Patents

Literature

1365 results about "Vibration attenuation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

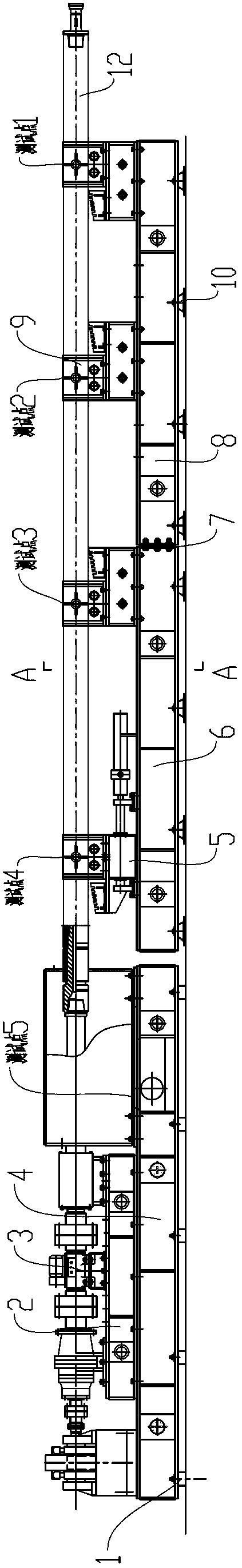

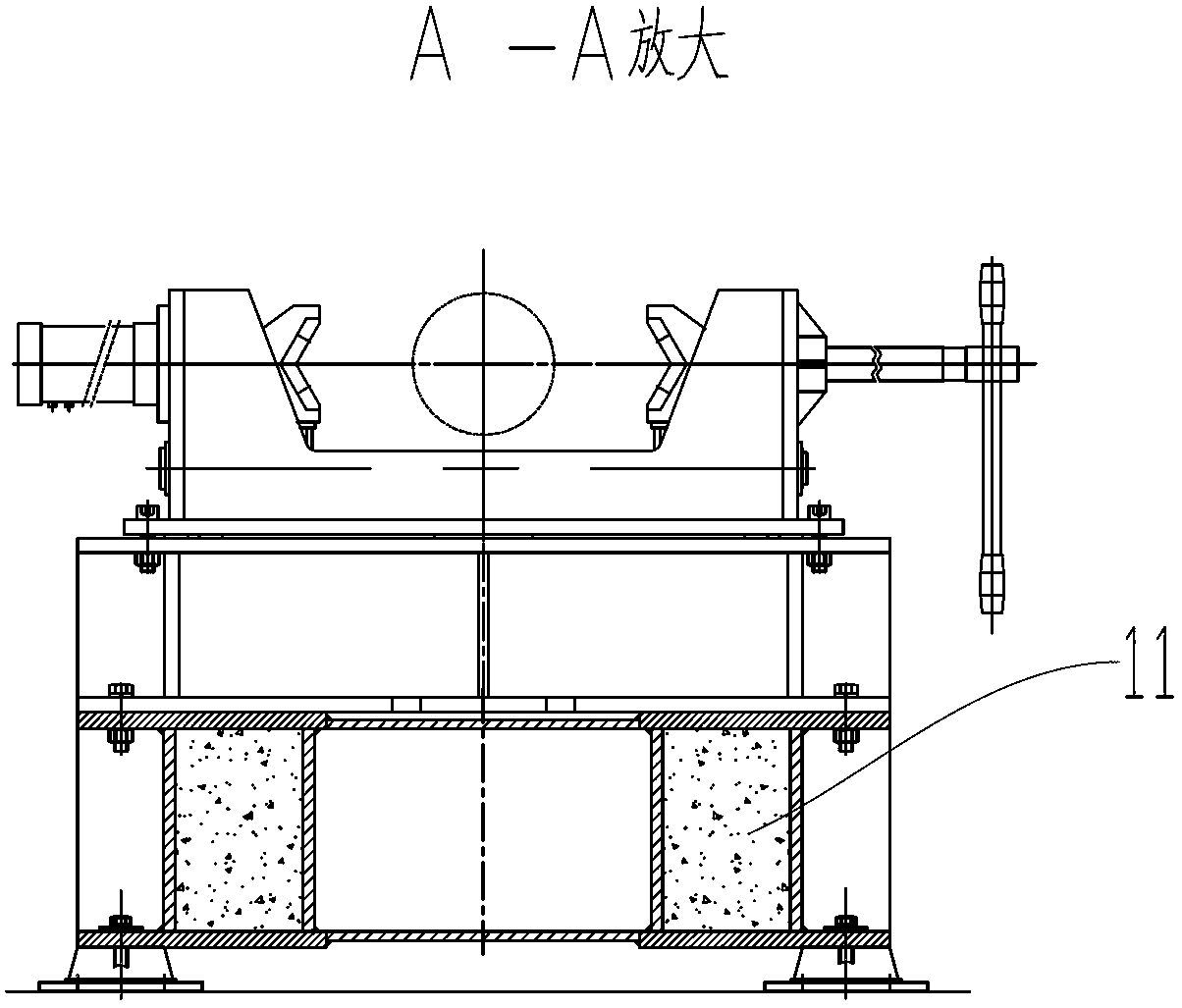

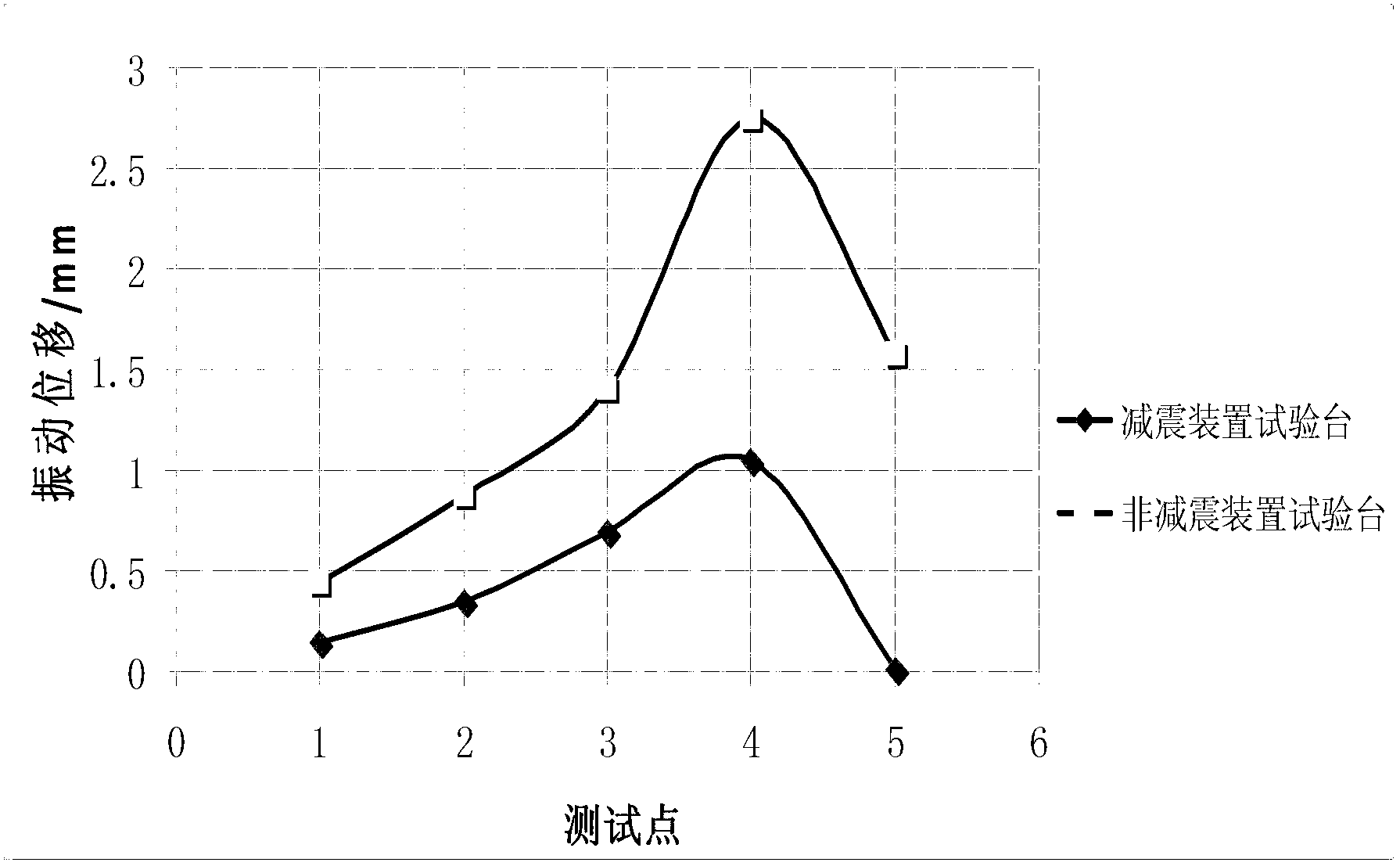

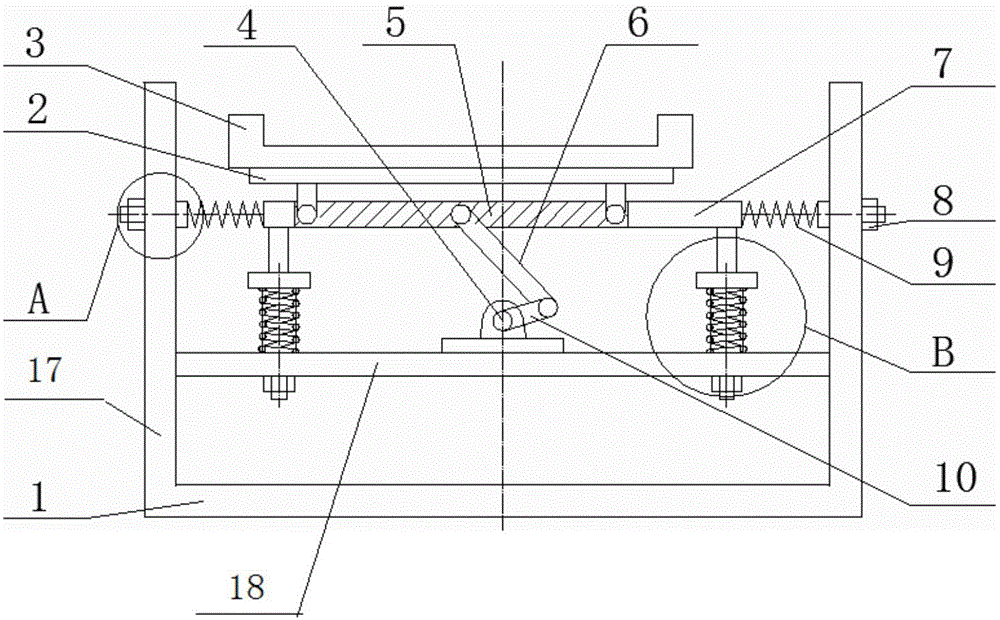

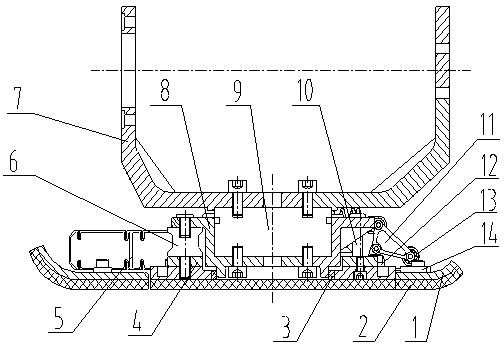

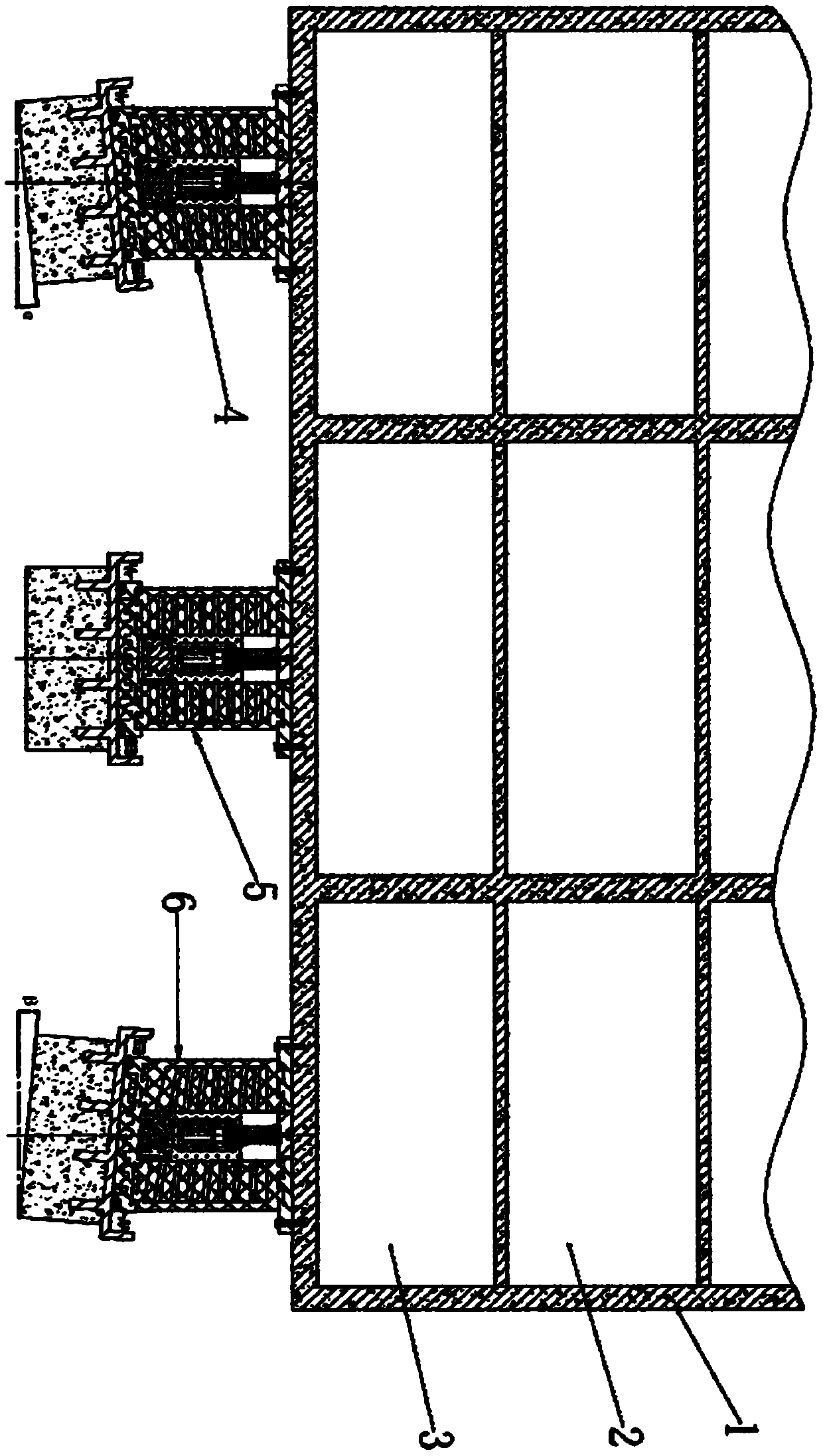

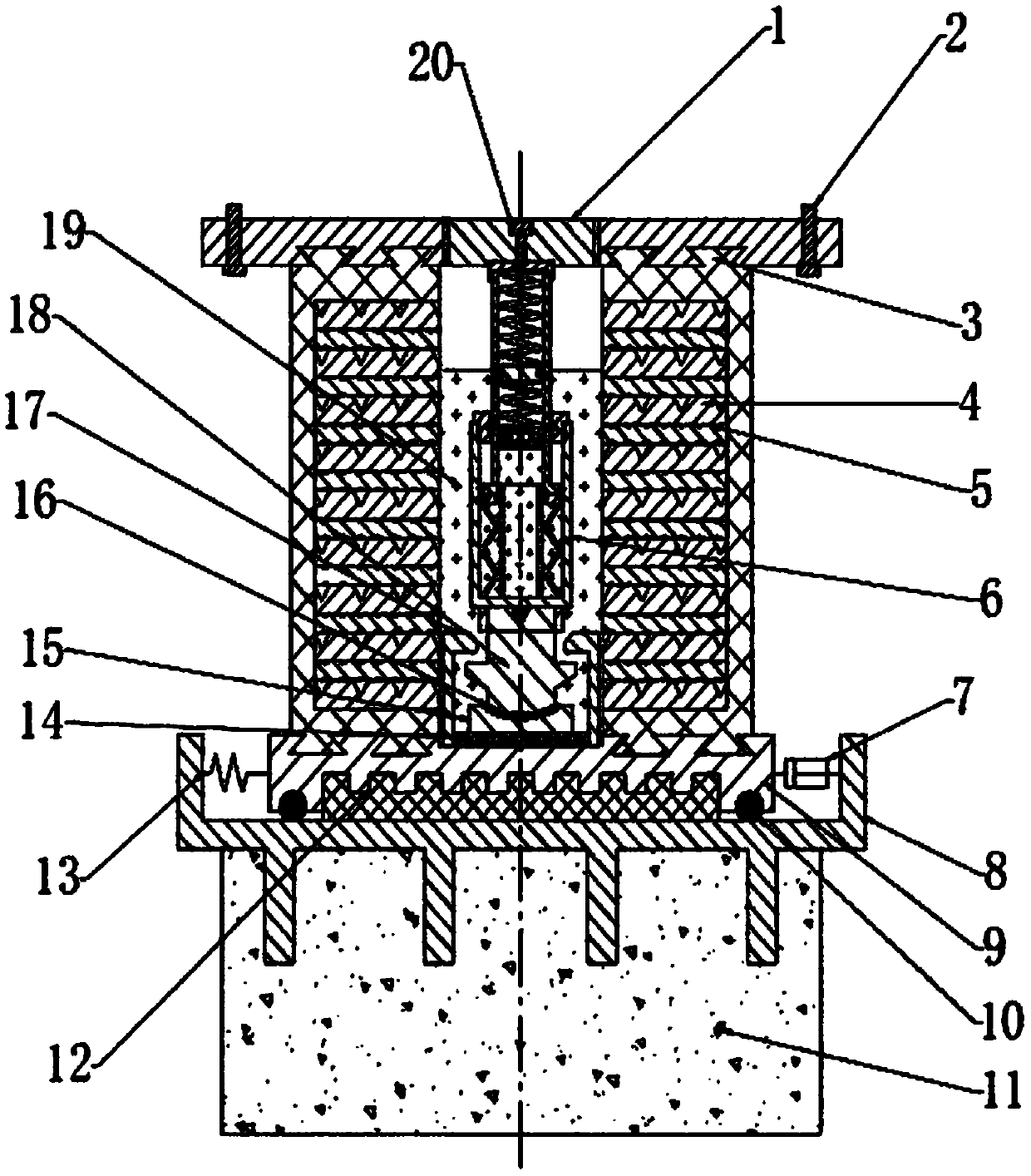

Combined vibration damper of screw drill complete machine test-bed and manufacturing method thereof

ActiveCN103245523AAchieve test accuracyThe test data is accurateStructural/machines measurementVibration attenuationResonance

