Patents

Literature

208results about How to "Increase incorporation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

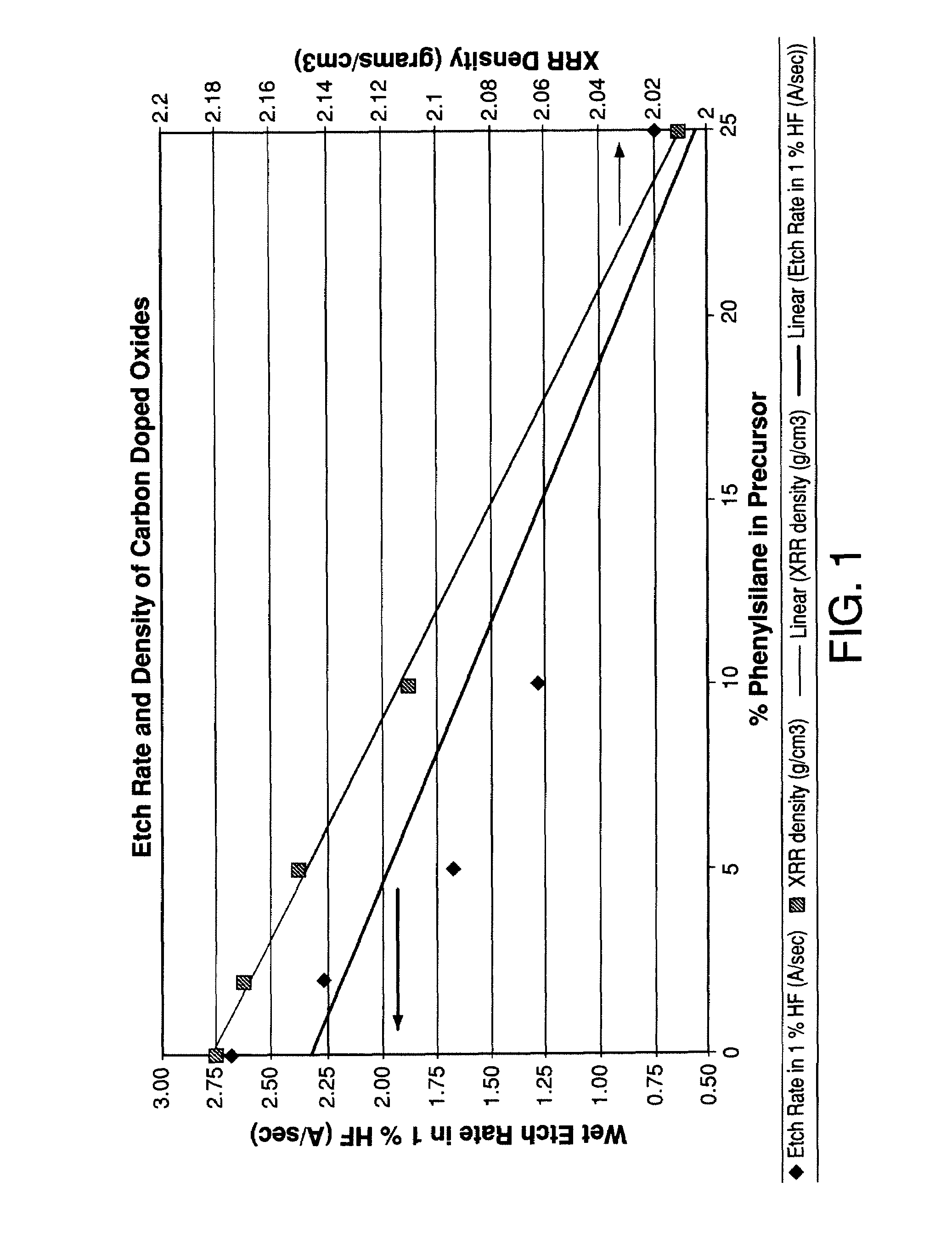

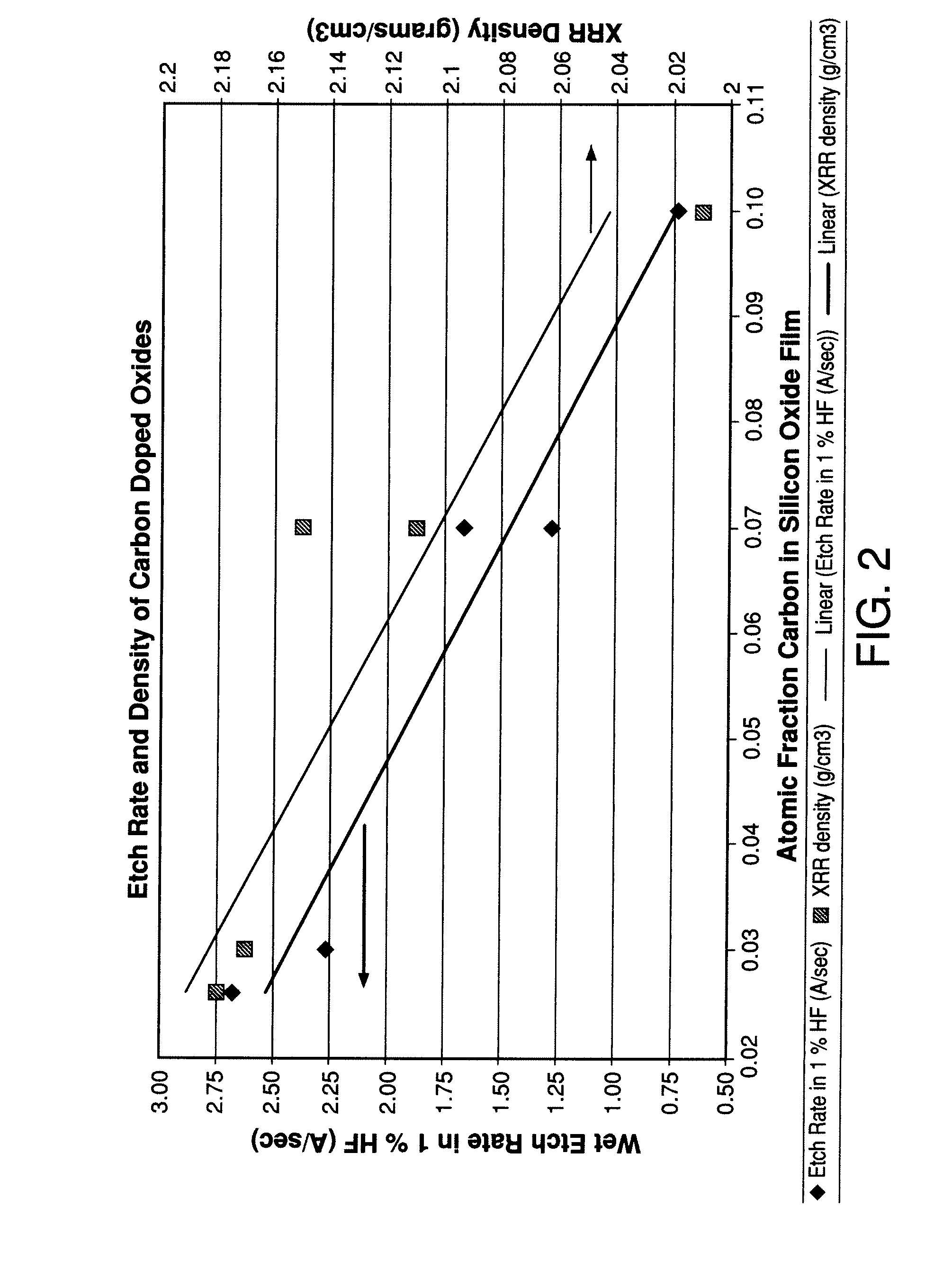

Organosilane compounds for modifying dielectrical properties of silicon oxide and silicon nitride films

InactiveUS20080124946A1Excellent etch resistanceIncreasing flow ratioSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSilicon oxideChemical Modifier

The present invention discloses a process for depositing a carbon containing silicon oxide film, or a carbon containing silicon nitride film having enhanced etch resistance. The process comprises using a silicon containing precursor, a carbon containing precursor and a chemical modifier. The present invention also discloses a process for depositing a silicon oxide film, or silicon nitride film having enhanced etch resistance comprising using an organosilane precursor and a chemical modifier.

Owner:VERSUM MATERIALS US LLC

Milled particles

InactiveUS6634576B2Increase incorporationOptimal for incorporationPowder deliveryInorganic non-active ingredientsParticulatesPolymer science

A process for milling a solid substrate in the milling chamber of a dispersion or media mill in the presence of a two or more compositions of milling media bodies is disclosed wherein all milling media bodies contribute to the grinding of the solid substrate and wherein at least one composition of media bodies provides fragments of milling media bodies that are retained with the milled solid substrate particles in the form of a synergetic commixture produced in the milling process. More specifically, a process is disclosed for preparing a synergetic commixture comprising small particles of a solid substrate and small particulates of a first material of a desired size comprising the steps of (a) providing to the milling chamber of a media mill a contents comprising a pre-mix of a solid substrate, a fluid carrier, a plurality of milling bodies of a first material having a fracture toughness Kc1, and a plurality of milling bodies of a second material having a fracture toughness Kc2; (b) operating the media mill to grind the solid substrate and degrade at least a portion of the milling bodies of first material to produce a dispersion in the fluid carrier comprising a synergetic commixture of small particulates of the first material and small particles of the solid substrate having a desired size equal to or less than a size Sp; (c) separating the dispersion from any milling bodies and solid substrate particles having a size larger than Sp; and (d) optionally removing the fluid carrier from the dispersion to form a synergetic commixture free of fluid and comprising the particles and the small particulates, wherein KC2 is greater than KC1.

Owner:RTP PHARMA +1

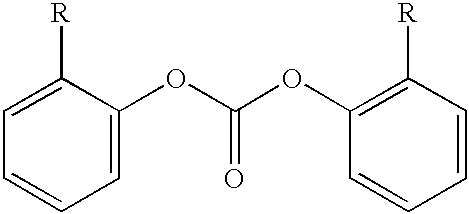

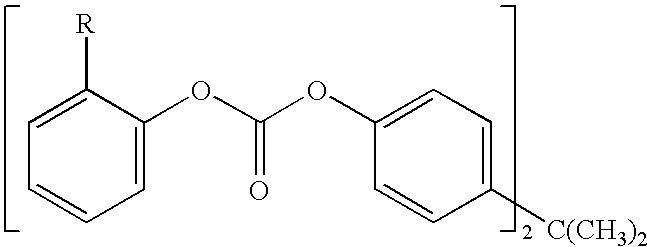

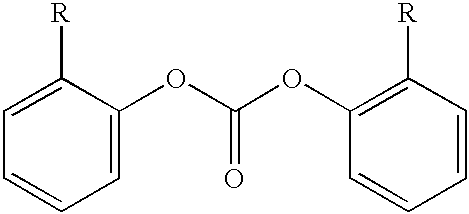

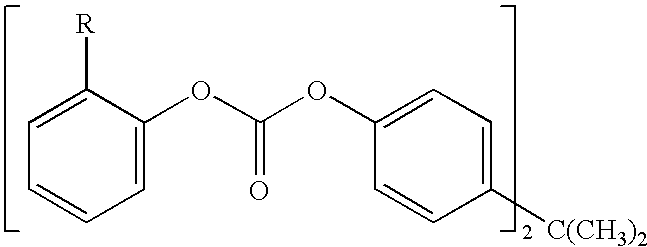

Method for end-capping polycarbonate resins and composition for use in same

A method for end-capping polycarbonate resins, comprising the step of processing a mixture comprising a polycarbonate having free hydroxyl-end groups and an end-capping reagent in a melt transesterification reaction to produce a polycarbonate resin, wherein the end-capping reagent comprises a mixture of: (a) at least one species of a symmetrical activated aromatic carbonate, and (b) at least one species of an optionally-substituted phenol, whereby said end-capping reagent reacts with at least some of the free hydroxyl end-groups of the polycarbonate to produce an end-capped polycarbonate resin.

Owner:SABIC GLOBAL TECH BV

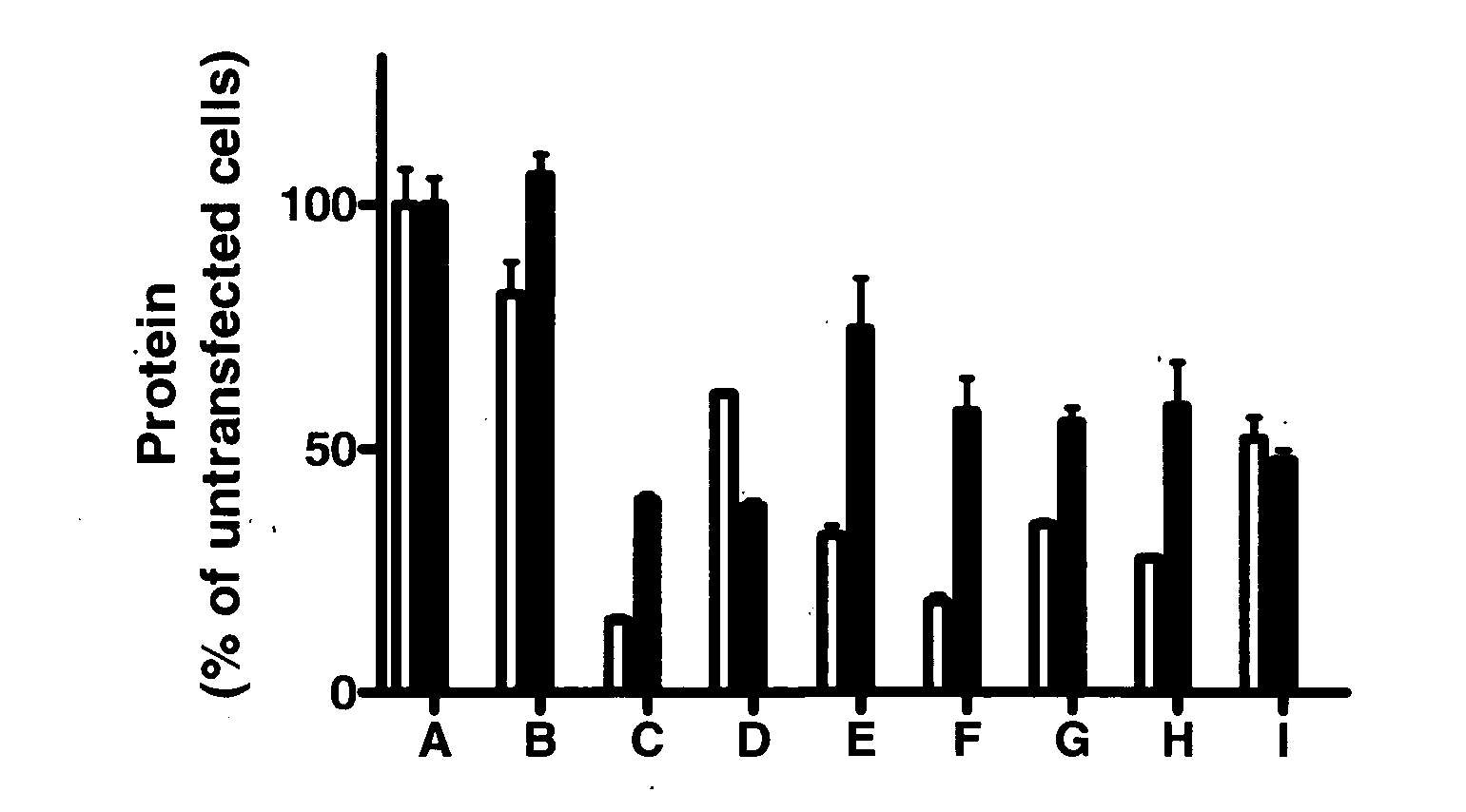

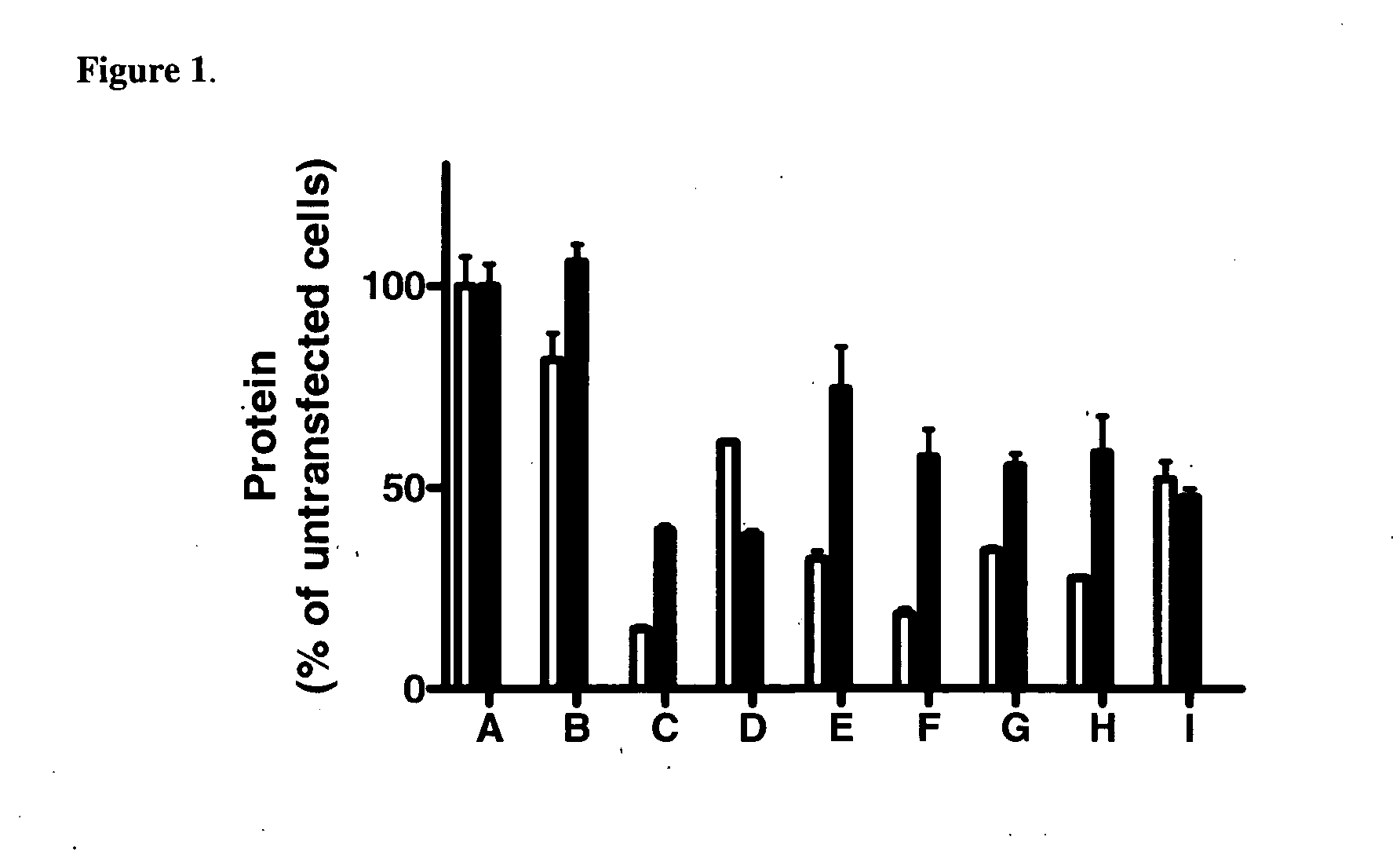

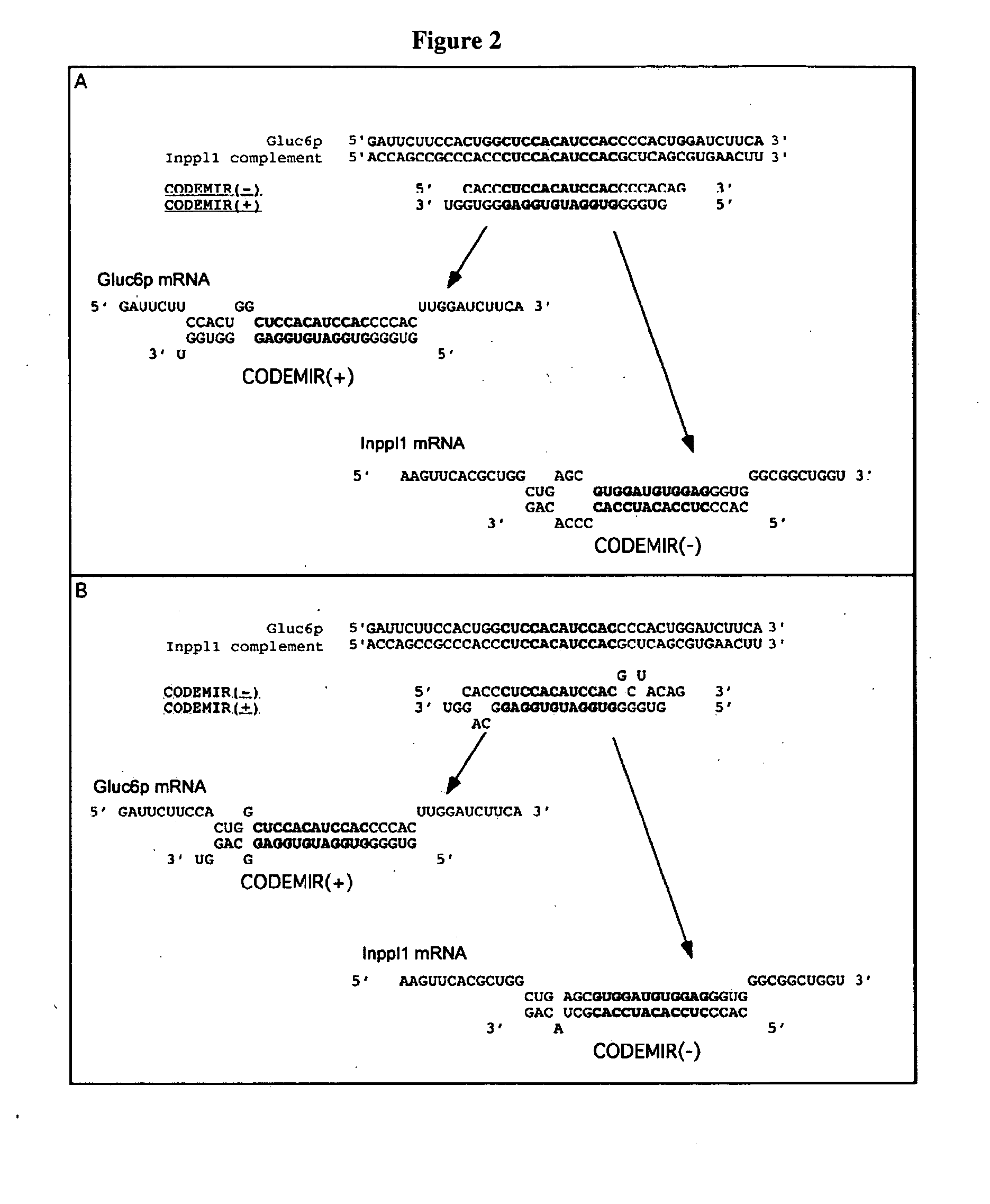

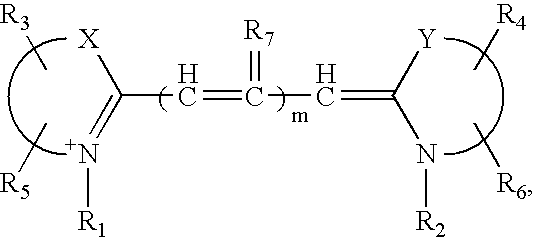

Multitargeting interfering RNAs having two active strands and methods for their design and use

