Patents

Literature

21526results about "Pipeline systems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

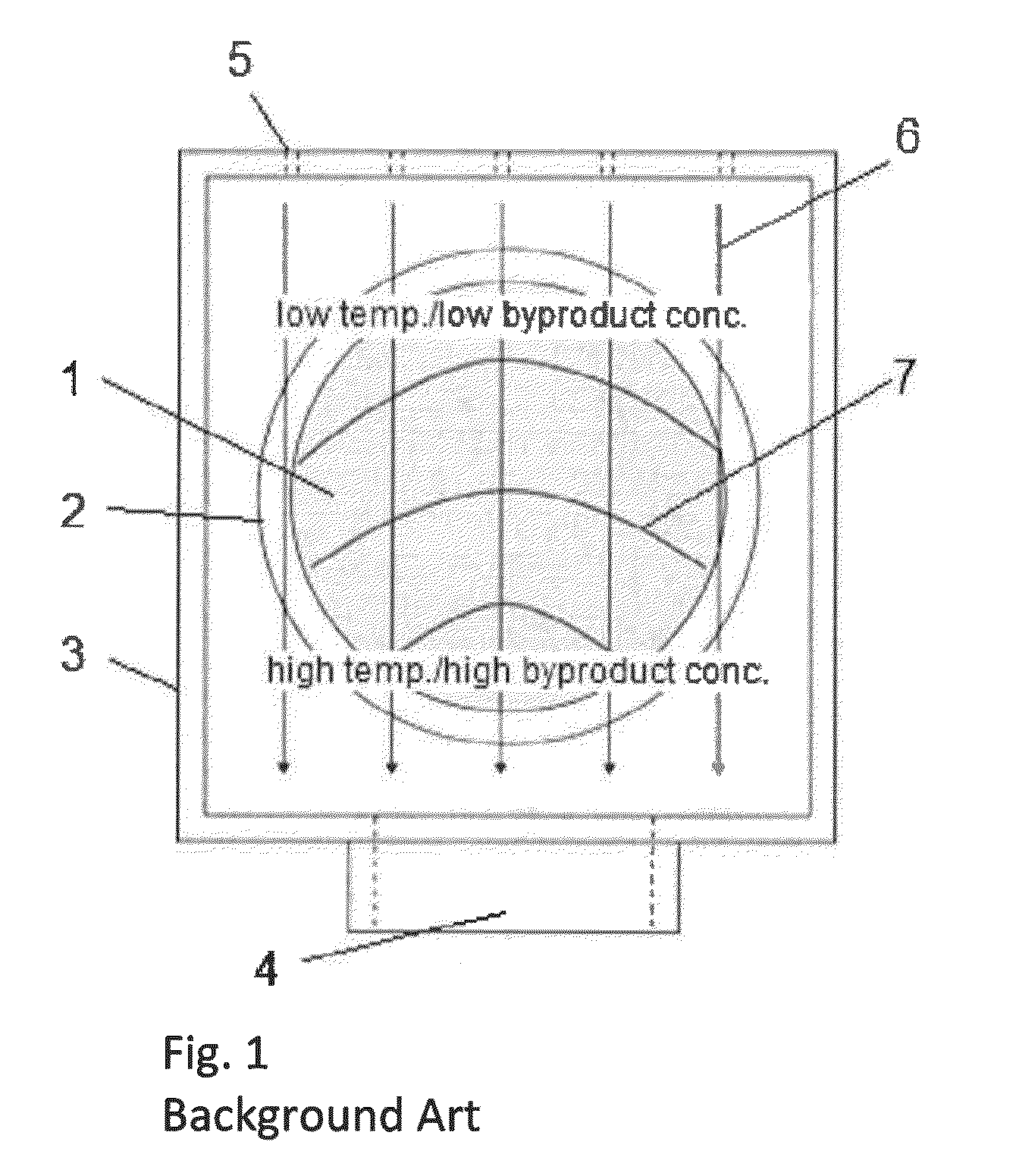

Irrigation and drainage based on hydrodynamic unsaturated fluid flow

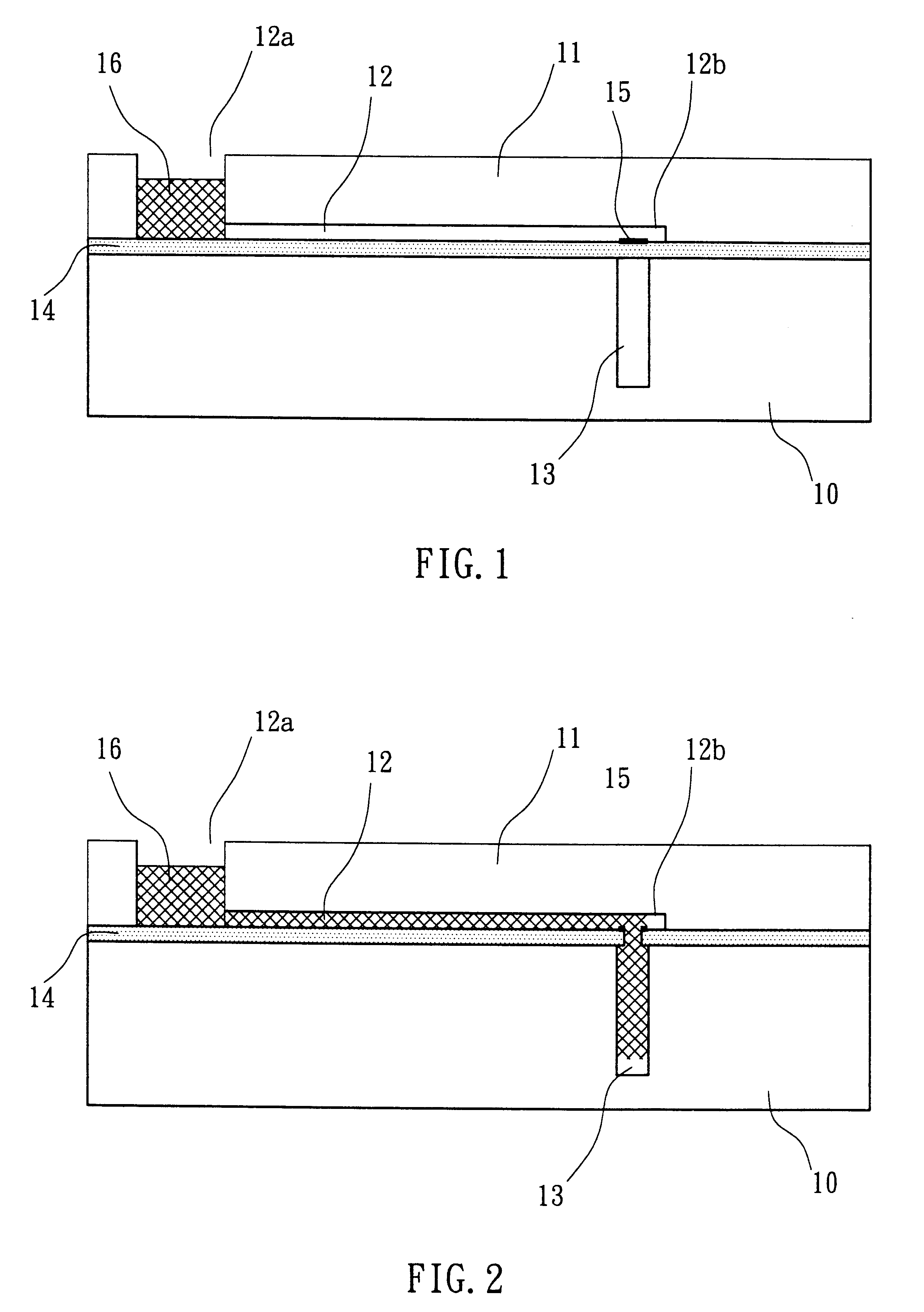

InactiveUS6918404B2Improve the level ofHigh porosityPipeline systemsMachines/enginesEnvironmental engineeringPorous microstructure

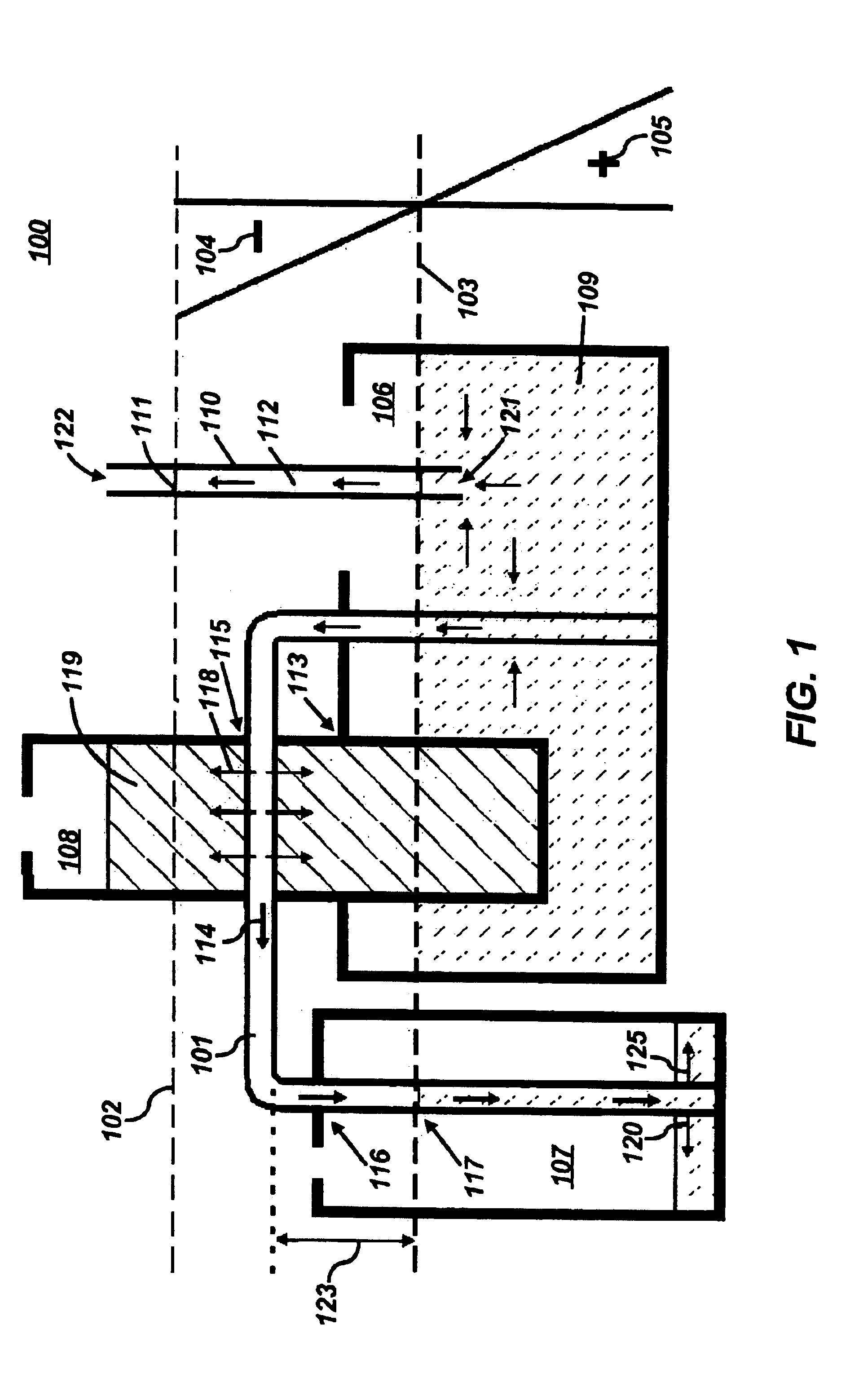

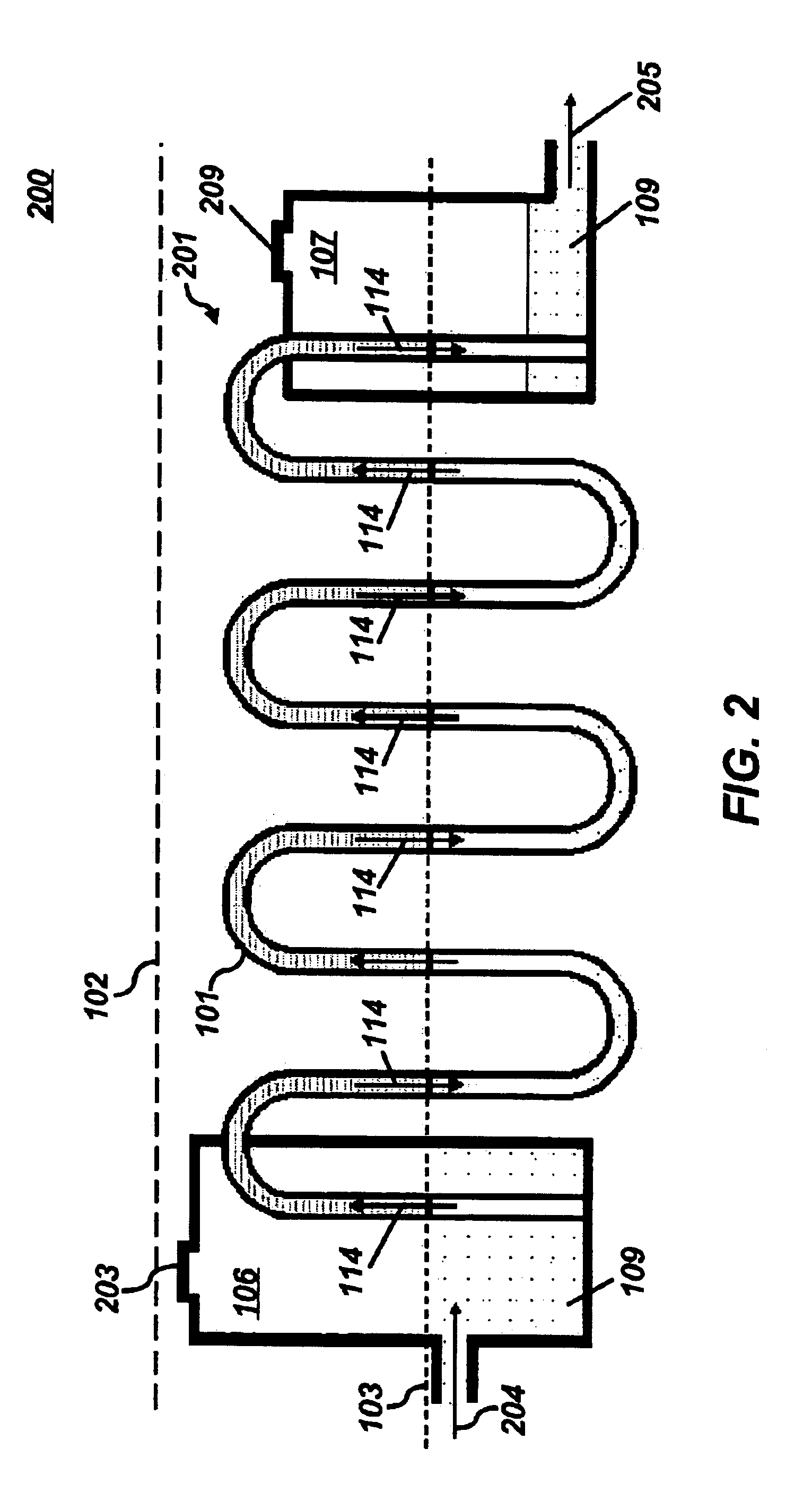

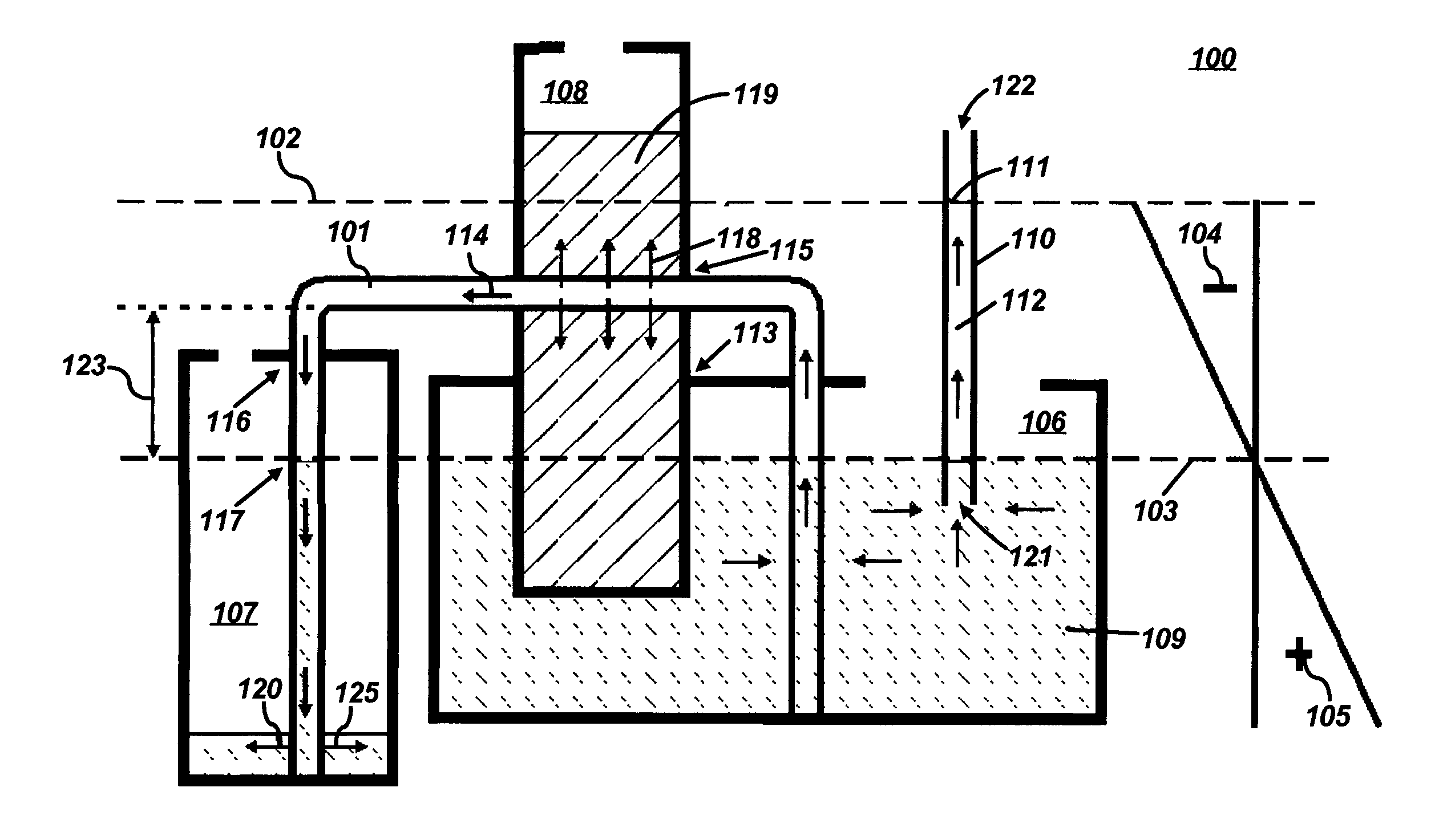

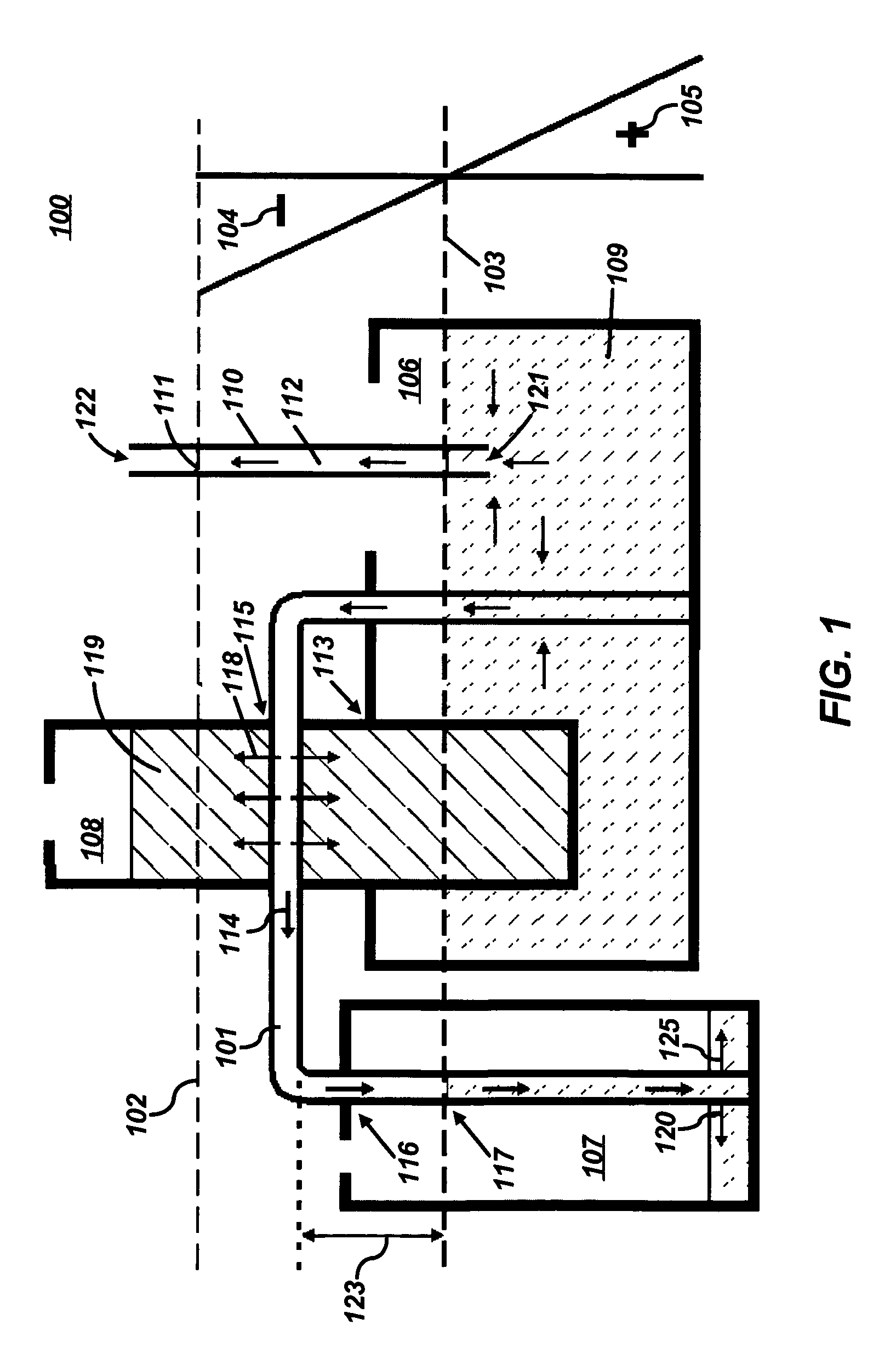

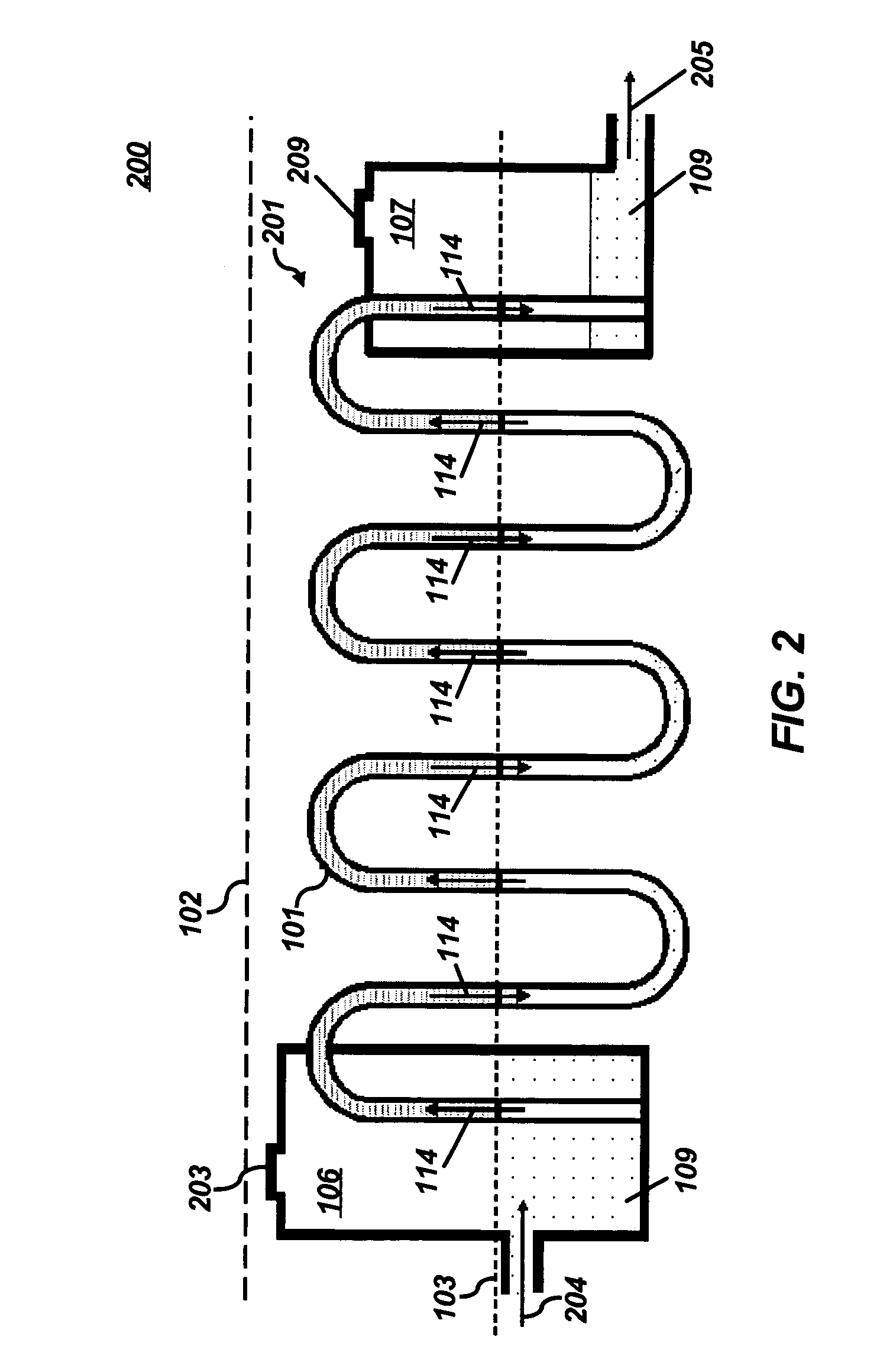

Irrigation and drainage systems are disclosed, including a saturated zone and at least one pipe in communication with the saturated zone. The pipe(s) can be configured to comprise a tubarc porous microstructure for conducting water from the saturated zone to an unsaturated zone in order to drain the water from the saturated zone. The water can be delivered from the saturated zone to the unsaturated zone through the tubarc porous microstructure, thereby permitting the water to be harnessed for irrigation or drainage through the hydrodynamic movement of the water from one zone of saturation or unsaturation to another.

Owner:TUBARC TECH

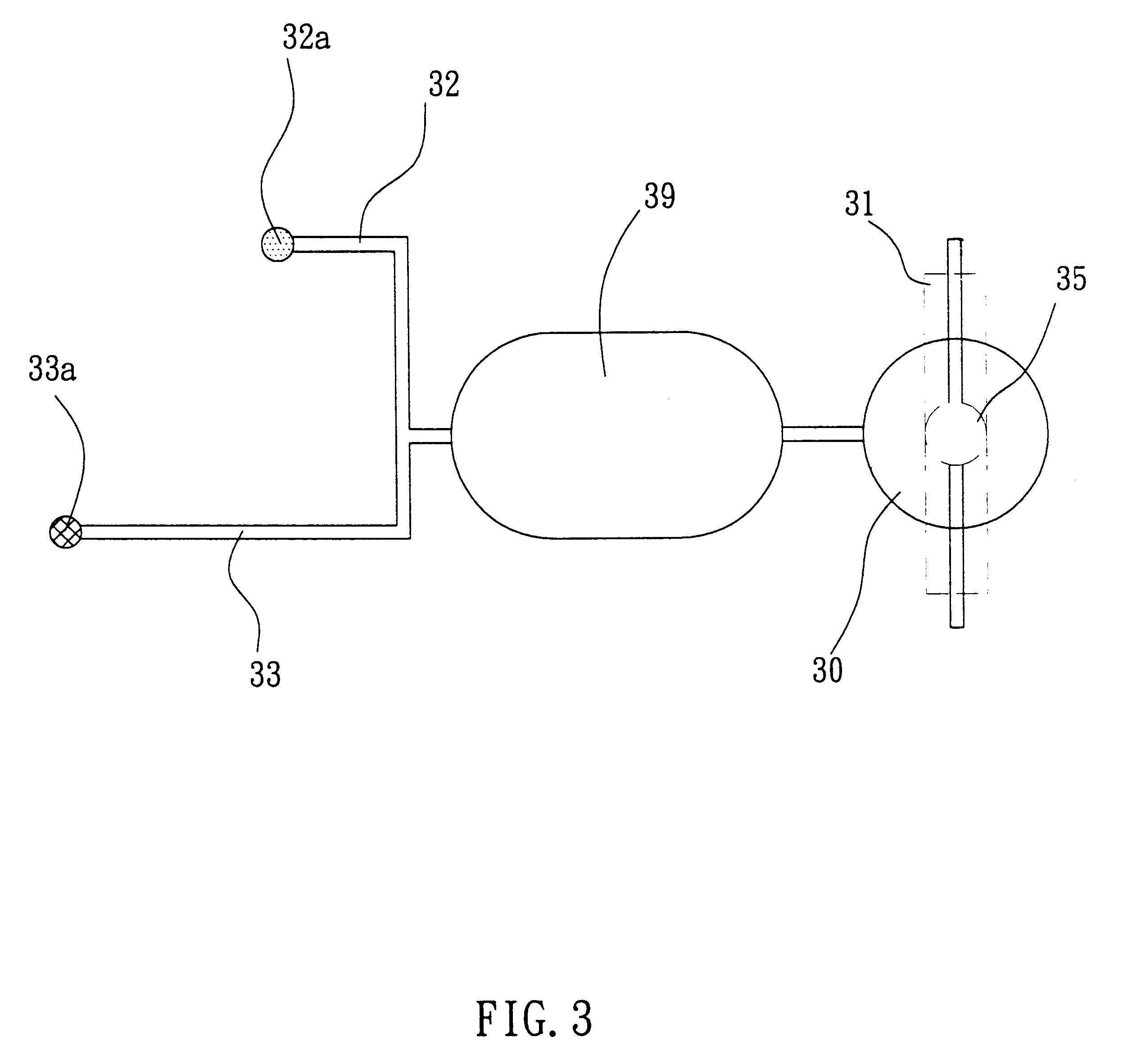

Ink refill and recharging system

InactiveUS7066586B2Improve reliabilityPrecise deliveryPipeline systemsPrintingEngineeringPrint-through

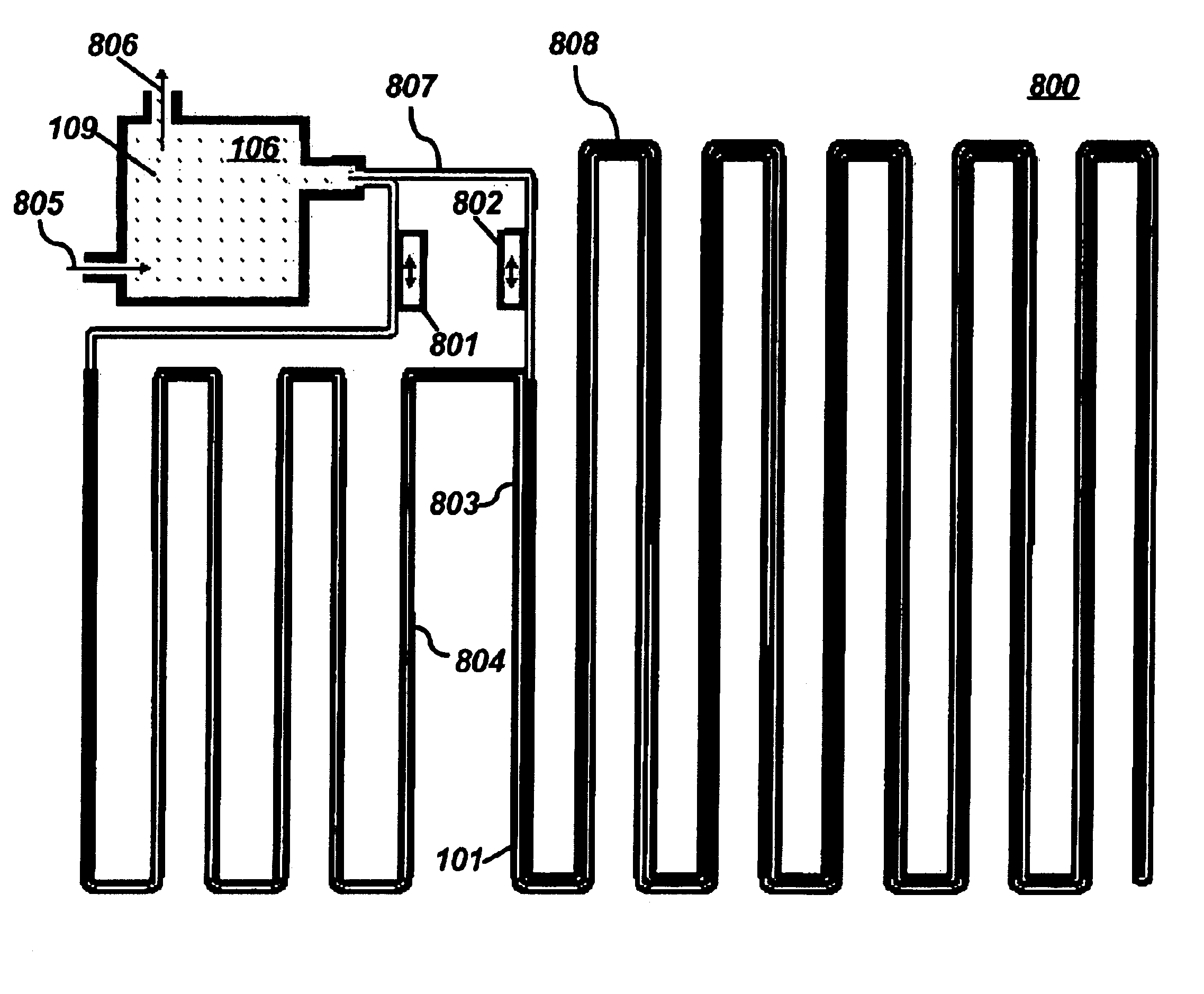

Ink refill systems are disclosed. In general, an ink source comprising a saturated zone and a tubarc porous microstructure for conducting ink from the saturated zone to an unsaturated zone are provided. The ink can be delivered from the saturated zone to the unsaturated zone through the tubarc porous microstructure, thereby permitting the ink to be harnessed for ink writing and / or printing through the unsaturated hydrodynamic flow of the ink from one zone of saturation or unsaturation to another.

Owner:TUBARC TECH

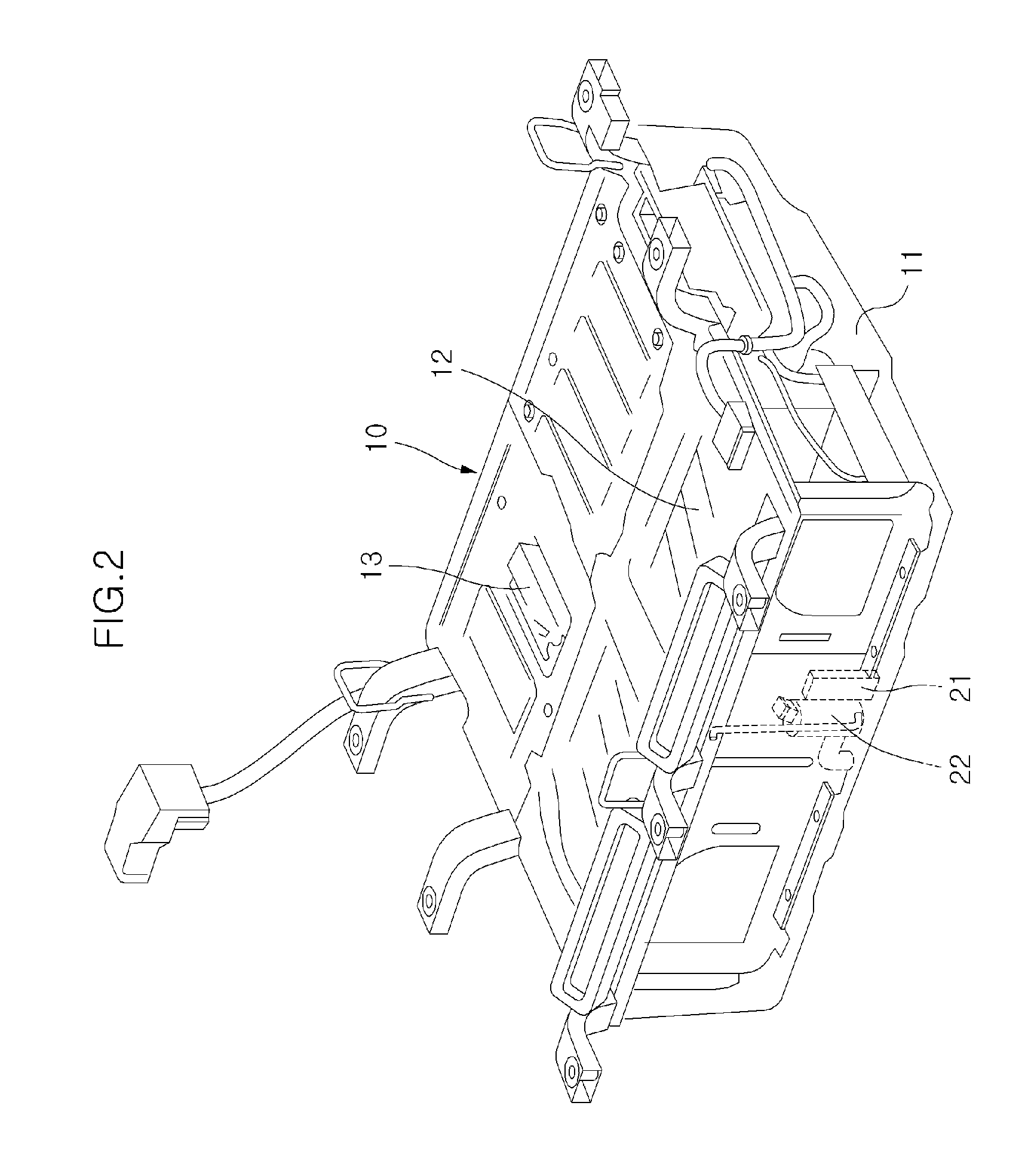

Water-discharging device of high voltage battery pack

InactiveUS20120132286A1Not to damageFunctional valve typesLevel controlAuto regulationWater discharge

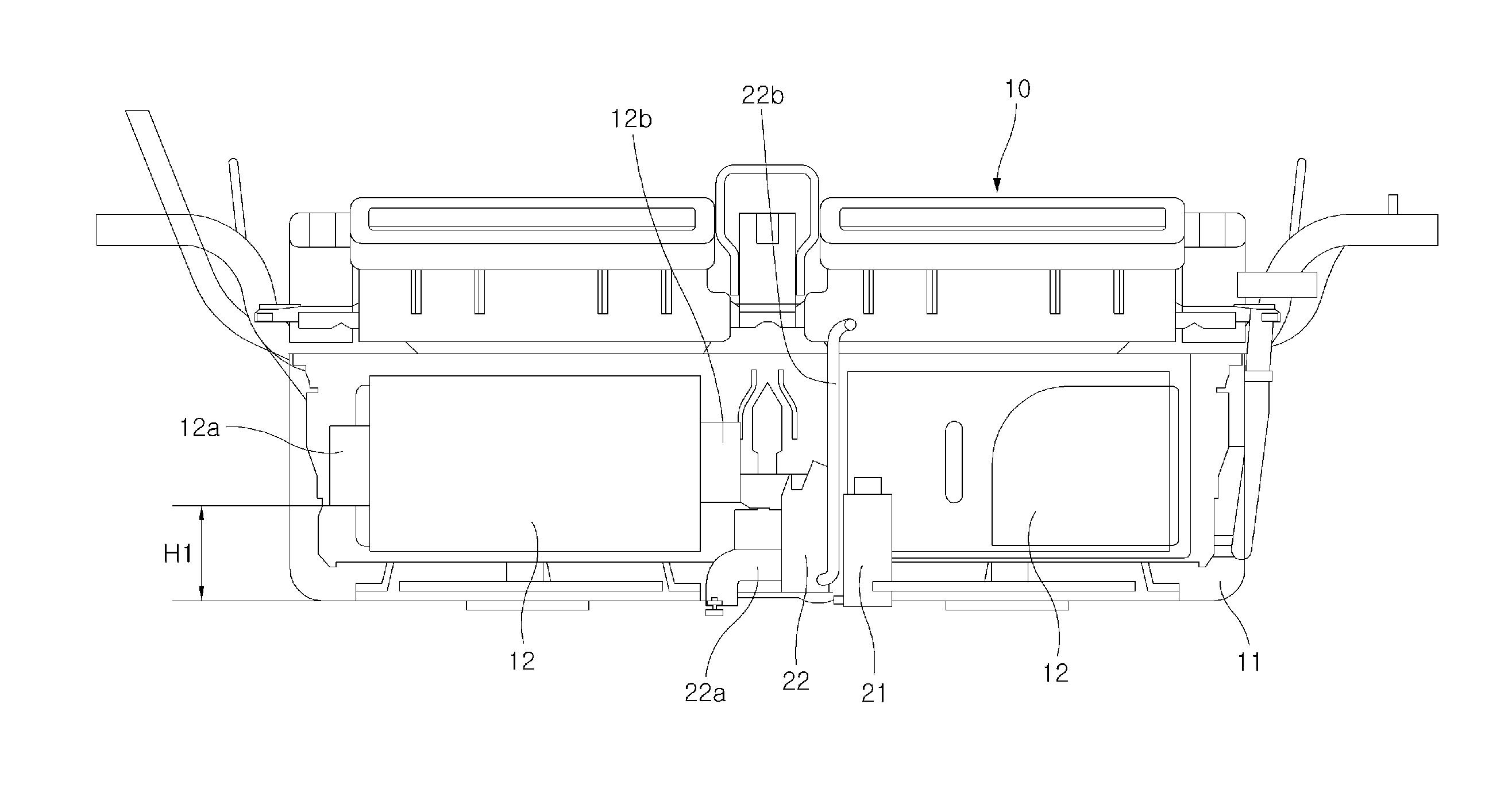

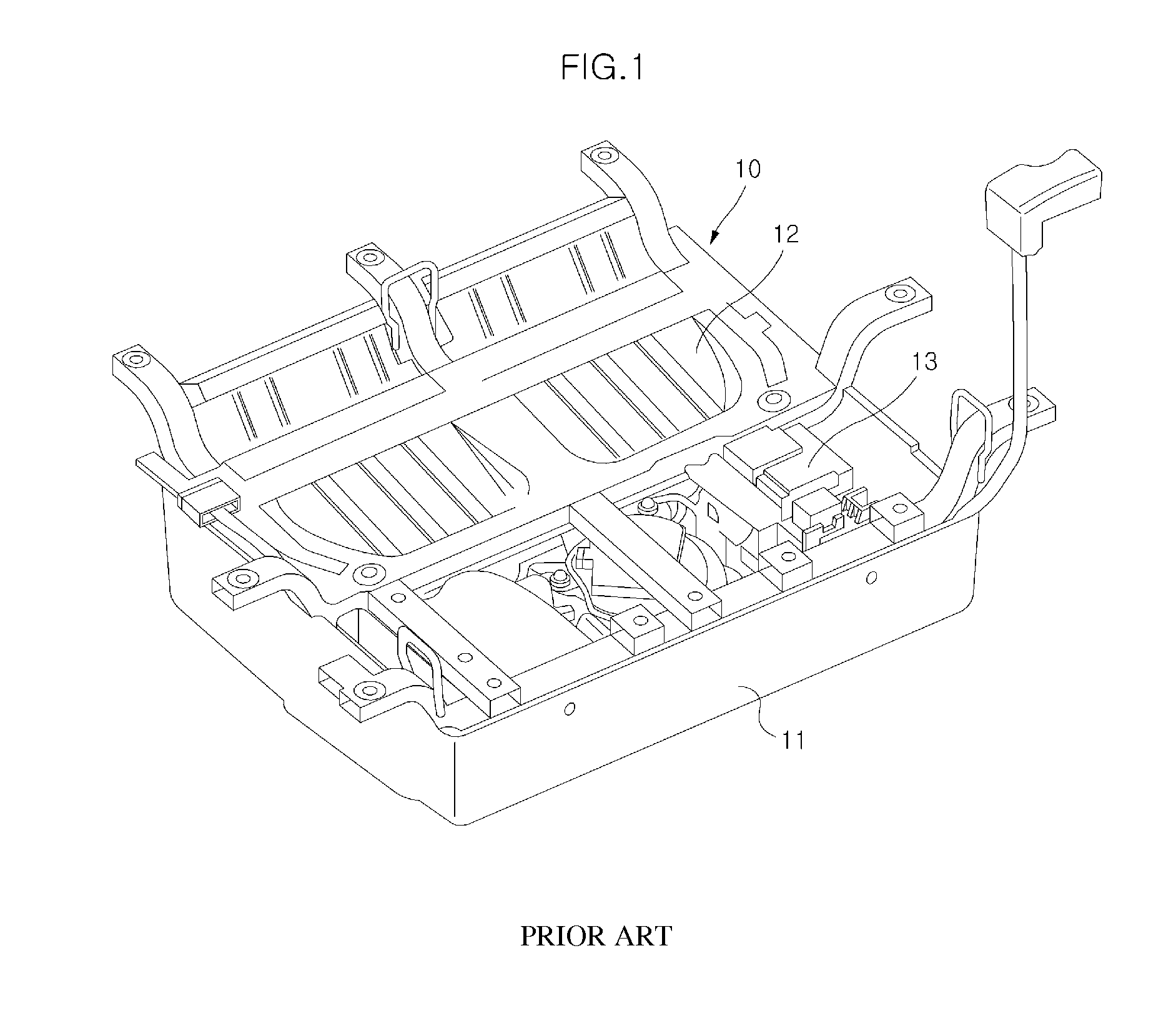

Disclosed is a water-discharging device of a high voltage battery pack that can automatically adjust the level of water collecting in an under cover such that high voltage parts, such as an expensive battery module and a BMS, equipped in the under cover are not damaged by the water, by making the BMS operate a water pump to forcibly discharge the water out of the under cover, when the water collects and increases in level in the under cover having a sealed structure.