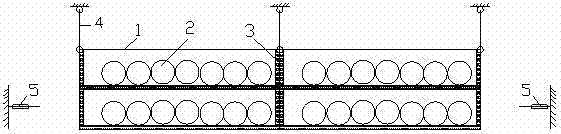

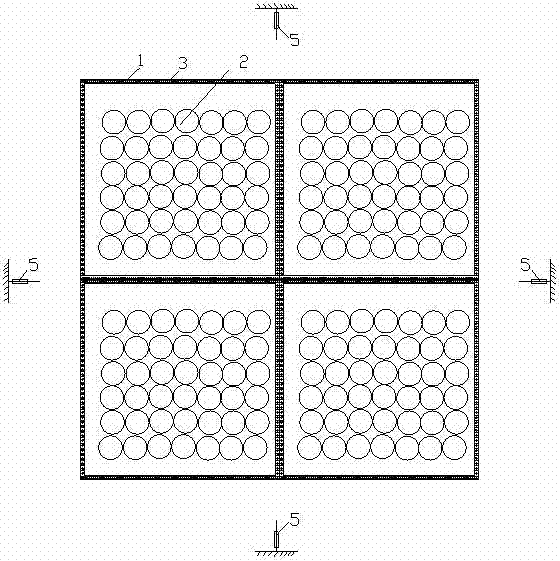

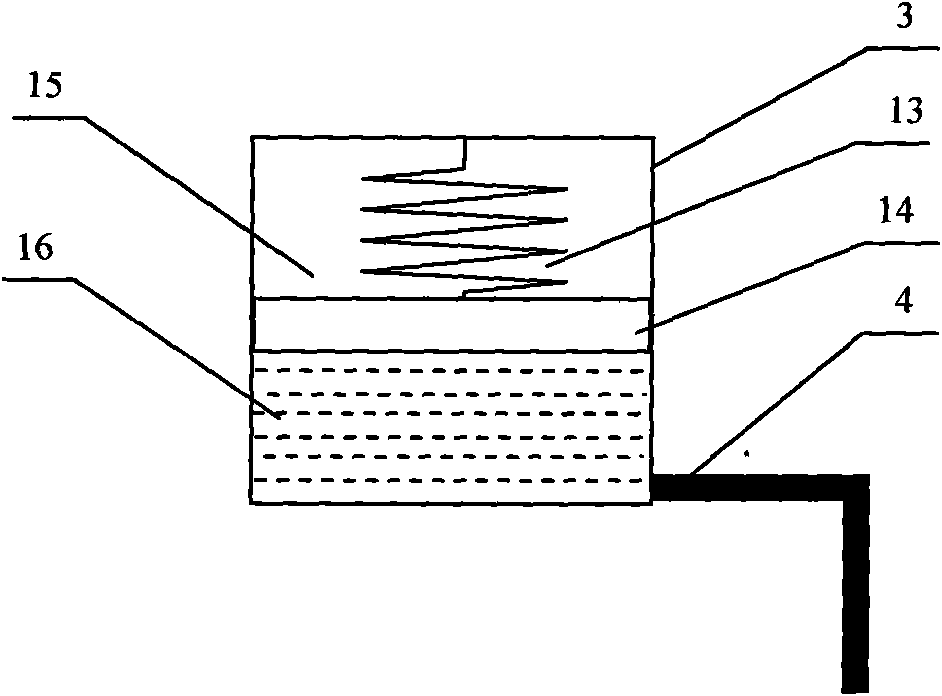

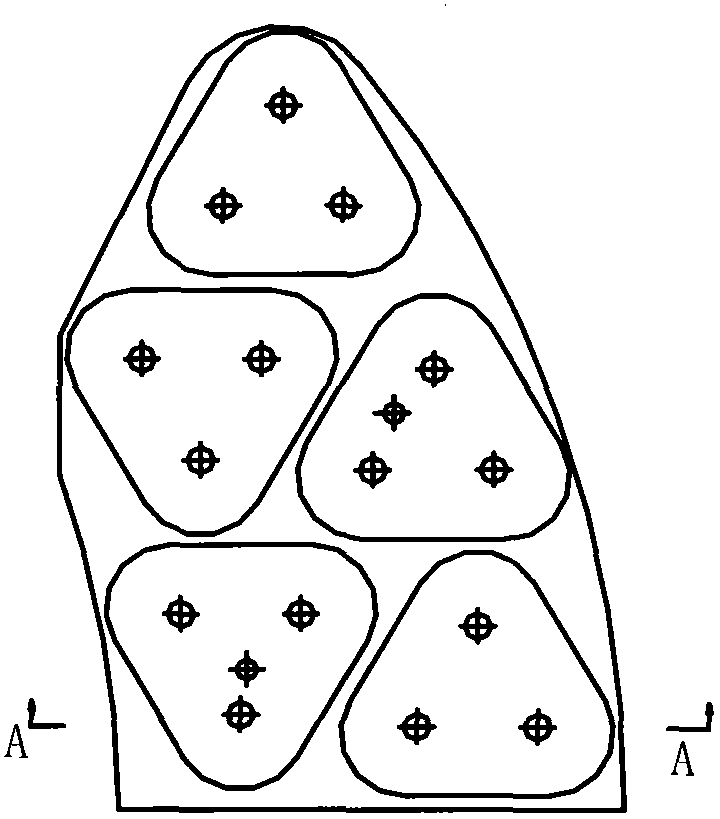

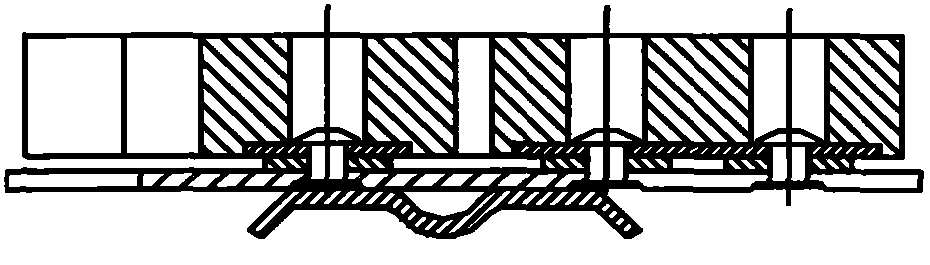

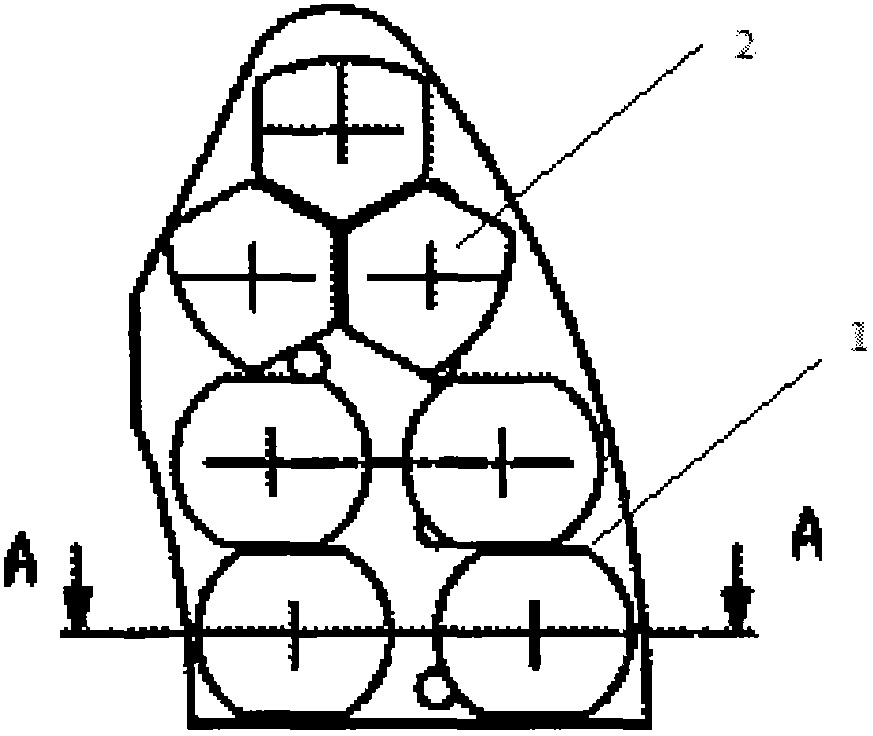

The invention discloses a combined vibration damper of a screw drill complete machine test-bed and a manufacturing method thereof. The combined vibration damper comprises a vibration attenuation base which comprises a loading system base, a first clamping system base and a second clamping system base, wherein the loading system base is arranged on an equipment foundation in a rigidity way; the first clamping system base and the second clamping system base are connected into a whole through a bolt and are arranged on the equipment foundation through a rubber vibration attenuation block; an interval of 30-50 mm is reserved between the loading system base and each clamping system base; the first clamping system base and the second clamping system base are respectively internally provided with a plurality of cubic cavities with an equal size; the volume of each cubic cavity is 0.1-0.2 cubic meter; discrete type balance weight sand is respectively filled into the cubic cavities, and the filling efficiency is 80-90 %; and the weight of the balance weight sand is 25-35 % of the total weight of the whole device. The test-bed is capable of restraining resonance and testing precisely in the testing process by the combined vibration damper, and the usage precision of surrounding working devices is not affected.

Owner:DEZHOU UNITED GASOLINEEUM MACHINERY

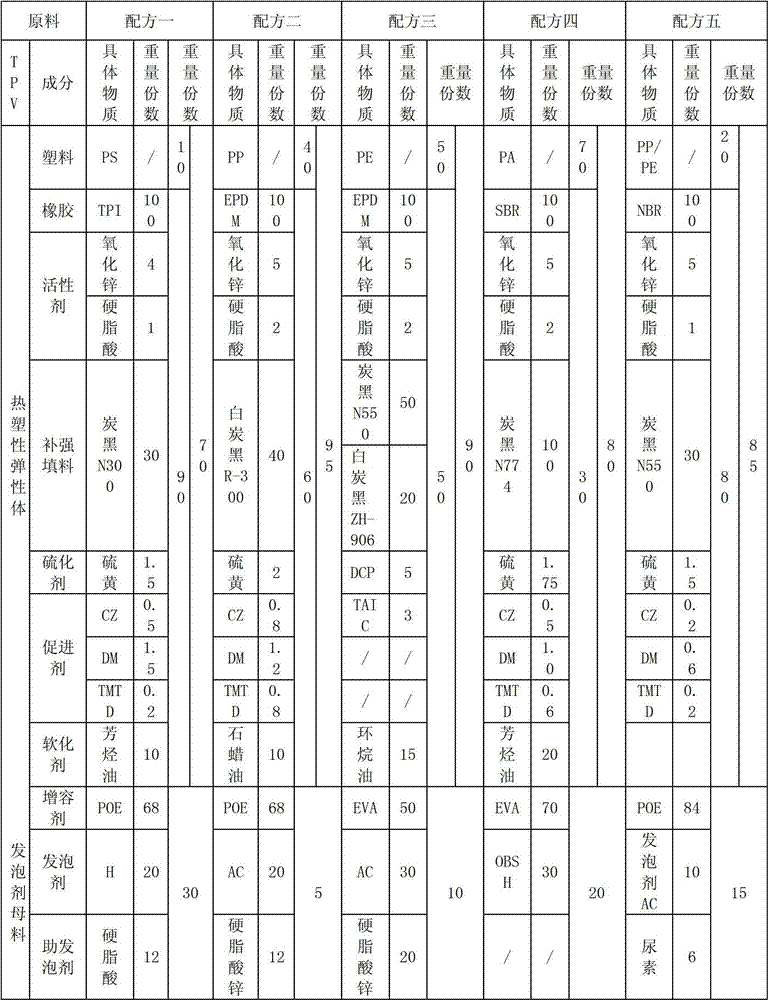

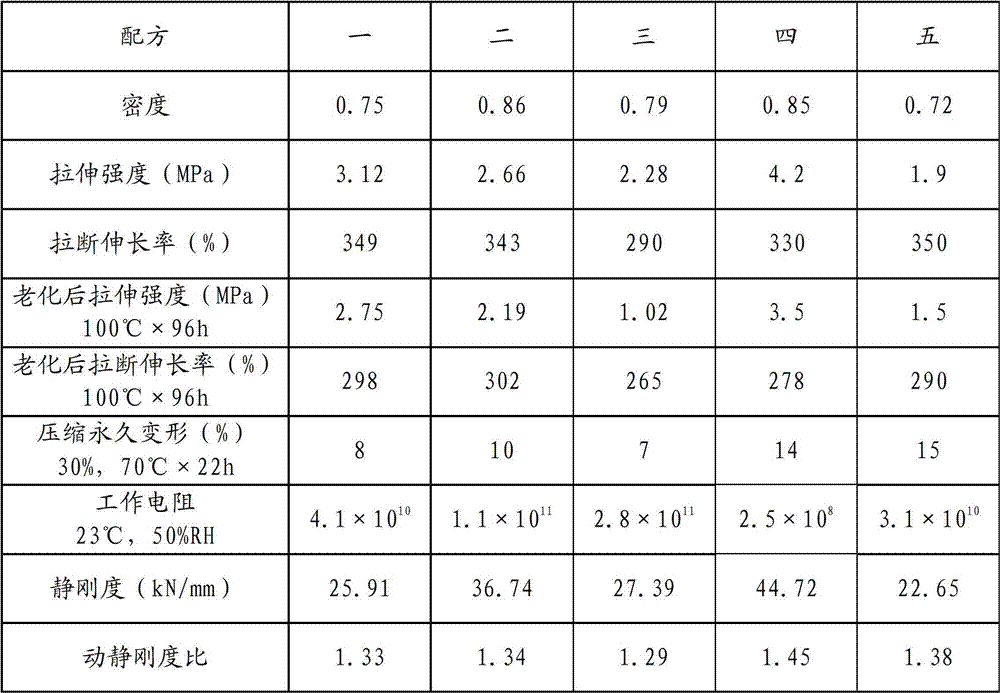

Thermoplastic elastomer micropore foaming material and preparation method thereof

The invention discloses a thermoplastic elastomer micropore foaming material and a preparation method thereof. The material comprises the following componnets in parts by weight: 70-95 parts of thermoplastic elastomer and 5-30 parts of foaming agent master batch. The preparation method comprises the following steps of: based on weight parts, placing 50-90 parts of compatibilizers, 6-30 parts of foaming agent and 4-20 parts of auxiliary foaming agents into a double-roller open mill for mixing to prepare foaming agent master batch; sequentially adding 100 parts of matrix rubber, 5-10 parts of active agent, 20-100 parts of reinforced fillers, 0-20 parts of softening agents, 0.5-5 parts of vulcanizing agents and 1-10 parts of accelerating agents into the open mill or an internal mixer for uniformly mixing to prepare a rubber compound; chopping the rubber compound and uniformly mixing the chopped rubber compound with 10-70 parts of plastics by a high-speed mixer; and extruding and pelleting the mixture to prepare thermoplastic vulcanizate (TPV) aggregates; and uniformly mixing the foaming agent master batch with the TPV aggregates to extrude and form again to prepare a high-performance micropore foaming material for vibration attenuation. The TPV foaming material is high in physical and mechanical properties and thermal ageing performance, is simple in process, can be widely popularized, and is suitable for being used in the field of rail transit.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

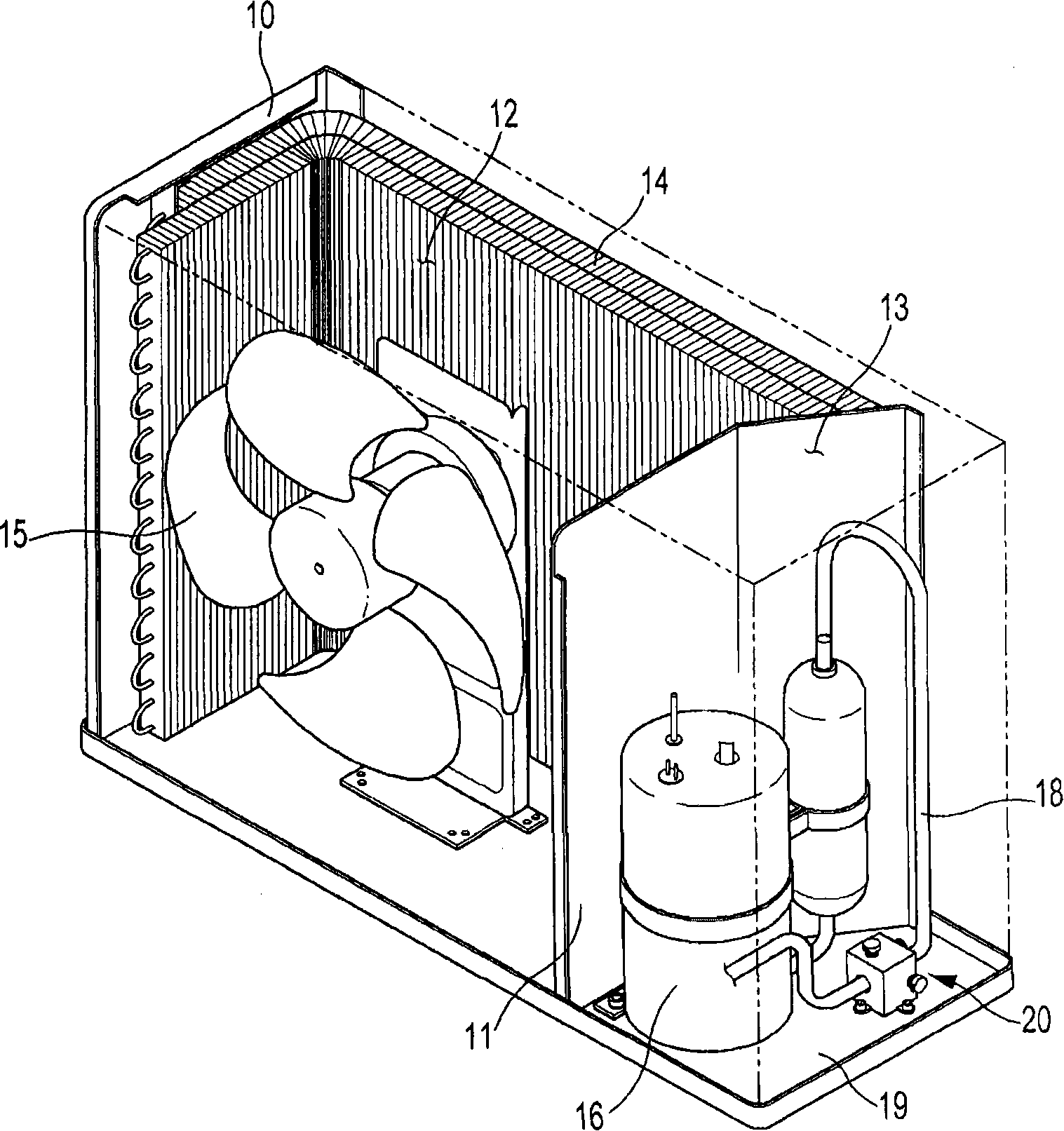

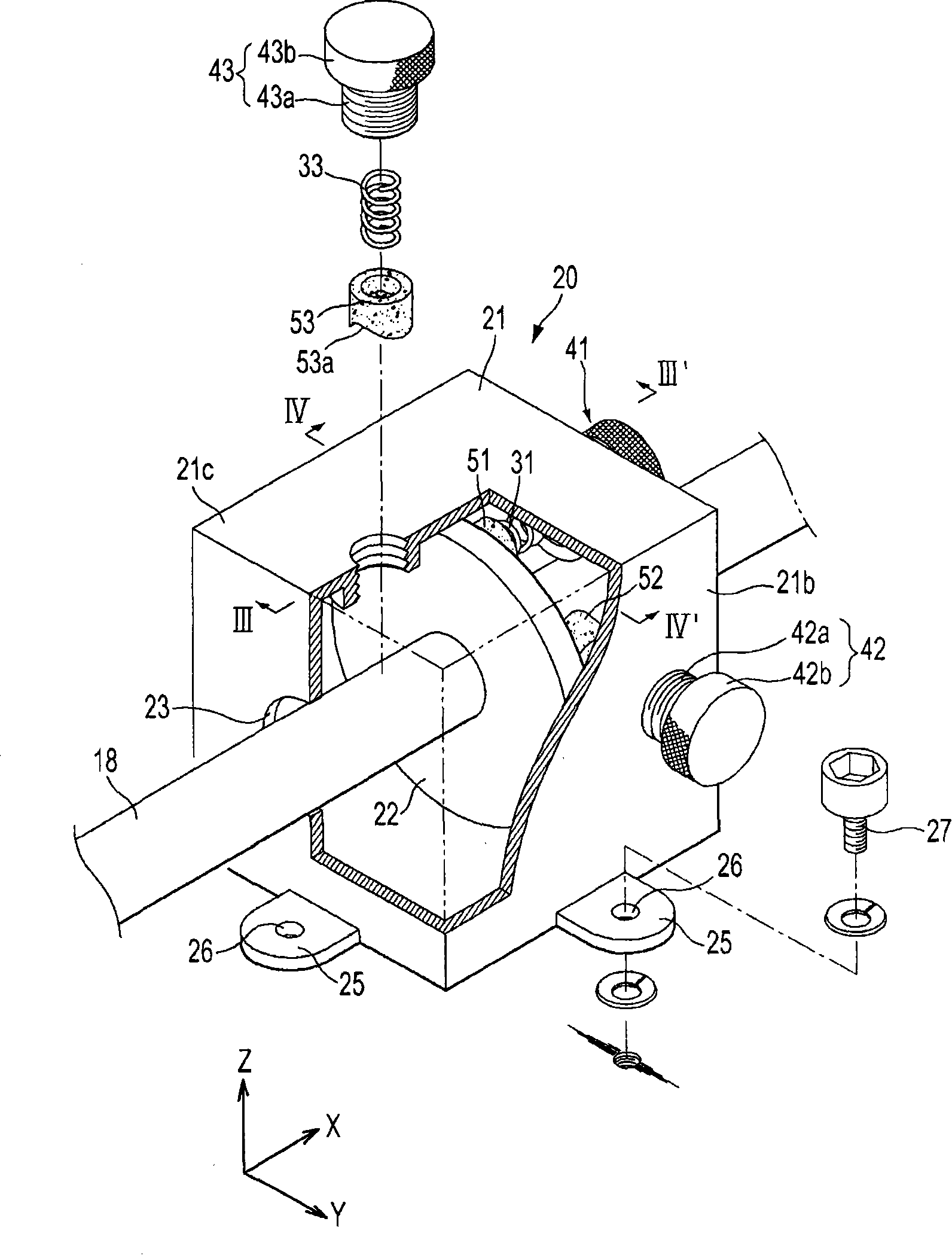

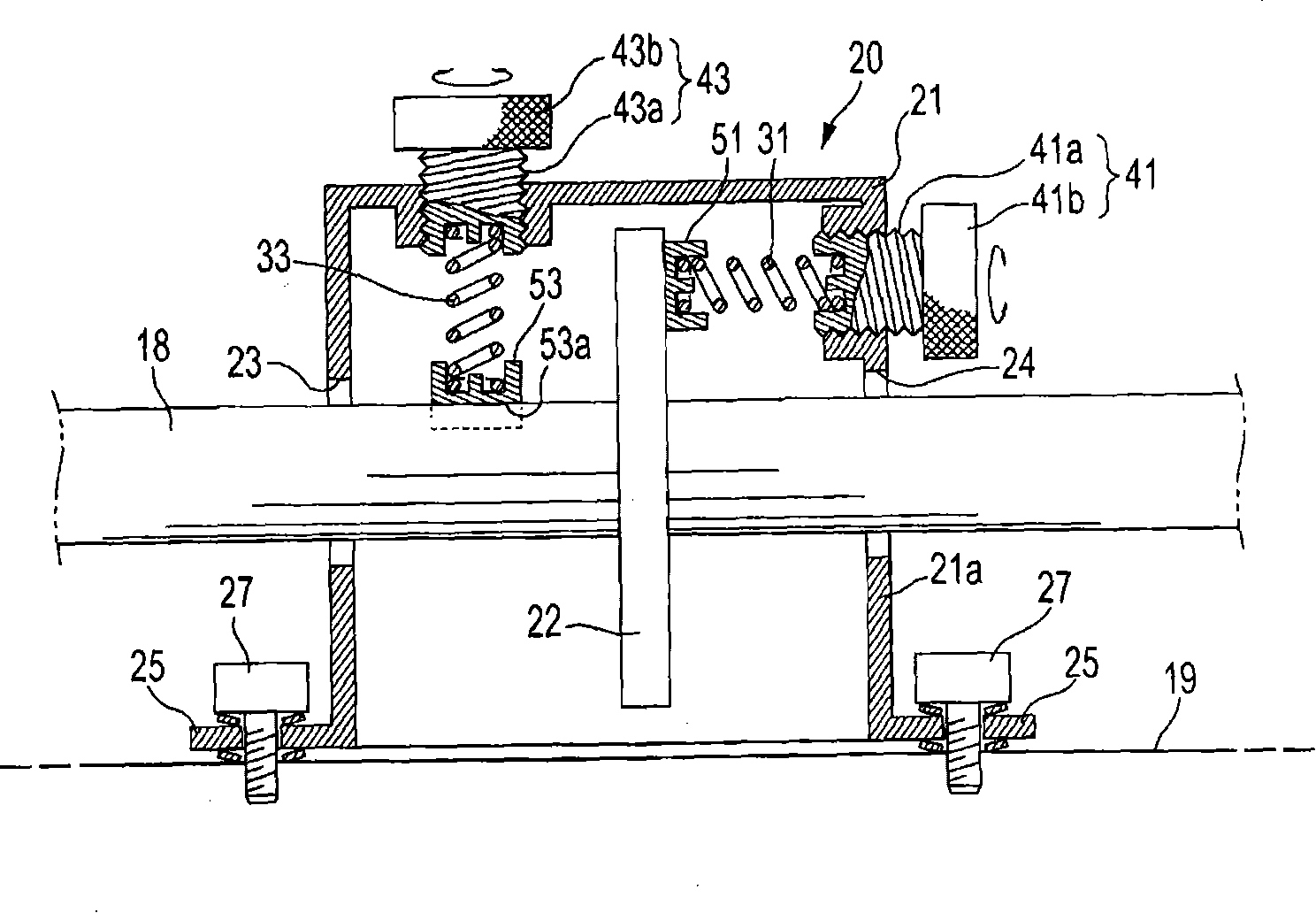

Tubing support device and air conditioner possessing the device

The invention discloses a tubing support device and an air-conditioner including the device, accordingly, vibration absorption ability can be adjusted according to the change of vibration properties of the tubing, in addition, compared with prior art, the invention further improves the vibration attenuation effect of the tubing. The disclosed tubing support device comprises: a fixing component fixed around the tubing in a state of separation from the tubing; a plurality of pressurization springs which pressurize the tubing respectively in a plurality of mutually-different directions; a plurality of pressure adjusting bolts which are respectively connected with the fixing component and used for respectively adjusting the pressure of the plurality of pressurization springs.

