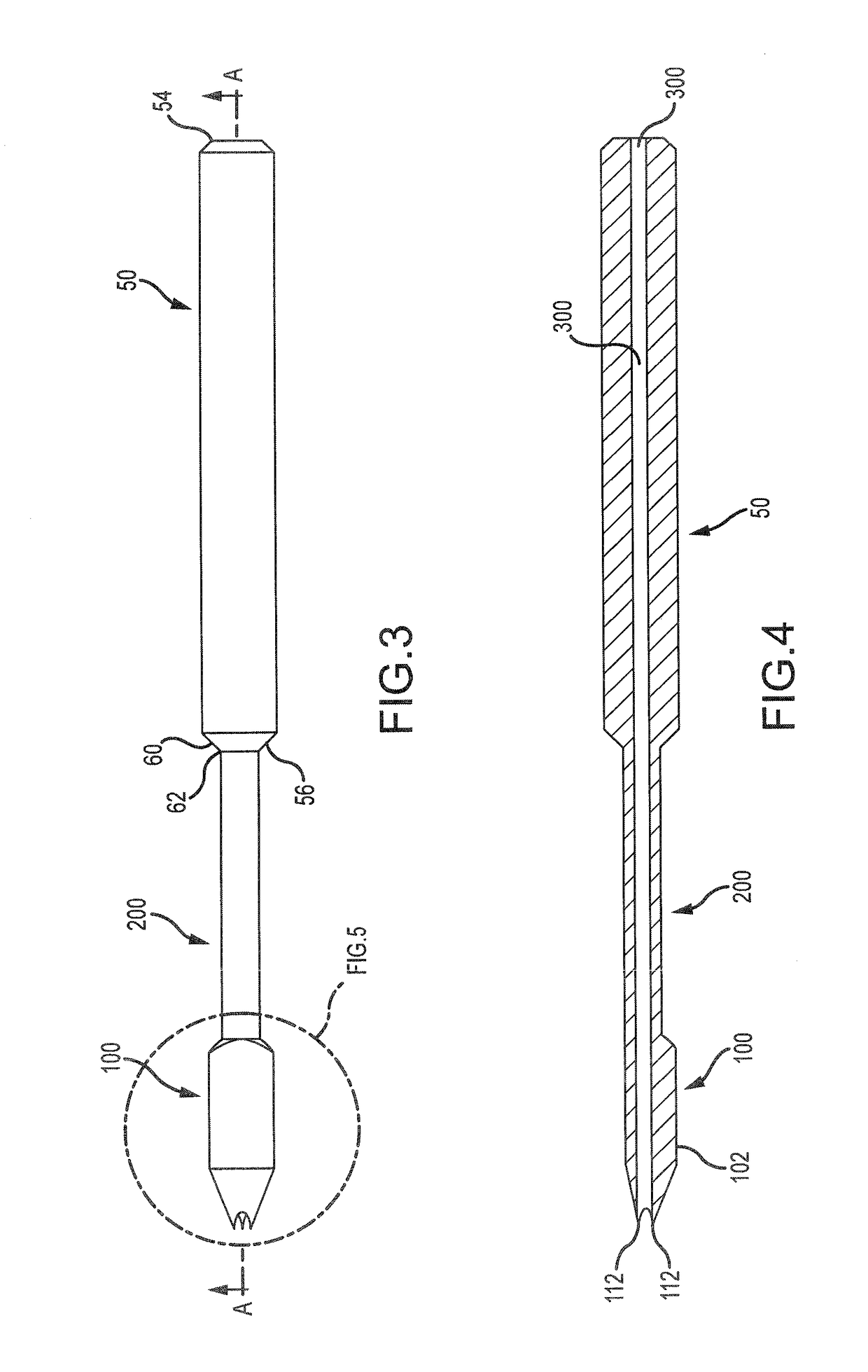

Tool for percutaneous joint cartilage destruction and preparation for joint fusion

A tool for scrubbing, removing tissue from the medullary cavity or joint cavity of a bone or removing cartilage and / or cortical bone from a joint cavity has a proximal end, a distal end, and a cannula extending therethrough. The distal end includes at least one scraping surface and / or cutting surface to soften marrow in the medullary cavity or joint cavity as the scraping and / or cutting surface(s) are rotated or otherwise moved relative to the medullary cavity or joint cavity. When used, the tool may be attached to a drill and the cannula receives a K-wire previously inserted into the medullary or joint cavity. The drill rotates the tool around the K-wire and pushes the tool over the K-wire into the medullary cavity or joint cavity.

