Patents

Literature

358results about How to "Lower filling costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

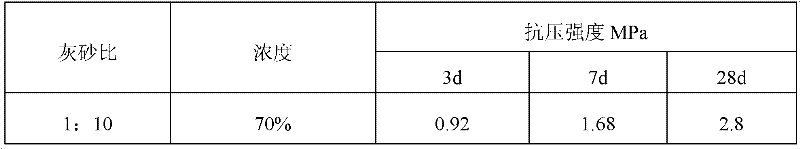

Cementing materials for filling, slurry and preparing and filling processes

InactiveCN1424275AReduce manufacturing costLess investmentSolid waste managementMaterial fill-upSlurrySulfur containing

A gelatining material similar to cream for filling underground working surface is preapred from the Ca-contained non-crystal and microcrystal material, alkali and / or sulfur contained exciting material, active material, aggregate and regulator. A filling slurry is prepared from said gelatining material, filling aggregate, fine particles, regulator and water through heating to at least 18 deg.C and proportional mixing.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +2

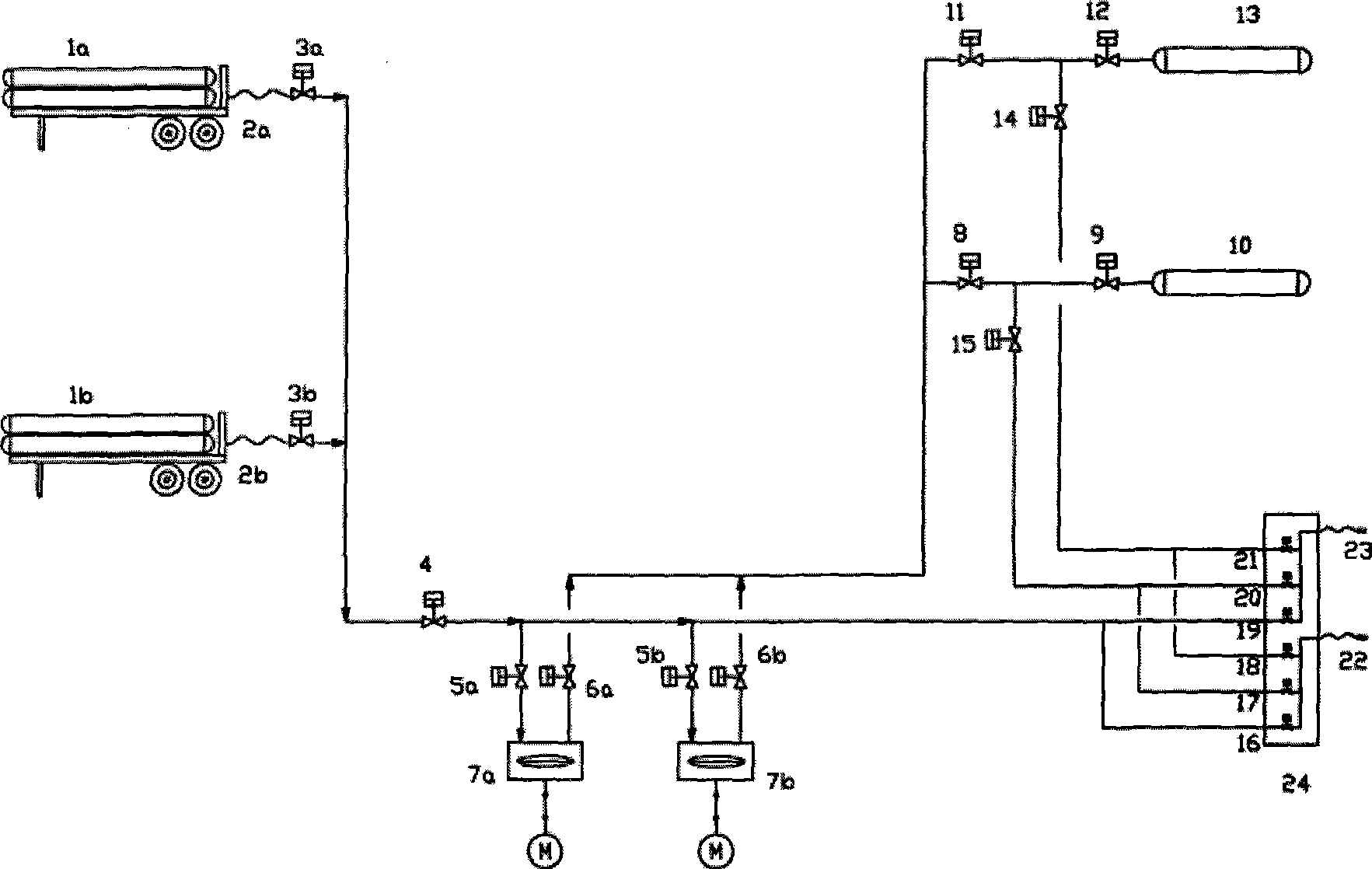

High-pressure hydrogen supply system for exterior hydrogen feeding hydrogenation stations

ActiveCN101418907ASimplified hydrogen supply processLow investment costContainer filling under pressureHigh pressure hydrogenData acquisition

The invention provides a high-pressure hydrogen supply system for an external supplying type hydrogen filling station, which can fill hydrogen fuel for fuel cell powered vehicles. The hydrogen supply system mainly comprises a pipe bundle hydrogen conveying vehicle, a fixed high-pressure hydrogen storage tank group, a parallel multi-compressor pressurizing system, a high-pressure hydrogen filling system, and a data acquiring, processing and safety monitoring system. The high-pressure hydrogen supply system takes the pipe bundle hydrogen conveying vehicle as a part of a hydrogen storage container of the hydrogen filling station and makes the pipe bundle hydrogen conveying vehicle a first stage of the staged hydrogen storage container, adopts the pressurizing system consisting of multiple compressors which are connected in parallel, and introduces the data acquiring, processing and safety monitoring system. The high-pressure hydrogen supply system has the advantages of adjustable hydrogen storage volume, large operation flexibility, cost conservation, convenient maintenance, high service efficiency and so on.

Owner:TONGJI UNIV

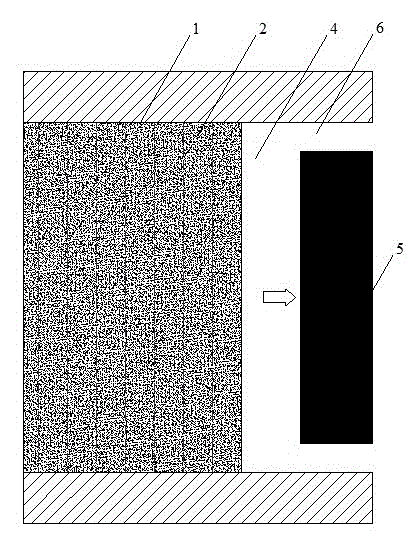

Sublevel fill-mining method

The invention discloses a sublevel fill-mining method. By utilizing the natural angle of repose characteristics of caving ores and dry mine fill and according to medium hole drilling device-adapted height and the ore-permitted exposed area, space and time at present, sublevel mining is carried out from the bottom to the top in the open-field state and the dry mine fill is adopted for filling in time. The sublevel fill-mining method has the advantages of an open-field method and a dry fill and sublevel caving method without sill pillar, thereby forming a novel sublevel dry fill-mining method without sill pillar, and is particularly applied to ore mines with large-scale ore body and high yield requirement. The top filling of a filling body is realized by the self-weight of the filling body; a vibratory roller or a device special for underground tamping is adopted to apply pressure to the filling body through a lane top plate to tamp the filling body in a vibration mode, so that the filling body generates a certain bearing force to the above ore body or the rock mass. The sublevel fill-mining method is a mining method which has the advantages of safety, high efficiency, high mining capacity, low loss and dilution, and low production cost.

Owner:HEBEI HAN XING INST OF MINE & METALLURGY DESIGN

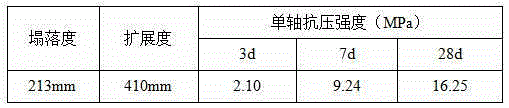

Mining foam paste filling material prepared by utilizing synergistic foaming method and preparation method thereof

ActiveCN103449837AReasonable allocation of resourcesLower filling costsCeramicwareFoaming agentActive component

The invention discloses a mining foam paste filling material prepared by utilizing a synergistic foaming method and a preparation method thereof, which are widely suitable for filling of coal mine gob areas, closure of laneways and construction of underground firewalls. The filling material comprises a component A and a component B, wherein the component A comprises an active component, a fine aggregate, a mineral foaming agent, an activating agent, a coagulant and the like; and the component B comprises a foaming agent, a foam stabilizing agent, a water reducing agent and the like. The key point is as follows: after fly ash is activated, the fly ash can be used for replacing part of cement for being used as a cementing material; and in addition, a concrete foaming technology is applied to the filling material, and the mineral foaming agent is innovatively applied to work in coordination with a concrete foaming agent for foaming, so that the foaming expansion performance, pumping performance and anti-seepage performance of the filling material are improved on the original basis, a gob area with a larger space can be filled under the condition of low cement consumption, and low consumption, environmental friendliness, energy conservation and easiness in pumping are realized.

Owner:ANHUI UNIV OF SCI & TECH

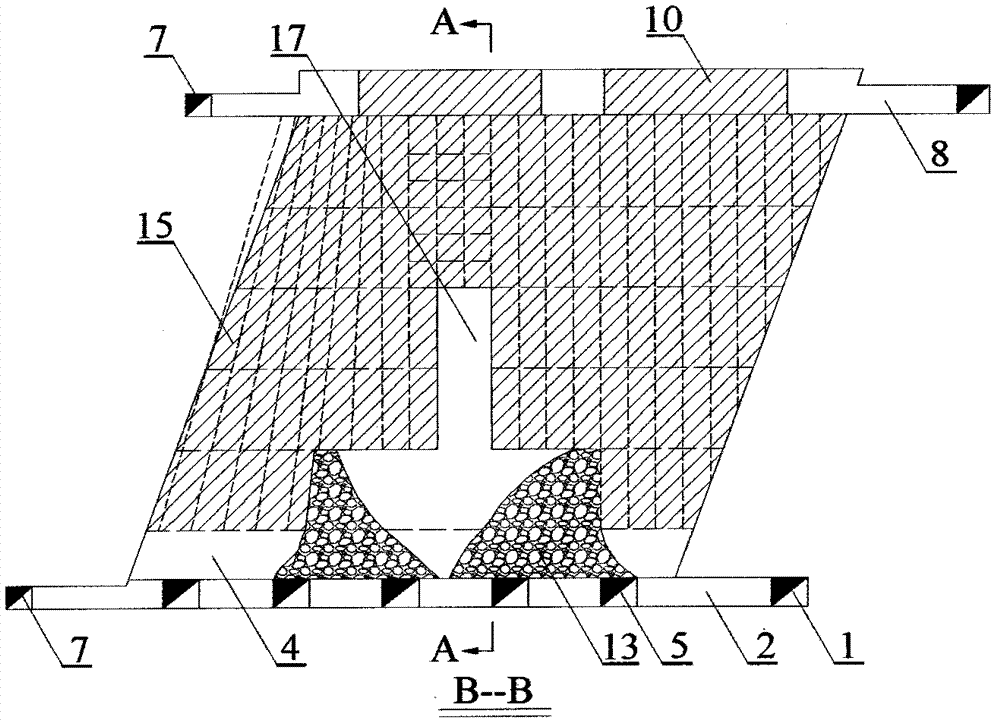

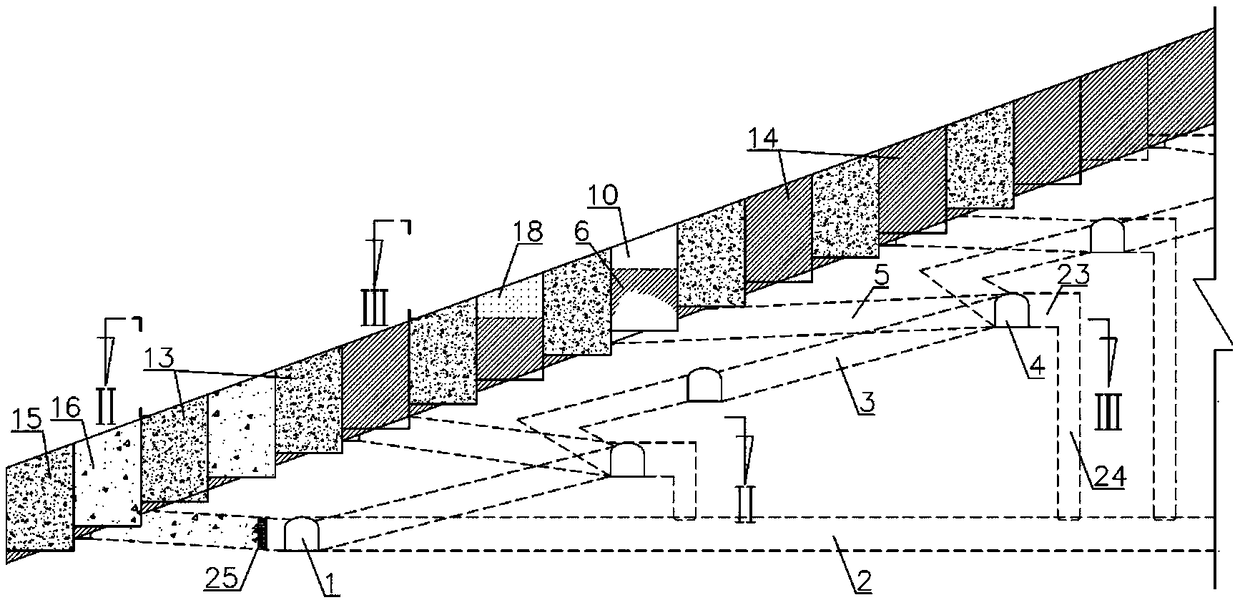

Room-and-pillar major-diameter longhole inverted-step-like segmented lateral caving subsequent filling mining method

InactiveCN102953732AImprove mining safetyGood for stope stabilityUnderground miningSurface miningRoom and pillar miningSingle stage

The invention discloses a room-and-pillar major-diameter longhole inverted-step-like segmented lateral caving subsequent filling mining method for a steeply-inclined medium-thick orebody and gently-inclined and inclined extremely-thick orebodies with steady surrounding rocks at upper and lower panels. The method is characterized in that: an orebody is divided into panels, then the panels are divided into continuous single-stage stoping units, and mining is carried out by using a stoping sequence of stoping one unit every other unit, i.e., mining a room at first and a pillar next; when mining a room, a V-shaped trench bottom structure is employed, a longhole drilling chamber is arranged at the upper part of stope, bar-shaped pillars are left to support the top plate of the chamber, a down-the-hole drill is used for drilling rocks, an explosion mode of light section VCR method underholing inverted-step-like lateral caving with a common emulsion explosive is employed, access roads towards the room for ore removal are arranged in the pillars, and cemented roof-contact filling is employed; and during stoping of the pillars, access roads for ore removal are dug towards the pillars in cemented bodies in the room, a stoping manner for the pillars is identical to that for the room, and non-cemented filling with tailings and waste is employed. The method provided by the invention has the advantages of high security, a low production cutting ratio, great production capacity, low operation cost and small loss and dilution of resources.

