Patents

Literature

69results about How to "Reduce support costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

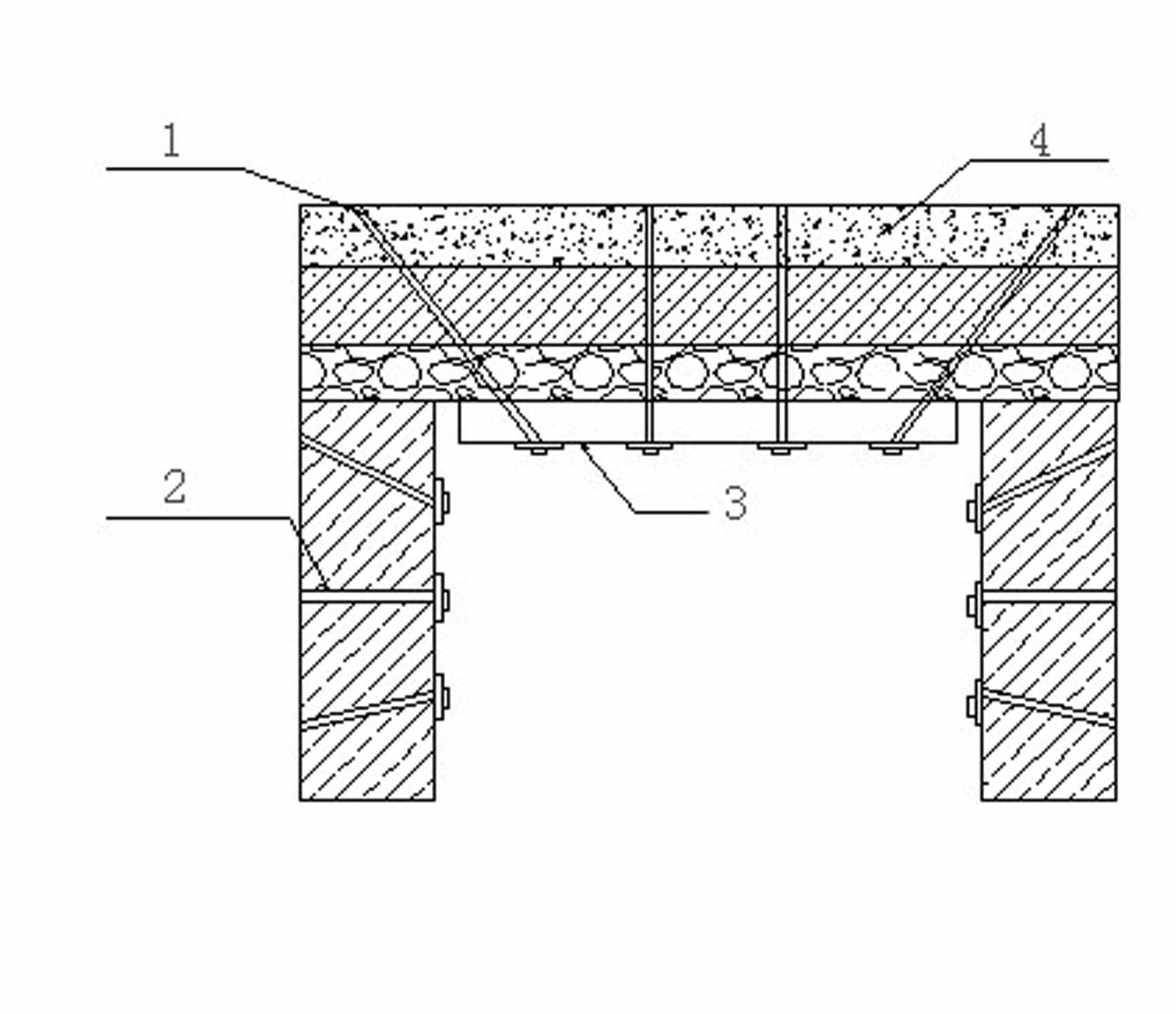

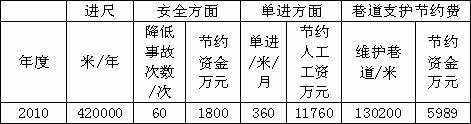

Supporting method of laneway under multiple goafs in ultra-close coal seam group

InactiveCN102425438ASolve the technical problems of roadway supportSolve support technical problemsAnchoring boltsProtective coversSocial benefitsEngineering

The invention specifically relates to a supporting method of a laneway under multiple goafs in an ultra-close coal seam group, which can be used for solving the problem of incomplete support of the laneway under the multiple goafs in the ultra-close coal seam group. The supporting method of the laneway under the multiple goafs in the ultra-close coal seam group comprises the following steps: performing preparation work, performing temporary supporting, laying a steel wire mesh, loading steel beams, mounting an anchor rod of a top plate, mounting the anchor rod of an upper part, mounting an anchor rope of the top plate and the like. By utilizing the effective supporting scheme according to the invention, the technical difficult problem of supporting the laneway under the multiple goafs in the ultra-close coal seam group in Datong mining area is solved, and the great safety economic effect and the great social benefits are achieved.

Owner:DATONG COAL MINE GRP

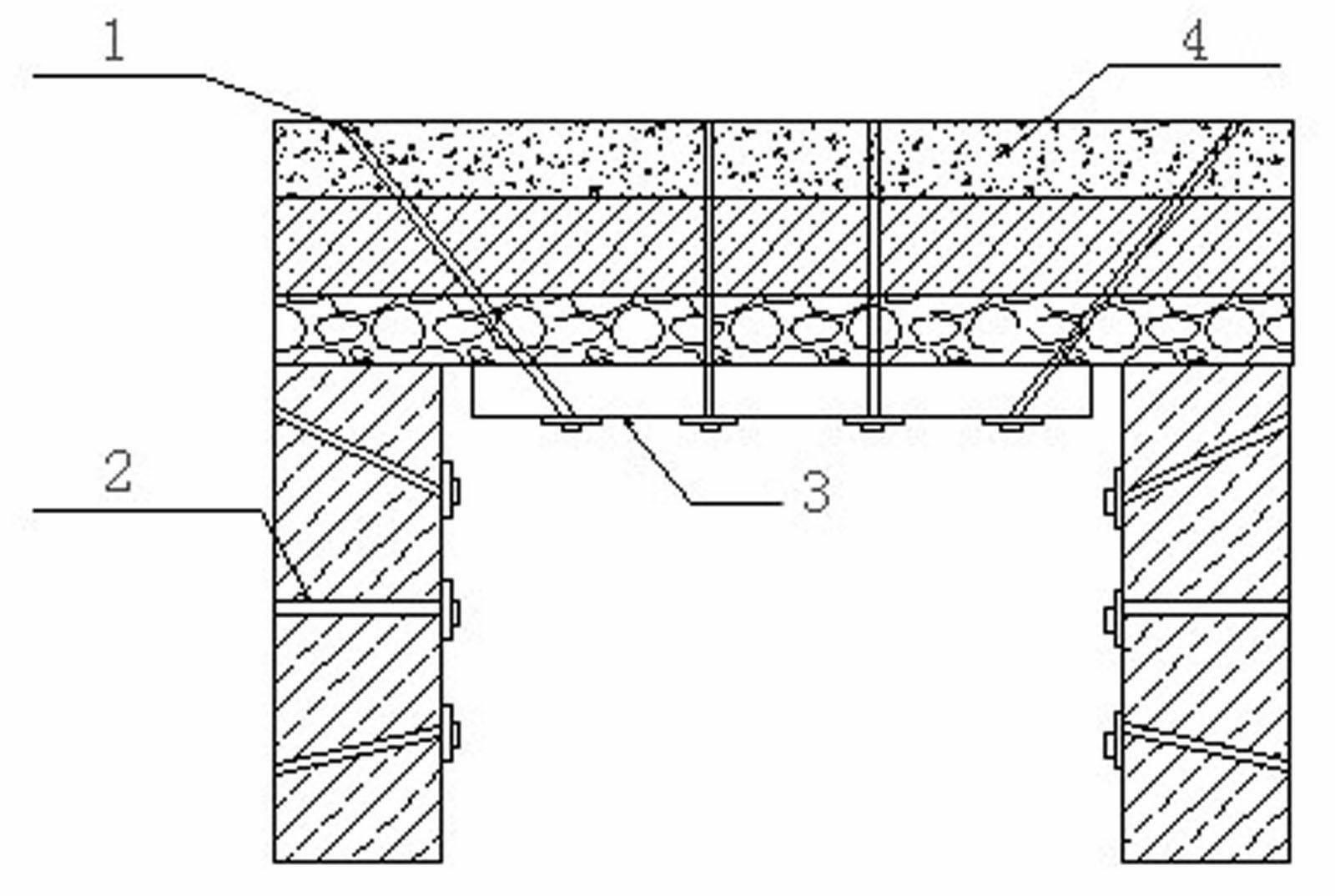

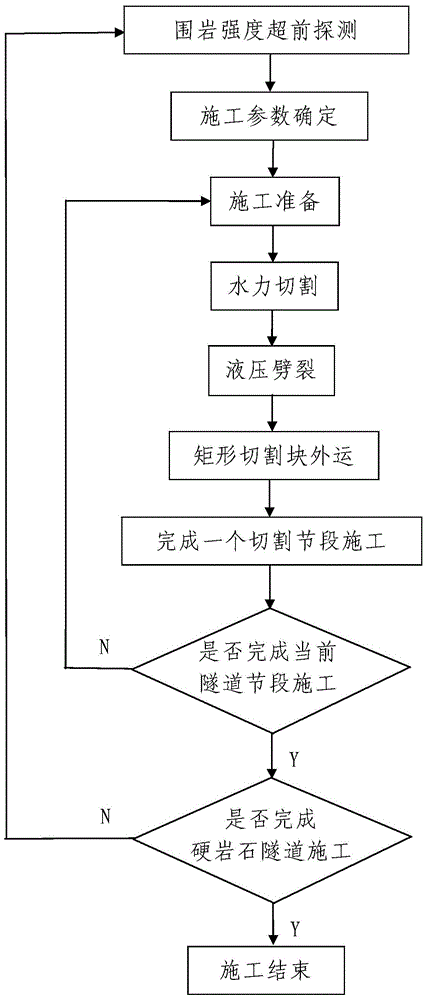

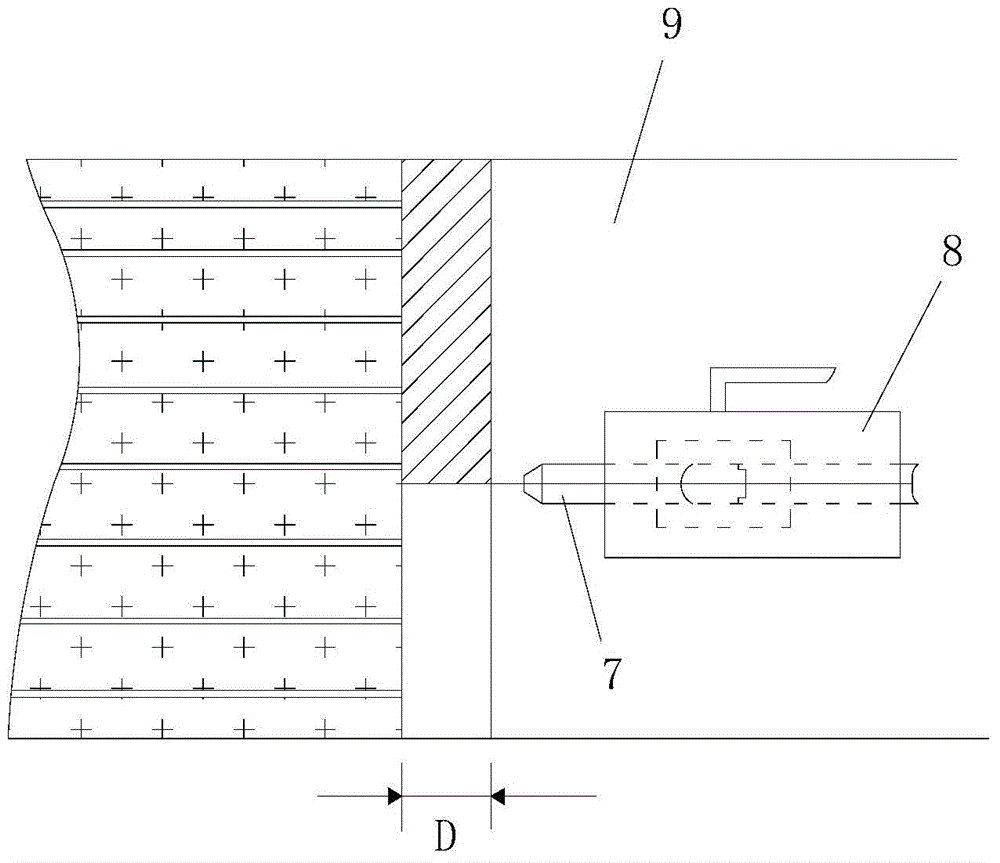

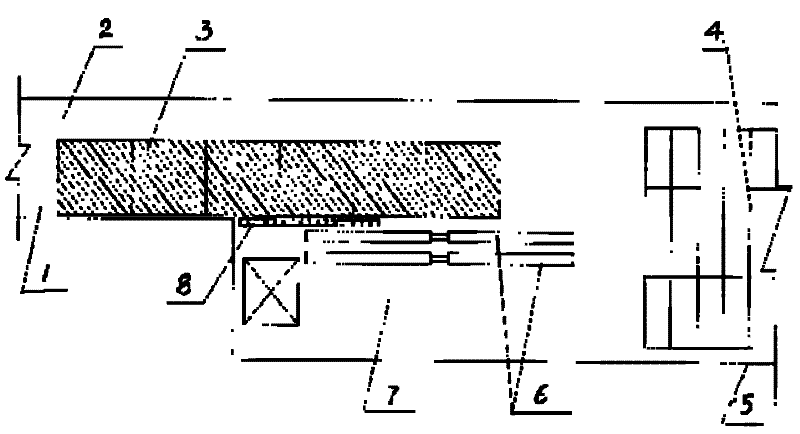

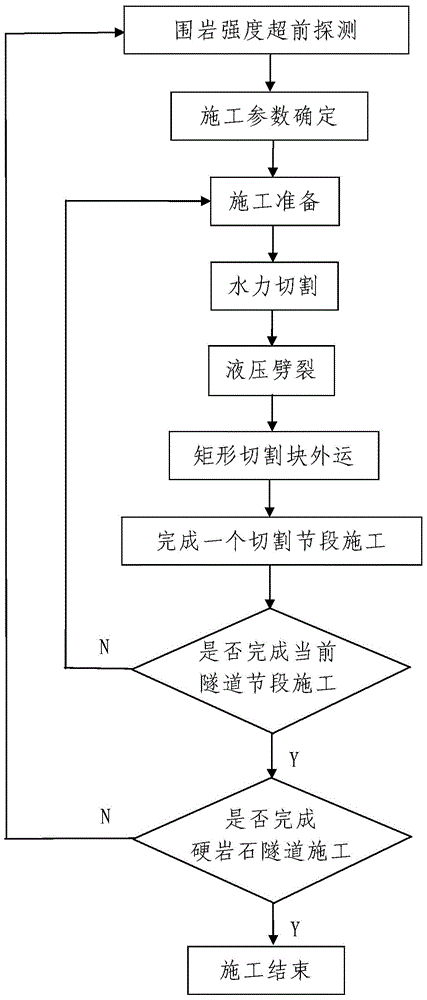

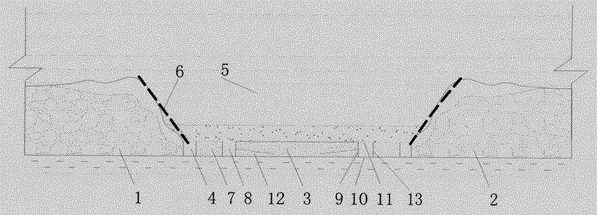

Hard rock tunnel construction method based on water power cutting

The invention discloses a hard rock tunnel construction method based on water power cutting. The hard rock tunnel construction method based on the water power cutting is characterized by constructing multiple tunnel sections from back to front along the longitudinal extending direction of a tunnel. When any one tunnel section is constructed, the process is as follows: 1, surrounding rock classification advanced detection; 2, construction parameter confirmation, wherein the confirmed construction parameters comprise cutting parameters of a water power cutting machine and split force of a hydraulic splitter; 3, current constructed tunnel section construction: constructing multiple cutting sections of the current constructed tunnel sections from back to front along the longitudinal extending direction of the tunnel, wherein when any one cutting section is constructed, the process is as follows: construction preparation, water power cutting, hydraulic splitting and rectangular cutting block outward transporting; 4, repeating steps one, two and three for many times until the construction process of the constructed hard rock tunnel is finished. The method provided by the invention is simple in steps, convenient to implement, lower in input cost, high in construction efficiency, good in construction effect, and can simply, conveniently and quickly finish the construction process of the hard rock tunnel.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

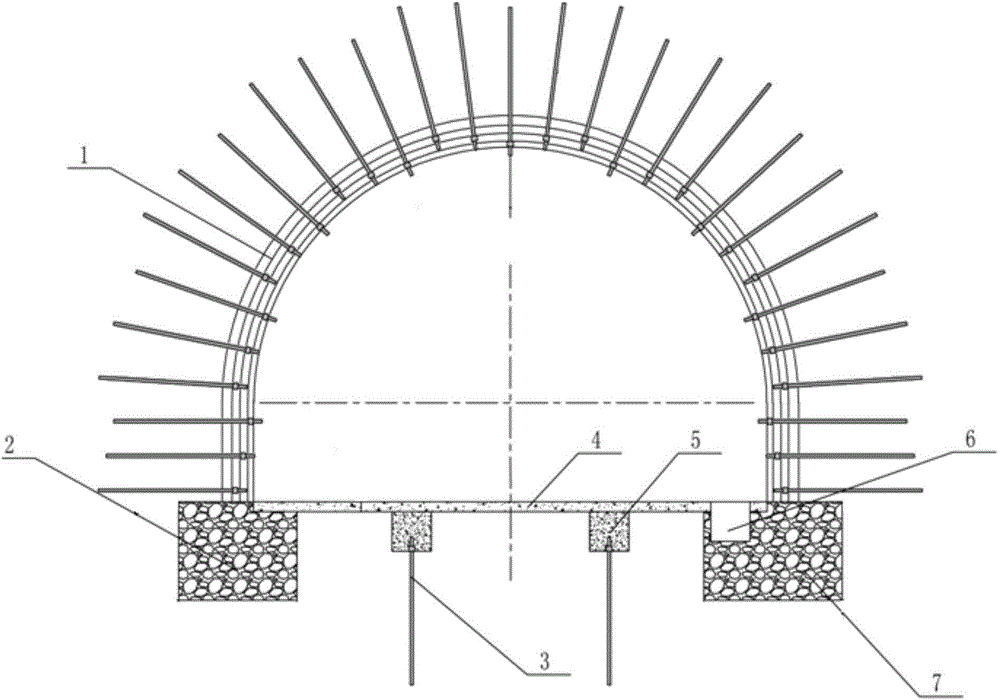

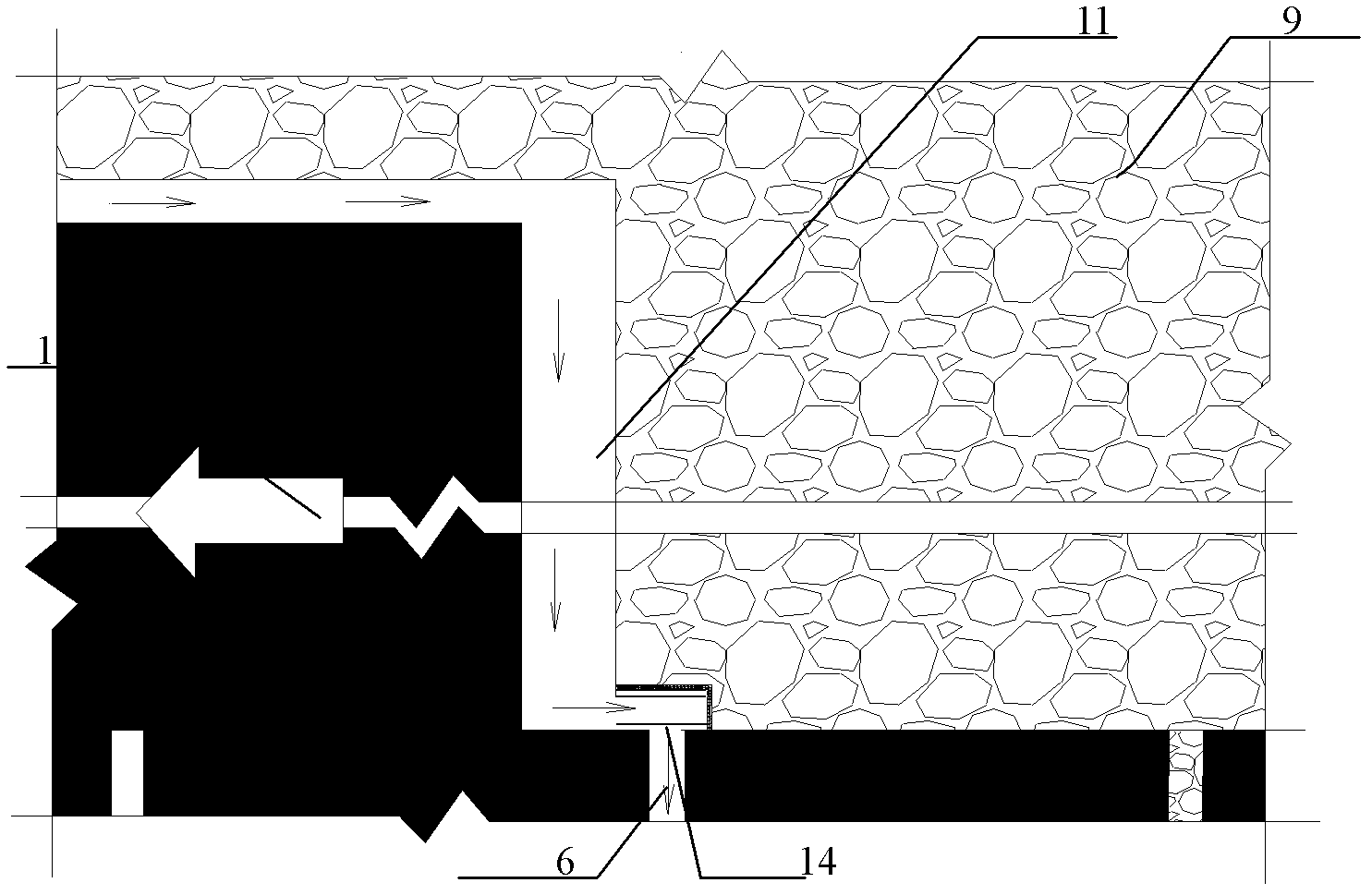

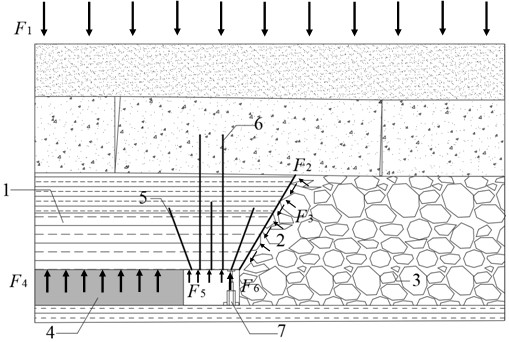

Large plate bottom supporting method for soft rock roadway

InactiveCN104612727AEliminate serious threatsAvoid damageMine roof supportsTunnel liningEngineeringRebar

The invention discloses a large plate bottom supporting method for a soft rock roadway. The large plate bottom supporting method includes the following specific steps that high-speed spraying concrete is adopted on side tops and two sides, four concrete spraying layers are formed, four layers of steel wire ropes and four layers of anchor rods are arranged in the four concrete spraying layers to form a tough sealing layer and construct a homogeneous and isotropic supporting ring body, initiative supporting is conducted on the roadway, a thin reinforcing mesh is arranged between the second spraying layer and the third spraying layer, the steel wire ropes and the thin reinforcing mesh are used together, concrete foundations are poured on two side bottoms of the roadway, a ditch is formed in the inner side of the right foundation, and a pressure releasing groove is excavated in the lower portion of a bottom plate of the roadway. The large plate bottom supporting method is more stable and more durable than traditional supporting, and a large amount of supporting cost is also reduced.