Owner:EXSOMED CORP

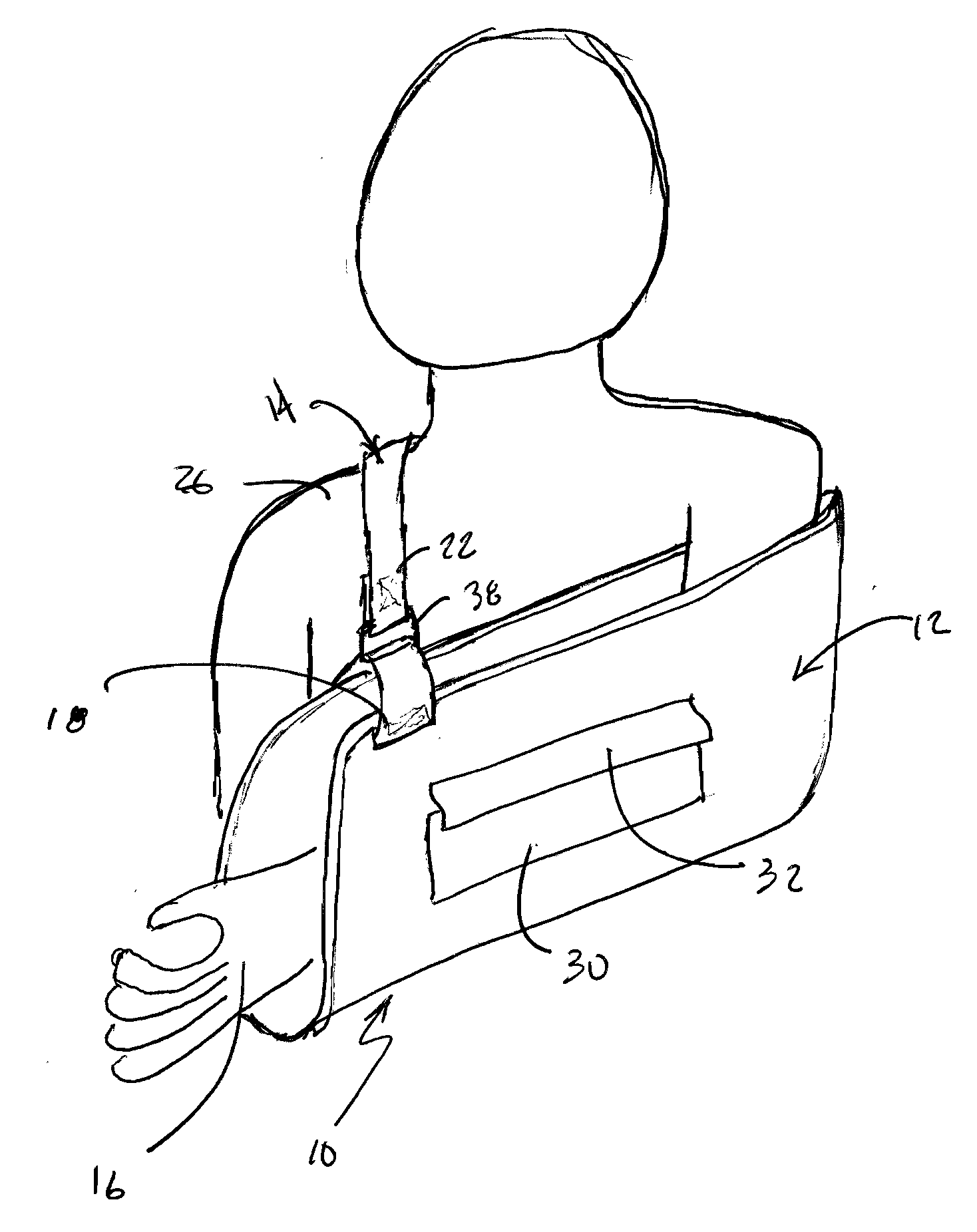

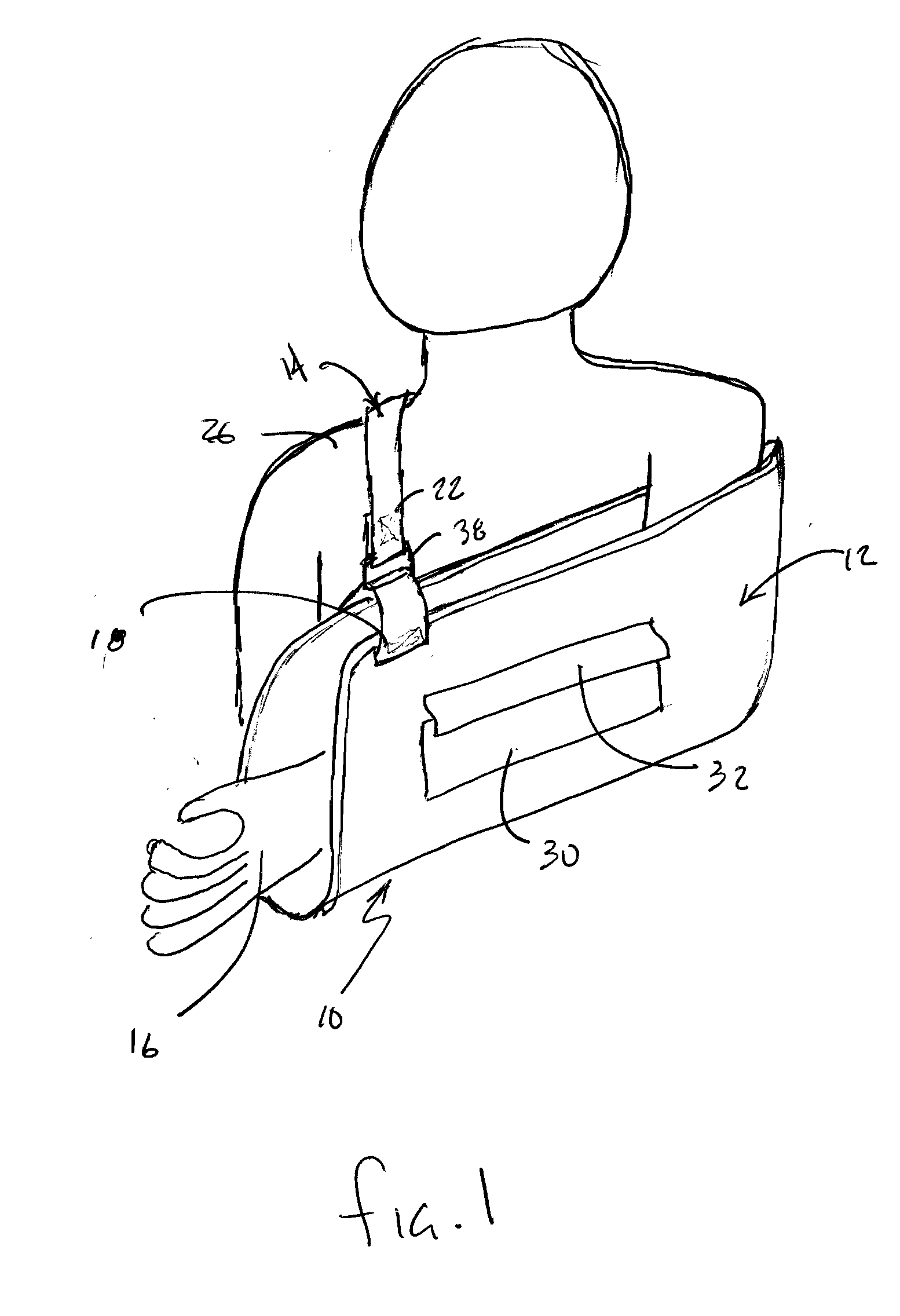

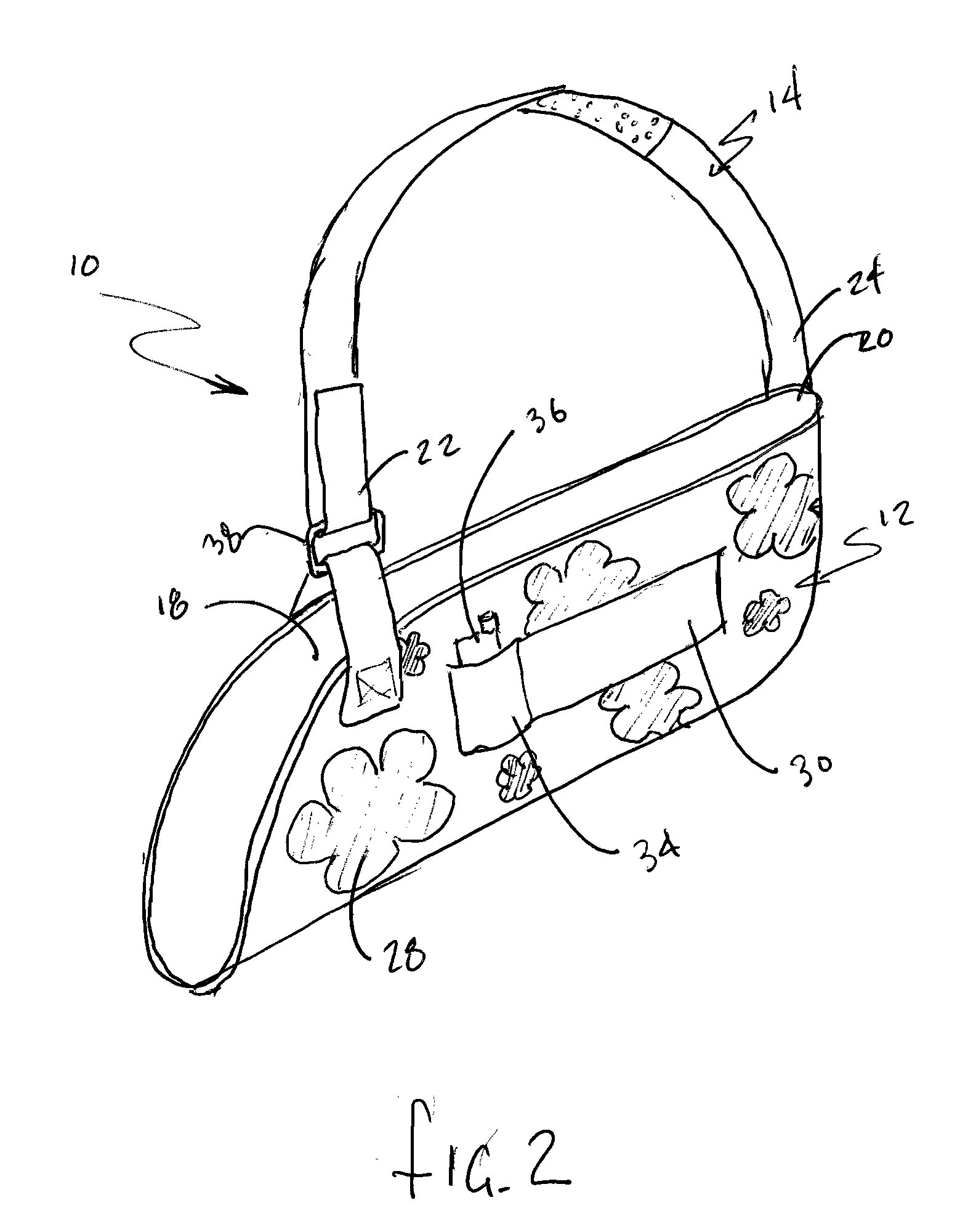

Sling design

InactiveUS20080015479A1Preventing strap bunchingPrevent creepRestraining devicesSuspensory bandagesModularityArchitectural engineering