Owner:HYUNDAI MOTOR CO LTD +1

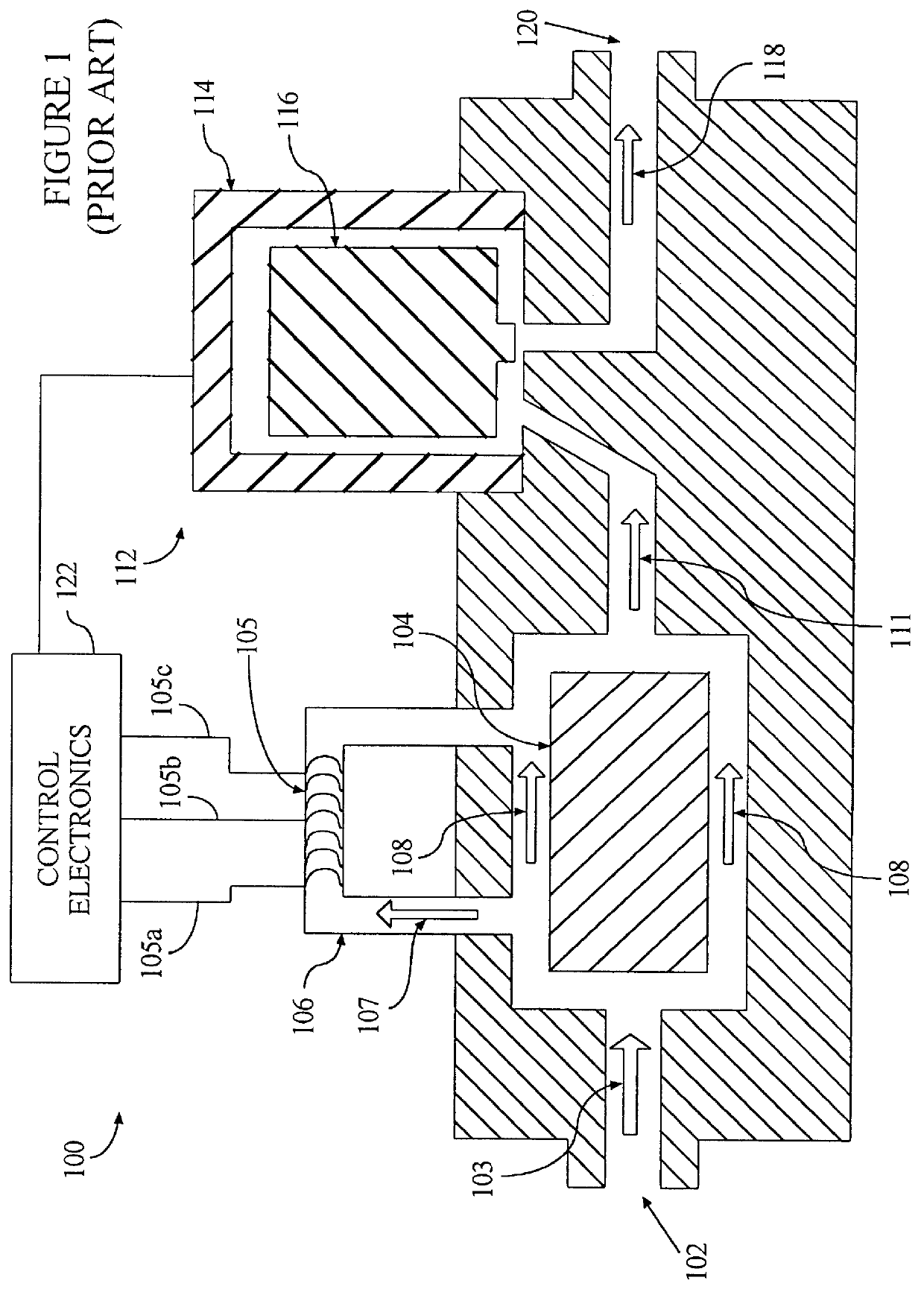

Method for wide range gas flow system with real time flow measurement and correction

InactiveUS6119710AAccurate measurementAccurate flowOperating means/releasing devices for valvesVolume/mass flow by thermal effectsDifferential pressureInlet valve

A gas delivery system accurately measures and optionally regulates mass flow rate in real time. A fluid conduit connects an inlet valve, calibration volume, flow restrictor, and outlet valve in series. Pressure and temperature sensors are coupled to the calibration volume. One or more pressure sensors may be attached across the flow restrictor. Alternatively, an absolute pressure sensor may be attached upstream of the flow restrictor. One embodiment of differential pressure sensors comprises a floating reference differential pressure sensor, including a first transducer attached to the fluid conduit upstream of the flow restrictor and a second transducer attached to the conduit downstream of the flow restrictor. In this embodiment, each transducer receives a reference pressure from a reference source, and optionally, after the calibration volume is charged, the floating reference differential pressure transducers are calibrated. When gas flow is initiated, differential and / or absolute pressure measurements are repeatedly taken, and a measured mass flow rate calculated thereon. Gas flow is adjusted until the measured mass flow rate reaches a target mass flow. Using the temperature / pressure sensors at the calibration volume, repeated calculations of actual flow rate are made to uncover any discrepancy between actual and measured mass flow rates. Whenever a discrepancy is found, the manner of calculating measured mass flow is conditioned to account for the discrepancy; thus, the measured mass flow rate more accurately represents the actual mass flow rate thereby providing an actual mass flow rate more accurately achieving the target mass flow rate.

Owner:CYBER INSTR TECH LLC AN ARIZONA LIMITED LIABILITY +1

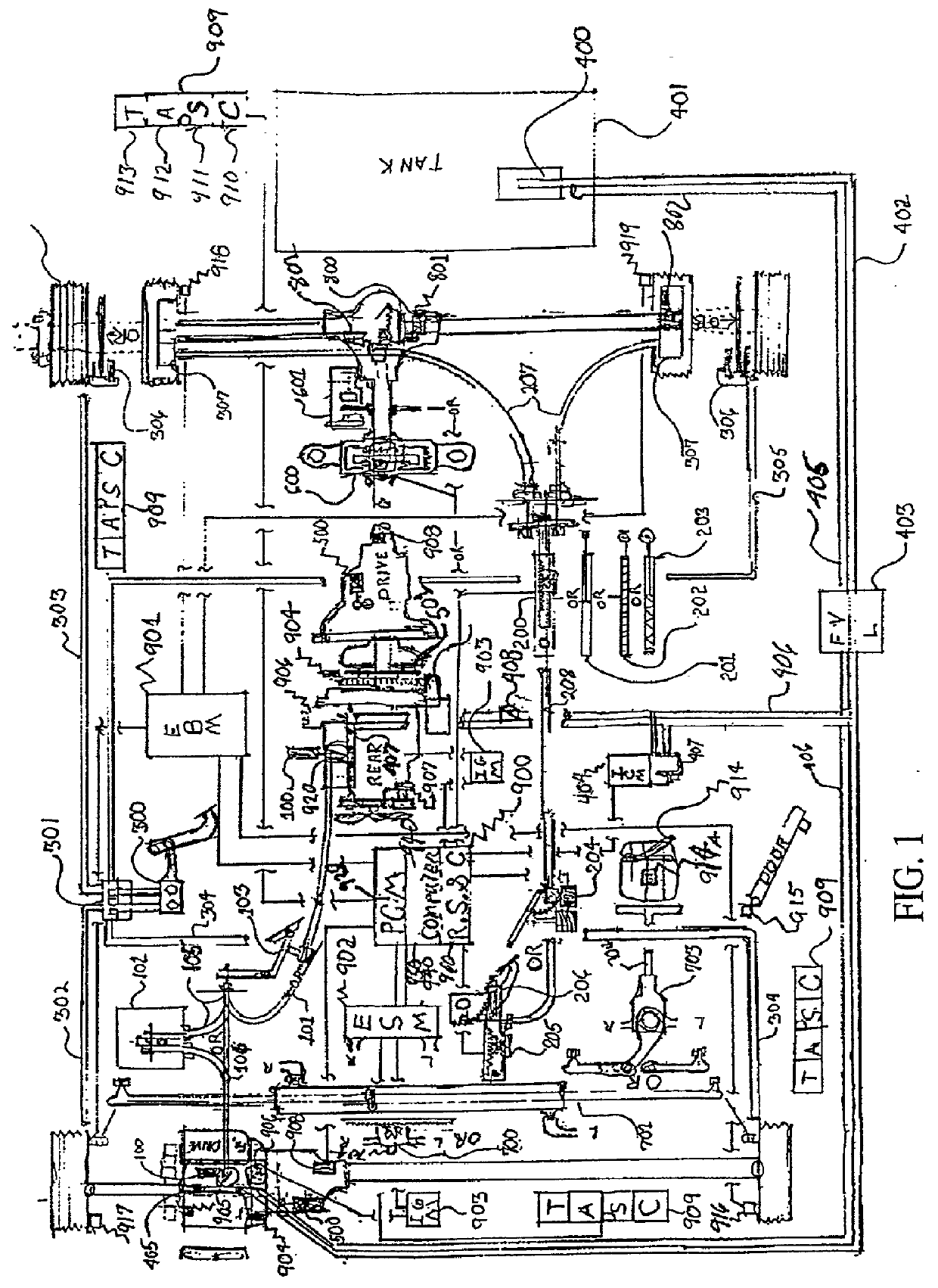

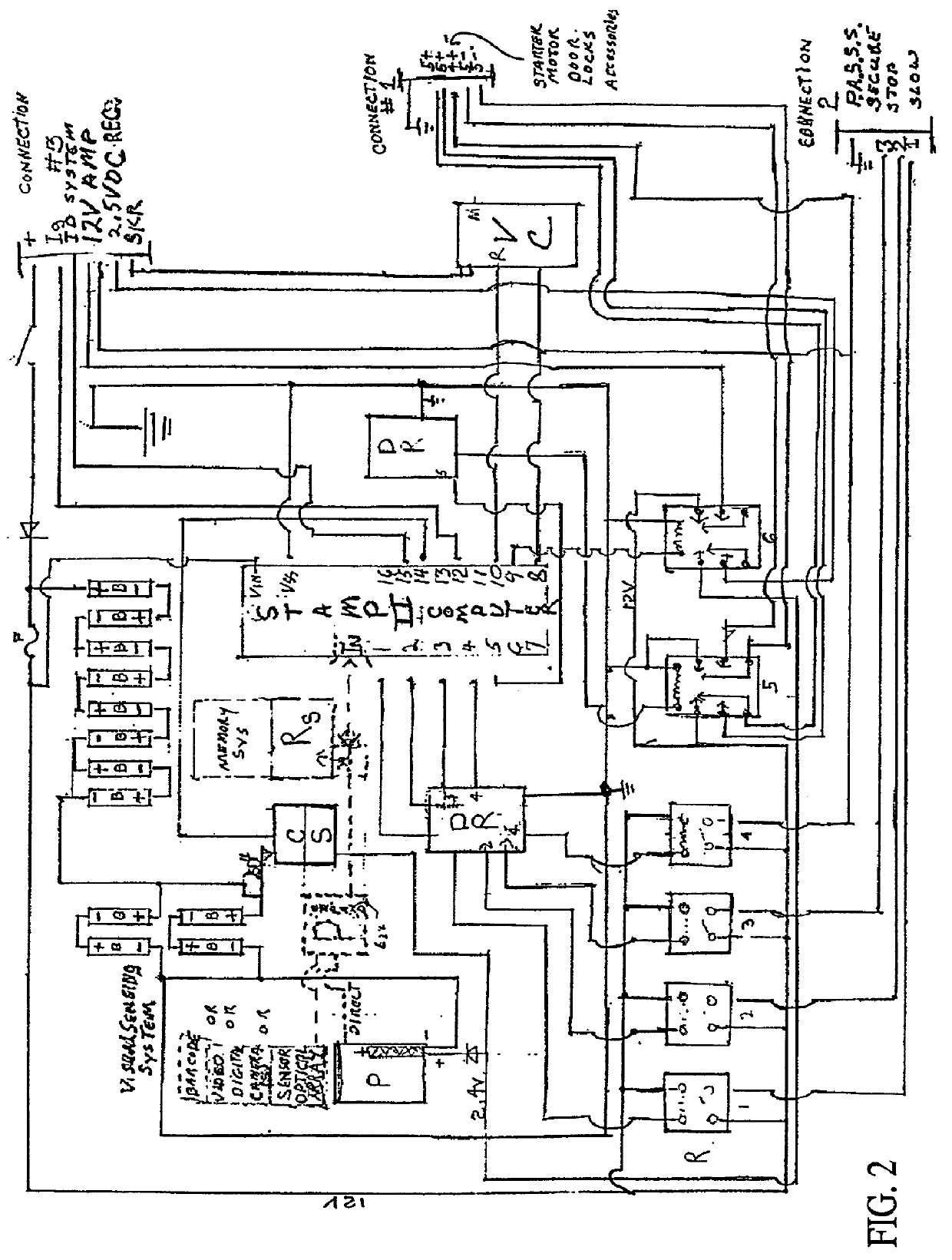

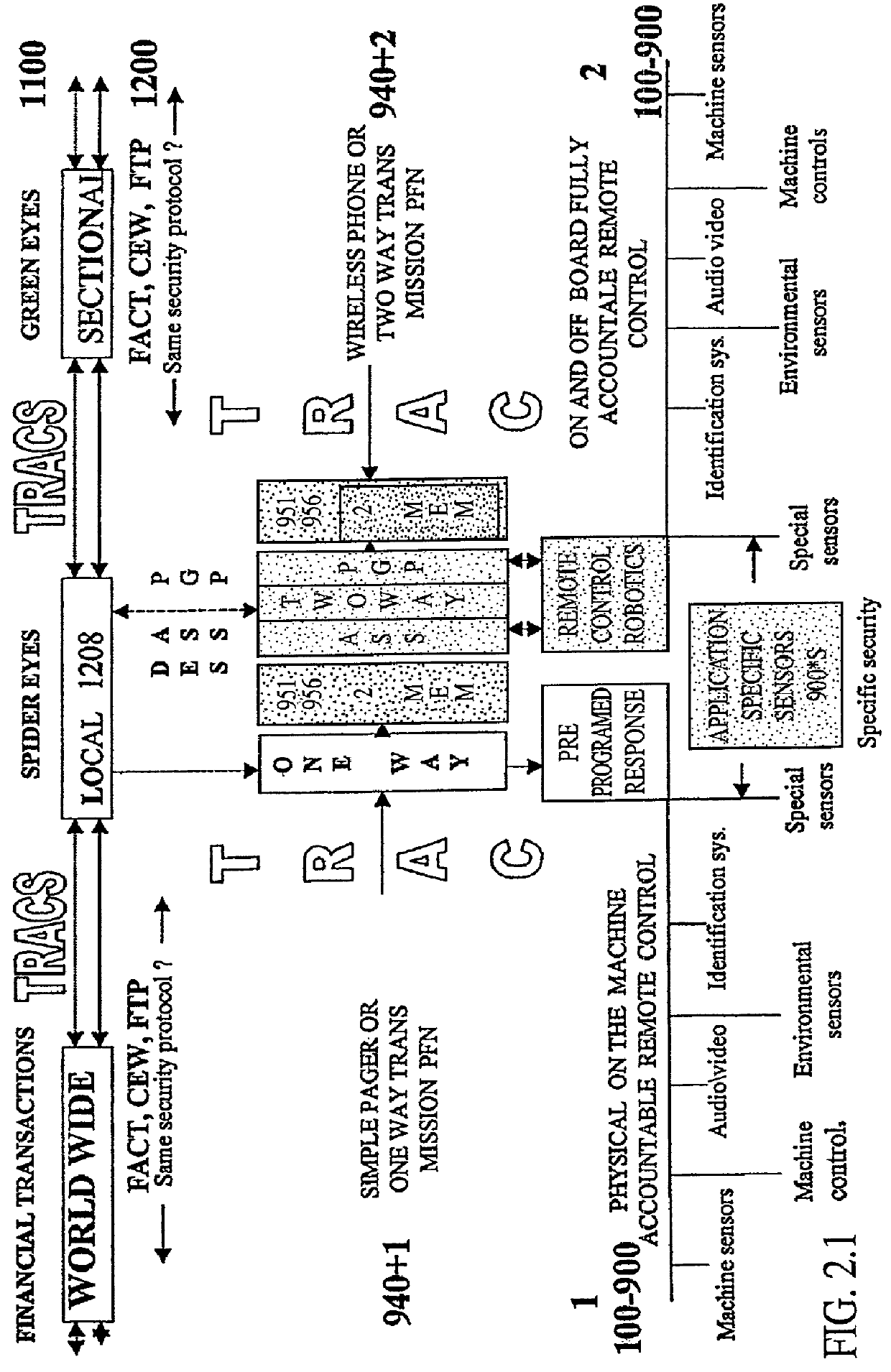

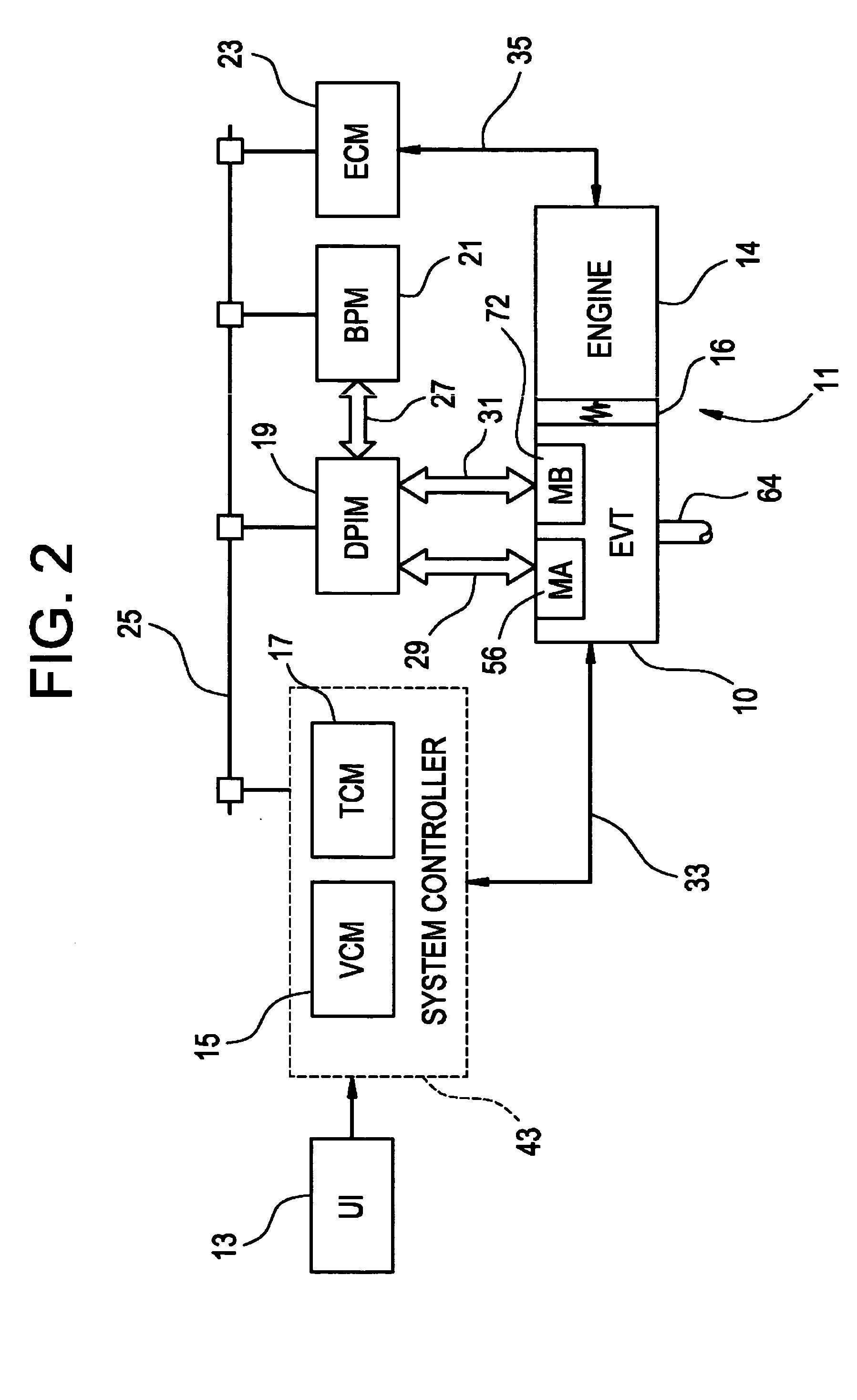

Electrically controlled automated devices to control equipment and machinery with remote control and accountability worldwide

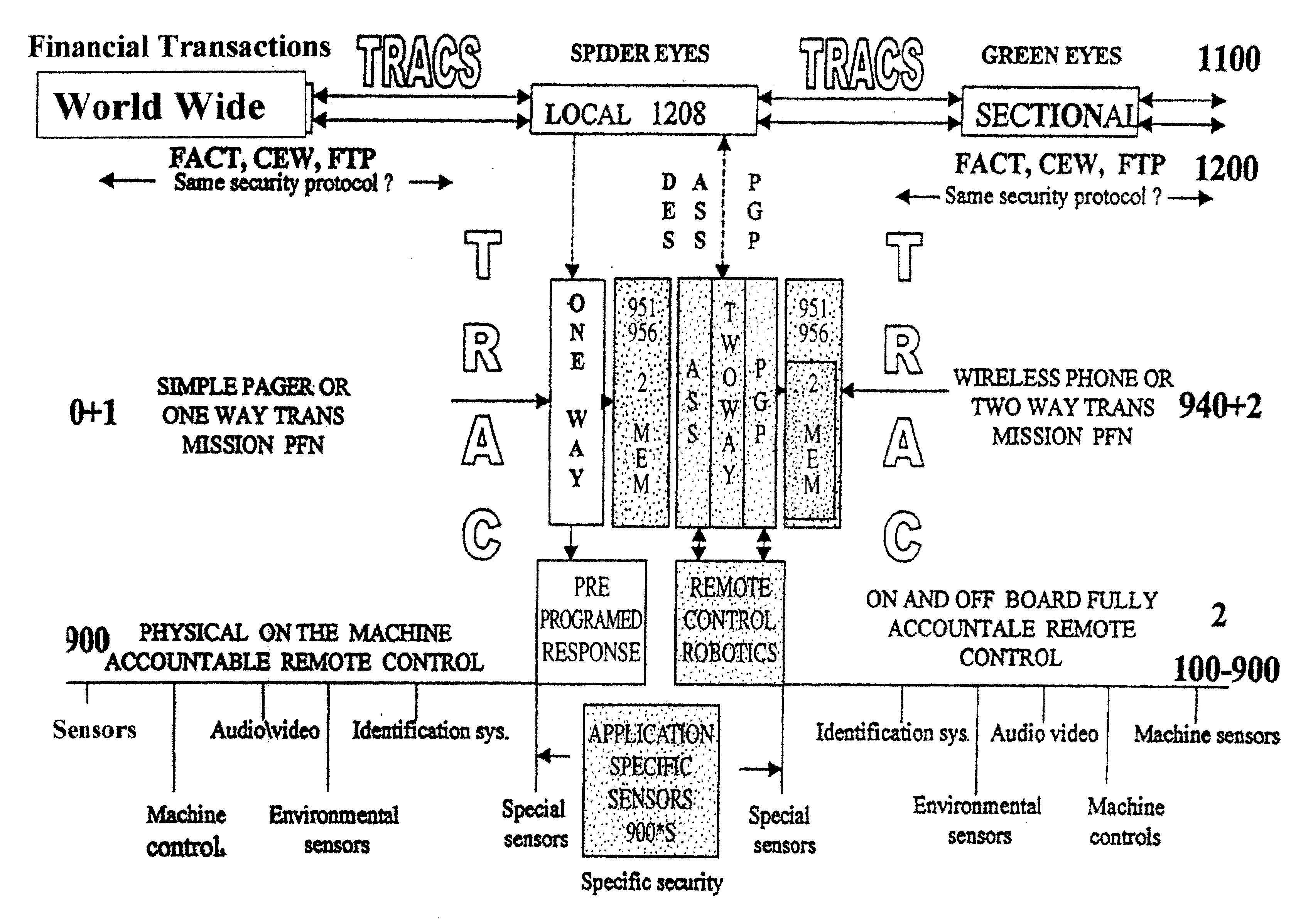

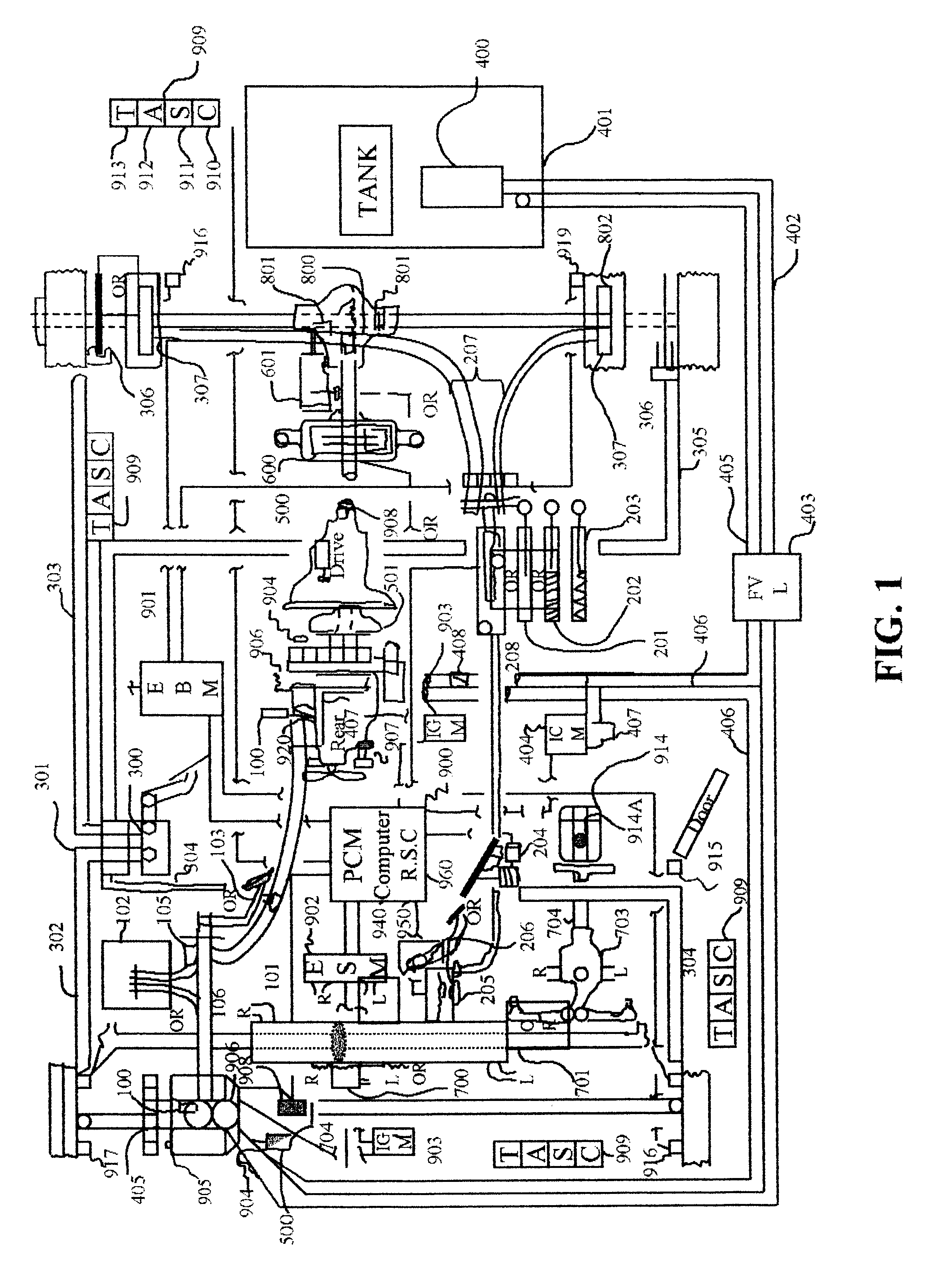

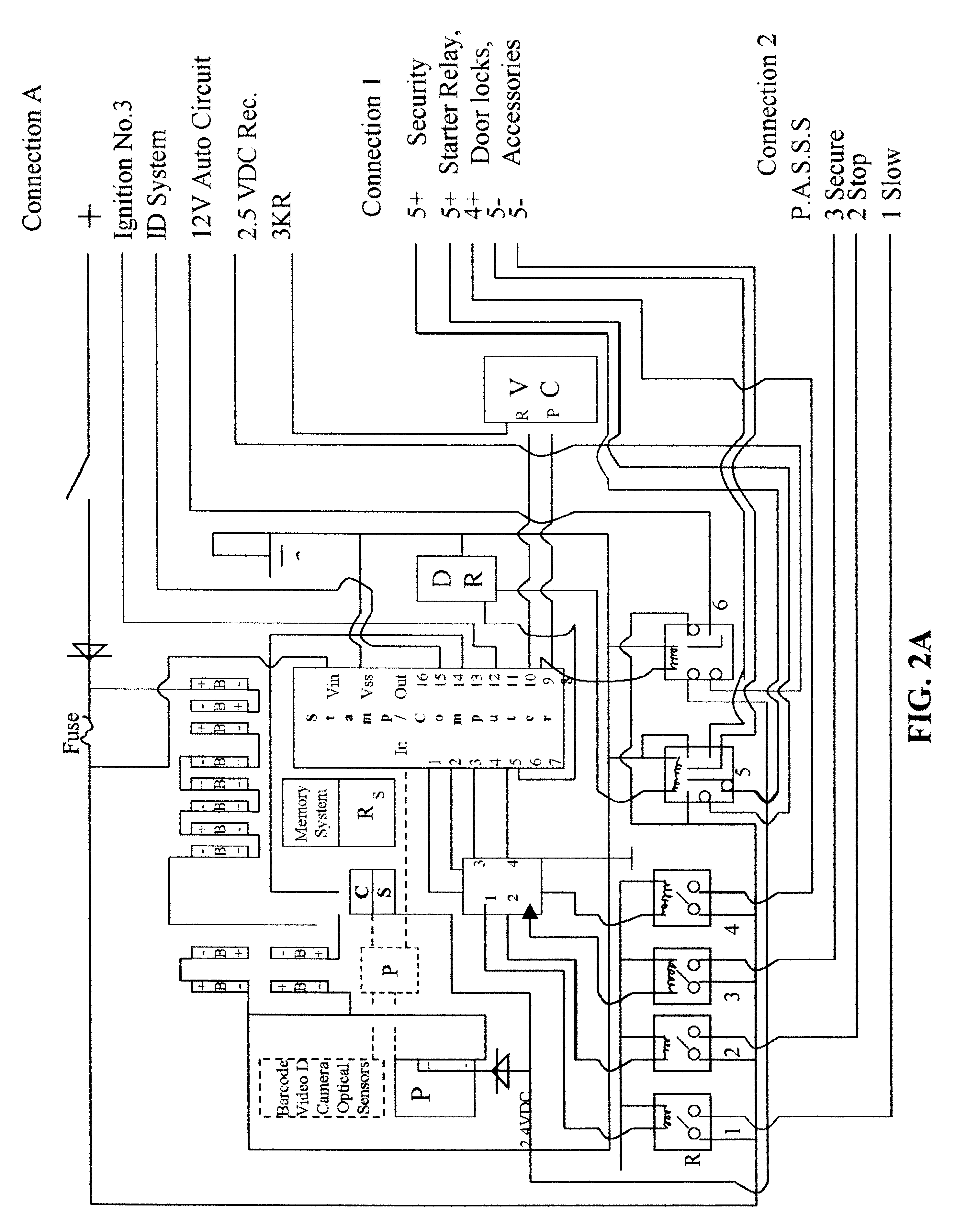

This application describes completely in many unique ways and detail all the devices to reduce a vehicle's speed and / or reduce a machines RPMs and / or stop any piece of equipment's as well as guide it if mobile through automated controls. First to slow it down, and guide it and / or control it if necessary (i.e., other pieces of equipment). Secondly it discusses how to stop any piece of equipment completely. And thirdly, the invention secures it in a safe stationary position either entirely or any number of specific moving parts. Many of these systems are initially here described to slow, reduce speed, steer, stop and / or secure equipment functions. However, they also can be used to increase a piece of equipment's functions. In other words their variations are completely capable to serve any remote or automated controls on a vehicle in the future to provide full robotics systems, e.g., for automated transportation systems, automated manufacturing, etc., either through individually isolated remote control systems and / or interfaced with other off-board systems through communication links, gateway computers, computer networks and the world wide web for inexpensive long distance monitoring and remote control. The invention focuses on the automobile industry but as has always been maintained throughout all these applications these devices and systems are designed to control every piece of equipment. The invention includes various accountable protocols and commercial developments to control speed, brake and steering for an automobile shut down to be performed through automation to a safe controlled secured deactivated state to be considered as a basis for a standard in aggressive vehicle remote control and / or to control and guide a vehicle and / or piece of equipment through many different automated systems.

