Double-clutch automatic transmission creeping control method

An automatic transmission, dual clutch technology, applied in the control device, driver input parameters, transportation and packaging, etc., can solve problems such as inability to judge the driver, signal failure, clutch disengagement, etc. The effect of car comfort guarantee and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

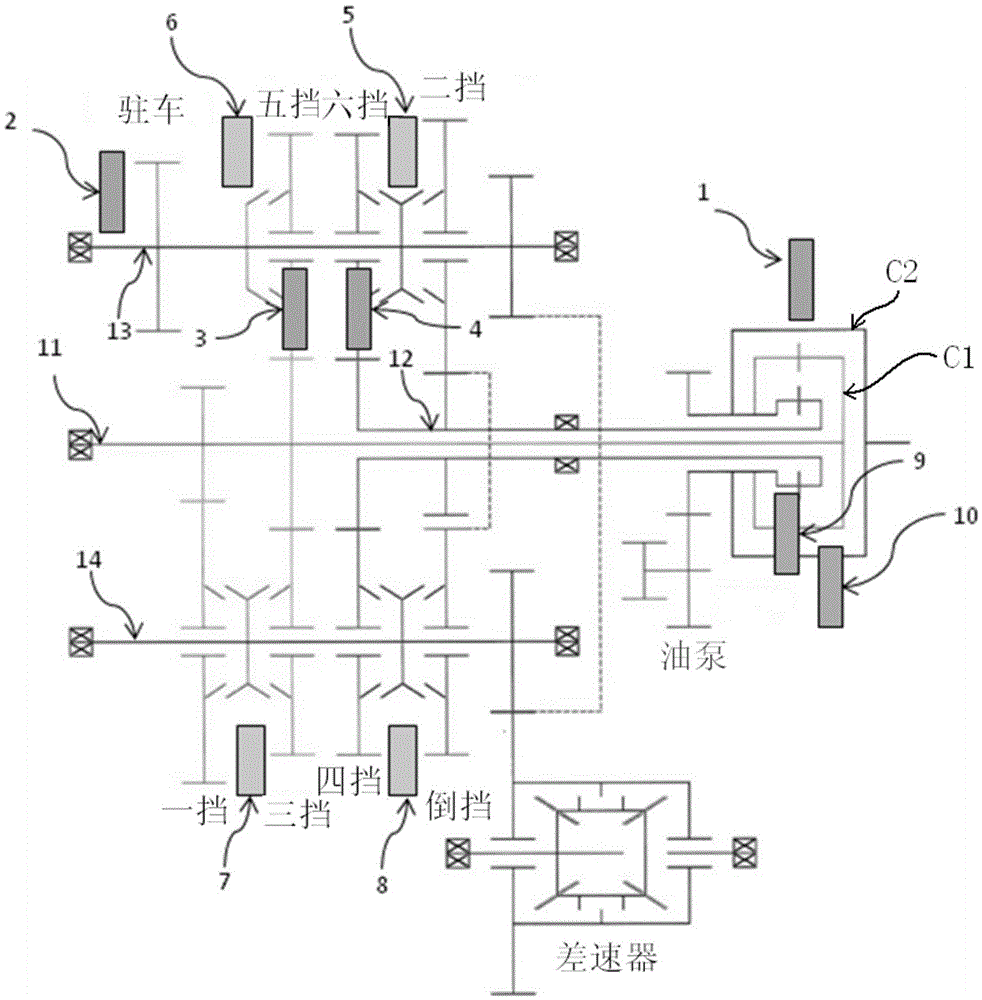

[0022] refer to figure 1 A typical dual-clutch automatic transmission has two clutches, a first clutch C1 and a second clutch C2. The inner input shaft 11 and the outer input shaft 12 are nested inside and outside and connected to the first clutch C1 and the second clutch C2 respectively. Each gear driving gear is arranged on the inner input shaft 11 and the outer input shaft 12 , and each gear driven gear is arranged on the first output shaft 13 and the second output shaft 14 . The oil pump fills the clutch with oil, so that the first clutch C1 and the second clutch C2 are engaged or disengaged respectively, so that the torque from the engine is transmitted to the inner input shaft 11 or the outer input shaft 12, and different gears are selected by using synchronizers and other devices Group kneading to realize parking, first to sixth gear, reverse gear and other functions. The clutch speed sensor 1 is used to collect the clutch speed signal, the output shaft speed sensor 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com