Test method of blasting vibration attenuation effect

A blasting vibration and attenuation effect technology, applied in measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve problems such as irregular vibration testing, lack of large-scale networking functions, and inability to analyze vibration attenuation effects, etc. The effect of avoiding network congestion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0023] Such as figure 1 , figure 2 As shown, in the present embodiment, the method for testing the blasting vibration attenuation effect proposed by the present invention includes the following steps:

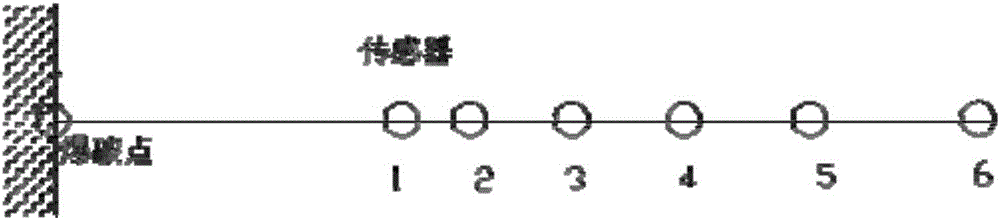

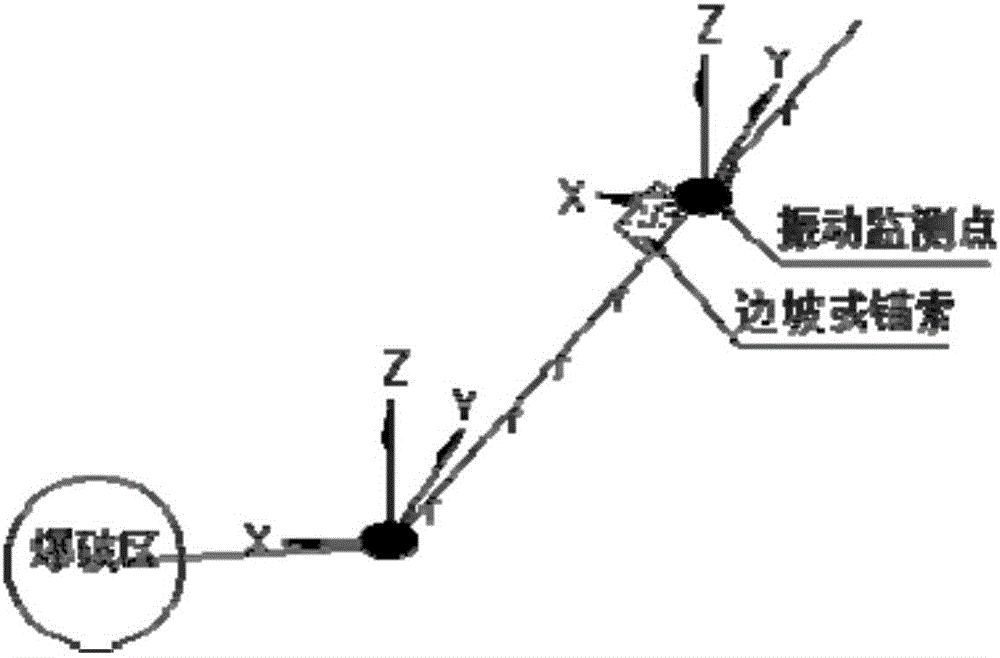

[0024] Step 1. Set up monitoring points on three radial lines with the blasting point as the center point in a close-in and far-sparse manner, and set six monitoring points on each radial line. The detection points and the blasting points are located on the same elevation;

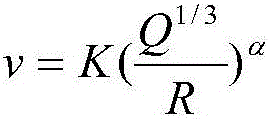

[0025] Step 2. Install the three-vector velocity sensor on the monitoring point. The distance between each sensor and the blasting point can be set to 10, 15, 25, 35, 50, and 70m, where the Z direction is vertical and the X direction points to the explosion source. is the horizontal radial direction, and the Y direction is the horizontal tangential direction. Number the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com