Owner:KLINE & WALKER

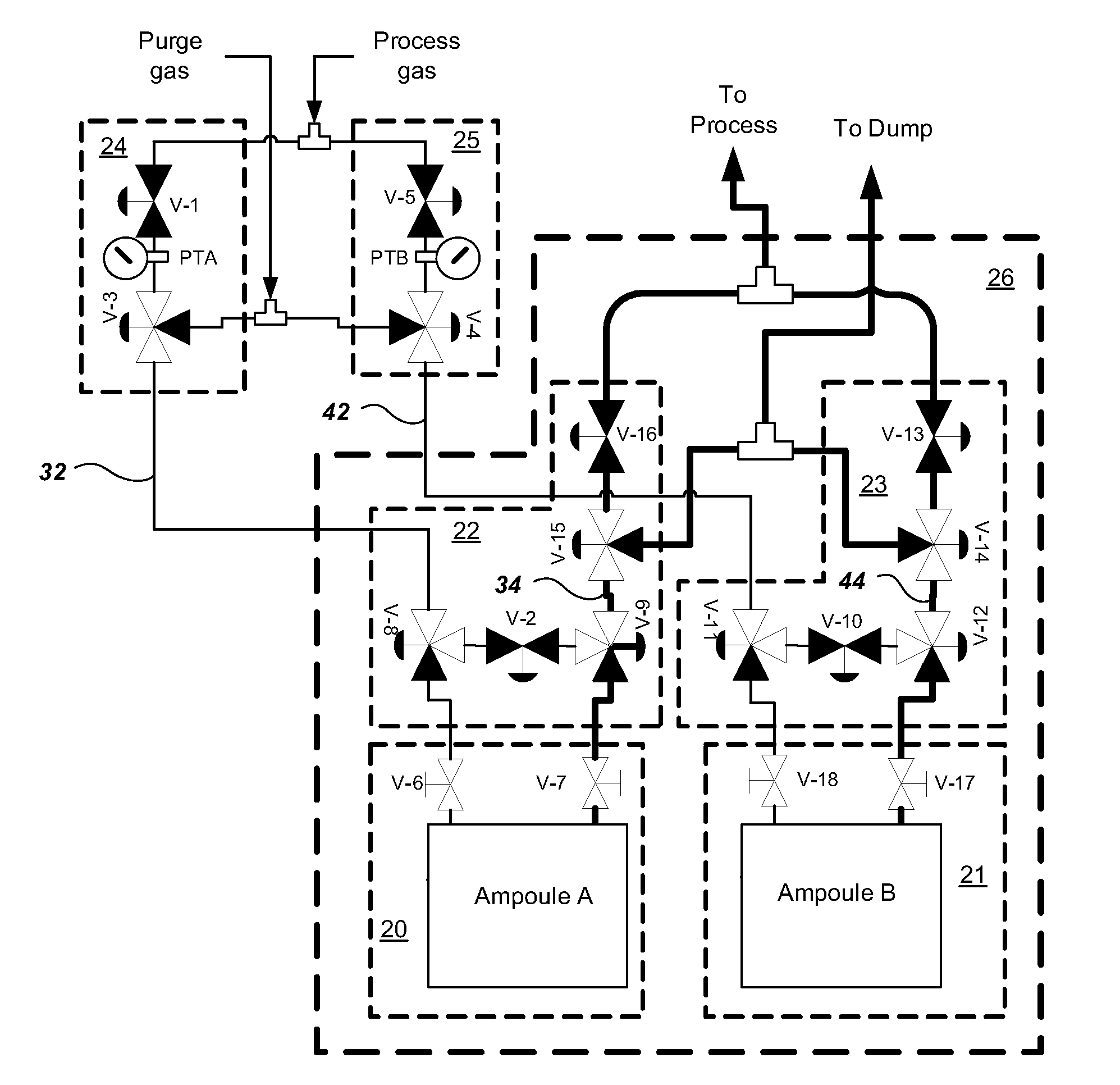

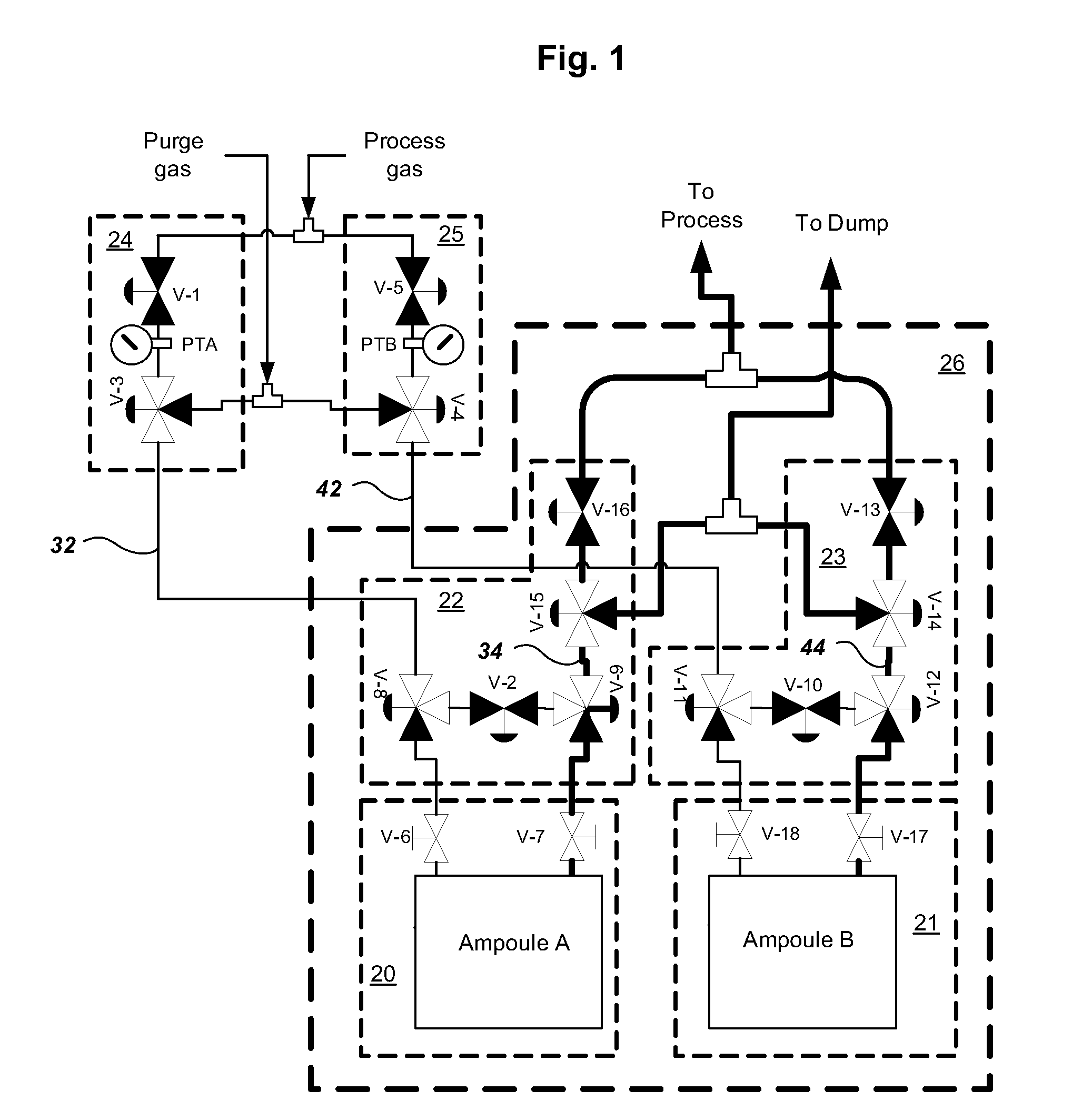

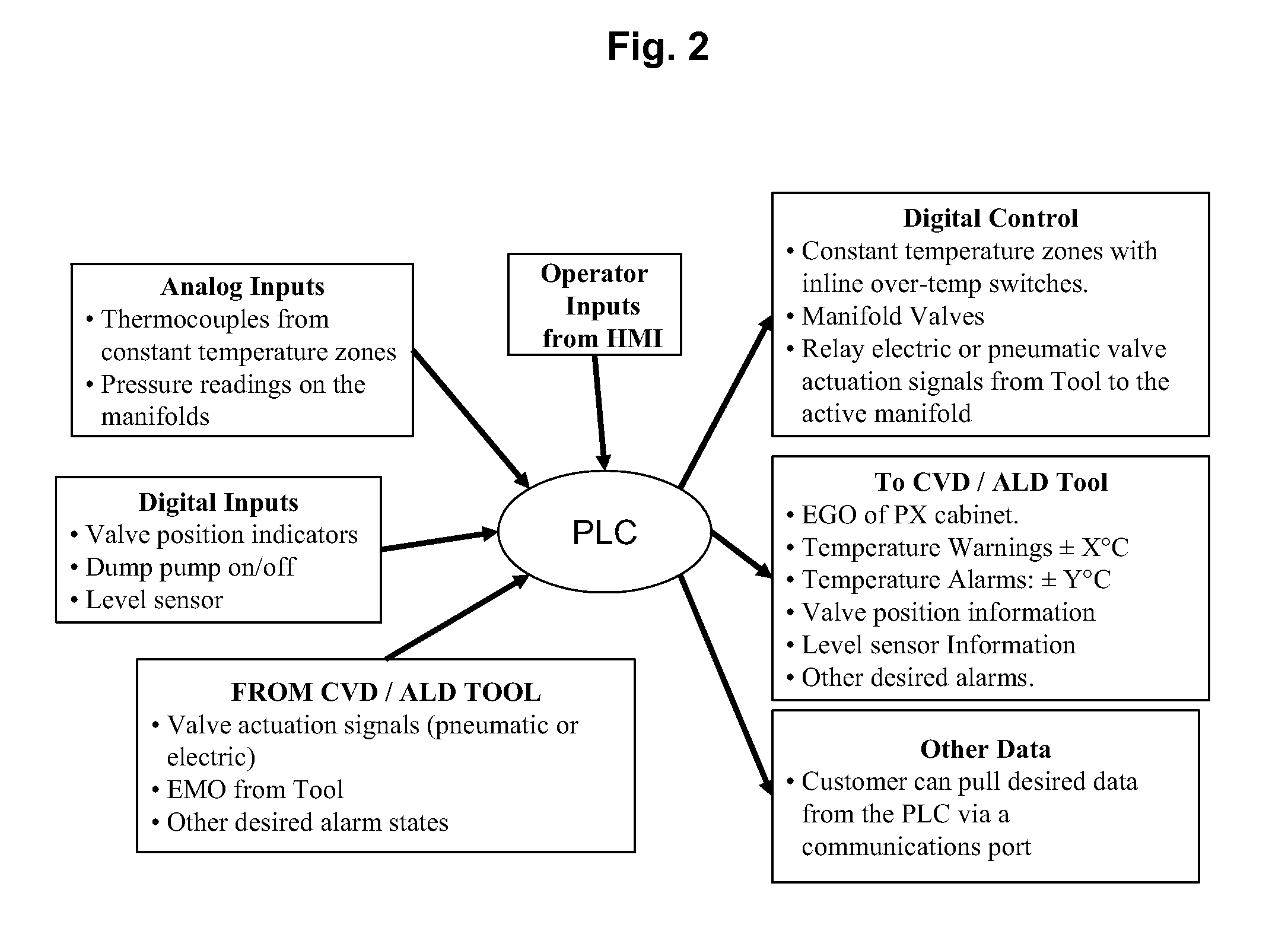

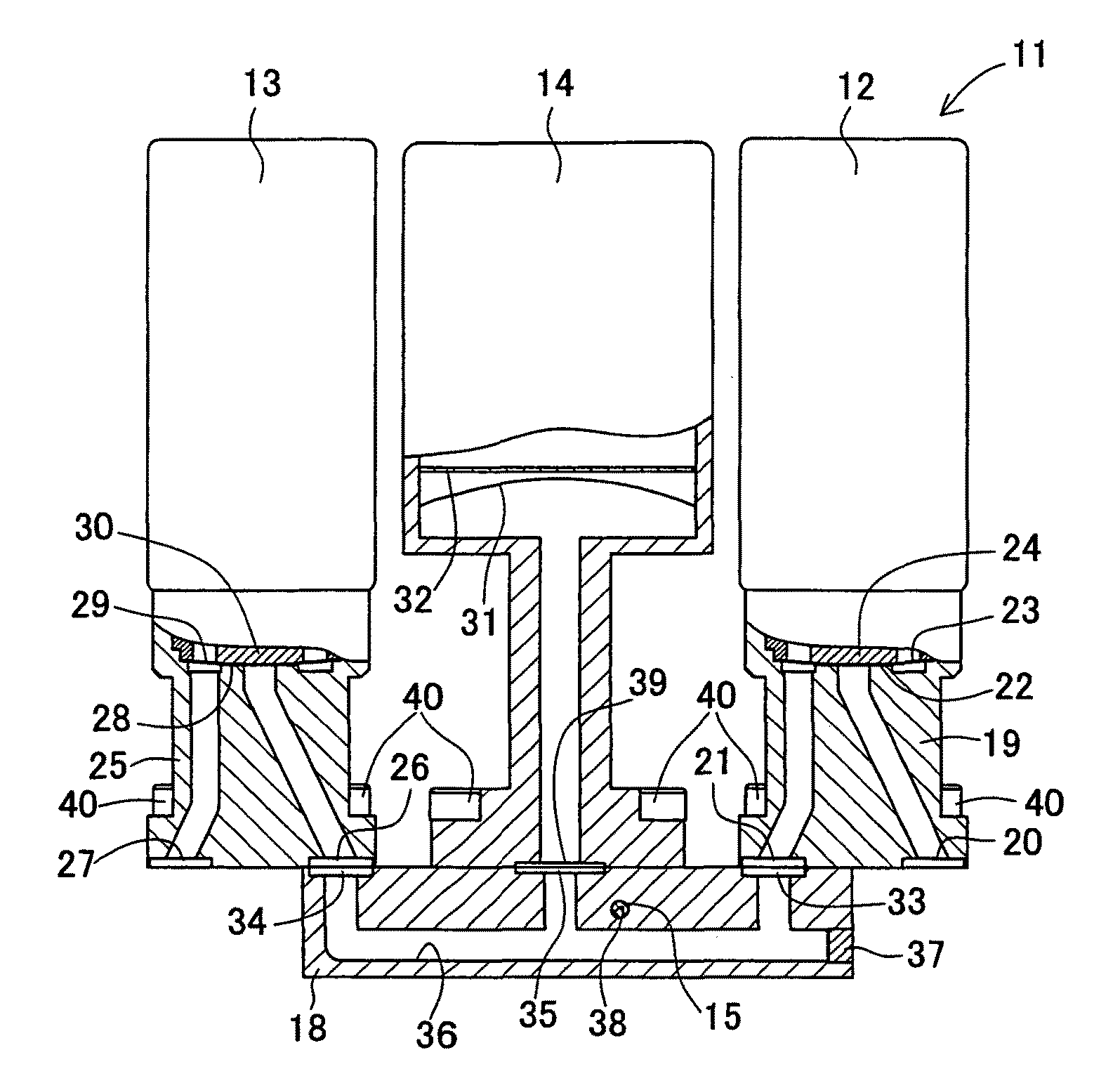

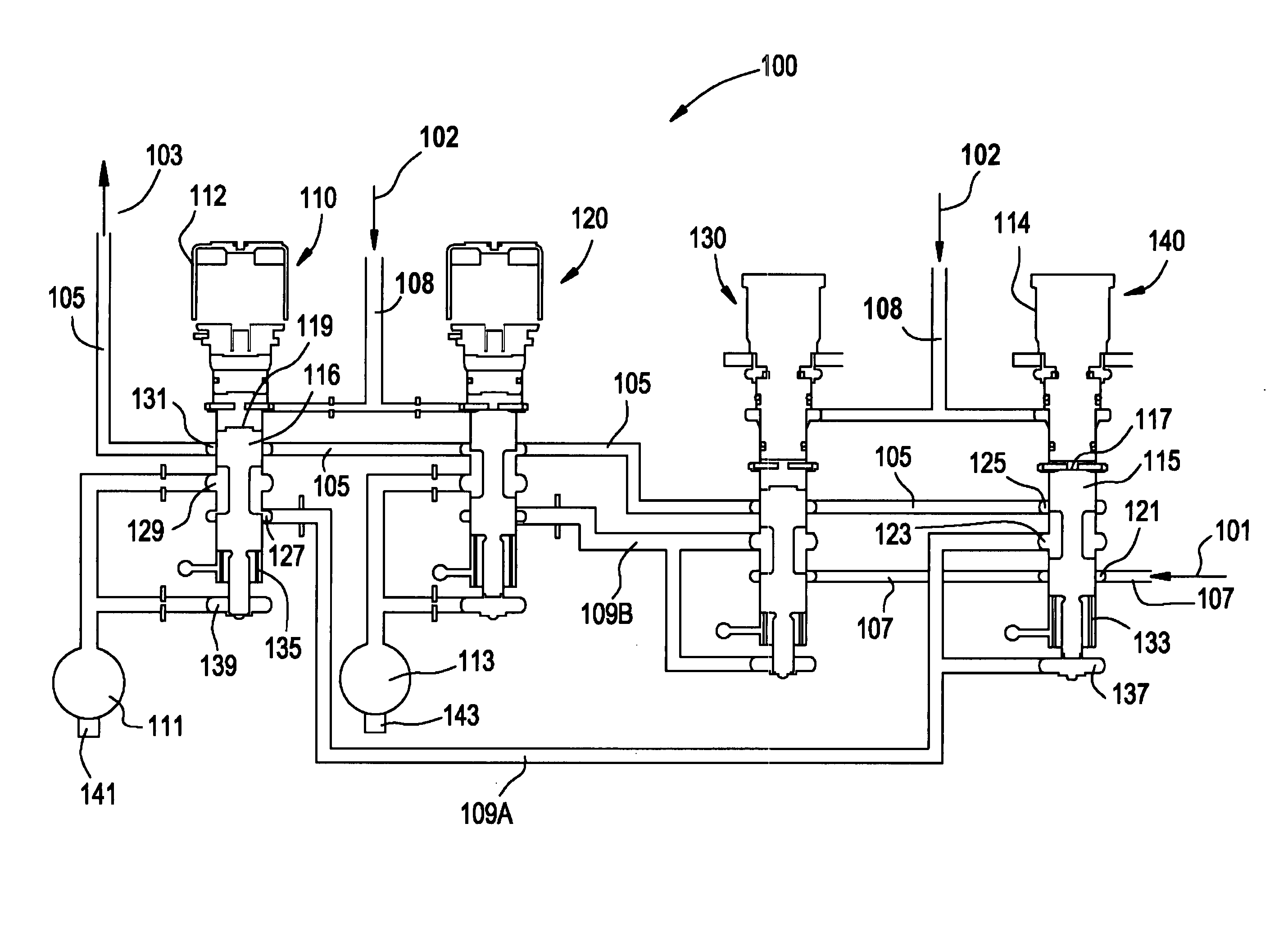

Multiple ampoule delivery systems

InactiveUS20090211525A1Easy to useReduce wasteLiquid surface applicatorsPipeline systemsSemiconductor materialsDelivery system

This invention relates to an integrated vapor or liquid phase reagent dispensing apparatus having a plurality of vessels and a plurality of carrier or inert gas feed / vapor or liquid phase reagent delivery manifolds, that may be used for continuously dispensing vapor or liquid phase reagents such as precursors for deposition of materials in the manufacture of semiconductor materials and devices.

Owner:PRAXAIR TECH INC

Electrically controlled automated devices to operate, slow, guide, stop and secure, equipment and machinery for the purpose of controlling their unsafe, unattended, unauthorized, unlawful hazardous and/or legal use, with remote control and accountability worldwide

InactiveUS20010056544A1The degree of freedom becomes largerElectrical controlVehicle fittingsRobotic systemsRobotics

This application describes completely in many unique ways and detail all the devices to reduce a vehicle's speed and / or reduce a machines RPM's and / or stop any piece of equipment's as well as guide it if mobile through automated controls. First to slow it down, and guide it and / or control it if necessary (i.e., other pieces of equipment). Secondly it discusses how to stop any piece of equipment completely. And thirdly, the invention secures it in a safe stationary position either entirely or any number of specific moving parts. Many of these systems are initially here described to slow, reduce speed, steer, stop and / or secure equipment functions. However, they also can be used to increase a piece of equipment's functions. In other words their variations are completely capable to serve any remote or automated controls on a vehicle in the future to provide full robotics systems, e.g., for automated transportation systems, automated manufacturing, etc., either through individually isolated remote control systems and / or interfaced with other off-board systems through communication links, gateway computers, computer networks and the world wide web for inexpensive long distance monitoring and remote control. The invention focuses on the automobile industry but as has always been maintained throughout all these applications these devices and systems are designed to control every piece of equipment. The invention includes various accountable protocols and commercial developments to control speed, brake and steering for an automobile shut down to be performed through automation to a safe controlled secured deactivated state to be considered as a basis for a standard in aggressive vehicle remote control and / or to control and guide a vehicle and / or piece of equipment through many different automated systems.

Owner:KLINE & WALKER

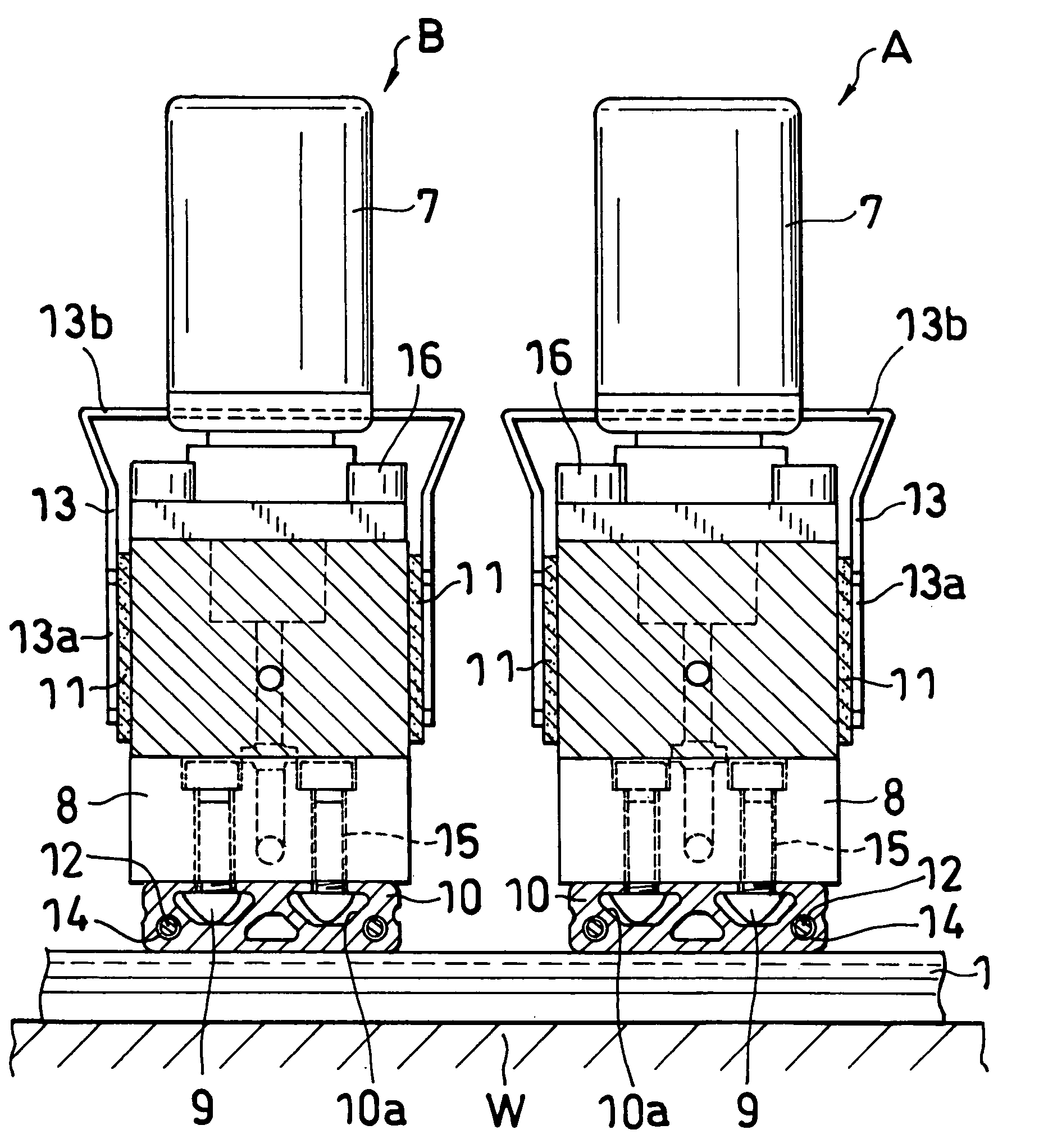

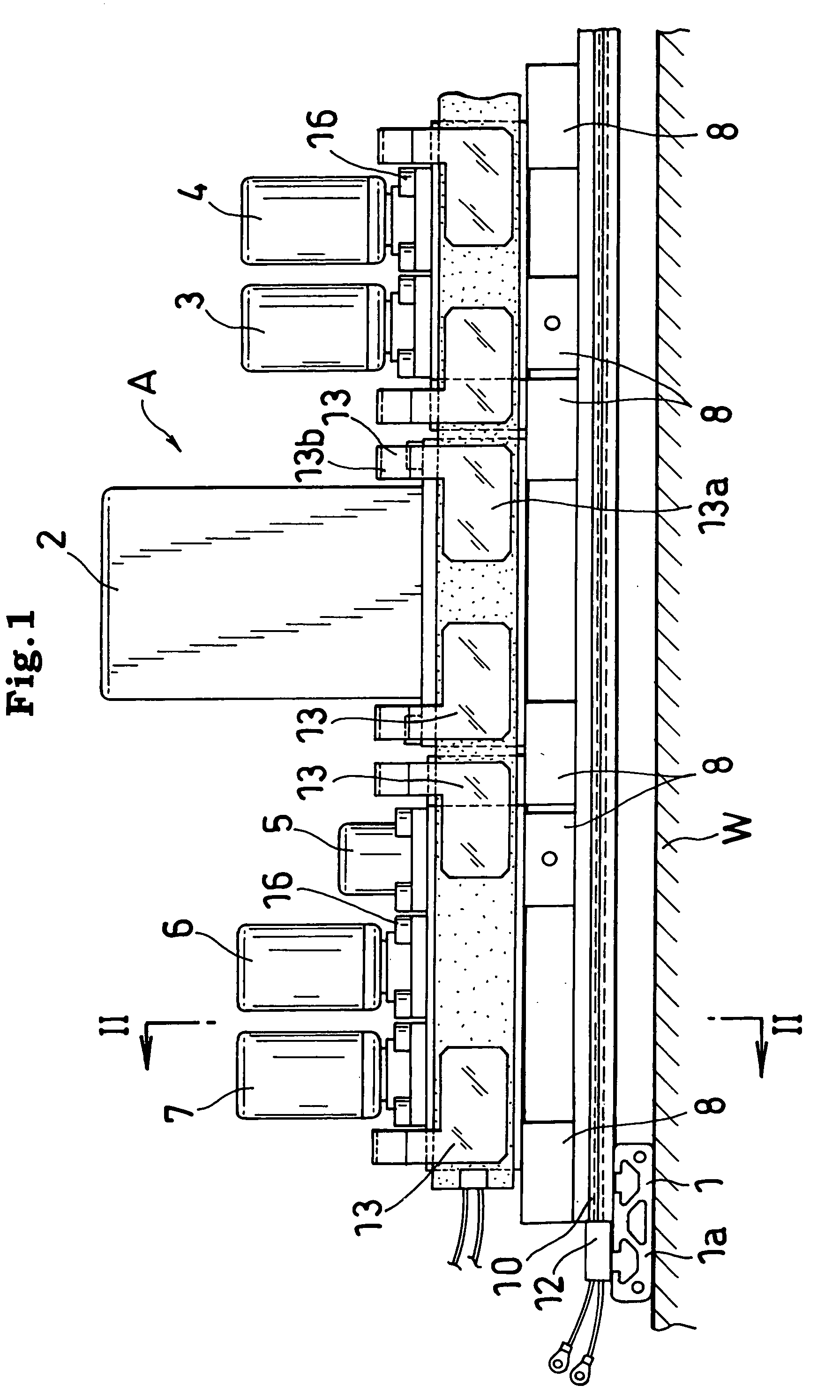

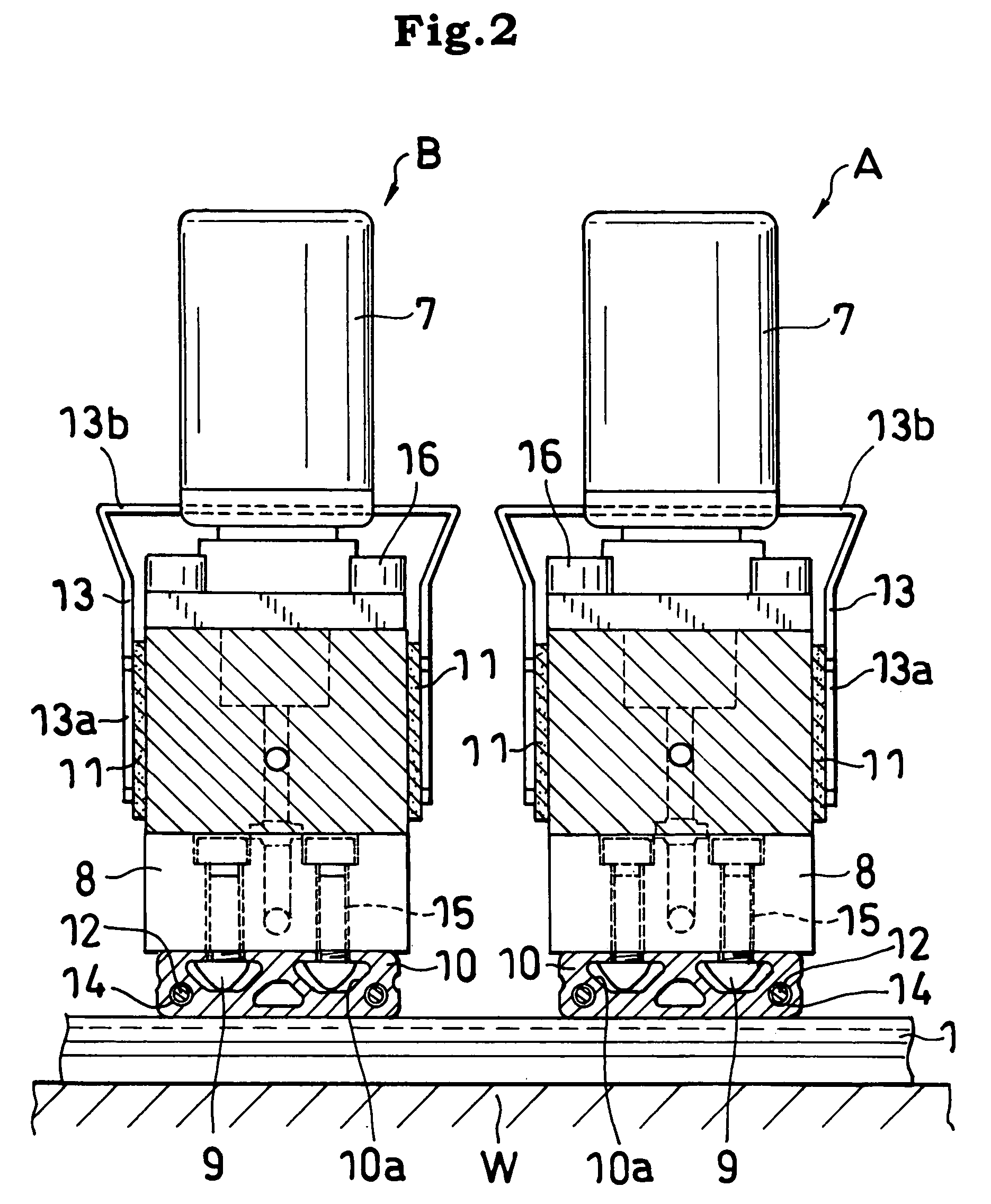

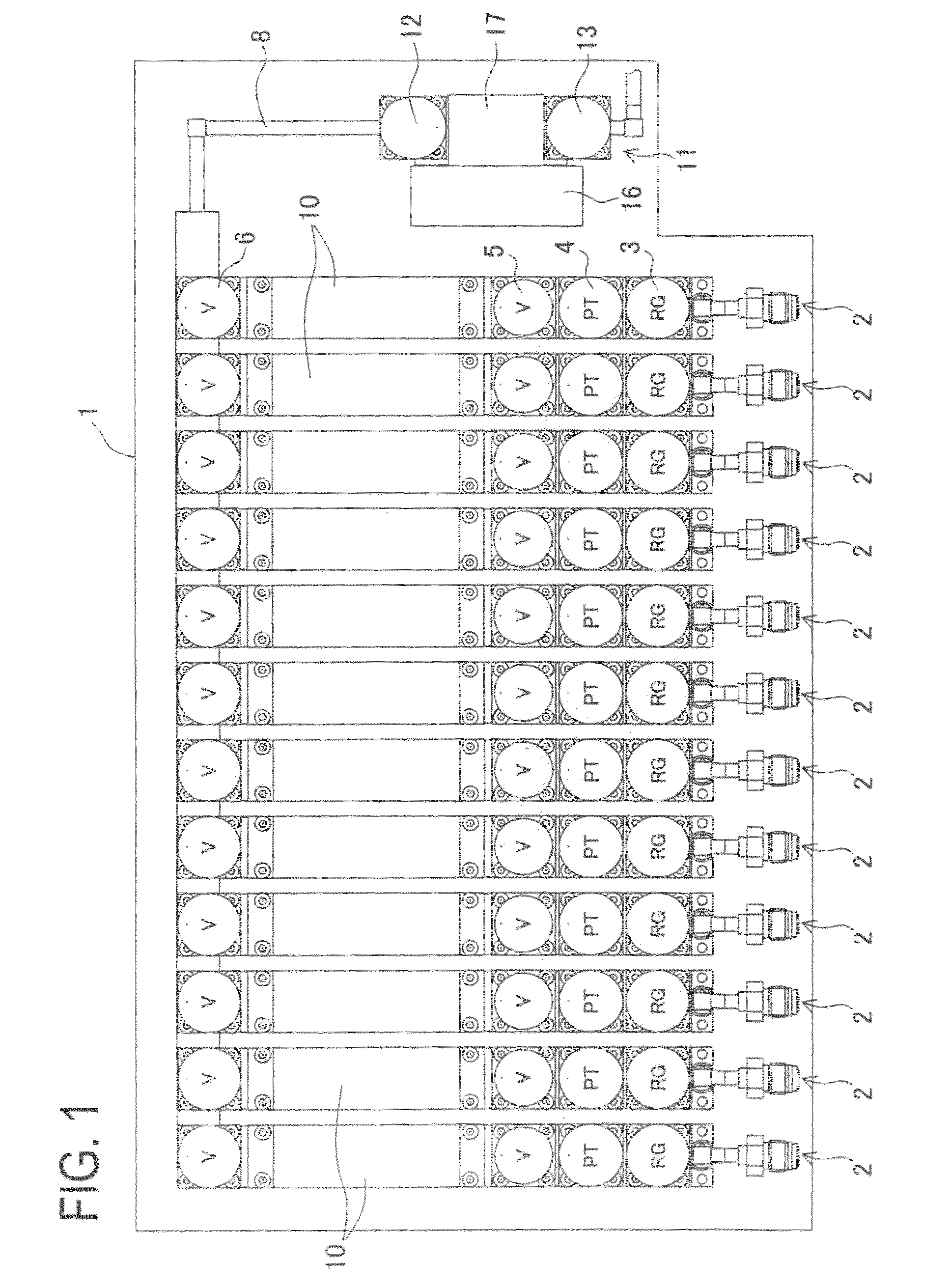

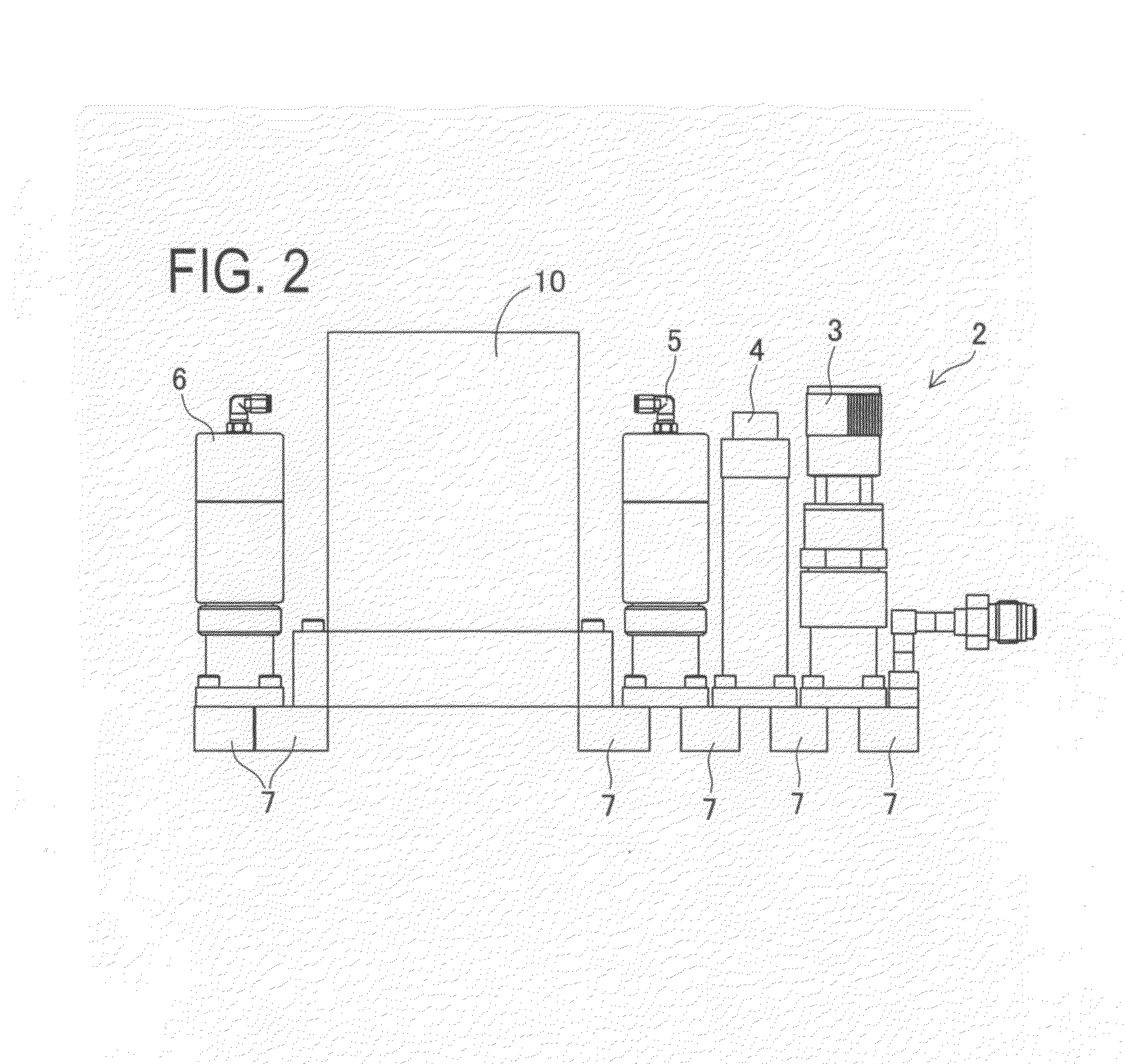

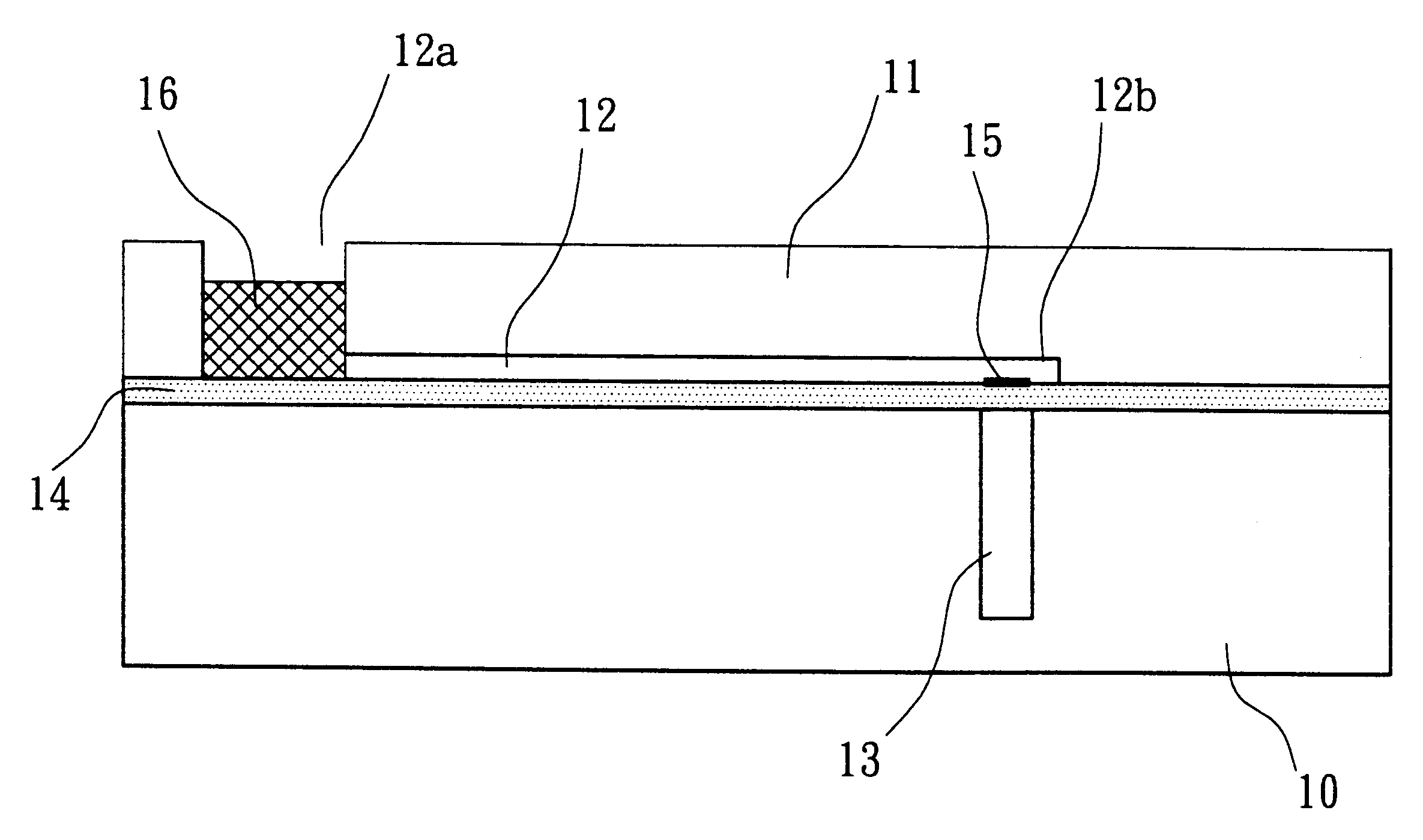

Fluid controller

InactiveUS20050229972A1Easy to assembleReadily availableValve members for heating/coolingServomotor componentsFluid controlPhysics

Each of lines A, B is provided on each of opposite sides thereof with a tape heater 11, and a space for positioning a tape heater holding clip 13 therein is provided in each of locations between adjacent fluid control devices. The tape heaters 11 are held from opposite sides thereof to the line by the clip 13. The lines A, B provided with the heaters are each mounted on a line support member 10 removably attached to a base member 1. The line support member 10 has a heater insertion bore 14 formed therein and extending longitudinally thereof. A sheath heater 12 is inserted into the bore 14.