InactiveUS20070269815A1Increase and decrease modulationReduced responseOrganic active ingredientsActivity regulationBioinformaticsRNA molecule

Interfering RNA molecules are now designed and produced with specificity for multiple binding sequences present in distinct genetic contexts in one or more pre-selected target RNA molecules and are used to modulate expression of the target sequences. The multitargeting interfering RNA molecules have two strands that target multiple target sites on one or more pre-selected RNA molecules. Such a multitargeting interfering RNA approach provides a powerful tool for gene regulation.

Owner:JOHNSON & JOHNSON RES PTY LTD

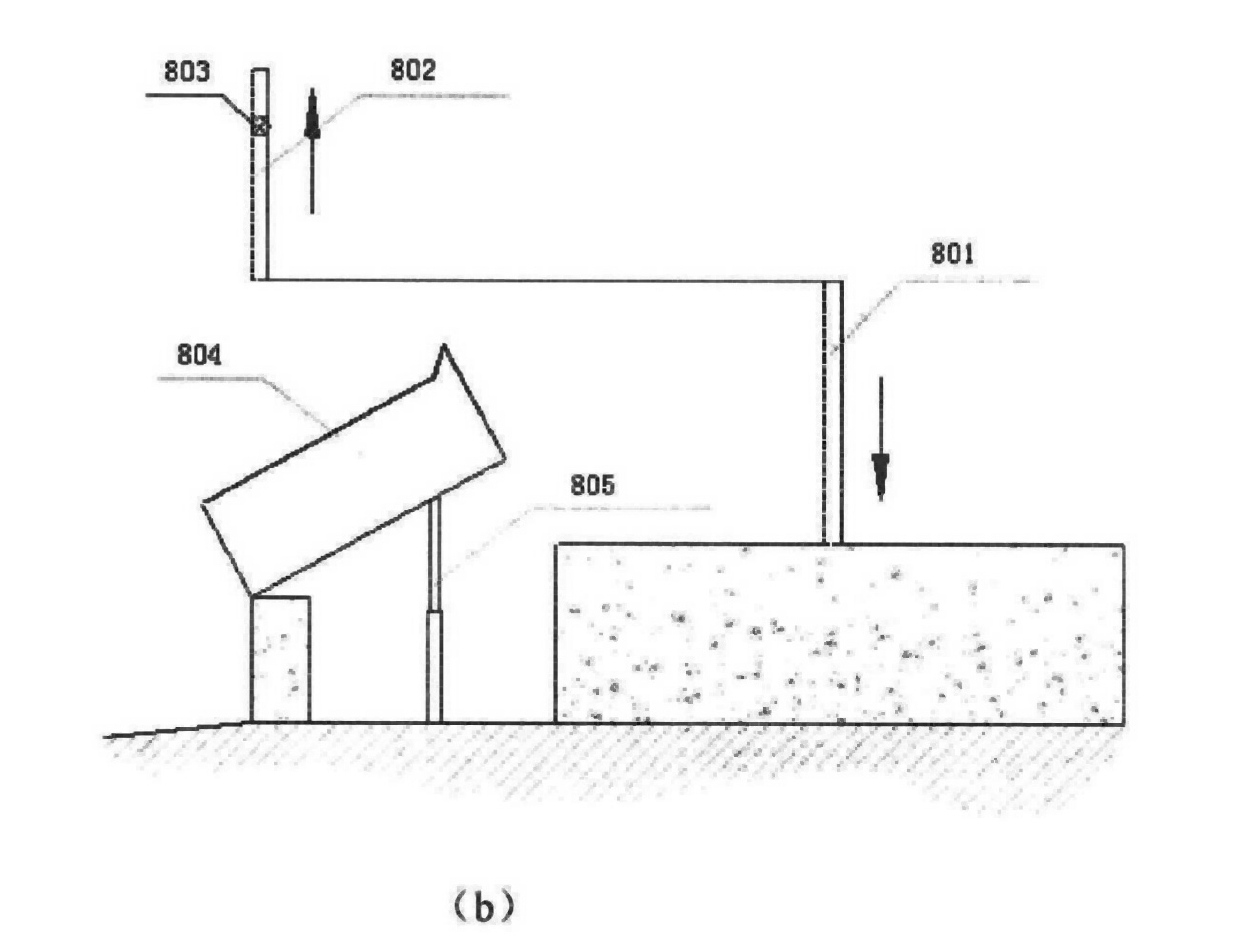

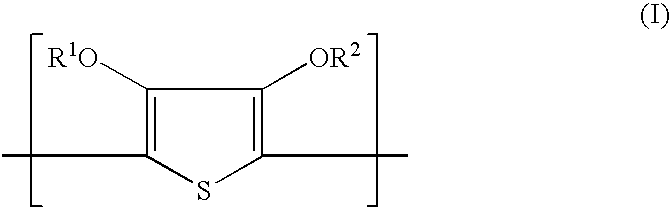

Thin film inorganic light emitting diode

InactiveUS6706551B2Economical and simpleEasy and economical to manufactureMaterial nanotechnologyPigmenting treatmentZinc sulfideLight-emitting diode

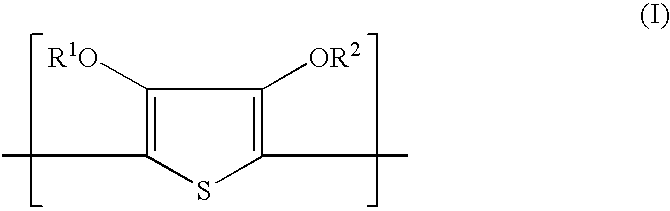

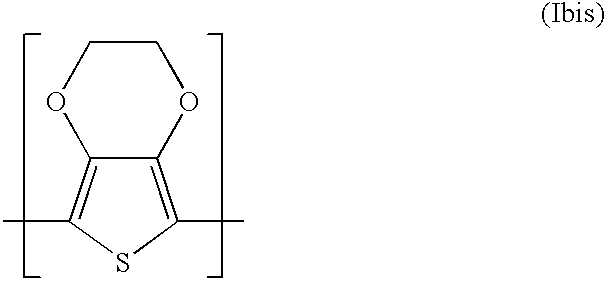

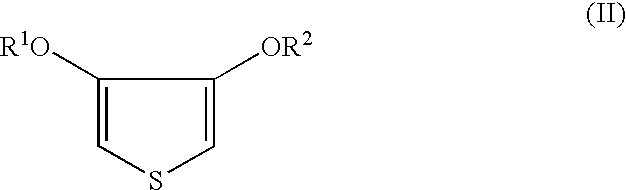

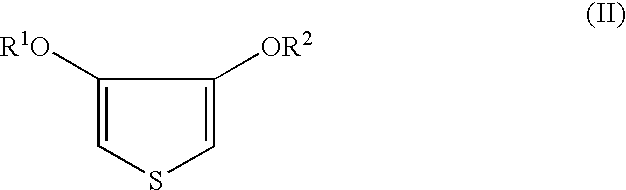

A method for the manufacturing of a Thin Film Inorganic Light Emitting Diode is disclosed. The device contains in one single layer or in a double layer a dispersion of zinc sulfide doped with a luminescent centre, and a water-compatible p-type semiconductive polymer, preferably a polythiophene / polymeric polyanion complex.

Owner:AGFA GEVAERT AG

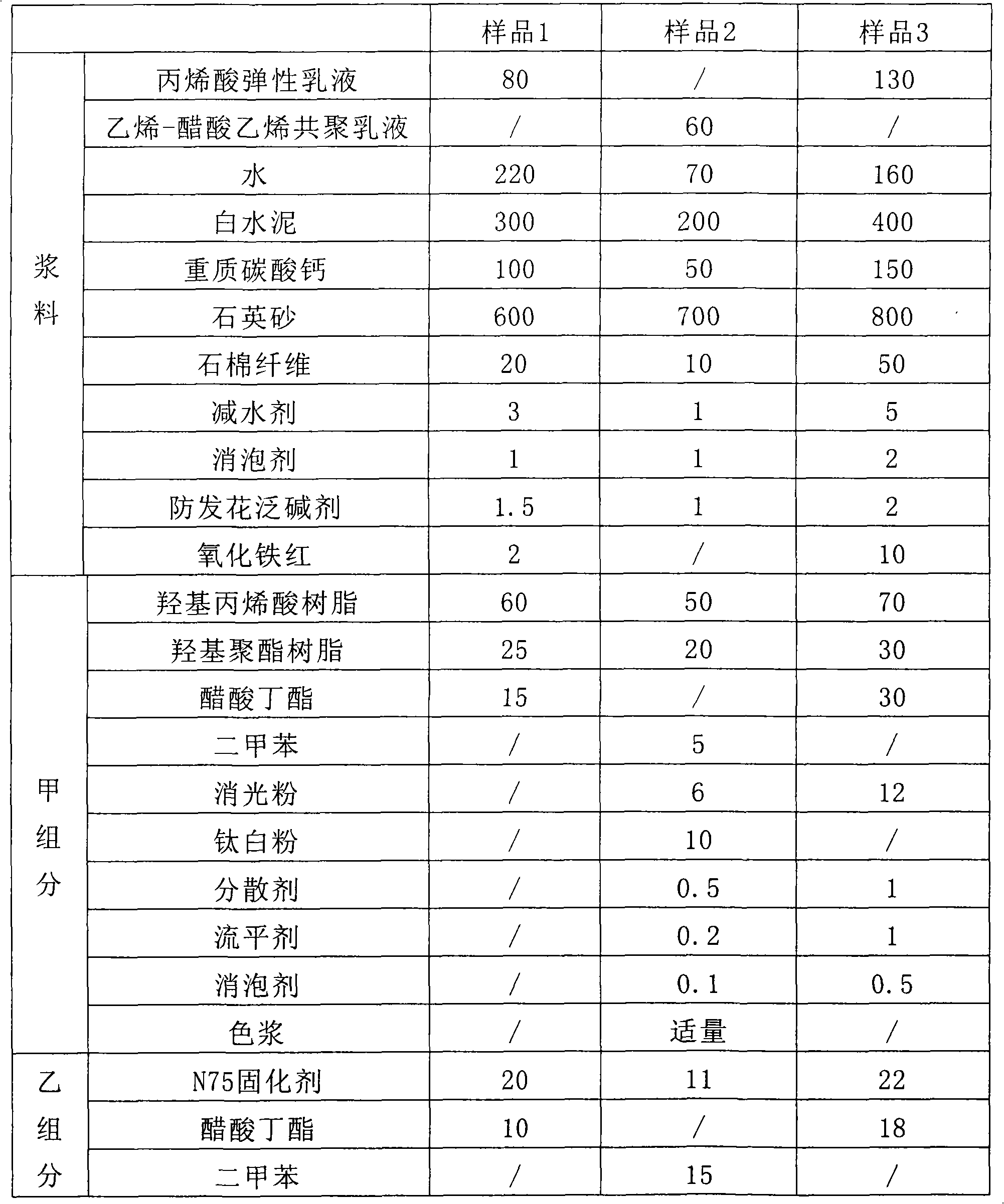

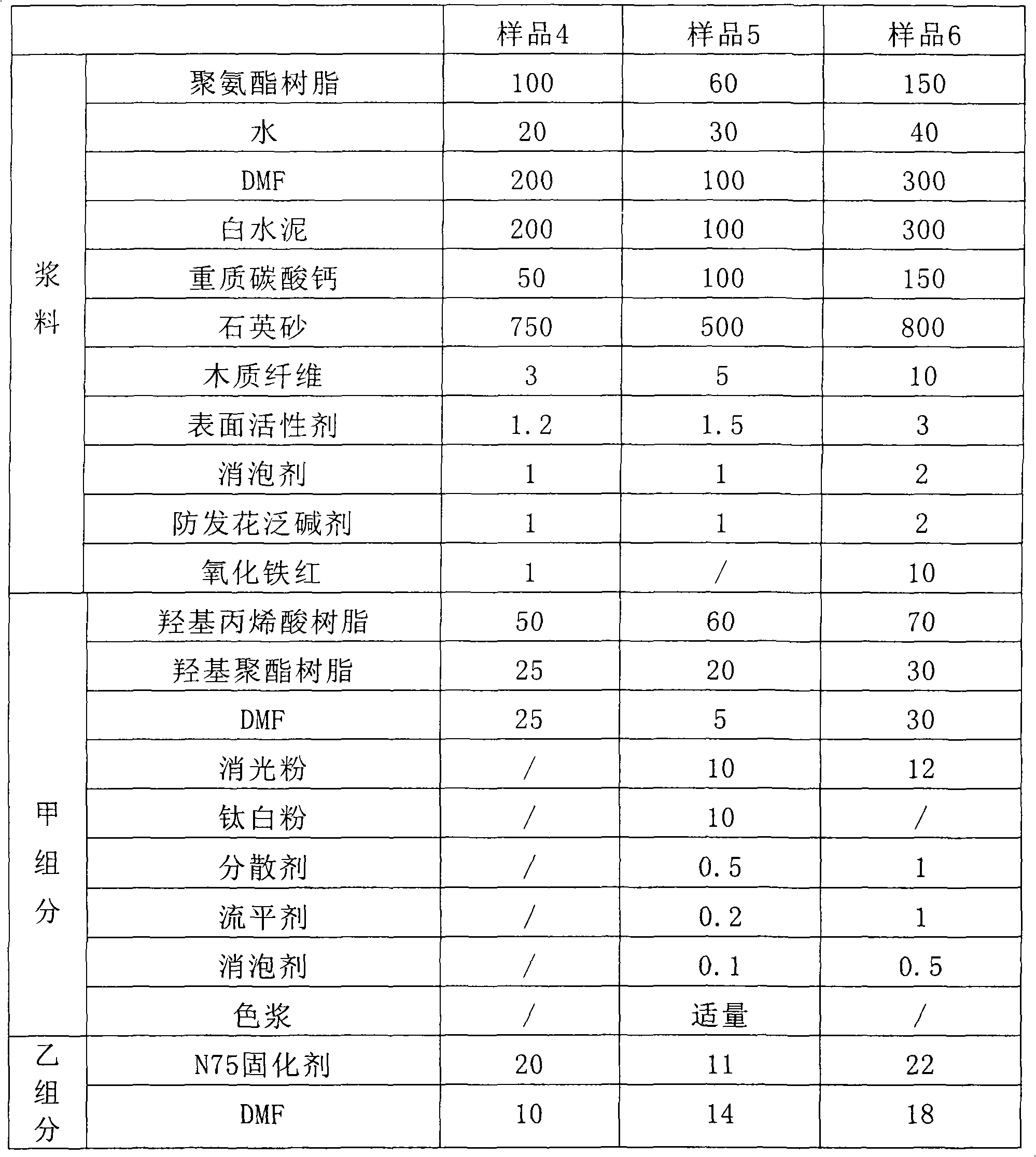

Flexible ceramic-like tile and production process thereof

The invention provides a face brick for decorating a building wall and a production technique, in particular to a decorative face brick adhered on the outer surface of a heat-insulating system of an external wall and the production technique of the face brick. The face brick adopts high molecular polymer and cement as gelled materials, quartz sand and / or calcium carbonate as aggregate, and acrylic acid polyurethane resin as glazed face. The face brick consists of polymers formed by cement and high molecular polymer particles, and has high strength, high tenacity, excellent resistance to pollution and light mass; the brick can release the temperature stress slowly and is easy to be cleaned. The production technique is simple and is suitable for large-scale production.