Owner:SAMSUNG ELECTRONICS CO LTD

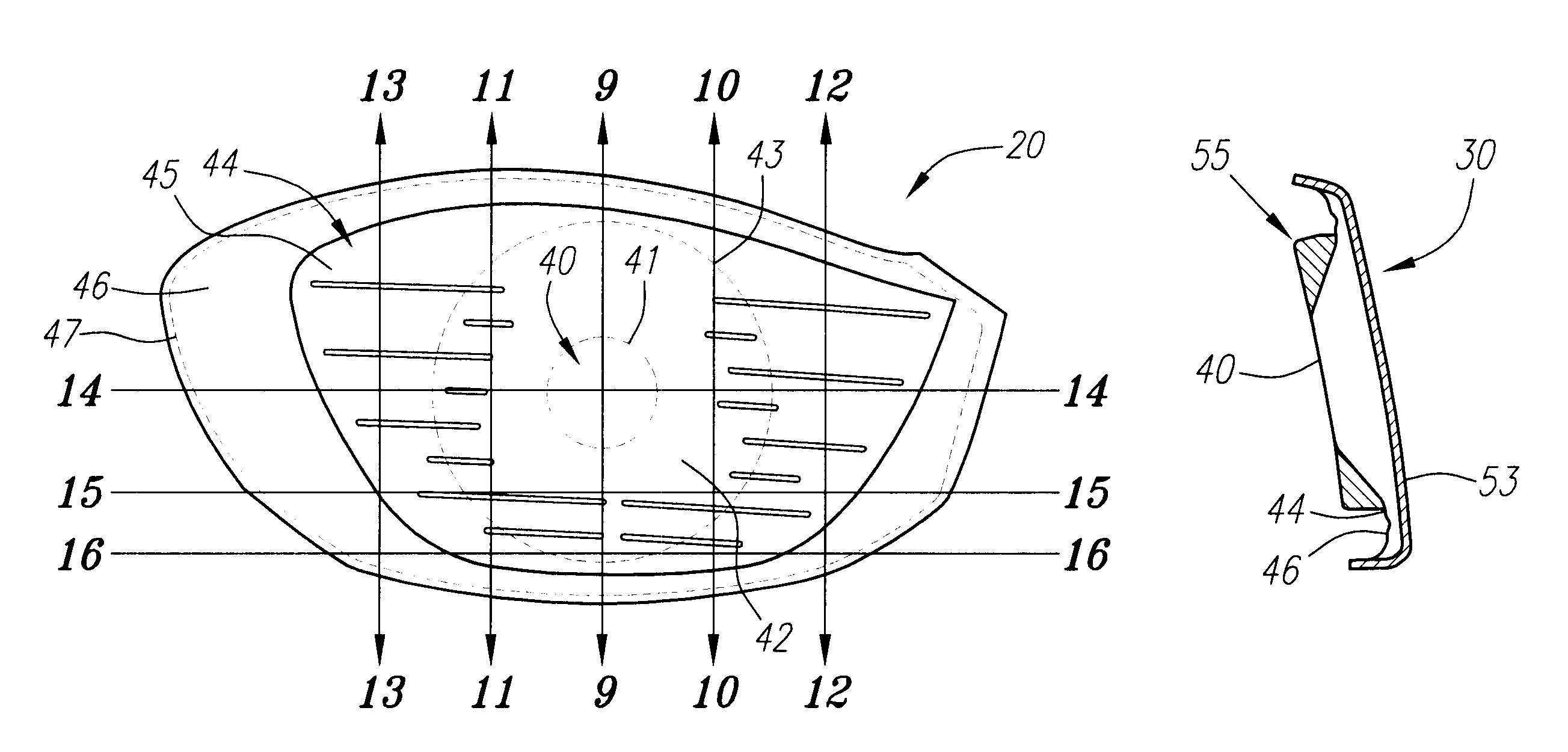

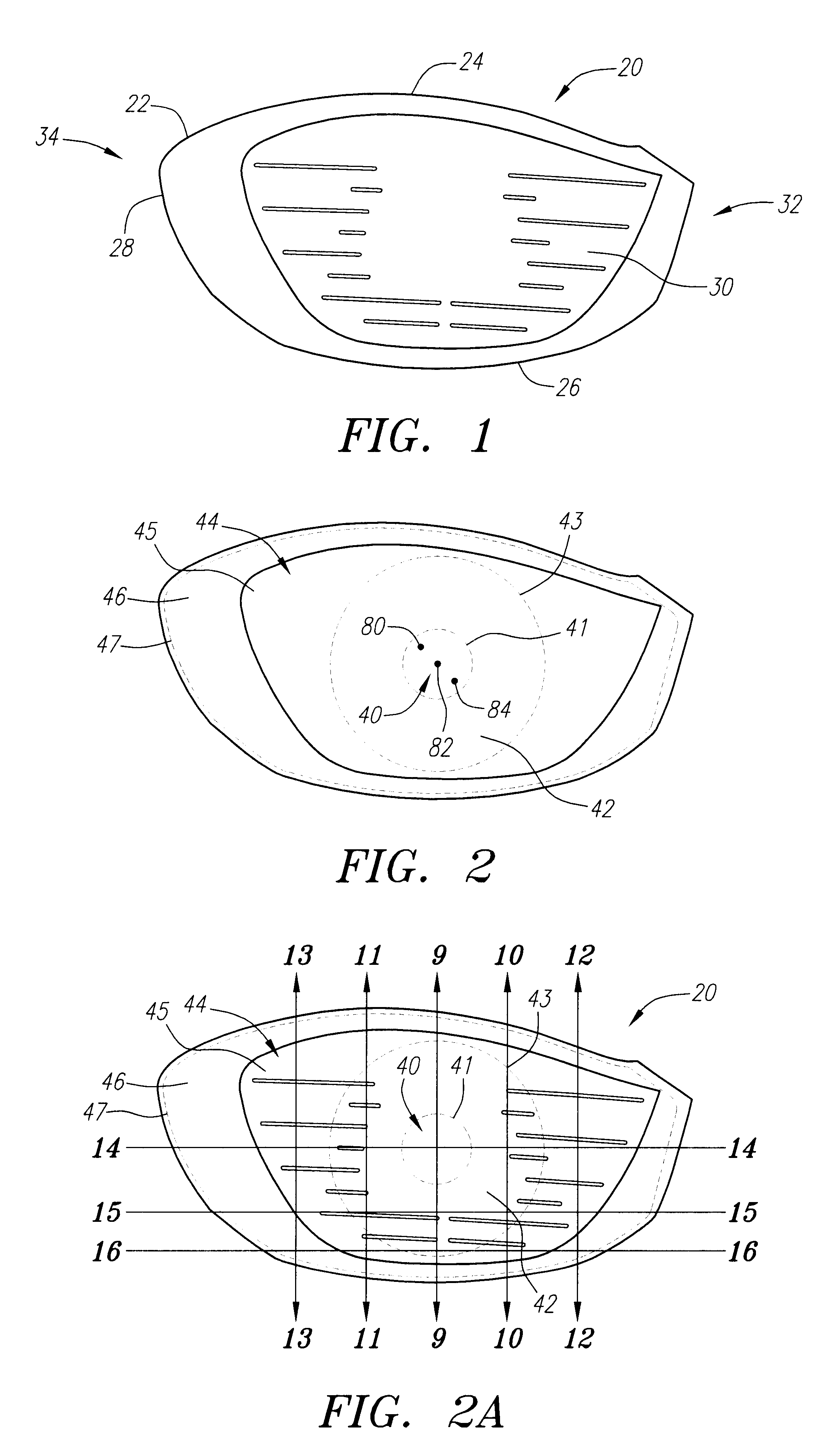

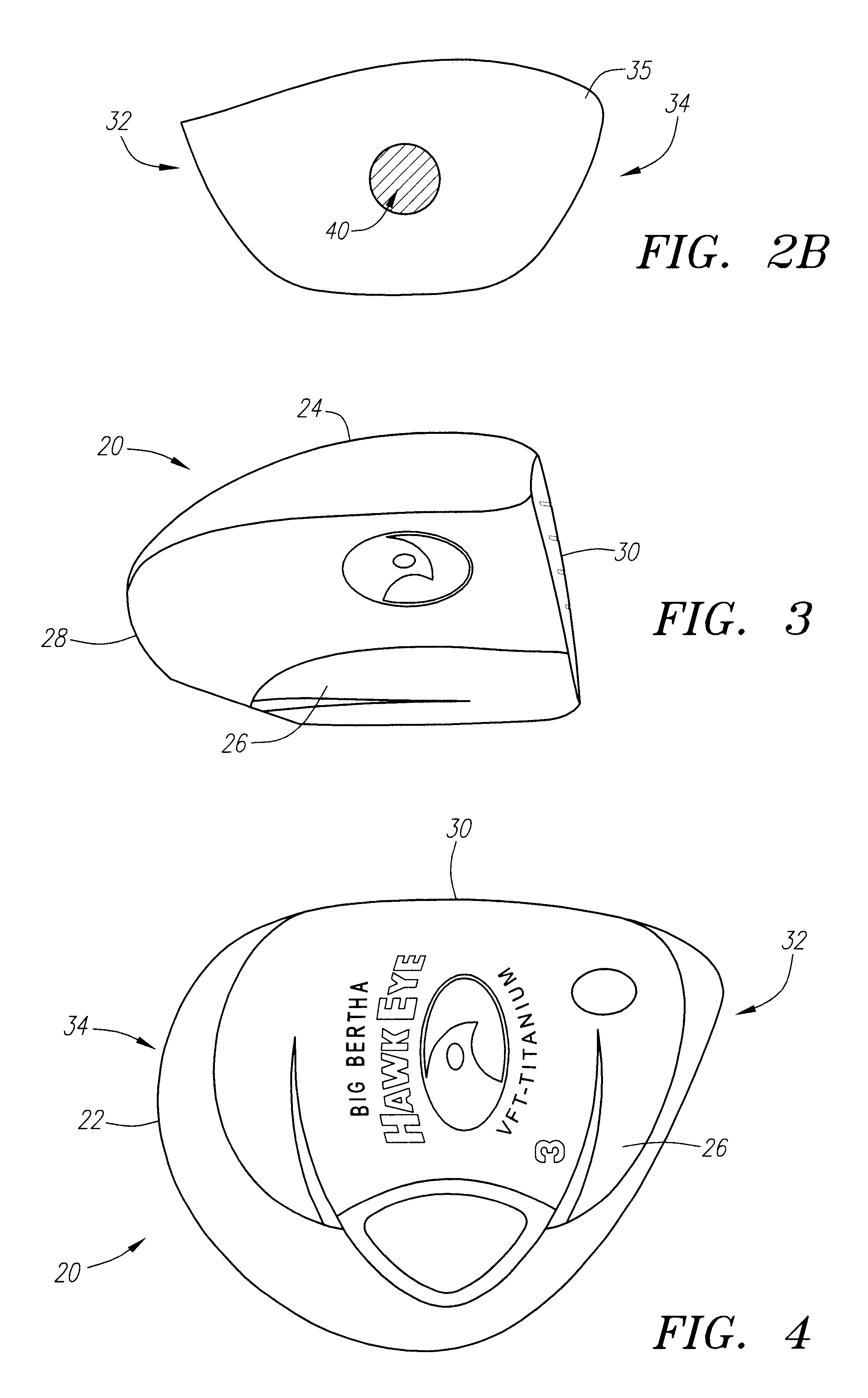

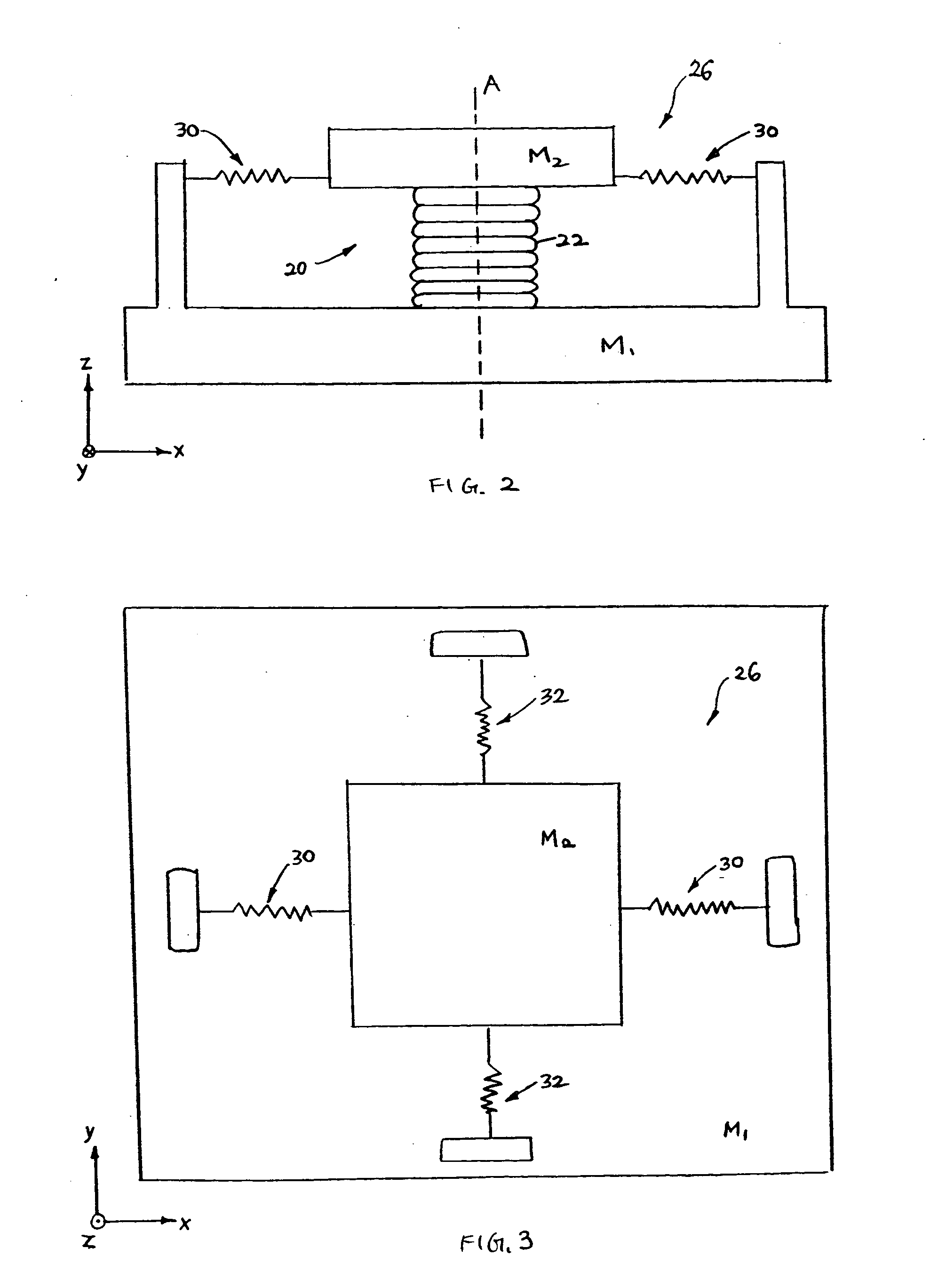

Golf club striking plate with vibration attenuation

A golf club head (20) having a striking plate (30) and means for vibration attenuation (35) disposed thereon. The vibration attenuation means (35) may be composed of a low-density. metallic, a polymer material, or a filled polymer material. The striking plate (30) may have a uniform thickness or a variable thickness. The overall thickness of the striking plate (30) and vibration attenuation means (35) is preferably in the range of 0.100 inch to 0.250 inch. The striking plate (30) is preferably composed of steel or titanium.

Owner:TOPGOLF CALLAWAY BRANDS CORP

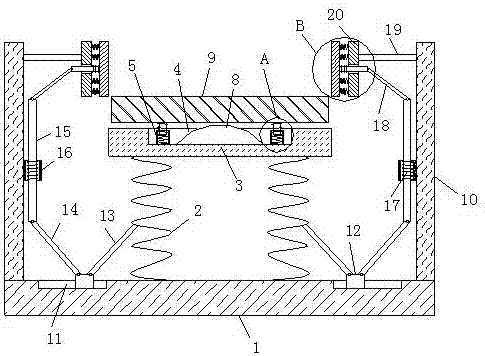

Vibrating screen

InactiveCN104646281AImplement location changesThe role of control screeningSievingScreeningVibration attenuationVibration amplitude

The invention relates to a vibrating screen. The vibrating screen comprises a foundation support, a horizontal vibration attenuation mechanism, a vertical supporting mechanism, a horizontal guide rail, a bracket and a motor, wherein the foundation support is provided with a horizontal supporting part and vertical supporting parts, and the vertical supporting parts are arranged on two ends of the horizontal supporting part; the horizontal vibration attenuation mechanism is connected with the vertical supporting parts of the foundation support; the vertical supporting mechanism is connected with the horizontal supporting part of the foundation support; the horizontal guide rail is respectively connected with the vertical supporting parts and the horizontal supporting part of the foundation support through the horizontal vibration attenuation mechanism and the vertical supporting mechanism; the bracket is used for fixing a screen assembly, and the bracket can be movably fixed on the horizontal guide rail through a slide block; the motor is installed on the foundation support, and a rotating shaft of the motor is connected with the slide block through a crank linkage mechanism. According to the vibrating screen of the invention, a spring is uniformly stressed, the service life is prolonged, and the vibration amplitude of the screen assembly can be conveniently adjusted.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

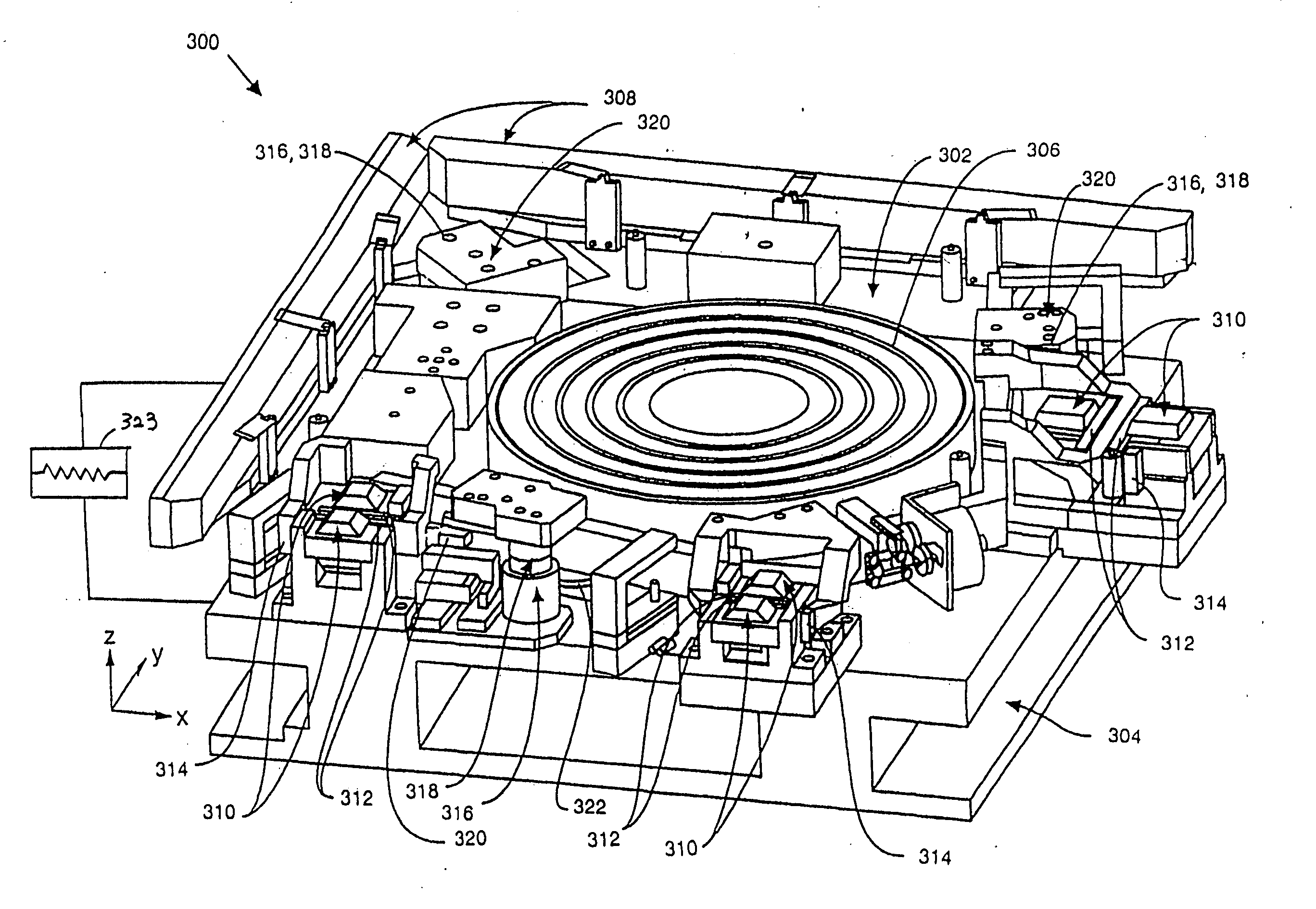

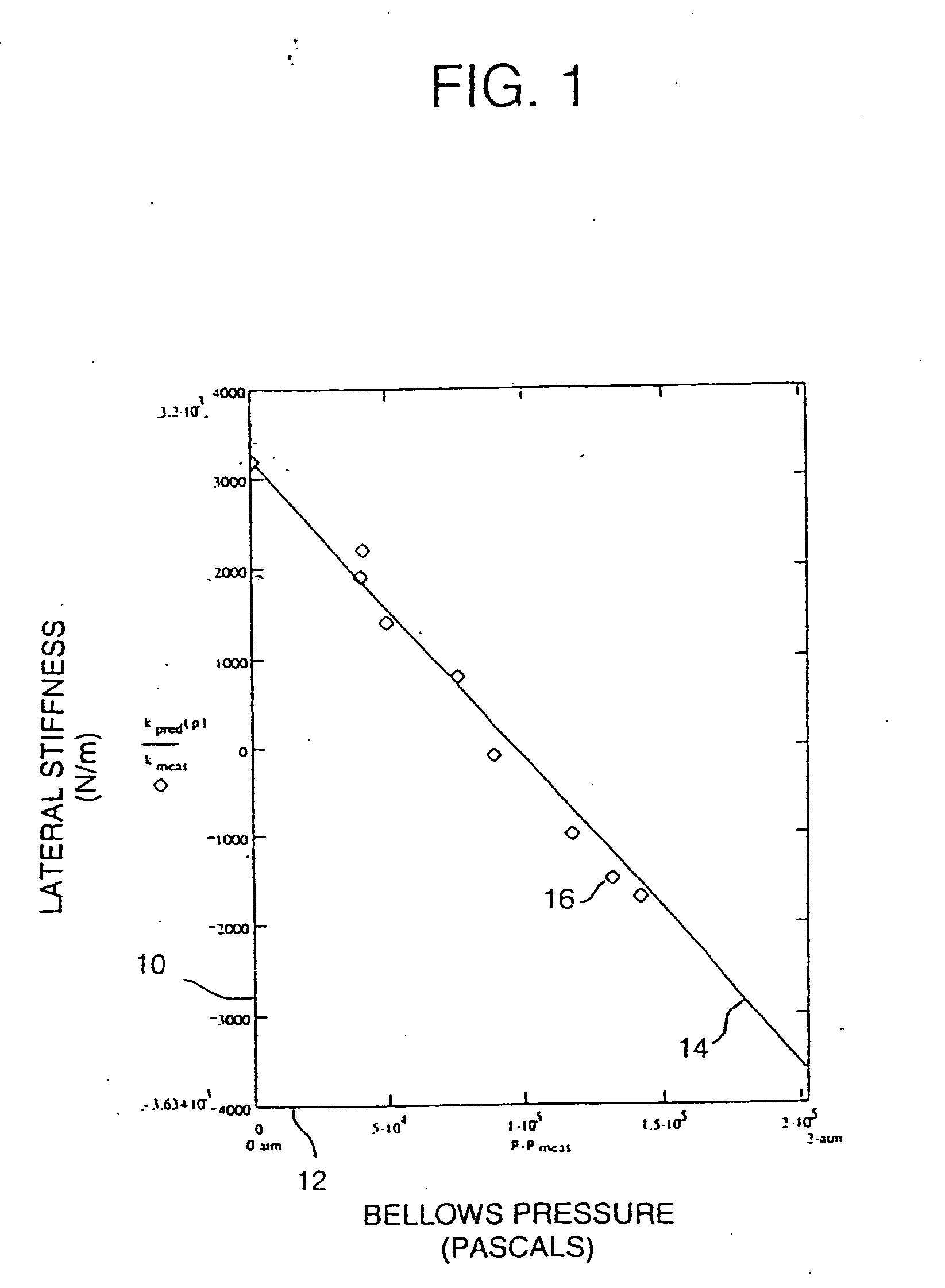

Bellows with spring anti-gravity device

ActiveUS20060060791A1Avoid spreadingIncrease lateral stiffnessElectric discharge tubesThermometers using material expansion/contactionVibration attenuationUltrasound attenuation

Embodiments of the present invention are directed to apparatus and methods of attenuating vibration, particularly for modern stepper machines and other types of vibration sensitive equipment. The attenuation system exhibits good vibration attenuation in the axial or support direction, and exhibits low or substantially zero lateral stiffness to prevent transmission of any vibrations between any of various portions of the machine. In one embodiment, an apparatus for attenuating transmission of lateral vibration between a first mass and a second mass comprises a vibration attenuation device including at least one bellows oriented along a support axis. The at least one bellows is connected between the first mass and the second mass and has an interior volume pressurized with a fluid to an internal fluid pressure which is greater than a zero-stiffness pressure such that the vibration attenuation device exhibits a negative lateral stiffness. A positive stiffness device is coupled between the first mass and the second mass. The positive stiffness device has a positive lateral stiffness which may be substantially equal to or greater than the negative lateral stiffness in magnitude.

