Patents

Literature

546 results about "Blasting vibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

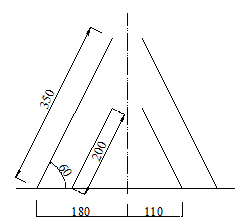

Hollow-hole rhombic parallel cut blasting damping method

InactiveCN102914226AReduce blasting vibration velocityReduce the impactBlastingDetonatorUnderground tunnel

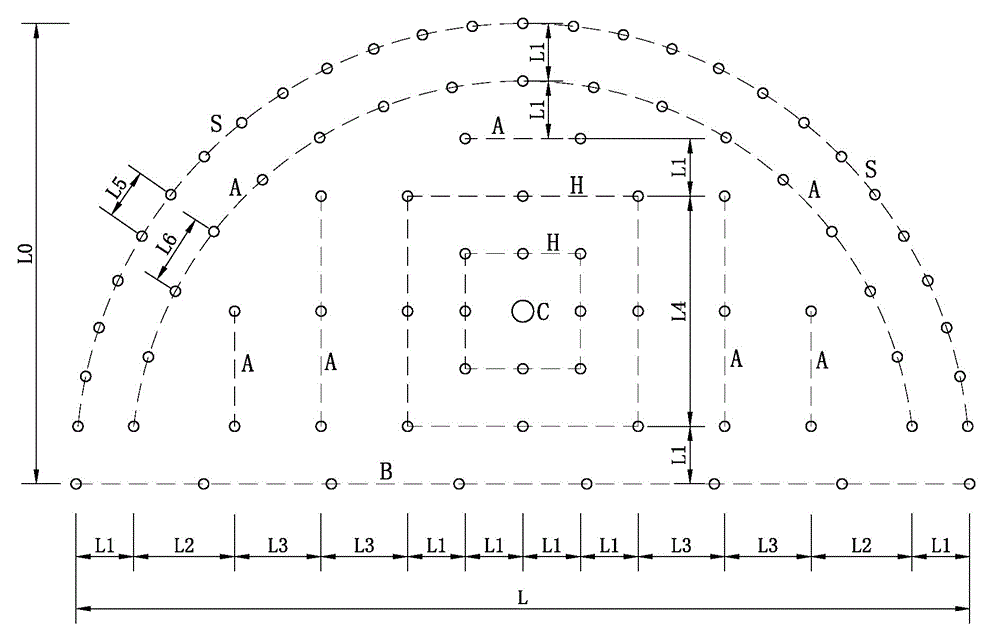

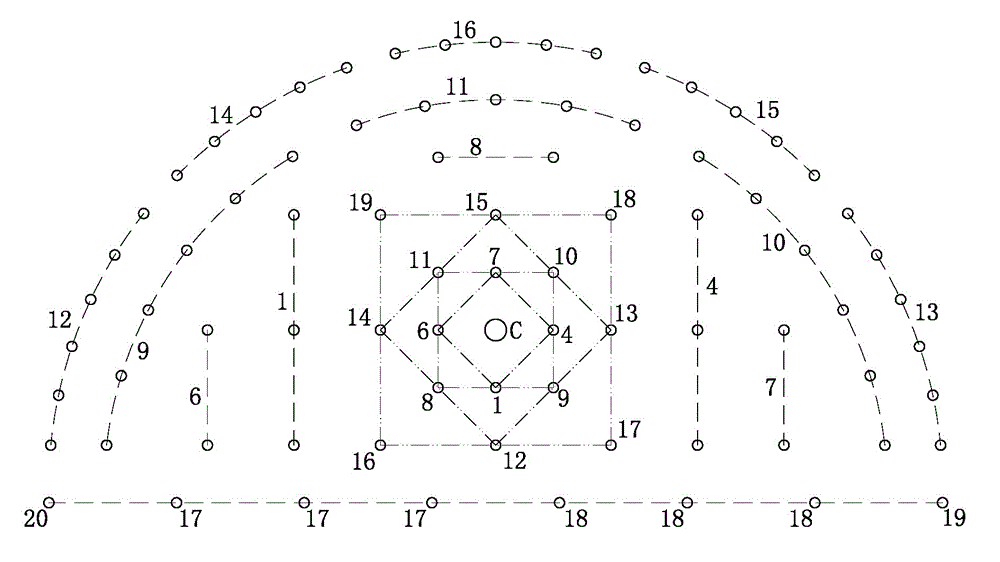

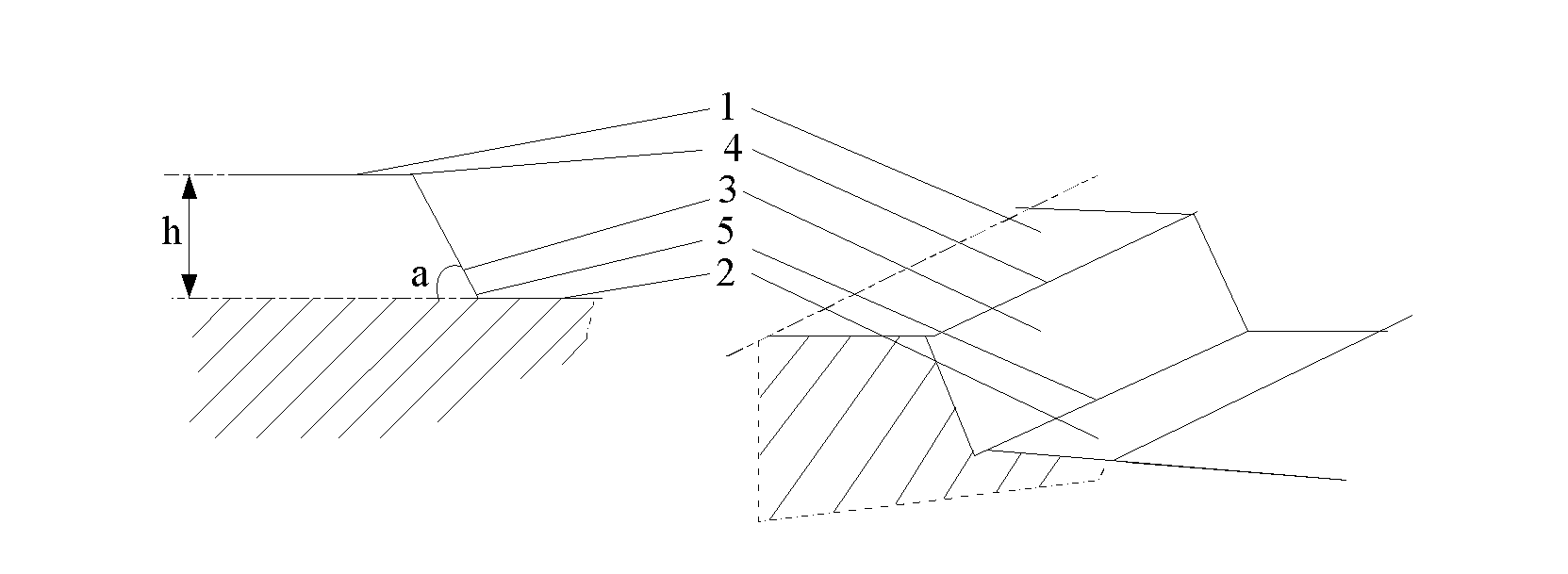

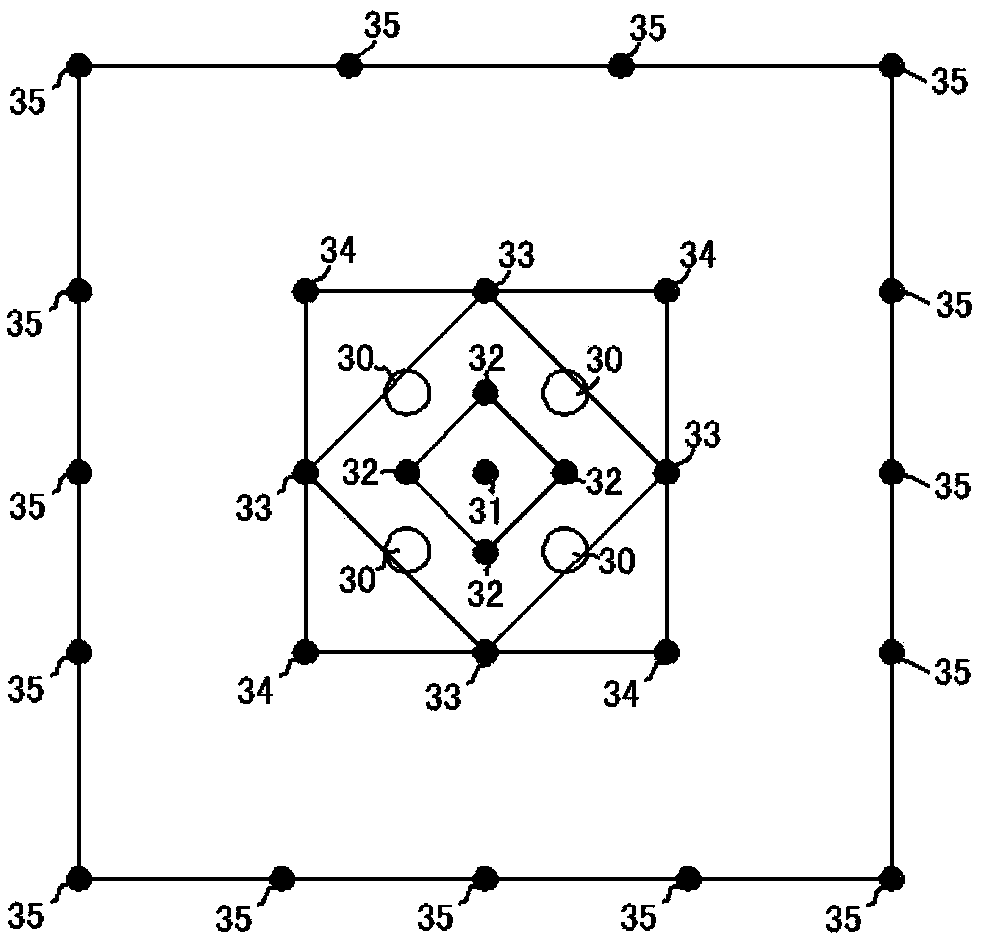

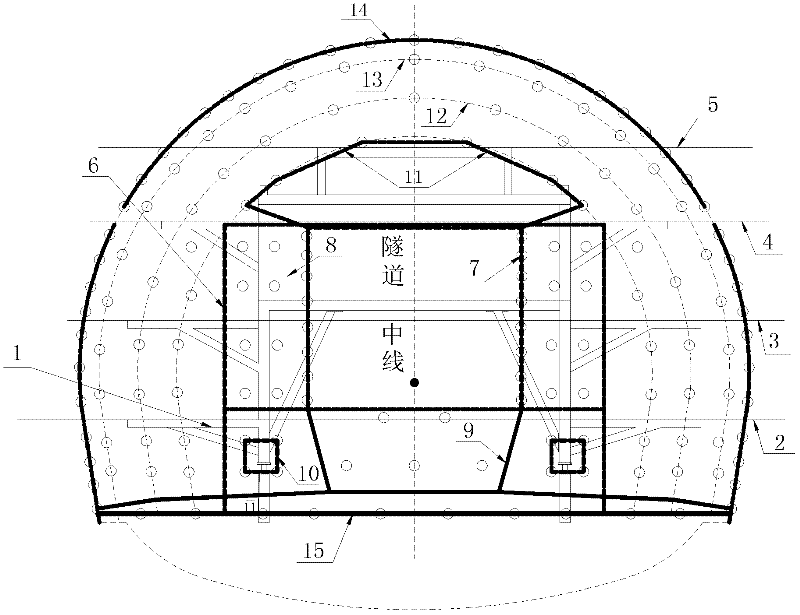

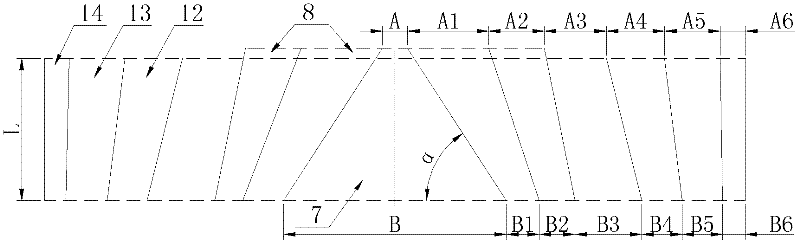

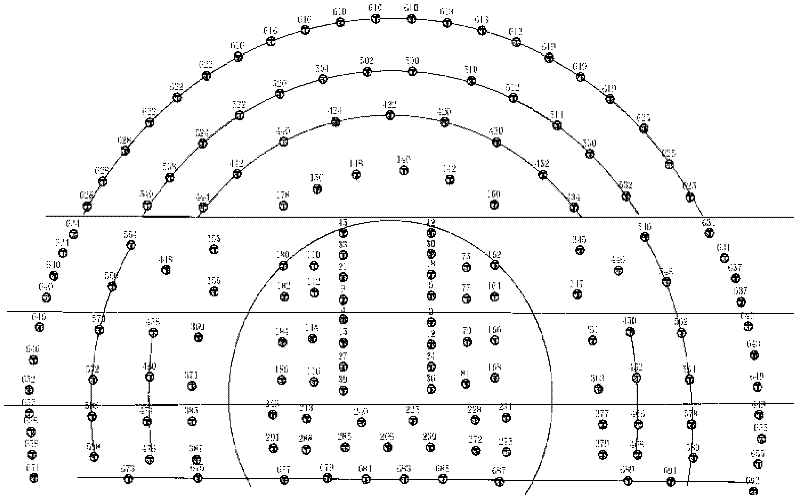

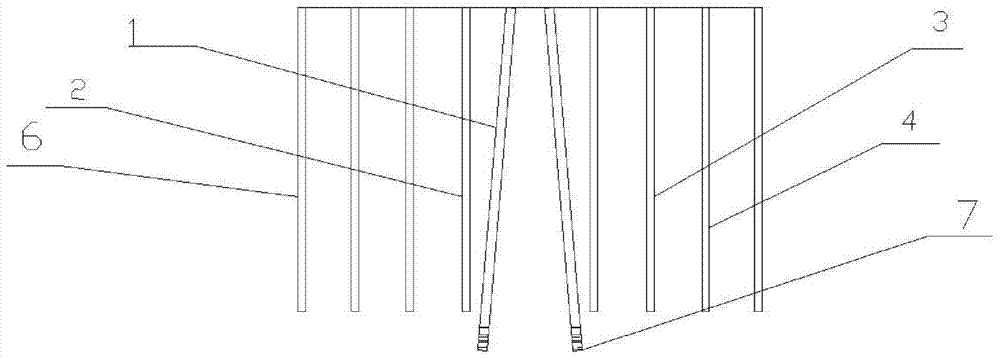

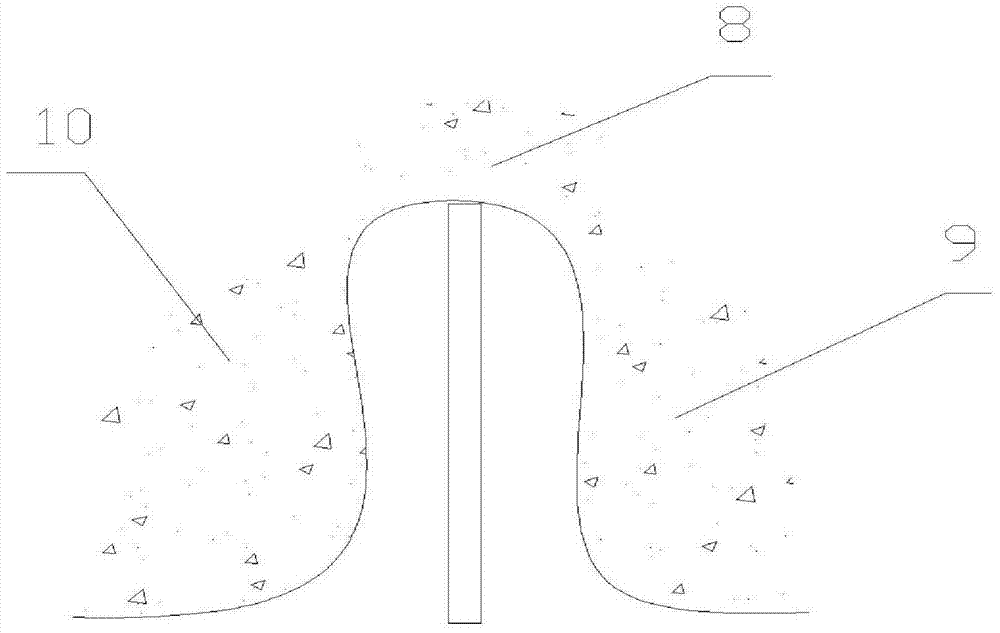

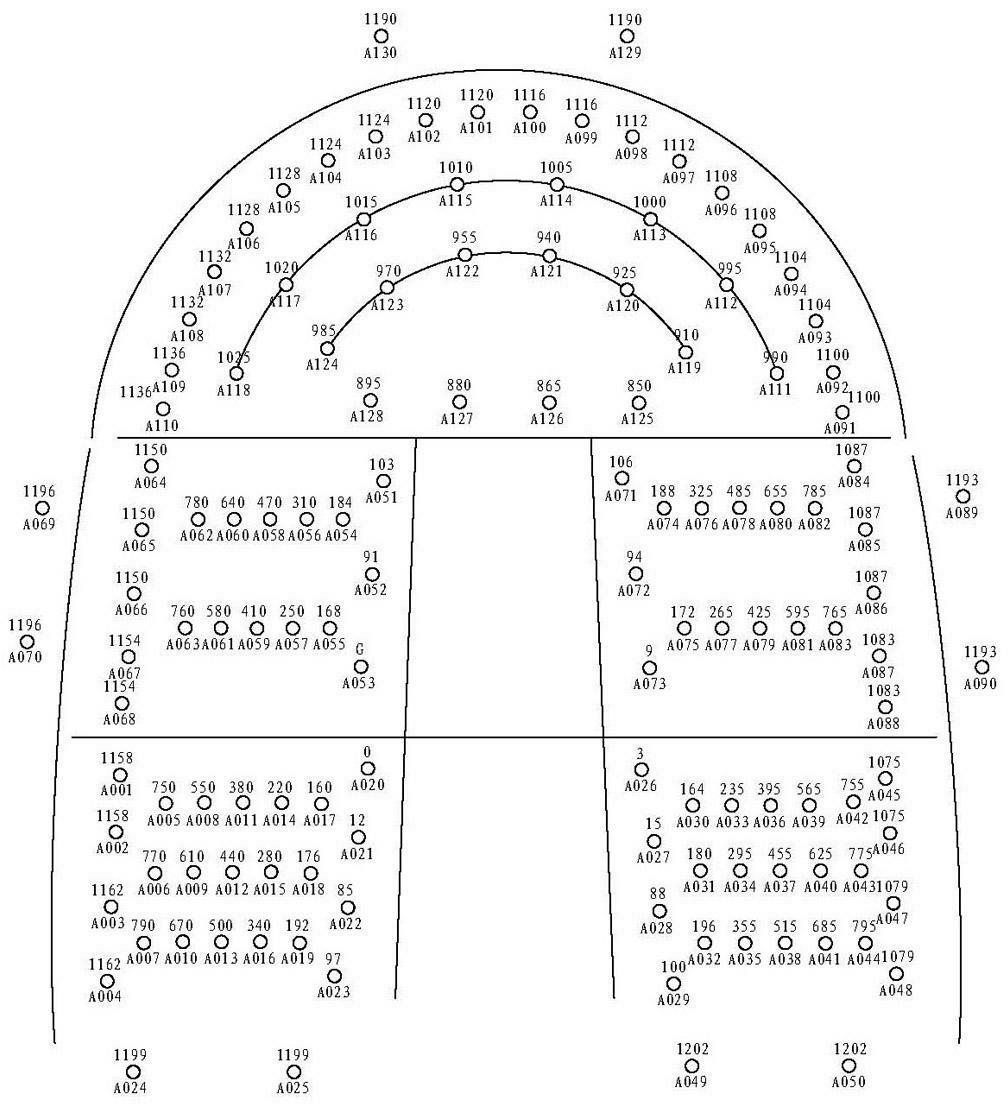

The invention relates to a hollow-hole rhombic parallel cut blasting damping method. Blasting tunneling is performed on the tunnel face of an underground tunnel. The construction method comprises using a down-the-hole drill to drill a hollow hole with the diameter of 90mm to 180mm at the position of the middle of the tunnel face of the tunnel; using a hammerdrill to drill a plurality of blast holes, enabling the blast holes to comprise cut holes, auxiliary holes, periphery holes and base plate holes which are expanded around the hollow hole; filling explosives and detonators, using stemming to seal the blast holes, adopting rock emulsion explosives, and using ordinary millisecond nonel detonators or high-precison millisecond nonel detonators; and detonating the explosives according to blast hole arranging orders and detonator delay time. The hollow-hole rhombic parallel cut blasting damping method has the advantages that when an urban subway underneath passes buildings at a close range in a granite stratum and old resident houses, the blast vibration speed can be effectively controlled, influences of blast vibration on the buildings and life of residents are reduced, and compared with a traditional wedge cut blasting scheme, the hollow-hole rhombic parallel cut blasting damping method enables the maximum blasting vibration speed to be reduced by 50%.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

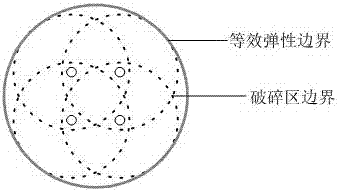

Vibration absorbing method for cut presplitting blasting

InactiveCN102927867AReduce vibration speedReduce the maximum blasting vibration velocityBlastingDetonatorEmulsion explosive

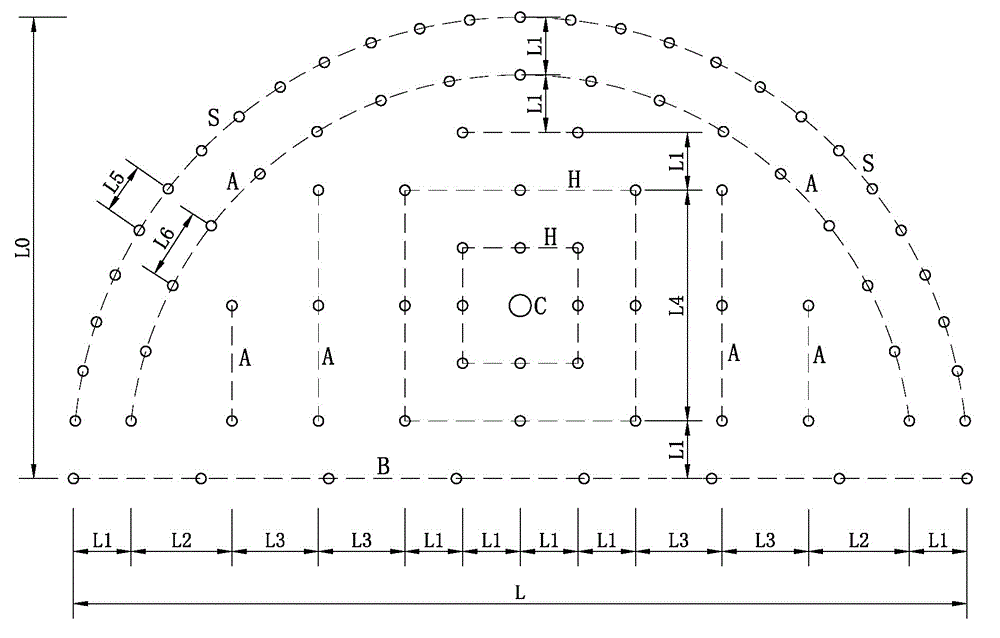

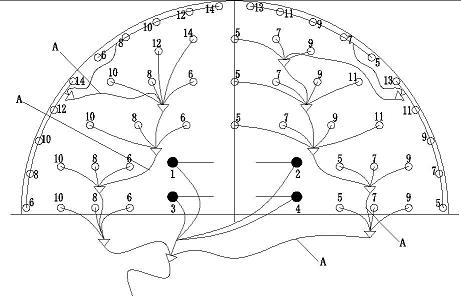

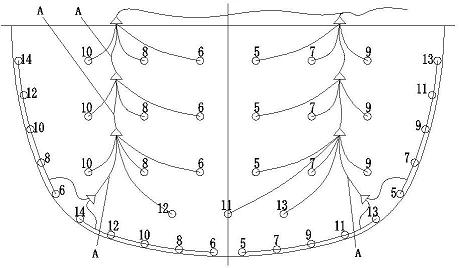

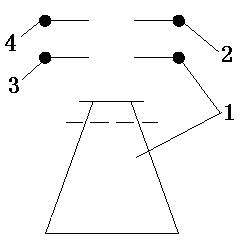

The invention relates to a vibration absorbing method for cut presplitting blasting, which comprises the steps that blasting tunneling is performed on a face of a subway tunnel; a gadder is used to drill blastholes including presplitting blastholes, cutholes, assistance holes, periphery holes and bottom plate holes; the presplitting blastholes are a group of transversely arranged blastholes that are located 500mm-600mm above the cutholes; the presplitting blastholes adopt mixed connected kerf cartridges for explosive loading; the cutholes, the assistance holes, the periphery holes and the bottom plate holes adopt common emulsion explosive loading, and adopt millisecond nonel detonators; and the presplitting blastholes, the cutholes, the assistance holes, the periphery holes and the bottom plate holes are initiated in sequence. The vibration absorbing method has the benefits that as a presplitting surface and a presplitting crushed zone are formed above the cutholes, the vibration is reduced and absorbed in transmission paths, the vibration velocity caused by the cut blasting is reduced obviously, and blasting vibration can be controlled effectively. Compared with the traditional smooth blasting, the maximum blasting vibration velocity can be reduced by 30%, and effects on protected heritages along a line are reduced.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