Owner:彭康

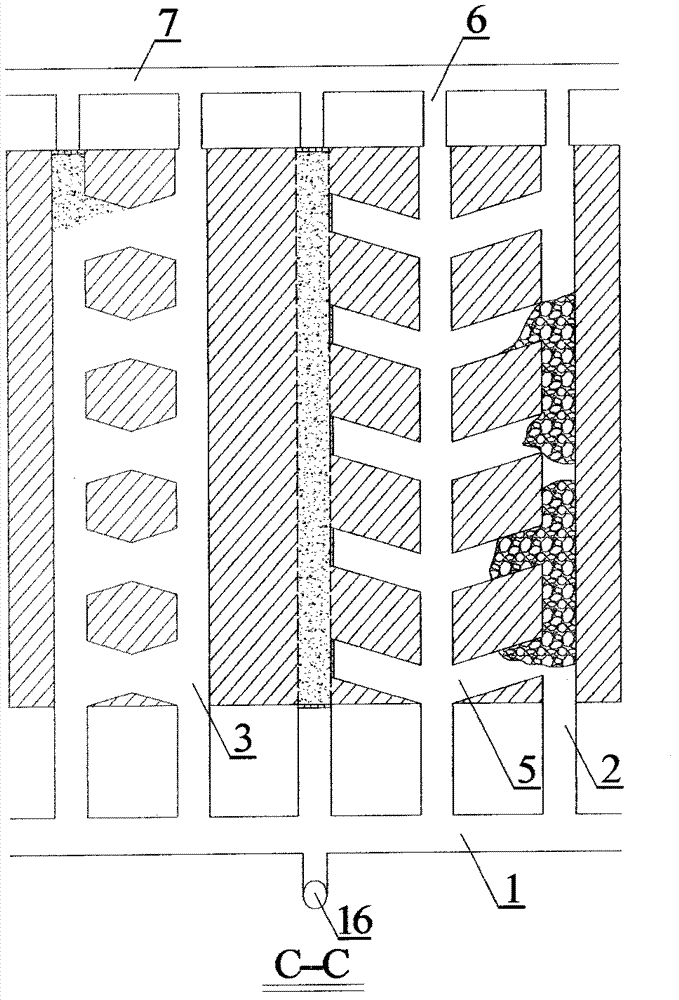

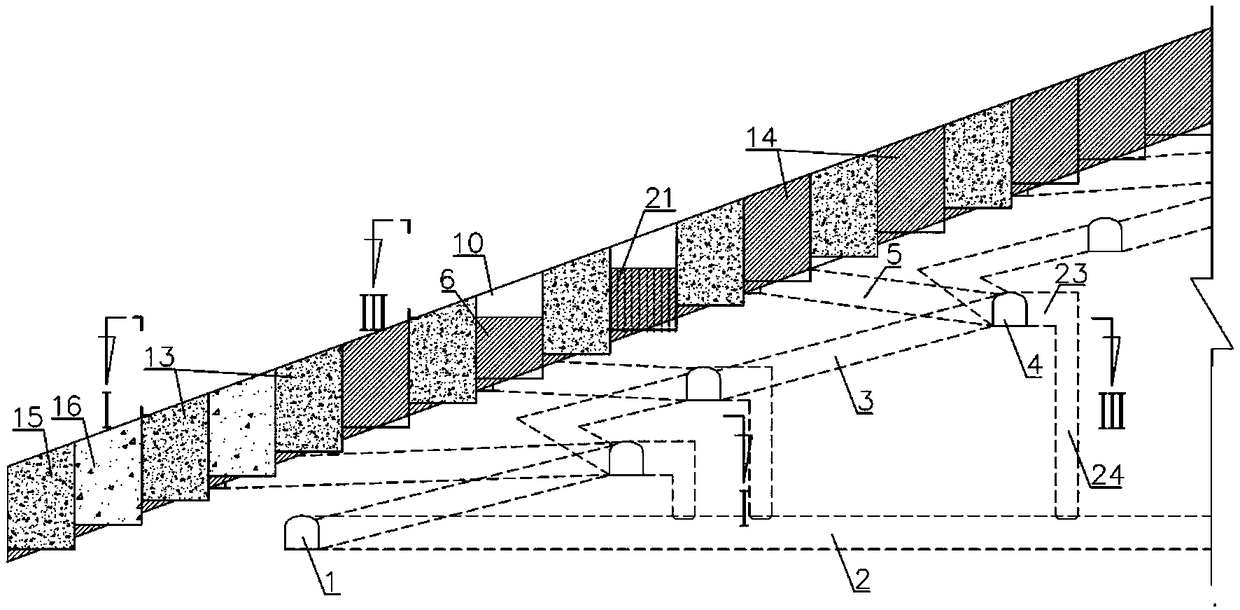

Boundary-controlled room column type sublevel open stoping subsequent stage filling mining method

InactiveCN103032070AImprove mining safetyMining safetyUnderground miningSurface miningEngineeringControl room

The invention discloses a boundary-controlled room column type sublevel open stoping subsequent stage filling mining method which is used for slight pitch-steep pitch very thick and big ore bodies with firm surrounding rocks of upper plates and lower plates. The method is characterized by comprising the following steps of: dividing a plate area of the ore body, incessantly dividing three ore rooms and two ore columns in the plate area, performing step-like retrusive sublevel rock drilling stage ore removal from an upper plate to a lower plate of the ore body by adopting bottom structures of V-shaped trenches, and connecting sublevel fringe drifts through a service raise; during mining of the ore rooms, respectively tunneling rock drilling cross drifts on the two sides of a stope, controlling the boundary of the stope by adopting pre-splitting blasting in side holes, arranging ore removal routes in the ore columns for ore removal, leaving a first sublevel in the middle ore room without mining, and performing top tight filling by adopting cemented bodies with different mixture ratios; and during the mining of the ore columns, tunneling the rock drilling cross drift at the center of the stope, arranging bilateral ore removal routes in the reserved sublevel in the middle ore room for serving the two ore columns for ore removal, and performing the top tight filling on the ore columns by adopting non-cemented bodies. The method has the advantages of high safety, great production capacity, low operation cost and low loss and dilution rate of ores.

Owner:彭康

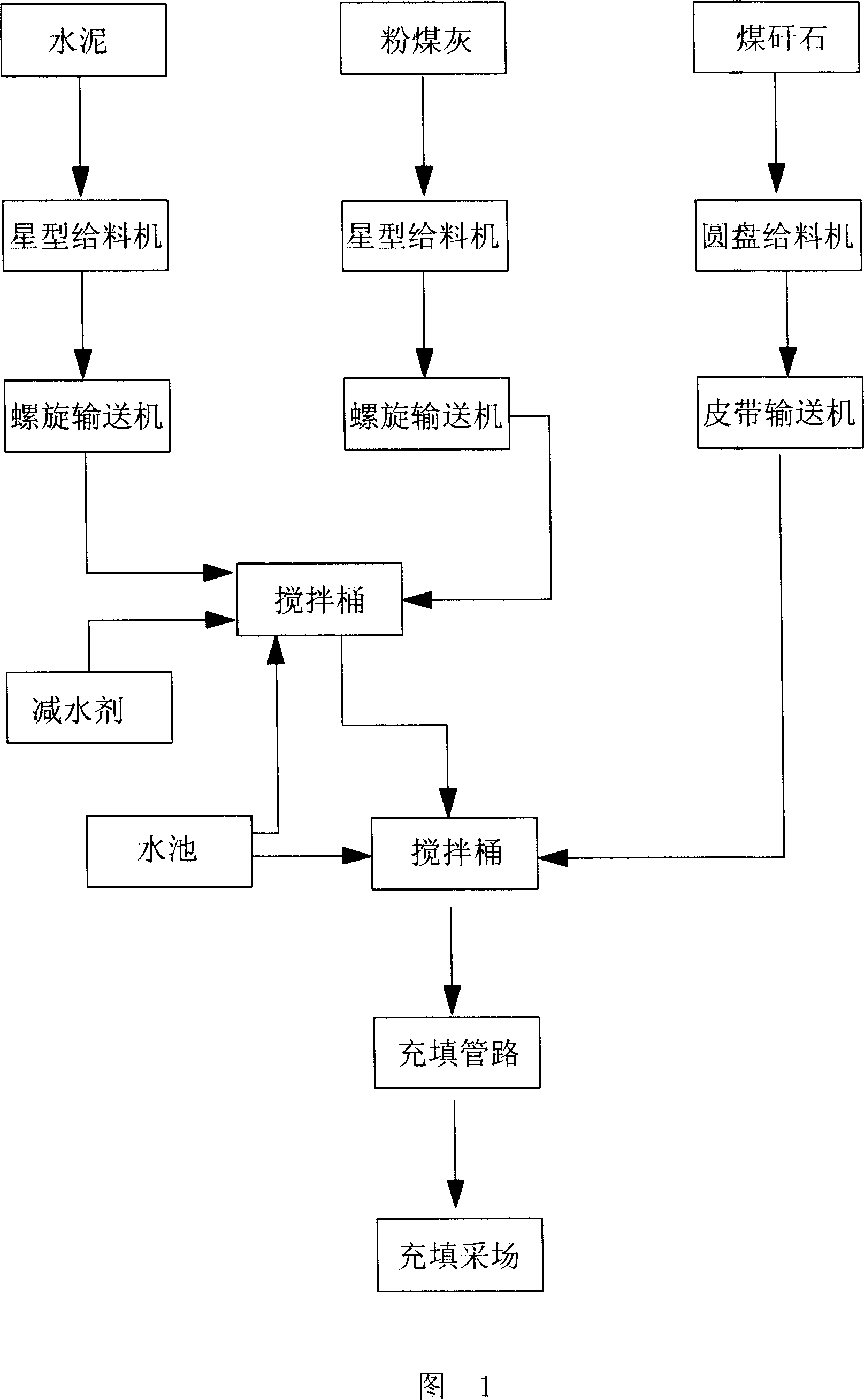

Paste-like backfill technology used in coal cutting area and the paste-like thereof

InactiveCN101008315AHigh content of dry ingredientsStrong dry material component contentMaterial fill-upWater leakageUltimate tensile strength

The invention relates to a paste self-flow stuff technique of coal mine and relative paste, which uses the coal gangue as main stuff. The invention is characterized in that the stuff technique comprises that mixing cement and powder coal into water to form pulp; adding coal gangue to form coal gangue suspension paste; using tube to self-flow transmit the paste into under-well stuff area to stuff the mining field. The invention uses coal gangue as main stuff material and uses self-flow stuff technique, with low cost and the application in the underground coal layer, to reduce the pollution of coal gangue. The inventive paste has high water contant and low water leakage, therefore, the stuff has high strength.

Owner:邸建友

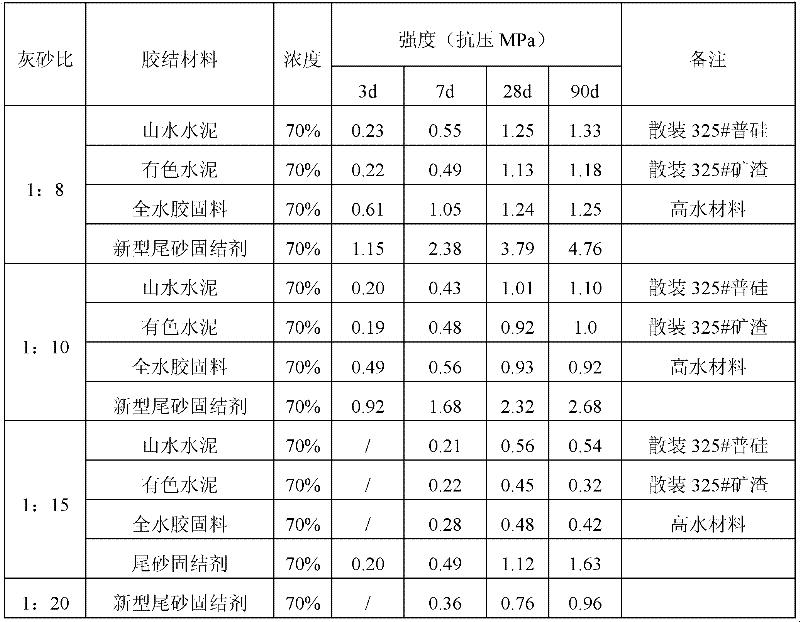

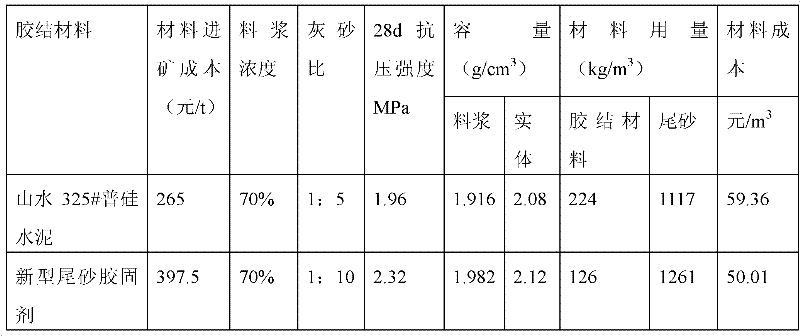

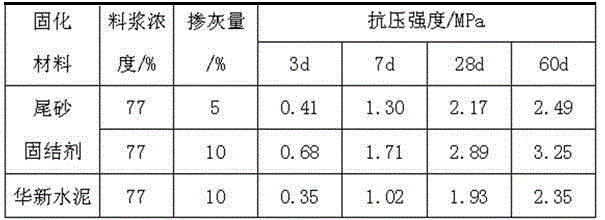

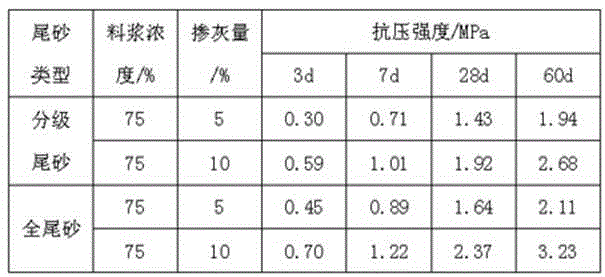

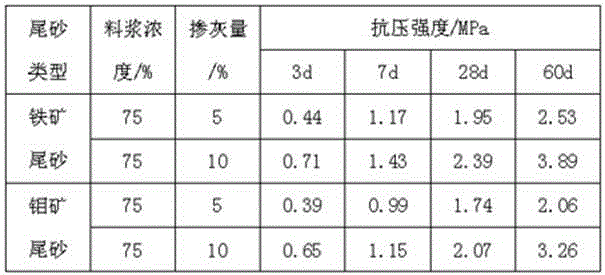

Novel tailing consolidator and preparation method thereof

The invention concretely relates to a novel tailing consolidator which uses fine powder ground from blast furnace water quenching slag as a main raw material and a preparation method of the consolidator. The consolidator is characterized in that the consolidator comprises, by mass concentration, 9 % to 17.54% of portland cement clinker, 10% to 17.54% of anhydrite, 6% to 10% of quicklime, 0.2 to 6 thousandths of Na2SO4, 0.2 to 0.5 thousandths of carboxymethyl cellulose, 5% to 10% of coal ash and 43.65% to 69.96% of the fine powder ground from the blast furnace water quenching slag. Each above component is dried by a dryer, put in a mixer to be evenly stirred, and conveyed to a bowl mill by a belt conveyer to be ground. The blast furnace slag discharged from a smeltery is used as the main raw material in the invention to reduce the cost and solve slag processing, so the consolidator has the advantages of low production cost, simple processing, and agile and convenient usage. A usage amount of the consolidator in the present invention is half or less than the usage amount of common cement under the same conditions with the same backfilling intensity.

Owner:淄博乾耀固结材料有限公司

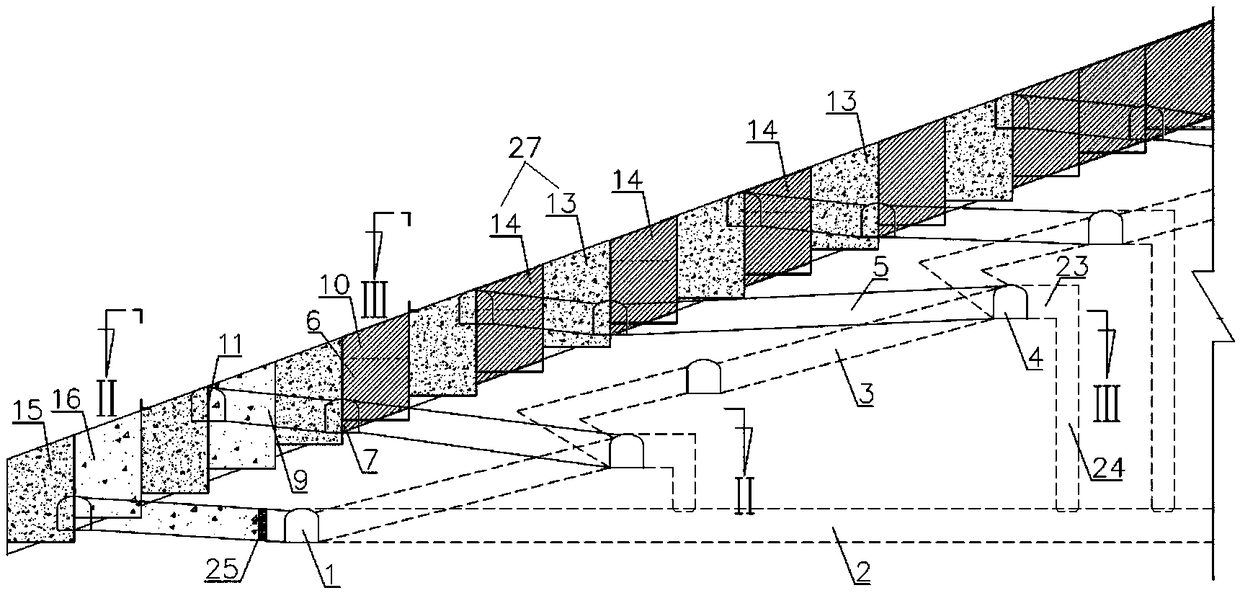

Mechanized mining method for gently-inclined medium-thick ore body

ActiveCN107869349AContinuous and efficient miningIncrease production capacityUnderground miningSurface miningMineralogyLoss rate

The invention provides a mechanized mining method for a gently-inclined medium-thick ore body, and belongs to the technical field of mining. The method comprises the following steps: dividing a gently-inclined medium-thick ore body into a panel area, dividing the ore body in the panel area into strips in a heading direction, driving a pseudo-inclined mining uphill roadway and a return air uphill roadway in the inclining direction of the ore body, driving a stope connecting roadway in a mining uphill direction and a return air uphill direction respectively, reserving a top safety ore pillar anda bottom safety ore pillar at the top and the bottom of each section respectively, and reserving a safety ore pillar between adjacent stopes in the heading direction of the ore body. The strips in the panel area is divided into one-step stopes and two-step stopes, the ore body is stoped at intervals sequentially from bottom to top, the one-step stopes are mined first, and then the two-step stopesare mined. After filling and final setting of all one-step and two-step stopes, uphill safety ore pillars, top safety ore pillars and bottom safety ore pillars are recovered. The method provided by the invention has the advantages of high mechanization degree, large production capacity, small mining and cutting work amount, high ore recovery rate, low lean loss rate and good safety.