Owner:NIKON CORP

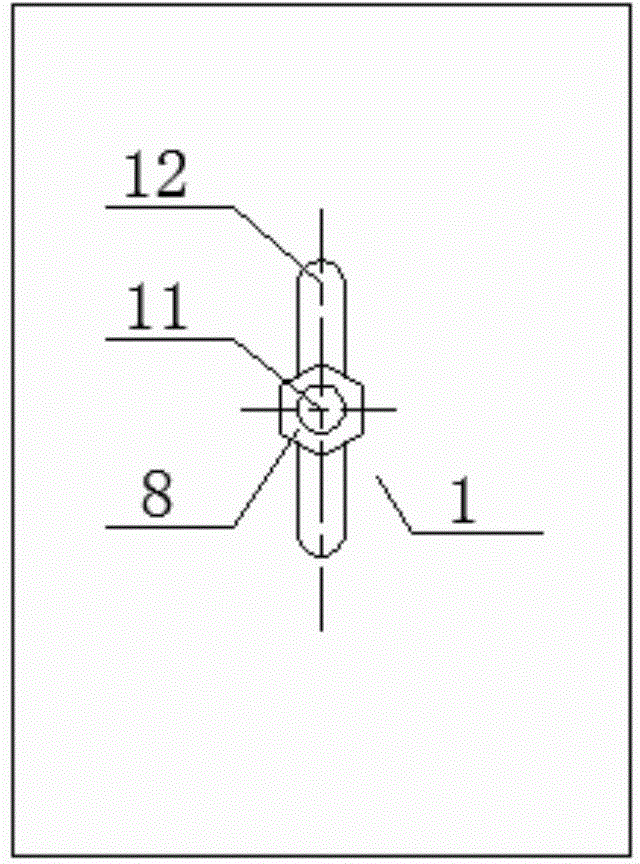

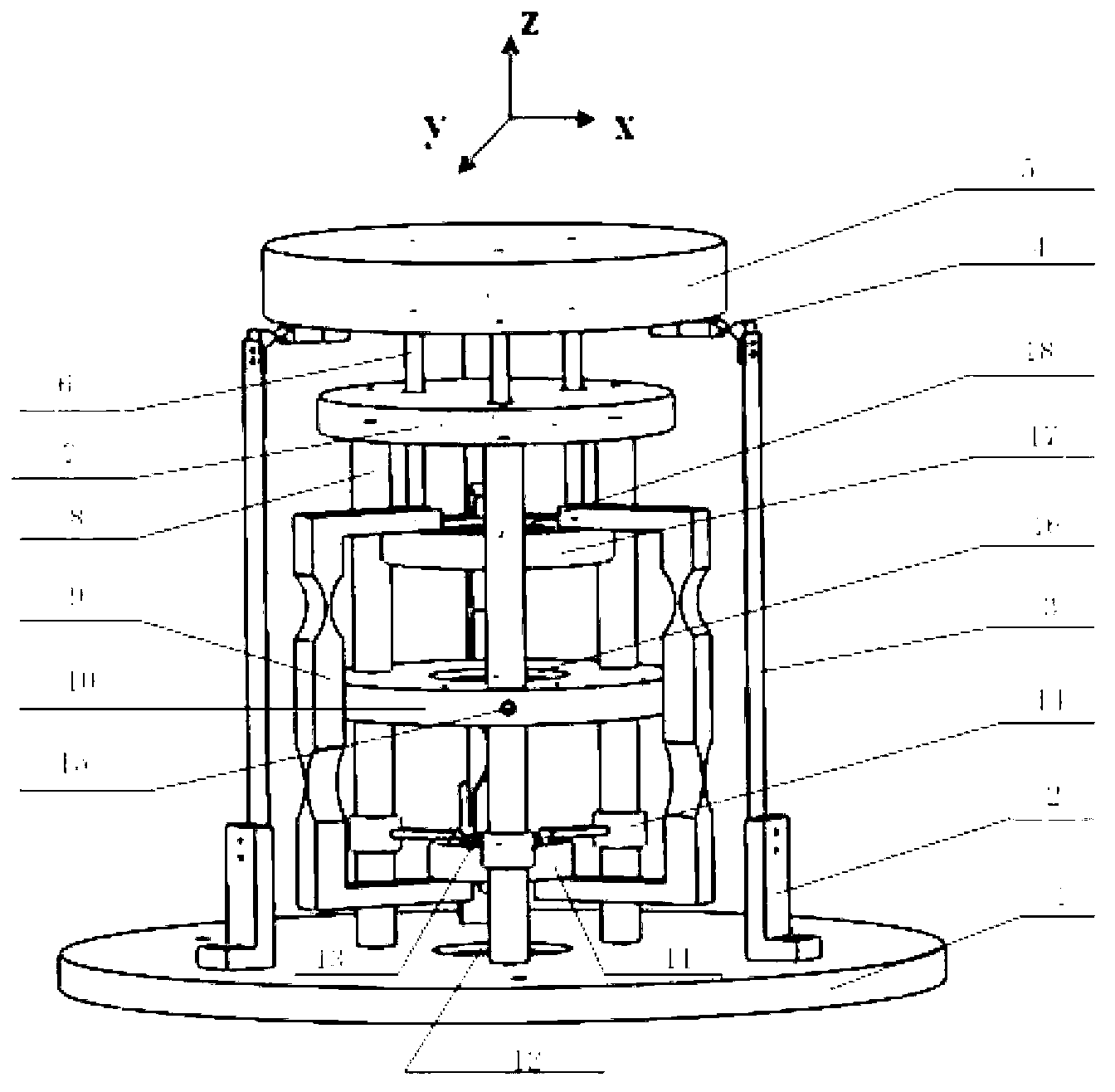

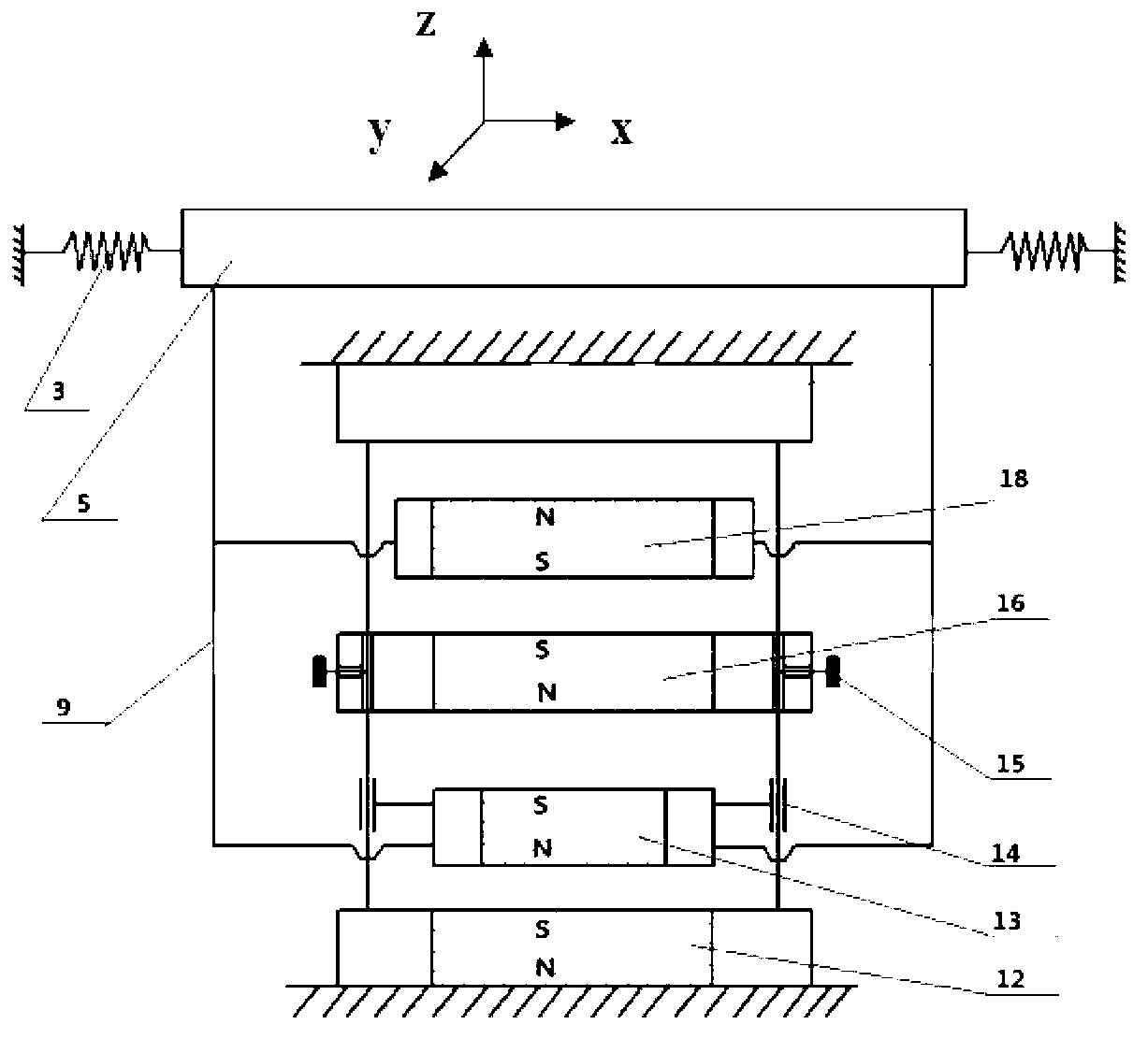

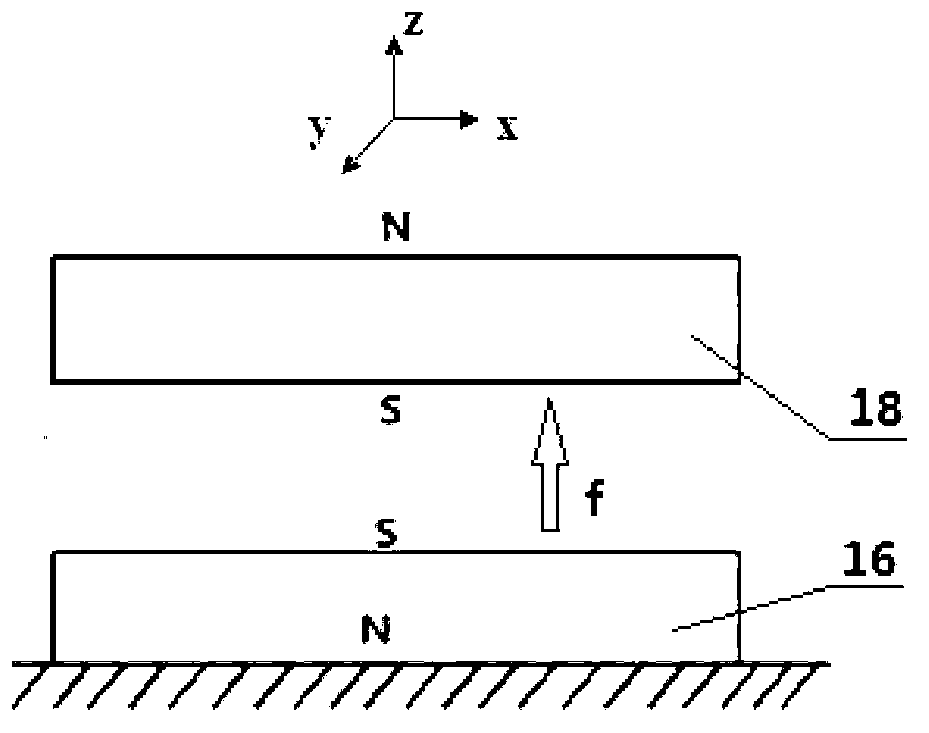

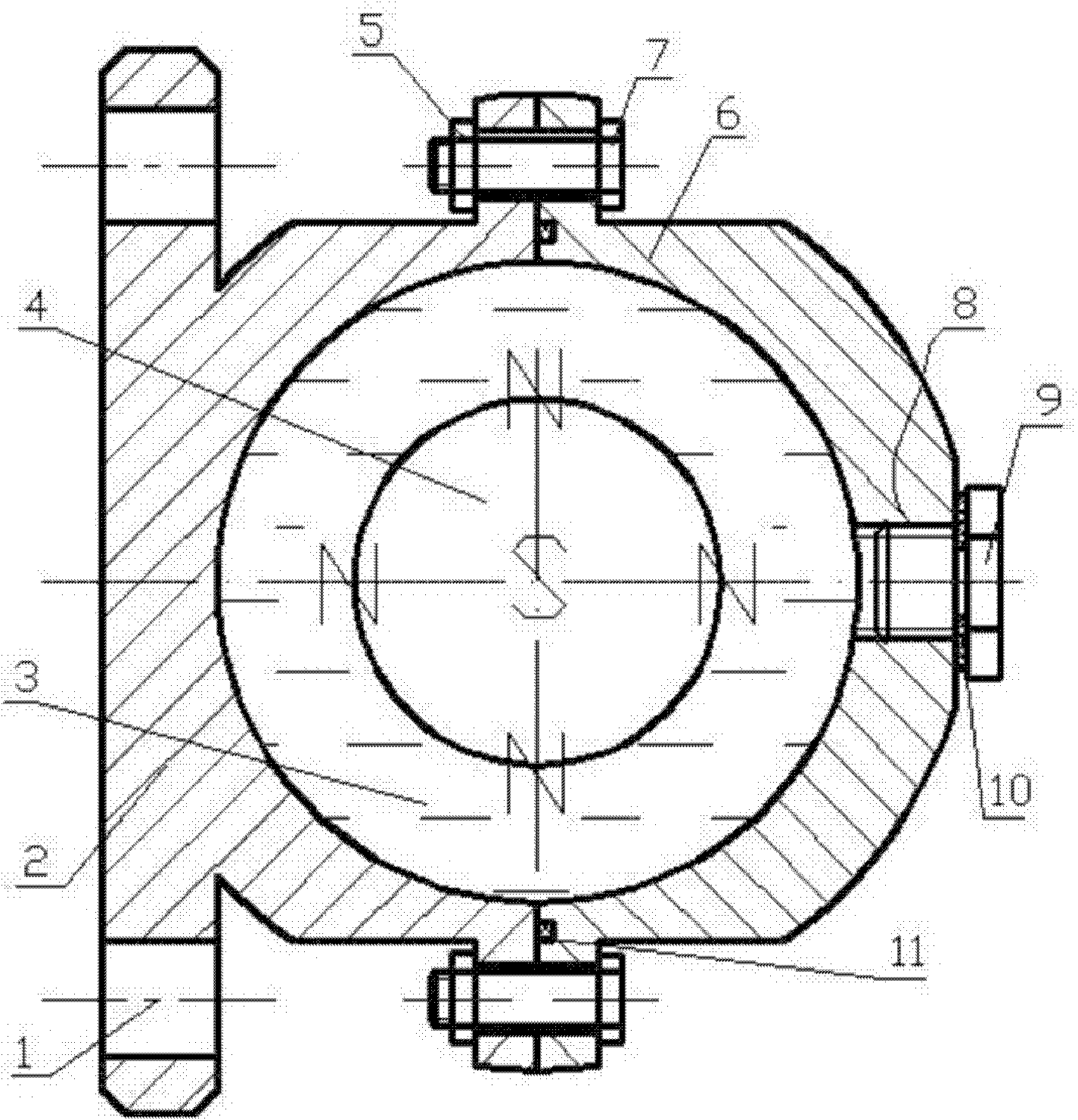

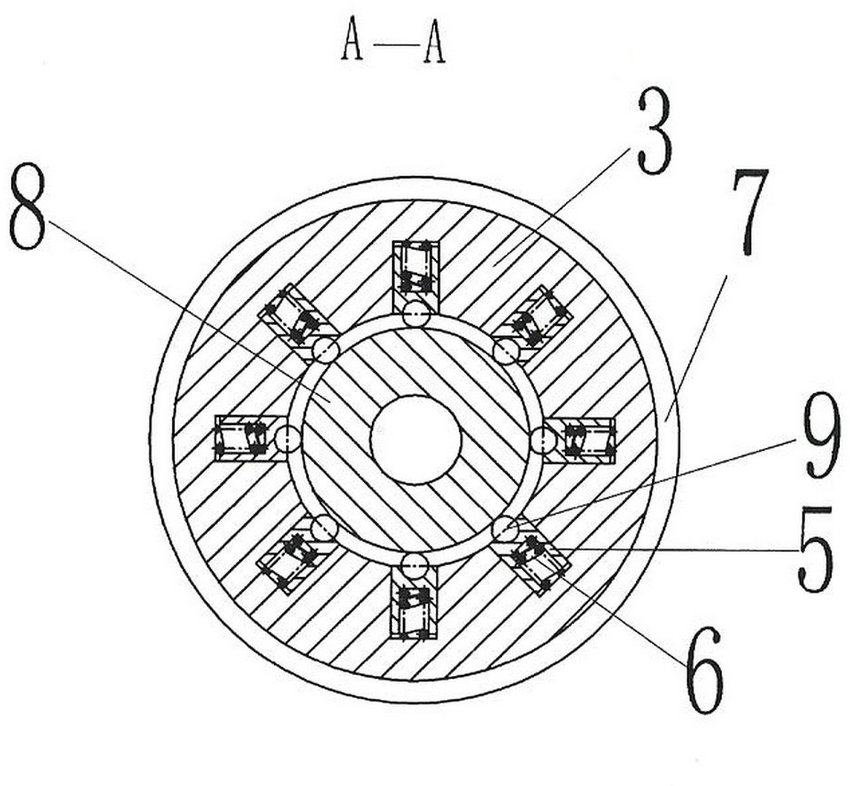

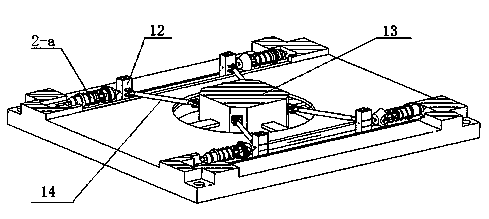

Three-degree-of-freedom ultralow frequency vibration absorber

ActiveCN103307195AReduce vibrationLower natural frequencyNon-rotating vibration suppressionVibration attenuationThree degrees of freedom

The invention provides a three-degree-of-freedom ultralow frequency vibration absorber which has a compact structure and belongs to the field of accurate vibration attenuation. The vibration absorber respectively utilizes the principle that the positive and negative rigidities are connected in parallel in three degrees of freedom to realize ultralow frequency vibration attenuation, greatly reduces the rigidity of the system on the premise of ensuring the bearing capacity of the system, and realizes the ultralow inherent frequency. The three-degree-of-freedom ultralow frequency vibration absorber adopts the manner that the magnetic positive rigidity and the magnetic negative rigidity are connected in parallel in the z direction and the manner that a flat spring and the magnetic negative rigidity are connected in parallel in the x direction and y direction, so that the integral structure is more compact, the ultralow inherent frequency is provided, excellent vibration attenuation effect is provided for medium-high frequency vibration interference, the low frequency vibration and the ultralow frequency vibration are effectively restrained, and the three-degree-of-freedom ultralow frequency vibration absorber is applicable to the accurate processing equipment and measuring equipment sensitive to vibrations.

Owner:HUAZHONG UNIV OF SCI & TECH

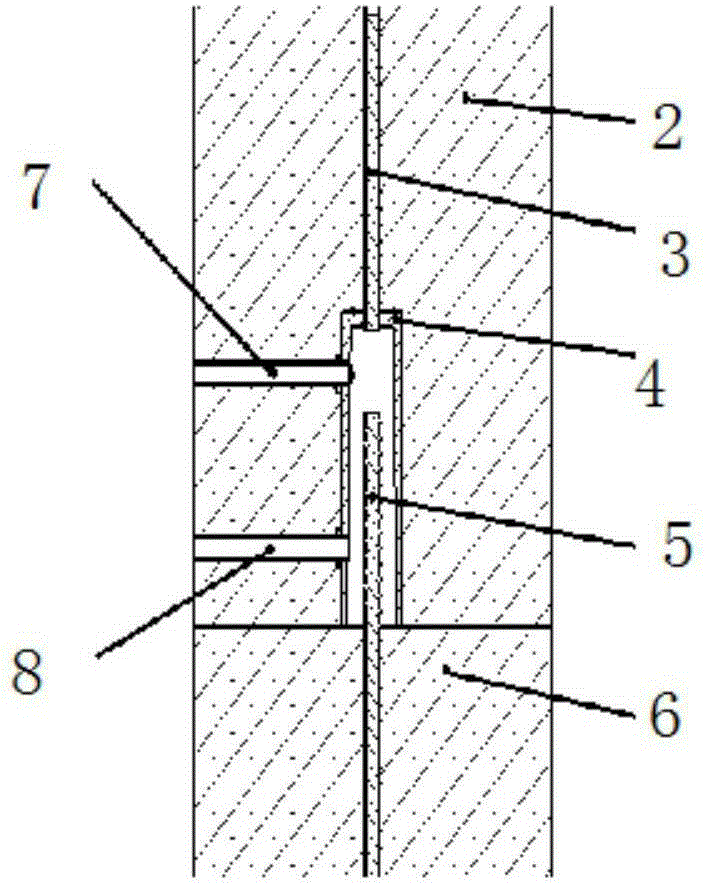

Method and detector for detecting grouting fullness of reinforcement sleeve of prefabricated concrete structure

ActiveCN105223344AQuality improvementMeet control needsUsing mechanical meansMaterial testing goodsVibration attenuationReinforced concrete

The invention relates to the technical field of quality detection of reinforced concrete, particularly to a method and a detector for detecting the grouting fullness of a reinforcement sleeve of a prefabricated concrete structure. According to the method and the detector for detecting the grouting fullness of the reinforcement sleeve of the prefabricated concrete structure, an MCU (microprogrammed control unit) transmits signals to a human-computer interaction unit and is connected with a signal receiving and processing device, a signal excitation device and a power supply respectively, the signal excitation device is connected with a lead of a damping vibration sensor, and the damping vibration sensor generates damping vibration waves after receiving excitation signals and transmits the damping vibration waves to the MCU. With the adoption of the detector and the detecting method, the damping vibration attenuation law of the sensor as well as the change relationship of the height of a concrete grouting material and the sensor can be distinguished, and whether the grouting material is full or not or whether the grouting fullness is qualified or not after solidification is accurately judged in a construction process.

Owner:BEIJING ZBL SCI & TECH

Spraying type polyurethane-carbamide damping vibration attenuation noise-reduction protection material

InactiveCN101665654ADo not cause harmNo flow phenomenonPolyurea/polyurethane coatingsEngineeringNoise reduction

The invention discloses a spraying type polyurethane-carbamide damping vibration attenuation noise-reduction protection material consisting of isopyknic components A and R. The isopyknic components Aand R are mixed by high-pressure impaction mixing equipment and then sprayed on a concrete substrate so as to instantly form a damping vibration attenuation noise-reduction protection coating layer with excellent property; the component A is a semi-prepolymer generated from isocyanate and polymer polyalcohol; and the component R is a mixture of end ammonia, polyether polyol, a diamines chain extender and an addition agent. The spraying type polyurethane-carbamide damping vibration attenuation noise-reduction protection material has the advantages of fast curing speed, good viscoelasticity, high intensity, excellent damping vibration attenuation noise-reduction property, and the like and can efficiently construct under a complex and severe environment condition.