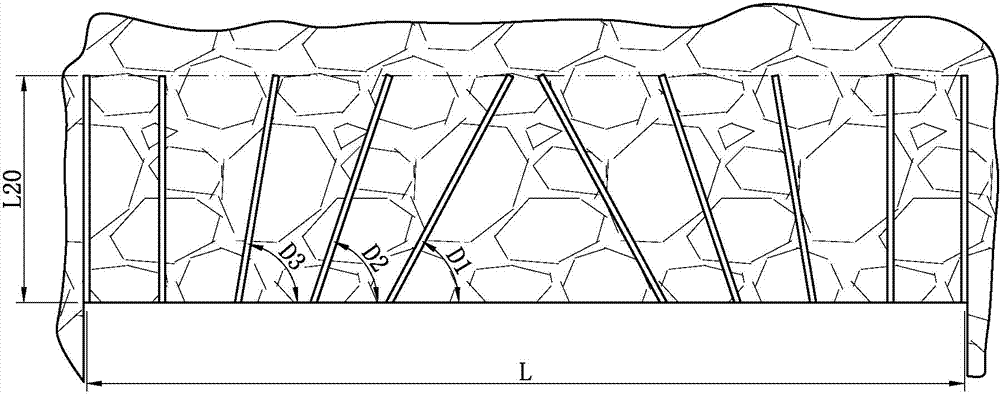

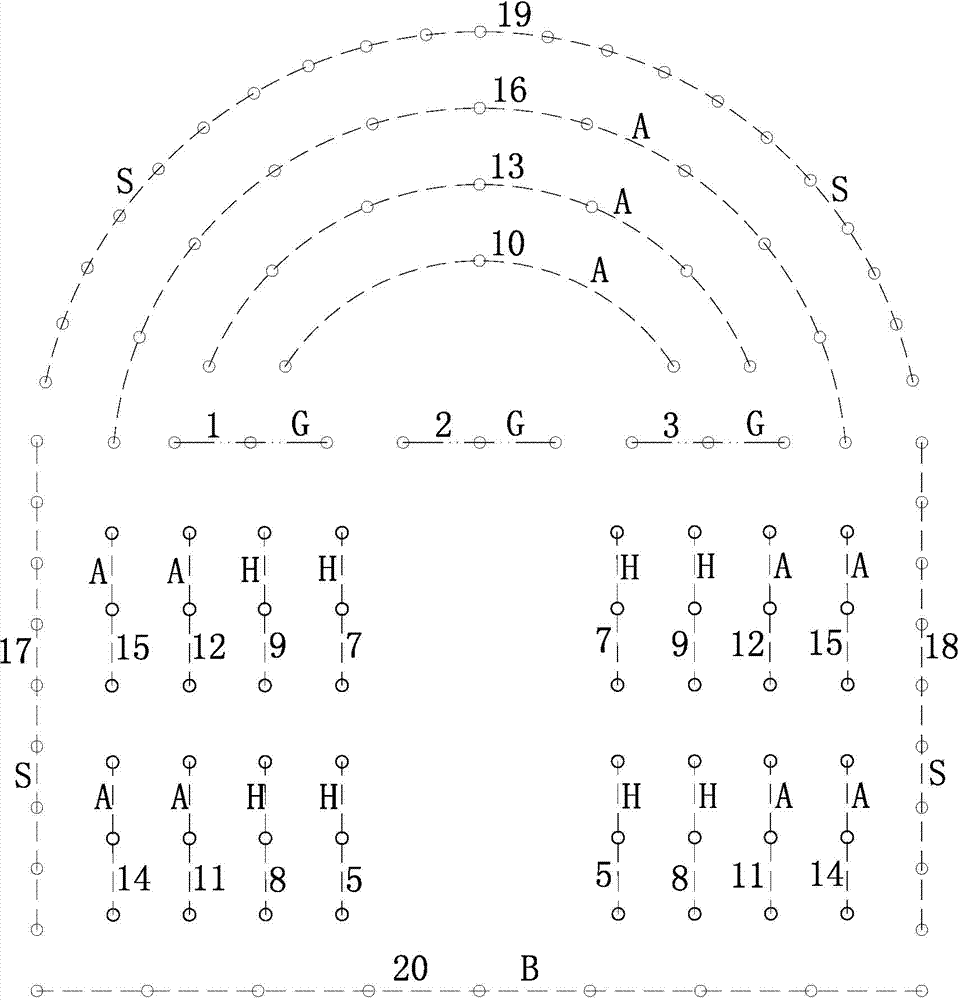

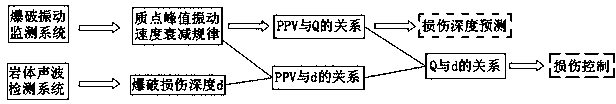

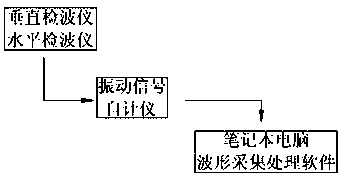

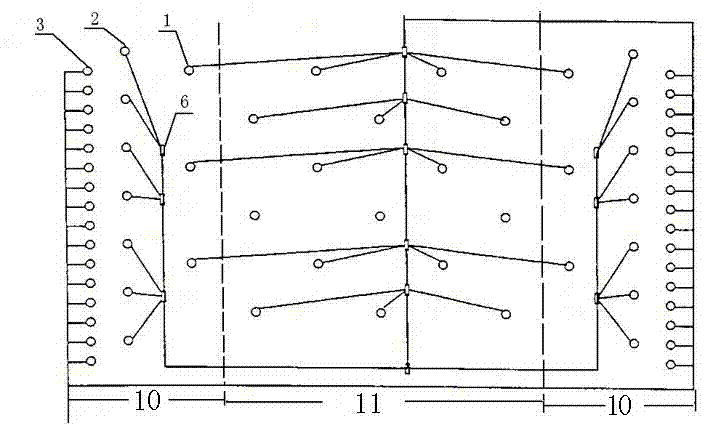

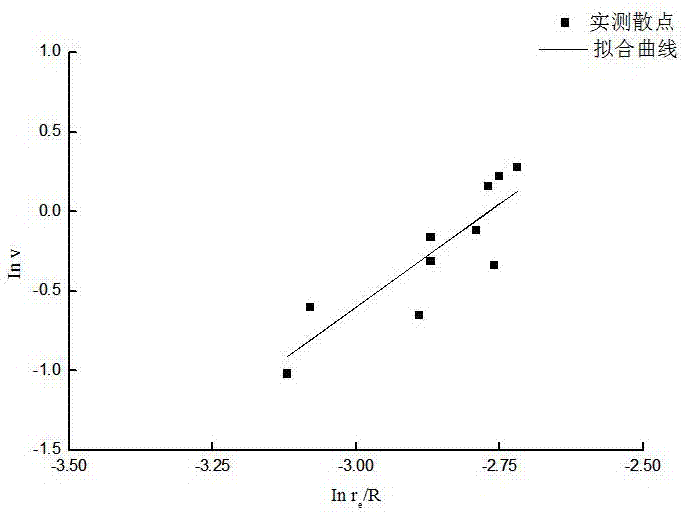

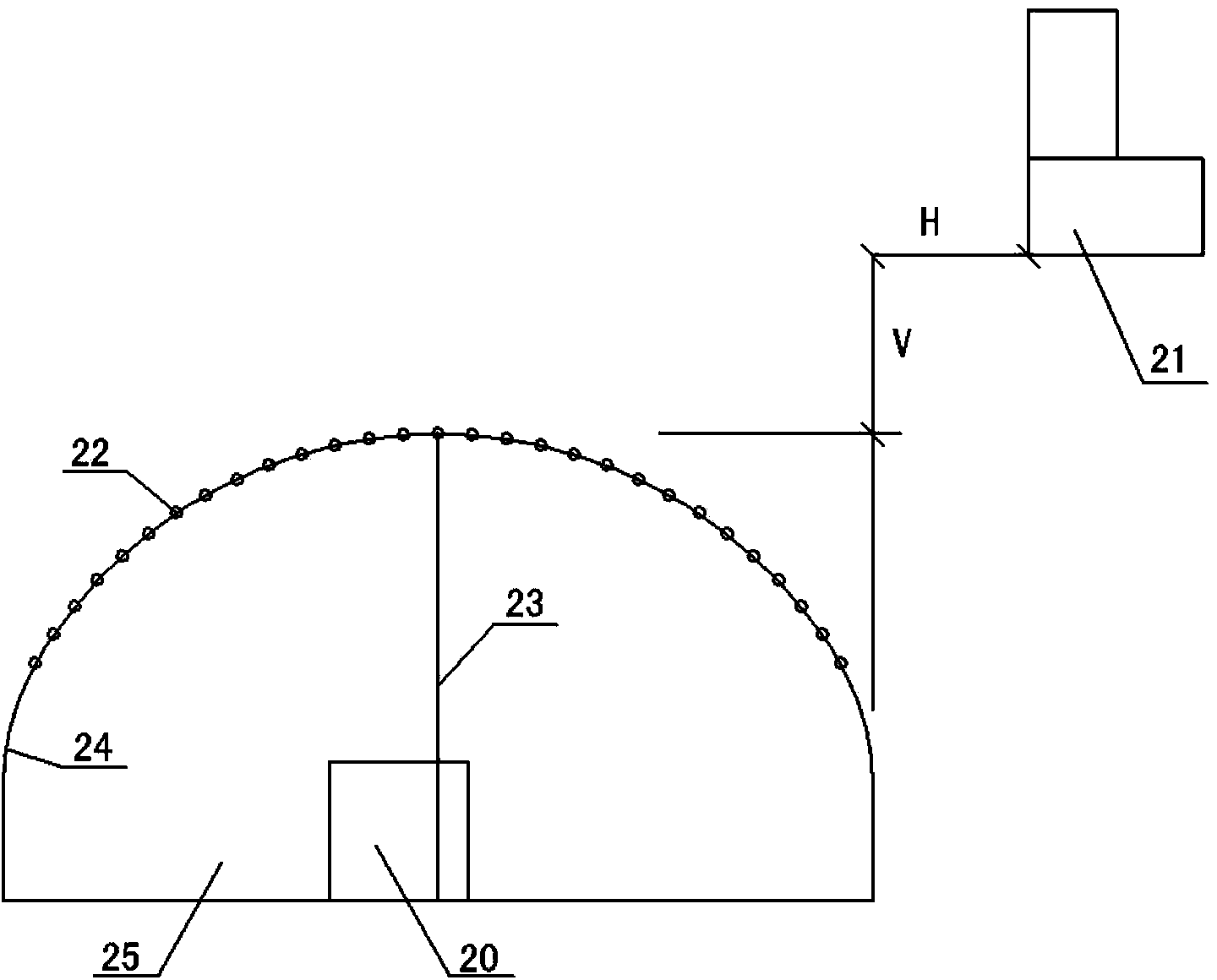

Method for controlling damage of slope pre-splitting blasting digging based on blast vibration test

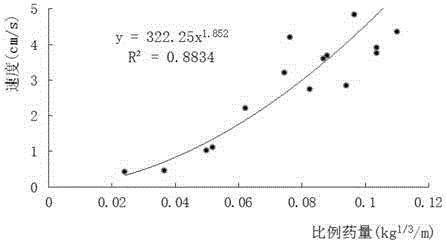

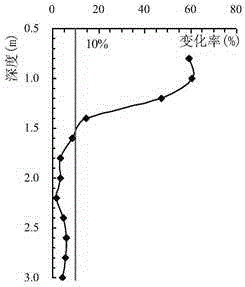

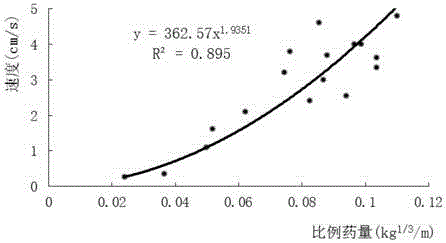

ActiveCN104390537ACost-effectiveEngineering promotion and application value is goodSeismologyBlastingStatistical relationBlasting vibration

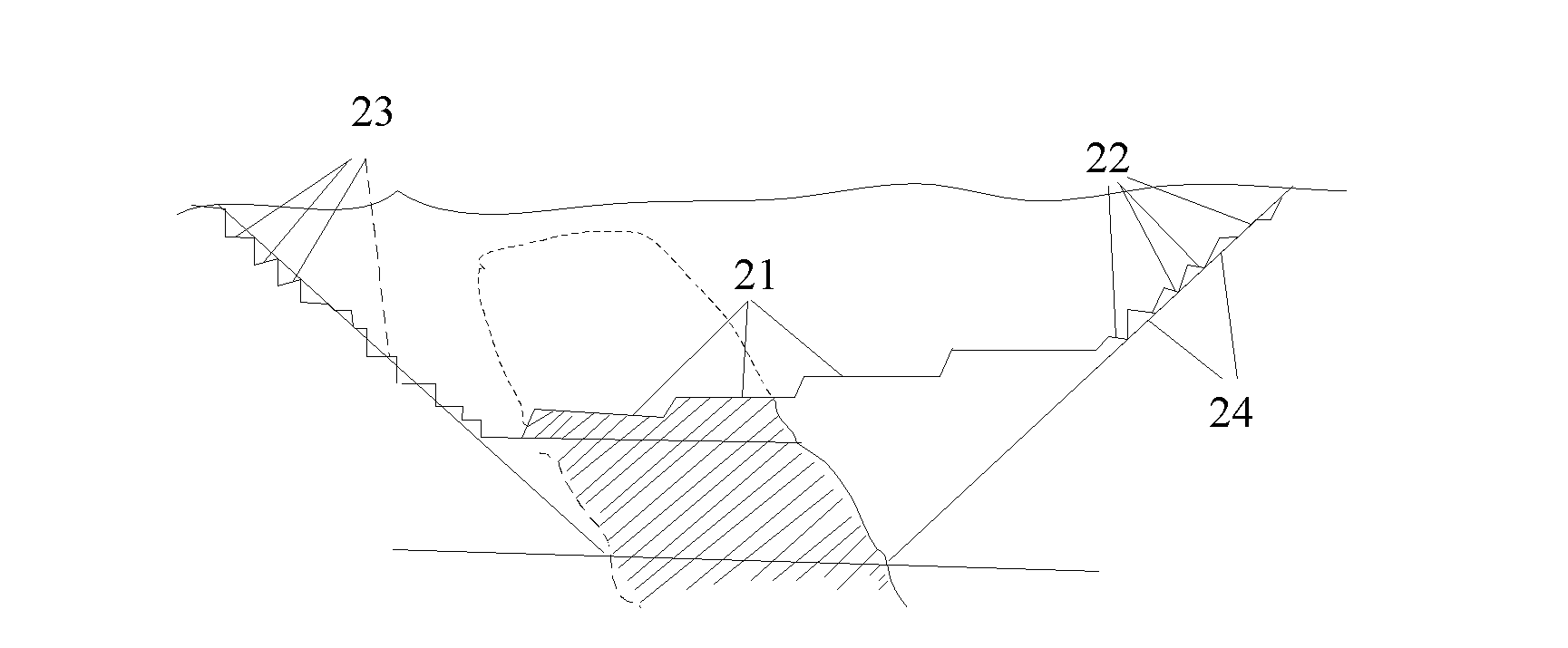

The invention relates to a method for controlling damage of slope pre-splitting blasting digging based on a blast vibration test. The method comprises the following steps: establishing a statistical relation between the blasting particle peak vibration velocity at a plurality of blasting center distances and the damage depth under different altitude difference conditions by utilizing the blasting digging for a few front steps on the basis of the acoustic detection for a slope blasting digging damage area and the corresponding blasting vibration monitoring, and then utilizing the particle peak vibration velocity induced during the slope bench blasting process to forecast the depth of the digging damage area, and offering a control proposal for single-bump explosive quantity. After the relation between the particle peak vibration velocity and the slope blasting digging damage area is established according to a blasting vibration test result of the front steps and the acoustic detection for the damage area, subsequent steps are only subjected to blasting vibration monitoring, and geological data is combined for comprehensively analyzing and adjusting, so that the depth of the slope digging damage area can be determined and the operation is convenient, quick, high-efficient and economical. The rock slope blasting digging damage can be controlled by controlling the maximum single-bump explosive quantity. The method has high engineering popularization and application values.

Owner:WUHAN UNIV

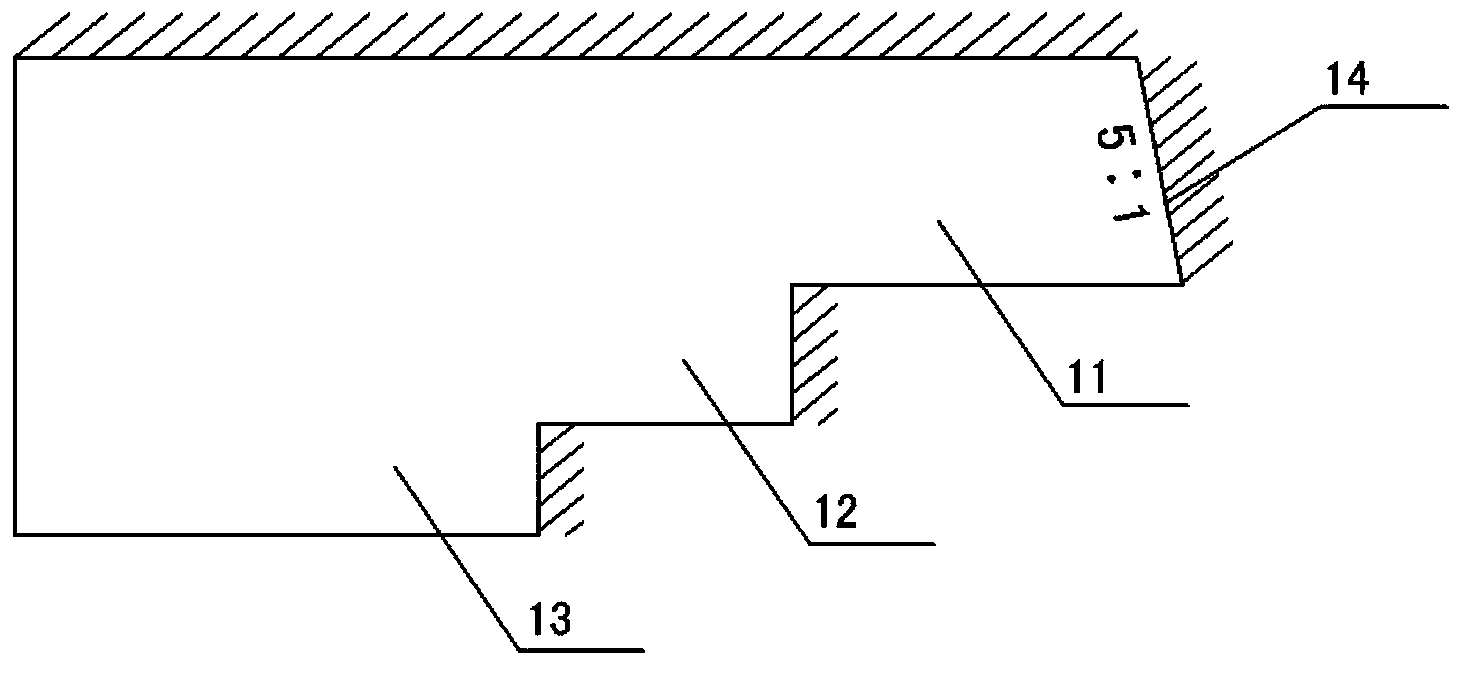

Multi-row micro-differential roadbed deep hole blasting construction method

The invention relates to a multi-row micro-differential roadbed deep hole blasting construction method, which comprises the following steps of: (1) selecting blasting parameters; (2) calculating security; (3) arranging a stair and a free face; (4) distributing holes and drilling holes; and (5) blasting. The blasting method is a multi-row deep hole millisecond micro-differential blasting method; and the blasting is performed by pull trough blasting and side slope blasting in a roadbed sequentially, wherein the pull trough blasting is loose blasting and the side slope blasting is precraking blasting. In the method, a shock conducting tube non-electric priming system micro-differential control blasting technology, a comprehensive blasting construction scheme of loose blasting, the deep hole millisecond micro-differential blasting technology and the roadbed side slope precraking blasting technology, and a wide-pitch and low-resistance hole distribution mode are adopted, so that explosivesand detonators are saved, the drilling mechanization degree is enhanced, the labor cost is reduced, the blasting effect is enhanced, the large rate of blast rocks is reduced, the material abandoning rate is reduced and harms of blasting vibration, impact waves, flying stones and the like are reduced; furthermore, when the blasting effect is enhanced and the stability of the blast roadbed side slope rocks is guaranteed, the absolute safety of blasting can be guaranteed.

Owner:HUITONG ROAD & BRIDGE CONSTR GROUP

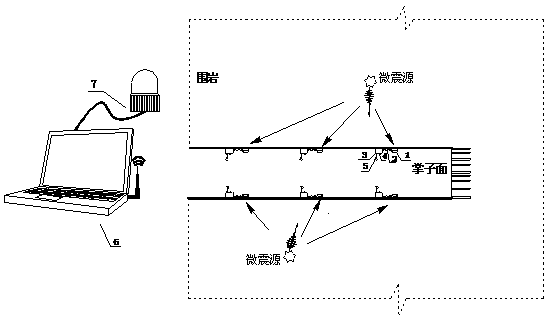

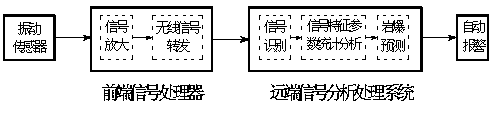

Deep rock mass rock blasting forecasting and early warning method based on blast vibration monitoring

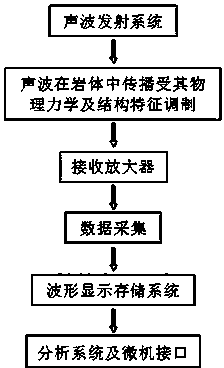

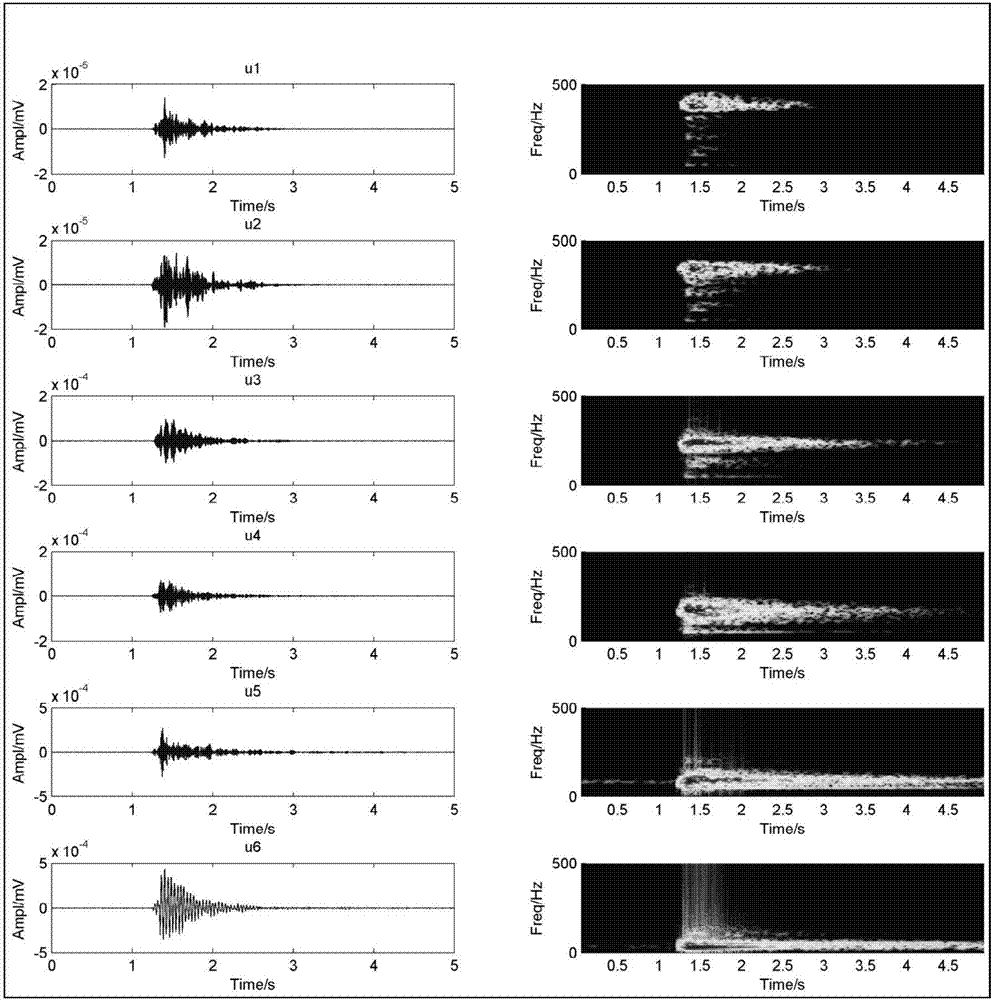

InactiveCN103777232AShort construction periodReduce volumeSeismologyFrequency spectrumMaterial resources

A deep rock mass rock blasting forecasting and early warning method based on blast vibration monitoring comprises the following steps: setting a blast vibration sensor, collecting a signal and converting the signal into an electric signal for recording, amplifying the electric signal through a signal amplifier, forwarding the electric signal to a far-end signal analyzing and processing system through a wireless electric signal transponder, transmitting the received signal to a vibration signal identification and filter system of a computer, carrying out spectral analysis, recognition and separation on the vibration waveform, extracting characteristic parameters of a separated wave signal, and forecasting or evaluating disasters. The deep rock mass rock blasting forecasting and early warning method based on blast vibration monitoring has the advantages that the deep rock mass rock blasting is forecast and warned early through signal analysis via vibration monitoring equipment, easiness, convenience and practicability are achieved, great manpower and material resource input is not required, site construction is not disturbed, flexibility and convenience are achieved, and the deep rock mass rock blasting forecasting and early warning method is high in adaptability to different projects.

