Floatation type brake pad for high speed train

A technology of high-speed trains and brake pads, which is applied in the direction of brake types, brake components, mechanical equipment, etc., can solve problems such as uneven brake pressure, reduced service life of brake pads, and inability to float, so as to ensure the working life, Equalize the brake pressure, use safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

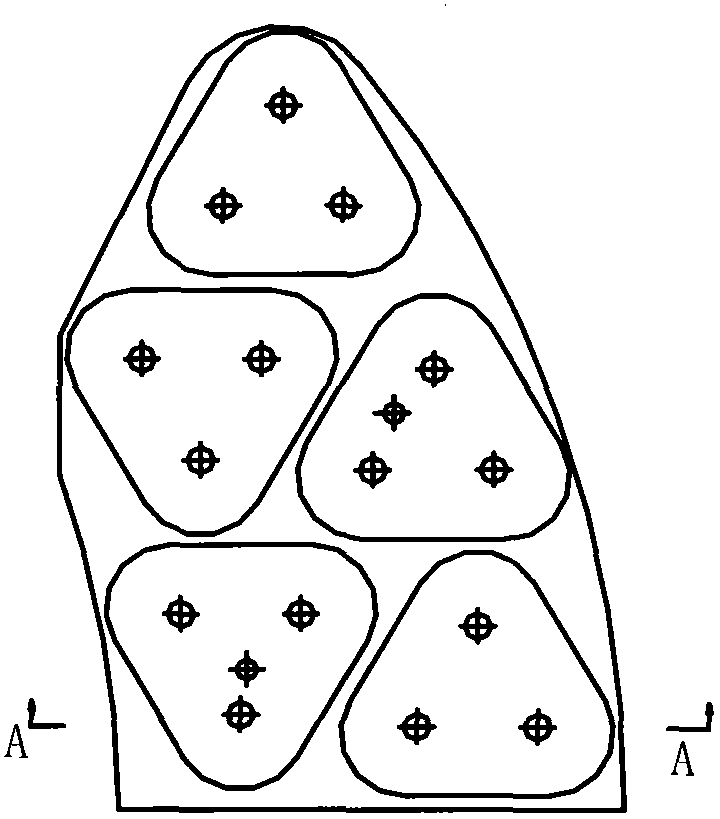

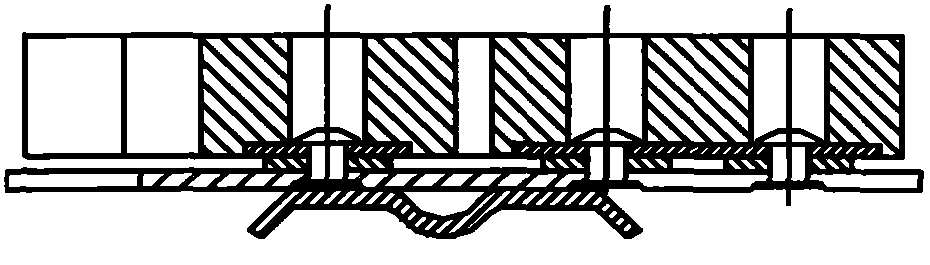

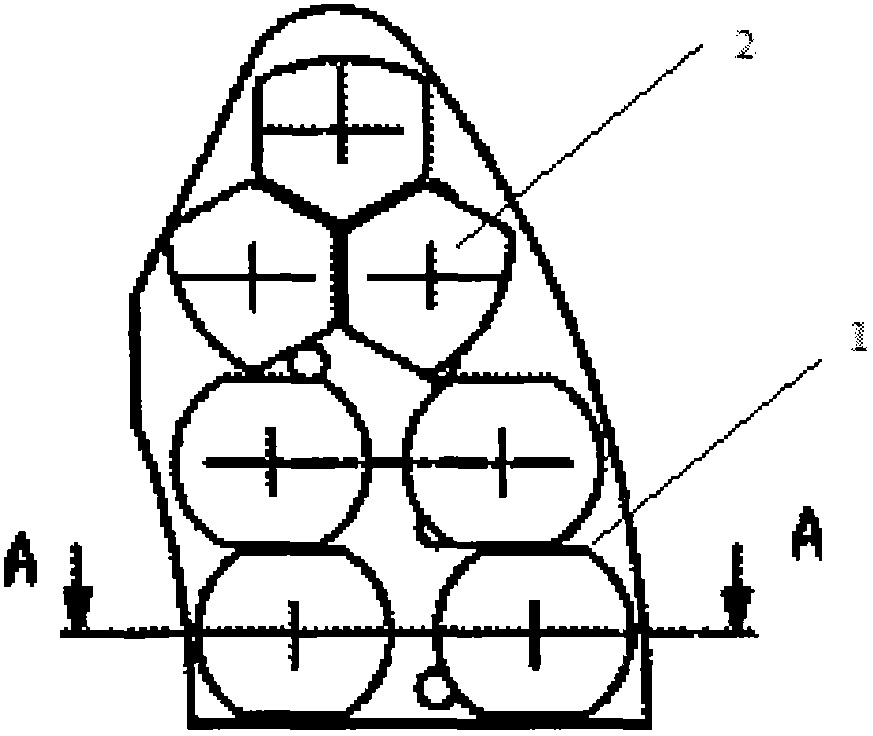

[0033] Such as Figure 3-6 As shown, the present invention includes a brake pad back plate 1 , several brake pad friction blocks 2 , several elastic support pieces 3 , several spring clips 4 and a dovetail 5 .

[0034] Such as Figure 7-8 As shown, the arc-shaped sole structure of the brake back plate 1 of the present invention is made of steel material. The brake back plate 1 is provided with a positioning installation spot-faced hole 101 connected with the elastic support piece 3 and connected with the spring clip 4 The installation spot facing hole 102, and the through hole 103 through which the guide connecting shaft of the brake friction block 2 passes; the brake back plate 1 is also provided with a mounting hole 104 riveted with the dovetail 5.

[0035] Such as Figure 9-10 As shown, the elastic supporting sheet 3 of the present invention is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com