Patents

Literature

338results about How to "High performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

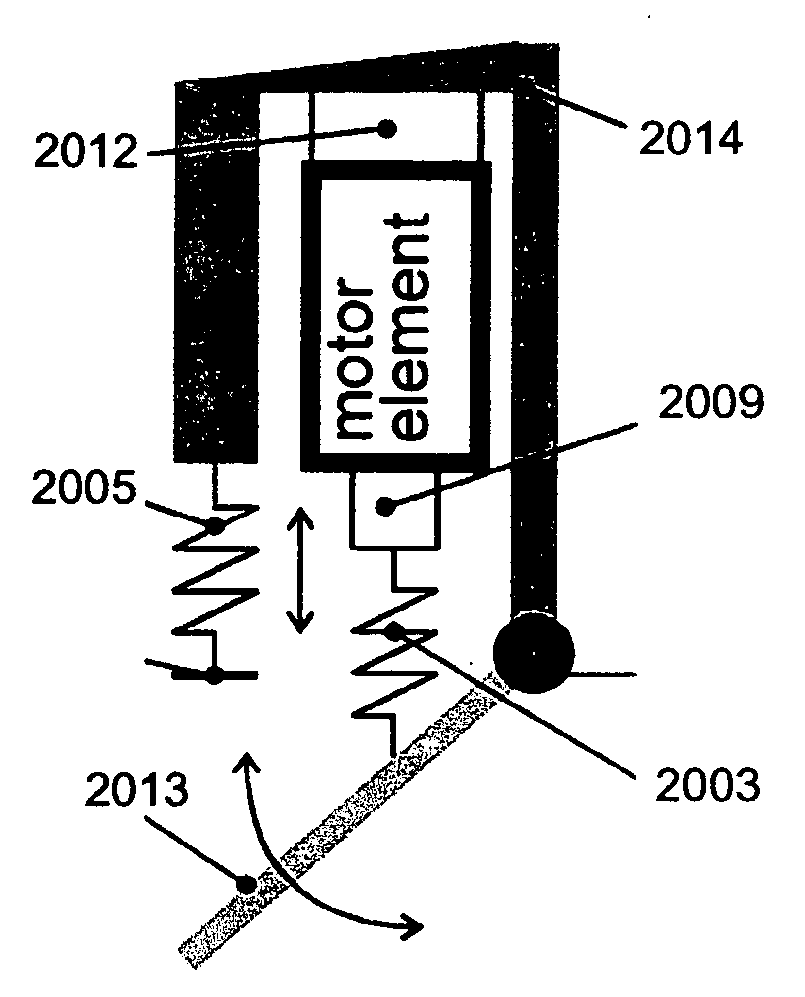

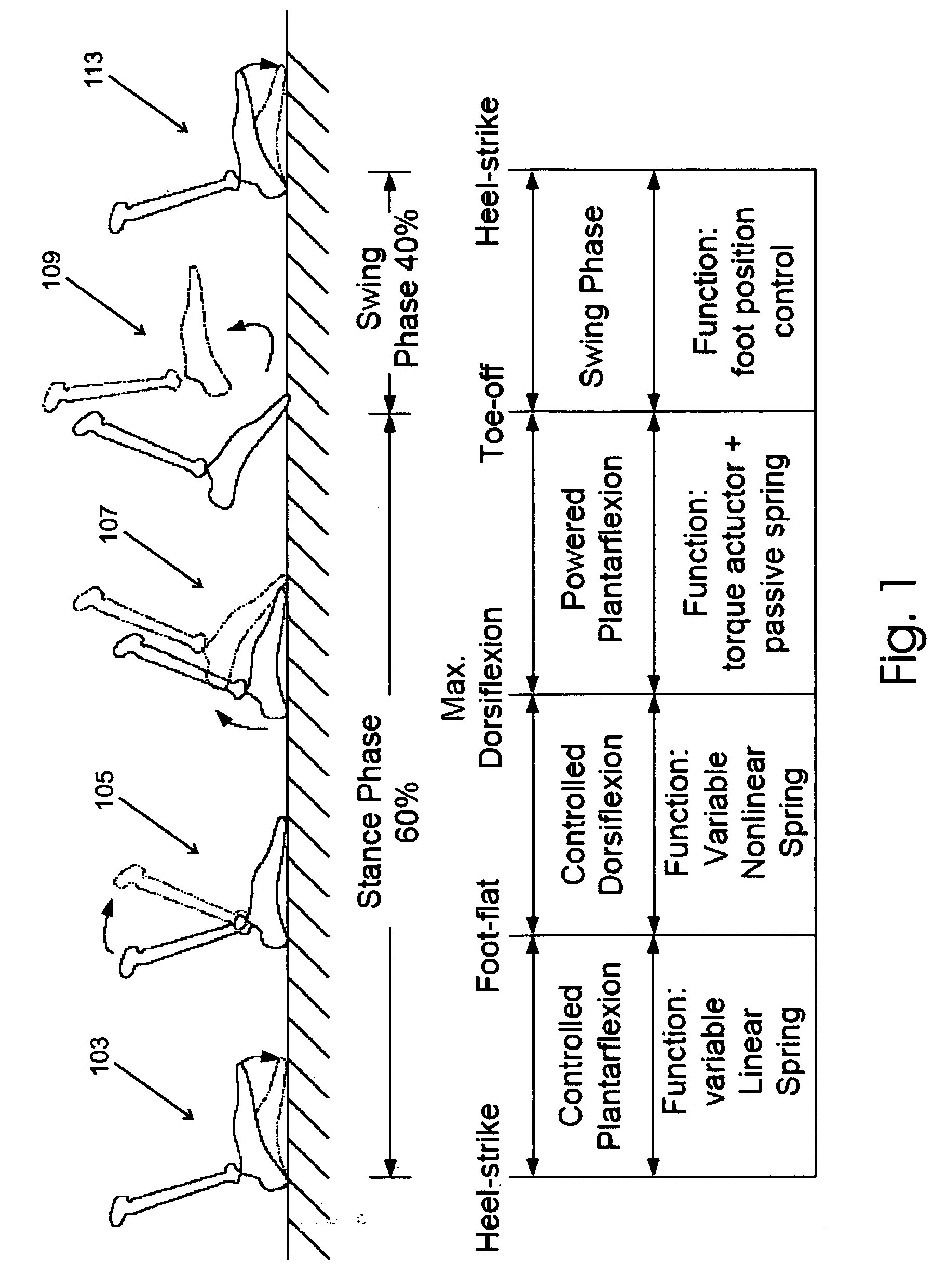

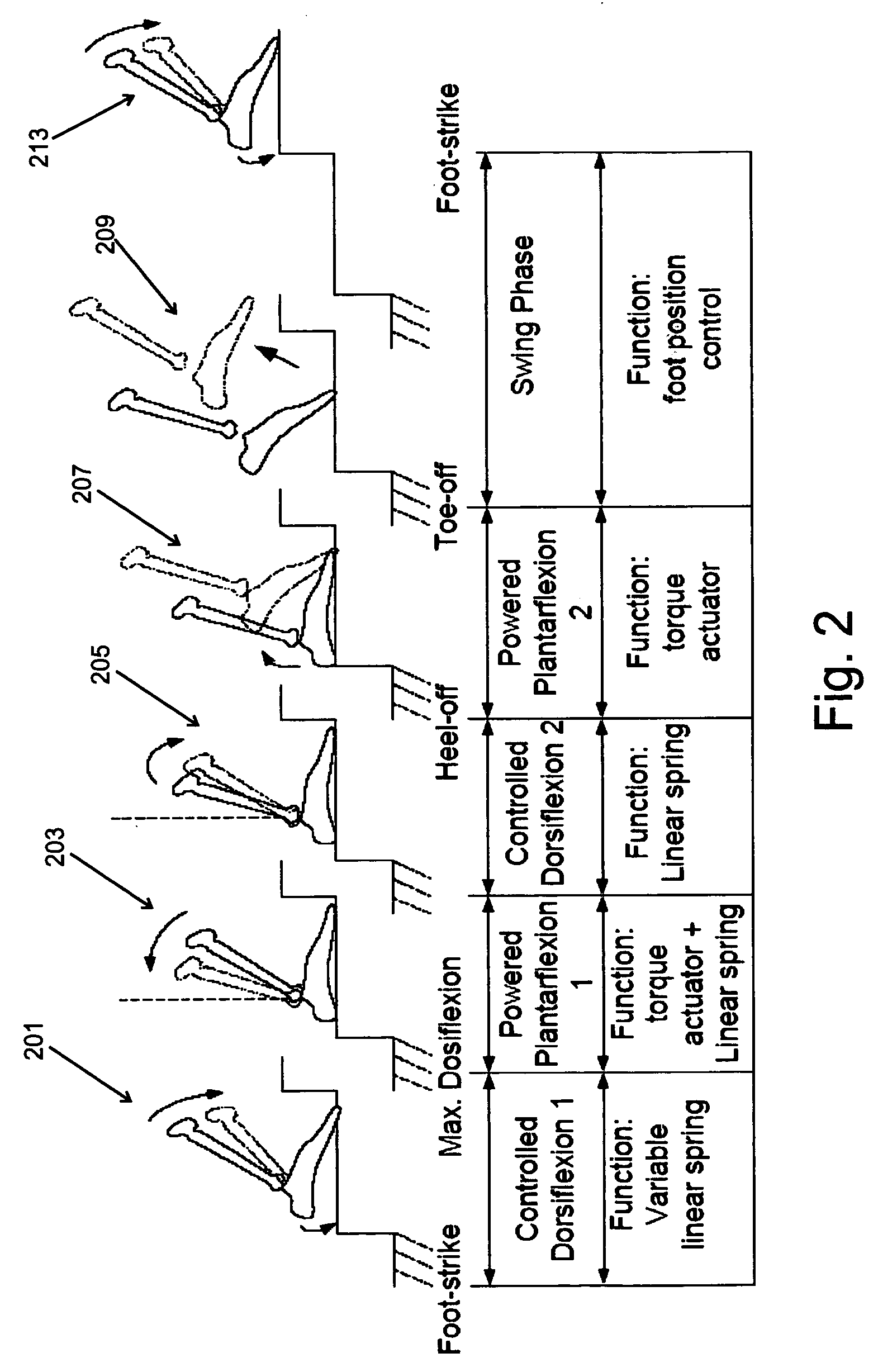

Artificial human limbs and joints employing actuators, springs, and variable-damper elements

InactiveUS20060249315A1High performanceLight weightArtificial legsManipulatorArtificial jointsSacroiliac joint

Biomimetic Hybrid Actuators employed in biologically-inspired musculoskeletal architectures employ an electric motor for supplying positive energy to and storing negative energy from an artificial joint or limb, as well as elastic elements such as springs, and controllable variable damper components, for passively storing and releasing energy and providing adaptive stiffness to accommodate level ground walking as well as movement on stairs and surfaces having different slopes.

Owner:MASSACHUSETTS INST OF TECH

Biodegradable high performance hydrocarbon base oils

InactiveUS6096940AHigh performanceSuperiorRefining to change hydrocarbon structural skeletonHydrocarbon by hydrogenationWaxSolvent

Discloses novel biodegradable high performance hydrocarbon base oils useful as lubricants in engine oil and industrial compositions, and process for their manufacture. A waxy, or paraffinic feed, particularly a Fischer-Tropsch wax, is reacted over a dual function catalyst to produce hydroisomerization and hydrocracking reactions, at 700 DEG F.+ conversion levels ranging from about 20 to 50 wt. %, preferably about 25-40 wt. %, sufficient to produce a crude fraction, e.g., a C5-1050 DEG F.+ crude fraction, containing 700 DEG F.+ isoparaffins having from about 6.0 to about 7.5 methyl branches per 100 carbon atoms in the molecule. The methyl paraffins containing crude fraction is topped via atmospheric distillation to produce a bottoms fraction having an initial boiling point between about 650 DEG F. and 750 DEG F. which is then solvent dewaxed, and the dewaxed oil is then fractionated under high vacuum to produce biodegradable high performance hydrocarbon base oils.

Owner:EXXON RES & ENG CO

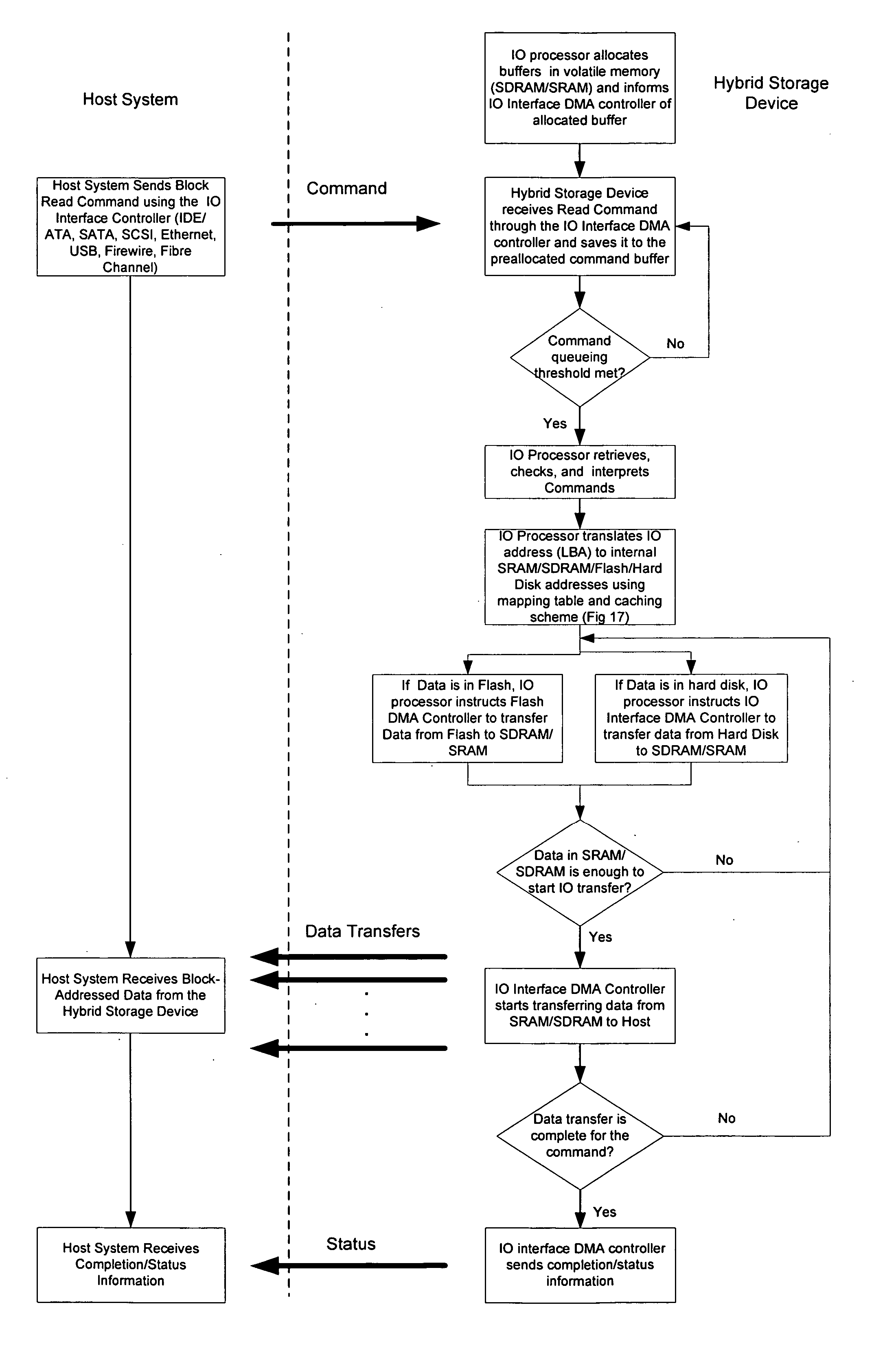

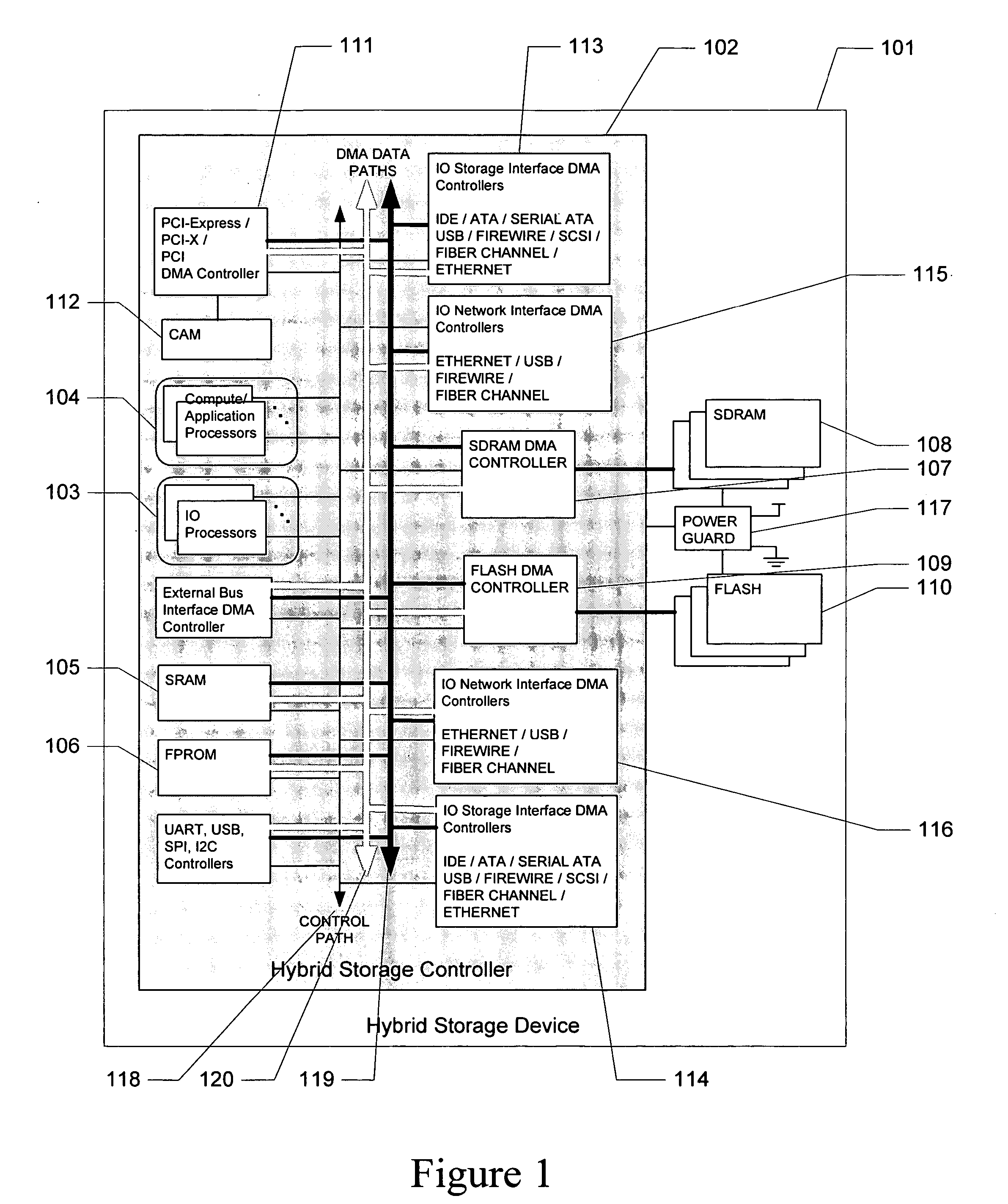

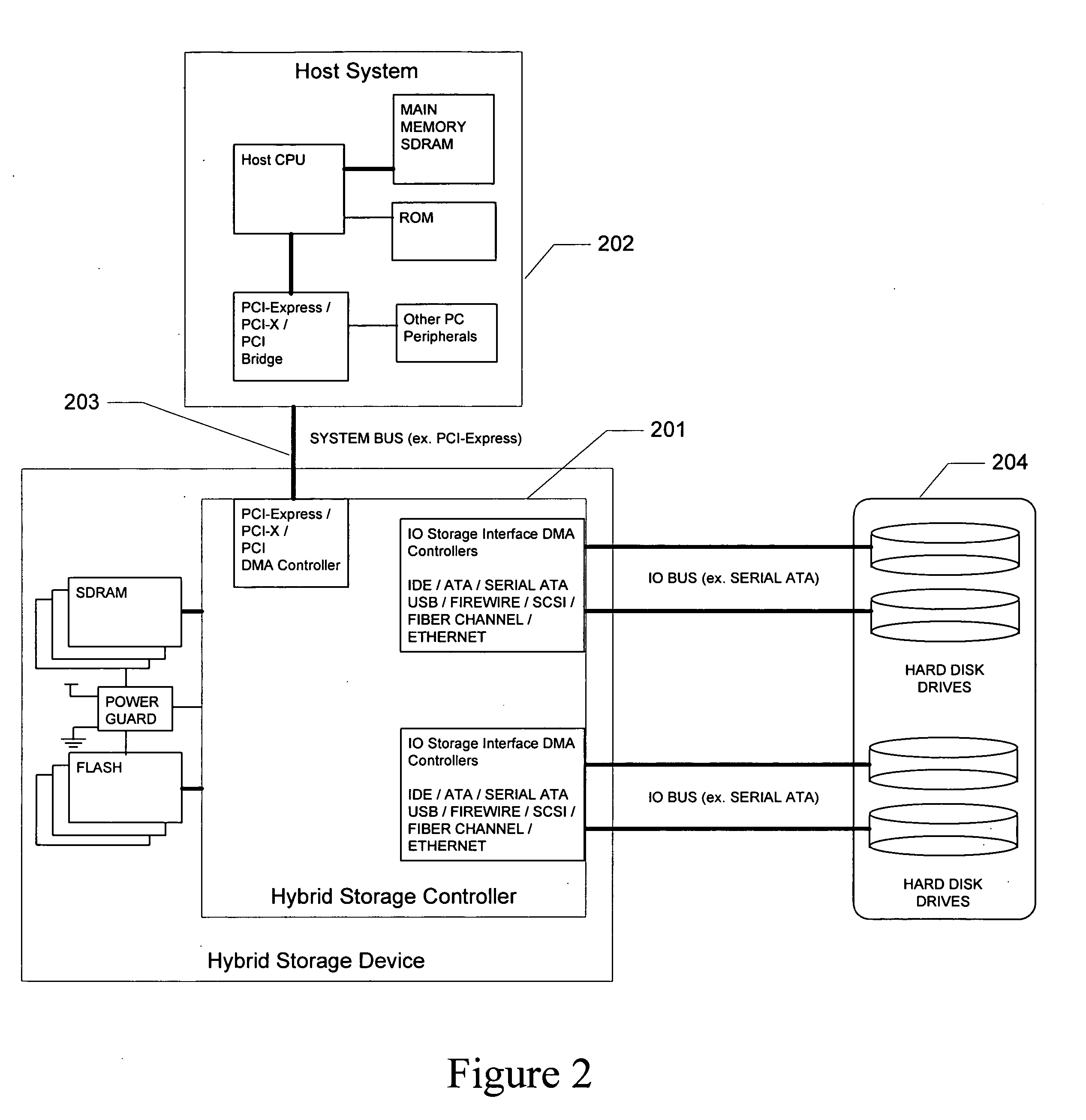

Hybrid Multi-Tiered Caching Storage System

ActiveUS20070288692A1High performanceHigh performance computer data storage solutionMemory architecture accessing/allocationMemory systemsHigh performance computationLogical address

A hybrid storage system comprising mechanical disk drive means, flash memory means, SDRAM memory means, and SRAM memory means is described. IO processor means and DMA controller means are devised to eliminate host intervention. Multi-tiered caching system and novel data structure for mapping logical address to physical address results in a configurable and scalable high performance computer data storage solution.

Owner:BITMICRO LLC

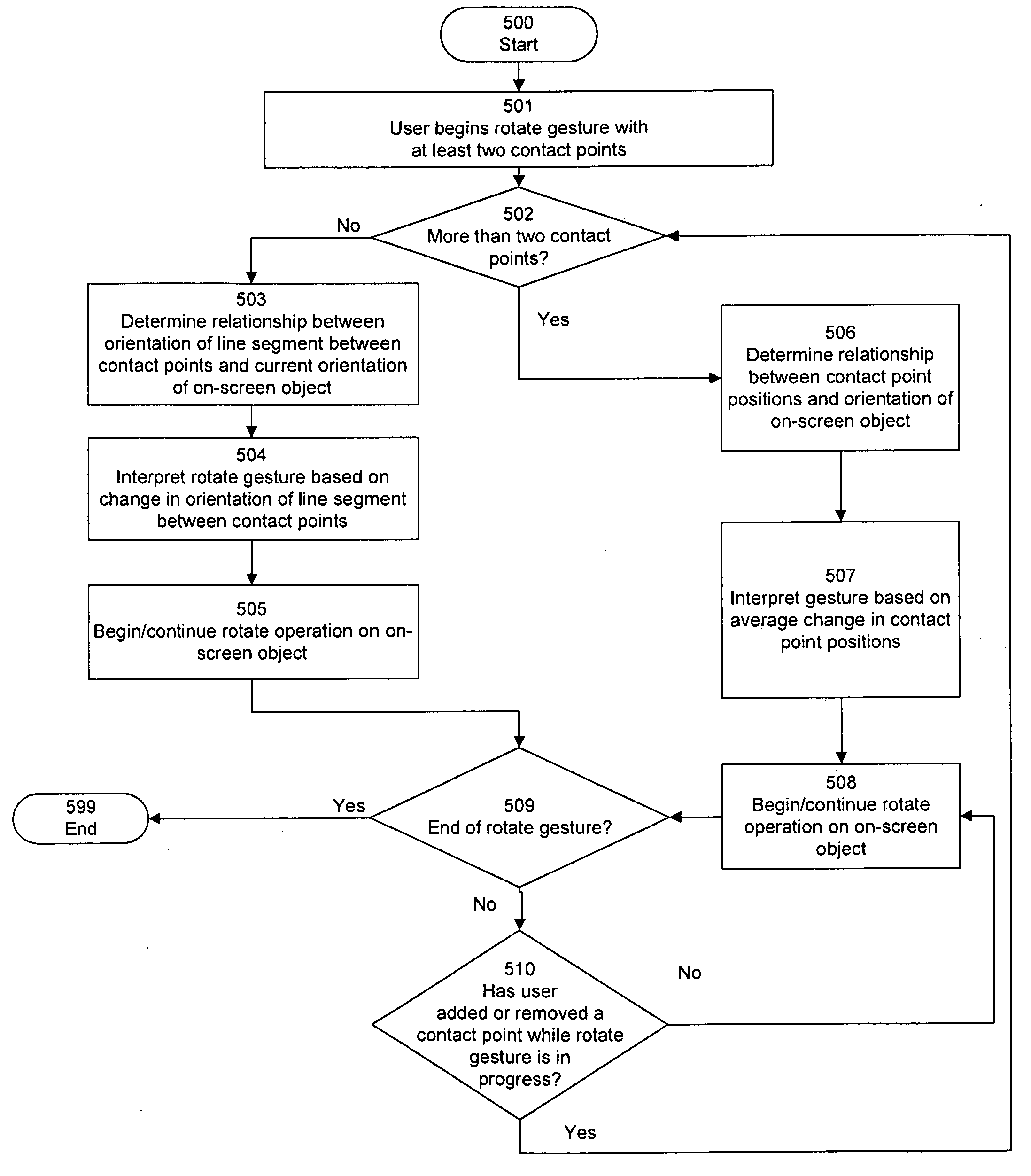

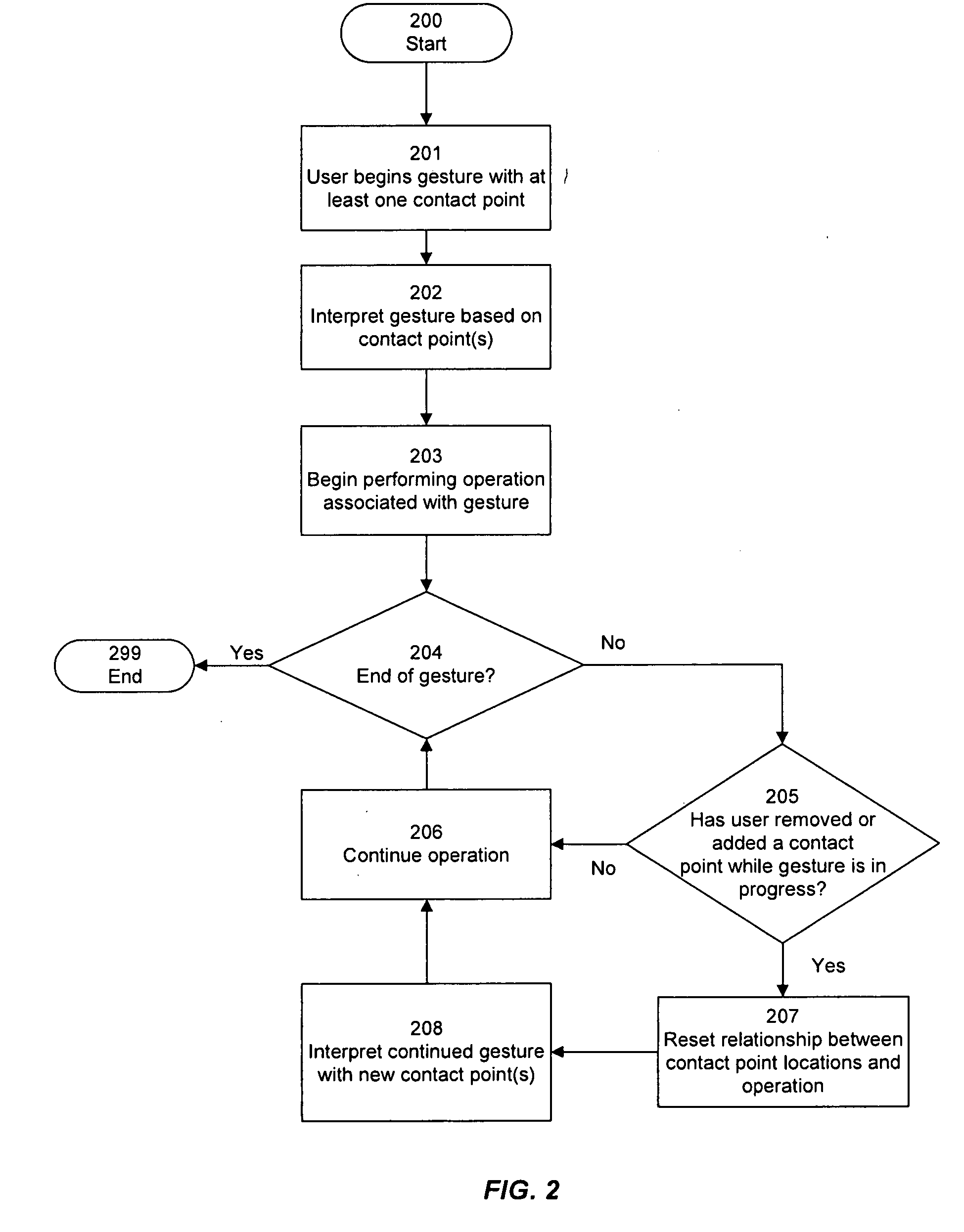

Interpreting Gesture Input Including Introduction Or Removal Of A Point Of Contact While A Gesture Is In Progress

InactiveUS20100162181A1Adjust magnitude and speedHigh performanceInput/output processes for data processingPoint locationMulti-touch

A touch-sensitive device accepts single-touch and multi-touch input representing gestures, and is able to changing a parameter of a gesture responsive to introduction or removal of a point of contact while the gesture is in progress. The operation associated with the gesture, such as a manipulation of an on-screen object, changes in a predictable manner if the user introduces or removes a contact point while the gesture is in progress. The overall nature of the operation being performed does not change, but a parameter of the operation can change. In various embodiments, each time a contact point is added or removed, the system and method of the present invention resets the relationship between the contact point locations and the operation being performed, in such a manner as to avoid or minimize discontinuities in the operation. In this manner, the invention avoids sudden or unpredictable changes to an object being manipulated.

