Patents

Literature

35results about How to "Improve the top rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

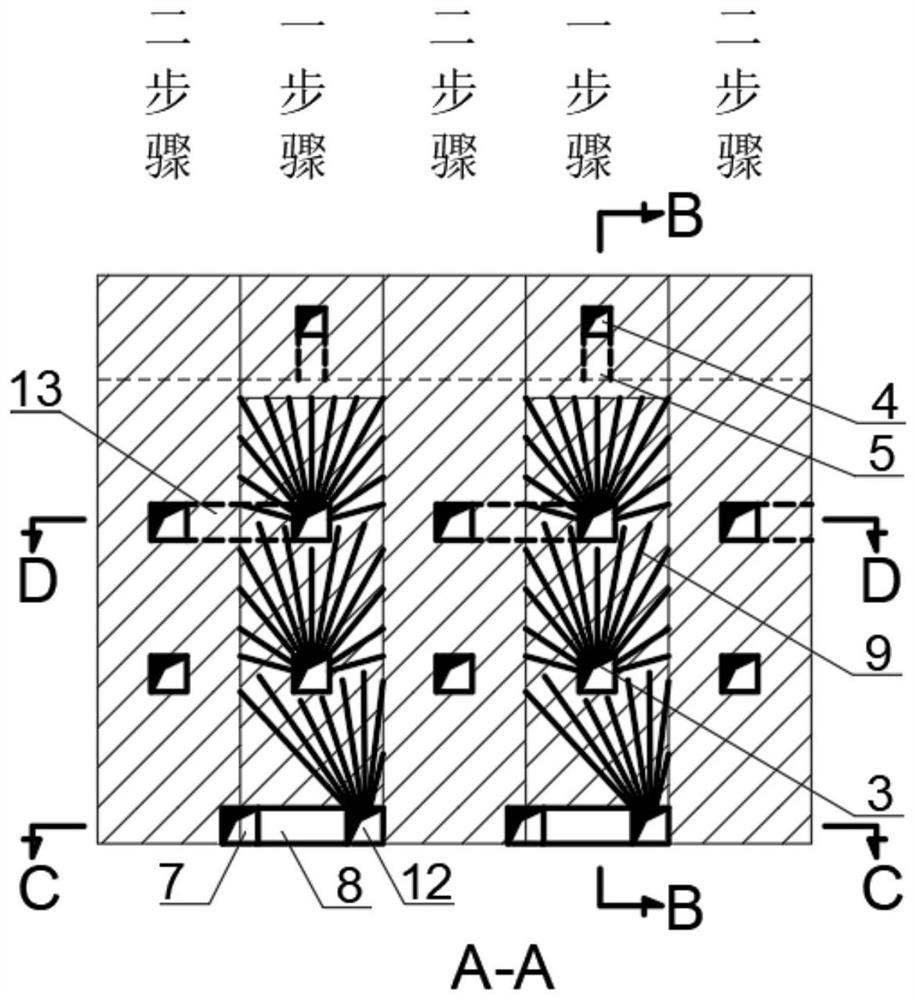

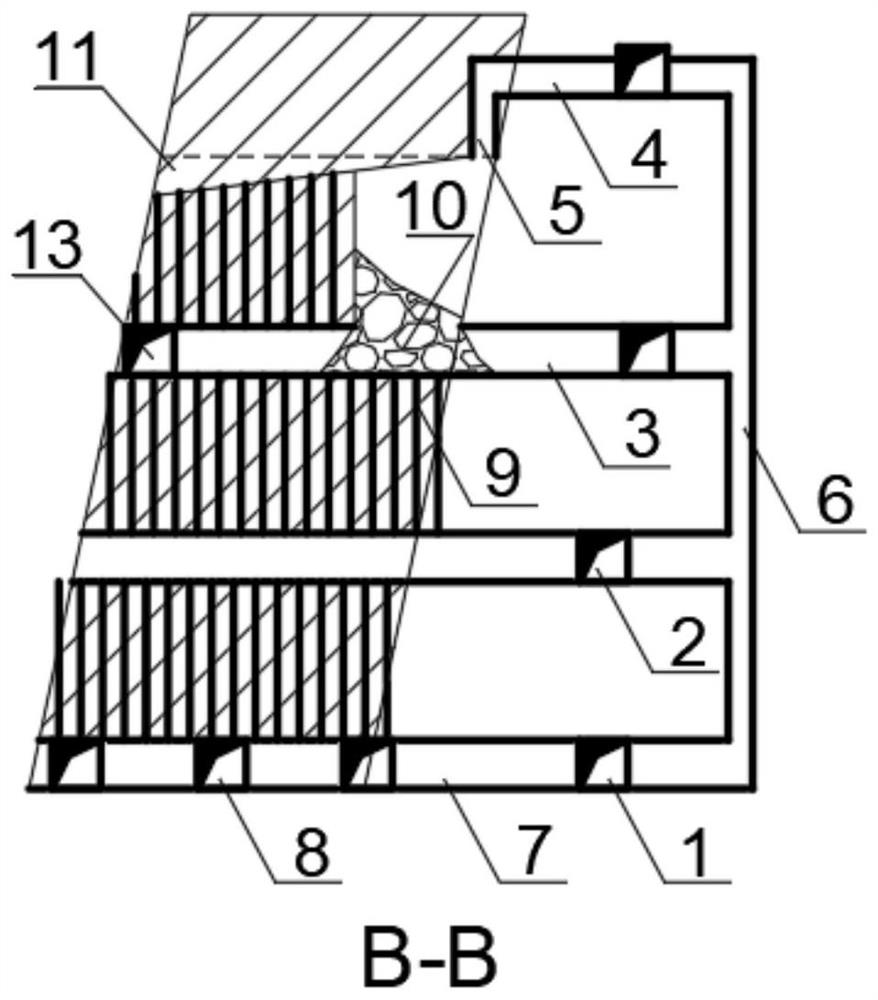

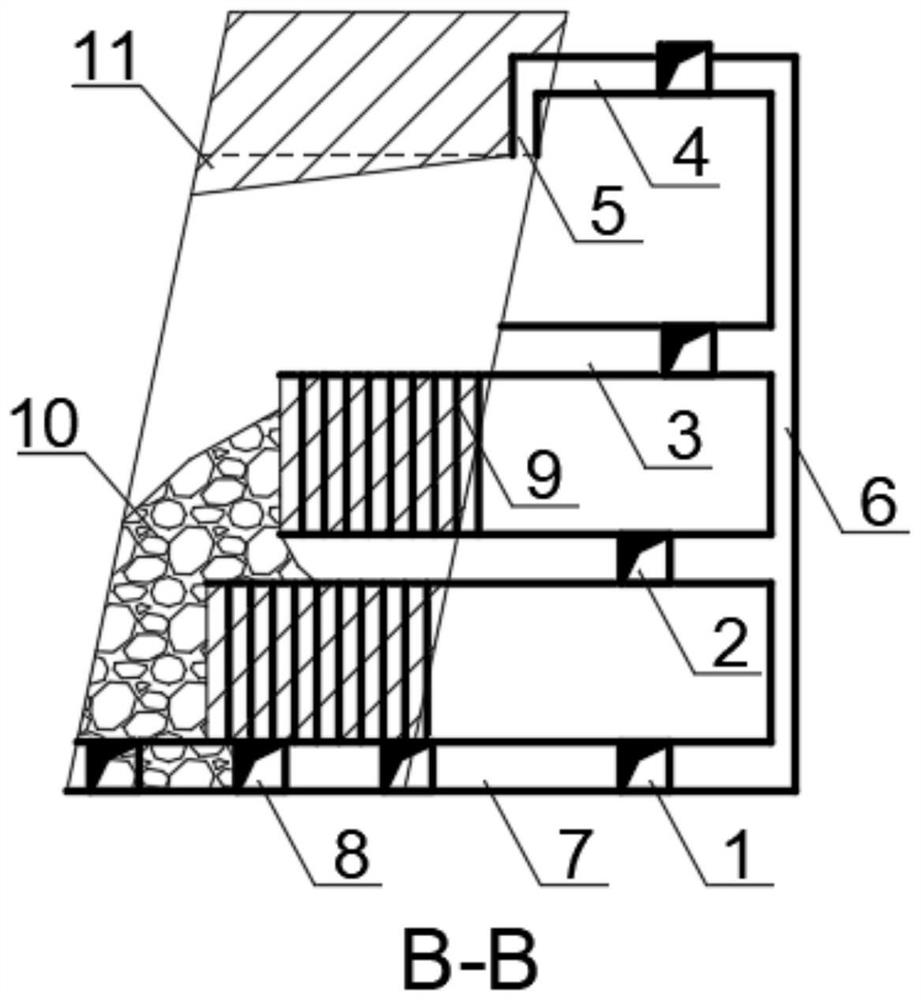

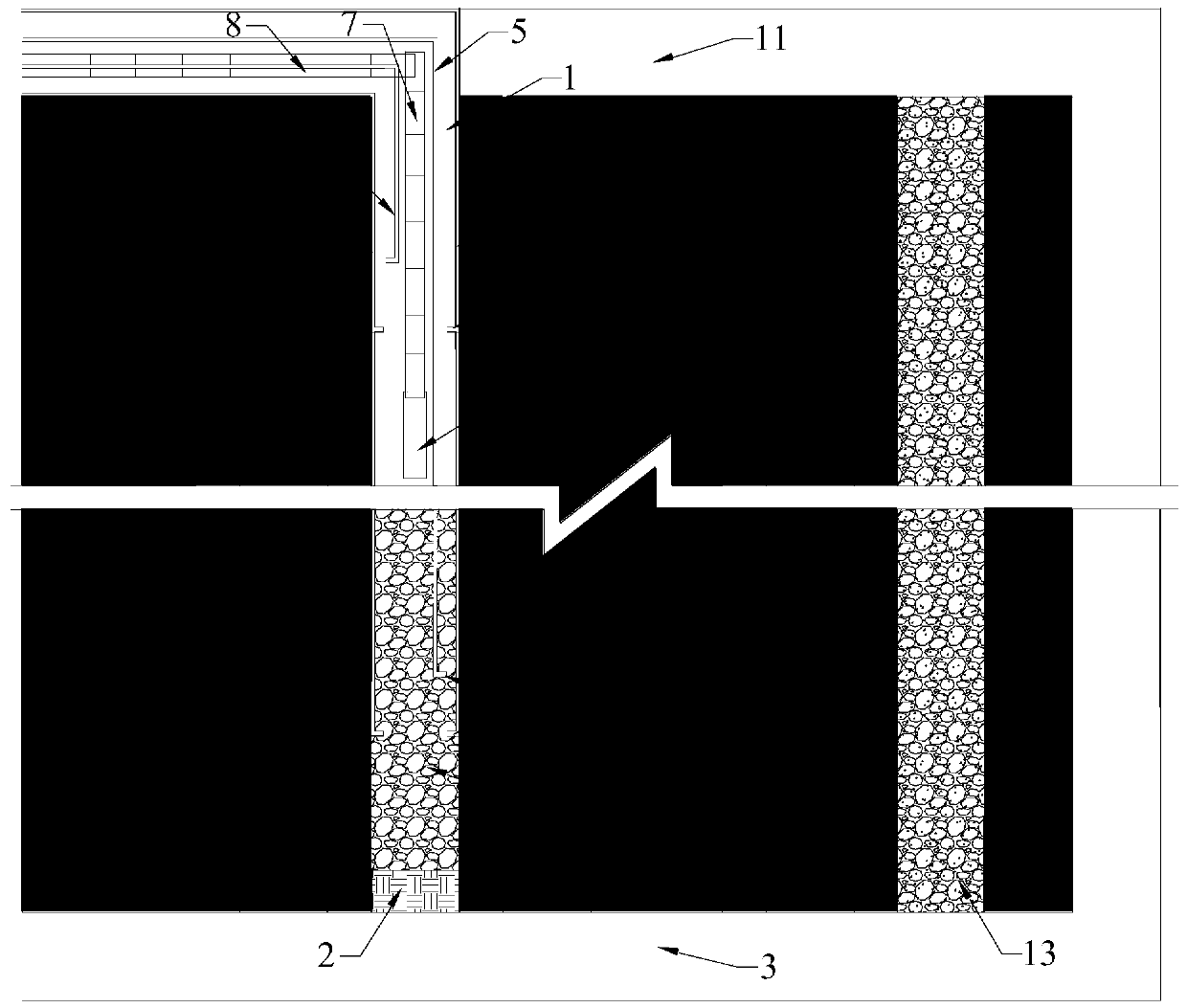

New method for mining open-pit mine sidewall mineral below construction

ActiveCN109026006AImprove support strengthHigh recovery rateUnderground miningSurface miningLandslideMulti segment