Owner:UNIV OF SCI & TECH BEIJING +1

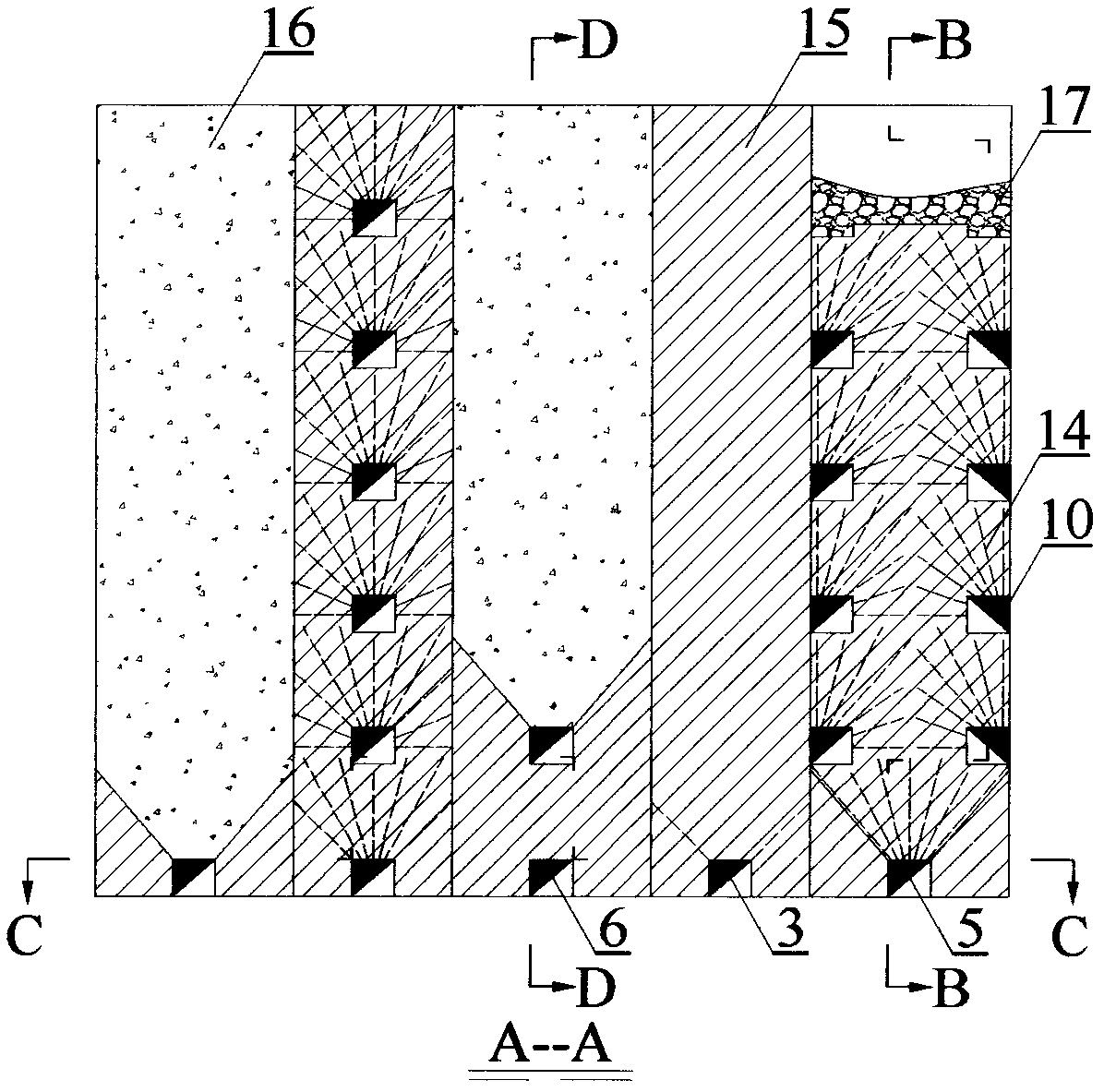

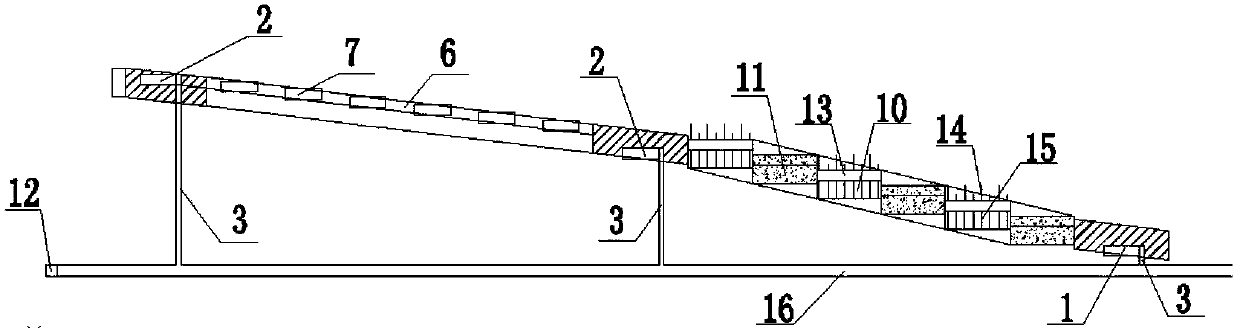

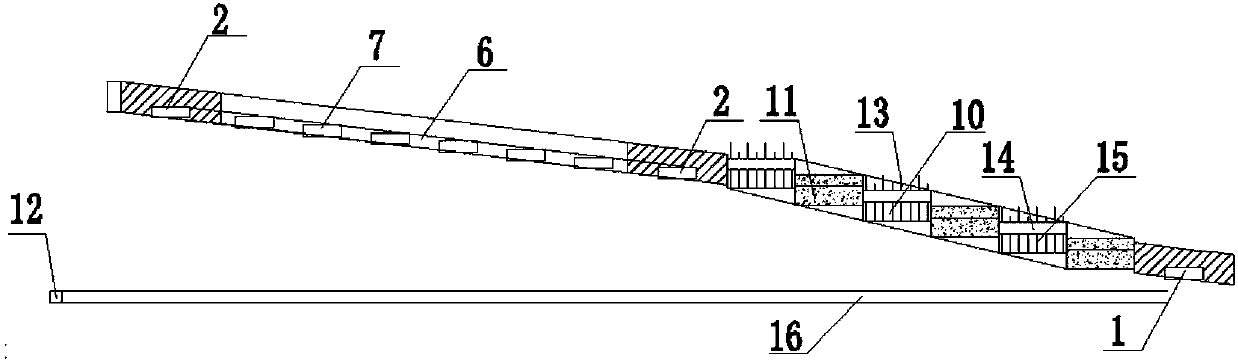

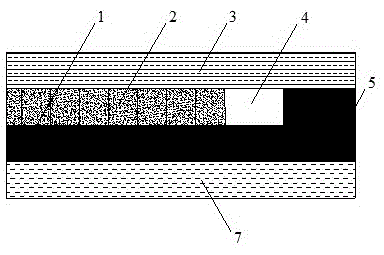

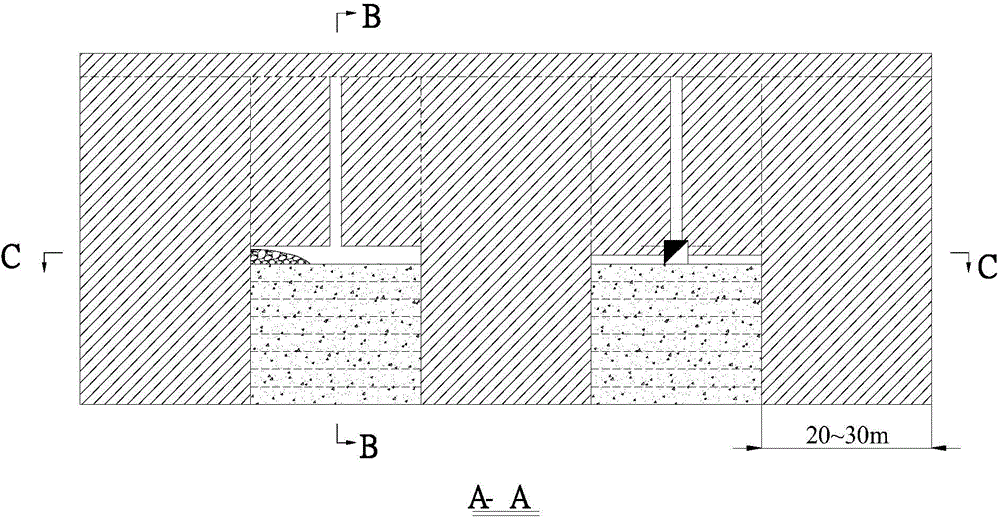

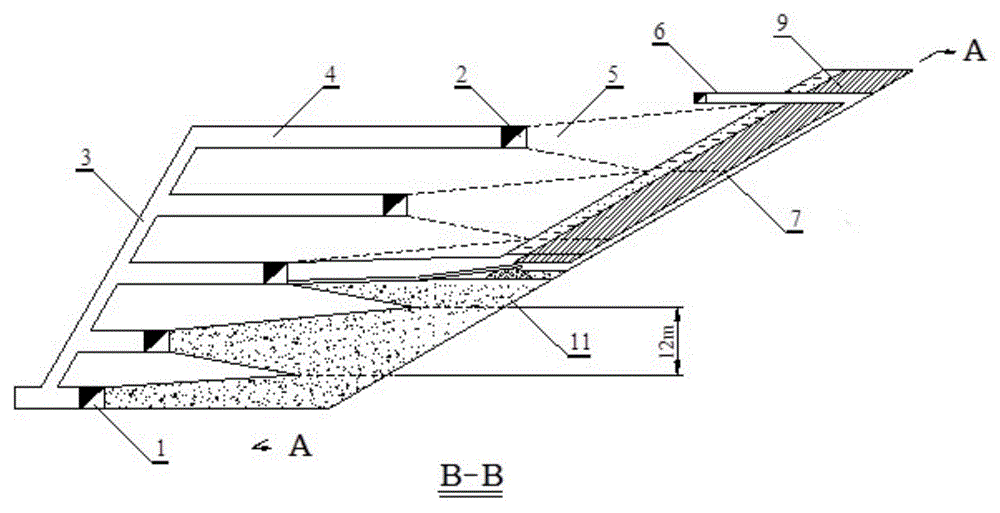

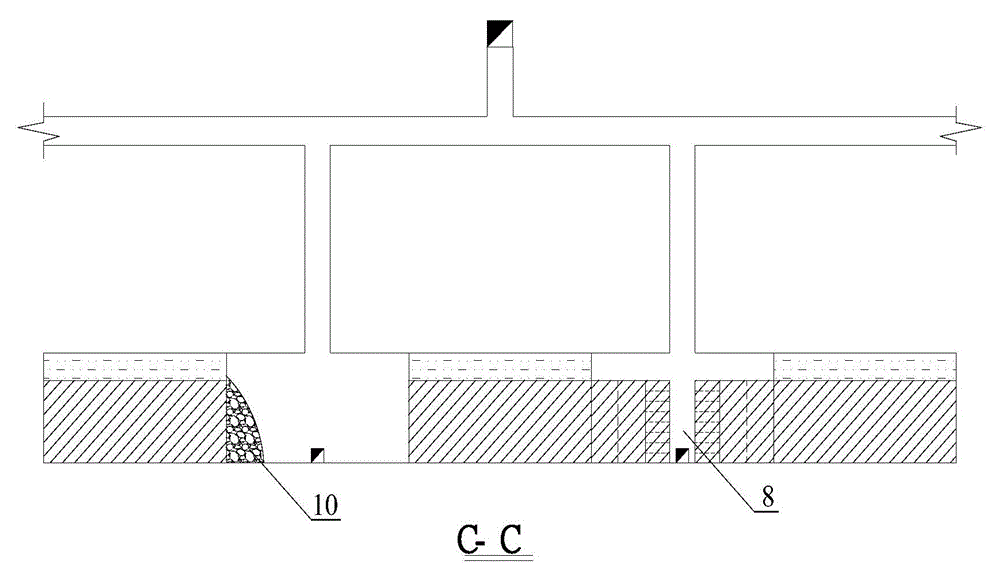

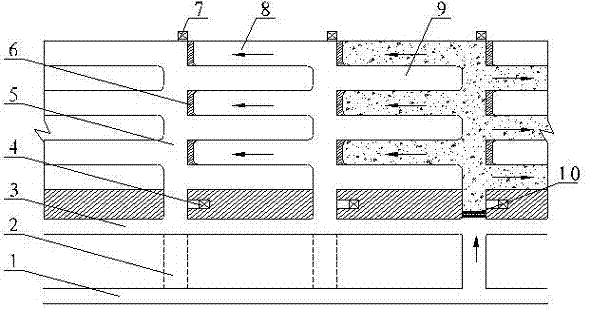

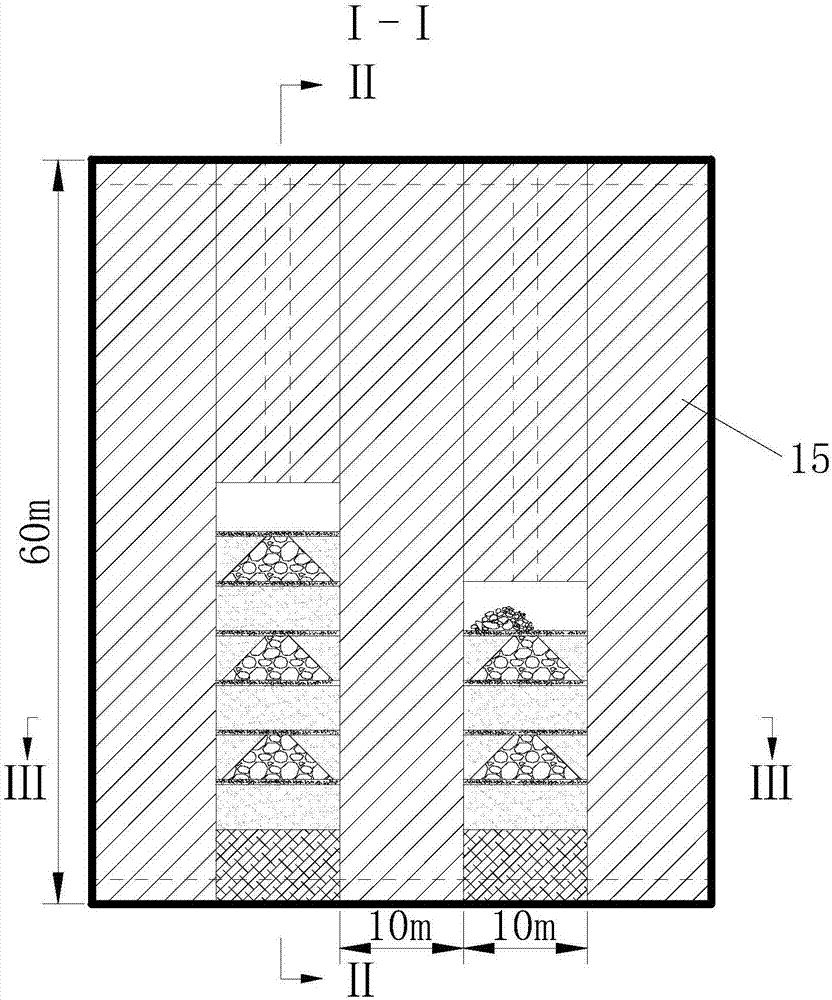

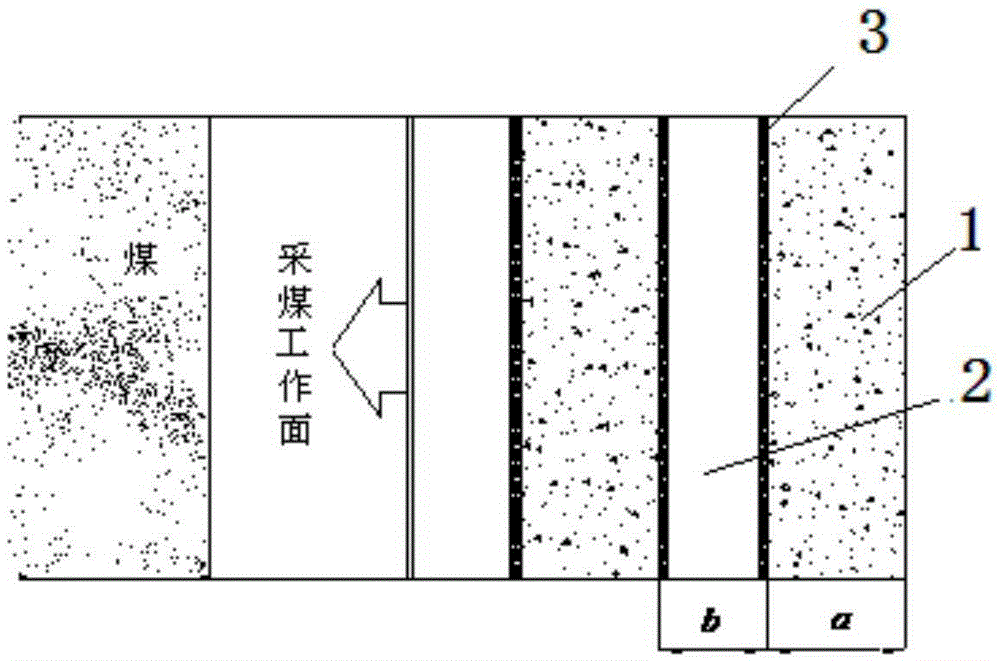

A layering and partially filling coal mining method of thick seams

InactiveCN104832178AImprove securityLower filling costsUnderground miningSurface miningCoal pillarMineralogy

The invention relates to a coal mining method suitable for thick seams under buildings, railroads and water bodies, and particularly relates to a layering and partially filling coal mining method of thick seams. The method includes reasonably dividing a thick seam into an upper layer and a lower layer; subjecting the upper layer to full-filling mining firstly; and after mining of the upper layer is finished and the upper layer is stabilized, subjecting the lower layer to strip gap filling mining by adopting the upper layer as a false roof. The method can reduce loss of resources of remaining coal pillars during thick seam mining, effectively controls ground depression, has important significance for efficient mining of thick seams under "buildings, railroads and water bodies" or thick seams needing ground protection, and achieves green, efficient and safe mining of coal mines.