Owner:QUALCOMM INC

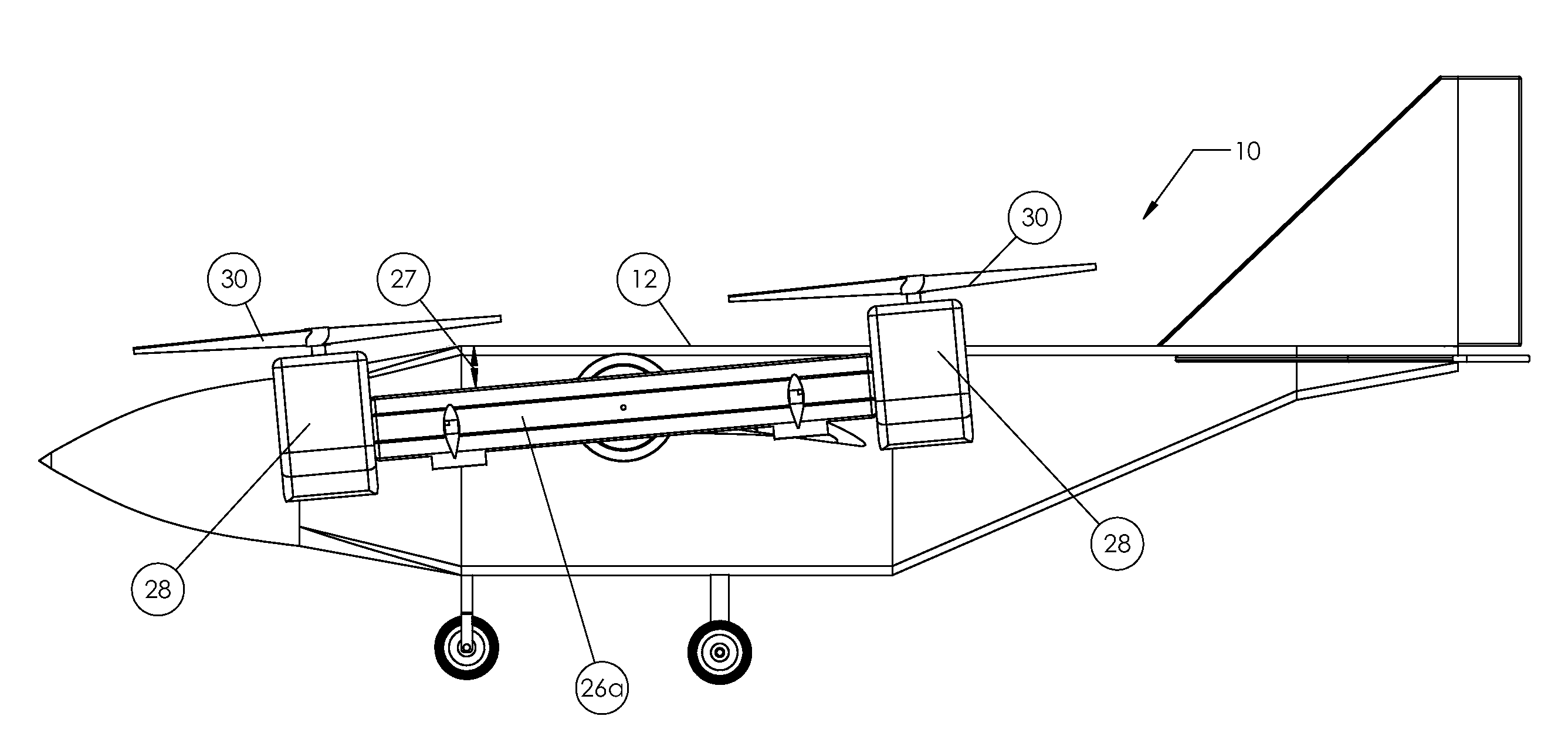

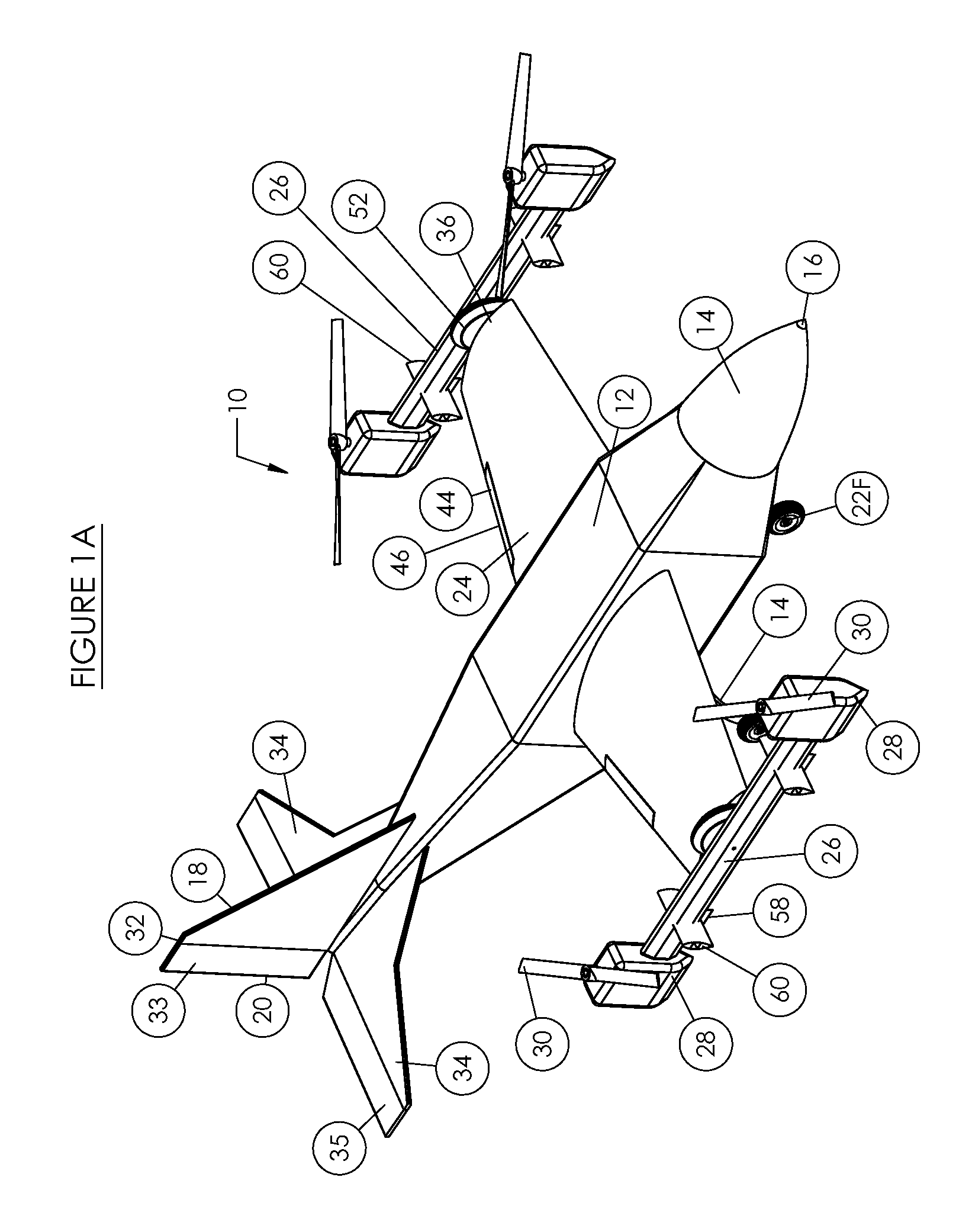

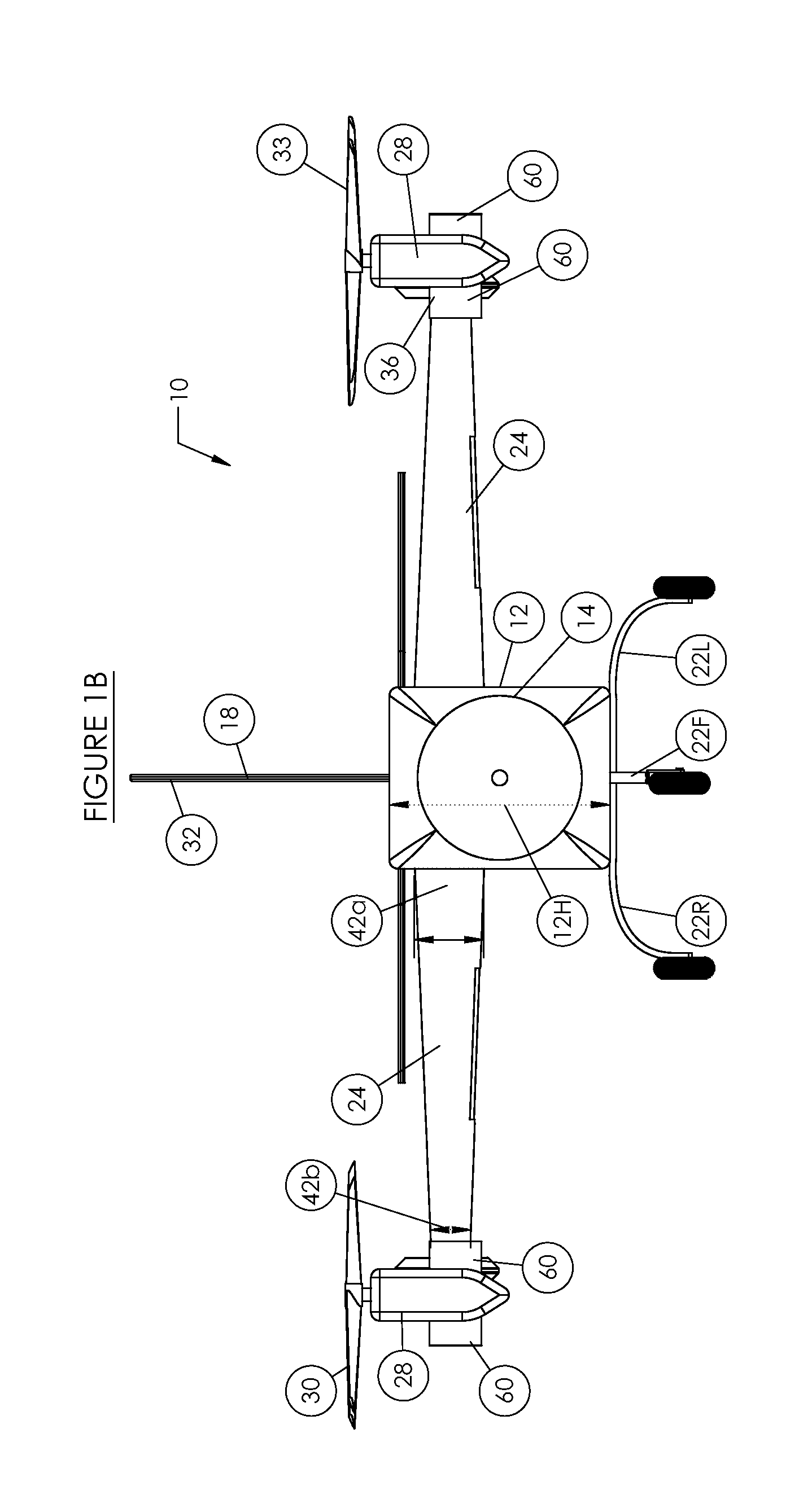

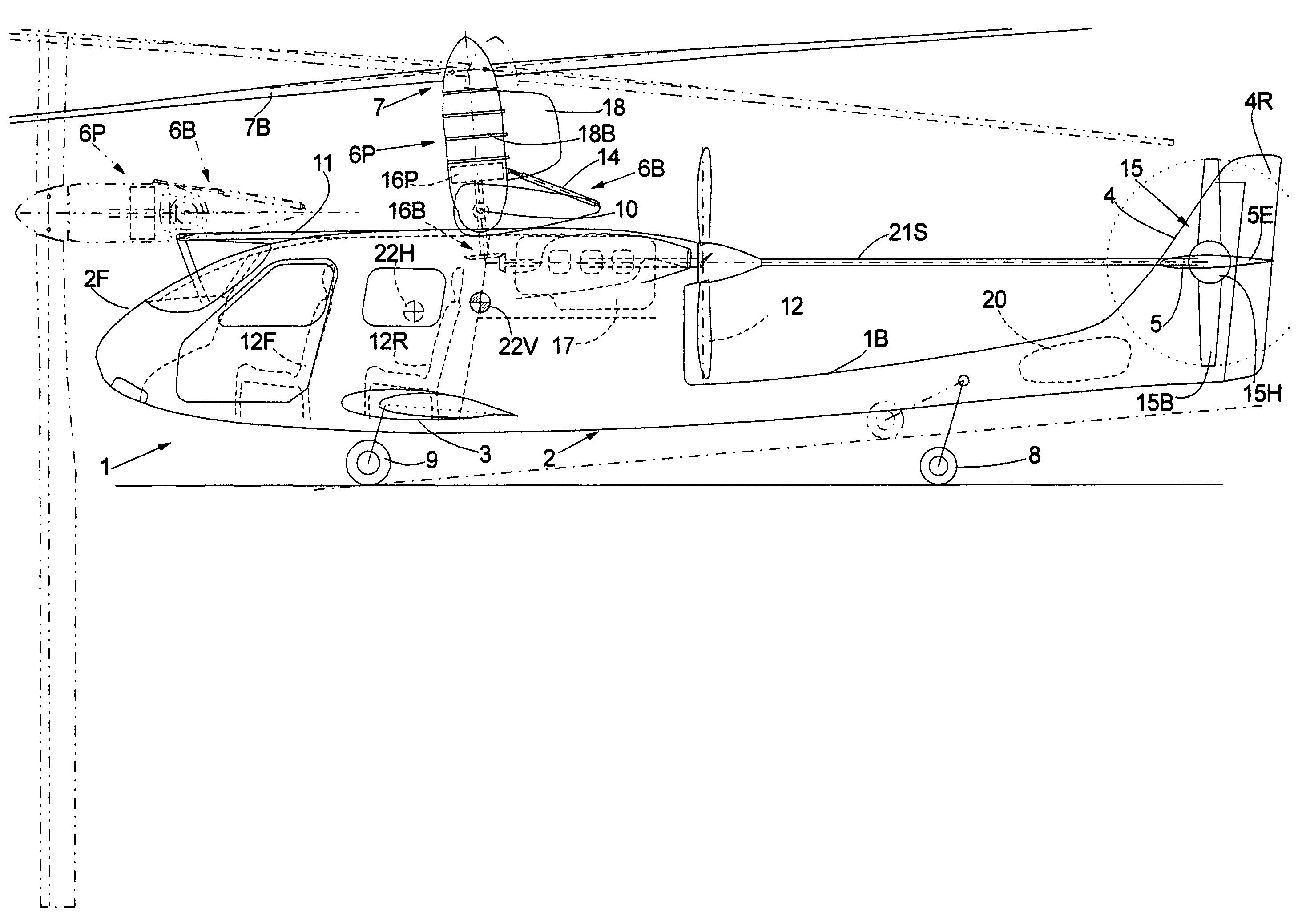

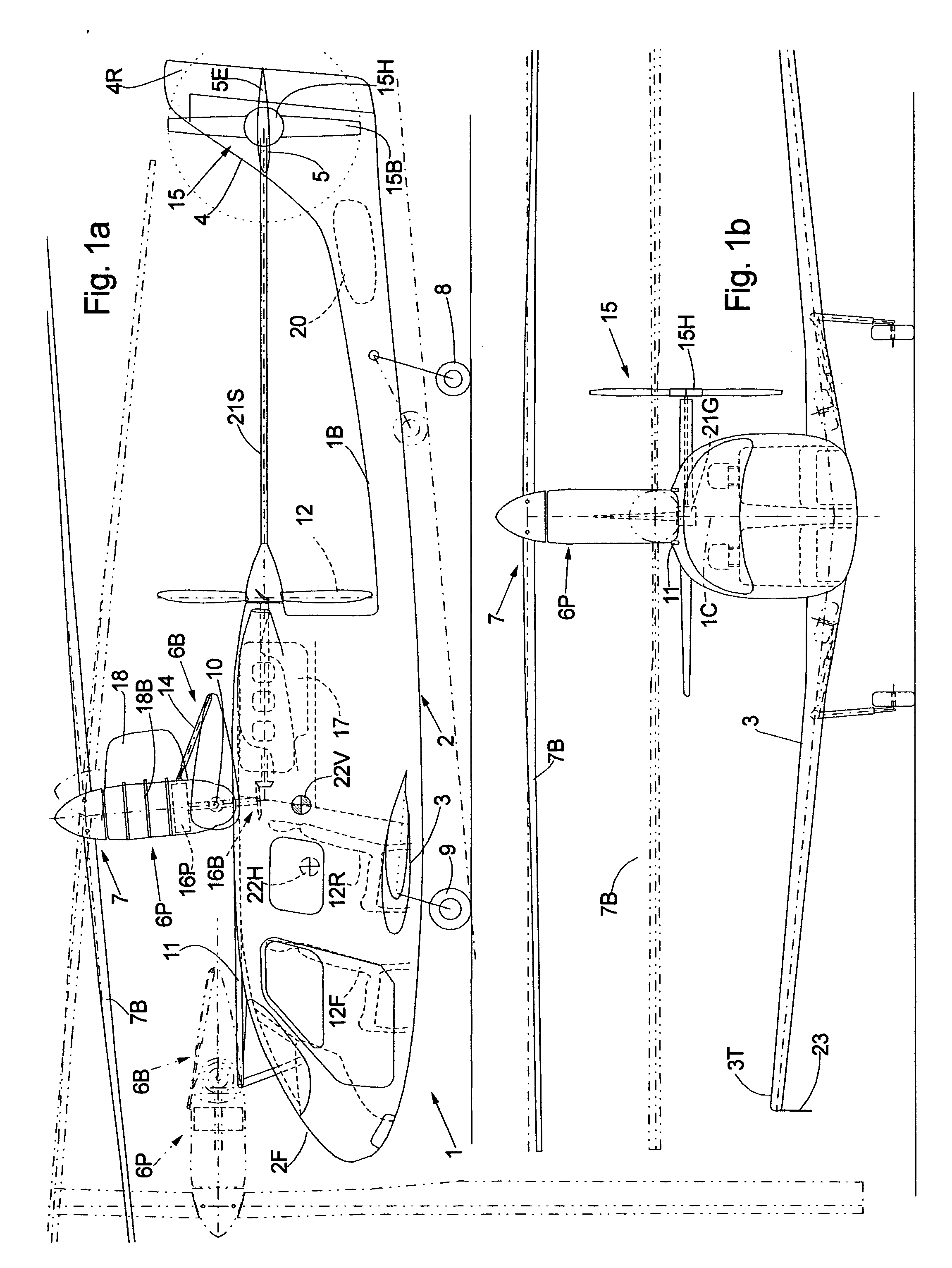

Aircraft with Wings and Movable Propellers

ActiveUS20120261523A1High liftHigh performanceVertical landing/take-off aircraftsRotocraftPropellerFlight vehicle

The invention is a flight vehicle, and methods of operation thereof, having wings and movable propeller assemblies which can be rotated to provide vertical and / or horizontal thrust. The propeller assemblies are configured to maximize available engine / propeller thrust and to prevent propwash from striking the wings of the aircraft.

Owner:SHAW DONALD ORVAL

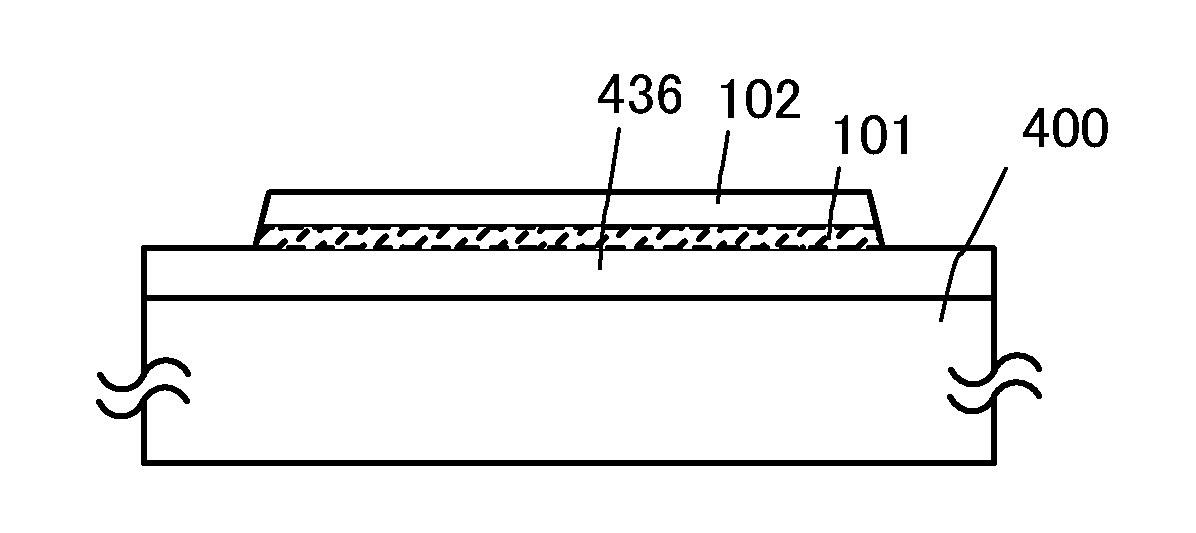

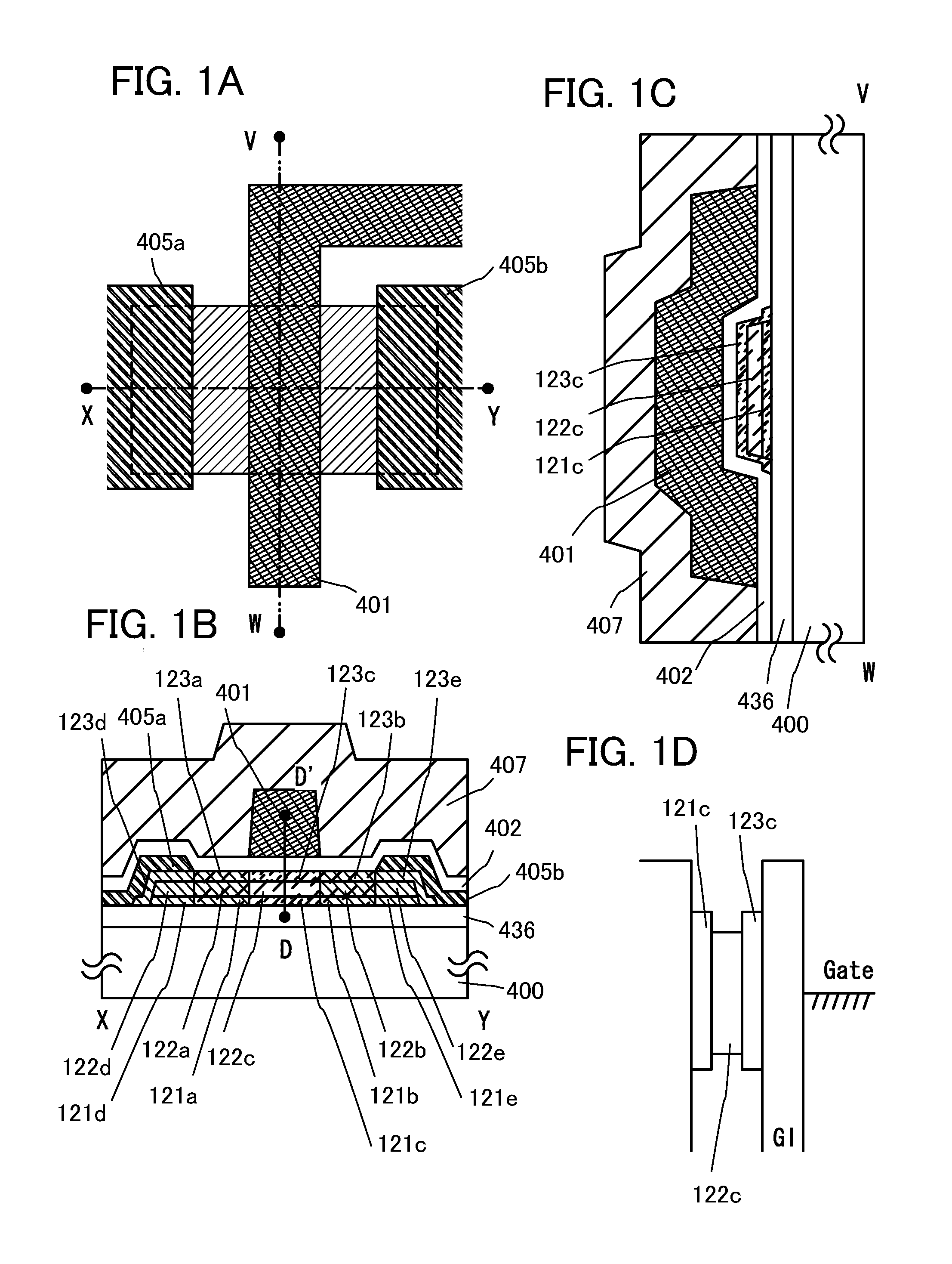

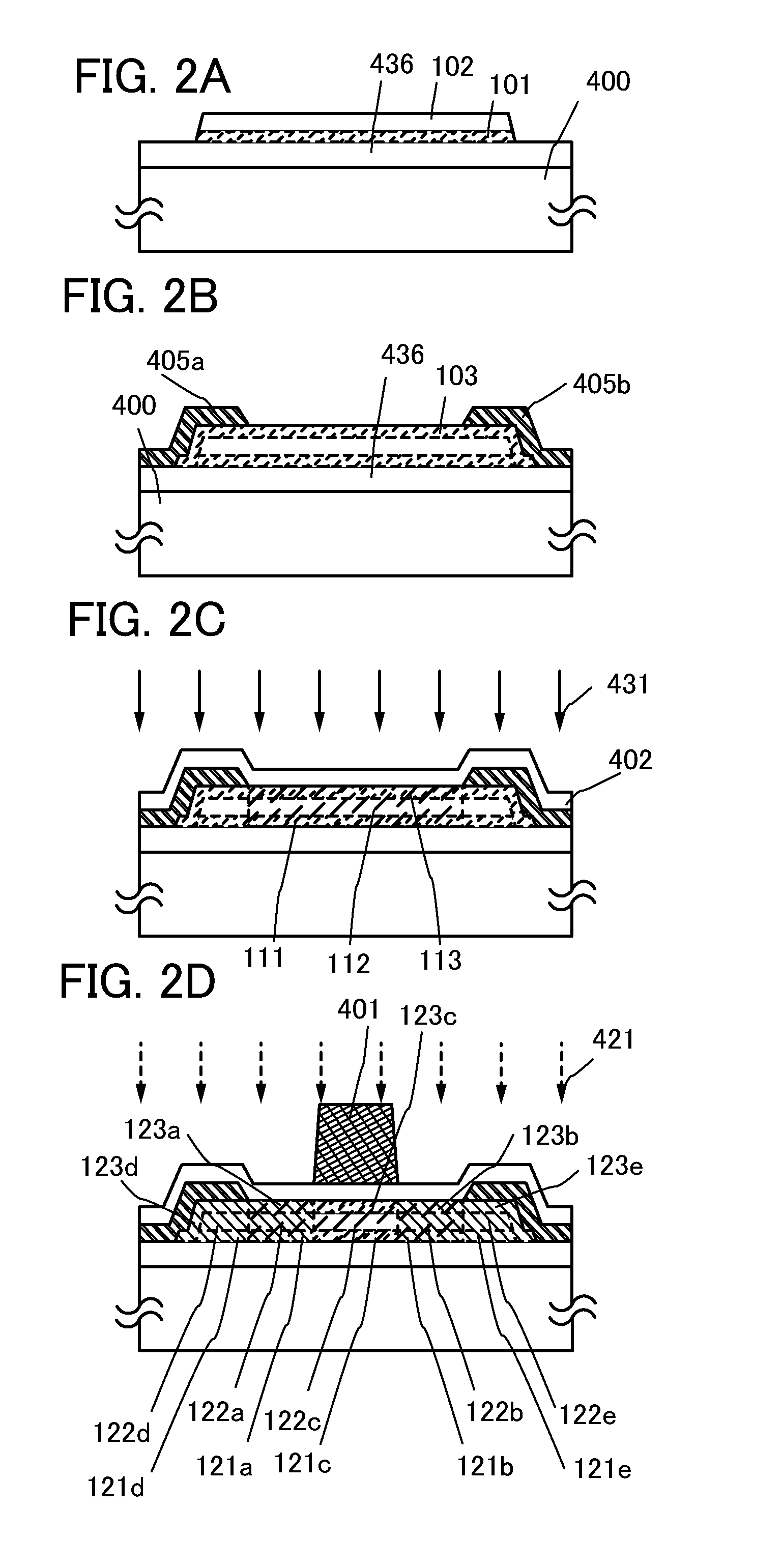

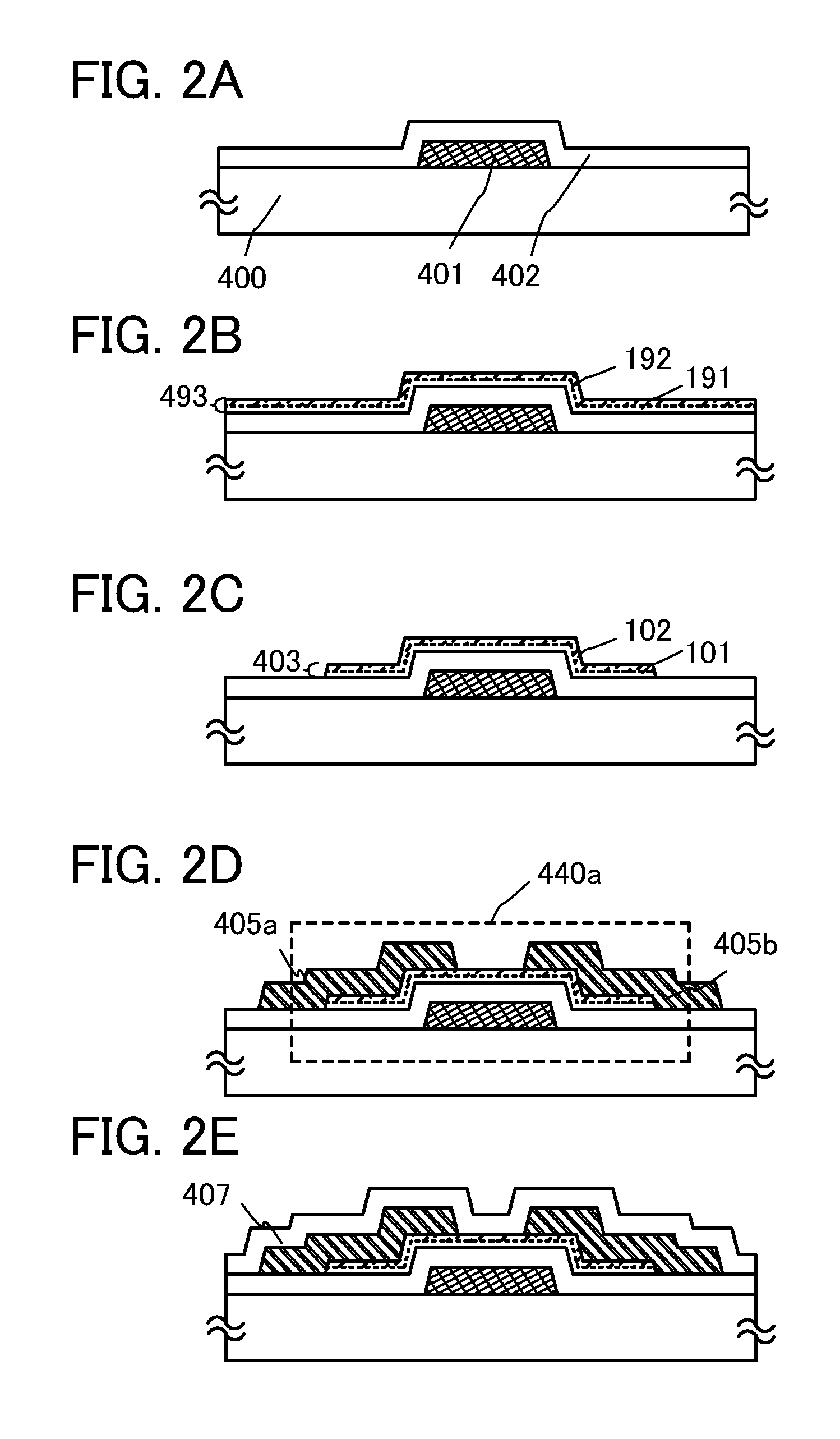

Semiconductor device and manufacturing method thereof

ActiveUS20120319183A1High performanceHigh-speed response and high-speed operationElectroluminescent light sourcesSemiconductor/solid-state device manufacturingOxide semiconductorOxide

One object of the present invention is to provide a structure of a transistor including an oxide semiconductor in a channel formation region in which the threshold voltage of electric characteristics of the transistor can be positive, which is a so-called normally-off switching element, and a manufacturing method thereof. A second oxide semiconductor layer which has greater electron affinity and a smaller energy gap than a first oxide semiconductor layer is formed over the first oxide semiconductor layer. Further, a third oxide semiconductor layer is formed to cover side surfaces and a top surface of the second oxide semiconductor layer, that is, the third oxide semiconductor layer covers the second oxide semiconductor layer.

Owner:SEMICON ENERGY LAB CO LTD

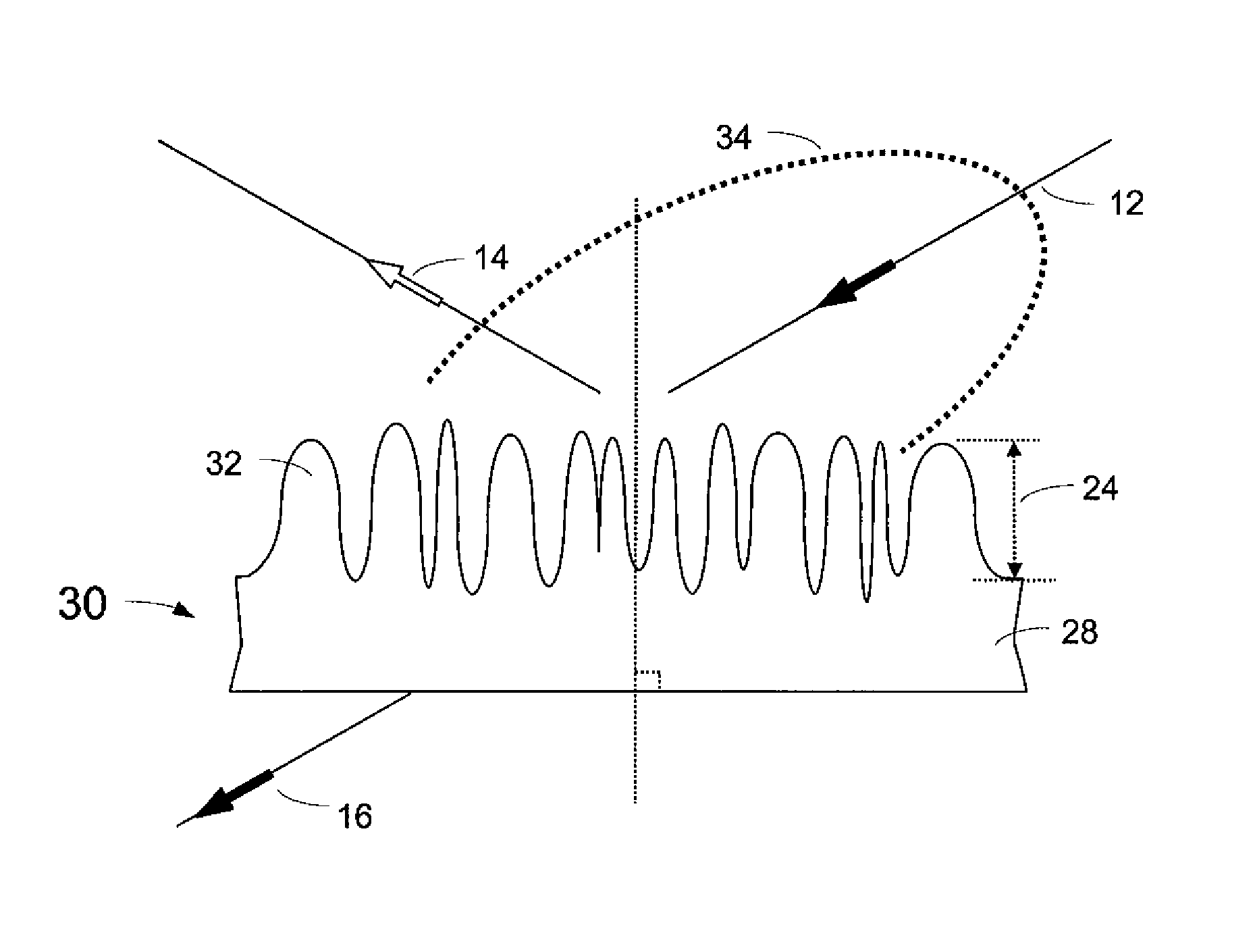

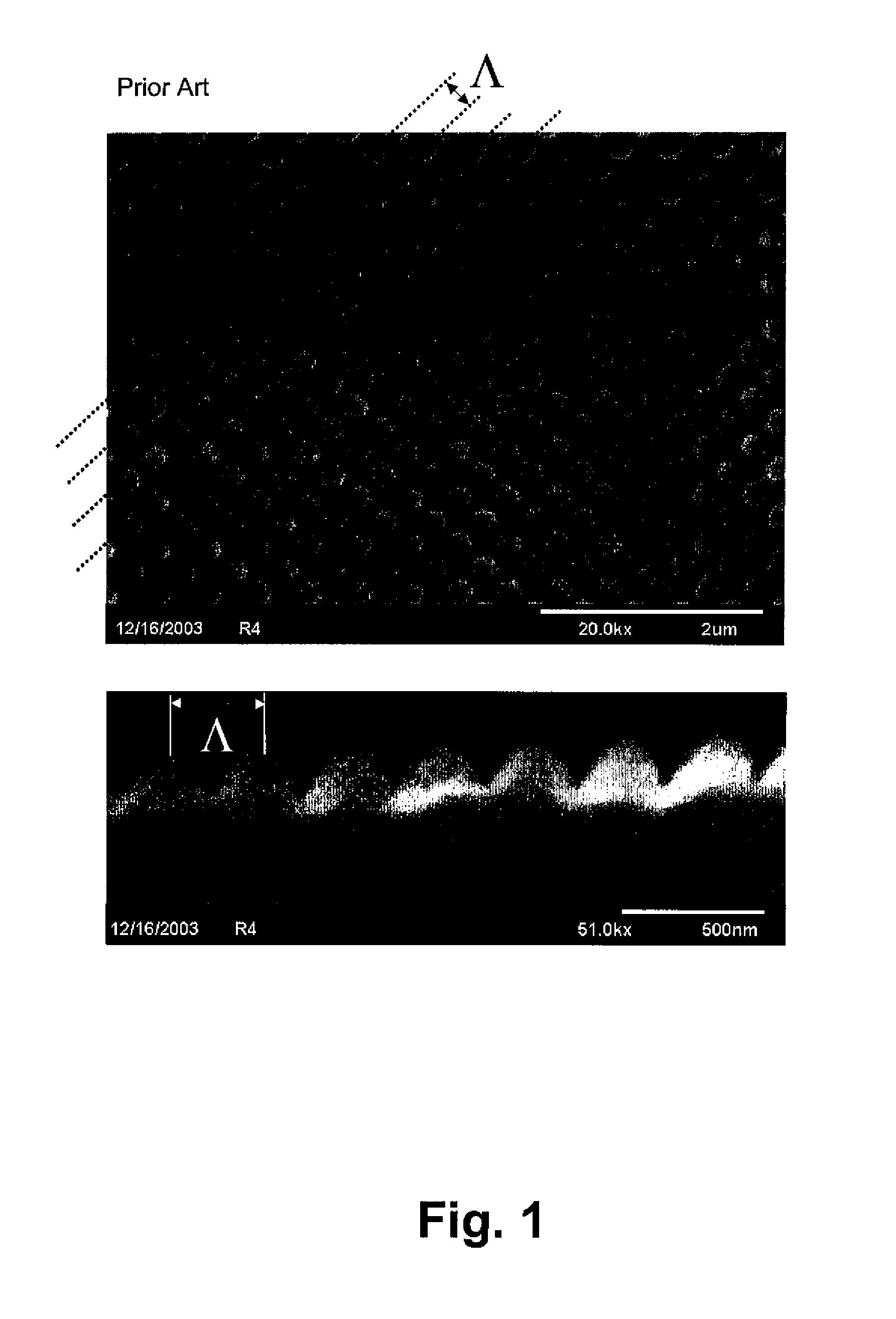

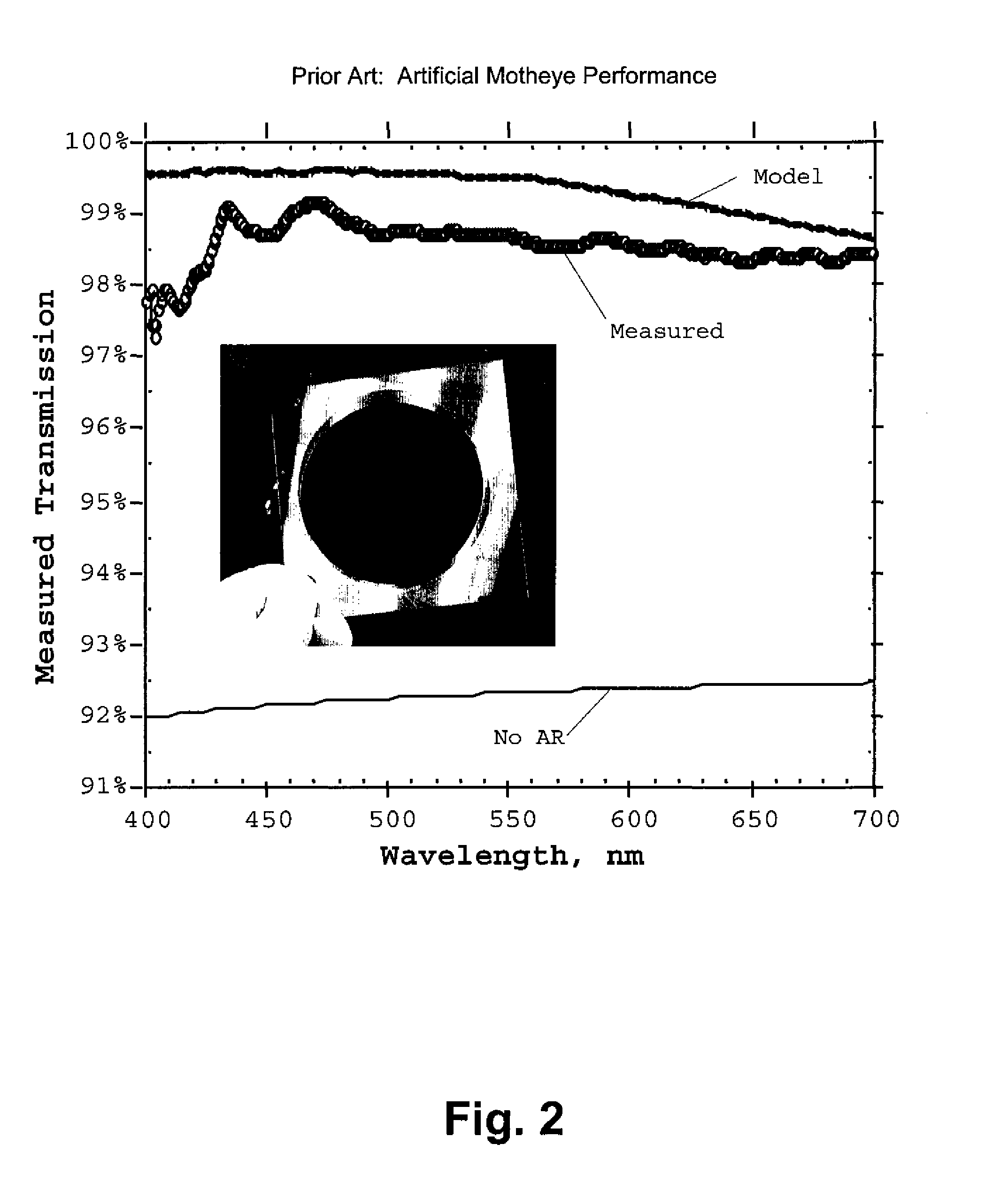

Random texture anti-reflection optical surface treatment

ActiveUS8187481B1High performanceLevelDecorative surface effectsOptical articlesSurface reliefSurface finishing

A surface relief structure consisting of a random distribution of surface features with varying feature profile and depth, is described. The texture serves to suppress the reflection of electromagnetic waves in the optical region of the spectrum without dispersing any portion of the spectrum by diffraction. Processes for fabricating the random distribution anti-reflecting textures in common materials are also described. The disclosed textures are particularly useful as anti-reflecting covers for displays, and as directly molded anti-reflecting surfaces in eyeglass lenses. Other applications such as covers for artwork, and improved solar cells are made practical by the invention.