Owner:WUHAN UNIV

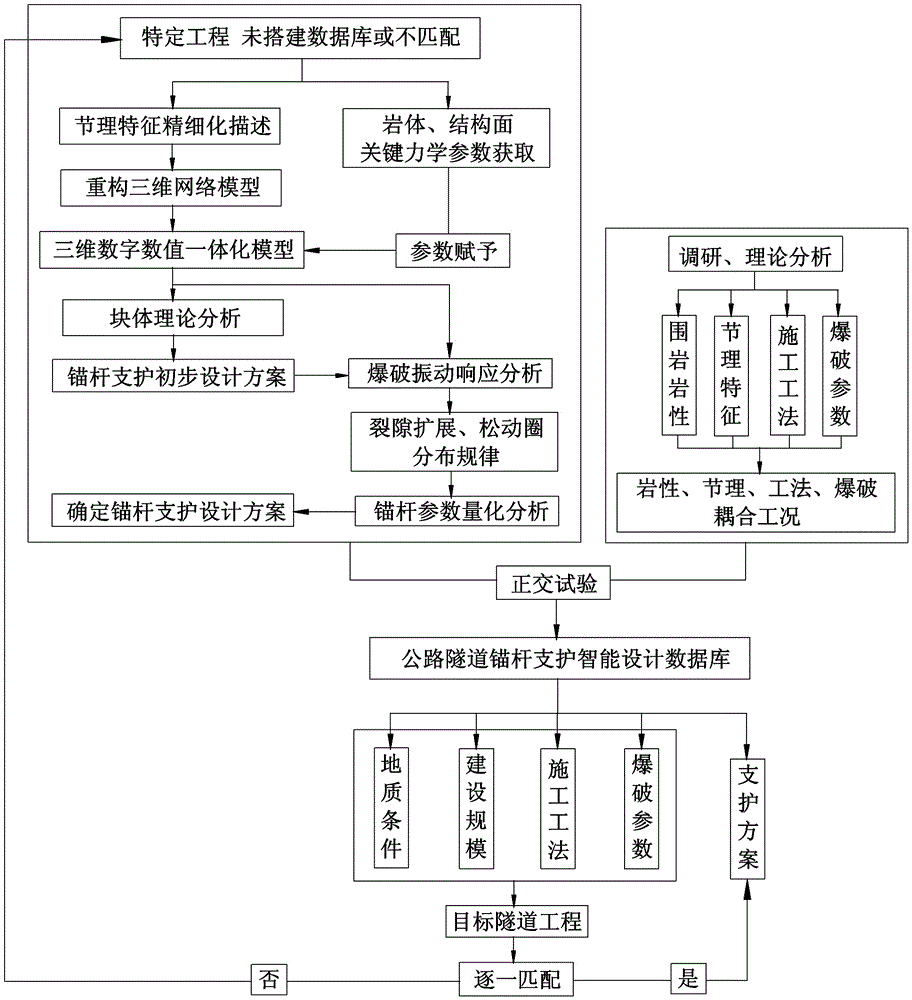

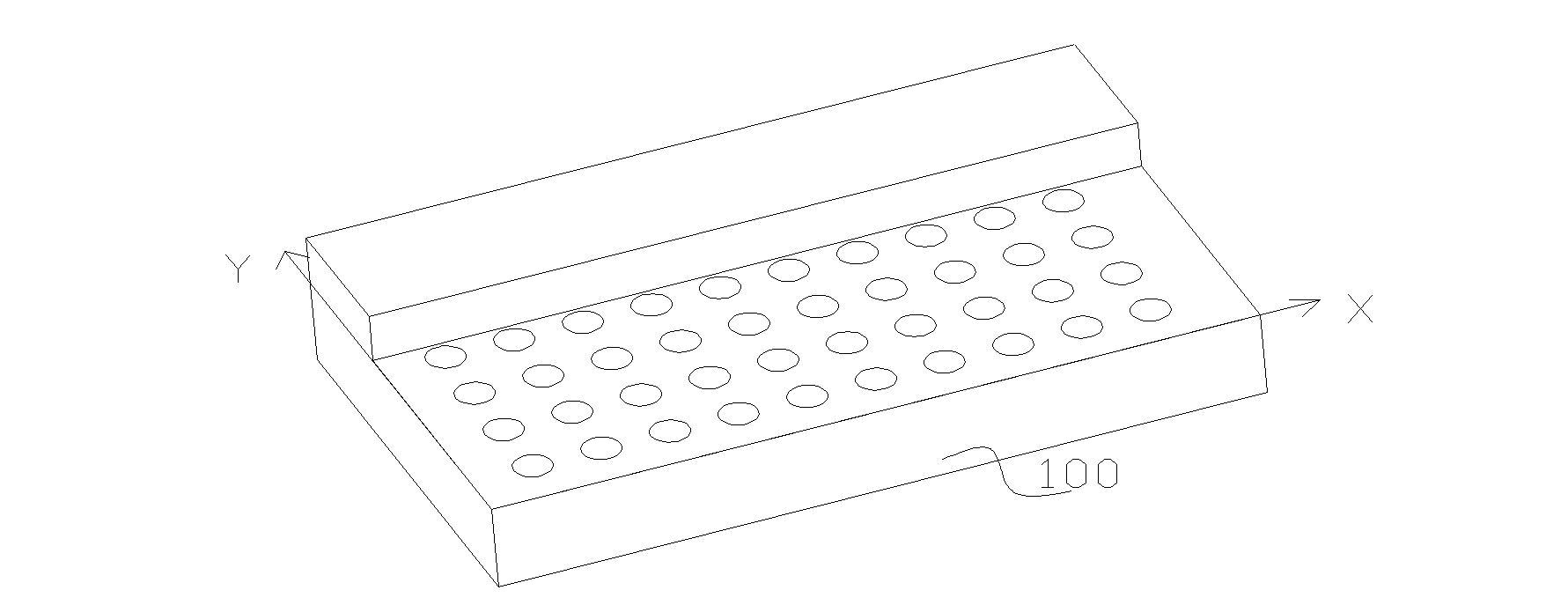

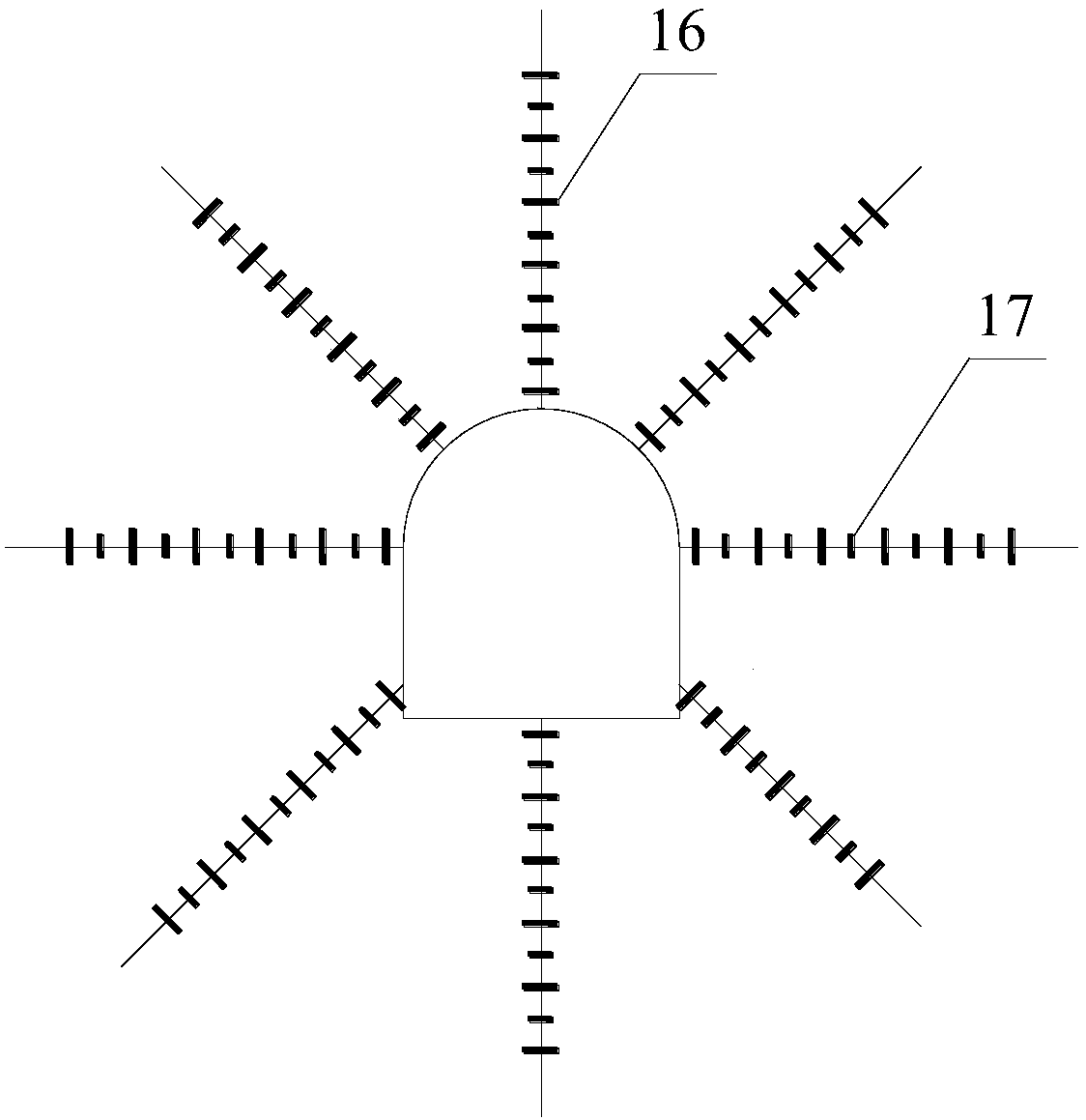

Design method of anchor bolt support for highway tunnel

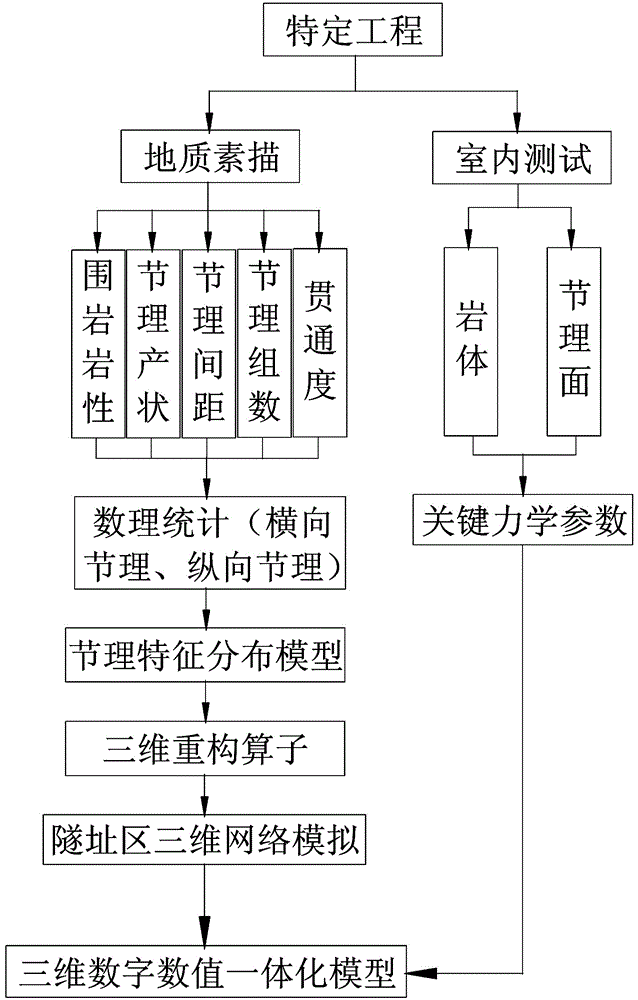

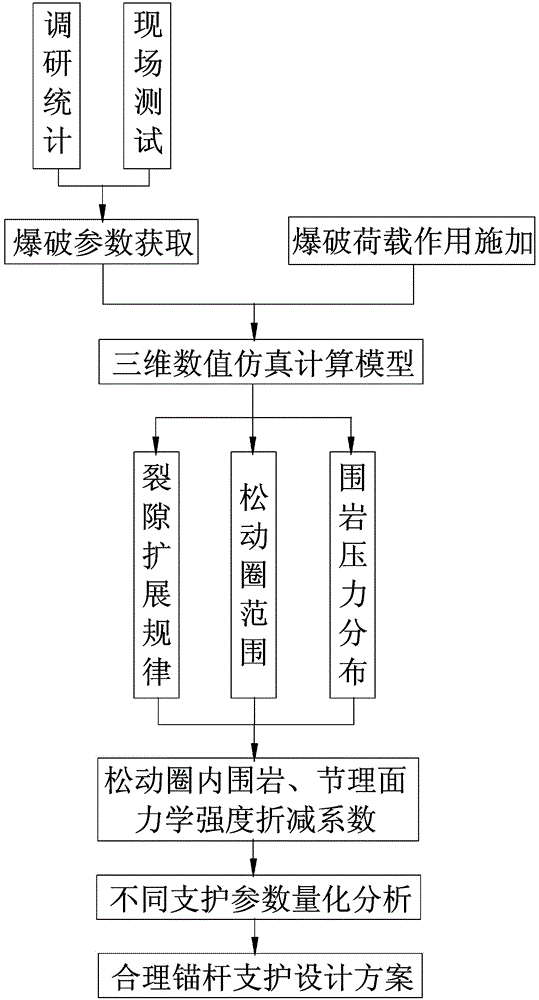

ActiveCN105787206AResolution cycleSolve operational problemsGeometric CADSpecial data processing applicationsBlasting vibrationDesign methods

The invention discloses a design method of an anchor bolt support for a highway tunnel. The method is characterized in that the design method of the anchor bolt support for the highway tunnel is designed on the basis of rock mass joint characteristics and blast vibration effects. The design method of the anchor bolt support for the highway tunnel comprises implementing steps as follows: step (1) establishing a three-dimensional digital and numerical value integrated model; step (2) proposing a preliminary scheme of the anchor bolt support; step (3) dynamically determining an anchor bolt support scheme and parameters which are suitable for an engineering; step (4) establishing an intelligent design database of the anchor bolt support for the highway tunnel; step (5) gradually improving the engineering applicability of the design scheme and the established database.

Owner:TONGJI UNIV +3

Method for forecasting rock blasting damage depth of nuclear power projects

ActiveCN106326546AIncrease workloadReduce the number of field trialsGeometric CADBlastingUltrasound attenuationVibration attenuation

The invention relates to a method for forecasting rock blasting damage depth of nuclear power projects. The method comprises the following steps of performing the blasting vibration testing to determine a site vibration attenuation rule; performing the sound wave testing to primarily determine the rock damage depth; performing the finite element numerical simulation, and calculating the rock particle vibration speed and rock blasting damage depth; respectively establishing the change rules of the particle peak vibration speed (1m away from a blasting source R) along with the rock blasting damage depth under the step blasting and pre-fracturing blasting types; substituting the explosive charging quantity Q0 of an actual section into the site blasting vibration attenuation rule and the change rules of the particle peak vibration speed along with the rock blasting damage depth, so as to forecast the blasting damage depth caused by the explosive charging quantity. The method has the characteristics that one part of site sound wave testing can be replaced with the numerical simulation, the site testing frequency is reduced, the field workload is reduced, and the construction efficiency is improved; the site blasting group hole effect is comprehensively considered, the forecasting is accurate, and the operation is convenient and rapid.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

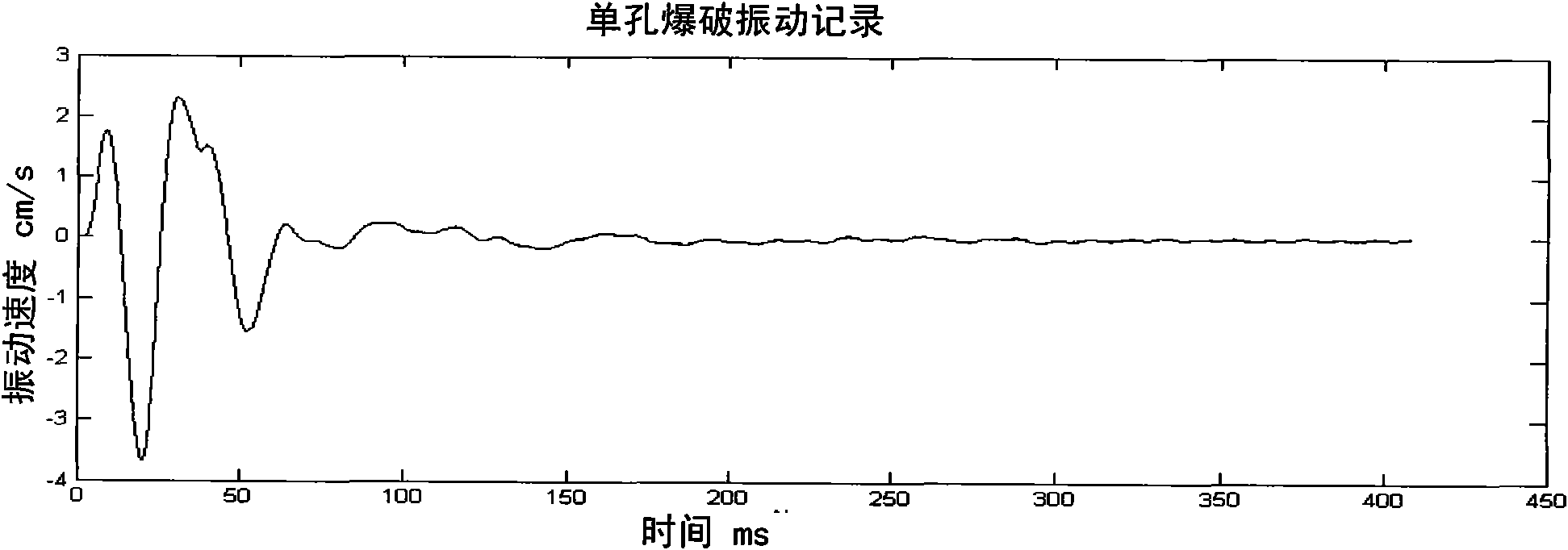

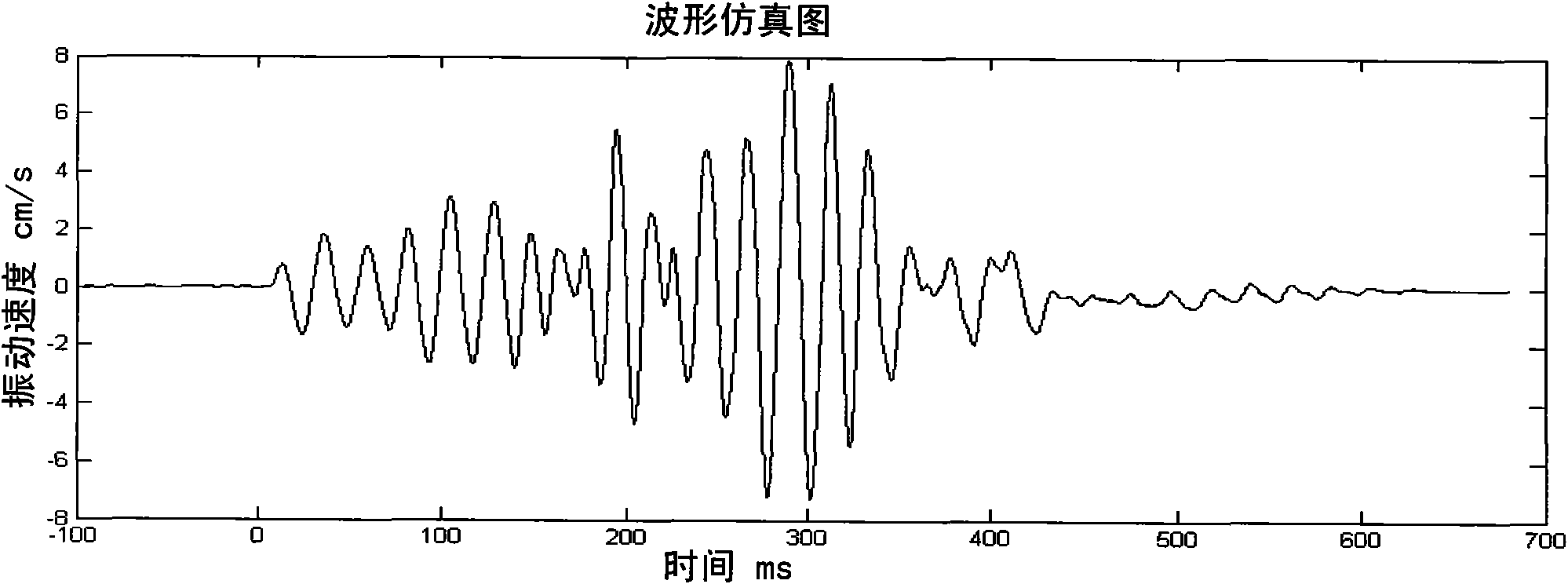

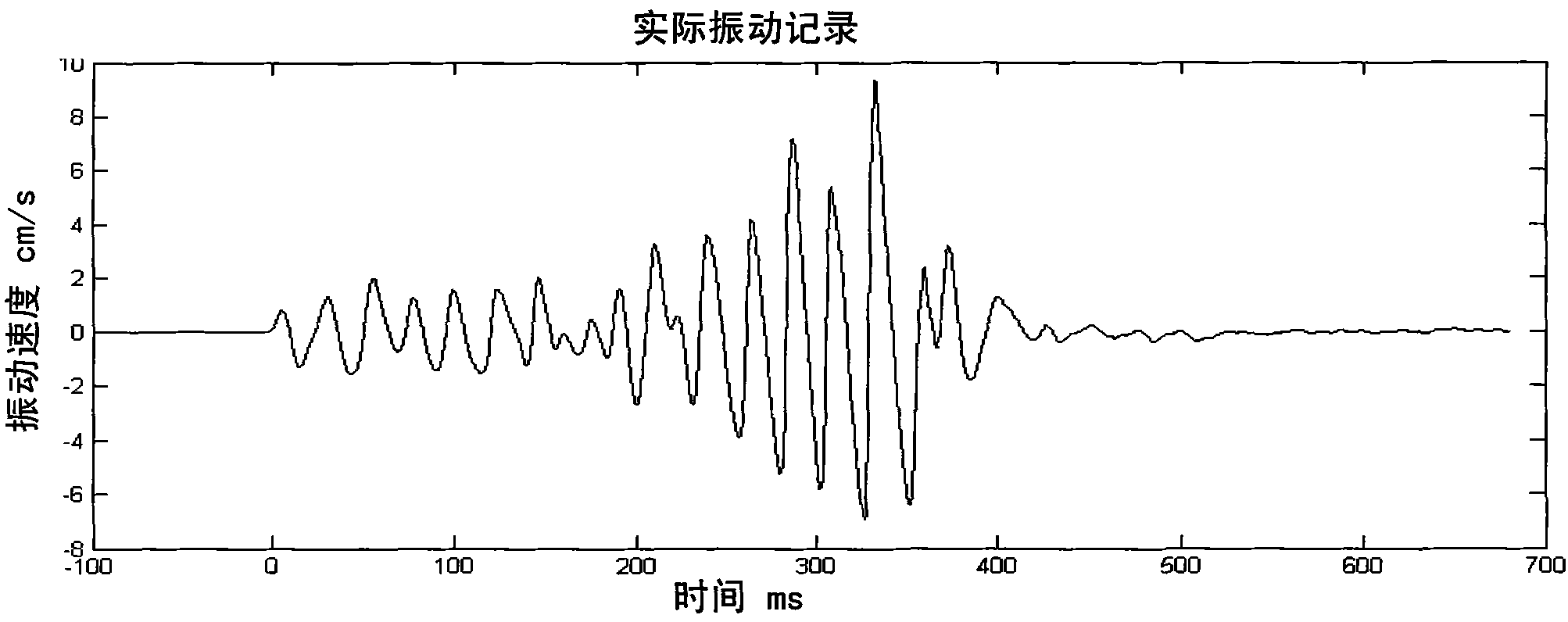

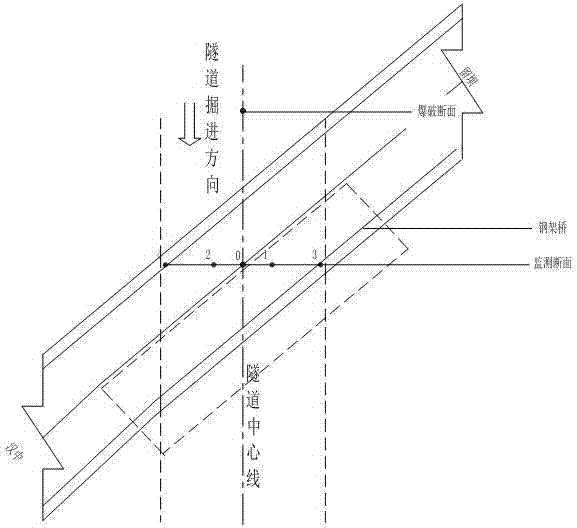

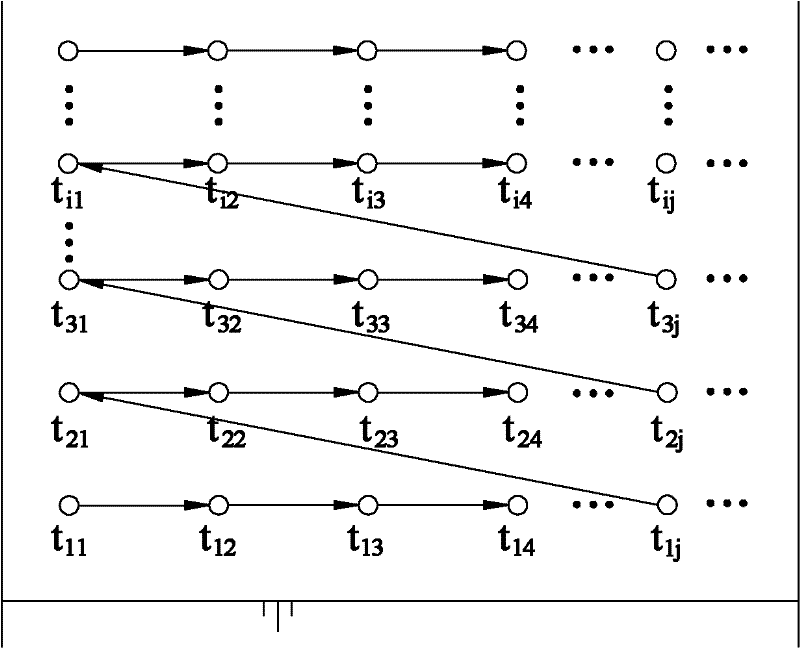

Blasting vibration predicting method

ActiveCN102135445AImprove accuracyIncrease credibilitySubsonic/sonic/ultrasonic wave measurementSeismologyDelayed timePeak value

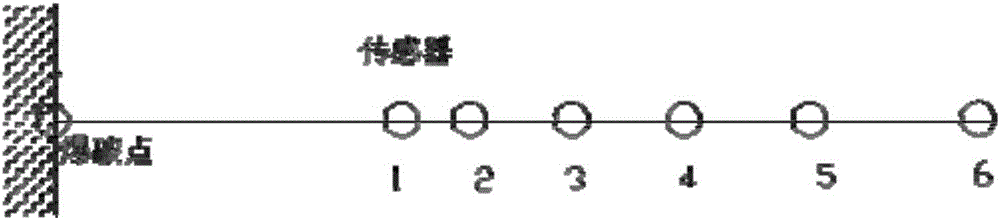

The invention provides a blasting vibration predicting method, which comprises the following steps of: firstly, determining a reference blasting hole and a plurality of vibration measuring points, and placing vibration meters on each vibration measuring point; blasting the reference blasting hole to obtain blasting vibration waveforms having different distance points; and finally, executing a blasting vibration waveform predicting process. In the prediction process, actual blasting vibration test data is obtained firstly, the blasting vibration waveforms and migration stacked delay time of each blast hole on a predicting target point are then calculated according to distance from the predicting target point to the each blast hole and the reference blasting hole, and the vibration waveform of the predicting target point can be obtained based on a vibration wave stacking principle. A blasting vibration predicting result which is obtained by adoption of the method really shows an influence of a topographic condition of a field on blasting vibration, and the integral vibration waveform of the predicting target point can be obtained; a predicted vibration velocity peak value of waveform particles is quite approximate to an actually-measured vibration velocity peak value, and a time difference between the predicted vibration velocity peak value and the actually-measured vibration velocity peak value is also quite small; and an analysis result is accurate and reliable, so that adjustment of a blasting scheme can be better guided.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

Stable-control blasting method for open-pit mine slopes

An embodiment of the invention discloses a stable-control blasting method for open-pit mine slopes, which relates to the technical field of exploitation of open-pit mines and is invented for solving the problem that damage of the slopes by blast vibration needs to be relieved so that the open-pit mine slopes can be highly stabilized. The method includes: quantity of priming explosive of a largest section in a blasting area close to an open-pit mine slope is limited; and delay time for open bench blast control rows of the blasting area close to the slope and blast holes corresponding to all the control rows are 1-4ms per hole-pitch meter, and delay time for rowed blast holes is 10-30ms per row-spacing meter. The stable-control blasting method is applicable to open-pit mining, and also applicable to hydropower engineering, excavation of large-sized underground workshop chambers, cutting engineering and the like, which need slope maintenance.

