Patents

Literature

530results about How to "Shorten grinding time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phosphate film-coated powder and preparation method thereof

InactiveCN101045828AUniform particlesParticle size distribution andNon-macromolecular adhesive additivesOther chemical processesDepolymerizationDouble decker

This invention relates to a method of preparing envelope powder. The shattering, depolymerization and coating processed at same time, and solid phase acid-base reaction participate the method. This envelope powder possess double-decker or three-layer structure, inner core is composed by oxide or hydrate or inorganic oxysalt, crust composed by inorganic oxysalt, envelope by aluminum phosphate or boron phosphate. This low cost powder be able to used as fortifier, power stuff, colorant and so on, applied to plastic, rubber, ceramics, dope, binder and paper, set foundation for popularization of ultramicro and nanometer powder.

Owner:张义纲 +1

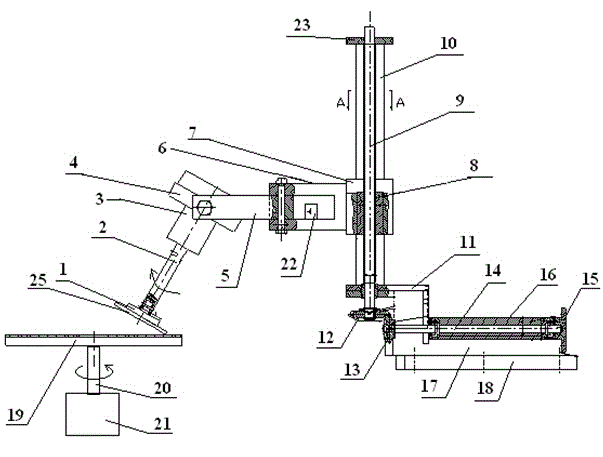

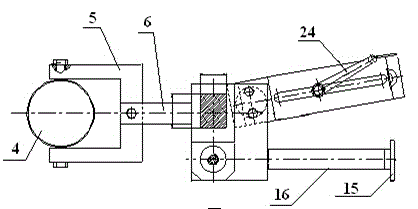

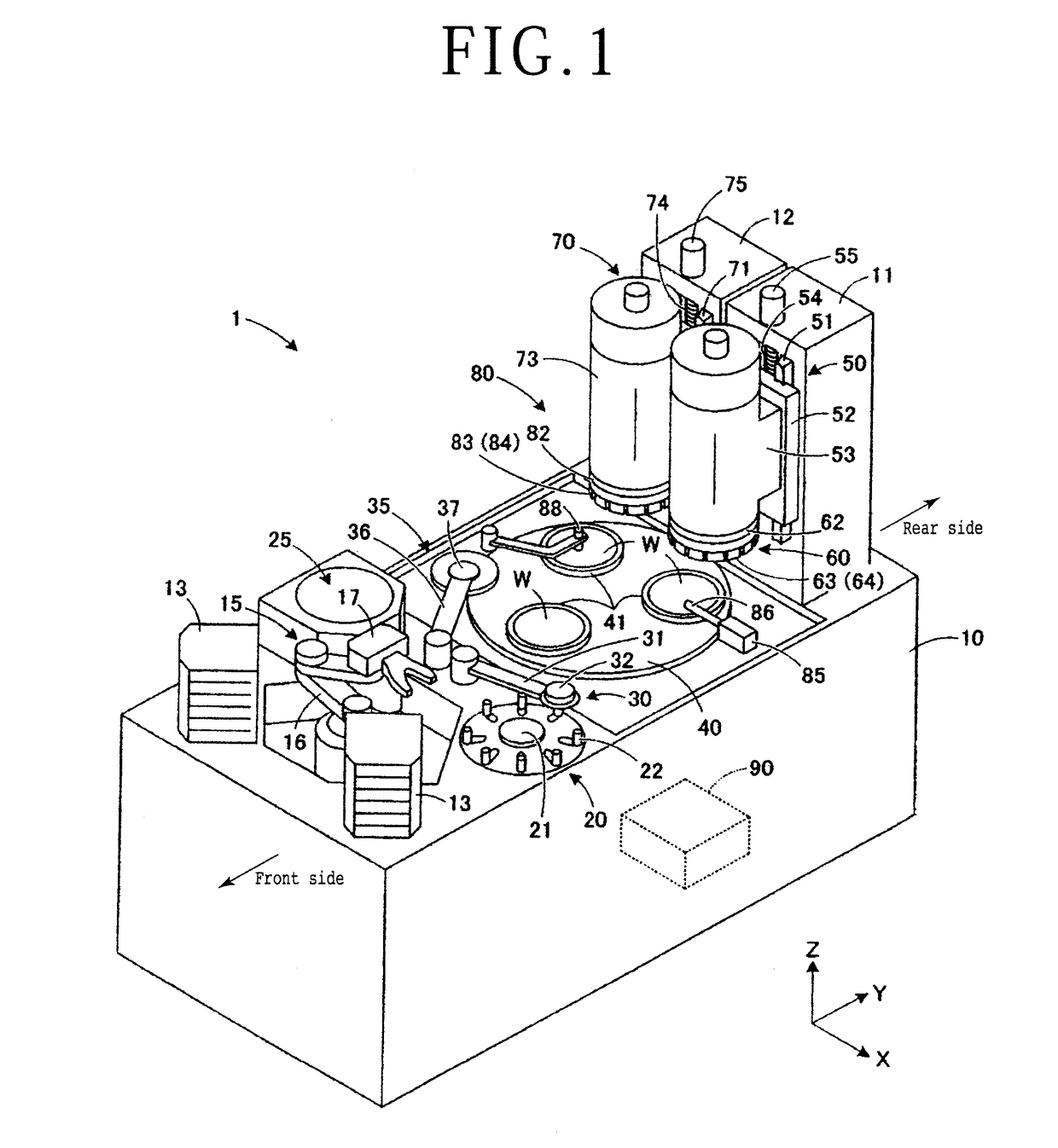

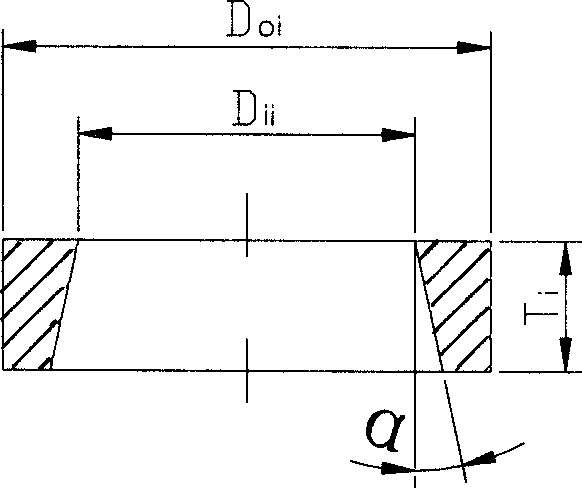

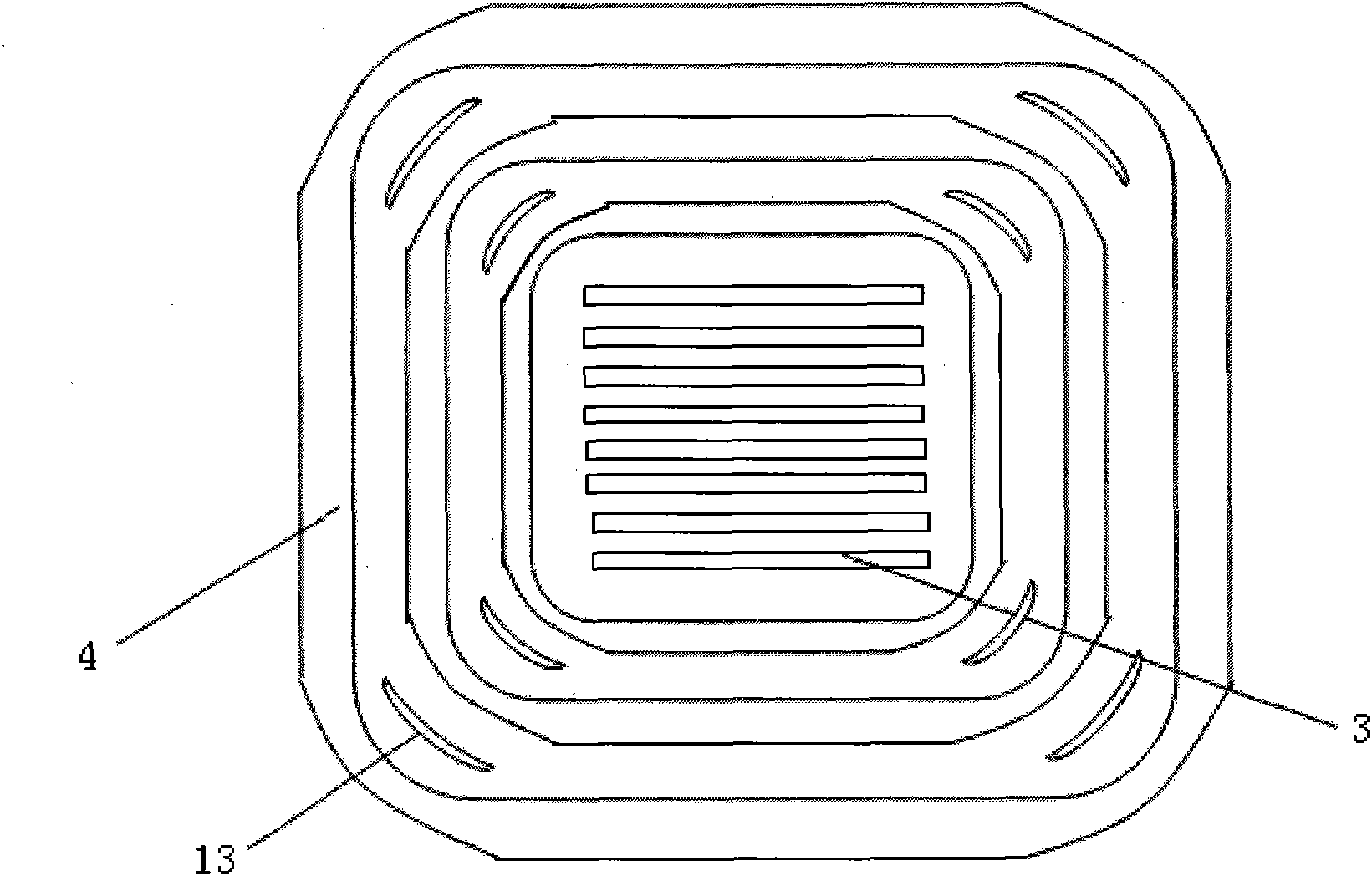

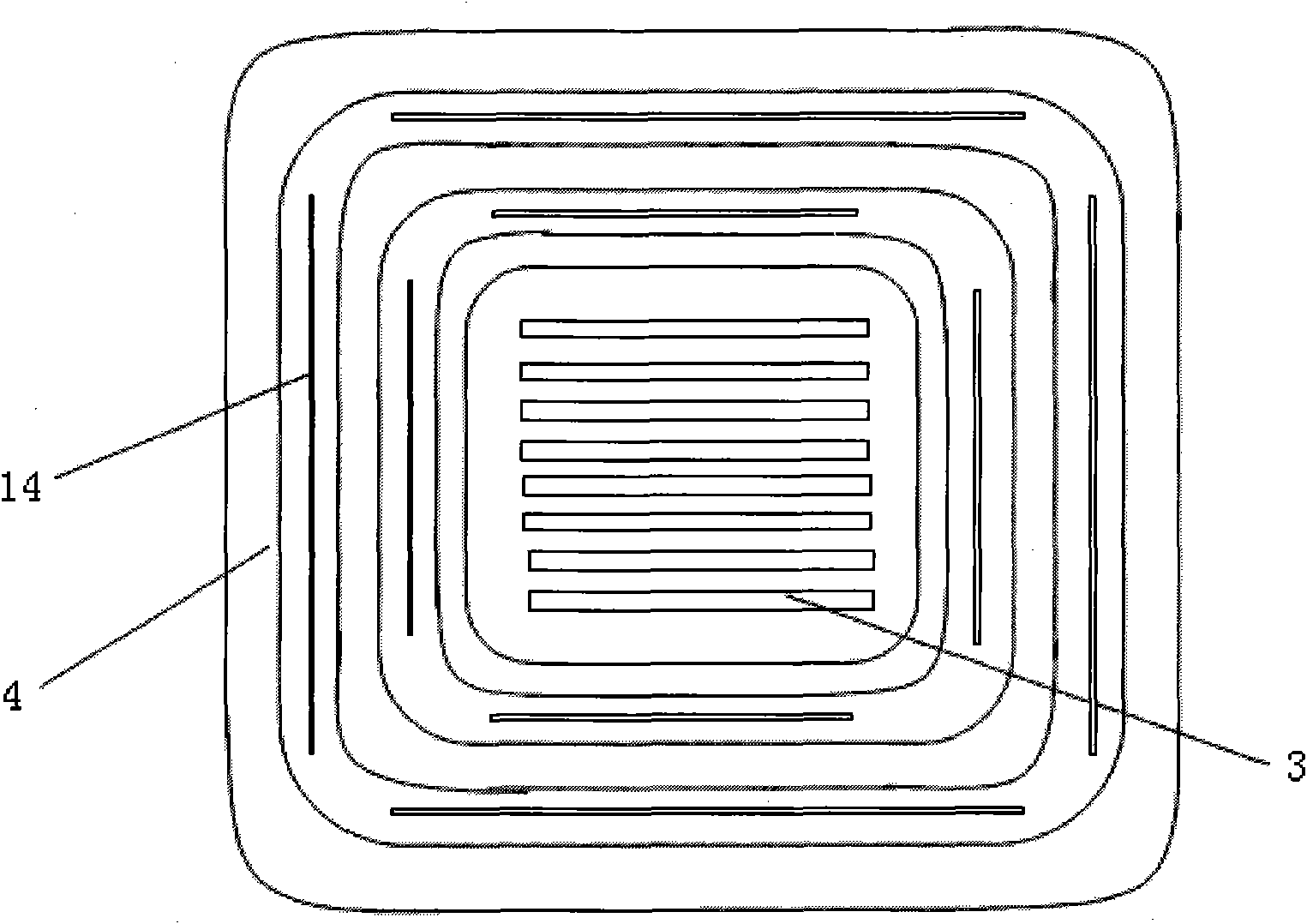

Silicon carbide wafer bevel grinding, milling and polishing machine and operation method thereof

ActiveCN104551900AAvoid chippingImprove processing qualityEdge grinding machinesPolishing machinesEngineeringDrive motor

The invention discloses a silicon carbide wafer bevel grinding, milling and polishing machine and an operation method thereof. The silicon carbide wafer bevel grinding, milling and polishing machine comprises a supporting sheet (1), a rotating shaft (2), a driving motor (3), a motor bracket (4), a vertical rotating arm (5), a horizontal rotating arm (6), a slide frame (7) and a screw rod (9) which are sequentially connected, wherein the lower end of the screw rod (9) is sequentially connected with a first cone gear (12), a second cone gear (13), an adjusting shaft (14) and a rotating wheel (15); a machining tool (19) of a silicon carbide wafer is arranged below the supporting sheet (1). The silicon carbide wafer bevel grinding, milling and polishing machine is reasonable in structural design, convenient to operate and high in working efficiency, bevel grinding, milling and polishing integrated machining can be performed on the silicon carbide wafer, the working efficiency is high, the roughness of a polished bevel can be smaller than 0.1 micron, the machining precision is high, and the applicability is high. The operation method can be applied to the bevel grinding, milling and polishing integrated machining on the silicon carbide wafer which is round or not round.

Owner:山东粤海金半导体科技有限公司

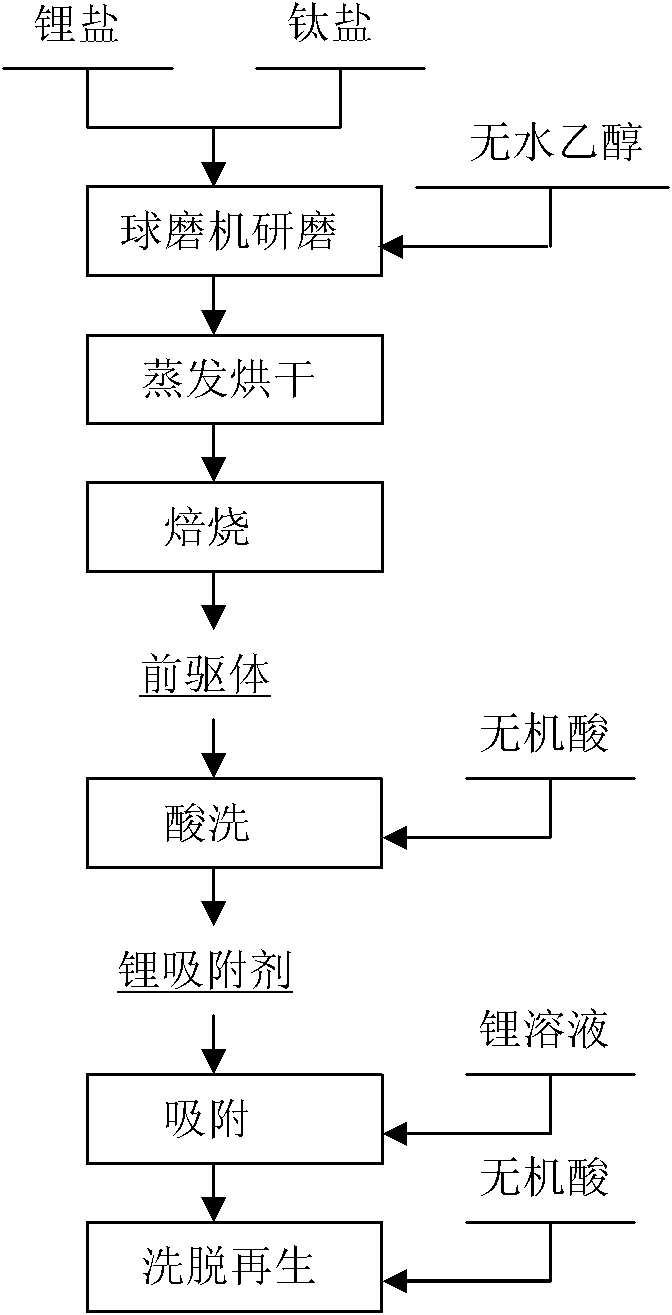

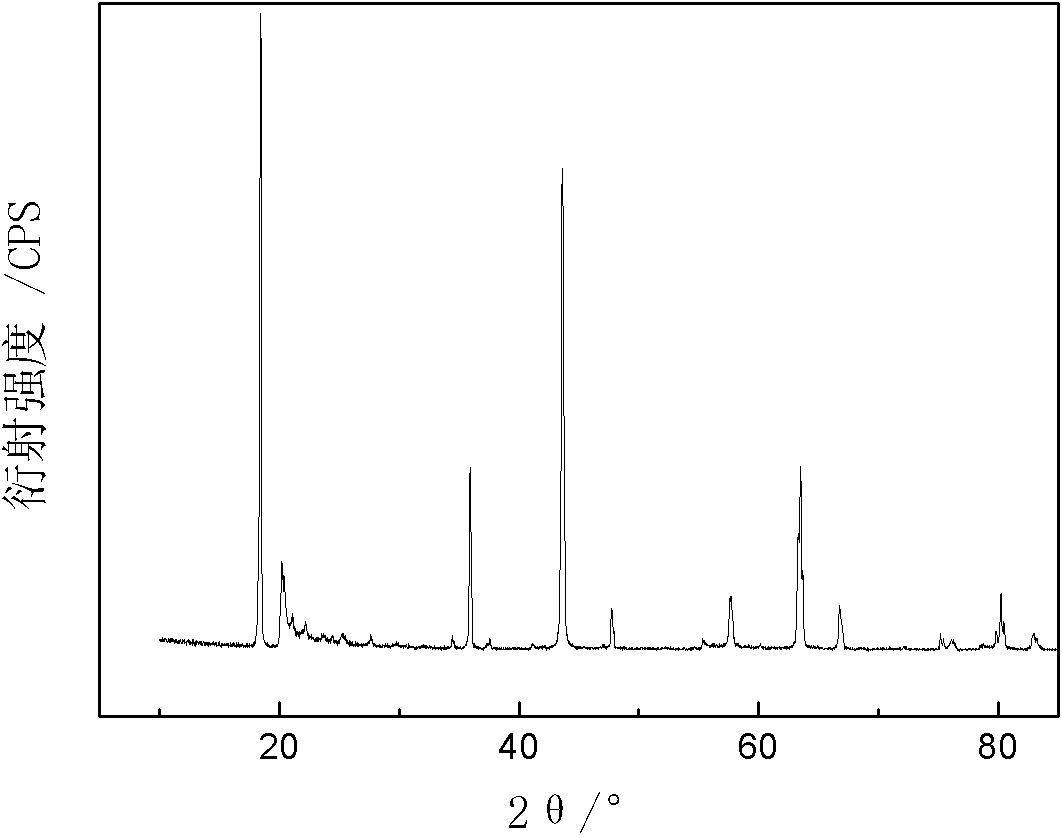

Lithium-titanium oxide type lithium ion sieve absorbent and method for preparing precursor thereof