Owner:CKD +1

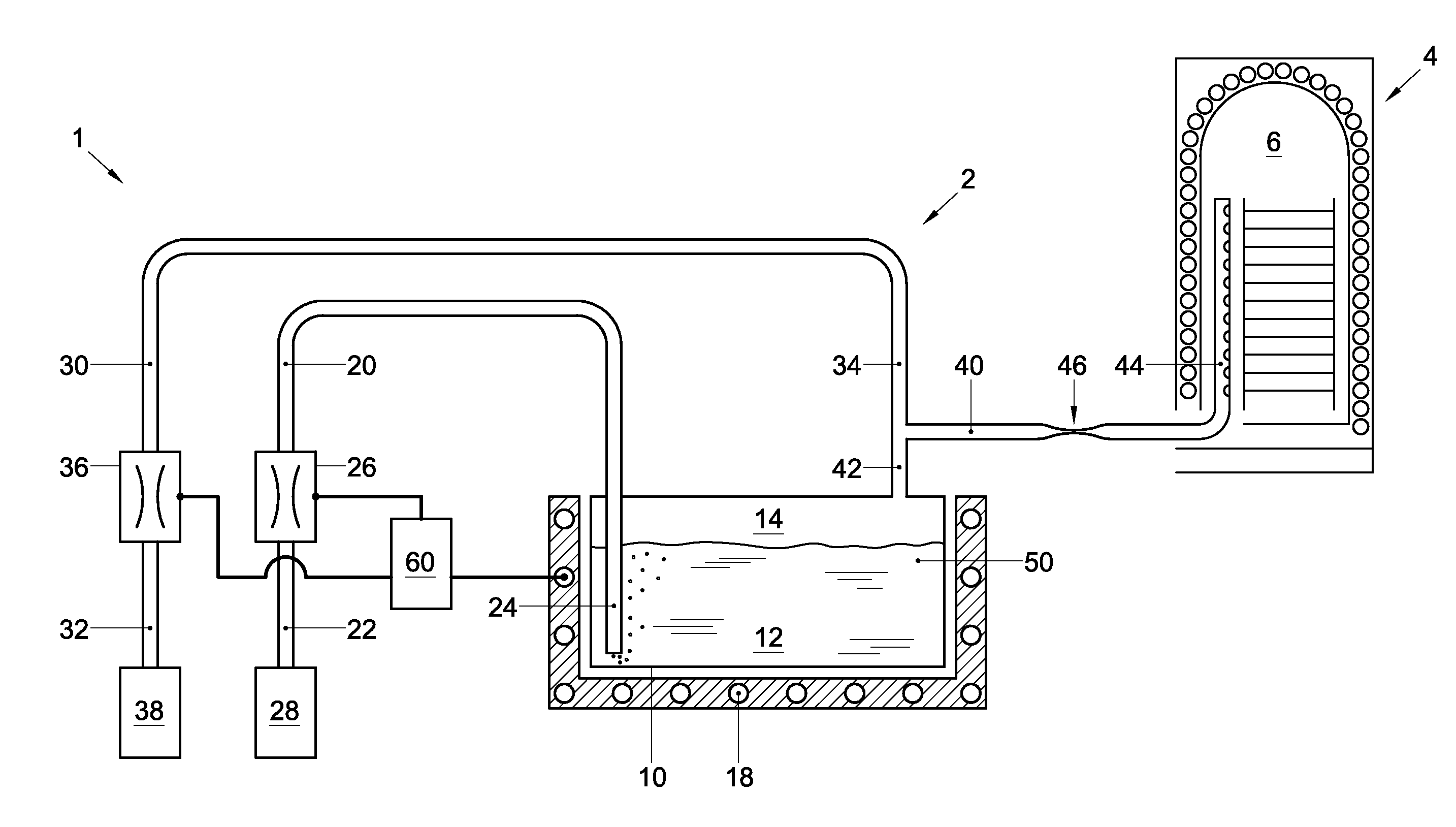

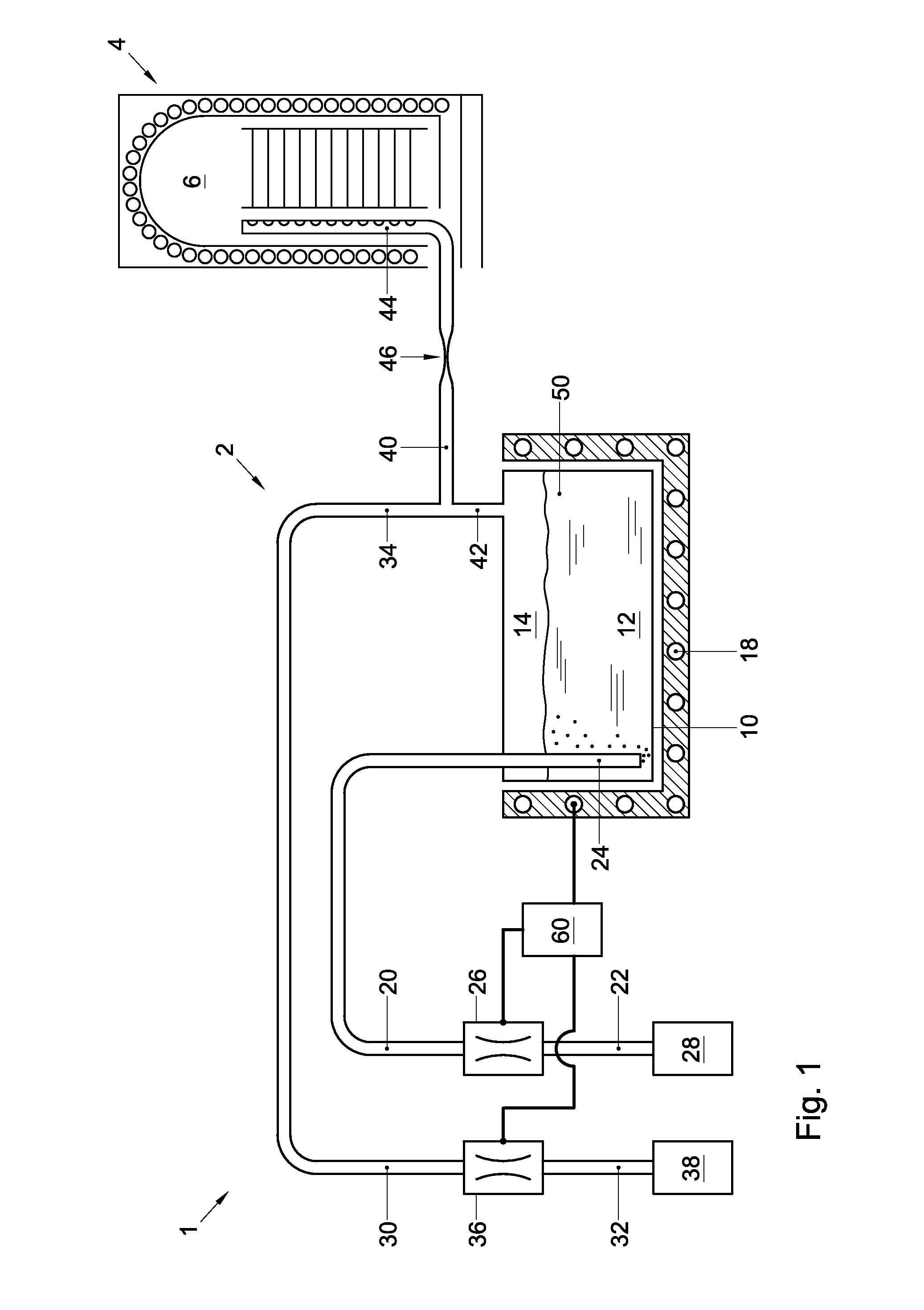

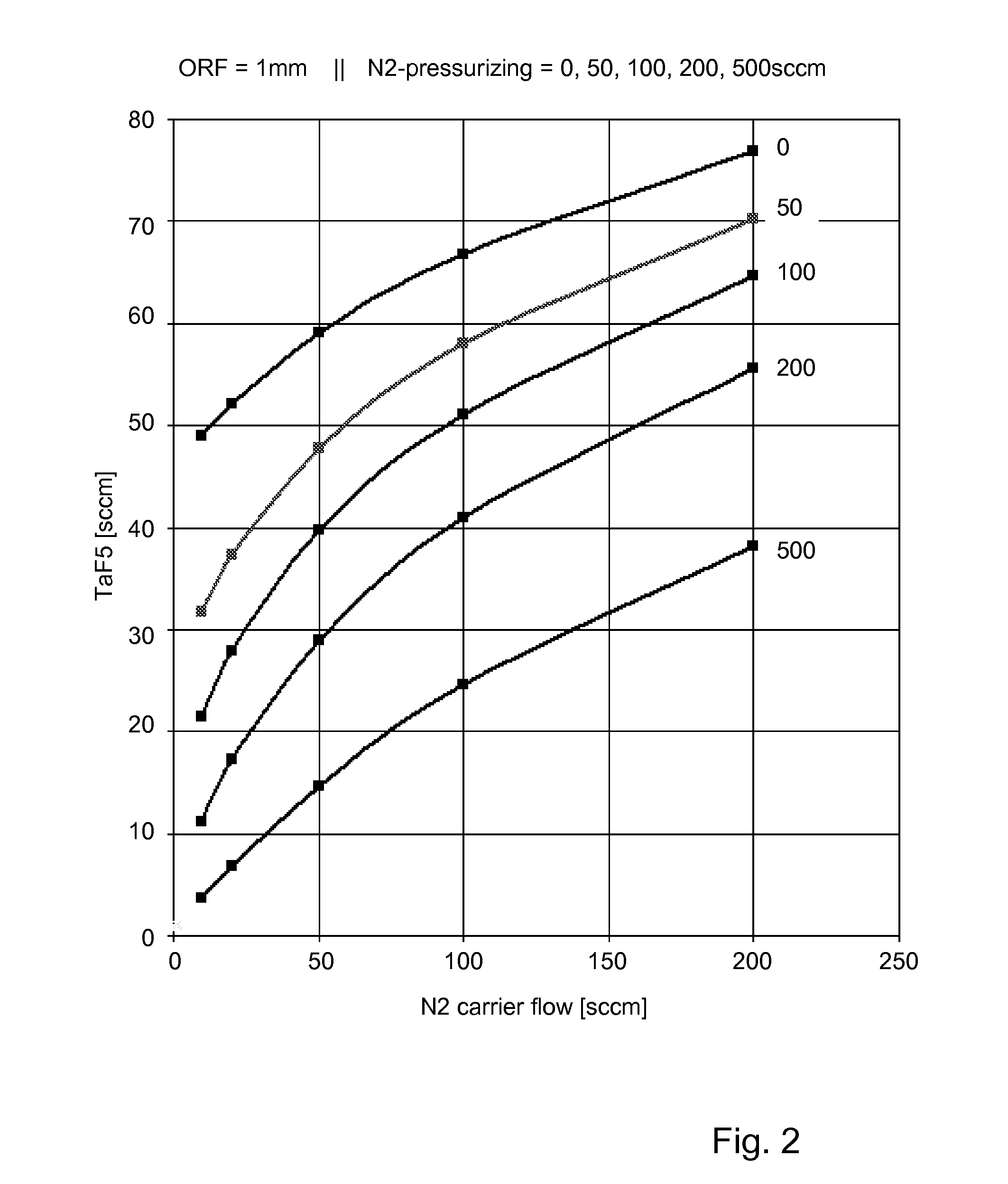

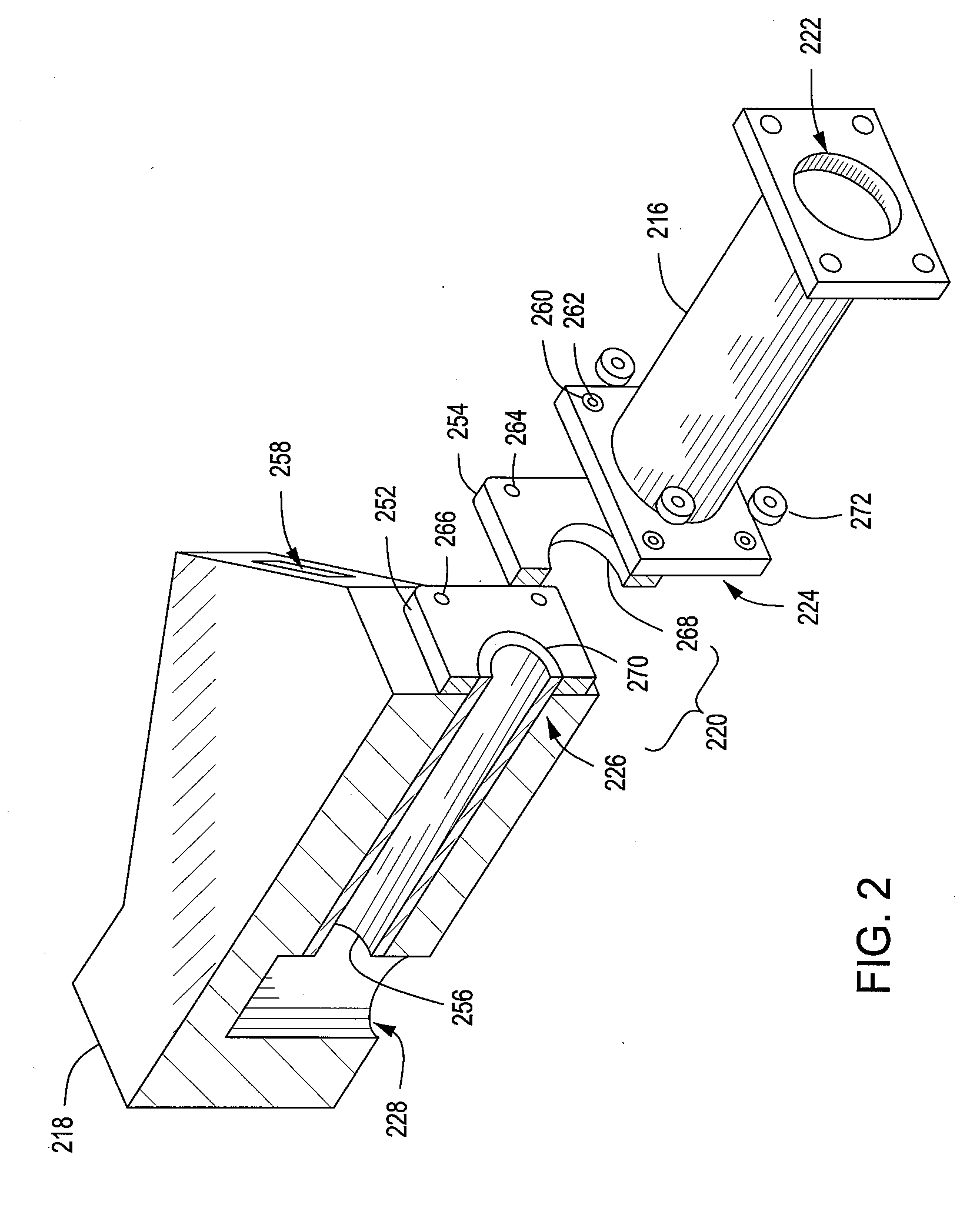

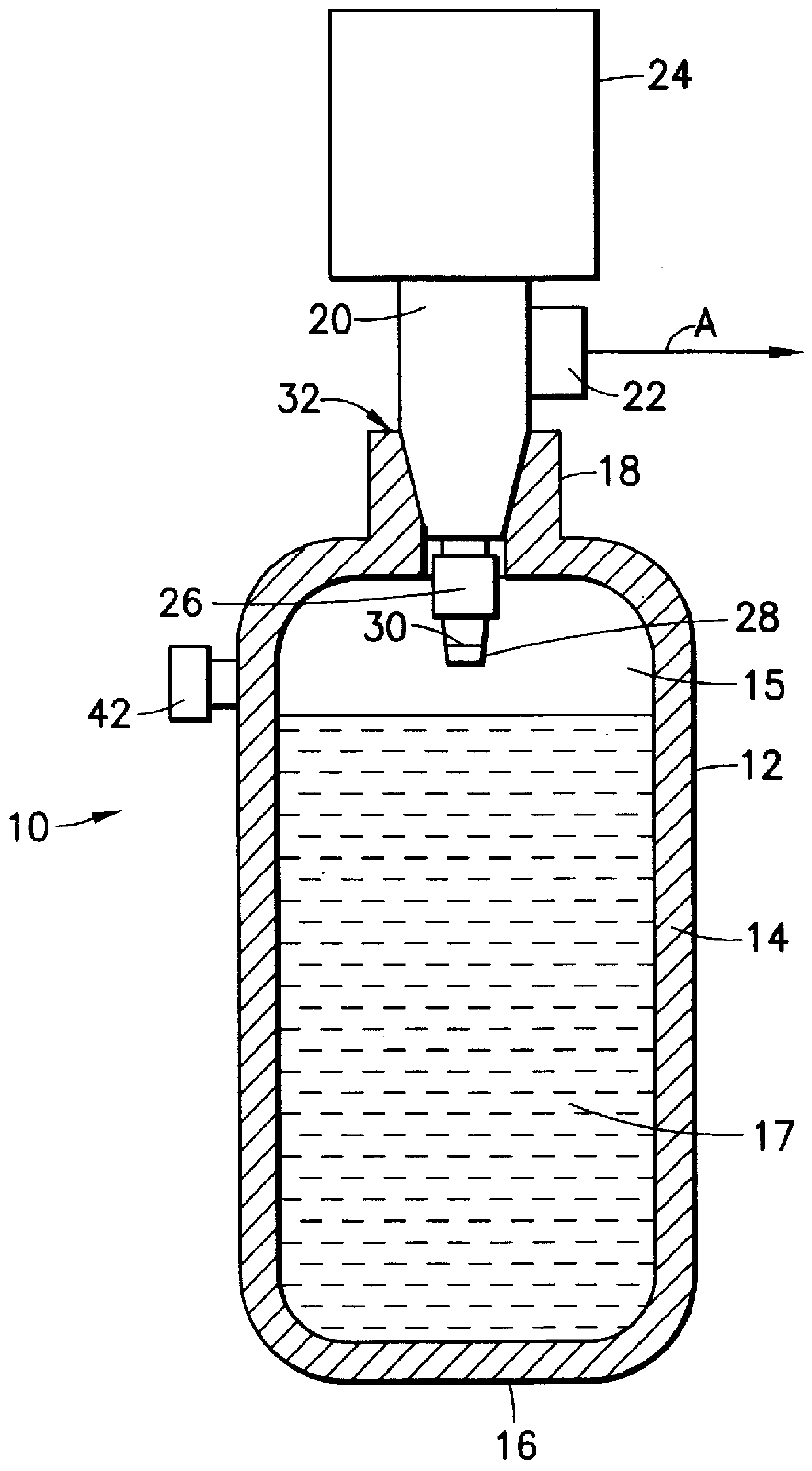

Bubbler assembly and method for vapor flow control

InactiveUS20120304935A1Mitigate and overcomeLess expensiveUsing liquid separation agentMixing methodsSource materialEngineering

Disclosed is a bubbler assembly. The bubbler assembly includes a vessel configured to contain a liquid source material and its vapor. It also includes a carrier gas supply line, a downstream end of which discharges in a lower portion of the vessel, and a gas outlet line, an upstream end of which is in fluid communication with an upper portion of the vessel. The gas outlet line includes a constriction. The bubbler assembly further includes a pressurizing gas supply line, a downstream end of which discharges in either the upper portion of the vessel or in the gas outlet line at a point upstream of the constriction.

Owner:ASM INTERNATIONAL

Manifold assembly

Embodiments of a manifold assembly are provided herein. In some embodiments, a manifold assembly includes a first manifold having a first inlet, for coupling to a high temperature fluid source, and a first outlet; a second manifold having a second inlet and a second outlet; and a connector portion coupling the first outlet of the first manifold to the second inlet of the second manifold, the connector portion includes a polymer block; and a thermal isolator disposed between the polymer block and the first manifold.

Owner:APPLIED MATERIALS INC

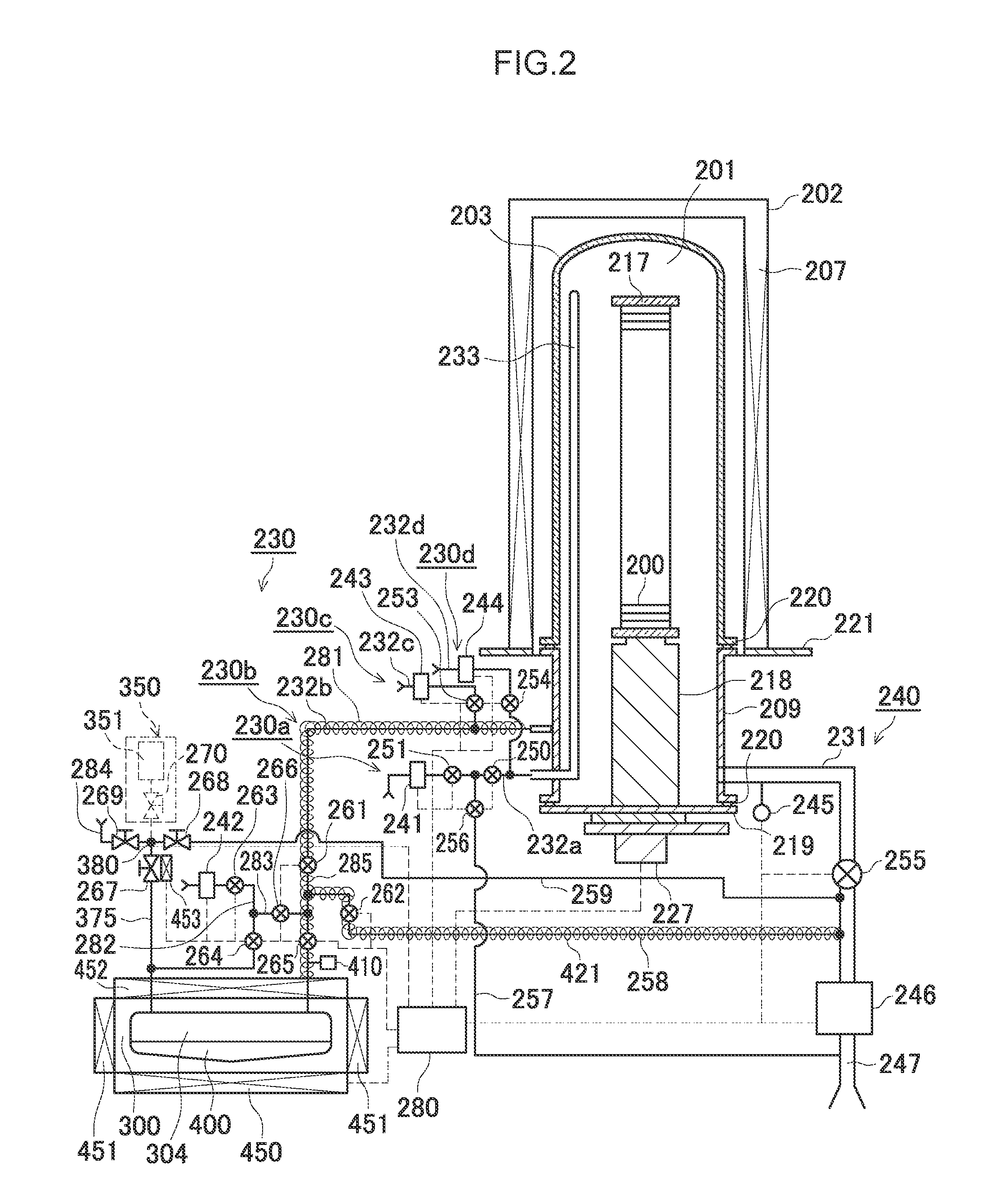

Substrate processing apparatus and solid raw material replenishing method

InactiveUS20120240858A1Simple configurationVacuum evaporation coatingSemiconductor/solid-state device manufacturingProduct gasProcess engineering

Disclosed is a substrate processing apparatus that includes: a processing chamber that accommodates a substrate; and a raw material supply system that sublimates a solid raw material to generate a gas raw material used for processing of the substrate, and supplies the generated gas raw material to the processing chamber. The raw material supply system includes: a solid raw material container that stores the solid raw material; a first piping connected between the solid raw material container and the processing chamber; and a second piping connected with the solid raw material container and equipped with an attachment portion to which a raw material replenishing container that holds the solid raw material for replenishment is attached.

Owner:KOKUSA ELECTRIC CO LTD +1

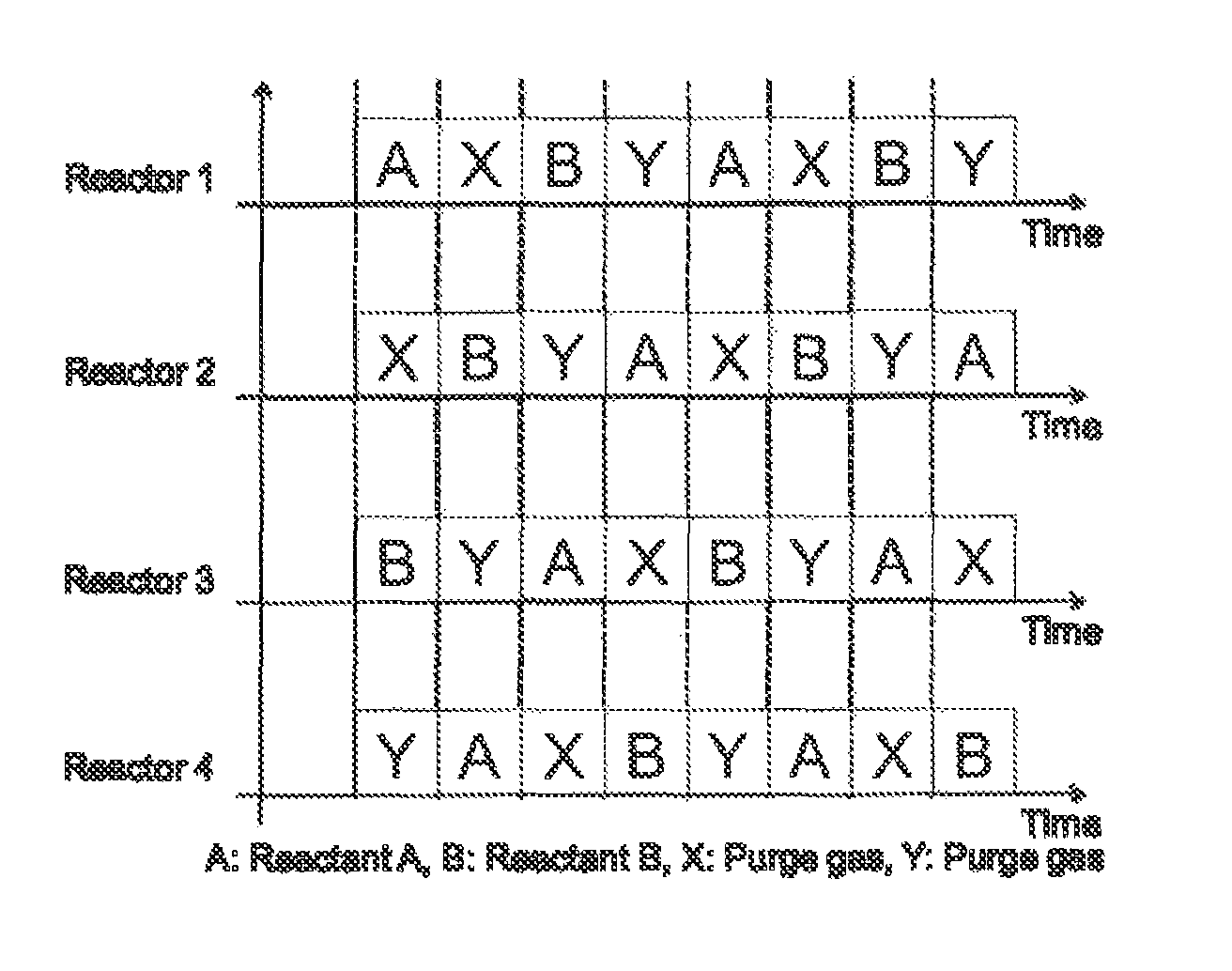

Method of parallel shift operation of multiple reactors

ActiveUS8911826B2Semiconductor/solid-state device manufacturingPipeline systemsProcess engineeringOutflow rate

A method of parallel shift operation of multiple reactors includes: (i) continuously supplying n gases numbered 1 to n simultaneously to n gas ports via n main gas lines, respectively, at a constant flow rate, wherein one of branch gas lines of each main gas line is in an open state so that the inflow rates of the respective reactors are equal, and the outflow rates of the respective reactors are equal; and (ii) while maintaining the inflow rates and the outflow rates of the respective reactors, simultaneously closing the one of the branch gas lines of each main gas line in the open state and opening another one of the branch gas lines of each main gas line so that different numbered gases are continuously supplied to the respective reactors in parallel without changing the inflow rates and the outflow rates of the reactors.

Owner:ASM IP HLDG BV

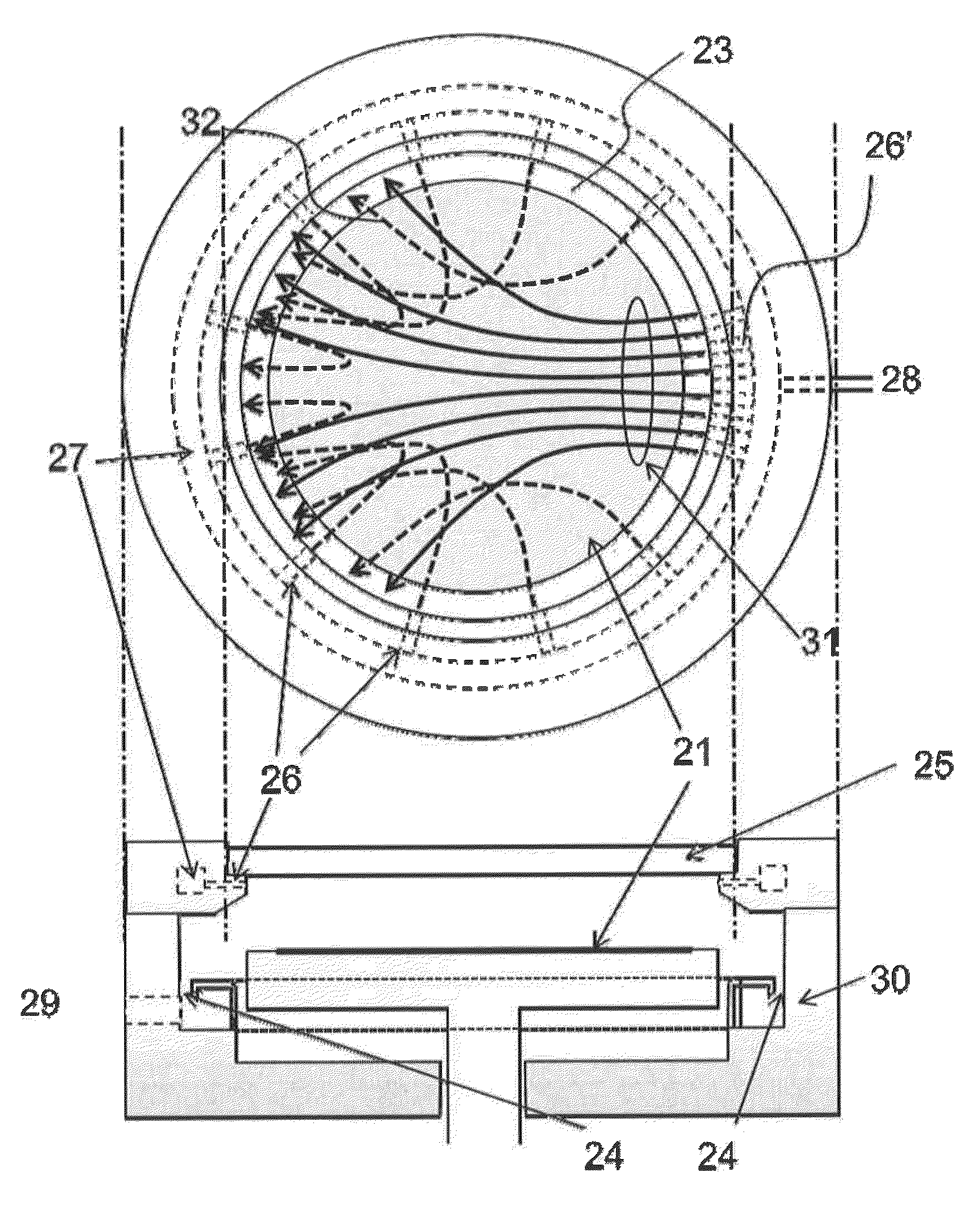

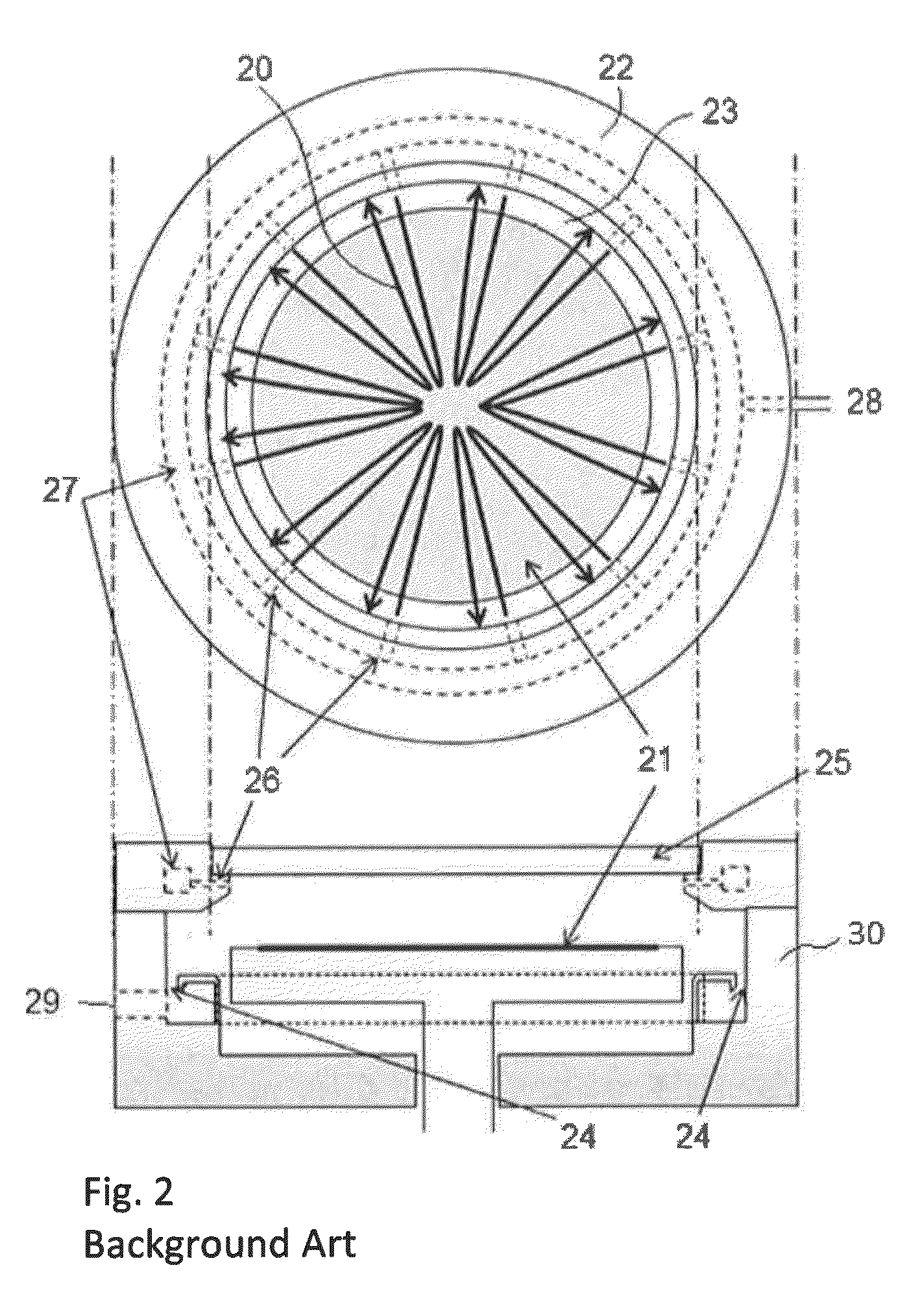

Method for supplying gas with flow rate gradient over substrate

ActiveUS8664627B1Reduce gradientIncrease concentrationMaterial analysis by optical meansPipeline systemsReaction chamberChemistry

A method for supplying gas over a substrate in a reaction chamber wherein a substrate is placed on a pedestal, includes: supplying a first gas from a first side of the reaction chamber to a second side of the reaction chamber opposite to the first side; and adding a second gas to the first gas from sides of the reaction chamber other than the first side of the reaction chamber so that the second gas travels from sides of the substrate other than the first side in a downstream direction.

Owner:ASM IP HLDG BV

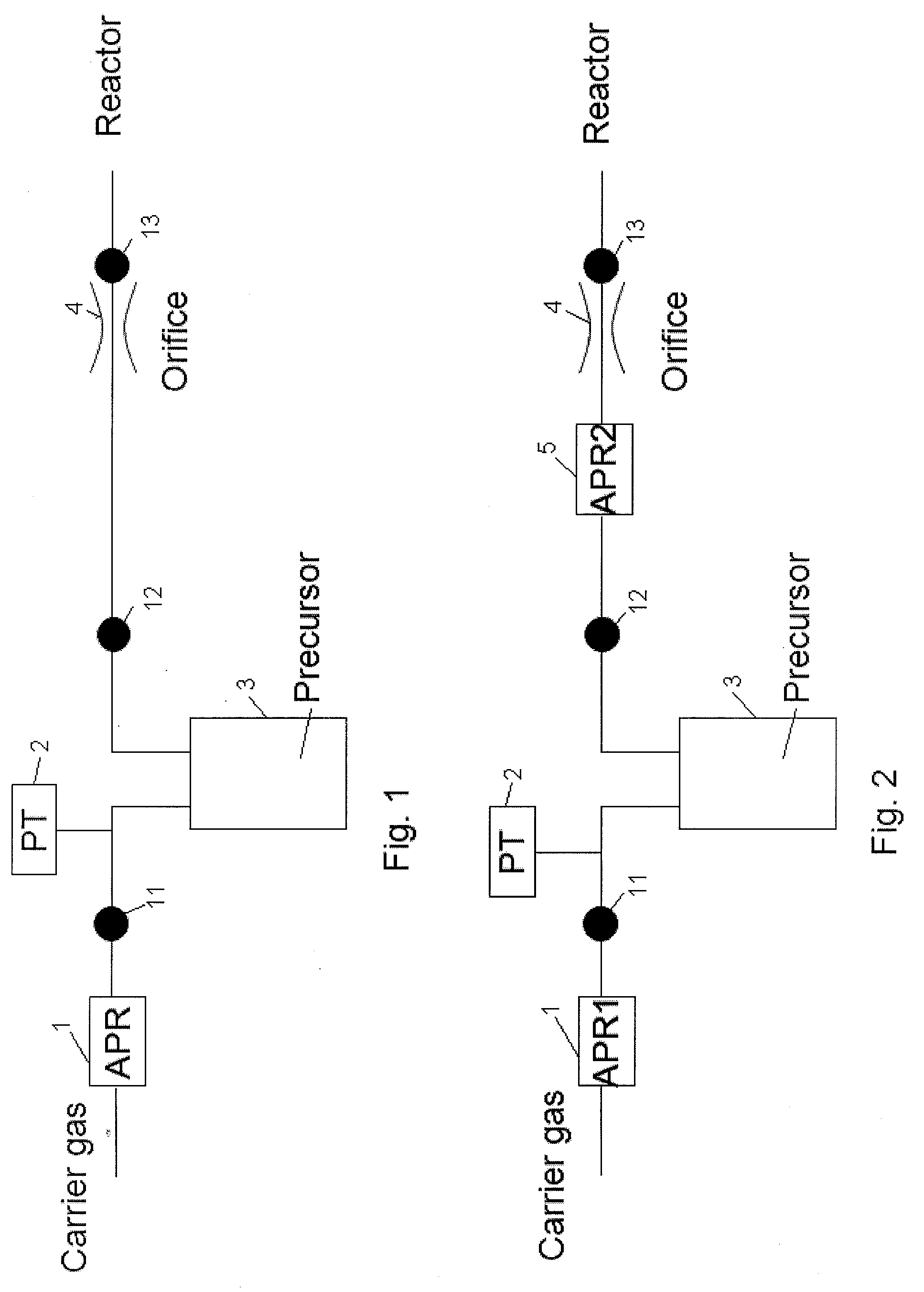

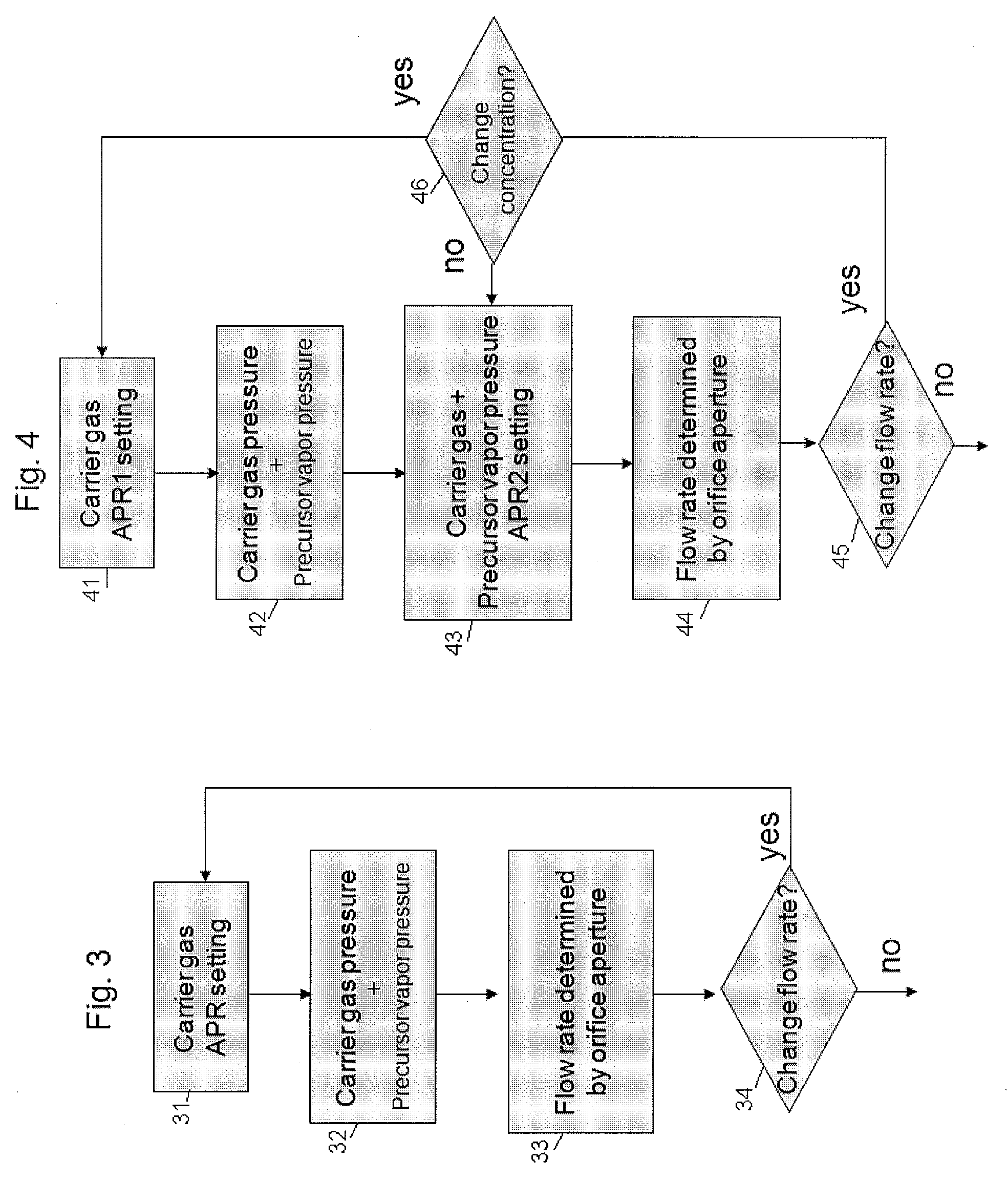

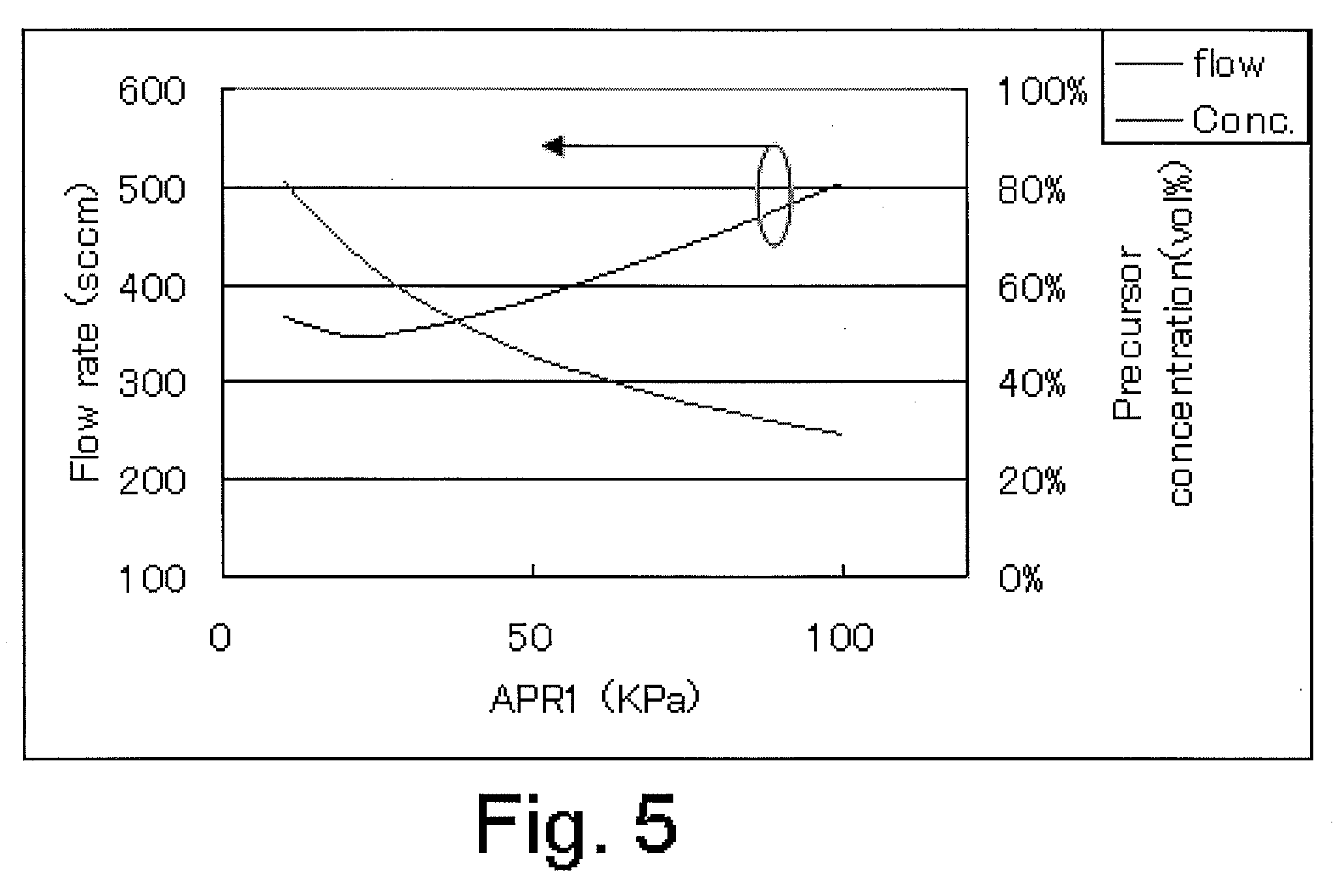

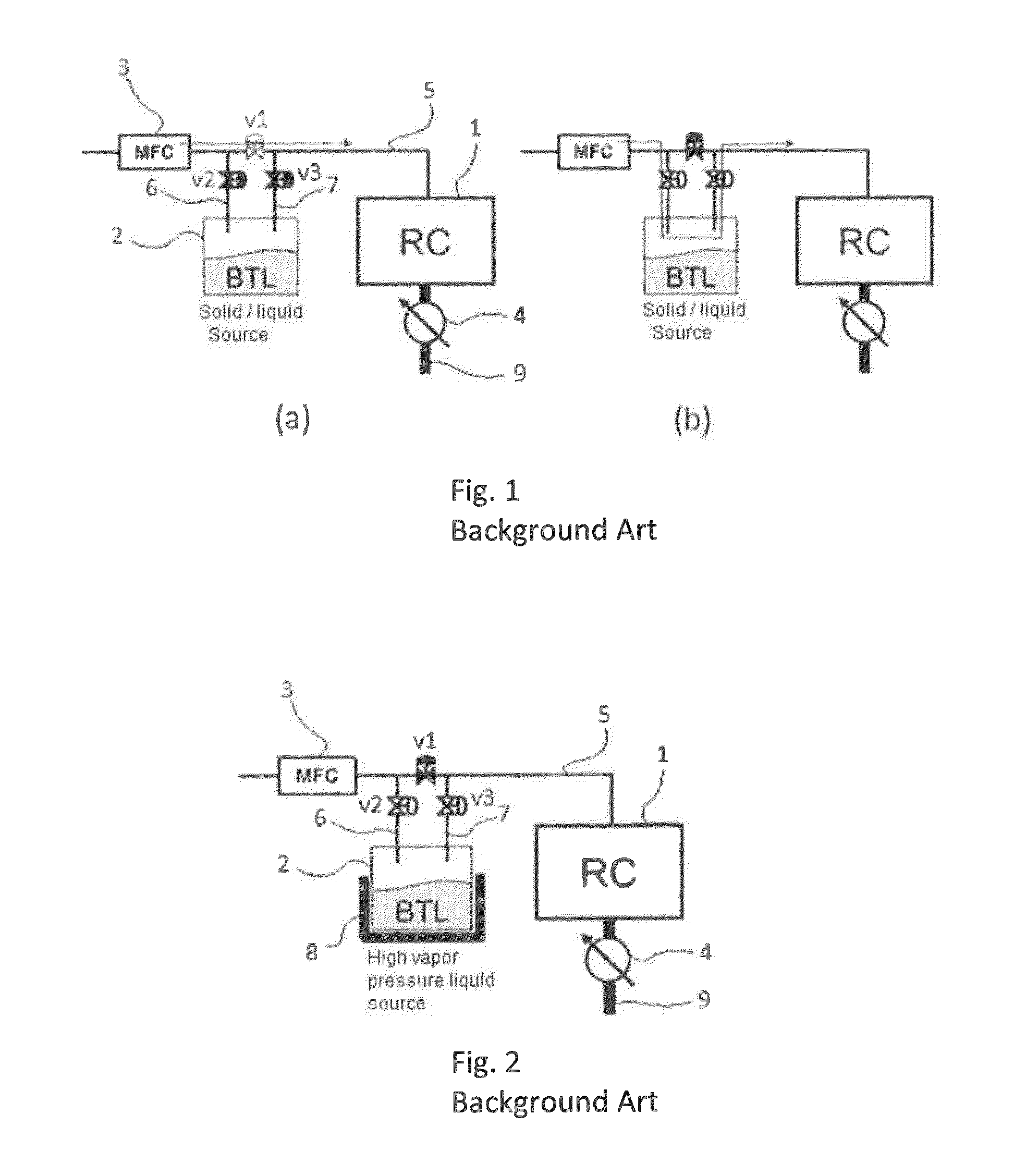

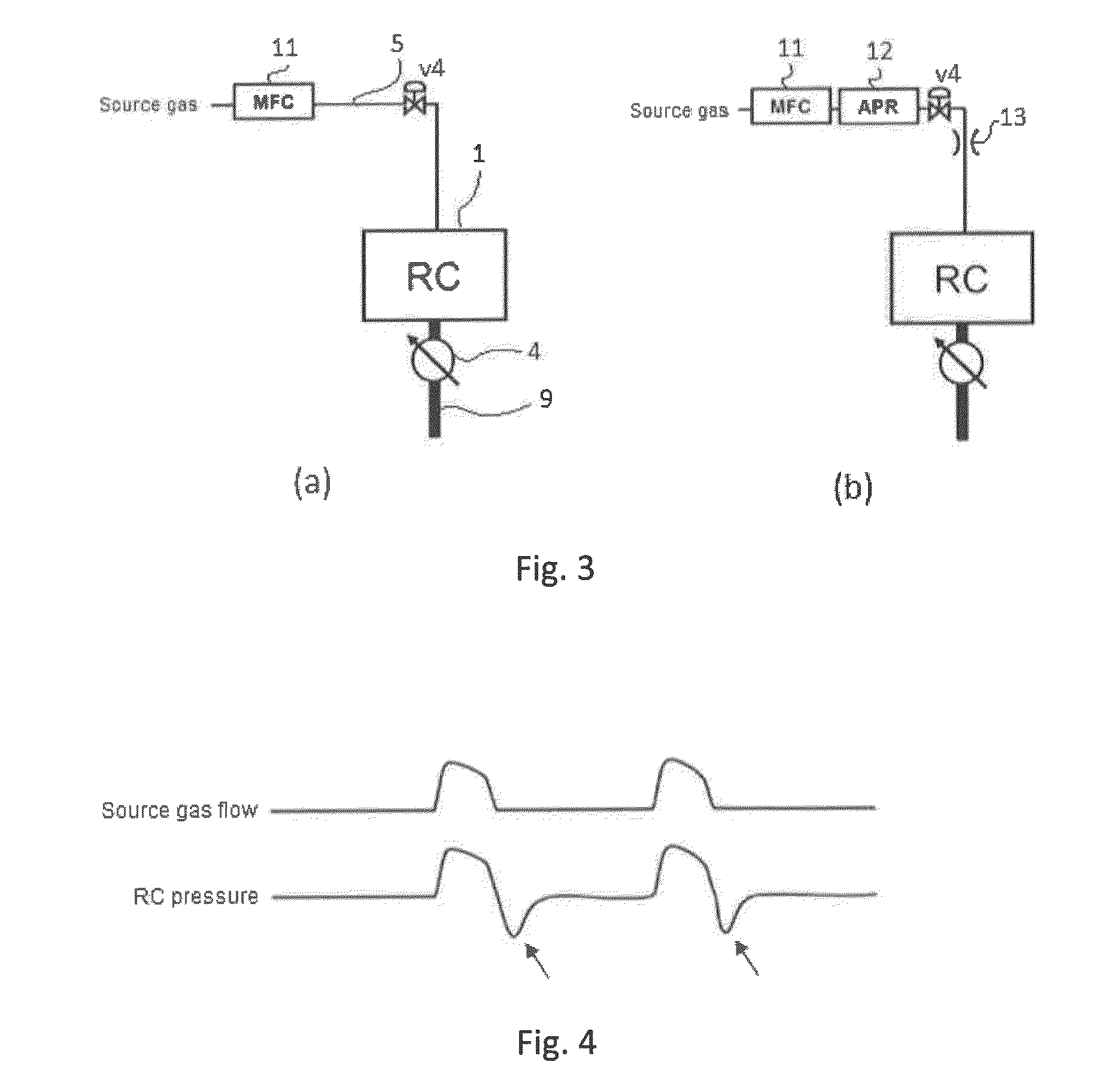

Method for controlling flow and concentration of liquid precursor

ActiveUS20100178423A1Material concentration can be controlledLine pressure can be accuratelyLiquid surface applicatorsVacuum evaporation coatingControl flowPressure regulator

A method for controlling flow and concentration of a liquid precursor includes: supplying a carrier gas to a first auto-pressure regulator and outputting therefrom the carrier gas at a first pressure to a precursor reservoir; outputting the mixture of the vaporized precursor and the carrier gas from the precursor reservoir; and supplying the mixture to a second auto-pressure regulator and outputting therefrom the mixture at a second pressure to a reactor via an orifice.