Owner:CHINA UNIV OF MINING & TECH

Clinker-free compound-type tailing consolidating agent as well as preparation and application for same

InactiveCN103145354ARealize resource utilizationIncrease profitClinker productionCinker content reductionSlagEngineering

The invention relates to a clinker-free compound-type tailing consolidating agent as well as a preparation and an application for the same, wherein the clinker-free compound-type tailing consolidating agent comprises the following components in percentage by weight: 55-72% of blast furnace water-quenched slag, 20-35% of desulfurization ash, and 2-15% of compound excitant. Via the clinker-free compound-type tailing consolidating agent disclosed by the invention, a new way is opened up for comprehensive utilization for the industrial solid wastes aforementioned, the cemented filling cost of tailing is reduced, and the purpose of treating wastes by using wastes is realized, thus obtaining remarkable, economic, social and environmental benefits.

Owner:HENAN AGRICULTURAL UNIVERSITY

Large-range goaf group filling method

InactiveCN103046955AGuarantee normal productionSimple filling processMaterial fill-upDrainagePipeRetaining wall

The invention relates to a large-range goaf group filling method and belongs to the technical field of mining engineering. According to the technical scheme, the method includes: dividing filling units, selecting filling material, and laying out filling pipes; calculating to determine the thickness of a filling retaining wall, performing site construction, reserving drain holes and filter holes in the filling retaining wall, and stacking a hillock inverted filter layer behind the filling retaining wall; laying filter pipes, allowing the filter pipes to extend out from the drain holes of the filling retaining wall; constructing a filling borehole, 133mm-150mm in diameter, at a highest point, applying the filling borehole as an overhead discharge point, ensuring roof contact, constructing the corresponding number of filling boreholes according to practical situation, and performing alternating filling. The large-range goaf group filling method has the advantages that filling process is simplified, filling efficiency is increased, plugging amount is decreased, filling amount is decreased, filling period is shortened, filling cost is lowered, and normal mine production is guaranteed.

Owner:HEBEI IRON & STEEL GRP MINING +2

Method for preparing coal mine filling paste by utilizing waste concrete

The invention discloses a method for preparing a coal mine filling paste by utilizing waste concrete, and belongs to the technical field of cementation filling materials. The method comprises the steps: crushing the waste concrete and coal gangue, sieving, and allowing to become a powder having the particle size smaller than 1 mm, a fine aggregate with the particle size of 1-5 mm and a coarse aggregate with the particle size of 5-15 mm; then adding an admixture, raw lime and a gypsum solid into the powder with the particle size of less than 1 mm, stirring uniformly, then carrying out ball milling, and thus obtaining an ultrafine powder with the specific surface area of greater than or equal to 300 m<2> / kg; and finally, mixing and stirring cement, the fine aggregate, the coarse aggregate, the ultrafine powder, a conditioning agent and water to obtain the coal mine filling paste. The waste concrete is fully recycled under a condition without calcination, and thus the problems of land occupation and ecological environment destruction are solved, besides, more adequate cheap raw materials are provided for coal mine filling and mining, the filling cost is reduced, and a foundation is laid for full implementation of a filling and mining technology.