Owner:HUAIBEI PINGYUAN SOFTROCK SUPPORTING ENG TECH

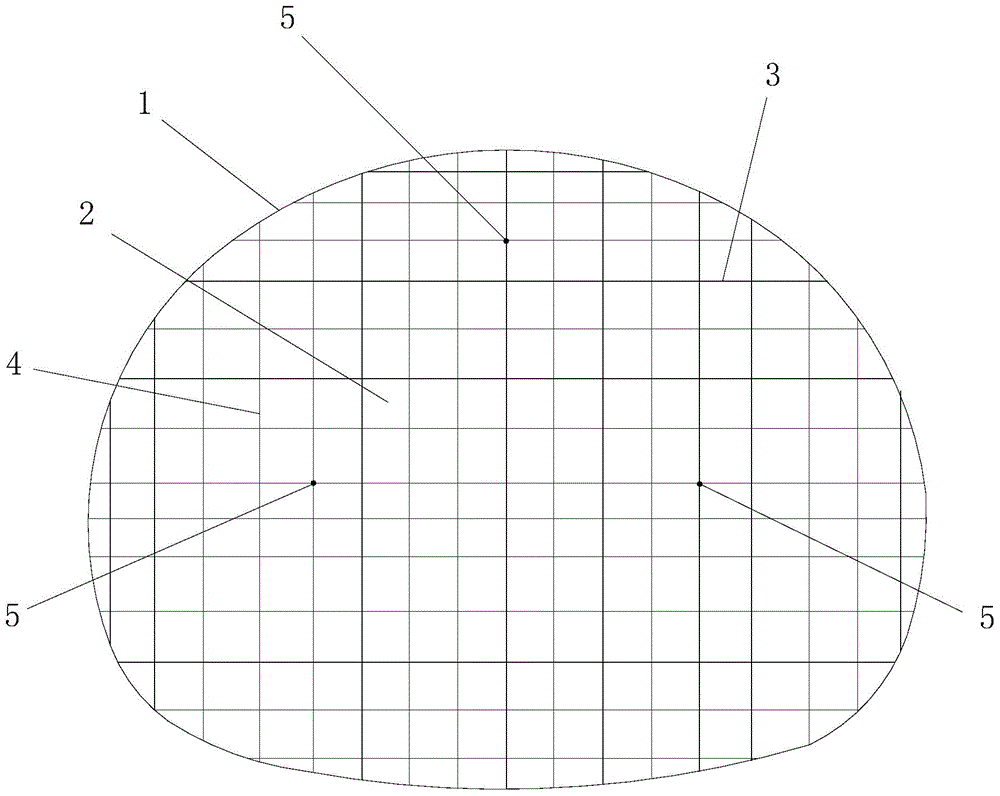

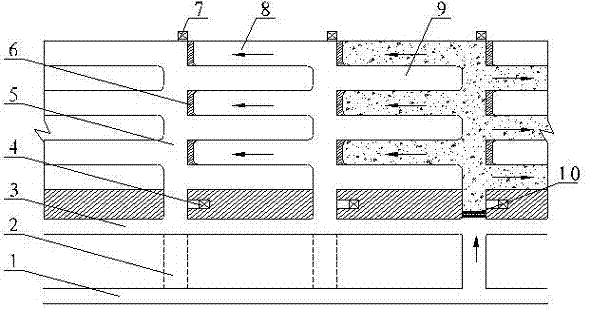

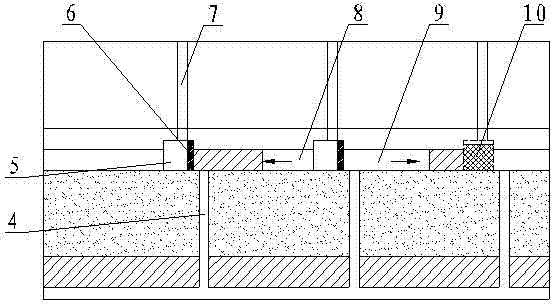

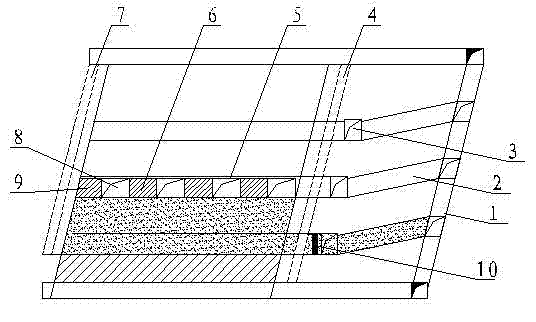

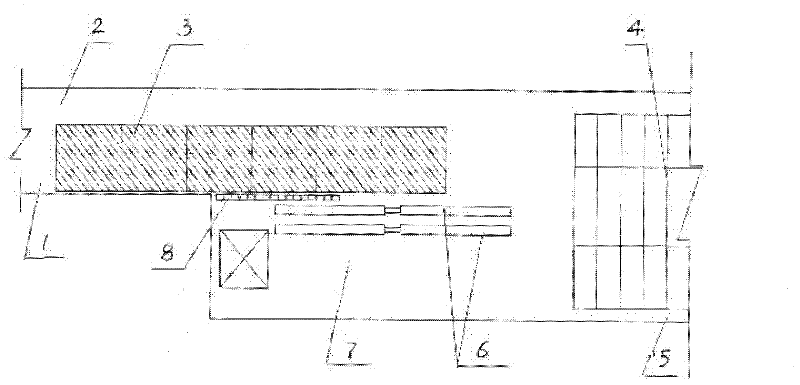

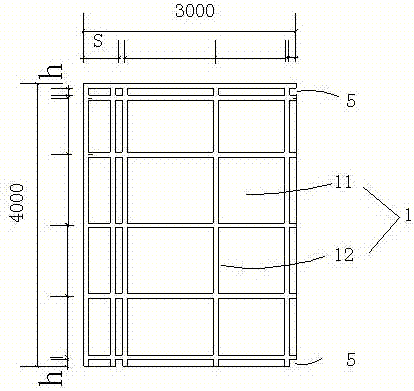

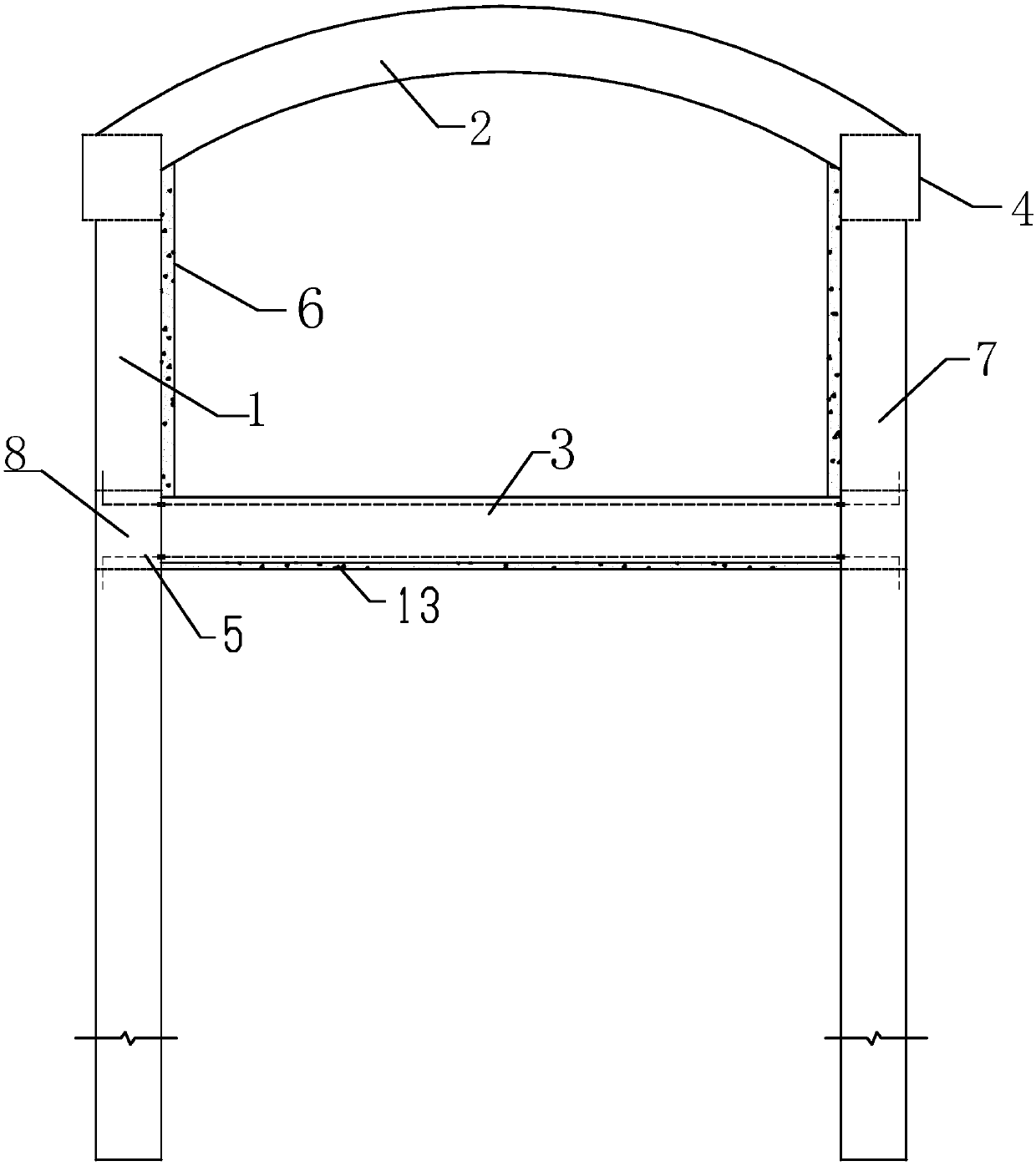

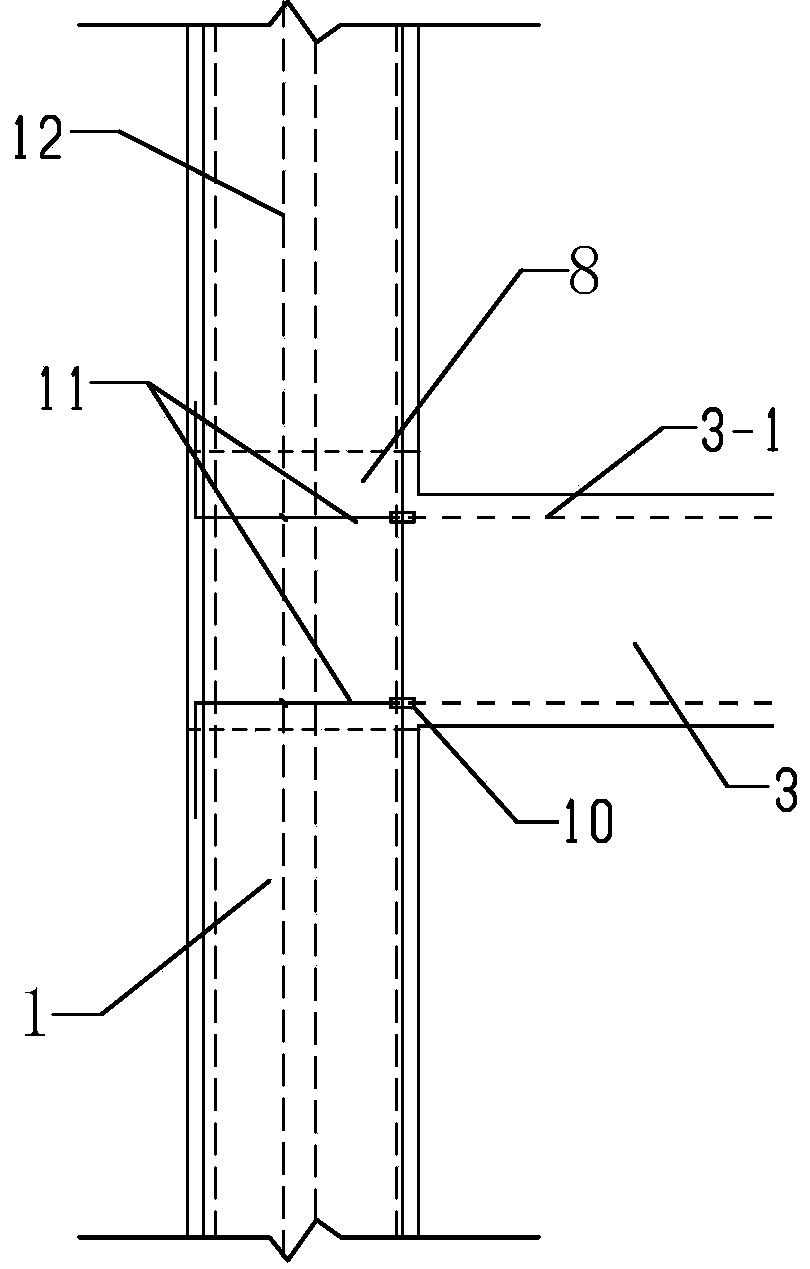

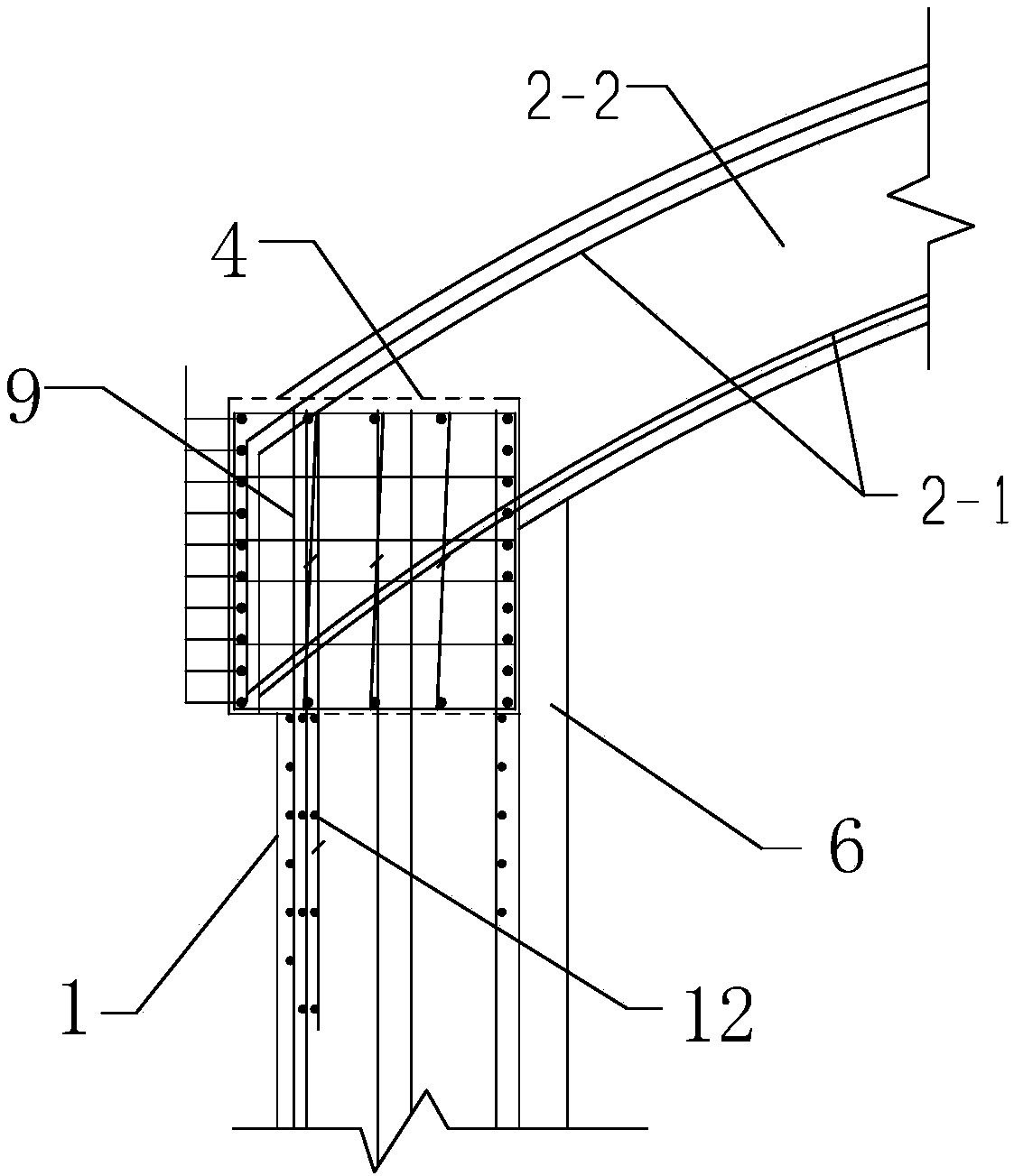

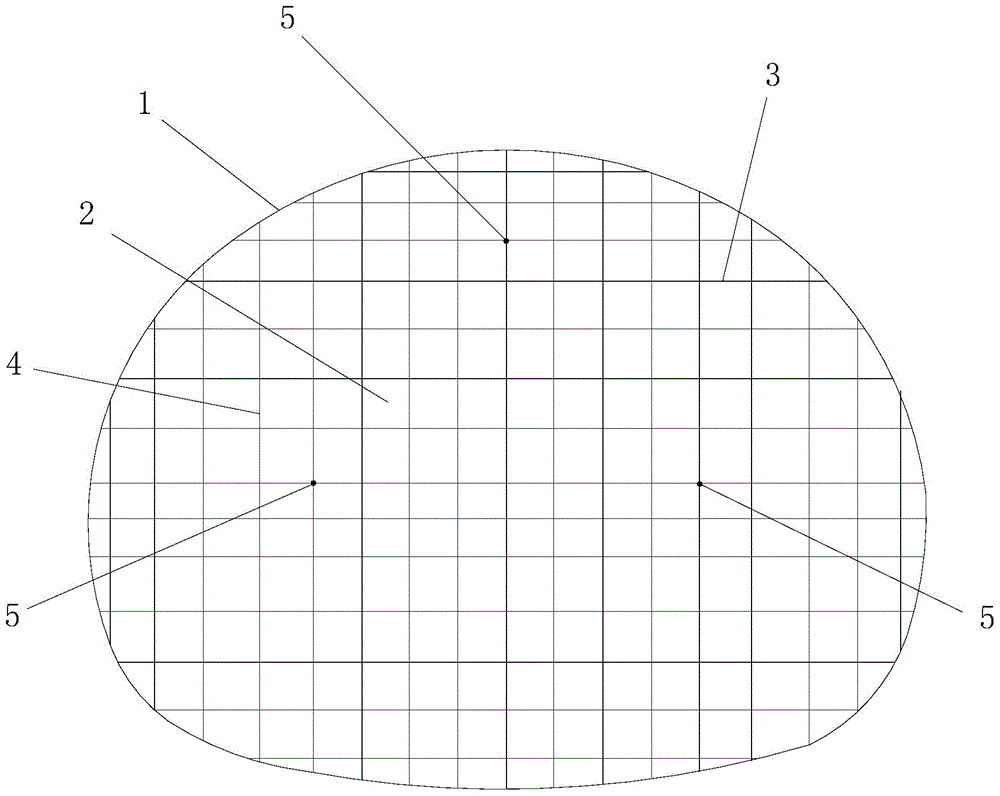

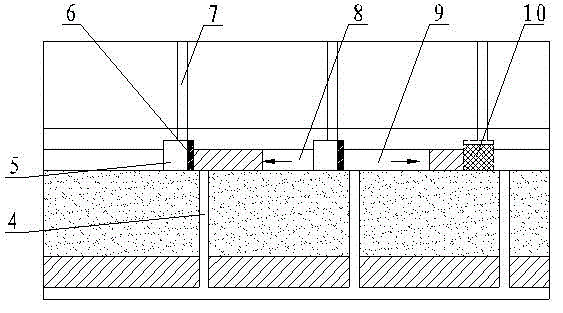

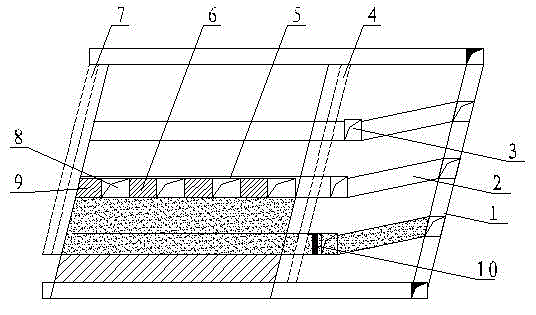

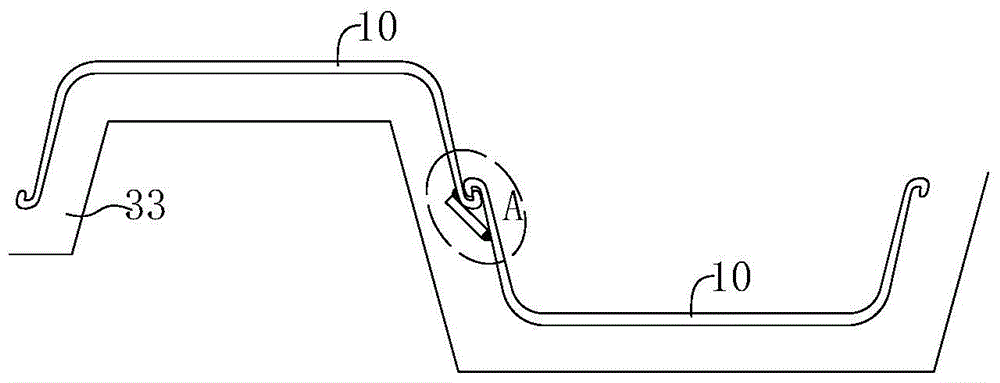

Stope route arrangement mode and method beneficial to roof-contacted filling

ActiveCN103615285ASimple process and construction managementReduce support costsMaterial fill-upFilling materialsEngineering

The invention provides a stope route arrangement mode and method beneficial to roof-contacted filling. The roof-contacted filling rate can reach above 90%, filling cost is low, and the process is simple. According to the stope route arrangement mode, a mining cutting roadway is arranged perpendicular to the moving direction of an ore body, extracting drifts at two wings of the mining cutting roadway are arranged in the moving direction of the ore body in a staggered mode, a chute is arranged in a surrounding rock section of the footwall of the mining cutting roadway, the height of the extracting drifts is 3m, the length of the first extracting drift is 14-18m, the length of the second extracting drift is 16-20m, and the height of the mining cutting roadway is 4.5m. According to the stope route arrangement method, a slope ramp linking way, a footwall stope layering linking roadway and the mining cutting roadway are constructed sequentially, and the chute and a return air filling shaft are communicated; the second extracting drift is constructed after the first extracting drift is finished; brushing extraction is carried out on a temporary jamb, the width of a central mining cutting roadway is 4.5-5m, and a top plate is shaped like an arch; waste stones are dumped into the second extracting drift, the height of a smooth chute is increased by 3.5m, a filling blocking wall is erected, and filling operation is finished when the liquid level of filling material slurry is higher than the top plate of the extracting drifts by 20-30cm.