Owner:北京博达晟业科技发展有限公司

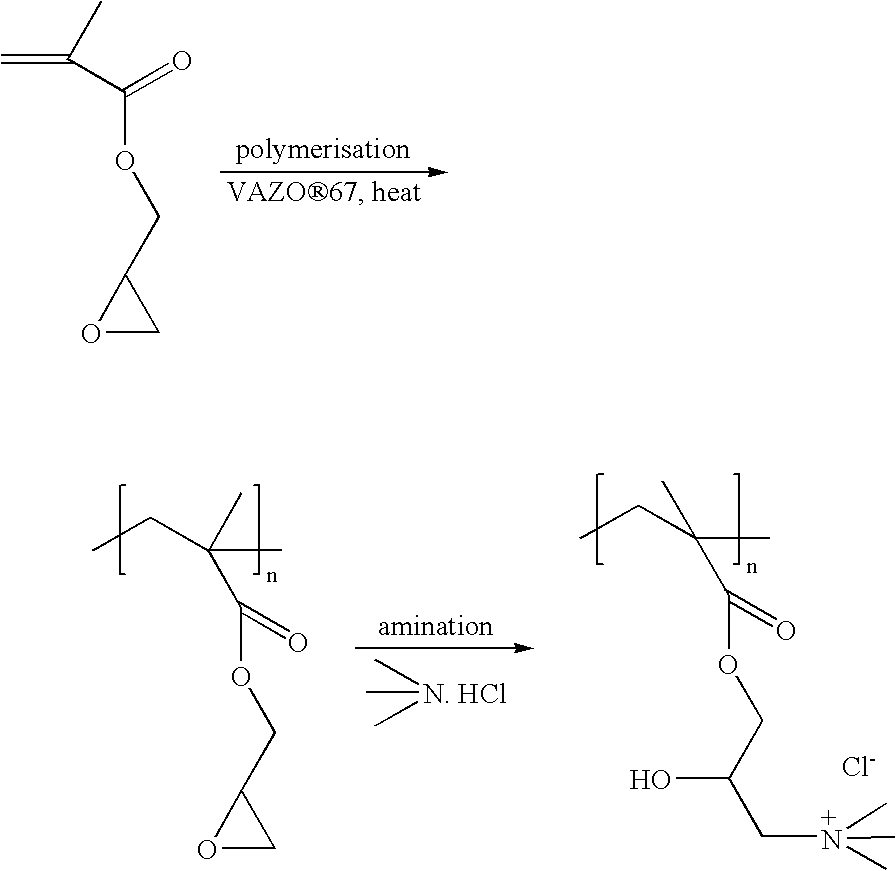

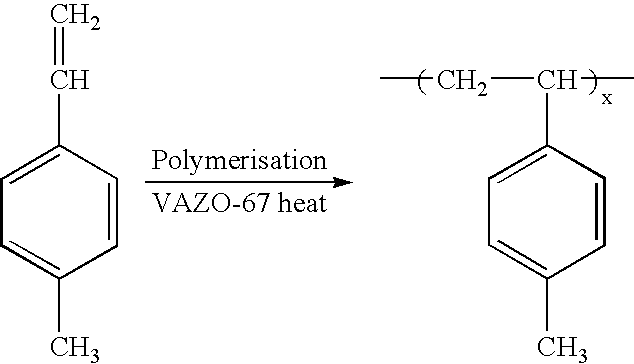

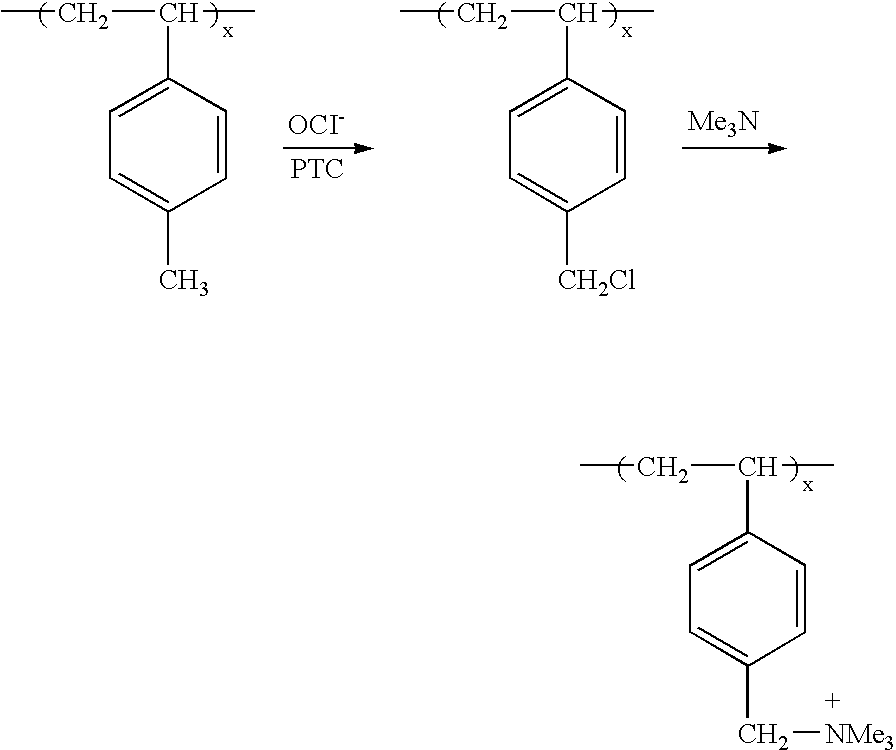

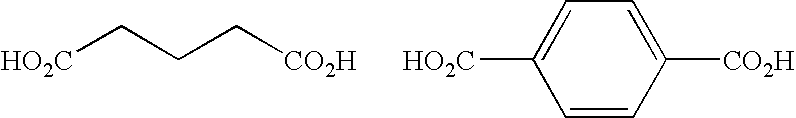

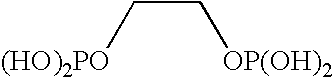

Polymer Beads Incorporating Iron Oxide Particles

InactiveUS20080099715A1Increase incorporationEasy to cleanIon-exchanger regenerationInorganic material magnetismPhysical chemistryIon exchange

The invention provides a process for preparing polymer beads incorporating magnetic iron oxide particles, which process comprises producing a dispersion having a continuous aqueous phase and a dispersed organic phase, the organic phase comprising one or more polymerisable monomers, magnetic iron oxide particles and an organophosphorus dispersing agent for dispersing the magnetic iron oxide particles in the organic phase, and polymerising the one or more polymerisable monomers to form the polymer beads incorporating the magnetic iron oxide particles; complexing and ion exchange resins prepared by this process; methods for separating transition metal ions and other ions from an aqueous solution using the complexing and ion exchange resins; and polymer beads comprising a polymeric matrix having magnetic iron oxide particles and organophosphorus dispersing agent dispersed substantially uniformly therein.

Owner:COMMONWEALTH SCI & IND RES ORG +1

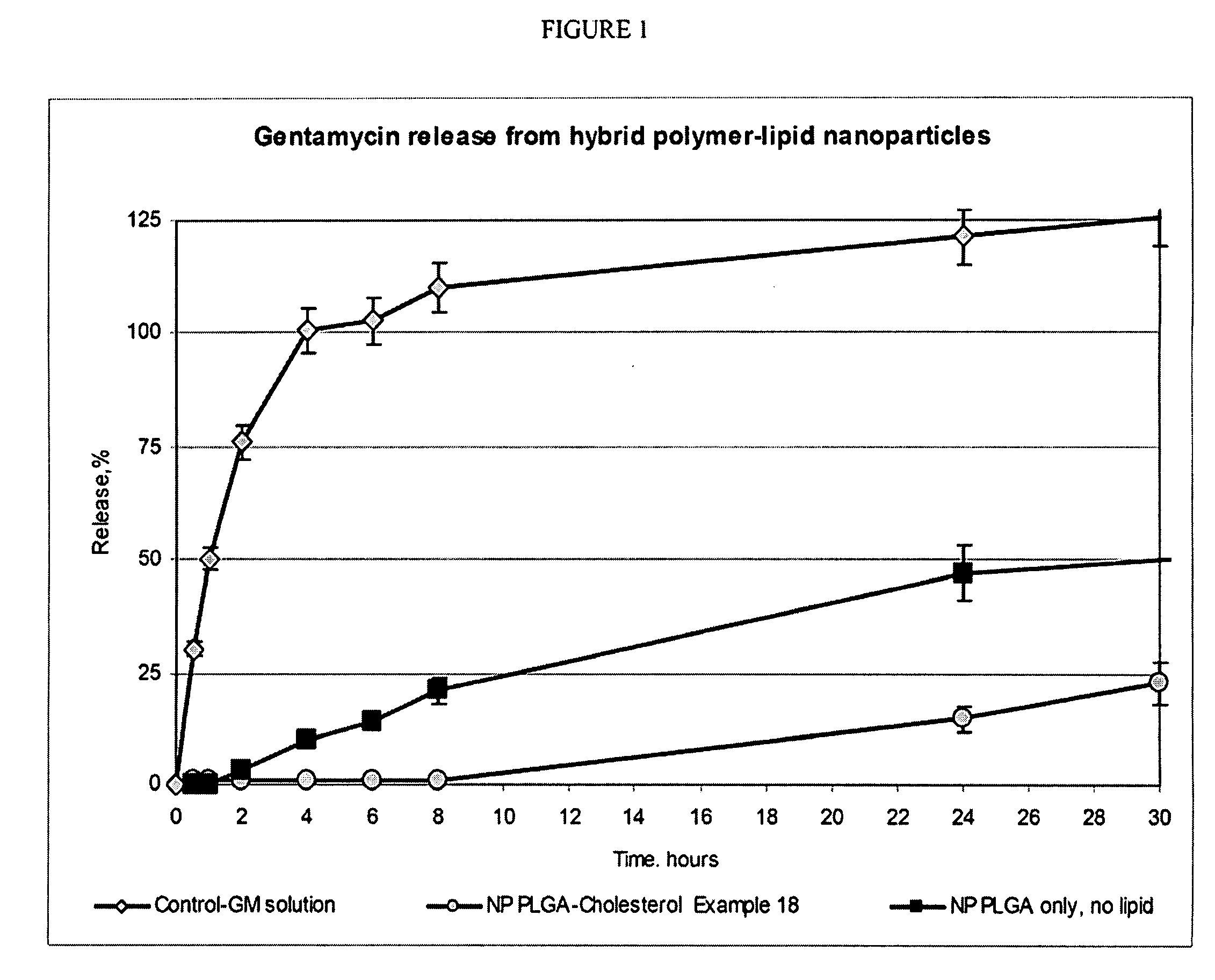

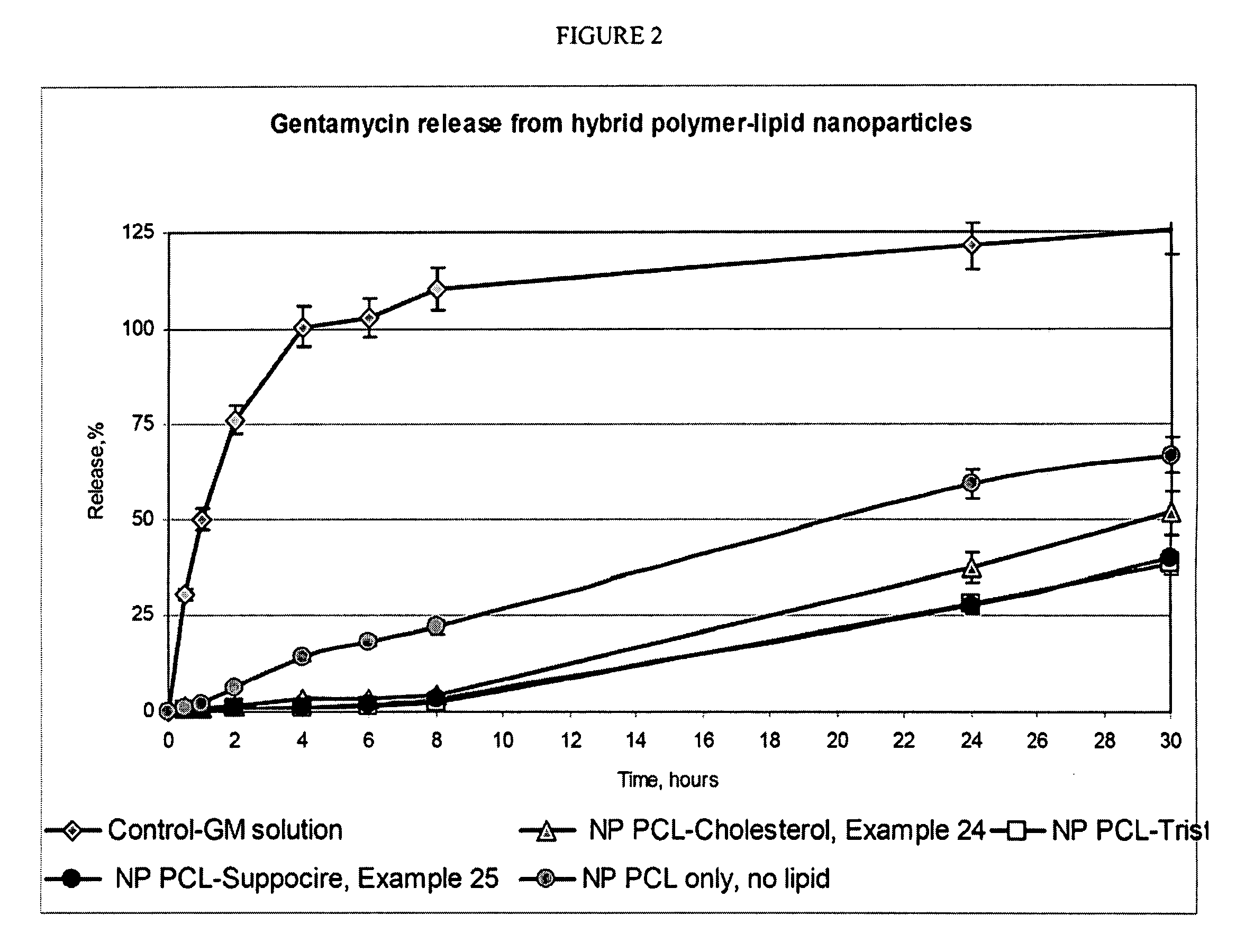

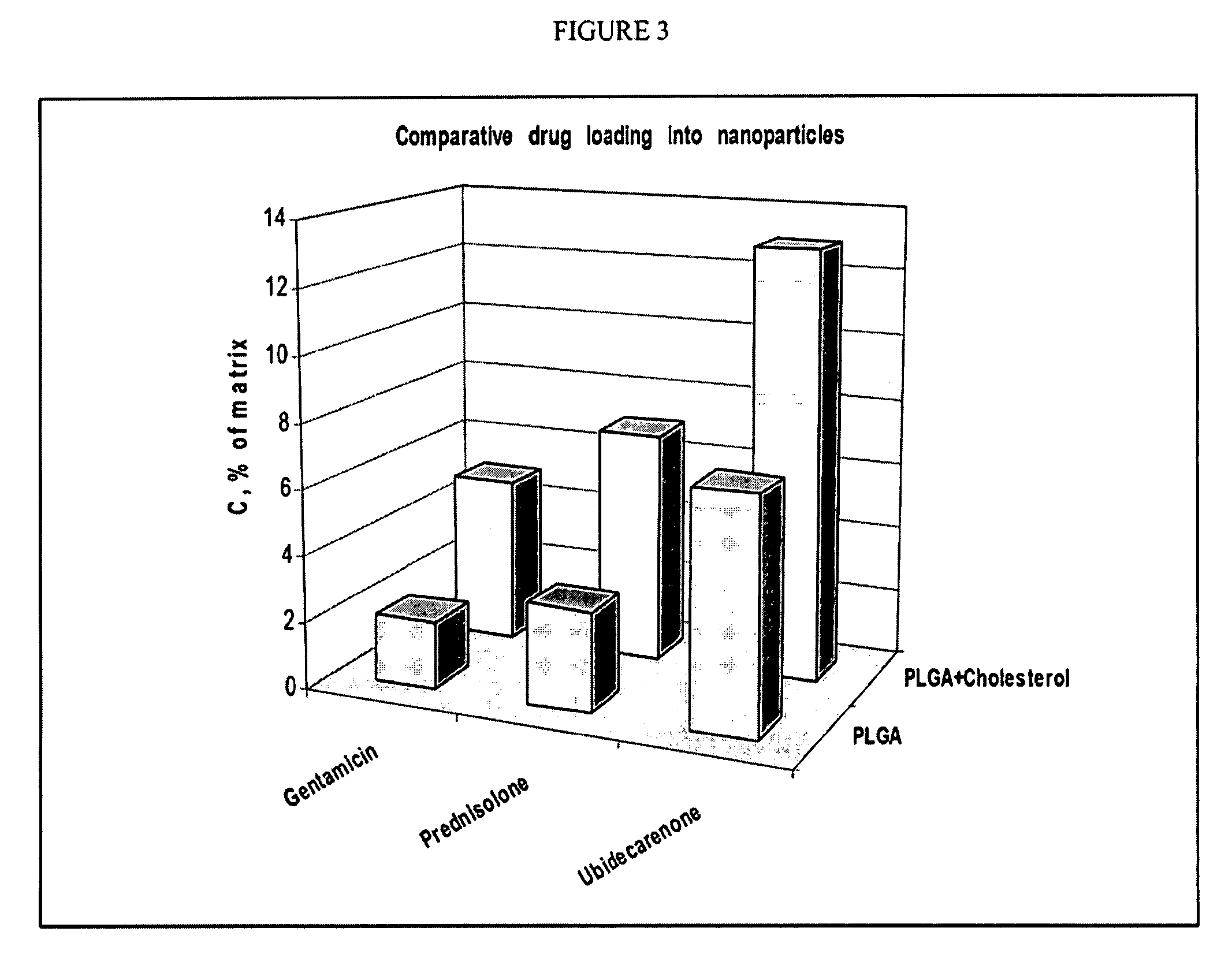

Hybrid lipid-polymer nanoparticulate delivery composition

The invention relates to a nanoparticulate colloidal delivery vehicle comprising a biodegradable polymer in combination with a hydrophobic lipid component. Variation of the lipid and polymer types and variation in the ratio between the polymer and lipid components allows regulation of drug loading and release rate.