Owner:TAIYUAN UNIV OF TECH

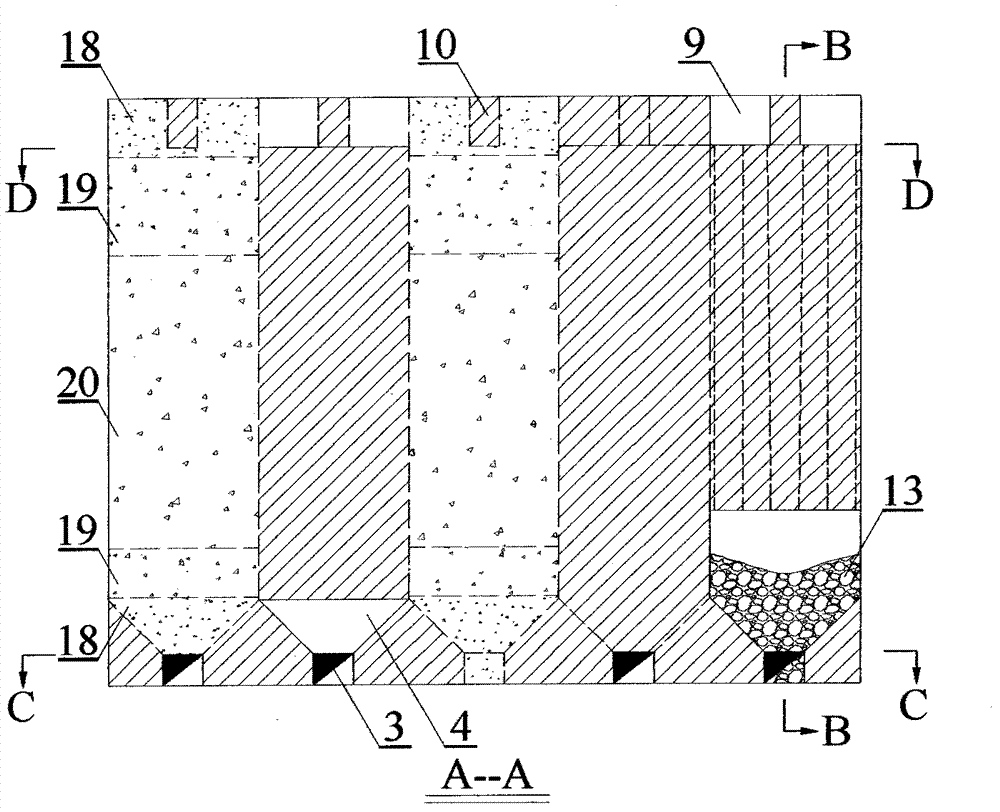

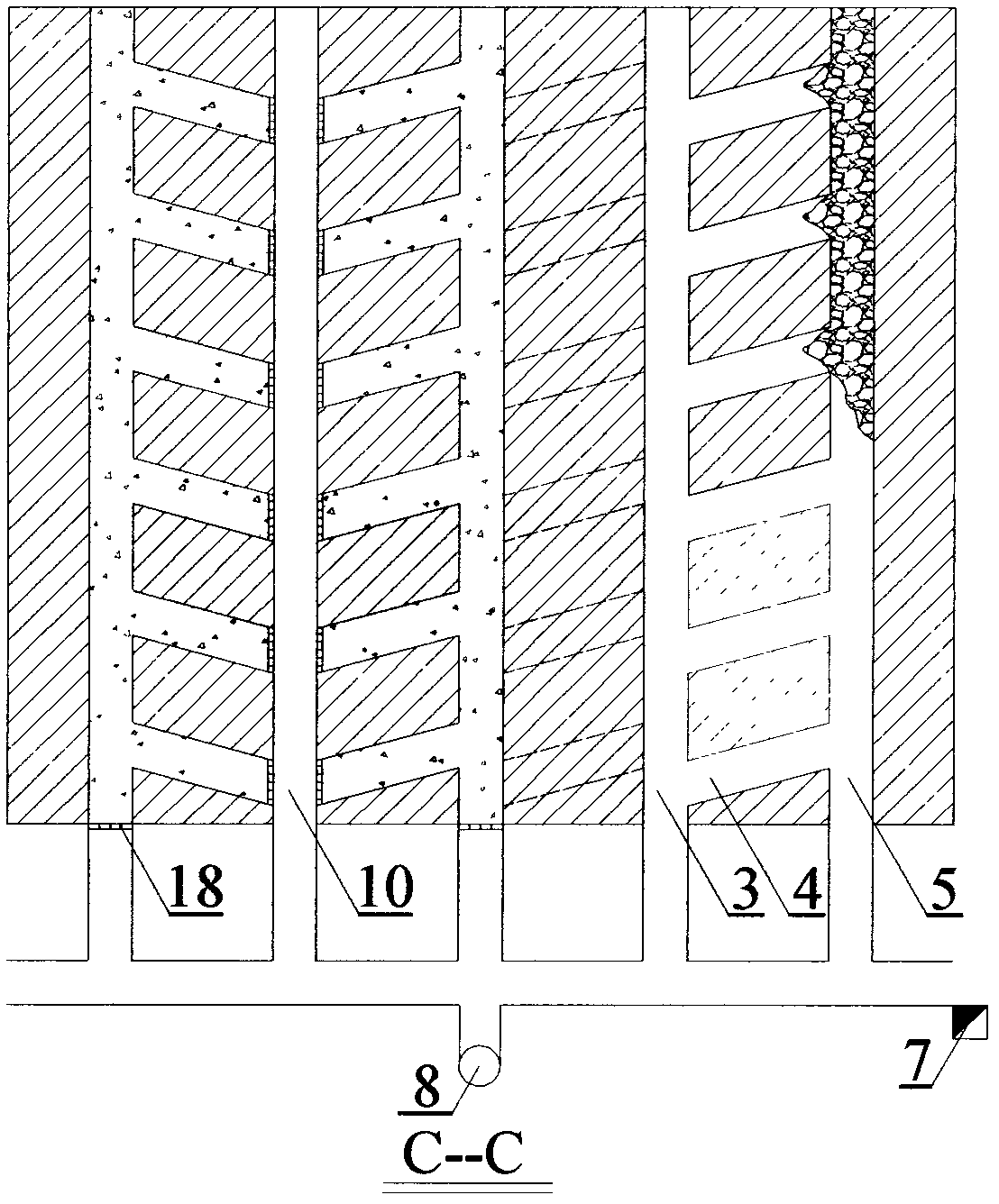

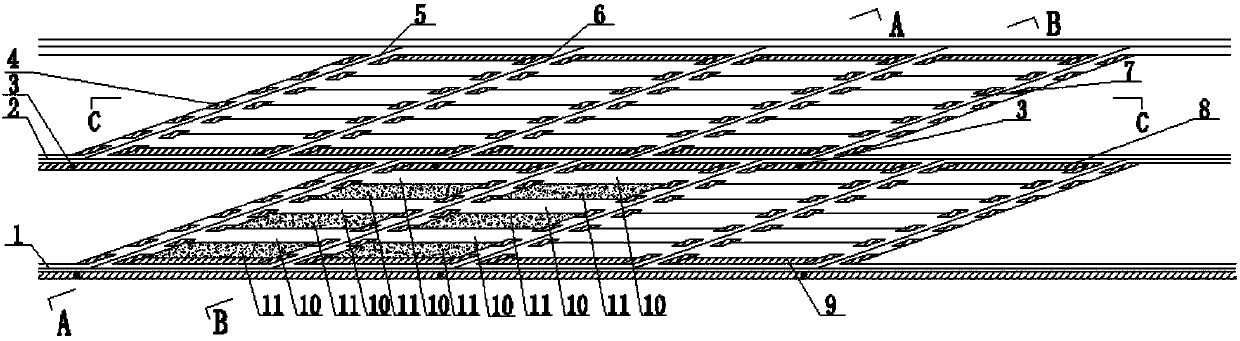

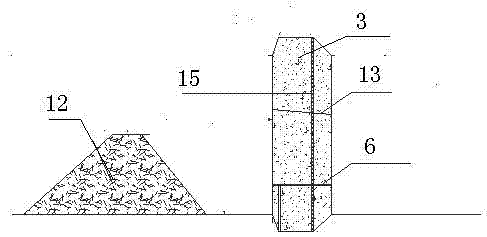

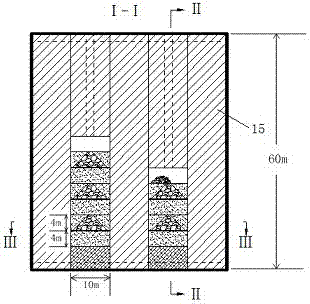

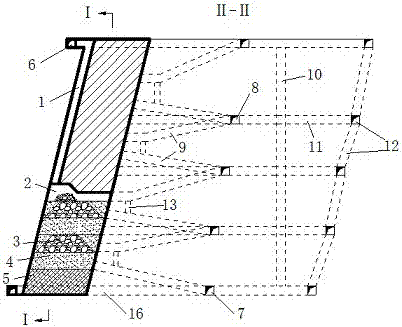

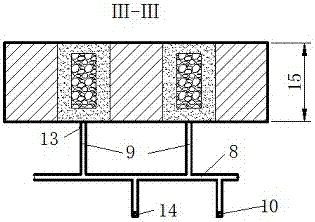

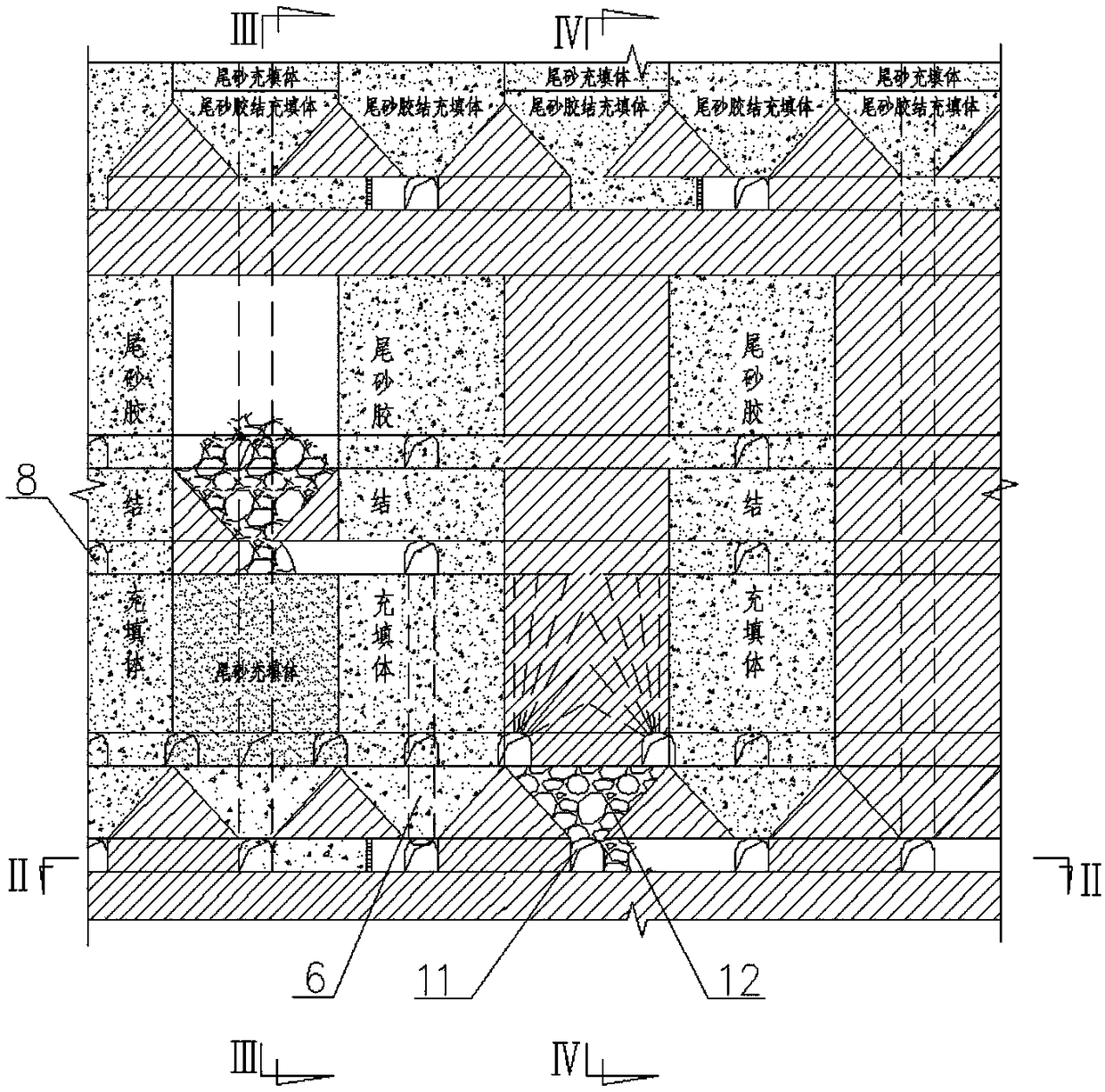

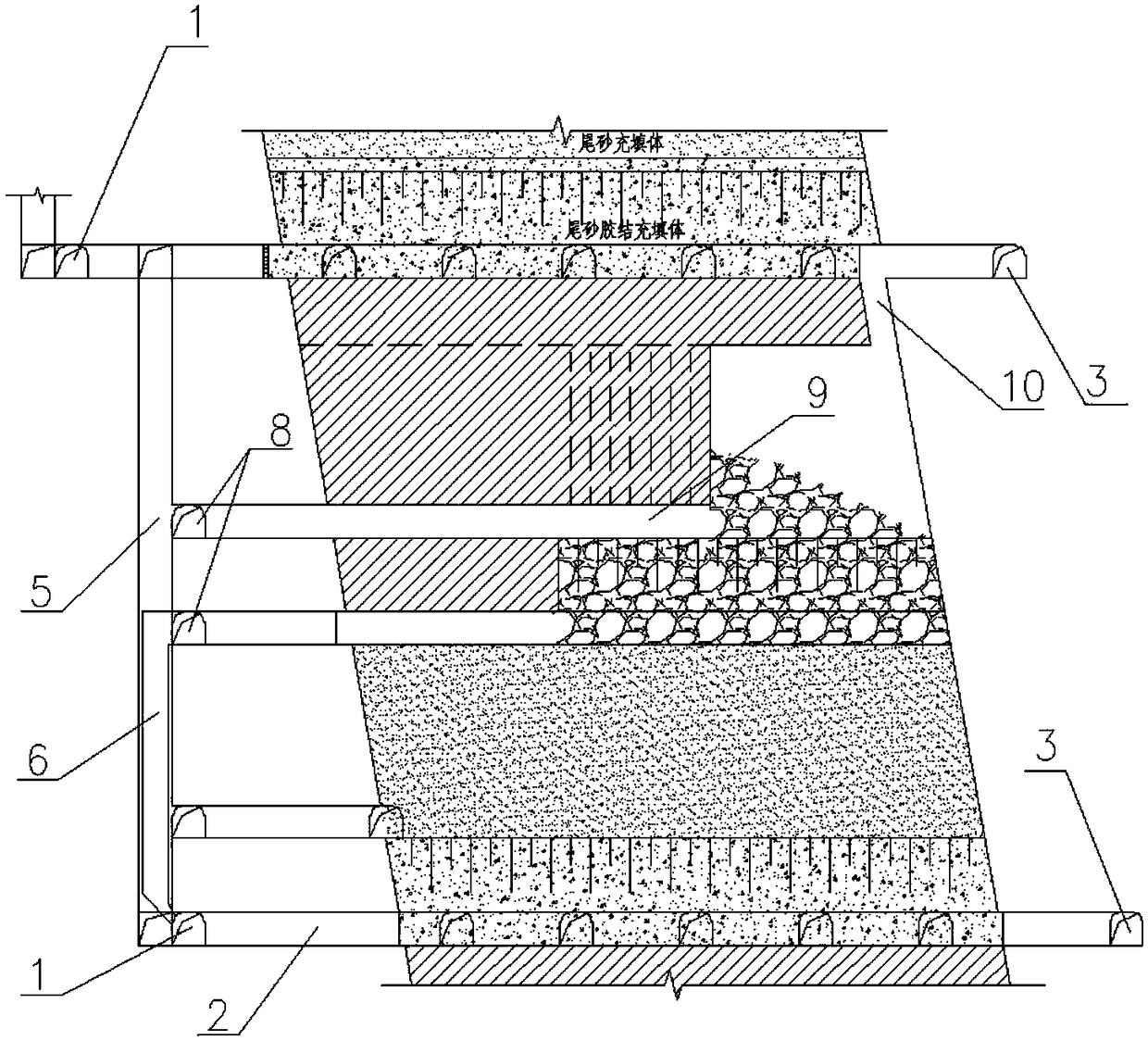

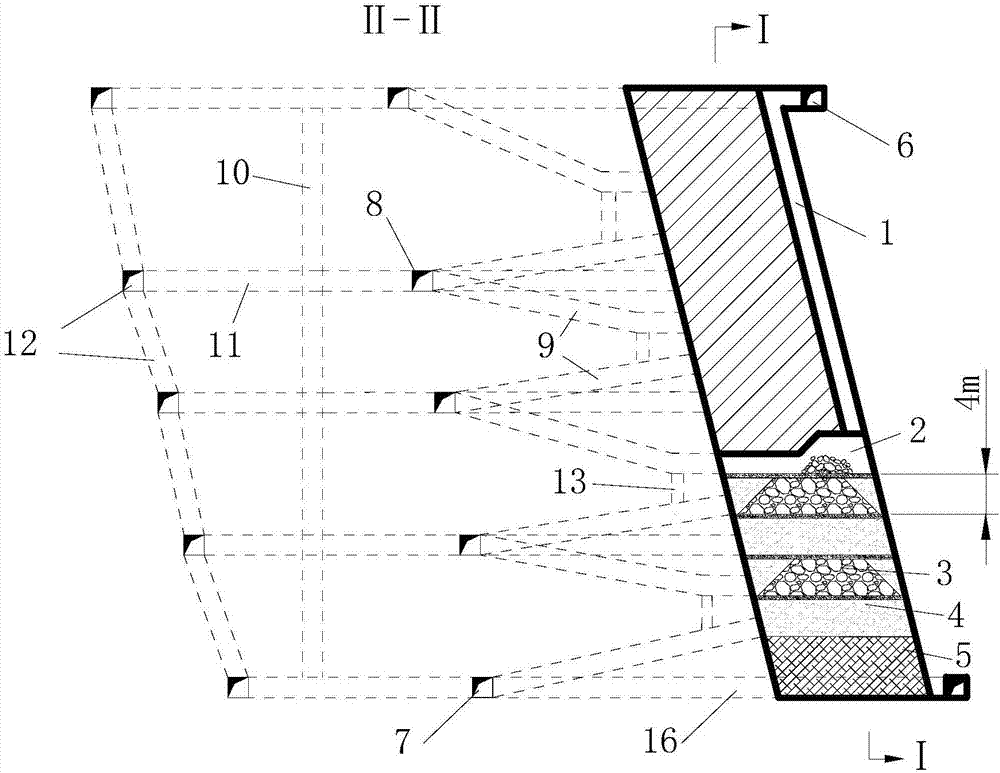

Waste rock and cementing layered wedge bonding filling mining technology and structure thereof

ActiveCN106869931AGuaranteed StrengthSafe and Efficient MiningUnderground miningSurface miningFilling materialsWedge bonding

The invention discloses a waste rock and cementing layered wedge bonding filling mining technology and a structure thereof. In the mining process through an upward horizontal cut and fill method, upward stoping and filling are conducted by adoption of layers with the depth being 3-4 m; three layers serve as a section; the first layer and the third layer are separately subjected to cementing filling through tailings; the second layer in the middle is filled with waste rock in a spaced and mixed mode; the bottom face pavement range is set according to the size of a stope, and a certain distance is kept from the periphery; and the periphery of a waste rock pile is still subjected to cementing filling through tailings, and the tailings are in contact and connection with cementing filling bodies of the upper layer and the lower layer. By adoption of the waste rock and cementing layered wedge bonding filling mining technology and the structure thereof, the problems that in the prior art, technologies are complex, the cost is high, the labor productivity and the ore block production capacity are relatively low, and waste rock cannot be reasonably applied are solved, and by adoption of a layered wedge bonding mixed filling method, the strength of the filling bodies is ensured, a large amount of downhole waste rock is consumed, cementing filling materials are saved, and the layered wedge bonding mixed filling method has the characteristics of being safe in operation, high in filling efficiency and low in cost.

Owner:GUANGXI GAOFENG MINE IND

Divided mining method for inclined medium-thick ore body with unstable false roof

ActiveCN104018836AOut of stopeReduce the dilution loss rateUnderground miningSurface miningEngineeringNo removal

The invention discloses a divided mining method for an inclined medium-thick ore body with an unstable false roof. The ore body is divided into panels along the strike, ore pillars of chambers are divided in the panels and a top pillar is reserved during stoping; an outside-vein slice drift, a layered linking roadway and a trackless stope preparation project of a chute mine are distributed on the upper panel of the ore body, and an upward air roadway is filled and is distributed at a position at the center of the ore pillars of the chambers and close to the lower panel; chambers are mined firstly and the ore pillars are mined secondly in the panels, and the chambers and the ore pillars are mined in an up-down layering manner; the stoping is performed from an ore removal crossdrift, the false roof and the ore body are mined in sequence, after ores are conveyed out by a carry-scraper, the false roof at the lower sub-layer is subjected to caving in advance by shallow holes, waste stones of the false roof are reserved in a stoping field, and the ore breaking compensation height is compensated in a layering filling manner, the stoping is performed on the lower sub-layer, and the laying caving is performed on the false roof after layering ore breaking and ore conveyed out, the operation is repeated for multiple times until the stoping field is stoped completely, and the bottom layer of the stoping field is filled to close to the back. By using the method, the operating safety, high mechanical degree, no removal of the waste stones of the false roof, low production cost, and low ore dilution loss can be realized.

Owner:CENT SOUTH UNIV

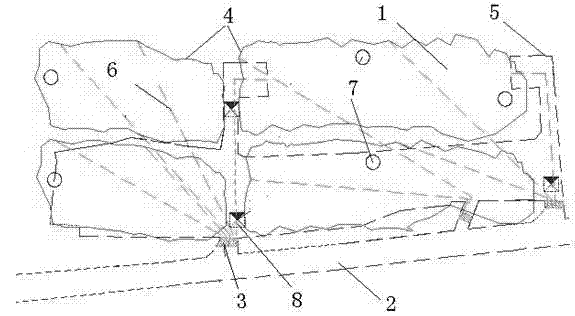

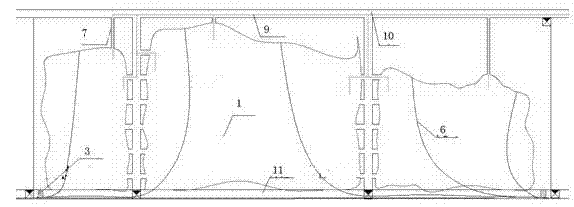

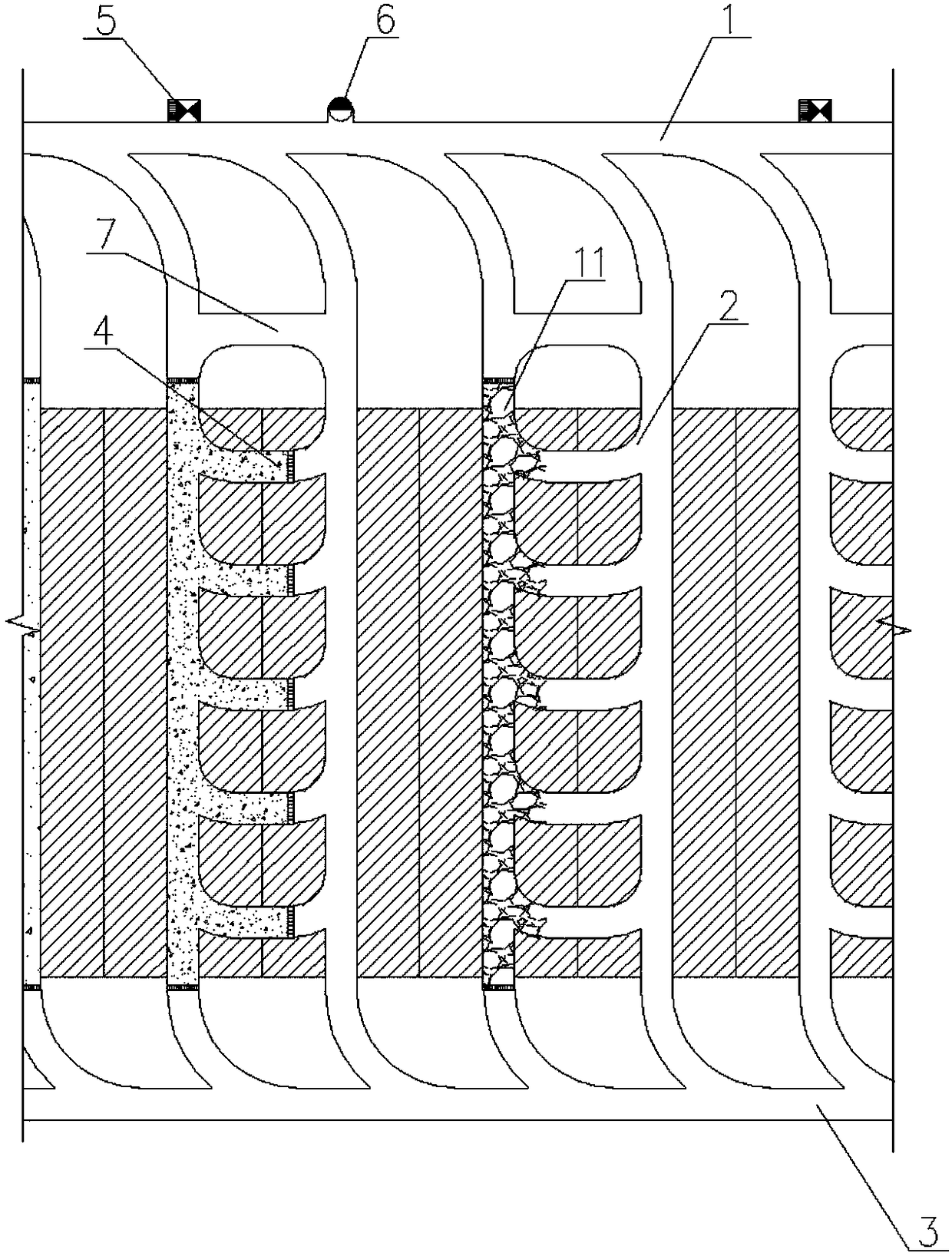

Stope route arrangement mode and method beneficial to roof-contacted filling

ActiveCN103615285ASimple process and construction managementReduce support costsMaterial fill-upFilling materialsEngineering

The invention provides a stope route arrangement mode and method beneficial to roof-contacted filling. The roof-contacted filling rate can reach above 90%, filling cost is low, and the process is simple. According to the stope route arrangement mode, a mining cutting roadway is arranged perpendicular to the moving direction of an ore body, extracting drifts at two wings of the mining cutting roadway are arranged in the moving direction of the ore body in a staggered mode, a chute is arranged in a surrounding rock section of the footwall of the mining cutting roadway, the height of the extracting drifts is 3m, the length of the first extracting drift is 14-18m, the length of the second extracting drift is 16-20m, and the height of the mining cutting roadway is 4.5m. According to the stope route arrangement method, a slope ramp linking way, a footwall stope layering linking roadway and the mining cutting roadway are constructed sequentially, and the chute and a return air filling shaft are communicated; the second extracting drift is constructed after the first extracting drift is finished; brushing extraction is carried out on a temporary jamb, the width of a central mining cutting roadway is 4.5-5m, and a top plate is shaped like an arch; waste stones are dumped into the second extracting drift, the height of a smooth chute is increased by 3.5m, a filling blocking wall is erected, and filling operation is finished when the liquid level of filling material slurry is higher than the top plate of the extracting drifts by 20-30cm.

Owner:南京银茂铅锌矿业有限公司

Recycling process of remaining interstall pillars of two-step mining method

InactiveCN108547618AReduce exposure heightPrevent avalancheUnderground miningSurface miningMining engineeringLower grade

The invention discloses a recycling process of remaining interstall pillars of a two-step mining method. The recycling process comprises two circulations of stoping and filling, so as to reduce the exposure height of filling bodies and surrounding rock of the top wall and the bottom wall, and to prevent dilapidation of the filling bodies and the surrounding rock of the top wall and the bottom wall. Bilateral entrance drilling-blasting is adopted. Places near the filling bodies of a mining room adopt a short delay presplitting blasting method which requires drilling more holes and filling fewerexplosives to reduce shaking of and destruction to the filling bodies of the mining room caused by explosion. A part of the ore, to be used as a temporary support, is retained in diggings during stoping. Rock drilling and ore removal are conducted in a roadway. Staff does not need to enter into the stope, so stoping safety is good, and production capability of ore blocks is high. The stoping is conducted from bottom to top, and then cemented filling is carried out with low-grade ore tailings. The recycling process effectively controls ground pressure in the mining stope. The stope roof, the top wall and the bottom wall and the filling bodies basically remain stable in the process of stoping and filling. The recycling process has the characteristics of being safe, efficient, low in cost and low in dilution loss, so the recycling process is especially suitable for the recycling of remaining interstall pillars which are difficult to exploit by using the two-step filling method for thickand large ores of metal mines with complex conditions.

Owner:CINF ENG CO LTD

Preparation method of gangue base mine cemented filling material

ActiveCN105152601AImprove utilizationEfficient and reasonable useSolid waste managementMaterials scienceGangue

The invention discloses a preparation method of a gangue base mine cemented filling material, and belongs to the field of mine filling materials. Cementing activity hidden in gangue is stimulated in a compound stimulation way, cement is partially replaced with the cementing activity to serve as a cementing material for cemented filling mining, and then the material is mixed with fine particle size gangue to be prepared into the mine cemented filling material. The process for preparing the mine cemented filling material is simple, large proportion dosage of gangue powder and cement is realized, the filling material has excellent mechanical property and stable conveying property, no segregation or no bleeding exists, the application of gangue in mine filling is broadened, the mine filling cost is reduced, the material conveying property is improved, at the same time, the purpose of effective use of gangue is realized, and mine filling is promoted to develop forward.