Owner:ZHUOLIWEI BEIJING TECH

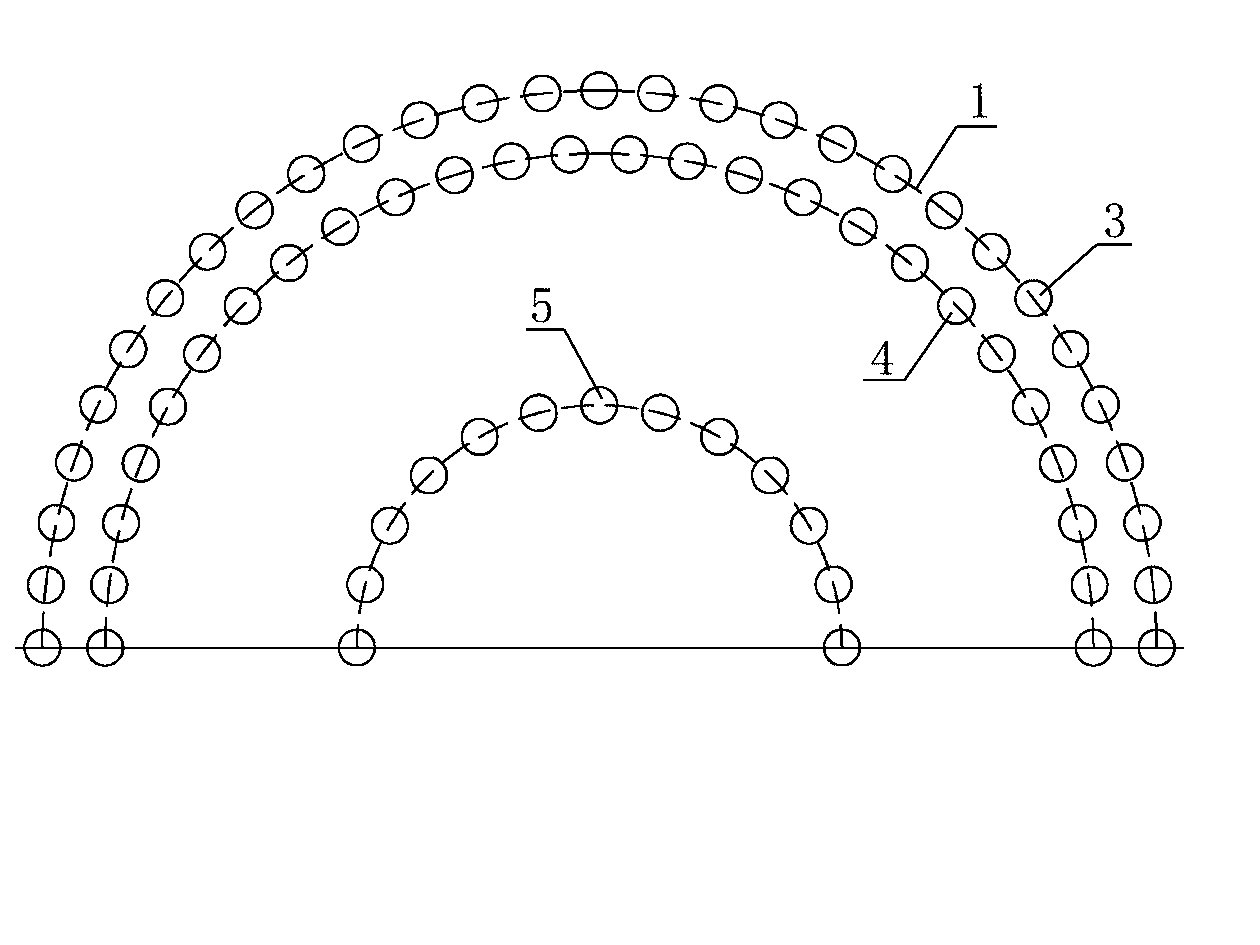

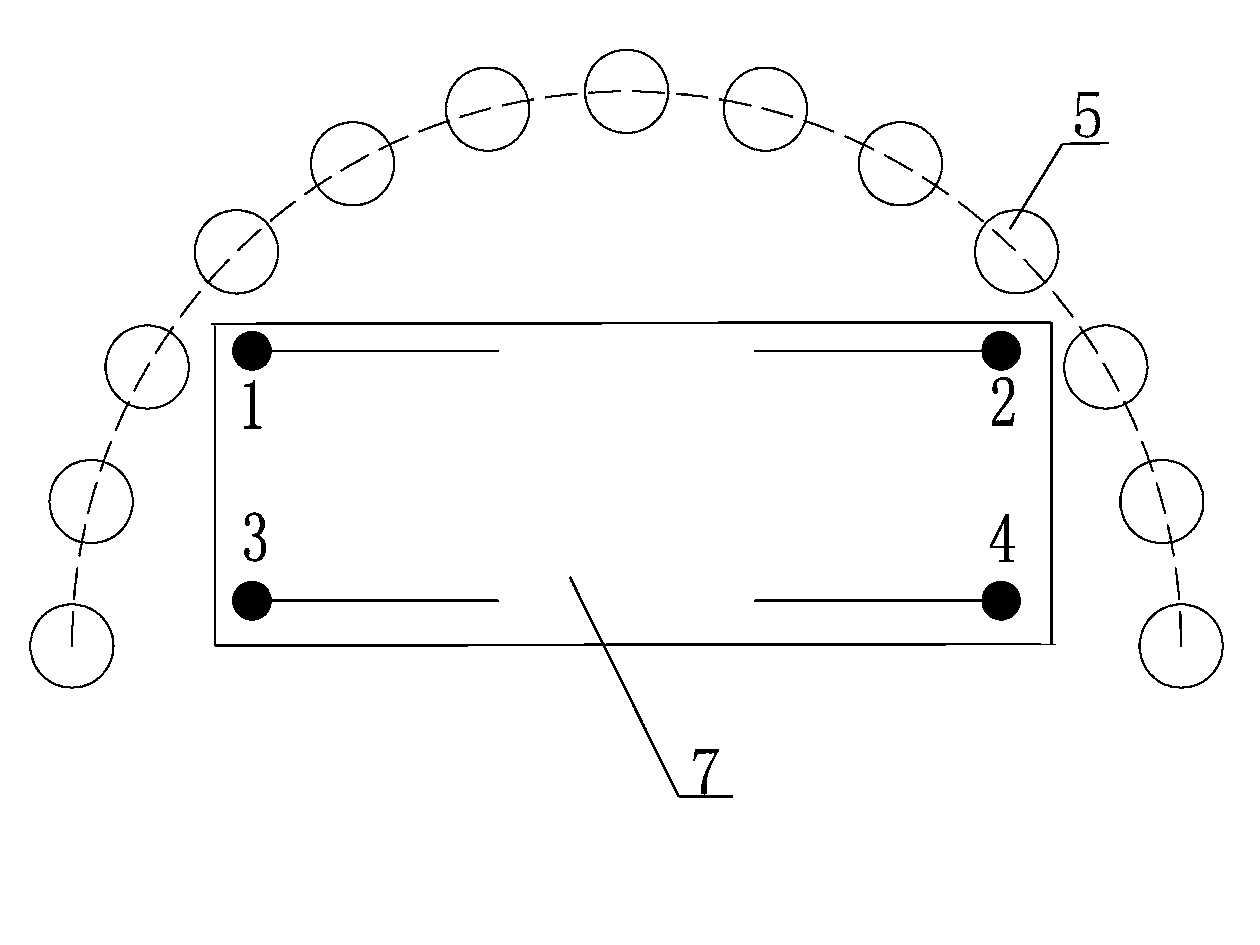

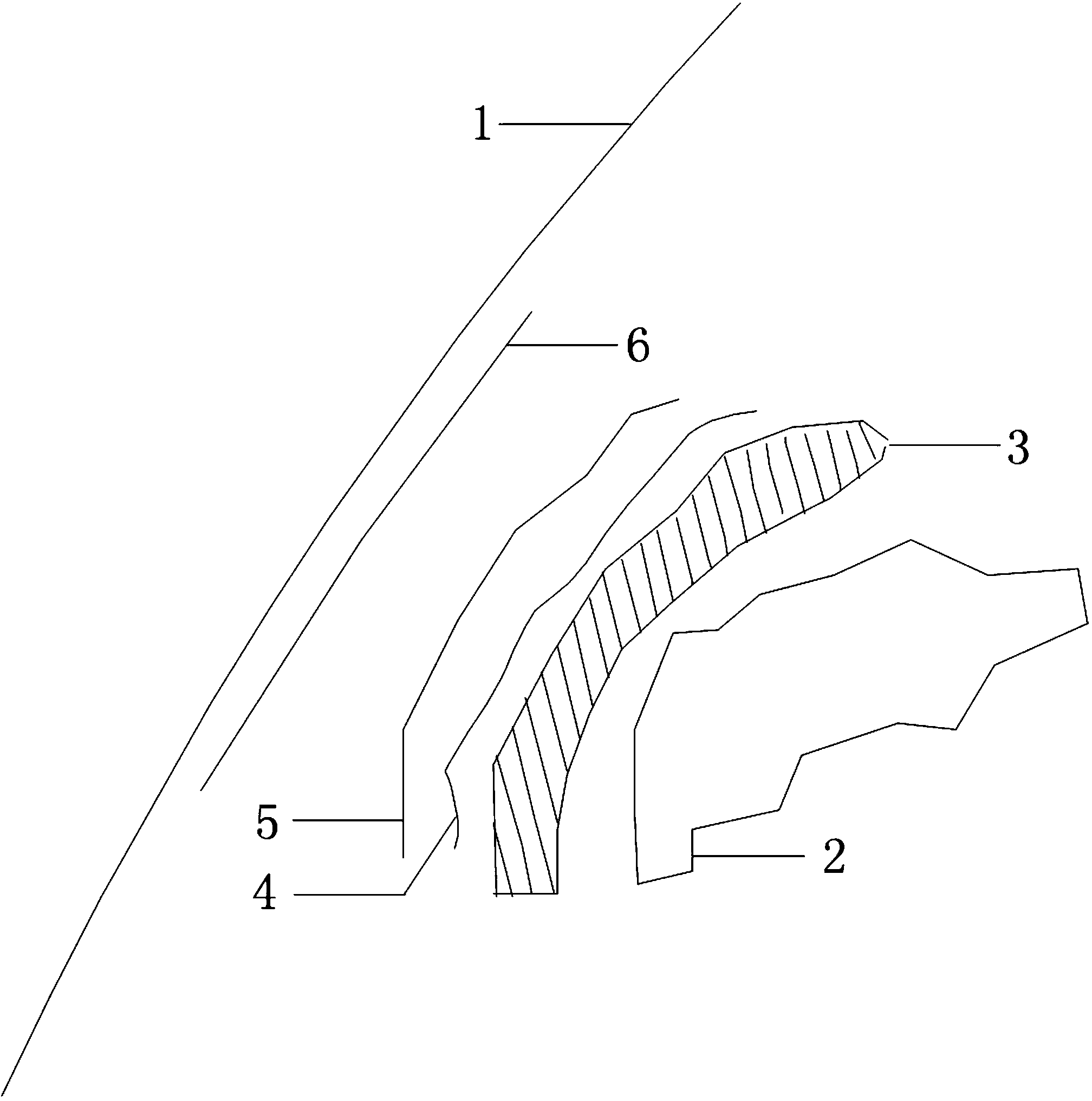

Construction method of tunnel shock relieve hole controlling blasting

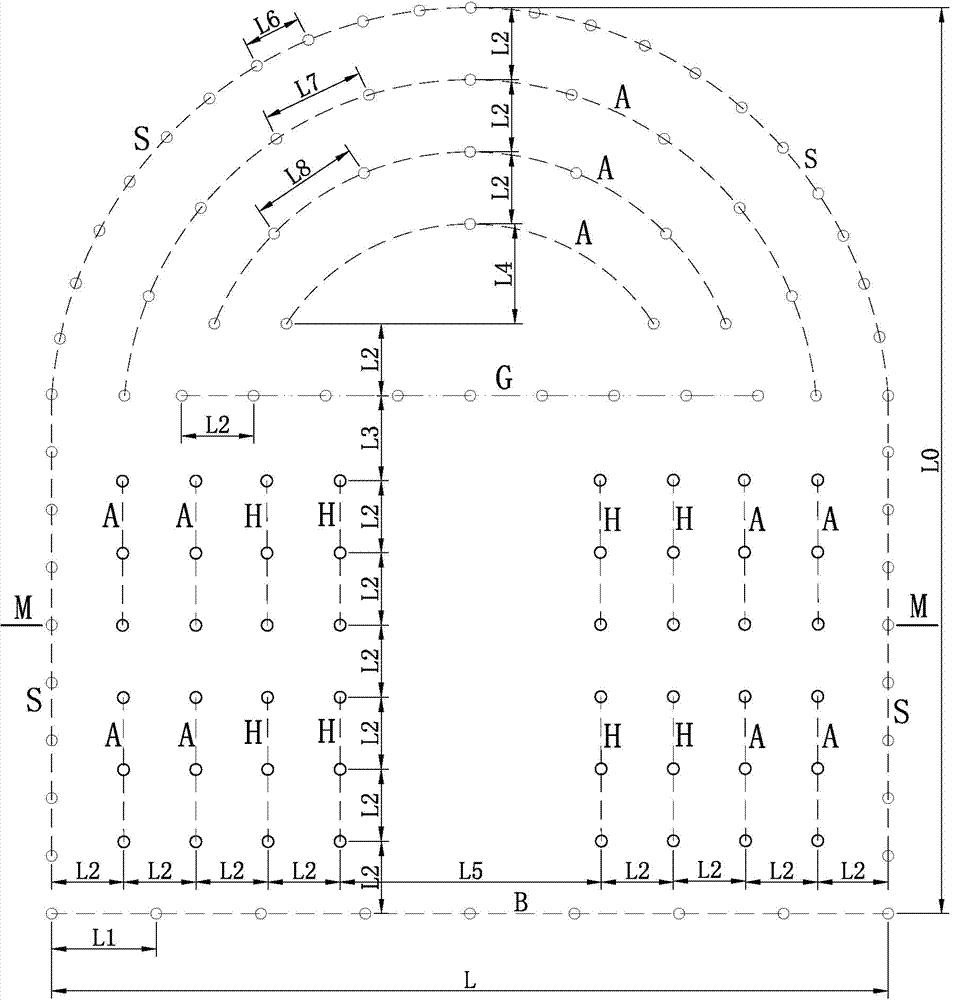

ActiveCN103175451AReduce blasting vibration velocityAvoid damageBlastingBlasting vibrationBuilding construction

The invention relates to a construction method of a tunnel shock relieve hole controlling blasting. Shock relieve holes are circumferentially distributed in the peripheries of an upper step arch part and a slotting zone, and a row of inner shock relieve holes and a row of outer shock relieve holes are especially formed in periphery hole zone of the upper step arch part, presplitting belt width of the periphery holes after blasting is increased, presplitting effect is strengthened, meanwhile through separating and cutting function of the shock relieve holes, explosive load is lowered, earthquake stress is reduced, and thus the target of reducing blasting vibration velocity is achieved. The construction method of a tunnel shock relieve hole controlling blasting can be widely applied to blasting construction in a tunnel mining construction, and especially to a city flourishing area and an area with a plurality of pipelines.

Owner:中国建筑土木建设有限公司

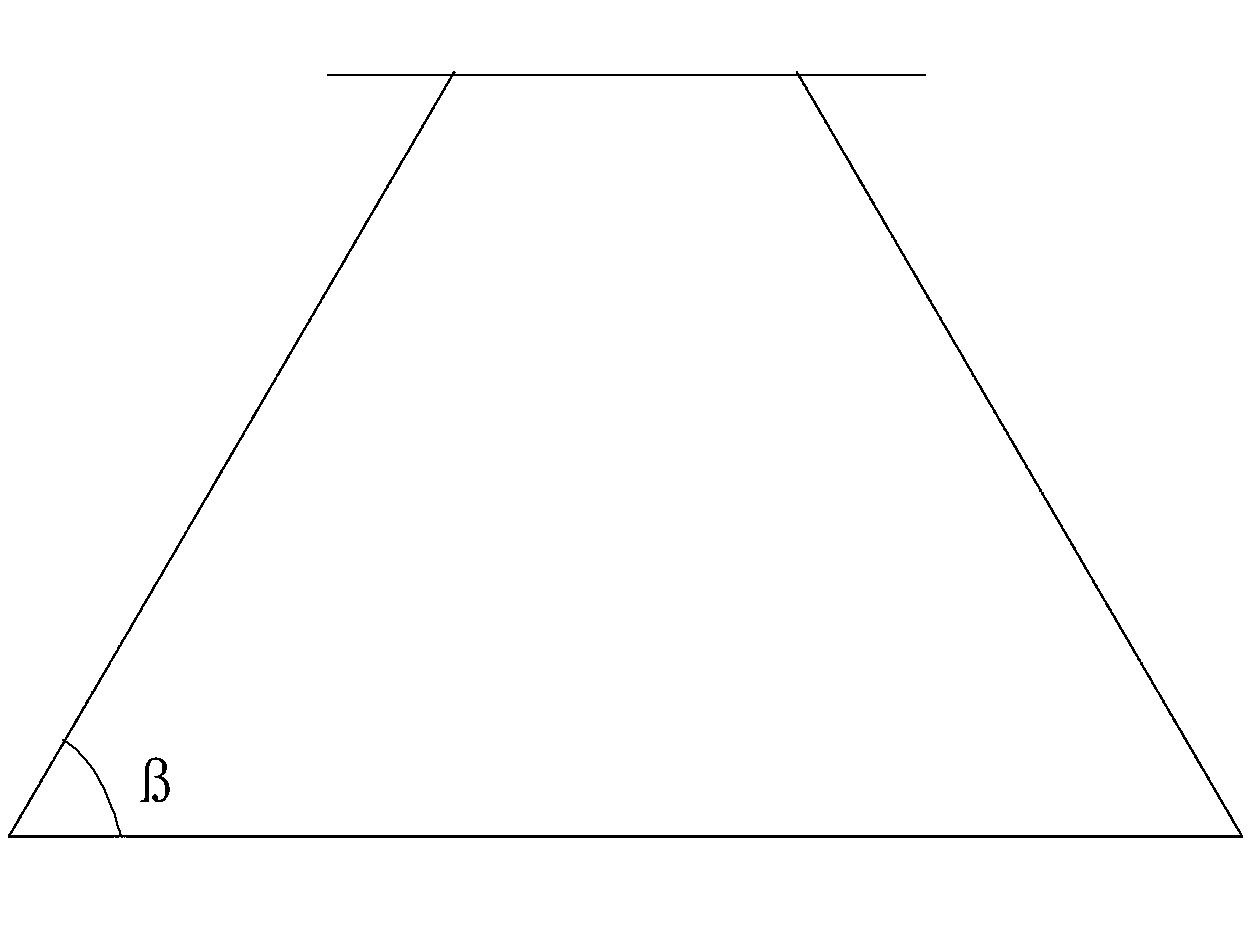

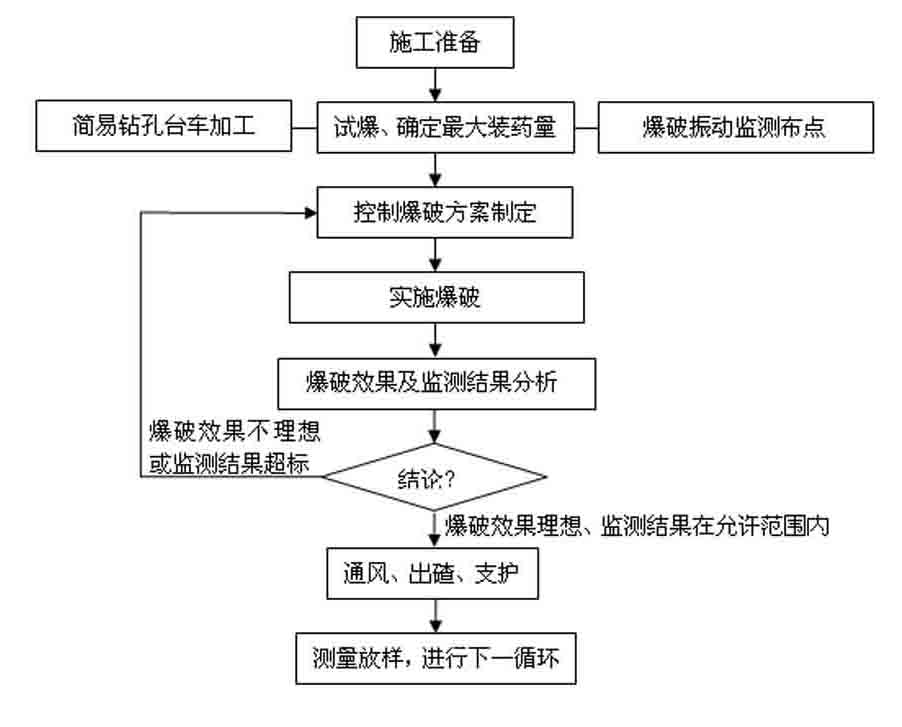

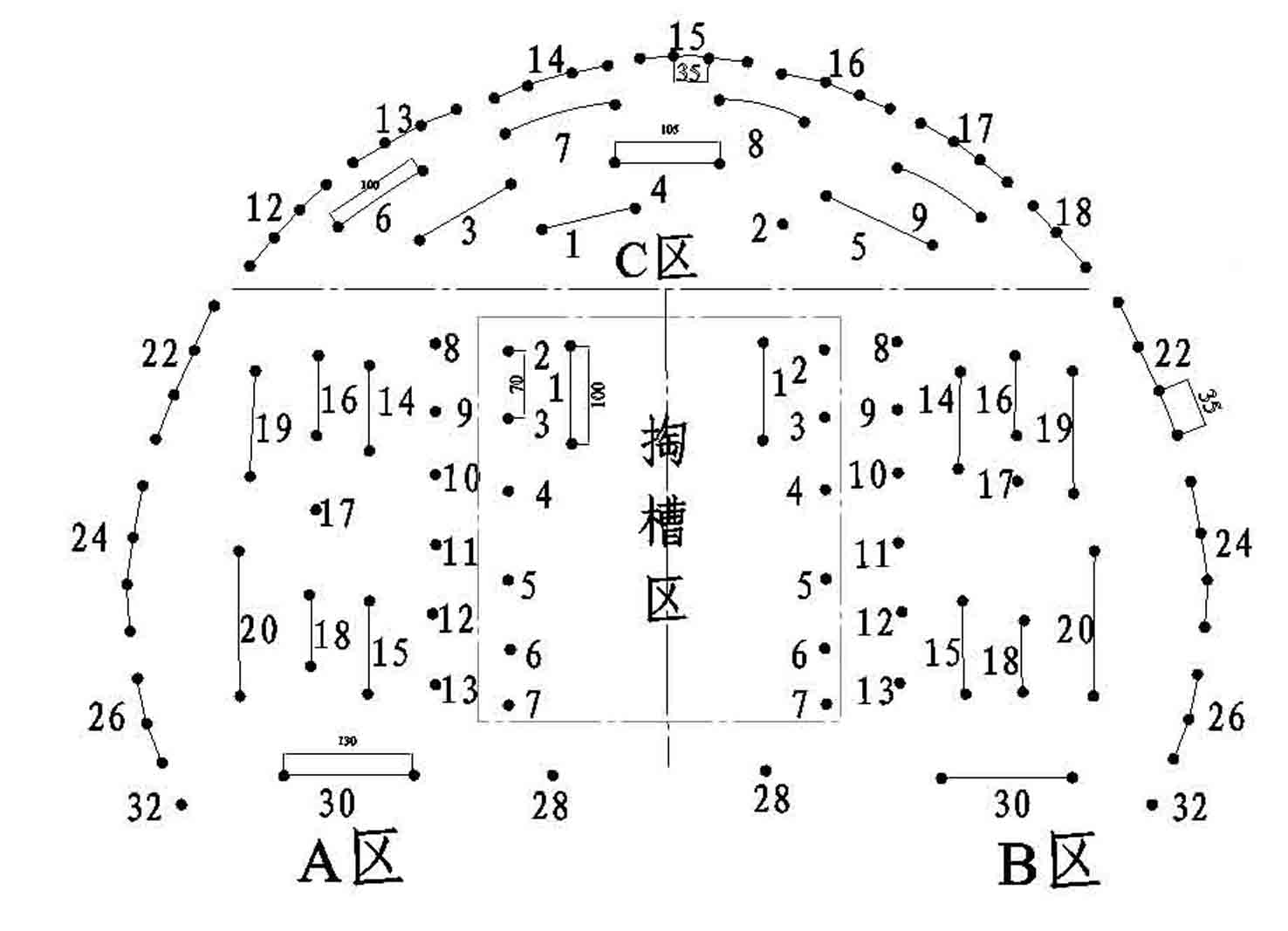

Controlled blasting construction method for shallow-buried large-section tunnel

ActiveCN102042786ASolve the problem of controlling blasting vibration exceeding the standardReduce processing timeBlastingDetonatorEngineering

The invention discloses a controlled blasting construction method for a shallow-buried large-section tunnel. The method comprises the following steps of: performing trail blasting so as to determine the maximum explosive load; drawing up a controlled blasting scheme, comprehensively analyzing the maximum explosive load of each delay detonator, the cross section of the tunnel, rock characteristic and the characteristic of an initiating explosive device according to a trail blasting result, drawing up a blasting scheme, dividing the entire cross section into a region A, a region B and a region C, wherein each region is provided with an initiation system, the region B delays by 12.5 milliseconds relative to the region A and the region C delays by (800+12.5) milliseconds relative to the region A, blasting in an instant electric detonator initiation mode and realizing full-cross-section blasting through an electronic delay initiator and the delay detonators; blasting; analyzing a blasting effect and a monitoring result; ventilating, mucking and supporting; and measuring and laying out for the next cycle. The method has the advantages of high speed and reliable result and solves the problem of standard exceeding of blasting vibration.