Owner:南京银茂铅锌矿业有限公司

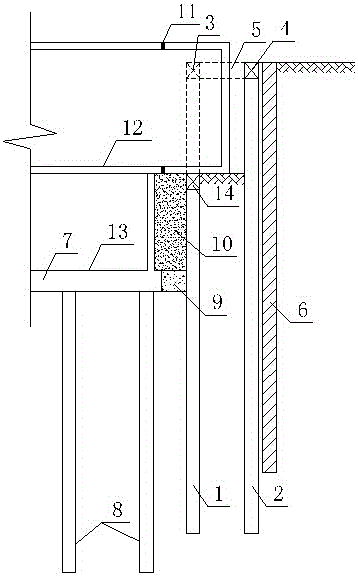

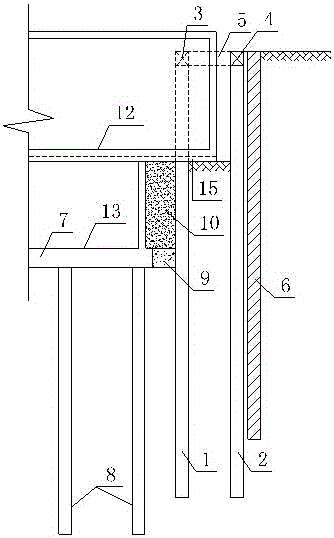

Double-row pile support structure capable of fully utilizing basement space and construction method of double-row pile support structure

The invention relates to a double-row pile support structure capable of fully utilizing basement space and a construction method of the double-row pile support structure, and belongs to the field of building construction and room buildings. A crown beam I is arranged on the top of a front row pile, and a crown beam II is arranged on the top of a rear row pile. The top of the front row pile and the top of the rear row pile are connected through a connecting beam I. A waterproof curtain pile is arranged in a pile rear soil body of the rear row pile. After a field is leveled, all project piles are constructed according to the design. A connecting beam II is poured on the top of the cut front row pile. The connecting beam II and a negative layer basement bottom plate are integrally poured. The part between the front row pile and a minus-two floor basement outer wall is filled with layering compaction filling soil. The part between the front row pile and a minus-two floor basement bottom plate is filled with plain concrete. According to the double-row pile support structure, double-row piles are changed into a single-row-pile structure with the same rigidity by means of the equal-rigidity replacement principle of the double row piles and the single row piles, the horizontal displacement of a support structure system can be controlled, and meanwhile the foundation pit support cost can be greatly reduced; and good economical efficiency is achieved in a foundation pit project with basements with multiple layers.

Owner:KUNMING UNIV OF SCI & TECH

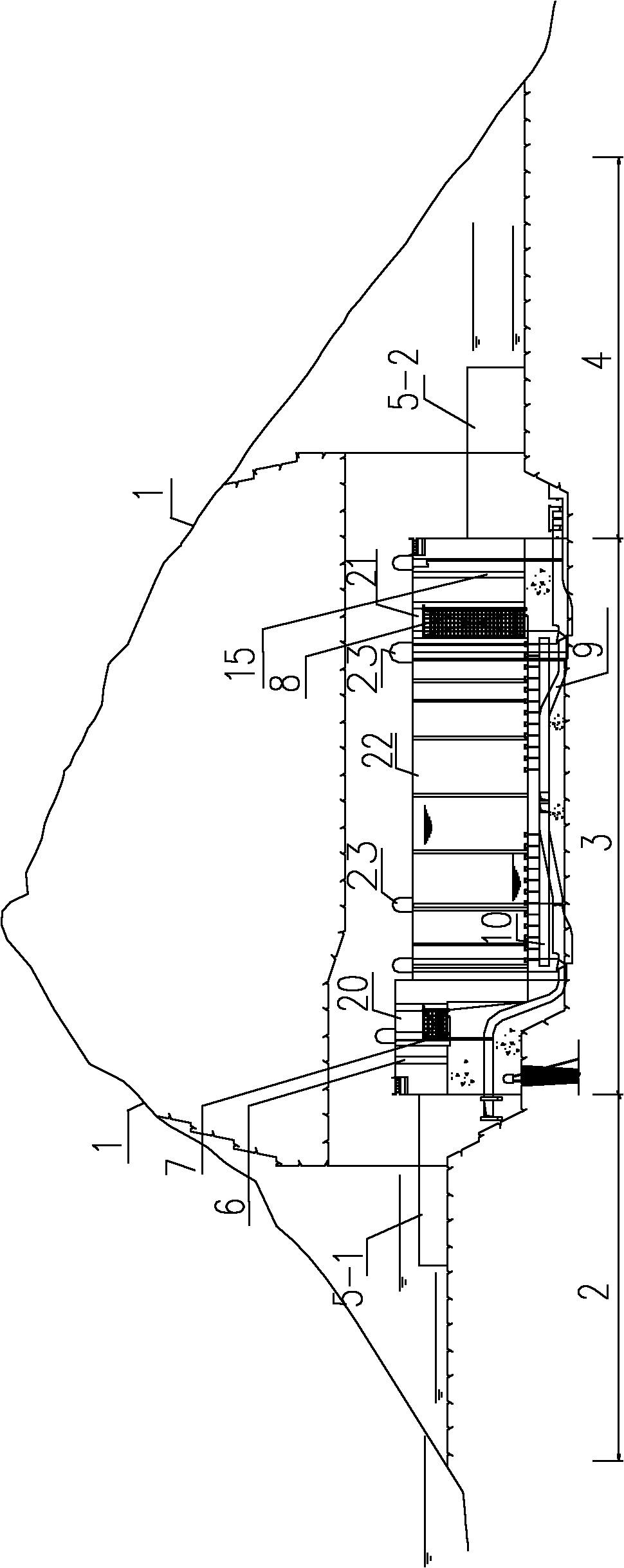

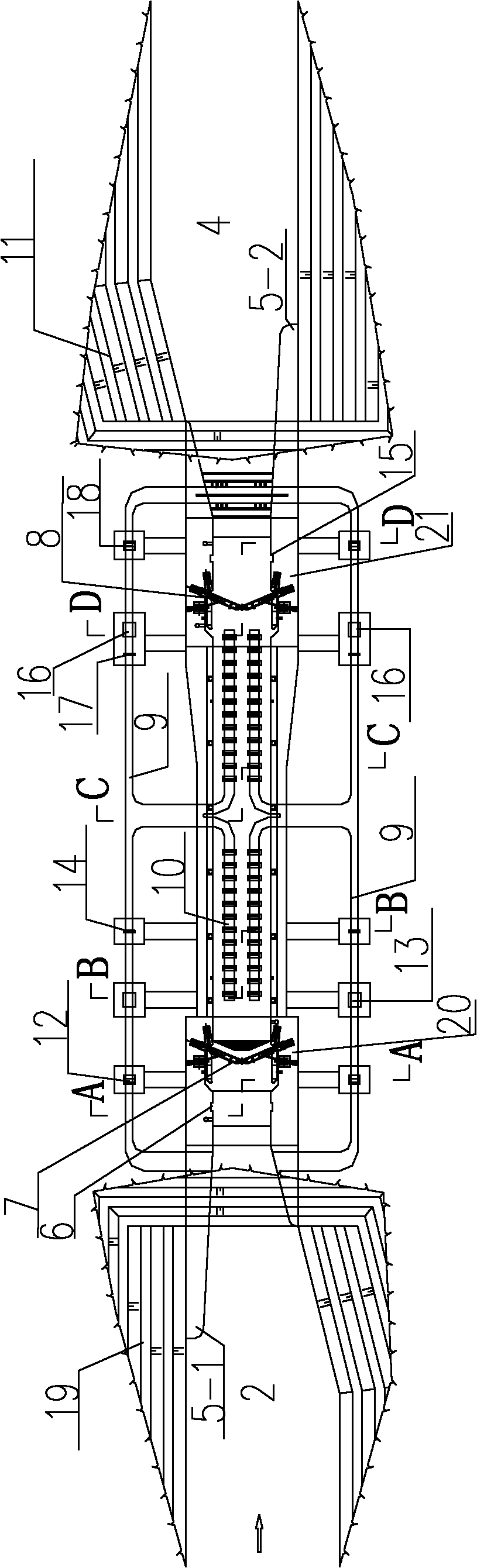

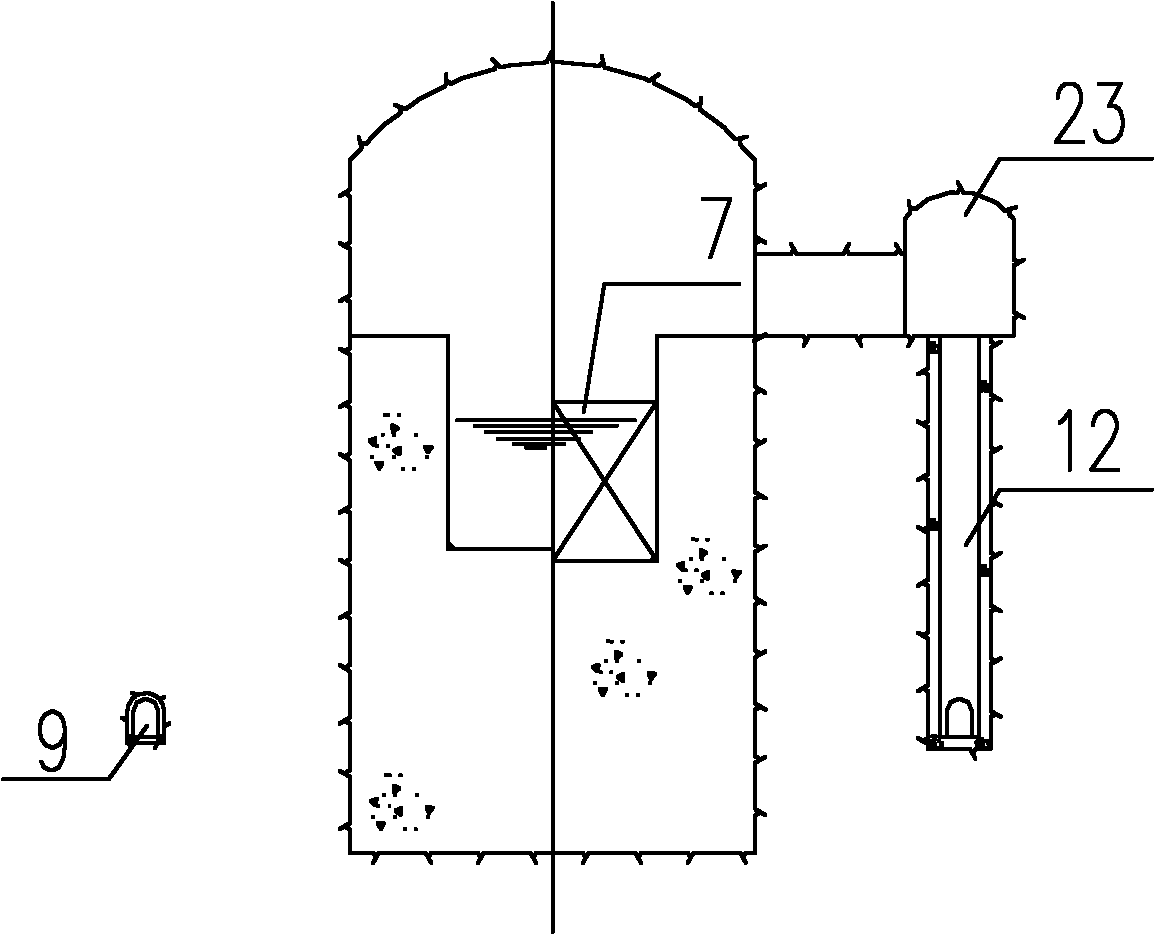

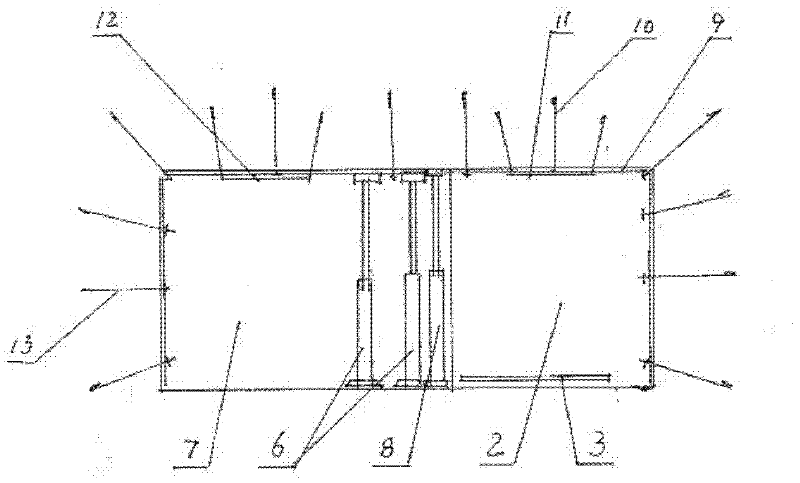

Underground shiplock arranged in mountain body

ActiveCN102134846AReduce support costsWill not form artificialDry-docksClimate change adaptationReinforced concreteWater block

The invention relates to an underground shiplock arranged in a mountain body, which comprises an upstream approach channel (2) and a downstream approach channel (4) for connecting a shiplock main body section (3), wherein the shiplock main body section (3) comprises an upper lock head (20), a lock chamber (22) and a lower lock head (21), an upstream water-blocking door slot (6) is arranged at theupper lock head (20) of the shiplock, an upstream working door (7) is arranged behind the upstream water-blocking door slot (6), a downstream working door (8) is arranged at the lower lock head (21) of the shiplock, a downstream access door slot (15) is arranged behind the downstream working door (8), and the shiplock adopts a reinforced concrete lining structure. When the shiplock is built on a water conservancy and hydropower junction in a high mountain and valley area, hole excavation is used for replacing open excavation, thereby greatly saving engineering quantity and cost of the shiplock; by matching with construction of a dam, the navigation conditions of an upstream river course and a downstream river course are improved, and a bright future is provided for enabling the river courses to expand the navigable mileage upstream and developing water transportation traffic in mountain areas.

Owner:长江设计集团有限公司

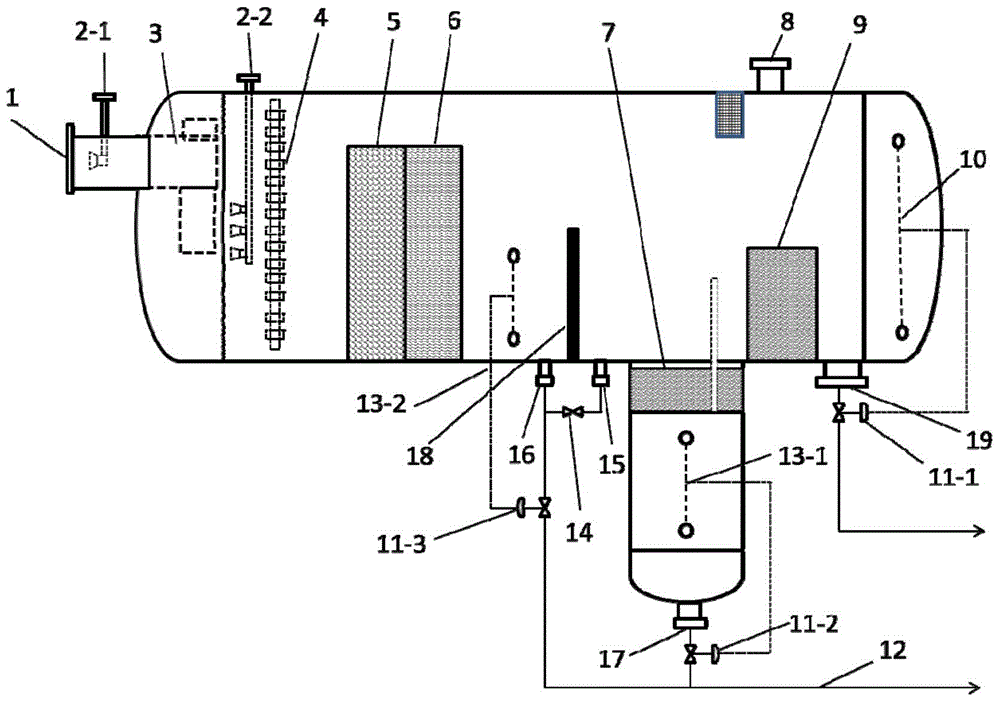

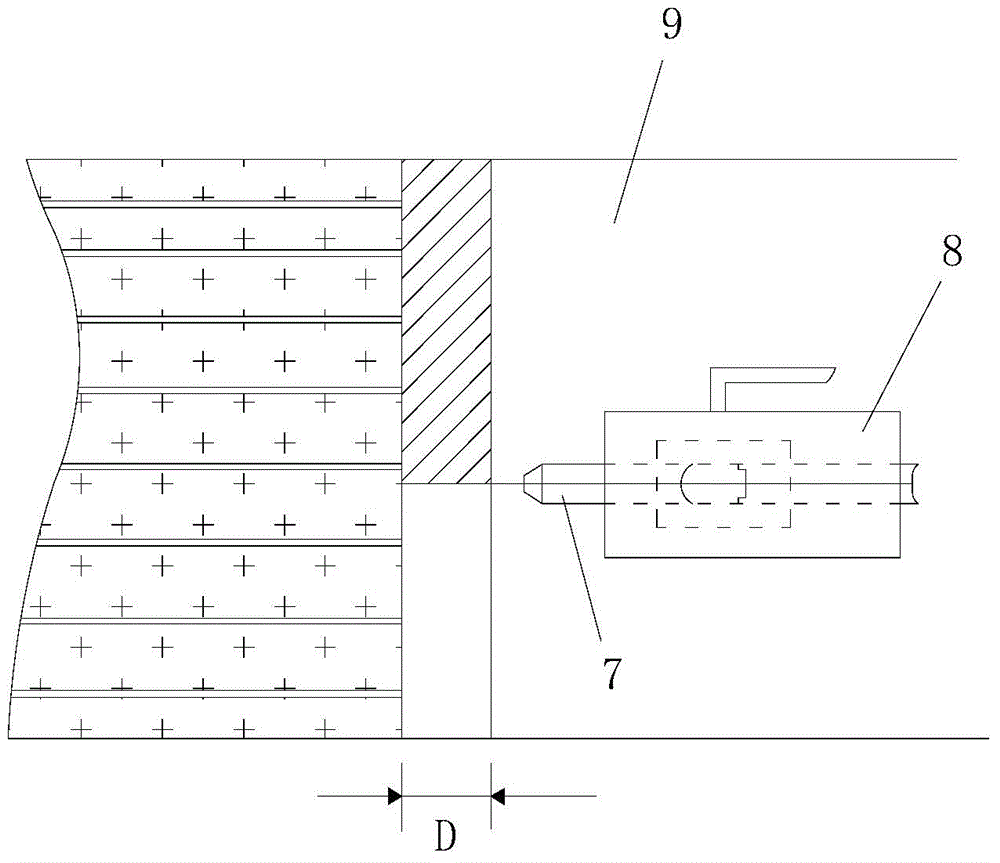

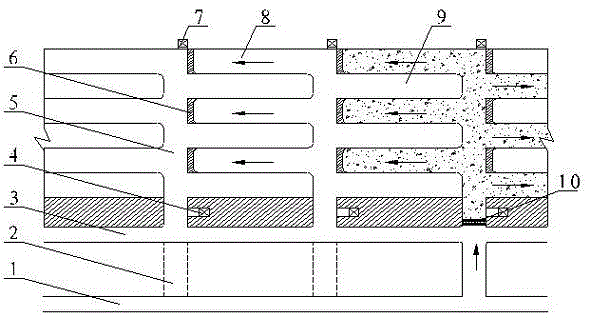

Method and device for strengthening oil-water separation and coupled desalting functions in cold low pressure separator

ActiveCN104667579AQuick degassingSimple structureLiquid separation auxillary apparatusTreatment with plural serial refining stagesFiberGas phase

The invention relates to a method and a device for strengthening oil-water separation and coupled desalting functions in a cold low pressure separator. The method comprises the following steps: performing countercurrent mixing on water-containing low-content oil and desalted water with the volume ratio of 0-1 percent at the inlet section, allowing the mixture to enter a T-shaped liquid-gas separator for being subjected to degassing treatment, rapidly separating the gas phase subjected to step-down flash in the low-content oil, and allowing the oil-water mixture to flow to a rectification distributor on the lower part of the low-pressure separator from a left seal head to a right seal head so as to realize uniform distribution on the radial section; rapidly separating the oil water by virtue of a coarse graining module and a CPI module sequentially, discharging one part of water, allowing oil and trace water (0-0.01 percent) to enter a deep separation section by virtue of a separator, performing deep dehydration on the oil by virtue of a fiber combined module, discharging the oil, performing further deep deoiling on the intercepted water by virtue of the combined fiber module, and discharging the water. According to the method and the device disclosed by the invention, the oil-water separation performance of the cold low pressure separator can be strengthened, the desalting function in the oil can be realized, the occupied area of the low pressure separator is reduced, and the defects of the conventional low pressure separator are overcome.

