Composite steel slag grinding aid

A composite steel slag and grinding aid technology, which is applied in the field of grinding aids, can solve the problems of inability to improve the grinding characteristics of steel slag, large particle content, and low early activity, and achieve the elimination of electrostatic effects, high grinding efficiency, and hydration The effect of activity improvement

Inactive Publication Date: 2012-06-20

WUHAN IRON & STEEL (GROUP) CORP +1

View PDF3 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The mineral components in steel slag are completely different from those in cement. That is, the inert component in steel slag is a solid solution with high iron content, and the active component is similar to cement active substances. Therefore, the use of existing cement grinding aids not only has the problems of long grinding time, low powder efficiency, low activity in the early stage of steel slag activity utilization, and large content of non-reactive particles. The finished steel slag still has the problems of low strength, small specific surface area, and less steel slag parameters when it is reused, which cannot achieve the purpose of improving the grinding characteristics of steel slag and increasing the activity of steel slag.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

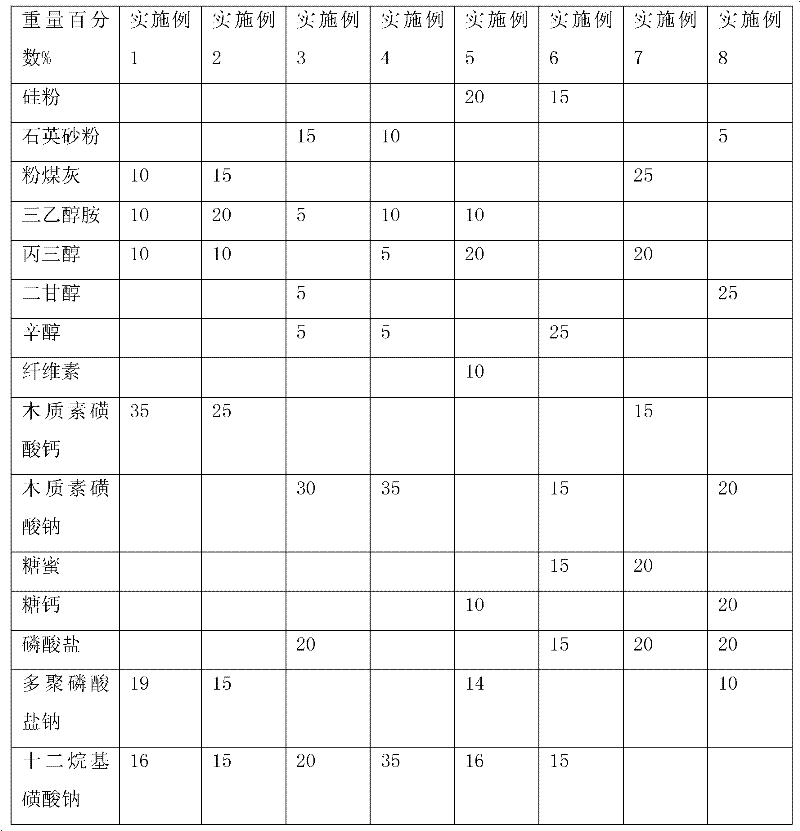

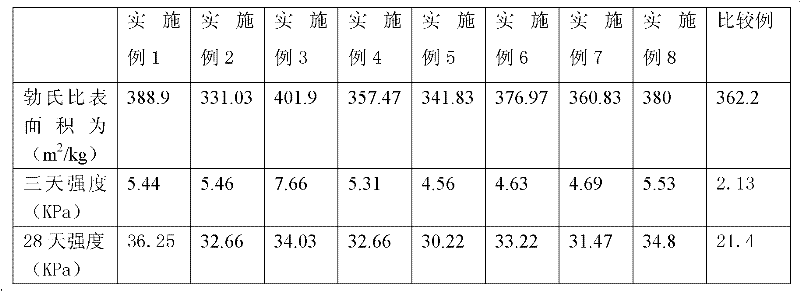

The invention relates to a composite steel slag grinding aid, which solves the problems that grinding aid in prior art is not suitable for grinding steel slag, the grinding time is long, the grinding efficiency is low, the activity of early period in active utilization of steel slag is low, and content of particles not participating reaction is high. The technical scheme comprises the components by weight percentage as follows: 15-30% of surfactant, 20-40% of grinding aid, 20-40% of adjustor, and 5-25% of carrier. The grinding aid provided by the invention can effectively shorten the grindingtime, improve the grinding characteristics and improve effective content of hydrated particles so as to improve the hydrating activity of steel slag. Ground steel slag has high strength, large comparison surface, and small doping amount to further improve the doping amount of steel slag recycled.

Description

technical field [0001] The invention relates to a grinding aid, in particular to a composite steel slag grinding aid. Background technique [0002] The existing commonly used grinding aids are mostly aimed at the cement production process, and the grinding aids commonly used in cement are mainly divided into three categories: polymeric inorganic salts, polymeric organic salts and composite compounds. Exist in liquid, solid and gaseous forms. Liquid grinding aids include amines, alcohols, some inorganic salts and water; gas grinding aids include water vapor, acetone gas and inert gas, etc.; solid grinding aids include colloidal carbon black, calcium stearate, inorganic salts Potassium ferrocyanide, stearic acid, etc. [0003] The mineral components in steel slag are completely different from those in cement. That is, the inert component in steel slag is a solid solution with high iron content, and the active component is similar to cement active substances. Therefore, the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B24/18C04B24/38

Inventor ZHOU XULINHOU HAOBOWU GAOMINGZHOU MINZHU XI

Owner WUHAN IRON & STEEL (GROUP) CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com