Owner:QINGDAO SHAMU INT TRADE

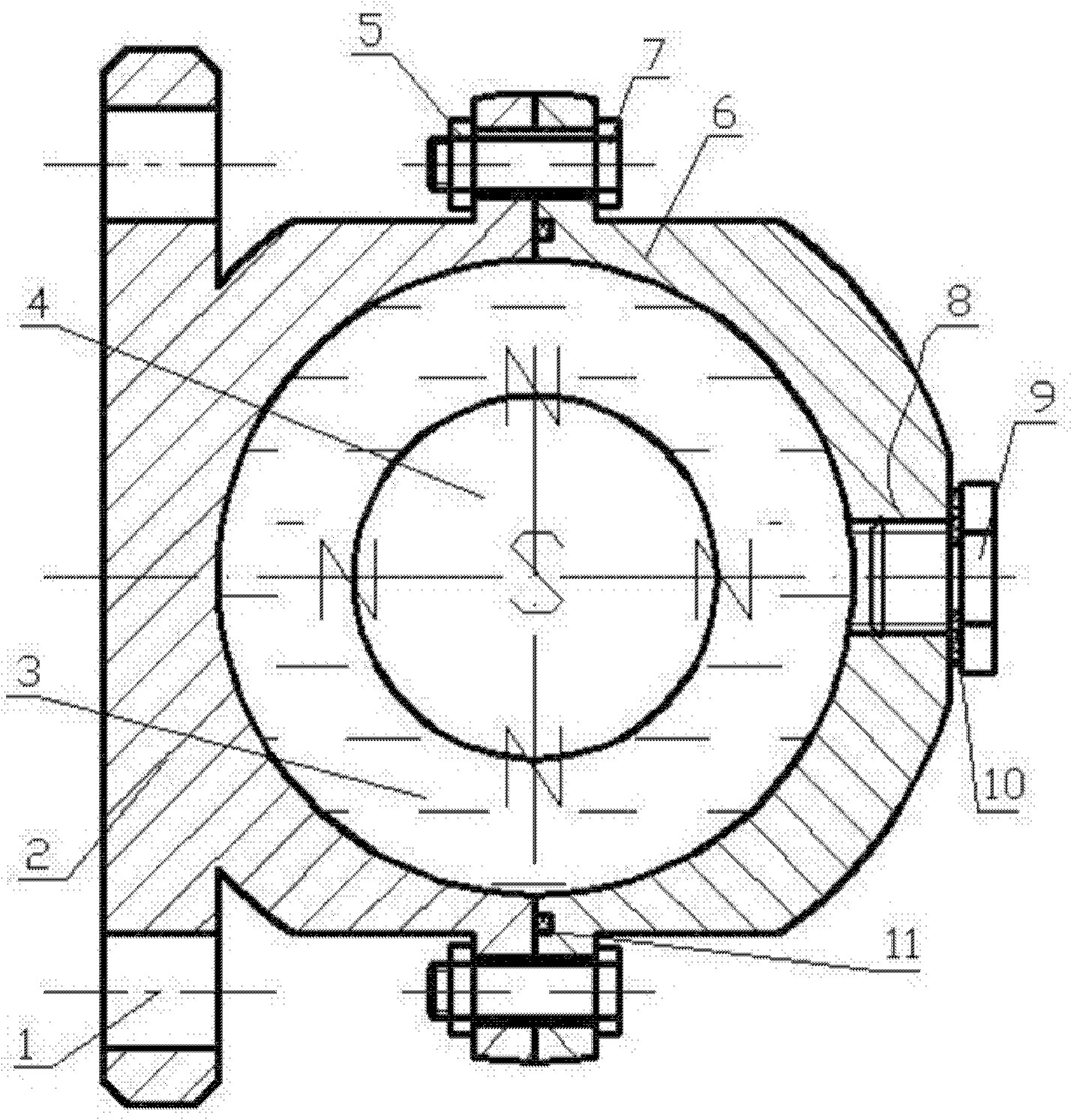

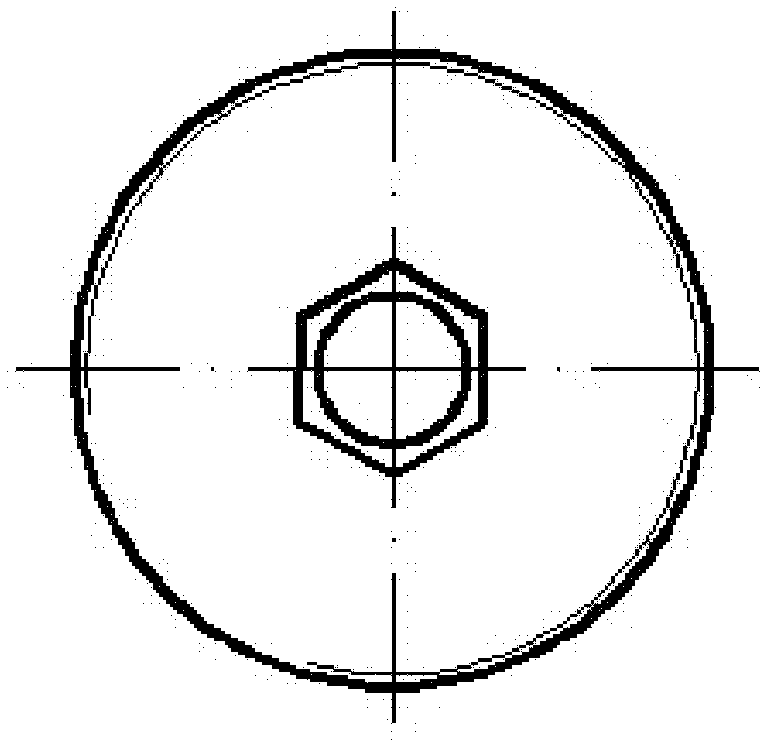

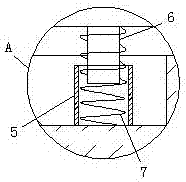

Magnetic liquid damping vibration attenuating device

InactiveCN102494070AWith damping effectGood vibration reduction effectMagnetic springsVibration attenuationEngineering

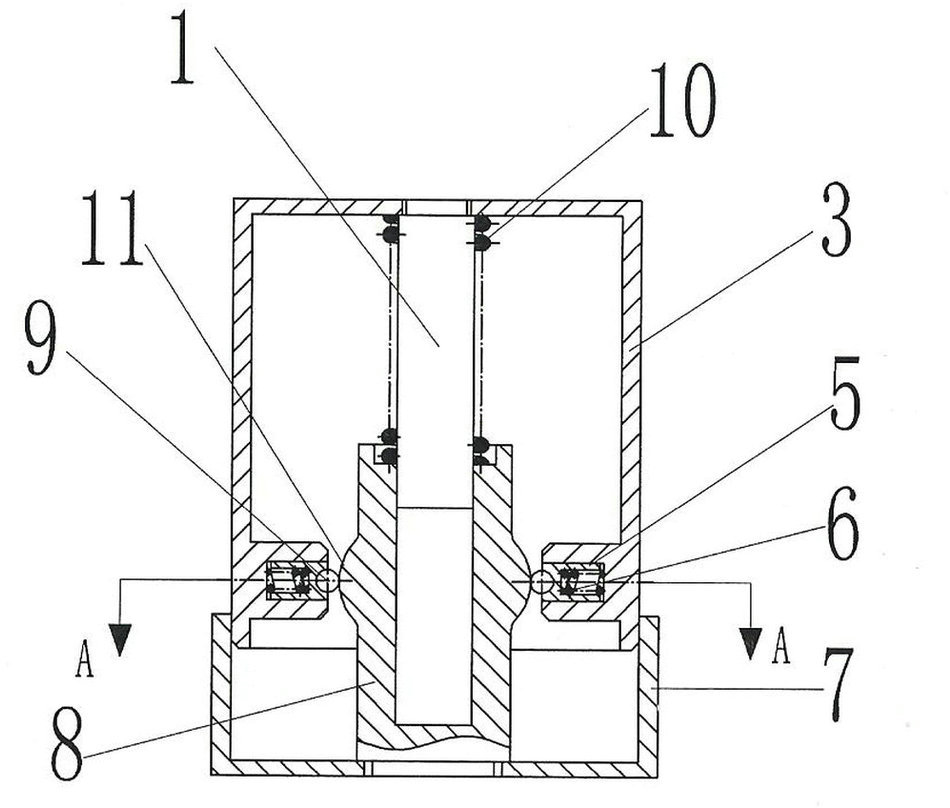

The invention discloses a magnetic liquid damping vibration attenuating device which is suitable for vibration attenuation for longer objects in a spacecraft and used for solving the problem of vibration attenuation in the spacecraft. The device comprises a non-magnet conductive shell (2), magnetic liquid (3), a permanent magnet (4), nuts (5), an end cover (6), bolts (7), screws (9), a sealing gasket (10) and an O-shaped sealing ring (11); the parts are connected as follows: the permanent magnet (4) is arranged in a cavity of the non-magnet conductive shell (2); the end cover (6) with the O-shaped sealing ring (11) is fixed on the end surface of the open end of the non-magnet conductive shell (2) by using the bolts (7) and the nuts (5); the cavity of the non-magnet conductive shell is full of magnetic liquid through a threaded hole and is sealed by using the screws and the sealing gasket. A cavity formed by the non-magnet conductive shell (2) and the end cover (6) is a ball-shaped cavity. The non-magnet conductive shell (2) and the permanent magnet (4) adopted by the device are in circular ball shapes, therefore, the magnetic liquid damping vibration attenuating device can be used for attenuating the vibration in any direction and good in vibration attenuating effect.

Owner:BEIJING JIAOTONG UNIV

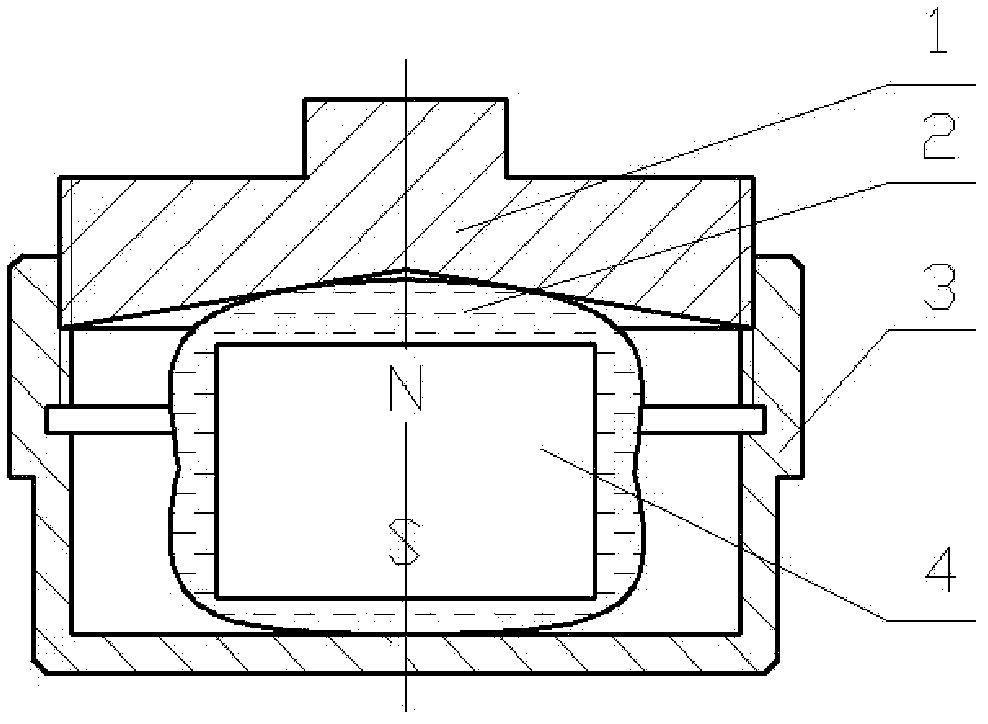

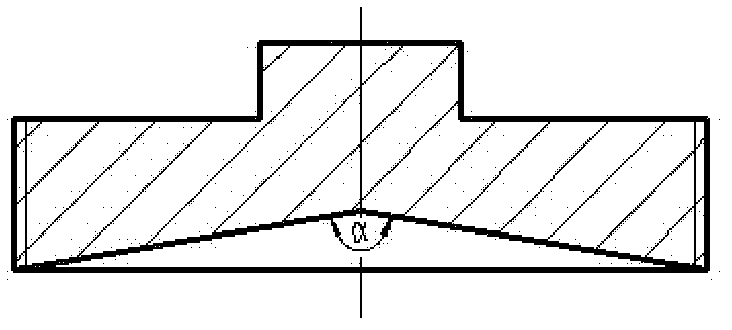

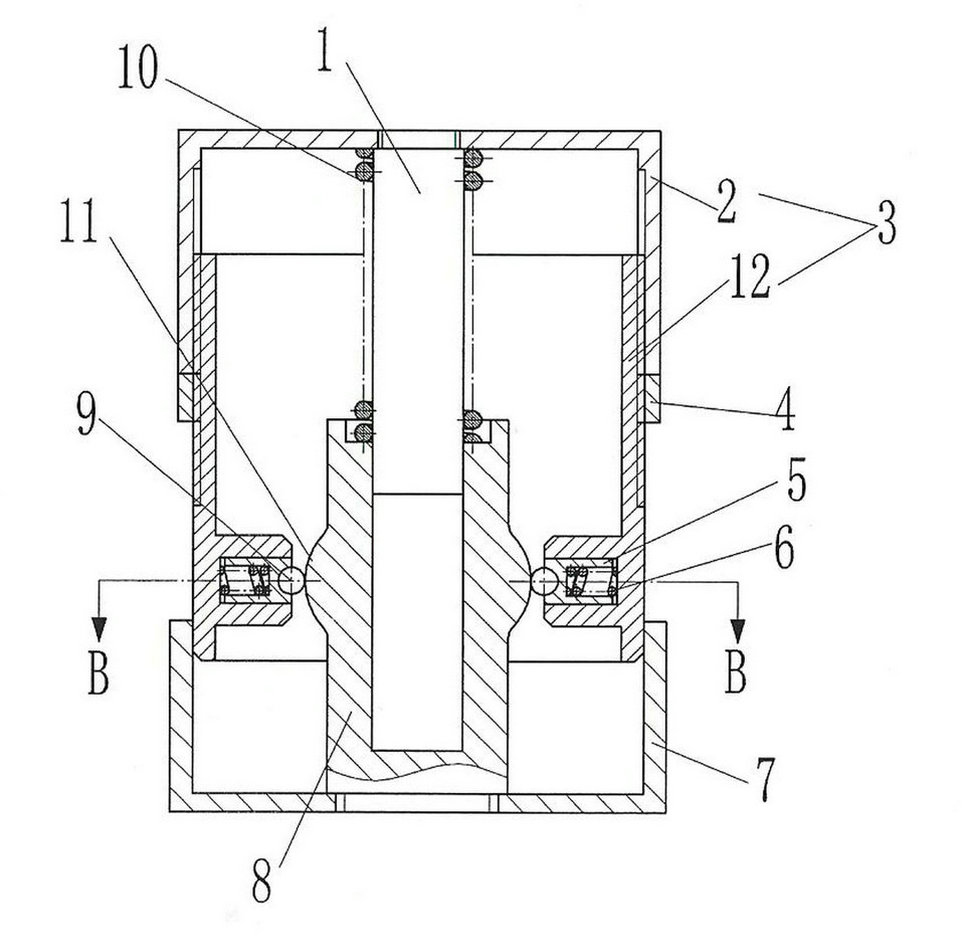

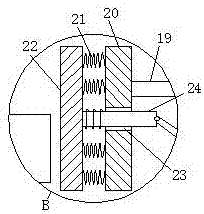

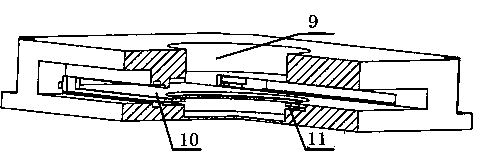

Magnetic liquid damping vibration attenuation device

InactiveCN102213285AGood vibration reduction effectMagnetic springsVibration attenuationMagnetic liquids

The invention discloses a magnetic liquid damping vibration attenuation device which is suitable for longer object vibration attenuation in a spacecraft and can be used for solving the vibration attenuation problem of longer object vibration attenuation in the spacecraft. The magnetic liquid damping vibration attenuation device comprises an end closure (1), a magnetic liquid (2), a non-magnetic-conductive shell (3) and a permanent magnet (4), wherein the permanent magnet (4) is installed in the cavity of the non-magnetic-conductive shell (3), the magnetic liquid (2) is injected into the cavity of the non-magnetic-conductive shell (3) and the end closure (1) is used for sealing. The device is very sensitive to the inertia force, the adopted end closure (1) with threads is provided with a taper angle, the taper angle is 140degrees -170degrees, the depth of the end closure screwed into the non-magnetic-conductive shell (3) can be adjusted so as to regulate the pressure applied to the magnetic liquid by the end closure (1), the permanent magnet is a cylinder, the vibration attenuation effect is good for the vibration with low frequency, small displacement and small acceleration characteristics.