Owner:ASM JAPAN

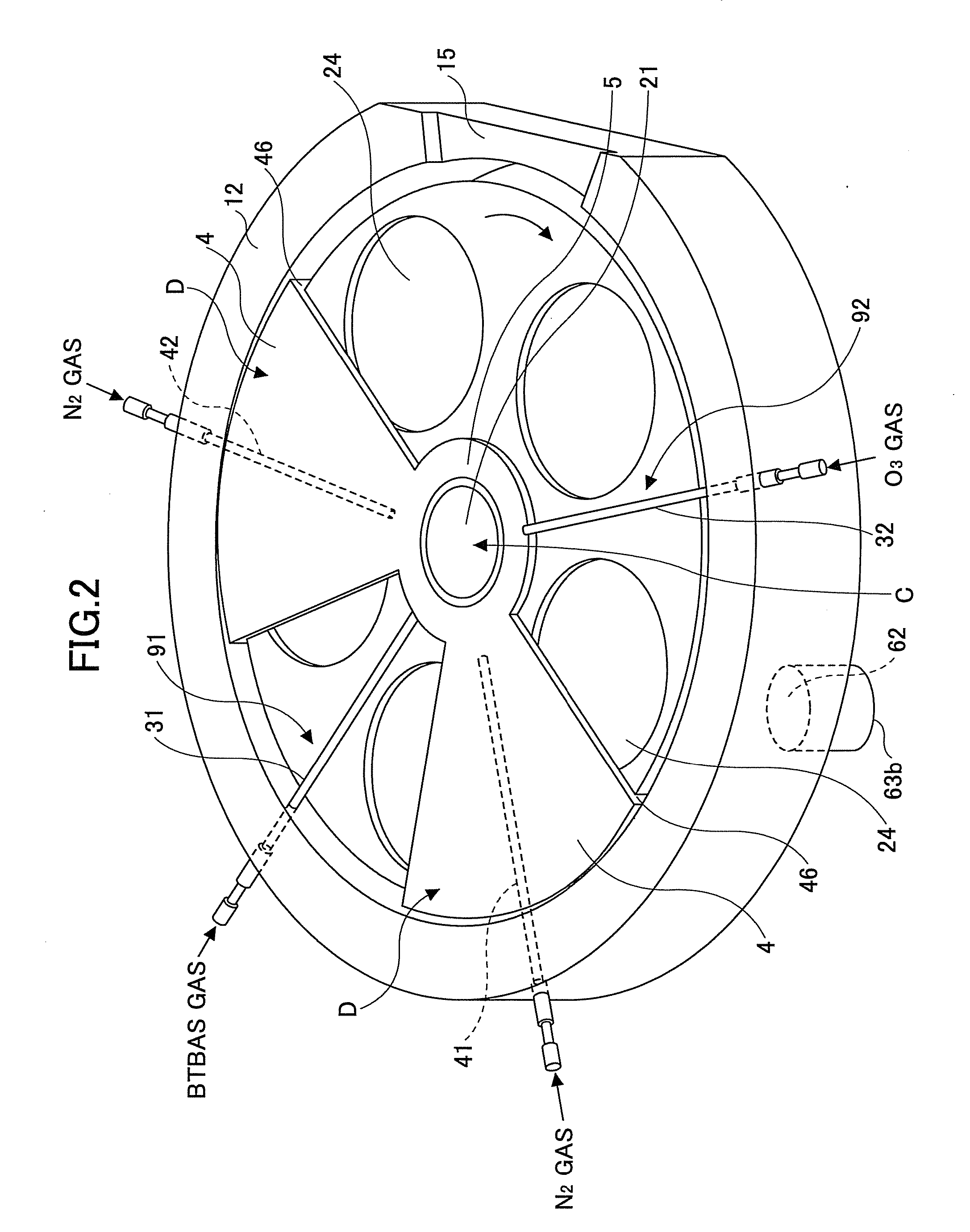

Substrate process apparatus, substrate process method, and computer readable storage medium

ActiveUS20110100489A1Servomotor componentsSemiconductor/solid-state device manufacturingDifferential pressureEngineering

A vacuum chamber is evacuated through a first evacuation passage provided with a first valve and a second evacuation passage provided with a second valve. An opening degree of the first valve is adjusted so that a pressure in the vacuum chamber becomes substantially equal to a process pressure P; an opening degree of a butterfly valve further provided in the second evacuation passage is adjusted to substantially equal to a set value determined by a table in order to set flow rates of gases to be evacuated through the first evacuation passage and the second evacuation passage to be substantially equal to corresponding set values determined by the recipe; and an opening degree of the second valve is adjusted so that a measurement value of a differential pressure gauge further provided in the second evacuation passage becomes substantially equal to a differential pressure written in the table.

Owner:TOKYO ELECTRON LTD

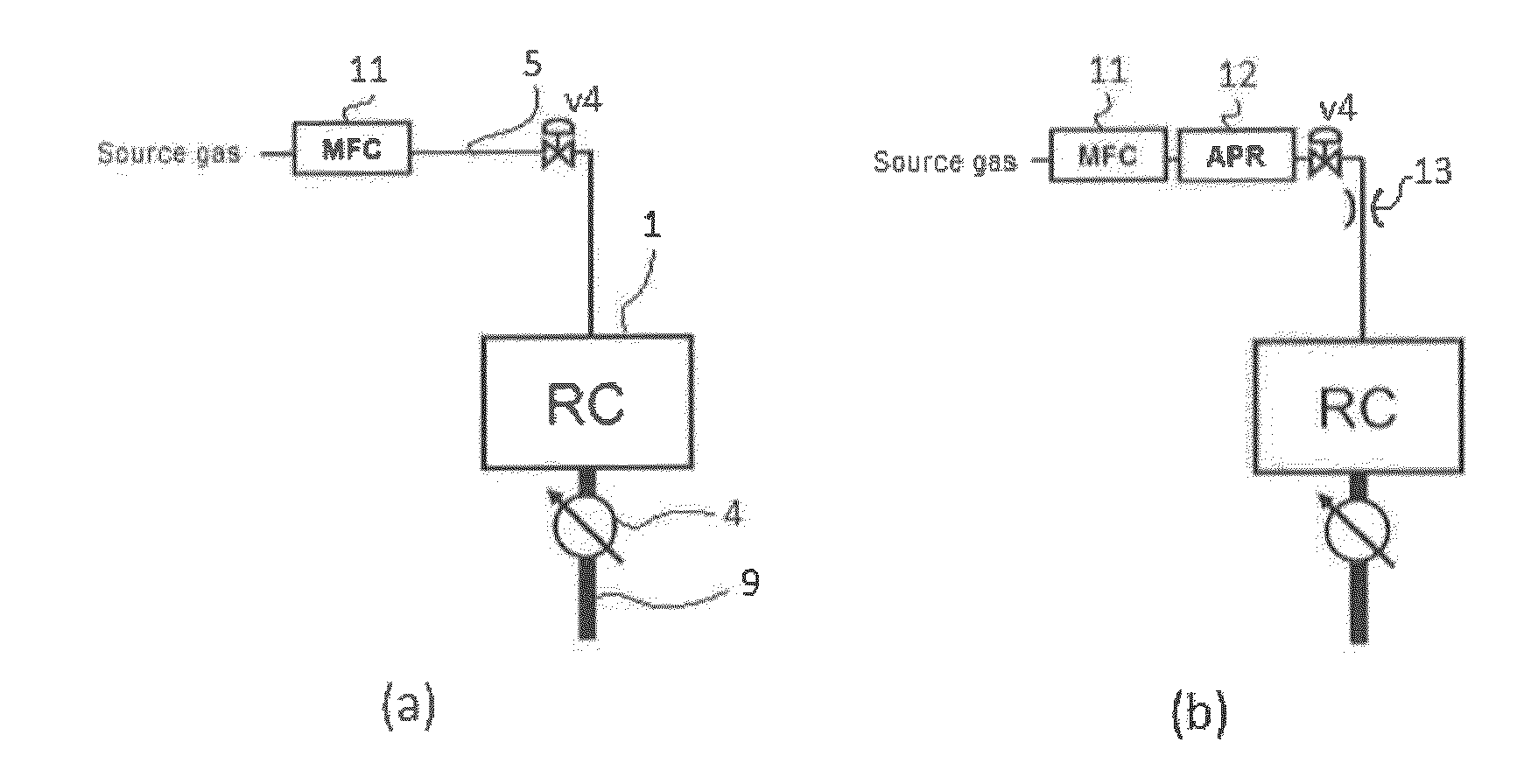

Method for Stabilizing Reaction Chamber Pressure

ActiveUS20150284848A1Suppress pressure fluctuationsIncrease vapor pressurePipeline systemsChemical vapor deposition coatingEngineeringProduct gas

A method stabilizes pressure of a reaction chamber during a process using a first gas and a second gas, wherein a gas inlet line is connected to the reaction chamber, and a second gas line and a first gas line are connected to another end of the gas inlet line. The method includes: feeding a first gas in pulses according to a waveform to the reaction chamber through the first gas line and the gas inlet line; and feeding a second gas in pulses according to a reverse waveform to the reaction chamber through the second gas line and the gas inlet line, wherein superimposed waveforms of the waveform and reverse waveform are made substantially or nearly fiat, thereby stabilizing pressure of the reaction chamber.

Owner:ASM IP HLDG BV

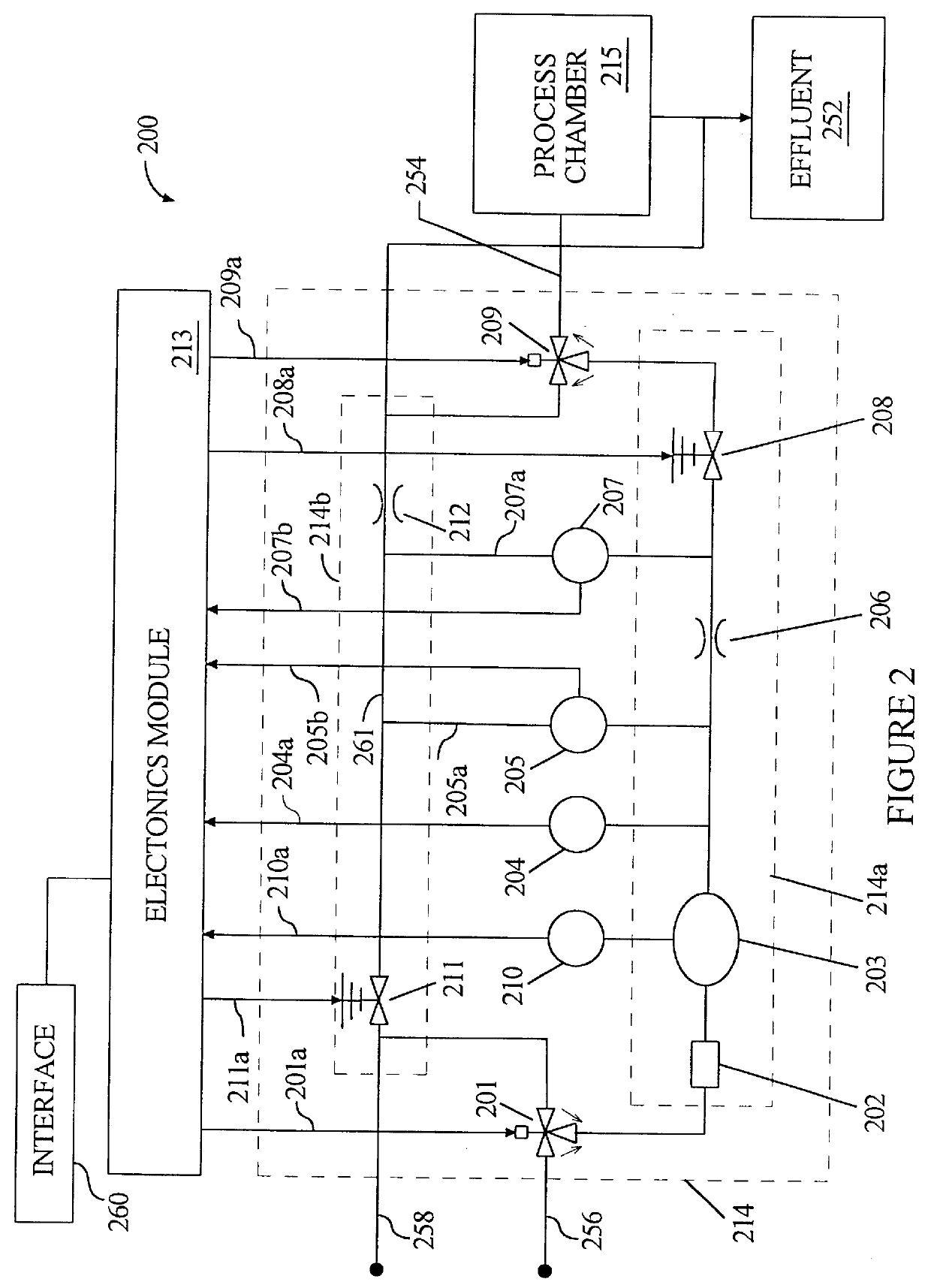

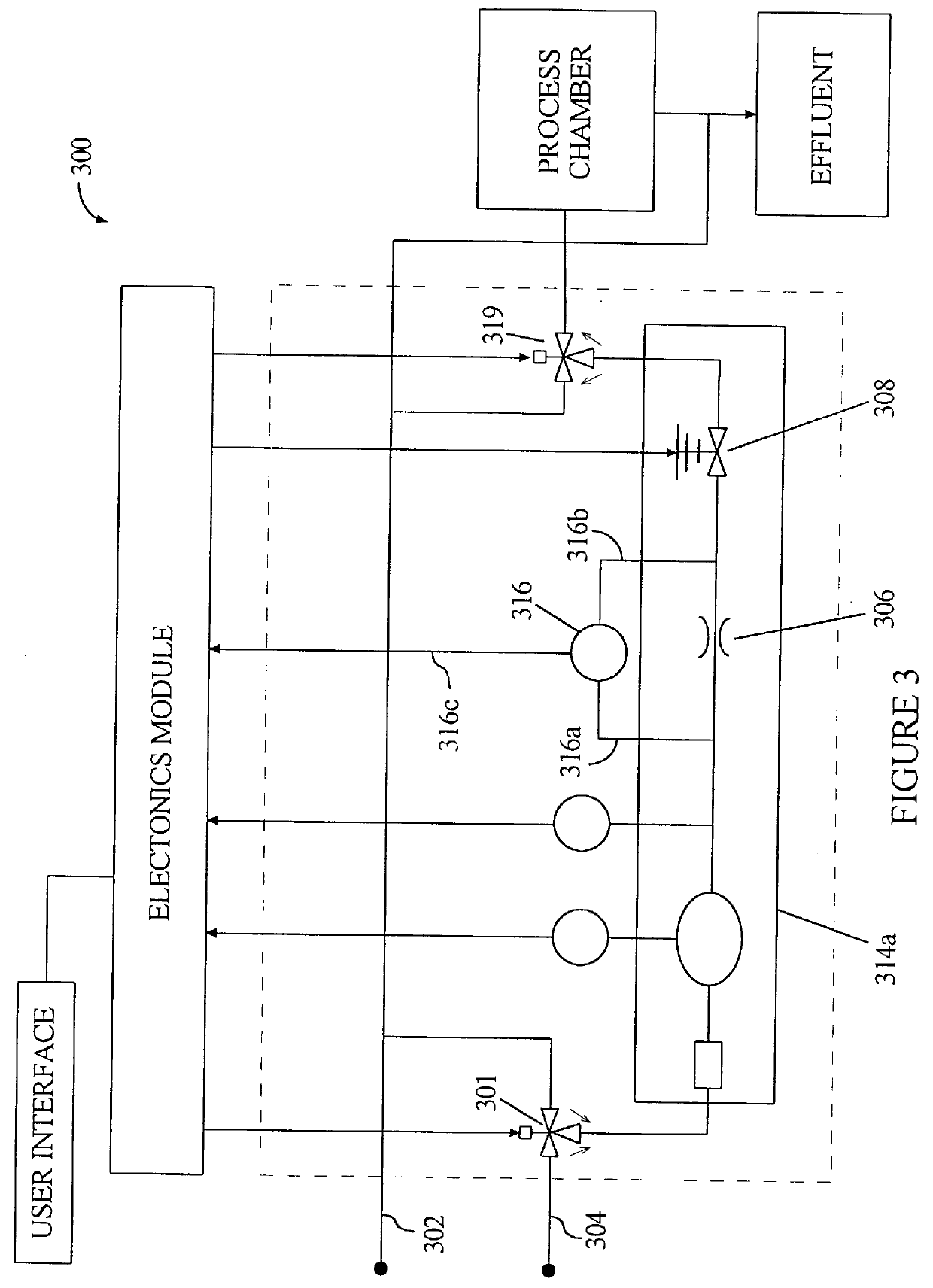

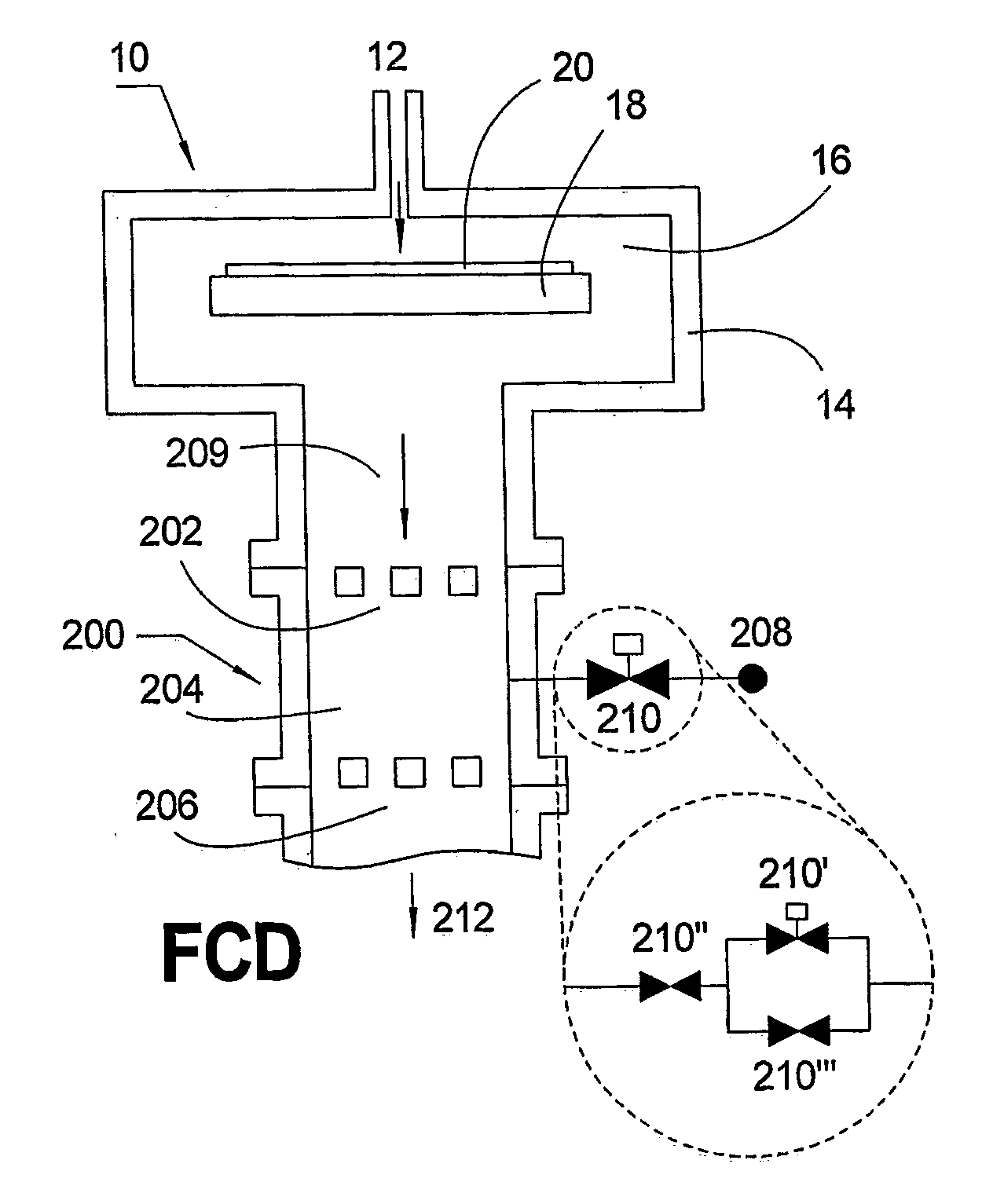

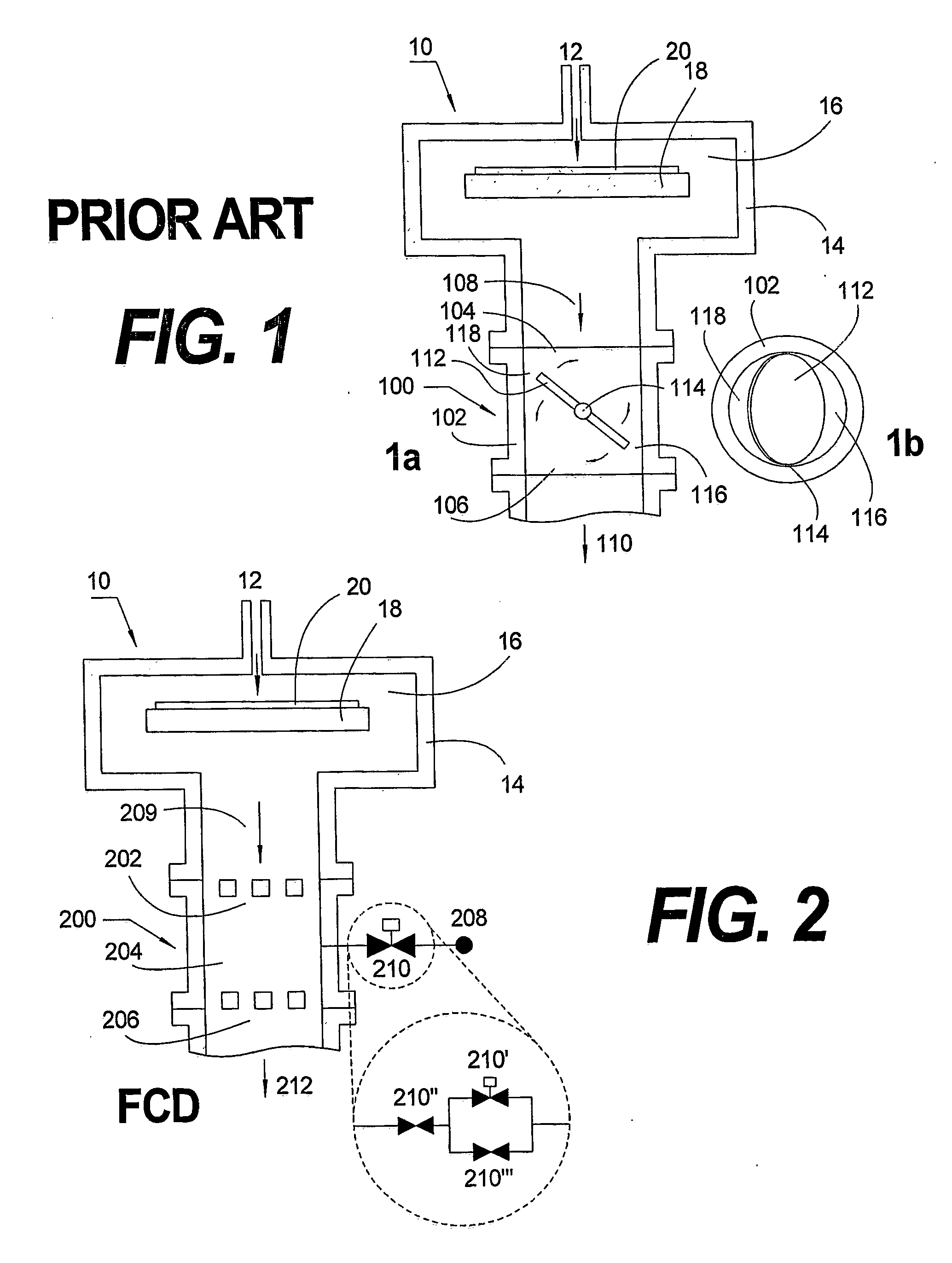

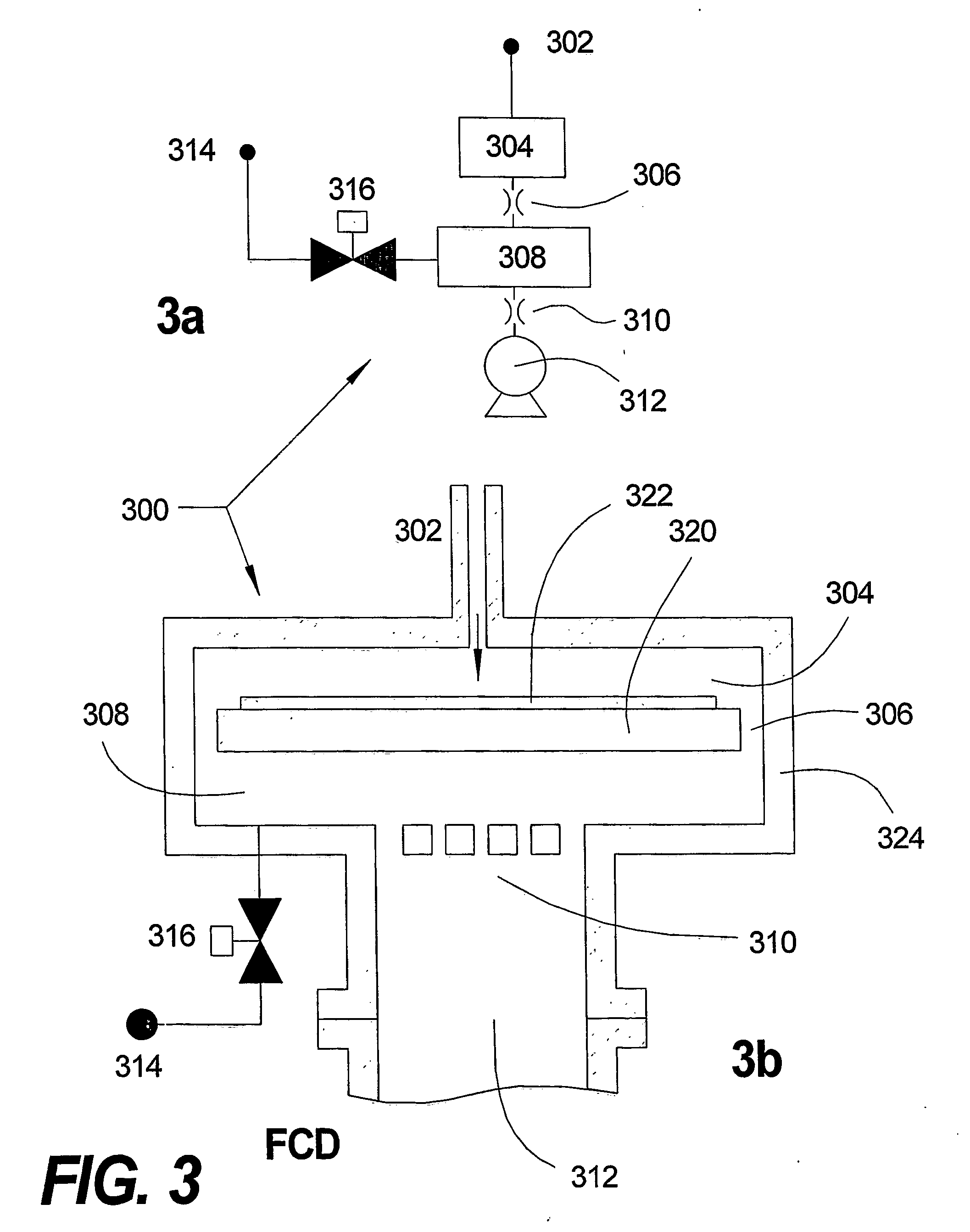

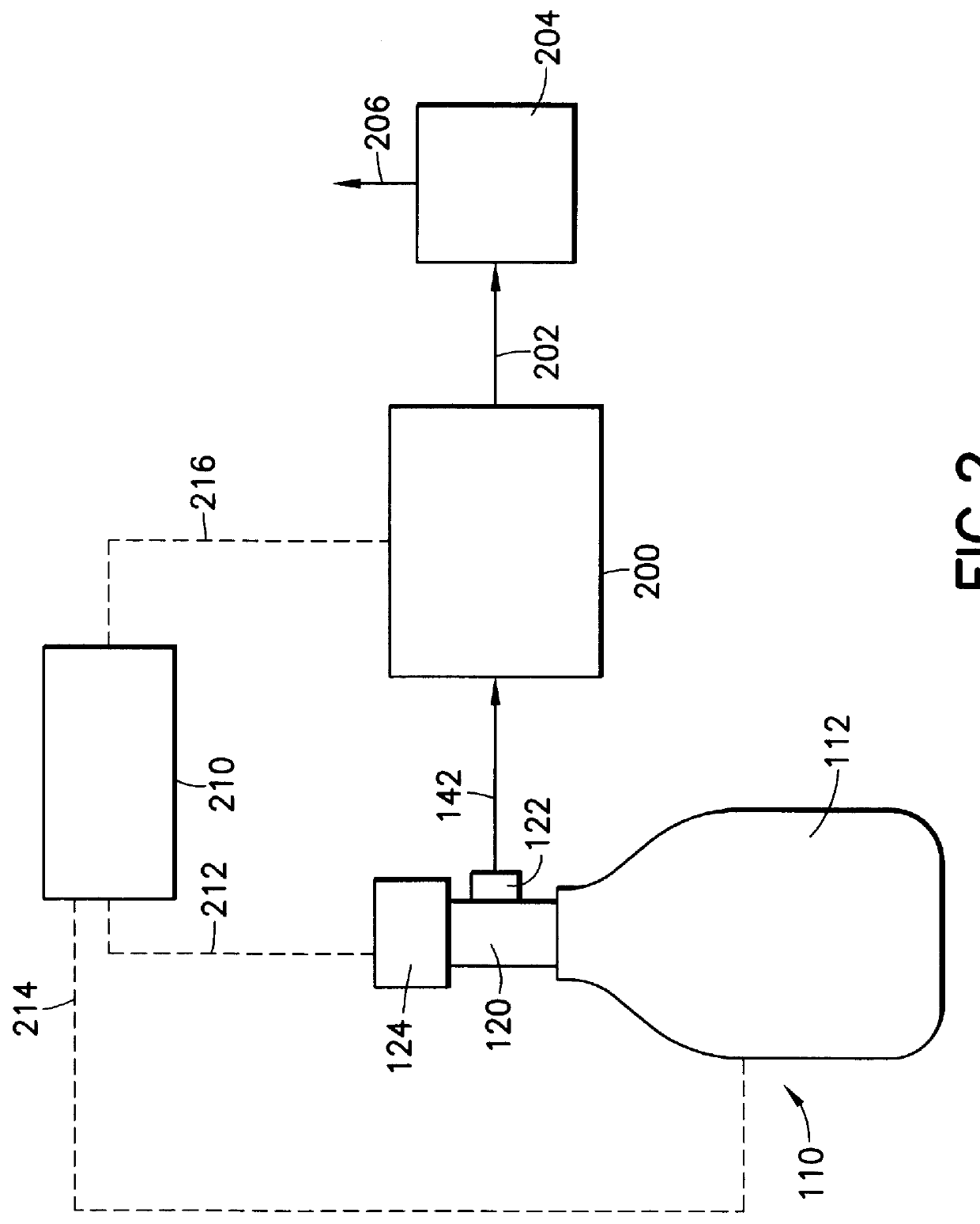

Apparatus and method for downstream pressure control and sub-atmospheric reactive gas abatement

InactiveUS20070012402A1Rapid responseOptimized and smooth flow passageSemiconductor/solid-state device manufacturingPipeline systemsReactive gasStream flow

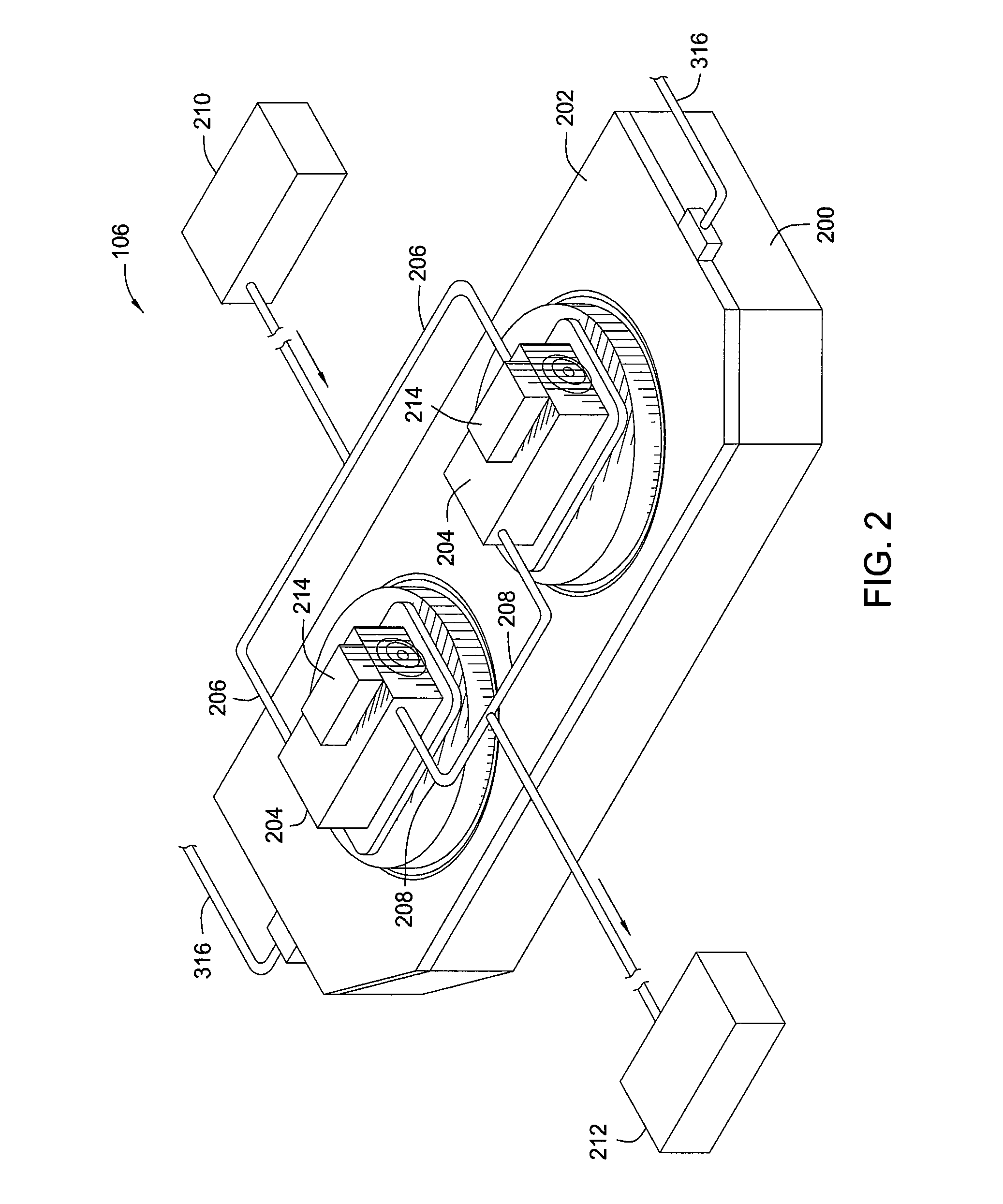

A sub-atmospheric downstream pressure control apparatus (200) includes a first flow restricting element (FRE) (202); a pressure control chamber (PCC) (204) located in serial fluidic communication downstream from the first FRE; a second FRE (206) located in serial fluidic communication downstream from the PCC; a gas source (208); and a flow controlling device (210) in serial fluidic communication downstream from the gas source and upstream from the PCC.

Owner:SUNDEW TECH

Gas flow rate verification unit

ActiveUS7716993B2Increase flow rateUniform pressureMultiple way valvesPipeline systemsEngineeringGas supply

A gas flow rate verification unit capable of enhancing reliability of gas flow rate verification. The gas flow rate verification unit has a first cutoff valve that is connected to a flow rate control device and to which gas is inputted, a second cutoff valve for discharging the gas, a communication member for allowing the first cutoff valve and the second cutoff valve to communicate with each other, a pressure sensor for detecting the pressure of the gas supplied between the first cutoff valve and the second cutoff valve, a temperature detector for detecting the temperature of the gas supplied between the first cutoff valve and the second cutoff valve, and a control means for verifying the flow of the gas flowing in the flow control device, the verification being performed by using both the result of the pressure detected by the pressure sensor and the result of the temperatures detected by the temperature detector. The volume (Vk) between the valve seat of the first cutoff valve and the valve seat of the second cutoff valve is equal to or less than the volume (Ve) between the outlet of the flow control device and the valve seat of the first cutoff valve.