Owner:ALPHARX

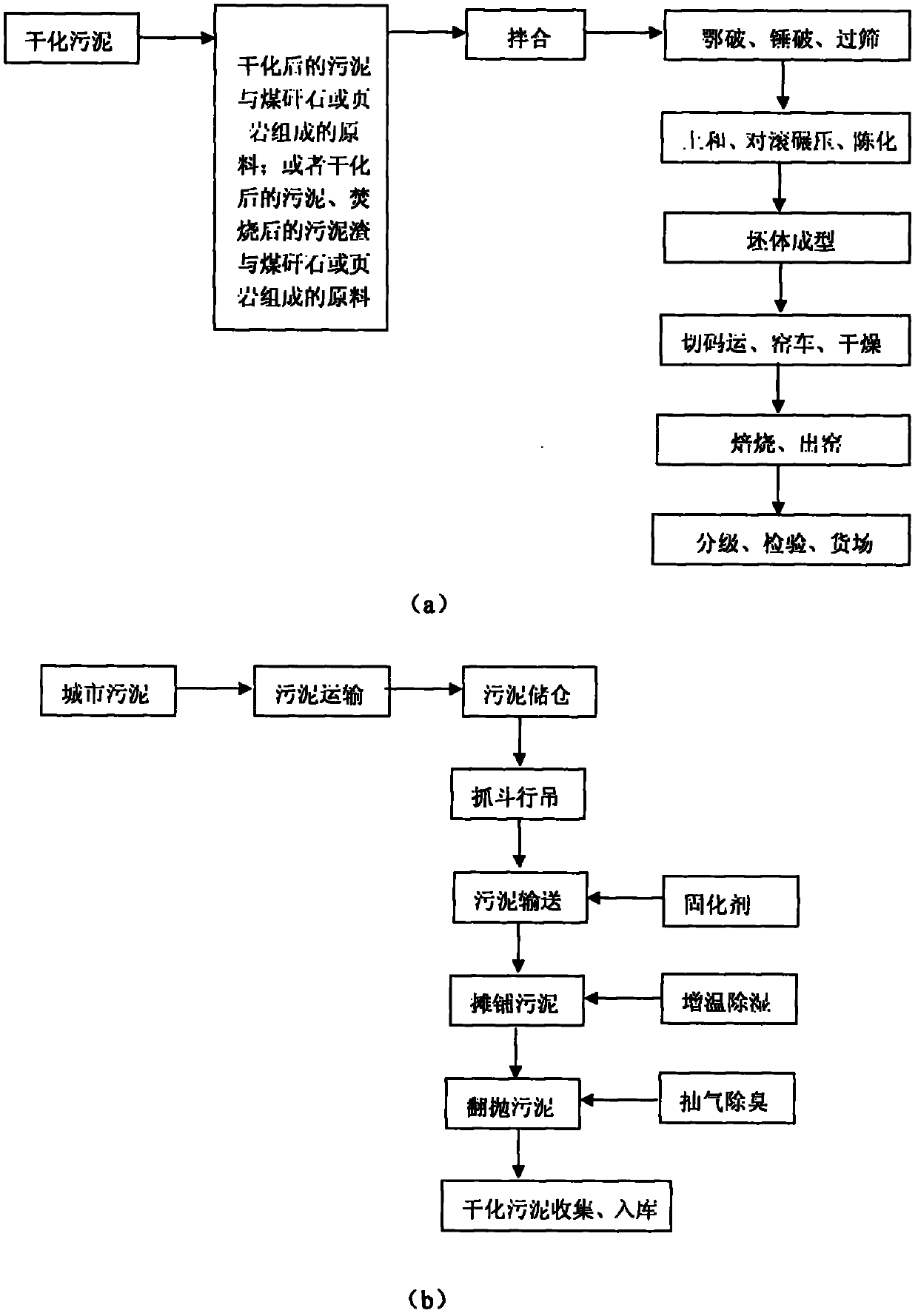

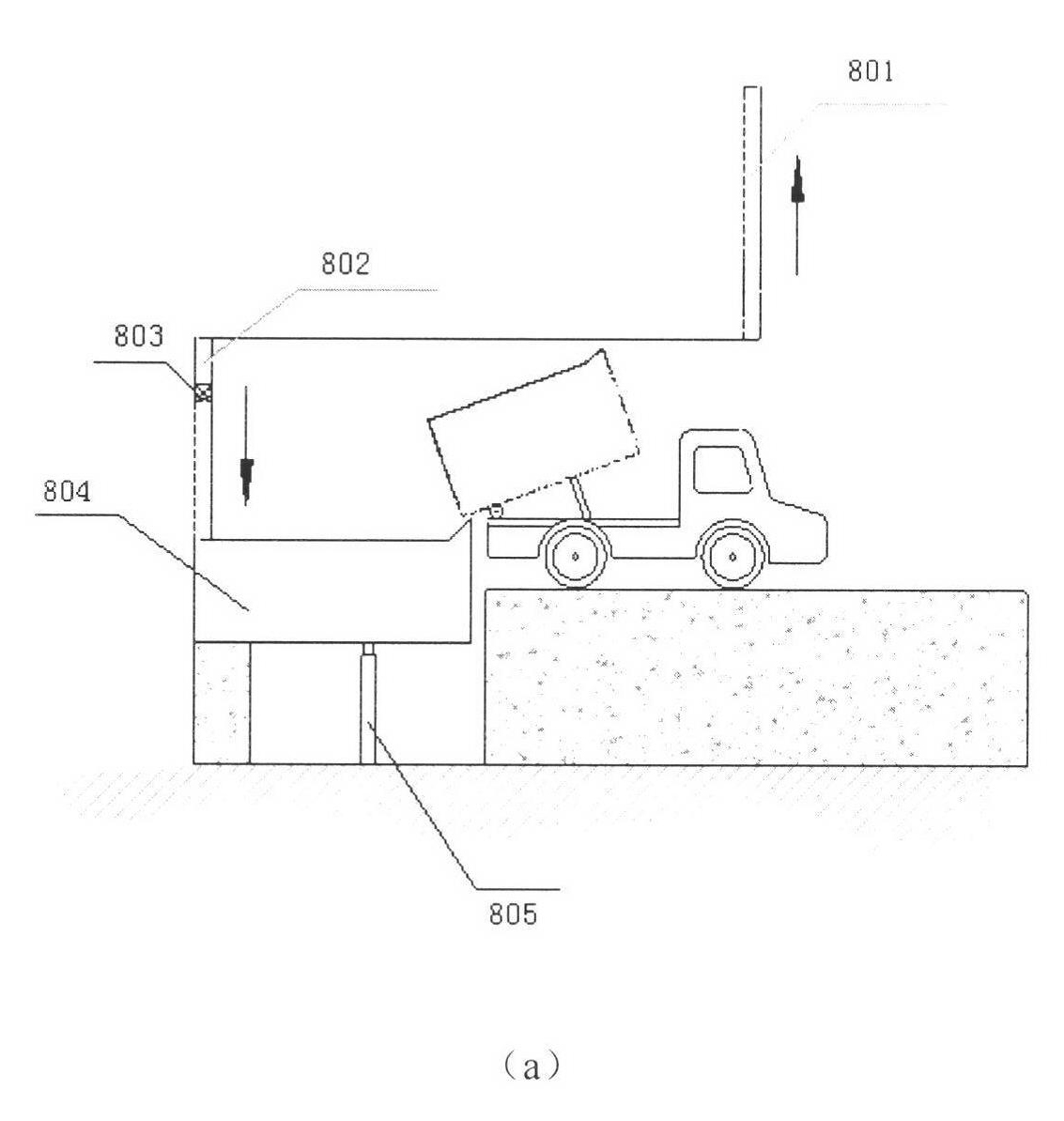

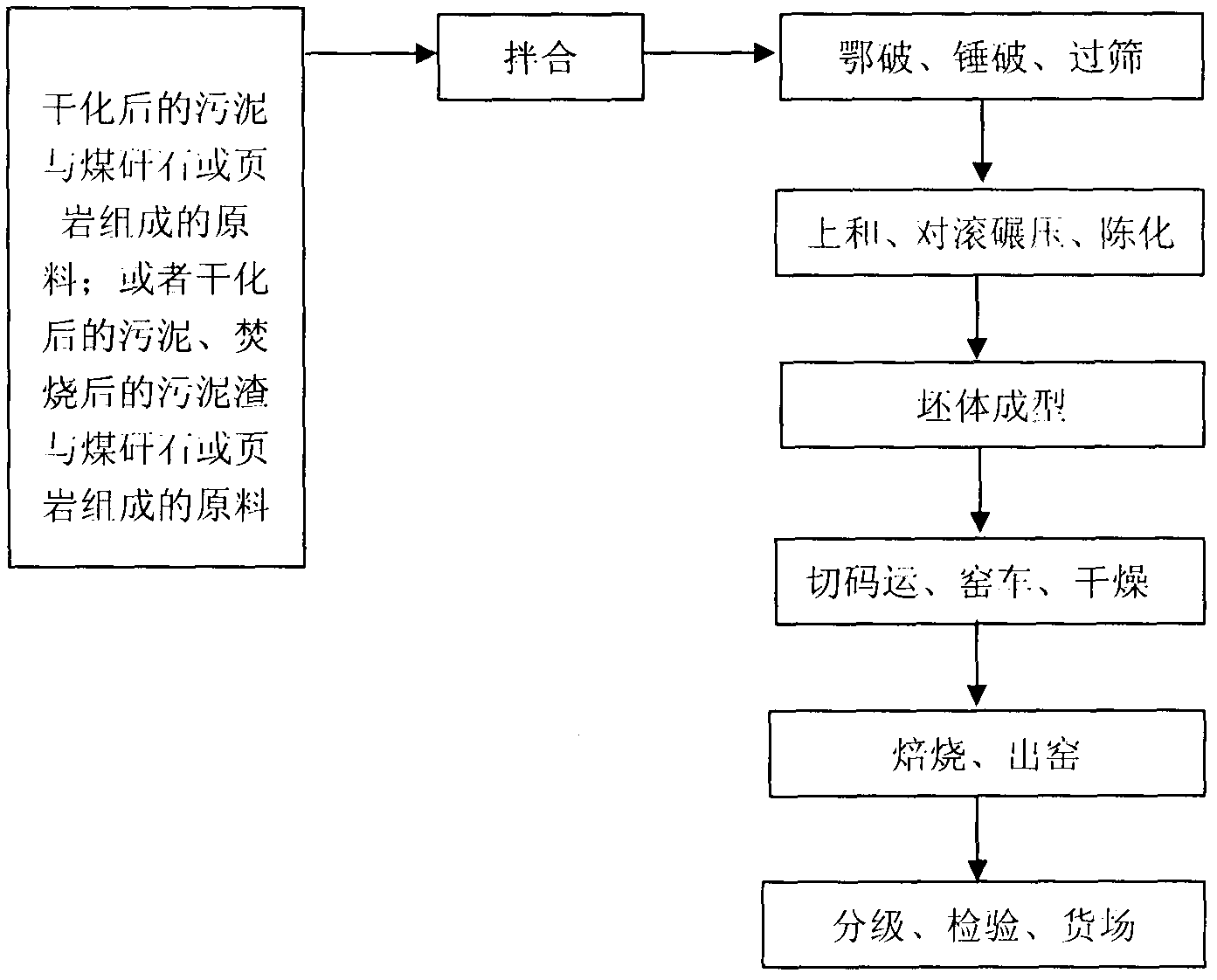

Method for brickmaking by comprehensive utilization of desiccated sludge

ActiveCN102381877AReduce moisture contentCrushed fullySludge treatment by de-watering/drying/thickeningEnergy based wastewater treatmentBrickSolar drying

The invention discloses a method for brickmaking by comprehensive utilization of desiccated sludge; sludge is desiccated and is used as a raw material for brickmaking; the method comprises the following steps: firstly transporting municipal sludge with water content of 80-85% to a sludge warehouse for sealing storage, grabbing the sludge in the sludge warehouse by controlling a grab bucket traveling boom through a PLC system, transferring the sludge to a feed hopper of a sludge feeding device, adding a curing agent into the feed hopper, fully stirring, transporting the sludge to a desiccationchamber of a desiccation device, performing desiccation in the desiccation chamber by solar energy and waste heat of a tunnel furnace so as to obtain sludge which is used as a material for brickmaking. The invention performs desiccation by using brickkiln waste heat and solar energy; the physical heat at a brick-baking tail part of the tunnel furnace is made full use of, which increases self heat, and saves a lot of energy; sludge is added into various raw materials, and no clay is used; with respect to baked brick production by using municipal sludge with a high mixing amount, the highest mixing amount of municipal sludge is up to 50%.

Owner:南京鑫翔环保产业有限公司

Roller with ink-repellent coating

InactiveUS20010051567A1Reduce solutionReduce contentShaft and bearingsMetal-working apparatusPolyolefinFluorocarbon

A roller comprising a roller core and a roller covering being composed of an elastomer or elastic plastic material is characterized in that the elastomer or elastic plastic material of the roller covering cadditionally comprises fluorinated polyolefin. Preferably, from 0.2 to 25% by weight of a fluorocarbon plastic, in particular of polytetrafluoroethylene powder or fiber, is incorporated into the roller coating material to improve the ink-repellent properties of the roller covering. In one embodiment, the fluorinated polyolefin is employed in the form of a fibrous material, e.g. a web or the like, provided with the coating material and wrapped around the roller to form a surface layer.

Owner:PAUL SAUER & WALZENFAB

Thin film Inorganic Light Emitting Diode

InactiveUS20020151094A1Economical and simpleEasy and economical to manufactureMaterial nanotechnologyPigmenting treatmentThin membraneZinc sulfide

A method for the manufacturing of a Thin Film Inorganic Light Emitting Diode is disclosed. The device contains in one single layer or in a double layer a dispersion of zinc sulfide doped with a luminescent center, and a water-compatible p-type semiconductive polymer, preferably a polythiophene / polymeric polyanion complex.

Owner:AGFA GEVAERT AG

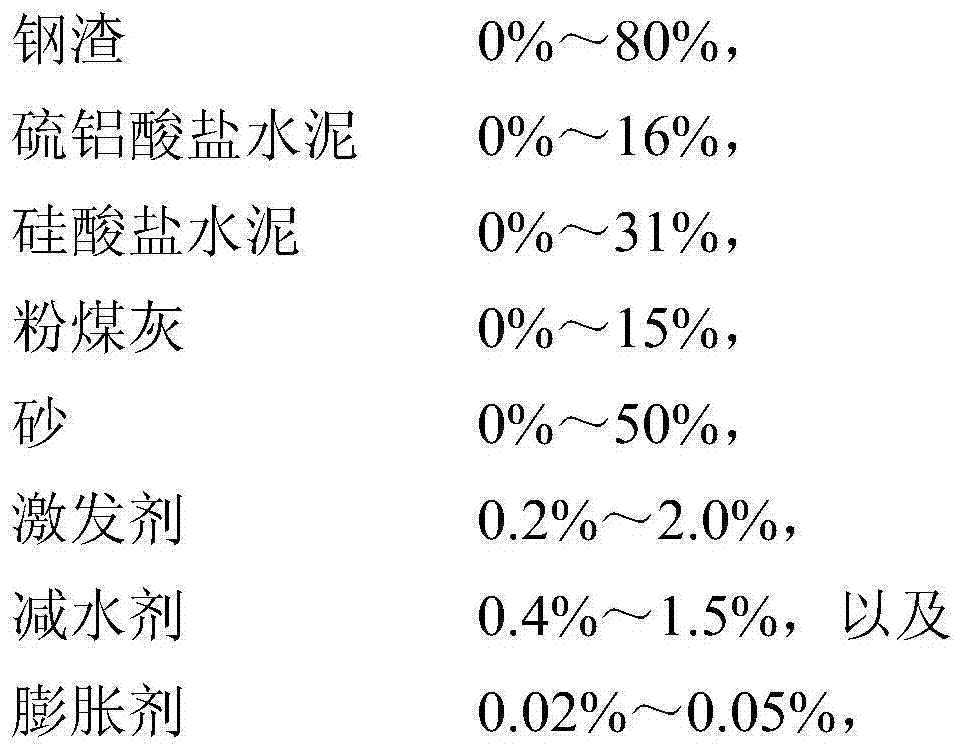

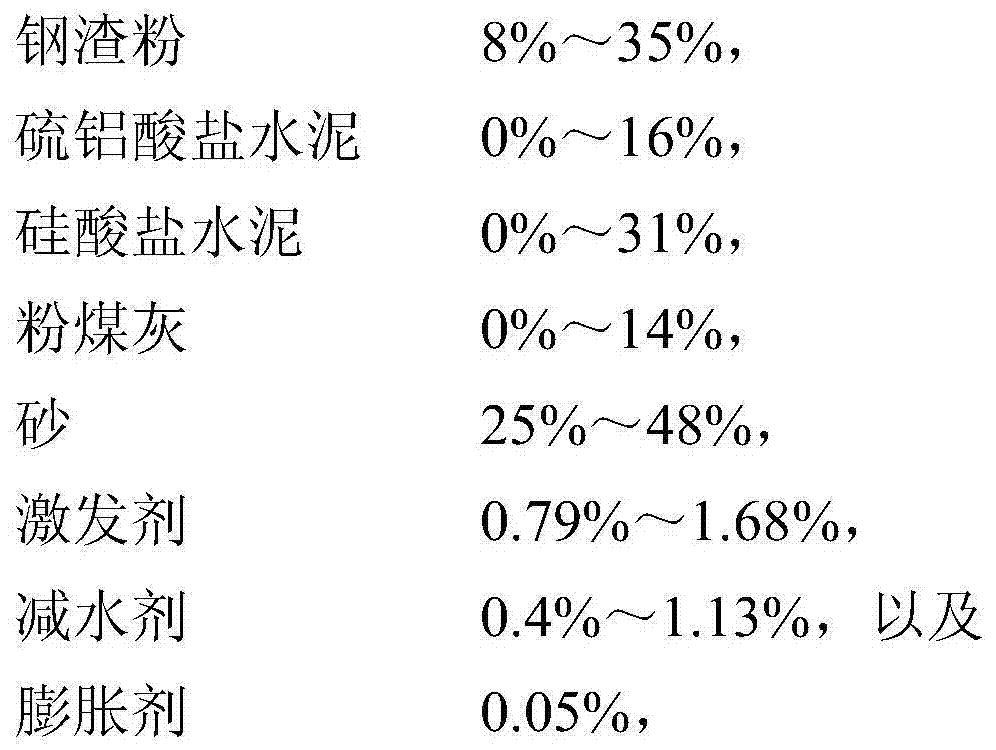

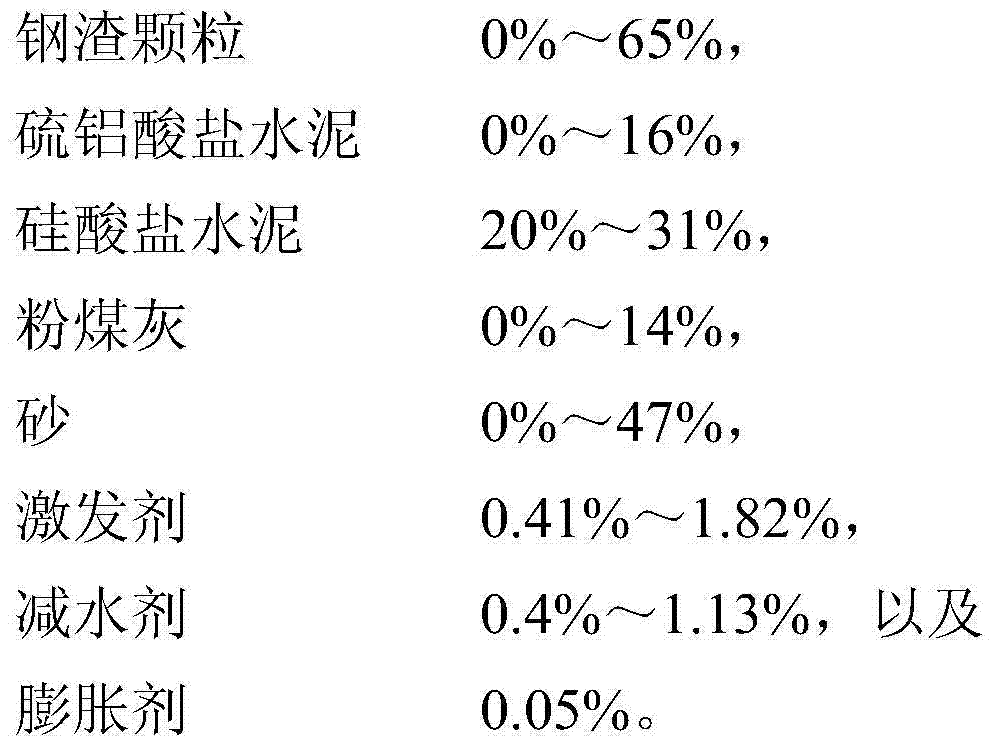

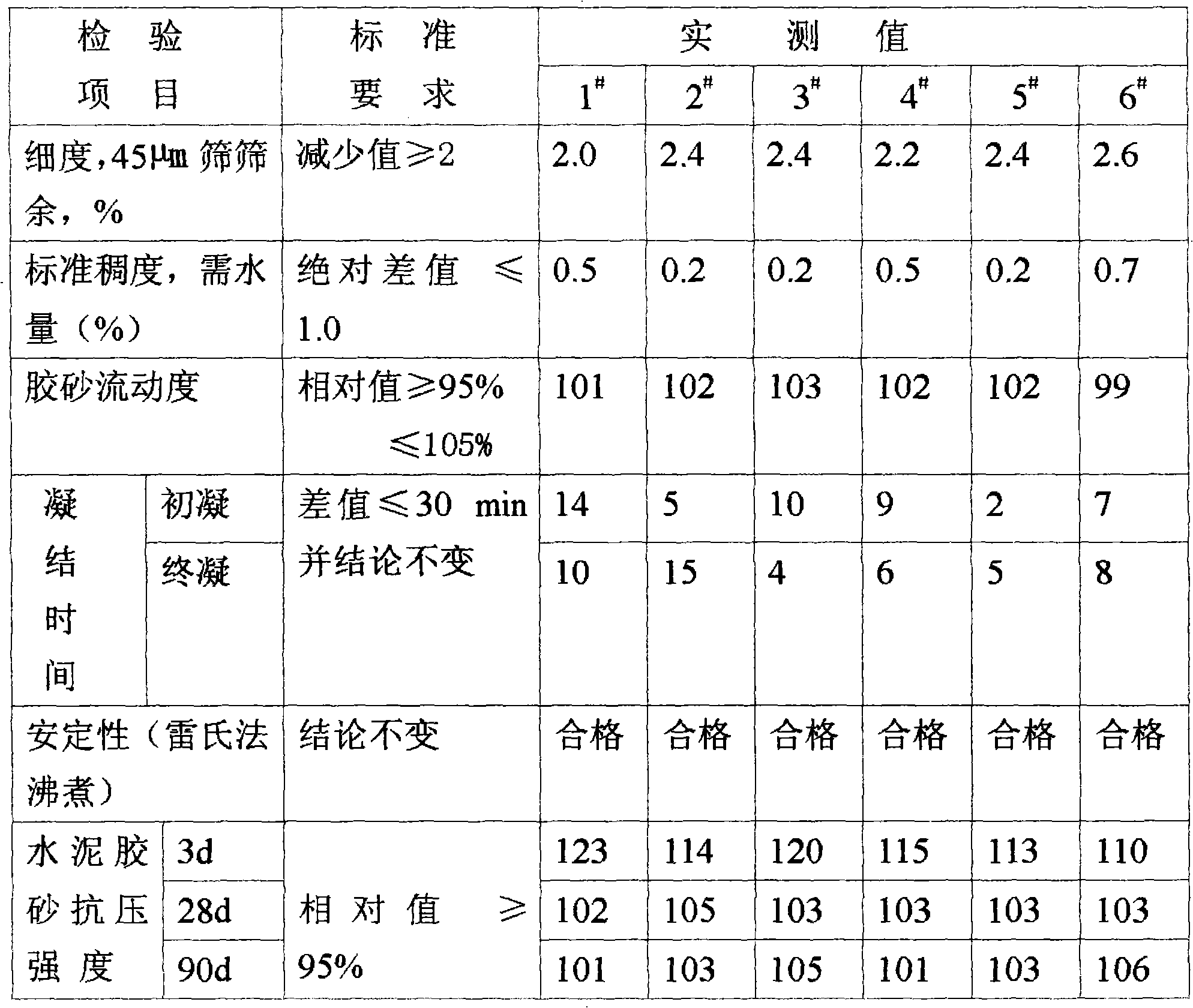

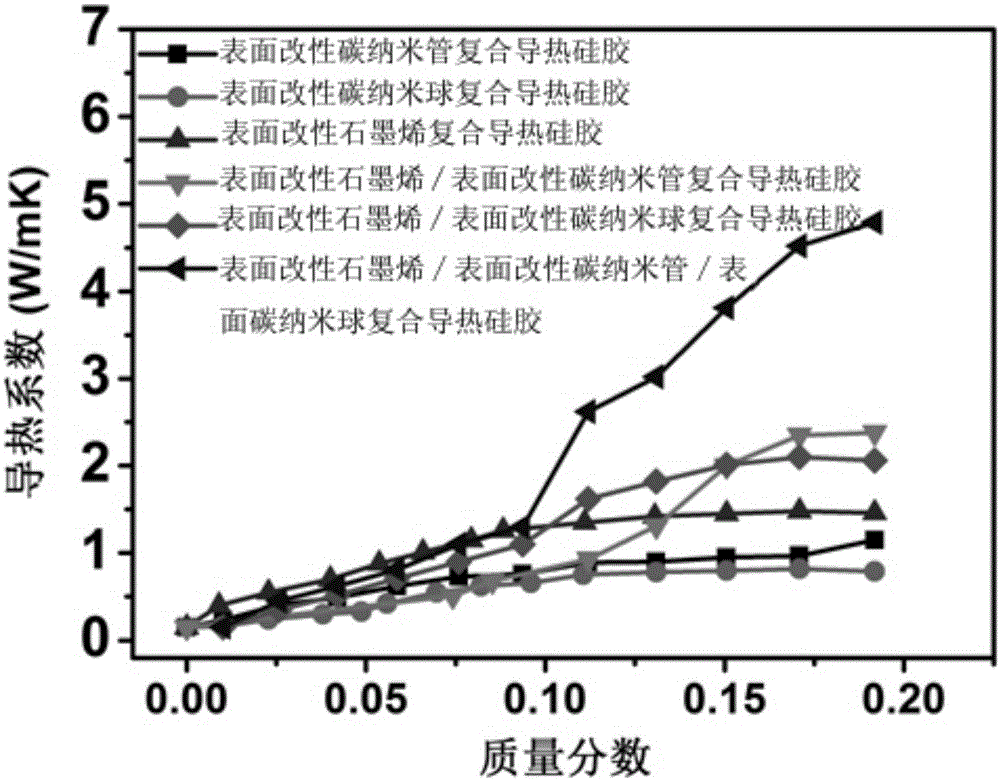

High-content steel slag grouting material

The invention relates to a high-content steel slag grouting material, which is prepared from the following raw materials by weight percent: 0%-8% of steel slag, 0%-16% of sulfoaluminate cement, 0%-31% of portland cement, 0%-15% of coal ash, 0%-50% of sand, 0.2%-2.0% of exciting agent, 0.4%-1.5% of water reducing agent and 0.02%-0.05% of expanding agent. The steel slag grouting material provided by the invention has the advantages of high steel slag content, high strength, no shrinkage and good mobility; the performance indexes of the steel slag grouting material meet the requirements of Technical Regulations of Cement-Based Grouting Material Application GB / T50448-2008; resources can be saved; solid wastes can be utilized; low carbon economy and resource recycling can be realized.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