InactiveCN101944600AWell mixedIncrease contact surfaceCell electrodesTitanium compoundsSalt lake brineTitanium oxide

The invention discloses a lithium-titanium oxide type lithium ion sieve absorbent and a method for preparing a precursor thereof, and relates to a method for preparing an inorganic absorbent for absorbing enriched lithium from salt lake brine, seawater and other liquid lithium resources. The method is characterized in that: titanium dioxide and lithium salt are taken as raw materials, ground by a ball grinder and dried so as to prepare a precursor Li2TiO3 of an ion sieve through a high-temperature solid-phase roasting method; and the lithium is eluted from the precursor Li2TiO3 by inorganic acid to prepare an ion sieve H2TiO3. The method has the advantage of simple technology, and the obtained ion sieve has the advantages of low solution loss and high adsorption capacity.

Owner:CENT SOUTH UNIV

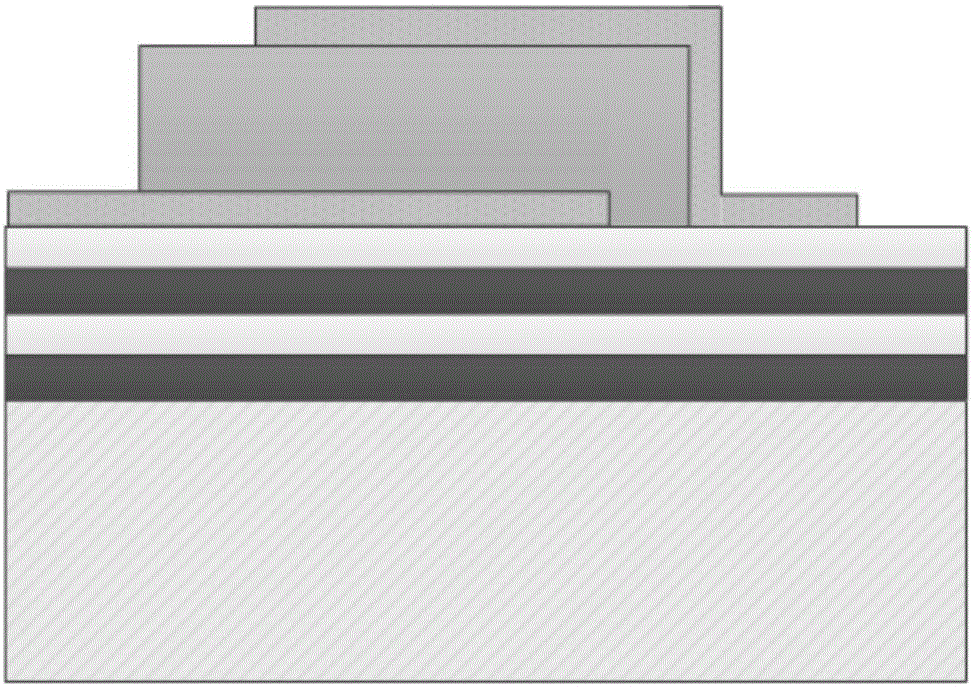

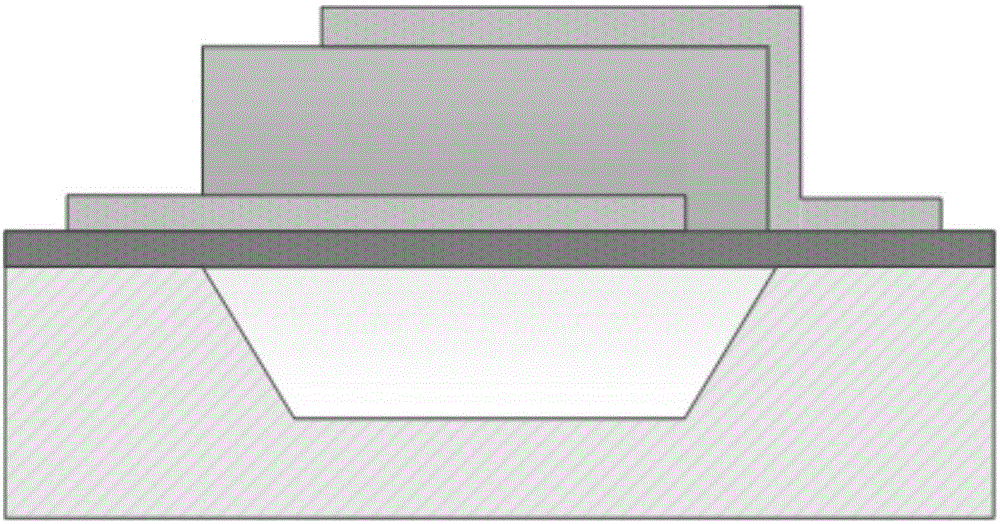

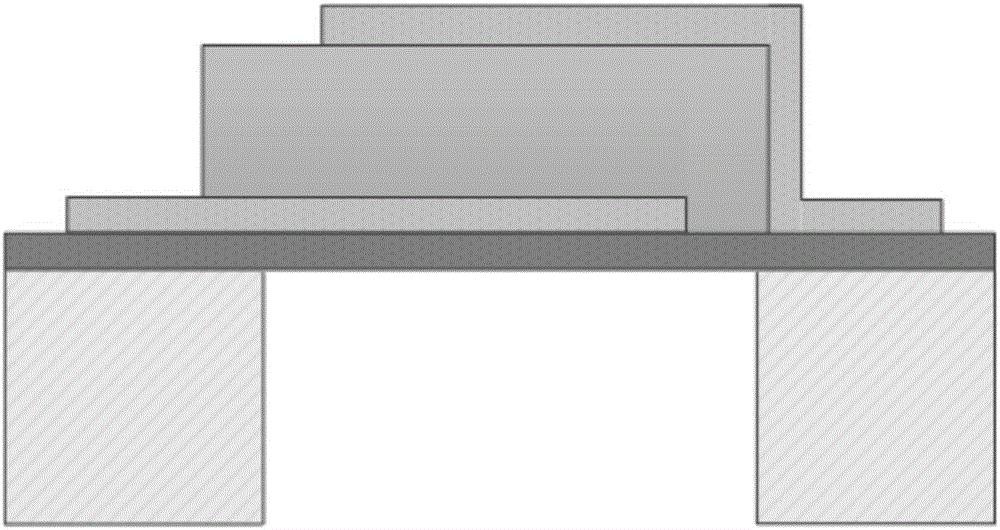

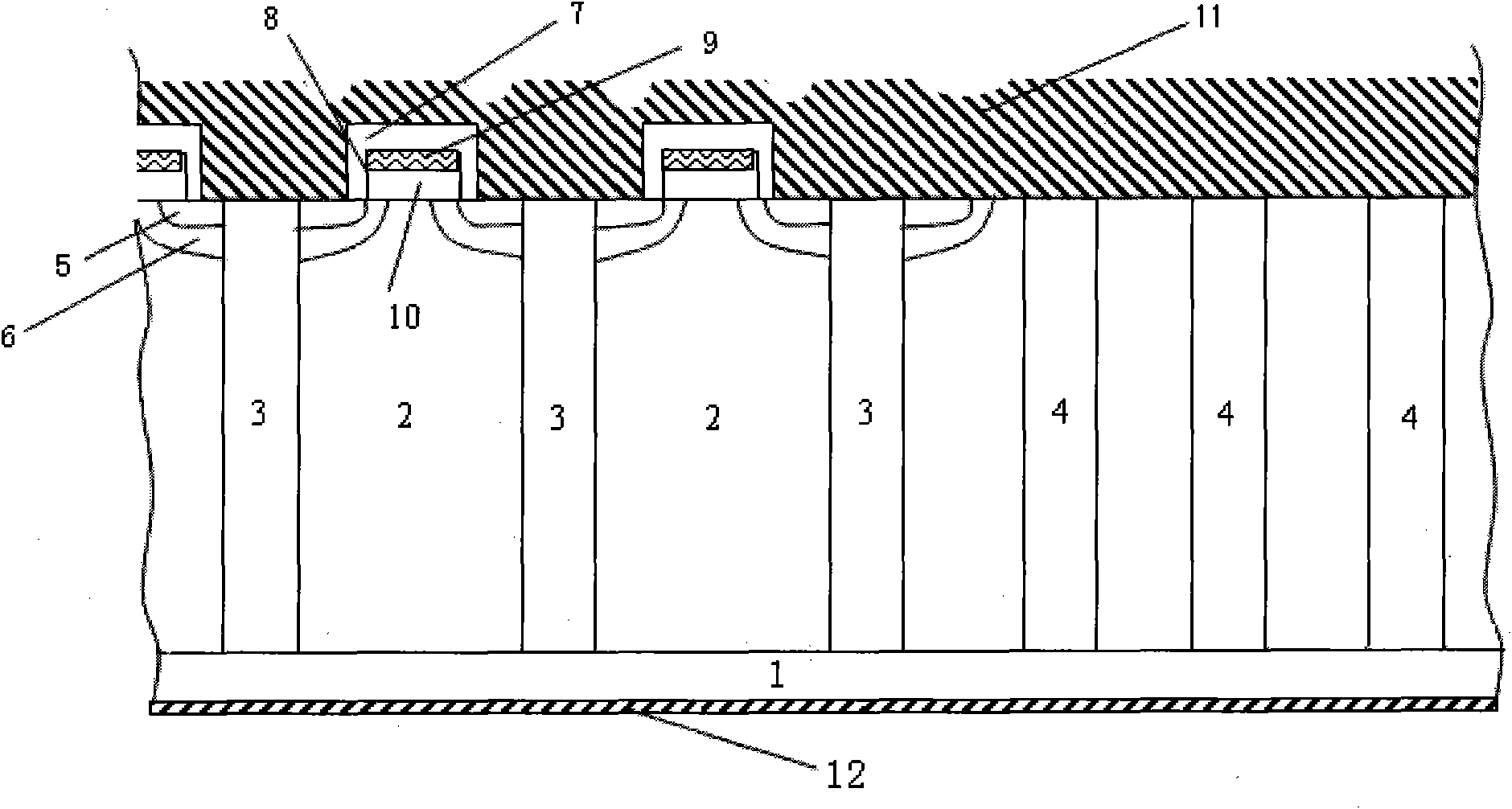

Cavity type film bulk acoustic resonator and preparation method thereof

InactiveCN107528561AReduce the thermal steady state temperatureHigh hardnessImpedence networksSteady state temperatureAmorphous silicon

The invention relates to a cavity type film bulk acoustic resonator, comprising a substrate, an isolation layer, a support layer, a bottom electrode layer, a piezoelectric layer and a top electrode layer that are sequentially arranged from bottom to top, wherein the middle part of the upper surface of the isolation layer is recessed downwards to form a groove, the groove is sealed by the support layer and the substrate to form a sealed cavity, the height of the lower surface of the sealed cavity is less than the height of the upper surface of the substrate, the lower surface of the sealed cavity is a flat surface, and the material of the support layer is SiC. And meanwhile, the invention also discloses a preparation method of the acoustic resonator. According to the cavity type film bulk acoustic resonator and the preparation method thereof disclosed by the invention, the structure of the device is stabilized by the SiC support layer, and the power capacity can be improved; the heat can be effectively dissipated, the thermal steady-state temperature of the device can be reduced, and good thermal stability can be achieved; and according to the method, amorphous silicon layers are removed by using an acetone solution lift-off process, a CMP process can be simplified, the grinding time can be reduced, the grinding uniformity can be improved, and the frequency stability and the rate of finished products of the device can be improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

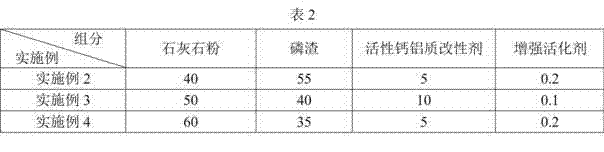

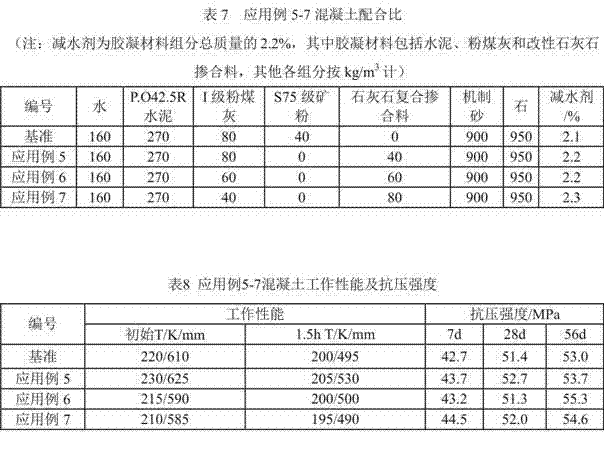

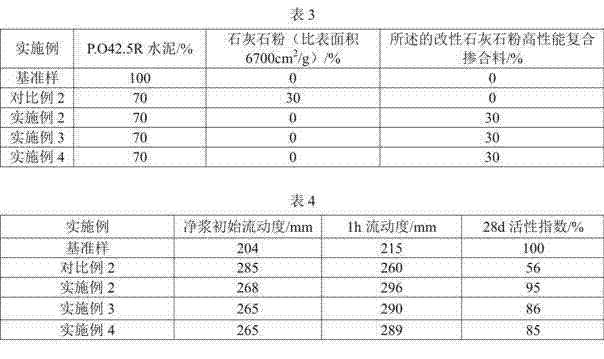

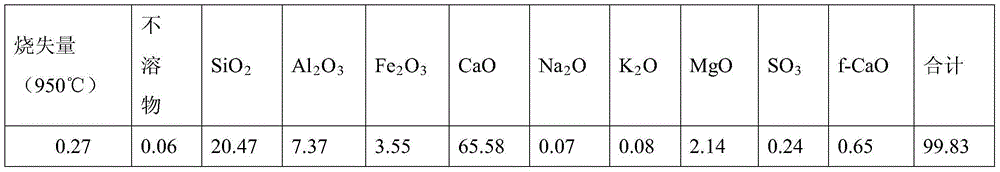

Modified limestone powder high-performance mineral admixture and preparation method thereof

The invention relates to a modified limestone powder high-performance mineral admixture and a preparation method thereof. The invention is characterized in that the modified limestone powder high-performance mineral admixture is prepared by mixing and grinding the following raw materials in parts by mass: 40-60 parts of limestone powder, 35-55 parts of phosphorus slag, 5-10 parts of active calcium aluminum modifier and 0.1-0.2 part of reinforced activator. The concrete mineral admixture prepared by the method solves the problems of high loss of concrete workability, low strength and the like in the common limestone powder admixture; when substituting 50-100% of I-grade fly ash or 20-50% of I-grade fly ash and 100% of S75-grade mineral powder in concrete by equal quality, the concrete mineral admixture can improve the concrete workability, and has the characteristics of quick development of early strength and stable later strength.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD +1