Owner:EAST CHINA UNIV OF SCI & TECH

Construction method for round underground continuous wall two-in-one structure

ActiveCN105256810AEasy to assembleGuarantee welding qualityArtificial islandsExcavationsPurlinReinforced concrete

The invention discloses a construction method for a round underground continuous wall two-in-one structure. The construction method includes the following steps that (1) bracket steel sheet piles are prefabricated, and round steel reinforced concrete enclosing purlins are prefabricated in a segmented mode; (2) pile sinking is carried out; (3) a foundation pit is excavated; (4) gaps in locking positions of the steel plate piles are blocked; (5) the round steel reinforced concrete enclosing purlins are assembled; (6) the foundation pit continues to be excavated downwards until the design depth is reached, and the gaps in the locking positions of the steel plate piles are continuously blocked through waterstop steel strips; (7) a bottom plate waterstop steel plate is welded to the inner side faces of the steel plate piles, and the bottom plate waterstop steel plate surrounds the inner side of a support in the circumferential direction in an endless shape; and (8) a cushion layer is laid, then a bottom plate is cast to reach a set thickness, and the bottom plate waterstop steel plate is made to stretch into the bottom plate. Through the construction method, the support cost for the foundation pit of an underground building can be reduced effectively; on the basis, the support is used as an outer wall of the underground building, the novel structure that the support and the outer wall are integrated is formed, and a foundation is laid for reducing the overall construction cost of the underground building.

Owner:JIANGSU DONGHENAN GEOTECHNICAL TECH CO LTD

Fast installation method of ten-million-ton scale fully mechanized caving face equipment

InactiveCN102392667ARealize parallel operationSpeed up the installation processMine roof supportsAnchoring boltsMode of transportTon

The invention discloses a fast installation method of ten-million-ton scale fully mechanized caving face equipment and belongs to sinking and driving engineering of mines. The method is innovatively characterized in that open-off cuts on a working surface are widen to improve the transportation mode and installation method of a hydraulic support and the supporting mode of the open-off cuts. By virtue of the improvements, the installation time of the ten-million-ton scale fully mechanized caving face equipment is realized, the construction period is shortened and the installation progress of the working surface is accelerated.

Owner:SHANDONG XINJULONG ENERGY

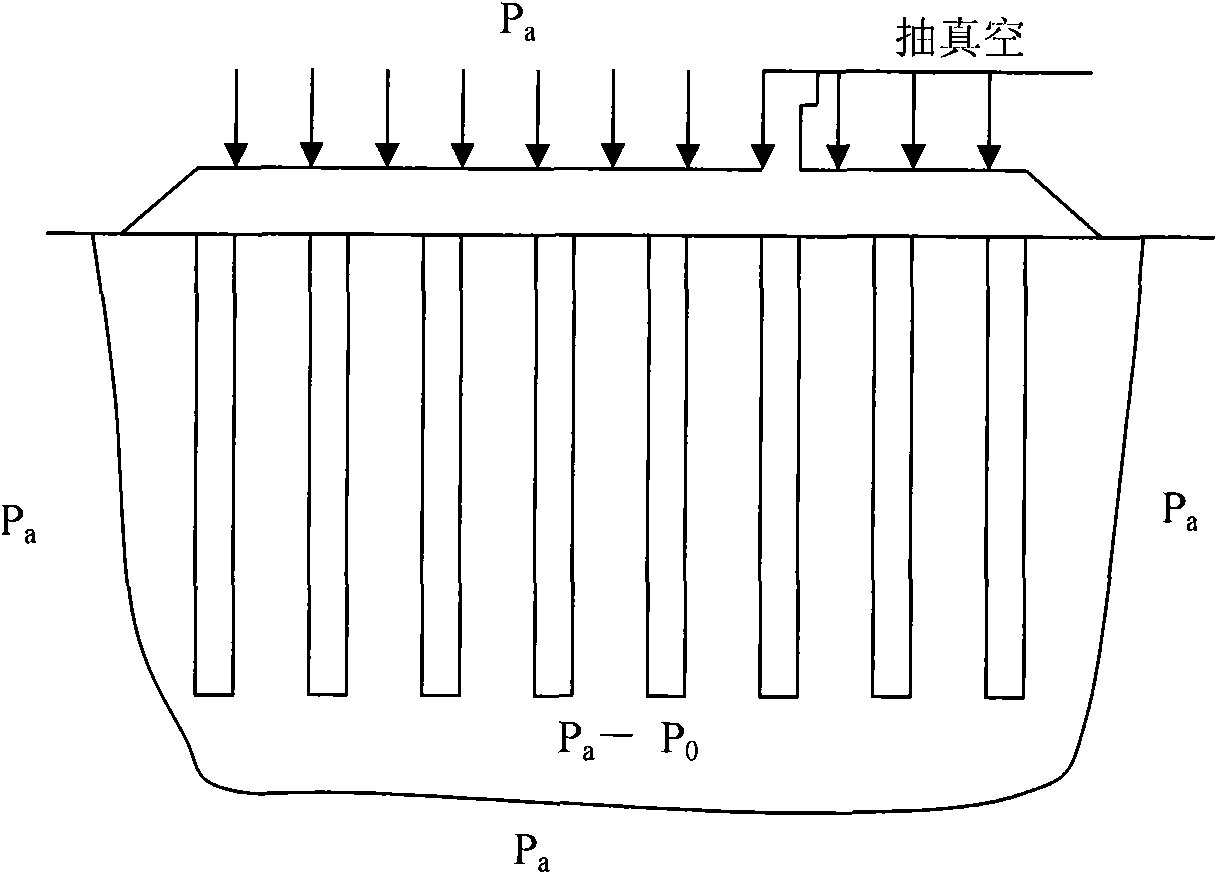

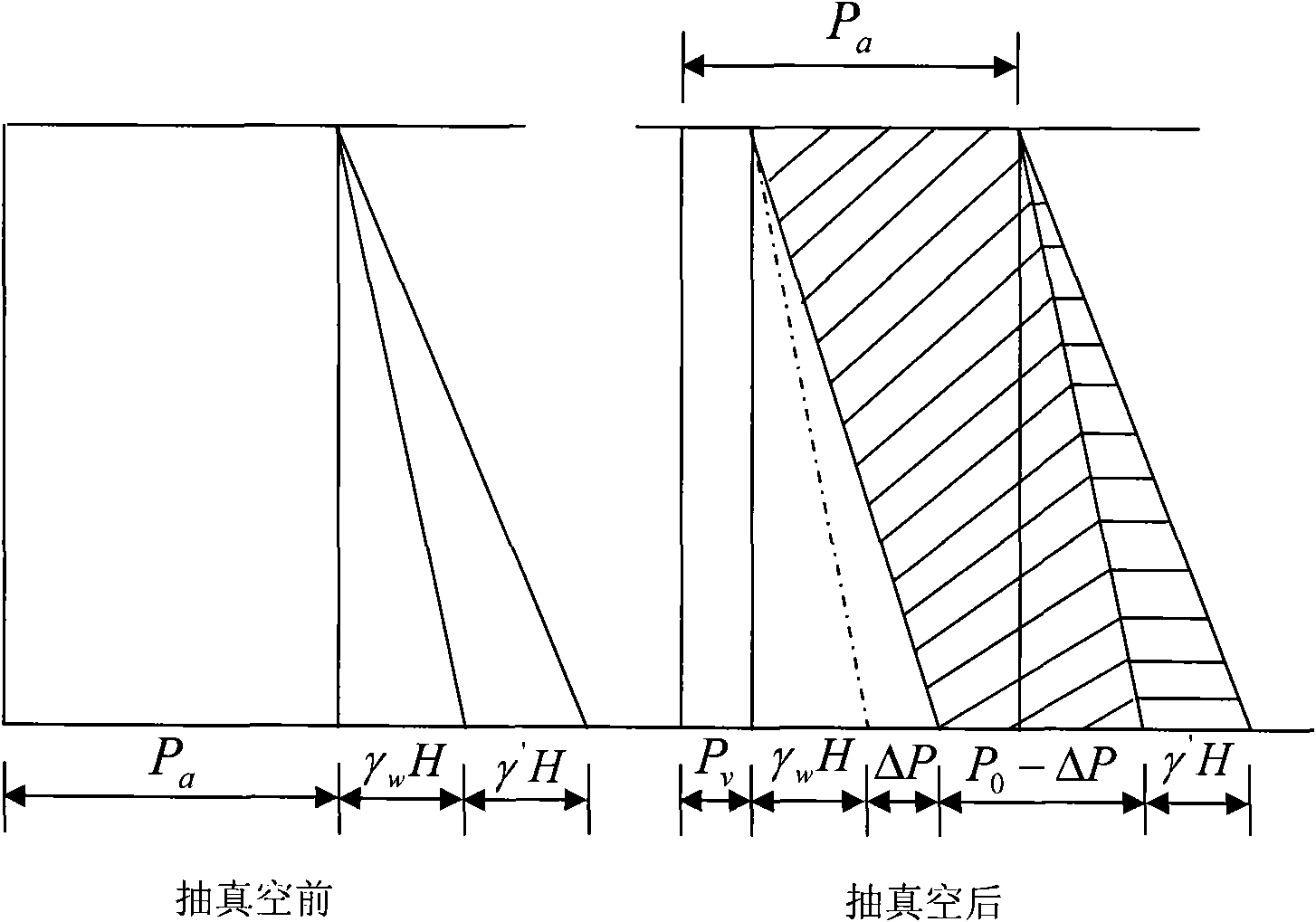

Retaining and protecting method for vacuum preloading foundation excavation at soft soil road section

InactiveCN101768951AHigh strengthImprove self-relianceExcavationsSoil preservationEngineeringVacuum pump

The invention discloses a retaining and protecting method for a vacuum preloading foundation excavation at a soft soil road section, which is used for vacuum preloading for the soft soil road section when in the retaining and protecting for the foundation excavation in the underpass construction of the soft soil road section. In the method, firstly, cement mixing piles are piled at the corresponding positions of the ground level road at the two sides of an underpass section and are used for enclosing and dividing the soft soil road section into a plurality of closed regions, plastic drainage boards are piled in each closed region at a certain interval, a sand cushion is laid at the ground of the closed region and is internally embedded with a strainer, and the sand cushion is covered by a sealing film to be isolated from atmosphere; then, a vacuum pump is communicated with the strainers in the sand cushion and exhausts the air in the sealing film; finally, the vacuum degree in the sealing film can be kept to be more than 80KPa; the degree of consolidation of the foundation is more than 80% when stopping the preloading for the underpass section, then the foundation excavation is excavated by the underpass section, and a retaining wall of the underpass section is arranged.