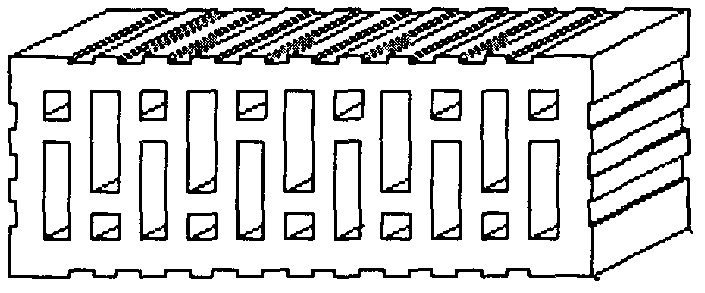

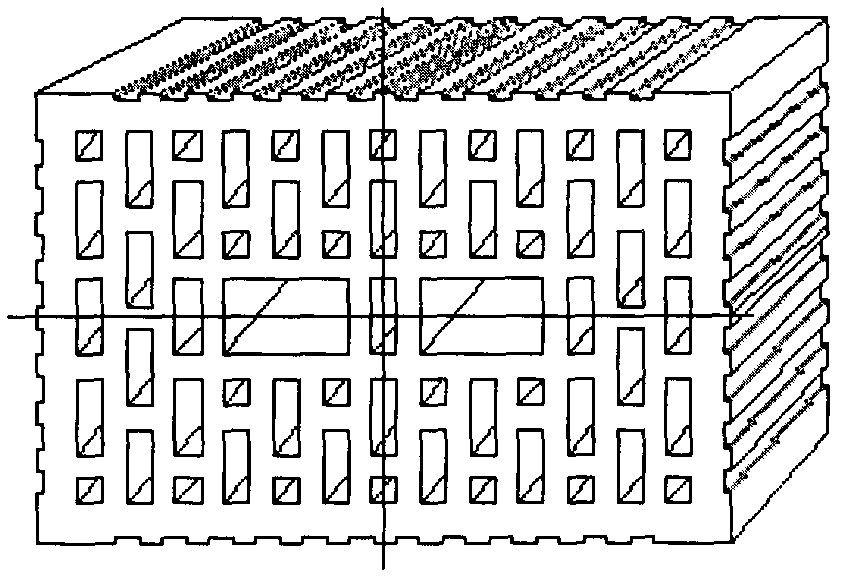

Technology for manufacturing brick by using dried sludge

The invention discloses a technology for manufacturing brick by using dried sludge. The process comprises the following steps: stirring mixed materials; pulverizing raw materials by jaw breaking and hammer breaking; evenly stirring; screening the pulverized mixed material by a vibrating screen; carrying out upward mixing and rolling lamination on the mixed material screened by the vibrating screen; putting into a brut cellar; conveying the aged raw material into a shaper by a conveyer belt to shape the blank; conveying into a drying kiln for drying by a cutting, stacking and transporting car;then, sintering in a calcining kiln; and obtaining common sintered bricks, porous bricks or hollow bricks after the sintering is finished. According to the technology, sludge instead of clay is addedinto various raw materials. On the aspect of producing sintered bricks with high doping volume by utilizing municipal sludge, the maximum municipal sludge doping amount can reach 50%. The technology has obvious breakthrough on the aspects of sludge decrement and reclamation, and sludge is consumed to realize the purpose of changing waste material into things of value.

Owner:南京鑫翔环保产业有限公司

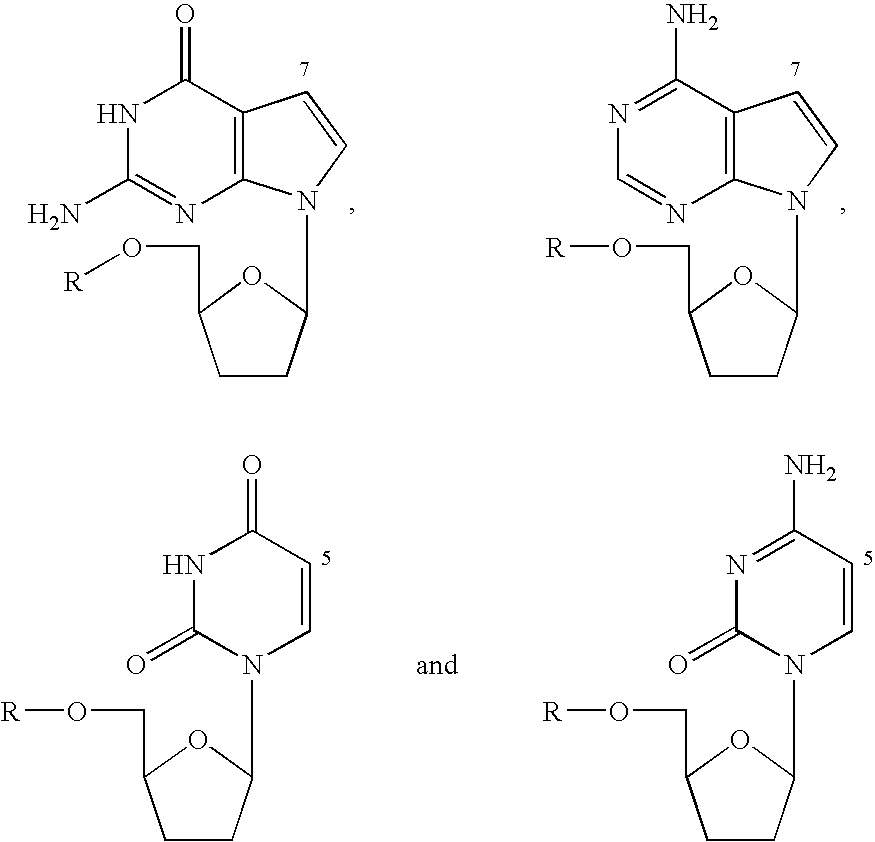

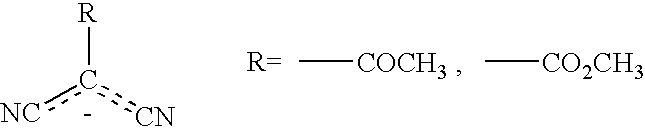

Dideoxy dye terminators

InactiveUS6949635B1Eliminate dye-induced compression artifactImprove uniformitySugar derivativesMicrobiological testing/measurementDye moleculePhotochemistry

A kit for DNA sequencing comprising a first, second, third and fourth dye terminator molecules, each of the dye terminator molecules comprising a dye molecule, a linker of at least 10 atoms in length and either ddATP, ddCTP, ddGTP or ddTTP as a mono or tri-phosphate and a thermostable DNA polymerase.

Owner:GE HEALTHCARE BIO SCI CORP

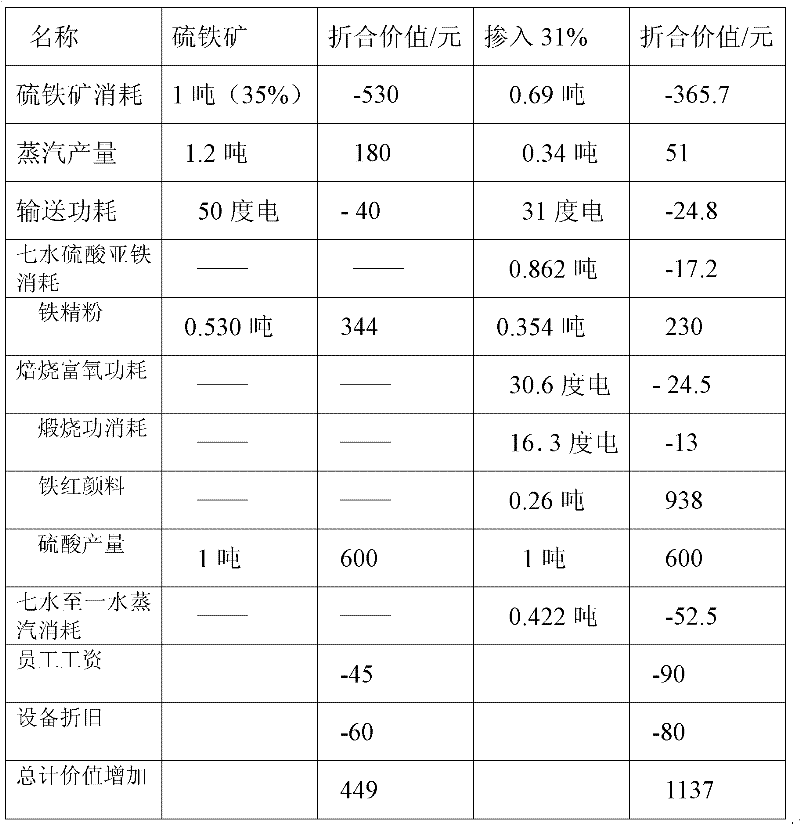

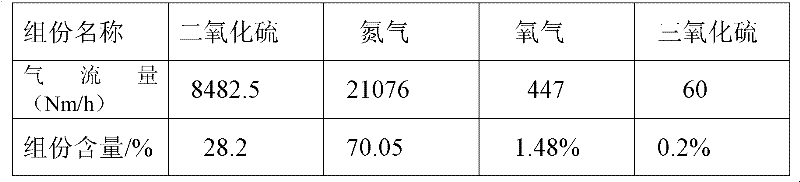

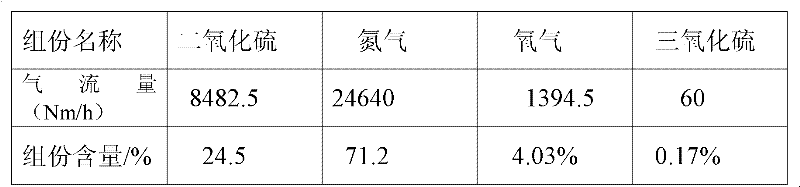

Process for co-producing sulfuric acid, fine iron powder and iron oxide red by ferrous sulfate heptahydrate and pyrite

ActiveCN102344124AIncrease incorporationImprove Pigment PerformanceSulfur compoundsEnergy inputResource utilizationFractionation

The invention provides a process for co-producing sulfuric acid, fine iron powder and iron oxide red by ferrous sulfate heptahydrate and pyrite and relates to the process technology of resource utilization of titanium dioxide byproduct solid waste ferrous sulfate. The process comprises the following steps: adopting titanium dioxide byproduct ferrous sulfate heptahydrate and pyrite as raw materials; increasing the mixing amount of the ferrous sulfate heptahydrate as much as possible through transforming the ferrous sulfate heptahydrate into ferrous sulfate monohydrate, oxygen-enriched roasting, preheating air in front of a furnace, controlling the sulfur content of the pyrite entering the furnace and the moisture and other technical means; and realizing the integrated co-production of the sulfuric acid, the fine iron powder and iron oxide red pigments through cinder fractionation, oxygen-enriched calcining and other process technologies. The process effectively improves the economic value of the heptahydrate ferrous sulfate and has an important significance on efficient and comprehensive utilization of the titanium dioxide byproduct solid waste ferrous sulfate heptahydrate.

Owner:HUNAN HENGGUANG TECH

Complex of a multimetal cyanide compound and methods of forming polyethercarbonate polyols

InactiveUS7268204B2Efficiently formedIrregular crystalline structureOrganic-compounds/hydrides/coordination-complexes catalystsPolyolCyanide

A method of forming a polyethercarbonate polyol enhances incorporation of CO2 into the polyethercarbonate polyol. The method provides a catalyst including a multimetal cyanide compound. The multimetal cyanide compound has an ordered structure defined by a cationic catalytic center and an anionic backbone with the anionic backbone spatially arranged about the cationic catalytic center. The anionic backbone is modified with a supplemental anionic spacer to affect the spatial arrangement and catalytic activity of the cationic catalytic center. The supplemental anionic spacer is incorporated into the multimetal cyanide compound to establish the general formula, M1a[M2b(CN)cMd3Xe]f, wherein M1, M2, and M3 are various metal ions and X is the supplemental anionic spacer. An H-functional initiator, an alkylene oxide, and CO2 are reacted in the presence of the modified multimetal cyanide compound to form the polyethercarbonate polyol.