Owner:TAIYUAN UNIV OF TECH

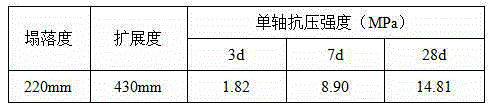

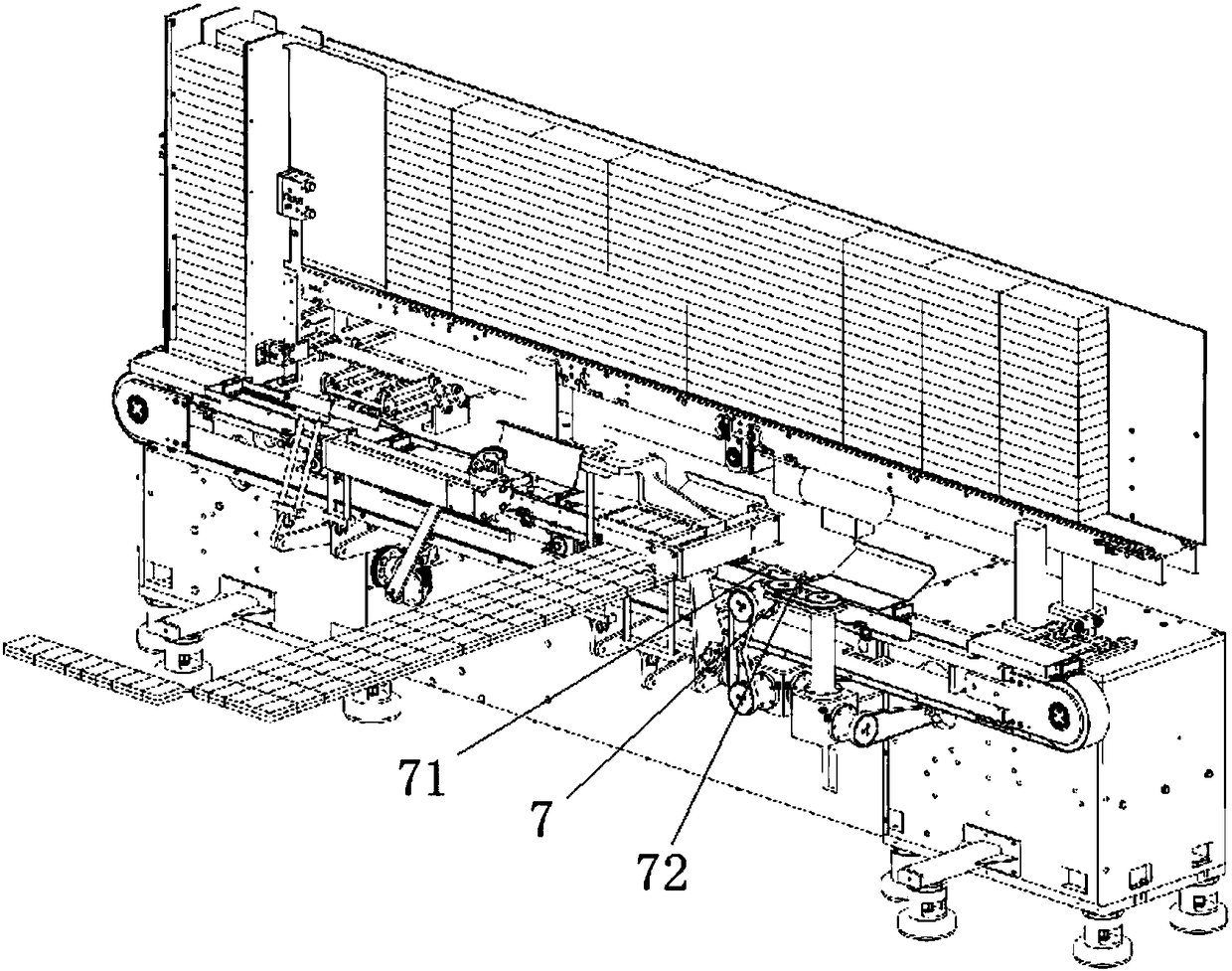

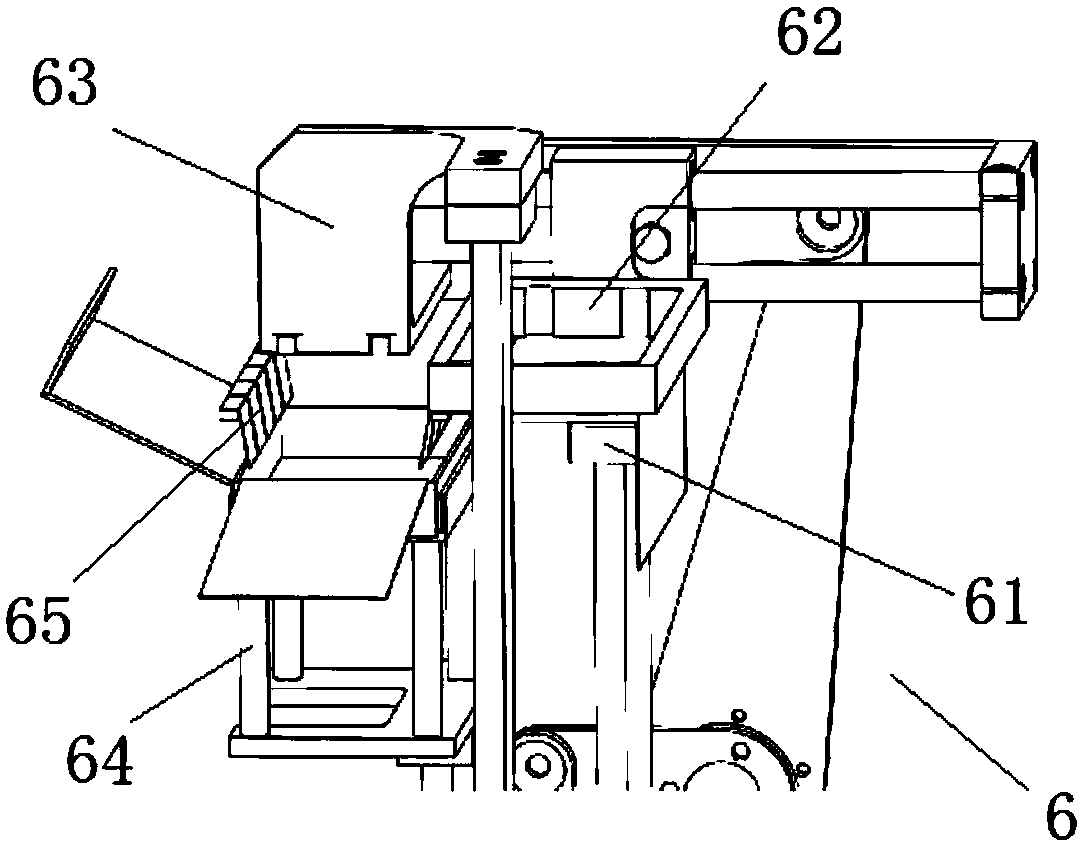

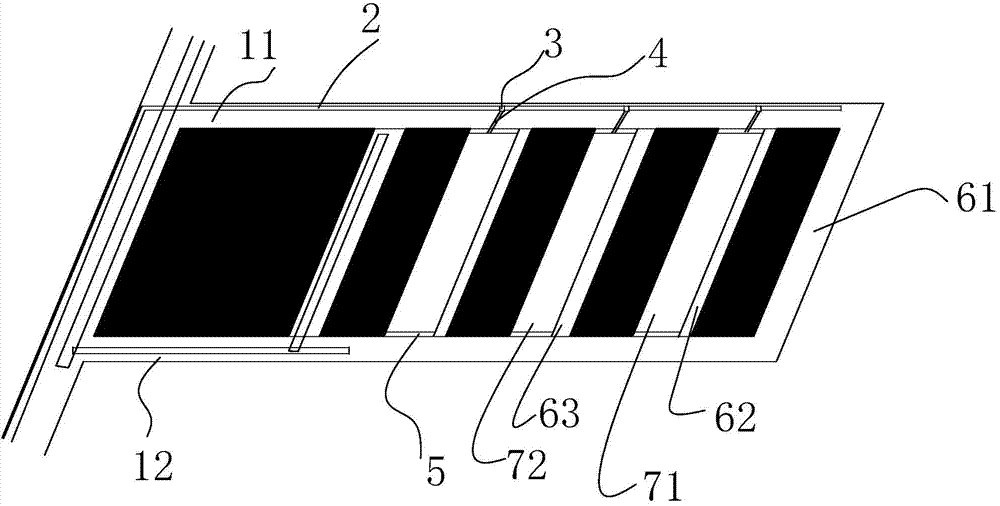

Equipment and method for filling hard cartons with cigarette packets

PendingCN108298142ARealize fully automatic fillingIncrease productivityPackagingProduction lineCarton

The invention relates to equipment and method for filling hard cartons with cigarette packets. The equipment comprises an equipment body, a carton conveying belt, a carton conveying mechanism, an uncapping mechanism, a paper suction mechanism, a filling mechanism, a paper covering mechanism, an output mechanism and a cigarette packet set conveying mechanism. The carton conveying belt is arranged at one side of the top of the equipment body, and in addition, multiple mold cartons are arranged on the carton conveying belt in an equally-spaced manner. The carton conveying mechanism, the uncappingmechanism, the paper suction mechanism, the filling mechanism, the paper covering mechanism and the output mechanism are sequentially arranged on the equipment body in the conveying direction of thecarton conveying belt and are in one-to-one correspondence with the mold cartons in position. The output end of the cigarette packet set conveying mechanism is connected with the filling mechanism, and the cigarette packet set conveying mechanism is used for conveying a cigarette packet set onto the filling mechanism. By means of the equipment and method, fully-automatic filling can be achieved; production efficiency is improved; the filling cost is lowered; the equipment can be in on-line connection with small box packaging equipment; and on-line production conducted through the equipment andupstream and downstream equipment of a production line is achieved.

Owner:河南施普盈科技有限公司

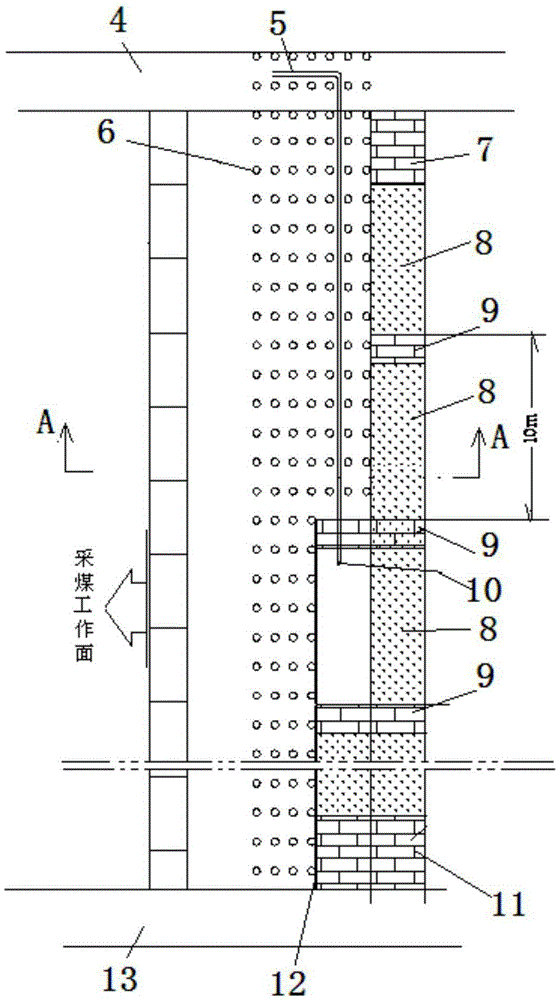

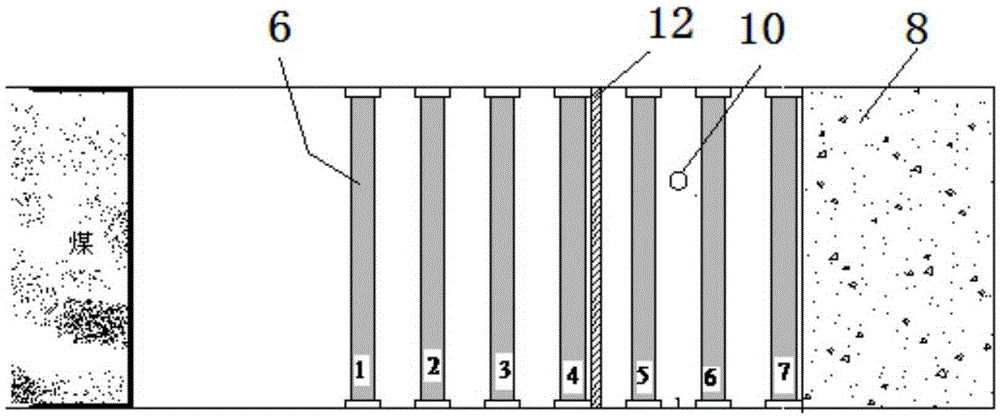

Interval skip-mining type filling coal mining method

InactiveCN103883350AIntegrity guaranteedReduce exerciseUnderground miningSurface miningFilling materialsSequential mining

The invention provides an interval skip-mining type filling coal mining method and belongs to the technical field of coal mine filling coal mining methods. The interval skip-mining type filling coal mining method comprises the steps that a first open-off cut is dug at the tail end of a butt entry, a second open-off cut is dug a certain distance away from the first open-off cut, and mining is conducted at the position of the second open-off cut with the wall type system coal mining method after the second open-off cut is well dug; a third open-off cut is dug a certain distance away from the second open-off cut, a gob formed after mining is conducted at the position of the second open-off cut is filled while the third open-off cut is dug, and the rest operation is conducted by analogy till mining is conducted on a mining stopping line. By the adoption of the interval skip-mining type filling coal mining method, mining can be conducted under the condition that the two ends are supported, sequential mining and sequential filling are achieved, the integrity of a base plate of a roof is guaranteed, movement of overlying rock is reduced, and the purpose of surface subsidence control is achieved; after mining with filling is completed, coal pillars left after mining do not need to be filled, filling materials are reduced, and filling cost is reduced.

Owner:SHANDONG UNIV OF SCI & TECH

Inorganic composite cementing material specialized for coal mine filling, and preparation method thereof

ActiveCN103553482AReduce manufacturing costReduce coal mine filling costsSolid waste managementIndustrial wasteToxic industrial waste

The invention discloses an inorganic composite cementing material specialized for coal mine filling, and a preparation method thereof. The inorganic composite cementing material is composed of the following raw materials: compound Portland cement or cement clinker, ordinary Portland cement, blast furnace slag micropowder, industrial waste gypsum, carbide slag, fly ash, an additive, citric acid and an excitant. The preparation method comprises the steps of drying all raw materials by a dryer; conveying the dried raw materials into a ball mill for milling; storing the dried raw materials in a raw material bin; conveying various raw materials to a mixer by a conveying melt; mixing uniformly; and then storing the mixture in a finished product warehouse. A filling paste provided by the invention can not be solidified or can be slightly solidified in 4 h and a slump degree is higher than 230 mm, can provide enough time for maintenance of filling equipment, prevents phenomena of tube plugging and waste tube caused by a long distance conveying pipe, can guarantee that mining work can be continuously carried out without mining column after demolding in 8 hours, increases mining output, increases resource mining rate, saves labor cost and increases production efficiency.