A sling construction is provided that includes an improved support strap for more uniformly distributing the weight of the supported arm of the wearer's shoulder while preventing strap bunching and creep. The strap is preferably formed from an elastomer or a rubber that is relatively compliant yet has a low coefficient of elongation. This allows the strap to be highly supportive of the sling while also conforming to the contour of the wearer's neck and shoulders in a manner that makes the strap and sling comfortable to wear. The inner contact surface of the strap includes nubs or raised features that prevent the strap from sliding. Further, the improved strap support construction may be used in a modular fashion in conjunction with standard sling pouches or with an enhanced sling pouch in order to greatly improve the performance and appearance of the sling.

Owner:SOSCIA SUSAN

Removable valve seat member for diaphragm valve

ActiveUS20070145321A1Prevent creepConstant compression forceDiaphragm valvesOperating means/releasing devices for valvesEngineeringDiaphragm valve

An apparatus and method for a diaphragm valve includes a valve body having a chamber in fluid communication with a first channel and a second channel. A diaphragm is disposed in the chamber, and a tapered seat member is at least partially disposed in the first channel. A sleeve is compressively disposed in the seat member between the seat member and the first channel to maintain a fluid tight seal between the seat member and the first channel. A valve member is movable to controllably urge the diaphragm into and out of engagement with the seat member to control flow of fluid between the first the first and second channel.

Owner:CRANE INSTR & SAMPLING INC

Linear motion guide unit with inside seal

ActiveUS7950852B2Bad working environmentImprove performanceLinear bearingsBearing componentsLinear motionForeign matter

An inside seal is installed in a recess open downward in the slider to keep load-carrying races kept free of foreign materials that have already crept into the inside of the slider. The inside seal is composed of a metallic core and a sealing member that includes a joint portion secured to the core and a major portion integral with the joint portion. The joint portion has a mating surface to come into engagement with a downward surface deep inside the recess cut in a carriage while the major portion includes a first lip to come into sliding engagement with a guide rail, a second lip come into abutment against an inward sidewall of the recess, and third lip to come into abutment against the downward surface.