Owner:黄正荣

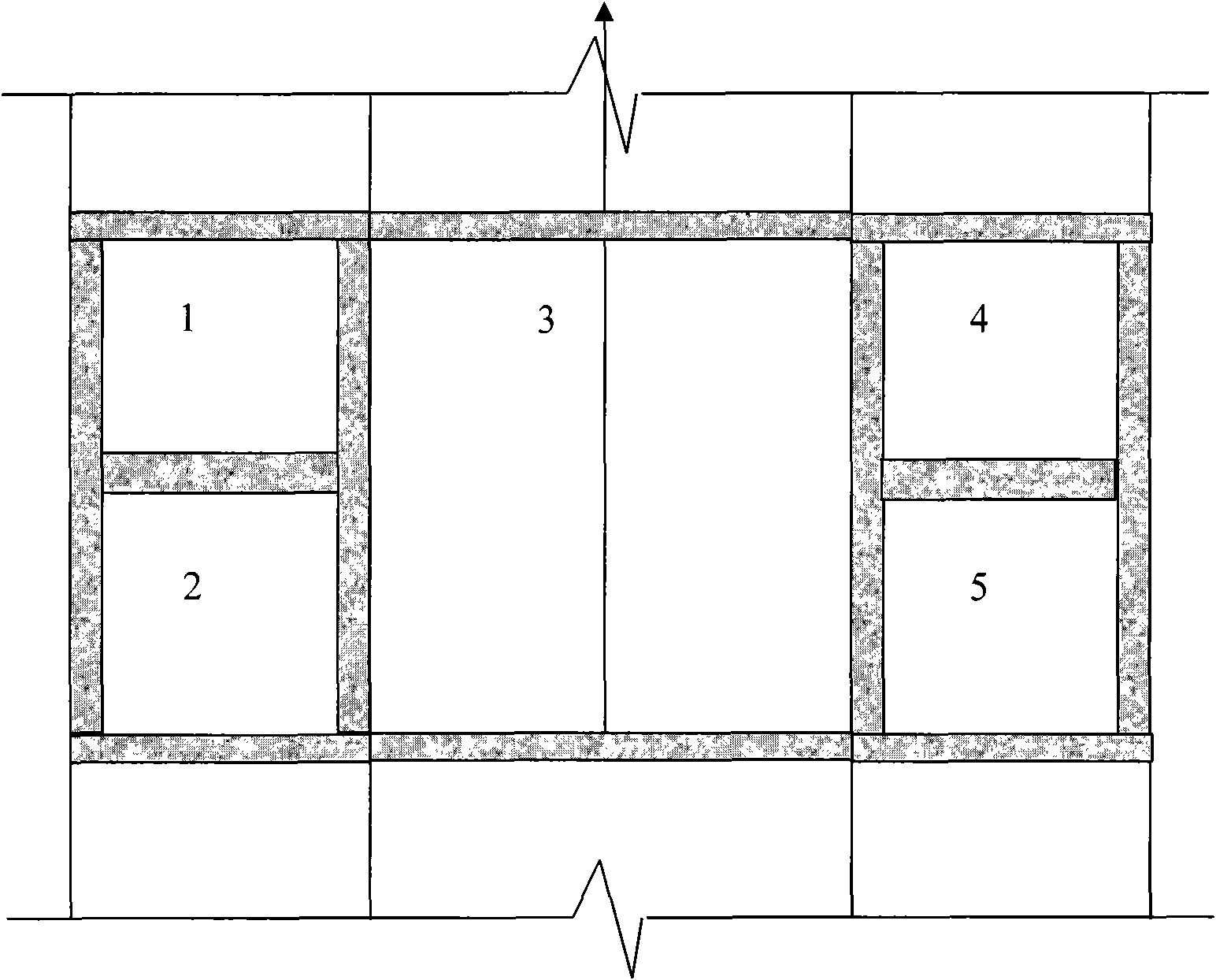

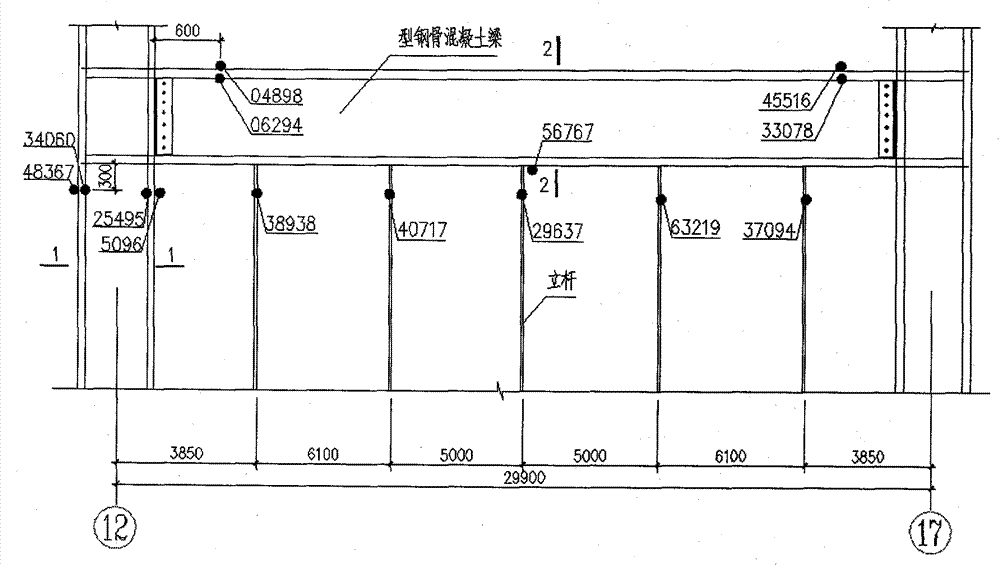

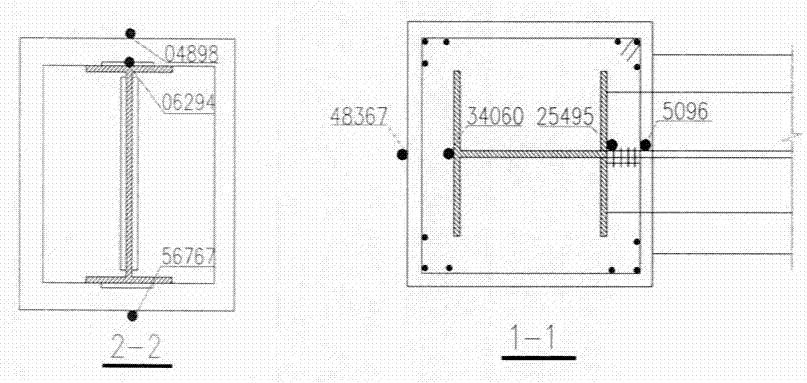

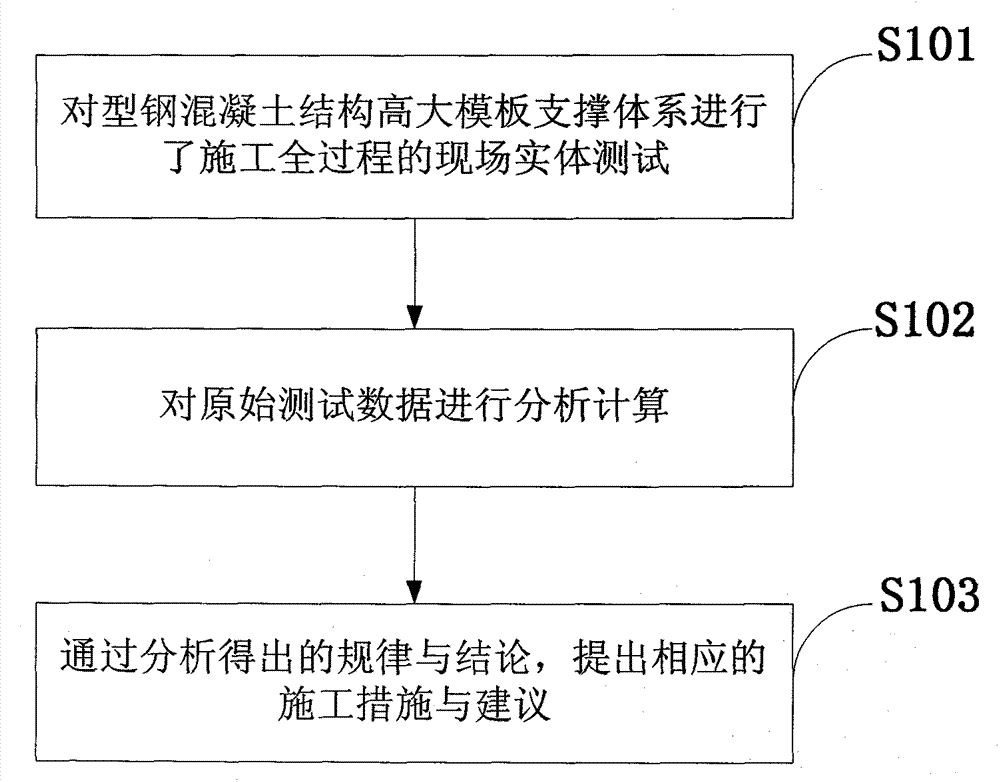

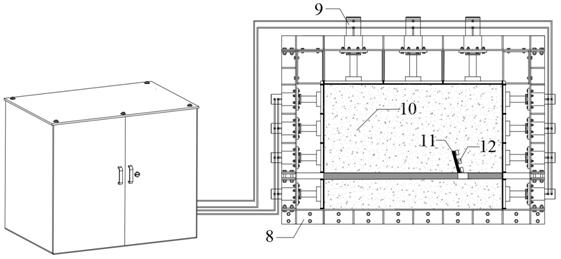

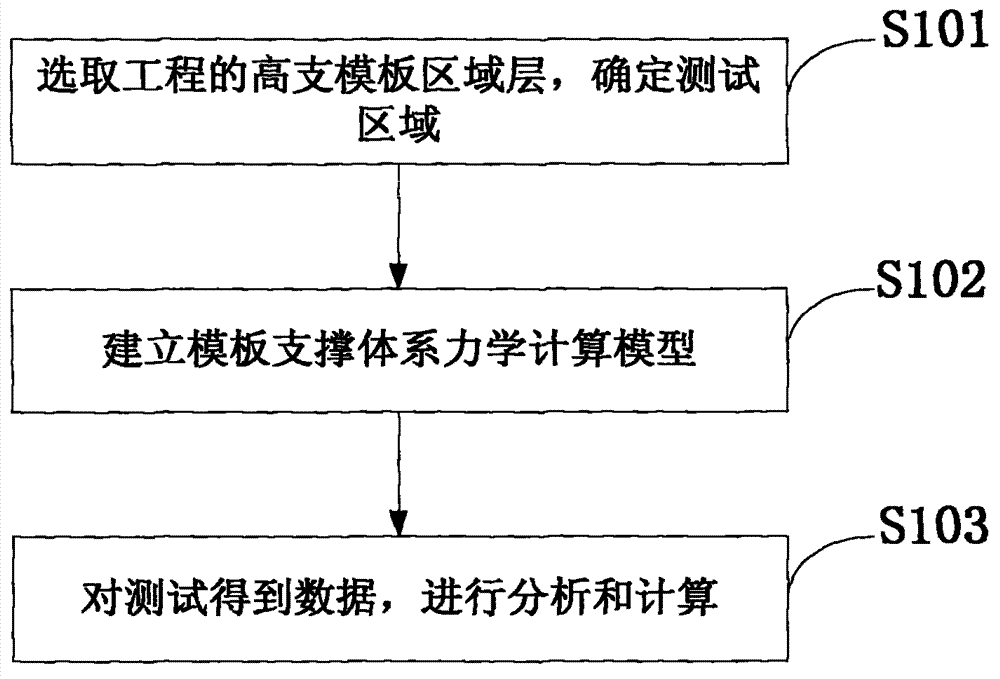

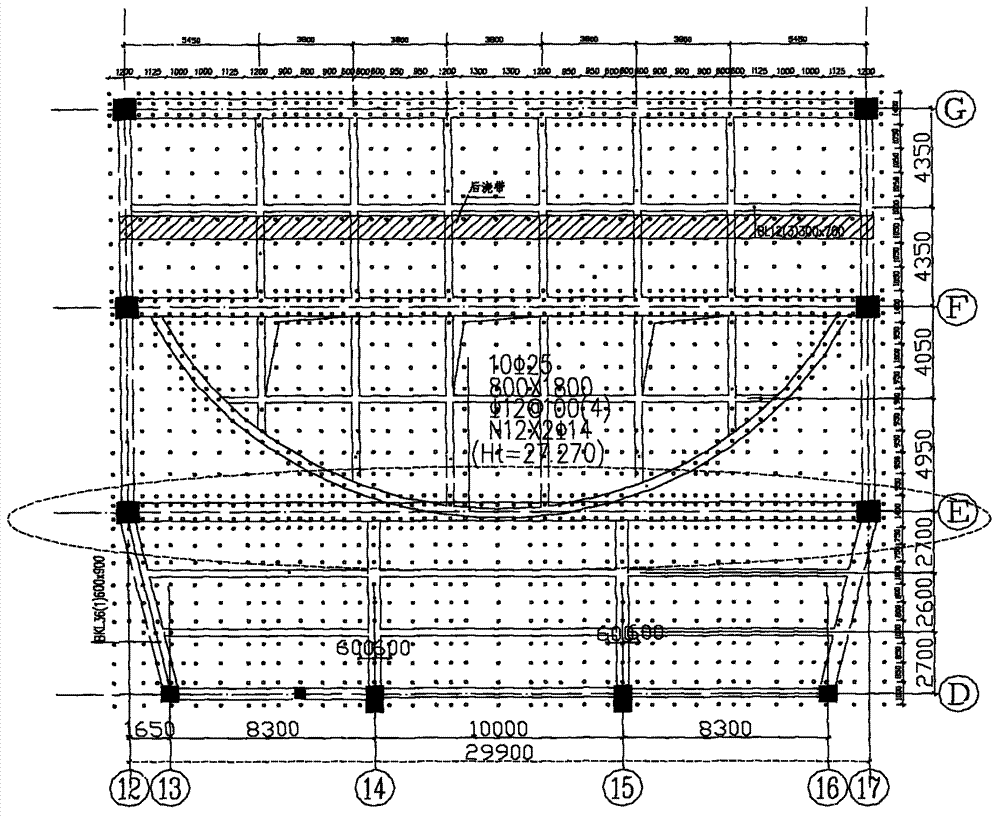

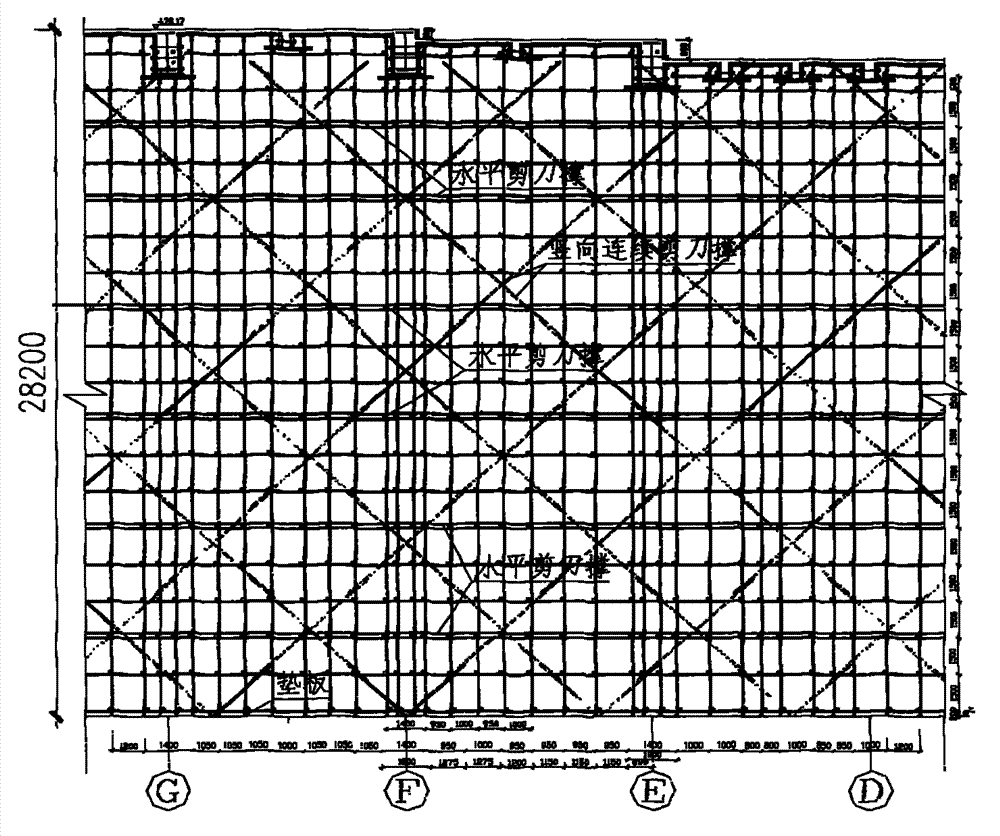

Actual deformation measurement method for high template support system of concrete structure

InactiveCN103674589AReduce support costsGuarantee the construction qualityStructural/machines measurementSupporting systemStructure system

The invention discloses an actual deformation measurement method for a high template support system of a concrete system. The method comprises the steps that in-situ real project measurement of the whole construction process is carried out on the high template support system of the section-steel concrete structure; original measurement data is analyzed and calculated; and corresponding construction measures and suggestions are provided based on rules and conclusion obtained via analysis. According to the method, the basis for a mechanical calculation model of the template support system is established by in-situ detecting and exploring the action mechanism of a time-dependent structure system which is supported by both the cast in situ structure and the template support during the construction stage, thereby providing basis for examining laboratory structure tests and theoretical analysis results, and also providing technical basis for mechanical analysis on the time-dependent structure system, controlling the safety of the template support system in the construction period and designing and optimizing a construction scheme; and template support is realized via the existing materials, thereby saving the cost of concrete template support, reducing the construction cost, increasing the construction speed, shortening the cyclic period, and ensuring the construction quality of the concrete structure.

Owner:广东省六建集团有限公司

Method for substituting reconstructed gangue bearing body for roadway protection coal post

InactiveCN101737068AReduce support costsGood stabilityUnderground miningSurface miningCement slurryCoal

The invention discloses a method for substituting a reconstructed gangue bearing body for a roadway protection coal post, which mainly comprises the following steps: directly crushing the underground gangue in a coal mine underground to form granules of below 5 centimeters, adding common silicate cement into the gangue, mixing the silicate cement and the gangue according to a proportion to form hollow precast blocks, and conveying the hollow precast blocks to a construction site; and when tunneling a roadway along goaf or roadway driving along next goaf, recovering one coal post reserved in the primary design while driving an anchor rod to a top plate of the coal post reserved in the primary design to support the top plate, then piling the precast blocks, building the recovered coal post part by the hollow precast blocks to form a bearing building body, and coating a layer of cement slurry on the wall surface of the building body to form a wall on one side of the roadway till the tunneling work is finished. The method has the advantages that: on the one hand, the roadway protection coal post is saved and the coal resource is fully reclaimed, and on the other hand, the method solves the reutilization problem of the gangue and develops a new path for the utilization of the underground gangue.

Owner:SHANDONG UNIV OF SCI & TECH

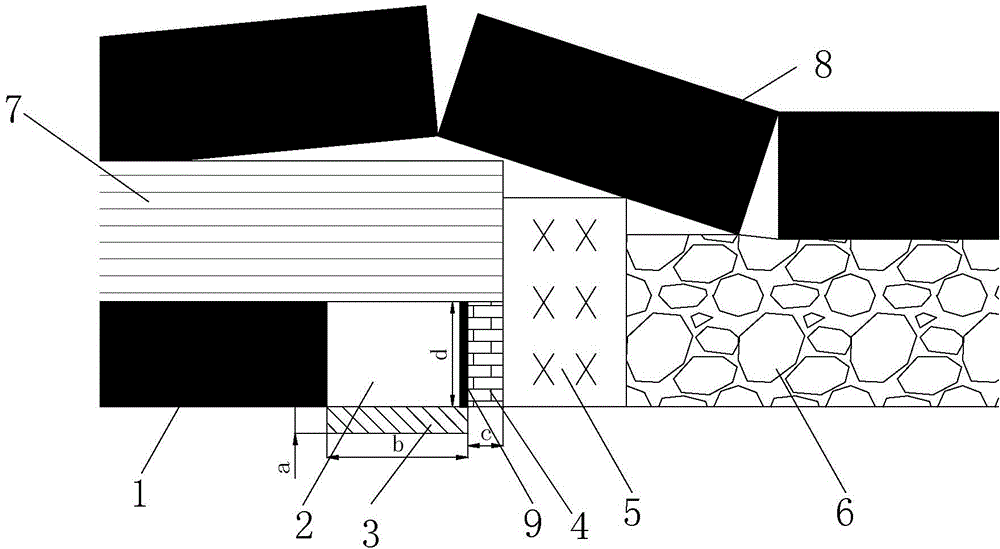

Mining roadway gob-side entry retaining method suitable for thin and medium thickness coal seams

ActiveCN104131834AReduce vertical stressReduce support costsMaterial fill-upFoaming agentEngineering

The invention relates to a mining roadway gob-side entry retaining method suitable for thin and medium thickness coal seams. The mining roadway gob-side entry retaining method comprises the following steps that (1) floor rock obtained by mining roadway dinting are used as raw materials, suitable cement is matched as a cementing material, and a flexible isolation body is built beside a roadway close to one side of a gob area; (2) cumulative blasting holes are drilled in the hard upper roof above the gob area, the blasting holes are located in the outer side of the isolation body, the side roof of the gob area is exploded and cut down, and thus a brickwork beam structure is formed by the cut-down roof and the overlaying rock on the roof; (3) after the isolation body and the cut-down roof are stabilized, a layer of foaming agent is sprayed on the surface of the isolation body. Compared with the existing gob-side roadway driving technology, by means of the mining roadway gob-side entry retaining method suitable for the thin and medium thickness coal seams, mining without coal pillars can be achieved, the mining rate of coal is improved, and section coal pillar losses and roadway supporting cost are reduced.

Owner:NORTH CHINA INST OF SCI & TECH

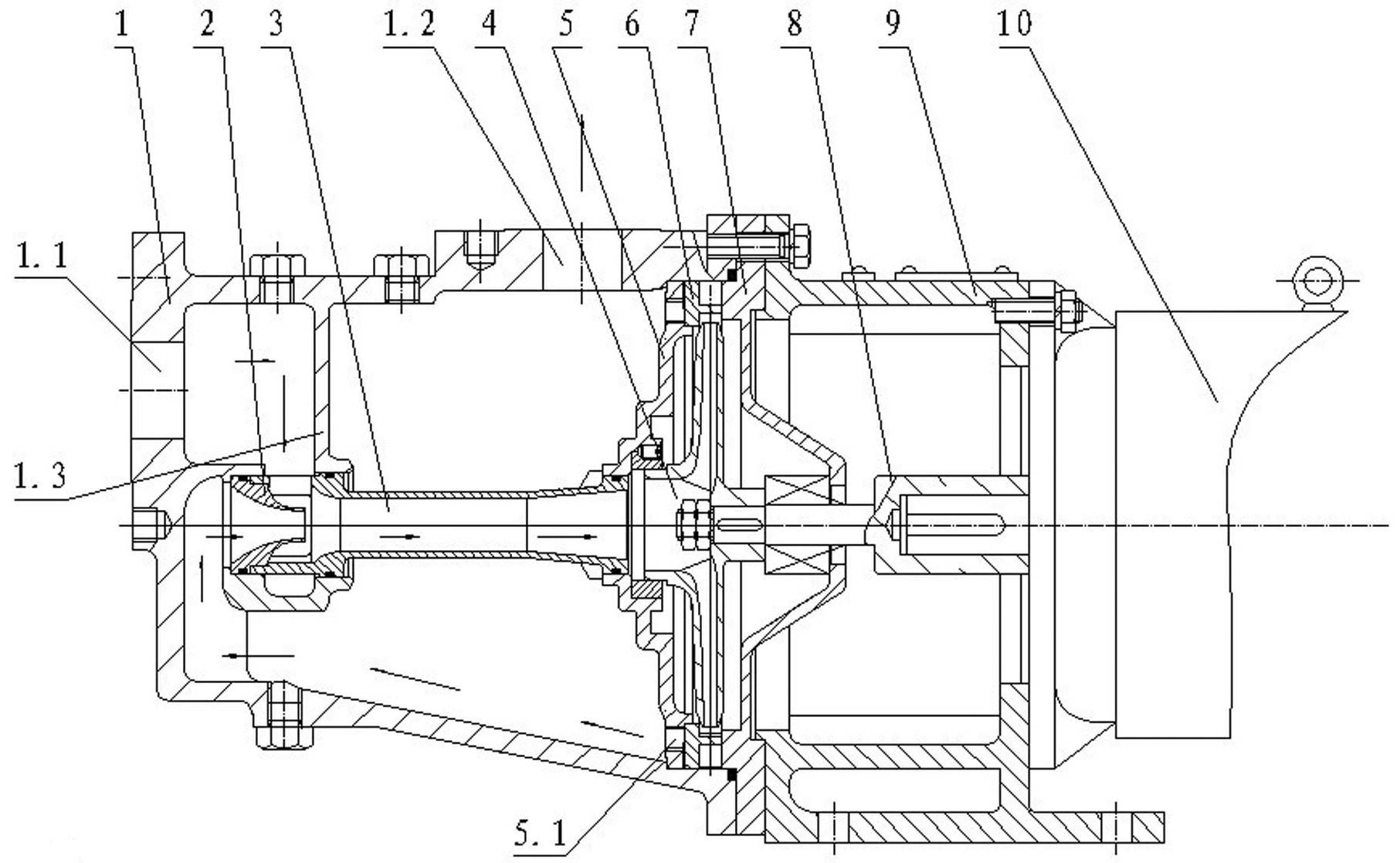

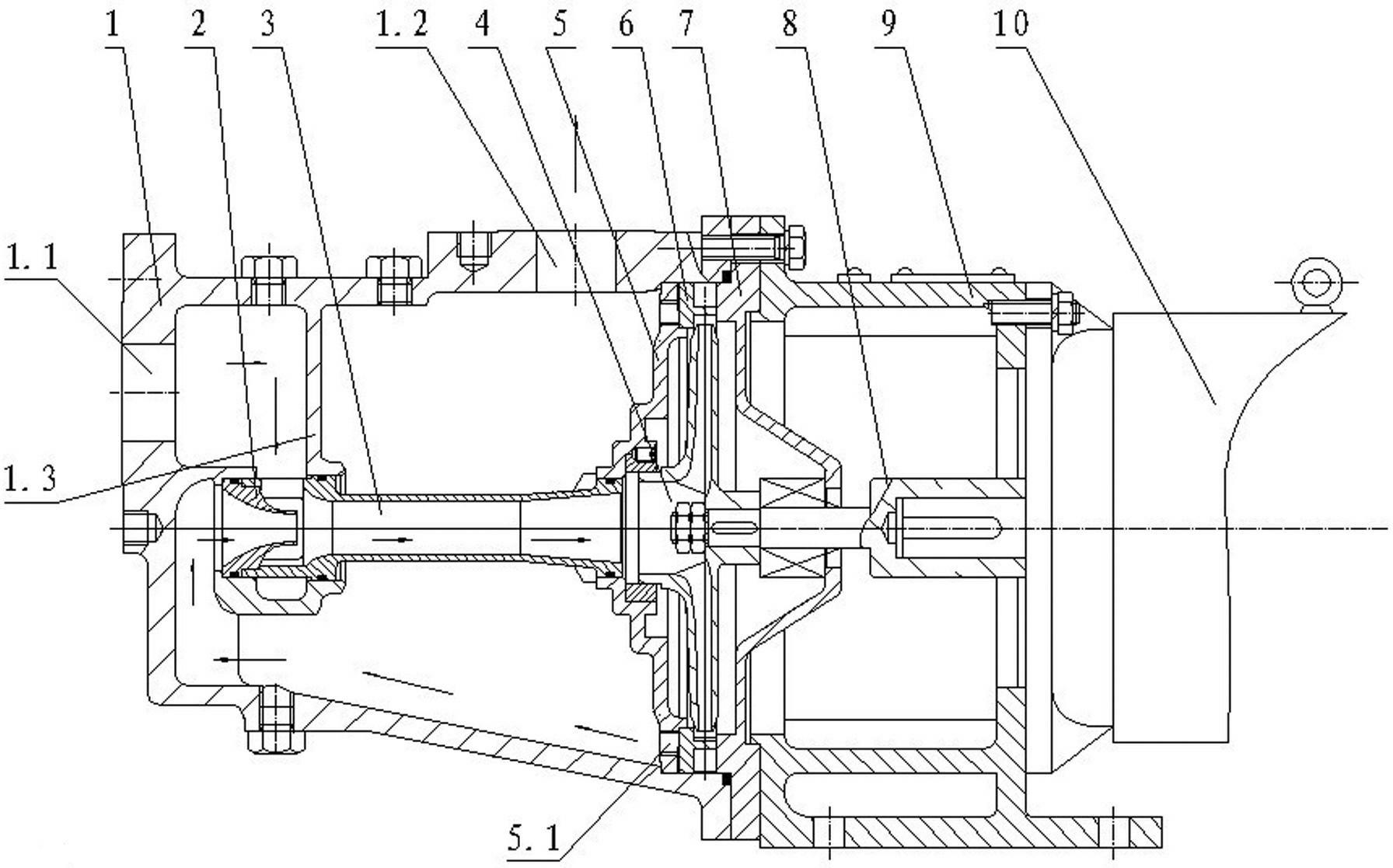

Jet self-sucking centrifugal water pump

ActiveCN102322424ACombination structure is simple and feasibleEasy to manufacturePriming pumpNon-positive displacement fluid enginesPump chamberEngineering

The invention discloses a jet self-sucking centrifugal water pump. The pump comprises a pump body, a nozzle, a diffuser, an impeller, an inner pump cover, a guide blade, an outer pump cover, a pump shaft, a bracket and a motor, wherein the motor is directly connected with the bracket; the pump shaft is coaxially connected with the motor; the impeller is arranged at the end of the pump shaft; two sides of the impeller are provided with a centrifugal pump chamber structure through matching of the outer pump cover, the guide blade and the inner pump cover; the opened end of the pump body is connected with the outer pump cover in a sealed mode, so that a centrifugal pump chamber is accommodated in the pump body; axial through holes are uniformly distributed on the end face of the inner pump cover and communicated with a water outlet cavity of the pump body; the diffuser is connected between the inner pump cover and a clapboard in the sealed mode; the end of the diffuser, which is positioned at one end of a water sucking port, is coaxially provided with the nozzle to form a jet pump structure; and the outlet of the diffuser is positioned at the inlet of the impeller. A jet pump and a centrifugal pump are integrated to achieve performance complementation; the jet pump helps the centrifugal pump to self-suck, the self-sucking process is short, and self-sucking capability is high; andthe pump has an integrated structure and is not required to be additionally provided with a self-sucking device, so that matching cost is saved, and the pump is particularly suitable to be used as a marine pump.

Owner:JIANGSU WANFENG MARINE EQUIP MFG

Ultra-close coal layer mining roadway distributing method

ActiveCN102425431AReduce labor intensityReduce the driving rate of 10,000 tonsTunnel/mines ventillationTunnelsMedicineCoal

The invention discloses an ultra-close coal layer mining roadway distributing method, which comprises the following steps that: a contact eye which is communicated with a return airway of a lower coal layer is bored above an upper coal layer cutting eye to form a primary air return system; an air return roadway which is lagged to maintain is bored on an outline of an originally-designed upper coal layer return airway, a contact eye which is communicated with the return airway of the lower coal layer is bored every 20 to 60m on the lagged maintained roadway to form a complete production system. The return airway which is lagged to maintain is a roadway which is formed through the maintenance of an individual strut after coal is mined on the upper coal layer, and the working face return airway of the upper coal layer is unnecessary to drive, so the tunneling rate per 10,000 tons can be reduced, the labor intensity of workers can be reduced, the discharge of recrement can be reduced, and the pressure on a transportation system can be reduced.