Owner:COHO HLDG

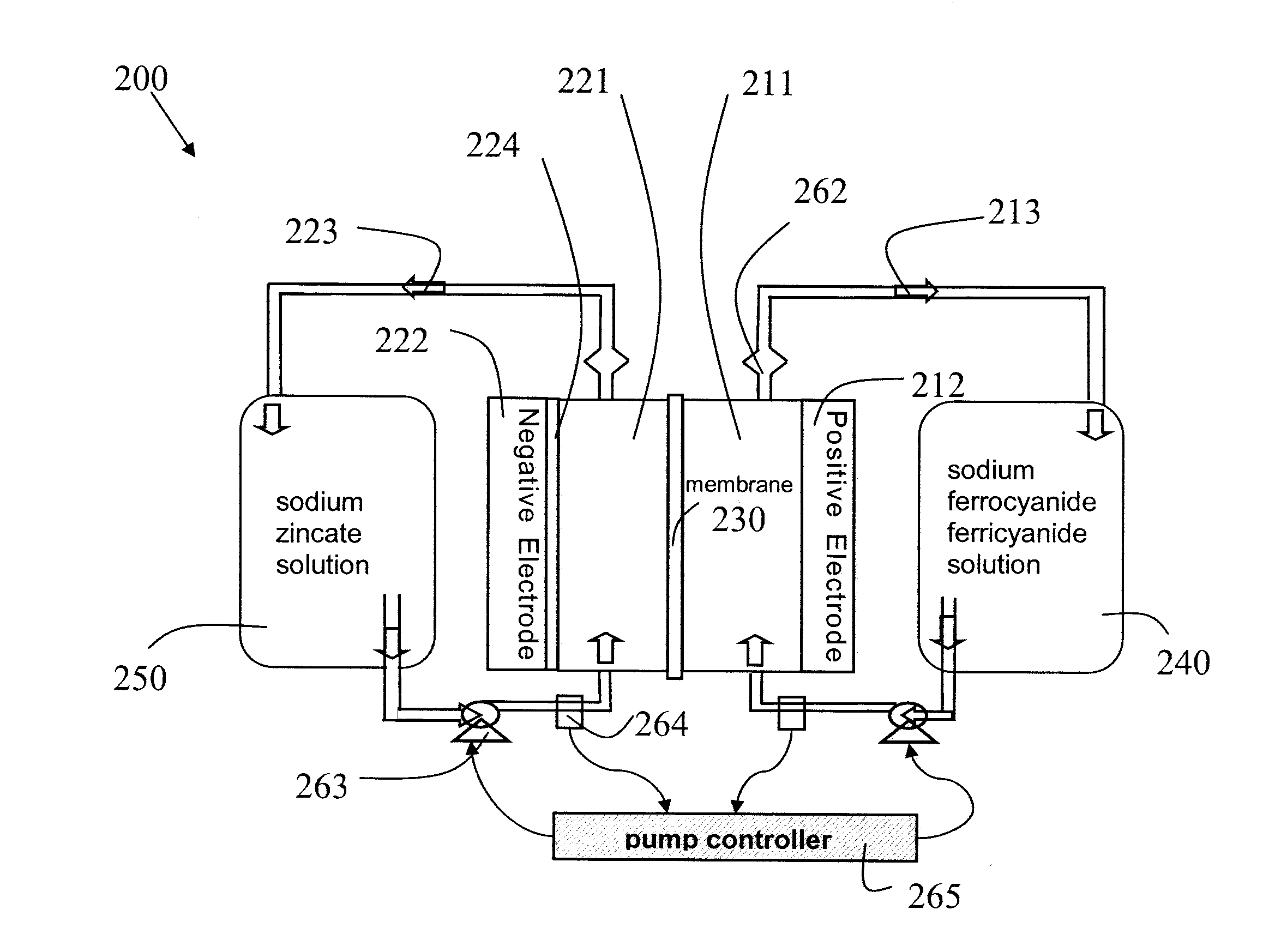

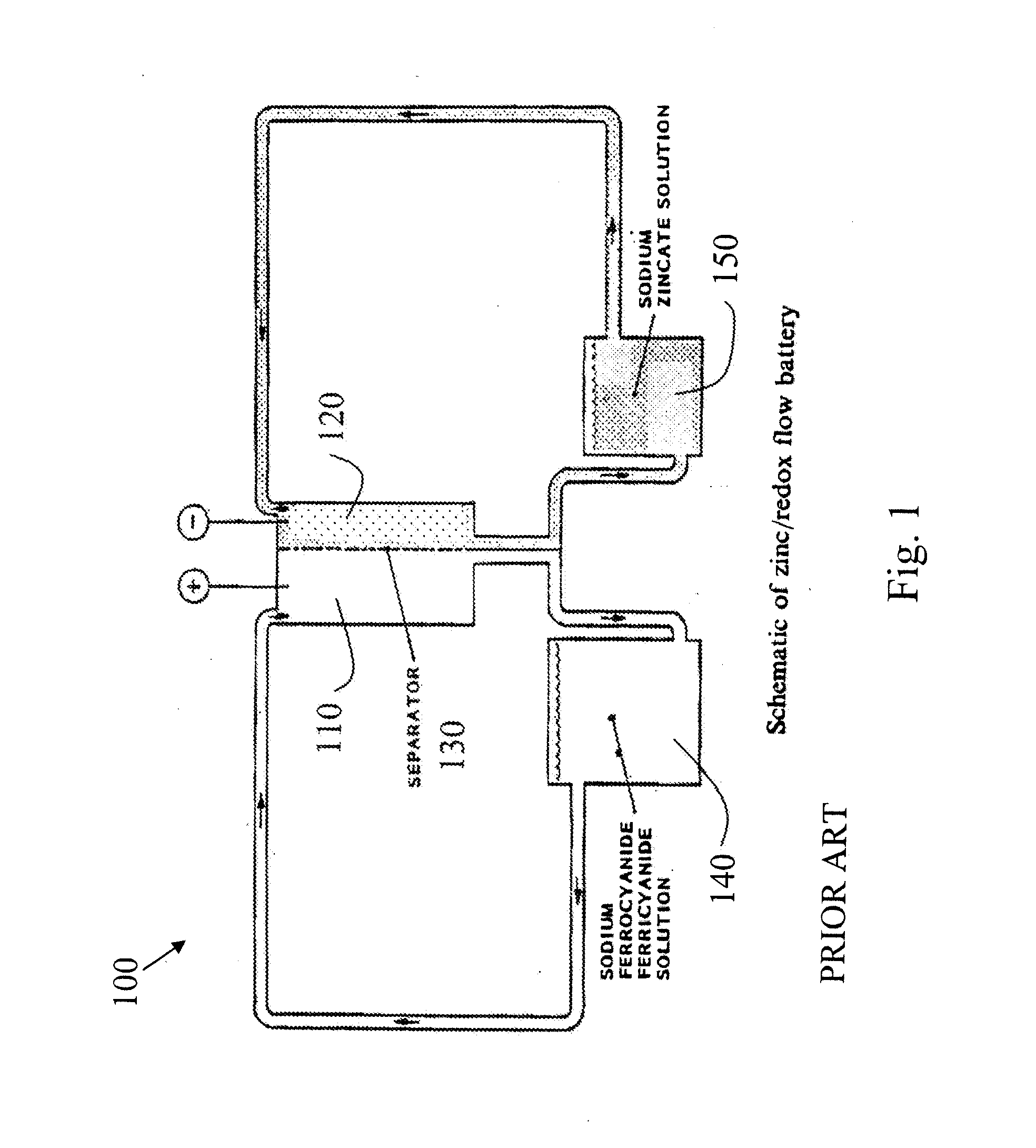

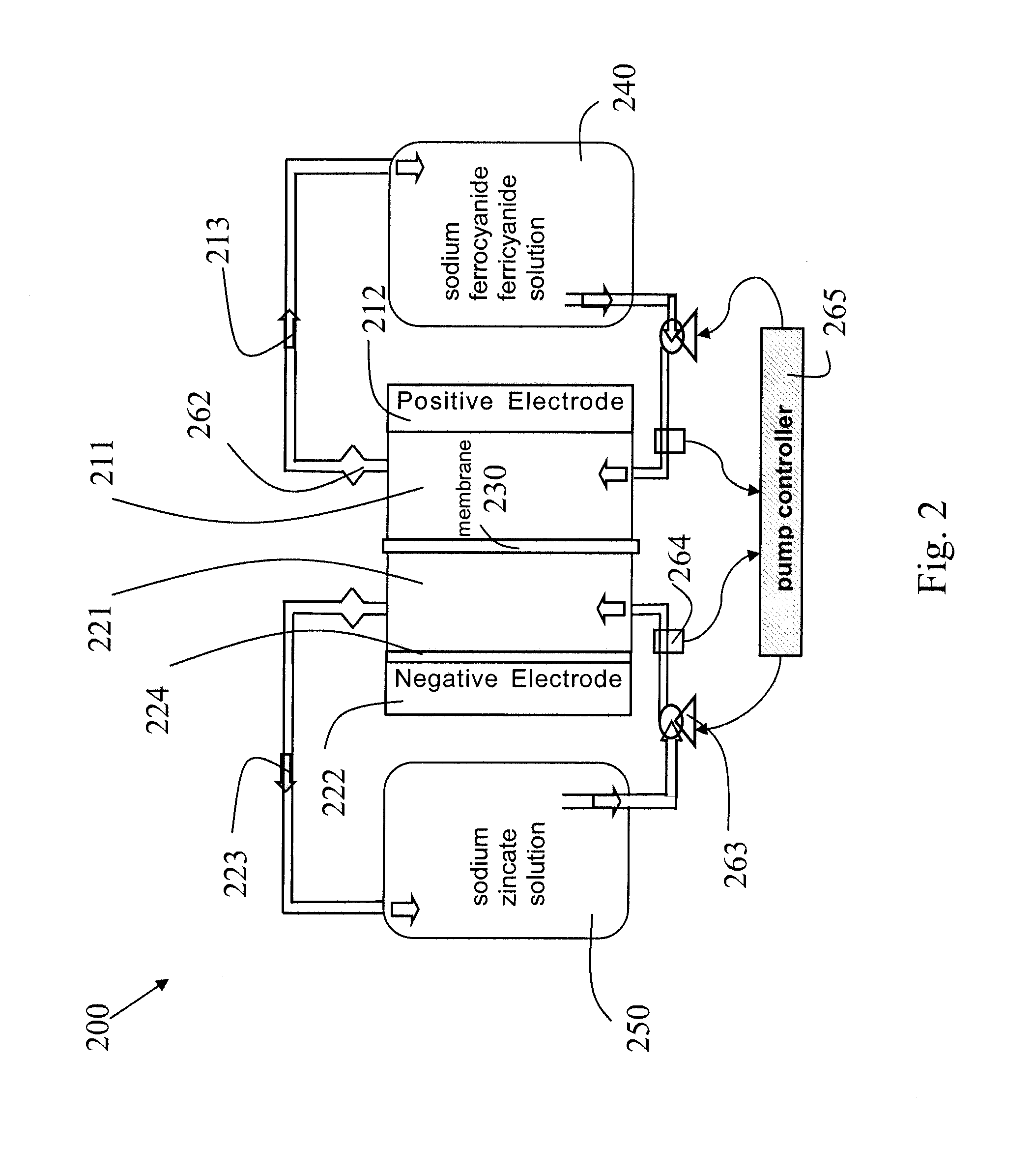

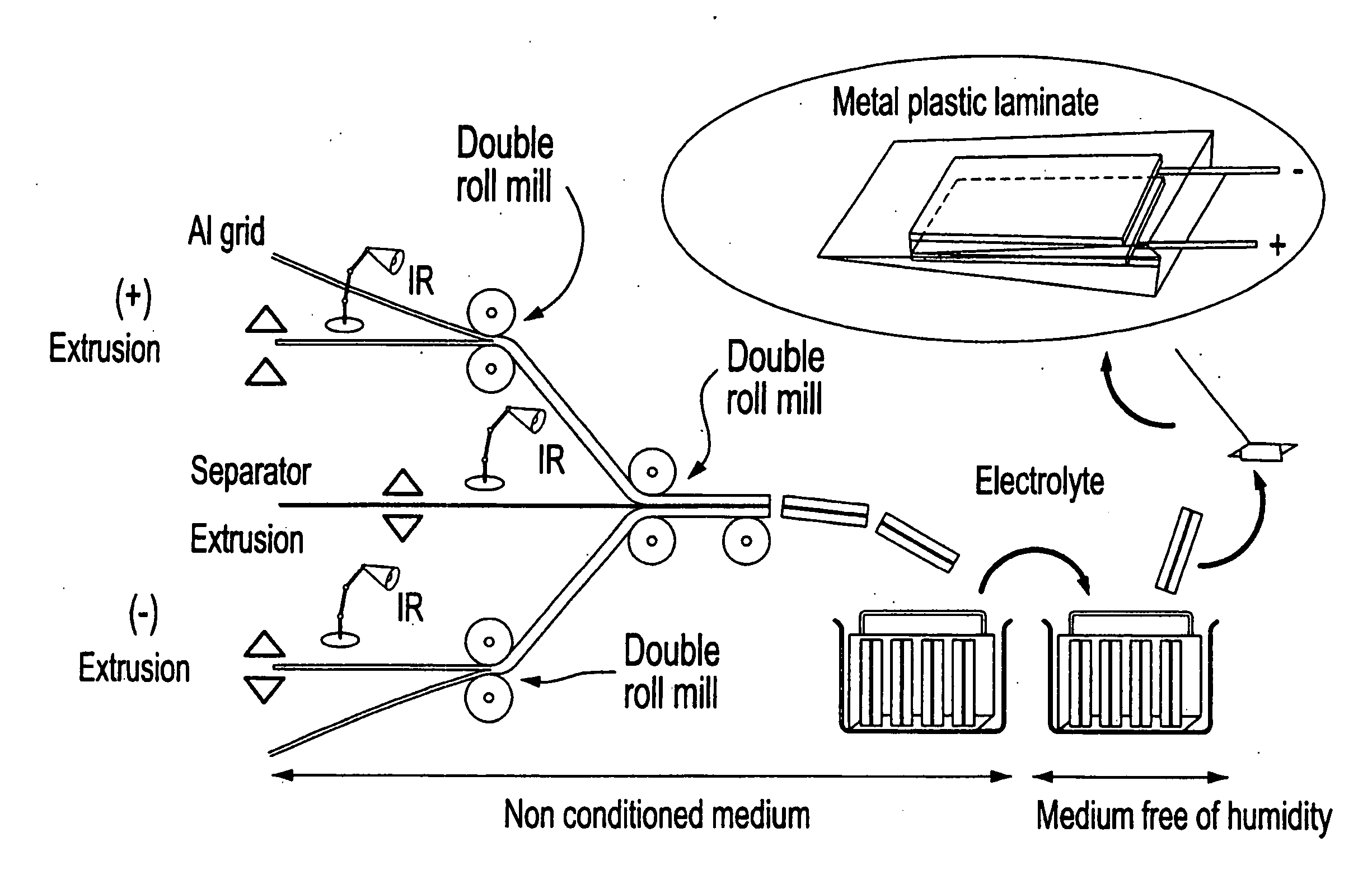

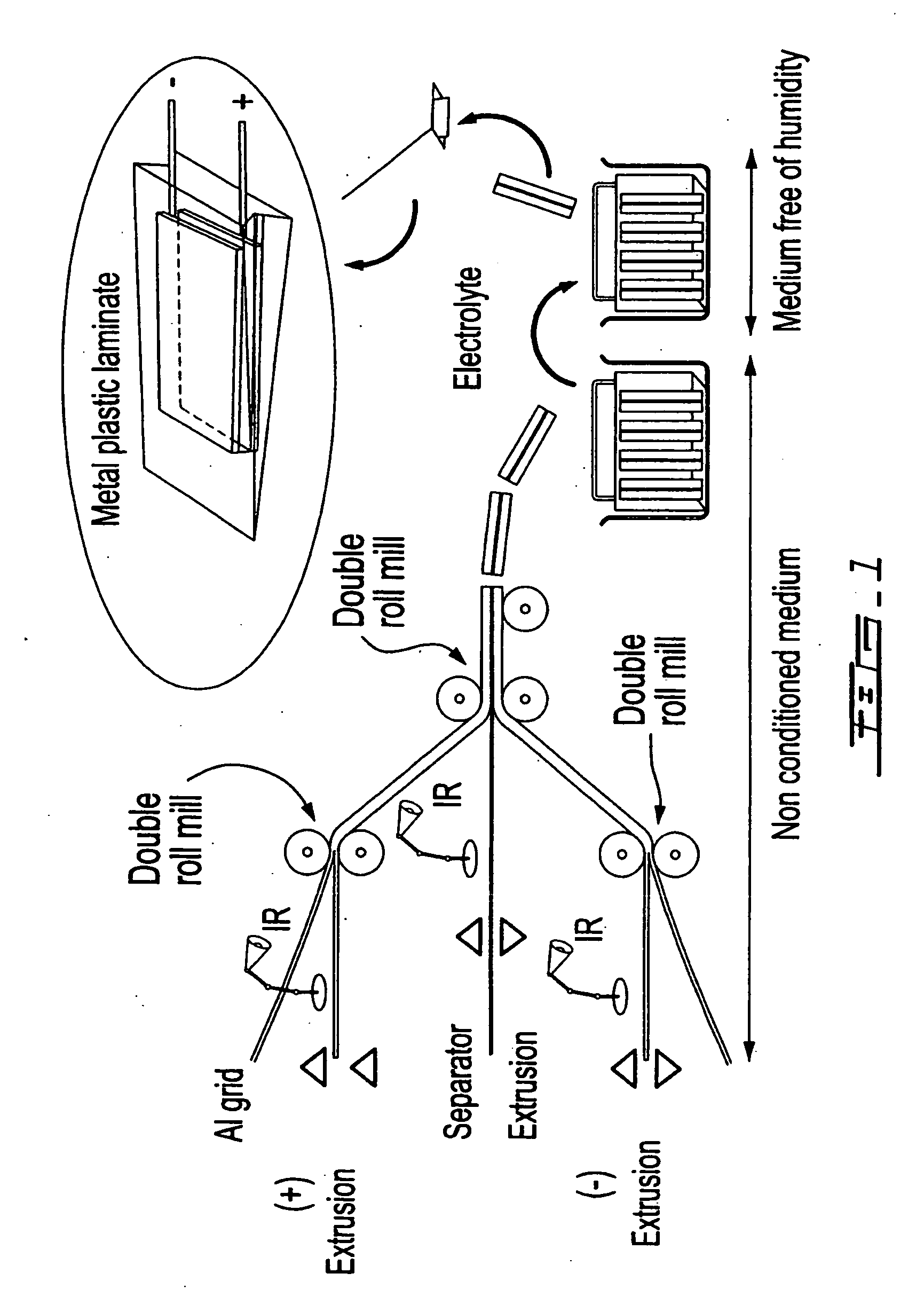

High performance flow battery

InactiveUS20110244277A1High performanceImprove the level ofElectrolyte moving arrangementsIndirect fuel cellsFerricyanideIon

High performance flow batteries, based on alkaline zinc / ferro-ferricyanide rechargeable (“ZnFe”) and similar flow batteries, may include one or more of the following improvements. First, the battery design has a cell stack comprising a low resistance positive electrode in at least one positive half cell and a low resistance negative electrode in at least one negative half cell, where the positive electrode and negative electrode resistances are selected for uniform high current density across a region of the cell stack. Second, a flow of electrolyte, such as zinc species in the ZnFe battery, with a high level of mixing through at least one negative half cell in a Zn deposition region proximate a deposition surface where the electrolyte close to the deposition surface has sufficiently high zinc concentration for deposition rates on the deposition surface that sustain the uniform high current density. The mixing in the flow may be induced by structures such as: conductive and non-conductive meshes; screens; ribbons; foam structures; arrays of cones, cylinders, or pyramids; and other arrangements of wires or tubes used solely or in combination with a planar electrode surface. Third, the zinc electrolyte has a high concentration and in some embodiments has a concentration greater than the equilibrium saturation concentration—the zinc electrolyte is super-saturated with Zn ions.

Owner:APPLIED MATERIALS INC

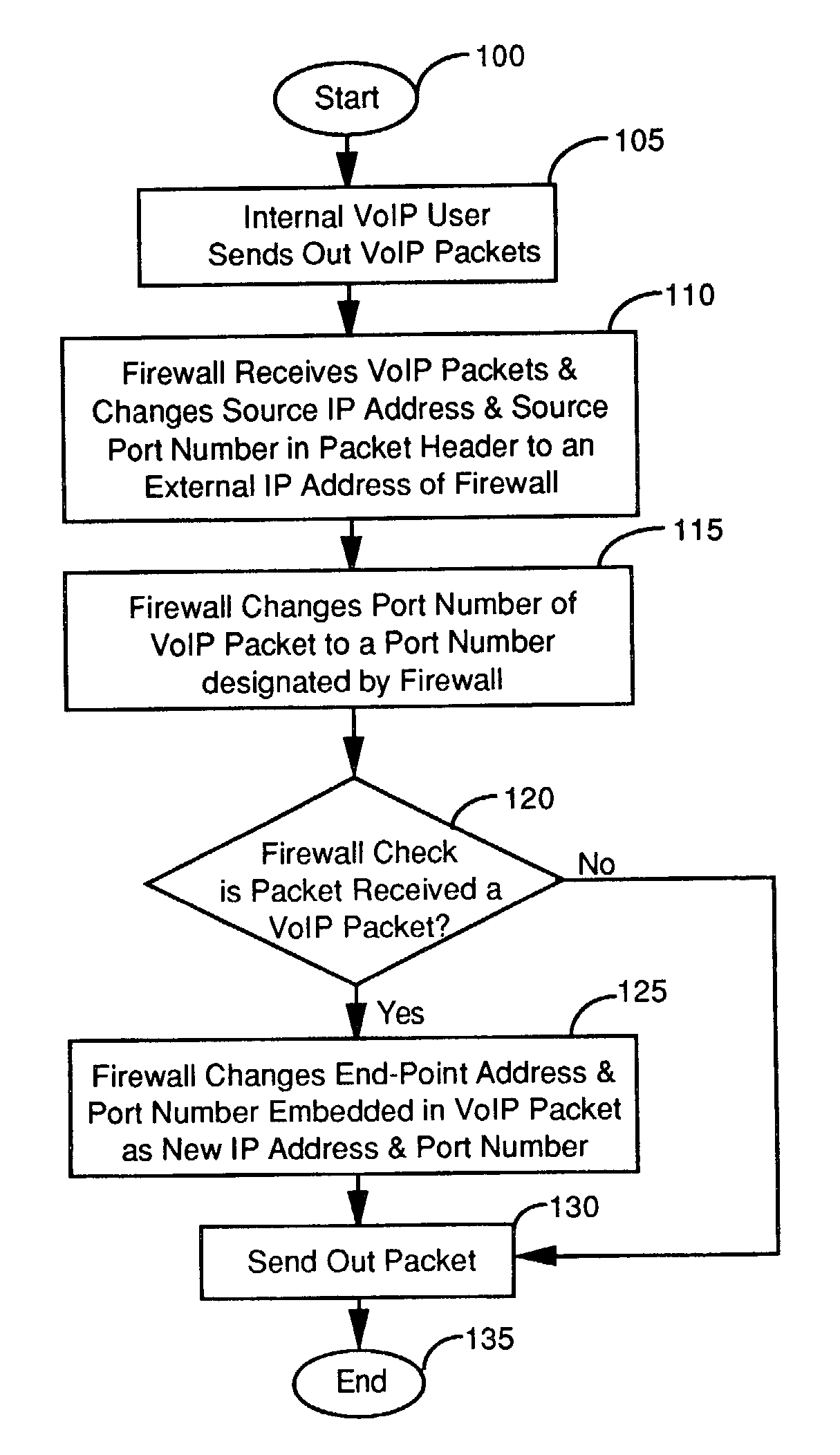

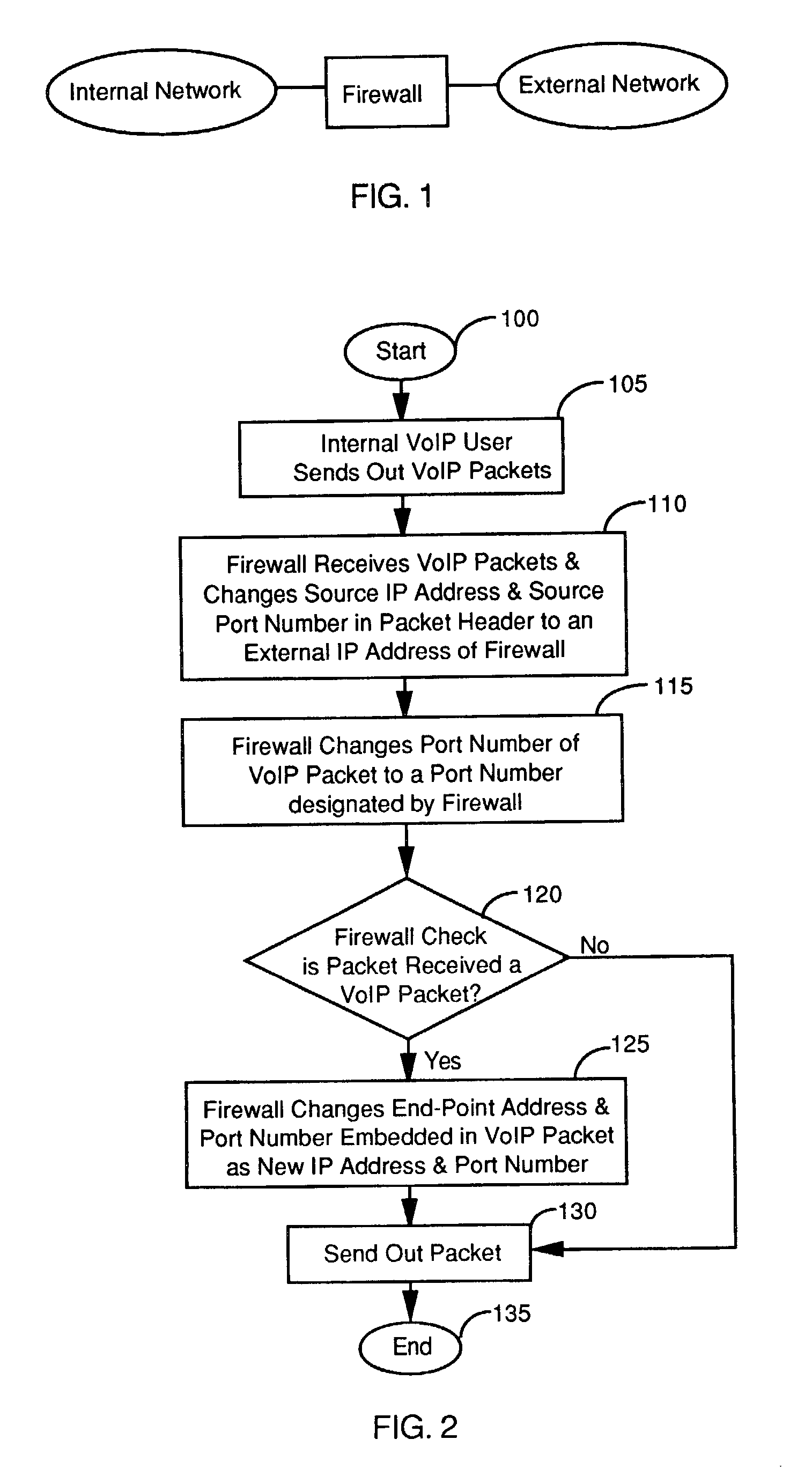

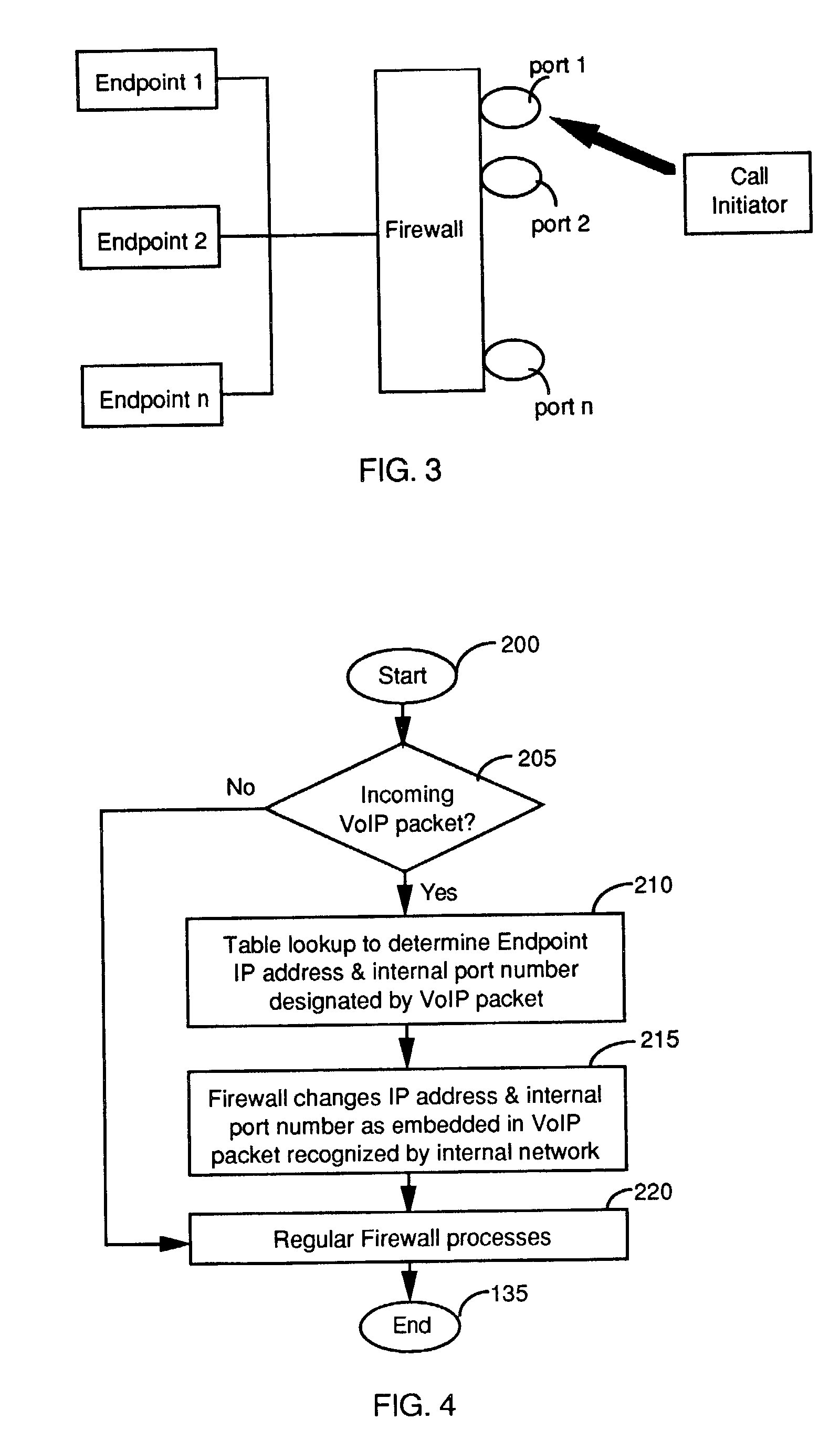

Firewall interface configuration and processes to enable bi-directional VoIP traversal communications

InactiveUS20040059942A1High safetyHigh performanceHardware monitoringMultiple digital computer combinationsData contentIp address

A firewall for interfaced between an internal and an external networks. The firewall includes a VoIP processor for detecting an outgoing VoIP packet sent from the internal network for changing data in a header of the VoIP packet and also changing data contents in the VoIP packet corresponding to data changed in the header to enable a bi-directional VoIP communication. In a preferred embodiment, the VoIP processor changes a source IP address and a port number in the header of the VoIP packet and also changes the data contents in the VoIP packet corresponding to the source IP address and the port number changed in the header to enable a bi-directional VoIP communication. In another preferred embodiment, the firewall further includes an external VoIP interface comprising a plurality of VoIP ports for receiving multiple incoming VoIP packets each designated with one of the VoIP ports. And, the VoIP processor further includes a VoIP port versus internal address table for identifying an internal address in the internal network for directing each of the incoming VoIP packets to the internal address identified.

Owner:FORTINET

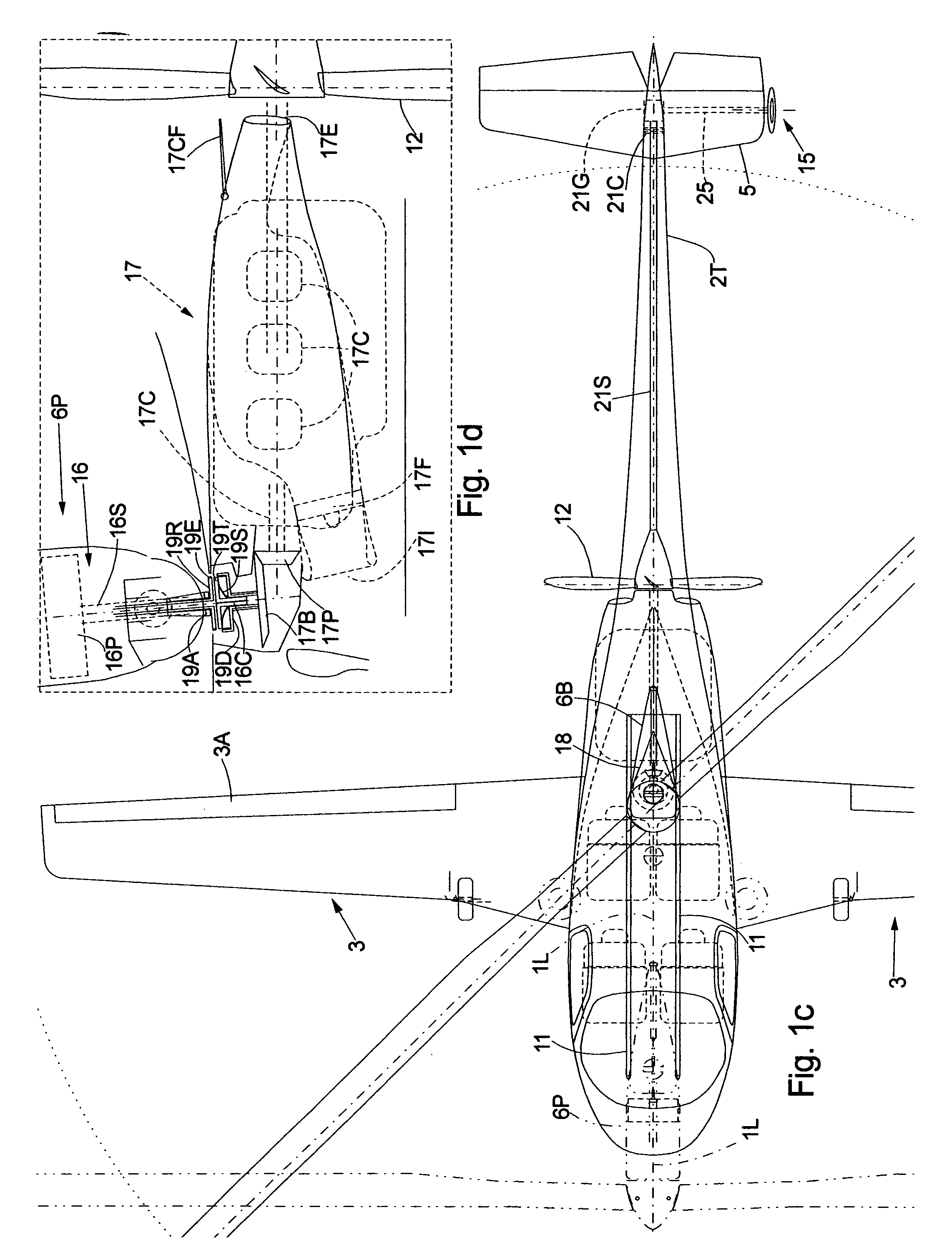

High performance VTOL convertiplanes

InactiveUS20050045762A1High performanceOperate cost competitiveAircraft navigation controlVertical landing/take-off aircraftsPropellerTurbofan

A single-tilt-rotor VTOL airplanes have a tiltable rotor attached to an elongated power pod containing the collective and cyclical pitch mechanism, and transmission. The power pod is pivotably attached to a base that is slidably mounted on a pair of slotted guide beams attached on top of the roof of the fuselage. The guide beams run longitudinally from the front of the aircraft to past the center of gravity (CG) of the aircraft in order to transport the power pod from the front section to the center section when converting from the horizontal cruising mode to the VTOL mode. In the horizontal cruising mode, the power pod perched horizontally on top of the fuselage front section with sufficient clearance for the rotor to rotate in front of the aircraft. Upon transitioning to the VTOL mode, a telescopic actuator is used to pivot the power pod vertically while a cable-winch system is used to move the entire power pod and base assembly rearwardly to stop at the center of gravity of the aircraft, and vice versa, thus allowing the power pod to travel significantly rearward and forward as required for proper balancing of vertical lift as the power pod pivots 90 degrees during transition from VTOL mode to the cruising mode. A single piston engine, or a single or pair of turbofan engines, mounted slightly to the rear of the CG, have drive shafts that can be clutched and mated onto respective receiving shaft from the transmission within the power pod in order to power the tiltable rotor. The engine is also attached to a propeller for horizontal propulsion, or if turbofan engines are used, jet thrust is generated for horizontal cruise. A small anti-torque rotor or ducted fan toward the tail of the aircraft is mechanically coupled to the engine via a drive shaft to provide the necessary side-way thrust to overcome the main rotor's torque. In the horizontal cruising mode, the tiltable rotor is allowed to windmill slowly at a minimum rotational speed necessary to maintain the integrity of the rotor blades. The same propulsion principle can be applied to VTOL airplanes having more than one tiltable rotor, thereby can potentially increase the speed, range and reliability of current twin-wing-mounted-tilt-rotor aircraft. A pair of high-aspect-ratio wings on both sides of the fuselage provide highly efficient lift during cruising flight with very little induced drag. Conventional horizontal and vertical tail planes are used for directional stability in the cruising mode.

Owner:PHAM ROGER N

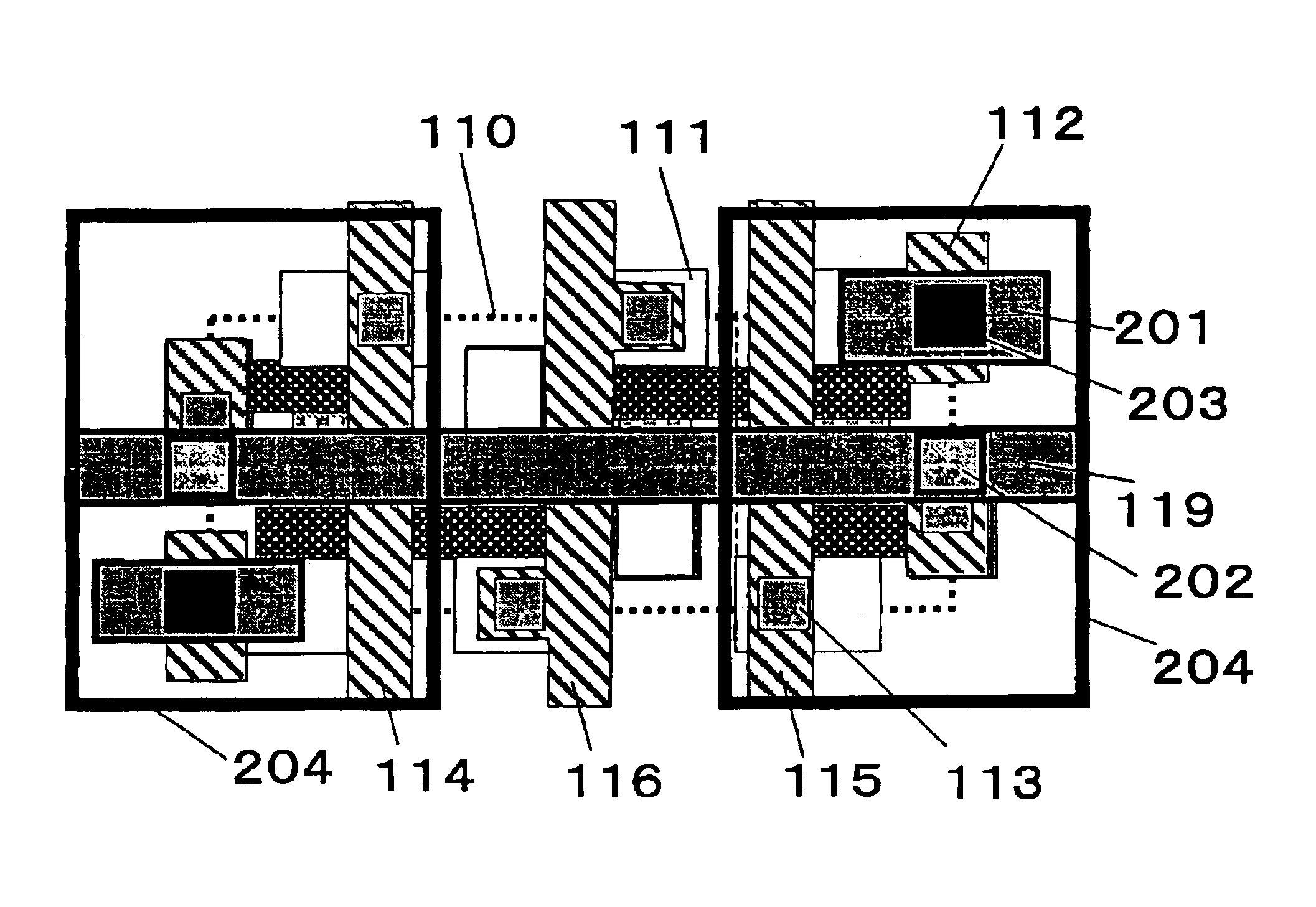

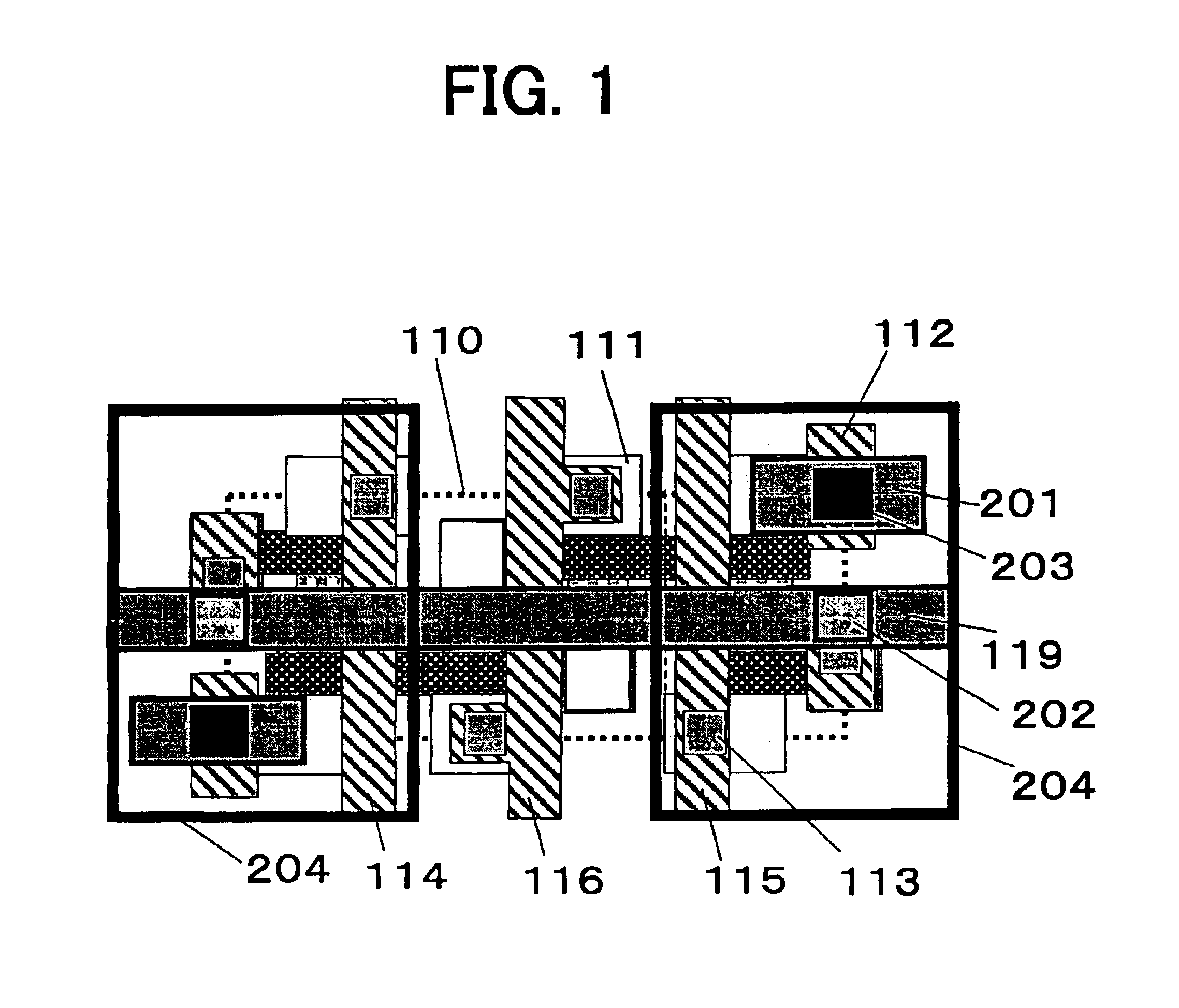

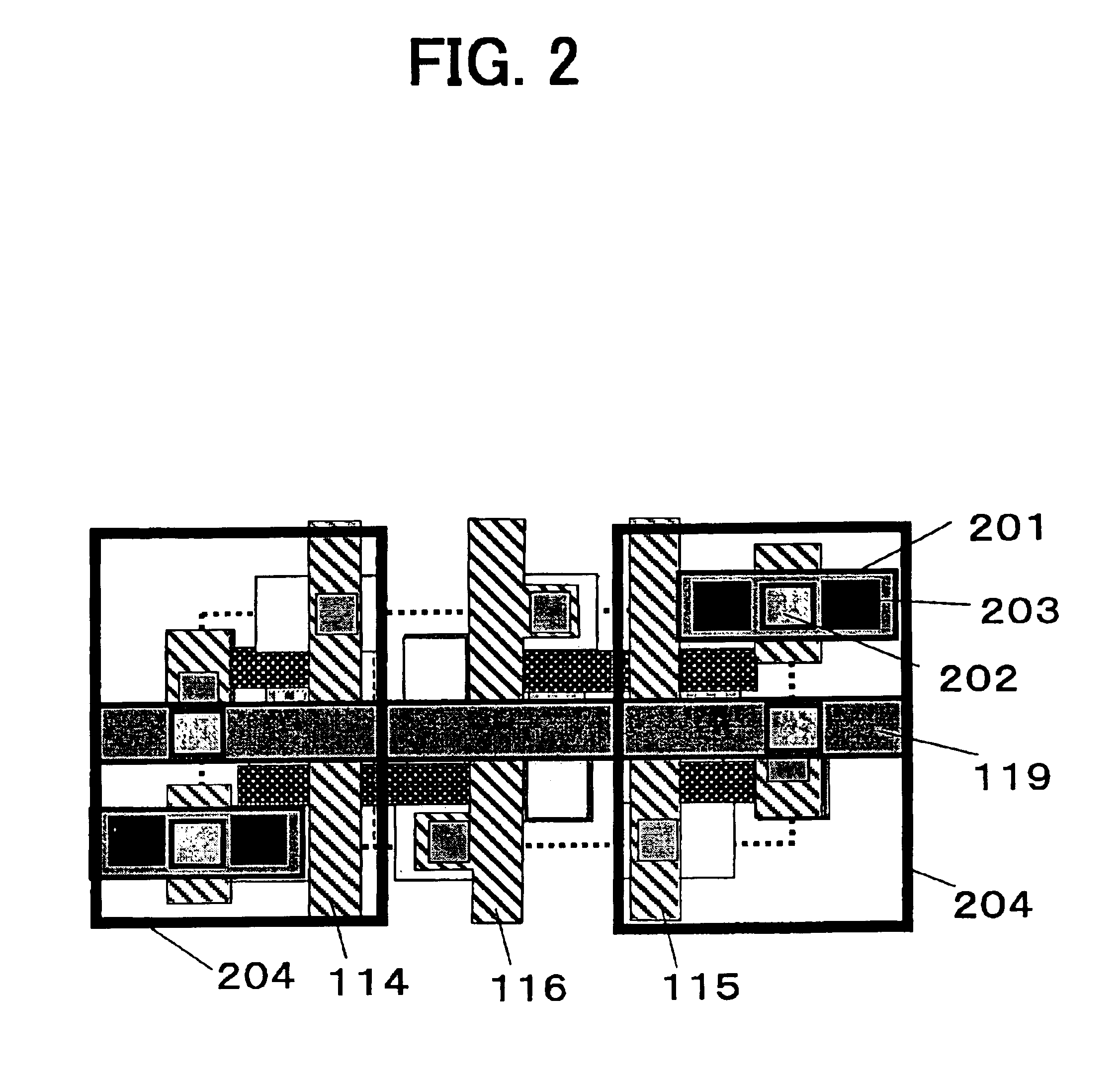

Semiconductor memory device

ActiveUS6922354B2Increase areaHigh performanceTransistorSolid-state devicesEngineeringSemiconductor memory

Positive / negative bit lines are arranged on a second-layer interconnection the VDD power supply interconnection is arranged between the positive / negative bit lines, the word line is arranged on a third-layer interconnection, and the VSS power supply interconnection is arranged on a fourth-layer interconnection. Alternatively, the word line is arranged on the second-layer interconnection, the positive / negative bit lines are arranged on the third-layer interconnection, the VDD power supply interconnection is arranged between the positive / negative bit lines, and the VSS power supply interconnection is arranged on the fourth-layer interconnection. Alternatively, the VDD power supply interconnection is arranged on the second-layer interconnection, the positive / negative bit lines are arranged on the third-layer interconnection, the word line is arranged on the fourth-layer interconnection, and the VSS power supply interconnection is arranged on the fifth-layer interconnection.