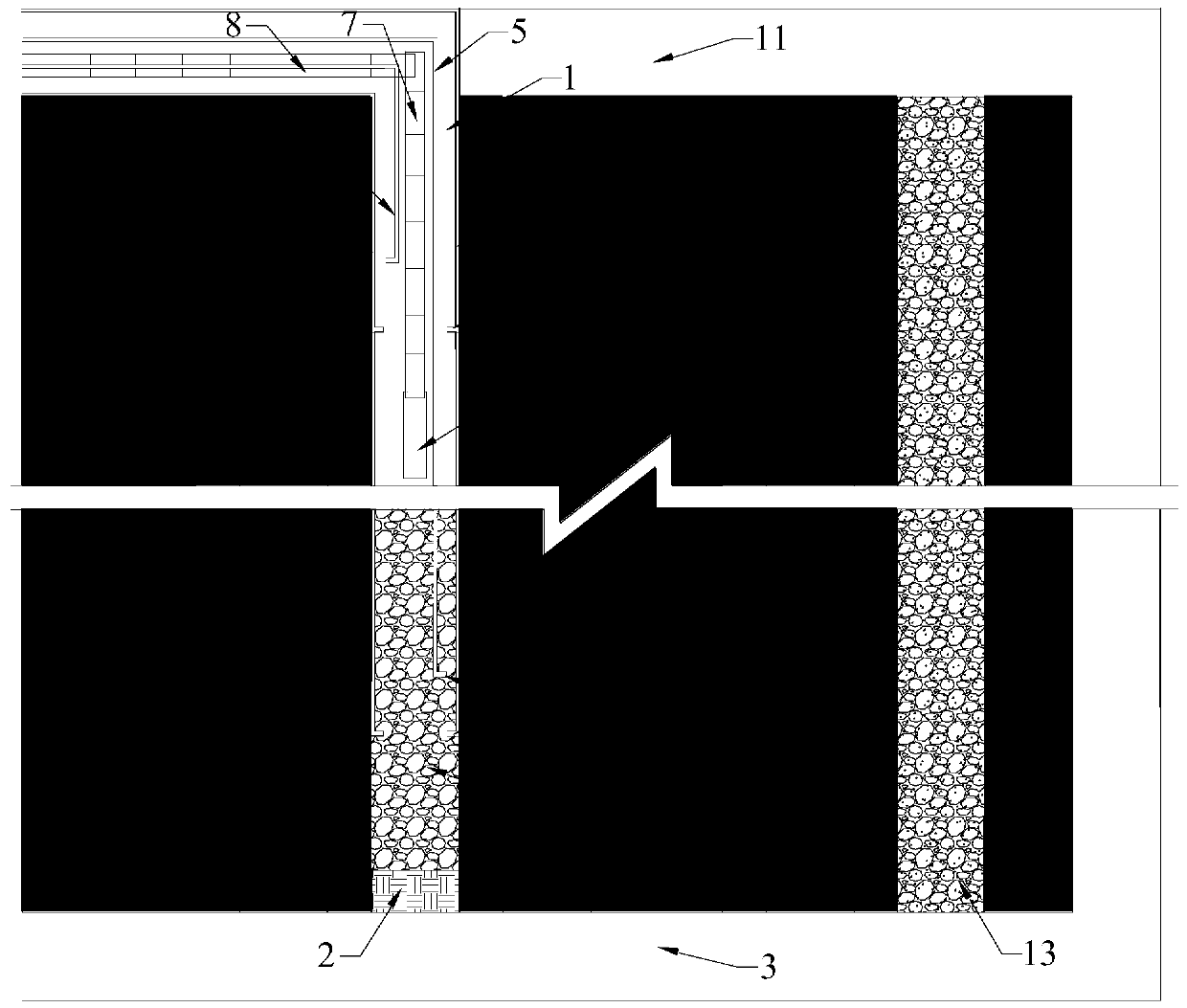

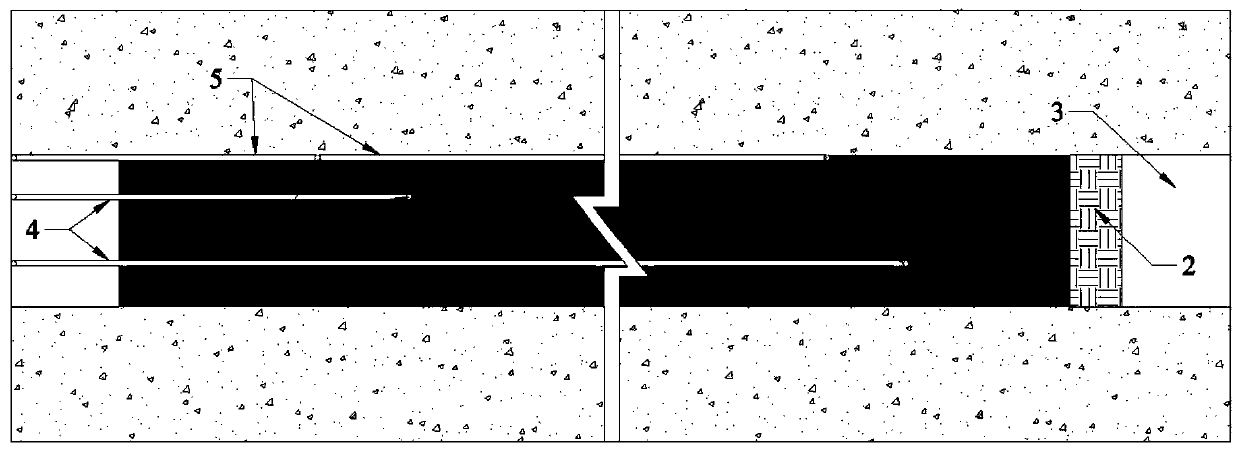

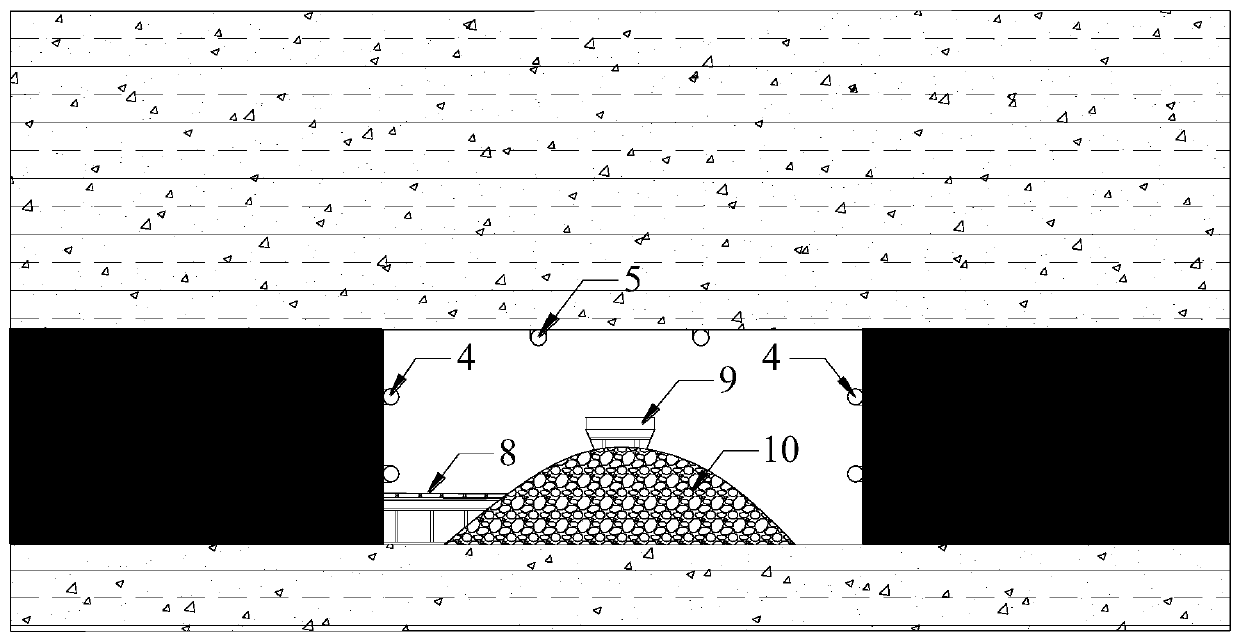

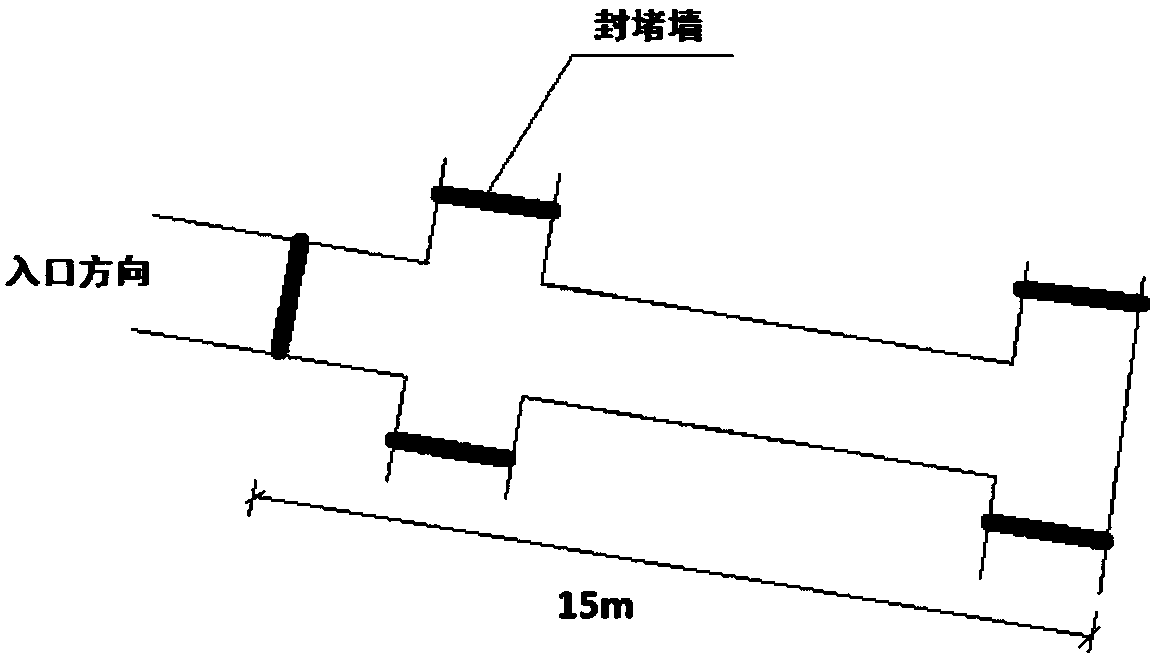

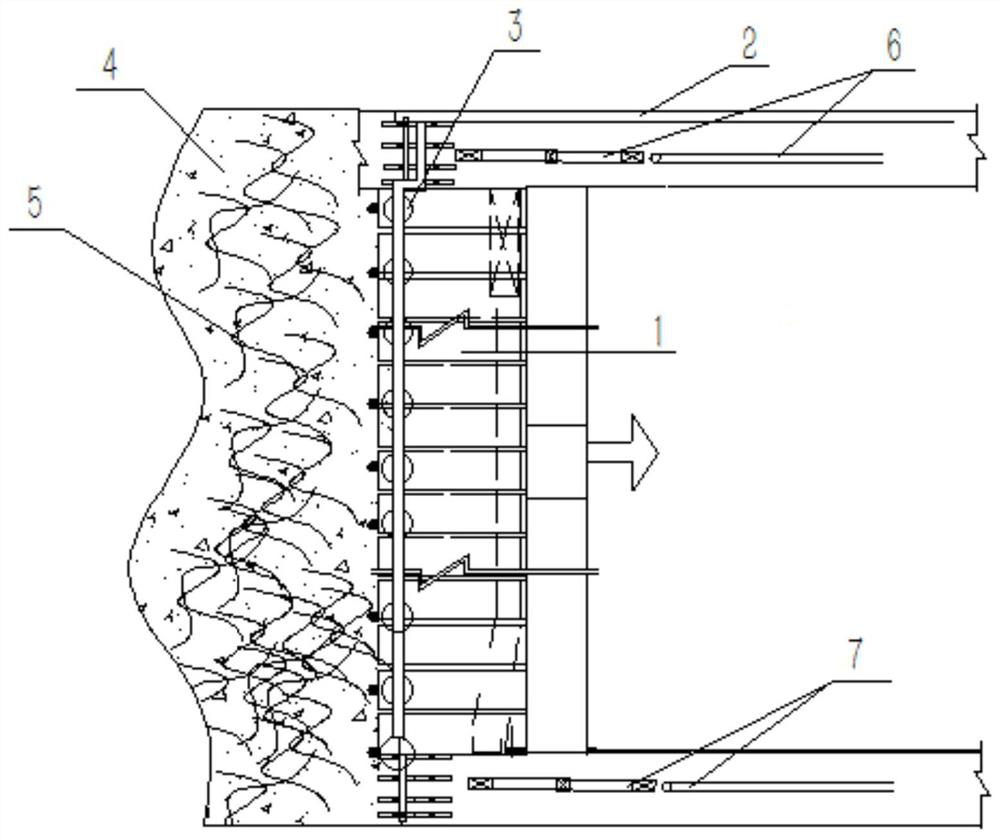

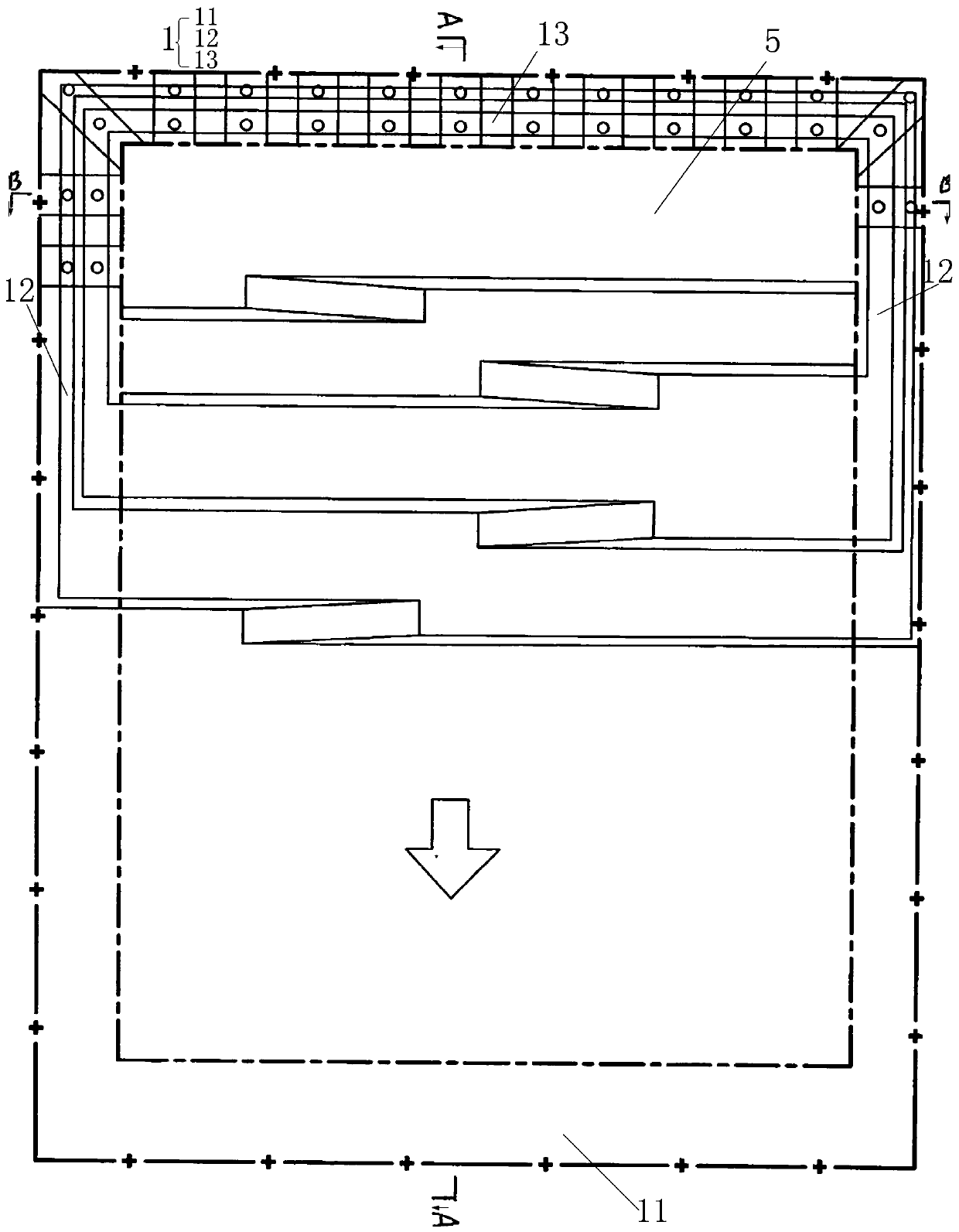

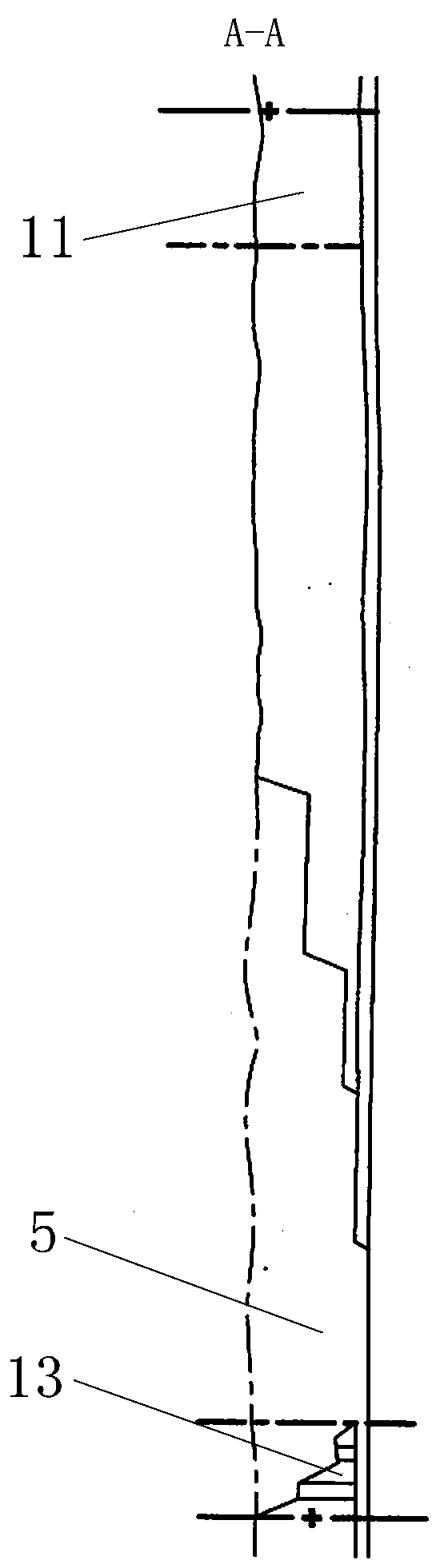

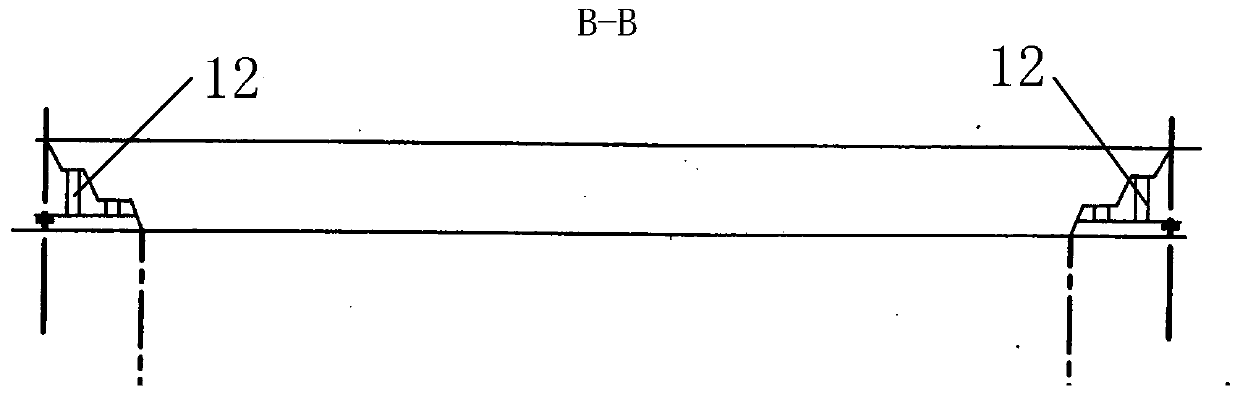

The invention provides a new method for mining an open-pit mine sidewall mineral below construction. The new method comprises: dividing each ore layer of the open-pit mine sidewall mineral below construction into a plurality of linear mining caverns along the inclination or trend of an ore body according to set width and height, and numbering in sequence; using mining equipment to first mine odd or even mining caverns, reserving odd or even mining caverns between even or odd mining caverns as ore pillars, performing mining-filling parallel operation on even or odd mining caverns, and filling the mined mining caverns in sequence after satisfying a filling space; when fillings in two adjacent mining caverns are solidified, then mining a mining cavern between the two adjacent mining caverns,and also performing mining-filling parallel operation on mining caverns to be mined later until multi-segment mining and filling of the various layers and thick ore bodies are completed. The mining method provided by the invention improves the strength of supporting a sidewall, reduces the risk of sidewall collapsing and landslide, has a high mineral recovery rate, and reduces pollution to environments such as atmosphere and soil.

Owner:内蒙古煤矿设计研究院有限责任公司 +1

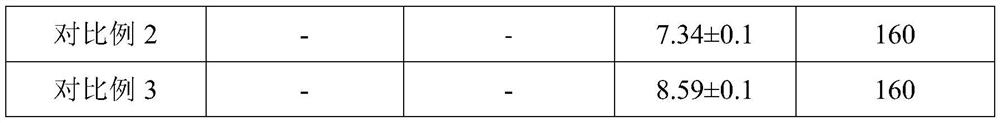

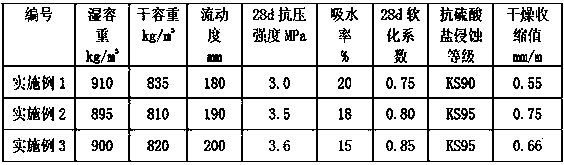

Optimization method of all-solid-waste cementing material and mixed aggregate filling slurry

PendingCN111312344ALow costIncrease profitComputational materials scienceInstrumentsSlagEconomic benefits

The invention discloses an optimization method of all-solid-waste cementing material and mixed aggregate filling slurry, and belongs to the technical field of filling mining. According to the method,the all-solid-waste filling cementing material is prepared through synergistic excitation of alkaline converter steel slag and industrial byproduct gypsum, and an all-solid-waste cementing material optimization model is established for proportion optimization by taking the cost of the cementing material as an optimization target and taking the strength and the volume expansion rate of a cemented filling body as constraint conditions. The invention further discloses an optimization method of the coarse and fine tailing mixed aggregate filling slurry by utilizing the all-solid-waste cementing material. The optimal design of the mixed aggregate filling slurry with the lowest filling cost is obtained by solving the optimal design model of the mixed filling slurry with the cost of the mixed filling slurry per unit volume as an optimization target and the strength and the volume expansion rate of the cemented filling body as constraint conditions. Solid wastes such as steel slag, industrialbyproduct gypsum and beneficiation tailings are applied to mining by a filling method, so that the filling mining cost is remarkably reduced, and the economic benefit and the environmental protectionbenefit of filling mining are improved.

Owner:HEBEI IRON & STEEL GRP MINING +2

Roof contact method for stope filling

The invention relates to the technical field of combustion water heaters, and relates to a roof contact method for stope filling. The roof contact method for the stope filling comprises the followingstep that a stope empty area is filled with slag to a certain height to obtain a residual empty area, the height of the residual empty area is measured, the position of the highest point is determined, a hollow anchor rod is installed at the highest point, and a filling pipe is installed on the hollow anchor rod; a first dewatering pipe and a dewatering pipe are installed at the highest point, anda third dewatering pipe and a second dewatering pipe are installed from top to bottom according to the height difference; and the opening between the residual empty area and an inlet or a connectingchannel is blocked, and then filling slurry is conveyed into the filling pipe to realize roof-contacted filling of the residual empty area. The roof contact method for the stope filling has the characteristics of realizing effective roof-contacted filling of the stope empty area, and effectively ensuring the strength of the stope empty area.

Owner:GUANGXI ZHONGJIN LINGNAN MINING CO LTD

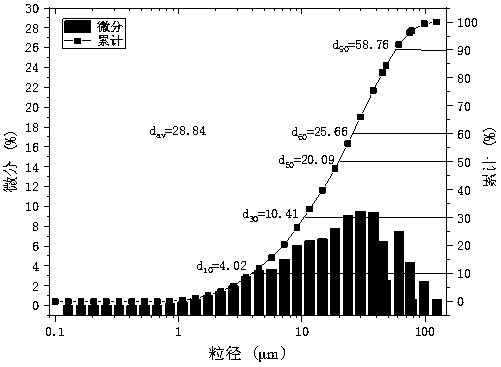

Proportion optimizing method of phosphogypsum-based all-solid waste filler for improving roof-contacted filling rate

ActiveCN110723952ALow costLow expansionChemical machine learningChemometricsMathematical modelEnvironmental engineering