Owner:新汶矿业集团设计研究院有限公司

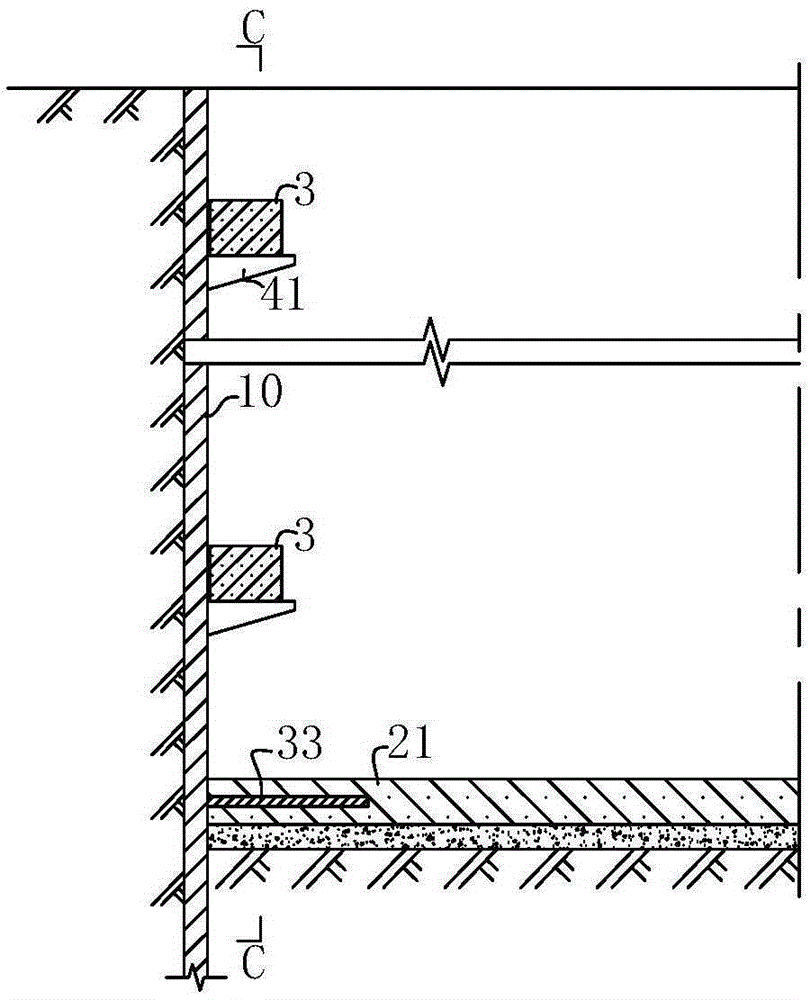

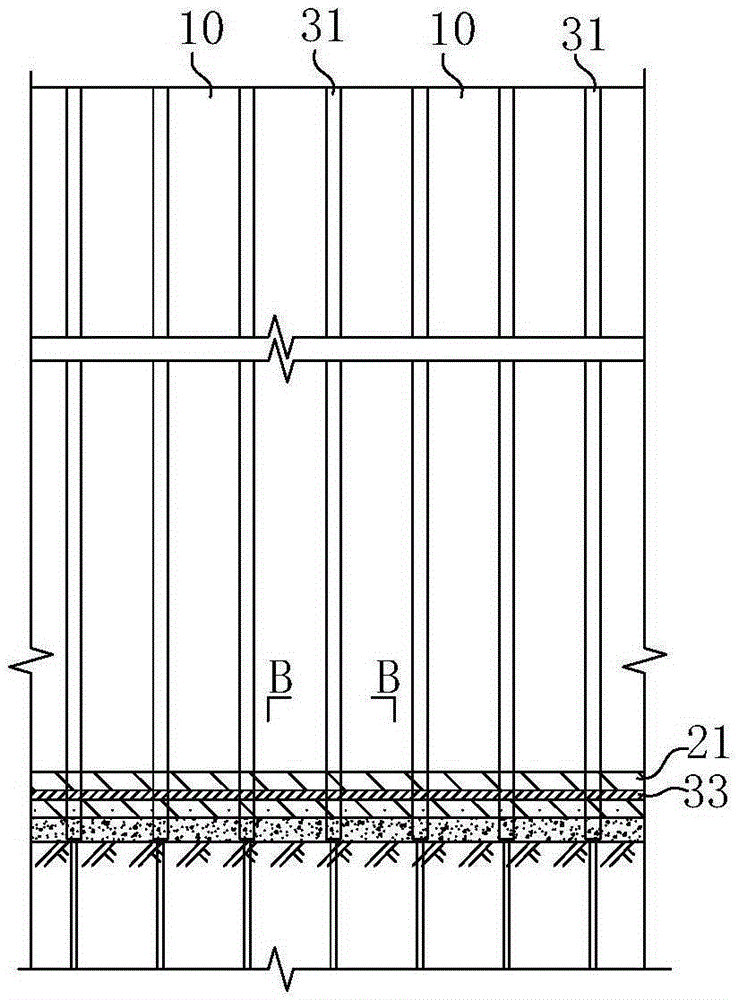

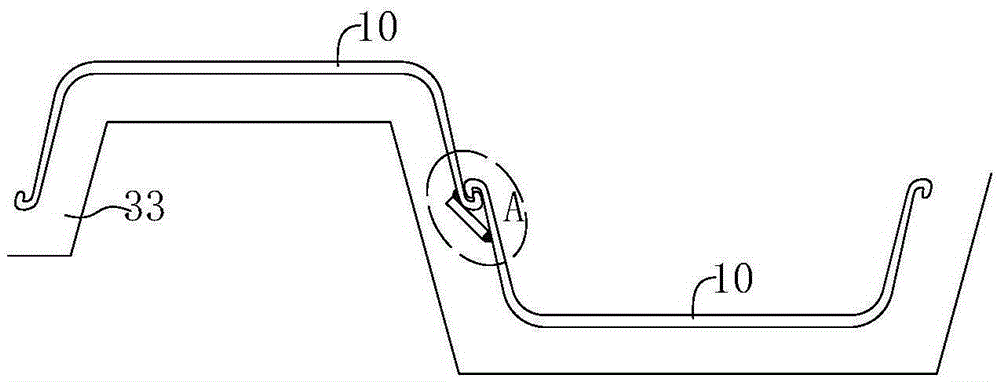

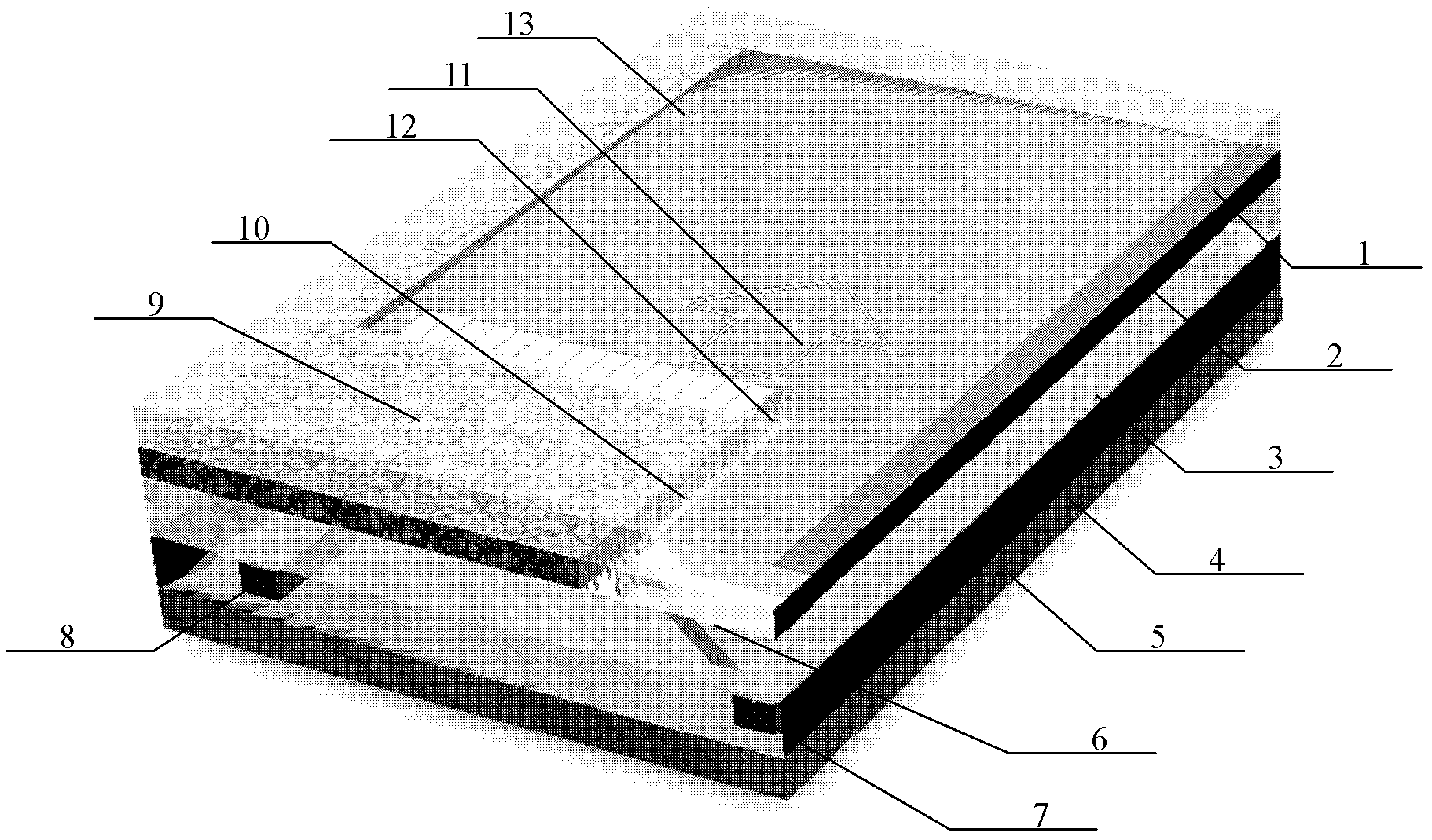

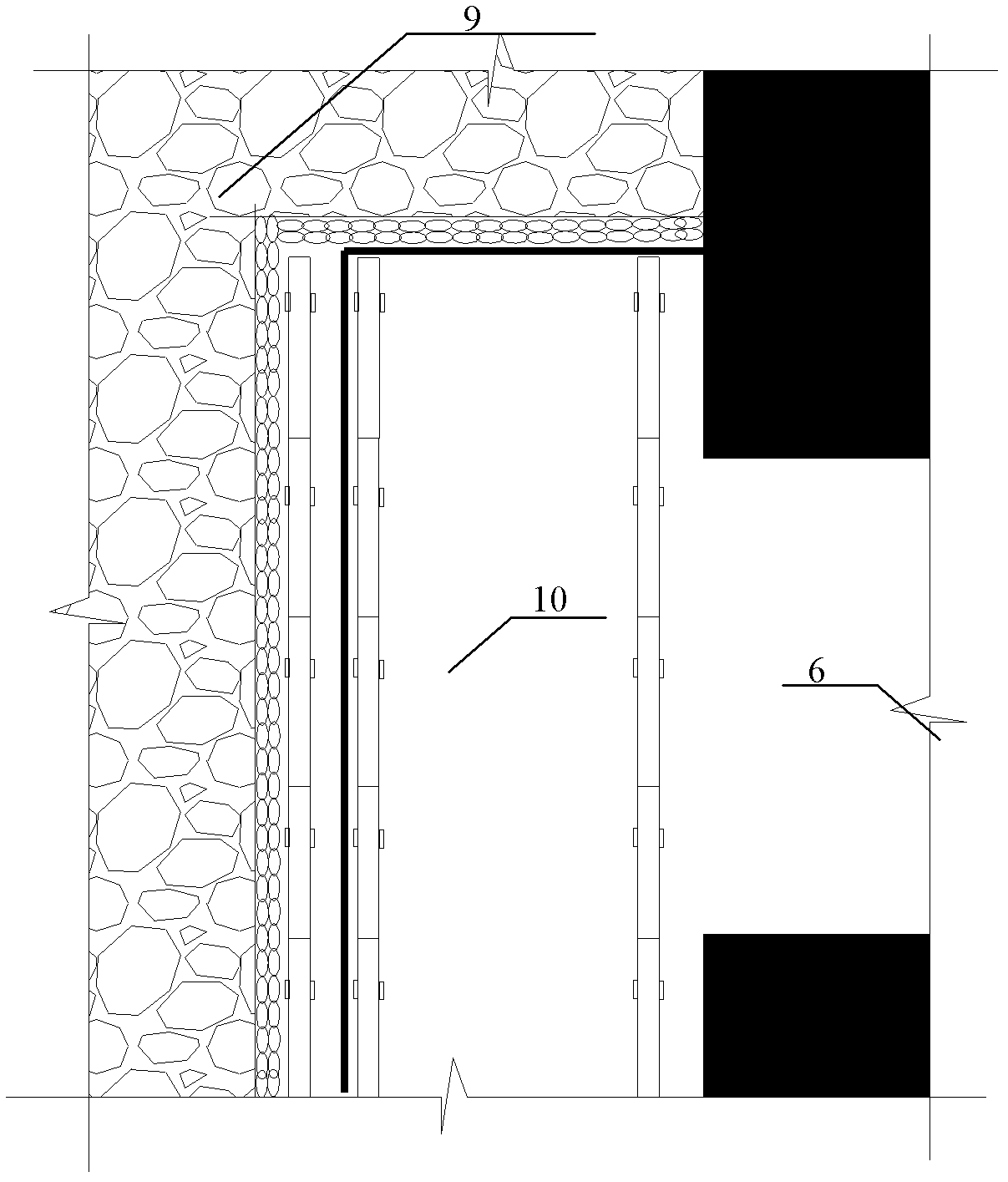

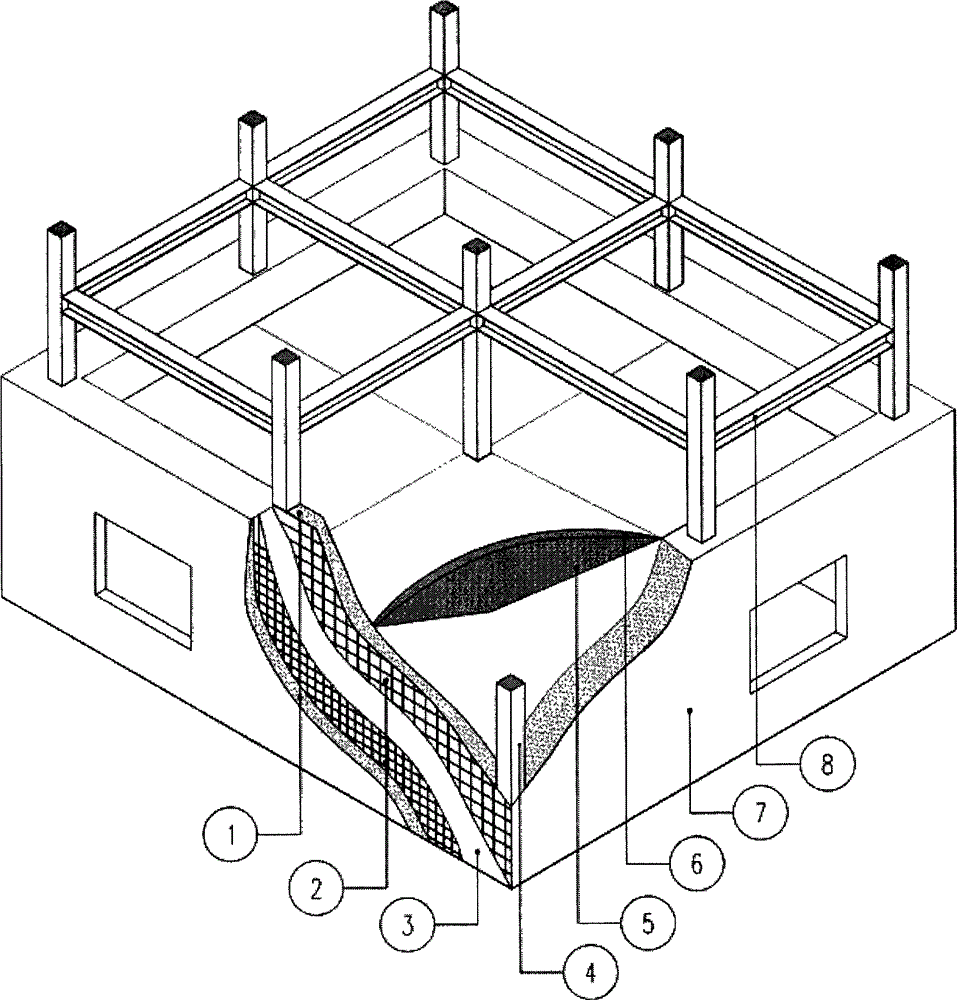

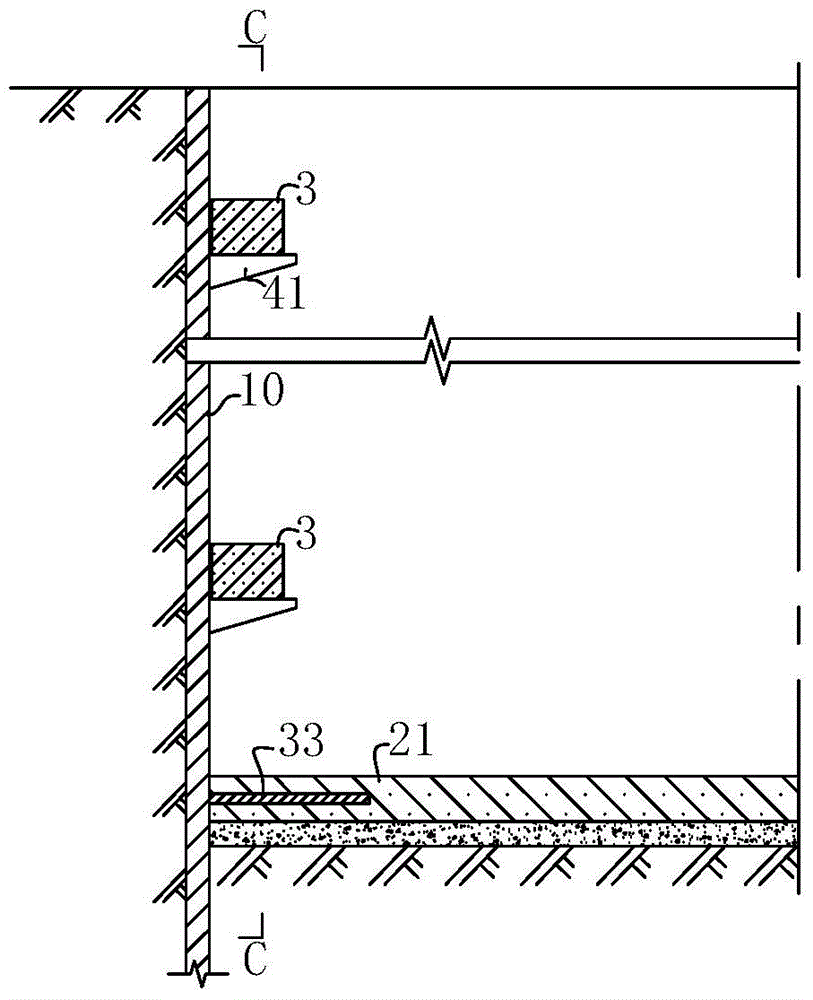

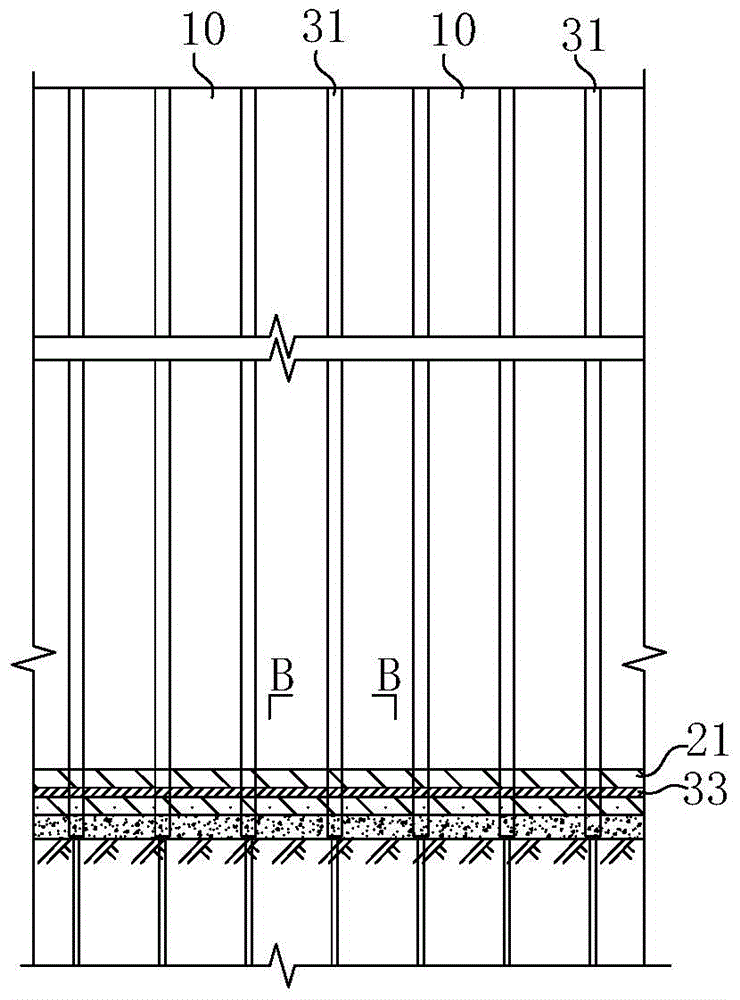

Steel concrete reinforced prefabricated energy-saving residential building system

InactiveCN106149866AImprove energy savingImprove insulation effectWallsFloorsFloor slabConcrete beams

The invention relates to a steel concrete reinforced prefabricated energy-saving residential building system, comprising: steel pipe columns with peripheral reinforcing fabric, H-beams with reinforcement, lateral force resistant support members, reinforced truss floor bearing slabs, Cl truss plates and cast-in-place concrete; the steel pipe columns with peripheral reinforcing fabric, the H-beams with reinforcement, the lateral force resistant support member, the reinforced truss floor bearing slabs, the CL truss plates and the cast-in-place concrete are assembled on a residential foundation into a residential (building) framework; upper forms are mounted around the framework, and concrete is cast in situ to integrate the steel pipe columns, exterior walls, beams and floor slabs; after the concrete solidifies and the forms are removed, and the residential (building) structure composed of the concrete-filled and concrete-clad steel pipe concrete columns, steel-keel concrete beams, the lateral force resistant support members, the CL exterior walls and cast-in-place concrete floor slabs (flooring) is formed. The steel concrete reinforced prefabricated energy-saving residential building system is suitable for factory production, prefabricated installation and mechanical casting and is a residential (building) system having a promising development prospect.