Owner:CKD

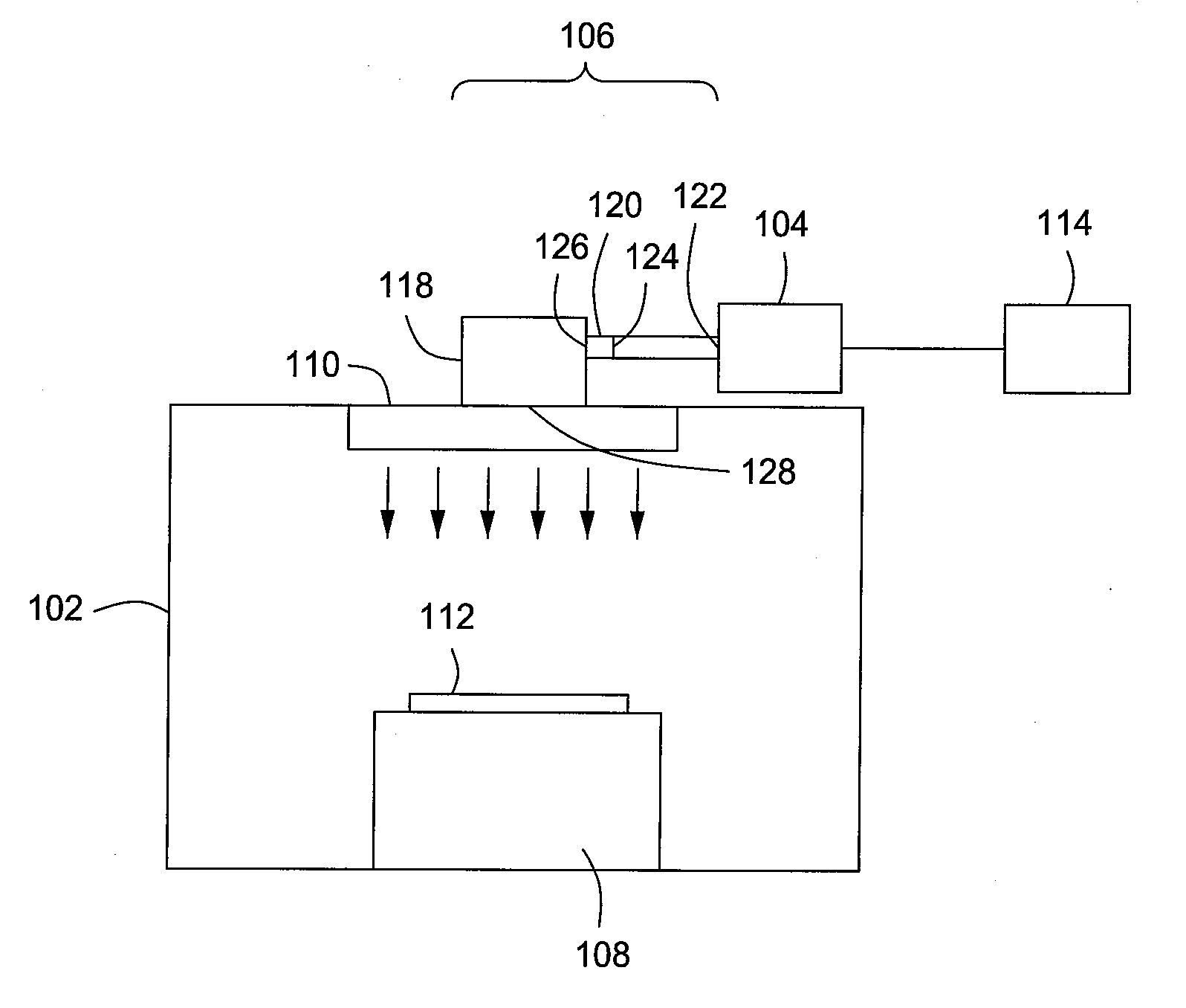

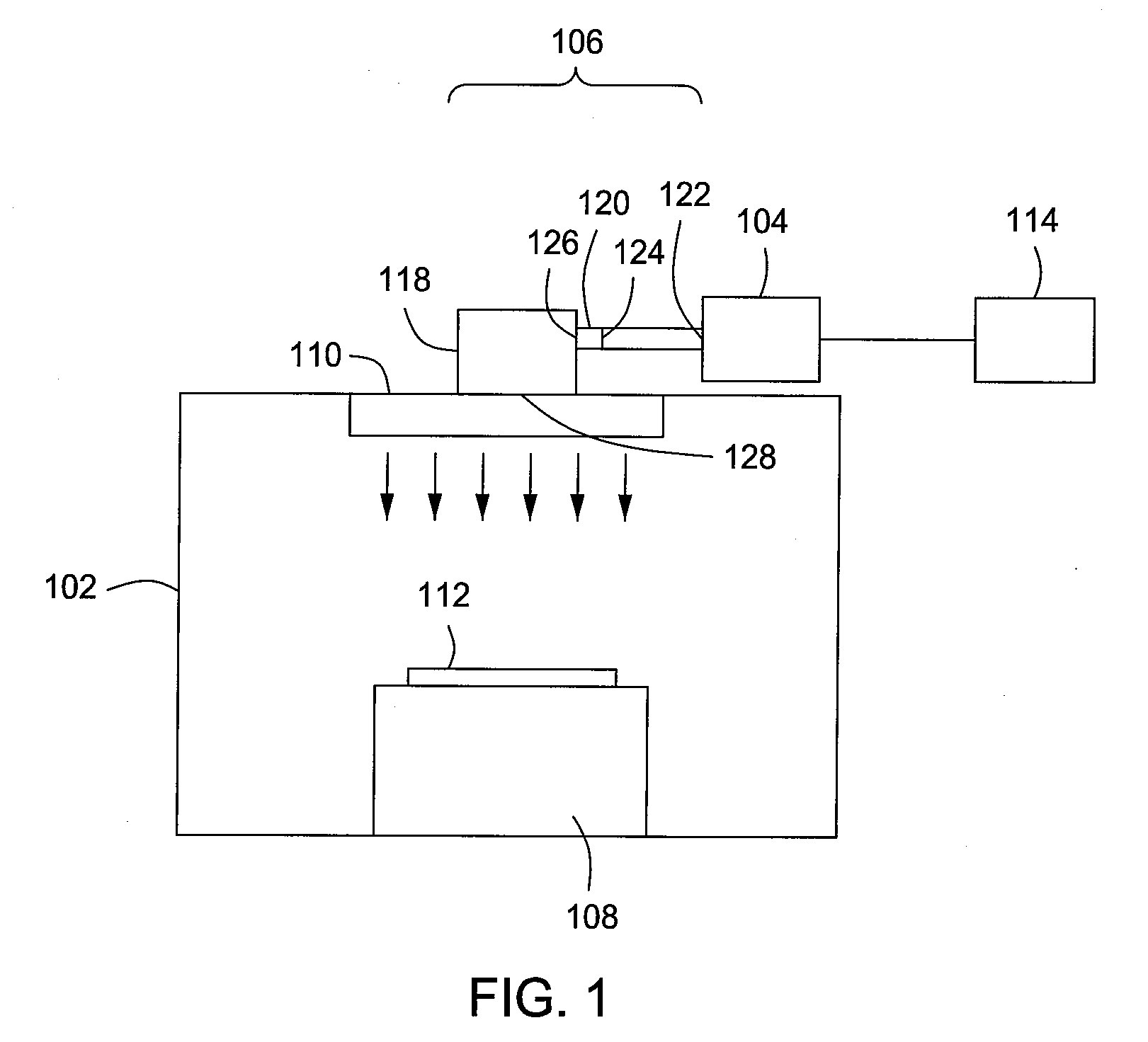

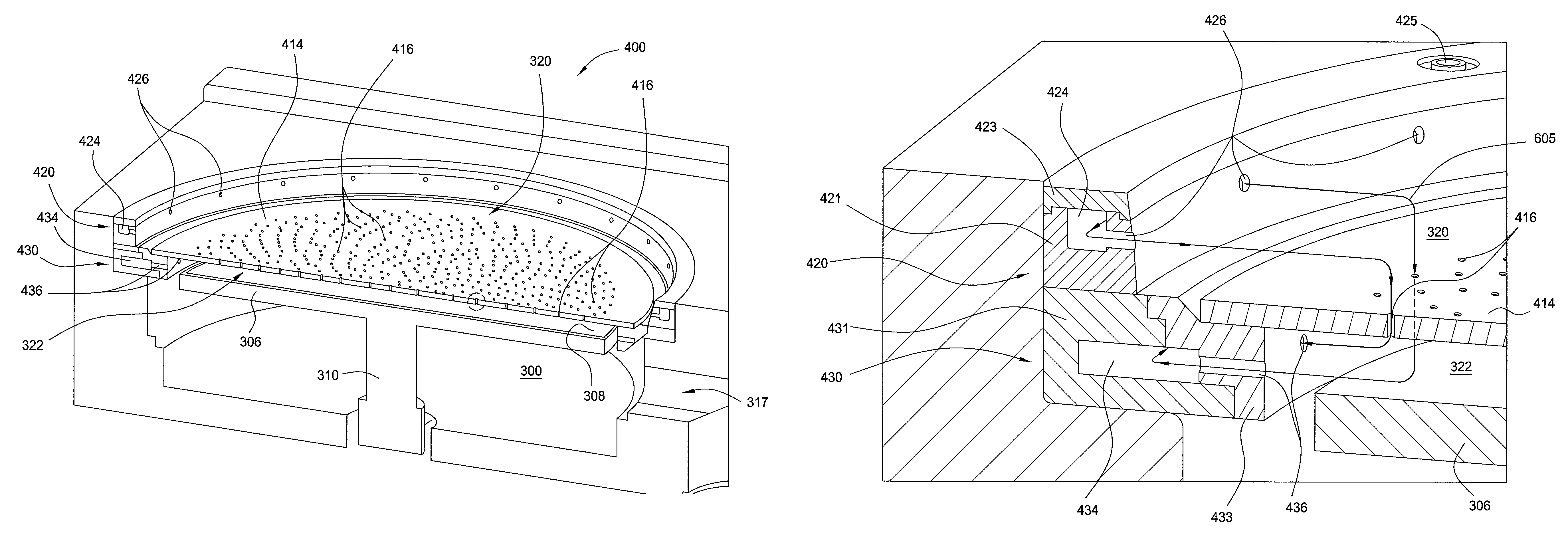

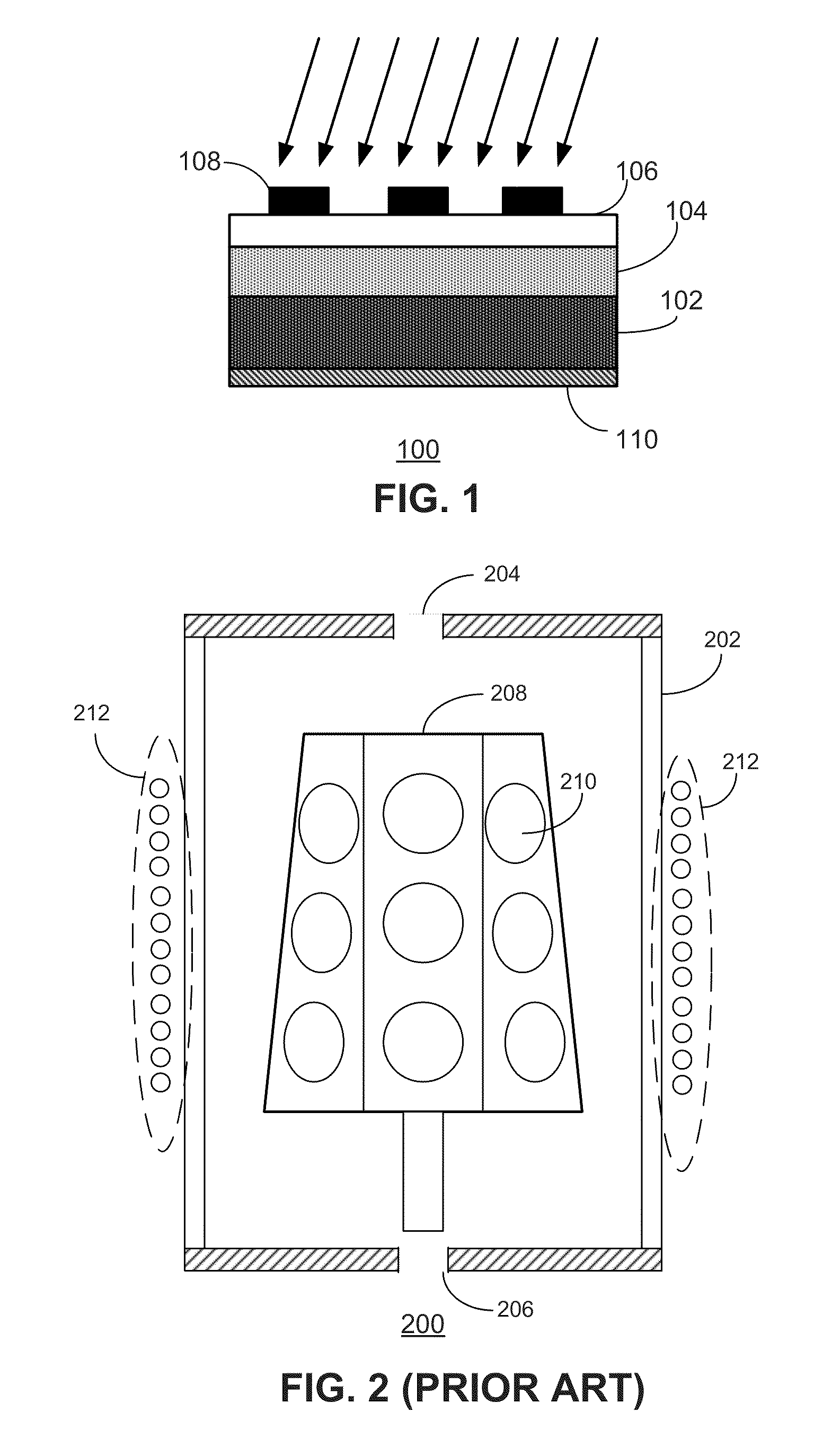

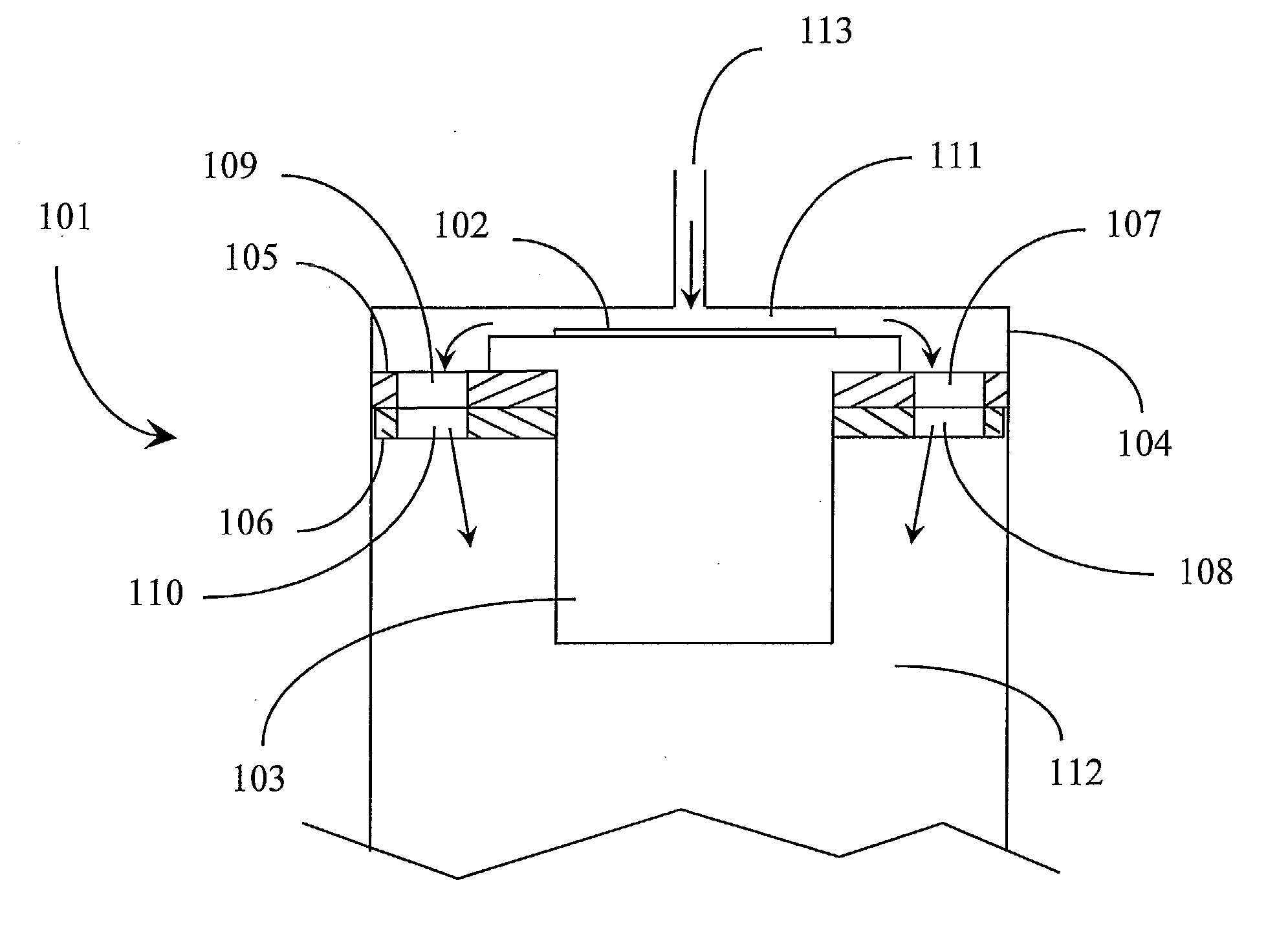

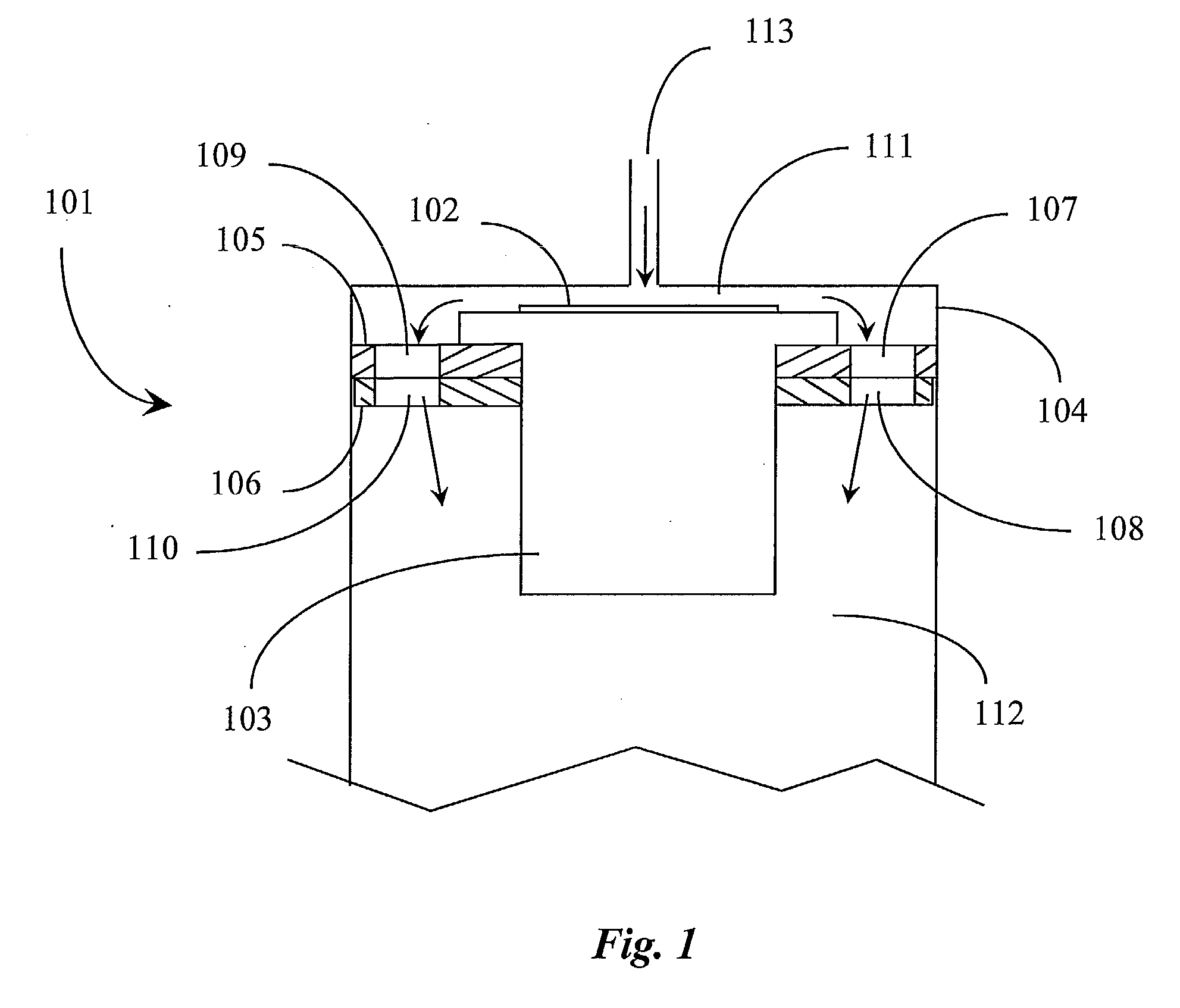

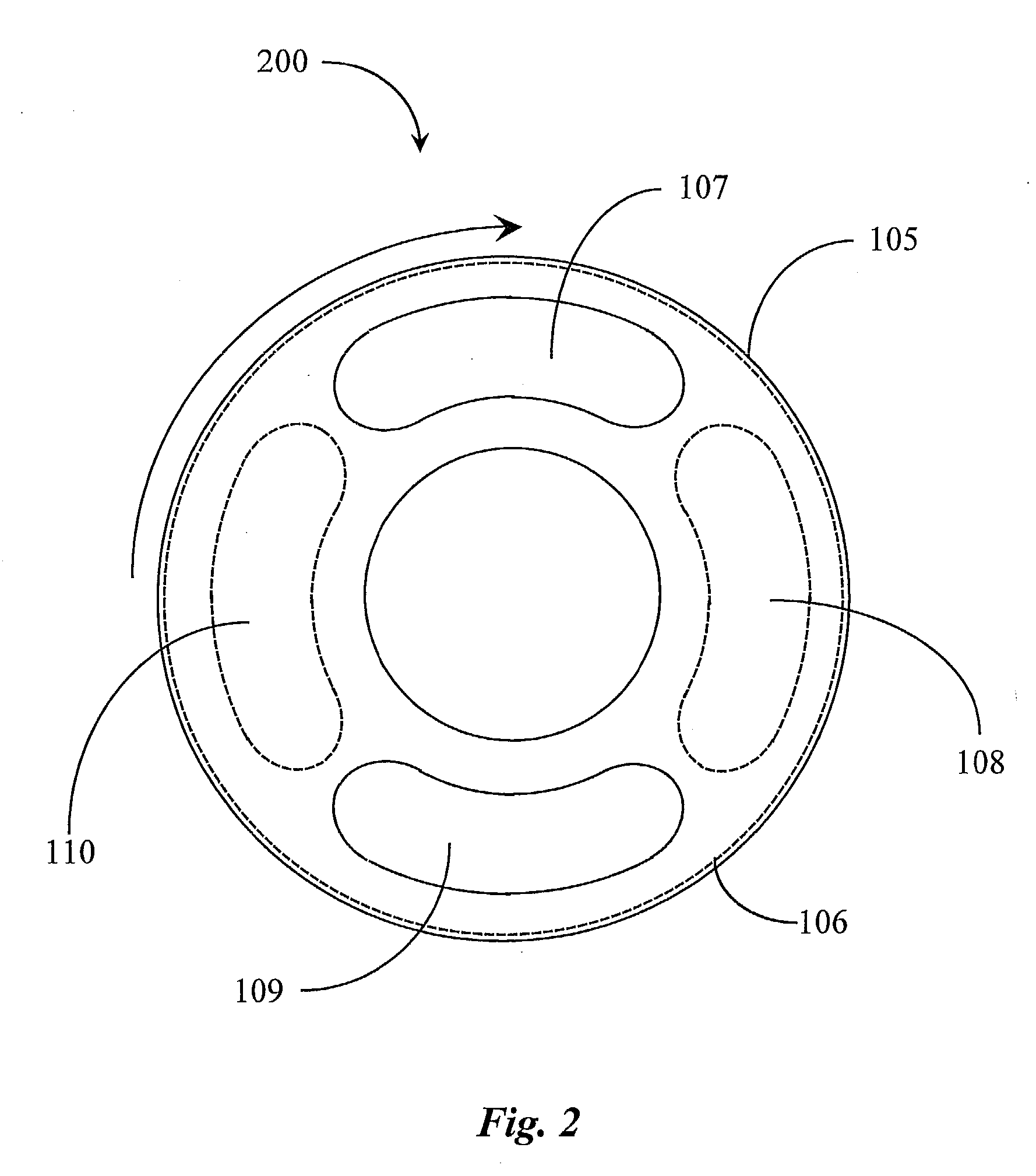

Quartz showerhead for nanocure UV chamber

Embodiments of the invention generally provide apparatuses and methods for controlling the gas flow profile within a processing chamber. In one embodiment, a processing tool includes an ultraviolet processing chamber defining a processing region, a substrate support, a window disposed between a UV radiation source and the substrate support, and a transparent showerhead disposed within the processing region between the window and the substrate support and having one or more transparent showerhead passages between upper and lower processing regions. The processing tool also includes a gas distribution ring having one or more gas distribution ring passages between a gas distribution ring inner channel and the upper processing region and a gas outlet ring positioned below the gas distribution ring, the gas outlet ring having one or more gas outlet passages between a gas outlet ring inner channel within the gas outlet ring and the lower processing region.

Owner:APPLIED MATERIALS INC

Process for producing emulsion and microcapsules and apparatus therefor

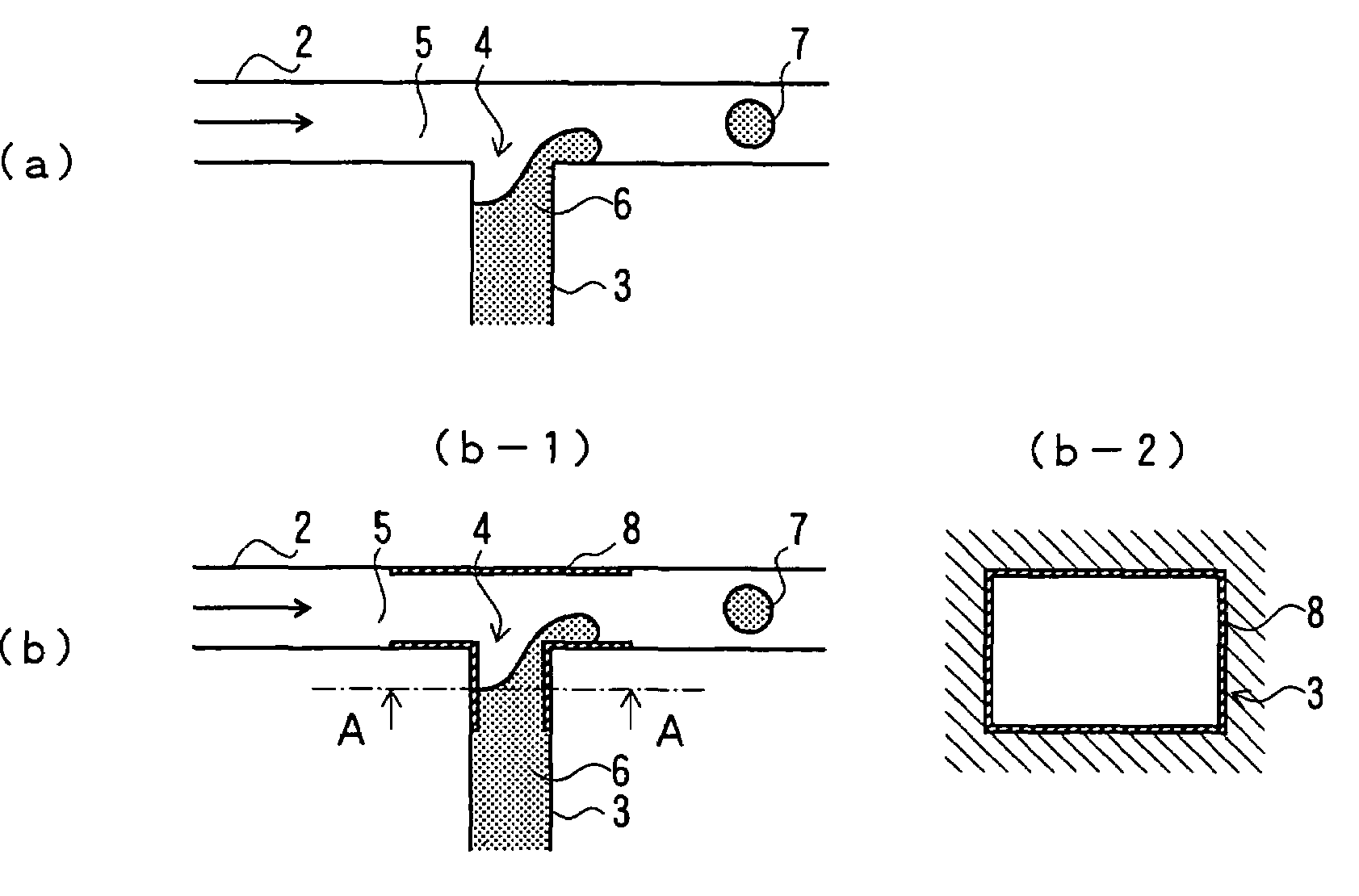

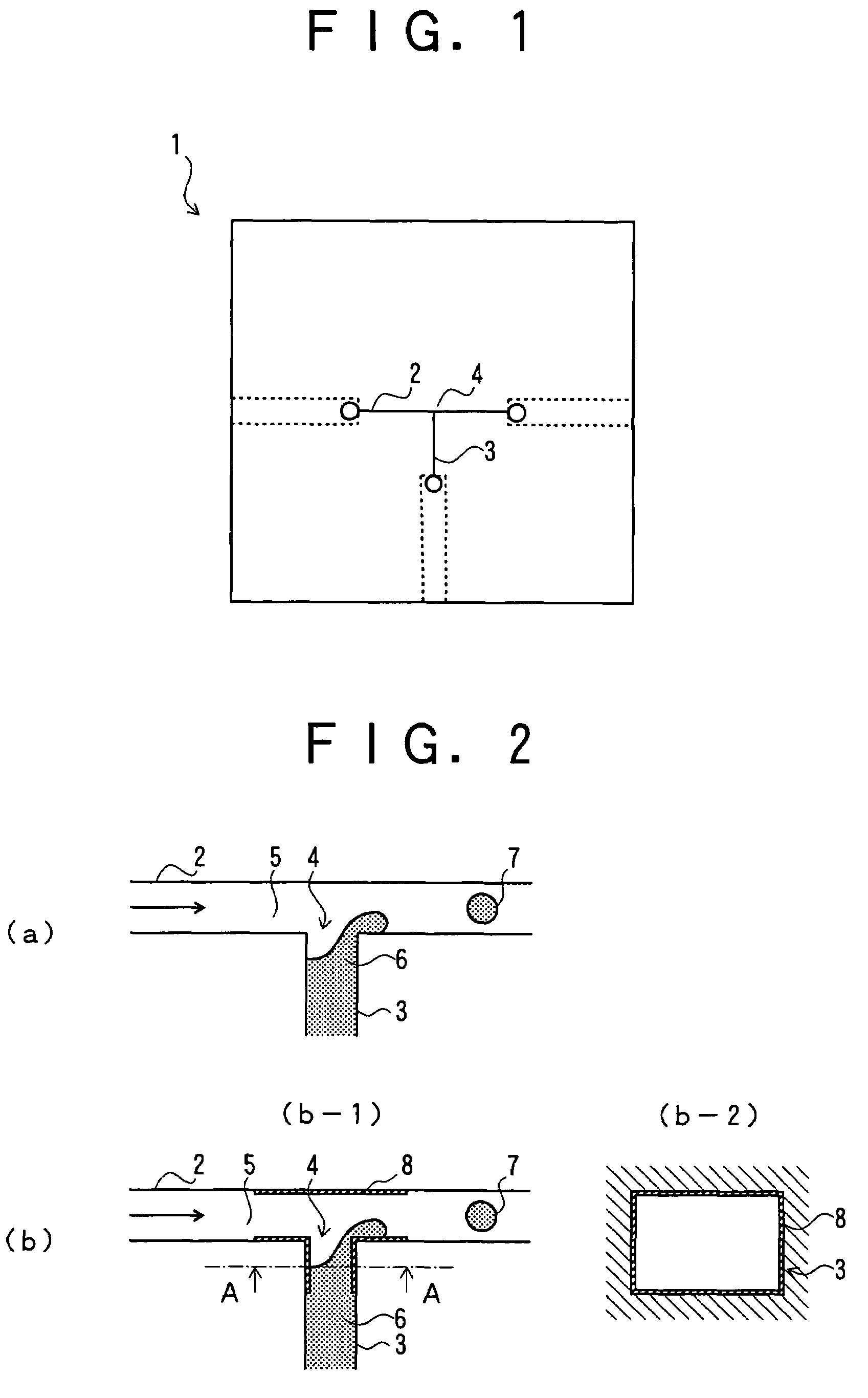

InactiveUS7268167B2Rapid productionSimple wayFlow mixersMixing methodsEmulsionMechanical engineering

Owner:JAPAN SCI & TECH CORP

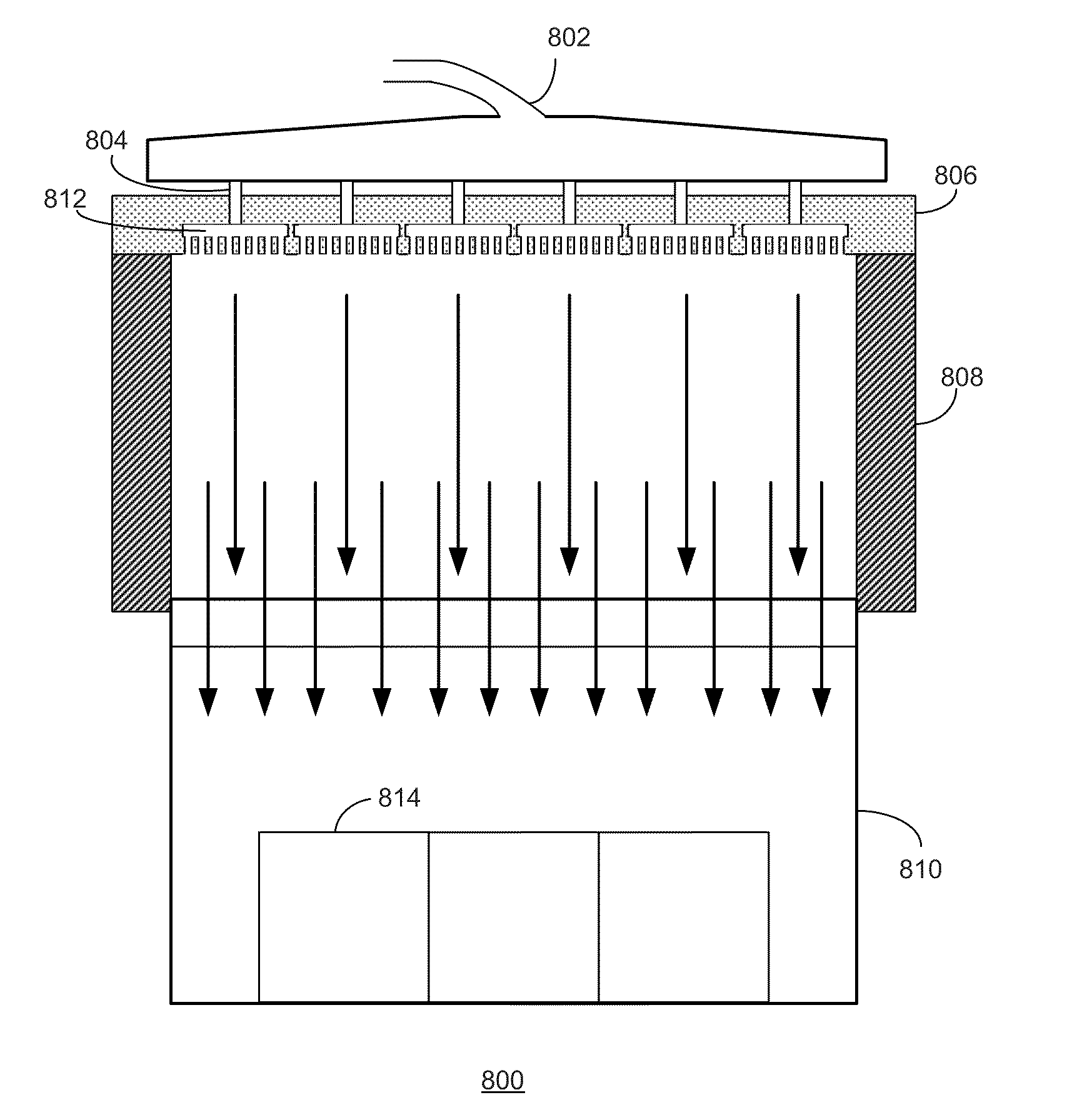

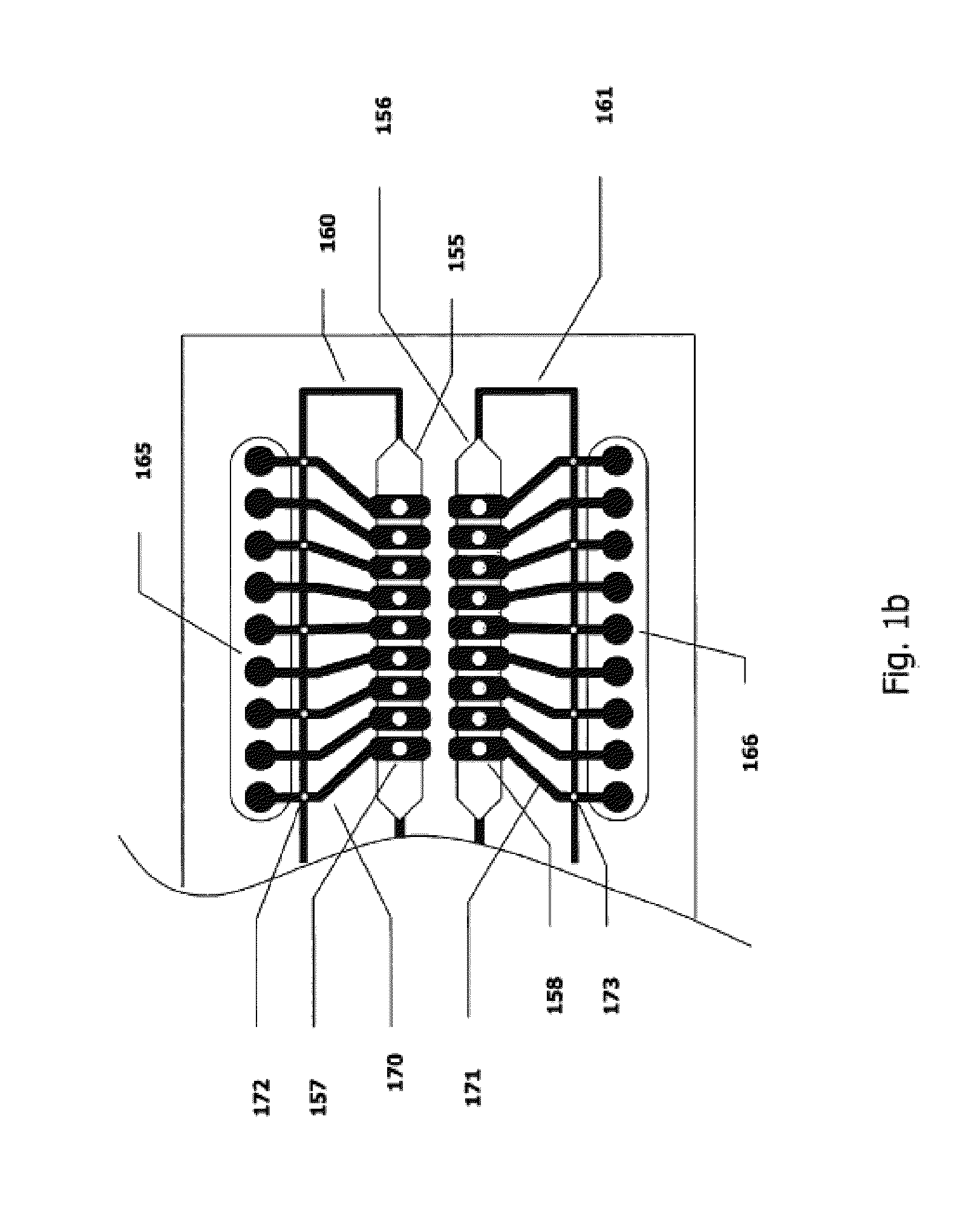

Multi-channel gas-delivery system

One embodiment of the present invention provides a gas-delivery system for delivering reaction gas to a reactor chamber. The gas-delivery system includes a main gas-inlet port for receiving reaction gases and a gas-delivery plate that includes a plurality of gas channels. A gas channel includes a plurality of gas holes for allowing the reaction gases to enter the reactor chamber from the gas channel. The gas-delivery system further includes a plurality of sub-gas lines coupling together the main gas-inlet port and the gas-delivery plate, and a respective sub-gas line is configured to deliver a portion of the received reaction gases to a corresponding gas channel.

Owner:TESLA INC

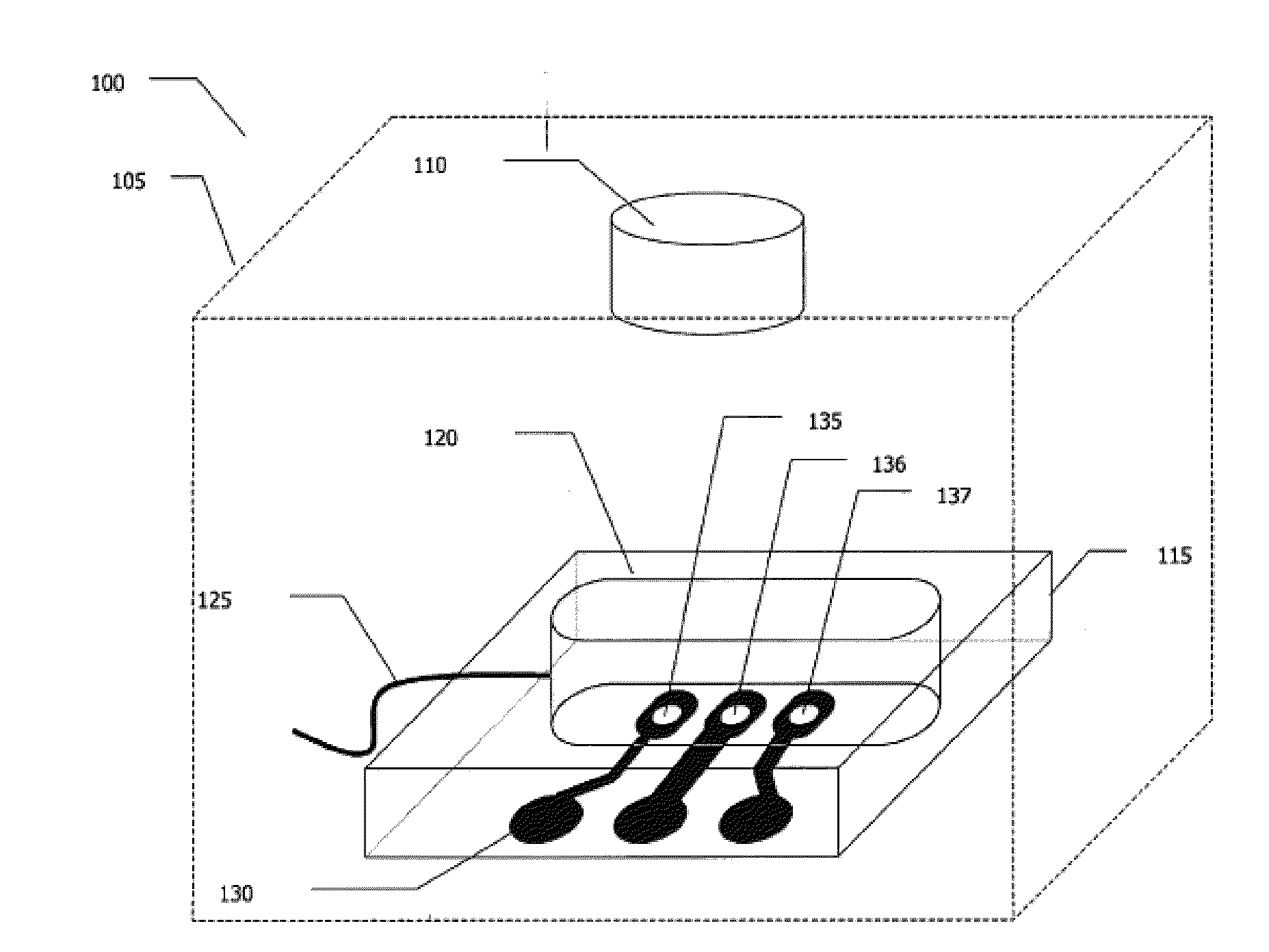

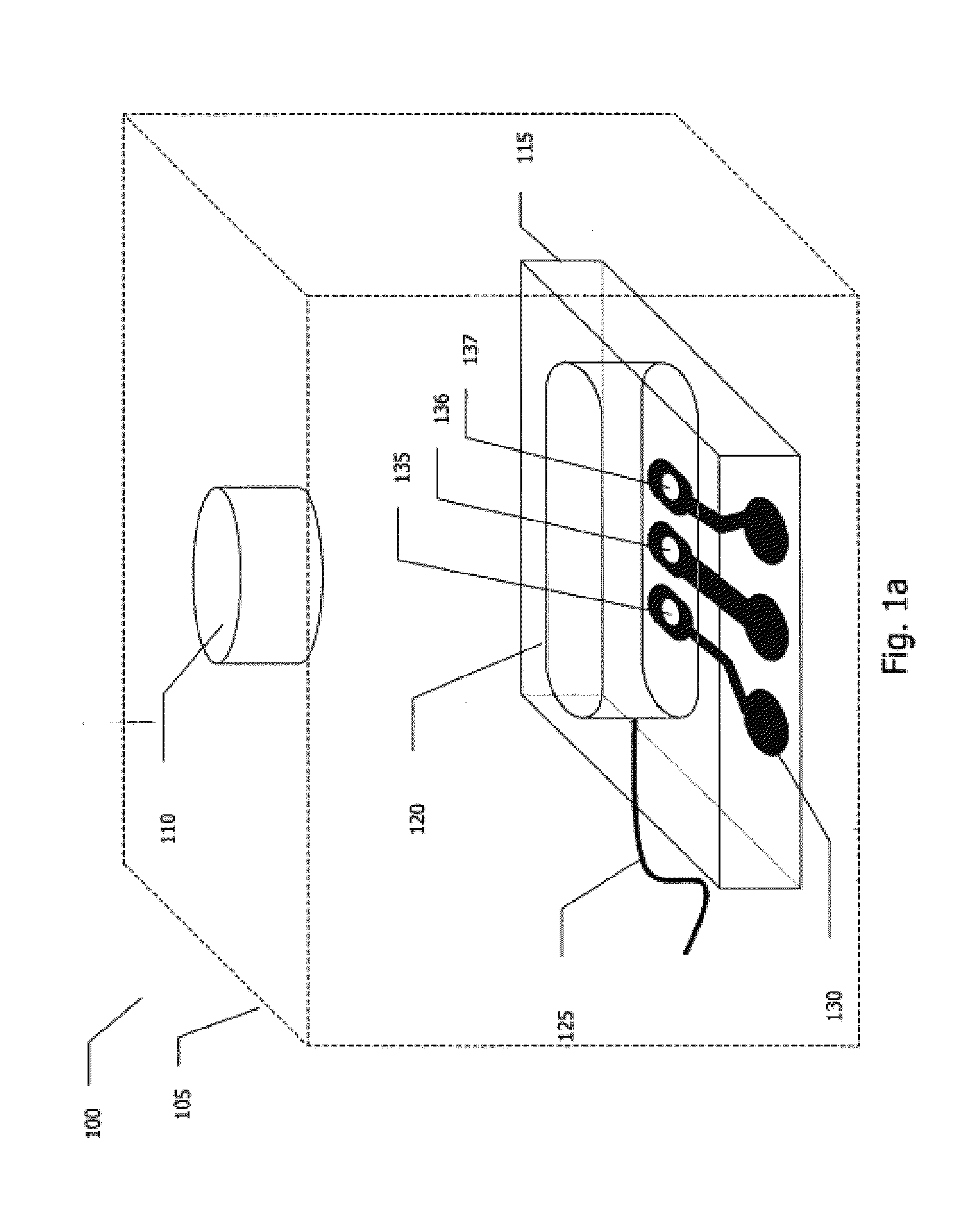

Microfluidic actuator

InactiveUS6521188B1Easy to prepareLow costCircuit elementsPressure pumpsEngineeringAtmospheric pressure

A simple microfluidic actuator includes a sealed vacuum chamber actuated by providing a current to a thin film heater, which in turn weakens and, under the atmospheric pressure differential, breaks a diaphragm sealing said vacuum chamber whereby the vacuum inside said chamber is released. By applying the microfluidic actuator to a microfluidic network the resulting pressure differential can be used to generate a pumping force with the microfluidic network. The chamber may be prepared in a silicon, glass, or plastic substrate. The diaphragm may be a metallic gas-impermeable film. A releasing member comprising a thin-film metallic heater is then microfabricated on the diaphragm. The assembly so prepared may be bonded to a glass or plastic substrate that contains a network of microchannels. The microfluidic actuator is suited for a microfluidic platform in generating driving powers for operations including pumping, metering, mixing and valving of liquid samples.

