Patents

Literature

9243results about How to "Increase flow rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

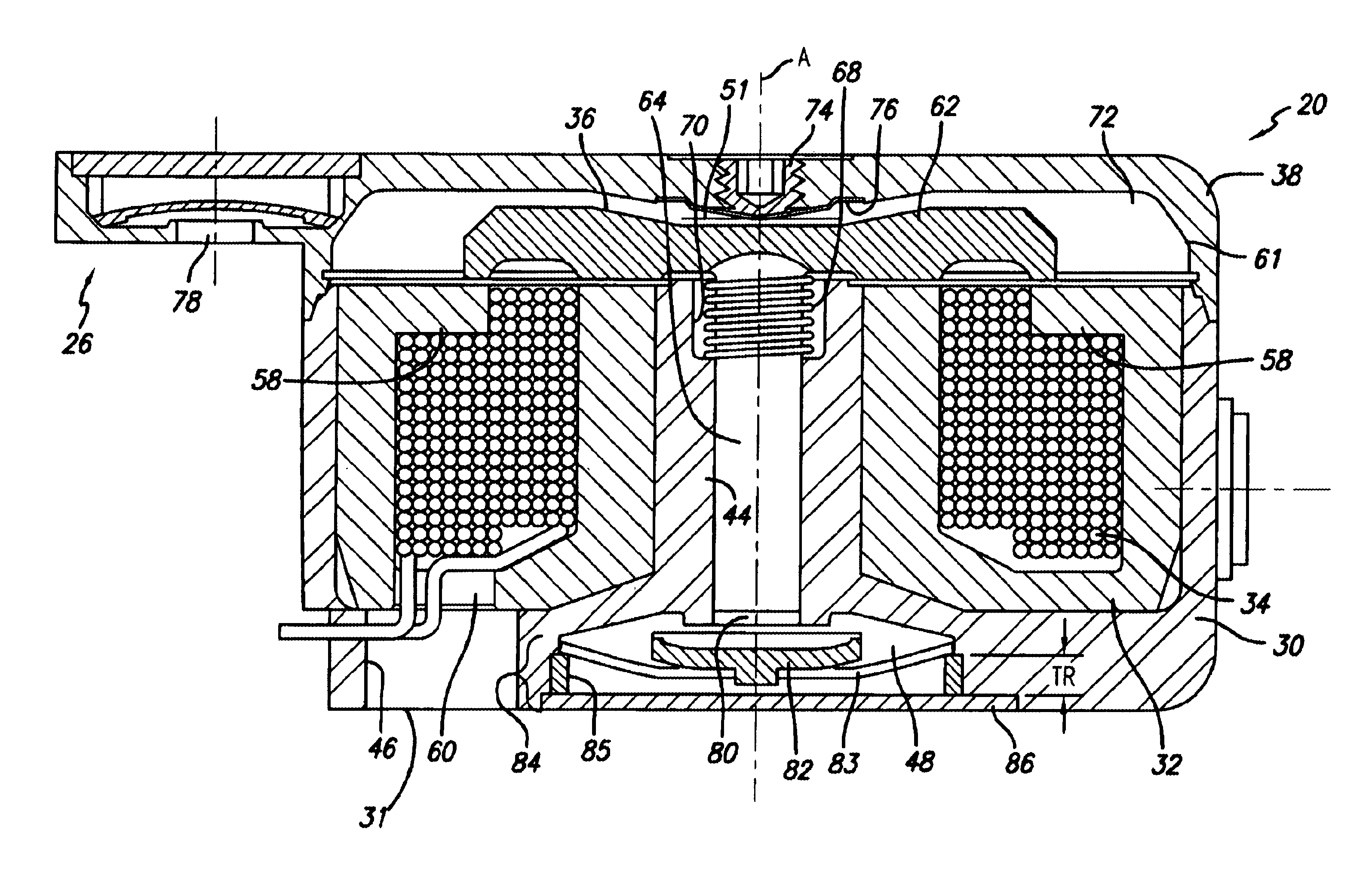

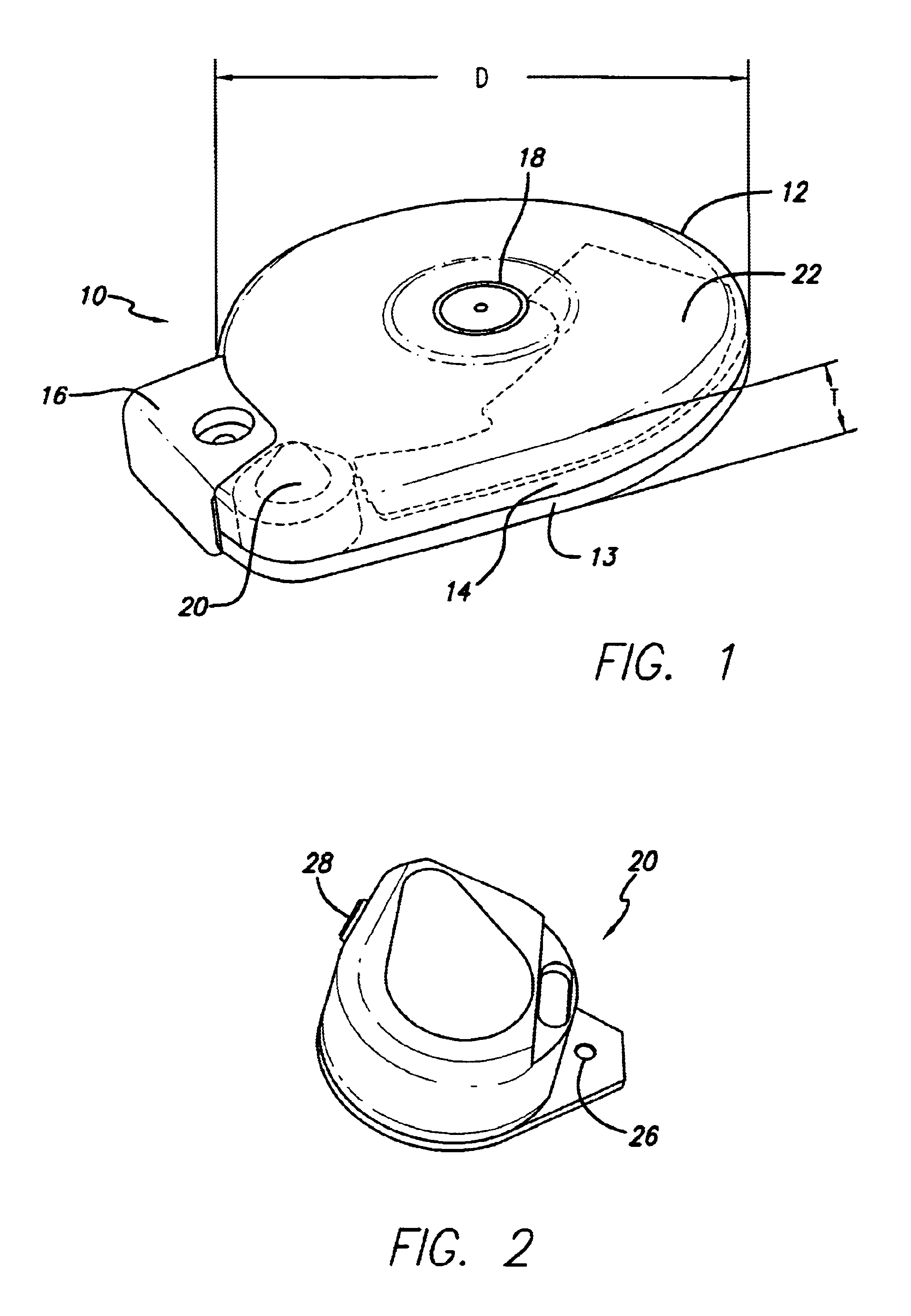

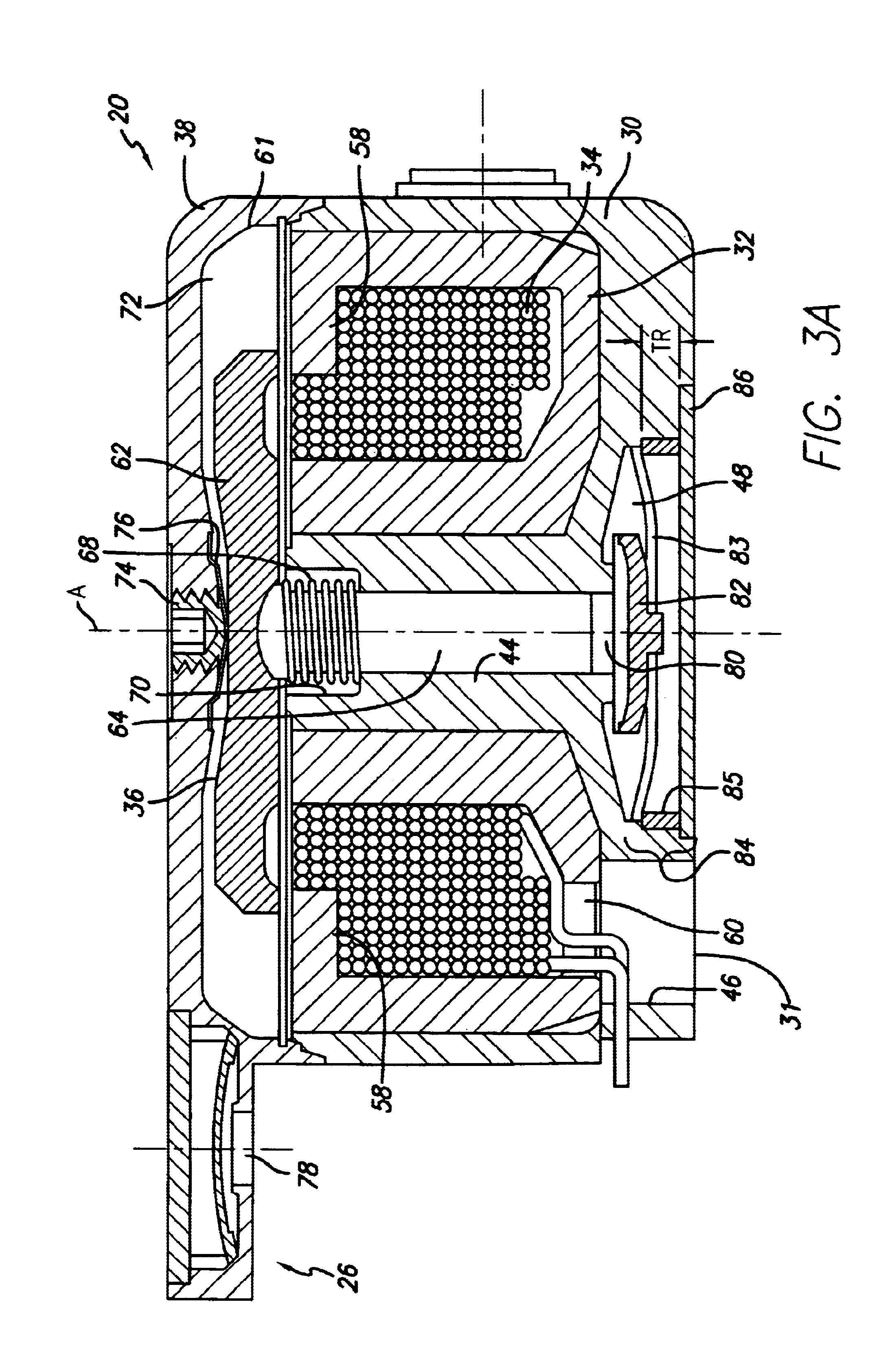

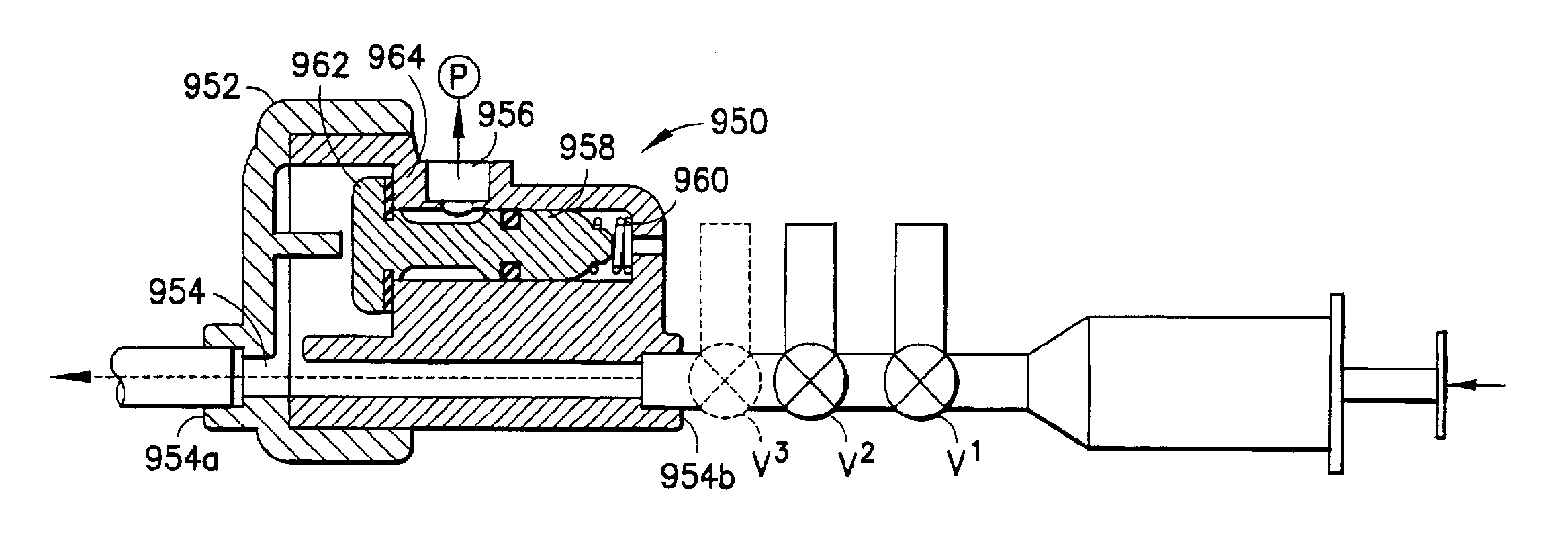

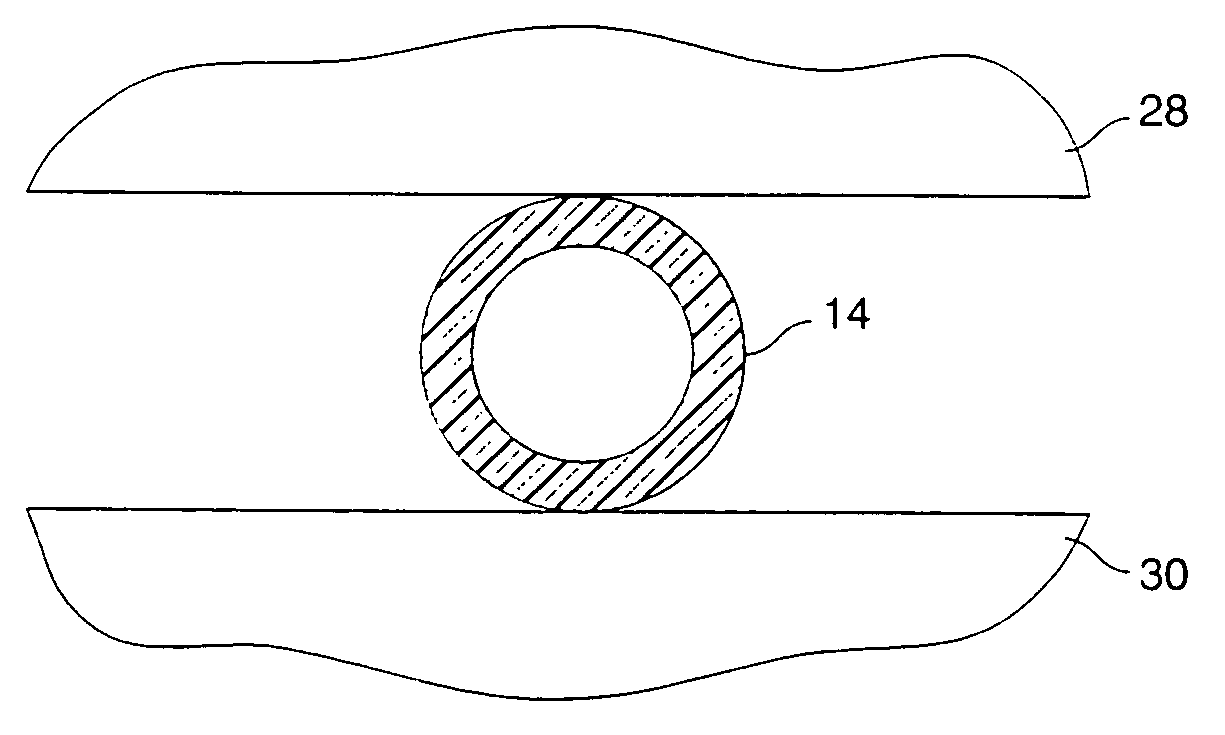

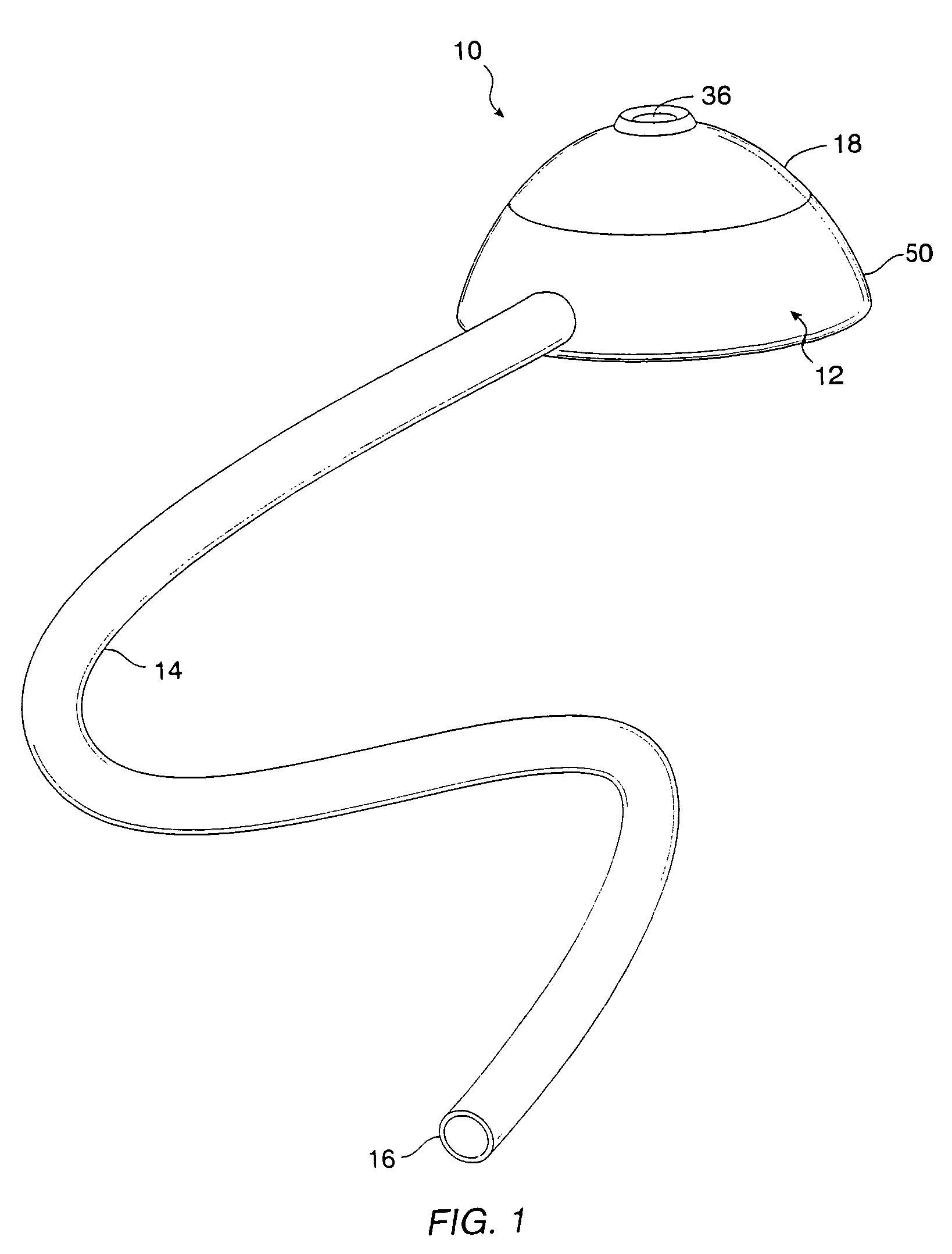

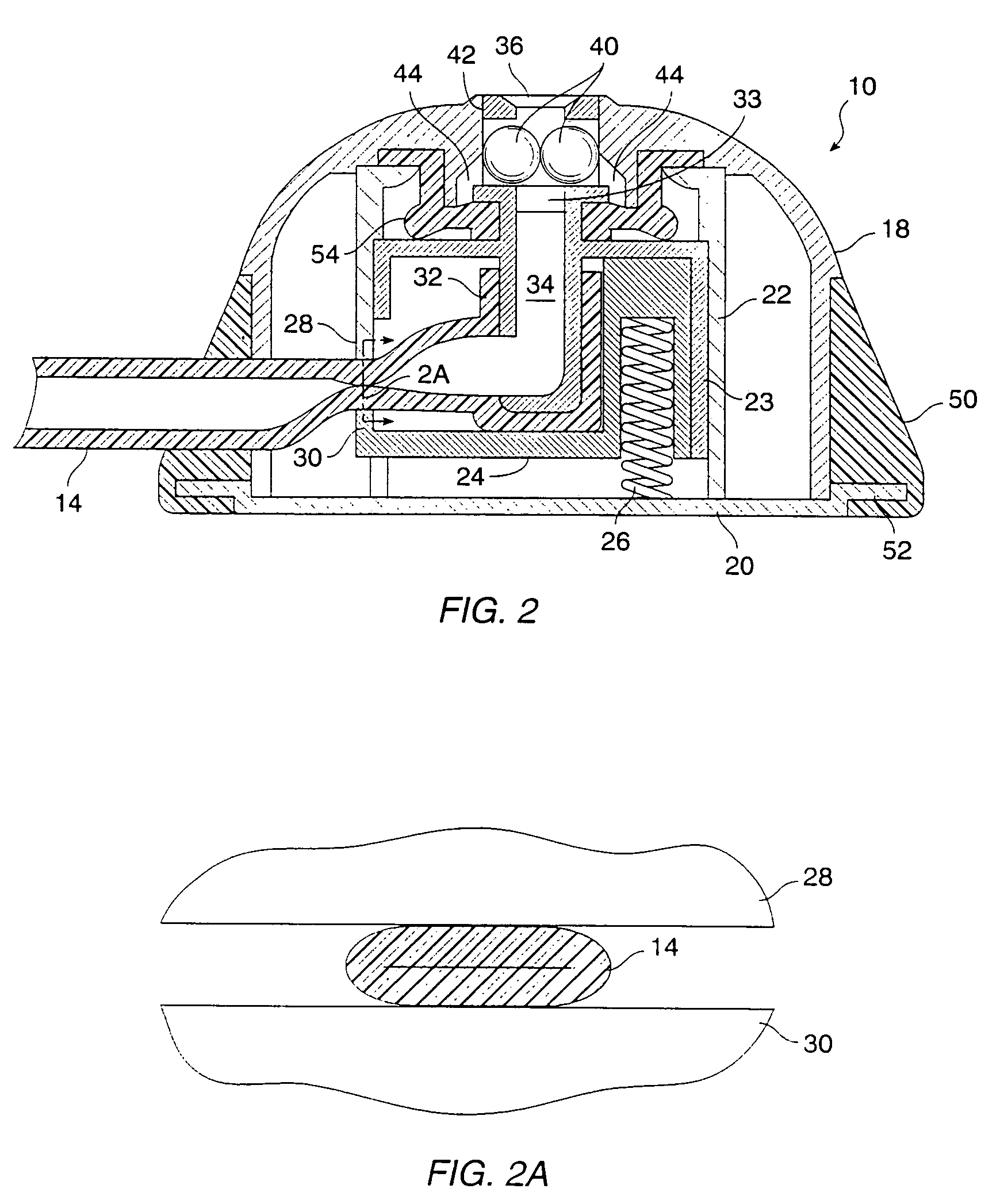

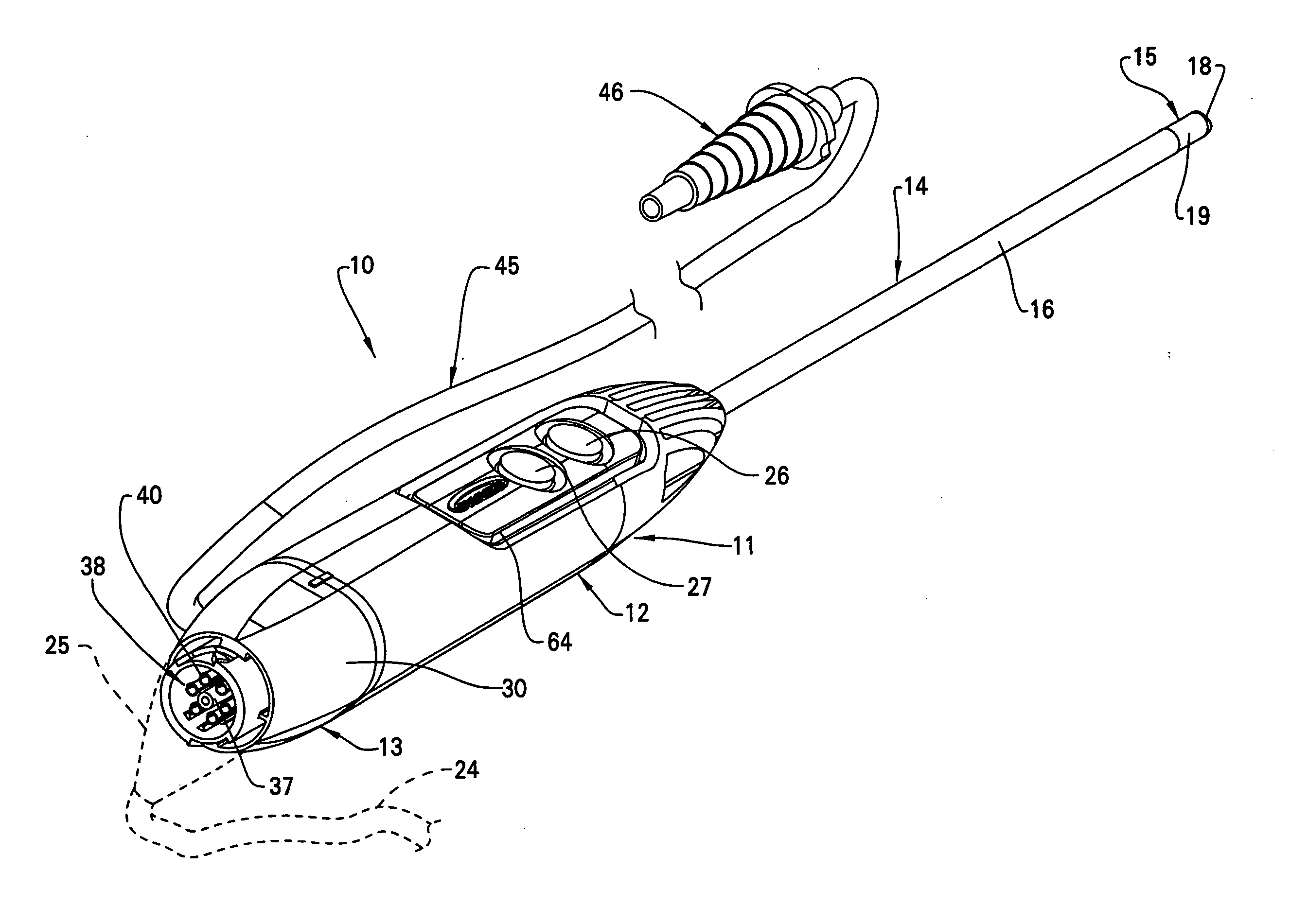

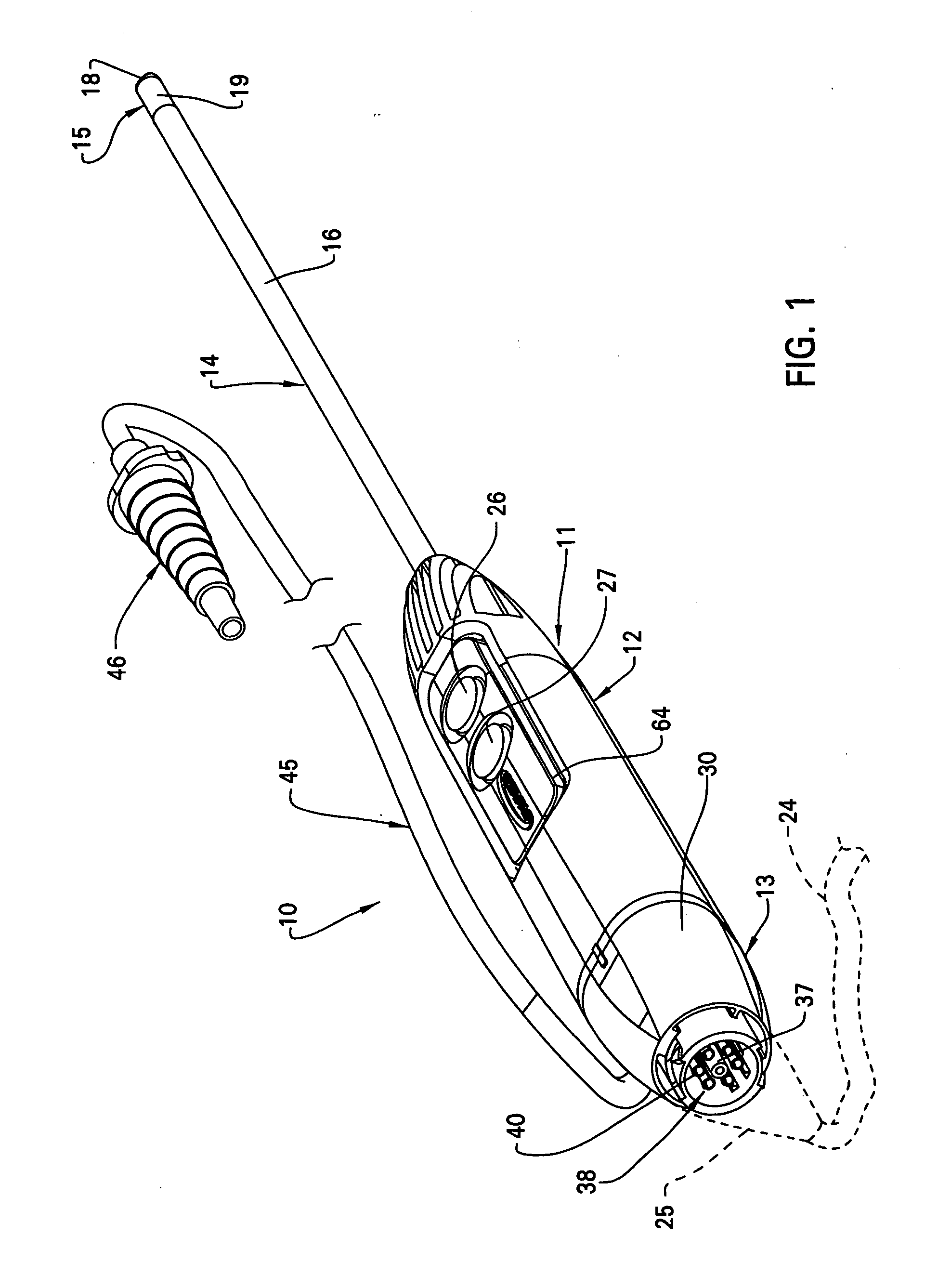

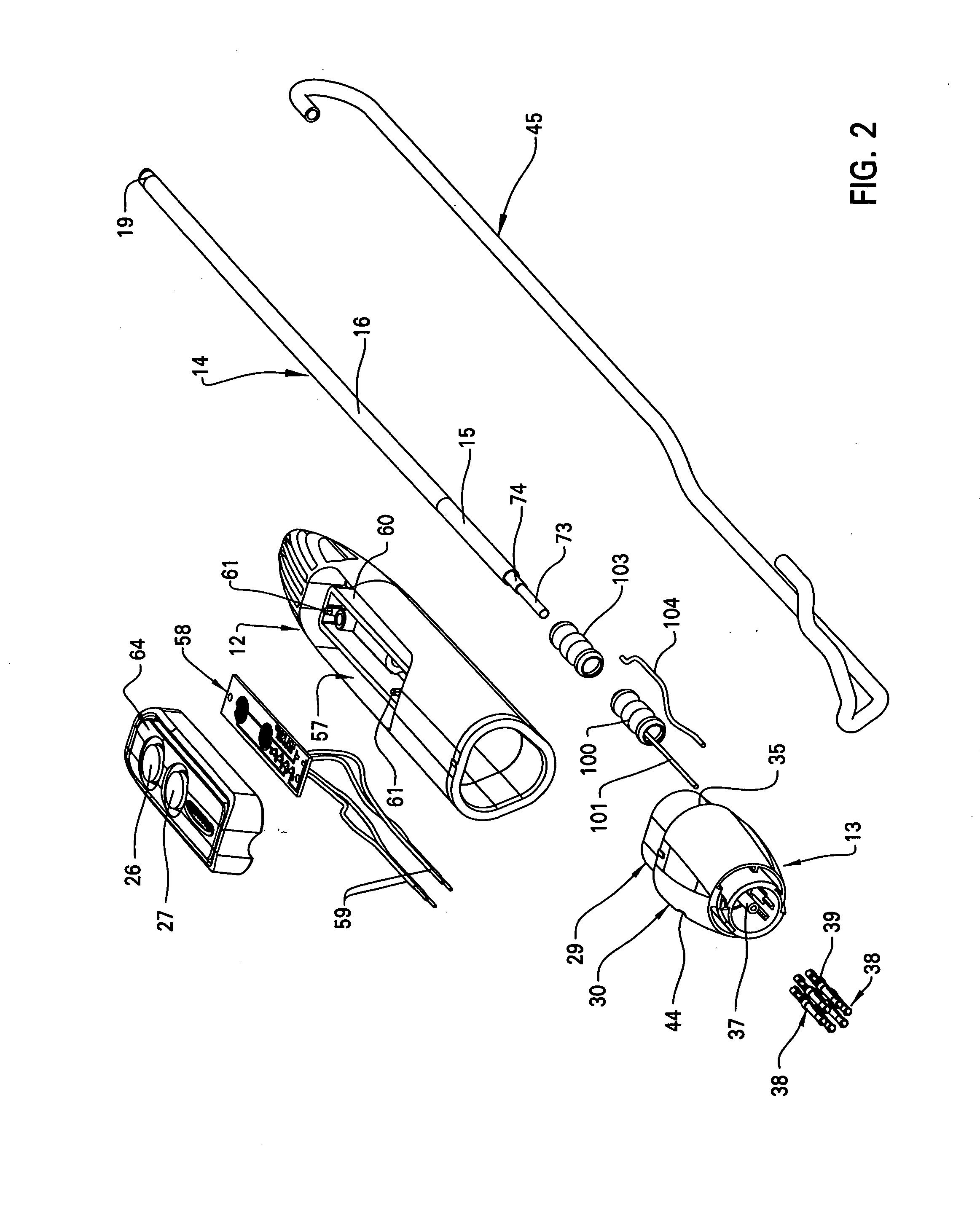

Infusion device and driving mechanism and process for same with actuator for multiple infusion uses

InactiveUS6932584B2Small thickness dimensionMinimize traumaIntravenous devicesPiston pumpsEngineeringActuator

Owner:MEDTRONIC MIMIMED INC

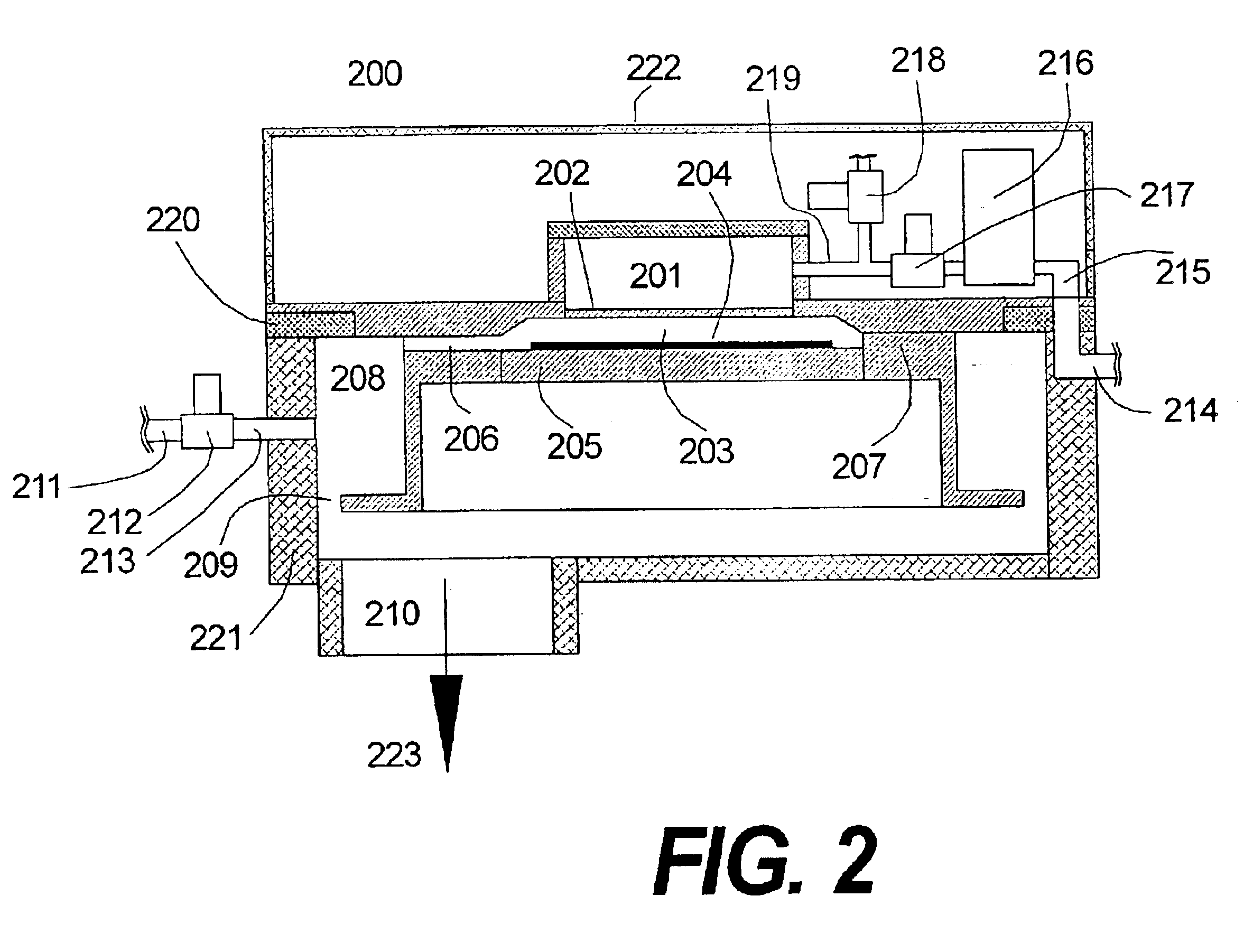

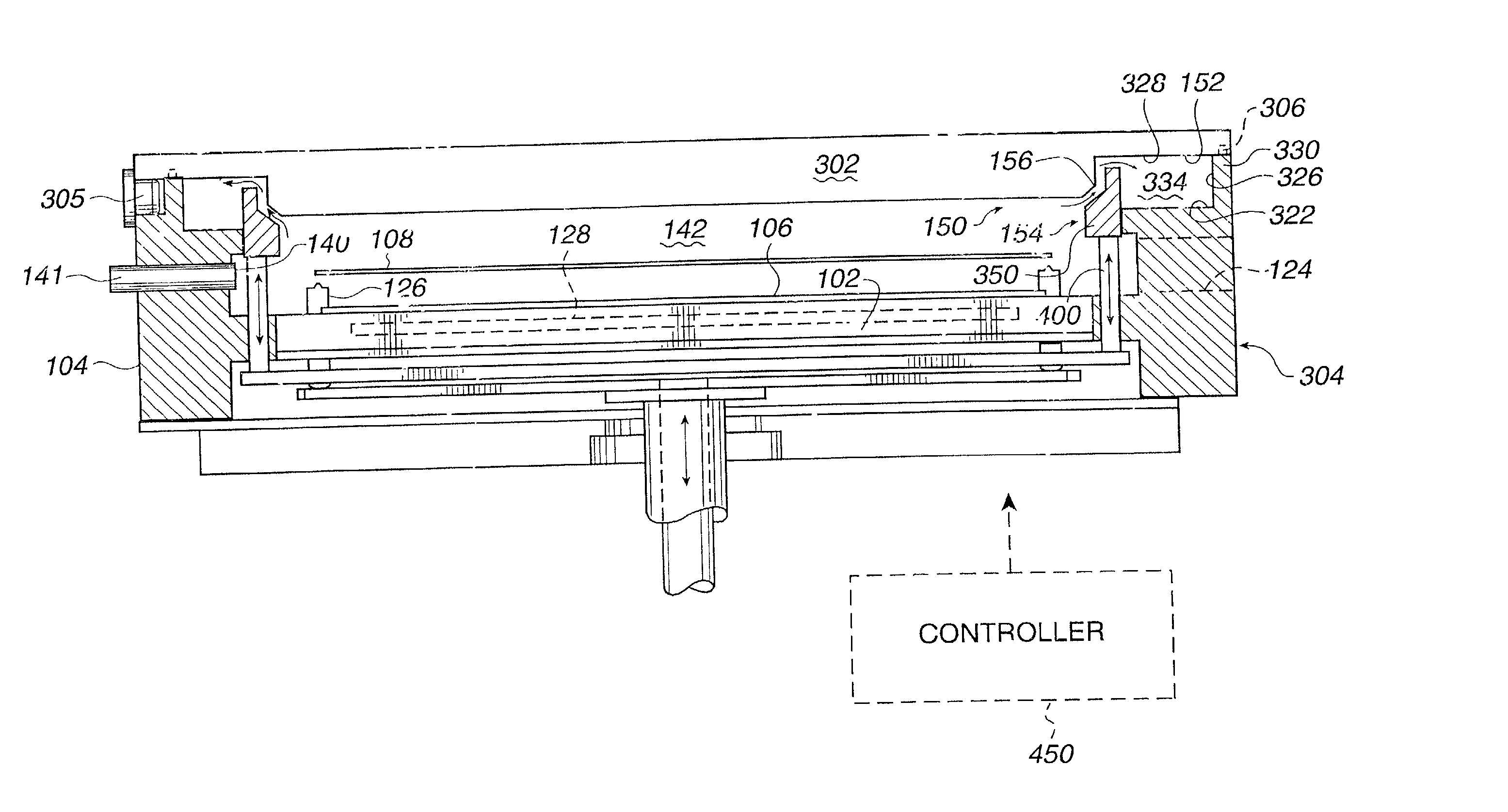

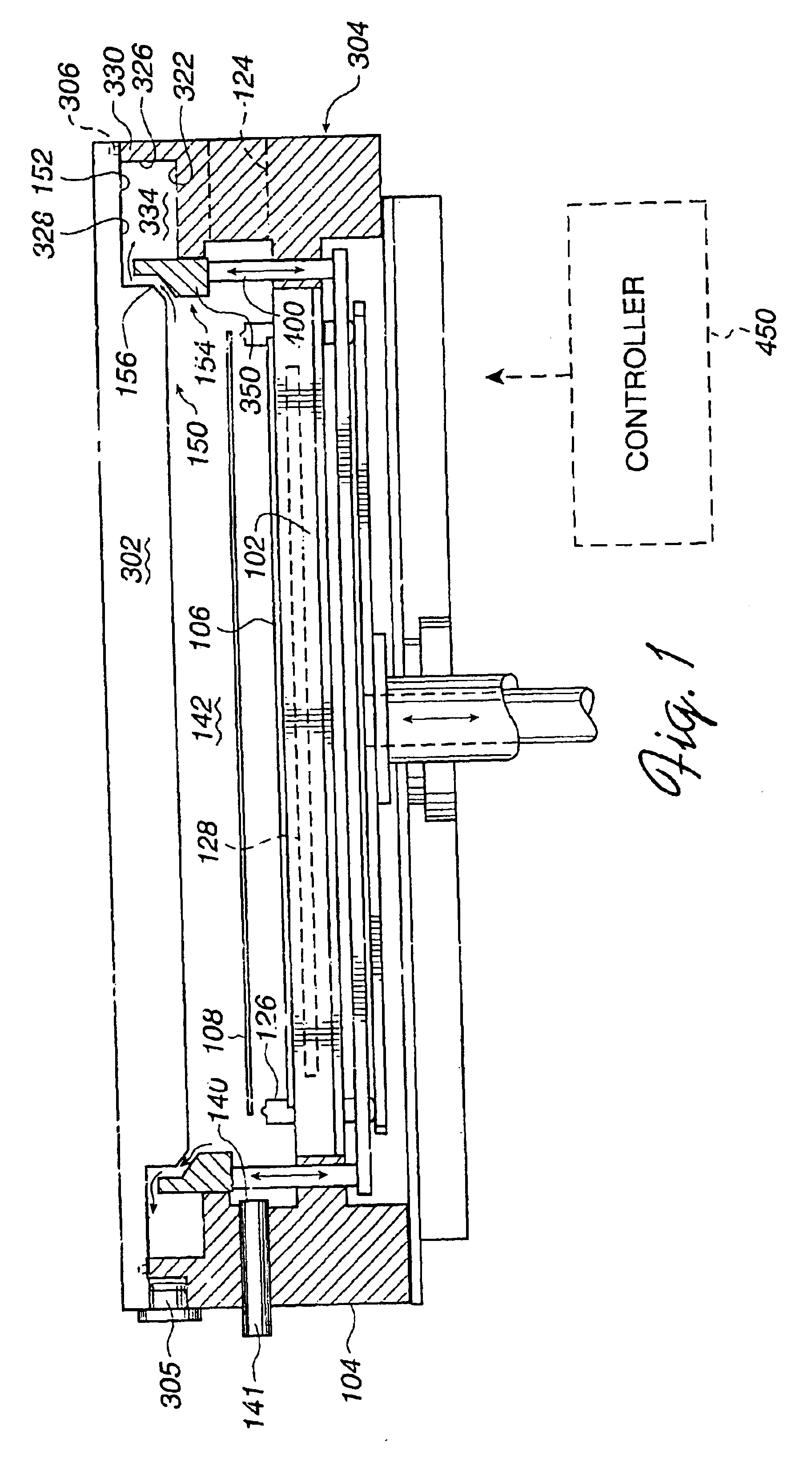

ALD apparatus and method

InactiveUS6911092B2Increase flow rateReduce flow rateSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringMechanical engineering

An apparatus and method for atomic layer deposition with improved efficiency of both chemical dose and purge is presented. The apparatus includes an integrated equipment and procedure for chamber maintenance.