Owner:谷玉花

Method for controlling surrounding rock of roof-cutting self-forming roadway

InactiveCN113669063ASimplify the support structure and support processReduce support costsMining devicesUnderground miningCoal miningStructure support

The invention provides a method for controlling surrounding rock of a roof-cutting self-forming roadway, and relates to the field of coal mining roadway safety. The method comprises the following steps of: quantifying supporting force and load force of a roadway roof-cutting area through technical means such as theoretical analysis, numerical test, indoor test and field monitoring, and establishing a supporting-load balance relationship; determining supporting parameters of anchoring and hydraulic supports according to the supporting-load balance relationship by taking anchoring supporting force and hydraulic support supporting force as controllable supporting force; and arranging the anchoring and hydraulic supports according to the structure of the roof-cutting area to control deformation of the roadway roof-cutting area, establishing a balance relationship between the supporting and load of the roof-cutting area, quantifying the effect of collapsed, crushed and expanded rock on a cutting seam surface and substituting the effect into the balance relationship, accurately obtaining the supporting parameters of the controllable supporting force, guiding the engineering field supporting structure and supporting process design, ensuring long-term safety and stability of the roadway and reducing the supporting cost.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +3

High strength environment friendly sprayed concrete

The invention relates to underground concrete for a coal mine, in particular to high strength environment friendly sprayed concrete, which solves the problems of safety loophole, higher roadway overhaul rate and high support cost of the existing shaft sprayed concrete. The high strength environment friendly sprayed concrete is prepared from a binding material and an accelerator which is 5% of mass percent of the binding material; the binding material is prepared from the following raw materials in parts by weight: 9 parts of 32.5 Portland cements, 1 part of MK-1 fortifier, 20 parts of machine-made sand, and 20 parts of detritus. The strength of the sprayed concrete can be obviously improved, sprayed disability and dust concentration can be reduced, morbidity of silicosis is reduced, surrounding rock deformation can be effectively controlled, roadway overhaul can be reduced, an underground roadway appearance is improved, safety production of a shaft is ensured, support cost is obviously reduced and economic benefits are obvious.

Owner:DATONG COAL MINE GRP

Composite supporting method used for ultra-deep comprehensive pipe rack foundation ditch in water crossing riverway

InactiveCN108951641ALess machineryReduce support costsArtificial islandsExcavationsEngineeringHigh pressure

The invention discloses a composite supporting method used for an ultra-deep comprehensive pipe rack foundation ditch in a water crossing riverway, and belongs to the technical field of underground urban comprehensive pipe rack deep foundation pit supporting. The method comprises the steps that firstly, a riverway cofferdam is constructed, and a drainage tube is mounted; secondly, riverway dredging within the construction range is carried out; thirdly, slope excavation to the top of a cast-in-place pile is carried out; fourthly, slope surface soil nails are put, and jet-anchor execution is carried out; fifthly, cast-in-situ bored pile construction is carried out; sixthly, a crown beam is constructed; seventhly, a pile back side high-pressure rotary jet grouting waterstop curtain is constructed; ninthly, excavation of foundation pit and construction of a crossed pipe rack main structure are carried out, after the lower foundation pit supporting and maintaining period is finished, earthwork on the foundation pit on the lower portion begins to be excavated and constructed, the earthwork is dug to the bottom at a time, and crossed main body structure is constructed. The currently-conventional supporting method is combined, supporting structure reliability is improved, construction cost is reduced, the construction proceed is quickened, and the influence on the environment and watercan be reduced.

Owner:CHINA MCC17 GRP

Recoverable and modular deep foundation pit construction process, recoverable module and deep foundation pit support

The invention provides a recoverable and modular deep foundation pit construction process, a recoverable module and a deep foundation pit support and belongs to the technical field of deep foundation pit excavation and supporting. The process comprises the following steps that a foundation pit is dug down; a first anchor cable hole is formed, a first anchor cable is put in, and a grouting stop plug is installed for grouting; a second anchor cable hole is formed, a second anchor cable is put in, and a grouting stop plug is installed for grouting; modules and connecting fasteners are installed; a prestressing force is exerted to the first anchor cable and the second anchor cable to for a first layer of supporting; the operations are repeated to form multiple layers of supporting; modules, anchor cables and connecting fasteners of the last layer of supporting are recovered, soil is backfilled to the bottom surface of the second layer of supporting till the first layer of supporting is recovered. A soil body surrounding a deep foundation pit is supported and retained by adopting the modules and anchor cables jointly, the modules can be recycled, and materials waste and construction cost are reduced.

Owner:河北建科唐秦建筑科技有限公司

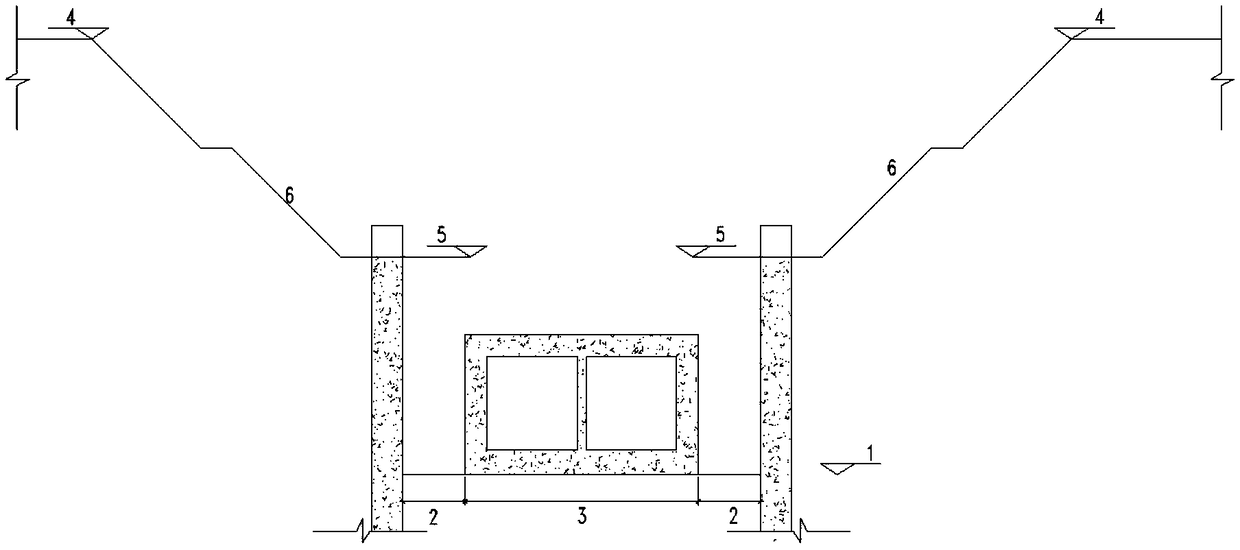

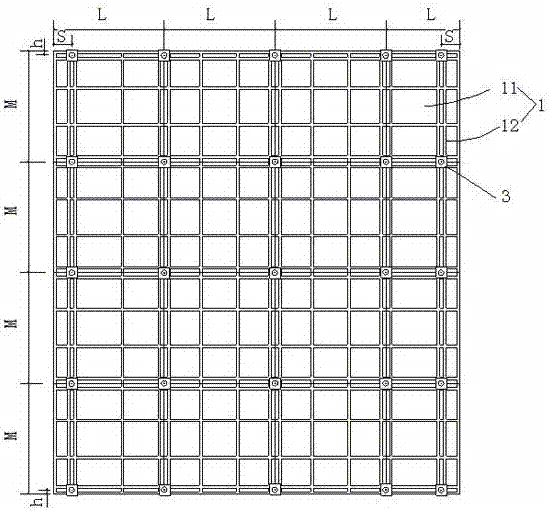

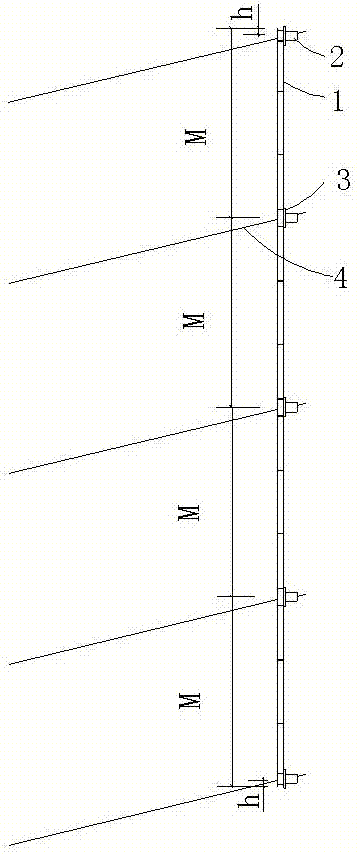

Underground comprehensive pipe gallery structure deeply buried in soft soil and construction method of underground comprehensive pipe gallery structure

PendingCN107794946AReduce support costsThe construction process is simple and fastArtificial islandsUnderwater structuresRebarReinforced concrete

The invention provides an underground comprehensive pipe gallery structure deeply buried in soft soil and a construction method of the underground comprehensive pipe gallery structure. The undergroundcomprehensive pipe gallery structure is a reinforced concrete box type structure with underground diaphragm walls buried in deep and thick soft soil 10 m below as side walls, hidden beams, top beamsand steel bar connectors are arranged on the underground diaphragm walls to be connected with a bottom plate and a top plate of a pipe gallery, and lining walls arranged in the underground diaphragm walls and the underground diaphragm walls are combined to be used as the side walls of the comprehensive pipe gallery. The elevation of the wall tops of the underground diaphragm walls is the same as that of the bottom of the top plate of the underground comprehensive pipe gallery, load-bearing bars of the top plate and wall top anchoring bars of the underground diaphragm walls are connected through the top beams, and the top plate of the comprehensive pipe gallery is formed. The hidden beams are arranged on the portions, corresponding to the bottom plate of the comprehensive pipe gallery, of the underground diaphragm walls and are connected through the steel bar connectors, and the bottom plate of the comprehensive pipe gallery is formed. According to the underground comprehensive pipe gallery structure, the problem that differential settlement is prone to being generated when the underground comprehensive pipe gallery passes through the deep and thick soft soil is solved, the foundation pit support cost is reduced, the construction process of the structure is simple, convenient and fast, and the structure is economical and reasonable.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

Pipeline installing method

The invention discloses a pipeline installing method. The pipeline installing method comprises the steps that a fastening belt is adopted for achieving temporary fastening of a first pipe base and a first pipe joint, and a first pipe base and pipe joint unit is formed; the first pipe base and pipe joint unit is hoisted into a base groove; the pipe inner bottom elevation of the first pipe joint inthe base groove is measured; gaps on the two sides between the first pipe joint and the first pipe base are closed; the preparing work for second pipe base and pipe joint unit installation is conducted; a second inserting port of a second pipe joint is inserted in a first port of the first pipe joint; the bell mouth end elevation of the position of a second bell mouth of the second pipe joint in the base groove is measured; a gap on the second bell mouth side between the second pipe joint and the second pipe base is closed; the steps from the fifth step to the eighth step are repeatedly conducted, and subsequent pipe base and pipe joint unit installation is finished; and cement mortar is poured into the positions between the pipe joints and the pipe bases in the same pipe base and pipe joint units and between the pipe bases between the adjacent pipe base and pipe joint units. According to the pipeline installing method, the hoisting frequency can be effectively reduced, and the advantage that construction is safe and reliable is achieved.