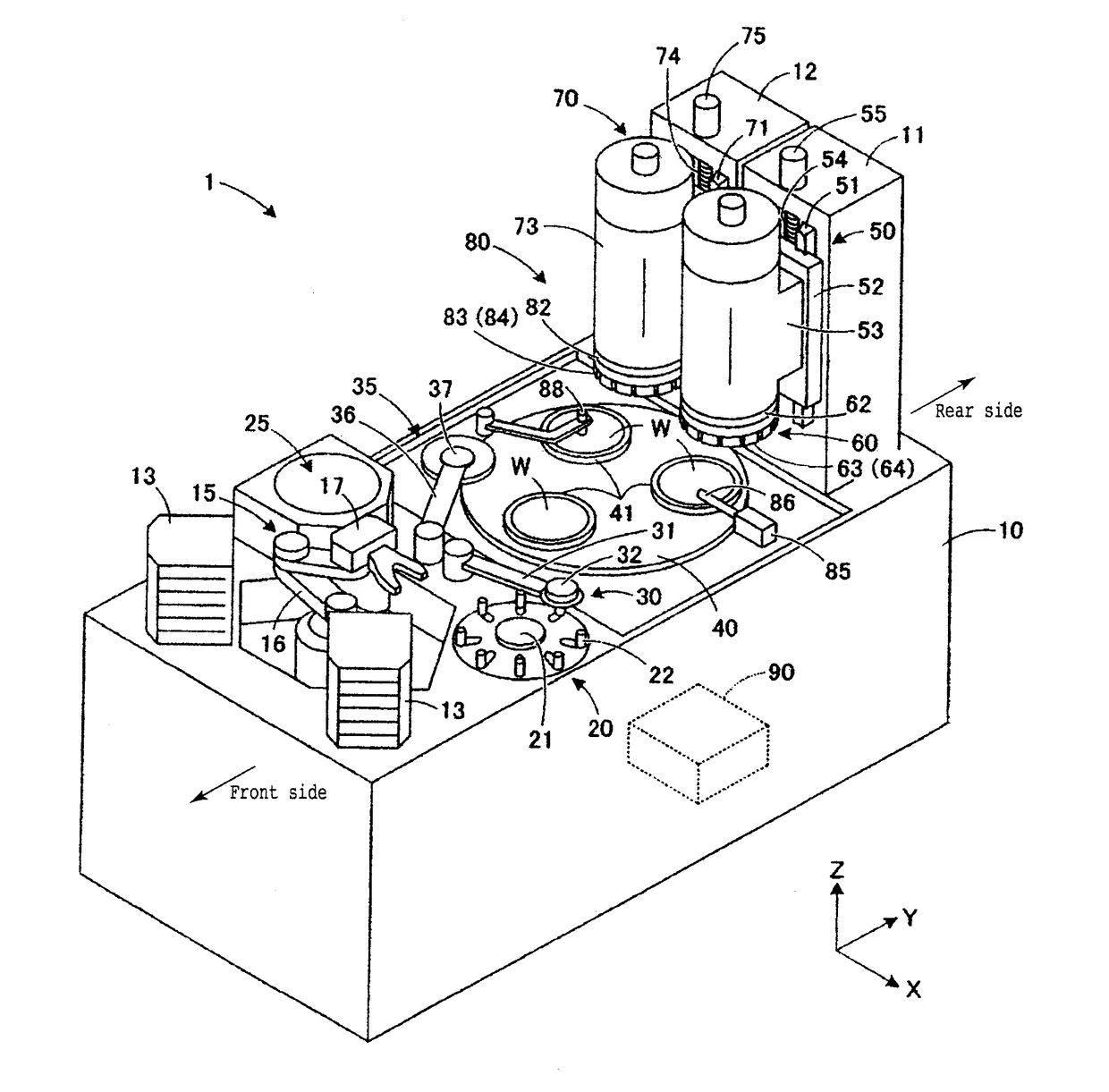

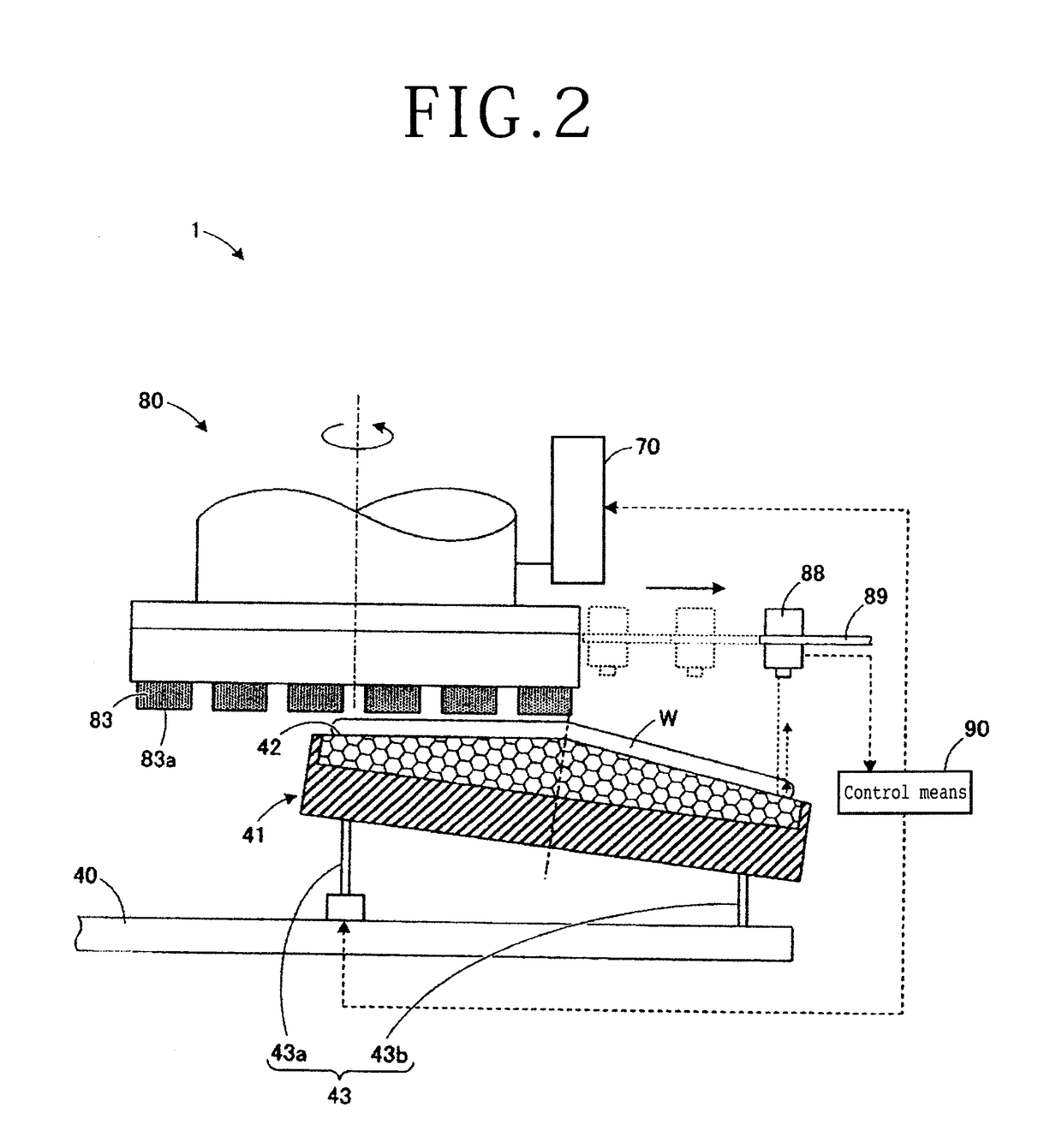

Grinding method

ActiveUS20170095902A1Reduces grinding timeShorten the time periodSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingGrindstoneMoving speed

A grinding method includes a pre-grinding step of grinding a plate-shaped workpiece to a thickness just before a finish thickness is reached using a finish grinding unit, a thickness measuring step of measuring a thickness of the workpiece after the pre-grinding step, a calculation step of calculating, from the measured thickness of the workpiece, a variation amount of the distance between a holding face of the chuck table and a grinding face of a finish grindstone before and after inclination adjustment of the chuck table, and a height adjustment step of adjusting, on the basis of the variation amount, the inclination of the chuck table while adjusting the height of the finish grinding unit so that the relative moving speed between the finish grindstone and the workpiece in a state in which the grinding face contacts with an upper face of the workpiece becomes equal to zero.

Owner:DISCO CORP

Casting blank heating method for controlling surface to generate ferric oxide structure

InactiveCN101144116AReduce adhesionShorten grinding timeWork treatment devicesRoll mill control devicesHeating timeScale structure

The present invention discloses a cast blank heating method for controlling the iron oxide scale structure generated on the surface in the steel rail production technical field. The method includes the steps that blanks are delivered into the preheating section of a heating furnace for preheating in different groups and in sequence according to the rolling process; then heating is performed in a first heating section and also a second heating section, heat soaking and heat preservation are performed in a heat soaking section, and the blanks are discharged from the furnace and rolled after the rolling temperature is achieved. Through the controlling of the blank heating time, the temperature and the atmosphere, the thickness of an iron protoxide loose layer in an iron oxide scale structure close to the steel substrate surface of a heated cast blank is lower than 50 percent, the thicknesses of other dense layers are higher than 50 percent, the depth of the decarburized layer of the rolled steel rail surface is controlled within 0.3 mm, and the roughness of the steel rail surface is lower than or equal to 0.2 mm.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

Wet-grinding gypsum with polycarboxylates

InactiveUS20090127360A1Highly effective for fluidizingReduce pressurePigmenting treatmentCement productionSlurryWet grinding

The process of the present invention includes obtaining a feed material having an initial median particle size. A solution of a polycarboxylate dispersant in water is formed, then the feed material is added to the solution to form a slurry. The slurry is wet-ground to reduce the median particle size of the feed material. Optionally, the total amount of polycarboxylate dispersant is divided into a plurality of doses that are added periodically over the total grinding time.

Owner:UNITED STATES GYPSUM CO

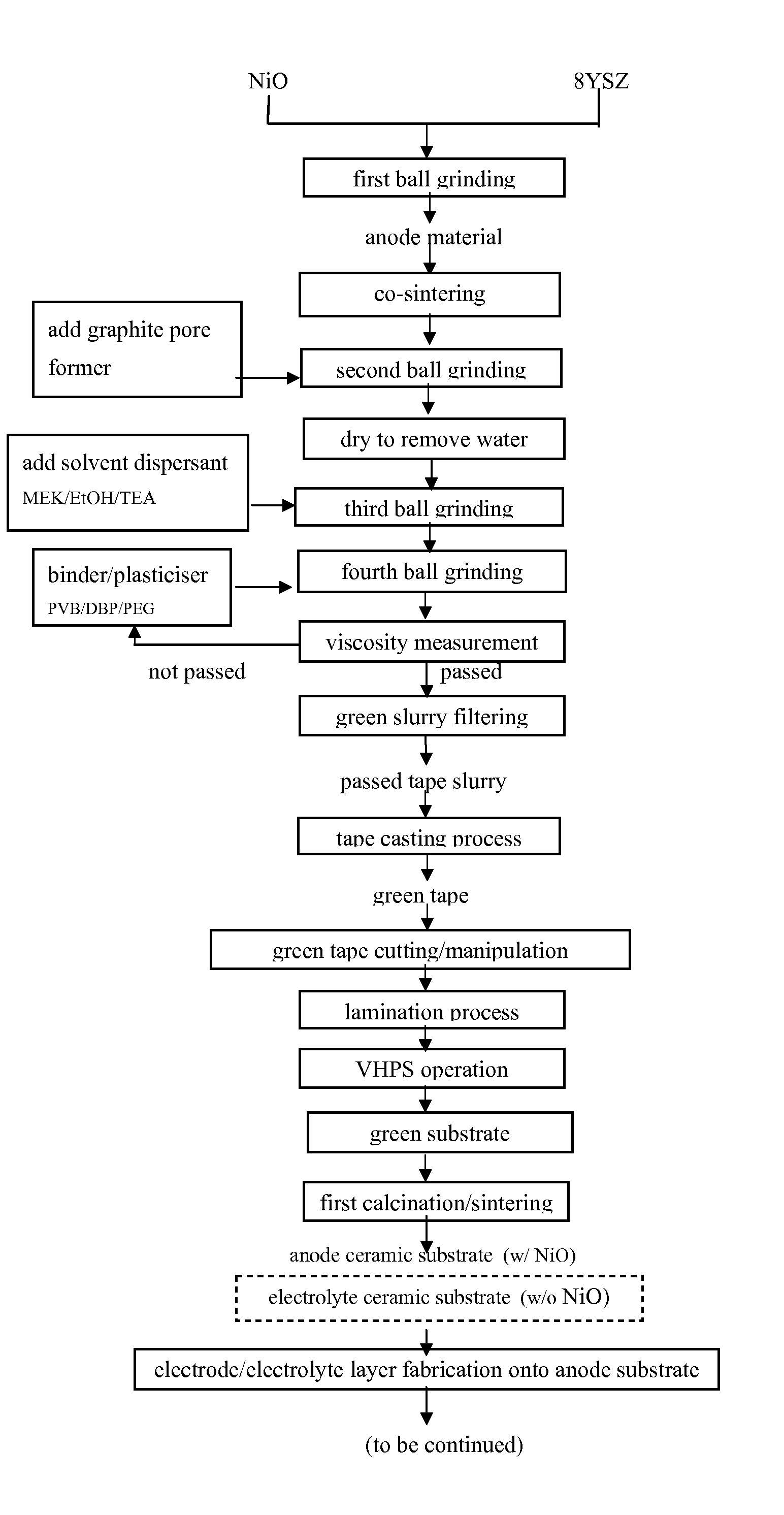

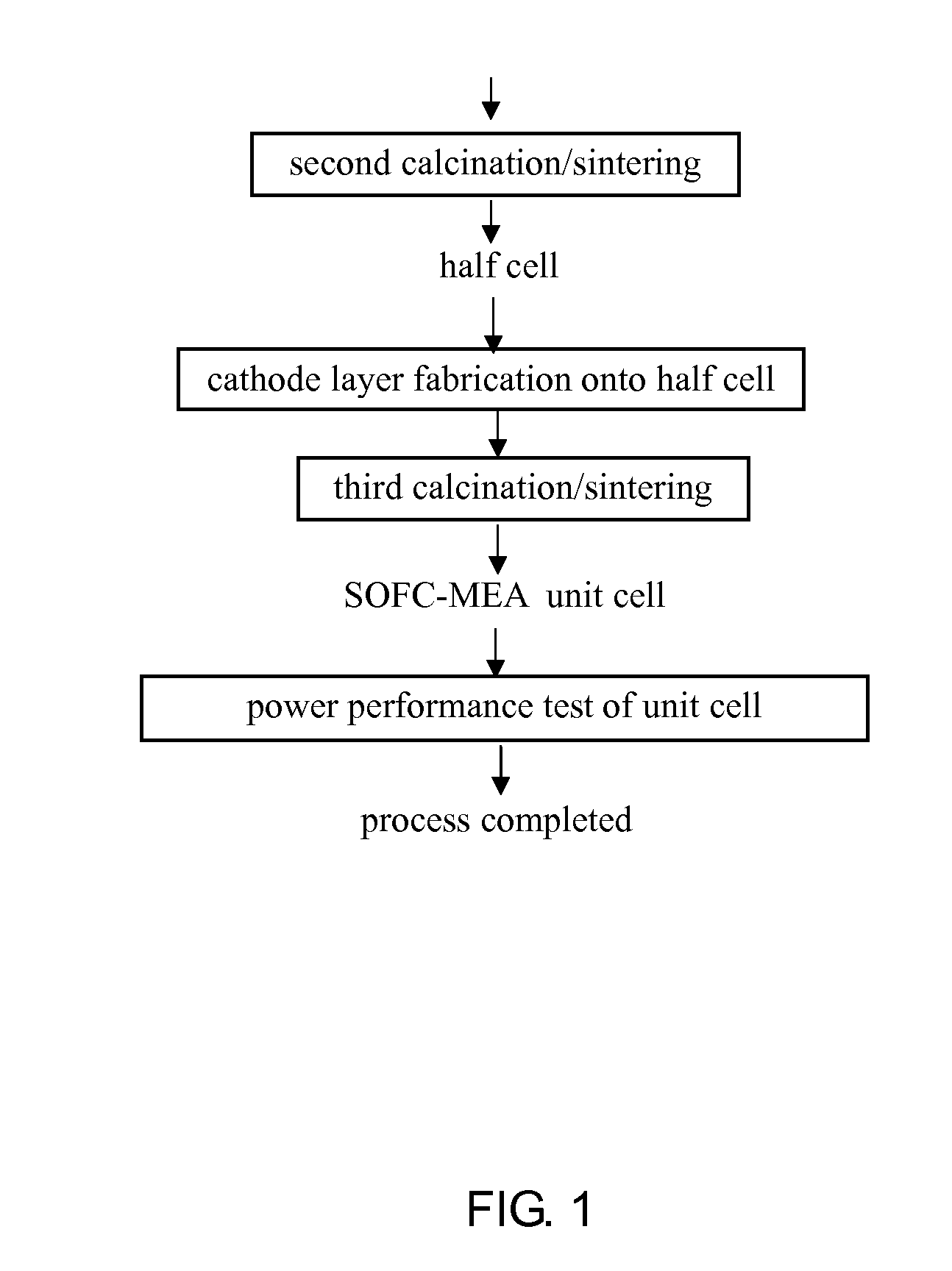

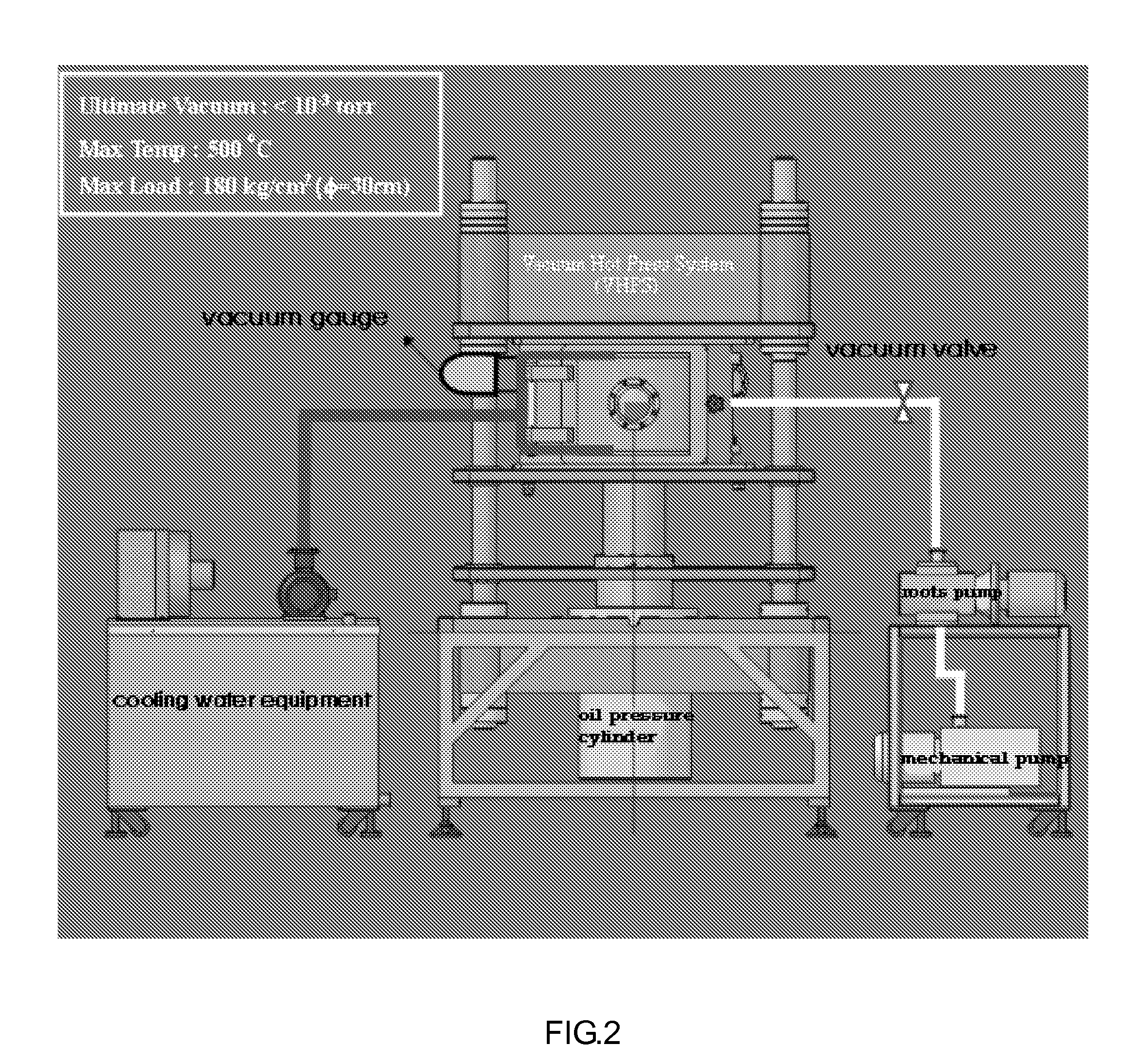

Novel synergistic process and recipe for fabrication of a high integrity membrane electrode assembly of solid oxide fuel cell

ActiveUS20090068373A1Improve integrityIncrease ratingsMolten spray coatingCell electrodesGreen tapeFuel cells

A recipe and two sequential processes for fabrication of electrode substrates of solid oxide fuel cells (SOFCs) are described in this invention. The typical recipe consists of 50˜86 wt % electrolyte (8YSZ) or 50˜80 wt % anode electrode (NiO / 8YSZ), 12˜22 wt % MEK (solvent 1), 5˜9 wt % EtOH (solvent 2), 1˜2 wt % TEA (dispersant), 0.5˜2 wt % DBP (plasticizer 1), 0.5˜2 wt % PEG (plasticizer 2), 3˜6 wt % PVB (binder), and 0.1˜10 wt % graphite (pore former). Two sequential processes include: 1. The process for preparation of the green tape slurry from materials of the recipe, 2. The synergistic process for fabrication of a high integrity membrane electrode assembly (MEA) of SOFC from the prepared electrode substrates.