Owner:NIPPON THOMPSON

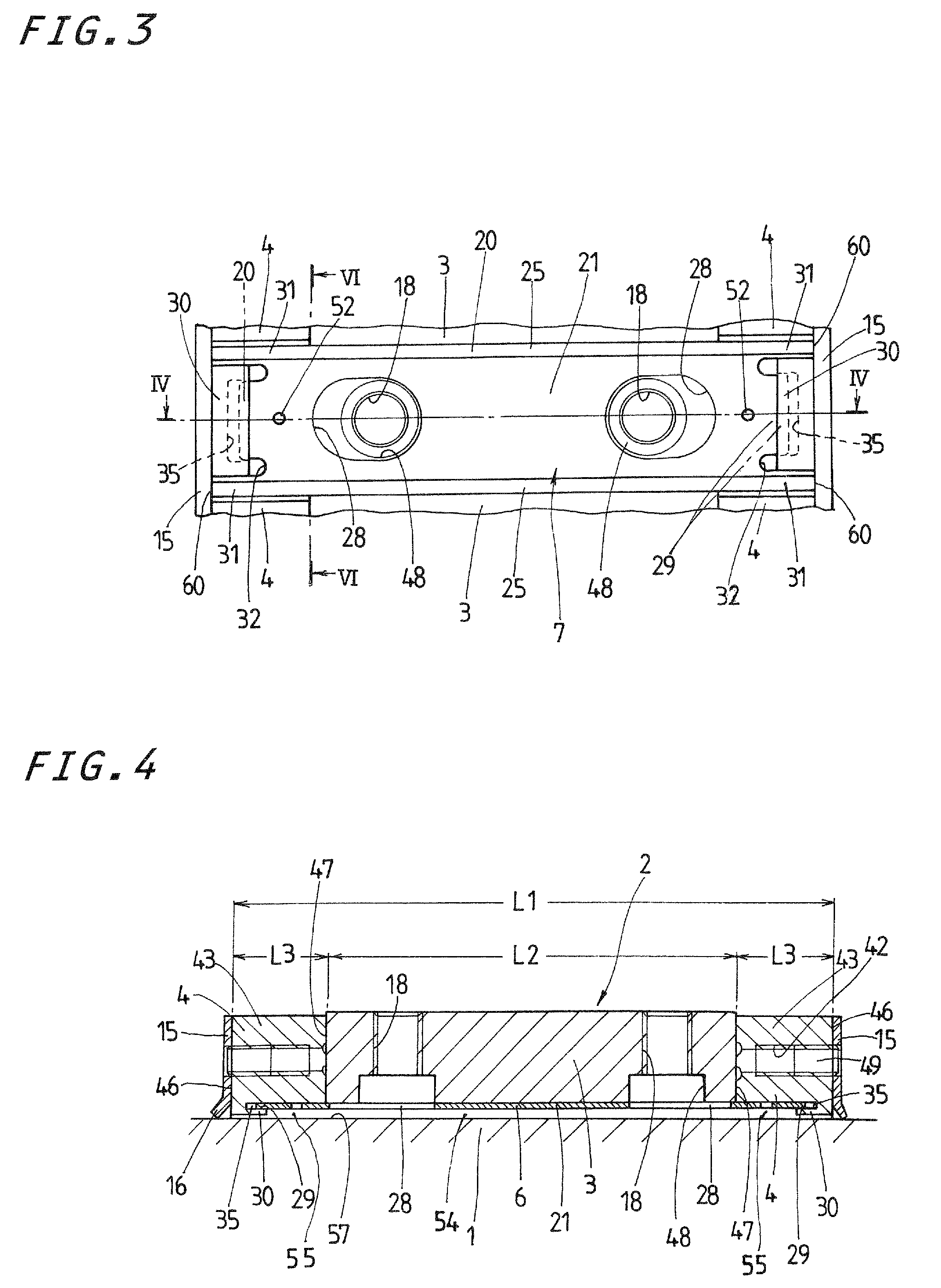

Polymer saturated salt water drilling solution suitable for drilling gas storage warehouse

InactiveCN103642473AControlled dissolutionPrevent collapseDrilling compositionSodium BentoniteFiltration

The invention discloses a polymer saturated salt water drilling solution suitable for drilling a gas storage warehouse. The polymer saturated salt water drilling solution is prepared from brine glue solution and bentonite slurry with mass percentage concentration of 4% according to a mass ratio of 1:1, wherein the brine glue solution comprises the following components in parts by mass: 100 parts of brine, 0.3-0.35 part of drilling solution coating agent, 1.5-1.7 parts of sulfonated phenolic resin, 1-1.05 parts of high-viscosity sodium carboxymethylcellulose, 1.0-1.10 parts of compound salt resisting filtration loss reducing agent, 1.5-1.6 parts of drilling solution collapse-proof dilute filtration loss reducing agent SN (Sulfanilamide) resin, 1.0-1.05 parts of sulfonated bitumen, 0.3-0.4 part of sodium carbonate, 0.4-0.45 part of caustic soda and solid industrial salt NaCl which is added till the brine glue solution is saturated. Through the polymer saturated salt water drilling solution suitable for drilling the gas storage warehouse, the pollution problem of the upper stratum slurry and the lower calcium mudstone can be well controlled; and the polymer saturated salt water drilling solution is capable of effectively preventing the collapse of the stratum under the casing pipe shoe and has good effects of controlling dissolution of the salt layer and preventing creep deformation of the slat layer.