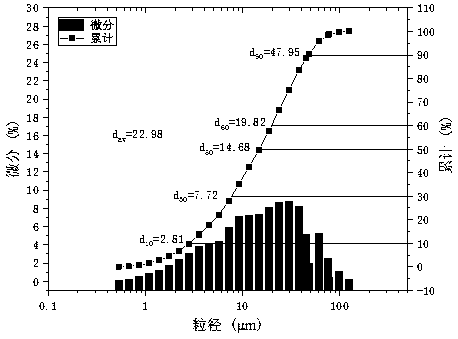

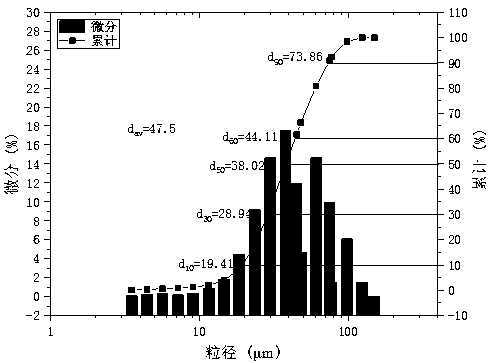

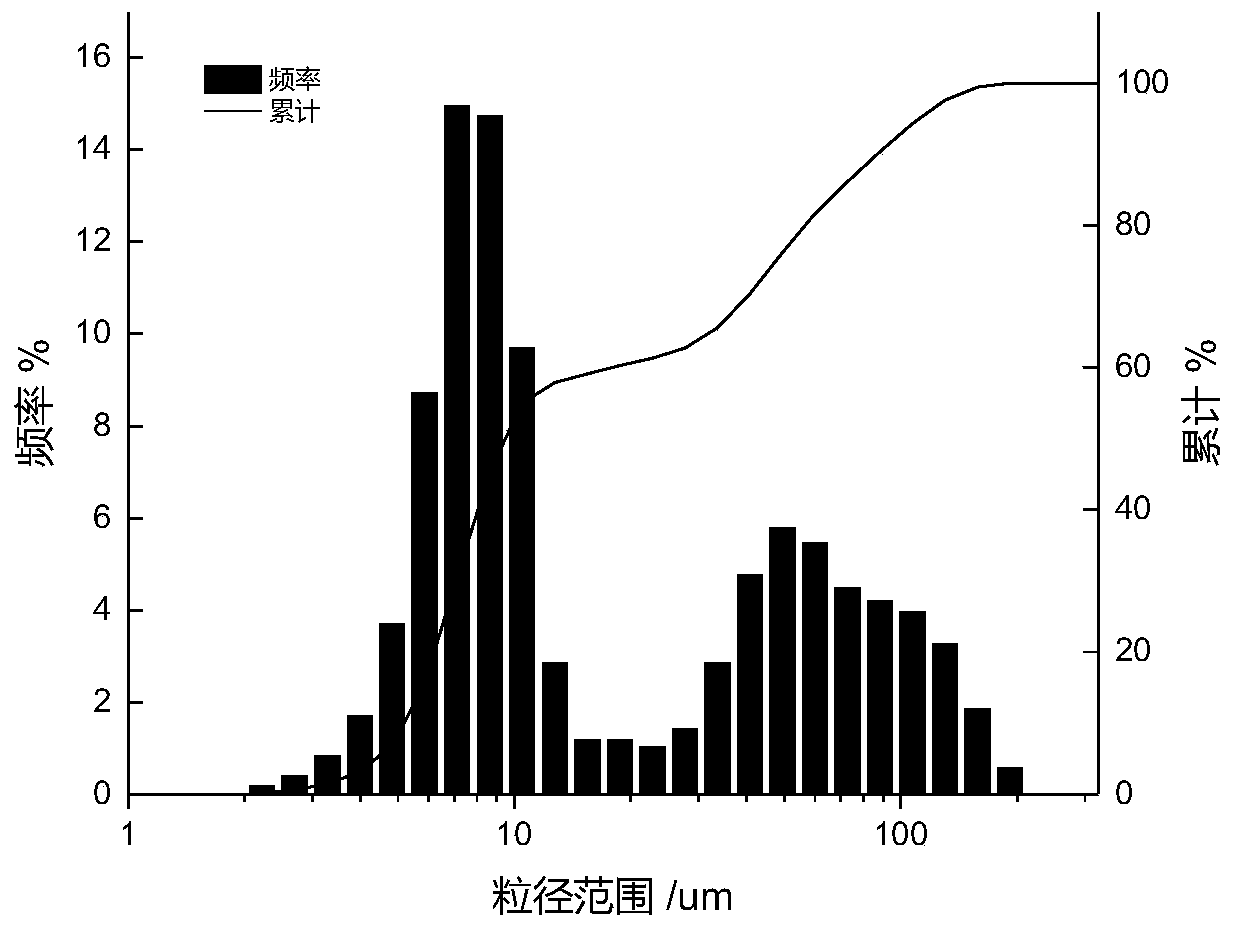

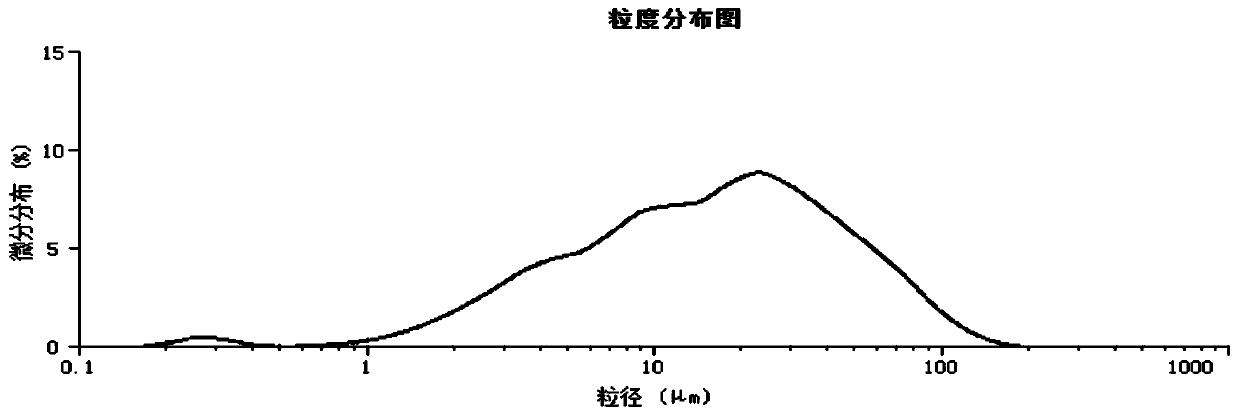

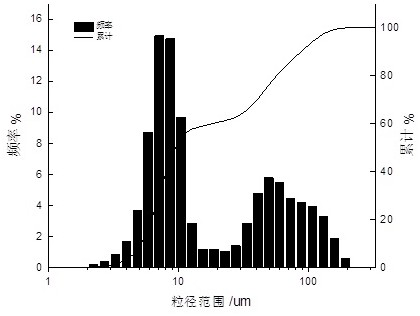

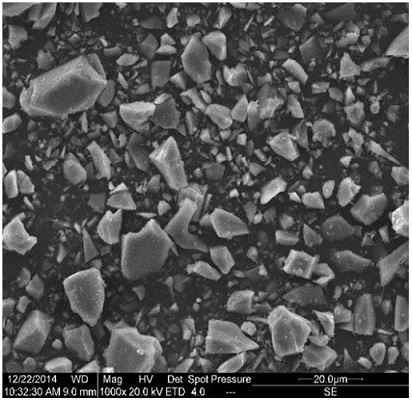

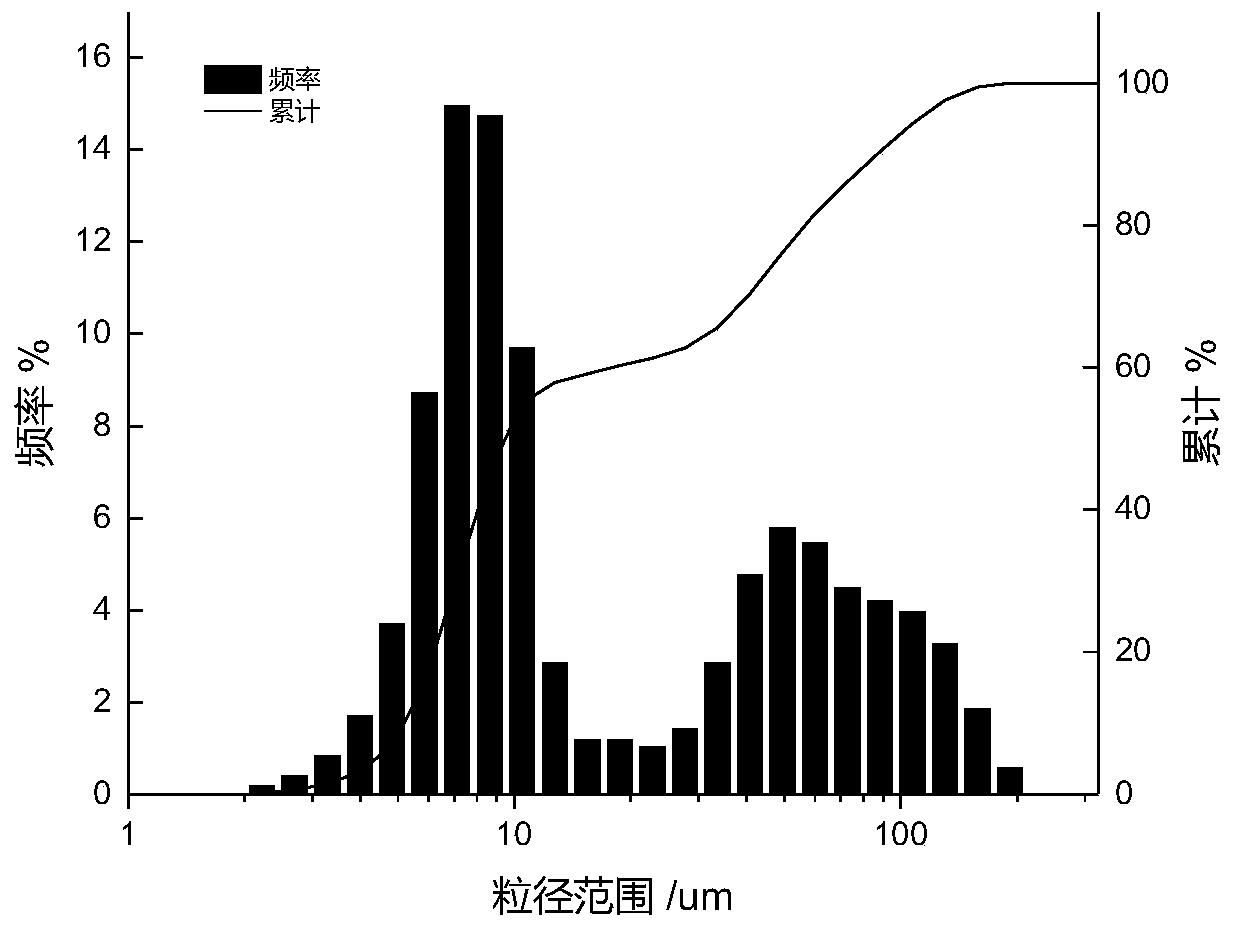

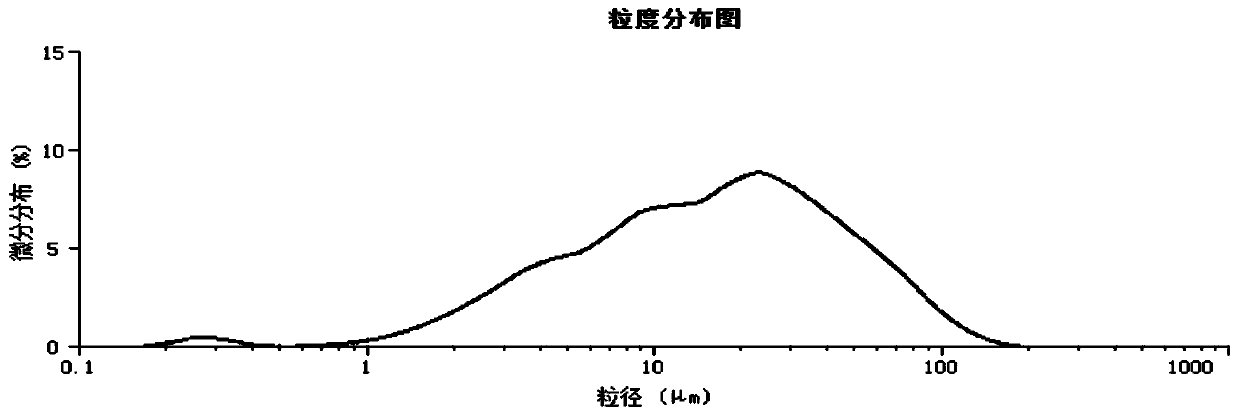

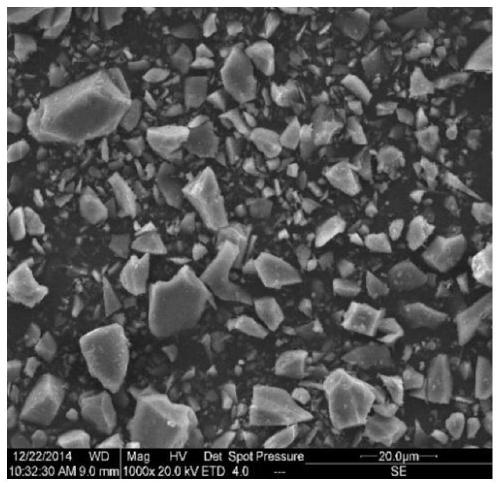

The invention provides a proportion optimizing method of a phosphogypsum-based all-solid waste filler for improving a roof-contacted filling rate, and belongs to the technical field of environment-friendly filling mining. The method comprises the following steps: firstly performing mineral analysis and a particle size test on phosphogypsum and low-quality solid waste; performing a strength test and an expansion rate test on a filling body with different proportions of the phosphogypsum-based all-solid waste filler; establishing a strength and expansion rate mathematical model of the filling body based on the test results; establishing a proportion optimization model of the a phosphogypsum-based all-solid waste filler; and finally solving the proportion optimization model to obtain an optimized proportion of the phosphogypsum-based all-solid waste filler. The method makes full use of the self expandability of the phosphogypsum, realizes the proportion optimal combination and synergy ofmultiple low-quality solid waste, can avoid deterioration of the strength of the filling body caused by excessive expansion of the filling body, and can make the swellability of the phosphogypsum exerted to the utmost extent on the basis of meeting the strength of the filling body, thereby improving the roof-contacted filling rate of filling stope.

Owner:UNIV OF SCI & TECH BEIJING +1

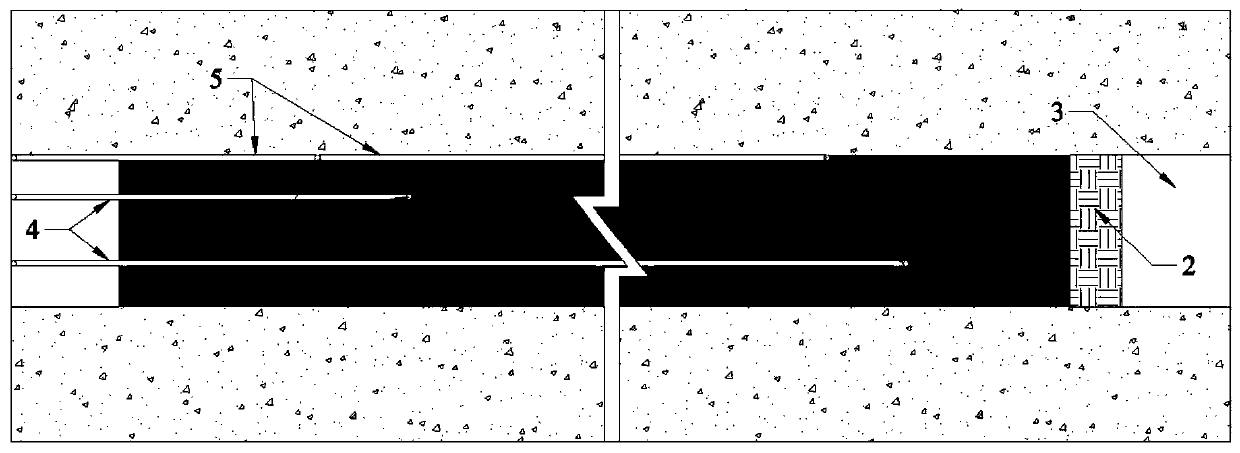

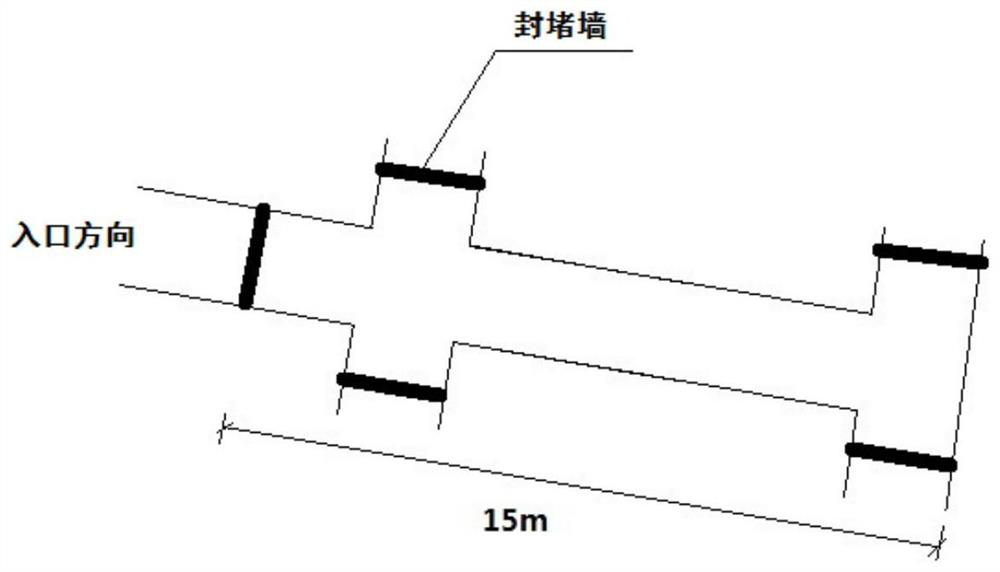

Method for mixing and filling gangue and high-water material

ActiveCN109826665AImprove the top rateImprove compactnessMaterial fill-upMining engineeringFilling materials

The invention discloses a method for mixing and filling gangue and high-water materials, which utilizes the high-water materials to supplement the filling gaps of the gangue, thereby achieving compactfilling and bearing a top plate of a goaf. The method comprises the following steps: step 1), a filling retaining wall is arranged on one side of a working face transportation roadway in a way of filling the high-water materials in bags after a filling connection roadway is dug and mined based on a long wall production system; step 2), high-water material filling pipelines is arranged on two sides of the filling connection roadway and the top plate; step 3), the gangue is thrown to the goaf; step 4), a high-water filling material retaining wall is arranged on one side of a working face returnairway after the gangue is thrown, an overflow hole is reserved, and the high-water filling materials are injected into the goaf for filling through reserved filling pipelines; step 5), the reservedoverflow hole is detected. Slurry overflow indicates that the filling is completed and stopped; step 6), the next mining and filling cycle is carried out at an interval of three filling connection roadways and coal pillars. The method effectively reduces the ground surface subsidence value of the mining area of the working face, and simultaneously greatly improves the roof connection rate and thecompactness of the filling body of the goaf.

Owner:CHINA UNIV OF MINING & TECH

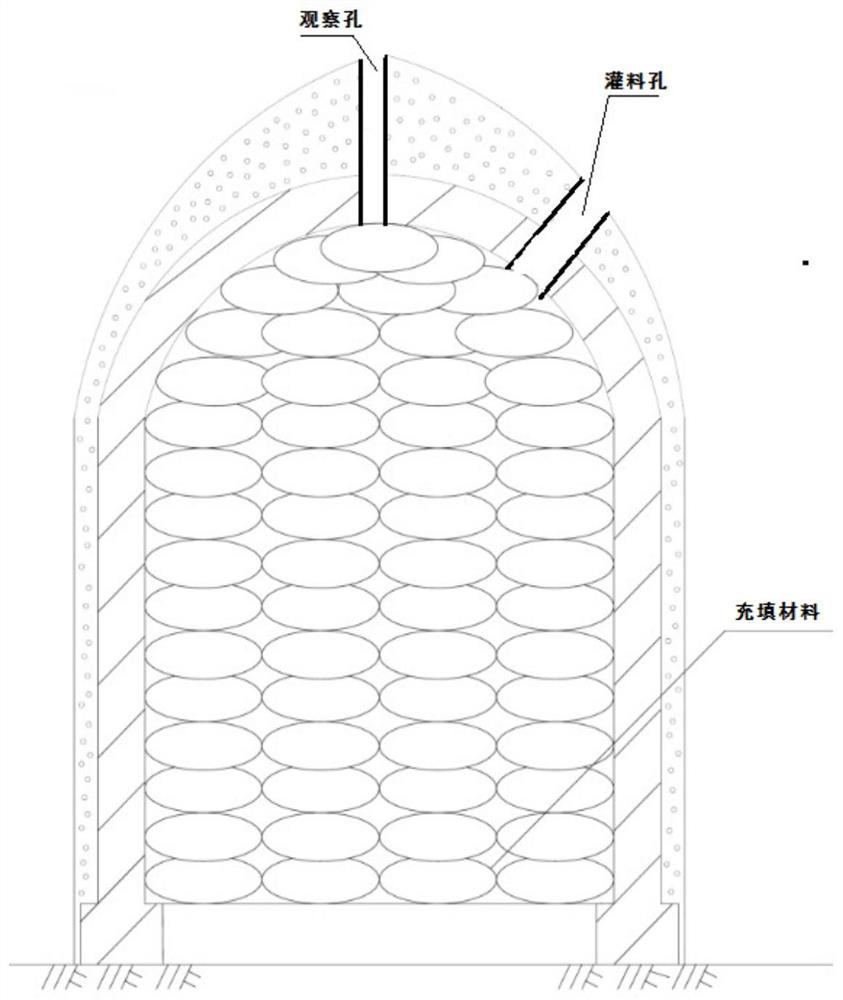

Environment-friendly handling method for abandoned underground air raid shelter

ActiveCN108316346AHigh strengthControl interferenceArtificial islandsUnderwater structuresTerrainSludge

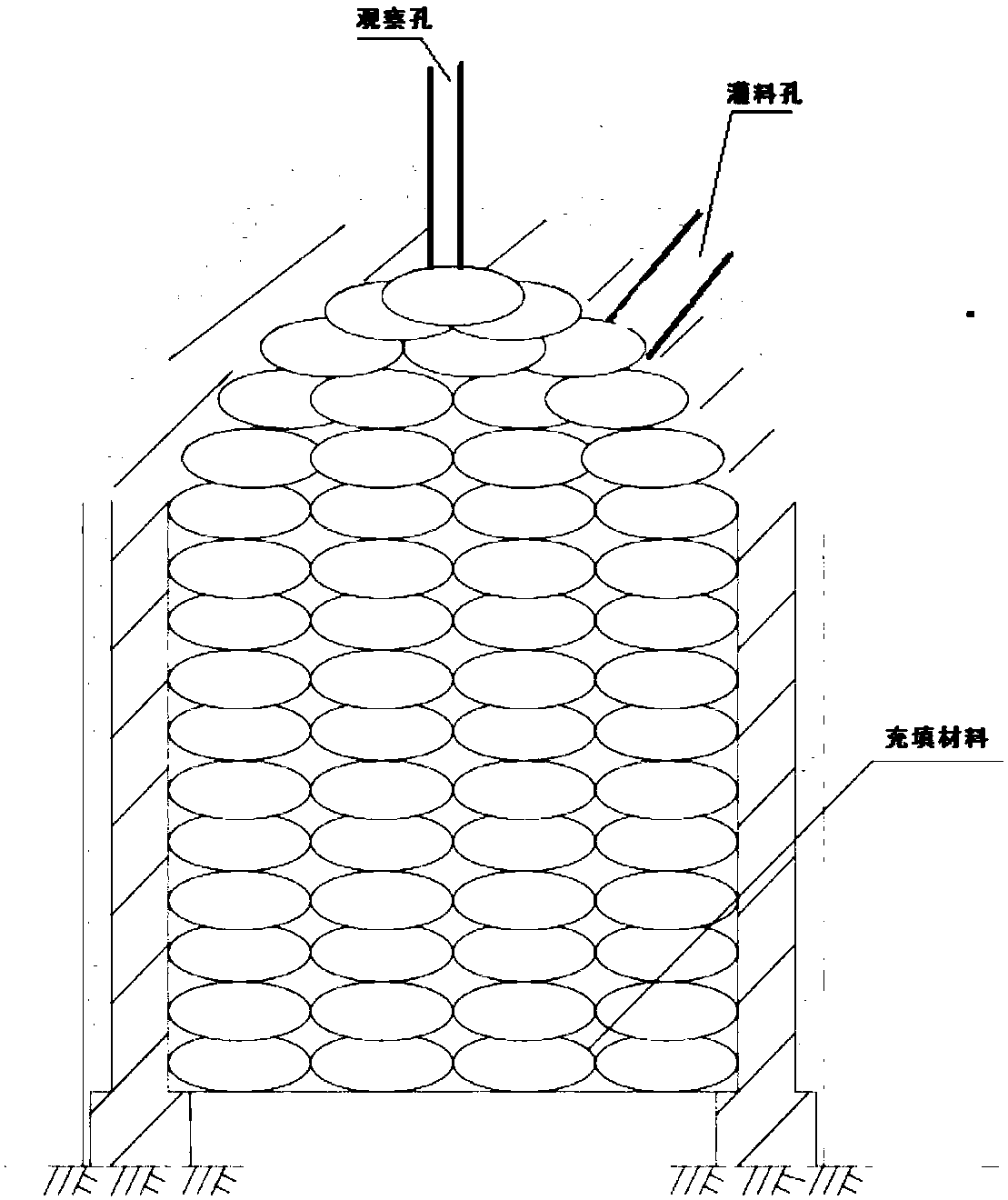

The invention discloses an environment-friendly handling method for an abandoned underground air raid shelter. The environment-friendly handling method is characterized by comprising the following steps that before filling, after field accumulated water is pumped and ventilation arrangement is completed, a curing agent is sprayed onto sludge from outside to inside in the channel direction, a powerful stirring head and a high-pressure water gun are combined and adopted to stir the sludge on site, and consolidated soil is formed; then, filling units are divided from inside to outside in the channel direction, a drill bit is adopted to drill the ground at the two ends of each unit downwards to penetrate through the arched top of the air raid shelter, light aggregate concrete is poured throughguide pipes, and end sealing walls are formed; the positions nearby the middles and two ends of the filling units are drilled to form filling holes and observing holes; finally, filling is conductedfrom bottom to top through the filling holes between every two sealing walls, the periphery and the top is subjected to filling in sequence, and materials are filled gradually from the low portion tothe high portion; and after the unit is filled, filling of the next unit is conducted. The environment-friendly handling method has the advantages that the strength of the filling body is improved, the filling effect is improved, disturbance to surrounding buildings is effectively controlled, the construction environment pollution is reduced, and visualization of the filling process is achieved.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Microbial cemented filling material for coal mines and preparation method thereof

InactiveCN111635178AReduce dosageHigh compressive strengthBacteriaMicroorganism based processesMicroorganismEthylic acid

The invention provides a preparation method of a microbial cemented filling material for a coal mine. The preparation method comprises the steps of culture of microorganisms for the coal mine, preparation of a calcium-based chitosan solution, preparation of a urea-calcium-based chitosan solution and preparation of a matrix. A preparation method of the calcium-based chitosan solution comprises heating a 12-15% chitosan-acetic acid solution, carrying out heat preservation, and adding anhydrous calcium chloride until the calcium ion content is 65-90 g / l. According to a preparation method of the matrix, the mass ratio of the coarse aggregate to the fine aggregate is (6-8): (1.4-2.5), and the average specific surface area of the coarse aggregate is 500-1500 m<2> / kg, and the average specific surface area of the fine aggregate is 1500-3000 m<2> / kg. The microbial cemented filling material for coal mine has the advantages of low microbial consumption, high compressive strength, high roof contact rate, small slump and low bleeding rate. The technical problems that an existing microorganism cemented filling material is large in use amount and poor in cemented filling effect are solved.