Owner:IND TECH RES INST

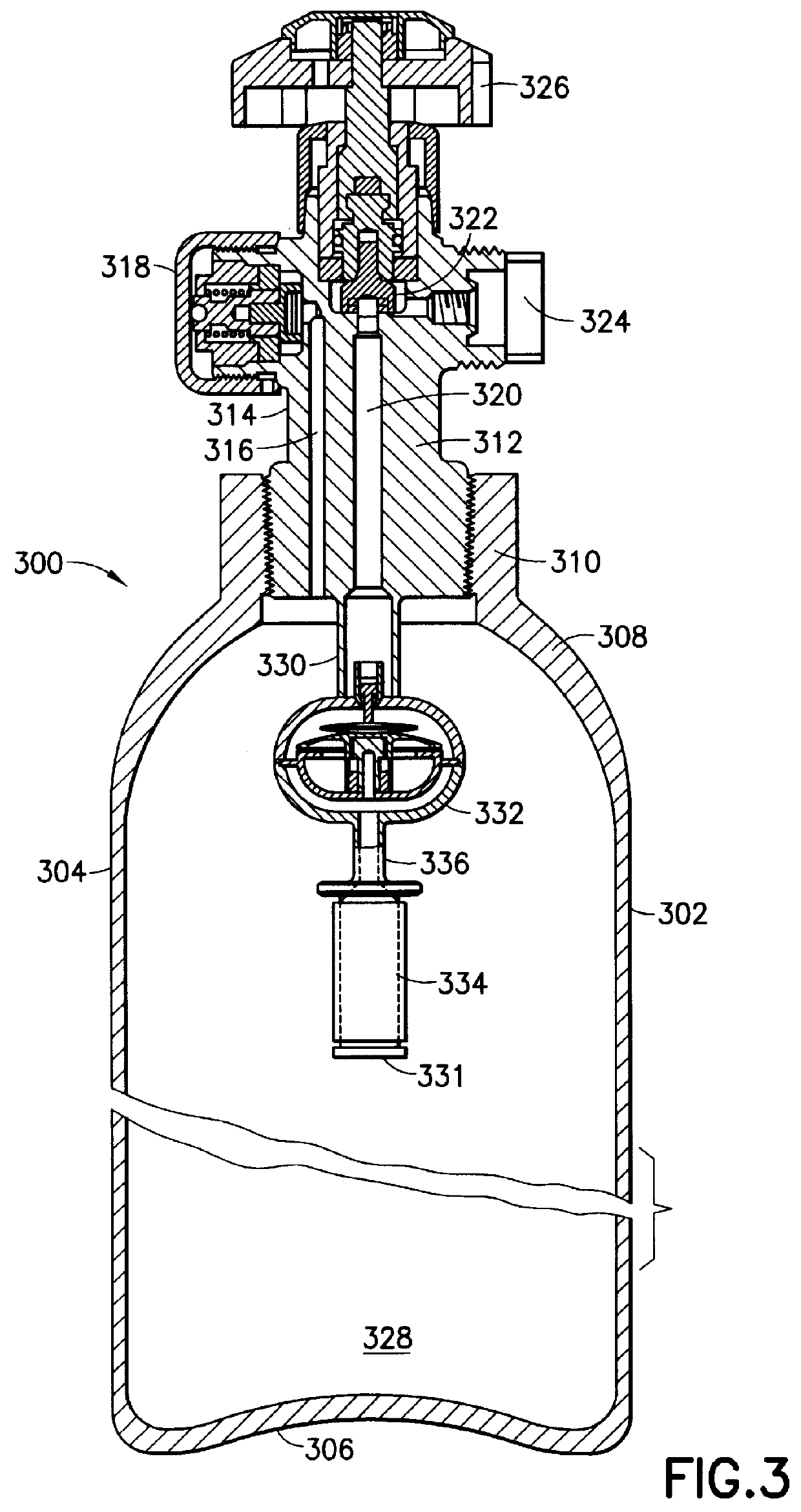

Fluid storage and dispensing system

InactiveUS6089027ACostPerformanceContainer filling methodsVacuum evaporation coatingSingle stageSorbent

A fluid storage and dispensing system comprising a vessel for holding a fluid at a desired pressure. The vessel has a pressure regulator, e.g., a single-stage or multi-stage regulator, associated with a port of the vessel, and set at a predetermined pressure. A dispensing assembly, e.g., including a flow control means such as a valve, is arranged in gas / vapor flow communication with the regulator, whereby the opening of the valve effects dispensing of gas / vapor from the vessel. The fluid in the vessel may be constituted by a liquid that is confined in the vessel at a pressure in excess of its liquefaction pressure at prevailing temperature conditions, e.g., ambient (room) temperature. In another aspect, the vessel contains a solid-phase sorbent material having sorbable gas adsorbed thereon, at a pressure in excess of 50 psig. The vessel may have a >1 inch NGT threaded neck opening, to accommodate the installation of an interior regulator.

Owner:ENTEGRIS INC

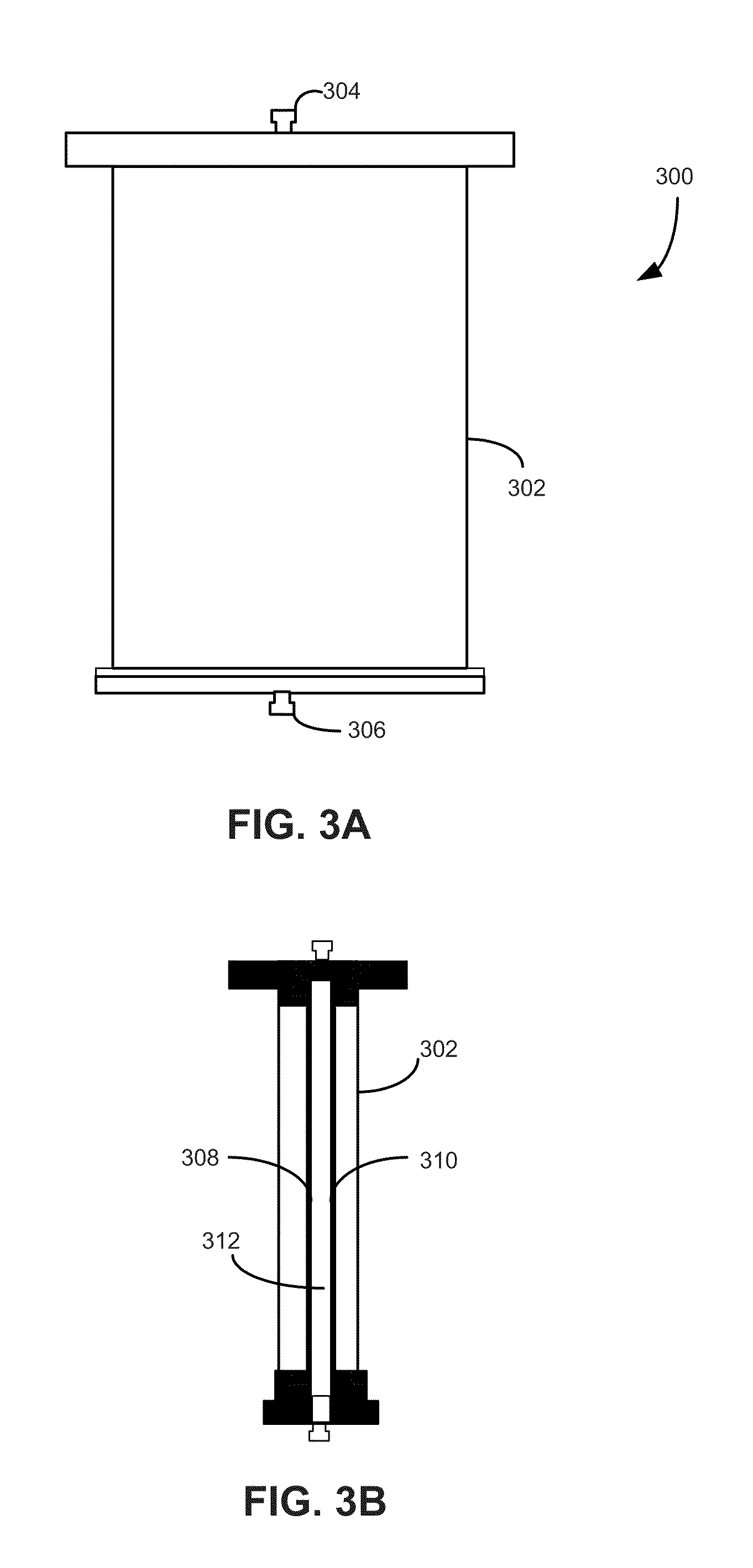

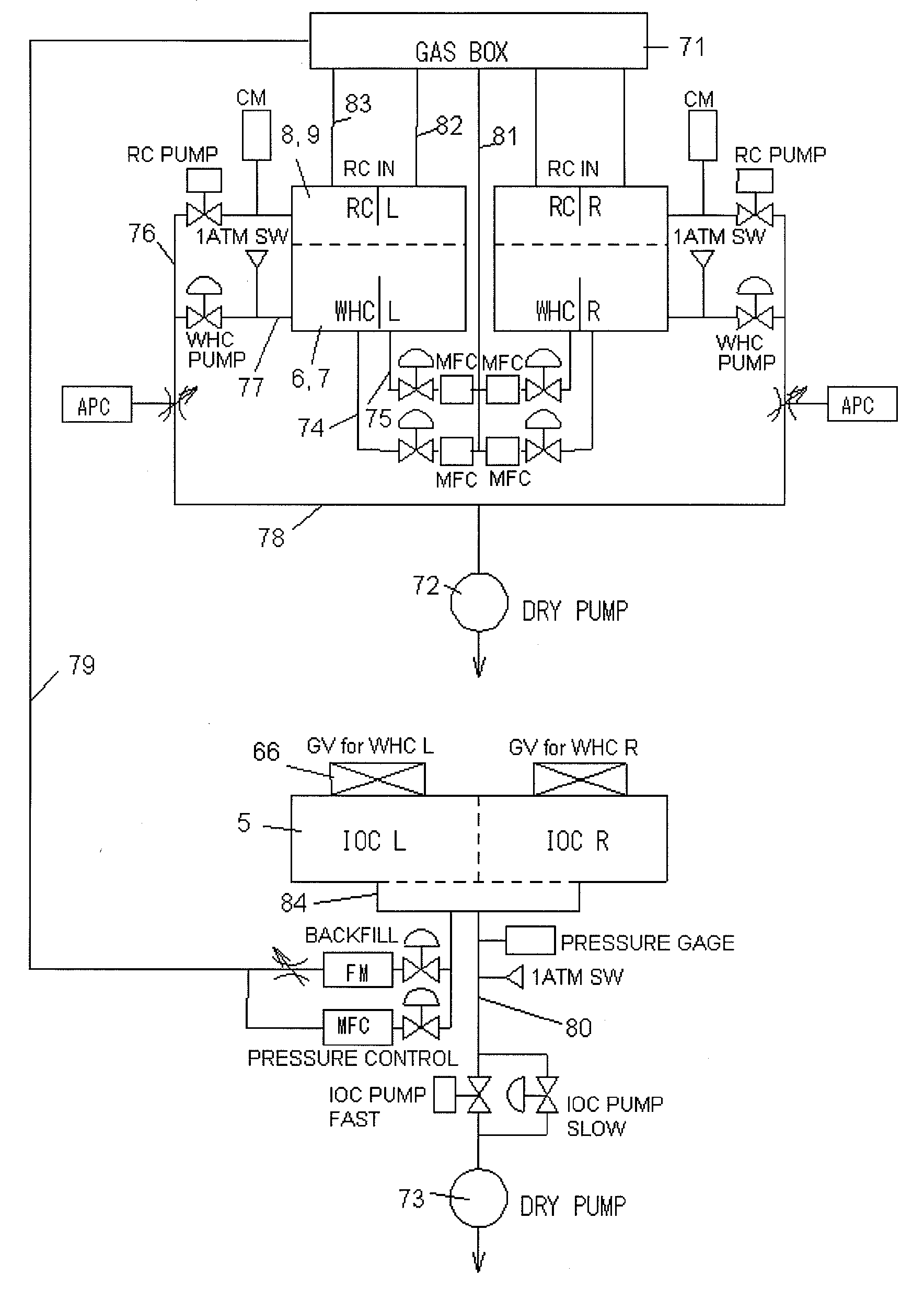

Pumping System for Atomic Layer Deposition

InactiveUS20070095283A1Semiconductor/solid-state device manufacturingPipeline systemsEngineeringReaction zone

A pumping apparatus for evacuating a reactant from a reactive region includes a vacuum able chamber, a hearth for supporting a workpiece, one or more gas introduction valves, one or more exhaust evacuation valves, and an adjustable valve providing one or more pathways there through formed by alignment of separate components of the valve, the components perforated with two or more openings to form the pathways.

Owner:GALEWSKI CARL JOHAN

Assay Cartridges and Methods of Using the Same

ActiveUS20110201099A1Easy sample collectionFacilitate assay processingBioreactor/fermenter combinationsHeating or cooling apparatusEngineeringSample chamber

Assay cartridges are described that have a detection chamber, preferably having integrated electrodes, and other fluidic components which may include sample chambers, waste chambers, conduits, vents, bubble traps, reagent chambers, dry reagent pill zones and the like. In certain embodiments, these cartridges are adapted to receive and analyze a sample collected on an applicator stick. Also described are kits including such cartridges and a cartridge reader configured to analyze an assay conducted using an assay cartridge.

Owner:MESO SCALE TECH LLC

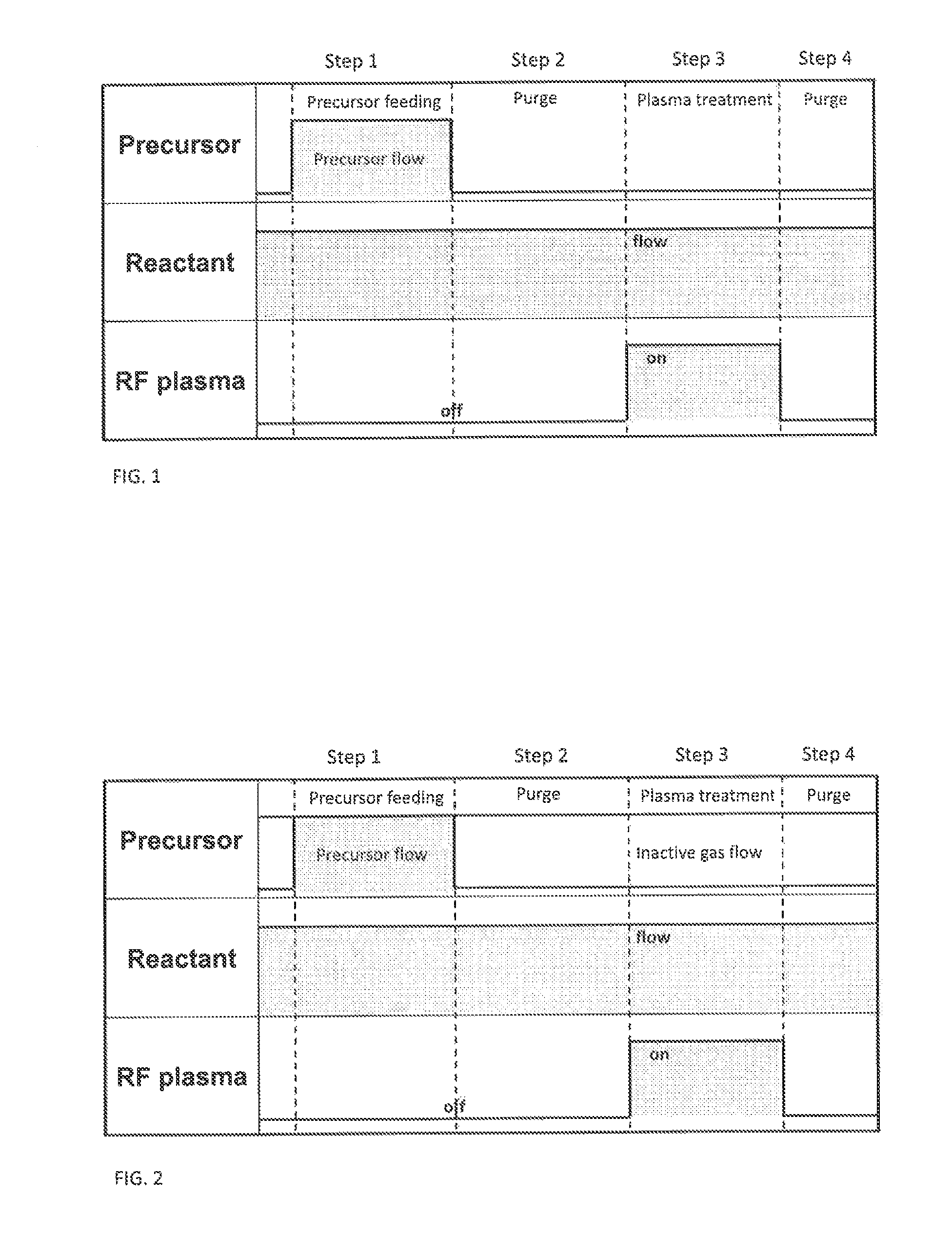

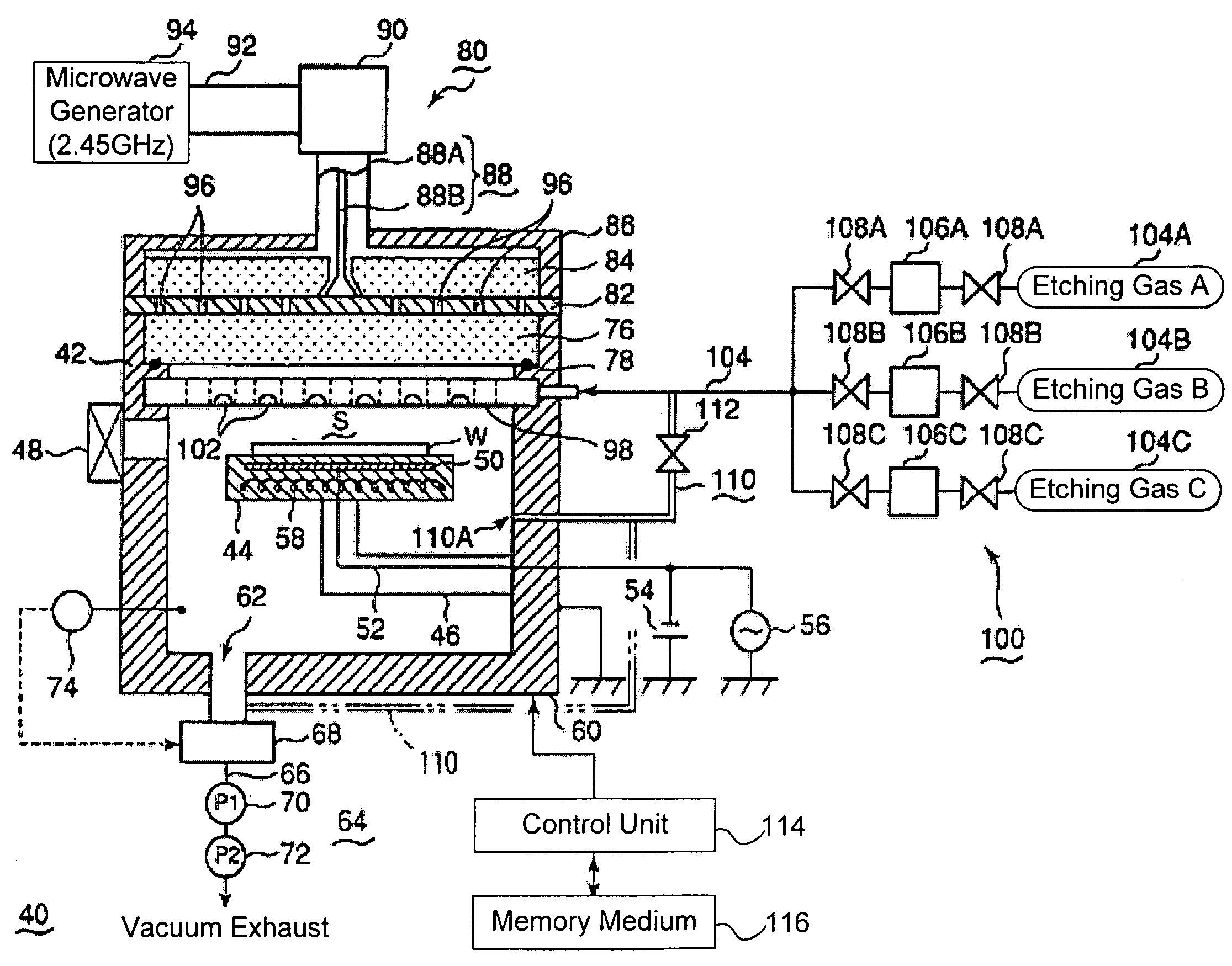

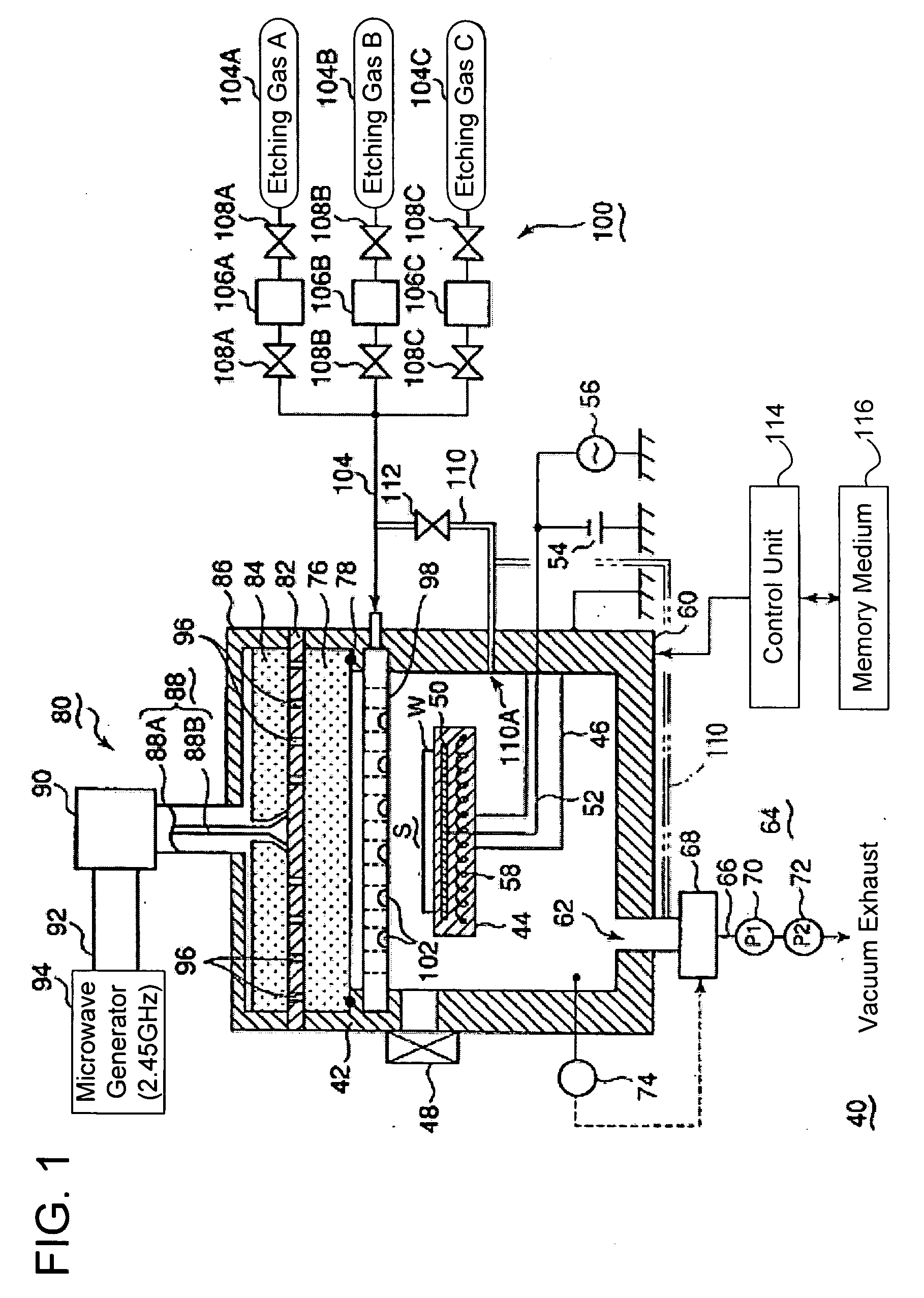

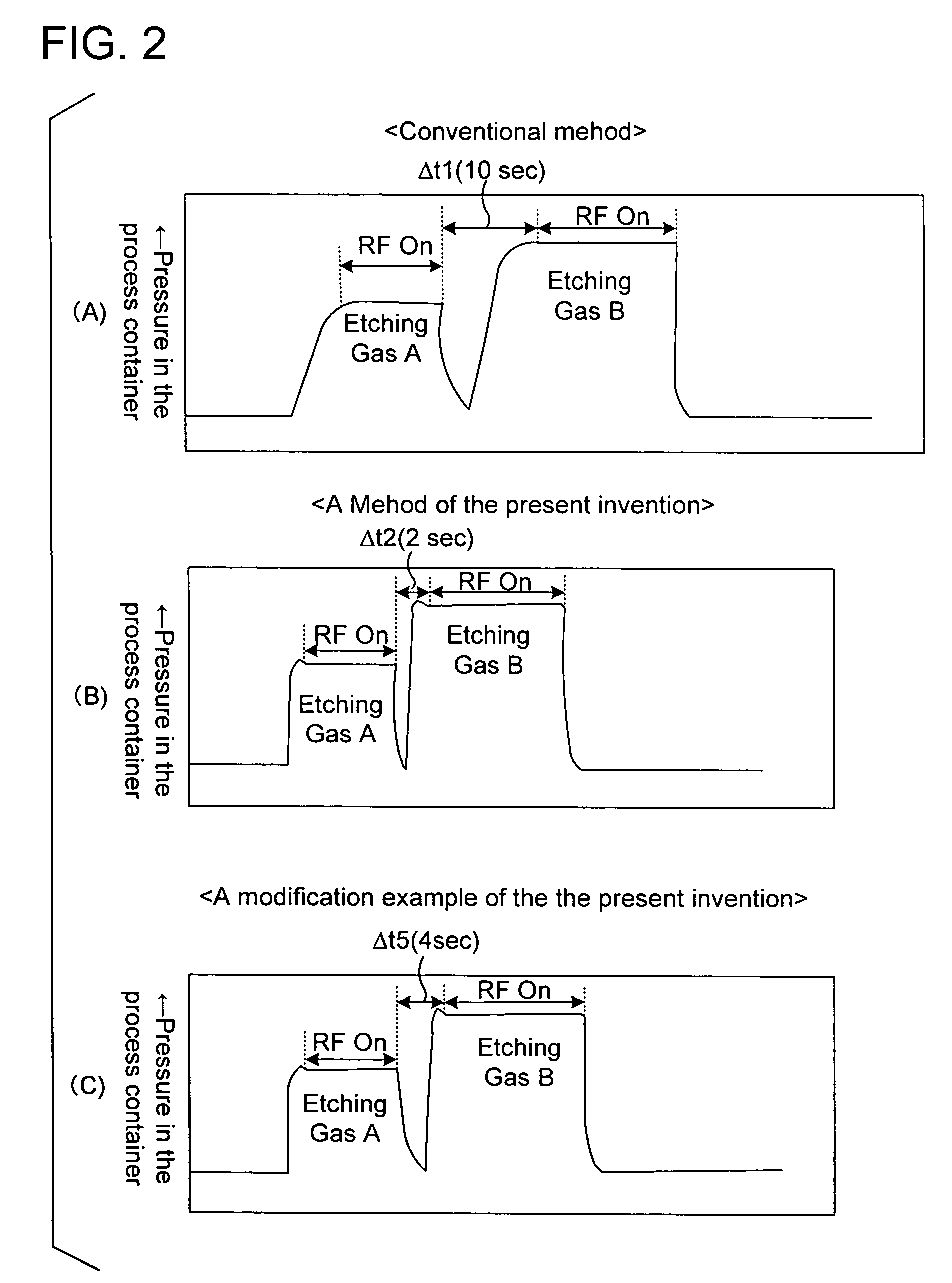

Processing Apparatus and Processing Method

ActiveUS20090053900A1Stable and fastAddressing slow performanceLiquid surface applicatorsElectric discharge tubesProduct gasEngineering

A processing apparatus includes a process container having a placing table for placing a processing object, an exhaust system having vacuum pumps and a pressure control valve for exhausting atmosphere in the process container. A gas injection unit having a gas ejection hole is provided in the process container, as well as a gas supplying unit for supplying a process gas to the gas injection unit. The entire process apparatus is controlled by a controlling unit. The control unit controls the exhaust system and the gas supplying unit. When starting a predetermined process, the process gas at a flow rate greater than a prescribed flow rate is supplied for a short time while exhausting the atmosphere in the process container by the exhaust system, and then the process gas at a prescribed flow rate is supplied.

Owner:TOKYO ELECTRON LTD

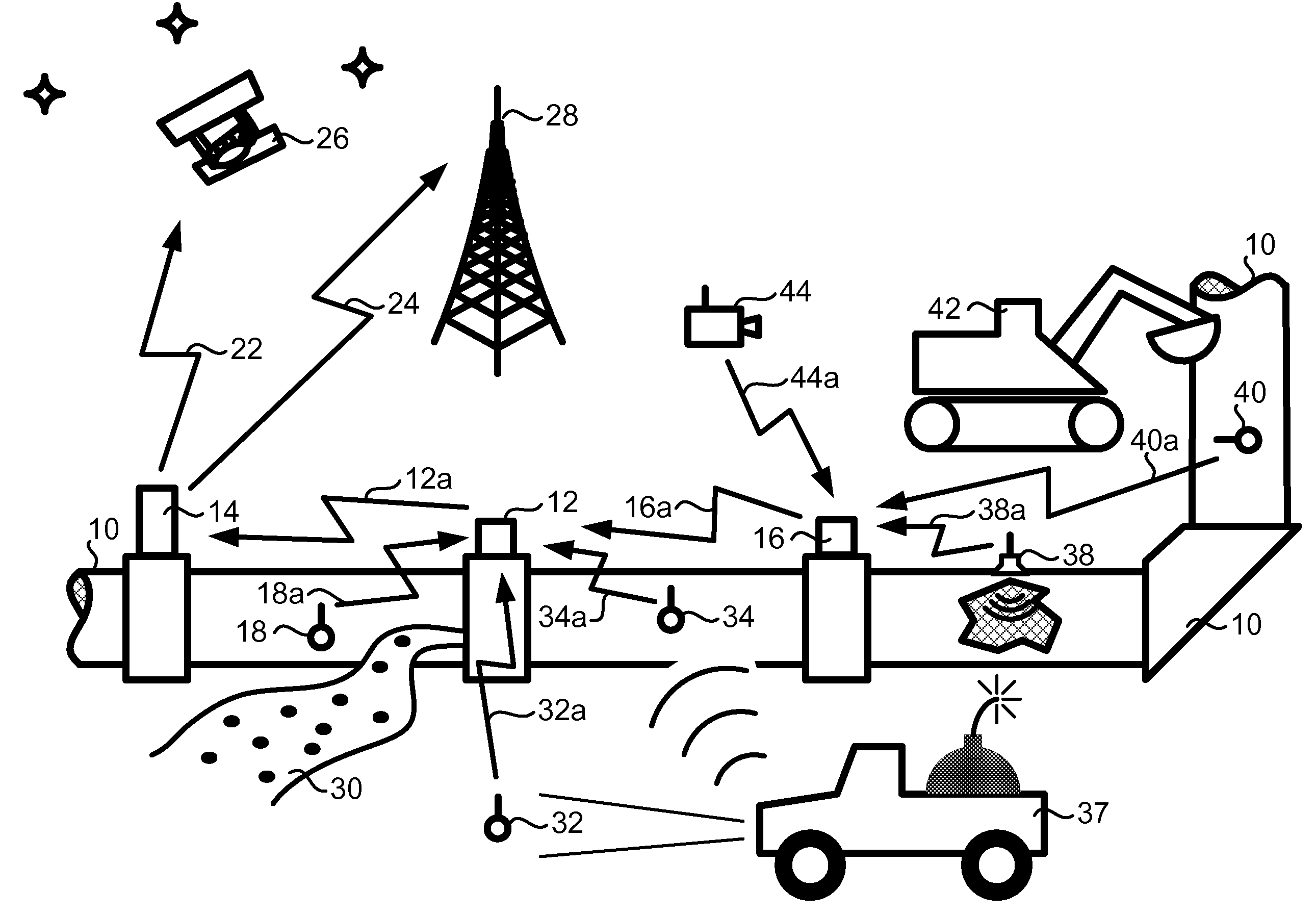

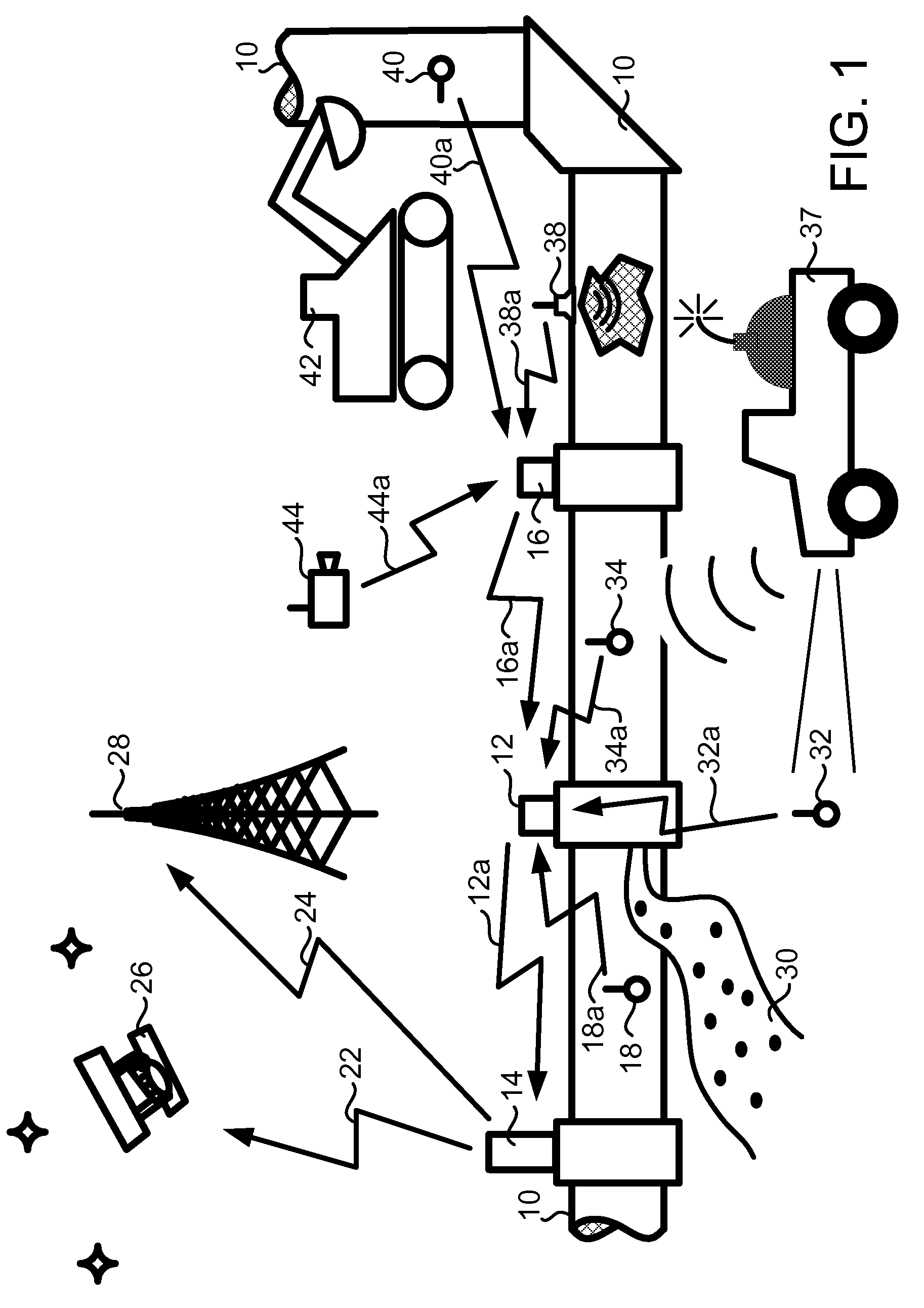

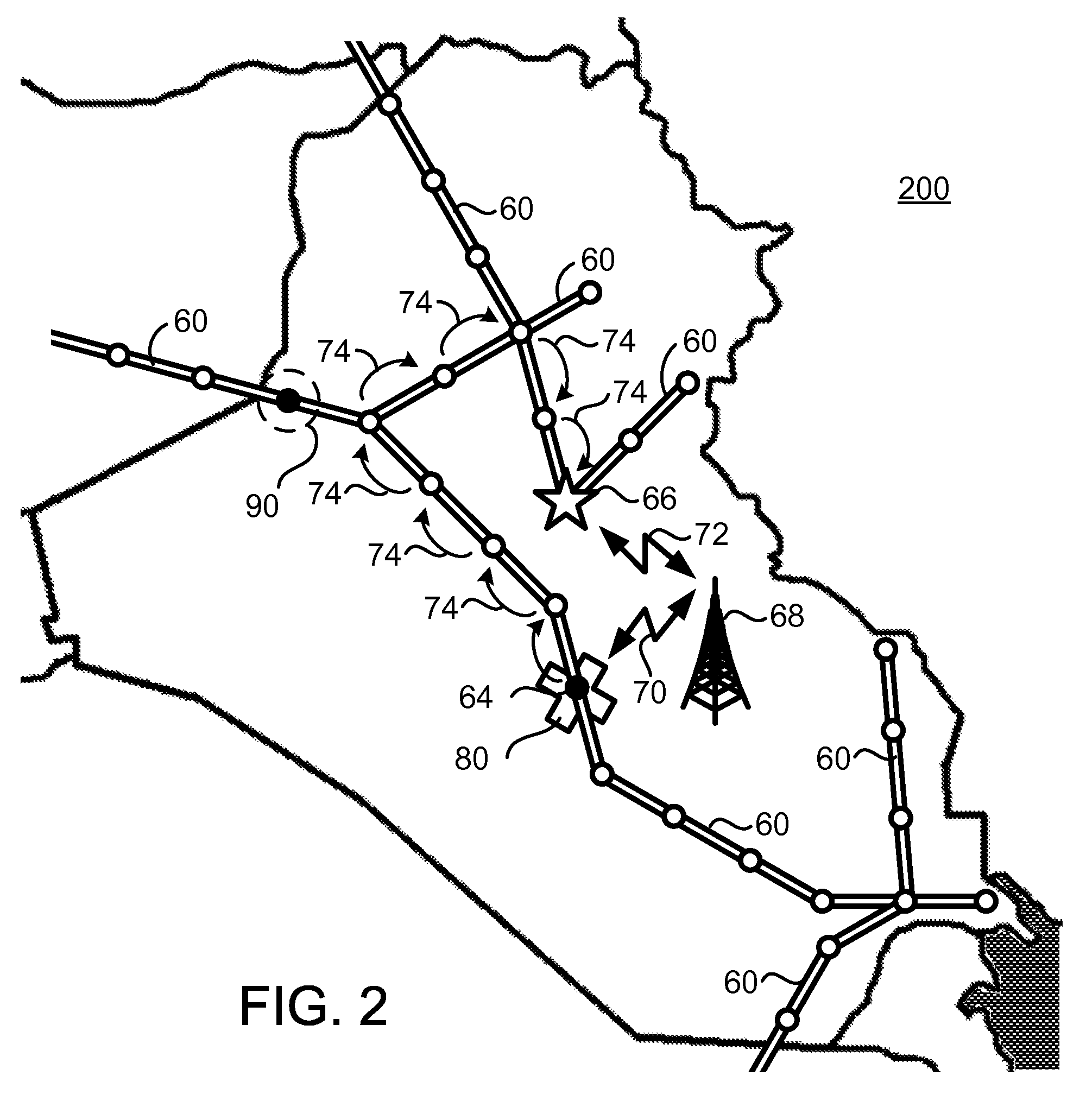

Sensor networks for monitoring pipelines and power lines

ActiveUS7705747B2Detection of fluid at leakage pointElectric signal transmission systemsEngineeringCommunication device

Owner:GOOGLE LLC

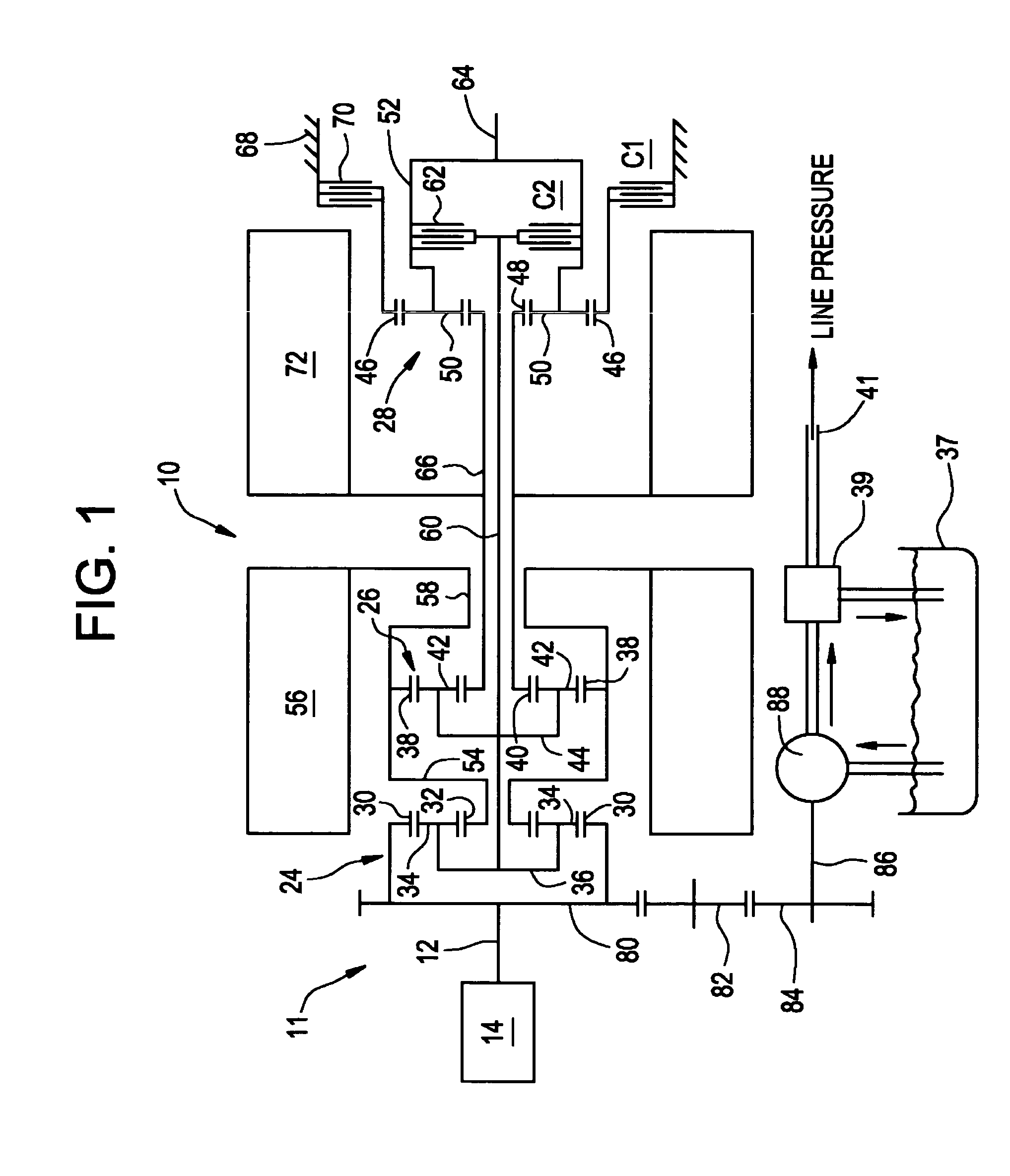

Control apparatus, method and diagnostic for hydraulic fill and drain

ActiveUS20050076958A1Improve robustnessHybrid vehiclesFluid-pressure actuator safetyControl theoryControl equipment

Hydraulic fill and drain of a clutch chamber is controlled with a blocking valve and a trim valve. The blocking valve selectively provides pressurized fluid to the trim valve which in turn selectively provides the pressurized fluid to the clutch chamber. Exhausting of the clutch chamber is effected through one of two alternate paths utilizing deactivation of one of the trim and blocking valves. Back up exhausting of the clutch chamber is effected through the other of the alternative paths. Such system allows for determination of valve failures and continued operation until such failures can be rectified.