Owner:CNPC BOHAI DRILLING ENG

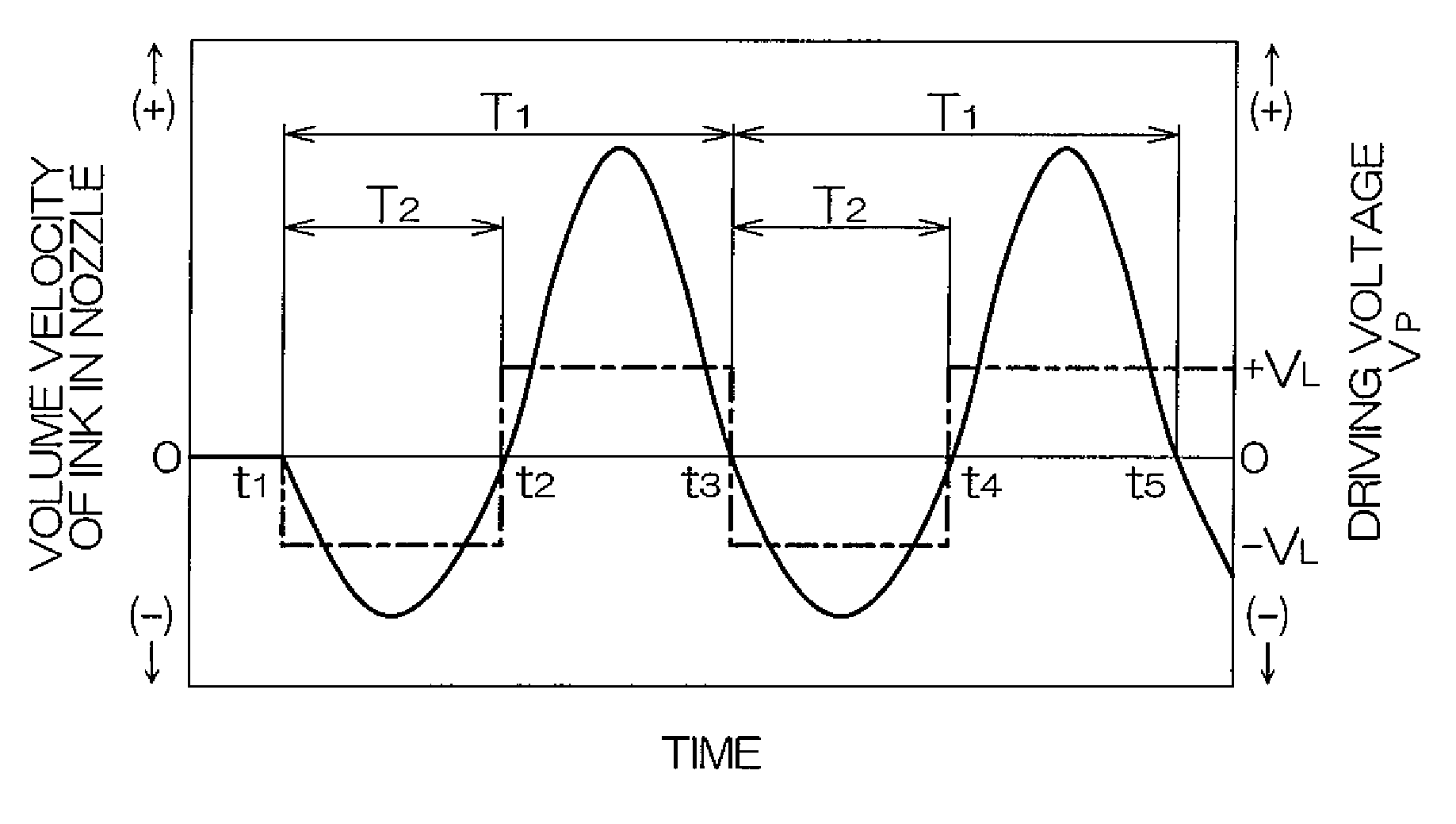

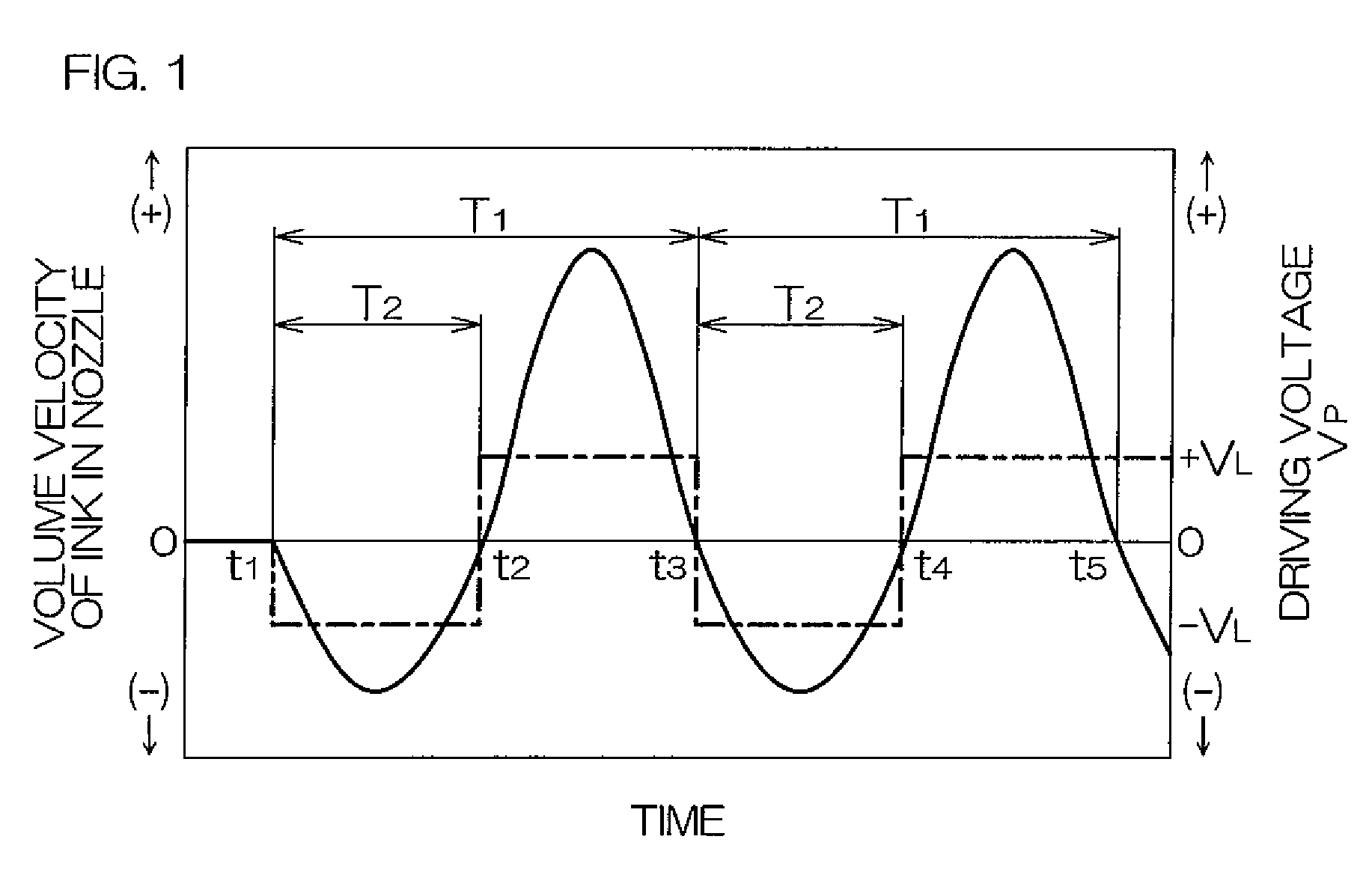

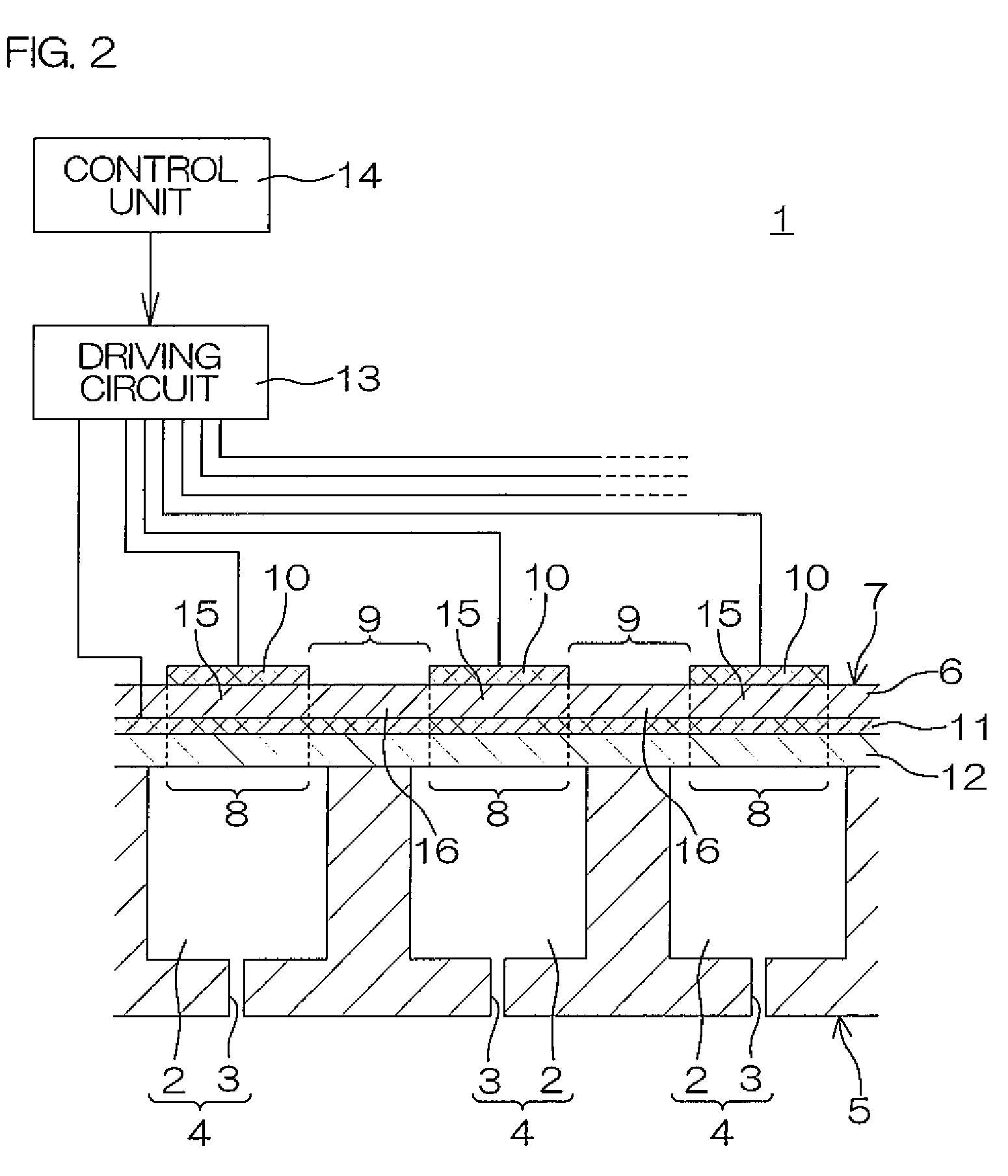

Method for driving liquid ejector

ActiveUS7896456B2Prevent creepReduce displacementPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesPiezoelectric actuatorsEngineering