Owner:BASF CORP

Method for supplying auxiliary material and receptacle for auxiliary material

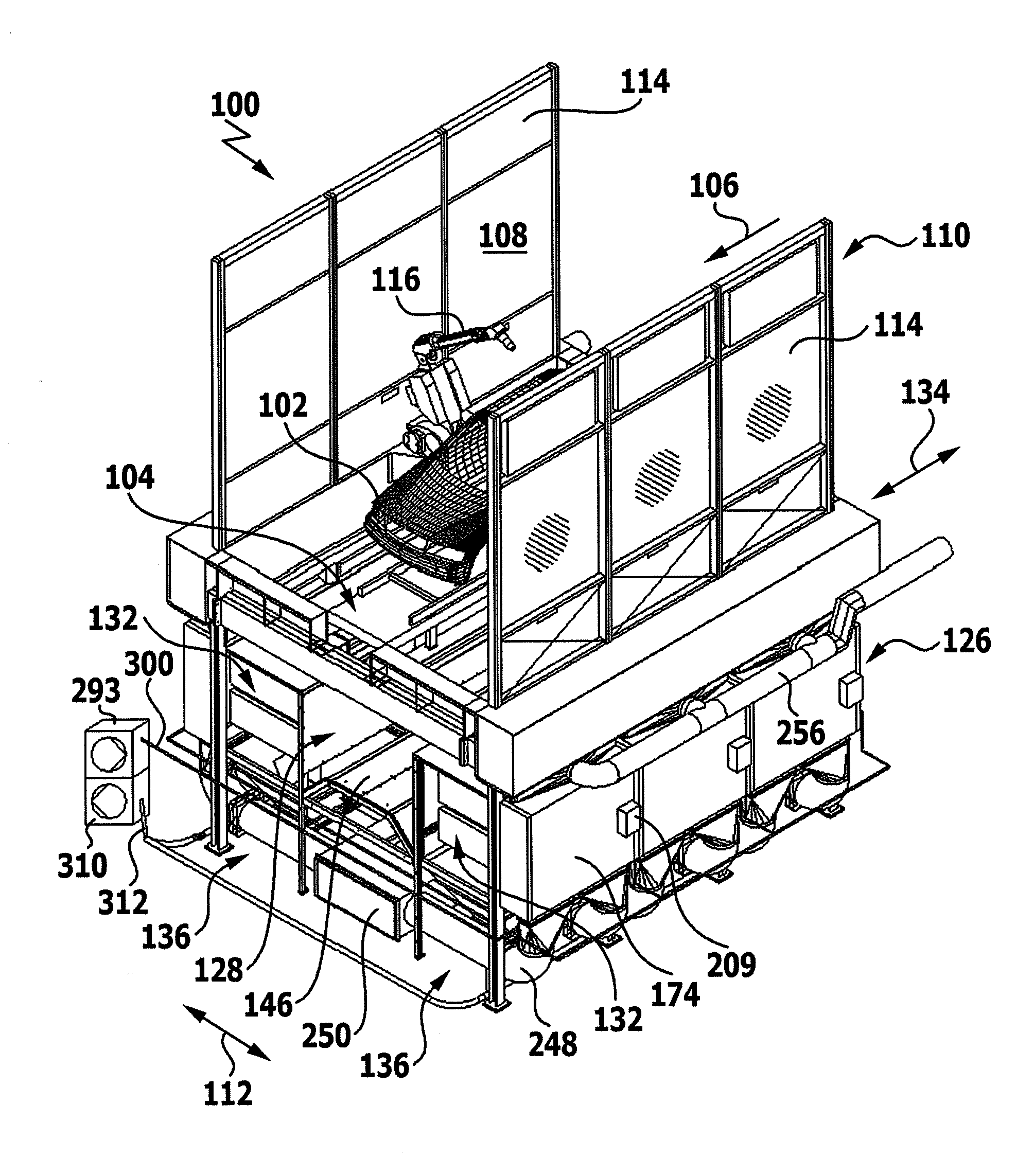

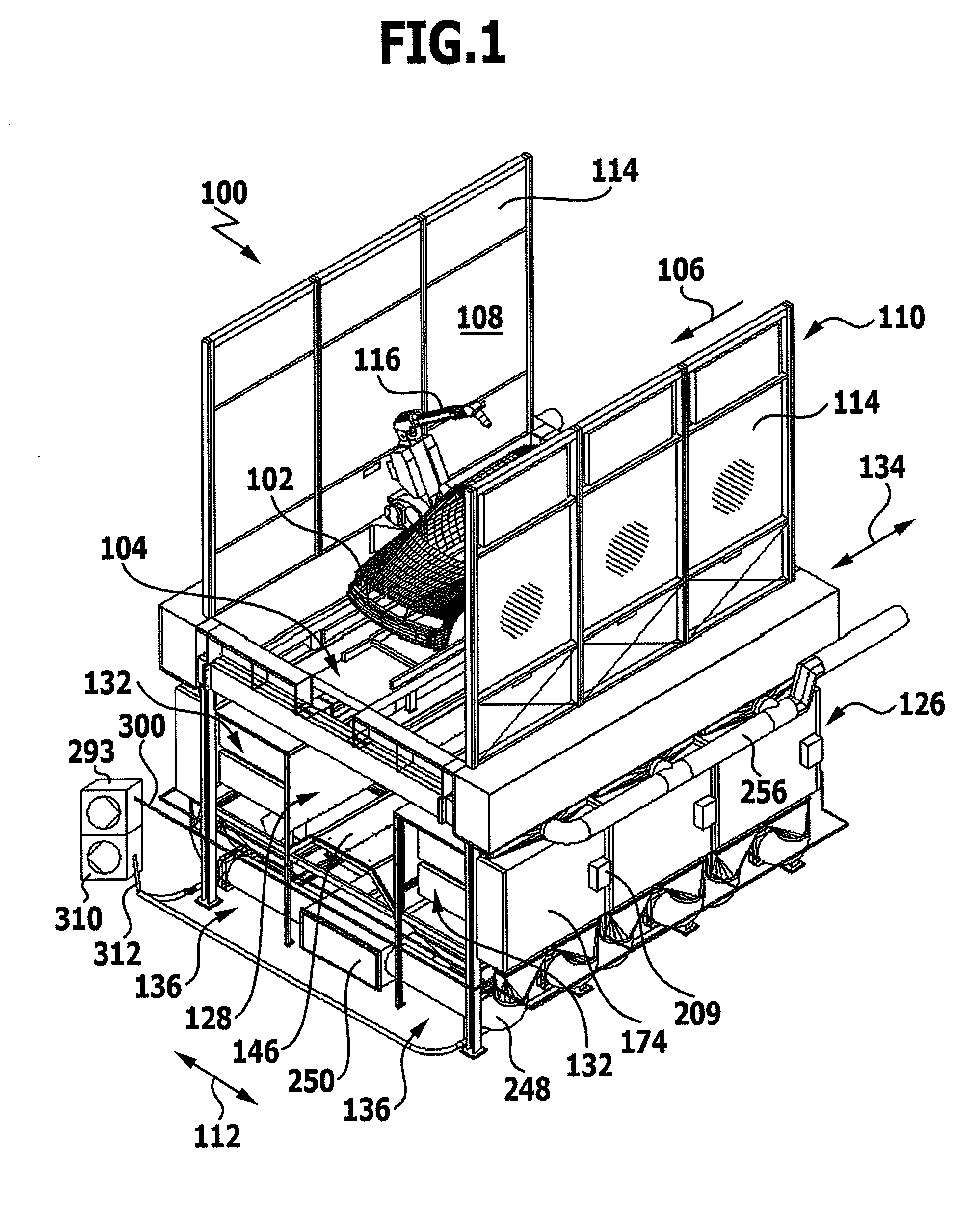

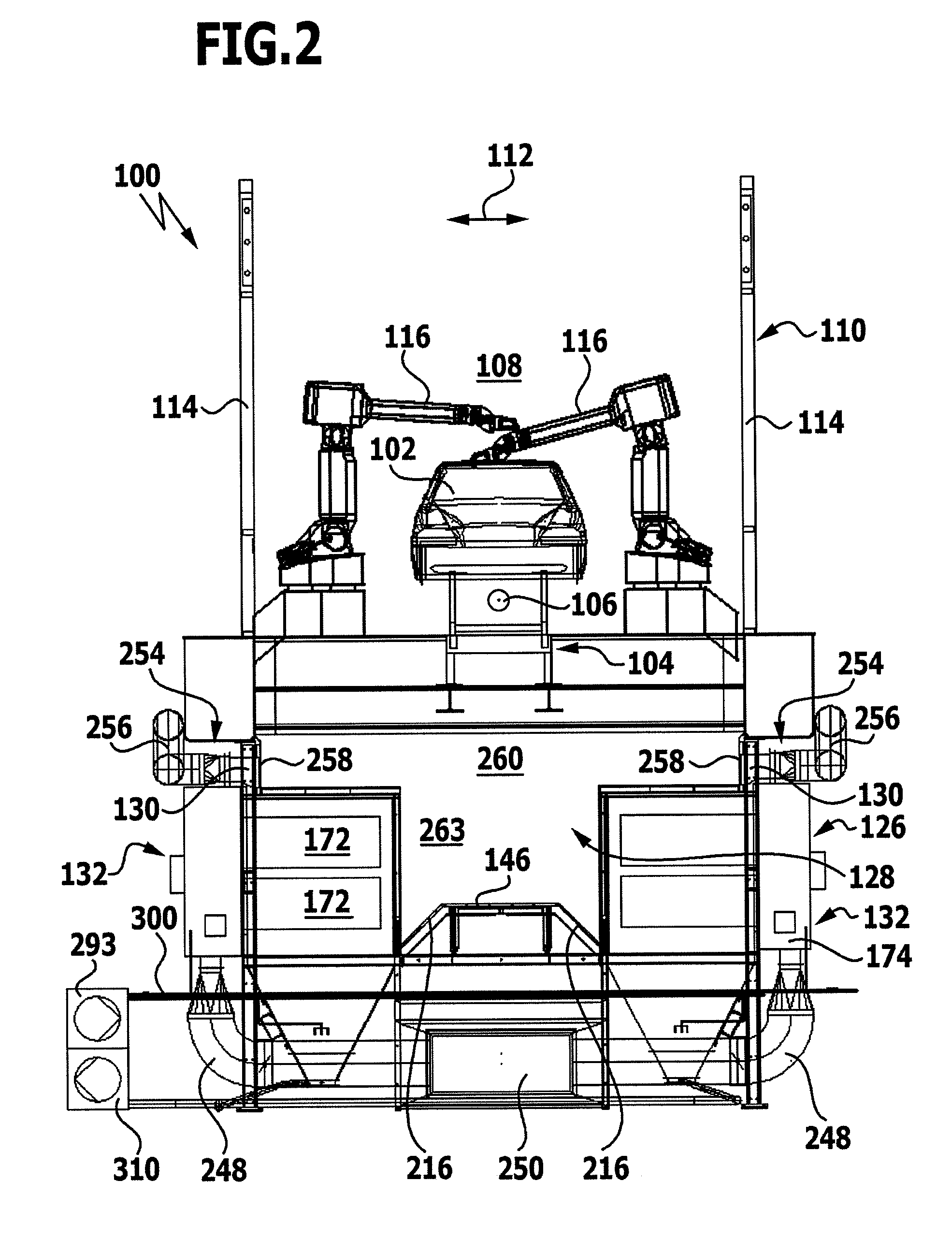

ActiveUS20100199912A1Increase incorporationSimple and efficientLiquid surface applicatorsLiquid degasificationLacquerProcess engineering

In order to provide a method for supplying fresh auxiliary material, which is added to a stream (120) of crude gas laden with wet paint overspray before the stream of crude gas passes through at least one filter element (172) for separating the overspray from the steam of crude gas, to at least one filter device (132) which comprises at least one receptacle (176) for auxiliary material, which is in its operating position, while the stream of crude gas is passing through the filter element, which method enables better action of the auxiliary material on the stream of crude gas and makes a particularly efficient supply of fresh auxiliary material to the at least one filter device possible, it is suggested that the fresh auxiliary material be supplied directly into the receptacle for auxiliary material while the receptacle for auxiliary material is in the operating position.

Owner:DUERR SYST AG

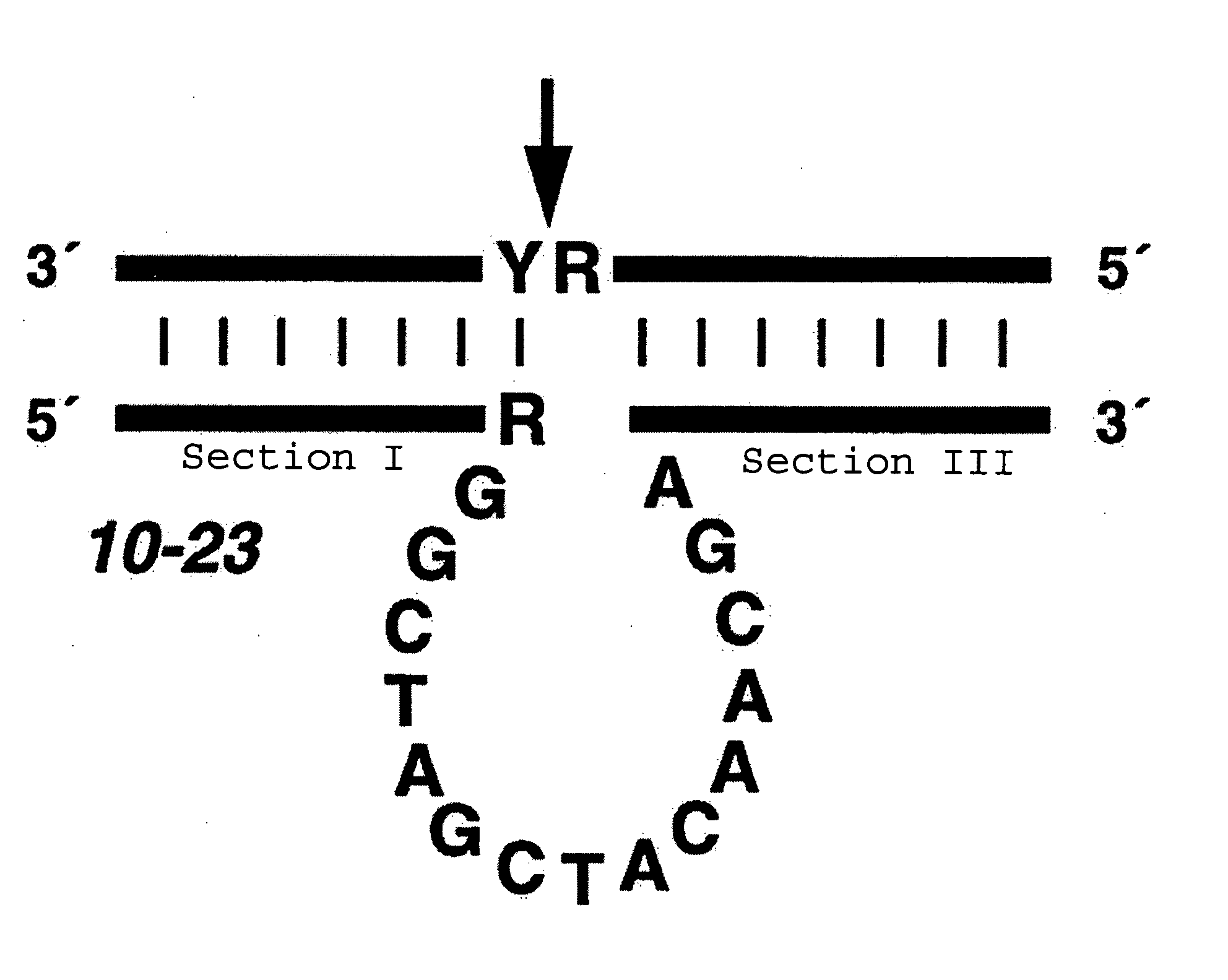

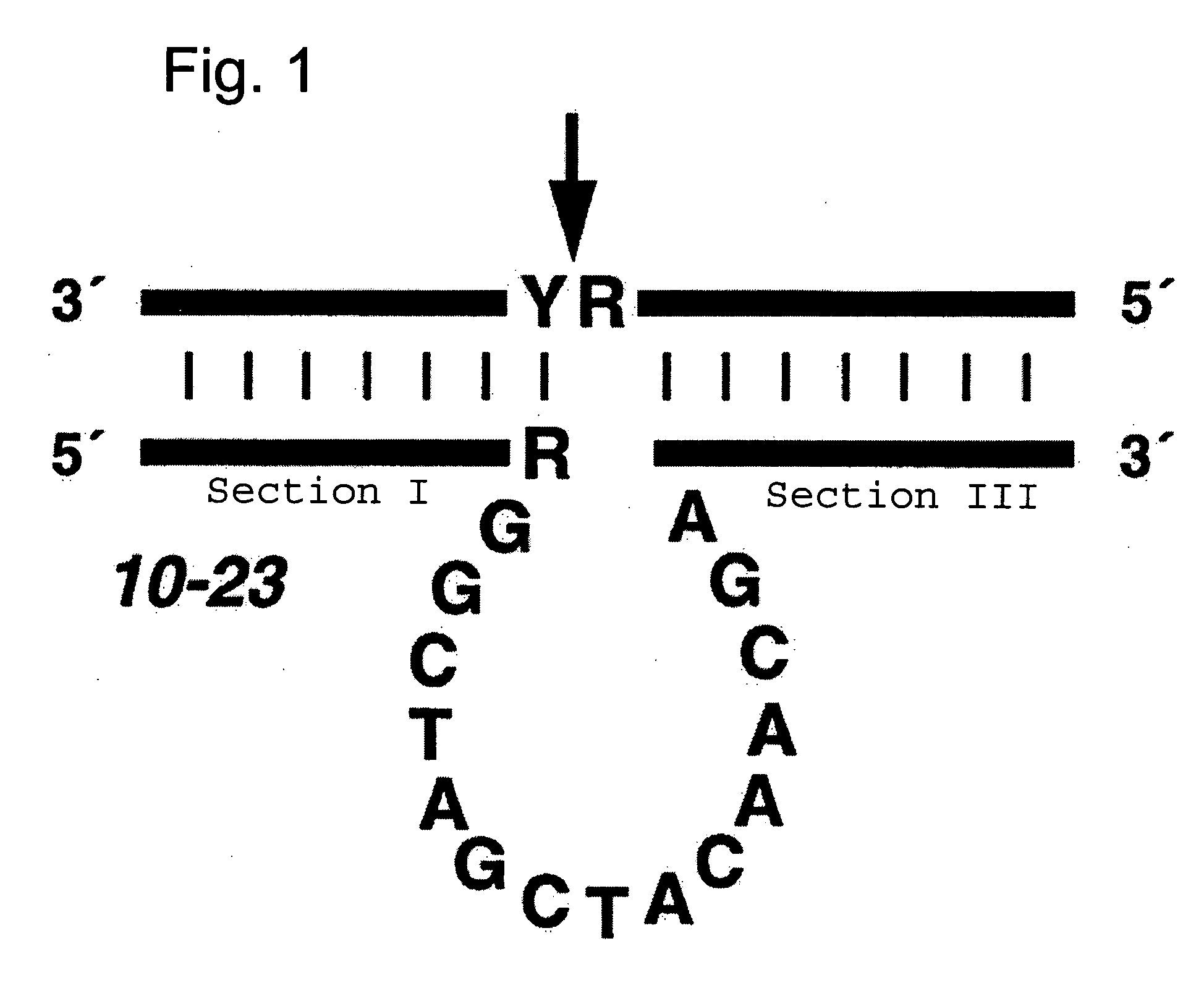

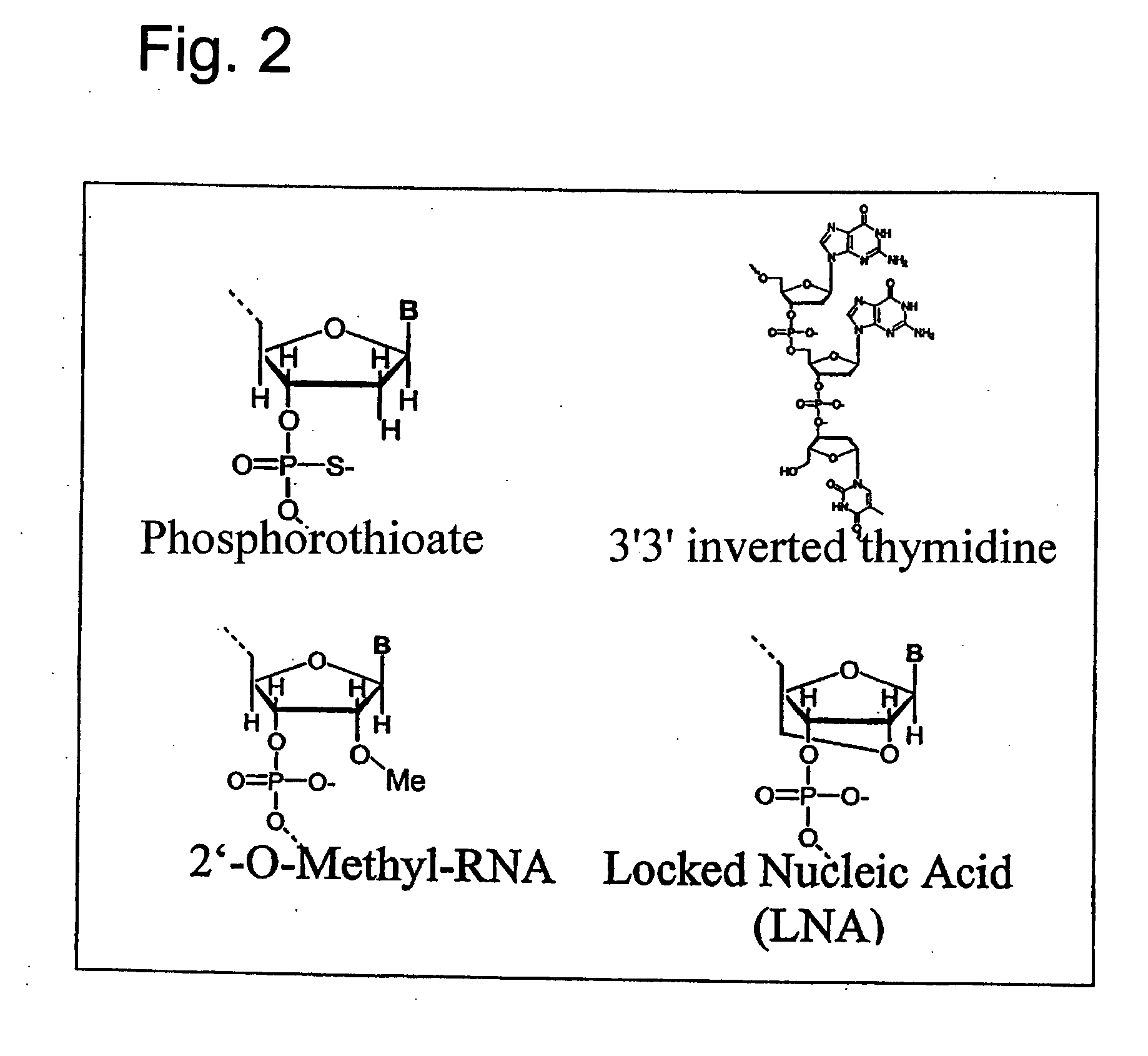

Effective and stable DNA enzymes

InactiveUS20060122136A1Promote degradationSame and high cleavage efficiencySugar derivativesHydrolasesMicroorganismNucleotide

The present invention relates to DNA enzymes of type 10-23 with certain modifications of specific nucleotides in the core sequence rendering the DNA enzymes particularly stable and additionally exhibiting substantially the same or a higher cleavage efficiency with respect to their substrate when compared against the corresponding unmodified DNA enzymes. The present application further provides host cells containing the DNA enzymes according to the invention. In addition there is provided a pharmaceutical formulation which contains the DNA enzymes or host cells according to the invention. The DNA enzymes and further subjects are directed in particular against the vanilloid receptor 1 (VR1), or picornaviruses. The present invention further provides small interference RNA molecules (siRNA) directed against VR1, and host cells containing the siRNA. The siRNA and corresponding host cells are suitable as pharmaceutical formulations or for the preparation of pharmaceutical formulations, in particular for the treatment of pain and other pathological conditions associated with VR1.

Owner:GRUNENTHAL GMBH

Method for end-capping polycarbonate resins and composition for use in same

A method for end-capping polycarbonate resins, comprising the step of processing a mixture comprising a polycarbonate having free hydroxyl-end groups and an end-capping reagent in a melt transesterification reaction to produce a polycarbonate resin, wherein the end-capping reagent comprises a mixture of:(a) at least one species of a symmetrical activated aromatic carbonate, and (b) at least one species of an optionally-substituted phenol, whereby said end-capping reagent reacts with at least some of the free hydroxyl end-groups of the polycarbonate to produce an end-capped polycarbonate resin.

Owner:SABIC GLOBAL TECH BV

Process for preparing organic phase-change material composite expanded perlite by emulsification method

InactiveCN101139181AHigh phase change energy storage heat capacitySimple preparation processEmulsionBuilding material

The present invention discloses a preparation process for organic phase change material composite expansion perlite materials in emulsification method, which comprises the following steps: the uniform and mixed emulsion is obtained by stirring and mixing the organic phase change materials and the emulsifying agents in the water, the temperature of which ranges from 20 to 100 Celsius system; the organic phase change material composite expansion perlite particles are obtained by adopting the decompression adsorption process to completely absorb and deliver the obtained emulsion into the expansion perlite by permeation. The present invention has the following advantages: organic phase change materials completely permeate into the internal pores of the expansion perlite particles and the larger adsorption force has an effect between the phase change materials and the pores of the expansion perlite after the phase change materials are emulsified, and the organic phase change materials are combined stably with the common building materials; a very strong adsorption force has an effect between the phase change materials and the pores of the expansion perlite after the phase change materials are emulsified, thus realizing high incorporation of the organic phase change materials and assuring that the phase change energy storing aggregates have high energy storing heat capacity; the preparation process is simple and is easy to be carried out and controlled, thus being beneficial to the industrialized popularization and application.