Owner:THE 2ND ENG OF THE 12TH BUREAU GROUP OF CHINA RAILWAY

Method for predicting peak vibration velocities of shallow-buried tunnel blasting construction surface particles

The invention relates to a method for predicting peak vibration velocities of shallow-buried tunnel blasting construction surface particles. The method comprises the following steps of: firstly obtaining a peak particle vibration velocity theoretical equation under a porous initiating condition on the basis of a principle that porous blasting is equivalent to single-hole blasting, and correcting the peak particle vibration velocity theoretical equation; carrying out linear regression analysis on a peak particle vibration velocity of a measurement point, fitting parameters, topography and geology-related coefficients and blasting vibration attenuation indexes, and substituting the parameters, the coefficients and the indexes into the peak particle vibration velocity theoretical equation under the porous initiating condition; and finally substituting a known blast hole radius, an explosive density, a charging diameter and a distance between a surface particle and a blasting source into the peak particle vibration velocity theoretical equation so as to calculate a peak vibration velocity of the surface particle. According to the method, the existing single-hole blasting theoretical equation is corrected to obtain the peak particle vibration velocity theoretical equation under the porous initiating condition, so that the influences, on the peak vibration velocity, of explosive nature, rock performance and charging parameters can be reflected, and the blasting peak vibration velocities of fixed points on the surface can be calculated according to the practical blasting parameters and geological conditions.

Owner:XIAN TECHNOLOGICAL UNIV

Adjacent existing railway steep mountain loosen control blast construction method

ActiveCN103629980AAgainst rockfall riskAvoid security risksBlastingMechanical crushingBlasting vibration

The invention relates to the field of railway construction, and in particular relates to an adjacent existing railway steep mountain loosen control blast construction method, comprising a pre-protecting step and a blasting step; the pre-protecting step comprise procedures of reinforcing and constraining an anchor rod steel wire gauze, exerting horizontal constraining force, building a concrete stopping retaining wall, mounting a profile steel protecting frame bent, and constructing a rock fall groove and a bamboo protecting frame bent; the blasting step comprises a trail blasting step and a formal blasting step; the trail blasting step comprises the procedures of minor diameter shallow hole control blasting, minor diameter air drill vertical drilling, large diameter deep hole control blasting and mechanical crushing. By designing the blasting order and screening the blasting parameter, the blasted rolling stones are effectively controlled, the security of the operation railway is guaranteed, the blasting harmful effect control such as blasting vibration and blasting flyrock can achieve rule and scene safety requirement, and the interference to surroundings is maximally reduced.

Owner:中铁二十三局集团第四工程有限公司

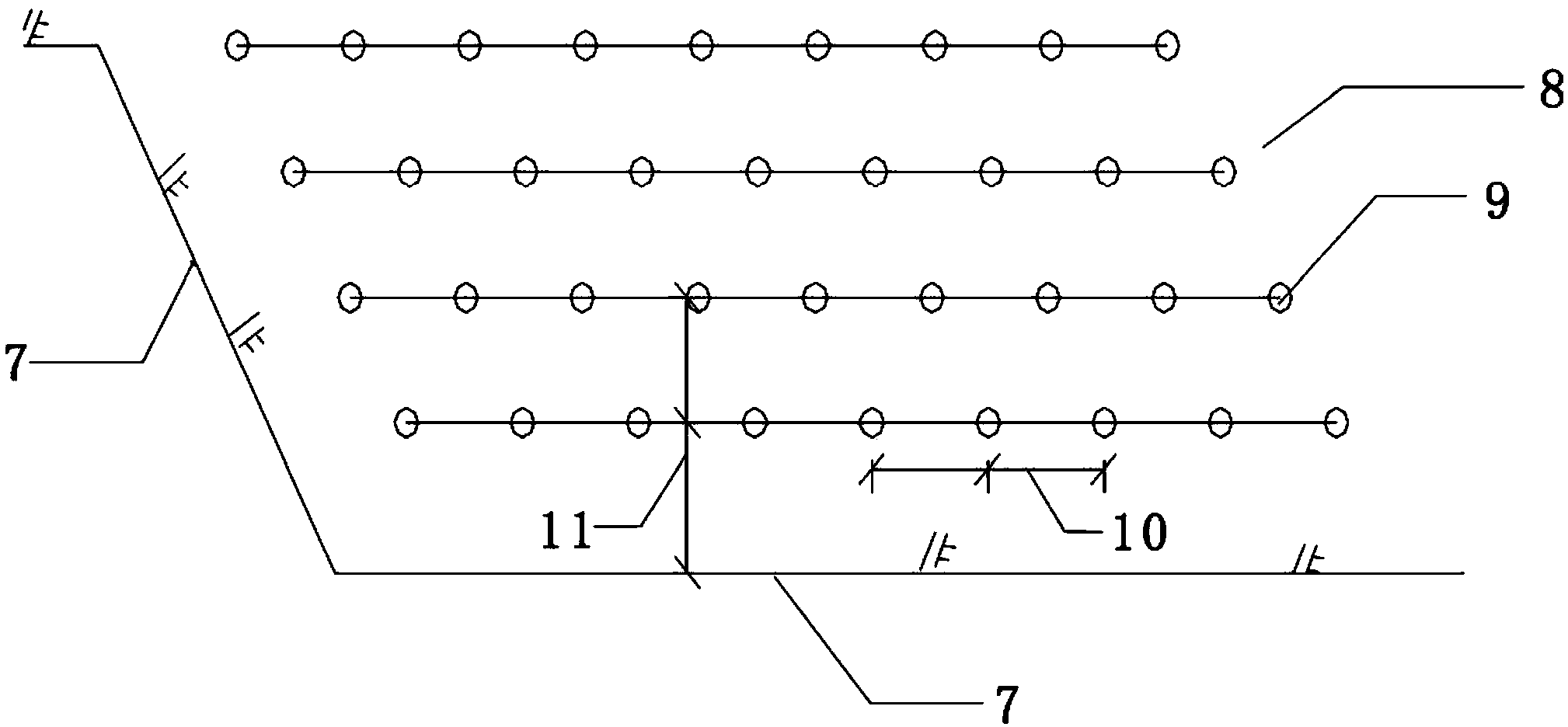

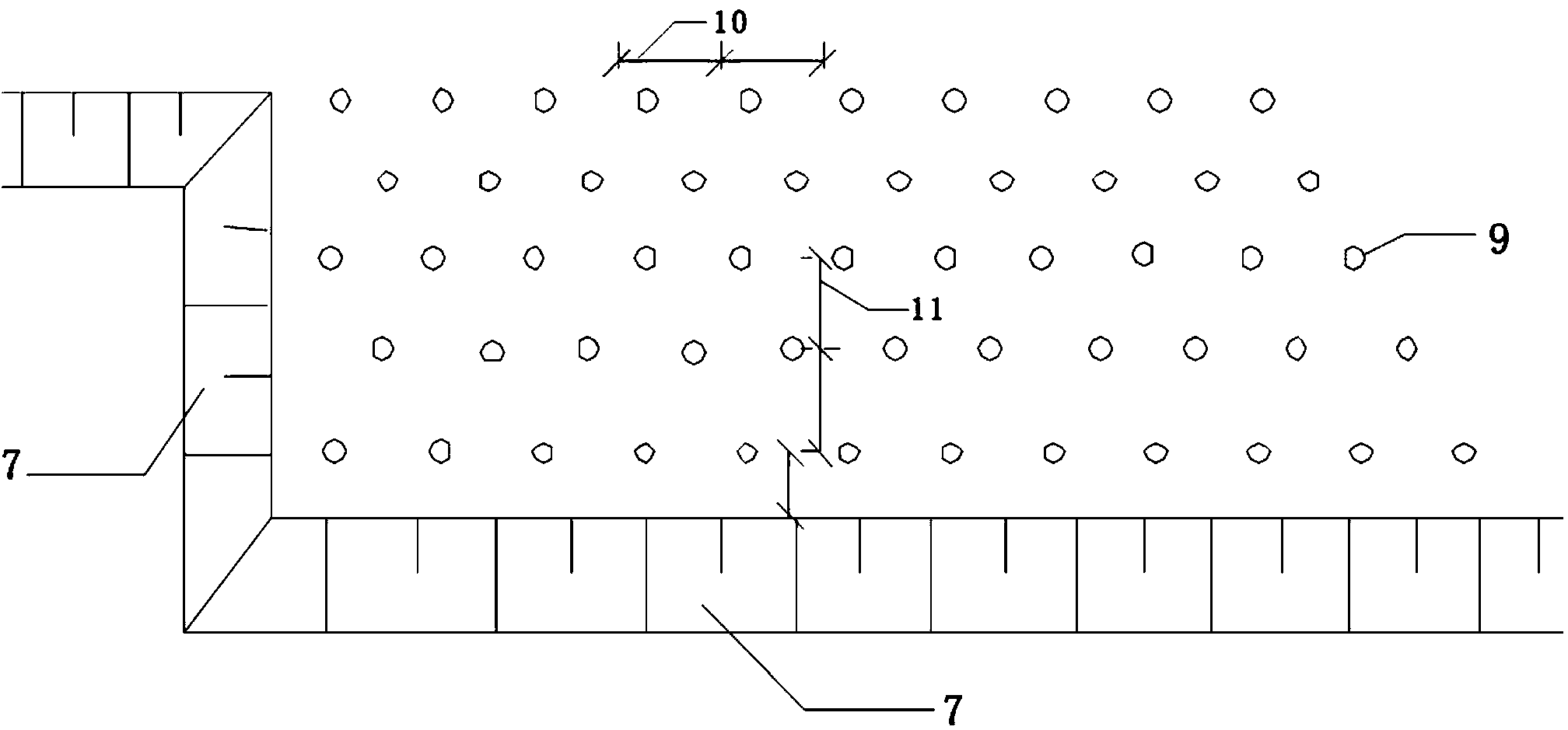

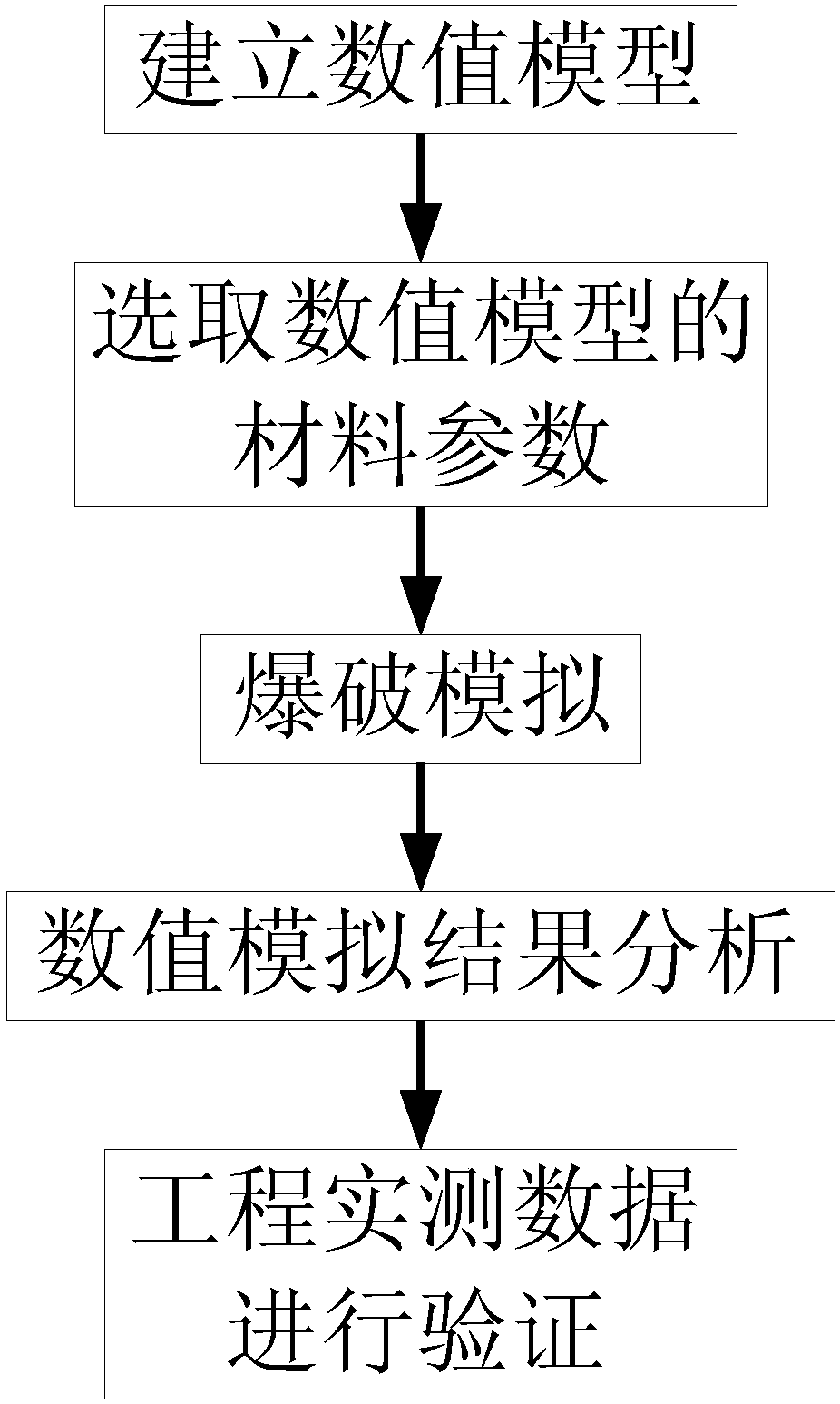

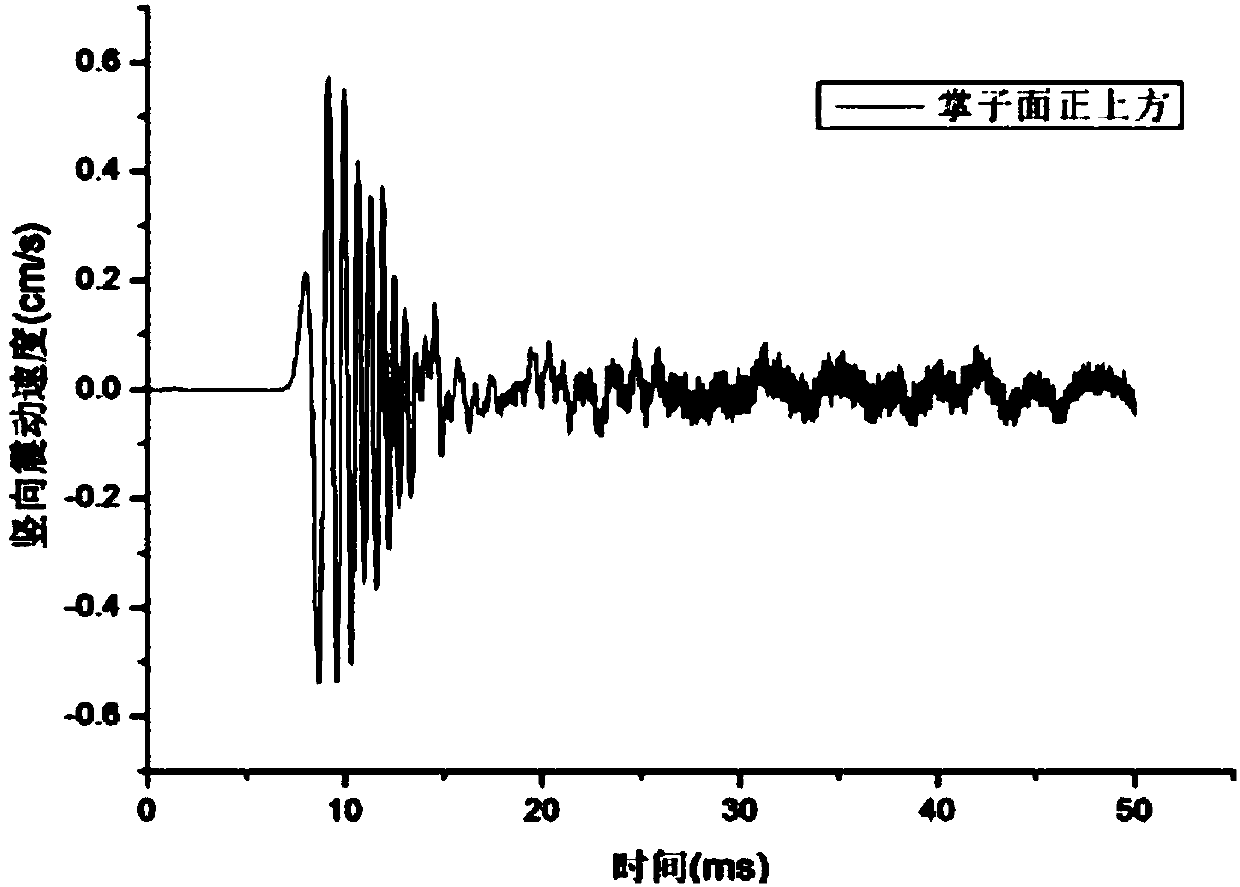

Blast construction method of shallow-buried railway tunnel in underneath pass of civil house weak segments

The invention discloses a blast construction method of a shallow-buried railway tunnel in underneath pass of civil house weak segments. The method includes the following steps that a, according to characteristics of the shallow-buried railway tunnel in underneath pass of the civil house weak segments, a numerical value model is established; b, material parameters corresponding to the numerical value model of the shallow-buried railway tunnel in underneath pass of the civil house weak segments are selected; c, blasting simulation of the shallow-buried railway tunnel in underneath pass of the civil house weak segments is performed; d, numerical value simulation results of different cutting blasting modes are analyzed; e, in combination with engineering measured data of blasting constructionfor the shallow-buried railway tunnel in underneath pass of the civil house weak segments, verification is performed so that the demands of blasting safety vibration control standards can be met. By the utilization of a power finite element method, numerical value simulation analysis is performed to research the rule of a blasting seism, verification is performed in combination with the engineering measured data, and therefore blasting vibration is reflected accurately to a certain degree. The blasting vibration reduction effect of a vibration reduction technical scheme is researched, bases are provided for making a vibration reduction blasting scheme for the tunnel in underneath pass of dense civil houses, and influences on the rule of seismic wave propagation by excavation of the tunnelare researched.

Owner:ZHONGJIAN SUIDAO CONSTR CO LTD

Comprehensive damping method for blasting of tunnel passing through heritage conservation building

ActiveCN103541734AReduce the total charge of blastingReduce the impact of vibrationTunnelsBlasting vibrationStep method

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD

Construction method for damped blasting of tunnels

InactiveCN102494571ASolve the contradiction of insufficient rankReduce the amount of explosivesBlastingDetonatorLeft half

The invention relates to a construction method for damped blasting of tunnels. The construction method is characterized in that a working face comprises cutting eyes, auxiliary eyes and peripheral eyes; an air drill is adopted for forming holes in sequence; the working face is divided into a left half-range face and a right half-range face for respectively distributing the segment positions of detonators, wherein the left half-range face adopts even segment positions, the right half-range face adopts odd segment positions; the auxiliary eyes and the peripheral eyes are respectively connected into a group according to 3-5 blastholes in one row; and detonators with same segment positions in different groups can be used repeatedly, and then all the groups are connected in sequence and in series by adopting two segments of detonators, so that the fine differences inside and outside the holes of the detonating tubes are combined together. According to the construction method, the damped blasting measure for combining the fine differences inside and outside the holes are adopted, the detonating tubes with fine differences are connected in parallel and in series for combined use, the detonators with same segment positions in different groups are allowed to be used repeatedly, and the blasting time of the detonators with same segment positions in different groups is staggered through serial two segments of detonators, so that the explosive amount for simultaneous blasting is reduced and the blasting vibration speed is effectively reduced.

Owner:DALIAN BRANCH OF CHINA CONSTR EIGHTH ENG DIV CORP +1

Controlled blasting construction method for rock foundation pit

The invention relates to a controlled blasting construction method for a rock foundation pit. The method comprises the following steps: detecting a cutting line; with the cutting line as a reference line, locating the periphery of a foundation pit to excavate a damping groove; vertically excavating a damping groove in the cutting line, wherein the interior of the damping groove is a blasting area and the exterior of the damping groove is a protective area; blasting and excavating the foundation pit: crushing rocks after blasting and removing slag; and cutting and blasting the foundation pit in a layered way: repeating excavation of the damping groove and blasting of the blasting area, excavating the damping groove in a layered way, blasting and excavating the foundation pit until the foundation pit is completely excavated. The damping groove is excavated in the excavating area of the rock foundation pit so as to stop blasting vibration propagation in the excavating area and reduce vibration influences on the rock wall and the surrounding structure of the foundation pit; a cutting reference is randomly corrected by using an outwardly moving rechecking line of the foundation pit cutting line so as to satisfy requirements on foundation pit excavating accuracy; the controlled blasting construction method for the rock foundation pit, provided by the invention, has the advantages of simple process and no damage to a foundation pit surrounding rock structure and is suitable for excavating various earth-rock foundation pits; both excavating efficiency and safety can be taken into account; and the foundation pit blasting safety and the foundation pit excavating accuracy are enhanced.

Owner:TAIXING FIRST CONSTR INSTALLATION

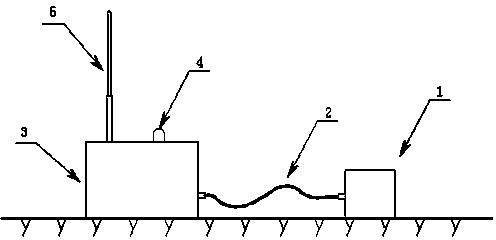

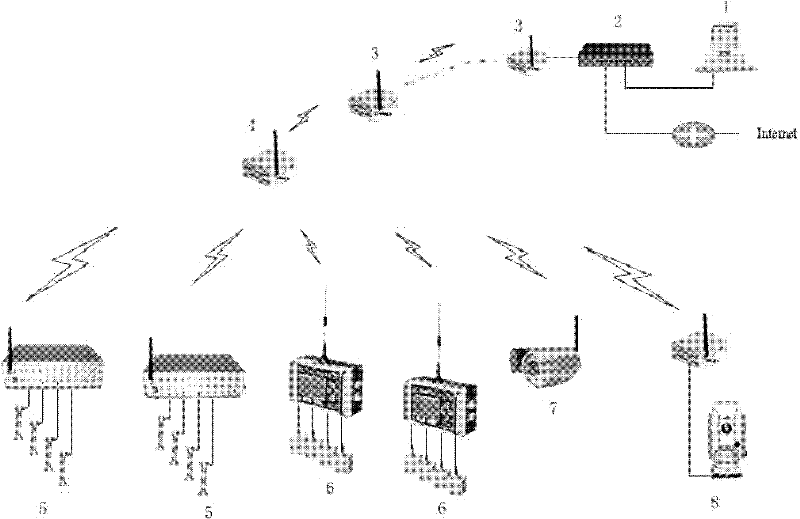

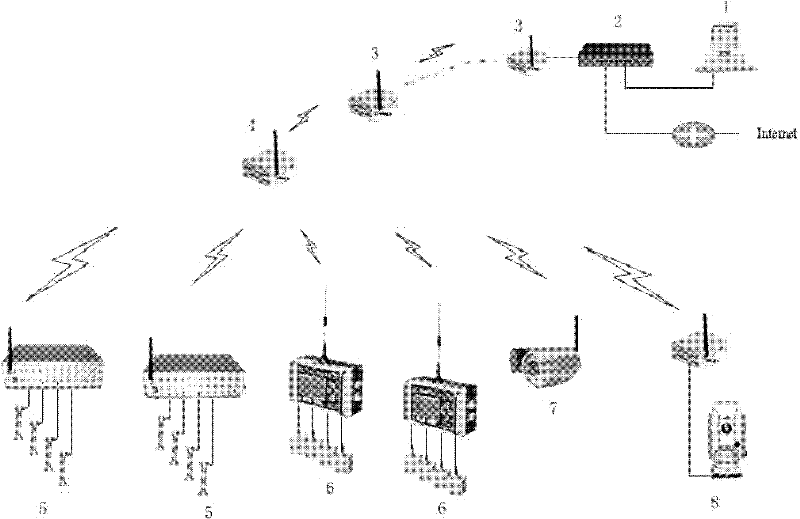

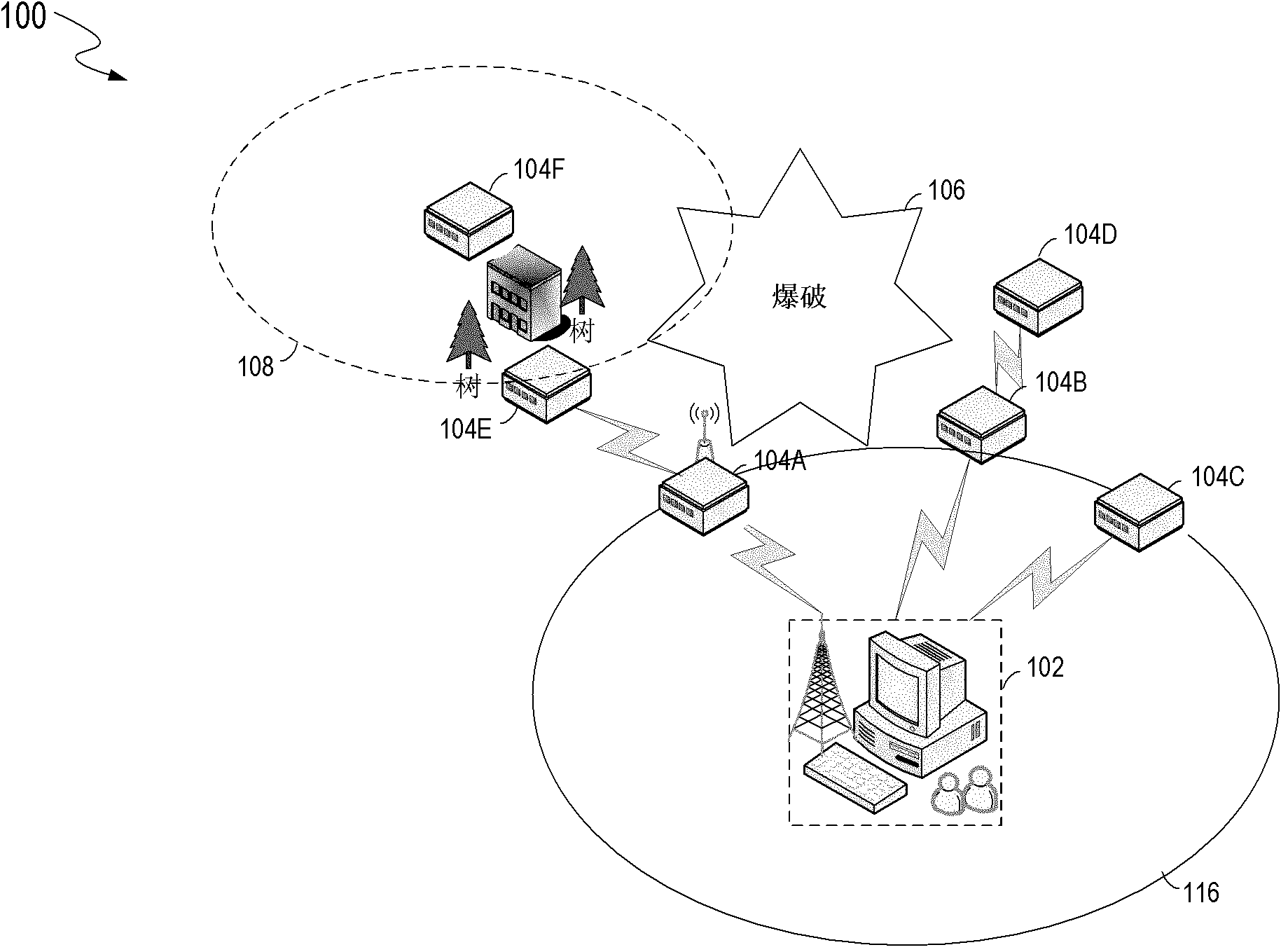

Summarized information monitoring system of tunnel

ActiveCN102608963AQuick collectionAccurate collectionProgramme total factory controlEngineeringBlasting vibration

The invention relates to a summarized information monitoring system of a tunnel. The summarized information monitoring system mainly comprises an automatic frequency monitor, an automatic blast vibration monitor, an automatic video acquiring monitor, an automatic three-dimensional section monitor, a wireless route repeater, a wireless high-speed repeater station, a network exchanger and a monitoring host. The monitoring host is connected with the network exchanger, the wireless high-speed repeater station and the wireless route repeater sequentially; the wireless route repeater is connected with the automatic frequency monitor, the automatic blast vibration monitor, the automatic video acquiring monitor and the automatic three-dimensional section monitor respectively; the automatic frequency monitor is connected with a vibration-wire sensor; and the automatic blast vibration monitor is connected with a three-direction or one-direction speedometer. The summarized information monitoring system disclosed by the invention can implement monitoring, pre-alarming and forecasting on surrounding rock pressure, rock mass vibration and clearance variation.