Owner:SUNDEW TECH

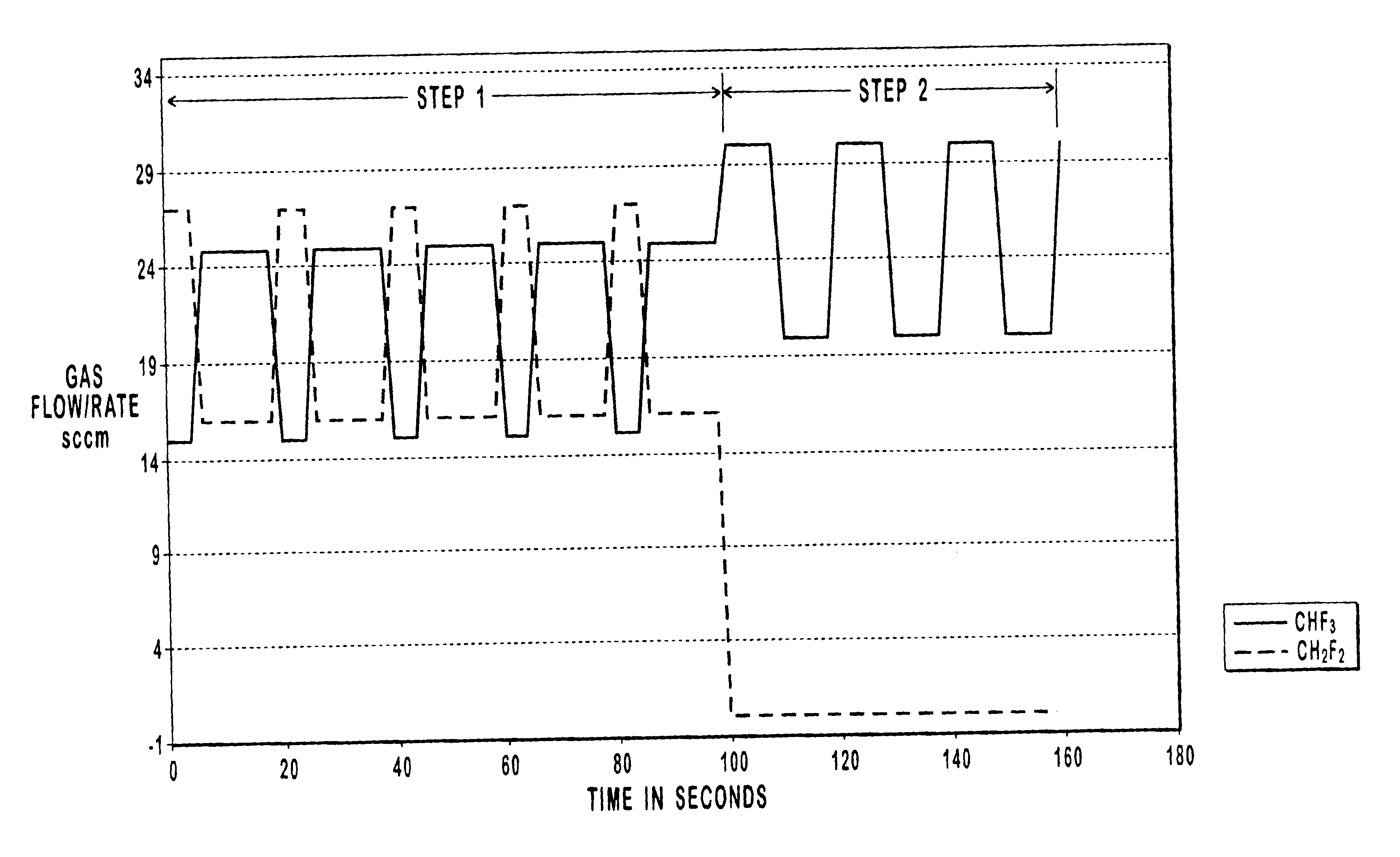

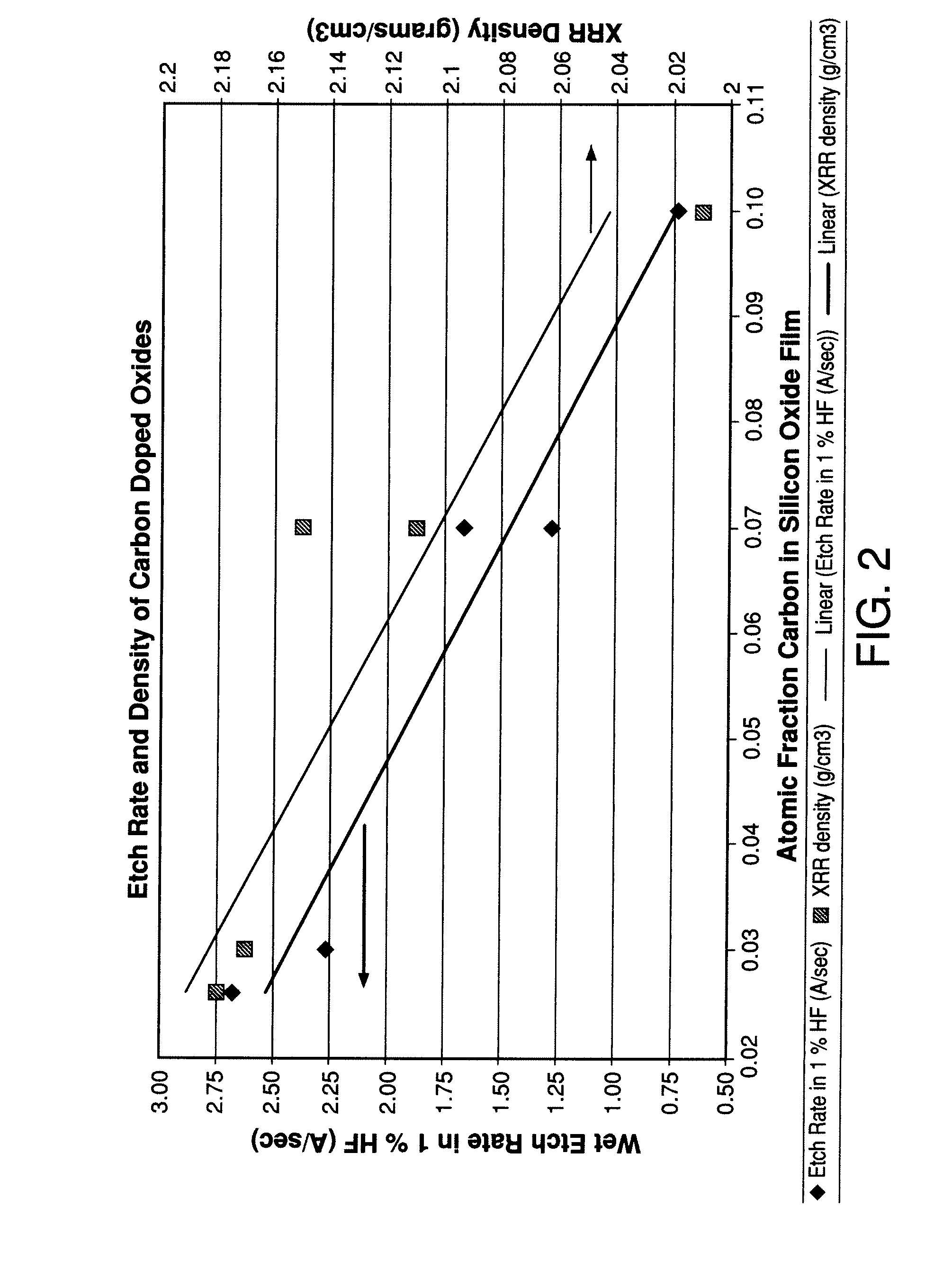

Gas pulsing for etch profile control

InactiveUS6784108B1Increase flow rateReduce flow rateElectric discharge tubesDecorative surface effectsEngineeringAnisotropic etching

Etch profile control with pulsed gas flow and its applications to etching such as anisotropic etching of high aspect ratio features and etching of self-aligned contact structures in various processes. Pulsing can be applied according to this invention to the flow rate of a gas such as an etchant gas, a gas that leads to the deposition of a protective layer, a gas that modifies the deposition of a protective layer, and a gas that modifies etching.

Owner:MICRON TECH INC

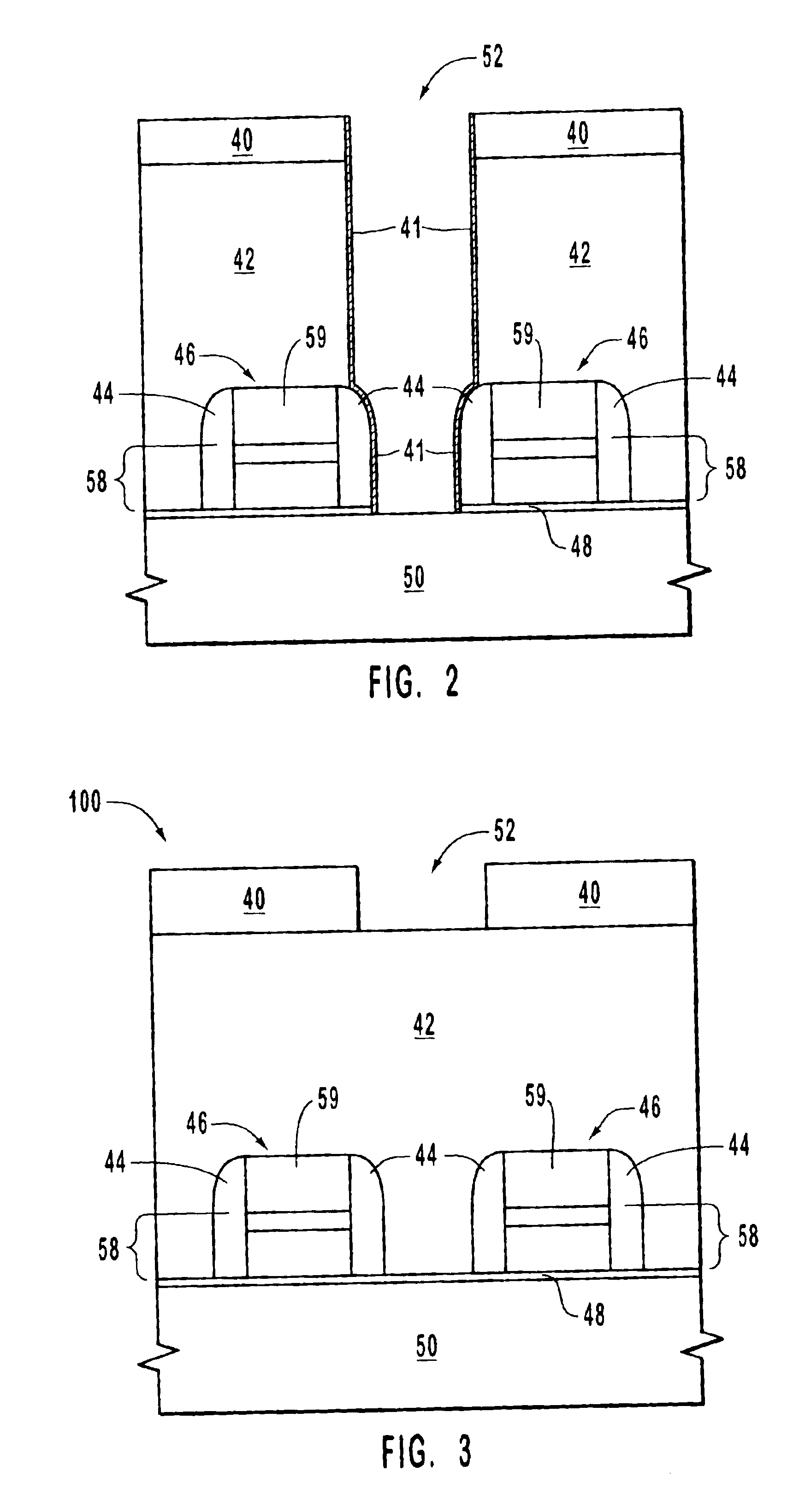

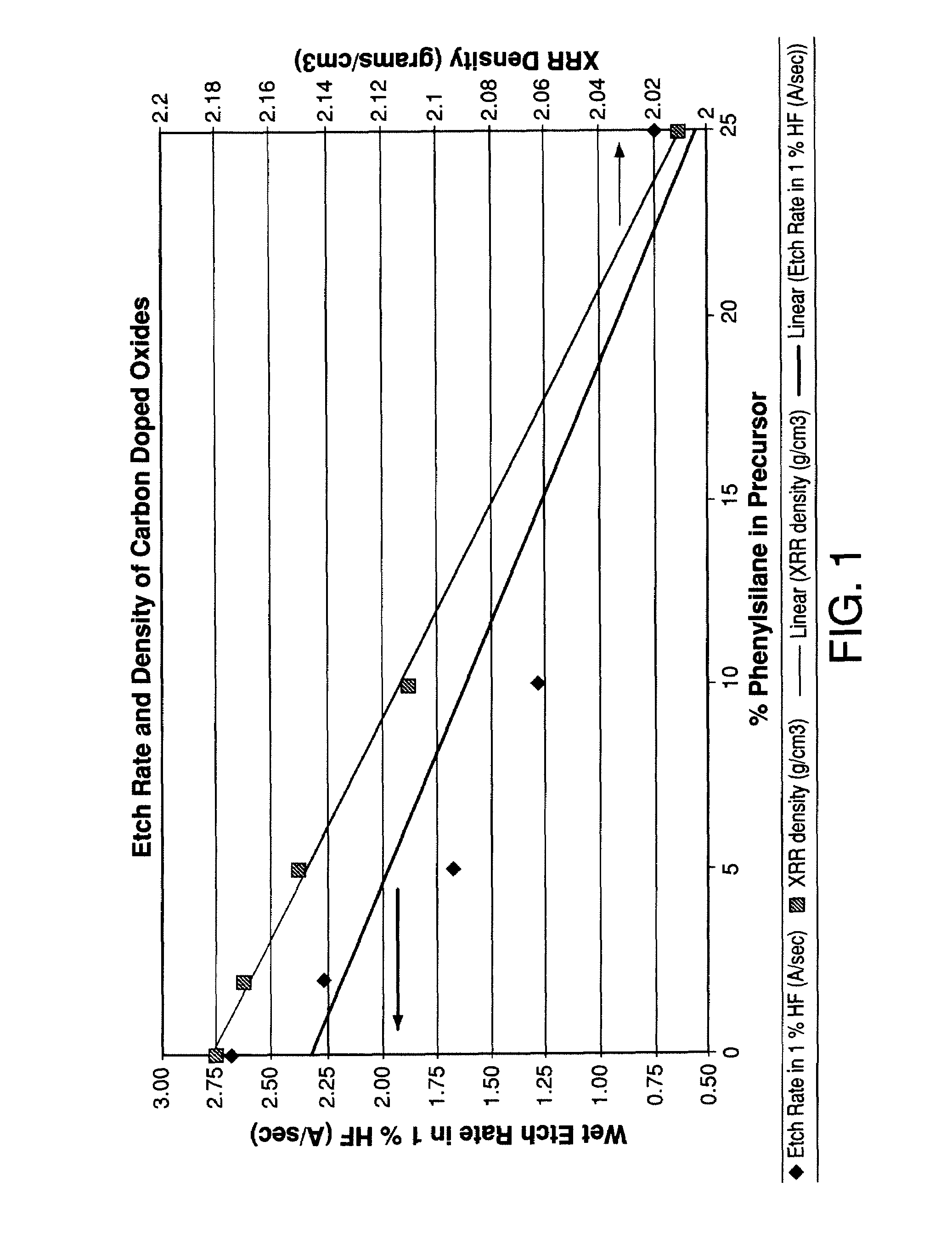

Organosilane compounds for modifying dielectrical properties of silicon oxide and silicon nitride films

InactiveUS20080124946A1Excellent etch resistanceIncreasing flow ratioSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSilicon oxideChemical Modifier

The present invention discloses a process for depositing a carbon containing silicon oxide film, or a carbon containing silicon nitride film having enhanced etch resistance. The process comprises using a silicon containing precursor, a carbon containing precursor and a chemical modifier. The present invention also discloses a process for depositing a silicon oxide film, or silicon nitride film having enhanced etch resistance comprising using an organosilane precursor and a chemical modifier.

Owner:VERSUM MATERIALS US LLC

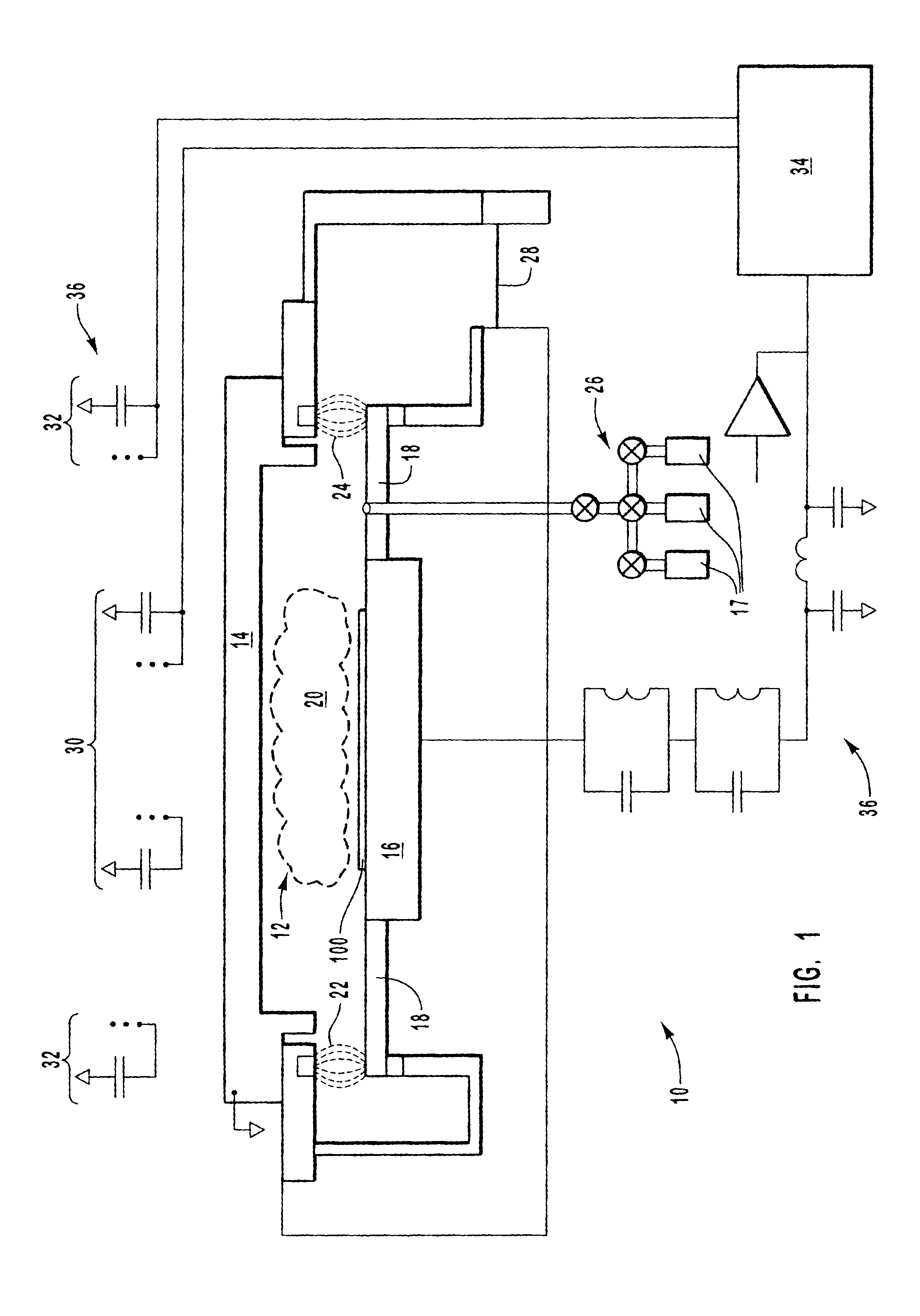

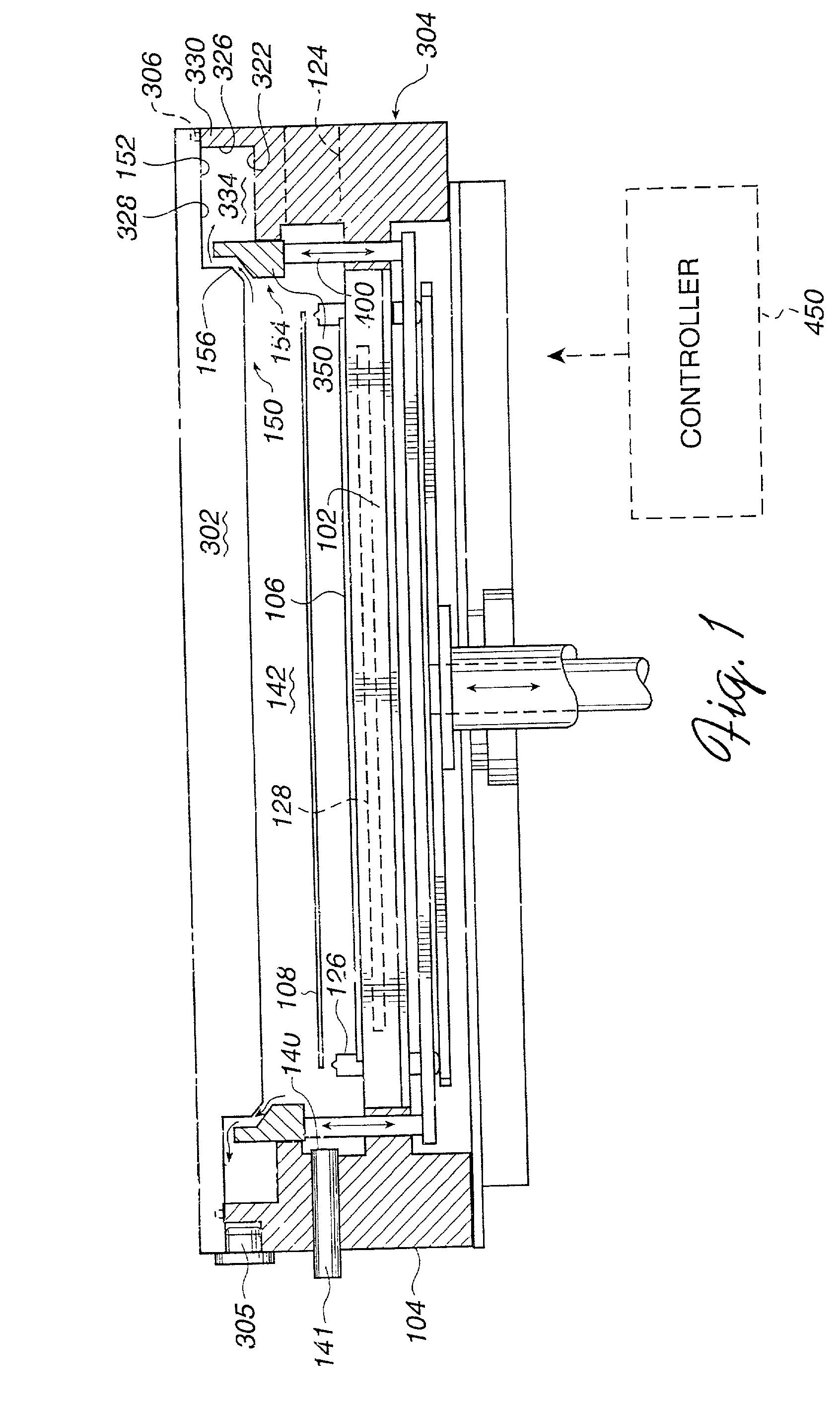

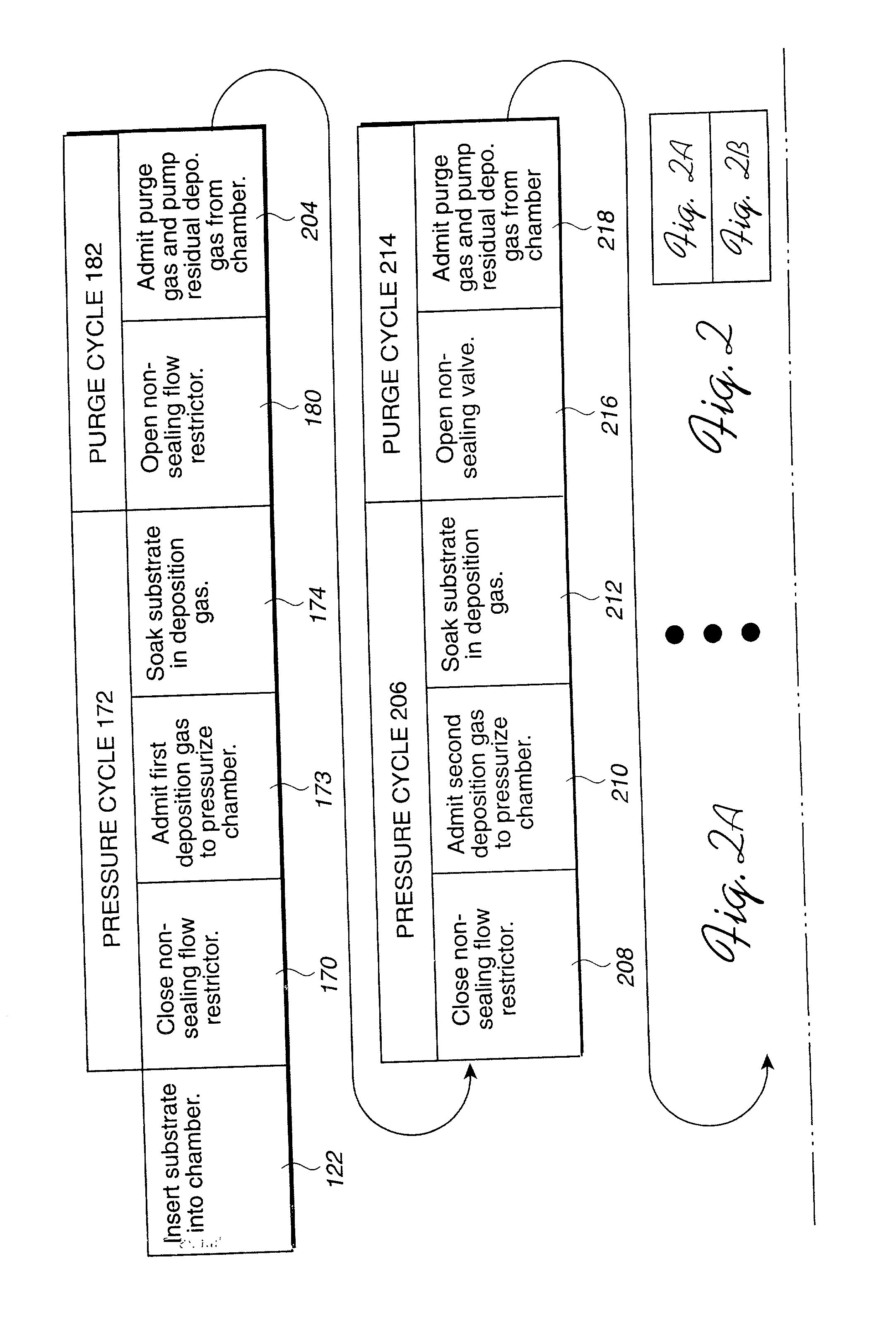

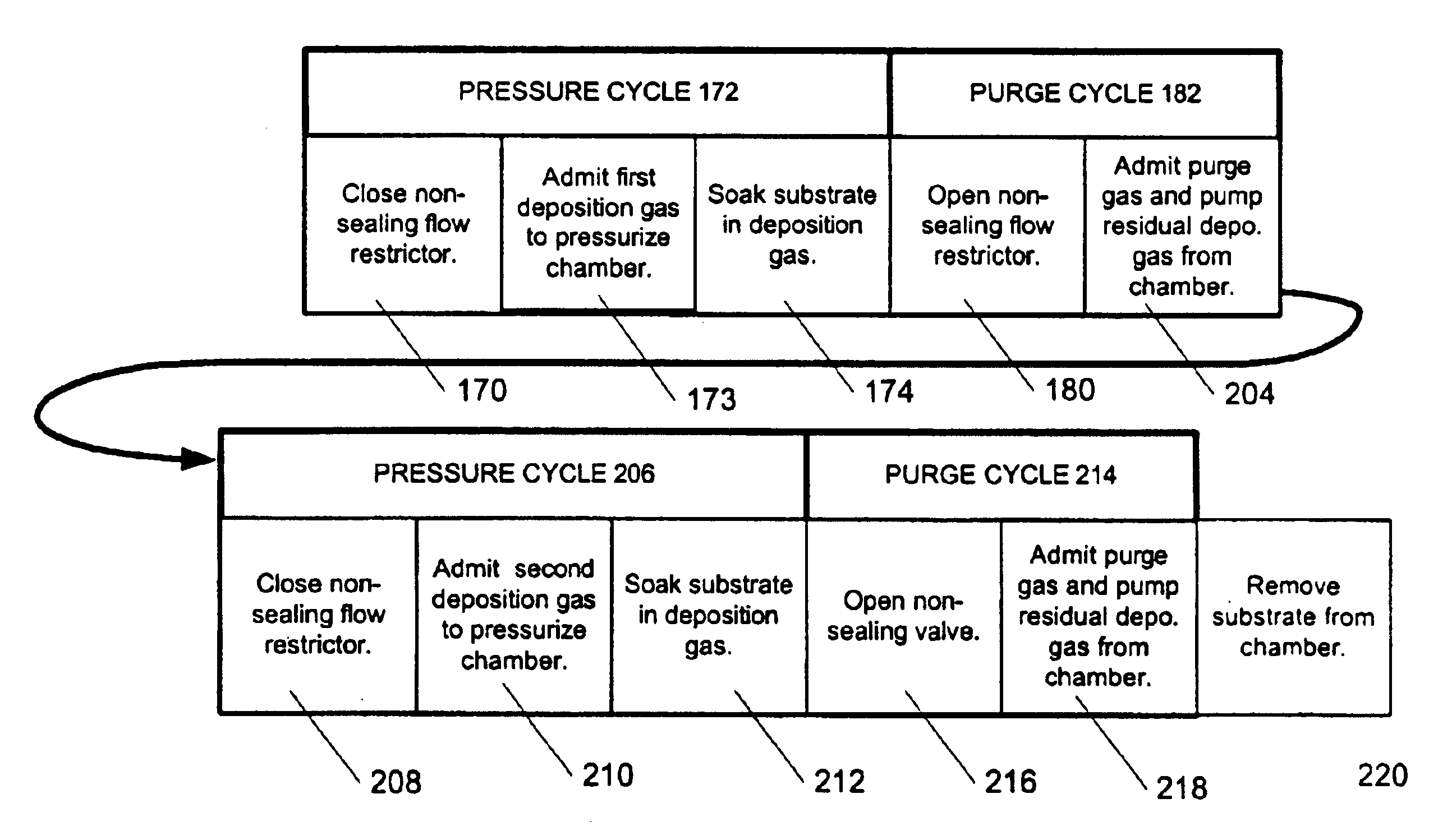

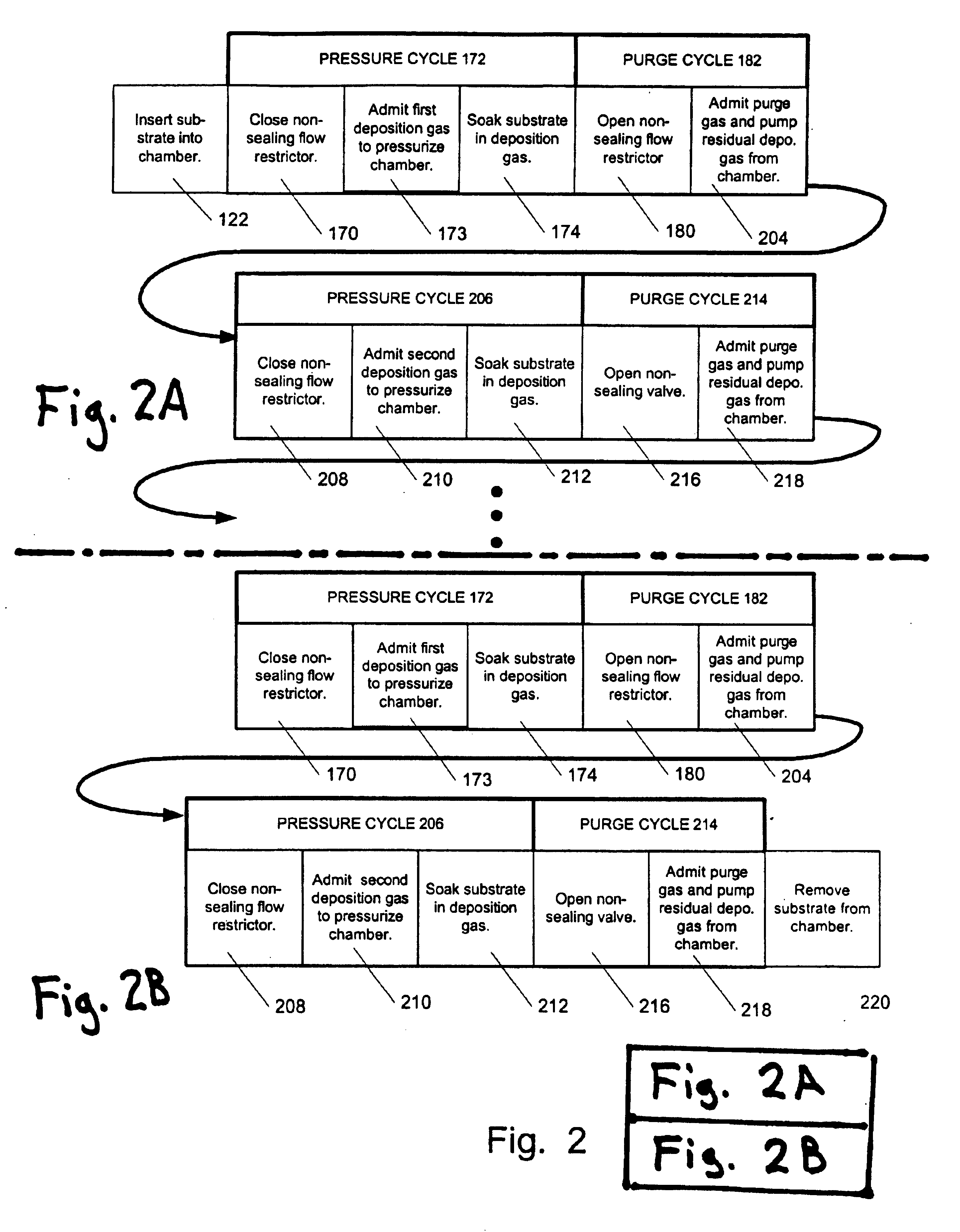

Variable flow deposition apparatus and method in semiconductor substrate processing

InactiveUS20030153177A1Facilitate rapid openingEasy to closeLiquid surface applicatorsVacuum evaporation coatingEngineeringMechanical engineering

In one embodiment of the present inventions, an exhaust outlet in a vacuum processing chamber includes a nonsealing flow restrictor which can facilitate rapid opening and closing of the flow restrictor in some applications. Because the flow restrictor is a nonsealing flow restrictor, the conductance of the flow restrictor in the closed position may not be zero. However, the flow restrictor can restrict the flow of an exhaust gas from the chamber to permit the retention of sufficient processing gas in the chamber to deposit a film on the substrate or otherwise react with the substrate. After a film has been deposited, typically in a thin atomic layer, the exhaust flow restrictor may be opened such that the flow restrictor conductance is significantly increased to a second, higher flow rate to facilitate exhausting residue gas from the chamber. The nonsealing flow restrictor may be closed again to deposit a second layer, typically of a different material onto the substrate. The nonsealing flow restrictor may be rapidly opened and closed to deposit alternating layers of a variety of materials onto the substrate.