Owner:SOCIONEXT INC

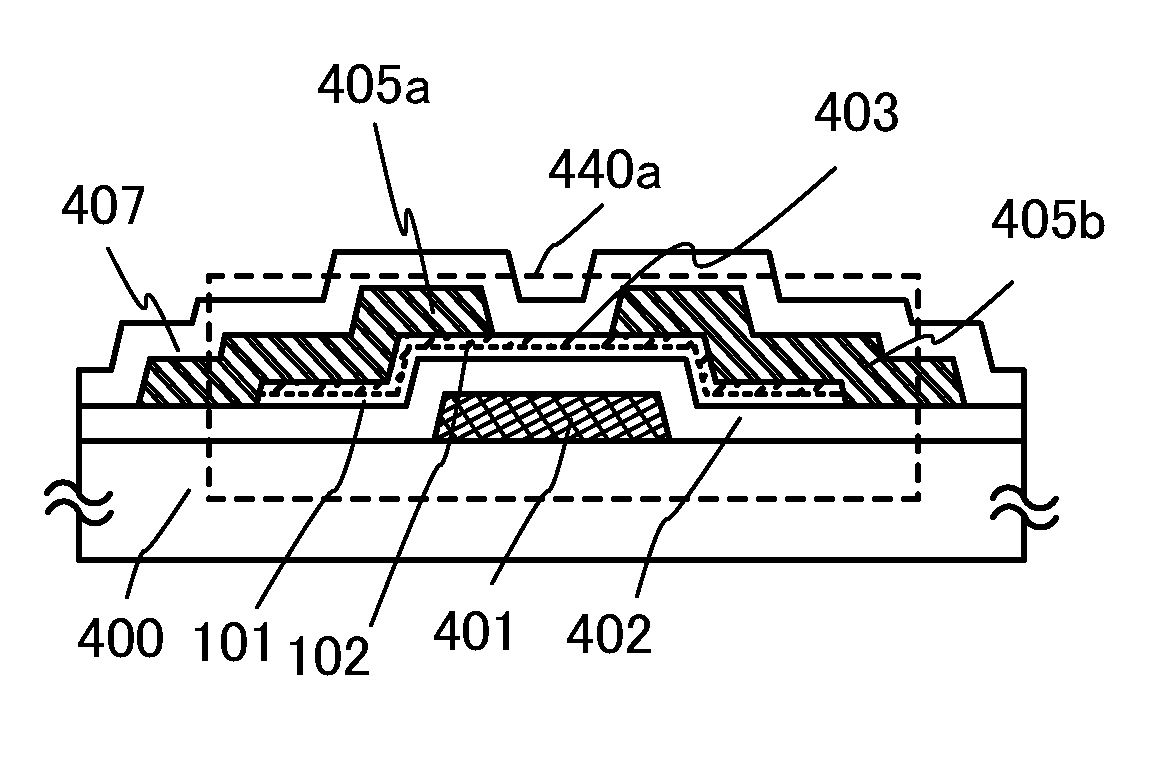

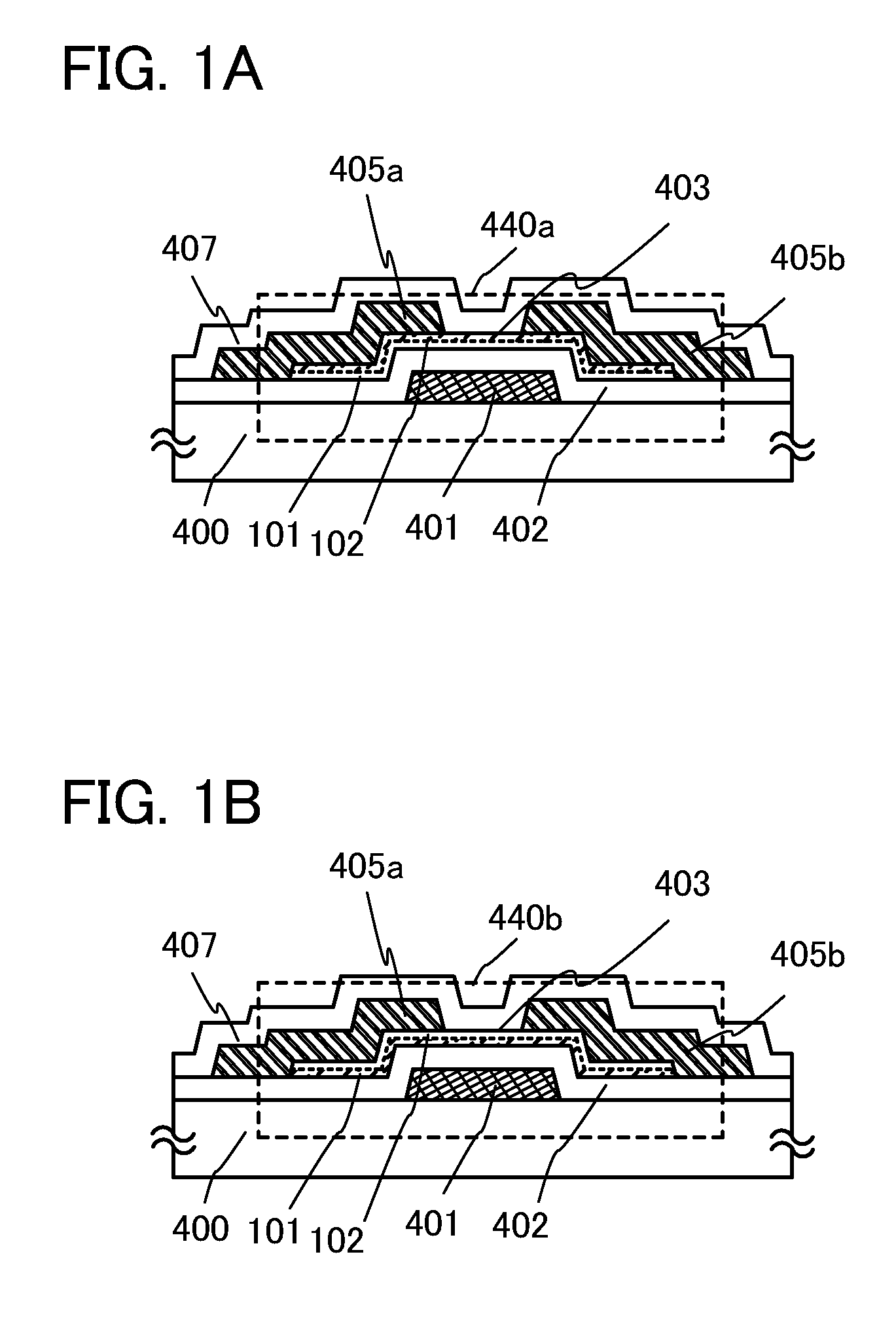

Semiconductor device and manufacturing method thereof

ActiveUS20130009219A1High performanceHigh accuracyTransistorElectroluminescent light sourcesOxide semiconductorBand gap

Provided are a transistor which has electrical characteristics requisite for its purpose and uses an oxide semiconductor layer and a semiconductor device including the transistor. In the bottom-gate transistor in which at least a gate electrode layer, a gate insulating film, and the semiconductor layer are stacked in this order, an oxide semiconductor stacked layer including at least two oxide semiconductor layers whose energy gaps are different from each other is used as the semiconductor layer. Oxygen and / or a dopant may be added to the oxide semiconductor stacked layer.

Owner:SEMICON ENERGY LAB CO LTD

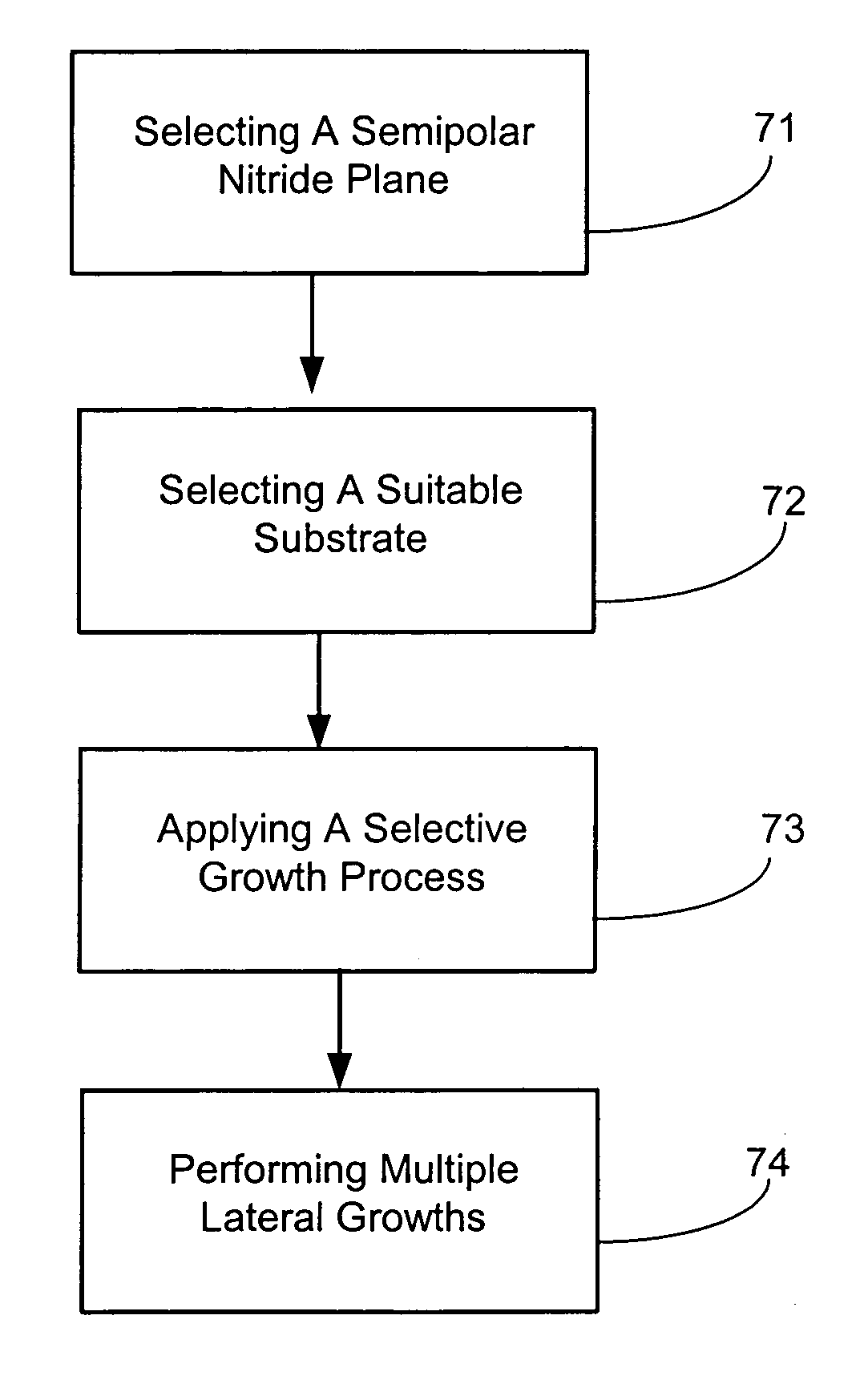

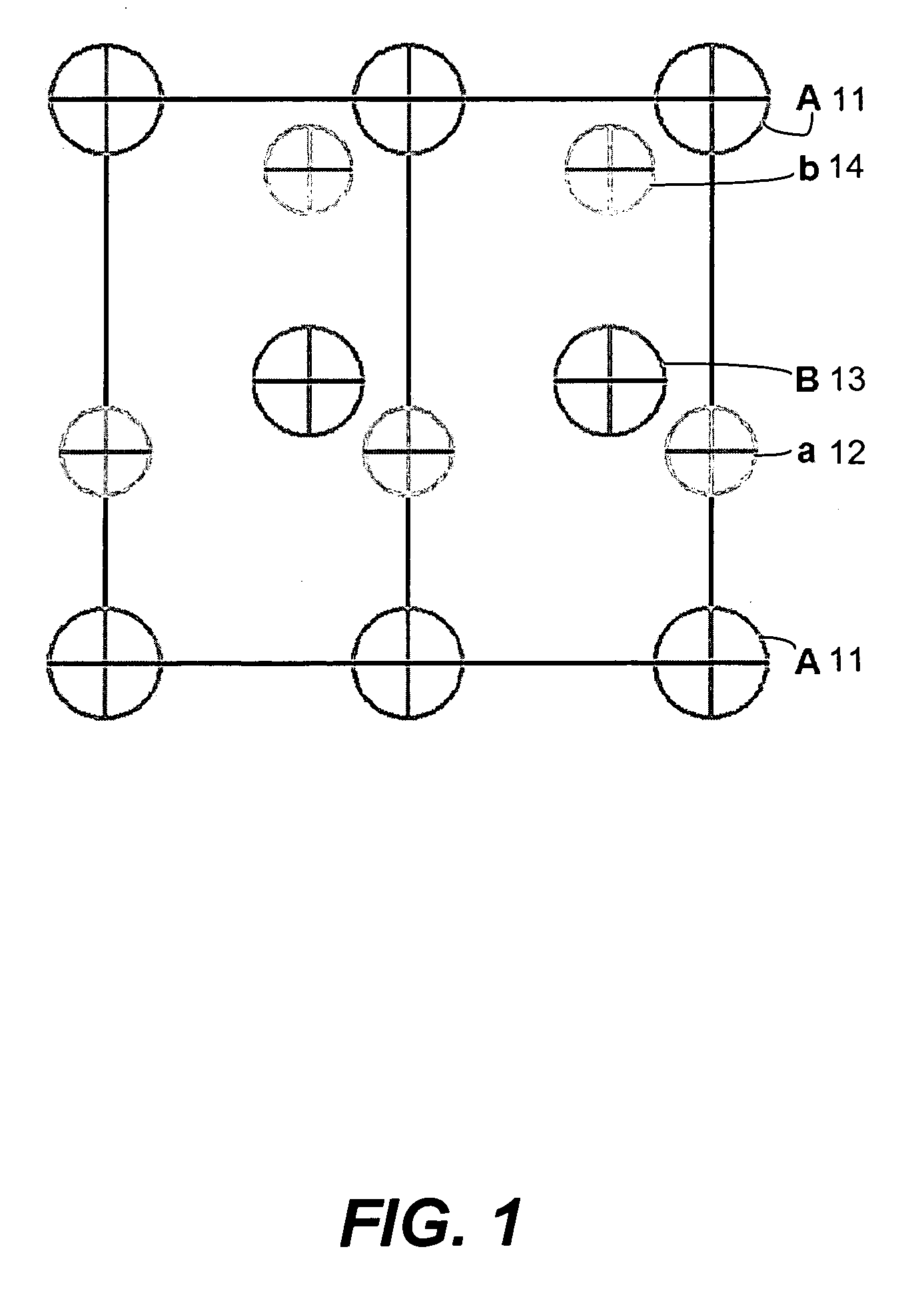

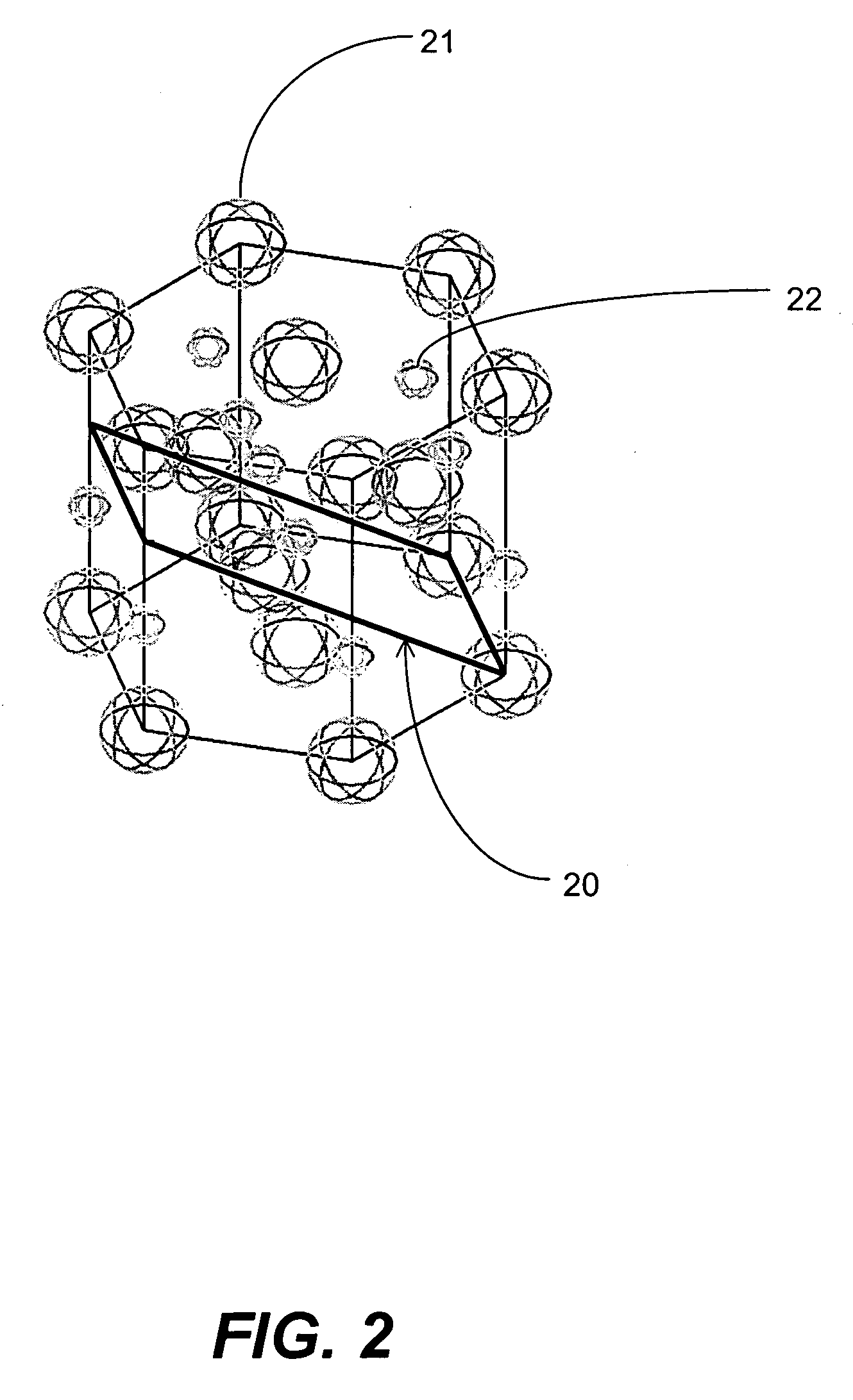

Lateral growth method for defect reduction of semipolar nitride films

ActiveUS20070015345A1Reduce defect densityHigh performancePolycrystalline material growthSemiconductor/solid-state device manufacturingCantileverEpitaxy

A lateral growth method for defect reduction of semipolar nitride films. The process steps include selecting a semipolar nitride plane and composition, selecting a suitable substrate for growth of the semipolar nitride plane and composition, and applying a selective growth process in which the semipolar nitride nucleates on some areas of the substrate at the exclusion of other areas of the substrate, wherein the selective growth process includes lateral growth of nitride material by a lateral epitaxial overgrowth (LEO), sidewall lateral epitaxial overgrowth (SLEO), cantilever epitaxy or nanomasking.

Owner:JAPAN SCI & TECH CORP

Electrode coated with a film obtained from an aqueous solution comprising a water-soluble binder, production method thereof and uses of same

ActiveUS20060166093A1High performanceProblem be overcomeElectrode thermal treatmentConductive materialWater solubleAqueous solution

The invention relates to a method of preparing an electrochemical electrode which is partially or totally covered with a film that is obtained by spreading an aqueous solution comprising a water-soluble binder over the electrode and subsequently drying same. The production cost of the electrodes thus obtained is reduced and the surface porosity thereof is associated with desirable resistance values.

Owner:HYDRO QUEBEC CORP

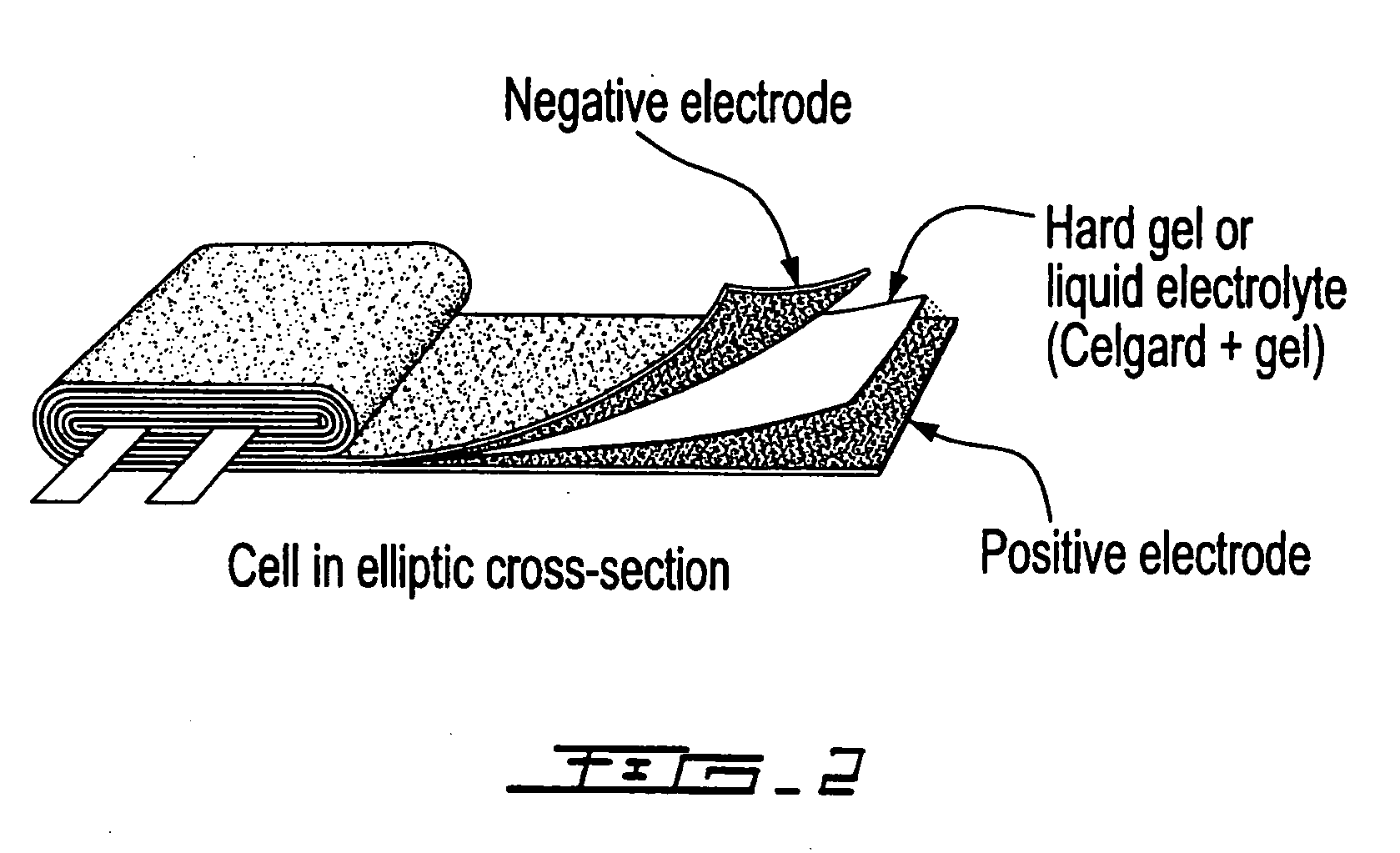

Distributed network security system and a hardware processor therefor

ActiveUS7415723B2High line rateHigh performanceData switching by path configurationMultiple digital computer combinationsNetwork security policyPacket processing

An architecture provides capabilities to transport and process Internet Protocol (IP) packets from Layer 2 through transport protocol layer and may also provide packet inspection through Layer 7. A set of engines may perform pass-through packet classification, policy processing and / or security processing enabling packet streaming through the architecture at nearly the full line rate. A scheduler schedules packets to packet processors for processing. An internal memory or local session database cache stores a session information database for a certain number of active sessions. The session information that is not in the internal memory is stored and retrieved to / from an additional memory. An application running on an initiator or target can in certain instantiations register a region of memory, which is made available to its peer(s) for access directly without substantial host intervention through RDMA data transfer. A security system is also disclosed that enables a new way of implementing security capabilities inside enterprise networks in a distributed manner using a protocol processing hardware with appropriate security features.

Owner:BLUE LOBSTER SERIES 110 OF ALLIED SECURITY TRUST I

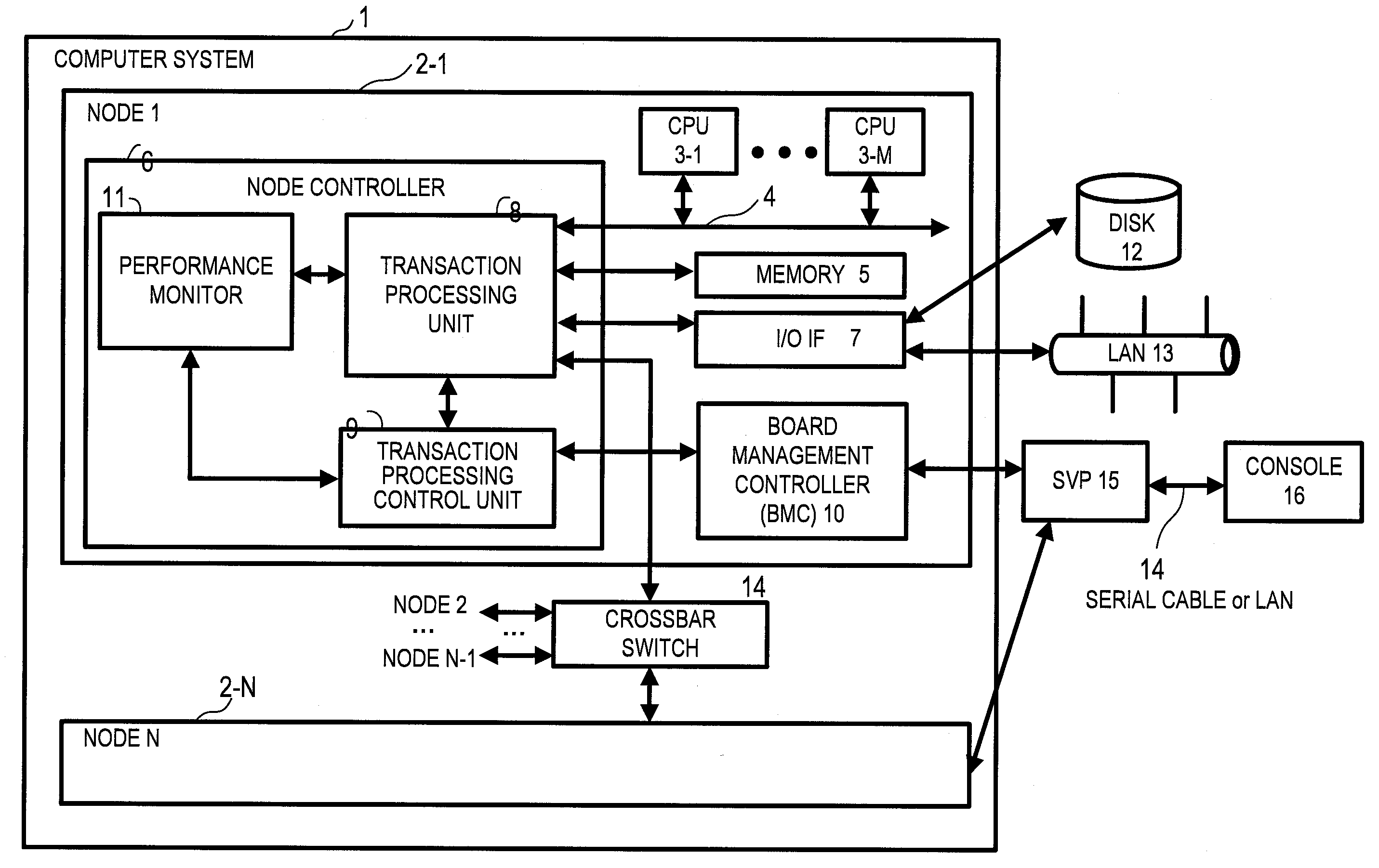

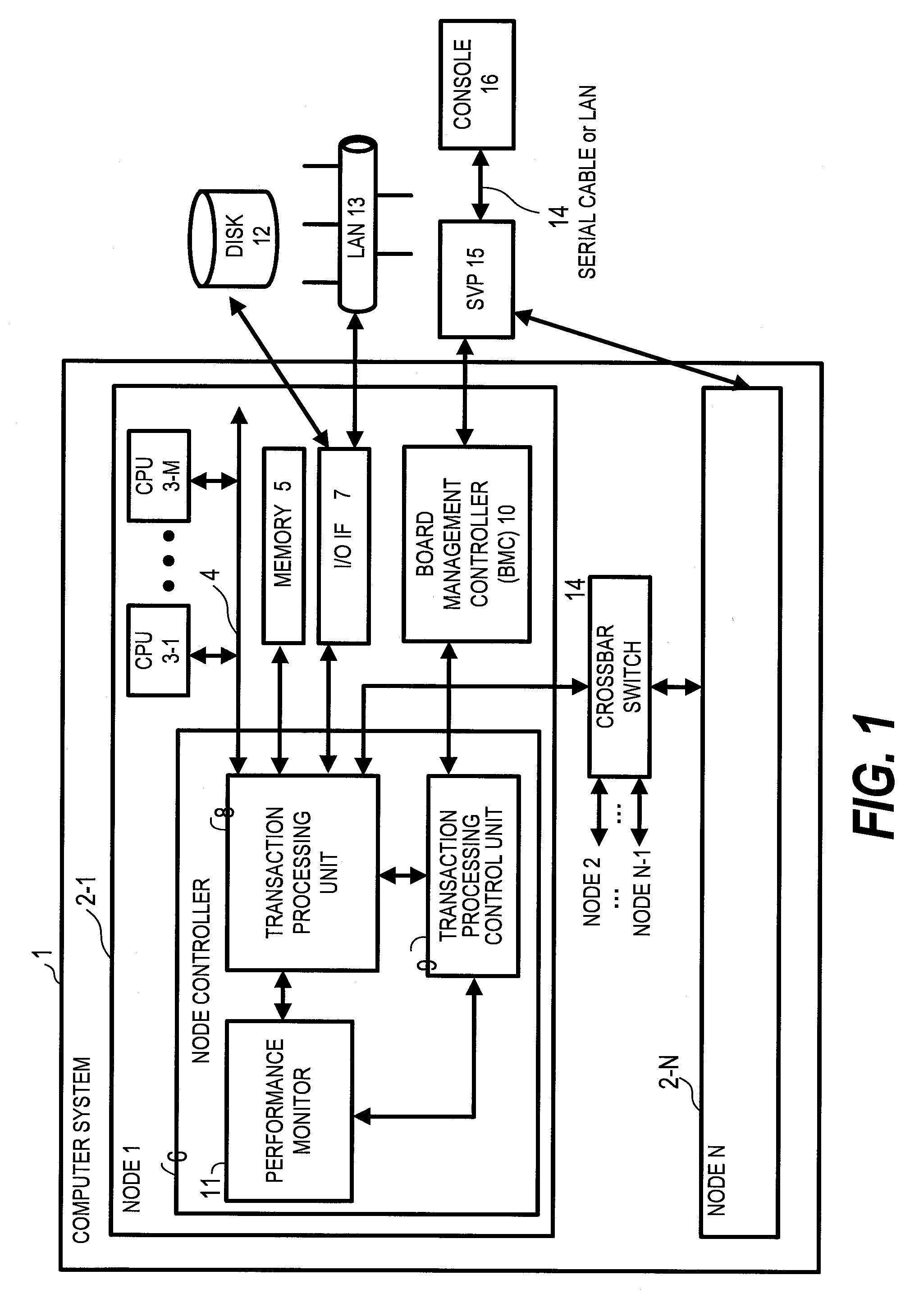

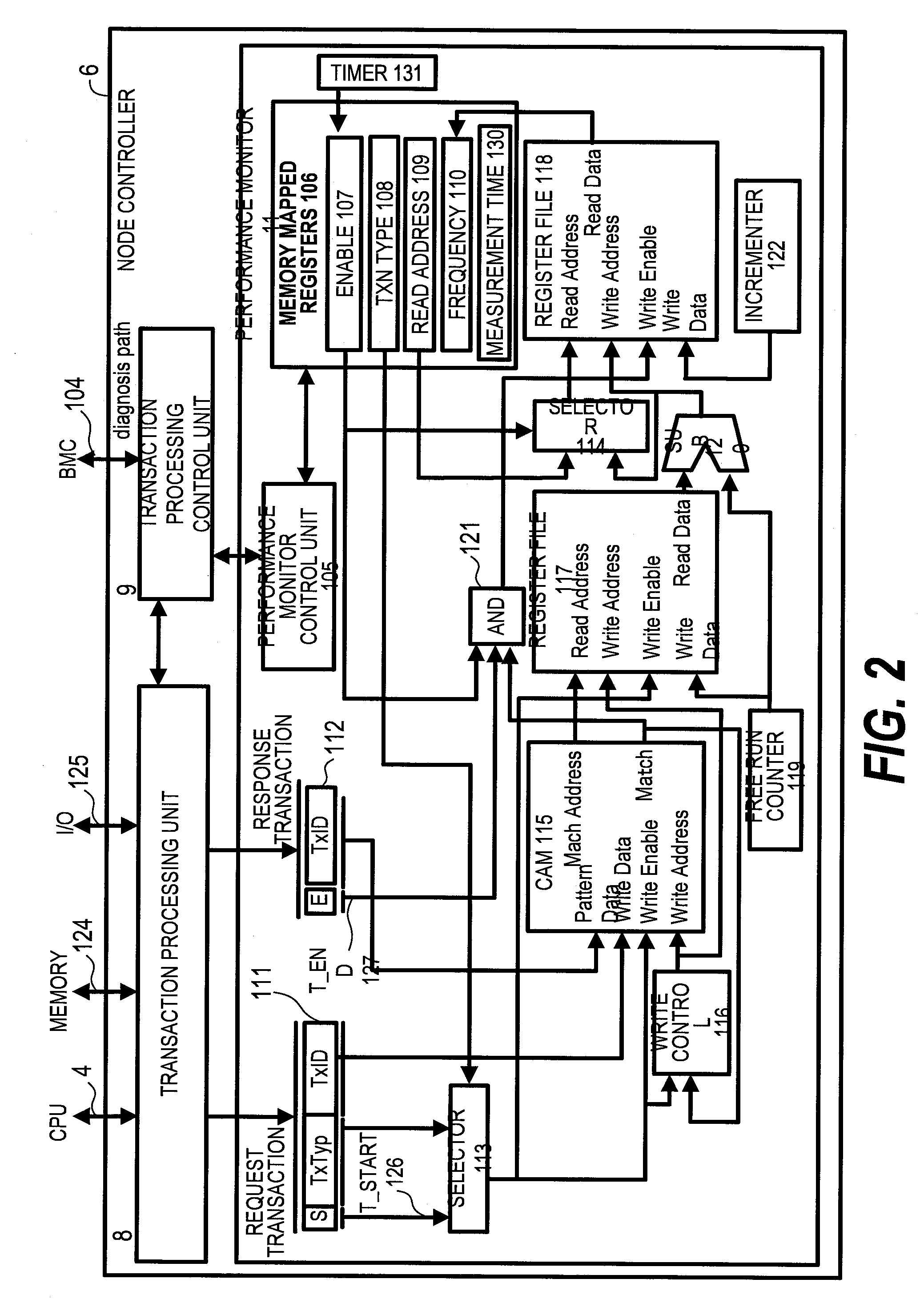

System and method for performance monitoring and reconfiguring computer system with hardware monitor

InactiveUS20080071939A1Improve performanceHigh performanceError detection/correctionMultiprogramming arrangementsFrequency countChipset

A judgment is made quickly about whether or not it is a memory or a chipset that is causing a performance bottleneck in an application program. A computer system of this invention includes at least one CPU, a controller that connects the CPU to a memory and to an I / O interface, in which the controller includes a response time measuring unit, which receives a request to access the memory and measures a response time taken to respond to the memory access request, a frequency counting unit, which measures an issue count of the memory access request, a measurement result storing unit, which stores a measurement result associating the response time with the corresponding issue count, and a measurement result control unit which outputs the measurement result stored in the measurement result storing unit when receiving a measurement result read request.