Owner:BEIJING JIAOTONG UNIV

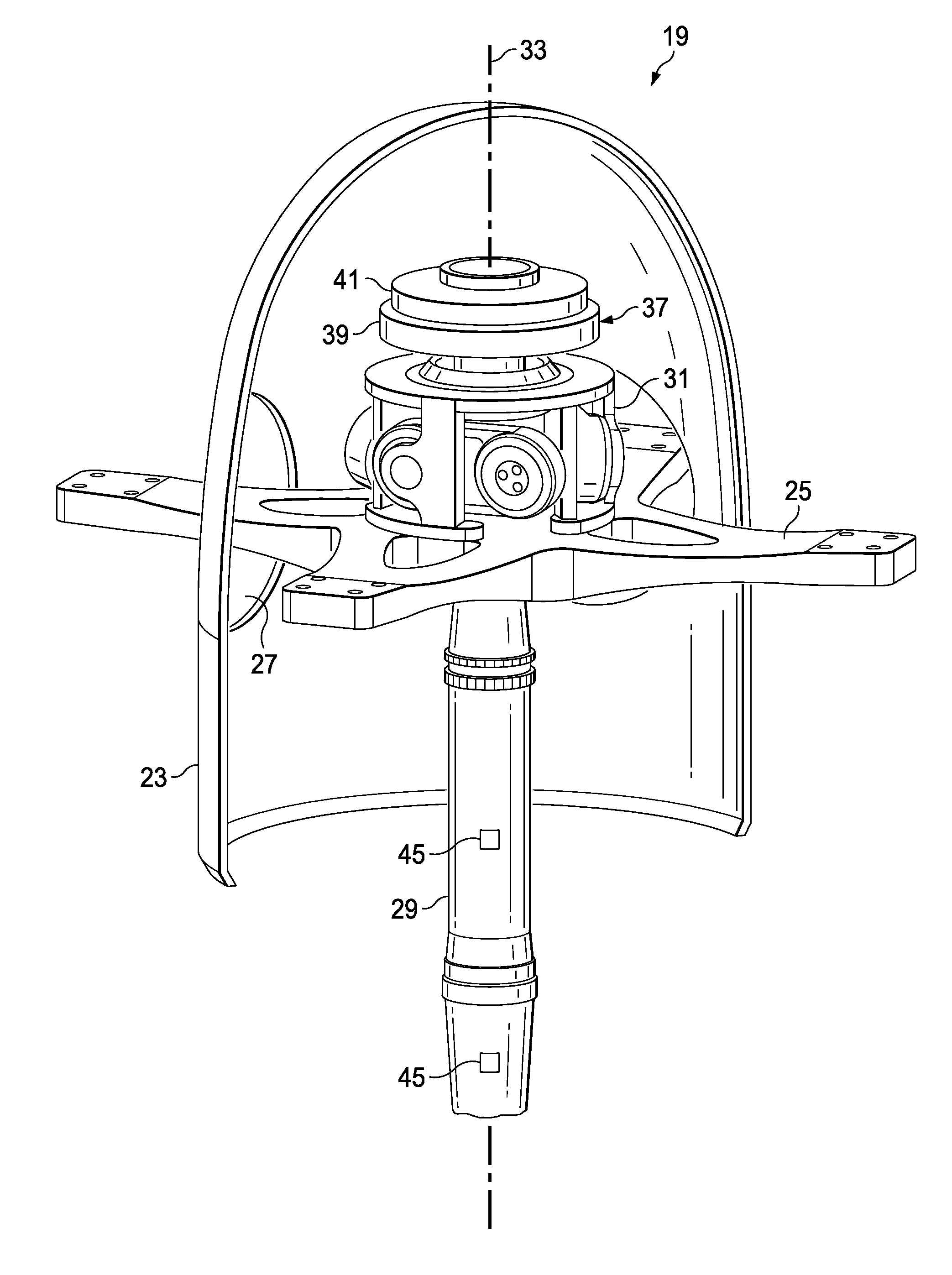

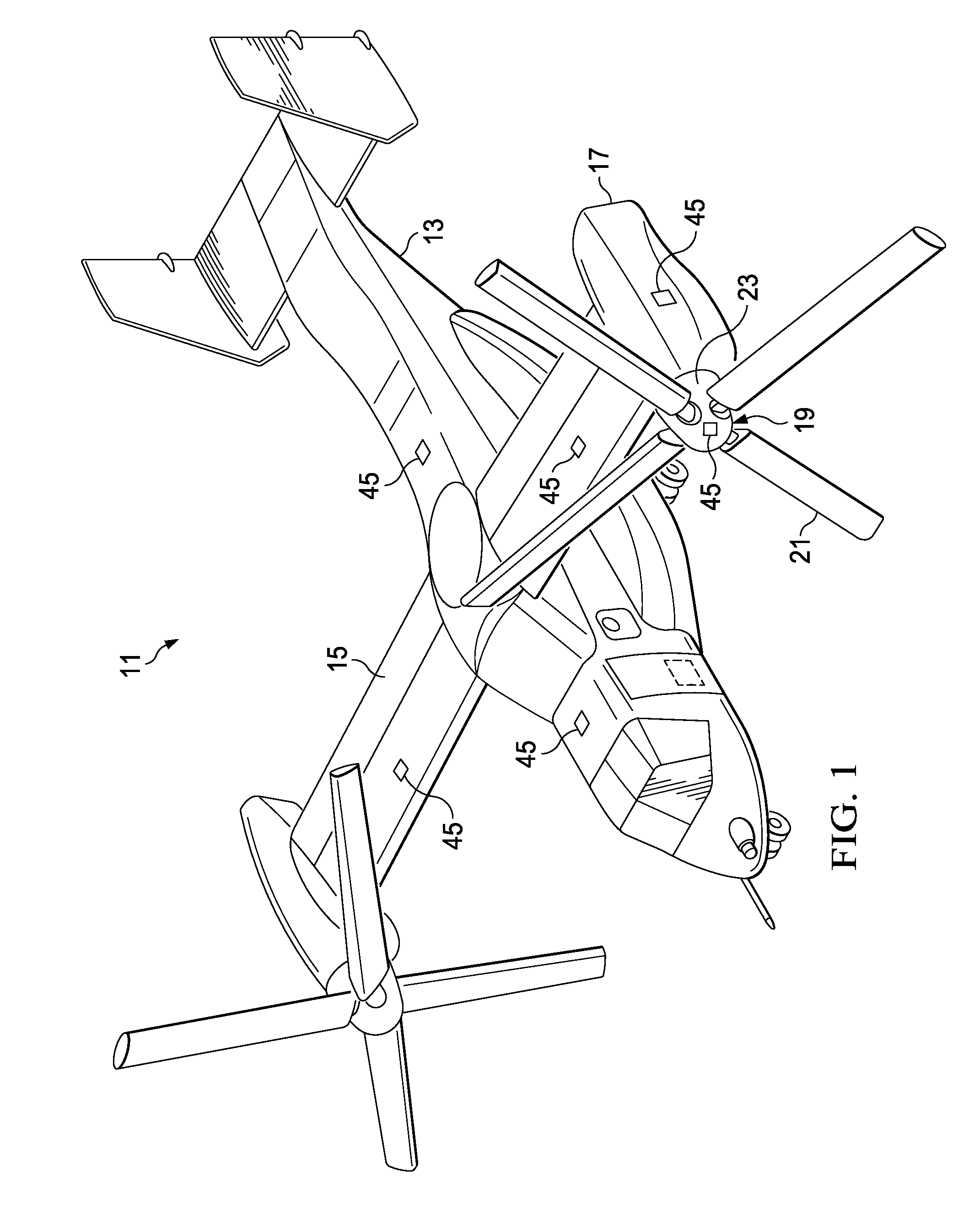

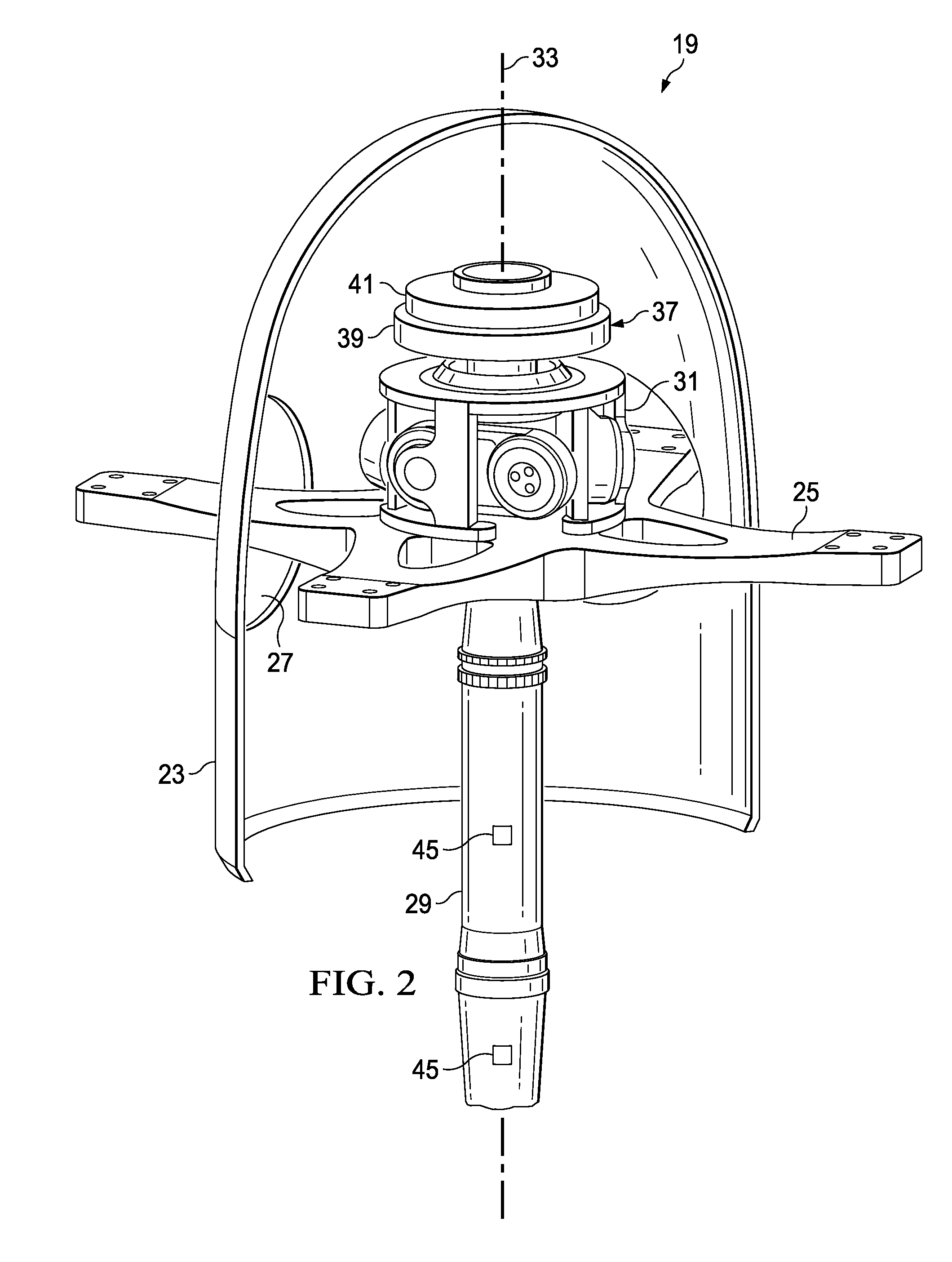

Active vibration control system with non-concentric revolving masses

ActiveUS20150203196A1Digital data processing detailsNavigation instrumentsVibration attenuationControl system

A vibration control system for a rotor hub provides vibration attenuation in an aircraft by reducing the magnitude of rotor induced vibratory. The system can include a force generating device attached to a rotor hub which rotates along with the rotor at the rotational speed of the rotor. Vibratory shear force is generated by rotating unbalanced weights each about an axis non-concentric with the rotor hub axis at high speed to create large centrifugal forces. The rotational speed of the weights can be a multiple of the rotor rotational speed to create shear forces for canceling rotor induced vibrations. The amplitude of the generated shear force is controlled by indexing the positions of the unbalanced weights relative to each other, while the phase of the shear force is adjusted by equally phasing each weight relative to the rotor.

Owner:BELL HELICOPTER TEXTRON INC

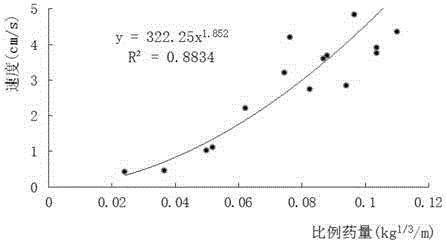

Method for forecasting rock blasting damage depth of nuclear power projects

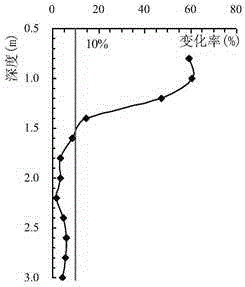

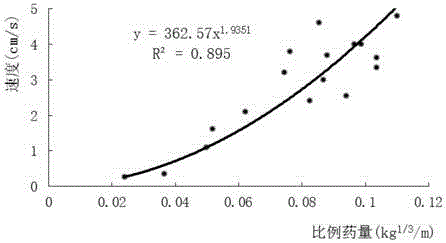

ActiveCN106326546AIncrease workloadReduce the number of field trialsGeometric CADBlastingUltrasound attenuationVibration attenuation

The invention relates to a method for forecasting rock blasting damage depth of nuclear power projects. The method comprises the following steps of performing the blasting vibration testing to determine a site vibration attenuation rule; performing the sound wave testing to primarily determine the rock damage depth; performing the finite element numerical simulation, and calculating the rock particle vibration speed and rock blasting damage depth; respectively establishing the change rules of the particle peak vibration speed (1m away from a blasting source R) along with the rock blasting damage depth under the step blasting and pre-fracturing blasting types; substituting the explosive charging quantity Q0 of an actual section into the site blasting vibration attenuation rule and the change rules of the particle peak vibration speed along with the rock blasting damage depth, so as to forecast the blasting damage depth caused by the explosive charging quantity. The method has the characteristics that one part of site sound wave testing can be replaced with the numerical simulation, the site testing frequency is reduced, the field workload is reduced, and the construction efficiency is improved; the site blasting group hole effect is comprehensively considered, the forecasting is accurate, and the operation is convenient and rapid.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

Buffer-type suspension-type particle tuning quality damper

InactiveCN102817423AIncrease consumptionImprove energy efficiencyShock proofingVibration attenuationEngineering

The invention relates to a buffer-type suspension-type particle tuning quality damper. The damper comprises a damping cavity, particle swarms, a buffer material, a steel cable and a limiting device. The damping cavity is rectangular or cylindrical, the damping cavity can be a single one or a plurality of damping cavities can be arranged horizontally or vertically, a layer of particle swarms is laid on a single cavity, an embedded part arranged inside a structure is hinged with the damping cavity through the steel cable, and the limiting device is arranged outside the damper so as to avoid damage of the structure due to excessive vibration. Under the action of wind or / and earthquakes, the device can vibrate along multiple directions horizontally, on one hand, through the natural vibration frequency of the tuning structure, on the other hand, through rolling, sliding, friction and collision transfer of the particle swarms and kinetic energy of a dissipative structure, after the buffer material is added, the energy dissipated by the collision is increased. The buffer material is added in the damping cavity, the damping cavity is suspended by using the steel cable, the vibration attenuation effect is better than that of a device with no buffer material, and the device provides vibration attenuation effects in more directions than a suspending device with a unidirectional hinge.

Owner:TONGJI UNIV

Rubber composition as rubber pad under rail

InactiveCN1368518AImprove mechanical propertiesImprove anti-aging propertiesVibration attenuationPolymer science

A composite rubber used as rubbe pad under rail contains matrix rubber 100 portions, promoter 1-5 portions, antiageing agent 1-3 portions, nanometre zinc oxide powder 2-10 portions, sulfurizing agent, 0.2-1.5 portions carbon black 30-60 portions, inorganic filler 30-60 portions, tetra-acicular zinc oxide eshisker 0.5-10 portions and coupling agent 0.2-5 portions. The said matrix rubber consists of natural rubber, styrene-butadiene rubber and cis-1,4-polybutadiene rubber. Its advantages are high static rigidity (50-70 mN / m), tensile strength, antiwear performance, vibration attenuation coefficient and noise-reducing effect.

Owner:RENTAI IND CHENGDU

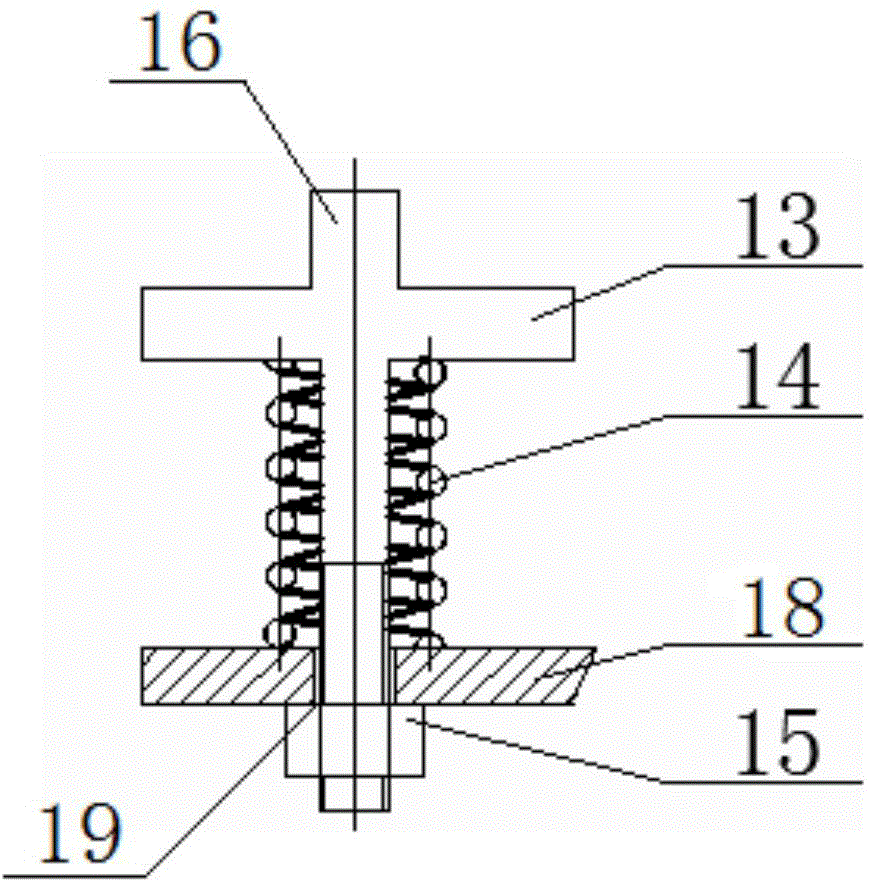

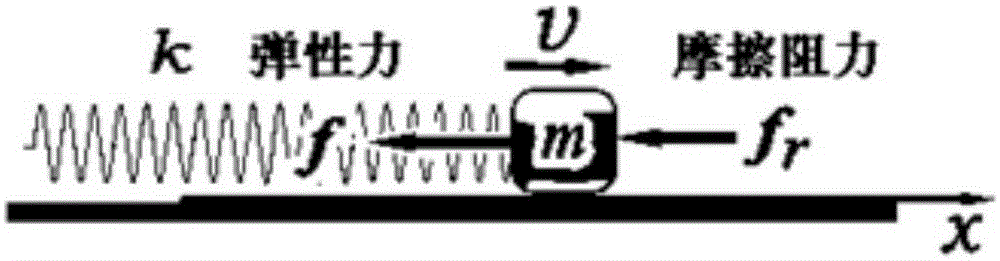

Ultralow frequency vibration isolator based on parallel connection of positive stiffness spring and negative stiffness spring

InactiveCN102619916AWith ultra-low frequency zero Hz vibration isolation performanceGuaranteed vibration isolation performanceShock absorbersDynamic stiffnessVibration attenuation

The invention discloses an ultralow frequency vibration isolator based on parallel connection of a positive stiffness spring and a negative stiffness spring, comprising a guide post, a sheath cover, a sliding block, a negative stiffness spring, a lower cover, a guide seat, a ball and a main spring. According to the invention, the main spring (a positive stiffness spring) is connected with the negative stiffness spring in parallel, thus a vibration damper can have the characteristics of high static stiffness and low dynamic stiffness, and zero-hertz ultralow frequency vibration isolation is realized; connection of a screw thread pair is adjusted, thus a stiffness curve of a vibration isolator is adjusted according to vibration isolation quality, and vibration isolation performance can be adjustable; and rolling friction is realized by adopting balls, thus frictional resistance is reduced. The ultralow frequency vibration isolator disclosed by the invention can be used as one component and is applicable to an environment under vibrational excitation, especially an environment under low frequency vibrational excitation, such as a vehicle seat, a suspension, precise instrument vibration isolation as well as vibration attenuation and seismic resistance.

Owner:JILIN UNIV

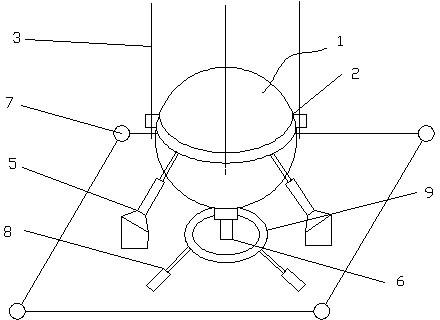

Tempering damper system used for improving wind resistance stability of transmission tower based on single pendulum model

ActiveCN102535674AGood stability against windEasy maintenanceShock proofingTransmission towerEngineering

The invention relates to a tempering damper system used for improving wind resistance stability of a transmission tower based on a single pendulum model. The damper system is composed of a spheroid mass block, a bracket, oil pressure type dissipation energy dampers, an oil pressure type anticollision damper, steel ropes and a buffering steel ring and the like, wherein the spheroid mass block is composed of a roundness steel disc; four groups of steel ropes support the lower half part of the spheroid mass block through the bracket and four groups of oil pressure type dissipation energy dampers are arranged around the bracket to achieve the purpose of energy consumption and vibration attenuation; in addition, when the swing amplitude of the spheroid mass block is oversize, and a tubular steel bar arranged below the bracket can collide the buffering steel ring so as to slow down the motion of the buffering steel ring; and the performance of the tempering damper system mainly depends on the size of rotational inertia, if the rotational inertia ratio of the tempering damper system to a controlled system is larger, the control effect is better. The tempering damper system is suitable for transmission towers of different tower types, is easy to install, and can obviously improve the wind resistance stability property of the transmission tower.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

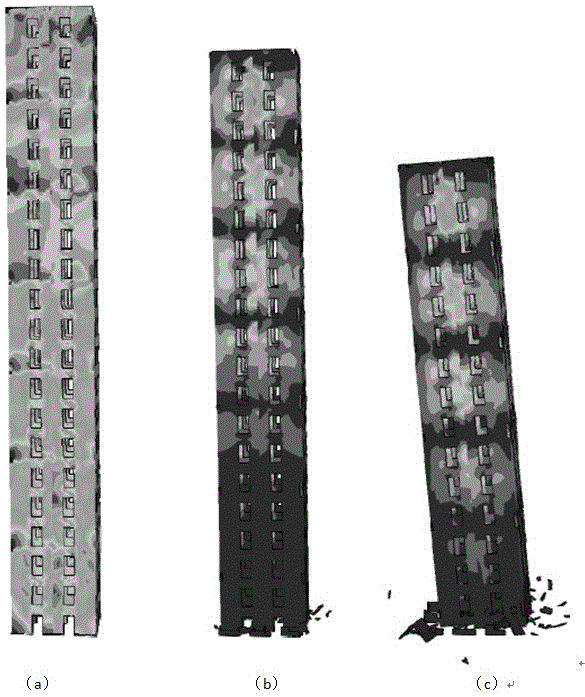

Mechanical equipment clamping conversion type vibration attenuation method

InactiveCN107091296AGood vibration dampingReduce lateral amplitudeNon-rotating vibration suppressionStands/trestlesVertical vibrationVibration amplitude

The invention discloses a mechanical equipment clamping conversion type vibration attenuation method. The vibration attenuation method includes the step that a vertical vibration attenuation mechanism is arranged below mechanical equipment to achieve vertical vibration attenuation on the mechanical equipment; and the vibration attenuation method is characterized by further comprising the step that the downward deforming motion transmission of the vertical vibration attenuation mechanism is converted into clamping of the two sides of the mechanical equipment on the mechanical equipment in the horizontal direction, the vibration amplitude of the mechanical equipment in the horizontal direction is limited, and the vibration amplitude of the mechanical equipment in the vertical direction is reduced. The mechanical equipment clamping conversion type vibration attenuation method has the beneficial effects that vibration attenuation of the mechanical equipment can be better achieved, and the vertical vibration amplitude and the horizontal vibration amplitude which are generated by the mechanical equipment are reduced.