Owner:INST NUCLEAR ENERGY RES ROCAEC

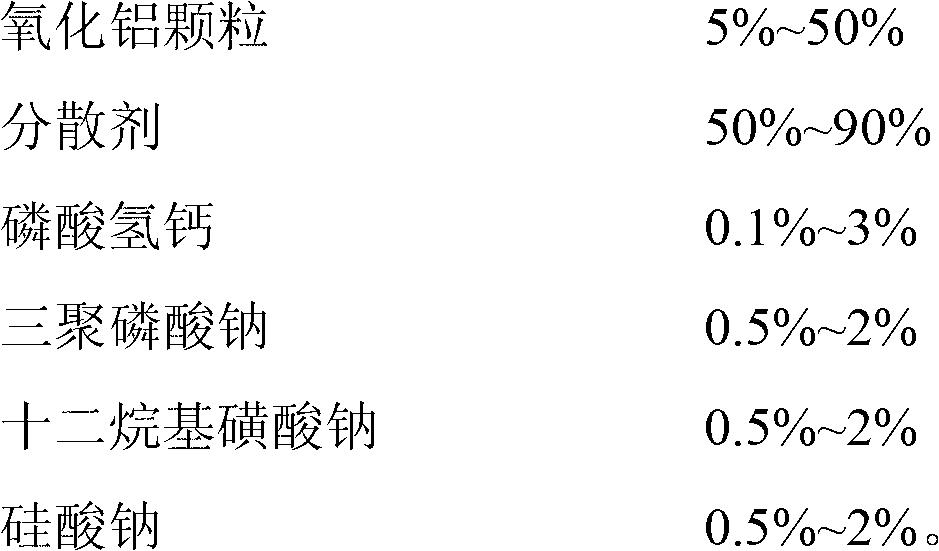

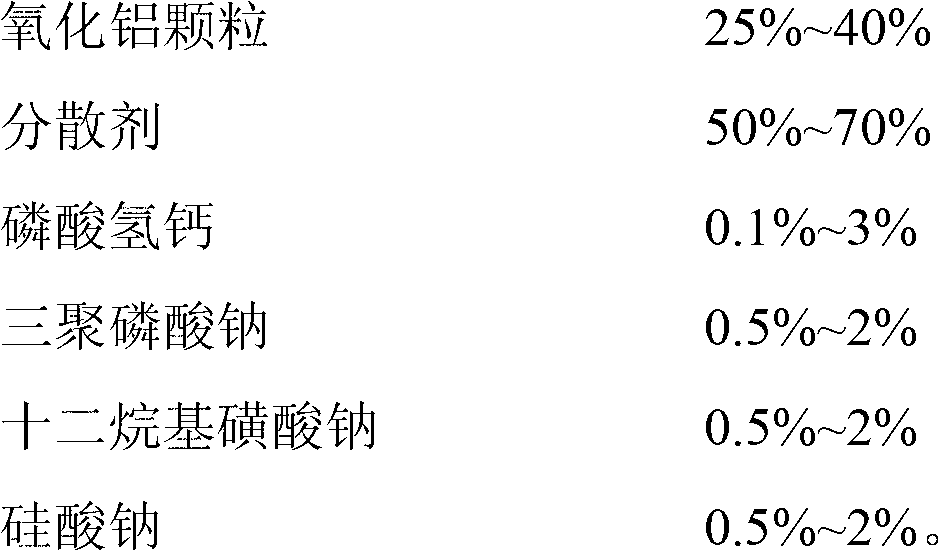

Foundry coating prepared from foundry resin sand regeneration power dust and method thereof

InactiveCN101259518AEmission reductionImprove performanceFoundry mouldsFoundry coresFoundrySodium silicate

The invention provides a formulation and a method for preparing the aggregate of a casting dope by utilizing the regenerated dust of casting resin bonded sand. The aggregate formulation includes: casting the regenerated dust of casting resin bonded sand and schmigel; casting the regenerated dust of casting resin bonded sand and bauxite; and casting the regenerated dust. The invention can be used for casting dopes like the casting resin bonded sand, clay sand, sodium silicate sand and lost foam, etc. The method includes: screening the regenerated dust of casting resin bonded sand, directly or grinding and mixing uniformly; preparing the aggregate of the dope. The prepared dope has the excellent performance. As the aggregate has the advantages of low manufacture cost, excellent performance and reducing the discharge of dust, the comprehensive utilization or circulating utilization of casting dust is realized; therefore, the formulation and the method have the excellent market competitive strength and the value of application.

Owner:KUNMING UNIV OF SCI & TECH

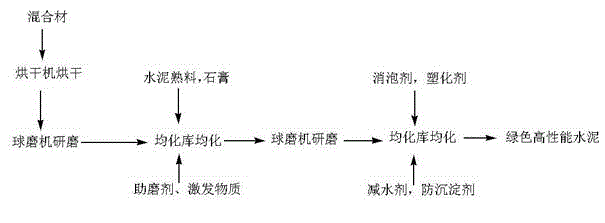

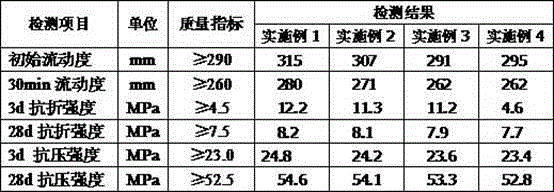

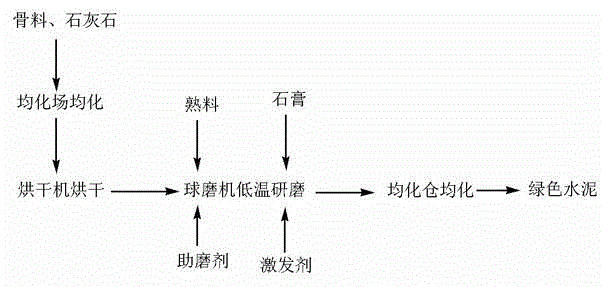

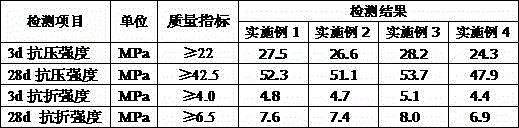

Environment-friendly high-performance cement and production method thereof

ActiveCN103601381AReduce crushing efficiencyImprove liquidityCement productionPlasticizerCement slurry

The invention provides environment-friendly high-performance cement which is characterized by consisting of the following raw materials in parts by weight: 50-60 parts of admixture, 32-40 parts of cement clinker, 6-8 parts of gypsum, 0.03-0.05 part of grinding aid, 3-5 parts of excitation substance, 0.05-0.1 part of antifoaming agent, 0.05-0.1 part of plasticizer, 0.03-0.05 part of anti-precipitating agent and 0.2-0.4 part of water reducing agent. In the environment-friendly high-performance cement provided by the invention, a large mixing amount of cement slurry can be realized by adopting a mechanical-chemical excitation production process, a great quantity of industrial waste residues can be consumed, the yield is increased, and the production cost is lowered; moreover, by adding a functional additive, the performance of the product is improved, and the needs of civil engineering are met.

Owner:广西云燕特种水泥建材有限公司

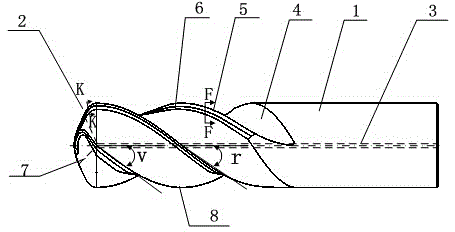

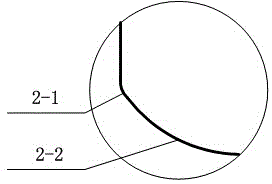

Milling cutter provided with equidistant arc head on eccentric shape flank surface and grinding method

InactiveCN104959667AAvoid vibrationExtend your lifeMilling cuttersWorkpiecesMilling cutterEngineering

The present invention relates to a milling cutter provided with an equidistant arc head on an eccentric shape flank surface and a grinding method, the cutter can reduce the vibration during the process of processing of different hardness of hardened steels for splicing of a mould, the cutter life and workpiece surface quality can be improved, the flank surface shape can be changed, and the cutter tip strength can be improved. The milling cutter is an overall hard alloy end milling cutter. The milling cutter includes a cutter shank (1) and the arc head (2), the arc head includes a large curvature arc (2-1) and a small curvature arc (2-2). Tooth-spacing angles are 87 degrees, 93 degrees, 87 degrees, and 93 degrees, tooth-spacing vertical angles are equal, helix angle (r) is 38 degrees, helix angle (v) is 40 degrees, and cutter end cutting edge flank surface (10) and circumferential cutting edge (6) are in eccentric shape. Front angle is in the range of 0-3 degrees, first clearance angle is in the range of 8-10 degrees, and second clearance angle is in the range of 15-22 degrees. The center position of the cutter is provided with cooling channels (3), the number of the cooling channels is four, and the four cooling channels respectively are located four cutting edge end tooth chip pockets. The present invention also provides a reference for the grinding of the cutter of the type.

Owner:HARBIN UNIV OF SCI & TECH

Preparation method of metallographic samples

InactiveCN108896339AAvoid it happening againEasy to observeWithdrawing sample devicesPreparing sample for investigationColloidMaterials science

The invention discloses a preparation method of metallographic samples. The preparation method includes the following steps: S1, a step of sampling, namely a step of cutting samples at the edge and center of a sample object; S2, a step of inlaying, namely a step of slowly guiding flows of colloid into an inlaying die through galvanized iron wires for curing; S3, a step of grinding; S4, a step of polishing; and S5, a step of corrosion, namely a step of corroding a metallographic detected surface with a corrosion solution. The method can effectively prevent bubbles from forming in the metallographic samples, improve the polishing effect, shorten the polishing time, facilitate metallographic observation of the metallographic detection surface, and improve the detection accuracy.

Owner:JIANGSU SCIENCE TEST TECHNOLOGY SERVICE CO LTD

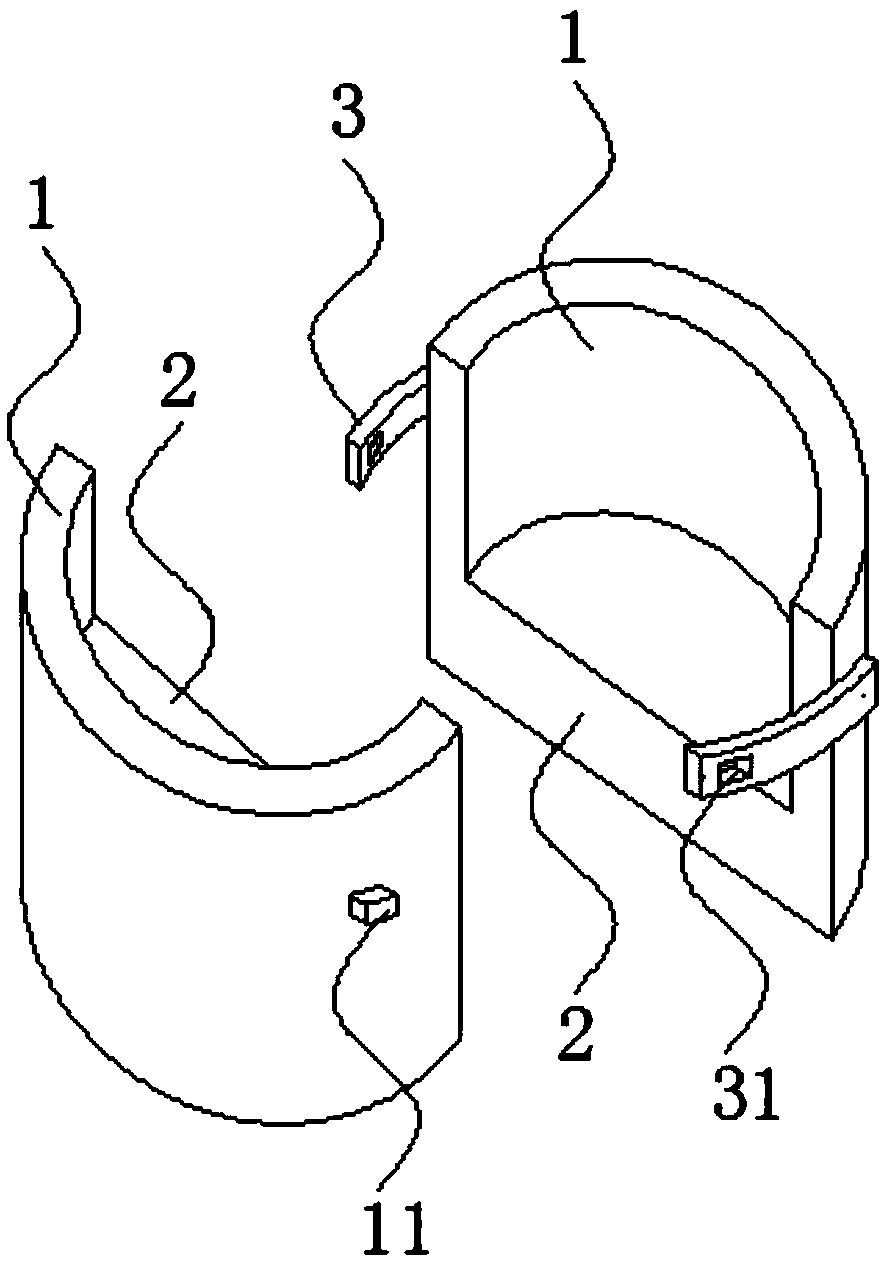

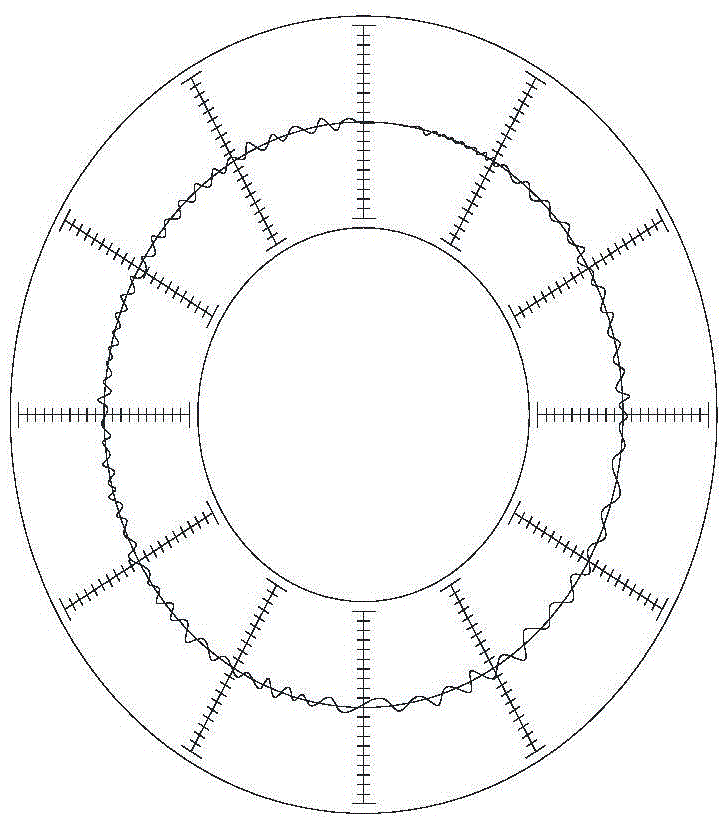

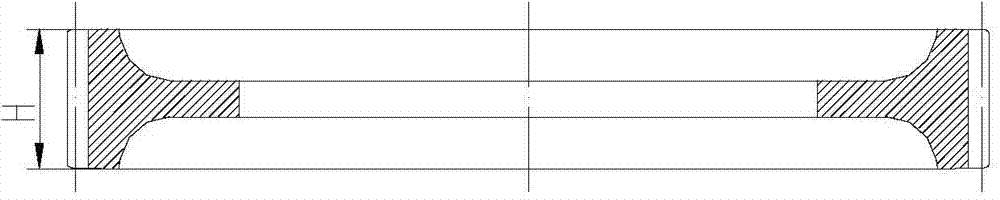

Machining method for inner ring and outer ring of conical roller bearing

The invention discloses a machining method for an inner ring and an outer ring of a conical roller bearing, and relates to a bearing machining method. The method is used for solving the problems that in existing bearing machining, detection omission is prone to occurrence in steel material detection, deformation is large after thermal treatment, grinding amount increase exists, grinding efficiency is reduced, product quality can be not ensured easily, and manufacturing cost is increased. The method includes the steps of firstly, conducting nondestructive examination of steel materials; secondly, cutting off examined steel materials; thirdly, forging an inner and outer one-piece sleeve ring; fourthly, conducting annealing; fifthly, lathing the inner and outer one-piece sleeve ring; sixthly, quenching the lathed inner and outer one-piece sleeve ring; seventhly, separating the sleeve ring into an inner ring and an outer ring; eighthly, conducting chamfering; ninthly, grinding the inner ring and the outer ring. The thermal treatment deformation is greatly reduced, the grinding residual amount is decreased, and grinding efficiency is improved; the method is suitable for machining the inner ring and the outer ring of the bearing.