Owner:ALLISON TRANSMISSION INC

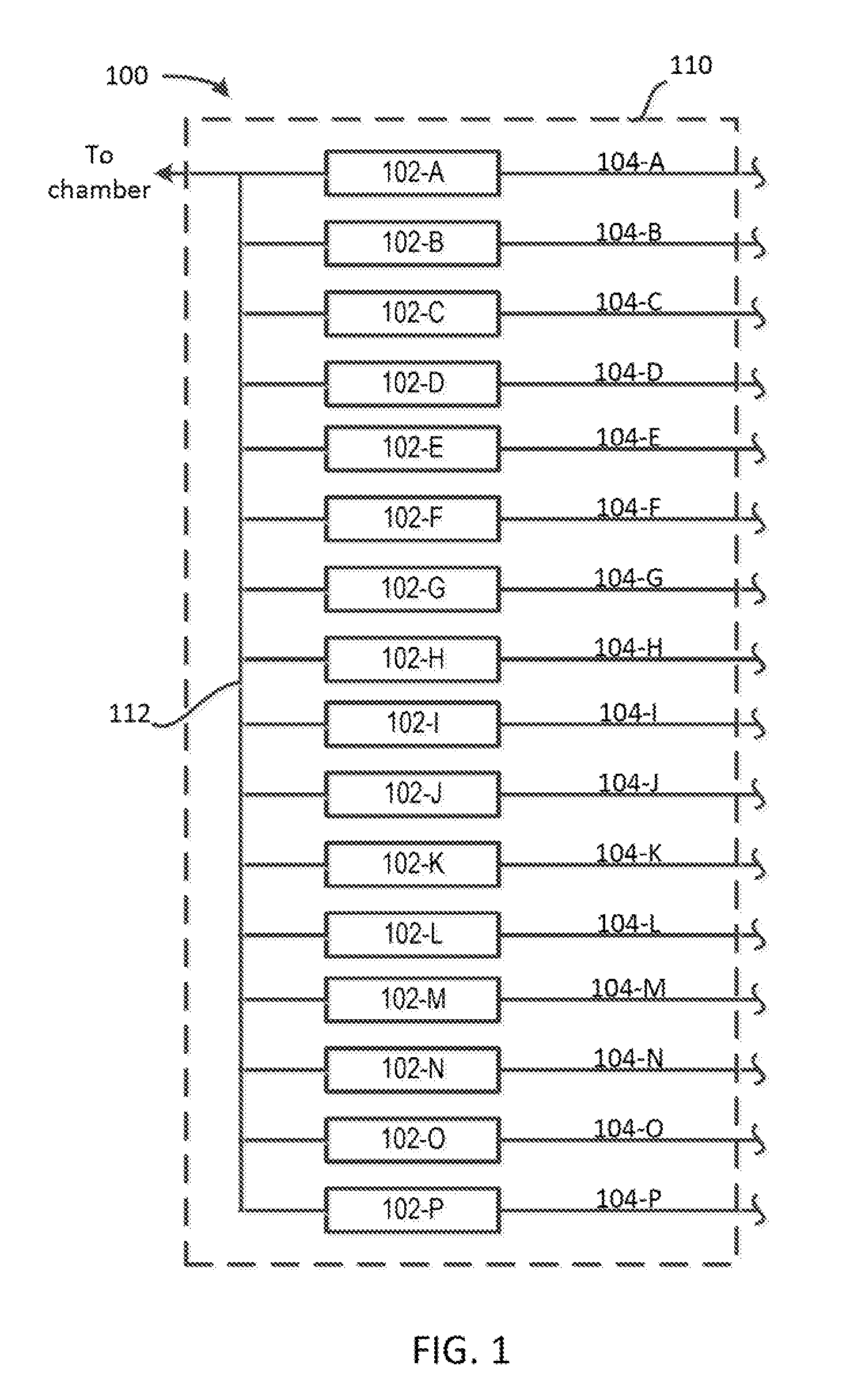

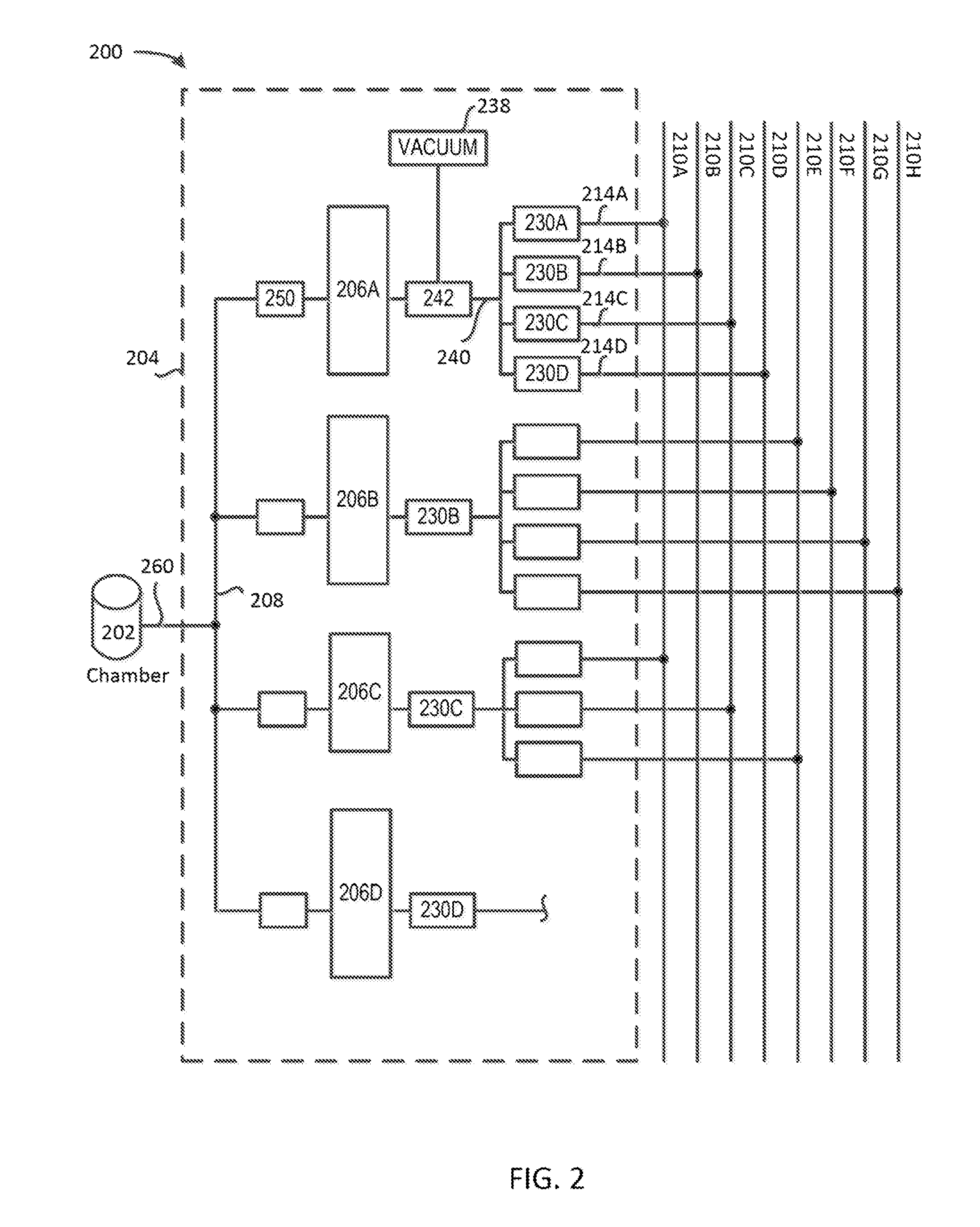

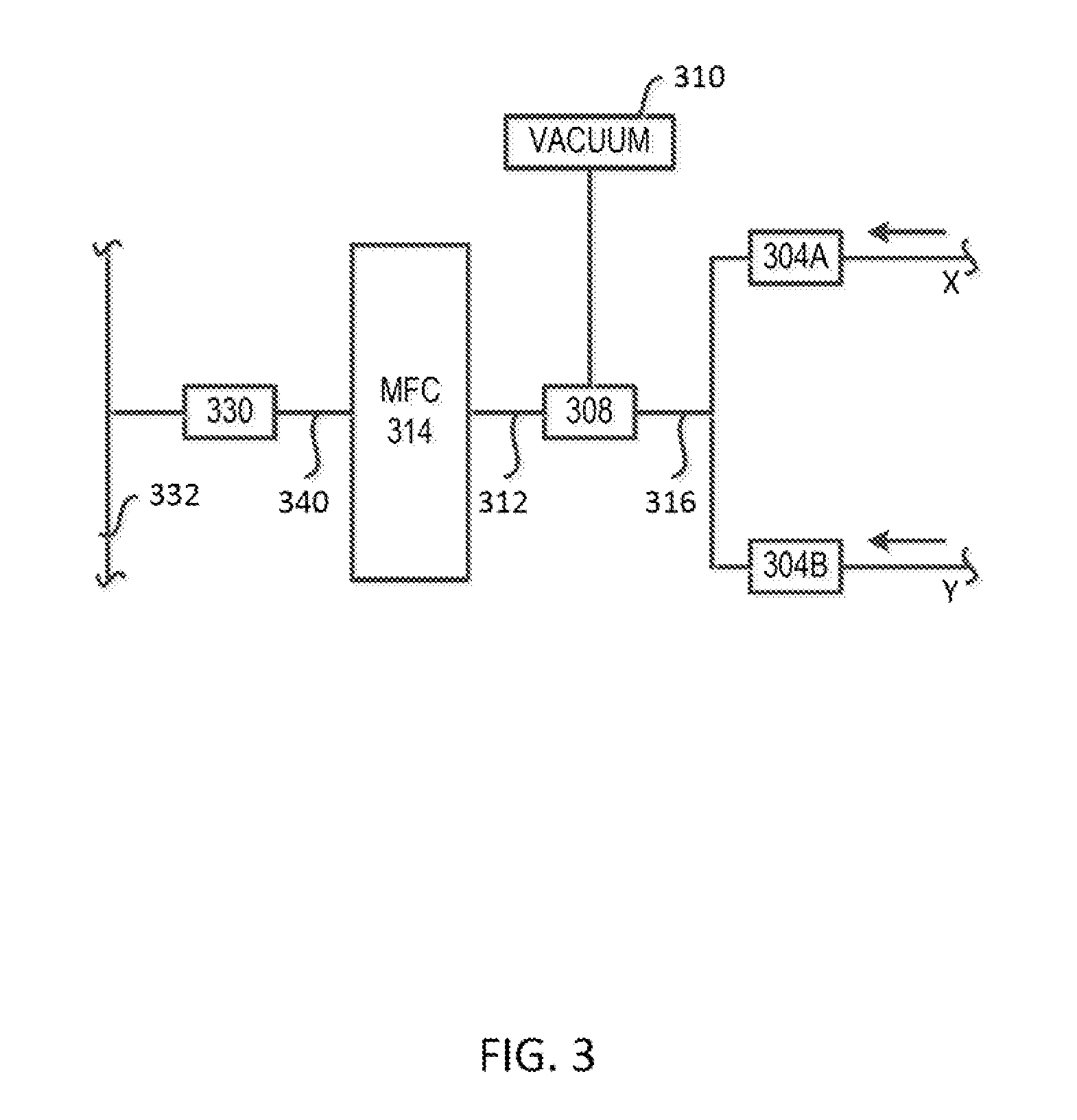

Gas supply systems for substrate processing chambers and methods therefor

ActiveUS20140182689A1Electric discharge tubesFlow control using electric meansMultiplexingProcess engineering

A gas supply subsystem for providing a set of process gases to a substrate processing chamber, the set of process gases being a subset of a plurality of process gases available to the substrate processing chamber. The gas supply subsystem has fewer multi-gas mass flow controllers than the number of available process gases, wherein multiple process gases are multiplexed at the input of one or more of the multi-gas mass flow controllers. Pump-purge may be employed to improve gas switching speed for the multi-gas mass flow controllers

Owner:LAM RES CORP

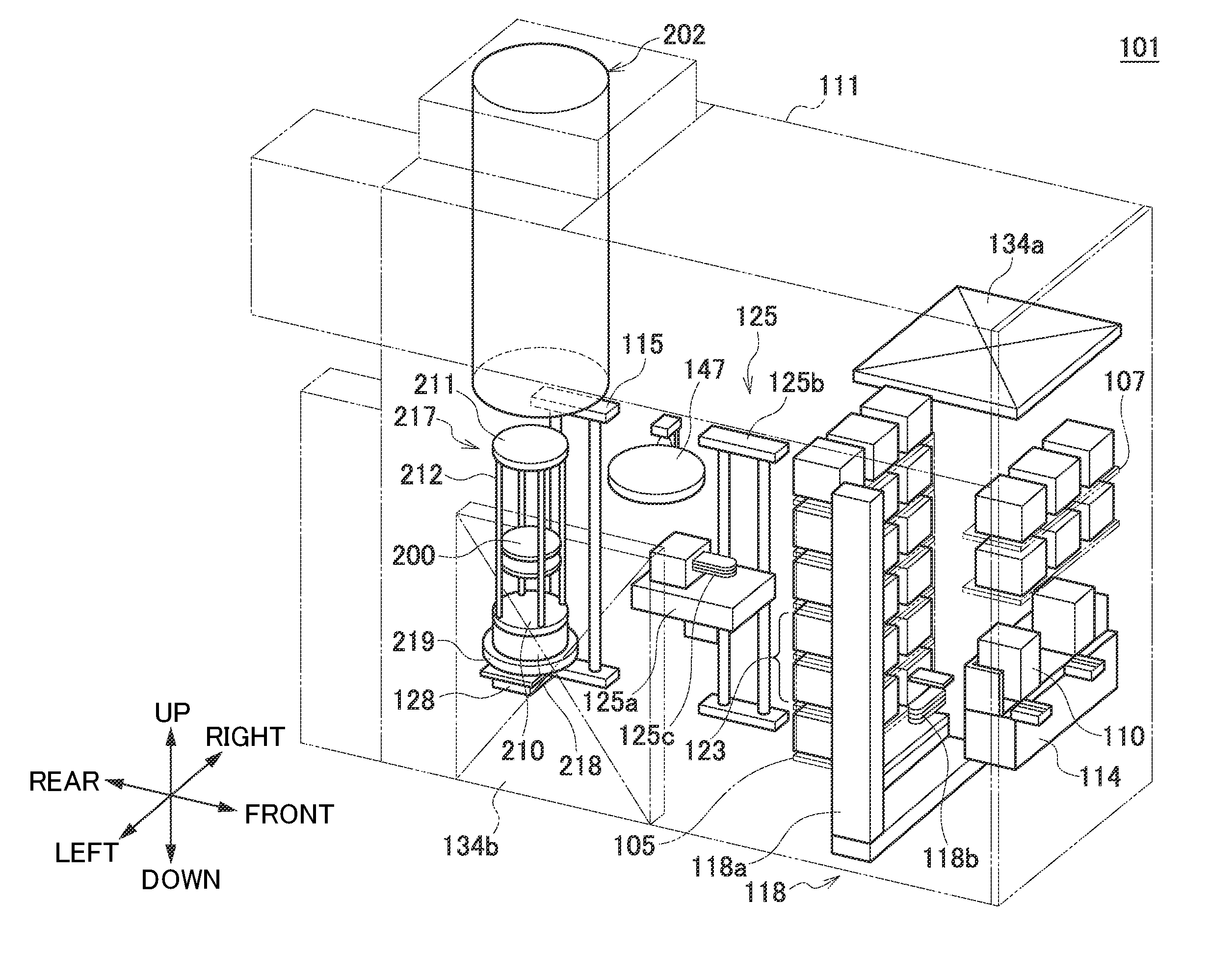

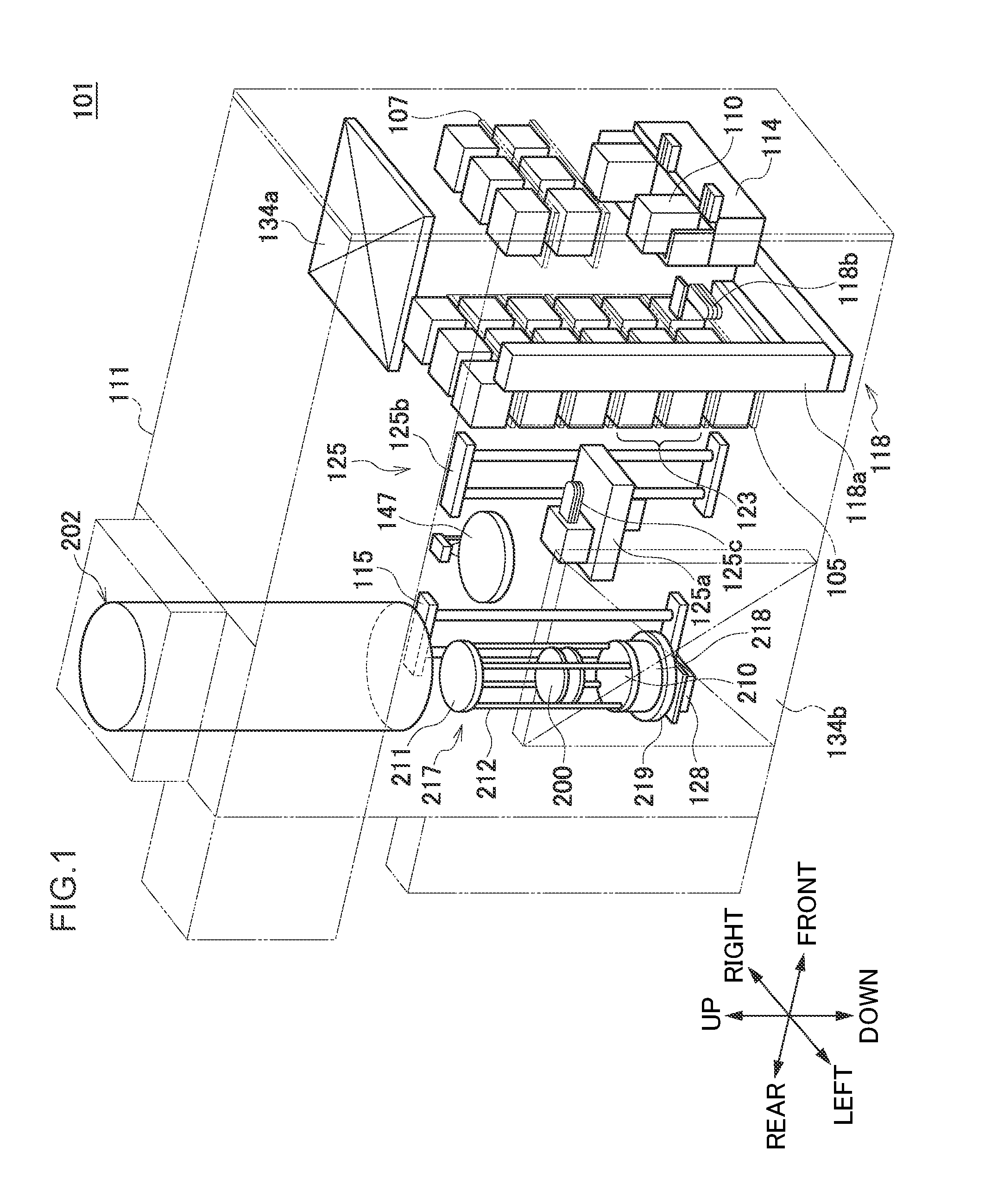

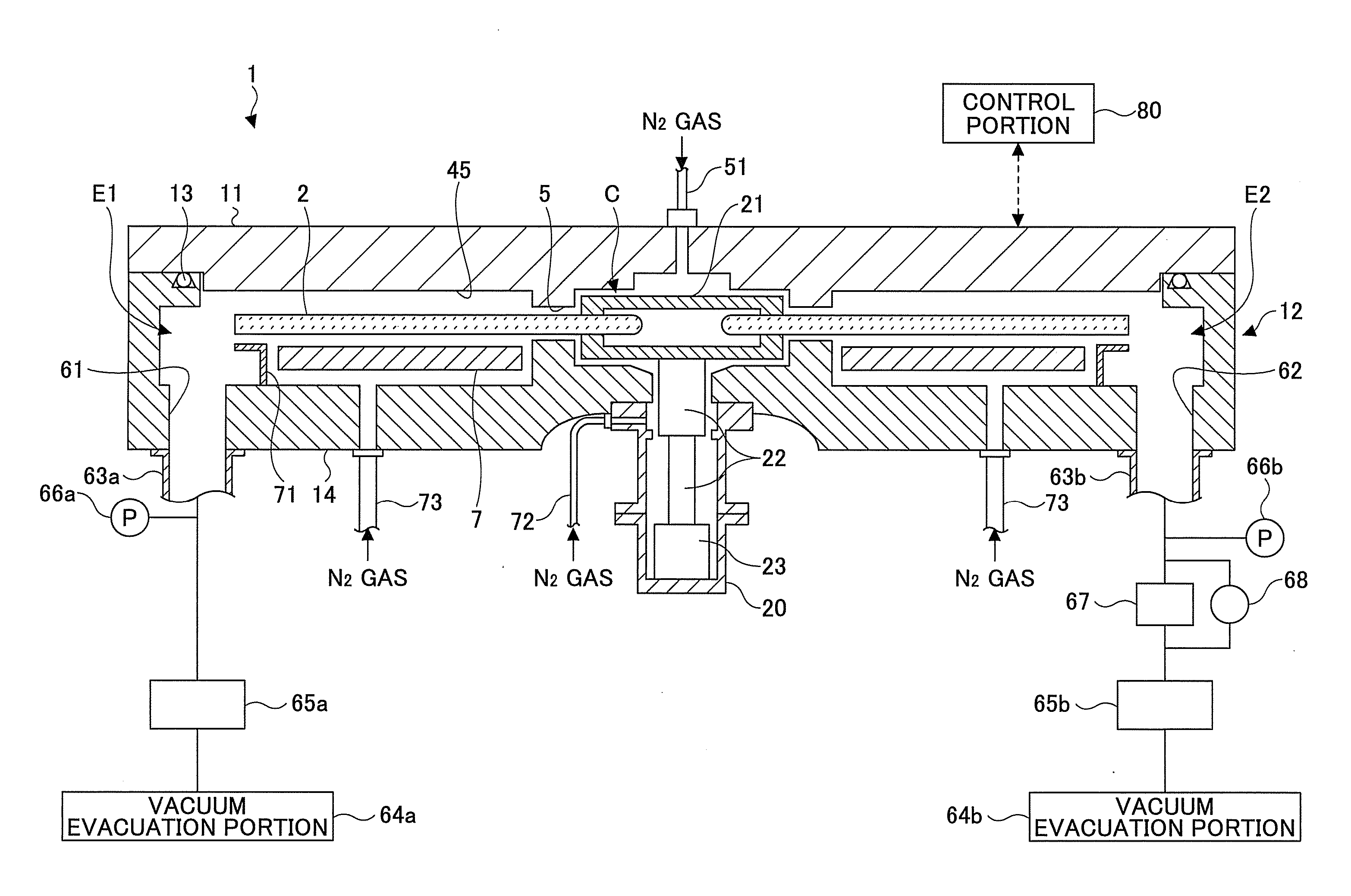

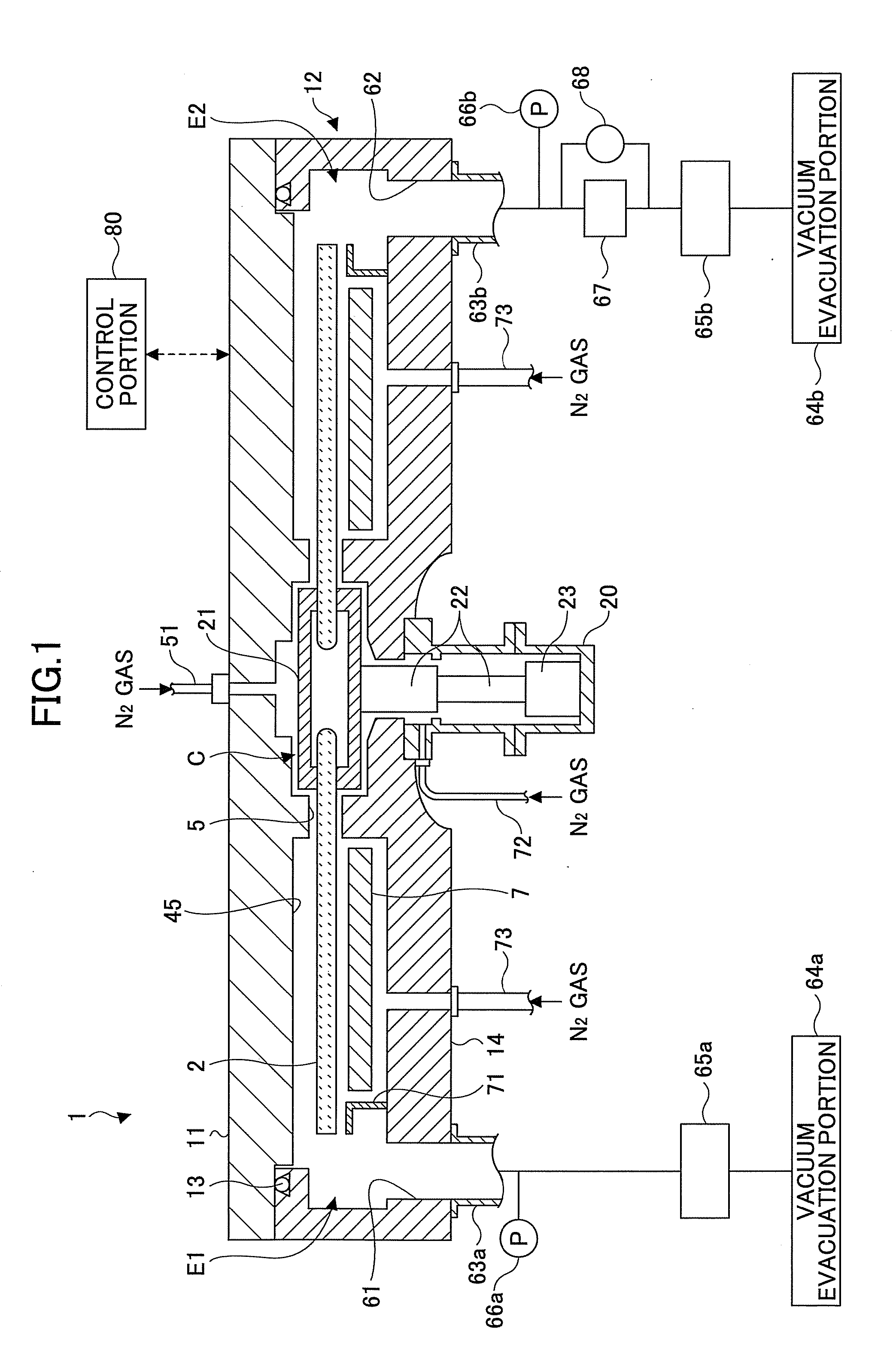

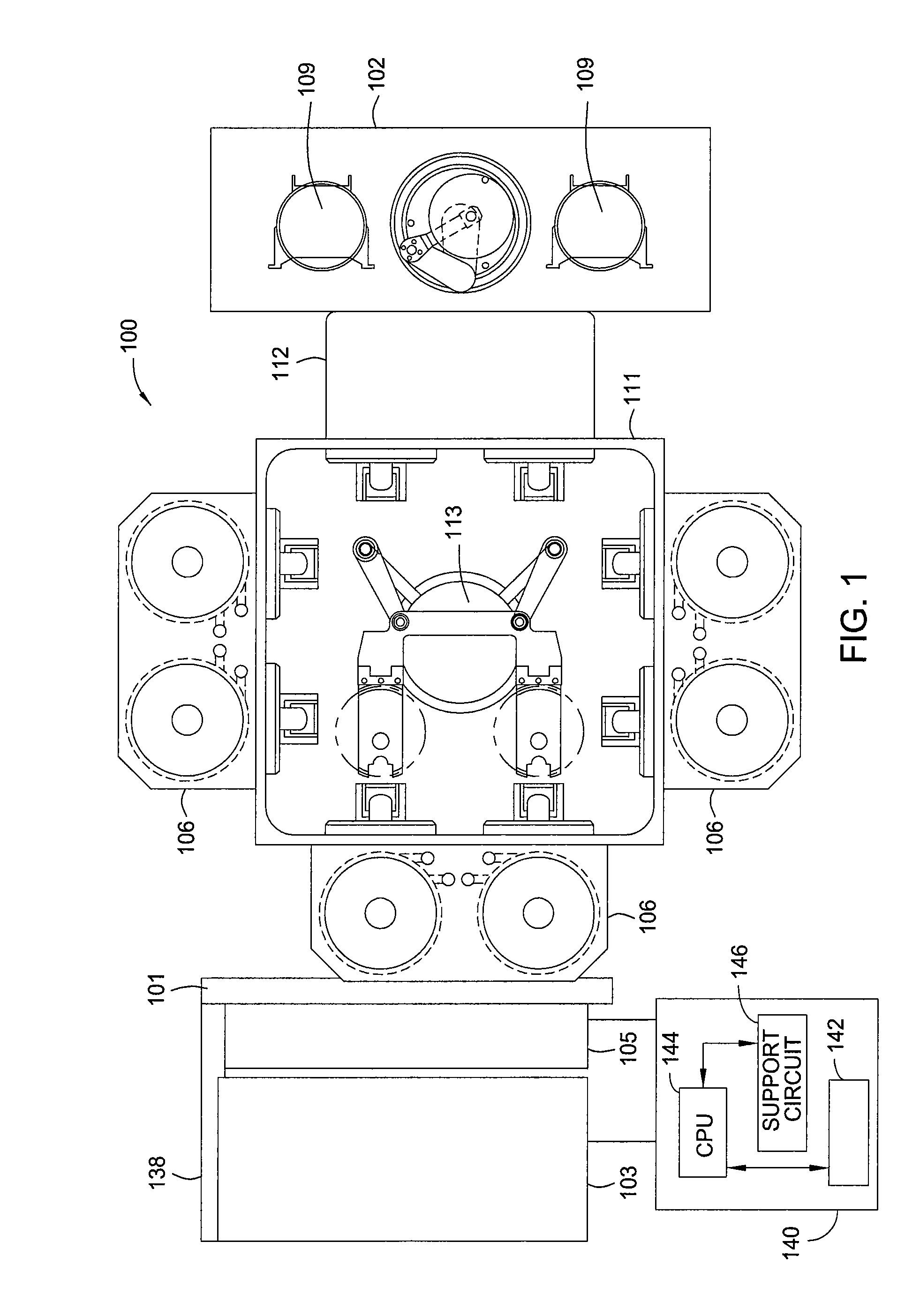

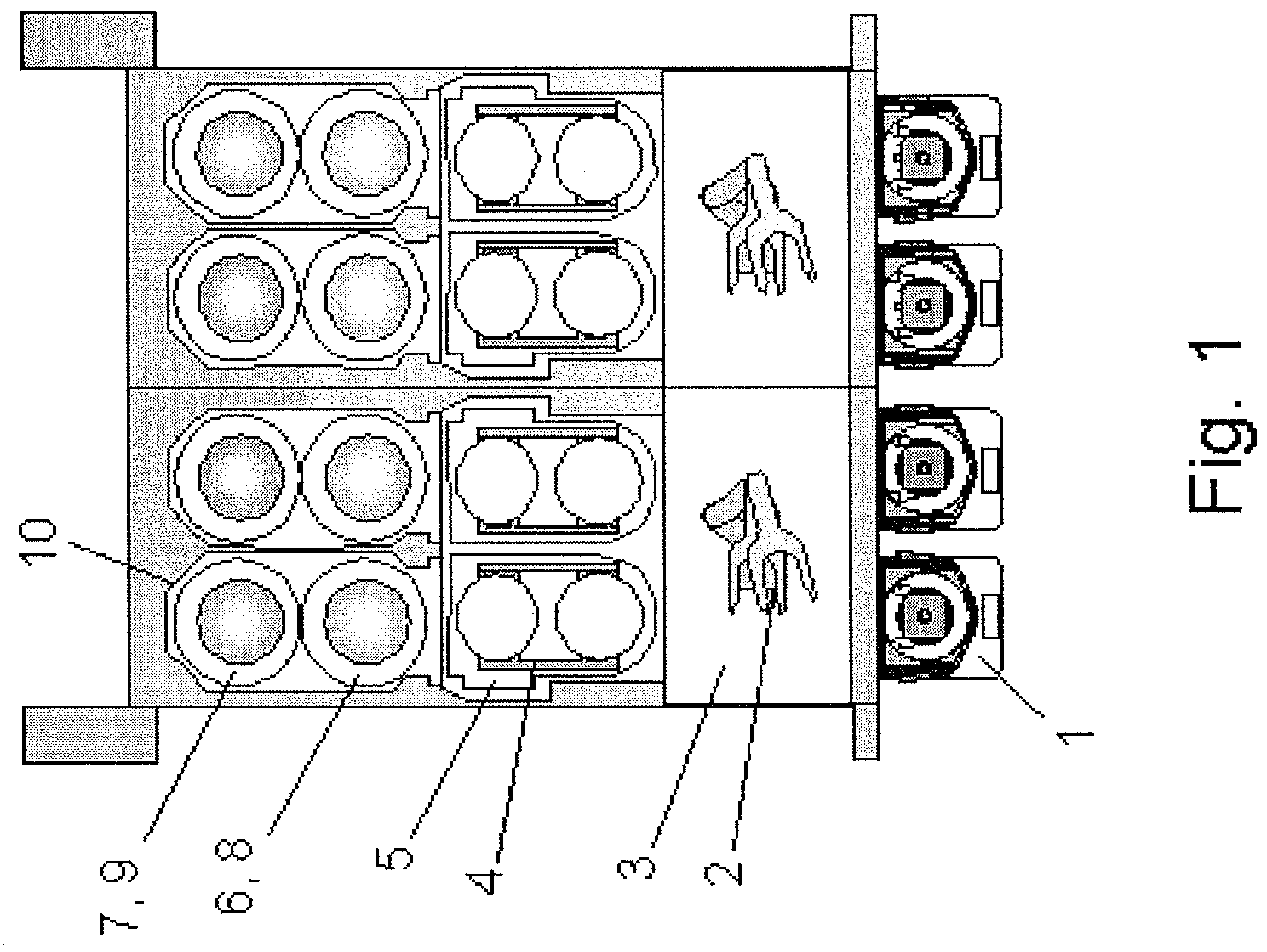

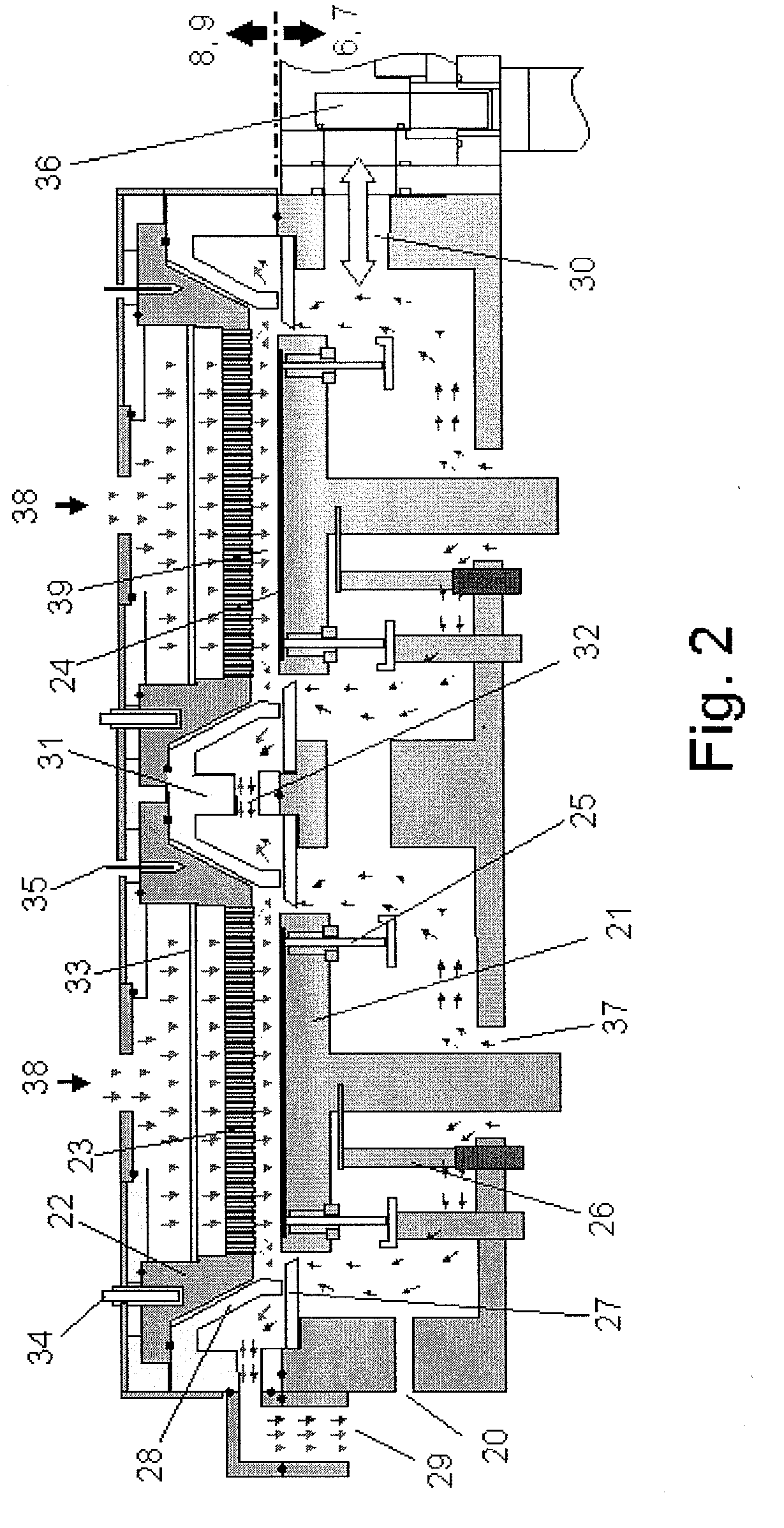

Multiple-Substrate Transfer Apparatus and Multiple-Substrate Processing Apparatus

InactiveUS20100147396A1Cost per throughputSmall footprintHollow article cleaningCombustion enginesEngineeringMechanical engineering

A multiple-substrate processing apparatus includes: a reaction chamber comprised of two discrete reaction stations aligned one behind the other for simultaneously processing two substrates; a transfer chamber disposed underneath the reaction chamber, for loading and unloading substrates to and from the reaction stations simultaneously; and a load lock chamber disposed next to the transfer chamber. The transfer arm includes one or more end-effectors for simultaneously supporting two substrates one behind the other as viewed in the substrate-loading / unloading direction.

Owner:ASM JAPAN +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com