Owner:YANGTZE NORMAL UNIVERSITY

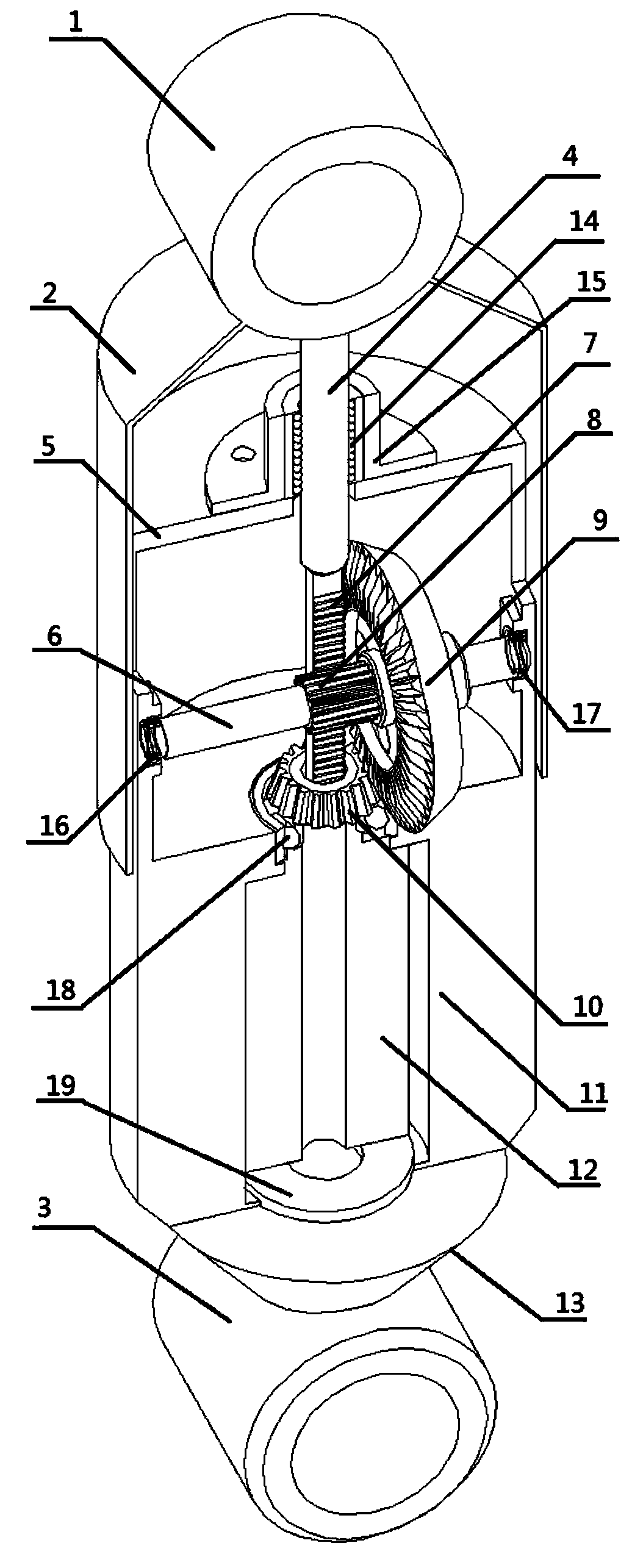

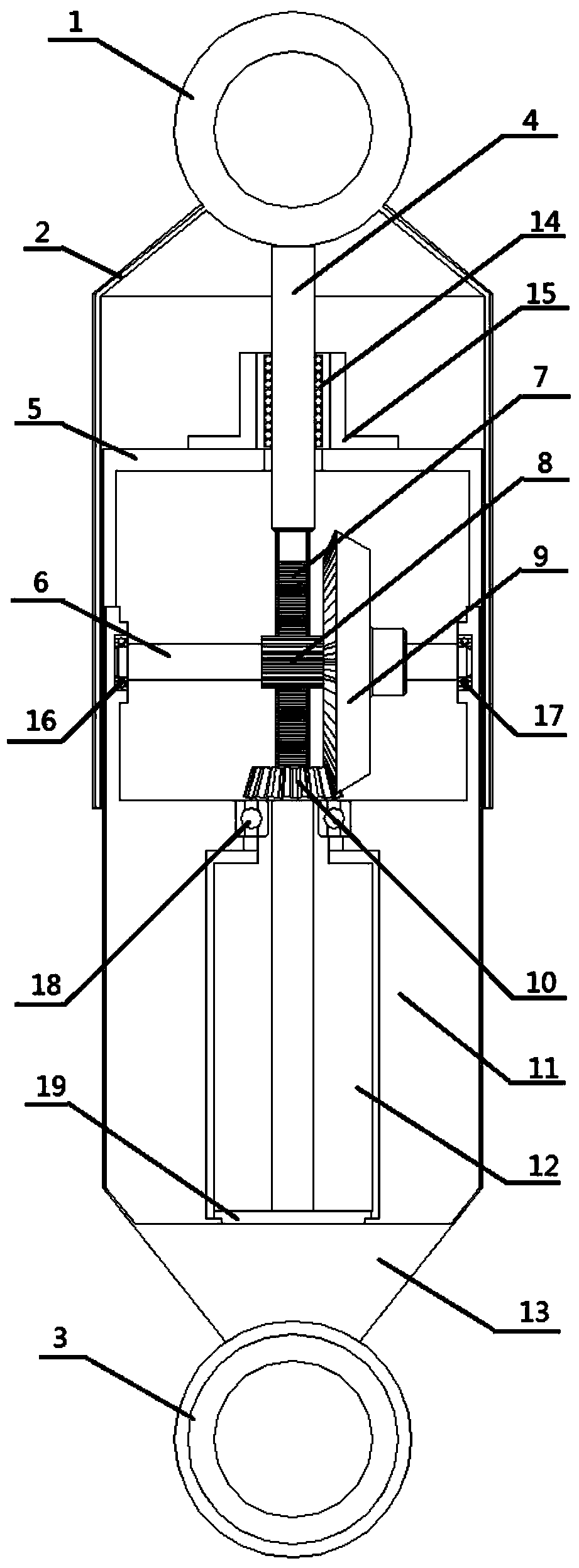

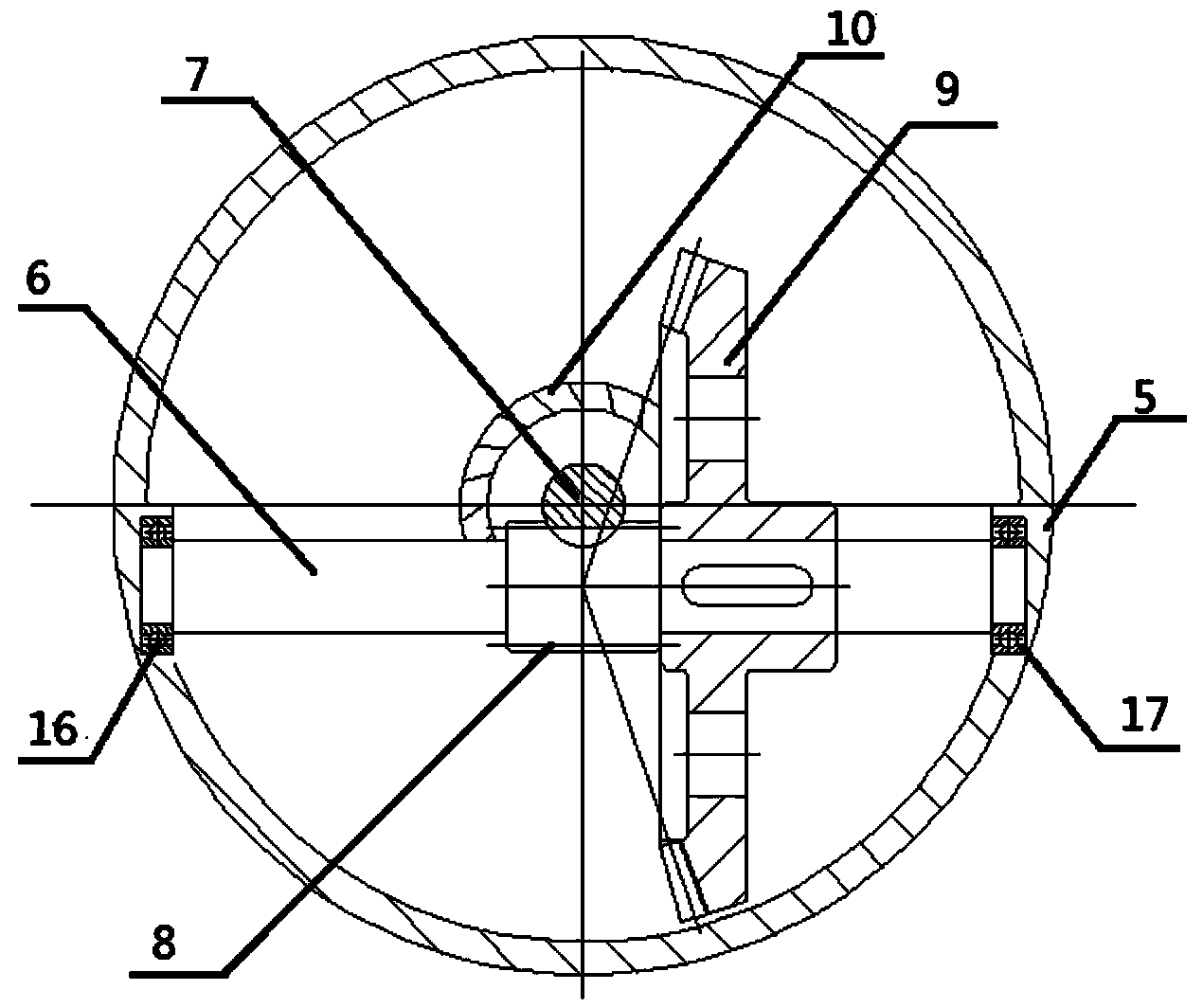

Pinion-and-rack rotating power generation car shock absorber

InactiveCN103591202AControl vibration dampingAchieve rotationMagnetic springsMachines/enginesVibration attenuationVehicle frame

The invention relates to a power generation type car vibration energy recycling shock absorber, and provides a pinion-and-rack rotating power generation car shock absorber which aims to recycle vibration energy of a car for power generation and enables the purposes of vibration attenuation and energy recovery to be achieved. The pinion-and-rack rotating power generation car shock absorber is formed by an upper hanging ring, a dust-proof cover, a lower hanging ring, an upper hanging ring rod, a shell, a shaft, a rack, a pinion, a big hypoid gear, a small hypoid gear, a motor stator, a motor rotor, a lower hanging ring connecting base, a linear bearing, a linear bearing pedestal, three rolling bearings and an end face bearing. The pinion-and-rack rotating power generation car shock absorber has the advantages that reciprocating vibration mechanical energy of a car frame and a car body of the car can be recycled and can be converted to rotating mechanical energy through the rack and the gears, the relative rotation of the motor rotor and the motor stator is achieved so that power generation can be carried out, and the vibration attenuation can be achieved through magnetic resistance torque between the stator and the rotor and gear meshing resistance.

Owner:CHINA AGRI UNIV

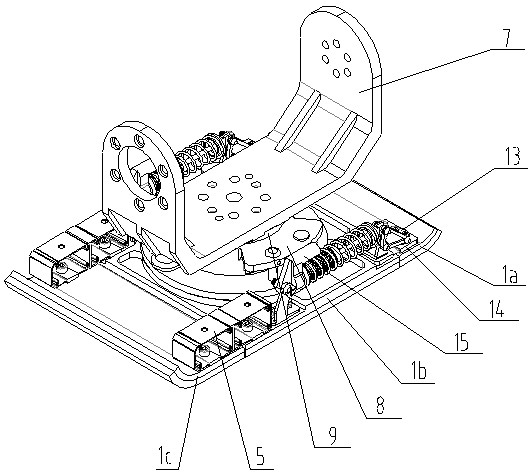

Robot foot mechanism with flexible joint

ActiveCN102180206AWalking smoothlyGait is smooth and naturalVehiclesVibration attenuationDegrees of freedom

The invention relates to a robot foot mechanism with flexible joints. The existing robot has poor foot impact adsorbing effect. The robot foot mechanism comprises toe plates, heel plates, sole plates, flexible hinges, spring plates, heel vibration attenuation devices, a six-dimensional force moment sensing device and an ankle support seat, wherein the toe plates and the sole plates are connected by the flexible hinges; the sole plates are connected with the heel plates by the spring plates; the bottom surfaces of the toe plates, the sole plates and the heel plates are provided with rubber layers; the flexible hinges, the spring plates and the vibration attenuation devices are all symmetrically arranged along the proceeding direction; each flexible hinge is formed by connecting two flexibly deformed rectangular rings and is formed by cutting and processing the whole line; each rectangular ring is provided with a groove vertical to the proceeding direction for adsorbing deformation; and the thickness of the middle of the spring plates is less than the thickness of two ends. In the robot foot mechanism, a humanoid robot can walk more stably by increasing the degree of freedom of passive toes, and the tread of the humanoid robot is more stable and natural.

Owner:小卡运动科技(南通)有限公司

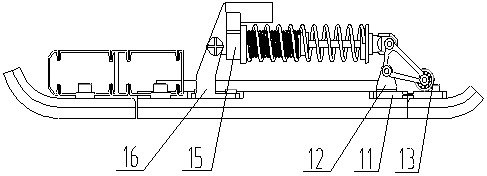

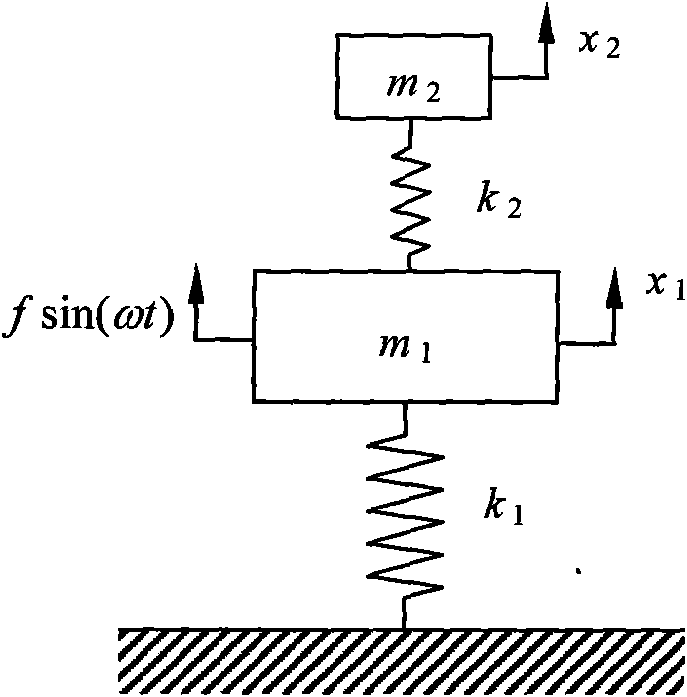

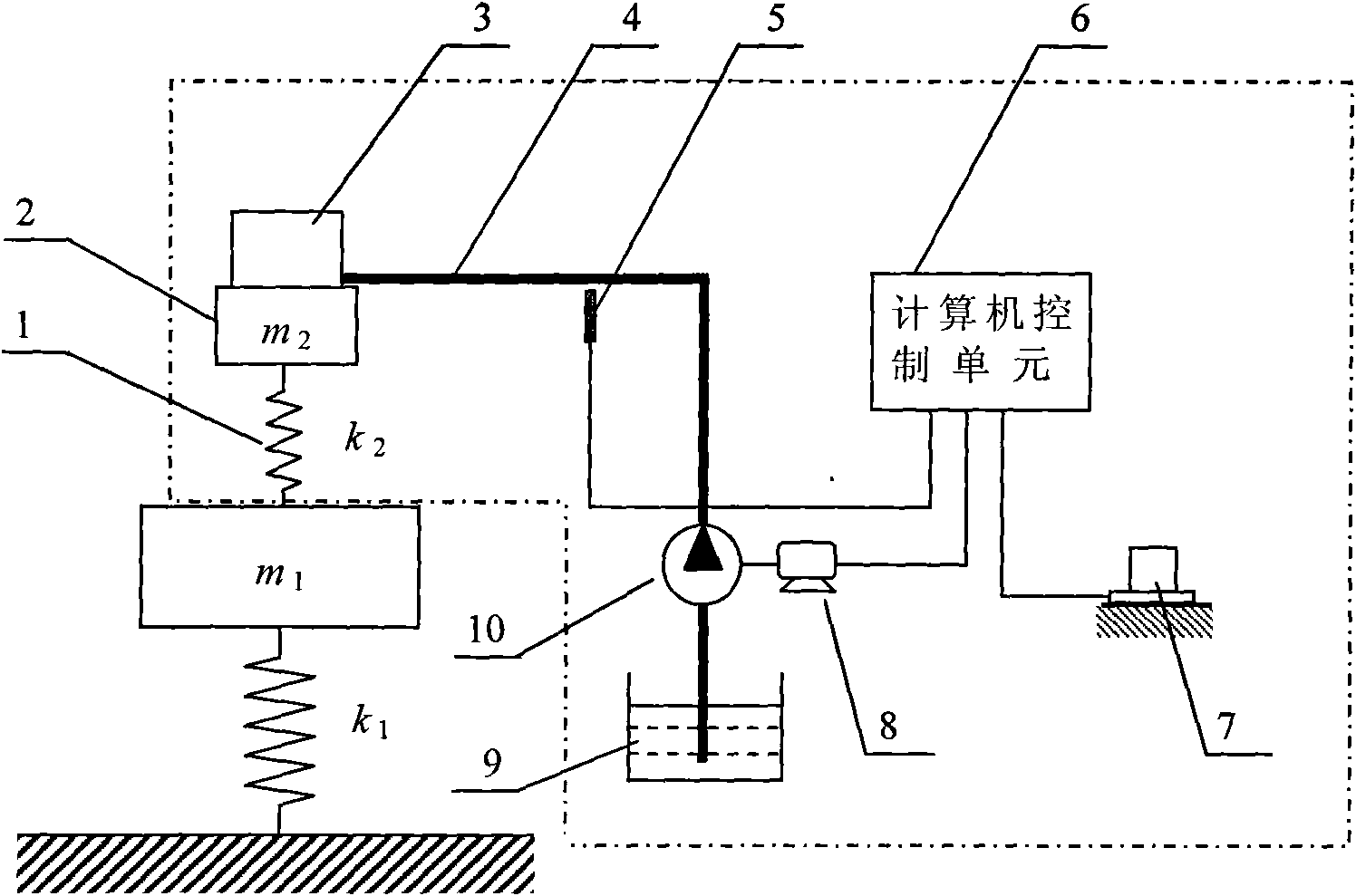

Vibration absorption device of adjustable natural frequency and engine with same

InactiveCN101639109AAbsorb vibrationReduce vibrationNon-rotating vibration suppressionVibration attenuationLiquid tank

The invention belongs to the technical field of vibration attenuation and vibration absorption of engineering structures and mechanical structures, and discloses a vibration absorption device of adjustable natural frequency and an engine with the same; wherein, the vibration absorption device of adjustable natural frequency is characterized by comprising a liquid storage tank, a liquid pump, a vibration absorption spring, a vibration absorption mass block arranged at the upper end of the vibration absorption spring, and an additional liquid tank fixed on the vibration absorption mass block. The additional liquid tank is divided into an upper air cavity and a lower liquid cavity by a piston, and the lower liquid cavity, the liquid pump and the liquid storage tank are sequentially connectedby a hose. The vibration absorption device of adjustable natural frequency is arranged on a mounting seat of the engine, and engine vibration is absorbed to the maximum extent by dynamically adjustingthe natural frequency of the vibration absorption device, thus reducing engine vibration.

Owner:CHANGAN UNIV

Shock-resistant energy-absorbing material and preparation method thereof

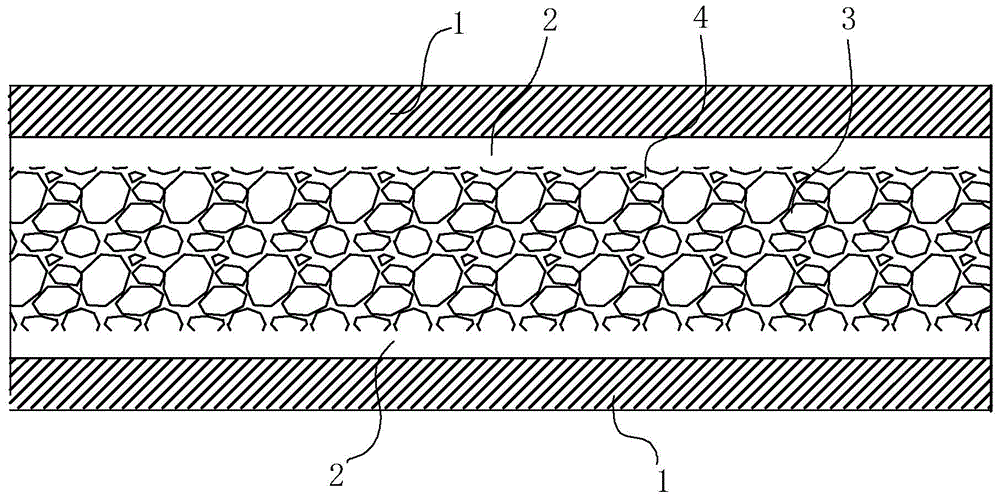

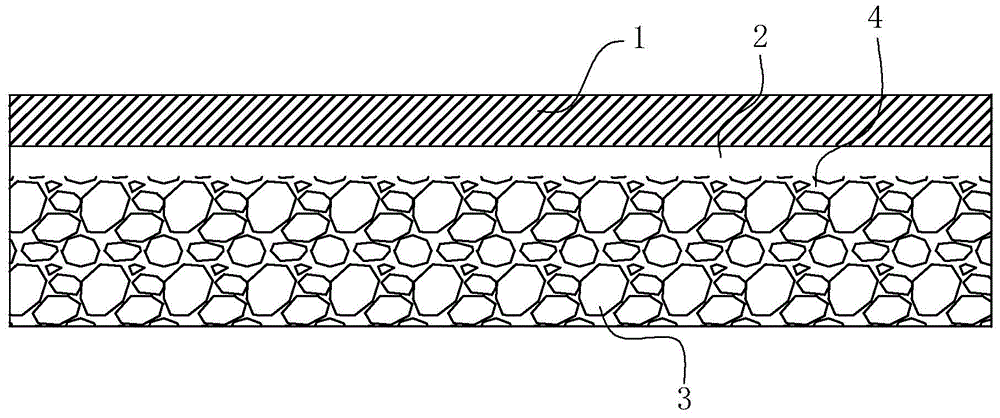

ActiveCN104647823AImprove impact resistance and energy absorption performanceReduce bond strengthMetal layered productsShock waveVibration attenuation

The invention relates to a shock-resistant energy-absorbing material. The shock-resistant energy-absorbing material is characterized by comprising a metal panel and a foamed metal layer, which are sequentially arranged from outside to inside, wherein the metal panel and the foamed metal layer are in vulcanization connection by a rubber layer. According to the shock-resistant energy-absorbing material, and rubber is adopted as a connecting body for integrally molding the metal panel and the foamed metal layer to prepare the novel shock-resistant energy-absorbing material; the three materials are different in elasticity and plasticity and can form a layer-by-layer protective system, stress waves, mechanical force and cracks on the former plate layer cannot be transmitted to the next plate layer, shock waves penetrate into gaps for multiple times, reflection is generated at the position of a gap interface, the damage of the shock waves to the whole composite board can be reduced and the shock-resistant energy-absorbing performance of the material is improved; the shock-resistant energy-absorbing material has good shock-resistant, energy-absorbing and damping vibration attenuation properties, the functional structure integration and the preparation process engineering are achieved, and the purposes that the anti-aging effect is achieved, the process is simplified and the production efficiency is improved are achieved.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH +1

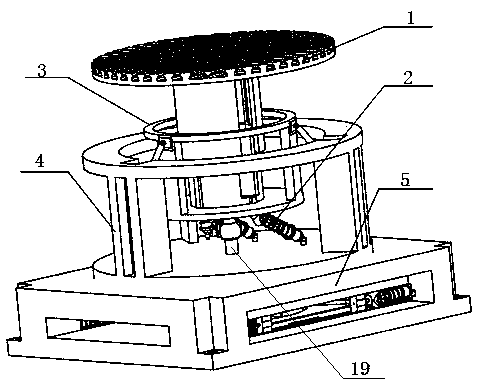

Six-degree-of-freedom parallel mechanism vibration attenuation platform

ActiveCN104214484AAchieving Nonlinear StiffnessSolve the problem of isolating low frequencyStands/trestlesVibration suppression adjustmentsEngineeringUltrasound attenuation

The invention discloses a six-degree-of-freedom parallel mechanism vibration attenuation platform. By setting a given structural parameter, the quasi-rigidness of the vibration isolation platform on a balance position and the nonlinear rigidness of the vibration isolation platform near the balance position can be realized, and the difficulty when the traditional linear vibration isolation system isolates the low-frequency or ultralow-frequency vibration can be solved; the rigidness and damping can be simply adjusted, the six-degree-of-freedom parallel mechanism vibration attenuation platform is suitable for the broadband-frequency vibration isolation and has good engineering applicability; while the supporting rigidness is high, the motion rigidness is low, the static deformation is small, the dynamic intrinsic frequency is low, and the vibration isolation effect is good; by flexibly adjusting the rigidness and damping, the intrinsic contradiction, i.e. the contradiction between the low-frequency vibration transfer rate and high-frequency vibration attenuation rate, for restricting the traditional vibration isolation system can be solved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Aramid fiber and carbon fiber blended yarn and production method thereof.

InactiveCN101864631ALow densityHigh temperature resistantLubricating devicesYarnYarnVibration attenuation

The invention discloses aramid fiber and carbon fiber blended yarn formed by blending aramid fiber and carbon fiber in a mass part ratio of 1:1. The production method of the aramid fiber and carbon fiber blended yarn adopts the aramid fiber and carbon fiber as raw materials in the mass ratio of 1:1 and comprises the following steps of: firstly, preprocessing the aramid fiber and the carbon fiber, i.e. preadding an oiling agent to release static electricity; and sequentially carrying out the working procedures of blending, blowing, carding, drawing, roving, spinning and self-winding to make the aramid fiber and carbon fiber blended yarn. By adopting the aramid fiber and carbon fiber blended yarn and the production method thereof, the blended yarn has the performances of low density, resistance of high temperature, corrosion, friction and aging, high vibration attenuation property, electric and thermal conduction and optical penetration, low heat expansion coefficient, electromagnetic shielding property by non-magnet, and the like.

Owner:江阴市海江纱厂有限公司

Rubber reinforced cement functional composite material and preparation method thereof

InactiveCN101857399AWith noise reductionWith sound insulationSolid waste managementNoise barrierAdhesive

The invention discloses a rubber reinforced cement functional composite material and a preparation method thereof. The rubber reinforced cement functional composite material is prepared from waste rubber and cement or cement mortars by the following steps of: applying coupling adhesives to surfaces of waste rubber grains and / or powder by using coupling agents; mixing the waste rubber grains and / or powder with the cement or the cement mortars; adding water into the rubber-cement mixed materials for uniform stirring, and performing pavement, pressing, demoulding and maintaining to obtain the functional composite material product having a high mechanical strength and endurance. The composite material has the characteristics of noise reduction, sound isolation, high impact resistance, damping vibration attenuation, wear resistance, static resistance, water resistance and the like, has the advantages of insulation, environmental protection and the like and can be used in the field of functional materials, such as buildings, roads, railways, tunnels, noise barriers and the like. The functional composite material and the method thereof also provide a new way for solving the global problem of 'black pollution' of increasing waste tyres and have a wide application prospect.