Owner:北京市政路桥锐诚科技有限公司

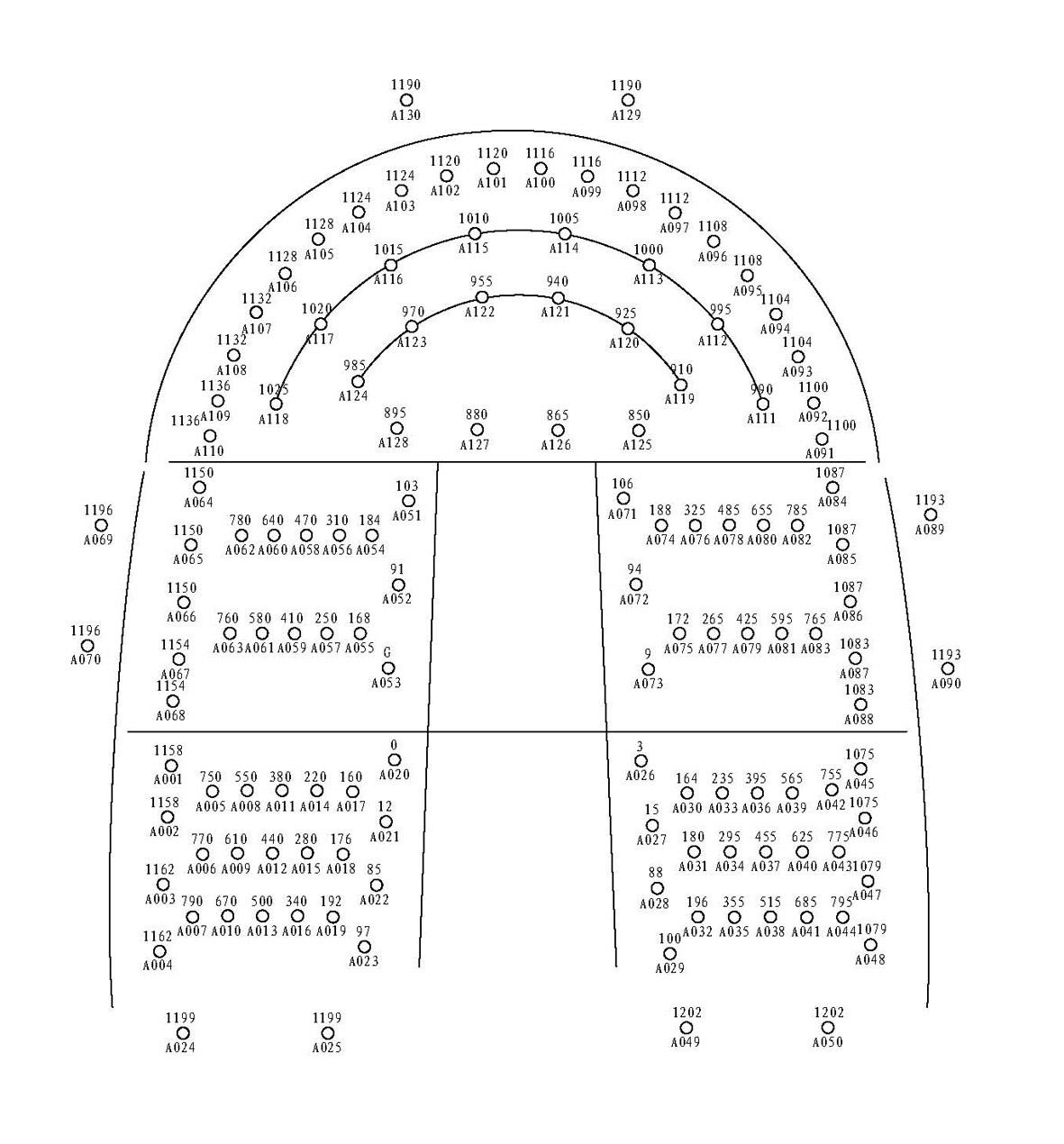

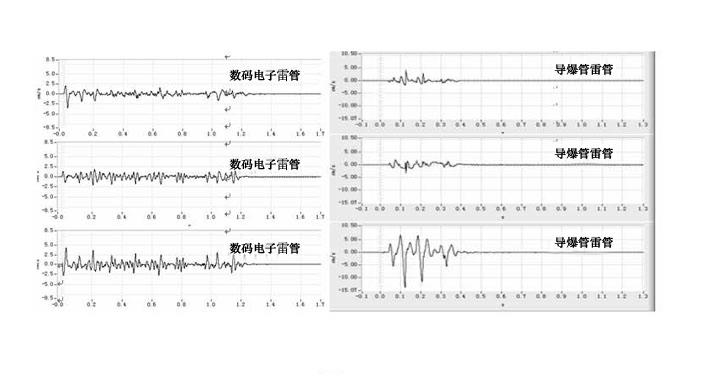

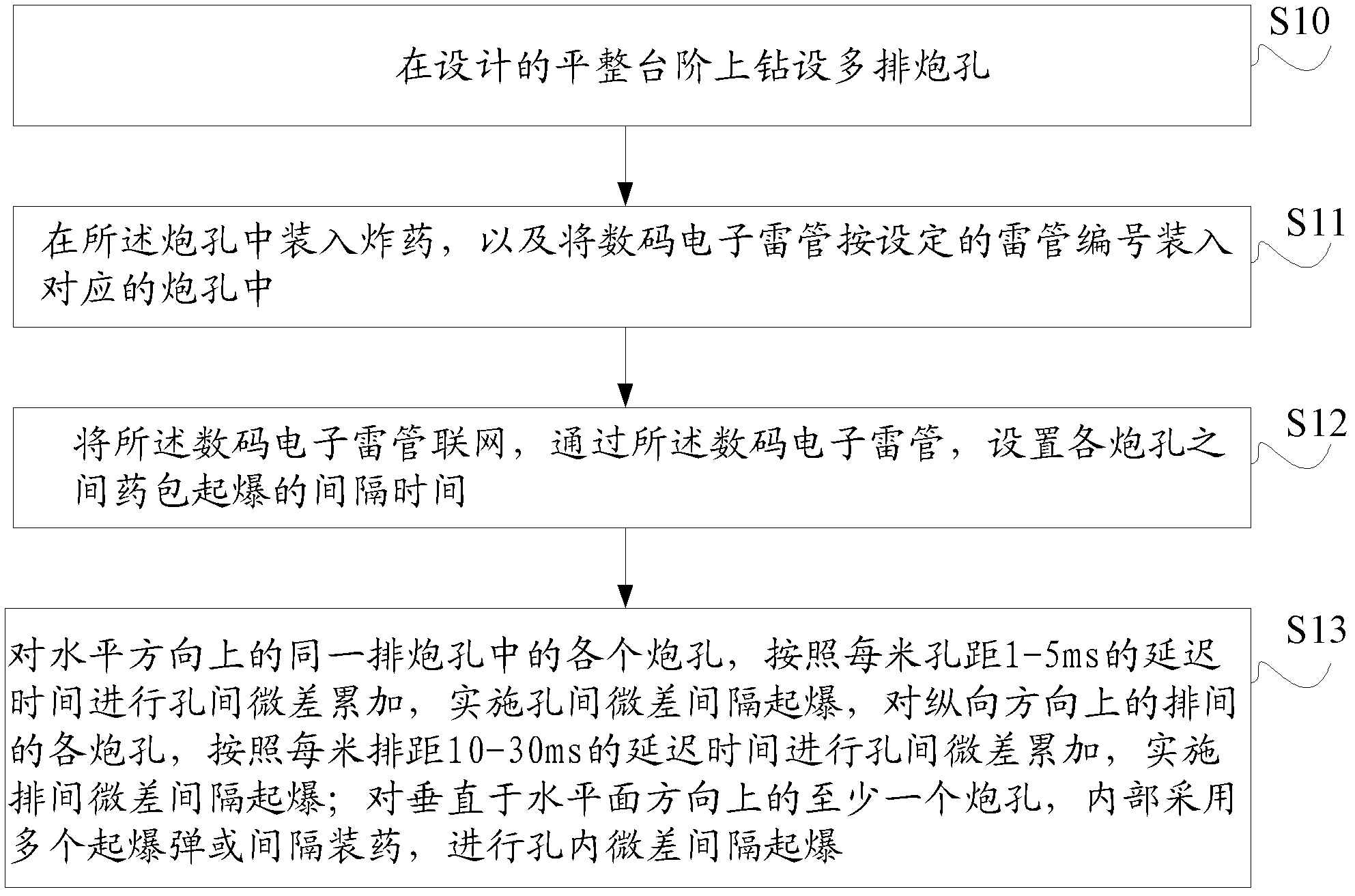

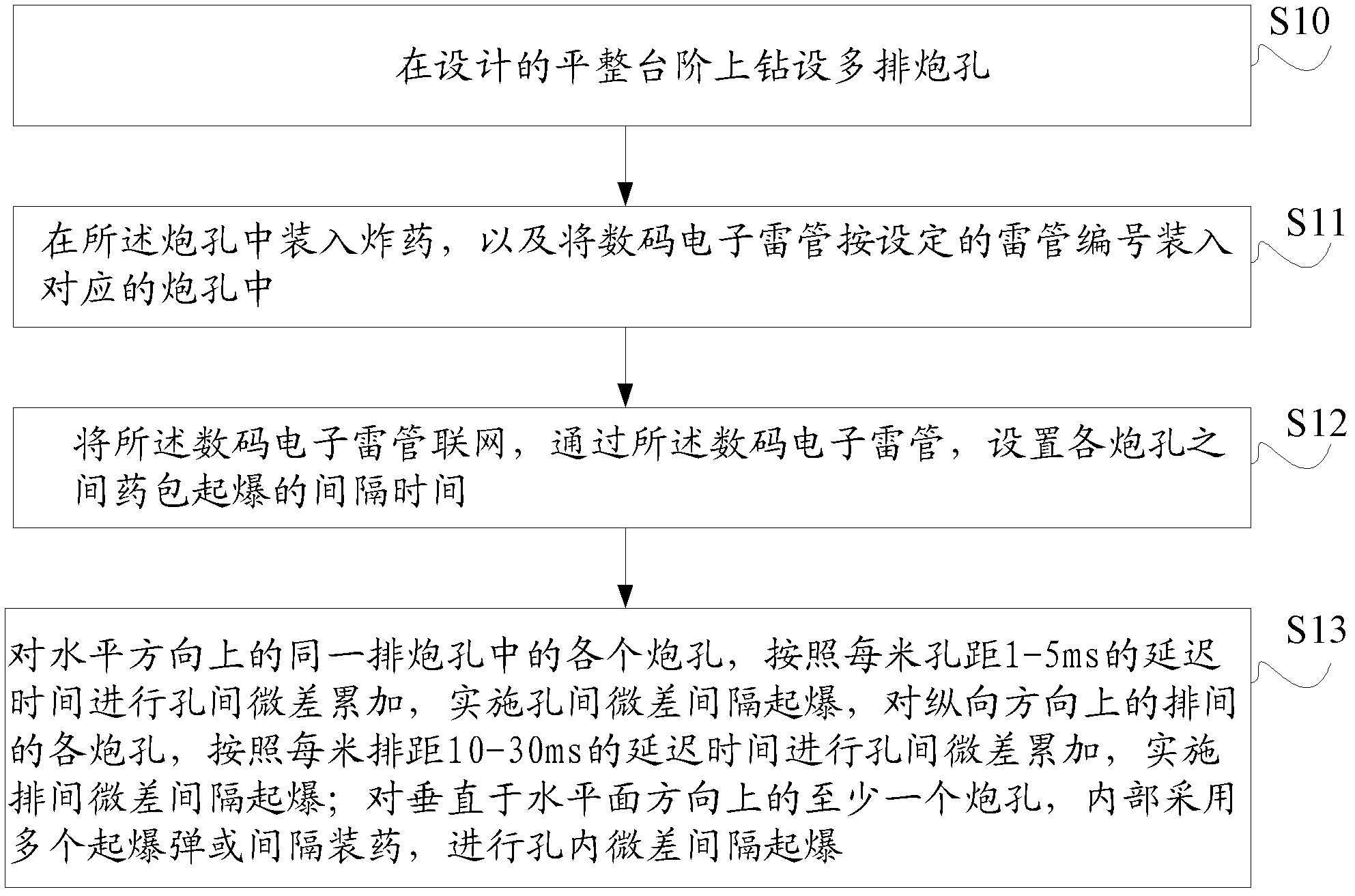

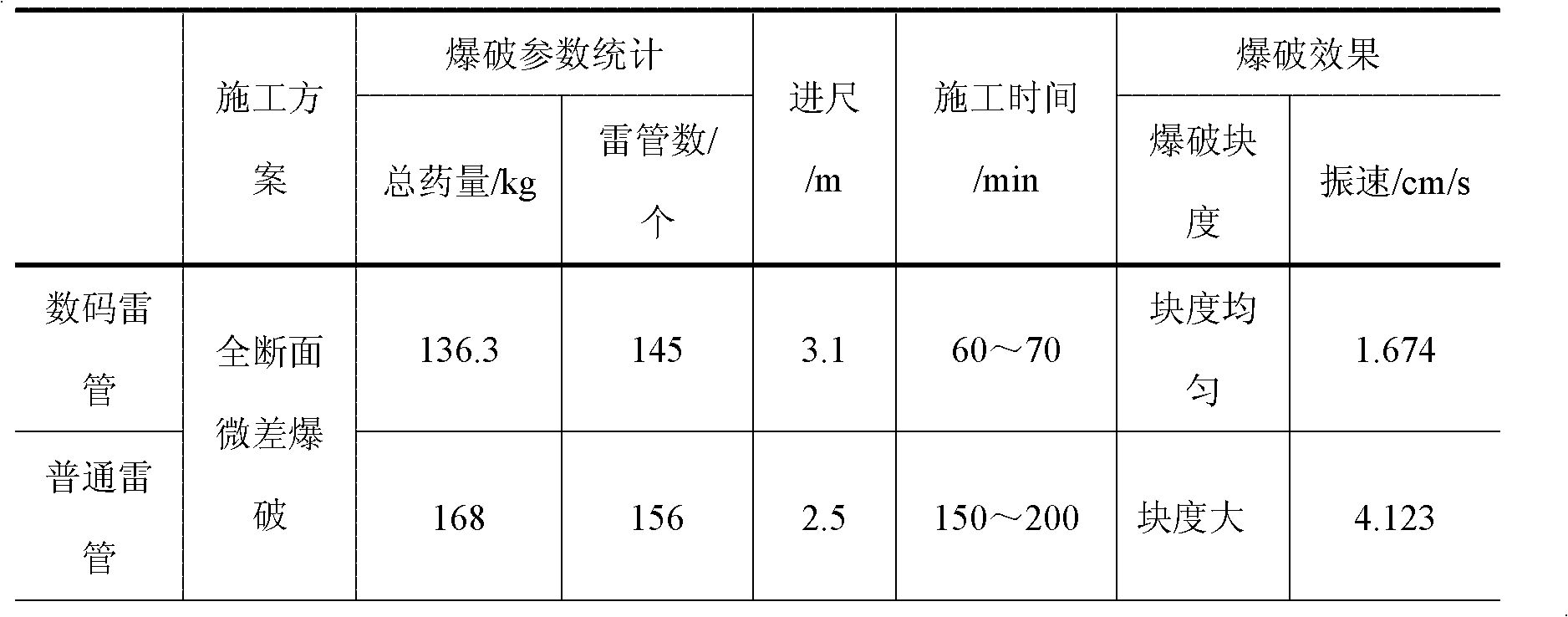

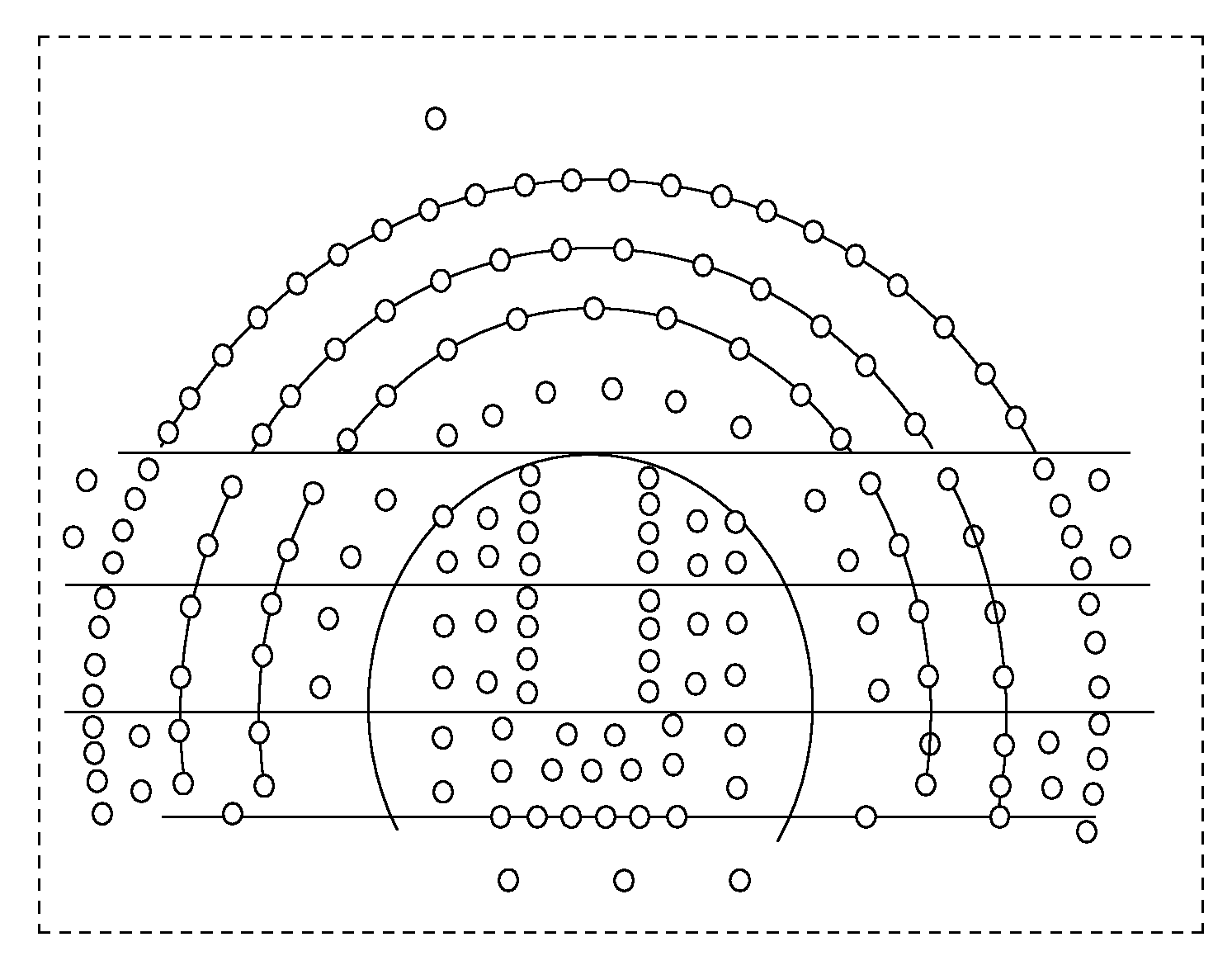

Full-face blasting vibration control construction method for tunnel electronic millisecond electric detonator

ActiveCN102506622AGuaranteed shock absorptionIncrease Single Cycle FootageBlastingDetonatorTime delays

The invention discloses a full-face blasting vibration control construction method for a tunnel electronic millisecond electric detonator, relating to the blasting vibration control technology. The method comprises the following step of: performing a full-face blasting damping control drilling-blasting design by combining blasting vibration requirements according to a tunnel engineering geological condition, an excavated section, an excavating method, a tunneling circulation footage, drilling machine tools and blasting equipment, wherein the drilling-blasting design is as follows: in order to realize the single blasting of cutting holes, auxiliary holes and base plate holes, peripheral holes which are blasted simultaneously are grouped, and the detonator time delay of each shot hole is set, so that the misphase blasting damping is realized; a use flow of the electronic millisecond electric detonator is designed, and the electronic millisecond electric detonator is used according to the flow; an analysis is carried out in the construction process according to the blasting effect and the vibration waveform obtained by blasting monitoring, information is fed back to guide the construction, and blasting parameters are adjusted continuously. The blasting construction method has the advantage of capability of obviously reducing the full-face blasting vibration.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

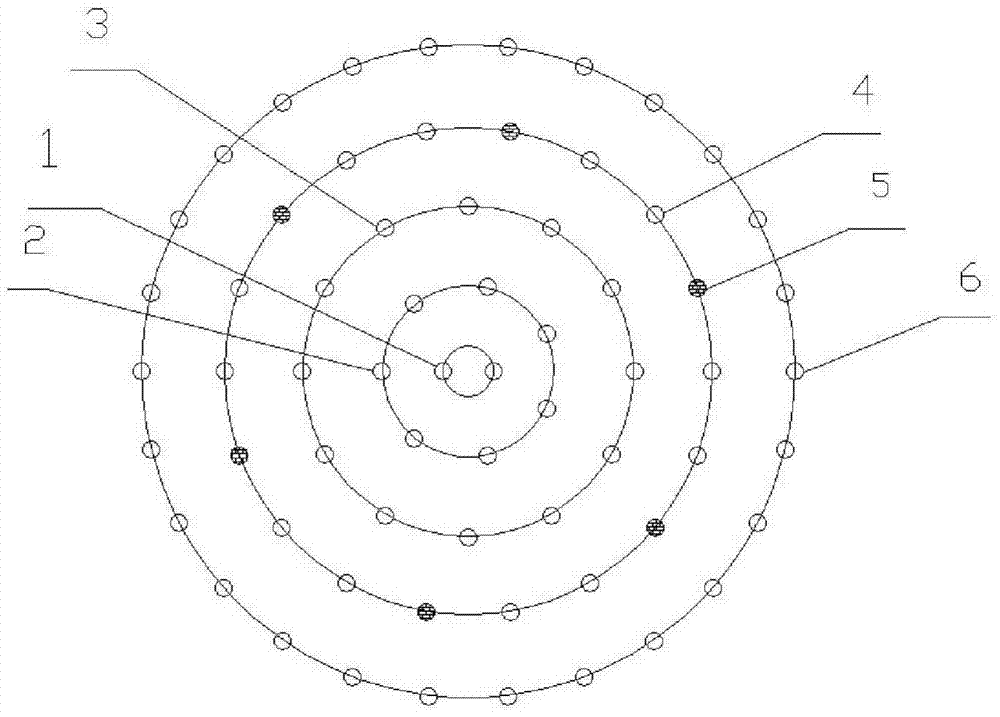

Test method of blasting vibration attenuation effect

InactiveCN106840381AAvoid congestionPlay a key role in data transferSubsonic/sonic/ultrasonic wave measurementUltrasound attenuationVibration amplitude