Owner:SHANDONG MASS ENERGY OF NEW MATERIAL

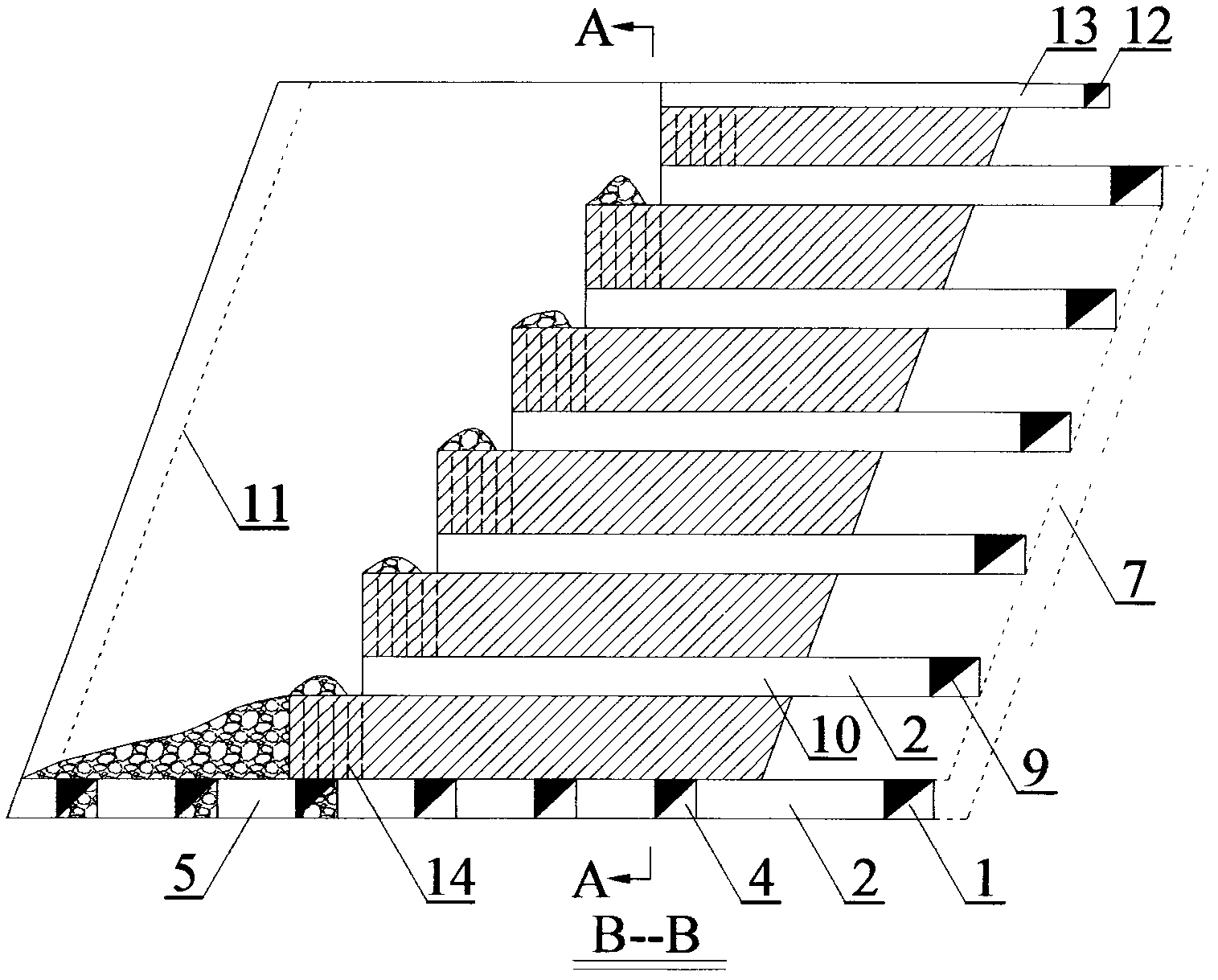

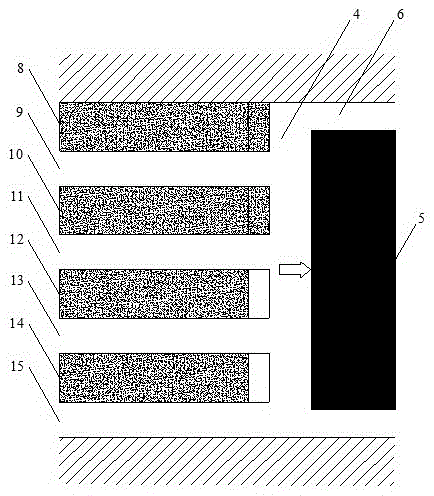

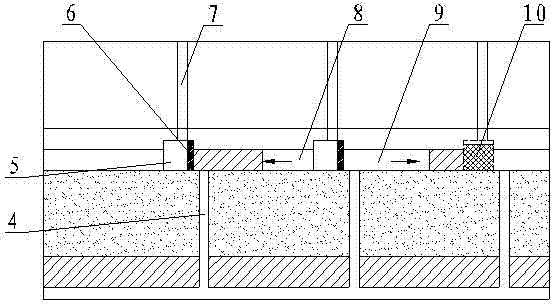

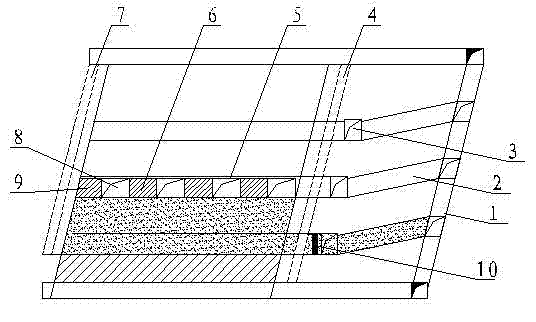

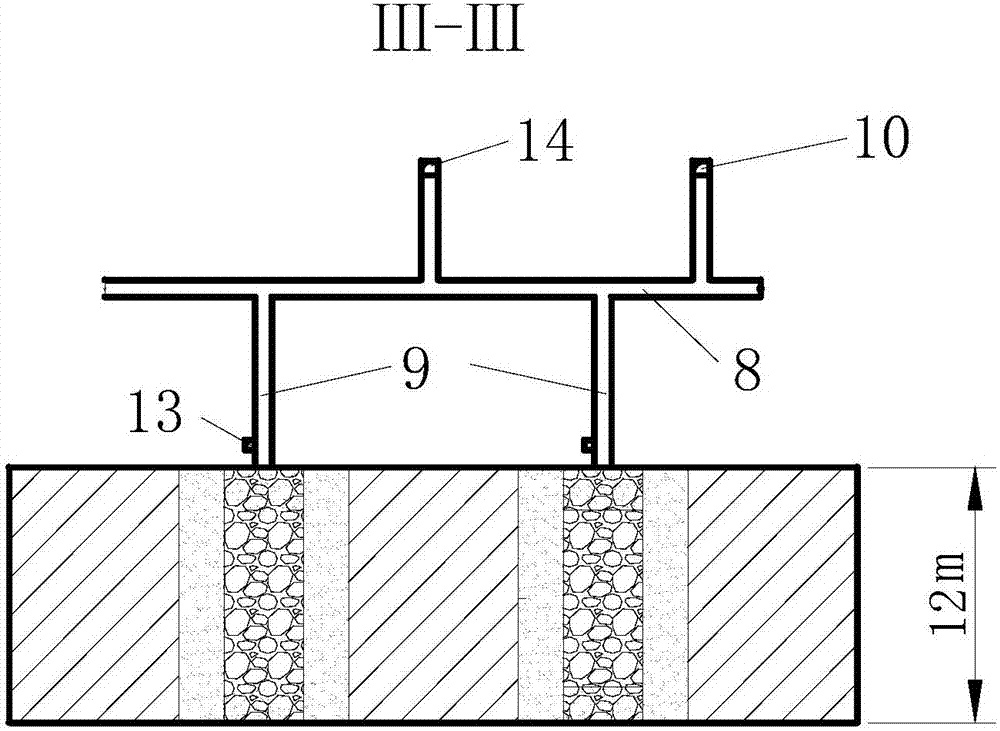

Mechanized upward-slicing wedging mixed filling mining method

ActiveCN106894817AIncrease profitGuaranteed StrengthUnderground miningSurface miningMining engineeringUltimate tensile strength

The invention discloses a mechanized upward-slicing wedging mixed filling mining method. When mining is conducted through the upward horizontal slicing filling process, upward stoping and filling are conducted with each slice being 3-4 m, and slices from bottom to top are alternately subjected to full tail sand cementing filling and waste stone wedging mixed filling. During wedging mixed filling, waste stone is stacked upward to form a quadrangular frustum pyramid. The laying range of the bottom waste stone is arranged according to the size of a stope, and certain spacing is kept with an adjacent stope. Tail sand cementing filling is still conducted on the two sides of a waste stone pile, and making contact with upper and lower layered tail sand cementing filling bodies is conducted, the whole strength of a mixed filling body is guaranteed, and dilution caused by caving of an ore body or surrounding rock at the time of being unstable is stopped. When the upward horizontal slicing filling process is adopted, the strength of the filling body can be guaranteed, and a large quantity of the downhole waste stone can be consumed, so that the waste stone is not out of a pit, and accordingly the cementing filling material is saved, and the filling cost is reduced effectively.

Owner:CENT SOUTH UNIV

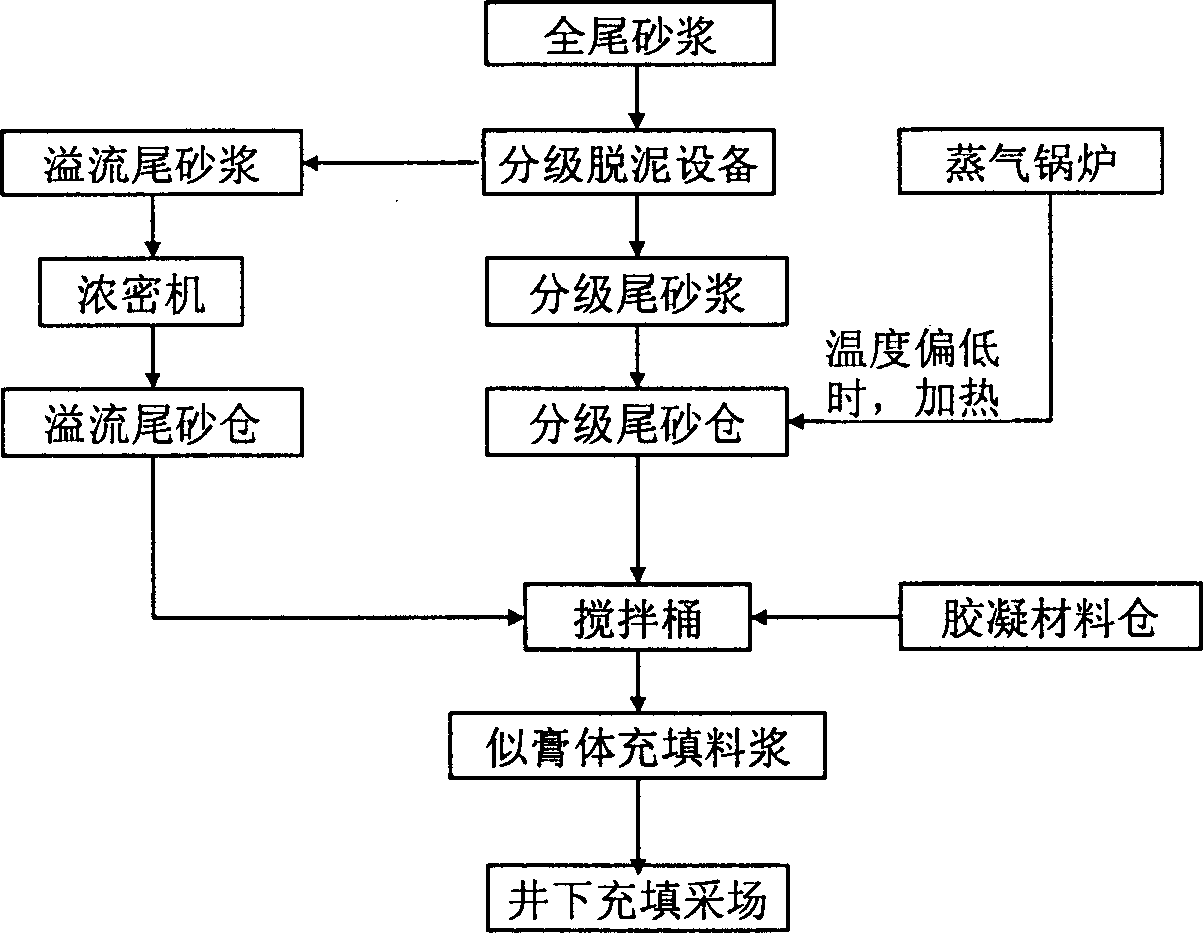

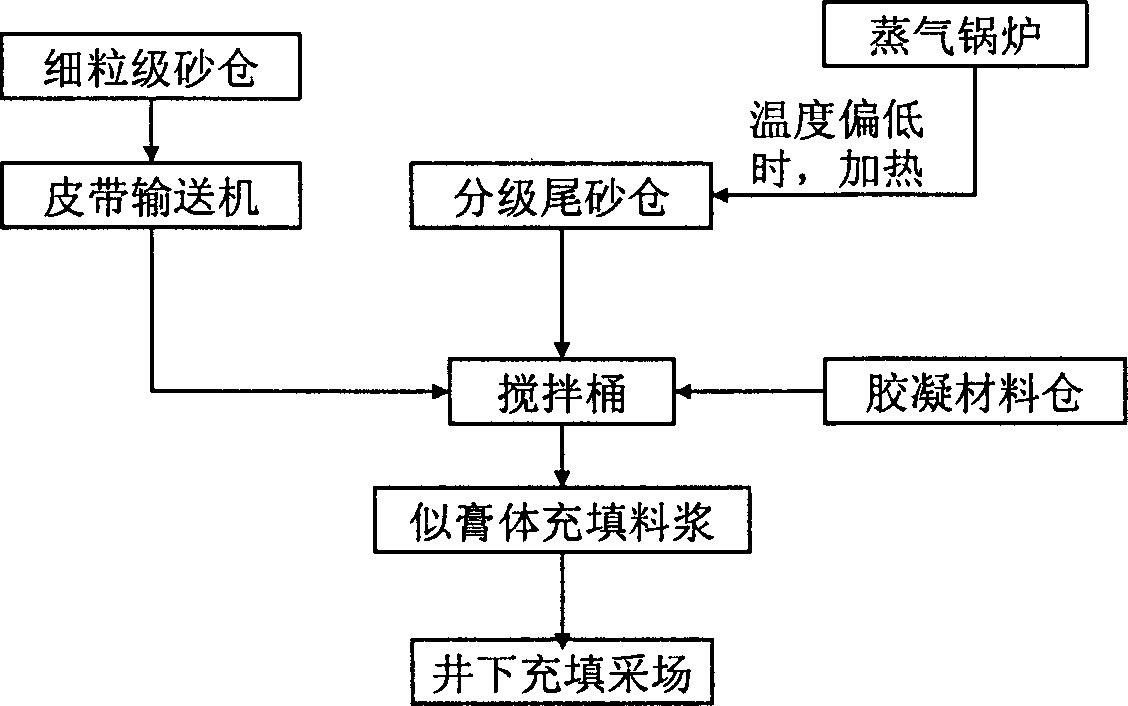

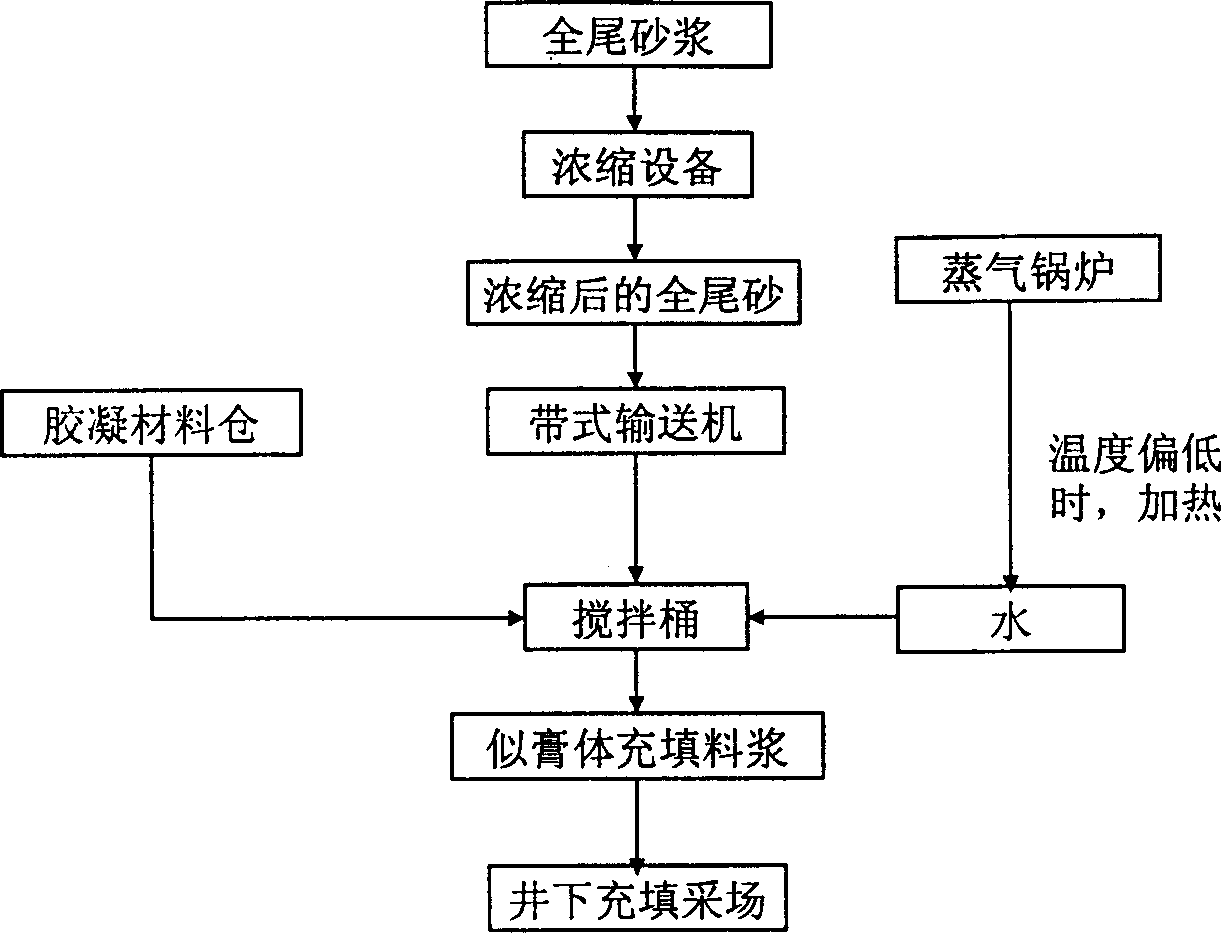

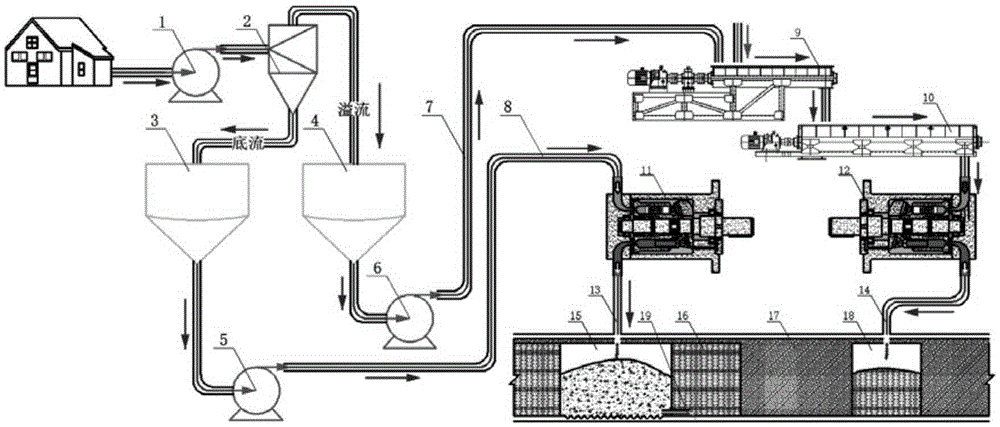

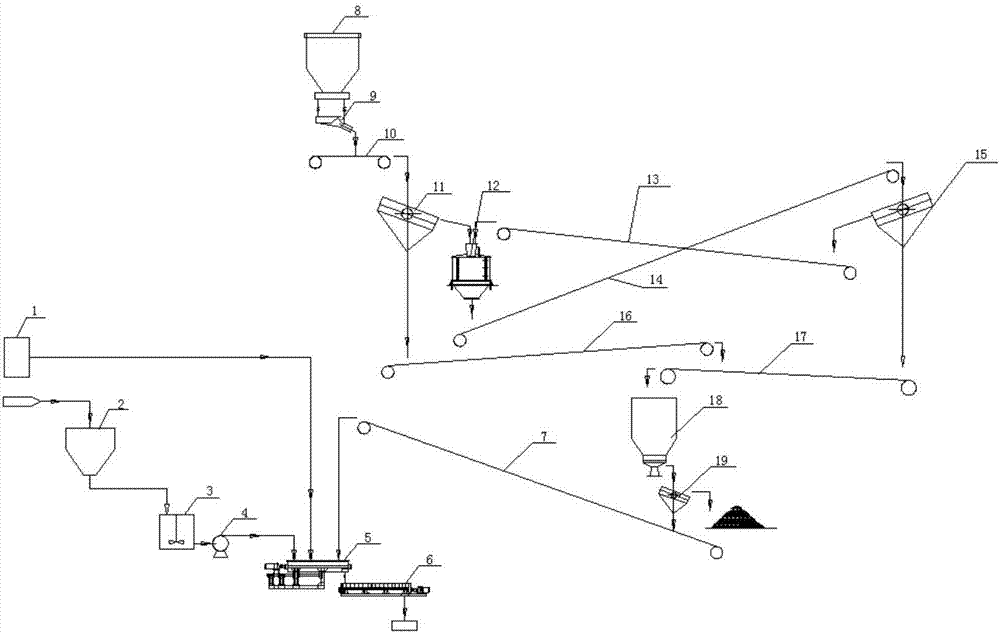

Grading zonal paste backfilling system and method for total tailings of metal minerals

The invention belongs to the field of total tailings paste backfilling and relates to a grading zonal paste backfilling system and method for total tailings of metal minerals. Total tailings of concentrating mills enter a hydrocyclone for grading through a slurry pump, and underflow and overflow of the total tailings are thickened into high-concentration tailings slurry through a thickener. Fine-grained high-concentration tailings slurry is delivered to a backfilling station by a pumping through a pipeline and is backfilled to a step 1 stope after being added with suitable cementing material, while thick-grained high-concentration tailings slurry self-flows or is pumped to a step 2 stope for backfilling, and thus non-cementing backfilling in the step 2 stope is achieved. The high-concentration graded coarse tailings have good water filtration, and a small amount of exudation is discharged out of a backfill through a water filtration facility erected at the stope during non-cementing backfilling. The grading zonal high-concentration backfilling of total tailings can be achieved, and the defect that superfine tailings are poor in dewatering performance can be well overcome.

