Hard rock tunnel construction method based on water power cutting

A technology for hydraulic cutting and tunnel construction, which is applied in tunnels, earthwork drilling, mining equipment, etc. It can solve the problems of high wear of cutting tools and roadheaders, affecting the overall stability of surrounding rock, vibration and noise disturbing residents, and achieves high construction efficiency. The effect of low construction cost and small vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

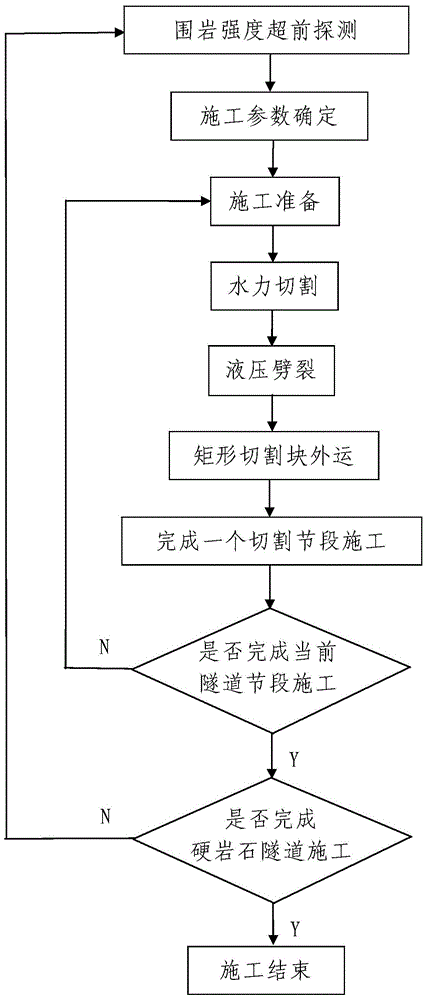

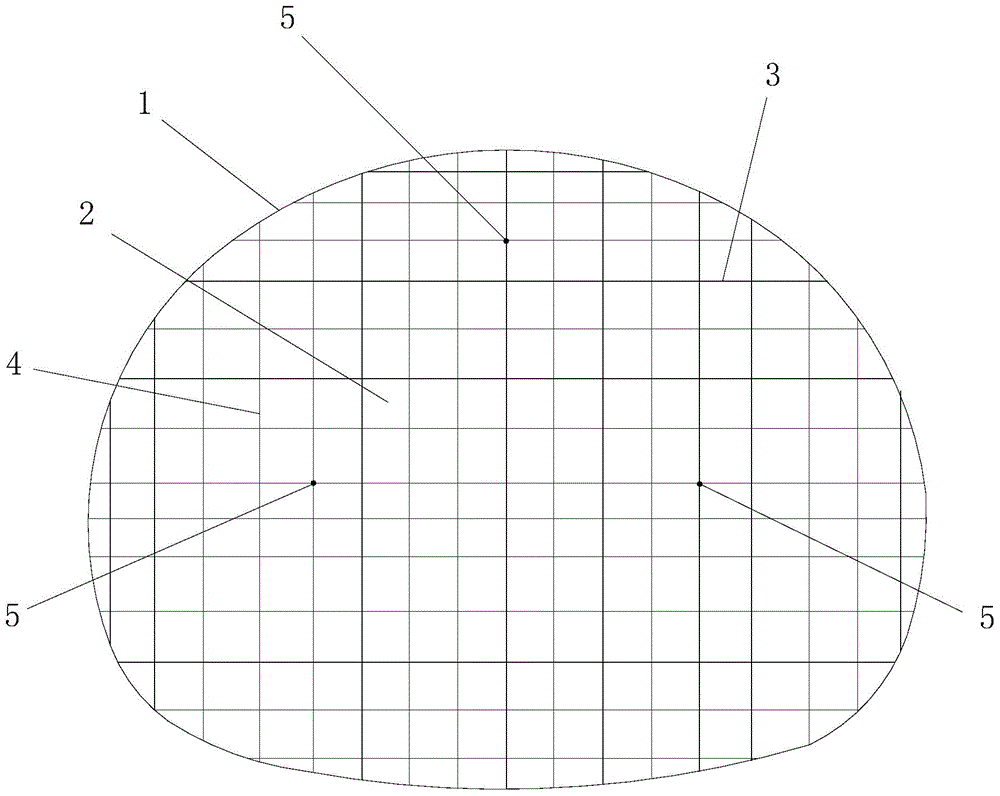

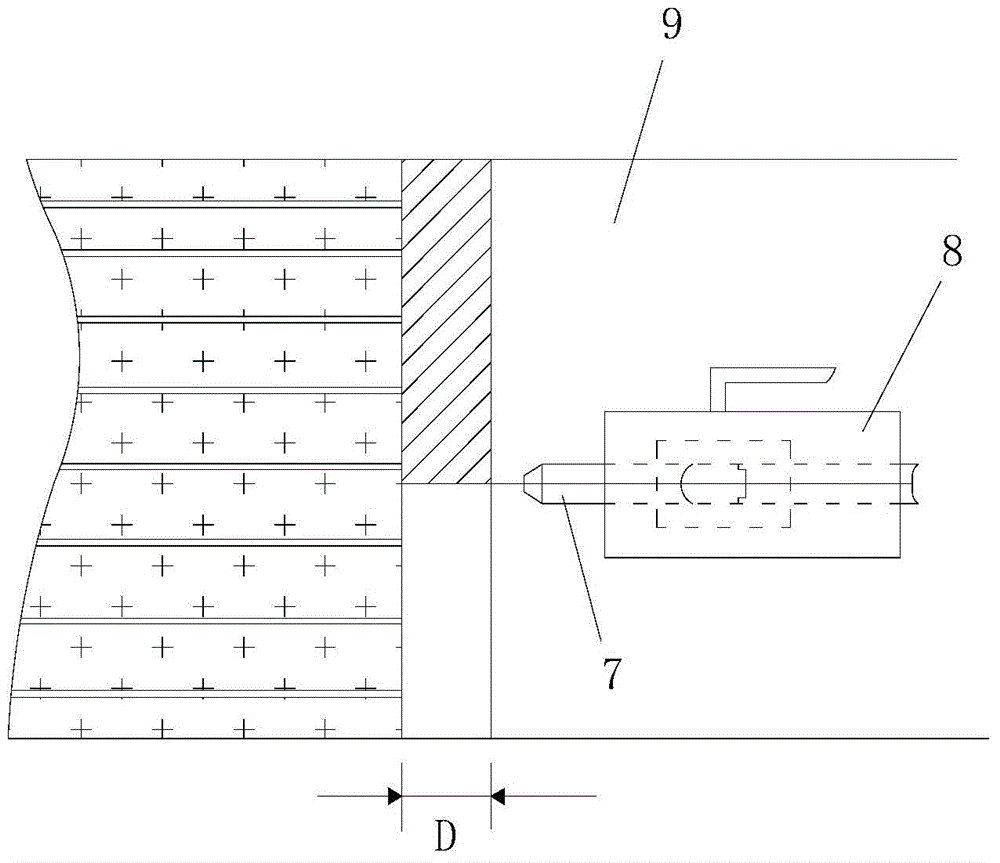

[0053] Such as figure 1 A kind of hard rock tunnel construction method based on hydraulic cutting is shown, along the longitudinal extension direction of the tunnel from back to front, the hard rock tunnel constructed is divided into multiple tunnel segments, and the construction methods of multiple tunnel segments are all The same; when constructing any tunnel segment in the hard rock tunnel constructed, the hydraulic cutting machine 8 is combined with the hydraulic splitting machine for construction, and the process is as follows:

[0054] Step 1. Advanced detection of surrounding rock strength: perform advanced detection of the surrounding rock strength of the currently constructed tunnel segment.

[0055] Step 2, construction parameter determination: according to the surrounding rock level determined in step 1, the construction parameters of the currently constructed tunnel segment are determined; the determined construction parameters include the cutting parameters of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com