Owner:KUNSHAN YUTENG MUNICIPAL ENG

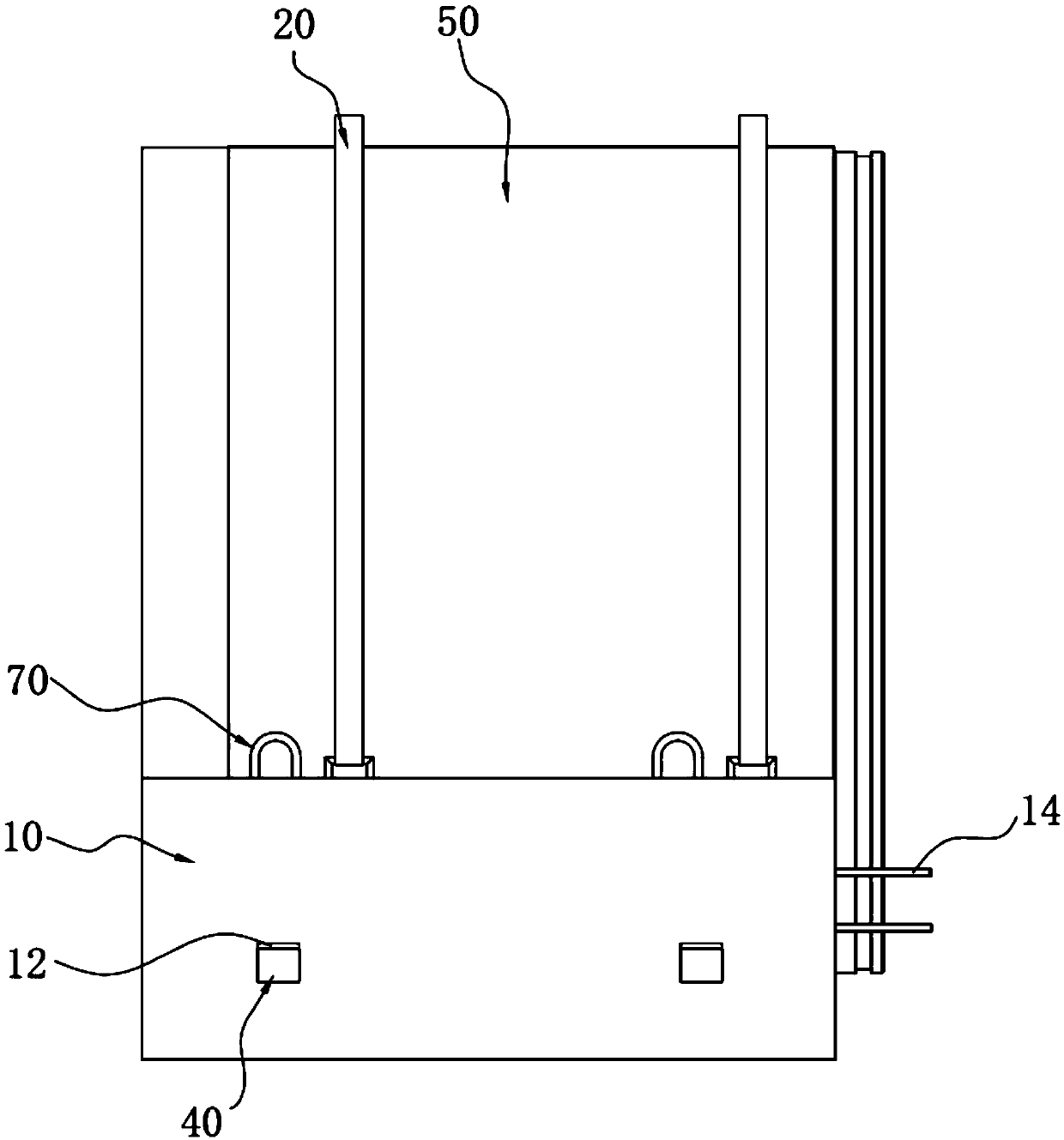

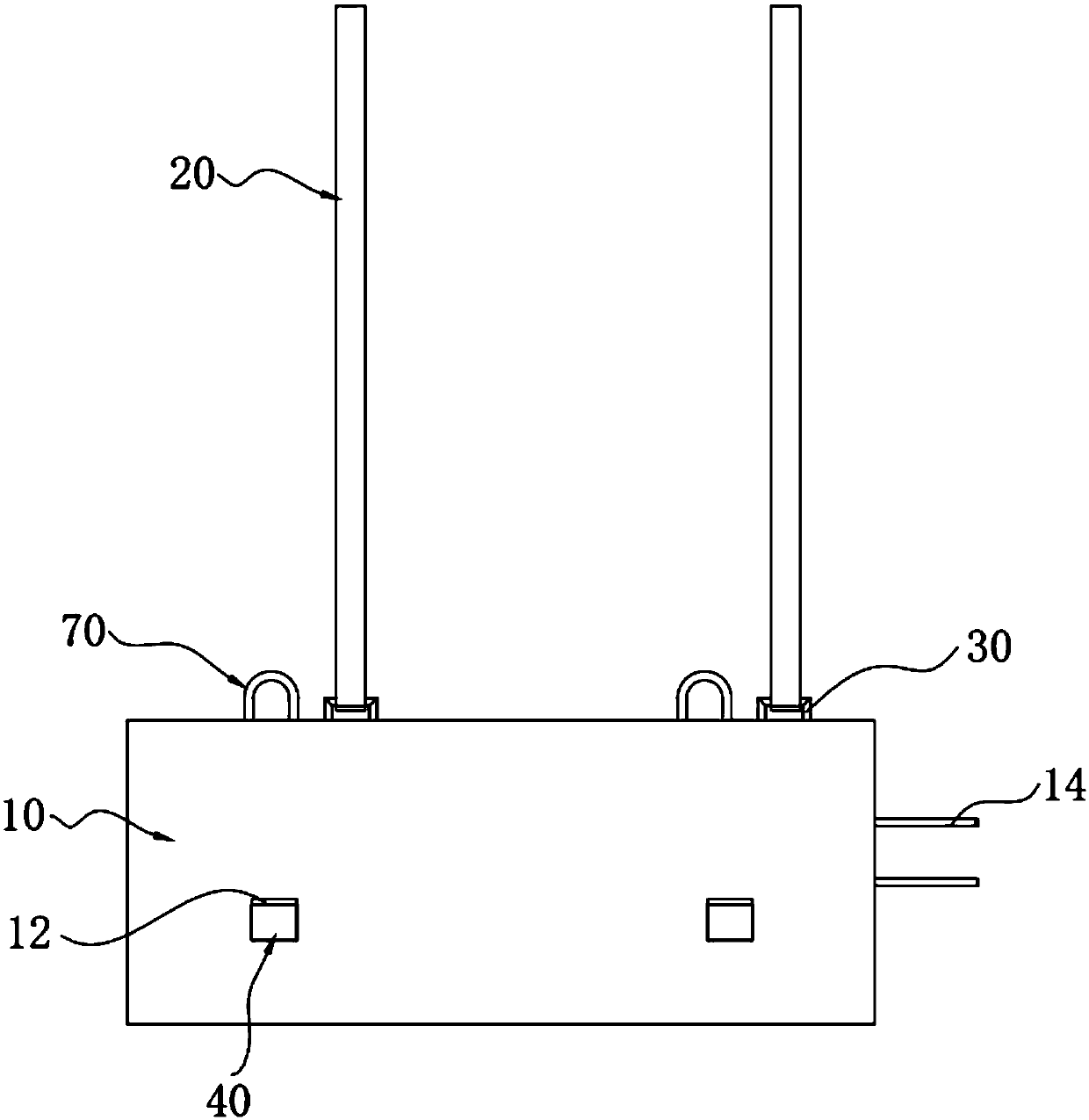

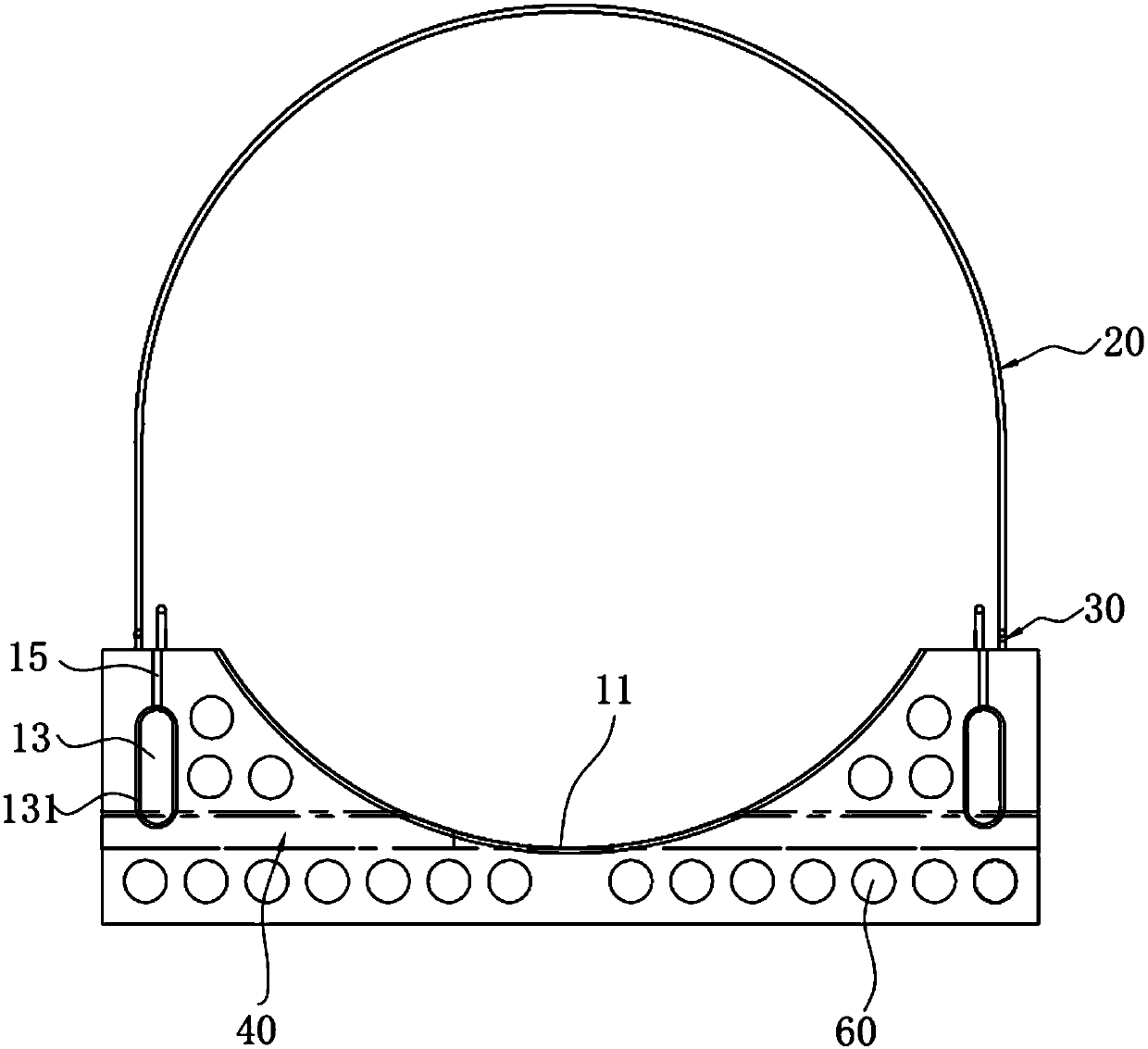

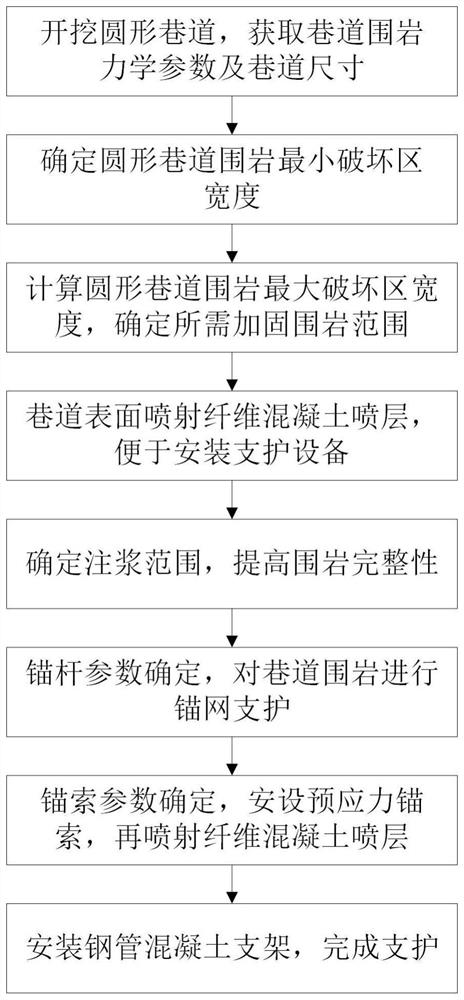

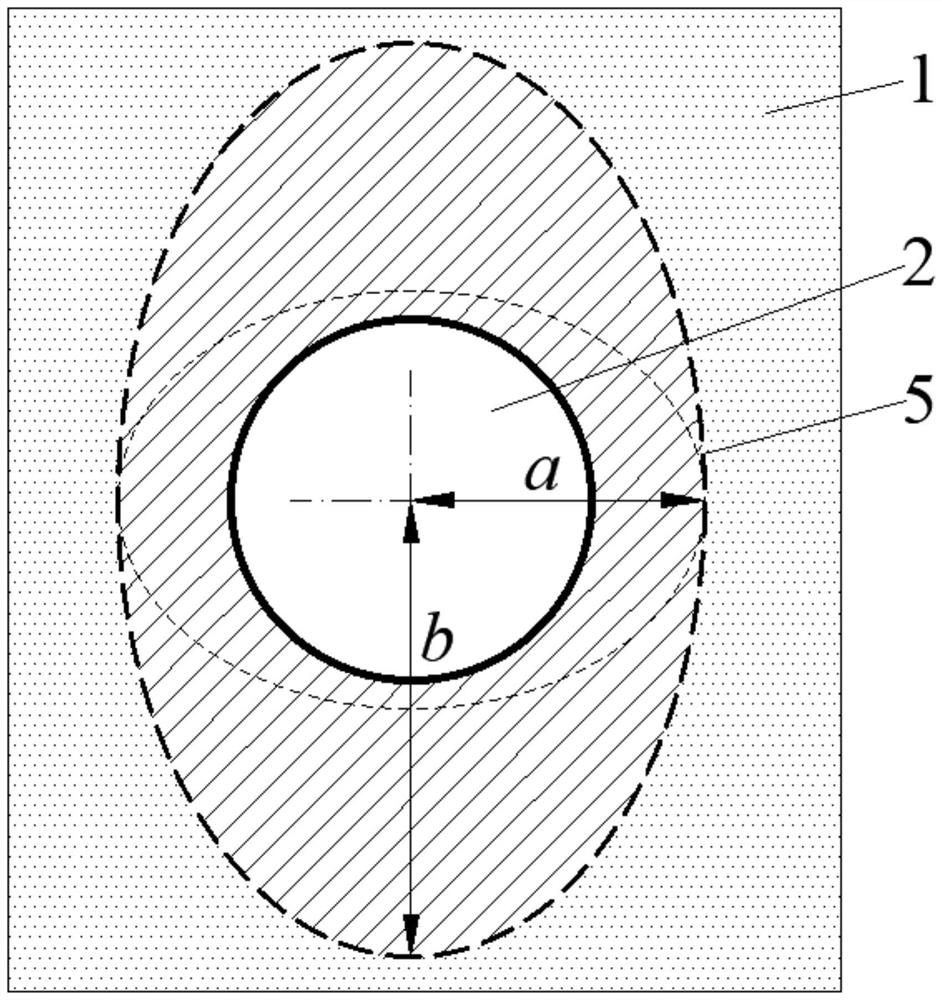

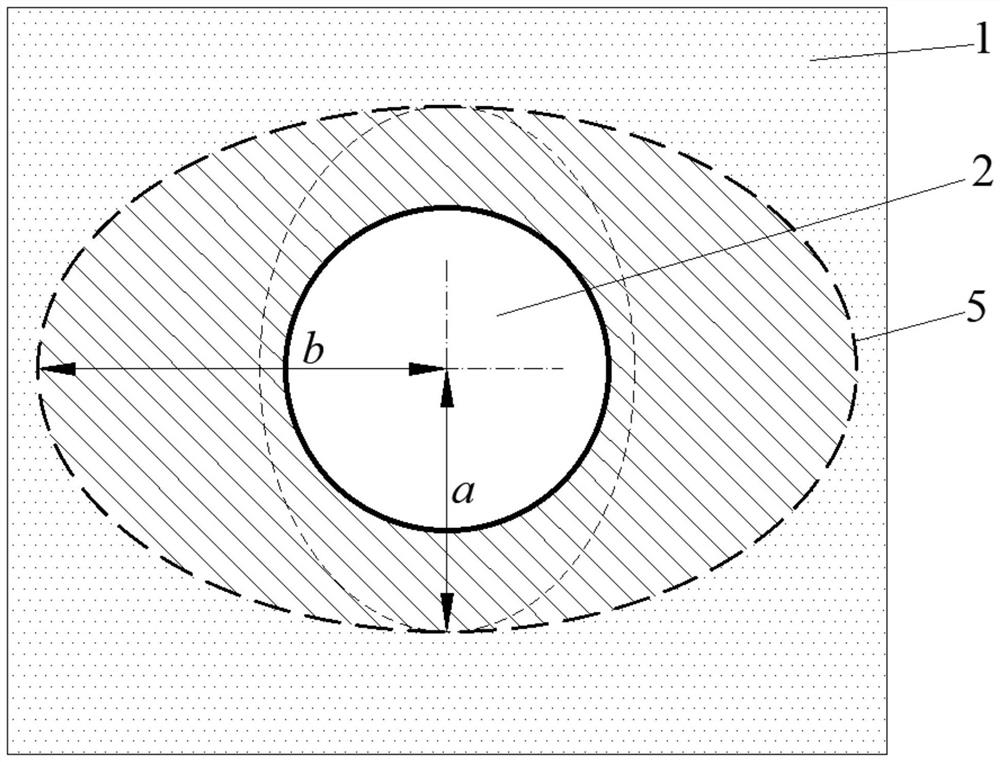

Deep circular roadway precise supporting method based on surrounding rock partition

PendingCN114687769AExert self-carrying abilityAvoid increased support costsUnderground chambersTunnel liningClassical mechanicsStructural engineering

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

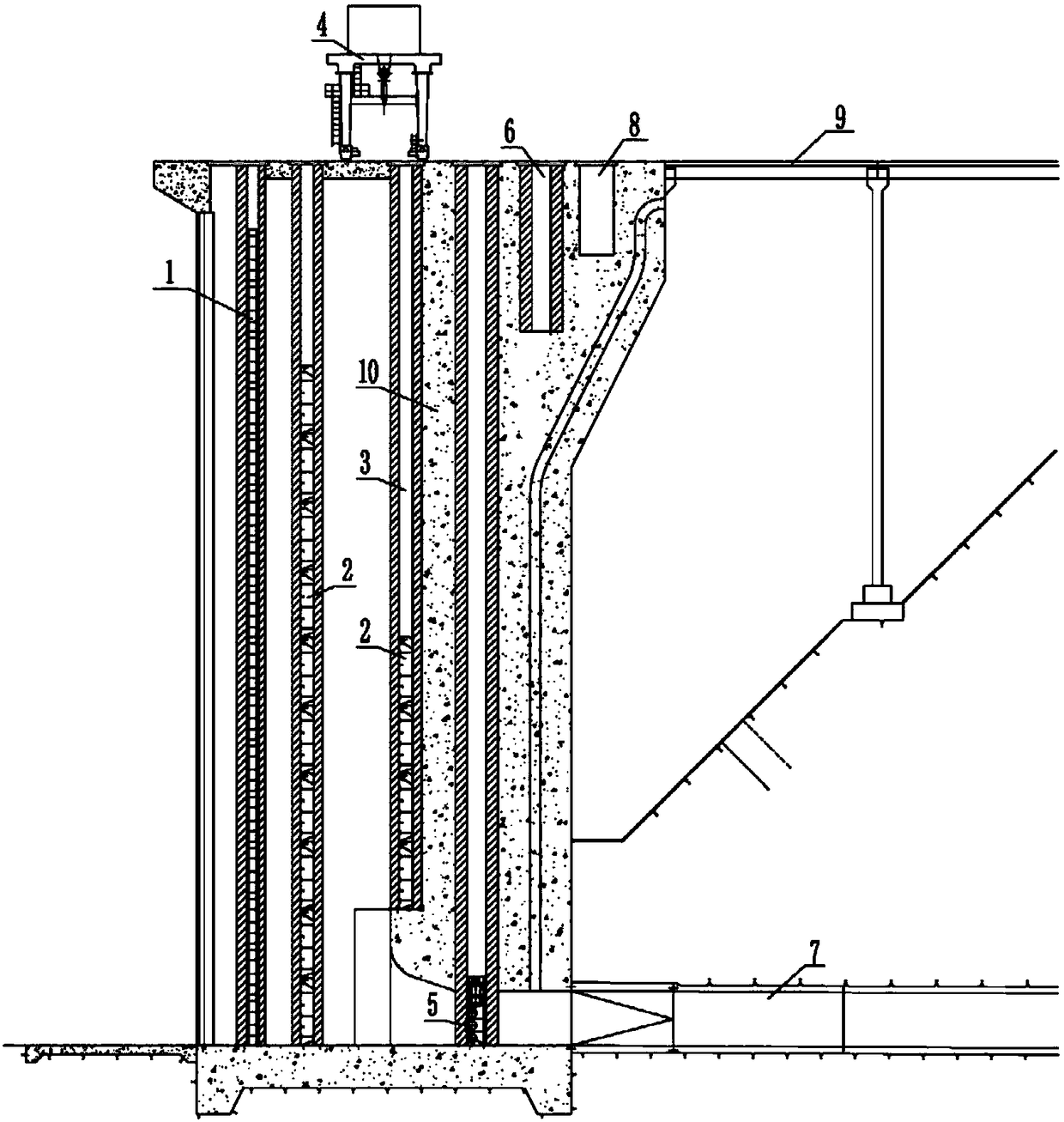

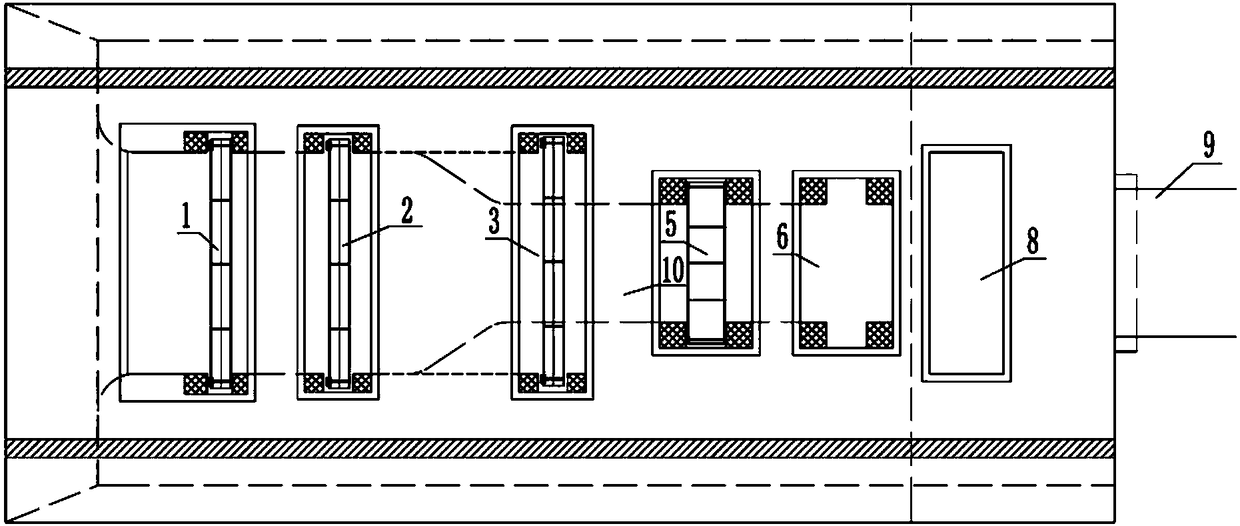

Independent water intake tower structure for entrances of water diversion tunnels of medium and small-flow water reservoirs

PendingCN108560497ASmall disturbance areaReduce support costsBarrages/weirsArtificial water canalsWater flowEngineering

The invention discloses an independent water intake tower structure for entrances of water diversion tunnels of medium and small-flow water reservoirs. The independent water intake tower structure comprises a trash rack, a stop log gate, a stop log gate warehouse, an overhauling gate, an overhauling gate warehouse, an opening and closing gantry crane, a trash cleaning grab bucket warehouse, a traffic bridge and a water diversion tunnel, wherein the trash rack, the stop log gate, the stop log gate warehouse, the overhauling gate, the overhauling gate warehouse and the trash cleaning grab bucketwarehouse are sequentially arranged along the water flow direction, so that one opening and closing gantry crane on a top platform of the water intake tower can be used for controlling the stop log gate and the overhauling gate, the stop log gate is lifted and lowered by the opening and closing gantry crane, and the surface water of the water reservoir is fetched for the ecological flow of downstream riverway and the farmland irrigation water. The independent water intake tower structure has the advantages that the stop log gate and the overhauling gate can be controlled by one gantry crane,so that the arrangement of a bent frame at the top of the tower and the opening and closing gantry crane in an opening and closing room is not needed; the quantity of excavation and support engineering of larger edge slopes due to side gate warehouses of the water intake tower can be reduced.

Owner:CHINA WATER RESOURCES BEIFANG INVESTIGATION DESIGN & RES

Thin spraying material for reinforcing, beautifying, supporting and sealing coal mine roadway

InactiveCN112796793AImprove stain resistanceImprove the level of quality standardizationUnderground chambersTunnel liningShotcreteToxic gas

The invention discloses a thin spraying material for reinforcing, beautifying, supporting and sealing a coal mine roadway. The thin spraying material comprises the following components: Portland cement, sand, stone, fly ash, polyurea rubber powder, acrylate copolymer emulsion, an accelerator, graphite, an additive, a water reducing agent and an auxiliary agent. The thin spraying material for reinforcing, beautifying, supporting and sealing the coal mine roadway has the characteristics of no toxic gas release, high construction speed, rust resistance, flame retardance, static resistance and the like, can effectively overcome the defects of low construction speed, poor labor environment, large auxiliary transportation amount, multiple potential safety hazards and the like in the existing concrete spraying technology, is a green and environment-friendly material for spraying the underground coal mine roadway, can be used for beautifying the roadway, improving the pollution resistance of the roadway and improving the quality standardization level of the roadway, and can perfectly replace underground paint or oil paint; and the bonding strength of the non-reactive thin spraying sealing material with a coal rock wall and a metal net reaches 2MPa or above, the adhesion force is high, the material is anti-aging and does not fall off, and weathering of a coal rock layer and corrosion of the metal net are effectively prevented.

Owner:江苏科巷矿山科技有限公司

Method for testing tall concrete formwork supporting system

InactiveCN103543025AReduce support costsReduce engineering costsStructural/machines measurementSupporting systemTest region

The invention discloses a method for testing a tall concrete formwork supporting system. The method includes the following steps of selecting a tall supporting formwork region layer of a project, determining a test region, building a mechanical calculation model of the formwork supporting system and analyzing and calculating data obtained through testing. According to the function mechanism that a cast-in-place concrete structure and a formwork support bear a time varying structure system in the construction stage is explored through on-site detection, a basis of the mechanical calculation model of the formwork supporting system is built, serves as a detection basis of laboratory structure tests and theoretical analysis results and provides a technical basis for mechanical analysis of the time varying system, control of safety of the formwork supporting system in the construction period and design and optimization of the construction scheme. Formwork supporting is achieved through on-site materials, the materials can be repeatedly used, concrete formwork supporting cost is reduced, project cost is reduced and the construction speed is improved.

Owner:广东省六建集团有限公司

A Construction Method of Hard Rock Tunnel Based on Hydraulic Cutting

The invention discloses a hard rock tunnel construction method based on water power cutting. The hard rock tunnel construction method based on the water power cutting is characterized by constructing multiple tunnel sections from back to front along the longitudinal extending direction of a tunnel. When any one tunnel section is constructed, the process is as follows: 1, surrounding rock classification advanced detection; 2, construction parameter confirmation, wherein the confirmed construction parameters comprise cutting parameters of a water power cutting machine and split force of a hydraulic splitter; 3, current constructed tunnel section construction: constructing multiple cutting sections of the current constructed tunnel sections from back to front along the longitudinal extending direction of the tunnel, wherein when any one cutting section is constructed, the process is as follows: construction preparation, water power cutting, hydraulic splitting and rectangular cutting block outward transporting; 4, repeating steps one, two and three for many times until the construction process of the constructed hard rock tunnel is finished. The method provided by the invention is simple in steps, convenient to implement, lower in input cost, high in construction efficiency, good in construction effect, and can simply, conveniently and quickly finish the construction process of the hard rock tunnel.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

Method for controlling stability of surrounding rock in gob-side entrydriving of working face of deep island

InactiveCN106761742AReduce resistanceReduce support resistanceUnderground chambersUnderground miningStress concentrationSupporting system

The invention discloses a method for controlling surrounding rock in gob-side entrydriving of a working face of a deep island. The method comprises the following steps of performing pre-cracking and top breaking before stoping of two adjacent working surfaces of the working face of the island, so as to avoid forming a hinge structure at the end surface of the working face, and avoid the hinged rock beam at the critical layer transferring the stoping stress of covering rock of the adjacent working faces to the working face; selecting a constant-drag large-deformation anchor bolt in a gob-side entrydriving support system, increasing the lengths of anchor bolts at the coal wall side and top plate side, deforming the anchor bolts to relieve pressure, and enabling anchor cables to transfer the concentrated stress of the surrounding rock to the farther physical coal wall; slantwise and downwards drilling pressure relief holes in the physical coal wall side with 3 to 4 cycle roof weighting paces in advance at the working face of the island; spraying slurry to the narrow coal column side. The method has the advantages that the stress concentration degree of the deep working face is effectively reduced, the drags of a bracket, a support column and support are reduced, the stoping efficiency of coal sources is improved, the safe and efficient stoping efficiency of the working face is also improved, and the major technical and economic benefits are realized.

Owner:XIAN UNIV OF SCI & TECH

A stope approach layout method and method beneficial to filling and roof connection

The invention provides a stope route arrangement mode and method beneficial to roof-contacted filling. The roof-contacted filling rate can reach above 90%, filling cost is low, and the process is simple. According to the stope route arrangement mode, a mining cutting roadway is arranged perpendicular to the moving direction of an ore body, extracting drifts at two wings of the mining cutting roadway are arranged in the moving direction of the ore body in a staggered mode, a chute is arranged in a surrounding rock section of the footwall of the mining cutting roadway, the height of the extracting drifts is 3m, the length of the first extracting drift is 14-18m, the length of the second extracting drift is 16-20m, and the height of the mining cutting roadway is 4.5m. According to the stope route arrangement method, a slope ramp linking way, a footwall stope layering linking roadway and the mining cutting roadway are constructed sequentially, and the chute and a return air filling shaft are communicated; the second extracting drift is constructed after the first extracting drift is finished; brushing extraction is carried out on a temporary jamb, the width of a central mining cutting roadway is 4.5-5m, and a top plate is shaped like an arch; waste stones are dumped into the second extracting drift, the height of a smooth chute is increased by 3.5m, a filling blocking wall is erected, and filling operation is finished when the liquid level of filling material slurry is higher than the top plate of the extracting drifts by 20-30cm.

Owner:南京银茂铅锌矿业有限公司

A construction method of a circular underground continuous two-wall integrated structure

ActiveCN105256810BEasy to assembleGuarantee welding qualityArtificial islandsExcavationsPurlinReinforced concrete

The invention discloses a construction method for a round underground continuous wall two-in-one structure. The construction method includes the following steps that (1) bracket steel sheet piles are prefabricated, and round steel reinforced concrete enclosing purlins are prefabricated in a segmented mode; (2) pile sinking is carried out; (3) a foundation pit is excavated; (4) gaps in locking positions of the steel plate piles are blocked; (5) the round steel reinforced concrete enclosing purlins are assembled; (6) the foundation pit continues to be excavated downwards until the design depth is reached, and the gaps in the locking positions of the steel plate piles are continuously blocked through waterstop steel strips; (7) a bottom plate waterstop steel plate is welded to the inner side faces of the steel plate piles, and the bottom plate waterstop steel plate surrounds the inner side of a support in the circumferential direction in an endless shape; and (8) a cushion layer is laid, then a bottom plate is cast to reach a set thickness, and the bottom plate waterstop steel plate is made to stretch into the bottom plate. Through the construction method, the support cost for the foundation pit of an underground building can be reduced effectively; on the basis, the support is used as an outer wall of the underground building, the novel structure that the support and the outer wall are integrated is formed, and a foundation is laid for reducing the overall construction cost of the underground building.

Owner:JIANGSU DONGHENAN GEOTECHNICAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com