Owner:宁波荣山新型材料有限公司

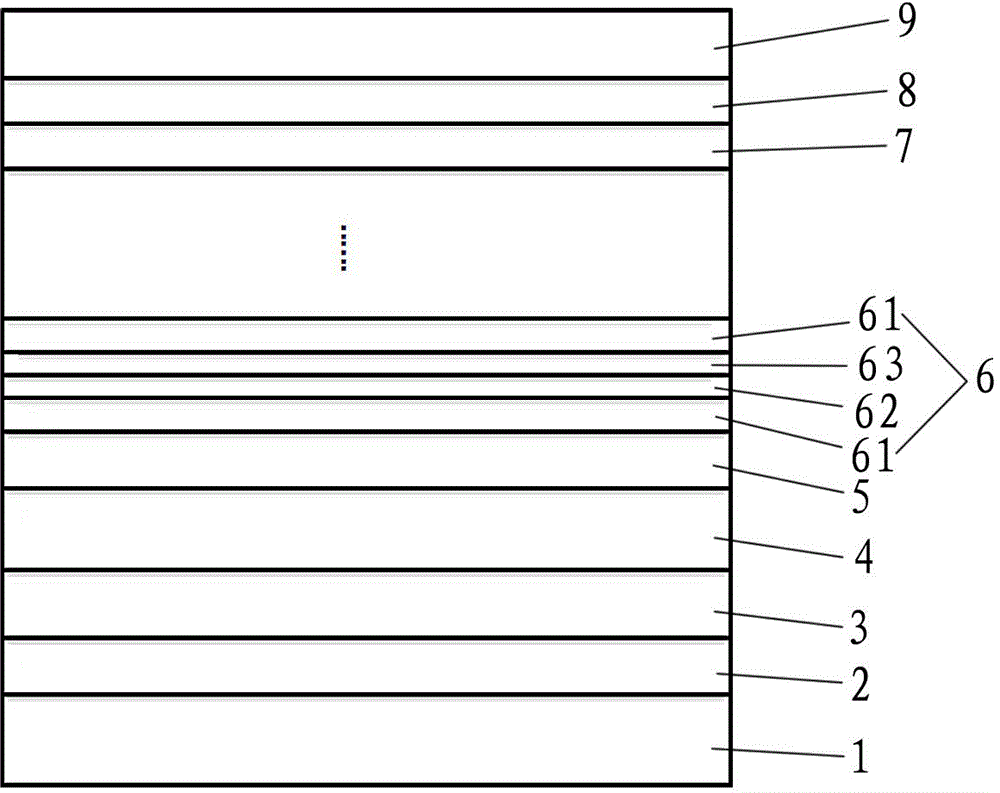

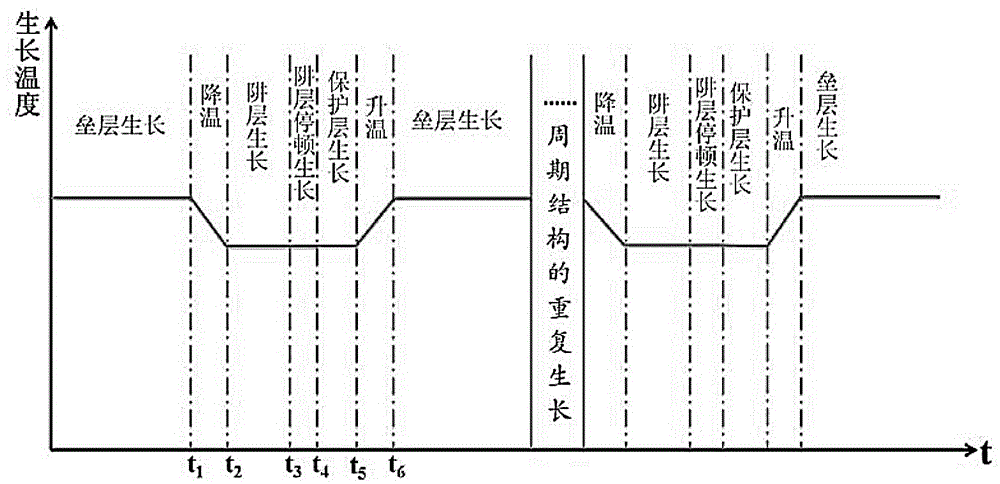

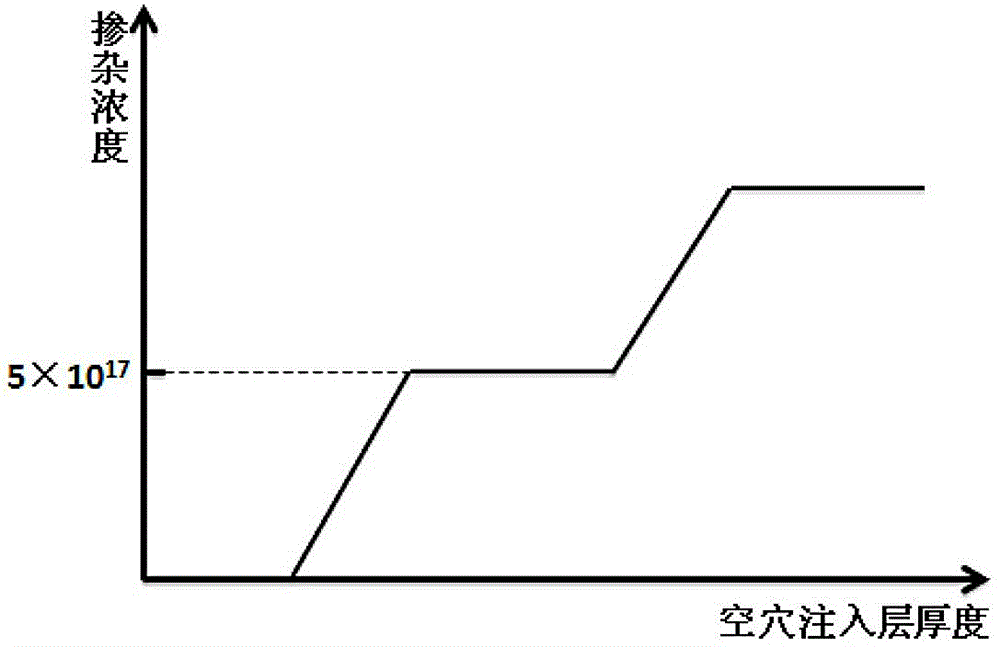

Method for growing LED epitaxial structure with high-quality InGaN/GaN active layer

ActiveCN104319330AQuality improvementImprove luminous efficiencySemiconductor devicesOptoelectronicsActive layer

The invention discloses a method for growing an LED epitaxial structure with a high-quality InGaN / GaN active layer. The InGaN / GaN active layer is grown by use of the steps of introducing a Ga source and NH3 to grow a GaN barrier layer of 8-5nm in the atmosphere of H2 serving as a main carrier gas, switching the main carrier gas to N2 and introducing the Ga source, an In source and the NH3 to grow an InxGa1-xN trap layer of 2-5nm, shutting down the Ga source and the In source while keeping normal introduction of the NH3 to stop the growth of the InxGa1-xN, turning on the Ga source to grow a GaN protective layer of 1-5nm, switching the main carrier gas to the H2 and introducing the Ga source and the NH3 to grow the GaN barrier layer of 8-5nm, and finally, repeating the second to fifth growth steps for 1-20 cycles. The method for growing the LED epitaxial structure with the high-quality InGaN / GaN active layer is capable of obtaining the high-quality InGaN / GaN active layer and improving the LED luminous efficiency.

Owner:XIAMEN CHANGELIGHT CO LTD

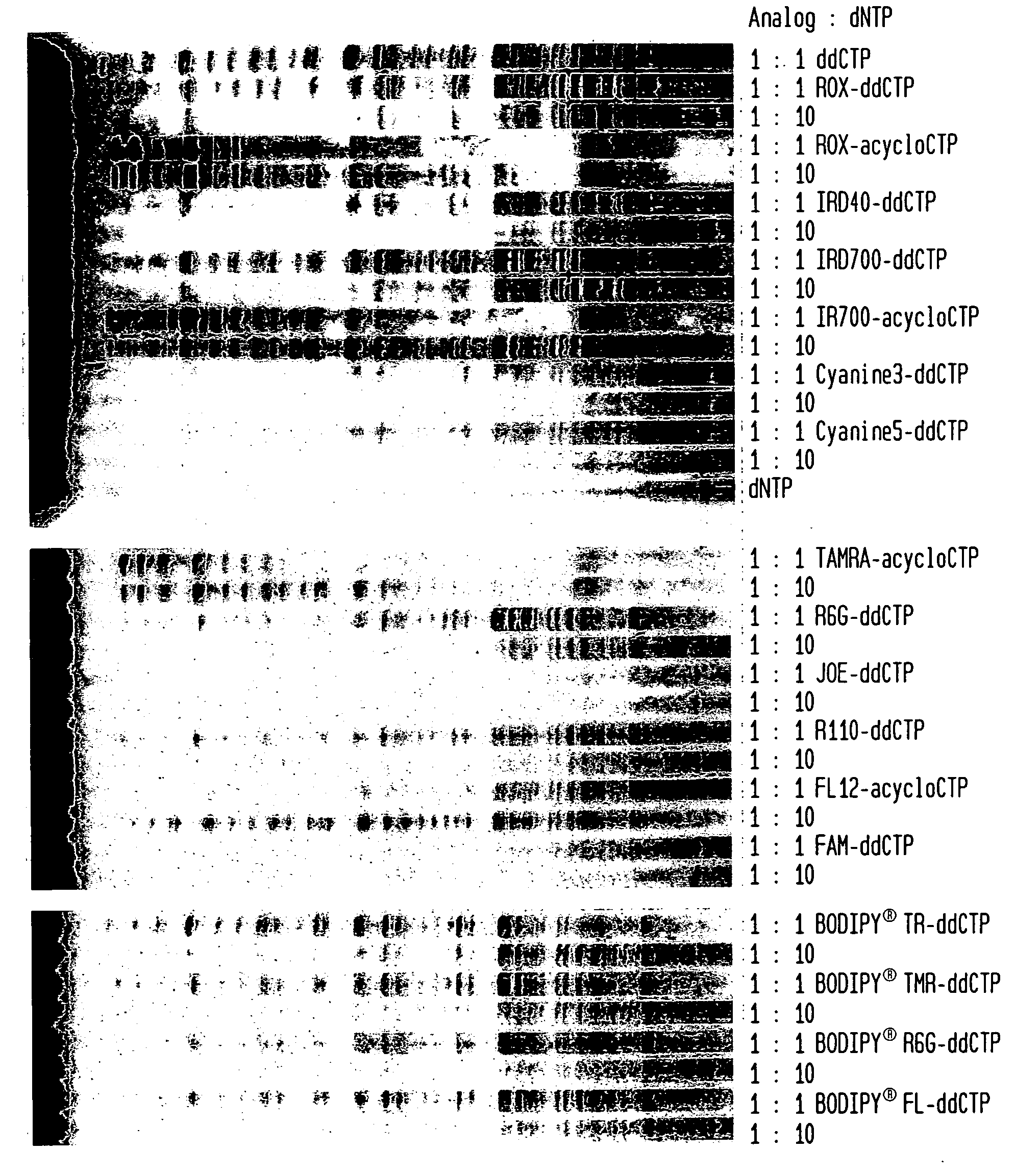

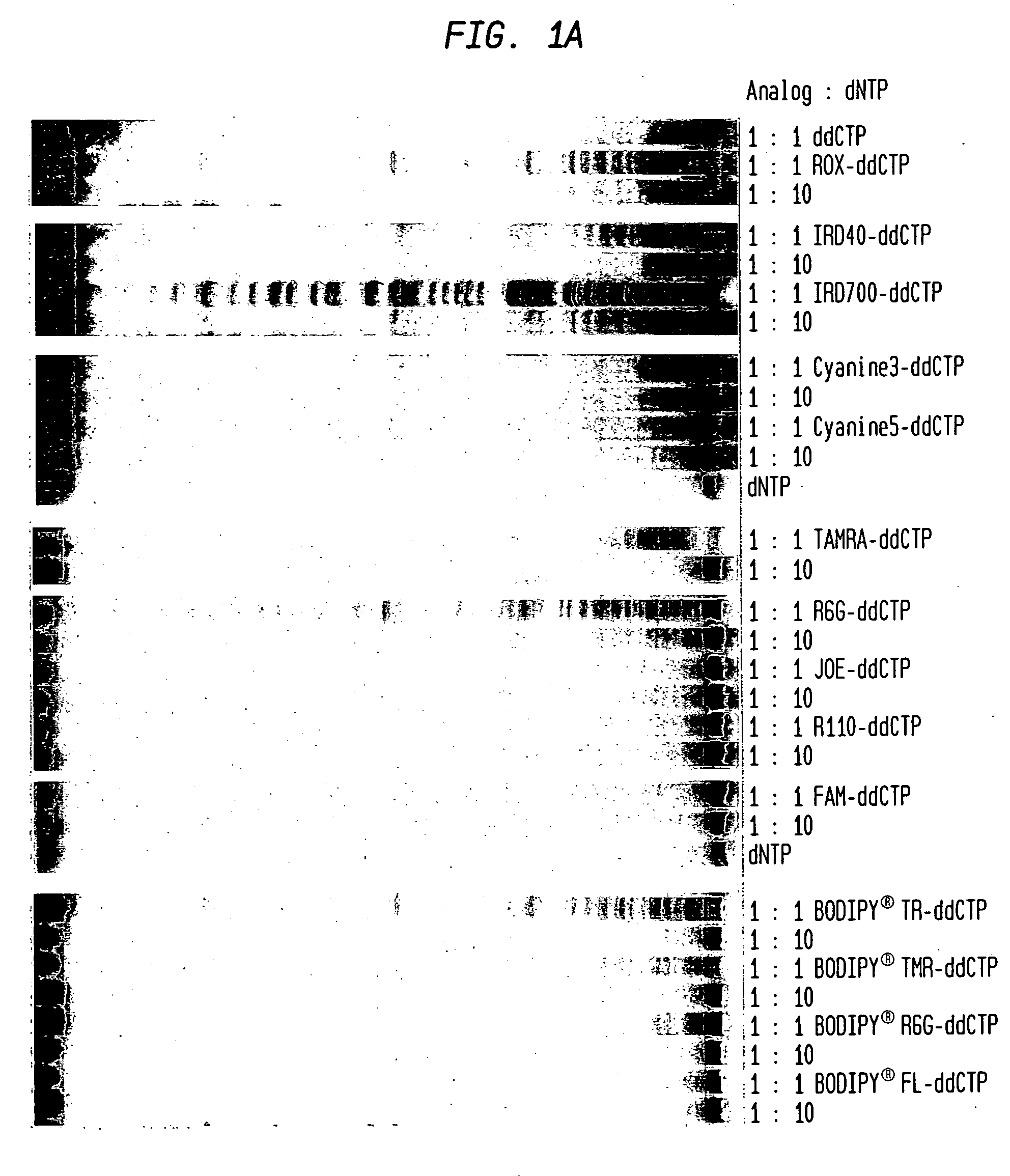

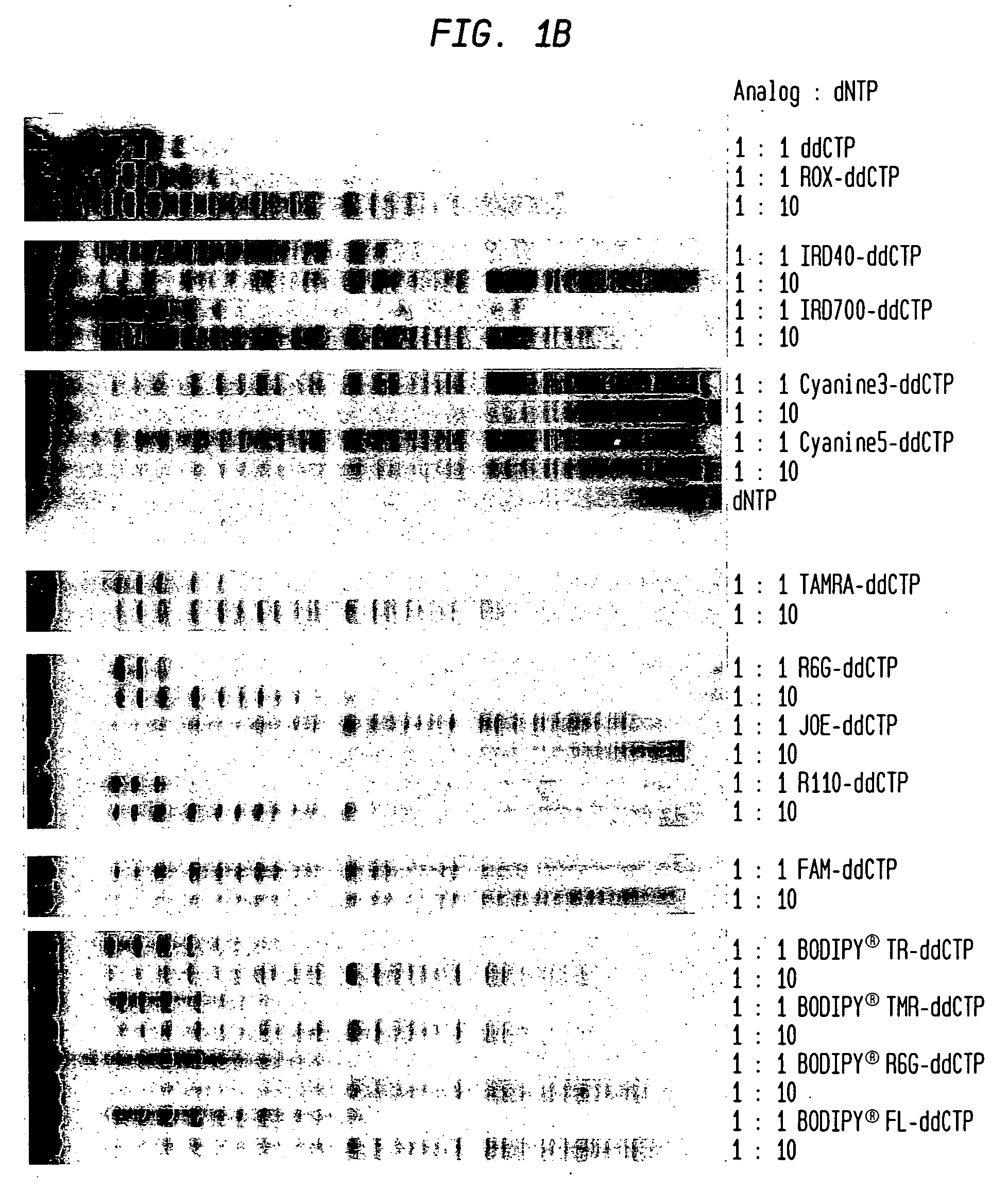

Incorporation of modified nucleotides by archaeon DNA polymerases and related methods

InactiveUS20060199214A1Efficiently incorporateEffective mergerBacteriaSugar derivativesEnzymeDNA polymerase

The present invention is directed toward improving the efficiency of chain terminator incorporation by Family B archaeon DNA polymerases. Previously, the low efficiency of ddNTP, and more especially dye-labeled ddNTP, incorporation has limited the usefulness of this group of DNA polymerases in protocols requiring chain terminator incorporation.

Owner:JACK WILLIAM +3

Method of forming a polyether-carbonate polyol using a CO2-philic compound or substituent

A method of forming a polyethercarbonate polyol enhances incorporation of CO2 into the polyethercarbonate polyol. The method provides a catalyst including a multimetal cyanide compound. An H-functional initiator, an alkylene oxide, and CO2 are reacted in the presence of the multimetal cyanide compound in a reactor. The method further provides a CO2-philic compound or a CO2-philic substituent. The CO2-philic compound and substituent enhance incorporation of the CO2 into the polyethercarbonate polyol and reduce formation of cyclic alkylene carbonates, such as cyclic propylene carbonate, which are undesirable byproducts.

Owner:BASF CORP

Ceramic material prepared from red mud, and preparation method of ceramic material

InactiveCN105693210AIncrease incorporationNot easy to burnCeramic materials productionClaywaresCeramic sinteringRed mud

The invention relates to a ceramic material prepared from red mud, and a preparation method of the ceramic material, belonging to the field of comprehensive utilization of resources of solid wastes. The ceramic material is prepared by mixing the following raw materials by mass percent: 10-70% of red mud, 0-60% of clay, 5-35% of silicon-rich aluminum raw material, 5-40% of quartz raw material and 0-30% of magnesium-rich raw material; the preparation method adopts the traditional ceramics preparation technology, and comprises the steps of crushing the raw materials, blending, grinding, granulating, molding and carrying out other technologies to form a ceramic green body, drying the ceramic green body, enabling the dried ceramic green body to enter a ceramic kiln, and firing to obtain the ceramic material product, wherein the sintering temperature is 1060-1180 DEG C, the sintering time is 35-70 minutes, the breaking strength value of the prepared ceramic material exceeds 35MPa, the water absorption value of the prepared ceramic material is less than 1%, and if a optimal ratio is adopted, the breaking strength value of the ceramic material exceeds 100MPa, and the water absorption value of the ceramic material is less than 0.5%. After the preparation method is adopted, the red mud can be used for producing general construction ceramics / ceramic sintered bricks and high-strength industrial ceramic materials; the preparation method is easy and feasible, and is beneficial to industrial production.