Owner:APPLIED MATERIALS INC

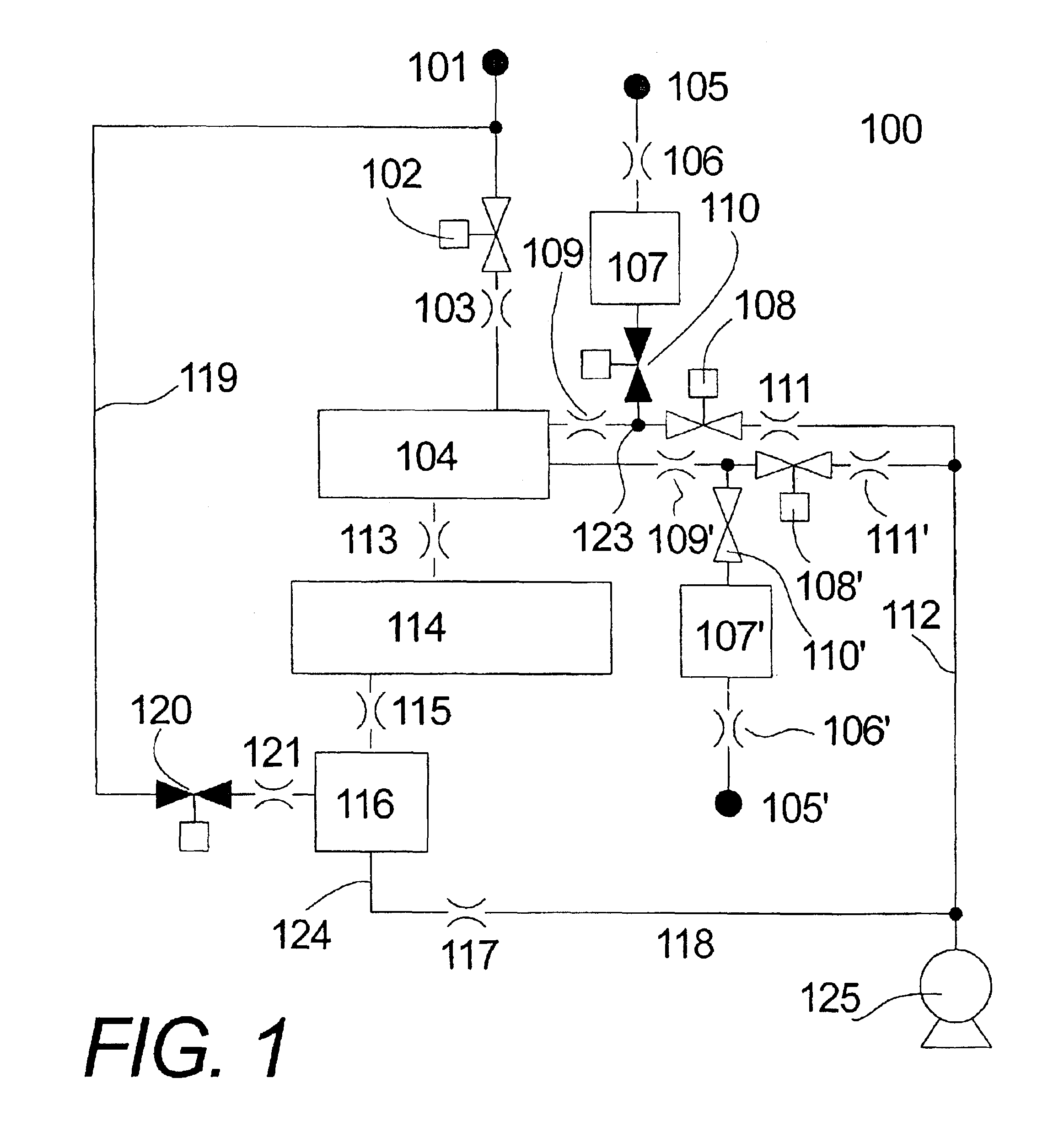

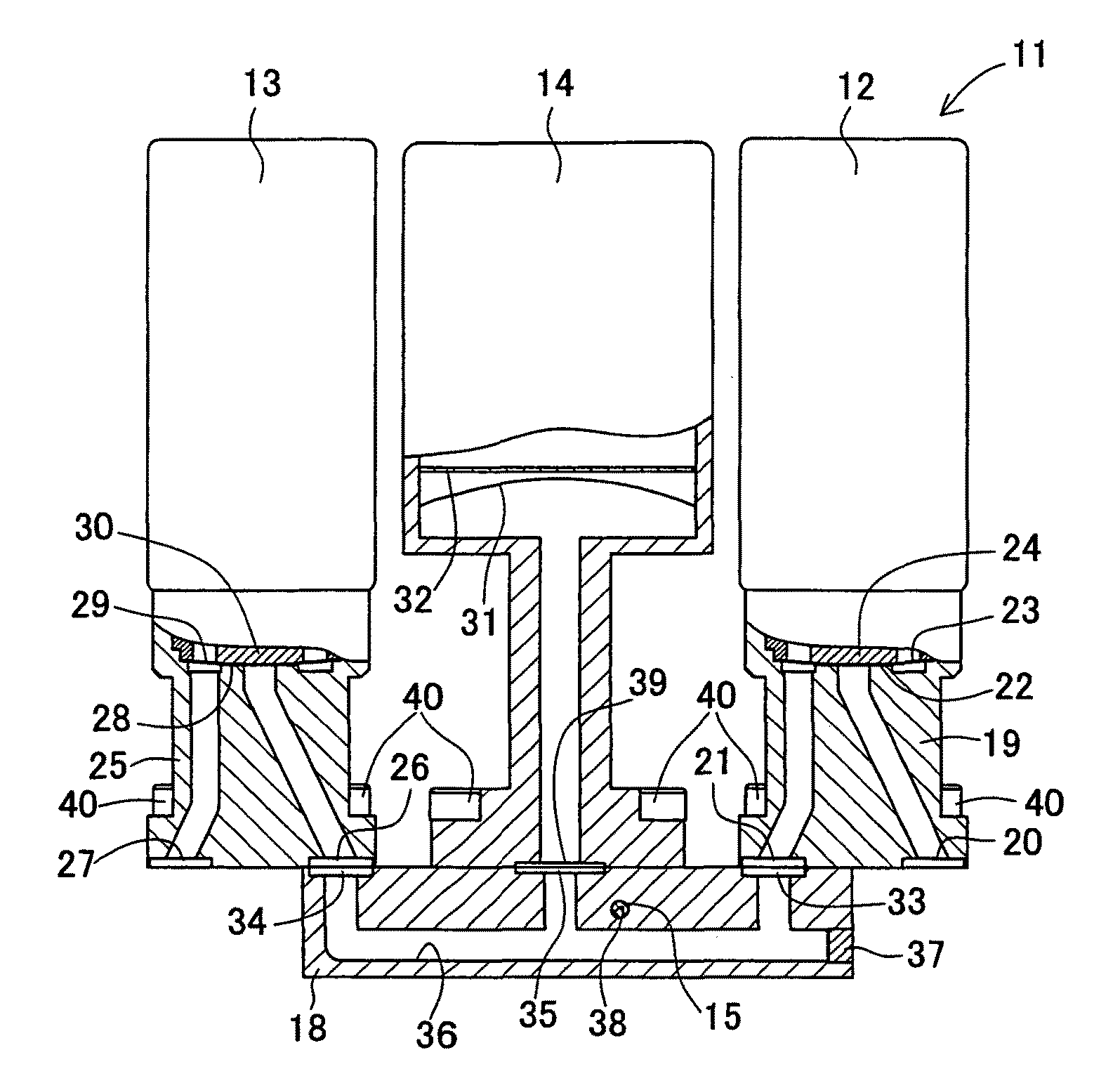

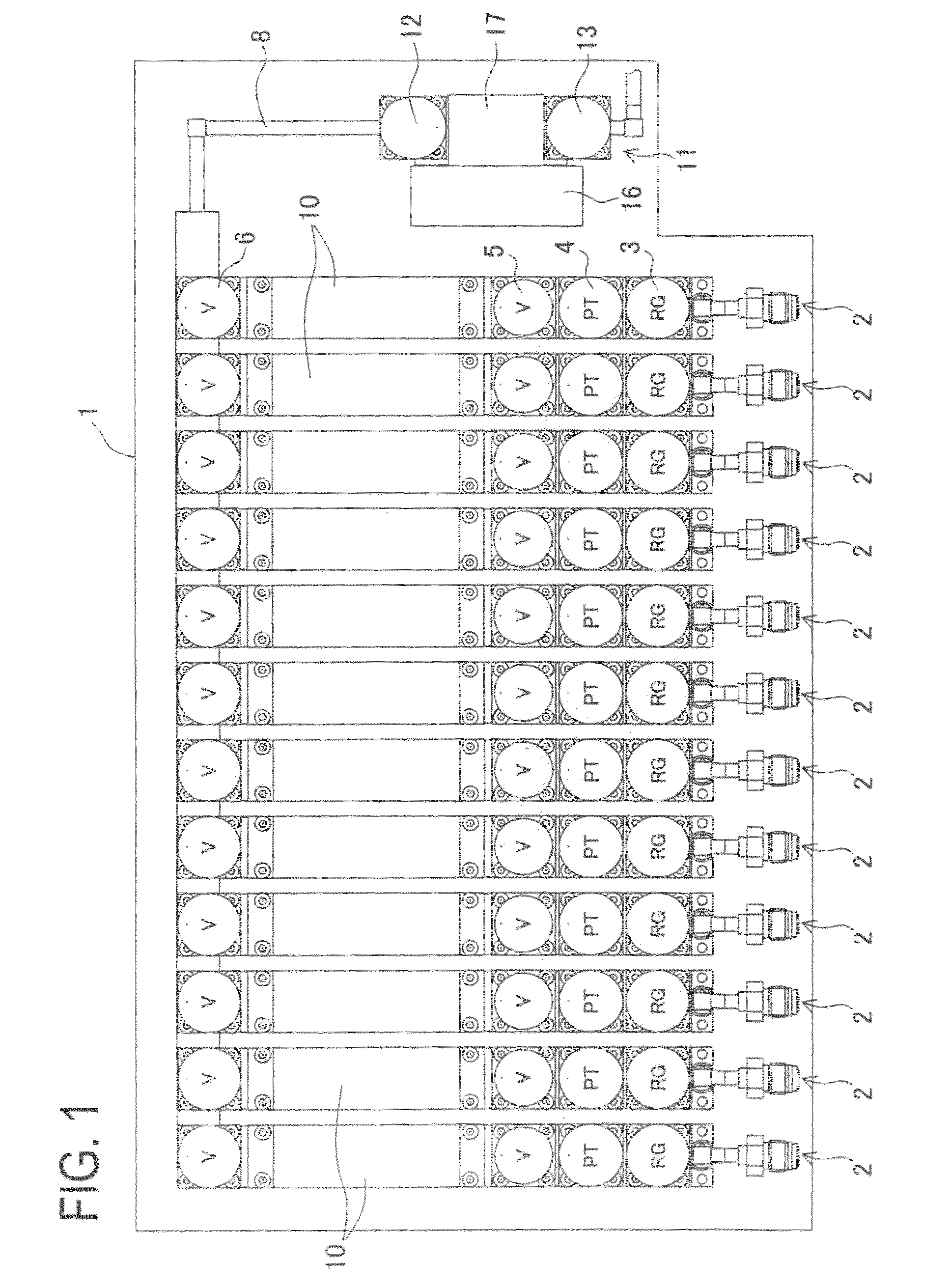

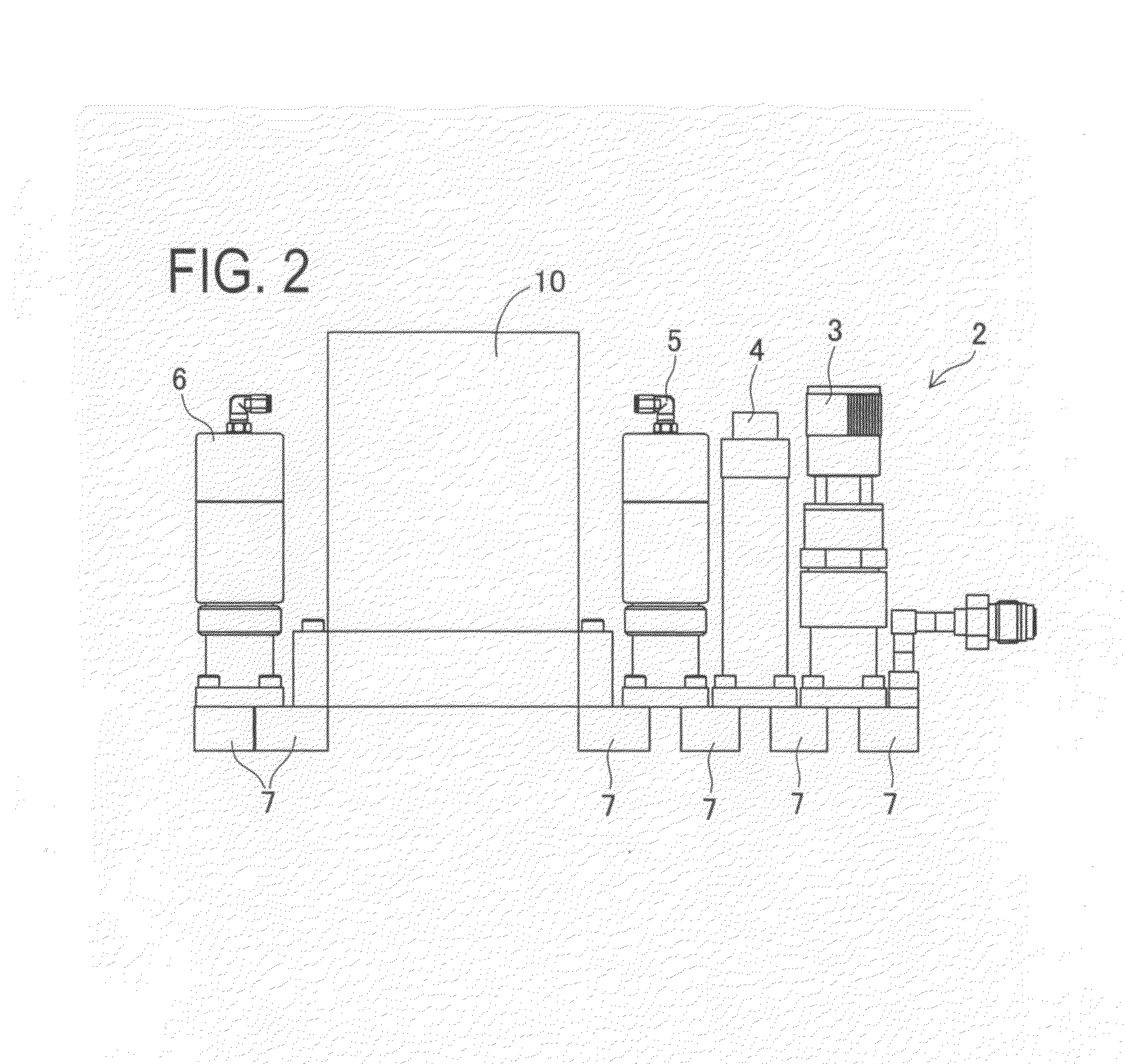

Gas flow rate verification unit

ActiveUS7716993B2Increase flow rateUniform pressureMultiple way valvesPipeline systemsEngineeringGas supply

A gas flow rate verification unit capable of enhancing reliability of gas flow rate verification. The gas flow rate verification unit has a first cutoff valve that is connected to a flow rate control device and to which gas is inputted, a second cutoff valve for discharging the gas, a communication member for allowing the first cutoff valve and the second cutoff valve to communicate with each other, a pressure sensor for detecting the pressure of the gas supplied between the first cutoff valve and the second cutoff valve, a temperature detector for detecting the temperature of the gas supplied between the first cutoff valve and the second cutoff valve, and a control means for verifying the flow of the gas flowing in the flow control device, the verification being performed by using both the result of the pressure detected by the pressure sensor and the result of the temperatures detected by the temperature detector. The volume (Vk) between the valve seat of the first cutoff valve and the valve seat of the second cutoff valve is equal to or less than the volume (Ve) between the outlet of the flow control device and the valve seat of the first cutoff valve.