Owner:HITACHI LTD

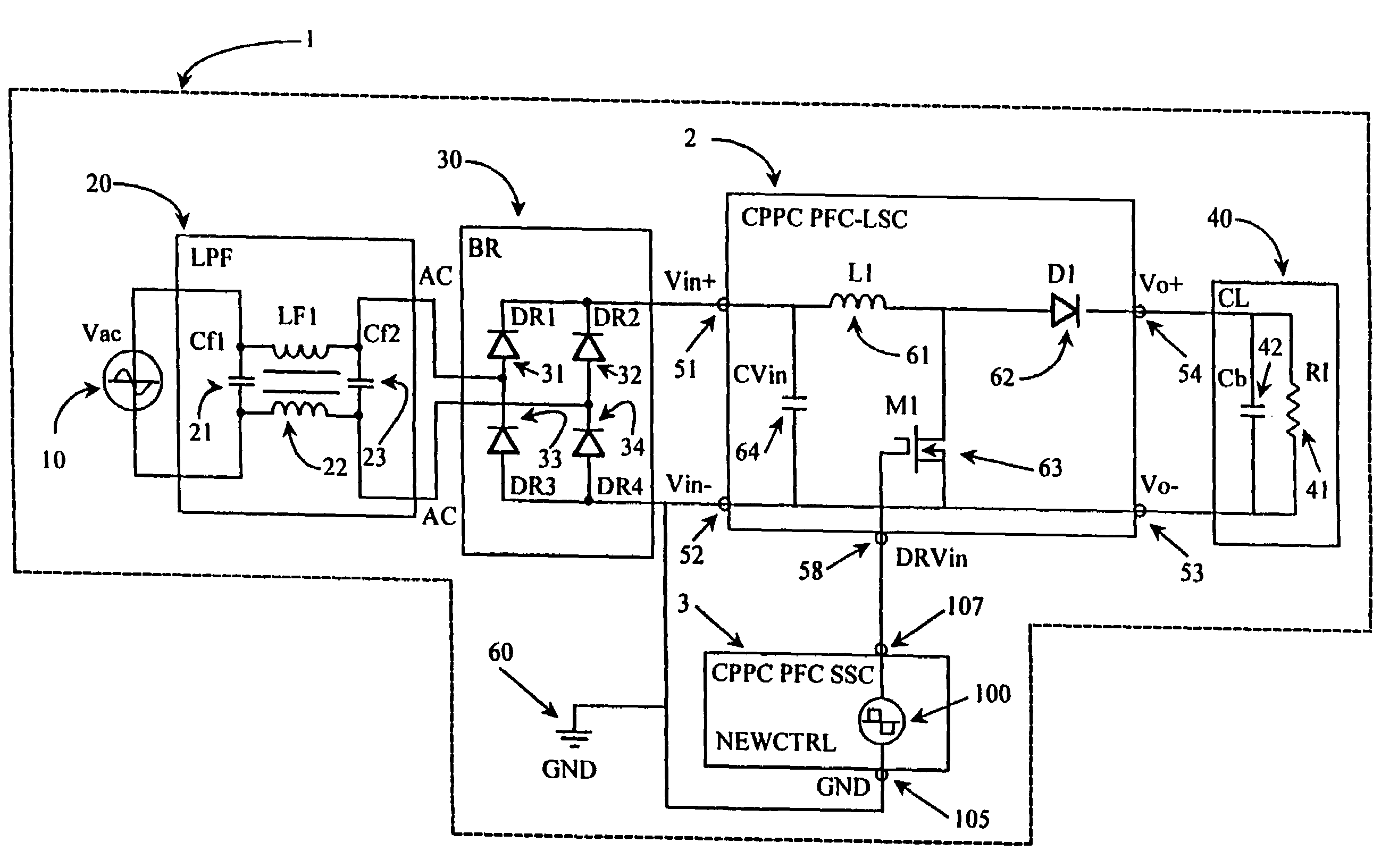

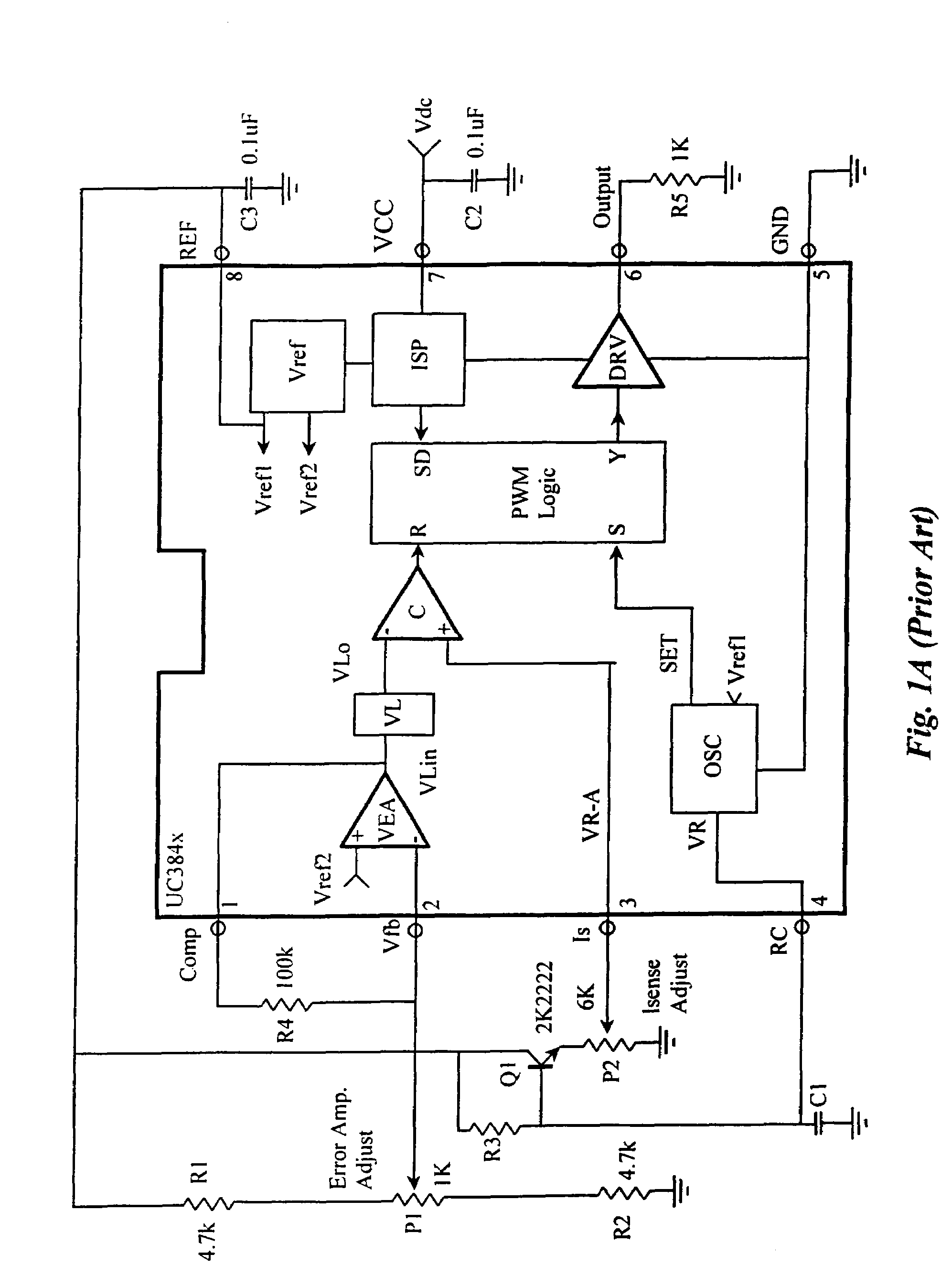

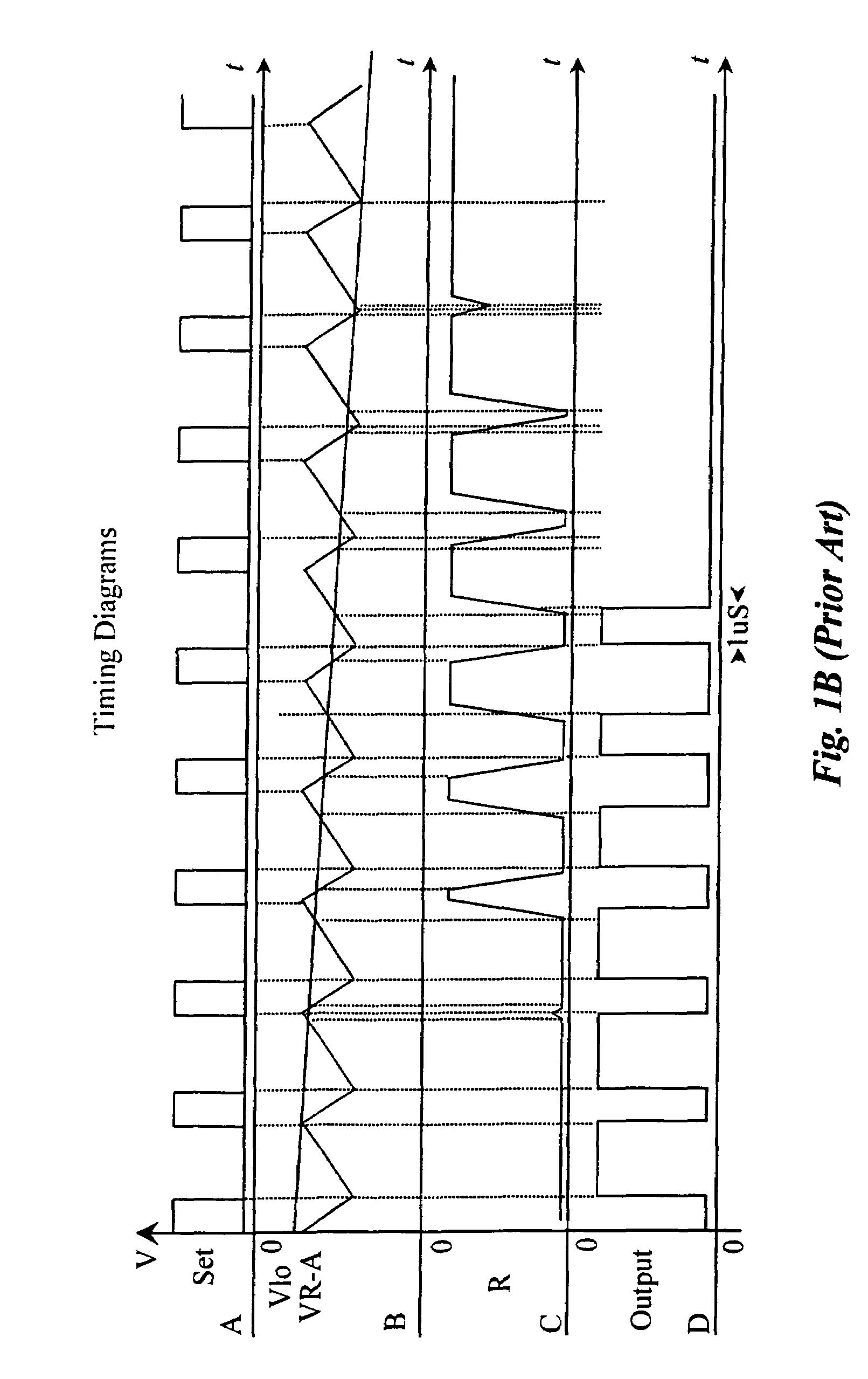

Method and system for power factor correction using constant pulse proportional current

InactiveUS7391630B2High performanceReduce problemAc-dc conversion without reversalEfficient power electronics conversionPower factor correctorPwm controller

A Power Factor Correction (PFC) system providing near unity power factor for an AC power source (VAC) connected to a complex load. The system includes a bridge rectifier, boost or buck-boost converter, complex load, and pulse width modulation (PWM) controller to provide pulses with variable duty cycle to a power switch. The invention is a constant pulse proportional current (CPPC) PWM controller that generates trains of pulses constant in frequency and duty cycle for one semi-cycle of the VAC. The duty cycle of the driving signal is modified by applying open-loop correction signals to summing nodes of PWM circuits. Since the PWM provides a constant train of driving pulses with constant duty cycle for one semi-cycle of the VAC, the current absorbed by the converter is contingent and linearly proportional to the voltage. Thus, the output current follows the voltage resulting in a power factor of near unity.

Owner:PF1

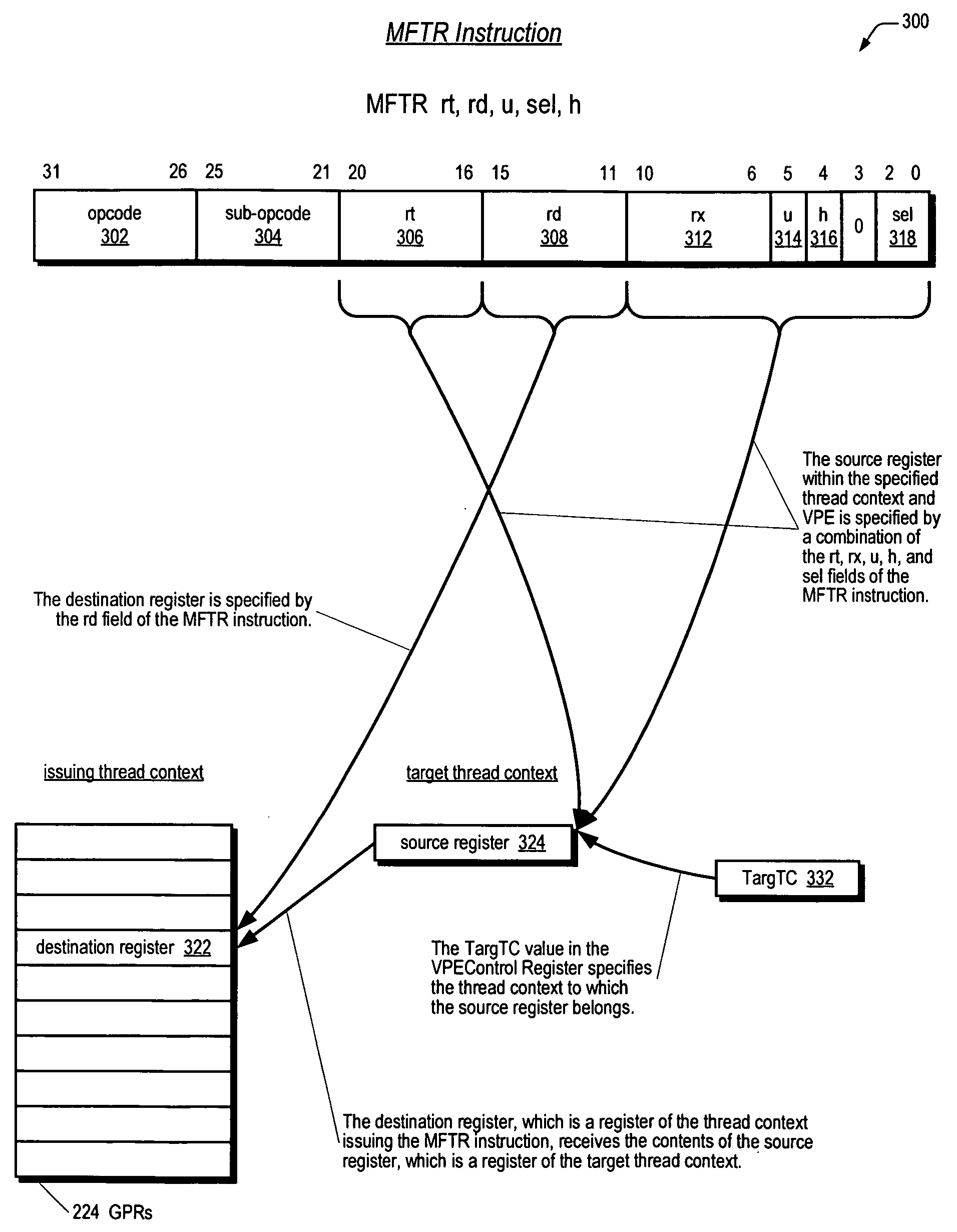

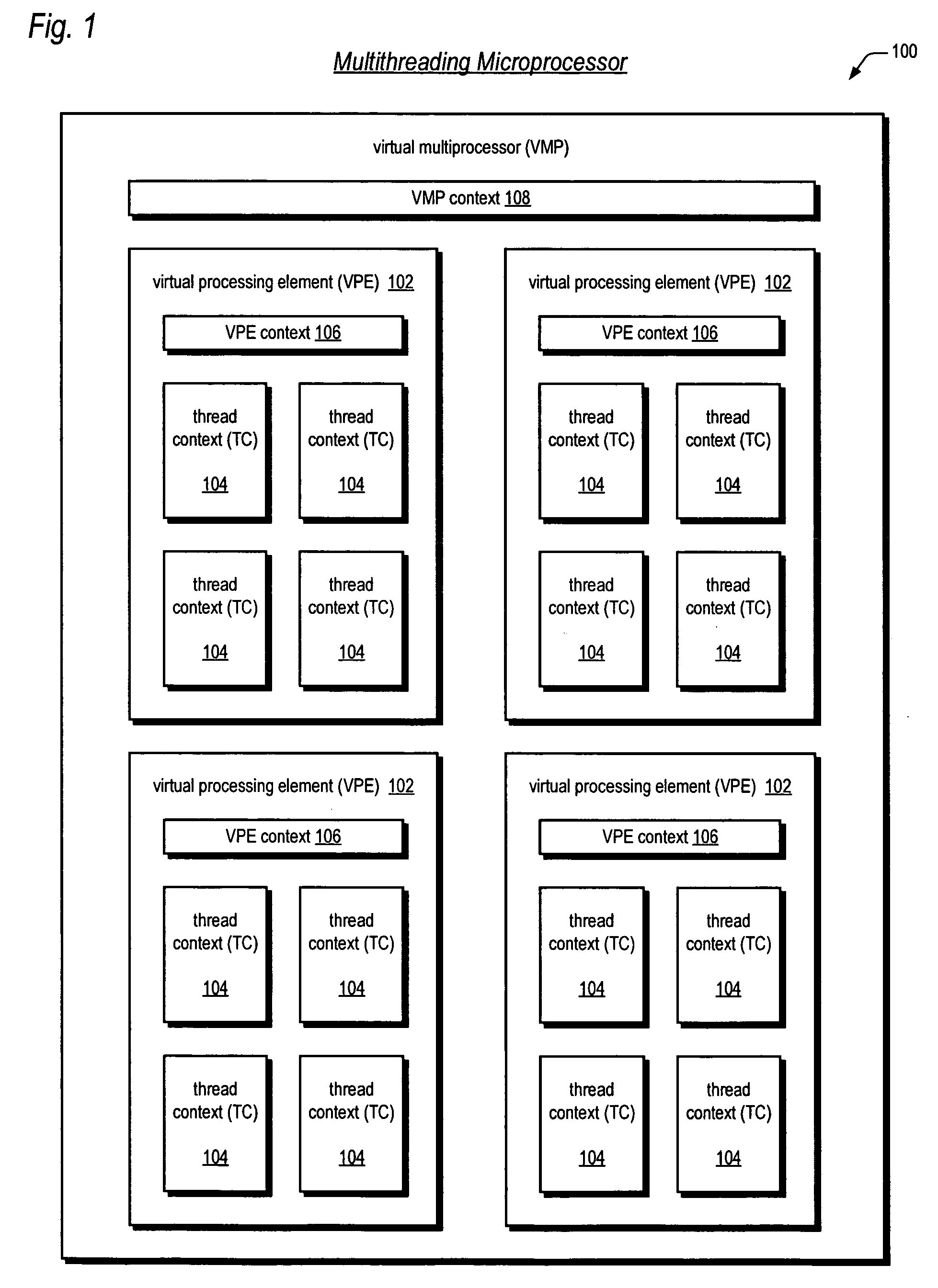

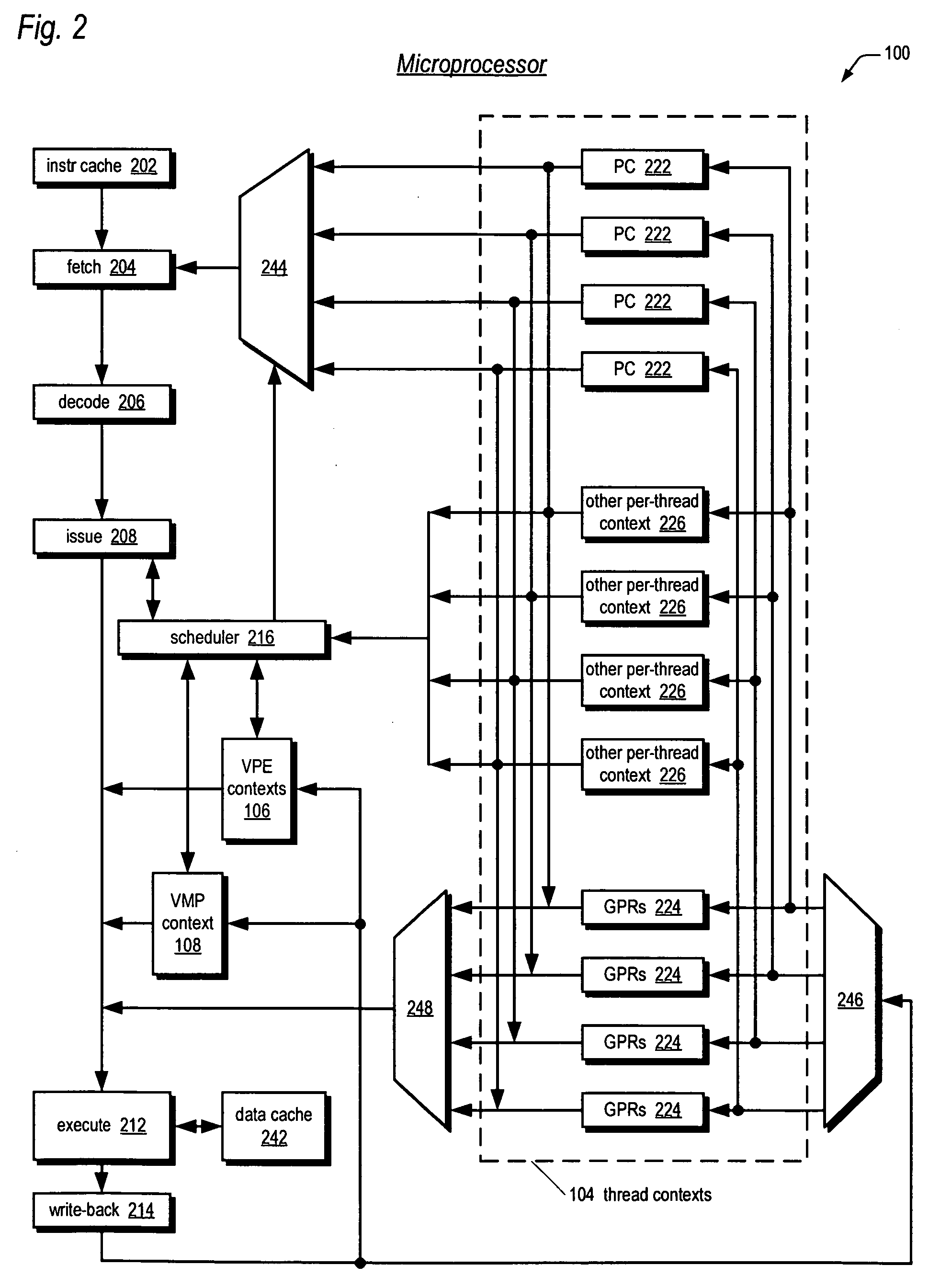

Preemptive multitasking employing software emulation of directed exceptions in a multithreading processor

ActiveUS20060161921A1Save chip area and powerHigh performanceSoftware engineeringRuntime instruction translationNon specificTimer

A multiprocessor computer system includes an exception domain having multiple thread contexts (TCs) each having a restart address register, and a timer that generates a periodic interrupt request to the exception domain. The exception domain selects an eligible TC to service the interrupt request, which is non-specific regarding which TC to select. A first interrupt handler executes on the selected TC to service the interrupt request to schedule a set of processes assigned by the SMP OS for execution on the selected TC, and write an address of a second interrupt handler to the restart address register of each TC other than the selected TC. The second interrupt handler schedules a plurality of sets of processes assigned by the SMP OS for execution on respective ones of the TCs other than the selected TC.

Owner:MIPS TECH INC

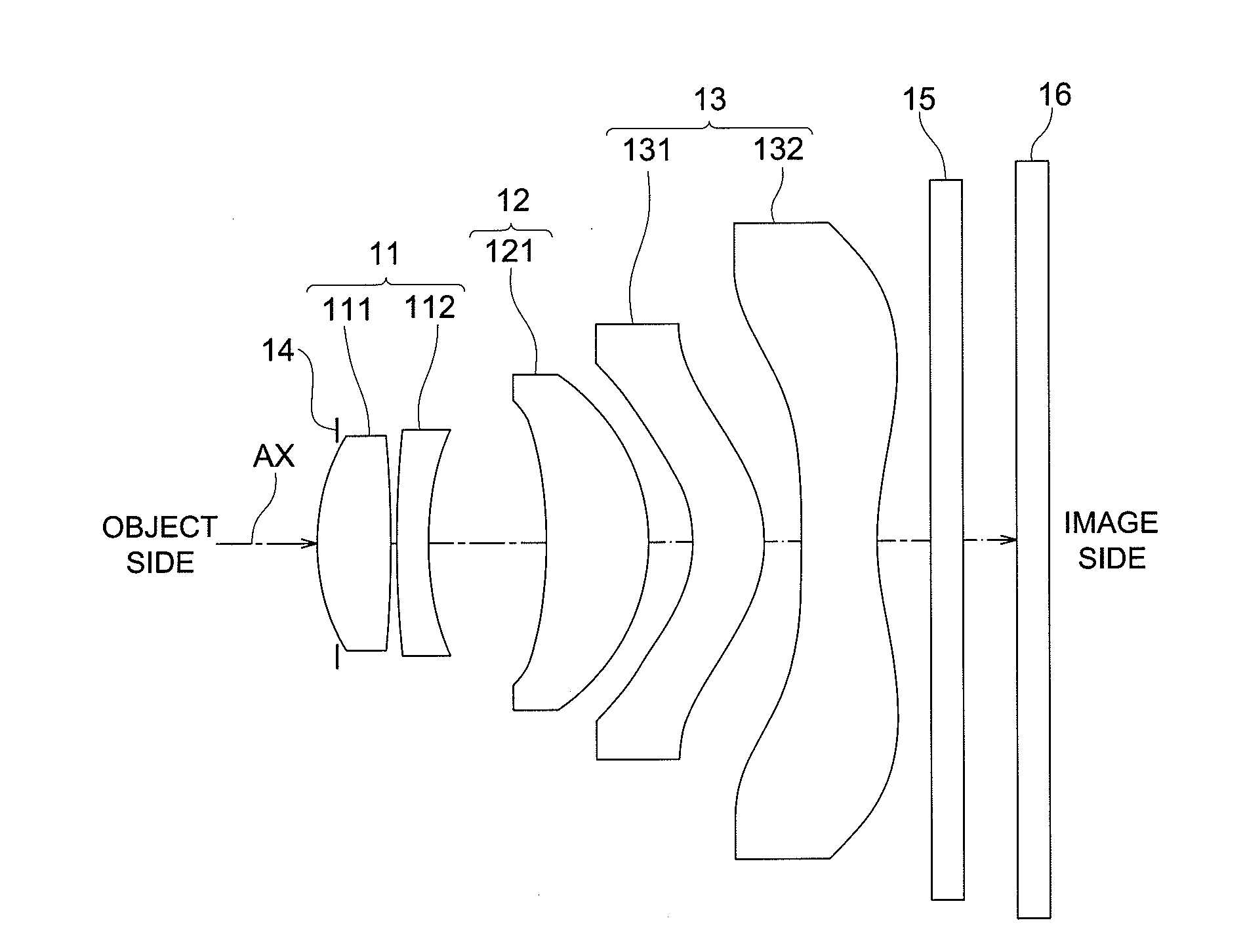

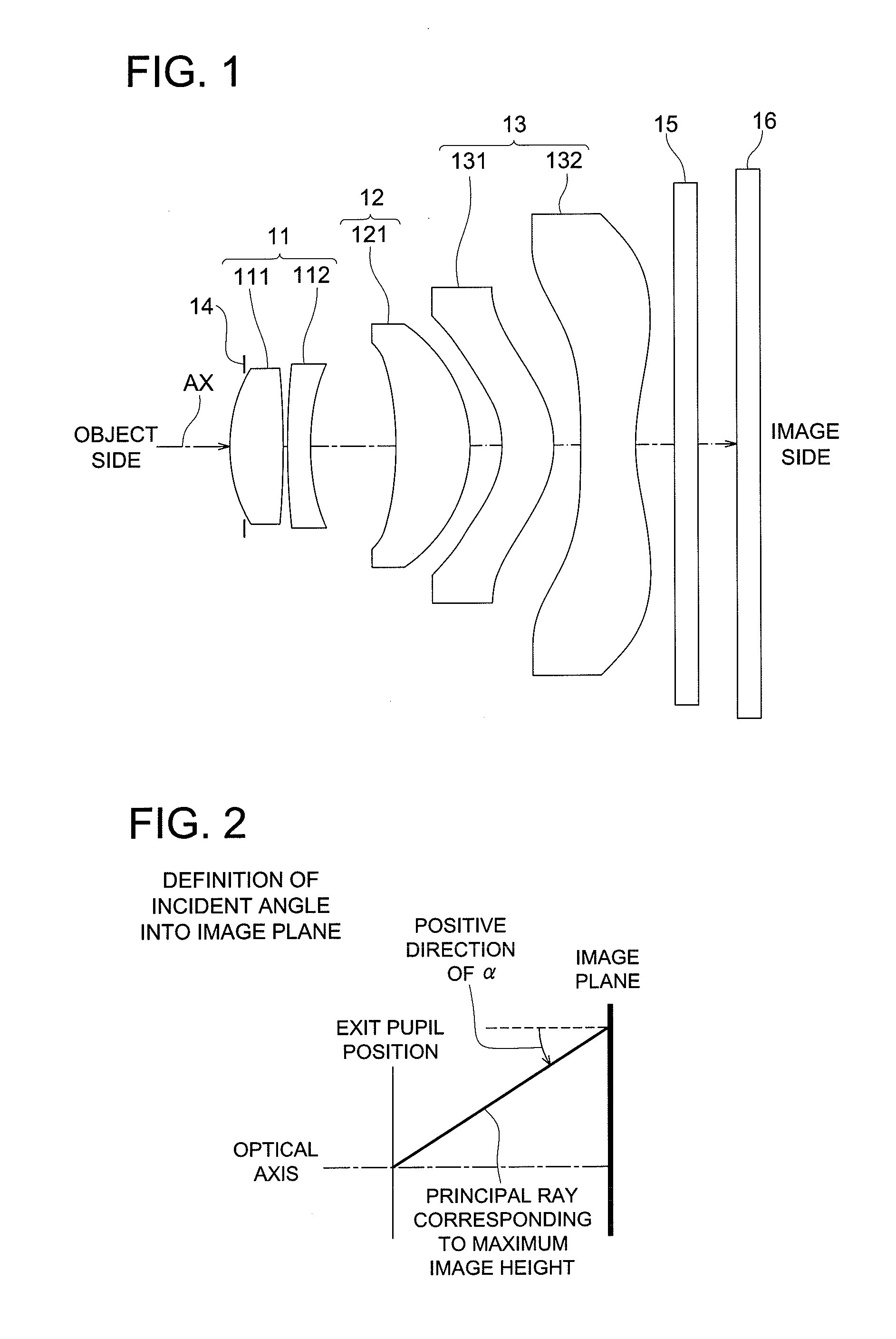

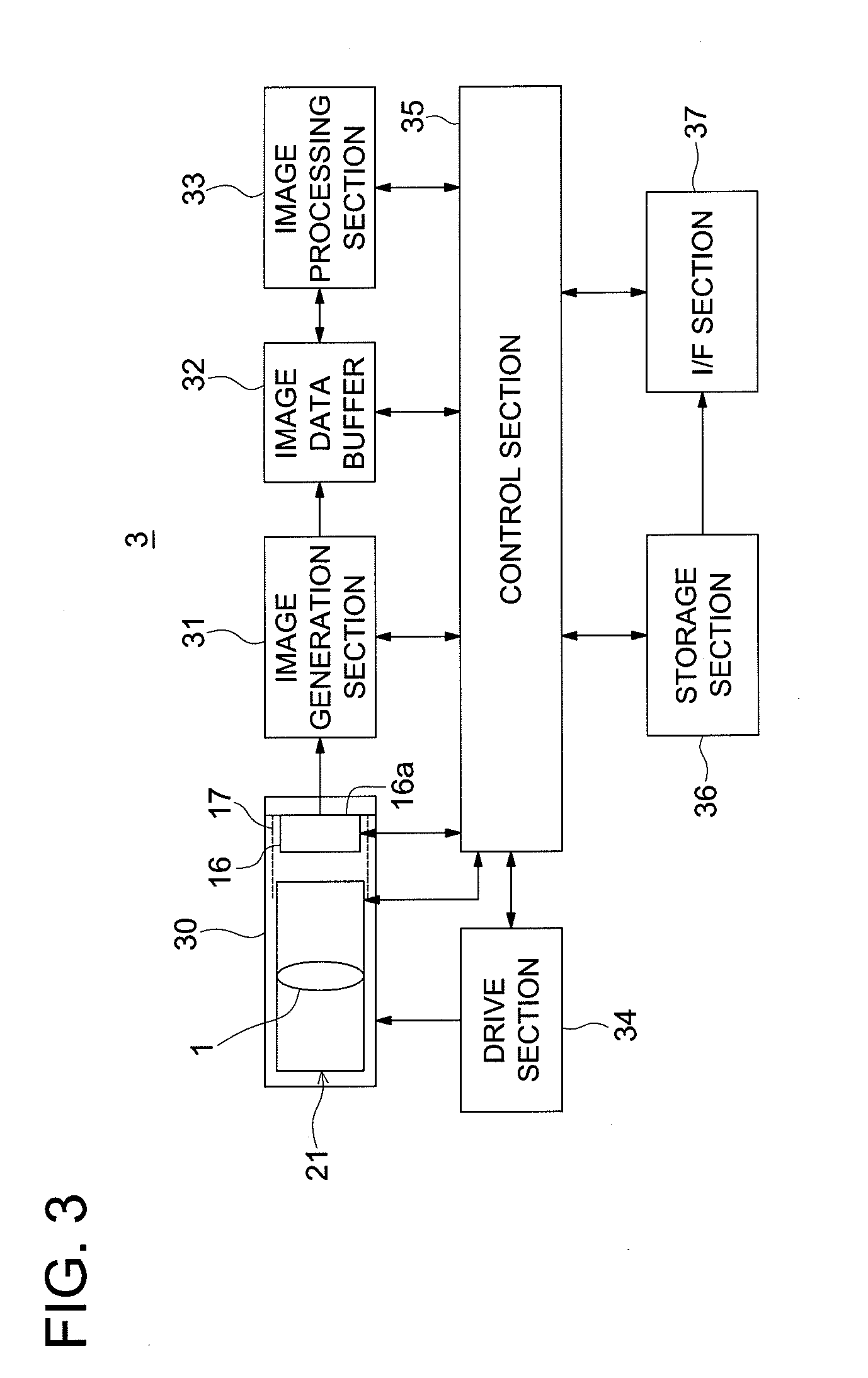

Single-Focus Optical System, Image Pickup Device, and Digital Apparatus

ActiveUS20110273611A1High performanceSmall performanceTelevision system detailsColor television detailsOptical powerPhysics

Provided is a single-focus optical system which is configured, in order from the object side to the image side, of a first to third lens groups and in which the first lens group and the third lens group are fixed with respect to a predetermined imaging surface, and the second lens group is moved in the optical axis direction to focus, wherein the first lens group comprises at least one positive lens and at least one negative lens, the second lens group comprises at least one positive lens, the third lens group comprises at least one lens having at least one aspheric surface and having a positive optical power at a peripheral portion thereof, and 5<|Δv1|<70 is satisfied where Δv1 is a maximum value of the Abbe number difference between the positive lens and the negative lens in the first lens group.