Owner:CHINA BUILDING MATERIALS ACAD

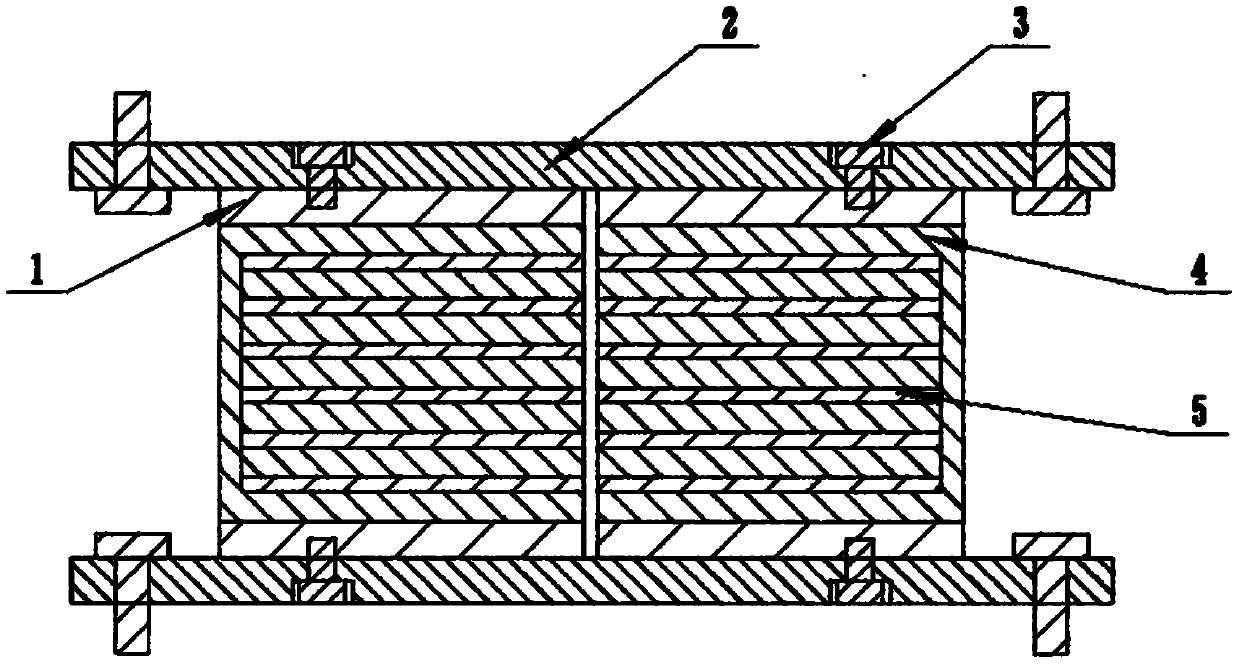

Building structure foundation module having three-dimensional shock isolation and vibration attenuation functions

ActiveCN109763581AReduce construction costsLow coefficient of sliding frictionClimate change adaptationProtective buildings/sheltersViscoelastic dampingVibration attenuation

The invention discloses a building structure foundation module having three-dimensional shock isolation and vibration attenuation functions. The building structure foundation module mainly comprises asteel structure small platform, a sliding support, a variable vertical stiffness combination laminated special rubber / steel plate support having a vertical self-regulating deformation capability, andviscoelastic damping energy absorption shock absorbers, wherein the centers of the viscoelastic damping energy absorption shock absorbers are connected in parallel; the sliding support uses an oily self-lubricating liquid phase-solid phase material, the coefficient of sliding friction is relatively low, the horizontal seismic component is effectively stopped from transferring to an upper structure, the shock absorber and a liquid / solid special rubber support having a damping characteristic are connected together in parallel and have a vibration attenuation effect, so that the effects of three-dimensional shock isolation, vibration attenuation and protection are achieved. The technical scheme has more sensitive and efficient actions on the earthquake.

Owner:李鑫

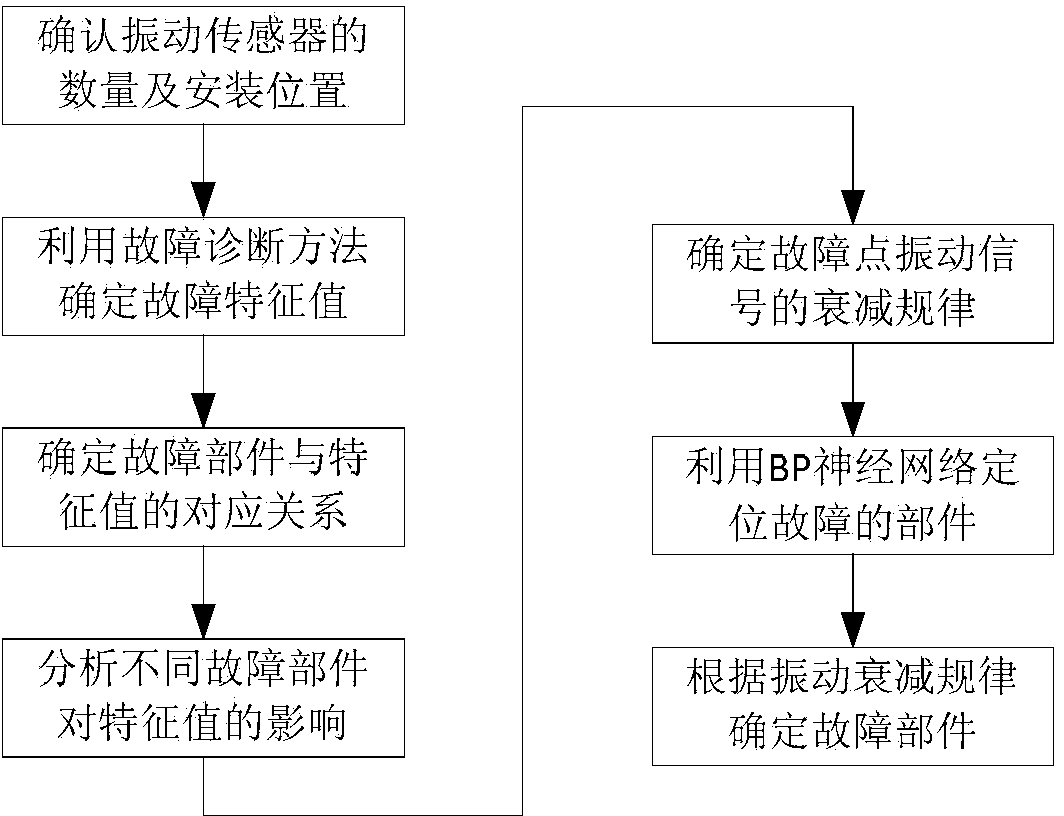

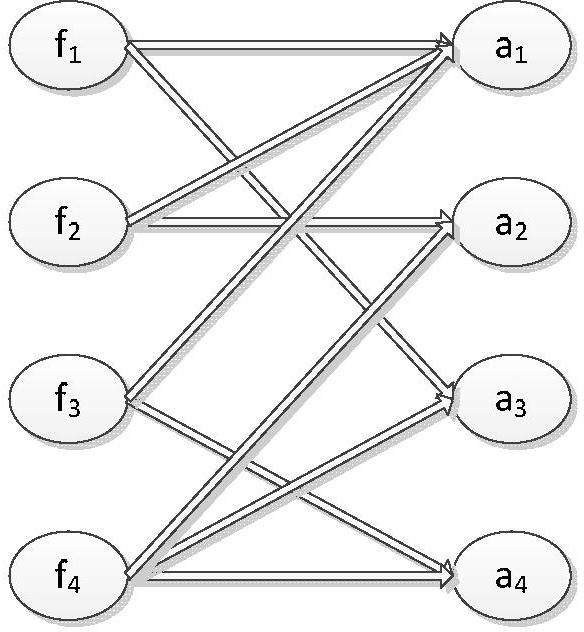

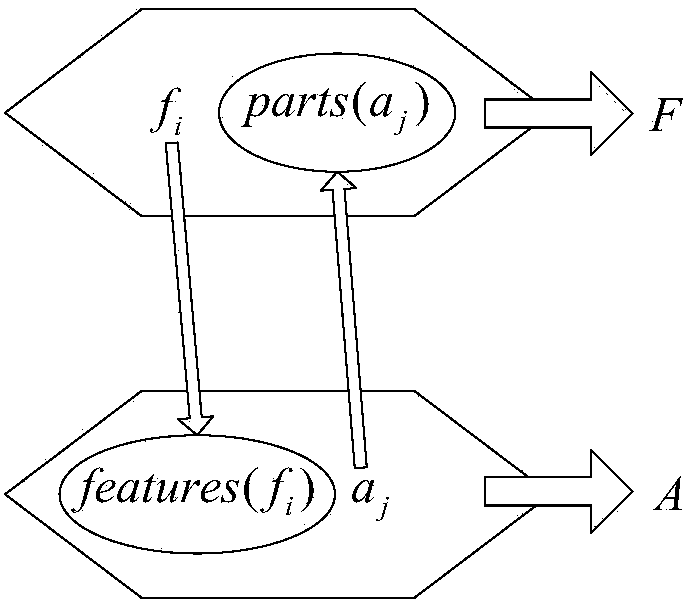

Multi-sensor fusion type fault locating method for gearbox of wind turbine generator

InactiveCN104048825ASolve the problem of fault locationMachine gearing/transmission testingAttenuation coefficientElectricity

The invention provides a multi-sensor fusion type fault locating method for a gearbox of a wind turbine generator. The multi-sensor fusion type fault locating method for the gearbox of the wind turbine generator comprises the seven steps that firstly, application conditions of a fault locating model are determined according to the inner structure of the gearbox and the positions and the number of vibration sensors; secondly, collected vibration signals are analyzed according to an existing fault diagnosis technology, and corresponding fault characteristic values are extracted; thirdly, a relation between a faulty component and a characteristic value set is established according to the parsimonious covering theory; fourthly, the position, the type and the degree of the fault of the gearbox are determined according to a gearbox endoscopy result; fifthly, the influences of different faulty components on vibration signals of multiple detecting points are analyzed, and a vibration attenuation coefficient is obtained; sixthly, fault diagnosis is conducted on obtained data according to the difference between the fault characteristic values and the BP neural network algorithm, and the fault is located to the component of a certain type; seventhly, the attenuation coefficient beta' k of the vibration signals are obtained and analyzed, and the position of the faulty component is determined by working out the smallest error delta with a comparison method, wherein delta=beta' k-beta k.

Owner:BEIHANG UNIV

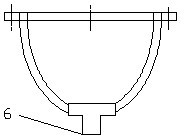

Floatation type brake pad for high speed train

InactiveCN102705405AAvoid bluePrevent thermal crackingBraking elementsVibration attenuationEngineering

The invention relates to a floatation type brake pad for a high speed train.. The floatation type brake pad is characterized by comprising a pad rear panel, a dovetail board, friction block bodies, an elastic supporting sheet and a round spring clip; the pad rear panel is in an arc half-sole structure; the elastic supporting sheet is provided with a spherical supporting surface and a center guide hole; the frication block is provided with a spherical supporting surface and a guide connection shaft with a clamping groove; the elastic supporting sheet, the round spring clip and the friction block bodies are in elastic floatation connection with the pad rear panel; the spherical supporting surface of the elastic supporting sheet and the spherical supporting surface at the root of a connection shaft of each friction block body are rotary, so that the balance of a braking force is realized; the three single-arc quadrilateral friction bodies in one group are mutually engaged and locked; and friction bodies of four cylindrical grinding column bodies are mutually engaged and locked in pairs. With the adoption of the floatation type brake pad provided by the invention, a maximum contact friction area can be obtained, so that a braking process is stable, and the functions of damping, vibration attenuation, noise reduction, heat radiation and the like can be achieved. The friction blocks are easy to replace; the operation cost is low; and the floatation type brake pad can be widely used for a braking system of the high speed train.

Owner:BEIJING TIANYISHANGJIA NEW MATERIAL

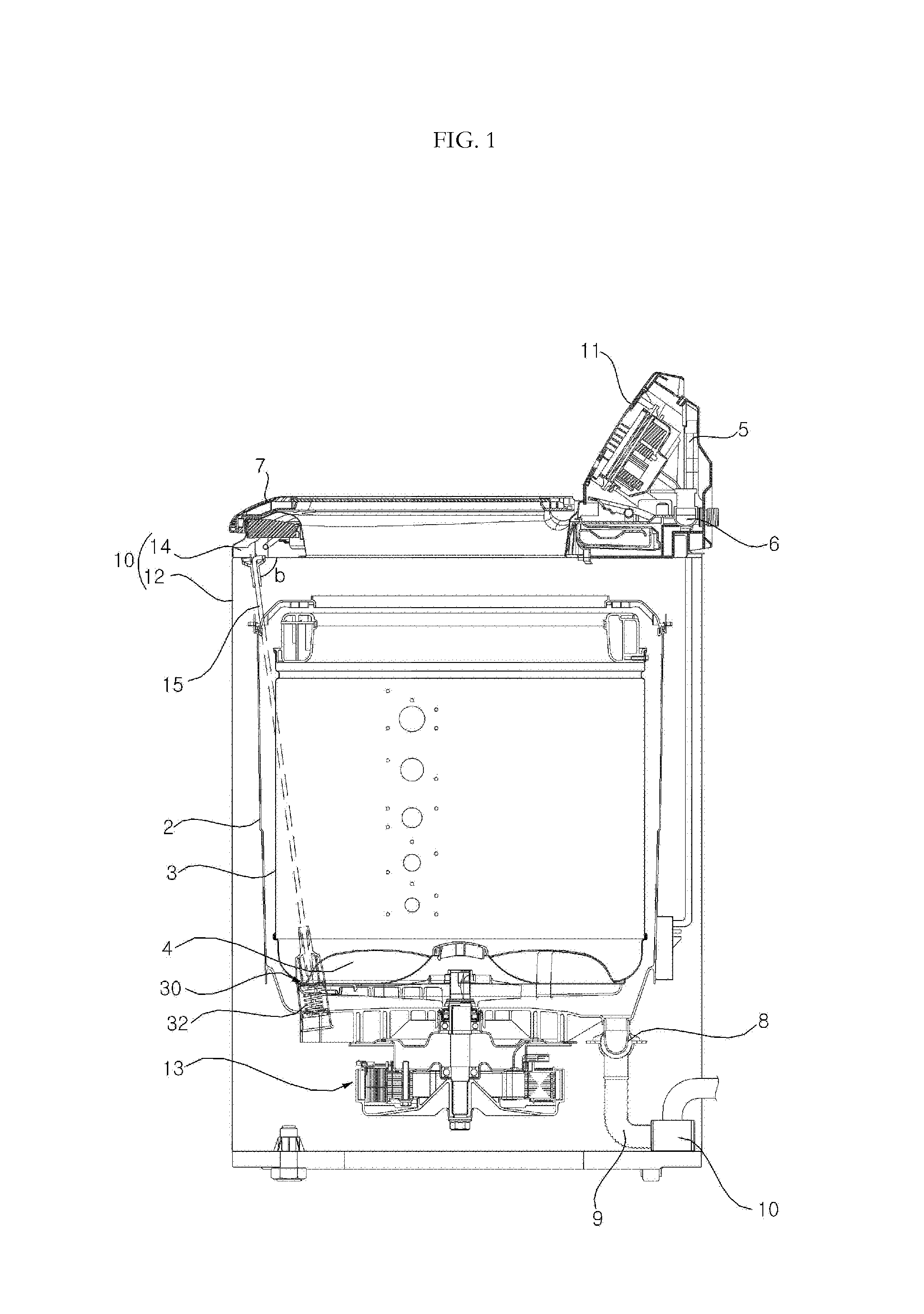

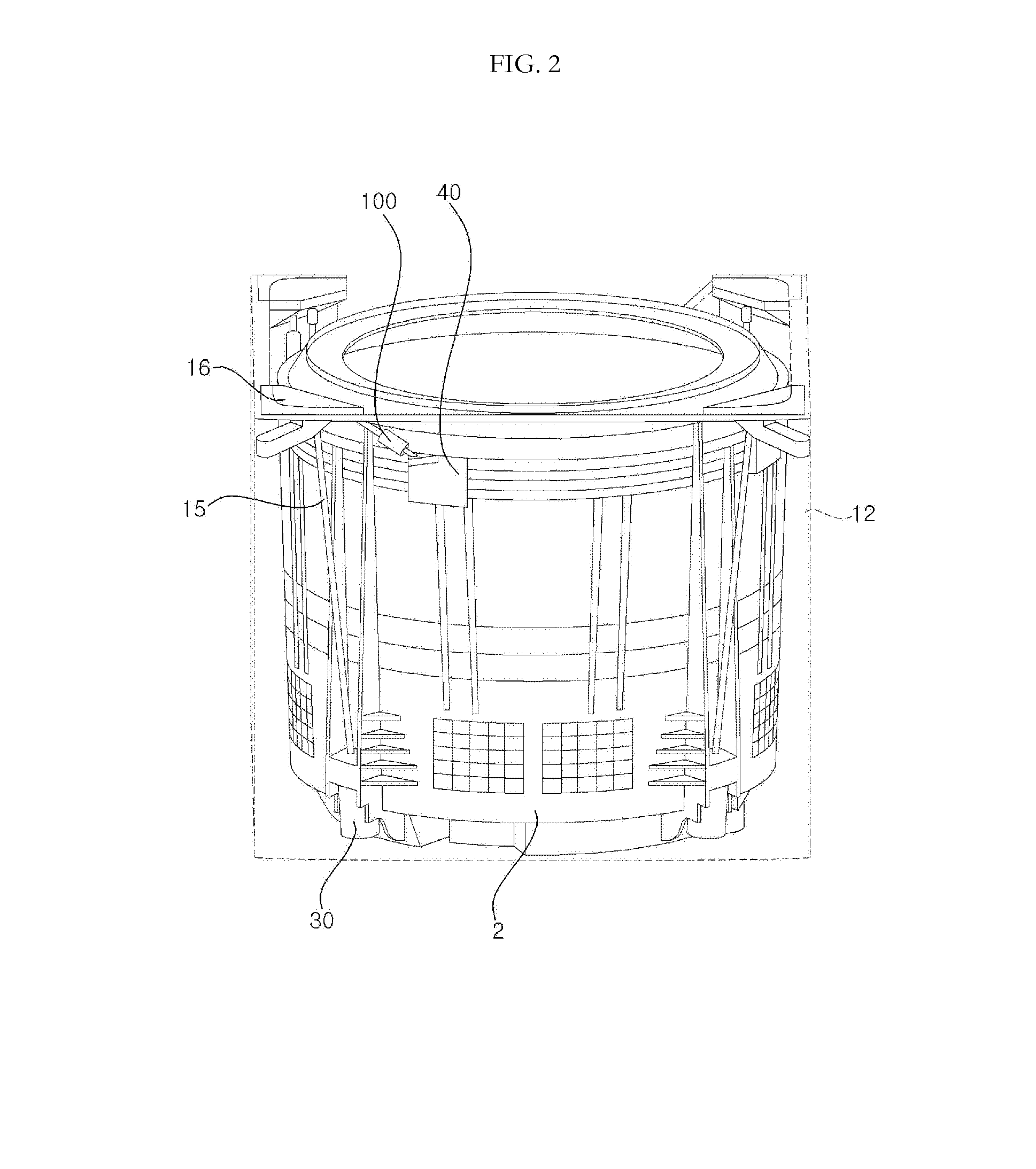

Washing machine

ActiveUS20140060120A1Non-rotating vibration suppressionOther washing machinesVibration attenuationEngineering

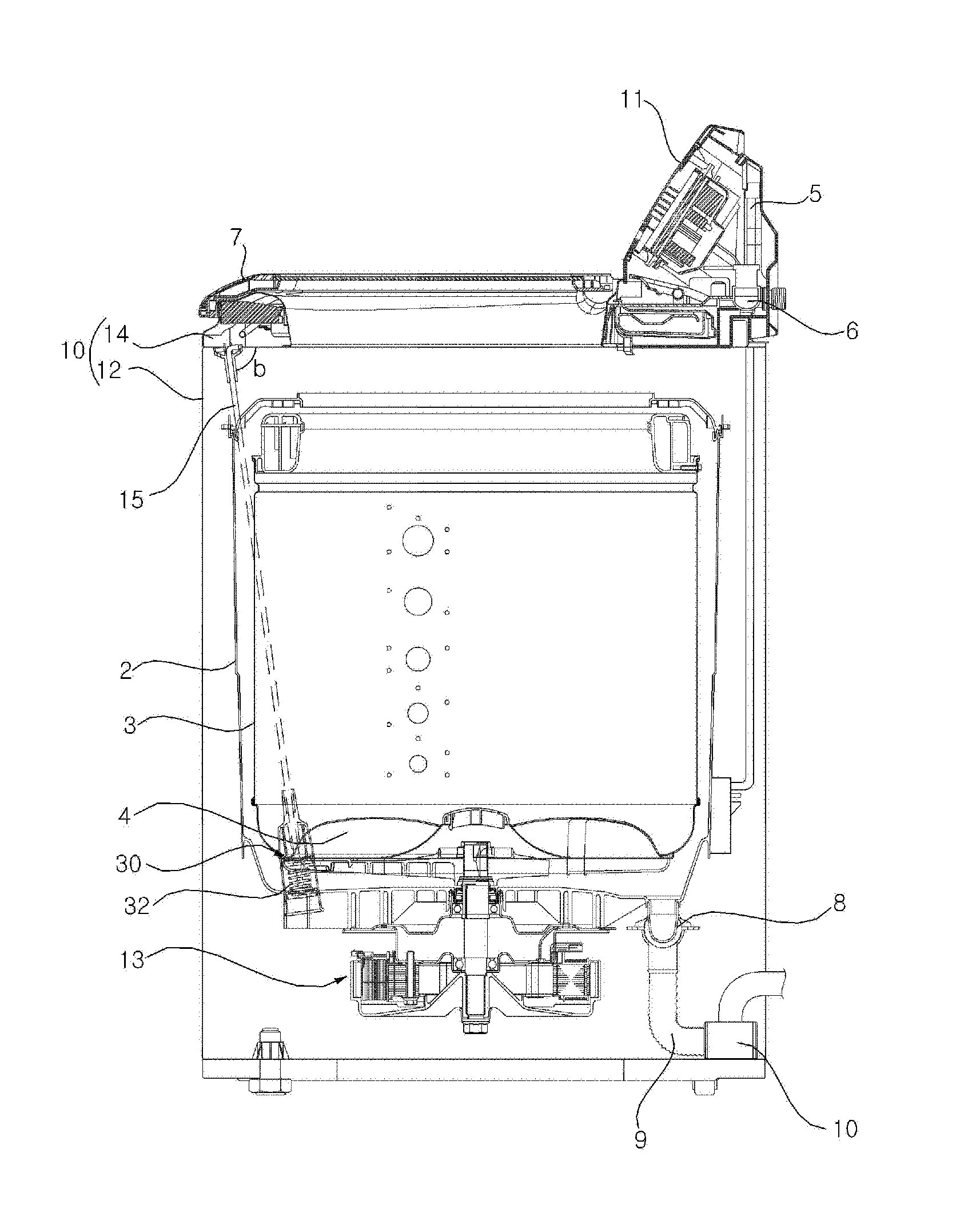

Disclosed is a washing machine including a casing, an outer tub located within the casing, at least one support member to suspend the outer tub from the casing, a suspension, provided at a lower side of the outer tub and connected to the at least one support member, to attenuate vibration of the outer tub and at least one horizontal vibration attenuation unit to attenuate horizontal vibration of the outer tub by the introduction of friction according to a horizontal displacement of the outer tub.

Owner:LG ELECTRONICS INC

Anti-collapse optimization design method of reinforced concrete shear wall structure

ActiveCN106407548AImprove the ability to resist local damageAvoid cascading collapseGeometric CADDesign optimisation/simulationVibration attenuationReinforced concrete

The invention relates to an anti-collapse optimization design method of a reinforced concrete shear wall structure, and belongs to the field of the disaster prevention and the vibration attenuation of a building structure. The method comprises the following steps of: firstly, according to an existing condition, carrying out the initial design of the structure; according to a current design code, through a preliminary structure design and shear wall arrangement situation, determining one or a plurality of possible structure weak positions, such as shear wall corners and the like, under an accidental event or an extreme disaster, introducing component damage and destruction; and adopting a finite element method to independently carry out elastic deformation checking calculation under the function of frequent-intensity earthquakes and elastoplasticity collapse analysis under the function of rare-intensity earthquakes on a shear wall structure model, returning to the above steps if collapse happens, and constantly carrying out cyclical adjustment on a structure design according to bearing capacity requirements until the design is optimal. By use of the design method disclosed by the invention, from an integral structure system, a process is simple, and working efficiency is high. A reference method and a solution are especially provided for the collapse caused by the damage and the destruction of an important component position structure, and have universal applicability.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com