Owner:CKD

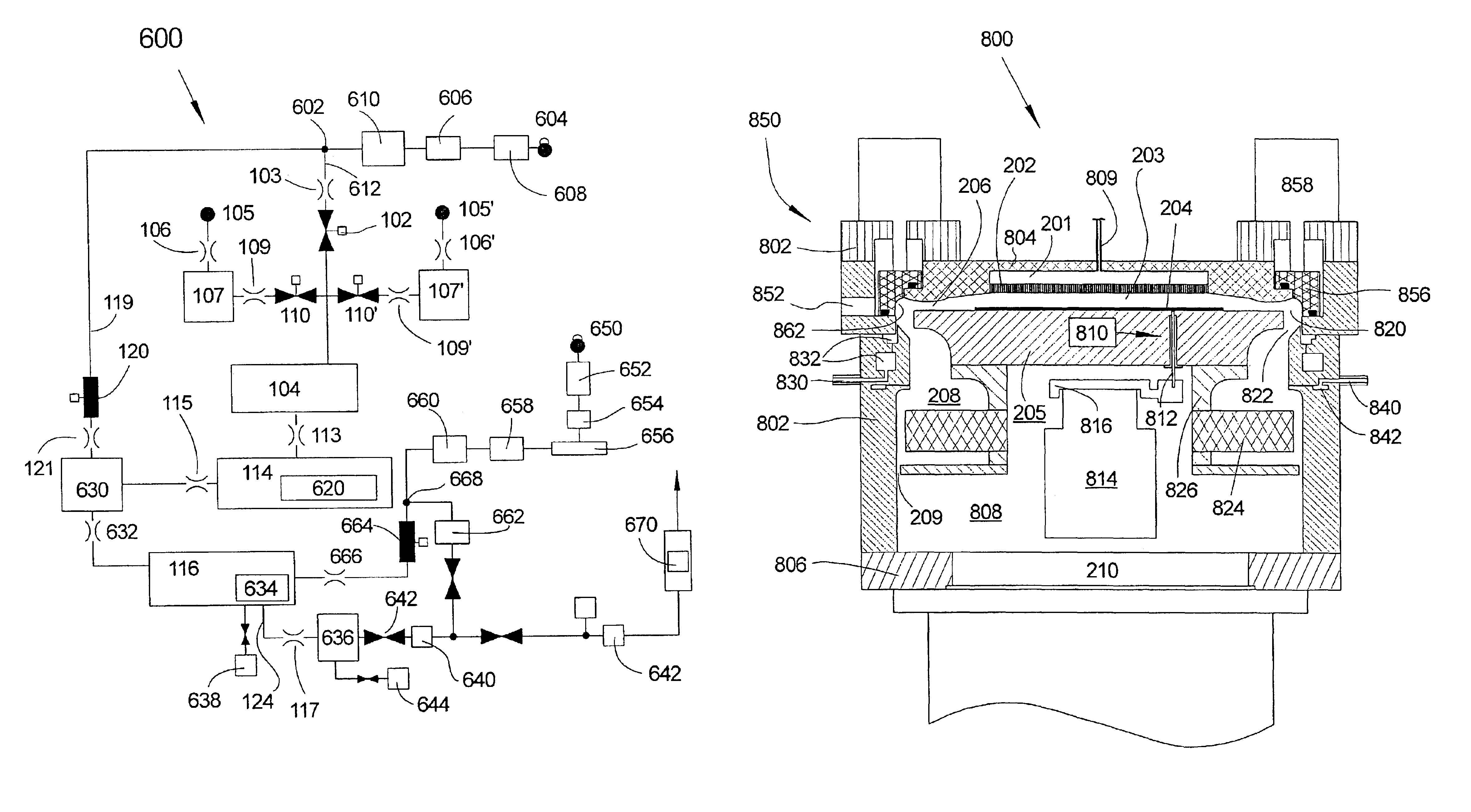

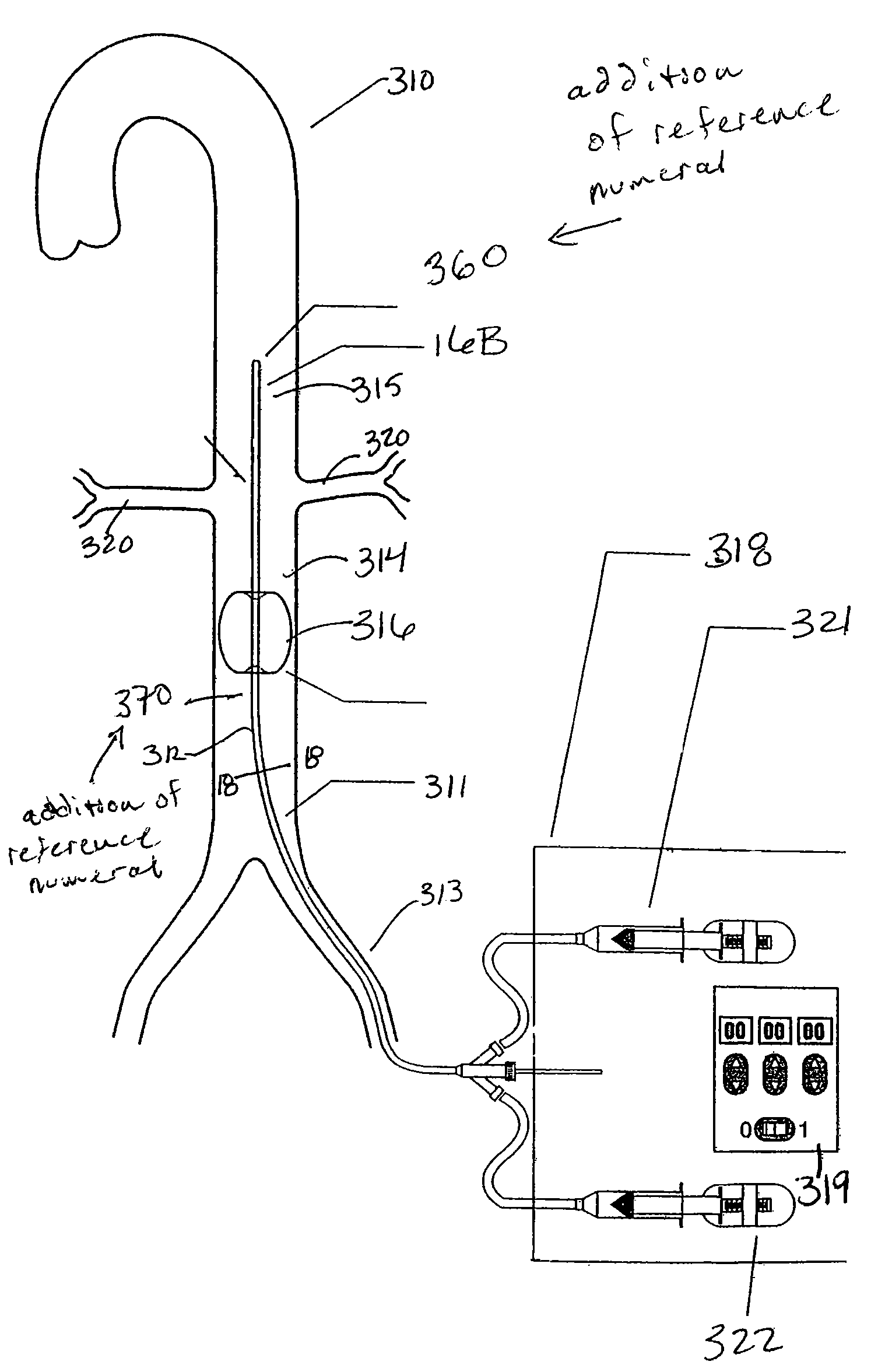

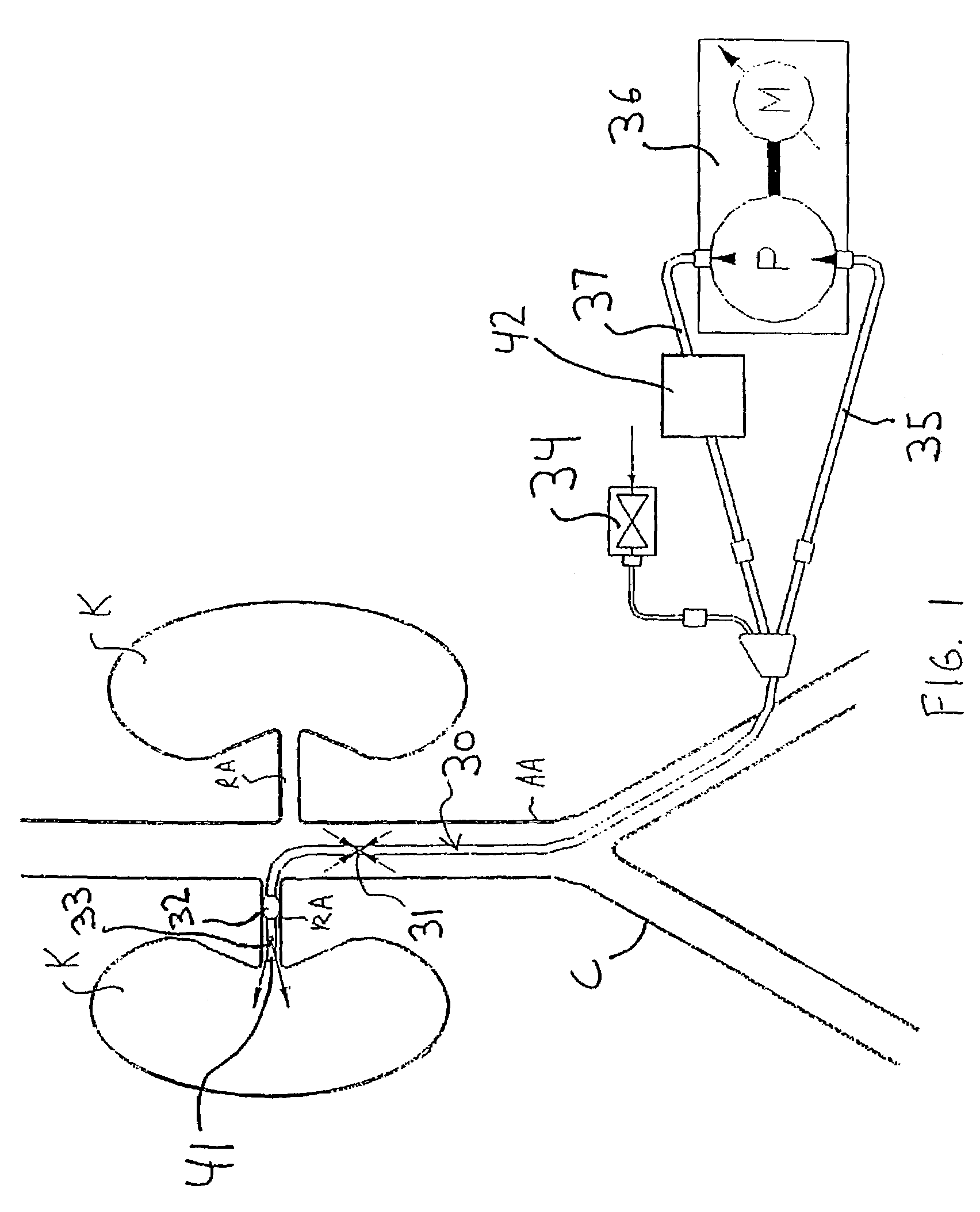

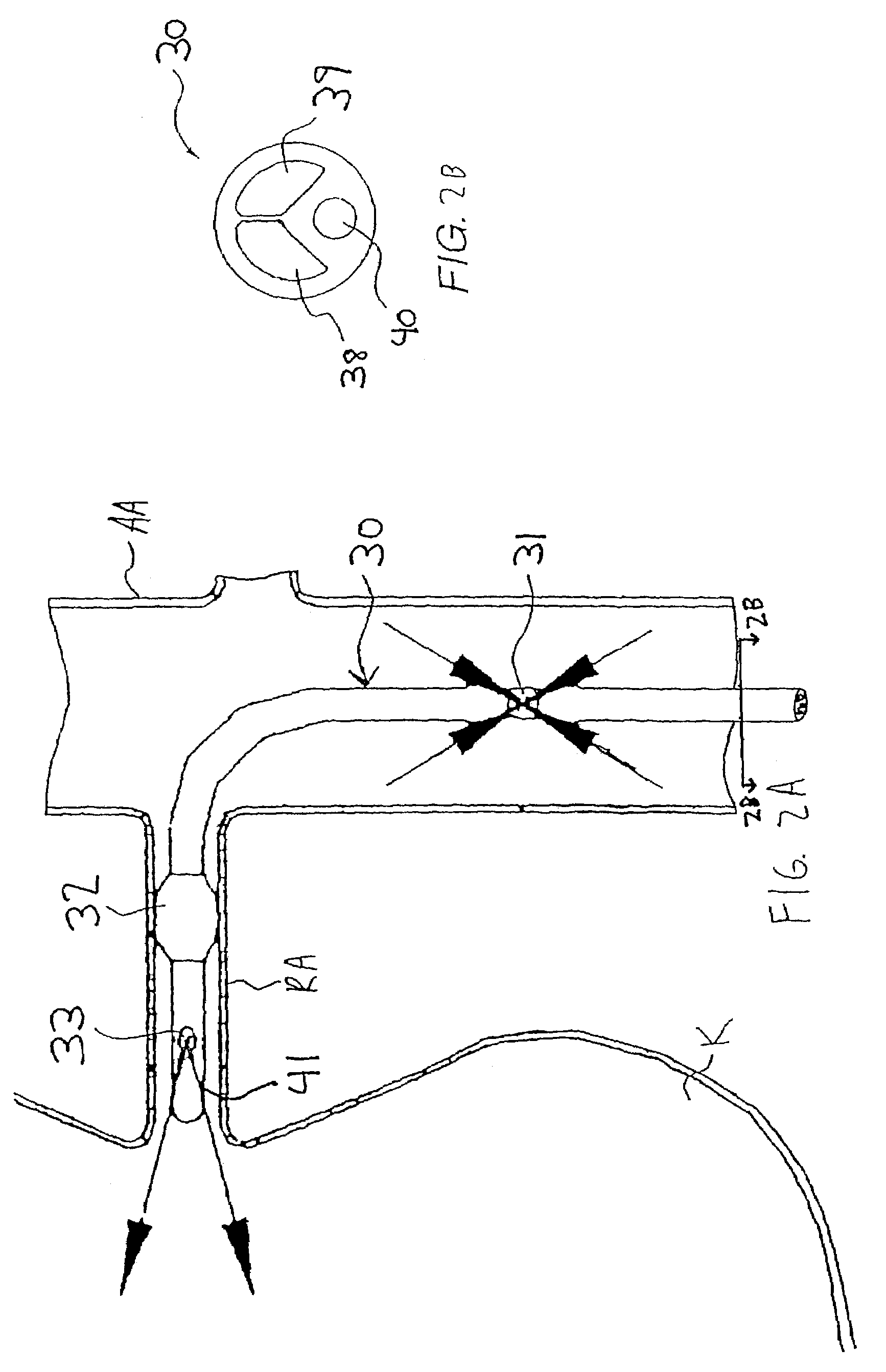

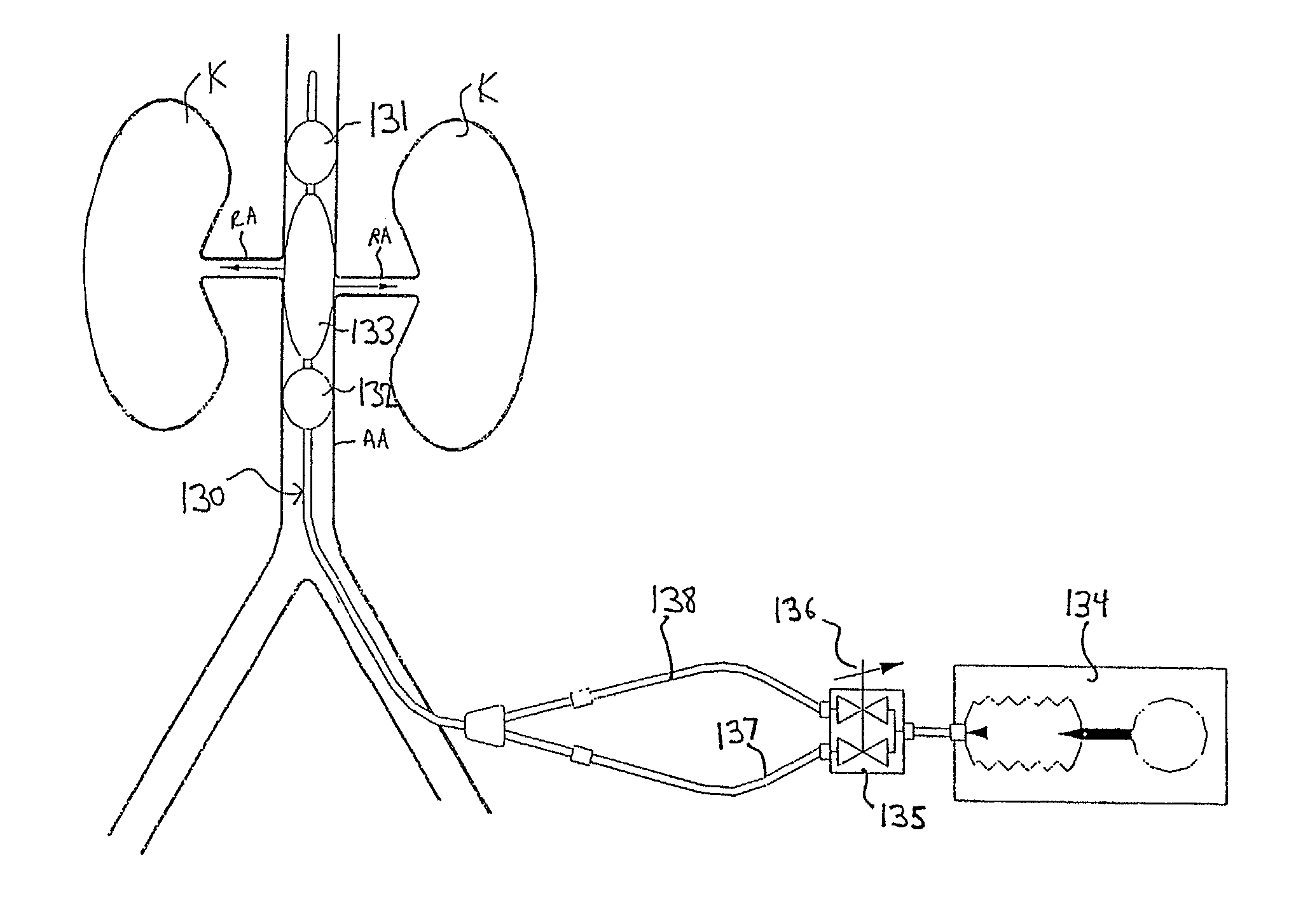

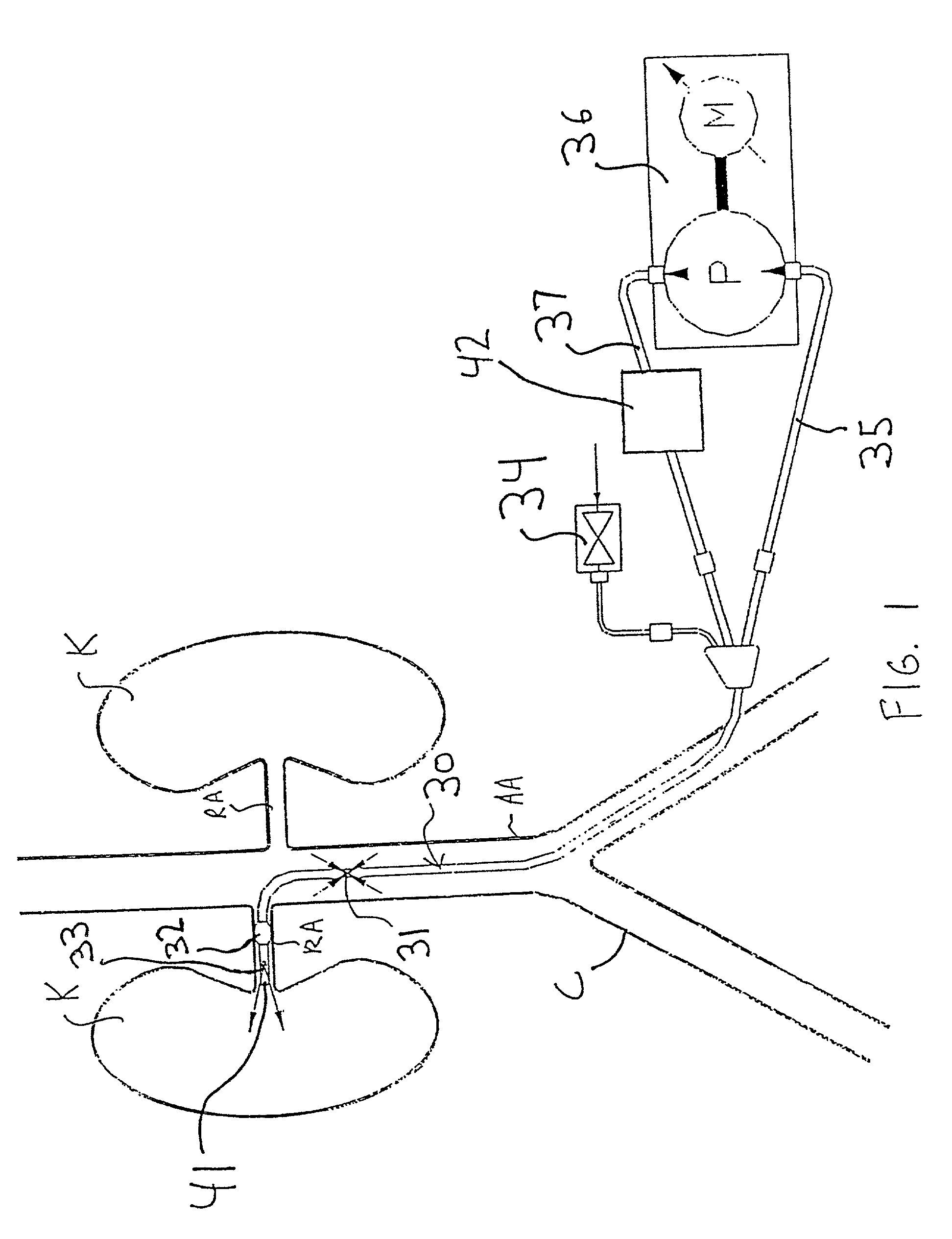

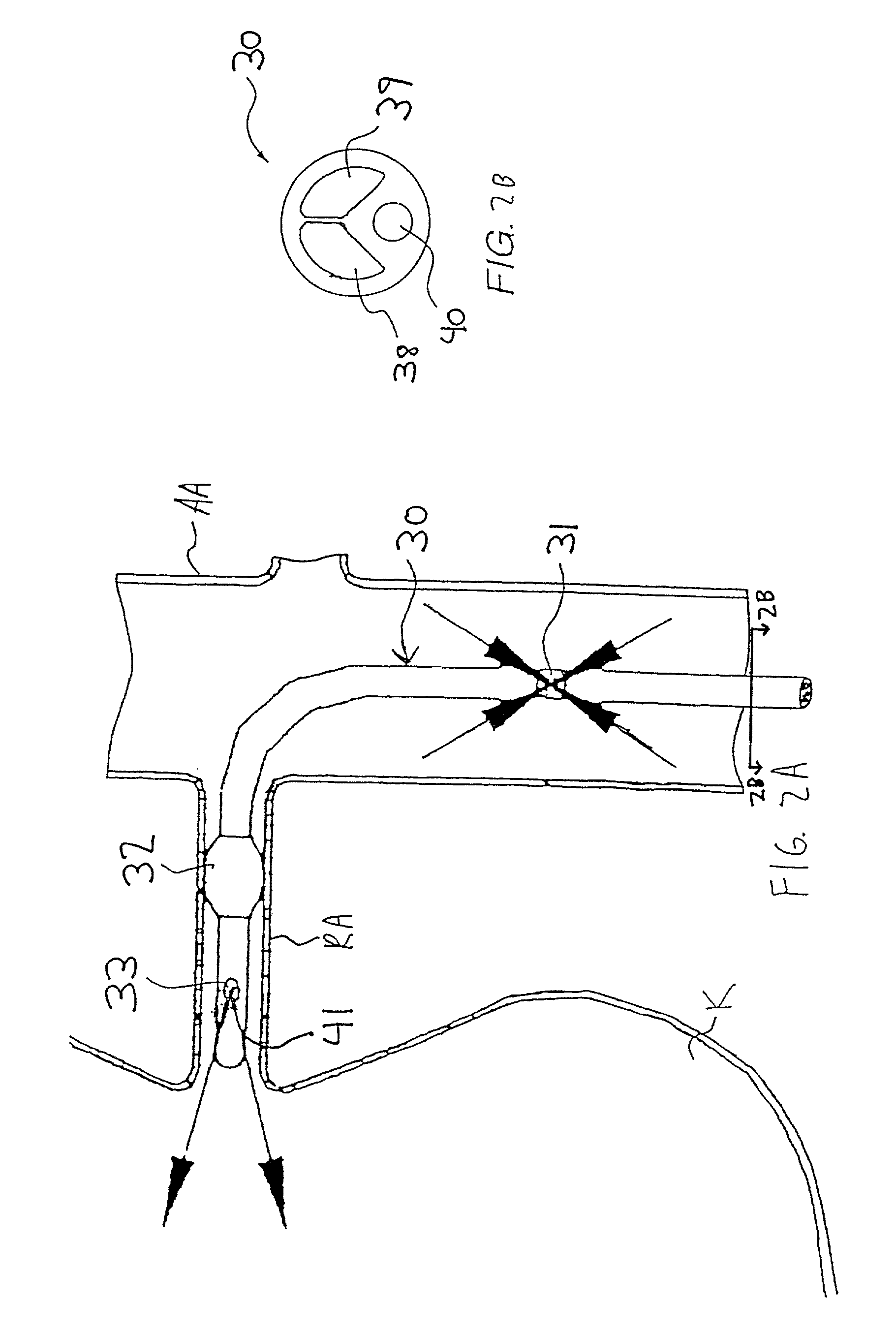

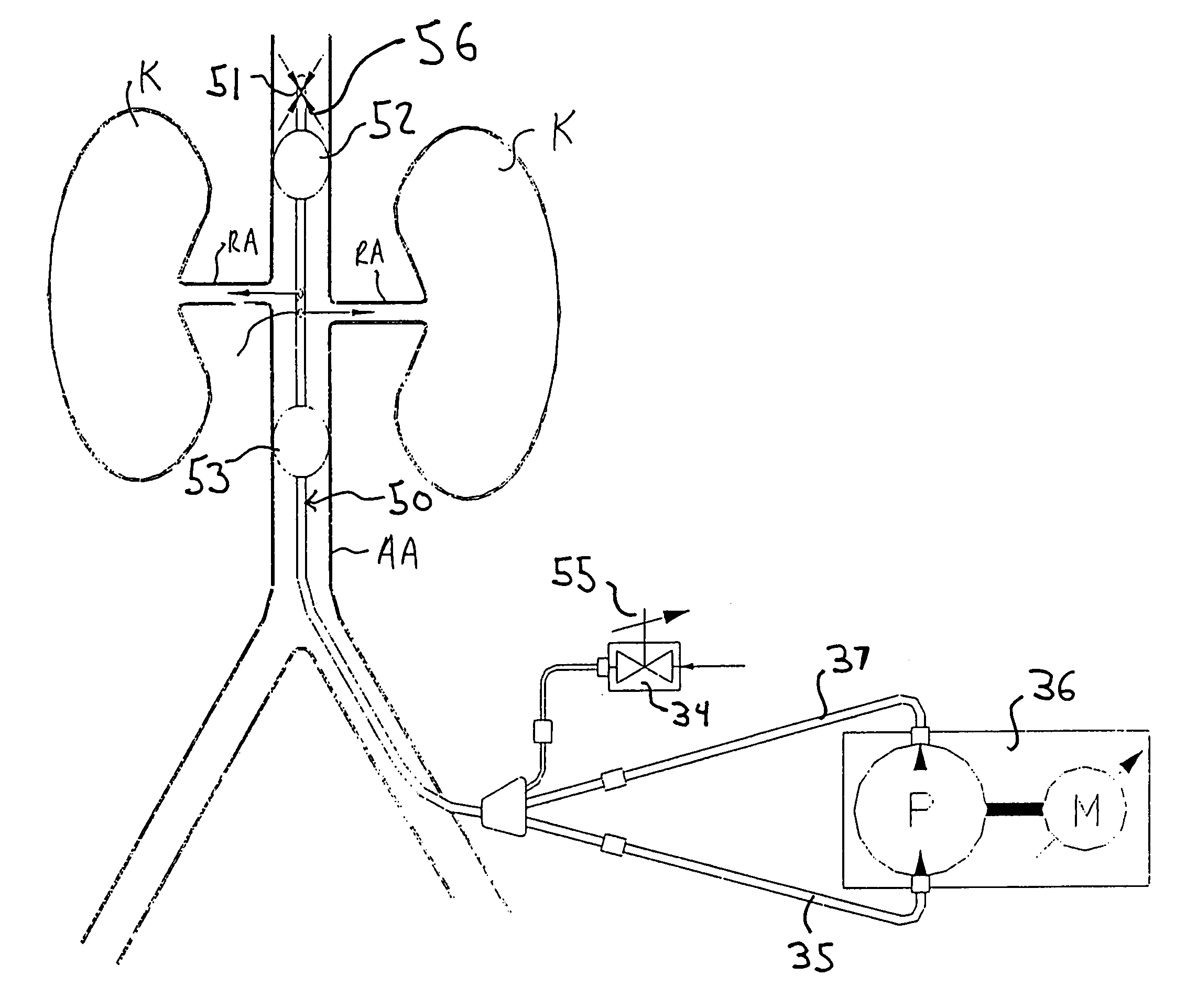

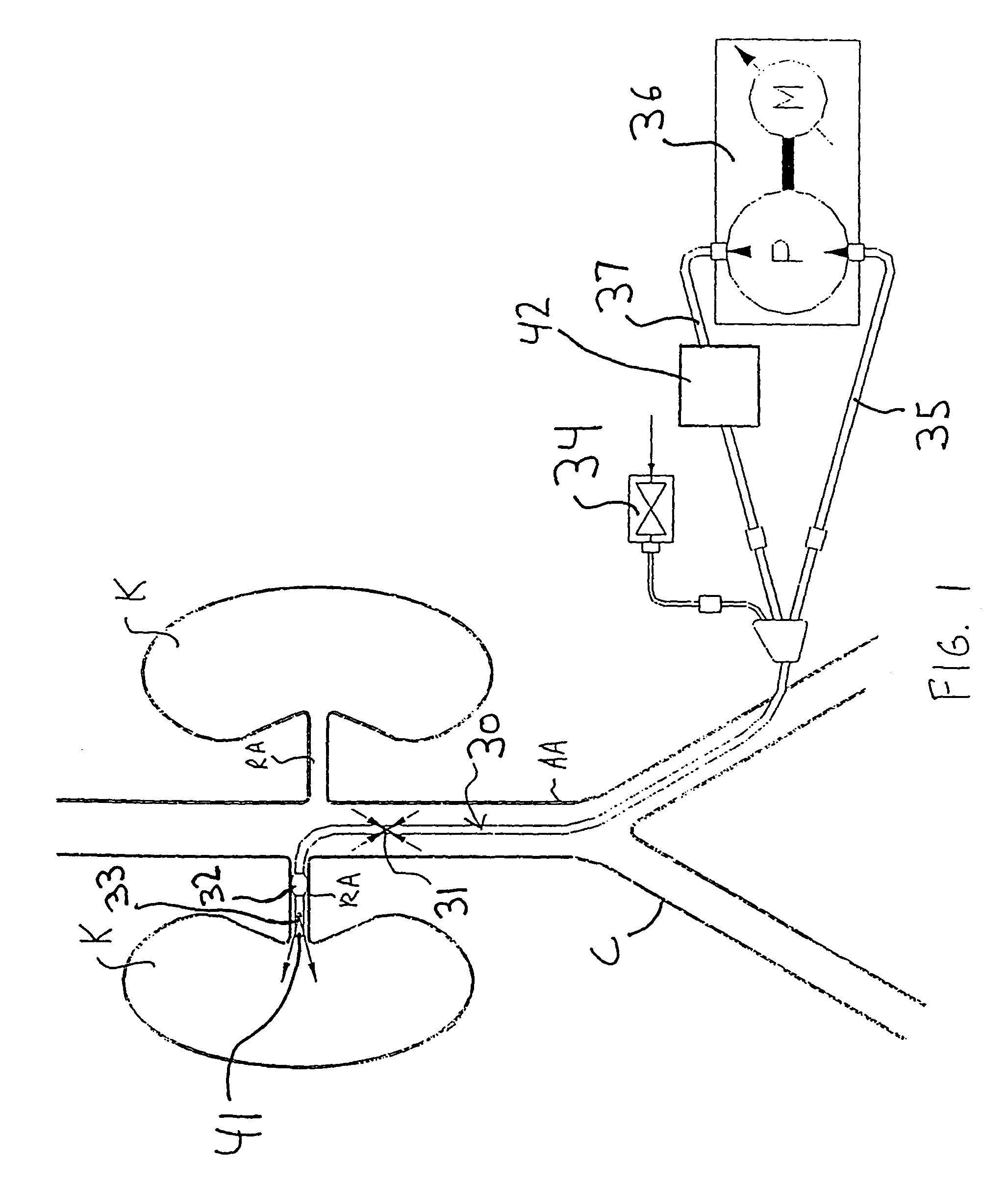

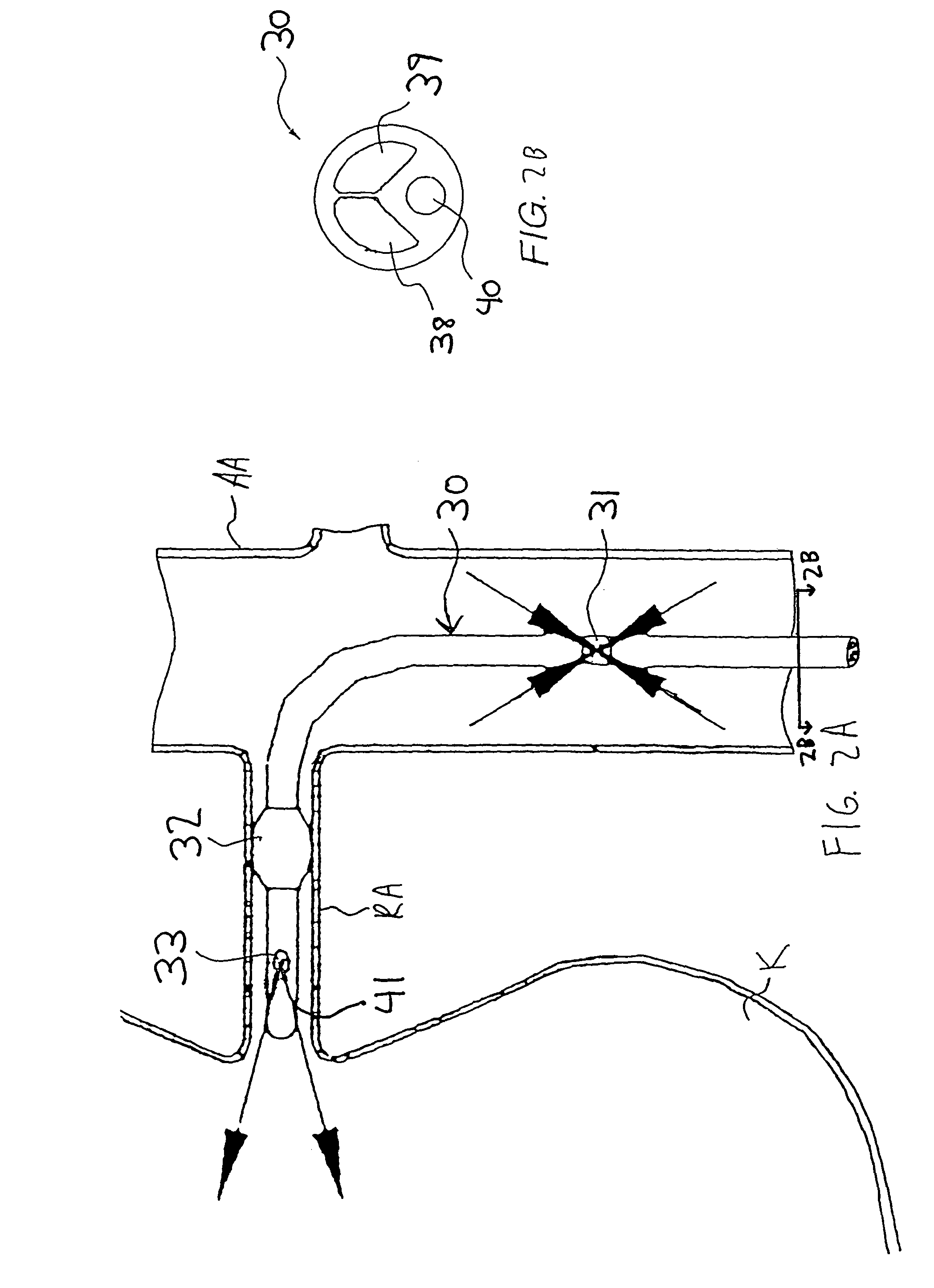

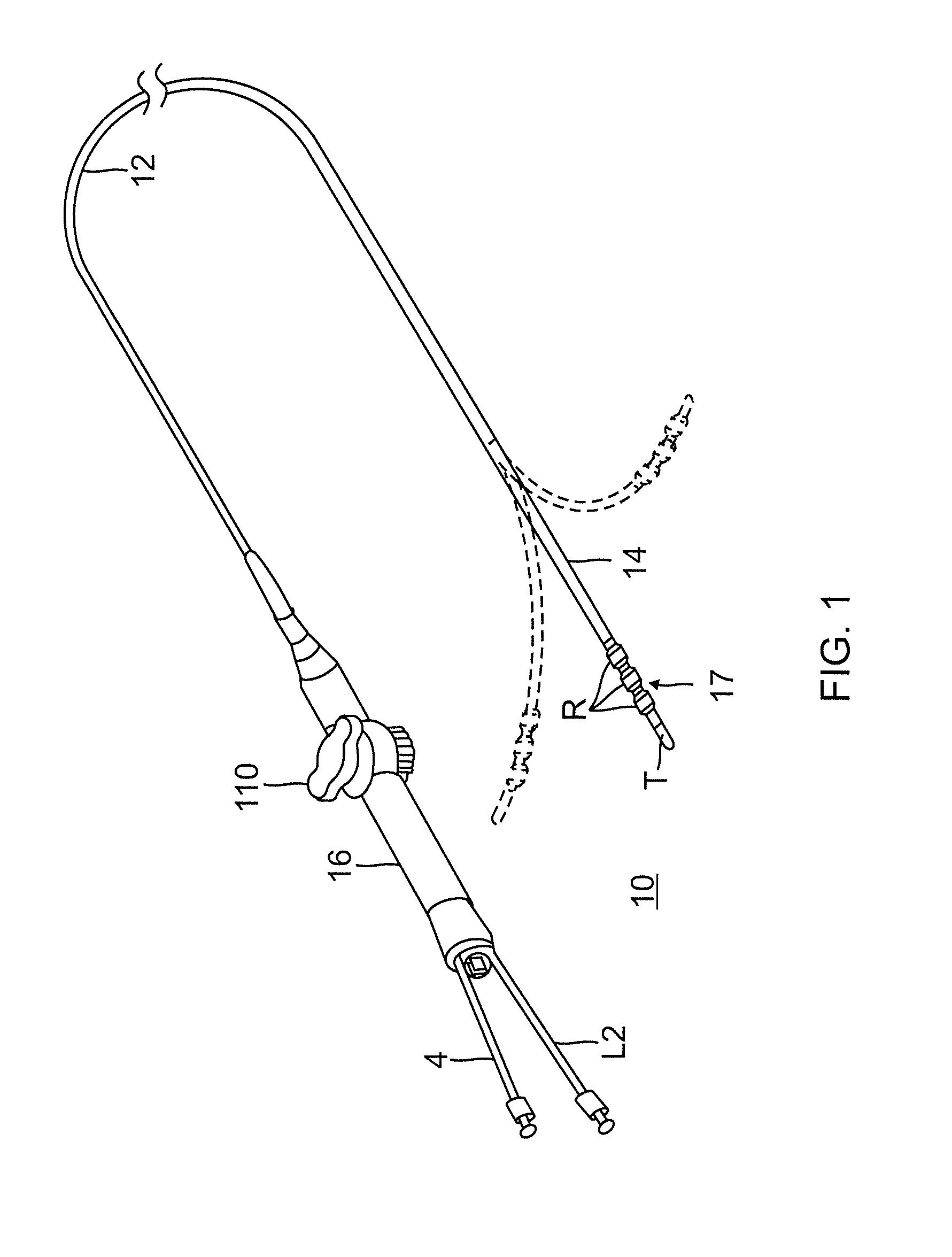

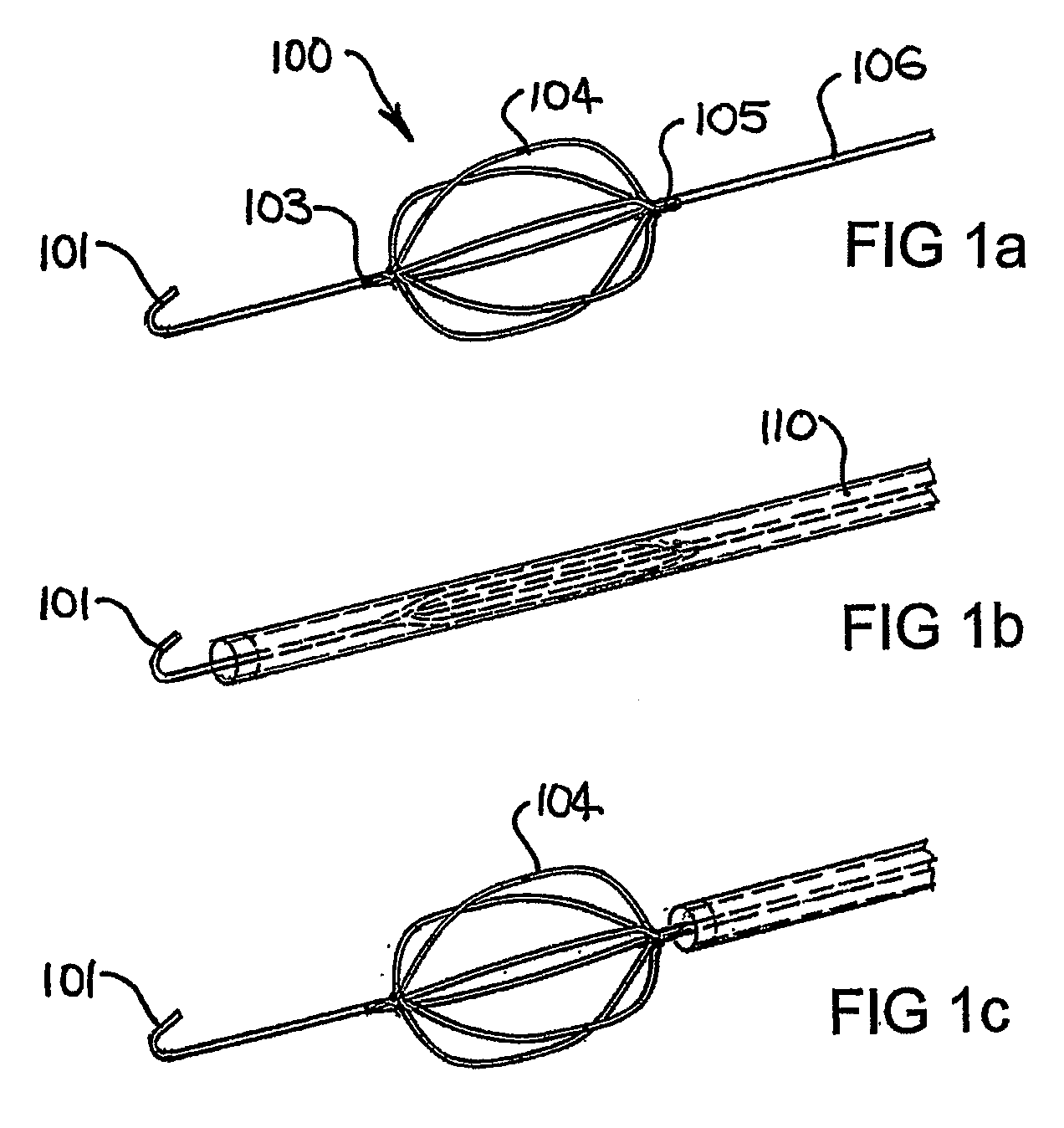

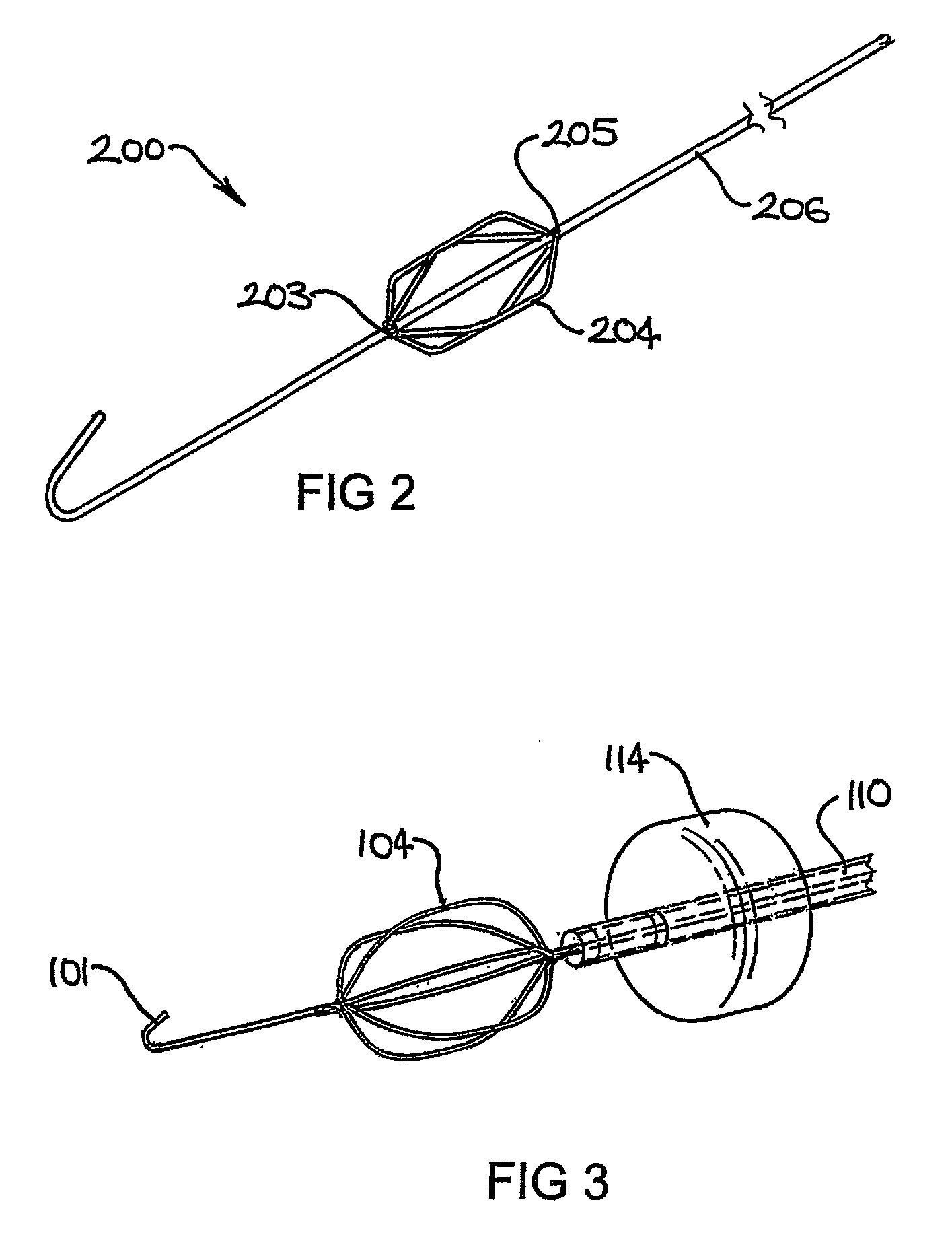

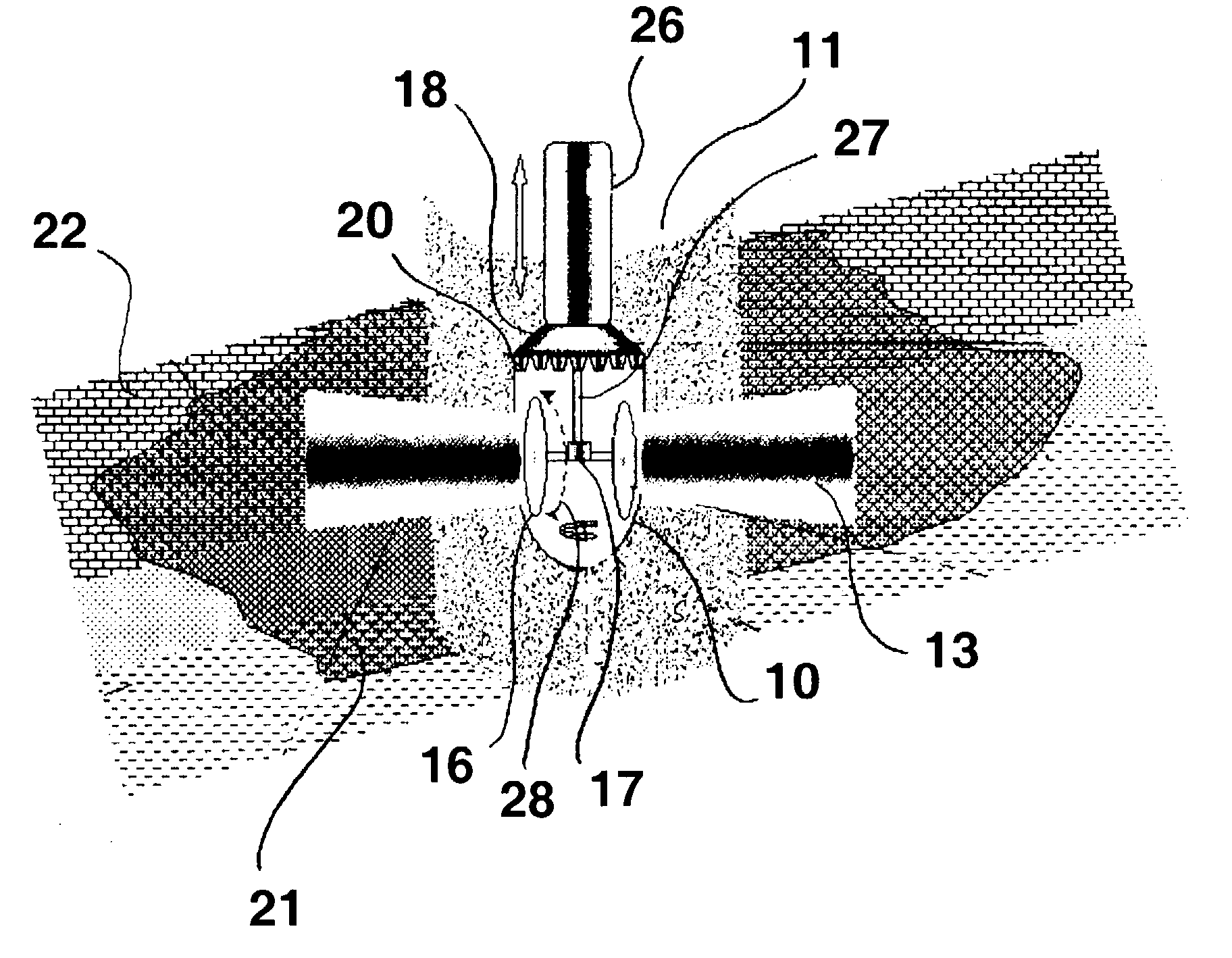

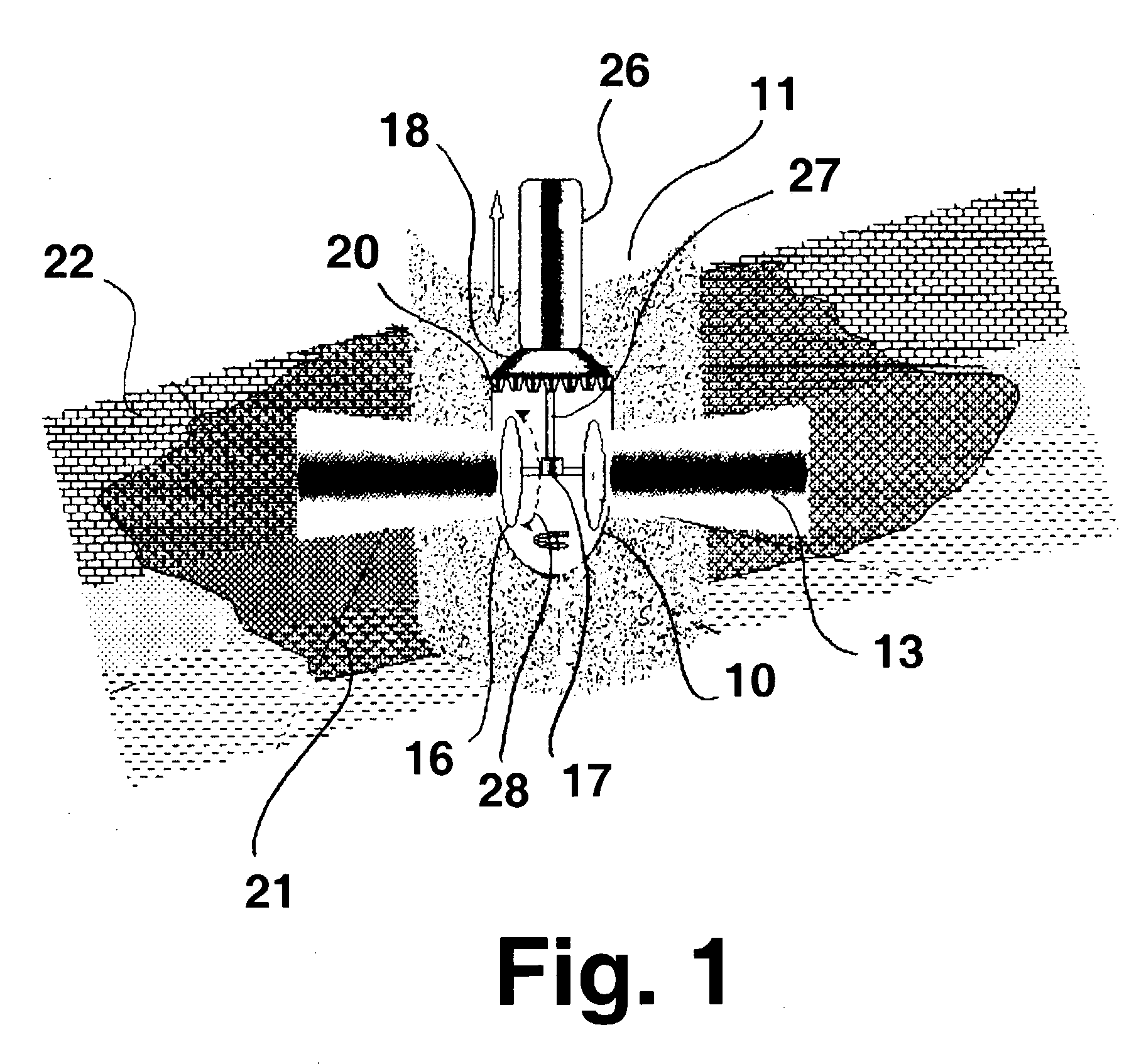

Apparatus and methods for treating congestive heart disease

InactiveUS7335192B2Increase blood flowImprove kidney functionBalloon catheterOther blood circulation devicesInsertion stentPeri-aortic

Methods and apparatus are provided for treating congestive heart by actively or passively enhancing perfusion to the renal arteries. A first embodiment comprises a specially configured balloon catheter and extracorporeal pump, wherein the pump operates in a “once-through” fashion or alternating volume displacement mode. In another embodiment the catheter includes a pair of balloons to isolate a region of the aorta, and a third balloon that directs flow into the renal arteries. In still further embodiments, a stent or cuff having a constricted region is deployed in or around the aorta, respectively, to create a backpressure upstream of the stent or cuff. Methods of enhancing renal perfusion also are provided.

Owner:ANGIODYNAMICS INC

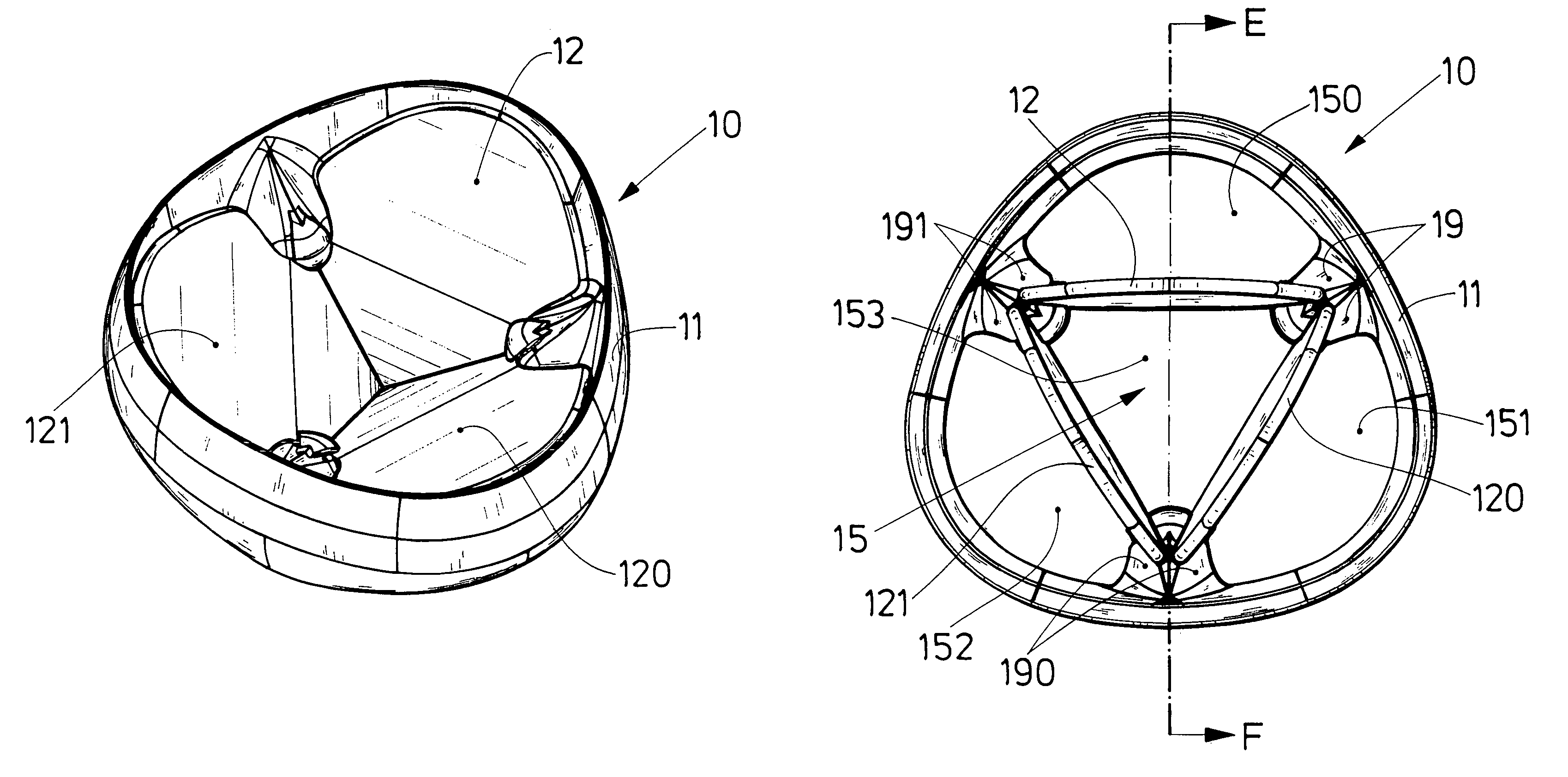

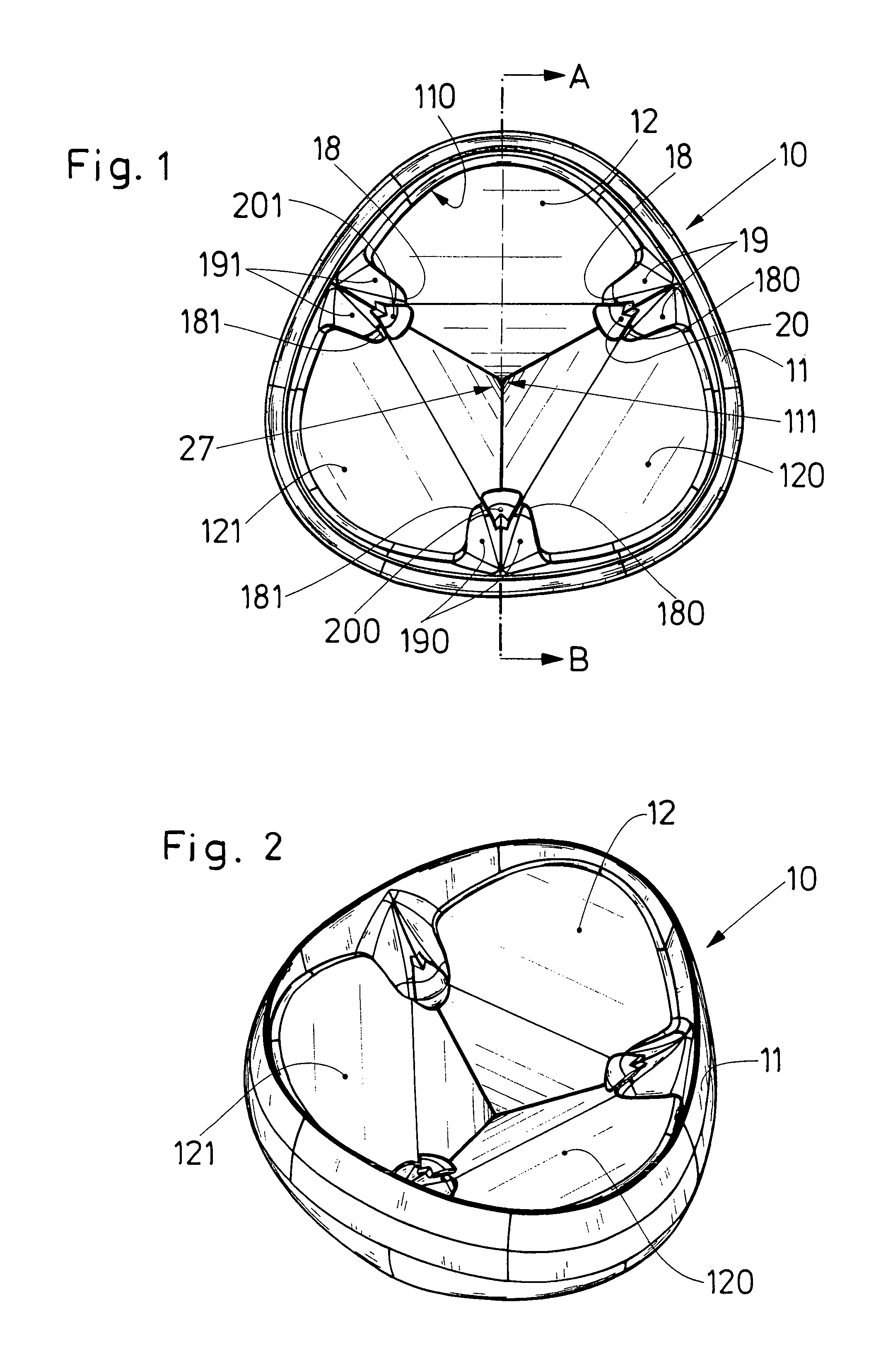

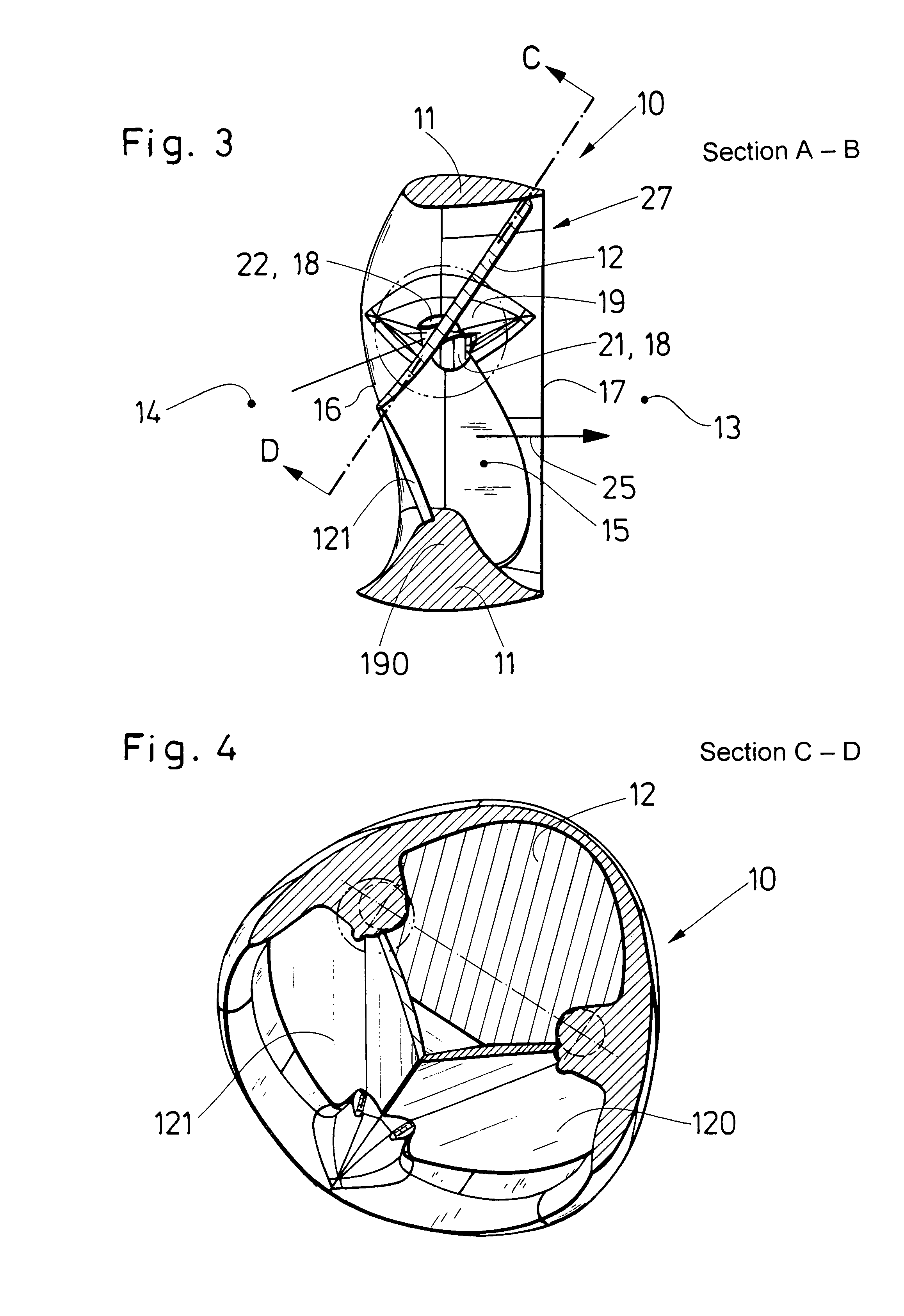

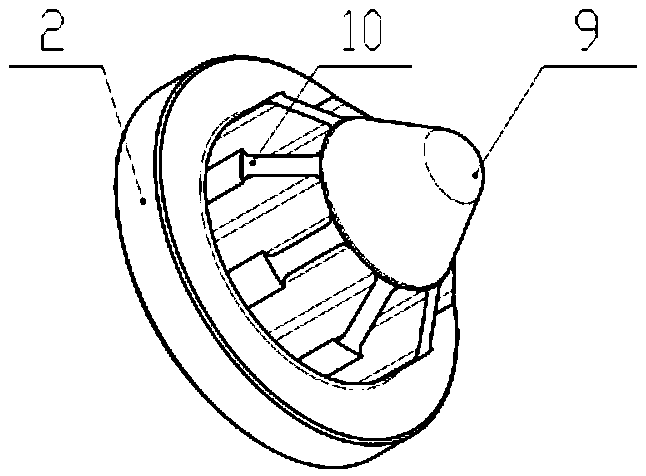

Artificial heart valve

InactiveUS6991649B2Increase flow ratePrevent thrombosisHeart valvesJoint implantsMitral valve leafletPivot joint