Owner:KONICA MINOLTA OPTO

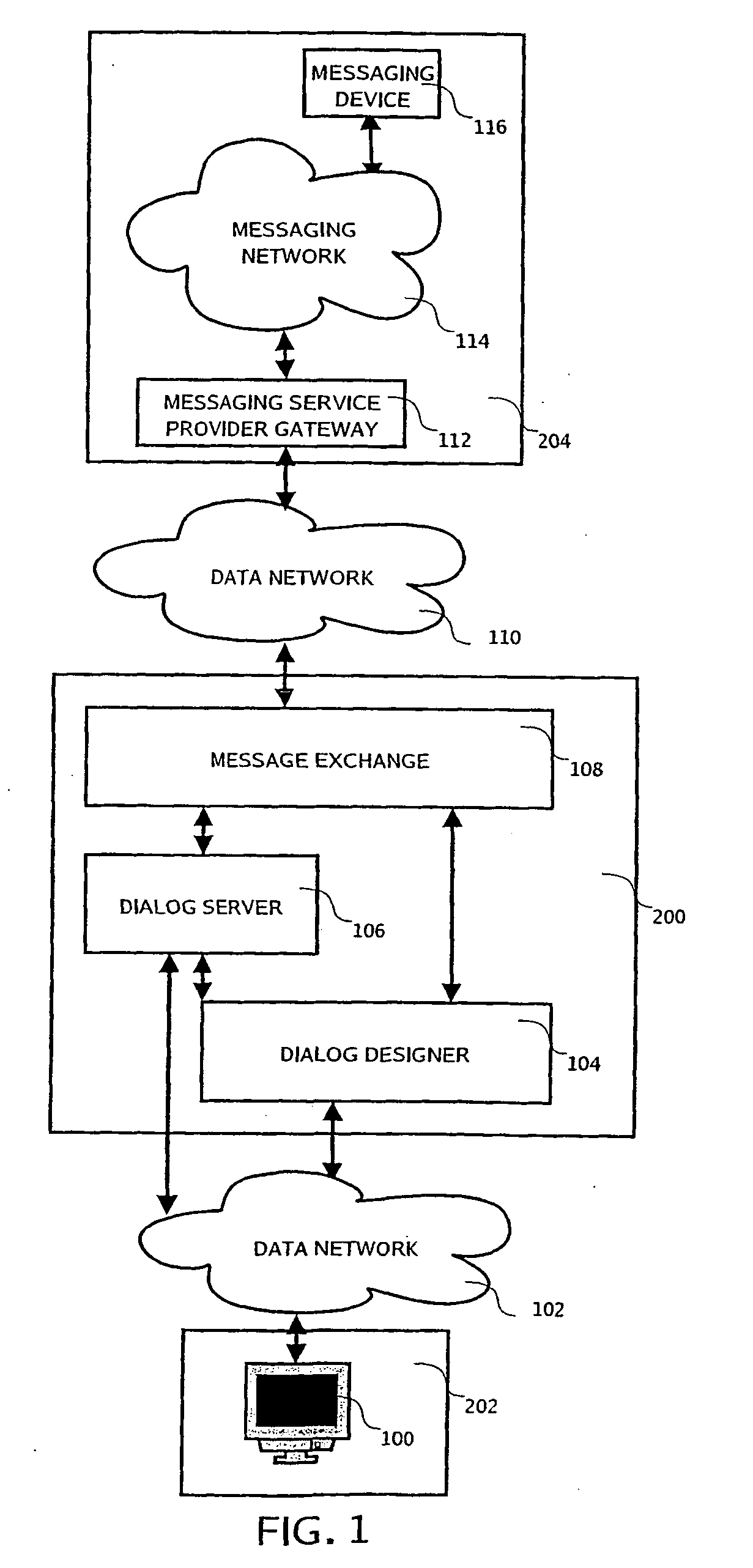

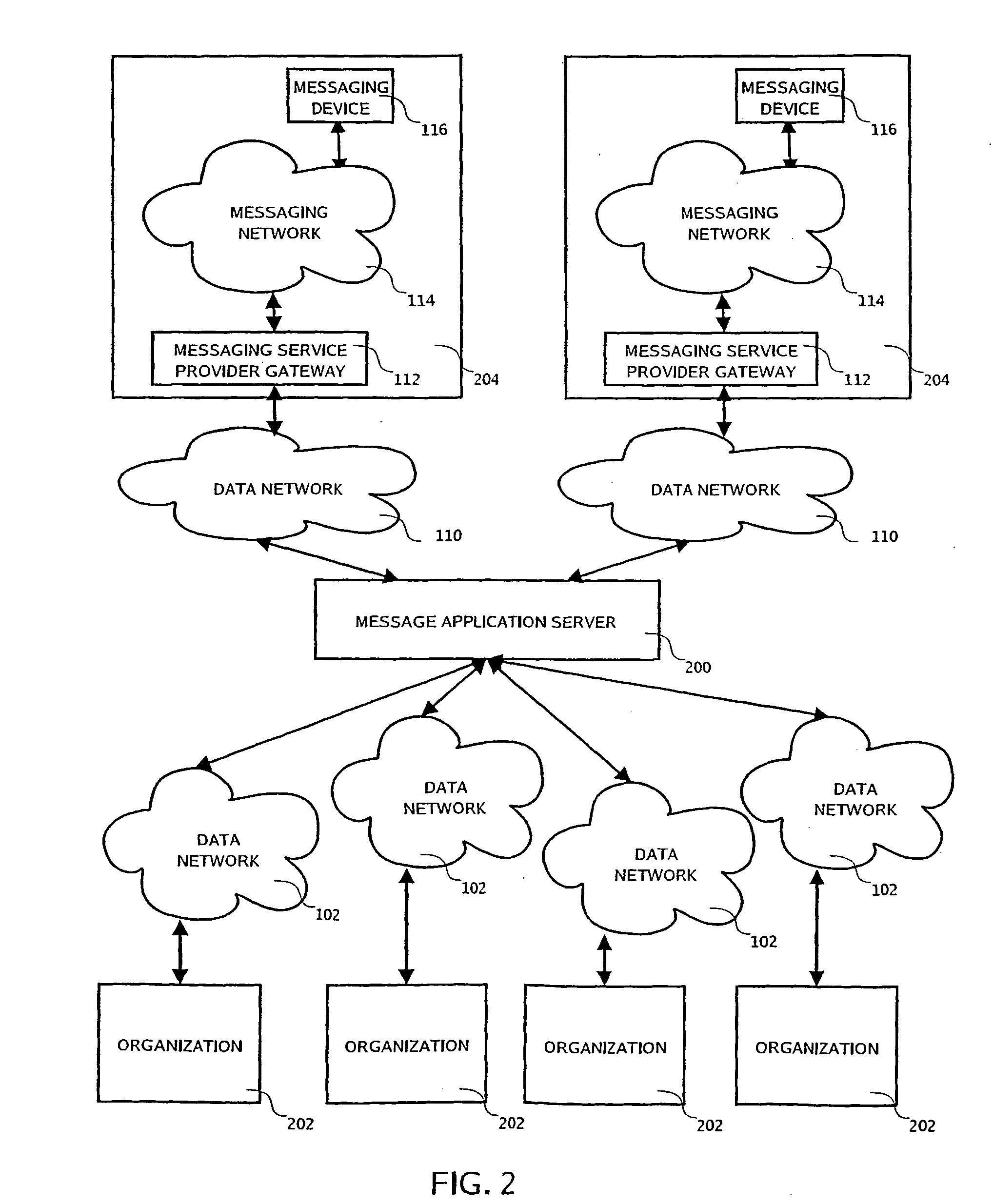

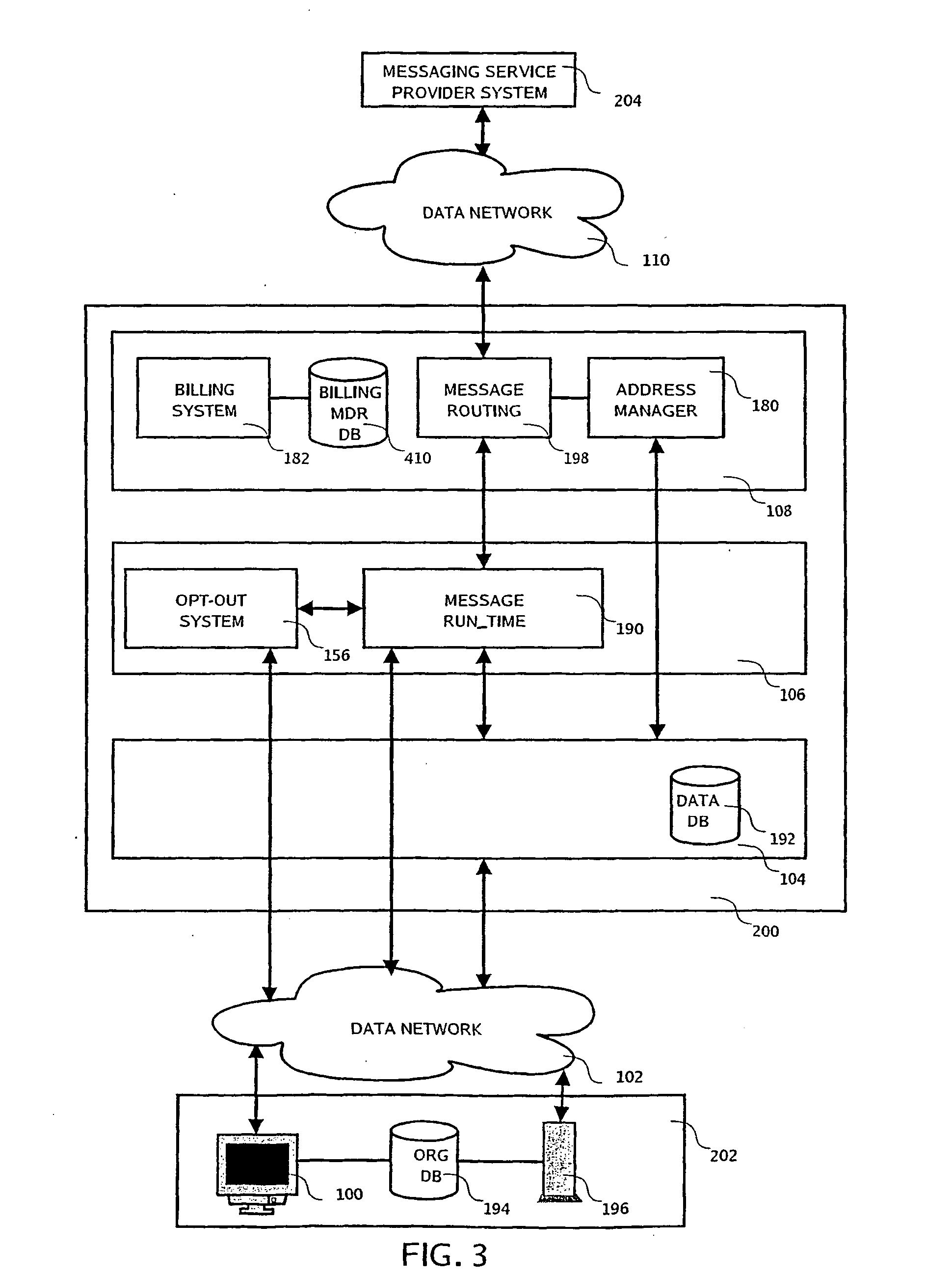

Integrated interactive messaging system and method

ActiveUS20050209861A1Strong business benefitHigh performanceSpecial service provision for substationDigital computer detailsMessage passingProgram instruction

There is provided herein a system and method for organizations to develop, test, execute and analyze messaging programs defining a message application server comprising: (a) a dialog designer configured to provide a user interface to organization's program designers and marketers, to allow for rapid program creation, to offer the ability to select the type of a program, to select the service addresses for a program, to schedule programs for execution, to upload messaging user data into lists, to create to segments, to download program result data, to test programs, to provide reports, including real-time reports, on messaging programs; (b) a dialog server configured to execute messaging programs by means of program instructions, to manage simultaneous programs, to store messaging user results and message delivery status, to maintain state and session context across message invocations for messaging users within an messaging program; (c) a message exchange configured to route messages to and from messaging service providers, to manage service addresses, to perform message billing and connected to messaging service providers; whereby organizations can execute messaging programs with messaging users by means of said messaging service providers.

Owner:FIRST AGGREGATOR LLC

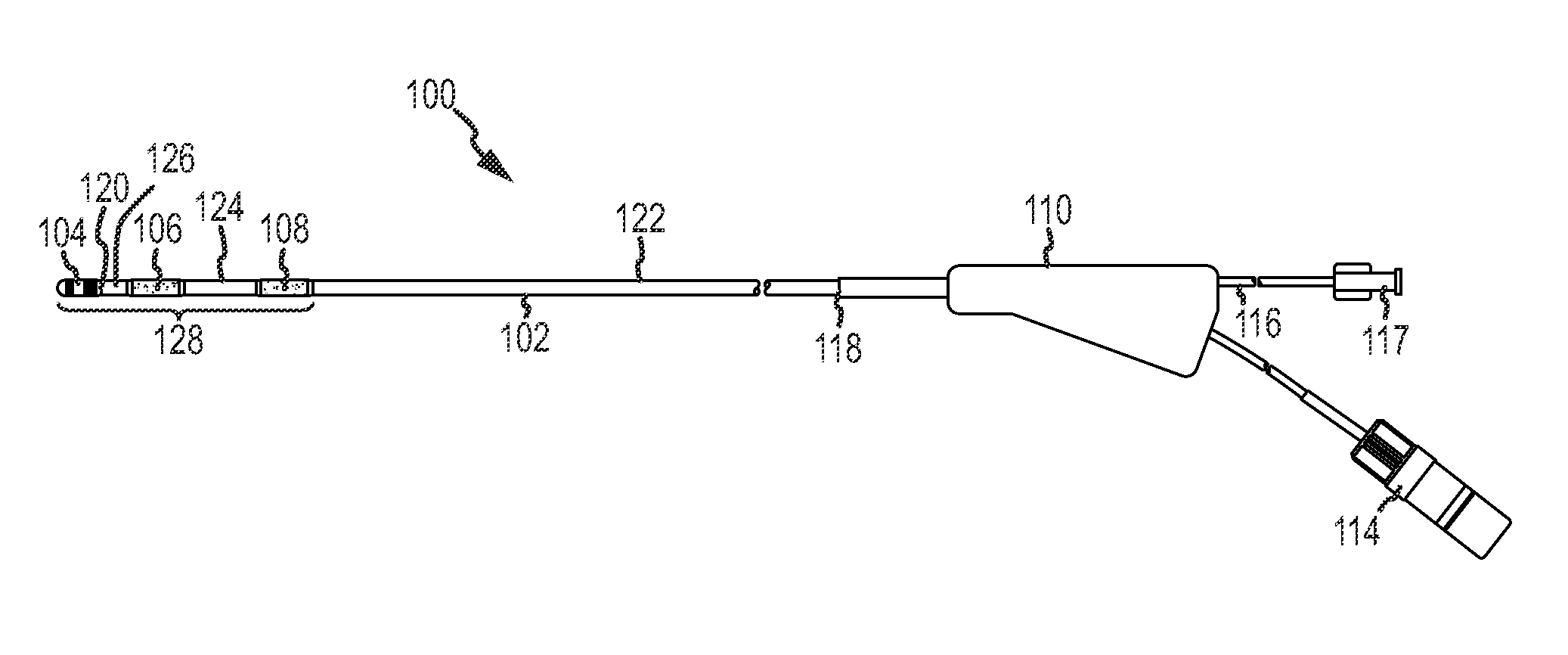

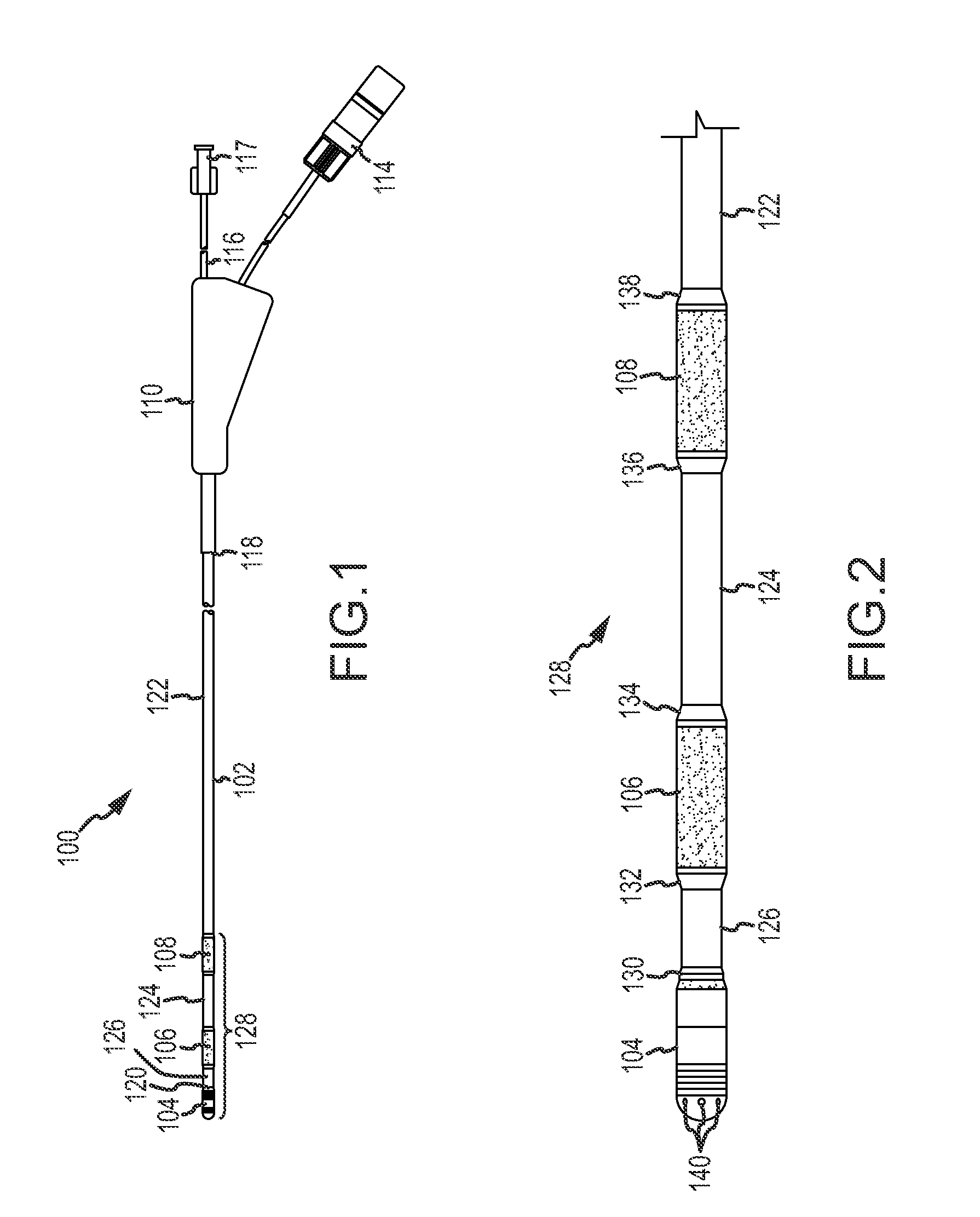

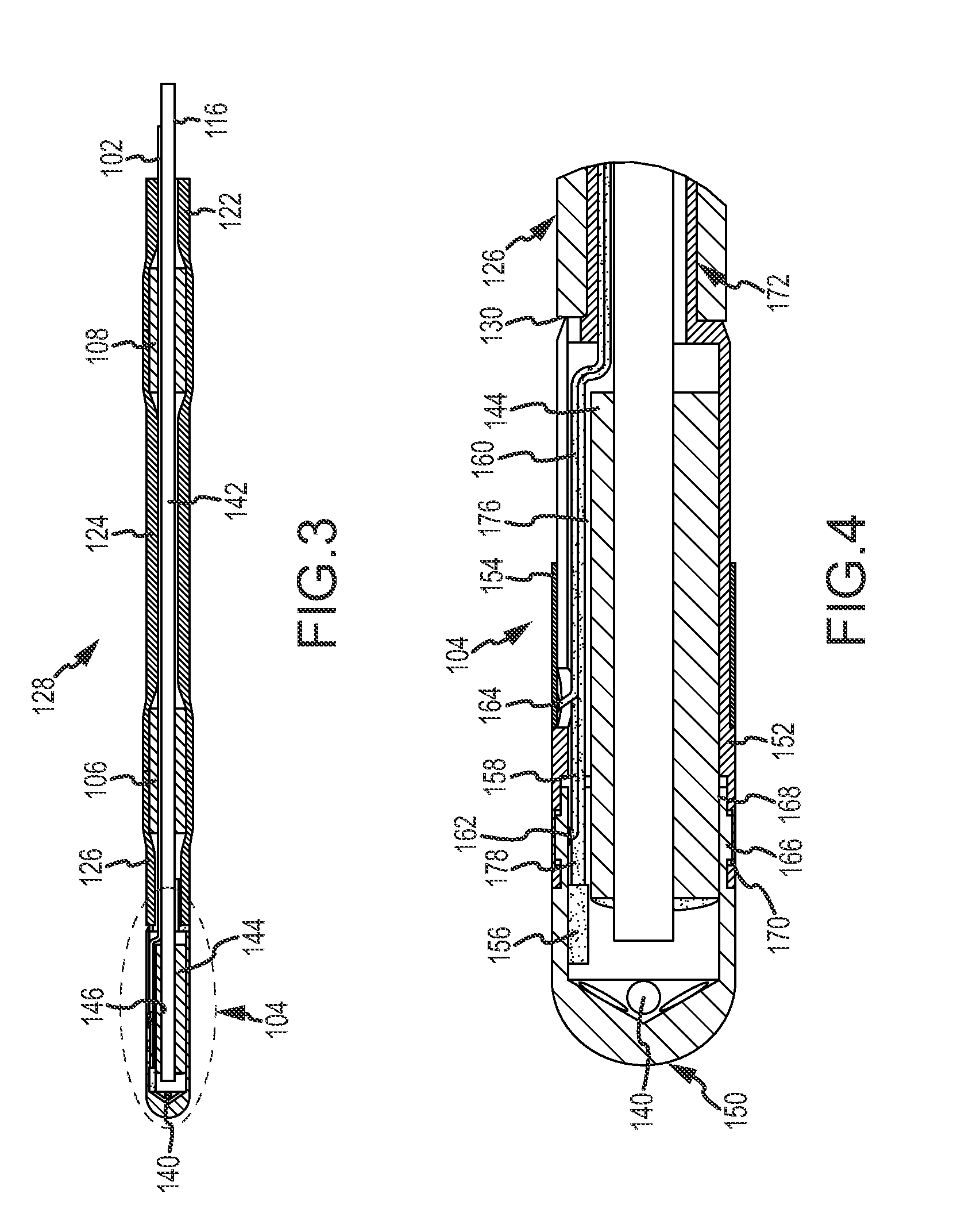

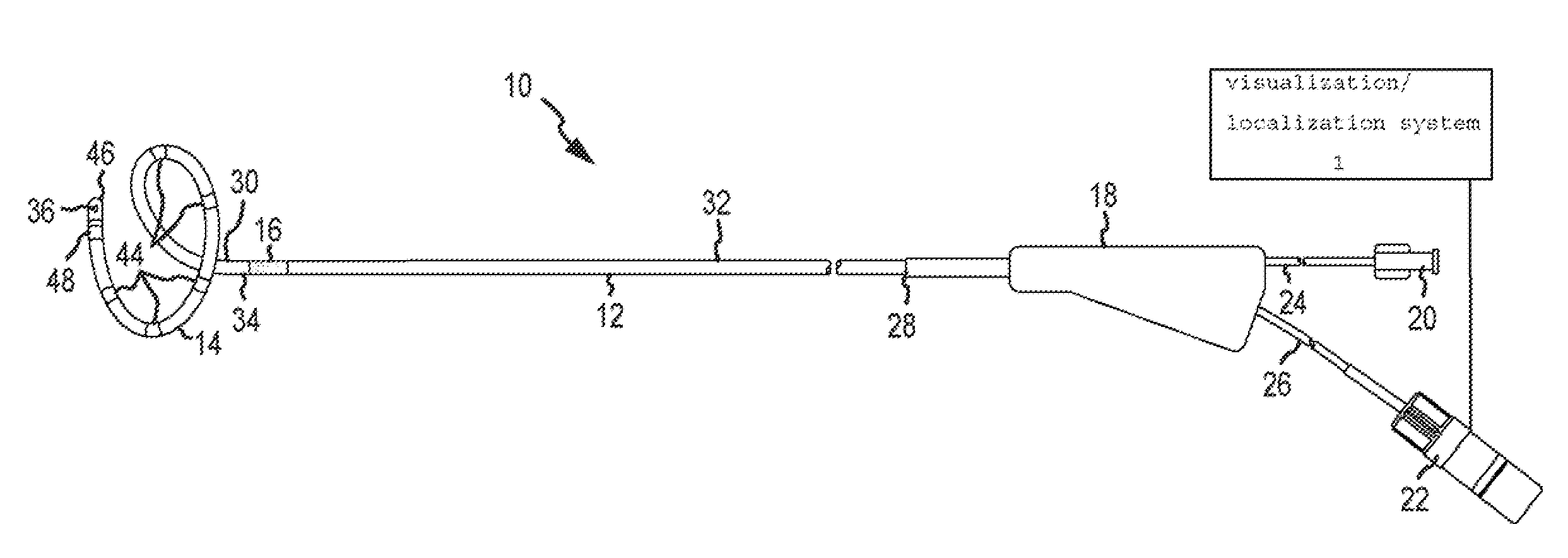

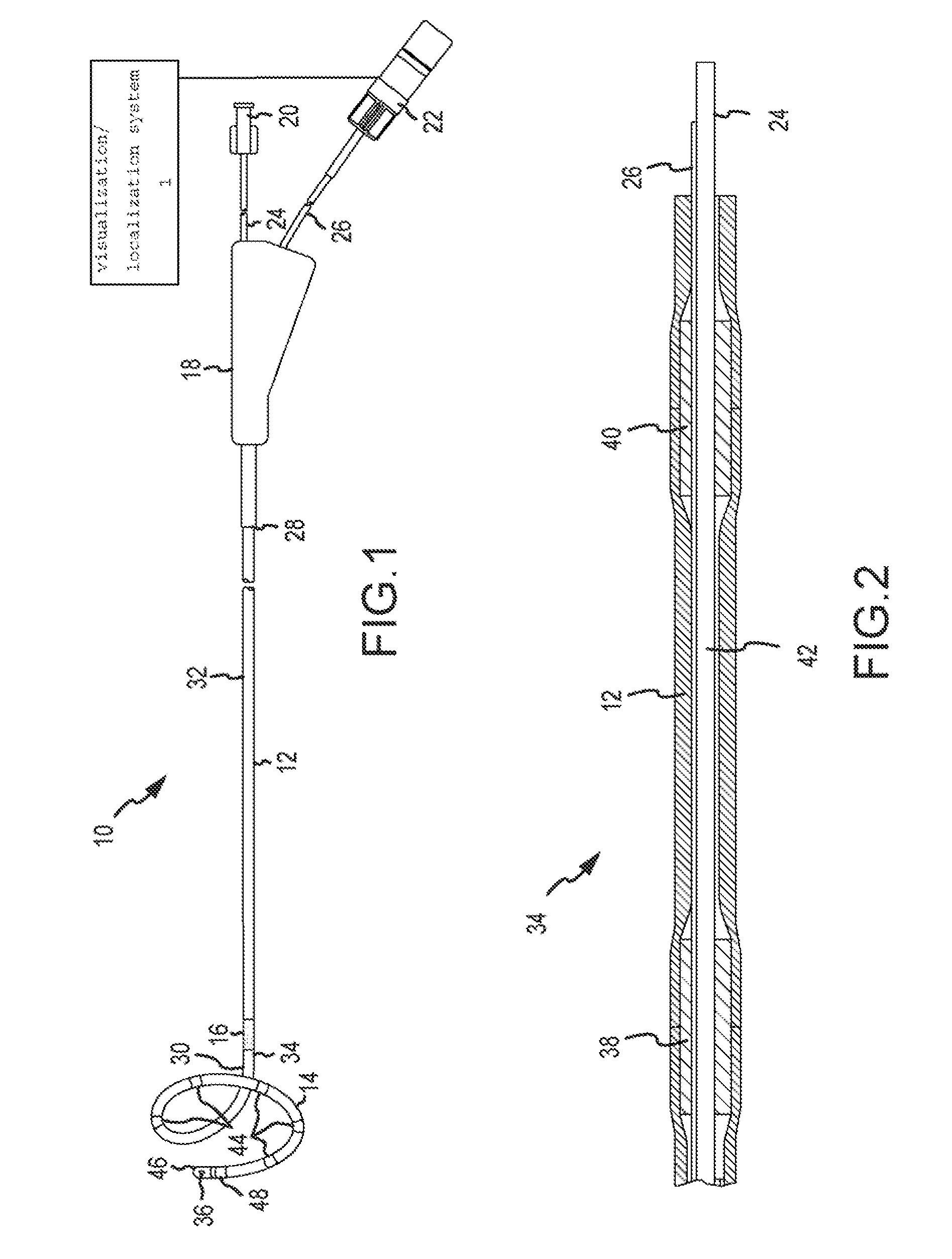

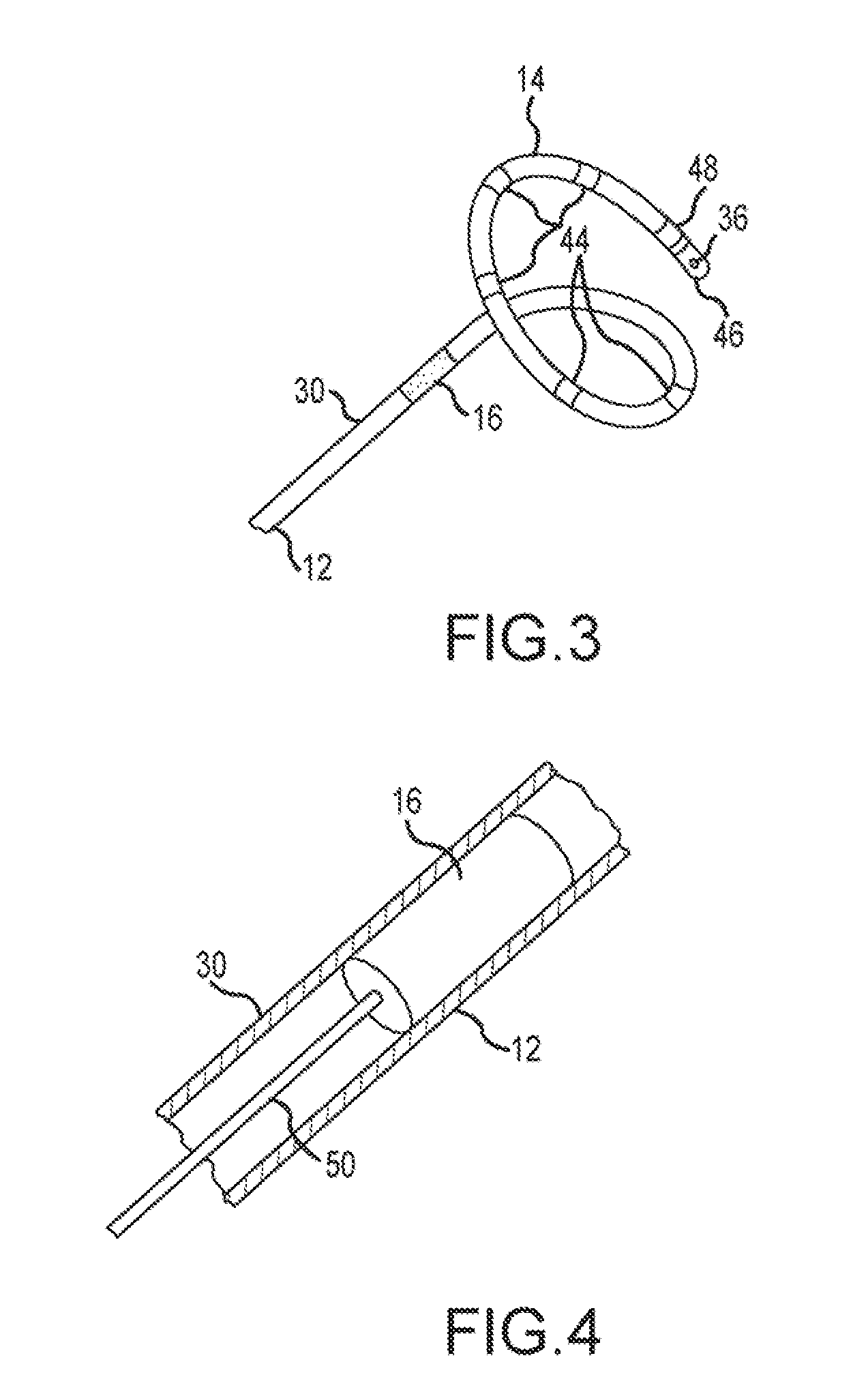

Magnetically guided catheter

ActiveUS20100174177A1Low costHigh performanceCatheterDiagnostic recording/measuringElectrically conductiveGuiding catheter

A catheter comprising a flexible tubing having a proximal end and a distal end. An electrode assembly is attached to the distal end of the flexible tubing. The electrode assembly includes an electrically conductive tip electrode and a coupler which is connected between the tip electrode and the distal end of the flexible tubing. The coupler and the tip electrode are coupled by an interlocking connection. A first magnet is at least partially housed in the coupler. A fluid lumen extends through the flexible tubing to the coupler. The fluid lumen extends completely through the first magnet and connects to at least one port formed in the electrode assembly. A second magnet is spaced from the electrode assembly along a longitudinal axis of the tubing. The first magnet and the second magnet are responsive to an external magnetic field to selectively position and guide the electrode assembly within a body of a patient.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

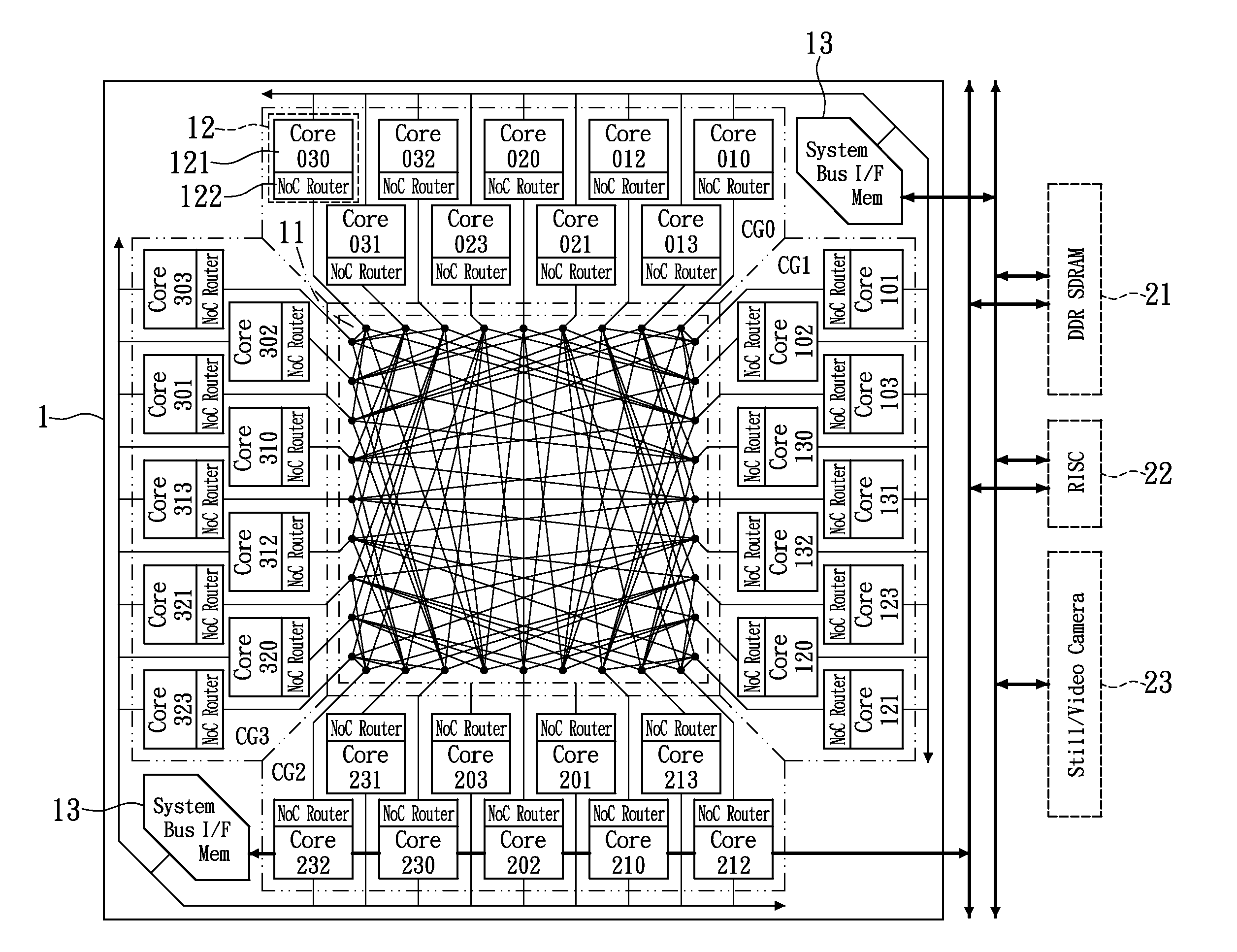

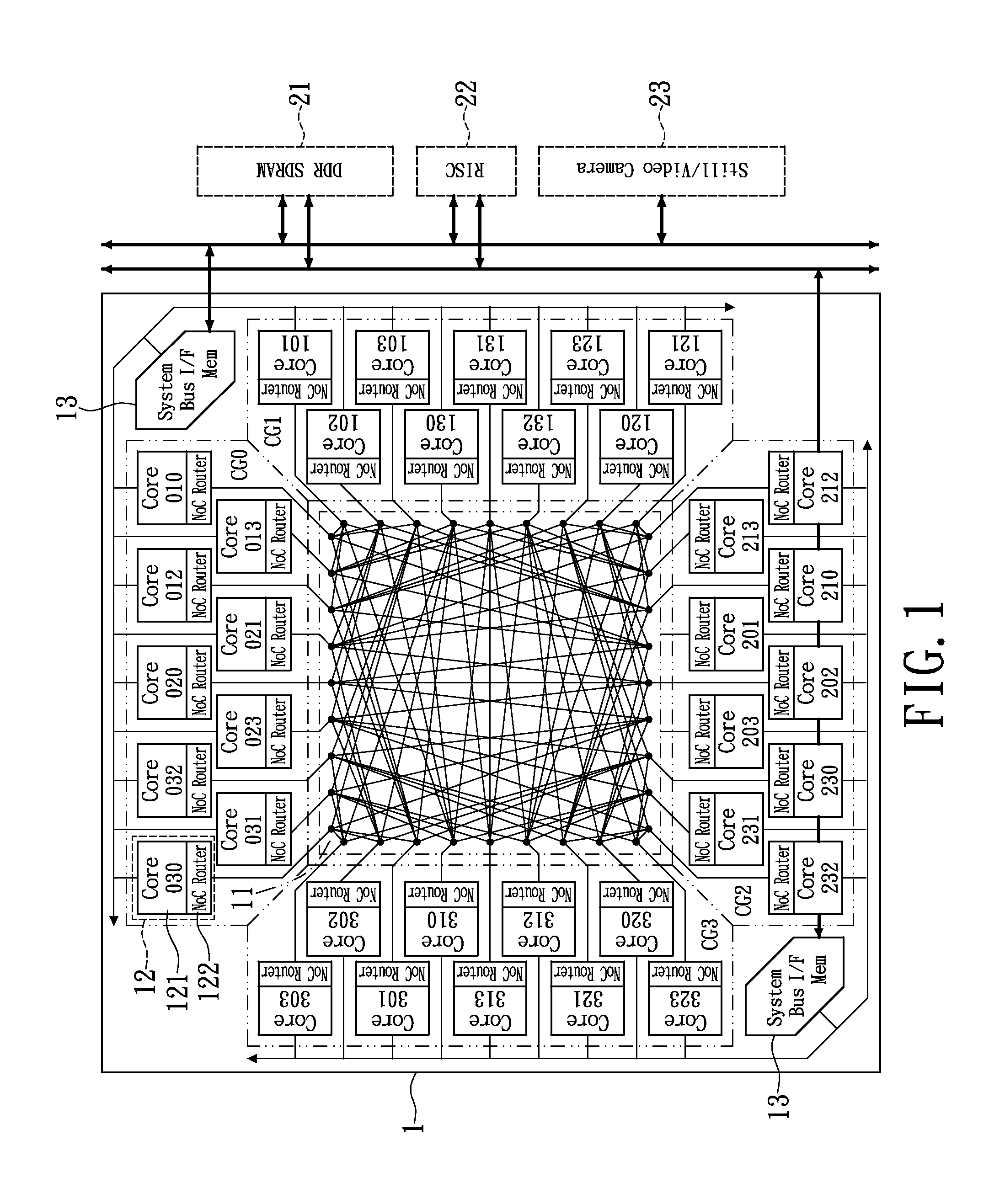

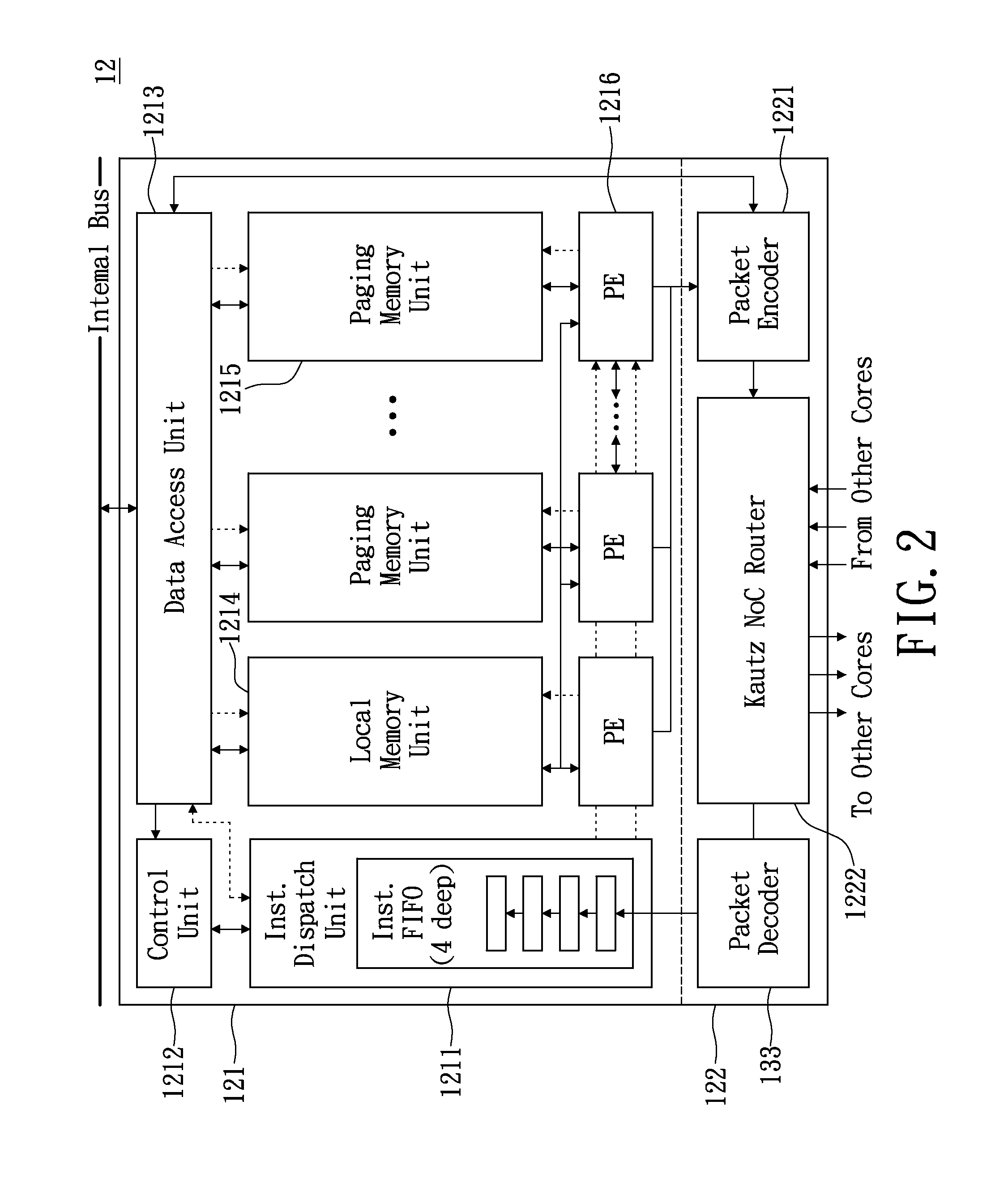

Network on chip processor with multiple cores and routing method thereof

ActiveUS20130219148A1High performanceHigh power efficiencyEnergy efficient ICTGeneral purpose stored program computerString lengthWord selection

An exemplary embodiment of the present disclosure illustrates a network on chip processor including multiple cores and a Kautz NoC. Each of the cores is assigned with an addressing string with L based-D words, and the addressing string does not have two neighboring identical words, wherein L present of an addressing string length is an integer larger than 1, D present of a word selection is an integer larger than 2. Each of the cores is unidirectionally link to other (D−1) cores through the Kautz NoC, and in the two connected cores, the last (L−1) words associated with the addressing string of one core are same as the first (L−1) words associated with the addressing string of the other core.