Owner:UNIV OF SCI & TECH BEIJING

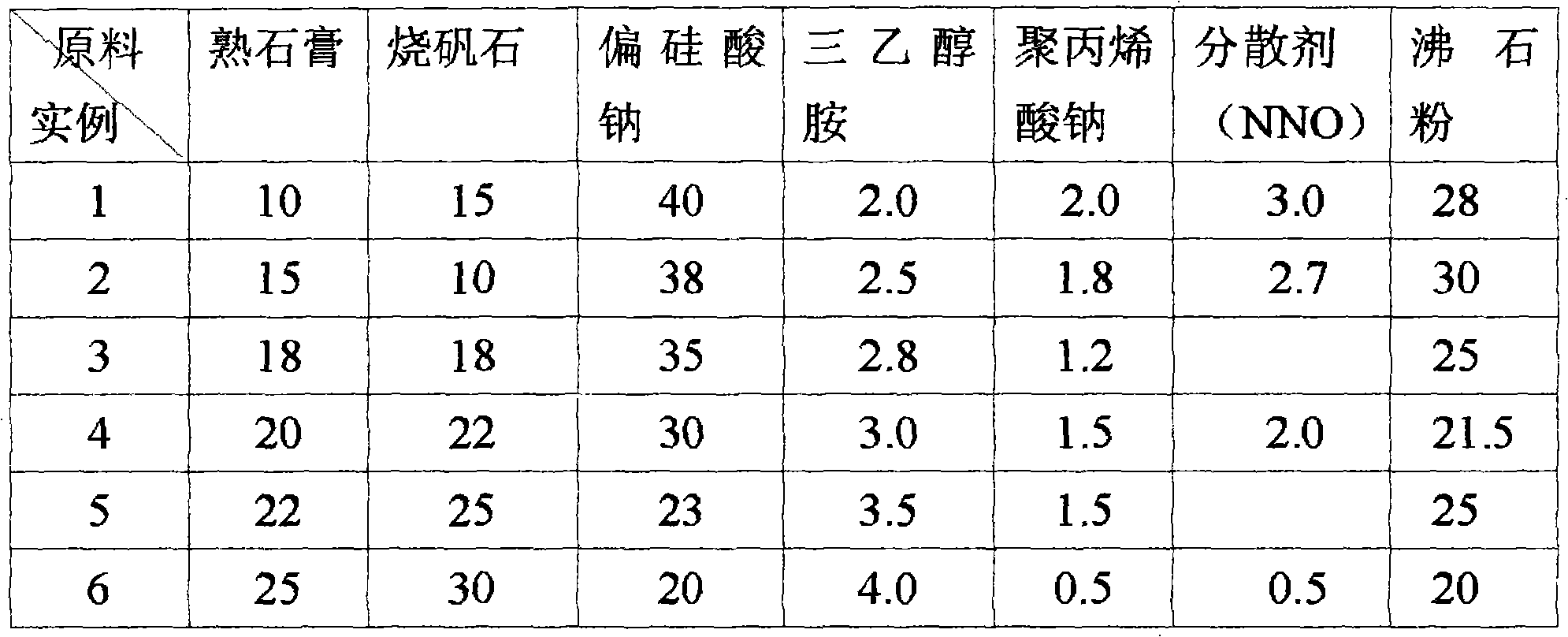

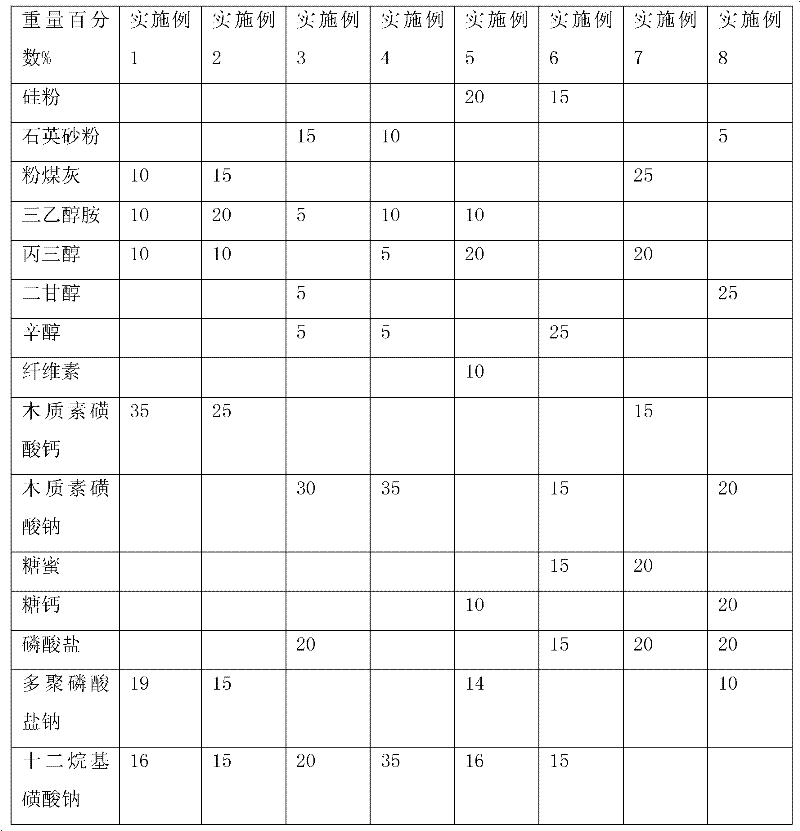

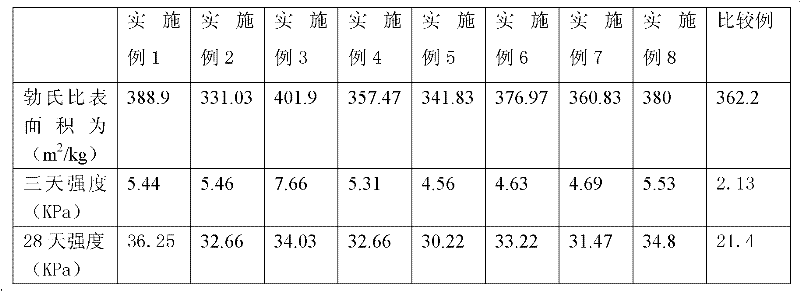

High efficiency cement composite grinding additive and preparation method thereof

InactiveCN101618955AIncrease incorporationIncrease productionSolid waste managementAluminiteSodium metasilicate

The invention discloses a high efficiency cement composite grinding additive, comprising the following raw materials by weight percent: 10-25% of calcined gypsum, 10-30% of calcined aluminite, 20-40% of sodium metasilicate, 2-4% of triethanolamine, 0.5-2% of polyacrylate, 0.5-3% of dispersant and 20-30% of zeolite powder. The preparation method of the high efficiency cement composite grinding additive comprises the following steps: first selecting raw materials, then dripping liquid raw materials-triethanolamine and polyacrylate TH-1100 with a liquid pump in zeolite powder, then preparing reinforced grinding component with a dry powder mixer, finally adding the reinforced grinding component, calcined gypsum, calcined aluminite, sodium metasilicate and dispersant in a kneader to mix for 20-30min and obtaining the product. The product has prominent grinding aid, and can increase the hourly output of mills by 10-15%, reduce the consumption of electricity, and increase the cement 3-day compression strength and the cement 7-day compression strength by more than 20% and the cement 28-day compression strength by 10-15%.

Owner:葫芦岛市辽西混凝土外加剂有限公司

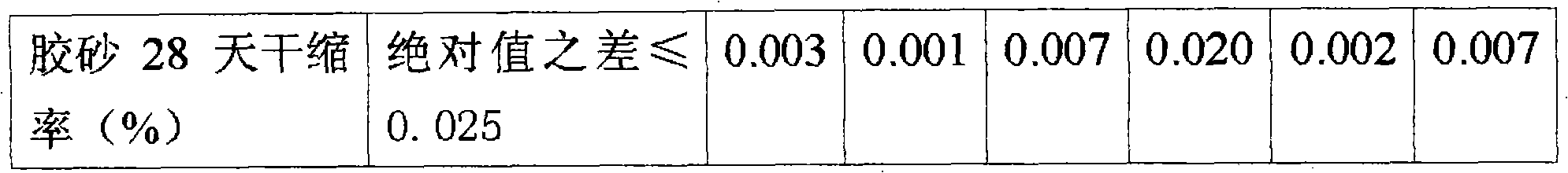

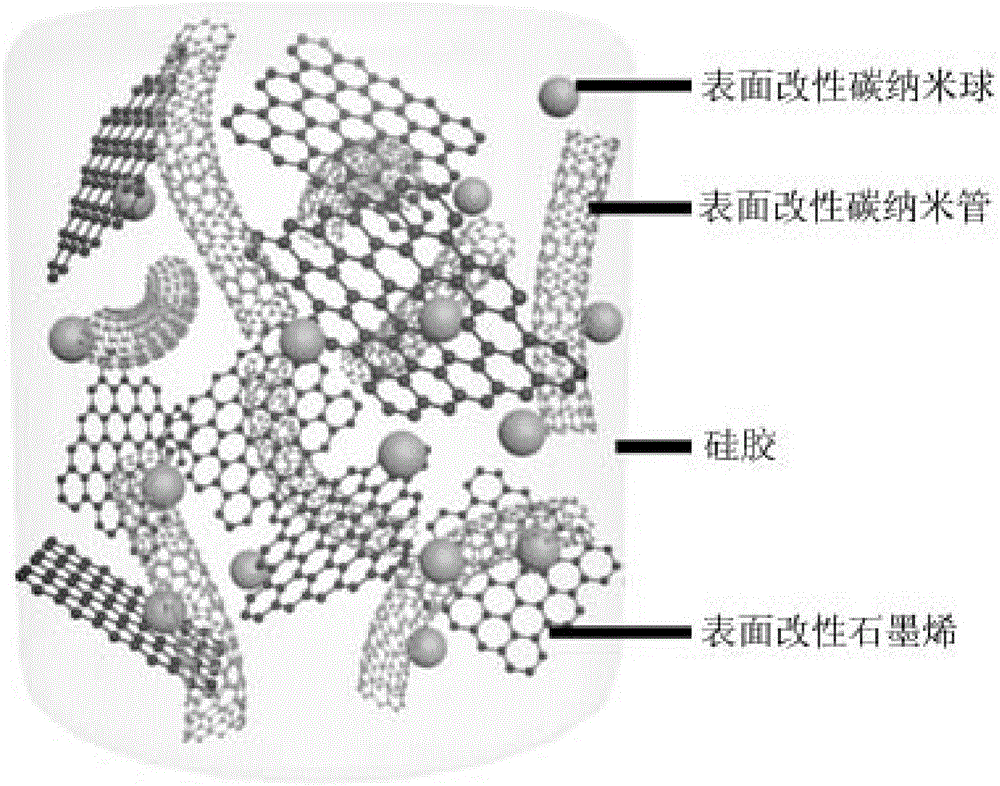

Point, line, surface three-dimensional carbon material composite heat-conduction silica gel and preparation method thereof

The present invention provides a point, line, surface three-dimensional carbon material composite heat-conduction silica gel and a preparation method thereof. The composite heat-conduction silica gel comprises, by weight, 0.1-30% of surface-modified graphene, 0.1-30% of surface-modified carbon nano-tubes, 0.1-30% of surface-modified carbon nano-spheres, and the balance of silica gel, wherein the sum of the mass fractions of the surface-modified graphene, the surface-modified carbon nano-tubes and the surface-modified carbon nano-spheres is more than or equal to 10%, a mass ratio of the surface-modified graphene to the surface-modified carbon nano-tubes to the surface-modified carbon nano-spheres is 1:0.5-2:0.5-4, and the surface-modified graphene, the surface-modified carbon nano-tubes and the surface-modified carbon nano-spheres are prepared through treatment modification with strong acids. According to the present invention, the solubilities and the dispersions of the graphene, the carbon nano-tubes and the carbon nano-spheres in the silica gel are effectively improved, and the three modified carbon materials form the stable and continuous three-dimensional heat-conduction network in the silica gel so as to substantially improve the thermal conductivity of the heat-conduction silica gel.

Owner:江苏华永烯科技有限公司

Ferro-nickel slag ceramic and preparation method thereof

ActiveCN107935555APromote fireImprove mechanical propertiesCeramic materials productionClaywaresCeramic sinteringCalcium in biology

The invention provides a ferro-nickel slag ceramic and a preparation method thereof. The preparation method comprises the following steps of selecting one or multiple of quartz, silicon and aluminum-rich raw material and calcium raw material; mixing 20 to 65wt% of ferro-nickel slag, 0 to 10wt% of quartz, 20 to 70wt% of silicon and aluminum-rich raw material and 0 to 30wt% of calcium raw material;grinding, granulating, forming, and firing, so as to obtain the ferro-nickel slag ceramic. The preparation method has the advantages that the ferro-nickel slag can be used in a batch way, the preparation method is simple, the implementing is easy, and the industrialized production is favorably realized; the crystal phases in the prepared building ceramic materials (ceramic tiles and ceramic sintering bricks), industrial ceramics and other ceramic materials contain one or multiple of anorthite, spinel, olivine and cordierite, the sintering is easy, and the mechanical property is excellent.

Owner:UNIV OF SCI & TECH BEIJING

Composite steel slag grinding aid

The invention relates to a composite steel slag grinding aid, which solves the problems that grinding aid in prior art is not suitable for grinding steel slag, the grinding time is long, the grinding efficiency is low, the activity of early period in active utilization of steel slag is low, and content of particles not participating reaction is high. The technical scheme comprises the components by weight percentage as follows: 15-30% of surfactant, 20-40% of grinding aid, 20-40% of adjustor, and 5-25% of carrier. The grinding aid provided by the invention can effectively shorten the grindingtime, improve the grinding characteristics and improve effective content of hydrated particles so as to improve the hydrating activity of steel slag. Ground steel slag has high strength, large comparison surface, and small doping amount to further improve the doping amount of steel slag recycled.

Owner:WUHAN IRON & STEEL (GROUP) CORP +1

Semidry-process sintering desulphurization slag autoclaved building block and production method thereof

InactiveCN102674799ASolve the problem of land occupationSolve secondary pollutionCeramic shaping apparatusBrickSlag

The invention relates to a semidry-process sintering desulphurization slag autoclaved building block and a production method thereof. The building block is made of the following components in percent by weight in a combined autoclaving way: 5-30 percent of semidry-process sintering desulphurization ash, 30-60 percent of steel slag, 25-30 of superfine slag powder and 1-10 percent of pebble. The production method comprises the steps of vibrating and molding the components according to the percent by weight and autoclaving after molding to obtain the semidry-process sintering desulphurization slag autoclaved building block. The semidry-process sintering desulphurization slag autoclaved building block and the production method thereof have the advantages that the desulphurization ash, waste steel slag and slag of iron and steel enterprises are fully utilized, the wastes are turned into valuable things, the materials such as lime, carbide slag, binder, early strength agent and cement are not added, the energy is saved, the mixing quantity of the waste slag is high, the strength of the produced bricks are higher, the production cost is low, the product quality is high and all technical indexes satisfy the national standard on building bricks; and the treatment and disposal efficiency of the waste slag of the iron and steel enterprises is improved, the development level of secondary resources is improved, the quantity of the used cement in the building material industry can be reduced and the economic and environmental values are higher.

Owner:武钢集团有限公司

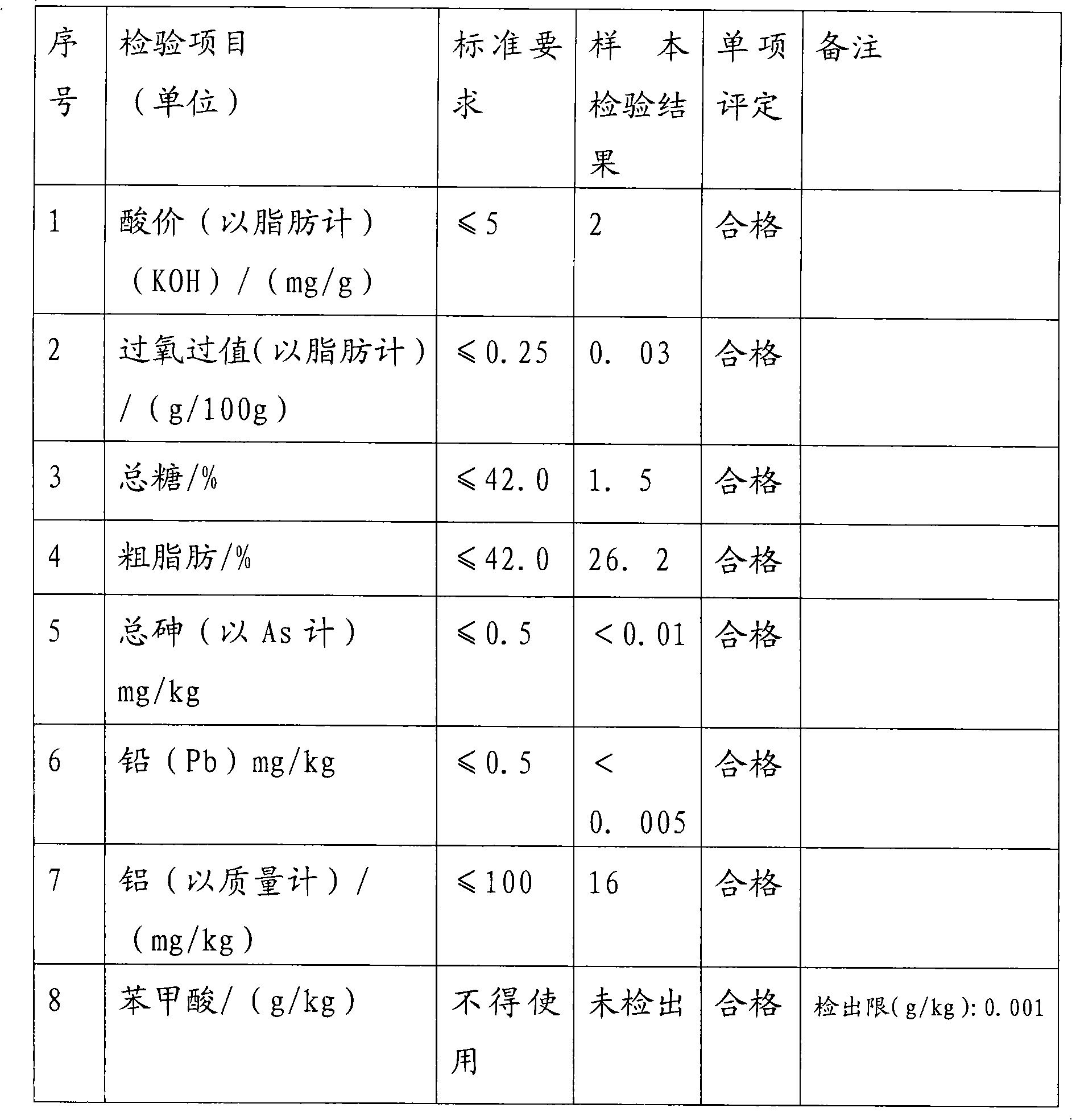

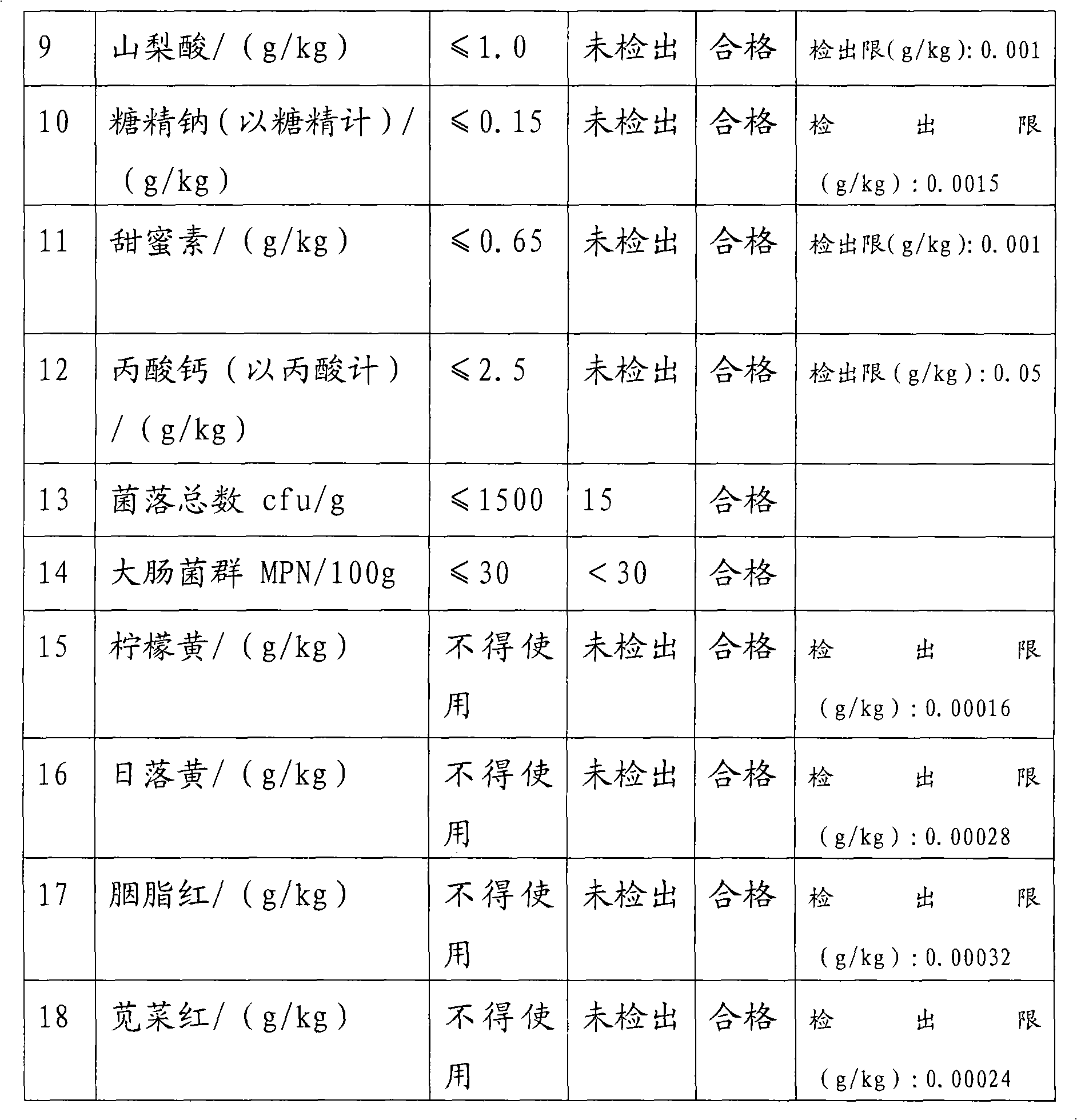

Preparation method of fried dough twists without additives

ActiveCN101965946ALower the targetMeet the requirements of food health and environmental protectionFood preparationFood additiveBitter taste

The invention discloses a preparation method of fried dough twists without additives, solving the problems of poor crisp taste of fried dough twists, damage to human body health, high oil absorption of fried dough twists existing in the traditional making of fried dough twists by inevitably adding food additives. The method of the invention comprises the following steps of: evenly mixing leaven and seasonings with water; adding flour and evenly kneading into dough; then, twisting the dough into long fried dough twists; and putting into a pot to fry, wherein high-temperature gluten breaking powder which accounts for 20-40 percent of the mass of the flour is also added to the raw materials and is prepared by the high-temperature anhydrous treatment of the flour. The invention has extremely simple production process, low production cost, no additive, low fat content and crisp taste without bitter taste and is suitable for all crowds.

Owner:王自义

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com