Owner:SIEVERS HANS HINRICH

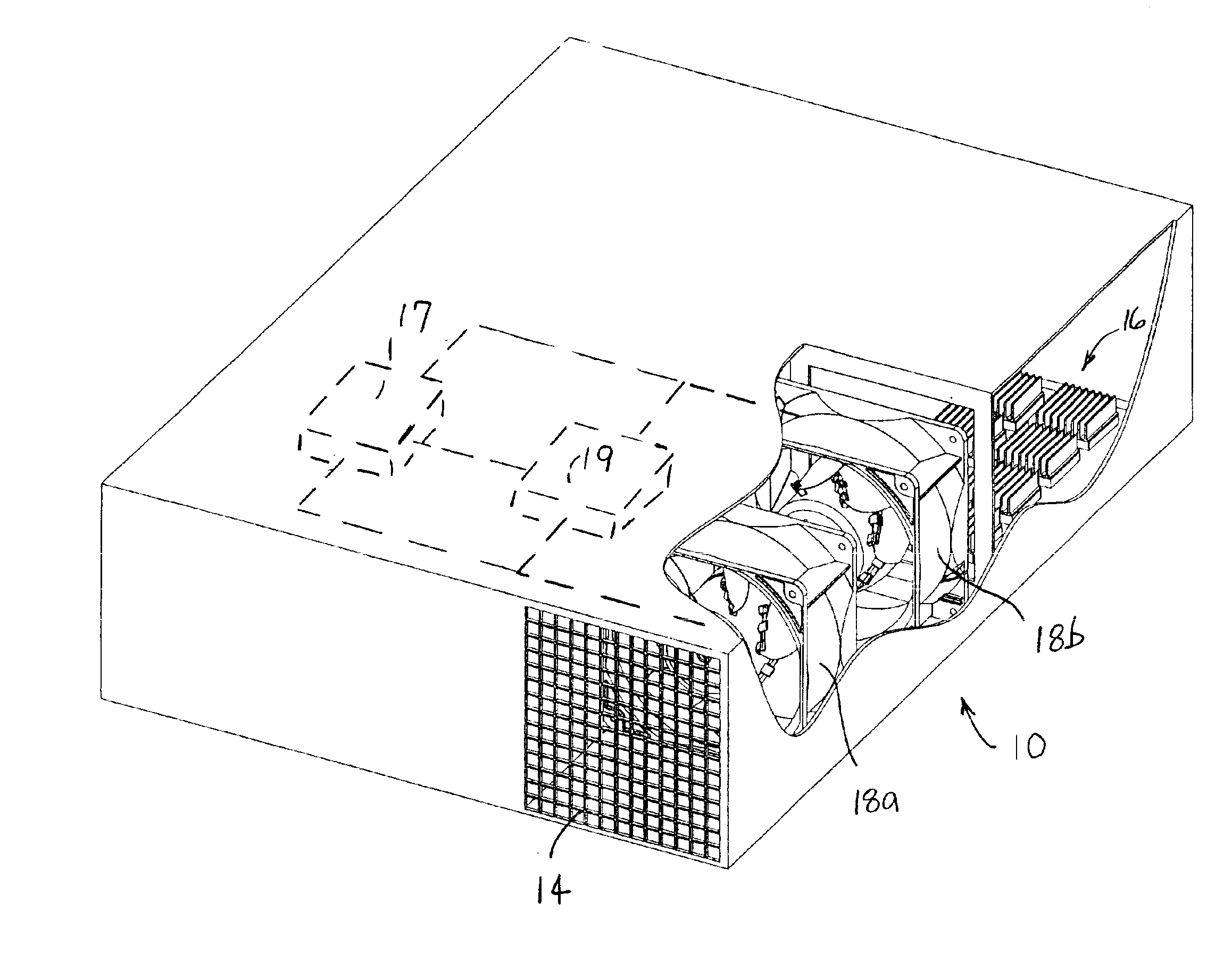

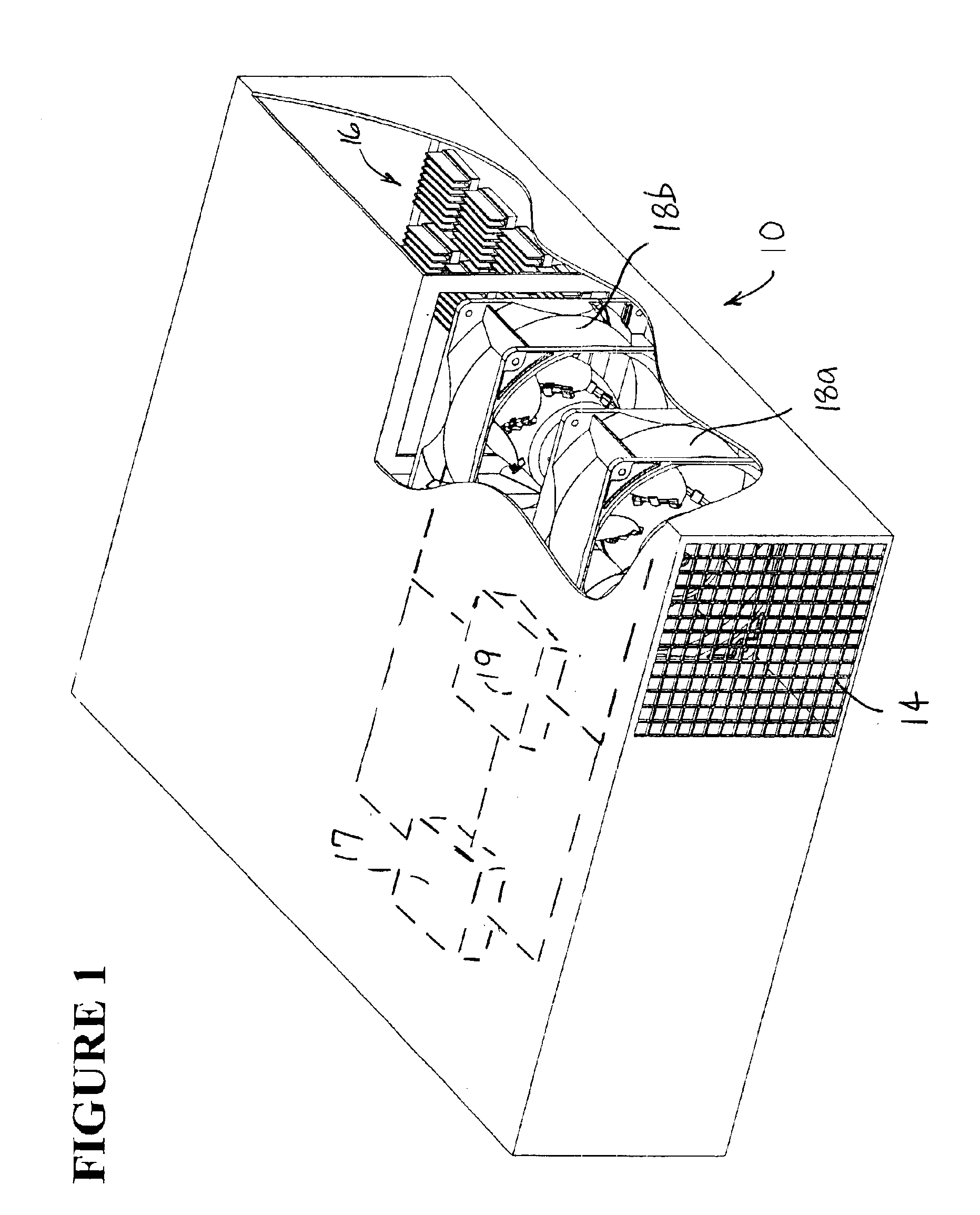

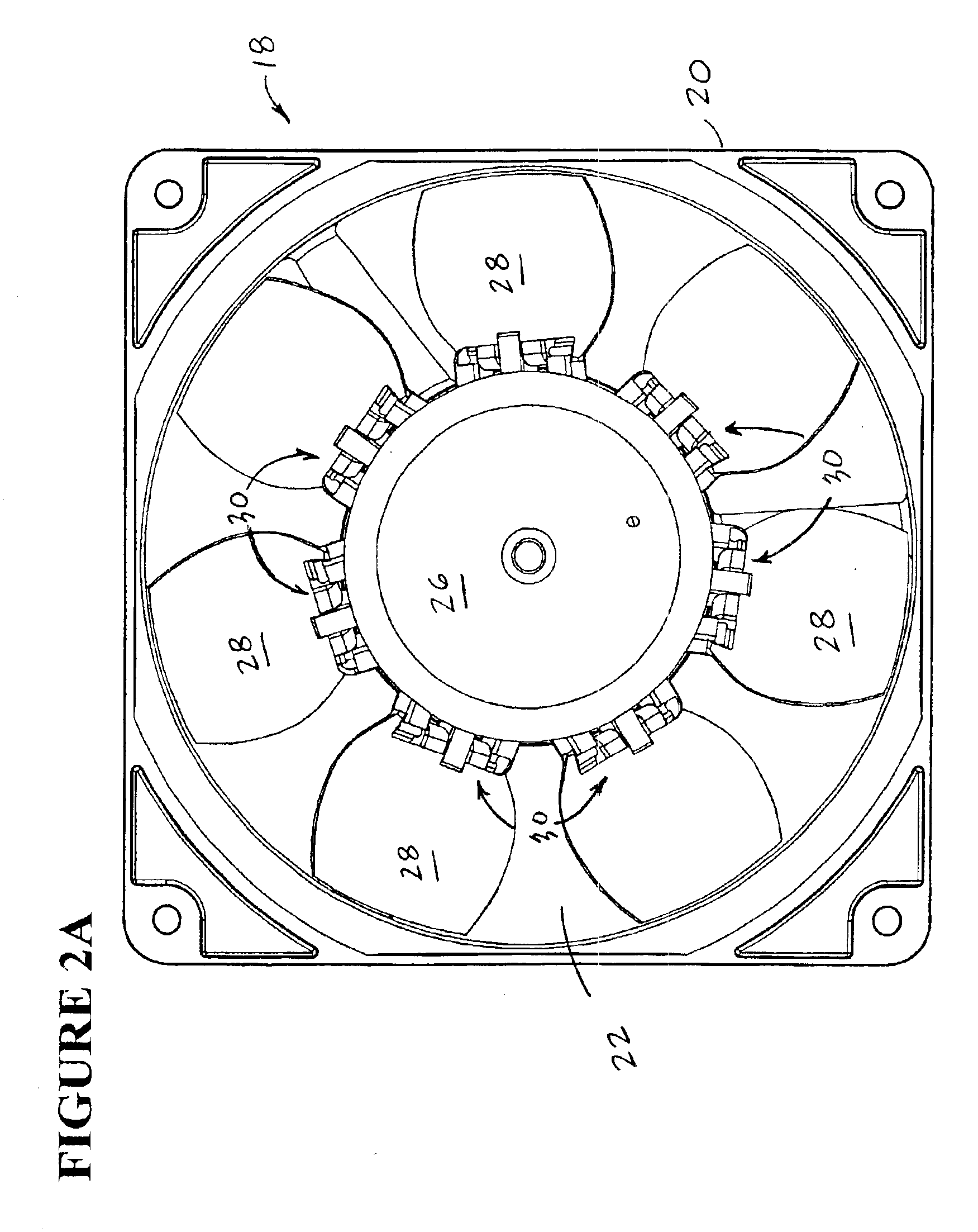

Fan with collapsible blades, redundant fan system, and related method

InactiveUS6860713B2Reduces fan inefficiencyPrevent undesirable blockagePropellersPump componentsFan bladeAirflow

A redundant fan system for a computer includes two fans installed in series with at least one of the fans having collapsible blades. A fan system of this type reduces the fan inefficiency caused when one fan in a series mounted pair is not operating, either because it is free-wheeling or in a locked rotor condition. When non-operational, the fan blades of the collapsible fan fold inward due to airflow generated by the operational fan over the collapsible blades. The ability of the blades to fold reduces the inefficiency of the operational fan, having less of an effect on fan life. Also, because the flow of air is less restricted, proper airflow can be maintained, thus preventing overheating of the computer.

Owner:NIDEC AMERICA CORP

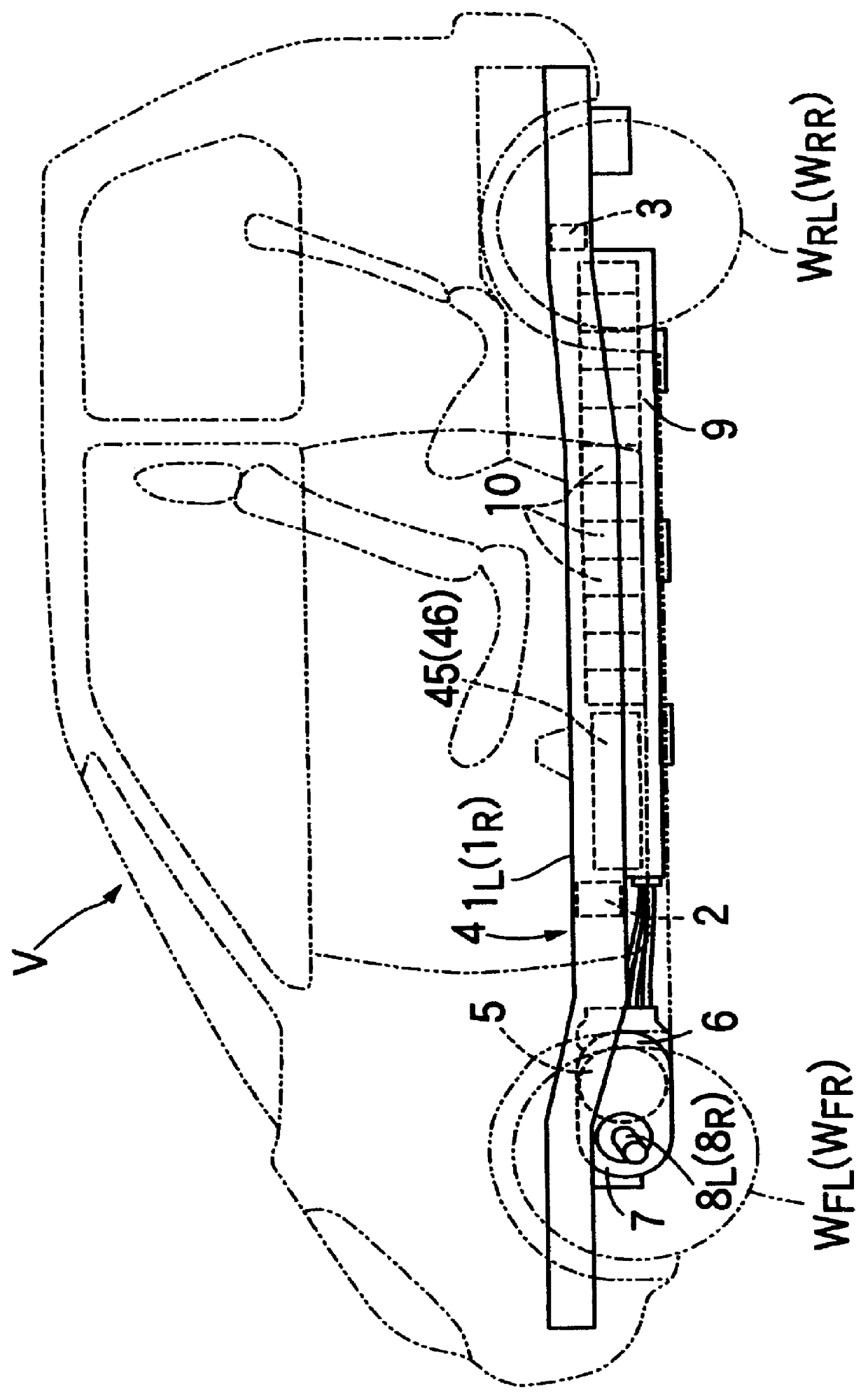

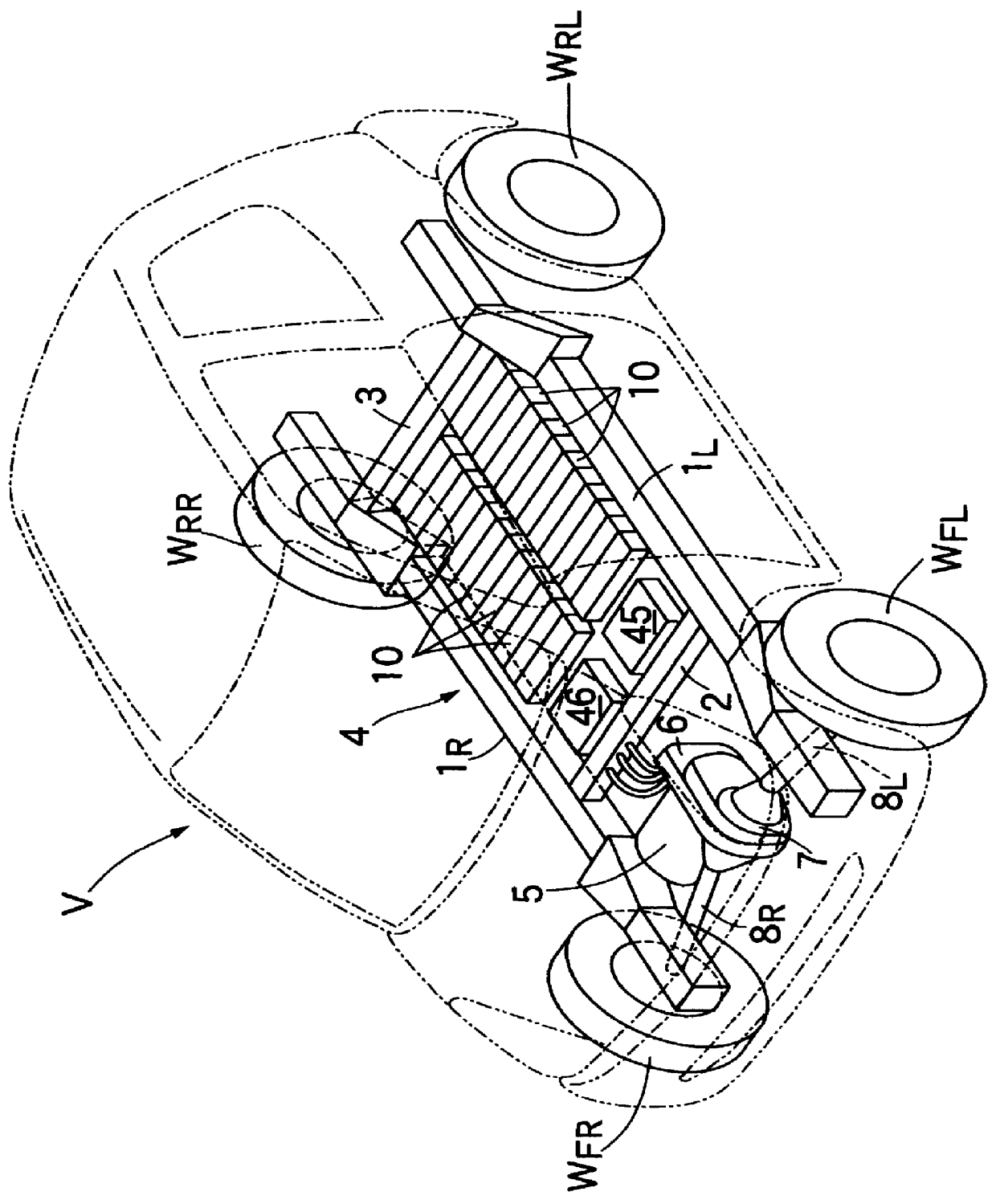

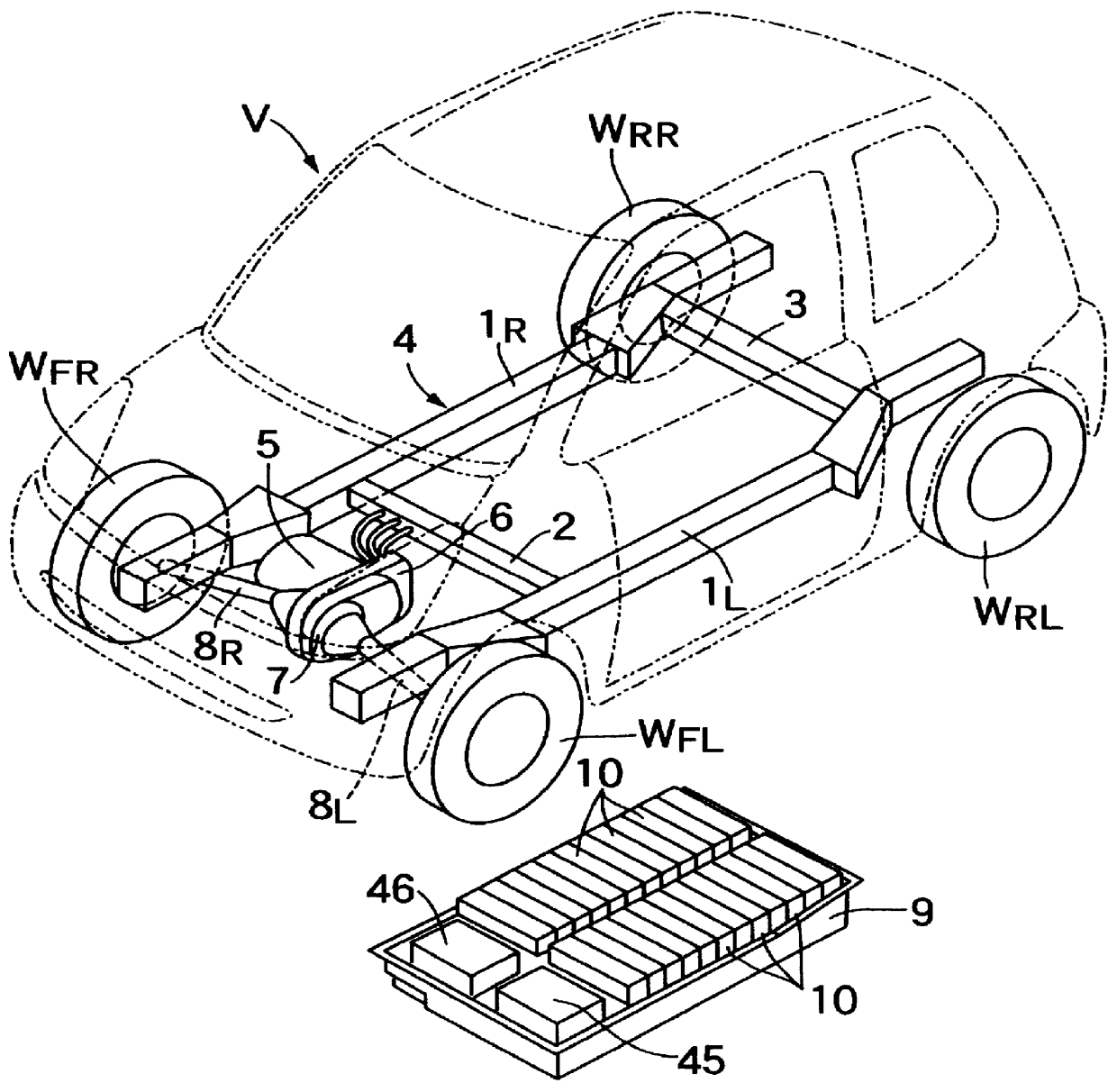

Cooling structure an electric vehicle

InactiveUS6094927AReliable coolingImprove cooling effectDomestic cooling apparatusLighting and heating apparatusAirflowThermal resistance

An electric vehicle includes plurality of batteries accommodated in a rear portion of a battery box, and an electric part is accommodated in an electric part accommodating chamber provided in a front portion of the battery box. Cooling air supplied from a cooling fan to the rear portion of the battery box cools the batteries having a large thermal resistance, while being passed through a first cooling air passage around outer peripheries of the batteries at a low flow rate. A second cooling air passage having a smaller sectional area than that of the first cooling air passage is provided below the electric part accommodating chamber, and cooling fins protruding downwards from the electric part are exposed within the second cooling air passage. The second cooling air passage extends continuously the first cooling air passage in a downstream direction of airflow, so that cooling air which has first cooled the batteries then cools the electric part having a smaller thermal resistance, while being passed through the second cooling air passage at a higher flow rate than that in the first cooling air passage.

Owner:HONDA MOTOR CO LTD

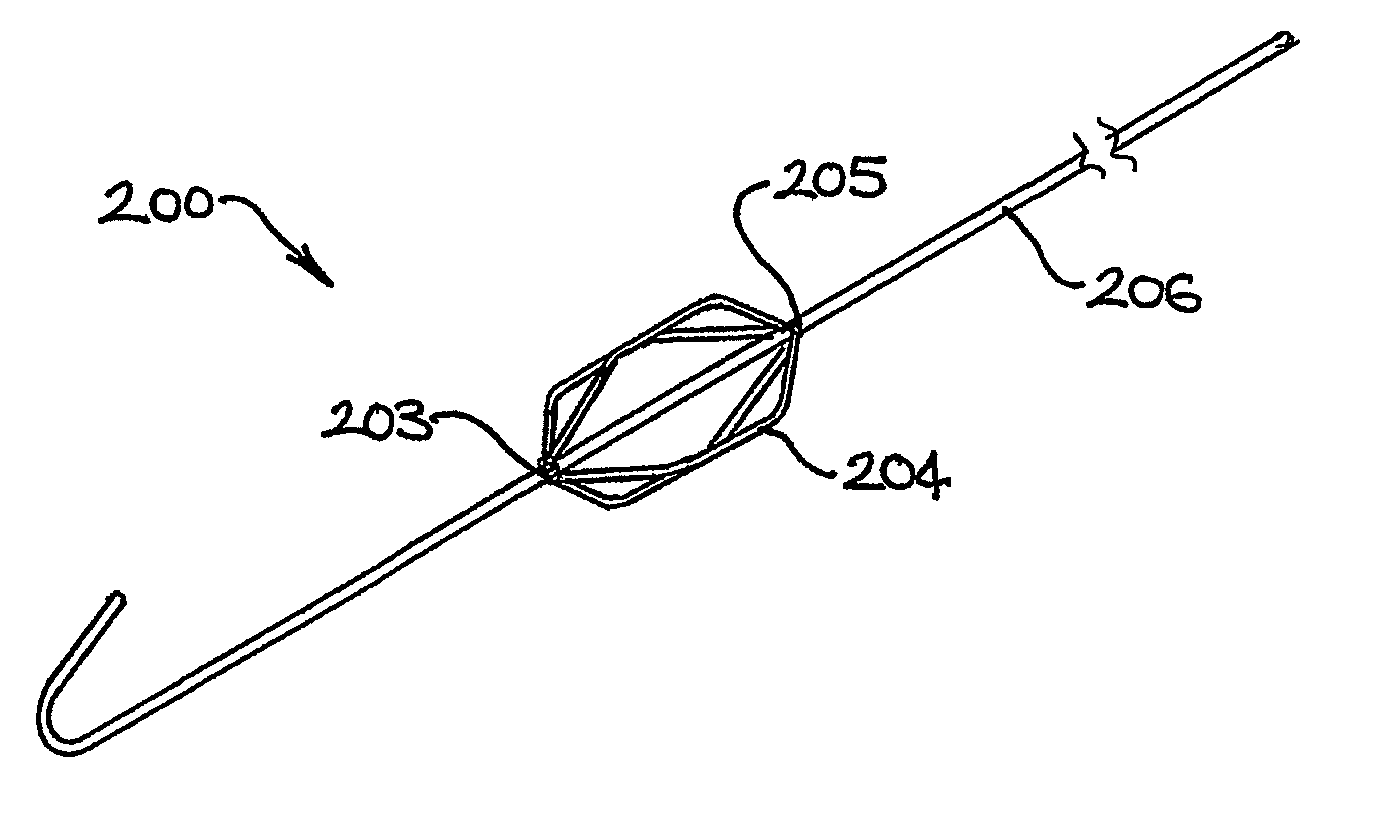

Apparatus and methods for treating congestive heart disease

InactiveUS7766892B2Improve kidney functionIncrease blood flowBalloon catheterOther blood circulation devicesInsertion stentPeri-aortic

Methods and apparatus are provided for treating congestive heart by actively or passively enhancing perfusion to the renal arteries. A first embodiment comprises a specially configured balloon catheter and extracorporeal pump, wherein the pump operates in a “once-through” fashion or alternating volume displacement mode. In another embodiment the catheter includes a pair of balloons to isolate a region of the aorta, and a third balloon that directs flow into the renal arteries. In still further embodiments, a stent or cuff having a constricted region is deployed in or around the aorta, respectively, to create a backpressure upstream of the stent or cuff. Methods of enhancing renal perfusion also are provided.

Owner:LIBRA MEDICAL SYST

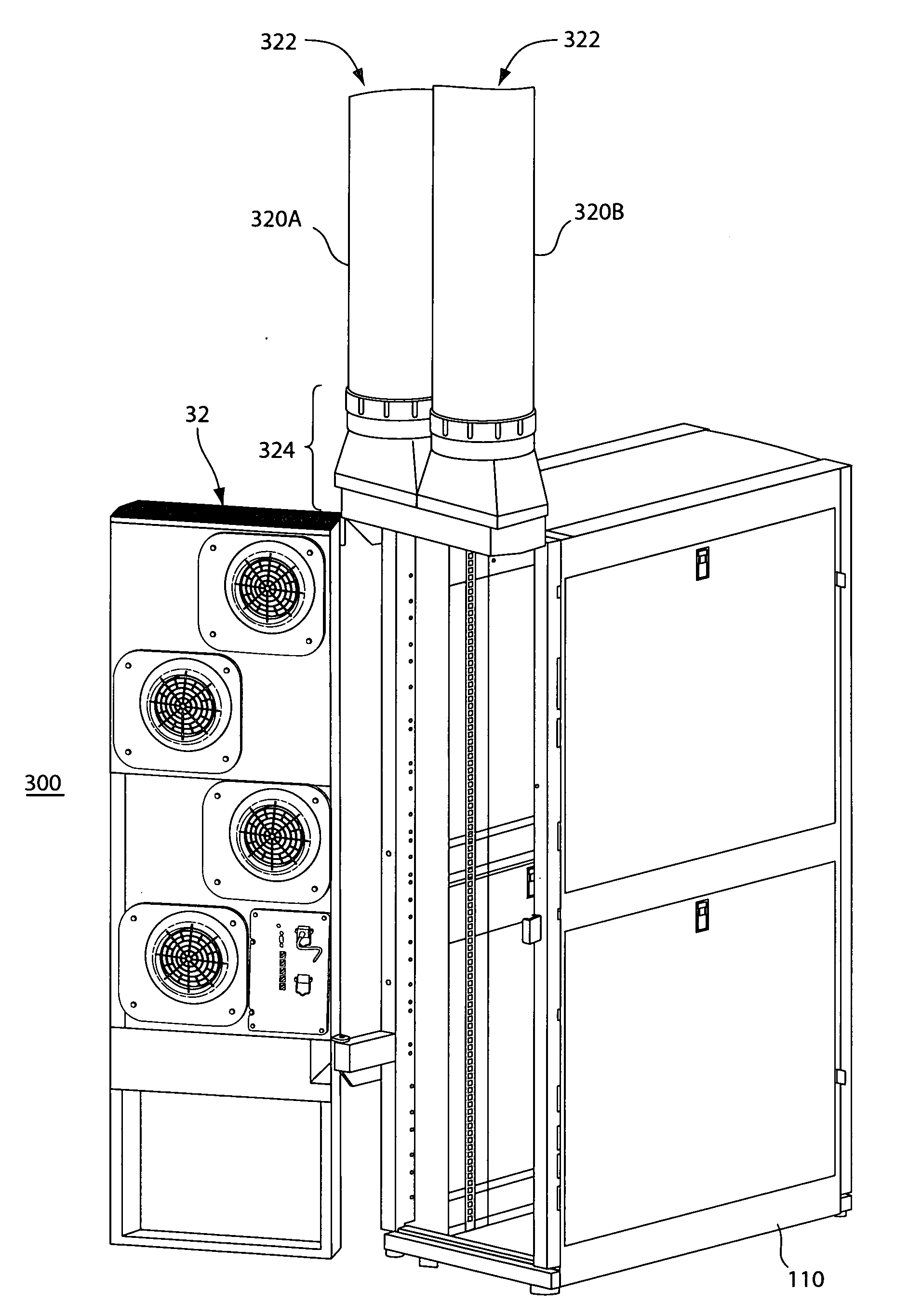

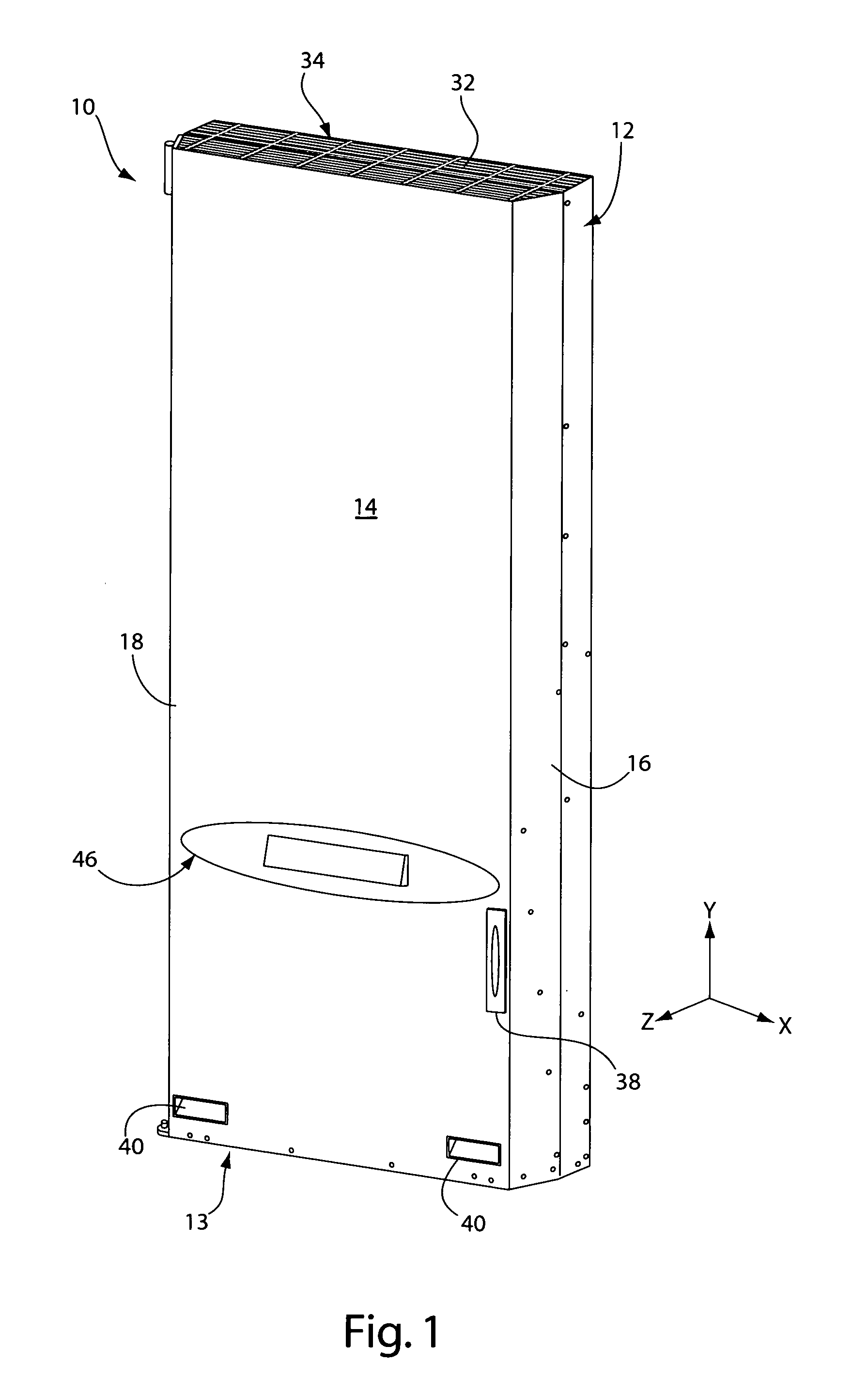

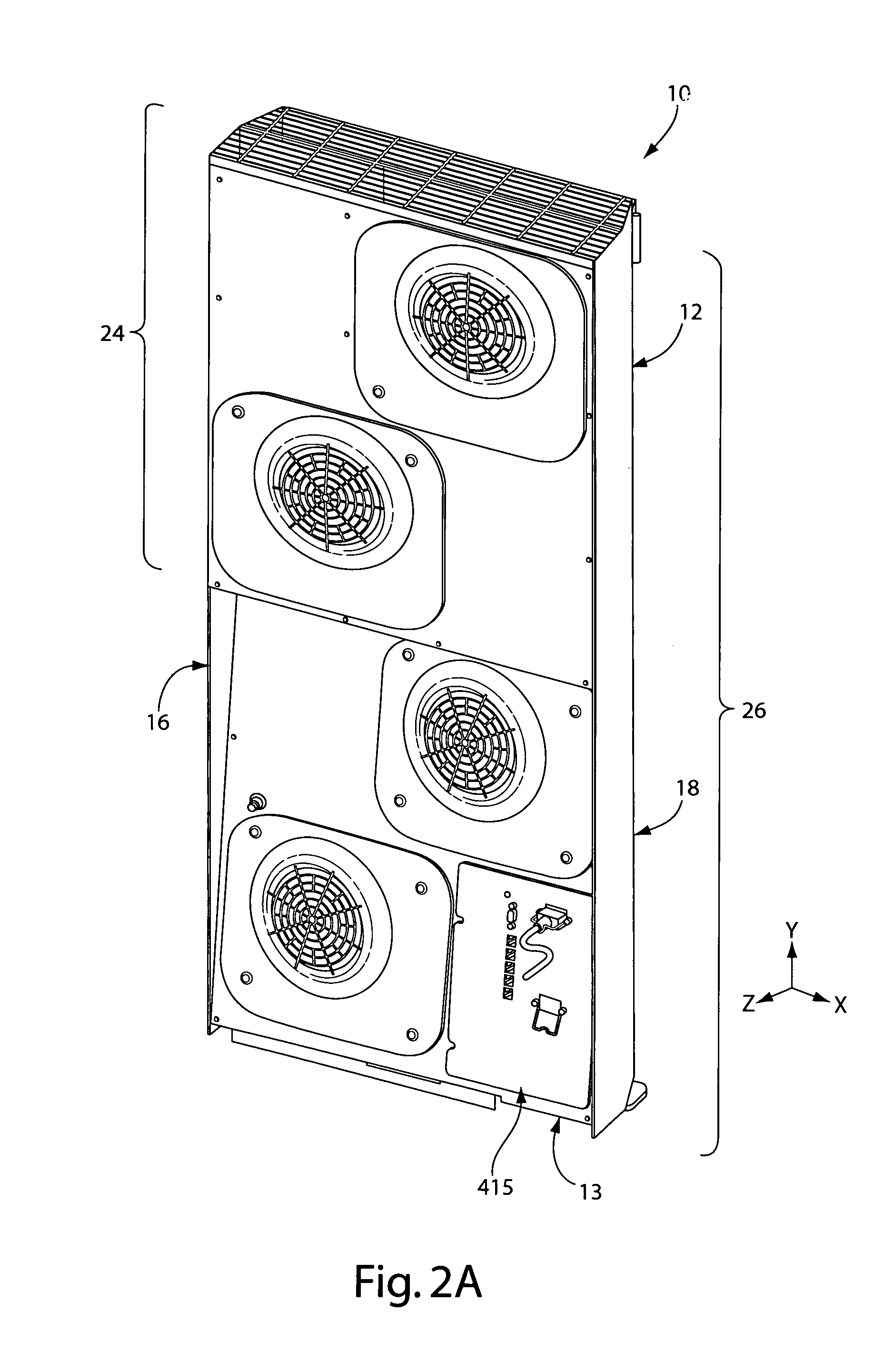

Air removal unit

ActiveUS20070171613A1Quickly and easily installReduce air resistance and air turbulenceCooling/ventilation/heating modificationsElectrical apparatus casings/cabinets/drawersExhaust fumesAirflow

An air removal unit configured for removing exhaust air from an equipment rack or enclosure includes multiple fans to achieve a high airflow capacity while defining a compact and portable structure. The unit removably installs along an exhaust side of an equipment rack or enclosure to provide capabilities for managing the thermal output of equipment, such as servers, CPUs, communications, internetworking and other types of equipment. The unit includes one or more upper fan modules and one or more lower fan modules positioned below the upper fan modules. The upper and the lower fan modules are arranged in a stacked configuration along the depth of the unit with the lower fan modules positioned in an offset orientation relative to the upper fan modules. The stacked configuration and the offset orientation of the fan modules help to incorporate multiple fans with the unit while maintaining the compact and portable design. The unit is further configured to serve as a door of an equipment rack or enclosure to thereby provide access to the unit and the rack or enclosure during operation. The unit can be incorporated with a ventilation system or a cooling air system associated with an equipment room or data center.