Owner:ANJIEYU BEIJING OILFIELD TECHNICAL SERVICES CO LTD

Comprehensive filling and roof-contacting method for stoping route

The invention discloses a comprehensive filling and roof-contacting method for a stoping route. The comprehensive filling and roof-contacting method comprises the following steps of: constructing eachstoping route downhill, performing roof-lifting at the head-on position of the stoping route to form a sand discharging chamber, performing roof-lifting at the inlet of the stoping route, erecting anupper-part open type filling retaining wall, enabling a filling pipeline to enter the stoping route from the upper part of the filling retaining wall, and erecting the filling pipeline to the sand discharging chamber along a roof of the stoping route; and during roof-contacting filling of the stoping route, realizing filling and roof-contacting by utilizing the natural slope of the roof of the stoping route and the pressure of slurry in the filling pipeline, and for a local uneven roof area, realizing local roof-contacting by utilizing vibration of the filling pipeline. According to the comprehensive filling and roof-contacting method disclosed by the invention, during roof-contacting filling, the roof-contacting condition is convenient to observe, the filling and roof-contacting processis simple, the cost is low, the requirement on the filling retaining wall is low, the safety is high, and popularization and application are facilitated.

Owner:南京银茂铅锌矿业有限公司

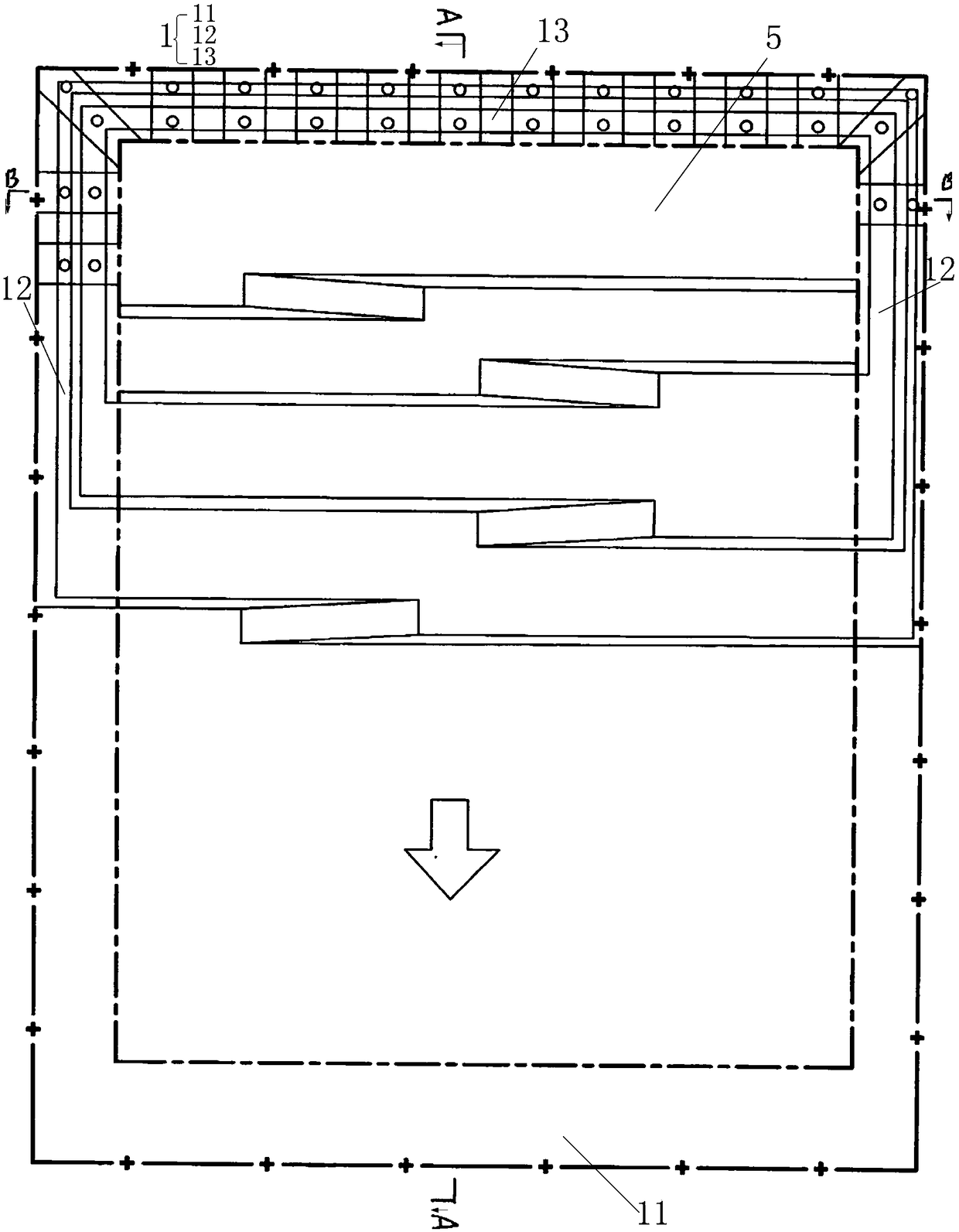

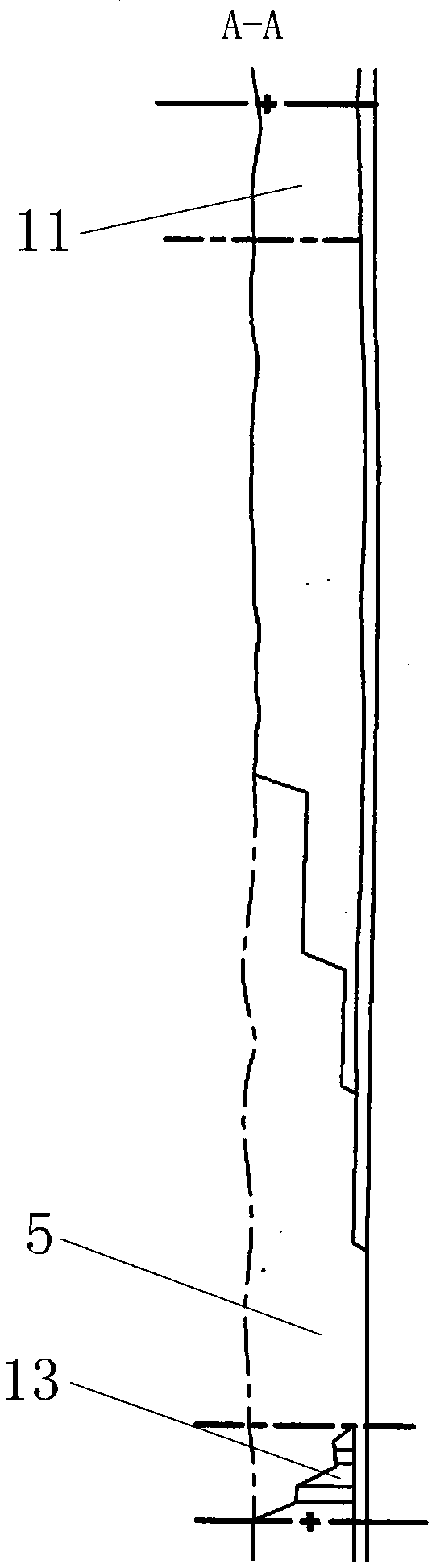

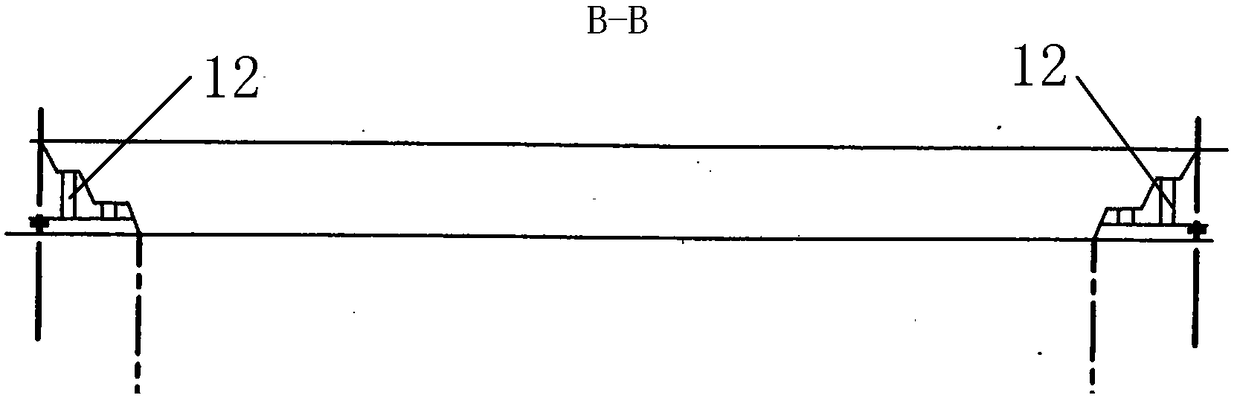

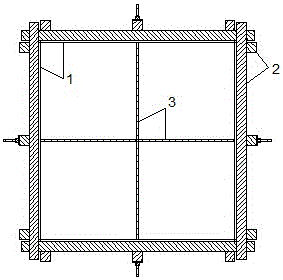

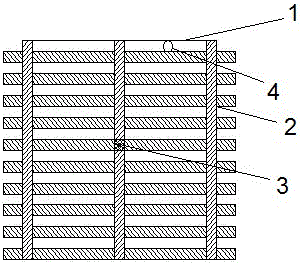

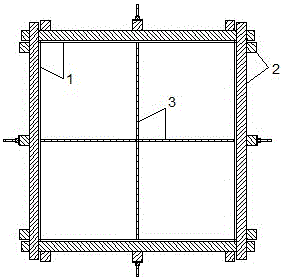

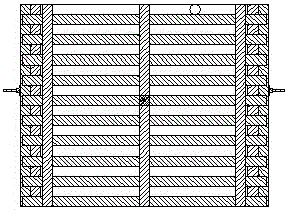

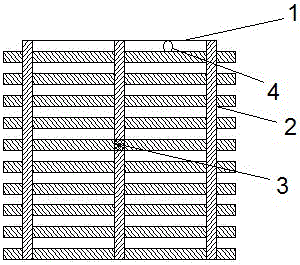

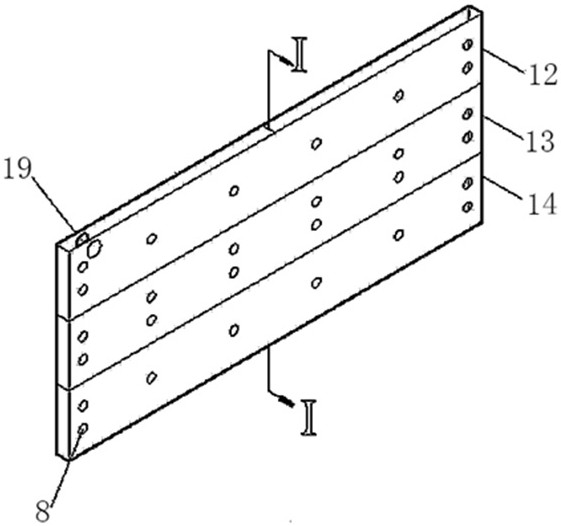

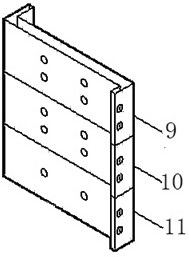

Stack column type filling formwork and using method thereof

The invention discloses a stack column type filling formwork and a using method thereof. The stack column type filling formwork is arranged below a top plate, supporting frames spliced together define a cuboid frame structure on the periphery, single supporting frames or integrated bodies formed by single-side-spliced supporting frames are arranged on the two opposite faces of the formwork respectively, and every two adjacent faces are formed by perpendicularly splicing supporting frames at the edges. Each supporting frame is composed of a baffle, framework sleepers and counter-pulled anchor ropes, wherein the framework sleepers are composed of a plurality of parallel transverse sleepers and three parallel vertical sleepers, the transverse sleepers and the vertical sleepers are arranged in a perpendicularly crossing mode, and the counter-pulled anchor ropes are arranged on the vertical sleepers in the formwork center on each side. The framework sleepers make direct contact with the top plate after being spliced to support the top plate. A filling opening is formed in the upper portion of the part, on one side of the formwork, of the baffle. After filling of the formwork, the overall compressive strength of filling columns is improved, the later compression amount of the filling columns is reduced, and the top sinking amount is reduced.

Owner:TAIYUAN UNIV OF TECH

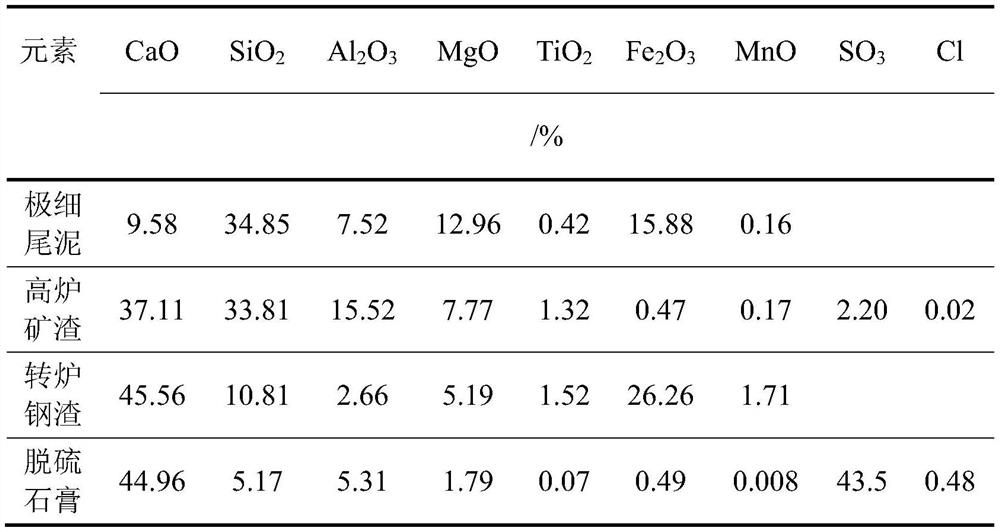

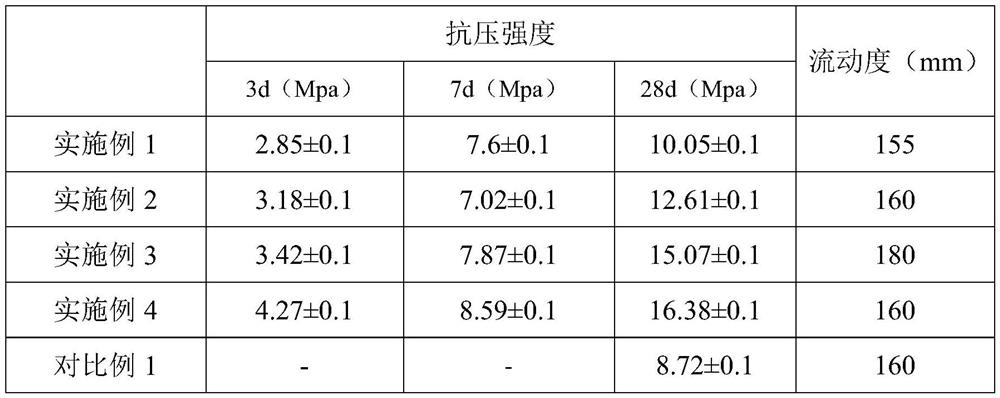

Paste filling material containing ultrafine tail mud as well as preparation method and application thereof

The invention relates to a paste filling material containing ultrafine tail mud as well as a preparation method and application of the paste filling material. The filling material is prepared from the following raw materials: a cementing material, aggregate and water, wherein the cementing material comprises the following components in parts by weight: 40-80 parts of converter steel slag, 5-30 parts of desulfurized gypsum and 0-20 parts of desulfurized ash; the aggregate comprises superfine tail mud; the mass ratio of the cementing material to the aggregate is 1: 4-6; the slurry concentration is 55-70%. According to the filling material, a large amount of superfine tail mud is utilized, good compressive strength (larger than or equal to 10 MPa) capable of being industrially applied is achieved without adding a water reducing agent, it is guaranteed that the filling material has good practical value, and the problem that the roof contact rate of a stope is not high is solved. The method is beneficial to solving the problems of reduction, harmlessness and recycling of industrial solid waste, solving the problem of tailing stockpiling, and promoting cooperative utilization of solid waste and hazardous waste and environmental protection; meanwhile, cyclic utilization of water resources is achieved through pre-plant return water, and therefore waste of the water resources is reduced.