Owner:哈尔滨汽车轴承有限公司

Slag-based whole tailing gravity-flow filling cementing material and filling slurry preparation method thereof

The invention relates to a slag-based whole tailing gravity-flow filling cementing material and a filling slurry preparation method thereof. Blast furnace slag is used as a main cementing material, and water glass is used as a slag exciting agent, thereby significantly improving the early-stage strength. According to the invention, hemihydrate gypsum is also added, which shortens the cementing time; quicklime is added to realize volume expansion of the slurry after cementation is started, and thus to improve the tight-filling rate of the filling material. Since the solid concentration is increased, the rheological property of the filling material is reduced; the addition of a powdery water reducer can improve the fluidity and reduce the bleeding rate with the proviso that the solid concentration of the filling slurry is maintained to be high, thus the filling slurry is more uniform and gravity-flow filling is realized. With the addition of the high-efficient water reducer and the cooperative use of citric acid and glucose retarders, the pipe blocking phenomenon caused by fluidity loss during whole tailing filling is improved.

Owner:山东黄金矿业(莱州)有限公司焦家金矿

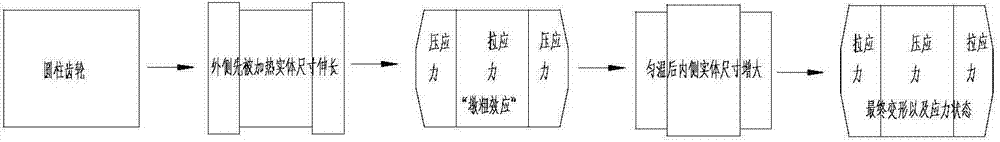

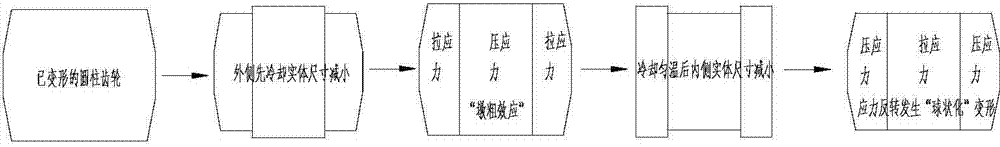

Carburizing and quenching method for cylindrical gear

InactiveCN104498965ACompensation corrects cone distortionEliminate internal stressSolid state diffusion coatingFurnace typesGear grindingElastic plastic

The invention relates to a carburizing and quenching method for a cylindrical gear, and belongs to the technical field of heat treatment. The method comprises the following steps: heating until the temperature exceeds elastic-plastic transformation temperature of low-carbon steel for primary preheating; heating until the temperature is less than the phase-transition temperature Ac1 of the low-carbon steel for preheating again; performing carburizing, high-temperature tempering, quenching, and low-temperature tempering. According to the carburizing and quenching method for the cylindrical gear, effective measures for inhibiting or removing deformation are respectively performed for a plurality of process stages and supplement each other and are organically combined, so that the deformation of the cylindrical gear carburizing and quenching thermal treatment can be obviously reduced, the preset grinding allowance of the gear can be properly decreased, and as a result, the gear grinding time is reduced, and conditions are created for lowering the gear manufacturing cost.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Wet-grinding gypsum with polycarboxylates

InactiveUS7861955B2Highly effective for fluidizingReduce pressurePigmenting treatmentCement productionSlurryWet grinding

The process of the present invention includes obtaining a feed material having an initial median particle size. A solution of a polycarboxylate dispersant in water is formed, then the feed material is added to the solution to form a slurry. The slurry is wet-ground to reduce the median particle size of the feed material. Optionally, the total amount of polycarboxylate dispersant is divided into a plurality of doses that are added periodically over the total grinding time.

Owner:UNITED STATES GYPSUM CO

Environment-friendly cement and production method thereof

ActiveCN103601382AReduce crushing efficiencyImprove liquidityCement productionMethods of productionToxic industrial waste

The invention discloses environment-friendly cement. The raw materials include various industrial waste residues, limestone, cement clinker, gypsum, a grinding aid and an excitation substance. The environment-friendly cement is characterized in that the weight parts of the raw materials are as follows: 50-60 parts of admixture, 32-40 parts of cement clinker, 4-8 parts of gypsum, 0.03-0.05 part of grinding aid and 3-5 parts of excitation substance. Since the production process of the environment-friendly cement adopts a low-temperature mechanical-chemical co-excitation technology, the mixing amount of the admixture is large, multiple industrial waste residues can be used as raw materials, the raw materials are widely available, the cost is low, a great quantity of industrial waste residues can be consumed, the waste is turned into wealth, and the performance of the obtained product is remarkably improved from the quality index.

Owner:广西云燕特种水泥建材有限公司

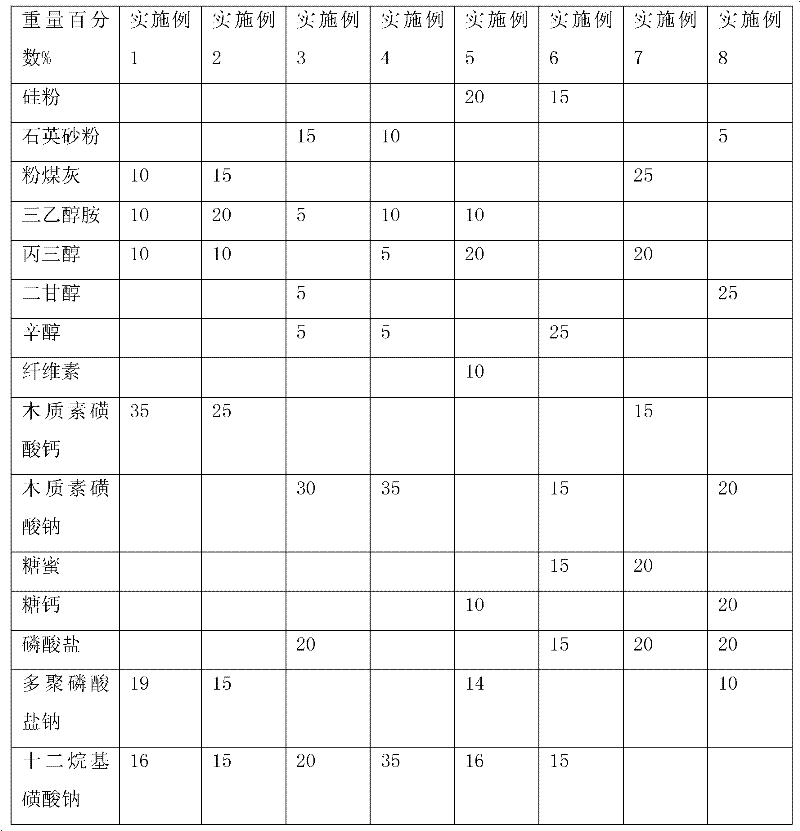

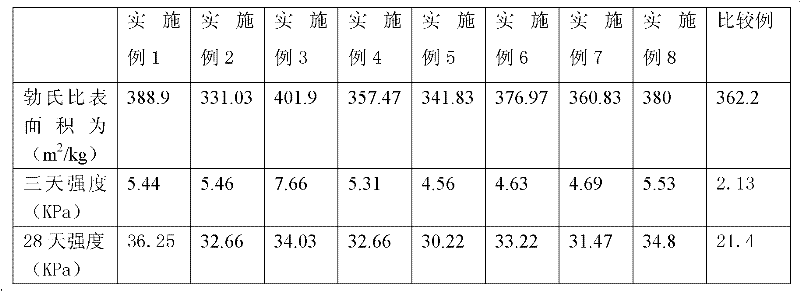

Composite steel slag grinding aid

The invention relates to a composite steel slag grinding aid, which solves the problems that grinding aid in prior art is not suitable for grinding steel slag, the grinding time is long, the grinding efficiency is low, the activity of early period in active utilization of steel slag is low, and content of particles not participating reaction is high. The technical scheme comprises the components by weight percentage as follows: 15-30% of surfactant, 20-40% of grinding aid, 20-40% of adjustor, and 5-25% of carrier. The grinding aid provided by the invention can effectively shorten the grindingtime, improve the grinding characteristics and improve effective content of hydrated particles so as to improve the hydrating activity of steel slag. Ground steel slag has high strength, large comparison surface, and small doping amount to further improve the doping amount of steel slag recycled.

Owner:WUHAN IRON & STEEL (GROUP) CORP +1

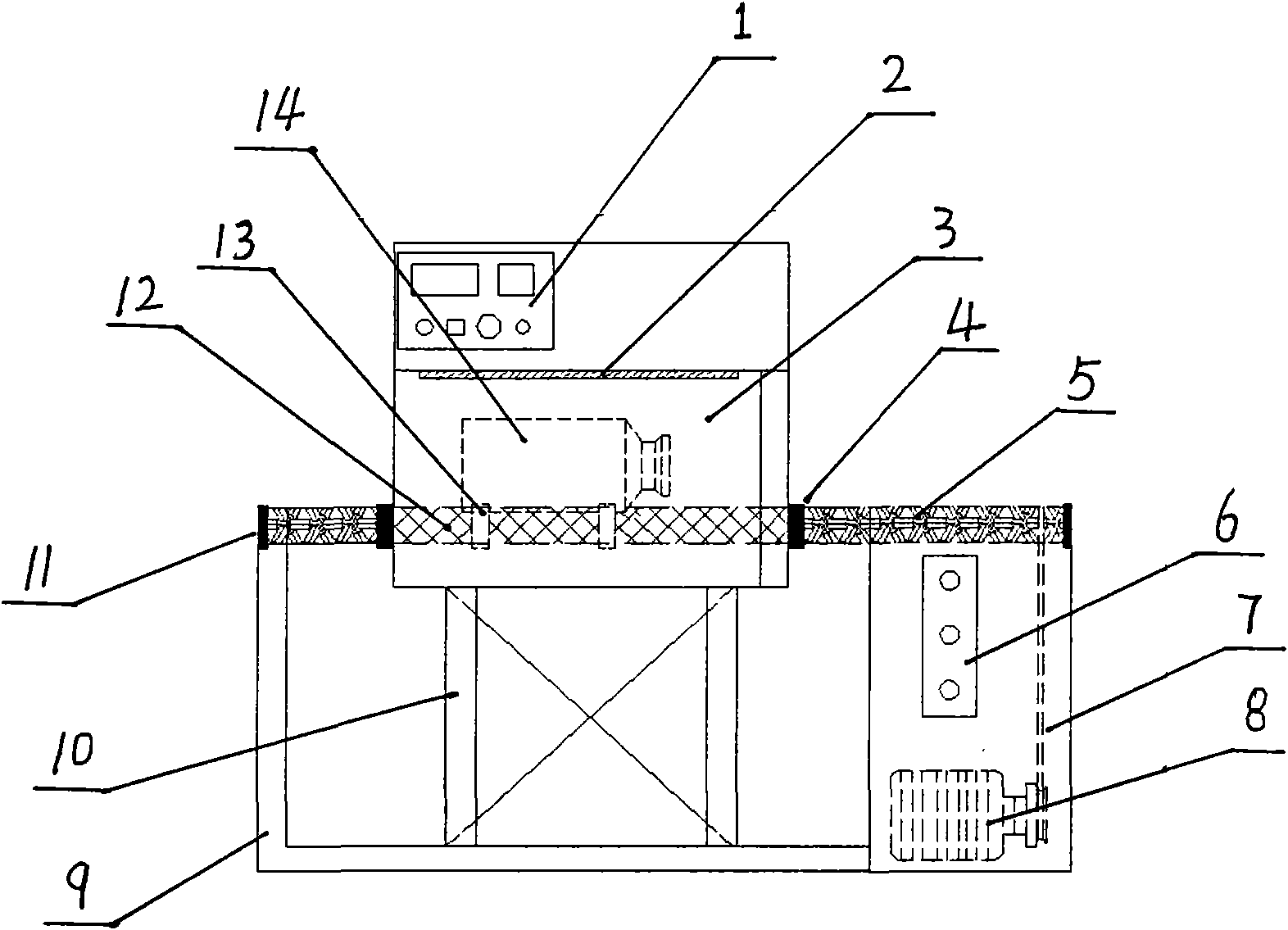

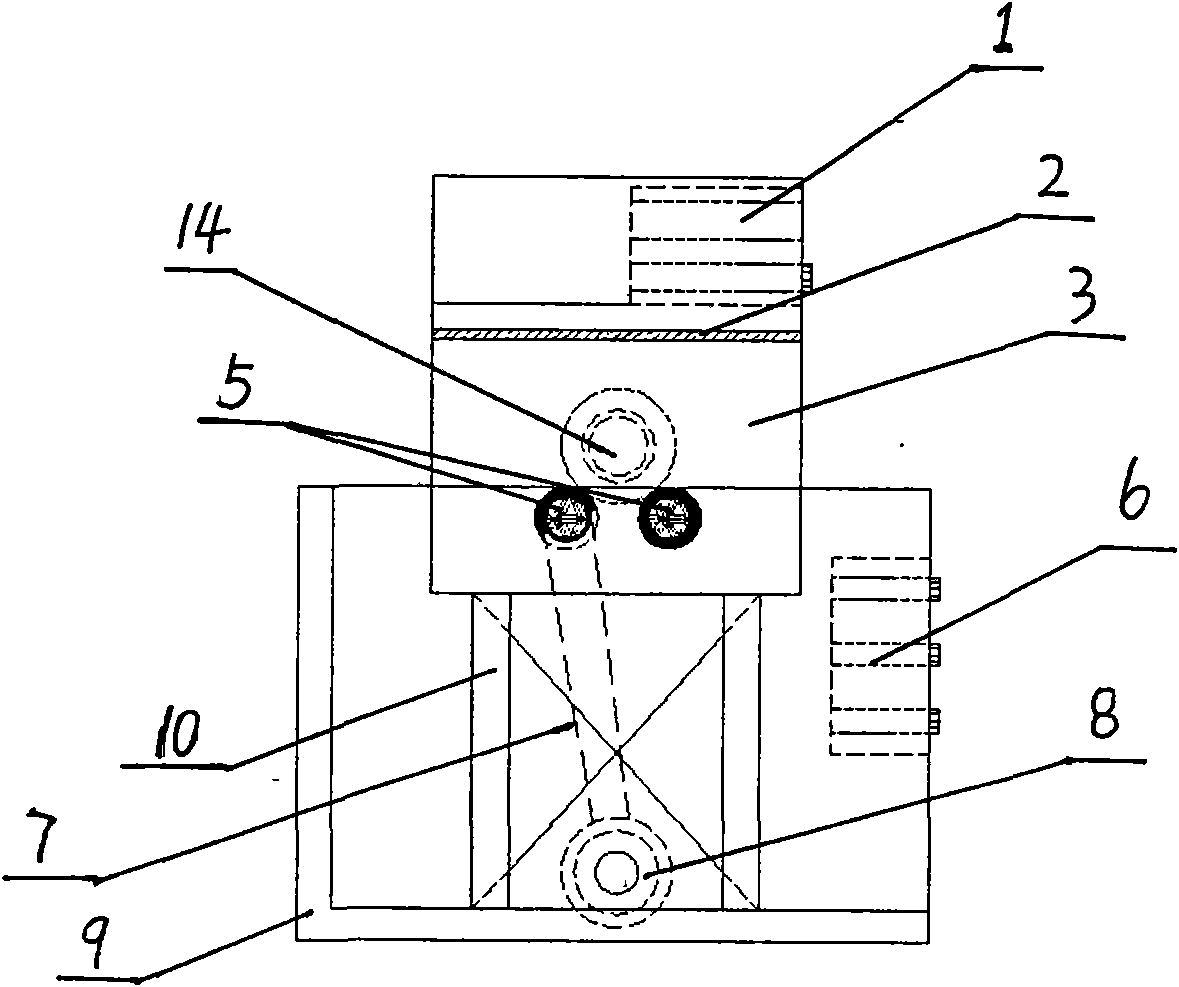

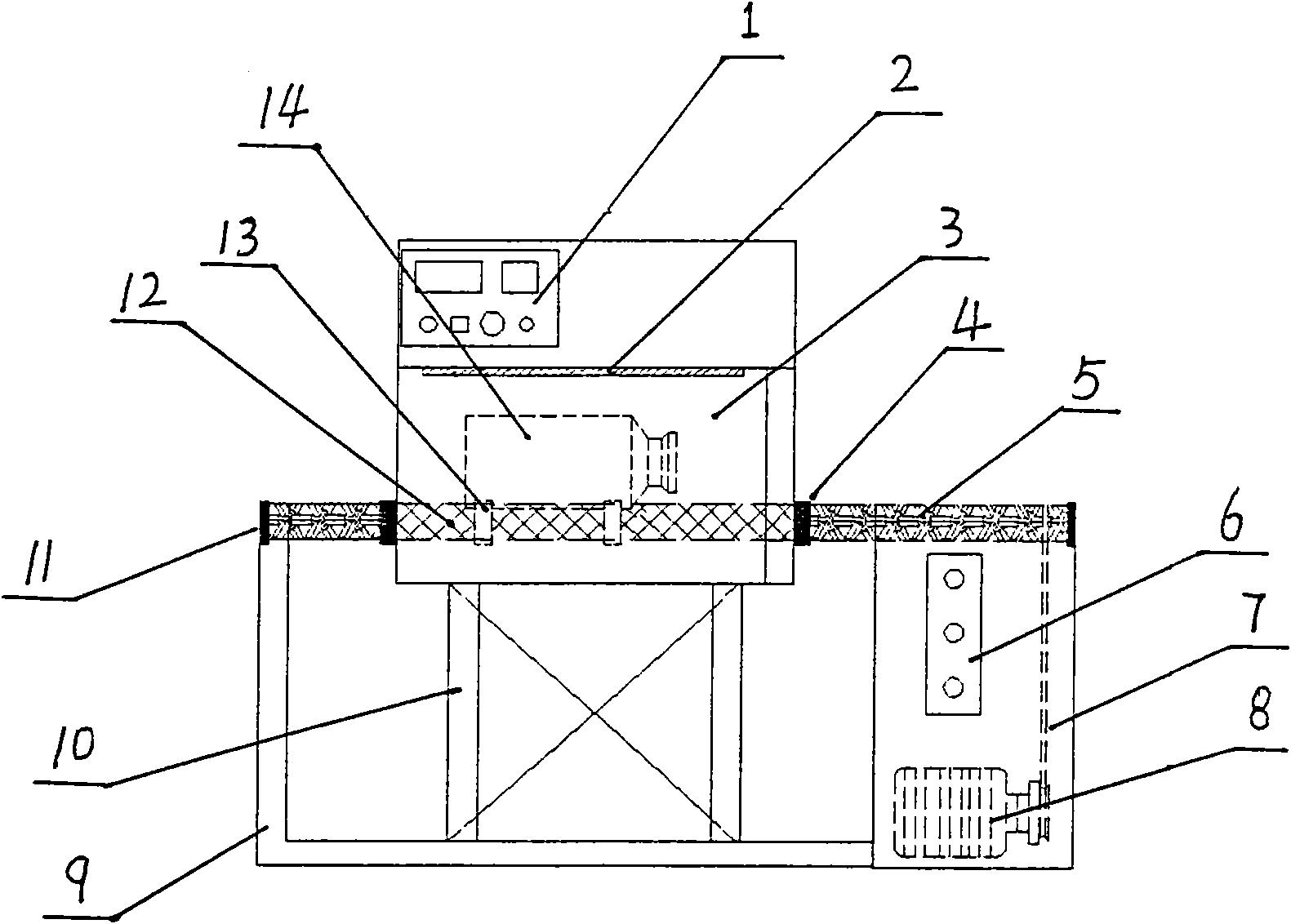

Roller grinder

InactiveCN101890387AEasy to GrindShorten grinding timeMicrowave heatingGrain treatmentsMotor driveEngineering

The invention discloses a roller grinder, which comprises parallel rolling shafts, a grinding controller, a belt, a motor, a base frame, a metal fixing piece and a grinding tank, wherein the parallel shafts are fixed on the base frame by the metal fixing piece; the motor drives the parallel rolling shafts to rotate through the belt; the grinding controller is connected with the motor and is fixedly arranged on the upper part of the motor; a grinding ball is arranged in the grinding tank; the middle parts of the parallel rolling shafts are connected with sections of quartz parallel rolls through metal casings; the quartz grinding tank is arranged on the quartz parallel rolls; the quartz parallel rolls and the quartz grinding tank are arranged in the inside of a microwave emitting cavity; the upper part of the quartz grinding tank is provided with a microwave generator and a microwave controller respectively; the microwave generator is connected to the microwave controller; the synchronous operation of microwave selective heating and grinding improves the heating efficiency during grinding and reduces ore grinding time and ore grinding power consumption; and the equipment is low in temperature and easy and safe to operate.