Owner:AMERICA POWER CONVERSION CORP

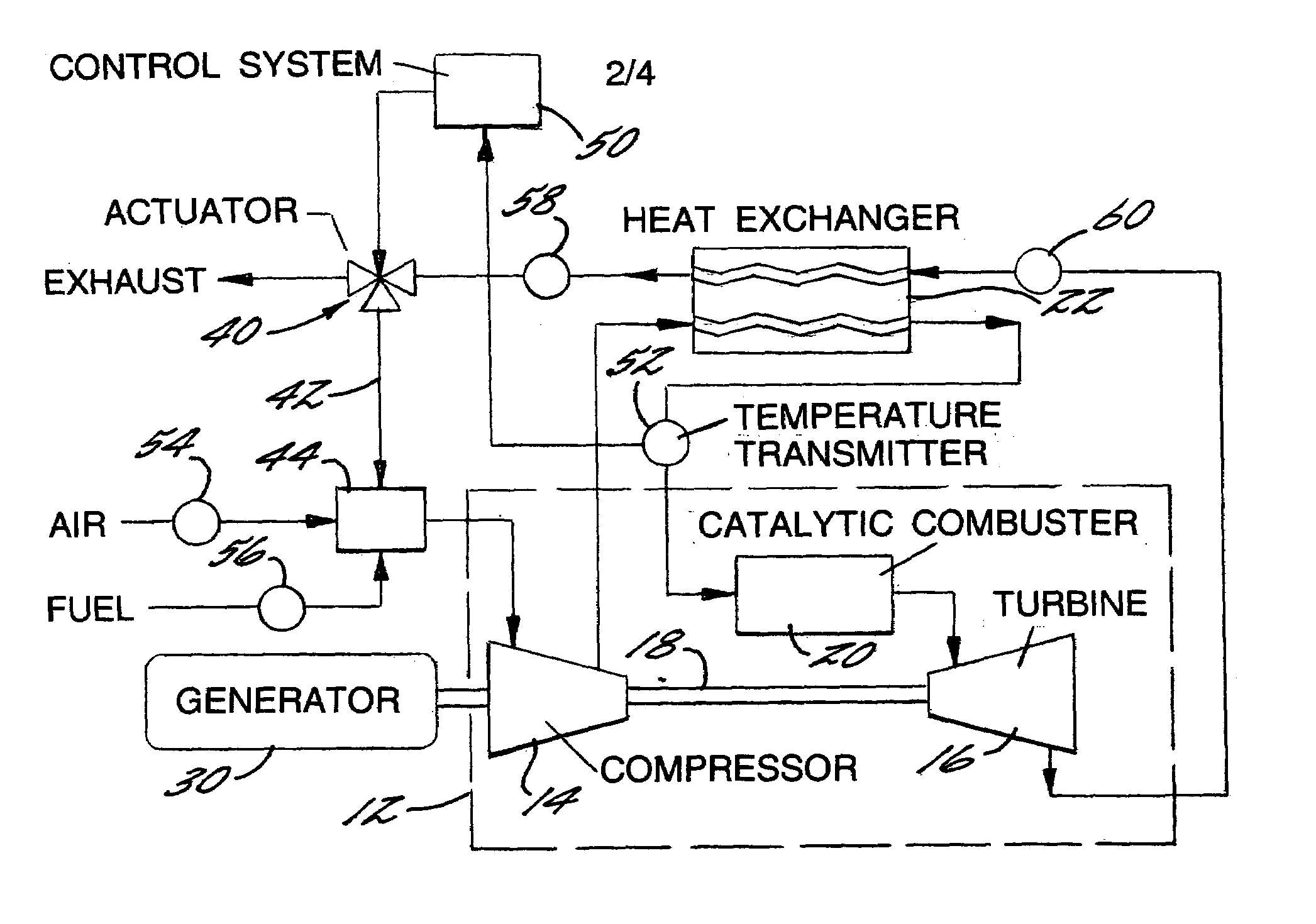

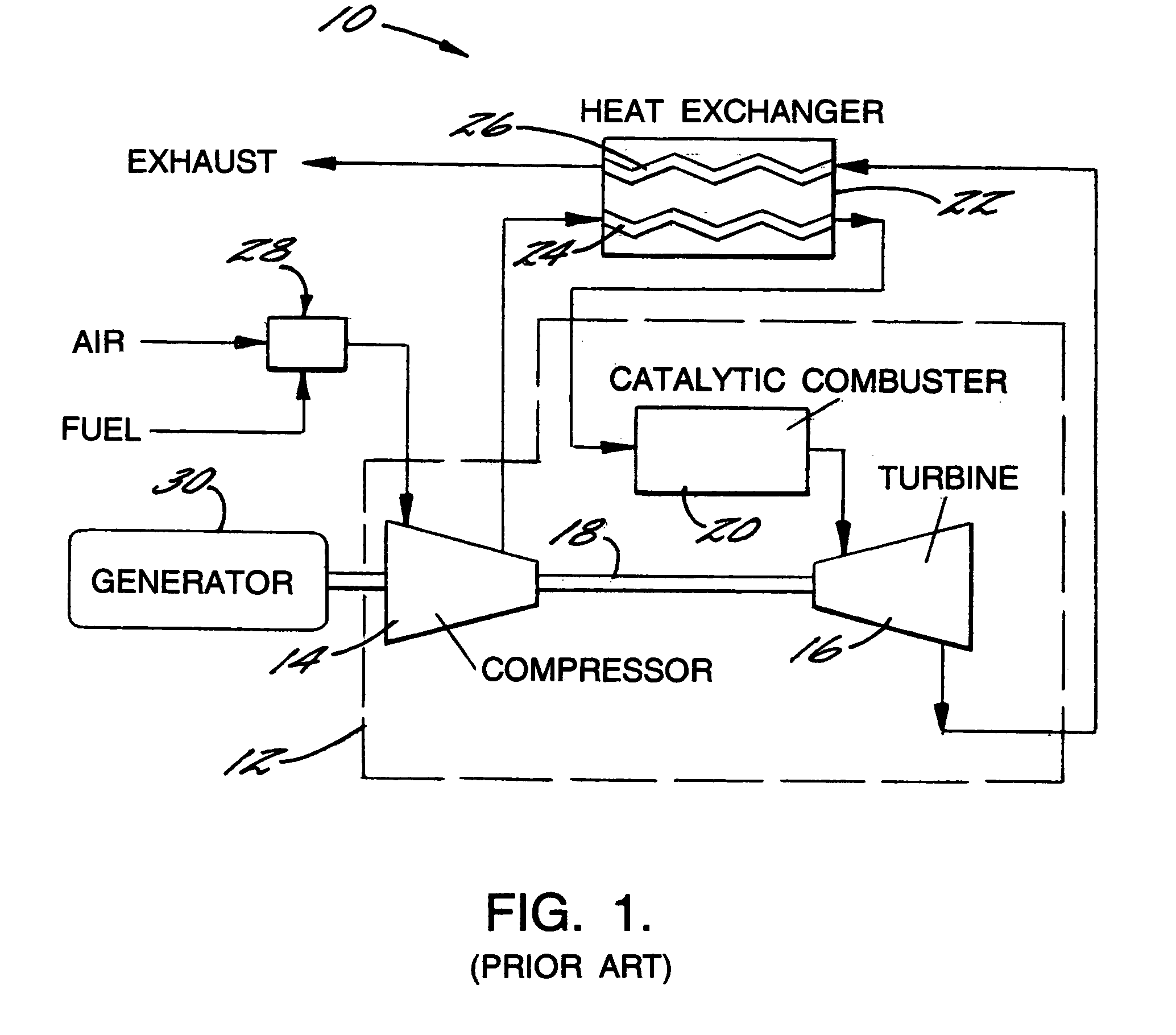

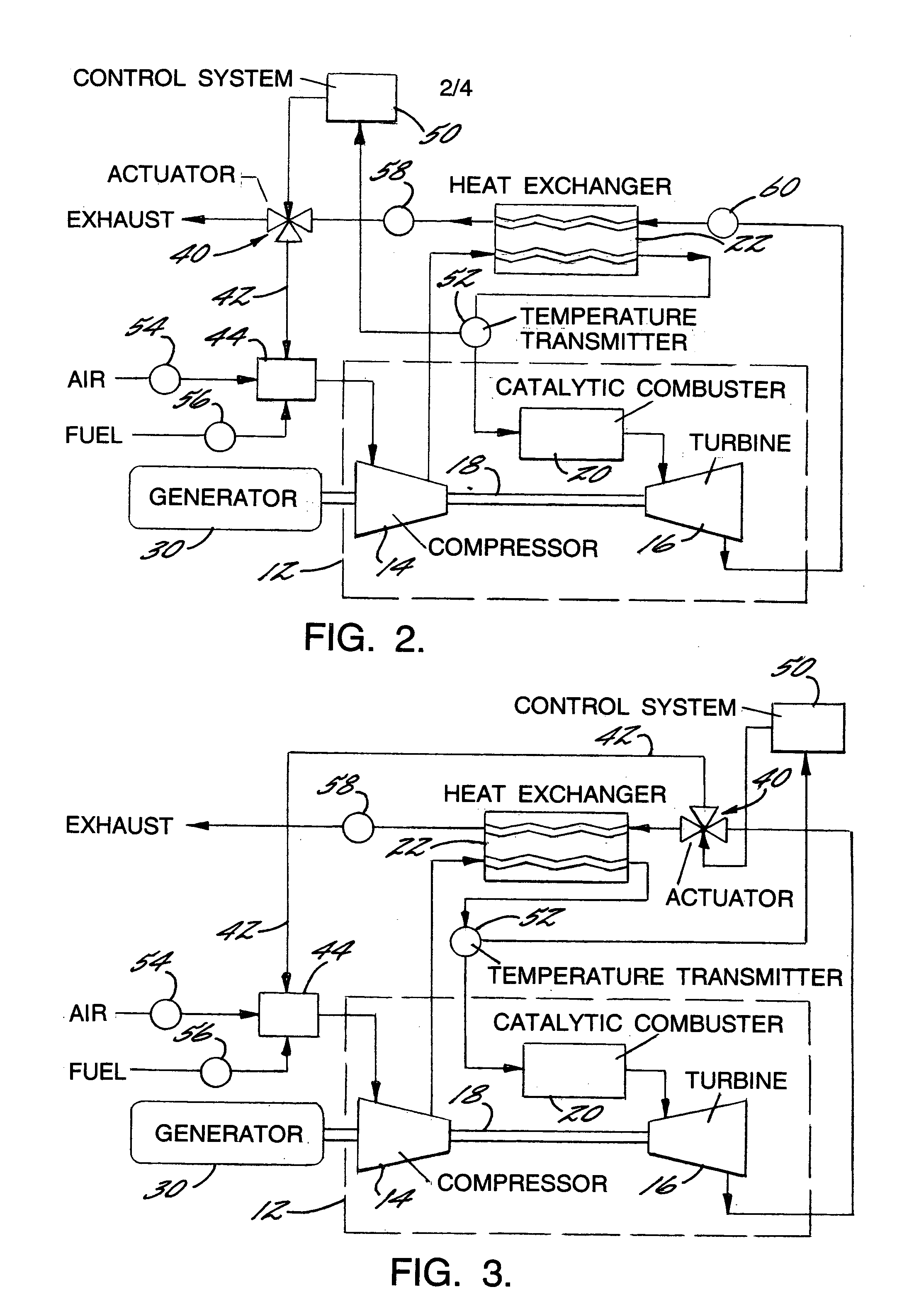

Recuperated gas turbine engine system and method employing catalytic combustion

InactiveUS7007487B2Maximize efficiencyReduce air pollutionTurbine/propulsion fuel supply systemsContinuous combustion chamberCombustorCold weather

A recuperated gas turbine engine system and associated method employing catalytic combustion, wherein the combustor inlet temperature can be controlled to remain above the minimum required catalyst operating temperature at a wide range of operating conditions from full-load to part-load and from hot-day to cold-day conditions. The fuel is passed through the compressor along with the air and a portion of the exhaust gases from the turbine. The recirculated exhaust gas flow rate is controlled to control combustor inlet temperature.

Owner:MES INT INC

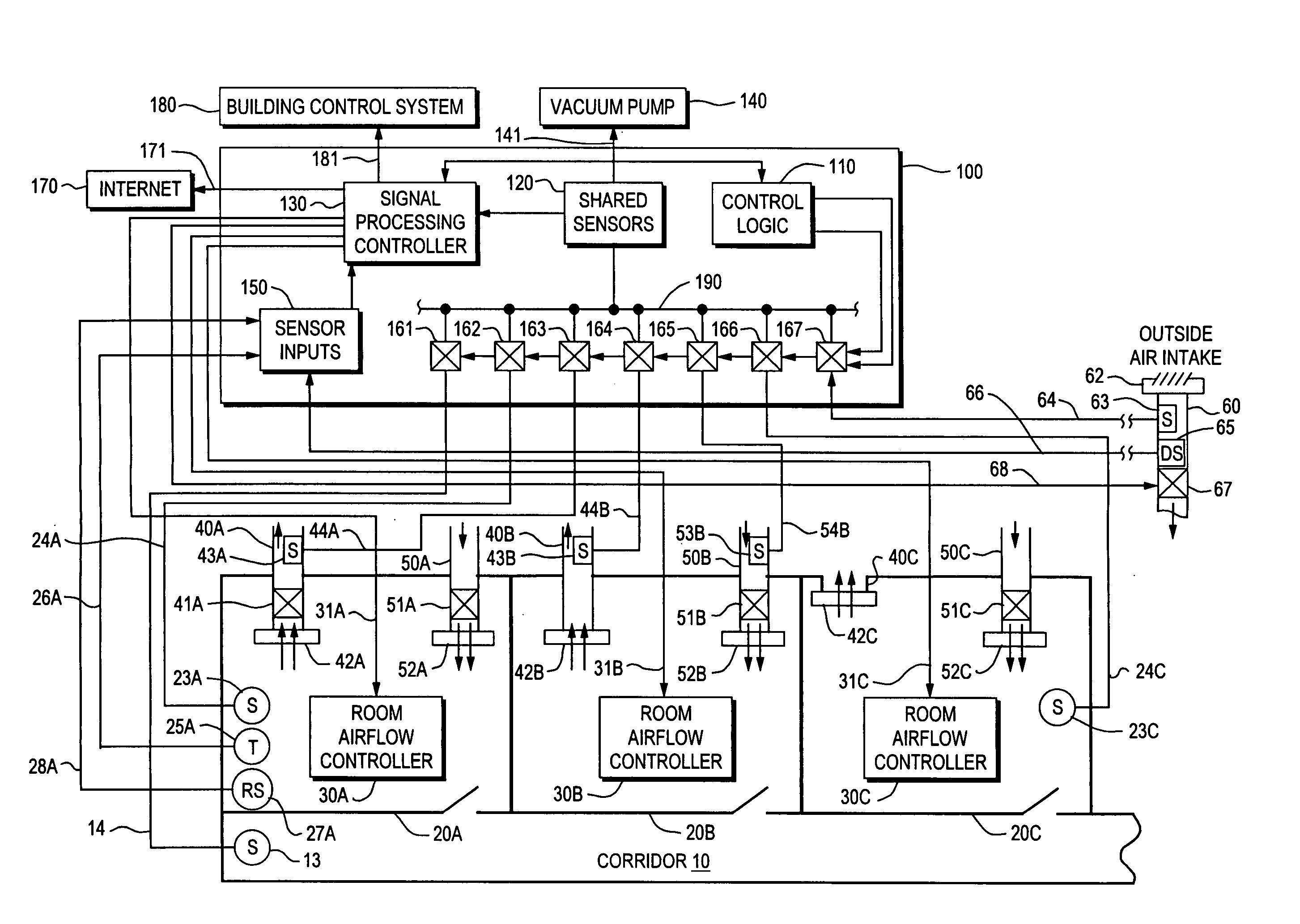

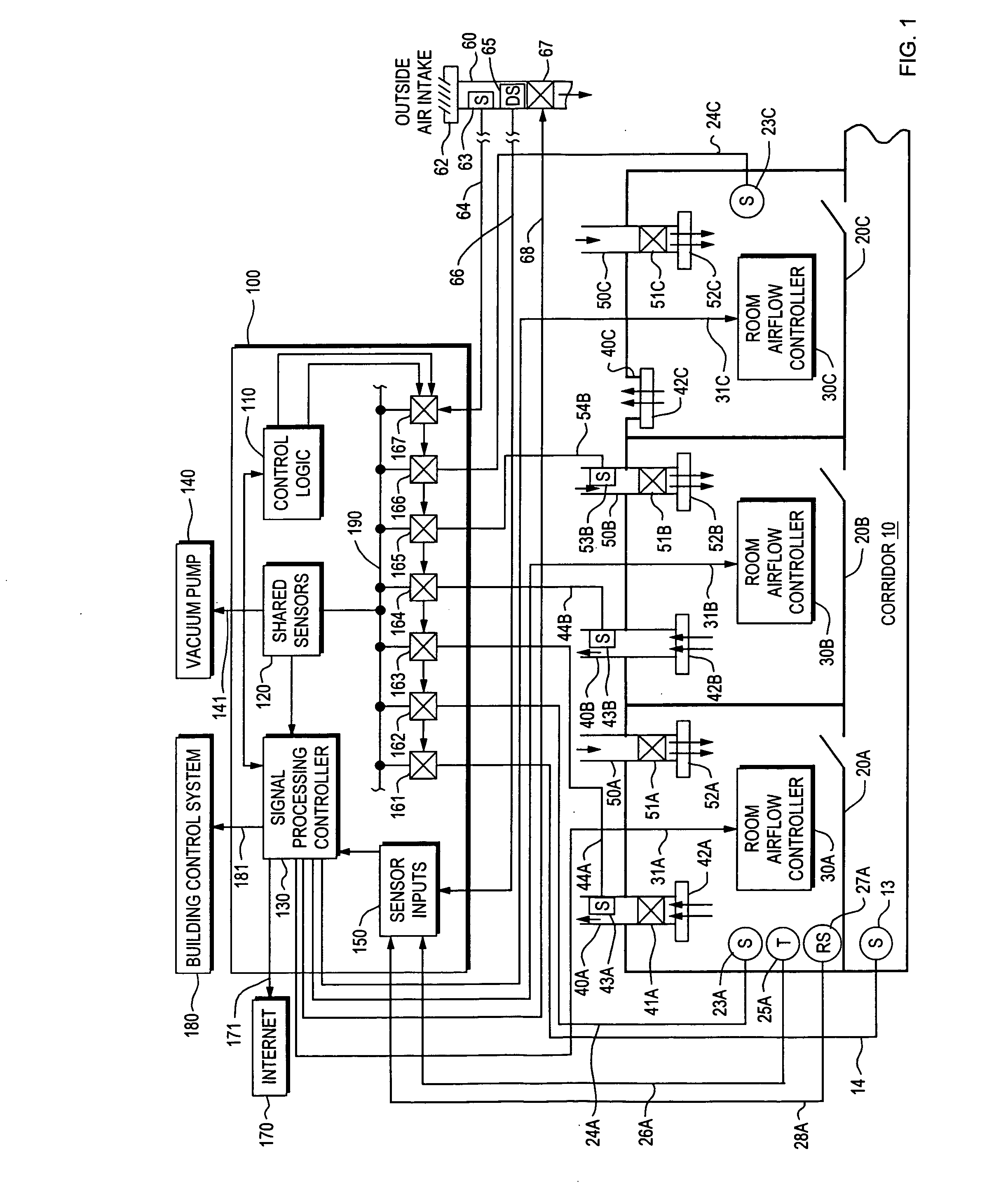

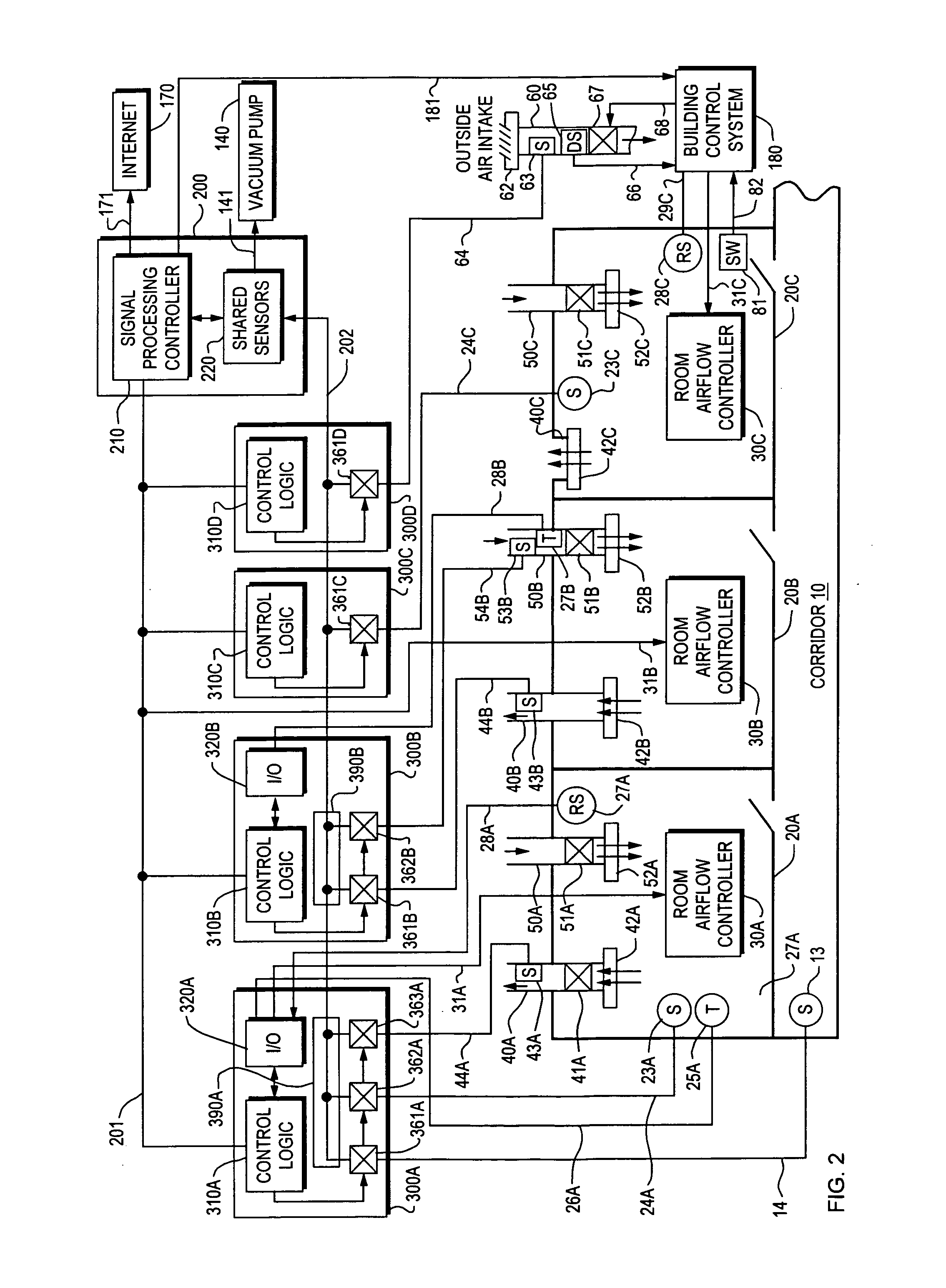

Multipoint air sampling system having common sensors to provide blended air quality parameter information for monitoring and building control

ActiveUS20060234621A1Improve accuracyMore accuratelySampled-variable control systemsSpace heating and ventilationAir monitoringQuality data

A system for monitoring air quality conditions, comprising, a multi-point air monitoring system comprising, a plurality of sensors for collecting air quality data from a plurality of at least partially enclosed areas; one or more data processing units for processing one or more air quality parameters based on the collected air quality data; and one or more communication devices for communicating the data from the sensor to the processing unit; and a signal processing controller that generates one or more blended air quality parameter signals via the multi-point air monitoring system based at least in part on one or more of the processed air quality parameters representative of data from a plurality of the sensors.

Owner:AIRCUITY

Apparatus and methods for treating congestive heart disease

InactiveUS7780628B1Increase blood flowImprove kidney functionBalloon catheterOther blood circulation devicesInsertion stentPeri-aortic

Methods and apparatus are provided for treating congestive heart by actively or passively enhancing perfusion to the renal arteries. A first embodiment comprises a specially configured balloon catheter and extracorporeal pump, wherein the pump operates in a “once-through” fashion or alternating volume displacement mode. In another embodiment the catheter includes a pair of balloons to isolate a region of the aorta, and a third balloon that directs flow into the renal arteries. In still further embodiments, a stent or cuff having a constricted region is deployed in or around the aorta, respectively, to create a backpressure upstream of the stent or cuff. Methods of enhancing renal perfusion also are provided.

Owner:ANGIODYNAMICS INC

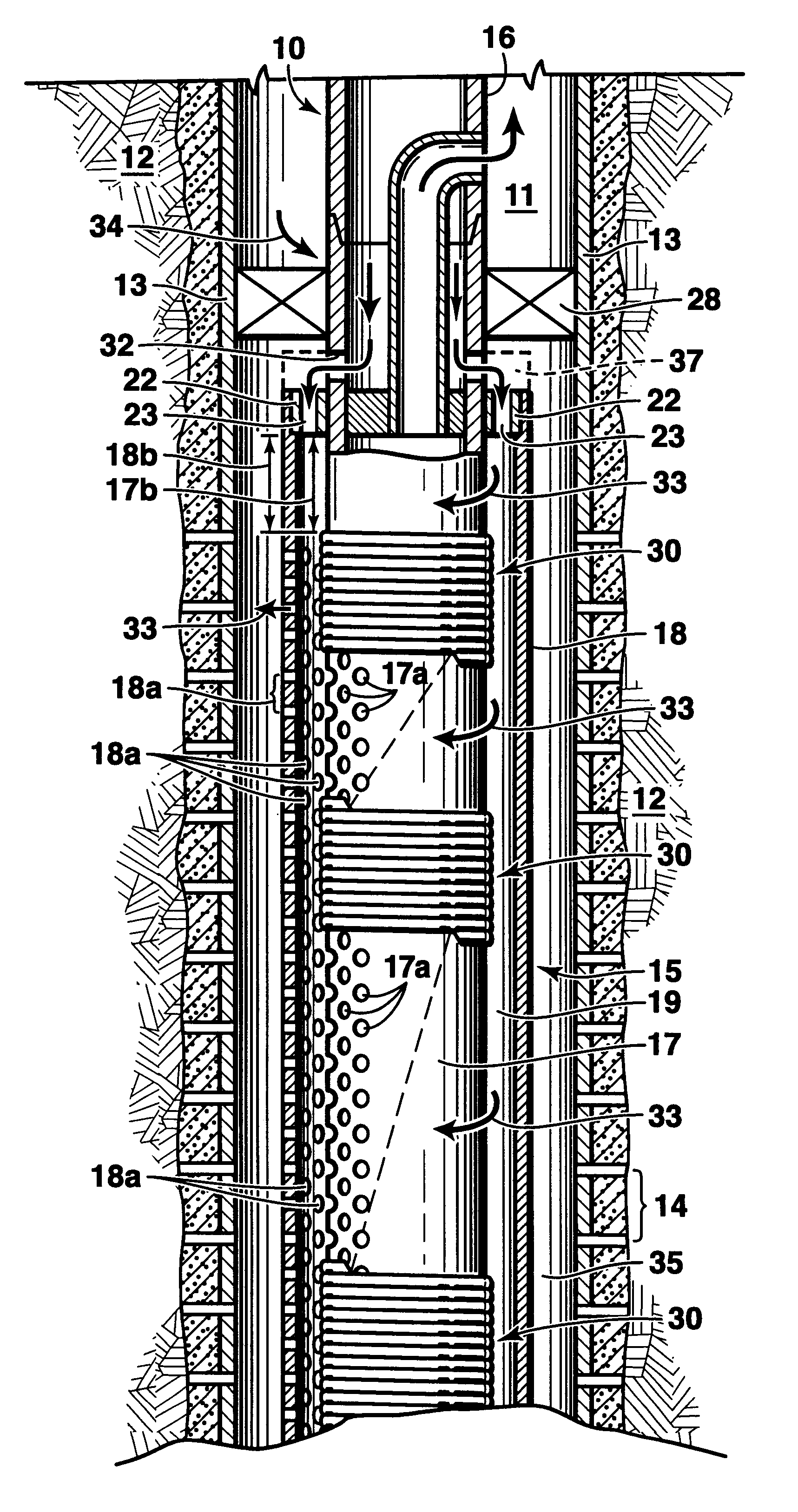

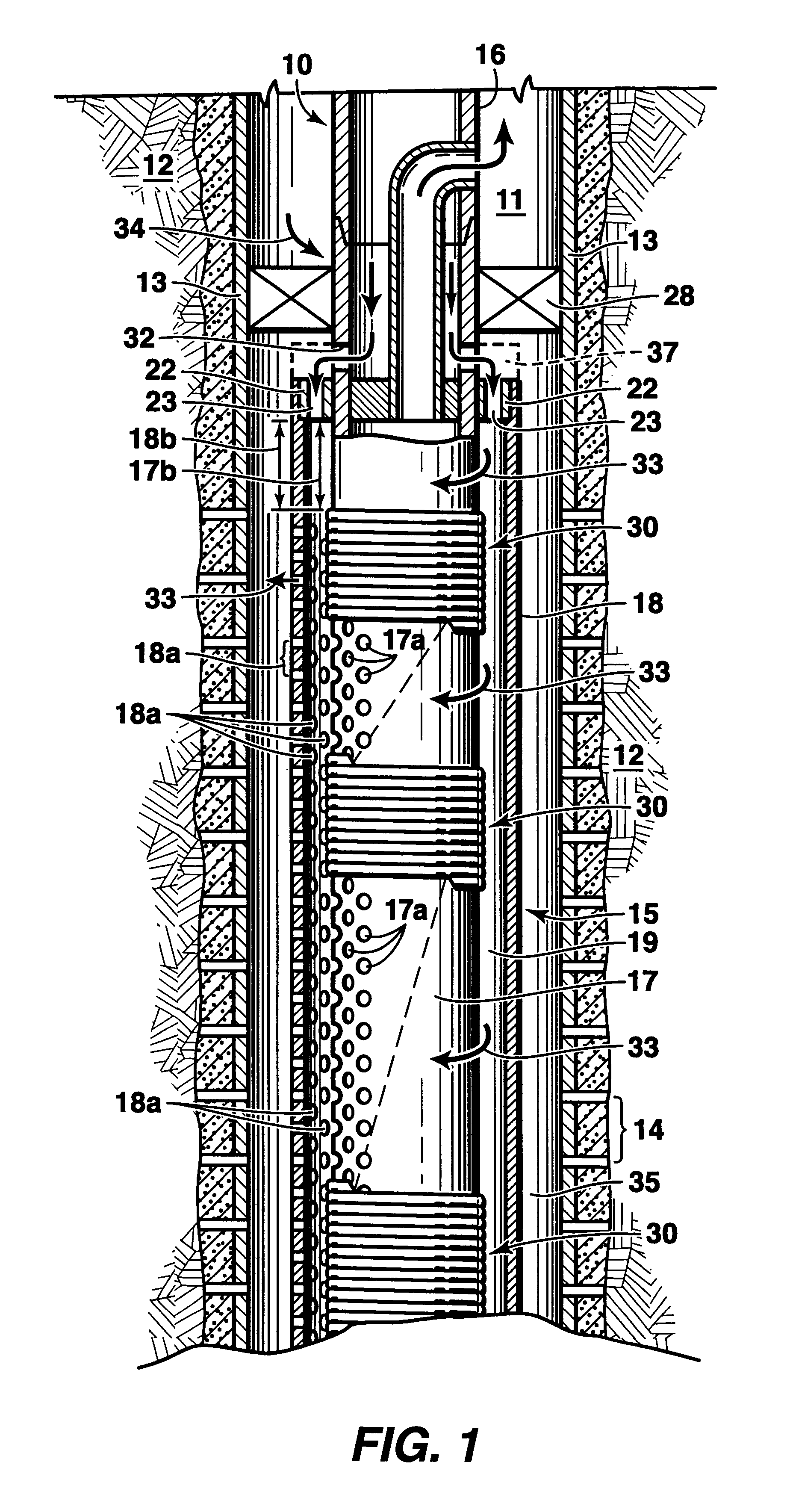

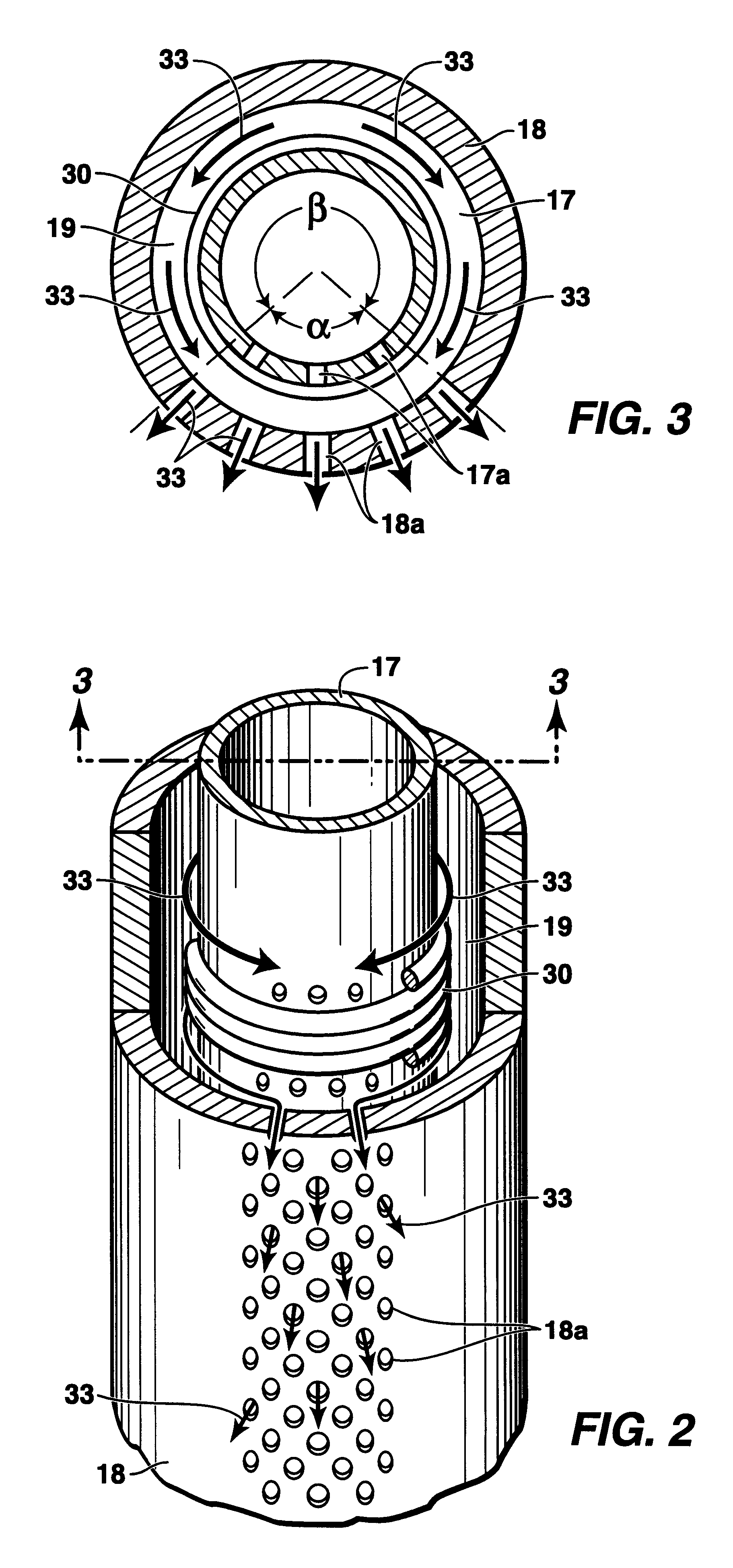

Well screen having an internal alternate flowpath

InactiveUS6220345B1High viscosityIncrease flow rateFluid removalDrinking water installationFracturing fluidEngineering

A well screen having an internal, blank alternate flowpath for delivering fracturing fluid / gravel slurry to different levels within a well annulus. The well screen includes an outer pipe which is positioned over a base pipe thereby forming an annulus therebetween. The circumference of each pipe has a perforated sector and a blank sector, both of which extend along their respective lengths. When assembled, the respective perforated sectors are aligned to form a perforated, production sector and the respective blank sectors are aligned to form the blank, alternate flowpath. The base pipe is wrapped with wire to prevent solids from flowing through the openings therein. Slurry is pumped into the annulus where it flows circumferently from the blank, alternate flowpath to exit into the well annulus through the openings in the perforated sector of the annulus.