Owner:上海宝钢新型建材科技有限公司 +3

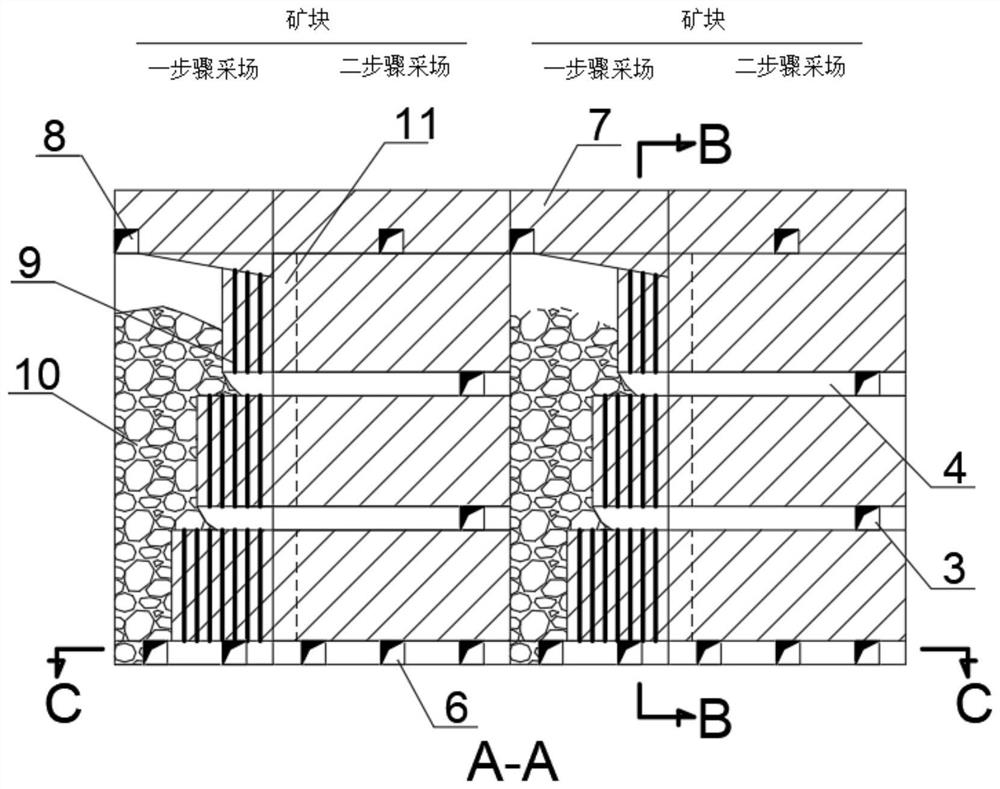

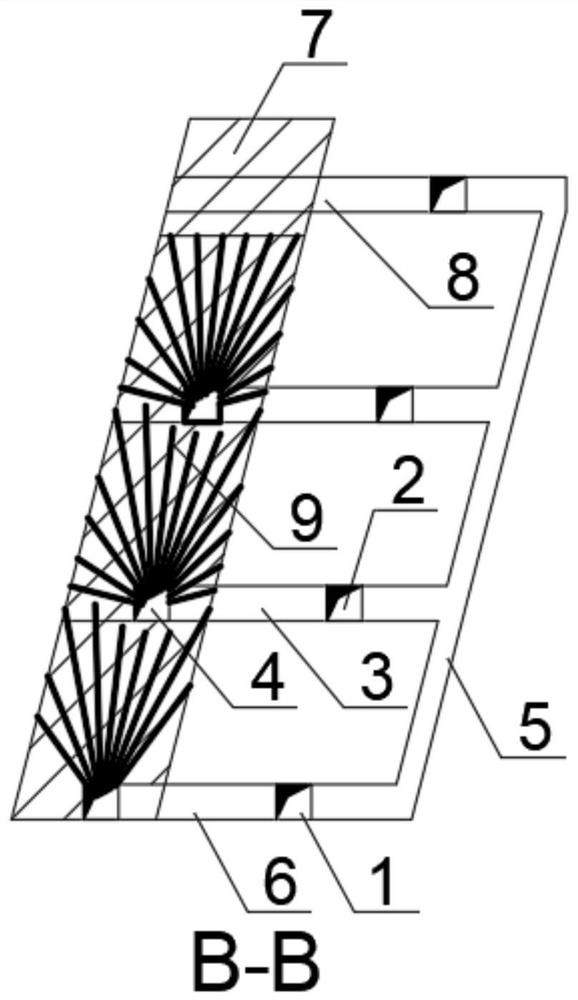

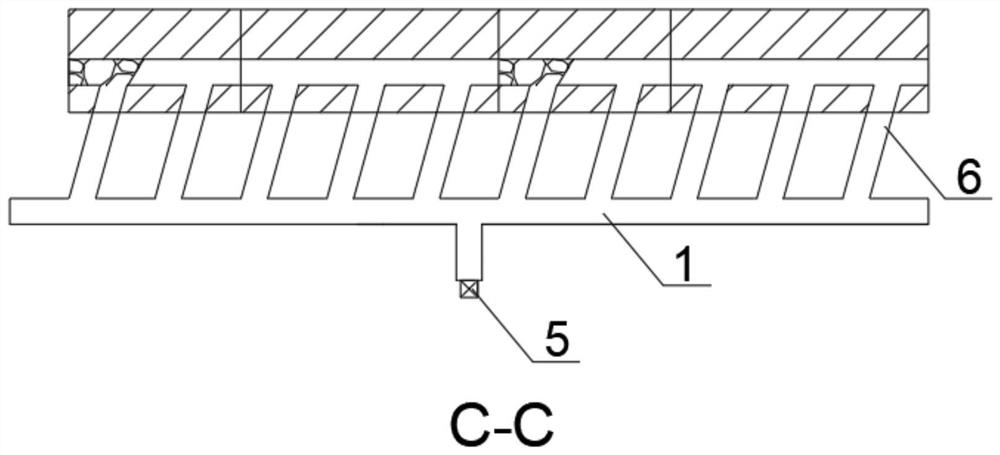

Open-stope subsequent filling mining method for thick and large ore body in segmented rock drilling stage

ActiveCN113530541AEnsure safetyImprove securityUnderground miningSurface miningMining engineeringRock cutting

The invention discloses an open-stope subsequent filling mining method for a thick and large ore body in a segmented rock drilling stage. Stopes are arranged in a direction vertical to the ore body; the first-step stope and the second-step stope are arranged at intervals; the first-step stope is firstly mined; a goaf is filled; then, the second-step stope is recovered; a goaf is filled; during the first-step stope recovery, the uppermost segment is firstly recovered; through controlling the hole bottom position of each positive row of blasting holes, a wedge-shaped top post is formed at the upper part during the recovery of the collapsed ore body; after the blasting of the uppermost segment is completed, each following segment is simultaneously recovered; after the recovery of the whole first-step stope is completed, high-intensity filling bodies are used for filling; after the intensity of the filling bodies of the first-step stope reaches the design index, the second-step recovery is started; during the second-step stope recovery, each segment is simultaneously recovered; and after the recovery is completed, low-intensity filling bodies are used for filling. The open-stope subsequent filling mining method has the advantages that the stope filling top connecting process is simple; the top connecting quality is ensured; the top connecting rate is high; the second-step stope recovery safety can be effectively improved, and the like.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST +1

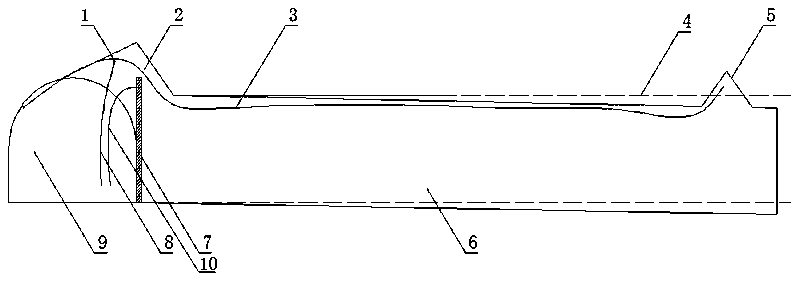

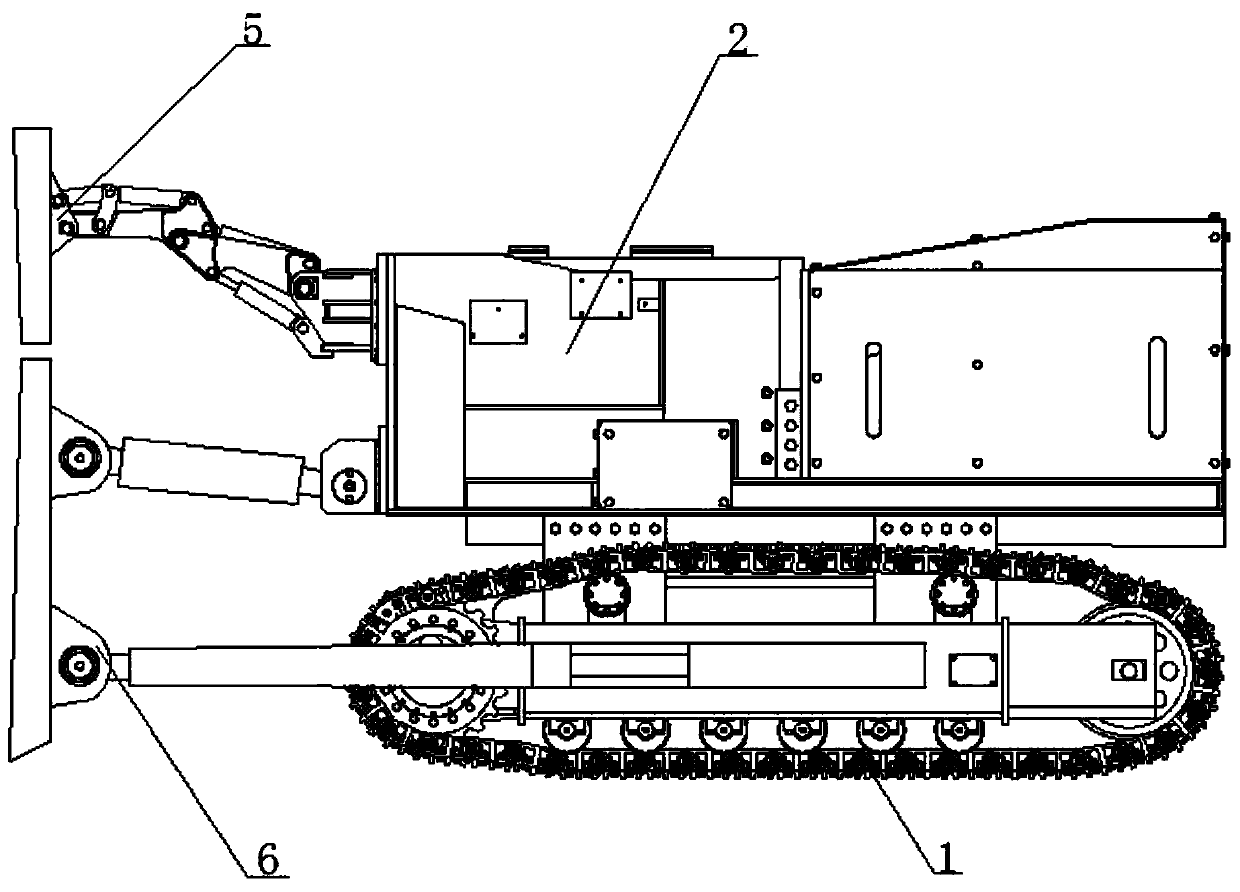

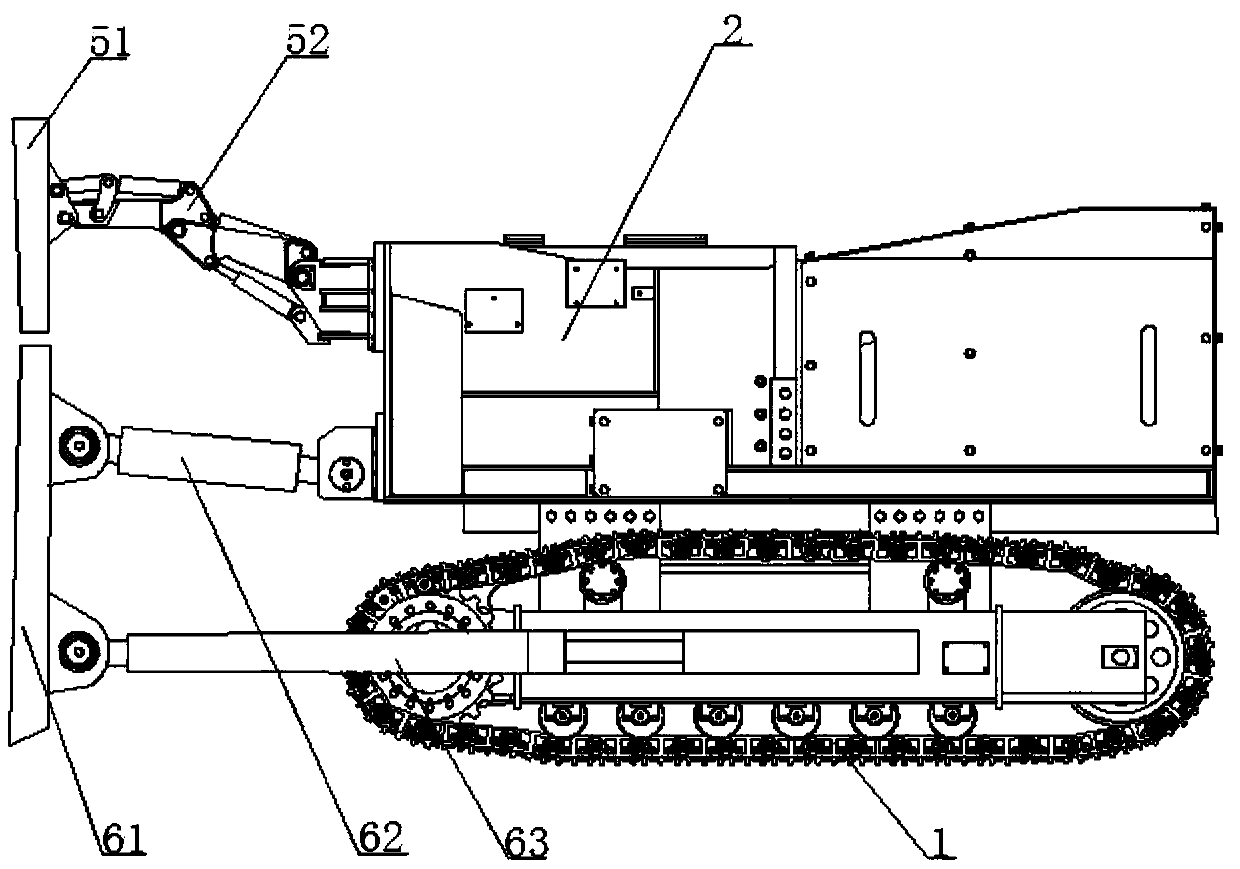

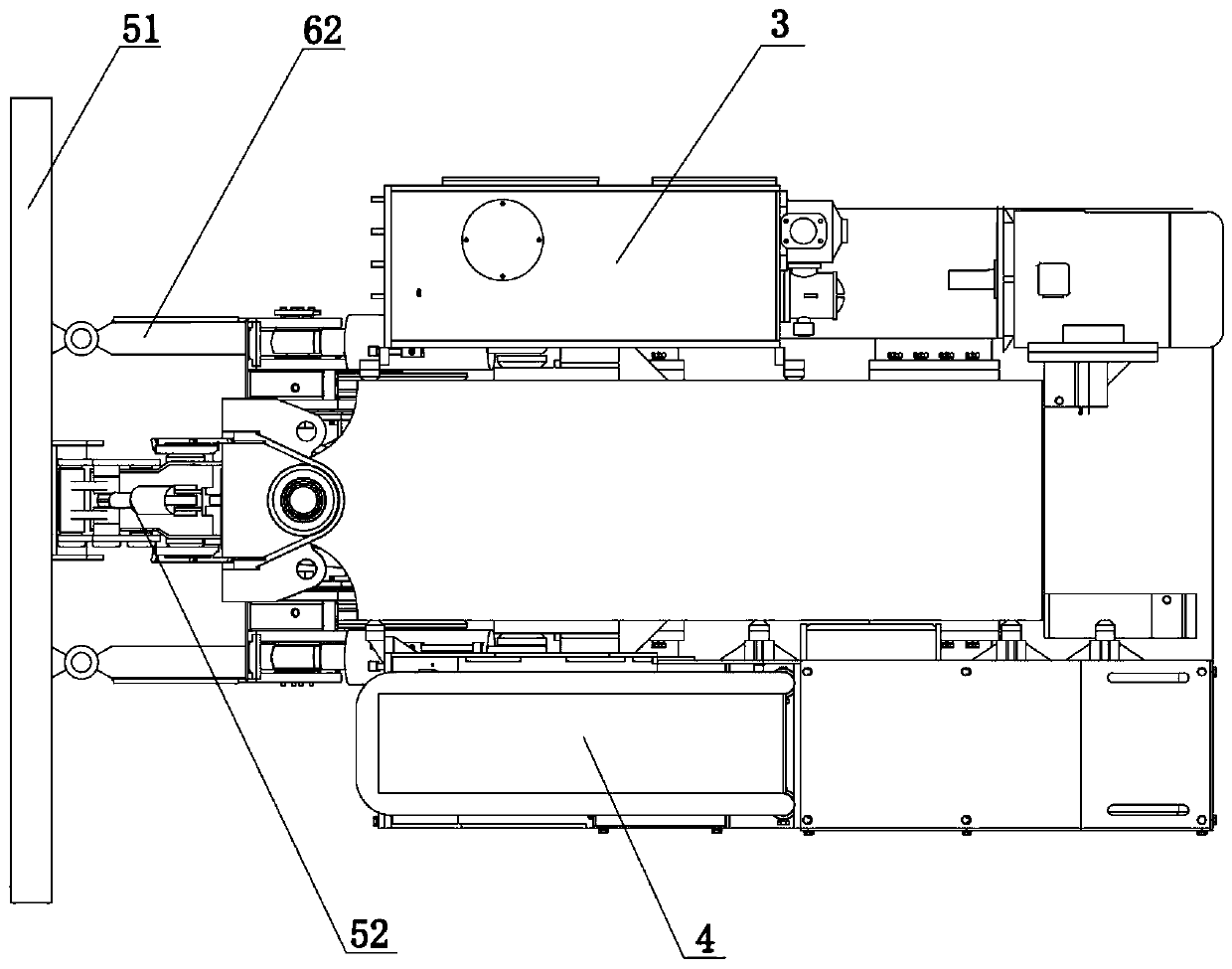

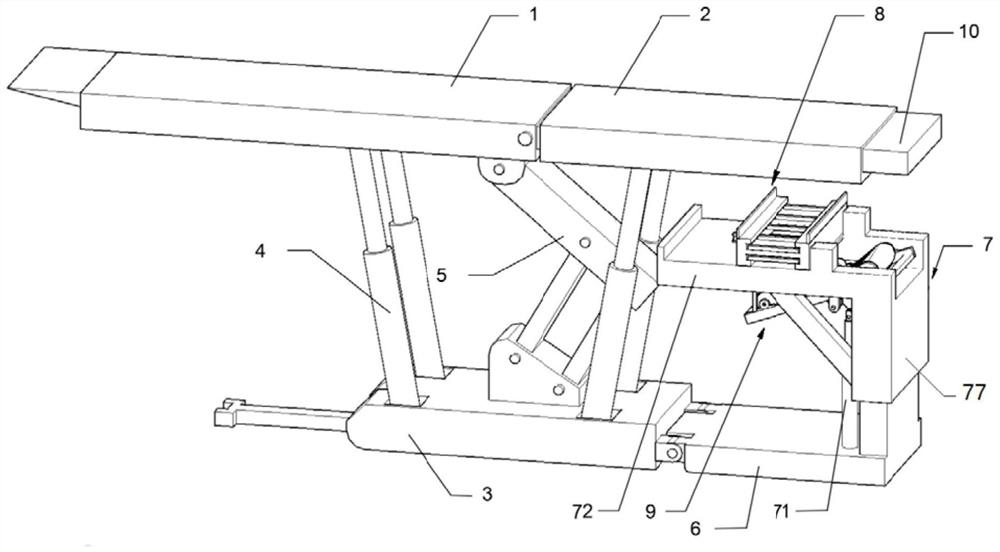

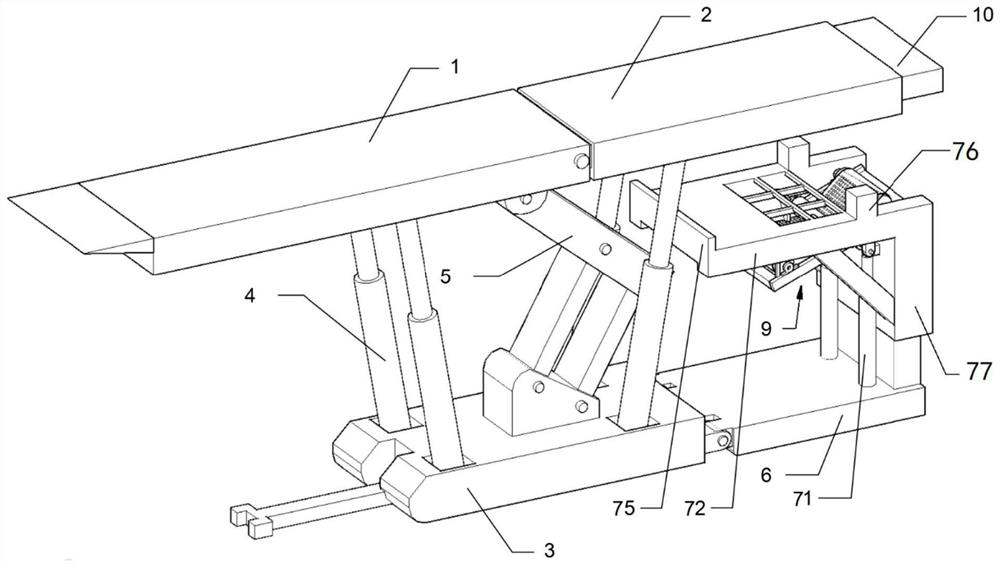

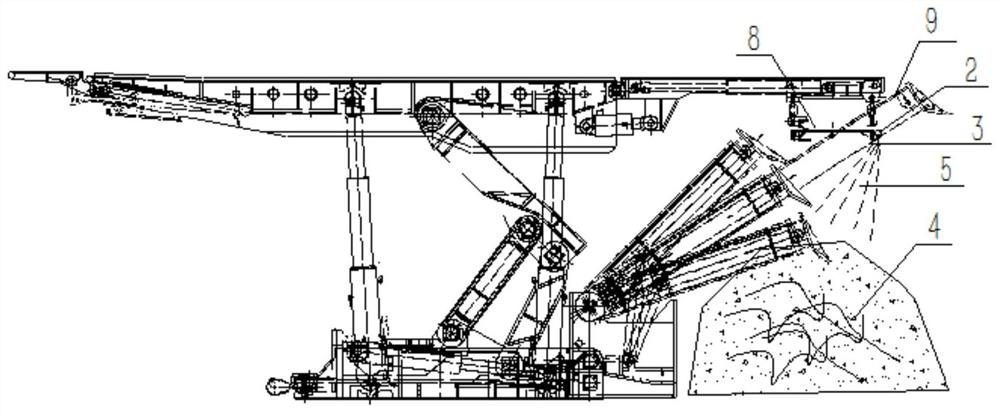

End slope mining goaf filling machine and filling method thereof

ActiveCN111520185AAutomate fillingFulfill filling needsMaterial fill-upMining engineeringHydraulic pump

The invention discloses an end slope mining goaf filling machine and a filling method thereof, and relates to the technical field of coal mine goaf gangue filling. The end slope mining goaf filling machine comprises a crawler walking part, a machine body, a driver control room, a hydraulic pump station, an upper push plate mechanism and a lower push plate mechanism. According to the disclosed theend slope mining goaf filling machine and the filling method thereof, roadways and large-section goaf after open-pit mine end slope mining can be filled, automatic goaf roadway filling is realized, and compacting and solidifying operations on filling materials can be carried out, so that the filling rate of the filling materials is ensured, the top contact rate of the filling materials is improved, the filling effect is enhanced, the problems of uneven filling, roof descending and the like are effectively prevented; and meanwhile, the filling machine is high in maneuverability, can be used incooperation with other conveying and filling equipment for open-pit mine end slope mining, further saves the filling cost, improves the filling effect, and has high innovativeness and wide practicability.