Owner:NAT TAIWAN UNIV

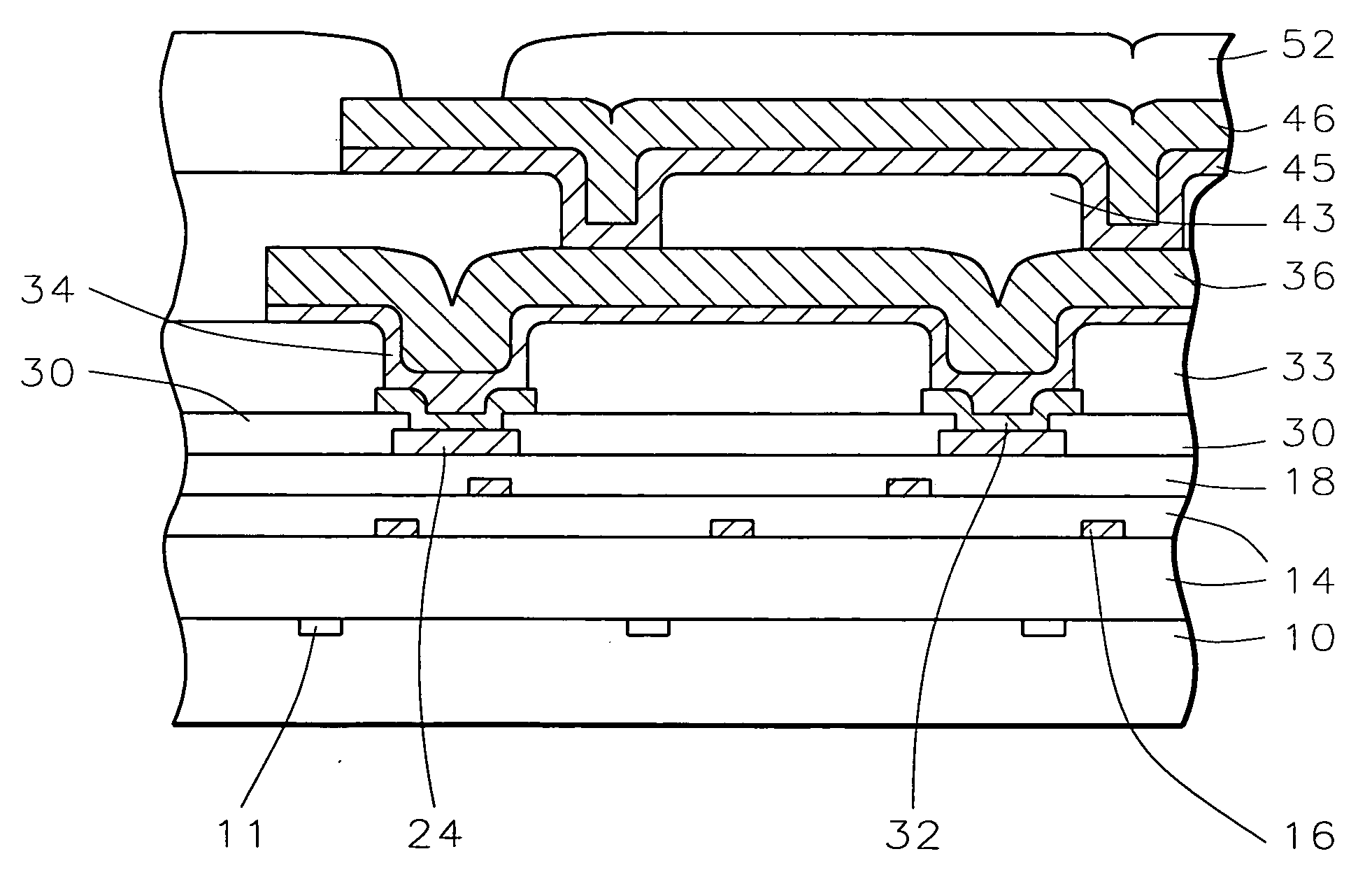

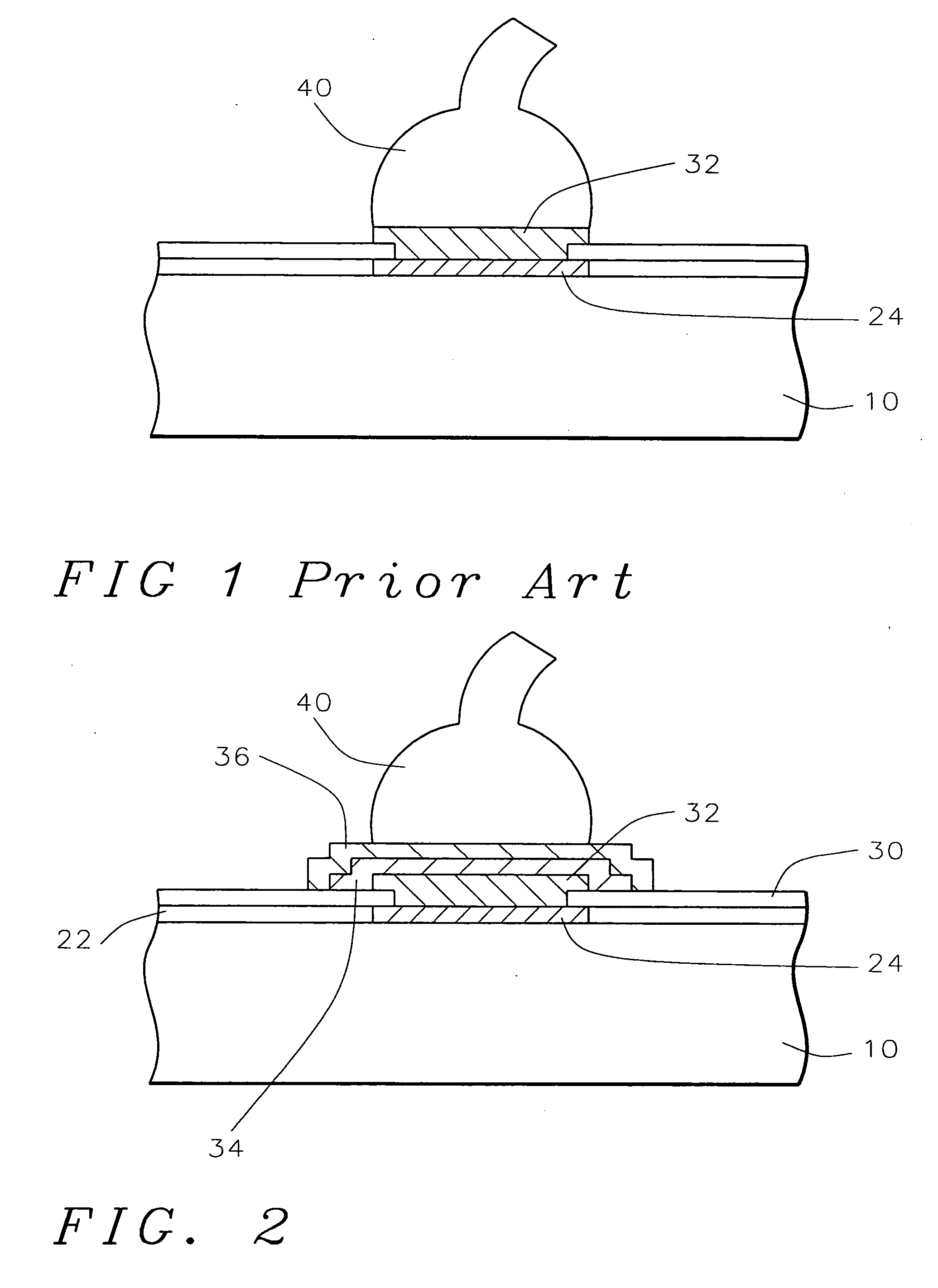

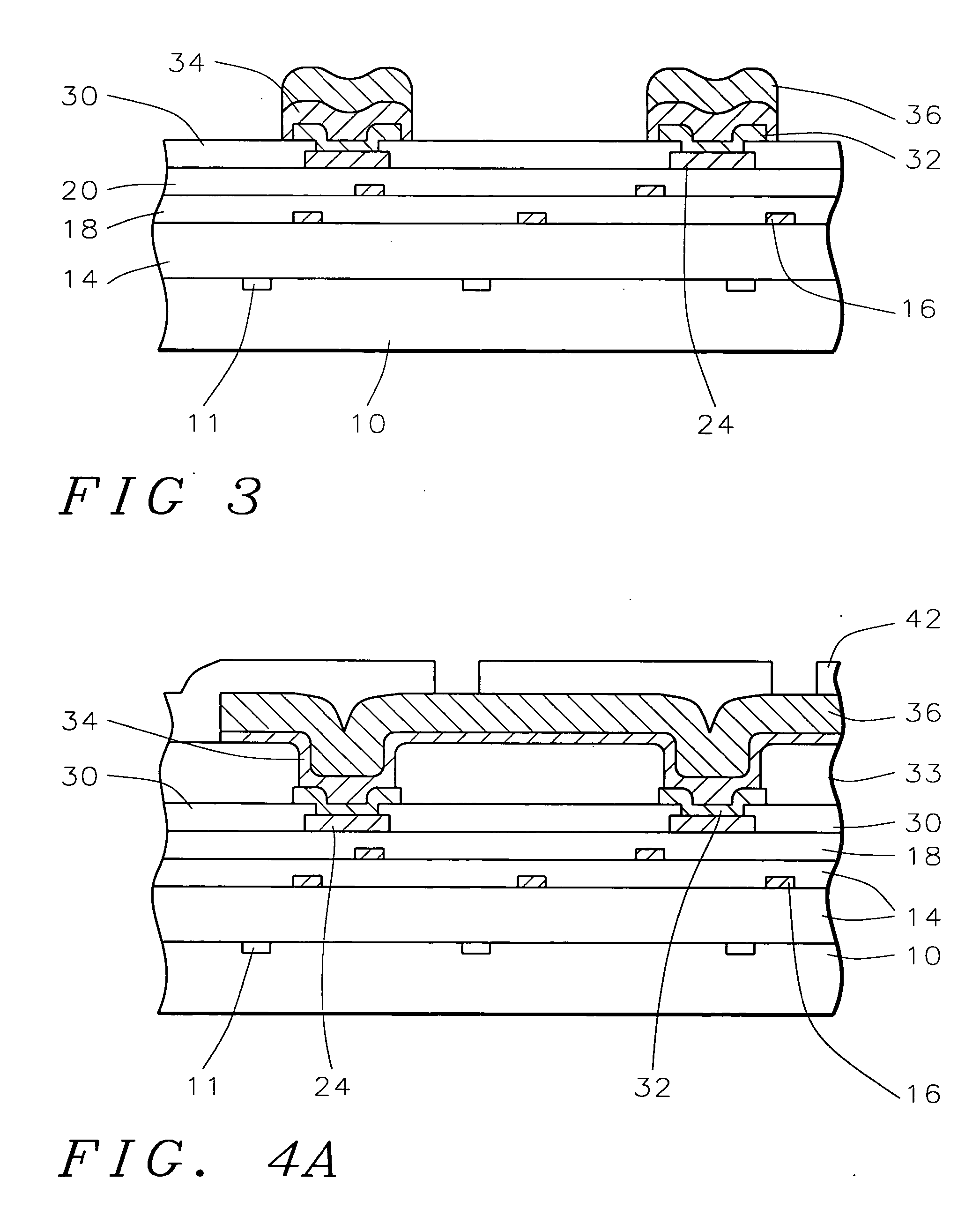

Post-passivation metal scheme on an IC chip with copper interconnection

InactiveUS20050017361A1High performanceSemiconductor/solid-state device detailsSolid-state devicesIntegrated circuitAluminium

In the present invention, copper interconnection with metal caps is extended to the post-passivation interconnection process. Metal caps may be aluminum. A gold pad may be formed on the metal caps to allow wire bonding and testing applications. Various post-passivation passive components may be formed on the integrated circuit and connected via the metal caps.

Owner:QUALCOMM INC

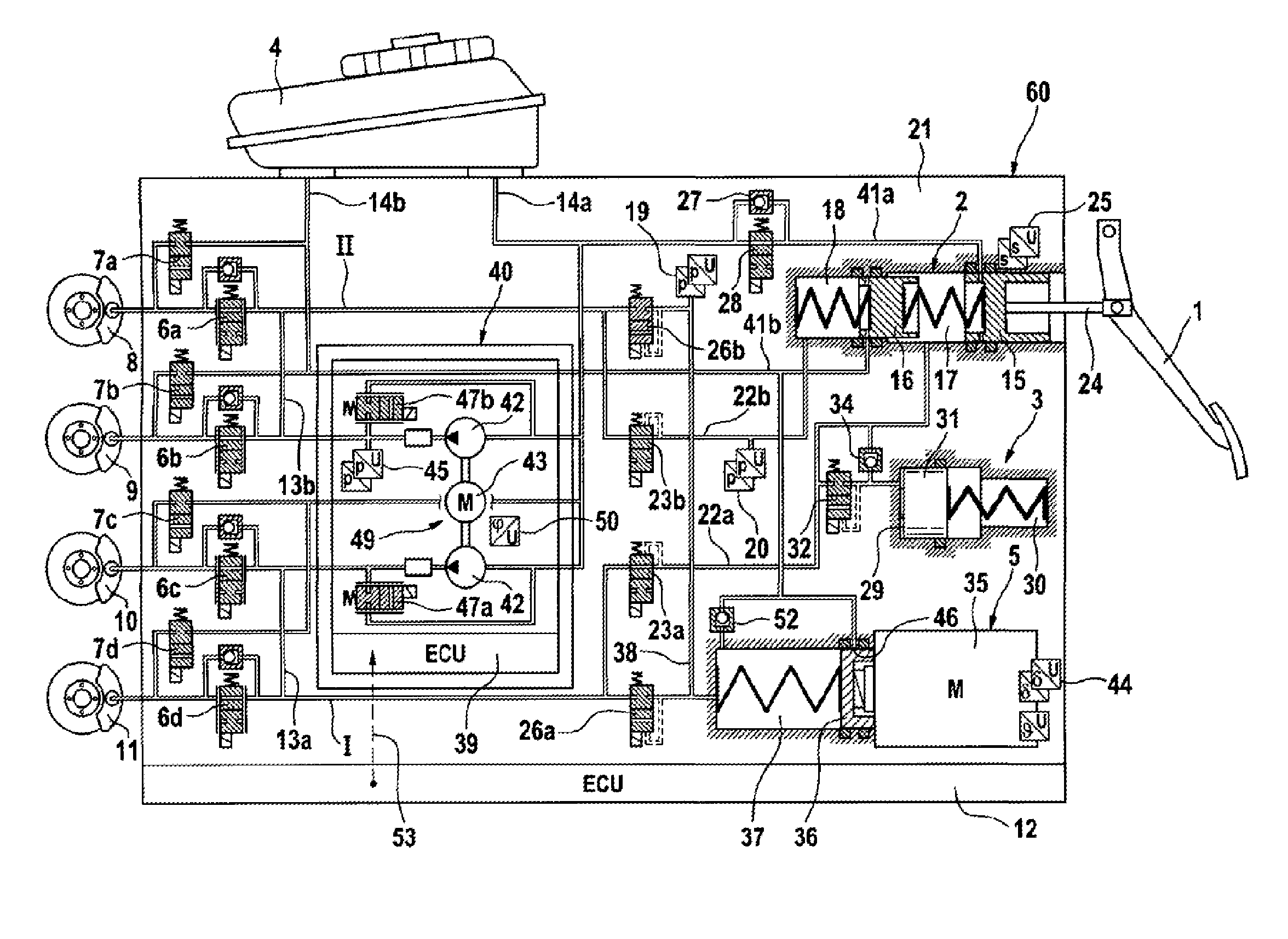

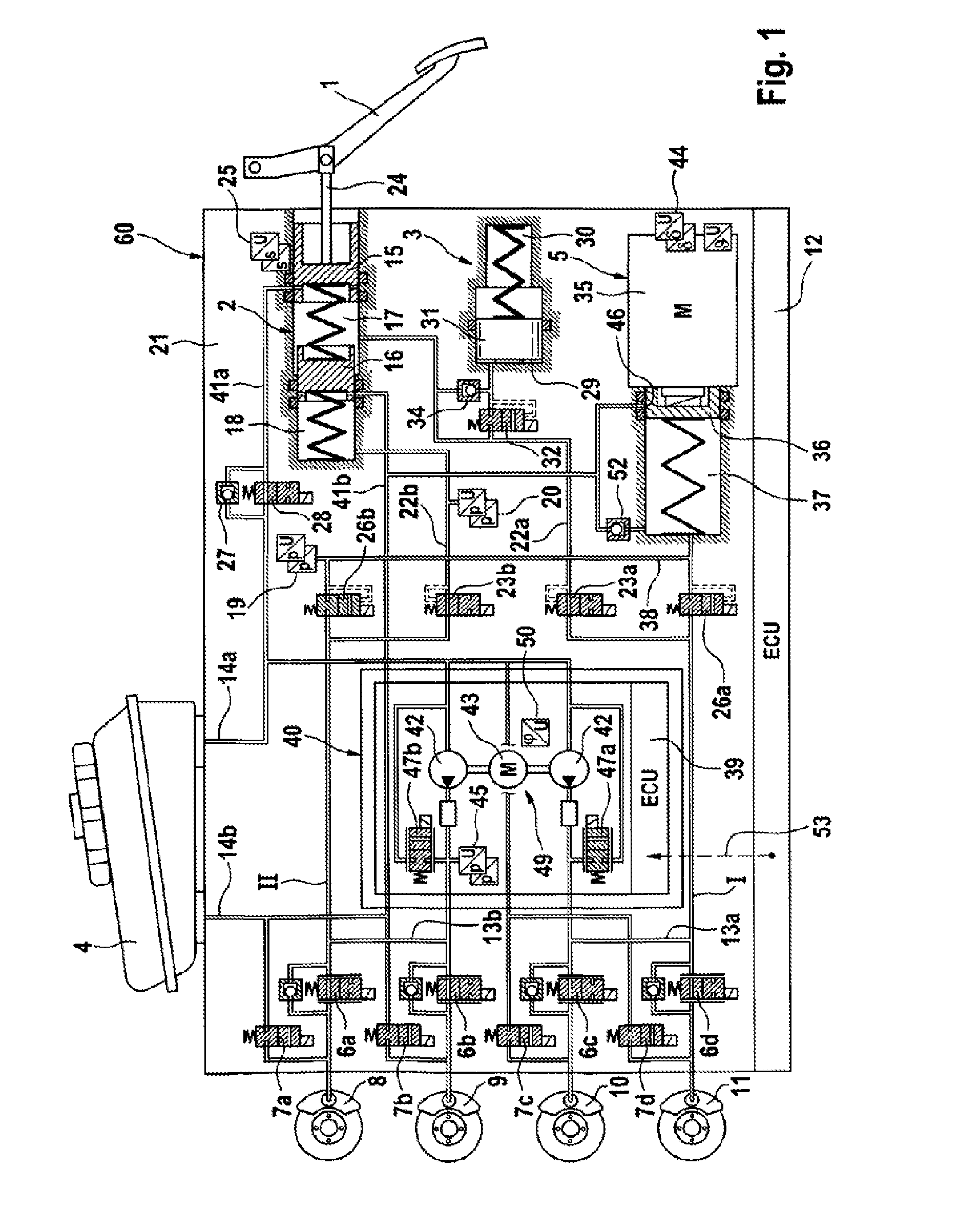

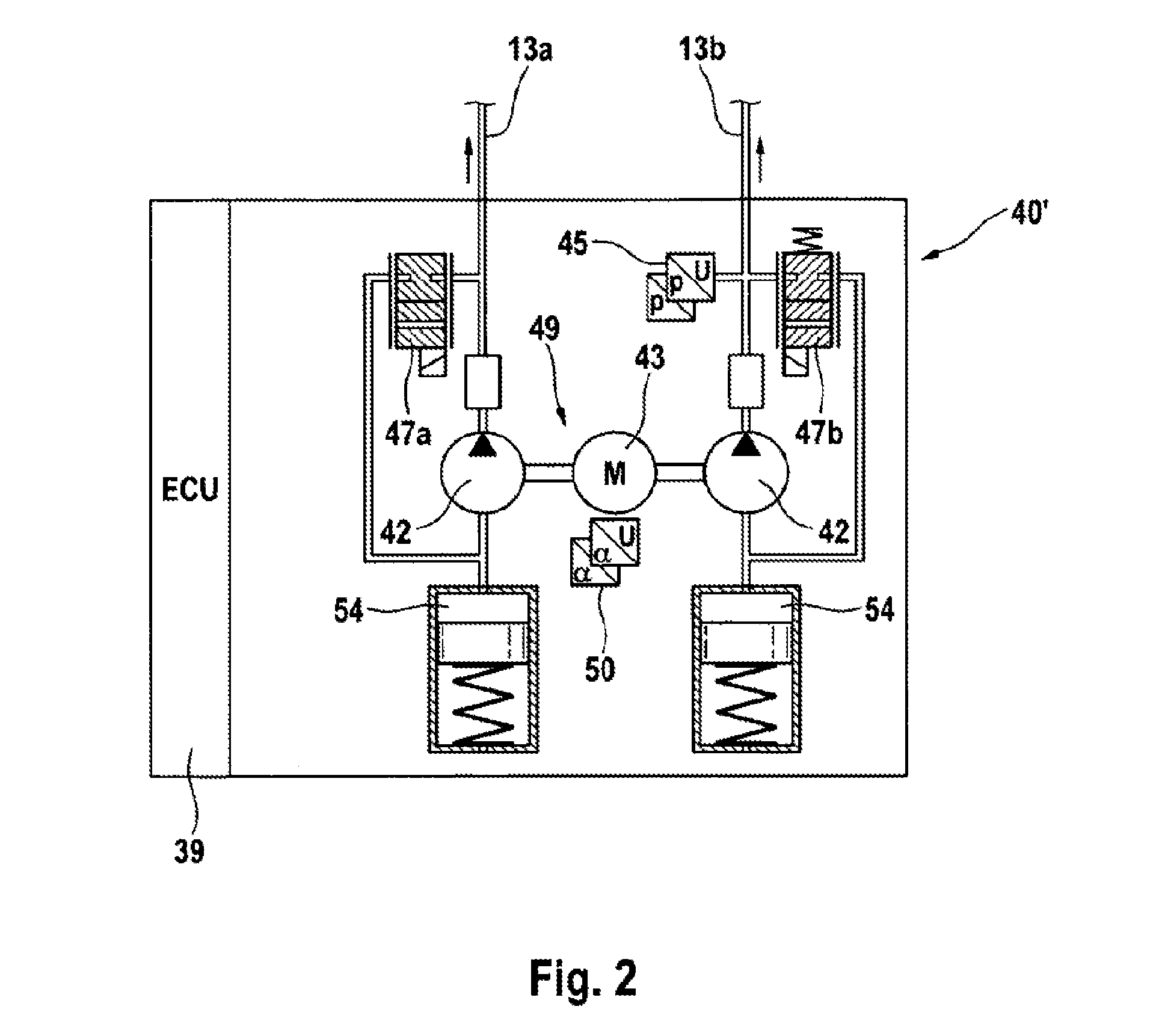

Brake System for Motor Vehicles and Method for Operating a Brake System

InactiveUS20140203626A1Shortening of brake pedal travelHigh performanceFluid braking transmissionBrake action initiationsElectronic control unitBrake pressure

A brake system includes a hydraulic actuating unit, which can be actuated by way of a brake pedal, a travel simulator interacting with the hydraulic actuating unit, a pressure medium reservoir under atmospheric pressure assigned to the hydraulic actuating unit, a first electrically controllable pressure supply device, a second electrically controllable pressure supply device, an electronic control unit and an electronically controllable pressure modulation device for setting wheel-specific brake pressures. The brake system preferably operates in a “brake-by-wire” mode but can also operate in a fallback mode. The second electrically controllable pressure supply device can provide boost volume during braking in a fallback mode.

Owner:CONTINENTAL TEVES AG & CO OHG

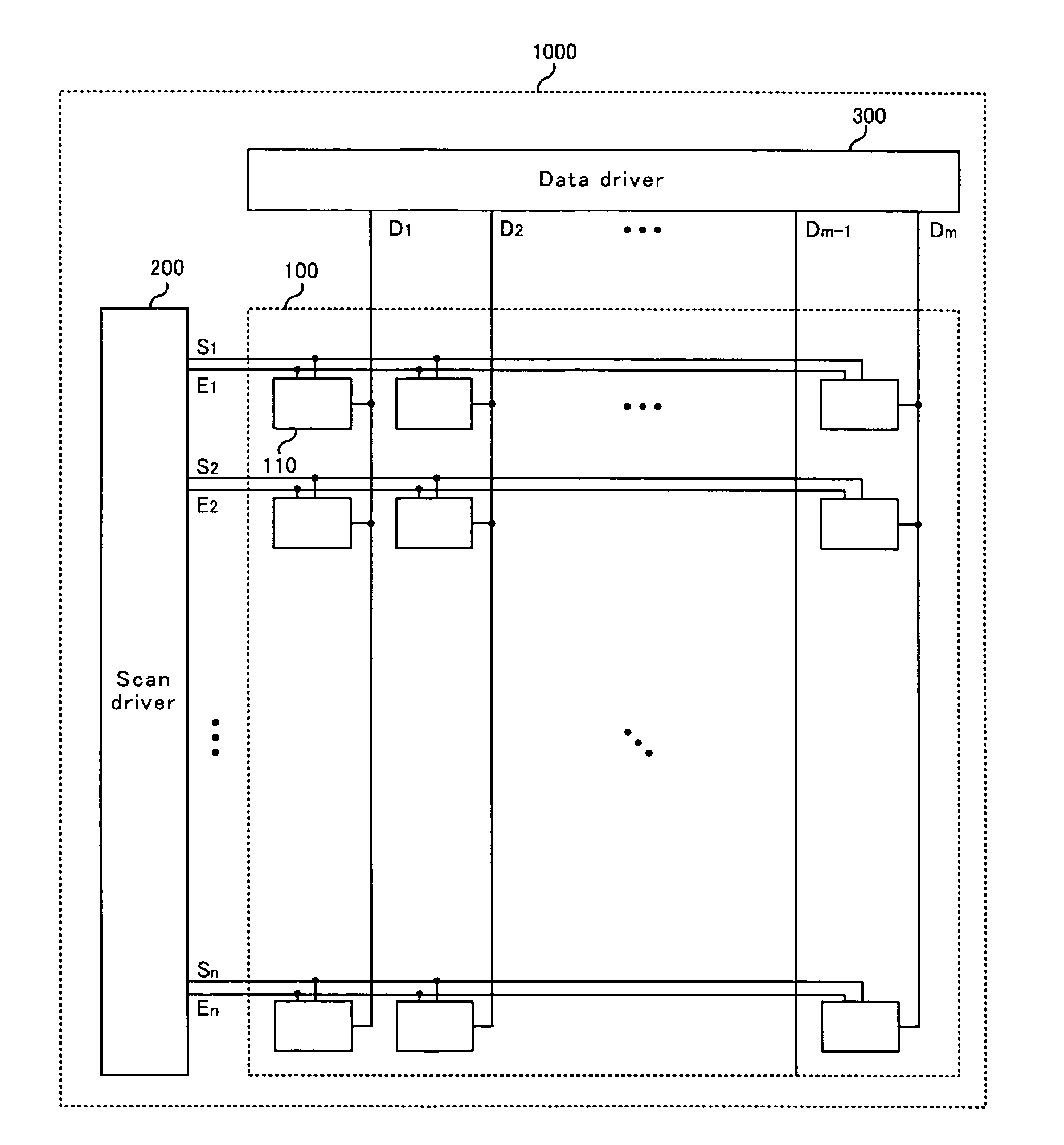

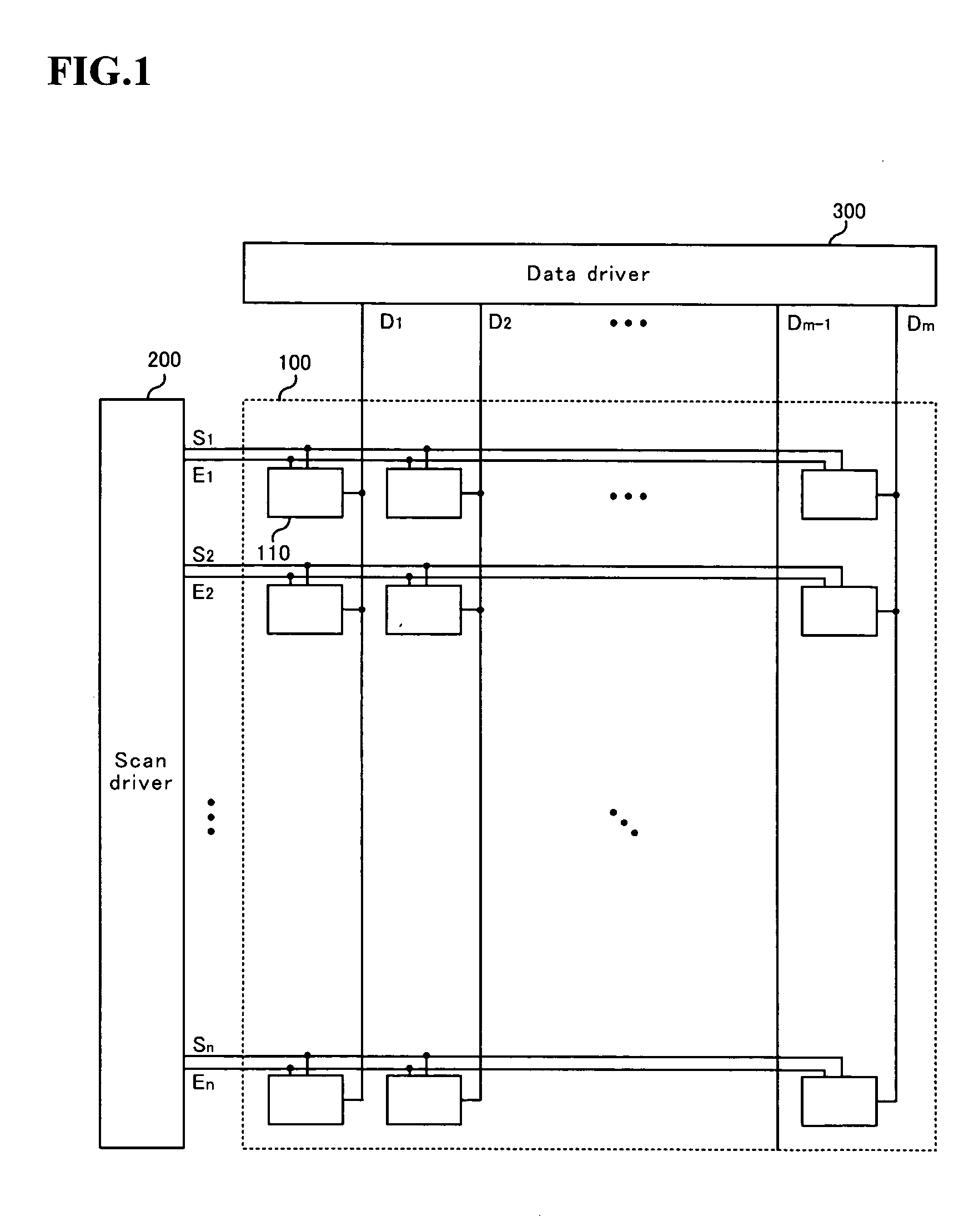

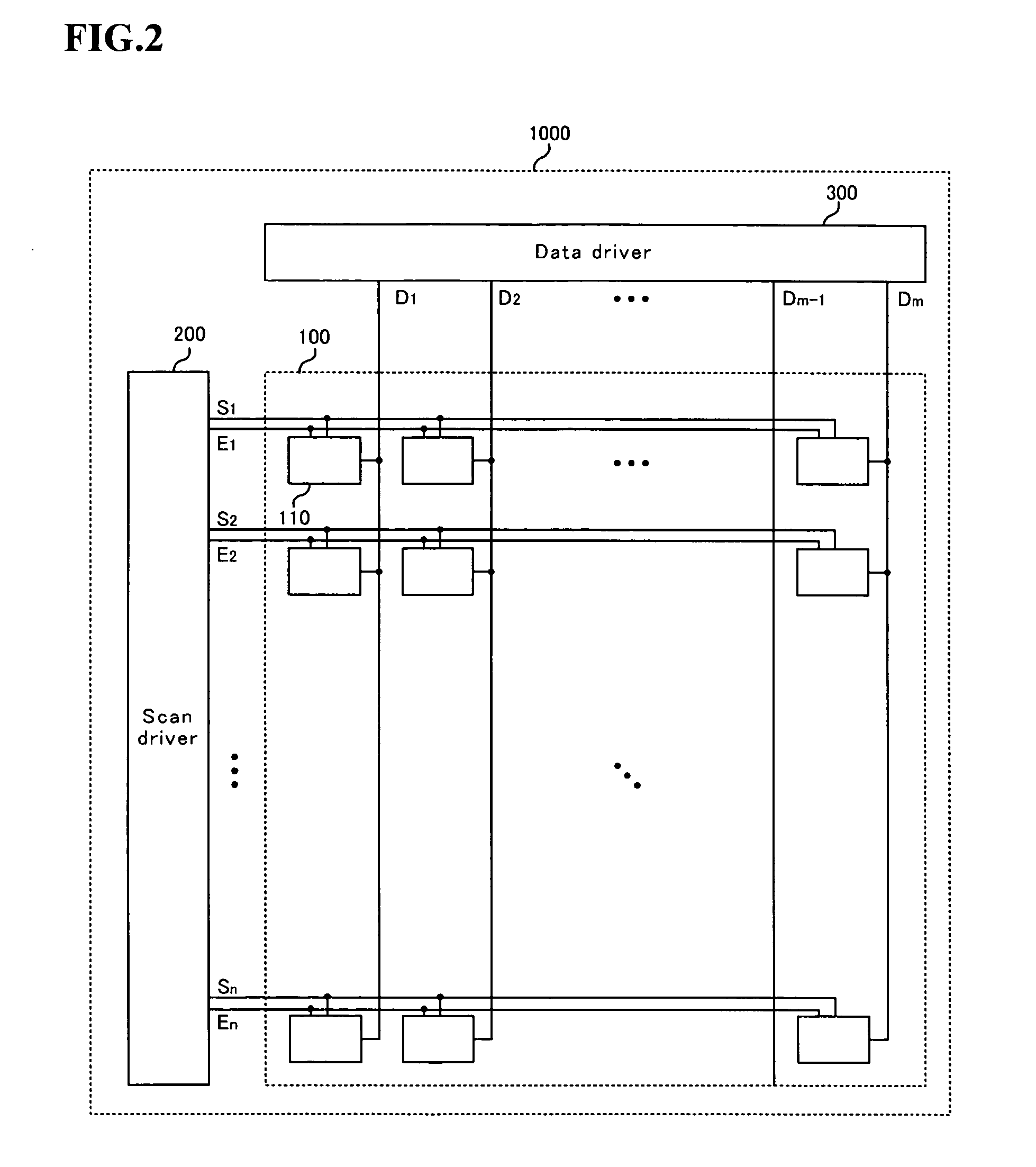

Data driving apparatus in a current driving type display device

ActiveUS20060077077A1High performanceHigh qualityElectric signal transmission systemsStatic indicating devicesData-drivenData lines

The present invention relates to a data driving apparatus for driving a current driving display device. A current output device of the data driving apparatus sequentially applies data signals to data lines. The data signals correspond to analog converted output currents. The current output device may include an analog output current converter for converting the analog converted output currents to analog output currents including a main signal and a sub-signal having a predetermined ratio therebetween, a switch for supplying the analog output currents including the main signal and the sub-signal according to a first control signal, and a current sample / hold circuit for sampling or holding the analog output currents including the main signal and the sub-signal according to a current sample / hold control signal.