Owner:SCHLUMBERGER TECH CORP +1

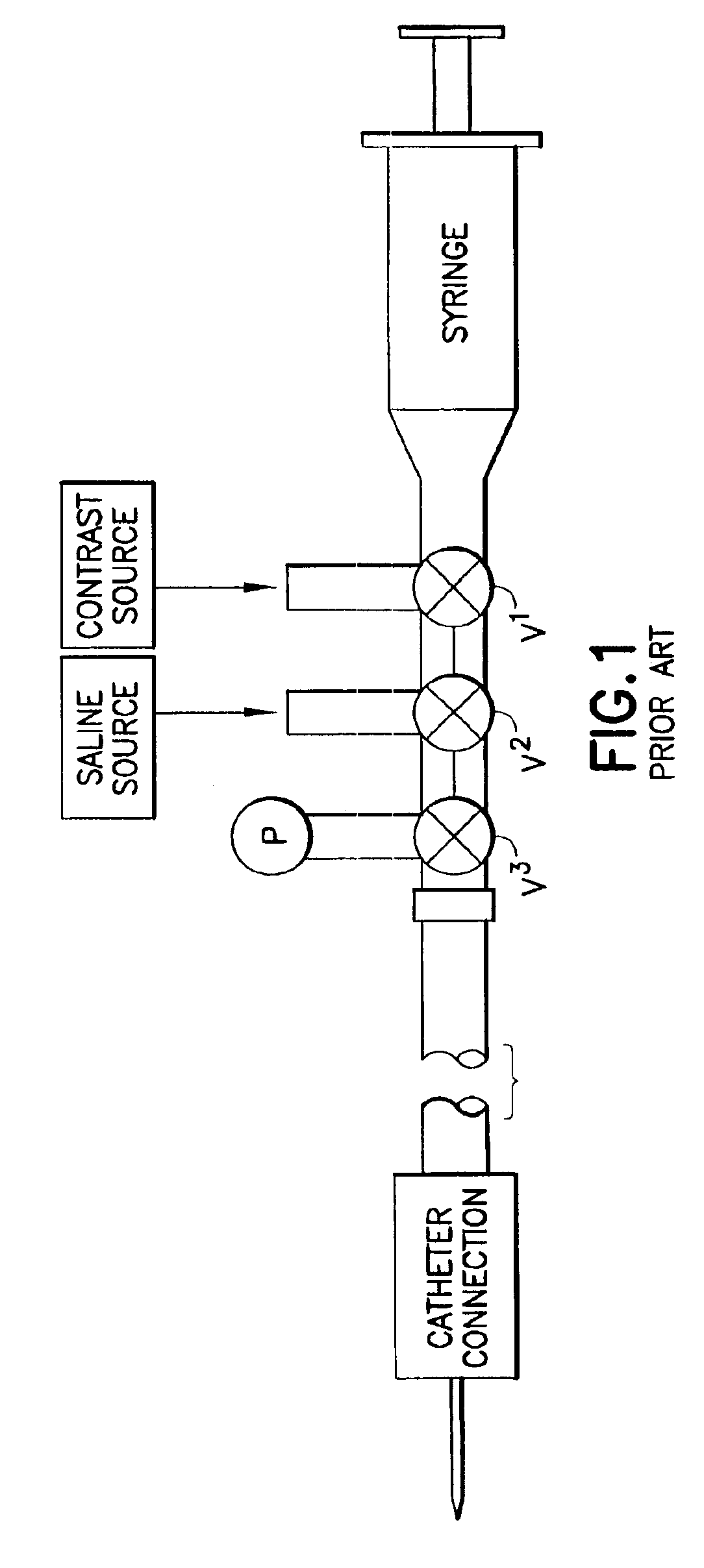

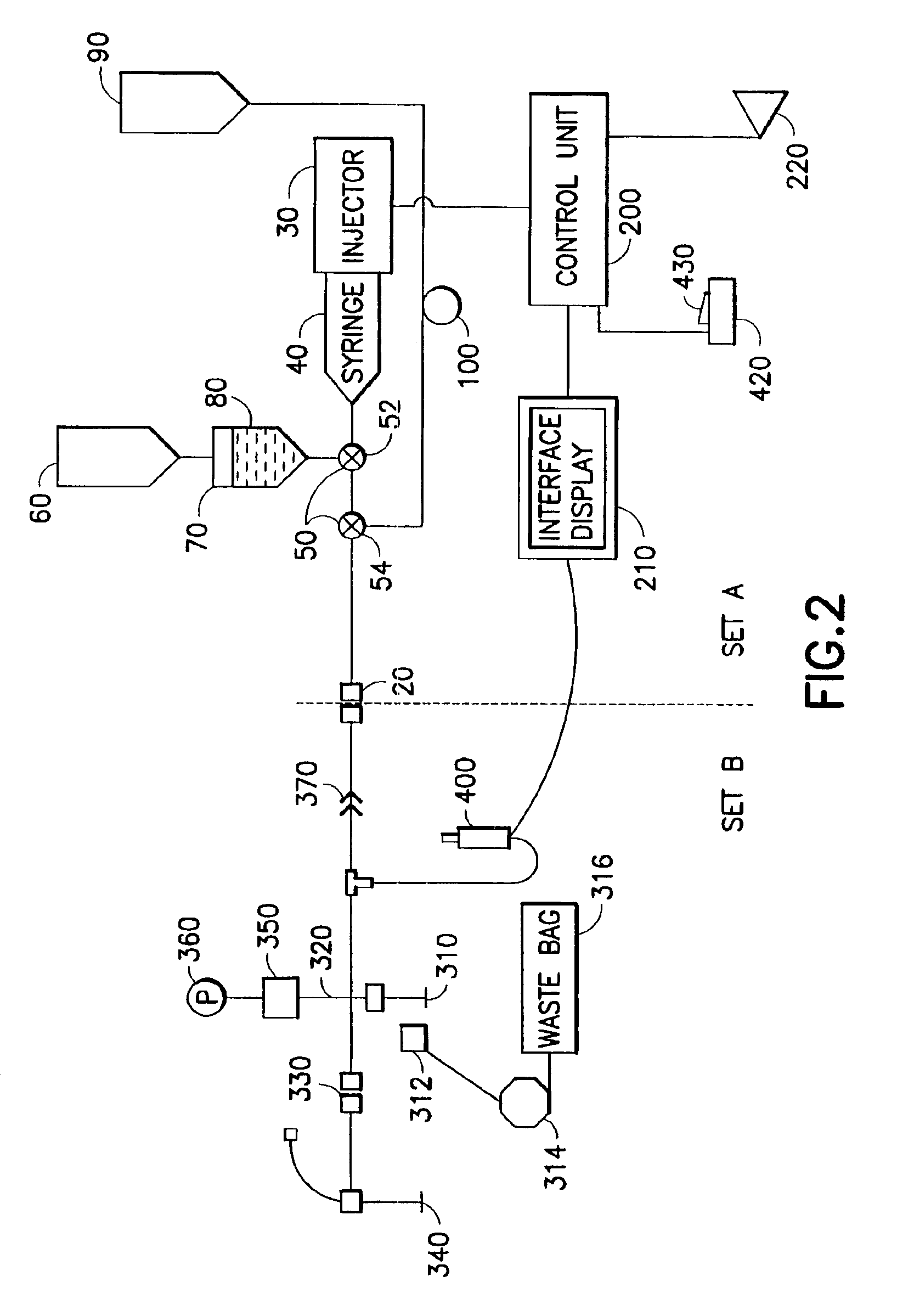

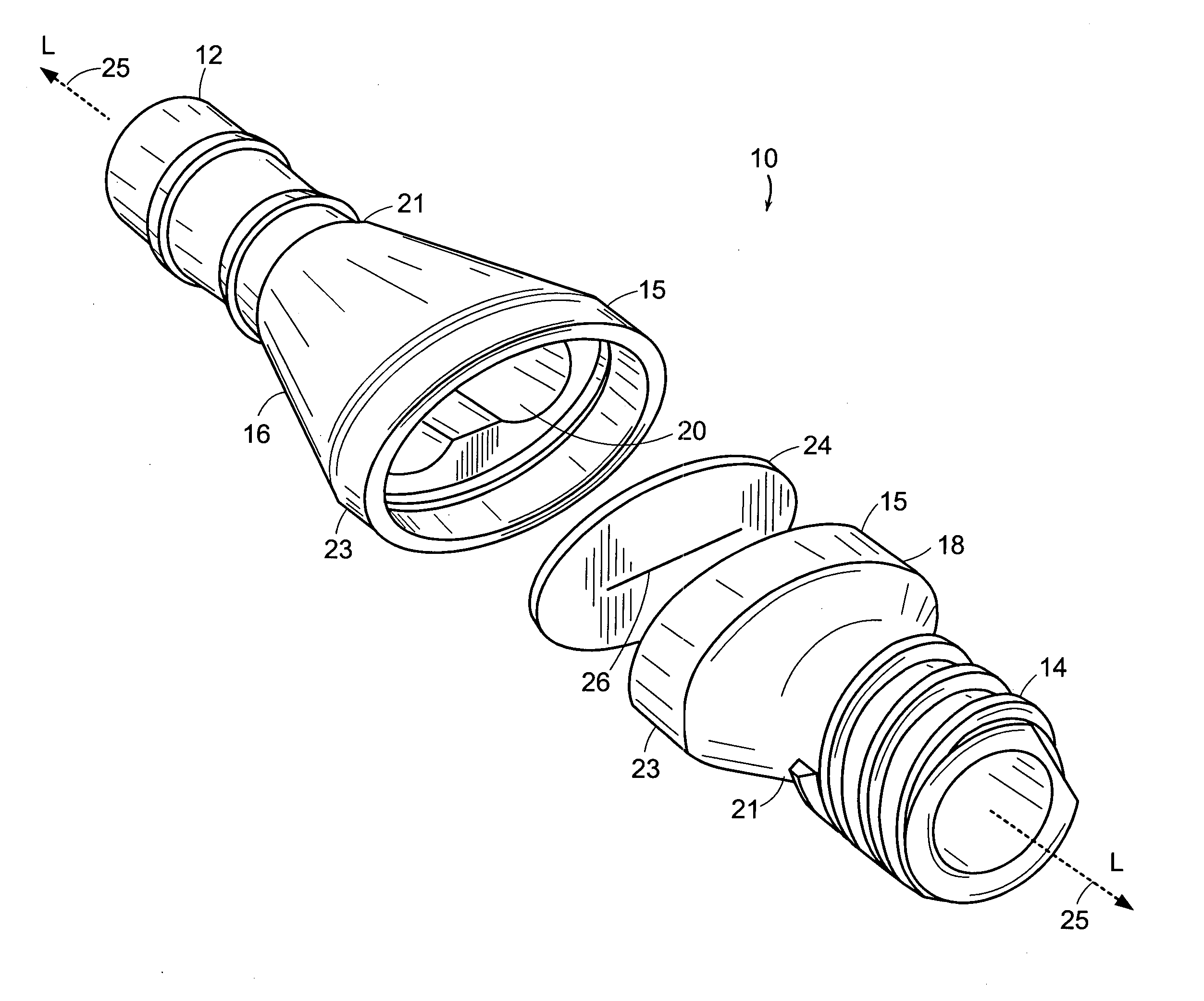

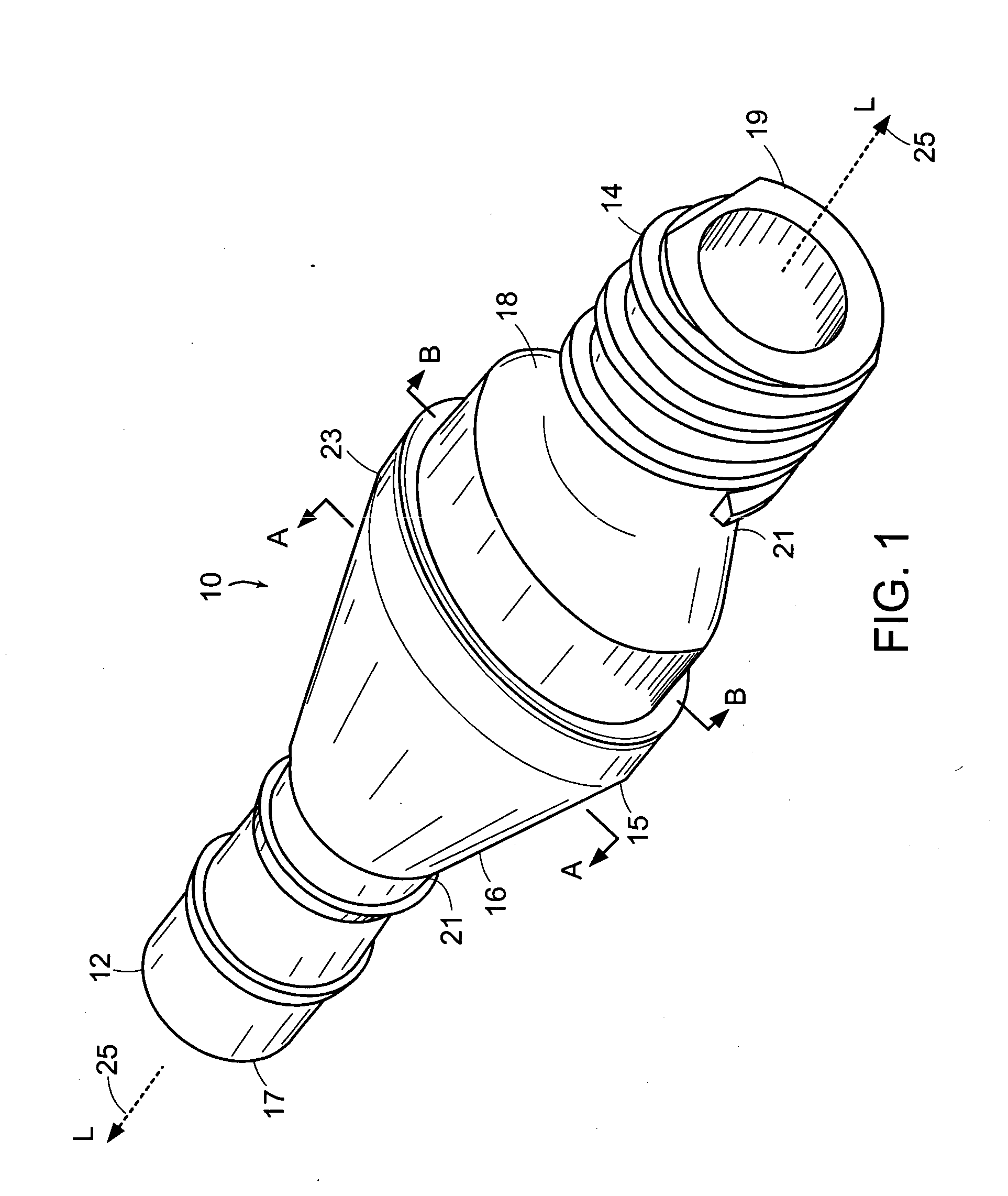

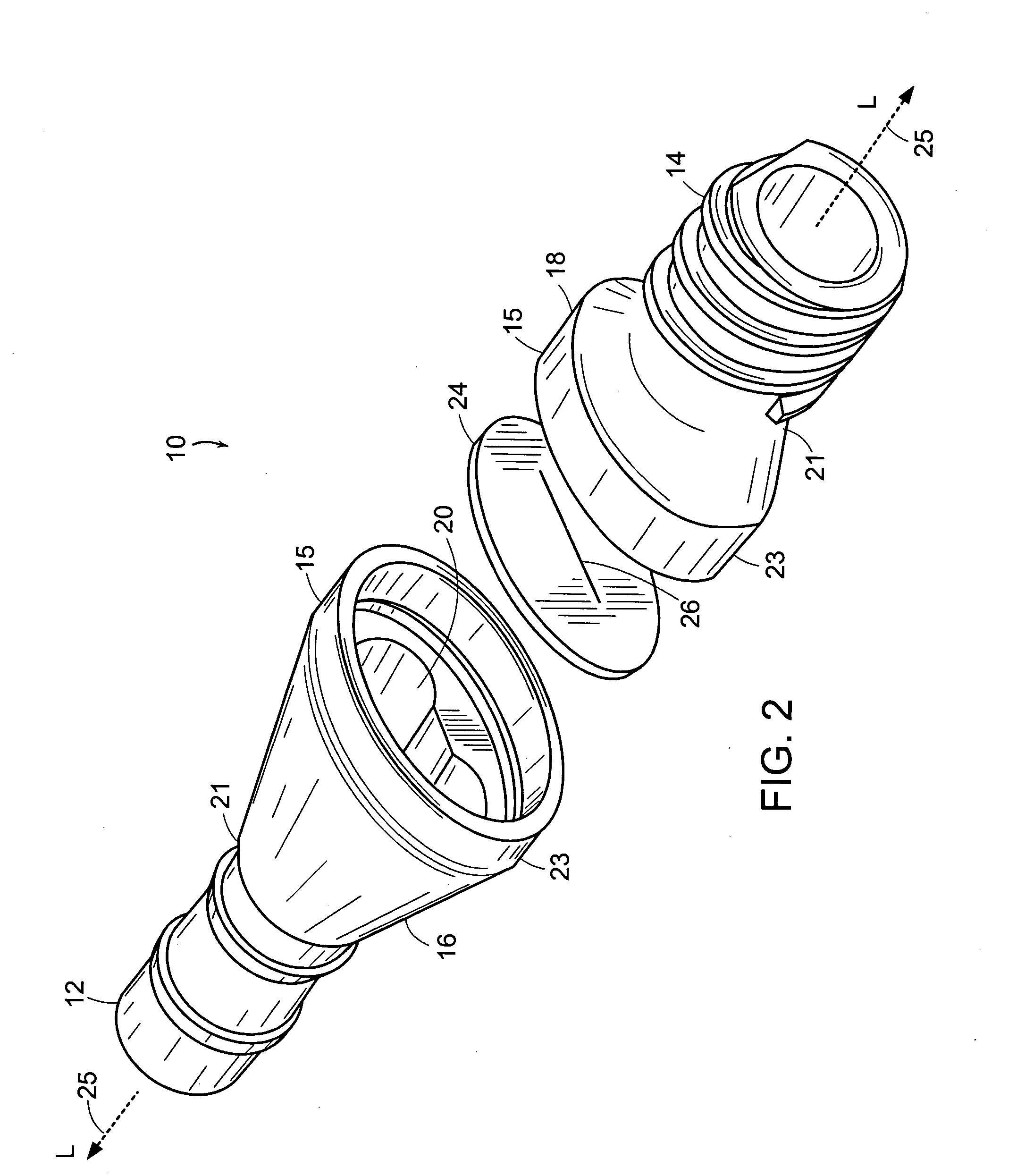

Pressure isolation mechanisms and fluid delivery systems including pressure isolation mechanisms

InactiveUS6866654B2Reduce and eliminate flowSmall sizeMedical devicesPressure infusionTransducerEngineering

A pressure isolation mechanism for use in a medical procedure includes a lumen, an isolation port in fluid connection with the lumen, and a valve having a first state and a second state. The first state occurs when the lumen and the isolation port are connected. The second state occurs when the lumen and the isolation port are disconnected. The lumen remains open for flow of fluid therethrough in the first state and in the second state. The valve is preferably spring-biased in the first state and is switchable to the second state when fluid pressure in the lumen reaches a predetermined pressure level. Alternately, an actuator can control the state of the valve. A pressure transducer can be in fluid connection with the isolation port of the pressure isolation mechanism. A fluid delivery system includes a syringe and a pressure isolation mechanism as described above.

Owner:MEDRAD INC.

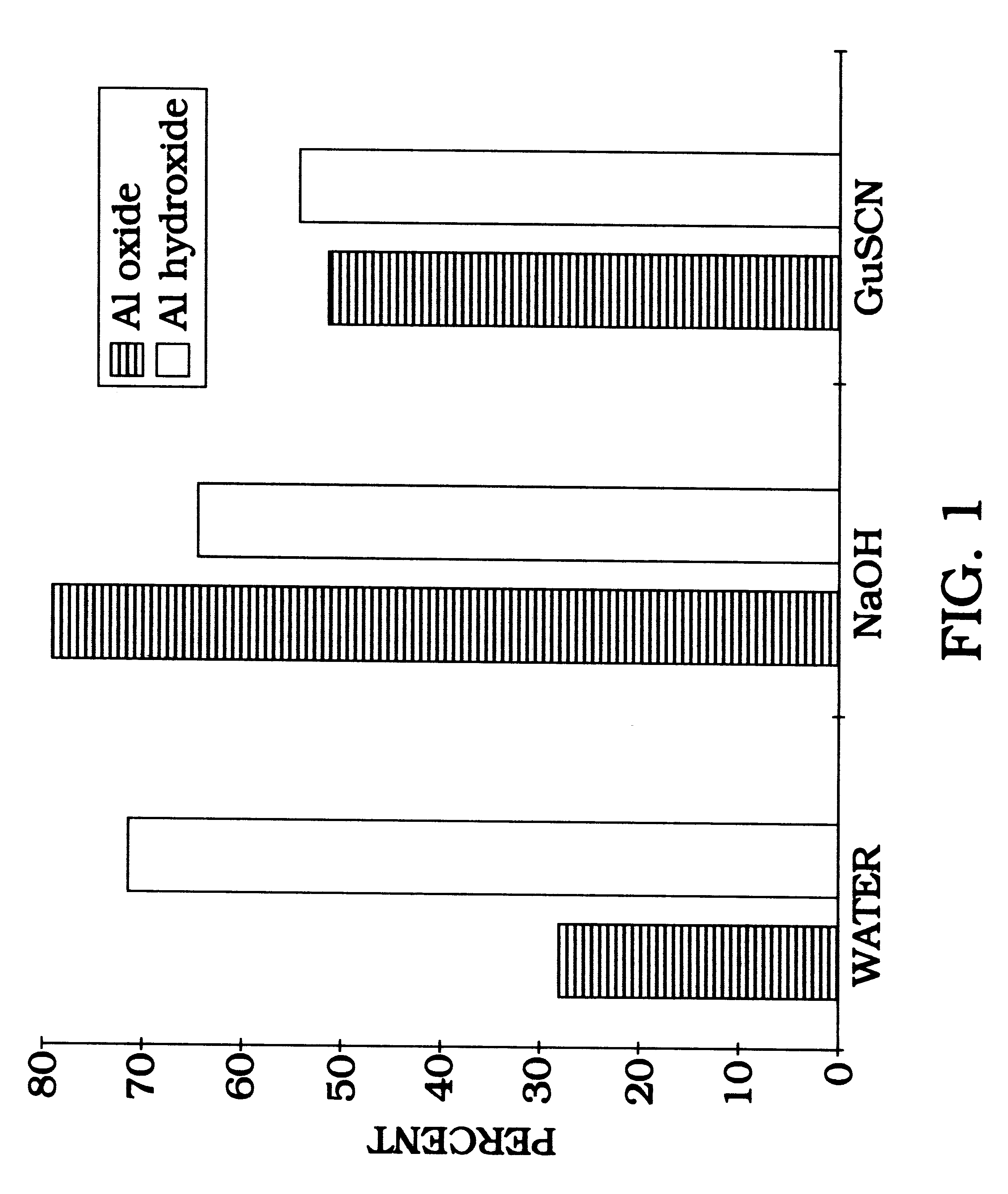

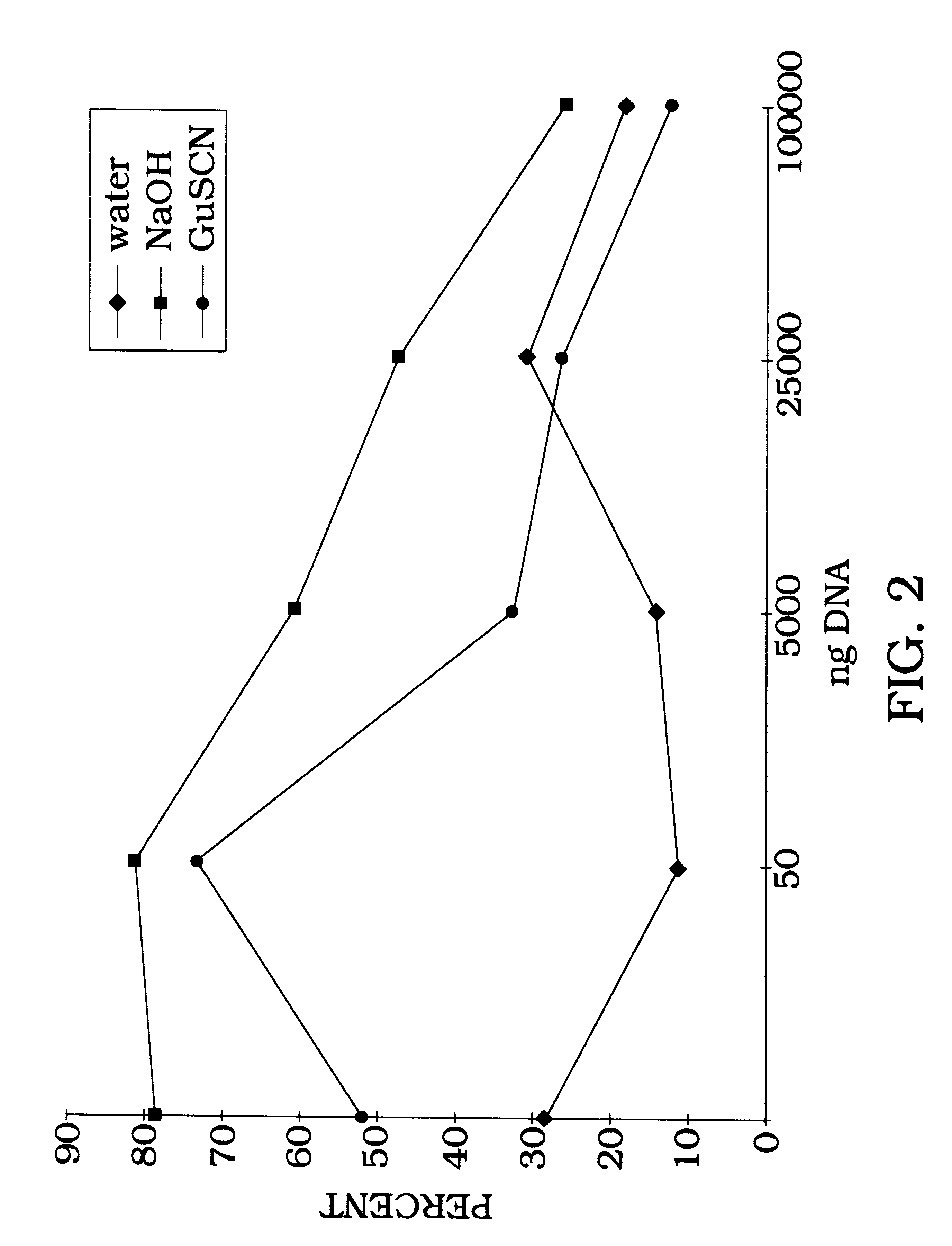

Nucleic acid archiving

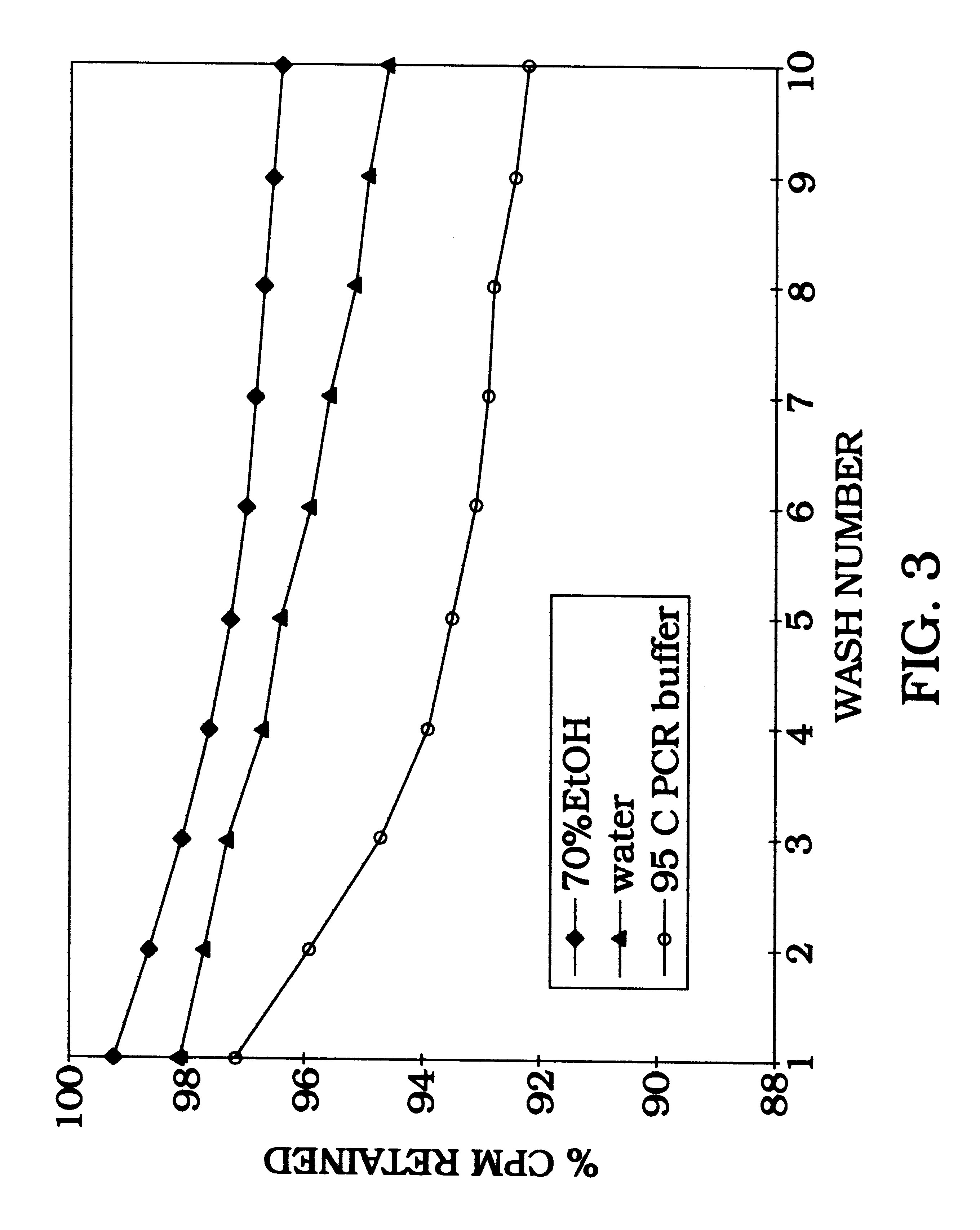

InactiveUS6291166B1Overcomes drawbackEasy to cleanBioreactor/fermenter combinationsBiological substance pretreatmentsRepeat analysisBlood plasma

This invention is directed to a process for irreversibly binding nucleic acid to solid phase and corresponding processes for the utilization thereof. Nucleic acid is bound to solid phase matrixes exhibiting sufficient hydrophilicity and electropositivity to irreversibly bind the nucleic acids from a sample. These processes include nucleic acid (double or single stranded DNA and RNA) capture from high volume:low concentration specimens, buffer changes, washes, and volume reductions, and enable the interface of solid phase bound nucleic acid with enzyme, hybridization or amplification strategies. The invention, solid phase irreversibly bound nucleic acid, may be used, for example, in repeated analyses to confirm results or test additional genes in both research and commercial applications. Further, a method is described for virus extraction, purification, and solid phase amplification from large volume plasma specimens.

Owner:APPL BIOSYSTEMS INC

Valve port and method for vascular access

InactiveUS7056316B1Reduce accessReduce riskPharmaceutical delivery mechanismMedical devicesLocking mechanismBiomedical engineering

Owner:VASCA

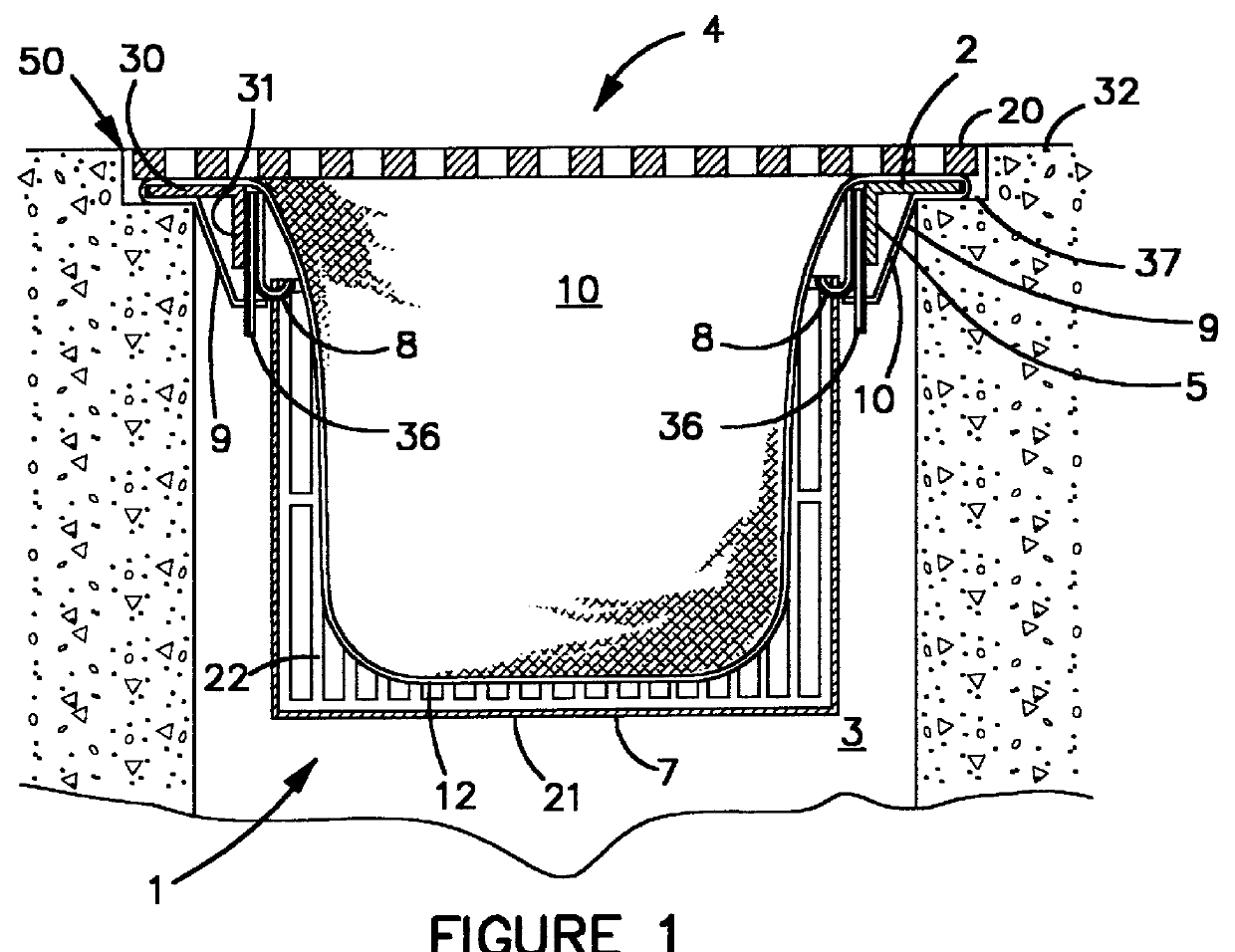

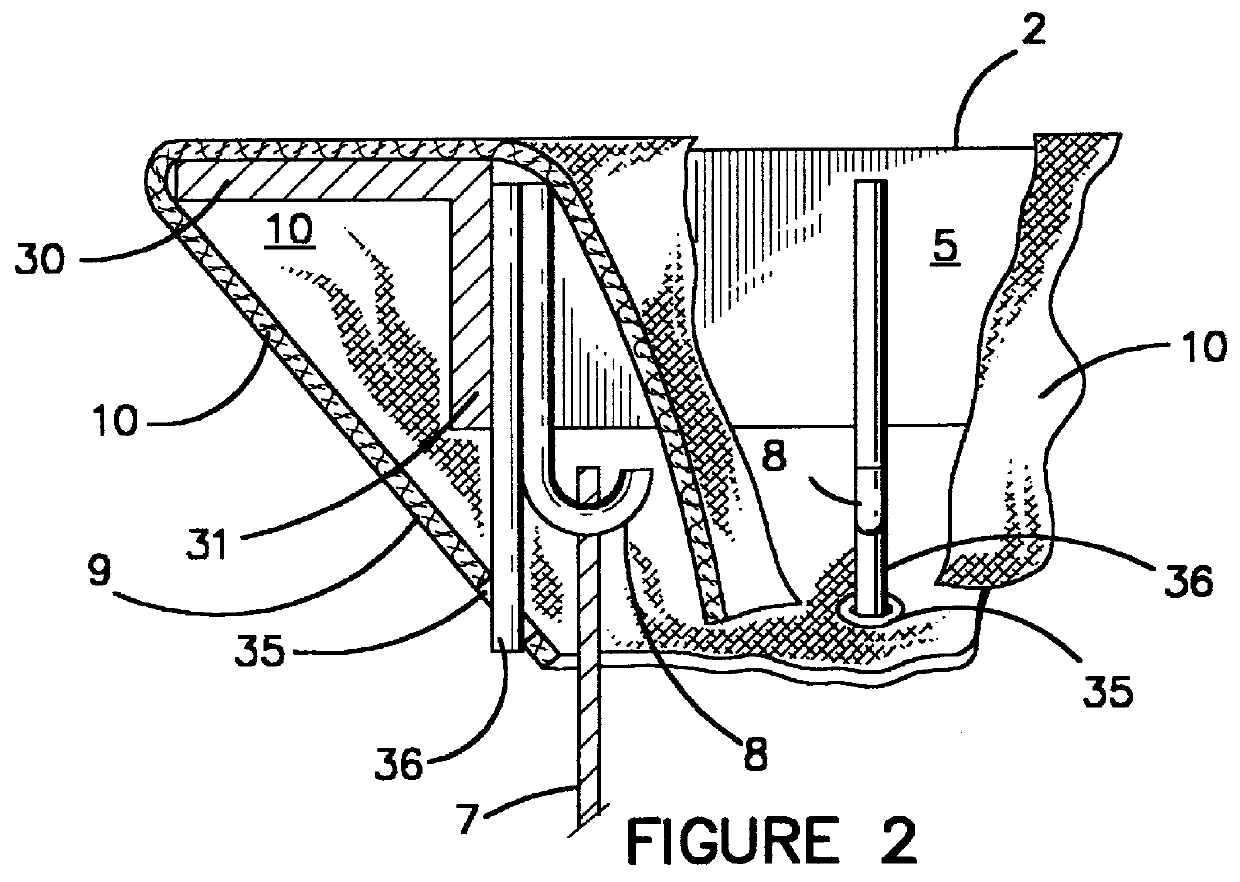

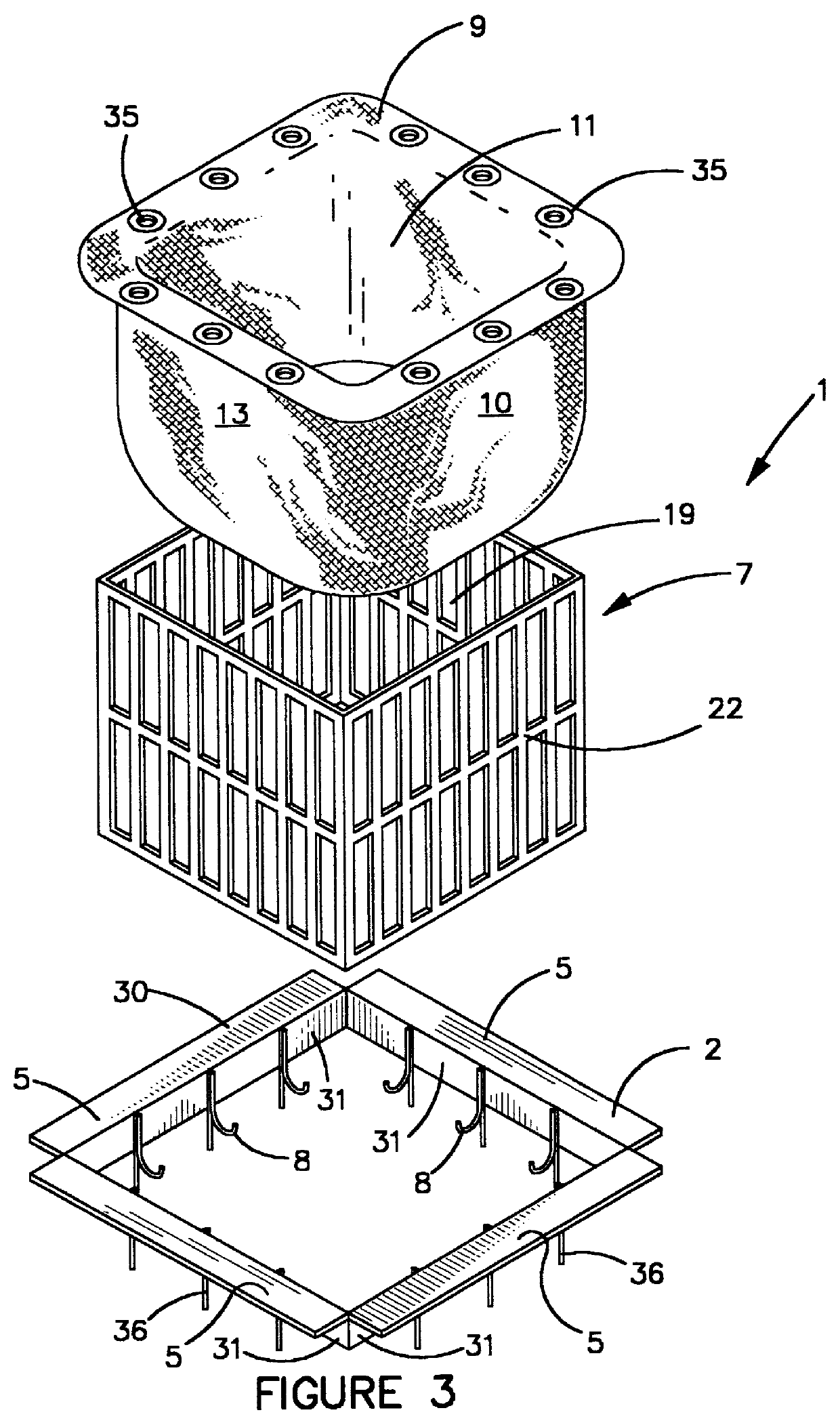

Storm drain liner

InactiveUS6086758AIncrease flow rateFatty/oily/floating substances removal devicesGround-workFilter systemEnvironmental engineering

A drain filtering system is disclosed, comprising a filter placed within a basket which is suspended from frame positioned underneath a drain grate atop the inlet to a storm drain. The filter is constructed from materials which filter out heavy metals and hydrocarbons from the water passing through. The filter also has overflow outlets to prevent back-up of storm water during periods of heavy rain. The basket is constructed from a corrosion resistant material, preferably high density polyethylene which can withstand the extreme pressures exerted by waste and water collected within the filter.

Owner:PACTEC

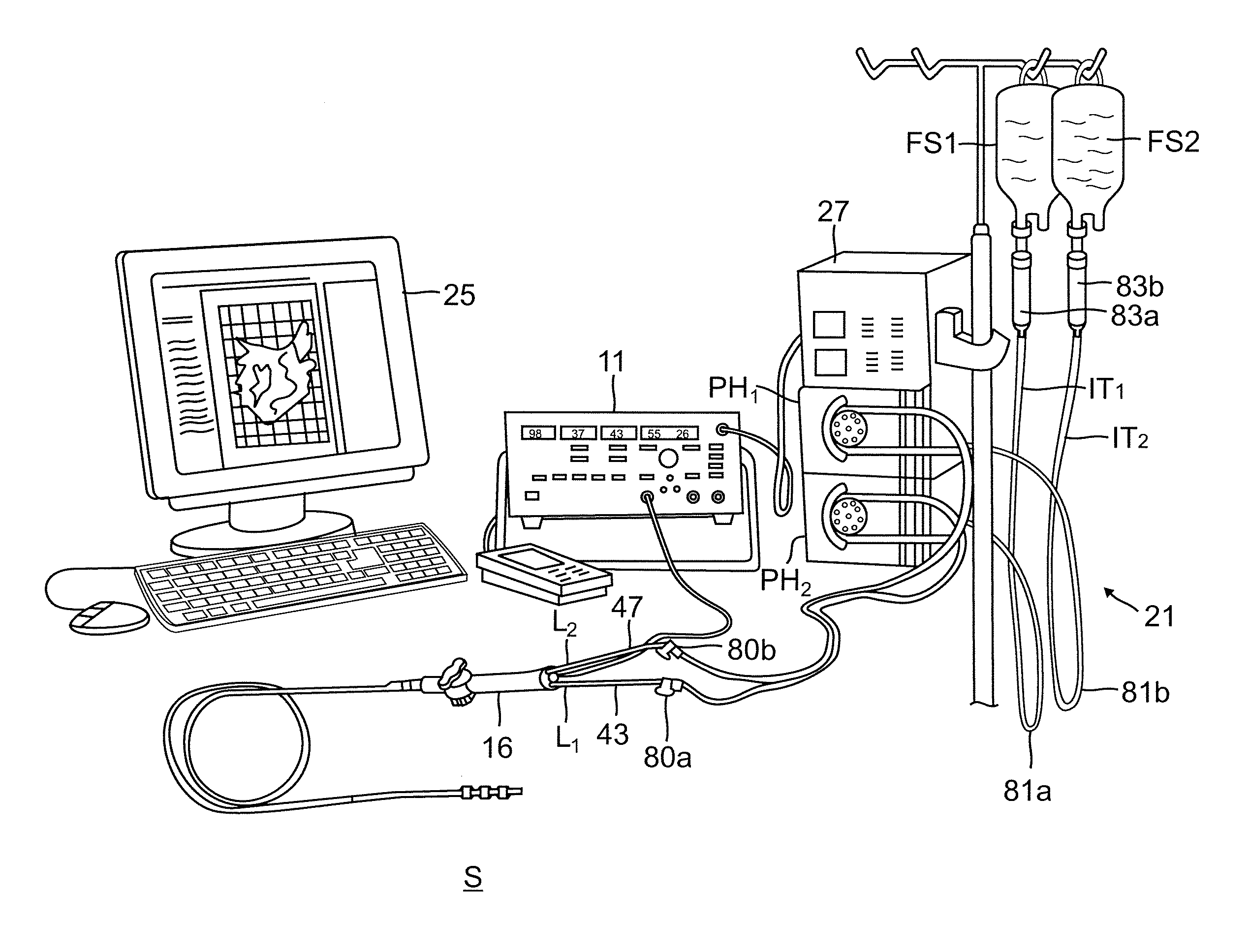

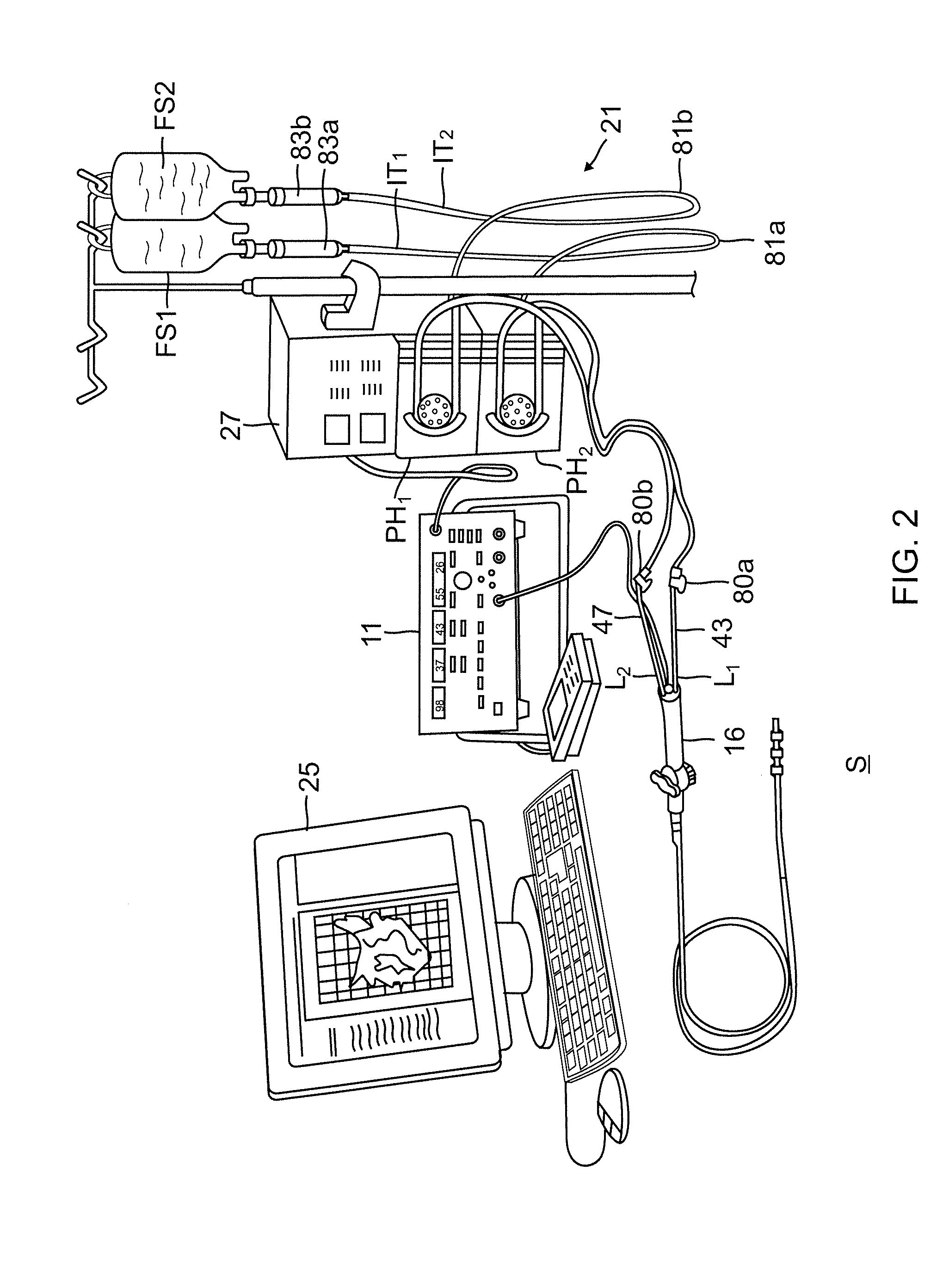

Integrated ablation system using catheter with multiple irrigation lumens

ActiveUS20130030426A1Limiting fluid loadingReduce driving stressDiagnosticsSurgical instruments for heatingPump headIrrigation fluids

A catheter adapted for ablation has multiple dedicated irrigation tubings to supply fluid to their respective electrode or set of electrodes. The tubings provide parallel flow pathways through the catheter where irrigation fluid is delivered to irrigated tip and / or ring electrodes which can accomplish uni-polar or bi-polar ablation. Such separate and dedicated fluid pathways allow fluid to be delivered to the corresponding electrode or set of electrodes at different flow rates. An integrated ablation system using such catheter has an ablation energy source and an irrigation pump with multiple pump heads that can operate independently of each other. An integrated irrigation tubing set is included to extend between the fluid source and the catheter, with each pump head being able to act on a different tubing that delivers fluid to a different electrode or set of electrodes.