Owner:CHINA UNIV OF MINING & TECH

Filling material suitable for waste underground civil air defence hole treatment and preparation method thereof

The invention discloses a filling material suitable for waste underground civil air defence hole treatment and a preparation method thereof. The filling material is characterized by being prepared from, by weight, 40-60 parts of cement, 15-35 parts of solid waste, 0.5-2 parts of water repellent, 0.1-0.3 part of plasticizer, 21.5-36.5 parts of water and 0.05-0.5 part of foamer. The invention further discloses the preparation method of the filling material. The method includes the steps of preparation and transportation of a cement-based slurry commercial concrete stirring station, preparation of engineering field foam and field mixing of cement-based slurry and the foam. The filling material has the advantages that the strength of a filling body is improved, the filling effect is improved,the interference in surrounding buildings is effectively controlled, pollution to the construction environment is relieved, the solid waste is utilized to the maximum degree, the filling cost is reduced, and very high application and popularization value is achieved.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

A Comprehensive Filling and Roofing Method of Mining Route

The invention discloses a method for comprehensive filling and roofing of a mining approach, comprising: downhill construction of each mining approach, raising the roof at the head of the mining approach to form a sand chamber, and at the same time raising the roof at the entrance of the mining approach And erect the upper open filling retaining wall, the filling pipeline enters the mining approach from the top of the filling retaining wall, and erects along the roof of the mining approach to the sand chamber; when the mining approach is connected to the roof and filled, the natural slope of the mining approach roof is used and the slurry pressure in the filling pipeline to realize the filling and roofing. For the local uneven roof area, the local roofing is realized by the vibration of the filling pipeline; when the roof is filled, the roofing situation is easy to observe, and the filling and roofing process is simple. The cost is low, the requirements for filling the retaining wall are low, and the safety is good, which is convenient for popularization and application.

Owner:南京银茂铅锌矿业有限公司

Physical and chemical combined roof contact method for stope filling

ActiveCN113236354AImprove the top rateHigh filling efficiencyMining devicesDesign optimisation/simulationEngineeringStructural engineering