Owner:SAMSUNG DISPLAY CO LTD

Movable magnet for magnetically guided catheter

ActiveUS20120035460A1High performanceImprove performanceElectrocardiographyMedical devicesMagnetGuide catheter

A catheter is disclosed having a flexible tubing with a proximal end and a distal end. The catheter comprising at least one movable magnet provided within the distal end of the flexible tubing. A control mechanism is operable to selectively activate the at least one movable magnet from the proximal end of the flexible tubing. The at least one movable magnet is responsive to an external magnetic field to position and guide the distal end of the flexible tubing within a body of a patient.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

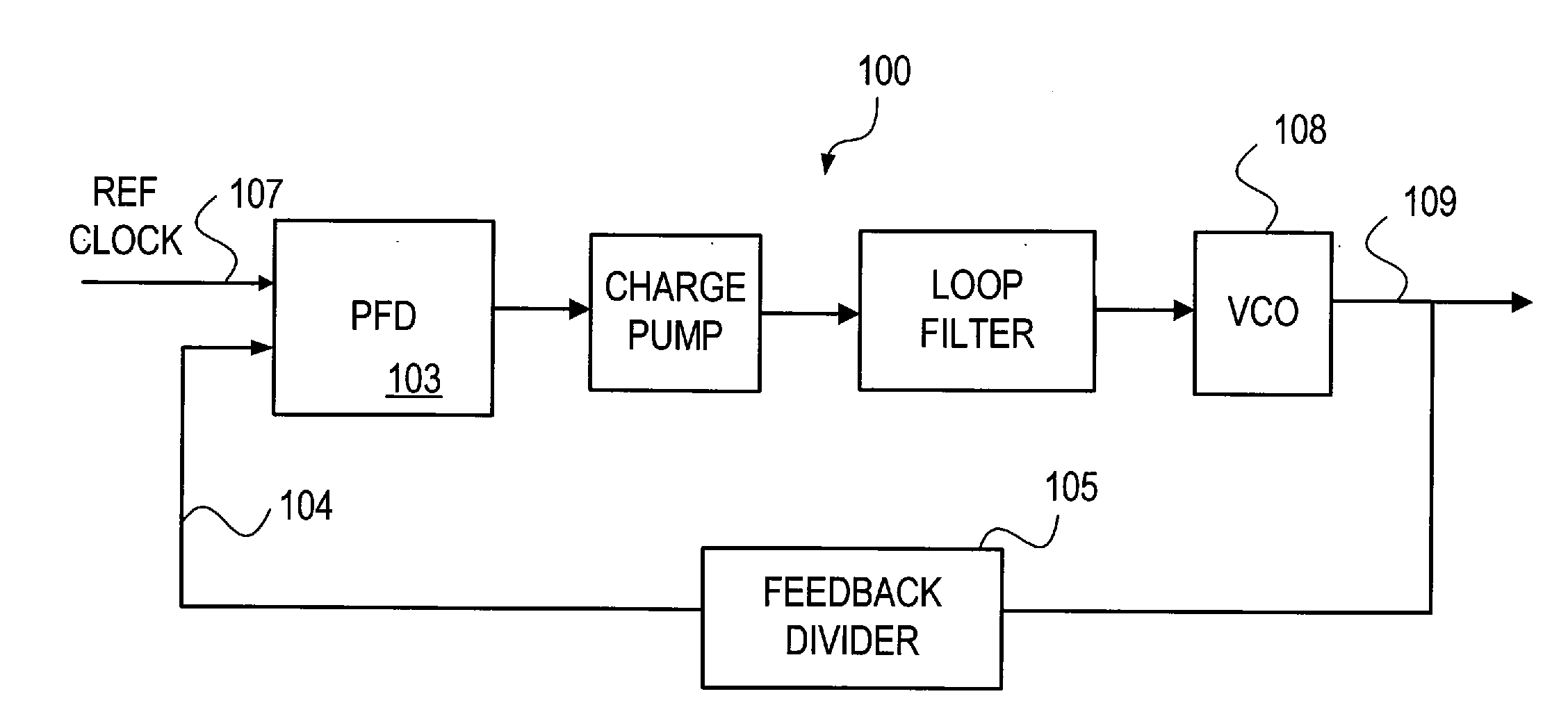

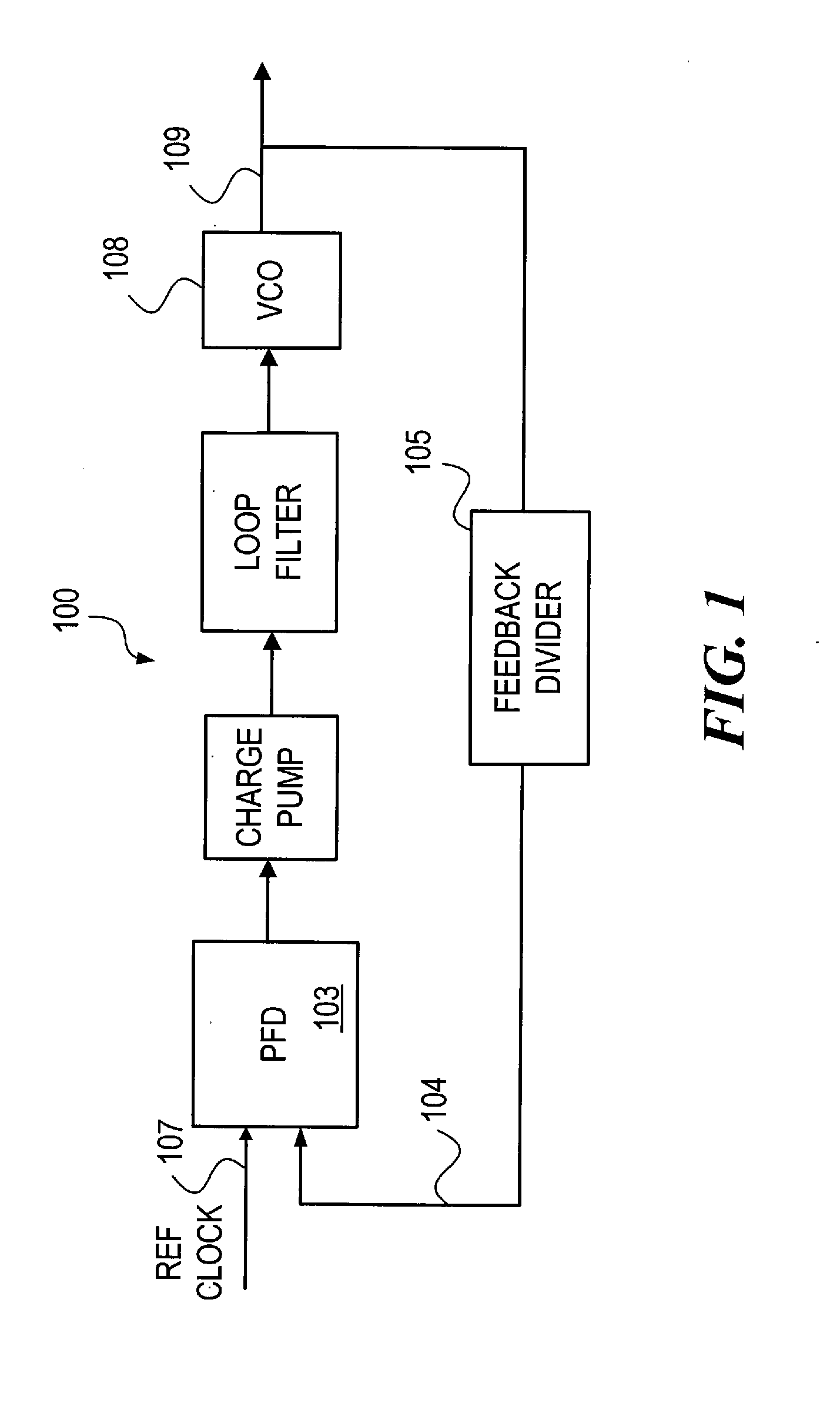

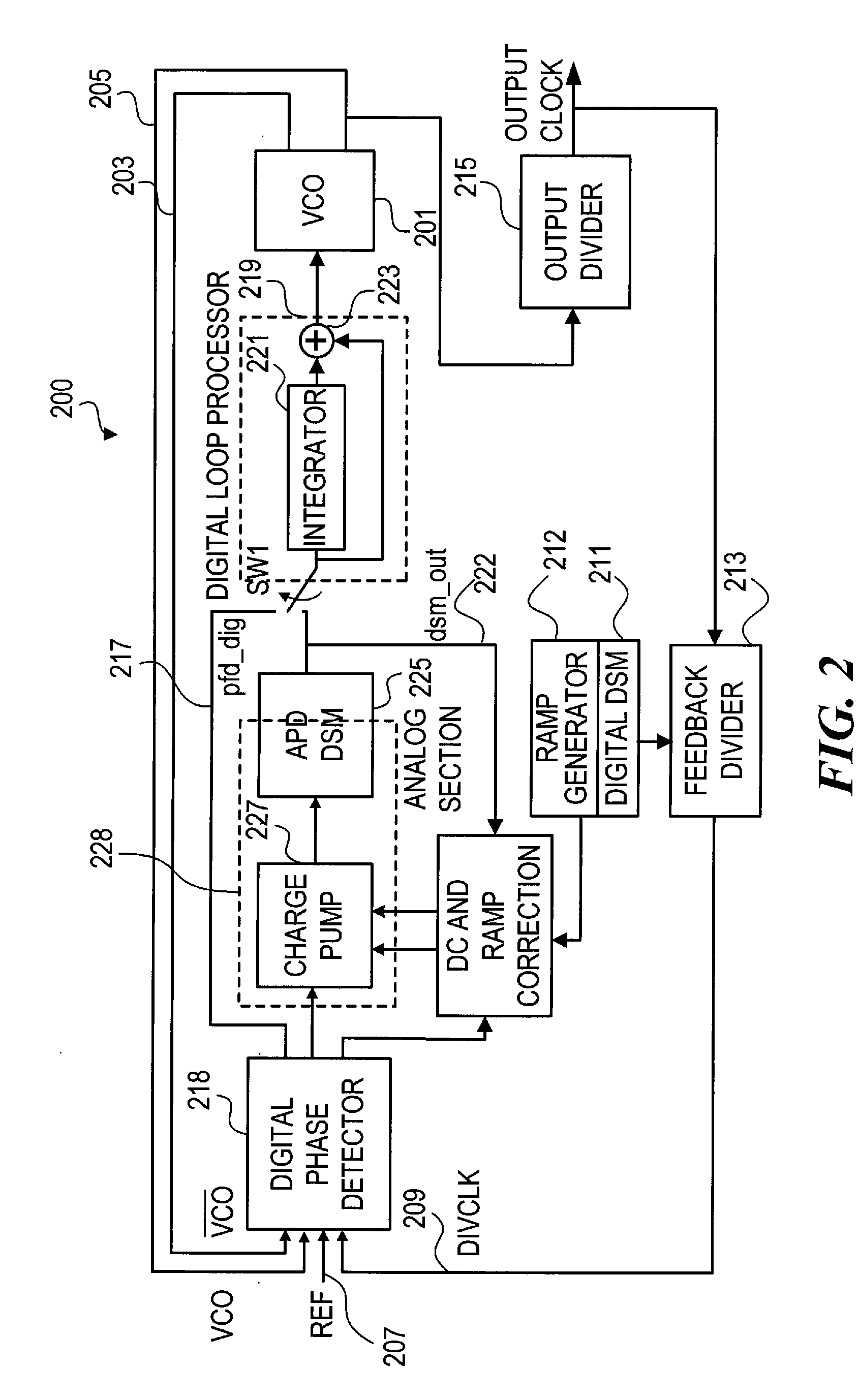

Dividerless pll architecture

ActiveUS20090015338A1High performanceLow powerPulse automatic controlPhase detectorPhase-locked loop

A phase-locked loop (PLL) achieves initial lock using a course fractional-N divider driving a binary phase detector. Once frequency lock is achieved, this divider may be turned off, while an adaptive phase detector takes over control of the PLL front end. The adaptive phase detector (APD) receives input directly from the VCO and the reference clock, deriving digital control signals and a precision phase detector output. The APD operates at the update rate, generating a digital delta sigma modulator (DSM) data stream output at the update rate. The APD automatically locks to a digitally generated ramp corresponding to an expected difference between the VCO output and the reference clock, while adaptively correcting for DC errors and ramp cancellation errors.

Owner:SILICON LAB INC

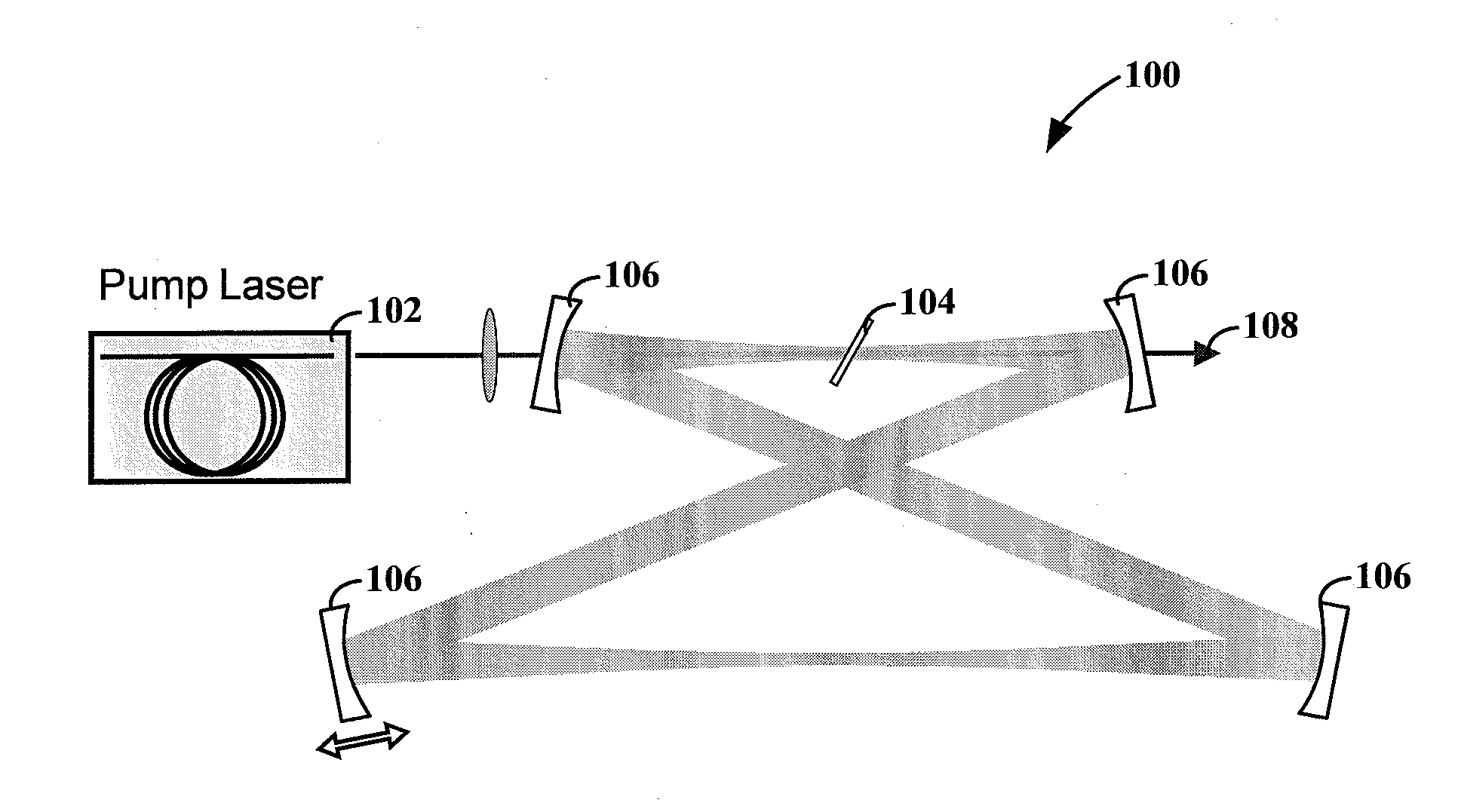

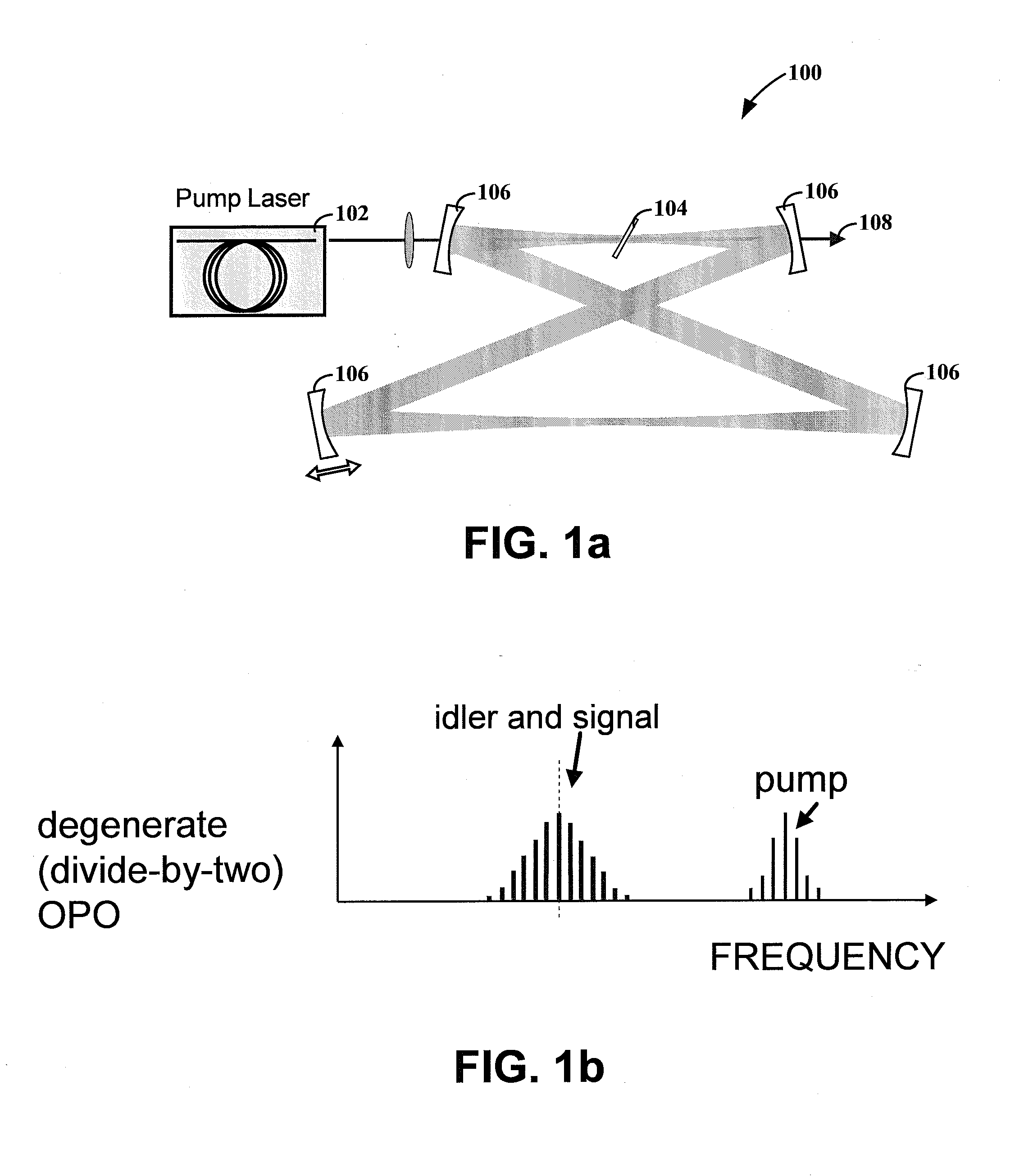

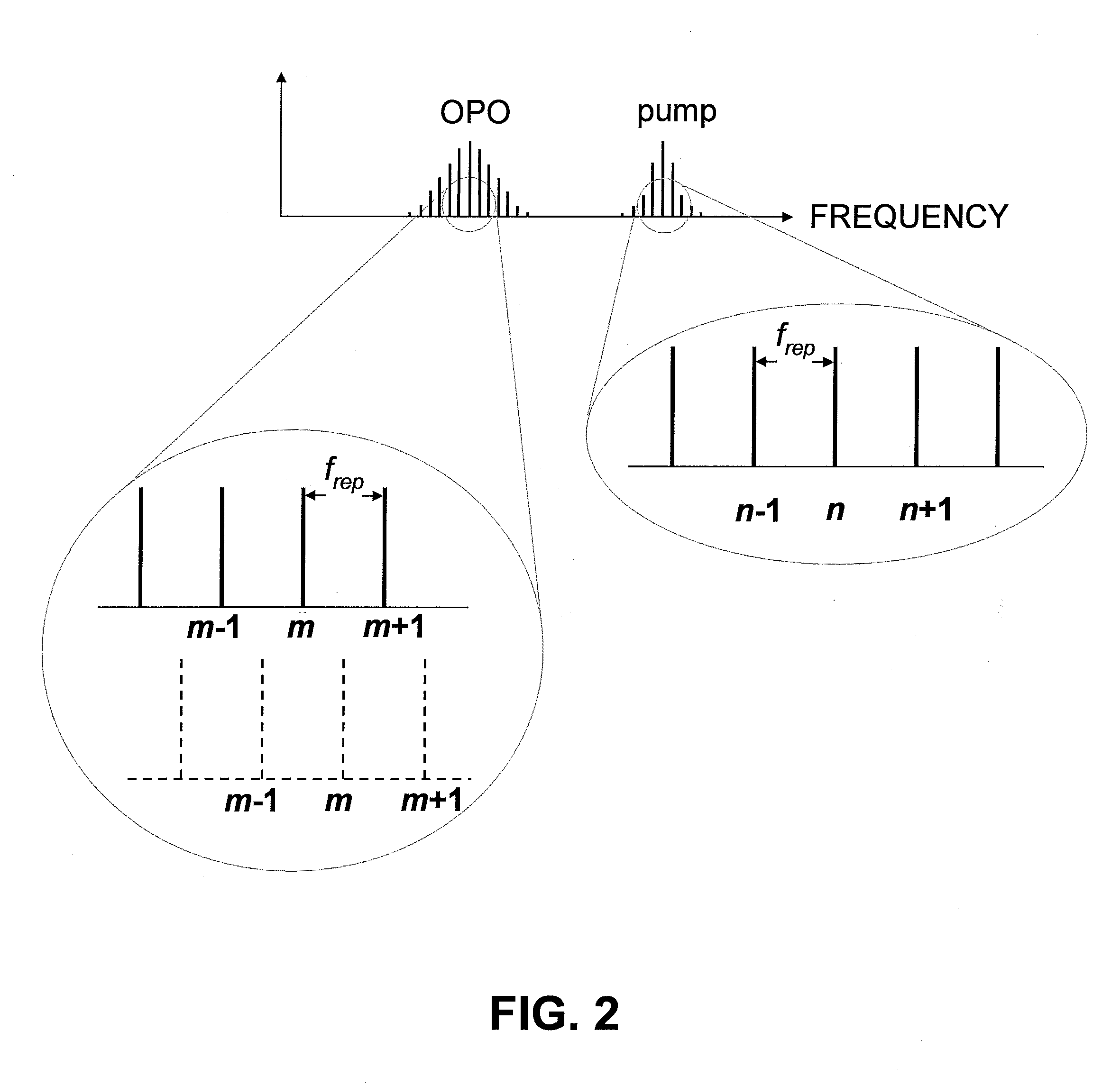

Infrared frequency comb methods, arrangements and applications

ActiveUS20110058248A1High performanceHigh specificityLaser detailsLight demodulationMid infraredResonator

Certain embodiments relate to and involve producing broadband phase-locked frequency combs in the near-infrared and mid-infrared spectral ranges. One such embodiment is directed to a system, with a pump laser and an optical parametric oscillator (OPO) resonator, that is configured to produce broad-bandwidth frequency combs in the near-infrared and mid-infrared frequency ranges. The pump laser is configured to produce femtosecond pulses of light having a pulse repetition rate. The optical parametric oscillator (OPO) resonator that is coupled to the pump laser for facilitating synchronous OPO pumping by matching a roundtrip time of the pulses of light within the OPO resonator with the pulse repetition rate of the pump laser. Among other more specific aspects, the OPO resonator can include a nonlinear optical gain element to provide broad-bandwidth parametric amplification, and optical elements to direct the pulses of light from the femtosecond laser to the nonlinear gain element and to direct subharmonic frequencies of the light out of the optical cavity.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

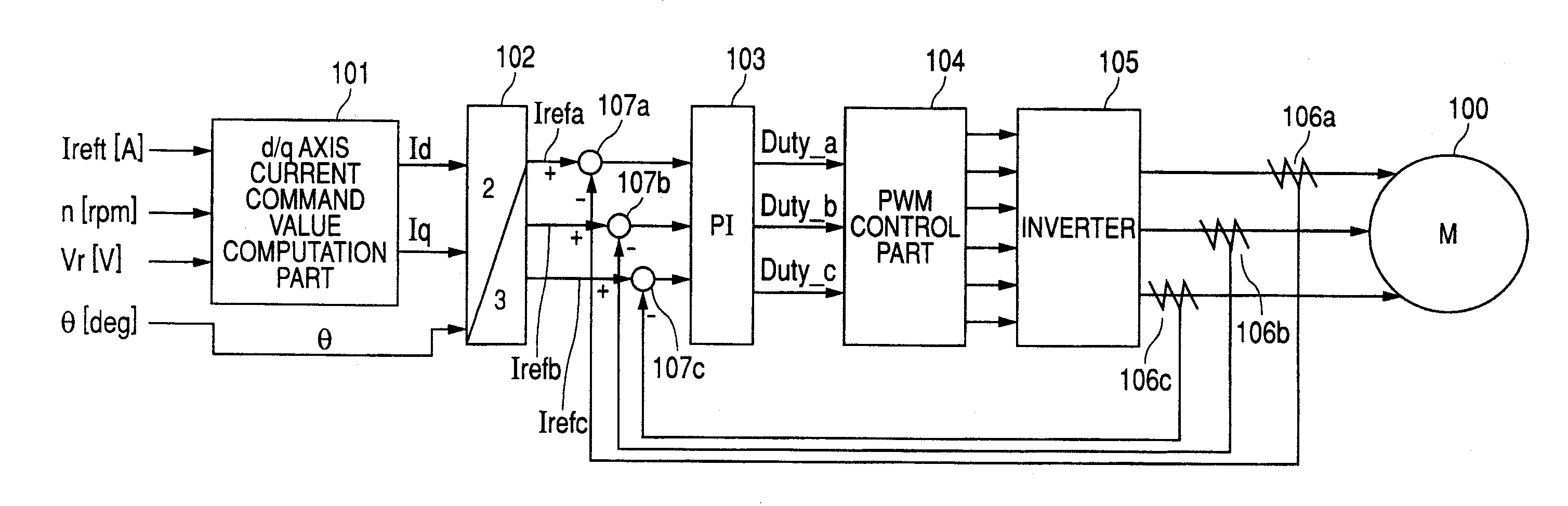

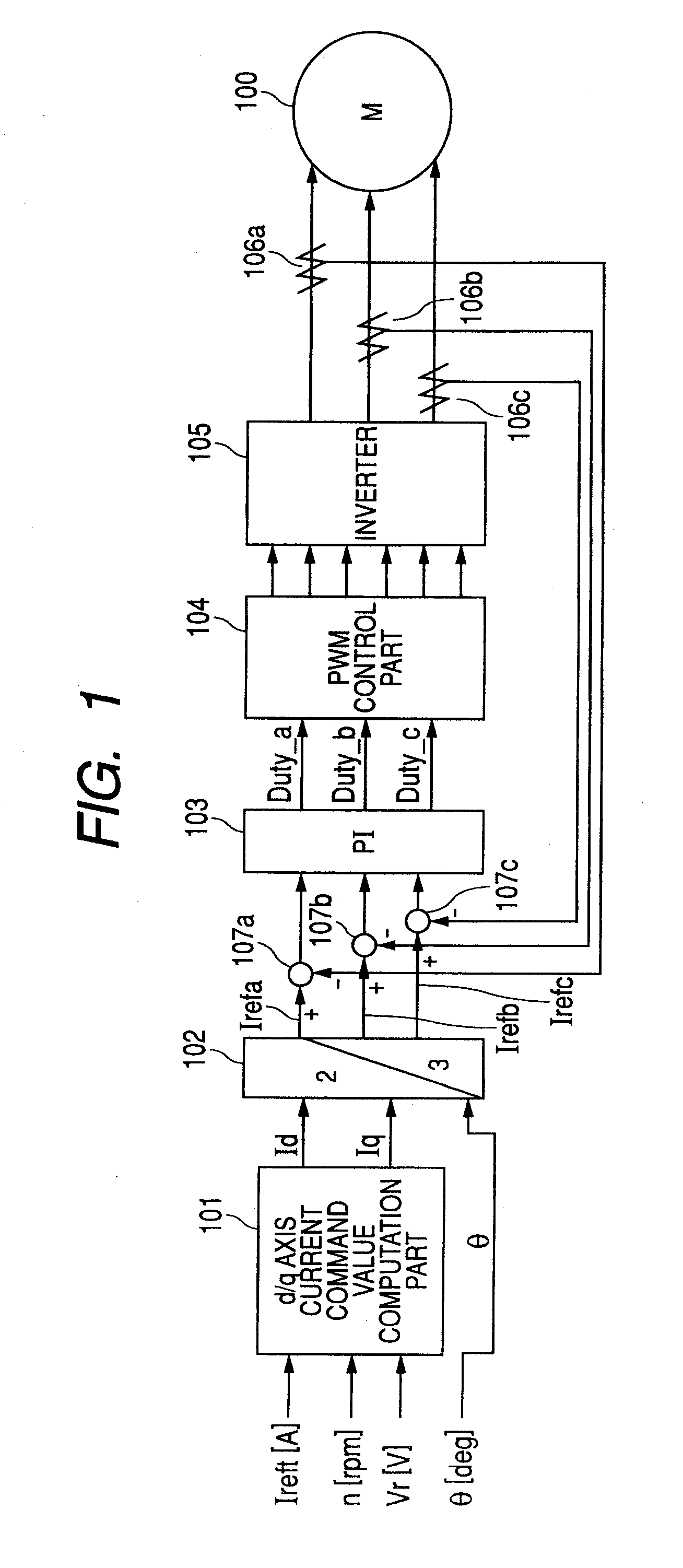

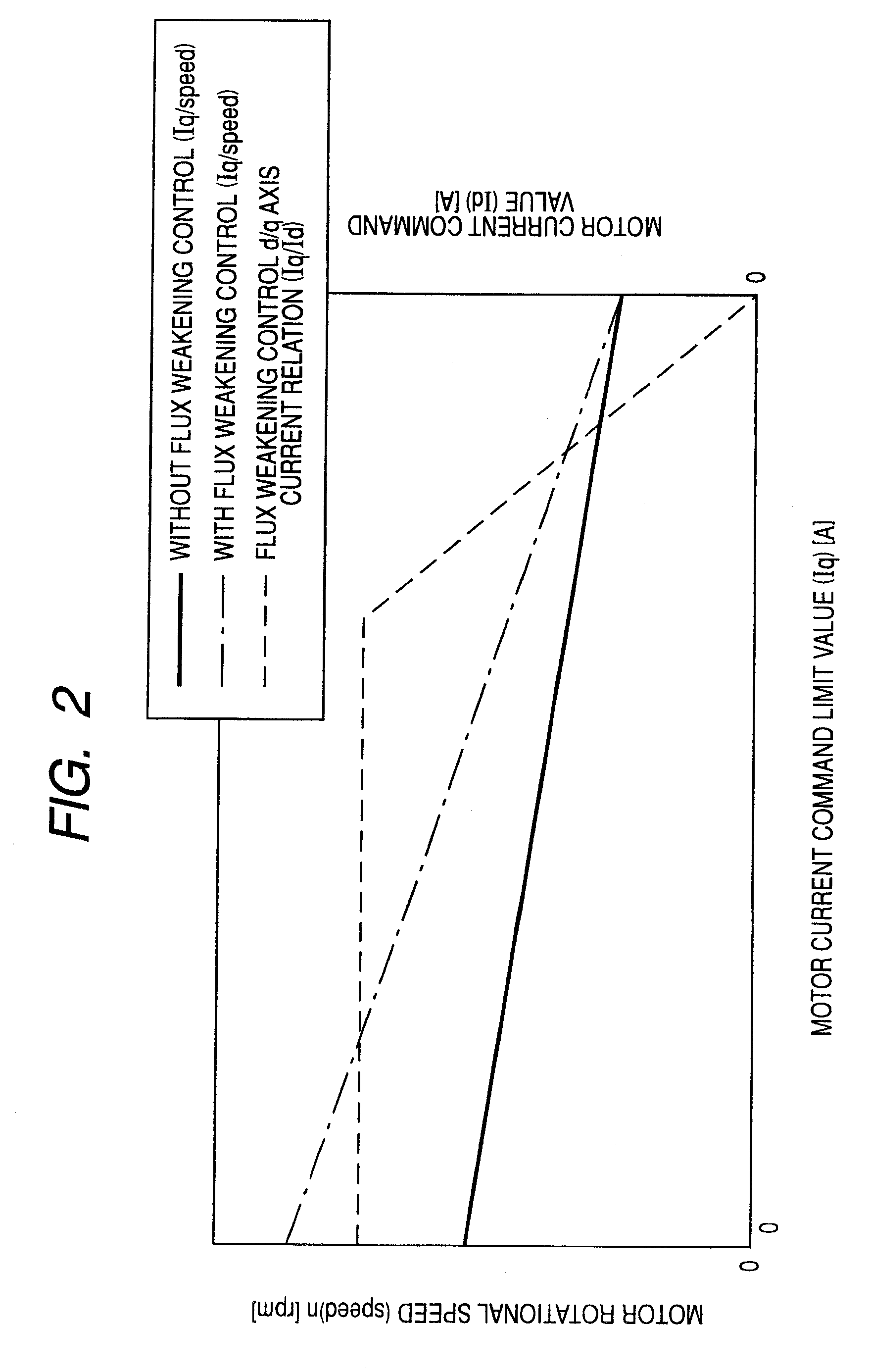

Motor drive control apparatus and electric power steering apparatus

InactiveUS20070107973A1High performanceReduce operational noiseVector control systemsElectrical steeringFlux weakeningEngineering

A motor drive control apparatus for controlling a motor has a main control part that performs a flux weakening control by a vector control of d-q axes and a rate-limit control part that controls a rate of change in a d axis current command value in the vector control. Further, there is provided a motor control apparatus for controlling a motor has a motor angular speed detection part that detects a motor angular speed of the motor and a motor control part having a current control system that controls the electric motor based on a motor current and a current command value. The motor control part calculate the current command value in which torque becomes constant by considering characteristics of the current control system based on a motor angular speed detected by the motor angular speed detection part.

Owner:NSK LTD

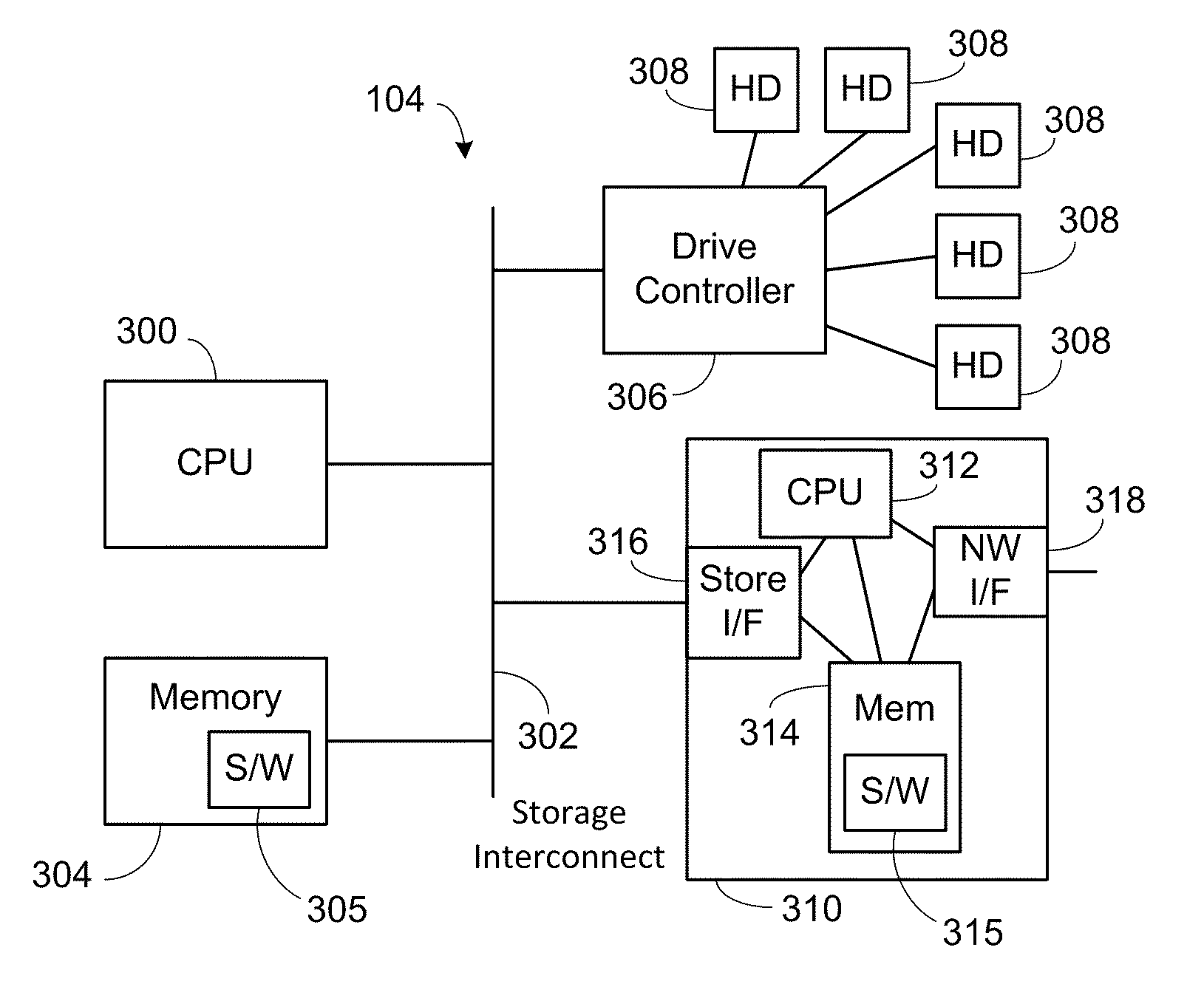

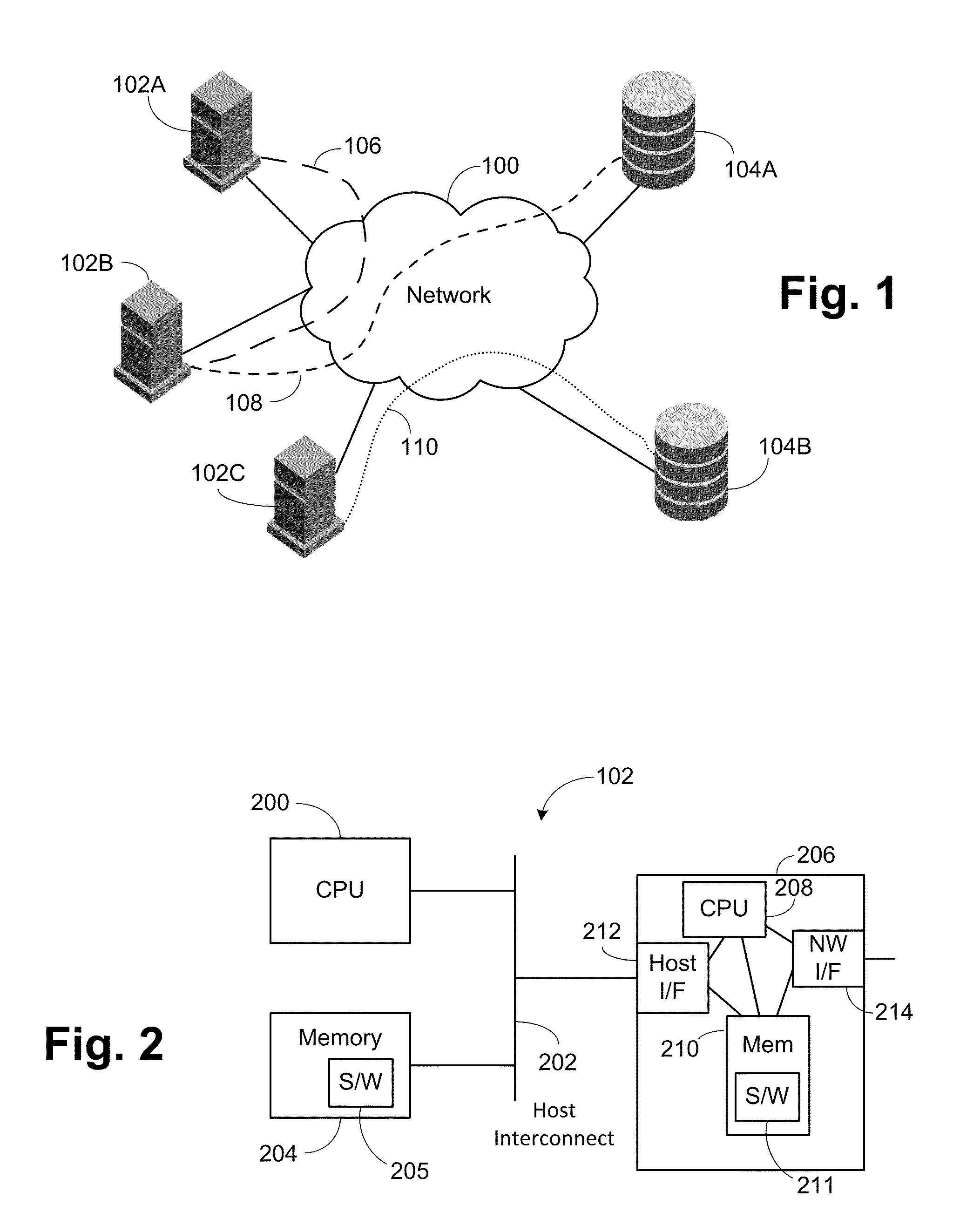

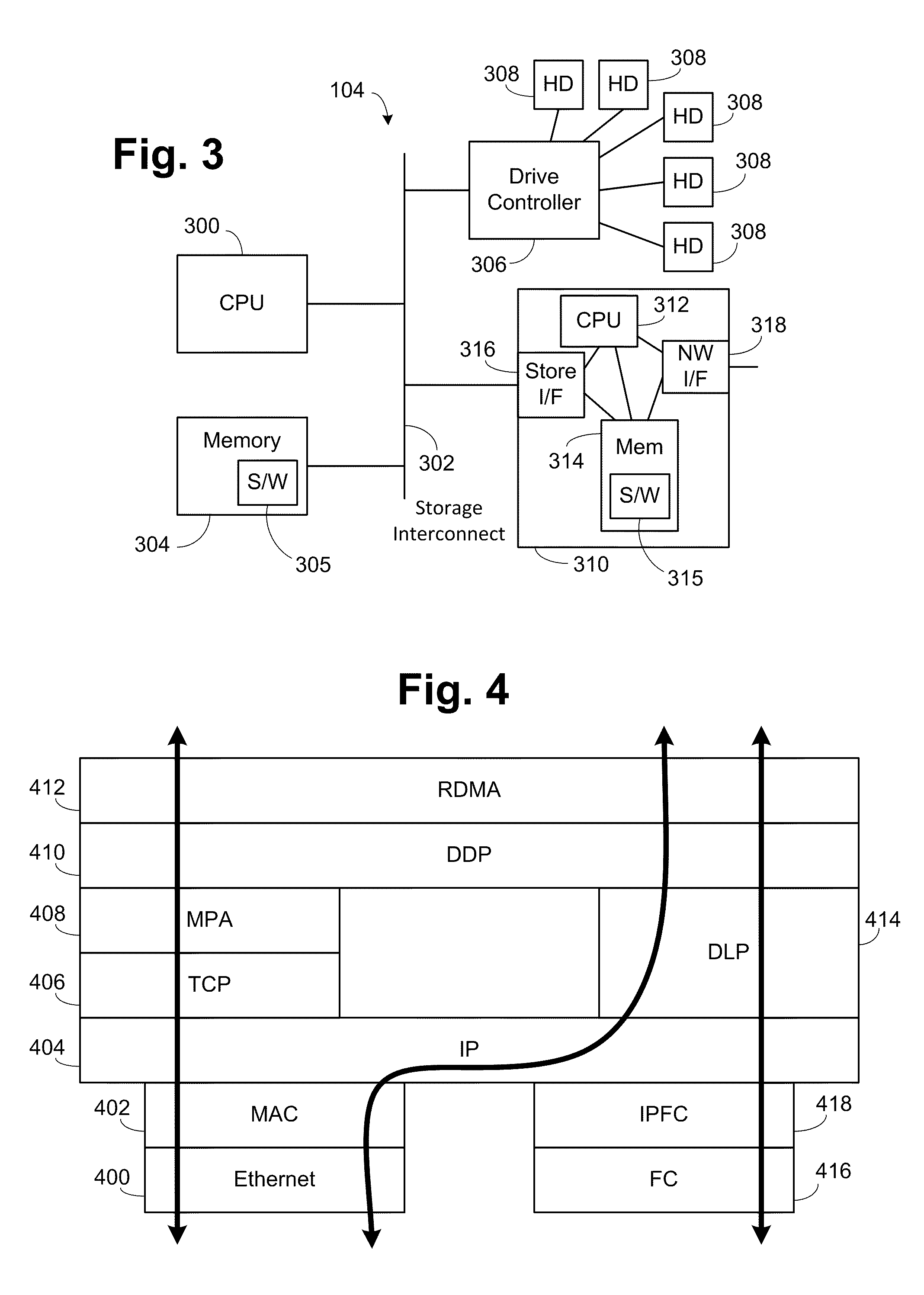

Simplified rdma over ethernet and fibre channel

InactiveUS20100183024A1High performanceSimple to implementError prevention/detection by using return channelData switching detailsIp layerTransmission protocol

A new transport protocol between the IP layer and the DDP layer for use with RDMA operations. The embodiments all operate on a CEE-compliant layer 2 Ethernet network to allow the new transport protocol to be simplified, providing higher performance and simpler implementation. The new protocol allows a CEE-compliant layer 2 Ethernet network to provide data networking using IP, storage using FCoE, and RDMA using IP and the new transport protocol, without suffering the previous performance penalties in any of these aspects.

Owner:BROCADE COMMUNICATIONS SYSTEMS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com