Owner:BIOSENSE WEBSTER (ISRAEL) LTD

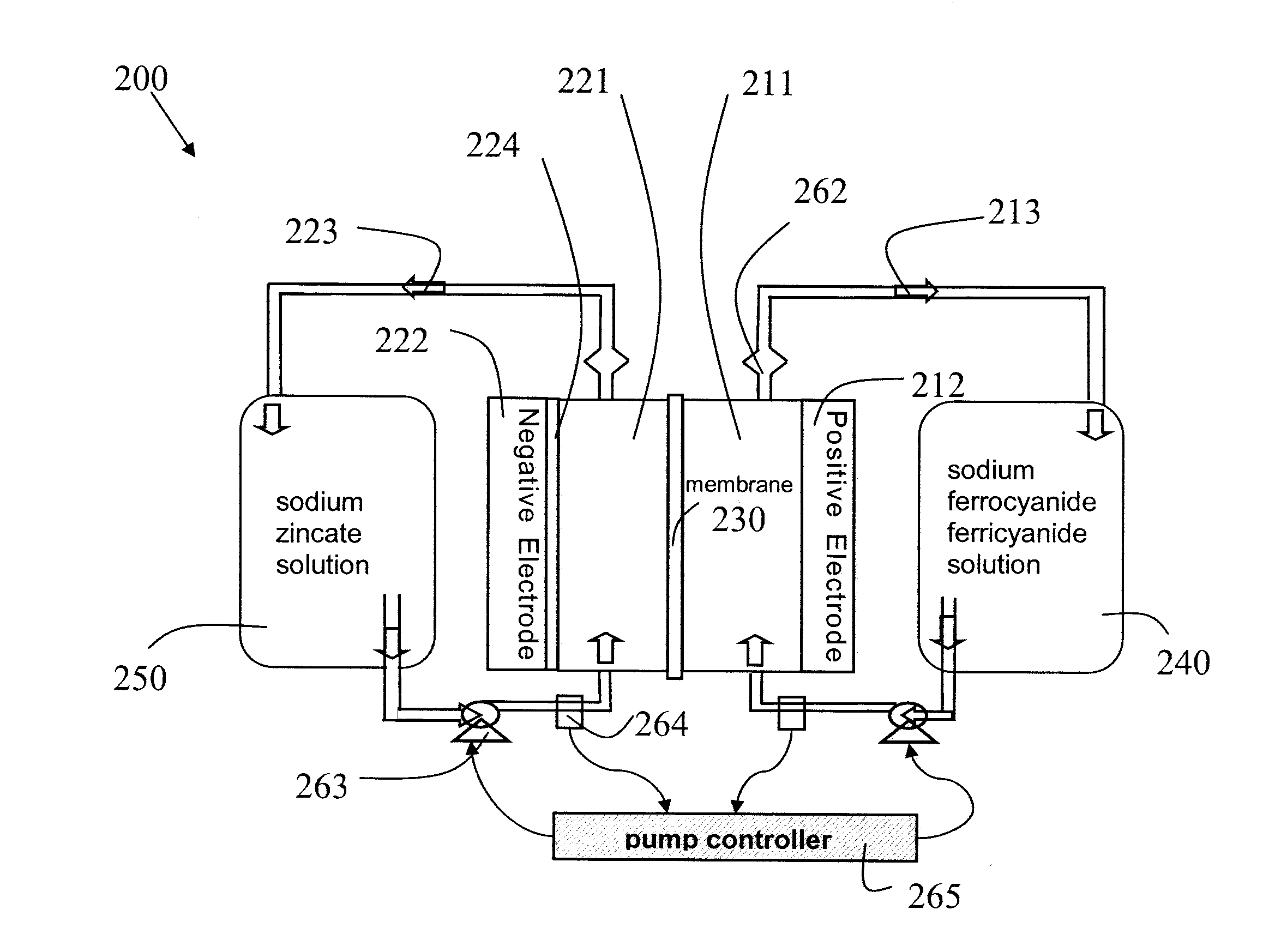

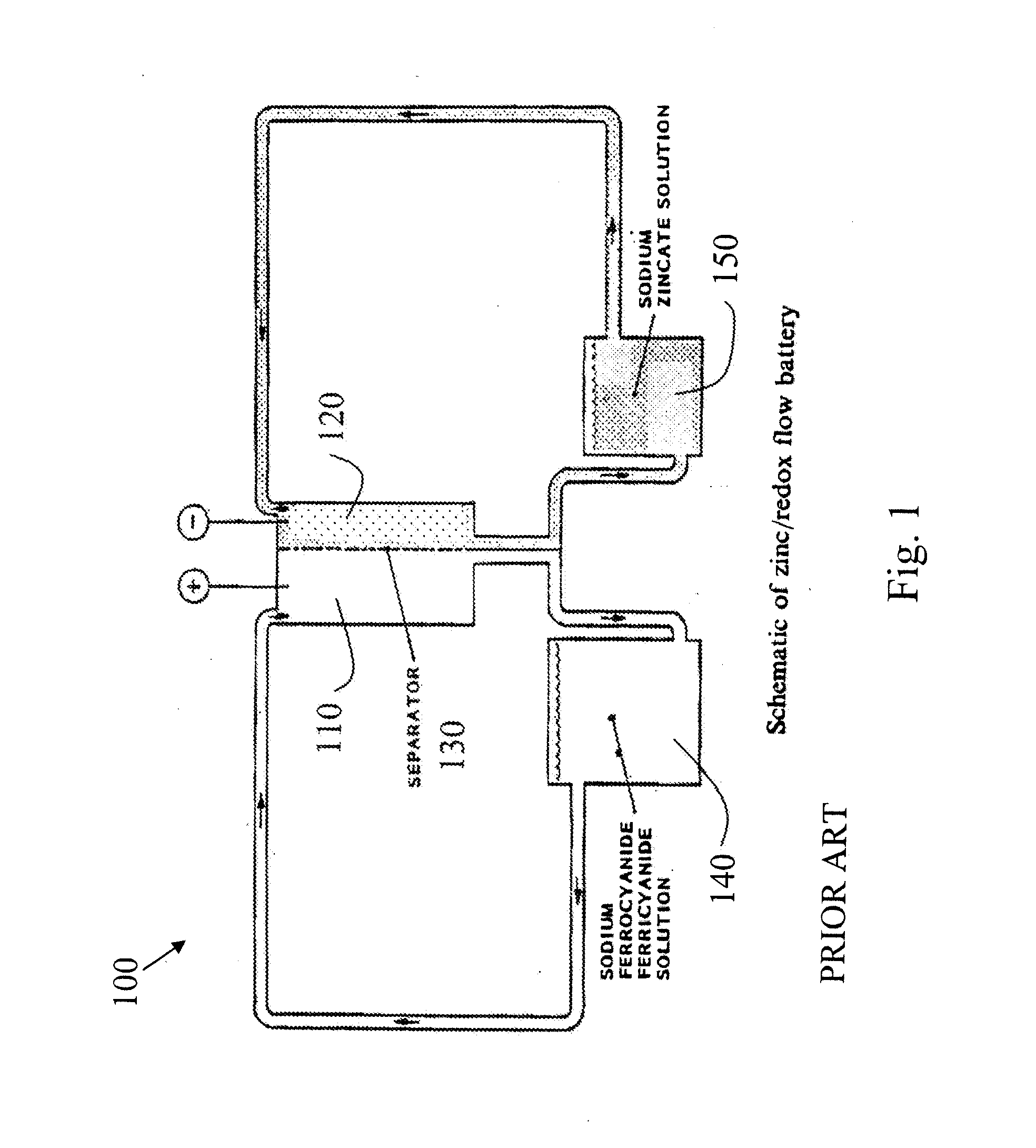

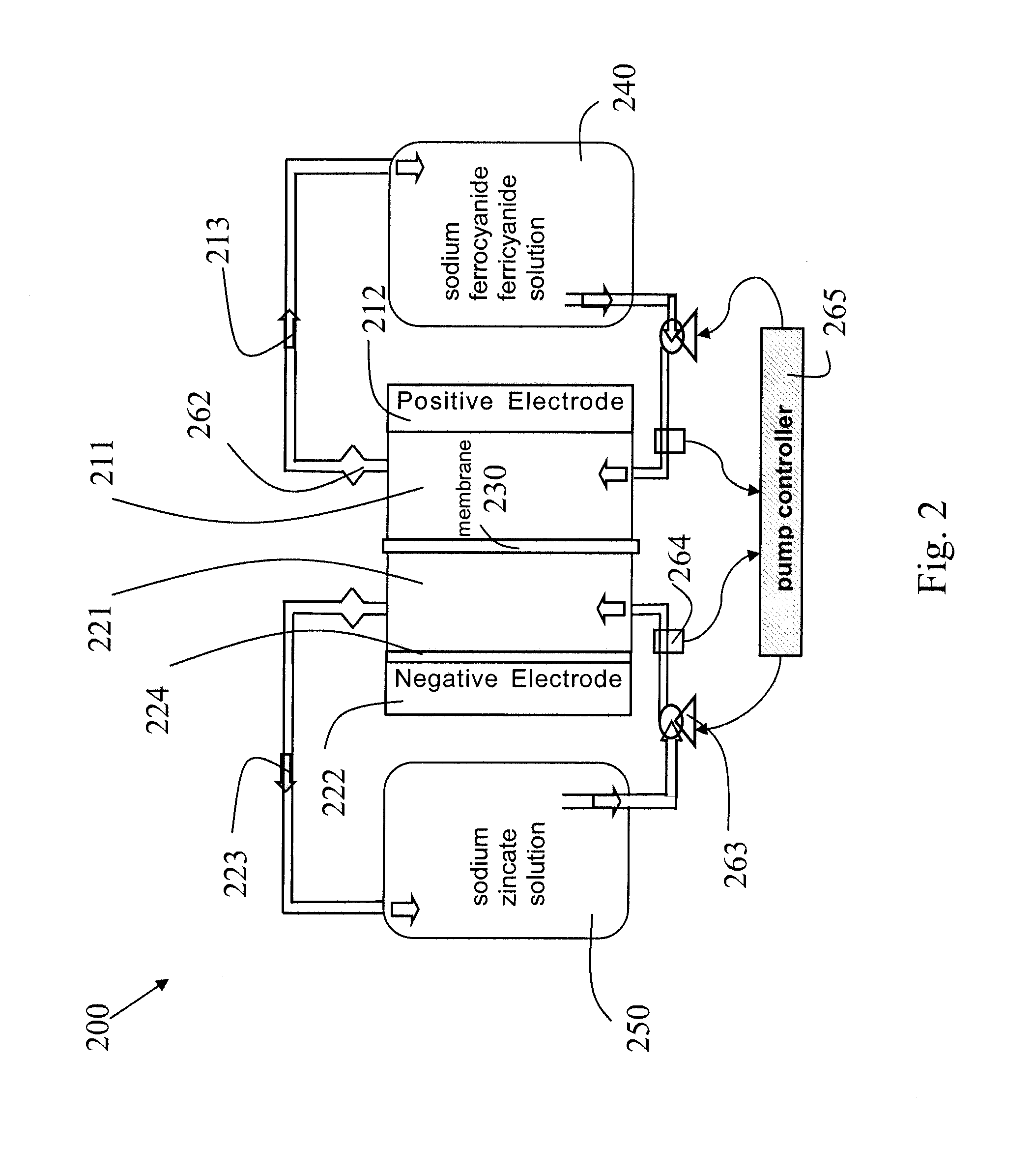

High performance flow battery

InactiveUS20110244277A1High performanceImprove the level ofElectrolyte moving arrangementsIndirect fuel cellsFerricyanideIon

High performance flow batteries, based on alkaline zinc / ferro-ferricyanide rechargeable (“ZnFe”) and similar flow batteries, may include one or more of the following improvements. First, the battery design has a cell stack comprising a low resistance positive electrode in at least one positive half cell and a low resistance negative electrode in at least one negative half cell, where the positive electrode and negative electrode resistances are selected for uniform high current density across a region of the cell stack. Second, a flow of electrolyte, such as zinc species in the ZnFe battery, with a high level of mixing through at least one negative half cell in a Zn deposition region proximate a deposition surface where the electrolyte close to the deposition surface has sufficiently high zinc concentration for deposition rates on the deposition surface that sustain the uniform high current density. The mixing in the flow may be induced by structures such as: conductive and non-conductive meshes; screens; ribbons; foam structures; arrays of cones, cylinders, or pyramids; and other arrangements of wires or tubes used solely or in combination with a planar electrode surface. Third, the zinc electrolyte has a high concentration and in some embodiments has a concentration greater than the equilibrium saturation concentration—the zinc electrolyte is super-saturated with Zn ions.

Owner:APPLIED MATERIALS INC

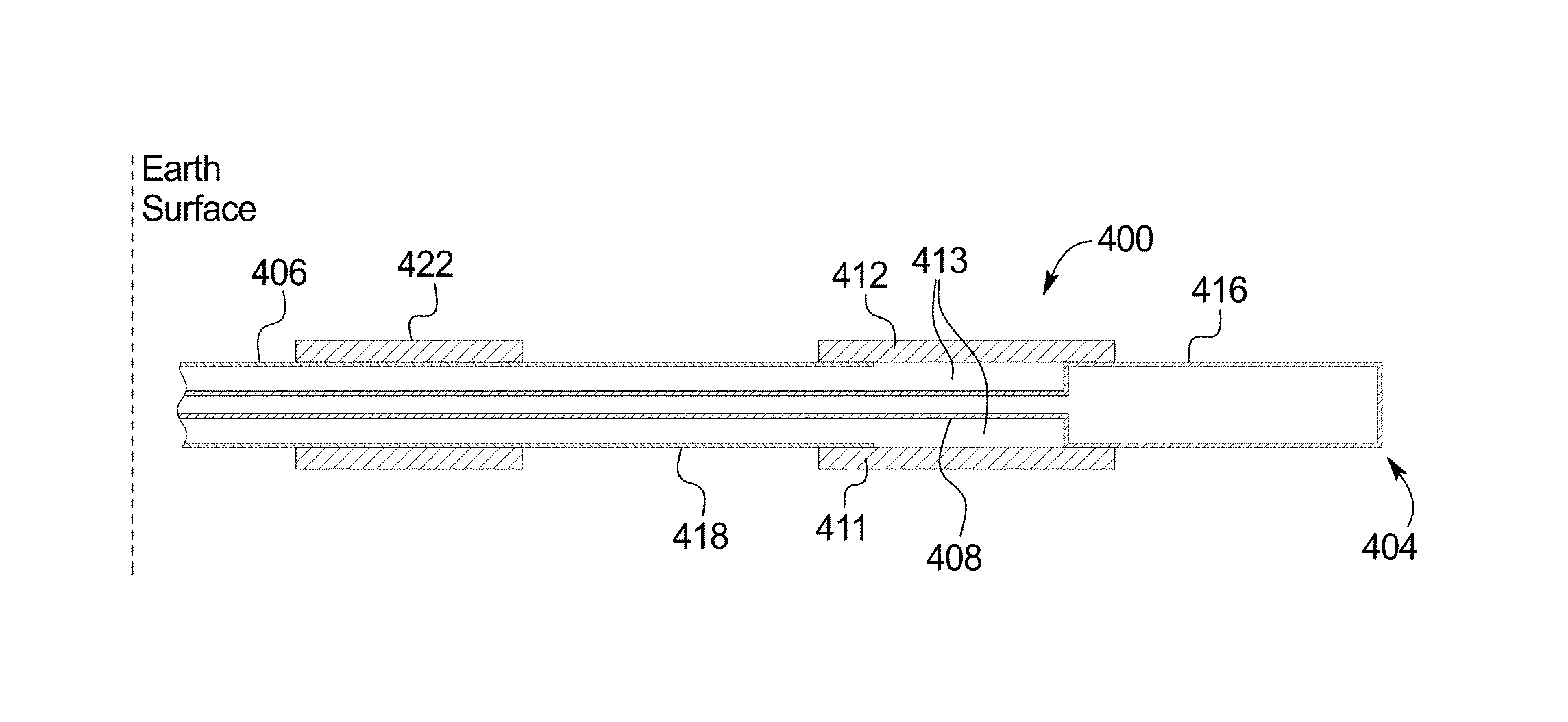

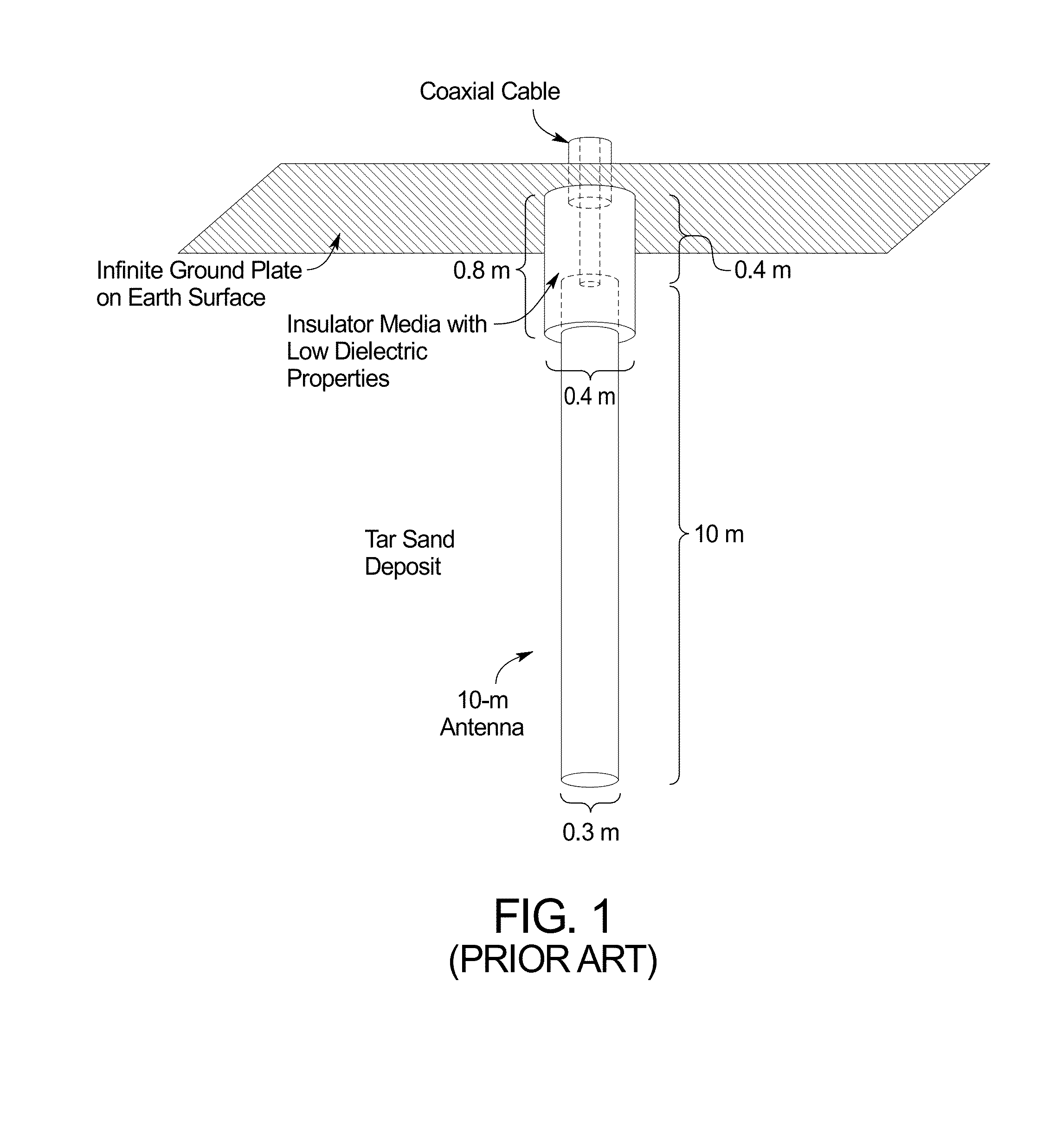

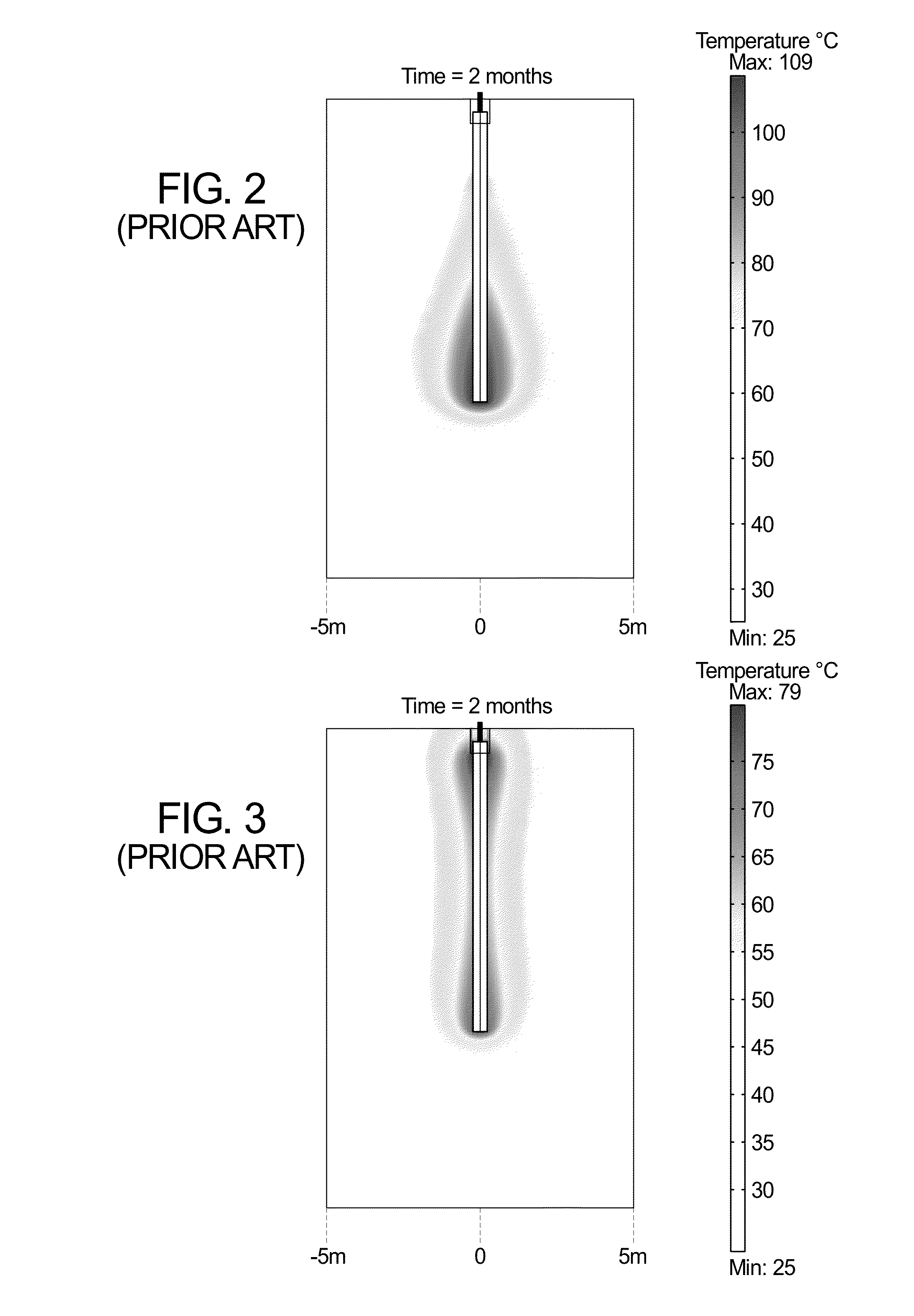

Stimulating production from oil wells using an RF dipole antenna

ActiveUS20140152312A1Reduced effectivenessLow thermal conductivityFluid removalDetection using electromagnetic wavesRf fieldElectrical conductor

A system emplaced in a subsurface formation configured to produce radio frequency (RF) fields for recovery of thermally responsive constituents includes coaxially disposed inner and outer conductors connected at an earth surface to an RF power source. The inner and outer conductors form a coaxial transmission line proximate said earth surface and a dipole antenna proximate said formation. The inner conductor protrudes from the outer conductor from a junction exposing a gap between the conductors to a deeper position within the formation. The RF power source is configured to deliver, via the conductors, RF fields to the formation. The system also includes at least one choke structure attached to said outer conductor at a distance at least ¼ wavelength above said junction. The choke structure is configured to confine a majority of said RF fields in a volume of said formation situated adjacent to said antenna.

Owner:PYROPHASE INC

Electrosurgical tool

ActiveUS20060235377A1Reduce overall outer diameterReduce the overall diameterSurgical instruments for heatingSurgical instruments for aspiration of substancesElectric energySurgical site

An electrosurgical tool for cauterizing or ablating targeted tissue, which tool includes a conductive outer shaft which defines a return or reference electrode, and a conductive inner tube disposed within the outer shaft. The inner tube defines both a suction pathway for removing fluid and / or surgical debris from the surgical site through the distal end of the tool, and a pathway for delivering electrical energy to an active electrode secured to the distal end of the suction tube.

Owner:STRYKER CORP

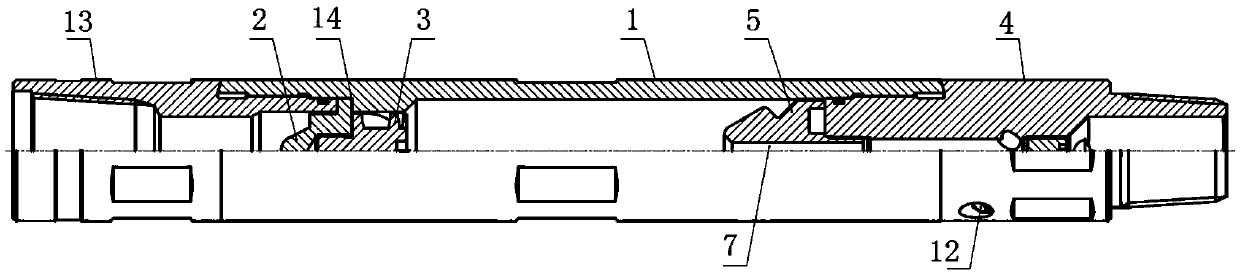

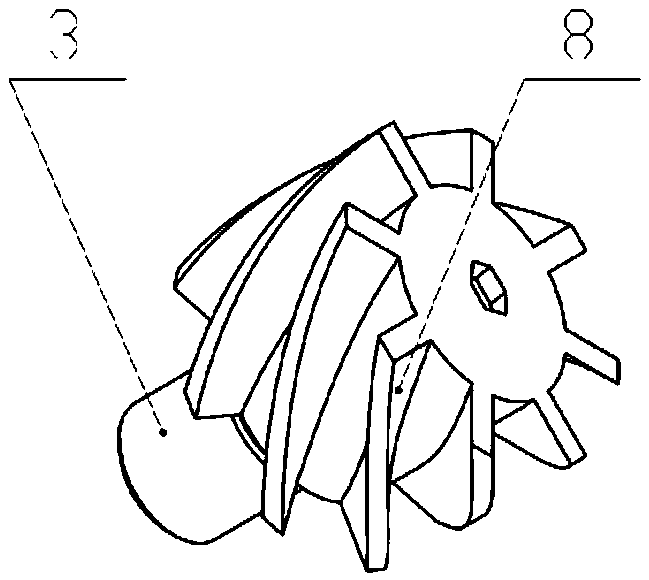

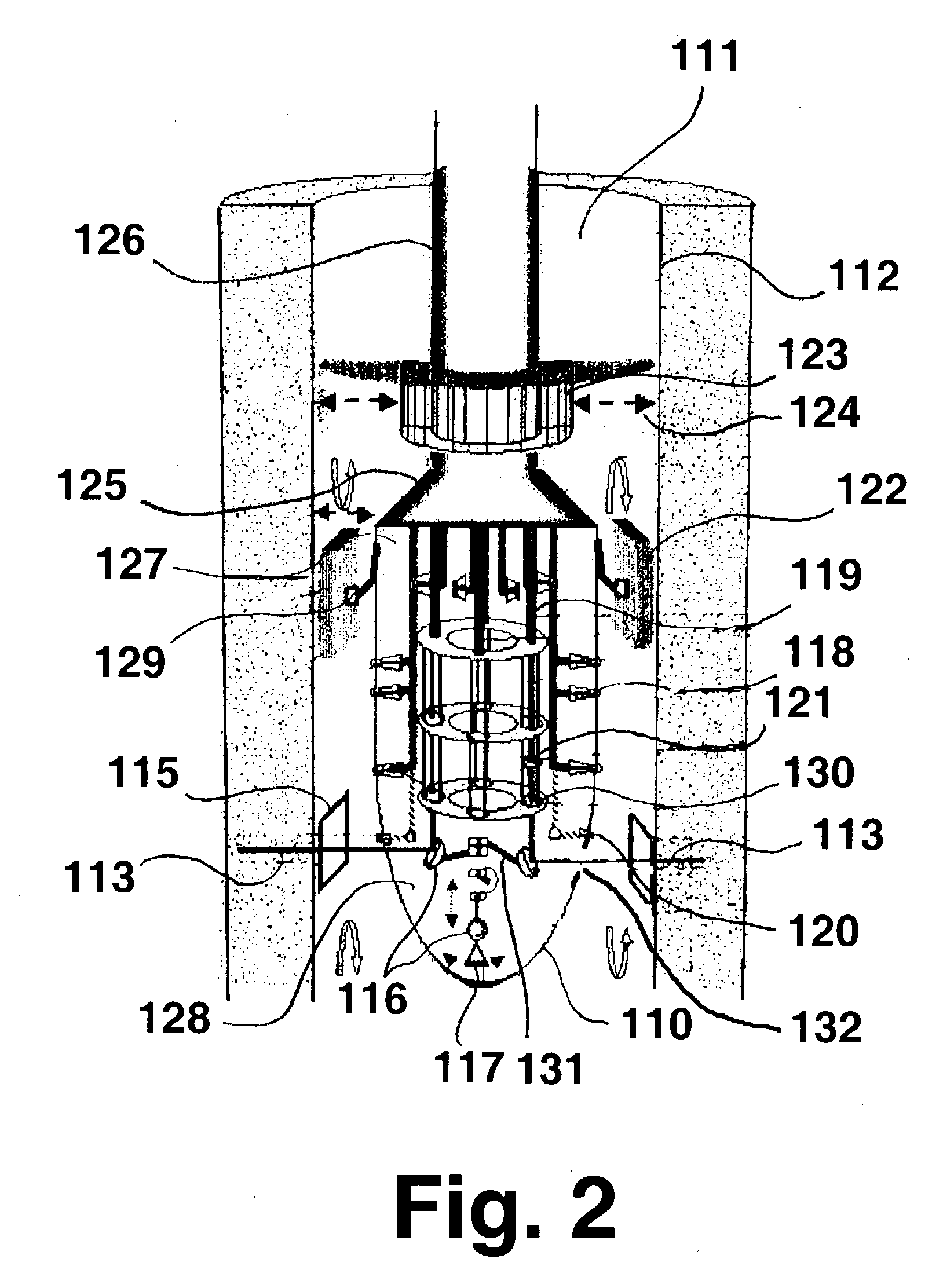

Downhole gas-liquid separation device and working method thereof

ActiveCN105536299AReduce in quantitySimple structureLiquid degasificationSeparation devicesEngineeringProduct gas

A downhole gas-liquid separation device comprises a barrel-shaped body, and a positioning wheel is fixedly installed in the body. A rotatable swirling wheel is installed on the positioning wheel and provided with spiral wheel blades, and the positioning wheel is provided with fluid channels. A lower connector is connected to the body, a diverting joint is arranged at the inner end, located in an inner cavity of the body, of the lower connector, a gas outlet channel is formed in the center of the diverting joint in a coaxial mode, and the outer side of the diverting joint is provided with liquid drainage channels. An interval is formed between the swirling wheel and the diverting joint. The downhole gas-liquid separation device is small in part number, simple in structure and lower in cost; the swirling wheel is driven to rotate when liquid passes through the swirling wheel to enable the liquid to generate centrifugal force and swirlingly flow in the inner cavity in the mode of being attached to the wall, the liquid in gas is gathered to the center, and then the liquid and the gas flow out through the liquid drainage channels formed in the outer side and the gas outlet channel formed in the center respectively, so that gas and liquid separation is achieved; accordingly, the liquid sent to a motor does not contain the gas, damage to the motor is avoided, and the service life of the motor is prolonged.

Owner:JEREH ENERGY SERVICES

Devices and Methods for Perfusing an Organ

The present invention provides devices and methods for use in the perfusion of organs and anatomical regions. In one aspect the present method provides a percutaneously deliverable device for supporting a vessel in a human or animal subject including means for supporting the vessel during delivery of a fluid thereto or collection of a fluid therefrom. In another aspect the invention provides a method for delivery or collection of a fluid to or from an organ or anatomical region in a human or animal subject, the method including the step of supporting a vessel associated with the organ or anatomical region. The devices and methods may be used to deliver, remove or recirculate a therapeutic agent to an organ or anatomical region.

Owner:OSPREY MEDICAL

Variable flow deposition apparatus and method in semiconductor substrate processing

InactiveUS6777352B2Facilitate rapid opening and closingImprove fatigueLiquid surface applicatorsVacuum evaporation coatingEngineeringMechanical engineering

Owner:APPLIED MATERIALS INC

Valved catheters including high flow rate catheters

InactiveUS20050049555A1Reduction of formationHigh flow rateMulti-lumen catheterEqualizing valvesAccidental ingestionCombined use

Owner:NAVILYST MEDICAL

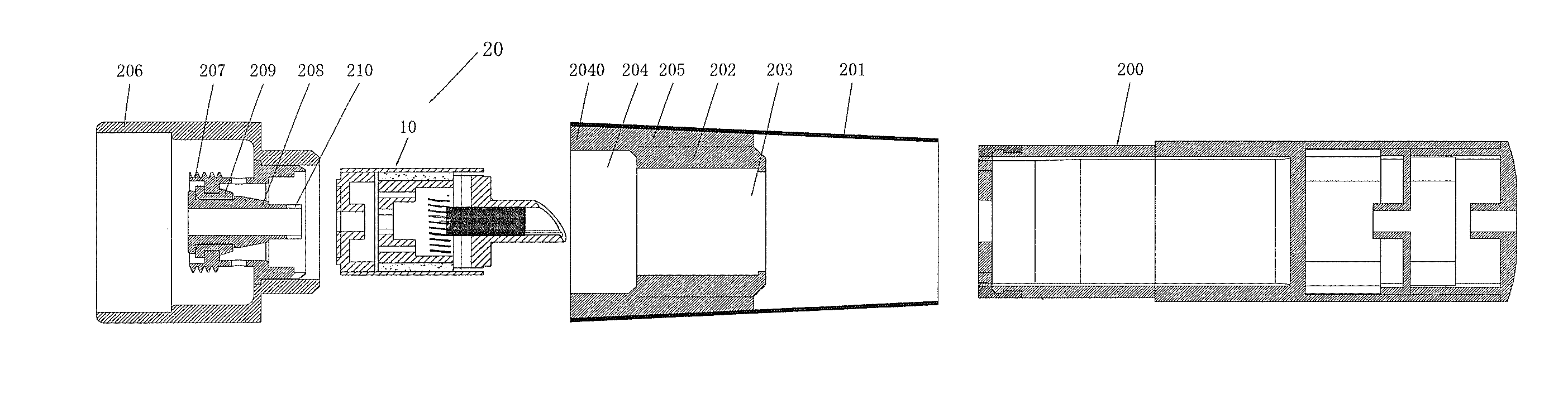

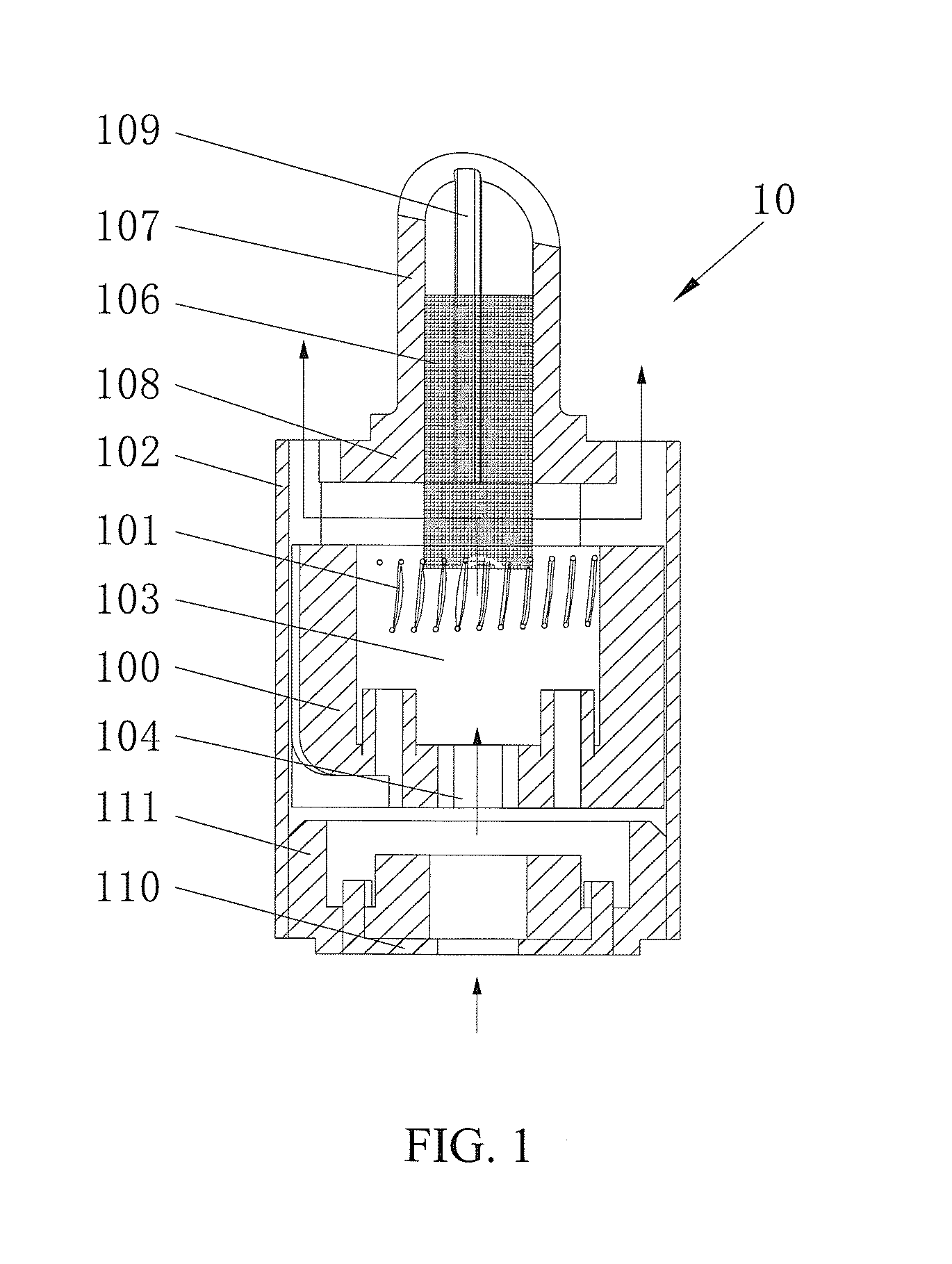

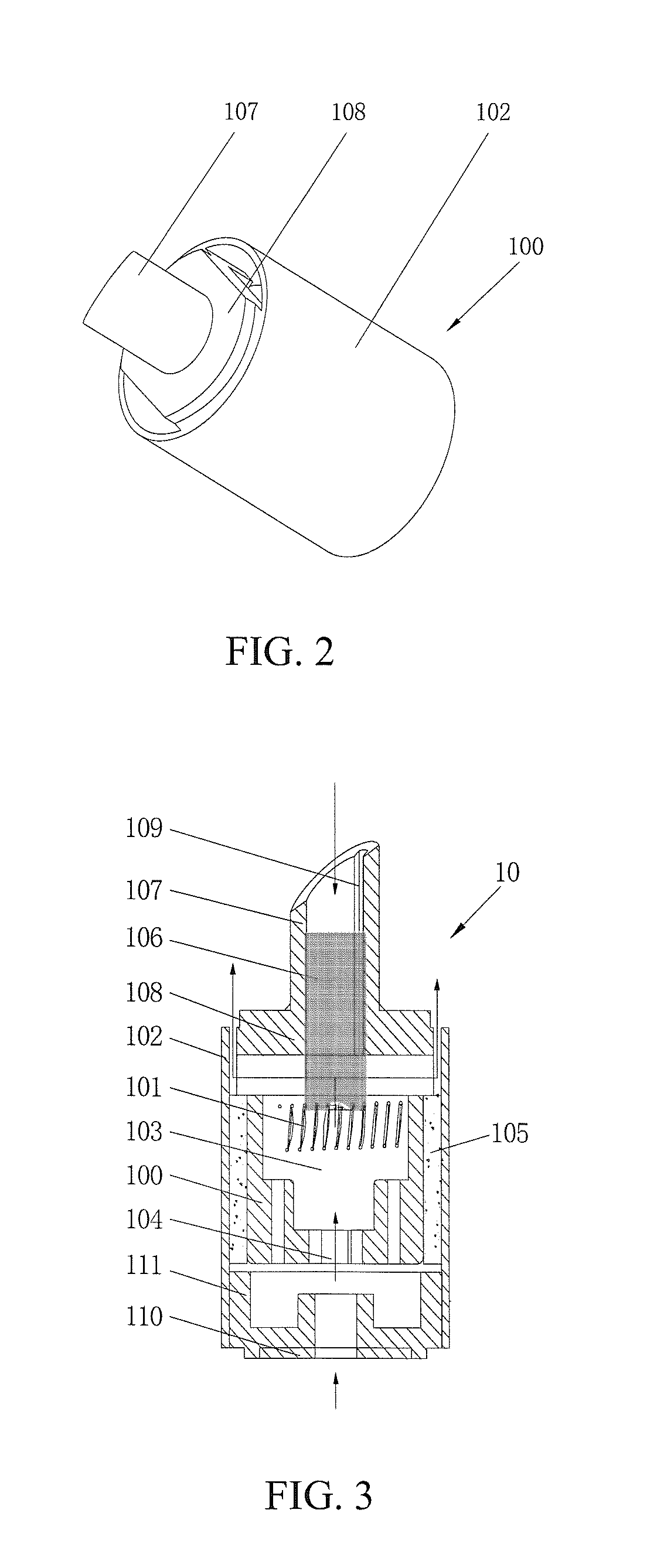

Replaceable universal atomizing head

InactiveUS20140190477A1Prevention of dry burningSimple structureMedical devicesTobacco devicesElectrical conductorEngineering

The present invention discloses a replaceable universal atomizing head, wherein the heating device is fixed in the atomizing chamber of the support base, and said liquid guiding member comprises a liquid guiding rope, a liquid guiding nozzle and a liquid guiding nozzle seat connected integrally with the liquid guiding nozzle, wherein one end of the liquid guide rope pierced from the liquid guiding nozzle seat and reaches heating device, further comprising a conductive ring, wherein said support base is fixed in the middle of the conductive ring cavity, pressing a wire connected to one end of the heating device between the conductive ring and the support base; the wall surface of the inner hole of the liquid nozzle and the liquid guiding nozzle seat provides a liquid guiding slot; one end of the liquid guiding nozzle seat is inserted into one end of the conductive ring cavity; the other end of conductive ring cavity provides a conductive member, which comprises a conductor and an insulator, wherein the conductor is fixed on the insulator and welds with wire connected to the other end of the heating device, wherein the insulator with vent holes is fastened in the conductive ring cavity. Atomizing head of the present invention has a simple structure, is easy to assemble, and is able to prevent dry combustion.

Owner:JOYETECH CHANGZHOU ELECTRONICS

Laser wellbore completion apparatus and method

InactiveUS20040206505A1Low viscosityIncrease flow rateDisloding machinesThermal drillingMolecular physicsWellbore

A method and apparatus for providing fluid flow into a wellbore in which an apparatus having at least one laser energy output is lowered into the wellbore and the at least one laser energy output is directed at a wall of the wellbore. At least a portion of the wall is heated using the at least one laser energy output, whereby flow of a fluid into the wellbore is initiated and / or- enhanced.

Owner:GAS TECH INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com