Comprehensive filling and roof-contacting method for stoping route

A technology of mining approach and filling slurry, which is applied to filling materials, mining equipment, earthwork drilling and mining, etc., can solve the problems of low application rate, long construction period, complicated process, etc., and achieve easy promotion, low filling cost, The effect of simple process and construction management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

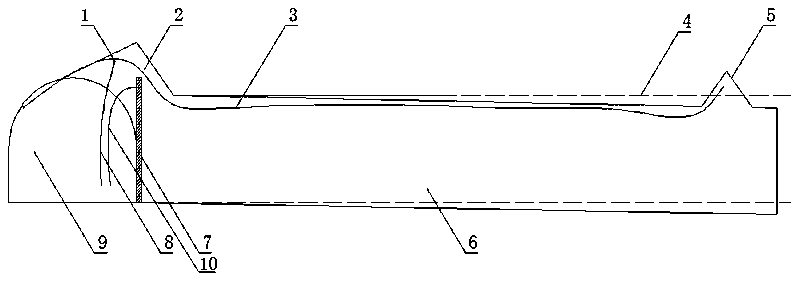

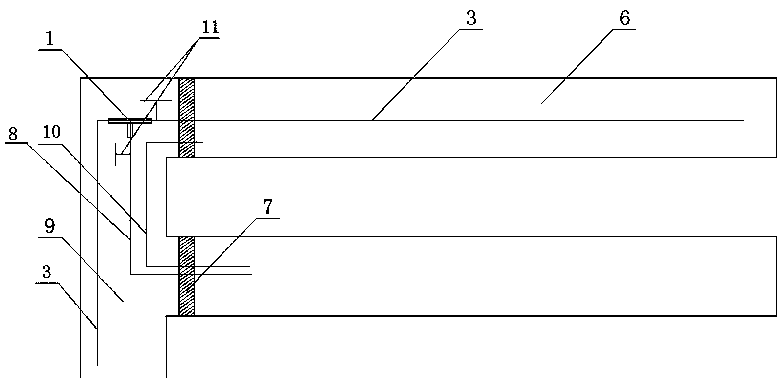

[0038] According to the attached Figure 1-2 The specific embodiment of the present invention is further described:

[0039] The comprehensive filling and roofing method of the mining approach proposed in this embodiment is as follows, see figure 1 and figure 2 :

[0040] (1) Each mining approach 6 in the stope or panel is constructed downward from the opening, with a slope of -1% to -5%, to ensure that the roof elevation at the head of the mining approach 6 is lower than the roof elevation at the opening of the mining approach 6 30cm to 60cm, if the length of the recovery approach 6 is less than 20 to 25m, a filling lane vertical to the direction of the recovery approach can be constructed at the head of each recovery approach to penetrate the adjacent 2 to 3 recovery approaches 6 .

[0041] (2) On the roof at a distance of 3 to 5 meters from the head of the mining access road 6, or at the roof at the middle point in the filling lane, lift the roof obliquely upwards to a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com