Cavity type film bulk acoustic resonator and preparation method thereof

A thin-film bulk acoustic wave and resonator technology, applied in the field of resonators, preparation of cavity-type thin-film bulk acoustic resonators, and cavity-type thin-film bulk acoustic resonators, can solve thermal stability, poor power capacity, and high processing costs , Complicated production and other issues, to achieve good thermal stability, reduce processing costs, and stable device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

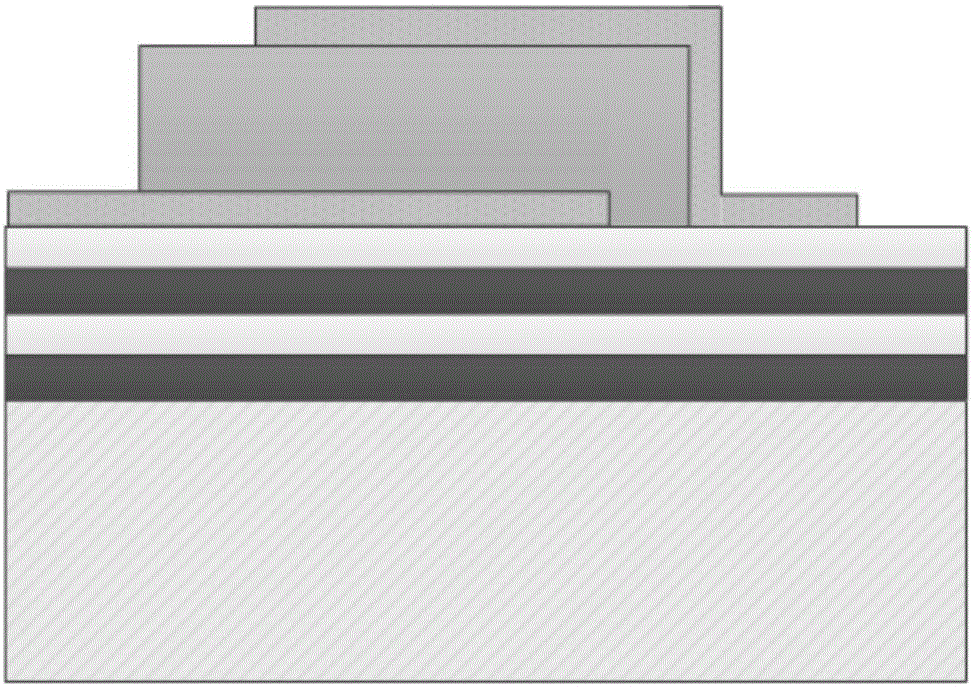

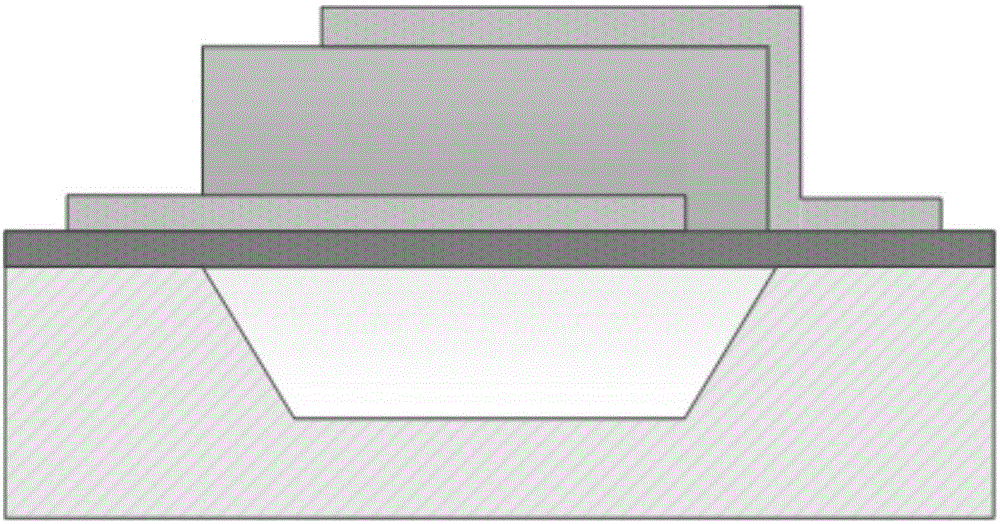

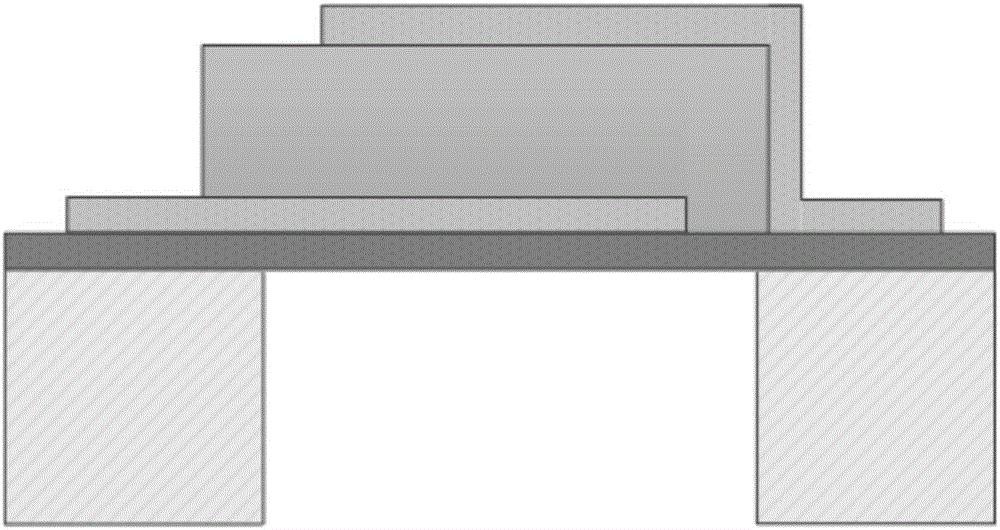

[0047] Such as Figure 4As shown, a cavity-type film bulk acoustic resonator includes a substrate 1, an isolation layer 2, a support layer 4, a bottom electrode layer 5, a piezoelectric layer 6, and a top electrode layer 7 arranged sequentially from bottom to top. The middle part of the upper surface of the layer 2 is depressed downward to form a groove, and the supporting layer 4 and the substrate 1 seal the groove to form a closed cavity 3, the height of the lower surface of the closed cavity 3 is lower than the height of the upper surface of the substrate 1, and the The lower surface of the closed cavity 3 is a flat surface; the piezoelectric layer 6 is arranged on the upper end of the support layer 4, the bottom electrode layer 5 is arranged in the middle of the lower end of the piezoelectric layer 6, and the lower end surface of the bottom electrode layer 5 is arranged on the support layer 4, the top electrode layer 7 is arranged in the middle of the upper end of the piez...

specific Embodiment

[0061] Such as Figure 4 As shown, a cavity-type film bulk acoustic resonator includes a substrate 1, an isolation layer 2, a support layer 4, a bottom electrode layer 5, a piezoelectric layer 6, and a top electrode layer 7 arranged sequentially from bottom to top. The middle part of the upper surface of the layer 2 is depressed downward to form a groove, and the supporting layer 4 and the substrate 1 seal the groove to form a closed cavity 3, the height of the lower surface of the closed cavity 3 is lower than the height of the upper surface of the substrate 1, and the The lower surface of the closed cavity 3 is a flat surface; the piezoelectric layer 6 is arranged on the upper end of the support layer 4, the bottom electrode layer 5 is arranged in the middle of the lower end of the piezoelectric layer 6, and the lower end surface of the bottom electrode layer 5 is arranged on the support layer 4, the top electrode layer 7 is arranged in the middle of the upper end of the pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com