The invention relates to a test method of a blasting vibration attenuation effect. The method comprises the following steps of setting monitoring points; installing a three-vector speed sensor; measuring and recording the position and the elevation of a seismic source center and the three-vector speed sensor; recording the number of the three-vector speed sensor and a connected signal collecting instrument; setting a door opening threshold value; performing blasting point blasting; collecting a blasting vibration signal by the signal collecting instrument, and transmitting the signal to a computer system and a server; analyzing the triggering demonstration and vibration amplitude and frequency change rules; automatically analyzing an attenuation effect model; selecting a vibration control standard; performing evaluation by combining the practically measured vibration amplitude. The test method has the advantages that the remote measurement and monitoring on blasting vibration are realized; data of each time blasting vibration is uploaded to the server at the first time; the blasting vibration characteristics are analyzed so as to provide data foundation for blasting vibration study; the practical engineering significance is realized in the aspects of strictly controlling the blasting seismic effect, realizing scientific monitoring, objectively analyzing the blasting vibration influence and the like.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

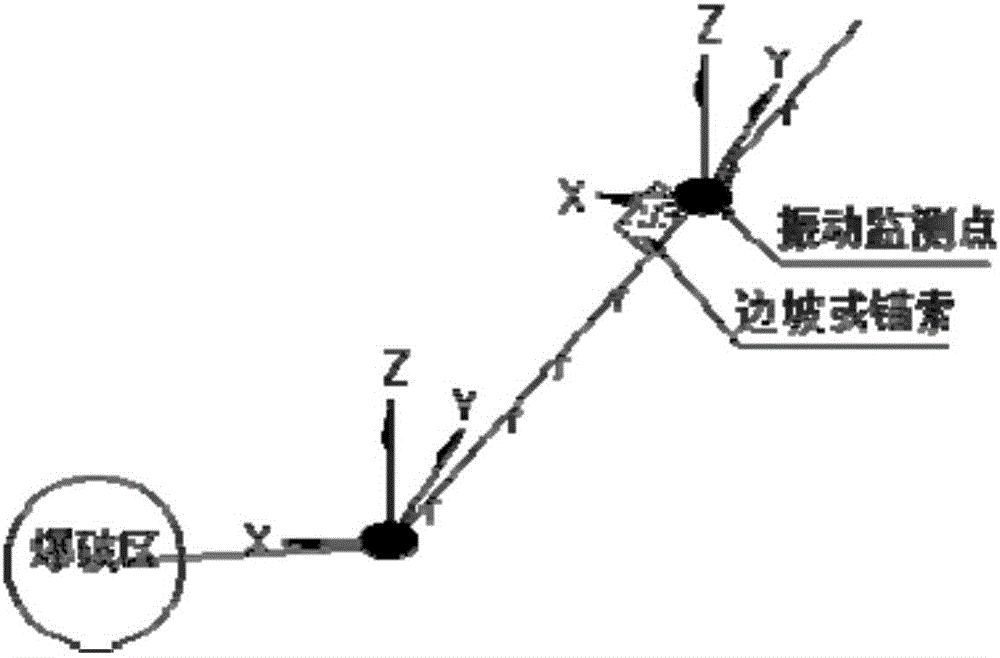

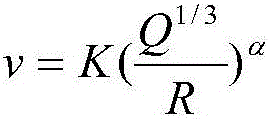

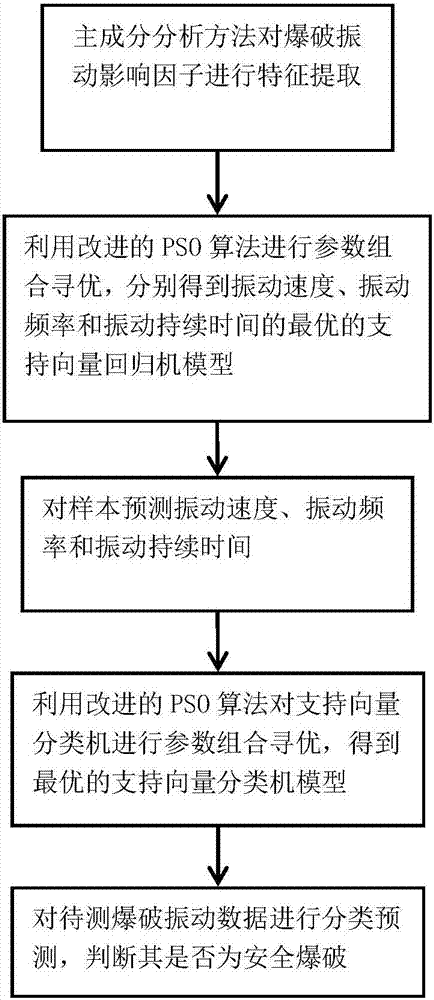

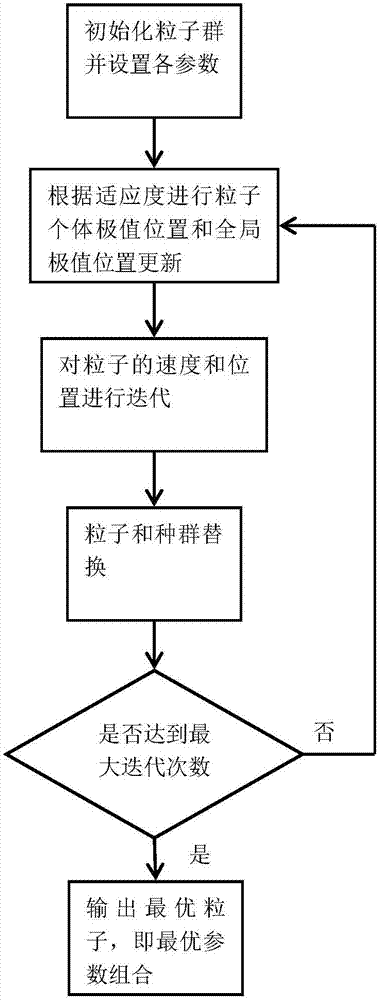

Blasting vibration predicting method based on particle swarm algorithm optimization support vector machine

InactiveCN106980877AOvercome the defect that it is easy to fall into local optimizationImprove forecast accuracyCharacter and pattern recognitionArtificial lifeFeature extractionSlack variable

The present invention provides a blasting vibration predicting method based on a particle swarm algorithm optimization support vector machine. According to the method, firstly, blasting vibration influence factors are subjected to feature extraction. Secondly, the kernel function, the penalty factor, the slack variable and the kernel parameters of the support vector machine are subjected to combined optimization thorough the improved PSO algorithm, and then an optimal support vector regression machine and an optimal support vector classifier model are respectively obtained. In this way, the classified prediction of blasting vibration data is realized. Compared with the traditional blasting vibration velocity predicting method for support vector machines, optimized combined parameters are obtained, so that the performances of models can be better improved. The prediction accuracy of models is improved, and the prediction accuracy of the blasting vibration strength is greatly improved.

Owner:陕西中爆安全网科技有限公司 +1

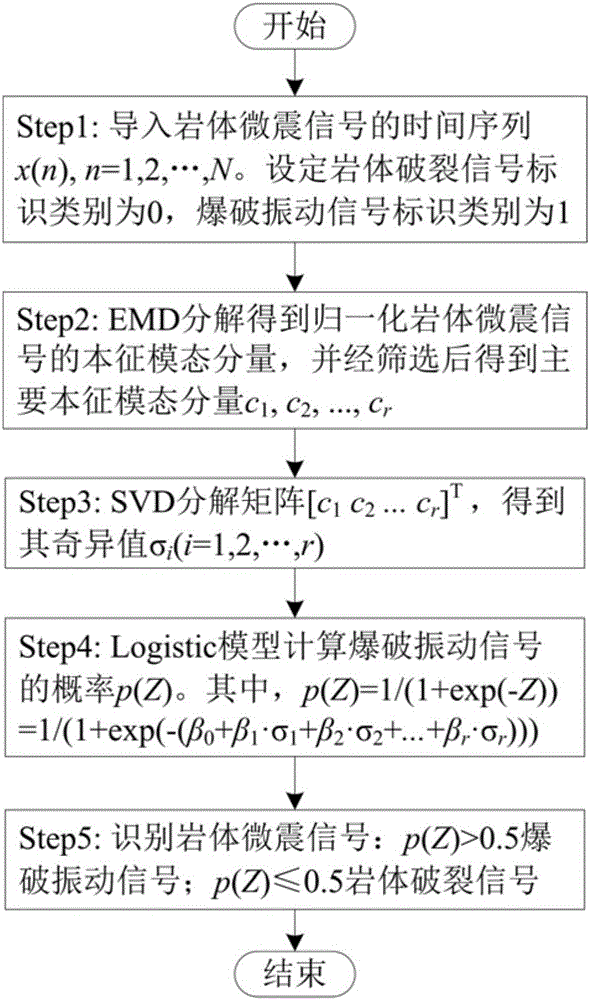

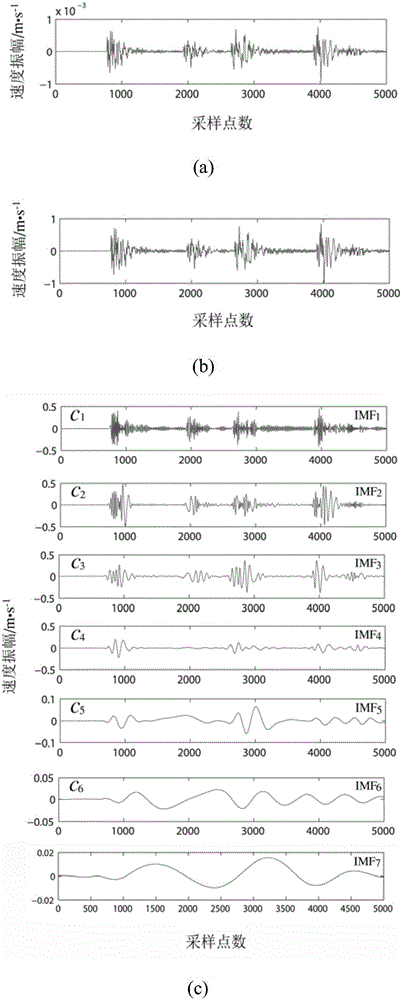

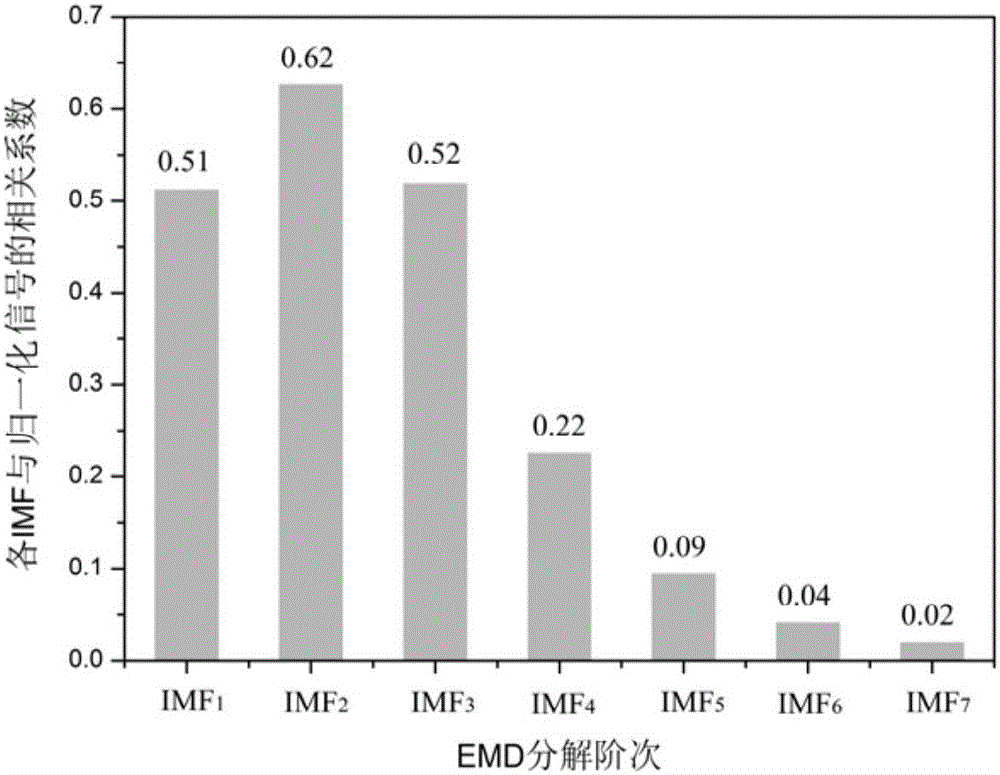

Nonlinear identification method for rock fracture signal and blasting vibration signal

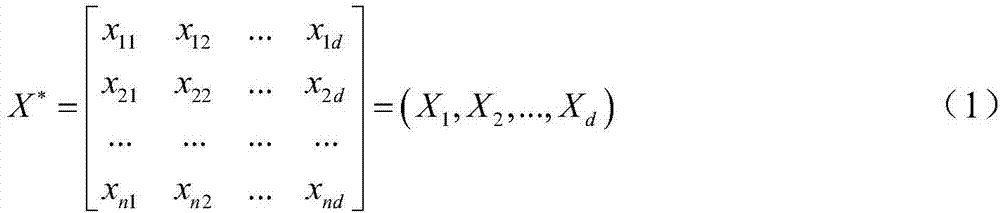

ActiveCN105740840ASolving Nonlinear RelationshipsImprove accuracyCharacter and pattern recognitionDecompositionBlasting vibration

The present invention discloses a nonlinear identification method for a rock fracture signal and a blasting vibration signal. The method comprises: step 1: importing a time sequence x(n) of a rock microseismic signal, wherein n=1, 2,..., N; step 2: performing decomposition to obtain intrinsic modality components of a normalized rock microseismic signal by EMD decomposition, and screening the intrinsic modality components to obtain main intrinsic modality components c1, c2,..., cr, wherein r is the number of the intrinsic modality components after screening; step 3: performing decomposition on a matrix [c1 c2... cr]T by SVD, so as to obtain a singular value signma i of the matrix, wherein i=1, 2,..., r; step 4:calculating a probability p(Z) of a blasting vibration signal by using a Logistic model; and step 5: identifying the rock microseismic signal, wherein p(Z)>= 0.5*(blasting vibration signal), and p(Z)<=0.58(rock fracture signal). The method has the characteristics of strong suitability and high accuracy and the like.

Owner:CENT SOUTH UNIV

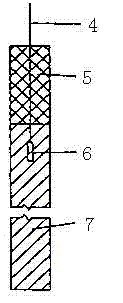

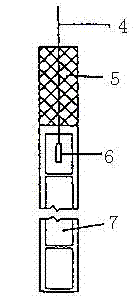

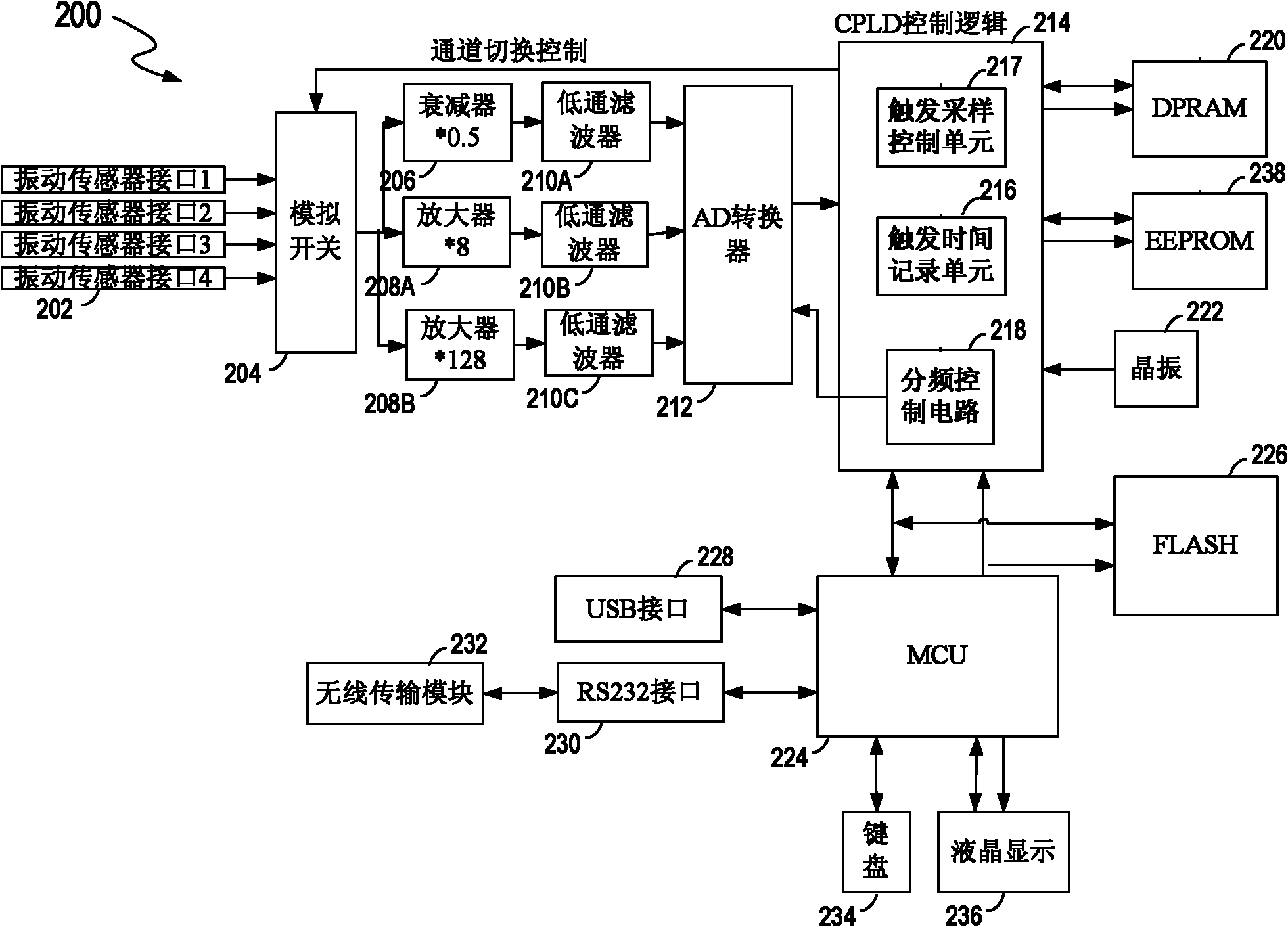

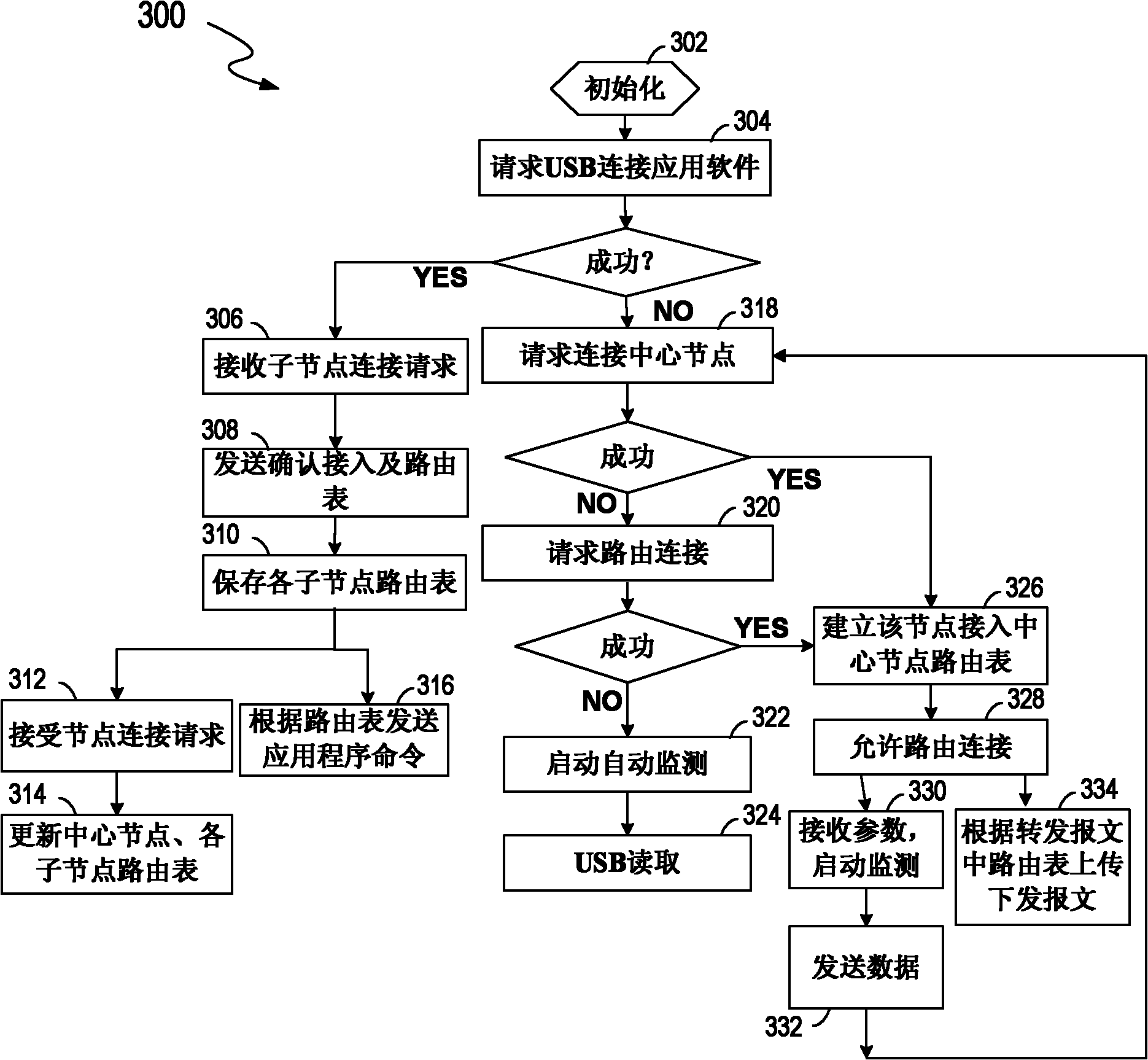

Wireless blasting vibration monitoring system capable of freely networking and control method

ActiveCN101975608AImprove securityEnsure safetyVibration measurement in solidsNetwork topologiesConvertersLow-pass filter

The invention discloses a wireless blasting vibration monitoring system capable of freely networking and a control method. A vibration sensor interface is respectively connected with a multi-channel analog switch which is connected with an attenuator and an amplifier which are in parallel, the attenuator and the amplifier are respectively connected with a low pass filter, the output end of the low pass filter is connected with the input end of an A / D converter, the output end of the A / D converter is connected with a CPLD (Complex Programable Logic Device) control logic which is respectively connected with a crystal oscillator, a DPRAM (Double Port Random Memory) and an EEPROM (Electrically Erasable Programmable Read - Only Memory), an MCU 224 (Microprogrammed Control Unit) is connected with the CPLD control logic, and a wireless transmission module is connected with the MCU through an RS232 interface. In the control method, an acquiring node is integrally initialized: a USB interface is requested to connect an application software; the acquiring node is successfully connected with a PC machine application software, the acquiring node as an acquiring center works; the acquiring node as an acquiring sub node works under the control of an acquiring center node; and the acquiring node as the acquiring sub node starts automatic monitoring. The invention has the advantages of convenient installation, low cost, high efficiency and stable signal, and solves the problem in the blasting vibration monitoring system.

Owner:WUHAN RSM INTELLIGENC GEOTECHN

Novel roadway blasting construction method

InactiveCN103575172AContour surface forming is regularGood free surfaceBlastingOblique cuttingEngineering

The invention discloses a novel roadway blasting construction method, belongs to the technical field of shaft building construction, and provides a novel cutting blasting shaft-forming construction method. Four kinds of blast holes are formed in a whole cross section of a roadway, wherein V-shaped ejection holes, cutting holes, auxiliary holes, interval cutting holes and peripheral holes are formed sequentially from inside to outside; and the cutting holes are formed on two sides of each auxiliary hole. Compared with other methods, free surfaces of the auxiliary holes is added, and the number of the free surfaces is increased from two to three; a blank hole is drilled at the interval of every two blast holes among the interval cutting holes and isn't filled with explosive; the oblique cutting angle of each ejection hole is 80-85 degrees, and a small amount of the explosive is filled in the ejection holes; and the reserved holes are taken as compensation space of the free surfaces and crushed rock mass during cutting hole blasting, and a throwing effect on rock mass after cutting hole blasting is realized. With the adoption of the novel interval cutting hole method, influences of blasting vibration on surrounding rock are reduced, the free surfaces are added, the cutting depth and the cutting size are increased, the blasting effect is improved, and the blasting efficiency is improved.