Owner:UNIV OF SCI & TECH BEIJING

Double-layered and bidirectional horizontal stripping open-stope backfilling mining method

ActiveCN108708726AReduce the number of installationsReduce the proportionUnderground miningSurface miningComputer science

The invention relates to the technical field of mining, in particular to a double-layered and bidirectional horizontal stripping open-stope backfilling mining method. The double-layered and bidirectional horizontal stripping open-stope backfilling mining method comprises the following steps: S7, separately forming two lower slice slicing stope openings in two sides of the tail of a vein connectionroadway, separately arranging lower slice stope connection roadways towards an lower slice stope of a stope in step one and an lower slice stope of a stope in step two from every lower slice stope; S8, continuing tunneling and arranging upper and lower slice connection roadways in the extension direction of the vein connection roadway from the tail of the vein connection roadway, and enabling thetails of the higher and lower slice connection roadways to be positioned between the two higher slice stopes of an adjacent horizontal stope below a horizontal stope in step S6; and S9, separately forming two upper slice stope openings in the two sides of the openings of the upper and lower slice connection roadways, separately arranging upper slice stope connection roadways towards an upper slice stope of the stope in step one and an upper slice stope of the stope in step two from every upper slice stope opening, and enabling the opening of each upper slice stope connection roadway to be positioned in the center of the corresponding upper slice stope.

Owner:CENT SOUTH UNIV

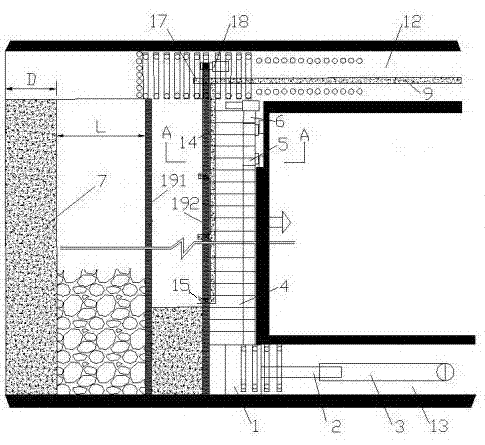

Full-mechanized coal mining coal-pillar-free sublevel filling coal mining method for steeply inclined coal seam strike

InactiveCN106968708ASettlement controlReduce distortionUnderground miningSurface miningLithologyMining engineering

The invention discloses a full-mechanized coal mining coal-pillar-free sublevel filling coal mining method for steeply inclined coal seam strike. According to the principle, the method includes the steps that after a steeply inclined coal seam field is divided into mining areas, a long-wall fully mechanized coal mining face is arranged along the coal seam strike, and after advancing in the coal mining face, a goaf is subjected to sublevel filling along the coal seam strike. According to the rock mechanics principle and the lithology of overlying rock of the coal mining face, the dimensions D and strength of sublevel filling bodies and the limited span L of sublevel filling are determined under the condition that the upper roof of the overlying rock is not broken. A filling-body filling area is divided into inclined sealing filling areas by sublevel small coal pillars and rectangular air bags, and paste filling is conducted in the sealing areas through pipelines. By means of the method, the filling amount can be reduced, the filling cost is lowered, the resource recovery rate is increased, and the safe, environmental-friendly and economical coal mining effects are achieved.

Owner:HUNAN UNIV OF SCI & TECH

High-early-strength filling material for coal mine goaf

InactiveCN104556917AHas early strength propertiesImprove liquiditySolid waste managementMaterial fill-upSuperplasticizerUltimate tensile strength

The invention relates to a high-early-strength filling material for a coal mine goaf. The high-early-strength filling material is prepared from the following components in parts by weight: 10-20 parts of quick-hardening sulphate aluminate cement, 40-80 parts of coal ash, 150-200 parts of coal gangue particles, 1-3 parts of a content-available superplasticizer and 0.1-1 part of a thickener. The high-early-strength filling material is used for filling the coal mine goaf and is remotely pumped, and is high in strength increase speed and filling efficiency, low in filling cost, safe and environmentally friendly. An experiment shows that the early strength of the high-early-strength filling material is high and can reach 10.0MPa, and the compressive strength can reach 18.0MPa in the 28th day.

Owner:XIANYANG DONGFANG YUHONG BUILDING MATERIAL CO LTD

Strip filling method of conventional mining face goaf pumping cementing materials

InactiveCN105332733AThere will be no collapse accidentsSinking is stable and controllableMaterial fill-upBody positionsSlurry

The invention discloses a strip filling method of conventional mining face goaf pumping cementing materials. The method includes: designing strip filling bodies in a goaf along an advancing direction, constructing a first small filling strip at determined strip filling body positions according to a principle that the intervals among rear four rows of support columns are filled when a conventional mining face advances to the seventh row of support columns, sequentially completing small filling sections from bottom to top along the inclination direction of the mining face in the same manner, and building an upper-end gangue wall on the lying side of an upper roadway so as to prevent gangue slurry from overflowing and form the first small filling strip; constructing a second small filling strip and the like according to the construction step of the first small filling strip until the design width of the strip filling bodies is reached. The method has the advantages that during the filling process and after the strip filling is completed, the method is good in roadway safety, good in strip forming quality, high in construction efficiency, low in filling cost, and the like.

Owner:SHANDONG UNIV OF SCI & TECH

Method for preparing carbon-fixation filling paste from waste concrete

InactiveCN109650805AAffect qualityIncrease carbon sequestrationGas treatmentDispersed particle separationCarbonizationToxic industrial waste

The invention discloses a method for preparing a carbon-fixation filling paste from waste concrete. The method comprises the following steps: industrial waste gas is dedusted, and then is mixed with normal temperature air, a waste concrete and a gangue mixture is crushed in the obtained industrial exhaust gas atmosphere, and coarse aggregates, fine aggregates and fine powder obtained after screening and carbon dioxide in the industrial exhaust gas undergo a carbonization reaction in a carbon fixation chamber; and the carbon-fixation coarse aggregates, the carbon-fixation fine aggregates, a filling paste additive, cement, phase change material microcapsules and water are stirred and mixed to form a filling body mixture, and the industrial exhaust gas is continuously injected in the stirring, mixing and conveying process of the filling paste to make the filling paste and the carbon dioxide in the industrial exhaust gas undergo the carbonization reaction in order to obtain the carbon-fixation filling paste. The carbonization reaction of the waste concrete and carbon dioxide is fully used, so the damages of the waste concrete to the environment are reduced, and the emission of greenhouse gases is reduced; and hydration heat is fully used in the carbonization reaction, so the filling effect of the carbon-fixation filling paste is good.

Owner:XUZHOU UNIV OF TECH

Technology for filling of gob under well with adhesive filling materials

InactiveCN106884675AImprove continuityLower filling costsMaterial fill-upCement mixing apparatusFilling materialsSlurry

The invention provides a technology for filling of a gob under a well with adhesive filling materials. First, tailing waste residues generated by a concentration plant are discharged from an ore-discharging valve at the bottom of a waste residue bin, fine materials are obtained through repeated crushing and sieving and transferred into a gravel finished product bin, then according to a proportion, the fine materials, ore slurry, adhesive materials and water are jointly fed into a filling slurry stirring system to be stirred uniformly to obtain the filling materials, and finally the filling materials are pumped into the gob under the well. The procedures where waste gravel is crushed during preparation of the filling slurry are simplified, and the procedure of ore grinding is omitted; the ore slurry generated by ore concentration of the concentration plant is adopted for improving the grade of the filling slurry, the stirring technology for the filling slurry is adjusted, continuity is achieved during preparation of the filling slurry, and filling cost is lowered.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

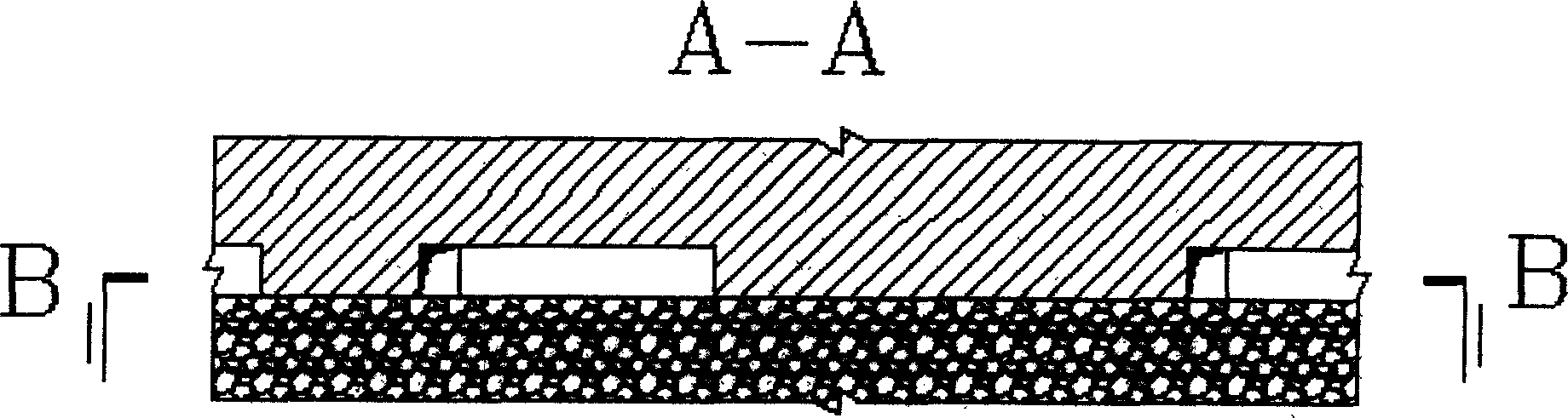

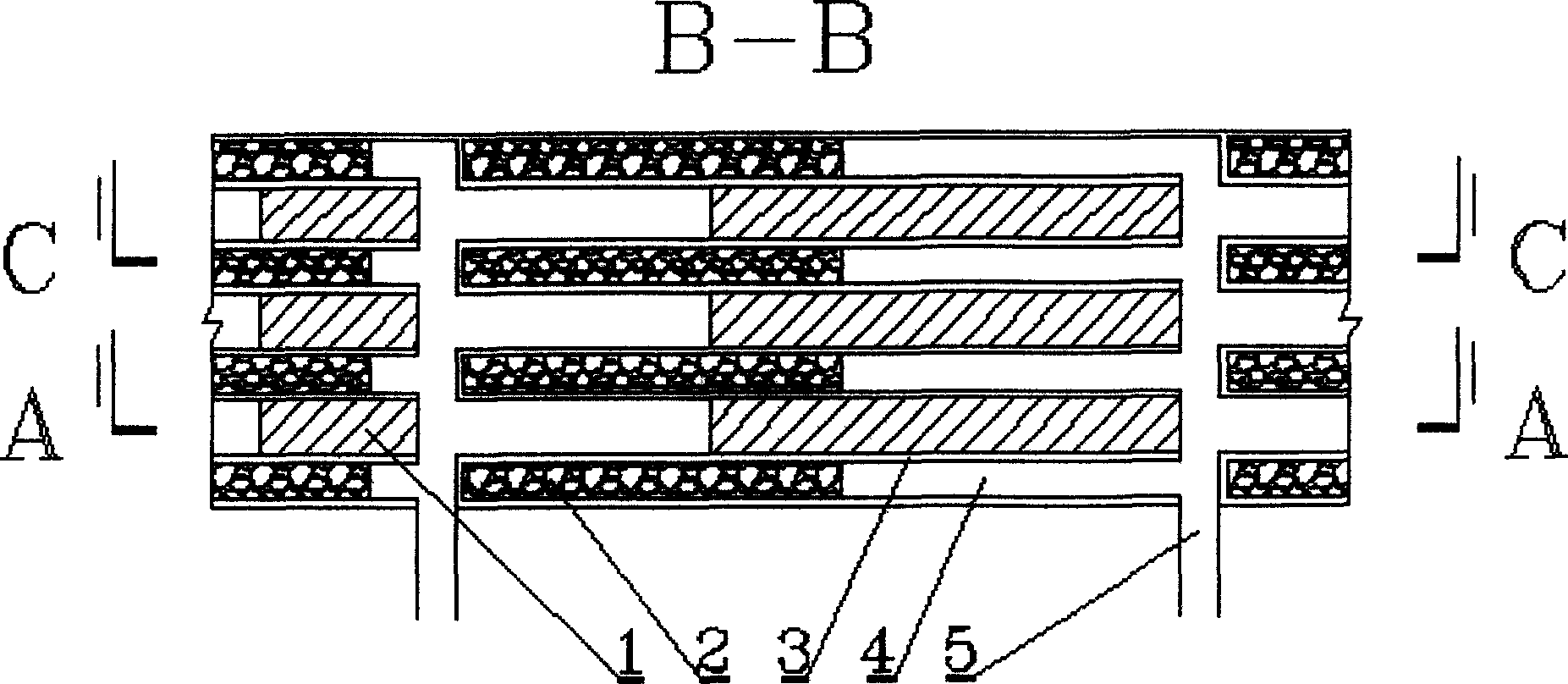

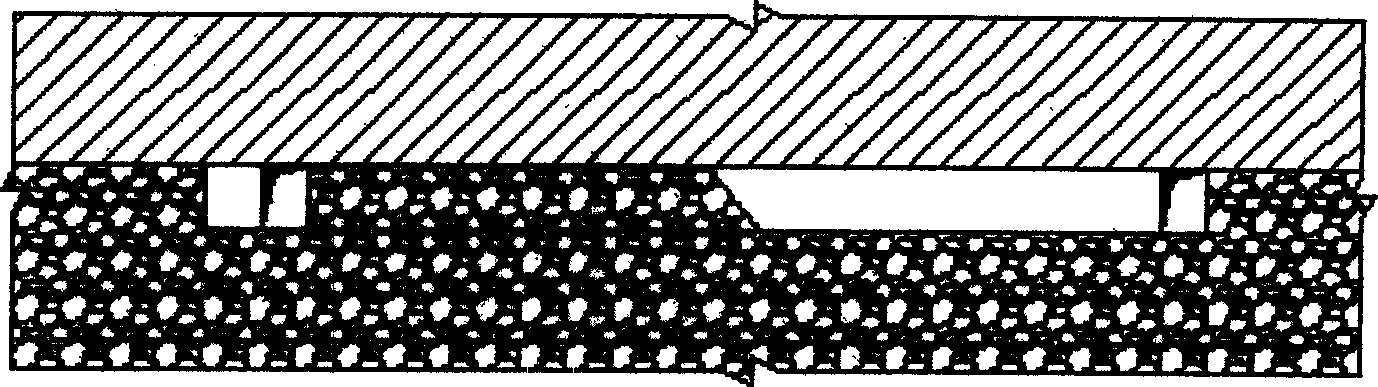

Upward spacing admission passage filling mining method

InactiveCN1693663ALower filling costsIncrease production capacityUnderground miningSurface miningEngineeringCoal

This invention discloses an upward spacing admission passage filling mining method. Its feature is that horizontal working type and dry filling are used in this method. The horizontal working type is that filling and coal winning work horizontal. When first period filled is back working, the second extracting route from the other end of the ore block. When second dry filling is backing to the other end of the block, the first extracting route of up layer is route from the other end of the block. Or first period filled is back working, the firs period of up layer extracting drift tailgate from the other end of the ore block. When up layer first dry filling is backing to the other end of the block, the second extracting route of up layer is route from the other end of the block. The first dry type filling is that supporting wall is built on two side of the route, steel dropper is pre-buried and filling is consolidated from inner part. Productive capacity can be increased by using this invention, filling cost can be reduced, and back production safety can be ensured. It is propitious to the mine of unstable ore and rock, low ore value and large productive capacity.

Owner:HEBEI HAN XING INST OF MINE & METALLURGY DESIGN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com