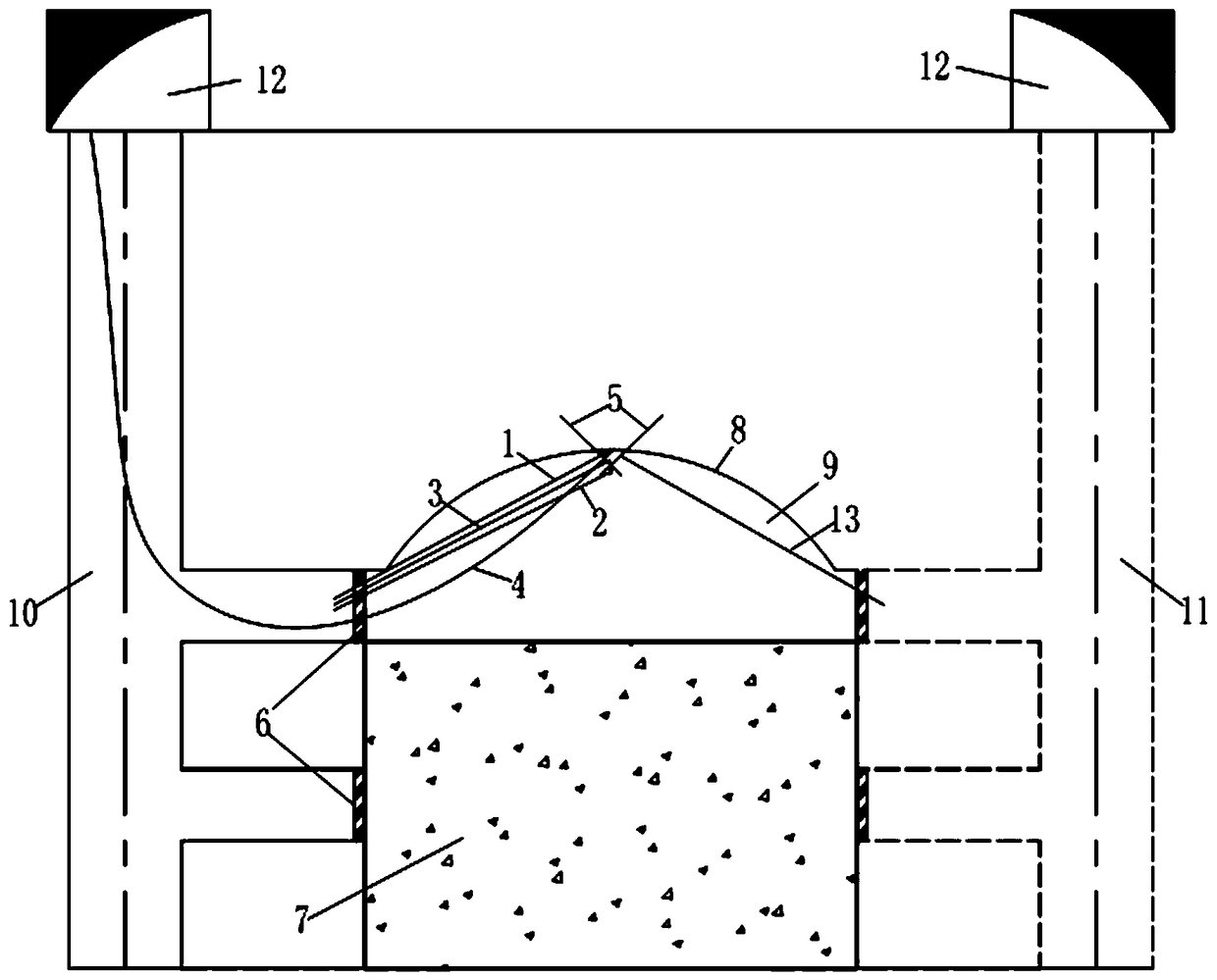

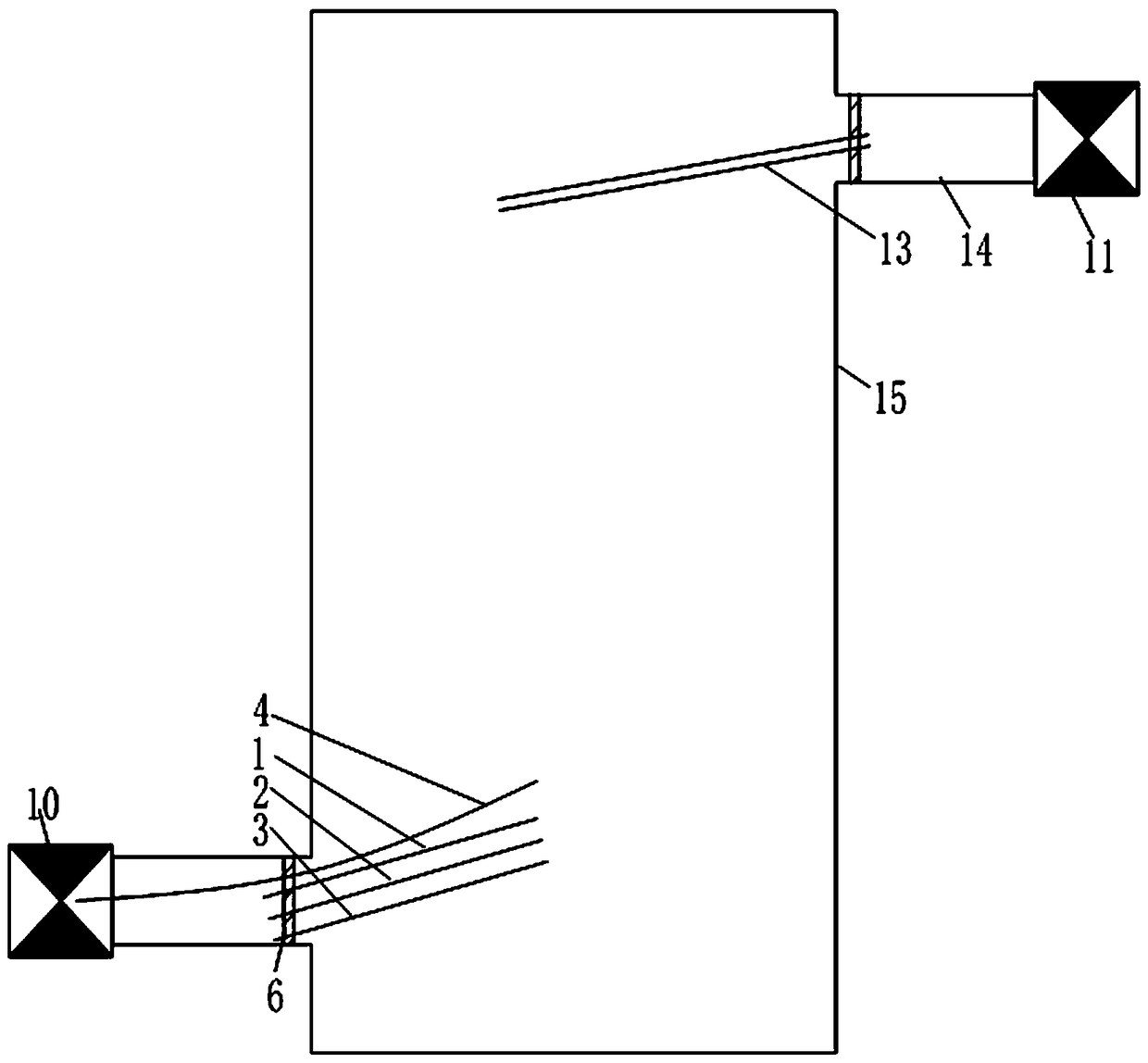

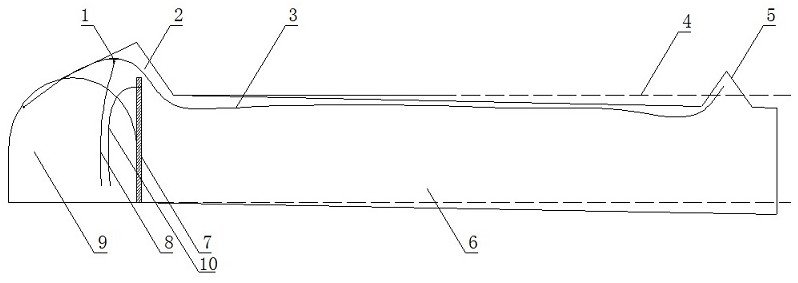

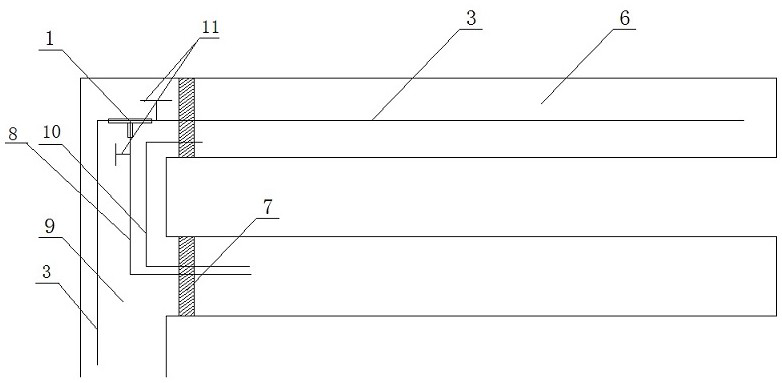

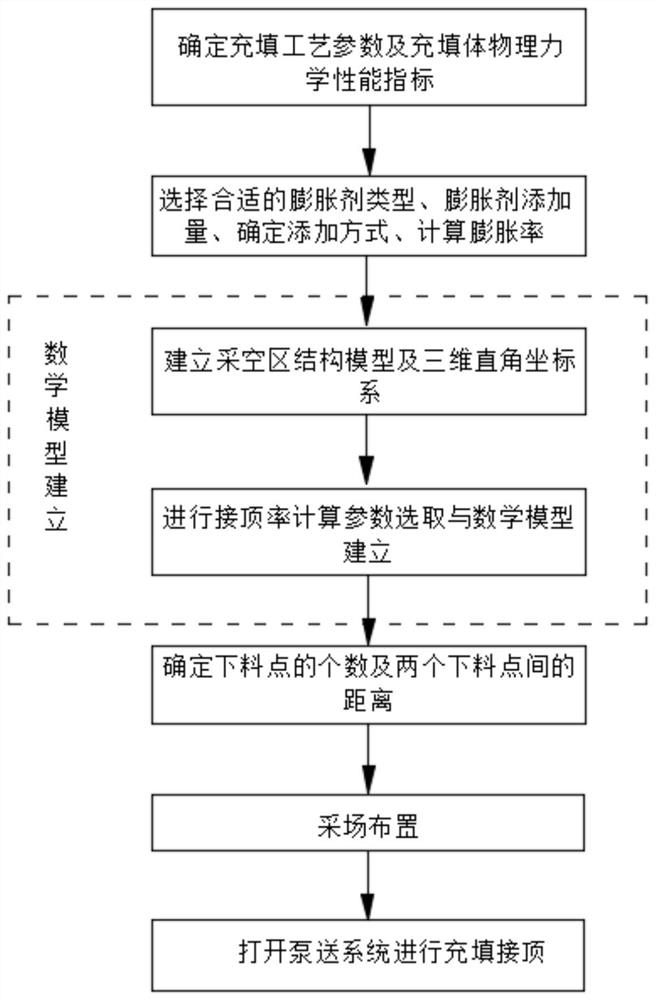

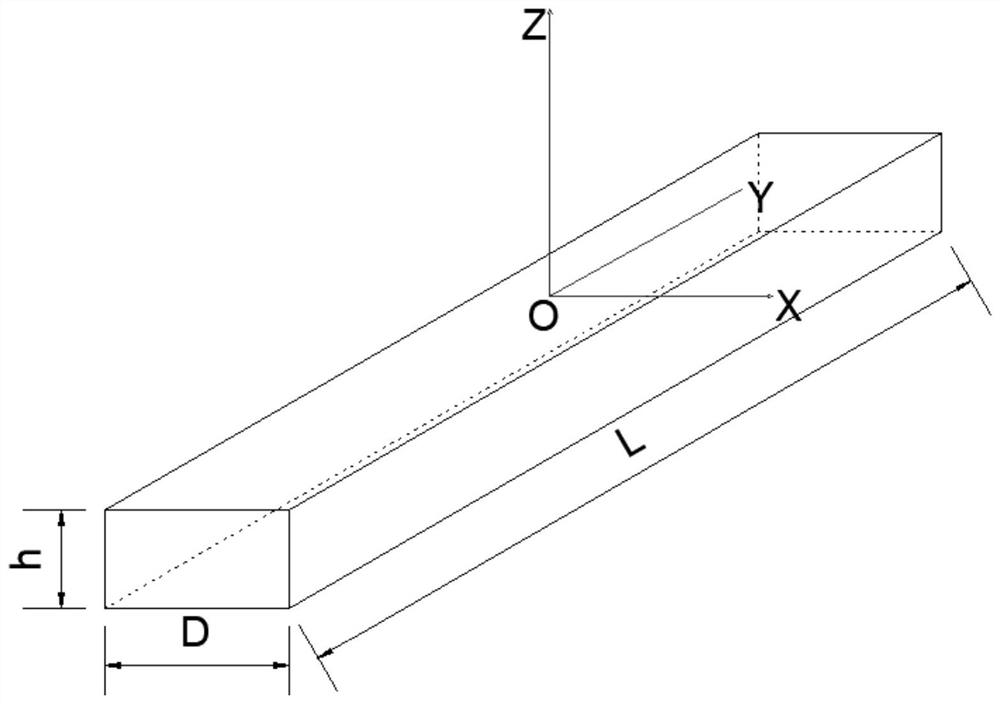

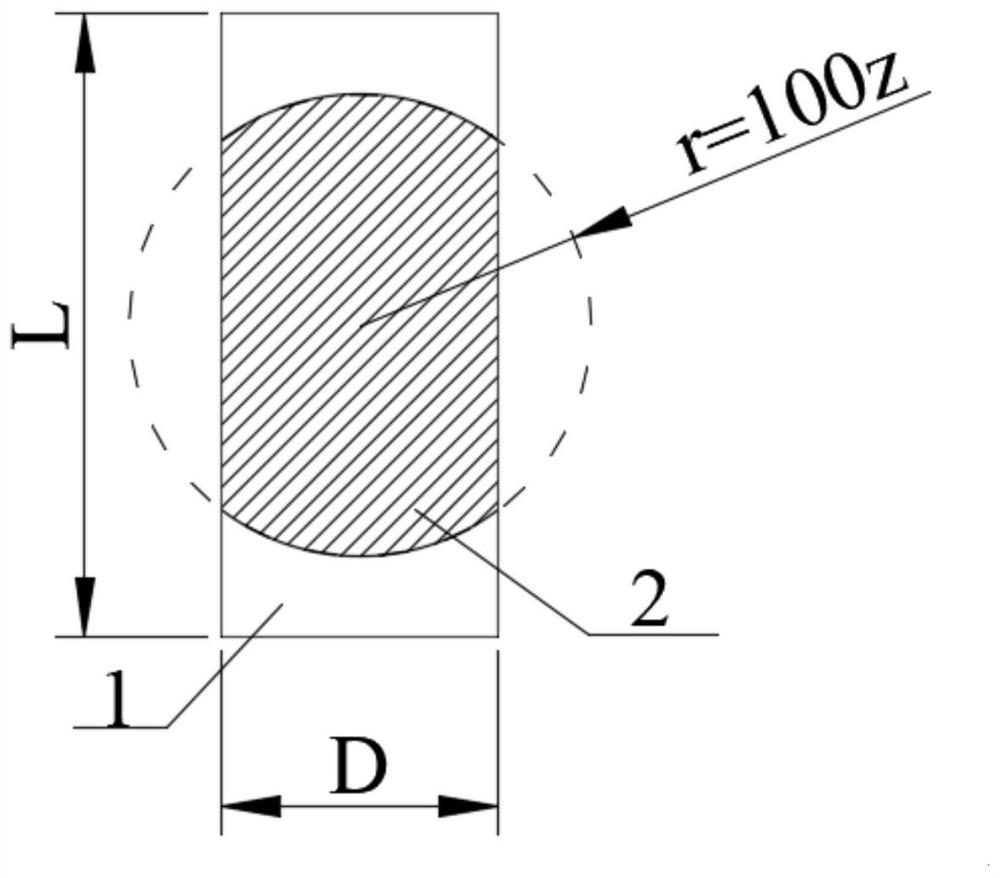

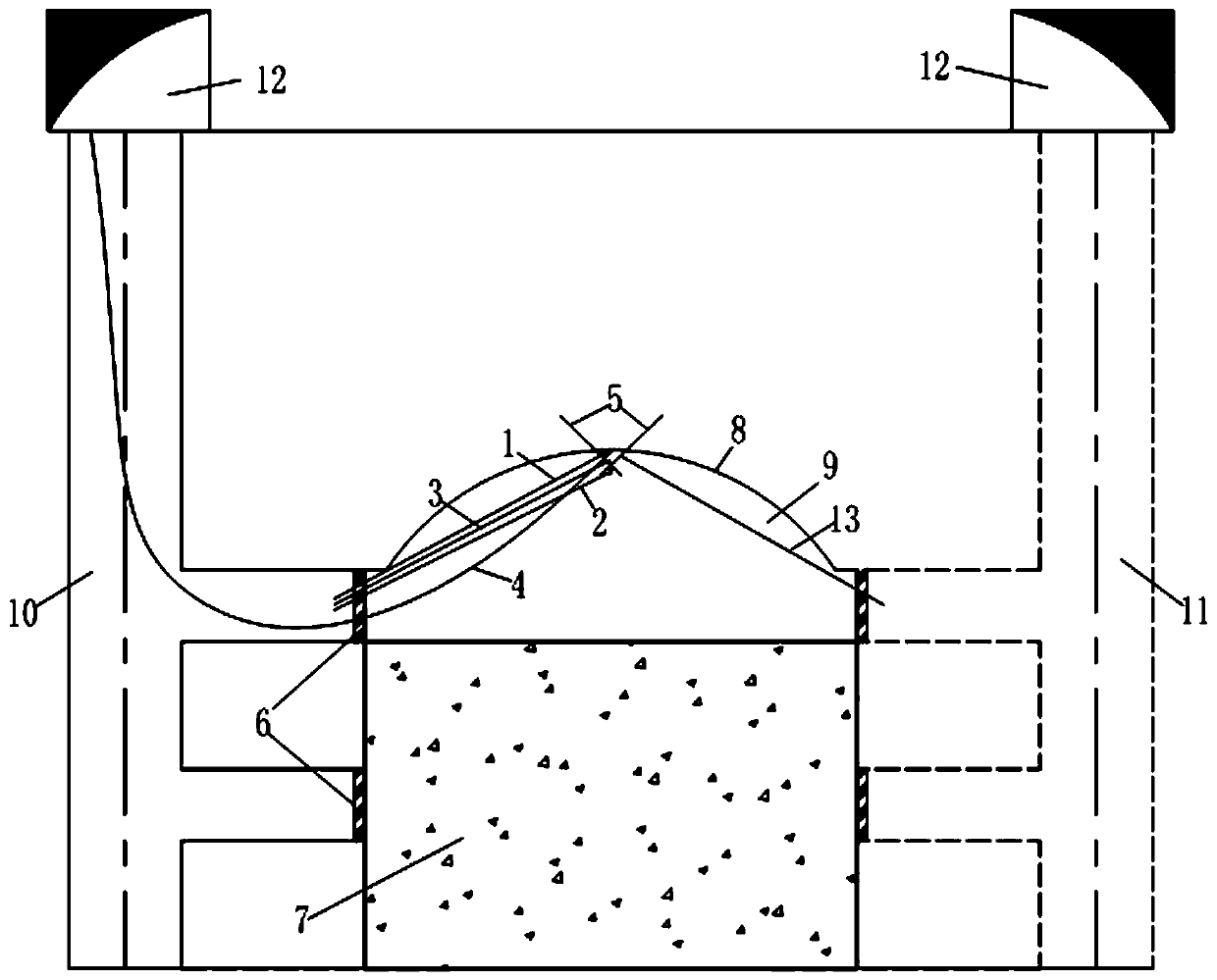

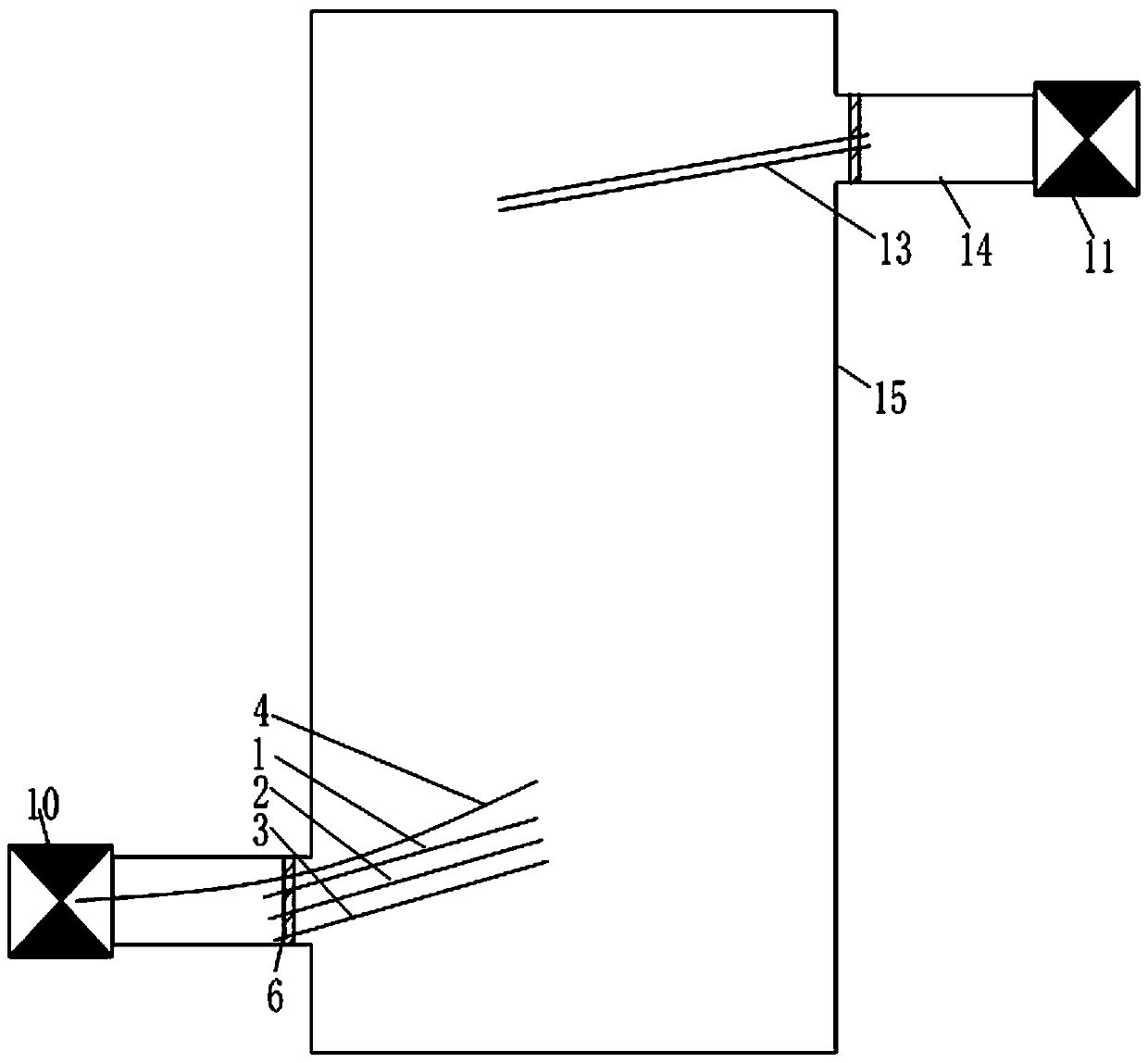

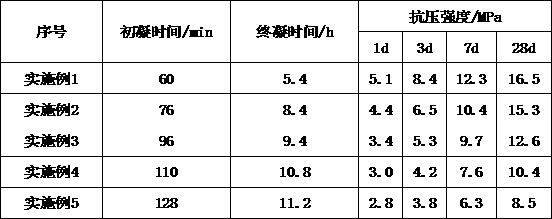

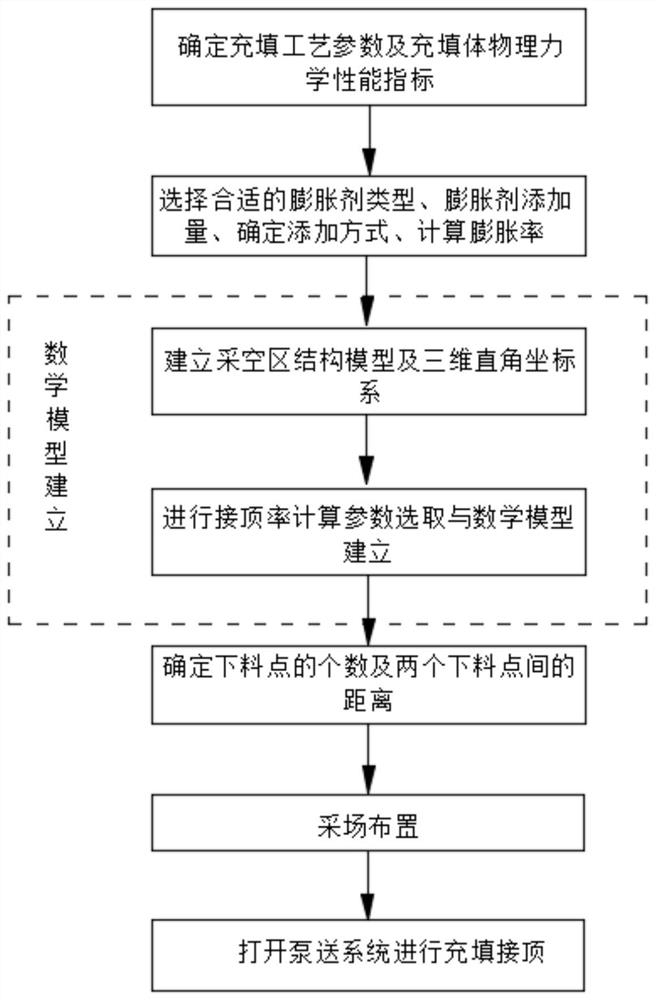

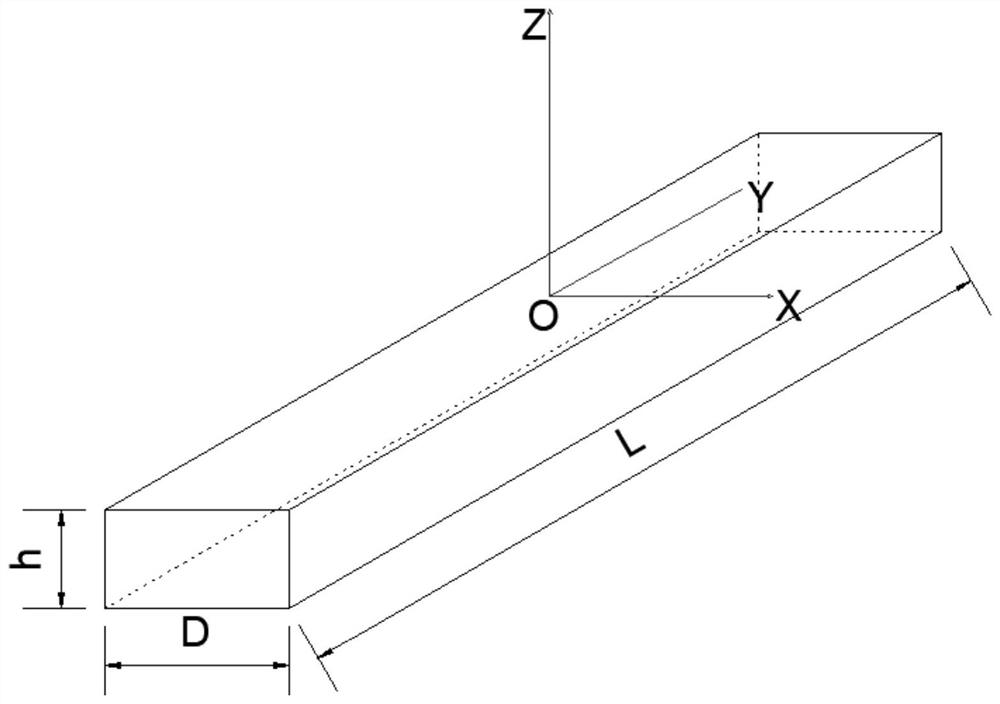

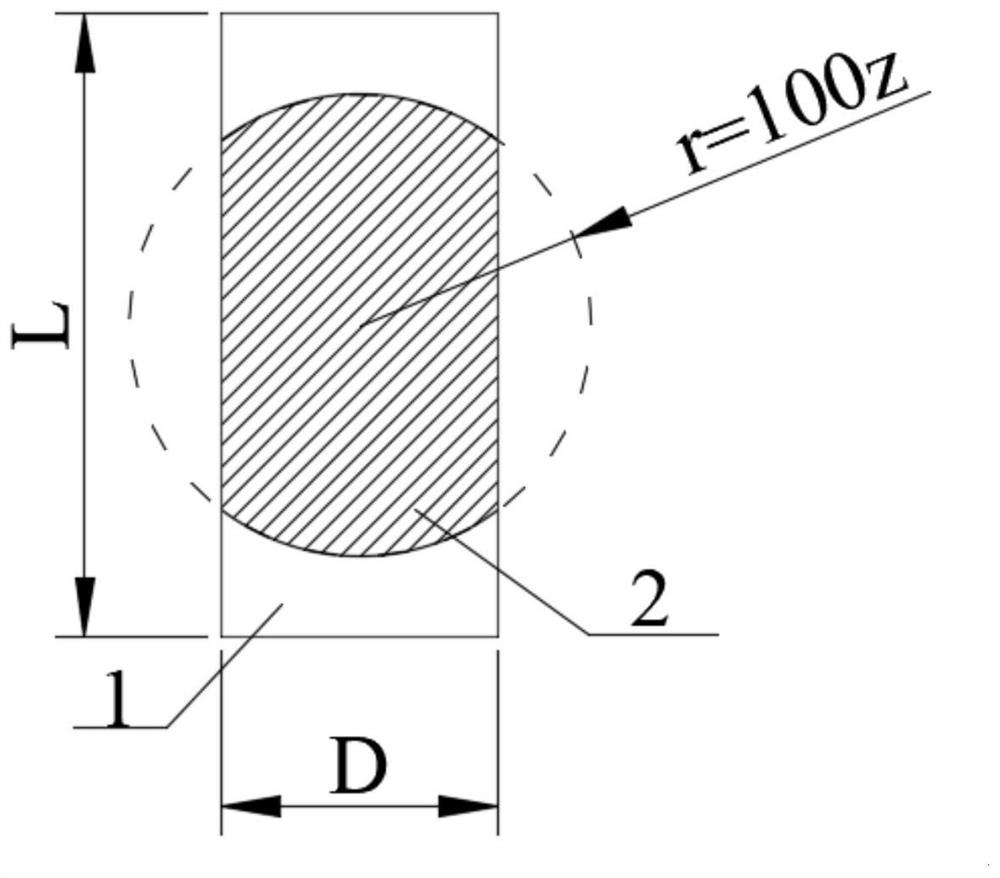

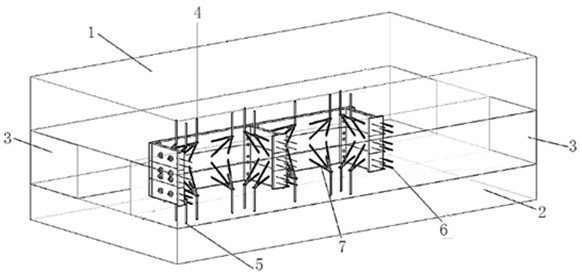

The invention provides a physical and chemical combined roof contact method for stope filling, and belongs to the technical field of filling. The method comprises the following steps of firstly, determining filling process parameters and physical and mechanical property indexes of a filling body according to actual production conditions of a mine, selecting a proper expanding agent type and an appropriate expanding agent addition amount, determining an expanding agent addition mode, and calculating an expansion rate; secondly, establishing a goaf structure model and a three-dimensional rectangular coordinate system according to goaf structure parameters, selecting roof contact rate calculation parameters, and establishing a mathematical model; then determining the number of blanking points and the distance between the two blanking points through comparison of different schemes according to the established roof contact rate mathematical model; and finally, arranging pipelines for filling roof contact. According to the method, a multi-point blanking method (physics) and an expanding agent adding method (chemistry) are fused to form a high-quality and high-efficiency filling roof contact method, the method has the advantages of safety, reliability and low cost and is suitable for roof contact of various mining methods, and the roof contact rate can be controlled and adjusted.

Owner:UNIV OF SCI & TECH BEIJING +1

A roof connection method for stope filling

The invention relates to the technical field of combustion water heaters, and relates to a roof contact method for stope filling. The roof contact method for the stope filling comprises the followingstep that a stope empty area is filled with slag to a certain height to obtain a residual empty area, the height of the residual empty area is measured, the position of the highest point is determined, a hollow anchor rod is installed at the highest point, and a filling pipe is installed on the hollow anchor rod; a first dewatering pipe and a dewatering pipe are installed at the highest point, anda third dewatering pipe and a second dewatering pipe are installed from top to bottom according to the height difference; and the opening between the residual empty area and an inlet or a connectingchannel is blocked, and then filling slurry is conveyed into the filling pipe to realize roof-contacted filling of the residual empty area. The roof contact method for the stope filling has the characteristics of realizing effective roof-contacted filling of the stope empty area, and effectively ensuring the strength of the stope empty area.

Owner:GUANGXI ZHONGJIN LINGNAN MINING CO LTD

A pile-type filling formwork and its application method

The invention discloses a stack column type filling formwork and a using method thereof. The stack column type filling formwork is arranged below a top plate, supporting frames spliced together define a cuboid frame structure on the periphery, single supporting frames or integrated bodies formed by single-side-spliced supporting frames are arranged on the two opposite faces of the formwork respectively, and every two adjacent faces are formed by perpendicularly splicing supporting frames at the edges. Each supporting frame is composed of a baffle, framework sleepers and counter-pulled anchor ropes, wherein the framework sleepers are composed of a plurality of parallel transverse sleepers and three parallel vertical sleepers, the transverse sleepers and the vertical sleepers are arranged in a perpendicularly crossing mode, and the counter-pulled anchor ropes are arranged on the vertical sleepers in the formwork center on each side. The framework sleepers make direct contact with the top plate after being spliced to support the top plate. A filling opening is formed in the upper portion of the part, on one side of the formwork, of the baffle. After filling of the formwork, the overall compressive strength of filling columns is improved, the later compression amount of the filling columns is reduced, and the top sinking amount is reduced.

Owner:TAIYUAN UNIV OF TECH

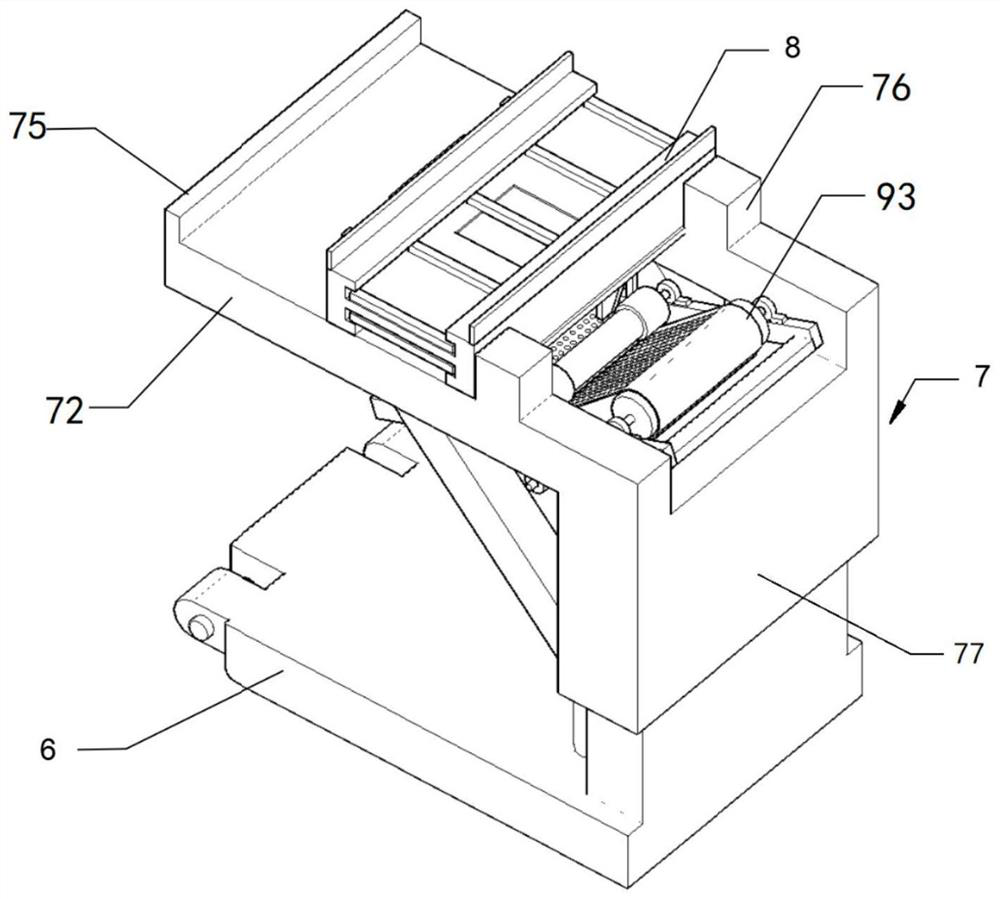

Fully-mechanized coal mining supporting and throwing type gangue filling hydraulic support

PendingCN113685214AImprove filling efficiencyImprove fill rateMaterial fill-upMine roof supportsThermodynamicsIndustrial engineering

The invention provides a fully-mechanized coal mining supporting and throwing type gangue filling hydraulic support. The installation mode of a bottom unloading scraper conveyor on the rear portion of a traditional fully-mechanized coal mining gangue filling hydraulic support is changed into a bearing mode from a hanging mode, the degree of freedom of the scraper conveyor on a bearing platform is greatly increased, chain ring connection between the scraper conveyor and the hydraulic support is avoided, and the hydraulic support is not affected by the width of a working face; and meanwhile, the width of a fully-mechanized coal mining gangue filling working face is increased, the structure and the size of a gangue throwing belt conveyor are optimized, the gangue filling efficiency and the filling roof contact rate are improved, the frame tail filling empty roof distance is reduced, and the gangue throwing inclination, the gangue throwing speed, the gangue throwing height and the gangue throwing distance are improved.