Owner:ANHUI UNIV OF SCI & TECH

Tunneling electron detonator blasting construction method

InactiveCN102095338AHigh delay accuracyMeet the design requirements of vibration reductionBlastingDetonatorEngineering

The invention discloses a novel blasting construction method. In the method, an electron detonator is used for blasting. The method also comprises the following steps of: designing a detonator arrangement diagram; detonating at least one detonator; analyzing a generated blasting vibration waveform; detonating a special detonator; and eliminating the blasting vibration to the maximum extent by a phase-stagger vibration damping technology. By the technology of the method, the blasting vibration is obviously reduced, full cross section blasting can be performed, circulating drilling footage is increased, blasting residues are well crushed and an obvious polished surface effect is achieved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD +1

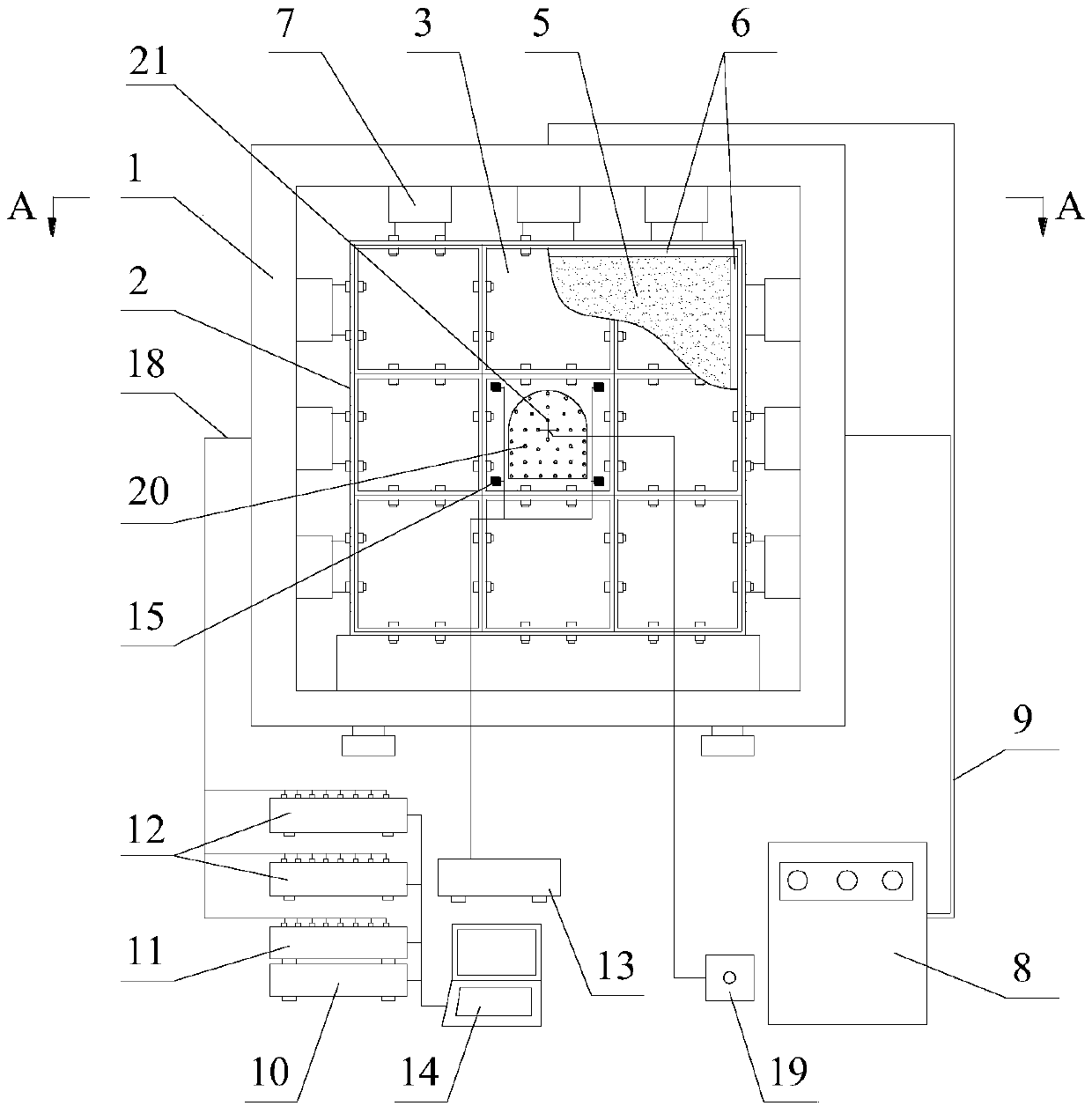

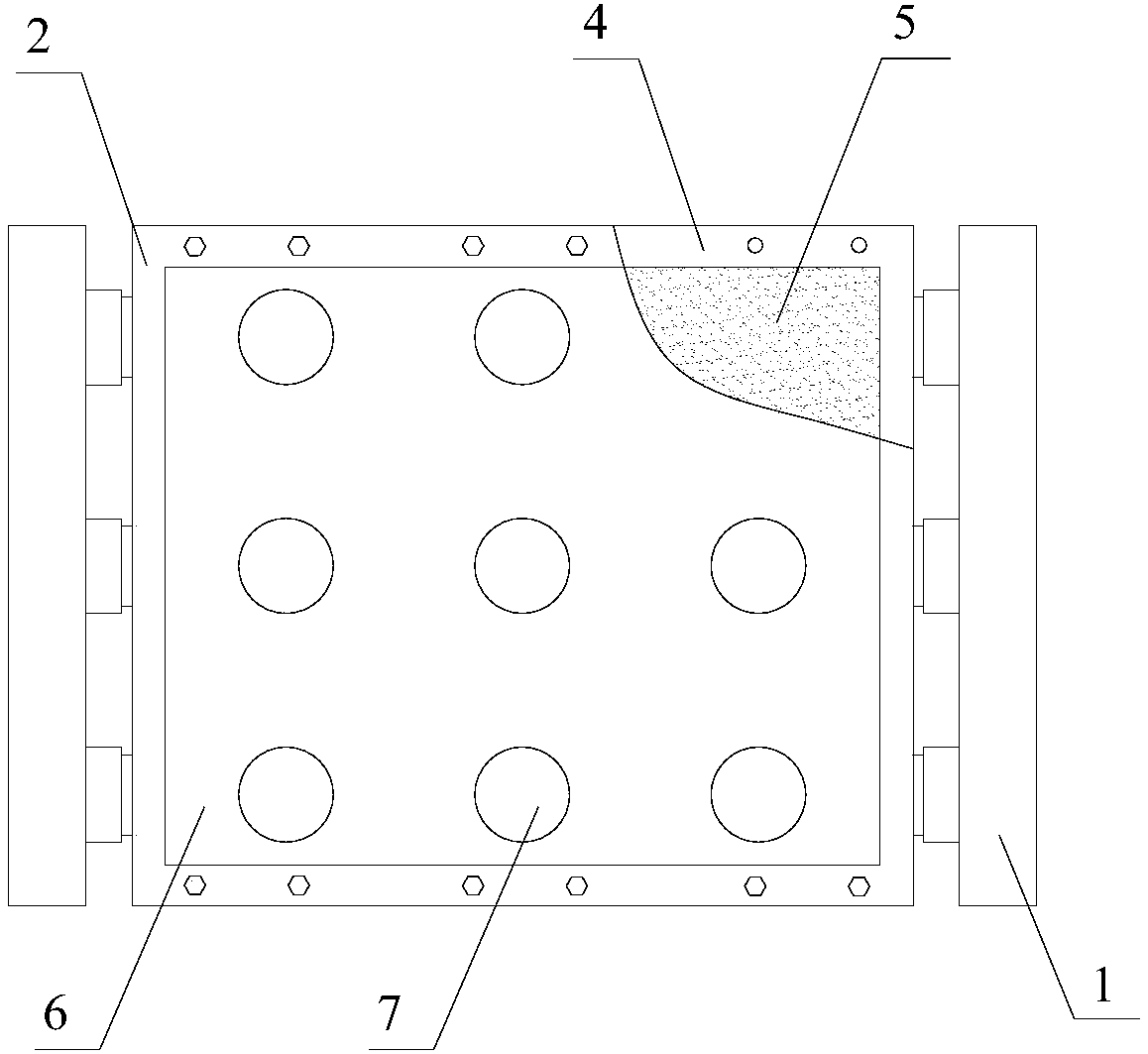

Device and method of test for simulation of deep-lying tunnel blasting excavation unloading

ActiveCN107796646AStructural/machines measurementHydro energy generationModel sampleData acquisition

Owner:CENT SOUTH UNIV

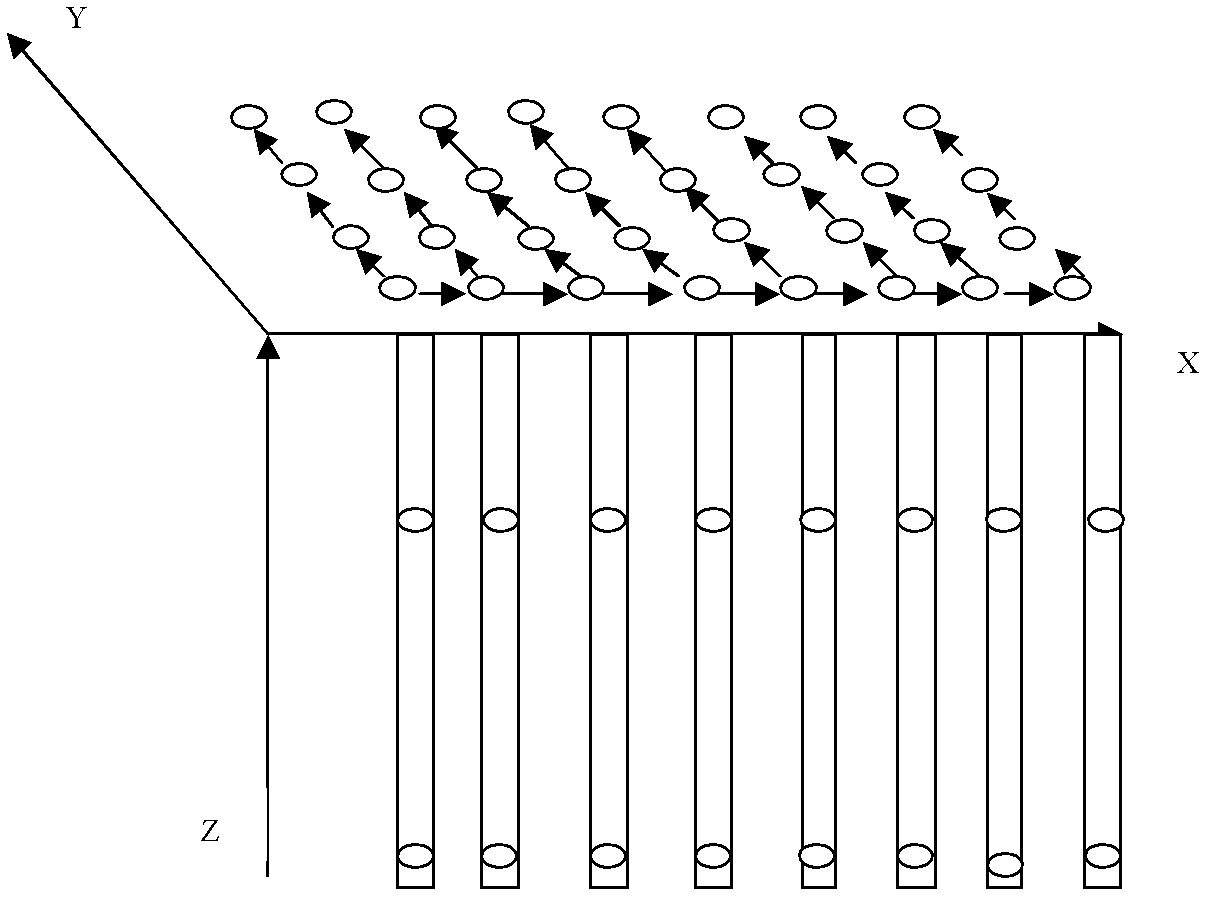

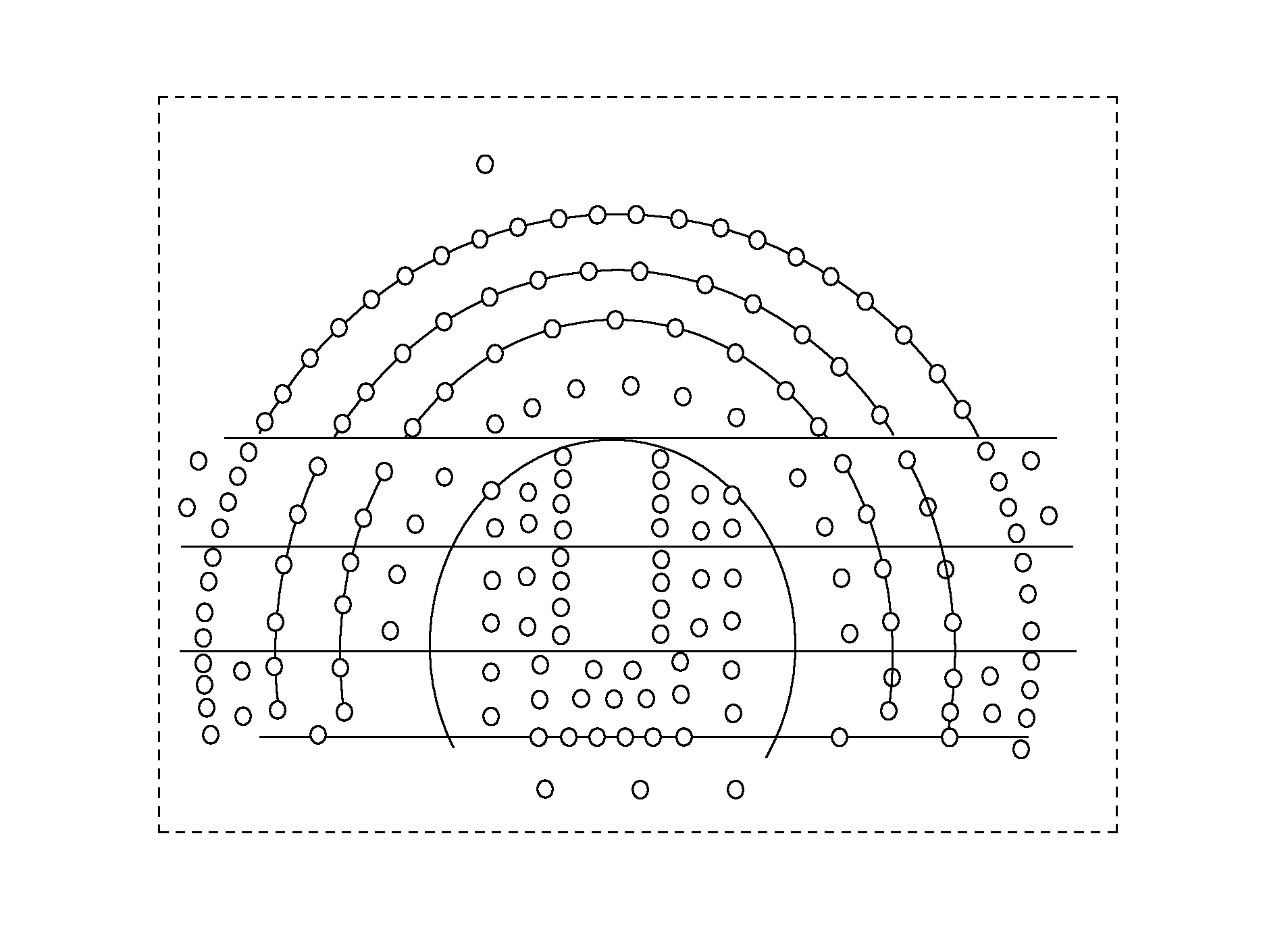

Open bench inter-hole differential control blasting method

ActiveCN102607353AImprove energy utilizationAvoid vibration peaksBlastingOpen-pit miningDelayed time

An embodiment of the invention discloses an open bench inter-hole differential control blasting method, which relates to the technical field of mining and is invented for solving the problems that resulting fragmentation degree needs to be better, blast vibration damage needs to be reduced, and large-scale blasting needs to be implemented effectively. The method includes: subjecting blast holes in a same row to inter-hole differential accumulation according to delay time of 1-5ms per hole-pitch meter, and performing inter-hole differential interval blasting; subjecting the blast holes in all rows to inter-hole differential accumulation according to the delay time of 10-30ms per row-spacing meter, and performing inter-row differential interval blasting; and filling at least one of the blast holes with a plurality of priming bombs or spaced charged explosive, and performing intra-hole differential interval blasting. The method is applicable to open-pit mining, and also applicable to large-scale earth-rock excavation engineering, large-scale hydropower engineering, large-scale civil engineering, large-scale underground workshop excavation and the like.

Owner:ZHUOLIWEI BEIJING TECH

Method for implementing full-face smooth blasting construction by using digital detonators

InactiveCN102305580AIncreased explosion fragmentationImprove the glossy effectBlastingDetonatorDetonation

The invention relates to a method for implementing a full-face smooth blasting construction by using digital detonators. The method comprises the following steps: (1) designing a blasting construction plan; (2) carrying out trial blasting; (3) numbering digital detonators; (4) setting delay blasting times for the digital detonators; (5) installing the digital detonators; (6) carrying out web connection; and (7) carrying out a digital detonator detonation process. Compared with a common blasting method, by using the method provided by the invention, the blasting fracture is increased by 40%, and the smooth effect is increased by 30%, the full-face blasting can be performed, and the circulation footage is increased; a blasting vibration control effect is obvious; and the construction cost is higher than that of the construction using a drilling and blasting method, but compared with other methods, the construction cost advantage is obvious, therefore, the method provided by the invention has remarkable social and economic benefits.

Owner:BEIJING JIAOTONG UNIV

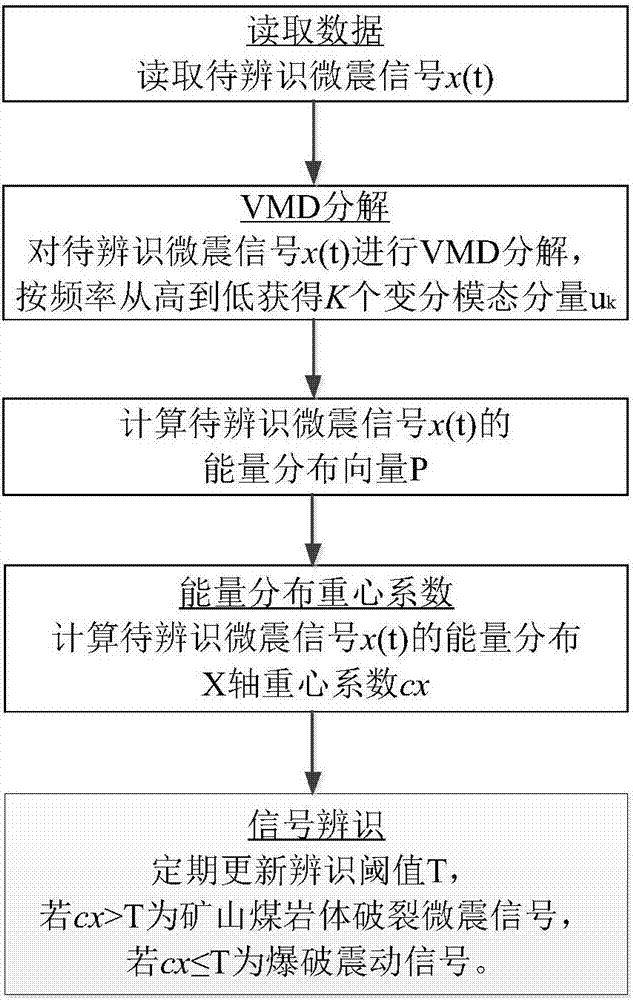

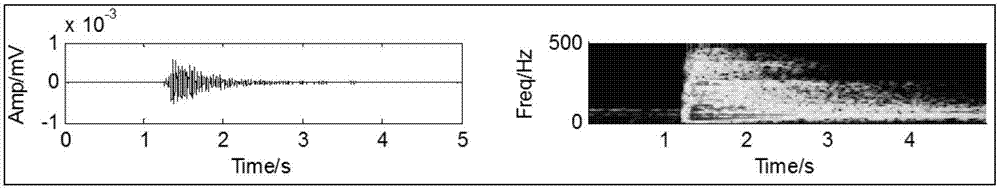

Mine micro-seismic signal identification method based on features of energy distribution

ActiveCN107505652AEfficient identificationAdaptableSeismic signal processingEnergy basedBlasting vibration

The invention discloses a mine micro-seismic signal identification method based on the features of energy distribution, which belongs to the field of signal analysis and identification. The method includes the following steps: reading a micro-seismic signal x(t) to be identified; carrying out VMD (Variational Mode Decomposition) on x(t) to get K variational modal components arranged in order according to the frequency from high to low; calculating the band energy of each modal component, and extracting the energy percentage of each modal component in the original signal to constitute an energy distribution vector P; calculating the energy distribution X-axis center-of-gravity coefficient cx on the basis of the energy distribution vector P; identifying the mine micro-seismic signal according to an identification threshold T: determining that the signal is a mine coal rock fracture micro-seismic signal if cx>T, and determining that the signal is a blasting vibration signal if cx<=T; and finally, adaptively updating the value of the identification threshold T. Through the method, a coal rock fracture micro-seismic signal and a blasting vibration signal can be distinguished. The method has the characteristics of strong adaptability, high accuracy, and the like.

Owner:SHANDONG UNIV OF SCI & TECH

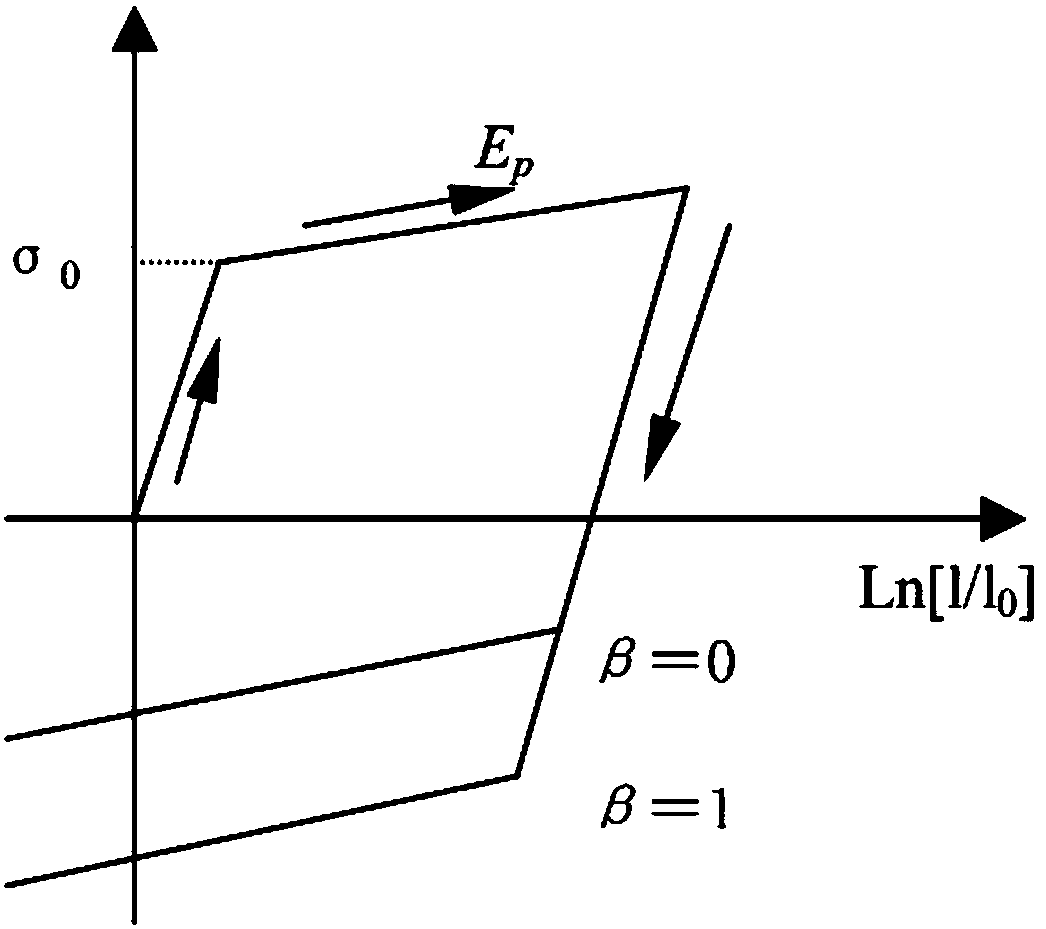

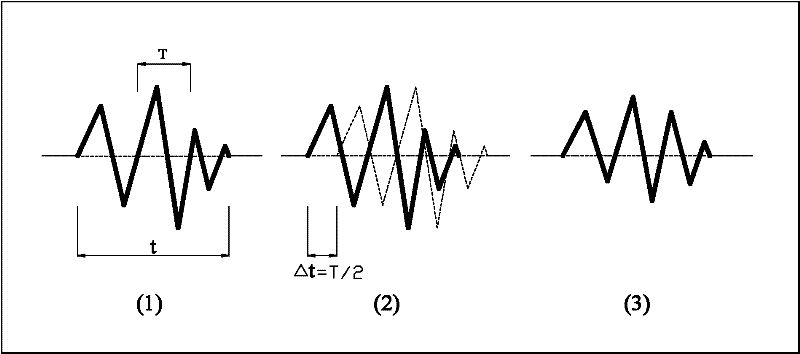

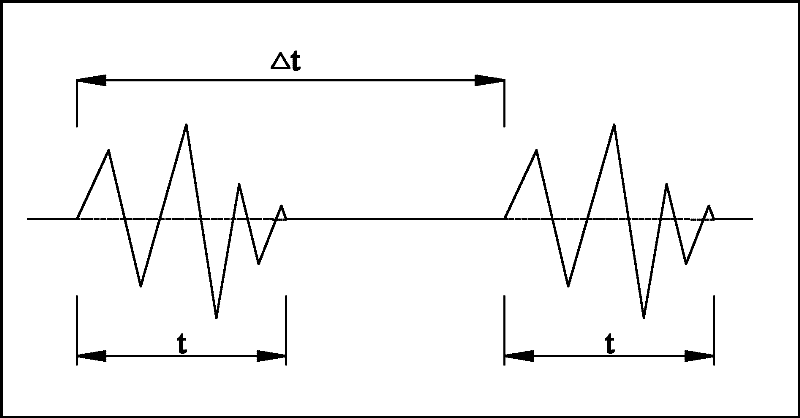

Initiation Control Method for Reducing Blasting Vibration Effect

InactiveCN102269553AEnsure safetyReduce the impact of blasting vibrationBlastingDetonatorVibration control

The invention discloses a detonation control method for reducing blasting vibration effect, which uses digital electronic detonators to reduce blasting vibration effects by controlling the number of each detonator section. One is: the selection of the number of detonator segments adopts the principle of mutual interference between blasting vibration peaks and troughs to reduce vibration, specifically: the delay time between the holes of each row of blast holes adjacent to the detonator detonator ΔTi = T / 2-1000*a / c, where T is the main vibration period of the blasting vibration, in milliseconds; ΔTi is the delay time between adjacent blastholes for sequential detonation, in milliseconds; a is the distance between blastholes, in meters; c is the propagation velocity of seismic waves in rocks, The unit is m / s; the inter-row delay between adjacent rows: ΔTj=nΔTi, ΔTj is the inter-row delay time, and the unit is millisecond; n is the number of adjacent front row detonator segments. The second method is: the selection of the number of each detonator section adopts the principle that the blasting vibration waves are independent of each other and vibration does not superimpose, that is, the inter-hole delay ΔTi=(1.0~1.5)t of sequentially detonating adjacent detonators.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com