Owner:HENAN POLYTECHNIC UNIV

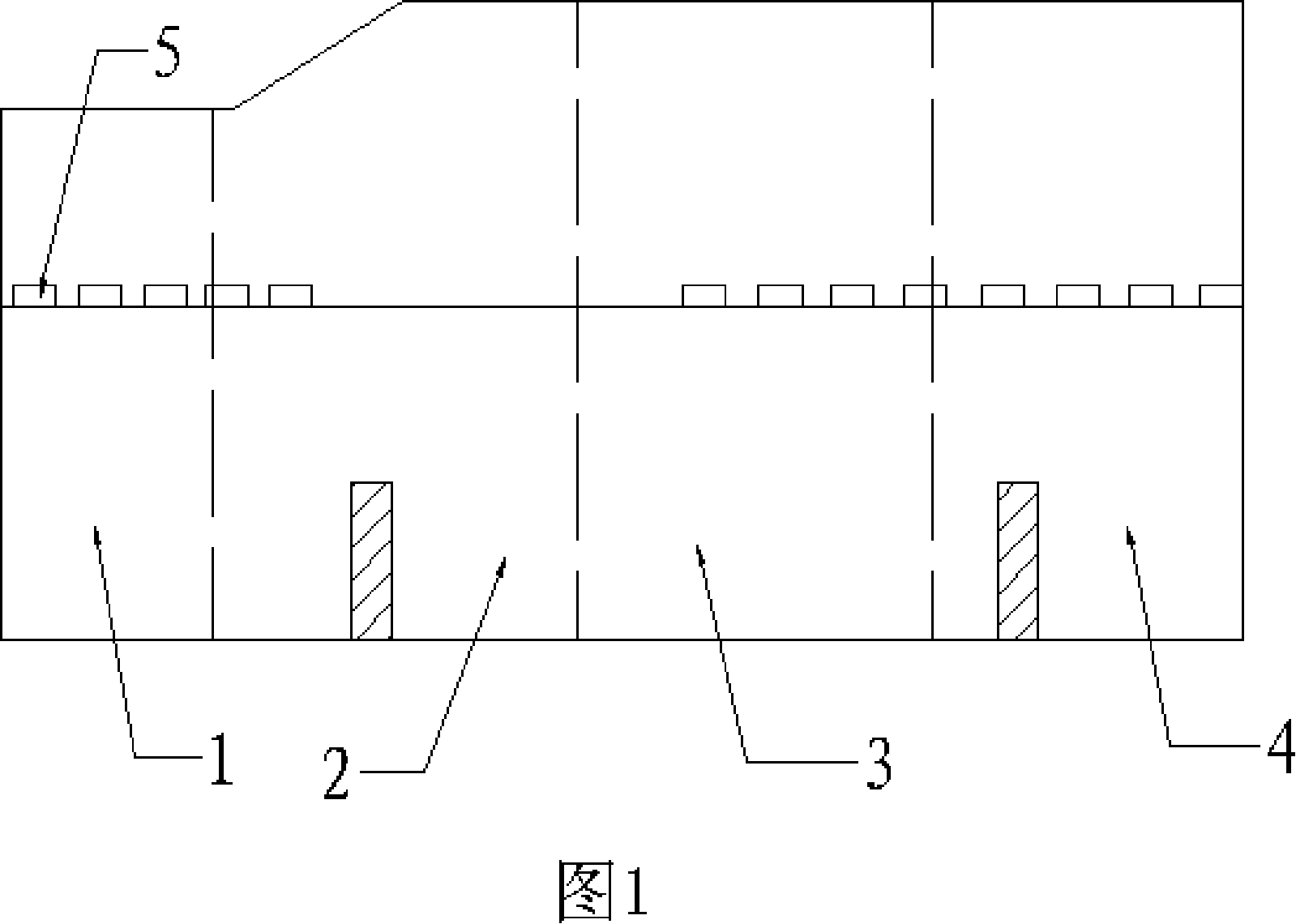

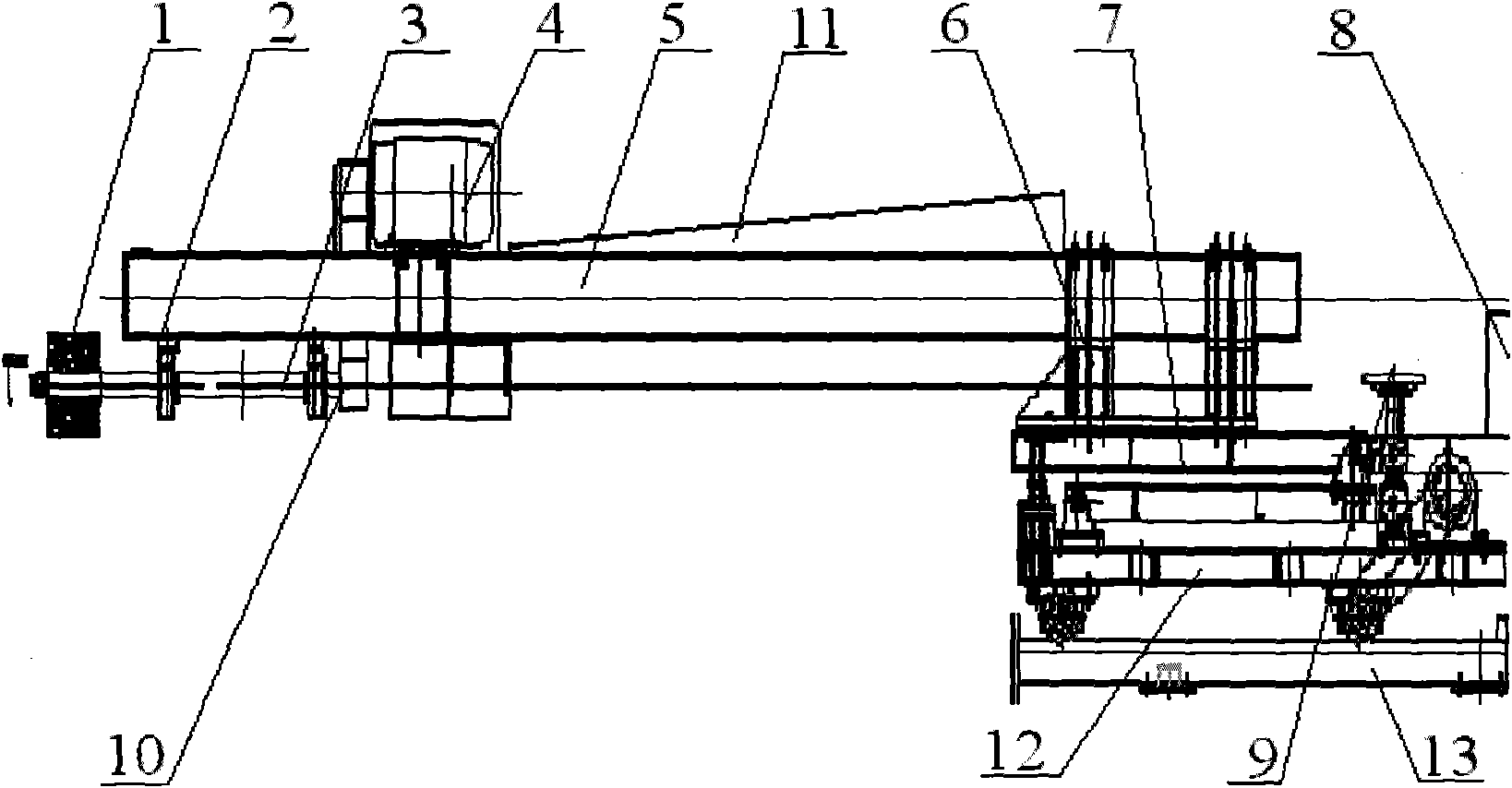

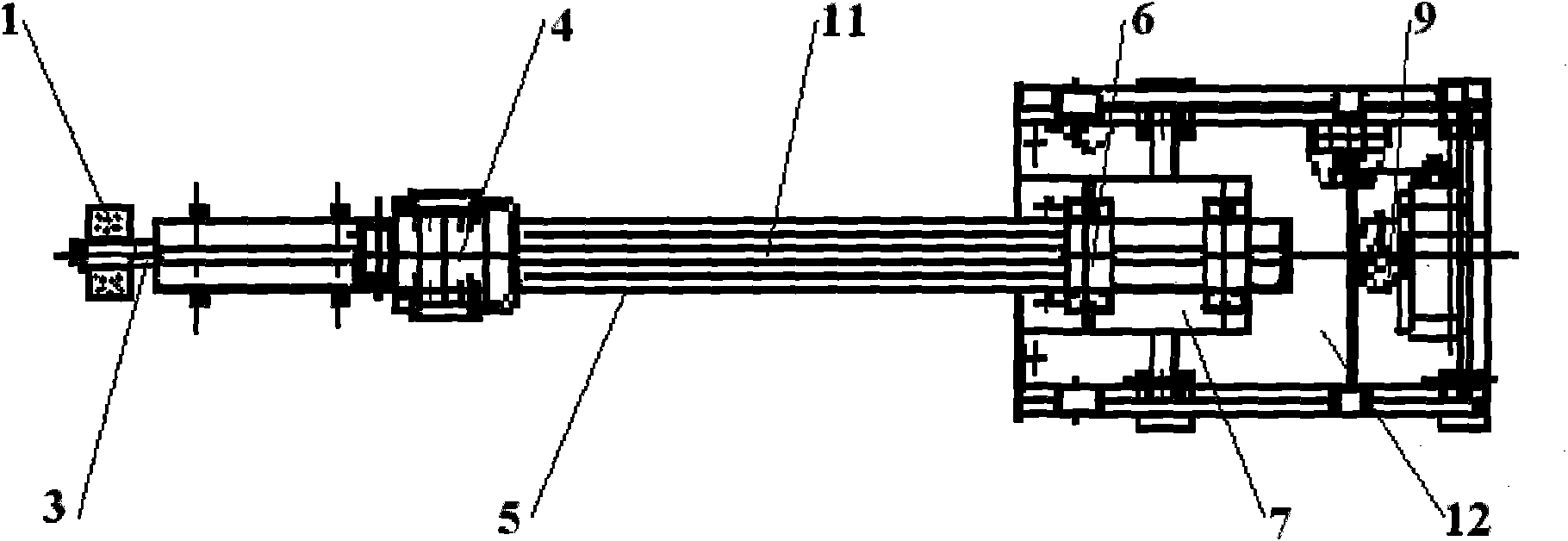

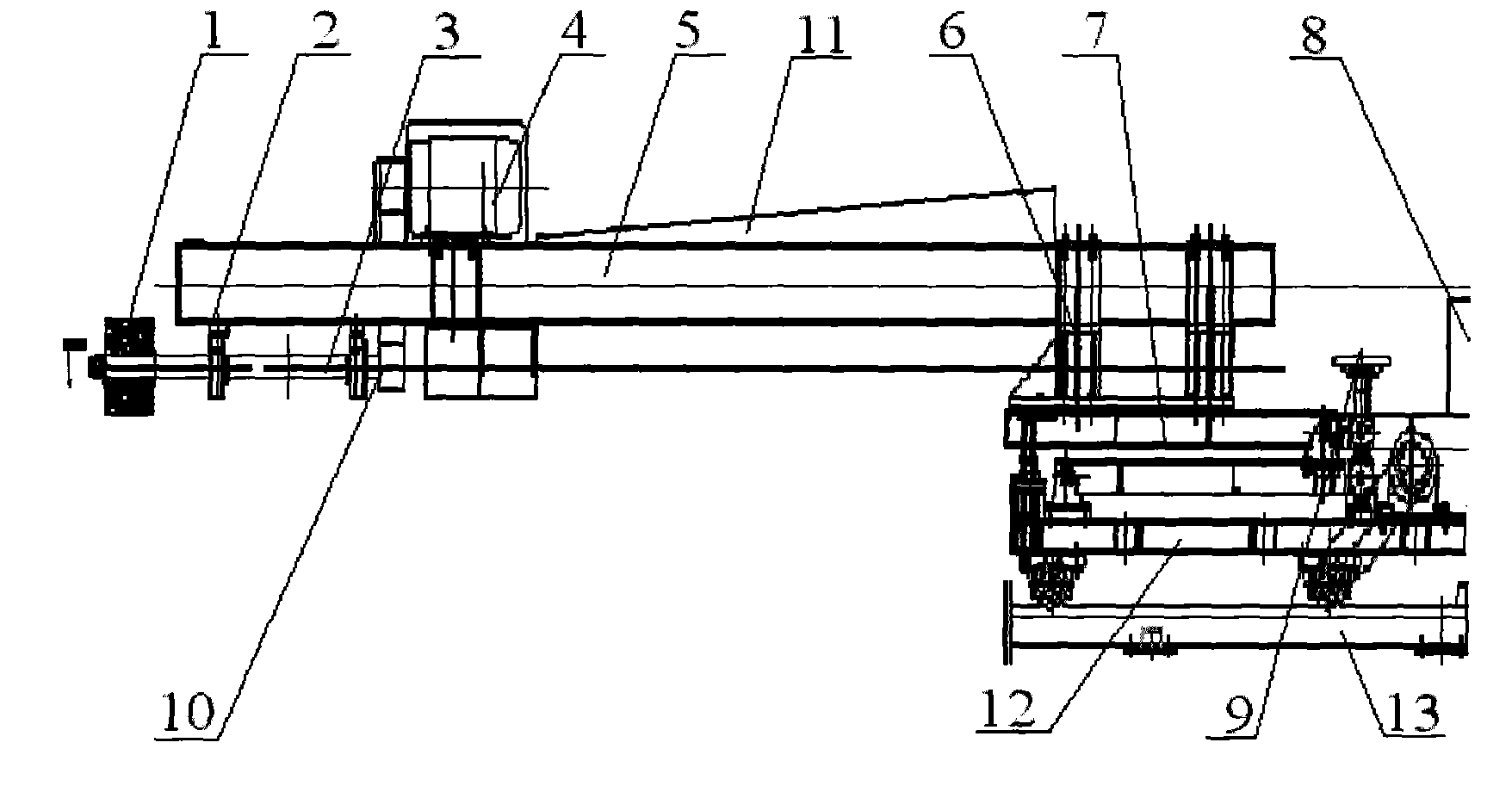

Grinding and driving mechanism of inner grinder of large-diameter cast iron pipe production line

ActiveCN101797706ASimple structureShorten the lengthRevolution surface grinding machinesEngineeringCast iron pipe

The invention discloses a grinding and driving mechanism of an inner grinder of a large-diameter cast iron pipe production line. The mechanism is provided with a grinding rod shaft bracket connected to a connecting seat of the inner grinder, and a grinding rod shaft is arranged on the front part of the grinding rod shaft bracket extending into a cast iron pipe through a bearing block, wherein the axis of the grinding rod shaft is longitudinally parallel to the grinding rod shaft bracket; and a driving motor is fixed on the grinding rod shaft bracket and connected with the grinding rod shaft through a belt transmission mechanism. The adoption of the technical scheme simplifies the structure of the inner grinder, decreases the length of the grinding rod shaft and reduces the number of supporting bearing blocks of the grinding rod shaft; in addition, the weight of the equipment mechanism is lightened, and under the condition that the power of a grinding electromotor keeps unchanged, the grinding time is reduced, and the replacement period of the grinding rod shaft is prolonged, thereby reducing the inventory of spare parts, greatly improving the production efficiency and reducing the production cost.

Owner:WUHU XINXING DUCTILE IRON PIPES

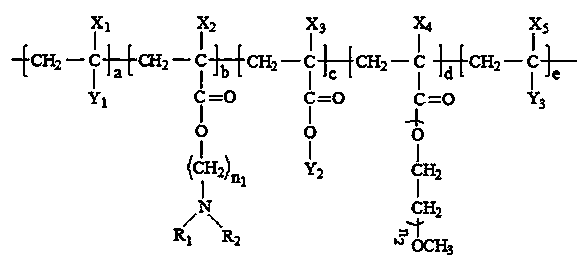

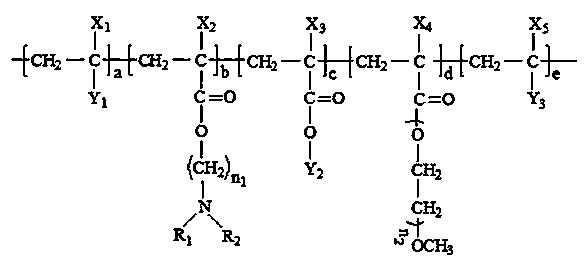

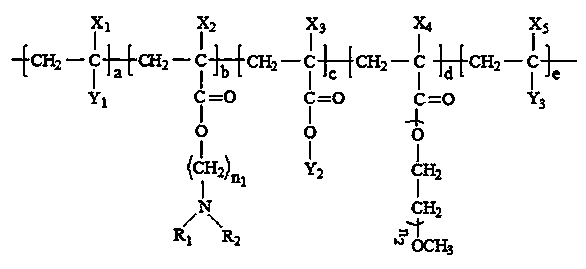

Solventtype block polymer dispersant

ActiveCN103897441AHigh purityHigh hiding powerOrganic dyesPigment treatment with macromolecular organic compoundsAcrylonitrileEthylene Homopolymers

The invention relates to a solvent type block polymer dispersant and a preparation method thereof, the molecular chain of the dispersant comprises an anchoring chain segment and a solvation chain segment, and has a structural formula shown in the specification. The solvent type block polymer dispersant fundamentally solves the defects of traditional dispersants, the molecular chain of the dispersant comprises the anchoring chain segment and the solvation chain segment, a homopolymer or copolymer of vinyl pyridine, vinyl imidazole, amino acrylate and other nitrogen-containing vinyl monomers is used as the pigment anchoring chain segment, a homopolymer or copolymer of nitrogen-free vinyl monomer such as acrylate, acrylonitrile and styrene is used as the solvation chain segment, and pigment flocculation and sedimentation during storage can be prevented.