Owner:中煤能源研究院有限责任公司

A mixed filling method of gangue and high-water materials

ActiveCN109826665BImprove the top rateImprove compactnessMaterial fill-upMining engineeringFilling materials

The invention discloses a method for mixing and filling gangue and high-water materials, which utilizes the high-water materials to supplement the filling gaps of the gangue, thereby achieving compactfilling and bearing a top plate of a goaf. The method comprises the following steps: step 1), a filling retaining wall is arranged on one side of a working face transportation roadway in a way of filling the high-water materials in bags after a filling connection roadway is dug and mined based on a long wall production system; step 2), high-water material filling pipelines is arranged on two sides of the filling connection roadway and the top plate; step 3), the gangue is thrown to the goaf; step 4), a high-water filling material retaining wall is arranged on one side of a working face returnairway after the gangue is thrown, an overflow hole is reserved, and the high-water filling materials are injected into the goaf for filling through reserved filling pipelines; step 5), the reservedoverflow hole is detected. Slurry overflow indicates that the filling is completed and stopped; step 6), the next mining and filling cycle is carried out at an interval of three filling connection roadways and coal pillars. The method effectively reduces the ground surface subsidence value of the mining area of the working face, and simultaneously greatly improves the roof connection rate and thecompactness of the filling body of the goaf.

Owner:CHINA UNIV OF MINING & TECH

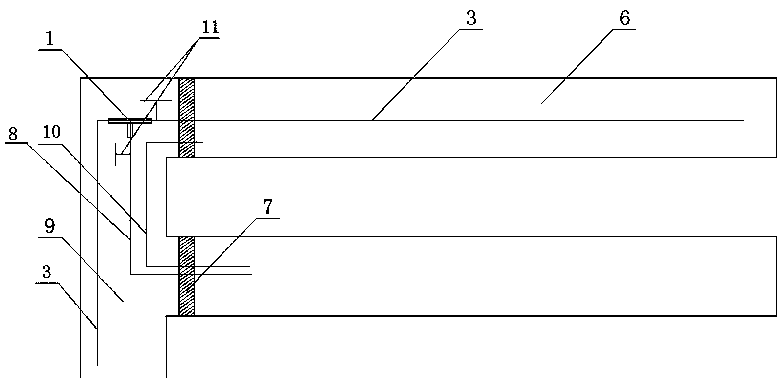

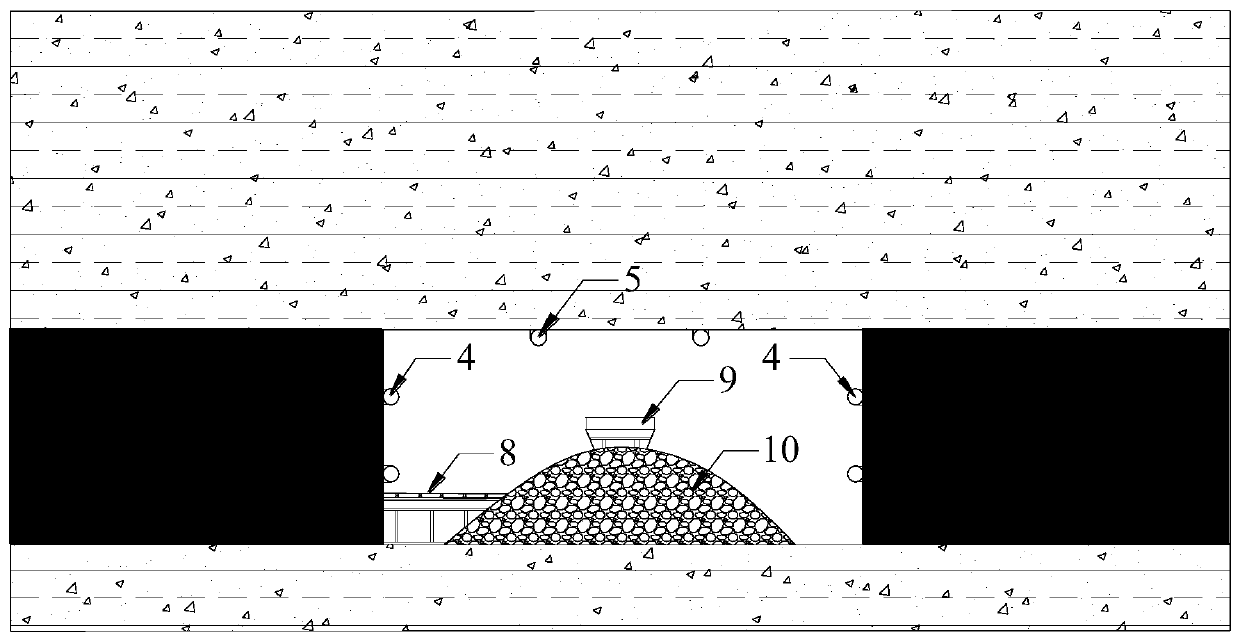

Back waste rock throwing guniting filling system and method based on fully-mechanized mining frame

The invention provides a rear waste rock throwing, guniting and filling system and method based on a fully-mechanized coal mining frame, and belongs to the field of coal mining. The rear waste rock throwing, guniting and filling system comprises at least one fully-mechanized coal mining waste rock throwing support capable of being arranged in a coal mining working face, and a tamping assembly is arranged on the side, close to a space to be filled, of each fully-mechanized coal mining waste rock throwing support; a scraper conveyor is arranged at the lower end of a rear beam of each fully-mechanized coal mining waste rock throwing support, a spray head is arranged on one side, close to a space to be filled, of each scraper conveyor, and each spray head is communicated with a slurry conveying pipeline; the method has the beneficial effects that the filling efficiency and the roof contact rate of the filling process of the original waste rock behind the fully-mechanized mining frame can be improved.

Owner:XINWEN MINING GROUP

A green treatment method for abandoned underground air defense tunnels

ActiveCN108316346BHigh strengthControl interferenceArtificial islandsUnderwater structuresSludgePipe

The invention discloses an environment-friendly handling method for an abandoned underground air raid shelter. The environment-friendly handling method is characterized by comprising the following steps that before filling, after field accumulated water is pumped and ventilation arrangement is completed, a curing agent is sprayed onto sludge from outside to inside in the channel direction, a powerful stirring head and a high-pressure water gun are combined and adopted to stir the sludge on site, and consolidated soil is formed; then, filling units are divided from inside to outside in the channel direction, a drill bit is adopted to drill the ground at the two ends of each unit downwards to penetrate through the arched top of the air raid shelter, light aggregate concrete is poured throughguide pipes, and end sealing walls are formed; the positions nearby the middles and two ends of the filling units are drilled to form filling holes and observing holes; finally, filling is conductedfrom bottom to top through the filling holes between every two sealing walls, the periphery and the top is subjected to filling in sequence, and materials are filled gradually from the low portion tothe high portion; and after the unit is filled, filling of the next unit is conducted. The environment-friendly handling method has the advantages that the strength of the filling body is improved, the filling effect is improved, disturbance to surrounding buildings is effectively controlled, the construction environment pollution is reduced, and visualization of the filling process is achieved.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

A medium-thick ore body trapezoidal top pillar staged rock drilling stage open field followed by filling mining method

ActiveCN113565506BImprove securityFilling and topping quality assuranceUnderground miningSurface miningMining engineeringRock cutting

The invention discloses a medium-thick ore body trapezoidal top pillar staged rock drilling stage open field followed by filling mining method, the ore blocks are arranged along the ore body trend, and the ore block is divided into a one-step stope and a two-step stope. One-step stope and use high-strength backfill to fill the goaf, one-step stope to form trapezoidal top pillars to facilitate filling and topping, one-step stope backfill strength reaches the design index and then recover the second-step stope, two-step stope After the stope is mined, it is filled with low-strength backfill. The invention has the advantages of simple stope filling and capping process, guaranteed capping quality, high capping rate, and can effectively improve the safety of two-step stope mining.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST +1

A kind of wet ash discharge base filling material and its preparation method and application

The invention relates to the technical field of mine filling materials, in particular to a wet ash discharge-based filling material and a preparation method and application thereof. The filling material includes the following components: 50-150 parts of gel material, 10-20 parts of activator, 2-5 parts of water retention and dispersant, 0.5-1.5 parts of water reducing agent, 0.5-1.5 parts of air-entraining agent, and swelling agent 0.5-1.5 parts; wherein, the gel material is composed of the following components by weight: 60-80 parts of wet fly ash, 10-20 parts of dry fly ash, and 10-20 parts of cement. In the present invention, wet discharge fly ash is used as the main gel material, and dry discharge fly ash and cement are used as auxiliary gel materials. A mine filling material with high stone body strength, good fluidity, good water retention, good suspension and dispersion, micro-expansion, easy transportation, low cost, environmental protection and energy saving is prepared.

Owner:山东塔罗斯智能装备有限公司

A New Method of Exploiting Overburden Minerals in Side Side of Open Pit Mine

ActiveCN109026006BImprove the top rateIncrease compaction rateUnderground miningSurface miningMining engineeringMineralogy

The invention provides a new method for mining an open-pit mine sidewall mineral below construction. The new method comprises: dividing each ore layer of the open-pit mine sidewall mineral below construction into a plurality of linear mining caverns along the inclination or trend of an ore body according to set width and height, and numbering in sequence; using mining equipment to first mine odd or even mining caverns, reserving odd or even mining caverns between even or odd mining caverns as ore pillars, performing mining-filling parallel operation on even or odd mining caverns, and filling the mined mining caverns in sequence after satisfying a filling space; when fillings in two adjacent mining caverns are solidified, then mining a mining cavern between the two adjacent mining caverns,and also performing mining-filling parallel operation on mining caverns to be mined later until multi-segment mining and filling of the various layers and thick ore bodies are completed. The mining method provided by the invention improves the strength of supporting a sidewall, reduces the risk of sidewall collapsing and landslide, has a high mineral recovery rate, and reduces pollution to environments such as atmosphere and soil.

Owner:内蒙古煤矿设计研究院有限责任公司 +1

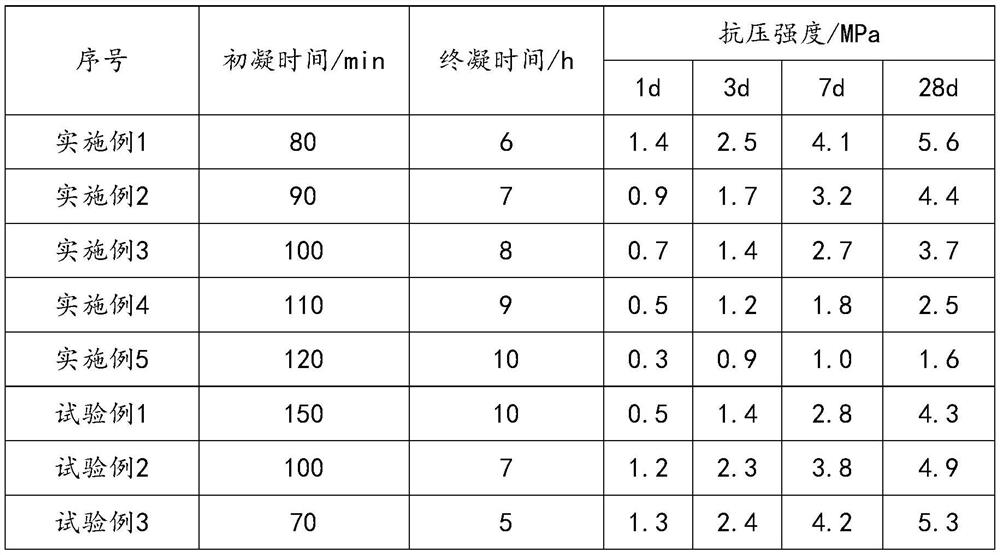

Optimizing method of phosphogypsum-based cementitious material to improve filling rate

ActiveCN111191387BLow costControl overexpansionDesign optimisation/simulationStrength propertiesProcess engineeringPhosphogypsum

The invention discloses an optimization method of a phosphogypsum-based cementitious material that improves the rate of filling and roofing. In the method, different ratios of phosphogypsum powders and activators are added to the filling aggregate to make cemented fillings with different ratios. Carry out the cemented filling body strength test and the filling body expansion rate test for the cemented filling body materials of different proportions, and obtain the test data of the cemented filling body strength and expansion rate of the cemented filling body materials with different proportions; adopt the quadratic polynomial Carry out stepwise regression analysis on the test data of the strength and expansion rate of the above-mentioned cemented filling body; take the 3d strength of the cemented filling body as the optimization goal, and take the 28d filling body expansion rate as the constraint condition, establish the ratio optimization model of the cementitious material; solve According to the above optimization model, the optimal proportion of the phosphogypsum-based cementitious material in the filling slurry can be obtained. This design method can realize low-cost and high-value resource utilization of phosphogypsum; it can realize low-cost and high-value utilization of phosphogypsum in filling mining.

Owner:HEBEI IRON & STEEL GRP MINING +1

Proportion optimization method of phosphogypsum-based solid waste filling material to improve filling rate

ActiveCN110723952BTake advantage of self-expansionMaximize expansibilityChemical machine learningChemometricsMathematical modelProcess engineering

Owner:UNIV OF SCI & TECH BEIJING +1

Acidic slag-based filling material and preparation method thereof

The invention relates to the technical field of mine filling, in particular to an acidic slag-based filling material and a preparation method thereof. The filling material disclosed by the invention is prepared from the following raw materials in parts by weight: 50-150 parts of acidic slag, 30-40 parts of high-alkalinity powder, 10-20 parts of ultrafine active powder, 1-5 parts of an acid-base regulator, 1-5 parts of a dispersion adsorbent, 2-10 parts of an expansion component, 0.5-1.5 parts of a thickening and water-retaining agent and 0.5-1.5 parts of a retarding and water-reducing agent. The invention also provides the preparation method of the filling material. The acidic slag-based filling material has the characteristics of high stone strength, good fluidity, good water retention, good suspension dispersibility, easy transportation, low cost, environmental protection and energy saving.

Owner:山东坊能新动能科学研究院有限公司

A physicochemical combined roofing method for stope filling

ActiveCN113236354BAdd lessEffective control of deformation movementMining devicesDesign optimisation/simulationMining engineeringMathematical model

The invention provides a physicochemical combined roofing method for stope filling, belonging to the technical field of filling. In this method, firstly, according to the actual production situation of the mine, determine the filling process parameters and the physical and mechanical performance indicators of the filling body, select the appropriate type of expansion agent, the amount of expansion agent added, determine the addition method of the expansion agent, and calculate the expansion rate; secondly, according to the structural parameters of the goaf , establish the structure model of the goaf and the three-dimensional rectangular coordinate system, select the calculation parameters of the topping rate and establish the mathematical model; then according to the established mathematical model of the topping rate, through the comparison of different schemes, determine the number of cutting points and two The distance between the blanking points; finally arrange the pipeline, and perform filling and topping. The method combines the multi-point cutting method (material) and the adding expansion agent method (chemical) to form a high-quality and high-efficiency filling and topping method, which is safe, reliable, low in cost, and can control and adjust the topping rate. Topping work for various mining methods.

Owner:UNIV OF SCI & TECH BEIJING +1

A method of using a segmented sealing device for strip partial filling and mining

ActiveCN111335893BImprove the top rateImprove fill rateUnderground miningSurface miningMining engineeringRock bolt

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

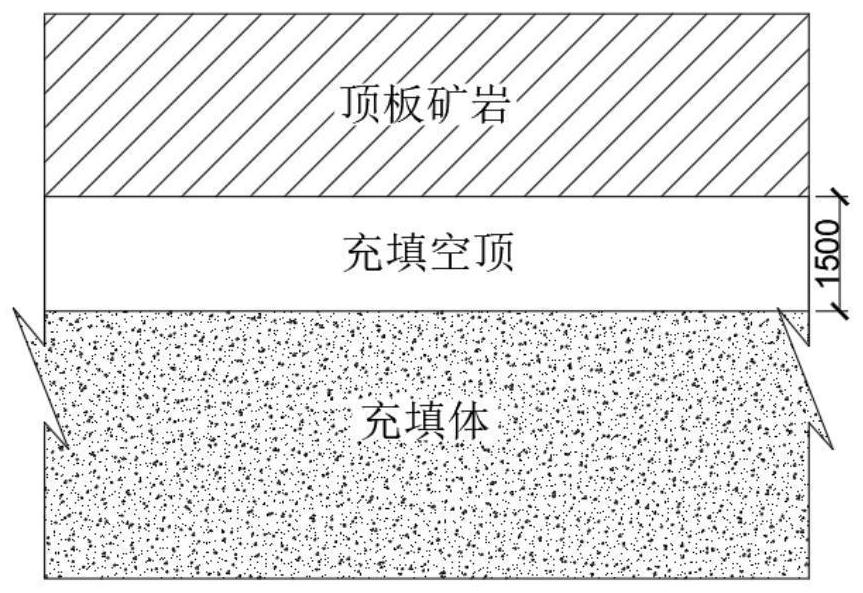

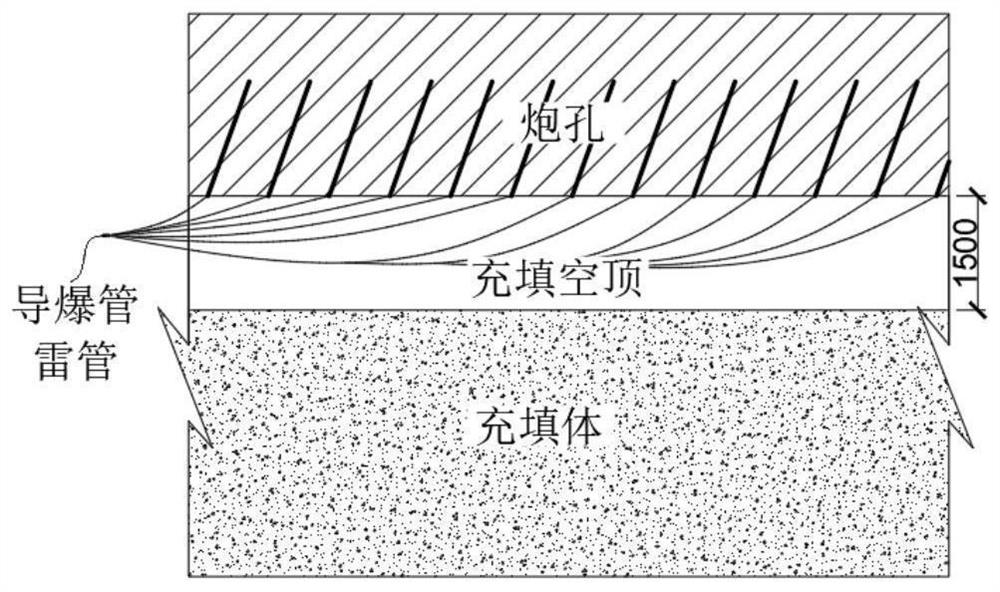

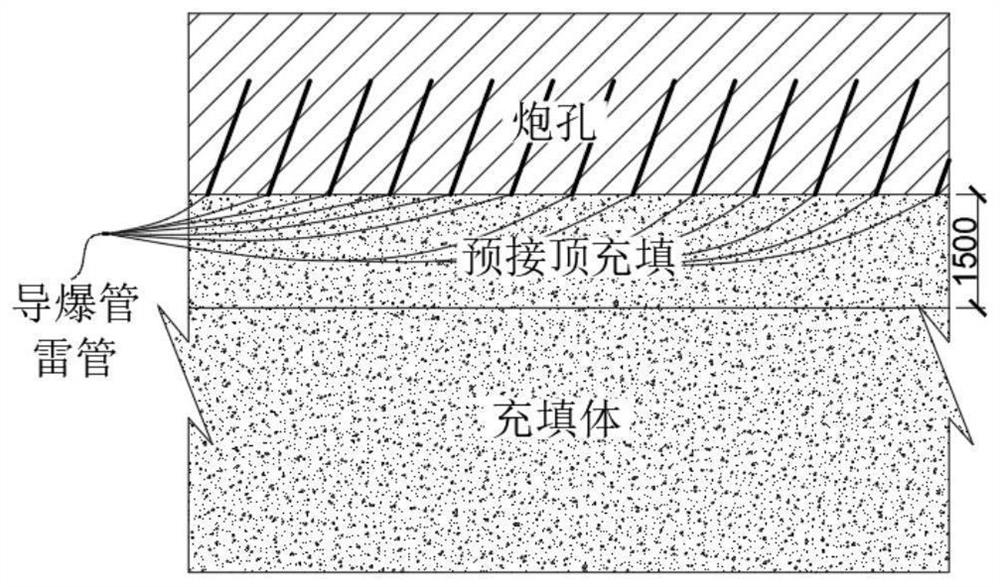

Filling roof-contacted method

InactiveCN114183194AMature technologyReduce difficultyDirectional drillingBlastingMining engineeringStructural engineering

The invention discloses a filling roof-contacted method, which comprises the following steps of: after stoping of a stope is finished, performing filling operation, and reserving an empty roof height relative to a top plate of the stope; when filling reaches the reserved empty roof height position, filling is stopped; after the filling body is solidified, upward blast holes are drilled in the top plate of the stope; charging explosives into the blast holes and connecting lines; the space with the reserved empty roof height is filled; and after the filling slurry is initially set, the blast holes are blasted, and roof contact is conducted through the broken expansion property of the blasted ore rock. According to the method, the hole arrangement range can be determined, the drilling depth of the top plate can be controlled and the top breaking range and the top breaking height can be adjusted according to the requirements of filling and roof-contacting, the adaptability is high, the roof-contacting rate is high, and the roof-contacting effect is good.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com