Owner:KYOCERA CORP

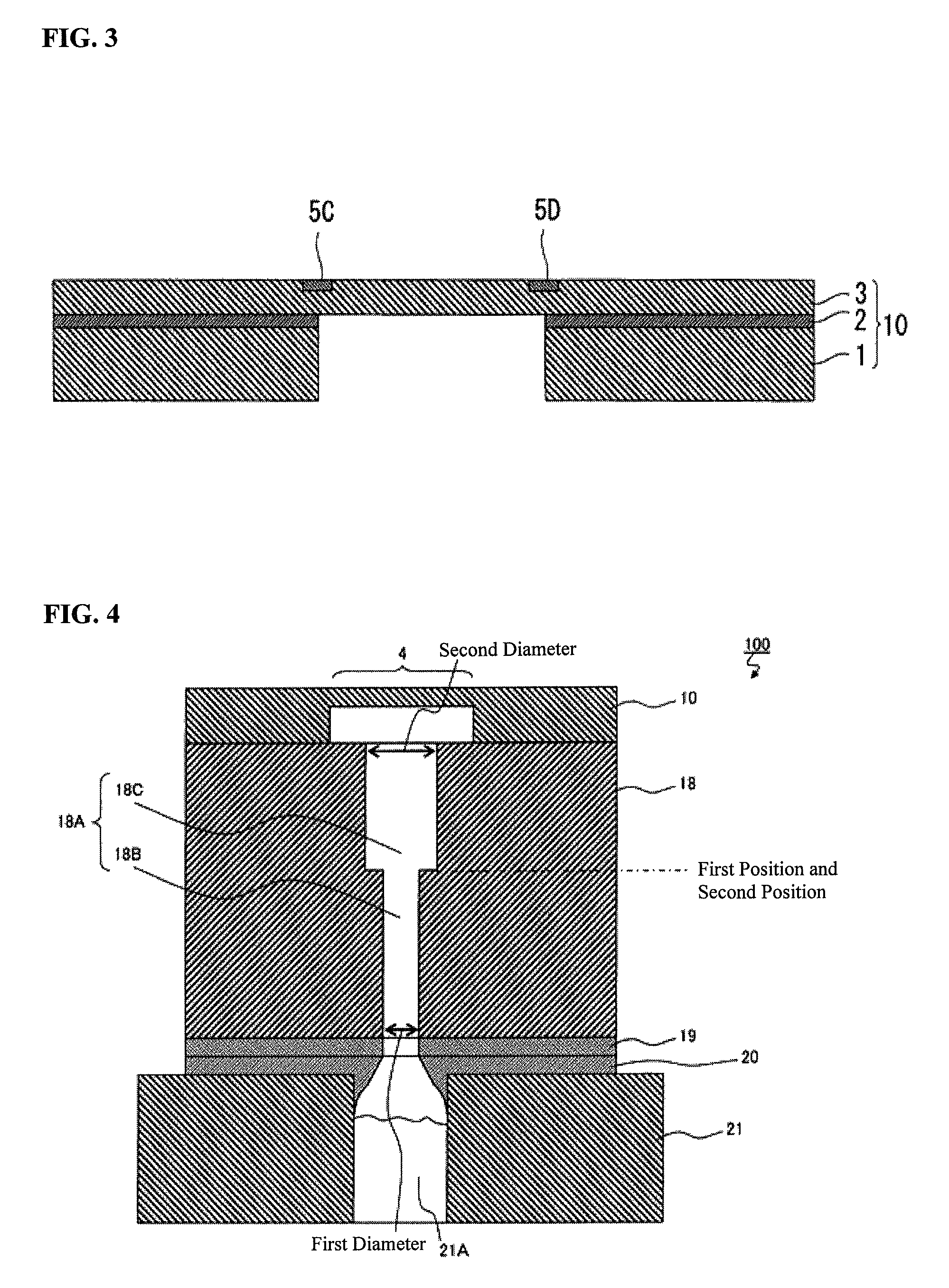

Pressure sensor and manufacturing method

ActiveUS8220338B2Avoid depositionPrevent creepMaterial analysis using sonic/ultrasonic/infrasonic wavesVibration measurement in fluidDifferential pressureEngineering

A semiconductor substrate, provided with a differential pressure diaphragm, and a glass pedestal, which is provided on the bottom side of the semiconductor substrate, are provided, wherein: the bottom surface of the semiconductor substrate and the top surface of the glass pedestal are bonded together; a pressure introducing hole is formed in the glass pedestal so as to pass through the glass pedestal, connecting between the top and bottom surfaces of the glass pedestal; the pressure introducing hole is formed with a first diameter for the pressure introducing hole at the bottom surface of the glass pedestal from the bottom surface of the glass pedestal to a first position; and a second diameter for the pressure introducing hole at the top surface of the glass pedestal is larger than the first diameter; where a metal thin film layer is deposited on the bottom surface of the glass pedestal.

Owner:YAMATAKE HONEYWELL CO LTD

Plumbum calcium alloy for starting type accumulators

InactiveCN101294248ASmall and uniform crystal grainsImprove and increase strengthElectrode carriers/collectorsMisch metalElectric-vehicle battery

The invention relates to a lead-calcium alloy used on a starting type storage battery, which is composed of a lead-calcium-tin alloy. The lead-calcium-tin alloy comprises calcium, tin, aluminum, misch metal and lead; the weight percentage of the calcium in the lead-calcium-tin alloy is 0.02 to 0.06 percent; the weight percentage of the tin in the lead-calcium-tin alloy is 0.10 to 1.0 percent; the weight percentage of the aluminum in the lead-calcium-tin alloy is 0.01 to 0.03 percent; the weight percentage of the misch metal in the lead-calcium-tin alloy is 0.01 to 1.00 percent; the other weight percentage is composed of the lead. Compared with prior art, an electric vehicle battery which is assembled by a lead-acid accumulator grid produced by using the lead-calcium alloy has the advantages of corrosion resistance, deep cycle, large-current discharge and long service life.

Owner:上海飞轮有色冶炼厂

Compressed seal for a movable joint

InactiveUS6983957B2Reduce capacityAvoid deformationAdjustable jointsPipe elementsEngineeringExpansion joint

A compressed seal expansion joint for fluidically connecting in a sealed relationship adjacent ends of two conduits adapted for carrying fluids of varying temperatures, the expansion joint comprising telescopically arranged outer and inner pipe members adapted to be connected to each of the conduits, the outer pipe member defining an annular packing chamber opening through its inner surface for containing at least two cylindrical guide rings disposed at opposite ends of the chamber, the rings being of a generally rectangular cross section having their long faces longitudinal to the members axis and selected of an elastic and semi-plastic packing composition pressurized by tensioned hoop bands circumscribing the outer pipe member and selected to elastically deform the outer pipe member and communicate a circumferentially compressive force to the guide rings so as to create bearing and frictional loadings and seal between guide ring surfaces and the pipe member surfaces during axial and rotational relative pipe member movement.

Owner:BETTINGER DAVID S

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com