Owner:NANTONG HANTAI CHEM

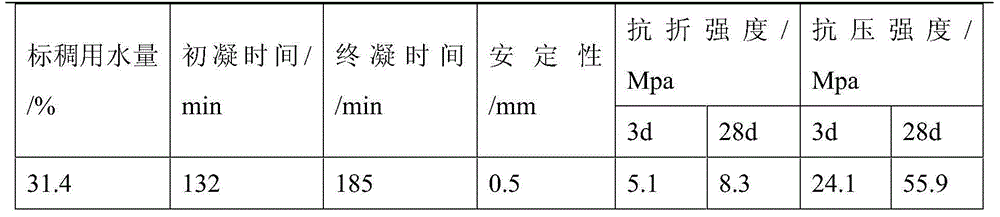

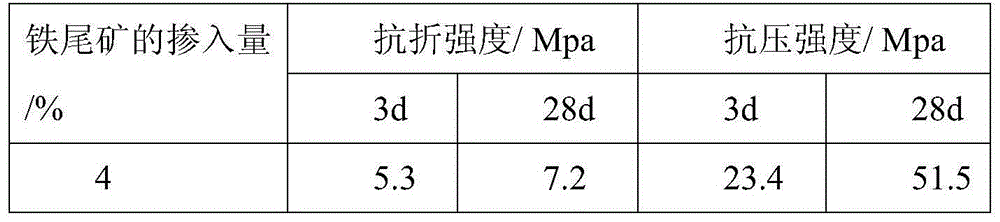

Preparation method for Portland cement with iron tailings

The invention provides a preparation method for Portland cement with iron tailings. The Portland cement comprises at least the following raw materials in percentage by weight: 60-70% of calcium oxide, 12-20% of silicon oxide, 5-20% of the iron tailings and 3-6% of aluminium oxide. The preparation method comprises the following steps: weighing the raw materials according to the mass ratio, and mixing uniformly and fine grinding the weighed raw materials; calcining the fine grinded raw materials in a high-temperature furnace, and drawing out and quenching the calcined raw materials to obtain clinkers; adding the iron tailings to the clinkers, mixing uniformly mixtures of the iron tailings and the clinkers, and fine grinding the mixtures to obtain the Portland cement with the iron tailings, wherein the mass of the added iron tailings is 1-8% of the total mass of the clinkers. The method provided by the invention can effectively use the iron tailings as raw materials for production to prepare the Portland cement with excellent quality, so that the deficiencies in the prior art can be overcome, the use of the iron tailings can be maximized, and the purposes of saving resources, reducing the production cost, protecting environment and the like can be realized.

Owner:北海诚钢矿业股份有限公司

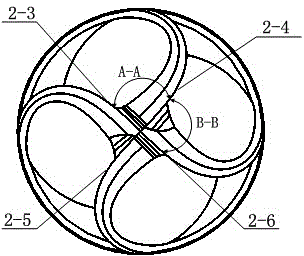

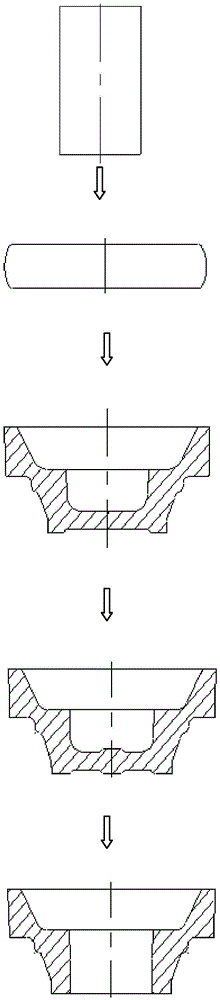

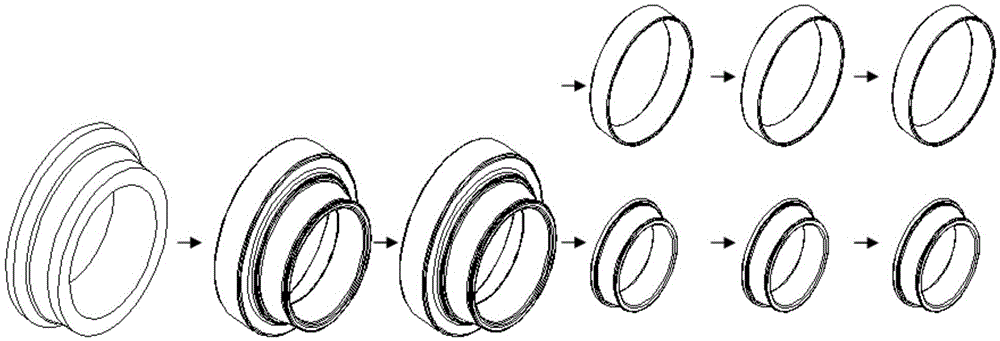

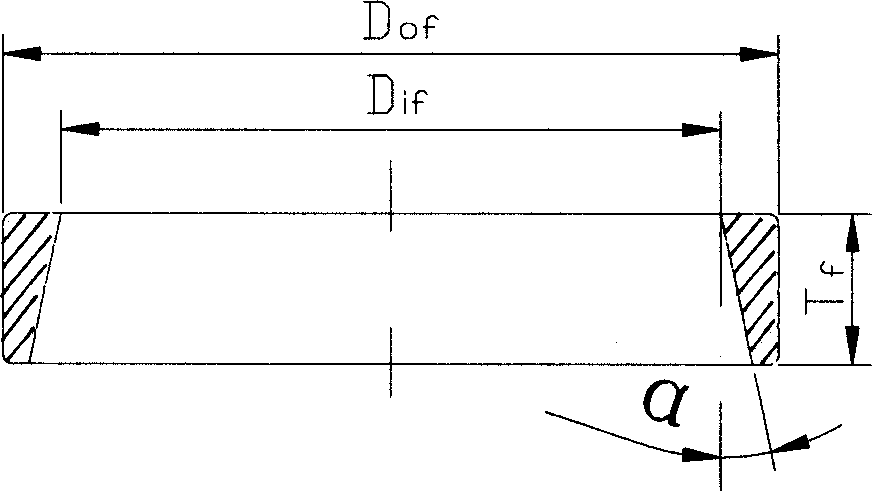

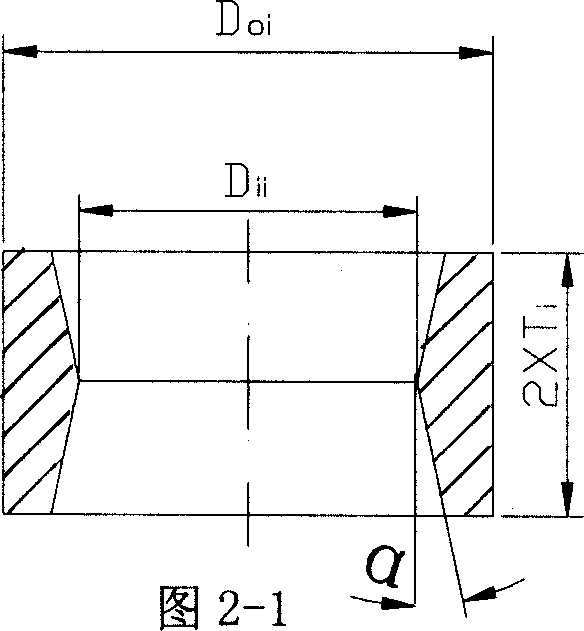

Method for forming two conical sestion ring pieces by once cold rolling spreading

InactiveCN1748898AGood physical and mechanical propertiesIncrease productivityMetal-working feeding devicesOther manufacturing equipments/toolsHeat deflection temperatureMechanical engineering

The present invention relates to method of forming conic cross section ring and has two technological schemes adopted, including integral rolling and spreading and split rolling and spreading. The present invention features that the cold rolling and spreading process includes the following steps: cutting rod into material sections; heating the material section to heat deformation temperature, upsetting, punching hole and punching connecting sheet to form integral blank; annealing; coarse turning to form integral blank for rolling and spreading; cold rolling and spreading in a rolling and spreading machine with V-slot core roller to form two conic rings; and turning to obtain two conic cross section rings. The present invention has the features of low cost, high production efficiency and high product quality.

Owner:WUHAN UNIV OF TECH

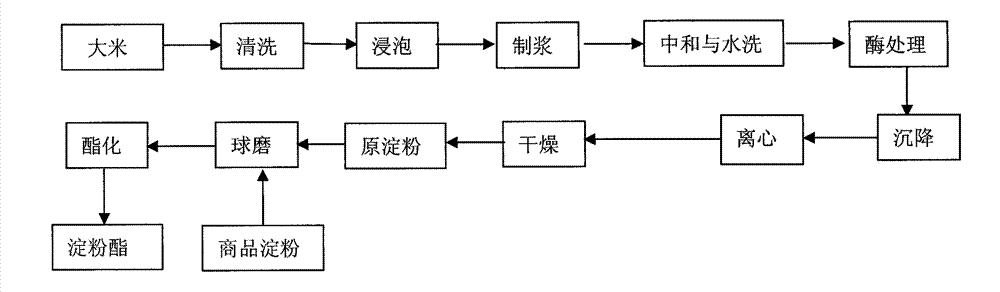

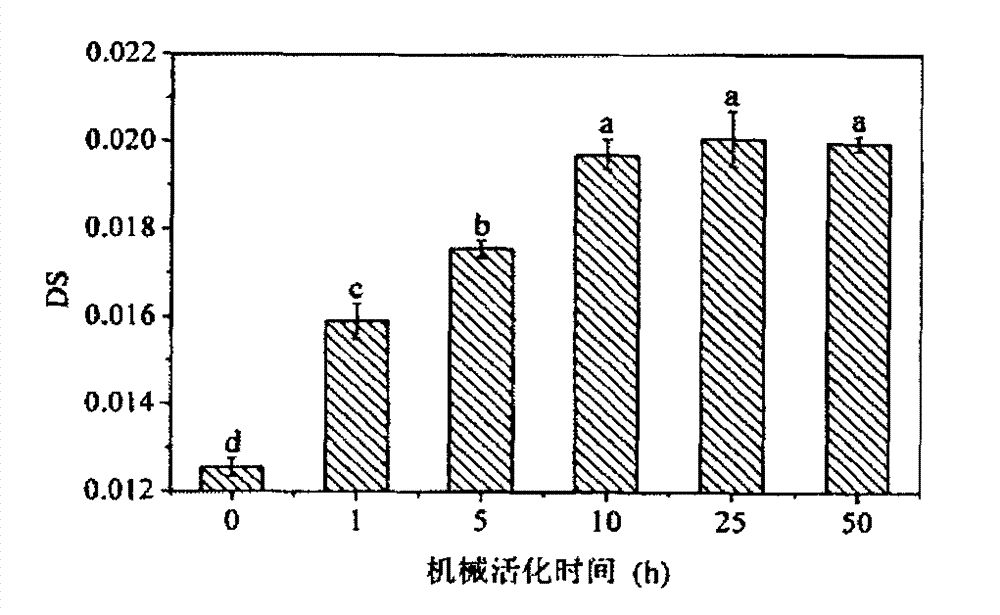

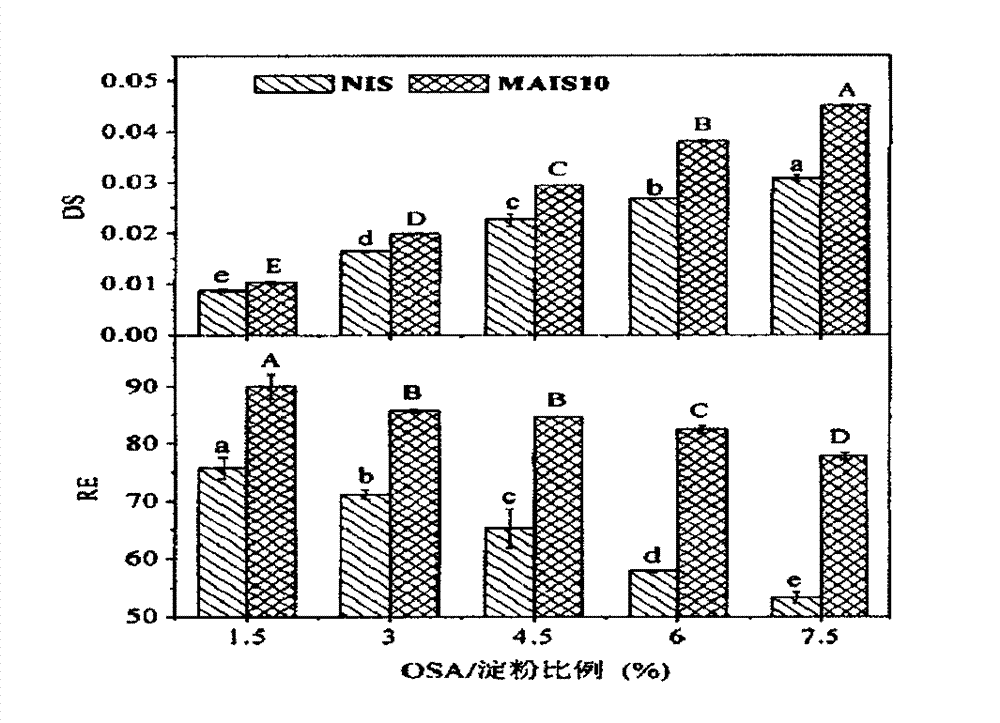

Method for preparing octenyl succinic acid modified starch and application thereof

InactiveCN102952198AEasy to GrindShorten grinding timeMilk preparationDough treatmentAlcoholDistilled water

The invention belongs to the technical field of preparation of starch, belongs to the technical field of preparation of modified starch, and in particular relates to a method for preparing octenyl succinic acid modified starch and application thereof. The method comprises the following steps of: drying the starch serving as a raw material and performing constant weight of the starch to reach a certain water content; grinding the starch to obtain activated starch; adding distilled water into the starch to oscillate and adding alkali to regulate pH; slowly adding octenyl succinic acid (OSA) into the starch; adding acid to neutralize after the reaction is finished; performing alcohol washing on the mixture; centrifugally collecting wet starch; drying the wet starch; pulverizing the wet starch; and screening to obtain the octenyl succinic acid modified starch. The method is characterized in that the raw material starch is mechanically activated before esterification reaction is carried out; and the reaction activity of the starch is increased, the substitution degree of the OSA is increased, the reaction time is shortened, the using amount of the alkali is reduced, and the production of the octenyl succinic acid modified starch is facilitated in a ball milling mode. The method can be used for food, such as starch glue, microcapsule wall materials, yoghourt, steamed sponge cakes, cakes and the like.

Owner:HUAZHONG AGRI UNIV

VOC free latex coalescent systems

InactiveUS20050014877A1Excellent film performanceEmission reductionFilm/foil adhesivesInksPolyesterEther

Combinations of essentially nonvolatile, unsaturated ethers and / or esters, and small proportions of low glass transition temperature (Tg) latex reins, as replacements for volatile organic compounds (VOCs) as coalescents and optionally reactive amines (as replacements for conventionally employed volatile amines / ammonia neutralizers, respectively), provides economical, low / no VOC-containing acrylic, styrenic copolymer, polyester, polyurethane and vinyl copolymer latex based coatings, paints, and inks; which outperform their conventional counterparts.

Owner:SUGERMAN GERALD

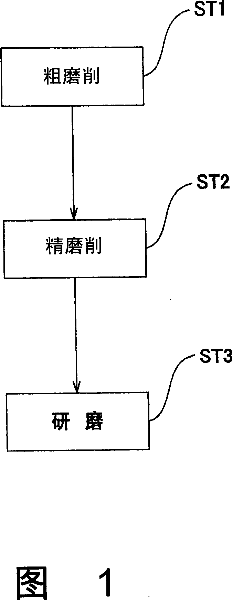

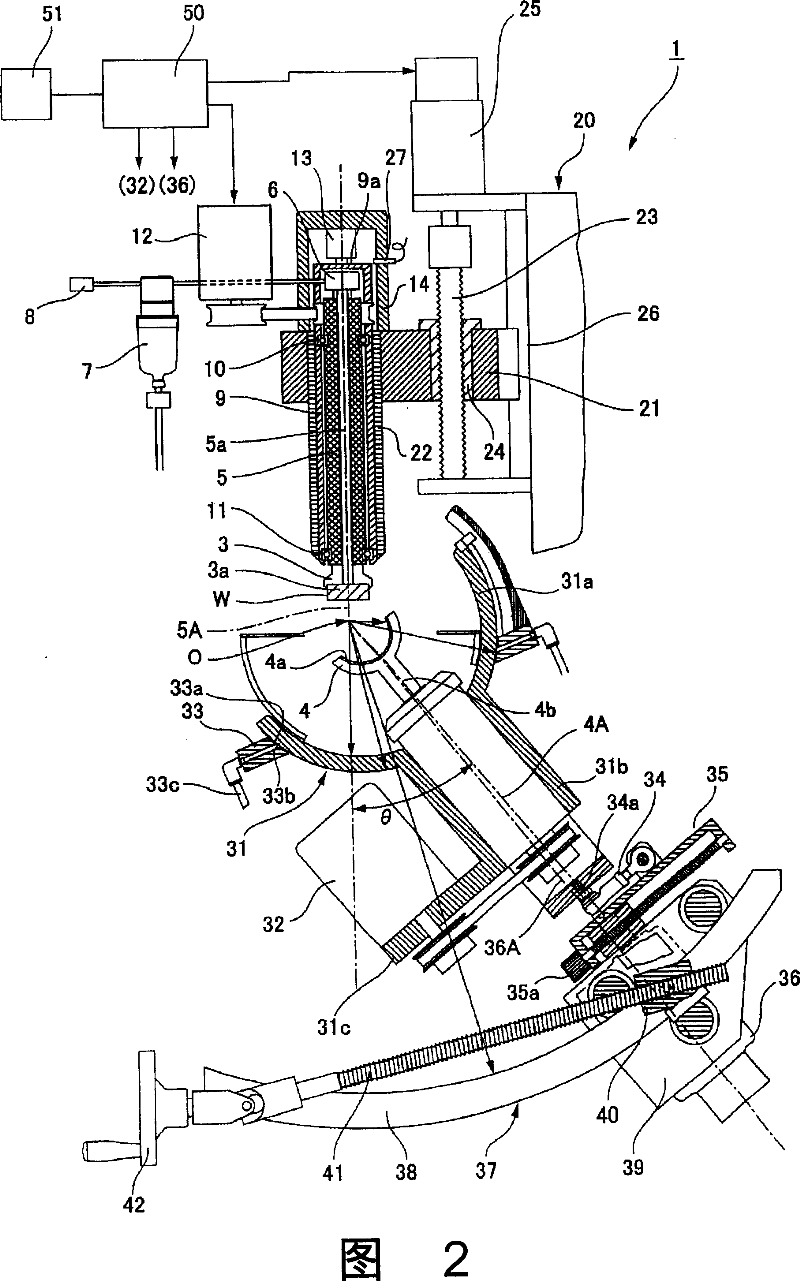

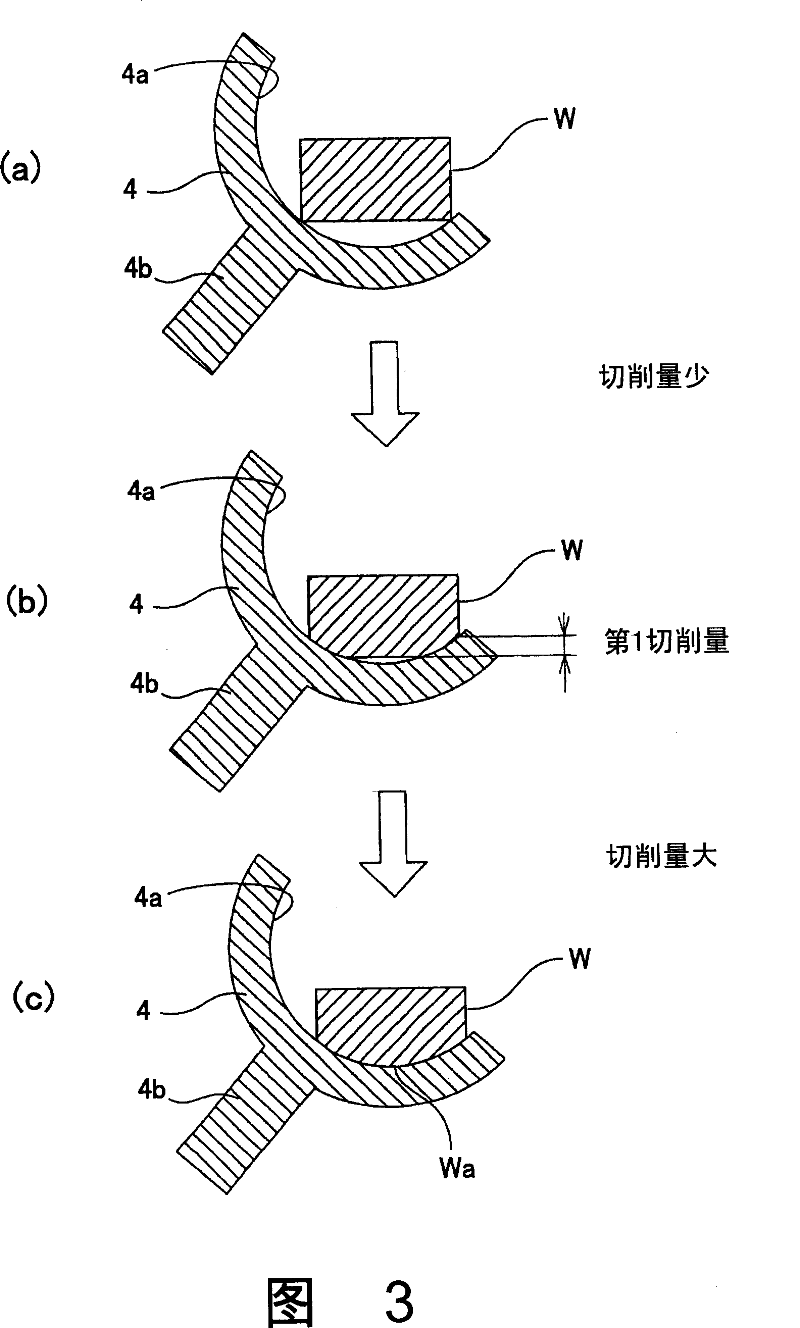

Grinding processing method for optical spherical lens

InactiveCN101041230ARationalizeProcessing time shortenedOptical surface grinding machinesGrinding drivesConcentration ratioMetallurgy

The invention relates to a grinding processing method for optical spherical lens, in which the fine grinding procedure can be used as single procedure to perform rough grinding. The rough grinding for optical spherical lens is performed at the following condition: 1) grinding disc of nucellus swing type performing the rough grinding of the said lens sheet; 2) using diamond tool of #300-#600 (average size : 60 mu m-30 mu m) and more than 50 of concentration ratio as rough grinding tool disc; setting the rotating speed of the said rough grinding tool disc as 2500rpm-3000rpm. Thus, the allowance of the next fine grinding procedure is about below 20 mu m, which can improve the surface roughness and sphere precision of the said rough grinding procedure. The fine grinding is single grinding procedure, which can realize the shortening of the abrasive machining time of the spherical lens and rationalization of the process management.

Owner:HARUCHIKA

Super-junction semiconductor device with groove-type terminal structure

ActiveCN102315247AShorten grinding timeImprove filling efficiencySemiconductor devicesActive devicesEngineering

The invention discloses a super-junction semiconductor device with a groove-type terminal structure. The super-junction semiconductor device comprises a semiconductor substrate, a first electrode, a semiconductor region, an active device, a base region, a source region, an insulation control electrode, a passivation insulating layer, a plurality of second grooves and a second electrode, wherein the semiconductor region comprises an active region and a terminal region; the active device is formed in the active region and comprises a plurality of first grooves arranged at equal intervals; the plurality of second grooves are formed in the terminal region; a semiconductor material with a second conductive type is filled in the first grooves and the second grooves; the second electrode is continuously coated on the passivation insulating layer and the second grooves; the surfaces of the second grooves are in a ring shape and encircle the active region, the corners of the annular second grooves are in an arc shape, and the other parts are in a straight line shape; and the width of the corners is not equal to that of straight line. By the super junction semiconductor device, a super-junction terminal structure can be optimized, and the epitaxial growth cost is reduced.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Production process of ceramic ball bearing ring

InactiveCN103009233AReduce pollutionImprove grinding efficiencyOther chemical processesLapping machinesBall bearingUltra fine

The invention relates to a production process of a ceramic ball bearing ring and belongs to the field of bearings. The production process of the ceramic ball bearing ring comprises a ring processing and shaping process and a grinding and polishing process, wherein the grinding and polishing process comprises the steps of rough grinding, fine grinding and ultra-fine grinding; and grinding agents at all the grinding stages in the process comprise a rough grinding agent, a fine grinding agent and an ultra-fine grinding agent. The production process has the beneficial effects that the grinding agents are matched with one another when in use in all the grinding stages; and the effects that the grinding efficiency is high, the pollution to a ceramic body is less, the grinding efficiency is improved, and the grinding time is reduced can be achieved.

Owner:大连大友高技术陶瓷有限公司

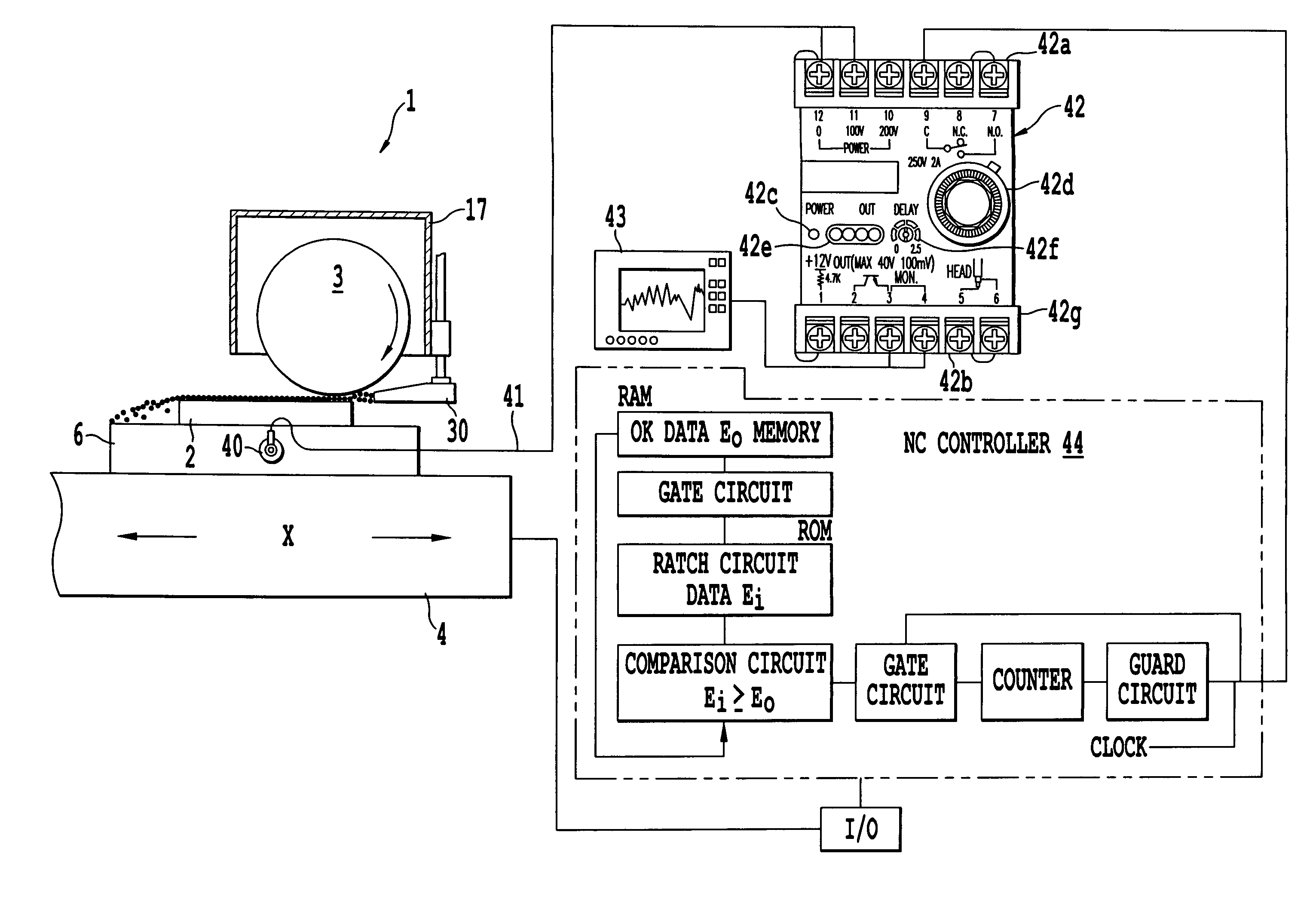

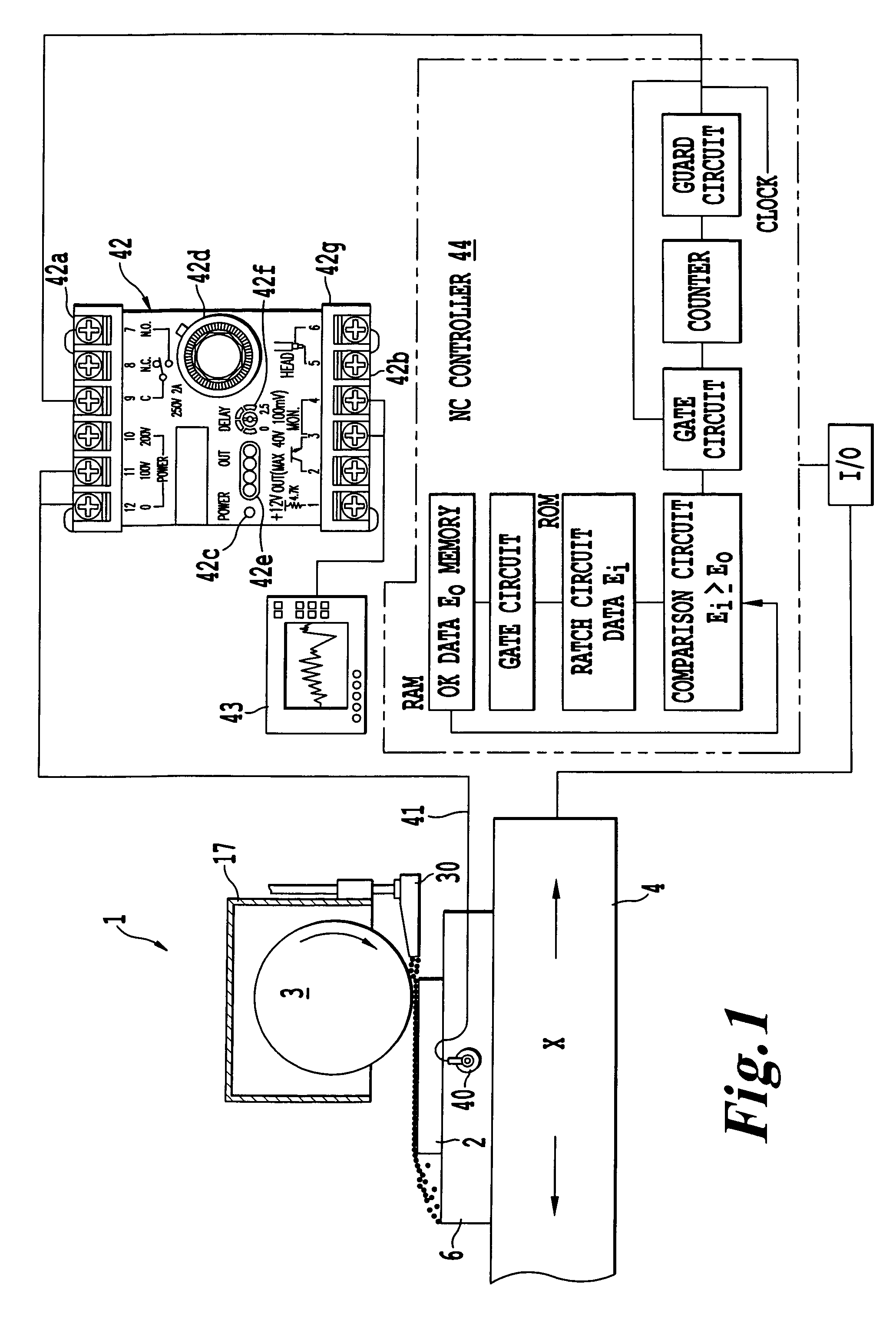

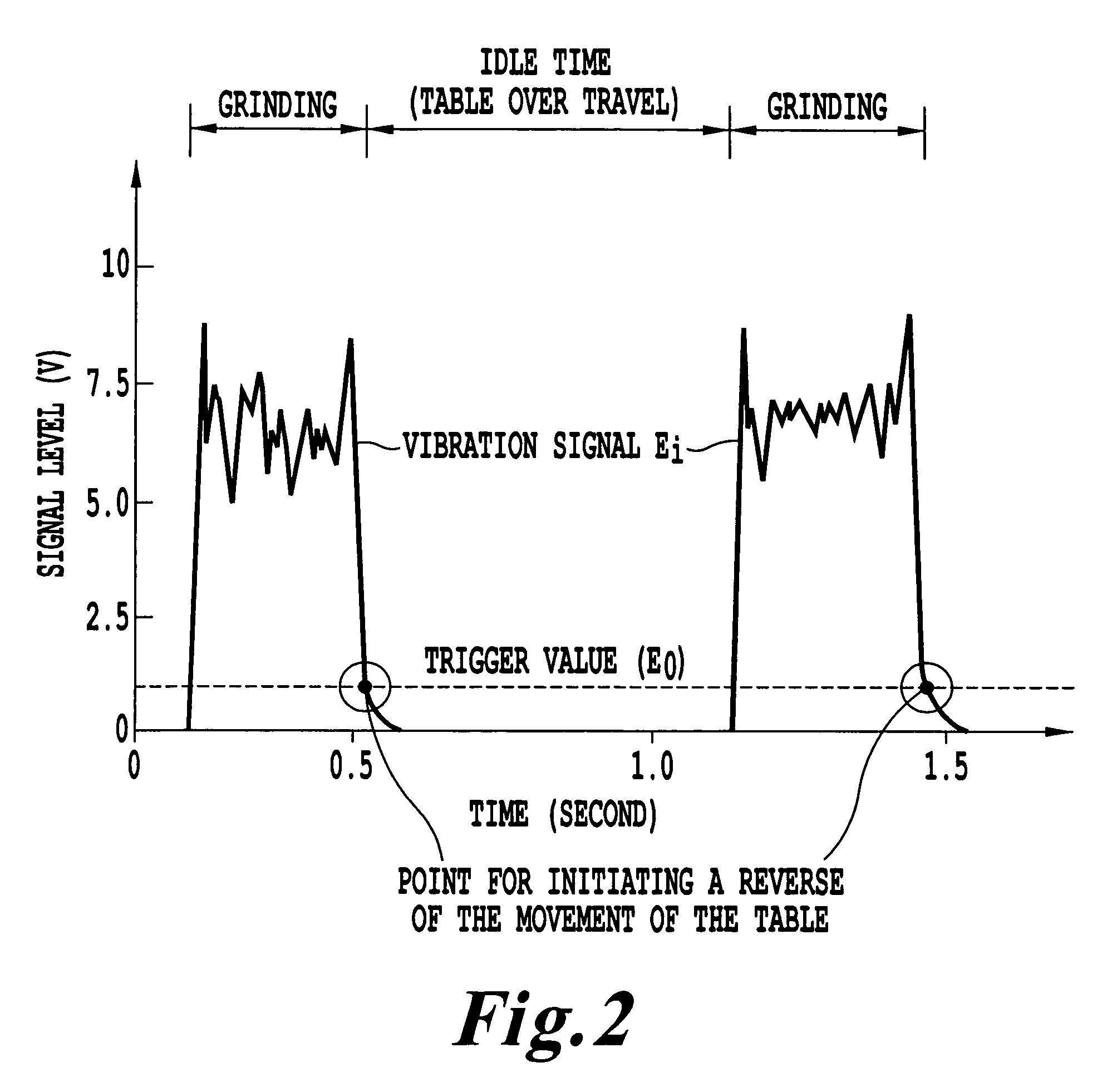

Grinding method of a workpiece and grinding apparatus

InactiveUS7056189B2Reduce movement distanceShorten grinding timeRevolution surface grinding machinesGrinding drivesControl systemVibratory signal

An adaptive work table-reciprocation control system and method that can reduce a grinding time. The system uses a vibration sensor head installed on a chuck surface in the vicinity of the workpiece to detect a vibration signal emitted from the contact zone between the grinding wheel and the workpiece. When the value of the vibration signals falls below a trigger level, a work table direction of motion is reversed.

Owner:OKAMOTO MACHINE TOOL WORKS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com